MicroMetl ECD-SRT12TA-D2, ECD-SRT34TA-D2, ECD-SRT05TA-D2 Installation Instructions Manual

MicroMetl

Small Rooftop Products

Select 3 to 12 ½ Tons

Accessory Ultra Low Leak Vertical Economizer

Installation Instructions

ECD-SRT12TA-D2, ECD-SRT34TA-D2, ECD-SRT05TA-D2 Series

*QR Code

Read these instructions completely before attempting to install the Vertical

Accessory Ultra Low Leak Economizer.

CONTENTS

Safety Consideration . . . . . . . . . . . . . . . . . . . . .1

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Economizer Sensor Usage. . . . . . . . . . . . . . . . . . . . .2

Accessories List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

W7220 Menu Structure. . . . . . . . . . . . . . . . . . . . .9-12

Controller Setup and Conguration. . . . . . . .13-15

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Barometric Relief and Return Pressure

Drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

*Jade W7220 Controller Addendum

*Certicate of Acceptance

Use QR Code Above to Access

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous dur to system pressure and electrical components. Only

trained and qualied service personnel should install, repair, or

service air-conditioning equipment.

Untrained personnel can perform the basic maintenance funtions.

All other operations should be performed by trained service

personnel. When working on air-conditioning equipment, observe

precautions in the literature, tags, and labels attached to the unit,

and other safety precautions that may apply.

Follow allsafety codes. Wear safety glasses and work gloves. Use

quenching cloth for unbrazing operations.

It is important to recognize safety information. This is the safetyalert symbol . When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal injury.

Table 1

!

California

& ASHRAE

Code

Compliant

Understand the signal words DANGER, WARNING, CAUTION,

and NOTE. These words are used with the safety-alert symbol.

DANGER identies the most serious hazards which will result

in severe personal injury or death. WARNING signies hazards

which could result in personal injury or death. CAUTION is used

to identify unsafe practices, which may result in minor personal

injury or product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation, reliability, or

operation.

CAUTION

!

Equipment Damage Hazard

Electrostatic discharge can short equipment circuitry. Ensure

that you are properly grounded before handling the unit.

WARNING

!

Electrical Shock Hazard

Can cause severe injury, death or property damage. Disconnect

power supply before beginning wiring, or making wiring

connections, to prevent electrical shock or equipment damage.

GENERAL (When ordered with controls)

The system utilizes the latest technology available for integrating

the use of free cooling with mechanical cooling for packaged

rooftop units. The solid-state control system optimizes energy

consumption, zone comfort, and equipment cycling by operating

the compressors when the outdoor-air temperature is too warm,

integrating the compressor with outdoor air when free cooling

is available, and locking out the compressor when outdoor-air

temperature is too cold. Demand control ventilation is supported.

This can be used with single or multiple speed indoor fans.

The MicroMetl Ultra Low Leak Economizer utilizes gear-driven

technology with a direct-mount spring return actuator that will close

upon loss of power. When ordering with controls, The Ultra Low

Leak Economizer comes standard with a Mixed Air Sensor (Also

called The Supply Air Temperature Sensor), and the option of

Adjustable Dry Bulb, Enthalpy, Differential Adjustable Dry Bulb, and

Differential Enthalpy Sensors. CO2 and Smoke Detectors Sensor

are an additional eld installed option.

Base Chasis/Curb Design (3-23 ton)

Economizer

Package Unit Chassis

ECD-SRT12TA

ECD-SRT34TA

ECD-SRT05TA

Chassis 1

Chassis 2

Chassis 3

Chassis 4a 48/50TC

Chassis 4b

Chassis 5 48/50TC D16 580J,558J 16D RGS,RAS 180 48/50HC D14 581J,551J 14D RGH,RAH 150

Chassis 5 N/A N/A N/A N/A N/A N/A N/A 50TCQ D14 548J 14D RHS 150 50HCQ D12 549J 12D RHH 120

Carrier Bryant ICP Carrier Bryant ICP Carrier Carrier Bryant ICP Carrier Bryant ICP

48/50TC

A04,A05,A06,

B04,B05,B06

48/50TC

A07,B07

48/50TC

A08,D08

A09,A12,

D09,D12,D14

48/50TC 48/50HC 48/50LC 50TCQ 48/50HCQ

580J,558J

04A,05A,06A,

04G,05G,06G

580J,558J

07A,07G

580J,558J

08A,08D

580J,558J

09A,12A,

09D,12D,14D

RGS,RAS

036,048,060

RGS,RAS 072

RGS,RAS

090,091

RGS,RAS

101,102,121

120,150

48/50HC A04 581J,551J 04A

48/50HC

A05,A06

48/50HC A07

48/50HC

D08,D09

581J,551J

05A,06A

581J,551J

07A

581J,551J

09D,12D

1

RGH,RAH

036

RGH,RAH

048,060

RGH,RAH

072

RGH,RAH

090,120

48/50LC A04

48/50LC

A05,A06

N/A N/A N/A N/A 50HCQ A07 549J 07A RHH 072

48/50LC 07

48/50LC

08,09,12

50TCQ

A04,A05

50TCQ

A06,A07

50TCQ

D08,D09,D12

N/A N/A N/A N/A N/A N/A

548J

04A,05A

548J

06A,07A

548J

08D,09D,12D

RHS

036, 048

RHS

060,072

RHS

090,102,120

50HCQ A04 549J 04A RHH 036

50HCQ

A05,A06

50HCQ

D08,D09

549J

05A,06A

549J

08D,09D

RHH

048,060

RHH

090,102

IMPORTANT: These economizers meet all the economizer

requirements as laid out in ASHRAE Standard 90.1-2010, Table

6.4.3.4.4 requirements and California’s Title 24 mandatory section

120.2 (fault detection and diagnostics) and prescriptive section

140.4 (life-cycle tests, damper leakage, sensor accuracy, etc).

Economizer must be installed perfectly square to avoid damper

leakage or damper binding. Squareness tolerance +/- 1/32”.

Standard barometric relief dampers provide natural building

pressurization control. An optional power exhaust system is available

for applications requiring even greater exhaust capabilities. The

power exhaust set point is adjustable at the controller.

See Table 1 for economizer package usage. See Table 2 for

packing contents.

Unpack and inspect economizer contents from carton. Contact

MicroMetl immediatly if any parts are missing or damaged.

Table 2 - Packaging List

Assembled Hood with Divider & Aluminum Filter(s)

Ultra Low Leak Damper Assembly

Self Drilling Screws

1/8" Gray Gasket

NOTE: The 12-pin jumper plug should be saved for future use, in

the event that the Ultra Low Leak Economizer is removed from the

unit. The jumper plug is not needed as long as the Ultra Low Leak

Economizer is installed.

10. If Ultra Low Leak Economizer will be operating under enthalpy

control, an enthalpy sensor will be used in place of the dry bulb

sensor.

11. Remove the indoor fan motor access panel. (See Fig. 10.)

Wiring

Harness

Actuator

(Hidden)

Outside Air

Temperature

Sensor or

nthalpy Sensor

Fig. 1 - Component Locations —

(Small Economizer Shown)

GENERAL

MicroMetl accessories simplify and minimize procedures on rooftop

applications. Read these instructions completely before beginning.

These installation instructions pertain to the vertical economizer.

1. Turn off unit power supply(s) and install lockout tag.

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury and/or

death.

Disconnect power supply and install lockout tag before attempting to

install accessory.

2. Remove the existing unit lter access panel. Raise the panel

and swing the bottom outward. The panel is now disengaged

from the track and can be removed. (See Fig. 4.)

3. Remove the indoor coil access panel and discard. (See Fig. 4.)

4. The hood is shipped with the Ultra Low Leak Economizer.

Remove hood from packaging.

NOTE: If the power exhaust accessory is to be installed on the unit,

the hood shipped with the Ultra Low Leak Economizer will not be

used and may be discarded. Save the aluminum lter for use in the

power exhaust hood assembly.

5. Set the Ultra Low Leak Economizer upright.

6. Slide the Ultra Low Leak Economizer assembly into the

rooftop unit. (See Fig. 7). On small and large cabinets be sure

to engage the rear Ultra Low Leak Economizer ange under

the tabs in the return-air opening of the unit base. (See Fig. 8)

7. Secure the Ultra Low Leak Economizer to unit along side and

bottom anges using the screws provided.

8. Remove the tape securing the relief dampers in place.

9. Remove and save the 12-pin jumper plug from the unit wiring

harness (located in the upper left corner of the unit). Insert the

Ultra Low Leak Economizer plug into the unit wiring harness.

Refer to Fig. 9 and 10A for wiring details.

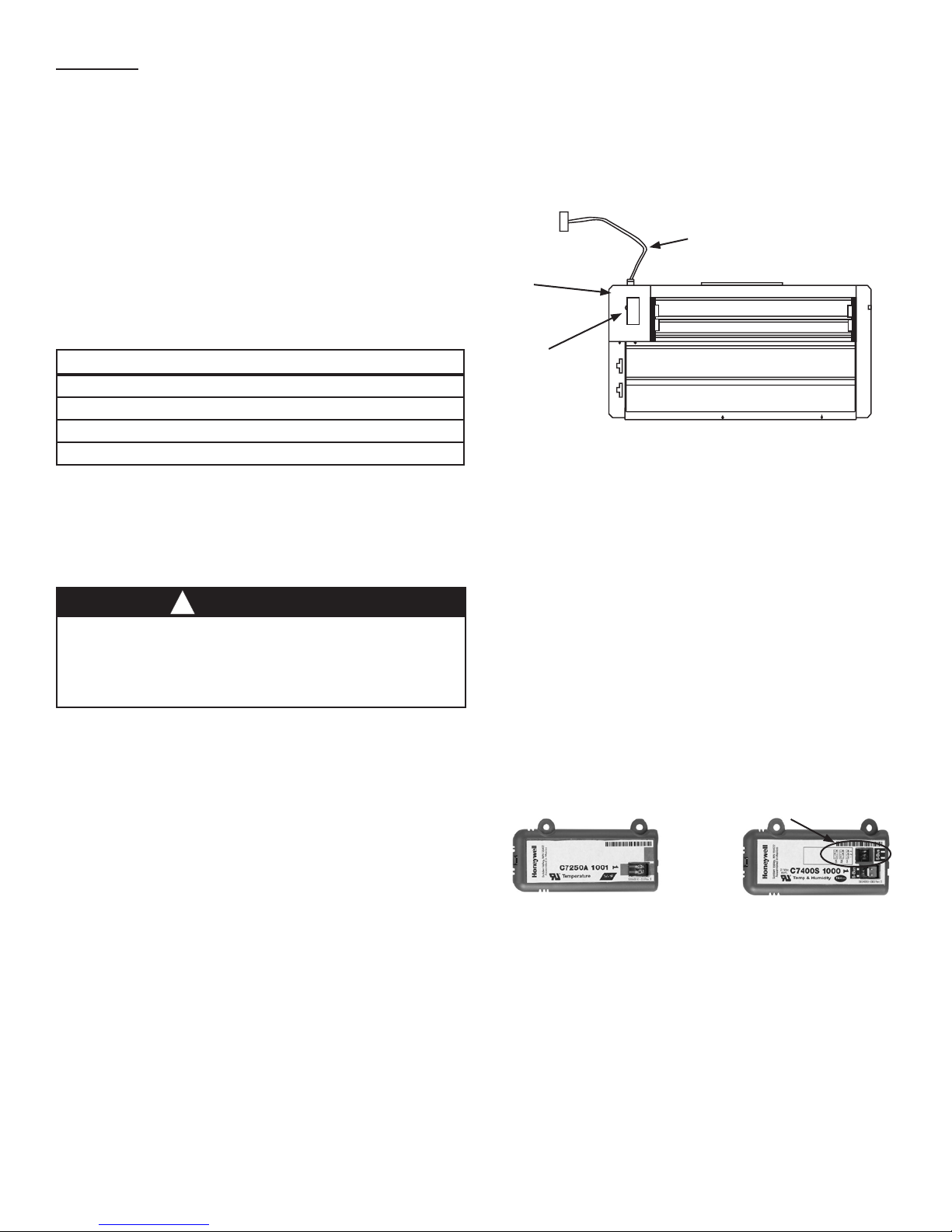

SENSOR & CONTROLS

JADE requires a C7250A for Mixed Air (MA) sensing. The C7250A

temperature sensors are 20k Negative Temperature Coefcient

(NTC). The C7250A MA sensor is required for all applications and

must be mounted in the unit’s mixed air stream (normally the fan

section) either directly to the sheet metal of the fan using selftapping sheet metal screws, or in the air stream using the duct

mounting kit. The C7250A must be wired into the two terminals

on JADE labeled “MAT”. The C7250A sensor must be used in all

applications.

Optional Enthalpy or Dry Bulb Sensor

Both are optional, but at least one must be chosen. The Dry Bulb

Sensor C7250A, or the Enthalpy Sensor C7400S gets wired into

JADE’s S-BUS terminals. Either must be placed under the Outside

Air Hood, or in full exposure to the outside air weather conditions.

Address Dip Switch array

Shipped for OA applications

20k-Ohm Dry Bulb Sensor SylkBus Sensor

NOTE: The protective lm on the dip switch is only necessary

during the factory assembly process. Simply push through the lm

to set the dip switches; this will not harm the device.

Once installed, a sensor can be changed to a different application

by simply changing the DIP switch setting and relocating to the

appropriate location.

2

0

500

1000

1500

2000

2500

0 0.05 0.1 0.15 0.2 0.25 0.3

RELIEF FLOW (CFM)

RETURN DUCT STATIC PRE SSURE (i n. wg )

Small

Cabinet

Large and

Extra

Large

Cabinet

0

1000

2000

3000

4000

5000

6000

0 0.1 0.2 0.3 0.4

RETURN AIR FLOW (CFM)

RETURN DUCT STATIC PRE SSURE DROP (in. wg)

Small Cabinet

Large Cabinet

Extra Large Cabinet

Mixed Air

Temperature

Sensor

Mounting

Location

Typical C7250 Sensor Location

Optional CO2 Sensor

Any CO2 Sensor which has a 0-10 Vdc output can be used. We

recommend the MicroMetl 9901-0051 Wall or Internal Duct Mount,

or the MicroMetl 9901-0052 External Duct Mount. CO2 connects

to the IAQ outputs of the JADE Controller.

Optional Smoke Detector

The JADE Controller is designed to allow a shutdown command

from devices similar to a Smoke Detector. A Smoke Detector

connects to the AUX inputs of the JADE Controller. However, if the

JADE Controller is previously programmed to interface with a heat

pump, this function may not be available. The only other option is

to route the power to the JADE through a smoke detector, therefore

removing the power if a re or smoke is detected. Normal default

for power off is often a complete closing of all outside dampers.

Warning: Any circumstance which involves emergency shutdown

should be carefully studied and written into company policy. Please

adhere to all applicable electrical, local, and re emergency codes

before integrating emergency devices into your HVAC scheme.

We recommend the MicroMetl 9901-0091 Smoke Detector.

Optional Power Exhaust

MicroMetl carries a large variety of Power Exhausts. To control the

Power Exhaust output, connect to (Ground) GND and EXH1-0 on

the JADE Controller.

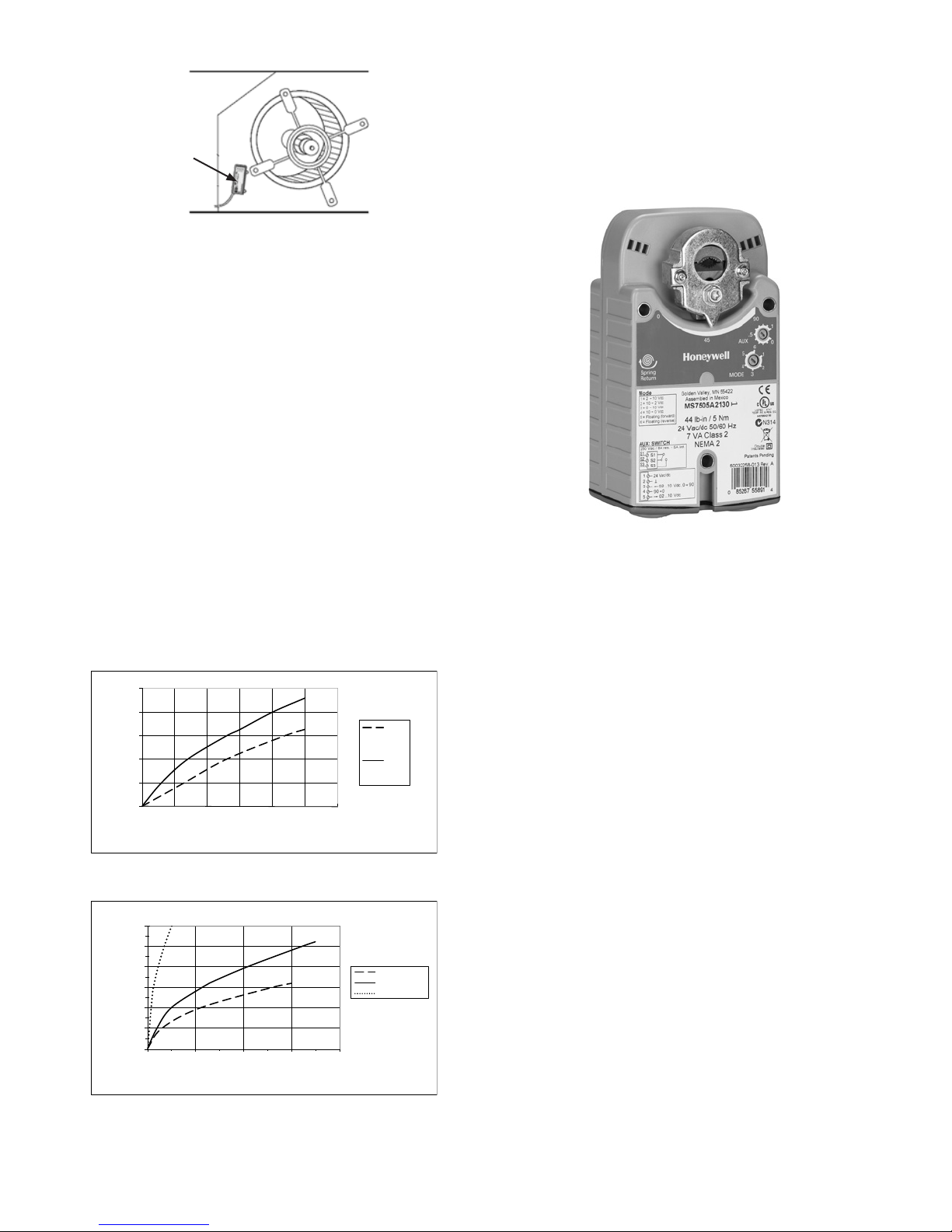

Actuator – Communicating

This Actuator Communicates to the JADE Controller and is

required by some codes. It works with JADE to provide improved

control, eld detection, diagnostics, and save time during setup

and testing. Connects to the S-bus and, ACT COM, and ACT 24+

on the JADE Controller.

STARTUP INSTRUCTIONS

Once the economizer and all electronics are correctly installed and

wired. Apply power to the system and wait sixty minutes before

checking for alarms. This allows time for all the congured devices

(e.g. sensors, actuator) to become operational. The exception is

the MA sensor which will alarm immediately! Upon power up (or

after a power outage or brownout), the W7220 controller module

begins a ve minute power up delay before enabling mechanical

cooling.

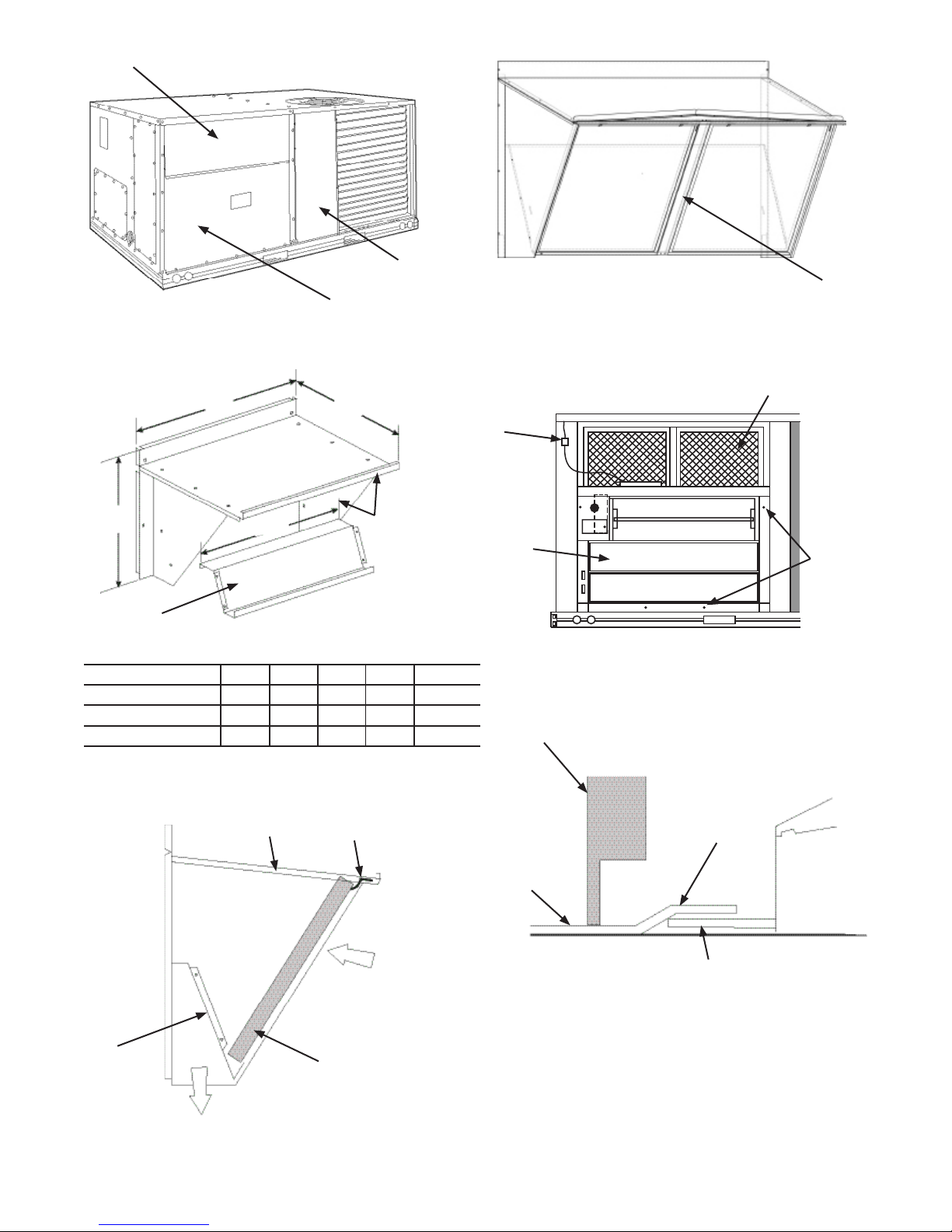

Fig. 2 - Barometric Relief Flow Capacity

Fig. 3 - Return Air Pressure Drop

3

Filter Access Panel

Fig. 4 - Typical Outdoor-Air Section

Outdoor-Air Opening and

Indoor Coil Access Panel

Access Panel Locations

A

B

Compressor

Access Panel

Hood Filter

Divider

Fig. 6A - Hood for Extra Large Cabinet

HVAC Unit Filters

Wiring

Harness

C

Hood Divider

D

Hood Top and

Side Assembly

Fig. 5 - Hood Assembly

ECONOMIZER P/N A B C D SHIP WT.

ECD-SRT12TA-D2 33.37” 17.43” 19.05” 29.5” 55 lb

ECD-SRT34TA-D2 40.37” 22.28” 24.48” 36.27” 80lb

ECD-SRT05TA-D2 52.92” 27.03” 33.41” 49.92” 98lb

NOTE: The ECD-SRT05TA-D2 Series hood has 2 aluminum

lters and a hood lter divider installed between the lters. (See

Fig. 6A.)

Hood Top

Filter Clip

Economizer

Fig. 7 - Ultra Low Leak Economizer Installed in

HVAC Unit

Unit Filter

Rack

Hold Down Tab

Unit Base

Insert

Screw in

Flanges

Hood

Divider

Barometric

Airow

Fig. 6 - Filter Installation

Outside Air

Cleanable

Aluminum Filter

Rear Flange

Fig. 8 - Rear Ultra Low Leak Economizer Flange

Installation (Small and Large Cabinet)

4

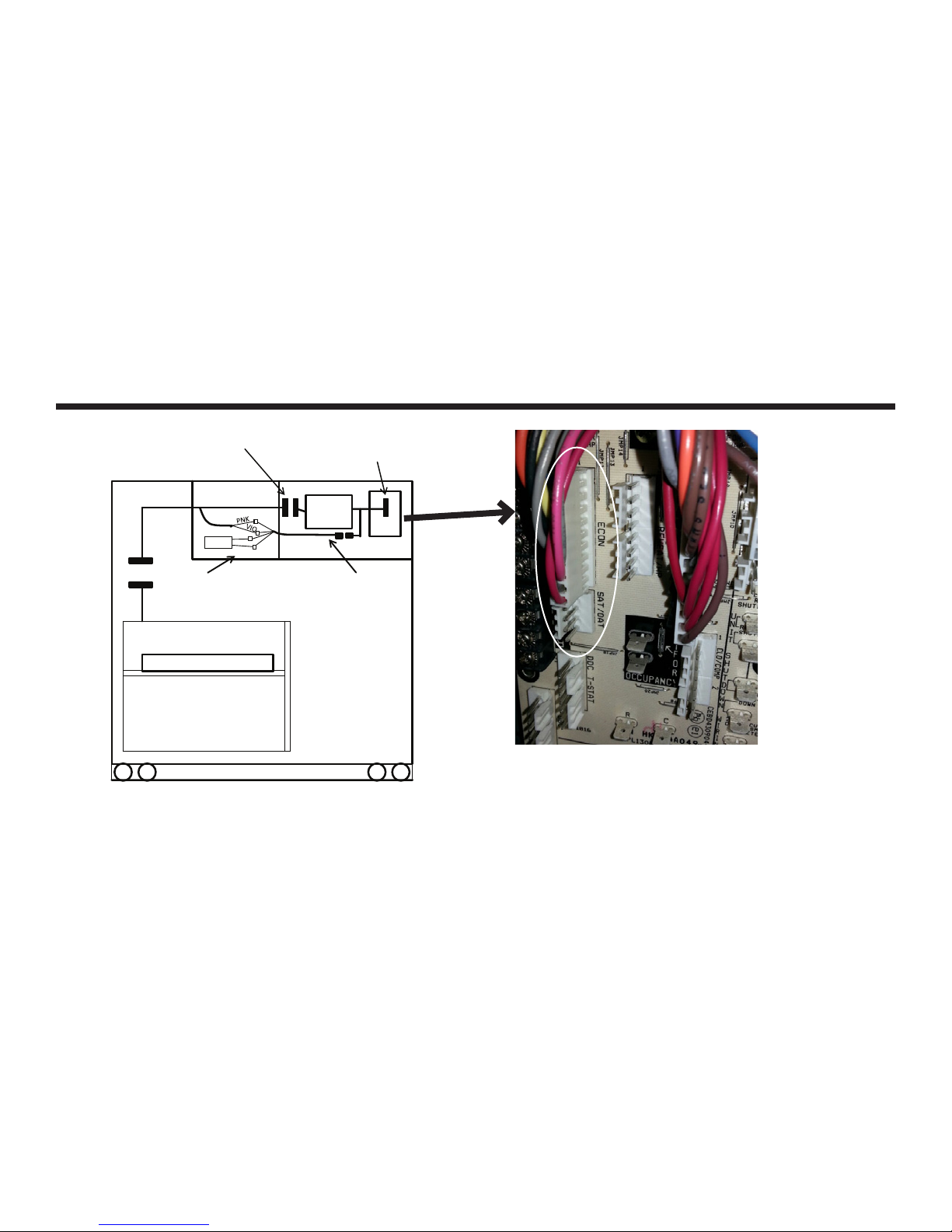

Plug 10-pin plug from

12. Locate the mixed (supply) air temperature sensor in the

economizer hardware bag. Mount the sensor in the indoor

fan section of the unit, see Figure 12. Locate the orange

and brown wires in the wire bundle in the indoor fan section.

Connect these orange and brown wires to the 2-wire harness

attached to the Sensor.

Mixed air default setting is 53°F and can be adjusted from 38°F

to 70°F.

13. While everything is open, install and wire any other accessories

and/or sensors as applicable and convenient, per their

installation instructions and/or the Conguration section of this

instruction. Some accessories require that unit ducting already

be installed.

NOTE: If also installing a power exhaust accessory, skip step 14

and follow the power exhaust instructions instead.

14. Install the Ultra Low Leak Economizer hood over the Ultra Low

Leak Economizer. Use screws provided.

15. The W7220 controller is shipped mounted to a bracket. Install

the controller / bracket in the top left corner of the unit control

box as shown in wiring diagram, Fig. 9 and 10A. Screw in

place through pre-punched holes.

16. For 1 and 2 speed units connect the plugs coming from the

controller as shown in wiring diagram, Fig. 9 and 10A.

NOTE: Provided harness will be connected as shown in Fig. 9

and 10A.

17. For 3 speed (48/50LC 07-12) units, the harness attached to

the W7220 controller must be removed, and can be discarded.

Locate harness shipped in plastic bag in the control box of unit.

Attach this harness to the W7220 controller as shown in Fig

10B and 10C.

NOTE: Harness provided with economizer is not used with 3 speed

(48/50LC 07-12) units.

18. Adjust controller settings (minimum position, outside air, etc.)

per instructions detailed later in this instruction.

19. Follow all local and other applicable codes.

Unplug the 10-pin plug from

PL6 from the Central Terminal

Board (in control box) and plug

into 10-pin plug from W7220

Indoor Blower

Section

SAT

PL6

Connect SAT sensor and Pink

and Violet wires from PL6 to

the 48TMHSRSE—A20

harness.

BRN

ORN

Control box

W7220 into ECONO

terminals on Central

Terminal Board

W7720

48TMHSRSE--A20

harness with 4- pin

plug

Central

Term Brd

See Picture

ECONO

Economizer X

Fig. 9 - Harness Detail

WIRING INSTRUCTIONS FOR SINGLE OR MULTIPLE SPEED

INDOOR FAN

A. Install W7220 (with harnesses attached) in unit control box.

See wiring diagram in instructions.

B. Unplug 10-pin plug shown above in picture, from Central

Terminal Board (CTB).

C. Attach 10-pin plug disconnected from (CTB) to 10- pin plug

harness from W7220 controller.

D. Connect other 10-pin plug from W7220 controller into ECONO

terminals on CTB. See picture above. On the 10-pin take the

red wire with a spade connector and connect it to "R" on the

CTB, take the brown wire with a spade connector and connect

it to "C" on the CTB.

E. Connect 4-pin plug from the W7220 controller to the 4-pin

harness provided with economizer accessory.

F. Route harness back to the indoor blower section of the unit.

G. Mount Supply (or Mixed) Air Temperature sensor, and connect

Brown and Orange wires from harness to the SAT.

H. Connect Pink and Violet wires from harness to the Pink and

Violet wires from PL6 economizer harness

5

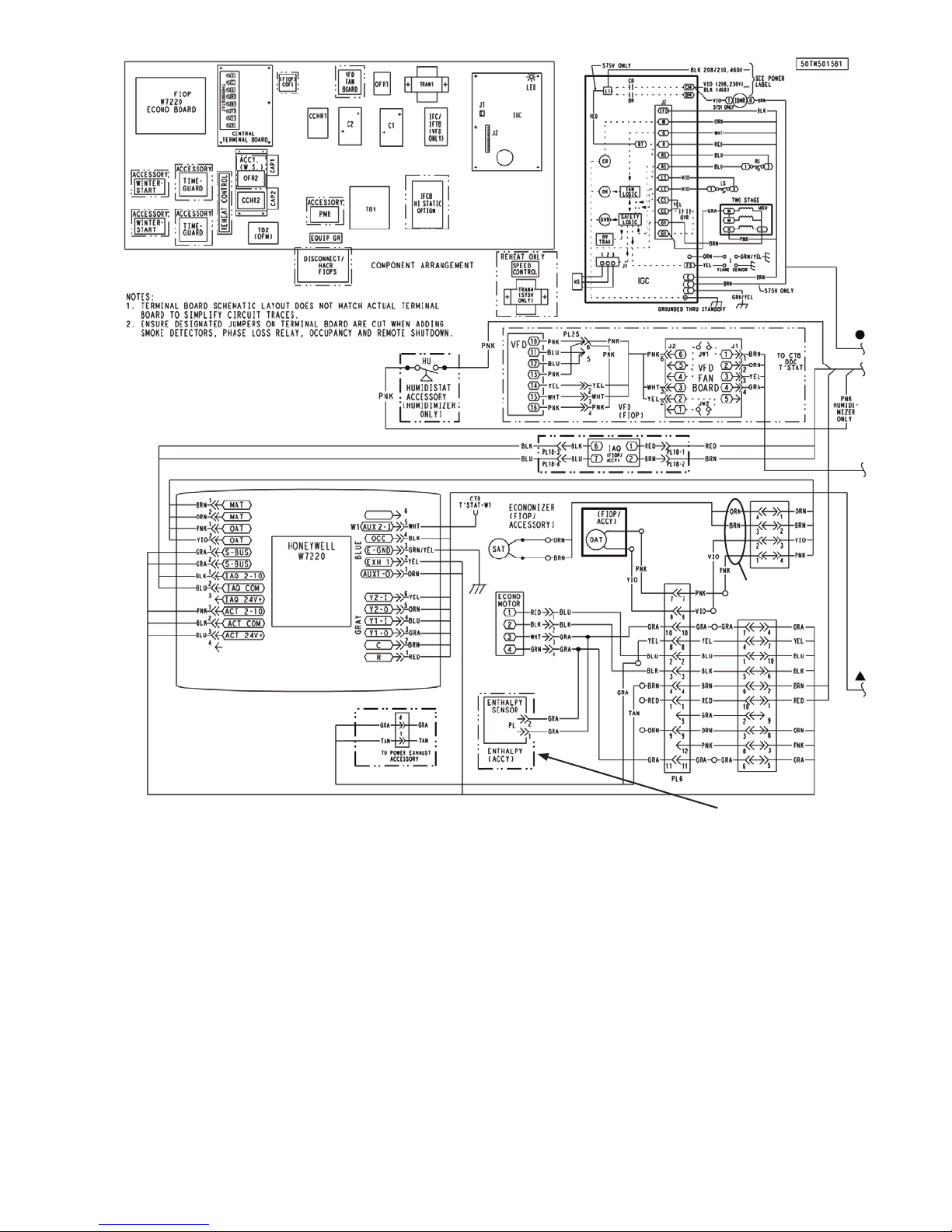

If using the OA enthalpy accessory,

the OAT must be removed. Set sensor

dip-switches, See Table 11.

Fig. 10A - Typical Wiring Diagram For 1 and 2 Speed Units

(2 Speed Diagram Shown)

48TMHSRSE--A20

Harness

6

Loading...

Loading...