RV-1805-C3

Application Manual

Date: November 2018

Revision N°: 3.1

Headquarters:

Micro Crystal AG

Mühlestrasse 14

CH-2540 Grenchen

Switzerland

Tel.

Fax

Internet

Email

+41 32 655 82 82

+41 32 655 82 83

www.microcrystal.com

sales@microcrystal.com

1/98

Micro Crystal

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

TABLE OF CONTENTS

1. OVERVIEW ........................................................................................................................................................ 6

GENERAL DESCRIPTION ......................................................................................................................... 6 1.1.

APPLICATIONS ......................................................................................................................................... 7 1.2.

2. BLOCK DIAGRAM ............................................................................................................................................. 8

PINOUT ...................................................................................................................................................... 9 2.1.

PIN DESCRIPTION .................................................................................................................................. 10 2.2.

FUNCTIONAL DESCRIPTION ................................................................................................................. 11 2.3.

DEVICE PROTECTION DIAGRAM ......................................................................................................... 11 2.4.

3. REGISTER ORGANIZATION .......................................................................................................................... 12

REGISTER OVERVIEW ........................................................................................................................... 12 3.1.

TIME AND DATE REGISTERS ................................................................................................................ 14 3.2.

ALARM REGISTERS ............................................................................................................................... 17 3.3.

CONFIGURATION REGISTERS.............................................................................................................. 20 3.4.

CALIBRATION REGISTERS ................................................................................................................... 25 3.5.

SLEEP CONTROL REGISTER ................................................................................................................ 27

3.6.

TIMER REGISTERS ................................................................................................................................. 28 3.7.

OSCILLATOR REGISTERS..................................................................................................................... 31 3.8.

MISCELLANEOUS REGISTERS ............................................................................................................. 32 3.9.

ANALOG CONTROL REGISTERS ......................................................................................................... 33 3.10.

ID REGISTERS ........................................................................................................................................ 35 3.11.

RAM REGISTERS .................................................................................................................................... 37 3.12.

REGISTER RESET VALUES SUMMARY ............................................................................................... 39 3.13.

4. DETAILED FUNCTIONAL DESCRIPTION ..................................................................................................... 40

2

I

C INTERFACE ....................................................................................................................................... 41 4.2.

BUS NOT BUSY ................................................................................................................................ 41 4.2.1.

BIT TRANSFER ................................................................................................................................ 41 4.2.2.

START AND STOP CONDITIONS ................................................................................................... 41 4.2.3.

DATA VALID ..................................................................................................................................... 42 4.2.4.

SYSTEM CONFIGURATION ............................................................................................................ 42 4.2.5.

ACKNOWLEDGE .............................................................................................................................. 42 4.2.6.

ADDRESSING ................................................................................................................................... 43 4.2.7.

WRITE OPERATION ......................................................................................................................... 44 4.2.8.

READ OPERATION AT SPECIFIC ADDRESS ................................................................................ 44 4.2.9.

READ OPERATION .......................................................................................................................... 45 4.2.10.

XT OSCILLATOR ..................................................................................................................................... 45 4.3.

RC OSCILLATOR .................................................................................................................................... 45 4.4.

RTC COUNTER ACCESS ........................................................................................................................ 45 4.5.

HUNDREDTHS SYNCHRONIZATION .................................................................................................... 46 4.6.

2/98

Micro Crystal

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

GENERATING HUNDREDTHS OF A SECOND ..................................................................................... 46 4.7.

WATCHDOG TIMER ................................................................................................................................ 46 4.8.

DIGITAL CALIBRATION .......................................................................................................................... 47 4.9.

XT OSCILLATOR DIGITAL CALIBRATION ...................................................................................... 47 4.9.1.

RC OSCILLATOR DIGITAL CALIBRATION ..................................................................................... 48 4.9.2.

AUTOCALIBRATION ............................................................................................................................... 50 4.10.

BASIC AUTOCALIBRATION OPERATION ............................................................................................ 50 4.11.

AUTOCALIBRATION OPERATION .................................................................................................. 50 4.11.1.

XT AUTOCALIBRATION MODE ....................................................................................................... 51 4.11.2.

RC AUTOCALIBRATION MODE ...................................................................................................... 51 4.11.3.

AUTOCALIBRATION FREQUENCY AND CONTROL ..................................................................... 51 4.11.4.

Cap_RC PIN ...................................................................................................................................... 52 4.11.5.

AUTOCALIBRATION FAILURE ........................................................................................................ 52 4.11.6.

FREQUENCY ACCURACY IN RC AUTOCALIBRATION MODE..................................................... 52 4.11.7.

A REAL WORLD EXAMPLE ............................................................................................................. 55 4.11.8.

RC AUTOCALIBRATION TIMING ACCURACY EXAMPLE ............................................................. 56 4.11.9.

POWER ANALYSIS ................................................................................................................... 57 4.11.10.

DISANDVANTAGES RELATIVE TO THE XT OSCILLATOR ................................................... 57 4.11.11.

XT OSCILLATOR FAILURE DETECTION .............................................................................................. 58 4.12.

INTERRUPTS ........................................................................................................................................... 58 4.13.

INTERRUPT SUMMARY .................................................................................................................. 58 4.13.1.

ALARM INTERRUPT AIRQ .............................................................................................................. 59 4.13.2.

COUNTDOWN TIMER INTERRUPT TIRQ....................................................................................... 59 4.13.3.

WATCHDOG TIMER INTERRUPT WIRQ ........................................................................................ 59 4.13.4.

BATTERY LOW INTERRUPT BLIRQ ............................................................................................... 59 4.13.5.

EXTERNAL INTERRUPT EIRQ ........................................................................................................ 59 4.13.6.

XT OSCILLATOR FAILURE INTERRUPT OFIRQ ........................................................................... 59 4.13.7.

AUTOCALIBRATION FAILURE INTERRUPT ACIRQ ...................................................................... 59 4.13.8.

SERVICING INTERRUPTS .............................................................................................................. 60 4.13.9.

POWER CONTROL AND SWITCHING ................................................................................................... 60 4.14.

AUTOMATIC SWITCHOVER SUMMARY ........................................................................................ 61 4.14.1.

BATTERY LOW FLAG AND INTERRUPT ........................................................................................ 61 4.14.2.

ANALOG COMPARATOR ................................................................................................................ 62 4.14.3.

PIN CONTROL AND LEAKAGE MANAGEMENT (POWER CONTROL) ........................................ 62 4.14.4.

POWER UP TIMING ......................................................................................................................... 63 4.14.5.

RESET SUMMARY .................................................................................................................................. 63 4.15.

POWER UP RESET .......................................................................................................................... 64 4.15.1.

WATCHDOG TIMER ......................................................................................................................... 64 4.15.2.

SLEEP ............................................................................................................................................... 65 4.15.3.

3/98

Micro Crystal

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

SOFTWARE RESET ................................................................................................................................ 65 4.16.

SLEEP CONTROL STATE MACHINE .................................................................................................... 65 4.17.

RUN STATE ...................................................................................................................................... 66 4.17.1.

SWAIT STATE (SLEEP_WAIT STATE) ............................................................................................ 66 4.17.2.

SLEEP STATE .................................................................................................................................. 66 4.17.3.

SLP PROTECTION ........................................................................................................................... 68 4.17.4.

PSWS, PSWB AND LKP ................................................................................................................... 68 4.17.5.

PIN CONTROL AND LEAKAGE MANAGEMENT (SLEEP CONTROL) .......................................... 68 4.17.6.

SYSTEM POWER CONTROL APPLICATIONS ...................................................................................... 69 4.18.

V

POWER SWITCHED .................................................................................................................. 69 4.18.1.

SS

V

POWER SWITCHED .................................................................................................................. 70 4.18.2.

DD

RESET DRIVEN ................................................................................................................................ 70 4.18.3.

INTERRUPT DRIVEN ....................................................................................................................... 71 4.18.4.

TYPICAL SYSTEM IMPLEMENTATION ................................................................................................. 71 4.19.

ALARMS ............................................................................................................................................ 72 4.19.1.

COUNTDOWN TIMER ...................................................................................................................... 72 4.19.2.

WAKE BUTTON/SWITCH ................................................................................................................. 72 4.19.3.

EXTERNAL DEVICE INPUT ............................................................................................................. 72 4.19.4.

ANALOG INPUT ................................................................................................................................ 72 4.19.5.

BATTERY LOW DETECTION ........................................................................................................... 72 4.19.6.

ERRORS ........................................................................................................................................... 72 4.19.7.

SAVING PARAMETERS .......................................................................................................................... 73 4.20.

POWER SWITCH ELECTRICAL CHARACTERISTICS ......................................................................... 73 4.21.

AVOIDING UNEXPECTED LEAKAGE PATHS ...................................................................................... 73 4.22.

SYSTEM POWER ANALYSIS ................................................................................................................. 73 4.23.

USING AN EXTERNAL RTC WITH POWER MANAGEMENT......................................................... 73 4.23.1.

MANAGING MCU ACTIVE POWER ................................................................................................. 74 4.23.2.

LOWER COST MCUs ....................................................................................................................... 74 4.23.3.

HIGH PERFORMANCE PROCESSORS .......................................................................................... 74 4.23.4.

TRICKLE CHARGER ............................................................................................................................... 74 4.24.

5. DIGITAL ARCHITECTURE SUMMARY .......................................................................................................... 75

6. ELECTRICAL SPECIFICATIONS .................................................................................................................... 76

ABSOLUTE MAXIMUM RATINGS .......................................................................................................... 76 6.1.

POWER SUPPLY PARAMETERS .......................................................................................................... 76 6.2.

OPERATING PARAMETERS .................................................................................................................. 78 6.3.

OSCILLATOR PARAMETERS ................................................................................................................ 78 6.4.

XT FREQUENCY CHARACTERISTICS .................................................................................................. 80 6.5.

XT FREQUENCY VS. TEMPERATURE CHARACTERISTICS ........................................................ 80 6.5.1.

V

SUPPLY CURRENT .......................................................................................................................... 81 6.6.

DD

4/98

Micro Crystal

RST

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

V

BACKUP

SUPPLY CURRENT ................................................................................................................... 85 6.7.

BREF ELECTRICAL CHARACTERISTICS ............................................................................................. 88 6.8.

2

I

C AC ELECTRICAL CHARACTERISTICS ........................................................................................... 89 6.9.

POWER ON AC ELECTRICAL CHARACTERISTICS ............................................................................ 90 6.10.

AC ELECTRICAL CHARACTERISTICS ........................................................................................ 91 6.11.

7. APPLICATION INFORMATION ....................................................................................................................... 92

OPERATING RV-1805-C3 ....................................................................................................................... 92 7.1.

OPERATING RV-1805-C3 WITH BACKUP BATTERY/SUPERCAP ..................................................... 93 7.2.

8. RECOMMENDED REFLOW TEMPERATURE (LEADFREE SOLDERING) .................................................. 94

9. PACKAGE ........................................................................................................................................................ 95

DIMENSIONS AND SOLDERPADS LAYOUT ........................................................................................ 95 9.1.

MARKING AND PIN #1 INDEX ................................................................................................................ 95 9.2.

10. PACKING & SHIPPING INFORMATION ......................................................................................................... 96

11. HANDLING PRECAUTIONS FOR CRYSTALS OR MODULES WITH EMBEDDED CRYSTALS ................ 97

12. DOCUMENT REVISION HISTORY .................................................................................................................. 98

5/98

Micro Crystal

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

RV-1805-C3

Extreme Low Power Real Time Clock / Calendar Module with I2C Interface

1. OVERVIEW

Ultra-low supply current (all at 3V):

- 17 nA with RC oscillator

- 22 nA with RC oscillator and Autocalibration (ACP = 512 seconds)

- 60 nA with crystal oscillator

Baseline timekeeping features:

- 32.768 kHz built-in “Tuning Fork” crystal oscillator with integrated load capacitor/resistor

- Counters for hundredths, seconds, minutes, hours, date, month, year, century, and weekday

- Alarm capability on all counters

- Programmable output clock generation (32.768 kHz to 1/year)

- Countdown timer with repeat function

- Automatic leap year calculation

Advanced timekeeping features:

- Integrated power optimized RC oscillator

- Factory calibrated frequency offset compensation to ± 2 ppm

- Advanced RC calibration to ± 16 ppm

- Automatic calibration of RC oscillator to the compensated crystal oscillator

- Watchdog timer with hardware reset

- Up to 512 bytes of general purpose RAM

Power management features:

- Integrated ~1 Ω power switch for off-chip components such as a host MCU

- System sleep manager for managing host processor wake/sleep states

- Reset output generator

- Supercapacitor trickle charger with programmable charging current

- Automatic switchover to V

- External interrupt monitor

- Programmable low battery detection threshold

- Programmable analog voltage comparator

I2C (up to 400 kHz) serial interface

Operating voltage 1.5-3.6 V

Clock and RAM retention voltage 1.5-3.6 V

Operating temperature –40 to +85 °C

All inputs include Schmitt Triggers

Available in small and compact package size, RoHS-compliant and 100% leadfree: C3: 3.7 x 2.5 x 0.9 mm

GENERAL DESCRIPTION 1.1.

BACKUP

The RV-1805-C3 Real Time Clock with Power Management provides a groundbreaking combination of ultra-low

power coupled with a highly sophisticated feature set. The power requirement is significantly lower than any other

industry RTC (as low as 17 nA). The RV-1805-C3 includes an on-chip oscillator to provide a minimum power

consumption, full RTC functions including battery backup and programmable counters and alarms for timer and

watchdog functions, and either an I2C serial interface for communication with a host controller. An integrated power

switch and a sophisticated system sleep manager with counter, timer, alarm, and interrupt capabilities allows the

RV-1805-C3 to be used as a supervisory component in a host microcontroller based system.

6/98

Micro Crystal

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

APPLICATIONS 1.2.

The RV-1805-C3 RTC module has been specially designed for ultimate low power consumption:

60 nA with crystal oscillator (at 3V)

22 nA with RC oscillator and Autocalibration (ACP = 512 sec. at 3V)

17 nA with RC oscillator (at 3V)

Permits to operate this RTC module several hours at Backup Supply Voltage using low-cost MLCC

These unique features make this product perfectly suitable for many applications:

Communication: Wireless Sensors and Tags, Handsets, Communications equipment

Metering: E-Meter / Heating Counter / Smart Meters / PV Converter

Outdoor: ATM & POS systems / Ticketing Systems

Medical: Glucose Meter / Health Monitoring Systems

Safety: Security & Camera Systems / Door Lock & Access Control

Consumer: Gambling Machines / TV & Set Top Boxes / White Goods

Automation: Data Logger / Home & Factory Automation / Industrial and Consumer Electronics

7/98

Micro Crystal

Cap_RC Control

Trickle Charge

BREF Control

Batmode IO

Analog Status

Output Control

Ext. RAM Addr.

User RAM

1D

00

17

14

20

26

2F

08

0F

10

3F

40

FF

Hundredths

Hours

Interrupt Mask

Control2

Control1

Status

Weekdays Alarm

Months Alarm

Hours Alarm

Minutes Alarm

Seconds Alarm

Hundredths Alarm

Weekdays

Years

Months

Minutes

Seconds

Timer Control

Sleep Control

Calibration XT

Square Wave SQW

Date Alarm

Oscillator Status

Oscillator Control

Timer Initial

Timer

Watchdog Timer

Date

System Control

logic

PSW

8

INPUT

OUTPUT

CONTROL

WDI

9

10

RST

3

Reset

Cap_RC

2

Xtal Osc

RC Osc

Divider

Divider

Calibration Engine

I2C-BUS

Interface

SCL

4

SDA

5

V

SS

6

V

DD

1

Power

Control

7

V

BACKUP

Analog

Compare

CLK/INT

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

2. BLOCK DIAGRAM

8/98

Micro Crystal

RV-1805-C3 Package:

#1 #5

#6#10

1805

#1 VDD

#10

RST

#2 Cap_RC

#9 WDI

#3 CLK/INT

#8 PSW

#4 SCL

#7 V

BACKUP

#5 SDA

#6 VSS

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

PINOUT 2.1.

9/98

Micro Crystal

Symbol

Pin #

Description

VDD 1 Primary power connection. If a single power supply is used, it must be connected to VDD.

Cap_RC

2

Autocalibration filter connection. A 47 pF ceramic capacitor should be placed between this pin and VSS for

improved Autocalibration mode timing accuracy.

INT/CLK

3

Clock Output / Interrupt. Primary interrupt output connection. It is an open drain output. An external pull-up

resistor must be added to this pin. It should be connected to the host device and is used to indicate when

the RTC can be accessed via the I2C interface.

INT/CLK

may be configured to generate several signals

as a function of the CLKS field (see CONFIGURATION REGISTERS, 11h - Control2).

INT/CLK

is also

asserted low on a power up until the RV-1805-C3 has exited the reset state and is accessible via the I2C

interface.

1.

INT/CLK

can drive the static value of the CLKB bit.

2.

INT/CLK

can drive the inverse of the combined interrupt signal IRQ (see INTERRUPTS).

3.

INT/CLK

can drive the square wave signal SQW (see CONFIGURATION REGISTERS, 13h –

Square Wave SQW) if enabled by SQWE.

4.

INT/CLK

can drive the inverse of the alarm interrupt signal AIRQ (see INTERRUPTS).

SCL 4 I2C Serial Clock Input. A pull-up resistor is required on this pin.

SDA 5 I2C Serial Data. A pull-up resistor is required on this pin.

VSS 6 Ground connection

V

BACKUP

7

Backup Supply Voltage. If a backup voltage is not present, V

BACKUP

is normally left floating or grounded, but

it may also be used to provide the analog input to the internal comparator (see ANALOG COMPARATOR).

Requires series resistor. The optimal total series impedance = V

BACKUP

power source ESR (Equivalent

Series Resistance) + external resistor value = 1.5 kΩ.

PSW

8

Power Switch Output. Secondary interrupt output connection. It is an open drain output. This pin can be left

floating if not used. PSW may be configured to generate several signals as a function of the PSWS field

(see CONFIGURATION REGISTERS, 11h - Control2). This pin will be configured as an ~1 Ω switch if the

PSWC bit is set.

1. PSW can drive the static value of the PSWB bit.

2. PSW can drive the square wave signal SQW (see CONFIGURATION REGISTERS, 13h Square Wave SQW) if enabled by SQWE.

3. PSW can drive the inverse of the combined interrupt signal IRQ (see INTERRUPTS).

4. PSW can drive the inverse of the alarm interrupt signal AIRQ (see INTERRUPTS).

5. PSW can drive the inverse or the not inverse of the timer interrupt signal TIRQ.

6. PSW can function as the power switch output for controlling the power of external devices (see

SLEEP CONTROL).

WDI

9

Watchdog Timer reset input connection. It may also be used to generate an External interrupt with polarity

selected by the EIP bit if enabled by the EIE bit. The value of the WDI pin may be read in the WDIS register

bit. This pin does not have an internal pull-up or pull-down resistor and so one must be added externally. It

must not be left floating or the RTC may consume higher current. Instead, it must be connected directly to

either VDD or VSS if not used.

RST

10

Reset Output. It is an open drain output. If this pin is used, an external pull-up resistor must be added to

this pin. If the pin is not used, it can be left floating. The polarity is selected by the RSTP bit, which will

initialize to 0 on power up to produce an active low output. See AUTOCALIBRATION FAILURE

INTERRUPT ACIRQ for details of the generation of

RST

.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

PIN DESCRIPTION 2.2.

10/98

Micro Crystal

INT/CLK

RST

ESD

Clamp

ESD

Clamp

ESD

Clamp

ESD

Clamp

V

BACKUP

V

SYS

(internal supply)

7

V

SS

6

CLK/INT

RST

ESD

Clamp

V

DD

1

All I/Os including:

3

4 SCL

5 SDA

8 PSW

9 WDI

10

Cap_RC

2

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

FUNCTIONAL DESCRIPTION 2.3.

The RV-1805-C3 is an extreme low power CMOS Real-Time Clock / Calendar module with built-in “Tuning-Fork”

crystal with the nominal frequency of 32.768 kHz and an on-chip auto-calibrated RC-oscillator; no external

components are required for the oscillator circuitry.

The oscillator frequency on all devices is tested not to exceed a time deviation of ± 20 ppm (parts per million) at

25°C, which equates to about ± 52 seconds per month.

This time accuracy can be further improved to ± 2 ppm (factory calibrated at 25°C) or better by individually

measuring the frequency-deviation in the application at a given temperature and programming a correction value

into the frequency compensation register.

Up to 512 bytes/registers of general purpose ultra-low leakage RAM enable the storage of key parameters when

operating on backup power.

The registers are accessed by selecting a register address and then performing read or write operations. Multiple

reads or writes may be executed in a single access, with the address automatically incrementing after each byte.

DEVICE PROTECTION DIAGRAM 2.4.

The following Figure illustrates the internal ESD structure. The ESD Clamp devices are not simple diodes and are

more complex structured. The VDD, V

supply, which route a positive ESD discharge to VSS. Note that the V

and V

supply present), the internal V

supplies dependent upon the mode of operation. In V

BACKUP

supply is switched to V

SYS

VDD is present and regardless if a supply is present on V

by additional internal circuitry. Note that V

onto the other digital I/O pads (

V

. In addition, there are simple diodes between V

SYS

shown in the diagram. These diodes take care of negative discharges to any of those pads.

Internal ESD structure:

and Cap_RC pins have these ESD clamps as well as the internal V

BACKUP

BACKUP

does not directly touch a pin, but all of the positive charge injected

SYS

BACKUP

, SCL, SDA, PSW, WDI and

and VSS as well as between the digital I/O pads and VSS as

SYS

by additional internal circuitry. In VDD mode (when

or not), the internal V

internal supply is switched between the VDD

SYS

mode (when VDD goes away with a V

BACKUP

supply is switched to VDD

SYS

) gets routed to this ESD clamp on

SYS

BACKUP

11/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

00h

Hundredths

80

40

20

10 8 4 2 1

01h

Seconds

GP0

40

20

10 8 4 2 1

02h

Minutes

GP1

40

20

10 8 4 2 1

03h

Hours (24 hour)

GP3

GP2

20

10 8 4 2 1

Hours (12 hour)

GP3

GP2

AM/PM

10 8 4 2 1

04h

Date

GP5

GP4

20

10 8 4 2 1

05h

Months

GP8

GP7

GP6

10 8 4 2 1

06h

Years

80

40

20

10 8 4 2 1

07h

Weekdays

GP13

GP12

GP11

GP10

GP9 4 2

1

08h

Hundredths Alarm

80

40

20

10 8 4 2 1

09h

Seconds Alarm

GP14

40

20

10 8 4 2 1

0Ah

Minutes Alarm

GP15

40

20

10 8 4 2 1

0Bh

Hours Alarm (24 hour)

GP17

GP16

20

10 8 4 2 1

Hours Alarm (12 hour)

GP17

GP16

AM/PM

10 8 4 2 1

0Ch

Date Alarm

GP19

GP18

20

10 8 4 2 1

0Dh

Months Alarm

GP22

GP21

GP20

10 8 4 2 1

0Eh

Weekdays Alarm

GP27

GP26

GP25

GP24

GP23 4 2

1

0Fh

Status

CB

BAT

WDF

BLF

TF

AF

EVF

X

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

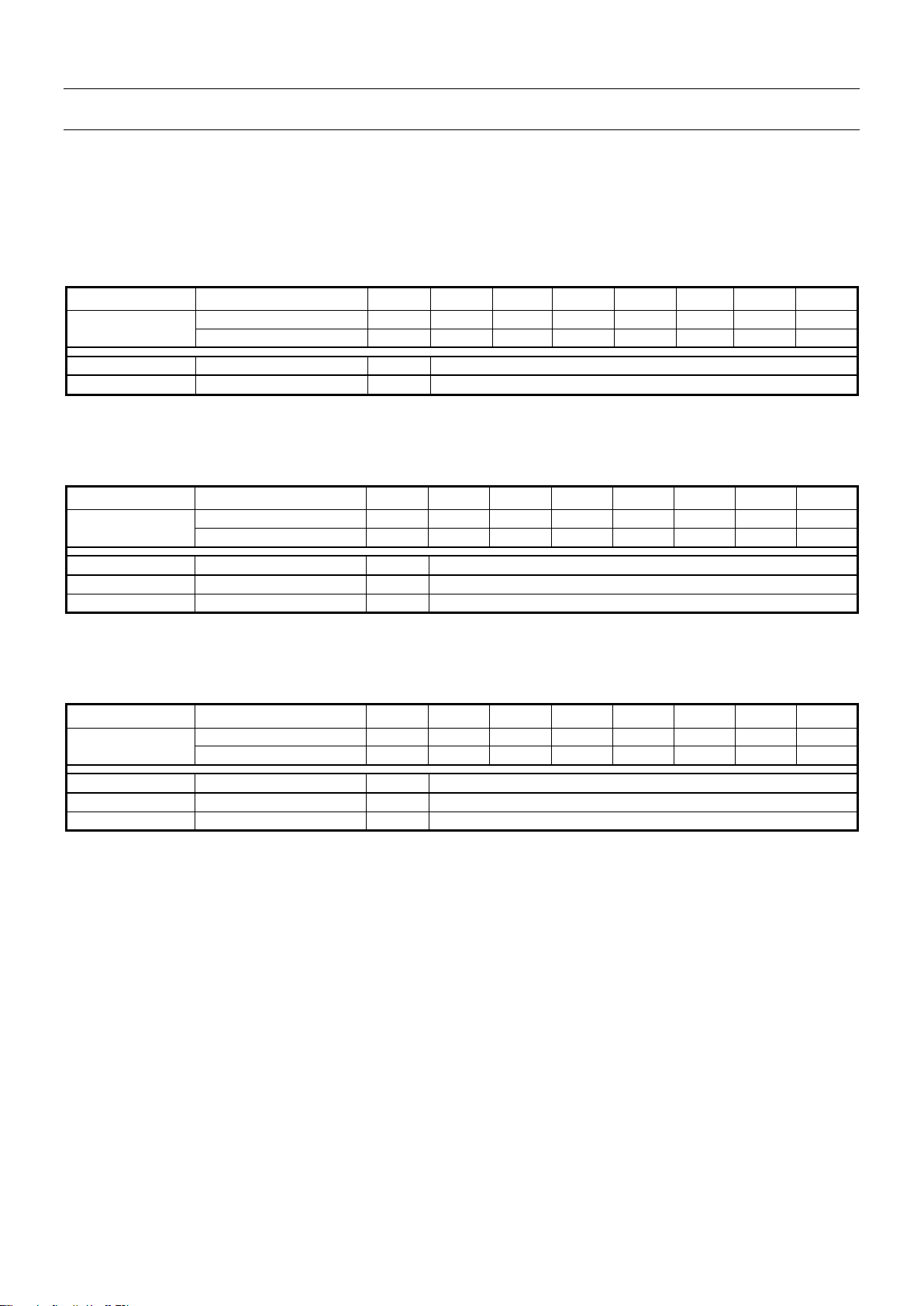

3. REGISTER ORGANIZATION

Registers are accessed by selecting a register address and then performing read or write operations. Multiple

reads or writes may be executed in a single access, with the address automatically incrementing after each byte.

The following tables Register Definitions (00h to 0Fh) and Register Definitions (10h to FFh) summarize the function

of each register. In the table Register Definitions (00h to 0Fh), the GPx bits (where x is between 0 and 27) are 28

register bits which may be used as general purpose storage. These bits are not described in the sections below. All

of the GPx bits are cleared when the RV-1805-C3 powers up, and they can therefore be used to allow software to

determine if a true Power On Reset (POR) has occurred or hold other initialization data.

REGISTER OVERVIEW 3.1.

Register Definitions (00h to 0Fh):

12/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

10h

Control1

STOP

12/24

PSWB

CLKB

RSTP

ARST

PSWC

WRTC

11h

Control2

RESERVED X PSWS

CLKS

12h

Interrupt Mask

CBE

IM

BLIE

TIE

AIE

EIE

X

13h

Square Wave SQW

SQWE

RESERVED

SQWS

14h

Calibration XT

CMDX

OFFSETX

15h

Calibration RC Upper

CMDR

OFFSETRU[13:8]

16h

Calibration RC Lower

OFFSETRL[7:0]

17h

Sleep Control

SLP

SLRST

EIP X SLF

SLW

18h

Countdown Timer

Control

TE

TM

TRPT

ARPT

TFS

19h

Countdown Timer

128

64

32

16 8 4 2 1

1Ah

Timer Initial Value

128

64

32

16 8 4 2 1

1Bh

Watchdog Timer

WDS

WDM

WD

1Ch

Oscillator Control

OSEL

ACAL

BOS

FOS

IOPW

OFIE

ACIE

1Dh

Oscillator Status Register

XTCAL

LKP

OMODE

RESERVED

OF

ACF

1Eh

RESERVED

RESERVED

1Fh

Configuration Key

CONFKEY

20h

Trickle Charge

TCS

DIODE

ROUT

21h

BREF Control

BREF

RESERVED

22h

RESERVED

RESERVED

23h

RESERVED

RESERVED

24h

RESERVED

RESERVED

25h

RESERVED

RESERVED

26h

Cap_RC Control

CAPRC

27h

IO Batmode Register

IOBM

RESERVED

28h

ID0 (Read only)

Part Number – MS Byte = 00011000 (18h)

29h

ID1 (Read only)

Part Number – LS Byte = 00000101 (05h)

2Ah

ID2 (Read only)

Revision – Major = 00010

Revision – Minor = 011

2Bh

ID3 (Read only)

Lot[7:0]

2Ch

ID4 (Read only)

Lot[9]

Unique ID[14:8]

2Dh

ID5 (Read only)

Unique ID[7:0]

2Eh

ID6 (Read only)

Lot[8]

Wafer

RESERVED

2Fh

Analog Stat. (Read Only)

BREFD

BMIN

RESERVED

VINIT

RESERVED

30h

Output Control Register

WDBM

X

WDDS

X

RSTSL X X

CLKSL

3Fh

Extension RAM Address

X

BPOL

WDIS

X

RESERVED

XADA

XADS

40h

:

7Fh

Standard RAM

RAM data (4 x 64 bytes = 256 bytes)

80h

:

FFh

Alternate RAM

RAM data (2 x 128 bytes = 256 bytes)

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

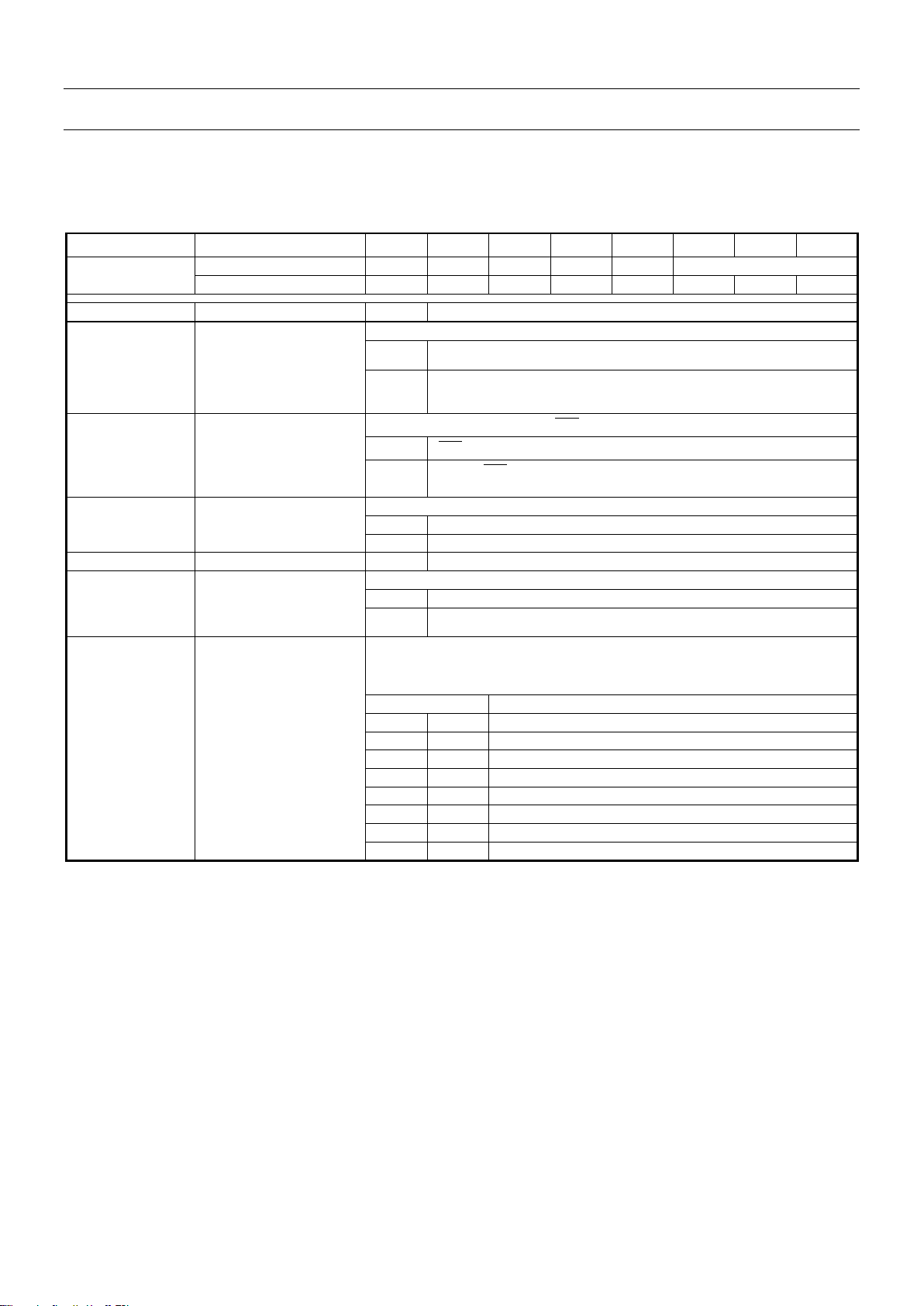

Register Definitions (10h to FFh):

13/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

00h

Hundredths

80

40

20

10 8 4 2 1

Reset 1 0 0 1 1 0 0 1

Bit

Symbol

Value

Description

7:0

Hundredths

00 to 99

Holds the count of hundredths of seconds, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

01h

Seconds

GP0

40

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP0

0 or 1

Register bit for general purpose use.

6:0

Seconds

00 to 59

Holds the count of seconds, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

02h

Minutes

GP1

40

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0 Bit

Symbol

Value

Description

7

GP1

0 or 1

Register bit for general purpose use.

6:0

Minutes

00 to 59

Holds the count of minutes, coded in BCD format.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

TIME AND DATE REGISTERS 3.2.

00h - Hundredths

This register holds the count of hundredths of seconds, in two binary coded decimal (BCD) digits. Values will be

from 00 to 99. Note that in order to divide from 32.768 kHz, the hundredths register will not be fully accurate at all

times but will be correct every 500 ms. Maximum jitter of this register will be less than 1 ms. The Hundredths

Counter is not valid if the RC Oscillator is selected.

01h - Seconds

This register holds the count of seconds, in two binary coded decimal (BCD) digits. Values will be from 00 to 59.

02h – Minutes

This register holds the count of minutes, in two binary coded decimal (BCD) digits. Values will be from 00 to 59.

14/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

03h

Hours

GP3

GP2

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0 Bit

Symbol

Value

Description

7

GP3

0 or 1

Register bit for general purpose use.

6

GP2

0 or 1

Register bit for general purpose use.

5:0

Hours

00 to 23

Holds the count of hours, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

03h

Hours

GP3

GP2

AM/PM

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP3

0 or 1

Register bit for general purpose use.

6

GP2

0 or 1

Register bit for general purpose use.

5

AM/PM

0

AM hours.

1

PM hours.

4:0

Hours

1 to 12

Holds the count of hours, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

04h

Date

GP5

GP4

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 1

Bit

Symbol

Value

Description

7

GP5

0 or 1

Register bit for general purpose use.

6

GP4

0 or 1

Register bit for general purpose use.

5:0

Date

01 to 31

Holds the current day of the month, coded in BCD format.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

03h - Hours

This register holds the count of hours, in two binary coded decimal (BCD) digits. Values will be from 00 to 23 if the

12/24 bit (see CONFIGURATION REGISTERS, 10h - Control1) is clear. If the 12/24 bit is set, the AM/PM bit will be

0 for AM hours and 1 for PM hours, and hour values will range from 1 to 12.

Hours Register (24 Hour Mode)

Hours Register (12 Hour Mode)

04h – Date

This register holds the current day of the month, in two binary coded decimal (BCD) digits. Values will range from

01 to 31. Leap years are correctly handled from 1900 to 2199.

15/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

05h

Months

GP8

GP7

GP6

10 8 4 2 1

Reset 0 0 0 0 0 0 0 1

Bit

Symbol

Value

Description

7

GP8

0 or 1

Register bit for general purpose use.

6

GP7

0 or 1

Register bit for general purpose use.

5

GP6

0 or 1

Register bit for general purpose use.

4:0

Months

01 to 12

Holds the current month, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

06h

Years

80

40

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0 Bit

Symbol

Value

Description

7:0

Years

00 to 99

Holds the current year, coded in BCD format.

When the Years register rolls over from 99 to 00 the Century bit CB will be

toggled (see CONFIGURATION REGISTERS, 0Fh - Status) if the CBE bit

is a 1 (see CONFIGURATION REGISTERS,12h - Interrupt Mask).

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

07h

Weekdays

GP13

GP12

GP11

GP10

GP09 4 2

1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP13

0 or 1

Register bit for general purpose use.

6

GP12

0 or 1

Register bit for general purpose use.

5

GP11

0 or 1

Register bit for general purpose use.

4

GP10

0 or 1

Register bit for general purpose use.

3

GP09

0 or 1

Register bit for general purpose use.

2:0

Weekdays

0 to 6

Holds the weekday counter value.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

05h - Months

This register holds the current month, in two binary coded decimal (BCD) digits. Values will range from 01 to 12.

06h - Years

This register holds the current year, in two binary coded decimal (BCD) digits. Values will range from 00 to 99.

07h - Weekdays

This register holds the current day of the week. Values will range from 0 to 6.

16/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

08h

Hundredths Alarm

80

40

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7:0

Hundredths Alarm

FFh

Once per hundredth in XT mode. Once per second in RC mode. ARPT bit

must be 7.

F0h to

F9h

Once per tenth in XT mode. Once per second in RC mode. ARPT bit must

be 7.

00 to 99

Holds the alarm value for hundredths of seconds, coded in BCD format. If

the ARPT bit is 0 to 6.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

09h

Seconds Alarm

GP14

40

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP14

0 or 1

Register bit for general purpose use.

6:0

Seconds Alarm

00 to 59

Holds the alarm value for seconds, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0Ah

Minutes Alarm

GP15

40

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP15

0 or 1

Register bit for general purpose use.

6:0

Minutes Alarm

00 to 59

Holds the alarm value for minutes, coded in BCD format.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

ALARM REGISTERS 3.3.

08h - Hundredths Alarm

This register holds the alarm value for hundredths of seconds, in two binary coded decimal (BCD) digits. Values will

range from 00 to 99. It holds the special values FFh and (F0h to F9h) when ARPT bit is 7. See TIMER

REGISTERS, 18h - Countdown Timer Control.

09h - Seconds Alarm

This register holds the alarm value for seconds, in two binary coded decimal (BCD) digits. Values will range from

00 to 59.

0Ah - Minutes Alarm

This register holds the alarm value for minutes, in two binary coded decimal (BCD) digits. Values will range from

00 to 59.

17/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0Bh

Hours Alarm

GP17

GP16

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0 Bit

Symbol

Value

Description

7

GP17

0 or 1

Register bit for general purpose use.

6

GP16

0 or 1

Register bit for general purpose use.

5:0

Hours Alarm

00 to 23

Holds the alarm value for hours, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0Bh

Hours Alarm

GP17

GP16

AM/PM

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP17

0 or 1

Register bit for general purpose use.

6

GP16

0 or 1

Register bit for general purpose use.

5

AM/PM

0

AM hours.

1

PM hours.

4:0

Hours Alarm

1 to 12

Holds the alarm value for hours, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0Ch

Date Alarm

GP19

GP18

20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP19

0 or 1

Register bit for general purpose use.

6

GP18

0 or 1

Register bit for general purpose use.

5:0

Date Alarm

01 to 31

Holds the alarm value for the date, coded in BCD format.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

0Bh - Hours Alarm

This register holds the alarm value for hours, in two binary coded decimal (BCD) digits. Values will range from 00

to 23 if the 12/24 bit (see CONFIGURATION REGISTERS, 10h - Control1) is clear. If the 12/24 bit is set, the

AM/PM bit will be 0 for AM hours and 1 for PM hours, and hour values will be from 1 to 12.

Hours Alarm Register (24 Hour Mode)

Hours Alarm Register (12 Hour Mode)

0Ch - Date Alarm

This register holds the alarm value for the date, in two binary coded decimal (BCD) digits. Values will range from

01 to 31. Leap years are correctly handled from 1900 to 2199.

18/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0Dh

Months Alarm

GP22

GP21

GP20

10 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

GP22

0 or 1

Register bit for general purpose use.

6

GP21

0 or 1

Register bit for general purpose use.

5

GP20

0 or 1

Register bit for general purpose use.

4:0

Months Alarm

01 to 12

Holds the alarm value for months, coded in BCD format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0Eh

Weekdays Alarm

GP27

GP26

GP25

GP24

GP23 4 2 1 Reset 0 0 0 0 0 0 0 0 Bit

Symbol

Value

Description

7

GP27

0 or 1

Register bit for general purpose use.

6

GP26

0 or 1

Register bit for general purpose use.

5

GP25

0 or 1

Register bit for general purpose use.

4

GP24

0 or 1

Register bit for general purpose use.

3

GP23

0 or 1

Register bit for general purpose use.

2:0

Weekdays Alarm

0 to 6

Holds the weekdays alarm value.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

0Dh - Months Alarm

This register holds the alarm value for months, in two binary coded decimal (BCD) digits. Values will range from 01

to 12.

0Eh - Weekdays Alarm

This register holds the alarm value for the day of the week. Values will range from 0 to 6.

19/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0Fh

Status

CB

BAT

WDF

BLF

TF

AF

EVF

X

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7

CB

Century bit. This bit will be toggled when the Years register rolls over from 99 to 00 if

the CBE bit is a 1 (see 12h - Interrupt Mask register).

Assuming that the current Year is in the 20xx century the CB bit has to be set to 1.

0

Assumes the century is 19xx or 21xx. – Default value

1

Assumes it is 20xx for leap year calculations.

6

BAT

(read only) – VBACKUP Power state

0

System is in POR or VDD Power state.

1

System is in VBACKUP Power state.

5

WDF

Watchdog Timer Flag

0

No Watchdog Timer timeout trigger detected.

1

The Watchdog Timer is enabled and is triggered, and the WDS bit is 0 (see

TIMER REGISTERS, 1Bh Watchdog Timer).

4

BLF

Battery Low Flag

0

No crossing of the reference voltage detected.

1

The battery voltage V

BACKUP

crossed the reference voltage selected by

BREF (see ANALOG CONTROL REGISTERS, 21h - BREF Control) in the

direction selected by BPOL (see RAM REGISTERS, 3Fh - Extension RAM

Address).

3

TF

Countdown Timer Flag

0

No zero detected.

1

Countdown Timer is enabled and reaches zero.

2

AF

Alarm Flag

0

No match detected.

1

The Alarm function is enabled and all selected Alarm registers match their

respective counters.

1

EVF

External Event Flag

0

No external trigger detected.

1

An external trigger is detected on the WDI pin. The EIE bit (see

CONFIGURATION REGISTERS , 12h - Interrupt Mask) must be set in

order for this interrupt to occur, but subsequently clearing EIE will not

automatically clear this flag.

0

X 0 Unused flag. Always 0.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

CONFIGURATION REGISTERS 3.4.

0Fh – Status

This register holds a variety of status bits. The register may be written at any time to clear or set any status flag. If

the ARST bit is set (see 10h - Control1), any read of the Status Register will clear interrupt flags in this register

(WDF, BLF, TF, AF and EVF). The bits CB and BAT are not affected.

20/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

10h

Control1

STOP

12/24

PSWB

CLKB

RSTP

ARST

PSWC

WRTC

Reset 0 0 0 1 0 0 1 1

Bit

Symbol

Value

Description

7

STOP

0

The clocking system is not stopped.

1

Stops the clocking system. The XT and RC Oscillators are not stopped. In

XT Mode the 32.768 kHz clock output will continue to run. In RC Mode, the

RC clock output will continue to run. Other clock output selections will

produce static outputs. This bit allows the clock system to be precisely

started, by setting it to 1 and back to 0.

6

12/24

0

The Hours register operates in 24 hour mode.

1

The Hours register operates in 12 hour mode.

5

PSWB

0 or 1

A static bit value which may be driven on the PSW pin. The PSWB bit

cannot be set to 1 if the LKP bit is 1 (see OSCILLATOR REGISTERS, 1Dh

– Oscillator Status).

4

CLKB

0 or 1

A static bit value which may be driven on the

INT/CLK

pin. This bit also

defines the default value for the square wave signal SQW when SQWE is

not asserted high. The default value of CLKB is 1 (high impedance).

3

RSTP

RST

Pin Polarity

0

The

RST

pin is asserted low.

1

The

RST

pin is asserted high.

2

ARST

Auto reset enable (Interrupt flags in Status register)

0

The interrupt flags must be explicitly cleared by writing the Status register.

1

A read of the Status register will cause the interrupt flags in the Status

register to be cleared (WDF, BLF, TF, AF, EVF).

1

PSWC

PSW Pin Control (1Ω / normal)

0

The PSW pin is a normal open drain output.

1

The PSW pin is driven by an approximately 1 Ω pull-down which allows the

RV-1805-C3 to switch power to other system devices through this pin.

0

WRTC

Write RTC

0

Prevents inadvertent software access to the Counters.

1

In order to write to any of the Counter registers (Hundredths, Seconds,

Minutes, Hours, Date, Months, Years or Weekdays).

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

10h - Control1

This register holds some major control signals.

21/98

Micro Crystal

INT/CLK

INT/CLK

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

11h

Control2

RESERVED X PSWS

CLKS

Reset 0 0 1 1 1 1 0 0

Set X to 0

0

Bit

Symbol

Value

Description

7:6

RESERVED

00 to 11

RESERVED

5

X

0 or 1

Unused, but has to be 0 to avoid extraneous leakage.

4:2

PSWS

PSW Pin Function Selection

000

Inverse of the combined interrupt signal IRQ if at least one interrupt is

enabled, else static PSWB

001

SQW if SQWE = 1, else static PSWB

010

RESERVED

011

Inverse AIRQ if AIE is set, else static PSWB

100

TIRQ if TIE is set, else static PSWB

101

Inverse TIRQ if TIE is set, else static PSWB

110

SLEEP signal

111

Static PSWB

1:0

CLKS

INT/CLK

Pin Function Selection

00

Inverse of the combined interrupt signal IRQ if at least one interrupt is

enabled, else static CLKB

01

SQW if SQWE = 1, else static CLKB

10

SQW if SQWE = 1, else inverse of the combined interrupt signal IRQ if at

least one interrupt is enabled, else static CLKB

11

Inverse AIRQ if AIE is set, else static CLKB

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

11h - Control2

This register holds additional control and configuration signals for the flexible output pins

Note that PSW and

are open drain outputs.

and PSW.

22/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

12h

Interrupt Mask

CBE

IM

BLIE

TIE

AIE

EIE

X

Reset 1 1 1 0 0 0 0 0

Bit

Symbol

Value

Description

7

CBE

Century Bit Enable

0

The CB bit will never be automatically updated.

1

The CB bit will toggle when the Years register rolls over from 99 to 00.

6:5

IM

Alarm Interrupt Mode.

This controls the duration of the Inverse AIRQ interrupt as shown below. The interrupt

output always goes high when the corresponding flag in the Status Register is cleared.

In order to minimize current drawn by the RV-1805-C3 this field should be kept at 3h.

00

Level (static) for both XT mode and RC mode.

01

1/8192 seconds for XT mode. 1/64 seconds for RC mode.

10

1/64 seconds for both XT mode and RC mode.

11

1/4 seconds for both XT mode and RC mode. – Default value

4

BLIE

Battery Low Interrupt Enable

0

Disables the battery low interrupt.

1

The battery low detection will generate an interrupt BLIRQ.

3

TIE

Timer Interrupt Enable

0

Disables the timer interrupt.

1

The Countdown Timer will generate a TIRQ interrupt signal and set the TF

flag when the timer reaches 0.

2

AIE

Alarm Interrupt Enable

0

Disables the alarm interrupt.

1

A match of all the enabled alarm registers will generate an AIRQ interrupt

signal.

1

EIE

External Interrupt Enable

0

Disables the external interrupt.

1

The WDI input pin will generate an external interrupt EIRQ when the edge

specified by EIP occurs (see CONFIGURATION REGISTERS, 12h Interrupt Mask).

0

X 0 Unused, but has to be 0 to avoid extraneous leakage.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

12h - Interrupt Mask

This register holds the interrupt enable bits and other configuration information.

23/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

13h

Square Wave SQW

SQWE

RESERVED

SQWS

Reset 0 0 1 0 0 1 1 0

Bit

Symbol

Value

Description

7

SQWE

Square Wave enable (internal SQW)

0

The square wave signal SQW is held at the static value of CLKB.

1

The square wave signal SQW is enabled.

6:5

RESERVED

00 to 11

RESERVED

4:0

SQWS

Square Wave selection (internal SQW)

00000

to

11111

Selects the frequency of the square wave signal SQW, as shown in the

following table. Note that some selections are not valid if the RC oscillator

is selected. Some selections also produce short pulses rather than square

waves, and are intended primarily for test usage.

SQWS

Square Wave Signal SQW Select

00000

1 century

(2)

00001

32.768 kHz

(1)

00010

8.192 kHz

(1)

00011

4.096 kHz

(1)

00100

2.048 kHz

(1)

00101

1.024 kHz

(1)

00110

512 Hz

(1)

– Default value

00111

256 Hz

(1)

01000

128 Hz

(3)

01001

64 Hz – highest calibrated frequency in RC mode

01010

32 Hz

01011

16 Hz

01100

8 Hz

01101

4 Hz

01110

2 Hz

01111

1 Hz

10000

½ Hz

10001

¼ Hz

10010

1/8 Hz

10011

1/16 Hz

10100

1/32 Hz

10101

1/60 Hz (1 minute)

10110

16.384 kHz

(1)

– highest calibrated frequency in XT mode

10111

100 Hz

(1)(2)

11000

1 hour

(2)

11001

1 day

(2)

11010

TIRQ

11011

Inverse TIRQ

11100

1 year

(2)

11101

1 Hz to Counters

(2)

11110

1/32 Hz from Autocalibration

(2)

11111

1/8 Hz from Autocalibration

(2)

(1)

Not applicable if the RC Oscillator is selected.

(2)

Pulses for Test Usage.

(3)

If the RC Oscillator is selected the frequency is typically 122 Hz.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

13h – Square Wave SQW

This register holds the control for the square wave signal SQW. Note that some frequency selections are not valid

if the RC Oscillator is selected.

24/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

14h

Calibration XT

CMDX

OFFSETX

Reset

0

Preconfigured (Factory Calibrated)

Bit

Symbol

Value

Description

7

CMDX

XT calibration adjust mode

0

Normal Mode, each adjustment step is ± 2 ppm. The calibration period is

32 seconds.

1

Coarse Mode, each adjustment step is ± 4 ppm. The calibration period is

16 seconds.

6:0

OFFSETX

-64 to

+63

The amount to adjust the effective time. This is a two's complement

number with a range of -64 to +63 adjustment steps (Factory Calibrated).

OFFSETX (7 Bits)

Unsigned value

Two’s complement

Correction value in ppm

(*)

CMDX = 0

CMDX = 1

011’1111

63

63

120.163

240.326

011’1110

62

62

118.256

236.511

:

:

:

: : 000’0001 1 1

1.907

3.815

000’0000 0 0

0.000

0.000

111’1111

127

-1

-1.907

-3.815

111’1110

126

-2

-3.815

-7.629

:

:

:

: : 100’0001

65

-63

-120.163

-240.326

100’0000

64

-64

-122.070

-244.141

(*)

Calculated with 5 decimal places (1’000’000/219 = 1.90735 ppm)

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

CALIBRATION REGISTERS 3.5.

14h - Calibration XT

This register holds the control signals for the digital calibration function of the XT Oscillator. This register is

initialized with a factory value which calibrates the XT Oscillator. The highest modified frequency is 16.384 kHz

(see XT OSCILLATOR DIGITAL CALIBRATION).

25/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

15h

Calibration RC Upper

CMDR

OFFSETRU

Reset

Preconfigured

Preconfigured (Factory Calibrated)

Bit

Symbol

Value

Description

7:6

CMDR

00 to 11

The calibration adjust mode for the RC calibration adjustment. CMDR

selects the highest possible calibration period used in the RC Calibration

process as shown in the following table.

5:0

OFFSETRU

000000

to

111111

The upper 6 bits of the OFFSETR field, which is used to set the amount to

adjust the effective time. OFFSETR is a two's complement number with a

range of -213 to +213-1 adjustment steps (Factory Calibrated). See Table 1.

CMDR

Calibration Period

Minimal Adjustment Step

Maximum Adjustment

00

8’192 seconds

+/-1.91 ppm

+/-1.56%

01

4’096 seconds

+/-3.82 ppm

+/-3.13%

10

2’048 seconds

+/-7.63 ppm

+/-6.25%

11

1’024 seconds

+/-15.26 ppm

+/-12.5%

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

16h

Calibration RC Lower

OFFSETRL

Reset

Preconfigured (Factory Calibrated)

Bit

Symbol

Value

Description

7:0

OFFSETRL

00h to

FFh

The lower 8 bits of the OFFSETR field, which is used to set the amount to

adjust the effective time. OFFSETR is a two's complement number with a

range of -213 to +213-1 adjustment steps (Factory Calibrated). See Table 1.

OFFSETR (14 Bits)

Unsigned value

Two’s

complement

Correction value in ppm

(*)

CMDR = 00

CMDR = 01

CMDR = 10

CMDR = 11

01’1111’1111’1111

8191

8191

15623

31246

62492

124985

01’1111’1111’1110

8190

8190

15621

31242

62485

124970 : : : : : :

:

00‘0000‘0000’0001

1 1 1.907

3.815

7.629

15.259

00‘0000‘0000’0000

0 0 0.000

0.000

0.000

0.000

11’1111’1111’1111

16383

-1

-1.907

-3.815

-7.629

-15.259

11’1111’1111’1110

16382

-2

-3.815

-7.629

-15.259

-30.518

: : : : : : :

10‘0000‘0000’0001

8193

-8191

-15623

-31246

-62492

-124985

10‘0000‘0000’0000

8192

-8192

-15625

-31250

-62500

-125000

(*)

Calculated with 5 decimal places (1’000’000/2

19

= 1.90735 ppm)

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

15h - Calibration RC Upper

This register holds the control signals for the fine digital calibration function of the low power RC Oscillator. This

register is initialized with a factory value which calibrates the RC Oscillator. The highest modified frequency is 64

Hz (see RC OSCILLATOR DIGITAL CALIBRATION).

16h - Calibration RC Lower

This register holds the lower 8 bits of the OFFSETR field for the digital calibration function of the low power RC

Oscillator. This register is initialized with a factory value which calibrates the RC Oscillator. The highest modified

frequency is 64 Hz (see RC OSCILLATOR DIGITAL CALIBRATION).

Table 1: Calibration RC

26/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

17h

Sleep Control

SLP

SLRST

EIP X SLF

SLW

Reset 0 0 0 0 0 0 0 0 Bit

Symbol

Value

Description

7

SLP

Sleep Request signal, see also SLEEP CONTROL STATE MACHINE

0

The Sleep Control State Machine is in RUN mode. If either STOP is 1 or no

interrupt is enabled, SLP will remain at 0 even after an attempt to set it to 1.

1

When set to 1, the Sleep Control State Machine will transition to the SWAIT

state as long as a valid interrupt is enabled. This bit will be cleared when

the Sleep Control State Machine returns to the RUN state.

6

SLRST

Reset

RST

when in SLEEP mode

0

RST

does not indicate the SLEEP state.

1

Asserts

RST

low when the Sleep Control State Machine is in the SLEEP

state.

5

EIP

External Interrupt polarity

0

The external interrupt will trigger on a falling edge of the WDI pin.

1

The external interrupt will trigger on a rising edge of the WDI pin.

4

X 0 Unused, but has to be 0 to avoid extraneous leakage.

3

SLF

Sleep Flag

0

No previous SLEEP state occurred.

1

Flag is set when the RV-1805-C3 enters Sleep Mode. This allows software

to determine if a SLEEP has occurred since the last time this bit was read.

2:0

SLW

Sleep Wait periods.

The number of ~8 ms waiting periods after SLP is set until the Sleep Control State

Machine goes into the SLEEP state. If SLW is not 0, the actual delay is guaranteed to

be between SLW and (SLW + 1) periods.

SLW

Wait time

000

0

The transition will occur with no delay.

001

1

8 to 16 ms

010

2

16 to 24 ms

011

3

24 to 32 ms

100

4

32 to 40 ms

101

5

40 to 48 ms

110

6

48 to 56 ms

111

7

56 to 64 ms

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

SLEEP CONTROL REGISTER 3.6.

17h - Sleep Control

This register controls the Sleep function of the Power Control system.

27/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

18h

Countdown Timer Control

TE

TM

TRPT

ARPT

TFS

Reset 0 0 1 0 0 0 1 1 Bit

Symbol

Value

Description

7

TE

Timer Enable

0

The Countdown Timer retains the current value. The clock to the Timer is

disabled for power minimization.

1

The Countdown Timer will count down.

6

TM

Timer Mode.

Along with TRPT, this controls the Countdown Timer Interrupt function as shown in

Table 2.

A Pulse interrupt will cause the inverse of the combined interrupt signal IRQ signal to

be driven low for the time shown in Table 2 or until the flag is cleared.

A Level Interrupt will cause the inverse of the combined interrupt signal IRQ signal to

be driven low by a Countdown Timer interrupt until the associated flag is cleared.

0

Pulse (TRPT is 0 or 1)

1

Level if TRPT = 0.

Pulse if TRPT = 1.

5

TRPT

Timer Repeat.

Along with TM, this controls the Countdown Timer Interrupt function as shown in Table

2.

0

Single is selected. The Countdown Timer will halt when it reaches zero.

If TM = 0, it allows the generation of periodic interrupts of virtually any

frequency.

If TM = 1, it is a Level.

1

Repeat is selected. The Countdown Timer reloads the value from the Timer

Initial register upon reaching 0, and continues counting.

4:2

ARPT

Alarm Repeat

0 to 7

These bits enable the Alarm Interrupt repeat function together with the

Hundredths Alarm register value, as shown in the following table.

1:0

TFS

Timer Frequency Selection

00 to

11

Select the clock frequency and interrupt pulse width of the Countdown

Timer, as defined in Table 2. The RC Pulse is a short negative going 100400 µs pulse.

ARPT

08h - Hundredths Alarm

register value

Repeat When

7

FFh

Once per hundredth (100 Hz)

(1)

F0h to F9h

Once per tenth (10 Hz)

(1)

00 to 99

Hundredths match (once per second)

(2)

6

Hundredths and seconds match (once per minute)

(2)

5

Hundredths, seconds and minutes match (once per hour)

(2)

4

Hundredths, seconds, minutes and hours match (once per day)

(2)

3

Hundredths, seconds, minutes, hours and weekday match (once per week)

(2)

2

Hundredths, seconds, minutes, hours and date match (once per month)

(2)

1

Hundredths, seconds, minutes, hours, date and month match (once per year)

(2)

0

Alarm Disabled

(1)

Once per second if RC Oscillator selected.

(2)

The Hundredths are not valid if the RC Oscillator is selected.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

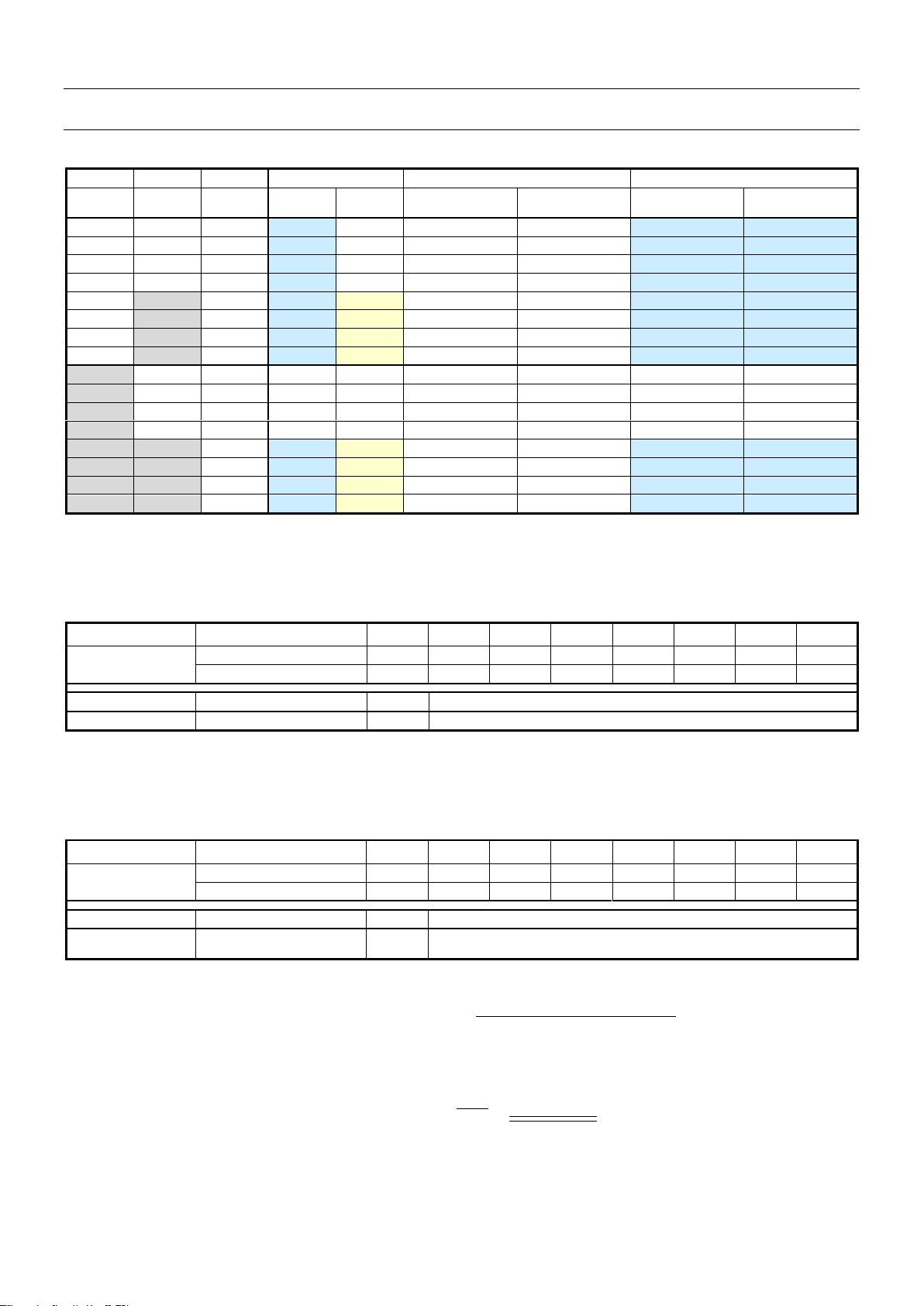

TIMER REGISTERS 3.7.

18h - Countdown Timer Control

This register controls the Countdown Timer function. Note that the TFS = 00 frequency selection is slightly different

depending on whether the 32.768 kHz XT Oscillator or the RC Oscillator is selected. In some RC Oscillator modes,

the interrupt pulse output is specified as RC Pulse. In these cases the interrupt output will be a short negative going

pulse which is typically between 100 and 400 µs. This allows control of external devices which require pulses

shorter than the minimum 7.8 ms pulse created directly by the RC Oscillator.

28/98

Micro Crystal

TM

TRPT

TFS

Interrupt signal

Countdown Timer Frequency

Interrupt Pulse Width

Pulse/

Level

Single/

Repeat

XT Oscillator

RC Oscillator

XT Oscillator

RC Oscillator

0 0 00

Pulse

Single

4096 Hz

Typ. 122 Hz

1/4096 s

Typ. 1/122 s

0 0 01

Pulse

Single

64 Hz

64 Hz

1/128 s

Typ. 1/122 s

0 0 10

Pulse

Single

1 Hz

1 Hz

1/64 s

1/64 s

0 0 11

Pulse

Single

1/60 Hz

1/60 Hz

1/64 s

1/64 s 0 1

00

Pulse

Repeat

4096 Hz

Typ. 122 Hz

1/4096 s

Typ. 1/122 s

0 1 01

Pulse

Repeat

64 Hz

64 Hz

1/128 s

Typ. 1/122 s

0 1 10

Pulse

Repeat

1 Hz

1 Hz

1/64 s

1/64 s

0 1 11

Pulse

Repeat

1/60 Hz

1/60 Hz

1/64 s

1/64 s 1 0

00

Level

Single

4096 Hz

Typ. 122 Hz

- - 1 0 01

Level

Single

64 Hz

64 Hz

-

-

1 0 10

Level

Single

1 Hz

1 Hz - - 1 0

11

Level

Single

1/60 Hz

1/60 Hz

-

-

1 1 00

Pulse

Repeat

4096 Hz

Typ. 122 Hz

1/4096 s

RC Pulse

1 1 01

Pulse

Repeat

64 Hz

64 Hz

1/4096 s

RC Pulse

1 1 10

Pulse

Repeat

1 Hz

1 Hz

1/4096 s

RC Pulse

1 1 11

Pulse

Repeat

1/60 Hz

1/60 Hz

1/4096 s

RC Pulse

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

19h

Countdown Timer

128

64

32

16 8 4 2 1

Reset 0 0 0 0 0 0 0 0 Bit

Symbol

Value

Description

7:0

Countdown Timer

0 to 255

The current value of the Countdown Timer in binary format.

Address

Function

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

1Ah

Timer Initial Value

128

64

32

16 8 4 2 1

Reset 0 0 0 0 0 0 0 0

Bit

Symbol

Value

Description

7:0

Timer Initial Value

0 to 255

The value in binary format reloaded into the Countdown Timer when it

reaches zero if the TRPT bit is a 1.

Extrem Low Power Real Time Clock / Calendar Module RV-1805-C3

Table 2: Countdown Timer Function Select

19h - Countdown Timer

This register holds the current value of the Countdown Timer. It may be loaded with the desired starting value when

the Countdown Timer is stopped.

1Ah - Timer Initial Value

This register holds the value which will be reloaded into the Countdown Timer when it reaches zero if the TRPT bit

is a 1. This allows for periodic timer interrupts (see calculation below).

Calculation of the period:

period = (Timer Initial Value + 1)

Countdown Timer Frequency

1

Example: For a period of 4 minutes (240 seconds) and with a Countdown Timer Frequency of 1 Hz (TFS = 10) a

Timer Initial Value of 239 is needed:

period = (239 + 1)

1

= 240 seconds

1 Hz

29/98

Micro Crystal

Address

Function

Bit 7

Bit 6

Bit 5