Micro Linear Corporation ML2288BCQ, ML2284CCP, ML2284CCS, ML2284CIP, ML2288BCP Datasheet

...

May 1997

ML2281, ML2282*,

ML2284#, ML2288#

Serial I/O 8-Bit A/D Converters with

Multiplexer Options

GENERAL DESCRIPTION

The ML2281 family are 8-bit successive approximation

A/D converters with serial I/O and configurable input

multiplexers with up to 8 input channels.

All errors of the sample-and-hold, incorporated on the

ML2281 family are accounted for in the analog-to-digital

converters accuracy specification.

The voltage reference can be externally set to any value

between GND and VCC, thus allowing a full conversion

over a relatively small voltage span if desired.

The ML2281 family is an enhanced double polysilicon

CMOS pin compatible second source for the ADC0831,

ADC0832, ADC0834, and ADC0838 A/D converters. The

ML2281 series enhancements are faster conversion time,

true sample-and-hold function, superior power supply

rejection, improved AC common mode rejection, faster

digital timing, and lower power dissipation. All parameters

are guaranteed over temperature with a power supply

voltage of 5V ±10%.

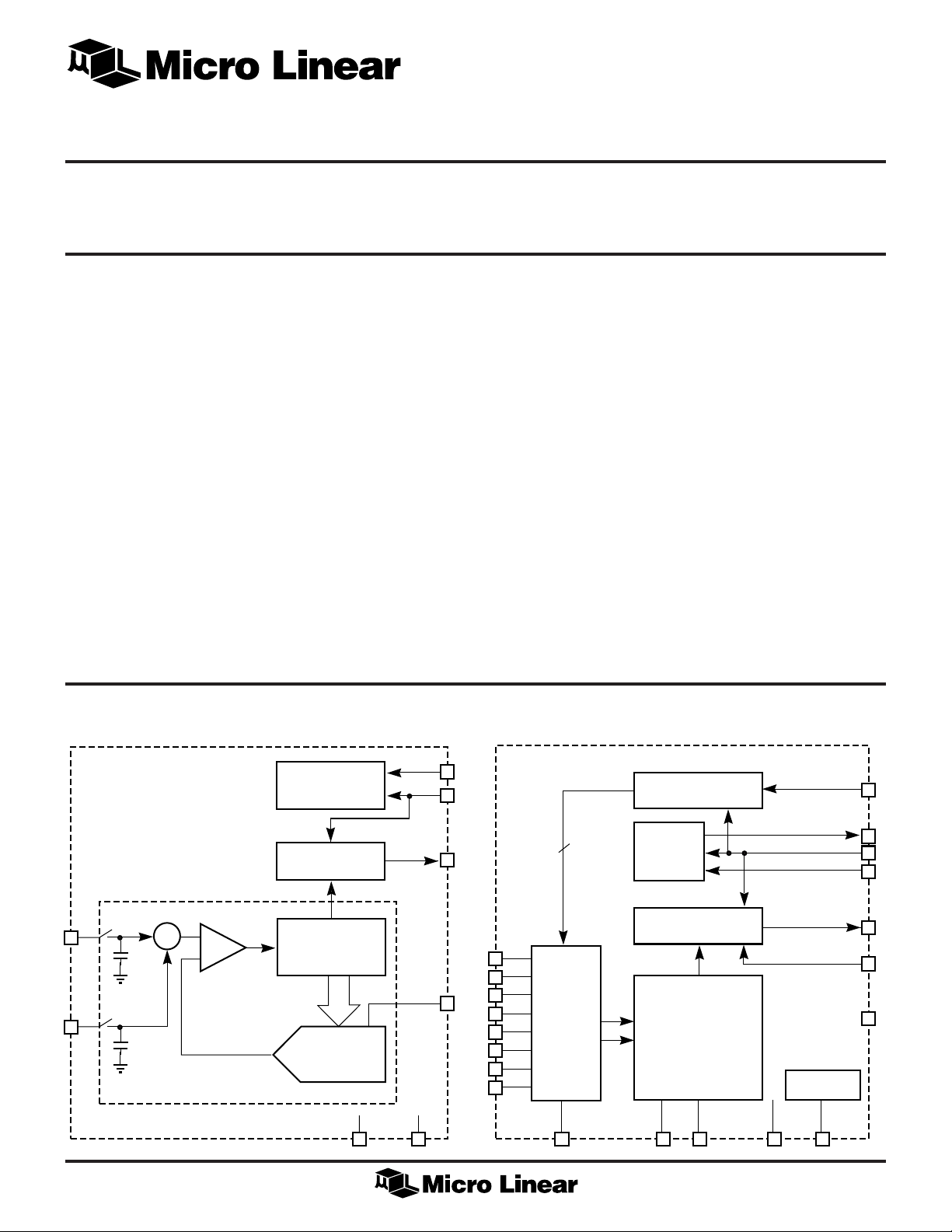

BLOCK DIAGRAM

ML2281

FEATURES

■ Conversion time: 6µs

■ Total unadjusted error: ±1/2LSB or ±1LSB

■ Sample-and-hold: 375ns acquisition

■ 2, 4 or 8-input multiplexer options

■ 0 to 5V analog input range with single 5V

power supply

■ Operates ratiometrically or with up to 5V

voltage reference

■ No zero or full-scale adjust required

■ ML2281 capable of digitizing a 5V, 40kHz sine wave

■ Low power: 12.5mW MAX

■ Superior pin compatible replacement for ADC0831,

ADC0832, ADC0834, and ADC0838

■ Analog input protection: 25mA (min) per input

■ Now in 8-Pin SOIC Package (ML2281, ML2282)

(* Indicates Part is Obsolete)

(# Indicates Part is End Of Life as Of July 1, 2000)

ML2288

ML2284

ML2284

(8-Channel SE or 4-Channel Diff Multiplexer)

(4-Channel SE or 2-Channel Diff Multiplexer)

(2-Channel SE or 1-Channel Diff Multiplexer)

A/D WITH SAMPLE & HOLD FUNCTION

V

IN+

V

IN–

8pF

8pF

+

+

Σ

COMP

–

–

CONTROL

AND

TIMING

OUTPUT

SHIFT-REGISTER

SUCCESSIVE

APPROXIMATION

REGISTER

D/A

CONVERTER

V

CC

GND

CLK

V

CS

DO

REF

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

COMMON

4-BIT

MULTIPLEXER

(ML2288 SHOWN)

AGND

INPUT

SHIFT-REGISTER

CONTROL

AND

TIMING

OUTPUT

SHIFT-REGISTER

A/D

CONVERTER

WITH

SAMPLE & HOLD

FUNCTION

V

REF

V

CC

DI

SARS

CLK

CS

DO

SE

DGND

SHUNT

REGULATOR

V+

1

ML2281, ML2282, ML2284, ML2288

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

COM

DGND

V

CC

V+

CS

DI

CLK

SARS

DO

SE

V

REF

AGND

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

TOP VIEW

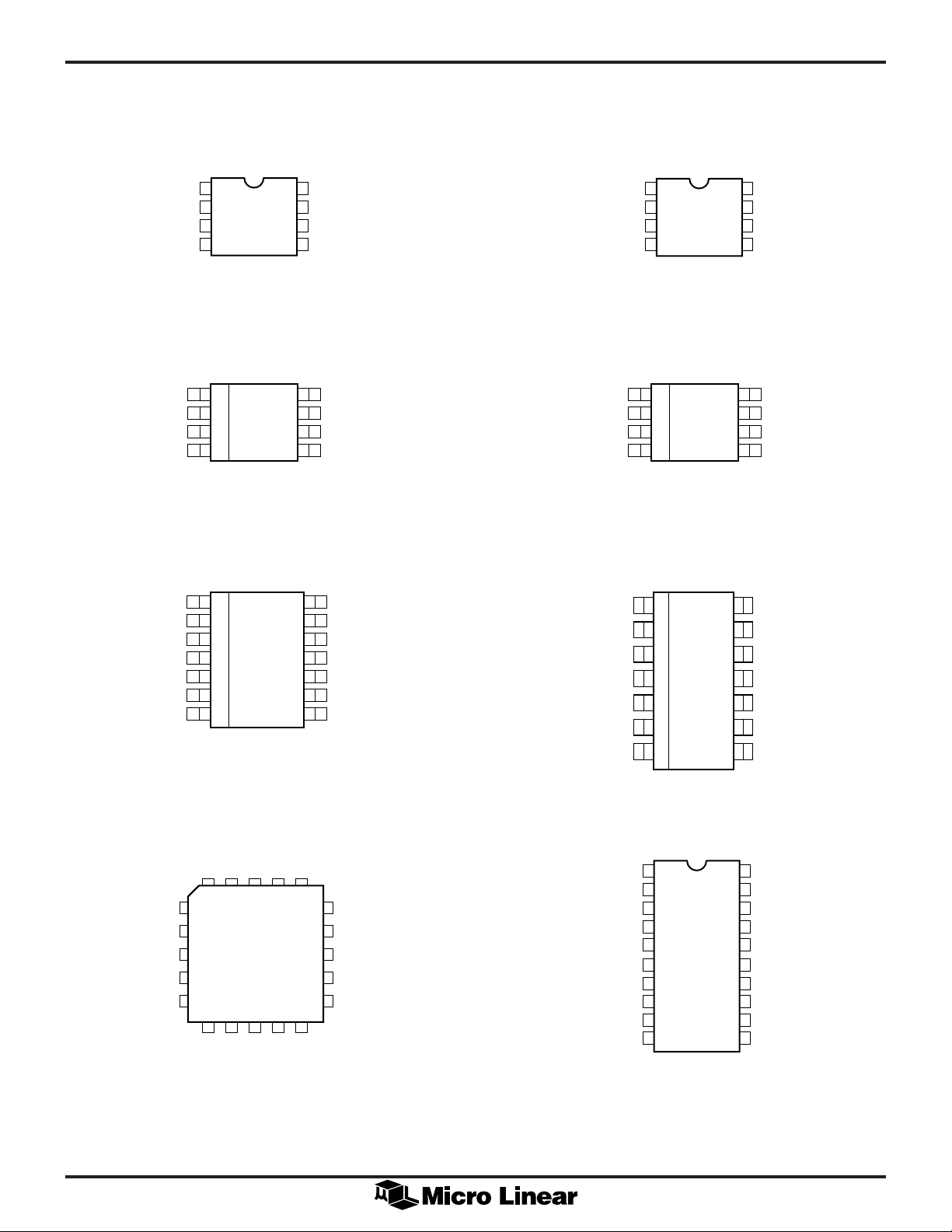

PIN CONFIGURATION

ML2281

Single Differential Input

8-Pin DIP

CS

V

IN+

V

IN–

GND

1

2

3

4

TOP VIEW

8

7

6

5

ML2281

8-Pin SOIC

V

IN+

V

IN–

GND

CS

1

2

3

4

TOP VIEW

8

7

6

5

ML2284

14-Pin SOIC

V

CLK

DO

V

CC

REF

V

CLK

DO

V

CC

REF

2-Channel MUX

CS

CH0

CH1

GND

CS

CH0

CH1

GND

4-Channel MUX

ML2282

8-Pin DIP

1

2

3

4

TOP VIEW

ML2282

8-Pin SOIC

1

2

3

4

TOP VIEW

ML2284

14-Pin DIP

V

8

CLK

7

DO

6

DI

5

8

7

6

5

CC (VREF

VCC (V

CLK

DO

DI

REF

)

)

2

V+

CS

CH0

CH1

CH2

CH3

DGND

1

2

3

4

5

6

7

TOP VIEW

14

13

12

11

10

V

CC

DI

CLK

SARS

DO

V

9

8

REF

AGND

V+

CS

CH0

CH1

CH2

CH3

DGND

1

2

3

4

5

6

7

14

13

12

11

10

V

CC

DI

CLK

SARS

DO

V

9

REF

AGND

8

TOP VIEW

ML2288

8-Channel MUX

20-Pin PCC

ML2288

8-Channel MUX

20-Pin DIP

CH2

CH1

CH0

VCCV+

CH3

CH4

CH5

CH6

CH7

3212019

4

5

6

7

8

910111213

COM

TOP VIEW

DGND

AGND

V

REF

18

CS

17

DI

16

CLK

15

SARS

14

DO

SE

PIN DESCRIPTION

ML2281, ML2282, ML2284, ML2288

NAME FUNCTION

V

CC

DGND Digital ground. 0 volts. All digital inputs and

AGND Analog ground. The negative reference voltage

CH0-7, Analog inputs. Digitally selected to be single

VIN+, VIN– ended (VIN) or; VIN+ or VIN– of a differential

COM Common reference point for analog inputs.

V

REF

SE Shift enable. Input controls whether LSB first

V+ Input to the Shunt Regulator.

Positive supply. 5V ± 10%

outputs are referenced to this point.

for A/D converter.

input. Analog range = GND - VIN - VCC.

A/D conversion is performed on voltage

difference between analog input and this

common reference point if single-end

conversion is specified.

Reference. The positive reference voltage for

A/D converter.

bit stream is shifted out on serial output DO.

If SE = 1, MSB first is shifted out only. If SE = 0,

an MSB first bit stream is shifted out, then a

second bit stream with LSB first is shifted out

after end of conversion.

NAME FUNCTION

DO Data out. Digital output which contains result

of A/D conversion. The serial data is clocked

out on falling edges of CLK.

SARS Successive approximation register status.

Digital output which indicates that a

conversion is in progress. When SARS goes

to 1, the sampling window is closed and

conversion begins. When SARS goes to 0,

conversion is completed. When CS = 1, SARS

is in high impedance state.

CLK Clock. Digital input which clocks data in on

DI on rising edges and out on DO on falling

edges. Also used to generate clocks for A/D

conversion.

DI Data input. Digital input which contains serial

data to program the MUX and channel

assignments.

CS Chip select. Selects the chip for multiplexer

and channel assignment and A/D conversion.

When CS = 1, all digital outputs are in high

impedance state. When CS = 0, normal A./D

conversion takes place.

3

ML2281, ML2282, ML2284, ML2288

ABSOLUTE MAXIMUM RATINGS

Absolute maximum ratings are those values beyond which

the device could be permanently damaged. Absolute

maximum ratings are stress ratings only and functional

device operation is not implied.

Current into V+ ...................................................... 15mA

Supply Voltage, VCC................................................. 6.5V

Voltage

Logic Inputs ........................................... –7 to VCC +7V

Analog Inputs ................................ –0.3V to VCC +0.3V

Input Current per Pin (Note 1) .............................. ±25mA

Storage Temperature ................................ –65°C to 150°C

Package Dissipation

at TA = 25°C (Board Mount) .............................800mW

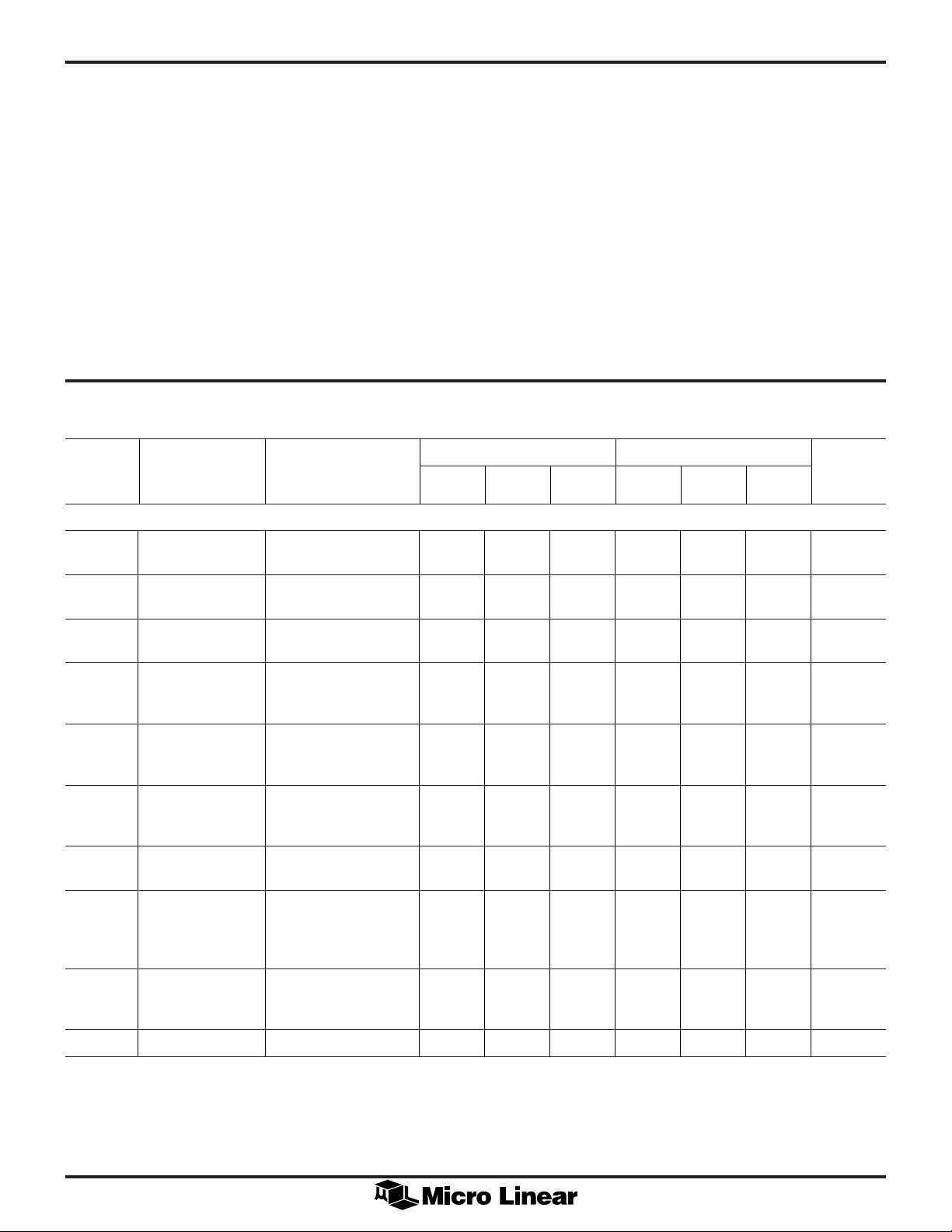

ELECTRICAL CHARACTERISTICS

Unless otherwise specified, TA = T

SYMBOL PARAMETER CONDITIONS MIN NOTE 3 MAX MIN NOTE 3 MAX UNITS

MIN

to T

MAX

, VCC = V

REF

Lead Temperature (Soldering 10 sec.)

Dual-In-Line Package (Molded) .......................... 260°C

Dual-In-Line Package (Ceramic) ......................... 300°C

Molded Chip Carrier Package

Vapor Phase (60 sec.) ..................................... 215°C

Infrared (15 sec.)............................................. 220°C

OPERATING CONDITIONS

Supply Voltage, VCC............................ 4.5VDC to 6.3V

Temperature Range (Note 2) ................. T

ML2281/2/4/8 BIX .................................. –40°C to 85°C

ML2281/2/4/8 CIX

ML2281/2/4/8 BCX ....................................0°C to 70°C

ML2281/2/4/8 CCX

= 5V ±10%, and f

ML228XB ML228XC

TYP TYP

= 1.333MHz.

CLK

MIN

- TA - T

DC

MAX

CONVERTER AND MULTIPLEXER CHARACTERISTICS

Total Unadjusted V

Error

Reference Input (Notes 4, 7) 10 15 20 10 15 20 kW

Resistance

Common-Mode (Notes 4, 8) GND V

Input Range –0.05 +0.05 –0.05 +0.05

DC Common-Mode Common mode voltage ±1/16 ±1/4 ±1/16 ±1/4 LSB

Error voltage GND to V

AC Common-Mode Common mode voltage ±1/4 ±1/4 LSB

Error GND to V

DC Power Supply VCC = 5V ±10% ±1/32 ±1/4 ±1/32 ±1/4 LSB

Sensitivity V

AC Power Supply 100mV

Sensitivity on V

Change in Zero 15mA into V+ ±1/2 ±1/2 LSB

Error from V

to Internal Zener (Note 5)

Operation

=5V VCC = N.C. V

CC

= VCC (Notes 4, 6) ±1/2 ±1 LSB

REF

,

REF

CC/2

= 5V

(Note 5)

0 to 50kHz (Note 5)

REF

(Note 5)

CC/2

- VCC +0.1V

, 25kHz sine ±1/4 ±1/4 LSB

P-P

(Note 5)

CC

CC

GND V

CC

V

V

V+ Input Resistance (Note 4) 20 35 20 35 kW

Internal Diode 15mA into V+ 6.9 6.9 V

Z

Regulated Breakdown (at V+)

4

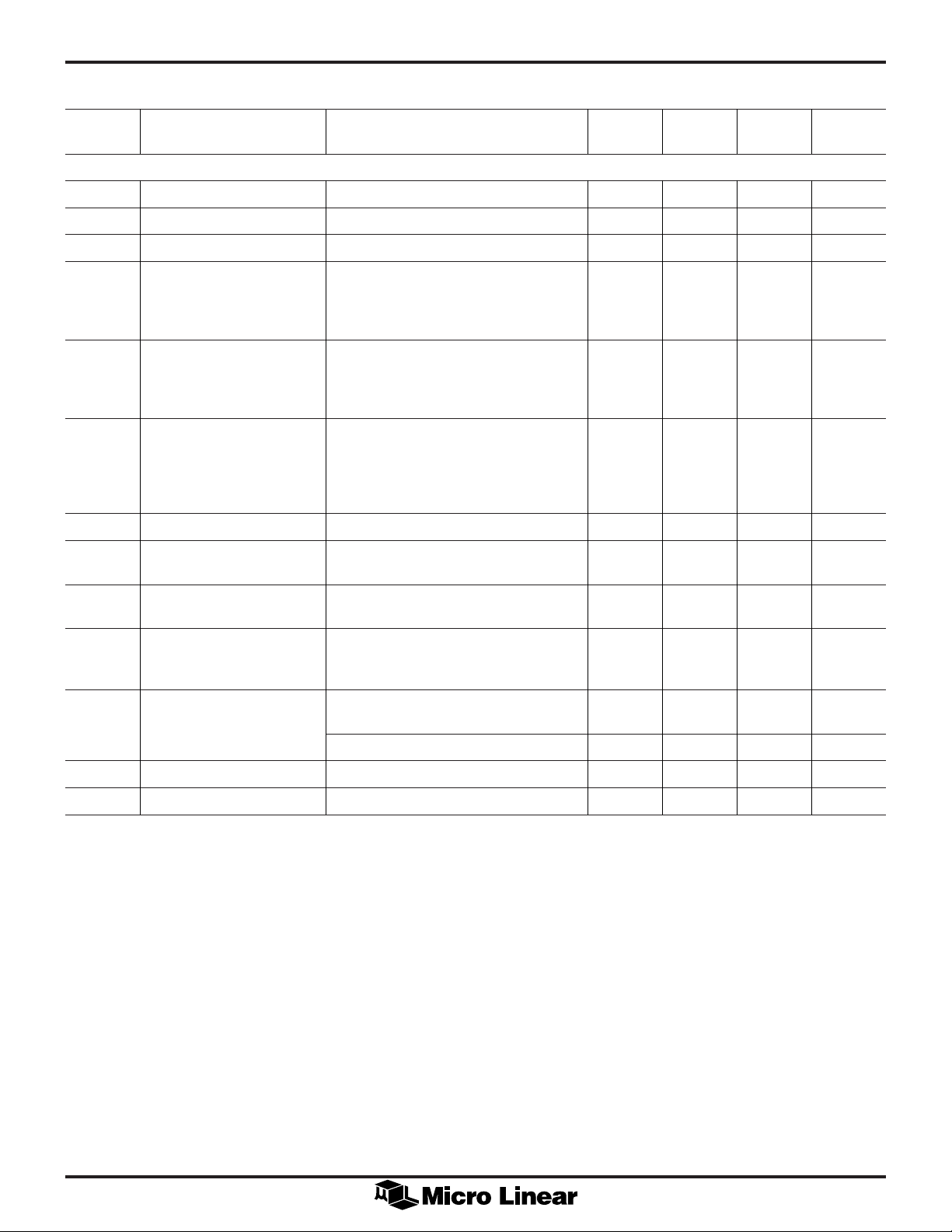

ML2281, ML2282, ML2284, ML2288

ELECTRICAL CHARACTERISTICS

(Continued)

ML228XB ML228XC

TYP TYP

SYMBOL PARAMETER CONDITIONS MIN NOTE 3 MAX MIN NOTE 3 MAX UNITS

CONVERTER AND MULTIPLEXER CHARACTERISTICS (CONTINUED)

I

OFF

Off Channel On channel = V

CC

–1 –1 µA

Leakage Current Off channel = 0V

(Notes 4, 9)

On channel = 0V +1 +1 µA

Off channel = V

CC

(Notes 4, 9)

I

ON

On Channel On channel = 0V –1 –1 µA

Leakage Current Off channel = V

CC

(Notes 4, 9)

On channel = V

CC

+1 +1 µA

Off channel = 0V

(Notes 4, 9)

DIGITAL AND DC CHARACTERISTICS

V

IN(1)

Logical “1” (Note 4) 2.0 2.0 V

Input Voltage

V

IN(0)

Logical “0” (Note 4) 0.8 0.8 V

Input Voltage

I

IN(1)

Logical “1” Input VIN = V

Current

I

IN(0)

Logical “0” Input VIN = 0V (Note 4) –1 –1 µA

Current

V

OUT(1)

Logical “1” I

Output Voltage

V

OUT(0)

Logical “0” I

Output Voltage

I

OUT

HI-Z Output V

Current V

I

SOURCE

Output Source V

Current

I

SINK

I

CC

Output Sink Current V

Supply Current ML2281, ML2284 1.3 2.5 1.3 2.5 mA

(Note 4) 1 1 µA

CC

= –2mA (Note 4) 4.0 4.0 V

OUT

= 2mA (Note 4) 0.4 0.4 V

OUT

= 0V (Note 4) –1 –1 µA

OUT

= V

OUT

OUT

OUT

CC

= 0V (Note 4) –6.5 –6.5 mA

= V

(Note 4) 8.0 8.0 mA

CC

11µA

ML2288 (Note 4)

ML2282 Includes ladder 1.8 3.5 1.8 3.5 mA

Current (Note 4)

5

ML2281, ML2282, ML2284, ML2288

ELECTRICAL CHARACTERISTICS

(Continued)

TYP LIMIT

SYMBOL PARAMETER CONDITIONS MIN NOTE 3 MAX UNITS

AC ELECTRICAL CHARACTERISTICS

f

CLK

t

ACQ

t

C

SNR Signal to Noise Ratio VIN = 40kHz, 5V sine. f

Clock Frequency (Note 4) 10 1.333 kHz

Sample-and-Hold Acquisition 1/2 1/f

Conversion Time Not including MUX adddressing time 8 1/f

= 1.333MHz 47 dB

ML2281 (f

SAMPLING

» 120kHz). Noise is sum of all

CLK

nonfundamental components up to 1/2

of f

SAMPLING

THD Total Harmonic Distortion VIN = 40kHz, 5V sine. f

ML2281 (f

SAMPLING

(Note 11)

= 1.333MHz –60 dB

CLK

» 120kHz). THD is sum of 2,

3, 4, 5 harmonics relative to fundamental

(Note 11)

IMD Intermodulation Distortion V

ML2281 f

= fA + fB. fA = 40kHz, 2.5V sine. –60 dB

IN

= 39.8kHz, 2.5V Sine, f

B

(f

SAMPLING

– fB), (2fA + fB), (2fA – fB), (fA + 2fB),

(f

A

» 120kHz). IMD is (fA + fB),

= 1.333MHz

CLK

(fA – 2fB) relative to fundamental (Note 11)

Clock Duty Cycle (Notes 4, 10) 40 60 %

CLK

CLK

t

SET-UP

CS Falling Edge or Data Input (Note 4) 130 ns

Valid to CLK Rising Edge

t

HOLD

Data Input Valid after (Note 4) 80 ns

CLK Rising Edge

t

, CLK Falling Edge to Output CL = 100pF (Note 4 & 12)

PD1

t

PD0

Data Valid Data MSB first 90 200 ns

Data LSB first 50 110 ns

t

, Rising Edge of CS to Data CL = 10pF, RL = 10k (see high impedance 40 90 ns

1H

t

0H

Output and SARS Hi-Z test circuits) (Note 5)

CL = 100pF, RL = 2k (Note 4) 80 160 ns

C

IN

C

OUT

Note 1: When the input voltage (VIN) at any pin exceeds the power supply rails (VIN < GND or VIN > VCC) the absolute value of current at that pin should be limited to 25mA

Note 2: 0°C to 70°C and –40°C to +85°C operating temperature range devices are 100% tested with temperature limits guaranteed by 100% testing, sampling, or by

Note 3: Typicals are parametric norm at 25°C.

Note 4: Parameter guaranteed and 100% production tested.

Note 5: Parameter guaranteed. Parameters not 100% tested are not in outgoing quality level calculation.

Note 6: Total unadjusted error includes offset, full-scale, linearity, multiplexer and sample-and-hold errors.

Note 7: Cannot be tested for ML2282.

Note 8: For V

Note 9: Leakage current is measured with the clock not switching.

Note 10: A 40% to 60% clock duty cycle range insures proper operation at all clock frequencies. In the case that an available clock has a duty cycle outside of these limits, the

Note 11: Because of multiplexer addressing, test conditions for the ML2282 would be V

Note 12: Since data, MSB first, is the output of the comparator used in the successive approximation loop, an additional delay is built in (see Block Diagram) to allow for

Capacitance of Logic Input 5 pF

Capacitance of Logic Outputs 5 pF

or less.

correlation with worst-case test conditions.

– ³ VIN+ the digital output code will be 0000 0000. Two on-chip diodes are tied to each analog input (see Block Diagram) which will forward conduct for

IN

analog input voltages one diode drop below ground or one diode drop greater than the V

analog inputs (5V) can cause this input diode to conduct—especially at elevated temperatures, and cause errors for analog inputs near full-scale. The spec allows

50mV forward bias of either diode. This means that as long as the analog V

correct. To achieve an absolute 0V to 5V input voltage range will therefore require a minimum supply voltage of 4.950V

tolerance and loading.

minimum time the clock is high or the minimum time the clock is low must be at least 300ns. The maximum time the clock can be high or low is 60µs.

(f

comparator response time.

» 95kHz); ML2288 VIN = 30kHz, 5V sine (f

SAMPLING

SAMPLING

» 89kHz).

or V

IN

= 34kHz, 5V sine (f

IN

supply. Be careful, during testing at low VCC levels (4.5V), as high level

CC

does not exceed the supply voltage by more than 50mV, the output code will be

REF

» 102kHz); ML2284 VIN = 32kHz, 5V sine

SAMPLING

over temperature variations, initial

DC

6

ML2281, ML2282, ML2284, ML2288

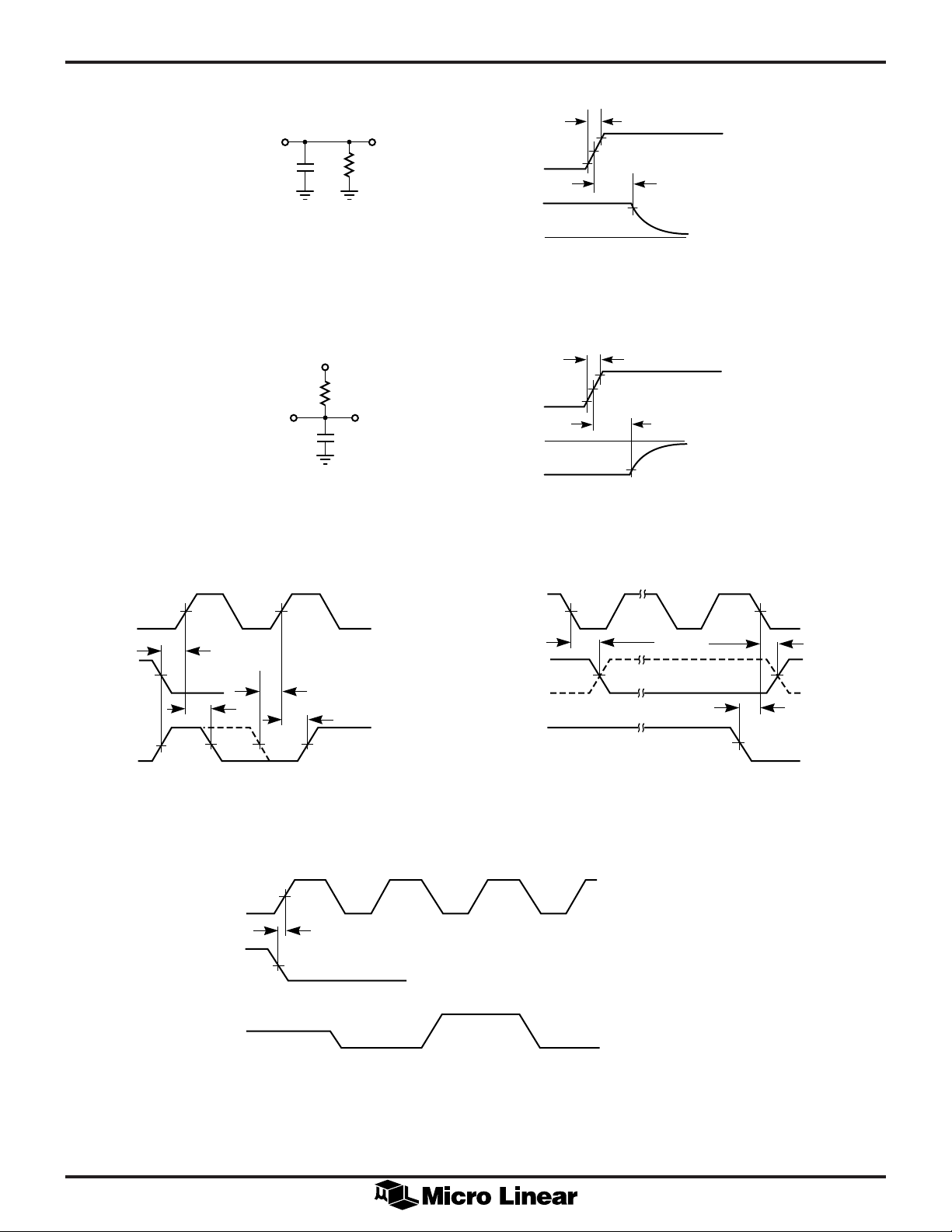

DATA

OUTPUT

DATA

OUTPUT

t

1H

V

CC

CS

R

C

L

L

DO AND

SARS OUTPUTS

t

0H

V

CC

R

L

C

L

DO AND

SARS OUTPUTS

CS

GND

V

OH

GND

V

GND

V

V

t

1H

t

r

90%

50%

10%

t

1H

90%

t

0H

t

50%

10%

t

r

90%

0H

10%

CC

CC

OL

Figure 1. High Impedance Test Circuits and Waveforms

CLK

CS

DATA

IN (DI)

Data Input Timing

t

SET-UP

t

HOLD

CLK

CS

t

SET-UP

t

HOLD

ML2281 Start Conversion Timing

t

SET-UP

START CONVERSION

CLK

DATA

OUT (DO)

Data Output Timing

t

PD0, tPD1

SE

t

SET-UP

t

PD0, tPD1

DO

BIT 7

(MSB)

Figure 2. Timing Diagrams

BIT 6

7

ML2281, ML2282, ML2284, ML2288

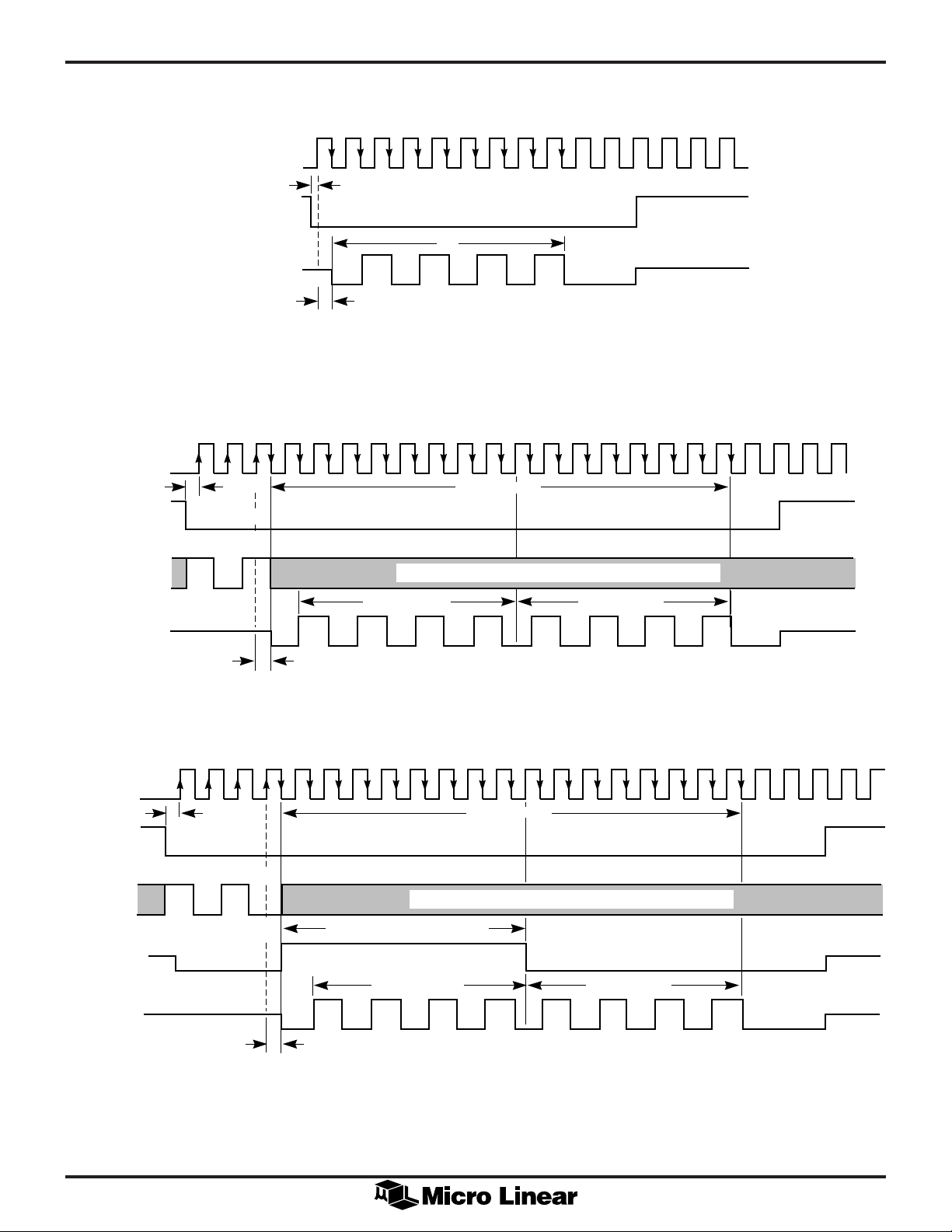

ML2281 Timing

1

234567891011

CLOCK (CLK)

t

SET-UP

CHIP SELECT (CS)

t

C

DATA OUT (DO)

SAMPLE & HOLD

ACQUISITION (t

1234567891011121314151617181920

CLOCK (CLK)

ACQ

HI-Z

)

76 543210

(MSB)

*LSB FIRST OUTPUT NOT AVAILABLE ON ML2281

ML2282 Timing

(LSB)

*

HI-Z

CHIP SELECT (CS)

DATA IN (DI)

DATA OUT (DO)

ACQUISITION (t

CLOCK (CLK)

CHIP SELECT (CS)

DATA IN (DI)

SAR STATUS (SARS)

ADDRESS MUX

START

BIT

SGL/DIF

HI-Z HI-Z

SAMPLE & HOLD

ACQ

t

SET-UP

)

ODD/

SIGN

DON’T CARE (DI DISABLED UNTIL NEXT CONVERSION CYCLE)

7654 321 123456

(MSB)

OUTPUT DATA

0

(LSB)

LSB FIRST DATAMSB FIRST DATA

7

(MSB)

ML2284 Timing

1234567891011121314151617181920

t

SET-UP

ADDRESS MUX

START

ODD/SIGN

BIT

DON’T CARE (DI DISABLED UNTIL NEXT CONVERSION CYCLE)

SGL/DIF SELECT

BIT 1

HI-Z HI-Z

A/D CONVERSION IN PROCESS

OUTPUT DATA

LSB FIRST DATAMSB FIRST DATA

DATA OUT (DO)

8

HI-Z HI-Z

SAMPLE & HOLD

ACQUISITION (t

ACQ

765432 012345

)

(MSB)

1

(LSB)

67

(MSB)

Figure 2. Timing Diagrams (Continued)

CLOCK (CLK)

ML2281, ML2282, ML2284, ML2288

ML2288 Timing

1234567891011121314151617181920212223242526

CHIP SELECT (CS)

DATA IN (DI)

SAR STATUS (SARS)

SE = “0”

DATA OUT (DO)

USING SE

TO CONTROL

LSB FIRST

OUTPUT

DO

START

SE

SAMPLE & HOLD

ACQUISITION (t

t

SET-UP

ADDRESS MUX

ODD/

SIGN

ACQ

SELECT

BIT 0

SELECT

BIT 1

)

DON’T CARE (DI DISABLED UNTIL NEXT CONVERSION CYCLE)

A/D CONVERSION IN PROCESS

765432 01234 5

(MSB)

7654321 0 1234567

BIT

SGL/DIF

HI-Z HI-Z

1

(LSB)

OUTPUT DATA

LSB FIRST DATAMSB FIRST DATA

DATA HELD LSB FIRST DATAMSB FIRST DATA

(LSB) (MSB)(MSB)

t

SET-UP

67

(MSB)

Figure 2. Timing Diagrams (Continued)

HI-ZHI-Z

HI-ZHI-Z

1.0

0.75

0.5

–55 C

LINEARITY ERROR (LSB)

0.25

25 C

0

0 0.01 0.1 1

CLOCK FREQUENCY (MHz)

125 C

Figure 3. Linearity Error vs f

VCC = 5V

V

= 5V

REF

CLK

9

ML2281, ML2282, ML2284, ML2288

1

V

= 5V

CC

f

= 1.333MHz

CLK

0.75

0.5

–55 C

LINEARITY ERROR (LSB)

0.25

0

0235

Figure 4. Linearity Error vs V

125 C

25 C

41

V

(VDC)

REF

Voltage

REF

1

0.75

0.5

OFFSET ERROR (LSB)

0.25

0

0235

V

REF

V

= 5V

CC

V

= 0V

IN

f

= 1.333MHz

CLK

T

= 25 C

A

(VDC)

Figure 5. Unadjusted Offset Error vs V

41

REF

Voltage

10

DI*

CS

ML2281, ML2282, ML2284, ML2288

17

18

CLK

CH0*

CH1*

CH2

CH3

CH4*

CH5*

CH6*

CH7*

COM*

V

REF

V

CC

V+*

DGND*

AGND*

RRRR R

16

V

CC

1

2

3

4

5

6

7

8

9

12

20

INPUT PROTECTION—ALL LOGIC INPUTS

5-BIT SHIFT-REGISTER

SGL/DIF

7V SHUNT

REGULATOR

ODD/

SIGN

MUX

ADDRESS

TO INTERNAL

CIRCUITRY

INPUT

13

16

17

18

NOTE 1

ANALOG

(EQUIVALENT)

V

CC

TO

INTERNAL

CIRCUITS

+

MUX

SELECT 0SELECT 1START

Σ

–

R

NOTE 1

C

C

LADDER

AND

DECODER

D

C

+

–

COMP

COMP

SAR

LOGIC

AND

LATCH

T

D

TIME

DELAY

DSTART 2

CS

B7

B6

B5

B4

B3

B2

B1

B0

LSB FIRST

CS

START

RRC

9-BIT

SHIFT

REGISTER

EOC

CS

EOC

13

CQR

DCQ

DCQ

C

R

D

D

R

R

Q

SE*

CS

DEOC

SARS*

15

CS

CS

CS

DSTART 1

CS

14

DO

MSB FIRST

PARALLEL XFR

TO SHIFT REGISTER

*SOME OF THESE FUNCTIONS/PINS ARE NOT AVAILABLE WITH OTHER OPTIONS.

NOTE 1: FOR THE ML2284 DI IS INPUT DIRECTLY TO THE D INPUT OF SELECT 1. SELECT 0 IS FORCED TO A “1”. FOR THE ML2282, DI IS INPUT DIRECTLY TO THE D

INPUT OF ODD/SIGN. SELECT 0 IS FORCED TO A “1” AND SELECT 1 IS FORCED TO A “0”.

Figure 6. ML2288 Functional Block Diagram

11

ML2281, ML2282, ML2284, ML2288

FUNCTIONAL DESCRIPTION

MULTIPLEXER ADDRESSING

The design of these converters utilizes a sample data

comparator structure which provides for a differential

analog input to be converted by a successive

approximation routine.

The actual voltage converted is always the difference

between an assigned “+” input terminal and a “–” input

terminal. The polarity of each input terminal of the pair

being converted indicates which line the converter expects

to be the most positive. If the assigned “+” input is less than

the “–” input, the converter responds with an all zeros

output code.

A unique input multiplexing scheme has been utilized

to provide multiple analog channels with software

configurable single ended, differential, or pseudo

differential options. The pseudo differential option will

convert the difference between the voltage at any analog

input and a common terminal. One converter package

can now accommodate ground referenced inputs and

true differential inputs as well as signals with some

arbitrary reference voltage.

A particular input configuration is assigned during the MUX

addressing sequence, prior to the start of a conversion. The

MUX address selects which of the analog inputs are to be

enabled and whether this input is single ended or

differential. In the differential case, it also assigns the

polarity of the analog channels. Differential inputs are

restricted to adjacent channel pairs. For example, channel 0

and channel 1 may be selected as a different pair but

channel 0 or channel 1 cannot act differentially with any

other channel. In addition to selecting the differential mode,

the sign may also be selected. Channel 0 may be selected as

the positive input and channel 1 as the negative input or

vice versa. This programmability is illustrated by the MUX

addressing codes shown in Tables 1, 2, and 3.

The MUX address is shifted into the converter via the DI

input. Since the ML2281 contains only one differential

input channel with a fixed polarity assignment, it does

not require addressing.

The common input line on the ML2288 can be used as a

pseudo differential input. In this mode, the voltage on the

COM pin is treated as the “–” input for any of the other

input channels. This voltage does not have to be analog

ground; it can be any reference potential which is common

to all of the inputs. This feature is most useful in single

supply applications where the analog circuitry may be

biased at a potential other than ground and the output

signals are all referred to this potential.

Since the input configuration is under software control, it

can be modified, as required, at each conversion. A channel

can be treated as a single-ended, ground referenced input

for one conversion; then it can be reconfigured as part of a

differential channel for another conversion. Figure 7

illustrates these different input modes.

SINGLE-ENDED MUX MODE

MUX ADDRESS ANALOG SINGLE-ENDED CHANNEL#

SGL/ ODD/

DIF SIGN 1 001234567COM

1000+ –

1001 + –

1010 + –

1011 + –

1100+ –

1101 + –

1110 + –

1111 +–

SELECT

DIFFERENTIAL MUX MODE

MUX ADDRESS ANALOG DIFFERENTIAL

CHANNEL-PAIR#

SGL/ ODD/

DIF SIGN 1 0 0 1234567

0000+–

0001 +–

0010 +–

0011 +–

0100–+

0101 –+

0110 –+

0111 –+

SELECT 0123

Table 1. ML2288 MUX Addressing 8 Single-Ended

or 4 Differential Channels

SINGLE-ENDED MUX MODE

MUX ADDRESS CHANNEL#

SGL/ ODD/

DIF SIGN 1 0123

10 0 +

10 1 +

11 0 +

11 1 +

SELECT

COM is internally tied to AGND

DIFFERENTIAL MUX MODE

MUX ADDRESS CHANNEL#

SGL/ ODD/

DIF SIGN 1 0123

00 0 + –

00 1 + –

01 0 – +

01 1 – +

SELECT

Table 2. ML2284 MUX Addressing 4 Single-Ended

or 2 Differential Channel

12

ML2281, ML2282, ML2284, ML2288

SINGLE-ENDED MUX MODE

MUX ADDRESS CHANNEL#

SGL/DIF ODD/SIGN 0 1

10 +

11 +

DIFFERENTIAL MUX MODE

MUX ADDRESS CHANNEL#

SGL/DIF ODD/SIGN 0 1

00 + –

01 – +

Table 3. ML2282 MUX Addressing 2 Single-Ended

or 1 Differential Channel

8 Single-Ended

+

0

+

1

+

2

+

3

+

4

+

5

+

6

+

7

COM (–)

8 Pseudo-Differential

+

0

+

1

+

2

+

3

+

4

+

5

+

6

+

7

COM (–)

V

+

BIAS

DIGITAL INTERFACE

The block diagram and timing diagrams in Figures 2-5

illustrate how a conversion sequence is performed.

A conversion is initiated when CS is pulsed low. This line

must me held low for the entire conversion. The converter is

now waiting for a start bit and its MUX assignment word.

A clock is applied to the CLK input. On each rising edge

of the clock, the data on DI is clocked into the MUX

address shift register. The start bit is the first logic “1” that

appears on the DI input (all leading edge zeros are

ignored). After the start bit, the device clocks in the next 2

to 4 bits for the MUX assignment word.

When the start bit has been shifted into the start location

of the MUX register, the input channel has been assigned

and a conversion is about to begin. An interval of 1/2

clock period is used for sample & hold settling through the

selected MUX channels. The SAR status output goes high

at this time to signal that a conversion is now in progress

and the DI input is ignored.

The DO output comes out of High impedance and

provides a leading zero for this one clock period.

When the conversion begins, the output of the

comparator, which indicates whether the analog input is

greater than or less than each successive voltage from the

internal DAC, appears at the DO output on each falling

edge of the clock. This data is the result of the conversion

being shifted out (with MSB coming first) and can be read

by external logic or µP immediately.

After 8 clock periods, the conversion is completed. The SAR

status line returns low to indicate this 1/2 clock cycle later.

4 Differential

V

0, 1

2, 3

4

5

6

7

BIAS

0, 1

2, 3

4, 5

6, 7

+ (–)

– (+)

+ (–)

– (+)

+ (–)

– (+)

+ (–)

– (+)

Figure 7. Analog Input Multiplexer Functional

Options for ML2288

Mixed Mode

+

–

–

+

+

+

+

+

COM (–)

+

The serial data is always shifted out MSB first during the

conversion. After the conversion has been completed, the

data can be shifted out a second time with LSB first,

depending on level of SE input. For the case of ML2288, if

SE = 1, the data is shifted out MSB first during the

conversion only. If SE is brought low before the end of

conversion (which is signalled by the high to low transition

of SARS), the data is shifted out again immediately after the

end of conversion; this time LSB first. If SE is brought low

after end of conversion, the LSB first data is shifted out on

falling edges of clock after SE goes low. For ML2282 and

2284, SE is internally tied low, so data is shifted out MSB

first, then shifted out a second time LSB first at end of

conversion. For ML2281, SE is internally tied high, so data is

shifted out only once MSB first.

All internal registers are cleared when the CS input is

high. If another conversion is desired, CS must make a

high to low transition followed by address information.

The DI input and DO output can be tied together and

controlled through a bidirectional µP I/O bit with one

connection. This is possible because the DI input is only

latched in during the MUX addressing interval while the

DO output is still in the high impedance state.

13

ML2281, ML2282, ML2284, ML2288

REFERENCE

The voltage applied to the reference input to these

converters defines the voltage span of the analog input

(the difference between V

IN MAX

and V

IN MIN

) over which

the 256 possible output codes apply. The devices can be

used in either ratiometric applications or in systems

requiring absolute accuracy. The reference pin must be

connected

to a voltage source capable of driving the reference input

resistance, typically 10k. This pin is the top of a resistor

divider string used for the successive approximation

conversion.

In a ratiometric system, the analog input voltage is

proportional to the voltage used for the A/D reference.

This voltage is typically the system power supply, so the

V

pin can be tied to VCC. This technique relaxes the

REF

stability requirements of the system reference as the analog

input and A/D reference move together maintaining the

same output code for a given input condition.

For absolute accuracy, where the analog input varies

between specific voltage limits, the reference pin can be

biased with a time and temperature stable voltage source.

The maximum value of the reference is limited to the V

CC

supply voltage. The minimum value, however, can be quire

small to allow direct conversion of inputs with less than 5V

of voltage span. Particular care must be taken with regard to

noise pickup, circuit layout and system error voltage sources

when operating with a reduced span due to the increased

sensitivity of the converter.

ANALOG INPUTS AND SAMPLE/HOLD

An important feature of the ML2281 family of devices is that

they can be located at the source of the analog signal and

then communicate with a controlling µP with just a few

wires. This avoids bussing the analog inputs long distances

and thus reduces noise pickup on these analog lines.

However, in some cases, the analog inputs have a large

common mode voltage or even some noise present along

with the valid analog signal.

The differential input of these converters reduces the effects

of common mode input noise. Thus, if a common mode

voltage is present on both “+” and “–” inputs, such as 60Hz,

the converter will reject this common mode voltage since it

only converts the difference between “+” and “–” inputs.

The ML2281 family have a true sample and hold circuit

which samples both “+” and “–” inputs simultaneously. This

simultaneous sampling with a true S/H will give common

mode rejection and AC linearity performance that is superior

to devices where the two input terminals are not sampled at

the same instant and where true sample and hold capability

does not exist. Thus, the ML2281 family of devices can

reject AC common mode signals from DC-50kHz as well as

maintain linearity for signals from DC-50kHz.

The signal at the analog input is sampled during the interval

when the sampling switch is closed prior to conversion

start. The sampling window (S/H acquisition time) is 1/2

CLK period wide and occurs 1/2 CLK period before DO

goes from high impedance to active low state. When the

sampling switch closes at the start of the S/H acquisition

time, 8pF of capacitance is thrown onto the analog input.

1/2 CLK period later, the sampling switch is opened and the

signal present at the analog input is stored. Any error on the

analog input at the end of the S/H acquisition time will

cause additional conversion error. Care should be taken to

allow adequate charging or settling time from the source.

If more charging or settling time is needed to reduce these

analog input errors, a longer CLK period can be used.

The ML2281X family has improved latchup immunity.

Each analog input has dual diodes to the supply rails, and

a minimum of ±25mA (±100mA typically) can be injected

into each analog input without causing latchup.

DYNAMIC PERFORMANCE

Signal-to-Noise-Ratio

Signal-to-noise ration (SNR) is the measured signal-to-noise

at the output of the converter. The signal is the RMS

magnitude of the fundamental. Noise is the RMS sum of all

the nonfundamental signals up to half the sampling

frequency. SNR is dependent on the number of quantization

levels used in the digitization process; the more levels, the

smaller the quantization noise. The theoretical SNR for a

sine wave is given by

SNR = (6.02N + 1.76)dB

where N is the number of bits. Thus for ideal 8-bit converter,

SNR = 49.92dB.

Harmonic Distortion

Harmonic distortion is the ratio of the RMS sum of

harmonics to the fundamental. Total harmonic distortion

(THD) of the ML2281 Series is defined as

2

4

V

1

252

THD

=

20

VVVV

+++

223

log

where V1 is the RMS amplitude of the fundamental and V2,

V3, V4, V5 are the RMS amplitudes of the individual

harmonics.

Intermodulation Distortion

With inputs consisting of sine waves at two frequencies, f

A

and fB, any active device with nonlinearities will create

distortion products, of order (m + n), at sum and difference

frequencies of mfA + nfB, where m, n = 0, 1, 2, 3… .

Intermodulation terms are those for which m or n is not

equal to zero. The (IMD) intermodulation distortion

specification includes the second order terms (fA + fB) and

(fA – fB) and the third order terms (2fA + fB), (2fA – fB),

(fA + 2fB) and (fA – 2fB) only.

14

ML2281, ML2282, ML2284, ML2288

ZERO ERROR ADJUSTMENT

The zero of the A/D does not require adjustment. If the

minimum analog input voltage value, V

IN MIN

is not ground,

a zero offset can be done. The converter can be made to

output 00000000 digital code for this minimum input

voltage by biasing any VIN– input at this V

IN MIN

value.

This utilizes the differential mode operation of the A/D.

The zero error of the A/D converter relates to the location

of the first riser of the transfer function and can be

measured by grounding the VIN– input and applying a

small magnitude positive voltage to the VIN+ input. Zero

error is the difference between the actual DC input

voltage which is necessary to just cause an output digital

code transition from 00000000 to 00000001 and the ideal

1/2 LSB value (1/2 LSB = 9.8mV for V

= 5.000VDC).

REF

FULL-SCALE ADJUSTMENT

The full-scale adjustment can be made by applying a

differential input voltage which is 1-1/2 LSB down from

the desired analog full-scale voltage range and then

adjusting the magnitude of the V

input or VCC for a

REF

digital output code which is just changing from 11111110

to 11111111.

ADJUSTMENT FOR AN ARBITRARY ANALOG

INPUT VOLTAGE RANGE

If the analog zero voltage of the A/D is shifted away from

ground (for example, to accommodate an analog input

signal which does not go to ground), this new zero

reference should be properly adjusted first. A VIN+ voltage

which equals this desired zero reference plus 1/2 LSB

(where the LSB is calculated for the desired analog span,

1 LSB = analog span/256) is applied to selected “+” input

and the zero reference voltage at the corresponding “–”

input should then be adjusted to just obtain the 00000000

to 00000001 code transition.

The full-scale adjustment should be made by forcing a

voltage to the VIN+ input which is given be:

V fs adjust V

IN MAX

where V

V

The V

REF

VV

−

()

+=−×

= high end of the analog input range

MAX

= low end (offset zero) of the analog range

MIN

15

.

MAX MIN

256

or VCC voltage is then adjusted to provide a

code change from 11111110 to 11111111.

SHUNT REGULATOR

A unique feature of ML2288 and ML2284 is the inclusion

of a shunt regulator connected from V+ terminal to

ground which also connects to the VCC terminal (which is

the actual converter supply) through a silicon diode as

shown in Figure 8. When the regulator is turned on, the

V+ voltage is clamped at 11VBE set by the internal resistor

ratio. The typical I-V of the shunt regulator is shown in

Figure 9. It should be noted that before V+ voltage is high

enough to turn on the shunt regulator (which occurs at

about 5.5V), 35kW resistance is observed between V+ and

GND. When the shunt regulator is not used, V+ pin

should be either left floating or tied to GND. The

temperature coefficient of the regulator is –22mV/°C.

12V

I + →

CURRENT LIMITING

RESISTOR, I+ ≤15mA

GND

Figure 8. Shunt Regulator

V+

28.8k

3.2k

3.2k

15mA

I+

SLOPE =

1

35k

5.5V

V+

6.9V

V

CC

Figure 9. I-V Characteristic of the Shunt Regulator

15

ML2281, ML2282, ML2284, ML2288

APPLICATIONS

CH0

ML2288 8051

CS

CLK

DI

DOCH7

P1

3

P1

2

P1

1

P1

0

8051 Interface and Controlling Software

MNEMONIC INSTRUCTION

START ANL P1, #0F7H ;SELECT A/D (CS = 0)

MOV B, #5 ;BIT COUNTER ¬ 5

MOV A, #ADDR ;A ¬ MUX BIT

LOOP 1: RRC A ;CY ¬ ADDRESS BIT

JC ONE ;TEST BIT

;BIT = 0

ZERO: ANL P1, #0FEH ;DI ¬ 0

SJMP CONT ;CONTINUE

;BIT = 1

ONE: ORL P1, #1 ;D1 ¬ 1

CONT: ACALL PULSE ;PULSE SK 0 ® 1 ® 0

DJNZ B, LOOP 1 ;CONTINUE UNTIL DONE

ACALL PULSE ;EXTRA CLOCK FOR SYNC

MOV B, #8 ;BIT COUNTER ¬ 8

LOOP 2: ACALL PULSE ;PULSE SK 0 ® 1 ® 0

MOV A, P1 ;CY ¬ DO

RRC A

RRC A

MOV A, C ;A ¬ RESULT

RLC A ;A(0) BIT ¬ AND SHIFT

MOV C, A ;C ¬ RESULT

DJNZ B, LOOP 2 ;CONTINUE UNTIL DONE

RETI

;PULSE SUBROUTINE

PULSE: ORL P1, #04 ;SK ¬ 1

NOP ;DELAY

ANL P1, #0FBH ;SK ¬ 0

RET

16

ML2281, ML2282, ML2284, ML2288

APPLICATIONS

5 V

0.01µF

(Continued)

DC

10kΩ

CLK

+

START

START

CLK

CLK

NC

5V

15

2

1

DC

18

16

15

11

CLK INT

CLK

SHIFT/

LOAD

(OR VIN)

CS

CLK

SARS

SIN

NC

10

V

REF

51kΩ (4)

MUX ADDRESS

PARALLEL INPUTS

INPUT SHIFT REGISTER

74HC165

1kΩ (8) 1/8 V

4567

ANALOG INPUTS

ML2288

5V

DC

START BIT

SGL/DIF

76543141312

GND

7

NC

DO

9

V

5V

V+DGNDAGND

V

CC

DO

CC

14

DC

CC

912345678

COM

0123

2019101112

D1

SE

DO

17

5V

DC

13

14

51kΩ

CLOSE TO

START THE

A/D CONVERSION

10kΩ

0.001µF

CLOCK

GENERATOR

114

CLR

OUTPUT SHIFT REGISTER

74HC164

CLK

CLK

QD

CLK

1.3kΩ (8)

1/2 74HC74

7

GND

8

CLK

Q

H

MSB DATA DISPLAY LSB

ML2288 “Stand-Alone” or Evaluation Circuit

V

CC

Q

A

345610111213

1

SI A

+10µF

2

SI B

5V

DC

17

ML2281, ML2282, ML2284, ML2288

V

CC

(5 VDC)

LM335

T

10kΩ

MIN

A

3kΩ

ADJ.

(+) V

V

IN

ML2281

VIN (–)

CC

V

REF

+

10µF

10kΩ

T

MAX

A

ADJ.

T

A

Low-Cost Remote Temperature Sensor

18

ML2281, ML2282, ML2284, ML2288

APPLICATIONS

+

V

IN

SETS ZERO

CODE VOLTAGE

2.7kΩ

VIN (+)

1kΩ

2V

DC

ZERO ADJ.

ML2281

VIN (–)

330Ω

(Continued)

V

CC

(5VDC)

V

CC

+

V

REF

+

10µF

1kΩ

3V

1µF

10kΩ

FS

ADJ.

VOLTAGE SPAN

SET

1.2kΩ

STRAIN GAUGE

LOAD CELL

300Ω/30mV FS

•

•

•

•

10V

USES ONE MORE WIRE THAN LOAD CELL ITSELF

TWO MINI-DIPs COULD BE MOUNTED INSIDE LOAD CELL

FOR DIGITAL OUTPUT TRANSDUCER

ELECTRONIC OFFSET AND GAIN TRIMS RELAX MECHANICAL

SPECS FOR GAUGE FACTOR AND OFFSET

LOW LEVEL CELL OUTPUT IS CONVERTED IMMEDIATELY FOR

HIGH NOISE IMMUNITY

330Ω

6.8kΩ

1kΩ

GAIN

2.7kΩ

10kΩ

1MΩ

+

–

DUAL

1MΩ

+

–

20kΩ

10kΩ

OFFSET

DUAL

20kΩ

5.1V

V

CC

V

REF

ML2281

–IN

+IN DO

10V

CLK

CS

Zero-Shift and Span Adjust: 2V - VIN - 5V

t

REF

TYPE J

+

T

1

–

t

REF

TYPE J

+

T

8

–

1kΩ

1kΩ

+

–

88.2k

+

–

88.2kΩ

Digital Load Cell

CH0

ML2288

910Ω

22kΩ

LM335

t

REF

1kΩ

TL064

+

–

TL064 TL064

820Ω

V

CC

2kΩ

CH7 SERIAL I/O

COM

–

+

V

CC

3kΩ

1kΩ

V

REF

20kΩ

V

CC

–

+

LM385

USES THE PSEUDO-DIFFERENTIAL MODE TO KEEP THE

DIFFERENTIAL INPUTS CONSTANT WITH CHANGES IN REFERENCE TEMPERATURE (T

Convert 8 Thermocouples with only One Cold-Junction Compensator

REF

)

19

ML2281, ML2282, ML2284, ML2288

APPLICATIONS

V

CC

V

IN

+

–

CONTROLLER PERFORMS A ROUTINE TO DETERMINE WHICH

INPUT POLARITY PROVIDES A NON-ZERO OUTPUT CODE.

THIS INFORMATION PROVIDES THE EXTRA BITS.

Obtaining 9-Bit Resolution

(Continued)

–

≤ 2.5V> 2.5V

(

(

+

V

REF

ML2281

V

CC

(5VDC)

0.1Ω

240kΩ

–

+

100Ω

R

R

VIN (–)

→

I

LOAD

V

CC

(5VDC)

15V

DC

OP

AMP

+

–

–15V

600Ω

DC

DIODE CLAMPING IS NOT NEEDED

VIN (+)

ML2281

V

(–)

IN

IF CURRENT IS LIMITED TO 25mA

V

CC

+

10µF

Protecting the Input

(2A FULL-SCALE)

V

CC

V

CC

(5VDC)

+

10µF

LOAD

2kΩ

V

XDR

XDR

1kΩ

ZERO

ADJ.

*V

(–) = 0.15V

IN

15% OF VCC ≤V

20kΩ

3kΩ

VIN (+)

VIN (–)*

CC

≤85% OF V

XDR

100Ω

ZERO

ADJ.

ML2281

9.1kΩ

–

+

1kΩ

FS

ADJ.

LM336

120kΩ

V

IN

ML2281

(+)

V

REF

3kΩ

+

1µF

Digitizing a Current Flow

V

CC

(5VDC)

V

CC

V

REF

CC

0.7 V

CC

+

10µF

+

1µF

10kΩ

–

1kΩ

+

FS

ADJ.

24kΩ

+

V

IN

VIN (+)

ML2281

VIN (–)

V

CC

(5VDC)

V

CC

+

10µF

10kΩ

FS

ADJ.

1kΩ

V

REF

+

1µF

–

+

SET FOR 3V

2kΩ

20

Operating with Ratiometric Transducers

Span Adjust: 0V - VIN - 3V

ML2281, ML2282, ML2284, ML2288

APPLICATIONS

(Continued)

→ →

4mA–20mA 1N4148

+

10µF

LM385–2.5V

LM385–2.5V

100Ω

47µF

10kΩ

47kΩ

24kΩ

5kΩ

1/6 74HC14

6.2kΩ

200kΩ

V

CC

+IN

–IN

V

REF

3.9kΩ

300kΩ

• ALL POWER SUPPLIED BY LOOP

• 1500V ISOLATION AT OUTPUT

CLK

ML2281

CS

DO

GND

100kΩ = 50kHZ

1000pF

INP

CD4024

VO5

6N139

OPTO COUPLER

5

68

V

50pF

100kΩ

10kΩ

23

CC

V

CC

V+

V

O

GND

CLK

CS

4mA–20mA Current Loop Converter

TRANSFORMER

TRW-TC-SSD-32

10kΩ

10kΩ

10kΩ

DI

2N2222

6V

470Ω

6V

470Ω

2N2222

2N2222

5

1

6V

8

6

5

6N139 HIGH GAIN

OPTOCOUPLER

3

7

2

6

4N28

4N28

2

3

1N4148

47kΩ

V

CC

100kΩ

V

CC

100kΩ

V

CC

6.8kΩ

V

OUT

+

100µF

1N4148

CLK

CS

D1

DO

• NO POWER REQUIRED REMOTELY

• 1500V ISOLATION

ML2288

V

CC

CC

8 ANALOG

CHANNELS

Isolated Data Converter

21

ML2281, ML2282, ML2284, ML2288

APPLICATIONS

(Continued)

ML2281

CLK

+

V

IN

V

–

CS

IN

START

LS193

LOAD

A5VBCD

CLK

COUNT

DOWN

B0

SRQ

DQ

Q

DQ

Q

DQ

Q

Sampling Rate 111kHz, Data Rate 1.33MHz

TMS320

SERIES

DSP

FSR

CLK

DRDO

CLK

START

CS

FSR

DO

1

234567891011121314

HI-Z HI-Z

D7 D6 D5 D4 D3 D2 D1 D0

Interfacing ML2281 to TMS320 Series

22

ML2281, ML2282, ML2284, ML2288

PHYSICAL DIMMENSIONS

0.020 MIN

(0.51 MIN)

(4 PLACES)

0.170 MAX

(4.32 MAX)

0.125 MIN

(3.18 MIN)

inches (millimeters)

Package: P08

8-Pin PDIP

0.365 - 0.385

(9.27 - 9.77)

0.055 - 0.065

(1.39 - 1.65)

8

PIN 1 ID

1

0.100 BSC

(2.54 BSC)

0.016 - 0.020

(0.40 - 0.51)

SEATING PLANE

0.240 - 0.260

(6.09 - 6.60)

0.015 MIN

(0.38 MIN)

0.299 - 0.335

(7.59 - 8.50)

0º - 15º

0.008 - 0.012

(0.20 - 0.31)

0.017 - 0.027

(0.43 - 0.69)

(4 PLACES)

0.055 - 0.061

(1.40 - 1.55)

0.189 - 0.199

(4.80 - 5.06)

8

PIN 1 ID

1

0.050 BSC

(1.27 BSC)

0.012 - 0.020

(0.30 - 0.51)

SEATING PLANE

Package: S08

0.148 - 0.158

(3.76 - 4.01)

0.059 - 0.069

(1.49 - 1.75)

8-Pin SOIC

0.228 - 0.244

(5.79 - 6.20)

0.004 - 0.010

(0.10 - 0.26)

0º - 8º

0.015 - 0.035

(0.38 - 0.89)

0.006 - 0.010

(0.15 - 0.26)

23

ML2281, ML2282, ML2284, ML2288

PHYSICAL DIMMENSIONS

14

PIN 1 ID

0.070 MIN

(1.77 MIN)

(4 PLACES)

0.170 MAX

(4.32 MAX)

0.125 MIN

(3.18 MIN)

1

inches (millimeters)

Package: P14

14-Pin PDIP

0.740 - 0.760

(18.79 - 19.31)

0.050 - 0.065

(1.27 - 1.65)

0.016 - 0.022

0.100 BSC

(2.54 BSC)

SEATING PLANE

(0.40 - 0.56)

0.240 - 0.260

(6.09 - 6.61)

0.015 MIN

(0.38 MIN)

0.295 - 0.325

(7.49 - 8.25)

0º - 15º

0.008 - 0.012

(0.20 - 0.31)

0.017 - 0.027

(0.43 - 0.69)

(4 PLACES)

0.055 - 0.061

(1.40 - 1.55)

14

1

0.012 - 0.020

(0.30 - 0.51)

0.337 - 0.347

(8.56 - 8.81)

PIN 1 ID

0.050 BSC

(1.27 BSC)

Package: S14

14-Pin SOIC

0.148 - 0.158

(3.76 - 4.01)

0.059 - 0.069

(1.49 - 1.75)

SEATING PLANE

0.228 - 0.244

(5.79 - 6.20)

0.004 - 0.010

(0.10 - 0.26)

0º - 8º

0.015 - 0.035

(0.38 - 0.89)

0.006 - 0.010

(0.15 - 0.26)

24

ML2281, ML2282, ML2284, ML2288

PHYSICAL DIMMENSIONS

20

PIN 1 ID

0.060 MIN

(1.52 MIN)

(4 PLACES)

0.170 MAX

(4.32 MAX)

0.125 MIN

(3.18 MIN)

1

inches (millimeters)

Package: P20

20-Pin PDIP

1.010 - 1.035

(25.65 - 26.29)

0.055 - 0.065

(1.40 - 1.65)

0.016 - 0.022

(0.40 - 0.56)

0.100 BSC

(2.54 BSC)

0.240 - 0.260

(6.09 - 6.61)

SEATING PLANE

0.015 MIN

(0.38 MIN)

0.295 - 0.325

(7.49 - 8.26)

0º - 15º

0.008 - 0.012

(0.20 - 0.31)

0.042 - 0.048

(1.07 - 1.22)

0.385 - 0.395

(9.78 - 10.03)

0.350 - 0.356

(8.89 - 9.04)

PIN 1 ID

6

0.050 BSC

(1.27 BSC)

0.026 - 0.032

(0.66 - 0.81)

0.013 - 0.021

(0.33 - 0.53)

1

11

SEATING PLANE

0.350 - 0.356

16

(8.89 - 9.04)

0.165 - 0.180

(4.19 - 4.57)

Package: Q20

20-Pin PLCC

0.385 - 0.395

(9.78 - 10.03)

0.146 - 0.156

(3.71 - 3.96)

0.042 - 0.056

(1.07 - 1.42)

0.009 - 0.011

(0.23 - 0.28)

0.025 - 0.045

(0.63 - 1.14)

(RADIUS)

0.100 - 0.110

(2.54 - 2.79)

0.200 BSC

(5.08 BSC)

0.290 - 0.330

(7.36 - 8.38)

25

ML2281, ML2282, ML2284, ML2288

ORDERING INFORMATION

ALTERNATE TOTAL TEMPERATURE

PART NUMBER PART NUMBER UNADJUSTED ERROR RANGE PACKAGE

SINGLE ANALOG INPUT, 8-PIN PACKAGE

ML2281BIP (Obsolete) ADC0831CCN ±1/2 LSB –40°C to 85°C Plastic DIP (P08)

ML2281BCP ADC0831BCN 0°C to 70°C Molded DIP (P08)

ML2281BCS (Obsolete — 0°C to 70°C Plastic SOIC (S08)

ML2281CIP (End of Life) ADC0831BCN ±1 LSB –40°C to 85°C Plastic DIP (P08)

ML2281CCP (End of Life) ADC0831CCN 0°C to 70°C Molded DIP (P08)

ML2281CCS (End of Life) — 0°C to 70°C Plastic SOIC (S08)

TWO ANALOG INPUTS, 8-PIN PACKAGE

ML2282BIP (Obsolete) ADC0832CCN ±1/2 LSB –40°C to 85°C Plastic DIP (P08)

ML2282BCP (Obsolete) ADC0832BCN 0°C to 70°C Molded DIP (P08)

ML2282BCS (Obsolete) — 0°C to 70°C Plastic SOIC (S08)

ML2282CIP (Obsolete) ADC0832BCN ±1 LSB –40°C to 85°C Plastic DIP (P08)

ML2282CCP (Obsolete) ADC0832CCN 0°C to 70°C Molded DIP (P08)

ML2282CCS (Obsolete) — 0°C to 70°C Plastic SOIC (S08)

FOUR ANALOG INPUTS, 14-PIN PACKAGE

ML2284BIP (Obsolete) ADC0834CCN ±1/2 LSB –40°C to 85°C Plastic DIP (P14)

ML2284BCP (Obsolete) ADC0834BCN 0°C to 70°C Molded DIP (P14)

ML2284BCS (Obsolete) — 0°C to 70°C Plastic SOIC (S14)

ML2284CIP (Obsolete) ADC0834BCN ±1 LSB –40°C to 85°C Plastic DIP (P14)

ML2284CCP (End of Life) ADC0834CCN 0°C to 70°C Molded DIP (P14)

ML2284CCS (Obsolete) — 0°C to 70°C Plastic SOIC (S14)

EIGHT ANALOG INPUTS, 20-PIN PACKAGE

ML2288BIP (Obsolete) ADC0838CCN ±1/2 LSB –40°C to 85°C Plastic DIP (P20)

ML2288BCP (Obsolete) ADC0838BCN 0°C to 70°C Molded DIP (P20)

ML2288BCQ (Obsolete) ADC0838BCV 0°C to 70°C Molded PCC (Q20)

ML2288CIP (Obsolete) ADC0838CCN ±1 LSB –40°C to 85°C Plastic DIP (P20)

ML2288CCP (Obsolete) ADC0838CCN 0°C to 70°C Molded DIP (P20)

ML2288CCQ (End of Life) ADC0838CCV 0°C to 70°C Molded PCC (Q20)

© Micro Linear 1997 is a registered trademark of Micro Linear Corporation

DS2281_82_84_88-01

Products described in this document may be covered by one or more of the following patents, U.S.: 4,897,611; 4,964,026; 5,027,116; 5,281,862; 5,283,483; 5,418,502; 5,508,570; 5,510,727; 5,523,940;

5,546,017; 5,559,470; 5,565,761; 5,592,128; 5,594,376; Japan: 2598946; 2619299. Other patents are pending.

Micro Linear reserves the right to make changes to any product herein to improve reliability, function or design.

Micro Linear does not assume any liability arising out of the application or use of any product described herein,

neither does it convey any license under its patent right nor the rights of others. The circuits contained in this

data sheet are offered as possible applications only. Micro Linear makes no warranties or representations as to

whether the illustrated circuits infringe any intellectual property rights of others, and will accept no responsibility

or liability for use of any application herein. The customer is urged to consult with appropriate legal counsel

before deciding on a particular application.

26

2092 Concourse Drive

San Jose, CA 95131

Tel: 408/433-5200

Fax: 408/432-0295

5/5/97 Printed in U.S.A.

Loading...

Loading...