Page 1

MicroRint - ServiceManual

046-22 Iss. 1.0 June 1998

Page 2

Contents

System Overview.........................................................................................................2

Figure 1 .......................................................................................................................2

Disassembling the MicroRint Computer for Circuit Investigation .......................... 3

Reassembling the MicroRint Computer ...................................................................4

Disassembling the Interrupter Transducer for Circuit Investigation......................5

Reassembling the Interrupter Transducer................................................................6

Circuit Description-Microcomputer

Overview.......................................................................................................................7

Address Bus............................................................................................................................................7

Reset.......................................................................................................................................................7

Keypad....................................................................................................................................................7

Real Time Clock......................................................................................................................................8

Display.....................................................................................................................................................8

Battery Monitoring...................................................................................................................................8

Power Supply..........................................................................................................................................8

Circuit Description-Interrupter Transducer

Overview....................................................................................................................... 9

Power supply ..........................................................................................................................................9

Battery monitor........................................................................................................................................9

Pressure monitor.....................................................................................................................................9

Shutter operation ....................................................................................................................................9

Parts List - MicroRint Computer ..............................................................................10

Parts List - Interrupter Transducer..........................................................................12

Technical Support.....................................................................................................14

Fault Analysis............................................................................................................15

Circuit Diagram - MicroRint Microcomputer...........................................................16

Circuit Diagram - Interrupter Transducer................................................................17

1

Page 3

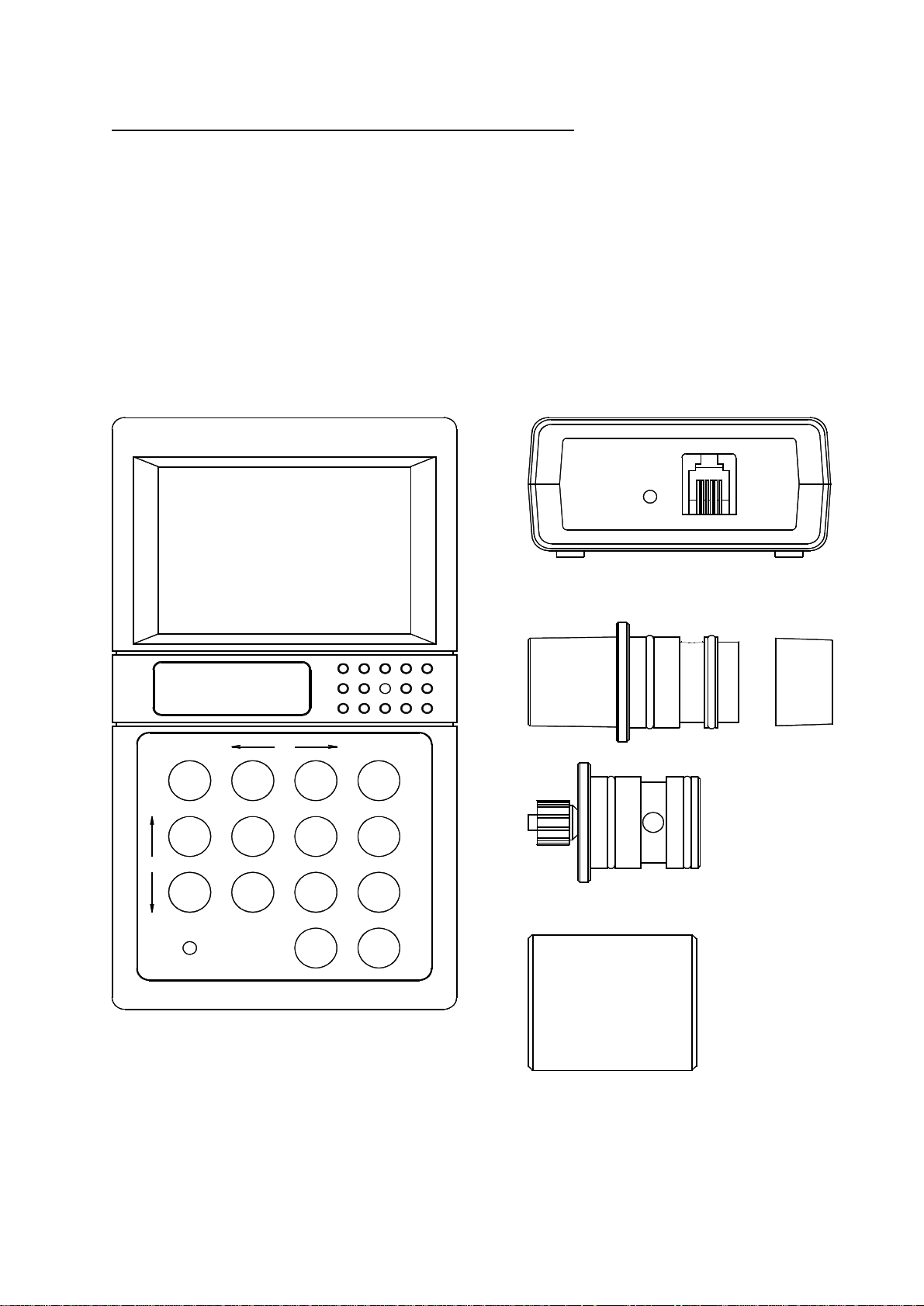

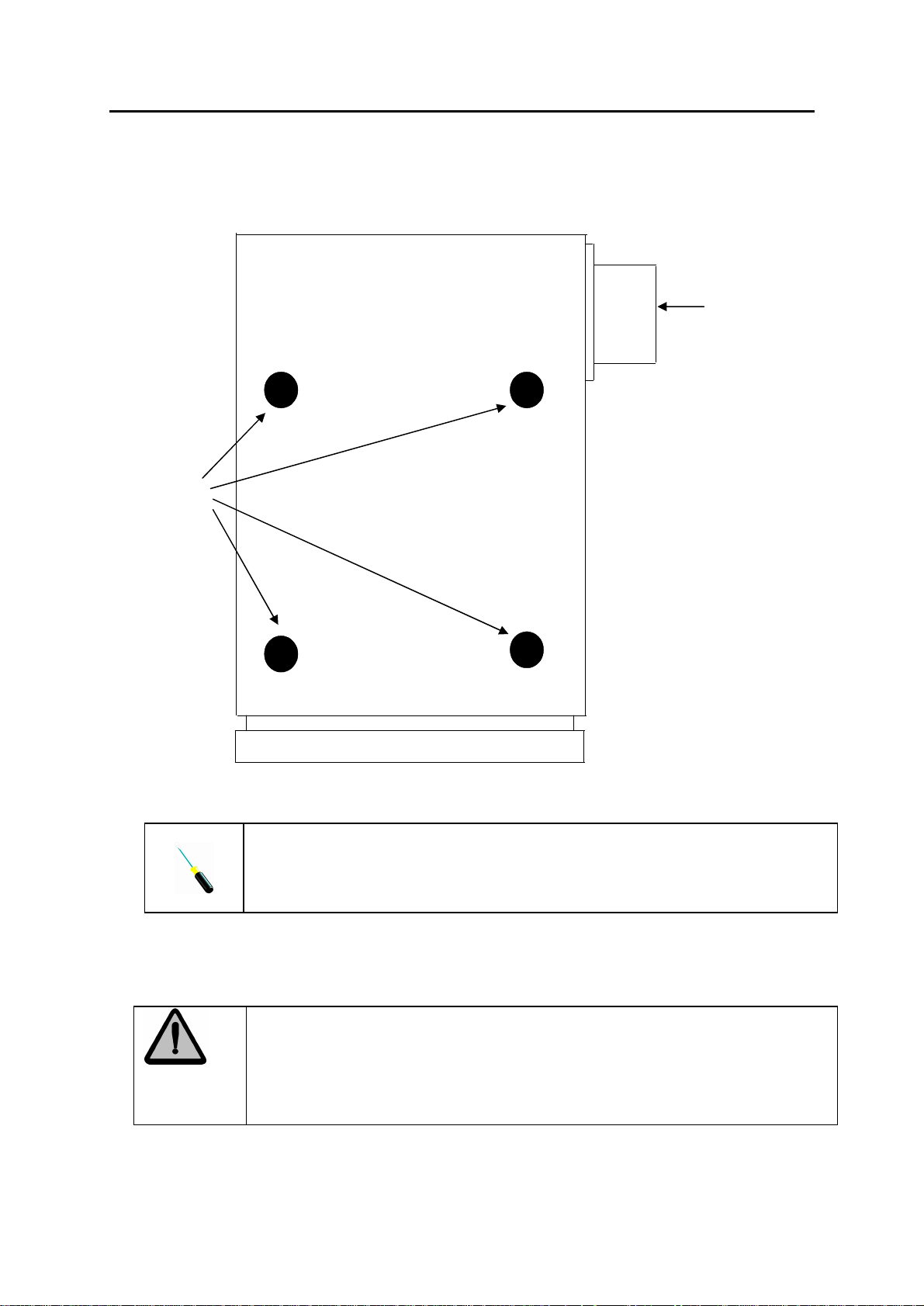

MicroRint Microcomputer - System Overview (Fig. 1)

Fig. 1

The Micro Medical MicroRint is a data recording airways resistance meter consisting of a

microcomputer unit (1) incorporating an LCD graphic display, data entry keypad, RS232 serial

interface and all associated circuitry. This is supplied with an interrupter transducer (2), resistive

element holder (3) resistive element (4) Pressure calibration adapter (5) and Mouthpiece adapter (6).

The MicroRint is powered by internal rechargeable Nickel Cadmium cells or by the mains adapter

supplied.

The interrupter transducer is used to measure the subject’s airways resistance in accordance with the

operating manual.

MicroRint

2

CHARGING

1

MicroRint

S

C

1

A

L

E

4 5

7 8

CHARGING

SCROLL

2

3

6

9

0

ON

OFF

DELETE

ENTER

3 4

5

6

2

Page 4

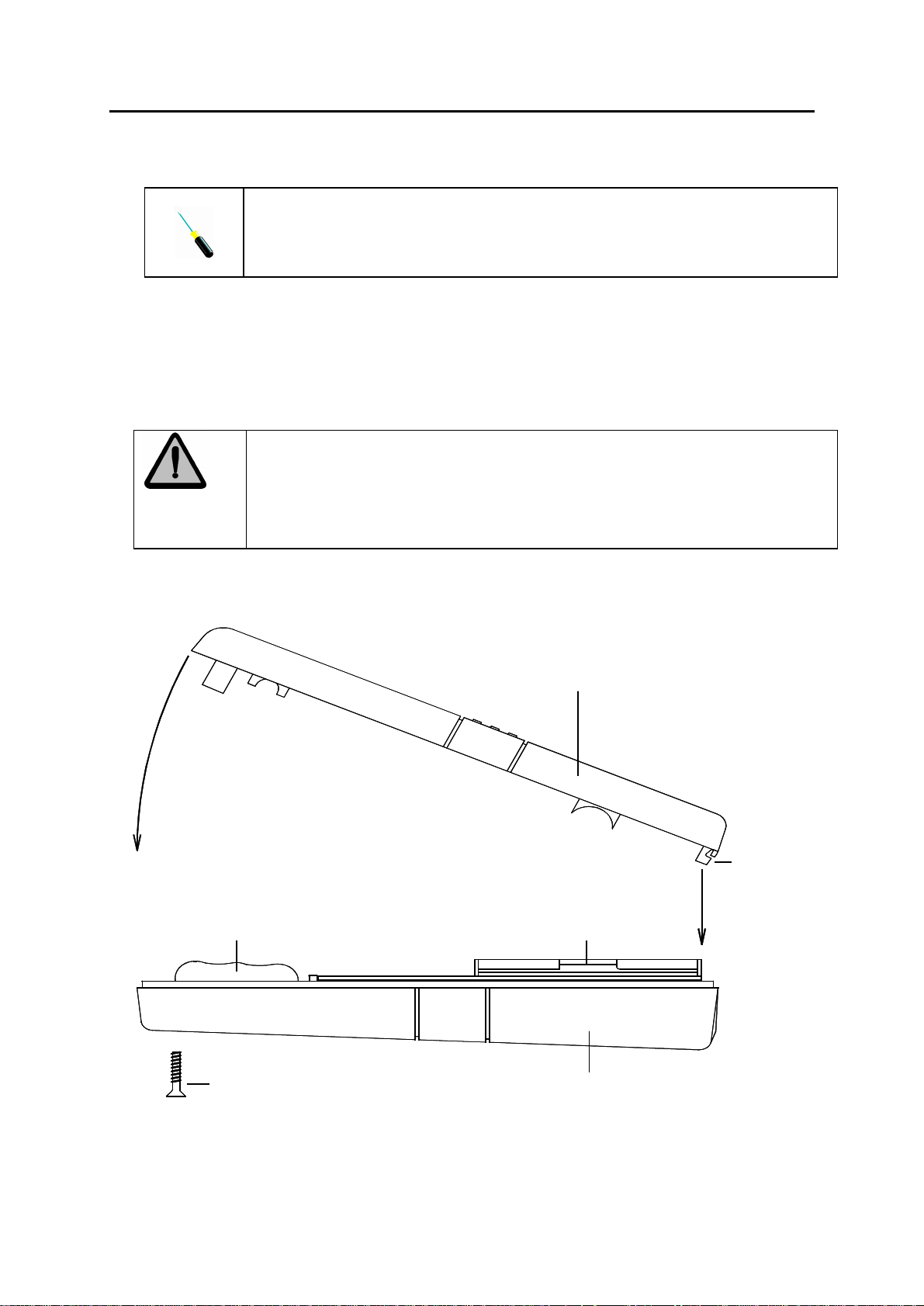

Disassembling the MicroRint Computer for Circuit Investigation

1. Disconnect all mains power supplies

We recommend that you use a Philip Number Zero screwdriver for the

following instruction.

2. Place the MicroRint face down to remove the two screws in the lower moulding, and put the

screws to one side.

3. Turn the unit face up and ease the upper and lower mouldings apart by lifting the top moulding at

an angle as illustrated in the diagram below until it becomes loose.

4. Reconnect mains power supply

5. The MicroRint is now ready for Circuit Investigation.

If you are not familiar with the operation of the MicroRint please read the

following section in this manual ‘Circuit Description’ and use the Circuit

diagrams at the back of this manual.

Top moulding

Locating

lugs

Battery pack

2 off screws

Display

Bottom moulding

3

Page 5

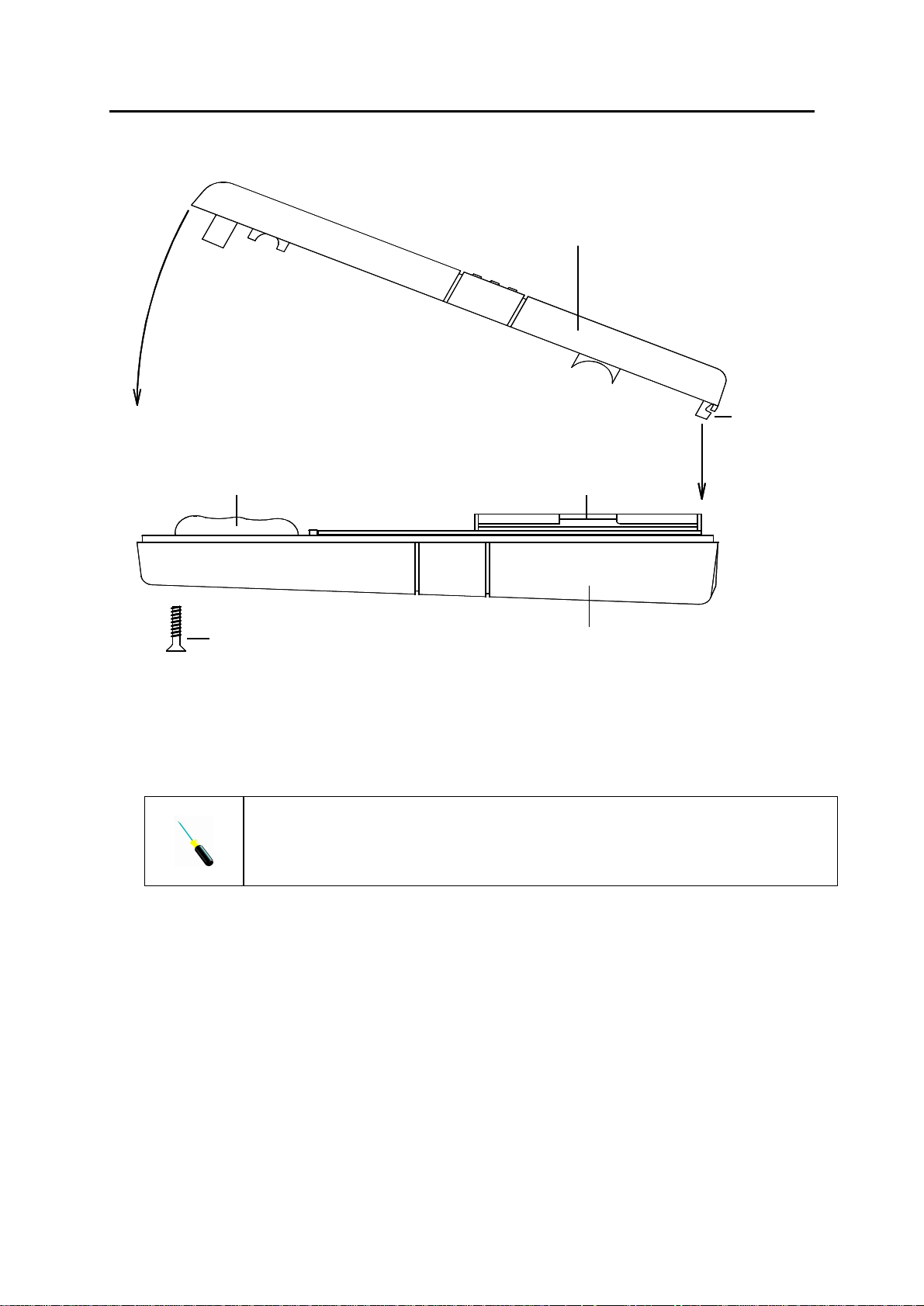

Reassembling the MicroRint Computer for Ready for Operation

Top moulding

Locating

lugs

Battery pack

2 off screws

1. Replace printed circuit board (If removed during investigation) into the bottom moulding.

2. Place the top moulding locating lugs into the bottom moulding at an angle as illustrated above.

3. Push the top moulding together with the bottom moulding making sure that there are no wires

caught between the top and bottom moulding.

We recommend that you use a Philip Number Zero screwdriver for the

following instruction.

4. Turn the unit face down and insert the two screws into the bottom moulding and secure.

5. The unit will now require calibration - Refer to operating manual.

Display

Bottom moulding

4

Page 6

Disassembling the Interrupter Transducer for Circuit Investigation

1. Disconnect the Interrupter Transducer from the MicroRint Computer

2. Remove the Resistive element holder and put to one side.

3. Remove the four rubber feet and put to one side.

RESISTIVE

ELEMENT

HOLDER

FOUR

RUBBER

FEET

Fig 2

We recommend that you use a Philip Number Zero screwdriver for the

following instruction.

4. Remove the four screws located under the rubber feet and put to one side.

5. Ease the moulding apart to reveal the circuitry.

6. The Interrupter Transducer is now ready for fault finding.

If you are not familiar with the operation of the MicroRint please read the

following section in this manual ‘Circuit Description’ and use the Circuit

diagrams at the back of this manual.

5

Page 7

Reassembling Interrupter Transducer

FOUR

RUBBER

FEET

RESISTIVE

ELEMENT

HOLDER

1. Push the two mouldings together ensuring that no tubing is caught between the two mouldings.

We recommend that you use a Philip Number Zero screwdriver for the

following instruction.

2. Replace the four screws into the moulding and secure

3. Replace the four rubber feet over the screws as shown above.

4. Push the resistive element holder into the Interrupter transducer.

5. The unit will now require calibration – Refer to operating manual.

6

Page 8

Circuit Description – Microcomputer

(Refer to Drawing (047-01)

Overview

The microprocessor control circuit carries out the spirometry routines, monitors the transducer

operation and keypad, and drives the display under the control of the program stored in the battery

backed RAM.

The power supply uses the mains adapter, internal Nickel-Cadmium (Ni-Cad) cells and an internal

lithium backup as its sources of energy. The supply provides 5 volts to the control circuit, -12 volts

supply for the display and RS232 driver circuit, 3 volts RAM backup, controls the charging current to

the Ni-Cad battery pack, and provides for battery management.

The microprocessor (IC1) communicates with the real time clock (IC6), the output latch (IC5), and the

display under the control of the program, stored in the RAM (IC2), using a multiplexed address and

data bus decoded by a data latch (IC3). The RAM, which is used both for program storage and for

temporary data storage, has a memory map which is partitioned by the action of the PAL (IC4) into

writable and non-writable areas.

Address bus

The microprocessor (IC1) uses a multiplexed address bus. The lower order address lines are latched

into IC3 with the address strobe (AS).

The program for the microprocessor (IC1) is stored in a 128kByte, battery backed static ram, (IC2).

As the address space of the processor is limited to 64kBytes the ram address space is paged using a

programmable array logic device (IC4). This device decodes address lines A1, A13, A14, A15, port

lines PD5, PA4, control line R/W, clock signal E, mode control lines MODA, MODB, and the external

reset line to provide the following outputs:

RAM address lines A15 and A16

Chip select lines (CS) for the display and latch (IC5)

Write enable (WR) for display, latch, and RAM

Read enable (RD) for the display

Output enable (OE) for the RAM

Reset

The reset circuit consists of a single chip reset (IC9) which holds the reset line (RES) low for 350ms

after the 5 volt supply has reached the threshold voltage of 4.5 volts. The reset signal is applied to the

microprocessor (IC1), display, programmable array logic device (IC4), and the printer driver processor

(IC17).

Keypad

The 12 keypad switches ( 0 to 9, ENTER and DELETE) are arranged in a 3 column by 4 row matrix.

When the keypad is being read by the processor the 3 columns are sequentially driven high by the

output latch (IC5 pins 19,16 and 15). The state of the 4 rows is read by the general purpose port PE4

to PE7 of the processor. The diodes in the package D2 isolate the outputs from IC5 to ensure that a

high current will not flow from an output set high to one set low if two keys are pressed

simultaneously. The ON and OFF keys are connected to the power control circuitry described in the

Power Supply section.

7

Page 9

Real Time Clock

The real time clock (IC6) is set by the processor during the factory set-up and may be set to the local

time zone –see operating manual. The processor communicates with the real time clock (RTC) with a

serial interface line to pin 5 of the RTC. The RTC is selected by the signal from pin 12 of the output

latch (IC5).

Display

The display is a custom graphic 128 by 64 dot LCD with in-built control circuitry. The contrast is

adjusted by varying the voltage on pin 3 between –6.5 and -11 volts with VR1. This potentiometer

varies the output of the voltage inverter, IC12.

Battery monitoring

The microprocessor contains eight, 8 bit analogue to digital converters. One of these, AN3 is used to

monitor the condition of the main supply (BAT1). The main supply is monitored at the input to the logic

5-volt regulator (IC11) and the user will be alerted to a low battery condition when the voltage falls

below 6 volts. The voltage is divided by two with R8 and R9 to bring the voltage within the range of

the A/D converter (5 volts). AN3 also detects when the external power supply has been applied. One

end of R10 is pulled to 0 volts when the external supply is not applied and the voltage read on the A/D

converter will be up to 4 volts for a fully charged battery. With the external supply applied, the voltage

will rise above 5 volts.

Power Supply

The power supply consists of linear 9 volt and 5 volt regulated supplies (IC7 and IC11), an adjustable

switching regulator (IC12) and a lithium backup battery (BAT2), together with the NI-CAD charging

circuit and low battery detector. The 9 volt regulator, IC7, is only operational when the mains adapter

is connected and effectively replaces the 7.2 volt battery pack (BAT1) as the two supplies are

connected through the dual diode D6. During this time the battery pack is trickle charged from the

external supply by the 25mA constant current source formed by TR6, D1, R4, and R7. The bridge

diode network, D4, provides protection against reverse polarity on the external supply. The inductors

L1 and L2 provide attenuation of conducted noise to the external supply. The terminal voltage of the

battery pack is monitored by an analogue input of the processor, AN3, through the potential divider

network formed by R8 and R9. R8 is connected to the 9 volt supply, which is only active when the

external supply is in use. The processor can detect when the external supply is in use as the

analogue input will rise to above full scale, 5 volts, when this occurs. The input to the 5-volt regulator

(IC11), and the voltage inverter (IC12), is controlled by TR5, which is turned on when the output of

IC10 A is high. IC10 (gates A and B) form a bi-stable latch controlled by the ON and OFF switches on

the keypad or by the microprocessor via TR1 and TR7.

8

Page 10

Circuit Description – Interrupter Transducer

(Refer to Drawing 046-10)

Overview

During measurement the interrupt transducer monitors tidal flow and provides for a means of

momentary airways occlusion during which time the pressure at the mouth is measured.

The flow is measured by monitoring the pressure across a resistive element using a high frequency

silicon solid state sensor.

Occlusion is provided by a fast acting rotary solenoid attached to a shutter. During occlusion the

pressure sensor is used to monitor the pressure developed at the mouth.

Power supply

The power supply consists of a voltage converter (IC6) which produces a 12v supply, an adjustable

regulator configured so as to produce a 10V supply for the pressure monitor circuit and a linear 5V

regulator (IC4).

The rechargeable Ni-cad battery pack is trickle charged from the 12V supply through R5 and D3. TR3,

R6 and R7 are not used.

Battery Monitor

The comparator (IC1A) compares a reference voltage (IC1A Pin 6) to the voltage developed across

the current sensing resistor (R9) when the shutter solenoid (M1) is activated. The output from this

comparator (Pin 7) is used to shutdown the A/D converter (IC5) when insufficient current is passing

through R9 during solenoid activity indicating a discharged battery. The Microcomputer unit will detect

that the A/D converter is shutdown during operation and will indicate a battery low condition to the

user on the LCD display.

Pressure Monitor

During solenoid operation the differential output of the pressure transducer (PT1) is applied to the

instrumentation amplifier configuration of IC2. The output from this amplifier is applied to the analogue

input of the A/D. Serial data is clocked out of the A/D by the SCLK input when CS is low.

Shutter Operation

The shutter solenoid is energised when the trigger input is taken to 5V, turning on TR1 and TR2.

When the valve is de-energised the shutter returns to the open position by the action of the internal

spring.

9

Page 11

Parts List - Microcomputer

Designation

IC1

IC2

IC3

IC4

IC5

IC6

IC7

IC8

IC9

IC10

IC11

IC12

IC15

R1 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R2 1M SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R3 1K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R4 27 OHMS SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R5 330 OHMS SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R6 1K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R7 10K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R8 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R9 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R10 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R11 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R12 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R13 1K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R14 33K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R15 330K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R16 10K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R17 10K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R18 4.7K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R19 4.7K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R20 3.3K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R21 3.3K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R22 3.9K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R23 1K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R24 100 OHMS SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R25 1M SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

RN1 4 WAY COMMONED 10K SIL NETWORK

VR1

C1 RUBYCON 22uF 35 VOLT ELECTROLYTIC CAPACITOR TYPE 35MH522M0563

C2 RUBYCON 47uF 16 VOLT ELECTROLYTIC CAPACITOR TYPE 16MH547M6357

C3 RUBYCON 47uF 16 VOLT ELECTROLYTIC CAPACITOR TYPE 16MH547M6357

C4 RUBYCON 47uF 16 VOLT ELECTROLYTIC CAPACITOR TYPE 16MH547M6357

C5 RUBYCON 47uF 16 VOLT ELECTROLYTIC CAPACITOR TYPE 16MH547M6357

C6 RUBYCON 47uF 16 VOLT ELECTROLYTIC CAPACITOR TYPE 16MH547M6357

C7 RUBYCON 47uF 16 VOLT ELECTROLYTIC CAPACITOR TYPE 16MH547M6357

C8 RUBYCON 47uF 16 VOLT ELECTROLYTIC CAPACITOR TYPE 16MH547M6357

C9 10nF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C10 15pF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C11 10nF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

(MC68HC11E1FN) MICROCONTROLLER

(KM681000BLG/BLG-L) SAMSUNG 1 MEG SURFACE MOUNT STATIC RAM

55 TO 150nS ACCESS TIME

(74HC573) SURFACE MOUNT OCTAL LATCH

(PALCE16V8Z25PC) AMD ZERO POWER CMOS PLD DIP PACKAGE

(74HC273) SURFACE MOUNT OCTAL D FLIP-FLOP

(PCF8583T) PHILIPS SURFACE MOUNT CLOCK CALENDER WITH 256 BYTE RAM

(LM2940T-9.0) LOW DROP OUT 9 VOLT 1 AMP REGULATOR

(74HC14) SURFACE MOUNT HEX SCHMITT INVERTOR

(DS1233D-10) DALLAS ECONO RESET

(4093) SURFACE MOUNT QUAD NAND GATE

(LM2931M-5.0) LOW DROP OUT 5 VOLT 100mA SURFACE MOUNT REGULATOR

(LT1054CS8) SURFACE MOUNT VOLTAGE CONVERTOR

(BU4S11) OR (BU4S01) RHOM INDIVIDUAL CMOS GATE

(T18 S/I S/B S/T 20KA) PHIER 20K LINEAR POTENTIOMETER

Description

10

Page 12

C12 10nF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C13 33pF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C14 33pF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C15 1nF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C16 1nF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

CD (X7) 100nF PHILIPS SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

TR1

TR2

TR3

TR4

TR5

TR6

TR7

LED T1/3mm ORANGE LED

D1

D2

D3

D4

D5

D6

D7

D8

D9

L1

L2

DISPLAY

SK1

SK2

SK3 10 WAY PIN HEADER

SK4

SK5

SPKR

X1 4.9152MHz CRYSTAL CAN STYLE HC49/4H

X2 32.768KHz CRYSTAL

BAT1 NI-CAD BATTERY PACK - 6 X AAA CELLS

BAT2

(DTC114EK) RHOM NPN DIGITAL TRANSISTOR

(DTC114EK) RHOM NPN DIGITAL TRANSISTOR

(DTB113EK) RHOM PNP DIGITAL TRANSISTOR

(DTA114EK) RHOM PNP DIGITAL TRANSISTOR

(FMMT591) ZETEX PNP TRANSISTOR - SOT23

(2SB1189) RHOM PNP TRANSISTOR - MPT (SOT89)

(DTC114EK) RHOM NPN DIGITAL TRANSISTOR

(IMN10) RHOM 3 DIODE ARRAY - IMD PACKAGE

(IMN10) RHOM 3 DIODE ARRAY - IMD PACKAGE

(IMN10) RHOM 3 DIODE ARRAY - IMD PACKAGE

(S1NB20) SHINDENGEN 1A BRIDGE RECTIFIER

(1SR154-400) RHOM 1A DIODE - PSM PACKAGE. ALTERNATIVE SHINDENGEN (D1F20)

(S1ZAS4) SHINDENGN 1.2A DUAL SCHOTTKY DIODE

(S1ZAS4) SHINDENGN 1.2A DUAL SCHOTTKY DIODE

(BAS19) SMALL SIGNAL DIODE SOT23 PACKAGE

(ZHCS750) ZETEX SMALL SIGNAL SCHOTTKY DIODE SOT23 PACKAGE

(NLC565050T-3R9K) TDK 3.9uH SURFACE MOUNT INDUCTOR

(NLC565050T-3R9K) TDK 3.9uH SURFACE MOUNT INDUCTOR

(DMF-50424N) OPTREX 128 X 64 GRAPHIC DISPLAY

(MDS4) 4 WAY MINI DIN SOCKET

(95001-2611) MOLEX 6 WAY DATA SOCKET

(MJ-179P) DC POWER SOCKET

(B 3B-PH-SM3-TB) 3 WAY PCB SOCKET FROM JST

(PKM35-4A0) MURATA PIEZO CERAMIC SOUNDER

(CR2040) 280mA-Hr 3V LITHIUM PCB MOUNTED BATTERY

11

Page 13

Parts List - Interrupter Transducer

Designation

IC1

IC2

IC3

IC4

IC5

IC6

IC7

IC8

TR1

TR2

TR3 NOT USED

R1 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R2 1.8K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 0805

R3 10K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 0805

R4 47 OHM SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 0805

R5 680 OHM SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R6 NOT USED

R7 NOT USED

R8 1M SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R9 0.1 OHM 0.25 WATT RESISTOR

R10 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R11 6.8K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R12 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R13 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R14 33K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R15 4.7K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R16 10K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R17 10K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R18 100K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R19 100K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R20 1M SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R21 1M SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R22 100K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R23 100K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R24 1.5K SURFACE MOUNT RESISTOR 0.125 WATT 1% SIZE 1206

R25 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R26 10K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R27 390 OHM SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R28 100K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

R29 1K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 0805

R30 4.7K SURFACE MOUNT RESISTOR 0.125 WATT 5% SIZE 1206

C1 NOT USED

C2 10nF MULTILAYER SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C3 10uF16V TANTALUM SURFACE MOUNT CAPACITOR

C4 100uF16V TANTALUM SURFACE MOUNT CAPACITOR

C5 100uF 25 VOLT ELECTROLYTIC CAPACITOR 0.1" PITCH

C6 47uF 16 VOLT ELECTROLYTIC CAPACITOR 0.1" PITCH

C7 100uF 16 VOLT ELECTROLYTIC CAPACITOR 0.1" PITCH

C8 100uF 16 VOLT ELECTROLYTIC CAPACITOR 0.1" PITCH

C9 1nF MULTILAYER SURFACE MOUNT CERAMIC CAPACITOR 5% SIZE 1206

(LM393M) DUAL LOW POWER SURFACE MOUNT COMPARATOR

(OP490GS) QUAD LOW POWER SURFACE MOUNT PRECISION OP-AMP

(LP2951CM) LOW DROP OUT ADJUSTABLE SURFACE MOUNT REGULATOR

(LM2931M-5.0) LOW DROP OUT 5 VOLT SURFACE MOUNT REGULATOR

(MAX187CCWE) SERIAL A/D ALTERNATIVE MAX189 SUFFIX (A,B OR C) CWE

(LT1054CS8) SURFACE MOUNT VOLTAGE CONVERTOR

(BU4S11) OR (BU4S01) INDIVIDUAL CMOS GATE

(ZRT040GC1) 4.01V SURFACE MOUNT REFERENCE (NOT USED WITH MAX187)

(ZTX869) E-LINE NPN TRANSISTOR

(ZTX869) E-LINE NPN TRANSISTOR

Description

12

Page 14

C10 1nF MULTILAYER SURFACE MOUNT CERAMIC CAPACITOR 5% SIZE 1206

C11 10nF MULTILAYER SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

C12 100pF CERAMIC CAPACITOR 0.1" PITCH

C13 100pF CERAMIC CAPACITOR 0.1" PITCH

C14 100pF CERAMIC CAPACITOR 0.1" PITCH

C15 100pF CERAMIC CAPACITOR 0.1" PITCH

C16 220nF MULTILAYER SURFACE MOUNT CERAMIC CAPACITOR SIZE 1206

D1 GENERAL PURPOSE SURFACE MOUNT 1A DIODE

D2 NOT USED

D3

D4

D5

BAT 5 x 1/3AA SIZE 110mA-hr SANYO BATTERY PACK

PT1

LED LOW CURRENT YELLOW LED

M1

(1N4148) GENERAL PURPOSE SMALL SIGNAL DIODE

(10BQ040) 1A SCHOTTKY SURFACE MOUNT DIODE

(10BQ040) 1A SCHOTTKY SURFACE MOUNT DIODE

(176PC07HD2) HONEYWELL 7" H20 PRESSURE TRANSDUCER

(GDAY 025 X20 B25) EMMESEM ROTARY SOLENOID 6.8V 7% DUTY 1.25 OHMS 65 DEG

13

Page 15

Technical Support

Great Britain and World Headquarters

Micro Medical Ltd

PO Box 6

Rochester

Kent ME1 2AZ

Telephone + 44 (0)1634 360044

Fax +44 (0)1634 360055

Web Site http://www.micromedical.com.uk

Email support@micromedical.com.uk

Contact Micro Medical Ltd for the local agent in your region or country for local service:

14

Page 16

Fault Analysis

The following analysis is only a guideline and should be carried out in a logical sequence. If the fault is

still apparent after the following suggestions then the unit should be fault found using the circuit

descriptions and circuit diagrams provided.

When the unit is turned on there is no display present

-Rotate contrast thumb wheel anti-clockwise to see if screen darkens.

-Connect charger to see if screen darkens and charging light illuminates.

When the unit is turned on the display is dark purple

-Rotate contrast thumb wheel clockwise to see if screen colour becomes lighter and characters are

displayed.

-Connect charger to see if screen characters appear.

The recorded values are low

-Ensure that the unit is calibrated – Refer to operating manual.

-Ensure that the mouthpiece holder is fully inserted into the interrupter transducer unit.

-Check that the resistive element is not damaged.

The shutter does not activate

-Check that the battery low message is not displayed on the LCD display

-Ensure that the interrupter transducer is connected to the microcomputer unit.

15

Page 17

16

Page 18

17

Loading...

Loading...