RV-3029

Application Manual

Date: March 2012 Revision N°: 2.0

Headquarters: Micro Crystal AG

Mühlestrasse 14

CH-2540 Grenchen

Switzerland

Tel.

Fax

Internet

Email

+41 32 655 82 82

+41 32 655 82 83

www.microcrystal.com

sales@microcrystal.com

1/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

TABLE OF CONTENTS

1. OVERVIEW ........................................................................................................................................................ 5

1.1. GENERAL DESCRIPTION ......................................................................................................................... 5

1.2. APPLICATIONS ......................................................................................................................................... 5

2. BLOCK DIAGRAM ............................................................................................................................................. 6

2.1. PINOUT ...................................................................................................................................................... 7

2.2. PIN DESCRIPTION .................................................................................................................................... 8

2.3. FUNCTIONAL DESCRIPTION ................................................................................................................... 8

2.4. DEVICE PROTECTION DIAGRAM ........................................................................................................... 9

3. REGISTER ORGANIZATION .......................................................................................................................... 10

3.1. REGISTER OVERVIEW ........................................................................................................................... 10

3.2. CONTROL PAGE REGISTER FUNCTION .............................................................................................. 11

3.2.1. CONTROL_1 (address 00h…bits description) .................................................................................. 11

3.2.2. CONTROL_INT (address 01h…bits description) .............................................................................. 11

3.2.3. CONTROL_INT FLAG (address 02h…bits description) ................................................................... 12

3.2.4. CONTROL_STATUS (address 03h…bits description) ..................................................................... 12

3.2.5. CONTROL_RESET (address 04h…bits description) ........................................................................ 13

3.3. WATCH PAGE REGISTER FUNCTION .................................................................................................. 13

3.3.1. SECONDS, MINUTES, HOURS, DAYS, WEEKDAYS, MONTHS, YEARS REGISTER ................. 13

3.3.2. DATA FLOW OF TIME AND DATE FUNCTION ............................................................................... 15

3.4. ALARM PAGE REGISTER FUNCTION .................................................................................................. 16

3.4.1. SECONDS, MINUTES, HOURS, DAYS, WEEKDAYS, MONTHS, YEARS ALARM REGISTER .... 16

3.5. TIMER PAGE REGISTER FUNCTION .................................................................................................... 18

3.6. TEMPERATURE PAGE REGISTER FUNCTION .................................................................................... 18

3.7. EEPROM DATA PAGE REGISTER FUNCTION ..................................................................................... 18

3.8. EEPROM CONTROL PAGE REGISTER FUNCTION ............................................................................. 19

3.8.1. EEPROM CONTROL (address 30h…bits description) ..................................................................... 19

3.8.2. XTAL OFFSET (address 31h…bits description) ............................................................................... 19

3.8.3. XTAL TEMPERATUR COEFFICIENT (address 32h…bits description) ........................................... 19

3.8.4. XTAL TURNOVER TEMPERATUR COEFFICIENT T0 (address 33h…bits description) ................. 20

3.9. RAM DATA PAGE REGISTER FUNCTION ............................................................................................ 20

4. DETAILED FUNCTIONAL DESCRIPTION ..................................................................................................... 21

4.1. POWER-UP, POWER MANAGEMENT AND BATTERY SWITCHOVER .............................................. 21

4.1.1. POWER UP SEQUENCE ................................................................................................................. 22

4.1.2. SUPPLY VOLTAGE OPERATING RANGE AND LOW VOLTAGE DETECTION ............................ 23

4.2. RESET ...................................................................................................................................................... 25

4.2.1. POWER-UP RESET, SYSTEM RESET AND SELF-RECOVERY RESET ...................................... 25

4.2.2. REGISTER RESET VALUES ............................................................................................................ 26

4.3. EEPROM MEMORY ACCESS ................................................................................................................. 28

2/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.4. TIMER FUNCTION ................................................................................................................................... 29

4.4.1. TIMER INTERRUT ............................................................................................................................ 31

4.5. ALARM FUNCTION ................................................................................................................................. 32

4.5.1. ALARM INTERRUPT ........................................................................................................................ 33

4.6. INTERRUPT OUTPUT INT ....................................................................................................................... 34

4.7. WATCH ENABLE FUNCTION ................................................................................................................. 35

4.8. SELF-RECOVERY SYSTEM ................................................................................................................... 35

4.9. CLOCK OUTPUT CLKOUT ..................................................................................................................... 36

5. COMPENSATION OF FREQUENCY DEVIATION AND FREQUENCY DRIFT vs TEMPERATURE ............ 37

5.1. TEMPERATURE CHARACTERISTICS TUNING FORK CRYSTAL....................................................... 37

5.2. COMPENSATION PRINCIPLE ................................................................................................................ 38

5.2.1. THERMOMETER AND TEMPERATURE VALUE ............................................................................ 39

5.2.2. SETTING THE FREQUENCY COMPENSATION PARAMETERS .................................................. 40

5.3. METHOD OF COMPENSATING THE FREQUENCY DEVIATION ......................................................... 41

5.3.1. CORRECT METHOD FOR TESTING THE TIME ACCURACY ....................................................... 42

5.3.2. TESTING THE TIME ACCURACY USING CLKOUT OUTPUT........................................................ 42

5.3.3. TESTING THE TIME ACCURACY USING INTERRUPT OUTPUT 1 Hz ......................................... 43

5.4. TIME ACCURACY OPT: A / OPT: B ....................................................................................................... 45

6. I2C INTERFACE ............................................................................................................................................... 47

6.1. I2C INTERFACE CHARACTERISTICS .................................................................................................... 47

6.2. I2C INTERFACE SYSTEM CONFIGURATION ........................................................................................ 47

6.3. BIT TRANSFER ....................................................................................................................................... 48

6.4. START AND STOP CONDITIONS .......................................................................................................... 48

6.5. ACKNOWLEDGE ..................................................................................................................................... 49

6.6. I2C INTERFACE PROTOCOL .................................................................................................................. 50

6.7. I2C DEVICE ADDRESSES ....................................................................................................................... 50

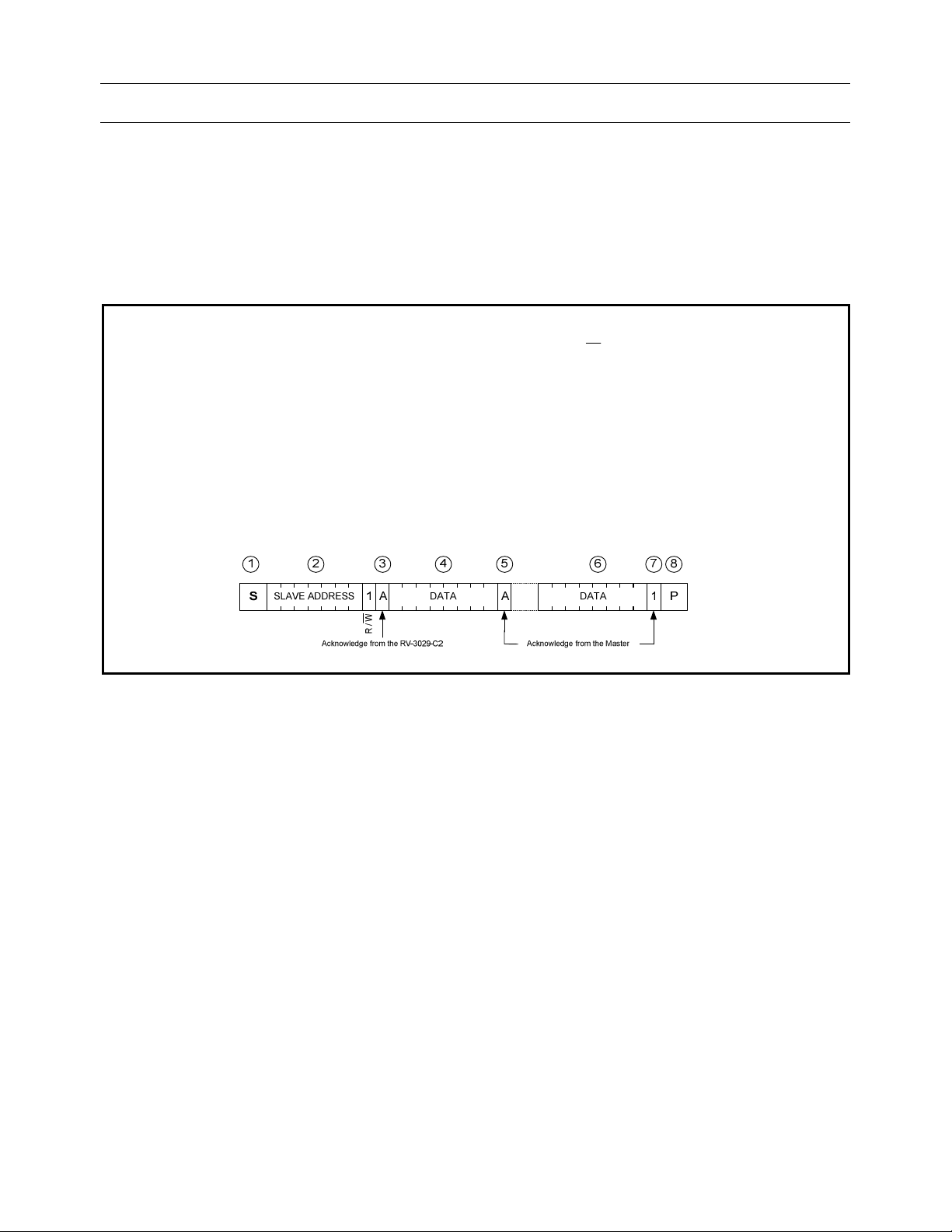

6.8. I2C INTERFACE READ AND WRITE DATA TRANSMISSION ............................................................... 51

6.8.1. WRITE MODE DATA TRANSMISSION ............................................................................................ 51

6.8.2. READ MODE DATA TRANSMISSION AT SPECIFIC ADDRESS.................................................... 52

6.8.3. READ MODE ..................................................................................................................................... 53

7. ELECTRICAL CHRACTERISTICS .................................................................................................................. 54

7.1. ABSOLUTE MAXIMUM RATINGS .......................................................................................................... 54

7.2. FREQUENCY AND TIME CHARACTERISTICS ..................................................................................... 54

7.3. STATIC CHARACTERISTICS ................................................................................................................. 55

7.4. I2C INTERFACE TIMING CHARACTERISTICS ...................................................................................... 56

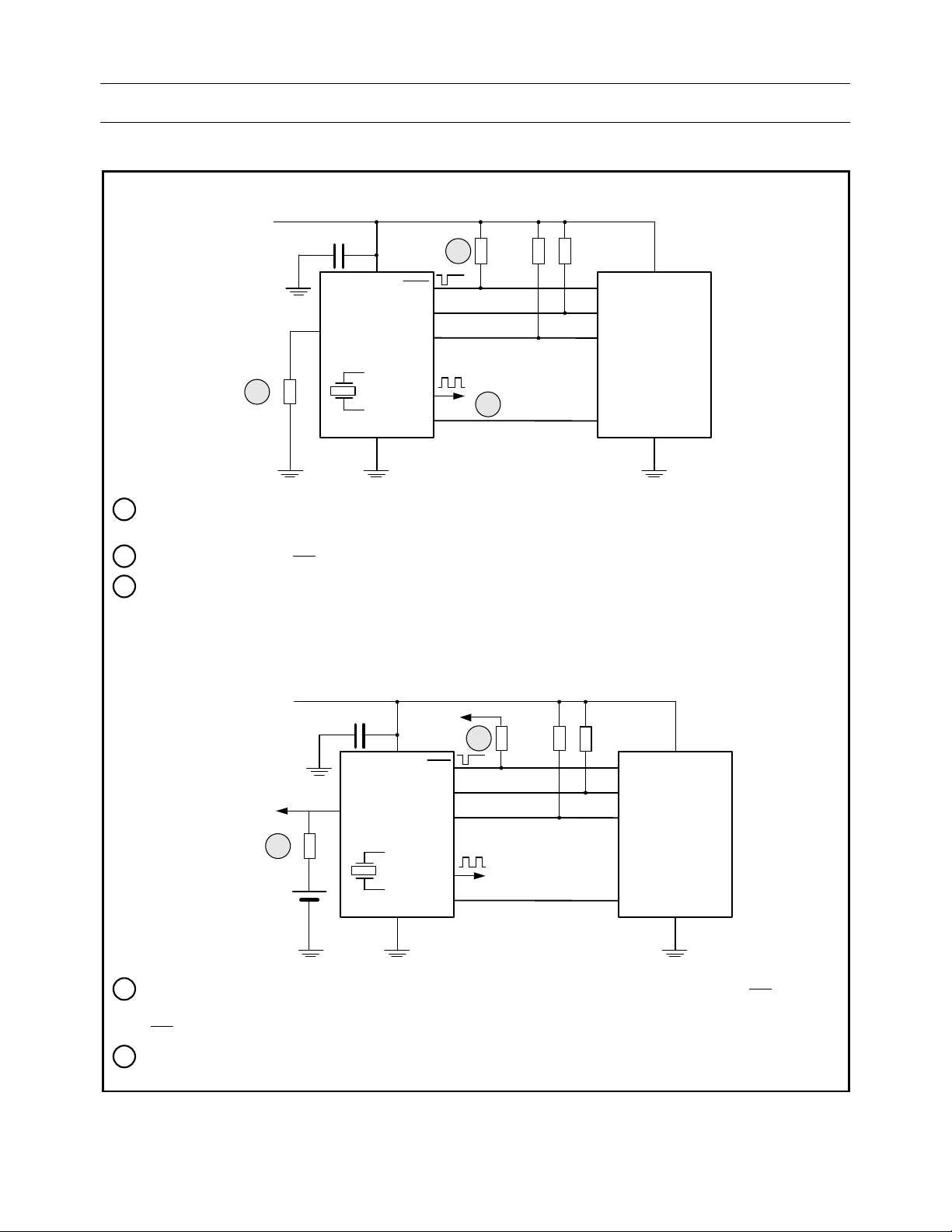

8. APPLICATION INFORMATION ....................................................................................................................... 58

8.1. RECOMMENDED REFLOW TEMPERATURE (LEADFREE SOLDERING) .......................................... 59

9. PACKAGES ..................................................................................................................................................... 60

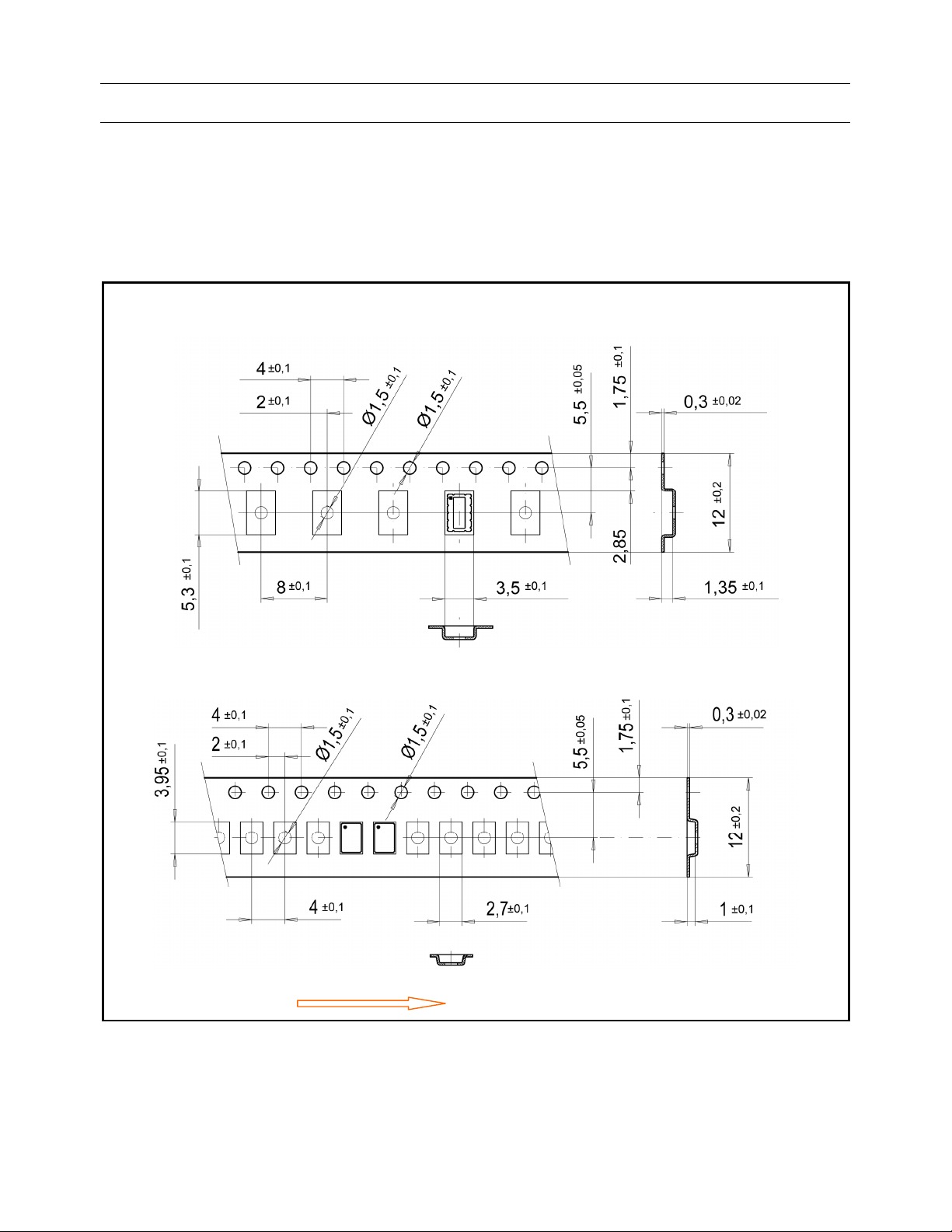

9.1. DIMENSIONS AND SOLDERPADS LAYOUT ........................................................................................ 60

3/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

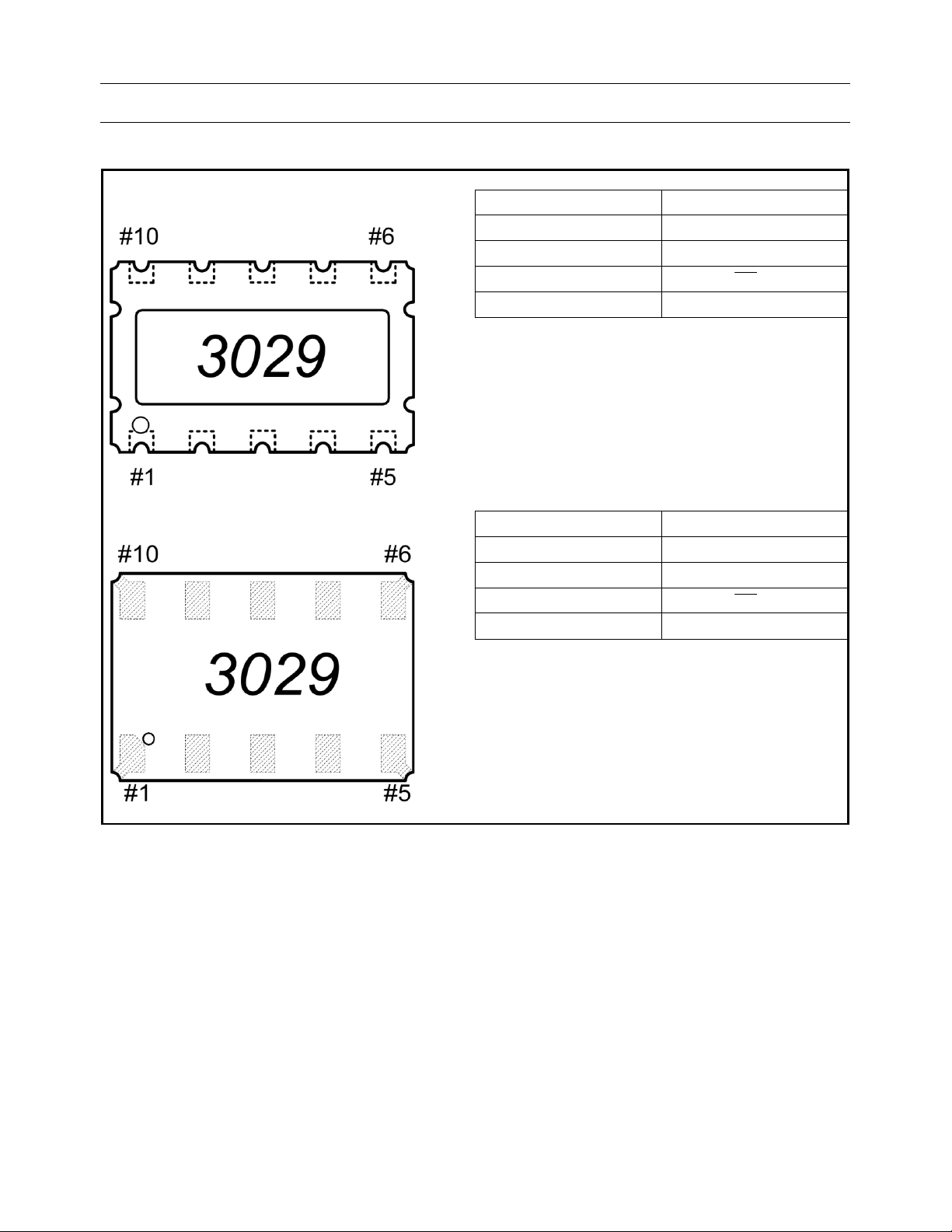

9.2. MARKING AND PIN #1 INDEX ................................................................................................................ 61

10. PACKING INFORAMTION ............................................................................................................................... 62

10.1. CARRIER TAPE ....................................................................................................................................... 62

10.2. PARTS PER REEL ................................................................................................................................... 63

10.3. REEL 13 INCH FOR 12 mm TAPE .......................................................................................................... 64

10.4. REEL 7 INCH FOR 12 mm TAPE ............................................................................................................ 65

11. HANDLING PRECAUTIONS FOR CRYSTALS OR MODULES WITH EMBEDDED CRYSTALS ................ 66

12. DOCUMENT REVISION HISTORY .................................................................................................................. 67

4/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

RV-3029

Highly accurate, DTCXO Temperature Compensated Real Time Clock / Calendar Module

with I2C Interface

1. OVERVIEW

• RTC module with built-in “Tuning Fork” crystal oscillating at 32.768 kHz

• Factory calibrated, all built-in Temperature Compensation circuitry

Time accuracy: Temperature Range Opt: A Opt: B

25°C +/- 3 ppm +/- 3 ppm

0°C to + 50°C +/- 4 ppm +/- 5 ppm

-10°C to + 60°C +/- 5 ppm +/- 10 ppm

-40°C to + 85°C +/- 6 ppm +/- 25 ppm

• Ultra low power consumption: 800nA typ @ VDD = 3.0V / T

• Wide clock operating voltage: 1.3 – 5.5V

• Wide interface operating voltage: 1.4 – 5.5V

• Extended operating temperature range: -40°C to +125°C

• I2C serial interface with fast mode SCL clock frequency of 400 kHz

• Provides year, month, day, weekday, hours, minutes and seconds

• Highly versatile alarm and timer functions

• Integrated Low-Voltage Detector, Power-On Reset and Self-Recovery System

• Main Power Supply to Backup Battery switchover circuitry with Trickle Charger

• Programmable CLKOUT pins for peripheral devices (32.768 kHz / 1024 Hz / 32 Hz / 1 Hz)

• Available in 2 different small and compact package sizes, RoHS-compliant and 100% leadfree:

C2: 5.0 x 3.2 x 1.2 mm

C3: 3.7 x 2.5 x 0.9 mm

1.1. GENERAL DESCRIPTION

The RV-3029 is a CMOS low power, real-time clock/calendar module with built-in Thermometer and Digital

Temperature Compensation circuitry (DTCXO). The temperature compensation circuitry is factory-calibrated and

greatly improves the time accuracy by compensating the frequency-deviation @ 25°C and the anticipated

frequency-drift over the temperature of the embedded 32.768 kHz “Tuning-Fork” crystal, even over the extended

Temperature Range -40°C to +125°C. Data is transferred serially via an I2C interface with a maximum SCL clock

frequency in fast mode of 400 kHz, the built-in word address register is incremented automatically after each

written or read data byte. Beyond standard RTC-functions like year, month, day, weekday, hours, minutes, seconds

information, the RV-3029 offers highly versatile Alarm and Timer-Interrupt function, programmable Clock-Output

and Low-Voltage Detector.

1.2. APPLICATIONS

The RV-3029 RTC module combines key functions with outstanding performance in a small ceramic package:

• Factory calibrated Temperature Compensation

• Extended temperature range up to +125°C

• Low Power consumption

• Smallest temperature compensated RTC module with embedded Xtal

These unique features make this product perfectly suitable for many applications:

• Automotive: Car Radio / GPS and Tracking Systems / Dashboard / Engine Controller /

Car Mobile & Entertainment Systems / Tachometers

• Metering: E-meter / Heating Counter

• Outdoor: ATM & POS systems / Surveillance & Safety systems / Ticketing systems

• All kind of portable and battery operated devices

• Industrial and consumer electronics

• White goods

5/67

-40°C to +125°C +/- 8 ppm +/- 30 ppm

amb

= 25°C

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

2. BLOCK DIAGRAM

CLKOUT

CLKOE

INT

V

DD

V

BACKUP

V

SS

SCL

SDA

32.768 kHz

Xtal

OSC

OUTPUT

CONTROL

I2C-BUS

2-wire

Serial

Interface

POWER

CONTROL

DIVIDER

and

TEMPERATURE

COMPENSATION

LOGIC

SYSTEM

CONTROL

LOGIC

TEMPERATURE

SENSOR

Control_1

Control_INT

Control_INT-Flags

Control_Status

Control_Reset

Seconds

Minutes

Hours

Date

Weekday

Month

Year

Seconds Alarm

Minutes Alarm

Hour Alarm

Day Alarm

Weekday Alarm

Month Alarm

Year Alarm

Timer Low

Timer High

Temperature °K

User EEPROM

2 Bytes

EE Ctrl

Xtal Deviation

Xtal Temp-Coef

Xtal T0 Temp

User RAM

8 Byte

User RAM

00

08

10

18

20

28

29

30

38

3F

6/67

Micro Crystal

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

2.1. PINOUT

C2 Package:

C3 Package:

#1 VDD #10 CLKOE

#2 CLKOUT #9 N.C.

#3 N.C.

#4 SCL

#8 V

#7

BACKUP

#5 SDA #6 VSS

#1 CLKOE #10 N.C.

#2 VDD #9 V

BACKUP

#3 CLKOUT #8 N.C.

#4 SCL

#7

#5 SDA #6 VSS

7/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

2.2. PIN DESCRIPTION

Symbol

VDD 1 2

CLKOUT 2 3

N.C. 3 8 Not Connected; internally used for test, do not connect other signals then ground

SCL 4 4 Serial Clock Input pin; requires pull-up resistor

SDA 5 5 Serial Data Input-Output pin; open-drain; requires pull-up resistor

VSS 6 6 Ground

INT

V

8 9 Backup Supply Voltage; tie to GND when not using backup supply voltage

BACKUP

N.C. 9 10 Not Connected; internally used for test, do not connect other signals then ground

CLKOE 10 1 CLKOUT enable/disable pin; enable is active HIGH; tie to GND when not using CLKOUT

Pin #

C2 C3

7 7 Interrupt Output pin; open-drain; active LOW

Description

Positive supply voltage; positive or negative steps in supply voltage may affect oscillator

performance, recommend 10 nF decoupling capacitor close to device

Clock Output pin; CLKOUT or

CLKOUT output push-pull /

function can be selected.(Control_1; bit7; Clk/Int)

INT

INT function open-drain requiring pull-up resistor

2.3. FUNCTIONAL DESCRIPTION

The RV-3029 is a highly accurate real-time clock/calendar module due to integrated temperature compensation

circuitry. The built-in Thermometer and Digital Temperature Compensation circuitry (DTCXO) provides improved

time-accuracy; achieved by measuring the temperature and calculating an expected correction value based on

precise, factory-calibrated Crystal parameters. The compensation of the frequency deviation @ 25°C and the

Crystal’s frequency-drift over the temperature range are obtained by adding or subtracting 32.768 kHz oscillator

clock-pulses. Beyond standard RTC-functions like year, month, day, weekday, hours, minutes, seconds

information, the RV-3029 offers highly versatile Alarm and Timer-Interrupt function, programmable Clock-Output

and Voltage-Low-Detector and a Main-Supply to Backup-Battery Switchover Circuitry and a 400 kHz I2C interface.

The CMOS IC contains thirty 8-bit RAM registers organized in 6 memory pages; the address counter is

automatically incremented within the same memory page. All sixteen registers are designed as addressable 8-bit

parallel registers, although, not all bits are implemented.

• Memory page #00 contains of five registers (memory address 00h and 04h) used as control registers

• Memory page #01 addresses 08h through 0Eh are used as counters for the clock function (seconds up to

years). The Seconds, Minutes, Hours, Days, Weekdays, Months and Years registers

are all coded in Binary-Coded-Decimal (BCD) format. When one of the RTC registers is

read, the content of all counters is frozen to prevent faulty reading of the clock/calendar

registers during a carry condition

• Memory page #02 addresses 10h through 16h define the alarm condition

• Memory page #03 addresses 18h and 19h are used for Timer function

• Memory page #04 address 20h provides the thermometer reading value

• Memory page #07 addresses 38h through 3Fh are available for user data

Additionally, the CMOS-IC contains six non-volatile 8-bit EEPROM registers organized in 2 memory pages; the

address counter is automatically incremented within the same memory page.

• EEPROM page #05 addresses 28h and 29h are available for EEPROM user data

• EEPROM page #06 contains of four registers (memory address 30h through 33h) used as non-volatile

control registers. These registers contain the factory programmed parameters of the

Crystal’s thermal characteristics, the frequency-deviation @ ambient temperature and

the Thermometer’s calibration values. In favour for the best time-accuracy, the factory

programmed registers (memory address 31h through 33h) shall not be changed by

the user without carefully studying its function

8/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

2.4. DEVICE PROTECTION DIAGRAM

9/67

Micro Crystal

Control page

Timer page

Temperature page

EEPROM

User

EEPROM Control page

RAM page

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

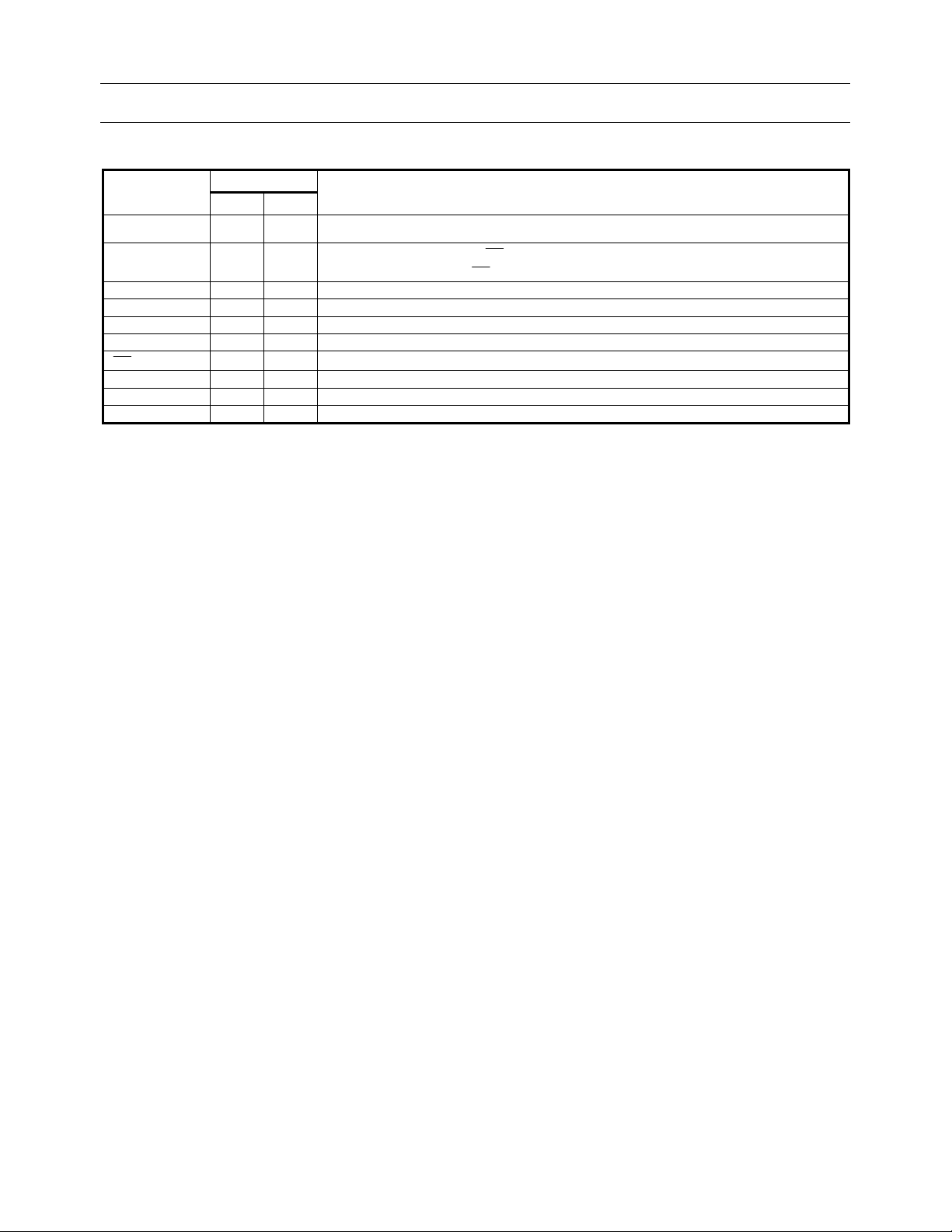

3. REGISTER ORGANIZATION

The registers are grouped into memory pages. The pages are addressed by the 5 most-significant-bits (MSB’s bits

7 – 3), the 3 least-significant-bites (LSB’s 2 – 0) select the registers within the addressed page.

30 RAM registers organized in 6 memory pages and 6 EEPROM registers organized in 2 memory pages are

available. During interface access, the page address (MSB’s 7 - 3) is fixed while the register address (LSB’s 2 - 0)

are automatically incremented. The content of all counters and registers are frozen to prevent faulty reading of the

clock/calendar registers during carry condition.

The time registers in the Clock and Alarm pages are encoded in the Binary Coded Decimal format (BCD) to simplify

application use. Other registers are either bit-wise or standard binary format.

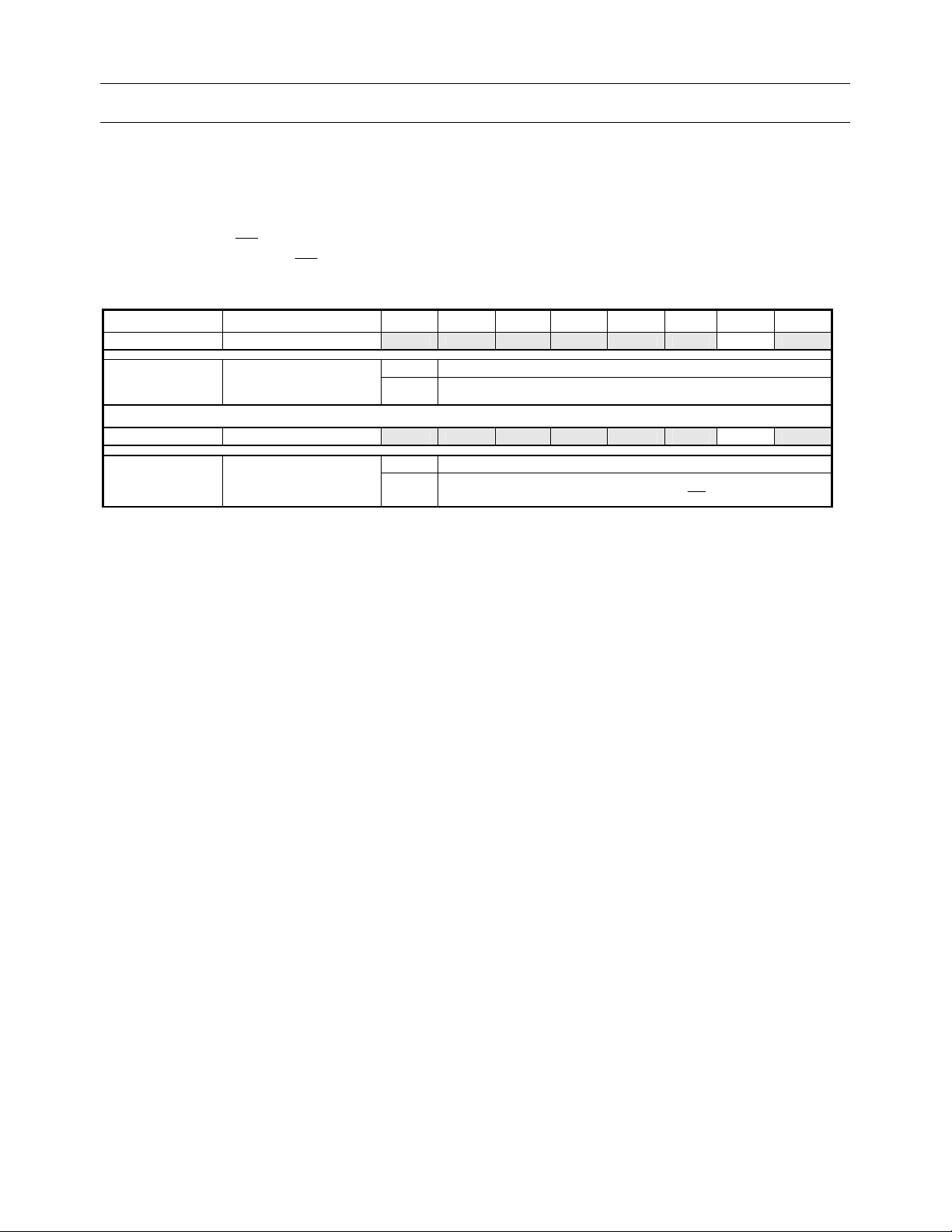

3.1. REGISTER OVERVIEW

Address

Page Address

Bit 7 - 3 Bit 2 - 0

000 00h Control_1

001 01h Control_INT

010 02h Control_INT Flag

011 03h Control_Status

100 04h Control_Reset

000

001

010

011

100

101

110

000

001

010

011

100

101

110

00000

Clock page

00001

Alarm page

00010

000

00011

00100

001

000 20h Temperature

000

00101

001

000

00110

001

010

011

000

00111

:

111

Bit positions labelled as “X” are not implemented and will return a “0” when read.

Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Hex

Clk/Int TD1 TD0 SROn EERE TAR TE WE

X X X SRIE V2IE V1IE TIE AIE

X X X SRF V2IF V1IF TF AF

EEbusy X PON SR V2F V1F X X

X X X SysR X X X X

08h Seconds

09h Minutes

0Ah Hours

0Bh Days

0Ch Weekdays

0Dh Months

0Eh Years

10h Second Alarm

11h Minute Alarm

12h Hour Alarm

13h Days Alarm

14h Weekday Alarm

15h Months Alarm

16h Year Alarm

18h Timer Low

19h Timer High

28h EEPROM User

29h EEPROM User

30h EEPROM Contr.

31h Xtal Offset

32h Xtal Coef

33h Xtal T0

X 40 20 10 8 4 2 1

X 40 20 10 8 4 2 1

X 12-24 20-PM 10 8 4 2 1

X X 20 10 8 4 2 1

X X X X X 4 2 1

X X X 10 8 4 2 1

X 40 20 10 8 4 2 1

AE_S 40 20 10 8 4 2 1

AE_M 40 20 10 8 4 2 1

AE_H X 20-PM 10 8 4 2 1

AE_D X 20 10 8 4 2 1

AE_W X X X X 4 2 1

AE_M X X 10 8 4 2 1

AE_Y 40 20 10 8 4 2 1

128 64 32 16 8 4 2 1

128 64 32 16 8 4 2 1

128 64 32 16 8 4 2 1

2 bytes of EEPROM for user data

R80k R20k R5k R1k FD1 FD0 ThE ThP

sign 64 32 16 8 4 2 1

128 64 32 16 8 4 2 1

X X 32 16 8 4 2 1

38h

:

User RAM

8 bytes of RAM for user data

3Fh

10/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

3.2. CONTROL PAGE REGISTER FUNCTION

3.2.1. CONTROL_1 (address 00h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

00h Control_1 Clk/Int TD1 TD0 SROn EERE TAR TE WE

Bit Symbol Value Description Reference

0

7 Clk/Int

6 TD1

5 TD0

4 SROn

3 EERE

2 TAR

1 TE

0 WE

3.2.2. CONTROL_INT (address 01h…bits description)

Applies INT function on CLKOUT pin

1 Applies CLKOUT function on CLKOUT pin

00

01

Select Source Clock for internal Countdown Timer See section 4.4.

10

11

0 Disables Self Recovery function

1 Enables Self Recovery function

0 Disables automatic EEPROM refresh every hour

1 Enables automatic EEPROM refresh every hour

0 Disables Countdown Timer auto-reload mode

1 Enables Countdown Timer auto-reload mode

0 Disables Countdown Timer

1 Enables Countdown Timer

0 Disables 1Hz Clock Source for Watch

1 Enables 1Hz Clock Source for Watch

See section 4.9.

See section 4.8.

See section 4.3.

See section 4.4.

See section 4.4.

See section 4.7.

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

01h Control_INT X X X SRIE V2IE V1IE TIE AIE

Bit Symbol Value Description Reference

7 to 5 unused X Unused

4 SRIE

3 V2IE

2 V1IE

1 TIE

0 AIE

0 Disables Self-Recovery INT

1 Enables Self-Recovery INT

0 Disables VLOW2 INT; “Low Voltage 2 detection”

1 Enables VLOW2 INT; “Low Voltage 2 detection”

0 Disables VLOW1 INT; “Low Voltage 1detection”

1 Enables VLOW1 INT; “Low Voltage 1detection”

0 Disables Countdown Timer INT

1 Enables Countdown Timer INT

0 Disables Alarm INT

1 Enables Alarm INT

See section 4.8.

See section 4.1.2.

See section 4.1.2.

See section 4.4.1.

See section 4.5.1.

Bit positions labelled as “X” are not implemented and will return a “0” when read.

11/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

3.2.3. CONTROL_INT FLAG (address 02h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

02h Control_INT Flag X X X SRF V2IF V1IF TF AF

Bit Symbol Value Description Reference

7 to 5 unused X Unused

0 No Self-Recovery Interrupt generated

4 SRF

Self-Recovery Interrupt generated if possible

1

deadlock is detected; clear flag to clear Interrupt

See section 4.6.

0 No VLOW2 Interrupt generated

3 V2IF

VLOW2 Interrupt generated when supply voltage

1

drops below VLOW2 threshold

See section 4.6.

0 No VLOW1 Interrupt generated

2 V1IF

VLOW1 Interrupt generated when supply voltage

1

drops below VLOW1 threshold

See section 4.6.

0 No Timer Interrupt generated

1 TF

Timer Interrupt generated when Countdown Timer

1

value reaches zero

See section 4.6.

0 No Alarm Interrupt generated

0 AF

Alarm Interrupt generated when Time & Date

1

matches Alarm setting

See section 4.6.

Bit positions labelled as “X” are not implemented and will return a “0” when read.

3.2.4. CONTROL_STATUS (address 03h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

03h Control_Status EEbusy X PON SR V2F V1F X X

Bit Symbol Value Description Reference

0 EEPROM is not busy

7 EEbusy

Flag is set when EEPROM page is busy due to

1

“write” or automatic EEPROM refresh in progress

6 unused X Unused

See section 4.3.

0 No Power-On Reset executed

5 PON

4 SR

Flag is set at Power-On, flag must be cleared by

1

writing “0”

No Self-Recovery Reset or System Reset has

0

been generated.

Flag is set when Self-Recovery Reset or System

1

Reset has been generated.

See section 4.1.

See section 4.2.1.

0 No VLOW2 Interrupt generated”

3 V2F

VLOW2 Interrupt generated when supply voltage

1

drops below VLOW1 threshold

See section 4.6.

0 No VLOW1 Interrupt generated”

2 V1F

VLOW1 Interrupt generated when supply voltage

1

drops below VLOW1 threshold

1 to 0 unused X Unused

See section 4.6.

Bit positions labelled as “X” are not implemented and will return a “0” when read.

12/67

Micro Crystal

1

)

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

3.2.5. CONTROL_RESET (address 04h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

04h Control_Reset X X X SysR X X X X

Bit Symbol Value Description Reference

7 to 5 unused X Unused

0 No System Reset will be executed

4 SysR

3 to 0 unused X Unused

Bit positions labelled as “X” are not implemented and will return a “0” when read.

Set bit = “1” triggers a System Reset. After the

1

restart of the logic, the SysR will be cleared and in

bit 4 “SR” in the register Control_Status will be set

See section 4.2.1.

3.3. WATCH PAGE REGISTER FUNCTION

Watch Page registers are coded in the Binary Coded Decimal (BCD) format; BCD format is used to simplify

application use.

3.3.1. SECONDS, MINUTES, HOURS, DAYS, WEEKDAYS, MONTHS, YEARS REGISTER

Seconds (address 08h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

08h Seconds X 40 20 10 8 4 2 1

Bit Symbol Value Description

7 X - Unused

6 to 0 Seconds 0 to 59 This register holds the current seconds coded in BCD format

Minutes (address 09h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

09h Minutes X 40 20 10 8 4 2 1

Bit Symbol Value Description

7 X - Unused

6 to 0 Minutes 0 to 59 This register holds the current minutes coded in BCD format

Hours (address 0Ah…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0Ah Hours X 12-24

20-PM

10 8 4 2 1

Bit Symbol Value Description

7 X - Unused

12 hour mode (AM/PM)

6 12-24

5 20-PM

4 to 0 Hours

24 hour mode

1)

User is requested to pay attention setting valid data only.

13/67

6 12-24

5 to 0 Hours1) 0 to 23 This register holds the current hours coded in BCD format

0 Selects 24-hour mode

1 Selects 12-hour (AM/PM) mode

0 Indicates AM

1 Indicates PM

1 to 12 This register holds the current hours coded in BCD format

0 Selects 24-hour mode

1 Selects 12-hour AM/PM mode

Micro Crystal

1

)

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

Days (address 0Bh…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0Bh Days X X 20 10 8 4 2 1

Bit Symbol Value Description

7 to 6 X - Unused

5 to 0 Days 1 to 31

1)

The RTC compensates for leap years by adding a 29th day to February if the year counter contains a value which is exactly divisible by 4;

including the year 00.

This register holds the current days coded in BCD format 1)

Weekdays (address 0Ch…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0Ch Weekdays X X X X X 4 2 1

Bit Symbol Value Description

7 to 3 X - Unused

2 to 0 Weekdays 1 to 7

Weekdays

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

This register holds the current weekdays coded in BCD format 1)

Sunday X X X X X 0 0 1

Monday X X X X X 0 1 0

Tuesday X X X X X 0 1 1

Wednesday X X X X X 1 0 0

Thursday X X X X X 1 0 1

Friday X X X X X 1 1 0

Saturday X X X X X 1 1 1

1)

These bits may be re-assigned by the user.

Months (address 0Dh…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0Dh Months X X X 10 8 4 2 1

Bit Symbol Value Description

7 to 5 X - Unused

4 to 0 Months 1 to 12

Months Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

January X X X 0 0 0 0 1

February X X X 0 0 0 1 0

March X X X 0 0 0 1 1

April X X X 0 0 1 0 0

May X X X 0 0 1 0 1

June X X X 0 0 1 1 0

July X X X 0 0 1 1 1

August X X X 0 1 0 0 0

September X X X 0 1 0 0 1

October X X X 1 0 0 0 0

November X X X 1 0 0 0 1

December X X X 1 0 0 1 0

1)

The RTC compensates for leap years by adding a 29th day to February if the year counter contains a value which is exactly divisible by 4;

including the year 00.

This register holds the current months coded in BCD format 1)

14/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

Years (address 0Eh…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0Eh Years X 40 20 10 8 4 2 1

Bit Symbol Value Description

7 X - Unused

6 to 0 Years 0 to 79

1)

The RTC compensates for leap years by adding a 29th day to February if the year counter contains a value which is exactly divisible by 4;

including the year 00.

This register holds the current year 20xx coded in BCD format1)

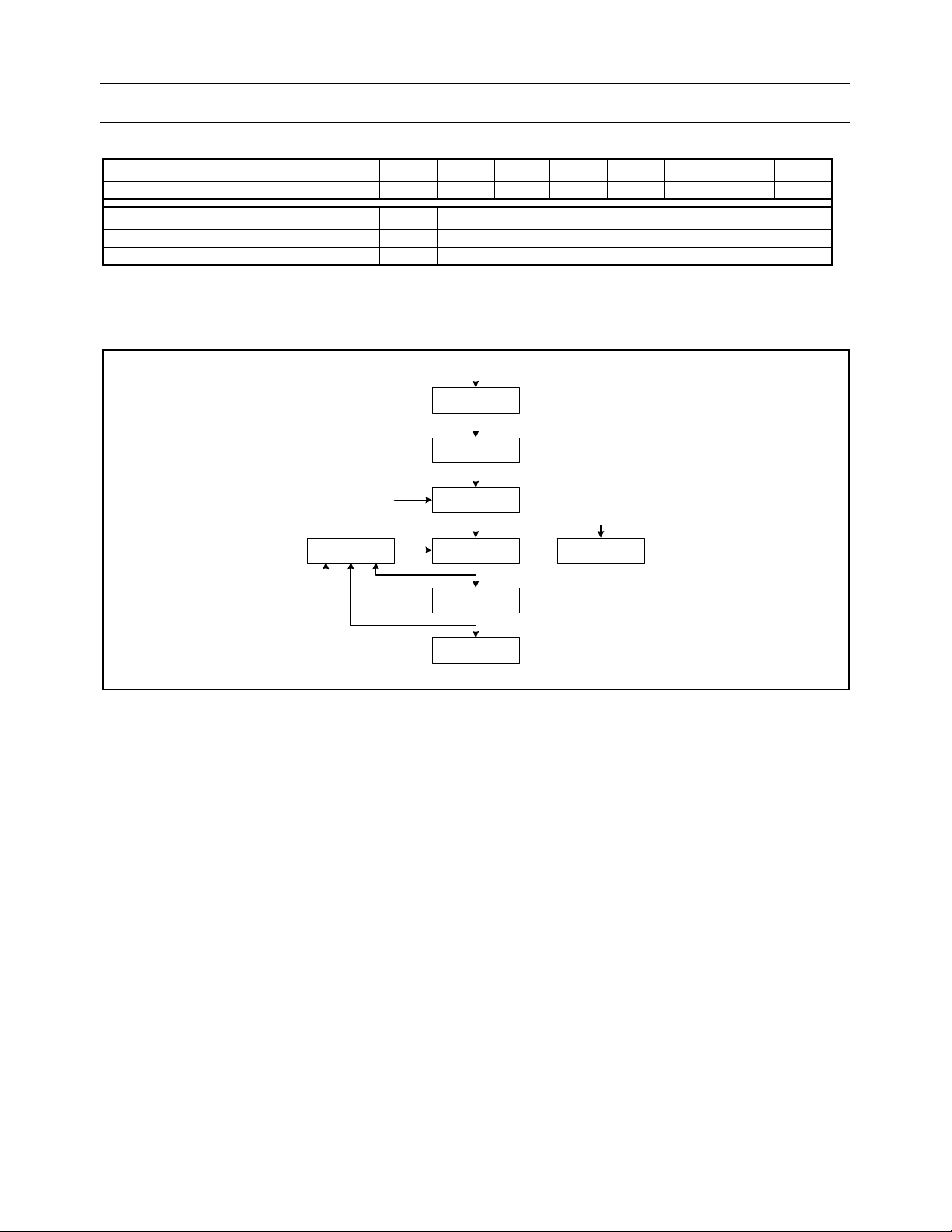

3.3.2. DATA FLOW OF TIME AND DATE FUNCTION

1 Hz tick

SECONDS

MINUTES

12_24 hour mode

LEAP YEAR

CALCULATION

HOURS

DAYS

MONTHS

YEARS

WEEKDAY

15/67

Micro Crystal

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

3.4. ALARM PAGE REGISTER FUNCTION

The Alarm Page registers contain alarm information. When one or more of these registers are loaded with a valid

second, minute, hour, day, weekday, month or year information and its corresponding alarm enable bit (AE_x) is

logic “1”, then that information will be compared with the current time / date information in the Watch Page

registers.

When all enabled comparisons first match (wired “AND”) and the AIE Flag (bit 0 in register Control_INT) is enabled,

then the AF Flag (bit 0 in register Control_INT) is set = “1” and an Interrupt signal becomes available at

Disabled Alarm registers which have their corresponding bit AE_X at logic “0” are ignored.

3.4.1. SECONDS, MINUTES, HOURS, DAYS, WEEKDAYS, MONTHS, YEARS ALARM REGISTER

Alarm Seconds (address 10h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

10h Second Alarm AE_S 40 20 10 8 4 2 1

Bit Symbol Value Description

7 AE_S

6 to 0 Seconds Alarm 0 to 59 These bits hold the Second Alarm information coded in BCD format

0 Second Alarm is disabled

1 Second Alarm is enabled

Alarm Minutes (address 11h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

11h Minute Alarm AE_M 40 20 10 8 4 2 1

Bit Symbol Value Description

7 AE_M

6 to 0 Minutes Alarm 0 to 59 These bits hold the Minute Alarm information coded in BCD format

0 Minute Alarm is disabled

1 Minute Alarm is enabled

Alarm Hours (address 12h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

12h Hours Alarm AE_H 12-24 20-PM 10 8 4 2 1

pin.

Bit Symbol Value Description

7 AE_H

6 X - Unused

12 hour mode (AM/PM)

5 20-PM

4 to 0 Hours Alarm 1 to 12

24 hour mode

16/67

5 to 0 Hours Alarm 0 to 23

0 Hour Alarm is disabled

1 Hour Alarm is enabled

0 Indicates AM

1 Indicates PM

These registers hold the Hours Alarm information coded in BCD format

when in 12 hour mode

These registers hold the Hours Alarm information coded in BCD format

when in 24 hour mode

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

Alarm Days (address 13h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

13h Days Alarm AE_D X 20 10 8 4 2 1

Bit Symbol Value Description

7 AE_D

6 X - Unused

5 to 0 Days Alarm 1 to 31 These registers hold the Day Alarm information coded in BCD

0 Day Alarm is disabled

1 Day Alarm is enabled

Alarm Weekdays (address 14h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

14h Weekday Alarm AE_W X X X X 4 2 1

Bit Symbol Value Description

7 AE_W

6 to 3 X - Unused

2 to 0 Weekday Alarm 1 to 7 These registers hold the Weekday Alarm information coded in BCD

0 Weekday Alarm is disabled

1 Weekday Alarm is enabled

Alarm Months (address 15h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

15h Months Alarm AE_M X X 10 8 4 2 1

Bit Symbol Value Description

7 AE_W

6 to 5 X - Unused

4 to 0 Months Alarm 1 to 12 These registers hold the Months Alarm information coded in BCD

0 Months Alarm is disabled

1 Months Alarm is enabled

Alarm Years (address 16h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

16h Year Alarm AE_Y 40 20 10 8 4 2 1

Bit Symbol Value Description

7 AE_Y

6 to 0 Year Alarm 0 to 79 These registers hold the Year Alarm information coded in BCD

17/67

0 Year Alarm is disabled

1 Year Alarm is enabled

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

3.5. TIMER PAGE REGISTER FUNCTION

The Timer Page contains 2 registers forming a 16-bit count down timer value.

Countdown Timer Value (addresses 18h / 19h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

18h Timer Low 128 64 32 16 8 4 2 1

19h Timer High 128 64 32 16 8 4 2 1

Address Symbol Value Description

18h Timer Low

19h Timer High

1 to 255

0 to 255

These bits hold the Low Countdown Timer Value in binary format

These bits hold the High Countdown Timer Value in binary format

3.6. TEMPERATURE PAGE REGISTER FUNCTION

The Temperature Page register contains the result of the measured temperature ranging from -60°C (=0d) to

+190°C (=250d) with 0°C corresponding to a content of =60d.

During read / write access, the content of the register Temperature is frozen in a cache memory to prevent faulty

reading.

When the Thermometer is disabled by ThE = “0” (bit 1 in register EEPROM_Control), the register Temperature at

address 20h can be externally written.

Temperature Value (address 20h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

20h Temperature 128 64 32 16 8 4 2 1

Address Symbol Value Description

20h Temperature

-60 to

+194°C

These bits hold the Temperature Value coded in binary format

3.7. EEPROM DATA PAGE REGISTER FUNCTION

The EEPROM Data Page contains 2 non-volatile EEPROM registers for user’s application.

Please see section 4.3 EEPROM MEMORX ACCESS for detailed instructions how to handle EEPROM read / write

access.

User EEPROM Data Registers (addresses 28h / 29h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

28h EEPROM User 128 64 32 16 8 4 2 1

29h EEPROM User 128 64 32 16 8 4 2 1

Address Symbol Value Description

28h EEPROM User

29h EEPROM User

0 to 255

0 to 255

EEPROM User Data (2 Bytes)

18/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

3.8. EEPROM CONTROL PAGE REGISTER FUNCTION

The EEPROM Control Page contains 4 non-volatile EEPROM registers.

With Register EEPROM Control, the settings for Trickle-Charger (bit 7-4), the CLKOUT frequency (bit 3&2) and the

Thermometer (bit 1&0) can be controlled.

The registers XTAL Offset, XTAL Coef and XTAL T0 contain the factory calibrated, individual crystal parameters to

compensate the frequency deviation over the temperature range.

Please see section 4.3 EEPROM MEMORY ACCESS for detailed instructions how to handle EEPROM read / write

access.

3.8.1. EEPROM CONTROL (address 30h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

30h EEPROM Control R80k R20k R5k R1k FD1 FD0 ThE ThP

Bit Symbol Value Description Reference

7 R80k

6 R20k

5 R5k

4 R1k

3 FD1

2 FD0

1 ThE

0 ThP

3.8.2. XTAL OFFSET (address 31h…bits description)

0 Disables 80 kΏ trickle charge resistor

1 Enables 80 kΏ trickle charge resistor

0 Disables 20 kΏ trickle charge resistor

1 Enables 20 kΏ trickle charge resistor

0 Disables 5 kΏ trickle charge resistor

1 Enables 5 kΏ trickle charge resistor

0 Disables 1.5 kΏ trickle charge resistor

1 Enables 1.5 kΏ trickle charge resistor

00

01

Selects Clock Frequency at CLKOUT pin See section 4.9.

10

11

0 Disables Thermometer

1 Enables Thermometer

0 Set Temperature Scanning Interval: 1 second

1 Set Temperature Scanning Interval: 16 seconds

See section 4.1.

See section 5.2.1.

See section 5.2.1.

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

31h XTAL Offset sign 64 32 16 8 4 2 1

Bit Symbol Value Description Reference

7 Sign

6 to 0 XTAL Offset1)

1)

The XTAL Offset register value is factory programmed according to the crystal’s initial frequency-tolerance. For best time-accuracy, the

content of this register must not be changed by the user.

0 - Deviation (slower) of 32.768kHz frequency at T0

1 + Deviation (faster) of 32.768kHz frequency at T0

0 to 121

Frequency Offset Compensation value

See section 5.2.2.

3.8.3. XTAL TEMPERATUR COEFFICIENT (address 32h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

32h XTAL Coef

Bit Symbol Value Description Reference

7 to 0 XTAL Coef1)

1)

The XTAL Coef register value is factory programmed according to the crystal parameters over temperature. For best time-accuracy, the

content of this register must not be changed by the user.

19/67

128 64 32 16 8 4 2 1

0 to 255

Quadratic Coefficient of XTAL’s Temperature Drift See section 5.2.2.

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

3.8.4. XTAL TURNOVER TEMPERATUR COEFFICIENT T0 (address 33h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

33h XTAL T0

x x 32 16 8 4 2 1

Bit Symbol Value Description Reference

7 to 6 x - Unused

5 to 0 XTAL T01) 4 to 67 XTAL’s Turnover Temperature in °C See section 5.2.2.

1)

The XTAL T0 register value is factory programmed according to the crystal parameters over temperature. For best time-accuracy, the

content of this register must not be changed by the user.

3.9. RAM DATA PAGE REGISTER FUNCTION

The RAM Data Page contains 8 RAM registers for user’s application.

User RAM Data Registers (addresses 38h to 3Fh…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

38h RAM User

--- ---

3Fh RAM User

Address Symbol Value Description

38h RAM User

--- --- ---

3Fh RAM User

128 64 32 16 8 4 2 1

128 64 32 16 8 4 2 1

128 64 32 16 8 4 2 1

0 to 255

RAM User Data (8 Bytes)

0 to 255

20/67

Micro Crystal

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4. DETAILED FUNCTIONAL DESCRIPTION

4.1. POWER-UP, POWER MANAGEMENT AND BATTERY SWITCHOVER

The RV-3029 has two power supply pins:

• VDD the main power supply input pin

• V

BACKUP

The RV-3029 has multiple power management function implemented:

• Automatic switchover function between main power supply and backup supply voltage. The higher supply

voltage is selected automatically, with a switchover hysteresis of 20mV

• Low supply voltage detection V

control bits are enabled

• Functions requiring a minimum supply voltage are automatically disabled if low supply voltage is detected

• Interface and CLKOUT are automatically disabled when the device operates in backup supply mode

• Programmable trickle charge circuitry to charge backup battery or supercap

Backup Switchover Circuitry Disables non-used Functions

the backup battery input pin

and V

LOW1

with the possibility to generate an

LOW2

if the corresponding

1

Trickle charge circuitry is enabled by software when selecting trickle-charge resistors. When back-up

supply switchover-circuitry switches to the backup supply voltage, trickle charge function is disabled.

2

The implemented backup switchover circuitry continuously compares VDD and V

connects the higher of them to the internal supply voltage V

The switchover hysteresis from VDD to V

3

When the device is operating at the V

BACKUP

and vice versa is typically 20mV.

BACKUP

supply voltage, non-used RTC functions are disabled to

INT

.

voltages and

BACKUP

ensure optimized power consumption:

• I2C interface Disabled when operating in V

• CLKOUT Disabled when operating in V

•

Enabled even when operating in V

• Trickle Charge Disabled when operating in V

21/67

BACKUP

BACKUP

BACKUP

mode

mode

BACKUP

mode

mode

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.1.1. POWER UP SEQUENCE

The device can be either powered up from main supply VDD or from backup supply V

BACKUP

.

During power-up, the chip is executing the following power-up procedure:

• The implemented battery switchover circuitry compares VDD and V

voltages and connects the higher

BACKUP

of them to supply the chip

• At power-up, the chip is kept in Reset state until the supply voltage reaches an internal threshold level.

Once the supply voltage is higher than this threshold level, a Reset is executed and registers are loaded

with the Register Reset Values described in section 4.2.2. REGISTER RESET VALUES

• After the Reset is executed and registers are loaded with the Register Reset Values, “PON” is set = “1” (bit

5 in Register Control-Status), it needs to be cleared by writing = “0”

• Once the supply voltage reaches the oscillator start-up voltage, the oscillator-circuitry starts the 32.768 kHz

“tuning-fork” Crystal typically within 500 ms

• Once the 32.768 kHz clocks are present, the Voltage Detector starts in fast mode to monitor the supply

voltage, the accelerated scanning of the supply voltage will slightly increase the current consumption.

• When a supply voltage >V

is detected, the fast mode voltage detection is stopped, and the EEPROM

Low2

read is enabled

• Configuration registers are loaded with the configuration data read from the EEPROM Control Page and

the bits V

Low1

and V

are reset = “0”

Low2

• If the Thermometer is enabled by “ThE” = “1” (bit 1 in register EEPROM_Control), the temperature is

measured and the frequency compensation value for time correction is calculated

• The RV-3029 becomes fully functional; the correct Time / Date information needs to be loaded into the

corresponding registers and bit 5 “PON” in Register Control-Status needs to be cleared by writing “0”

Note 1:

During power up, the Low Voltage Detection is monitoring the supply voltage at an accelerated scan rate

increasing the current consumption of the device.

Once power supply voltage exceed V

threshold, the flags V

LOW2

LOW1

and V

are cleared and the scan rate for

LOW2

the low voltage detection is set to 1 second to ensure optimized power consumption.

Note 2:

Please not the different meaning of the “PON”; “V

Low1

” and “V

Low2

” Flags:

PON

“PON” Flag is set after Power-Up Reset is executed

• Indicating that time & date information are corrupted

V

Low1

V

Flag is set when supply voltage drops below V

Low1

threshold

Low1

• Indicating that the Thermometer might have been disabled due to low supply voltage and the temperature

compensation was operating for a while with the last temperature reading causing bigger time-deviation

V

Low2

V

Flag is set when supply voltage drops below V

Low1

threshold

Low2

• Indicating a risk that the 32.768kHz might have stopped due to low supply voltage and that the time & date

information might be corrupted

22/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

Example Power Up sequence, Low Voltage detection and Backup Supply switchover

1

Power Up Reset is executed; registers are loaded with Reset Values. PON flag is set at Power up

indicating that time / date information likely are corrupted.

Low voltage detection flags V

2

PON Flag needs to be cleared by software writing “0”.

3

Trickle charge circuitry for backup battery can be enabled by software.

4

Switchover to the backup supply voltage when VDD drops below VDD < (V

5

Low voltage detection sets V

6

Low voltage detection sets V

7

Switchback from backup supply voltage to main supply voltage when VDD rise above VDD > (V

8

V

LOW1

and V

Flags need to be cleared by software writing “0”.

LOW2

and V

LOW1

Flag when supply voltage drops V

LOW1

Flag when supply voltage drops V

LOW2

are automatically cleared.

LOW2

threshold.

LOW1

threshold.

LOW2

– 20mV).

BAT

+ 20mV).

BAT

4.1.2. SUPPLY VOLTAGE OPERATING RANGE AND LOW VOLTAGE DETECTION

The RV-3029 has built-in low supply voltage detection which periodically monitors supply voltage levels vs. V

and V

thresholds.

LOW2

LOW1

If low supply voltage is detected, the corresponding flags V

LOW1

and V

are set = “1”. Device functions critical to

LOW2

low supply voltage are disabled.

During power up, the Low Voltage Detection is monitoring the supply voltage at an accelerated scan rate. If power

supply voltage exceed V

threshold, the flags V

LOW2

LOW1

and V

are cleared and the scan rate for the low voltage

LOW2

detection is set to 1 second.

23/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

Minimum Supply Voltage and Low Voltage Detection

V

5.5 V

5.0 V

4.0 V

3.0 V

2.0 V

DD

V

V

LOW 1

2.1 V

DD max

5.5 V

Supply

Voltage

Timekeeping

Function

Timekeeping not guaranteed

Fully Operating

Temperature

Compensation /

Thermometer

Thermomerter active

Temperature Compensation Operating

Thermomerter inactive, last value frozen

I2C Interface

Function

Interface active

Interface active with reduced speed

EEPROM

Function

EEPROM Write

EEPROM Read

V

PROG

2.2 V

V

LOW 2

1.0 V

1.3 V

0 V

At first power-up, the supply voltage has to exceed V

threshold to enable and correctly setup all function of

LOW1

the device.

Timekeeping Function:

Keeping track of Time & Date depends on the 32.768kHz oscillator operates safely over the specified

temperature range. Timekeeping function is guaranteed for a supply voltage down to V

threshold, below this

LOW2

voltage the 32.768kHz oscillator may stop and the time & date information might be corrupted.

Temperature Compensation:

The Frequency Compensation Unit “FCU” operates with supply voltages down to V

Thermometer requires a supply voltage of ≥ V

threshold. Supply voltages below V

LOW1

threshold. The

LOW2

threshold will

LOW1

automatically disable the Thermometer; the last correct temperature reading is frozen in the register

“Temperature”. The Frequency Compensation Unit continues to operate with the last temperature-reading down

to a supply voltage ≥ V

threshold.

LOW1

I2C interface:

The I2C interface operates with max. SCL clock rate down to a supply voltage of ≥ V

V

LOW1

and V

threshold, the interface still operates at reduced SCL clock rate.

LOW2

threshold. Between

LOW1

EEPROM read / write access:

EEPROM read access is possible down to a supply voltage of ≥ V

EEPROM write cycle requires a minimum supply voltage of ≥ V

PROG

threshold.

LOW2

of 2.2V.

24/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.2. RESET

A Reset can be initiated by 3 different ways:

• Power On Reset (automatically initiated at power-up)

• Software Reset (can be initiated by software)

• Self-Recovery System Reset (automatically initiated if enabled by Software and possible deadlock is

detected)

4.2.1. POWER-UP RESET, SYSTEM RESET AND SELF-RECOVERY RESET

Power On Reset:

A Reset is automatically generated at Power On. After Power On Reset has been executed, bit 5 “PON” in Register

Control_Status is set = “1”, it needs to be cleared by writing = “0”.

System Reset:

A Software Reset can be initiated when the System-Reset command “SysR” is set =”1” (bit 4 in Register

Control_Reset). If a System-Reset is executed, the “SR” Flag (bit 4 in Register Control_Status) is set = “1”, needs

to be cleared by writing = “0”.

It is generally recommended to make a System Reset by Software after power-up.

Note:

Please consider the Register Reset Values shown in section 4.2.2. After a Reset has been executed, SelfRecovery System “SROn” (bit 4 in Register Control_1) is set = “1” and Self-Recovery INT Enable “SRIE” (bit 4 in

Register Control_INT) is set = “0”.

Self-Recovery System Reset:

A Self-Recovery System Reset will be automatically initiated when the Self-Recovery function is enabled by bit 4

“SROn” in Register Control_1 is set “1” and internally a possible deadlock-state is detected. If a Self-Recovery

System Reset is executed, the bit 4 “SR” in Register Control_Status is set “1” and need to be cleared by writing “0”.

After a Self-Recovery System Reset is executed and Register Reset Values were written, bit 4 “SRF” in Register

Control_INT Flag is set “1” and needs to be cleared by writing “0”.

In case of a Self Recovery System Reset is executed, an Interrupt is available if Self-Recovery-INT function is

Enabled by bit 4 “SRIE” in Register Control_INT is set “1”.

The purpose of the Self Recovery function is to generate an internal System Reset in case the on-chip state

machine goes into a deadlock. The function is based on an internal counter that is periodically reset by the control

logic. If the counter is not reset on time, a possible deadlock is detected and a System Reset will be triggered. The

System Reset is executed latest after 2 temperature- or voltage-monitoring periods defined in Thermometer Period

bit 0 “ThP” in Register EEPROM Control, i.e. latest after 2 or 32 seconds.

Note:

Please consider the Register Reset Values shown in section 4.2.2. After a Reset has been executed, SelfRecovery System bit 4 “SROn” in Register Control_1 = “1” and Self-Recovery INT Enable “SRIE” in Register

Control_INT = “0”.

25/67

Micro Crystal

Control page

1)

2

)

3

)

Timer page

Temperature page

EEPROM User

EEPROM Control page

RAM page

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

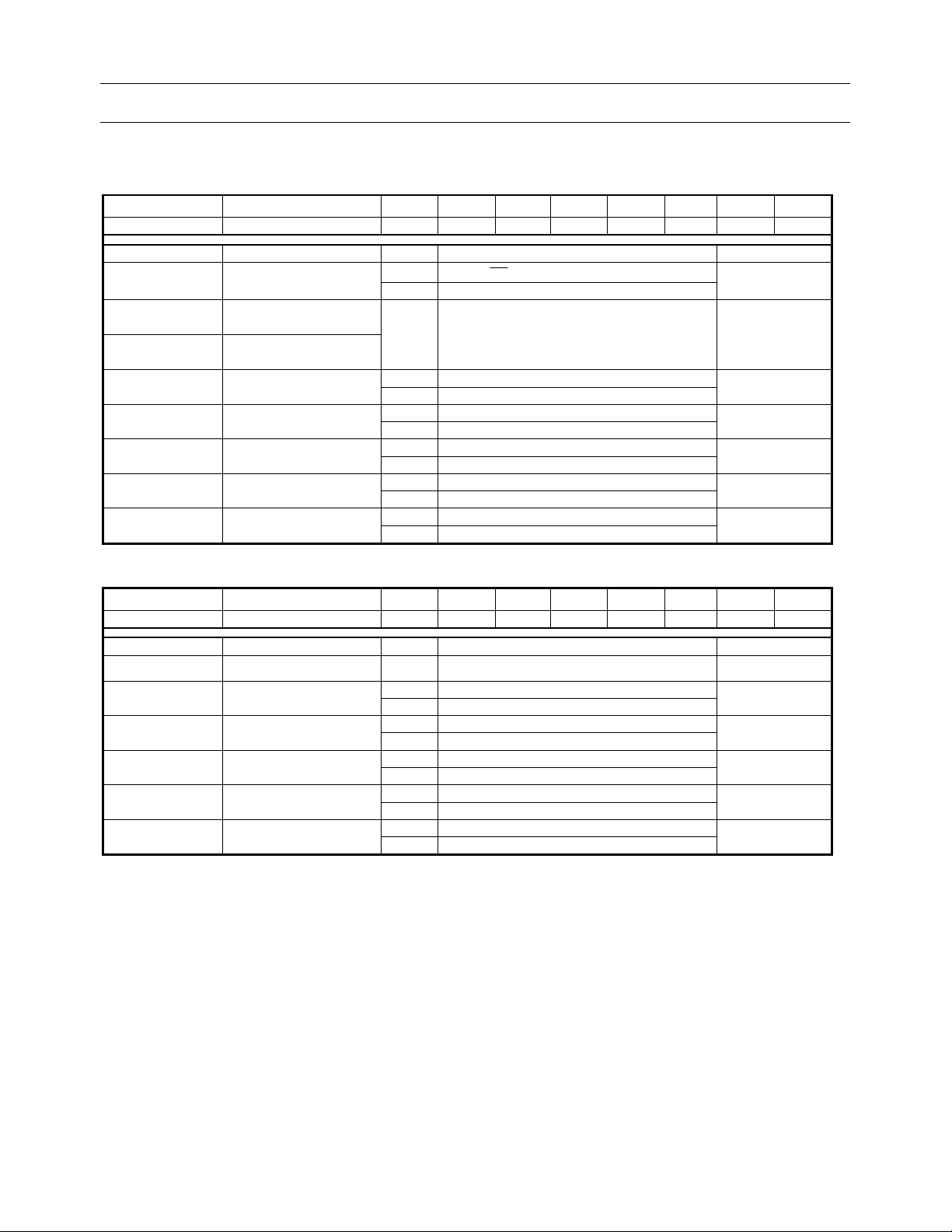

4.2.2. REGISTER RESET VALUES

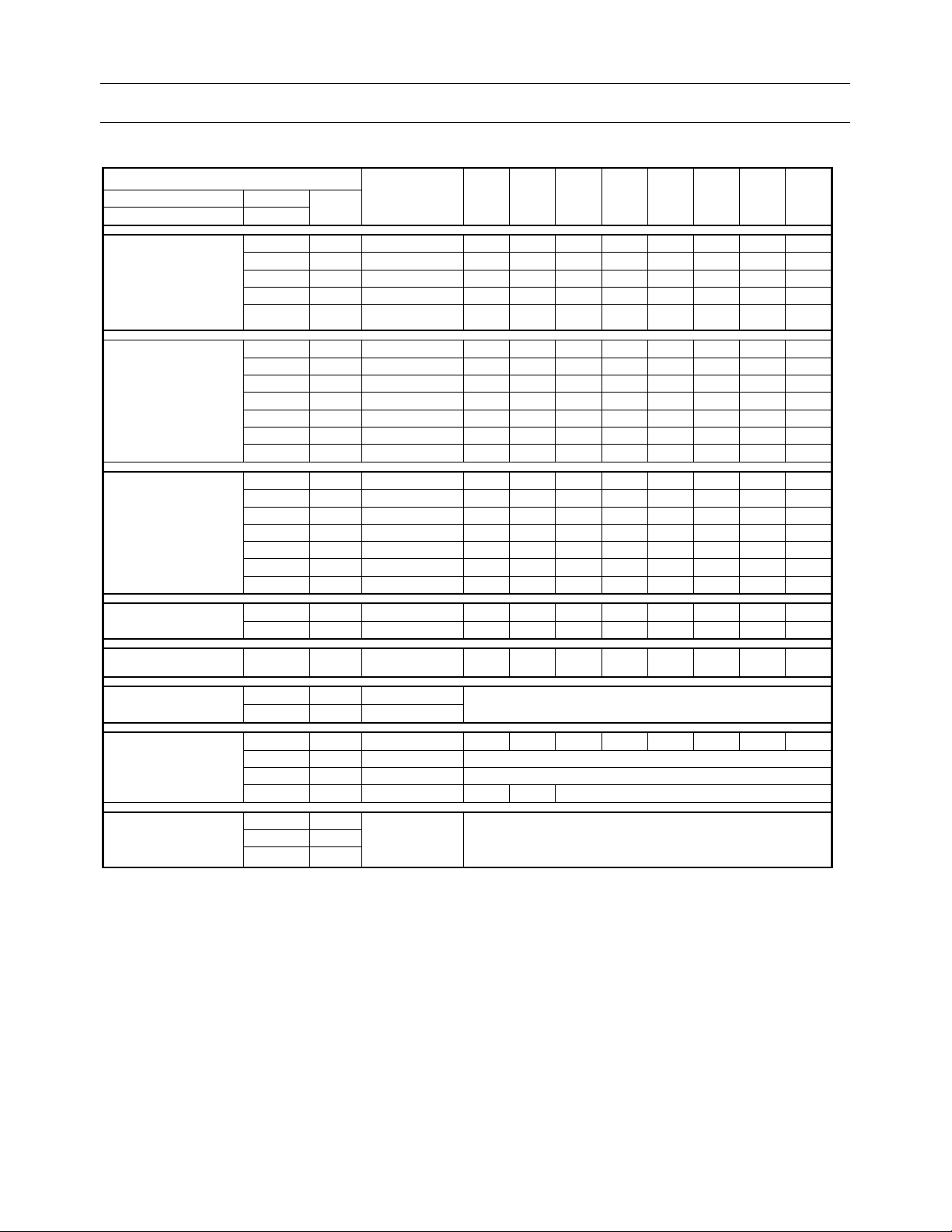

Address

Page Address

Bit 7 - 3 Bit 2 - 0

000 00h Control_1

001 01h Control_INT - - -

010 02h Control_INT Flag - - -

011 03h Control_Status EEbusy X

100 04h Control_Reset - - -

000

001

010

011

100

101

110

000

001

010

011

100

101

110

00000

Clock page

00001

Alarm page

00010

000

00011

00100

001

000 20h Temperature X X X X X X X X

000

00101

001

000

00110

001

010

011

000

00111

:

111

– bits labelled as – are not implemented.

X bits labelled as X are undefined at power-up and unchanged by subsequent resets.

1)

SRF flag (bit 4 in register Control_INT Flag) will be set = “1” after a Self Recovery System Reset was executed.

2)

PON flag (bit 5 in register Control_Status) will be set = “1” after a Power On Reset was executed.

3)

SR flag (bit 4 in register Control_Status) will be set = “1” after a System or Self recovery Reset was executed.

4)

EEPROM Control default data are set by factory; data might be reprogrammed by customer and will remain unchanged during power down or

any Reset executed.

Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Hex

1 0 0 1 1 0 0 1

0 0 0 0 0

0

0 0 0 0

0

0

X X X X

0

- - - -

08h Seconds - X X X X X X X

09h Minutes - X X X X X X X

0Ah Hours - X X X X X X X

0Bh Days - - X X X X X X

0Ch Weekdays - - - - - X X X

0Dh Months - - - X X X X X

0Eh Years - X X X X X X X

10h Second Alarm

11h Minute Alarm

12h Hour Alarm

13h Days Alarm

14h Weekday Alarm

15h Months Alarm

16h Year Alarm

AE_S

AE_M

AE_H

AE_D

AE_W

AE_M

AE_Y

X X X X X X X

X X X X X X X

X X X X X X X

- X X X X X X

- - - - X X X

- - X X X X X

X X X X X X X

18h Timer Low X X X X X X X X

19h Timer High X X X X X X X X

28h EEPROM User

29h EEPROM User

30h EEPROM Contr.

31h Xtal Offset

32h Xtal Coef

0 4) 0 4) 0 4) 0 4) 0 4) 0 4) 1 4) 0 4)

Factory setting: Xtal frequency deviation

Factory setting: Xtal temperature coefficient

33h Xtal T0 - -

2 bytes of EEPROM for user data

Factory setting: Xtal T0 temperature

38h

:

User RAM 8 bytes of RAM for user data

3Fh

26/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

After Reset, the following mode is entered:

- CLKOUT is selected at CLKOUT pin, default frequency is 32.768 kHz defined in register EEPROM

Control

- Timer and Timer Auto-Reload mode are disabled; Timer Source Clock frequency is set to 32Hz

- Self Recovery function is enabled

- Automatic EEPROM Refresh every hour is enabled

- 24 hour mode is selected, no Alarm is set

- All Interrupts are disabled

- At Power-On Reset, “PON” Flag is set = “1” and has to be cleared by writing = “0”

- At Self-Recovery Reset or System Reset, “SR” Flag is set = “1” and has to be cleared by writing = “0”.

27/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.3. EEPROM MEMORY ACCESS

The EEPROM Memory has a built-in automatic EEPROM Refresh function, controlled by “EERE” (bit 3 in register

Control_1). If enabled, this function automatically refreshes the content of the EEPROM Memory Pages once an

hour.

The “EEbusy” will be set = “1” (bit 7 in register Control_Status) if the EEPROM Memory Pages are busy due to

write or automatic refresh cycle is in progress. “EEbusy” goes = “0” when writing is finished, EEPROM Memory

Pages shall only be accessed when not busy, i.e. when “EEbusy” = “0”.

A special EEPROM access procedure is required preventing access collision between the internal automatic

EEPROM refresh cycle and external read / write access through interface.

• Set “EERE” = “0” Automatic EEPROM Refresh needs to be disabled before EEPROM access.

• Check for “EEbusy” = “0” Access EEPROM only if not busy

• Set “EERE” = “1” It is recommended to enable Automatic EEPROM Refresh at the end of

read / write access

• Write EEPROM Allow 10ms wait-time after each written EEPROM register before checking for

EEbusy = “0” to allow internal data transfer

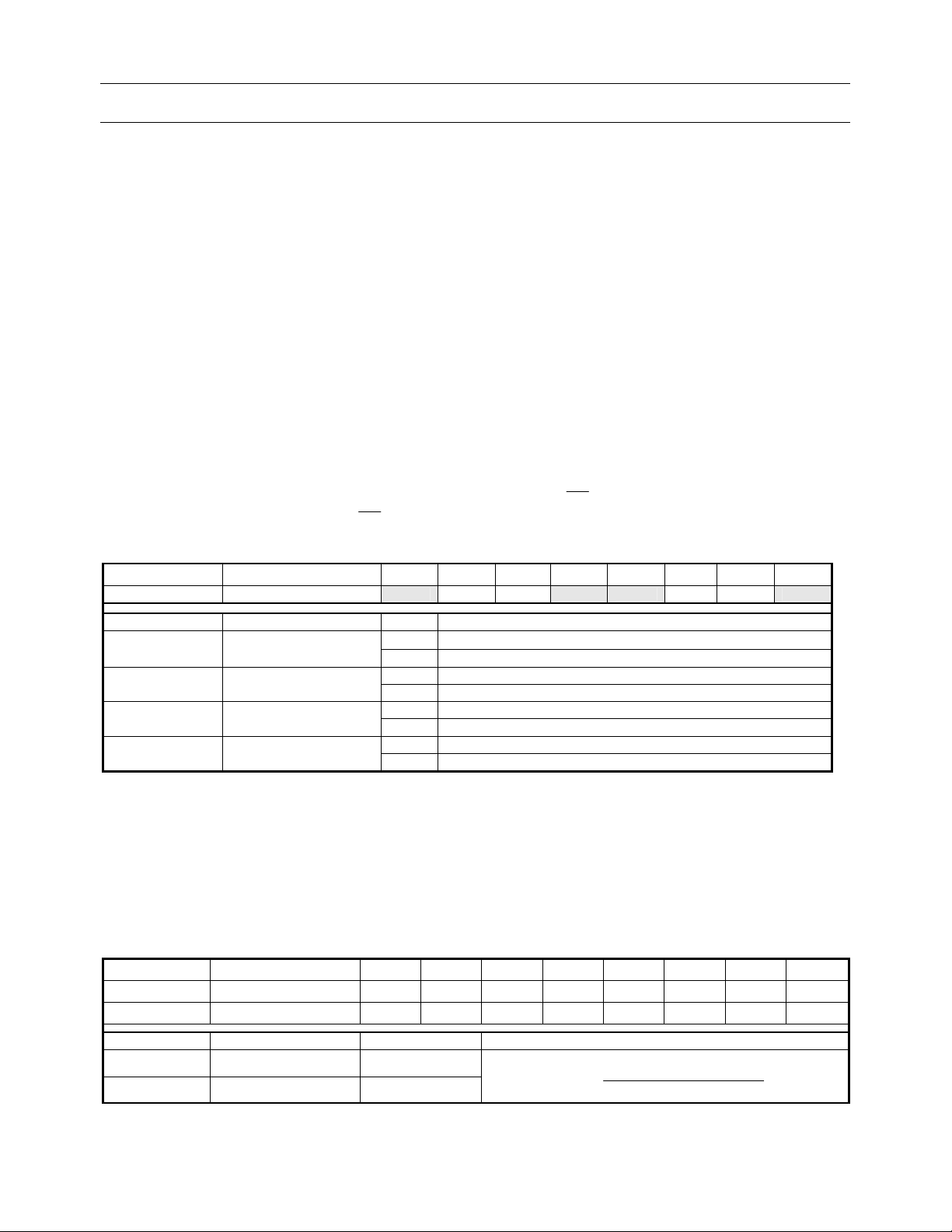

Read access: Write access:

Disable automatic Disable automatic

Clear EERE

EEPROM refresh EEPROM refresh

No

EEbusy = 0?

Check if EEPROM is busy? Check if EEPROM is busy?

Yes

EEPROM read access EEPROM write access

Read EEPROM

is permitted is permitted

Yes

Next read?

Wait 10ms to allow

internal EEPROM write

No

Enable automatic Wait until previous

Set EERE = 1

EEPROM refresh write cycle is finished

Enable automatic

EEPROM refresh

Note:

A minimum power supply voltage of V

= 2.2V is required during the whole EEPROM write procedure; i.e. until

PROG

“EEbusy” = “0”.

28/67

No

Write EEPROM

No

Yes

Clear EERE

EEbusy = 0?

Yes

Wait

10ms

EEbusy = 0?

Yes

Next write?

No

Set EERE = 1

Micro Crystal

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.4. TIMER FUNCTION

The RV-3029 offers different Alarm and Timer functions which allow simply generating highly versatile timingfunctions.

The Countdown Timer is controlled by the register Control_1. Bit 1 “TE” enables the Timer function; bits 5 & 6

“TD0” and “TD1” determine one of 4 Timer Source Clock frequencies (32 Hz, 8 Hz, 1 Hz, or 0.5Hz).

The Timer counts down from a software-loaded 16-bit binary value ,n’, “Timer Low” (bit 0-7 at address 18h) and

“Timer High” (bit 0-7 at address 19h). Values, n’ from 1 to 65536 are valid; loading the counter with ,n’ = “0”

effectively stops the timer. The end of every Timer countdown is achieved when the Timer Counter value ,n’

reaches = “0”.

Countdown Timer can be set in Automatic Reload mode by “TAR” = “1” (bit 2 of register Control_1), the counter

automatically re-loads Timer countdown value, n’ and starts the next Timer period. Automatic reload of the

countdown value ,n’ requires 1 additional timer source clock. This additional timer source clock has no effect on the

first Timer period, but it has to be taken into account since it results in a Timer duration of ,n+1’ for subsequent

timer periods.

The generation of Interrupts from the Countdown Timer function is enabled by “TIE” = “1” (bit 1 in register

Control_INT). If Timer Interrupt is enabled by “TIE” = “1”, the Timer Flag “TF” (bit 1 in register Control_INT Flag) will

be set = “1” at the end of every Timer countdown. The Interrupt signal

(bit 1 in register Control_INT Flag), the

signal can be cleared by clearing the “TF” = “0”.

Control of the Countdown Timer Functions (address 00h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

00h Control_1 Clk/Int

Bit Symbol Value Description

6 TD1

5 TD0

2 TAR

1 TE

00 Timer Source Clock Frequency: 32 Hz

01 Timer Source Clock Frequency: 8 Hz

10 Timer Source Clock Frequency: 1 Hz

11 Timer Source Clock Frequency : 0.5 Hz

0 Disables Countdown Timer Auto-Reload mode

1 Enables Countdown Timer Auto-Reload mode

0 Disables Countdown Timer

1 Enables Countdown Timer

TD1 TD0

The Timer Source Clock Frequency “TD0” & “TD1” and the Timer Auto Reload mode “TAR” can only be written

when the Timer is stopped by “TE” = “0” (bit 1 in register Control_1).

The Countdown Timer values in “Timer Low” and “Timer High” can only be written when the Timer is stopped by

“TE” = “0” and Timer Auto Reload mode is disabled “TAR” = “0”.

Register Countdown Timer (addresses 18h / 19h…bits description)

Register 18h is loaded with the low byte of the 16-bit Countdown Timer value ,n’

Register 19h is loaded with the high byte of the 16-bit Countdown Timer value ,n’

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

18h Timer Low 128 64 32 16 8 4 2 1

19h Timer High 128 64 32 16 8 4 2 1

Bit Symbol Value Description

18h Timer Low xx01 to xxFF

19h Timer High 00xx to FFxx

Countdown value = n

Countdown period

follows the condition of Timer Flag “TF”

TAR TE

n

Frequency Clock Source

SROn EERE

=

WE

29/67

Micro Crystal

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

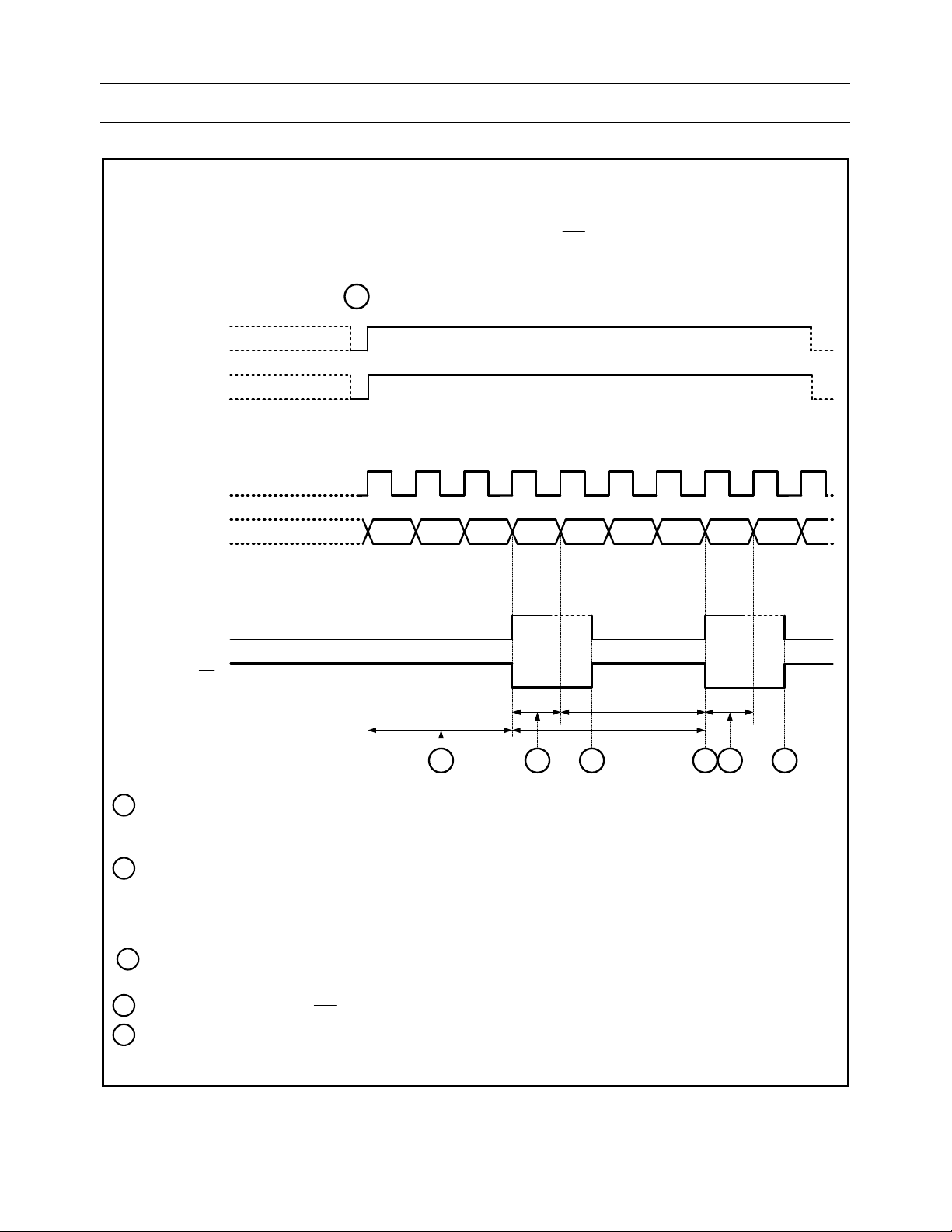

Example Countdown Timer function with Timer in Auto Reload mode

In this example, the Countdown Timer is set to Automatic Reload Mode, the Countdown Timer value is set = “3”.

Automatic reload of the countdown value ,n’ requires 1 additional Timer Source Clock. This additional timer

source clock has no effect on the first Timer period but it has to be taken into account since it results in a Timer

duration of ,n+1’ for subsequent timer periods. The Interrupt signal (

) is cleared by clearing the Timer Flag

“TF” = “0”.

1

TE

TAR

Timer Source

Clock Frequency

TD0 / TD1

Countdown Timer

Value

TF

INT

XX

03

02

n

2 4 5 4

Auto

01

Reload

03 02 01 03 02

nTSC

n +1

3

Auto

Reload

TSC

3

1

Timer Source Clock Frequency TD0 / TD1 can only be modified when Timer is disabled “TE” = “0”

Countdown Timer value ,n’ in “Timer Low” and “Timer High” only can be modified when Timer “TE” = “0”

and Timer Auto Reload “TAR” = “0” are both disabled.

2

Duration of first Timer Period

The additional timer source clock for automatic reload of the countdown Timer value ,n’ has no effect on

the first Timer Period.

=

n

Frequency Clock Source

3 Timer Automatic Reload mode “TAR” requires one Timer Source Clock period for automatic reload of the

Countdown Timer value ,n’.

4

To reset Interrupt signal (

5

When Countdown Timer is in automatic reload mode, one additional timer source clock has to be taken

), Timer Flag “TF” has to be cleared by writing = “0”.

into account since it results in a Timer duration of ,n+1’ for subsequent timer periods.

30/67

Micro Crystal

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.4.1. TIMER INTERRUT

The generation of Interrupts from the Countdown Timer function is enabled by “TIE” = “1” (bit 1 in register

Control_INT). If Timer Interrupt is enabled by “TIE” = “1”, the Timer Flag “TF” (bit 1 in register Control_INT Flag) will

be set = “1” at the end of every Timer countdown.

The Interrupt signal

“TF” and the Interrupt signal (

follows the condition of Timer Flag “TF” (bit 1 in register Control_INT Flag), the Timer Flag

) remain set until cleared by software writing “TF” = “0”.

Timer Interrupt Control (addresses 01h / 02h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

01h Control_INT X X X SRIE V2IE V1IE

bit 1 TIE

02h Control_INT Flag X X X SRF V2IF V1IF

bit 1 TF

Bit positions labelled as “X” are not implemented and will return a “0” when read.

0 TF is disabled, no Timer Interrupt generated

TF is enabled, Timer Interrupt generated when Countdown Timer value

1

reaches zero and TF is set “1”

0 No Timer Interrupt generated

Timer Flag is set “1” when TIE is enabled and Countdown Timer value

1

reaches zero, TF needs to be cleared to clear INT

TIE

TF

AIE

AF

31/67

Micro Crystal

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.5. ALARM FUNCTION

Every Alarm Register in Alarm Page can be individually enabled by setting bit 7 (AE_x) = “1”. Disabled alarm

registers which have their bit “AE_x” at logic = “0” are ignored.

When one or more of these registers are loaded with a valid second, minute, hour, day, weekday, month or year

information and its corresponding alarm enable bit (AE_x) is logic = ”1”, then that information will be compared with

the current time / date information in Watch Page registers.

Alarm function Blockdiagram

check now signal

SECOND AEN

SECOND ALARM

=

SECOND TIME

MINUTE AEN

MINUTE ALARM

=

MINUTE TIME

HOUR AEN

HOUR ALARM

=

HOUR TIME

DAY AEN

DAY ALARM

=

DAY TIME

WEEKDAY AEN

WEEKDAY ALARM

=

WEEKDAY TIME

MONTH AEN

MONTH ALARM

=

MONTH TIME

YEAR AEN

YEAR ALARM

=

YEAR TIME

1

0

1

0

1

0

AIE

1

0

1

0

1

0

1

0

&

AF

INT

to reset INT,

clear AF by writting = 0

32/67

Micro Crystal

INT

INT

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.5.1. ALARM INTERRUPT

The generation of Interrupts from the Alarm function is enabled by “AIE” = “1” (bit 0 in register Control_INT).

When all enabled Alarm comparisons first match (wired “AND”) and the Alarm Interrupt is enabled by, the Alarm

Flag “AF” (bit 0 in Register Control_INT Flag) is set to logic = “1”. The Interrupt signal (

) follows the condition of

“AF”.

The Interrupt signal

Flag “AF” and the Interrupt signal (

follows the condition of Alarm Flag “AF” (bit 0 in register Control_INT Flag), The Alarm

) remain set until cleared by software writing “AF” = “0”.

Once bit “AF” has been cleared, it will only be set again when the time increments and matches the alarm condition

once more.

Alarm Interrupt Control (addresses 01h / 02h…bits description)

Address Function Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

01h Control_INT X X X SRIE V2IE V1IE TIE

0 AIE

02h Control_INT Flag X X X SRF V2IF V1IF TF

0 AF

Bit positions labelled as “X” are not implemented and will return a “0” when read.

0 AF is disabled, no Alarm Interrupt generated

AF is enabled, AF is set “1”and Alarm Interrupt generated when all

1

enabled Alarm comparisons first match

0 No Alarm Interrupt generated

Alarm Flag is set “1” when all enabled Alarm comparisons first match,

1

needs to be cleared to clear INT

AIE

AF

Example for Alarm Flag and Alarm INT

Example where “Minute Alarm” is enabled and set to 45 and no other Alarm is enabled.

If bit AIE is enabled, the

pin follows the condition of bit 0 “AF” in register Control_INT Flag at address 02h.

33/67

Micro Crystal

INT

INT

INT

INT

INT

INT

INT

INT

INT

INT

INT

INT

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.6. INTERRUPT OUTPUT INT

An active LOW Interrupt signal is available at

The

is an open-drain output and requires a pull-up resistor to VDD.

pin.

Interrupts may be sourced from five places:

• Alarm function

• Countdown Timer function

• V

• V

detection

LOW1

LOW2

detection

• System Reset function

All Interrupt signals follow the condition of their corresponding flags in the bits 0 to 4 of register Control_INT Flag at

address 02h.

Alarm Interrupt:

Generation of Interrupts from the Alarm function is enabled via “AIE” = “1” (bit 0 in register Control_INT). If “AIE” is

enabled, the

(

), the corresponding flag “AF” needs to be cleared by writing = “0”, clearing “AF” will immediately clear

pin follows the condition of Flag “AF” (bit 0 in register Control_INT Flag). To clear Interrupt signal

.

Timer Interrupt:

Generation of Interrupts from the Countdown Timer is enabled via “TIE” = “1” (bit 1 in register Control_INT). If “TIE”

is enabled, the

signal (

), the corresponding flag “TF” needs to be cleared by writing = “0”, clearing “TF” will immediately clear

pin follows the condition of Flag “TF” (bit 1 in register Control_INT Flag). To clear Interrupt

.

V

Interrupt:

LOW1

Generation of Interrupts from the Voltage Low 1 detection is enabled via “V1IE” = “1” (bit 2 in register Control_INT).

If “V1IE” is enabled, the

Interrupt signal (

), both corresponding flags “V1IF” (bit 2 in register Control_INT Flag) and “V1F” (bit 2 in

pin follows the condition of Flag “V1IF” (bit 2 in register Control_INT Flag). To clear

register Control_Status) need to be cleared by writing = “0”.

V

Interrupt:

LOW2

Generation of Interrupts from the Voltage Low 2 detection is enabled via “V2IE” = “1” (bit 3 in register Control_INT).

If “V2IE” is enabled, the

Interrupt signal (

), both corresponding flags “V2IF” (bit 3 in register Control_INT Flag) and “V2F” (bit 3 in

pin follows the condition of Flag “V2IF” (bit 3 in register Control_INT Flag). To clear

register Control_Status) need to be cleared by writing = “0”.

System Reset Interrupt:

Generation of Interrupts from the System Reset function is enabled via “SRIE” = “1” (bit 4 in register Control_INT).

If “SRIE” is enabled, the

Interrupt signal (

), both corresponding flags “SRF” (bit 4 in register Control_INT Flag) and “SR” (bit 4 in register

pin follows the condition of Flag “SRF” (bit 4 in register Control_INT Flag). To clear

Control_Status) need to be cleared by writing = “0”.

34/67

Micro Crystal

INT

INT

DTCXO Temperature Compensated Real Time Clock / Calendar Module RV-3029

4.7. WATCH ENABLE FUNCTION

The function Watch Enable function “WE” (bit 0 in register Control_1) enables / disables the 1 Hz clock for the

watch function. After power-up reset, the bit “WE” is automatically set = “1” and the 1 Hz clock is enabled.

Setting “WE” = “0” stops the watch-function and the time circuits can be set and will not increment until the stop is

released. Setting “WE” = “1” allows for accurate start of the time circuits triggered by an external event.

“WE” will not affect the clock outputs at CLKOUT.

4.8. SELF-RECOVERY SYSTEM

The purpose of the Self-Recovery System is to automatically generate an internal Reset in case the on-chip state

machine goes into a deadlock. A possible source for such a deadlock could be disturbed electrical environment like

EMC problem, disturbed power supply or any kind of communication issues on the I2C interface.

The function of the Self-Recovery System is based on internal counter that is periodically reset by the Control

Logic. If the counter is not reset in time, a Self-Recovery Reset will be executed, at the latest after 2 thermometer

scanning interval periods, i.e. 2 or 32 seconds.

The Self-Recovery System is enabled / disabled by “SROn ” (bit 4 in register Control_1), it is automatically enabled

“SROn” = “1” after power-up by the register reset values, see section 4.2.2. REGISTER RESET VALUES.

Thermometer scanning interval is defined with “ThP” (bit 0 in register EEPROM_Control).

Generation of Interrupts from the System Reset function is enabled via “SRIE” = “1” (bit 4 in register Control_INT).

If “SRIE” is enabled, the

Interrupt signal (

), both corresponding flags “SRF” (bit 4 in register Control_INT Flag) and “SR” (bit 4 in register

Control_Status) need to be cleared by writing = “0”.