Page 1

A76 service manual

Page 2

2

content

1、 Product introduce..………..p3-p4

2、 Disassembly guide ……….p5-p17

3、Structure parts diagram…..p18

4、 Repairing guide …………...p19-p29

Page 3

3

Product introduce

Page 4

4

Product introduce

Model :MA76

Product size:146 * 75.3 *10.4

Platform:MTK6572,dual-core 1.2GHz

Memory: 4GB+4Gb (Nand&sdram+RAM)

System:Android 4.2

Frequency band: WCDMA:2100,GSM:900/1800MHz

Battery: 2000mAh

charger: Travel charger

USB cable: MICRO 5PIN

earphone: 3.5jack

LCD&TP: 5.0 FWVGA, Capacitance TP, multi-point touch

Camera:0.3M and 5.0M CMOS

Support:BT2.1,WIFI,FM,NTC。

Support:3D graphics accelerator,accelerator sensor, distance sensor, light

feeling sensor。

Page 5

5

Hot gun

Tweezer

Solder iron

Tommy bar

Cross Screw driver

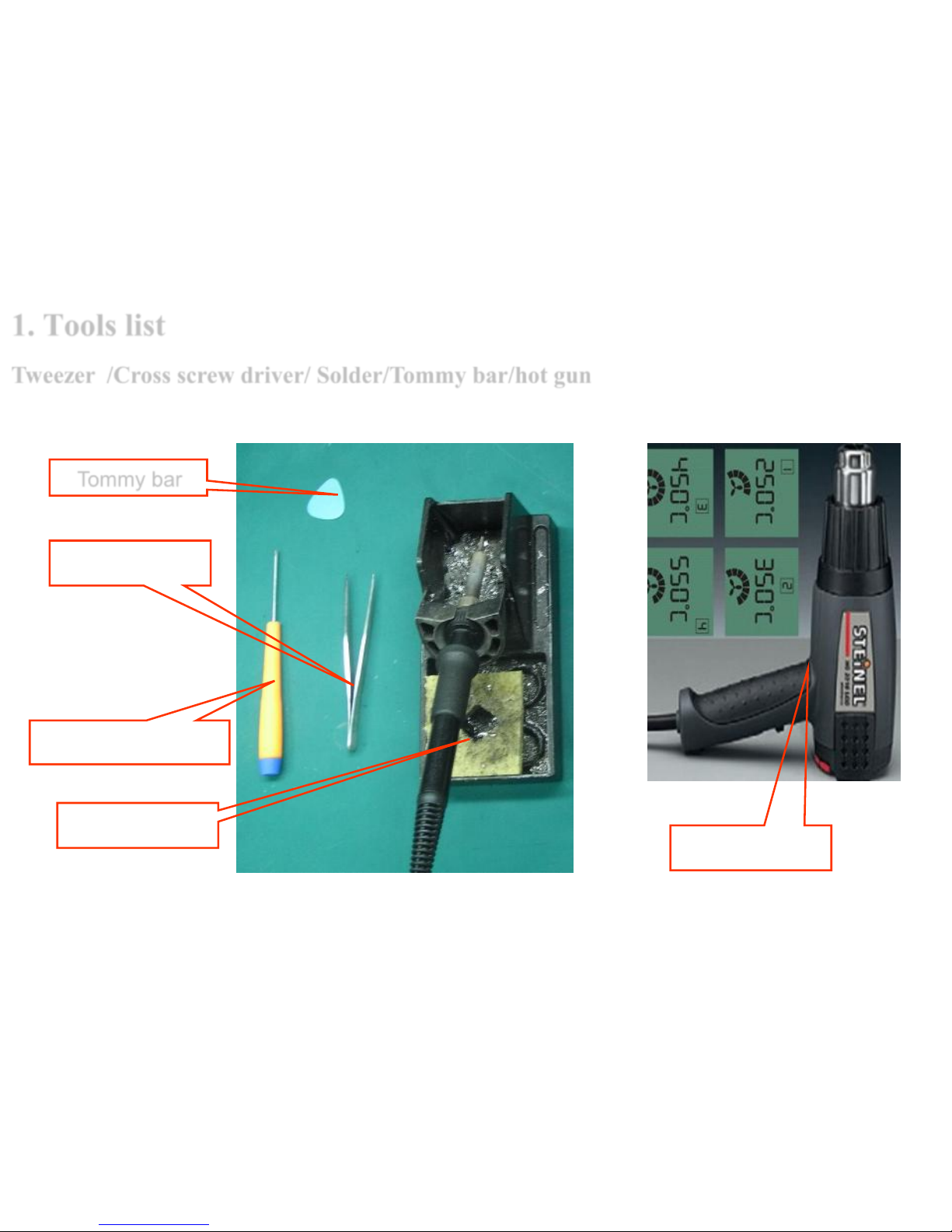

1. Tools list

Tweezer /Cross screw driver/ Solder/Tommy bar/hot gun

Disassembly guide

Page 6

6

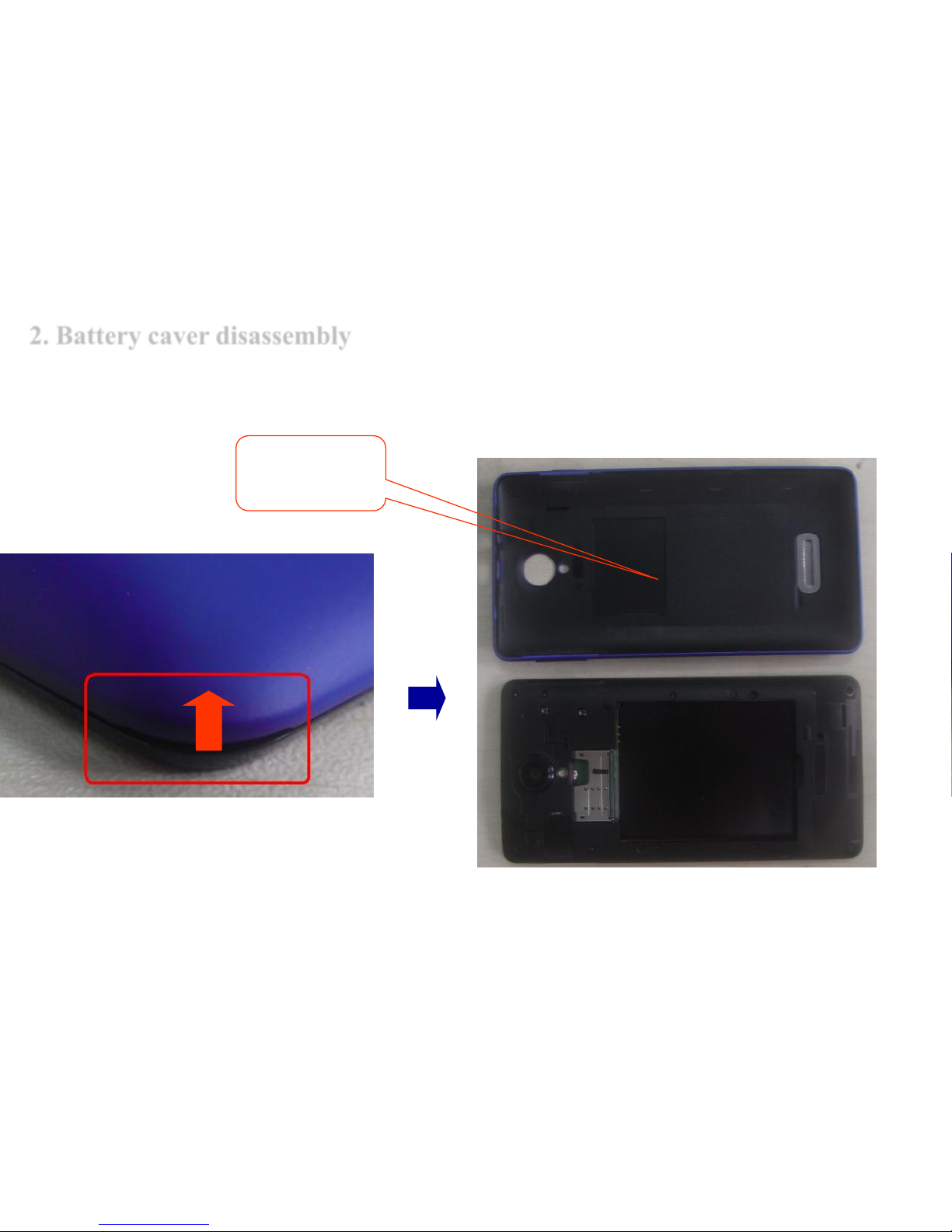

2. Battery caver disassembly

open the battery cover

,

as the Fig. 1

Fig. 1

Disassembly guide

Battery

cover

Page 7

7

3. Back caver disassembly

1) Unscrew 12 screws in back cover ,as the Fig.2;

Fig. 2

Disassembly guide

Page 8

8

Fig. 3

2) Disassemble back cover with Tommy bar ,as the Fig.3;

Disassembly guide

Back

cover

SPK

Page 9

9

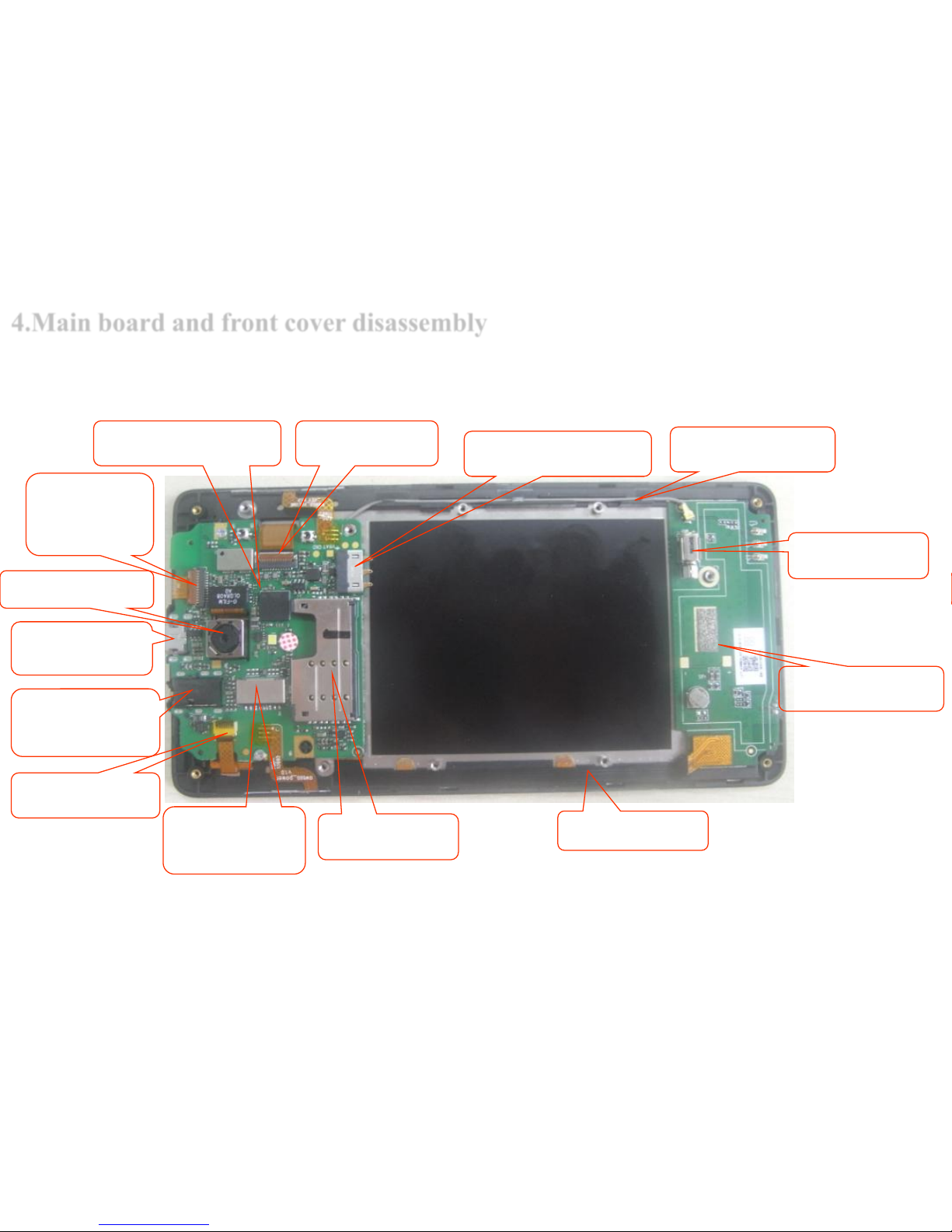

4.Main board and front cover disassembly

1)The main components of distribution,as the fig.4;

Fig.4

Disassembly guide

LCD con. Main PCBA

1.2M

CAM con.

8M CAM.

USB con.

Earphoe

con.

TP con.

T card

con.

SIM con.

Battery con.

Main FPC

vibrator

Sub PCBA

RF cable

Page 10

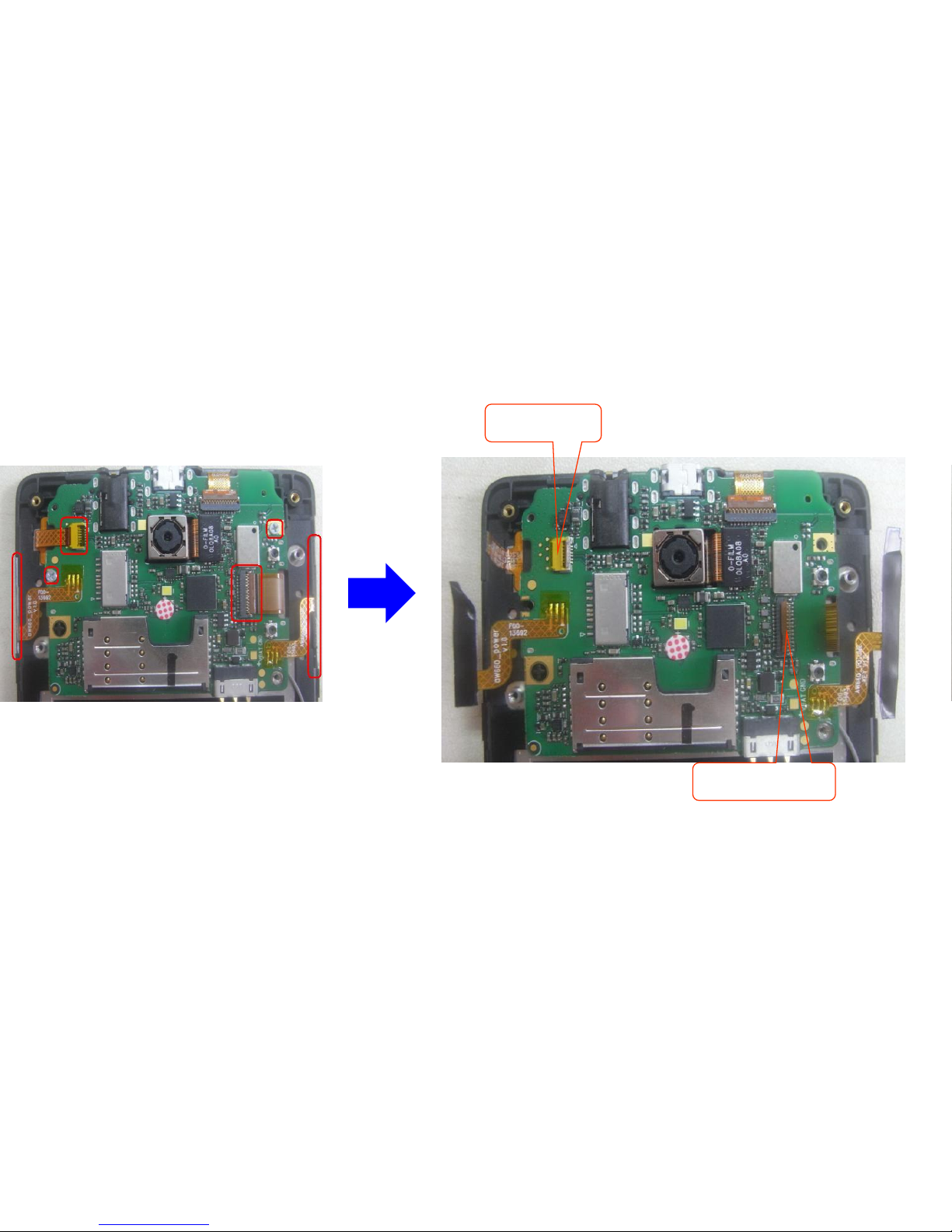

2)remove two screws and open the LCD con.& TP con. ,and remove the

volume key FPC & power key FPC as the fig.5;

10

Fig.5

Disassembly guide

LCDcon.

TPcon.

Page 11

3)open the main board and remove the RF cable con. And main FPC

con..as the FIG.6

11

Fig.6

Disassembly guide

Main FPC con. RF cable con.

Main board

Page 12

remove the light sensor and 0.3M camera,as the fig.7;

12

5. 0.3M and 5M camera & light sensor disassembly

Fig.7

Disassembly guide

5M cam.

0.3M cam.

Light sensor&holder

Light sensor con.

Page 13

13

Fig.8

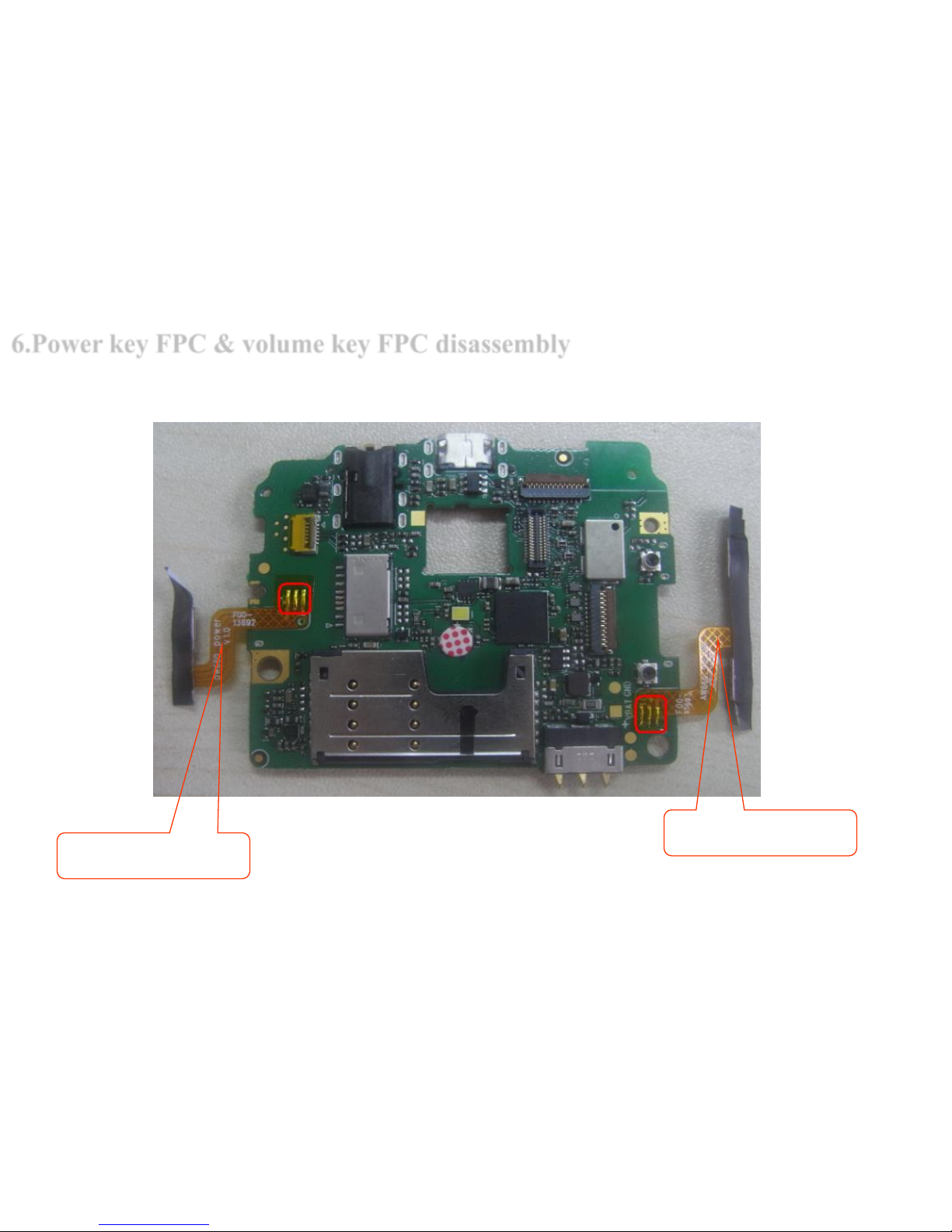

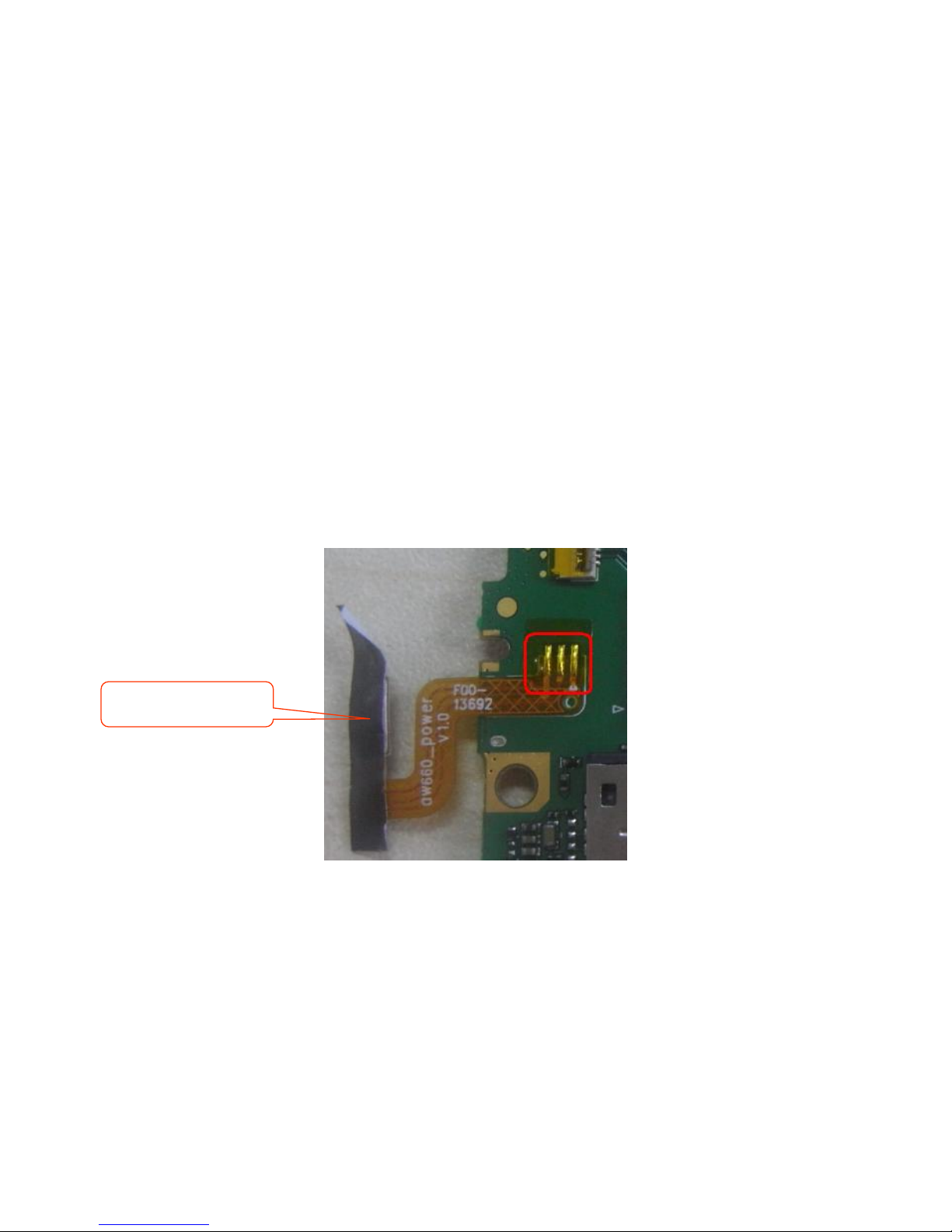

6.Power key FPC & volume key FPC disassembly

remove the power key FPC and volume key FPC with the iron,as the fig.8;

Disassembly guide

Power key

FPC

Volume key

FPC

Page 14

14

Fig.9

remove the Speaker camera and receiver,as the FIG.9;

7. Speaker & receiver disassembly

Disassembly guide

receiver

Page 15

15

Fig.10

8. RF cable and Main FPC disassembly

Remove the RF cable and Main FPC ,as the fig.10

Disassembly guide

RF cable

Main FPC

Page 16

16

Fig.11

9. Sub PCBA disassembly

remove the sub PCBA from the ,as the fig.11;

Disassembly guide

Sub PCBA

vibrator

Page 17

17

Fig.12

10.MIC disassembly

Remove the MIC,as the fig.12;

Disassembly guide

MIC con.

Page 18

18

Structure parts diagram

Battery

cover

Back

cover

3in1 module

(LCD, TP & front cover

RF cable

SPK

5M camera

0.3M camera

sub PCBA

Main

PCBA

Light

sensor

Sensor

holder

receiver

Main FPC

Page 19

19

Repairing guide

1. LCD

a. Check if the SW is correct, otherwise to upgrade the SW;

b. Check the LCD if is ok, otherwise change a new LCD;

c. If that the LCD loose, re-assemble the LCD and test;

d. Checking the LCD connector if is ok, otherwise re-solder it or change a new one;

e. Checking the circuit around the LCD connector.

LCD

connector

Page 20

20

2. Camera

a. Checking the camera is assemble ok, re-assemble the camera and test;

b. Using the good camera to do cross test, it can check if the camera is ok;

c. Checking the camera connector if is ok as below picture, otherwise to

re-solder or change a new one;

d. Checking the circuit around the camera connector.

Repairing guide

Back Camera

connector

Front Camera

connector

Page 21

21

3. TP

a. Checking the SW and upgrade the SW;

b. Checking the FPC of TP and re-assemble it;

c. Using the good TP to do cross test;

d. Checking the TP connector, otherwise re-solder or change a new one;

e. Checking the circuit around the TP connector.

Repairing guide

TP Connector

Page 22

22

4.Ring

a. Checking the shrapnel of speaker if is ok;

b. Checking the resistance of speaker if is ok, otherwise to change a new

one;

c. Checking the FPC if is ok;

d. Checking SPK-FPC if connector with sub-board is ok.

Repairing guide

Page 23

23

5.receiver

a. Checking the shrapnel of receiver if is ok;

b. Checking the resistance of receiver if is ok, otherwise to

change a new one;

c. Checking the connector point on the main board if is ok, as

below picture;

c. Checking the receiver circuit if is ok.

Repairing guide

Page 24

a. Checking the MIC and Vibrator is cold soldering, re-solder it;

b. Change the MIC and Vibrator;

c. Checking the circuit of MIC and Vibrator;

d. Checking the FPC if connect ok.

24

6.MIC and Vibrator

Repairing guide

MIC con.

Page 25

a. Checking the shrapnel of earphone if is ok;

b. Checking the connector point on the main board if is ok, as below

picture;

c. Change earphone connector;

c. Checking the circuit of earphone.

25

7. Earphone

Repairing guide

earphone

Page 26

a. Checking the voltage of battery if is 3.8-4.2V and connect ok;

b. Upgrade the SW;

b. Checking the power on key and circuit around it.;

26

8.No Power On

Repairing guide

Power On

Page 27

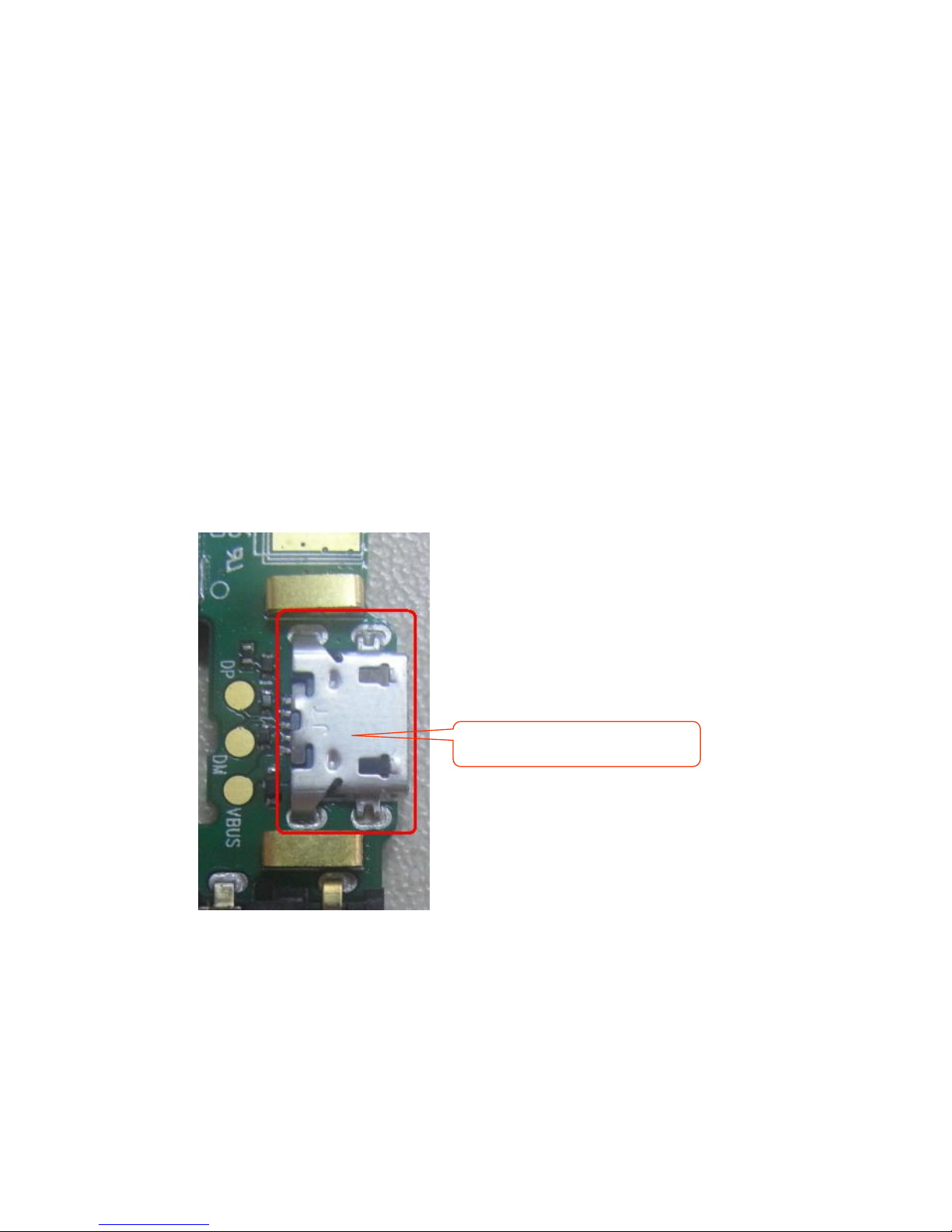

a. Checking the voltage of battery if is over 3.4V;

b. Checking the charger and USB cable if is ok;

c. Checking the USB connector and circuit if is ok.

27

9.No charging

Repairing guide

USB Connector

Page 28

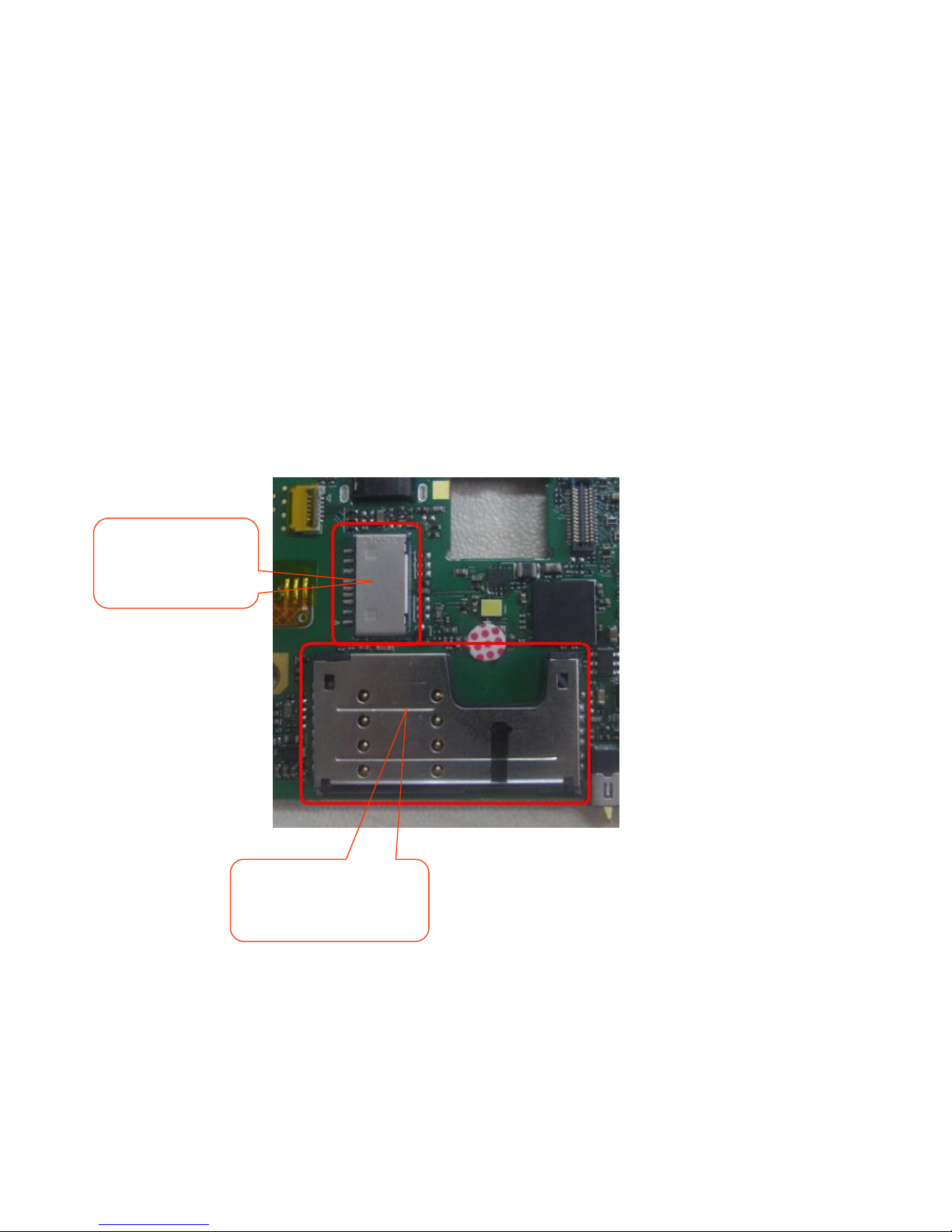

a. Checking the connector of T –card and SIM card;

b. Change the connector of T –card and SIM card;

28

10.No SIM card and No memory card

Repairing guide

T-card

connector

SIM

Connector

Page 29

a. Checking RF line if that is broken;

b. Checking RF line assemble if is ok;

29

11.Signal

Repairing guide

RF connector

Sub-board RF

connector

Page 30

End

Q&A

Loading...

Loading...