Page 1

microHAM © 2015 All rights reserved

SMΩRF

RF VECTOR

SIGNAL METER

microHAM

fax: +421 2 4594 5100

e-mail: support@microham.com

homepage: www.microham.com

Version – 1.4

8 April, 2016

1

Page 2

microHAM © 2015 All rights reserved

TABLE OF CONTENTS

CHAPTER PAGE

1. FEATURES AND FUNCTIONS ................................................................................................... 4

2. IMPORTANT WARNINGS .......................................................................................................... 5

3. HARDWARE DESCRIPTION ...................................................................................................... 5

Front Panel ..........................................................................................................................6

Rear Panel ........................................................................................................................... 7

4. INSTALLATION .......................................................................................................................... 8

5. OPERATION …........................................................................................................................... 9

Sensor Selection ................................................................................................................. 9

Bar Graphs Scales and Ranges........................................................................................... 9

6. SCREEN …............................................................................................................................... 11

SCREEN: Status Bar ........................................................................................................ 11

SCREEN: Edit Mode ........................................................................................................ 12

SCREEN: Two Point Measurements ................................................................................ 12

SCREEN: Bar Graph Functions ....................................................................................... 13

SCREEN: Bar Graph Settings ........................................................................................... 14

SCREEN: Tone Generator ................................................................................................16

SCREEN: Screens Menu ..................................................................................................18

7. SINGLE SENSOR SCREEN TEMPLATES ............................................................................... 20

STANDARD Screen .......................................................................................................... 20

LARGE Screen ................................................................................................................. 21

PSK Screen ...................................................................................................................... 22

TUNE Screen .................................................................................................................... 23

TECHNICAL Screen ........................................................................................................ 24

OSCILLOSCOPE Screen .................................................................................................. 26

SPECTRUM Screen ......................................................................................................... 29

AUTO Mode ..................................................................................................................... 31

8. DUAL SENSORS SCREEN TEMPLATES ................................................................................ 31

2TX Screen ....................................................................................................................... 32

PA Screen …..................................................................................................................... 33

4IN Screen ........................................................................................................................ 35

9. MAIN MENU .…........................................................................................................................ 37

10. SYSTEM MENU ....................................................................................................................... 37

METER MODE ................................................................................................................... 38

Miscellaneous Settings ....................................................................................................... 40

Brightness Settings .......................................................................................................... 41

LAN Settings ..................................................................................................................... 42

Power Saving .....................................................................................................................43

Time and Date .................................................................................................................. 45

Backup and Restore .......................................................................................................... 46

Screens Management ........................................................................................................47

11. SENSOR 1 MENU ..................................................................................................................... 49

Sensor Details .................................................................................................................... 49

Sensor Cables Table ........................................................................................................ 49

Sensor Cables Calibration ................................................................................................. 51

100% Power Levels ............................................................................................................ 51

Antenna Cables ................................................................................................................ 52

Miscellaneous .................................................................................................................. 54

Copy Settings .................................................................................................................... 55

2

Page 3

microHAM © 2015 All rights reserved

12. ALARM 1 MENU ....................................................................................................................... 56

Alarms Handling and Operation .........................................................................................56

Alarm Settings .................................................................................................................... 57

SWR Alarm ...................................................................................................................... 60

LOW POWER Alarm ........................................................................................................ 61

HIGH POWER Alarm ........................................................................................................ 62

PSK IMD Alarm ..................................................................................................................62

ARCING Alarm ................................................................................................................... 63

13. DATA STRUCTURE DIAGRAM ................................................................................................. 64

14. SENSORS ….............................................................................................................................. 65

15. REMOTE CONTROL ….............................................................................................................. 66

HTTP Server ….................................................................................................................. 66

VNC Server …..................................................................................................................... 68

Remote Control Application ................................................................................................ 69

16. TECHNICAL SPECIFICATION …...............................................................................................71

17. PACKAGE CONTENT …............................................................................................................ 75

18. WARRANTY …........................................................................................................................... 75

DECLARATION OF CONFORMITY ........................................................................................ 76

3

Page 4

microHAM © 2015 All rights reserved

1 – FEATURES AND FUNCTIONS

SMΩRF™ is unique metering instrument, the most powerful and accurate, in-line vector RF power meter to date

with accuracy rivaling the professional instruments. Has tons of extra features, and very high level of user

customization to fit every hamshack, every operator's needs.

SMΩRF™ connects to RF signal by remote sensor (coupler), available in several models for power levels from

miliwatts up to 12kW and frequencies up to 500MHz. HF + 6m sensors provide sample of passing current (I) and

voltage (U) on its LOAD port. VHF and UHF sensors provide sample of forward (FWD) and reflected (REF)

power to meter. The meter can simultaneously measure two independent signals from any two sensors and

shows measurement results on its front panel or computer.

Main features:

• Operating frequency from 1.8 – 500MHz.

• Signed phase measurement.

• Two points of measurement, at the sensor point and at the antenna point.

• Phase measurement between sensors.*

• Real time temperature compensation in meter and sensor.

• Dual, high speed, three color, user adjustable auto-ranging LED bar graphs with configurable peak hold.

• Every meter and every sensor individually factory calibrated for best accuracy. Temperature controlled,

computer automatized calibration setup makes over 10,000 calibration points in each meter and over 100

points in each sensor. Calibrated per port for level, frequency, phase, and temperature.

• Very wide viewing angle, sunlight readable, high contrast graphics OLED display.

• Multiple, user configurable display screens for powers, impedance, waveform, spectrum, PSK, SO2R …

• User configurable alarms in three importance levels (warning, alarm, fault) for two power ranges on per

sensor, per band basis for SWR, Low Power and High Power alerts.

Connectivity:

• Internet enabled, native IEEE 802.3 Ethernet port for remote connectivity.

• Internal web server for simple access from the computer browser for status checking, maintenance and

firmware updates, no drivers, no specialized software installation.

• TCP port for high speed remote control applications, open protocol.

• High purity, DDS based test signal generator (single/dual tone, noise) for linearity and bandwidth tests.

• iLINK port for simplified connection to our interfaces.

• Two keying, pass thru ports and RS232 serial port for legacy connections.

• Well featured Auxiliary port for future expansions (wall mount 7 segment LED displays, analog meter).

Other features:

• Internal speaker for audible alerts.

• Internet synchronized real time clock.

• Ambient light sensor for display and led bars brightness control.

• Free Remote Control application for Windows and OS-X.

• EMI shielded, aluminum die cast enclosure.

Internal processing highlights:

• 210 MIPS, 32bit floating point Cortex M4 DSP processor for extremely fast updates and accurate

calculation of complex functions.

• hi-grade, parallel 16bit ADC, sampled at 125ksps.

• 24bit DAC at 160ksps for signal generator.

* Both sensors are of the same type (U/I or FWD/REF), connected by the same length leads and operating at the same frequency.

4

Page 5

microHAM © 2015 All rights reserved

2 - IMPORTANT WARNINGS

ALWAYS check the polarity of the 13.8 V power supply

before you connect it to the meter.

If you use meter without sensors,

NEVER exceed 26dBm level to the meter's IN RF ports.

If you use some accessory injecting DC power to the coaxial cable,

connect it ALWAYS behind the LOAD port of any CHF sensor.

DO NOT connect OUT ports to inductive, AC or >24VDC loads.

DO NOT place meter on hot surfaces.

DO NOT touch the sensor under RF power.

ALWAYS backup your settings prior firmware update.

3 - HARDWARE DESCRIPTION

SMΩRF system consists of two parts, sensor and meter.

Sensor is a box, inserted in transmission line (coaxial cable) between source of power (transceiver or power

amplifier) and the load (antenna). Depending on used sensor, it provides sample of current (I) and voltage (U) on

transmission line, or forward (FWD) and reflected (REF) power sample. All HF sensors are U/I type with current

and voltage transformers inside. All VHF/UHF sensors are FWD/REF type directional couplers. All sensors have

internal micro-controller and EEPROM memory for calibration data storage. Micro-controller measures internal

temperature of the coupler and provides these data on request to the meter.

Meter connects to sensor's sample outputs, and measures their magnitude and phase at a rate of 125,000

samples per second as well as internal and sensor temperature. Captured data are than corrected by four

dimensional calibration tables taken during individual calibration for magnitude, phase, frequency and

temperature for both sensor and meter. Meter then further processes the captured data. For some type of

measurements where high data rate is required (alarms, oscilloscope and spectrum screens), raw data are

used. For measurements where stability and smoothness is more important, data are additionally filtered in

various IIR or FIR filters according to their nature. Computed results are than provided on meter's front panel or

computer screen through Ethernet port. Thanks to powerful DSP CPU in the meter and optimized code, meter is

capable to do all above tasks in real time and at the same time provide DDS based tone generator output for

some kind of specific measurements.

5

Page 6

microHAM © 2015 All rights reserved

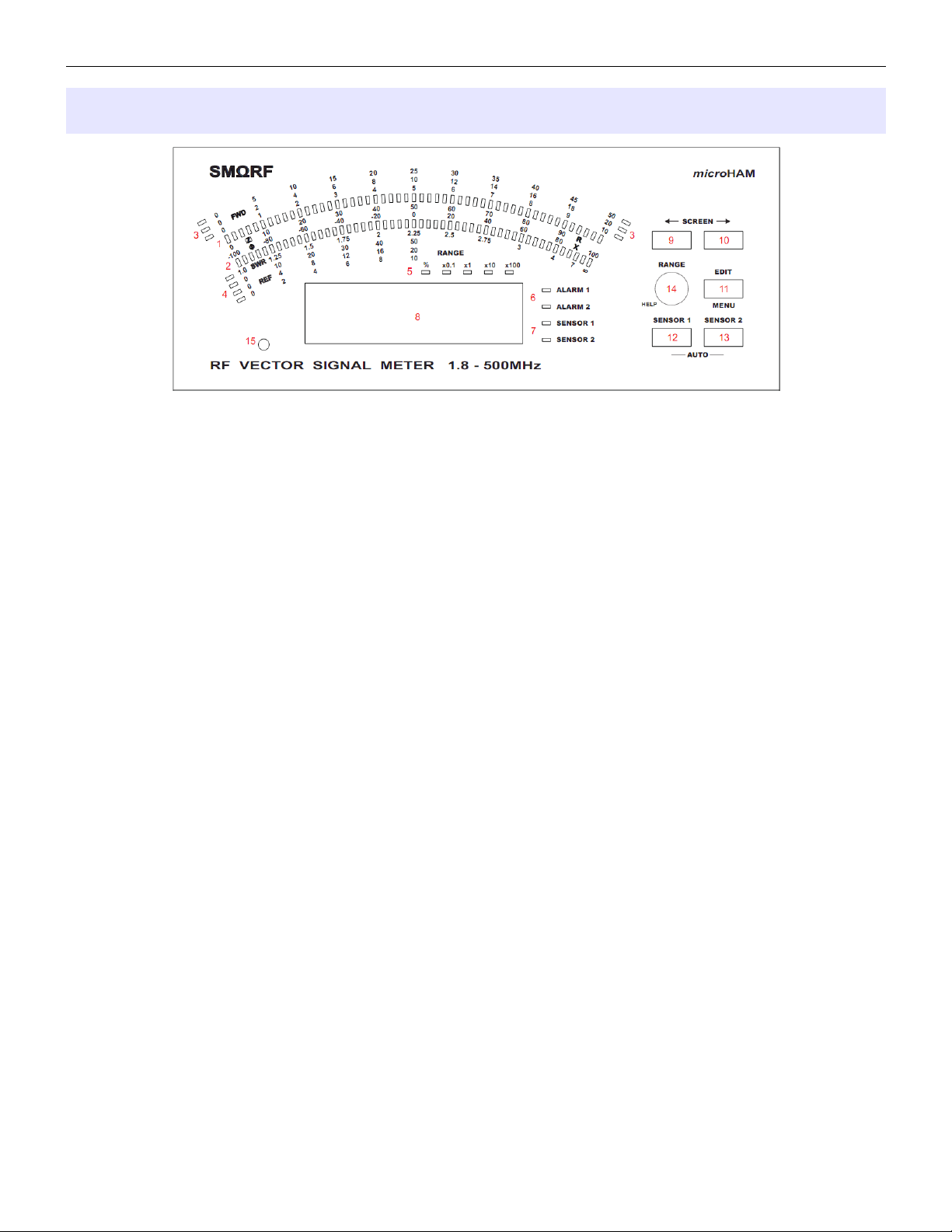

Front Panel

1. TOP BAR GRAPH

2. BOTTOM BAR GRAPH

3. TOP BAR GRAPH SCALE INDICATOR

4. BOTTOM BAR GRAPH SCALE INDICATOR

5. BAR GRAPH SCALE RANGE INDICATOR

◦ green color indicates top bar graph range

◦ red color indicates bottom bar graph range

◦ yellow color indicates same range for both bar graphs

6. ALARM INDICATORS

◦ green color indicates warning

◦ red color indicates alarm

◦ flashing red color indicates fault

7. SENSOR INDICATORS

8. MAIN DISPLAY

9. LEFT ← SCREEN ROTATION BUTTON

◦ button serves as left navigation button in EDIT mode and MENU system

10. RIGHT → SCREEN ROTATION BUTTON

◦ button serves as right navigation button in EDIT mode and MENU system

11. EDIT/MENU BUTTON

◦ short press enters EDIT mode and allows editing outlined fields on current screen

◦ pressing and holding for one second enters MENU system of the meter

12. SENSOR 1 BUTTON

◦ when pushed briefly together with SENSOR 2 button, meter switches to the AUTO mode and automatically

focuses to the first sensor passing sensing nonzero power

◦ when pushed and held together with SENSOR 2 for one second, meter switches to the DUAL mode and displays

special screens designed for two sensors measurements

◦ button serves as up navigation button in MENU system.

13. SENSOR 2 BUTTON

◦ when pushed briefly together with SENSOR 1 button, meter switches to the AUTO mode and automatically

focuses to the first sensor passing sensing nonzero power

◦ when pushed and held together with SENSOR 1 for one second, meter switches to the DUAL mode and displays

special screens designed for two sensors measurements

◦ button serves as down navigation button in MENU system

14. ROTARY KNOB

◦ when rotated sets top bar graph range

◦ when pushed and rotated sets bottom bar graph range

◦ changes selected value in EDIT mode and MENU system

◦ when pushed in EDIT or MENU system, it pop ups short help for selected item

◦ during ALARM condition push snoozes or resets active alarm

15. AMBIENT LIGHT SENSOR

◦ measures ambient light for automatic brightness control of bar graphs and main display

6

Page 7

microHAM © 2015 All rights reserved

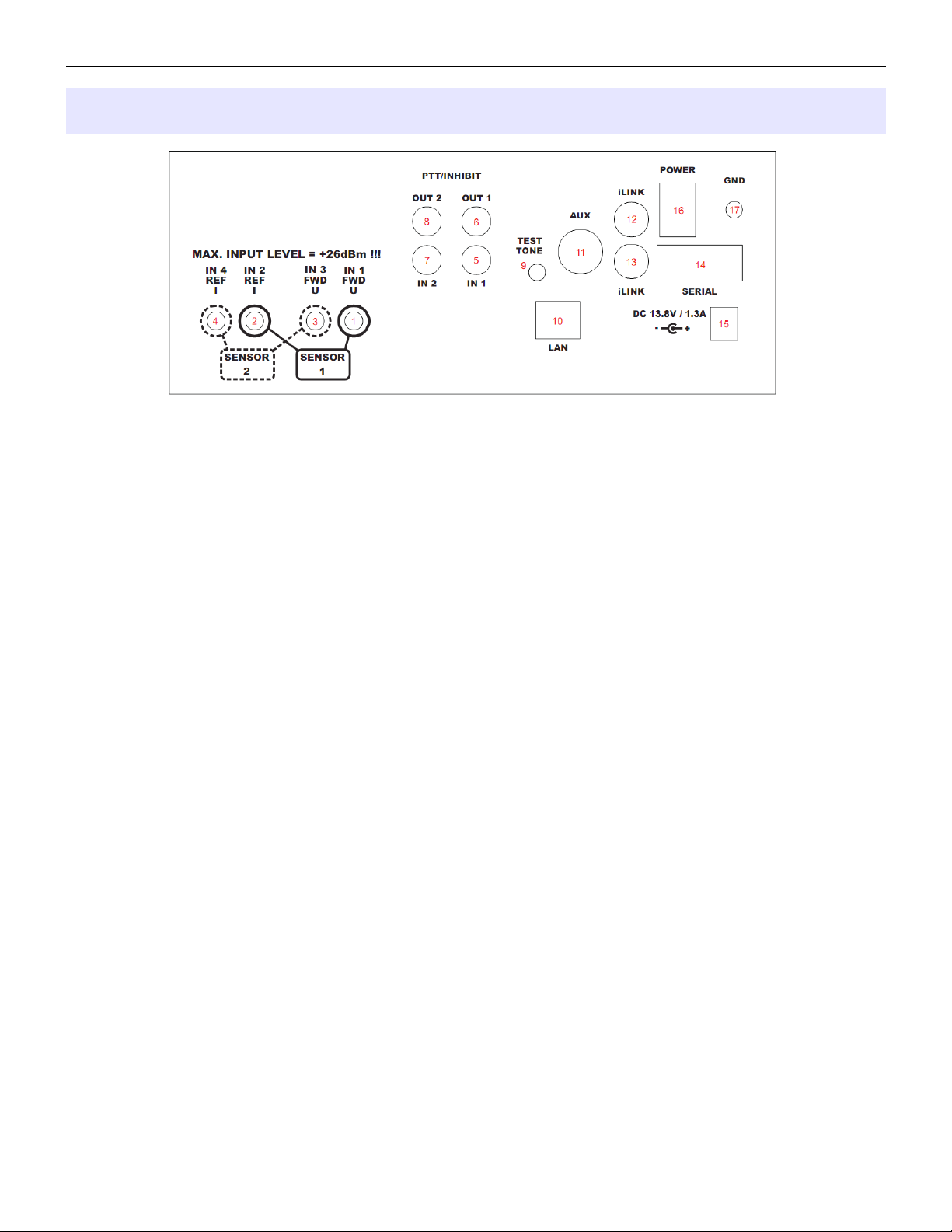

Rear Panel

1. SENSOR 1 FORWARD (FWD) or VOLTAGE (U) SAMPLE INPUT

◦ FWD/U connection port of SENSOR 1

◦ serves as INPUT 1 in 4 INPUT mode

2. SENSOR 1 REFLECTED (REF) or CURRENT (I) SAMPLE INPUT

◦ REF/I connection port of SENSOR 1

◦ serves as INPUT 2 in 4 INPUT mode

3. SENSOR 2 FORWARD (FWD) or VOLTAGE (U) SAMPLE INPUT

◦ FWD/U connection port of SENSOR 2

◦ serves as INPUT 3 in 4 INPUT mode

4. SENSOR 2 REFLECTED (REF) or CURRENT (I) SAMPLE INPUT

◦ REF/I connection port of SENSOR 2

◦ serves as INPUT 4 in 4 INPUT mode

5. PTT / INHIBIT IN1

◦ configurable input coupled to SENSOR 1

6. PTT / INHIBIT OUT1

◦ configurable output coupled to SENSOR 1

7. PTT / INHIBIT IN2

◦ configurable input coupled to SENSOR 2

8. PTT / INHIBIT OUT2

◦ configurable output coupled to SENSOR 2

9. TEST TONE

◦ internal tone generator output, 4 pole 3.5mm jack

10. LAN

◦ IEEE 802.3 Ethernet port

11. AUX

◦ Accessory port

12. iLINK

◦ first iLINK port for connection to iLINK enabled microHAM devices

13. iLINK

◦ second iLINK port for connection to iLINK enabled microHAM devices

14. SERIAL

◦ RS232 port for general low speed connectivity

15. DC 13.8V

◦ power input, max. 16V, center positive, shell negative

16. POWER SWITCH

17. GROUNDING SCREW

7

Page 8

microHAM © 2015 All rights reserved

4 – INSTALLATION

1. Connect sensor to the meter

• Connect U or FWD sample output of the sensor to the meter's SENSOR 1 – U/FWD input using

supplied SMA – SMA cable. It isn't important which one of two supplied SMA – SMA cables you use,

but keep the calibration certificate of the cable and mark it to reflect the connection (SENSOR

#SN/U). Later you can enter calibration table of the cable from the certificate sheet to the meter

memory in SENSOR MENU. It will slightly improve metering accuracy but you will need to pair

calibration table to the cable, each is individually calibrated in the factory.

• Connect I or REF sample output of the sensor to the meter's SENSOR 1 – I/REF input using second

SMA – SMA cable. Again, keep the calibration certificate of the cable and mark it to reflect the

connection (SENSOR #SN/I).

• If you are connecting the second sensor,

use SENSOR 2 ports on meter in the

same manner as for SENSOR 1 above.

2. Connect sensor to the transceiver and the

antenna

• Connect antenna port of your transceiver

or power amplifier to the sensor's TX

port.

• Connect your antenna to the LOAD port

of the sensor.

3. Connect meter to the transceiver or

microHAM interface

• Connect supplied miniDIN6 – miniDIN6

cable from iLINK port of the meter to the

iLINK port on microHAM interface. If you have multiple microHAM interfaces and you are unsure

where to connect iLINK port, please refer to METER MODE chapter for more details.

• If you don't have our interface, or you have interface without iLINK port, please refer to ALARM

SETTINGS chapter for more details. This connection is not necessary for SMΩRF functionality, but

when used, SMΩRF can protect your TX chain using internal ALARMs.

4. Connect power to the meter

• Connect 13.8V DC power supply to the DC power jack of the meter. DC power jack is standard

2.1/5.5 mm power jack, use supplied plug if you haven't one.

• Observe the polarity!!! Center is positive (+), shell is negative (-).

• Use well regulated and filtered power supply capable to provide 1.3A.

• Connect grounding lead from your central grounding point in the shack to the ground terminal screw

on the meter.

5. Turn power On

• Flip the power switch on the rear panel.

• After power up, meter checks for presence of sensors on its inputs. When the meter finds a new

sensor, it copies calibration data from the sensor's memory to the meter's memory. Each sensor has

built in a large calibration table, transfer of these data to meter may take several minutes. Be patient

and don't worry, it is just a one time procedure and happens only on the very first connection to the

new sensor. When done, meter will automatically switch to one of the metering screens.

6. Select metering mode

• Press and hold MENU button for a second. Using ← / → buttons select SYSTEM MENU. Press

briefly MENU to enter. Select METER MODE. Press briefly MENU to enter.

• If you are connecting second sensor or both sensors at the same time, please refer to METER

MODE chapter to understand what metering mode means and does in order to use correct one for

your purpose. Otherwise select SINGLE RADIO / SINGLE SENSOR mode by rotary knob. Press

MENU briefly to register.

8

Page 9

microHAM © 2015 All rights reserved

5 – OPERATION

Operating SMΩRF is easy and intuitive, but to use it effectively and to maximal pleasure, it is important to

understand its structure and relationship between data and settings.

SENSOR SELECTION

First basic selection on SMΩRF is a

SENSOR focus. If you have only one

SENSOR, it is just the matter of pressing

bottom SENSOR 1 button [12]. Press

bottom SENSOR 1 button briefly to

change focus to that sensor. When

SENSOR 1 is selected, red SENSOR 1

indicator [7] is steadily lit.

If SMΩRF has both sensors installed,

there are more options. For manual

selection of the sensor press SENSOR 1 [12] or SENSOR 2 [13] button. SENSOR 2 focus is indicated by green

SENSOR 2 [7] indicator.

When SENSOR 1 and SENSOR 2 buttons are pressed briefly together, meter switches to AUTO mode. In

AUTO mode, meter switches focus automatically to the first sensor which detects power. Activated AUTO mode

is indicated by gently flashing SENSOR 1 or SENSOR 2 indicator [7].

AUTO mode is useful for multiband HF+VHF/UHF transceivers where meter automatically switches between

sensors according to operating band (HF vs VHF or UHF). For SO2R contesting setups where only one

transceiver transmits at a time, AUTO mode is invaluable.

When SENSOR 1 button and SENSOR 2 buttons are pushed and held together for one second, meter switches

to DUAL mode. When meter switches to the DUAL mode, it provides measurement results of both sensors at

the same time.

Please note, AUTO mode and DUAL mode availability depends on selected METER MODE. It will be described

in details later, just to not panic if you can't do it right now :-) .

BAR GRAPHS SCALES and RANGES

Bar graphs in SMΩRF are well featured and deeply customized indicators capable of displaying much more than

just power or SWR. The selection of what is actually shown on the bar graph - one of available power readings

(forward, reflected, delivered, all these variants at antenna) or parts of the complex impedance or SWR - can be

quickly set in SCREEN EDIT mode (described below). Full functionality and settings of bar graphs will be

described in separate BAR GRAPHS SETTINGS chapter, here, handling of scales and ranges is described.

At the very beginning one important note to remember. Information presented on bar graphs are always related

to one sensor, either SENSOR 1 or SENSOR 2 according to the SENSOR selection (see above). In DUAL

mode, it is possible to select whether the bar graph shows data of SENSOR 1 or SENSOR 2 individually but both

bar graphs show data of one sensor. Remote Control application on computer shows four (4) bar graphs in

DUAL mode.

Both TOP BAR [1] and BOTTOM BAR [2] has its own POWER reading scale. There are three (3) linear scales

for each in 10/20/50 full scale divisions, and five RANGE multipliers: x0.1, x1, x10, x100, x1000. Last x1000

9

Page 10

microHAM © 2015 All rights reserved

multiplier is indicated by flashing x100 indicator. Bottom power reading scale is shortened to half. Final value is

given by multiplying indicated value on the current scale by RANGE multiplier.

Current scale on TOP bar is indicated by one of SCALE indicators [3], and current RANGE is indicated by one of

RANGE indicators [5]. BOTTOM bar scale is indicated by its own SCALE [4] and RANGE indicator [5]. While

scale indicators for top and bottom bar are separate, range indicators are shared and differentiated by color.

TOP bar uses GREEN range indicator, BOTTOM bar RED indicator. When RANGE multiplier for both bars is the

same (rare but may happen), RANGE indicator is YELLOW.

Any selected power type for top and/or bottom bar graph is always shown in W [Watt] units. When bar shows

POWER, both bars can have independently defined four (4) power ranges, and for each power range one of

three (3) available colors can be assigned, for each band, each screen separately. These ranges and not related

to scale ranges described above, they may start and end anywhere from 0W up to maximal power. Advantage of

colored ranges is readability. When you set for example 50-100W range to be shown in red color, power from

50-100W will always be shown in red color, regardless of scale range (it doesn't matter if you are in 100W scale

or 2000W scale). In this way you can make some nicely visible important power areas like optimal driving power

for amplifier, maximal power to certain antenna etc ...

When bottom bar [2] shows SWR instead of reflected power, it is indicated by YELLOW SWR scale indicator [4].

SWR has its own, specialized scale divided to four (4) linear sub-scales in order to achieve fast, simple and

precise readout. SWR from 1.0 to 3.0 - the most important section - has linear division of 0.05 per bar segment.

It takes 80% of the bar length. SWR from 3.0 to 4.0 has division of 0.2 per segment, from 4.0 to 7.0 division 1 per

segment, while SWR 7 segment is lit when SWR is up to 10. Last but one shows SWR from 10 to 15, last one

everything higher than 15. Same as for the power, also for SWR four (4) custom color ranges can be defined in

the BOTTOM BAR MENU, on per band basis, settings follow the same segmented scale, but this time in a same

division and ranges as are defined SWR sub-scales.

When bars are configured to show parts of Complex Impedance, the two scales printed in between the two LED

bars are used. Scale above the central line applies to the top bar graph and shows Resistance R or Absolute

value of Impedance |Z| in 0 - 100Ω range. Scale below the central line applies to the bottom bar graph and

shows Reactance X or Phase angle Φ in -100 to +100Ω or -100 to +100º range.

Bar graphs can operate in MANUAL or AUTO RANGE mode. ROTARY KNOB [14] is used to select the mode

and to select range in MANUAL mode. When rotated in CW direction it changes range from the lowest (least

sensitive) to the highest respectively. When rotated in CCW direction, very last CCW position is AUTO RANGE.

In AUTO RANGE mode meter switches range upward immediately but down-ranges with timeout. BARS

DOWNRANGING timeout is adjustable in SYSTEM MENU | MISCELLANEOUS if you don't like the default

value.

When rotary knob is depressed and rotated, it changes ranges for bottom bar in a same manner as for top bar.

In MANUAL mode it is possible to overload current range. Overloaded range is indicated by fast flashing SCALE

indicator [3]. Each range allows 2% overload without overload indication. Since bar graphs are software driven,

there is no damage even if they are hugely overloaded for a long time, don't worry if it happens.

Last but one CCW range position of the rotary knob is percentage (%) range. When enabled, it is indicated by %

RANGE indicator [5]. This range is useful for instant checking if everything is as should be, because 100% power

level is always full deflection on linear scale without any range switching. 100% power levels can be precisely set

on per sensor, per band basis in SENSOR MENU according to your specific requirements or available power.

100% power level value is also used in TUNE SCREEN, optimized SCREEN for tuning manual Power Amplifiers

or Antenna Tuners.

10

Page 11

microHAM © 2015 All rights reserved

6 – SCREENS

SMΩRF provides measurement results in form of SCREENs. Every SCREEN is a group of measurements and

settings for Main display [8], Bar Graphs [1],[2], Alarms [6] and Tone Generator. Up to 16 screens can be

associated to each of SENSOR1 and SENSOR2, separately. The dedicated top ← [9] / → [10] buttons switch

between SCREENs of one sensor. Each SCREEN in the sequence can be turned on or off in the SYSTEM

MENU | SCREENS MANAGEMENT MENU.

Internally, SCREENs are built on layout templates. The template defines, how the measurement results are

presented on main display [8], if they are displayed numerically (classic digital wattmeter appearance) or also

graphically (oscilloscope, spectrum or PSK screens). There are several built in templates covering most of

situations user can face during regular operation, contesting as well as experimenting on antennas, amplifiers or

matching networks.

Bottom line:

Main Display template (including all related settings) + Bar Graphs (including all their settings) + Alarms

(individually enabled/disabled) + Tone Generator (including all its settings) forms one SCREEN.

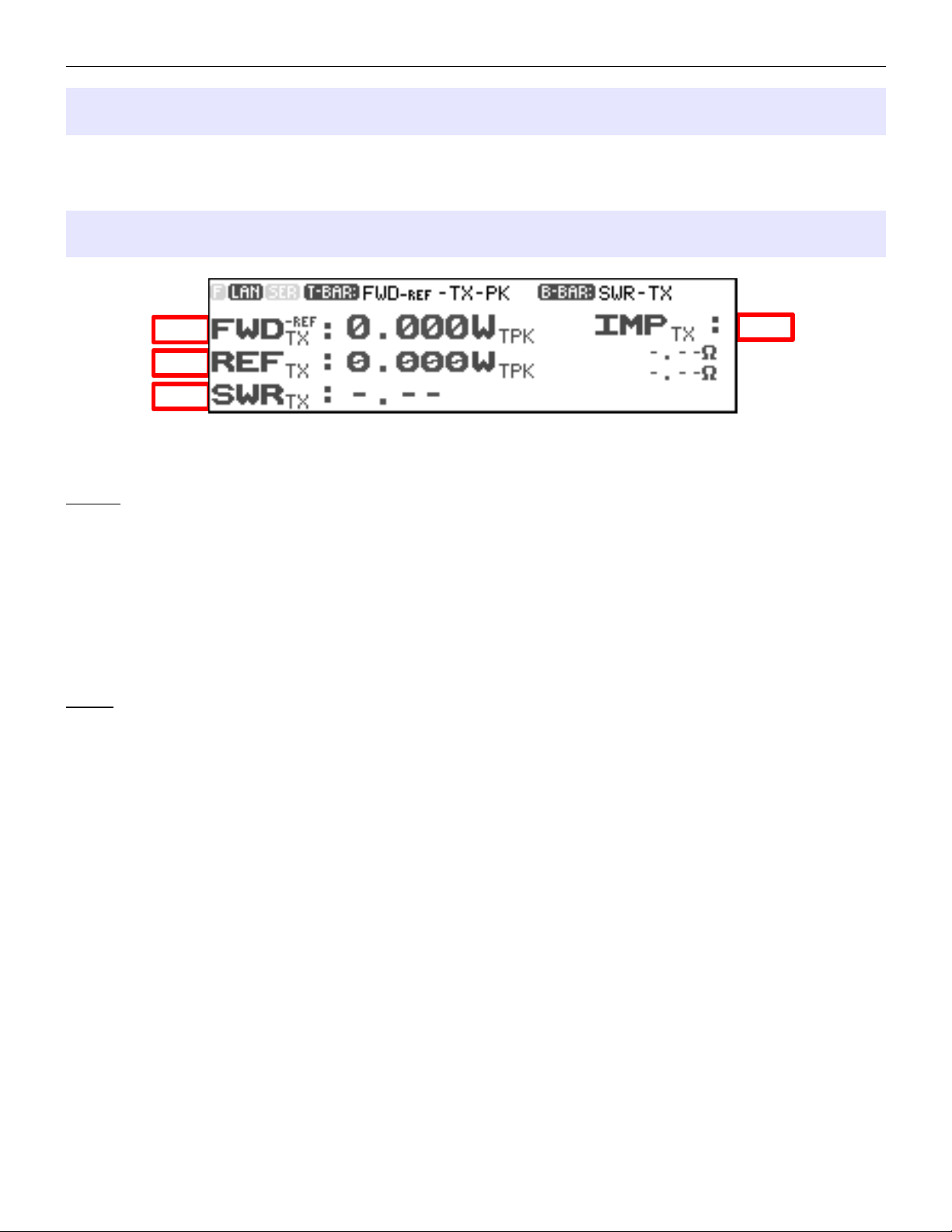

STATUS BAR

On top of each screen, status indicators and bar graphs

function choice (or current antenna cable choice) is shown.

1. Frequency validity

• Using the calibration data, each measured sample undergoes an adjustment procedure, which needs

to know the frequency of incoming signal, therefore is important to see it on all the time. If measured

signal is very low in power, it may happen that the signal is too weak to measure its frequency, while

its amplitude is still well measurable to show the power. In this case the F indicator is off and meter

uses last measured frequency.

• If SMΩRF is connected and coupled to microHAM device over iLINK port (MKII, MK2R+, SM, SMD),

it receives exact operating frequency from this device even if transceiver is not transmitting. Coupling

is set on a coupled device and on the SMΩRF is coupling indicated by i indicator. When indicator lit

in half brightness, SMΩRF confirms frequency reception. When is fully illuminated, SMΩRF confirms

transmit status update from a coupled device.

2. LAN port status

• Indicates Ethernet port state and connection status.

• When off, SMΩRF is not connected to LAN

• When lit in half brightness, SMΩRF is physically connected to LAN but there is no active connection

from a computer.

• When is fully illuminated, LAN port is opened by remote device or computer.

3. Serial port status

• When lit, serial port transfers data.

4. T-BAR: Top Bar Graph data or ANT-S1/ANT-S2: Selected Antenna Cable

• Shows what data are shown on TOP Bar graph.

• Shows antenna cable selected for current frequency band for SENSOR1/SENSOR2

5. B-BAR: Bottom Bar Graph data or ANT-S1/ANT-S2: Selected Antenna Cable

• Shows what data are shown on BOTTOM Bar Graph.

• Shows antenna cable selected for current frequency band for SENSOR1/SENSOR2

11

Page 12

microHAM © 2015 All rights reserved

EDIT MODE

Built in SCREENs can be very easily customized in real time, cloned for the same layout but different

parameters, copied between sensors etc. As was written above, to each sensor up to 16 screens can be

associated, doesn't matter if they are built in, customized or cloned. You can have the same screen cloned with

same settings for main display because you like the template but you need different settings for bar graphs (for

example because you want slower movement on SSB) or for whatever reason.

To enter EDIT mode push briefly EDIT button [11]. To exit EDIT MODE push briefly EDIT button again.

In EDIT mode main display [8] shows some fields outlined. Outlined fields are parameters that can be changed,

customized. Basic and globally applicable golden rule is: “What is outlined, it can be changed”.

Outline around the parameter which fades in and out means that the parameter is selected and can be changed

by Rotary Knob. To move selection between parameters use ← and → SCREEN buttons.

Built-in HELP

If you are unsure what some parameter means, push the rotary knob for short help. By rotating knob while you

are in the help window, you can scroll between all available choices and read at the same time what it means or

does. Push the knob or EDIT button to register new choice and exit from help window.

We've put a lot of effort to make short help available for virtually every item possible to change. Once you

read this manual completely, built-in help system should refresh your memory and make you able to set what you

want without reaching for this manual again. Hope you find the built-in help useful.

TWO POINT MEASUREMENTS, TX and ANT subscripts, - REF

When you look at most of SCREENs you certainly wonder what these TX and ANT subscripted suffixes means.

They present another unique feature of the SMΩRF called “two point measurement”.

Thanks to the calibration correction, SMΩRF provides very accurate measurements related to the outer plane of

the LOAD connector at the sensor. This point is in SMΩRF language called TX Feed Point and data measured

at this point are shown with TX suffix after the data type, like FWDTX for the forward power or SWRTX for Standing

Wave Ratio.

Having measured all data at the TX Feed Point, SMΩRF can mathematically work out powers and transmission

line parameters at the end of the cable where cable connects your antenna and show what happens there, how

much power is actually radiated. This point is called ANT Feed Point and data at this point are shown with ANT

suffix after the data type, like FWD

data are calculated rather than measured, SMΩRF includes precise models of over 30 commonly used coaxial

cables to choose from. Accuracy of provided results is directly related to the manufacturing differences of the

cable to its specification, accuracy of the user entered cable length and accuracy of the TX feed point

measurements. Good cable matches specifications within 5% according to cable manufacturer claims, how

accurately you measure and enter physical cable length is up to you. The SENSOR MENU - ANTENNA

CABLES chapter deals with antenna cables in more detail. Please note, by default SMΩRF uses lossless 50Ω

cable model for all ANT Feed Points

to avoid any confusion while you

aren't familiar with this feature. It

doesn't matter if you choose TX or

ANT Feed Point until you edit

ANTENNA CABLES table. Till than

result will be the same, providing

values of TX Feed point in both cases.

for the forward power or SWR

ANT

for Standing Wave Ratio. Although these

ANT

12

Page 13

microHAM © 2015 All rights reserved

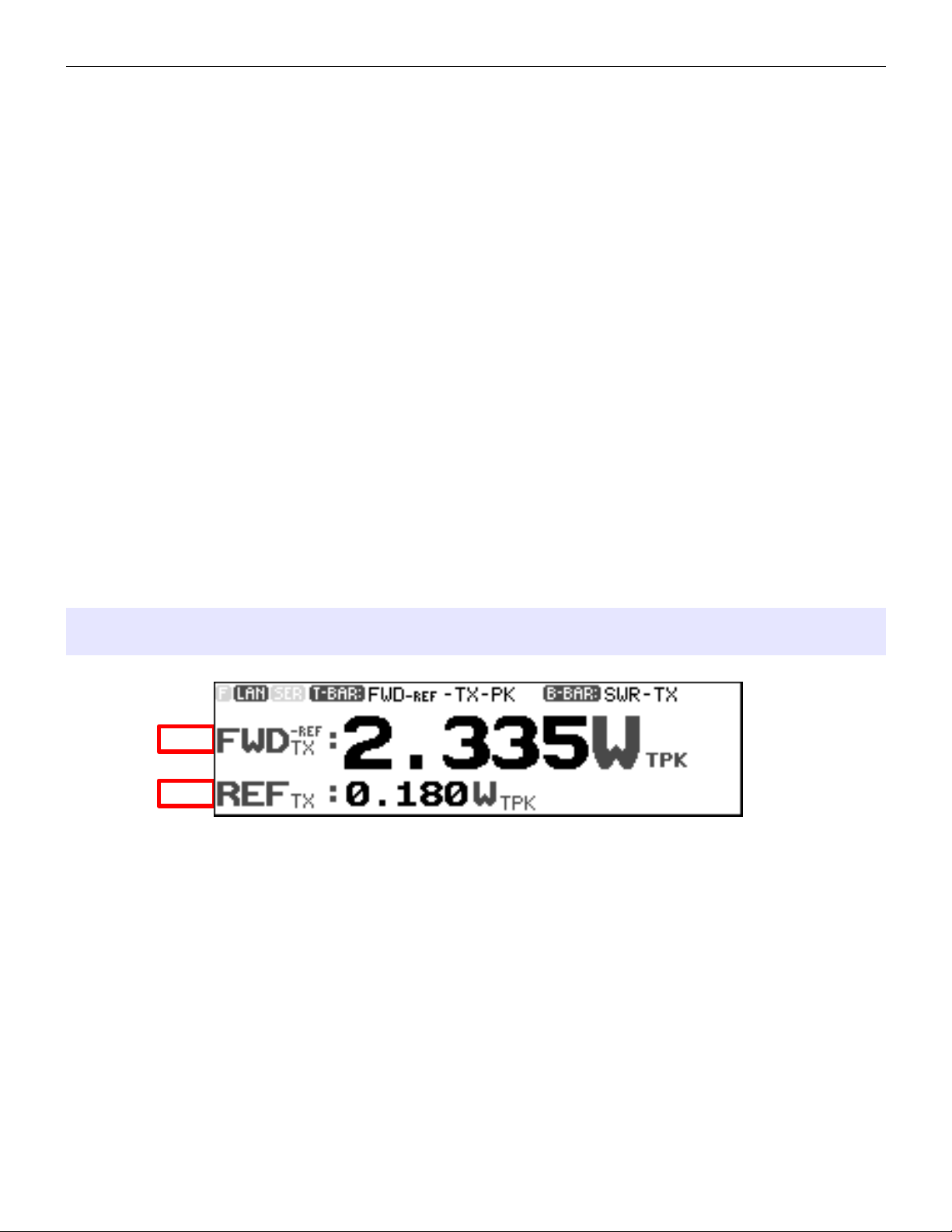

-REF

Another suffix used in provided measurements is superscripted -REF as in FWD

TX

-REF abbreviation appears only after forward power (FWD) and stands for delivered power, power which was

transferred to the cable or to the antenna, cleared of reflected power.

FWD

FWD

-REF

= (Forward Power – Reflected Power) ; delivered power to the coaxial cable connecting antenna

TX

-REF

= (Forward Power – Reflected Power) ; actual delivered power to the antenna

ANT

BAR GRAPHS FUNCTIONS

How bar graphs scales and ranges work was already explained, now we look at bar graphs functions and

settings. While settings for top and bottom bar graph are almost identical, function sets available for each are

much different.

Please note, bar graph function and settings are remembered separately for each SENSOR and each

SCREEN. It means that you can have different bar graph behavior for every screen or screen copy. Anyway,

when you are happy with new settings and you want to just clone them to another screen or sensor you can copy

bar graph settings in SYSTEM MENU – SCREEN MANAGEMENT (described later).

To change function of the bar graph you have to enter EDIT mode and select field (parameter) right next to

T-BAR: or B-BAR: icon in top STATUS bar, depends on if you want to change top or bottom bar function. When

parameter is selected, you can change function by rotating the knob.

TOP BAR GRAPH FUNCTIONS

1. FWD

• Peak envelope forward power minus reflected power (delivered power) at the TX feed point.

2. FWD

• Average forward power minus reflected power (delivered power) at the TX (Sensor) feed point.

– TX – PK

-REF

– TX – AVG

-REF

3. FWD – TX – PK

• Peak envelope forward power at the TX (Sensor) feed point.

4. FWD – TX – AVG

• Average forward power at the TX (Sensor) feed point.

5. FWD

• Peak envelope forward power minus reflected power at the ANT (Antenna) feed point.

6. FWD

• Average forward power minus reflected power at the ANT (Antenna) feed point.

– ANT – PK

-REF

– ANT – AVG

-REF

7. FWD – ANT – PK

• Peak envelope forward power at the ANT (Antenna) feed point.

8. FWD – ANT – AVG

• Average forward power Power at the ANT (Antenna) feed point.

9. Z – TX – R

• Real part of rectangular coordinates complex impedance at the TX (Sensor) point.

10. Z – TX – |Z|

• Absolute value of polar coordinates complex impedance at the TX (Sensor) point.

11. Z – ANT – R

• Real part of rectangular coordinates complex impedance at the ANT (Antenna) feed point.

12. Z – ANT – |Z|

• Absolute value of polar coordinates complex impedance at the ANT (Antenna) feed point.

13

Page 14

microHAM © 2015 All rights reserved

BOTTOM BAR GRAPH FUNCTIONS

1. SWR – TX

• Standing Wave Ratio at the TX (Sensor) feed point.

2. SWR – ANT

• Standing Wave Ratio at the ANT (Antenna) feed point.

3. REF – TX – PK

• Peak envelope reflected power at the TX (Sensor) feed point.

4. REF – TX – AVG

• Average reflected power at the TX (Sensor) feed point.

5. REF – ANT – PK

• Peak envelope reflected power at the ANT (Antenna) feed point.

6. REF – ANT – AVG

• Average reflected power power at the ANT (Antenna) feed point.

7. Z – TX – X

• Imaginary part of rectangular coordinates complex impedance at the TX (Sensor) feed point.

8. Z – ANT – X

• Imaginary part of rectangular coordinates complex impedance at the ANT (Antenna) feed point.

9. Z – TX – Φ

• Phase value of polar coordinates complex impedance at the TX (Sensor) feed point.

10. Z – ANT – Φ

• Phase value of polar coordinates complex impedance at the ANT (Antenna) feed point.

11. Z – TX – R + jX

• Dual display of rectangular coordinates complex impedance.

R (green) + jX (red) at the TX (Sensor) feed point.

12. Z – ANT – R + jX

• Dual display of rectangular coordinates complex impedance.

R (green) + jX (red) at the ANT (Antenna) feed point.

13. Z – TX – |Z|Φ

• Dual display of polar coordinates complex impedance.

|Z| (green) Φ (red) at the TX (Sensor) feed point.

14. Z – ANT – |Z|Φ

• Dual display of polar coordinates complex impedance.

|Z| (green) Φ (red) at the ANT (Antenna) feed point.

BAR GRAPHS SETTINGS

To change bar graph settings you have to enter TOP LED BAR or BOTTOM LED BAR menu. We haven't

described MENU system yet, but these two MENU items have shortcuts from the main display screen, so we can

do it a bit later. To enter in by shortcut, you have to go to the EDIT mode by pushing briefly EDIT button and

selecting T-BAR: or B-BAR: icon in STATUS bar. When icon is selected push EDIT button again and you will be

directly moved to the TOP or the BOTTOM LED BAR MENU, depends if you have pushed EDIT button on TBAR: or B-BAR: icon respectively.

Bar graph settings for top and bottom bar graph are same, only difference is that bottom bar graph has additional

settings for SWR colors.

1. MODE

• Changes bar graph drawing mode. DOT draws just one segment of actual value, BAR draws all

segments from left up to actual value.

2. AVG ATTACK/DECAY

• Sets averaging time constants used for average values (AVG).

Range: 0 – 2000ms, Step: 10ms.

14

Page 15

microHAM © 2015 All rights reserved

3. PK ATTACK

• Sets attack time used for peak values (PK).

Range: 0 – 200ms, Step: 1ms.

4. PK DECAY

• Sets decay time used for peak values (PK).

Range: 0 – 200ms, Step: 1ms.

5. PEAK HOLD

• Turns ON/OFF peak hold function. When enabled, peak value is held on its position as one segment.

Higher peak value resets lower peak value.

6. HOLD TIME

• Sets how long the peak segment will be lit on its position. Occurrence of higher peak value during the

hold will restart this time.

Range: 0 – 20s, Step: 100ms.

7. P-H DECAY

• Sets decay time for peak-hold segment.

Range: 0 – 20s, Step: 100ms.

8. EDIT POWER COLOR TABLE

• Defines four (4) custom power ranges and colors on per band basis.

Example:

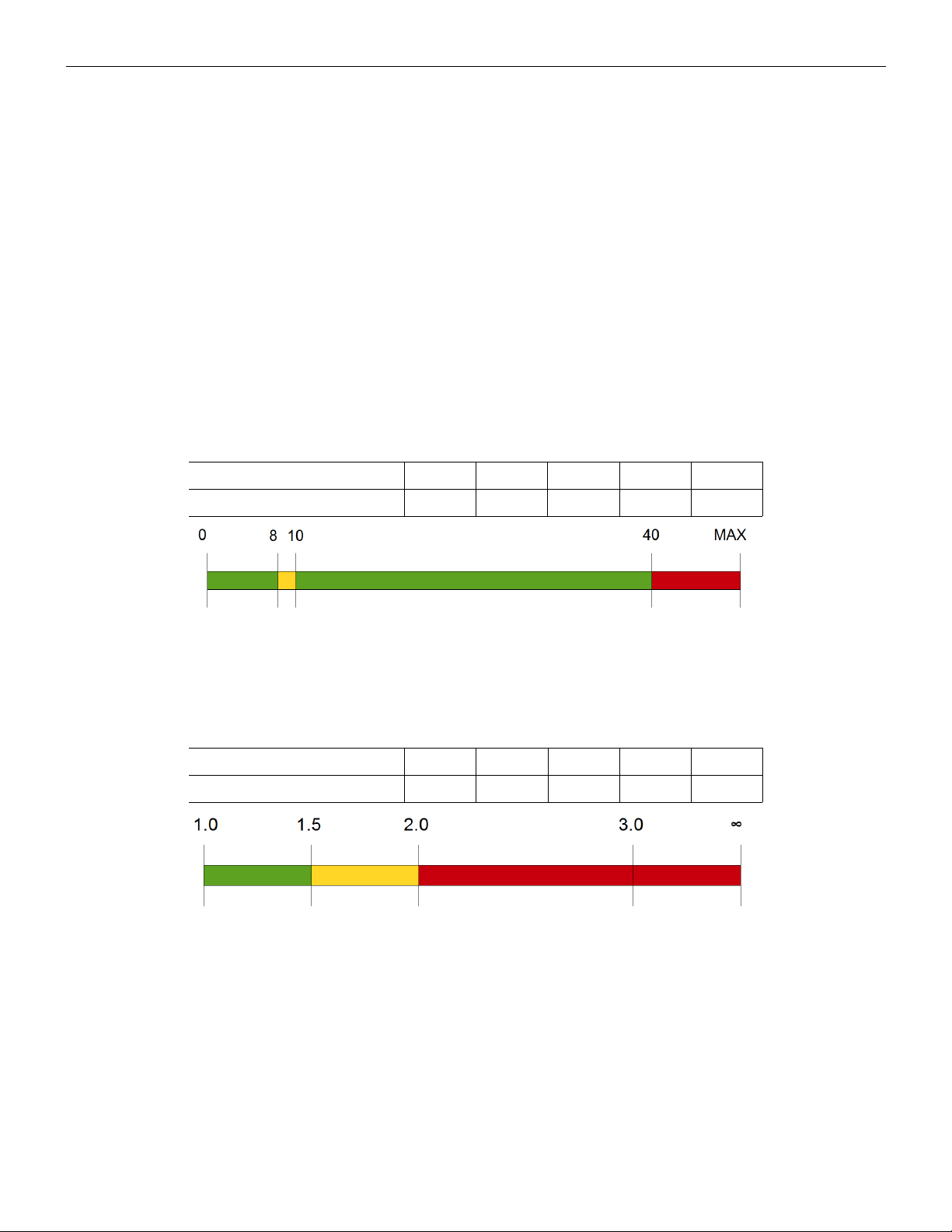

BAND COLOR POWER COLOR POWER COLOR POWER COLOR

160m GRN 8W YEL 10W GRN 40W RED

10. EDIT SWR COLOR TABLE

• Defines four (4) custom SWR ranges and colors on per band basis.

Applicable to bottom bar graph only.

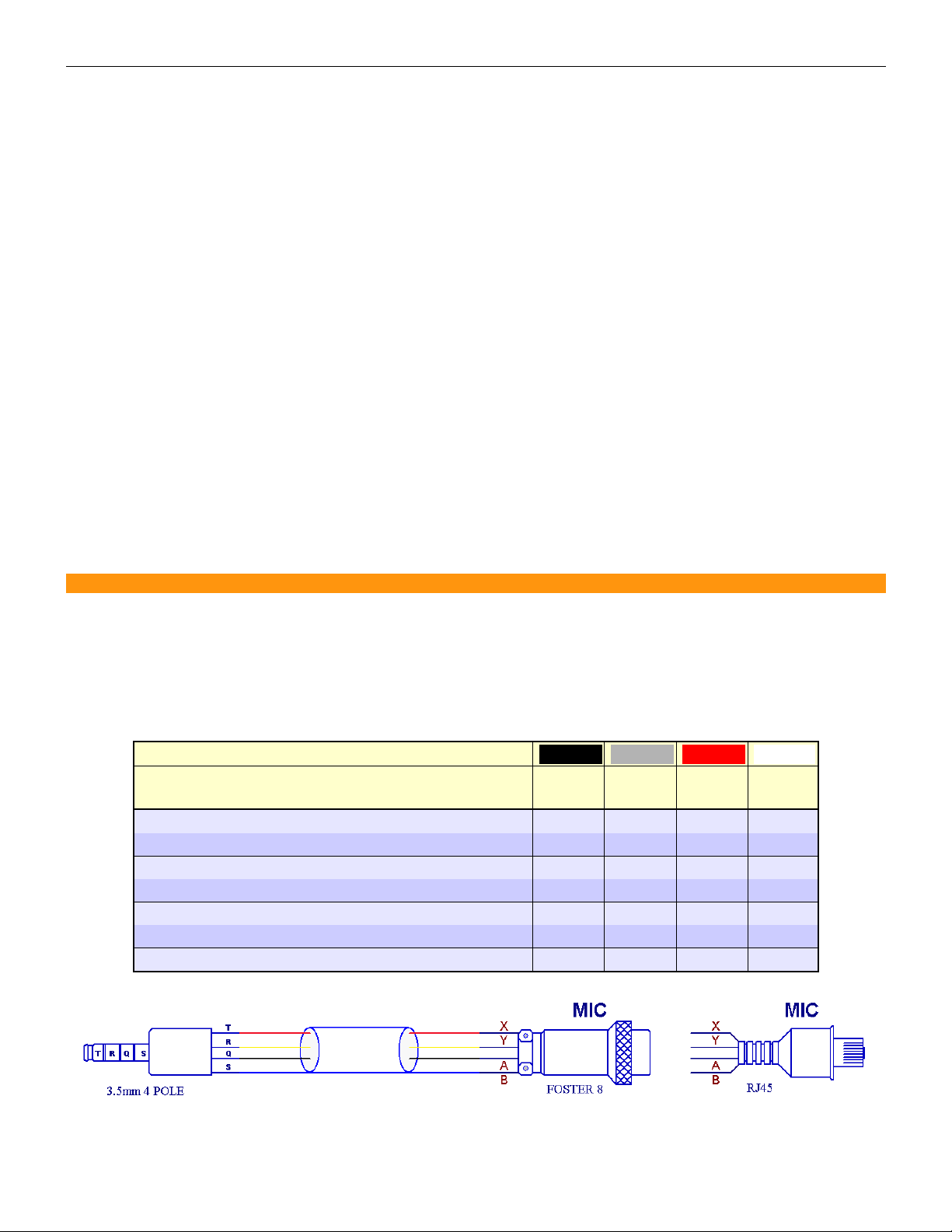

Example:

BAND COLOR POWER COLOR POWER COLOR POWER COLOR

160m GRN 1.50 YEL 2.00 RED 3.00 RED

15

Page 16

microHAM © 2015 All rights reserved

MENU SYSTEM - INTRODUCTION

In above chapter we mentioned MENU system. To edit all parameters, tables and functions, SMΩRF has

extensive, still easy to understand MENU system. MENU system has a tree structure always starting from the

root MAIN MENU, having separate branches for global settings - SYSTEM MENU, sensor related settings SENSOR 1, 2 MENU, alarms settings for each sensor - ALARM 1, 2 MENU and four (4) MENU items for each

SCREEN: TOP LED BAR, BOTTOM LED BAR, SCREEN MENU and TONE GENERATOR.

Push and hold for one second MENU button [11] to enter into root MAIN MENU tree. MENU system has autoexit, it means that to exit MENU you have to pass through any branch of the MENU tree by repeatedly briefly

pressing MENU button, until reaching the end of the given branch-chain and returning to the main SCREEN.

In BAR GRAPH SETTINGS chapter we have described TOP LED BAR MENU and BOTTOM LED BAR MENU.

Now we are going to take a look at last two MENU items coupled to the SCREEN, and it is TONE GENERATOR

and SCREEN MENU.

TONE GENERATOR

Tone generator can be considered as an independent instrument built-in the SMΩRF. It can be used

independently and simultaneously with other SMΩRF functions for many different measurements on transceiver

and power amplifier. Since Tone Generator is a part of the SCREEN, it remembers its settings for each SCREEN

separately.

Output can be set to generate single sine wave and two tone signal from 150Hz up to 10kHz in 1Hz resolution,

white and pink noise, and amplitude or frequency sweep. Generated output signal works in continuous or single

shot mode with adjustable time duration.

Transformer isolated output is compatible with both balanced and unbalanced microphone inputs, output level is

adjustable over 100dB range in peak-to-peak volts. Output jack contains also open collector PTT keying output,

always active when generator generates some signal. Audio PTT output has large, fixed 100ms lead time to

prevent any kind of hot switching.

Internally generator works on DDS principle in 32-bit precision, using 214 long sample look-up table for quarter

period of the sine waveform. Output is sent to the differential 24bit D/A converter clocked at 160ksps rate.

TONE GENERATOR SETTINGS

1. OUTPUT

• START/STOP choice enables or disables generator output. When generator is in the SINGLE shot

mode, output is automatically disabled when generation TIME expires.

2. SIGNAL

• SINGLE TONE generates single, sine wave tone of the frequency defined in FREQ.1 field and of

amplitude defined in LEVEL1 field.

• DUAL TONE generates dual tone. FREQ.1 and LEVEL 1 fields defines frequency and amplitude of

the first tone, FREQ. 2 and LEVEL 2 fields defines frequency and amplitude of the second tone.

• WHITE NOISE generates white noise signal of LEVEL 1 amplitude.

• PINK NOISE generates pink noise signal of LEVEL 1 amplitude.

• AMPLITUDE SWEEP generates amplitude sweep with linear or logarithmic response according to

the SCALE field definition and of frequency defined in FREQ. 1 field. Amplitude is swept from the

LEVEL 1 to the LEVEL 2, duration is defined in the TIME filed.

• FREQUENCY SWEEP generates sweep in frequency with linear or logarithmic response according

to the SCALE field definition and of amplitude defined in LEVEL 1 field. Frequency is swept from the

16

Page 17

microHAM © 2015 All rights reserved

FREQ. 1 to the FREQ. 2, duration is defined in the TIME field.

3. MODE

• SINGLE/CONTINUOUS.

If CONTINUOUS, generator generates output signal until stopped manually. If SINGLE, generator

generates output only for time specified in the TIME field, then stops automatically.

4. TIME

• Specifies duration of the output signal generation for the single shot mode, and specifies the ramp

time/repetition rate of sweeps. Range: 10 – 9900ms, Step: 10/100ms.

5. SCALE

• Sets LINEAR or LOGARITHMIC response characteristic for sweeps.

6. FREQ. 1

• Specifies frequency for the first tone or starting frequency for the frequency sweep.

Range: 150Hz – 9999Hz, Step: 1Hz.

7. FREQ. 2

• Specifies frequency for the second tone or final frequency for the frequency sweep.

Range: 150Hz – 9999Hz, Step: 1Hz.

8. LEVEL 1

• Specifies amplitude for the first tone or starting signal level for the amplitude sweep.

Range: 1μV – 130mVp-p, Step: 1

9. LEVEL 2

• Specifies amplitude for the second tone or final signal level for the amplitude sweep.

Range: 1μV – 130mVp-p, Step: 1

10. MONITOR

• Enables and sets monitoring level of signal generator output through internal speaker.

Please note, if you do require extreme output signal purity, keep it OFF.

CONNECTING TONE OUTPUT TO THE TRANSCEIVER

Tone generator output is located at the rear panel, at the TEST TONE jack. Its output is designed to be directly

connected to the microphone jack of all common transceivers, however, user is supposed to build own cable

according to following instructions. Jack is 3.5mm, 4 pole type. Audio uses two poles for microphone signal and

microphone ground. PTT uses another two poles for PTT and PTT ground. PTT ground is internally connected to

the system ground of the meter, audio ground is isolated. Use shielded cable and chart below, shield has to be

used for PTT ground (PTT GND).

Microphone pin index A B X Y

Signal name PTT PTT

GND

MIC MIC

GND

Mobile Icom (RJ45 jack microphone) 4 7 6 5

Desktop Icom (Foster 8 jack microphone) 5 6 1 7

Kenwood TS-480 (RJ45 jack microphone) 5 4 3 6

Kenwood & Elecraft (Foster 8 jack microphone) 2 8 1 7

Mobile Yaesu (RJ45 jack microphone) 6 7 5 4

Desktop Yaesu, TenTec (Foster 8 jack microphone) 6 5 8 7

TenTec (Foster 4 jack microphone) 3 4 1 2

17

Page 18

microHAM © 2015 All rights reserved

SCREEN MENU

This menu serves for setting up the SCREEN to meet user requirements. SCREEN Menu contains data which

are the same (but independently adjustable) for each SCREEN, as well as data specific to particular SCREEN

e.g. trigger source for Oscilloscope screen or display type for Spectrum screen. These specific data will be

explained in individual SCREEN TEMPLATE chapters, here we describe common settings for all screens.

1. AVG ATTACK/DECAY

• Sets averaging time constants used for average values (AVG).

Range: 0 – 2000ms, Step: 10ms.

2. UPDATE

• Sets update rate of numerical AVG values.

Range: 0 – 1000ms, Step: 10ms

3. PEAK HOLD

• Sets for how long the peak value is kept displayed till resets to new, lower peak value. Higher peak

value overwrites old peak value immediately.

4. TUNE JUMP

• Enables or disables automatic switching to TUNE screen when SMΩRF detects tuning signal. When

this function is enabled, SMΩRF inspects incoming signal waveform and if waveform matches

defined criteria for “tuning detection” automatically jumps to the TUNE screen. When tuning signal

disappears (waveform changes character), screen returns back from TUNE to original screen.

Special ability of the SMΩRF is to suppress power overshoots. These

overshoots can be caused by poor power supply regulation and ALC.

Virtually every transceiver generates overshoots at the beginning of

transmission until ALC loop stabilizes (hundreds μs up to several ms).

Exact time and amplitude of overshoots can be easily measured on the

Oscilloscope screen (described later).

Oscilloscope screen showing ALC overshot on initial

dot of CW signal (“bump” on leading edge).

SMΩRF has very fast measurement and reliably captures every overshoot with multiple samples. Once you are

aware that this happens, it can be annoying to see “bumped” peak and peak hold values on regular basis every

time ALC loop timeouts and transceiver generates new overshoot. To help with this problem, SMΩRF allows to

turn on filter to SUPPRESS OVERSHOOTS.

5. SUPPRESS OVERSHOOTS

• YES enables overshoot suppressing filter. This function is not generally applicable to all screens

when enabled. Advanced metering screens like the Oscilloscope or the Spectrum screens

intentionally do not suppress overshoots. Also please note, that suppression filter will have impact to

peak reading amplitude of SSB signals, where peaks of short duration are normal. Therefore for SSB

screens is recommended to turn suppression off (NO).

6. TIME

• Sets time used by overshoot suppressing filter. Exact value is specific to every transceiver and can

be measured on the Oscilloscope screen. Good value to start with is 2ms.

18

Page 19

microHAM © 2015 All rights reserved

SCREEN ALARMS

Alarms settings and adjustments will be described in details in separate chapters, but now it is necessary to put

in some introduction.

SMΩRF has built-in five (5) type of user configurable alarms in three (3), “importance” levels. Each alarm

“importance” level (Warning, Alarm, Fault) can be individually configured for related action (visibility, audibility

and TX break) for two power levels on per sensor, per band basis.

There are three (3) commonly used alarms – SWR Alarm, High Power Alarm, and Low Power Alarm and two

advanced alarms – PSK IMD alarm and ARCING alarm.

While Alarms settings are individual for each sensor, their settings apply to all sensor's SCREENs.

SCREEN MENU allows further setting, individually enable or disable each level of main three alarms (SWR, HiPower, Lo-Power) on per screen basis. For example, in this way you can disable Warning and Alarm level

keeping just Faults of SWR or Low Power alarms in specific measurement screens (oscilloscope) or entirely

disable Low Power alarm for PSK screen, etc etc … as you wish to best fit to your needs.

To enable (YES) or disable (NO) particular importance level of the alarm, select required cell in the table and turn

the knob.

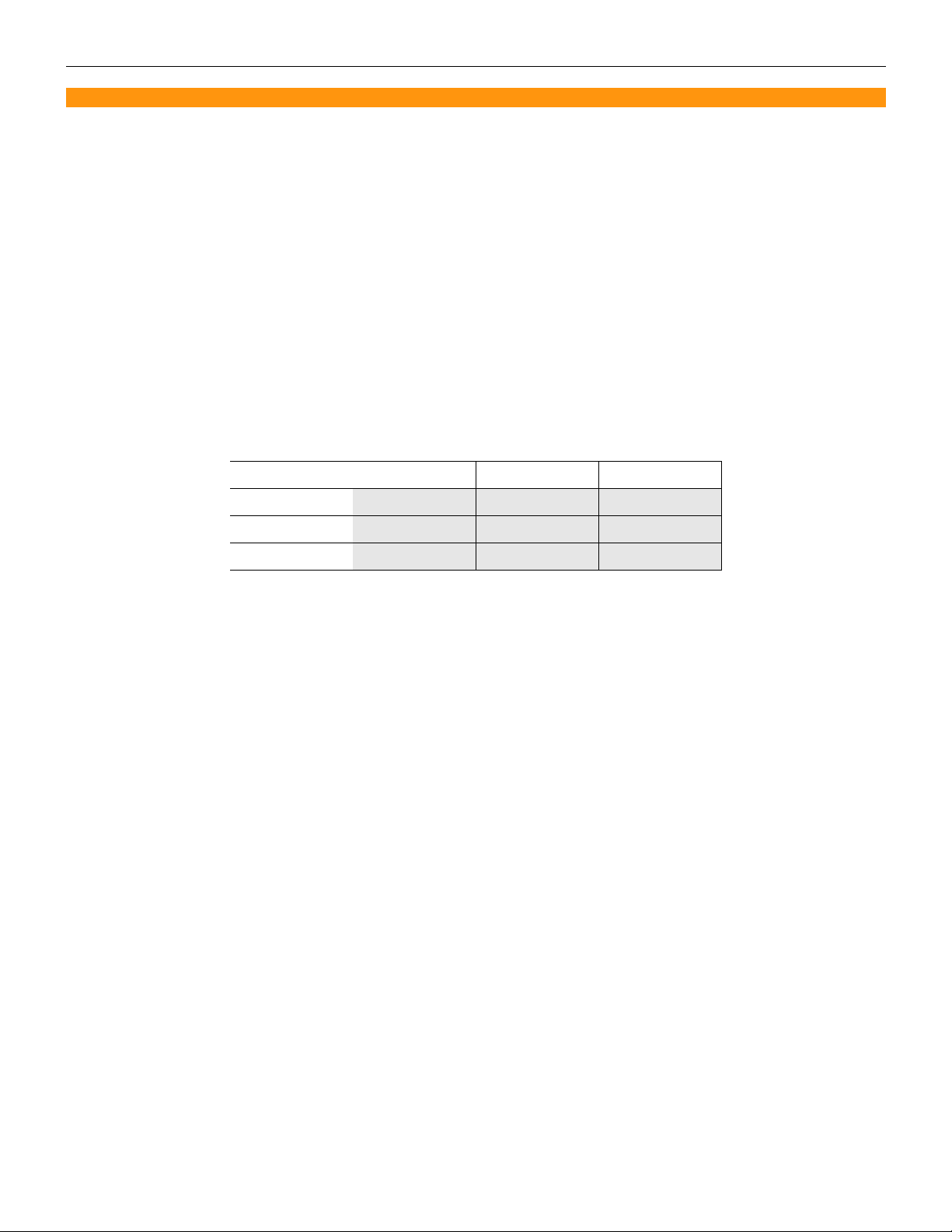

WARNING ALARM FAULT

SWR NO YES YES

Hi-POWER NO YES YES

Lo-POWER NO NO YES

19

Page 20

microHAM © 2015 All rights reserved

7 - SINGLE SENSOR SCREEN TEMPLATES

In following chapters we are going to describe single sensor SCREEN templates, their purpose of use, settings

and available functions.

STANDARD SCREEN

1

4

2

3

Standard screen is a general screen providing four (4) user configurable measurements. Each measurement is

related to one of two points of measurements (TX or ANT), has its numerical value, UNIT and TYPE.

UNITS:

Standard screen supports three (3) configurable power units:

• Watts [W]

• Decibels referenced to 1mW [dBm]

• Decibels referenced to 1W [dBW]

For example:

0dBm = 1mW, 50dBm = 100W, 53dBm = 200W, 60dBm = 1kW

0dBW = 1W, 20dBW = 100W, 23dBW = 200W, 30dBW = 1kW.

TYPE:

After the UNIT field, TYPE is displayed as subscript. SMΩRF supports four power types:

• PK – Peak Envelope Power

• AVG – Average Power. Averaging time is defined in the SCREEN MENU.

• TPK – Total Peak Power. Maximal peak power achieved within one transmission cycle.

• TAV – Total Average Power. Average power of one transmission cycle.

Available measurements:

1. FORWARD POWER

• FWD

TX

-REF

Peak envelope forward power minus reflected power (delivered power) at the TX feed point.

• FWD

ANT

-REF

Peak envelope forward power minus reflected power (delivered power) at the ANT feed point.

• FWD

TX

Forward power at the TX (Sensor) feed point.

• FWD

ANT

Forward power at the ANT (Antenna) feed point.

20

Page 21

2. REFLECTED POWER

• REF

TX

Reflected power at the TX (Sensor) feed point.

• REF

ANT

Reflected power at the ANT (Antenna) feed point.

3. REFLECTION

• SWR

TX

Standing Wave Ratio at the TX (Sensor) feed point.

• SWR

ANT

Standing Wave Ratio at the ANT (Antenna) feed point.

• RL

TX

Return Loss [dB] at the TX (Sensor) feed point.

• RL

ANT

Return Loss [dB] at the ANT (Antenna) feed point.

4. IMPEDANCE

• IMP

TX

Rectangular coordinates R + jX complex impedance at the TX (Sensor) feed point.

• IMP

TX

Polar coordinates |Z|Φ complex impedance at the TX (Sensor) feed point.

• IMP

ANT

Rectangular coordinates R + jX complex impedance at the ANT (Antenna) feed point.

• IMP

ANT

Polar coordinates |Z|Φ complex impedance at the ANT (Antenna) feed point.

microHAM © 2015 All rights reserved

LARGE SCREEN

1

2

Large screen is a screen providing two (2) user configurable measurements when there is no need to monitor

many parameters at once, rather have non-disturbing, transparent, fast and as large as possible readout of basic

parameters. Good for contesting or as general screen for users preferring large digits.

Available measurements:

1. FORWARD

• FWD

Peak envelope forward power minus reflected power (delivered power) at the TX feed point.

• FWD

Peak envelope forward power minus reflected power (delivered power) at the ANT feed point.

• FWD

Forward power at the TX (Sensor) feed point.

• FWD

Forward power at the ANT (Antenna) feed point.

TX

ANT

TX

ANT

-REF

-REF

21

Page 22

2. REFLECTION

• REF

TX

Reflected power at the TX (Sensor) feed point.

• REF

ANT

Reflected power at the ANT (Antenna) feed point.

• SWR

TX

Standing Wave Ratio at the TX (Sensor) feed point.

• SWR

ANT

Standing Wave Ratio at the ANT (Antenna) feed point.

• RL

TX

Return Loss [dB] at the TX (Sensor) feed point.

• RL

ANT

Return Loss [dB] at the ANT (Antenna) feed point.

microHAM © 2015 All rights reserved

PSK SCREEN

1

PSK screen is the specialized screen for PSK operating mode enthusiasts. It supports PSK in all speeds (31, 63,

128, 250, 500) providing numerical readout of IMD products together with waveform and spectrum displays.

Scope display shows vertically auto-ranged RF waveform monitor for fixed horizontal time, optimized for PSK

speed. Spectrum display shows relative level of fundamental frequency and first three, odd order harmonics of

the PSK signal in decibels as a difference to fundamental component. Level of these harmonics has main impact

to the output signal purity. They are shown dimmed when their level is too low to be certain for IMD quantification

(below dynamic range).

All measurements on this screen are related to the TX feed point. Forward power is fixed in Watt [W] units, type

is adjustable. Reflections (1) can be set to SWR or REF power. Reflected power unit is fixed to Watt [W], using

same type as forward power.

IMD and spectrum display is updated during IDLE cycles of the PSK transmission, during data transfer IMD

measurement gets dimmed and spectrum display cleared. Below the scope display, verbally evaluated quality of

the PSK signal (Q:) is located, for users not very familiar with IMD figures.

PSK screen has special SCREEN MENU setting for the PSK speed. It can be set to AUTO detection or one of

available speeds (31.5, 63, 128 …). When speed is set to AUTO, update rate of IMD values has half the rate.

If you like PSK mode and you are interested in having clean signal, this screen will help you to adjust your driving

level.

22

Page 23

microHAM © 2015 All rights reserved

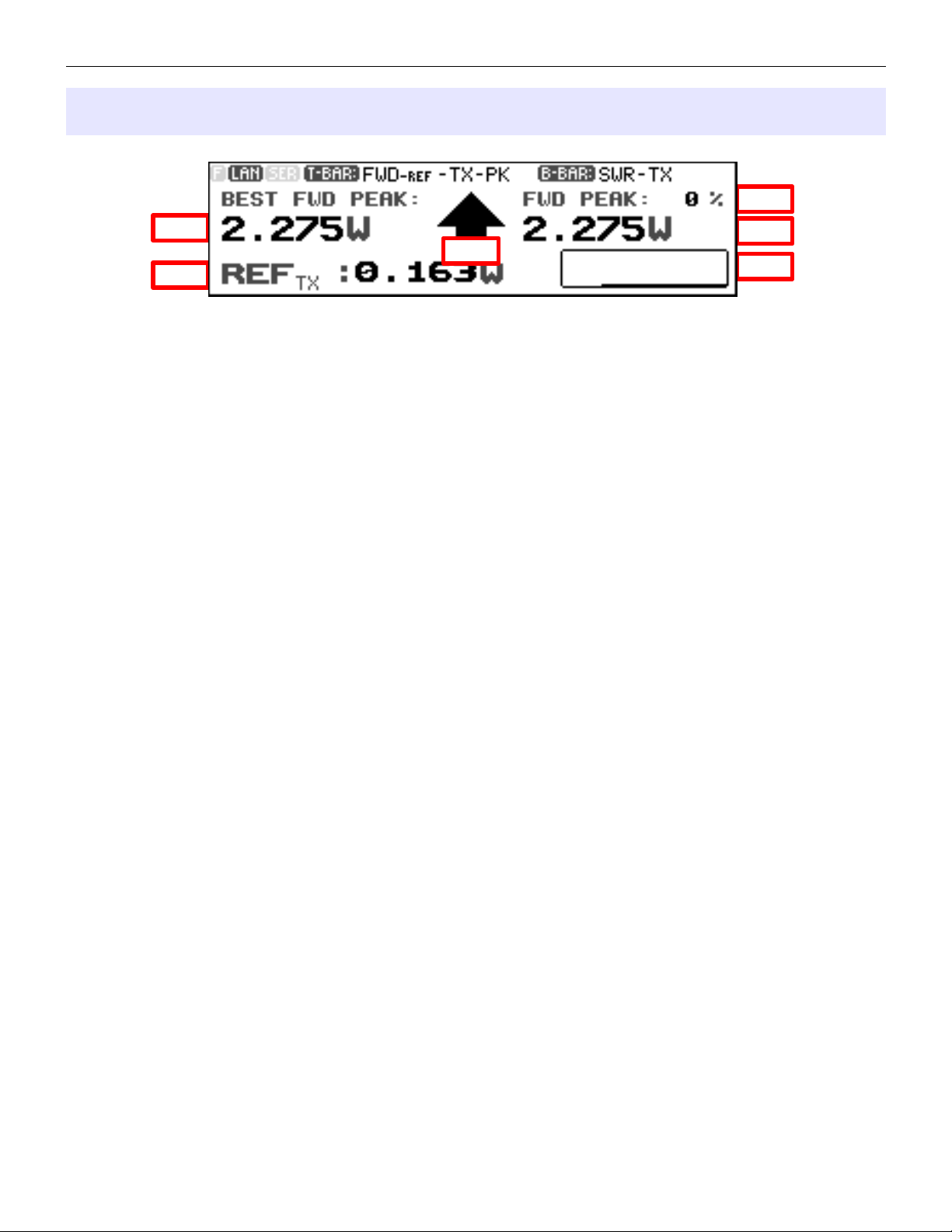

TUNE SCREEN

3

1

1

5

2

TUNE screen is specialized screen helping to tune manual Power Amplifiers or Antenna Tuners. It provides two

forward power readings (1), reflection measurement (2), ratio of current power to user adjustable 100% power

level set in SENSOR MENU displayed in percents (3), tuning progress display (4) and instant tuning status

indicator (5).

1. FORWARD POWER

• BEST FWD PEAK shows maximal peak power in Watts [W] achieved from the start of tuning and is

equivalent to the Total Peak Power (TPK) power type. Resets on exit from TUNE screen (switch to

another screen), either manual or automatic.

• FWD PEAK shows instant peak power in Watts [W] and is equivalent to Peak Envelope Power (PK)

type.

2. REFLECTION

• REF

Reflected power [W] at the TX (Sensor) feed point.

• REF

Reflected power [W] at the ANT (Antenna) feed point.

• SWR

Standing Wave Ratio at the TX (Sensor) feed point.

• SWR

Standing Wave Ratio at the ANT (Antenna) feed point.

• RL

Return Loss [dB] at the TX (Sensor) feed point.

• RL

Return Loss [dB] at the ANT (Antenna) feed point.

TX

ANT

TX

ANT

TX

ANT

4

3. PERCENTAGE

• Shows ratio of current power to 100% power level, in percents. In other words, it shows what is your

instant power compared to desired 100% power level you have set in SENSOR MENU. When it

shows 100%, your output power is tuned exactly to where you want to be.

4. TUNING PROGRESS DISPLAY

• Displays power level progress in time, slowly rolling from left to right, new values coming from the

right. Vertical scale is linear in Watts, range is set in % while dim line near the top shows 100% level.

It serves as a progress bar and helps to quickly recognize if tuning peak you already had wasn't

better than your current tuning peak.

5. INSTANT TUNING STATUS INDICATOR

• Shows instant status of the tuning by well visible arrow.

• Outlined DOWN ARROW means that instant peak power is decreasing.

• Outlined UP ARROW indicates that instant power is rising, but its value is lower than the highest,

already achieved peak BEST FWD PEAK power.

23

Page 24

microHAM © 2015 All rights reserved

• Filled UP ARROW informs that instant power is rising and at the same time it is the highest achieved

peak power. BEST FWD PEAK updates to new maximum.

• CHECKMARK means that 100% power level has been achieved, tuning is done. At the same time

SMΩRF plays the sound notification through internal speaker.

TUNE screen has special SCREEN MENU setting for the 100% level sound notification. Volume of the

notification can be set from 0 – 100%.

It is worth to note again that to the TUNE screen can be selected manually by ← and → buttons as any other

screen, but it is also possible to jump here automatically from any other single sensor screen when SMΩRF

detects tuning attempt, and if that screen has enabled AUTO JUMP TO TUNE screen in its SCREEN MENU.

All above features provide effective aid to quickly tune your power amplifier or antenna tuner, especially when

screen is combined with Z – TX – R+jX or Z – TX – |Z|Φ complex impedance reading on bottom bar graph.

TECHNICAL SCREEN

So far we have described screens designed for regular, day to day operation or contesting. Now we are going to

describe screens which you normally don't use every day, but are extremely helpful for TX signal chain checking,

troubleshooting, experimenting on antennas and matching networks or bench measurements.

1

2

6

3

5

4

TECHNICAL screen is the screen designed to provide complete overview of electrical parameters for both of two

point measurement points, TX and ANT simultaneously. There are total thirteen (13) values for power, reflection,

voltage, current, complex transmission line parameters as well as series and parallel equivalent circuits. Screen

is vertically divided to two sides, the left side shows measurements at the TX (sensor) point, the right side shows

computed values at the ANT (Antenna) feed point. Outlined center field shows losses in the antenna feed line.

1. FORWARD POWER

• Shows peak power for both TX and ANT points in Watts [W], dBm or dBW units.

2. REFLECTION

• REF

Reflected power for both TX and ANT points in Watts [W], dBm or dBW units.

• SWR

Standing Wave Ratio for both TX and ANT points.

• RL

Return Loss [dB] for both TX and ANT points.

3. VOLTAGE, CURRENT

• Shows voltage and current for both TX and ANT points.

• pk = Peak value of voltage and current

• p-p = Peak-To-Peak value of voltage and current

• rms = Root-Mean-Square value of voltage and current

24

Page 25

microHAM © 2015 All rights reserved

4. TL PARAMETERS

• R, X

Rectangular coordinates complex impedance for both TX and ANT points.

Z = R + jX; R = Resistance [Ω], X = Reactance [Ω]

• |Z|Φ

Polar coordinates complex impedance for both TX and ANT points.

Z = |Z|ejΦ; |Z| = Impedance magnitude [Ω], Φ = Phase [º]

• G, B

Rectangular coordinates complex admittance for both TX and ANT points.

Y = G + jB; G = Conductance [S], B = Susceptance [S]

• Y, Φ

Polar coordinates complex admittance for both TX and ANT points.

Y = |Y|ejΦ; |Z| = Admittance magnitude [S], Φ = Phase [º]

• Γ, Γ

Rectangular coordinates complex reflection coefficient for both TX and ANT points.

Γ = Re {Γ} + j Im {Γ}; Real and Imaginary part of the reflection coefficient Γ

• Γ, Φ

Polar coordinates complex reflection coefficient for both TX and ANT points.

Γ = |Γ|ejΦ; |Γ| = Reflection coefficient magnitude, Φ = Phase [º]

5. REACTANCE EQUIVALENT CIRCUIT

• Switches between series (s) and parallel (p) reactance equivalent circuit.

6. TRANSMISSION LINE LOSS

• Shows total loss in transmission line from the TX feed point to the ANT feed point. Value can be

presented in Watts [W], dBm or dBW units.

Screen has no special settings in SCREEN MENU and by default is not shown between SCREENs rotation.

Visibility can be turned on in SYSTEM MENU | SCREENS MANAGEMENT | SENSOR x SCREENS ORDER.

25

Page 26

microHAM © 2015 All rights reserved

OSCILLOSCOPE SCREEN

Oscilloscope screen is another great feature of the SMΩRF. Serves for waveform inspection, overshoots

visualization, lead and tail time measurements etc etc … It mimics standard digital bench oscilloscope but since

SMΩRF is an instruments for RF power measurements, it is optimized for this job, and adds some features you

will not find on any standard digital oscilloscope.

“We have put a lot of attention to the oscilloscope screen because oscilloscope is the most important instrument in

any electronic lab. Due to high speed requirements, vertical resolution and limited accuracy, RF measurements on

bench oscilloscope is tricky and inaccurate or demands very expensive model. And it is a task where SMΩRF's

oscilloscope screen brings several advantages. It has no hardware-defined ranges and uses full dynamic range of the

meter. That means it cannot be overloaded and cursors show exact value of amplitude even if they are not visible or

hugely offset. Additionally it provides vertical ranges in Watts and dBm, not only in Volts. Both vertical and horizontal

axes are fully labeled by actual value, not by common value/div style for faster readout. You won't need to count

divisions and multiply by current range, you will immediately see where you are. We hope you will find it useful and

enjoy it.”

CONTROLS:

1. MODE

Sets oscilloscope operating mode:

• ROLL – Rolling mode

• AUTO – Automatic Acquisition mode

45

3

6

12

In Rolling mode screen scrolls from the right to left while new data appears on the right side. Speed

of scrolling depends on horizontal timebase (3). Changing horizontal or vertical scale restarts

scrolling. Scrolling waveform can be stopped anytime by moving MODE selection to the next right

STOP position.

Please note, in Rolling mode trigger has no sense and its adjustment is not available.

Similar to AUTO trigger setting on common oscilloscopes. Screen in the AUTO mode is overwritten

every time input signal causes a trigger condition. If there is no trigger, after a short period the screen

starts to be refreshed continuously. The consequence is, that if the signal disappears, even if there

was a trigger previously, the display is cleared after a short period. It is a general oscilloscope screen

most suitable for periodic signals.

7

• NORM – Normal Acquisition mode

NORM mode is in behavior very similar to the AUTO mode, difference is that when signal disappears,

waveform stays on display until new signal, matching the trigger condition arrives.

• SNGL – Single Shot Acquisition mode

Single shot mode is true memory mode. It captures waveform of the input signal immediately when it

passes the trigger condition. Acquisition than automatically stops and waveform stays on display for

further analysis.

To restart capturing, move the knob from the STOP icon to the right. Icon will show SNGL until after

new waveform is captured again.

26

Page 27

microHAM © 2015 All rights reserved

2. TRIGGER

Sets trigger level. While trigger level is adjusted, its position is indicated by vertical line on the scope

screen and numerical value is shown at Δ position in the table located on the right side.

Δ sign is temporary changed to T sign. When trigger control is not selected, trigger level is still indicated

by small T sign on inner left side of Y axis.

Trigger's horizontal, X axis position is always zero (0) but actual zero position on the screen (Horizontal

Time Offset) can be adjusted by the horizontal control. Additional trigger settings are available in the

SCREEN MENU (polarity, source).

3. HORIZONTAL

Sets scope time base, horizontal (X axis) scale and offset.

Turning knob changes Horizontal Time Offset, moves the zero time position (trigger) across the screen.

Maximal left position is set by range and sampling memory, maximal right position is the right end of

screen. When knob is pushed and turned, it changes Horizontal Time Scale. Horizontal scale units are

shown in next field and are set automatically according to actual range. Contrary to regular oscilloscopes,

SMΩRF provides labeled scale division.

4. VERTICAL

Sets scope vertical (Y axis) scale and offset.

Turning knob changes Vertical Amplitude Offset. When knob is pushed and turned, it changes Vertical

Amplitude Scale. Again, scale is fully labeled. Units of Y vertical scale can be changed in next right field.

Volts [V] are referenced to the characteristic impedance, and Watts [W] or decibels [dBm] are related to

the Forward power at the TX feed point.

5. CURSORS MODE

SMΩRF provides two cursors (CURSOR 1 and CURSOR 2) for measurements on captured waveform.

They can work in two modes: Tracking and Free mode.

In Tacking mode indicated by CT icon, Y position of the cursor is stuck to the waveform while X position

can be adjusted. In Free mode indicated by CF icon, both X and Y positions of the cursor can be

adjusted. On screen, cursors are indicated by a small square labeled 1 or 2.

6. CURSORS

Cursors can be controlled by placing selection to cursor 1 or 2 field. Their position in amplitude and time

is numerically presented in table on the right side of display. Bottom line of the table with Δ sign shows

difference between CURSOR 1 and CURSOR 2 for both amplitude and time.

Cursors have slightly different control according to their mode. In Tracking mode turning the knob on

selected cursor changes its horizontal time position. When pushed and turned, the other cursor changes

its time position. It simplifies manipulation with both cursors.

In Free mode both cursors must be controlled separately. Turning the knob on selected cursor changes

its horizontal time position, when pushed and turned it changes its vertical position.

7. TONE

TONE field is a shortcut to built-in Tone Generator START/STOP function. When icon is lit, Tone

Generator generates defined output. Its output is defined in MAIN MENU | TONE GENERATOR and

settings are unique for the Oscilloscope screen because Tone Generator is a part of SCREEN settings.

Just repeating what has already been said :-)

Oscilloscope screen has two special SCREEN MENU items.

1. ACQUISITION TYPE defines how sampled signal is shown on display when more than one sample per

display point is available (depends on the time base).

• MAXIMUM

Uses peak value from samples captured for one display point. This choice should be used when you

want to capture short pulses or you do not want to miss a peak in lower horizontal ranges.

27

Page 28

microHAM © 2015 All rights reserved

• AVERAGE

Uses averaged value from samples captured for one display point. This choice should be used when

smoothness of provided waveform is more important than peaks.

• MIN-MAX

It is a special acquisition type providing two waveforms on display. Lower is related to minimal value

of the measured signal, higher to peak value of measured signal. This choice is useful to visualize

noise or hum on measured signal.

Oscilloscope uses peak samples from A/D convertor incoming at fixed rate of 125 thousands samples per

second. For easier to use decade ranges, low ranges or advanced acquisitions, scope uses real time decimation

and interpolation operations. Therefore minimal and maximal horizontal (timebase) ranges are the same for all

acquisition types.

2. TRIGGER EDGE defines triggering condition.

• FWD RISING, rising edge of the Forward power

• FWD FALLING, falling edge of the Forward power

• IN RISING, logical rising edge (PTT activated) of the PTT IN input

• IN FALLING, logical falling edge (PTT deactivated) of the PTT IN input

Both IN rising and falling edges includes 0.5ms software debouncing as IN input is usually driven by

mechanical contact. Processing latency adds additional 0.2ms.

28

Page 29

microHAM © 2015 All rights reserved

SPECTRUM SCREEN

Spectrum screen is similar screen to the Oscilloscope screen but visualizes data in the frequency domain instead

of oscilloscope's time domain. It uses SMΩRF's peak detector data and with help of Digital Signal Processing

(DSP) translates them into frequency domain using Fast Fourier Transformation (FFT).

CONTROLS:

1. FREQUENCY

Sets frequency (X axis) scale

and offset.

Turning knob changes

Horizontal Scale, maximal and

minimal frequency. Horizontal scale is in Hertz [Hz]. There are three linear horizontal scales and three

logarithmic horizontal scales available. There is no equivalent of “horizontal offset” setting.

2. AMPLITUDE

Sets amplitude (Y axis) scale and offset.

Turning knob changed Amplitude Offset. When pushed and turned, it changes Vertical Amplitude Scale.

Scale is labeled in decibel [dB] units.

3. CURSORS MODE

Same as in Oscilloscope screen, SMΩRF provides two cursors (CURSOR 1 and CURSOR 2) for

measurements on computed spectrum image. They work in two modes: Tracking and Free mode.

In Tracking mode, indicated by CT icon, Y position of the cursor is stuck to the waveform while X position

can be adjusted. In Free mode, indicated by CF icon, both X and Y positions of the cursor can be

adjusted. On screen,cursors are indicated by small square labeled 1 or 2.

4. CURSORS

Cursors can be controlled by placing selection to cursor 1 or 2 field. Their position in amplitude and

frequency is numerically presented in in table on the right side of display. Bottom line of the table with Δ

sign shows difference between CURSOR 1 and CURSOR 2 for both amplitude and frequency.

Cursors have slightly different control according to their mode. In Tracking mode turning the knob on

selected cursor changes its horizontal frequency position. When pushed and turned, the other cursor

changes its frequency position. It simplifies manipulation with both cursors.

In Free mode both cursors must be controlled separately. Turning the knob on selected cursor changes

its horizontal position, when pushed and turned it changes its vertical position.

3

4

2

1

5

5. TONE

TONE field is shortcut to built-in tone generator START/STOP function. When icon is lit, tone generator

generates defined output. Its output is defined in MAIN MENU | TONE GENERATOR and settings are

unique for the Spectrum screen.

Spectrum screen has a special SCREEN MENU item - DISPLAY TYPE which defines how peak hold values are

represented on display. Peak value is kept individually for each frequency considering time of its appearance.

• LINE selection draws peak value as line

• AREA selection draws peak value as faded area

Please note, SPECTRUM screen uses RF envelope data obtained from the peak detector (similar to diode

detection). Therefore do not expect to see the spectrum image of SSB signals as you know them from your

digital modes program, SDR or panadapter. Phase information of the peak detected SSB signal is lost and

cannot be accurately reconstructed for unknown modulation signal. However, it still shows proper spectrum

image of AM signals, as well as occupied bandwidth in CW mode.

29

Page 30

intentionally left blank

microHAM © 2015 All rights reserved

30

Page 31

microHAM © 2015 All rights reserved

AUTO MODE

AUTO mode is a special operating mode of the SMΩRF which can be applied for any single sensor screen. In

AUTO mode, meter makes automatic sensor focus to the first sensor from which detects power. Unfocused