Page 1

Operating Manual

IP-921

900MHz Wireless Ethernet Bridge/Serial Gateway

Document: IP9xx Series.OM.F200.Rev3.3wc

May 2011

Page 2

Important User Information

Warranty

Microhard Systems Inc. warrants that each product will be free of defects in material and workmanship for a period of one (1)

year for its products. The warranty commences on the date the product is shipped by Microhard Systems Inc. Microhard Systems

Inc.’s sole liability and responsibility under this warranty is to repair or replace any product which is returned to it by the Buyer

and which Microhard Systems Inc. determines does not conform to the warranty. Product returned to Microhard Systems Inc. for

warranty service will be shipped to Microhard Systems Inc. at Buyer’s expense and will be returned to Buyer at Microhard Systems Inc.’s expense. In no event shall Microhard Systems Inc. be responsible under this warranty for any defect which is caused

by negligence, misuse or mistreatment of a product or for any unit which has been altered or modified in any way. The warranty

of replacement shall terminate with the warranty of the product.

Warranty Disclaims

Microhard Systems Inc. makes no warranties of any nature of kind, expressed or implied, with respect to the hardware, software,

and/or products and hereby disclaims any and all such warranties, including but not limited to warranty of non-infringement,

implied warranties of merchantability for a particular purpose, any interruption or loss of the hardware, software, and/or product,

any delay in providing the hardware, software, and/or product or correcting any defect in the hardware, software, and/or product,

or any other warranty. The Purchaser represents and warrants that Microhard Systems Inc. has not made any such warranties to

the Purchaser or its agents MICROHARD SYSTEMS INC. EXPRESS WARRANTY TO BUYER CONSTITUTES MICRO-

HARD SYSTEMS INC. SOLE LIABILITY AND THE BUYER’S SOLE REMEDIES. EXCEPT AS THUS PROVIDED, MI-

CROHARD SYSTEMS INC. DISCLAIMS ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PROMISE.

MICROHARD SYSTEMS INC. PRODUCTS ARE NOT DESIGNED OR INTENDED TO BE USED IN

ANY LIFE SUPPORT RELATED DEVICE OR SYSTEM RELATED FUNCTIONS NOR AS PART OF

ANY OTHER CRITICAL SYSTEM AND ARE GRANTED NO FUNCTIONAL WARRANTY.

Indemnification

The Purchaser shall indemnify Microhard Systems Inc. and its respective directors, officers, employees, successors and assigns

including any subsidiaries, related corporations, or affiliates, shall be released and discharged from any and all manner of action,

causes of action, liability, losses, damages, suits, dues, sums of money, expenses (including legal fees), general damages, special

damages, including without limitation, claims for personal injuries, death or property damage related to the products sold hereunder, costs and demands of every and any kind and nature whatsoever at law.

IN NO EVENT WILL MICROHARD SYSTEMS INC. BE LIABLE FOR ANY INDIRECT, SPECIAL, CONSEQUENTIAL,

INCIDENTAL, BUSINESS INTERRUPTION, CATASTROPHIC, PUNITIVE OR OTHER DAMAGES WHICH MAY BE

CLAIMED TO ARISE IN CONNECTION WITH THE HARDWARE, REGARDLESS OF THE LEGAL THEORY BEHIND

SUCH CLAIMS, WHETHER IN TORT, CONTRACT OR UNDER ANY APPLICABLE STATUTORY OR REGULATORY

LAWS, RULES, REGULATIONS, EXECUTIVE OR ADMINISTRATIVE ORDERS OR DECLARATIONS OR OTHERWISE, EVEN IF MICROHARD SYSTEMS INC. HAS BEEN ADVISED OR OTHERWISE HAS KNOWLEDGE OF THE

POSSIBILITY OF SUCH DAMAGES AND TAKES NO ACTION TO PREVENT OR MINIMIZE SUCH DAMAGES. IN THE

EVENT THAT REGARDLESS OF THE WARRANTY DISCLAIMERS AND HOLD HARMLESS PROVISIONS INCLUDED

ABOVE MICROHARD SYSTEMS INC. IS SOMEHOW HELD LIABLE OR RESPONSIBLE FOR ANY DAMAGE OR INJURY, MICROHARD SYSTEMS INC.'S LIABILITY FOR ANYDAMAGES SHALL NOT EXCEED THE PROFIT REALIZED BY MICROHARD SYSTEMS INC. ON THE SALE OR PROVISION OF THE HARDWARE TO THE CUSTOMER.

Proprietary Rights

The Buyer hereby acknowledges that Microhard Systems Inc. has a proprietary interest and intellectual property rights in the

Hardware, Software and/or Products. The Purchaser shall not (i) remove any copyright, trade secret, trademark or other evidence

of Microhard Systems Inc.’s ownership or proprietary interest or confidentiality other proprietary notices contained on, or in, the

Hardware, Software or Products, (ii) reproduce or modify any Hardware, Software or Products or make any copies thereof, (iii)

reverse assemble, reverse engineer or decompile any Software or copy thereof in whole or in part, (iv) sell, transfer or otherwise

make available to others the Hardware, Software, or Products or documentation thereof or any copy thereof, except in accordance

with this Agreement.

IP9xx Series

© Microhard Systems Inc. CONFIDENTIAL 2

Page 3

Important User Information (continued)

IP9xx Series

About This Manual

It is assumed that users of the products described herein have either system integration or

design experience, as well as an understanding of the fundamentals of radio communications.

Throughout this manual you will encounter not only illustrations (that further elaborate on the

accompanying text), but also several symbols which you should be attentive to:

Caution or Warning

Usually advises against some action which could result in undesired or

detrimental consequences.

Point to Remember

Highlights a key feature, point, or step which is noteworthy. Keeping

these in mind will simplify or enhance device usage.

Tip

An idea or suggestion to improve efficiency or enhance usefulness.

Information

Information regarding a particular technology or concept.

© Microhard Systems Inc. CONFIDENTIAL 3

Page 4

Important User Information (continued)

Regulatory Requirements

To satisfy FCC RF exposure requirements for mobile transmitting devices, a separation

distance of 23cm or more should be maintained between the antenna of this device and

persons during device operation. To ensure compliance, operations at closer than this

WARNING

distance is not recommended. The antenna being used for this transmitter must not be

co-located in conjunction with any other antenna or transmitter.

This device can only be used with Antennas listed in Appendix D. Please contact

Microhard Systems Inc. if you need more information or would like to order an antenna.

IP9xx Series

WARNING

MAXIMUM EIRP

FCC Regulations allow up to 36dBm Effective Isotropic Radiated Power (EIRP).

Therefore, the sum of the transmitted power (in dBm), the cabling loss and the antenna

WARNING

gain cannot exceed 36dBm.

EQUIPMENT LABELING

This device has been modularly approved. The manufacturer, product name, and FCC

and Industry Canada identifiers of this product must appear on the outside label of the

WARNING

end-user equipment.

SAMPLE LABEL REQUIREMENT:

For IP921/SIP921 OEM Series For IP920A OEM Series, IP920LC

921 Series 920 Series

FCCID: NS906P21

IC: 3143A-06P21

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received including interference that may cause

undesired operation.

FCCID: NS905P20

IC: 3143A-05P20

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference,

and (2) this device must accept any interference

received including interference that may cause

undesired operation.

Please Note: These are only sample labels; different products contain different identifiers. The

actual identifiers should be seen on your devices if applicable.

© Microhard Systems Inc. CONFIDENTIAL 4

Page 5

IP9xx Series

CSA Class 1 Division 2 Option

CSA Class 1 Division 2 is Available Only on

Specifically Marked Units

If marked this for Class 1 Division 2 – then this product is available

for use in Class 1, Division 2, in the indicated Groups on the product.

In such a case the following must be met:

The transceiver is not acceptable as a stand-alone unit for use in

hazardous locations. The transceiver must be mounted within a

separate enclosure, which is suitable for the intended application.

Mounting the units within an approved enclosure that is certified for

hazardous locations, or is installed within guidelines in accordance

with CSA rules and local electrical and fire code, will ensure a safe

and compliant installation.

The antenna feed line; DC power cable and interface cable must be

routed through conduit in accordance with the National Electrical

Code.

Do not connect or disconnect equipment unless power has been

switched off or the area is known to be non-hazardous.

Installation, operation and maintenance of the transceiver should be

in accordance with the transceiver‘s installation manual, and the

National Electrical Code.

Tampering or replacement with non-factory components may

adversely affect the safe use of the transceiver in hazardous

locations, and may void the approval.

The wall adapters supplied with your transceivers are NOT Class 1

Division 2 approved, and therefore, power must be supplied to the

units using the screw-type or locking type connectors supplied from

Microhard Systems Inc. and a Class 1 Division 2 power source within

your panel.

If you are unsure as to the specific wiring and installation guidelines

for Class 1 Division 2 codes, contact CSA International.

© Microhard Systems Inc. CONFIDENTIAL 5

Page 6

Revision History

Revision 3.3 September 2010

IP9xx Series

Added VLAN Information, misc formatting and updates.

Revision 3.2 April 22, 2008

Added SIP921 Section

Revision 3.1 December 01, 2007

Based on: Ref. 6.1.2 FPGA Version 1R4, Software Version 2.0.0; Ref. 6.1.8/Radio Info. Version 3.1092ip

Updated formatting, added Appendix C.

Revision 3.0 May 07, 2007

Based on: Ref. 6.1.2 FPGA Version 1R4, Software Version 2.0.0; Ref. 6.1.8/Radio Info. Version 3.1092ip

Revision 2.0 November 20, 2006

Based on: Ref. 6.1.2 FPGA Version 1R4, Software Version 1.3.4; Ref. 6.1.8/Radio Info. Version 3.1082ip

© Microhard Systems Inc. CONFIDENTIAL 6

Page 7

IP9xx Series

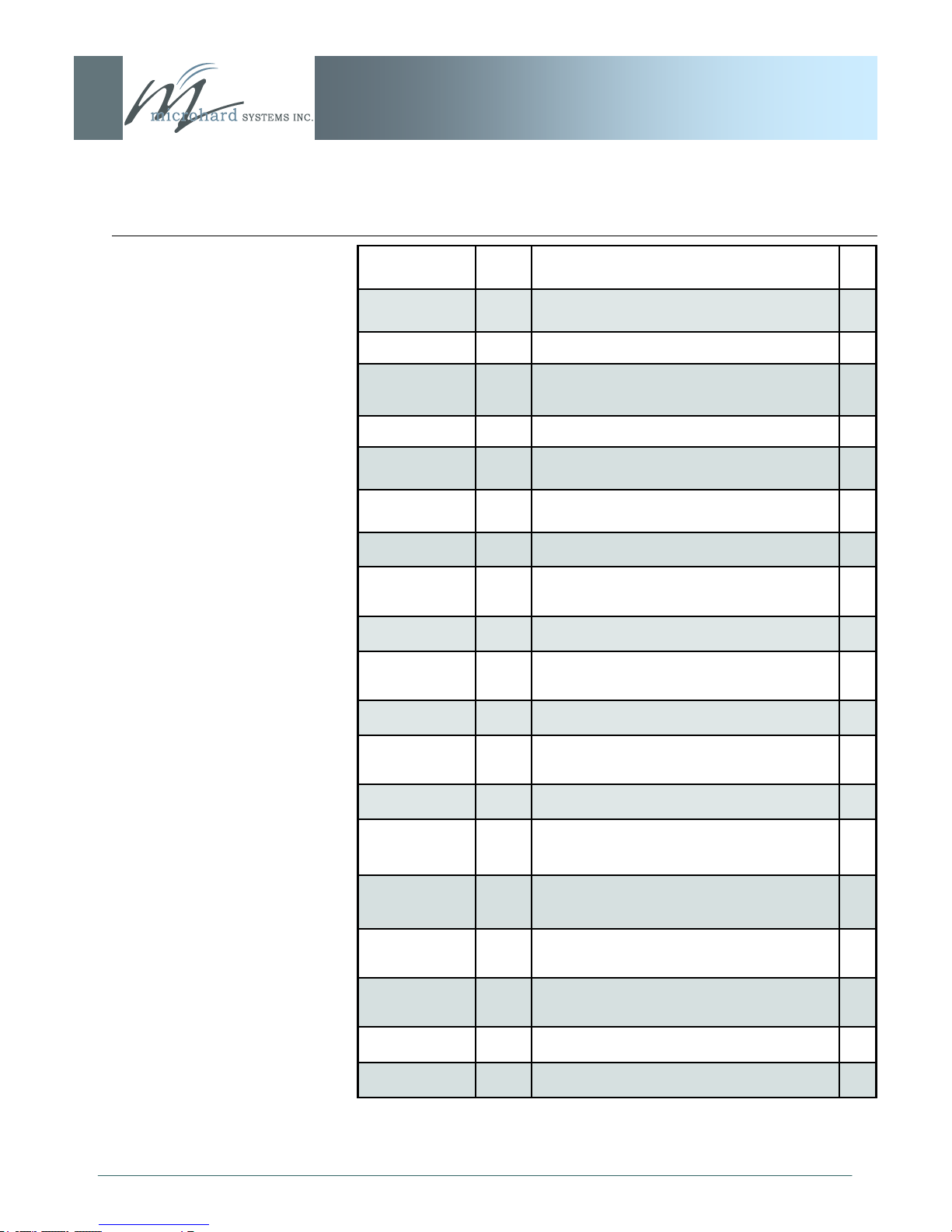

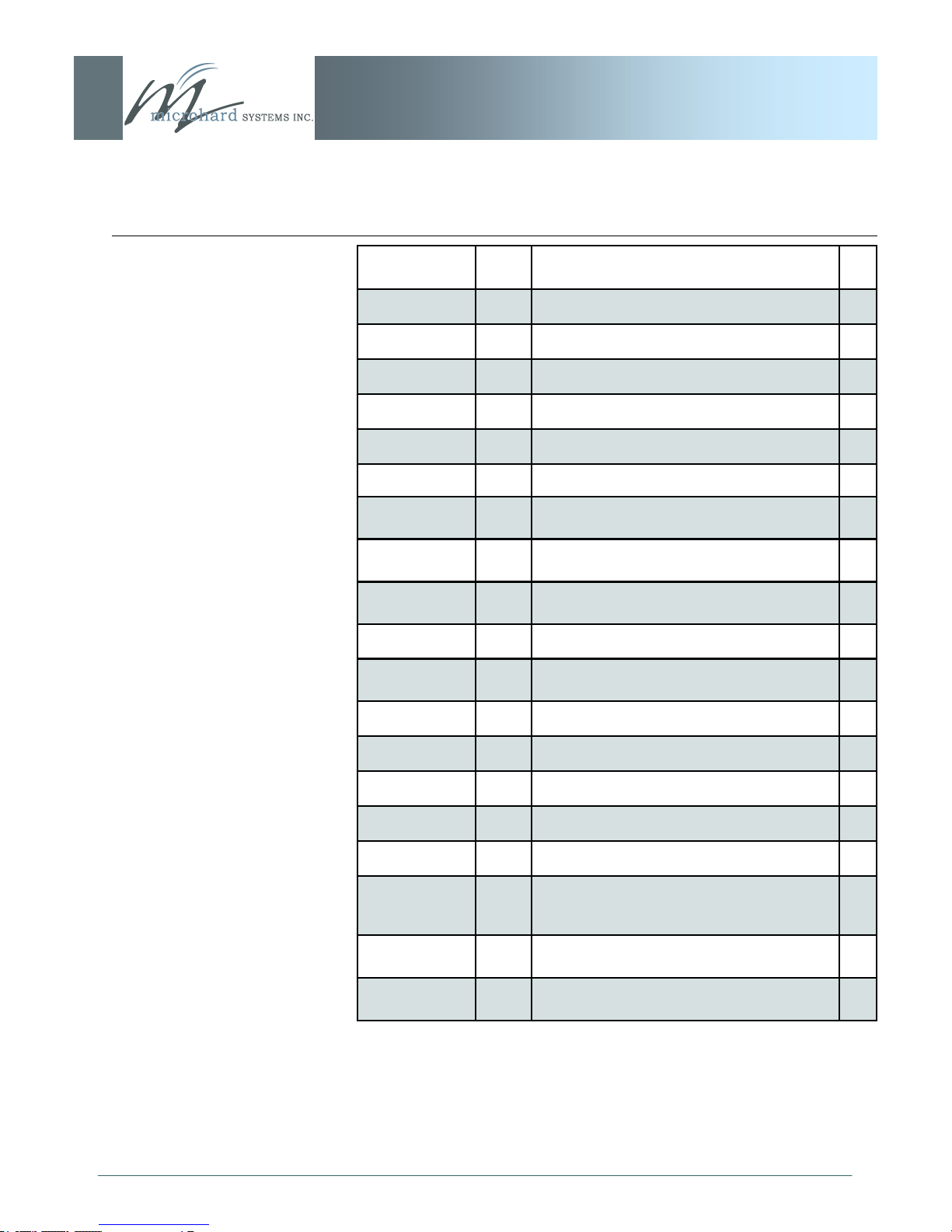

Table of Contents

1.0 Overview 10

1.1 Performance Features ............................................................................................................... 12

1.2 Specifications ............................................................................................................................ 12

2.0 QUICK START 13

2.1 Factory Default/Reset Method ................................................................................................... 13

2.2 Text User Interface Method ....................................................................................................... 15

2.21 Required Materials ......................................................................................................... 15

2.22 Set-Up Procedure .......................................................................................................... 15

3.0 Hardware Features 19

3.1 IP9xx Connections ..................................................................................................................... 19

3.1.1 Front ............................................................................................................................... 19

3.1.2 Rear ................................................................................................................................ 21

3.2 IP9xx Indicators ......................................................................................................................... 23

3.2.1 Front ............................................................................................................................... 23

3.2.2 Rear ................................................................................................................................ 24

3.3 SIP921 Connections .................................................................................................................. 25

3.3.1 SIP921 Pin-Out Description ........................................................................................... 26

4.0 Operating Modes 29

4.1 Master ....................................................................................................................................... 29

4.2 Repeater .................................................................................................................................... 29

4.3 Remote ...................................................................................................................................... 29

5.0 Network Topologies 30

Note: This section includes examples of configurations for each of the following:

5.1 Point-to-Point (PTP) .................................................................................................................. 30

5.2 Point-to-Multipoint (PMP) .......................................................................................................... 32

5.3 Peer-to-Peer (P2P) .................................................................................................................... 35

5.4 Everyone-to-Everyone (E2E)..................................................................................................... 38

6.0 Configuration 39

6.1 Web User Interface .................................................................................................................... 40

6.1.1 Logon Window ............................................................................................................... 41

6.1.2 Welcome Window .......................................................................................................... 43

6.1.3 System Configuration ..................................................................................................... 44

6.1.4 Network Configuration .................................................................................................... 47

6.1.4.1 Local IP Configuration ..................................................................................... 48

6.1.4.1.1 Bridge ............................................................................................ 48

6.1.4.1.2 Router ........................................................................................... 52

6.1.4.1.2.1 Wireless Port IP Configuration ............................. 53

6.1.4.1.2.2 VPN Configuration ................................................. 53

6.1.4.2 NTP Server Configuration ............................................................................... 57

continued...

© Microhard Systems Inc. CONFIDENTIAL 7

Page 8

IP9xx Series

Table of Contents (continued)

6.1.4.3 DHCP Server Configuration ............................................................................ 59

6.1.4.3.1 Bridge ............................................................................................ 59

6.1.4.3.2 Router ............................................................................................ 59

6.1.4.4 SNMP Agent Configuration ............................................................................. 65

6.1.4.5 Bridge Configuration ........................................................................................ 71

6.1.4.6 Quality of Service ............................................................................................ 72

6.1.4.7 VLAN ....................................................................................................... 74

6.1.5 Radio Configuration ....................................................................................................... 77

6.1.6 COM1 and COM2 Configuration .................................................................................... 95

6.1.7 Security Configuration .................................................................................................. 107

6.1.7.1 Admin Password Configuration ..................................................................... 109

6.1.7.2 Upgrade Password Configuration ................................................................. 107

6.1.7.3 Wireless Encryption Configuration ................................................................ 110

6.1.7.4 Discovery Service Configuration ................................................................... 114

6.1.7.5 UI (User Interface) Access Configuration ...................................................... 116

6.1.7.6 Authentication Configuration ......................................................................... 118

6.1.7.7 Firewall Configuration .................................................................................... 121

6.1.7.7.1 Policies ........................................................................................ 122

6.1.7.7.2 Rules ............................................................................................ 125

6.1.7.7.3 Port Forwarding ........................................................................... 129

6.1.7.7.4 MAC List ...................................................................................... 131

6.1.7.7.5 Blacklist........................................................................................ 133

6.1.7.7.6 Reset Firewall to Factory Default ................................................ 135

6.1.8 System Information ...................................................................................................... 137

6.1.9 System Tools ............................................................................................................... 143

6.1.9.1 System Maintenance ..................................................................................... 144

6.1.9.2 Reboot System .............................................................................................. 145

6.1.9.3 Reset System to Default ................................................................................ 146

6.1.9.4 Radio Channels Noise Level ......................................................................... 147

6.1.9.5 Network Discovery......................................................................................... 149

6.1.9.6 Logout ............................................................................................................ 150

6.2 Text User Interface .................................................................................................................. 151

7.0 Installation 155

7.1 Path Calculation ...................................................................................................................... 158

7.2 Installation of Antenna System Components .......................................................................... 159

7.2.1 Antennas ...................................................................................................................... 160

7.2.2 Coaxial Cable ............................................................................................................... 161

7.2.3 Surge Arrestors ............................................................................................................ 161

7.2.4 External Filter ............................................................................................................... 162

© Microhard Systems Inc. CONFIDENTIAL 8

Page 9

IP9xx Series

Table of Contents (continued)

Appendices

Appendix A: DiscoverIP Utility ....................................................................................................... 163

Appendix B: Upgrade Procedure (DOS Prompt) ........................................................................... 165

Appendix C: RS485 Wiring ............................................................................................................ 167

Appendix D: Approved Antennas .................................................................................................. 168

Appendix E: Mounting Dimensions ............................................................................................... 169

Appendix F: Serial Interface .......................................................................................................... 170

Appendix G: SIP921 Customer Interface Schematic ..................................................................... 171

© Microhard Systems Inc. CONFIDENTIAL 9

Page 10

1.0 Overview

A BRIDGE separates two network

segments within the same logical

network (subnet).

A ROUTER forwards data across

internetworks (different subnets).

A SERIAL GATEWAY allows

asynchronous serial data to enter

(as through a gate) the realm of IP

communications.

The serial data is encapsulated

within UDP or TCP packets.

IP9xx Series

The IP Series is a high-performance wireless ethernet bridge and

serial gateway. Alternately, a Master IP Series unit may be configured to operate as a wireless ethernet router (and serial gateway).

When properly configured and installed, long range communications

at very high speeds can be achieved.

The IP Series operates within the 902-928MHz ISM frequency band,

employing frequency hopping spread spectrum (FHSS) and also, for

1.1Mbps operation, digital transmission service (DTS) technology.

They provide reliable wireless ethernet bridge functionality as well

gateway service for asynchronous data transfer between most equipment types which employ an RS232, RS422, or RS485 interface.

The small size and superior performance of the IP Series makes it

SCADA

remote telemetry

traffic control

industrial controls

remote monitoring

LAN extension

ideal for many applications. Some typical uses for this modem:

1.1 Performance Features

GPS

wireless video

robotics

display signs

fleet management

© Microhard Systems Inc. CONFIDENTIAL 10

transmission within a public, license-exempt band of the radio

spectrum1 - this means that the modems may be used without

access fees or recurring charges (such as those incurred by

cellular airtime)

maximum allowable transmit power (1 Watt)

longest range

transparent, low latency link providing reliable wireless IP/

ethernet communications with constant baud rate over

distance

Key performance features of the IP Series include:

1 920-928MHz, which is license-exempt within North America, may need to be

factory-configured differently for other areas: contact Microhard Systems Inc.

Page 11

1.0 Overview

IP9xx Series

1.2 Specifications

Refer to the Specifications Sheet supplied to you for your particular model.

© Microhard Systems Inc. CONFIDENTIAL 11

Page 12

1.0 Overview

IP9xx Series

each unit supports all modes of operation (Master, Repeater,

Remote)

Repeater may also be used concurrently as a Remote unit

flexible wireless networking: point-to-point, point-to-multipoint,

peer-to-peer, store and forward repeater

communicates with virtually all PLCs, RTUs, and serial devices

through either one of two available RS232 interface, RS422, or

RS485

fastest serial rates: 300 baud to 921kbps

advanced serial port supports legacy serial devices, including

RTS, CTS, DSR, DTR, and DCD.

Easy to manage through web- or text-based user interface, or

SNMP

wireless firmware upgrades

system wide remote diagnostics

32-bit CRC, selectable retransmission

advanced security features

industrial temperature specifications

DIN rail mountable

Optional Class 1 Div 2

Available as OEM solution

© Microhard Systems Inc. CONFIDENTIAL 12

Supporting co-located independent networks and with the ability to

carry both serial and IP traffic, the IP Series supports not only network growth, but also provides the opportunity to migrate from

asynchronous serial devices connected today to IP-based devices

in the future.

Page 13

2.0 Quick Start

Use the MHS-supplied power

adapter or an equivalent power

source.

To ensure that the IP Series unit is

at its DEFAULT factory settings,

once it has powered-up and the

SYS LED is ON (after 1 minute),

press and hold the front CFG

button for 8 seconds - the SYS

LED will initially blink, then be on

solid, and then the unit will reset.

Note: Some OEM customers will

have their specific factory defaults

loaded.

IP9xx Series

This QUICK START guide will enable you to promptly establish basic

IP connectivity between a pair of IP Series in a point-to-point (ref.

5.1) configuration.

Note that the units arrive from the factory with a Radio Configuration

of ‗Remote‘ and the Local Network setting configured as ‗Static‘ (IP

Address 192.168.1.254, Subnet Mask 255.255.255.0, and Gateway

192.168.1.1).

2.1 Factory Default/Reset Method

2.11 Required Materials

2 IP Series (with (or set to) factory default configura

tion), each with Power Adapter and Rubber Ducky

Antenna

1 PC with NIC (ethernet) card

1 Crossover patchcable (ethernet)*

*dependent on desired test set-up

2.12 Set-Up Procedure

Connect a Rubber Ducky antenna to each IP Series.

Connect the Power Adapters to available 120VAC out-

lets, and to the IP Series. The SYS LED will blink for

approximately 1 minute while it readies itself for operation.

Using CROSSOVER ethernet patchcable, connect PC

NIC card to rear ETHERNET connection on IP Series.

(PC must have its Network Settings (TCP/IP Properties)

set to STATIC with an IP Address of (e.g.) 192.168.1.10

and a Subnet Mask of 255.255.255.0.)

Open a Web Browser and enter the IP Address

(192.168.1.254) of the IP Series into the URL address

line.

Refer to Section 6.1.1 re LogOn.

continued...

© Microhard Systems Inc. CONFIDENTIAL 13

Page 14

2.0 Quick Start

IP9xx Series

Refer to Section 6.1.4.1 re Network (IP) Configuration

and assign the unit a new unique IP Address.

Refer to Section 5.1 and, as per the example settings

given, configure unit as MASTER.

Repeat the above for the other IP Series, giving it a new

unique IP Address and configuring it as a REMOTE

(5.1).

With both units powered-on, in proximity to each other,

and configured as per the above, their RSSI LEDs

should be illuminated, and their TX LED should be ON or

flashing.

With the PC connected to one of the IP Series units, en-

ter the IP Address of ‗the other‘ unit: its LogOn window

should appear via the wireless connection.

.

© Microhard Systems Inc. CONFIDENTIAL 14

Page 15

2.0 Quick Start

Use the MHS-supplied power

adapter or an equivalent power

source.

IP9xx Series

2.2 Text UI Method

(See Section 6.2 for more information re the Text User Interface.)

2.21 Required Materials

2 IP Series (with factory default configuration), each

with Power Adapter and Rubber Ducky Antenna

1 PC with NIC (ethernet) card and COM (serial) port

with HyperTerminal (or equivalent) application

1 Available connection to LAN*

1 Crossover patchcable (ethernet)*

1 MHS Diagnostic Cable (P/N MHS044000, black)

*dependent on desired test set-up

2.22 Set-Up Procedure

Connect a Rubber Ducky antenna to each IP Series.

Connect the Power Adapters to available 120VAC out-

lets, and to the IP Series.

Connect the MHS Diagnostic Cable to COM2 (front) of

one IP Series and the other end to an available COM

port on the PC.

Run HyperTerminal (or equivalent terminal program) on

the PC and configure it for the COM port chosen above,

115200bps, 8 data bits, no parity, 1 stop bit, and no flow

control.

Activate the HyperTerminal connection.

A login prompt will appear. Enter admin.

At the password prompt, enter admin.

continued...

© Microhard Systems Inc. CONFIDENTIAL 15

Page 16

2.0 Quick Start

View the PC ‘s NETW OR K

SETTINGS (TCP/IP Properties) to

determine an appropriate IP

Address, Subnet Mask, and

Gateway for the IP Series.

(For basic testing, the Gateway

value is not critical.)

If a connection is being made to a

network (LAN), check with the

Network Administrator for an

available static IP address(es) so

as not to potentially create an IP

address conflict.

IP9xx Series

Select Option B: Network Configuration, then

A: Local IP Config, then

A: IP Address Mode, then

A: static

Input suitable (for your PC/network) values for:

IP Address

Subnet Mask

Gateway

Press U to SAVE the configuration changes.

Press [Esc] twice to return to the MAIN MENU.

Select Option C: Radio Configuration, then

B: Operation Mode, then

A: Master, then

I: Network Type, then

B: Point-to-Point, then

J: Destination Unit, then

enter the number 20 [Enter]

Press U to SAVE the configuration changes.

Press [Esc] to return to the MAIN MENU.

Press Q to Quit.

The IP Series configured above is now the MASTER IP Series for

your Point-to-Point IP Series network.

Remove the connection from the MASTER IP Series‘s COM2 port

and move it to the other IP Series.

Press [Enter]

A login prompt will appear. Enter admin.

At the password prompt, enter admin.

continued...

© Microhard Systems Inc. CONFIDENTIAL 16

Page 17

2.0 Quick Start

IP9xx Series

Select Option B: Network Configuration, then

A: Local IP Config, then

A: IP Address Mode, then

A: static

Input suitable (for your PC/network) values for:

IP Address

Subnet Mask

Gateway

Press U to SAVE the configuration changes.

Press [Esc] twice to return to the MAIN MENU.

Select Option C: Radio Configuration, then

B: Operation Mode, then

C: Remote, then

F: Unit Address, then

enter the number 20 [Enter]

I: Network Type, then

B: Point-to-Point, then

J: Destination Unit, then

enter the number 1 [Enter]

Press U to SAVE the configuration changes.

Press [Esc] to return to the MAIN MENU.

Press Q to Quit.

The IP Series configured above is now the REMOTE IP Series for

your Point-to-Point IP Series network.

With these two IP Series on a test bench, and configured as per the

preceding, a wireless link will be present between the two units. This

may be confirmed by noting that the RSSI (3 front panel LEDs) are

illuminated.

Next, the ethernet connections will be made.

continued...

© Microhard Systems Inc. CONFIDENTIAL 17

Page 18

2.0 Quick Start

To connect an IP Series to a PC,

an ethernet CROSSOVER (not a

straight-through) cable must be

used.

IP9xx Series

The ethernet connections are dependent upon what is available to

work with for the test configuration. For the purposes of this QUICK

START, the assumption is that a LAN connection is available (with

Internet connectivity) and that the PC is connected to this LAN.

Disconnect the PC‘s LAN connection from its NIC card

and insert the now ‗loose end‘ of the ethernet patchcable

into the rear ETHERNET RJ45 connector at the rear of

the MASTER IP Series.

Using a CROSSOVER cable, connect the PC‘s NIC card

RJ45 jack to the ETHERNET RJ45 connector on the REMOTE IP Series.

At this point there is a wireless connection between the PC and the

LAN, and you should be able to go about your typical networking activities, including accessing the Internet (via the LAN).

Also, by opening a web browser and entering the IP address of either

IP Series, you will be taken to the respective unit‘s Web User Inter-

face LOGIN window.

If communications not available as outlined above:

Verify the RSSI LEDs on the front of each IP Series are

illuminated.

Verify TX (red) LED activity on the front of each IP Se-

ries.

Observe the rear of each IP Series, specifically the

ETHERNET connection: the green LINK LED should be

illuminated (indicating proper cabling) and the amber

(ACTIVITY LED) should also be flickering—indicating

DATA traffic at the ETHERNET connector.

If using Windows XP, the firewall function could inhibit

desired data traffic. Anti-virus software may also have a

negative impact.

© Microhard Systems Inc. CONFIDENTIAL 18

Page 19

3.0 Hardware Features

IP9xx Series

The IP Series is a fully-enclosed unit ready to be interfaced to

external devices.

Any IP Series may be configured as a Master, Repeater (or

Repeater/Slave), or Slave. This versatility is very convenient from a

‘sparing‘ perspective, as well for convenience in becoming very

familiar and proficient with using the device: if you are familiar with

one unit, you will be familiar with all units.

3.1 IP9xx Connections

3.1.1 Front

Image 3A: Front View of IP Series

On the front of the IP Series are, from left to right:

COM2 Port (DCE)

CFG pushbutton

TX LED

RX LED

SYS LED

RSSI LEDs (3)

© Microhard Systems Inc. CONFIDENTIAL 19

Page 20

3.0 Hardware Features

IP9xx Series

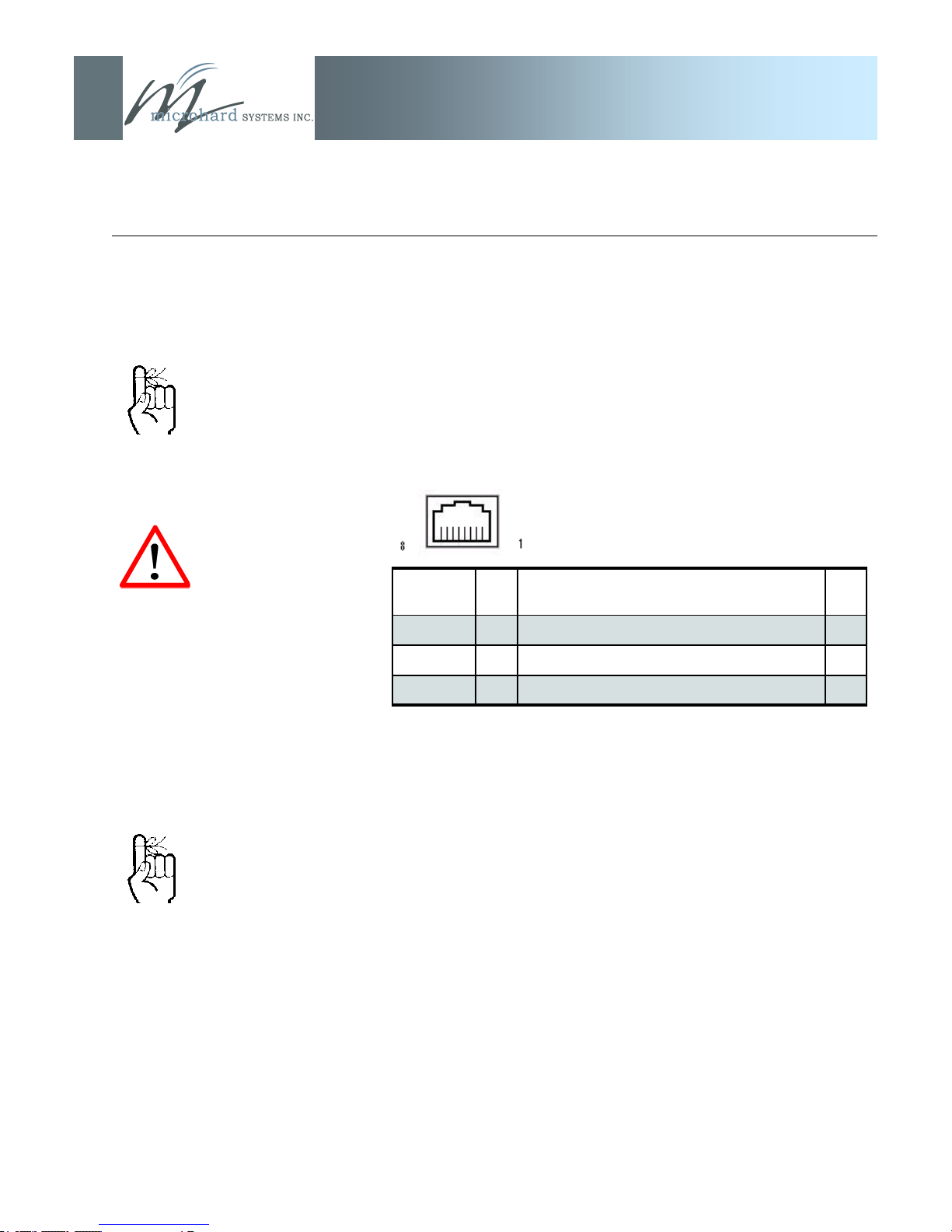

The COM2 port is NOT an

Ethernet port.

DO NOT connect to COM2

pins other than those

identified in Table 3A, and for

their described function.

The CFG button (and ‘default‘

IP address 192.168.1.39) are

ONLY used for the purpose of

upgrading firmware.

The ‘default‘ IP address is

NOT available for accessing

the Web User Interface.

The COM2 Port (DCE) is used for two purposes:

Text User Interface (local console port) at 115.2kbps

(using MHS-supplied BLACK RJ45-DE9 cable (P/N

MHS044000) and HyperTerminal (or equivalent).

User data (serial, RS-232, wired for RxD, TxD, and SG)

Pin Name No. Description In/

Out

RxD 2 Receive Data O

TxD 3 Transmit Data I

SG 5 Signal Ground

Table 3A: COM2 Pin Description

CFG Button

Holding this button depressed while powering-up the IP Series will

boot the unit into FLASH FILE SYSTEM RECOVERY mode. The

default IP address for system recovery (only - not for normal access

to the unit) is static: 192.168.1.39.

(For more information on performing a firmware upgrade, see

Appendix B and Section 6.1.9.1.)

If the unit has been powered-up for some time (>1 minute),

depressing the CFG Button for 8 seconds will result in FACTORY

DEFAULTS being restored, including a static IP address of

192.168.1.254. This IP address is useable in a Web Browser for

accessing the Web User Interface.

© Microhard Systems Inc. CONFIDENTIAL 20

Page 21

3.0 Hardware Features

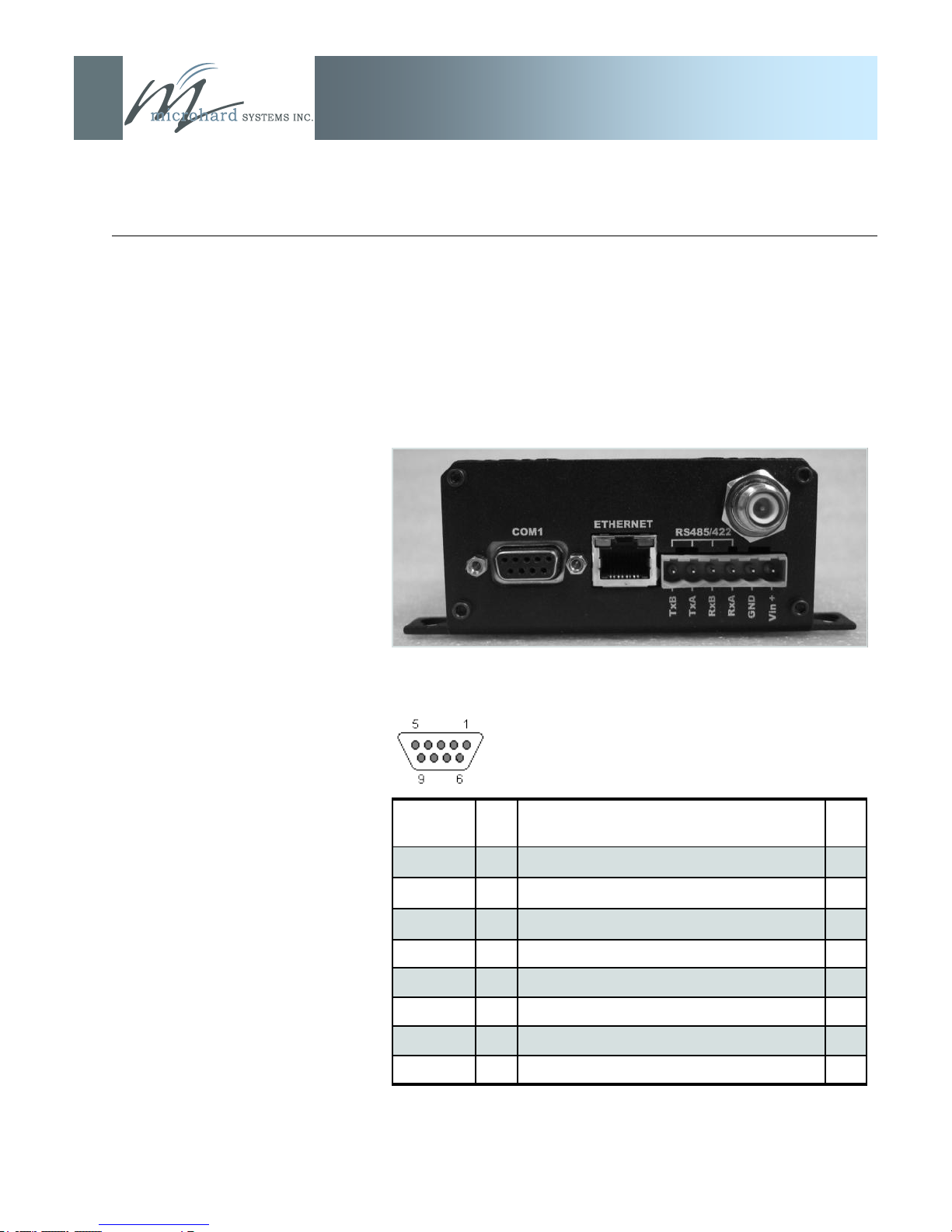

3.1.2 Rear

COM1 Port (DCE) on the rear of the IP Series is used for RS232

serial data (300 baud to 230.4kbps) communications.

RS422/485 Port used to interface the IP Series to a DTE with the

same interface type (300 baud to 921kbps).

Either the RS232 or RS422/485 interface is used for ‗COM1‘ data

traffic.

IP9xx Series

Image 3B: Rear View of IP Series

See Appendix F for a full description of the COM1

RS-232 interface functions.

© Microhard Systems Inc. CONFIDENTIAL 21

Pin Name No. Description In/

Out

DCD 1 Data Carrier Detect O

RXD 2 Receive Data O

TXD 3 Transmit Data I

DTR 4 Data Terminal Ready I

SG 5 Signal Ground

DSR 6 Data Set Ready O

RTS 7 Request To Send I

CTS 8 Clear To Send O

Table 3B: COM1 (RS-232) Pin Assignment

Page 22

3.0 Hardware Features

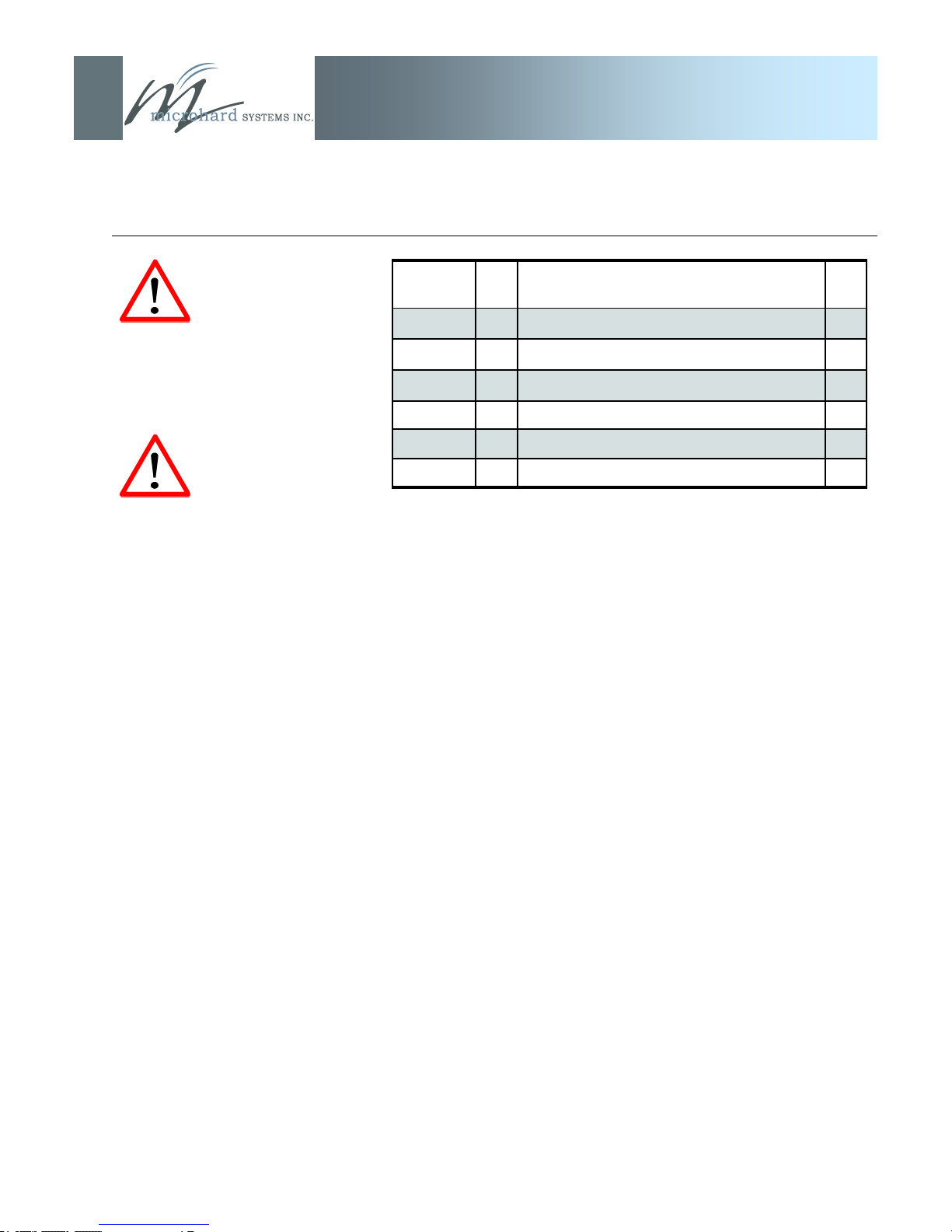

IP9xx Series

Caution: Using a power

supply that does not provide

proper voltage may damage

the IP Series.

Caution: DO NOT connect

POWER to the DATA

SIGNAL pins of the Phoenixtype connector.

Pin Name No. Description In/

Out

TxB (D+) 1 Non-Inverting Driver Output O

TxA (D-) 2 Inverting Driver Output O

RxB (R+) 3 Non-Inverting Driver Input I

RxA (R-) 4 Inverting Driver Input I

GND 5 Ground (Power and Signal)

Vin+ 6 Positive Voltage Supply Input (12-30VDC) I

Table 3C: Phoenix-type Connector Pin Assignment

Antenna Connector

The IP Series uses a reverse polarity TNC (RP-TNC) connector.

Microhard Systems Inc. can provide external cabling and antennas

suited to a variety of applications where the standard rubber ducky

antenna is not adequate.

Refer to Appendix D for a listing of approved antennas.

© Microhard Systems Inc. CONFIDENTIAL 22

Page 23

3.0 Hardware Features

IP9xx Series

DO NOT cycle power during

DO NOT cycle power during

the ‗Upgrading‘ process:

the ‗Upgrading‘ process:

doing so will corrupt the flash

doing so will corrupt the flash

file system and the IP Series

file system and the IP Series

will not boot properly. If this

will not boot properly. If this

occurs, the system can only

occurs, the system can only

be restored using the

be restored using the

recovery procedure.

recovery procedure.

3.2 IP9xx Indicators

3.2.1 Front Indicators

Alarm LED (Amber)

Located at top/left of COM2 port, illuminates when there is a load/

transmitter impedance mismatch—indicating a possible problem in

the antenna system.

MHX Status LED (Green)

Located at top/right of COM2 port, illuminates when the MHX core

module is powered-up and okay.

TX LED

The transmit (TX) LED is illuminated when the IP Series is

transmitting data wirelessly.

RX LED

This LED, when illuminated, indicates that the modem is

synchronized and/or receiving valid packets of data.

SYS LED

The System Status LED operation is described in the following

table:

System Mode SYS LED Status

Normal On

Recovery Fast Blink (3 per second)

Loading (e.g. on normal power-up) Slow Blink (1 every 2 seconds)

Upgrading Slow Blink (1 every 2 seconds)

Table 3D: SYS LED Operation

Upon initial application of power the SYS LED will be illuminated for

approximately 20 seconds, after which time it will being to blink

slowly (loading) for an additional 25 seconds, then stay ON

‗solid‘ (indicating it has achieved its specific operational status).

© Microhard Systems Inc. CONFIDENTIAL 23

Page 24

3.0 Hardware Features

IP9xx Series

When initially cabling between

devices, pay close attention to

the Activity LED to confirm that

proper patchcable types are

being used.

Receive Signal Strength Indicator (RSSI) (3x Green) LEDs

As the received signal strength increases, so does the number of

illuminated RSSI LEDs, starting with the furthest left. RSSI is

calculated based on the last four valid recieved packets. For robust

wireless communications performance, strive for a minimum of 2

RSSI LEDs being lit.

Initially, a remote unit‘s RSSI LED‘s will ‗scan‘ (cycle from right to

left, each LED being on for 300ms in turn). Once the unit acquires

synchronization with the network, a ‗steady‘ RSSI reading will be

displayed.

A Master updates its RSSI indication upon receiving valid packets

from remote units. It takes into consideration packets received from

both Repeaters and Remotes.

A Repeater will base its RSSI reading on valid packets received

from Slaves; if the Slaves are silent for 2 seconds, the Repeater will

display an RSSI value based on valid packets received from the

Master.

Signal strength is calculated based on the last four valid received

packets with correct CRC.

3.2.2 Rear Indicators

Collision LED (Amber)

Located at top/left of the ETHERNET connector, illuminates when

there is a collision on the ethernet interface.

Activity LED (Green)

Located at top/right of the ETHERNET connector, illuminates when

there is data activity present on the ethernet interface.

© Microhard Systems Inc. CONFIDENTIAL 24

Page 25

3.0 Hardware Features

IP9xx Series

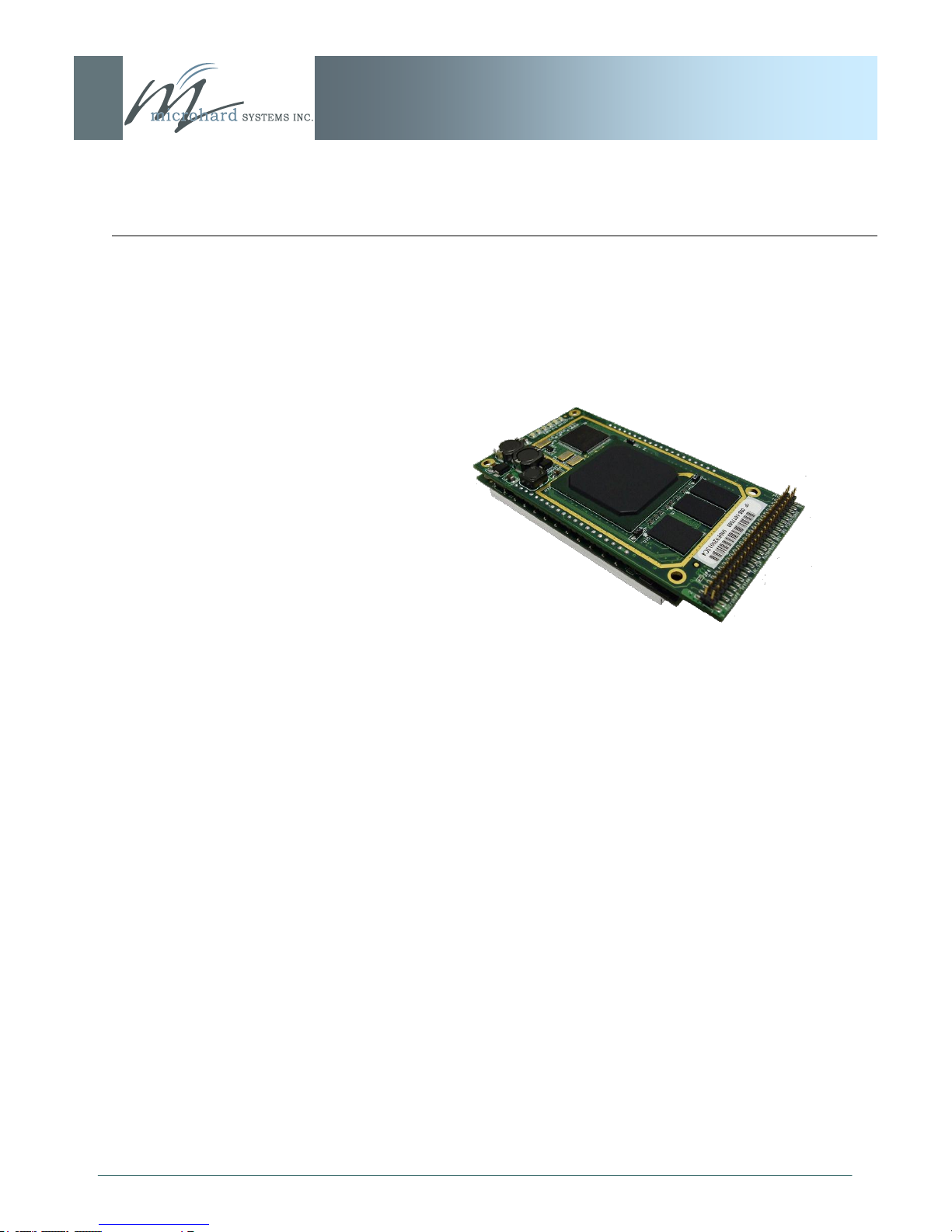

3.3 SIP921 Connections

The SIP921 introduces a small form factor and single header interface for complete integration into OEM applications. The SIP921 incorporates all of the IP9xx functionality, features, configuration and

performance into a single module.

The SIP Series OEM module features include:

Single OEM header.

Ready-to-wire Ethernet.

Dedicated diagnostics serial port (TTL).

TTL Level Data Port fully equipped with the signals

Status/Diagnostic output signals for system status, RSSI,

The Pin-out and signal descriptions are described on the following

pages. An example customer interface schematic can be found in

Appendix G.

Image 3C: Bottom View of SIP921 Module

necessary to derive RS232/485/422 interfaces.

Ethernet etc.

© Microhard Systems Inc. CONFIDENTIAL 25

Page 26

3.0 Hardware Features

IP9xx Series

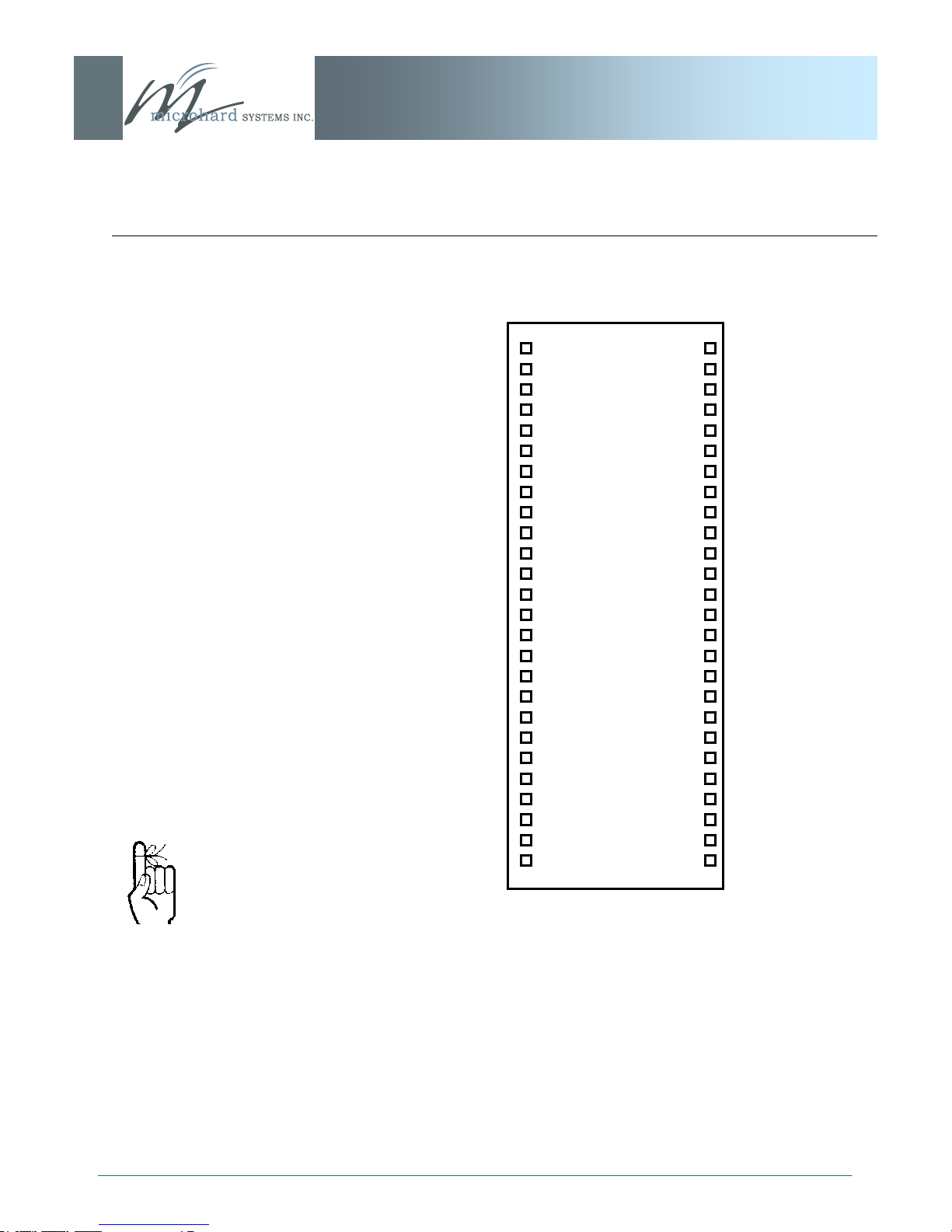

3.3.1 SIP921 Pin-Out Description

Vcc

Vcc

GND

GND

NC

NC

NC

NC

NC

TXD0

NC

CTS0

RTS0

!RXD1

DTR0

GND

CAT1

CAT2

LINK LED

RXD0_485

DE_485

!RE_485

NC

RSSI_LED3

RSSI_LED2

RSSI_LED1

1

3

5

7

9

11

13

15

17

19

21

23

SIP921

25

27

29

31

33

35

37

39

41

43

45

47

49

51

JP4

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

52

VRF

!CONFIG

+3V3 FPGA

+3V3

NC

NC

NC

NC

NC

NC

CTS1

RTS1

TXD1

DCD0

DSR0

GND

CAT4

CAT3

ACTIVITY LED

!RXD0_232

!RSMODE

!RESET

NC

SYS LED

TX LED

RX LED

Pins 9-18 are reserved for factory

use. Do not use these pins for

any other purpose.

Inputs and outputs are TTL Level

unless otherwise specified.

© Microhard Systems Inc. CONFIDENTIAL 26

Drawing 1: SIP921 52-pin OEM Connector Pin-out

The above drawing depicts a bottom view of the SIP921 connector.

The corner pins (1, 2, 51, and 52) are printed directly upon it for

convenient reference.

A full description of the various pin connections and functions is

provided on the pages that follow.

Page 27

3.0 Hardware Features

IP9xx Series

Pin Name No. Description In/

Out

Vcc 1,3 Positive supply voltage for the module (9-30

VDC)

VRF 2 Voltage Output (4.5VDC) O

!CONFIG 4 Active low input signal to put the module into

FLASH FILE SYSTEM RECOVERY mode.

GND 5,7 Ground reference for logic, radio and I/O pins.

+3V3 FPGA 6 Voltage Output ON during sleep mode.

(3.3VDC)

+3V3 8 Voltage Output OFF during sleep mode.

(3.3VDC)

NC 9-18 *Reserved for factory use.*

TXD0 19 Data Port. Transmit Data. Logic Level Output

from the modem.

NC 20-21 *Reserved for future use.*

CTS1 22 Diagnostics Port. Clear To Send. Active low

output.

CTS0 23 Data Port. Clear To Send. Active low output. O

RTS1 24 Diagnostics Port. Request To Send. Active low

input.

O

O

O

O

I

I

I

© Microhard Systems Inc. CONFIDENTIAL 27

RTS0 25 Data Port. Request To Send. Active low input. I

TXD1 26 Diagnostics Port. Transmit Data. Logic level

output from modem.

RXD1 27 Diagnostics Port. Receive Data. Logic level

input into the modem.

DCD0 28 Data Port. Data Carrier Detect. Active low

output.

DTR0 29 Data Port. Data Terminal Ready. Active low

input.

DSR0 30 Data Port. Data Set Ready. Active low output. O

GND 31-32 Ground reference for logic, radio, and I/O pins

Table 3E: SIP921 Pin-Out Description

O

I

O

I

Page 28

3.0 Hardware Features

IP9xx Series

Pin Name No. Description In/

Out

CAT1 33 Ethernet RJ45 Pin 1.

CAT4 34 Ethernet RJ45 Pin 4.

CAT2 35 Ethernet RJ45 Pin 2.

CAT3 36 Ethernet RJ45 Pin 3.

LINK LED 37 Ethernet LINK LED O

ACTIVITY LED 38 Ethernet Activity LED O

RXD0_485 39 Data Port. RS485 Receive Data Logic level

input into the modem.

RXD0_232 40 Data Port. RS232 Receive Data Logic level

input into the modem.

DE_485 41 Date Port. RS485 Driver Output Enable. Avtive

High Output.

!RSMODE 42 Sleep mode indication output. Active Low. O

!RE_485 43 Data Port. RS485 Receiver Output Enable.

Active low output.

!RESET 44 Active low input will reset module I

NC 45-46 *Reserved for future use.*

RSSI_LED3 47 Receive Signal Strength Indicator 3. O

RSSI_LED2 49 Receive Signal Strength Indicator 2. O

RSSI_LED1 51 Receive Signal Strength Indicator 1. O

SYS LED 48 This output indicates system status. Normal

Operation = Solid, Recovery = Fast Blink (3/s),

Loading/Upgrading = Slow Blink (1 every 2s)

TX LED 50 Output indicates module is transmitting data

over the RF channel.

O

O

O

O

I

I

© Microhard Systems Inc. CONFIDENTIAL 28

RX LED 52 Output indicates receive and synchronization

status.

Table 3E: SIP921 Pin-Out Description (continued)

O

Page 29

4.0 Operating Modes

Throughout this manual,

‗Remote‘ refers to a Remote

as defined in Section 4.4; the

general term ‗remote‘ applies

to an IP Series Repeater and/

or Remote - i.e. non-Master

IP9xx Series

An IP Series may be configured for any operating mode: this is very

convenient for purposes of sparing and becoming familiar with their

configuration menus.

4.1 Master

One per network, the source of synchronization for the system. The

Master controls the flow of data through the system.

4.2 Repeater

Required only if necessary to establish a radio path between a Master and Remote(s); stores and forwards the data sent to it. Synchro-

nizes to Master and provides synchronization to ‗downstream‘ units.

If a local device is attached to a Repeater‘s serial data port, the Re-

peater will also behave as a Remote (aka Repeater/Remote).

As they are added to a radio network it is good practice to use the

values 2-17, sequentially, for Repeater Unit Addresses.

Adding one or more Repeaters within a network will HALVE the

throughput; the throughput is halved only once, i.e. it does not decrease with the addition of more Repeaters.

If there is a ‗radio (signal) path‘ requirement to provide Repeater

functionality, but throughput is critical, the repeating function may be

accomplished by placing two IP Series at the Repeater site in a ‗back

-to-back‘ configuration. One IP Series would be configured as a Re-

mote in the ‗upstream‘ network; the other a Master in the

‗downstream‘ network. Local connection between the modems

would be accomplished with a crossover cable (for the ethernet connection). Each modem would require its own antenna; careful consideration should be given with respect to antenna placement and IP

Series configuration.

4.3 Remote

Endpoint/node within a network to which a local device is attached.

Communicates with Master either directly or through one or more

Repeaters. See Sections 5.3 and 5.4 for information regarding

‗Slave-to-Slave‘ communications.

© Microhard Systems Inc. CONFIDENTIAL 29

Page 30

5.0 Network Topologies

The RADIO network topology

determines the paths

available for the movement of

data.

Take this important fact into

consideration when selecting

a network topology.

IP9xx Series

The IP Series may be configured to operate in a number of different

operating modes and participate in various network topologies.

Note: This section describes radio network topologies in general

and includes examples of corresponding Radio Configuration settings. Refer to section 6 for further detailed information regarding

configuration options.

5.1 Point-to-Point (PTP)

In a Point-to-Point network, a path is created to transfer data between Point A and Point B, where Point A may be considered the

Master modem and Point B a Remote. Such a PTP network may

also involve one or more Repeaters (in a store-and-forward capacity) should the radio signal path dictate such a requirement. (Note

that a Repeater may also concurrently function as a Remote, i.e. it

may pass data to and from an attached device(s).)

A PTP configuration may also be used in a more dynamic sense:

there may be many Remotes (and Repeaters) within such a net-

work, however the Master may have its ‗Destination Address‘

changed as and when required to communicate with a specific remote unit.

An example of a basic PTP network consisting of two IP Series is

on the next page.

Notes re Example 5.1.1:

Configuration options are based upon the chosen Op-

The DESTINATION UNIT for the MASTER is the UNIT

For a PTP system, RETRANSMISSIONS on a MAS-

erating Mode of the unit: select the Operating Mode

first.

ADDRESS of the REMOTE, and vice versa (noting that

the MASTER‘s Unit Address (not visible) is preset, and

must remain as, ‗1‘).

TER is not as critical a setting as it is in a Point-toMultipoint (PMP) system.

© Microhard Systems Inc. CONFIDENTIAL 30

Page 31

5.0 Network Topologies

IP9xx Series

Example 5.1.1

Image 5A: PTP Example 5.1.1: Master

Image 5B: PTP Example 5.1.1: Remote

© Microhard Systems Inc. CONFIDENTIAL 31

Page 32

5.0 Network Topologies

IP9xx Series

5.2 Point-to-Multipoint (PMP)

In a Point-to-Multipoint network, a path is created to transfer data

between the Master modem and numerous remote modems. The

remote modems may simply be Remotes with which the Master

communicates directly, and/or Remotes which communicate via

Repeaters. Some or all of the Repeaters may also act as Remotes

in this type of Network, i.e. the Repeaters are not only storing and

forwarding data, but are also acting as Remotes. Such Repeaters

may be referred to as ‗Repeater/Remotes‘.

Example 5.2.1

A 4-node network consisting of a Master, 1 Repeater, and 2 Remotes. 1 Remote is to communicate with the Master through a Repeater; the other is to communicate directly with the Master.

Refer to Section 6.1.4 for

import ant information

regarding the configuration of

a P M P M a s t e r ‘ s

Retransmissions.

© Microhard Systems Inc. CONFIDENTIAL 32

Image 5C: PMP Example 5.2.1: Master

There is no DESTINATION UNIT displayed as, in PMP,

the DESTINATION is preset to 65535: the BROADCAST address (‗multipoint‘).

RETRANSMISSIONS are set to 0. Refer to Section

6.1.4 for more information.

There is a REPEATER in this example network, there-

fore the MASTER‘s ‗Repeater‘ configuration option is

set to Yes.

Page 33

5.0 Network Topologies

Example 5.2.1 (continued)

IP9xx Series

When bench testing PMP with

a REPEATER in the network,

configure the REMOTE to

sync h r o n i z e to t h e

REPEATER via t he

R E M OT E ‘s R O AM I N G

ADDRESS field. If this is not

done, with the REMOTE in

close proximity to the

MASTER and its ROAMING

set as 1 (default), the

REMOT E will simply

synchronize with (and pass

data directly to) the MASTER,

bypassing the REPEATER

altogether.

Image 5D: PMP Example 5.2.1: Repeater

The ROAMING address for the REPEATER is set to 1:

the UNIT ADDRESS of the MASTER. This means that

this REPEATER will synchronize to, and communicate

directly with, the MASTER.

There is no DESTINATION UNIT field for remote units

in a PMP network: the destination is predefined as

‗1‘ (the MASTER ‗point‘).

On the following page are the configurations for the REMOTES.

Remote 20‘s ROAMING ADDRESS is set to 2, the

UNIT ADDRESS of the REPEATER. This Remote will

synchronize to the Repeater and communicate via the

Repeater to the Master.

Remote 30‘s ROAMING ADDRESS is set to 1 (the

UNIT ADDRESS of the MASTER): it will synchronize

to, and communicate directly with, the MASTER.

© Microhard Systems Inc. CONFIDENTIAL 33

Page 34

5.0 Network Topologies

Example 5.2.1 (continued)

IP9xx Series

Each modem in any network

must have a unique Unit

Address.

Image 5E: PMP Example 5.2.1: Remote 20

Image 5F: PMP Example 5.2.1: Remote 30

© Microhard Systems Inc. CONFIDENTIAL 34

Page 35

5.0 Network Topologies

A P2P network requires a

Master modem.

The data being transmitted

from one Remote to another

in P2P mode is transferred

via the Master.

IP9xx Series

5.3 Peer-to-Peer (P2P)

P2P mode is used for communications between pairings of remote

modems,

e.g. Remote 20 can exchange data with (only) Remote 30,

Remote 21 can exchange data with (only) Remote 35, etc.

The Master will resend the data incoming to it from both Remotes to

both/all Remotes; one Remote‘s data has a Destination Unit being

the other Remote and vice versa.

Example 5.3.1

A device located at a pump station must communicate bidirectionally with another device at a water tank. The MASTER IP

Series must reside in an office at a separate location.

© Microhard Systems Inc. CONFIDENTIAL 35

Image 5G: P2P Example 5.3.1: Master

All IP Series within a particular network must be configured to have

the same Network Type.

continued...

Page 36

5.0 Network Topologies

Example 5.3.1 (continued)

IP9xx Series

Image 5H: P2P Example 5.3.1: Remote 25

Image 5I: P2P Example 5.3.1: Remote 35

© Microhard Systems Inc. CONFIDENTIAL 36

Page 37

5.0 Network Topologies

An E2E network requires a

Master modem.

The data being transmitted

from remote units in an E2E

network travels to the Master

and is then re-broadcast to all

other remotes.

IP9xx Series

5.4 Everyone-to-Everyone (E2E)

E2E mode is used for communications between all remote modems,

i.e. data from every modem is broadcast to every other

modem in the network.

Considering the amount of data re-broadcasting (via the Master), it

is a very bandwidth-intensive network topology.

Example 5.4.1

1 Master and 3 remote units must all communicate with each other.

© Microhard Systems Inc. CONFIDENTIAL 37

Image 5J: E2E Example 5.4.1: Master

There is no DESTINATION UNIT configuration option

as the DESTINATION is predefined to be the broadcast

address (65535) when in E2E mode.

Page 38

5.0 Network Topologies

Example 5.4.1 (continued)

IP9xx Series

Each unit must have its

own unique Unit Address.

Image 5K: E2E Example 5.4.1: Remote

The Remotes will all be configured as per the above screen capture, with the exception of the UNIT ADDRESS. Each Remote (of

the 3 in this example) must have its own unique UNIT ADDRESS,

e.g. 50, 51, and 52.

© Microhard Systems Inc. CONFIDENTIAL 38

Page 39

6.0 Configuration

IP9xx Series

The following factors must be considered when preparing to configure the modems:

the application

network topology

physical distribution of the network

data interface requirements

Components involved in the configuration process of the IP Series:

interfacing with the modem, and

selecting and inputting the desired operational parame-

ters

Interfacing to the IP Series for the purpose of initially configuring it

may be accomplished in one of two ways:

front COM2 connector, Microhard Systems Inc. DE9-

RJ45 Diagnostics Cable (P/N MHS044000, black), and a

PC running terminal communications program (e.g.

HyperTerminal), or

rear ETHERNET (RJ45) port, ethernet crossover cable,

and PC running Microhard Systems Inc. DiscoverIP utility and Web Browser application.

All configuration of the IP Series is accomplished with a PC. There

are no DIP switches to set; switches which may subsequently become inadvertently misadjusted or intermittent.

© Microhard Systems Inc. CONFIDENTIAL 39

Page 40

6.0 Configuration

The modem will arrive from

the factory with DHCP

enabled and a unique random

Class D IP address.

The DiscoverIP utility is

utilized to ‘discover‘ the IP

address of the IP Series (not

other devices on network) so

that you may specifically

address it (in Web Browser

URL line) for configuration

purposes.

IP9xx Series

6.1 Web User Interface

Initial configuration of an IP Series using the Web User (Browser)

Interface (Web UI) method involves the following steps:

connect IP Series ETHERNET port to PC NIC card using an

ethernet crossover cable

apply power to the IP Series and wait approximately 1 minute

for the system to load

run Microhard Systems Inc. DiscoverIP Utility on the PC (see

Appendix A for complete details on this convenient utility)

within the DiscoverIP Utility window, click on the desired unit‘s

IP address (verify displayed MAC address with MAC address

printed on sticker on bottom of unit)

logon window appears; log on

configure IP Series as desired.

In this section, all aspects of the Web Browser Interface, presented

menus, and available configuration options will be discussed.

© Microhard Systems Inc. CONFIDENTIAL 40

Page 41

6.0 Configuration

IP9xx Series

6.1.1 Logon Window

Upon successfully accessing the IP Series using a Web Browser,

the Logon window will appear.

For security, do not allow the

web browser to remember the

User Name or Password.

It is advisable to change the

login Password (see Section

6.1.6.1). Do not FORGET the

new password as it cannot be

recovered.

Image 6A: Logon Window

The factory default User Name is: admin

The default password is: admin

Note that the password is case sensitive. It may be changed

(discussed further along in this section), but once changed, if

forgotten, may not be recovered.

© Microhard Systems Inc. CONFIDENTIAL 41

Page 42

6.0 Configuration

IP9xx Series

When entered, the password appears as ‘dots‘ as shown in the

image below. This display format prohibits others from viewing the

password.

The ‗Remember my password‘ checkbox may be selected for

purposes of convenience, however it is recommended to ensure it

is deselected - particularly once the unit is deployed in the field -

for one primary reason: security.

© Microhard Systems Inc. CONFIDENTIAL 42

Image 6B: Logon Window With Password Input

Soft Buttons

OK

Inputs the selected values into the IP Series for processing.

Cancel

Cancels the logon process.

Page 43

6.0 Configuration

IP9xx Series

6.1.2 Welcome Window

The Welcome window displays the specific IP Series‘ name

(entered as the Radio Description in the System Configuration

menu). This name quickly confirms the ‘identity‘ of the unit being

perused and appears in all menu windows.

© Microhard Systems Inc. CONFIDENTIAL 43

Image 6C: Welcome Window

Also displayed is various ‗version‘ information:

Hardware Version - applicable to the motherboard of

the IP Series

Software Version - this software resides on the

motherboard and is also referred to as the unit‘s

‘firmware‘

FPGA Version - Field Programmable Gate Array -

resides on the motherboard and relates to the interface

between the motherboard and radio module

Page 44

6.0 Configuration

IP9xx Series

6.1.3 System Configuration

As per the previous section, the Radio Description is defined within

this menu, as are an assortment of other configuration options.

Image 6D: System Configuration Window

System Operation Mode

The radio button options presented here determine whether the IP

Series unit will operate at a BRIDGE or a ROUTER. Only a

MASTER unit should ever be configured as a router.

Select the System Operation Mode ‗first‘, i.e. prior to configuring

other options within the unit.

Values

Bridge

Bridge

Router

© Microhard Systems Inc. CONFIDENTIAL 44

Page 45

6.0 Configuration

The Radio Description must

not be confused with the

Network Name (Radio

Configuration menu). The

Network Name MUST be

exactly the same on each unit

within an IP Series network.

IP9xx Series

Radio Description

The Radio Description is simply a convenient identifier for a specific

IP Series, e.g. Pump Station 5, 123 Main Street, etc. This feature is

most welcome when accessing units from afar with large networks:

a convenient cross-reference for the unit‘s IP address. This ‗name‘

appears in all menu windows. It has no bearing on the unit‘s

operation.

Values

default is model-dependent

up to 30 characters

Date (yyyy-mm-dd)

The calendar date may be entered in this field. Note that the

entered value is lost should the IP Series lose power for some

reason.

Values

2007-05-07 (varies)

valid date values, where

yyyy = 4-digit year

mm = 2-digit month

dd = 2-digit day

Time (hh:mm:ss)

The calendar date may be entered in this field. Note that the

entered value is lost should the IP Series lose power for some

reason.

Values

11:27:28 (varies)

valid time values, where

hh = 2-digit hours

mm = 2-digit minutes

ss = 2-digit seconds

© Microhard Systems Inc. CONFIDENTIAL 45

Page 46

6.0 Configuration

IP9xx Series

UTC Time Offset (+/-hh:mm)

Input the Universal Coordinated Time offset in this field, if so

desired. + indicates that local time is ahead of UTC time; - behind.

Values

00:00

valid time values, where

hh = 2-digit hours

mm = 2-digit minutes

Console Timeout (s)

This value determines when the console connection (made via

COM2) will timeout after becoming inactive.

Values

seconds

60

0-65535

© Microhard Systems Inc. CONFIDENTIAL 46

Soft Buttons

Synchronize with NTP Server

Useable to have related parameters on this page updated

with current time values when valid NTP Server information

has been configured and the service is enabled within the

modem (see Section 6.1.3.2 for additional information).

Submit

Write parameter values into IP Series memory.

Reset

Restore ‗currently‘ modified parameter values to those

which were previously written into IP Series memory.

Page 47

6.0 Configuration

IP9xx Series

6.1.4 Network Configuration

The Network Configuration menu consists of a number of

submenus, all of which provide various options pertaining to

configuring the units to be part of an IP network. These settings do

not effect the ‗radio‘ communications network aspect of the system,

however, be mindful of the Network Type (Radio Configuration

menu) as that dictates the possibilities for the flow of network data.

For a basic implementation, only the Local IP Configuration

(submenu) options need to be defined.

© Microhard Systems Inc. CONFIDENTIAL 47

Image 6E: Network Configuration, Top Level Menu

The Ethernet MAC address (as displayed above) is that of the

ETHERNET interface located at the rear of the IP Series.

The Wireless MAC address is for internal purposes.

Page 48

6.0 Configuration

DHCP: Dynamic Host

Configuration Protocol may

be used by networked

devices (Clients) to obtain

unique network addresses

from a DHCP server.

Advantage:

Ensures unique IP addresses

are assigned, from a central

point (DHCP server) within a

network.

Disadvantage:

The address of a particular

device is not ‗known‘ and is

also subject to change.

STATIC addresses must be

tracked (to avoid duplicate

use), yet they may be

permanently assigned to a

device.

IP9xx Series

6.1.4.1 Local IP Configuration

6.1.4.1.1 Bridge

This submenu, along with Radio Configuration settings, are the

minimum which must be considered when implementing any IP

Series network.

It must be determined if the unit is to be either:

assigned an IP address (by a DHCP server), or

given a static (unchanging) IP address.

Once the above is ascertained, the items within this submenu may

be configured.

© Microhard Systems Inc. CONFIDENTIAL 48

Image 6F: Network Configuration (Bridge), Local IP Configuration

Submenu

IP Address Mode

If ‗static‘ is selected, the three following fields (see Image 6F) are to

be manually populated with values which will suit the network/

devices to which the IP Series is connected.

continued...

Page 49

6.0 Configuration

If DHCP mode is selected,

but there is no DHCP server

available, after the DHCP

timeout period the units will

default to function simply as a

‘wireless bridge‘.

IP9xx Series

IP Address Mode (continued)

If ‗DHCP‘ is selected, the three following fields (see Image 6F) will

be automatically populated by the DHCP server. The DHCP

Timeout value may be manually modified from the factory default

value.

Note that the factory default setting is DHCP.

Values

dhcp

static

dhcp

Within any IP network, each

device must have its own

unique IP address.

A SUBNET MASK is a bit

mask that separates the

network and host (device)

portions of an IP address.

The ‗unm asked‘ portion

leaves available the

information required to

identify the various devices

on the subnet.

IP Address

If DHCP is selected (see above), a unique IP address will be

assigned to the IP Series; if STATIC IP address mode has been

selected, enter a suitable value for the specific network.

Values

192.168.1.254

valid value is specific to the

network

Subnet Mask

For a small private network with IP addresses appearing similar to

192.168.1.xx (Class C address), the standard 255.255.255.0

subnet mask may be applicable.

If DHCP mode is selected (see above/top), the DHCP server will

populate this field.

Values

255.255.255.0

valid value is specific to the

network

© Microhard Systems Inc. CONFIDENTIAL 49

Page 50

6.0 Configuration

A GATEWAY is a point within

a network that acts as an

entrance to another network.

In typical networks, a router

acts as a gateway.

IP9xx Series

IP Gateway

If the IP Series devices are integrated into a network which has a

defined gateway, then, as with other hosts on the network, this

gateway‘s IP address will be entered into this field. If there is a

DHCP server on the network, and the IP Address Mode (see

previous page) is selected to be DHCP, the DHCP server will

populate this field with the appropriate gateway address.

In a very small network (e.g. point-to-point, and STATIC IP Address

Mode), the gateway value is not critical. The IP address of the

most significant device on the overall network may be entered, or, if

only two IP Series‘s are being used, make the gateway of IP Series

No. 1 = IP address of IP Series No. 2; gateway of IP Series No. 2 =

IP address of IP Series No. 1. The idea behind this approach is: If

an IP Series at ‗one end‘ of a wireless link receives a packet it is

unsure where to send, send it to the other end of the wireless link

(i.e. the other IP Series) where it was quite likely destined.

A simple way of looking at what the gateway value should be is: If

a device has a packet of data is does not know where to send, send

it to the gateway. If necessary - and applicable - the gateway can

forward the packet onwards to another network.

Values

192.168.1.1

valid value is specific to the

network

DHCP Timeout

This value determines for how long the IP Series will await to

receive information from a DHCP server. If this timeout expires, the

unit will assign itself a random Class D IP address (and subnet

mask) and function simply as a wireless bridge.

Values

seconds

60

1-65535

© Microhard Systems Inc. CONFIDENTIAL 50

Page 51

6.0 Configuration

IP9xx Series

DNS Mode

The setting determines whether the IP Series unit will have its DNS

Server information entered manually (static) or if it will obtain the

information (provided it is available) via the connected network.

Values

static

automatic

Preferred DNS Server

If DNS Mode is static, enter valid IP Address of accessible

Preferred DNS Server in this field.

Values

0.0.0.0

valid DNS Server IP address

Alternate DNS Server

If DNS Mode is static, enter valid IP Address of accessible Alternate

DNS Server in this field.

Values

© Microhard Systems Inc. CONFIDENTIAL 51

0.0.0.0

valid DNS Server IP address

Soft Buttons

Submit

Write parameter values into IP Series memory.

Reset

Restore ‗currently‘ modified parameter values to those

which were previously written into IP Series memory.

Page 52

6.0 Configuration

Only the MASTER IP Series

unit may be configured as a

Router.

IP9xx Series

6.1.4.1 Local IP Configuration

6.1.4.1.2 Router

If the IP Series unit has been configured as a Router (under the

System Configuration menu), the Network Configuration will

present some additional options to those presented if the unit was

configured as a Bridge.

The Ethernet Port IP Configuration applies to the ‗wired‘ port (at

rear of IP Series unit), which may also be considered as the WAN

(Wide Area Network) port.

The Wireless Port IP Configuration applies to the LAN (Local Area

Network): the LAN consists of the devices, and IP Series units,

connected to each other via the wireless (radio) network.

© Microhard Systems Inc. CONFIDENTIAL 52

Image 6G: Network Configuration (Router), Local IP Configuration

Submenu

Refer to the preceding section for configuring the Ethernet Port,

keeping in mind that the settings apply only to the ‗wired‘

connection of the MASTER unit.

There are two other options to be discussed further on the following

pages:

Wireless Port IP Configuration

VPN Configuration

Page 53

6.0 Configuration

IP9xx Series

6.1.4.1.2.1 Wireless Port IP Configuration

Within any IP network, each

device must have its own

unique IP address.

Image 6H: Network Configuration (Router), Wireless Port IP

Configuration Submenu

This address MUST be STATIC (i.e. DHCP is not applicable).

IP Address

Values

192.168.2.1

valid value is specific to the

network, typically a Class C

private IP

Subnet Mask

For a small private network with IP addresses appearing similar to

192.168.1.xx (Class C address), the standard 255.255.255.0

subnet mask may be applicable.

Values

255.255.255.0

valid value is specific to the

network

© Microhard Systems Inc. CONFIDENTIAL 53

Page 54

6.0 Configuration

IP9xx Series

Preferred DNS Server

If applicable, enter valid IP address of Preferred DNS Server which

exists within the LAN (the wireless subnet) in this field.

Values

0.0.0.0

valid DNS Server IP address

Alternate DNS Server

If applicable, enter valid IP address of Alternate DNS Server which

exists within the LAN (the wireless subnet) in this field.

Values

0.0.0.0

valid DNS Server IP address

Soft Buttons

Submit

Write parameter values into IP Series memory.

Reset

Restore ‗currently‘ modified parameter values to those

which were previously written into IP Series memory.

© Microhard Systems Inc. CONFIDENTIAL 54

Page 55

6.0 Configuration

VPN: Virtual Private Network.

A communications path

connecting a device on a

WAN with a device on a LAN.

IP9xx Series

6.1.4.1.2.2 VPN Configuration

Image 6I: Network Configuration (Router), VPN Configuration

Submenu

A Virtual Private Network (VPN) may be configured to enable a direct

communications link between one device on the WAN and another

VPN Status

Enable (default) enables the service; Disable disables it.

on the LAN.

Values

Enable

Enable

Disable

VPN Admin Password

Select a unique password of 32 characters maximum, casesensitive.

Values

© Microhard Systems Inc. CONFIDENTIAL 55

admin

32 characters maximum

Page 56

6.0 Configuration

IP9xx Series

VPN Admin Repeat Password

Enter the same unique password of 32 characters maximum, casesensitive, which was entered in the preceding/above field.

Values

admin

32 characters maximum

Soft Buttons

Submit

Write parameter values into IP Series memory.

Reset

Restore ‗currently‘ modified parameter values to those

which were previously written into IP Series memory.

© Microhard Systems Inc. CONFIDENTIAL 56

Page 57

6.0 Configuration

NTP may be used to

synchronize the time in the IP

Series within a network to a

reference time source.

IP9xx Series

6.1.4.2 NTP Server Configuration

The Network Time Protocol (NTP) feature may be ENABLED,

provided there is an NTP server available and its IP address or

‘name‘ is entered in the appropriate field.

© Microhard Systems Inc. CONFIDENTIAL 57

Image 6G: Network Configuration, NTP Server Config. Submenu

NTP Server Status

Note that if NTP Server Status is ENABLED, the ‗Synchronize with

NTP Server‘ soft button on the System Configuration menu will be

available for use.

Leave as DISABLED (default) if a server is not available.

Values

Disable

Disable

Enable

Page 58

6.0 Configuration

IP9xx Series

NTP Server (IP/Name)

IP address or domain name for NTP server (on local LAN or

website (provided that Internet access is available)) is to be entered

in this field if the NTP Server Status is configured as ENABLED.