MicroM HM 525 INSTRUCTION MANUAL

HM 525

MICROTOME CRYOSTAT

HM 525

INSTRUCTION MANUAL

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

CERTIFICATION

MICROM International GmbH certifies that this instrument has been tested and

checked carefully. Its technical data was verified before shipment to be in

accordance with the published specifi cations.

The instrument complies with applicable international safety regulations.

WARRANTY

This MICROM product is warranted against defects in material and workmanship for

a period of 1 year. Parts which prove to be defective during the warranty period will be

repaired or replaced free of charge by MICROM International GmbH. No other

warranty is expressed or implied. Unauthorized modification or repair by third party

persons will void the warranty.

The warranty will expire in case of improper or wrong use of the instrument and in

case the warning and precautionary messages are not observed. MICROM

International GmbH is not liable for any occurring damage.

Errors and ommissions excepted. Subject to amendment and improvement without

further notice.

This instruction manual will be supplied together with each instrument. Further

copies can be ordered at the nearest MICROM sales office by giving the serial

number of the instrument, the number of the instruction manual and the date of

issue.

This instruction manual is available in the following languages:

Cat. No.

German: 387778

English: 387779

French: 387780

Spanish: 387781

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

INTENDED USE

Dear Customer,

Before putting the instrument into operation, please read these operating

instructions carefully to familiarize yourself with its proper operation and

functions.

The MICROM cryostat HM 525 is a highly efficient cryostat for sectioning

techniques in routine and research.

Only skilled or specially trained personnel must operate the microtome

cryostat, i.e. placing the specimen onto a chuck, sectioning and transferring

sections onto a slide. The listed and marked safety measures as well as the

regulations and hygiene measures of your respective lab must strictly be

observed.

MICROM Ser. No. :..................................................

Please check the MICROM Ser. No. on the type plate, which is placed on the

rear side of your instrument and enter this number here. This way, questions

and service can be handled faster.

Instruction Manual No. 387779

Issued on July 13, 2004

MICROM International GmbH

Robert-Bosch-Strasse 49

D-69190 Walldorf

Telefon: (06227) 836-0

Telefax: (06227) 836-111

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

Intended Use

Table of Contents

EC Certificate of Conformity

Safe ty Precautions

PART 1 INTRODUCTION

1-1 Description of the HM 525

1-2 Technical data HM 525

PART 2 OPERATING INSTRUCTIONS

2-1 Setting up the cryostat

2-2 Initial turn-on

2-3 Basic operational rules

2-3-1 Actual and set value of the chamber temperature

2-3-2 Defrosting the evaporator

2-3-3 Interrupting a defrosting cycle

2-3-4 Emptying the defrosting liquid

2-3-5 Illumination of the cryo chamber

2-3-6 Freezing on a specimen

2-3-8 Specimen orientation with zero positioning

2-3-9 Handwheel lock

2-4 Cutting process

2-4-1 Cutting movement and retraction

2-4-2 Setting section thickness and trimming thickness

2-5 Feed

2-5-1 Specimen coarse feed

2-5-2 Memory function

2-5-3 Trimming and first cuts

2-5-4 Fine feed

2-6 Indication of cutting processes

2-6-1 Section counter

2-6-2 Sum of section thicknesses

2-6-3 Remaining travel to front end position

2-6-4 Setting the real time

2-7 Knife carriers

2-7-1 Standard knife carrier

2-7-2 Disposable blade carrier

2-7-3 Disposable blade carrier EC 70

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

2-8 Error code indication

2-8-1 Definition of the error codes

2-9 Accessories

2-9-1 Standard equipment

2-9-2 Additional equipment

PART 3 THEORY OF OPERATION

3-1 Microtome cooling, defrost cycle

3-2 Cutting movement

3-3 Specimen coarse feed and trimming stages

PART 4 WORKING WITH THE CRYOSTAT

4-1 Preparations on the microtome and inside the cooling chamber

4-2 Freezing on the specimen

4-3 Orientation and trimming of specimens

4-4 Temperature list for cryo sectioning

4-5 Sectioning and taking off sections

4-6 How to avoid malfunctions

4-6-1 Possible sources of errors – cause and removal

PART 5 MAINTENANCE AND CARE OF THE CRYOSTAT

5-1 Shutting-off for cleaning

5-2 Removing the microtome

5-3 Cleaning and care of the microtome

5-4 Cleaning the cooling lamella

part 6conditions for the transportation of the instrument

6-1 Taking back the instrument for repair or routine maintenance

6-2 Disposal of the instrument after final shutdown

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

EC Certificate of Conformity

Name and address of MICROM International GmbH

the manufacturer: Robert-Bosch-Straße 49

D-69190 Walldorf

Product designation: Microtome Cryostat

Type reference: HM 525

Notification to Competent Authorities:

These medical device have been registered with the German authority as “Microtomes” under

the EDMA-classification code: 23-06-02

The designated product complies with the laid down regulation:

DIRECTIVE 98/79/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL

of 27 October 1998

on in vitro diagnostic medical devices

The designated product complies with the EC regulations by strictly observing the following

norms:

DIN EN ISO 14971:2001-03

Medical devices - Application of risk management to medical devices (ISO 14971:2000).

DIN EN 61010-1:2002-08

Safety requirements for electrical equipment for measurement, control and laboratory use - Part 1:

General requirements (IEC 61010-1:2001).

DIN EN 61010-2-101:2003-09

Safety requirements for electrical equipment for measurement, control and laboratory use - Part 2-101:

Particular requirements for In -Vitro-Diagnostic-(IVD)-Medical instruments.

DIN EN 61326:2002-03

Electrical equipment for measurement, control and laboratory use - EMC requirements (IEC 613261:1997 + A1:1998 + A2:2000); German version EN 61326:1997 + A1:1998 + A2:2001

DIN EN ISO 9001:2000

Quality management systems - Requirements (ISO 9001:2000)

Hans Heid Walldorf, 15 June 2004

Managing Director

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

SAFETY PRECAUTIONS

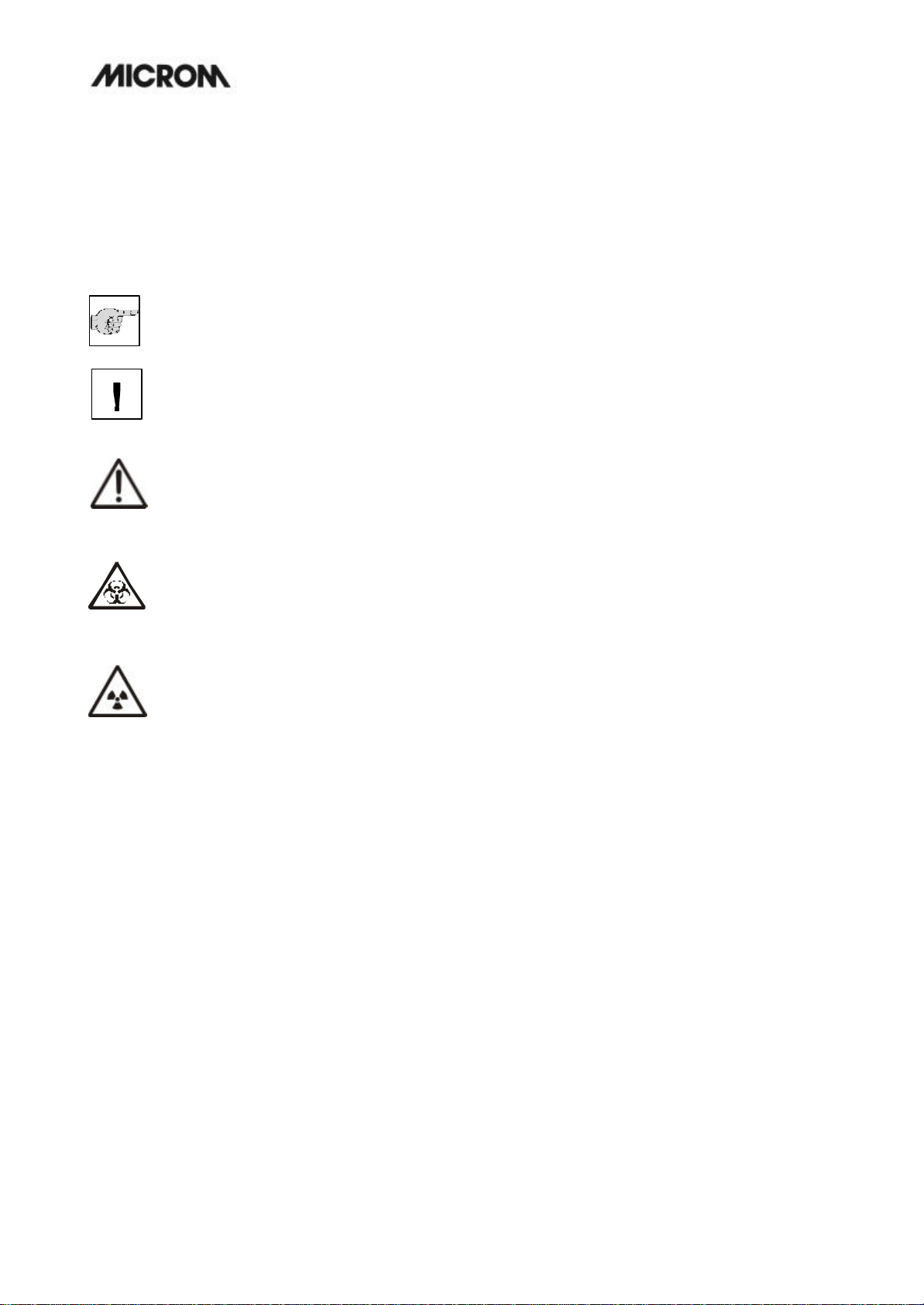

WARNING SIGNALS AND SYMBOLS

The installation and routine use of the HM 525 is easy and safe if the instructions in this manual are being

observed.

Biohazard:

Warning of biological danger.

Note:

Special instructions regarding operation of the instrument.

Warning:

Special prec autionary measures to prevent damage to equipment. For a long lifetime of the

equipment, please observe these instructions carefully.

Caution – general danger spot:

The instruction manual must strictly be observed whenever this symbol is visible on the instrument.

Radioactivity:

Warning of radioactive danger.

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

SAFETY PRECAUTIONS

C A U T I O N !

The operator's safety is affected, when the instrument is not operated in accordance

with this instruction manual.

Please observe the following general precautions during operation of this

instrument. Failure to comply with these precautions violates safety standards and

the intended use of the instrument. MICROM International GmbH is not liable for

misuse of the instruments and failure to comply with basic safety requirements.

INSTRUMENT GROUNDING

To avoid injury from electrical current, the instrument must be connected with the protective earth. The

instrument is equipped with a three wire ground plug. The power outlet must be connected to the protective

earth and must meet the International Electrotechnical Commission (IEC) regulations.

CAUTION: MAINS VOLTAGE

Never remove instrument covers during operation. Component replacements as well as adjustments must only

be made by trained service personnel. Unplug the unit before removing or opening the covers.

DANGER IN EXPLOSIVE ENVIRONMENT

The instrument must not be operated in the presence of flammable gases.

HAZARD OF FROSTBITE

Avoid permanent touching of metal parts inside the cryostat microtome chamber as frostbite may occur at

unprotected hands and arms.

HAZARD OF RADIOACTIVE RADIATION

When working with radioactive specimens observe all applicable radiation safety procedures. When working

with radioactive contaminated material, appropriate safety and disinfection measures must be carried out.

According to the rules and regulations concerning the handling of radioactive contaminated material of the

respective laboratory, safety clothing (e.g. particle mask, gloves, protective shoe covers) must be worn.

Radioactive contaminated waste must be disposed of according to the respective regulations.

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

HAZARD OF INFECTION

Use the appropriate safety and disinfection measures when working with infectious specimens.

According to the rules and regulations concerning the handling of infectious/radioactive contaminated material

of the respective laboratory, safety clothing (e.g. particle mask, gloves, protective shoe covers) must be worn.

HAZARD OF BIOLOGICAL DANGER

Specimens used during the intended operation of the instrument might potentially be infectious. For this

reason, it is recommended to observe the general laboratory regulations concerning protection against danger

of infection.

Information on decontamination media, their use, dilution and effective range of application can be read in the

Laboratory Biosafety Manual : 1984 of the World Health Organization.

HAZARD OF MALFUNCTION

To avoid the hazard of malfunction of an instrument, it must only be operated in a controlled electromagnetic

environment. This means, that transmitters suc h as mobile phones must not be operated in their close vicinity.

In case of malfunctions and/or service work, please turn off the instrument and contact your local dealer.

CARE IN USING MICROTOME KNIFE

To diminish the danger of being injured by the knife or blade, use the knife guard when adjusting specimen and

knife. If possible, the specimen should be clamped in before the knife is inserted into the knife holder. Before

changing the knife holder, always remove blade or knife! Unused knives should always be kept in a knife case.

Never place the knife with the cutting edge upwards. Never try to catch a dropping knife!! Never check the

sharpness of the cutting edge with your fingers. The cutting edge is extremely sharp!

WASTE DISPOSAL

All debris, waste, defrosting liquid as well as infectious and radioactive contaminated material from operation

must be disposed of in accordance with the respective regulations of the lab. Disinfection and cleaning liquids

as well as section waste must be disposed of according to the respective regulations for special waste!

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

Fig. 1

HM 525

1 INTRODUCTION

1-1 DESCRIPTION OF THE HM 525

Open top cryostat. Stainless steel cooling

chamber. Chamber temperature regulation variable

from +5°C down to –35°C.

Graphic LED-display of set and actual

temperatures, electronic control with user-oriented

touchpad keyboard, battery-buffered memory and

self-diagnostic system.

Automatic defrosting and in addition a manual

defrost cycle which can be activated when needed.

Defrost interrupt on keystroke request.

Integrated fast freezing device down to max.

–60°C via Peltier element.

Sliding window with heater. Integrated fluorescent

lamp for cryo-chamber. Brush shelf and storage

space inside the cryo chamber. Large, flat storage

space on top of the housing with integrated storage

space for marked slides.

Rotary Microtome with backlash and maintenancefree cross roller bearings in stainless steel. Electromechanical feed system.

Section thickness setting from 1 to 20 microns;

up to 10 µm in 1 µm -increments,

up to 20 µm in 2 µm -increments,

Trimming thickness setting from 10 to 500 microns;

up to 100 µm in 10 µm -increments,

up to 300 µm in 50 µm increments and

up to 500 µm in 100 µm -increments.

Specimen retraction during the return stroke with

optical indication. Horizontal feed range 28 mm.

Vertical cutting stroke 60 mm.

Max. specimen size 70 x 55 mm.

Motorized coarse feed in two directions.

Limit indication and automated switch off at front

and rear limits of horizontal travel.

Section counter and indication of sum of section

thicknesses with reset-button. Indication of

remaining travel.

Mechanical handwheel brake in the lower reversal

point of the specimen orientation.

Fine orientation of specimen 8° universally in x/yaxis with zero device. Rotatable on Z-axis, 360°.

Basic outfit with 3 x 30 mm chucks, 1 x 40 mm

chuck, 118 ml MICROM freezing medium, 100 ml

cryostat oil, brush shelf and section waste tray,

consisting of two parts.

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

1-2 TECHNICAL DATA HM 525

Chamber temperature control: .........................................................................+5°C to -35°C

Fast freezing station via Peltier element

depending on the chamber temperature: ..................................................down to max. -60°C

Defrosting: automatic defrosting, adjustable.............. with temperature control

manual immediate defrosting

Microtome: Section thickness range: ........................................... 1 - 500 µm

Fine section thickness range: ...................................... 1 - 20 µm

Resolution: ................................................... 1 µm for 1 - 10 µm

................................................................... 2 µm for 10 - 20 µm

Trimming thickness range:........................................ 10 - 500 µm

Resolution:............................................... 10 µm for 10 - 100 µm

..............................................................50 µm for 100 - 300 µm

............................................................ 100 µm for 300 - 500 µm

Specimen retraction during return travel..............................40 µm

Vertical specimen stroke ............................................... 60 mm

Horizontal specimen movement........................................28 mm

Read-outs: Five-digit LED-display: section thicknesses, section counter, sum of

section thicknesses, remaining travel to front end position and

chamber temperature

Coarse feed: .............................. motorized, graduated, single and continuous

Size of chucks: ................................................................................30, 40 mm

........................................................ special sizes upon request

Specimen orientation: x - and y - axes: ...................... universal 8° with zero positioning

z - axis: .................................................................. up to 360°

Cooling chamber illumination

Sliding window

Cutting drive: ............................................................ manually via handwheel

Cutting area: ....................................... horizontal specimen movement 28 mm

.................................................vertical specimen stroke 60 mm

All temperatures refer to an ambient temperature of +20°C!

Cont'd on page -2-

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

2

HM 525

1-2 TECHNICAL DATA HM 525

Handwheel brake: ...............................................................................mechanical

Transportation and storage conditions

Storage temperature range: -20°C up to +50°C

Operating conditions: .......................+5°C up to +35°C (at a max. rel. humidity of 60%)

...................................................... altitude up to 2000 m M.S.L.

.....................................................................for indoor use only

........................................ Floor loading requirements: 230 kg/m2

Power requirements: ....................................................... 100 V/50 Hz, 12 A, +/-10%

........................................................ 100 V/60 Hz, 12 A, +/-10%

........................................................ 115 V/60 Hz, 12 A, +/-10%

................................................. 220...230 V/50 Hz, 6 A, +/-10%

..........................................................220 V/60 Hz, 6 A, +/-10%

..........................................................240 V/50 Hz, 6 A, +/-10%

Internal protection

Primary circuits:

Transformer: ..................................................................T5.0AH, 100...115 V

..................................................................T2.5AH, 220...240 V

Illumination: ..................................................................T0,8AH, 100...115 V

..................................................................T0,4AH, 220...240 V

Secondary circuits:

Window heating: .................................................................................... T2,5AH

CPU: ........................................................................11 VAC/T0.5AH

Panel: ........................................................................11 VAC/T0.5AH

Stepping motor/valve: ........................................................................24 VAC/T2.5AH

Fast freezing station: .................................................................... 2.3/8 VAC/T8.0AH

Pollution degree: ............................................................................................. 2

Overvoltage category: ..............................................................................................II

Sound pressure: .................................................................................. 45 dB(A)

............................. measured with 1 m distance to the instrument

Fluids and gases: ................................................................cooling agent: R404a,

............................................... filling amount: 100...120 V: 250 g

.................................................................... 220...240 V: 230 g

Dimensions: ... Wide (w/o handwheel): 640 mm, deep: 760 mm, high: 1200 mm

Weight: ................................................ 143 kg (depending on the model)

All temperatures refer to an ambient temperature of +20°C!

page -2-

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

3

HM 525

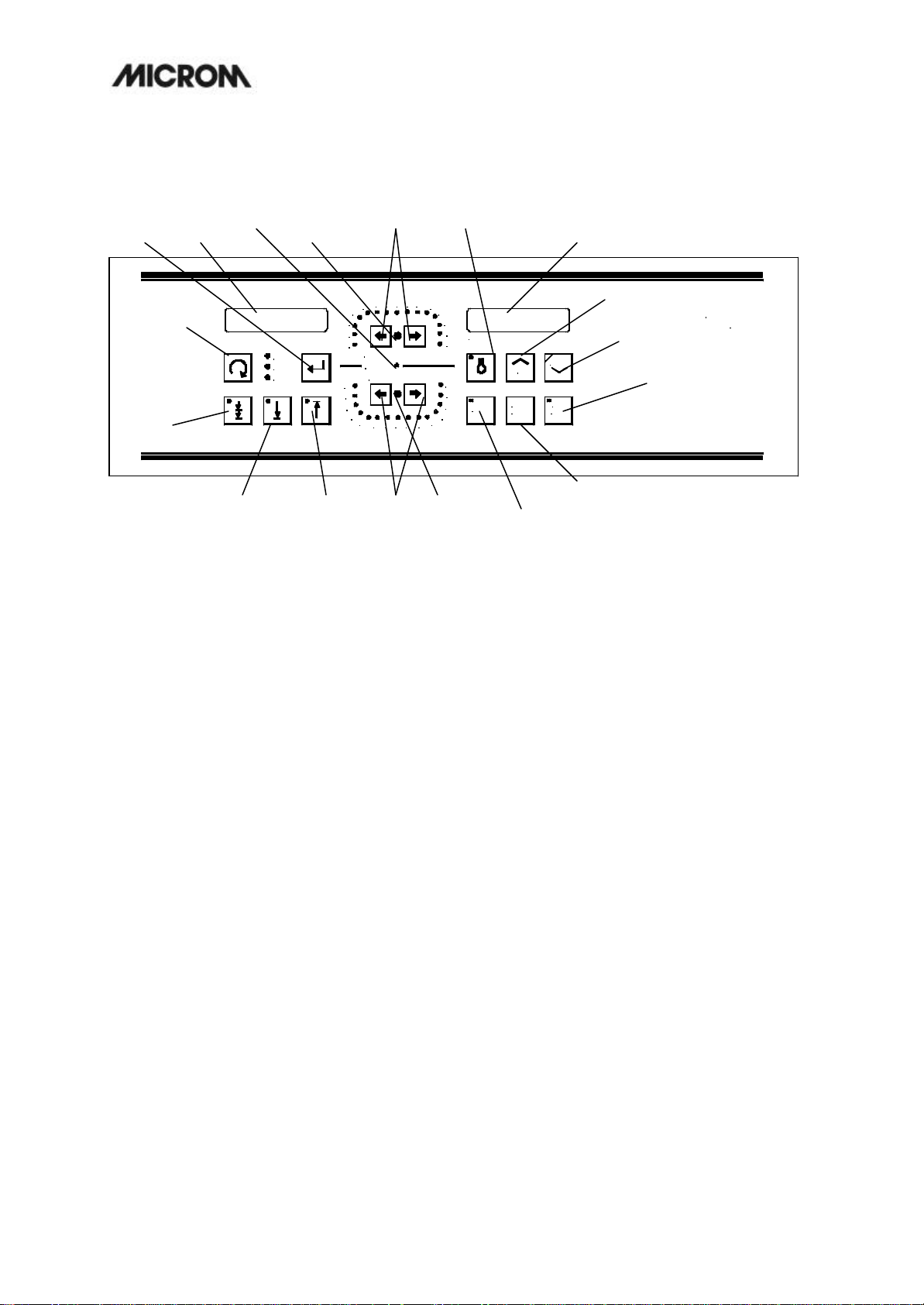

10 9

35

13

15

18

4 2 1 11

17

COUNT

SUM

TRAVEL

8

7 6

1 = LED retraction

2 = Section thickness setting

3 = Trimming thickness setting

4 = LED fine feed

5 = LED trim feed

6 = Coarse feed, backwards

7 = Coarse feed, forwards

8 = Trim button

9 = Scroll button

7 8 9 10 12

6

5

4

3

2

SECTION THICKNESS µm

RETRACT

TRIM THICKNESS µm

10

20

30

40

50

60 70 80 100 150

14

16

18

20

22

500

400

300

250

200

CHAMBER TEMPERATURE ° C

UP

DEFR

MEMO

TIME

P

DOWN

INTER

RUPT

16

MICROM

14

12

10 = Display, left

11 = Reset button

12 = Memory button

13 = Setting defrost time

14 = Interruption defrosting cycle

15 = Down button and activation of Peltier element

16 = Up button

17 = Chamber illumination

18 = Display, right

HM 520

Fig. 2

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

4

HM 525

3

1

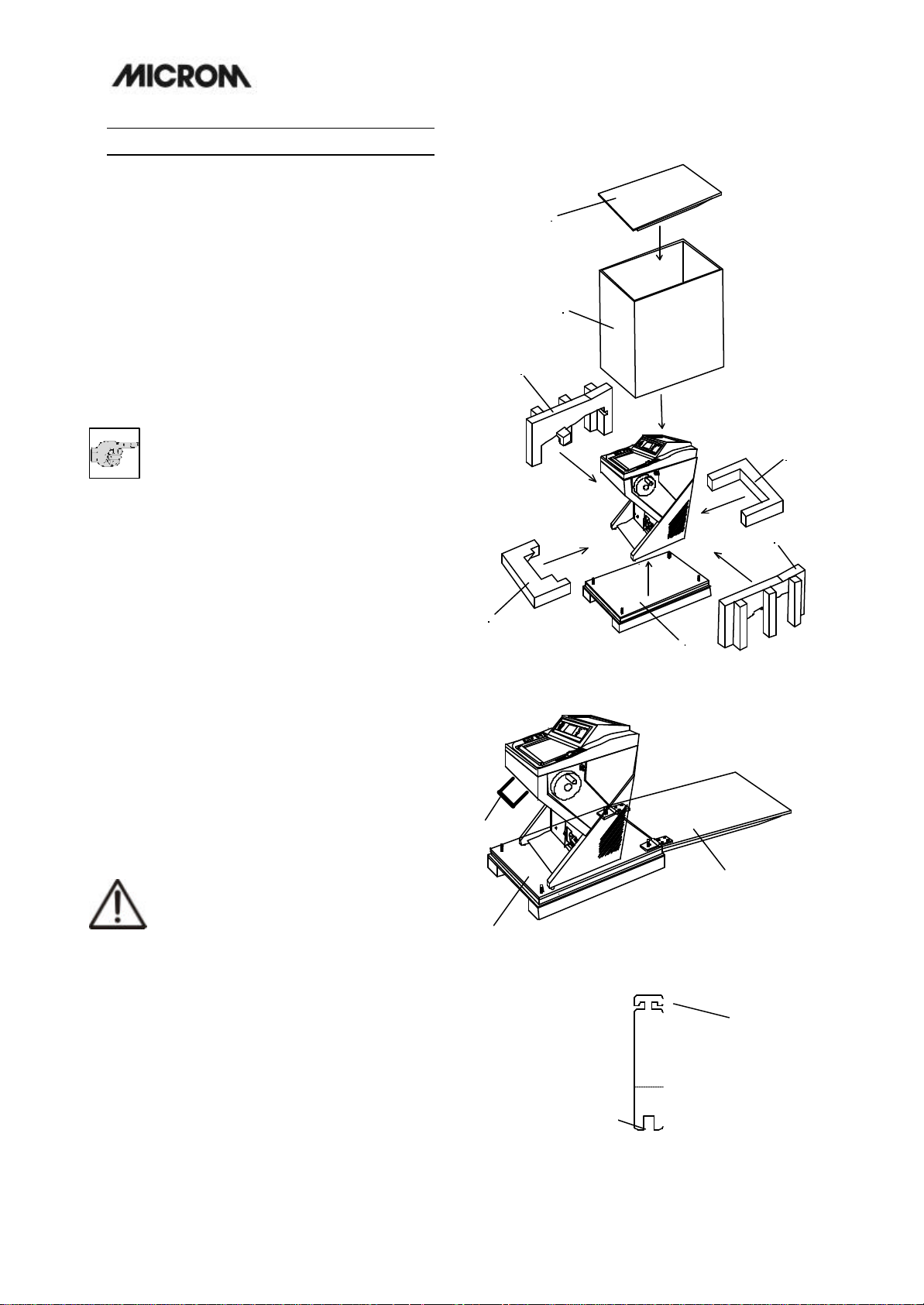

2 OPERATING INSTRUCTIONS

2-1 SETTING UP THE CRYOSTAT

Unpacking the instrument:

??Cut through the three packing straps and

remove the packing.

??Remove the upper wooden cover (fig. 3.1).

??The hinges of the upper wooden cover are

secured with tape.

??Remove this tape.

??Lift the packing (fig. 3.2) over the instrument.

??Remove the upper and lower supporting foams

(fig. 3. 3, 3.4, 3.5, 3.6) from the cryostat.

Note:

The upper wooden cover now serves as

an incline (fig. 3a.1) on which the

cryostat can be moved from the palett

to the floor by using the handle (fig. 3a.2)

??The hinges of the upper wooden cover (fig. 3.1)

are inserted into the screws of the bottom

plate (fig. 3a.3). The correct side for this is

marked with arrows.

??The tool (fig. 3b.2, size 30) for the height

adjustment of the setting feet of the cryostat is

packed together with the accessories of the

cryostat (separate carton on the foot rest of

the cryostat).

??Turn the setting feet completely upwards via

this tool so that the cryostat stands with its

rollers on the bottom plate (fig. 3a.3).

??Via the handle (fig. 3a.2) roll the cryostat from

the bottom plate (fig. 3a.3) over the wooden

cover (fig. 3a.1). In doing so, the rear side of

the instrument must show to the incline (fig.

3a.1).

Caution:

The instrument is very heavy. While the

instrument rolls down on the incline, it

must be guaranteed that the instrument

does not move in an uncontrolled way.

??Now the cryostat can be rolled to its site of

installation.

??For possible return shipments, please keep

the packing.

1

2

3

HM550MVD

0

1

2

3

6

7

5

4

Fig. 3

2

3

HM550M

0

1

Fig. 3a

1

2

Fig. 3b

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

5

HM 525

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

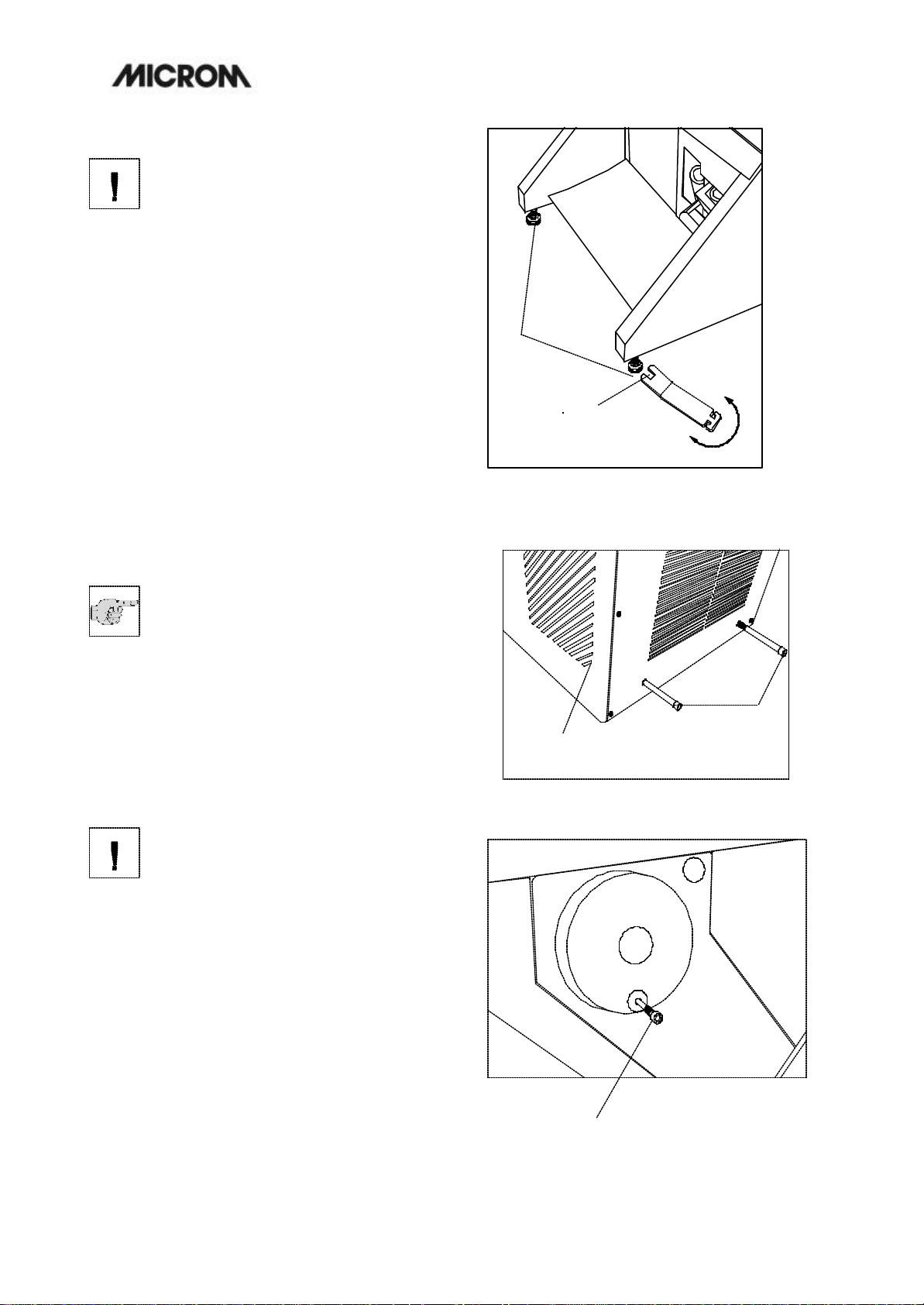

Warning:

The instrument must only be moved in

standing or slightly tilted (approx. 30°)

position.

Choose installation site that

??enough ventilation for the cooling system is

guaranteed.

??the distance between wall and rear panel is

approx. 15 cm. For this, install the distance

bolts (fig. 4a.1).

??the suction areas (fig. 4a.2) on either side are

kept free.

??the mains switch for separating the instrument

from the power supply is accessible any time.

Moreover, the installation site must be free

from:

??draught by open doors or by air conditioning

systems.

??direct exposure to sunlight into the cooling

chamber.

Note:

Both measures reduce the formation of

frost and therefore result in more

favourable work conditions. A high air

moisture as well as high ambient temperatures

reduce the maximum performance of the

instrument.

?? To fix the complete unit, tighten the screws

(fig. 4.1) by using the attached tool.

?? Install the separate packed handwheel

handle.

Warning:

Instead of the handwheel handle, a

transportation screw (fig. 4b.1) is

inserted into the handwheel. This way,

the handwheel is tightly and securely connected

with the housing of the cryostat. It is

absolutely necessary to remove this

transportation screw before the initial turnon!

?? Loosen the transportation screw (fig. 4b.1)

via the Allan key, size 6.

?? Now fix the separately packed handwheel

handle on the handwheel with the attached

screw by means of the Allan key.

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

1

SW13

Fig. 4

1

2

Fig. 4a

Fig. 4b

1

HM 525

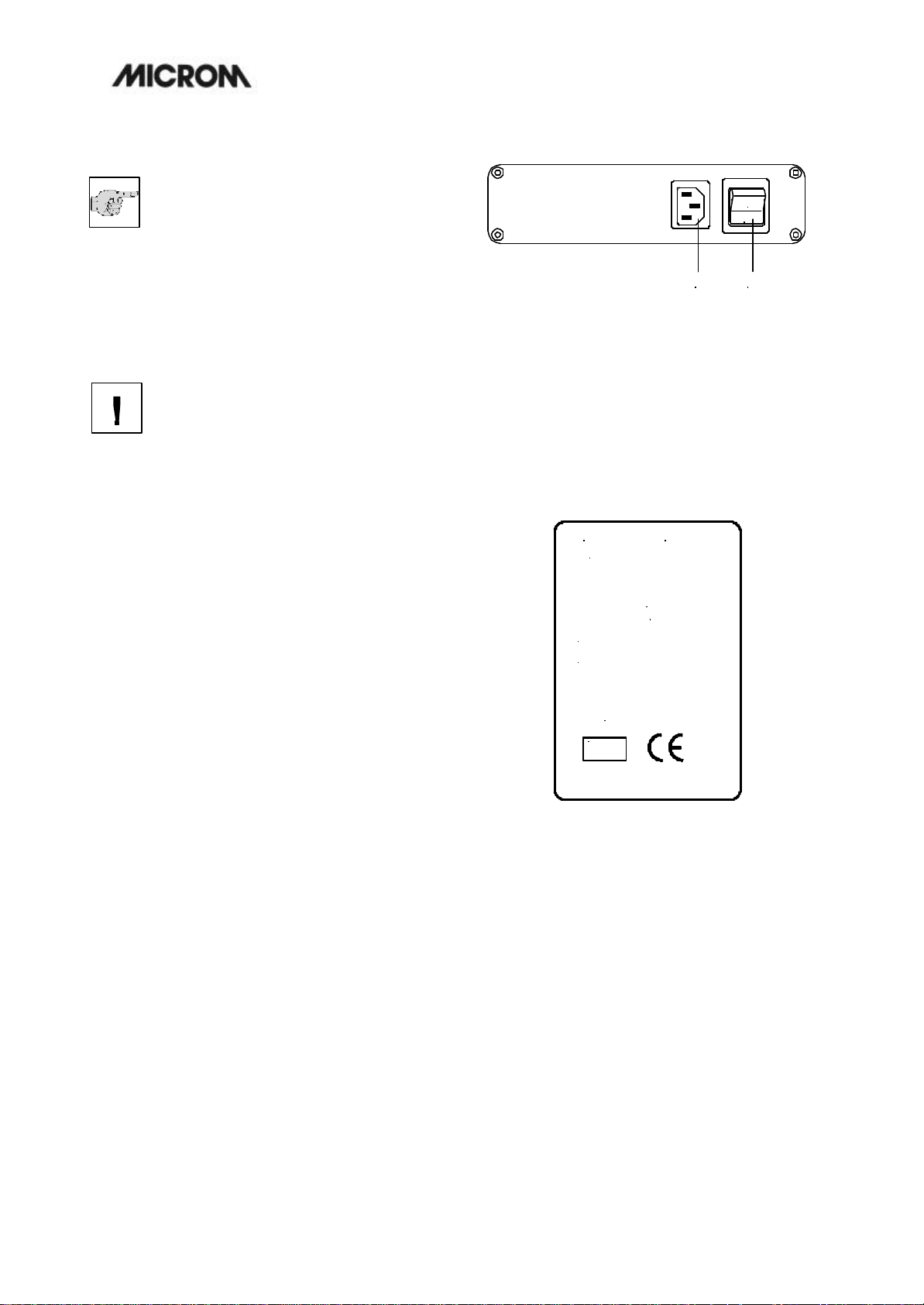

1

2

2-2 INITIAL TURN-ON

Note:

The kind of the used examination

materials and all special conditions for

their processing, pre-treatment and, if

necessary, storage as well as instrument

controls for correct and safe operation is in the

responsibility of the operator.

The operator is also responsible for special

equipment and materials and/or reagents for the

operation of the instrument.

Warning:

Before turning on the instrument for the

first time, please check if the power

requirements indicated on the type

plate (fig. 6) correspond to the power supply

voltage being used.

??No other instruments should be connected to

the circuit used for the cryostat, as the

compressor needs high surge currents when

started.

??Do not use multi-socket power outlets with

small wire sizes for the supply of the

instrument.

??We recommend to immediately install all

accessories belonging into the cryo chamber,

e.g. blade carrier.

??The instruction manual of the instrument can

be found in the separate carton which is

placed on the foot part of the cryostat.

??Connect the power line of the instrument to

the power outlet.

??Turn on the power switch (fig. 5.1) on the rear

side of the instrument.

??Close the heated sliding window and cool

down the instrument.

The cooling phase will take several hours

depending on the set chamber temperature.

1 = Power switch

2 = Mains plug

MICROM

Chamber

Refr.: R 404a

Amount: _ _ _ _ _kg

Max. Press.: 1900kPa

69190 Walldorf, Germany

Type HM 520_

Type HM 525

Ser. No. _ _ _ _

Cat. No. _ _ _ _ _ _

_ _A /_ _ _V _ _ Hz

Made in Germany

GmbH

I V D

I

0

Fig. 5

Fig. 6

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

HM 525

2-3 BASIC OPERATIONAL RULES

After having turned on the instrument, the two

displays show the set chamber temperature as

well as the number of sections, the section

thickness sum as well as the remaining travel to

the front end position. Section thicknesses are

indicated via LEDs.

2-3-1 ACTUAL AND SET VALUE OF

THE TEMPERATURE

The cooling of the microtome chamber can be

controlled by the corresponding part of the

operating controls. The actual temperature of

the microtome chamber is shown in °C on the

digital display (fig. 7.1). Briefly press the UP - or

DOWN-button (fig. 7.2 or 7.3), the set value of

the temperature in the microtome chamber is

shown for approx. 2 sec. Afterwards, the display

shows again the actual value of the temperature

of the microtome chamber. To change the set

value, press permanently the UP-button (fig.

7.2) or DOWN-button (fig. 7.3). The UP-button

leads to higher, the DOWN-button to lower

temperatures.

The valid range of the set value goes from +5°C

down to -35°C. If the UP -button is used beyond

the limit of +5°C, the display shows

" - - -" and the temperature control is turned off.

Using the DOWN-button the cooling system is

turned on again.

CHAMBER TEMPERATURE ° C

P

DOWN

UP

2 3

MEMO

DEFR

TIME

INTER

RUPT

1

Fig. 7

MICROM International GmbH

Robert-Bosch-Str. 49

D- 69190 Walldorf

Loading...

Loading...