Page 1

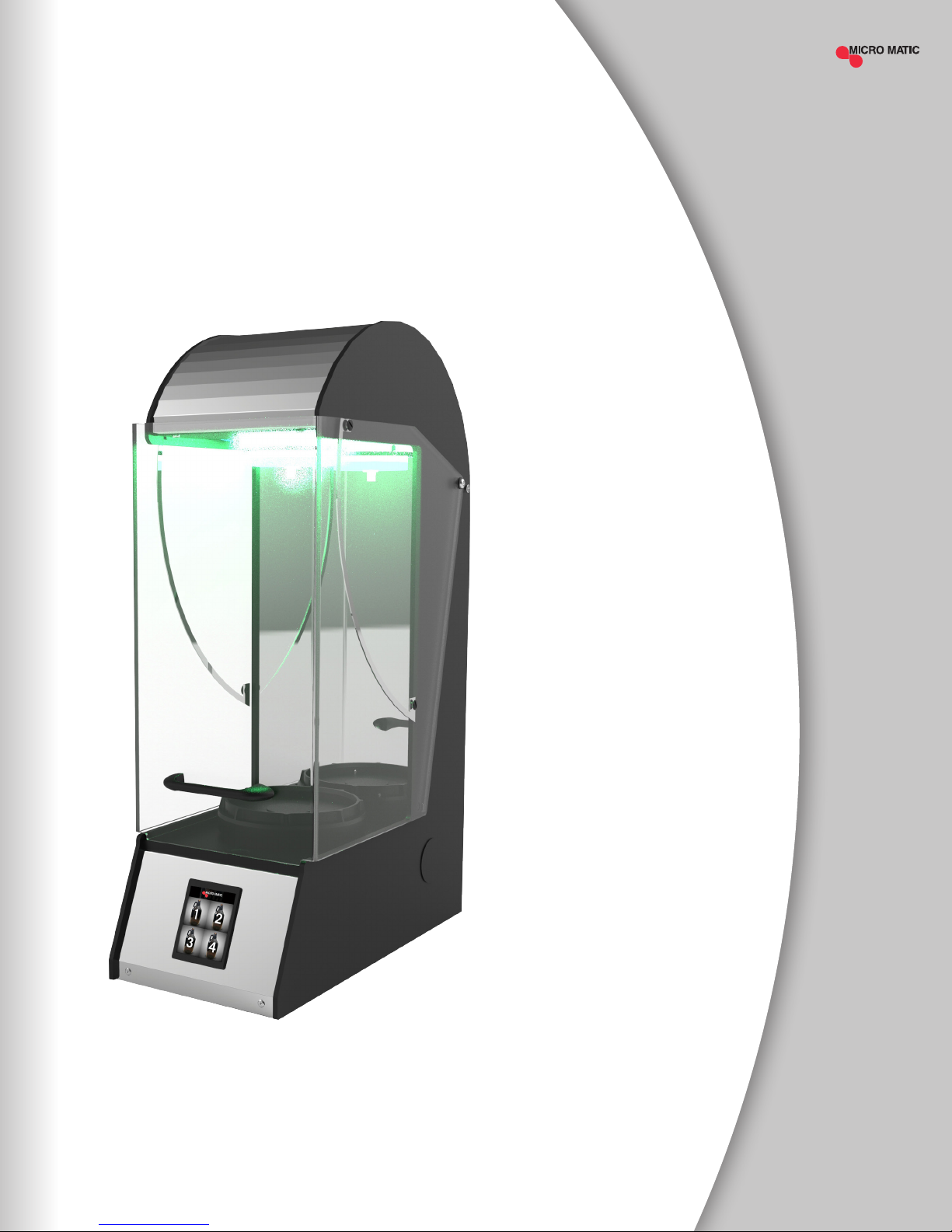

INSTALLATION, USE & MAINTENANCE GUIDE

GROWLER

FILLER

GF-14515-G2

SAFETY

FIRST!

READ INSTRUCTIONS

COMPLETELY

Before getting started

please read this user

manual and at all times

follow the important

safety instructions.

VERSION 1.0

Page 2

TABLE OF

CONTENTS

1 GENERAL INFORMATION ........................................................................................................ 4-5

1.1 TERMS USED ...................................................................................................................... 4

1.2 LIMITATION OF LIABILITY ............................................................................................... 4

1.3 COPYRIGHT PROTECTION ............................................................................................... 4

1.4 CUSTOMER SERVICE ........................................................................................................ 4

1.5 GUARANTEE CONDITIONS .............................................................................................. 5

2. BASIC SAFETY ........................................................................................................................ 6-7

2.1 INTENDED USE ................................................................................................................. 6

2.1.1 GROWLER ........................................................................................................................ 6

2.1.2 PRODUCT ......................................................................................................................... 6

2.1.3 MISAPPLICATION .......................................................................................................... 6

2.1.4 SPACE REQUIREMENTS ................................................................................................ 7

2.1.5 WORKING ENVIRONMENT ............................................................................................ 7

2.2 CHANGES AND CONVERSIONS ...................................................................................... 7

2.3 SAFETY DEVICES .............................................................................................................. 7

3. TRANSPORT AND INSTALLATION ........................................................................................... 8

4. STRUCTURE AND FUNCTION .............................................................................................. 8-11

4.1 INLET ................................................................................................................................... 8

4.2 PROTECTIVE COVER ......................................................................................................... 9

4.3 CYLINDER PLATFORM ...................................................................................................... 9

4.4 CONTROL PANEL .............................................................................................................. 9

4.5 HOSE CONNECTIONS ..................................................................................................... 10

5. TECHNICAL SPECIFICATIONS ............................................................................................... 11

6. CONTROL PANEL PRESETS .................................................................................................... 12

6.1 FILLING PROCESS ........................................................................................................... 12

6.2 OPERATING STATUS ....................................................................................................... 12

7. CONTROLS AND INDICATORS ..........................................................................................13-15

7.1 FILLING NOZZLE ............................................................................................................. 13

7.2 PROTECTIVE COVER ....................................................................................................... 13

7.3 MAIN SWITCH ..................................................................................................................13

| 2

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 3

7.4 CONTROL PANEL ............................................................................................................ 14

7.4.1 "STANDBY" SCREEN .....................................................................................................14

7.4.2 "PRODUCTS" SCREEN .................................................................................................. 14

7.4.3 "GROWLER" SCREEN .................................................................................................... 15

7.4.4 "FILLING" SCREEN ........................................................................................................ 15

7.4.5 "CLEANING" SCREEN ................................................................................................... 15

7.4.6 "CLEANING" SCREEN ................................................................................................... 15

8. INSTALLATION AND FIRST CLEANING................................................................................. 16

8.1 SWITCHING "ON" THE DEVICE ...................................................................................... 16

8.2 BASIC CLEANING ............................................................................................................ 16

9. FILLING A GROWLER .......................................................................................................... 16-17

9.1 INSERTING/FILLING/REMOVING THE GROWLER ...................................................... 16

9.2 PAUSING OR ABORTING THE FILLING PROCESS ...................................................... 17

10. CLEANING AND MAINTENANCE ....................................................................................17-19

10.1 GROWLER DEDICATED FOR CLEANING.....................................................................18

10.2 CLEANING .................................................................................................................18-19

11. CONFIGURATION ..............................................................................................................20-27

11.1 REPORTING BUTTON .................................................................................................... 20

11.2 EVENT MEMORY BUTTON ........................................................................................... 20

11.3 SETTINGS BUTTON ......................................................................................................21

11.3.1 GENERAL BUTTON .................................................................................................... 21

11.3.2 WORKFLOW BUTTON ................................................................................................ 22

11.3.3 PRODUCTS BUTTON .................................................................................................. 22

11.3.4 DISPLAY BUTTON ...................................................................................................... 22

11.3.5 OPERATION BUTTON ................................................................................................ 23

11.3.6 CLEANING BUTTON ................................................................................................... 23

11.3.7 BOTTLES BUTTON ..................................................................................................... 24

11.3.8 TEXTS BUTTON .......................................................................................................... 24

12. PROGRAMMING DIFFERENT SIZE GROWLERS ............................................................ 25-27

13. TROUBLESHOOTING ............................................................................................................. 28

14. WARRANTY ............................................................................................................................. 29

| 3MICROMATIC.COM SUPPORT (866) 327-4159

Page 4

GENERAL

1

The contents of these operating instructions enable safe and proper handling of the Growler

Filler. Read the operating instructions completely before operating the lling machine. And

always keep the operating instructions within easy reach of the Growler Filler. The illustrations

in this manual may be different from the actual device.

INFORMATION

1.1 TERMS USED

DANGER

Causes serious injury or

death if not observed.

WARNING

Can result in serious injury

or death if not observed.

ATTENTION

May cause minor or

moderate injury.

NOTICE

Useful information or

general information.

1.2 LIMITATION OF LIABILITY

The manufacturer accepts no liability for:

• Damage caused by incorrect operation

• Inappropriate use

• Inadequate maintenance or cleaning

• Failure to observe the technical documentation

• Technical modications by the user

• Use of non-approved spare parts

1.3 INTELLECTUAL PROPERTY AND COPYRIGHT PROTECTION

All rights reserved. Any - including, but not limited to - duplication, dissemination and other

uses of the texts, graphics or other representations without the consent of the manufacturer.

Contact Information:

Micro Matic USA, Inc.

2364 Simon Court

Brooksville, FL 34604

1.4 CUSTOMER SERVICE

Micro Matic USA, Inc.

2386 Simon Court

Brooksville, FL 34604

(866) 327-4159

| 4

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 5

1.5 GUARANTEE CONDITIONS

The operator is obliged to:

• Meet local laws and regulations for the bottling of beverages

• Perform regular maintenance

• Perform regular rinsing and cleaning operations

| 5MICROMATIC.COM SUPPORT (866) 327-4159

Page 6

BASIC

2

SAFETY

2.1 INTENDED USE

The lling device is used for lling containers, hereinafter referred to as "growlers". Beverages

hereinafter referred to as "product". The operational safety of the lling device is only ensured

when used as intended. The use is only considered as intended if:

• The limits of applicability are observed.

• Carry out cleaning and maintenance according to the operating instructions.

• Cleaning and maintenance intervals according to the operating instructions and upon

request of the lling device.

The lling device is intended only for the processing of low-risk foodstuffs. Installation of the

growler ller is after prior installation by professionals for commercial use.

NOTE: When using the machine, be sure to use adequate hygiene before, during and after the

operation. Perform the cleaning and disinfection as described in chapter 10.

2.1.1 GROWLER

A growler is used for transporting or storing beverages. Suitable container, which corresponds

to the limits of applicability. These include:

• Drink Growlers

• Carafes

NOTE: Do not use any other vessels or growlers than those in these operating instructions.

NOTE: Before using the growlers, be sure that they are not cracked, chipped, etc.

NOTE: Danger of damage to the seal of the inlet by the use of growlers with low wall thickness

or sharp-edged growler opening. Leaks, deformation, and breakage of the growler can result.

• Only use growlers with a thick wall thickness.

• Make sure that the growler opening is completely on the lling seal.

• Visual inspection with the protective cover closed.

2.1.2 PRODUCT

The lling device is operated with beer. As soon as the product supply is empty, no liquid may

ow through the hose line. The system used must be checked by a qualied installer for leaks.

NOTE: The lling device may only be used with the instructions given in the operating instructions.

2.1.3 MISAPPLICATION

The lling device is intended for commercial and not for industrial use! No growlers or

beverages other than those described in the operating instructions may be used with the

lling device. The bottom and opening of the growler must be perpendicular to their vertical

axis. The Filler is not intended for use in conjunction with any high-risk foods. The use of

damaged, cracked or thin-walled growlers or growlers with a sharp-edged opening is not

permissible. The use of corrosive, oily, strongly acidic, caustic or other aggressive substances

(non-food) is prohibited. Filling other liquid foods other than those described in the operating

instructions is not permitted. Filling of gaseous substances (other than CO2) is prohibited.

| 6

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 7

2.1.4 SPACE REQUIREMENTS

DIMENSIONS MEASUREMENT (CM/INCHES)

Height 63 cm / 24.8"

Width 21 cm / 8.25"

Depth 40 cm / 15.74"

GROWLER MEASUREMENT (CM/INCHES)

Growler Diameter <12cm / 4.75"

Height 25 to 33cm / 9.84 to 12.99"

Make sure that:

• There is enough room to open the protective cover.

• There is enough room at the rear so that the hose lines can be connected.

2.1.5 WORKING ENVIRONMENT

The work environment of the unit must meet the required country and product-specic

requirements. Install the device so the protective cover can be opened easily and the hoses

are not kinking. The lling device is intended exclusively for use in well ventilated interior

spaces. The room temperature must be between 32 and 90˚F.

NOTE: Regularly clean the device according to the instructions in this manual to avoid

hygienic deciencies. Be careful when using the unit and the following hygiene requirements:

• Regularly clean the Growler lling nozzle and keg coupler. Make sure that the device is free

of product residues, mold, and bacteria.

• Use only clean growlers with the device.

2.2 CHANGES AND CONVERSIONS

Alterations and conversions of the lling device, which are not found in the instructions are

expressly prohibited. In the case of unauthorized changes, without explicit permission from

the manufacturer, will void any warranty claim.

2.3 SAFETY DEVICES

Protective Cover

The lling region of the lling device is provided with a protective cover. The protective cover

is equipped with two independent Reed Contacts, through which the lling device recognizes

when the protective cover is closed. Filling, cleaning, and ushing are only available when the

protective cover is closed.

WARNING

Risk of dangerous accumulations of carbon dioxide (CO2) in conned spaces or containers.

Carbon dioxide can be toxic at elevated concentrations.

• Ensure that the device is installed only by qualied personnel.

• Ensure adequate ventilation of the rooms in which the unit is installed and operated.

• Ventilate cabinets or areas below the unit. CO2 will collect at the lowest point rst.

| 7MICROMATIC.COM SUPPORT (866) 327-4159

Page 8

TRANSPORT

3

The lling unit is delivered in a cardboard box or air-packed in foam. It is recommended to

use the packaging of the ller for later transport and storage. Do not operate the unit if it is

damaged. Immediately contact Customer Service.

AND INSTALLATION

STRUCTURE

4

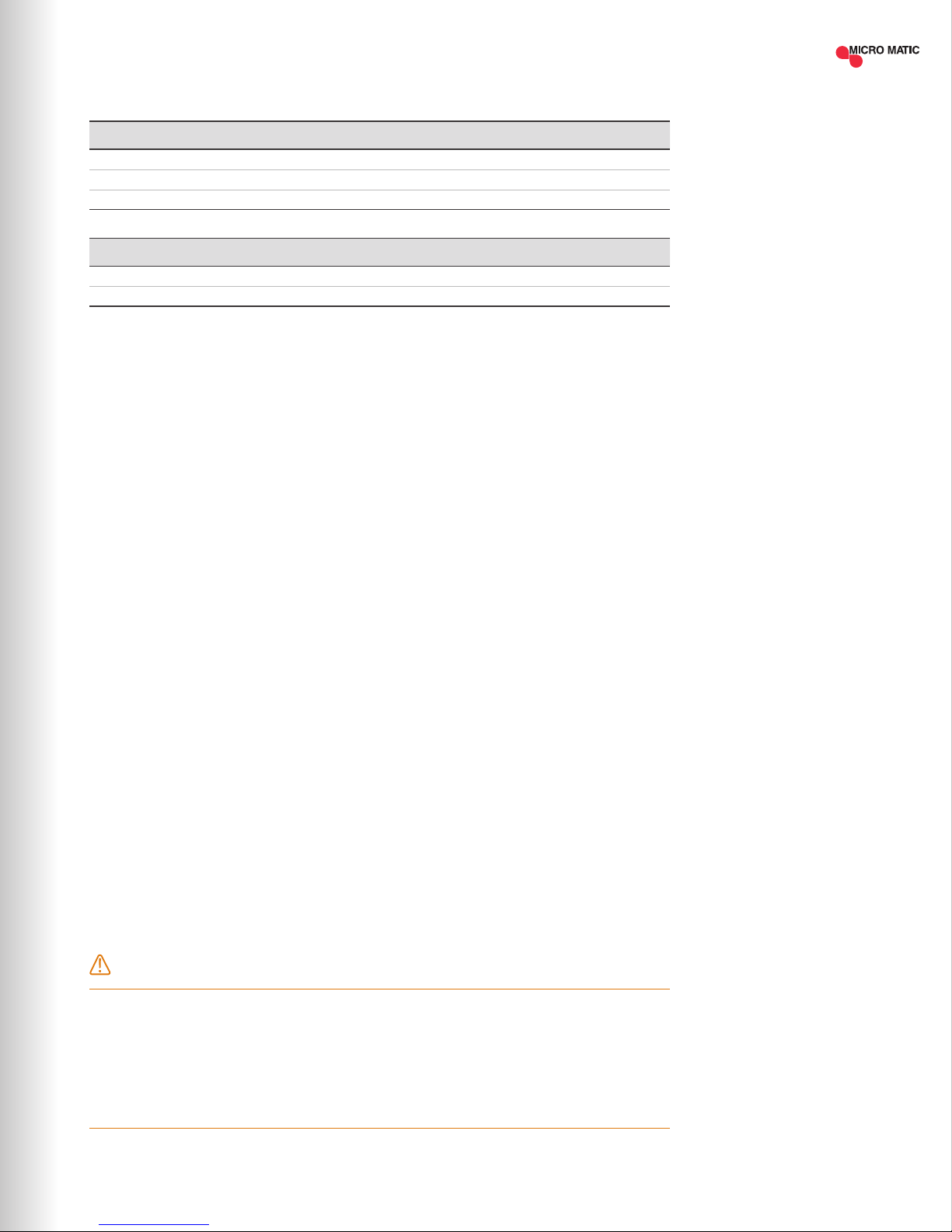

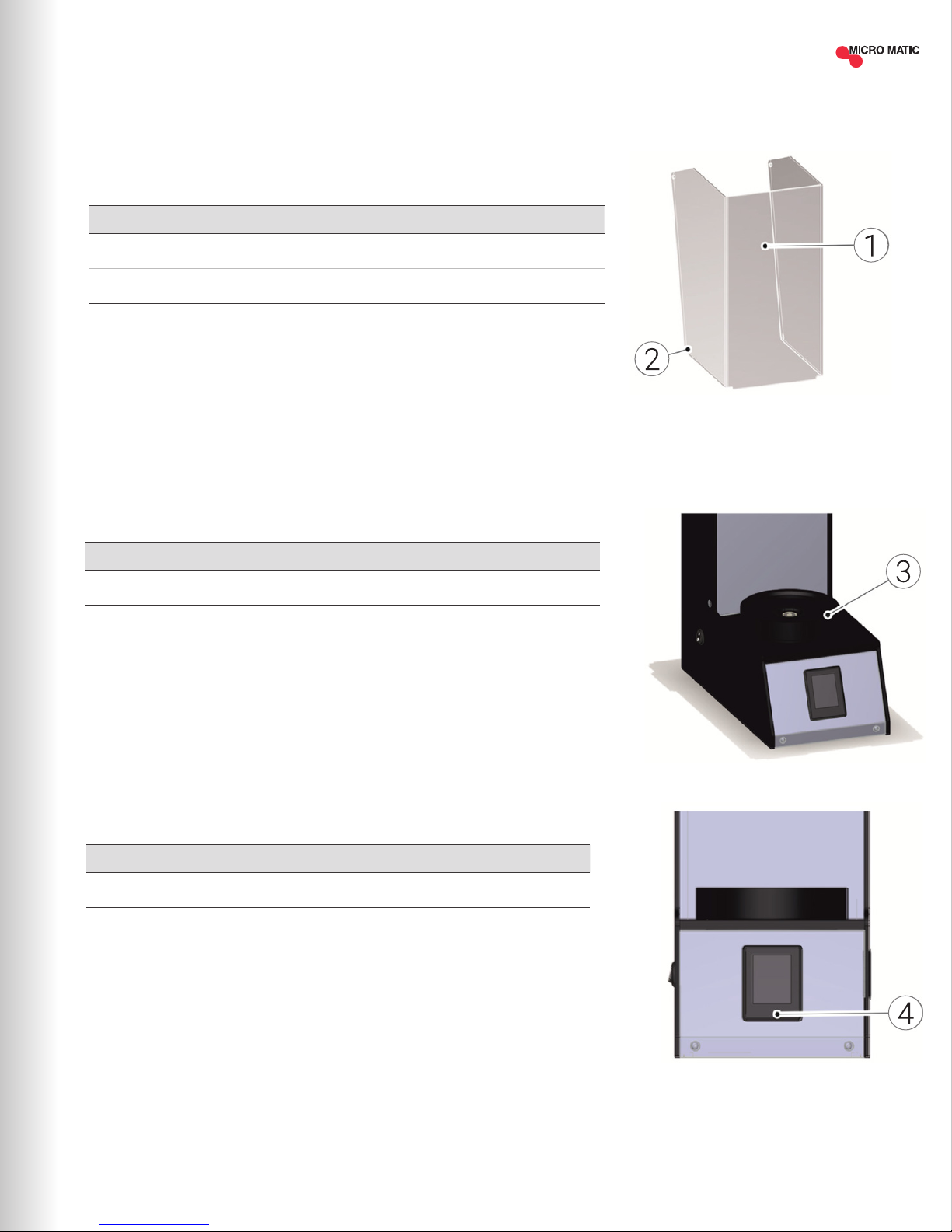

ITEM DESCRIPTION

1 Main switch

2 Protective cover

3 Filling nozzle

4 Growler platform

AND FUNCTION

2

3

4

5 Control panel

1

4.1 INLET

ITEM DESCRIPTION

6 Growler seal

7 LED lighting

8 Product outlet

9 Drain opening

Functionality

The spring-loaded lling nozzle activates a micro switch when a growler is inserted between

inlet and cylinder, and thus allows lling, cleaning, and ushing. The seal prevents the escape

of gas or liquid from the growler. The LED lighting serves as a light source and shows by

colored lighting. Operation status of the lling device is indicated by the LED lighting.

8

7

6

7

9

5

6

8

| 8

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 9

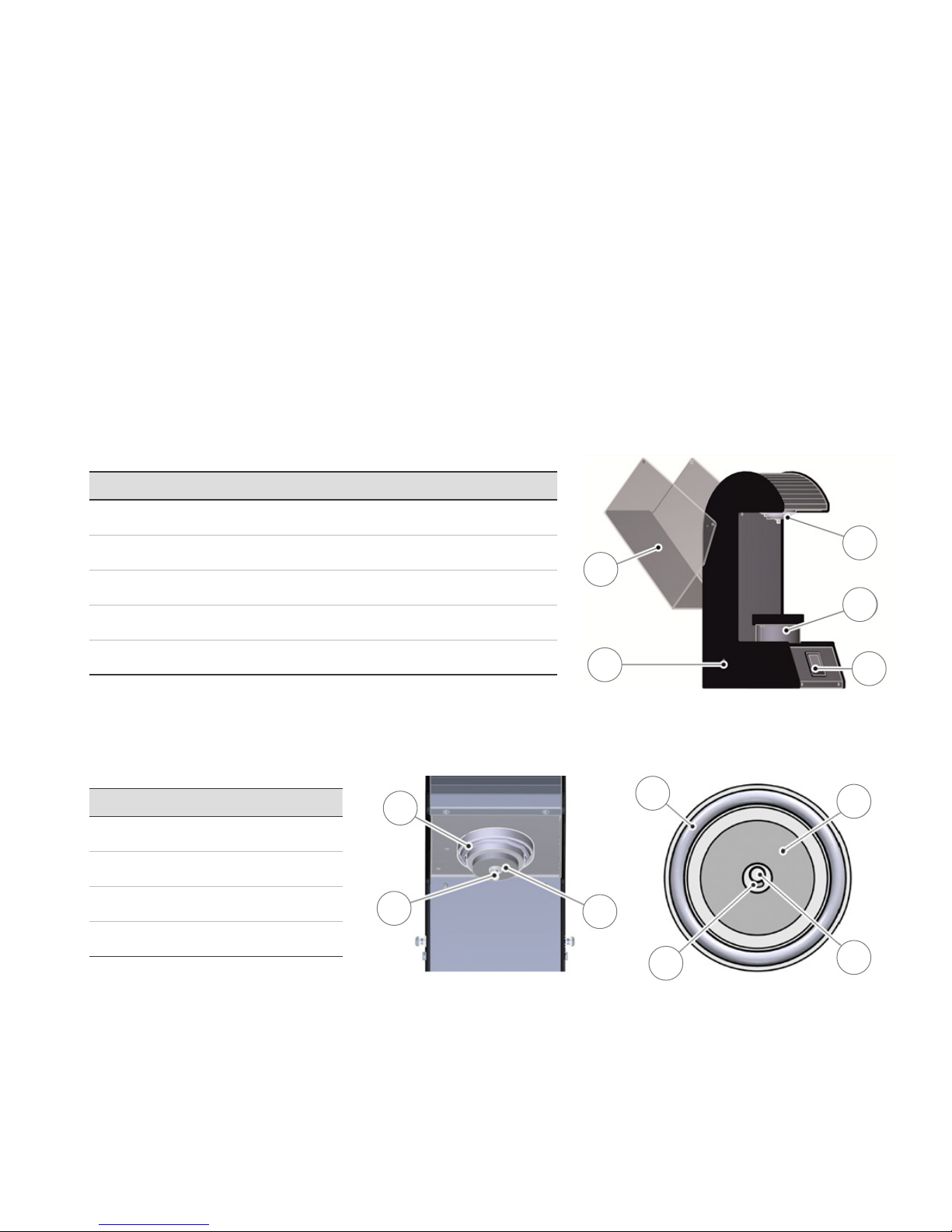

4.2 PROTECTIVE COVER

The transparent protective cover prevents access to the growler during the lling,

cleaning or ushing, and is designed to protect the user.

Construction

ITEM DESCRIPTION

1 Protective cover

2 Independent reed (magnetic) contacts (right / left)

Operation of Cover

The protective cover can be pivoted upwards until it stops. Once the lid is open, a

growler can be placed inside. During the lling process, the protective cover must be

closed. The device recognizes that the cover is closed.

4.3 CYLINDER PLATFORM

The growler platform serves as a base for a growler or an adapter.

Construction

ITEM DESCRIPTION

3 Platform

Functionality

A pneumatic cylinder under the growler rack lifts the growler or the cleaning adapter,

and clamps it between the growler platform and the lling nozzle.

4.4 CONTROL PANEL

The control panel is a color touch screen display. It displays the operating status of

the unit and allows for input during operation.

Construction

ITEM DESCRIPTION

4 Touchscreen

Functionality

On the control panel, you are able to access the lling, rinsing or cleaning features.

The control panel displays process steps, error messages, and settings.

| 9MICROMATIC.COM SUPPORT (866) 327-4159

Page 10

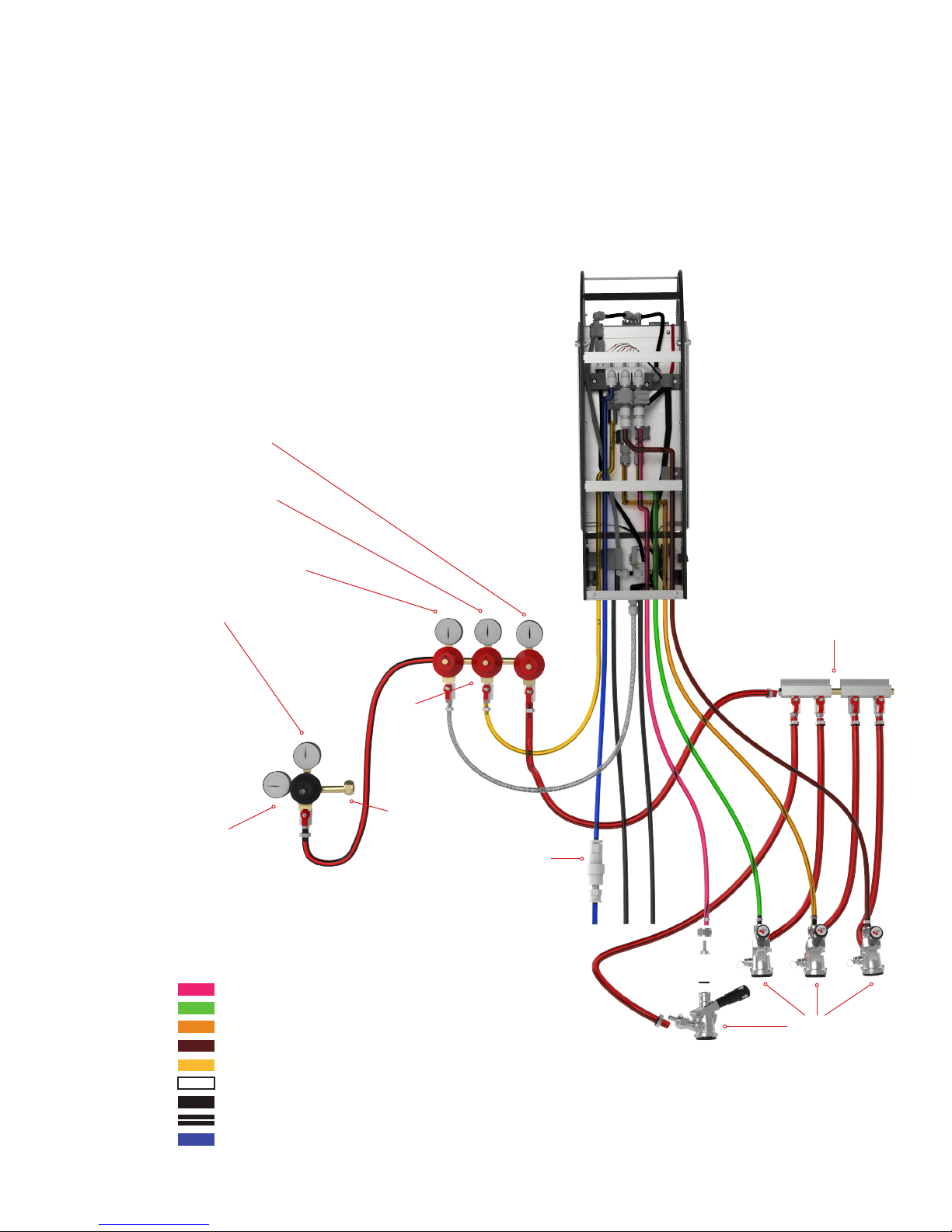

4.5 HOSE CONNECTIONS

The hose connections are used to connect the tubes to the lling unit.

Functionality

The supply lines for the product, water and gas are connected to the lling

device. The drainage line is used for the removal of excess growler contents, or

it can be used to drain cleaning uid when used with a quick release. Optionally,

compressed air can be used for the lift cylinder.

Pressure to the Kegs (Beers)

Typically, 12-15 PSI

CO2 Growler Purge Pressure

1 PSI higher than the beer

pressure (15-17 PSI)

Pneumatic Pressure (Platform Lift)

25-30 PSI Typically

Primary Pressure

40-50 PSI Typically

942B

Primary Regulator

GF-14515-G2

Growler Filler

(Back Cover Removed)

751-019

Gas Distributor

8033

Secondary

Regulators

Attach to CO2 Cylinder

1750352C

Water Regulator

(Included with Growler Filler)

Tube Color Reference

Beer 1 = Red

Beer 2 = Green

Beer 3 = Orange

Beer 4 = Brown

CO2 Purge = Yellow

CO2 Cylinder = White

Drain = Black

Drain = Double Black

Water = Blue

| 10

GROWLER FILLER INSTALLATION, USE & MAINTENANCE GUIDE

7485BS

Keg Couplers

Page 11

TECHNICAL

5

MECHANICAL/ELECTRICAL

Designation Growler Filler

Type Growler Filler 4 product V1

Power Standby 6W - Max. 75W

Operating Voltage 120VAC

Lift Cycle Max. 65 PSI

Filling Pressure Max. 43 PSI

Weight (when the growler is empty) 44 LBS

APPLIED PRESSURES PRESSURE (PSI)

Product Max. 43 PSI

Water Max. 43 PSI

CO

2

Lift Cycle Pressure

(must be dry and oil-free)

SPECIFICATIONS

Max. 43 PSI

Max. 65 PSI

| 11MICROMATIC.COM SUPPORT (866) 327-4159

Page 12

CONTROL PANEL

6

6.1 FILLING PROCESS

The lling process consists of the following process steps:

DESCRIPTION DURATION

Lift Growler 2.0 seconds

Gas Flooding 3.0 seconds

Pressure Build-up 3.0 seconds

Filling Timeout (Fill%) 240.0 seconds

Blow Out Filling Nozzle 2.0 seconds

Vent Gas 10.0 seconds

6.2 OPERATING STATUS

PRESETS

The current operating status of the lling device is indicated by the LED ring around the

lling nozzle default settings. List Operation Indicators:

STATUS LED FREQUENCY COLOR

Standby On Slow White

Ready On Slow Green

Error Flash Fast Red

Filling On Slow White

Filling Pause Flash Medium Yellow

Filling End Flash Fast Green

Rinsing On Slowly Blue

Cleaning On Medium White Blue

| 12

GROWLER FILLER INSTALLATION, USE & MAINTENANCE GUIDE

Page 13

CONTROLS

7

7.1 FILLING NOZZLE

The LED lighting around the lling head indicates the operation status of the unit using

colors and different ashing frequencies.

7.2 PROTECTIVE COVER

The protective cover can be opened by lifting using the handle. During the lling process,

the protective cover must remain closed. If the protective cover is opened during lling or

cleaning the process will be stopped. Pressure will be vented from the growler.

AND INDICATORS

7.3 MAIN SWITCH

The main switch can turn the lling device on ( "I") and off ( "O")

| 13MICROMATIC.COM SUPPORT (866) 327-4159

Page 14

7.4 CONTROL PANEL

7.4.1 "STANDBY" SCREEN

The control panel and indicators displayed can be

customized to the products and growlers used.

Colors, text, and images may differ from the gures.

While the device status is “Standby” the lling device is

inactive. Touch the Control panel to access the operating

status to the "product" screen.

This gure represents an example.

As part of the setup conguration, a standby timeout is

dened. After the standby time has passed the device will

change from the operating menus to the standby menu. The

default setting for Standby timeout is 10 seconds.

7.4.2 "PRODUCTS" SCREEN

The images of the products are congurable.

The images to the right are examples of the default.

CLEANING BUTTON

The Cleaning button opens the "cleaning" menu

on the control panel. Then there is access to

choose between "rinse" and "clean".

PRODUCT BUTTON

The Product button selects the pictured product for the

next lling and opens the screen "Growlers."

MAIN MENU

Hold the top red bar for 10 seconds to enter the

conguration menu.

Cleaning screen

| 14

GROWLER FILLER, USE & MAINTENANCE GUIDE

The default passcode is "12345"

Page 15

7.4.3 "GROWLER SCREEN"

7.4.4 "FILLING" SCREEN

The user can select which growler they

[X] BUTTON

are going to ll.

The button [X] cancels the selection

and opens the previous screen.

"START" BUTTON

This button will start or pause the lling.

"STOP" BUTTON

This button will end the lling process.

7.4.5 "CLEANING" SCREEN

[X] BUTTON

The button [X] cancels the selection and opens the previous screen.

RINSE BUTTON

Launches rinsing

Displays the current ushing

Stops the ush

CLEAN BUTTON

Opens the "cleaning" screen.

7.4.6 "CLEANING" SCREEN

[X] BUTTON

The button [X] cancels the selection and opens the previous screen.

PRODUCT LINE SELECTION

The Product Line Selection eld selects the line for the cleaning process. Multiple

selections are possible. An activated selection eld includes a check inside the frame.

"START" BUTTON

The Start button starts the cleaning process and allows the line cleaner to pause as

often as desired during the process.

"STOP" BUTTON

The Stop button stops the cleaning process.

| 15MICROMATIC.COM SUPPORT (866) 327-4159

Page 16

INSTALLATION

8

After the device is successfully and connected, the installer will perform the

initial conguration.

8.1 SWITCHING "ON" THE DEVICE

Engage the main switch to turn the power on ( "I").

8.2 BASIC CLEANING

Clean the growler ller before the initial start. Clean the exterior of the unit daily.

AND FIRST CLEANING

FILLING

9

Follow these steps to ll a growler with product. Make sure that the growler ller

is properly set up and mounted.

NOTE: GROWLER FILLER IS FACTORY PROGRAMMED FOR STANDARD

64 OZ GROWLERS

A GROWLER

9.1 INSERTING / FILLING / REMOVING THE GROWLER

Proceed as follows to place the growler for the lling process:

1. OPEN THE PROTECTIVE COVER

a) Swing the protective cover upward until it stops.

2. POSITION THE GROWLER

a) Place the growler in the middle of the growler platform.

b) When the growler is too short to reach the lling head, use an adapter (optional -

contact Micro Matic sales) to raise the growler allowing it to create a seal with the

lling head.

NOTE: Pay attention to make sure that the growler is stable on the platform. If the

growler is not stable, it could damage the unit or the growler. Verify that protruding

handles, straps, and fasteners, do not stop the protective cover from closing.

3. CLOSE PROTECTIVE COVER

a) Swing the Protective Cover down until it stops.

4. PRESS THE TOUCH SCREEN "START"

a) Follow screen prompts

5. REMOVING THE GROWLER:

a) Open the protective cover completely.

b) Remove the growler.

c) Close the protective cover.

| 16

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 17

9.2 PAUSE OR CANCEL FILLING

You have the option to pause or cancel the lling prematurely.

a) Press the play button to pause the lling process.

b) Press the pause button to resume the lling process.

WARNING

Lack of hygiene can occur by not properly cleaning the device using approved cleaning

solutions for cleaning the product lines and the exterior of the unit. If the product over ows,

then areas that have been impacted by the spill should be cleaned immediately.

• Use only for cleaning and disinfecting the device appropriate and recommended by the

manufacturer cleaning / disinfecting agents

CLEANING AND

10

Cleaning Canister

The cleaning canister (sold separately) serves to provide detergents for the cleaning

procedure.

Functionality

The cleaning container uses CO2 to push water and cleaning agent into the lling device

via the product line. Remove the lid to ll the cleaning container with the appropriate

cleaning chemical solution.

Cleaning Chemicals

To clean the growler ller, you need different cleaning chemicals for the following areas:

• Cleaning the product lines and growler ller

• External cleaning of surfaces

Cleaning the Product Lines

A caustic solution is suitable for the cleaning of the product lines. The detergent in liquid

form is added to the water in the cleaning canister.

The Growler Filler has two functions for cleaning:

• Rinsing function - ushes unit with clean water.

MAINTENANCE

CLEANING CANISTER

with valves installed

Part No. 201-420

CLEANING CHEMICAL

Part No. MM-B68

• Cleaning function - ushes the unit with a caustic cleaner.

When cleaning the exterior, use a scratch-free cloth and a disinfectant for beer

dispensers, which complies with the national hygiene standards.

| 17MICROMATIC.COM SUPPORT (866) 327-4159

Page 18

Cleaning Button

The Cleaning button opens the "cleaning" screen.

After 14 days, a notication will appear that the unit needs to be cleaned.

10.1 GROWLER DEDICATED FOR CLEANING

A cleaning growler and rinsing growler are needed for the rinsing and cleaning.

Designate a growler that will only be used during cleaning and a growler that

will only be used during rinsing.

Inserting cleaning growler:

1. OPEN PROTECTIVE COVER

2. POSITION THE CLEANING GROWLER

3. CLOSE PROTECTIVE COVER

DANGER

Risk of electric shock when preforming maintenance or repairs to the unit in

areas where electrical components are present. Contact with electricity can

cause serious injury.

• Turn off the power at the main switch ("O").

• Disconnect the device from the power supply by unplugging the unit from

the wall outlet.

10.2 CLEANING

Proceed as follows to perform the cleaning process.

Tools Required:

• Cleaning Canisters

NOTE: It is suggested to have a dedicated canister for water only, and a dedicated canister

with cleaning solution.

• Detergent

• Clear glass growler designated for cleaning

NOTE: Use proper personal protective equipment when using the cleaning chemicals.

Follow all directions provided by the manufacturer on proper handling of materials.

Cleaning Instructions

1. FILL CANISTER WITH WATER

a) Fill the cleaning container with lukewarm water.

b) Replace lid on cleaning canister.

2. START CLEANING PROCESS

a) Press on the touch screen to open the products menu. Touch water faucet icon in the

upper left corner of products screen.

| 18

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 19

b) Press the clean button to open the options for cleaning.

c) Select the check box of the line to be cleaned. Multiple selections are possible.

3. FLUSH THE FILLING DEVICE WITH WATER

a) Couple keg couplers to the cleaning canister lled with luke warm water.

b) Engage couplers to ll the canister with CO

2

c) Press the “Start” Icon on the control panel.

d) Allow water to ush all of the beer out of the lines.

4. ADD CLEANING CHEMICAL TO WATER IN CANISTER

a) Partially Fill the cleaning canister with lukewarm water, add (3) measuring caps of

3.33oz of Micro Matic Beer Line Cleaner per gallon.

b) Replace lid on cleaning canister.

5. SOAKING THE LINE WITH BEER LINE CLEANER

a) Tap the cleaning canister with the keg couplers.

b) Press the start icon on the control panel and ll all of the lines with Beer Line Cleaner.

c) Press the pause icon once the lines have been lled with Chemical. Wait 20 minutes

while the chemical soaks in the line.

d) After the chemical has soaked in the line for 20 minutes, press the play button to ush

the unit with chemical for another 10 seconds.

e) Carefully remove the cleaning growler and empty the contents. The growler contains

caustic, and care must be taken when disposing of the contents.

f) Rinse the growler out with cool clean water.

g) Replace the growler on the platform.

i ) Remove cleaning canister and replace with canister lled with rinse water.

h) Engage the keg couplers on the cleaning canister lled with water.

j) Activate the cleaning process again and allow the device to ush water though the

system for 1 minute. Emptying growler is necessary.

k) Press the “Stop” Icon.

l) Empty the contents of the growler and rinse out the growler.

m) Place the growler on the platform select all of the products. Press the start icon and

ll the growler with water.

n) Press the “Stop” icon and remove the growler. Use pH paper to test the pH of the water.

If the level is not below 8, repeat the rinse for 2 minutes. Continue to repeat until pH is

below 8>.

6. FILLING PRODUCT LINES

a) Select all of the product lines.

b) Untap all of the keg couplers from the water lled canister and tap the couplers to the

corresponding keg.

c) Press the “Start” icon and push the water out of the product lines. Once all of the

product lines have been cleared, press the stop icon.

d) Resume lling growlers in the regular manner.

| 19MICROMATIC.COM SUPPORT (866) 327-4159

Page 20

11CONFIGURATION

HIDDEN MENU

Using the main menu, operators can change the default settings that to better control the

lling process.

• Press the red header on the products menu for over ten seconds.

• Then a passcode entry screen will appear. The factory default pass code is 12345. The

changing of settings should only be done by qualied personnel.

11.1 REPORTING MENU

This screen shows how many growlers of each product have been lled.

The count can be reset as desired.

11.2 EVENT MEMORY BUTTON

The event memory button opens the "Event log" screen on the control panel:

The "event log" screen displays a history of all completed tasks on the device. Activities

such as cleaning and lling can be selected to view additional details. Up and down

scrolling by arrows is possible.

| 20

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 21

11.3 SETTINGS BUTTON

The Settings button opens the "Settings" screen on the control panel which has further

buttons for settings:

GENERAL

WORKFLOW

PRODUCTS

DISPLAY

SERIAL INTERFACE

OPERATION

CLEANING AND BOTTLES

TEXTS

11.3.1 GENERAL BUTTON

The General button will open the "General" screen on the control panel.

Here you will nd settings for:

LOGIN CODES: Open the menu on the device and enter the login code to enter the Extended

service menu on the device.

BACKLIGHT TIMEOUT: (0 = no dimming the display backlighting is always on)

STANDBY TIMEOUT: (the time is changed according to the in the standby screen)

LANGUAGE: (English, German, French, Italian)

LOGIN CODES

Open the menu on the device and enter the login code to enter the Extended service menu

on the device

| 21MICROMATIC.COM SUPPORT (866) 327-4159

Page 22

LANGUAGE

Choose your language: English, German, French, Italian

11.3.2 WORKFLOW

Workow button opens the "Workow" screen on the control panel:

LOADING (duration from start button to gas ooding)

GAS FLOODING (continuous ooding with gas)

PRESSURIZING (duration of applying pressure prior to lling)

BOTTLING TIMEOUT (elapsed time before lling process is automatically canceled)

INLET BLOWING OUT (time to empty the inlet or to blow out of the product)

VENTING (duration of the nal vent)

11.3.3 PRODUCTS

VIEW: By pressing the view button, selct, create and change products.

CALIBRATION: By pressing the calibration screen, calibrate each product for ow metr

steps/oz. The button portioning opens the "portioning" screen. Select (active or inactive)

products, to indicate the number of pulses / liter as the ow rate.

TITLE BAR: By pressing the title bar, select how menus should be displayed (title bar

color, title text color, and font size).

MONITORING DELAY: Watching ow rate before recognizing empty product.

11.3.4 DISPLAY

The button dislay will open the "Display" screen on the control panel:

GENERAL: Choose between displaying buttons with gradient or without.

STANDBY PICTURE: Select a desired standby image.

BACKGROUND COLOR: Change the background color

DECIMAL: Specify the desired separator for decimal values.

| 22

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 23

BACKGROUND COLOR

Change the background color

LED LIGHTING

Set the LED display for:

STANDBY MODE

READY (protective cover closed)

ERROR (such as protective cover open)

FILLING

FILLING PAUSE

FILLING END (protective cover not yet open)

RINSE

CLEAN

Changes can be made here for color, blinking / ashing, and frequency.

11.3.5 OPERATION BUTTON

The Workow utton opens the screen “Work Flow" on the control panel:

PAUSE AND RESUME FILLING OPERATIONS PAUSED.

AUTO CONTINUE FILLING OPERATIONS AFTER THE SET TIME.

AUTOMATIC DISCARD PAUSED FILLING OPERATIONS AFTER THE SET TIME.

IMMEDIATE CHANGE TO THE STANDBY SCREEN AFTER A FILLING.

11.3.6 CLEANING BUTTON

Settings for:

ACTIVATE THE CLEANING BUTTON THE SCREEN "CLEANING"

DURATION OF THE FLUSHING OF THE INLET AND OUTLET

(THROUGH THE EXHAUST VALVE)

DURATION OF THE FLUSHING OF THE COMPENSATOR

FLUSHING INTERVAL OF THE DEVICE

CLEANING INTERVAL OF THE DEVICE

| 23MICROMATIC.COM SUPPORT (866) 327-4159

Page 24

11.3.7 BOTTLES BUTTON

The Bottles opens the "growler-button" screen on the control panel:

PRESENTATION

Chose between default growlers or create new growlers to background color,

text color, font size.

Modify the image of the growlers.

PORTIONING

Select (active or inactive) growlers

Adjust lling volume in ounces

TITLE BAR

By pressing the Title bar, select how menus should be

displayed (title bar color, title text color, and font size).

11.3.8 TEXTS BUTTON

Here changes can be made to the texts of

the products and growlers.

| 24

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 25

PROGRAMMING

12

12.1 ACTIVATION INSTRUCTIONS FOR 32OZ GROWLER

Start at home screen. Hold down red bar until you get the password screen.

Enter 12345 and then press the check mark.

Select SETTINGS and then select BOTTLES

INSTRUCTIONS

Select VIEW and Select BOTTLE 1

| 25MICROMATIC.COM SUPPORT (866) 327-4159

Page 26

Scroll down with arrow and highlight GROWLER SIZE 2

by touching the screen. Select the picture icon.

Use right arrow until screen shows 32 oz bottle picture then select the

check mark.

Select check mark.

Select the X.

| 26

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 27

Select Portioning.

Select Bottle 1.

Hit the CE button THREE times.

Type in 1.00 then hit the check button. Hit the X button FOUR times to return to

the main homescreen.

MICROMATIC.COM ORDER TOLL-FREE 1-866-327-4159 | 27| 27MICROMATIC.COM SUPPORT (866) 327-4159

Page 28

ERROR AND

13

ERROR DESCRIPTION HANDLING

PROTECTIVE COVER OPEN

ERROR GROWLER!

ERROR CLEANING ADAPTER

ERROR LIMIT • Limit switch defect.

PRODUCT EMPTY

TROUBLESHOOTING

• Close the protective cover to the continue cleaning, rinsing or lling.

• Protective cover defective.

• Reed Contacts faulty: Check the magnets and vcontact.

• Growler is too small: Replace with appropriate matching adapter and growler for

the lling process.

• Growler missing: Place a suitable growler on the Growler platform.

• Cleaning Growler is missing: Place the cleaning growler on the platform

• Growler platform does not raise up to seal against lling head. Check the gas

supply pressure.

• Lift cylinder gas not present.

• Keg is empty. Connect a new keg.

• Monitoring delay too short.

• Defective ow meter.

EQUIPMENT RINSING

OVERDUE!

LINE CLEANING OVERDUE • Cleaning interval expired: Do one cleaning cycle before lling device use.

NO ENTRIES POSSIBLE /

BLACK SCREEN

GROWLER IS NOT FILLED

GROWLER PLATFORM DOES

NOT RAISE TO SEAL AGAINST

FILLING HEAD

FOAMY BEER

• Rinsing interval expired: Run a ushing cycle before you use the lling device.

• Check that the lling device is connected.

• Start the lling unit again by means of it turn the main switch off and on.

• If the screen is damaged, contact Customer Service.

• Check the product lines and CO2.

• Check the amount of product.

• Check calibration.

• Check the CO2 connection for leaks.

• Check the supply pressure of the lifting cylinder gas.

• Check if the gas is empty or the pressure to is too low.

• Leaking lines.

• Empty product.

• Pressure settings.

| 28

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 29

WARRANTY

14

STANDARD TERMS & CONDITIONS FOR USE OF PRODUCT. LIMITED WARRANTY.

INDEMNIFICATION.

By opening the packaging containing this product or by using such product in any

manner, you are consenting and agreeing to be bound by the following terms and

conditions. You are also agreeing that the following terms and conditions constitute

a legally valid and binding contract that is enforceable against you. If you do not

agree to all of the terms and conditions set forth below, you must promptly return

the product for a full refund prior to using the product in any manner.

ALL SALES ARE SUBJECT TO AND EXPRESSLY CONDITIONED UPON THE TERMS

AND CONDITIONS CONTAINED HEREIN, AND UPON PURCHASER’S ASSENT

THERETO. NO VARIATION OF THESE TERMS AND CONDITIONS SHALL BE BINDING

UPON MICRO MATIC USA, INC. UNLESS AGREED TO IN WRITING AND SIGNED BY

AN AUTHORIZED REPRESENTATIVE OF MICRO MATIC. Purchaser, by accepting the

product shall be deemed to have assented to the terms and conditions set forth

herein, notwithstanding any terms contained in any prior or later communications

from purchaser and whether or not Micro Matic shall specically or expressly

object to any such terms.

To the maximum extent permitted by law, with respect to Product proved to Micro

Matic’s satisfaction to be defective or nonconforming, Purchaser’s exclusive remedy

and Micro Matic’s maximum liability hereunder in any case is expressly limited to, at

Micro Matic’s election, (i) the repair or replacement of the Product without charge or

refund of the purchase price, upon return of the Product in accordance with Micro

Matic’s instructions above, or (ii) the repayment of, or crediting the Purchaser with,

an amount equal to the purchase price of the Product. To the maximum extent

permitted by law, Micro Matic is not responsible for, and Purchaser releases

Micro Matic from direct, special, punitive, incidental or consequential damages of

any kind arising from any use or failure of, or related in any way to the Product,

or based upon any contract, tort, strict liability or other legal or equitable theory,

including without limitation loss of beverage, loss of gas, loss of sales, loss of work,

downtime, or for any other labor or any other expense, damage or loss including

personal injury or property damage, unless such personal injury or property damage

is caused by Micro Matic’s gross negligence, even if Micro Matic has been advised

of the possibility of such damage or loss. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

USE OF PRODUCT

Purchaser agrees that no rights or licenses under Micro Matic’s patents shall be

implied from the sale of the Product, and Purchaser does not receive any right

under Micro Matic’s patent rights hereunder.

PURCHASER HEREBY GRANTS TO MICRO MATIC A NONEXCLUSIVE, WORLDWIDE,

UNRESTRICTED, ROYALTY-FREE, FULLY PAID-UP LICENSE, WITH THE RIGHT TO

GRANT AND AUTHORIZE SUB-LICENSES, UNDER ANY AND ALL PATENT RIGHTS IN

INVENTIONS COMPRISING MODIFICATIONS, EXTENSIONS, OR ENHANCEMENTS

MADE BY PURCHASER TO THE PRODUCT OR TO THE MANUFACTURE OR USE OF

THE PRODUCT (“IMPROVEMENT PATENTS”), TO MAKE, HAVE MADE, USE, IMPORT,

OFFER FOR SALE OR SELL ANY AND ALL PRODUCT; EXPLOIT ANY AND ALL

METHODS OR PROCESSES; AND OTHERWISE EXPLOIT IMPROVEMENT PATENTS

FOR ALL PURPOSES.

INFORMATION

Matic that Purchaser will use the Product in accordance with the Product label and

the instructions in this manual and in accordance with the practices of a reasonable

person and all laws and regulations now and hereinafter enacted; and Purchaser

shall not misuse the Product in any manner. Purchaser shall not reverse engineer,

decompile, disassemble or modify the Product. Purchaser acknowledges that Micro

Matic retains ownership or license rights of all patents, trademarks, trade secrets

and other proprietary rights relating to or residing in the Product and Purchaser

receives no rights to such intellectual property rights by virtue of its purchase of

Product other than as expressly set forth herein. Purchaser shall have no right to

use any trademarks owned or licensed to Micro Matic without the express written

permission of Micro Matic.

RELEASE AND INDEMNITY

By operating this Product, the Purchaser hereby takes full responsibility for any

risks associated with its use. Purchaser agrees to fully release, discharge, disclaim

and renounce any and all claims, demands, actions, causes of action and/or suits

in law or equity, now existing or hereafter arising, whether known or unknown,

against Micro Matic, and its ofcers, directors, employees, agents, successors

and assigns (collectively the “Released Parties”), with respect to the use of the

Product. Purchaser agrees to fully protect, defend, and indemnify, hold harmless the

Released Parties from and against all liability, losses, damages, costs, or expenses

of any nature, including without limitation, reasonable attorney’s fees, which they

may at any time suffer, incur, or be required to pay resulting from or arising out of (i)

any ordinary hazards that may be present in the normal operation of the Product; (ii)

any claim of injury, illness, or death resulting from consuming beverages dispensed

by the Product, whether or not prepared as specied by the Product; (iii) any hazards

from the use or misuse of the Product; (iv) any claim that the Product is defective,

negligently designed or manufactured in any manner, or otherwise determined to

be the cause of injury or death to persons, or damage to property, or both; (v) any

claim that the Product or the manufacture, sale, or labeling of the Product fails to

comply with any governmental requirement, or the labeling on the Product, or on

or within the packaging for the Product (including any instructions or warnings), is

inadequate in any manner; (vi) any claim that the Product should have been recalled

pursuant to any governmental requirement; (vii) Micro Matic’s negligence or willful

misconduct in supplying the Product; or (viii) any injuries, losses, or damages

(compensatory, direct, incidental, consequential or otherwise) of any kind arising in

connection with or as a result of possession or use of the Product. Purchaser shall

fully cooperate with the Released Parties in the investigation and determination of

the cause of any accident involving the Product which results in personal injury or

property damage and shall make available to the Released Parties all statements,

reports, recordings and tests made by Purchaser or made available to Purchaser by

others. If you do not consent to this indemnication, you must promptly return the

Product for a full refund prior to using the Product in any manner.

Purchaser acknowledges that, unless otherwise indicated on the Product label,

the Product has not received approval from any federal, state or local regulatory

agencies. Purchaser has the responsibility and hereby expressly assumes the risk

to learn the hazards involved in using the Product. Purchaser also has the duty to

warn Purchaser’s customers, employees, agents, assigns, ofcers, successors and

any auxiliary or third party personnel of any and all risks involved in using or handling

the Product. Purchaser agrees to comply with instructions furnished by Micro Matic

relating to the use of the Product and expressly represents and warrants to Micro

MICROMATIC.COM ORDER TOLL-FREE 1-866-327-4159 | 29| 29MICROMATIC.COM SUPPORT (866) 327-4159

| 29MICROMATIC.COM SUPPORT (866) 327-4159

Page 30

NOTES

| 30

GROWLER FILLER, USE & MAINTENANCE GUIDE

Page 31

NOTES

MICROMATIC.COM ORDER TOLL-FREE 1-866-327-4159 | 31| 31MICROMATIC.COM SUPPORT (866) 327-4159

Page 32

FOR MORE INFORMATION, TROUBLESHOOTING OR SERVICE PLEASE CALL SUPPORT AT (866) 327-4159

| 32

01938-D1018 ©2018 Micro Matic USA, Inc. All Rights Reserved. Micro Matic reserves the right to change specifications without notice.

Loading...

Loading...