Respiratory Pressure Meter

Operating Manual

Federal (USA) law restricts this device to sale by or on the

order of a physician or licensed practitioner.

Micro Direct, Inc.

803 Webster Street

Lewiston, ME 04240

1-800-588-3381

www.mdspiro.com

064-45 US

Issue 1.4

September 2016

Table of Contents

Introduction ......................................................................... 1

Package Contents .............................................................. 2

PUMA PC Software ............................................................ 2

Contraindications ................................ ................................ 4

Warnings and Cautions ...................................................... 4

Indications for Use .............................................................. 5

Operation – mouth pressures (PImax/MIP + PEmax/MEP) . 6

PImax (MIP) Test ................................................................ 7

PEmax (MEP) Test ............................................................. 7

Operation – SNIP (Sniff Nasal Inspiratory Pressure) ........... 8

SNIP Test ........................................................................... 9

Switching Off ...................................................................... 9

Battery Low Voltage Indication ......................................... 10

Battery Replacement ........................................................ 10

Cleaning Instructions ........................................................ 11

External Surfaces of the Spirometer ................................. 11

Sterilization ....................................................................... 11

Cleaning accessories ........................................................ 12

Calibration ........................................................................ 12

Servicing ........................................................................... 14

Product Lifetime ................................................................ 14

Trouble Shooting Information ............................................ 15

Symbols ............................................................................ 22

Specifications ................................................................... 23

Consumables / Supporting Products ................................. 24

1

Introduction

The respiratory pressure meter is a hand held instrument

designed for rapid assessment of inspiratory and expiratory

muscle strength. The unit can measure the maximum

inspiratory and expiratory mouth pressures, MIP and MEP,

and the Sniff Nasal Inspiratory Pressure, SNIP. The result

of each measurement is presented in units of cmH2O gauge

pressure on the liquid crystal display screen.

The unit is easy to operate, battery powered and is supplied

with all the necessary attachments required for immediate

use.

The functionality of the unit may be greatly increased when

connected to a PC running PUMA software. This

application has many advanced features including:

Real time display of pressure/time curves

Overlay of successive curves

Predicted values

Patient database

Incentive display

Maneuver quality check

Maneuver variability measurement

2

Package Contents

The respiratory pressure meter is supplied with the

following items: -

1. Microcomputer unit

2. Rubber mouthpiece (Cat. No. MTH6400)

3. Alkaline PP3 battery

4. Expiration pressure valve assembly (Cat. No. ASS1221)

5. Inspiration pressure valve assembly (Cat. No. ASS1222)

6. Calibration screwdriver

7. Nasal probe sample pack (Cat. No. NPROBE01 x-small;

NPROBE02 small; NPROBE03 medium and

NPROBE04 large)

8. Nasal probe adapter (Cat. No. ASS1091)

9. Mouth pressure bacterial filters (Cat. No. FIL6050)

3 2 4

6 8 2

9

1

SNIP

MIP / MEP

OFF

3 1 7

4

5

3

PUMA PC Software

The functionality of the portable MicroRPM is greatly

increased when connected to the PUMA PC Software, via

an RS232 cable to the Serial Port on the side of the unit.

PUMA PC Software is available as a free download from

http://www.carefusion.co.uk/our-products/respiratorycare/cardio-pulmonary-diagnostics/pulmonary-functiontesting/spirometers/spirometry-software-and-firmwaredownloads.

The PUMA PC Software is unique, user friendly multi

windows platform for the performance, storage and analysis

of the respiratory muscle strength measurement of PImax or

MIP (Maximum Inspiratory Pressure), PEmax or MEP

(Maximum Expiratory Pressure) and SNIP (Sniff Nasal

Inspiratory Pressure). In addition, PUMA PC Software offers

the user features such as live graphical displays, predicted

values, printing formats, incentives, trends, post medication

or exercise comparisons and additional fatigue indicators.

4

Note: The Respiratory Pressure Meter should only be

connected to a computer that is manufactured in

accordance with EN 60601-1.

Note: Keep the PC out of reach of the patient at all times.

Contraindications

Pathological conditions resulting in relatively large

pressure swings in the abdomen or thorax.

Aneurisms

Uncontrolled hypertension

Urinary incontinence

Warnings and Cautions

The following terms are used as follows in this manual

Caution: Possibility of injury or serious damage

Warning: Conditions or practices that could result in

personal injury

Please Note: Important information for avoiding damage to

the instrument or facilitating operation of the instrument.

Note: The device should be used by qualified personnel

trained in lung function testing.

CAUTION: Read the manual before use.

CAUTION: For batteries, do not attempt to charge, connect

improperly, or dispose of in fire as there is possibility of

leakage or explosion. Follow manufacturer’s

recommendation for proper disposal.

5

WARNING: The instrument is not suitable for use in the

presence of explosive or flammable gases, flammable

anesthetic mixtures or in oxygen rich environments.

CAUTION: Bacterial filters are single patient use. If used on

more than one patient, there is a risk of cross-infection.

Repeated use may increase air resistance and lead to an

incorrect measurement.

PLEASE NOTE: The product and the battery you

have purchased should not be disposed of as

unsorted waste. Please utilize your local recycling

facility for the disposal of this product.

PLEASE NOTE: Degree of protection against Ingress of

Water is IPX0.

CAUTION: When you connect the Respiratory Pressure

Meter to other equipment, always make sure that the whole

combination complies with the international safety standard

IEC 60601-1 for medical electrical systems. During

measurements, connect the Respiratory Pressure Meter

only to computers that comply with IEC/EN 60601-1 /

ANSI/AAMI ES60601-1:2005.

Indications for Use

The MicroRPM (Respiratory Pressure Meter) is a hand held

diagnostic instrument designed for rapid assessment of

inspiratory and expiratory muscle strength. The unit can

measure the maximum inspiratory and expiratory mouth

pressures, MIP and MEP, and the Sniff Nasal Inspiratory

6

Pressure, SNIP. The system is intended for use with adults

and pediatric patients over the age of 3 years in hospitals,

physician offices, laboratories and occupational health

testing environments.

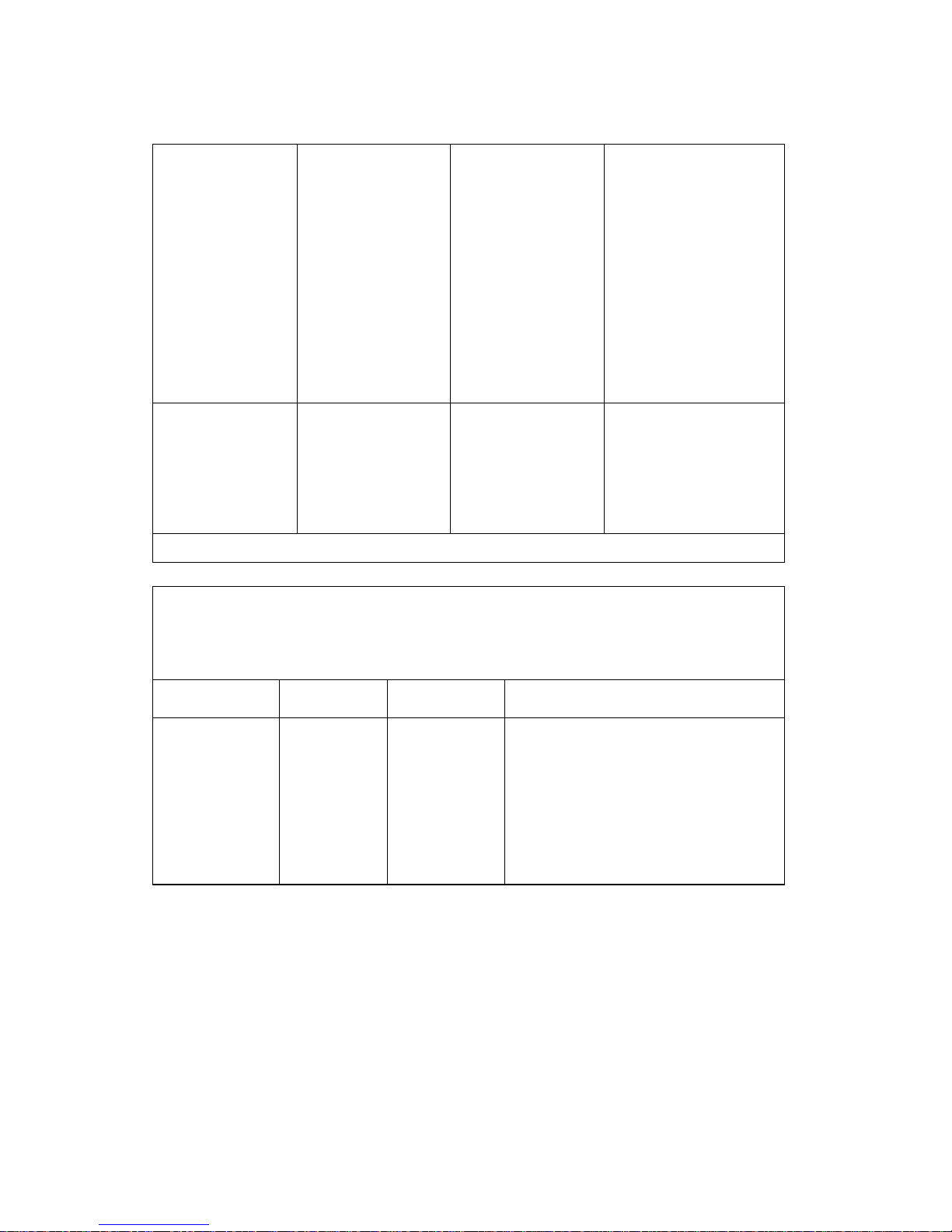

Operation – mouth pressures (PImax/MIP +

PEmax/MEP)

Insert the battery into the battery compartment at the rear of

the MicroRPM.

Fit the required pressure valve assembly (‘Inspiratory’ for

PImax (MIP), ‘Expiratory’ for PEmax (MEP)) into the

MicroRPM; insert a new bacterial filter into the pressure

valve assembly and then the rubber flanged mouthpiece

onto the bacterial filter as shown below.

7

PImax (MIP) Test

Slide the MicroRPM switch from the “off” position to the

MIP/MEP position, while applying no pressure to the

mouthpiece. Rotating segments will be displayed while the

unit performs an auto-zero function.

When the MicroRPM is ready a ‘beep’ will be heard and ‘0’

will be displayed.

To perform the test, instruct the subject to insert the

mouthpiece into the mouth, ensuring the flange is positioned

over the gums and inside the lips, while the ‘bite blocks’ are

between the teeth.

The subject should then exhale to RV (Residual Volume),

lungs empty, then perform a ‘Mueller’ maneuver, a forced

inhalation against the MicroRPM with as much effort as

possible for as long as possible (minimum of 2 seconds).

The display will report the result, the maximum average

inspiratory pressure sustained over a 1 second period of the

test, in centimeters of water (cmH20). Ideally, the subject

should repeat this test three times to establish the best

value.

PEmax (MEP) Test

Slide the MicroRPM switch from ‘Off’ to ‘MIP/MEP’, while

applying no pressure to the mouthpiece. Rotating segments

will be displayed while the unit performs an auto-zero

function.

When the MicroRPM is ready a ‘beep’ will be heard and ‘0’

displayed.

To perform the test, instruct the subject to insert the

mouthpiece into the mouth, ensuring the flange is positioned

8

over the gums and inside the lips, while the ‘bite blocks’ are

between the teeth.

The subject should then inhale to TLC (Total Lung

Capacity), lungs full, then perform a ‘Valsalva’ maneuver, a

forced exhalation against the MicroRPM with as much effort

as possible for as long as possible (minimum 2 seconds).

The display will report the result, the maximum average

expiratory pressure sustained over a 1 second period of the

test, in cmH2O. Ideally, the subject should repeat this test

three times to establish a best value.

To repeat either the PImax or PEmax tests, the MicroRPM

must first be returned to the ‘Off’ position.

Operation – SNIP (Sniff Nasal Inspiratory Pressure)

Insert the battery into the rear of the MicroRPM.

Fit the nasal probe adapter into the MicroRPM and then

attach the correct size nasal probe, as shown below.

Nasal probe

2

Microcomputer unit

Nasal plug

adapter

9

The correct size (1-4) can be determined by fitting a nasal

probe to the unit then firmly inserting the nasal probe into a

nostril. Instruct the subject to block the open nostril with a

finger and then to attempt a sniff. The correct nasal probe

has been selected once there is not leakage around the

nasal probe.

SNIP Test

Slide the MicroRPM switch from ‘Off’ to ‘SNIP’, while

applying no pressure to the nasal probe. Rotating segments

will be displayed while the unit performs an auto-zero

function.

When the MicroRPM is ready a ‘beep’ will be heard and ‘0’

displayed.

To perform the test, instruct the subject to insert the chosen

nasal probe firmly into a nostril, while ensuring the other

nostril remains open throughout the test.

The subject should then breathe normally and at the end of

a normal tidal expiration, FRC (Functional Residual

Capacity), be instructed to perform a short, sharp voluntary

sniffing maneuver with as much effort as possible.

The display will report the result, the peak inspiratory nasal

pressure, in cmH2O.

On subsequent tests, the MicroRPM will continue to display

the highest SNIP value, overwriting previous values. Ideally,

the subject should repeat this test 10-15 times to determine

the highest value.

Switching Off

The MicroRPM is switched off by sliding the switch back to

the ‘Off’ position.

10

Battery Low Voltage Indication

The battery level is checked when the unit is switched on.

When the battery is nearly exhausted ‘bAt’ is displayed

before the auto-zero procedure begins. The unit may be

used when this occurs provided the test is performed

immediately. The battery should be replaced as soon as

possible.

When the battery is completely exhausted, the unit will beep

twice and turn itself off immediately after turning on.

Note: If the respiratory pressure meter is not used for long

periods, the battery should be removed to prevent damage

to the instrument by possible leakage.

Battery Replacement

Locate the sliding cover situated on the rear of the unit,

toward the bottom of the device.

Place your thumb over the round thumb indent, press gently

and slide the cover to the right to remove it from the unit.

Lift the old battery out and holding the battery terminal by

the plastic body, pull it off the old battery.

Plug the new battery into the battery terminal, taking care

that the correct polarity is observed.

Push the battery back into the battery holder and replace

the battery cover onto the guides. Slide the battery cover to

the left until it is fully in place.

Note: Please remove the battery if the meter is likely to be

unused for some time.

11

CAUTION: Do not open the battery cover when the device

is turned on.

CAUTION: The operator should not touch the contacts of

the battery and the patient at the same time.

Please Note: Dispose of the waste battery in accordance

with your local waste battery regulations.

Cleaning Instructions

Disinfection of contaminated parts is only effective after

careful preliminary cleaning. Please follow the

manufacturer’s instructions for the solution you are using.

The device must not be wiped with any aqueous solutions

and must not be exposed to solvents e.g. alcohol, chloride

solutions, as there are electronic components inside that will

be permanently damaged.

CAUTION: Switch off the device before cleaning.

External Surfaces of the Spirometer

CAUTION: Do not attempt to wash or immerse the

Respiratory Pressure Meter in water or cleaning fluid, as

there are electronic components inside that will be

permanently damaged.

The external surfaces of the pressure meter and the

inspiratory and expiratory valves may be wiped with a

disinfection wipe such as a Protex wipe (order #48-70). This

should be performed after every patient.

Sterilization

The rubber flanged mouthpieces can be sterilized using

ETO – Ethylene Oxide Sterilization.

12

Cleaning accessories

The MicroRPM unit is protected from contamination by the

Bacterial Filter (36-FIL6050) during mouth pressures

measurements.

The Rubber Flanged Mouthpiece (MTH6400), the Expiratory

and Inspiratory Pressure Valve Assembly (ASS1221 and

ASS1222) and the Nasal Probes (NPROBE01, NPROBE02,

NPROBE03, NPROBE04), however, may be immersed in a

cold sterilizing solution. Rinse thoroughly and allow to dry

before reassembly.

Important note: Used mouthpieces and Nasal Probes,

which are not sterilized, must be disposed of immediately

after each use.

If there are changes on the material surfaces (cracks,

brittleness) the respective parts must be disposed of.

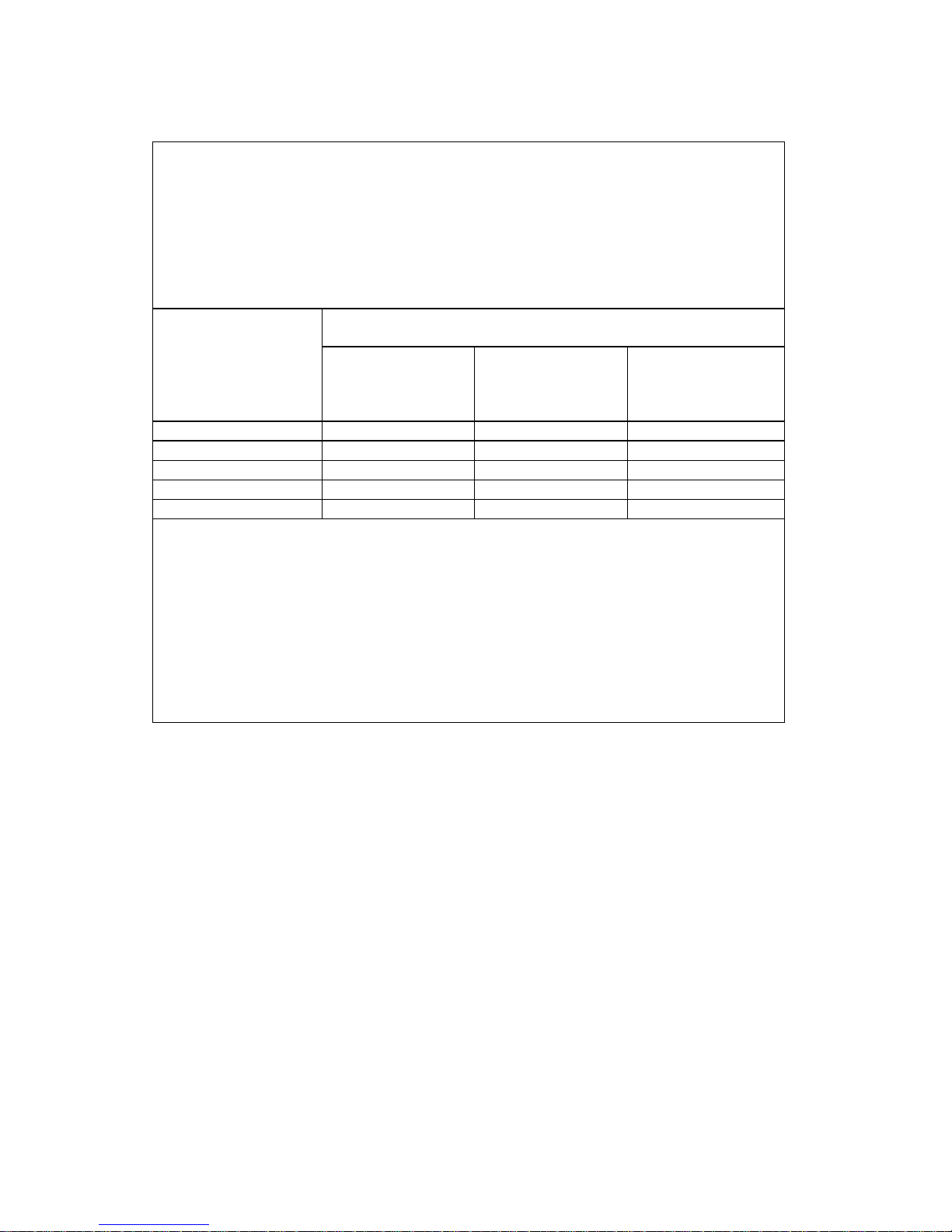

Calibration

Calibration is factory set and should remain stable

indefinitely. However, calibration may be checked by

connecting the device to a manometer as shown below:

Manometer

cm H O

2

0

2

1

3

6

4

5

8

7

9

Syringe

10

Connecting

line

Female

Luer

T Piece

Nasal plug

adapter

13

Turn the respiratory pressure meter on to the SNIP position.

Very slowly fill the syringe until a negative pressure of

between 200 and 300 cmH2O is obtained on the

manometer.

The reading on the respiratory pressure meter should be

within 3% of the manometer reading.

If adjustment is required, the following procedure must be

followed.

The calibration may only be adjusted in a positive direction

as the meter monitors the peak pressure value. Therefore,

if the respiratory pressure meter reading was greater than

the manometer reading the calibration screw must be turned

anti-clockwise a few turns before calibration is attempted.

Serial

port

Calibration

screw

Connect the respiratory pressure meter to the manometer

as previously shown. Fill the syringe to obtain the required

negative pressure and turn the calibration screw slowly in a

clockwise direction until the same value is displayed on the

meter.

14

Servicing

If your unit requires service or repair, please see page 24

for contact details.

A full service manual including circuit diagrams and parts list

is available on request.

Product Lifetime

The MicroRPM is designed for a product lifetime of five

years.

15

Trouble Shooting Information

Should you encounter problems operating your MicroRPM

unit, please consult the table below:

Problem

Possible Cause

Solution

Unit will not turn

on

Battery is

spent/discharged

Replace the

battery

Slide switch

connection

Return unit for

servicing

Display shows

reading before

test has been

performed

Internal tubing to

pressure sensor

kinked

Return unit for

servicing

Safety Designation per IEC 60601-1

Type of protection against electrical

shock

Internally powered

Equipment

Degree of protection against

electrical shock

Type B applied part

Power Equipment

Battery

Battery Life

2000 tests

Degree of Electrical connection

between equipment and patient

Equipment designed

as non-electrical

connection to the

patient

Degree of mobility

Portable

Mode of operation

Continuous

Classifications according to IEC 60601-1

Respiratory Pressure Meter

Applied part, type B

WARNING: No modification of this equipment is allowed.

16

WARNING: Do not connect devices that are not specified

as part of the system

Note: When you connect other equipment to the unit,

always make sure that the whole combination complies with

the international safety standard IEC 60101-1 for medical

electrical systems. During measurements, connect the

MicroRPM only to computers that comply with IEC/EN

60601-1 / ANSI/AAMI ES60601-1:2005.

WARNING: The user must not touch any conductive parts

and the patient at the same time.

Electromagnetic Compatibility (EMC) to EN606011:2007

WARNING: Use of portable phones or other radio frequency (RF)

emitting equipment near the system may cause unexpected or

adverse operation.

The MicroRPM has been tested to EN60606-1-2:2007, regarding

the ability to operate in an environment containing other

electrical/electronic equipment (including other medical devices).

The purpose of this testing is to ensure that the MicroRPM is not

likely to adversely affect the normal operation of other such

equipment and that other such equipment is not likely to adversely

affect the normal operation of the MicroRPM.

Despite the testing of the MicroRPM that has been undertaken,

normal operation of the MicroRPM can be affected by other

electrical/electronic equipment and portable and mobile RF

communications equipment.

As the MicroRPM is medical equipment, special precautions are

needed regarding EMC (electromagnetic compatibility).

It is important that the MicroRPM is configured and installed /put

into service, in accordance with the instructions/guidance provided

herein and is used only in the configuration as supplied.

17

Changes or modifications to the MicroRPM may results in

increased emissions or decreased immunity of the MicroRPM in

relation to EMC performance.

The MicroRPM should be used only with the accessories (RS232

cables) supplied (which are referenced in the accessories section

of this manual). None of the MicroRPM cables should be

extended in length by the user.

If any cables are extended by the user or non-approved

accessories are used, this may result in an increased level of

emissions or decreased level of immunity, in relation to the

MicroRPM’s EMC. None of the MicroRPM accessories should be

used with other devices, as this may result in an increased level of

emissions or decreased level of immunity, in relation to the other

devices’ EMC.

The MicroRPM has a minimum basic performance – The

respiratory pressure readings on the product must remain within a

tolerance of +/- 3%, and the unit firmware must not cease

responding. Warning: In the vent the product is operated in the

presence of significant electromagnetic fields (particularly in the

frequency range 40-60MHz) while in the PC connected mode,

ensure the results on the unit and PC are the same. If the results

differ, then relocating the product away from sources of

interference should resolve any issue.

WARNING: The MicroRPM should not be used adjacent to or

stacked with other equipment. If adjacent or stacked use with

other equipment is necessary, the MicroRPM and the other

equipment should be observed/monitored, to verify normal

operation in the configuration in which it will be used.

18

Guidance and Manufacturer’s Declaration – Electromagnetic Emissions

The MicroRPM is intended for use in the electromagnetic environment specified

below. The customer or the user of the MicroRPM should assure that it is used in

such an environment

Emission Test

Compliance

Electromagnetic Environment Guidance

RF emissions

CISPR 11

Group 1

The MicroRPM uses RF energy only for

its internal function. Therefore, its RF

emissions are very low and are not likely

to cause any interference in nearby

electronic equipment

RF emissions

CISPR 11

Group B

The MicroRPM is suitable for use in all

establishments, including residential

establishments and those directly

connected to the public low-voltage

power supply network that supplies

buildings used for domestic purposes

Harmonic emissions

IEC61000-3-2

Not Applicable

Voltage fluctuations /

flicker emissions

IEC61000-3-3

Not Applicable

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

The MicroRPM is intended for use in the electromagnetic environment specified

below. The customer or the user of the MicroRPM should assure that it is used in

such an environment.

Immunity Test

IEC 60601 Test

Level

Compliance

Level

Electromagnetic

Environment -

Guidance

Electrostatic

discharge (ESD)

IEC61000-4-2

+/- 6 kV contact

+/- 8 kV air

+/- 6 kV contact

+/- 8 kV air

Floors should be

wood, concrete or

ceramic tile. If floors

are covered with

synthetic material, the

relative humidity

should be at least

30%

Electrical fast

transient / burst

IEC61000-4-4

+/- 2 kV for power

supply lines

+/- 1 kV for input /

output lines

+/- 1 kV for

input/output lines

Mains power quality

should be that of a

typical commercial or

hospital environment

Surge

IEC61000-4-5

+/- 1 kV line(s) to

line(s)

+/- 2 kV line(s) to

earth

Not Applicable

Mains power quality

should be that of a

typical commercial or

hospital environment

19

Voltage dips,

short

interruptions and

voltage

variations on

power supply

input lines

IEC61000-4-11

< 5% UT

(> 95% dip in UT)

For 0.5 cycle

40% UT

(60% dip in UT) for

5 cycles

70% UT

(30% dip in UT) for

25 cycles

<5% UT (> 95%

dip in UT) for 5 s

Not Applicable

Mains power quality

should be that of a

typical commercial or

hospital environment.

If the user of the

MicroRPM requires

continued operation

during power mains

interruptions, it is

recommended that

the MicroRPM be

powered from an

uninterruptible power

supply or a battery

Power frequency

(50/60 Hz)

Magnetic field

IEC61000-4-8

3 A / m

3 A / m

Power frequency

magnetic fields should

be at levels

characteristic of a

typical location in a

typical commercial or

hospital environment.

NOTE UT is the a.c. mains voltage prior to application of the test level.

Guidance and Manufacturer’s Declaration – Electromagnetic Immunity

The MicroRPM is intended for use in the electromagnetic environment specified

below. The customer or the user of the MicroRPM should assure that it is used in

such an environment.

Immunity

Test

IEC 60601

Test Level

Compliance

Level

Electromagnetic Environment Guidance

Portable and mobile RF

communications equipment should

be used no closer to any part of the

MicroRPM, including cables, than

the recommended separation

distance calculated from the

equation applicable to the frequency

of the transmitter.

20

Conducted RF

IEC61000-4-6

Radiated RF

IEC61000-4-3

3 Vrms 150

kHz to 80

MHz

3 V/m 80

Mhz to 2.5

Ghz

3 V

3 V/m

Recommended separation

distance (d)

d = 1.2√P

d = 1.2√ P 80 MHz to 800 MHz

d = 2.3√ P 800 MHz to 2.5 GHz

Where P is the maximum output

power rating of the transmitter in

watts (W) according to the

transmitter manufacturer and d is

the recommended separation

distance in meters (m).

Fields strengths from fixed RF

transmitters, as determined by an

electromagnetic site survey,

a

should be less than the compliance

level in each frequency range. b

Interference may occur in the

vicinity of equipment marked with

the following symbol:

NOTE 1 At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic

propagation is affected by absorption and reflection from structures, objects and

people.

a

Field strengths from fixed transmitters, such as base stations for radio (cellular /

cordless) telephones and land mobile radios, amateur radios, AM and FM radio

broadcast and TV broadcast cannot be predicted theoretically with accuracy. To

assess the electromagnetic environment due to fixed RF transmitters, an

electromagnetic site survey should be considered. If the measured field strength in

the location in which the MicroRPM is used exceeds the applicable RF compliance

level above, the MicroRPM should be observed to verify normal operation. If

abnormal performance is observed, additional measures may be necessary, such as

re-orientating or relocating the MicroRPM

b

Over the frequency range 150 kHz to 80 MHz, field strengths should be less than 3

V / m

21

Recommended separation distances between portable and mobile RF

communications equipment and the MicroRPM

The MicroRPM is intended for use in an electromagnetic environment in which

radiated RF disturbances are controlled. The customer or the user of the MicroRPM

can help prevent electromagnetic interference by maintaining a minimum distance

between portable and mobile RF communications equipment (transmitters) and the

MicroRPM as recommended below, according to the maximum output power of the

communications equipment.

Rated Maximum

Output Power of

Transmitter in

Watts (W)

Separation Distance in Meters (m) according to

Frequency of Transmitter

150 KHz to 80

MHz

d = 1.2 √ P

80 MHz to 800

MHz

d = 1.2 √ P

800 MHz to 2.5

GHz

d = 2.4 √ P

0.01

0.12

0.12

0.23

0.1

0.38

0.38

0.73

1

1.2

1.2

2.3

10

3.8

3.8

7.3

100

12

12

23

For transmitters rated at a maximum output power not listed above, the

recommended separation distance d in meters (m) can be estimated using the

maximum output power rating of the transmitter in Watts (W) according to the

transmitter manufacturer.

NOTE 1 At 80 MHz and 800 MHz, the separation distance for the higher frequency

range applies.

NOTE 2 These guidelines may not apply in all situations. Electromagnetic

propagation is affected by absorption and reflection from structures objects and

people.

22

Symbols

Type B device

In accordance with Directive 93/42/EEC

Disposal in compliance with your local recycling

facility

Consult the instructions for use

Date of Manufacture

Manufacturer

Serial Number

Single Patient Use

Rx only

Federal U.S. law restricts this device to sale by or

on the order of a physician (Rx only)

23

Specifications

Measurements

Maximum Expiratory Pressure (MEP)

Maximum Inspiratory Pressure (MIP)

Sniff Nasal Inspiratory Pressure (SNIP)

With PumaTM

Maximum Rate of Pressure

Development (MRPD)

Maximum Rate of Relaxation (MRR)

Operating Pressure

+/- 300 cmH2O (+/- 5 PSID)

Burst Pressure

+/- 700 CmH2O (+/- 20 PSID)

Accuracy

+/- 3%

Resolution

1 cmH2O

Power Supply

Single Alkaline 9V battery

Dimensions

~6.5” x 2.5” x 1”

Weight (Unit with battery)

~ 6 ounces

Weight (in carry case)

~1 pound 10 ounces

Operating Temperature

32 – 104 0F

Operating Humidity

30% - 90% RH

Storage & Transport

Temperature

-4 – 158 0F

Storage & Transport

Humidity

10% - 90% RH

24

Consumables / Supporting Products

Cat. No. Description

MTH6400 Rubber mouthpiece

ASS1221 Expiration pressure valve assembly

ASS1222 Inspiration pressure valve assembly

FIL6050 Mouth pressure bacterial filters

NPROBE00 Nasal probes sizes 1 to 4

NPROBE01 Extra small nasal probes (10 per box)

NPROBE02 Small nasal probes (10 per box)

NPROBE03 Medium nasal probes (10 per box)

NPROBE04 Large nasal probes (10 per box)

ASS1091 Nasal probe adapter

48-70 Protex Disinfectant Wipe (100/canister)

To place an order for consumables/supporting products

or for general enquiries please contact Micro Direct on:

Tel: (207) 786-7808

Toll-Free: (800) 588-3381 (US and Canada only)

Fax: (207) 786-7280

Email: sales@mdspiro.com

support@mdspiro.com

Website: www.mdspiro.com

Loading...

Loading...