Micro Linear Corporation ML4435CP, ML4435CS, ML4435IP, ML4435IS Datasheet

PRELIMINARY

ML4435 Sensorless BLDC Motor Controller

GENERAL DESCRIPTION

The ML4435 provides all the circuitry for sensorless

speed control of 3 phase Brushless DC Motors. Controller

functions include start-up circuitry, Back EMF commutation control, Pulse Width Modulation (PWM) speed control, pulse-by-pulse current limiting, motor coasting, and

under-voltage protection.

Motor starting is accomplished by commutating the motor

at a low frequency to produce low speed motion. The

low speed motion is used to generate a Back EMF signal.

A back EMF sampling circuit locks on to the motors position and controls commutation timing by forming a phase

locked loop (PLL). The commutation control circuitry also

outputs a speed feedback signal used in the speed control

loop. The speed control loop consists of an error amplifi er

and PWM comparator that produces a PWM duty cycle

for speed regulation. Motor current is limited by a pulseby-pulse PWM shutdown comparator that is tripped by

the voltage across an external current sense resistor. Commutation control, PWM speed control, and current limiting are combined to produce the output driver signals.

Six output drivers are used to provide gating signals to an

external 3 phase bridge power stage sized for the Brushless DC (BLDC) motor voltage and current requirements.

Additional functions include a motor coast function and

an under voltage lock out circuit to shut down the output

drivers in the event of a low voltage condition on the VCC

to the ML4435.

FEATURES

n Proprietary back-EMF sensing commutation technique

for motor communication without hall effect sensors

n PWM pulse-by-pulse current limiting to protect motor

and FET drivers

n Stand-alone operation; motor starts and stops with

power applied to the IC*

n Soft-start function limits start-up current

n PWM speed control for effi ciency and minimum FET

sizing

n Onboard under voltage lock out and power fail detect

n Tach output senses commutation of the motor

* Some External Components Required.

May, 2000PRELIMINARY DATASHEET

PRELIMINARY

ML4435

WARRANTY

Micro Linear makes no representations or warranties with respect to the accuracy, utility, or completeness of the contents of

this publication and reserves the right to make changes to specifi cations and product descriptions at any time without notice.

No license, express or implied, by estoppel or otherwise, to any patents or other intellectual property rights is granted by this

document. The circuits contained in this document are offered as possible applications only. Particular uses or applications

may invalidate some of the specifi cations and/or product descriptions contained herein. The customer is urged to perform

its own engineering review before deciding on a particular application. Micro Linear assumes no liability whatsoever,

and disclaims any express or implied warranty, relating to sale and/or use of Micro Linear products including liability

or warranties relating to merchantability, fi tness for a particular purpose, or infringement of any intellectual property

right. Micro Linear products are not designed for use in medical, life saving, or life sustaining applications.

© Micro Linear 2000. is a registered trademark of Micro Linear Corporation. All other trademarks are

the property of their respective owners.

Products described herein may be covered by one or more of the following U.S. patents: 4,897,611; 4,964,026; 5,027,116;

5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940; 5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376;

5,652,479; 5,661,427; 5,663,874; 5,672,959; 5,689,167; 5,714,897; 5,717,798; 5,742,151; 5,747,977; 5,754,012;

5,757,174; 5,767,653; 5,777,514; 5,793,168; 5,798,635; 5,804,950; 5,808,455; 5,811,999; 5,818,207; 5,818,669; 5,825,165;

5,825,223; 5,838,723; 5.844,378; 5,844,941. Japan: 2,598,946; 2,619,299; 2,704,176; 2,821,714. Other patents are pending.

PRELIMINARY DATASHEET

May, 20002

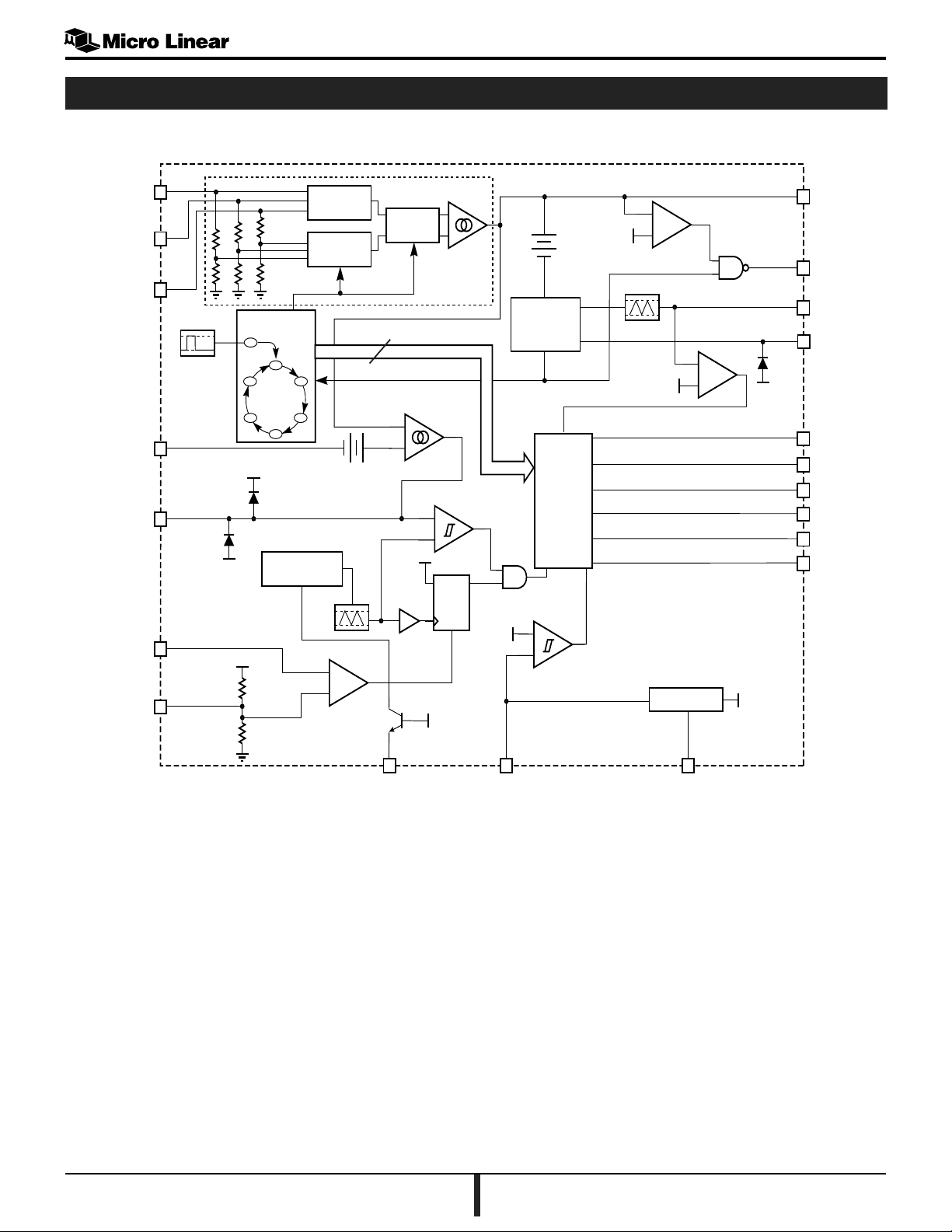

BLOCK DIAGRAM

FB A

14

FB B

15

FB C

16

COMMUTATION

STATE MACHINE

R

3µs

SPEED SET

SPEED COMP

ISENSE

SOFT START

POWER ON

RESET PULSE

5

3

1

19

F

E

8.2 + 0.7V

2.2 + 0.7V

1V

225kΩ

225kΩ

NEUTRAL

5.8kΩ

2.9kΩ

TRIANGLE WAVE

SIMULATOR

A

B

C

D

LEVEL SHIFT

GENERATOR

CURRENT LIMIT

COMPARATOR

MUX

SPEED FB

–

+

COMP

–

PRELIMINARY

SIGN

CHANGER

6

+

0.7V

+

–

BACK

EMF SAMPLER

SPEED

ERROR AMP

+

–

PWM

COMPARATOR

+

–

5V

DQ

R

VREF + 0.7V

+

–

VOLTAGE

CONTROLLED

OSCILLATOR

GATING

LOGIC

AND

OUTPUT

DRIVERS

PULSE-BY-PULSE

CURRENT LIMIT

8.7V

+

–

+

LEVEL

0.97V

SHIFT

0.7V

COAST

UVLO COMPARATOR

COMP

–

1.5V

6V REFERENCE

+

COMP

–

0.9V

VREF

ML4435

18

SPEED FB

2

TACH

20

CVCO

RVCO

4

7

HA

8

HB

9

HC

11

LA

12

LB

13

LC

6

RT VCC GND

1710

ML4435 Block Diagram

May, 2000 PRELIMINARY DATASHEET 3

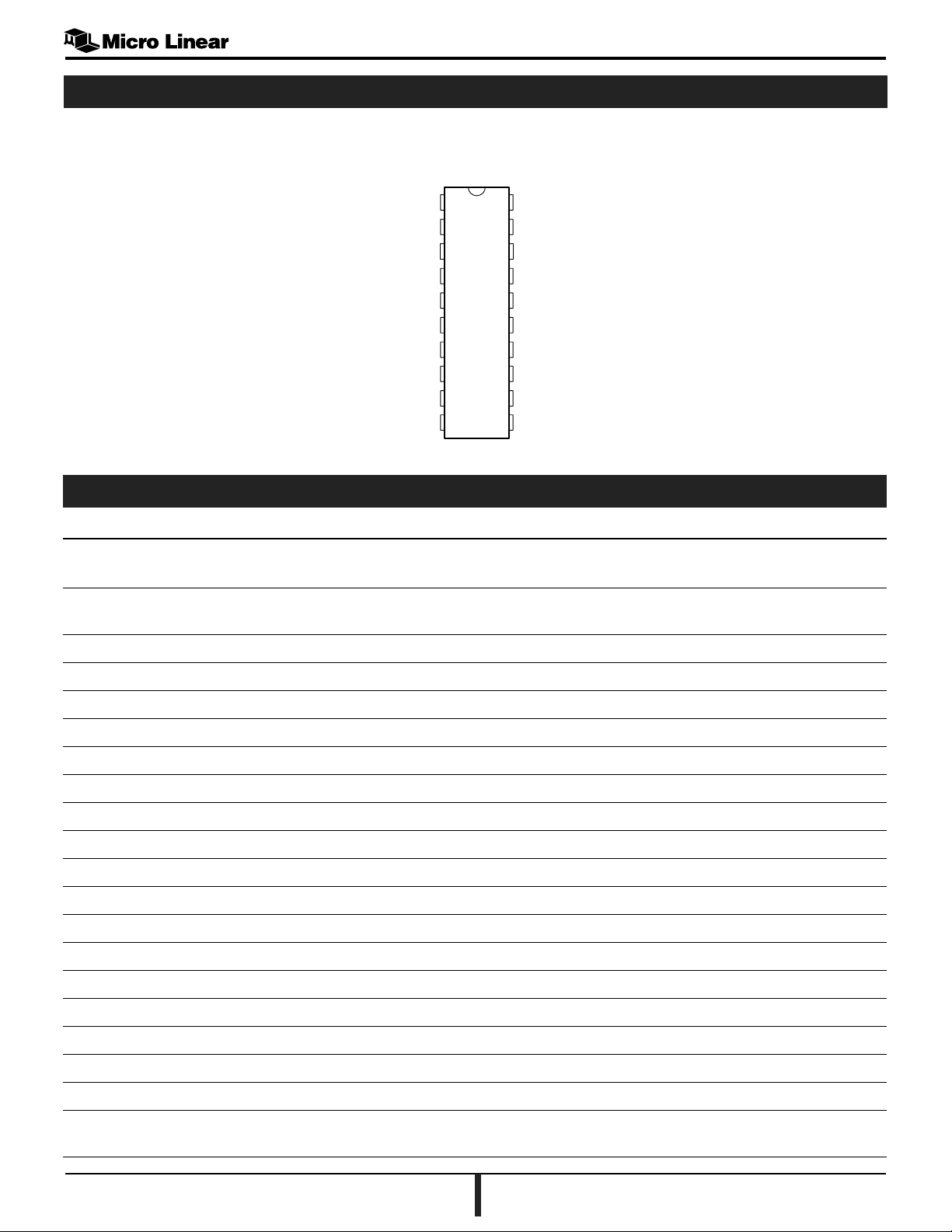

PIN CONFIGURATION

PRELIMINARY

ML4435

20-P n PDIP P20

20-P n SOIC S20

ISENSE

TACH

SPEED COMP

RVCO

SPEED SET

RT

HA

HB

HC

VCC

2

3

4

5

6

9

0

TOP VIEW

20

9

6

5

4

3

2

CVCO

SOFT START

SPEED FB

ND

FB C

FB B

FB A

LC

LB

LA

ML4435

PIN DESCRIPTIONS

PIN NAME FUNCTION

1 ISENSE Motor current sense input which triggers pulse by pulse current limit when

ISENSE exceeds 0.55V

2 TACH A clock output of 6 pulses per commutation cycle when SPEED FB is greater

than 0.97V otherwise the TACH output is at 5V

3 SPEED COMP Connection node for speed loop compensation components

4 RVCO Connection node for external resistor to set VCO frequency

5 SPEED SET DC input for setting motor speed

6 RT External resistor from this pin to ground controls the IC's PWM timing (frequency)

7 HA High-side output driver for motor phase A

8 HB High-side output driver for motor phase B

9 HC High-side output driver for motor phase C

10 VCC Power Supply input

11 LA Low-side output driver signal for motor phase A

12 LB Low-side output driver signal for motor phase B

13 LB Low-side output driver signal for motor phase C

14 FB A Back EMF signal input for motor phase A

15 FB B Back EMF signal input for motor phase B

16 FB C Back EMF signal input for motor phase C

17 GND Signal and power ground

18 SPEED FB Connection node for back-EMF sensing compensation components

19 SOFT START Connection node for external soft start capacitor which reduces start up current

20 CVCO Connection node for external capacitor to set VCO frequency. Forcing this input

below 1.5V causes the commutation to stop and the motor to coast

PRELIMINARY DATASHEET

May, 20004

PRELIMINARY

FUNCTIONAL DESCRIPTION

ML4435

COMPONENT SELECTION

Selecting external components for the ML4435 requires

calculations based on the motor’s electrical and mechanical parameters. The following is a list of the motor parameters needed to for these calculations:

The maximum DC motor supply voltage V MOTOR (V)

The maximum operating current I MAX (A)

The winding resistance measured line to line Rl-l Ω

The number of magnetic poles N (Unitless)

The Back EMF constant Ke (V s/RAD)

The torque constant Kτ (N m/A) of the motor (Kτ = Ke

in SI units)

The maximum speed of operation RPMMAX (RPM)

The moment of inertia J (Kg m2 ) of the motor and its

load

The viscous damping factor ζ (Unitless) of the motor and

its load

If one or more of the above values is not known, it is

still possible to pick components for the ML4435, but

some experimentation may be necessary to determine the

optimal values. All quantities are in SI units unless otherwise specifi ed. The following formulas and component

selection graphs should be considered as a starting point

from which to optimize the application. All calculations

for capacitors and resistors should be used as the fi rst

approximation for selecting the closest standard value.

SUPPLY VOLTAGE AND ON-CHIP VOLTAGE

REFERENCE

OUTPUT DRIVERS

The output drivers LA, LB, LC, HA, HB, and HC provide

totem pole output drive signals for a 3 phase bridge power

stage. All control functions in the ML4435 translate to

outputs at these pins. LA, LB, LC provide the low side drive

signals for phases A, B, and C of the 3 phase power stage

and are 12V active high signals. HA, HB, and HC provide

the high side signals for phases A, B, and C of the 3 phase

power stage and are 12V active low signals.

CURRENT LIMITING IN THE 3 PHASE BRIDGE

POWER STAGE

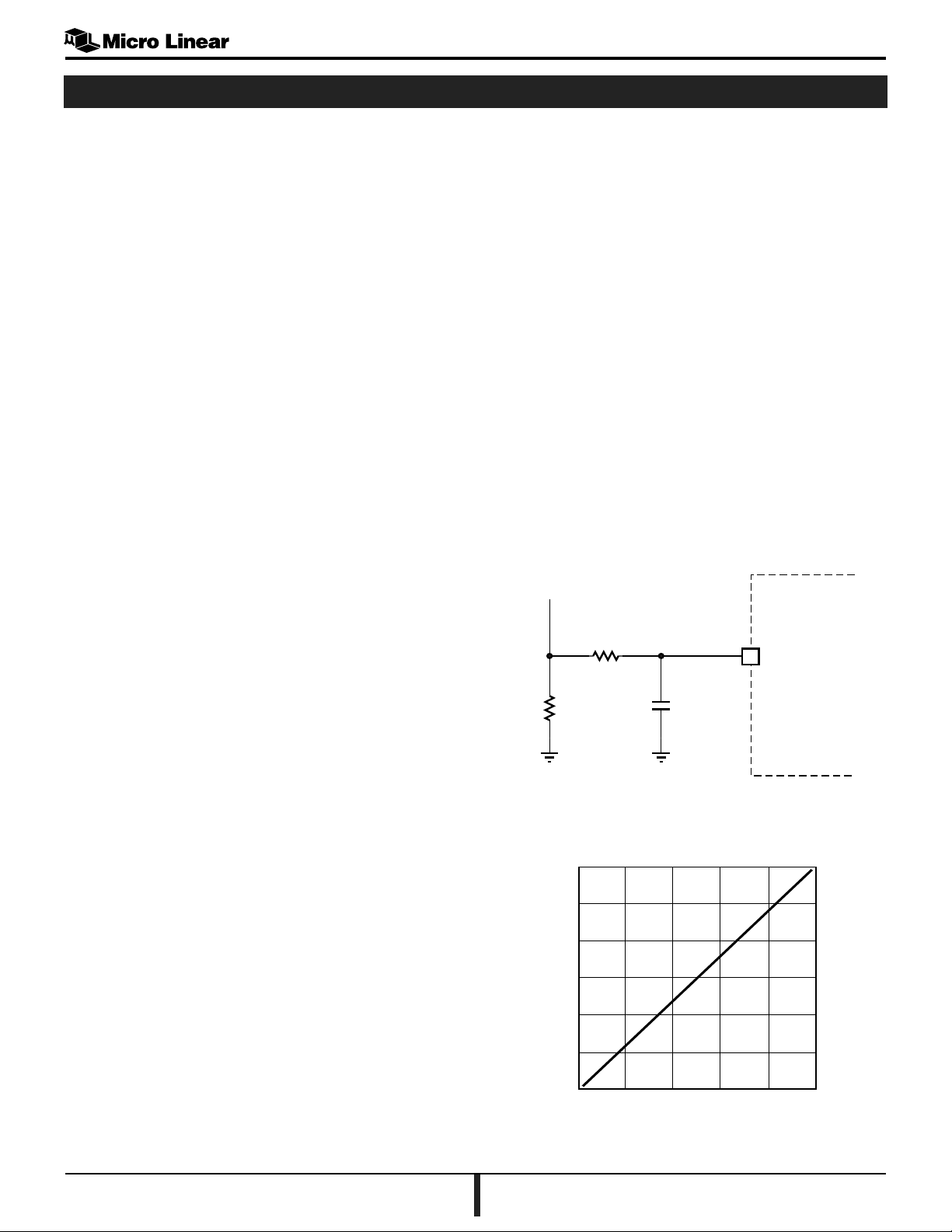

A current sense resistor RSENSE shown in Figure 1 is

installed in the 3 phase power stage to regulate the maximum current in the power stage and the BLDC motor.

Current regulation is accomplished by shutting off the

output drivers LA, LB, and LC for the remainder of the

PWM period if the voltage across RSENSE exceeds the

current limit threshold set by the SOFT START (pin 19).

The maximum power dissipated in RSENSE is shown in

Figure 2.

RSENSE

R

C

ISENSE

VCC

The supply voltage at VCC (pin 10) is nominally

12V ± 10%. A bypass capacitor of 0.1µF to ground as

close as possible to VCC (pin 10) is recommended.

RT

An internal 6V reference is generated inside the ML4435.

The reference appears on RT (pin 6). A resistor to ground

on RT sets the PWM frequency. This resistor can be

replace with a potentiomenter for use in setting the speed

command. This topic is discussed under the PWM SPEED

CONTROL section. Note: Buffer this pin with an op amp

with at least a 1MΩ input impedance if external circuits

are necessary.

May, 2000 PRELIMINARY DATASHEET 5

Figure 1. Current Limit with RSENSE

6

5

4

3

RSENSE Po er Rat n W

2

0

02

Figure 2. RSENSE Power vs. Motor Current

4

IMAX [MOTOR] A

60

Loading...

Loading...