Micrometl Knockdown Curb Installation Manual

Knockdown Curb

Install Guide

Foremost HVAC Accessory Manufacturer

Table of Contents

Topic Page Number

Topic Page Number

General 1

General 1

Knockdown Assembly 2

Cut Opening 3

Flashing The Curb 4

Duct Attachment 5

Apply Gasket 6

Equipment Supports 7

IMPORTANT: Please read all installation instructions and safety precaustions before beginning. These

installation instructions are to be used as a general quideline only!

GENERAL

The MicroMetl Knockdown Curb ships unassembled, can be easily

stored in your inventory, and is your least expensive option when it

comes to rooftop curbs. With the use of some basic tools, it is easily

eld assembled.

The most common curb height is fourteen inches. MicroMetl offers

other standard heights, as well as your choice of any pitch, or custom

height variation, to best t your rooftop requirements. Please contact

Customer Service with your special requests and requirements.

SAFETY PRECAUTIONS

Improper installation, adjustment(s), alteration(s), service or

maintenance can cause property damage, injury or death.

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components.

Only trained and qualied service personnel should install, repair,

or service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions

such as replacing lters. All other operations should be performed

by trained service personnel. When working on air-conditioning

equipment, always observe precautions in the literature, tags and

labels attached to the unit, and other safety precautions which may

apply!

To avoid any property damage or personal injury, it is the installer’s

responsibility to be certain that the installation will not impair the

function of this curb, or the unit to be installed.

Check and disconnect all gas and electrical connections before

installing your new curb and rooftop unit.

WARNING

!

To prevent injuries and rain damage, do not leave roof

opening uncovered. If installation is not completed

immediately after roof opening is cut and framed, provide

an adequate temporary cover for the roof opening.

TOOLS NEEDED

Rubber Mallet

5/16” Hex Head Driver or Socket

Tape Measure 7/16” Socket

7/16” Combination Wrench

Level

UNPACK & INSPECT

Reference the Product Submittal for your specic part number and an

illustration of all necessary parts. Unpack, locate all parts, and inspect

curb for missing parts or damages. Contact MicroMetl’s Customer

Service Department immediately with any questions or concerns.

All hardware used for these assembly procedures is included with

your curb. Do not tighten any hardware until the curb is completely

level, square, and installed in a suitable position on the roof with

proper alignment to the roof/unit opening(s).

OBSERVE PROPER CLEARANCES AND

OBSTRUCTIONS

Before installing your roof curb, check unit nameplate or RTU

manufacturer’s weight, and observe their requirement(s) for correct

and proper clearances. Additionally, check the clearances of the

new unit to other items on the roof, exhaust fans, walls, and other

roof top units.

Secure any wiring or pipes arising through the curb to be connected

to the new rooftop unit. Be certain to identify any possible obstructions

which could interfere with a crane’s path if required.

1

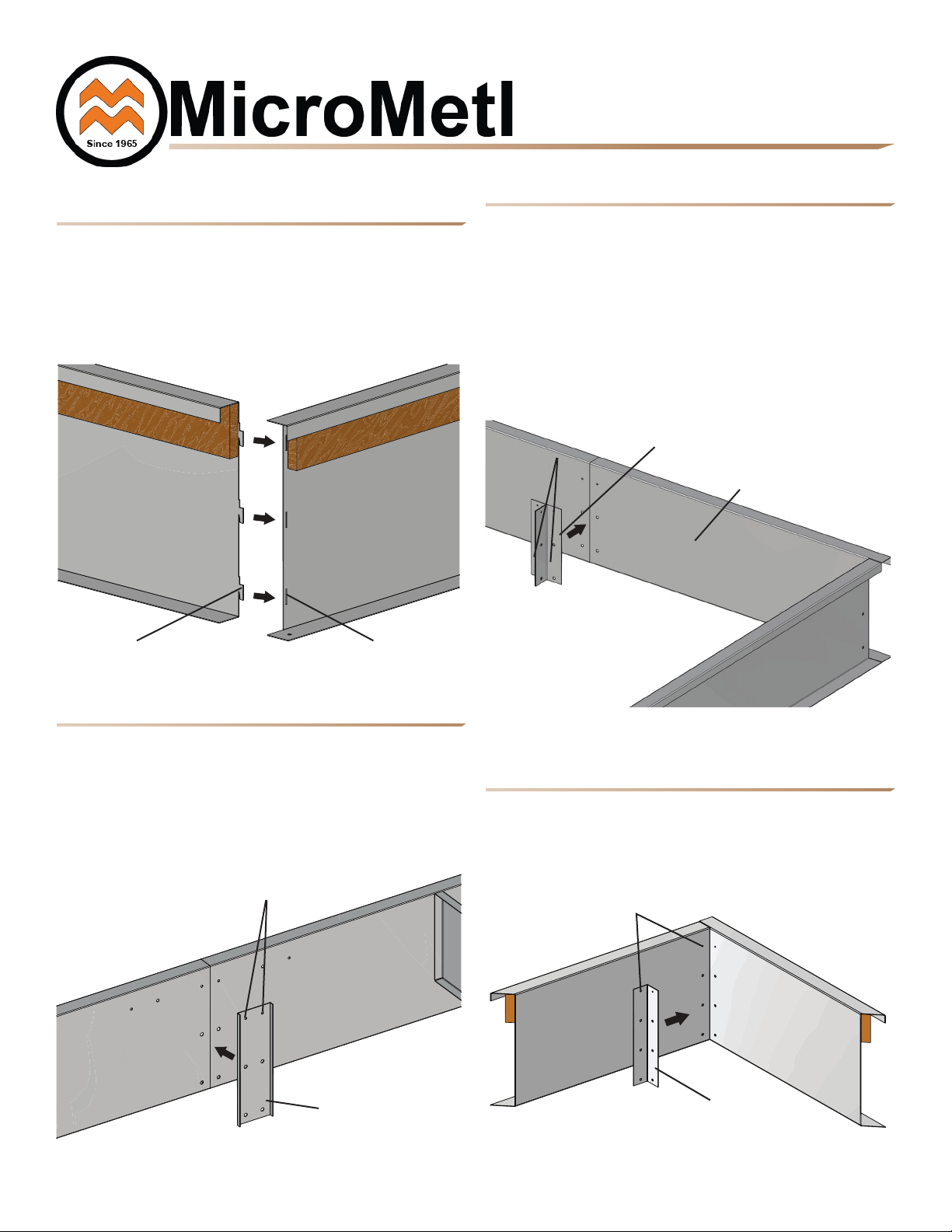

ASSEMBLE SIDES AND ENDS USING

MICROLOCK TABBED ENDS

The tabbed ends were developed at MicroMetl allowing the curb to

be assembled with just a rubber mallet. Bring together a curb side,

and a curb end. Simply t the tab into the slot, and with minimum

pressure, the corners securely lock into place. Be certain not to

join incorrect pieces. This style curb requires much more effort to

disassemble. Do not strike with too much force and damage the

curb. Repeat for the assembly of all corners.

90 DEGREE JOINING BRACKETS

Some long curb sides and ends may require a joining bracket. The

joining bracket combines long pieces together using the provided 90

degree corner bracket as shown in Illustration - 90 Degree Joining

Brackets. Place and secure the metal brackets on the inside of

the curb. It is designed to align with the pre-punched holes in the

knockdown curbs where the seams join, and must be installed on

the inside of the curb. Insert supplied bolts from the outside of the

curb, and through the brackets where the two anges meet, secure

into place. Insert wood screws at the top of the bracket and insert

from the inside of the curb.

Wood screws at top only

Curb Side Brackets

(Use 2 corner brackets

per side)

Curb Short Side

Tabbed End Slotted End

Illustration - Sides & Ends Assembly

JOINING BRACKETS

Some long curb sides and ends may require a joining bracket which

combines long pieces together using the factory provided at bracket

as shown in illustration - Joining Brackts. It is designed to align with

the pre-punched holes in the knockdown curbs where the seams

join, and must be installed on the inside of the curb. Insert supplied

bolts from the outside of the curb and secure. Insert wood screws at

the top of the bracket and insert from the inside of the curb.

Wood screws at top only

Joining Bracket

Illustration - 90 Degree Joining Brackets

ASSEMBLE SIDES & ENDS

90 DEGREE CORNER BRACKET

Bring together curb side and curb end. Place the small corner bracket

on the inside of your new knockdown curb and align with the prepunched holes. Insert the bolts from the outside of the curb. Repeat

for the assembly of all corners.

Wood screw

at top only

Bracket

Illustration - Joining Brackets

2

Illustration - Sides & Ends

Corner Bracket Assembly

Loading...

Loading...