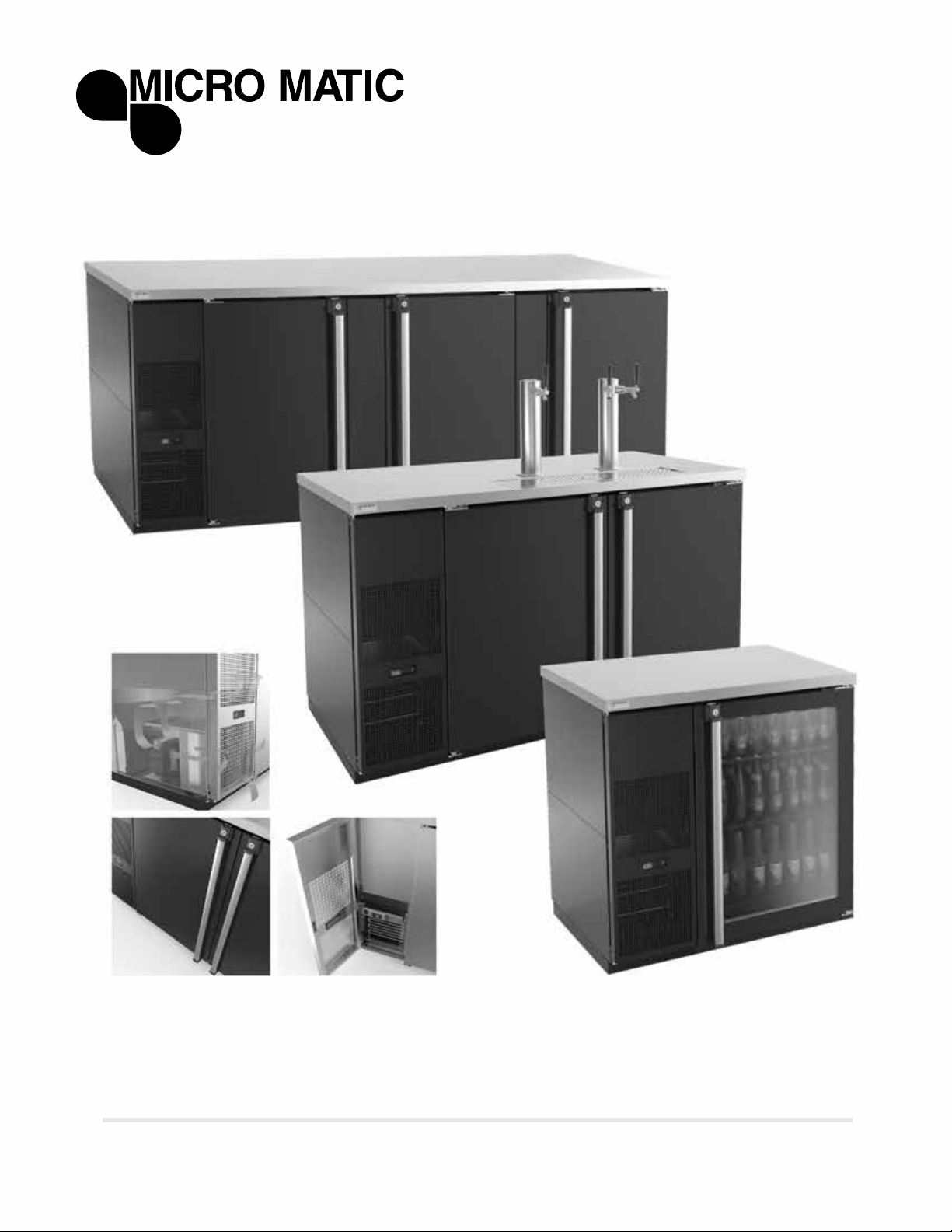

PRO-LINE™ REFRIGERATION E-SERIES

USER MANUAL

// www.micromatic.com

™

CONTENTS

1 RECEIVING AND INSPECTING 3

2 SPECIFICATIONS 4

3 INSTALLATION 5

3.1 UNCRATING 5

3.2 SEALING 5

3.3 CLEANING OF CABINET 5

3.4 LOCATION 6

3.5 TAPPING INSTRUCTIONS 7

3.6 DATA PLATE 8

3.7 ELECTRICAL CONNECTIONS 8

3.8 SHELVING INSTALLATION 9

4 OPERATIONS 9

4.1 MECHANICAL TEMPERATURE CONTROL 9

4.2 DESCRIPTION OF BUTTONS ON THE CONTROLLER 10

4.3 ELECTRONIC TEMPERATURE CONTROL 11

4.4 DEFROST 12

5 MAINTENANCE 13

5.1 STAINLESS STEEL CARE AND CLEANING 13

5.2 CLEANING THE CONDENSER COIL 14

5.3 DRAIN MAINTENANCE 15

6 TROUBLESHOOTING 16

7 WIRING DIAGRAMS 17

8 WARRANTY 19

9 TECHNICAL INFORMATION 20

// www.micromatic.com

2

1 // RECEIVING AND INSPECTING

Upon receiving your new Micro Matic Pro-Line™ Refrigeration E-Series™ equipment,

check the package and the unit for any damages that may have occurred during

transportation. Visually inspect the exterior of the package. If damaged, open and

inspect the contents with the carrier. Any damage should be noted and reported on

the delivering carrier’s receipt.

In the event that the exterior is not damaged, yet upon opening, there is concealed

damage to the equipment notify the carrier immediately. Notication should be made

verbally as well as in written form. Request an inspection by the shipping company of

the damaged equipment. Retain all crating material until inspection has been made.

Finally, contact Micro Matic.

Open the compressor compartment housing and visually inspect package. Be sure

lines are secure and base is intact.

A NOTE FROM OUR QUALITY CONTROL MANAGER

Congratulations on your new purchase. We would like to welcome you to the Micro

Matic team. The unit in front of you is a great piece of equipment that will become one

of your most reliable tools in your daily operations for years to come!

Prior to shipping your unit, our trained service technicians tested your unit for a period

of 12 hours. This performance test was recorded and a copy of the results is included

with this service manual. During this test, our highly qualied personnel inspected your

machine for leaks, lose components, and improper noise levels. We also tested the

cooling performance in an effort to give you the best and most reliable unit possible.

// www.micromatic.com

3

2 // SPECIFICATIONS

Crated

Model Doors Tower Faucets Kegs HP AMP

Weight

Length Width Height BTU

(lbs)

MDD23-E 1 1 1 1 1/6 2.5 172 24.5" 30.5" 40" 850 5.64 oz

MBB/DD36-E 1 1 1 1 1/6 3.6 172 36.75" 29.5" 40" 850 6.35 oz

MBB/DD58-E 2 2 3 3 1/3 6.5 318 59.5" 29.5 37" 2400 9.8 oz

MBB/DD68-E 2 2 3 3 1/3 6.5 359 69.5" 29.5" 37" 2400 9.8 oz

MBB/DD78-E 3 2 4 4 1/3 6.5 377 80" 29.5" 37" 2400 9.8 oz

MBB/DD94-E 3 2 4 5 1/3 6.5 406 95.5" 29.5" 37" 2400 9.8 oz

Voltage 115v 60Hz

Crated

Model Doors Shelves HP AMP

Weight

Length Width Height BTU

(lbs)

MBB58DT-E 2 3 1/3 6.5 318 59.5" 29.5 37" 2400 9.8 oz

MBB58GDT-E 2 3 1/3 6.5 318 59.5" 29.5 37" 2400 9.8 oz

MBB58GSDT-E 2 3 1/3 6.5 318 59.5" 29.5 37" 2400 9.8 oz

MBB58SDT-E 2 3 1/3 6.5 318 59.5" 29.5 37" 2400 9.8 oz

Voltage 115v 60Hz

Refrigerant

Charge

(R-134 a)

Refrigerant

Charge

(R-134 a)

// www.micromatic.com

4

3 // INSTALLATION

3.1 UNCRATING

Cut and remove the outer packaging. Cut the (4) four clamps that hold the refrigerator

to the skid lift the unit off the skid. If machine was laid down during this operation leave

the cabinet up right for 24 hours before plugging into power source. To install draft

arm, rst place rubber washer over draft arm mounting holes in cabinet top and put

beer line connector down through hole. Next secure draft arm with four bolts provided.

To retain complete mobility of the cooler, the accessory CO2 tank (up to ve pounds in

size) must be placed inside the cabinet.

3.2 SEALING

WHEN SANITATION CODES REQUIRE SEALING TO FLOOR, THIS METHOD MAY

BE USED

1. Tip cabinet and apply a bead of silicone seal on bottom edge of the base.

2. Return cabinet to upright position and using proper equipment, lift cabinet into location.

Heavy appliances should not be used on the same circuit with the cooler.

CAUTION: If an extension cord is necessary, use only a three wire grounding type of

wire, size 16 AWG or heavier; do not exceed 20 feet in length. The use of ungrounded

cords or overloaded circuit voids compressor warranty.

3.3 CLEANING OF CABINET

The exterior of the cabinet is either black vinyl or stainless steel and should be cleaned

only with lukewarm water, taking care not to scratch the surface. Mild detergents are

also recommended. The interior can be cleaned in a similar manner. THE CONDENSER

MUST BE CLEANED AT REGULAR INTERVALS. FAILURE TO DO SO CAN CAUSE

COMPRESSOR MALFUNCTION AND WILL VOID WARRANTY.

Clean approximately every six months, depending upon usage, dust, etc. Pull cabinet

away from wall and thoroughly vacuum the condenser and surrounding surfaces.

// www.micromatic.com

5

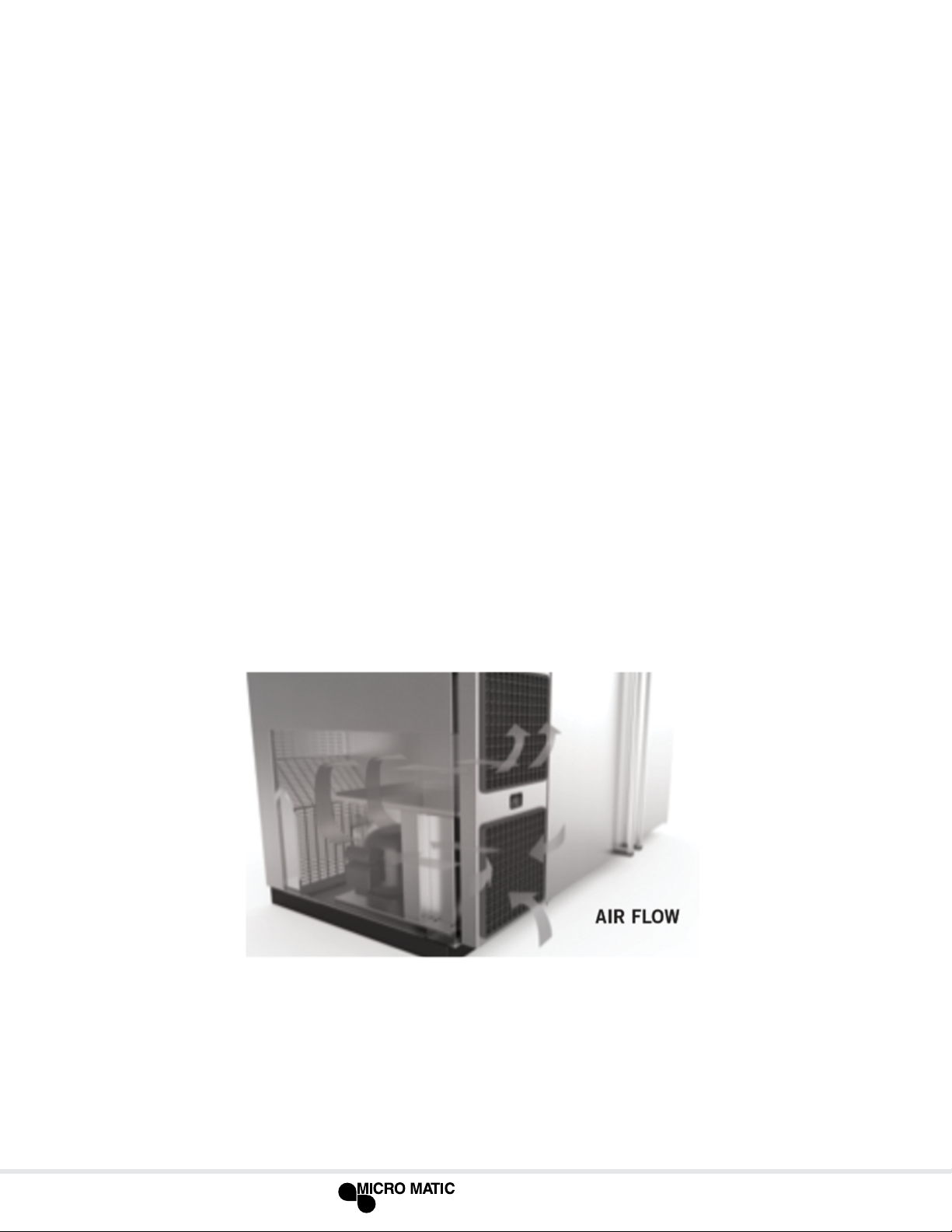

3.4 LOCATION

Units represented in this manual are intended for indoor use only. Be sure the location

chosen has a oor strong enough to support the total weight of the unit and contents.

For the most efcient operation, be sure to provide good air circulation inside and

outside of the unit.

NOTICE: This cooler is designed to maintain your beer temperature within the most

desirable range of 32° to 38°F. You can expect this temperature with the proper

temperature control setting and in a normal environment. It is important to understand

that when the beer is purchased, it must be installed inside the cooler as soon as

possible to avoid excessive warm-up of the beer. If this happens, it may take many

hours for the temperature to be reduced to the desirable range. No provision is made

for rapid cooling of beer which has become too warm.

INSIDE CABINET

The rst cleaning must be made when you unpack the unit and before switching it on.

Clean it with water and a mild detergent.

OUTSIDE CABINET

Be sure the unit has good air circulation in front. Avoid hot corners and locations near

stoves and ovens. The place where the refrigerator is placed must be open and free of

dust and debris.

// www.micromatic.com

6

3.5 TAPPING INSTRUCTIONS

The largest keg this cooler accepts is a half keg. The Sankey type is the most modern

and easiest of all to tap with the available taps. The type of keg and tap you use

will depend on the brand of beer your purchase. Your beer distributor can provide

additional instructions and tips on how to maintain the beer to your satisfaction.

Following these tapping instructions, place the keg in front of cabinet for tapping. After

all connections are complete and checked for leaks, place the CO2 bottle in the rear

(inside) of cabinet with the pressure gage visible for reading, then place the keg in

position, allowing the door to be closed completely without interference. Make certain

that beer line and keg are not touching the evaporator.

HOW TO TAP A KEG OF BEER (SANKEY-TYPE)

1. Connect line from pressure source to gas nipple (use clamp). Using coupling

washer connect beer line to thread on probe. Holding ats on probe with wrench

tighten wing nut or hex nut on beer hose.

2. Align tap with lugs in barrel, insert tap.

3. Turn tap body handle ¼ turn clock wise until tight to secure tap to barrel. Turn on

pressure regulator.

4. Pull out tap handle and push down, tapping keg – beer will ow to faucet.

// www.micromatic.com

7

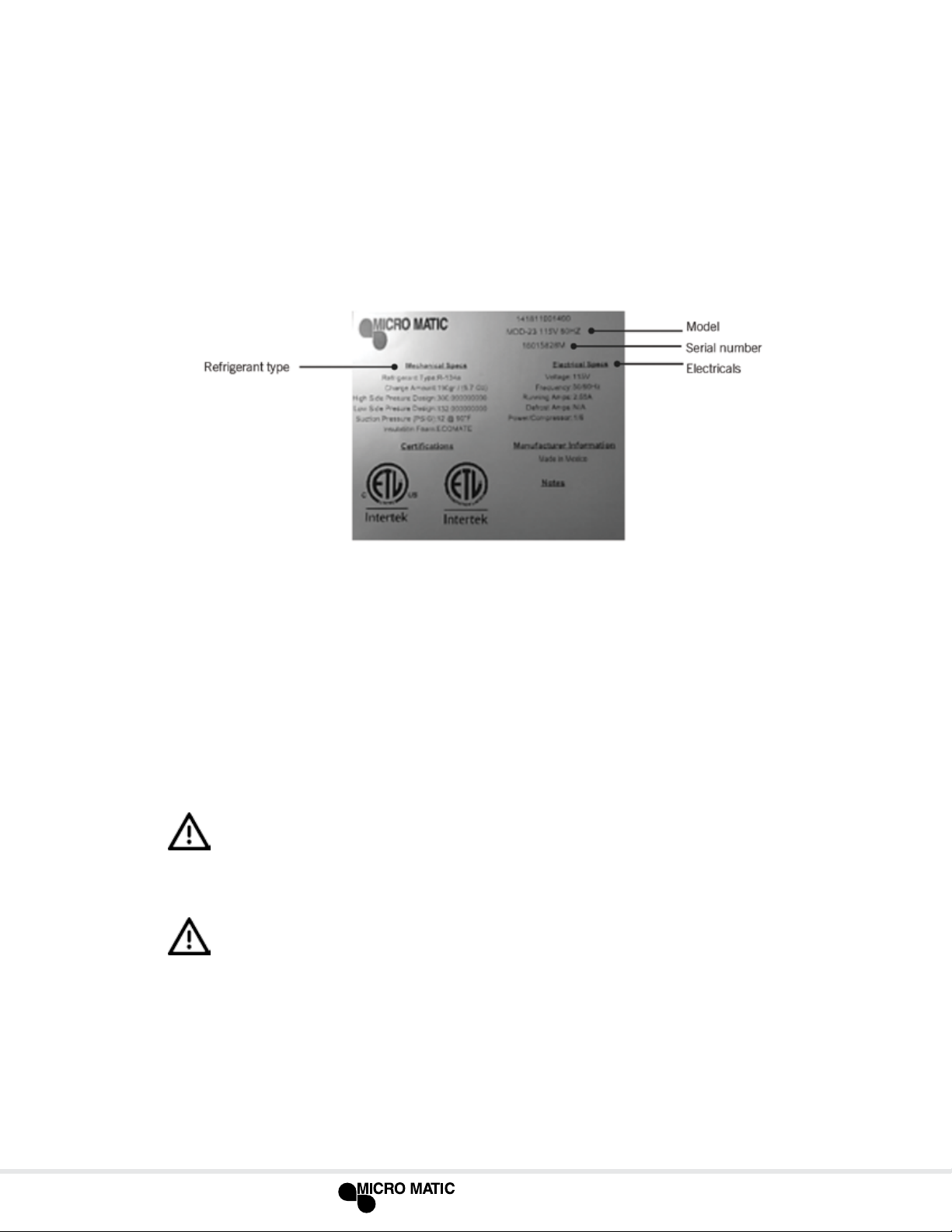

3.6 DATA PLATE

The data plate in located inside the unit, near the top front left corner. Under no

circumstances should the data plate be removed from the unit. The data plate is

essential to identify the particular features of your unit and is of great benet to

installers, operators and maintenance personnel. It is recommended that, in the event

the data plate is removed, you copy down the essential information in this manual for

reference before installation.

3.7 ELECTRICAL CONNECTIONS

Refer to the amperage data in this manual or on data plate and your local code or the

National Electrical Code to be sure unit is connected to the proper power source. Verify

correct incoming voltage according to the Data Plate information.

A protected circuit of the correct voltage and amperage must be run for connection

of the supply cord. Unit must be grounded and connected in accordance with NEC

Article 422 Appliances.

DANGER: Power must be turned off and disconnected from the power source

whenever performing maintenance, repair or cleaning the condensing unit. If

unit still running when power is off, disconnect power at the circuit breaker

before unplugging the unit.

WARNING: Unit and compressor warranties are void if failure is due to improper

electrical installation.

// www.micromatic.com

8

3.8 SHELVING INSTALLATION

1. Hook shelf rails onto shelf pilasters

2. Position all two shelf rails equal in distance from the oor for level shelves.

3. Wire shelves are oriented so that cross support bars are facing down.

4. Place shelves on shelf clips making sure all corners are seated properly.

4 // OPERATIONS

4.1 MECHANICAL (ANALOG) TEMPERATURE CONTROL

Before you connect the unit to the power supply, verify the thermostat is NOT in the OFF

position (the position of the thermostat must be different than zero). If the thermostat

is in the OFF position, the compressor will not run. Keep in mind, the evaporator fan

and lights will still have power while the thermostat is in the OFF position.

The knob of the thermostat is the temperature controller. This is located inside the

cabinet. Please be sure that the knob of thermostat is pointing to the yellow arrow

(Figure #3). This position is recommended by the factory to assure correct function of

the equipment (see Figure #1 below).

NOTE: Keep in mind, if you move the knob to a different position than the

position recommended from factory, the temperature will change, as well.

The knob position near the number one, gives you the warmest temperature and the

knob position near the number seven, gives you the coldest temperature.

// www.micromatic.com

9

4.2 DESCRIPTION OF BUTTONS ON MODELS WITH DIGITAL CONTROLLER

The Pro-Line

desirable range of 36° to 38°F. You can expect the Pro-Line™ unit to maintain

temperature with the proper temperature control setting and in a normal environment.

If a different setting is desired, follow these

instructions to adjust the thermostat.

™

dispenser is designed to maintain keg temperature within the most

To display target set point,

in programming mode

it selects a parameter or

conrms an operation

To start a manual defrost

(only XR02CX)

In programming mode it

browses the parameter

codes or increases the

displayed value

In programming mode it

browses the parameter

codes or decreases the

displayed value

Symbol Mode Operation

On Compressor enabled

Flashing Anti short cycle delay enabled (AC parameter)

On Defrost in progress

Flashing Dripping in progress

On Measurement unit

Flashing Programming mode

On Measurement unit

Flashing Programming mode

10

// www.micromatic.com

4.3 ELECTRONIC (DIGITAL) TEMPERATURE CONTROL

HOW TO SEE THE SET POINT

1. Push and immediately release the key, the set point will be displayed.

2. Push and immediately release the key or wait about ve (5) seconds to return

to normal display.

HOW TO CHANGE THE SET POINT

1. To change the set point number, push the key for more than two (2) seconds.

2. The number of the set point will be displayed and the “ ” or “ ” LED will blink.

3. To change the set number push the arrow up or down keys within ten (10) seconds.

4. To hold the new set point number push the key again or wait ten (10) seconds.

NOTE: The minimum value that you can set in the controller is 32°F (0°C) and the

maximum value you can set is 40°F (4.4°C)

4.4 DEFROST

The equipment with electronic controller will not require manual defrost due the

equipment has an automatic defrost every 6 hours. If a manual defrost is required

push and hold the defrost button for 5 seconds then the equipment will start defrost.

For equipment with manual thermostat a manual defrost could be required, unplug the

equipment from the power supply for 15 minutes and leave the door open. Continue

until ice melts.

// www.micromatic.com

11

5 // MAINTENANCE

5.1 STAINLESS STEEL CARE AND CLEANING

Proper cleaning of stainless steel requires soft cloths; never use steel pads, wire

brushes or scrapers!

Cleaning solutions need to be alkaline or non-chloride cleaners. Any cleaner containing

chlorides will damage the protective lm of the stainless steel. Chlorides are also

commonly found in hard water, salts, household and industrial cleaners. If cleaner

containing chlorides is used be sure to rinse repeatedly and dry thoroughly upon

completion.

Routine cleaning of stainless steel can be done with soap and water. Extreme stains

or grease should be cleaned with a non-abrasive cleaner and plastic scrub pad. There

are also stainless steel cleaners available which can restore and preserve the nish of

the steel's protective layer.

Never use an acid based cleaning solution! Many food products have an acidic content

which can deteriorate the nish. Be sure to clean ALL food products from any stainless

steels surface. Common items include peppers, tomatoes and other vegetables.

5.2 CLEANING THE CONDENSER COIL

DANGER: Power must be turned off and disconnected from the power source

whenever performing maintenance, repair or cleaning the condensing unit.

Disconnect unit from power supply. Remove front bottom panel and carefully slide out

the condensing unit. The condenser coil requires regular cleaning; recommended is

every 30 – 60 days, depending on the accumulation of dust and grease.

If the buildup on the coil consists of only light dust and debris the condenser coil can

be cleaned with a simple brush. Heavier dust build up may require a vacuum or even

compressed air to blow though the condenser coil.

If heavy grease is present there are de-greasing agents available for refrigeration

use and specically for the condenser coils. The condenser coil may require a spray

with the de-greasing agent and then blown through with compressed air. Be sure all

electrical and mechanical parts are dry before turning on the power. Never use a high

pressure water wash for this cleaning procedure as water can damage the electrical

components located near or at the condenser coil! Do not place lter material in front

of condenser coil. This material blocks air-ow to the coil similar to having a dirty coil!

12

// www.micromatic.com

If you keep the condenser clean you will minimize your service expense and lower

your electrical costs. Failure to maintain a clean condenser coil can initially cause high

temperatures and excessive run times. Continuous operation with dirty or clogged

condenser coils can result in compressor failures.

Neglecting the condenser coil cleaning procedures WILL VOID YOUR WARRANTY

associated with the compressor or cost to replace the compressor!

To put back the condensing unit in its place, slide in the unit carefully. BE SURE

DRAIN PIPE IS LOCATED OVER THE PAN. Replace front bottom panel.

5.3 DRAIN MAINTENANCE

Each unit has a drain located inside the unit which removes the condensation from

the evaporator coil and evaporates it at an external condensate evaporator pan. Each

drain can become loose or disconnected from moving or bumping the drain. IF YOU

NOTICE EXCESSIVE WATER ACCUMULATION ON THE INSIDE OF THE UNIT

be sure the drain tube is connected from the evaporator housing to the condensate

evaporator drain pan.

IF WATER IS COLLECTED UNDERNEATH THE UNIT you may want to check the

condensate evaporator drain tube to be sure it is still located inside the drain pan. The

leveling of the unit is important as the units are designed to drain properly when on a

level surface, if your oor is not level this can also cause drain problems. Be sure all

drain lines are free of obstructions; typically food products are found blocking drain

lines causing water to back up and overow the drain pan.

// www.micromatic.com

13

5.4 PROCEDURE TO INSTALL THE AIR CHANNELS AND DRAFT TOWERS

(ONLY “DD” MODELS)

MODELS: MDD23-E, MDD58-E, MDD68-E, MDD78-E & MDD94-E

This procedure describes how to install the air channel needed to provide cold air

directly into the beer towers.

TOOLS NEEDED: Philips screwdriver

STEP 1 Locate the gaskets and bolts included in with your Tower. Place gasket

over the pre-drilled holes and place the 4 screws thru the tower base.

Align the tower with screws and gasket to the cabinet top as shown

below while dropping the beer line(s) thru the top of the unit (Figure #1).

STEP 2 Tighten the screws using the nuts found in your tower box (Figure #2).

STEP 3 Identify the “COLD AIR HOSE” (Figure #3) which is found inside of

the equipment.

STEP 4 Introduce the “COLD AIR HOSE” (Figure #4) which is found inside of

the equipment into the tower’s base hole.

Push the cold air hose as far as possible up into the tower body. Be sure

and secure cold air hose by hooking on to beer hose elbow.

14

// www.micromatic.com

6 // TROUBLESHOOTING

Sometimes, working failures are due to simple causes which can be solved by the user.

Before asking for the help of a qualied technician, you have to do some verication.

These failures are not covered by the warranty:

1. Refrigeration does not work.

a. Check the unit is still connected to power supply.

2. Refrigerator does not reach temperature.

a. Check the thermostat is not in OFF position.

b. Check the unit is not on defrost cycle.

c. Check gasket is in good condition and door is sealed.

d. Check fan is moving. Open the door press and hold door switch for verication.

e. Don’t put any food inside until unit is at temperature.

f. Be sure castors or legs were installed.

3. There is water under the refrigerator.

a. Check the drain pipe is over the pan.

b. Check cabinet is level.

// www.micromatic.com

15

WIRING DIAGRAMS

MDD23-E

16

// www.micromatic.com

MDD/BB36-94-E

Electronic

Controller

PROBES NTC

AMB. PROBE

dixell XR02CX

L

N

BLUE

BROWN

BROWN

Red Display

COM/VC

L

BLK SMOOTH

BLK STRIPED

YELLOW

BROWN

ROCKER SWITCH

EVAP

FAN

LINE NEUTRE

JUNCTION

BOX

BLUE

BROWN

BLUE

GDN

NEUTRE

BLK SMOOTH

BLK SMOOTH

BLK STRIPED

SIGNAL FROM

CONTROLLER

BLK BLK

WHT

COMP

BLK

COND

BLUE

FAN

GDN

LIGHT SWITCH

WHITE

BLUE

LAMP's

Piloto

BLUE

NOTE: The lamp is only included for glass door models,

check with your sales representative.

GDN

// www.micromatic.com

17

8 // WARRANTY

One Year Parts & Labor Warranty: Micro Matic warrants to

the rst-end-user purchaser (the “User”) that the Micro

Matic brand equipment sold here under, except for parts

and accessories which carry the warranty of a supplier

(the “Equipment”) will be free from defects in material

and factory workmanship under normal conditions of use

and maintenance for a period of (1) one year from the

date of Installation (Warranty Commencement date), but

in no event to exceed (15) fteen months from the date of

shipment. Warranty is Not Transferable

Warranty Coverage: If there is a defect in material or factory

workmanship covered by this Warranty reported to Micro

Matic during the period the applicable Warranty is in force

and effect, Micro Matic will repair or replace, at Micro

Matic’s option, that part of the Equipment that has become

defective. Micro Matic will cover labor cost within one year

from the Warranty Commencement date or 15 months

from shipment date, whichever occurs rst. Micro Matic

shall bear all labor costs in connection with the installation

of these replacement parts, provided that, the installation is

conducted by Micro Matic or its authorized representative.

Charges for warranty travel time to round trip total of (2) two

hours or up to 100 miles total. Any charges exceeding those

stated herein or overtime rates must have prior authorization

by Micro Matic.

Additional Four Year Compressor Part Warranty: In addition

to the warranty set above. Micro Matic warrants the

compressor (part only) for an additional four (4) years

based on the installation date. This warranty is for defects

both in workmanship and material under the normal and

proper use and maintenance service. The four (4) year

extended warranty only applies to hermetically sealed

parts of the compressor and does not apply to any other

part or component, including, but not limited to cabinet,

temperature control, refrigerant, motor starting equipment,

fan assembly, or any other electrical or mechanical

component.

The original purchaser shall be responsible for returning the

defective compressor to Micro Matic prepaid. This warranty

shall be void if the compressor, in Micro Matic’s sole

judgment, has been subjected to misuse, neglect, alteration

or accident, operated contrary to the recommendations

specied by the Unit manufacturer, repaired or altered by

anyone other than Micro Matic in any way so as, in Micro

Matic’s sole judgment, to affect its quality or efciency or if

the serial number has been altered, defaced or removed.

This warranty does not apply to a compressor in any

unit that has been moved from the location where it was

originally installed.

Parts Warranty Coverage: Micro Matic warrants all new

machine parts produced or authorized by Micro Matic to be

free from defects in material and workmanship for a period

of 90 days from the Warranty Commencement Date. If any

defect in material and workmanship is found to exist within

the warranty period, Micro Matic will replace the defective

part without charge. Defective parts become the property

of Micro Matic.

Micro Matic will have no responsibility to honor claims

received after the date the applicable Warranty expires.

Notwithstanding the foregoing, any claim with reference to

the Equipment or any parts therefore for any cause shall be

deemed waived unless submitted by the User to Micro Matic

within thirty (30) days after the date the User discovered,

or should have discovered, the claim. In connection with

all claims under this Warranty, Micro Matic will have the

right, at its own expense, to have its representatives inspect

the Equipment at the User’s premises and to request all of

User’s records pertaining to the Equipment to determine

whether a defect exists, whether the conditions set forth in

this Warranty have been satised, and whether or not the

applicable Warranty is in effect.

Exclusions from and Conditions to Warranty Coverage: This

Warranty does not cover parts or accessories, which (a) carry

the warranty of a supplier or (b) are, abused. Application of

this Warranty is further conditioned upon the following:

Installation: The Equipment must be properly installed in

accordance with Micro Matic installation procedures.

No Alteration. The Equipment must not have been modied

or altered from its condition at the date of original installation.

Proper Maintenance and Operation: The Equipment must be

properly maintained and operated in accordance with Micro

Matic maintenance and operating procedures. All service,

labor and parts must be acquired from Micro Matic or its

authorized service representative for the User’s area.

This warranty is void if failure is a direct result of handling

and/or transportation, re, water, accident, misuse, acts of

god, attempted repair by unauthorized persons, improper

installation, if serial number has been removed or altered,

or if unit is used for purpose other than it was originally

intended.

Failure to comply with any of these conditions will void this

Warranty. In addition, this Warranty does not cover defects

due to apparent abuse, misuse or accident.

The foregoing warranty is in lieu of and excludes all other

warranties not expressly set forth herein, whether express

or implied by operation of law or otherwise, including but

not limited to any representation of performance and any

implied warranties of title, non-infringement, merchantability

or tness for a particular purpose. No other warranties

are authorized on behalf of Micro Matic unless specically

issued by Micro Matic. Micro Matic shall have no liability

for incidental or consequential losses, damages including

without limitation or expenses, loss of sales, spoiled food,

prots or goodwill, claims whether or not on account of

refrigeration failure or punitive or exemplary damages

directly or indirectly arising from the sale, handling or use

of the Equipment or from any other cause relating thereto,

whether arising in contract, tort, warranty, strict liability or

otherwise.

Micro Matic’s liability here under in any case is expressly

limited, at Micro Matic’s election, to repair or replacement

of Equipment or parts therefore or to the repayment of, or

crediting the user with, an amount equal to the purchase

price of such goods.

18

// www.micromatic.com

9 // TECHNICAL INFORMATION

If further technical information is needed, please contact the Service Department

directly. Please have the model number and serial number.

Service Support: (800) 544-0400

servicerequest@nordon.com

// www.micromatic.com

19

www.micromatic.com // 866-327-4159

NORTHEAST

4601 Saucon Creek Road

Center Valley, PA 18034

(610) 625-4464

(610) 625-4466 (Fax)

SOUTHEAST

2364 Simon Court

Brooksville, FL 34604

(352) 799-6331

(352) 796-2429 (Fax)

01726-D0216 ©2016 Micro Matic USA, Inc. All Rights Reserved.

CENTRAL

10726 North Second Street

Machesney Park, IL 61115

(815) 968-7557

(815) 968-0363 (Fax)

WEST

19791 Bahama Street

Northridge, CA 91324

(818) 701-9765

(818) 701-9844 (Fax)

Loading...

Loading...