User Guide

DRAFT VERSION - INTERNAL USE ONLY

TesTORK

Wireless Test Torque System

DOCUMENT NAME: TBD REV 0

DRAFT VERSION - INTERNAL USE ONLY

USER GUIDE COPYRIGHT AND DISCLAIMER

DRAFT VERSION - INTERNAL USE ONLY

Tesco Corporation (“TESCO”) has made every effort to ensure that this document contains accurate

and current information for the TESCO Torque Turn System, however, the document is intended to

be used in conjunction with a complete training program and on-site supervision and TESCO

does not warrant or guarantee that the information contained herein is either complete or accurate in

every respect, and the reader hereby protects, indemnifies and holds harmless Tesco Corporation

together with its directors, officers, employees and agents from and against all liability for personal

injury, death or property damage to any person arising directly or indirectly from the use by the reader

of the information contained in the document.

All information in this document is proprieta

Tesco Corporation. This document shall not be used, copied or reproduced in whole or in part, nor

shall be revealed in any manner to outside parties without prior written permission from Tesco

Corporation. All prints and copies shall be returned upon job completion unless otherwise specified in

writing by Tesco Corporation.

Windows® is a registered trademark of Microsoft Corporation

Tesco Corporation © 2013. All rights reserved.

3993 W. Sam Houston Parkway No., Suite 100

Telephone: (713) 359-7000

After Market Sales and Service Contact

Toll Free North America: 1-877-TESCO-77

International: 713-359-7295

ry and confidential, and shall remain the sole property of

in the United States and other countries.

Contact Information

Corporate Head Office

Houston, Texas, 77043

USA

www.tescocorp.com

www.tescoparts.com

Fax: (713) 359-7001

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 I WWW.TESCOPARTS.COM

REVISION INFORMATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Revision Information

Version Date Description of Changes

Rev 0 August 2013 First release of document

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 II WWW.TESCOPARTS.COM

USER GUIDE TABLE OF CONTENTS

DRAFT VERSION - INTERNAL USE ONLY

T

ABLE OF

Compliance Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VII

RSS-GEN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VII

Electromagnetic Compatibility Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VII

FCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VII

IC RSS 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .VII

Industry Canada RF Exposure Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VIII

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VIII

4.1.1 IEC 60079-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VIII

C

HAPTER

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

C

HAPTER

1: A

2: S

C

ONTENTS

BOUT THIS DOCUMENT

YSTEM OVERVIEW

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Data logging and reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Data Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How the TesTORK system works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

What’s Included in the TesTORK kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Software Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Select Job dialog box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Existing Jobs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

New Job. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Data fields on left Side of Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Connections Side Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

View All Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Add New Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Edit Current Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Drilling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pipe Tally Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Reports Side Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Hardware Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

About WTTTS side panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

C

HAPTER

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 III WWW.TESCOPARTS.COM

3: I

NSTALLATION AND START UP

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TABLE OF CONTENTS USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Pre-Installation Activities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Verify Casing Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Pre-Job Component Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Pre-job system test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

On-Site Rig Up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Installing the TesTORK sub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

System Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Turning the TesTORK on or off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Use the following procedures to turn the TesTORK sub on or off: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

To turn on the TesTORK sub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

To turn off the TesTORK sub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Starting TesTORK Manager software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

To start TesTORK Manager software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

To check connection between the TesTORK sub and TesTORK Manager software. . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

C

HAPTER

Pre-job Activity List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4: O

PERATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Log a Passed Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Log a Failed Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Force Past a Failed Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Manual Shoulder Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

To manually set the shoulder point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Pipe Tally . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Reports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

C

HAPTER

Computer Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

System Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

System Settings Dialog Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

5: S

YSTEM SETTINGS AND ADMINISTRATION

Minimum Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Supported Operating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Running WTTS Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

To run TesTORK Manager software from a USB flash drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

To run TesTORK Manager software from the host computer desktop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

To start TesTORK Manager software automatically when the host computer starts . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

To start TesTORK software for the first time on a host computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . .49

C

HAPTER

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 IV WWW.TESCOPARTS.COM

6: TESCO B

ASE RADIO

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

USER GUIDE TABLE OF CONTENTS

DRAFT VERSION - INTERNAL USE ONLY

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Electromagnetic Compatibility Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

FCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

IC RSS 210. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Industry Canada RF Exposure Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.1.1 CSA 22.2 No. 213 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.1.2 ANSI/ISA 12.12.01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

User Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Environmental. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Contact Closures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Digital Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

A

PPENDIX

Cautions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Torque Sub Battery Changing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A

PPENDIX

Job Safety Analysis Worksheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Torque Turn System: Pre-Job Information Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Torque Turn System: Required Data Sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-7

Torque Turn System: Tool Kit Inventory Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Torque Turn System: Inventory Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

Torque Turn System: Final Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

A

PPENDIX

Torque and RPM Wireless Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

A: C

HANGING THE BATTERY

B: TTS C

C: TTS G

HECKLISTS AND FORMS

ENERAL ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 V WWW.TESCOPARTS.COM

TABLE OF CONTENTS USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 VI WWW.TESCOPARTS.COM

E

DRAFT VERSION - INTERNAL USE ONLY

LECTROMAGNETIC COMPATIBILITY NOTICE

FCC

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

IC RSS 210

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may not cause interference, and (2) this

device must accept any interference, including interference that may cause undesired

operation of the device.

USER GUIDE

S

AFETY

Le présent appareil est conforme aux CNR d’Industrie

radio exempts de licence. L’exploitation est autorisée aux deux conditions suivantes : (1)

l’appareil ne doit pas produire de brouillage, et (2) l’utilisateur de l’appareil doit accepter

tout brouillage radioélectrique subi, même si le brouillage est susceptible d’en compromettre

le fonctionnement.

The TESCO TesTORK is intended to be used in locations where hazardous gases may likely

be present. It meets the requirements of IEC-60079-11 for use in Zone 1 Group IIB.

Note: Only units with either a Special Inspection sticker or

Model Certification label shall be used in locations where

hazardous gases may be present.

Canada applicables aux appareils

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 VII WWW.TESCOPARTS.COM

COMPLIANCE AND COMPATIBILITY USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

4.1.1 IEC 60079-11

THIS EQUIPMENT IS SUIT ABLE FOR USE IN ZONE 1, GAS GROUP IIB, OR NONHAZARDOUS LOCATIONS ONLY.

Warning! EXPLOSION HAZARD - SUBSTITUTION OF

!

Avertissement! RISQUE D’EXPLOSION - LA SUBSTITUTION

!

Warning! The TESCO TESTORK UNIT MUST ONLY BE

!

COMPONENTS MAY IMPAIR SUITABILITY FOR

ZONE 1.

DES COMPOSANTS PEUT RENDRE CE MATERIEL

INACCEPTABLE POUR LES EMPLACEMENTS DE

ZONE 1.

ASSEMBLED AND OPERATED BY QUALIFIED

PERSONNEL

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 VIII WWW.TESCOPARTS.COM

C

DRAFT VERSION - INTERNAL USE ONLY

HAPTER

C

ONTENTS

This document contains the following information for the TESCO Wireless Torque Turn System (WTTS):

• System overview

• Rig up, configuration and calibration

• Operation

• Ch ecklists and general syst

1: A

BOUT

em information

T

HIS

D

OCUMENT

USER GUIDE

C

ONVENTIONS

This document uses signal words and symbols to identify the hazards that a person may

encounter while assembling, maintaining, servicing or operating this product.

Danger!

!

Warning!

!

Caution

!

Indicates that the situation could endanger the life of the operator

or other personnel if procedures are not followed correctly.

Indicates that the situation could present a serious risk of harm to

personnel or severe damage to equipment if procedures are not

followed correctly.

Indicates that the situation could cause damage to equipment if

the procedure is not followed correctly.

Note

Indicates additional information that will enable the user to

complete the task more easily.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 1 WWW.TESCOPARTS.COM

ABOUT THIS DOCUMENT USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 2 WWW.TESCOPARTS.COM

C

DRAFT VERSION - INTERNAL USE ONLY

HAPTER

This chapter provides an overview of the functionality and features of the TesTORK Wireless

Torque Monitoring System.

I

NTRODUCTION

The T esT ORK W ireless Torque Monitoring System was developed by TESCO to complement

the TESCO Casing Running Tool (CRT). The TesTORK enables operators to accurately monitor torque vs. turns and torque vs.

systems. RPM is also monitored.

2: S

YSTEM

time when making up connections using TESCO top drive

O

VERVIEW

USER GUIDE

The TesTORK is wireless in operation and functio

The only connection required is an AC power supply to the base radio.

ns independently of other rig equipment.

Features

The TesTORK provides the following operational features:

• Real time monitoring of torque

• Torque load is measured against both time

connection.

• Operators can define the characteristics of a sa

connection data specifying torque limits, turn values and hold time for the shoulder and

peak toque target.

• During a connection attempt, the user inte

torque load vs. time and torque load vs. number of turns. The speed (RPM) of the casing

during a connection attempt can also be viewed.

• A summary of data from the connection attem

when the connection attempt is complete

• Connection attempts are identified as being either a pass or a fail. The operator can also

ntify a connection as being a forced pass or forced fail. Comments must be added to

ide

connections identified in this way.

• Information and data defining a job can be specified be

includes company details, casing data, shoulder data and peak torque data values. Some

data can also be changed during a job.

• The TesTORK is calibrated to measure between 0-5

calibrated regularly

load applied by the top drive during casing connections

and number of turns for each casing

tisfactory casing connection by entering

rface (UI) displays real time data showing

pt is immediately displayed on the UI

fore a job begins. Information

0000 ft-lbs of toque and can be re-

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 3 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

• The TesTORKmakes efficient use of battery life which is continually monitored. To

preserve battery life, the TesTORK will enter sleep mode after a period of no

communication between itself and the base radio.

• The TesTORK uses an auto hunt mode to establish wireless connection with the base

radio

Data logging and reports

The TesTORK provides the following data logging and reporting functionality:

• Torque, turn and time data for every connection is logged at 100 times per second

• Every connection attempt is logged

• Operators are prompted to enter comments for failed connections. Comments

added following a successful connection.

• Logs and displays connec tion number, casing depth and

nection

• Reports can be generated that provide information

summaries, and connection details (i.e. shoulder torque values, peak torque values and

number of turns)

• A connection can be abandoned if two complete turns (or less) are not completed

and the result displayed

can also be

the reason for every failed con-

on job statistics, section detail or

Data Configuration

The TesTORK software provides the following data configuration options and functionality:

• Connection data defining the characteristics of a sa

changed at any time during a job

Note: The TesTORK flags and logs all changes to connection data

during a job.

• All connection data is saved for future use. This reduces the time required to enter data

manually by allowing the operator to reuse similar data from a previous job

• Data is displayed and logged

Note: Units cannot be changed during a connection pr oc ess .

in metric or Imperial units for every connection.

tisfactory casing connection can be

User Interface

The TesTORK user interface (UI) has the following features:

• TesTORK software is automatically installed a

have to manually install the program onto a computer

• Operators can enter data and navigate the TesTORK screens with either a touch screen

(only some

• Interactive torque vs. time and turns graph reports are

• Use pan and zoom controls to view details at any point on the graph

• View torque vs. time, torque vs. turn, or torque vs. time and turns

• Show or hide RPM data by clicking a single button

laptop computers) or mouse click

nd runs from the client CD; users do not

displayed enabling the operator to:

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 4 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

H

OW THE TES

The TesTORK system is comprised of the following components:

• TesTORK sub

• TesTORK housing

• Base radio (connects to the computer hosting TesTORK Manager software)

• TesTORK Manager software and host computer

TORK

SYSTEM WORKS

The TesTORK sub is installed between the top drive

TesTORK sub provide torque, tension and rotational data. This data is transmitted to the base

radio by a wireless transmitter located in the TesTORK housing. The TesTORK sub and TesTORK housing are a single unit referred to as the T

The base radio supplies torque, tension and rot

ware‘s host computer.

The combination of TesTORK system components enable

nection data using the TesTORK Manager software‘s user interface.

See “Appendix C: TTS General Assembly” for the general schematic overview.

W

HAT’S INCLUDED IN THE TES

The TesTORK kit consists of the following items:

• TesTORK with built in wireless transmitter

• Base radio

• Computer

• Custom battery pack.

• Printer with power cord, USB cord, paper and

• USB patch cord

and casing drive system. Sensors in the

esTORK.

ational data to the TesTORK Manager soft-

the operator to view and log con-

TORK

KIT

ink cartridges

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 5 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

S

OFTWARE OVERVIEW

This section provides an overview of T esT ORK software including the main screen and dialog

boxes available from the main screen.

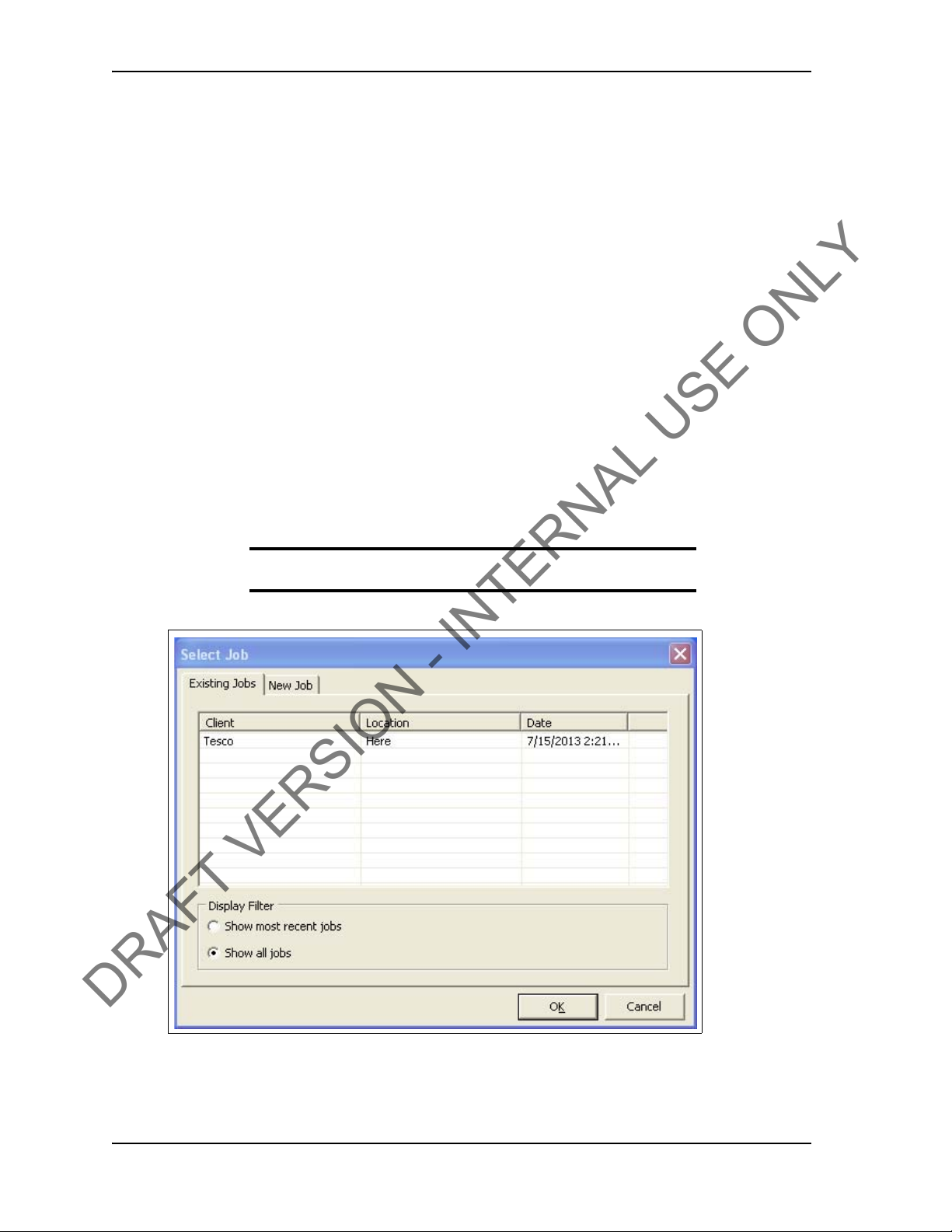

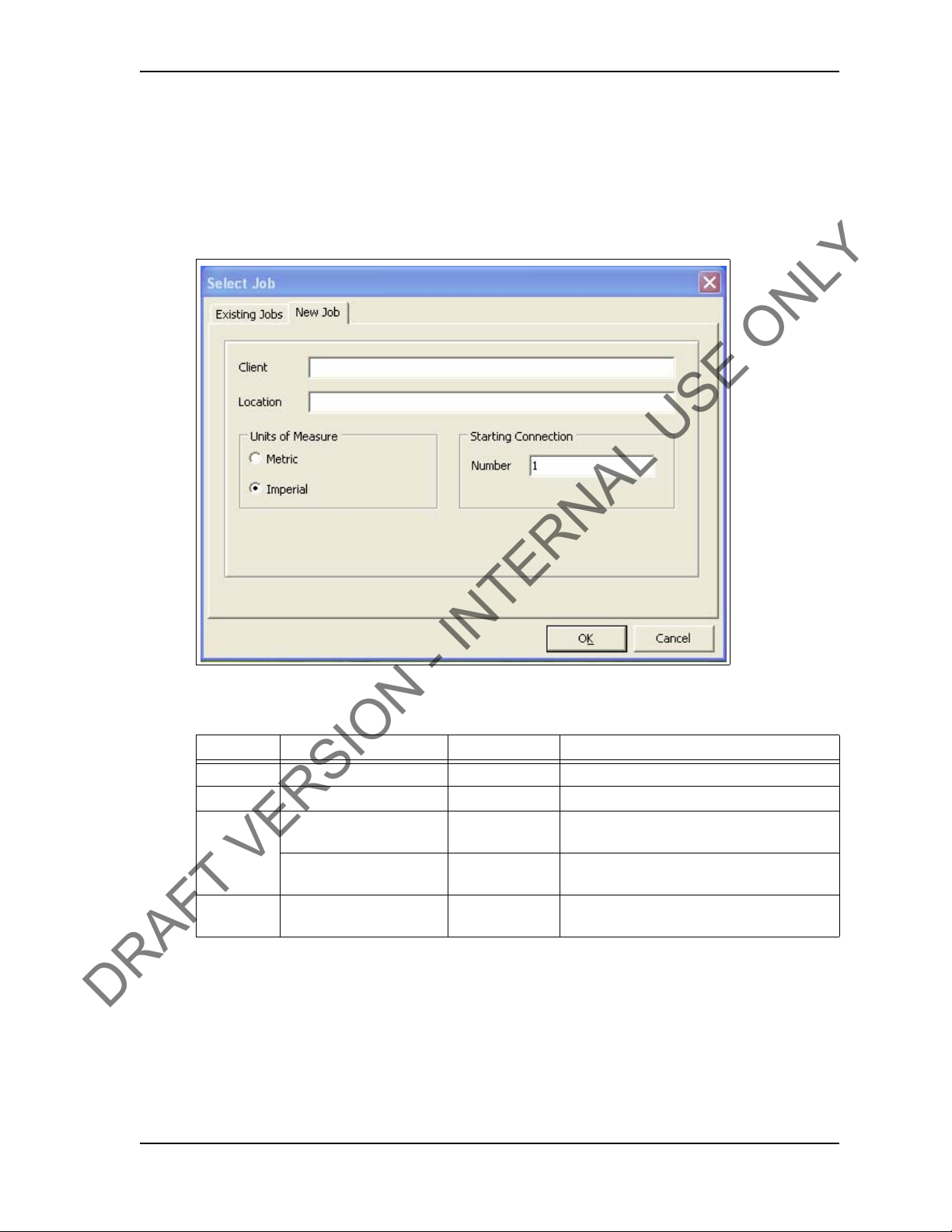

Select Job dialog box

The Select Job dialog box appears after starting TesTORK software. This dialog box enables

the operator to resume work on an existing job, or start a new job.

Two tabs are available in the Se

• Existing Jobs

• New Job

Existing Jobs

The Existing Jobs t

immediately resume work on that job. TesTORK software saves information and connection

data from each job monitored by the software.

Figure 2-1: Existing Jobs tab

ab provides a list of exiting jobs and enables the operator to select a job and

Note: If no job is selected, the most recent job is automatically restarted when the OK button is clicked.

lect Job dialog box:

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 6 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

New Job

The New Job tab

enables the operator to begin a new job by entering information and

connection data that define the job. Information is first entered in the New Job tab. The Create

New Job dialog box then appears enabling the operator to enter further information and

connection data.

Figure 2-2: New Job tab

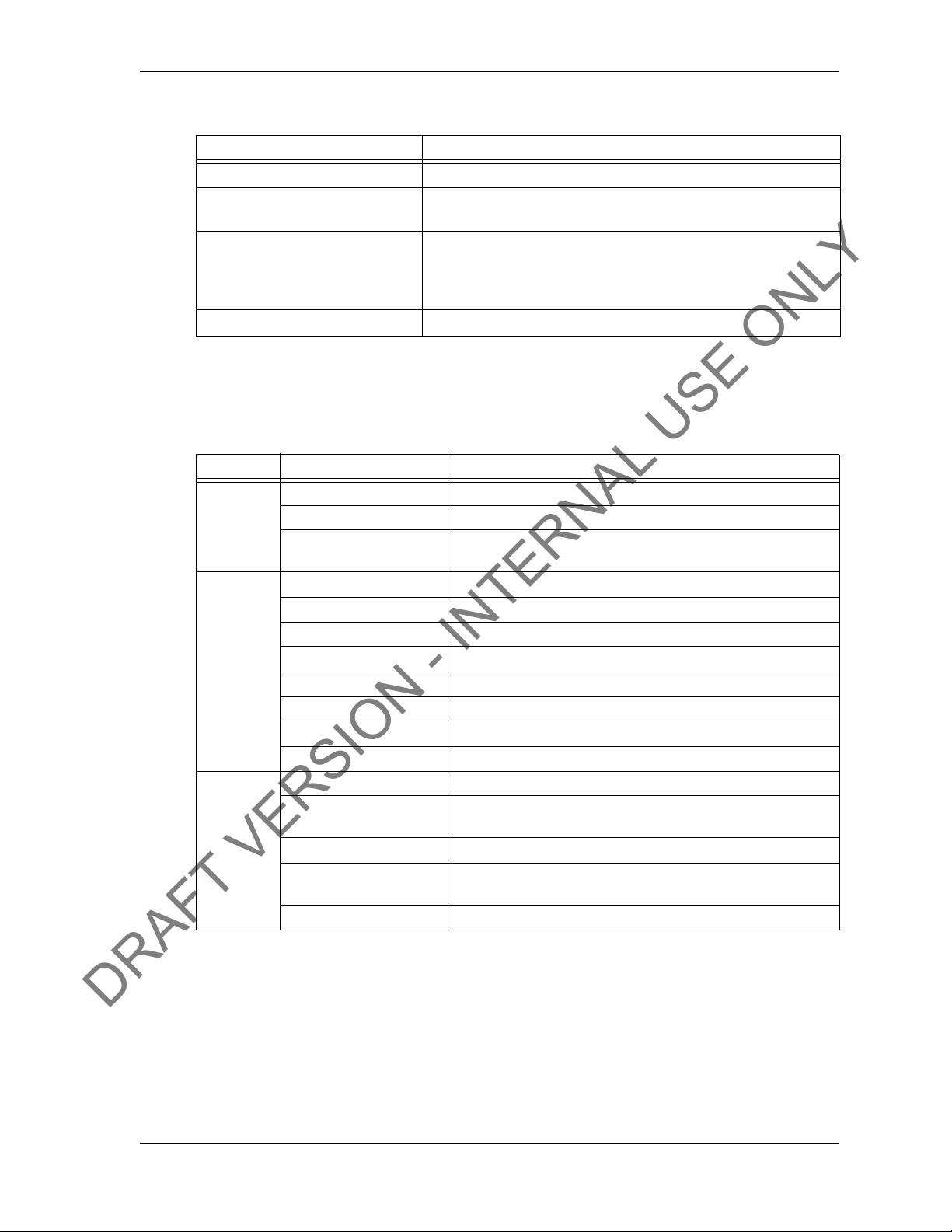

The following items are available in the New Jobs ta

Table 2-1: Create New Job dialog box

Group Item Functionality Description

Client Text box Input of text information

Location Text box Input of text information

Units of

Measure

Starting

Connection

Metric Radio button Configures all data to be displayed in imperial

Imperial Radio button Configures all data to be displayed in metric

Number Text box Defines starting connection number

b:

unit

units

s

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 7 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

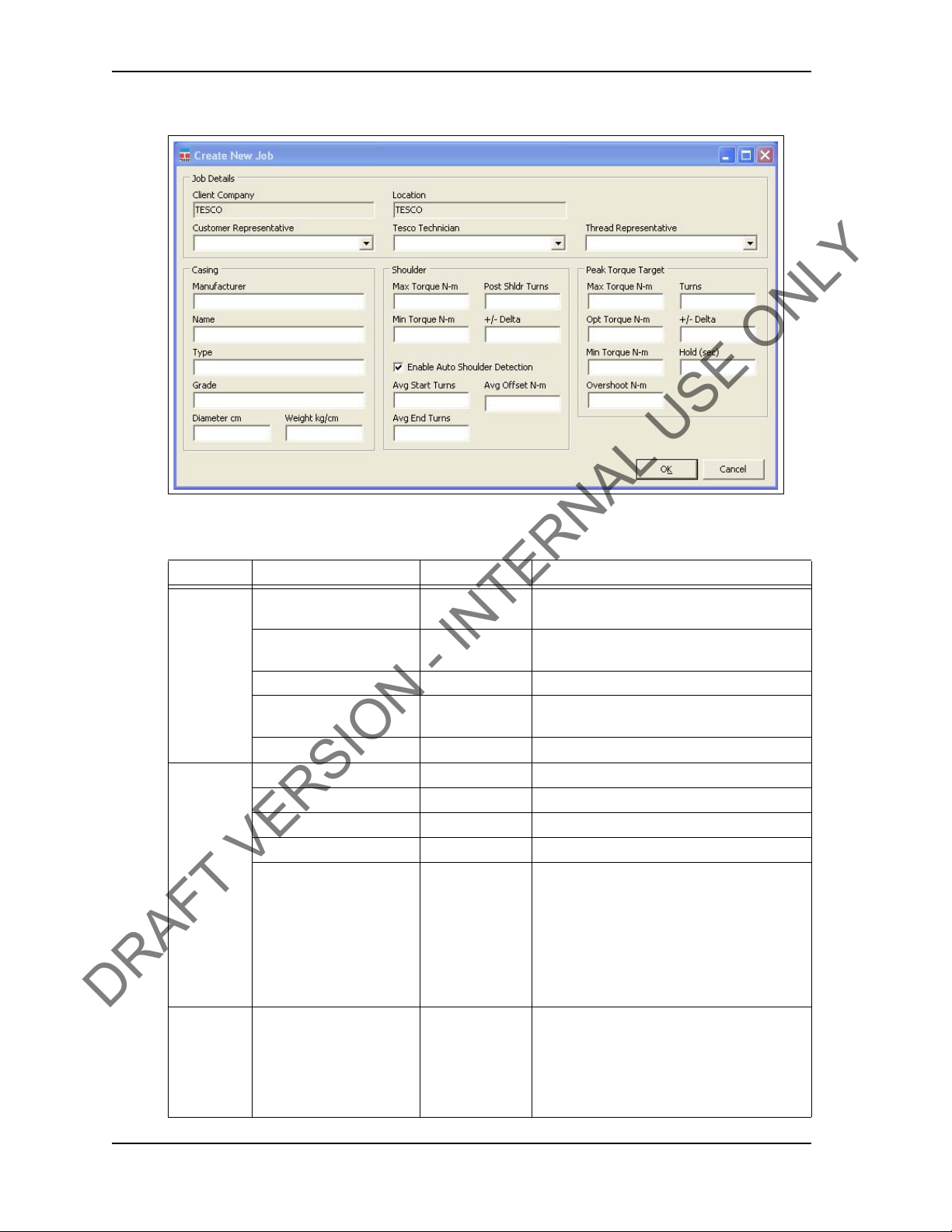

Figure 2-3: Create New Job dialog box

The following items are available in the Create New Job d ialog box:

Table 2-2: Create New Job dialog box:

Group Item Functionality Description

Job Details Client Company Text box Displays the name of the company typed in

the New Job tab

Location Text box Displays the name of the location typed in the

New Job tab.

Customer Representative Text box Representative from the customer

Tesco Technician Text box TESCO technician entering the job and

connection data

Thread Representative Text box Independent thread expert

Casing Manufacturer Text box Casing manufacturer

Name Text box Representative from casing manufacturer

Type Text box Type of casing

Grade Text box Steel grade of casing

Diameter cm Text box Casing diameter value. A correct casing

diameter

of RPM. A metric or diameter vale can be

entered pending on the units of measure

selection made in the Select Job tab.

For information on selecting how units are

displayed, see Table 2-1 on page 7.

Weight kg/cm Text box Casing weight value. A metric or diameter

vale can be

measure selection made in the Select Job tab.

For information on selecting how units are

displayed, see Table 2-1 on page 7.

value is vital for accurate calculation

entered pending on the units of

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 8 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Table 2-2: Create New Job dialog box:

Group Item Functionality Description

Shoulder

Peak Torque

Target

Test runs are required to determine the number of turns and the shoulder torque value. Use

the Stream Check function. For more information.

Max Torque Text box Maximum post-shoulder target range

Min Torque Text box Minimum post-shoulder target range

Post Shldr Turns Text box

+/- Delta Text box

Avg Start Turns Text box

Avg End Turns Text box

Avg Offset ft-lb Text box

Auto-Shoulder Mode Check box When the auto-shoulder mode is selected the

Consult your casing manufacturer for the information used in this parameter group.

Max Torque ft-lb Text box Maximum allowable torque value. A torque

Opt Torque ft-lb Text box Optimal torque value

Min Torque ft-lb Text box Minimum allowable torque value. A Torque

Turns Text box Number of turns required to reach peak torque

+/- Delta Text box Allowable variance in number of turns

Hold (sec) Text box Time required to maintain the optimal torque

Overshoot ft-lb Text box Increased torque value generated by the

The amount the casing should turn after

‘shouldering’ occurs; this value is typically

very low.

Allowable variance for the post-shoulder

turn.

Sets the turn count that pre-shoulder

averaging begins at

Sets the turn count that pre-shoulder

averaging ends at

Sets the shoulder torque value above the

pre-shoulder average

shoulder point can be moved (manually)

value above this setting results in a failed

connection result.

value below this setting results in a failed

connection result.

required to reach peak torque

setting. During this time, var

optimal torque range result in a failed

connection result.

momentum of the top driv

connection is fully tightened

iances outside the

e when the casing

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 9 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

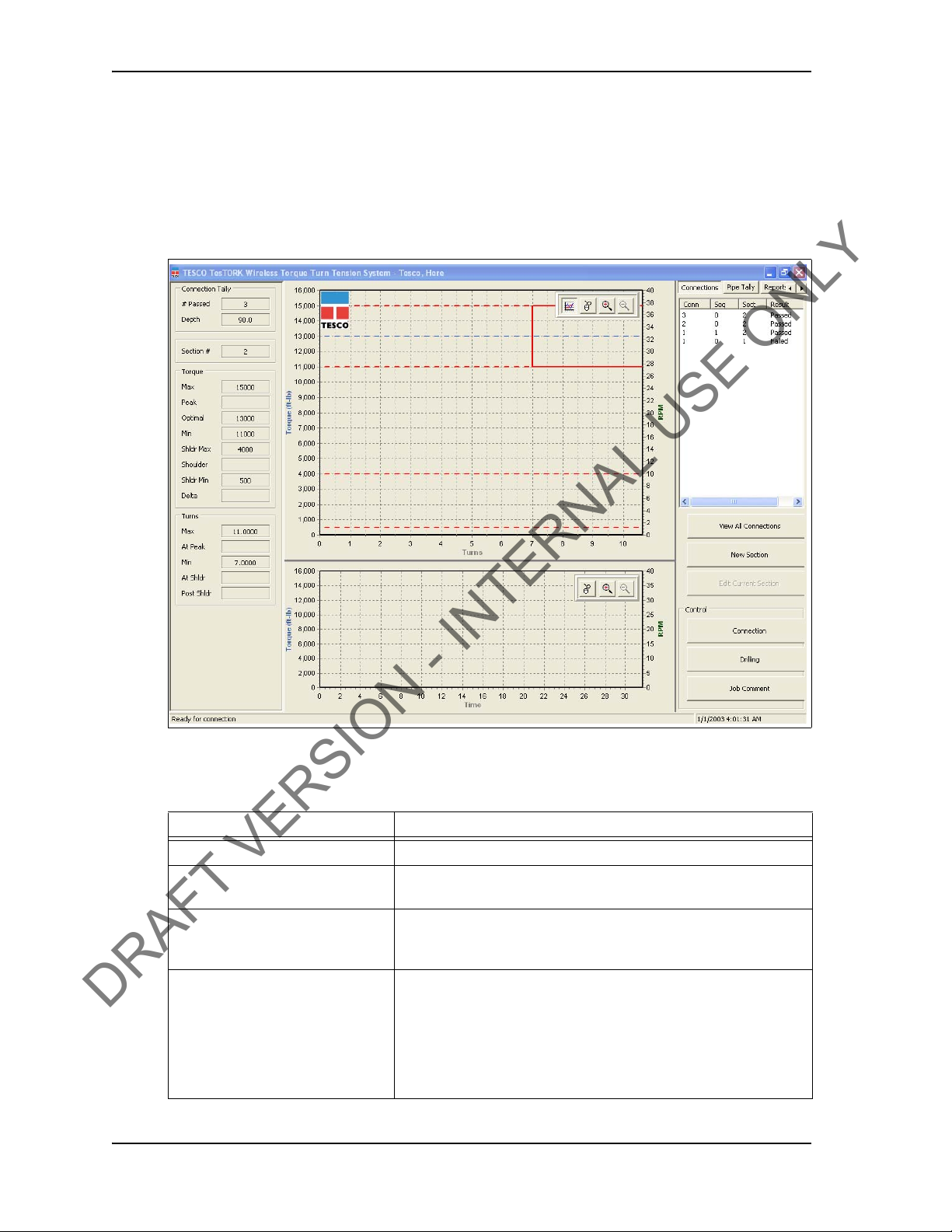

Main screen

The main screen appears after starting TesTORK so

ftware and beginning a job. The main

screen provides access to information and dialog boxes that enable the operator to accurately

monitor torque, turns and RPM while making up connections. The main screen also provides

access to data from previous connection attempts, reports and hardware configuration options.

Figure 2-4: Main screen

The following items are available from the

Table 2-3: Main Screen Interface Elements

Item

Footer bar Contains connection status information

Data fields on the left side of the

screen

Graphs Display torque (and RPM) vs. turns and torque (and RPM) vs. time

Connections button Provides access to the following dialog boxes:

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 10 WWW.TESCOPARTS.COM

Displays number of passed connections, depth, torque values, turn

values, shoulder and post-shoulder torque and turn data

Information is displayed in real time as the connection progresses.

•View All Connections

•New Section

•Edit Current Section

•Connection

•Drilling

•Job Comment

main screen:

Data/Notes

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Table 2-3: Main Screen Interface Elements

Item Data/Notes

Pipe Tally

Reports

Hardware

About WTTS

tab Enables the operator to view a list of all connection attempts

tab Enables the operator to view and print data section and connection

data

tab Enables the operator to view hardware configuration information.

Administrators are able to access and configure the System Settings

dialog box

tab Enables the operator to view

TesTORK software version information

Data fields on left Side of Screen

The following data is available on the left side of the screen:

Table 2-4: Data fields on left side of screen

Group Item Description

Connection

Tally

Torque Max Value entered in Create New Job or Add New Section dialog box

Turns Max V alue entered in Create New

# Passed Number of connections categorized as being passed

Depth Current total depth of casing

Section # Every change to job

new section number

Peak Peak torque value during a connection attempt

Optimal V alue entered in Create New

Min V alue entered in Create New Job or Add New Section dialog box

Shldr Max Value entered in Create New

Shoulder System or manually defined value

Shldr Min Value entered in Create New Job or Add New Section dialog box

Delta Value entered in Create New

At Peak How many turns taken to reach the peak torque value during a

connection attempt

Min V alue entered in Create New Job or Add New Section dialog box

At Shldr How many turns taken to reach the shoulder value during a

connection attempt. System

Post Shldr Value entered in Create New Job or Add New Section dialog box

information and connection data creates a

Job or Add New Section dialog box

Job or Add New Section dialog box

Job or Add New Section dialog box

Job or Add New Section dialog box

or manually defined value

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 11 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

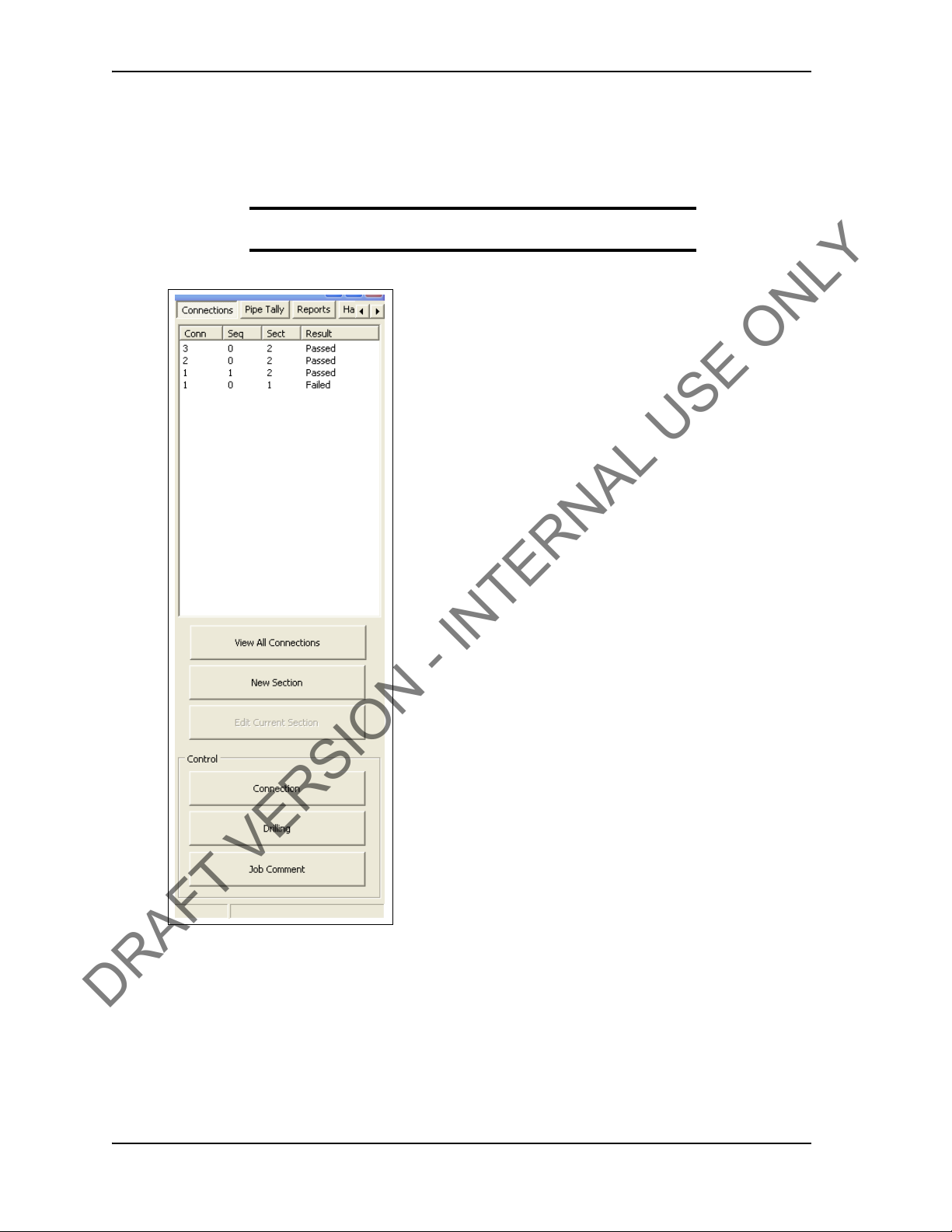

Connections Side Panel

The Connections side panel enables the operator to access the following dialog boxes and

windows:

Note: A list of the results from each attempted connection is also

displayed when the Connections button is clicked.

Figure 2-5: Connections side panel

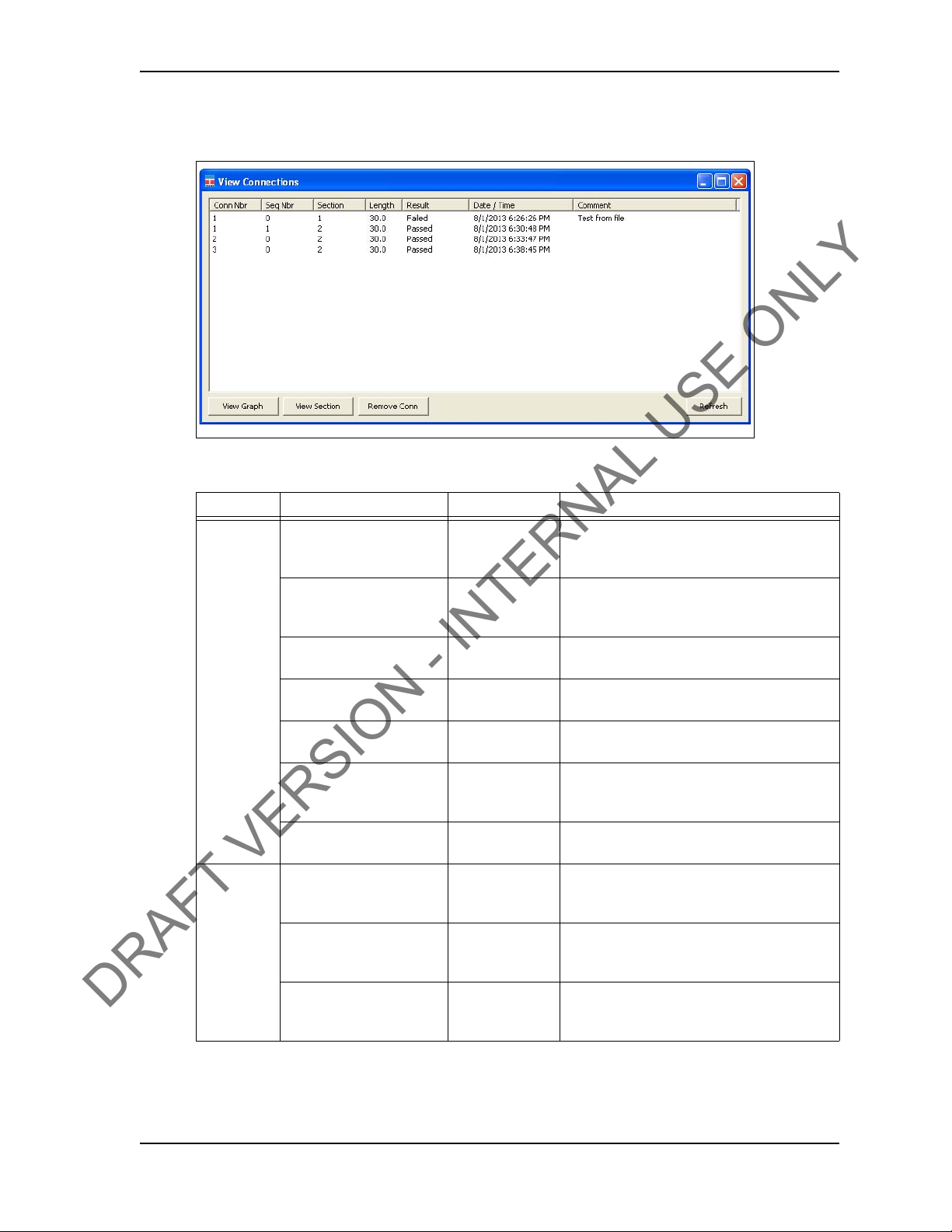

View All Connections

Clicking the V

window containing details of all casing connections made as part of the current job. The View

Connections window also features buttons that enable the operator View Graph, View Section

and Remove Conn (remove connection).

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 12 WWW.TESCOPARTS.COM

iew All Connections button enables the operator to access the View Connections

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Figure 2-6: View Connections Window

Table 2-5: View Connections Window:

Group Item Functionality Description

Columns Conn Nbr

(Connection Number)

Seq Number

(Sequence Number)

Section Displays the

Length Displays casing

Result Display

Date/Time Displays time

Comments Displays

Button View Graph Displays the

View Section Displays job

Remove Conn

(remove connection)

Displays the

connection

number

Displays the

sequence

number

ction

Se

length

connection result

and date

ormation

inf

Comments

graph of the

selected item.

information and

connection dat

Removes the last

connection

attempt

a.

Running total of connections made

Number of attempts made on a connection

Section number

Length of casing used in connection

Can be a passed, failed or forced pass

connection

Displays the exact time and date of each

connection attempt

The operator can enter comments

Displays the graphed connection data from

the selected connection attempt

Displays the job information and connection

data for the selected connection attempt

Removes the last connection attempt from a

job

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 13 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

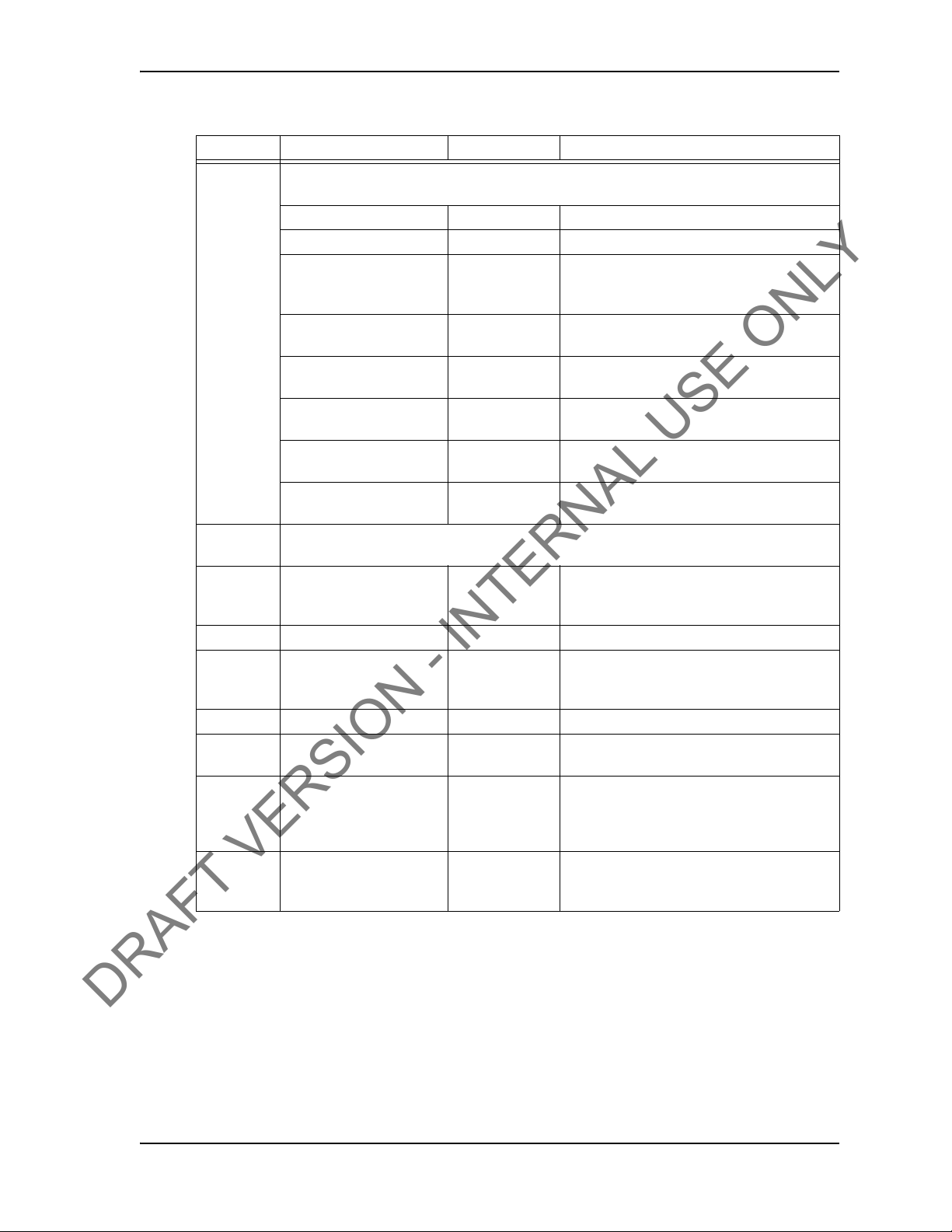

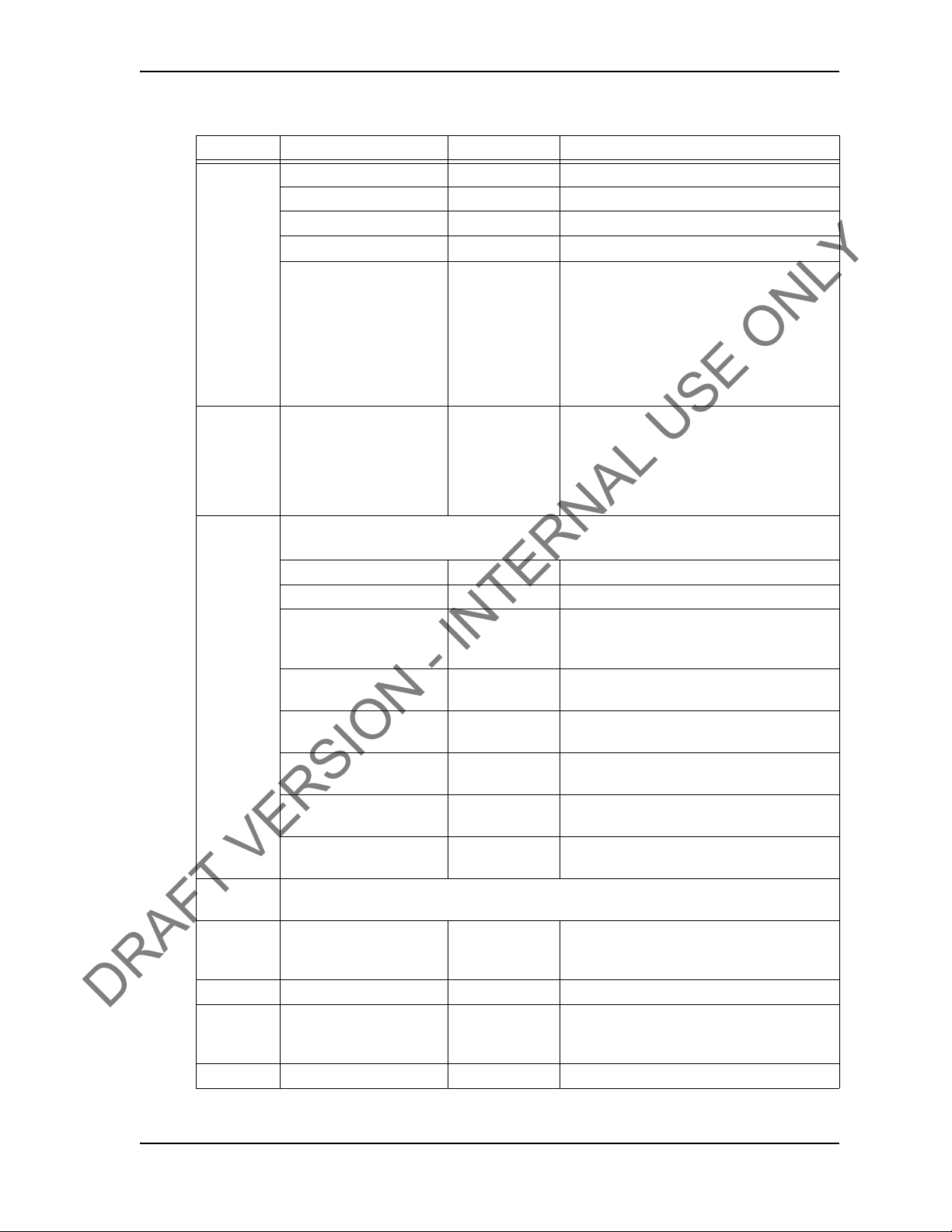

Add New Section

The Add New

Section window enables the operator to make revisions to the job details and

connection data. A new section is created each time a change is made to the job details and

connection data following a connection attempt.

However, changes can be made to the job details and

connection data without creating a new

section if a connection has not yet been attempted.

Figure 2-7: Add New Section Window

Table 2-6: Add New Section Window:

Group Item Functionality Description

Job Details Client Company Text box Displays the name of the company typed in

the New Job tab

Location Text box Displays the name of the location typed in the

Job tab.

New

Customer Representative Text box Representative from the customer

Tesco Technician Text box TESCO technician entering the job and

connection data

Thread Representative Text box Independent thread expert

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 14 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Table 2-6: Add New Section Window:

Group Item Functionality Description

Casing Manufacturer Text box Casing manufacturer

Name Text box Representative from casing manufacturer

Type Text box Type of casing

Grade Text box Steel grade of casing

Diameter cm Text box Casing diameter value. A correct casing

Shoulder

Peak Torque

Target

diameter

of RPM. A metric or diameter vale can be

entered pending on the units of measure

selection made in the Select Job tab.

For information on selecting how units are

displayed, see Table 2-1 on page 7.

Weight kg/cm Text box Casing weight value. A metric or diameter

vale can be entered pending on the units of

measure selection made in the Select Job tab.

For information on selecting how units are

displayed, see Table 2-1 on page 7.

Test runs are required to determine the number of turns

the Stream Check function. For more information.

Max Torque Text box Maximum post-shoulder target range

Min Torque Text box Minimum post-shoulder target range

Post Shldr Turns Text box

+/- Delta Text box

Avg Start Turns Text box

Avg End Turns Text box

Avg Offset ft-lb Text box

Auto-Shoulder Mode Check box When the auto-shoulder mode is selected the

Consult your casing manufacturer for the information used in this parameter group.

Max Torque ft-lb Text box Maximum allowable torque value. A torque

Opt Torque ft-lb Text box Optimal torque value

Min Torque ft-lb Text box Minimum allowable torque value. A Torque

Turns Text box Number of turns required to reach peak torque

The amount the casing should turn after

‘shouldering’ occurs; this value is typically

very low.

Allowable variance for the post-shoulder

turn.

Sets the turn count that pre-shoulder

averaging begins at

Sets the turn count that pre-shoulder

averaging ends at

Sets the shoulder torque value above the

pre-shoulder average

shoulder point can be moved (manually)

value above this setting results in a failed

connection result.

value below this setting result

connection result.

value is vital for accurate calculation

and the shoulder torque value. Use

s in a failed

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 15 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Table 2-6: Add New Section Window:

Group Item Functionality Description

+/- Delta Text box Allowable variance in number of turns

required to reach peak torque

Hold (sec) Text box Time required to maintain the optimal torque

setting. During this time, variances outside the

optimal torque range result in a failed

connection result.

Overshoot ft-lb Text box Increased torque value generated by the

momentum of the top driv

connection is fully tightened

e when the casing

Edit Current Selection

Enables the operator to makes changes to a curre

nt section’s job information and connection

data if no connection attempt has yet been made within that section. If a connection attempt

has been made, the button is not functional.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 16 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Connection

The Conn

ection dialog box enables the operator to begin monitoring a connection attempt.

Once a connection attempt is complete, the Connection dialog box displays the connection

result pass or fail. The operator can accept the connection result or assigned a Forced Pass

designation to a connection attempt that failed.

The Con

nection dialog box also enables the operator to start a streaming checking and monitor

connection data without logging the data. The operator can also add comments associated wit

each connection attempt and edit casing length data.

Figure 2-8: Connection Window

Table 2-7: Connection Window Dialog

Group Field/Element Name Data/Notes

Communications Status Bar Provides information on the connection status

between the TesTORK and TesTORK Manager

software. The following connection status messages

can be displayed:

•Hunting and TesTORK Manager software

•Idl

TORK and TesTORK Manager software

treaming - TesTORK Manager software is reiev-

•S

ing connection data from the TesTORK

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 17 WWW.TESCOPARTS.COM

No connection between the TesTORK

e - Connection is established between the Tes-

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Table 2-7: Connection Window Dialog (Continued)

Grou

p Field/Element Name Data/Notes

Connection Number Increments with every passed or forced pass

connection. Remains the same for a failed connection

attempt.

Length (ft) Length of current casing (not including

Stream Check

Start Starts logging a connection attempt. Once the casing

Stop Stops logging the connection attempt once complete

Set Shoulder Enables the operator to manually set a shoulder point.

Mark Connection As Enables the operator to record a connection attempt

Comment Enables the operator to add a comment to any

Displays connection data without logging the data.

has completed two turns, logging cannot be aborted

and the result is recorded.

and returns connection status to Idle status.

If TesTORK Manager software doesn’t automatically

detect a shoulder, this button is set by default.

as a Pass, Failed or Forced Passed. A comment must

be added if a connection result is over ridden or the

connection attempt failed.

connection attempt. However

added to a Failed or Forced Passed. attempt.

, comments must be

thread)

Drilling

The Drilling Control dialog box enables the operat

or to view torque and turns data without the

data being logged. Data is updated every second rather than at 100 times a second.

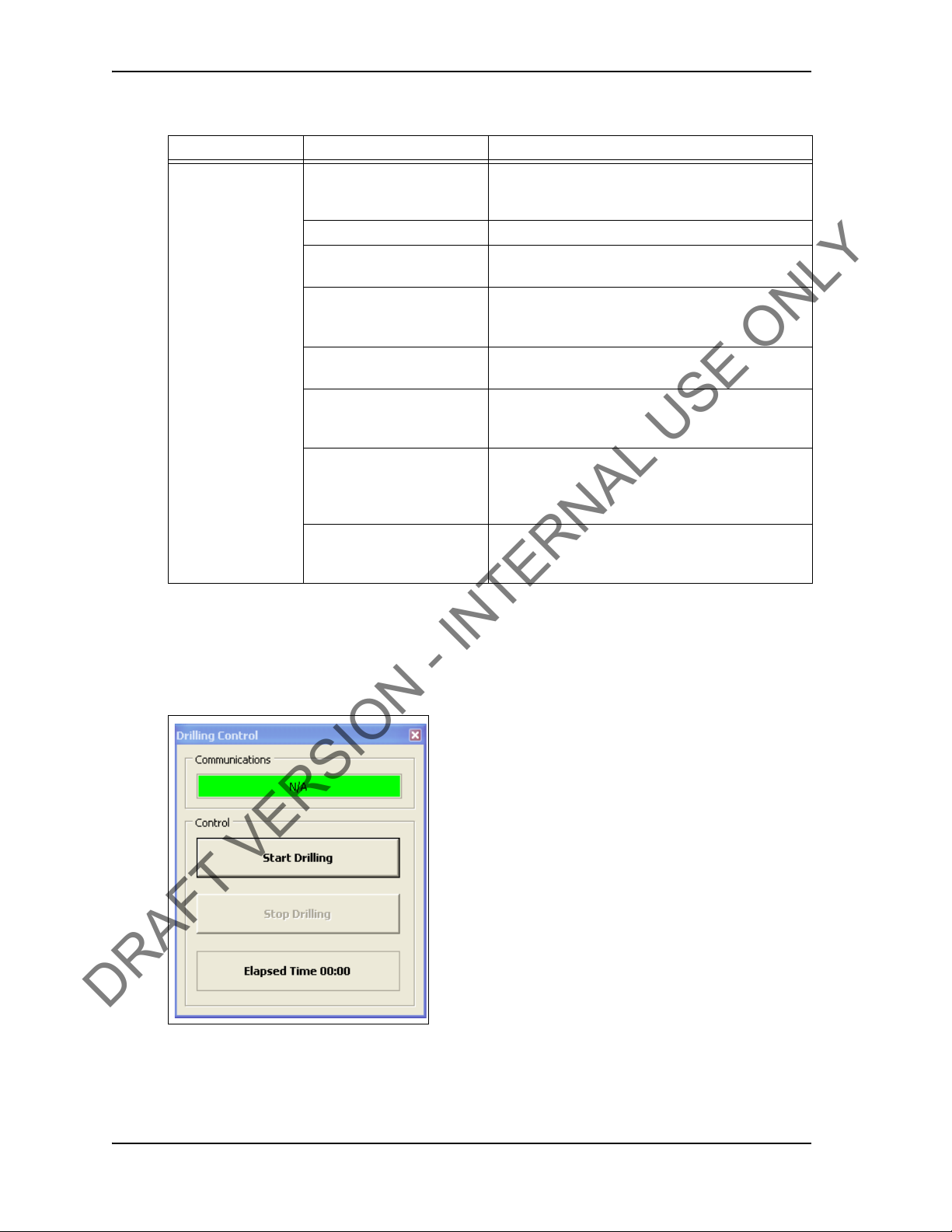

Figure 2-9: Drilling Control Window

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 18 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Table 2-8: Drilling Control Window Dialog

Group Field/Element Name Data/Notes

Communications Status Bar Provides information on the connection status

between the TesTORK and TesTORK Manager

software. The following connection status messages

can be displayed:

•Hunting and TesTORK Manager software

•Idle - Connection is established between the TesTORK and TesTORK Manager software

Streaming - T

connection data from the TesTORK

Control Start Dr il ling Starts displaying torque and turns data

Stop Drilling Returns TesTORK Manager software to Idle mode

Elapsed Time Time since the St

Figure 2-10: Job Comments Window

No connection between the TesTORK

esTORK Manager software is reieving

art button was pressed

Table 2-9: Job Comments Dialog

Group Field/Element Name Data/Notes

Add Comment Enables the operator to add comments about a job

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 19 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Pipe Tally Side Panel

The Pipe Tally side panel displays a list of all connection attempts. When a connection attempt

is selected the connection data associated with the attempt is displayed:

Figure 2-11: Pipe Tally Window

Table 2-10: Pipe Tally Dialog

Group Field/Element Name Data/Notes

Pipe Tally Conn (Connection) Connection number

Length Casing length

Sect (Section) Section number

Date/Time Time and date connection attempt was started

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 20 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Reports Side Panel

The Reports side panel displays the Report Sel ection window By selecting from the drop down

menu, an operator can view accumulated data from a job. Data includes job statistics, individual section details, combined section details and job comments.

Figure 2-12: Reports Window

Table 2-11: Reports Window Dialog

Group Field/Element Name Data/Notes

Report Selection Type

(Drop Down Menu)

Range (All or

Preview (Button) Displays report

Note: For a complete description of each report and the information available, see “Reports” on page 46.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 21 WWW.TESCOPARTS.COM

Range) Display all items or a range of items

Job Statistics

Sections (detail)

Sections (summary)

Connections

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Hardware Side Panel

The Hardware side panel displays information about the Wireless Torque Turn Tension Sys-

tem.

Figure 2-13: Hardware Window

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 22 WWW.TESCOPARTS.COM

USER GUIDE SYSTEM OVERVIEW

DRAFT VERSION - INTERNAL USE ONLY

Table 2-12: Hardware Window Dialog

Group Field/Element Name Data/Notes

Item Ctrl Port Type

(Control Port Type)

Ctrl Port Desc

(Control Port Description)

Ctrl Port Cmds Tx System information

Ctrl Port Resp Rx System information

Ctrl Port Pkt Errs System information

Ctrl Port Bytes Tx System information

Ctrl Port Bytes Rx System information

Ctrl Port Last Resp System information

Device Type System information

Device Status System information - Status is Idl

Raw Data Logging System information

Cal’d Data Logging System information

Data Port Type System information

Data Port Desc System information

Data Port Cmds Tx System information

Data Port Resp Rx System information

Data Port Pkt Errs System information

Data Port Bytes Tx System information

Data Port Bytes Rx System information

Data Port Last Resp System information

Buttons Configuration Enables access to the T

Clear Stats **Please supply description

System information

System information

e when

communication is established between the

TesTORKand TesT ORK Manager software

esTork System Settings

dialog box. A password is required. For more

information on using the TesTork System Settings

dialog box, see “System Settings Dialog Box” on

page 53.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 23 WWW.TESCOPARTS.COM

SYSTEM OVERVIEW USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

About WTTTS side panel

The About WTTTS side panel displays the TESCO Wireless Torque Turn Tension System

(WTTTS) Version as well as TESCO contact information.

Figure 2-14: About WTTTS Window

Table 2-13: About WTTTS Dialog Box

Group Field/Element Name Data/Notes

About WTTTS Version The Current Software Version of the TESCO WTTTS.

Contact Information TESCO Corporation Contact Information

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 24 WWW.TESCOPARTS.COM

C

DRAFT VERSION - INTERNAL USE ONLY

HAPTER

This chapter provides information on installing and starting The TesTORK Wireless Torque

Monitoring System‘s hardware and software components.

3: I

NSTA LLATION AND

S

TART UP

USER GUIDE

PRE-I

The installation process consists of th

• Pre-installation activities

Note: Once a job has been defined, the TesTORK system components must be inspected and verified before goin g to the job

site.

• Pre-job component inspection

• On-site rig-up procedures

• Installing the Torque Sub

• System start-up

e following general procedures:

NSTALLATION ACTIVITIES

Verify Casing Data

Before traveling to the casing running job site, ensure the following information about the casing has been collected from the fiel

881031 in “Appendix B: TTS Checklists and Forms”).

• casing weight

• casing size

• approximate lengths (tally sheet)

• connection types

d supervisors at TESCO (see Pre-Job Information checklist

Pre-Job Component Inspection

Complete the following steps to ensure that the TesTORK system is complete and functional

before traveling to the job site.

1. Ens

2. Check all

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 25 WWW.TESCOPARTS.COM

ure that all TesTORK components are present in the pelican case(s).

cables for wear or damaged ends. If damage is detected, or if a cable is

suspect, pin out the cord and verify its condition.

INSTALLATION AND START UP USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

3. Connect the system together and verify that data is being received at the computer

and most importantly check the battery life. If battery life is not enough to complete

the job, install new lithium D size batteries before going to site.

Note: See “Appendix A: Changing The Battery” for more information.

4. After completing the initial system verification and confirming that all the required

components are present, repack all of the items into the pelican case(s) and crate.

ON-S

5. Submit the completed checkl

kit prepared for the upcoming job.

6. Use

form 881027 as a reference; see “Appendix B: TTS Checklists and Forms”

ist to the supervisor to confirm that there is a complete

Pre-job system test

Ensure a pre-job system test is completed (i.e. communication can be established between the

TesTORK and TesTORK Manager software) before traveling to the job site.

For example:

1. Connect all equipment.

2. Switch on

3. Ens

Manager software

computer

ure connection has been established between the TesTORK and TesTORK

ITE RIG UP PROCEDURES

Complete the following steps to ensure that the correct placement of the TesTORK system’s

hardware components after arriving at the job site.

Danger! The printer (and memory stick if used) mus t only

!

Danger! Ensure each piece of equipment has the

!

Caution: The base radio must be positioned with its antenna in line

of sight with the TesTORK.

!

1. Report to on-site supervisor(s) for orientation and initial introductions.

2. Go to

of the TesTORK system.

3. Place the ma

4. Connect the

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 26 WWW.TESCOPARTS.COM

be used in a safe area.

appropriate rating for the location for where it will

be positioned.

the rig floor and determine hardware placement for the major components

jor TesTORK system components.

major TesTORK system components.

USER GUIDE INSTALLATION AND START UP

DRAFT VERSION - INTERNAL USE ONLY

I

NSTALLING THE TES

Content or cross reference TBD

TORK

SUB

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 27 WWW.TESCOPARTS.COM

INSTALLATION AND START UP USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

S

YSTEM START UP

After the on-site rig up procedures have been completed and the TesTORK has been installed,

the TesTORK system is ready to start.

Once started, the TesTORK system is ready to be

attempts.

Note: For information on using TesTORK system to monitor and

log connection attempts, see “Operation” on page 33.

Start the TesTORK system by completing the following procedures:

1. T

urn on the TesTORK

tart TesTORK Manager software

2. S

gin monitoring and logging connection

Turning the TesTORK on or off

When the TesTORK is turned on it will automatically start looking for a wireless signal from

base radio. The TesTORK automatically connects to the base radio (and TesTORK Manager

software) once a connections is established.

Note: The TesTORK sub is automatically powered off when it

does not have a wireless connection for 15 minutes or more.

Therefore, when not in use for an extended period on the rig, dis

connect power to the receiver to preserve the batteries in the TesTORK.

-

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 28 WWW.TESCOPARTS.COM

USER GUIDE INSTALLATION AND START UP

On button

Light tube

DRAFT VERSION - INTERNAL USE ONLY

Use the following procedures to turn the TesTORK sub on or off:

To turn on the TesTORK sub

Push the Power

Figure 3-1: Turning on the TesTORK

The light tube located above the power button will flash five times

To turn off the TesTORK sub

button on the side of the TesTORK sub.

Push the Power

The power button will flash five times.

button on the side of the TesTORK sub.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 29 WWW.TESCOPARTS.COM

INSTALLATION AND START UP USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Starting TesTORK Manager software

Use the following procedures to start TesTORK Manager software and check that connection

has been established between the TesTORK sub and TesTORK Manager software.

To start TesTORK Manager software

1. Ens

ure the computer hosting TesTORK Manager software is powered up and the

desktop is displayed on the screen.

2. Double-click the T

estTORKManager program icon located on the Desktop.

The Se

Note: If this is the first time starting TesTORK Manager software

on the host computer, a dialog box appears confirming that a job

directory must be set befor e starting the software. Browse to and

select (create) a suitable folder, and then click OK.

TesTORK Manager software uses the selected folder to store log files

containing configuration and connection data from each job started in the

software.

lect Job dialog box appears.

3. Select one of the following options:

If you want to: Complete these steps:

Start an existing job

a. Ensure the Existing Jobs tab is selected.

The Existing Jobs dialog box appears.

b. Sel

ect a job, and then click OK.

Note: Use the Display Filter buttons to display the most recent jobs

or all jobs.

The TesTORK Manager software main screen appears.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 30 WWW.TESCOPARTS.COM

USER GUIDE INSTALLATION AND START UP

DRAFT VERSION - INTERNAL USE ONLY

If you want to: Complete these steps:

Create a new job

a. Click the New Jobs tab.

The New Jobs dialog box appears.

ype a client name in the Client box.

b. T

ype a location in the Location box.

c. T

d. Sel

e. Type a starting connection number in the Starting Connection box.

f. Cl

g. T

h. Click OK.

ect a unit of measure using the Units of Measure radio buttons.

ick OK.

The Create New Job Window appears

ype the relevant information or data in the text boxes.

Note: For a description of each text box item, see Figure 2-3 on

page 8.

The TesTORK Manager software main screen appears.

To check connection between the TesTORK sub and TesTORK Manager software

1. On

Figure 3-2: Connections dialog box

the main screen, click the Connections button.

The Co

nnections dialog box appears.

2. Check the Communications status box

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 31 WWW.TESCOPARTS.COM

INSTALLATION AND START UP USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

The message Idle is displayed when communication between the TesTORK and TesTORK Manager software is established.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 32 WWW.TESCOPARTS.COM

C

DRAFT VERSION - INTERNAL USE ONLY

HAPTER

This chapter provides information on using the various features of TesTORK Wireless Torque

Monitoring System.

4: O

USER GUIDE

PERATION

PRE-

Information in this chapter include

• Pre-job activity list

•Overview

• Connections

s:

JOB ACTIVITY LIST

Ensure the following activities have been completed before using the procedures in this chapter.

T able 1: Pre-job task list

Activity Reference

Pre-installation activities

On-site rig-up procedures

Installation of the TesTORK sub

System Start-up

Ensuring connection has been established between the TesTORK sub and

TesTORK Manager software.

page 25

page 26

page 27

page 28

page 31

Note: For more information on checking the connectivity between

the TesTORK sub and TesTORK Manager software, see

check connection between the TesTORK sub and TesTORK Manager software” on page 31.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 33 WWW.TESCOPARTS.COM

“To

OPERATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

O

VERVIEW

The T esTORK system system’s different features and functionality are accessed by clicking on

buttons at the top right side of the screen. As each button is clicked, the dialog box on the right

side of the screen changes enabling access to the features and functionality associated with

each button.

Figure 4-1: Connections tab a nd Buttons

The following operational features and

functionality are available by clicking the buttons at

the top right side of the screen.

Table 2: Operational features

Button Enables the operator to:

Connections •View information on completed connec-

tions

•Add a new section by updating the connection configuration data

•Log a connection attempt

•Monitoring a drilling operation

•Add a job comment

Pipe Tally View a list of connections

Reports View and print reports providing information

atistics, sections, connections and job

job st

comments

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 34 WWW.TESCOPARTS.COM

USER GUIDE OPERATION

DRAFT VERSION - INTERNAL USE ONLY

C

ONNECTIONS

Click the Connections button to access the following features:

T able 3: Pre-job task list

Side panel Use this feature to: Reference

Connection

•Log a passed connection

•Log a failed connection

•Force past a failed connection

Drilling

Job Comment

View All Connections

New Section

Edit Current Section

Continually monitor torque and RPM at the at

the top drive during a drilling operation

Add a comment about the job

View information on each connection attempt

for the current job.

The following Information is available:

•Graphs showing the connection attempt

data

• Configuration data used for each connection attempt

Begin a new section by changing the job

details or connection configuration data.

Edit a new section before a connection

attempt has been made

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 35 WWW.TESCOPARTS.COM

OPERATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

Connection

Use the following procedures to:

Table 4:

Procedure Description

Log a passed connection

Log a failed connection

Force past a failed connection It is possible to force a Pass status on a failed connection if the

operator has determined that the connection is correct, but

tTesTORK Manager software has not recognized it as such.

One situation in which a failed connection might be forced is

when the threaded coupling on the top of the casing has been

removed. This can cause faults to occur. Torquing two

connections at once can create a fault alarm as the shoulders

might not synchronize and the applied/registered torque might be

more erratic than what was set as parameters for Fail status. In

this case, it is permitted to force a Pass status if the correct end

result torque is achieved. The comment section allows comments

regarding the reason for the pass; comments are required for all

force failed or force passed connections. In addition, the option to

increase the connection number to account for the double joint is

available.

Another situation where a force pass connection might occur is if

the operator clicks the Start button after the casing has already

turned a number times. This will produce a fault that indicates

shouldering occurred too early and/or the optimum torque was

achieved within too few turns. If it is confirmed that the connection

is actually correct, then force pass the connection.

Log a Passed Connection

Use the following procedure to accept the Pas

tem and continue to the next connection.

1. On

the main screen, click the Connections button.

sed status assigned to a connection by the sys-

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 36 WWW.TESCOPARTS.COM

USER GUIDE OPERATION

DRAFT VERSION - INTERNAL USE ONLY

The Connections dialog box appears.

Figure 4-2: Connections dialog box

Note: Change the casing length if required.

Note: The connection number is automatically assigned the next

number in the sequence.

Note: Click Stream Check to display connection data without

logging a connection attempt or determining a shoulder point.

To close the Conn

check, click Stream Check.

2. Click Start.

TesTORK Manager software is now ready to begin logging and displaying connection data.

Note: No data is displayed until the top drive operator begins a

connection attempt.

3. Start a connection attempt.

ections dialog box after performing a stream

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 37 WWW.TESCOPARTS.COM

OPERATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

TesTORK Manager software begins logging and displaying connection data.

Figure 4-3: Connection data

4. When the Torque and RPM values reach zero, click Stop.

Figure 4-4: Torque and RPM values

5. T

ype comments in the Comment text box, if required.

6. Click Save.

The connection number and length are added to the running totals and the connec-

data is logged.

tion

Log a Failed Connection

Use the following procedure to accept the F

and continue to the next connection.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 38 WWW.TESCOPARTS.COM

ailed status assigned to a connection by the system

USER GUIDE OPERATION

DRAFT VERSION - INTERNAL USE ONLY

1. On the main screen, click the Connections button.

The Connections dialog box appears.

Figure 4-5: Connections dialog box

Note: Change the casing length if required.

Note: The connection number is automatically assigned the next

number in the sequence.

Note: Click Stream Check to display connection data without

logging a connection attempt or determining a shoulder point.

To close the Conn

check, click Stream Check.

2. Click Start.

TesTORK Manager software is now ready to begin logging and displaying connection data.

Note: No data is displayed until the top drive operator begins a

connection attempt.

3. Start a connection attempt.

ections dialog box after performing a stream

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 39 WWW.TESCOPARTS.COM

OPERATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

TesTORK Manager software begins logging and displaying connection data.

Figure 4-6: Connection data

4. When the Torque and RPM values reach zero, click Stop.

Figure 4-7: Torque and RPM

Failed is displayed

ype comments in the Comment text box.

5. T

Note: A comment must be typed in the Comment text box before

clicking Save.

6. Click Save.

in the Mark Connection drop-down list.

The connection number and length are added to the running totals and the connection

data is logged.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 40 WWW.TESCOPARTS.COM

USER GUIDE OPERATION

DRAFT VERSION - INTERNAL USE ONLY

Force Past a Failed Connection

Use the following procedure to assign a For

Failed status by the system, and continue to the next connection.

1. On

Figure 4-8: Connections dialog box

the main screen, click the Connections button.

The Connections dialog box appears.

ce Past result to a connection attempt assigned

Note: Change the casing length if required.

Note: The connection number is automatically assigned the next

number in the sequence.

Note: Click Stream Check to display connection data without

logging a connection attempt or determining a shoulder point.

To close the Conn

check, click Stream Check.

2. Click Start.

TesTORK Manager software is now ready to begin logging and displaying connection data.

Note: No data is displayed until the top drive operator begins a

connection attempt.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 41 WWW.TESCOPARTS.COM

ections dialog box after performing a stream

OPERATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

3. Start a connection attempt.

TesTORK Manager software begins loggin

Figure 4-9: Connection data

g and displaying connection data.

4. Wh

Figure 4-10: Torque and RPM

5. Select Forced

6. T

en the Torque and RPM values reach zero, click Stop.

Failed is displayed

ype comments in the Comment text box.

Note: A comment must be typed in the Comment text box before

clicking Save.

in the Mark Connection drop-down list.

Pass from the Mark Connection drop-down list.

7. Click Save.

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 42 WWW.TESCOPARTS.COM

USER GUIDE OPERATION

DRAFT VERSION - INTERNAL USE ONLY

The connection number and length are added to the running totals and the connection data is logged.

M

ANUAL SHOULDER OPERATION

TesTORK Manager software enables the operator to manually change the shoulder point to

any desired point. The program then recalculates the delta turn and delta torque from the new

shoulder point values.

When a new job folder is created, the shoulder detection met

Auto Mode. In Auto Mode, everything works the same as previously described. If the shoulder

detection method needs to be changed to

ialog box and select manual shoulder.

tion d

Note: Notice the Shoulder Target values have been disabled and

the Shoulder Target Mode has been changed to Manual Shoul-

der. Th

has been selected.

Note: Selecting Manual Shoulder disables alarms associated

with automatic shouldering.

To manually set the shoulder point

**Needs finishing

Use the following procedure to manually set

1. On

e Main Screen also indicates that Manual Shoulder mode

the main screen, click the Connections button.

MANUAL, then the operator must go to the Connec-

the shoulder point.

hod automatically defaults to

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 43 WWW.TESCOPARTS.COM

OPERATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

The Connections dialog box appears.

Figure 4-1 1: Con ne ctions dialog box

Note: Change the casing length if required.

Note: The connection number is automatically assigned the next

number in the sequence.

Note: Click Stream Check to display connection data without

logging a connection attempt or determining a shoulder point.

To close the Conn

check, click Stream Check.

2. Click Start.

TesTORK Manager software is now ready to begin logging and displaying connection data.

Note: No data is displayed until the top drive operator begins a

connection attempt.

3. Start a connection attempt.

ections dialog box after performing a stream

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 44 WWW.TESCOPARTS.COM

USER GUIDE OPERATION

DRAFT VERSION - INTERNAL USE ONLY

P

IPE TALLY

Clicking the Connections button enables access to the following features:

• View All Connections

• New Section

• Edit Current Section

Control buttons. Use these buttons to log connection attempts and monitor an

attempts.

Note: For screen shots and a description of each dialog box elements, see

Use the Connections button to access the following features:

• View All Connections

• New Section

“Pipe Tally Side Panel” on page 20.

d log connection

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM

INTL: 713-359-7295 45 WWW.TESCOPARTS.COM

OPERATION USER GUIDE

DRAFT VERSION - INTERNAL USE ONLY

R

EPORTS

The following section provide3s information on the different reports available from the TesTORK Manager software.

Figure 4-12: Summary Report Window

Table 4-1: Summary Report Window Dialog

Group Field/Element Name Data/Notes

Charts Final Torque vs Final Turns

Shoulder Torque vs Shoulder

Turns

Delta Torque vs Delta Turns

CONTACT: 1-877-TESCO-77 WIRELESS TORQUE TURN SYSTEM WWW.TESCOCORP.COM