Micro Linear Corporation ML4411ACS, ML4411CS Datasheet

Sensorless Spindle Motor Controller

GENERAL DESCRIPTION

The ML4411 provides complete commutation for delta or

wye wound Brushless DC (BLDC) motors without the need

for signals from Hall Effect Sensors. This IC senses the

back EMF of the three motor windings (no neutral

required) to determine the proper commutation phase

angle using Phase Lock Loop techniques. This technique

will commutate virtually any 3-phase BLDC motor and is

insensitive to PWM noise and motor snubbing. The

ML4411 is architecturally similar to the ML4410 but with

improved braking and brown-out recovery circuitry.

Included in the ML4411 is the circuitry necessary for a

Hard Disk Drive microcontroller driven control loop.

The ML4411 controls motor current with either a constant

off-time PWM or linear current control driven by the

microcontroller. Braking and Power Fail are also included

in the ML4411.

The timing of the start-up sequencing is determined by the

micro, allowing the system to be optimized for a wide

range of motors and inertial loads.

May 1997

ML4411*/ML4411A**

The ML4411A includes a comparator on the P3 output to

prevent cross-conduction.

FEATURES

■ Back-EMF commutation provides maximum torque

for minimum “spin-up” time for spindle motors

■ Accurate, jitter-free phase locked motor speed

feedback output

■ Linear or PWM motor current control

■ Easy microcontroller interface for optimized start-up

sequencing and speed control

■ Power fail detect circuit with delayed braking

■ Drives external N-channel FETs and P-channel FETs

■ Back-EMF comparator detects motor rotation after

power fail for fast re-lock after brownout

The ML4411 modulates the gates of external N-Channel

power MOSFETs to regulate the motor current. The IC

drives P-Channel MOSFETs directly.

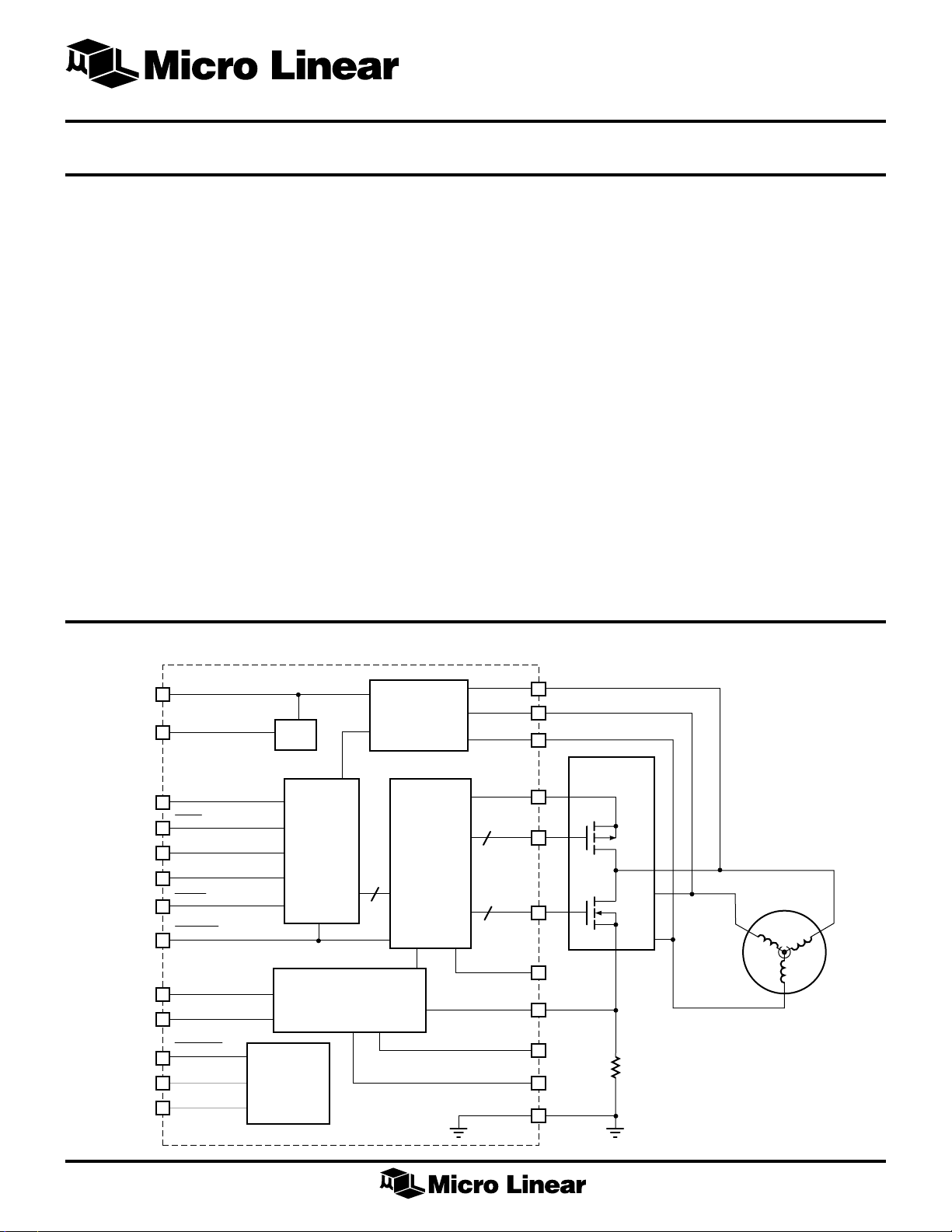

BLOCK DIAGRAM

RC

20

C

VCO

14

VCO/TACH OUT

15

RESET

16

I

RAMP

21

ENABLE E/A

18

BRAKE

26

DIS PWR

8

I

CMD

28

I

LIMIT

27

PWR FAIL

17

+5

19

VCC

25

VCO

LOGIC

AND

CONTROL

LINEAR OR PWM

CURRENT CONTROL

POWER

FAIL

DETECT

BACK-EMF

SAMPLER

GATE

DRIVE

6

* This Product Is Obsolete

** This Product Is End Of Life As Of August 1, 2000

PH1

22

PH2

23

PH3

24

POWER

DRIVERS

BLDC

MOTOR

PATENTED

3

3

VCC2

P1-3

N1-3

C

BRK

I

SENSE

C

C

OTA

GND

4

7

12

OS

13

6

1

1

ML4411/ML4411A

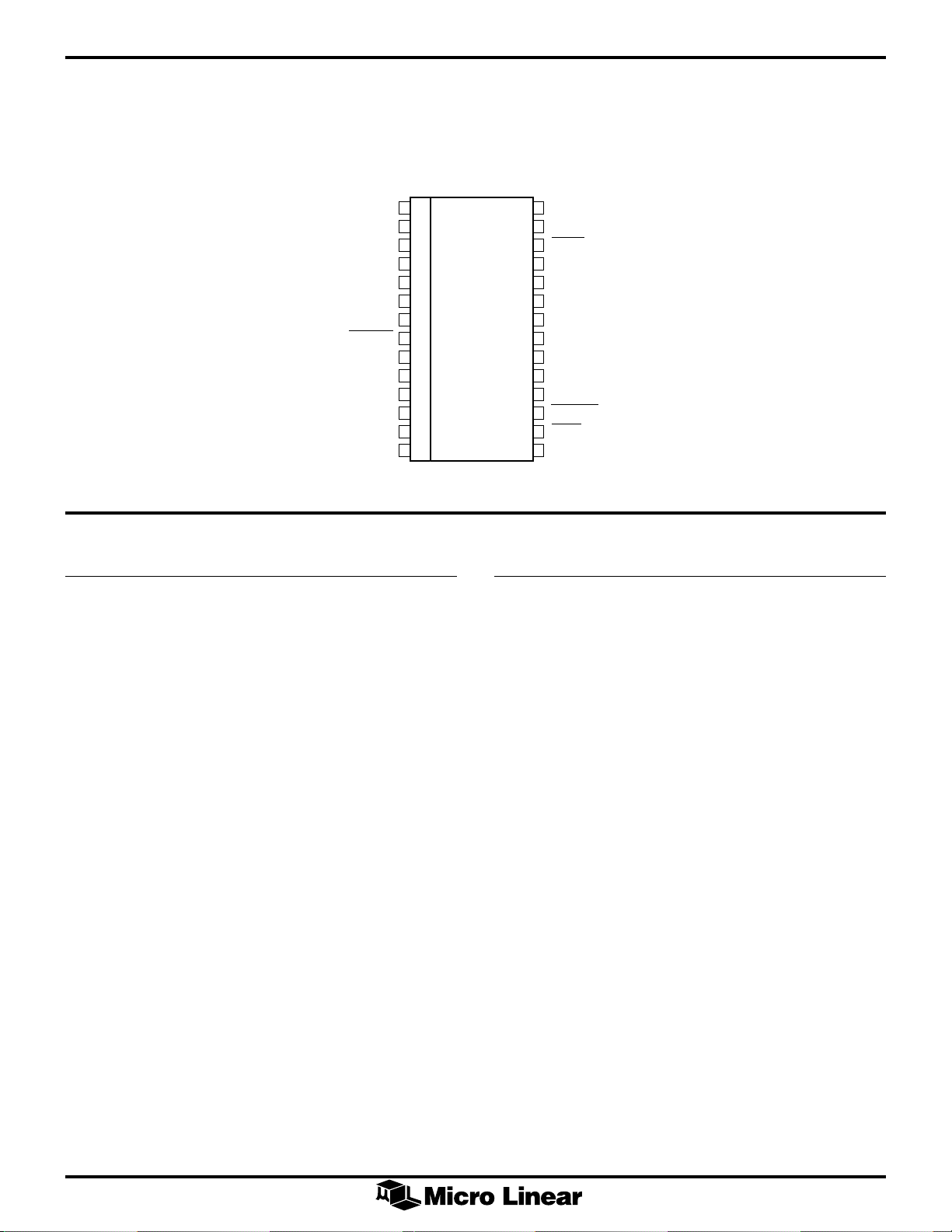

PIN CONFIGURATION

ML4411

28-Pin SOIC (S28W)

GND

VCC2

C

OTA

C

BRK

DIS PWR

N1

N2

N3

I

SENSE

C

C

VCO

1

P1

2

P2

3

4

P3

5

6

7

8

9

10

11

12

13

OS

14

TOP VIEW

I

28

I

27

BRAKE

26

VCC

25

PH3

24

PH2

23

PH1

22

I

21

RC

20

+5V

19

ENABLE E/A

18

PWR FAIL

17

RESET

16

VCO/TACH OUT

15

CMD

LIMIT

RAMP

PIN DESCRIPTION

PIN NAME FUNCTION PIN NAME FUNCTION

1 GND Signal and Power Ground

2 P1 Drives the external P-channel

transistor driving motor PH1

3 P2 Drives the external P-channel

transistor driving motor PH2

4V

CC2

12V power and power for the

braking function

5 P3 Drives the external P-channel

transistor driving motor PH3

6C

OTA

Compensation capacitor for linear

motor current amplifier loop

7C

BRK

Capacitor which stores energy to

charge N-channel MOSFETs for

braking with power off.

8 DIS PWR A logic 0 on this pin turns off the N

and P outputs and causes the TACH

comparator output to appear on TACH

OUT

9-11 N1, N2 N3 Drives the external N-channel

MOSFETs for PH1, PH2, PH3

12 I

13 C

SENSE

OS

Motor current sense input

Timing capacitor for fixed off-time

PWM current control

14 C

VCO

Timing capacitor for VCO

15 VCO/TACH Logic Output from VCO or TACH

OUT comparator

16 RESET Input which holds VCO off and sets the

IC to the RESET condition

17 PWR FAIL A “0” output indicates 5V or 12V is

under-voltage. This is an open

collector output with a 4.5ký pull-up

to +5V

18 ENABLE E/A A ”1” logic input enables the error

amplifier and closes the back-EMF

feedback loop

19 +5V 5V power supply input

20 RC VCO loop filter components

21 I

RAMP

Current into this pin sets the initial

acceleration rate of the VCO during

start-up

22 PH1 Motor Terminal 1

23 PH2 Motor Terminal 2

24 PH3 Motor Terminal 3

25 V

CC

12V power supply. Terminal which is

sensed for power fail

26 BRAKE A ”0” activates the braking circuit

27 I

LIMIT

Sets the threshold for the PWM

comparator

28 I

CMD

Current Command for Linear Current

amplifier

2

ML4411/ML4411A

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

Supply Voltage (pins 4, 25) ........................................ 14V

OPERATING CONDITIONS

Temperature Range ........................................0°C to 70°C

VCC Voltage +12V (pin 25) ........................... 12V ± 10%

+5V (pin 19) ................................................ 5V ± 10%

I(RAMP) current (Pin 21)................................. 0 to 100µA

I Control Voltage Range (pins 27, 28) ................ 0V to 7V

Output Current (pins 2, 3, 5, 9,10,11) .................±150mA

Logic Inputs (pins 16, 17, 18, 25) .................... –0.3 to 7V

Junction Temperature ............................................ 150°C

Storage Temperature Range ..................... –65°C to 150°C

Lead Temperature (Soldering 10 sec.) .................... 150°C

Thermal Resistance (qJA) ...................................... 60°C/W

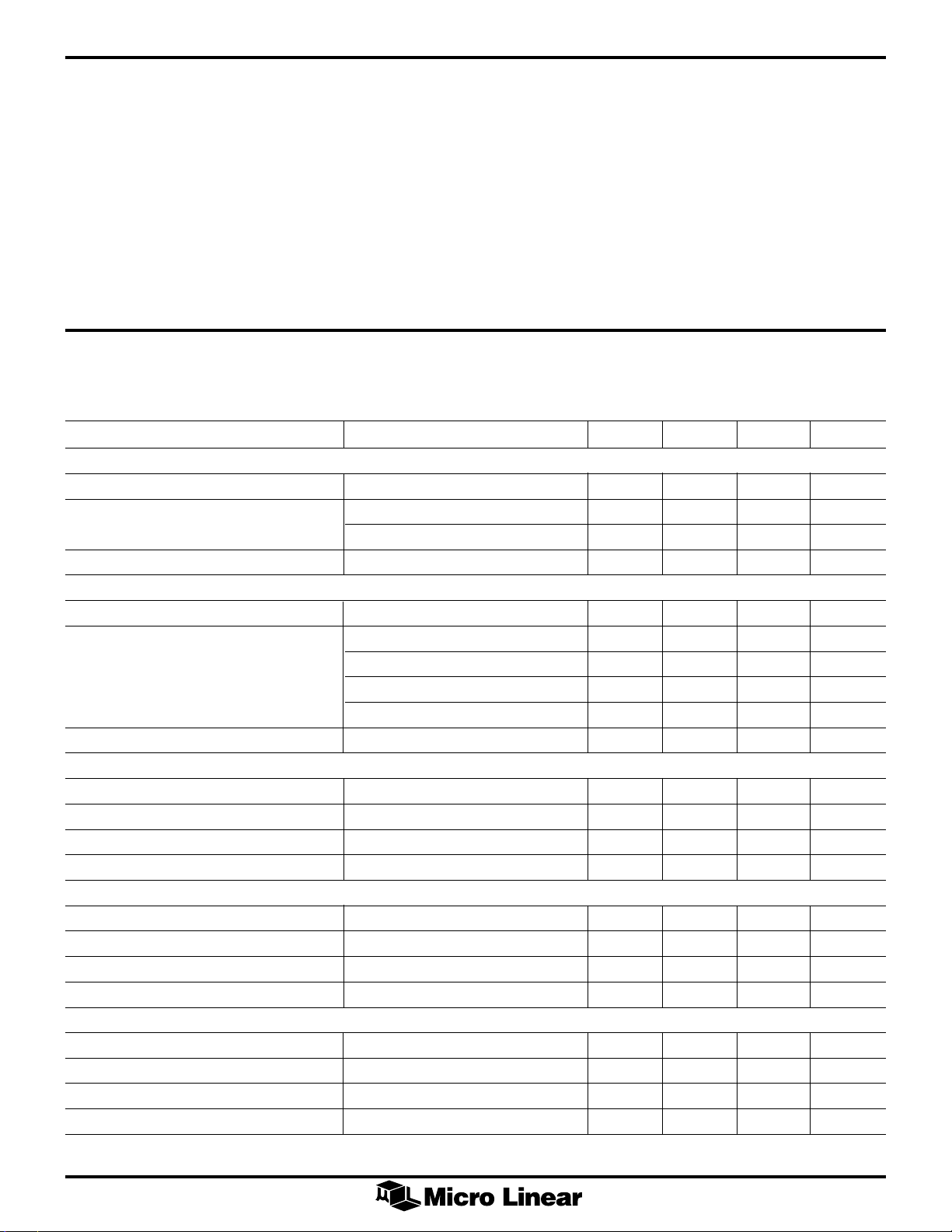

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, TA = Operating Temperature Range, V

C

= 0.02µF

OS

PARAMETER CONDITIONS MIN TYP MAX UNITS

Oscillator (VCO) Section (V

Frequency vs. V

Frequency V

Reset Voltage at C

Sampling Amplifier (Note 1)

V

RC

I

RC

V

PIN21

Motor Current Control Section

I

Gain V

SENSE

One Shot Off Time 12 25 33 µs

I

Transconductance Gain 0.19 mmho

CMD

I

, I

CMD

LIM

Power Fail Detection Circuit

12V Threshold 9.1 9.8 10.5 V

Hysteresis 150 mV

5V Threshold 3.8 4.25 4.5 V

Hysteresis 70 mV

Logic Inputs

Voltage High (VIH)2V

Voltage Low (VIL) 0.8 V

Current High (IIH)V

Current Low (IIL)V

PIN 20

VCO

Bias Current VIN = 0 0 –100 –400 nA

PIN16

= 5V)

1V - V

VCO

V

VCO

Mode = 0 125 250 mV

State R 125 250 mV

V

PIN18

V

PIN18

V

PIN18

V

PIN18

R

PIN21

PIN27

= 2.7V –10 1 10 µA

IN

= 0.4V –500 –350 –200 µA

IN

- 10V 300 Hz/V

PIN20

= 6V 1450 1800 2150 Hz

= 0.5V 70 140 210 Hz

= 0V, R

= 5V, State A, V

= 5V, State A, V

= 5V, State A, V

= 39ký to +5V 1.0 1.1 1.20 V

= 5V, 0V - V

RAMP

PIN28

= V

CC

= 39ký 70 100 130 µA

= 4V 30 50 90 µA

PH2

= 6V –13 2 13 µA

PH2

= 8V –30 –50 –90 µA

PH2

- 2.5V 4.5 5 5.5 V/V

= 12V, R

CC2

SENSE

= 1ý, C

OTA

= C

VCO

= 0.01µF,

3

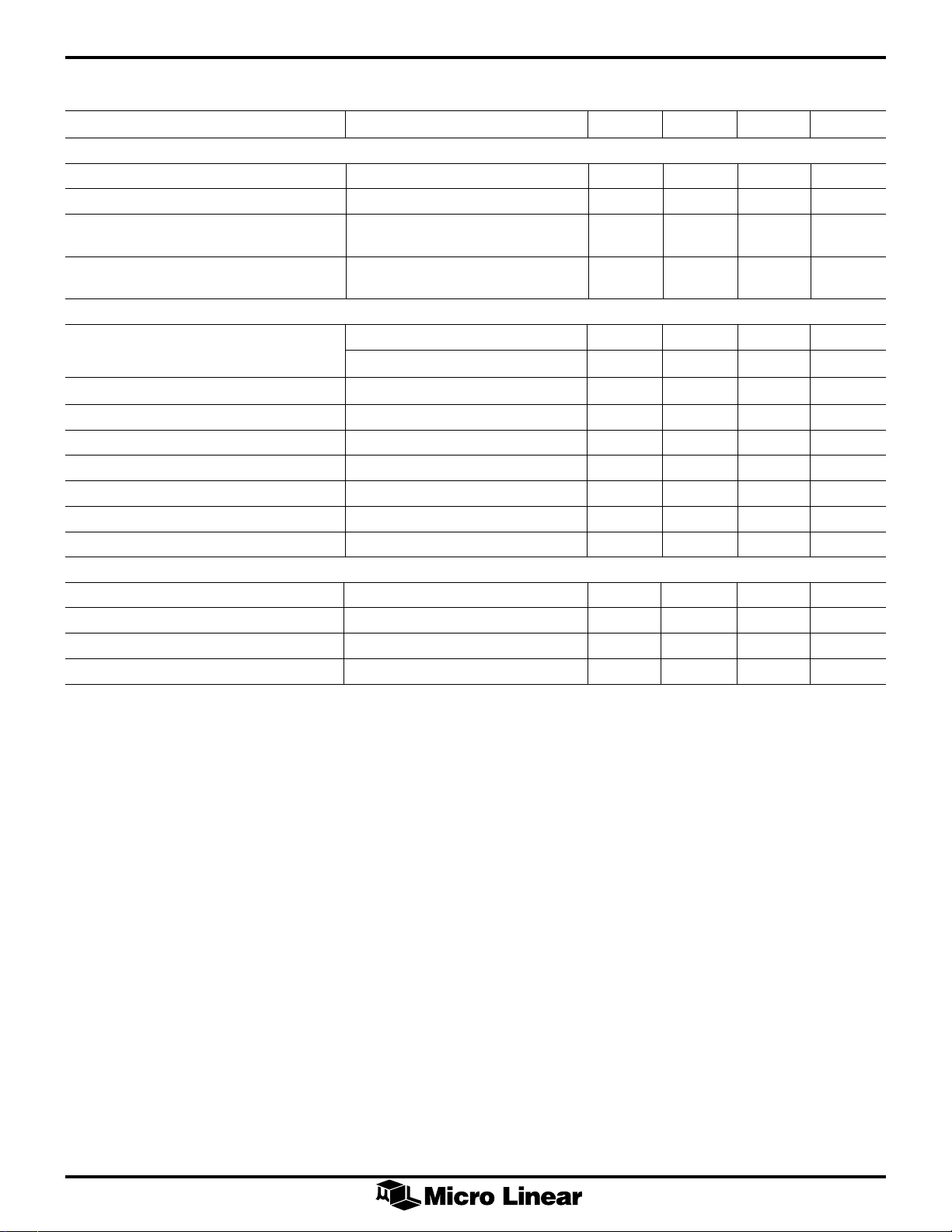

ML4411/ML4411A

ELECTRICAL CHARACTERISTICS (Continued)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Braking Circuit (V

Brake Active Threshold 0.8 1.2 1.6 V

PIN 26 Bias Current V

N-Channel Leakage V

Current VCC, V

C

BRK

Outputs (I

CMD

= I

IP Low VP = 0.8V 5 7 19.5 mA

VP High IP = –10µA VCC – 0.4 V

P3 Comparator Threshold V

VN High V

VN Low IN = 1mA 0.2 0.7 V

LOGIC Low (VOL)I

VCO/TACH V

OH

POWER FAIL V

Supply Currents (N and P Outputs Open)

5V Current 34mA

V

Current 38 50 mA

CC

V

Current ML4411 2 3 mA

CC2

V

Current ML4411A 2.6 3.75 mA

CC2

Note 1. For explanation of states, see Figure 5 and Table 1.

OH

PIN17

LIMIT

= 0V)

= 2.5V)

= 0V 0.3 1 µA

PIN26

, V

CC

V

PIN17

V

PIN7

V

= 0.4V 2 4 mA

P

PIN12

OUT

I

OUT

I

OUT

= 0V 0 0.06 10 nA

CC2

= 0V, VN = 4V

CC2

= 0V, V

= 3V 20 85 µA

PIN26

= 6V

= 0V V

– 1.6 V

CC2

– 3.2 10 VCC – 1.2 V

CC2

– 0.8 V

CC2

= 0.4mA 0.5 V

= –100µA 2.4 V

= –10µA V

PIN19

– 0.2 V

PIN19

– 0.1 V

PIN19

V

4

FUNCTIONAL DESCRIPTION

ML4411/ML4411A

The ML4411 provides closed-loop commutation for

3-phase brushless motors. To accomplish this task, a VCO,

integrating Back-EMF Sampling error amplifier and

sequencer form a phase-locked loop, locking the VCO to

the back-EMF of the motor. The IC also contains circuitry

to control motor current with either linear or constant offtime PWM modes. Braking and power fail detection

functions are also provided on chip. The ML4411 is

designed to drive external power transistors (N-channel

sinking transistors and PNP sourcing transistors) directly.

Start-up sequencing and motor speed control are

accomplished by a microcontroller. Speed sensing is

accomplished by monitoring the output of the VCO,

which will be a signal which is phased-locked to the

commutation frequency of the motor.

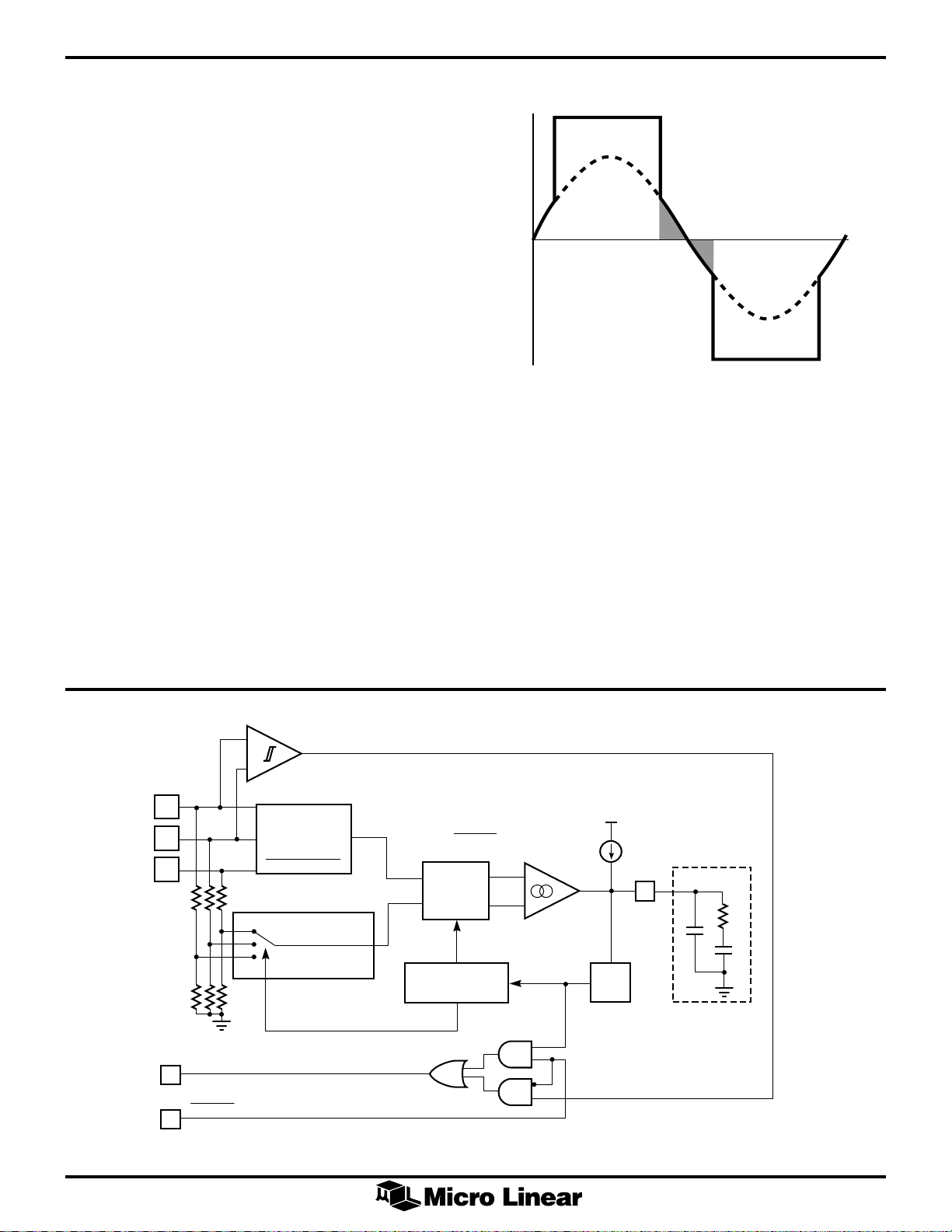

BACK-EMF SENSING AND COMMUTATOR

The ML4411 contains a patented back-EMF sensing

circuit which samples the phase which is not energized

(Shaded area in figure 2) to determine whether to increase

or decrease the commutator (VCO) frequency. A late

commutation causes the error amplifier to charge the

filter (RC) on pin 20, increasing the VCO input while

early

commutation causes pin 20 discharge. Analog speed

control loops can use pin 20 as a speed feedback voltage.

The input impedance of the three PH inputs is about 8Ký

to GND. When operating with a higher voltage motor, the

PH inputs should be divided down in voltage so that the

maximum voltage at any PH input does not exceed VCC.

NEUTRAL

0 60 120 180 240 0300

Figure 2. Typical motor phase waveform with Back-EMF

superimposed (Ideal Commutation)

VCO AND PHASE DETECTOR CALCULATIONS

The VCO should be set so that at the maximum frequency

of operation (the running speed of the motor) the VCO

control voltage will be no higher than VCC

– 1V. The

MIN

VCO maximum frequency will be:

F POLES RPM

=× ×005.

MAX

where POLES is the number of poles on the motor and

RPM is the maximum motor speed in Revolutions Per

ΦA

ΦB

ΦC

8K

8K

VCO /TACH OUT

DIS PWR

ROTATION

+

SENSE

–

NEUTRAL

SIMULATOR

ΦA + ΦB + ΦC

MULTIPLEXER

Va – Vb

=

I

RC

8K

6

SIGN

CHANGER

COMMUTATION

LOGIC

a

+

b

–

FIGURE 1. BACK EMKF sensing block diagram

+

I(PIN 21)

LOOP FILTER

RC

R

C1

C2

VCO

5

Loading...

Loading...