Page 1

Operating Manual

Pico Series - P900

900MHz Spread Spectrum Modem

Document: Pico Series P900 Operating Manual.v1.8.7

Date: June 2016

Firmware: v1.19

150 Country Hills Landing NW

Calgary, Alberta

Canada T3K 5P3

Phone: (403) 248-0028

Fax: (403) 248-2762

www.microhardcorp.com

Page 2

Important User Information

Warranty

Microhard Systems Inc. warrants that each product will be free of defects in material and workmanship for a period of one (1) year for its

products. The warranty commences on the date the product is shipped by Microhard Systems Inc. Microhard Systems Inc.’s sole l iability and

responsibility under this warranty is to repair or replace any product which is returned to it by the Buyer and which Microha rd Systems Inc.

determines does not conform to the warranty. Product returned to Microhard Systems Inc. for warranty service will be shipped to Microhard

Systems Inc. at Buyer’s expense and will be returned to Buyer at Microhard Systems Inc.’s expense. In no event shall Microhar d Systems

Inc. be responsible under this warranty for any defect which is caused by negligence, misuse or mistreatment of a product or for any unit

which has been altered or modified in any way. The warranty of replacement shall terminate with the warranty of the product.

Warranty Disclaims

Microhard Systems Inc. makes no warranties of any nature of kind, expressed or implied, with respect to the hardware, softwar e, and/or

products and hereby disclaims any and all such warranties, including but not limited to warranty of non -infringement, implied warranties of

merchantability for a particular purpose, any interruption or loss of the hardware, software, and/or product, any delay in pr oviding the hardware, software, and/or product or correcting any defect in the hardware, software, and/or product, or any other warranty. The Purchaser

represents and warrants that Microhard Systems Inc. has not made any such warranties to the Purchaser or its agents MICROHARD SY STEMS INC. EXPRESS WARRANTY TO BUYER CONSTITUTES MICROHARD SYSTEMS INC. SOLE LIABILITY AND THE

BUYER’S SOLE REMEDIES. EXCEPT AS THUS PROVIDED, MICROHARD SYSTEMS INC. DISCLAIMS ALL WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PROMISE.

MICROHARD SYSTEMS INC. PRODUCTS ARE NOT DESIGNED OR INTENDED TO BE USED IN ANY LIFE SUPPORT

RELATED DEVICE OR SYSTEM RELATED FUNCTIONS NOR AS PART OF ANY OTHER CRITICAL SYSTEM AND ARE

GRANTED NO FUNCTIONAL WARRANTY.

Indemnification

The Purchaser shall indemnify Microhard Systems Inc. and its respective directors, officers, employees, successors and assign s including any

subsidiaries, related corporations, or affiliates, shall be released and discharged from any and all manner of action, causes of action, liability,

losses, damages, suits, dues, sums of money, expenses (including legal fees), general damages, special damages, including wit hout limitation, claims for personal injuries, death or property damage related to the products sold hereunder, costs and demands of eve ry and any kind

and nature whatsoever at law.

IN NO EVENT WILL MICROHARD SYSTEMS INC. BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL, INCIDENTAL, BUSINESS INTERRUPTION, CATASTROPHIC, PUNITIVE OR OTHER DAMAGES WHICH MAY BE CLAIMED TO ARISE

IN CONNECTION WITH THE HARDWARE, REGARDLESS OF THE LEGAL THEORY BEHIND SUCH CLAIMS, WHETHER IN

TORT, CONTRACT OR UNDER ANY APPLICABLE STATUTORY OR REGULATORY LAWS, RULES, REGULATIONS, EXECUTIVE OR ADMINISTRATIVE ORDERS OR DECLARATIONS OR OTHERWISE, EVEN IF MICROH ARD SYSTEMS INC. HAS

BEEN ADVISED OR OTHERWISE HAS KNOWLEDGE OF THE POSSIBILITY OF SUCH DAMAGES AND TAKES NO ACTION TO

PREVENT OR MINIMIZE SUCH DAMAGES. IN THE EVENT THAT REGARDLESS OF THE WARRANTY DISCLAIMERS AND

HOLD HARMLESS PROVISIONS INCLUDED ABOVE MICROHARD SYSTEMS INC. IS SOMEHOW HELD LIABLE OR RESPONSIBLE FOR ANY DAMAGE OR INJURY, MICROHARD SYSTEMS INC.'S LIABILITY FOR ANYDAMAGES SHALL NOT EXCEED

THE PROFIT REALIZED BY MICROHARD SYSTEMS INC. ON THE SALE OR PROVISION OF THE HARDWARE TO THE CUSTOMER.

Proprietary Rights

The Buyer hereby acknowledges that Microhard Systems Inc. has a proprietary interest and intellectual property rights in the Hardware,

Software and/or Products. The Purchaser shall not (i) remove any copyright, trade secret, trademark or other evidence of Micr ohard Systems

Inc.’s ownership or proprietary interest or confidentiality other proprietary notices contained on, or in, the Hardware, Soft ware or Products,

(ii) reproduce or modify any Hardware, Software or Products or make any copies thereof, (iii) reverse assemble, reverse engin eer or decompile any Software or copy thereof in whole or in part, (iv) sell, transfer or otherwise make available to others the Hardware , Software, or

Products or documentation thereof or any copy thereof, except in accordance with this Agreement.

© Microhard Systems Inc. Confidential 2

Page 3

Important User Information (continued)

About This Manual

It is assumed that users of the products described herein have either system integration or design experience, as well as an understanding of the fundamentals of radio communications.

Throughout this manual you will encounter not only illustrations (that further elaborate on the accompanying text), but also several symbols which you should be attentive to:

Caution or Warning

Usually advises against some action which could result in undesired or

detrimental consequences.

Point to Remember

Highlights a key feature, point, or step which is noteworthy. Keeping

these in mind will simplify or enhance device usage.

Tip

An idea or suggestion to improve efficiency or enhance usefulness.

© Microhard Systems Inc. Confidential 3

Page 4

Important User Information (continued)

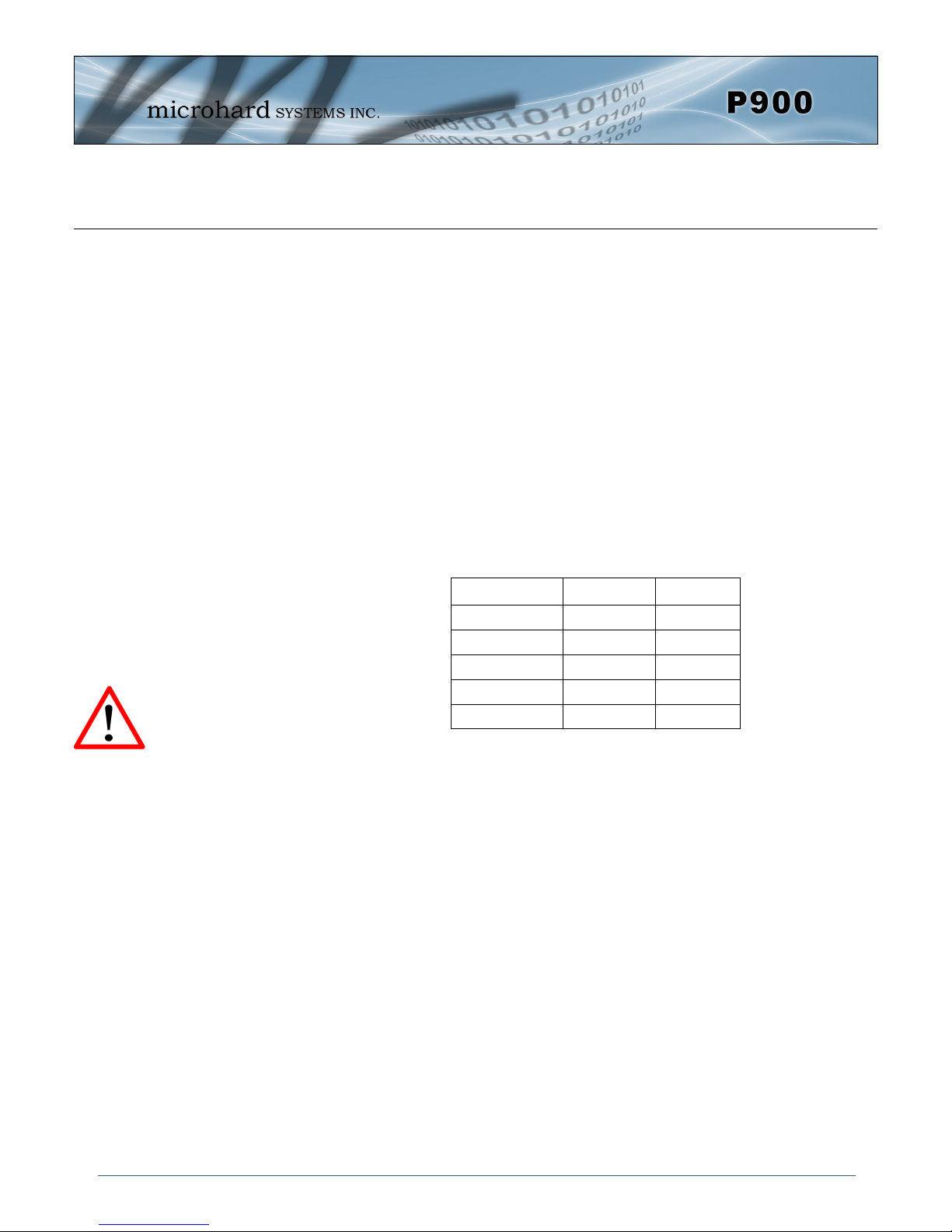

Regulatory Requirements

To satisfy FCC RF exposure requirements for mobile transmitting devices, a separation distance

of 23cm or more should be maintained between the antenna of this device and persons during

device operation. To ensure compliance, operation at closer than this distance is not

recommended. The antenna being used for this transmitter must not be co-located in conjunction

WARNING

with any other antenna or transmitter.

This device can only be used with antennas designed for use with 900 MHz products. Please

contact Microhard Systems Inc. if you need more information or would like to order an antenna.

WARNING

WARNING

MAXIMUM EIRP

FCC Regulations allow up to 36dBm Effective Isotropic Radiated Power (EIRP). Therefore, the

sum of the transmitted power (in dBm), the cabling loss and the antenna gain cannot exceed

36dBm.

EQUIPMENT LABELING

This device has been modularly approved. The manufacturer, product name, and FCC and

Industry Canada identifiers of this product must appear on the outside label of the end-user

equipment.

SAMPLE LABEL REQUIREMENT:

For P900

FCCID: NS913P900

IC: 3143A-13P900

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received including interference that may cause

undesired operation.

Please Note: These are only sample labels; different products contain different identifiers. The

actual identifiers should be seen on your devices if applicable.

© Microhard Systems Inc. Confidential 4

Page 5

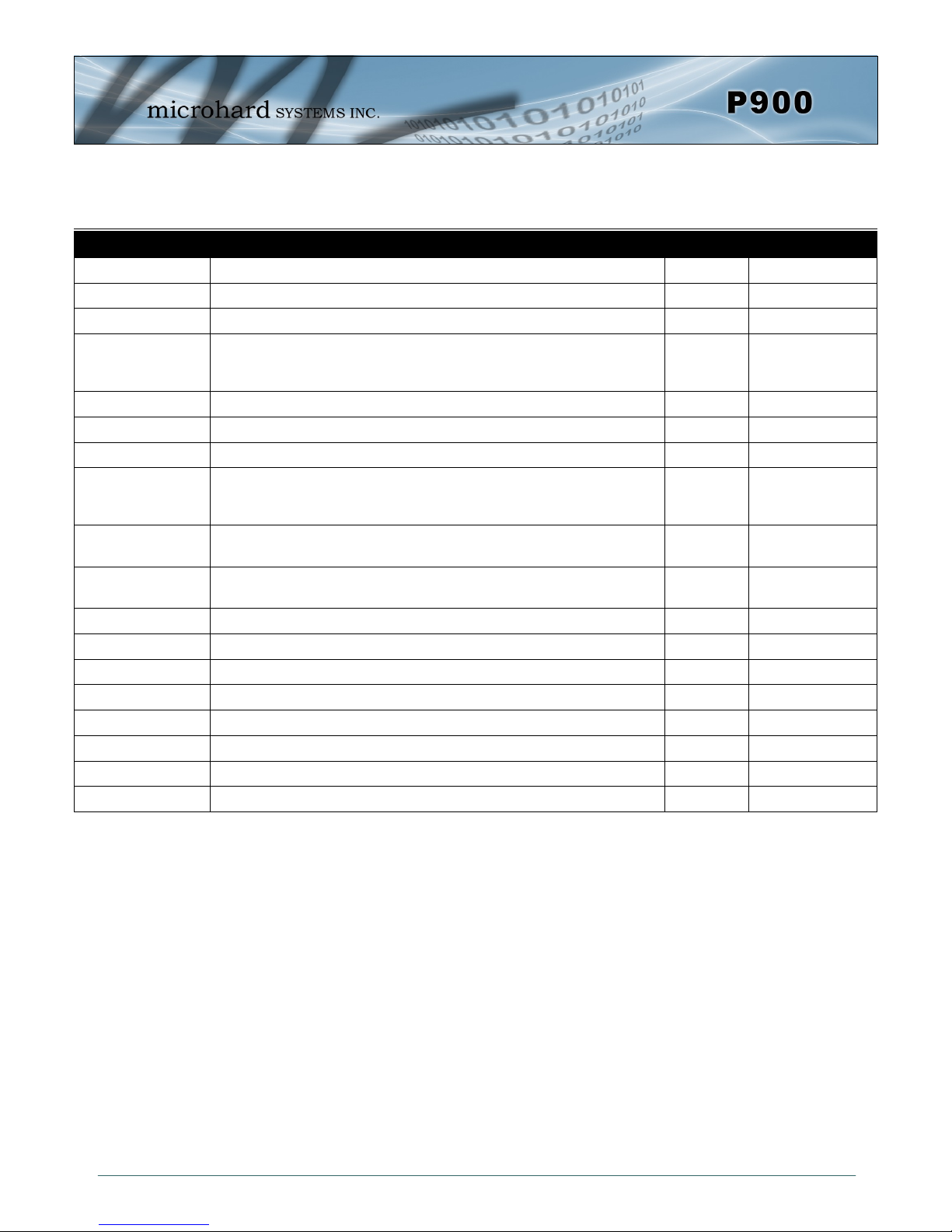

Revision History

Revision Description Initials Date

1.0 Draft PEH Mar 2013

1.1 Firmware v1.0 PEH Sept 2013

1.2 Official Release. Firmware v1.0. Added PTP, PMP Modes PEH Sept 2013

1.21 Added Pad Landing and Solder Mask/Paste diagrams, expanded Mesh

description, modified pins descriptions, added AT command firmware

upgrade, misc formatting corrections.

1.22 Misc Corrections PEH Feb 2014

1.3 Added RS485 Support (S142). Firmware required v1.06. PEH July 2014

1.4 Update for firmware v1.09 SG/PEH Dec 2014

1.5 Update for firmware v1.10—Added link rate 57.6 kbps, minor bugs

fixed. Added register S225 - Compression (must be set to zero for compatibility with older versions).

1.6 Update for firmware v1.11 - Added link rate 115.2 kbps. Added AT&S3

to enable RS485 driver.

1.7 Update for firmware v1.14 - Removed AT&S3, Added AT&K1 to use

CTS to control the Transmitter of RS485 driver chip.

1.8 Added P900-ENC drawings, connectors and LED descriptions PEH Sept 2015

1.81 Added P900-ENC Optional mounting Bracket. Misc updates. PEH Oct 2015

1.8.2 Modified description of S232. PEH Jan 2016

1.8.3 Updated Enclosed DB9 RS232/485 Pins. PEH Feb 2016

1.8.4 Added S159, S177 for AES Encryption PEH Feb 2016

1.8.5 Pin corrections PEH Feb 2016

1.8.6 Added MST reflow and baking instructions, misc corrections. PEH June 2016

1.8.7 Added Pico-MHX Adapter Board PEH June 2016

PEH Sept 2013

SG/PEH Jan 2015

PEH Jan 2015

PEH Aug 2015

© Microhard Systems Inc. Confidential 5

Page 6

Table of Contents

1.0 Overview 10

1.1 Performance Features ........................................................................................................ 10

1.2 Specifications ..................................................................................................................... 11

2.0 Hardware Description 12

2.1 OEM Mechanical Drawing .................................................................................................. 13

2.1.1 Recommended Solder Mask (Pad Landing) .............................................................................14

2.1.2 Recommended Solder Paste Pattern .......................................................................................15

2.1.3 OEM Connectors ....................................................................................................................15

2.1.4 SMT Temperature Profile ........................................................................................................16

2.1.5 Baking Instructions (MSL) .......................................................................................................16

2.2 OEM Pin Descriptions ........................................................................................................ 17

2.3 OEM Minimum Connection Requirements ........................................................................ 20

2.4 Electrical Characteristics ................................................................................................... 21

2.4.1 Test Conditions.....................................................................................................................21

2.4.1.1 Minimum and Maximum Values ...............................................................................21

2.4.1.2 Typical Values .........................................................................................................21

2.4.1.3 Loading Capacitor ...................................................................................................21

2.4.1.4 Pin Input Voltage .....................................................................................................21

2.4.2 Absolute Maximum Ratings..................................................................................................22

2.4.3 Operating Conditions ...........................................................................................................22

2.4.3.1 Operating Conditions at Power-up / Power-down ......................................................22

2.4.3.2 Voltage Characteristics ............................................................................................22

2.4.3.3 Current Characteristics ............................................................................................23

2.4.3.4 IO Port Characteristics .............................................................................................24

2.4.3.5 12-bit ADC Characteristics .......................................................................................25

2.5 P900 to n920 Pin-outs......................................................................................................... 27

2.6 P900 Enclosed ..................................................................................................................................28

2.6.1 P900 Enclosed Mechanical Drawings ......................................................................................29

2.6.2 P900 Enclosed Mounting Bracket (Optional) ............................................................................30

2.6.3 P900 Enclosed Connectors & Indicators ..................................................................................31

3.0 Mesh Configuration 33

3.1 Configuration/Unit Modes .................................................................................................. 33

3.1.1 Command Mode .....................................................................................................................33

3.1.2 Data mode ..............................................................................................................................34

3.2 Mesh Network ..................................................................................................................... 35

3.2.1 Operating Modes / Unit Types .................................................................................................35

3.2.2 Configuration Using Factory Defaults.......................................................................................39

AT&F1 - Primary Coordinator ..................................................................................................40

AT&F2 - Mesh Remote ...........................................................................................................41

AT&F3 - Secondary Coordinator..............................................................................................42

Standby Coordinator ...............................................................................................................43

3.2.3 Unit Addressing ......................................................................................................................44

3.2.4 Collision Mitigation ..................................................................................................................45

3.2.4.1 Channel Access Mode .............................................................................................45

3.2.4.2 Carrier Sense ..........................................................................................................46

3.2.4.3 TX Profile & Ranking ...............................................................................................48

3.2.5 Retransmissions .....................................................................................................................49

3.2.6 Network Synchronization.........................................................................................................49

3.2.7 Routing...................................................................................................................................50

3.2.8 Hop Pattern ............................................................................................................................55

© Microhard Systems Inc. Confidential 6

Page 7

Table of Contents (continued)

4.0 Point to Point Configuration 57

4.1 Configuration/Unit Modes .................................................................................................. 57

4.1.1 Command Mode .....................................................................................................................57

4.1.2 Data mode ..............................................................................................................................58

4.2 Point to Point Network ....................................................................................................... 59

4.2.1 Operating Modes / Unit Types .................................................................................................59

4.2.2 Configuration Using Factory Defaults.......................................................................................61

AT&F10 - PP Master ...............................................................................................................62

AT&F11 - PP Slave/Remote ....................................................................................................63

AT&F12 - PP Repeater ...........................................................................................................64

4.2.5 Retransmissions .....................................................................................................................65

4.2.6 Network Synchronization.........................................................................................................65

4.2.7 Hop Pattern ............................................................................................................................66

5.0 Point to Multipoint Configuration 68

5.1 Configuration/Unit Modes .................................................................................................. 68

5.1.1 Command Mode .....................................................................................................................68

5.1.2 Data mode ..............................................................................................................................69

5.2 Point to Multipoint Network ............................................................................................... 70

5.2.1 Operating Modes / Unit Types .................................................................................................70

5.2.2 Configuration Using Factory Defaults.......................................................................................73

AT&F7 - PMP Master ..............................................................................................................74

AT&F8 - PMP Slave/Remote ...................................................................................................75

AT&F9 - PMP Repeater ..........................................................................................................76

5.2.3 Unit Addressing ......................................................................................................................77

5.2.4 Retransmissions .....................................................................................................................77

5.2.5 Network Synchronization.........................................................................................................77

5.2.6 Hop Pattern ............................................................................................................................78

6.0 Register/Command Reference 80

6.1 AT Commands................................................................................................................... 80

A Answer .................................................................................................................................80

g, G Spectrum Analyzer ................................................................................................................80

In Identification .........................................................................................................................80

login Enable login password ..........................................................................................................81

M Mesh Diagnostics Menu ........................................................................................................81

N Advanced Spectrum Analyzer ................................................................................................82

&Fn Load Factory Default Configuration ........................................................................................82

&V View Configuration ................................................................................................................82

&W Write Configuration to Memory ..............................................................................................82

6.2 Settings (S) Registers ....................................................................................................... 83

S0 Power-up Mode.....................................................................................................................83

S2 Escape Character .................................................................................................................83

S80 Transmit Profiles ...................................................................................................................83

S81 CS Threshold ........................................................................................................................83

S83 Records TTL .........................................................................................................................84

S85 Distance to Master (PP/PMP) ................................................................................................84

S86 Distance from Master (PP/PMP) ............................................................................................84

S87 Enable S105 as MAC (Mesh) ................................................................................................84

S101 Operating Mode (Mesh) .........................................................................................................85

S101 Operating Mode (PP/PMP) ....................................................................................................85

S102 Serial Baud Rate ...................................................................................................................85

S103 Wireless Link Rate ................................................................................................................85

S104 Network ID/Address ..............................................................................................................86

© Microhard Systems Inc. Confidential 7

Page 8

Table of Contents (continued)

6.2 Settings (S) Registers (continued)

S105 Unit Address .........................................................................................................................86

S106 Hop Pattern ..........................................................................................................................86

S108 Output Power ........................................................................................................................86

S109 Hop Interval ..........................................................................................................................87

S110 Data Format ..........................................................................................................................87

S111 Packet Min Size ....................................................................................................................88

S112 Packet Max Size ...................................................................................................................88

S113 Packet Retransmissions ........................................................................................................88

S115 Repeat Interval......................................................................................................................88

S116 Character Timeout ................................................................................................................88

S118 Roaming (PP/PMP) ...............................................................................................................89

S123 Average RSSI (Mesh) ...........................................................................................................89

S123 RSSI from Master (dBm) (PP/PMP) .......................................................................................89

S124 RSSI from Slave (dBm) (PP/PMP) .........................................................................................89

S126 Attempt Before Re-Route (Mesh) ...........................................................................................89

S130 No Sync Data Intake .............................................................................................................89

S133 Network Type ........................................................................................................................90

S140 Destination Address ..............................................................................................................90

S141 Repeaters Y/N (PP/PMP) ......................................................................................................90

S142 Serial Channel Mode (RS232/485).........................................................................................90

S143 Sleep Mode ..........................................................................................................................90

S144 Sleep Time ...........................................................................................................................91

S145 Wake Time ...........................................................................................................................91

S146 Tx Done Timeout, 1/4 ............................................................................................................91

S151 Quick Sync Packets (Mesh) ...................................................................................................91

S153 Address Tag .........................................................................................................................91

S158 Forward Error Correction (FEC) Mode ...................................................................................92

S159 Encryption Mode (AES) .........................................................................................................92

S163 CRC Check on Diag Port .......................................................................................................93

S177 Binary Encryption Key ...........................................................................................................93

S180 Hop Zone ..............................................................................................................................93

S181 Secondary Hop Zone ............................................................................................................93

S183 DCD Pulse Period (PP/PMP) .................................................................................................93

S184 Data Time to Live (Mesh) ......................................................................................................94

S206 Secondary Hop Pattern .........................................................................................................94

S214 Number of Aloha Slots (Mesh) ...............................................................................................94

S215 Number of Mesh Slots (Mesh) ...............................................................................................94

S216 Mesh Duty Cycle (Mesh) .......................................................................................................94

S217 Protocol Type ........................................................................................................................95

S218 Input Framing ........................................................................................................................95

S219 Routing Request TTL (Mesh) .................................................................................................95

S220 Mesh Coordinator Rank (Mesh) .............................................................................................95

S221 Mesh TDMA Slot to Tx (Mesh) ...............................................................................................95

S222 Roaming Mode (Mesh) ..........................................................................................................95

S223 Routing (Mesh) .....................................................................................................................96

S224 Standby Trip Level (Mesh) .....................................................................................................96

S225 Compression Mode ...............................................................................................................96

S232 Max Buffer in Storage ............................................................................................................96

S234 Master Ch. Request Timeout (PMP) ......................................................................................97

S235 PP Routing TTL (PP) .............................................................................................................97

S236 Max Buffer Out Storage .........................................................................................................97

S244 Channel Access Mode...........................................................................................................97

S245 Cost of Hop in Mesh ..............................................................................................................97

S247 Country Code (Read Only) ....................................................................................................97

S248 Sync Timeout ........................................................................................................................98

© Microhard Systems Inc. Confidential 8

Page 9

Table of Contents (continued)

S249 Packets per Hop Tx Limit (PP/PMP) ......................................................................................98

S250 Master Bandwidth % (PMP) ...................................................................................................98

S251 Master Hop Allocation Timeout (PMP) ...................................................................................98

S252 Slave Ch. Allocation Timeout (PMP) ......................................................................................98

6.3 Serial Interface Commands .............................................................................................. 99

&Cn Data Carrier Detect (DCD) .....................................................................................................99

&Dn Data Terminal Ready (DTR) ..................................................................................................99

&K Handshaking .........................................................................................................................99

&Sn Data Set Ready (DSR) ..........................................................................................................99

7.0 Installation 100

7.1 Path Calculation .............................................................................................................. 102

7.2 Installation of Antenna System Components ................................................................ 103

7.2.1 Antennas ............................................................................................................................ 103

7.2.2 Coaxial Cable ..................................................................................................................... 104

7.2.3 Surge Arrestors ................................................................................................................... 104

7.2.4 External Filter ...................................................................................................................... 104

Appendices

Appendix A: AT Command Quick Reference ..................................................................................... 105

Appendix B: Settings (S) Register Quick Reference .......................................................................... 106

Appendix C: AT Utility Firmware Upgrade Procedure........................................................................ 107

Appendix D: AT Command Firmware Upgrade .................................................................................. 108

Appendix E: Development Board Serial Interface .............................................................................. 109

Appendix F: Pico Reference Schematic............................................................................................. 110

Appendix G: Pico-MHX Adapter Board ............................................................................................... 111

Appendix H: Approved Antennas ....................................................................................................... 113

© Microhard Systems Inc. Confidential 9

Page 10

1.0 Overview

The Pico Series P900 is capable of delivering high-performance wireless serial communications in robust and secure Mesh, Point to Point or Point to Multipoint topologies.

The Pico Series is available as a low cost OEM module, for the ultimate in design integration.

When properly configured and installed, long range communications at very high speeds can

be achieved.

Pico Series modules operate within the 902-928 MHz ISM frequency band, using frequency

hopping spread spectrum (FHSS) technology, providing reliable wireless asynchronous data

transfer between most equipment types which employ a serial interface.

The small size and superior performance of the Pico Series makes it ideal for many applications. Some typical uses for this modem:

SCADA

remote telemetry

traffic control

industrial controls

remote monitoring

fleet management

GPS

metering

1.1 Performance Features

Key performance features of the Pico Series include:

transmission within a public, license-exempt band of the radio spectrum1 - this

means that the modems may be used without access fees or recurring charges

(such as those incurred by cellular airtime)

transparent, low latency link rates up to 276 kbps

communicates with virtually all serial based devices

supports a robust true Mesh operation with auto-routing

wide temperature specification

maximum allowable transmit power (1 Watt)

32 bits of CRC, selectable retransmission and forward error correction

separate diagnostics port - transparent remote diagnostics and online network

control

ease of installation and configuration - the P900 utilizes a subset of standard AT-

style commands, similar to those used by traditional telephone line modems

3.3V logic level compatibility

1

902-928 MHz, which is license-free within North America; may need to be factory-configured dif-

ferently for some countries, contact Microhard Systems Inc. for details.

robotics

display signs

railway signaling

© Microhard Systems Inc. Confidential 10

Page 11

1.0 Overview

1.2 Pico Series P900 Specifications

Electrical/General

Frequency: 902 - 928 MHz

Spreading Method: Frequency Hopping

Band Segments: Selectable via Freq. Zones

Error Detection: 32 bits of CRC, ARQ

Data Encryption: 128, 196 or 256-bit AES Encryption (Requires export

(Optional) permit outside US and Canada.)

Range: 40 miles (60km)

Output Power: 100mW to 1W (20-30dBm)

Sensitivity:

Serial Baud Rate: Up to 230.4 kbps asynchronous

Caution: Using a power

supply that does not

provide proper voltage or

current may damage the

modem.

Link Rate: Up to 276 kbps

Environmental

Operation Temperature: -40oF(-40oC) to 185oF(85oC)

Humidity: 5% to 95% non-condensing

Mechanical

Dimensions: Approx: 1.05” (26.5mm) X 1.3” (33mm) X 0.13”(3.5mm)

Weight: Approx: 5 grams

Connectors: Antenna: UFL

Data: 80 Pin/Pad SMT

Link Rate 10-6BER 10-3BER

57.6 kbps -111 dBm -114 dBm

115.2 kbps -110 dBm -113 dBm

172 kbps -108 dBm -111 dBm

230 kbps -107 dBm -110 dBm

276 kbps -106 dBm -109 dBm

© Microhard Systems Inc. Confidential 11

Page 12

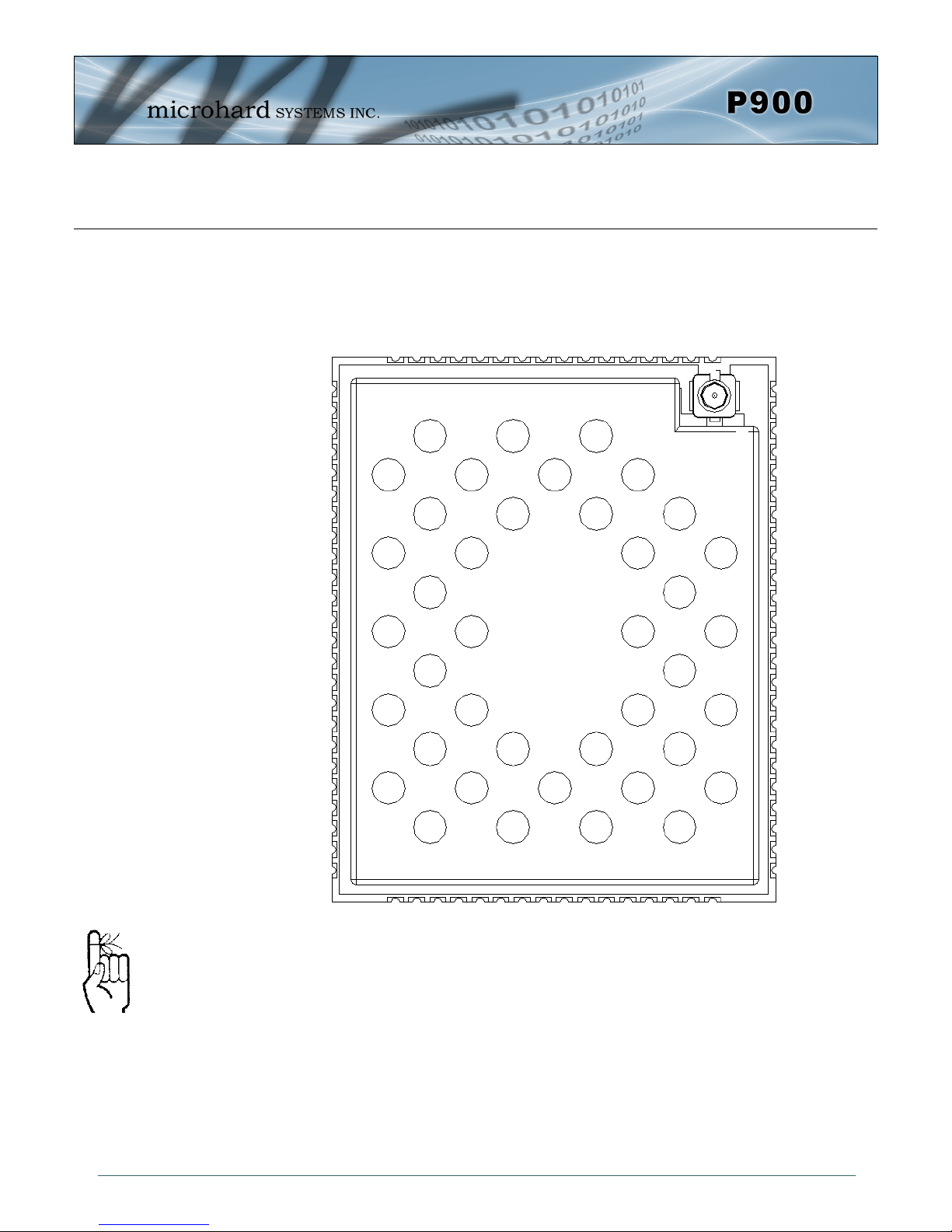

2.0 Hardware Description

The Pico Series P900 Modem modules are available as a low cost OEM module. This OEM

version supplies all the required raw signals to allow the unit to be tightly integrated into

applications to efficiently maximize space and power requirements. The Microhard

development board can provide a convenient evaluation platform to test and design with the

module. (Contact Microhard Systems for details)

Any P900 Series module may be configured as a Primary Coordinator, Secondary

Coordinator, Standby Coordinator or Remote in a Mesh Topology, or a Master, Repeater or

Remote in a PP or PMP Topology. This versatility is very convenient from a ’sparing’

perspective, as well for convenience in becoming familiar and proficient with using the

module: if you are familiar with one unit, you will be familiar with all units.

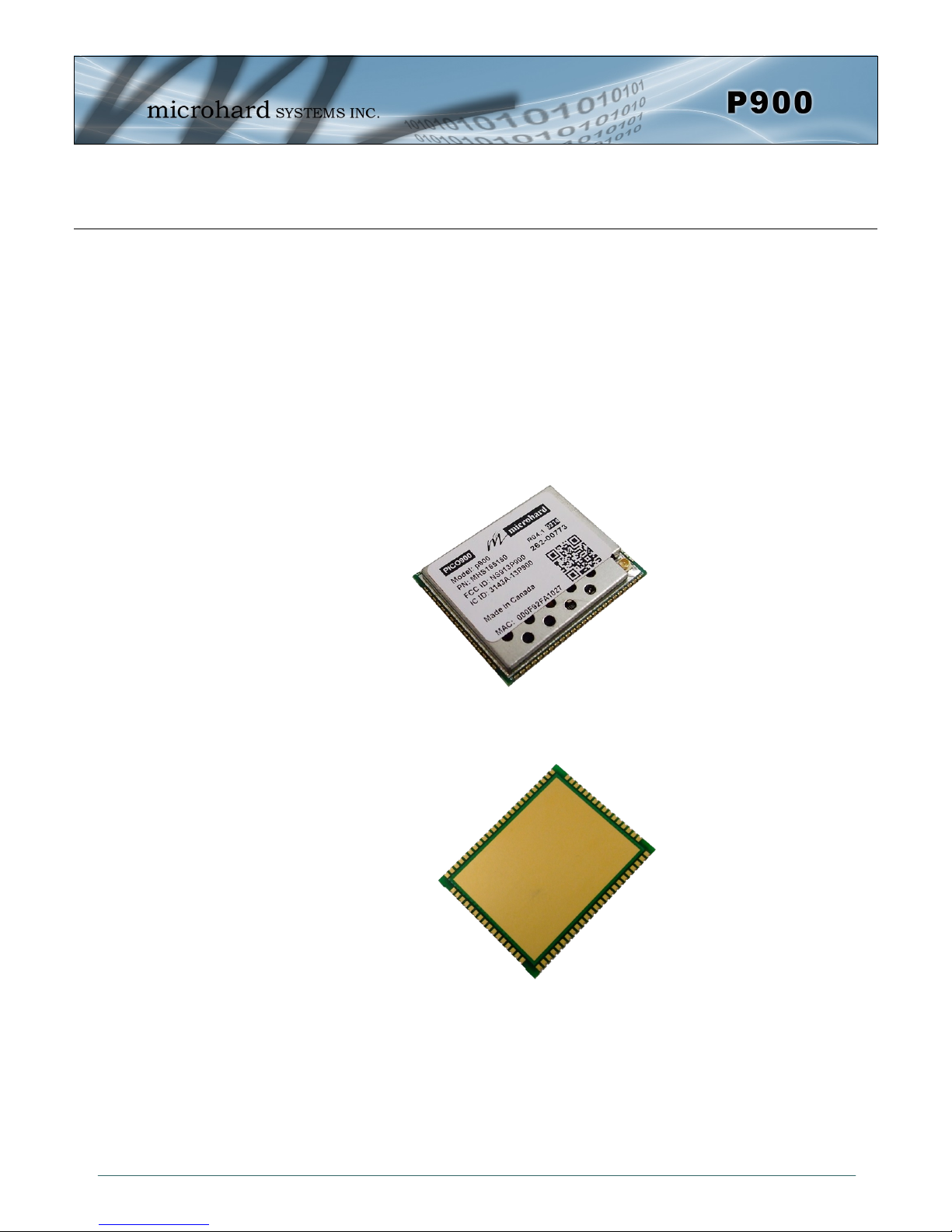

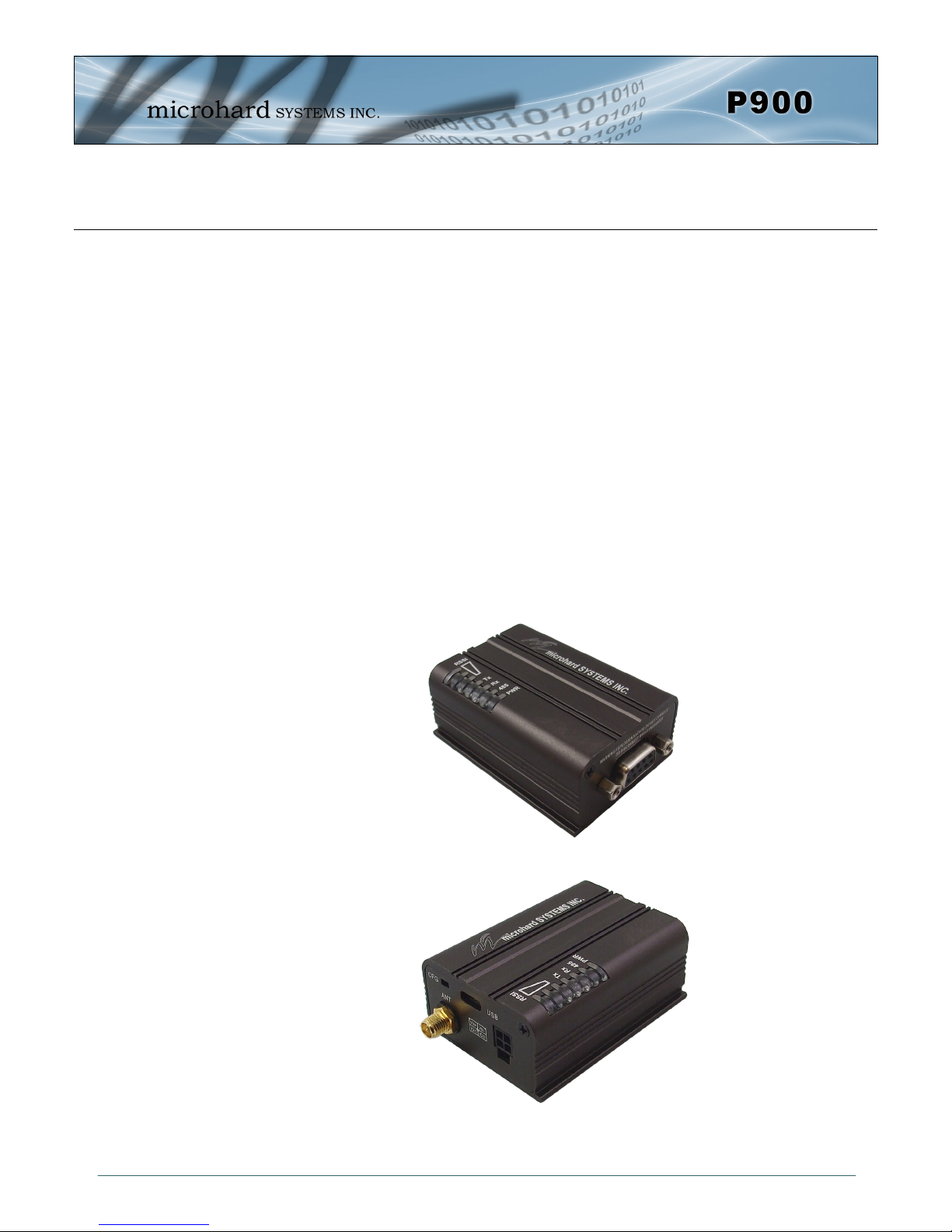

Image 2-1: Pico P900 Top View

Image 2-2: Pico P900 Bottom View

© Microhard Systems Inc. Confidential 12

Page 13

33

26.5

3.68

2.31

33

3.5

0.80

1.27

1.18

22.35

28.70

30.01

2.16

19.85

1.50

3.41

2.0 Hardware Description

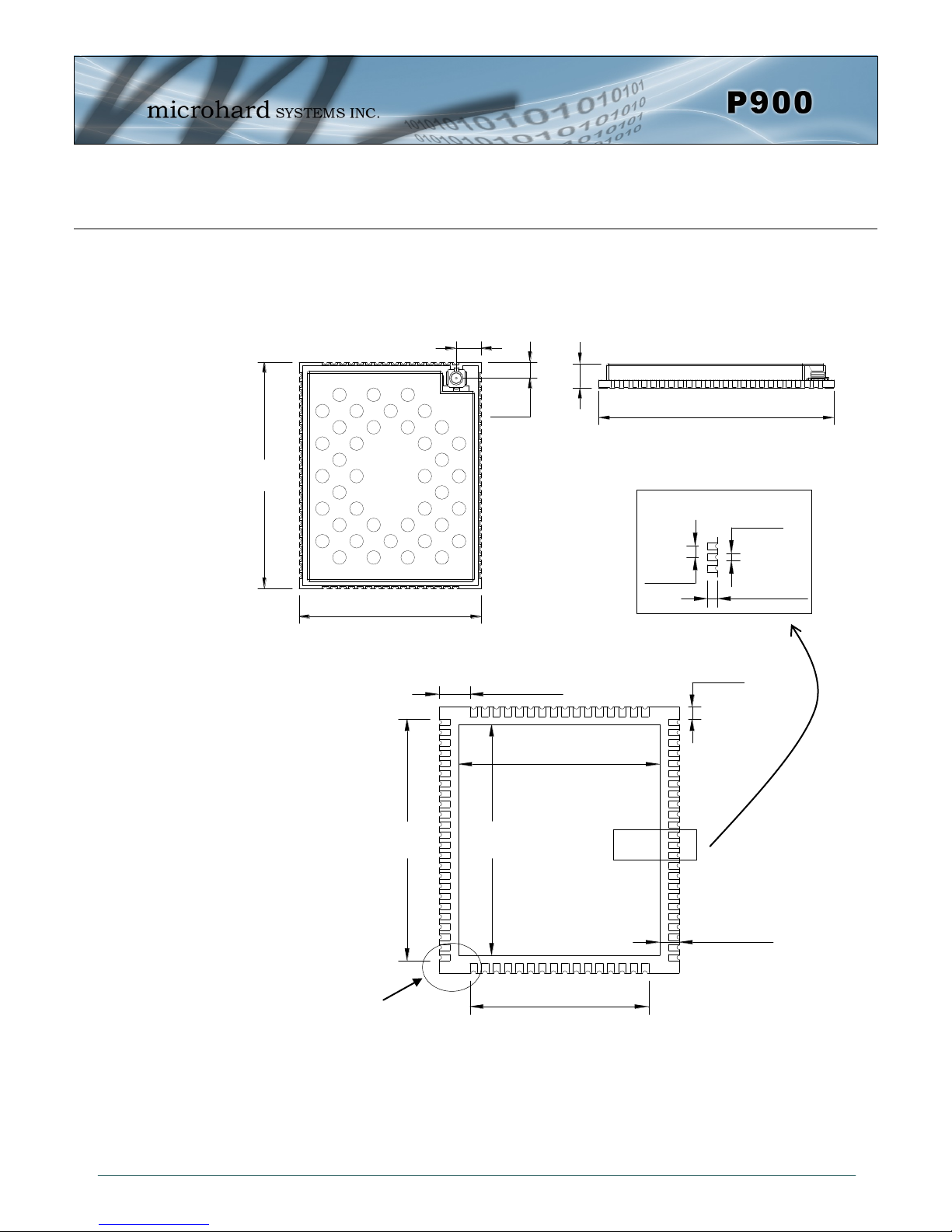

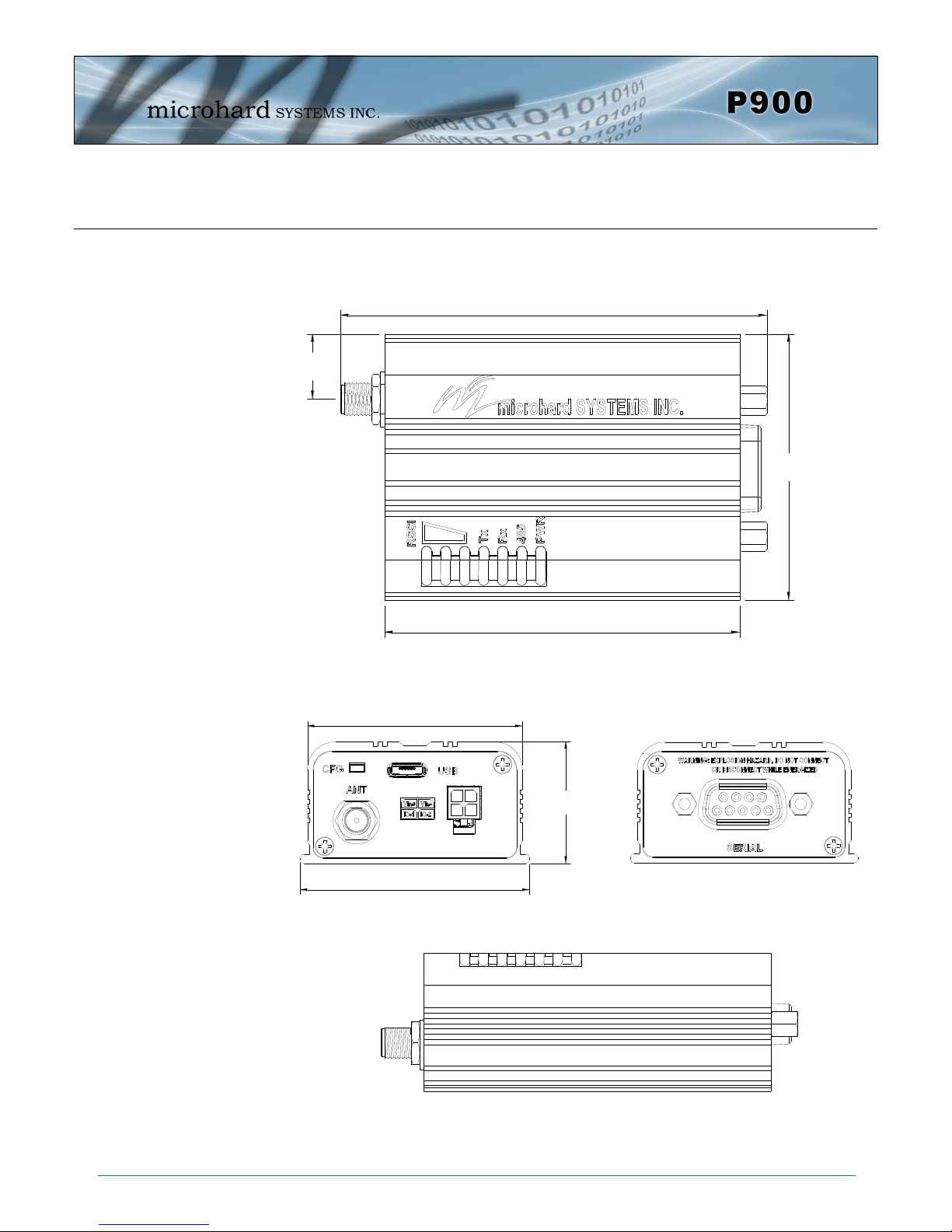

2.1 Mechanical Drawings

The P900 OEM Modules have an extremely small form factor as seen in Drawing 3-3 below.

(2)

(2)

(A)

Detail

(2)

© Microhard Systems Inc. Confidential 13

See Notes

(2)

Units: millimeters

Ground Plane

Bottom View

Drawing 2-1: P900 OEM Mechanical

(1)

(A)

Detail

1. Ground plane must be connected to GND for required heat dissipation.

2. Due to manufacturing methods additional PCB material may be

present on the corners that cannot be removed. Designs should

allow for a small tolerance of this additional material, ± 0.25mm

Page 14

1.27

0.81

1.83

22.35

30.02

0.99

19.86

28.70

27.99

34.34

2.0 Hardware Description

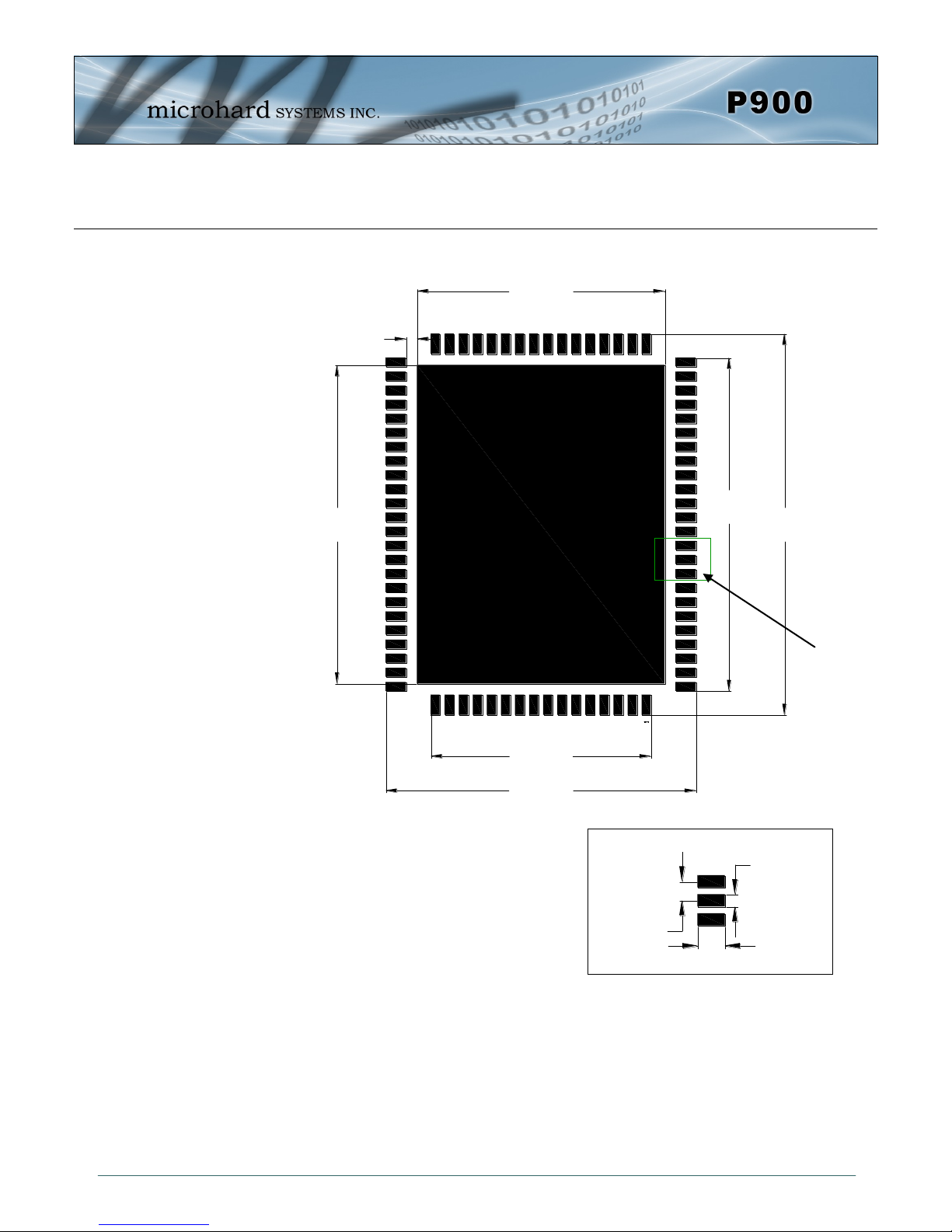

2.1.1 Recommended Solder Mask (Pad Landing)

Units: millimeters

Drawing 2-2: P900 Recommended Solder Mask

Detail

(B)

Detail

(B)

© Microhard Systems Inc. Confidential 14

Page 15

19.91

30.0734.39

28.04

2.18

1.88

2.55

1.27

1.03

0.86

3.50

3.38

4.12

1.00

2.0 Hardware Description

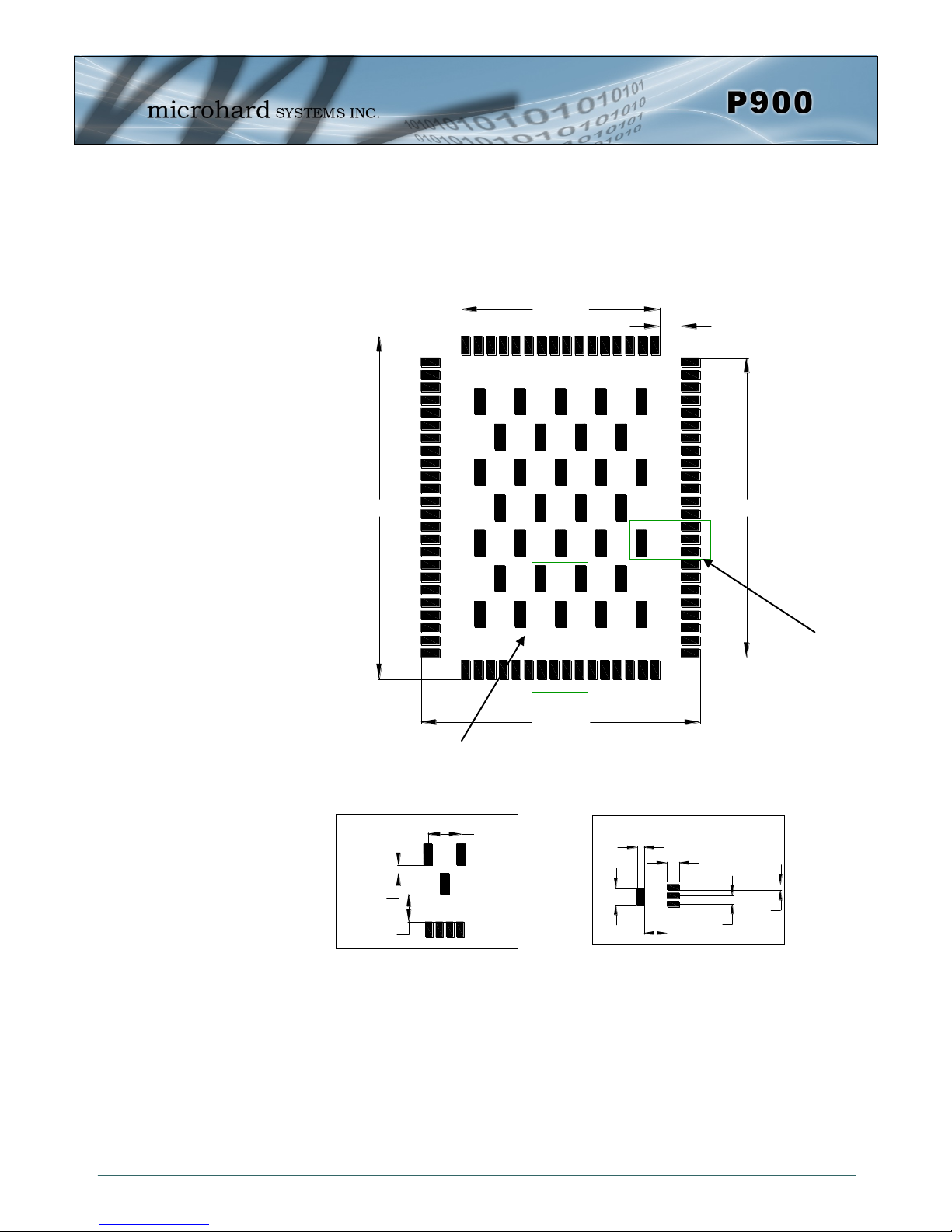

2.1.2 Recommended Solder Paste Pattern

(D)

Detail

Units: millimeters

(D)

Detail

Drawing 2-3: P900 Recommended Solder Paste

2.1.3 OEM Connectors

Antenna

All P900 OEM Modules use an UFL connector for the antenna connection.

Data

The interface to the P900 OEM module is a tight integration using 80 pad SMT connections.

Detail

(C)

Detail

(C)

© Microhard Systems Inc. Confidential 15

Page 16

2.0 Hardware Description

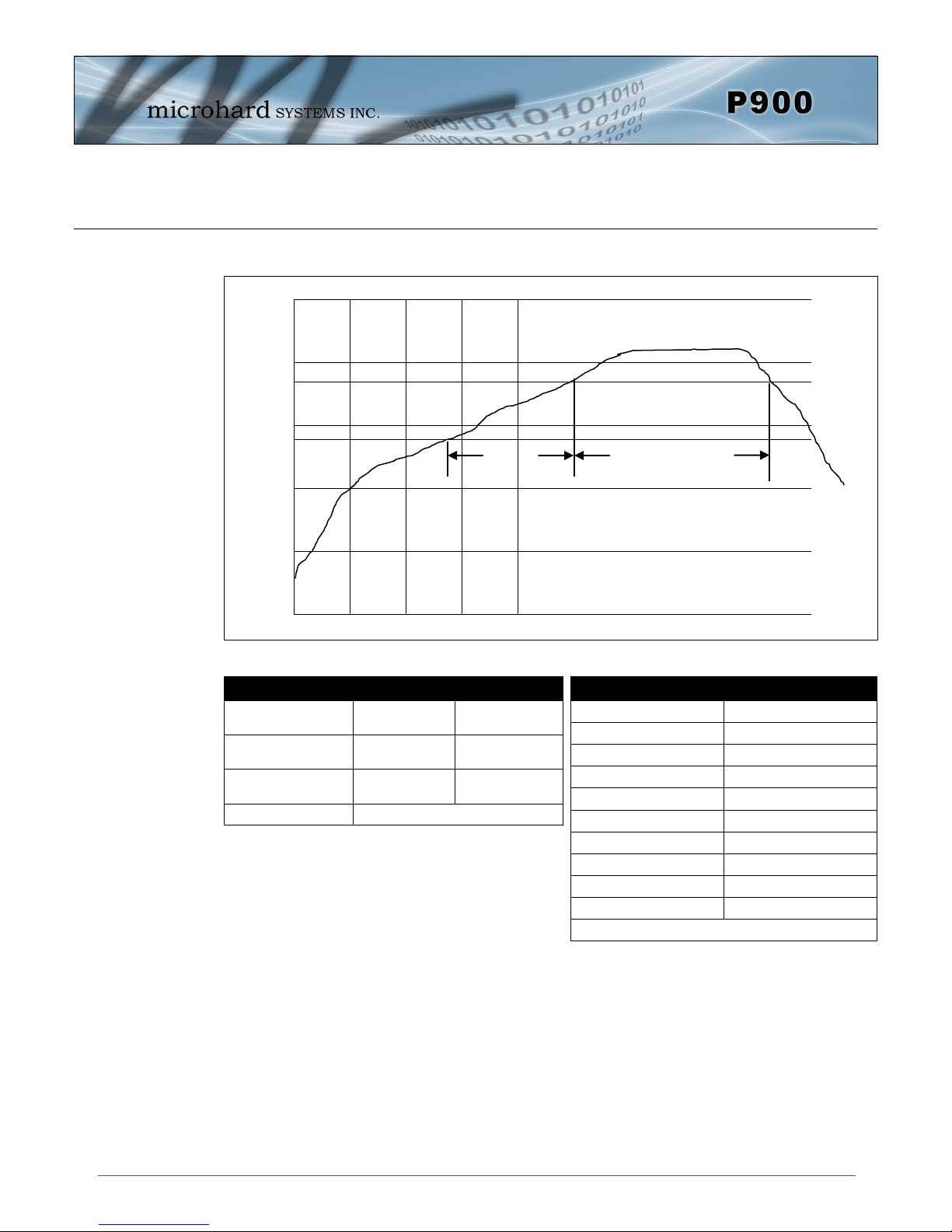

2.1.4 SMT Temperature Profile

300

240

217

180.0

165

T

MAX

=255oC

2.42(oC/s)

60~100s

120.0

60.0

0.0

Drawing 2-4: Reflow Profile

Temperature Zone Time Parameter

Preheat zone:

(40oC - 165oC)

Soak Zone:

(165oC - 217oC)

Reflow zone:

(>217oC)

Cooling zone Cooling rate: 2oC/s ≤ Slope ≤ 5oC/s

Table 2-1: Reflow Parameters

- Heating rate:

60 - 100s -

120s Peak reflow:

0.5oC/s-2oC/s

255oC

120s

Zone Temperature (oC)

1 120

2 140

3 160

4 180

5 215

6 255

7 255

8 255

9 250

10 130

Chain Speed: 60cm/min

Table 2-2: Oven Temperature Profile

2.1.5 SMT Baking Instructions (MSL)

The P900 OEM modules must be baked before mounting, the following baking instruction should be followed for the best results:

a) Minimum of 8 to 12 hours at 125°C +/- 5°C for high-temperature device containers.

b) Unused modules should be stored at ≤ 10% RH

© Microhard Systems Inc. Confidential 16

Page 17

2.0 Hardware Description

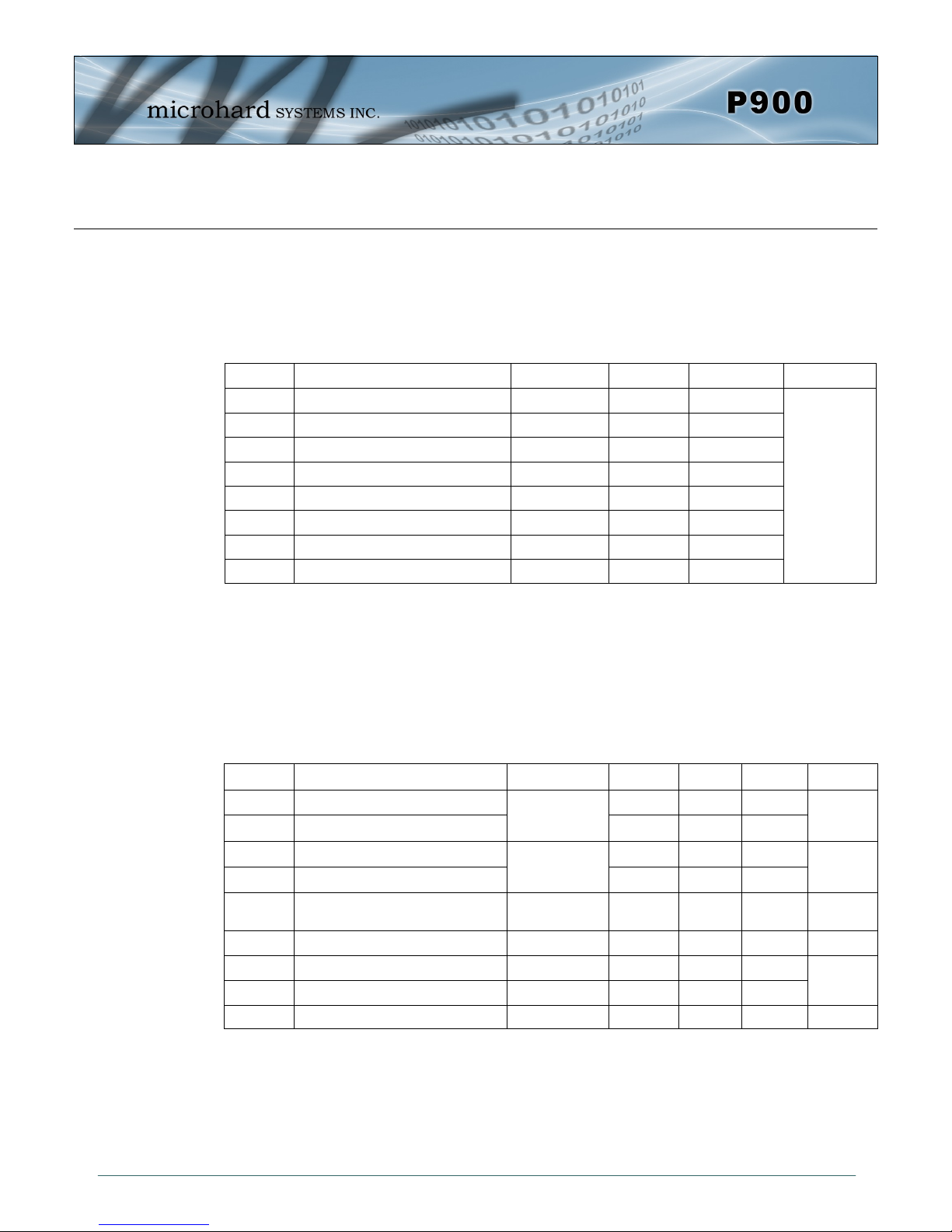

2.2 Pico OEM Pin Descriptions

GND

1

GND

DNC

DNC

DNC

DNC

DNC

USR1 - GPS/1PPS

USR2 - Alarm

USR3

I/O1

I/O2

I/O3

I/O4

USR AO0

USR AN0

USR AN1

GND

USBDP

USBDM

RSSI LED1

RSSI LED2

RSSI LED3

LED RX

LED TX

80 79 78 77 76 75 74 73 72 71 70 69 68

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Reserved

Reserved

GND

GND

GND

GND

GND

DNC

DNC

DNC

DNC

DNC

Pico Series

P900

(Top View)

GND

GND

GND

67 66 65

64

Vcc

63

Vcc

62

Vdd

61

Reserved

60

Reserved

59

Reserved

58

Reserved

57

Reserved

56

Reserved

55

Reserved

54

Reserved

53

Reserved

52

Reserved

51

CANRX

50

CANTX

49

Reserved

48

Reserved

47

Wakeup_usr

46

!CONFIG

45

!RESET

44

RSMode

43

Reserved

42

Vbat

41

40 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25

GND

Inputs and outputs are

3.3V nominal (3.0V min

— 3.6V max) unless

otherwise specified.

The above drawing depicts a top view of the P900-OEM Module. The corner pads (1, 25, 41,

and 65) are printed directly on the bottom of the PCB for easy identification.

A full description of the connections and function of each pin is provided on the pages that

follow.

© Microhard Systems Inc. Confidential 17

Reserved

GND

GND

Serial RING

Serial RxD

Serial TxD

Serial DSR

Serial CTS

Serial DTR

Serial DCD

Serial RTS

Control RxD

USR SCK

Control TxD

Drawing 2-5: Pico P900 80-pin OEM Connection Info

GND

GND

Page 18

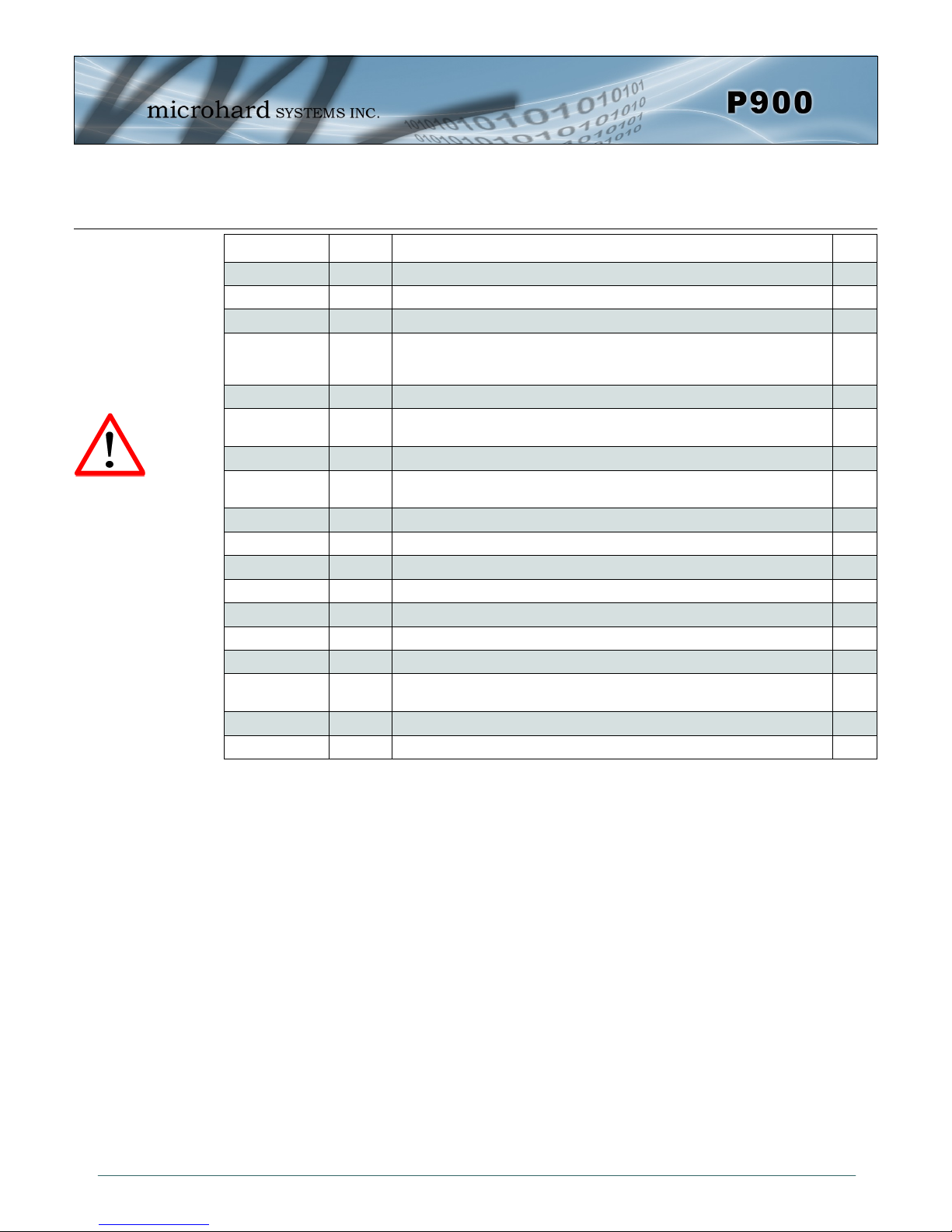

2.0 Hardware Description

Caution: During power up

or reset, output pins from

the Pico are in an unknown

state. It is advised to use

pull up or pull down

resisters as appropriate.

Pin Name No. Description

GND 1,17,25-26,39-

DNC 2,3,4,5,6 Reserved for factory use only.

USR1 –

GPS/1PPS

USR2 - Alarm 8

USR3 9

I/O 1,2 10,11 Digital Outputs. 3.3 V Output @ 3mA maximum. O

I/O3,4 12,13 Future Use I/O

USR_ANO0 14

USR_AN0

USR_AN1

USBDP 18

USBDM 19

LED_1 (RSSI1) 20 Receive Signal Strength Indicator 1. Active high, cannot drive LED

LED_2 (RSSI2) 21 Receive Signal Strength Indicator 2. Active high, cannot drive LED

LED_3 (RSSI3)

LED_RX 23 Active high output indicates receive and synchronization status.

LED_TX 24 Active high output indicates module is transmitting data over the RF

Serial RING 27

Serial RxD 28 Receive Data. Logic level input into the modem. It is recommended

Serial TxD 29 Transmit Data. Logic level Output from the modem. It is

Serial DSR 30

Serial CTS 31

Serial DTR 32 Data Terminal Ready. Active low input. I

Serial DCD 33 Data Carrier Detect. Active low output. O

Serial RTS 34 Request To Send. Active low input. I

USR SCK 35

41,65-67,75-80

Ground reference for logic, radio, and I/O pins.

*Currently Not Supported. For Future Expansion*

7

*Reserved for future use.*

*Reserved for future use.*

*Currently Not Supported. For Future Expansion*

15

Analog Inputs. 0 to 3V input, 12 bit. I

16

*Currently Not Supported. For Future Expansion*

*Currently Not Supported. For Future Expansion*

directly. Requires current limiting resistor. 8mA maximum.

directly. Requires current limiting resistor. 8mA maximum.

22

Receive Signal Strength Indicator 3. Active high, cannot drive LED

directly. Requires current limiting resistor. 8mA maximum.

Active high, cannot drive LED directly. Requires current limiting

resistor. 8mA maximum.

channel. Active high, cannot drive LED directly. Requires current

limiting resistor. 8mA maximum.

Internally connected to GND through a 22kΩ resistor. In RS485

modes the RING line is set high and is normally used to enable the

receiver of the RS485 driver.

to wire this pin out through a zero ohm resister to a header and

jumper block for external access to the serial port for modem

recovery procedures.

recommended to wire this pin out through a zero ohm resister to a

header and jumper block for external access to the serial port for

modem recovery procedures.

Data Set Ready. Active low output. The DSR line may be used to

enable the transmitter of the RS485 driver chip.

Clear To Send. Active low output. The CTS line may be used to

enable the transmitter of the RS485 driver chip.

*Currently Not Supported. For Future Expansion*

Dir

I

O

O

O

O

O

O

O

O

O

I

O

O

O

I

© Microhard Systems Inc. Confidential 18

Table 2-3: Pico Series Pin Description

Page 19

2.0 Hardware Description

Caution: During power up

or reset, output pins from

the Pico are in an unknown

state. It is advised to use

pull up or pull down

resisters as appropriate.

Pin Name No. Description

Reserved 36

Control RxD 37 Diagnostics receive data. Logic level input from a PC to the module. I

Control TxD 38 Diagnostics transmit data. Logic level output from module to a PC. O

Vbat 42 Input voltage sensing analog input line, up to 60VDC maximum. Used to

Reserved 43

RSMode 44

!RESET 45 Active low input will reset the module. I

!CONFIG 46 Active low input signal to put module into default serial interface (RS232) and

!Wakeup_usr 47 Active high input used to wake the model from sleep mode. I

Reserved 48

Reserved 49

CANTX 50

CANRX 51

Reserved 52-61

Vdd 62 Positive voltage supply voltage for the digital section of the module (3.3V). I

Vcc 63,64 Positive voltage supply voltage for the radio module (3.3V). The Vcc lines are

Reserved 68,69

DNC 70-74 Reserved for factory use only.

*Reserved for future use.*

measure the main supply voltage. User design must add a 10kΩ 1% 1/16W

resistor in series.

*Reserved for future use.*

Internally connected to GND through a 10kΩ resistor. *Reserved for future

use.*

default baud rate (9600/8/N/1) during power up. Pull high or leave floating.

*Reserved for future use.*

*Reserved for future use.*

*Currently Not Supported. For Future Expansion*

*Currently Not Supported. For Future Expansion*

*Reserved for future use.*

internally connected together.

*Reserved for future use.*

Table 2-3: Pico Series Pin Description (continued)

Dir

O

I

I

I

All serial communications signals are logic level (0 and 3.3V). DO NOT connect RS-232 level

(+12, -12VDC) signals to these lines without shifting the signals to logic levels.

© Microhard Systems Inc. Confidential 19

Page 20

2.0 Hardware Description

2.3 Minimum Connection Requirements

3.3V

62 63 64

VCC

VDD

Antenna

UFL

Optional

RS-232

Driver

29 Serial TxD

28 Serial RxD

P900

GND Pins

1 17 25 26 39 40 41 65 66 67 78 79 80

© Microhard Systems Inc. Confidential 20

Drawing 2-6: P900 Minimum Connection Block Diagram

Page 21

2.0 Hardware Description

2.4 Electrical Characteristics

2.4.1 Test Conditions

Unless otherwise specified, all voltages are referenced to Vss(GND).

2.4.1 Minimum and Maximum Values

Unless otherwise specified the minimum and maximum values are guaranteed in the worst

conditions of ambient temperature, supply voltage and frequencies.

Data based on characterization results, design simulation and/or technology characteristics

are indicated in the table footnotes and are not tested in production. Based on

characterization, the minimum and maximum values refer to sample tests and represent the

mean value plus or minus three times the standard deviation (mean±3Σ).

2.4.1.2 Typical Values

Unless otherwise specified, typical data are based on TA = 25 °C, VDD = 3.3 V. They are given

only as design guidelines and are not tested.

Typical ADC accuracy values are determined by characterization of a batch of samples from

a standard diffusion lot over the full temperature range, where 95% of the devices have an

error less than or equal to the value indicated (mean±2Σ).

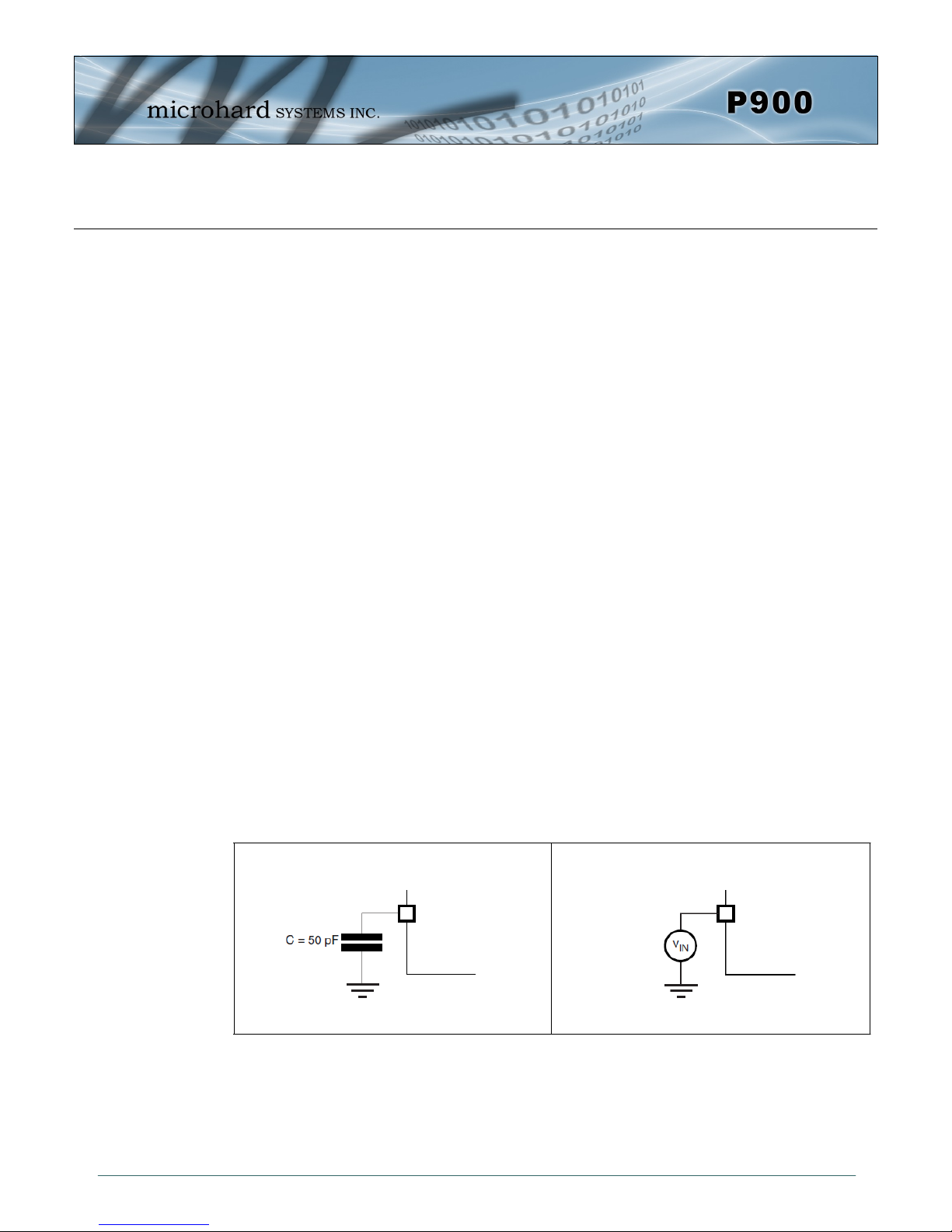

2.4.1.3 Loading Capacitor

The loading conditions used for pin parameter measurement are shown in Figure 2-1.

2.4.1.4 Pin Input Voltage

The input voltage measurement on a pin of the Pico is described in Figure 2-2.

Figure 2-1 Pin Loading Conditions

© Microhard Systems Inc. Confidential 21

Pico pin

Figure 2-2 Pin Input Voltage

Pico pin

Page 22

2.0 Hardware Description

2.4.2 Absolute Maximum Ratings

Stresses above the absolute maximum ratings listed in Table 2-2: Voltage Characteristics

and Table 2-3: Current Characteristics may cause permanent damage to the device. These

are stress ratings only and functional operation of the device at these conditions is not

implied. Exposure to maximum rating conditions for extended periods may affect device

reliability.

Symbol Ratings Min Max Unit

VCC/VDD External main supply voltage. 0 3.8

VIN Input voltage on any pin. -0.3 VDD+0.3

V

Table 2-4 Voltage Characteristics

Symbol Ratings Max Unit

I

Total current into Pico Series (source). 70

VDD

I

Total current out of Pico Series (sink). 70

VSS

I

Output current sunk by any I/O and control pin. 20

IO

Output Current sourced by any I/O and control pin. -8

Table 2-5 Current Characteristics

mA

2.4.3 Operating Conditions

2.4.3.1 Operating Conditions at Power-up / Power-down

The parameters given in Table 2-4: Operating Conditions at Power-up/ Power-down are

derived from tests performed under the ambient temperature ratings of the Pico Series.

Symbol Parameter Min Max Unit

VDD

VDD rise time rate. 0 ∞

VDD fall time rate. 20 ∞

Table 2-6 Operating Conditions at Power-up/Power-down

µs/V t

2.4.3.2 Operating Conditions Voltage Characteristics

The parameters given in Table 2-5: Operating Conditions Voltage Characteristics are

derived from tests performed under the ambient temperature ratings of the Pico Series.

Symbol Ratings Min Max Unit

VCC External radio supply voltage. 3.3

VDD External digital supply voltage. 3.0 3.6

1. The modem will not be able to transit at full power if V

© Microhard Systems Inc. Confidential 22

(1)

3.6

Table 2-7 Operating Conditions Voltage Characteristics

is less than 3.3VDC.

CC

V

Page 23

2.0 Hardware Description

2.4.3.3 Operating Conditions Current Characteristics

The parameters given in Table 2-6: Operating Conditions Current Characteristics are

derived from tests performed under the ambient temperature ratings of the Pico Series. Test

conditions measured while Vcc = 3.3V, VDD = 3.3V, Frequency 915MHz and ambient

temperature of 25oC.

Symbol Ratings Min Typ Max Unit

I

Radio current 100% TX @ 1W 1250 1500

VCC(TX)

I

Radio current 100% TX @ 500mW 375 500

VCC(TX)

I

Radio current 100% TX @ 100mW 180 250

VCC(TX)

I

Radio current 100% RX @ 1W 75 100

VCC(RX)

I

VCC(RX-RUN)

I

VCC(IDLE)

I

VDD(RUN)

I

VDD(IDLE)

Radio RX running 40 75

Radio Idle current 2.5 3.5

Digital current 45 50

Digital idle current 5

mA

Table 2-8 Operating Conditions Current Characteristics

2.4.3.4 I/O Port Characteristics

General Input / Output Characteristics

The parameters given in Table 2-7: I/O Static Characteristics are derived from tests

performed under the ambient temperature ratings of the Pico Series. All I/Os are CMOS and

TTL compliant. I/O’s refer to all input and outputs of the Pico Series.

Symbol Parameter Conditions Min Typ Max Unit

VIL

VIH

VIL

VIH

V

I

RPU

RPD

CIO

1. Hysteresis voltage between Schmitt trigger switching levels. Based on characterization, not tested in production.

2. Pull-up and pull-down resistors can be used on input/output pins.

Input low level voltage

Input high level voltage 2 VDD+0.5

Input low level voltage

Input high level voltage 0.65 VDD VDD+0.5

IO Schmitt trigger voltage

hys

hysteresis

Input leakage current

lkg

Weak pull-up equivalent resistor

Weak pull-down equivalent resistor

I/O pin capacitance

(1)

(2)

Table 2-9 I/O Static Characteristics

VSS ≤ VIN≤ VDD

(2)

TTL ports

CMOS ports

VIN = VSS

VIN = VDD

-0.5 0.8

-0.5 0.35 VDD

200

±1

30 40 50

30 40 50

8

V

V

mV

µA

kΩ

pF

© Microhard Systems Inc. Confidential 23

Page 24

2.0 Hardware Description

Output Driving Current

The GPIOs (general purpose input/outputs) can sink or source up to +/-8 mA, and sink

+20 mA (with a relaxed VOL).

In the user application, the number of I/O pins which can drive current must be limited to

respect the absolute maximum rating specified in Section 2.5.2:

● The sum of the currents sourced by all the I/Os on VDD cannot exceed the absolute maximum rating

I

(see Table 2-3).

VDD

The sum of the currents sunk by all the I/Os on VSS cannot exceed the absolute maximum rating I

(see Table 2-3).

Output Voltage Levels

Unless otherwise specified, the parameters given in Table 2-8 are derived from tests

performed under ambient temperature and VDD supply voltage ratings of the Pico Series. All I/Os are

CMOS and TTL compliant.

VSS

Symbol Parameter Conditions Min Max Unit

Output low level voltage for an I/O pin

(1)

V

OL

V

OH

V

OL

V

OH

V

OL

V

OH

1. The IIO current sunk by the device must always respect the absolute maximum rating specified in Table 2-3 and the sum of IIO (I/O ports and control

2. The IIO current sourced by the device must always respect the absolute maximum rating specified in Table 2-3 and the sum of IIO (I/O ports and

3. Based on characterization data, not tested in production.

when 8 pins are sunk at same time

Output high level voltage f or an I/O pin

(2)

when 8 pins are sourced at same time

Output low level voltage for an I/O pin

(1)

when 8 pins are sunk at same time

Output high level voltage f or an I/O pin

(2)

when 8 pins are sourced at same time

Output low level voltage for an I/O pin

(1)(3)

when 8 pins are sunk at same time

Output high level voltage f or an I/O pin

(2)(3)

when 8 pins are sourced at same time

pins) must not exceed I

control pins) must not exceed I

.

VSS

.

VDD

Table 2-10 Output Voltage Characteristics

TTL port

IIO = +8mA

CMOS port

IIO = +8mA

IIO = +20mA

0.4

V

VDD-0.4

0.4

V

2.4

1.3

V

VDD-1.3

Input / Output AC Characteristics

The values of input/output AC characteristics are given in Table 2-9.

Symbol Parameter Conditions Min Max Unit

t

Output high to low f all time

f(IO)out

t

Output low to high level rise time 125

r(IO)out

t

EXTlpw

Pulse width of external signals used as

interrupts.

CL = 50 pF

1 ms

125

ns

© Microhard Systems Inc. Confidential 24

Table 2-11 Input / Output AC Characteristics

Page 25

2.0 Hardware Description

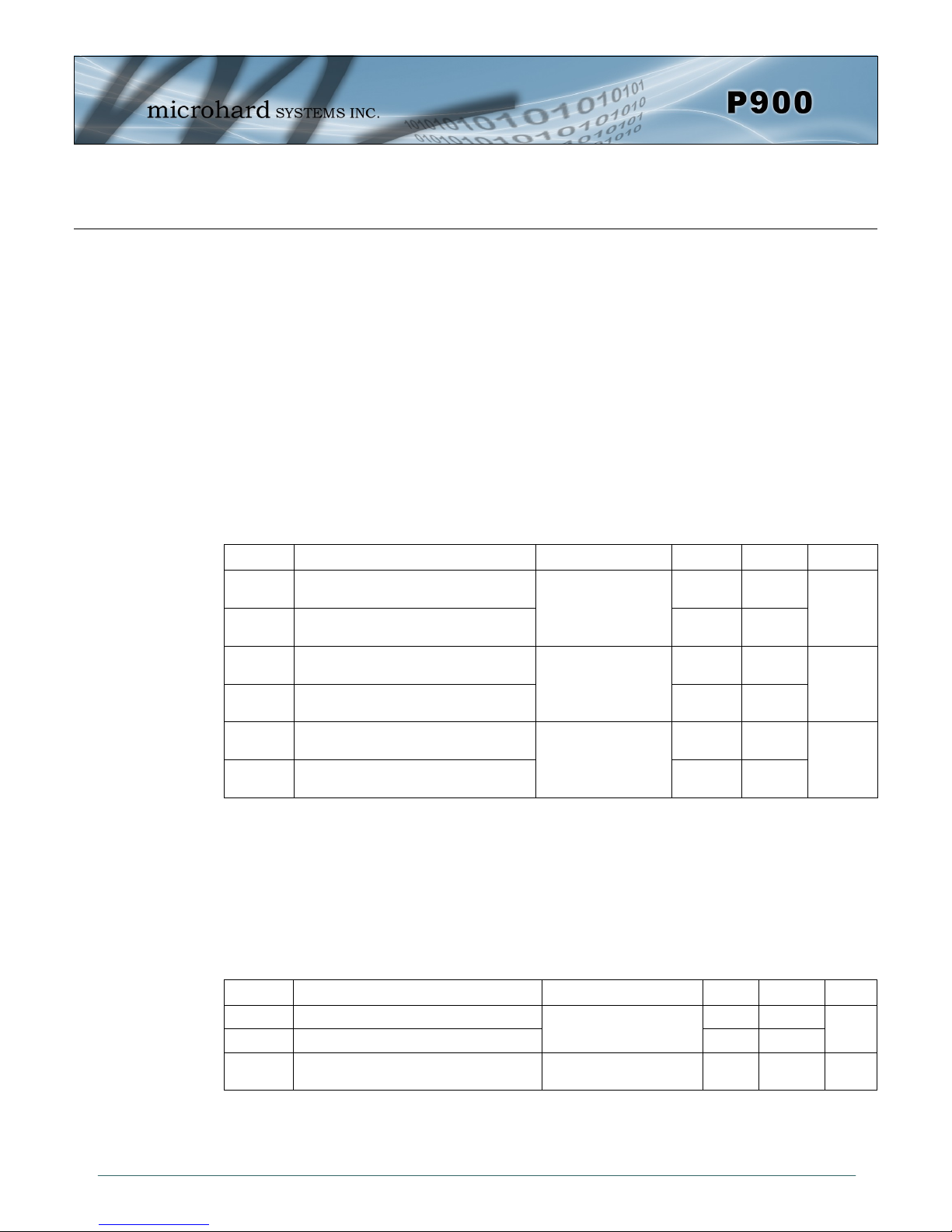

NRST Pin Characteristics

The NRST pin input driver uses CMOS technology. It is connected to a permanent pull-up

resistor, RPU (see Table 2-7).

Symbol Parameter Conditions Min Max Unit Typ

V

NRST Input low level voltage -0.5 0.7

IL(NRST)

V

IH(NRST)

V

hys(NRST)

RPU Weak pull-up equivalent resistor VIN=VSS 30 50 kΩ 40

VNF NRST Input pulse 300 ns

NRST Input high level voltage

NRST Schmitt trigger voltage hysteresis mV 200

Table 2-12 NRST Pin Characteristics

2 VDD+0.5

V

Pico Series

Figure 2-3 Recommended NRST Pin Protection

2.4.3.5 12-bit ADC Characteristics

The parameters given in Table 2-11: ADC Characteristics are derived from tests performed

under the ambient temperature and supply voltage ratings of the Pico Series.

Symbol Parameter Min Max Unit

V

Conversion voltage range 0 3.0 V

AIN

R

Symbol Parameter Test Conditions Typ Max Unit

ET

EO

EG

ED

EL

External input impedance

AIN

Total unadjusted error

Offset error

Gain error

Differential linearity error

Integral linearity error

Table 2-13 12-bit ADC Characteristics

Table 2-14 ADC Accuracy

0 1.2 kΩ

1.3 2

1 1.5

0.5 1.5

0.7 1

0.8 1.5

LSB TA = 25OC

© Microhard Systems Inc. Confidential 25

Page 26

2.0 Hardware Description

ADC Accuracy Characteristics

[1LSB

= 3.0/4096]

IDEAL

Figure 2-4 ADC Accuracy Characteristics

© Microhard Systems Inc. Confidential 26

Page 27

2.0 Hardware Description

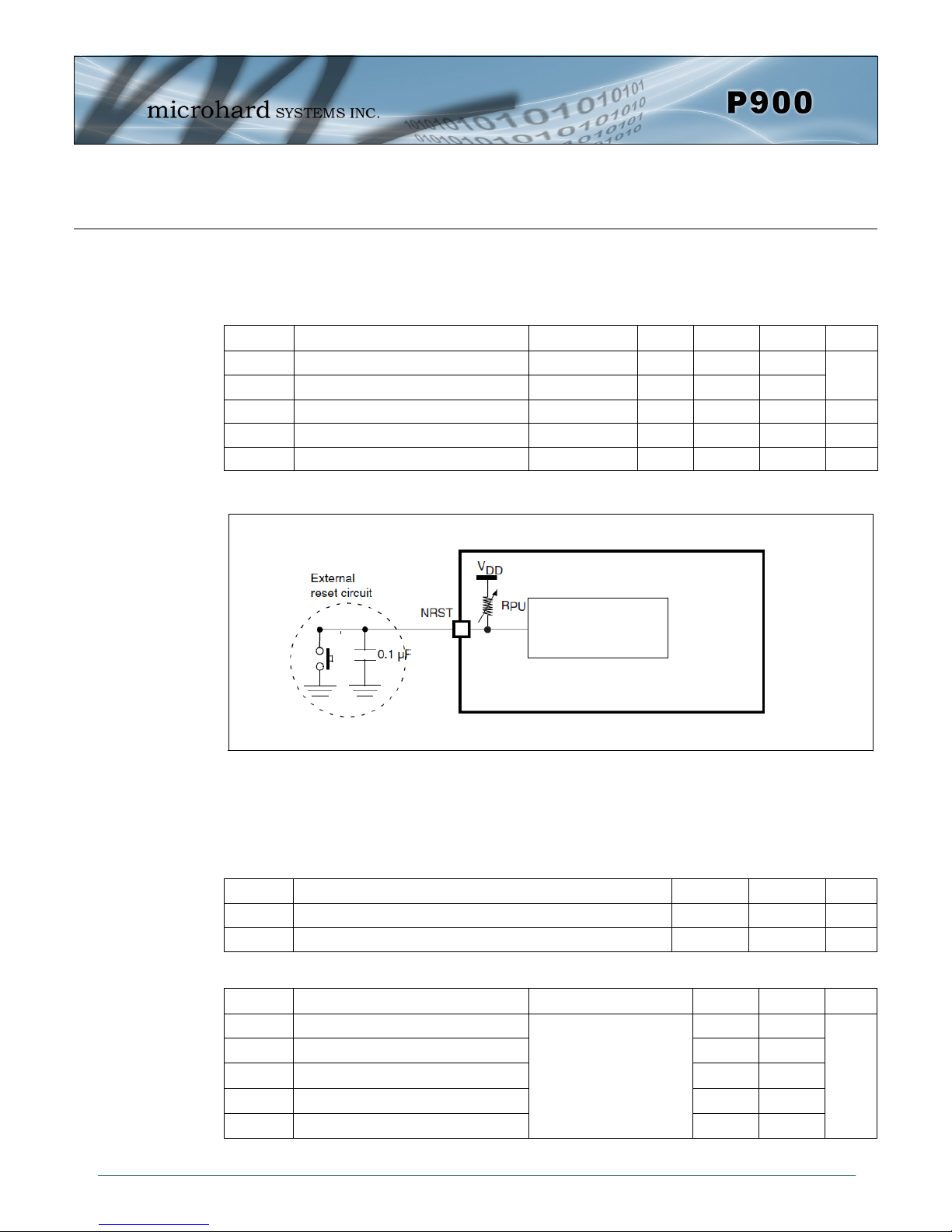

2.5 P900 to Nano n920 Pin-Outs

The following table shows a pin-out comparison between the P900 and the n920. This table

may be useful for customers who current have the n920 who wish to migrate to the P900

platform.

Pin Name P900 Pin No. n920 Pin No. Description

USR1 7 35

USR2 8 37

USR3 9 39

USR_AN0 15 9

USBDP 18 25

USBDM 19 21

LED_1 (RSSI1) 20 30 Rec eive Signal Strength Indicator 1.

LED_2 (RSSI2) 21 28 Rec eive Signal Strength Indicator 2.

LED_3 (RSSI3)

For detailed pin

descriptions refer to

Section 2.3 Pin Description.

LED_RX 23 22 Active high output indicates receive and synchronization status.

LED_TX 24 24 Active high output indicates module is transmitting RF data.

Serial RING 27 38

Serial RxD 28 42 Receive Data. Logic level input into the modem.

Serial TxD 29 44 Transmit Data. Logic level Output from the modem.

Serial DSR 30 36 Data Set Ready. Active low output.

Serial CTS 31 32 Clear To Send. Active low output.

Serial DTR 32 40 Data Terminal Ready. Active low input.

Serial DCD 33 46 Data Carrier Detect. Active low output.

Serial RTS 34 34 Request To Send. Active low input.

USR SCK 35 50

Control RxD 37 20 Diagnostics receive data.

Control TxD 38 18 Diagnostics transmit data.

Vbat 42 17 Battery Voltage sensing analog input line.

RSMode 44 19

!RESET 45 15 Active low input will reset the module.

!CONFIG 46 13 A ctive low input signal to put module into default serial mode.

Wakeup_usr 47 11 Active high input used to wake the model from sleep mode.

!Bootpgm_mode 48 7

CANTX 50 12

CANRX 51 10

Vdd 62 Positive voltage supply voltage for the digital section of the module (3.3V).

Vcc 63,64 Positive voltage supply voltage for the radio module (3.3V).

Vcc2 75,76,77 N/A

*Currently Not Supported. For Future Expansion*

*Reserved for future use.*

*Reserved for future use.*

Analog Input 0. *Future Use.*

*Currently Not Supported. For Future Expansion*

*Currently Not Supported. For Future Expansion*

22 26

51,53,55,57,59

Receive Signal Strength Indicator 3.

*Reserved for future use.*

*Currently Not Supported. For Future Expansion*

*Reserved for future use.*

*Reserved for future use.*

*Currently Not Supported. For Future Expansion*

*Currently Not Supported. For Future Expansion*

*Reserved for future use.*

Table 2-15: P900 to Nano n920 Pin Description

© Microhard Systems Inc. Confidential 27

Page 28

2.0 Hardware Description

2.6 P900 Enclosed

The Pico Enclosed provides a standalone P900 with standard interfaces for Data, Power and

Antennas. The P900 Enclosed is ideal for base stations or applications where complicated

integration of the OEM module is not required, but a modem with a small footprint is still

required. The P900 Enclosed can also be used to quickly evaluate the features and

performance of the P900 modems.

The P900 Enclosed provides quick access to several of the interfaces of the P900, such as:

Input Power (9-30VDC)

Power LED (Blue)

RS232/RS485 Data Interface

RSSI LED Indicators (Green)

TX/RX LED Indicators (Red/Green)

CONFIG Button

Antenna

USB Port (Diagnostic Port)

I/O pins (Future Development)

© Microhard Systems Inc. Confidential 28

Image 2-4: P900 Enclosed

Page 29

65.40

78.48

49.00

12.00

46.00

26.00

49.00

2.0 Hardware Description

2.6.1 P900 Enclosed Dimensional Drawings

Drawing 2-7: P900 Top View

Drawing 2-8: P900 Enclosed End Views

© Microhard Systems Inc. Confidential 29

Drawing 2-9: P900 Enclosed Side View

Notes: The dimension unit is mm.

Page 30

12.5

12.5

20.1

23.7

4.0

4.0

12.2

17.2

65.2

47.4

45.0

30.0

54.0

20.1

2.0 Hardware Description

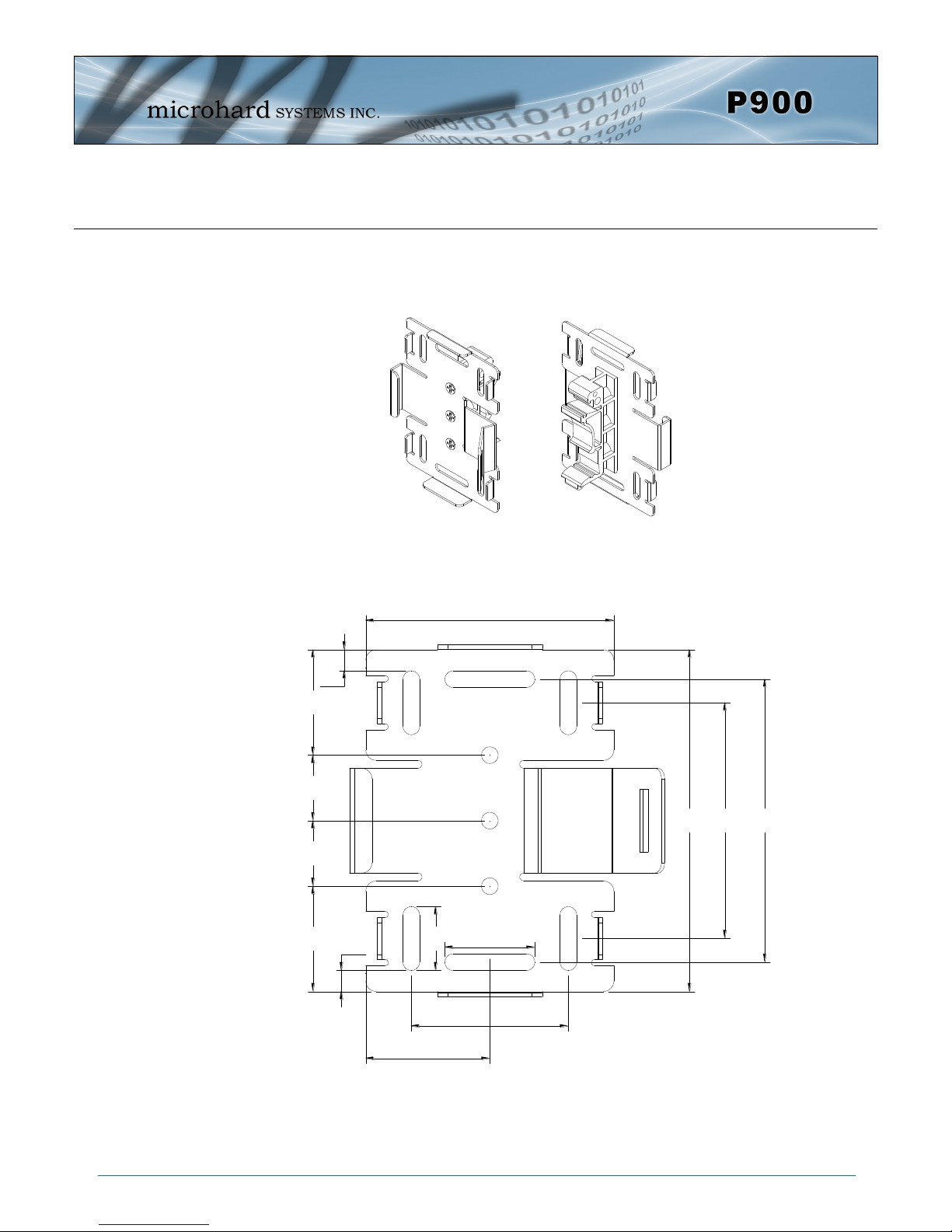

2.6.2 P900 Enclosed Mounting Bracket (Order Option)

Drawing 2-10: P900 –ENC Mounting Bracket Front/Rear (Shown optional TS35 DIN Rail Mount)

© Microhard Systems Inc. Confidential 30

Drawing 2-11: P900 –ENC Mounting Bracket Top View

Notes: The dimension unit is mm.

Page 31

2.0 Hardware Description

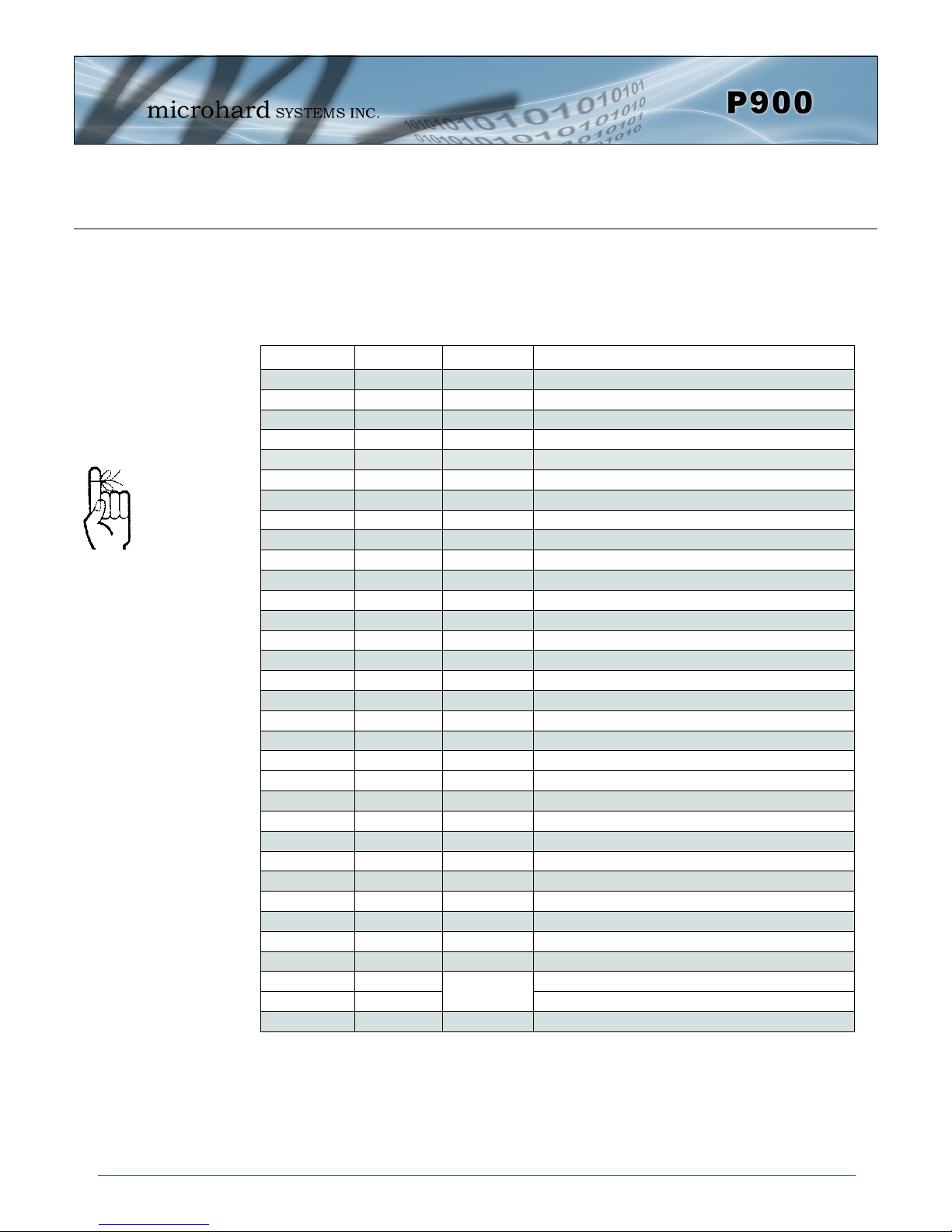

2.6.3 P900 Enclosed Connectors & LED Indicators

Drawing 2-12: Connectors & LED’s (Top & End)

PWR (Blue)

This LED will illuminate when the P900 Enclosed is connected to a power source (9-30 VDC)

485 (Blue)

This LED will illuminate when the P900 Enclosed Data port is configured as a RS485 port.

(Register S142 Serial Channel Mode set to RS485 and Handshaking set to &K1)

TX LED (Red)

When illuminated, this LED indicates that the modem is transmitting data over the air.

RX LED (Green)

This LED indicates that the modem is synchronized and has received valid packets.

Receive Signal Strength Indicator (RSSI) (3x Green)

As the received signal strength increases, starting with the furthest left, the number of active

RSSI LEDs increases. Signal strength is calculated based on the last four valid received

packets with correct CRC. The value of RSSI is reported in S123.

MODE Unit Type

COMMAND All OFF OFF OFF

DATA P.Coordinator

DATA - during sync.

acquisition

DATA - when

synchronized

S.Coordinator

S.Coordinator

Remote/

Standby

S.Coordinator

Remotes/

Standby

RX/SYNC TX RSSI 1,2,3

ON while receiving valid

data

OFF OFF Cycling with 300ms ON time

ON while synced ON when

LED STATUS

ON while

Transmitting data

transmitting

1-3 ON in proportion to signal

strength received from remotes.

1-3 ON in proportion to signal

strength received from Coordinator

© Microhard Systems Inc. Confidential 31

Table 2-16: LED Operation

Page 32

Vin+

Vin-

IO-1

IO-2

2.0 Hardware Description

CFG Button

Holding this button while powering-up the modem will boot the unit into COMMAND mode:

the default serial interface will be active and temporarily set to operate at its default serial

settings of RS232 and 9600/8/N/1.

USB

Micro-AB USB Port. Internal USB to Serial Converter.

Provides access to the Serial Diagnostics Port.

The SERIAL (RS232/485 Port (DCE)) on the

Enclosed model is for:

RS232/485 Serial data when in DATA

MODE, or

for configuring the modem when in

COMMAND MODE.

Vin+/Vin– is used to power the unit. The input Voltage

range is 9-30 Vdc.

IO-1 / IO-2

Programmable I/O. Not currently supported in firmware.

Future Development.

ANT

RP-SMA Female Bulkhead Antenna connector.

Caution: Using a

power supply that

does not provide

proper voltage may

damage the modem.

Drawing 2-13: Connectors & LED’s (Front & Back)

Pin

No.

1 DCD

2 RXD TX- Data-

3 TXD RX+

4 DTR

5 Ground

6 DSR

7 RTS RX-

8 CTS TX+ Data+

9 N/C

Table 2-17: Data DB9 Pin Assignments

RS232

RS485

Full-Dup

RS485

Half-Dup

© Microhard Systems Inc. Confidential 32

Page 33

3.0 Mesh Configuration

To begin configuration, the P900 must be mounted into a either a Microhard supplied development board (with factory attached interface card), or be mounted into a customer designed

platform. The P900 is configured using AT commands through the Data port, or using special

diagnostic commands through the Diagnostic Port. Refer to Section 2: Hardware Descrip-

tion for information related to interfacing to, or powering the module.

To issue AT commands through the Data port, the P900 must first be set into Command

Mode as described below.

3.1 Configuration/Unit Modes

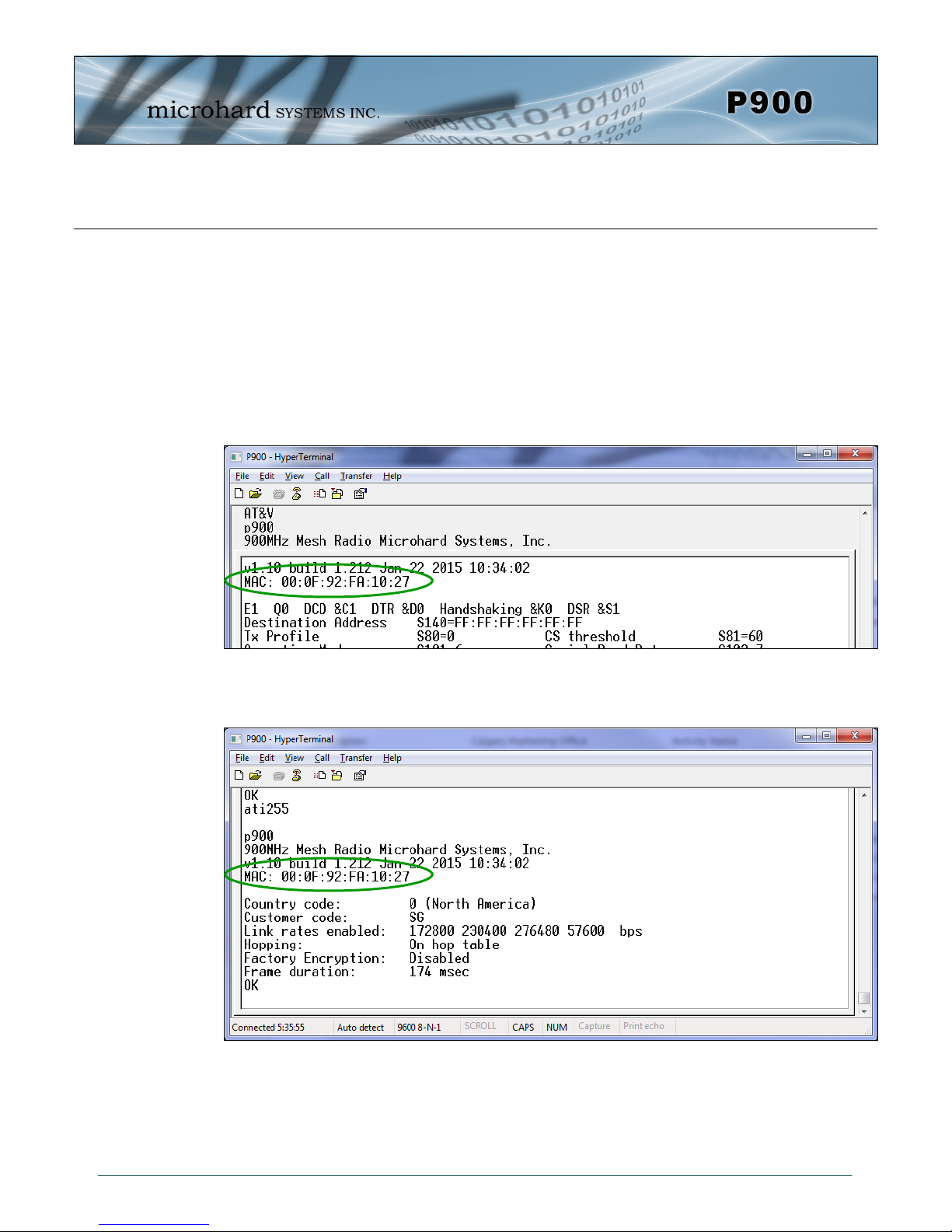

3.1.1 Command Mode

the P900 module is offline (data is not passing through the unit via it’s local data lines

or RF communications)

if installed in a Development Board, the only LED illuminated will be the blue power

LED.

the P900’s configuration options (registers) may be viewed and modified using AT

commands.

Two methods are typically used to place the Pico Series into Command Mode.

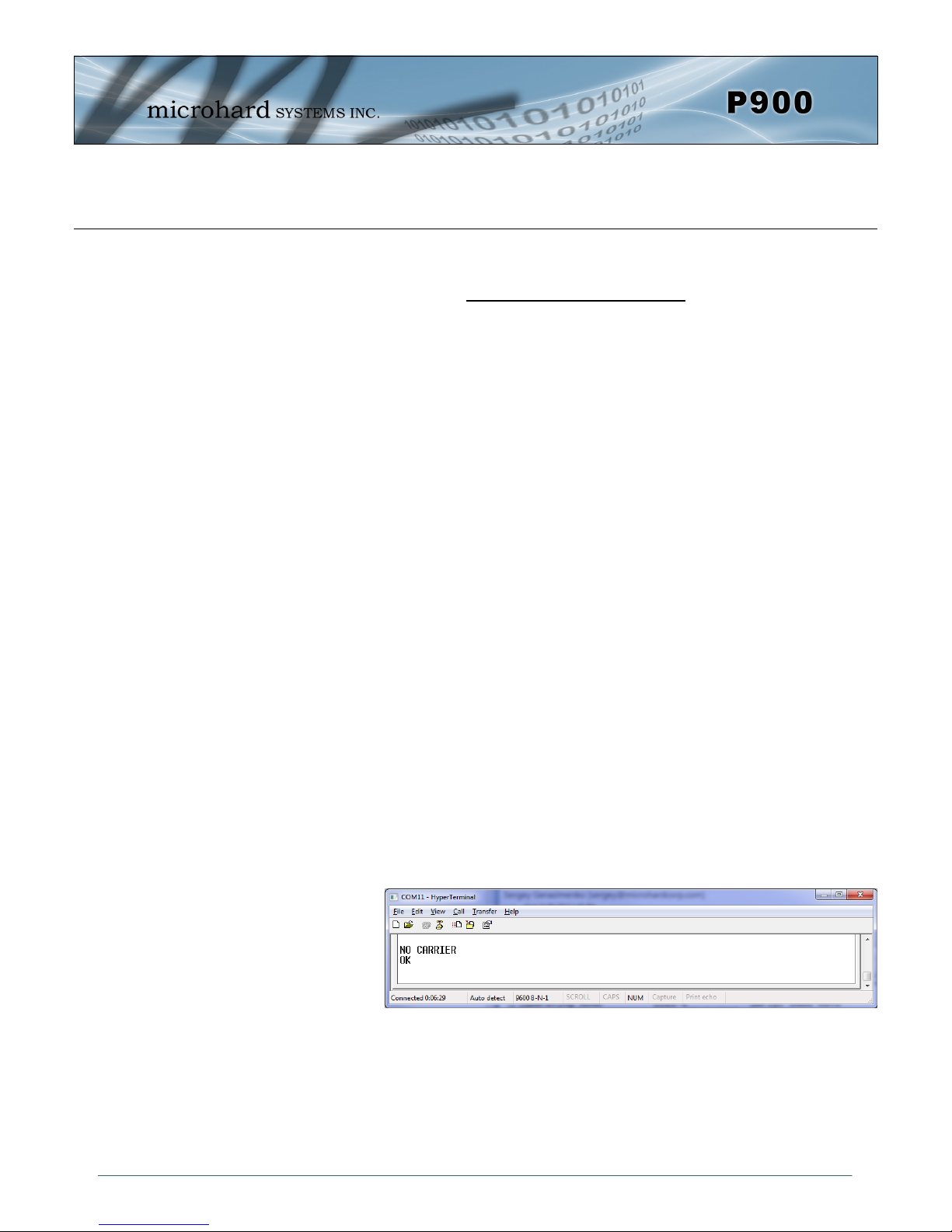

1. Force to Command Mode

Power down off the Development Board assembly.

Connect a 9-pin straight-through serial cable from the PC serial port to the rear RS-

232 port (DATA) of the modem.

Launch a terminal communications program (e.g. HyperTerminal) and configure for

9600 bps, 8 data bits, No parity, 1 stop bit (8N1), no flow control

press and hold the CONFIG button

continue to press the CONFIG button and apply power to the modem

release the CONFIG button

On power up the terminal session window should show “NO CARRIER OK” as seen

below:

the P900 is now in command mode, and AT commands can be used to configure or

query the settings. AT&V will display the current configuration, and the registers can

be queried using the ATSXXX=? Command where XXX = the register number. Help is

available using the ATSXXX /? Command.

Any and all changes must be written to NVRAM using the AT&W command.

Image 3-1: Command Mode

© Microhard Systems Inc. Confidential 33

Page 34

3.0 Mesh Configuration

2. Escape from Data Mode

With the P900 powered up and ‘online’, connect a 9-pin straight-through serial cable

from the PC serial port to the RS-232 DATA port on the dev board.

Launch a terminal program (e.g. HyperTerminal) and configure for the P900’s estab-

lished serial baud rate parameters (PC & modem must match).

Pause 1 second, type ‘+++’ , pause 1 second: the monitor should show the module

response of ‘NO CARRIER OK’

The P900 is now in command mode, and AT commands can be used to configure or

query the settings.

Entering the AT&V command as shown will show the current configuration as seen

below: (The data displayed varies based on network and unit type.)

3.1.2 Data Mode

Data Mode is the normal operational state of all deployed P900 modules. In this mode the module is

prepared to exchange data as per its configuration settings. Available LED indications can provide an

indication of the data exchange (TX and RX LEDs).

To enter DATA mode from COMMAND mode, enter the command: ATA [Enter]

Image 3-2: Command Mode

Image 3-3: Command Mode - AT&V Display

© Microhard Systems Inc. Confidential 34

Page 35

3.0 Mesh Configuration

3.2 Mesh Network

In a Mesh Network Topology, radios can communicate with each other directly or, if required, through

another mesh node. In traditional Point to Multipoint (PMP) and Point to Point (PP or PTP) network topologies a Master is used to not only keep the network synchronized in frequency and time

(synchronization), but all data is also routed through the Master. Using Mesh, data can be sent directly

between devices without the need to route all data through a single unit, which, when offline, brings

down the entire network.

In situations where a direct path is not available between source and destination units, routing can be

enabled to find and provide route information to ensure that data is delivered to the required destination.

A Mesh network can be designed in such a way that redundant paths are available for data transfer,

unknown routes can be auto discovered, and the best path is used to reach the intended destination. If

a path or route changes due to a unit going offline, or moving such as in a mobile application, the network can heal itself by finding a new path to the destination. All this is done without data being routed

through a single point as seen in traditional PMP and P2P networks. Routing features can be enabled

on any unit, coordinators or remotes. Enabling routing on multiple units provides the greatest redundancy, eliminating the risk of any single point of failure.

Any frequency hopping network, even a Mesh Network requires that at least one unit be tasked with the

job (primary coordinator) of making sure all units in the network are hopping at the same time, on the

same frequency. This is accomplished by sending out synchronization data for all units to hear. If the

network grows, or additional coverage is required, additional units can also be tasked with the job of

synchronization (secondary coordinators).

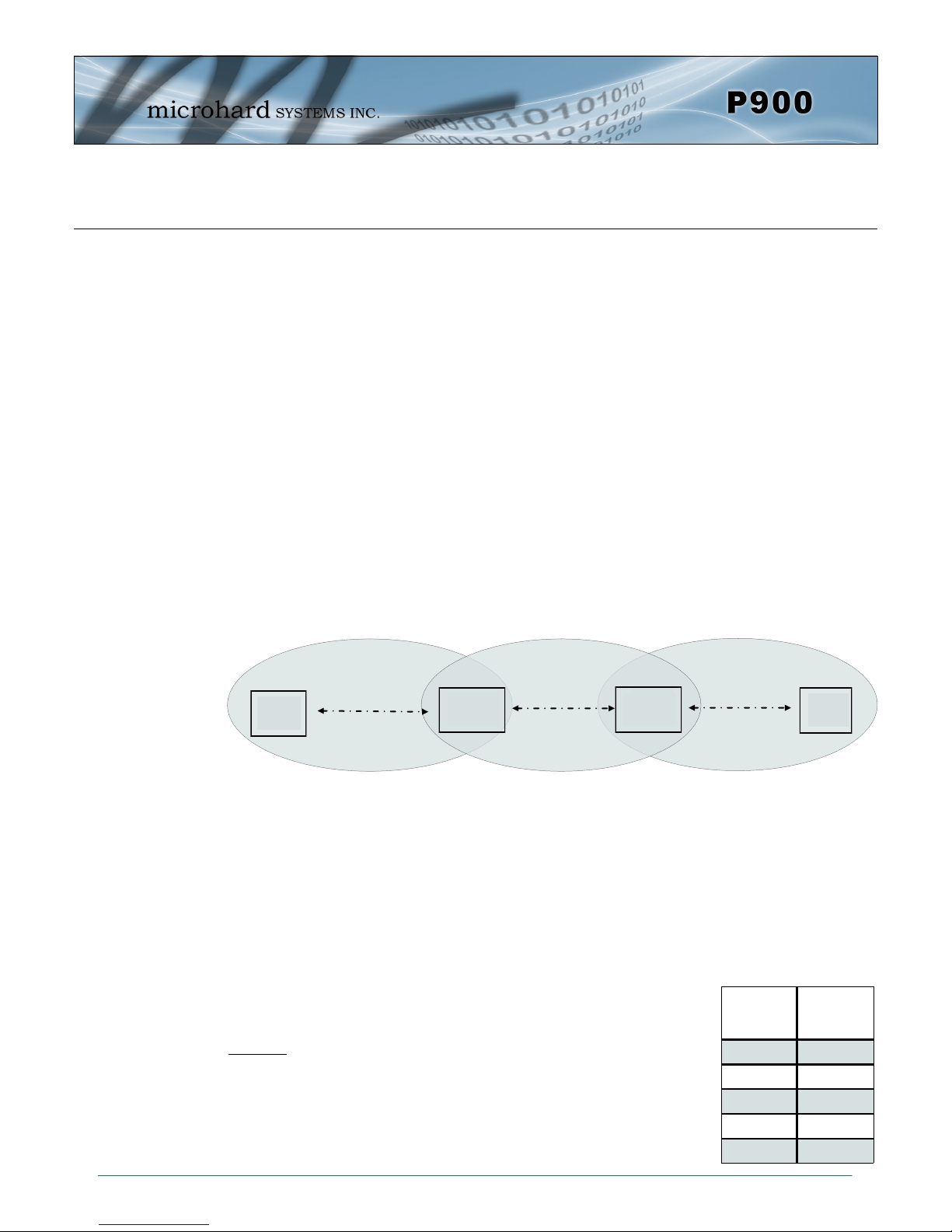

As seen in the illustration below, there are many paths that data could take to each any destination in a

Mesh network. Mesh Networking generally results in achieving extensive network redundancy. Mesh is

enabled by setting register S133 to 2 or 3 (for Mesh with Roaming) (ATS133=2 or ATS133=3, Network

Type).

Mesh

Mesh

Mesh

Mesh

Mesh

© Microhard Systems Inc. Confidential 35

Mesh

Drawing 3-1: Mesh Network Topology

Mesh

Page 36

3.0 Mesh Configuration

3.2.1 Operating Modes / Unit Types

In a Microhard Mesh Network, there are four unit types or operating modes that are available: the Primary Coordinator, the Secondary Coordinator, the Standby Coordinator, and the Remote. Any P900

module can be configured to perform any of these roles, the paragraphs and diagrams that follow attempt to describe the purpose of each unit.

The Primary Coordinator’s role is to provide network synchronization for the system, which ensures all

units are active and able to communicate as required. In any Mesh Network, there can only be a single

Primary Coordinator. Additional coordinators can be deployed for redundancy and/or, to extended network coverage to areas not serviced by the Primary Coordinator. For any units to be able to communication in a Mesh Network, they must be able to hear synchronization data from a coordinator.

What if the Primary Coordinator goes offline or fails? A second unit, called a Standby Coordinator can

be deployed to monitor the network synchronization level, and take over the duties of the Primary Coordinator should it ever fail. For this reason the primary coordinator should not be used to interface with an

end device, but rather left to perform the duties of network synchronization. If used to interface with an

end device, and it fails, the Standby Coordinator will have a unique units address, different from that of

the Primary Coordinator. Any data that was destined for the Primary Coordinator will not automatically

be routed to the Standby Coordinator.

Although routing can be enabled on a Primary Coordinator, data is not automatically routed through the

Primary, or any other coordinator for that matter. This is mentioned to stress that the role of a coordinator of any type is to simply keep the network synchronized in time and frequency.

The diagram below shows a unit configured as a Primary Coordinator. Any other mesh unit that can

hear the Primary Coordinator can participate in a Mesh Network.

Primary

Coordinator

Mesh

© Microhard Systems Inc. Confidential 36

P.C.

Mesh

Drawing 3-2: Primary Coordinator

Mesh

Page 37

3.0 Mesh Configuration

Secondary Coordinators are used to extend the coverage of the Primary Coordinator. More than one

Secondary Coordinator can be used for redundancy or to ensure adequate network coverage. A Secondary Coordinator must be able to communicate with the Primary Coordinator and/or another Secondary

Coordinator to ensure proper synchronization to the units it services.

Although any and all units in a Mesh Network can be designated as a secondary coordinator, the number and placement of coordinators deployed should be taken into consideration. The reason for this is

that network synchronization is achieved by occasionally sending synchronization packets. The greater

the number of coordinators deployed, the more sync data that will be broadcast on the network, and the

higher the potential for collisions. During each Mesh Frame (or hop), a certain number of slots are set

aside for network synchronization data, allowing coordinators an opportunity to send their sync data.

Adding a large number of Secondary Coordinators may require changing the values for the both the

number of sync slots in a mesh frame and the interval at which Secondary Coordinators send sync data.

Increasing the number of sync slots gives more opportunity for sync data to be transmitted, but it adds

system latency as more time during each frame is spent on synchronization. Decreasing the interval that

synchronization packets are sent by each coordinator, results in it taking a long time for units to synchronize with the network once they have been brought online. Ideally a balance between the two can

be found which minimizes the impact of the overall system performance. It should also be clear at this

point, that adding an excessive number of coordinators may not be the best design practice.

Secondary Coordinators are ideal candidates for being configured for routing. As they are generally

positioned to provide coverage for multiple units. More than 1 unit should be configured for routing.

Should one unit go offline, another with routing also enabled can continue to provide routing services.

The following illustration shows the previous network coverage being extended by adding a secondary

coordinator.

Primary

Coordinator

P.C.

Mesh

Mesh

Secondary

Coordinator

S.C

Mesh

Mesh

Mesh

© Microhard Systems Inc. Confidential 37

Drawing 3-3: Secondary Coordinator

Page 38