Page 1

MICRO FENCE

3

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

RICHARD WEDLER’S

U.S. Pat. # 5,299,609

Made in the USA

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

TABLE OF CONTENTS

PREFACE............................................................................................................................. 2

EASUREMENT – THE CORE PHILOSOPHY OF MICRO FENCE

M

GETTING STARTED............................................................................................................. 2

HECK YOUR PACKING LIST

C

TANDARD ACCESSORIES

S

PTIONAL EDGE-GUIDE ACCESSORIES

O

............................................................................................... 2

.................................................................................................. 3

............................................................................... 3

ATTACHING THE MICRO FENCE TO YOUR ROUTER...................................................... 5

BASIC MEASURING PROCEDURES - “DIAL THE DIFFERENCE.”.................................. 5

MICRO FENCE TECHNIQUES............................................................................................. 7

ADOES

(D

FLUTING

SLOTTING

ABBETING

, R

EEDING

/ R

/ V

EINING

ORTISE

, M

ORMICA TRIMMING

, F

, V-G

& T

ROOVES

ENON

, S

ECESSES FOR HINGES

, R

IRCLES

, C

LIDING DOVETAILS

MAINTENANCE.................................................................................................................. 10

HECKING PARALLEL ALIGNMENT OF THE GUIDE SHAFTS

C

DJUSTING TORQUE OF THE LOCK NUT AND WAVE WASHER

A

LEAN MICRO FENCE IS A HAPPY MICRO FENCE

A C

OUTER ADJUSTMENTS

R

EPLACING WOOD FENCES

R

................................................................................................... 11

............................................................................................... 12

............................................................ 11

READING RECOMMENDATIONS ..................................................................................... 12

.................................................. 2

ORTISING LOCKS

, M

, C

URVED

RREGULAR EDGES

& I

,

)

...................................................... 10

............................................... 11

,

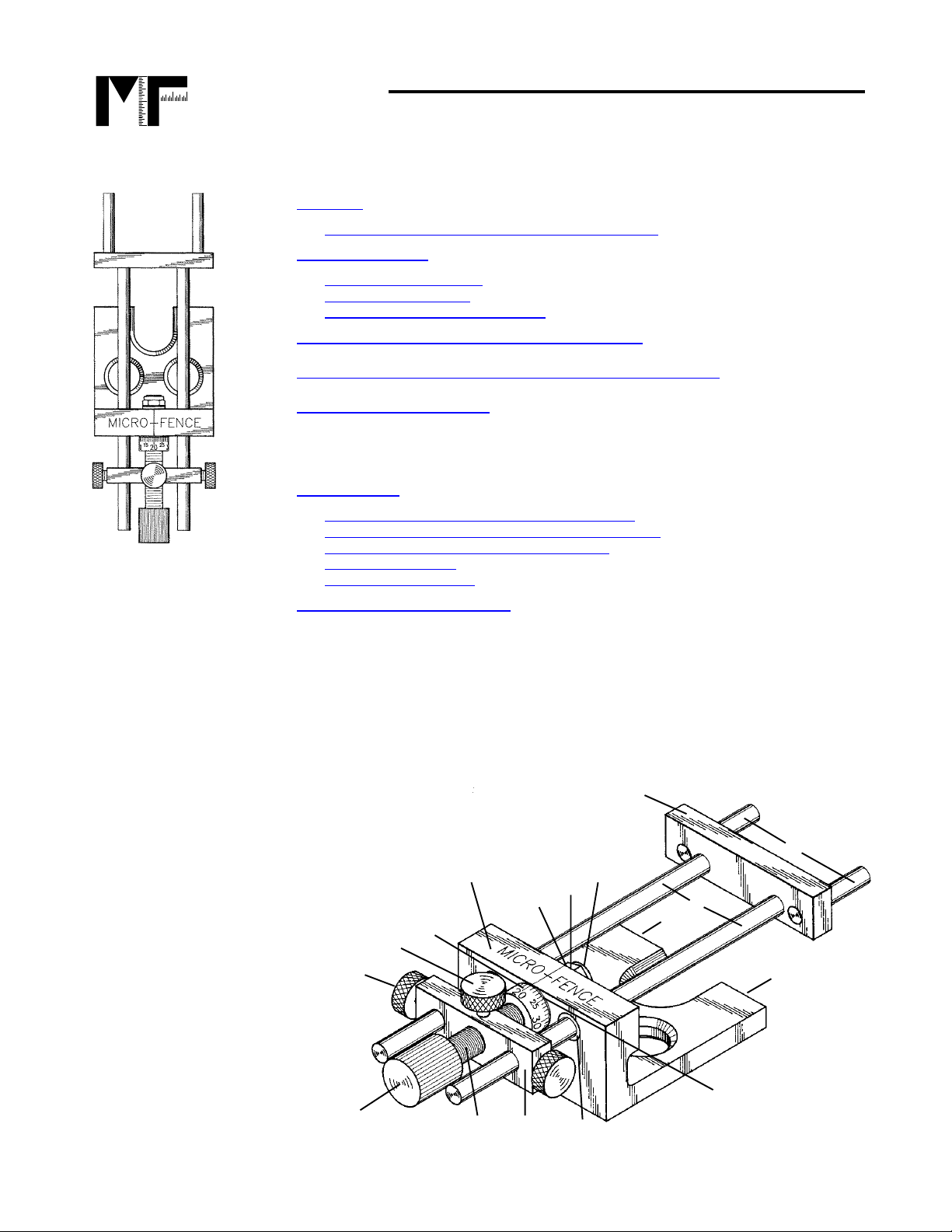

We suggest that you take a few moments and familiarize yourself with the name s of our

parts by referring to the drawing below.

1

Leadscrew adjusting

Knob

2

Brass Locking

Thumbscrews (Long) for

approximate positioning

3

Brass Locking

Thumbscrew (Short) for

Spindle Locking

4

Stainless Steel Lead

Screw/Spindle

5

Laser-Etched

Micrometer Dial

6

Spindle Bar

7

Main Body

8

Mounting Bar

(Interchangeable to

fit other routers)

9

Stainless S teel Guide

Shafts

10

Mounting Pins (Vary

according to router

model)

11a

8-32 Tapped holes

(To attach wood

fence or half-rounds)

12

Press fit bushings

13

Thrust Washer

14

Thrust Washer

5

2

1

7

4

15

Me t al Wave Washer

16

Lock Nut

16

15

14

6

12

8

10

9

11a

11a

13

Fig. 1

1

Page 2

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

PREFACE

Measurement – the core philosophy of Micro Fence

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Most woodworkers would probably agree that the router is

the

most versatile tool in the

woodshop. We contend that an edge guide is the most versatile accessory that works with

the router. It can do a myriad of different woodworking jobs. Whether the work piece is

straight or curved, the primary function of the fence is to guide the router bit in a path parallel

to the edge. Your Micro Fence is the first and only edge guide to provide you with reliable

and accurate settings of the distance between the fence and the router bit. Borrowing directly

from the machine-tool trade, it features a built-in micrometer that measures in thousandthsof-an-inch to make

any

set-up precise, efficient and repeatable.

GETTING STARTED

Check Your Packing List

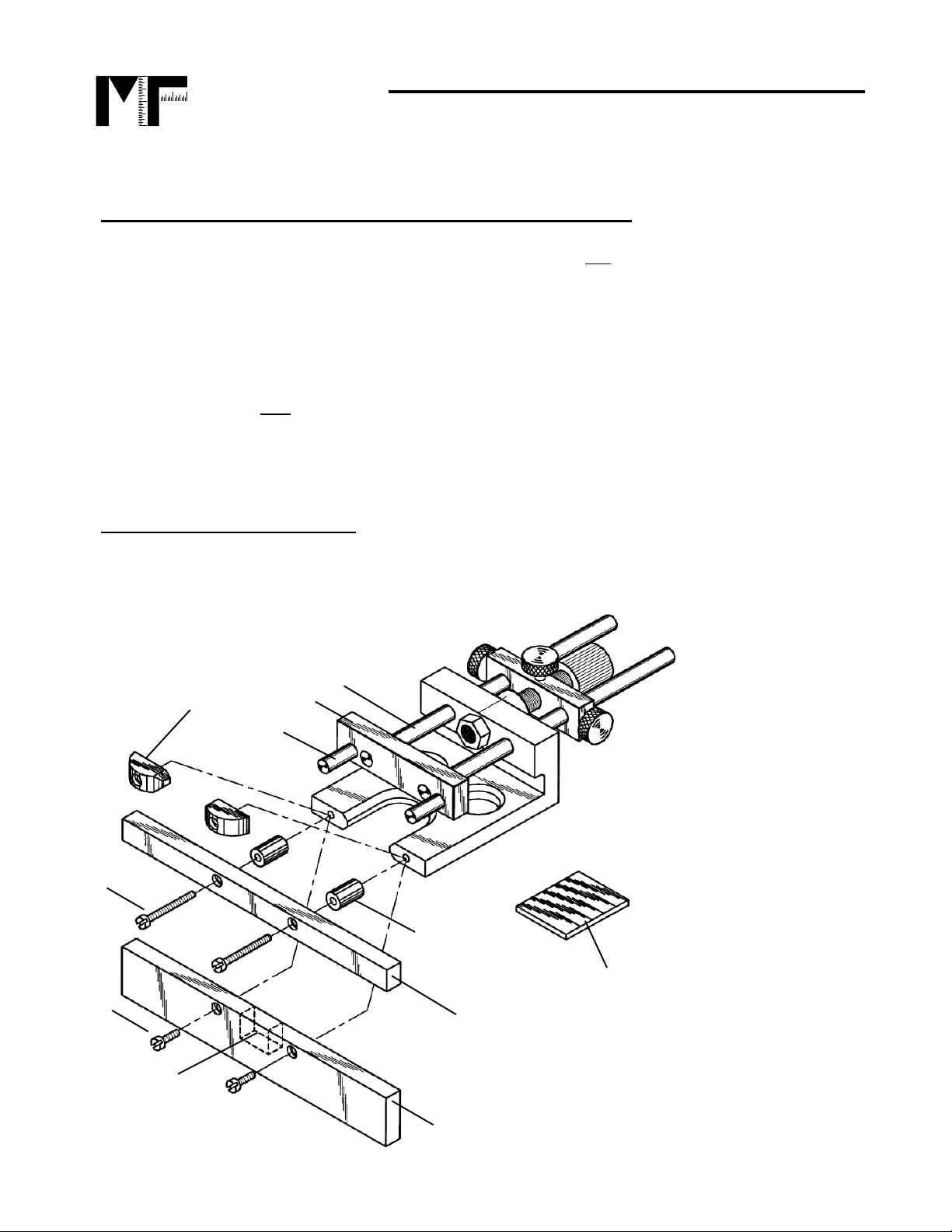

Your Micro Fence comes with the parts and accessories shown in Fig. 2. These standard

accessories make your fence an extremely versatile tool.

Fig. 2

9

19

8

19b or c

19a

2

18a

19d or e

11

18

8

Mounting Bar

9 Stainless Steel Guide Shafts

10

Mounting Pins

11

Low Profile Wood Fence

18

Deep Profile Wood Fence

18a

Notch for bit pass through

19

Half-round inserts

19a

8-32 x ½” Fillister Screw

19b

8-32 x 1¼” Fillister Screw

19c

8-32 x 1¾” Fillister Screw

19d

5/8” Delrin Spacers

19e

1¼” Delrin Spacers

D

Rubber Pad

D

Page 3

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

Standard Accessories

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Either the

low profile

(#11), or

deep profile

(#18)

wooden fence faces

may be attached to

the main body, (using the 8-32 tapped holes on the end of the Micro Fence body, (Fig. 1,

#11a)). The low profile is useful for most straight-line operations occurring inboard from an

edge, and will clear ¾” material on a work bench or work surface. The height of the deep

profile fence allows it to be notched, (Fig. 2 # 18a), so that the bit can be enveloped by the

fence for rabbeting or flush-trimming operations. It’s also useful for shallow “pocket” cutting

as required for stopped flutes, lock or hinge recesses, dados or mortises.

A pair of

Delrin half-round inserts

(#19) comes with each edge-guide. When installed on

the main body, (using the same Fig. 1, #11a holes as the profile fences), they provide two

points of contact so the fence can ride along arcs, circles or irregular edges. (See Fig. 2).

Note: Since the inserts mount on 2” centers, using the edge guide on small radiused edges,

(particularly under 2”), is not only difficult, but will result in a cut that is not parallel to the

edge.

A pair of

Delrin extension spacers

(#19d or e) is included to provide additional reach,

permitting settings that align the fence with the far side of the bit for flush-trim operations,

such as Formica or veneer trimming. A second, longer set of 8-32 screws, either 1¼” or 1 ¾”

(#19b or c) depending on which router your fence fits, is provided in your parts bag for

installation of the extensions.

Rubber pad

(D): The black rubber pad included in your parts bag prevents the jaws of pliers

from damaging the stainless steel guide shafts or mounting pins during installation and/or

removal. (Care should be taken that the plier’s teeth are not so sharp as to cut through the

pad when pressure is applied).

Optional Edge-Guide Accessories:

Mounting Bars

for Different Routers: The Micro Fence System can be

adapted for use on virtually any router or laminate trimmer on the

market today simply by changing the mounting bar and pins

(Figs.1 & 2, #’s 8 & 10). The guide shafts, (Figs.1 & 2, #9)

are threaded and can be changed out easily.

Sub-base Assemblies:

These allow the Micro Fence System to be used

Mounting Bar

on laminate trimmers. These sub-bases come with two cross-drilled

posts that provide points of attachment.

Our

Stop Collar Sets

are matched sets of four brass collars fitted with nylon-tipped

setscrews. Locking the collars on the guide shafts allows you to “memorize” the position of

the guide for a particular cut and return to it to that position later, without having to re-

3

Page 4

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

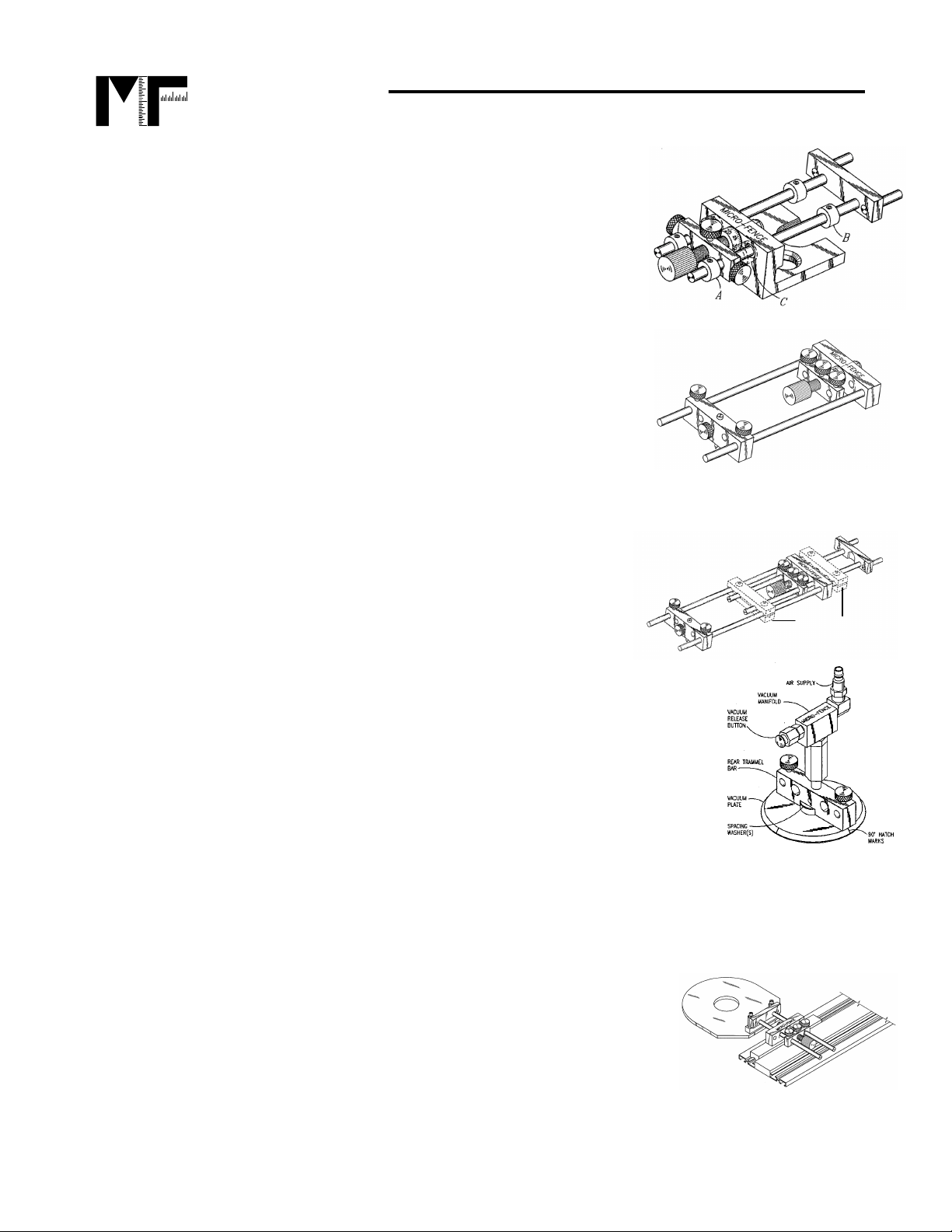

measure. (A, B and C in the diagram to the right represent possible stop

collar placements). They may be used to locate cuts that must be in

relation to one another, (such as flutes or reeds); to memorize the

amount of offset when enlarging single cuts with a second pass,

(dadoes for under-sized plywood); or, when installed on our

Circle Jig, to position concentric cuts, (like the inside and

outside diameters of a ring or wheel).

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

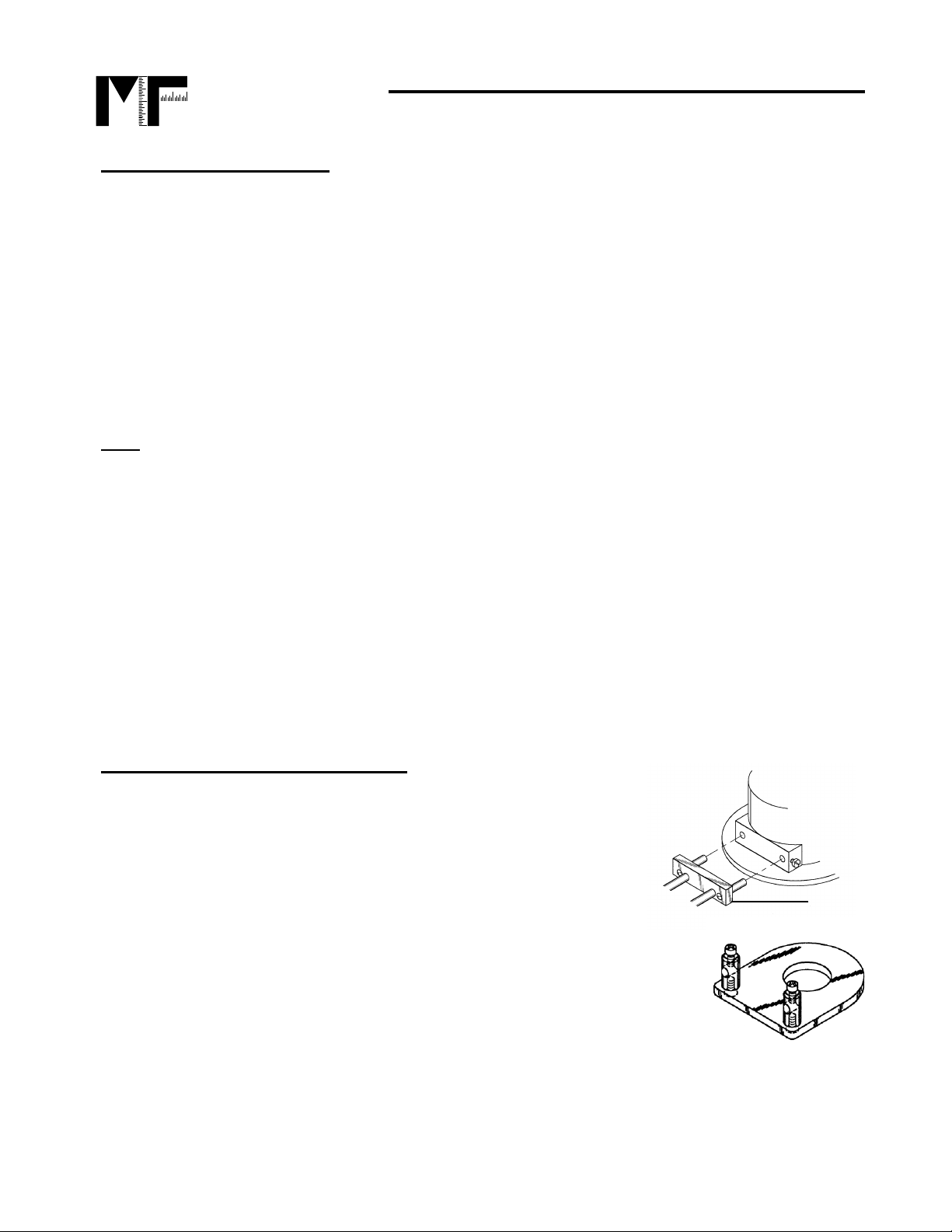

The

Circle Jig Attachment (CJA)

: Our Circle Jig Attachment can be mounted

on the guide shafts (Fig.1, #9) in place of the edge guide for circular

cutting requirements. The standard attachment allows you to rout

circles and arcs from 6 in. to 48 in. in diameter. Longer rods

(24” or 36”) are available for larger diameter work.

The following accessories are available for use with our Circle Jig:

Stabilizer Bars:

These maximize the rigidity of our Circle Jig

when making larger circles or taking heavier cuts. A clamping

device, stabilizer bars grip all four rods of the jig o nce your

final settings have been made, shown here on the Circle Jig

Complete.

Vacuum Center Accessory (VCA):

This accessory eliminates the

need to drill a pilot hole to secure the center pivot when routing circles.

Your air compressor provides the vacuum necessary to hold the center

in place. Developed initially for the solid surface and formica trades,

the VCA can provide efficient set-ups and unblemished work surface

on any cabinet-grade material including plywoods and surfaced

lumber.

Circle Jig Attachment

Stabilizer Bars

Ellipse Jigs:

When connected to the two centers on this jig, our Circle Jig can cut ellipses

or ovals in a great variety of shapes and sizes. The Ellipse Package provides all the plates,

centers, slides and linkage you need to turn your Circle Jig into a far more versatile tool.

“Tru-Grip Clamp” Interface:

By fitting this accessory to our

Circle Jig, the Micro Fence will slide along the extrusion of a

“Tru-Grip Pro Ft’r” clamp. This guides the router in a straight line,

for dadoes, grooves or decorative cuts across any flat surface.

See our latest brochure or visit our website at www.microfence.com for more information and pricing on our accessories.

4

Page 5

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

ATTACHING THE MICRO FENCE TO YOUR ROUTER

The Micro Fence you ordered includes the appropriate mounting

bar, pins and screws to fit the router you have specified. Once

you have removed the fence from its packaging and checked

all parts for tightness, simply slide the mounting pins into

the existing holes in your router’s base and install the

screws we supply to lock the fence onto the router.

(If your router already has the necessary

locking screws, keep the set supplied

with your Micro Fence for backup.)

Tip:

using your edge guide. These include the mounting pins and guide shafts where

they are threaded into the mounting bar, the screws holding the fence on the router,

and the brass locking thumbscrews that position the fence and lock the spindle.

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Fig. 3

Care should be taken to check that all threaded joints are firmly tightened before

BASIC MEASURING PROCEDURES

“Dial the Difference.”

The Micro Fence was designed to allow very accurate adjustments when using it in

conjunction with a dial caliper. Both tools are calibrated in .001 increments. To set the router

for any basic cut, use this simple

Loosen the two brass locking thumbscrews (Fig. 1, #2), and preset the Micrometer

Tip:

two-step

method:

Dial to 0.50 (it’s the same as zero), before starting. This practice makes the

arithmetic between cuts simple.

Step 1:

Set the fence at a position that approximates the distance between the edge of the

stock and the desired router bit cutting location. Make a test cut on a piece of scrap wood.

Step 2:

Measure the distance between the edge of the work piece and the cut with your dial

calipers.* Calculate the difference between this measurement and the desired measurement

(by simple subtraction), and then use the adjustment dial on the Micro Fence to reposition

the fence relative to the bit by this amount.

Example A:

Measuring the test cut shows an edge-to-bit distance of 1.133” inches. The

desired distance is 1.250”, (a difference of .117”). The adjustment dial is used to move the

fence .117” farther away from the bit.

The two most common measurements are 1.) the size of the cut itself and/or 2.) the distance the

*

cut occurs from an edge or previous cut.

5

Page 6

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

Tip:

pushes it away. Remember that routers rotate clockwise, (when viewed from

above). Your feed should be counter-clockwise in most operations to avoid “climb

cutting.” Take it easy.

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Turning the spindle clockwise draws the bit toward the fence; counter-clockwise

NEVER force your router in any application

.

Example B:

Here’s another way you can use Micro Fence’s precision ad justability to your

advantage:

Lumber and plywood today aren’t usually precise in their dimension, (e.g., ¾” plywood is

frequently manufactured as much as 1/16” under-size). If it were full size, a ¾” piece would

measure .750”. In reality, however we frequently find goods that measure anywhere from

.690 to .750. When a snug fit is crucial for joinery or aesthetic considerations, you can use

the Micro Fence with an under-sized bit to create tight fitting joints.

Let’s say the plywood parts you wish to join measure .710” thick. Starting with a 5/8 in.

diameter straight bit, rout a groove and measure its width (bits don’t always cut exactly the

size they’re supposed to). If it measures .625” wide, adjust the dial on the Micro Fence to

reposition the fence by .085” (subtract the actual cut dimension from the thickness of your

material), then take second cut. The second pass will widen the gro ove to .710” to fit your

plywood.

It’s always a good idea when cutting joinery to include a little clearance. When joining

Tip:

¾” plywood, for instance, we recommend routing grooves or dadoes .010 -.015 wider

than the stock’s thickness (.720” - .725” for the example above). This makes joints

easier to assemble and allows room for the wood to swell when glue is applied to the

joint.

Reading Calipers

This example reads .818”. Read the inch

and/or 1/10 inch from the scale on the beam

(.800”). Read the 1/100 and 1/1000 inch from

the dial (.018”).

To set zero: Wipe the lower jaw faces clean and

loosen the bezel locking screw (under the Dial).

Close the two lower jaws and rotate the bezel

until the needle points to zero. Re-tighten the

bezel lock to secure the bezel ring in its new

position.

Your calipers will measure inside, outside,

depth and offset dimensions. It can also be

used as a gauge by setting the beam locking

screw at whatever dimension you wish to test.

:

6

Inside

Measurement

Outside

Measurement

Bezel

Lock

Beam Lock

Beam

Thumb

Wheel

Page 7

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

MICRO FENCE TECHNIQUES

There are many routing jobs that Micro Fence makes easier and more precise. Below are

some examples of these jobs and the techniques we recommend for their execution.

I. Dadoes:

To cut any size dado, use the technique described in Example B on page 6. Make an initial

cut with a bit smaller than the thickness of the stock you’re working with, measure the first

cut, then take a second pass after adjusting the fence to widen the first cut by the desired

amount. Dadoes of virtually any width can be accomplished with this two-cut method.

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

a. Parallel Dadoes: Fitting your Micro Fence with the

Circle Jig Attachment allows you to rout any number

of straight, parallel dadoes. First, attach the aluminum

fence supplied with the Circle Jig to the bottom of

either trammel bar. The aluminum fence is designed

to reach down into the last cut you made, allowing you

to make repetitive dadoes at equal spacing, (or at any

spacing you choose).

II. Rabbeting:

Rabbet cuts can be accomplished with the same two-cut approach used for

dadoes. Notching the deep profile wooden fence, (Fig.2, #18a), will let you use any portion of

your router bit. Measure your first cut with the back end of your dial calipers and then dial the

appropriate adjustment for any dimension you require.

III. Mortise and Tenons:

The Micro Fence can help you cut snug-fitting mortises using the same basic two-cut

approach described above in the dado section.

a. The tenon can be cut most efficiently on the table saw, making vertical and

horizontal passes against the saw fence. Once it is cut, measure it with a dial

caliper to determine its width and length.

b. Draw a center line on the stock that is to receive the mortise and rest the tenon on

it to mark the limits of the mortise cut using the tenon itself for your template.

c. Using a multi-spur or Forstner bit in a drill press, drill along the center-line to clean

out the majority of material fro m the mort is e .

d. Set your Micro Fence, with the deep-profile wooden fence installed, at an

approximate distance a little shy of the finished tenon dimension and take a cut

from each side of the stock. (The bit should be cutting on the far side of the

mortise from where the wood fence is riding). This technique will automatically

center the cut on your stock.

e. Measure the result of these initial cuts with a dial caliper.

f. Dial ½ of the difference between the existing mortise and the size of the tenon you

wish to accommodate, add ½ of any clearance you’d like to have, and make your

final cuts.

7

Page 8

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

IV. Recesses for Hinges:

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

a. Butt hinges: First measure the width of the hinge leaf. Place the fence at an

approximate setting with either the low or deep profile wooden fence face installed

on the Micro Fence body. Measure the test cut, and then adjust the setting to

accommodate the width of the leaf. Draw pencil lines on the door edge to show the

length of the hinge. Once the recesses are cut, chisel out the radius corners left by

your router bit with a sharp paring chisel.

b. SOSS Hinges: This “invisible” hinge offers an attractive alternative to standard

hinges, but has always presented some difficult challenges with its installation

requirements. Two cuts of differing length and depth must be made on the same

centerline. A first, deeper cut to house the body of the hinge is followed by a

second, more shallow one to accept the face plate. The centerline for these cuts

can be found by running one test cut at an approximate setting in scrap material

the same thickness as your finished piece. Measure the material left on each side

of your test cut and dial one half the difference between them in the appropriate

direction.

V. Mortising Locks:

Centering the mortise for a lock or strike plate can be easily accomplished by taking one test

cut in material the same size as that of your actual piece. Measure the material left on either

side of your cut and compare them. Dial one-half of their difference in the appropriate

direction to position the bit precisely on the centerline of the work.

VI. Fluting/Reeding:

a. Three or Five Flute Groupings: Assuming your stock is straight and parallel, a

centered flute is first routed, from which other cuts are referenced. On a piece of

scrap material of the same width, run a test cut at approximate position. Measure

the distance from the edge of your material to the edge of the cut flute on each

side. Dial one-half the difference between these two measurements in the

appropriate direction to center the cut. Successive flutes are placed using the

same test cut principle, though your correcting cuts are no longer divided in half.

b. Four Flute Groupings: Your first approximate setting is used to make cuts from

each side of the work piece. This leaves a “land” in the center, which is the

dimension you will match after re-setting the fence for the next two flutes. Do your

test cut, and then dial the difference to the proper setting and run the “outboard”

flutes.

c. Note: Our Stop Collars can be used to “memorize” a cut position before resetting

the fence to another position. Inlay Work:

Measure the inlay you wish to install. If its dimension doesn’t match the diameter

of a standard router bit, pick a bit of smaller dimension. After an initial inlay recess

is cut, enlarge it with a second pass by dialing the desired dimension on the Micro

Fence. We recommend a trial run in scrap material to insure desired results before

8

Page 9

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

TIP:

This allows an element of insurance if the fence wanders away from the edge during

the first pass. The second cut, after adjusting the fence outward, will clean up any

irregularity.

VII. Formica Trimming:

Setting up your router with the bit flush to the front surface of the deep-profile wooden fence

allows you to make “flush-trim” cuts, such as those needed to trim formica or wood veneer.

Settings can be tested and adjusted in one-thousandth-of-an-inch increments for immaculate

flush cuts.

These setups may require that the wooden fence be notched to allow the bit to be positioned

inside it and to extend far enough below the sub-base of the router to cut through the

thickness of the material you wish to trim. Each Micro Fence is designed with sufficient

clearance between the router sub-base and the top of the fence to accommodate the

thickness of plastic laminate. Two delrin spacers (either 5/8” or 1 ¾”) are included with each

edge guide to provide additional reach for this type of setup. (See Fig. 2, #19d or e).

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

doing the final installation in your actual project. (Allowing .002-.003 tolerance may

prevent the inlay material from splitting or breakage during installation).

When installing inlay in curved or circular pieces, always cut the inside radius first.

VIII. Circles:

Our Circle Jig Attachment accessory works in conjunction with our basic edge guide or can

be purchased as a totally separate tool (called the Circle Jig Complete). The CJA simply

slides on to the same guide shafts, (Fig. 1, #9), and provides a trammel pin from which to

swing the router to perform radius cuts. The standard attachment provides capability for 6”48” diameters. Longer rods are available for diameters up to as large as 12 feet. A separate

instructional booklet comes with each Circle Jig Attachment.

IX. Straight Edges – Edge Profiling:

The deep profile wooden fence, (Fig.2, #18), can be

installed with the extensions provided in your parts bag, (Fig.2, #’s 19d or e), to reach

settings that “envelop” the router bit completely or in part. When completely enveloped, flush

trimming can be accomplished, (see VII above). Partial enveloping of your bit will allow edge

profiling for details like bevels, ogees or over-rounds.

X. Curved and Irregular Edges:

a. Installing the half-round inserts (Fig.2, 19) provides two points of contact with your

workpiece to allow your fence to follow curves.

b. Using angled or curved fences to guide cuts: You can use the drilled and tapped

holes on the end of the Micro Fence body, (#11a in Fig. 1, p.1), to attach any sort

of attachment that you fabricate yourself. e.g. “V” shaped wooden fences to follow

circles.

9

Page 10

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

XI. Slotting and Veining:

XII. “V” Grooves

are frequently used in desk or table-top construction to separate solid

See VI above.

wood surrounds from plywood center fields. “V” grooves allow different rates of expansion

and contraction to occur without cracking finishes. As a design element, they add a sense of

depth to a surface or to separate contrasting woods for dramatic effect.

XIII. Sliding Dovetails:

Useful in the manufacture of table or drawer extension slides, these sliding joints can be

made to whatever tolerances are necessary given the species of wood you’re using.

Hardwoods like maple or beech are popular choices. The control over tolerances that your

Micro Fence provides can produce silky smooth travel. Test cuts and measurement of the

pin or tail dimensions will tell you how far to move the fence on successive passes to

produce the results you prefer. (As a bench- mark starting place, include approximately .010”

clearance).

MAINTENANCE

Your Micro Fence has been thoroughly checked during it’s assembly for smooth and

accurate operation. There are a number of alignments and tension adjustments that are

critical to the unit’s proper functioning. In the normal course of use, you may need to check

these settings and readjust them if necessary.

Checking parallel alignment of the guide shafts

The guide shafts (either 7” or 12”) must be parallel to one another in both horizontal and

vertical planes (see Fig 1, #9). Test the vertical alignment by simply placing the mounting

bar and guide shaft assembly on a smooth, flat surface (a table saw, jointer bed, etc.), and

tap lightly on the end of each guide shaft with the tip of your finger. Any motion indicates a

misalignment that will adversely affect the way in which the shafts slide through the body and

spindle bar.

Apply pressure in the appropriate direction

to correct the misalignment and re-test on

the flat surface. Pay special attention to insure

that the readjustments have not loosened the shafts

in the mounting bar. If necessary, re-tighten, using the

rubber pad and either your fingers or pliers to achieve

firm tightness.

The horizontal alignment can be checked visually by

simply installing the guide shafts in the main body of the Micro Fence. They should slide into

the Delrin bushing without deflection, and pass on through the appropriate holes in the

spindle bar without significant resistance, (though a little is OK). Fluid motion should be

checked by sliding the guide shaft/mounting bar assembly back and forth a few times.

Fig.4

10

Page 11

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

Be sure to tighten all threaded parts. A loose gu ide shaft will compromise the rigidity of your

edge guide. This holds true for the mounting pins as well.

seated.

Adjusting torque of the Lock Nut and Wave Washer

The “feel” (tightness or looseness) of the adjustment screw (spindle) can be set by

increasing or relieving the compression of the wave washer (Fig 1, #15), located between

the two Delrin thrust washers (Fig 1, #14) under the nylock nut (Fig 1, #16). The lock nut

requires a 7/16” wrench. Th e more tightly co mpressed the wa ve washer is, the stiffer th e feel

of the spindle as it turns. If excessively loosened, lateral deflection of your fence is possible.

As a rule, the nylock nut should be as tight as possible without making the spindle

uncomfortably difficult to turn with your thumb and forefinger.

Cleaning your Micro Fence

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

Keep all threaded parts

firmly

Keep your Micro Fence as clean and dust-free as possible with compressed air or a soft

brush. An occasional drop of light oil under the spindle lock thumbscrew will keep the lead

screw turning smoothly. Our choice is Phil’s Tenacious Oil, which can be purchased at

many bicycle shops. We recommend cleaning and lubricating the stainless steel guide

shafts with a good silicone-free dry lubricant. At our fa ctory, we use Dynaglide during the

assembly process. If you wish, it can be ordered directly from us by calling

800-480-6427.

Router adjustments

Router motors operate at high rpm, and typically are prone to vibration from even slight misalignments. Collet wear and accumulated dirt can have a negative effect on the way the bits

rotate and cut. Other factors that affect a router’s cutting quality include the sharpness and

accuracy of the bits’ edge grind, and concentricity of the bits’ cutting surface relative to the

shank. Keep your router clean and in good working order and buy only good quality router

bits. Use only sharp bits. (Easy-Off oven cleaner works well to remove pitch.)

Under normal circumstances, the brass thumbscrews that lock the stainless steel guide

shafts and adjustment-screw spindle should withstand router vibration and hold fast.

However, if there’s lots of vibration (some routers simply vibrate more than others), the

thumbscrews may loosen and subsequently cause your edge-guide to slip out of position. If

this occurs, we strongly recommend first checking the router’s collet for wear. Improper bit

installation or over tightening can cause the collet to become “sprung”, and affect its gripping

capability or the trueness of the bits’ rotation. Installing a slice of rubber tubing with ¼” I.D.

under the heads of the thumbscrews can help to absorb excess vibration and prevent

inadvertent loosening.

It is normal for the brass lock-screws on your Micro Fence to tarnish. Their original luster can

be restored by polishing them with fine steel wool or Scotchbrite abrasive pads. We use a

drill press or cordless drill with hand-tightened chuck to spin them while firm pressure is

applied with the polishing material.

11

Page 12

MICRO FENCE

MICRO FENCE EDGE-GUIDE SYSTEM

Email: microfence@microfence.com Website: www.microfence.com

Replacing wood fences

13160 Saticoy St. N. Hollywood, CA 91605 Phone 1-800-480-6427

You can make your own wooden replacement fences, (or order them from us directly

480-6427

). The wooden fences are attached with 8-32 X ½” fillister head screws. They are

--800-

positioned on 2” centers and require 3/16” through holes with ¼” counter-bores, 3/16” deep.

Use the hole spacing of your Micro Fence’s stock wood fences as a pattern or

Tip:

template when making new or custom fences.

READING RECOMMENDATIONS

Hylton

, Bill and

Matlack,

Techniques and Jigs Any Woodworker Can Use

by St. Martin’s Press, 1993. ISBN 0-87596-577-6 (hardcover)

Kirby,

Ian –

The Accurate Router, Quick Setups and Simple Jigs,

Bethel, CT, distributed by Lyons Press, NY, NY, 1998. ISBN 0-9643999-7-0

Warner

, Pat –

The Router Book, A Complete Guide to the Router and Its Accessories

The Taunton Press, Inc., Newtown, CT, 2001. ISBN 1-56158-423-1

Fred –

Woodworking with the Router, Professional Router

, Rodale Books, Emmaus, PA, distributed

Cambrium Press,

,

Warner

, Pat –

Fast, Easy & Accurate Router Jigs

, Popular Woodworking Books, an

imprint of F&W Publications, Inc., Cincinnati, Ohio, 1999. ISBN 1-55870-486-8 (alk. paper)

Warner

, Pat –

The Router Joinery Handbook

, Popular Woodworking Books, an imprint of

F&W Publications, Inc., Cincinnati, OH, 1998. ISBN 1-55870-444-2 (alk. Paper)

Warner

, Pat –

Getting the Very Best From Your Router

, Betterway Books, an imprint of

F&W Publications, Inc., Cincinnati, OH, 1996. ISBN 1-55870-399-3 (alk. Paper)

12

Loading...

Loading...