Micro Matic JOETAP JT-CTMG Maintance Manual

SAFETY FIRST!

READ INSTRUCTIONS COMPLETELY

Before getting started please read this

user manual and at all times follow

the important safety instructions.

JT-CTMG

JOETAP ® BARISTA

NITRO & STILL

BEVERAGE DISPENSER

ON-DEMAND NITROGENATED BEVERAGES

FROM CONCENTRATE

INSTALLATION, USE & MAINTENANCE GUIDE

v1.0

Listed by Edison Testing Laboratories.

Conforms to UL & NSF Standards.

2 | JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE 855-4JOETAP / (866) 327-4159 / MICROMATIC.COM

ROUTINE MAINTENANCE & CLEANING

SAFETY & PROCEDURAL NOTICES .............................................................4

RECEIVING & INSPECTING .......................................................................6

SPECIFICATIONS ....................................................................................... 6

DIMENSIONS ............................................................................................7

COMPONENTS ..........................................................................................8

LOCATION & INSTALLATION ....................................................................... 9

MAKING ADJUSTMENTS ..........................................................................15

GENERAL OPERATION ............................................................................. 20

ROUTINE MAINTENANCE & CLEANING ....................................................21

TROUBLESHOOTING ...............................................................................22

DECOMMISSIONING ................................................................................24

TERMS OF USE. WARRANTY. INDEMNIFICATION. ....................................26

855-4JOETAP / (866) 327-4159 / MICROMATIC.COM JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE | 3

SAFETY NOTICES

As you work on this equipment, be sure to pay close attention to the safety notices in this

manual and any warning/caution labels on the unit. Disregarding the notices may lead to

serious injury and/or damage to the equipment.

Read and understand ALL applicable OSHA (Occupational Safety and Health Administration)

safety regulations and/or national and local codes before operating this unit.

Throughout this manual, you will see the following types of safety notices:

WARNING

Text in a Warning box alerts

you to a potential personal

injury situation. Be sure to

read the Warning statement

before proceeding and work

carefully.

CAUTION

Text in a Caution box alerts

you to a situation in which

you could damage the

equipment. Be sure to read

the Caution statement

before proceeding and work

carefully.

PROCEDURAL NOTICES

As you work on this equipment, be sure to read the procedural notices in this manual.

These notices supply helpful information, which may assist you as you work.

Throughout this manual, you will see the following types of procedural notices:

NOTICE

Text in a Notice box provides

you with information that

may help you perform

a procedure more

efciently. Disregarding this

information will not cause

damage or injury, but it may

slow you down as you work.

Indicates information

considered important but

not hazard related.

NOTE: Text set off as a “Note:” provides you with simple, but useful, extra information about

the procedure you are performing.

4 | JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE 855-4JOETAP / (866) 327-4159 / MICROMATIC.COM

READ THESE BEFORE PROCEEDING

NOTE: Save these instructions.

NOTE: We reserve the right to make product improvements at any time. Specifications and

design are subject to change without notice.

CAUTION

Proper installation, care and

maintenance are essential

for maximum performance

and trouble-free operation

of your equipment. Read and

understand this manual. It

contains valuable care and

maintenance information.

If you encounter problems

not covered by this manual,

do not proceed, contact us.

We will be happy to provide

assistance.

NOTICE

Routine adjustments and

maintenance procedures

outlined in this manual are

not covered by the warranty.

WARNING

PERSONAL INJURY POTENTIAL

Do not operate equipment

that has been misused,

abused, neglected,

damaged, or altered/

modied from that of

original manufactured

specications.

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

THIS MANUAL MUST BE READ AND UNDERSTOOD BEFORE THE

INSTALLATION AND OPERATION OF THIS DISPENSER

855-4JOETAP / (866) 327-4159 / MICROMATIC.COM JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE | 5

WARNING

PERSONAL INJURY POTENTIAL

Do not operate equipment

that has been misused,

abused, neglected,

damaged, or altered/

modied from that of

original manufactured

specications.

RECEIVING & INSPECTING

Upon receiving your new JoeTap® countertop nitro and still beverage dispenser, check

the package and the unit for any damages that may have occurred during transportation.

Visually inspect the exterior of the package. If damaged, open and inspect the contents with

the carrier. Any damage should be noted and reported on the delivering carrier’s receipt.

In the event that the packaging is not damaged, yet upon opening, there is concealed

damage to the equipment, notify the carrier immediately. Notification should be made

verbally as well as in written form. Request an inspection by the shipping company of the

damaged equipment. Retain all crating material until inspection has been made. Finally,

contact Micro Matic.

UNCRATING:

1. Cut and remove theouter packaging

2. Lift theunit off theskid

3. If unit was laid down during this operation, leave upright for 24 hours before plugging

into power source

SPECIFICATIONS

Part No. Description Beverage Package Shipping Weight

JT-CTMG

JoeTap® Barista, countertop dispenser and nitrogen package Bag in Box (BiB)

169 lbs

77 kg

Operating Performance

Compressor 1/6 HP

BTU per hour 1135

Condenser HP 1/6

Ambient Temperature Range 45-100° F

Inlet Water Temperature 45-90° F

Ice Bath Capacity 2 gal

Approval

Air Clearance around unit 6" (153mm)

Plumbing

Electrical Requires 2-wire plus ground at 120V, single phase, 60 Hz, 15 amp min. dedicated service

Warranty 1 year parts and labor warranty. All warranty work is handled through JoeTap® certied service agents.

Listed by Edison Testing Laboratories.

Conforms to UL & NSF Standards.

ETL Listed. Conforms to UL 471

& NSF 18. Certied to CSA C22.2

No.120

20-50 psi (138-621 kPa) Machine supplied with 3/8" male barb tting

Requires oor drain

Running Amps

Voltage 115/60/1

Plug Type NEMA-5-15P

Cord Length 6'

Refrigerant R-134a

Charge 5.5 oz / 160g

5.0A (0.5A for Nitrogen Generator / 4.5A

for JoeTap® Countertop System)

6 | JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE 855-4JOETAP / (866) 327-4159 / MICROMATIC.COM

NOTE: We have developed this manual as a reference guide for the owner/operator and

606.97 [23.90]

547.65 [21.56]

installer of this equipment. Please read this manual before installation or operation of

the machine. A qualified service technician must perform installation and start-up of this

equipment. If you cannot or are not qualified to correct the service problem, call your service

provider or distributor. Always have your model and serial number available when you call.

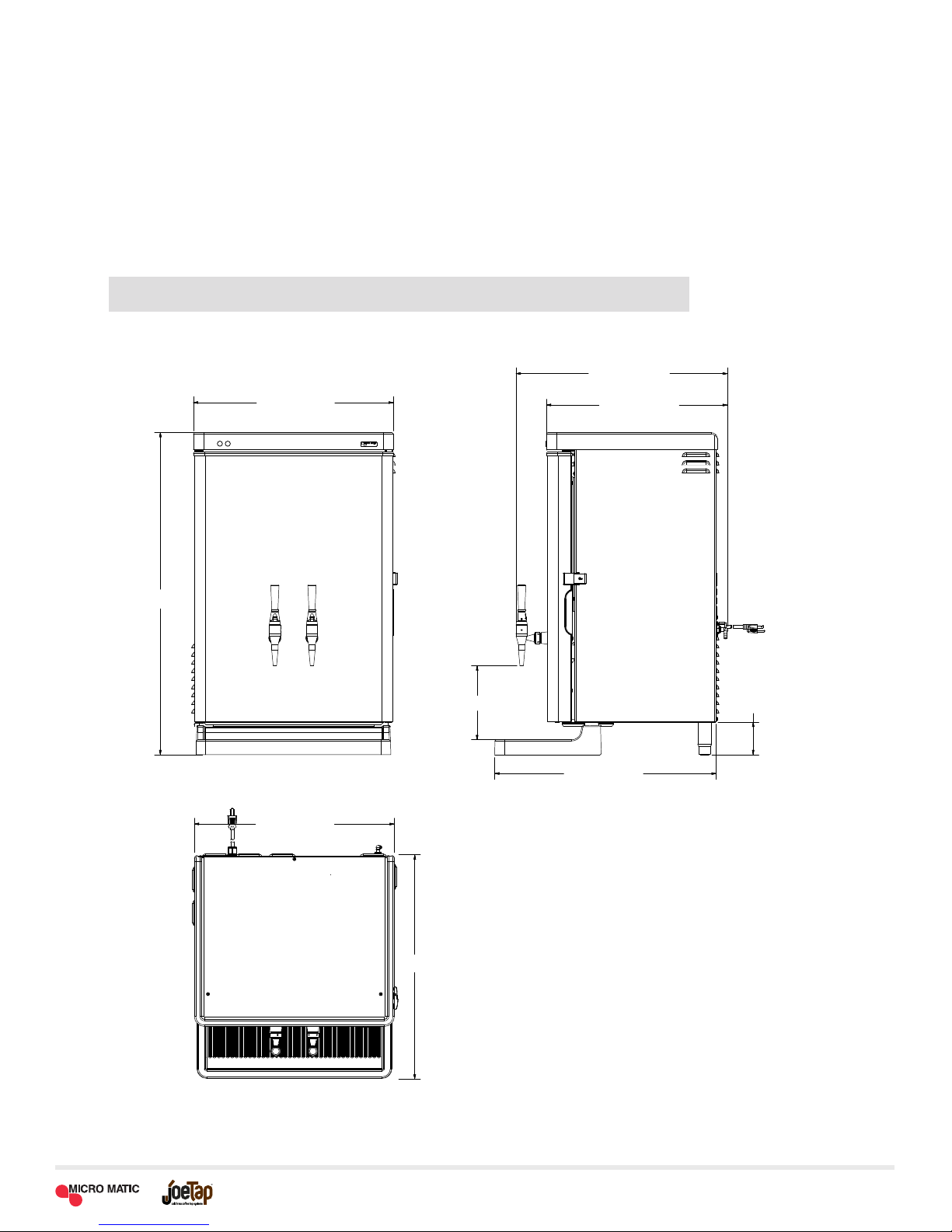

DIMENSIONS

FRONT SIDE

578.62 [22.78]

881.65 [34.71]

547.65 [21.56]

TOP

547.65 [21.56]

202.36 [7.97]

495.66 [19.51]

606.97 [23.90]

88.90 [3.50]

UP TO 4"

WITH ADJUSTMENT

855-4JOETAP / (866) 327-4159 / MICROMATIC.COM JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE | 7

606.97 [23.90]

STILL FAUCET

NITRO FAUCET

VOLTAGE REG ULATOR GAUGE

GENERATOR ON/OFF

INDICATOR LIGHT

SYSTEM ON/OFF

INDICATOR LIGHT

CONTROL PANEL

COMPONENTS

N2 GENERATO R

GAS RESERVOIR GAUGE

N2 REGULATOR

ADJUSTMENT SCREW

N2 REGULATOR

PRESSURE GAUGE

WATER INLET PO RT

ELECTRICAL HAZARD

WARNING LABEL

(3" X 3")

SERIAL NUMBER/

NAME /CERTIFICATION

LABEL (3" X 5")

POWER CORD

DATE OF MANUFACTURE

LABEL

SHOWN WITH DOOR OPEN AND CHILLER SHROUD REMOVED

INCLUDED

(1) Drip tray

(1) Countertop Nitro and Still Beverage Dispenser with built in N2 Generator

(1) 6' section of ½" I.D. x 7/8" O.D. drain line

(2) Stainless stout faucets

(2) Black faucet handles

(1) John Guest: 3/8" stem x 3/8" barb elbow (for water inlet)

GAS OUT BUTTON

GAS IN BUTTON

GAS OFF BUTTO N

PRODUC T PUMP BUTTON

WATER PUMP BUTTON

STILL FAUC ET WATER

FLOW CONTRO L VALVE

SCHOLLE BIB

CONNECTOR FITTING

ELECTRICAL HAZARD

WARNING LABEL

(3" X 3")

CHILLER CO NTROL

BIB PRODUCT

STORAGE AREA

CHILLER AIR

INLET SHROUD

NOTE: Serial# and unit name label with electrical specifications/requirements located on

backside of JT-CTMG.

8 | JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE 855-4JOETAP / (866) 327-4159 / MICROMATIC.COM

INSTALLATION

NOTE: These instructions are provided to assist the qualified installer. Contact your distributor

or call JoeTap/Micro Matic for information regarding start-up services.

INSTALLATION LOCATION REQUIREMENTS

The JT-CTMG may be island-mounted or installed on a front or rear counter. Locate the

unit so the following requirements are satisfied. This system is for indoor use only and must

NOT be placed in an area where a water jet or similar high-pressure sprayer could be used.

LOCATION & SURFACE

• Footprint: 21.56" (548 MM) W x 34.05"(865 MM) H x 17.24"(438 MM) D plus an additional

6" clearance to the left, right and rear of the machine.

• Weight: surface must be able to support weight of the dispenser, water/ice bath and BIB

product stored inside (165 LBS fully loaded).

• Level surface: The JT-CTMG must be level horizontally from right to left and front to rear.

• If surface penetration is necessary, the hole should be at least 2" in diameter and

be closed/sealed once the power cord, drain line and water supply line are in place

and connected.

• Avoid placing the dispenser near heat sources such as radiators, ovens, refrigeration

equipment, and direct sunlight.

NOTICE

Failure to follow these

guidelines may affect

warranty coverage.

CAUTION

Cutting the countertop

may decrease its strength.

Counter should be braced

to support the dispenser

countertop weight plus

product storage capacity

and weight of ice/water

bath.

WATER SUPPLY

• Flow rate must be at least .7 GPM

• Pressure cannot exceed 50 PSI

• Temperature: 45˚ F – 90˚ F

• Cannot contain sediment equal to or larger than 5 microns.

• Must consist of NSF-61 compliant components.

• Must be plumbed with in-line water shutoff valve and backflow prevention device.

• A screen of at least 100 mesh (100 strands per 1" [25 MM]) must be installed immediately

upstream of the backflow prevention device.

• Water hardness cannot exceed 75 PPM

• Cannot be plumbed to demineralized water: a water supply with little or no mineral

content will yield flat beverages.

WARNING

Only trained and certied

electrical, plumbing and

refrigeration technicians

should service this unit.

WARNING

All wiring and plumbing must

conform to national and

local codes.

855-4JOETAP / (866) 327-4159 / MICROMATIC.COM JOETAP® BARISTA INSTALLATION, USE & MAINTENANCE GUIDE | 9

Loading...

Loading...