Quattro Ultima

User's Guide

Micromass UK Limited

Floats Road

Wythenshawe

M23 9LZ

Tel: +44 161 945 4170 Fax: +44 161 998 8915

Tudor Road

Altrincham

WA14 5RZ

Tel: +44 161 282 9666 Fax: +44 161 282 4400

http://www.micromass.co.uk

The instrument is marked with this symbol where high voltages are

present.

The instrument is marked with this symbol where hot surfaces are

present.

The instrument is marked with this symbol where the user should refer to

this User's Guide for instructions which may prevent damage to the

instrument.

Warnings are given throughout this manual where care is required to avoid personal

injury.

If the instrument is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

This manual is a companion to the MassLynx NT User's Guide supplied with the

instrument.

All information contained in these manuals is believed to be correct at the time of

publication. The publishers and their agents shall not be liable for errors

contained herein nor for incidental or consequential damages in connection with

the furnishing, performance or use of this material. All product specifications, as

well as the information contained in this manual, are subject to change without

notice.

Code: 6666511

Issue 3

© Micromass Ltd.

Quattro Ultima

User's Guide

Hardware Specifications

Dimensions 11

Weights 11

Lifting and Carrying 12

Power 13

Environment 13

Water Cooling 13

Exhausts 13

Rotary Pumps 13

API Gas Exhaust 13

Nitrogen 14

CID Gas 14

Quattro Ultima

User's Guide

Contents

Instrument Description

Overview 15

Vacuum System 16

Ionisation Techniques 17

Atmospheric Pressure Chemical Ionisation 17

Electrospray 17

Nanoflow Electrospray 17

Sample Inlet 17

MS Operating Modes 18

MS-MS Operating Modes 18

The Daughter Ion Spectrum 19

The Parent Ion Spectrum 20

MRM: Multiple Reaction Monitoring 21

The Constant Neutral Loss Spectrum 22

Data System 22

Front Panel Connections 23

Desolvation Gas and Probe Nebuliser Gas 23

Capillary / Corona 23

ESI / APcI 23

Front Panel Controls and Indicators 24

Status Display 24

Vacuum LED 24

Operate LED 24

Flow Control Valves 25

Divert / Injection Valve 25

Table of Contents

Quattro Ultima

User's Guide

Rear Panel Connections 26

Internal Layout 30

Event Out 26

Contact Closure In 26

Analog Channels 26

MUX 27

Data System 27

Water 28

Nitrogen Gas In 28

Exhausts 29

CID Gas 29

Power Cord 29

Mains Switch 29

Fuses 29

Rotary Control 29

ESD Earth Facility 29

Electronics 30

Mechanical Components 32

Routine Procedures

Start Up Following a Complete Shutdown 33

Preparation 33

Pumping 36

Measuring the Analyser Pressure 37

Using the Instrument 37

Start Up Following Overnight Shutdown 37

Preparation for Electrospray Operation 38

Preparation for APcI Operation 40

Operate 42

Automatic Pumping and Vacuum Protection 42

Overview 42

Protection 42

Transient Pressure Trip 42

Pump Fault 43

Power Failure 43

Tuning 44

Calibration 44

Data Acquisition 44

Data Processing 44

Setting Up for MS-MS Operation 44

Parent Ion Selection 44

Fragmentation 45

Shutdown Procedures 46

Emergency Shutdown 46

Overnight Shutdown 46

Complete Shutdown 47

Table of Contents

Tuning

Quattro Ultima

User's Guide

Automatic Start up and Shutdown 48

The Shutdown Editor 48

The Auto Control Tasks Page 49

The Shutdown Editor Toolbar 51

Loading Startup and Shutdown Files 52

Saving a Startup or Shutdown File 52

Printing Startup and Shutdown Files 53

Creating Startup and Shutdown Files 54

Running Startup and Shutdown Files 54

Overview 55

The Tune Page 56

Printing Tune Information 56

Experimental Record 56

Saving and Restoring Parameter Settings 56

Modifying the Peak Display 58

Changing the Display 60

Customise Plot Appearance 60

Trace 61

Intensity 61

Grid 61

AutoTune 62

Ion Mode 63

Scope Parameters 64

Gas Controls 64

Ramp Controls 64

Resetting the Zero Level 65

Controlling Readbacks 66

Changing Tune Parameter Settings 67

Source Voltages 67

Data Acquisition

Starting an Acquisition 69

Starting an Acquisition from the Tune Page 69

Parameters 70

Multiple Samples 71

Process 72

Automated Analysis of Sample List 72

Monitoring an Acquisition 74

The Acquisition Status Window 74

Chromatogram Real-Time Update 74

Spectrum Real-Time Update 74

Table of Contents

Quattro Ultima

User's Guide

Instrument Data Thresholds 75

System Manager 79

Stopping an Acquisition 80

The Function List Editor 80

MaxEnt 76

Profile Data 76

Centroid Data 76

SIR Data 76

Ion Counting Threshold 77

Profile Data - Spike Removal 78

Analog Data 79

Introduction 80

The Function List Editor Toolbar 82

Adding a New Function 82

Modifying an Existing Function 83

Copying an Existing Function 83

Removing a Function 83

Changing the Order of Functions 83

Setting a Solvent Delay 84

Analog Channels 84

Saving and Restoring a Function List 85

Setting up a Full Scan Function 86

Mass (m/z) 86

Cone Voltage 86

Method 86

Scan Duration (secs) 87

APcI Probe 87

Setting up a SIR Function 88

Channels 88

Method 89

Retention Window 89

Setting up MS-MS Scanning Functions 90

Mass 90

Collision Energy 92

Setting up a MRM Function 93

Setting up a Survey Function 93

Survey and MSMS Template Pages 94

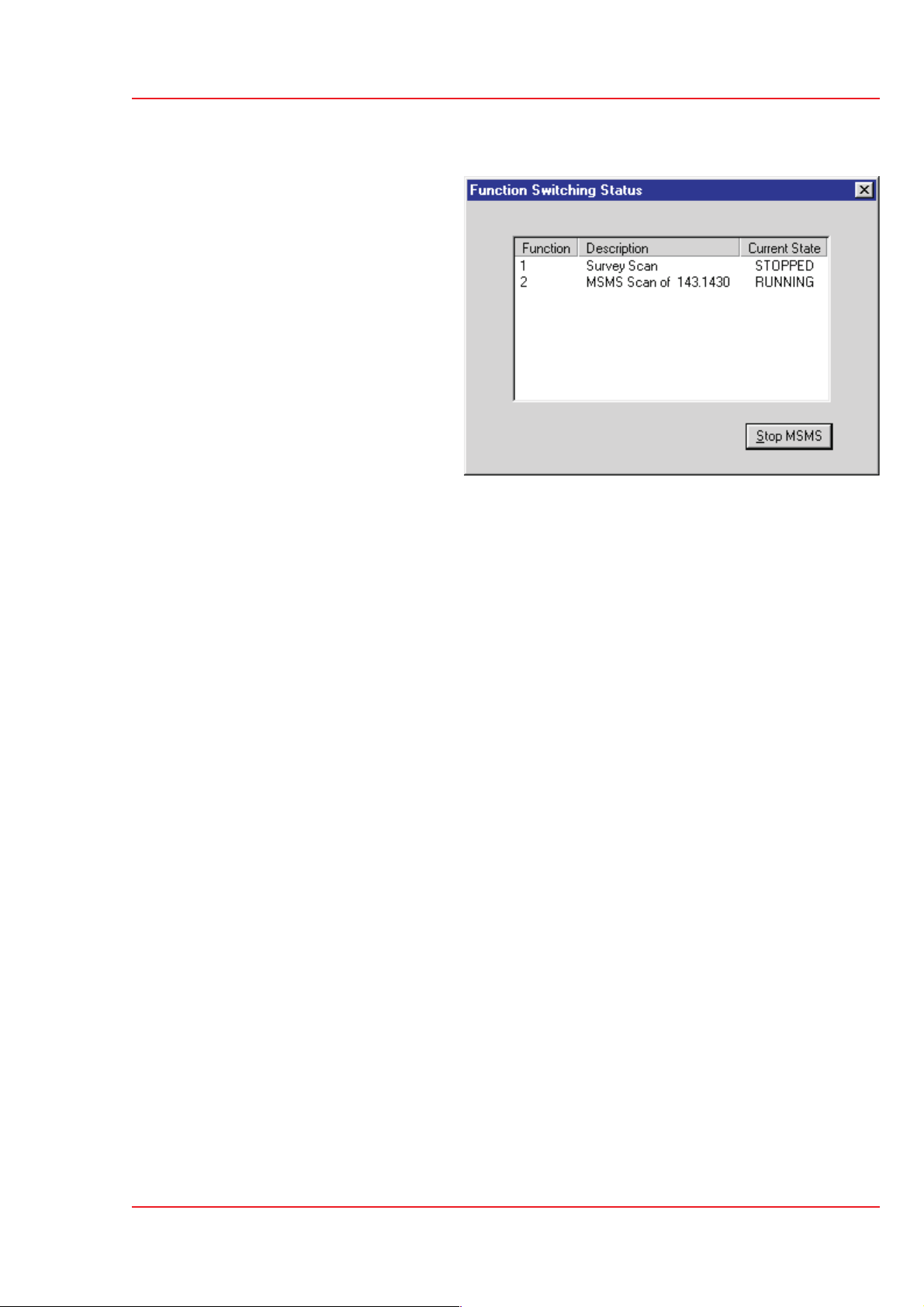

MS to MSMS Switching 95

MSMS to MS Switching 97

Including and Excluding Masses 98

Monitoring Acquisitions 99

Mass Calibration

Introduction 101

Overview 102

Calibration Types 102

The Calibration Process 103

Table of Contents

Quattro Ultima

User's Guide

Electrospray 103

Introduction 103

Preparing for Calibration 104

Reference Compound Introduction 104

Tuning 104

Instrument Threshold Parameters 105

Calibration Options 106

Selecting the Reference File 106

Removing Current Calibrations 106

Selecting Parameters 107

Automatic Calibration Check 107

Calibration Parameters 108

Mass Measure Parameters 109

Performing a Calibration 110

Acquisition Parameters 112

Starting the Calibration Process 114

Checking the Calibration 116

Calibration Failure 118

Incorrect Calibration 120

Manual Editing of Peak Matching 121

Saving the Calibration 121

Verification 122

Electrospray Calibration with PEG 124

Atmospheric Pressure Chemical Ionisation 125

Introduction 125

Preparing for Calibration 126

Reference Compound Introduction 126

Tuning 126

Calibration Options 126

Selecting Reference File 126

Removing Current Calibrations 126

Selecting Calibration Parameters 126

Performing a Calibration 127

Static Calibration 127

Scanning Calibration and Scan Speed Compensation 132

Calibration Failure 135

Incorrect Calibration 136

Manual Editing of Peak Matching 137

Saving the Calibration 137

Manual Verification 138

Electrospray

Introduction 141

Post-column Splitting 144

Megaflow 145

Changing Between Flow Modes 145

Table of Contents

Quattro Ultima

User's Guide

Operation 146

Checking the ESI Probe 147

Obtaining an Ion Beam 148

Tuning and Optimisation 148

Megaflow Hints 154

Removing the Probe 154

Sample Analysis and Calibration 155

General Information 155

Typical ES Positive Ion Samples 156

Typical ES Negative Ion Samples 156

Chromatographic Interfacing 157

LC-MS Sensitivity Enhancement 158

Nanoflow Electrospray

Overview 159

Installing the Interface 160

Operation of the Camera System 163

Using the Microscope 163

Glass Capillary Option 164

Restarting the Spray 165

Nano-LC Option 166

Installation 166

Operation 167

Changing Options 168

Atmospheric Pressure Chemical Ionisation

Introduction 169

Preparation 170

Checking the Probe 171

Obtaining a Beam 172

Calibration 173

Hints for Sample Analysis 174

Tuning for General Qualitative Analysis 174

Specific Tuning for Maximum Sensitivity 174

Corona Current 175

Probe Position 175

Probe Temperature 175

Desolvation Gas 175

Removing the Probe 176

Maintenance and Fault Finding

Introduction 177

Cooling Fans and Air Filters 177

Table of Contents

Quattro Ultima

User's Guide

The Vacuum System 178

Vacuum Leaks 179

Pirani Gauge 179

Active Inverted Magnetron Gauge 179

Gas Ballasting and Rotary Pump Oil Recirculation 180

Oil Mist Filter 181

Foreline Trap 181

Rotary Pump Oil 182

The Source 183

Overview 183

Cleaning the Cone Gas Nozzle and Sample Cone 184

Removing and Cleaning the Ion Block 188

Removing and Cleaning the Ion Tunnel Assembly 192

Reassembling and Checking the Source 194

The Discharge Pin 195

The Electrospray Probe 196

Overview 196

Replacement of the Stainless Steel Sample Capillary 198

The APcI Probe 200

Cleaning the Probe Tip 200

Replacing the Probe Tip Heater 201

Replacing the Fused Silica Capillary 202

The Analyser 204

The Detector 204

Electronics 205

Fuses 205

Analog PCB 205

RF Power PCB 205

Power Backplane #2 205

Pumping Logic PCB 205

Power Sequence PCB 205

Rear Panel 205

Fault Finding Check List 206

No Beam 206

Unsteady or Low Intensity Beam 206

Ripple 206

High Noise Level in MRM Analyses 207

Chemical Noise 207

Electronic Noise 208

High Back Pressure 208

General Loss of Performance 209

Cleaning Materials 210

Preventive Maintenance Check List 211

Weekly 211

Monthly 211

Three-Monthly 211

Four-Monthly 211

Table of Contents

Quattro Ultima

User's Guide

Reference Information

Overview 213

Editing a Reference File 214

Positive Ion 215

Horse Heart Myoglobin 216

Polyethylene Glycol 216

PEG + NH4

Sodium Iodide and Caesium Iodide Mixture 217

Sodium Iodide and Rubidium Iodide Mixture 217

Negative Ion 218

Horse Heart Myoglobin 218

Mixture of Sugars 218

Sodium Iodide and Caesium Iodide (or Rubidium Iodide) Mixture 219

Preparation of Calibration Solutions 220

PEG + Ammonium Acetate for Positive Ion Electrospray and APcI 220

PEG + Ammonium Acetate for Positive Ion Electrospray

(Extended Mass Range) 220

Sodium Iodide Solution for Positive Ion Electrospray 221

Method 1 221

Method 2 221

Sodium Iodide Solution for Negative Ion Electrospray 221

+

216

Table of Contents

Dimensions

180mm

Quattro Ultima

User's Guide

Hardware Specifications

200mm

(pumping line)

1325mm

535mm

Weights

120mm

(ventilation)

700mm

Instrument: 150kg (330lb)

Data system

(computer, monitor and printer): 60kg (130lb)

Rotary pumps

E2M28: 40kg (90lb)

E1M18: 32kg (72lb)

Transformer (optional): 100kg (220lb)

Hardware Specifications

Page 11

Quattro Ultima

User's Guide

Lifting and Carrying

Warning: Persons with a medical condition, for example a back injury, which

prevents them from handling heavy loads should not attempt to lift the

instrument.

Before lifting the instrument proceed as follows:

Vent and power down the instrument.

Disconnect the instrument from the power and water supplies.

Disconnect power and tubing connections to the rotary pump from the rear of

the instrument.

Disconnect the API gas inlet and the exhaust lines from the rear of the

instrument.

Disconnect all connections to LC equipment.

If the instrument is to be moved over a large distance or in a confined space it is

recommended that any probes are removed from the API source.

The weight of the instrument is 150kg (330lb). Lifting equipment or suitably trained

personnel are required to lift or lower the instrument.

UK Health and Safety guidelines recommend that a minimum of six trained and

suitable personnel are required to lift a unit of this weight. The instrument should be

lifted from underneath the frame with one person at each corner of the instrument

supporting the instrument in line with, or close to, the feet upon which the instrument

stands. Two further people should support the instrument centrally.

Caution: Under no circumstances should the instrument be lifted by the probe or

the source enclosure.

Before undertaking any lifting, lowering or moving of the instrument:

•

Assess the risk of injury.

•

Take action to eliminate the risk.

•

Plan the operation.

•

Use trained people.

•

Refer to local or company guidelines before attempting to lift the instrument.

Micromass accept no responsibility for any injuries or damage sustained while lifting

the instrument.

Hardware Specifications

Page 12

Power

Environment

Short term variance (1.5 hours): ≤2°C (≤4°F)

Quattro Ultima

User's Guide

Instrument: 230V (+10%, -14%), 13A

Data system: 100-120V or 200-240V, 13A

Pumps: 230V (+10%, -14%), 13A

Ambient temperature: 15-28°C (59-82°F)

Overall heat dissipation

(excluding LC

and optional water chiller): 4.2kW maximum

Water Cooling

Heat dissipation into the water: 200W

Exhausts

Rotary Pumps

The rotary pumps must be vented to atmosphere (external to the laboratory) via a

fume hood or industrial vent.

API Gas Exhaust

The API gas exhaust must be vented to atmosphere (external to the laboratory).

Caution: The API gas exhaust line must not be connected to the rotary pump

exhaust line. In the event of an instrument failure, rotary pump exhaust could be

admitted into the source chamber producing severe contamination.

Humidity: Relative humidity ≤70%

Hardware Specifications

Page 13

Quattro Ultima

User's Guide

Nitrogen

A supply of dry, oil-free nitrogen at 6-7 bar (90-100 psi) is required.

CID Gas

Argon is required as collision gas. The supplied gas should be dry, of high purity

(99.9%) and at a pressure of approximately 350 mbar (5 psi).

Caution: The lines supplying nitrogen to the instrument must be clean and dry.

If plastic tubing is used it must be made of Teflon. The use of other types of

plastic leads to contamination of the instrument.

Caution: Operating with the CID gas at a significantly higher pressure results in

a fault.

Hardware Specifications

Page 14

Overview

Quattro Ultima

User's Guide

Instrument Description

Sample Inlet

Sampling Cone

and Ion Block

Ion Tunnels

Prefilter 1

Samples

from the liquid

introduction system

are introduced at

atmospheric pressure into the

ionisation source.

Ions are sampled through a series of orifices.

The ions are filtered according to their mass to charge

ratio ( ).

m

The mass separated ions undergo collision induced decomposition.

The fragment ions are filtered according to their mass to charge ratio.

The transmitted ions are detected by the photomultiplier detection system.

The signal is amplified, digitised and presented to the MassLynx NT™ data system.

Quadrupole 1

MassLynx NT

Data System

Collision Cell

Prefilter 2

Quadrupole 2

Detector

The Micromass Quattro Ultima is a high performance benchtop triple quadrupole mass

spectrometer designed for routine LC-MS-MS operation. Quattro Ultima may be

coupled to:

•

a HPLC system with or without an autosampler.

•

an infusion pump.

•

a syringe pump.

Ionisation takes place in the source at atmospheric pressure. These ions are sampled

through a series of orifices into the first quadrupole where they are filtered according

to their mass to charge ratio (m).

The mass separated ions then pass into the hexapole collision cell where they either

undergo collision induced decomposition (CID) or pass unhindered to the second

quadrupole. The fragment ions are then mass analysed by the second quadrupole.

Finally the transmitted ions are detected by a conversion dynode, phosphor and

photomultiplier detection system. The output signal is amplified, digitised and

presented to the data system.

Instrument Description

Page 15

Quattro Ultima

User's Guide

Vacuum System

Vacuum is achieved using two direct drive rotary pumps, and two turbomolecular

pumps.

The rotary pumps are mounted on the floor external to the instrument. The E1M18

pumps the ion source block, while the E2M28 pumps the first ion tunnel and also

backs the turbomolecular pumps. The E1M18 has an automatic gas ballast control

valve mounted in the oil return line from the mist filter. This solenoid valve is opened

whenever the E1M18 is switched on, allowing continuous recirculation of the pump

oil provided that the manual gas ballast valve on the pump is left open.

The turbomolecular pumps evacuate the analyser and ion transfer region. These pumps

are both water cooled.

Vacuum measurement is by an active inverted magnetron (Penning) gauge for the

analyser and a Pirani gauge for the gas cell. The Penning gauge acts as a vacuum

switch, switching the instrument out of the

OPERATE mode if the pressure is too high.

The speed of each turbomolecular pump is also monitored and the system is fully

interlocked to provide adequate protection in the event of a fault in the vacuum

system, a failure of the power supply or vacuum leaks.

Instrument Description

Page 16

Ionisation Techniques

Two atmospheric pressure ionisation techniques are available.

Atmospheric Pressure Chemical Ionisation

Atmospheric pressure chemical ionisation (APcI) generally produces protonated or

deprotonated molecular ions from the sample via a proton transfer (positive ions) or

proton abstraction (negative ions) mechanism. The sample is vaporised in a heated

nebuliser before emerging into a plasma consisting of solvent ions formed within the

atmospheric source by a corona discharge. Proton transfer or abstraction then takes

place between the solvent ions and the sample. Eluent flows up to 2 ml/min can be

accommodated without splitting the flow.

Electrospray

Electrospray (ESI) ionisation takes place as a result of imparting a strong electrical

field to the eluent flow as it emerges from the nebuliser. producing an aerosol of

charged droplets. These undergo a reduction in size by solvent evaporation until they

have attained a sufficient charge density to allow sample ions to be ejected from the

surface of the droplet (“ion evaporation”).

Quattro Ultima

User's Guide

A characteristic of ESI spectra is that ions may be singly or multiply charged. Since

the mass spectrometer filters ions according to their mass-to-charge ratio, compounds

of high molecular weight can be determined if multiply charged ions are formed.

Eluent flows up to 1 ml/min can be accommodated although it is often preferable with

electrospray ionisation to split the flow such that 100 to 200 µl/min of eluent enters

the mass spectrometer.

Nanoflow Electrospray

The optional nanoflow interface allows electrospray ionisation to be performed in the

flow rate range 5 to 1000 nanolitres per minute.

For a given sample concentration, the ion currents observed in nanoflow are

comparable to those seen in normal flow rate electrospray. Great sensitivity gains are

therefore observed when similar scan parameters are used, due to the great reductions

in sample consumption.

Sample Inlet

Sample is introduced from a suitable liquid pumping system along with the nebulising

gas to either the APcI probe or the electrospray probe. For nanoflow electrospray,

metal coated glass capillaries allow the lowest flow rates to be obtained while fused

silica capillaries are used for flow injection analyses or for coupling to nano-HPLC.

Instrument Description

Page 17

Quattro Ultima

User's Guide

MS Operating Modes

Source MS1 Collision Cell MS2 Detector

MS1 Collision Cell MS2

MS

MS2

The MS1 mode, in which MS1 is used as the mass filter, is the most common and

most sensitive method of performing MS analysis. This is directly analogous to using

a single quadrupole mass spectrometer.

The MS2 mode of operation is used, with collision gas present, when switching

rapidly between MS and MS-MS operation. It also provides a useful tool for

instrument tuning and calibration prior to MS-MS analysis, and for fault diagnosis.

Resolving RF Only (Pass all masses)

RF Only (Pass all masses) Resolving

MS-MS Operating Modes

The basic features of the four common MS-MS scan functions are summarised below.

Daughter Ion

Spectrum

(parent mass selection)

MS1

Static

Collision

Cell

MS2

Scanning

Parent Ion

Spectrum

Multiple Reaction

Monitoring

Constant Neutral

Loss Spectrum

Instrument Description

Page 18

Scanning

Static

(parent mass selection)

Scanning (synchronised

with MS2)

RF only

(pass all

masses)

Static

(daughter mass

selection)

Static

(daughter mass

selection)

Scanning (synchronised

with MS1)

The Daughter Ion Spectrum

This is the most commonly used MS-MS scan mode. Typical applications are:

Structural elucidation (for example peptide sequencing).

•

Method development for MRM screening studies:

•

Identification of daughter ions for use in MRM “transitions”.

Optimisation of CID tuning conditions to maximise the yield of a specific

daughter ion to be used in MRM analysis.

Example:

Daughters of the specific parent at m 609 from reserpine in electrospray

positive ion mode.

Quattro Ultima

User's Guide

The result:

MS1

static at m/z 609

(parent mass)

Collision Cell

RF only

(pass all masses)

MS2

scanning from

m/z 100 to 650

Instrument Description

Page 19

Quattro Ultima

User's Guide

The Parent Ion Spectrum

Typical application:

Structural elucidation.

•

Complementary or confirmatory information (for daughter scan data).

Example:

Parents of the specific daughter ion at m 195 from reserpine in electrospray

positive ion mode.

The result:

MS1

scanning from

m/z 50 to 650

Collision Cell

RF only

(pass all masses)

MS2

static at m/z 195

(daughter mass)

Instrument Description

Page 20

MRM: Multiple Reaction Monitoring

This mode is the MS-MS equivalent of SIR (Selected Ion Recording). As both MS1

and MS2 are static, this allows greater “dwell time” on the ions of interest and

therefore better sensitivity (~100×) compared to scanning MS-MS.

Typical application:

Rapid screening of “dirty” samples for known analytes.

•

Drug metabolite and pharmacokinetic studies

Environmental, for example pesticide and herbicide analysis.

Forensic or toxicology, for example screening for target drugs in sport.

Example:

Monitor the transition (specific fragmentation reaction) m 609 → 195 for

reserpine in electrospray positive ion LC-MS-MS mode.

Quattro Ultima

User's Guide

Collision Cell

MS1

static at m/z 609

(parent mass)

The result:

MRM does not produce a spectrum as only one transition is monitored. As in

SIR, a chromatogram is produced.

Time

LC-MRM

!

High specificity

!

Good signal / noise

RF only

(pass all masses)

!

!

Poor signal / noise

static at m/z 195

(daughter mass)

Time

LC-MS

Low specificity

MS2

Instrument Description

Page 21

Quattro Ultima

User's Guide

The Constant Neutral Loss Spectrum

The loss of a specific neutral fragment or functional group from an unspecified parent

or parents.

Typical applications:

Screening mixtures, for example during neonatal screening, for a specific class

•

of compound that is characterised by a common fragmentation pathway.

MS1

scanning

Collision Cell

RF only

(pass all masses)

MS2

scanning

The scans of MS1 and MS2 are synchronised. When MS1 transmits a specific

parent ion, MS2 “looks” to see if that parent loses a fragment of a certain mass.

If it does it registers at the detector.

The result:

The “spectrum” shows the masses of all parents that actually lost a fragment of a

certain mass.

Data System

The PC based data system, incorporating MassLynx NT™ software, controls the mass

spectrometer detector and, if applicable, the HPLC system, autosampler, syringe

pump, divert valve or injector valve.

The PC uses the Microsoft Windows NT graphical environment with colour graphics

and provides for full user interaction with either the keyboard or mouse.

MassLynx NT provides full control of the system including setting up and running

selected HPLC systems, tuning, acquiring data and data processing.

Analog inputs can be read by the data system so that, where applicable, a trace from a

conventional LC detector (for example UV or fluorescence) can be stored

simultaneously with the acquired mass spectral data. A further option is the ability to

acquire UV photodiode array detector data.

Comprehensive information detailing the operation of MassLynx NT is contained in

the MassLynx NT User’s Guide.

Instrument Description

Page 22

Front Panel Connections

Quattro Ultima

User's Guide

CAPILLARY / CORONA

ESI / APci

VACUUM

OPERATE

C.I.D. GAS

INJECTOR

STANDBY

DESOLVATION

GAS

NEBULISER

CONE GAS

LOAD

INJECT

LC Connection

High Voltage

Connection

Source

Connection

Desolvation Gas and Probe Nebuliser Gas

The PTFE gas lines for the desolvation gas and probe nebuliser gas are connected to

the front of the instrument using threaded metal fittings.

Capillary / Corona

The electrical connection for the ESI capillary or the APcI discharge pin is via the

coaxial high voltage connector.

ESI / APcI

The electrical connection for the APcI probe or the ESI heater is via the multi-way

connector. This is removed from the front panel by pulling on the metal sleeve of the

plug. Both the electrospray and APcI heaters use this connector.

Desolvation

Gas

Nebuliser

Gas

Instrument Description

Page 23

Quattro Ultima

C

User's Guide

Front Panel Controls and Indicators

CID Gas

ontrol

CAPILLARY / CORONA

ESI / APci

VACUUM

OPERATE

Cone Gas

Control

STANDBY

DESOLVATION

GAS

NEBULISER

C.I.D. GAS

INJECTOR

Desolvation

Gas Control

Nebuliser

Gas Control

CONE GAS

LOAD

INJECT

Status Display

The display on the front panel of the instrument consists of two 3-colour light emitting

diodes (LEDs).

The display generated by the Vacuum LED is dependent on the vacuum status of the

instrument. The Operate LED depends on both the vacuum status and whether the

Operate mode has been selected from the Data System.

The status of the instrument is indicated as follows:

Vacuum LED

Pumping Steady amber Pump fault Flashing red

Operate LED

Standby No indication

State Vacuum LED State Vacuum LED

Vented No indication Vacuum OK Steady green

State Operate LED State Operate LED

Transient pressure

trip

Steady amber

Operate Steady green RF trip Flashing red

Instrument Description

Page 24

Flow Control Valves

The Desolvation Gas, Cone Gas and Nebuliser needle valves are five-turn

valves. The CID Gas valve is a fifteen-turn valve. The flow increases as the valve is

turned counterclockwise.

Caution: To prevent damage to the CID Gas valve, take care not to

over-tighten when turning the supply off.

Divert / Injection Valve

Quattro Ultima

User's Guide

Load

Divert / Injection

Valve

The optional divert / injection valve may be used in several ways depending on the

plumbing arrangement:

•

As an injection valve, with the needle port and sample loop fitted.

•

As a divert valve, to switch the flow of solvent during a LC run.

•

As a switching valve to switch, for example, between a LC system and a syringe

pump containing calibrant.

This valve is pneumatically operated, using the instrument’s nitrogen supply.

Note that the valve is connected such that the nitrogen supply is always

connected to the valve, irrespective of the flow to the source and probe.

Control of the valve is primarily from the data system. The two switches marked

Load and Inject enable the user to override control of the valve when making loop

injections at the instrument.

Inject

Instrument Description

Page 25

Quattro Ultima

User's Guide

Rear Panel Connections

Event Out

Four outputs, Out 1 to Out 4, are provided to allow various peripherals to be

connected to the instrument. Switches S1 to S4 allow each output to be set to be

either a contact closure (upper position) or a voltage output (lower position).

Out 1 and Out 2, when set to voltage output, each have an output of 5 volts. The

voltage output of both Out 3 and Out 4 is 24 volts.

During a sample run Out 1 closes between acquisitions, and is used typically to

enable an external device to inject the next sample. The three remaining outputs are

reserved for future developments.

Contact Closure In

In 1 and In 2 inputs are provided to allow external device to start sample acquisition

once the device has performed its function (typically sample injection).

SCOPE

DATA SYSTEM

X

1V

+- +-

Y

CH3

MUX

1V

ANALOG CHANNELS EVENT OUT

CLOSURE

1V

IN

IN 2IN 1

CH4

1V

CONTACT

CH2

CH1

REFER TO

MANUAL BEFORE

CONNECTING TO

THESE PORTS

!

CAUTION !

OUT 4OUT 3OUT 2OUT 1

S4S3S2S1

Analog Channels

Four analog channel inputs are available, for acquiring simultaneous data such as a

UV detector output. The input differential voltage must not exceed one volt, though

full scale automatically adjusts from 1mV to 1V.

Instrument Description

Page 26

MUX

This 6-way connector connects the instrument to the MUX control base.

Data System

This RJ45 connector connects the instrument to the data system using the network

cable supplied.

Quattro Ultima

User's Guide

Instrument Description

Page 27

Quattro Ultima

y

User's Guide

Power

Cord

Electrostatic

Discharge

Earth (Ground)

Point

Rotary Pump

Control

Mains

Switch

Fuses

Water

Backing

Line

Source

Pumping Line

Hexapole

Pumping Line

To Rotar

Pumps

Water is used to cool the turbomolecular pumps.

CID Gas

Exhaust

Gas

ROTARY PUMP

CONTROL

ROTARY PUMP

CONTROL

CID

GAS

NITROGEN GAS

OUTLET INLET

Nitrogen

Gas In

1

0

ESD

EARTH

FACILITY

OUT IN

10 AMP (T)

10 AMP (T)

WATER

Water

Connections

Nitrogen Gas In

The nitrogen supply (100 psi, 7 bar) should be connected to the Nitrogen Gas In

push-in connector using 6mm PTFE tubing. If necessary this tubing can be connected

to ¼ inch tubing using standard ¼ inch fittings.

Caution: Use only PTFE tubing or clean metal tubing to connect between the

nitrogen supply and the instrument. The use of other types of plastic tubing

results in chemical contamination of the source.

Instrument Description

Page 28

Exhausts

CID Gas

Quattro Ultima

User's Guide

The exhaust from the rotary pump should be vented to atmosphere outside the

laboratory.

The gas exhaust, which also contains solvent vapours, should be vented via a separate

fume hood, industrial vent or cold trap.

The gas exhaust should be connected using 10mm plastic tubing connected to

the push-in fitting.

Caution: Do not connect these two exhaust lines together as, in the event of an

instrument failure, rotary pump exhaust could be admitted into the source

chamber producing severe contamination.

Argon is required as collision gas. See Hardware Specifications for details.

Power Cord

The mains power cord should be wired to a suitable mains outlet using a standard

plug. For plugs with an integral fuse, the fuse should be rated at 13 amps.

Mains Switch

The mains switch switches mains power to the instrument.

Fuses

Refer to Maintenance and Fault Finding for details of rear panel fuses, and all other

instrument fuses.

Rotary Control

Mains power to the two rotary pumps is controlled by the data system using one of

these two sockets. The other socket is connected to the solenoid valve situated in the

oil return tube on the E1M18 pump.

ESD Earth Facility

A suitable wrist band should be connected to this point when handling sensitive

electronic components, to prevent damage by electrostatic discharge.

Instrument Description

Page 29

Quattro Ultima

User's Guide

Internal Layout

Electronics

High Voltage

Power Supplies (4)

Transputer Processor

Card (TPC)

Analogue PCB

Control PCB

Scan Control PCB

RF Control (Upper) PCB

Analyser

Turbomolecular

Pump

Low Voltage

Power

Supplies (2)

Pumping

Logic PCB

Power

Sequence

PCB

RF Control (Lower) PCB

RF Generators

Turbomolecular

Pumps

Power Supply

Instrument Description

Page 30

Quattro Ultima

User's Guide

The main electronics modules of the system are:

Two low voltage power supplies.

•

Four high voltage power supplies, plugged into the backplane below the analyser

•

housing.

These supply the detector system and the high voltages for the source and

electrospray probe.

Two RF generators, bolted to the side of the analyser housing.

•

Pumping Logic PCB.

•

This controls the turbomolecular pumps, the pumping sequence, the gas valves

and the solenoids. It also controls the phosphor and dynode voltages.

Power Sequence PCB.

•

This PCB examines the vacuum, operate and interlock signals in order to

control the switching of various supplies. Also on this PCB is a module

delivering the photomultiplier voltage.

Transputer Processor Card (TPC).

•

This contains the transputer array and controls data acquisition and control

functions, as well as interfacing to the PC.

•

Analog PCB

This PCB controls the source heater and focussing voltages.

•

Control PCB

This supplies various lens voltages to the source and first hexapole.

•

Scan Control PCB

This PCB produces control signals for mass, resolution, function energy,

collision energy and pre-filter energy.

•

RF Generator Control (Upper) PCB

This controls the RF and DC voltages applied to the first quadrupole. It also

supplies the collision cell voltages.

•

RF Generator Control (Lower) PCB

This controls the RF and DC voltages applied to the second quadrupole.

Instrument Description

Page 31

Quattro Ultima

User's Guide

Mechanical Components

Air Filter

(behind cover)

Source

Housing

Analyser

Housing

Source

Turbomolecular

Pump

Detector

Active Inverted

Magnetron

(Penning) Gauge

Pirani

Gauge

The main internal mechanical components of the instrument are:

•

The source housing, inside which are the ion tunnels.

The ion tunnels are sometimes referred to as the “RF lenses”.

•

The analyser housing, containing the two quadrupoles and the gas cell.

•

The detector, attached to the rear of the analyser housing.

•

Two 250 litre/second turbomolecular pumps, one pumping each of the above

housings.

•

The active inverted magnetron (Penning) gauge and the Pirani gauge, both

clamped to the underside of the analyser housing.

•

The air filter, held in the louvered cover at the left side of the front of the

instrument.

Instrument Description

Page 32

Routine Procedures

Start Up Following a Complete Shutdown

Preparation

If the instrument has been unused for a lengthy period of time, proceed as follows:

Check the level of oil in

the rotary pump sight

glass. Refill or replenish as

necessary as described in

the pump manufacturer’s

literature.

Connect a supply of dry,

high purity nitrogen to the

connector on the service

panel at the rear of the

instrument. Adjust the

outlet pressure to 7 bar

(100 psi).

Gas

Ballast

Exhaust

Quattro Ultima

User's Guide

Oil Mist

Filter

Filler

Plug

Oil Level

Indicator

Drain

Plug

Connect a supply of argon

to the CID Gas connector on the service panel at the rear of the instrument.

Adjust the outlet pressure to approximately 350 mbar (5 psi).

Connect the water supply to the connections at the rear of the instrument.

CID Gas

Nitrogen

Gas In

ROTARY PUMP

CONTROL

ROTARY PUMP

CONTROL

CID

GAS

NITROGEN GAS

OUTLET INLET

1

0

ESD

EARTH

FACILITY

WATER

OUT IN

10 AMP (T)

10 AMP (T)

Water

Connections

Routine Procedures

Page 33

Quattro Ultima

User's Guide

Check that the rotary pump control box is connected to Rotary Control at the

rear of the instrument, and to the rotary pumps. Check that the solenoid valve on

the E1M18 rotary pump is connected to the other Rotary Control socket.

REFER TO

MANUAL BEFORE

Data System

Connection

SCOPE

X

Y

MUX

DATA SYSTEM

CONNECTING TO

THESE PORTS

CONTACT

CH2

CH1

1V

+- +-

CH3

1V

ANALOG CHANNELS EVENT OUT

CLOSURE

1V

CH4

1V

IN

IN 2IN1

Mains

Switch

Rotary Pump

Control

!

CAUTION !

S4S3S2S1

OUT 4OUT 3OUT 2OUT 1

1

ROTARY PUMP

CONTROL

ROTARY PUMP

CONTROL

CID

GAS

NITROGEN GAS

OUTLET INLET

0

ESD

EARTH

FACILITY

OUT IN

10 AMP (T)

10 AMP (T)

WATER

Exhaust

Gas

Check that the instrument, rotary pump control box, data system and other

peripheral devices (LC equipment, printer etc.) are connected to suitable mains

supplies.

Check that the data system is connected to the mass spectrometer via the

network cable.

Check that the rotary pump exhaust is connected to a suitable vent.

Check that the exhaust gas from the instrument is connected to a separate vent.

Caution: Do not connect the two exhaust lines together. In the event of an

instrument failure, rotary pump exhaust could be admitted into the source

chamber, producing severe contamination.

Switch on the mains to the mass spectrometer using the switch situated on the

service panel at the rear of the instrument.

Routine Procedures

Page 34

Quattro Ultima

User's Guide

Switch on the data system.

As supplied Windows NT is automatically activated following the start-up

sequence whenever the data system is switched on.

Windows NT and MassLynx NT can be configured to prevent unauthorised

access. Consult the system administrator for any passwords that may be

requested.

When the data system has booted up, double-click on on the Windows

desktop.

Launch the tune page by clicking on .

Routine Procedures

Page 35

Quattro Ultima

User's Guide

Pumping

Caution: To minimise wear to the lubricated components of the rotary pump, the

manufacturers recommend that the pump is not started when the oil temperature

is below 12°C.

Pump down time may be decreased

by closing the isolation valve of

the source during pump down.

Isolation

Valve

Select Other from the menu bar at

the top of the tune page.

Click on Pump.

The rotary pump and the

turbomolecular pumps start

simultaneously.

The Vacuum LED on the front of

the instrument shows amber as the

system pumps down.

When the system has reached

operating vacuum the LED changes to a steady green, indicating that the

instrument is ready for use.

Ensure that the gas ballast valve on the E1M18 rotary pump is open.

The E1M18 rotary pump is operated with its gas ballast valve open at all times.

If the E2M28 rotary pump oil has been changed or replenished, open the gas

ballast valve on this pump. See the pump manufacturer’s literature for details.

Rotary pumps are normally noticeably louder when running under gas ballast.

Caution: The instrument should not be vented while the E2M28 rotary pump is

running under gas ballast. See Maintenance and Fault Finding for more

information.

If opened, close the gas ballast valve on the E2M28 rotary pump when the pump

has run under gas ballast for 30 minutes.

Routine Procedures

Page 36

Measuring the Analyser Pressure

The analyser pressure may be monitored via the active inverted magnetron (Penning)

gauge.

Caution: To maximise the life of the gauge it is recommended that the gauge is

switched on only when the pressure needs to be monitored. Leaving the analyser

pressure displayed for long periods necessitates frequent (every 2 to 4 months)

cleaning of the Penning gauge.

This gauge operates by generating a high voltage discharge within the vacuum

chamber. The magnitude of the discharge current is then measured and used to

calculate the analyser pressure. An undesirable characteristic of this type of

gauge is the slow build up of sputtered material in the discharge region,

eventually leading to failure of the gauge.

To switch on the gauge:

Quattro Ultima

User's Guide

Press or select Options, Pressure Monitor from the tune page.

There is a delay of 10 seconds before the pressure is displayed.

To switch off the gauge:

Press or select Options, Peak Editor from the tune page.

The analyser pressure is not recorded in the experimental record file unless the

pressure window is displayed prior to starting the acquisition. However, the gas

cell pressure (monitored by the gas cell Pirani gauge) is always recorded.

Using the Instrument

Quattro Ultima is now almost ready to use. To complete the start up procedure and

prepare for running samples, follow the instructions in Start Up Following Overnight

Shutdown in the following pages.

Start Up Following Overnight Shutdown

The instrument will have been left in standby mode under vacuum.

It is recommended that the data system is left on overnight. However, if the data

system has been switched off, switch it on as described in the preceding section.

The display on the front of the instrument displays a steady green Vacuum

LED indicating that the instrument is ready for use.

Routine Procedures

Page 37

Quattro Ultima

User's Guide

Preparation for Electrospray Operation

Source

Thumb Nuts

Probe

Thumb Nuts

If the corona discharge pin is fitted, proceed as follows:

Disconnect the gas and electrical connections from the front panel.

Unscrew the probe thumb nuts and remove the probe

Undo the three thumb screws and remove the probe adjustment flange and

glass tube.

Disconnect the APcI high voltage cable from the socket positioned at the

bottom right corner of the source flange.

Remove the corona discharge pin from its mounting contact, and fit the

blanking plug.

Glass

Tube

Probe

Adjustment Flange

Ensure that the source enclosure (consisting of the glass tube and the probe

adjustment flange) is in place.

Connect the source’s gas line to Desolvation Gas on the front panel. Tighten

the nut to ensure a good seal.

Check that the lead of the probe adjustment flange is plugged into the socket

labelled ESI / APcI on the front panel.

Routine Procedures

Page 38

Replace the glass tube and adjustment flange.

Cleanable

Baffle

Exhaust

Liner

Blanking

Plug

Quattro Ultima

User's Guide

Corona

Discharge

Pin

Mounting

Contact

High Voltage

Socket

Take the electrospray probe and connect its gas line to Nebuliser on the front

panel.

Connect the liquid flow of a LC system or syringe pump to the probe.

Insert the probe into the source and tighten the two thumb nuts to secure the

probe firmly.

Plug the probe lead into Capillary / Corona on the front panel.

On the MassLynx top-level window, click on to launch the tune page.

The top line of the tune page indicates the current ionisation mode.

If necessary, change the ionisation mode using the Ion Mode command.

Set Source Temp to 100°C and Desolvation Temp to 20°C.

Warning: Operating the source without the source enclosure results

in solvent vapour escape and the exposure of hot surfaces and high

voltages.

Warning: The ion source block can be heated to temperatures of 150°C, and is

maintained at the set temperature when the source enclosure is removed.

Touching the ion block when hot may cause burns to the operator.

Routine Procedures

Page 39

Quattro Ultima

User's Guide

Preparation for APcI Operation

Source

Thumb Nuts

Glass

Tube

Probe

Thumb Nuts

Probe

Adjustment Flange

If the corona discharge pin is not fitted, proceed as follows:

Disconnect the gas and electrical connections from the front panel.

Unscrew the probe thumb nuts and remove the probe.

Undo the three thumb screws and remove the probe adjustment flange and

glass tube.

Remove the blanking plug from the discharge pin mounting contact and fit

the corona discharge pin, ensuring that the tip is in-line with the tip of the

sample cone.Connect the APcI high voltage cable between

Capillary / Corona and the socket positioned at the lower right edge of

the source flange.

Ensure that the source enclosure (consisting of the glass tube and the probe

adjustment flange) is in place.

Connect the source’s gas line to Desolvation Gas on the front panel. Tighten

the nut to ensure a good seal.

Check that the lead of the probe adjustment flange is plugged into the socket

labelled ESI / APcI on the front panel.

Routine Procedures

Page 40

Replace the glass tube and adjustment flange.

Quattro Ultima

User's Guide

Blanking

Plug

Sample

Cone

Corona

Discharge

Pin

Mounting

Contact

High Voltage

Socket

Take the APcI probe and connect its gas line to Nebuliser on the front panel.

Connect the liquid flow of a LC system or syringe pump to the probe.

Insert the probe into the source and tighten the two thumb nuts to secure the

probe firmly.

On the MassLynx top-level window, click on to launch the tune page.

The top line of the tune page indicates the current ionisation mode.

If necessary, change the ionisation mode using the Ion Mode command.

Set Source Temp to 150°C.

Warning: Operating the source without the source enclosure results

in solvent vapour escape and the exposure of hot surfaces and high

voltages. Allow the glass source enclosure to cool after a period of

operation at high flow rates before removal.

Warning: The ion source block can be heated to temperatures of 150°C, and is

maintained at the set temperature when the source enclosure is removed.

Touching the ion block when hot may cause burns to the operator.

The liquid flow should not be started until the gas flow and probe heater are

switched on with the probe inserted.

Routine Procedures

Page 41

Quattro Ultima

User's Guide

Operate

On the MassLynx top-level window, click on to launch the tune page.

The top line of the tune page indicates the current ionisation mode.

If necessary, change the ionisation mode using the Ion Mode command.

Depending on the chosen mode of ionisation, set Desolvation Temp or

APcI Probe Temp to 20°C.

Click on on the MassLynx tune page.

The instrument goes into the operate mode only if the probe adjustment flange is

in place and a probe is inserted.

On the tune page, press or select Gas, Gas to turn on the source and probe

gases.

Set Desolvation Gas to a flow of 150 litres/hour and adjust Nebuliser to

maximum.

The system is now ready for operation. To obtain an ion beam refer to Obtaining an

Ion Beam in either the Electrospray or the Atmospheric Pressure Chemical Ionisation

section.

Automatic Pumping and Vacuum Protection

Overview

The instrument is protected against vacuum system faults due to:

malfunction of the vacuum pumps.

excessive pressure.

excessive temperature.

The pump down sequence is fully automated, a command from the data system

switching on the rotary pump and turbomolecular pumps simultaneously.

Protection

Transient Pressure Trip

If the vacuum gauge detects a pressure surge above the factory set trip level of

-3

10

mbar, and if the instrument is in the operate mode, the following events occur:

The critical source, analyser and detector voltages are switched off.

The Operate LED shows a steady amber.

Routine Procedures

Page 42

Quattro Ultima

User's Guide

The Vacuum LED shows a steady amber.

Acquisition continues, although no mass spectral data are recorded.

When the pressure recovers, the voltages are restored and the Vacuum and Operate

LED’s are steady green.

Any further deterioration of the system vacuum results in a pump fault and the system

is shut down.

Pump Fault

A pump fault causes the following to occur:

The turbomolecular pumps stop pumping.

On the display the Vacuum LED flashes red.

The Operate LED is extinguished.

As the turbos slow down the vent valve opens, the rotary pump switches off and

the system is vented.

The pumps do not switch on again unless requested to do so.

A pump fault can occur as a result of:

•

Over temperature of the turbomolecular pumps.

If the water cooling fails, then the turbomolecular pumps switch off when their

temperature becomes too high.

•

Vacuum leak.

Refer to “Maintenance and Fault Finding” later in this manual.

•

Malfunction of the turbomolecular pumps.

Refer to the pump manufacturer’s manuals.

•

Malfunction of the rotary pump.

Refer to the pump manufacturer’s manuals.

Power Failure

In the event of an unexpected power failure, proceed as follows:

Switch OFF the power to the instrument at the wall mounted isolation switch.

When power is restored, follow the start up procedure as described earlier in this

chapter.

Routine Procedures

Page 43

Quattro Ultima

User's Guide

Tuning

Information concerning the tuning of Quattro Ultima is provided in Tuning later in this

document. Refer also to Electrospray, Nanoflow Electrospray and Atmospheric

Pressure Chemical Ionisation for tuning information specific to those techniques.

Calibration

Information concerning the calibration of Quattro Ultima is provided in Mass

Calibration later in this document.

Data Acquisition

The mechanics of the acquisition of sample data are comprehensively described in

Data Acquisition later in this document.

Data Processing

The processing of sample data is comprehensively described in the MassLynx NT

User’s Guide. Refer to that publication for full details.

Setting Up for MS-MS Operation

The following notes provide a worked example for the acquisition of daughter ion

data. The experiment is performed in the ESI positive mode using reserpine as a

model analyte. Reserpine, admitted by constant infusion at a concentration of 50 pg/µl,

provides a stable and persistent source of ions for instrument tuning in both the MS

and MS-MS modes of operation.

The basic sequence of events is as follows:

•

Tuning MS1.

•

Tuning MS2.

•

Parent ion selection.

•

Fragmentation.

More detailed information on these processes can be found in Tuning and Data

Acquisition later in this manual.

Parent Ion Selection

For maximum sensitivity in daughter ion analysis the centre of the parent ion selected

by MS1 must be accurately found. The nominal mass of the parent is first determined

(if unknown) by viewing it in MS mode:

Routine Procedures

Page 44

Quattro Ultima

User's Guide

Set up a 1 box display on the tune page and set Function to MS Scan.

Observe the candidate parent ion in the display and determine its nominal mass.

In this example the reserpine ion at z 609 is used as a model parent.

The accurate top of the parent ion can be found experimentally by performing a

“daughter ion scan” over a restricted mass range in the absence of collision gas.

On the tune page set Function for peak 2 to Daughter Scan.

Place the mouse cursor on the Set mass for peak 2 and type in the nominal mass

of the parent ion selected by MS1, in this case 609.

Vary the Set value between 608.5 and 609.5 while optimising the intensity of

the non-fragmented parent ion in the tune display.

The Set mass giving maximum intensity is used for future MS-MS experiments.

Fragmentation

Set up a wide range daughter ion scan by adjusting the Mass and Span

parameters for peak 2.

At this point, with the collision gas off, a few daughter ions of low intensity may be

visible. These are the products of unimolecular dissociations.

Argon (99.9% pure) is recommended as the collision gas.

Select Gas, Collision Gas.

Adjust CID Gas on the front panel to admit sufficient gas to attenuate the

parent ion peak by about 50%.

Adjust the Entrance, Collision and Exit parameters in the Analyser menu to

produce the desired degree of fragmentation. (These parameters are interactive in

MS-MS operation.)

In daughter ion analysis maximum transmission (sensitivity) can be achieved by the

following adjustments:

•

Optimising Collision.

•

Optimising Exit.

•

Optimising Entrance.

•

Optimising the collision gas pressure using the CID Gas needle valve.

Additionally, transmission can be improved at the expense of specificity by reducing

HM Resolution 1 and increasing Ion Energy 1 on the Analyser window. In most

cases, where chemical interference with the parent ion is not acute, the loss of

specificity is negligible.

Routine Procedures

Page 45

Quattro Ultima

User's Guide

Shutdown Procedures

Emergency Shutdown

In the event of having to shut down the instrument in an emergency, proceed as

follows:

Switch OFF the power at the wall mounted isolation switch(es), if fitted. If not,

switch the power off at the rear of the instrument and switch off all peripherals.

Isolate any LC systems to prevent solvent flowing into the source.

A loss of data is likely.

Overnight Shutdown

When the instrument is to be left unattended for any length of time, for example

overnight or at weekends, proceed as follows:

Switch off the LC pumps.

On the MassLynx top-level window, click on to launch the tune page.

Click on .

This changes from green to grey indicating that the instrument is no longer in

operate mode.

Undo the finger-tight connector on the probe to release the tubing leading from

the LC system.

Before disconnecting the probe, it is good practice to temporarily remove the

probe and flush it of any salts, buffers or acids.

If APcI is being used, switch off the probe heater or reduce it to ambient

temperature.

Caution: Leaving the APcI probe hot with no gas or liquid flow shortens the

lifetime of the probe heater.

Select Gas followed by Gas to turn off the supply of nitrogen gas.

If the instrument is not to be used for a long period of time:

Reduce Source Temp to 60°C.

Routine Procedures

Page 46

Complete Shutdown

If the instrument is to be left unattended for extended periods, proceed as follows:

Switch off the LC pumps.

On the MassLynx top-level window, click on to launch the tune page.

Click on on the tune page.

This changes from green to grey indicating that the instrument is no longer in

operate mode.

Undo the finger-tight connector on the probe to release the tubing leading from

the LC system.

Before disconnecting the probe, it is good practice to temporarily remove the

probe and flush it of any salts, buffers or acids.

Quattro Ultima

User's Guide

If APcI is being used, switch off the probe heater or reduce it to ambient

temperature.

Caution: Leaving the APcI probe hot with no gas or liquid flow shortens the

lifetime of the probe heater.

Select Gas, Gas to turn off the supply of nitrogen gas.

Select Other from the menu bar at the top of the tune page. Click on Vent.

The rotary pump and the turbomolecular pumps switch off. When the

turbomolecular pumps have run down to half of their normal operating speed

the vent valve opens and the instrument is vented to atmosphere.

Exit MassLynx.

Shut down the computer.

Switch off all peripherals.

Switch off the power to the instrument using the switch on the rear panel of the

instrument.

Switch off power at the wall mounted isolation switches.

If the instrument is to be switched off for more than one week:

Drain the oil from the rotary pump according to the manufacturer’s instructions.

Routine Procedures

Page 47

Quattro Ultima

User's Guide

Automatic Start up and Shutdown

MassLynx comes with automatic startup and shutdown files which are run when

Startup or Shutdown is selected from the Run menu.

These are found in the C:\Masslynx\Shutdown directory and are called

ShutDownxxx.acl and StartUpxxx.acl where xxx refers to the instrument

configuration.

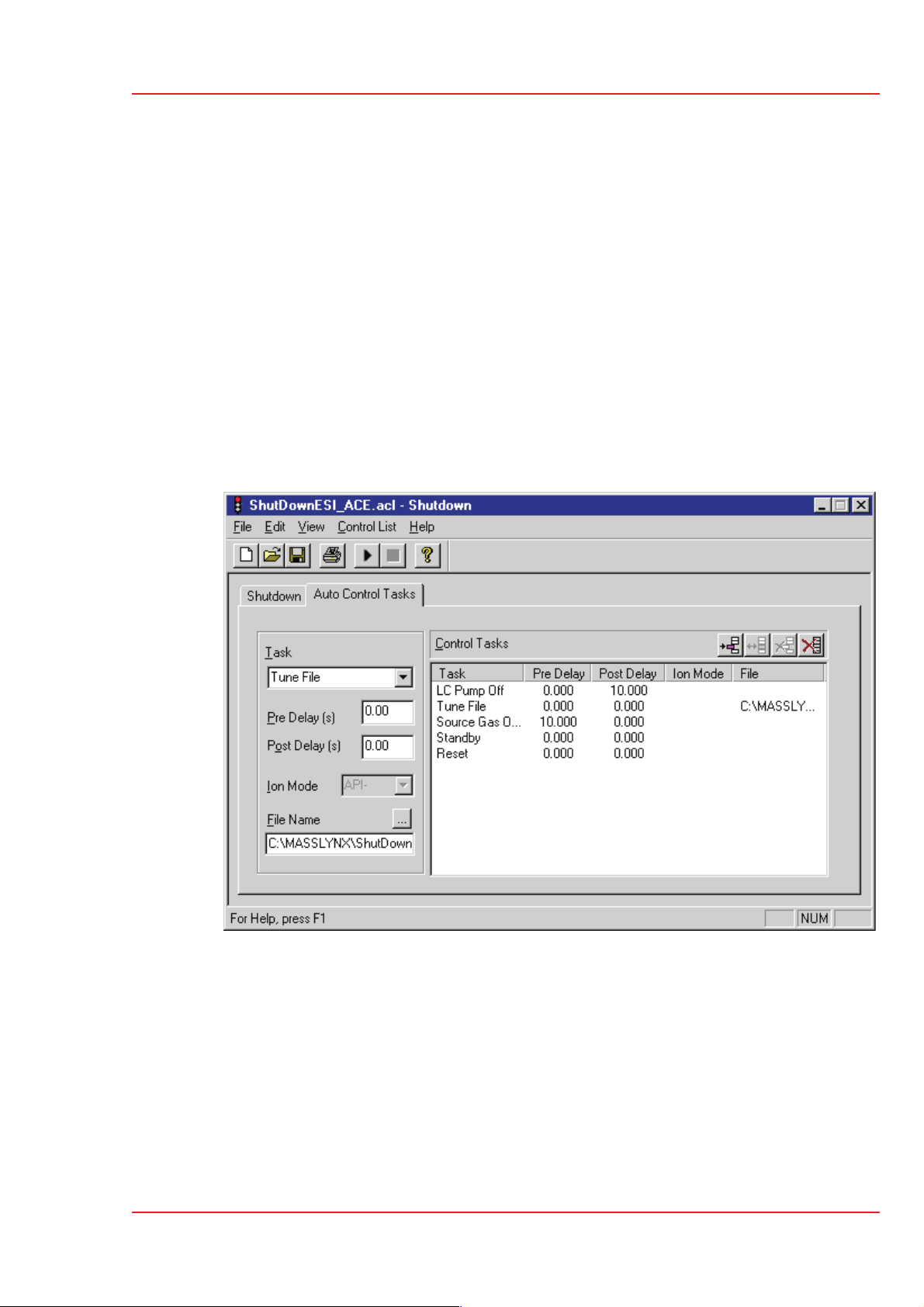

The Shutdown Editor

The shutdown editor allows the automatic startup and shutdown procedures to be

modified or new procedures to be created. To access the editor:

Select Edit Shutdown from the MassLynx Run menu.

Check the Enable Startup before batch box to perform the startup tasks

when a sample list is submitted.

Check the Enable Shutdown after batch box to perform the shutdown tasks

after a batch of samples has completed.

Enter a time in the Shutdown XX.XX minutes after batch or error box at

which to perform the shutdown tasks.

Routine Procedures

Page 48

There is an option to perform the shutdown tasks immediately after an error occurs or

after the time defined in the Shutdown XX.XX minutes after batch or error

box. If the Enable Shutdown on error box is checked then the shutdown tasks are

performed after the defined time.

The Enable immediate Shutdown on error box is grayed out if this option

is selected.

If the Enable immediate Shutdown on error box is checked then the shutdown

tasks are performed as soon as the error is detected.

The Enable immediate Shutdown on error box is grayed out if this option

is selected, but the shutdown time can still be changed as this applies to the

Enable Shutdown after batch option.

The Auto Control Tasks Page

Quattro Ultima

User's Guide

Task is a dropdown list box with all the available tasks.

Pre Delay is the length of time that elapses before the current task is performed.

Post Delay is the length of time that elapses after the current task has been

completed and before the next task is started. For example. a Post Delay of

60 seconds, in the Vent Instrument task, means that there is a delay of 60 seconds

before the next task is started, to allow the machine to vent fully.

Ion Mode is a dropdown list box with all the available ionisation modes.

Routine Procedures

Page 49

Quattro Ultima

User's Guide

File Name is selected from the browser displayed when is pressed, or is typed in

giving the full path name.

To add a task:

To insert a task:

Select a task from the dropdown task list box.

Enter the required parameters.

Press .

If this is a new task timetable the task is added to the end of the list. If a task

has been inserted into the task timetable then all subsequent tasks are added

after the inserted task. To add a task to the end of the timetable after inserting a

task, click twice with the left mouse button below the last entry in the timetable

and then add the new task.

Click on the entry in the task timetable before which the new task is to be

inserted.

Select a task from the dropdown task list box.

Enter the required parameters.

Press .

To modify a task:

Click on the entry in the task timetable.

The details for the task are displayed in the fields on the left of the screen.

Change the required parameters.

Press .

To delete a task:

Click on the entry in the task timetable.

The details for the task are displayed in the fields on the left of the screen.

Press .

To delete all tasks:

Press .

Routine Procedures

Page 50

To change the width of a column:

Position the mouse pointer on the heading between two columns until

appears.

Click the left mouse button and drag until the column is the required width.

The Shutdown Editor Toolbar

Toolbar Button Menu Equivalent Purpose

Quattro Ultima

User's Guide

File… New

File… Open

File… Save

or

File… Save As

File… Print Print a startup or shutdown file

Control List… Run List Run a startup or shutdown file

Control List… Stop List Stop a startup or shutdown file

Help… Help Topics Invoke help

Create a new startup or shutdown

file

Open an existing startup or shutdown

file

Save a startup or shutdown file

Routine Procedures

Page 51

Quattro Ultima

User's Guide

Loading Startup and Shutdown Files

To open a startup or shutdown file:

Press or select Open from the File menu.

This displays the open file dialog.

Select a data file and press Open.

Saving a Startup or Shutdown File

To save a startup or shutdown file

Press or select Save or Save As from the File menu.

If this is a new file, or if the Save As option has been selected, the Save As

dialog is displayed.

Type a name into the File Name box and press Save.

Routine Procedures

Page 52

Printing Startup and Shutdown Files

To print a startup or shutdown file:

Press , or select Print from the File menu.

This displays the print dialog.

Quattro Ultima

User's Guide

Select the printer, print range and number of copies and press OK.

Routine Procedures

Page 53

Quattro Ultima

User's Guide

Creating Startup and Shutdown Files

To create a startup or shutdown file

Press , or select New from the File menu.

Running Startup and Shutdown Files

If Startup or Shutdown is selected from the Run menu, or from the shutdown

editor control list menu, then the automatic startup and shutdown files are run.

To run a different startup or shutdown file:

Open the required file in the shutdown editor and press , or select Run List

from the shutdown editor control list menu.

To stop running this file:

Press , or select Stop List from the shutdown editor control list menu.

Routine Procedures

Page 54

Overview

Quattro Ultima

User's Guide

Tuning

Before sample data are acquired, the instrument should be tuned and, for the highest

mass accuracy, calibrated using a suitable reference compound.

•

Consult the relevant section of this manual for information concerning source

tuning procedures in the chosen mode of operation.

•

Adjust the tuning parameters in the Source and Analyser menus to optimise

peak shape and intensity at unit mass resolution.

•

Care should be taken to optimise the value of the collision energy. Note that, in

Daughter and Parent modes, Collision and Exit are interactive

parameters.

Tuning

Page 55

Quattro Ultima

User's Guide

The Tune Page

To display the tune page:

Press on the MassLynx screen MS panel.

Refer to the fold-out page at the end of this section for details of the tune page layout.

Printing Tune Information

To print a report, containing a copy of the tune peak information displayed on the

screen along with a record of each parameter setting:

Press , or select Print from the tune page File menu.

This report is not configurable by the user.

Experimental Record

Tuning parameters are stored with every data file as part of the experimental record.

The tuning parameters for a particular data file can be viewed or printed from the data

browser, see the MassLynx NT User Guide, Selecting and Viewing Data, for more

information.

Saving and Restoring Parameter Settings

Whole sets of instrument tuning parameters can be saved to disk as a named file and

then recalled at a future date.

A tune parameter file contains the latest settings for the source controls for all

supported ionisation modes not just the ionisation mode currently selected. Tune

parameter files also contain settings for the analyser, inlet set points and peak

display.

To save the current tune parameters with the existing file name:

Press , or choose Save from the tune page File menu.

Press Save.

Tuning

Page 56

To save the current tune parameters with a new file name:

Select Save As from the tune page File menu.

Enter a new file name or select an existing file from the list displayed.

Press Save.

Quattro Ultima

User's Guide

If the selected file already exists on disk a warning is displayed. Press Yes to

overwrite the existing information or No to enter a different file name.

To restore a saved set of parameters:

Press , or choose Open from the tune page File menu.

Select the required tuning parameter file, either by typing its name or by

selecting from the list displayed.

Press Open.

Tuning

Page 57

Quattro Ultima

User's Guide

Modifying the Peak Display

The tune peak display is modified using either the tune peak controls, or the mouse

directly on the display. To select peaks:

Press , or select Options, Peak Editor.

Choose the peaks to be displayed by checking the appropriate boxes.

For each active peak select the Mass, Span and Gain.

To change the function:

Select the function for the peak from the drop down list.

For MS-MS functions, Set is enabled allowing the mass of the parent, daughter,

neutral loss or neutral gain ion to be entered.

To change the tune mass:

Click and drag the mouse within the bounds of the axis to draw a “rubber band”

around the region of interest.

Release the button.

This range is redisplayed to fill the window. The mass displayed in the Mass

box is the mass at the centre of the window.

This operation can be repeated as often as required.

Pressing once displays the previous magnification range and mass, pressing

it a second time returns to the default settings.

or:

Enter a value in the Mass box for the required peak and press Return.

This becomes the default, so if the range is altered with the mouse and is

pressed twice Mass returns to this value.

or:

Tuning

Page 58

Position the cursor at the top of the peak window, just below the line showing

the gain.

When appears, click the left mouse button and drag until the required mass

is displayed in the Mass box and at the top of the window.

This becomes the default, so if the range is altered with the mouse and is

pressed twice Mass returns to this value.

Quattro Ultima

To change the span of a peak:

Press the left mouse button at one end of the region of interest and, without

releasing the button, drag the mouse horizontally to the other end.

As the mouse is dragged a “rubber band” stretches out to indicate the selected

range.

Do not go beyond the bounds of the axis.

Release the mouse button to re-display the selected range filling the current

window.

This operation can be repeated as often as required.

Pressing once displays the previous magnification range, pressing it a

second time returns to the default settings.

User's Guide

or:

Enter a value in the Span box for the required peak and press Return.

This becomes the default, so if the range is altered with the mouse and is

pressed twice Span returns to this value.

To change the gain of a peak

Double click on the line above the peak which shows the gain, to double the

gain applied to that peak.

Double click below the peak to half the gain.

or:

Press the left mouse button at one end of the region of interest and, without

releasing the button, drag the mouse vertically to the other end.

As the mouse is dragged, a “rubber band” stretches out to indicate the selected

range.

Do not go beyond the bounds of the axis.

Release the mouse button to re-display the selected range filling the current

window.

or:

Enter a value in the Gain box for the required peak and press Return.

Tuning

Page 59

Quattro Ultima

User's Guide

Changing the Display

To change the display using the mouse:

Click in the peak display area with the right mouse button to

display the pop up menu.

The display area for each peak can be individually changed, e.g.

the peak colour for peak 1 can be red and for peak 2 green etc.

Customise Plot Appearance

To change the colour of the background and traces and to change the number of traces

displayed:

Select Customise, Plot Appearance.

The Customise Plot Appearance dialog is displayed.

To change the colours on the

display:

Press Newest Trace,

Background or

Trace Fill and select a

new colour from the

dialog displayed.

To change the number of

traces:

Use to change the

number, or enter a new

value in the

Visible Traces box,

within the range 2 to 20.

If more than one trace is displayed then the older traces can be displayed in a different

shade to the new ones:

Drag the Colour Interpolation slider toward the full position. The colour of

the old traces is shown in the Trace colour sample (new->old) field.

Tuning

Page 60

Trace

Intensity

Quattro Ultima

User's Guide

From the pop-up menu:

Select the Trace, Outline option to display the peak outline only.

or:

Select the Trace, Fill option to fill the trace with the trace fill colour.

or:

Select the Trace, Min/Max option to show the minimum and maximum data

points only.

The option selected has a tick next to it.

Grid

Select either Intensity, Relative Intensity or Intensity,

Absolute Intensity as required.

Select Intensity, Normalise Data to display normalised data.

The options selected each have a tick next to them.

The options allow vertical and horizontal grid lines to be independently displayed or

hidden.

Selected options have ticks next to them. Selecting an option a second time

deselects the option.

Tuning

Page 61

Quattro Ultima

User's Guide

AutoTune

MassLynx can automatically

tune the mass spectrometer in

both APcI and electrospray

ionisation modes. AutoTune

ramps the settings for the

tuning parameters until they

are optimised to give the best

intensity, resolution and peak

shape.

To run AutoTune:

Press on the tune

page to turn on the API

gas, and select

Operate.

Choose AutoTune from the tune

page Options menu.

Press Setup to define the

AutoTune setup parameters.

There are two levels of AutoTune:

•

A full AutoTune starts from a

default set of tuning parameters.

•

A maintenance AutoTune starts from the current tuning parameters set in the

tune page and can be quicker than a full AutoTune.

A maintenance AutoTune can only be performed if the instrument is already

reasonably well tuned. If the current tuning is too poor AutoTune gives an error

and request a full AutoTune.

The Tune Mass parameter sets the mass to be tuned on. When satisfied with the

AutoTune setup parameters:

Press OK to exit.

Tuning

Page 62

Press Start.

The AutoTune status bar is updated to show the progress of AutoTune.

The following steps are performed:

•

Parameter initialisation and instrument checks

Ensuring that essential status indicators read correctly.

Quattro Ultima

User's Guide

Checking that values are defined for all the user controllable instrument