Page 1

Super Spiro - Service Manual

056-09 Issue. 1.0 November 1999

Page 2

Contents

Exploded isometric view Page 3

Parts list Page 4

System overview Page 5

Transducer Page 6

Disassembly instructions Page 7

Re-assembly instructions Page 8

Circuit description Page 9

Microprocessor circuit Page 9

Flash disk Page 10

Serial interface Page 10

Transducer interface Page 10

Frame store Page 10

FPGA Page 11

Keypad circuit Page 11

Real time clock circuit Page 12

Sound generator circuit Page 12

Printer control circuit Page 12

Expansion Page 12

Printer driver circuit Page 12

Technical support Page 13

Fault analysis Page 14

Circuit diagrams

Micro processor circuit Page 15

FPGA circuit Page 16

Keypad circuit Page 17

Real time clock circuit Page 18

Printer circuit Page 19

Printer driver 1 Page 20

Printer driver 2 Page 21

2

Page 3

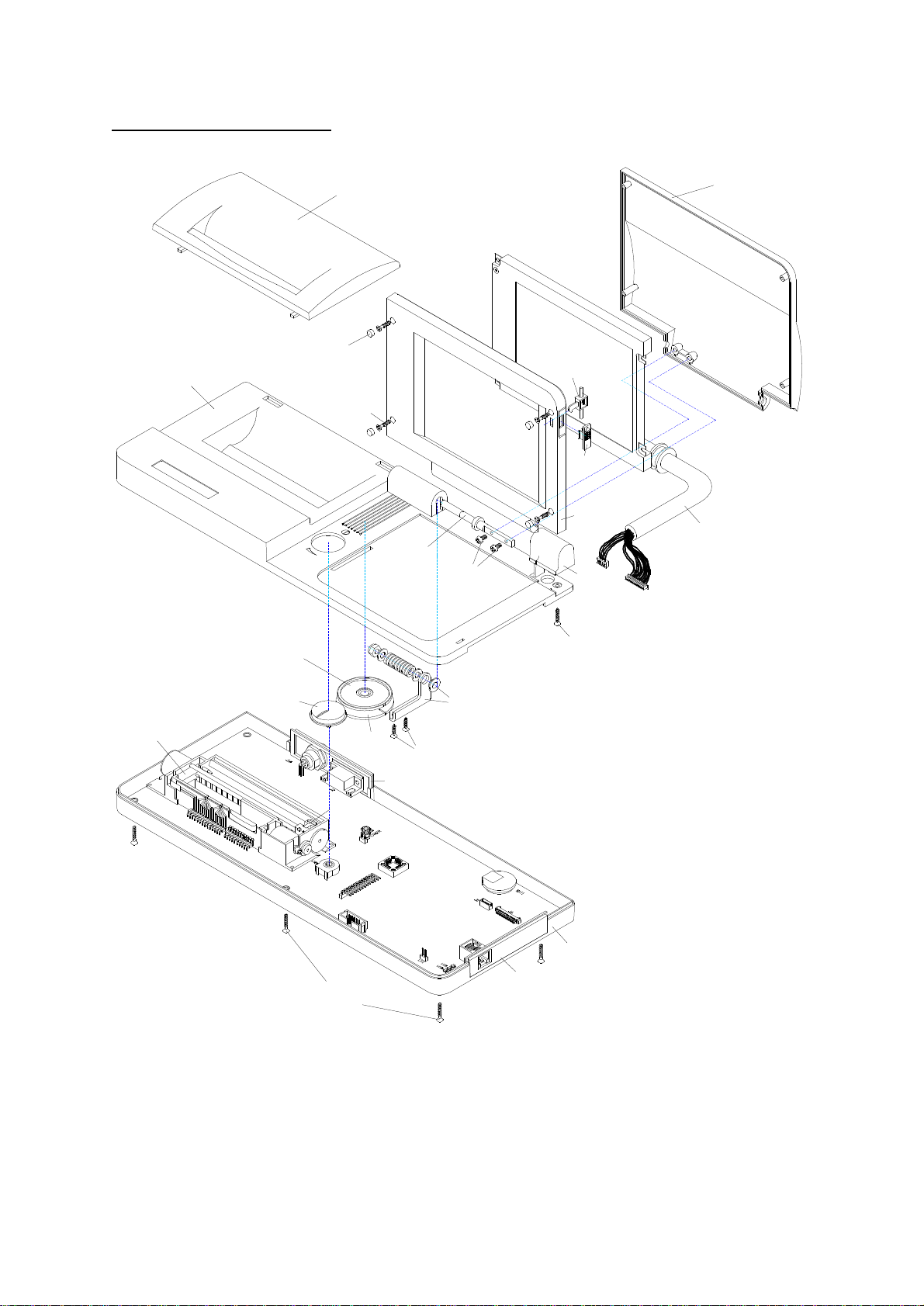

Exploded Isometric View

Item 15

Item 1

Item 10

Item 16

Item 8

Item 20

Item 21

Item 22

Item 12

Item 14

Item 23

Item 13

Item 9

Item 2

Item 11

Item 18

Item 9

Item 7

Item 4

Item 6

Item 17

Item 5

Item 3

Item 19

3

Page 4

Parts List

ITEM No.

1 TOP MOULDING MLD5611A

2 BACK PANEL MLD5615C

3 SIDE PANEL MLD5615B

4 DISPLAY CABLE ASSEMBLY ASS5624

5 BOTTOM MOULDING MLD5612A

6 HINGE BLOCK MLD5618

7 DISPLAY FRONT MLD5613

8 DISPLAY BACK MLD5614

9 DISPLAY HINGE ASSEMBLY ASS5601

10 PAPER COVER MLD5617

11 CSK SELF TAPPING SCREW 9mm LONG SCR5604

12 SPEAKER SPKR100

13 SPEAKER COVER MLD5620

14 CONTRAST WHEEL MLD5621

15 SCREW COVER MLD5616

16 CSK SELF TAPPING SCREW 8mm LONG SCR5602

17 CSK SELF TAPPING SCREW 13mm LONG SCR5601

18 M3 MACHINE SCREW 6mm LONG SCR0306

19 CSK SELF TAPPING SCREW 18mm LONG SCR4700

20 DISPLAY LATCH MLD5619

21 DISPLAY LATCH BUTTON MLD5622

22 PRINTER MECHANISM PTR4200

23 THERMAL PRINT HEAD TPH3000

DESCRIPTION MICRO MEDICAL PT No.

4

Page 5

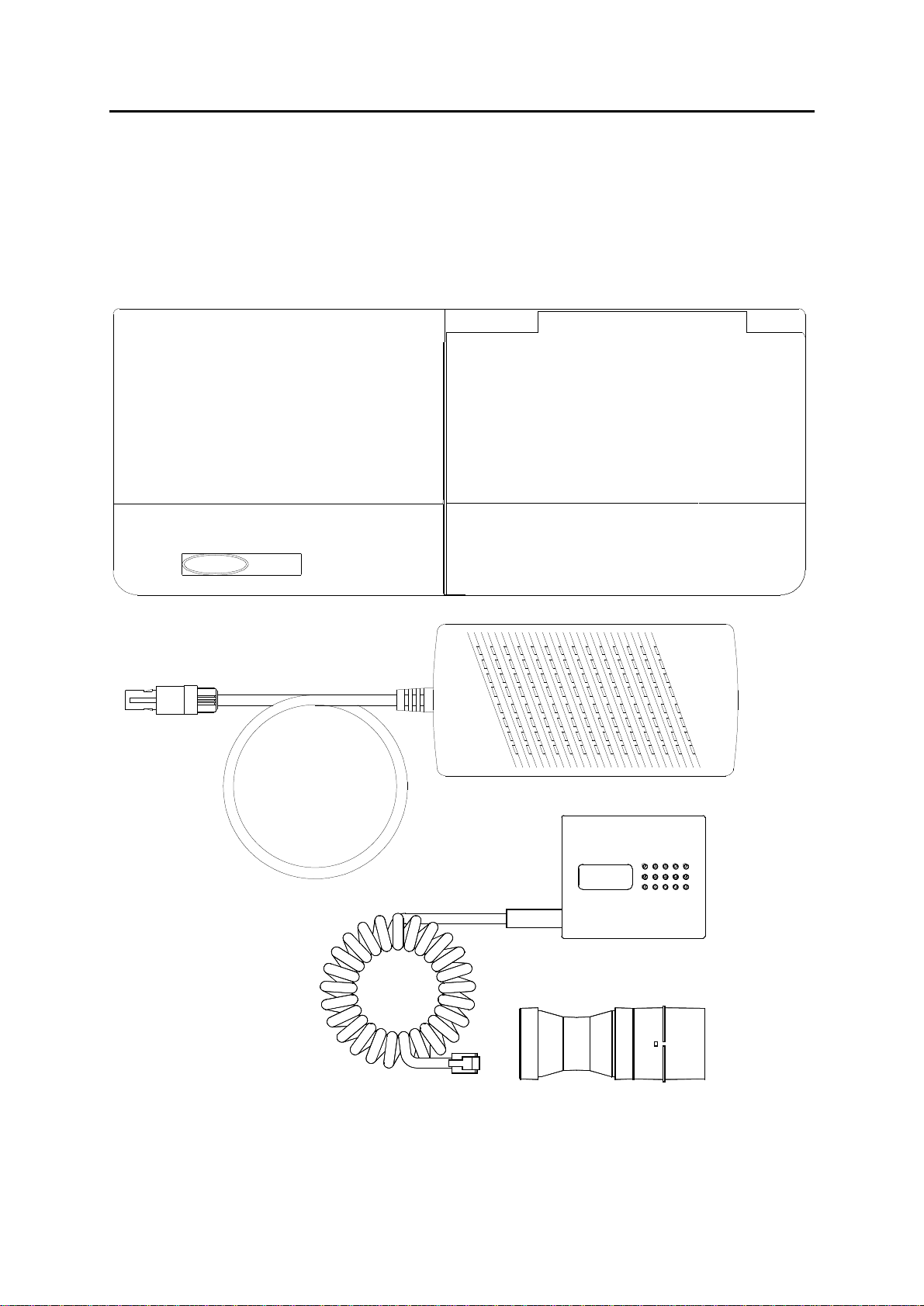

Super Spiro - System Overview (Fig. 1)

The Micro Medical Super Spiro is a data recording spirometer consisting of a microcomputer

unit (1) incorporating a 1/4VGA colour LCD display, data entry keypad, RS232 serial interface and all

associated circuitry. It is supplied with a digital volume transducer (2), disposable mouthpieces,

transducer holder (3) and mains adapter (4). The Super Spiro is powered by a universal mains

adapter (4).

When testing a subject the transducer is inserted into the holder which is plugged into the

microcomputer unit. The digital volume transducer is used to measure the subjects expired flow and

volume in accordance with the operating manual.

1

super

spiro

4

Micro

Medical

3

2

5

Page 6

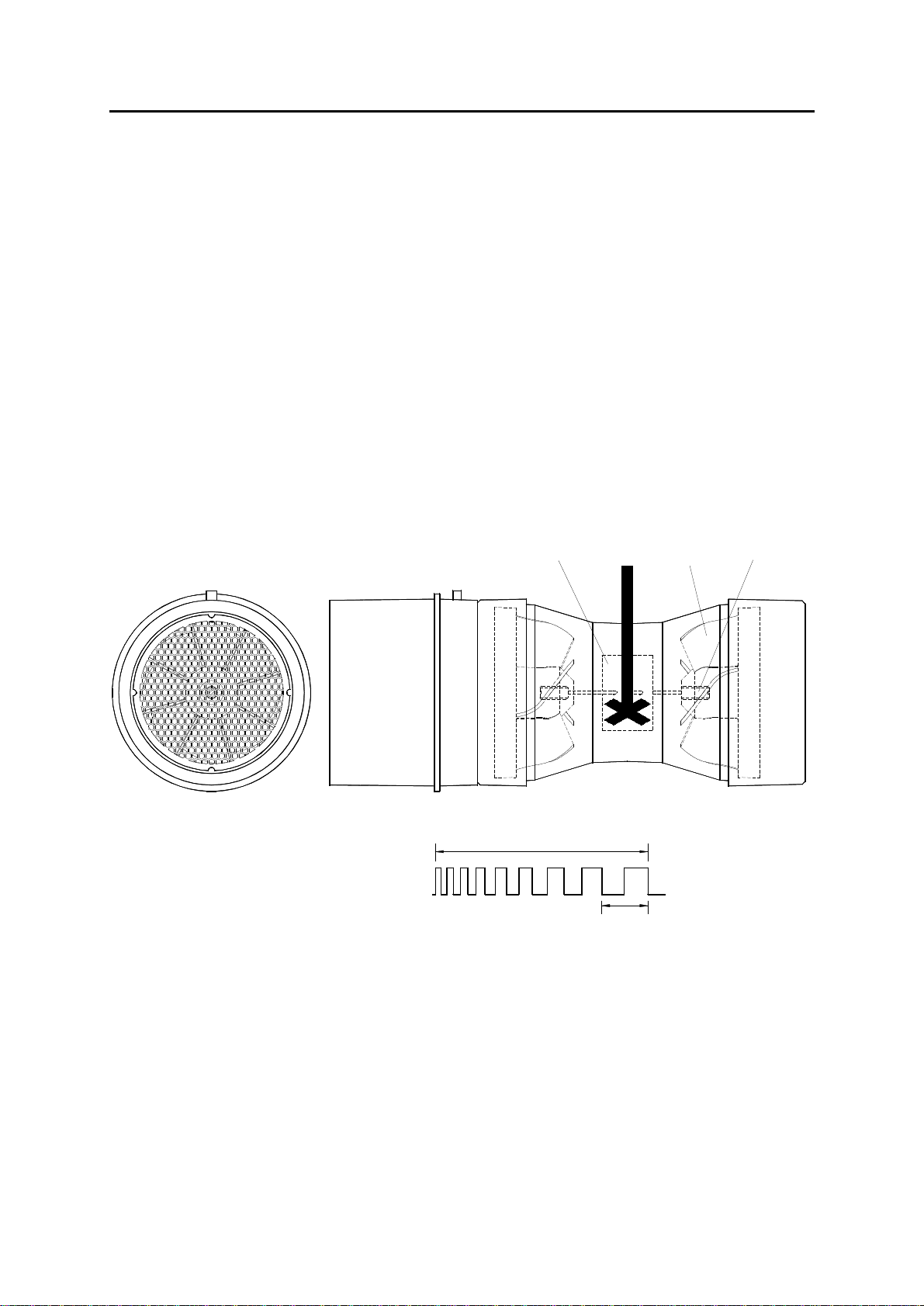

Transducer (Fig. 2)

The Micro Medical digital volume transducer consists of an acrylic tube with a vane positioned

between two swirl plates. The low inertia vane is attached to a stainless steel pivot, which is free to

rotate on two jewelled bearings mounted at the centre of the swirl plates. As air is passed through the

transducer the swirl plates create a vortex, which causes the vane to rotate in a direction dependant

upon the direction of airflow. The number of rotations is proportional to the volume of air passed

through the transducer and the frequency of rotation is proportional to the flow rate. The transducer

housing consists of a main body that contains a pair of light emitting diodes (LED’s) and

phototransistors. The transducer is fixed to the mouthpiece holder which pushes into the main body

and is captured by an “O” ring seal. The LED’s produce infra red beams which are interrupted by the

vane twice per revolution. This interruption is sensed by the phototransistors. The output from the

collector of each phototransistor will be a square wave with a phase difference between the two of +

or - 90 degrees depending upon the direction of flow.

There is no routine maintenance required for the transducer other than cleaning according to

the instructions in the operating manual.

Micro Medical Digital Volume Transducer

Volume proportional to the number of pulses

Flow proportional to the puse frequency

Rotating

vane

Volume = k X No. of pulses

Infra red

emitter

Infra red

detector

Swirl

plate

Flow = k / pulse period

Jewelled

bearing

6

Page 7

Disassembling the Super Spiro for Repairs

Main Unit

1. Disconnect all mains power supplies

2. Remove paper roll and paper roll housing cover, and put to one side

We recommend that you use a Philip Number Zero screwdriver for the following

instruction.

3. Place the Super Spiro face down to remove the six screws (Item 19) in the lower moulding, and

put the screws to one side.

4. Turn the unit face up before easing the upper and lower mouldings apart.

5. Reconnect mains power supply

6. The Super Spiro is now ready for fault finding.

Display Console

1. Remove the 4 screw covers (item 15) and dispose of.

We recommend that you use a Philip Number Zero screwdriver for the following

instruction.

2. Remove the 4 screws (item 16) and put to one side.

3. Carefully remove the display front panel (item 7) and put to one side.

4. Carefully pull the display away from the display back moulding (item 8).

5. Unplug the 2 connectors from the main display.

6. The display backlight is now ready for replacement.

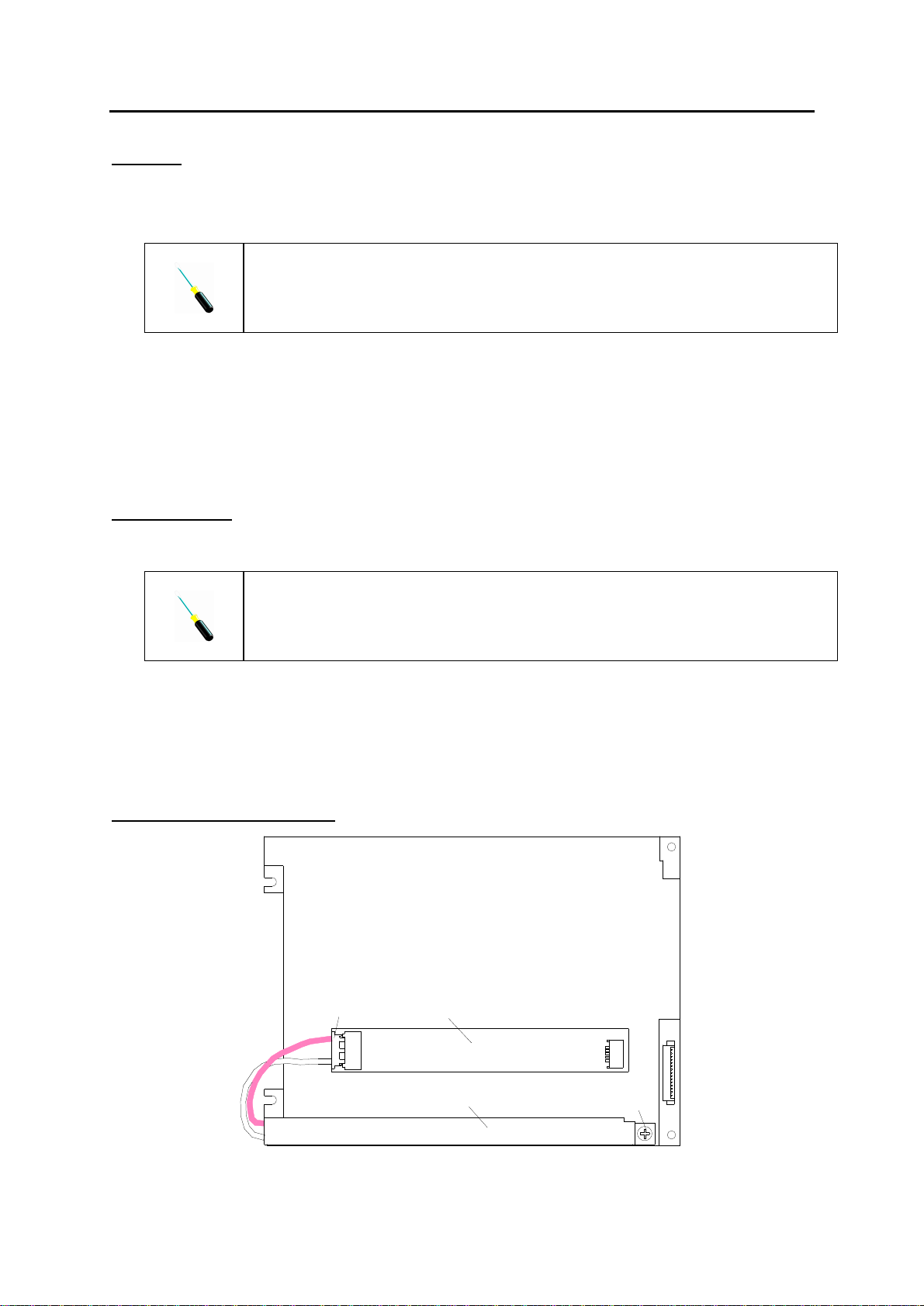

Display backlight replacement

DISPLAY (REAR VIEW)

CFL CONNECTOR INVERTOR BOARD

CFL UNIT

1. Place the display face down on a clean work surface

7

FIXING SCREW

I

T

KCS3224A CFL UN

Page 8

2. Unplug the connector from the Invertor board situated on the back of the display.

We recommend that you use a Philip Number Zero screwdriver for the following

instruction.

3. Loosen the fixing screw located on the CFL unit.

4. Slide the CFL unit to the opposite direction to the arrow mark (located on the CFL unit) and pull

the unit gently up.

5. Safely dispose of the CFL unit.

6. Take a new CFL unit and position in the original place.

7. Slide the CFL unit in the direction of the arrow.

8. Tighten the fixing screw to secure the CFL unit.

9. Reconnect the connector on the CFL unit to the invertor board.

Reassembling the Superspiro after repairs

Main unit

1. Disconnect all mains power supplies

2. Position the top moulding over the bottom moulding and ensure that they both mate ensuring that

the contrast wheel (item 14) is correctly located.

3. Place the Super Spiro face down and insert the six screws.

4. Turn the unit face up and connect the mains supply.

5. Turn the unit and offer up the paper roll as explained in the operating manual.

6. Replace the paper cover.

7. The Super Spiro is now ready for operation.

Display console

1. Reconnect the 2 connectors on item 4 to the plugs on the display ensuring correct polarity.

2. Position the display over the locating pillars on the display back panel (item 8).

3. Position the display front panel (item 7) over the display.

4. Secure the display using 4 screws (item 16)

5. Replace the 4 screw covers (item 15).

8

Page 9

Circuit Description

The Super Spiro board was designed primarily to interface with the Micro Medical Spirometer turbine,

but the interface was kept open ended so that other modules, for example, airways resistance by the

interrupter method (Rint) can be attached. Furthermore, a 9 pin ‘D’ type connector was also designed

in to allow other ‘customer special’ modules to be attached. Provision was given to add a mezzanine

board for customer special interface circuitry to be connected.

The main features of the design are:

Intel 80386EX micro controller.

2 Mbytes of DRAM (only 1 Meg is used).

512 Mbytes of Flash EPROM for programme. (256K used)

2 Mbytes of Flash EPROM as Flash disk memory.

Dual frame store of 320 X 240 X 8 pixels.

Second frame store can be scrolled horizontally or vertically.

Frame store, key pad, Dram etc. are all controlled by single FPGA chip.

Boot software can be downloaded using the JTAG port.

In built printer and printer controller.

Serial port for external PC communication / external printer.

RJ11 interface to Micro Medical modules.

The following paragraphs describe the circuits printed at the end of this manual. Signal and

component names shown on the circuit diagrams are printed in bold type.

Microprocessor circuit (Drawing 056-02)

The board is controlled by an Intel 80386EX, U14, running at 25 MHz. The crystal oscillator, U15, of

50MHz drives the processor, as twice the operating frequency is required. U10 (MAX 824) controls

the reset of the processor, such that it resets the processor if the supply voltage drops below 4.6V.

The processor requires a high active reset line whilst the rest of the board requires a low active reset.

The start up program is stored in U20, a 512 Mbytes Flash EEPROM – TE28F160S. This is selected

by the signal UCS (U14 pin 1) which is always active on start up. The reset of the chip select lines

are then programmed by the boot routine.

The program memory has two major parts, the boot section and non-boot section. The boot section is

secured, and can only be programmed if the link LK1 is present and VPPEN (U14 pin 110) is

enabled, supplying VCC to pin 13 of U19. This section is programmed with a boot loader via the onboard socket, J9. Whilst this is happening the processor goes into suspend mode, and all its pins are

then available in a long shift register. By entering a correct sequence of code, via J9, the boot loader

can be programmed into U19. Once this is done, the link is removed and processor is reset and it

would then run the boot loader, thus allowing further software to be downloaded. The rest of U19 is

filled with kernel software that controls the flash disk as well as most I/O functions, just as the BIOS

does in the PC.

U18 is 1M X 16 (2 Mbytes) DRAM which is the main RAM of the processor. Only 640 K is directly

available to the processor, and 128 K is used for storing the display image temporarily (see later).

The DRAM refresh and address multiplexing is controlled by U13 – Xilinx XC4006E FPGA. The chip

select for the DRAM, UC3, is mapped for 0 - $BFFFF, but $A0000 - $BFFFF is frame store memory,

so UC3 is only valid if frame store is invalid. This will become clearer in the Frame Store section.

Q23, Q24 and U22A are used to switch on 5 volts to VPP of Flash EEPROM. This gives extra

security against any part of the program becoming corrupted by software. However, the software can

write the non-boot section, by enabling the VPP line and following the EEPOM erase/write algorithm.

Chances of both these events accidentally happening are very small. Nevertheless, the boot software

is completely protected by the absence of Link LK1.

9

Page 10

Flash Disk (Drawing 056-02)

The flash disk, U20, behaves just like a PC floppy disk drive except that it is non-removable. Its size

is 2 Mbytes with sector size of 512 bytes. The main difference is that there is a finite number

(approximately 100,000) of times the sectors can be written, so an intelligent disk operating system is

employed to rotate the sectors round, and delete the others when no system activity is envisaged.

Delete takes few milliseconds. The Flash Disk is mapped at $C8000 - $CBFFF (16K blocks). There

are 128 pages of 16K, and the pages are controlled by 8 bit latch U17, which holds the page number

(higher addresses) of the Flash disk.

The board is designed to accommodate a larger 4 Mbytes device with 256 pages.

The MSB of the page line (U17/19) is connected to green led. This is mainly used for testing of the

board and has no other significance.

Serial Interface (Drawing 056-02)

U4 (MAX3223) converts logic levels to RS232 levels. J3, a 9-pin female D type connector, is used as

the external RS232 port. The signal pins are such that it can make one to one connection with the PC

serial port. It has the facility to use hardware handshaking lines CTS and RTS, but these are currently

not used. If power supply is required from the RS232 connection, say to drive a serial to parallel

converter, then fuse FS2 can be fitted to give 5V on pin 4

J3 pin connections.

1 N/C

2 TX

3 RX

4 5V*

5 GND

6 N/C

7 CTS

8 RTS

9 N/C

* If fuse connected.

Transducer Interface (Drawing 056-02)

The connector, J13, is used for connecting to Micro Medical transducers, namely Spirometer turbine,

Rint and NEP transducers. It is a 6-pin interface, though for turbine, the middle 4 lines are used. 12V

power is available on pin 5 and GND on pin 4. The rest of pins are multifunction, and can be

configured in various ways, either as inputs, outputs or SPI bus. Pins 2 and 3 have schmitt trigger

inputs connected to it, mainly for turbine operation.

Frame Store (Drawing 056-03)

Frame Stores are mapped from address $A0000 to $BFFFF (128 Kbytes). Although, the actual

display is 320 X 240 pixels, the frame store is organised as 512 X 256 pixels. This organisation

makes the design much simpler. The frame store memory U11 and U12 are both high speed static

RAM, U11 being a fixed frame store (A) and U12 a scrolling frame store (B). They overlay on top of

each other and their mode can be controlled by I/O register in the FPGA, U13. It can be organised as

A on B, B on A, A only or B only. A on B means that where the A data is 0, B data is displayed. This

allows a border to be displayed on fixed screen, and a waveform scrolled inside the window.

During read, both the memories are multiplexed, so that its data can be read in one cycle. The

display requires data as 8 bits, with r1, g1, b1, r2, g2, b2, r3, g3 as the first byte, b3, r4, g4, b4, r5, b5,

g5, r5 as the second byte and so on. The data from frame store is available as pixel 1, pixel 2 etc.

with each pixel being 8 bits. The FPGA has the necessary look up table to display 64 colours (bits 0 –

10

Page 11

bits 5) and converts pixel data to RGB data as required by LCD. This is a complex operation and is

beyond the scope of this document. It is sufficient to know that the RGB data is sent out to LCD via

J11.

DISP_FRAME signal is a single line, active low pulse at the start of every frame.

DISP_LOAD is a single, active low, clock pulse at the start of every line.

DISP_CLK clocks the data DISP_D0 – DISP_D7 into the display.

DISP_CNTL enables the display.

U25 is a DC to DC converter to give 26.4 volts from 5V supply. This is the bias voltage for the LCD

display. It can be slightly adjusted by VR1 to give better contrast at different viewing angles.

J10 is a back light connector that provides power to the back light. Q22 is used to enable the back

light. It was designed for power saving, but since the unit only operates on mains, this feature is not

currently used. VR3 controls the back light intensity in some back light modules, but this feature is not

in the modules currently fitted.

The frame store data can be saved quickly in the RAM that resides in the same address space, using

a block transfer. This is done by first programming the CS3 line to address space $A0000 - $AFFFF.

Since $B0000 - $BFFFF is now not the part of CS3, the FPGA will map it to DRAM. The whole 64K

page can be transferred from $A0000 (frame store) to $B0000 (RAM). The CS3 line is then

programmed for $B0000 - $BFFFF allowing $B0000 (frame store) page to be transferred to $A0000

(RAM) page. CS3 is then restored back to $A0000 - $BFFFF.

Restoring the screen is inverse of the above procedure.

FPGA (Drawing 056-03)

This device controls most of the circuitry not controlled by the processor. The program for the FPGA

resides in serial EEPROM, U8, and is downloaded once on power up. The processor monitors the

FPGADONE line to ensure that FPGA is programmed before commencing, otherwise, the DRAM will

not be operational.

Besides DRAM, the FPGA controls the LCD display, keypad, sound chip, and most of chip select

lines. These CS lines can be programmed in the processor, but this can be further qualified in the

FPGA if necessary. There are some spare serial enable lines for an additional 9 pin I/O port and the

mezzanine expansion board.

Keypad Circuit (Drawing 056-04)

The keypad consists of a matrix of 25 keys together with a separate paper feed key and on/off key.

The matrix is read by successively pulling the columns of the matrix low, KEYOUT[0..4], and reading

the state of the rows, KEYIN[0..4], to determine which key has been pressed. KEYOUT[0..4] and

KEYIN[0..4] are connected directly to the FPGA (see 056-03). The diodes, D7and D8, prevent

current flowing between the lines of KEYOUT[0..4] in the event of two keys on the same row being

depressed simultaneously. The resistor network, RN5, bias KEYIN[0..4] to VCC.

The on/off switch is used to apply the 5V from the external power supply to the circuit, VCC, and

turning the unit on. When the on/off key is depressed, the pull up resistor, R3, is pulled to ground.

R3, C17 and the schmitt input gate U3A form a de-bounce circuit whose output is applied to the clock

input of a bi-stable latch, U2B, that is powered directly from 5V and is active all the time the power

supply is plugged in. The output of the latch is applied to Q19 that in turn switches the series pass

transistor, Q20, to connect 5V to VCC. The latch, U2B, is also controlled by the set and reset inputs.

By taking the set input to 5V the unit will be turned on and by taking the reset input to 5V the unit will

be turned off regardless of the clock input. The set input is asserted by either the real time clock

alarm output, RTC_INT (see 056-05), or by the POWER_ON signal from the processor (see 056-02).

The reset input is asserted or by the POWER_OFF signal from the processor.

11

Page 12

Real Time Clock Circuit (Drawing 056-05)

The real time clock, U16, is set by the processor during the factory set-up and may be adjusted using

the configuration module. The processor communicates with the real time clock through a bidirectional serial interface line, RCA_DATA, is clocked by RTS_CLK, and is selected by RTC_SEL.

The processor (see 056-02) generates these three control lines.

Sound Generator Circuit (Drawing 056-05)

The various sounds used in the spirometry tests are generated by U7 and associated components.

This device contains the addressable, pre-programmed sounds and is controlled by the lines,

SNDCNT[0..5], generated by the FPGA (see 056-03).

Printer Control Circuit (Drawing 056-06)

The printer driver uses a single chip micro-controller, U6, with on board program memory and RAM to

receive serial data from the microprocessor, U14, and control the printer mechanism. The

asynchronous serial lines PRNTDATA and PRNTACK are used by U14 to send and receive data to

and from U6. The signal BUSY generated by U6 is used to control the flow of data from U14 and PF

is generated by the paper feed key.

The printer mechanism uses stepper motors to drive the print head and paper feed. Each stepper

motor uses four lines, driven sequentially. The order in which the lines are driven determines the

direction of rotation. The thermal print head uses eight heater elements. The stepper motors and

print head signals are generated on port A and B (active high) of U6. Timing for Port A and B is

derived from an adjustable oscillator comprising of U9 and associated components. Adjusting VR2

varies the oscillator frequency and consequently the period for which the thermal elements are

energised. This in turn adjusts the print density. After the micro-controller is first reset, the print head

is driven to the left until the end switch is activated. The end switch consists of a normally closed pair

of contacts accessed at pins 1 and 2 of the printer connector J2. The end switch is detected by PD5

on the micro-controller.

Expansion (Drawing 056-05)

J8 and J12 are 10-pin header connectors that allow a mezzanine card to be fitted. This is used for

future customer special circuitry. Similarly, J14 is placed near the output plate on the right side of the

unit to allow customer special signals to be connected to the mezzanine board or to the processor

directly.

Printer Driver Circuits (Drawings 056-07 and 056-08)

The outputs from port A and B of U6 drives the two stepper motors and eight thermal elements

through the high current transistors Q1 to Q16 in common emitter configuration. Diodes D1 to D4 are

used to dissipate the inductive fly-back from the stepper motors and elements.

Power Supply

An external, dual voltage, supply provides 5.5 volts and 12 volts to socket J1 (Drawing 056-05). This

power supply has a universal input, is factory sealed, and contains no user serviceable parts.

12

Page 13

Technical Support

Great Britain and World Headquarters

Micro Medical Ltd

PO Box 6

Rochester

Kent ME1 2AZ

Telephone + 44 (0)1634 360044

Fax +44 (0)1634 360055

Web Site http://www.micromedical.com.uk

Email support@micromedical.com.uk

Contact Micro Medical Ltd for the local agent in your region or country for local service:

13

Page 14

Fault Analysis

The following analysis is only a guideline and should be carried out in a logical sequence. If the fault

is still apparent after the following suggestions then the unit should be fault found using the circuit

descriptions and circuit diagrams provided.

When the unit is turned on there is no display present

-Ensure charger is turned on at the mains.

FVC readings are low

-Remove turbine from transducer housing. Taking the turbine, move it slowly through the air and

check that the vane is not sticking.

The unit does not record any blows

-Inspect transducer housing connector for damage.

-Check that transducer housing lead is properly connected to the RJ11 socket.

-Remove turbine from transducer housing. Taking the turbine, move it slowly through the air and

check that the vane is not sticking.

-Blow into transducer housing and move transducer head cable around to check for breaks in the

cable.

14

Page 15

UADS

S

B

P

N

UWR

URD

0.1UF

TP25

TURB2

VCC

1110

R33

10K

VPPEN

PWR_OFFPWR_ONRTC_SELRTC_CLK

RTC_DATA

FPGADONE

CS0

UCS1

UCS2

UCS3

ONLINE

PRNBUSY

R8

UCS5

VCC

VCC

C63

0.1UF

TP3

GND

VCC

C62

1UF

VCC

RESET-

D[0..15]

A[1..21]

R37

10K

LK1

1

2

LINK2

TP24

GND

VCC

U14

119

RESET

125

CLK2

44

NA#

35

BS8#

34

READY

98

NMI

79

SMI#

110

P1.0/DCD0#

111

P1.1/RTS0#

113

P1.2/DTR0#

114

P1.3/DSR0#

115

P1.4/RI0#

116

P1.5/LOCK#

117

P1.6/HOLD

121

P1.7/HLDA

133

P2.0/CS0#

134

P2.1/CS1#

135

P2.2/CS2#

136

P2.3/CS3#

137

CS4

0R

R54

10K

140

142

143

80

81

87

89

91

92

93

94

101

102

103

104

100

96

99

128

122

127

139

123

106

84

86

85

82

27

28

129

107

P2.4/CS4#

P2.5/RXD0

P2.6/TXD0

P2.7/CTS0#

P3.0/TMROUT0

P3.1/TMROUT1

P3.2/INT0

P3.3/INT1

P3.4/INT2

P3.5/INT3

P3.6/PWRDOWN

P3.7/COMCLK

INT4/TMRCLK0

INT5/TMRGATE0

INT6/TMRCLK1

INT7/TMRGATE1

BUSY#/TMRGATE2

PEREQ/TMRCLK2

ERROR#/TMROUT2

DRQ1/RXD1

DACK1#/TXD1

DRQ0/DCD1#

DACK0#/CS5#

EOP#/CTS1#

DSR1#/STXCLK

DTR1#/SRXCLK

RTS1#/SSIOTX

RI1#/SSIORX

TCK

TDI

TMS

TRST#

FLT#

FA80386EX25L

VCC

R53

470R

132

LED2

GREEN

CS6#/REFRESH#

VCC

C46

0.1UF

M/IO

SMIACT

WDTOUT

TDO

CLKOUT

ADS

W/R

LBA

BHE

BLE

UCS

43

32

31

D/C

29

37

RD

38

WR

4

45

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

C47

0.1UF

A1

46

A2

48

A3

49

A4

52

A5

53

A6

54

A7

55

A8

56

A9

57

A10

58

A11

59

A12

61

A13

62

A14

63

A15

64

A16

66

A17

67

A18

68

A19

70

A20

71

A21

73

74

76

78

130

42

40

5

D0

6

D1

7

D2

8

D3

10

D4

12

D5

13

D6

14

D7

15

D8

17

D9

19

D10

20

D11

21

D12

22

D13

23

D14

25

D15

1

2

124

26

112

C45

0.1UF

C66

0.1UF

REFRESH

C74

0.1UF

TP20

UCS

C58

0.1UF

TP11

CS0

CS4

D0

D1

D2

D3

D4

D5

D6

D7

R29

33R

CS0

C21

0.1UF

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

FA14

FA15

FA16

FA17

FA18

FA19

FA20

FA21

VCC

11

13

14

17

18

1

3

4

7

8

D[0..15]

A[1..21]

32

28

27

26

25

24

23

22

20

19

18

17

13

12

11

10

14

54

55

15

U17

G

CLK

1D

2D

3D

4D

5D

6D

7D

8D

74FCT377

VCC

VPPEN

CLK25MHZ

C52

0.1UF

8

7

6

5

4

3

2

UCS0

UBHE

UBLE

U20

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

CE0

CE1

OE

WE

VPP

TE28F320J5100

1Q

2Q

3Q

4Q

5Q

6Q

7Q

8Q

R50

100K

C61

0.1UF

TP15

CS4

2

5

6

9

12

15

16

19

BYTE

D10

D11

D12

D13

D14

D15

STS

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

RP

WP

NC

NC

FA14

FA15

FA16

FA17

FA18

FA19

FA20

FA21

1 2

C50

0.1UF

33

35

38

40

44

46

49

51

34

36

39

41

45

47

50

52

31

53

16

56

29

30

VCC

U22A

SN74HC14

VSS

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

RESET-

C60

0.1UF

U19

25

A1

A0

24

A2

23

A3

22

A4

21

A5

20

A6

19

A7

18

A8

8

A9

7

A10

6

A11

5

A12

4

A13

3

A14

2

A15

1

A16

48

A17

17

A18

16

A19

26

UCS

28

11

13

28F400B5T80

U22D

9 8

SN74HC14

UUCS

TP16

VPP_EN

VCC

D9

5.6V

32

1

5V

Title

A3

Date: 5-Oct-1999 Sheet of

File: G:\tempd\056-02.sch Drawn By:

Q24

DTC114EKA

C4

0.1UF

Super Spiro - Processor circuit

Number RevisionSize

D0

A1

D1

A2

D2

A3

D3

A4

D4

A5

D5

A6

D6

A7

D7

A8

A9

D8

A10

D9

A11

D10

A12

D11

A13

D12

A14

D13

A15

D14

A16

D15

A17

A18

BYTE

CE

OE

RP

WE

WP

VPP

LED1

3

GREEN

R36

1

100R

056-02 1.0

TP4

GND

29

D0

31

D1

33

D2

35

D3

38

D4

40

D5

42

D6

44

D7

30

D8

32

D9

34

D10

36

D11

39

D12

41

D13

43

D14

45

D15

47

12

14

L

i

URD

UWR

1

R52

2

470R

VCC

23

Q23

FMMT549

R35

10K

TP28

GND

J3

DB9

VCC

R30

10R

FS2

300mA

1

6

2

7

3

8

4

9

5

J13

1

2

3

4

5

6

RJ11

INT1

INT2

STXCLK

SSIOTX

SSIORX

PRNTACK

PRNTDATA

J7

MOLEX 4PIN

U22F

13 12

SN74HC14

VCC

5

C41

0.1UF

1UF

12V VCC VCC

1

2

3

4

4

2

4

C51

2

16

9

17

8

1

14

C26

0.1UF

2

4

3

C25

0.1UF

R49

3K3

C72

1nF

R20

0R

VCC

VCC

U10

VCC

WDI

GND

MAX824_EUKM

U15

VCC

GND

50MHz

U4

R1 IN

R2 IN

T1 OUT

T2 OUT

EN

FON

C1+

C1 V+

MAX3223CAP

R48

3K3

C71

1nF

R51

470R

RES

RES

CLK

EN

RS232 TTL

TP21

TURB1

3 4

5 6

1

2

3

1

3

1

R1 OUT

R2 OUT

T1 IN

T2 IN

INVALID

FOFF

U22B

U22C

SN74HC14

LED3

RED

C2+

C2 -

V-

15

10

13

12

11

20

5

6

7

SN74HC14

3

UREADY

TP1

VCC

TX TP2RX

C24

C23

0.1UF

SND_EOM

RTC_INT-

J9

1

2

3

4

5

6

7

8

9

10

HEADER 5X2

U22E

SN74HC14

15

Page 16

UD[0..15]

UA[1..21]

UBHE

UBLE

UWR

URD

UREADY

REFRESH

UCS0

UCS1

UCS2

UCS3

UCS5

INT1

INT2

CLK25MHZ

KEYIN[0..4]

KEYOUT[0..4]

VCC

R21

10K

FPGADONE

EXP[0..4]

SNDCNTL[0..5]

SEREN[0..4]

UD[0..15]

UA[1..21]

Flash Disk C8000 - CBFFF

Display A0000 - BFFFF

Display Reg (I/O) 200 - 20F

DRAM 00000 - DFFFF

SPARE

KEYIN[0..4]

KEYOUT[0..4]

U8

17

VP

CEO

RES

XC17512L

D

CLK

CE

14

6

VCC

R22

100K

EXP[0..4]

SNDCNTL[0..5]

SEREN[0..4]

VCC

R26

100K

VCC

TP27

TP29

TP26

VCC VEE

DISP_ CLK

MEM_D0

MEM_D1

MEM_D2

MEM_D3

MEM_D4

MEM_D5

MEM_D6

MEM_D7

DISP_ LD

DISP_ FR AME

J11

CON15

VCC

J10

1

2

3

1 3

VR3

10K

4

5

B_5B-ZR

Back Light Connector

TP22

VEE

D11

3

ZHCS750

R39

C75

680K

R40

36K

Title

Number RevisionSize

A3

Date: 5-Oct-1999 Sheet of

File: G:\tempd\056-03.sch Drawn By:

+

C73

100pF

22UF/35V

Super Spiro - FPGA circuit

056-03 1.1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

VEE

26.4V

C70

0.1UF

33R

33R

33R

33R

RN6D

D0

D1

D2

D3

D4

D5

D6

D7

NC

Q22

DTC114EKA

C64

+

U21

7

4

MAX629ESA

VCC

TP23

DISP_ CNT L

13

14

15

17

18

19

20

21

1

21

L1

47UH

1

2

C44

C69

0.1UF

U13

XC4006E-3PQ160C_VIDEO

33

UD0

UD1

UD2

UD3

UD4

UD5

UD6

UD7

UA1

UA2

UA3

UA4

UA5

UA6

UA7

UA8

UA9

UA10

UA11

UA12

UA13

UA14

UA15

UA16

UA17

UA18

UA19

UA20

KEYIN0

KEYIN1

KEYIN2

KEYIN3

VCC

R34

100K

KEYIN4

KEYOUT0

KEYOUT1

KEYOUT2

KEYOUT3

KEYOUT4

2

4

8

EXP2

EXP3

EXP4

27

4K7

UD0

32

UD1

31

UD2

30

UD3

28

UD4

27

UD5

26

UD6

25

UD7

154

UA1

153

UA2

152

UA3

150

UA4

149

UA5

148

UA6

147

UA7

146

UA8

145

UA9

144

UA10

143

UA11

140

UA12

139

UA13

138

UA14

137

UA15

135

UA16

134

UA17

133

UA18

132

UA19

130

UA20

155

UBHE

156

UBLE

157

UWR

158

URD

159

READY

2

REFRESH

125

CS1

126

CS2

127

CS3

128

CS4

129

CS5

123

INT1

116

INT2

124

CLK25MHZ

113

KEYIN0

109

KEYIN1

112

KEYIN2

111

KEYIN3

115

KEYIN4

105

KEYOUT0

106

KEYOUT1

107

KEYOUT2

108

KEYOUT3

114

KEYOUT4

82

PROGRAM

117

DIN

119

CCLK

80

DONE

59

INIT

6

TDI

121

TDO

7

TCK

13

TMS

40

M0

38

M1

42

M2

EXP0

EXP1

18

36

RN9C

4K7

4K7

DISP_CNTL

DISP_LOAD

DISP_FRAME

MEMA_OE

MEMA_WE

MEMB_WE

SNDCNTL0

SNDCNTL1

SNDCNTL2

SNDCNTL3

SNDCNTL4

SNDCNTL5

DISP_D0

DISP_D1

DISP_D2

DISP_D3

DISP_D4

DISP_D5

DISP_D6

DISP_D7

DISP_CLK

MEM_A0

MEM_A1

MEM_A2

MEM_A3

MEM_A4

MEM_A5

MEM_A6

MEM_A7

MEM_A8

MEM_A9

MEM_A10

MEM_A11

MEM_A12

MEM_A13

MEM_A14

MEM_A15

MEM_A16

MEM_D0

MEM_D1

MEM_D2

MEM_D3

MEM_D4

MEM_D5

MEM_D6

MEM_D7

MEMA_CS

MEMB_CS

MEMB_OE

DRA0

DRA1

DRA2

DRA3

DRA4

DRA5

DRA6

DRA7

DRA8

DRA9

DRRAS

DRCASU

DRCASL

DROE

DRWE

SEREN0

SEREN1

SEREN2

SEREN3

SEREN4

43

44

45

46

47

48

49

50

52

53

54

55

83

77

75

73

71

68

66

64

67

69

76

72

62

65

58

57

56

85

87

89

92

90

88

86

84

78

74

63

95

94

93

22

21

18

17

4

5

8

9

11

12

23

15

16

14

24

37

36

35

34

104

102

96

99

97

98

103

0.1UF

MEM_A0

MEM_A1

MEM_A2

MEM_A3

MEM_A4

MEM_A5

MEM_A6

MEM_A7

MEM_A8

MEM_A9

MEM_A10

MEM_A11

MEM_A12

MEM_A13

MEM_A14

MEM_A15

MEM_A16

MEM_D0

MEM_D1

MEM_D2

MEM_D3

MEM_D4

MEM_D5

MEM_D6

MEM_D7

4 5

33R

3 6

33R

2 7

33R

1 8

33R

4 5

33R

3 6

33R

1 8

33R

2 7

33R

SEREN0

SEREN1

SEREN2

SEREN3

SEREN4

SNDCNTL0

SNDCNTL1

SNDCNTL2

SNDCNTL3

SNDCNTL4

SNDCNTL5

TP9

MEM A_ S EL

4 5

33R

1 8

33R

2 7

33R

3 6

33R

3 6

33R

4 5

33R

2 7

33R

1 8

33R

C49

C42

C53

C43

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

OE

WE

CS2

CS1

100K

0.1UF

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

Contrast

13

C48

C39

0.1UF

0.1UF

13

D0

14

D1

15

D2

17

D3

18

D4

19

D5

20

D6

21

D7

1

NC

2

UD0

3

UD1

4

UD2

5

UD3

7

UD4

8

UD5

9

UD6

10

UD7

35

UD8

36

UD9

37

UD10

38

UD11

40

UD12

41

UD13

42

UD14

43

UD15

6

VR1

-

5

+

C59

0.1UF

0.1UF

MEM_A0

MEM_A1

MEM_A2

MEM_A3

MEM_A4

MEM_A5

MEM_A6

MEM_A7

MEM_A8

MEM_A9

MEM_A10

MEM_A11

MEM_A12

MEM_A13

MEM_A14

MEM_A15

MEM_A16

LCAS

TP17

+

VCC

18

19

20

21

24

25

26

27

28

29

15

31

32

30

14

4 8

0.1UF

12

11

10

9

8

7

6

5

27

26

23

25

4

28

3

31

2

24

29

30

22

U18

KM416C1200BT-6

C33

0.1UF

U5A

1

U11

KM681000BLG-7

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

RAS

UCAS

LCAS

OE

WE

0.1UF

VCC

TP10

MEMB_ SEL

RAS

UCAS

TP18

TP19

2

3

LM2904D

C28

0.1UF

MEM_D0

MEM_D1

MEM_D2

MEM_D3

MEM_D4

MEM_D5

MEM_D6

MEM_D7

U5B

LM2904D

C38

0.1UF

C67

C31

0.1UF

4 5

3 6

2 7

1 8

MEM_A0

MEM_A1

MEM_A2

MEM_A3

MEM_A4

MEM_A5

MEM_A6

MEM_A7

MEM_A8

MEM_A9

MEM_A10

MEM_A11

MEM_A12

MEM_A13

MEM_A14

MEM_A15

MEM_A16

C68

0.1UF

RN8D

33R

33R

33R

33R

4 5

3 6

2 7

1 8

12

11

10

9

8

7

6

5

27

26

23

25

4

28

3

31

2

24

29

30

22

RN7D

33R

33R

33R

33R

1 8

2 7

3 6

4 5

U12

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

OE

WE

CS2

CS1

KM681000BLG-7

0.1UF

VCC

32

1

BKLGTEN

C65

0.1UF

47 UF /1 0 V

86

1

SHDN

ISET

REF

POL

LX

FB

C34

0.1UF

5

3

2

7

R38

1M0

16

Page 17

PWR_ON-

N

A

PWR_OFF-

47UF/16V

5V

RTC_INT-

l

t

FS3

1A

C3

C19

+

0.1UF

MINIRELAY (RS345-022)

D5

3

ZHCS750

2 3

5V

R5

100K

R6

OR

32

5V

R4

100K

32

Q18

FMMT489

Q17

FMMT489

R12

8K2

R9

8K2

R10

2K0

R7

2K0

C20

0.1UF

C18

0.1UF

1

1

1 2

4 5

2

1

Q20

FMMT717

1

R11

100R

32

8

9

U3B

5

6

78 RL1

Q19DTC114EKA

4093

1

U3C

4093

C27

+

47UF/16V

10

4

VCC

13

12

C22

0.1UF

C57

+

47UF/16V

KEYOUT[0..4]

KEYIN[0..4]

8

U2B

9

S

D

Q

CLK

Q

R

4013

10

U3A

11

3

4093

5V

KEYOUT[0..4]

KEYIN[0..4]

1

2

D7

IMN10

9

esc

del

.

ON/OFF

1

2

3

1

2

3

4

F1

F2

F3

1

4

7

F4

2

5

890

F5

6

3

PAPER

FEED

6

KEYOUT0

KEYOUT1

KEYOUT2

KEYOUT3

KEYOUT4

KEYIN0

KEYIN1

5V

R3

100K

5V

C17

0.1UF

KEYIN2

KEYIN3

KEYIN4

PAPERFEED-

VCC

4 5

1 8

3 6

2 7

6

5

4

RN5D

RN5A

RN5C

RN5B

R16

D8

IMN10

100K

100K

100K

100K

100K

5

4

1

2

3

8

5

7

6

10

12

13

11

J6

KEYPAD

6

14

C16

0.1UF

3

D5Q

VCC

CLK

GN D

4

7

U2A

1

S

2

Q

R

4013

147

U3D

12

13

4093

17

C15

0.1UF

11

Title

A3

Date: 5-Oct-1999 Sheet of

File: G:\tempd\056-04.sch Drawn By:

Super Spiro - Keypad circuit

Number RevisionSize

1.0056-04

Page 18

RTC_SELRTC_CLK

RTC_DATA

SNDCNTL[0..5]

VCC

R31

10K

SNDCNTL[0..5]

TP12

VCC

VCC

C56

0.1UF

C54

33PF

TP13

TP14

RTC_ D A TA

RTC_SCL K

RTC_SEL

X2

32.786KHz

1

2

3

A0

VDD

OS CI

6

5

SCL

SDA

U16

PCF8583T

OS CO

INT

VSS

3

8

7

4

D10

BAV70

VCC

SEREN[0..4]

BAT1

1

2

R32

10K

3.6V

1 3

2

C55

0.1UF

RTC_INT-

EXP[0..4]

SEREN[0..4]

SEREN4

SEREN0

SEREN1

SEREN2

SEREN3

EXP[0..4]

R2

10K

STXCLK

SSIOTX

SSIORX

C8

0.1UF

U1

3

VDD

2

DQ

1

GND

DS1821

VCC

Resettable Fuse

FS4

R44

0R

R41

0R

R45

0R

R42

0R

R46

0R

R43

0R

R47

0R

300mA

VCC

J14

DB9

1

6

2

7

3

8

4

9

5

12V

J12

1

2

3

4

5

6

Header for expansion card

7

8

9

10

HEADER 10

SND_EOM

SNDCNTL1

SNDCNTL0

SNDCNTL2

SNDCNTL3

SNDCNTL4

SNDCNTL5

TP5

SND_EN

VCC

C36

0.1UF

1

Speaker Output

2

VCC

C35

+

47UF/16V

C32

0.1UF

J5

CON3

VCC

1

2

3

Record Input

R13

R15

10K

10K

U7

ISD2532S

1

A0

2

A1

3

A2

4

A3

5

A4

6

A5

7

A6

9

A7

10

A8

23

CE

24

PD

27

P/R

25

EOM

22

OVF

26

XCLK

VCCD

VCCA

VSSD

VSSA

AUXIN

ANAIN

ANAOUT

MICREF

AGC

28

16

12

13

14

SP+

15

SP-

11

20

21

18

17

MIC

19

C29

0.1UF

J4

Molex 2 pin R/A

C11

0.1UF

EXP0

EXP1

EXP2

EXP3

EXP4

C12

+

47 U F /16V

12V 5V

FS1

500mA

12V

VCC

J8

1

2

3

4

5

Header for expansion card

6

7

8

9

10

HEADER 10

J1

CON4

1

Power Connector

2

3

4

Resetable Fuse.

Title

Super Spiro - RTC circuit

Number RevisionSize

A3

Date: 5-Oct-1999 Sheet of

File: G:\tempd\056-05.sch Drawn By:

056-05 1.0

18

Page 19

5V

R23

100K

C40

820pF

U9A

1 2

4069UB

RESET-

PRNTDATA

PRNTACK

PFONLINE-

U9B

3 4

4069UB

TP7

PRNT_DATA

U9E

11 10

4069UB

U9C

5 6

4069UB

VCC

R19

10K

PAPERFEED-

C37

X1

33PF

4.0MHz

R14

10K

U9D

9 8

4069UB

C30

33PF

43

42

1

2

41

32

33

34

35

36

37

39

4

3

18

23

40

R17

1K

U6

OSC1

PA7

OSC2

PA6

PA5

PA4

RST

IRQ

PA3

PA2

TCAP

PA1

TCMP38PA0

PB0

PD0/RDI

PB1

PD1/TDO

PB2

PD2/MISO

PB3

PD3/MOSI

PB4

PD4/SCK

PB5

PD5/SS

PB6

PD7

PB7

PC0

PC1

PC2

NC

PC3

PC4

NC

PC5

NC

PC6

NC

PC7

NC

MC68HC05C9ACFN(44)

TP6

PRNT_CLK

C5

0.1uf

OUT0

OUT0

OUT1

OUT1

OUT2

OUT2

OUT3

OUT3

OUT4

OUT4

OUT5

OUT5

OUT6

OUT6

OUT7

OUT7

VCC

R18

10K

R1

1K

J2

5V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

CON25

Head Motor

Paper Feed Motor

0.1UF

5

6

7

8

9

10

11

12

13

14

15

16

17

19

20

21

31

30

29

28

27

26

25

24

47UF/ 1 6 V

056-07 056-07.SCH

OUT0

IN0

OUT0

IN0

OUT1

IN1

OUT1

IN1

OUT2

IN2

OUT2

IN2

OUT3

IN3

OUT3

IN3

OUT4

IN4

OUT4

IN4

OUT5

IN5

OUT5

IN5

OUT6

IN6

OUT6

IN6

OUT7

IN7

OUT7

IN7

BUSY

TP8

PRNT_BUSY

P

i

n

C2

+

C1

C7

0.1UF

C6

+

4 7 U F / 1 6 V

IN0

IN0

IN1

IN1

IN2

IN2

IN3

IN3

IN4

IN4

IN5

IN5

IN6

IN6

IN7

IN7

056-08 056-08.SCH

R24

22K

R25

150K

Q21

3 2

FMMT489

1

1 3

VR2

20K

D6

ZHCS750

R27

2K2

R28

22K

23

U9F

13 12

4069UB

VCC VDD

Title

Super Spiro - Printer circuit

Number RevisionSize

A3

Date: 5-Oct-1999 Sheet of

File: G:\tempd\056-06.sch Drawn By:

056-06 1.0

19

Page 20

5V

D1

UMN1

Q3

32

5V

13245

Q4

FMMT489

1

D2

UMN1

32

Q1

32

FMMT489

1

Q2

32

FMMT489

1

FMMT489

1

RN1

IN0

IN1

IN2

IN3

IN4

IN5

IN6

IN7

8

7

6

8

7

6

1

2

3

45

1K0

RN2

1

2

3

45

1K0

Q5

FMMT489

1

32

FMMT489

1

C10

0.1UF

13245

Q6

32

C9

0.1UF

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

Q7

FMMT489

1

32

Q8

32

FMMT489

1

OUT6

OUT7

Title

A3

Date: 5-Oct-1999 Sheet of

File: G:\tempd\056-07.sch Drawn By:

Super Spiro - Printer driver 1

Number RevisionSize

056-07 1.0

20

Page 21

5V

D3

UMN1

Q11

32

5V

13245

13245

Q13

FMMT489

1

D4

UMN1

32

Q9

32

FMMT489

1

Q10

32

FMMT489

1

FMMT489

1

RN3

IN0

IN1

IN2

IN3

IN4

IN5

IN6

IN7

8

7

6

8

7

6

1

2

3

45

1K0

RN4

1

2

3

45

1K0

FMMT489

1

Q12

32

FMMT489

1

C14

0.1UF

Q14

32

C13

0.1UF

OUT0

OUT1

OUT2

OUT3

OUT4

OUT5

FMMT489

1

21

Q15

32

Q16

32

FMMT489

1

OUT6

OUT7

Title

Super Spiro - Printer driver 2

Number RevisionSize

A3

Date: 5-Oct-1999 Sheet of

File: G:\tempd\056-08.sch Drawn By:

056-08 1.0

Loading...

Loading...