Page 1

Systemhaus fr Automatisierung

µCAN.8.dio-BOX

Manual Digital I/O-Module

Version 2.00

MicroControl GmbH & Co. KG

Junkersring 23

D-53844 Troisdorf

Fon: 02241 / 25 65 9 - 0

Fax: 02241 / 25 65 9 - 11

http://www.microcontrol.net

Page 2

Table of contents

μCAN.8.dio-BOX 2

1. Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 General Safety Regulations . . . . . . . . . . . . . . . . . 6

2. Operation of μCAN.8.dio-BOX . . . . . . . . . . . . . . . . . . . 8

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Project Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Module Layout. . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 Operation Area. . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 Maximum System Layout. . . . . . . . . . . . . . . . . 12

3.4 Case Dimensions . . . . . . . . . . . . . . . . . . . . . . . 14

4. Assembly and Disassembly . . . . . . . . . . . . . . . . . . . . . 16

4.1 Safety Regulations . . . . . . . . . . . . . . . . . . . . . . 16

4.2 General Information . . . . . . . . . . . . . . . . . . . . . 17

4.3 Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.4 Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.1 Potential Basics. . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 EMC Considerations. . . . . . . . . . . . . . . . . . . . . 21

5.2.1 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.2 Shielding of cables . . . . . . . . . . . . . . . . . . . 22

5.2.3 CAN Cable . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 CAN Bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5 Address Selection . . . . . . . . . . . . . . . . . . . . . . . 27

5.6 Baudrate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.7 Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6. Digital Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Function principle / High Side Version . . . . . . . 30

6.2 Function principle / Low Side Version. . . . . . . . 31

6.3 Pinning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7. Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1 Network Status. . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1.1 Signalling of CAN controller status . . . . . . . 35

Page 3

Table of contents

3 μCAN.8.dio-BOX

7.1.2 Signalling of Network and CAN status . . . . . 36

7.2 Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.3 Signal Status . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3.1 High Side Version . . . . . . . . . . . . . . . . . . . . . 37

7.3.2 Low Side Version . . . . . . . . . . . . . . . . . . . . . 37

8. CANopen Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.2 Network Management . . . . . . . . . . . . . . . . . . . 40

8.3 SDO Communication . . . . . . . . . . . . . . . . . . . . 42

8.3.1 SDO Abort Protocol . . . . . . . . . . . . . . . . . . . 43

8.4 Object Dictionary . . . . . . . . . . . . . . . . . . . . . . . 44

8.4.1 Communication Profile. . . . . . . . . . . . . . . . . 45

8.4.2 Device Profile . . . . . . . . . . . . . . . . . . . . . . . . 52

8.4.3 Manufacturer Specific Objects . . . . . . . . . . . 56

8.5 Heartbeat Protocol . . . . . . . . . . . . . . . . . . . . . . 57

8.6 PDO Communication . . . . . . . . . . . . . . . . . . . . 59

8.6.1 Transmission Modes . . . . . . . . . . . . . . . . . . . 60

8.6.2 Receive-PDO . . . . . . . . . . . . . . . . . . . . . . . . 61

8.6.3 Transmit PDO. . . . . . . . . . . . . . . . . . . . . . . . 63

8.6.4 Synchronisation Message . . . . . . . . . . . . . . . 65

8.7 Emergency Message . . . . . . . . . . . . . . . . . . . . . 66

9. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Page 4

μCAN.8.dio-BOX MicroControl Version 2.00 Page 4

1

Remarks on CE-conformance of μCAN-modules

μCAN-modules which have CE-conformance label, have passed

test specifications of EU-criteria 89/336/EWG "Electromagnetic

Emission and Immunitiy" and standardized European norms

(EN).

Papers of declaration for EU-conformance, according to Art.10 of

EN, are available at:

MicroControl GmbH & Co. KG

Junkersring 23

D-53844 Troisdorf

Germany

MicroControl reserves the right to modify this manual and/or

product described herein without further notice. Nothing in this

manual, nor in any of the data sheets and other supporting documentation, shall be interpreted as conveying an express or implied warranty, representation, or guarantee regarding the

suitability of the products for any particular purpose. MicroControl does not assume any liability or obligation for damages, actual or otherwise of any kind arising out of the application, use of

the products or manuals.

The products described in this manual are not designed, intended, or authorized for use as components in systems intended to

support or sustain life, or any other application in which failure of

the product could create a situation where personal injury or

death may occur.

© 2016 MicroControl GmbH & Co. KG, Troisdorf

No part of this documentation may be copied, transmitted or

stored in a retrieval system or reproduced in any way including,

but not limited to, photography, magnetic or other recording

means, without prior written permission from MicroControl

GmbH & Co. KG.

Page 5

Page

5 MicroControl Version 2.00 μCAN.8.dio-BOX

1

Page 6

General Safety Regulations Safety Regulations

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 6

1

1. Safety Regulations

Symbol Explanation

Attention !

This symbol marks a paragraph which explains possible danger.

This danger might cause a damage to the system / plant or damage to personnel.

Note

This symbol marks a paragraph which contains useful information for the work with the device or which gives just a hint.

1.1 General Safety Regulations

Attention !

Please read the following chapter in any case, because it contains important information about the secure handling of

electrical devices.

This paragraph gives important information about the conditions

of use. It was written for personnel which is qualified and trained

on electrical devices.

Qualified and trained personnel are persons who fulfil at least

one of the following conditions:

You know the safety regulations for automated machines and

you are familiar with the machine.

You are the operator for the machine and you have been trai-

ned on operation modes. You are familiar with the operation

of devices described in this manual.

You are responsible for setting into operation or service and

you are trained on repairing automated machines. In addition you are trained in setting electrical devices into operation,

to connect the earthing conductor and to label these devices.

Terms of use The devices described in this manual can only be used for the

mentioned applications. Other devices used in conjunction have

to meet the safety regulations and EMI requirements.

Page 7

Safety Regulations General Safety Regulations

Page

7 MicroControl Version 2.00 μCAN.8.dio-BOX

1

To

Attention !

ensure a trouble free and safe operation of the device please

take care of proper transport, appropriate storage, proper assembly as well as careful operation and maintenance.

Hints for Installati-onPlease take care to observe the actual local safety regulations.

If devices are used in a fixed machine without a mains switch for

all phases or fuses, this equipment has to be installed. The fixed

machine must be connected to safety earth.

If devices are supplied by mains please take care that the selected input voltage fits to the local mains.

Safety Notice If devices are supplied by 24V DC, this voltage has to be isolated

from other voltages.

The cables for power supply, signal lines and sensor lines must

be installed in a way that the device function is not influenced by

EMI.

Devices or machines for industrial automation must be constructed in a manner that an unintentional operation is impossible.

By means of hardware and software safety precautions have to

be taken

Attention !

in order to avoid undefined operation of a automated

machine in case of a cable fraction.

If automated machines can cause damage of material or personnel in case of a malfunction the system designer has to take care

for safety precautions. Possible safety precautions might be a

limit switch o

r locking.

Page 8

Overview Operation of μCAN.8.dio-BOX

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 8

2

2. Operation of μCAN.8.dio-BOX

2.1 Overview

The μCAN.8.dio-BOX is the right solution for digital I/O-signals

via CAN.

Fig. 1: Digital I/O-Module μCAN.8.dio-BOX

The development in automation towards decentralized „intelligent“ systems makes the communication between these components quite important.

Modern automated systems require the possibility to integrate

components from different manufacturers. The solution for this

problem is a common bus system.

All these requirements are fulfilled by the μCAN.8.dio-BOX module. The μCAN.8.dio-BOX runs on the standard fieldbus CAN.

Typical applications for the μCAN.8.dio-BOX are industrial automation, transportation, food industry and environmental technology.

Page 9

Operation of μCAN.8.dio-BOX Overview

Seite

9 MicroControl Version 2.00 μCAN.8.dio-BOX

2

The μCAN.8.dio-BOX runs with the protocol

according to the device profile CiA 401. Other protocol stacks are

available on request.

space saving and

compact

The μCAN.8.dio-BOX is designed for heavy duty applications.

The aluminium cast ensures protection class IP65. The compact,

space saving case gives the freedom to mount the module in

many places.

inexpensive and

service friendly

The quick and easy integration of the μCAN.8.dio-BOX in your

application reduces the development effort. Costs for material

and personnel are reduced. The easy installation makes maintenance and replacement quite simple.

Page 10

Module Layout Project Planning

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 10

3

3. Project Planning

The chapter Project Planning contains information which are important for the system engineer when using the μCAN.8.dioBOX. These information include case dimensions and conditions

of use.

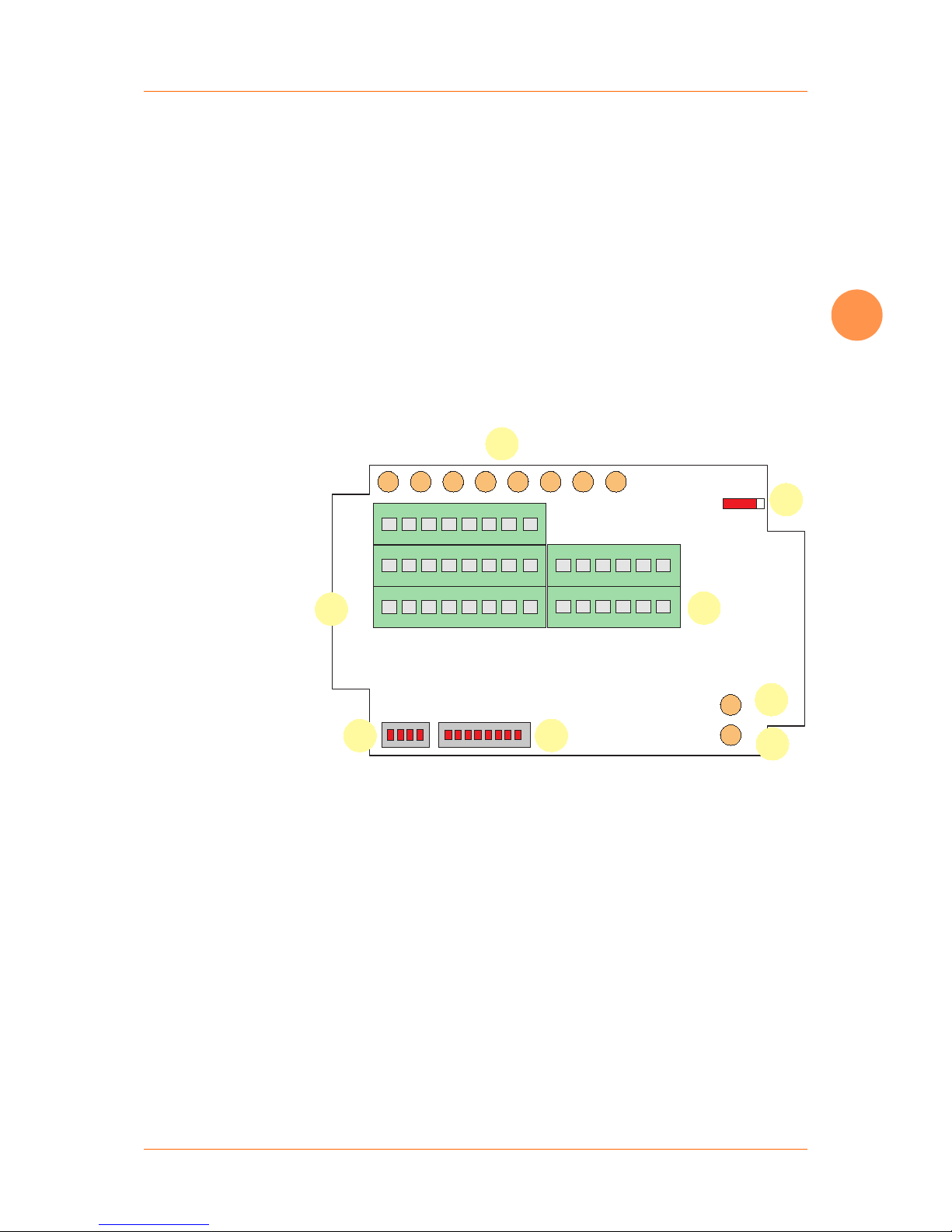

3.1 Module Layout

The following figure shows the top view of the μCAN.8.dio-BOX

PCB. Use the figure to identify the terminal blocks, LED’s and DIPswitches.

1: Baudrate switch

2: Module address / ID

3: Bi-color LED for module status

4: Bi-color LED for network status

5: Terminal block for Power / CAN

6: Switch for CANbus termination

7: Bi-color LED for signal status

8: Terminal block for digital signals

Modul IDBaud

Term

Off/On

CAN_H

CAN_L

GND

V+

V-PWR

V+PWR

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

I/O_8

NS

MS

1

2

4

3

6

5

7

8

Abb. 2: Top view of the μCAN.8.dio-BOX PCB

Page 11

Project Planning Operation Area

Page

11 MicroControl Version 2.00 μCAN.8.dio-BOX

3

3.2 Operation Area

The μCAN.8.dio-BOX is a robust field module for acquisition and

manipulation of digital signals via the CANbus. Every module can

handle up to 8 digital I/O-signals. The port direction of each terminal (input / output) is configured via software. It is not required to setup DIP-switches or jumpers for a configuration change.

The module has a power supply range of 8V - 60V DC.

The PCB is incorporated in a robust case of protection class IP65.

The μCAN.8.dio-BOX is suited for mounting outside the switch

cabinet. Long wires for actors or sensors are not longer necessary.

Influence of EMI is reduced.

The μCAN.8.dio-BOX needs four wires for connection to the power supply and CAN bus. Special CAN bus cables are available as

accessories (refer to Ordering Information).

Page 12

Maximum System Layout Project Planning

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 12

3

3.3 Maximum System Layout

For an operational system at least one network manager (or supervisor system) must be connected to the bus. This network manager might be a PLC or PC equipped with a CAN card. Every

μCAN.8.dio-BOX module is an active node.

A CANopen network manager can handle up to 127 network slaves (refer to Fig. 3, “Maximum System Layout”). Every module

gets a unique address, which is set up via a DIP switch. The CANbus bus is connected through the μCAN modules. The last module in the network must be terminated by a termination switch

(refer to “Termination” on page 29).

ID 1

NetworkManager

ID 2 ID 127

Abb. 3: Maximum System Layout

Page 13

Project Planning Maximum System Layout

Page

13 MicroControl Version 2.00 μCAN.8.dio-BOX

3

The maximum cable length depends on the selected baudrate.

The following table shows the maximum cable length recommended by the CAN in Automation (http://www.can-cia.org).

These distances can be realized with the μCAN.8.dio-BOX.

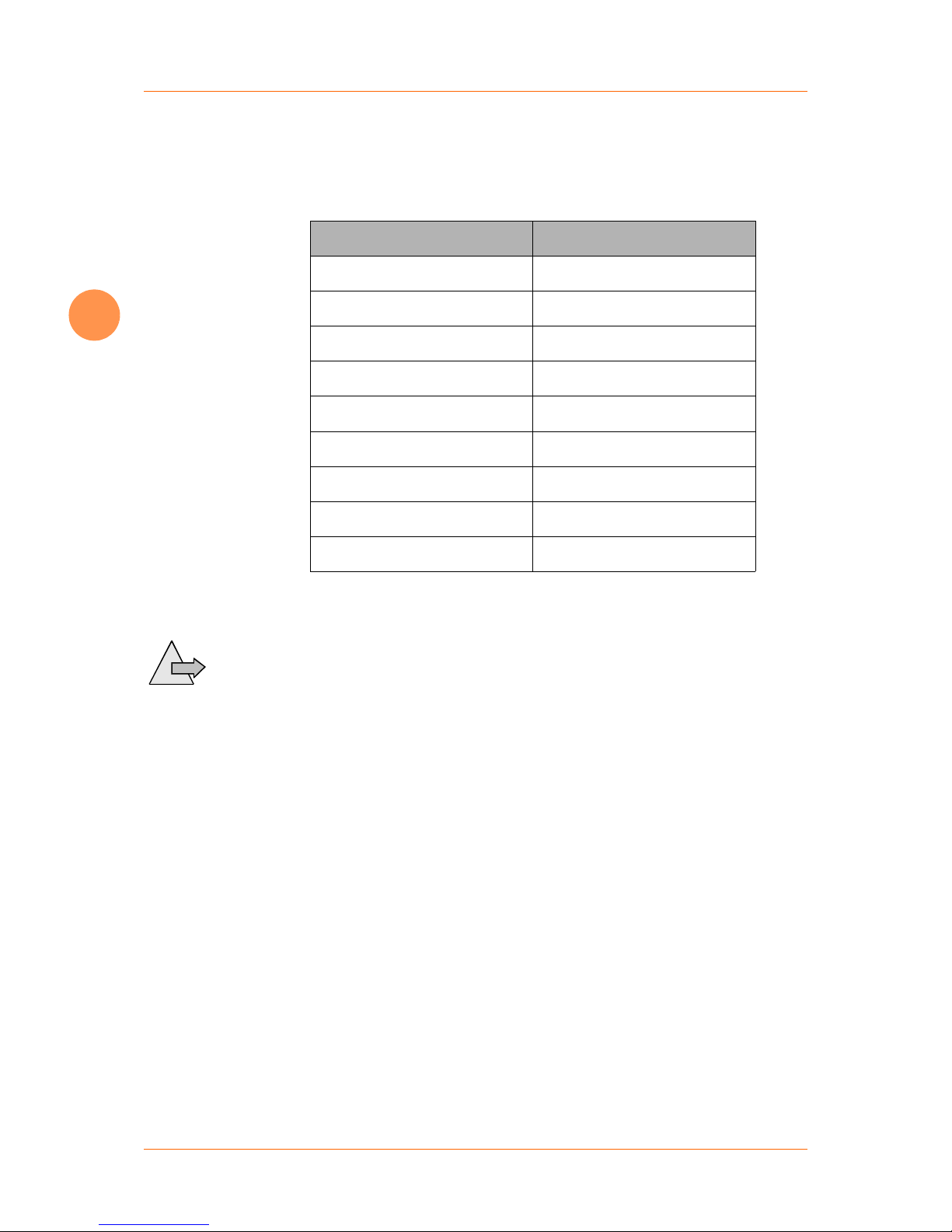

Tabelle 1: Dependence of baudrate from cable length

Baudrate in kBit/s Cable length in m

1000 25

800 50

500 100

250 250

125 500

100 650

50 1000

20 2500

10 5000

It is

Note

recommended by the CAN in Automation not to use the

baudrate 100 kBit/s in new CANopen systems.

Page 14

Case Dimensions Project Planning

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 14

3

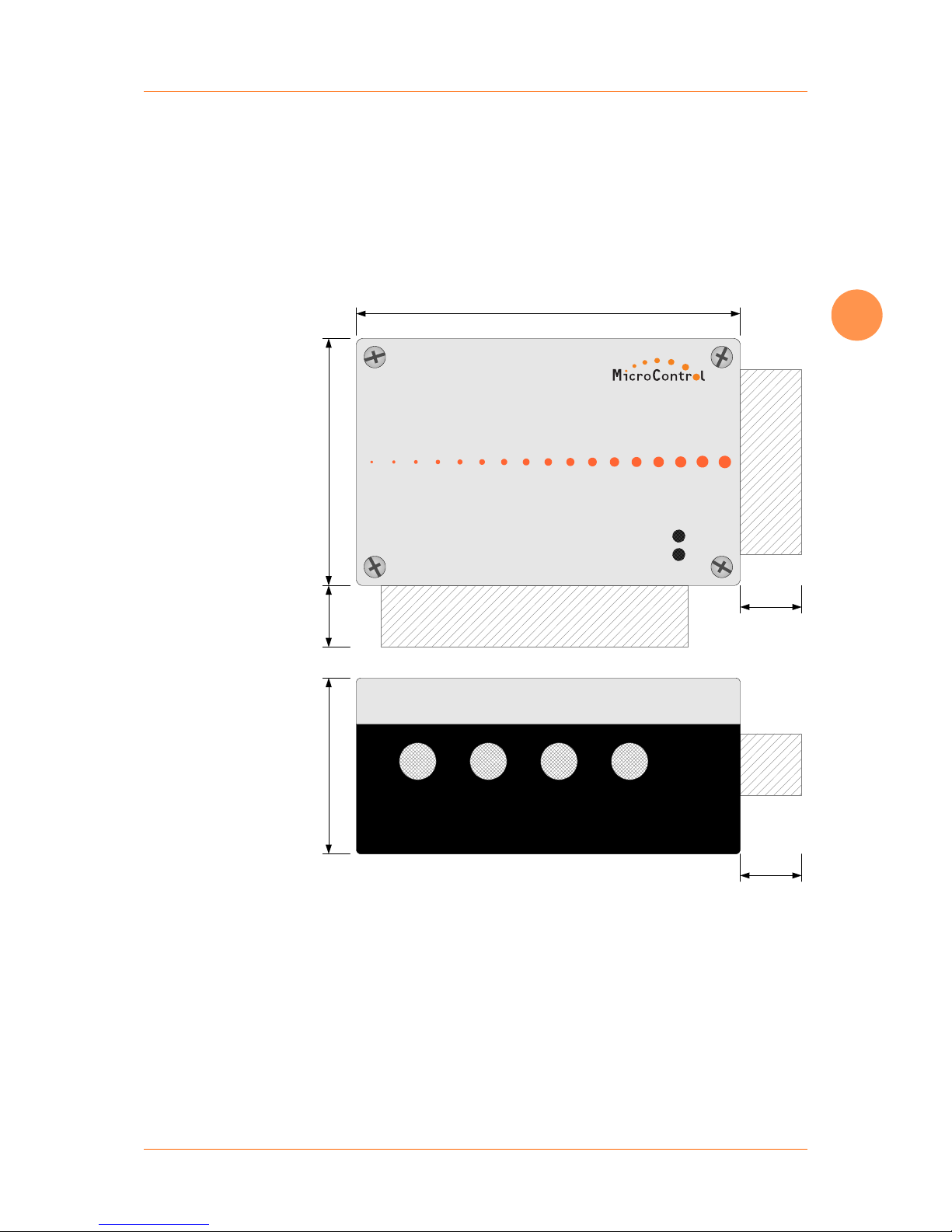

3.4 Case Dimensions

The case dimensions of the module are given in the drawing below. The high protection class IP65 of the module allows an assembly at places with a harsh environment. It is possible to

mount the module inside a switching cabinet as well as direct on

a machine. Please check the technical data section for detailled

information about maximum environment conditions.

125mm

80mm57mm

ON / CAN

ERROR

CAN

Systemhaus für Automatisierung

20mm

20mm

20mm

Abb. 4: Case dimensions

Page 15

Project Planning Case Dimensions

Page

15 MicroControl Version 2.00 μCAN.8.dio-BOX

3

Page 16

Safety Regulations Assembly and Disassembly

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 16

4

4. Assembly and Disassembly

4.1 Safety Regulations

This paragraph gives important information about the conditions

of

Attention !

use. It was written for personnel which is qualified and trained

on electrical devices.

Qualified and trained personnel are persons who fulfill at least

one of the following conditions:

You know the safety regulations for automated machines and

you are familiar with the machine.

You are the operator for the machine and you have been trai-

ned on operation modes. You are familiar with the operation

of devices described in this manual.

You are responsible for setting into operation or service and

you are trained on repairing automated machines. In addition you are trained in setting electrcal devices into operation,

to connect the earthing conductor and to label these devices.

Terms of Use The devices described in this manual can only be used for the

mentioned applications. Other devices used in conjuction have to

meet the safety regulations and EMI requirements.

To ensure a trouble free and safe operation of the device please

take

Attention !

care of proper transport, appropriate storage, proper assem-

bly as well as careful operation and maintenance.

Page 17

Assembly and Disassembly General Information

Page

17 MicroControl Version 2.00 μCAN.8.dio-BOX

4

4.2 General Information

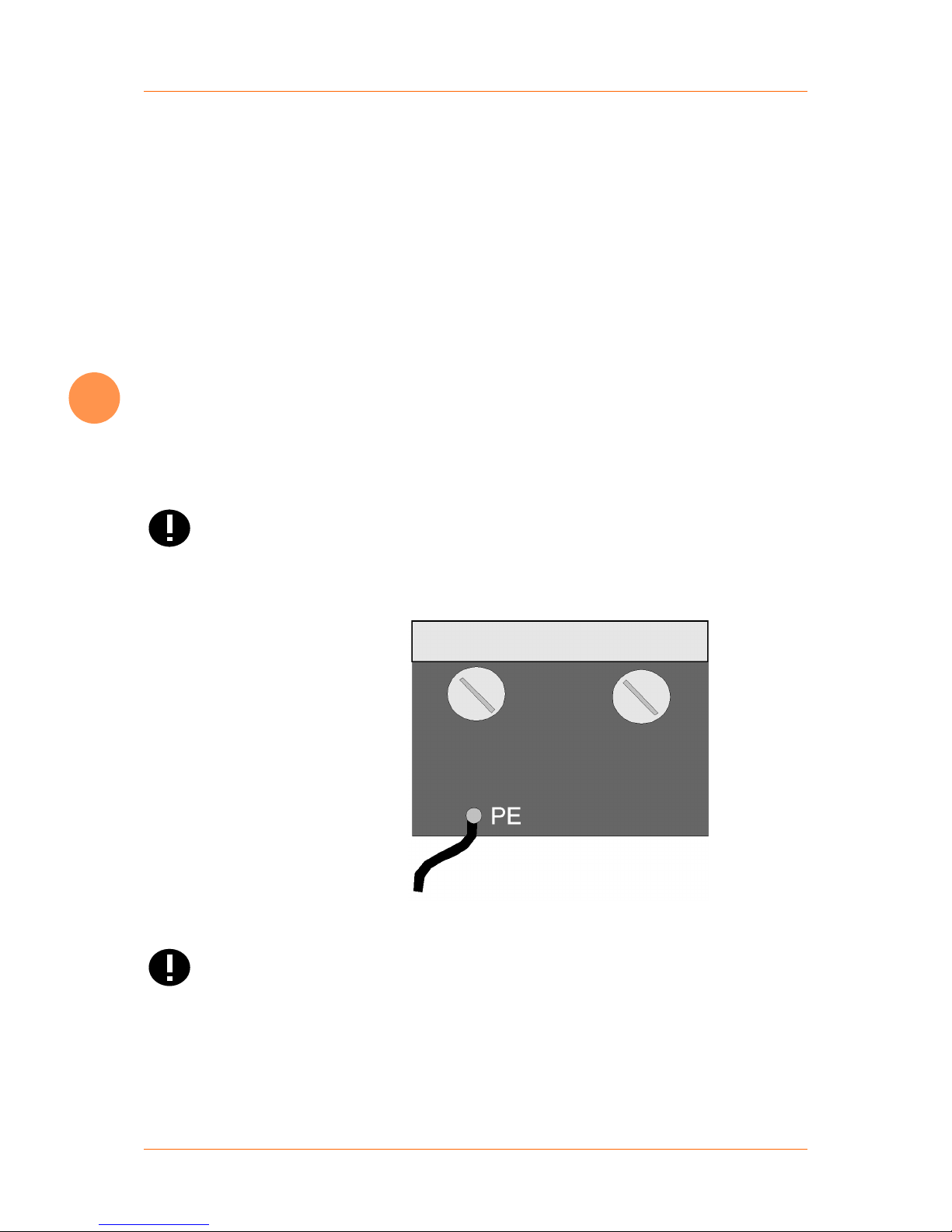

Assembly The µCAN modules should be assembled on an at least 2 mm

thick mounting plate or direct in the plant. The module is fixed

with 2 screws of type M4, which are plugged into the bottom part

of the case. You find an assembly template in the appendix of this

manual.

Power Supply You need a cable with two conductors for power supply. The ca-

ble is inserted from the right side into the case, where the terminals for power supply are located. However it makes sense to use

a cable with four conductors in order to run the CAN bus over the

same cable.

Earthed Conductor The non-fused earthed conductor is connected at the terminal

outside the case (refer to Fig. 5, “Connection of earthed conductor”). The non-fused earthed conductor may not lead inside the

case because of EMI.

The

Attention !

non-fused earthed conductor may not lead inside the µCAN

case and may not be connected to a terminal inside the case.

Abb. 5: Connection of earthed conductor

Attention !

Operation of the µCAN module is only permitted with closed

case.

Page 18

Assembly Assembly and Disassembly

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 18

4

4.3 Assembly

Assembly is performed with help of the template attached to this

manual. With the template all necessary bore-holes for screws of

type M4 can easily be drilled. If the module is directly fixed to the

machine make sure to take the proper drill size for tapping.

When fixing several modules at the same place please make

sure

Note

to leave some area for the PG screws.

For a quick identification of the modules during operation you

may use paper sticker. Please write down the ID that is set for the

module.

Please make sure that the first node and the last node in the CAN

network

Note

is terminated with a resistor (refer to “Termination” on

page 29).

Page 19

Assembly and Disassembly Disassembly

Page

19 MicroControl Version 2.00 μCAN.8.dio-BOX

4

4.4 Disassembly

Please make sure to disconnect the power supply from the device

first!

Open the cover from the module and remove the temperature

sensors first. Now you can remove the cables for CAN bus and

power supply from the terminals.

Unlock the fixing screws and remove the module. For a safe

transport remove the PG screws and close the cover again.

Page 20

Potential Basics Installation

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 20

5

5. Installation

5.1 Potential Basics

The potential environment of a system that is realized with μCAN

modules is characterized by following features:

The CAN bus potential is isolated from the power supply.

The electronic of the μCAN modules is isolated from the po-

wer supply.

All μCAN modules have a separate power supply.

All I/O signals are optically isolated from the CAN bus poten-

tial.

Page 21

Installation EMC Considerations

Page

21 MicroControl Version 2.00 μCAN.8.dio-BOX

5

5.2 EMC Considerations

EMC (Electromagnetic Compatibility) is the ability of a device to

work in a given electromagnetic environment without influencing this environment in a not admissible way.

All μCAN modules fit these requirements and are tested for electromagnetic compatibility in a EMC laboratory. However a EMC

plan should be done for the system in order to exclude potential

noise sources.

Noise signals can couple in different ways. Depending on that

way (guided wave propagation or non-guided wave propagation) and the distance to the noise source the kinds of coupling are

differentiated:

DC Coupling

If two electronic circuits use the same conductor we speak of a

DC coupling. Noise sources are in that case: starting motors, frequency converters (switching devices in general) and different

potentials of cases or of the common power supply.

Inductance Coupling

An inductance coupling is given between two current-carrying

conductors. The current in a conductor will cause a magnetic field

which induces a voltage in the second conductor (transformer

principle). Typical noise sources are transformer, power cables

and RF signal cables.

Capacitive Coupling

A capacitive coupling is given between two conductors which

have a different potential (principle of a capacitor). Noise sources

are in that case: parallel running conductors, static discharge and

contactors.

RF Coupling

A RF coupling is given when electromagnetic fields hit a conductor. This conductor works like an antenna for the electromagnetic

field and couples the noise into the system. Typical noise sources

are spark plugs and electric motors. Also a radio set might be a

noise source.

To reduce the impact of noise sources please take care to follow

the basic EMC rules.

Page 22

EMC Considerations Installation

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 22

5

5.2.1 Grounding

General All inactive metal plates must be grounded with low impedance.

By this step all elements of the system will have the same potential.

Please take care that the ground potential never carries a dangerous voltage. The grounding must be connected to the safety

earth.

Grounding of

μCAN-Modules

The µCAN modules are grounded by the contact which is mounted under one of the PG screws (see fig. 5, “Connection of

earthed conductor”). Additional contacts can be mounted under

the PG screws for shielding purposes on demand. The ground

potential may not be connected to a terminal inside the case.

Grounding of other

modules

If µCAN modules are shipped in a plastic case they have to be

grounded with a metal tape.

5.2.2 Shielding of cables

If noise is coupled to a cable shield it is grounded to safety earth

via the metal cover. The cable shields have to be connected to

the safety earth with low impedance.

Cable Types For installation of the µCAN module you should only use cable

with a shield that covers at least 80% of the core. Do not use cable with a shield made from metallized foil because it can be damaged very easy and has not a good shielding.

Cable Layout In general the cable shield should be grounded on both ends.

The cable shield should only be grounded on one end if an attenuation is necessary in the low frequency range. The cable shield

can not be grounded on both ends for temperature sensors. The

grounding on one end of the cable is necessary if

there is no contact to the safety earth possible,

analogue signals with only a few mV or mA are transmitted

(temperature sensors).

Page 23

Installation EMC Considerations

Page

23 MicroControl Version 2.00 μCAN.8.dio-BOX

5

5.2.3 CAN Cable

The CAN cable must meet the requirements of ISO11898. The

cable must meet the following specifications:

Tabelle 2: Specifications of CAN bus cable

Parameter Value

Impedance 108 - 132 Ohm (nom. 120 Ohm)

Specific Resistance 70 mOhm/Meter

Specific Signal Delay 5 ns/Meter

The CAN bus cable is connected to the µCAN.8.dio-BOX module

via terminals inside the case. For the pinning of the terminal refer

to “CAN Bus” on page 26 of this manual.

Do not confuse the signal lines of the CAN bus, otherwise communication

Attention !

between the modules is impossible. The shield of the

CAN bus cable may never lead inside the µCAN case. Never

connect the shield to one of the terminals inside the case.

Page 24

Power Supply Installation

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 24

5

5.3 Power Supply

The μCAN.8.dio-BOX modules are designed for industrial applications. By means of a DC/DC converter the CANbus of the module is isolated from the supply voltage. The supply voltage must

be within the range from 8 V DC to 60 V DC. The input is protected against confusing the poles.

Please make sure not to confuse the poles when connecting the

power supply. The positive supply is connected to the terminal

V+. The positive supply for the output stage is connected to the

terminal V+PWR.

The negative supply is connected to the terminal GN

D. The negative supply for the output stage is connected to the terminal V-

PWR.

Modul IDBaud

Term

Off/On

CAN_H

CAN_L

GND

V+

V-PWR

V+PWR

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

I/O_8

NS

MS

1

2

4

3

6

5

7

8

Supply for electronic

Supply for output stage

Abb. 6: Connection of power supply

The output stage can be supplied via a separate power source or

links have to be made between V+ and V+PWR as well as GND

and V-PWR.

The

Attention !

maximum supply voltage for the output drivers is 50V DC.

The maximum supply voltage for the electronic is 60V DC. Higher voltages will destroy the electronic.

Page 25

Installation Power Supply

Page

25 MicroControl Version 2.00 μCAN.8.dio-BOX

5

The terminals GND and V-PWR are not linked internally. The maximum potential difference between these terminals may not exceed 50mV.

You

Note

must always connect the power supply for the output stage,

even if the module is only used in a digital input configuration.

A cable shield may not lead into the housing or may not be connected to a

Attention !

terminal inside the housing. Cable shields have to be

connected to the terminals outside the housing.

Page 26

CAN Bus Installation

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 26

5

5.4 CAN Bus

The two wires of the CAN bus are connected to the appropriate

terminals.

To

Note

reduce the influence of EMI please take care that the CAN bus

cable does not cross the wires of the signal lines.

The CAN bus line with positive potential must be connected to

the terminal CAN_H. The CAN bus line with negative potential

must be connected to the terminal CAN_L.

Modul IDBaud

Term

Off/On

CAN_H

CAN_L

GND

V+

V-PWR

V+PWR

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

I/O_8

NS

MS

1

2

4

3

6

5

7

8

CAN bus

Abb. 7: Connection of CAN bus

If you confuse the poles the communication on the bus will not

be possible. The

Attention !

shield of the CAN bus may not lead into the housing and may not be connected to a terminal inside the housing.

Cable shields have to be connected to the terminals outside the

housing.

If you use a Sub-D connector with 9 pins (according to CiA standard), the

Note

conductor CAN_H is connected to pin 7 and the con-

ductor CAN_L is connected to pin 2.

Page 27

Installation Address Selection

Page

27 MicroControl Version 2.00 μCAN.8.dio-BOX

5

5.5 Address Selection

Address selection of the μCAN.8.dio-BOX module is done via a

8-pin DIP-switch, marked "Modul-ID" which is located at the bottom of the PCB. Selection of the address may be done with a

small screw driver.

1 2 3 4 5 6 7 8

OFF

Modul ID

Abb. 8: Setup of module address (here address 9 is shown)

The 8-pin DIP-switch sets the binary code for the module

address. The first pin of the switch (marked with ’1’) represents

bit 0 of a byte. The last pin of the switch (marked with ’8’) represents bit 7 of a byte.

Valid module addresses are within the range from 1..127, resp.

01h..7Fh.

Attention !

Each node within a CANopen network must have a

unique module address (Node ID). Two nodes with the same

Node ID are not allowed.

The selected address is read during initialization of the module,

after Power-on or Reset. The module runs with the selected Node

ID until a new Node ID is selected and a Reset is performed (via

the CAN bus) or the power supply is switched off

Switch 8 must always be in OFF position. Do not put all switches

in the

Attention !

OFF position. In these configurations the module will not

start to communicate on the bus.

Page 28

Baudrate Installation

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 28

5

5.6 Baudrate

Baudrate selection of the μCAN.8.dio-BOX module is done via a

4-pin DIP-switch, marked "Baud" which is located at the bottom

of the PCB. Selection of the baudrate may be done with a small

screw driver.

1 2 3 4

OFF

Baud

Abb. 9: Setup of baudrate (here 1 MBit/s is shown)

The 4-pin DIP-switch sets the binary code for the module baudrate. The first pin of the switch (marked with ’1’) represents bit 0 of

a byte. The last pin of the switch (marked with ’4’) represents bit

3 of a byte.

The supported baudrates of the μCAN.8.dio-BOX module are given in the following table. The values are recommended by the

CiA.

Tabelle 3: Setup of baudrate

Baudrate (kBit / s) 1 2 3 4

1000 1 0 0 1

800 0 0 0 1

500 1 1 1 0

250 0 1 1 0

125 1 0 1 0

100 0 0 1 0

50 1 1 0 0

20 0 1 0 0

10 1 0 0 0

Page 29

Installation Termination

Page

29 MicroControl Version 2.00 μCAN.8.dio-BOX

5

5.7 Termination

The modules at both ends in the CAN network have to be terminated with a resistor of 120 ohms. That means the modules at

the end of the bus line are not reflecting back power and the

communication can not be disturbed.

For termination of the μCAN.8.dio-BOX the "Term" switch must

be turned from position "Term Off“ to position "Term On“.

Modul IDBaud

Term

Off/On

CAN_H

CAN_L

GND

V+

V-PWR

V+PWR

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

I/O_8

NS

MS

1

2

4

3

6

5

7

8

Termination off

Abb. 10: Termination of CANbus

Please make sure that only the devices at both ends of a CAN bus

Attention !

are terminated.

Page 30

Function principle / High Side Version Digital Signals

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 30

6

6. Digital Signals

The μCAN.8.dio-BOX has eight digital I/O terminals. The terminal blocks are labeled with "I/O_1" to "I/O_8" from left to right

on the PCB.

Please keep the basics of EMI rules in mind when planning the

wiring. Only proper wiring and EMI precautions make sure that

the module runs without trouble.

6.1 Function principle / High Side Version

Configuration of each terminal (Input or Output) is performed

via CANopen. In "Digital Input" mode the Power-MOSFET is always off. The input voltage at the terminal is compared with a

reference voltage, which is set to V+

PWR / 2 (level is 50% of the

output stage supply voltage).

Logik

V+PWR

R

in

I/O

Abb. 11: Schematic digital I/O terminal / High Side Version

Page 31

Function principle / Low Side Version Digital Signals

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 31

6

In "Digital Output" mode the Power-MOSFET is driven via the

control logic. The logic block detects over current, short current

and thermal overload.

Tabelle 4: Electrical Parameters

Parameter Value

V+PWR 10 .. 50 V

Impedance R

in

24,2 kOhm

I

out

1,4 A maximal

Switching Level 0,5 * V+PWR

6.2 Function principle / Low Side Version

In "Digital Input" mode the Power-MOSFET is always off. The input voltage at the terminal is compared with a reference voltage,

which is set to V+PWR / 2 (level is 50% of the output stage supply voltage).

Logik

R

in

I/O

Abb. 12: Schematic digital I/O terminal / Low Side Version

Page 32

Function principle / Low Side Version Digital Signals

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 32

6

In "Digital Output" mode the Power-MOSFET is driven via the

control logic.

Attention !

In the Low Side Version there is no monitoring of over current

and short circuit. Also there is no signalling by LED or EMCY-messages ( please refer to “Emergency Message” on page 66 ).

Although the digital outputs are protected against overload conditions by means of thermal protection of the drivers. In constant

overlaod condition the driver will switch On and Off the load so

that there will be a PWM. If still remaining the overload condition

at last the driver will be completely switched off - until thermal

conditions are inside the driver´s specification again.

Tabelle 5: Electrical Parameters

Parameter Value

V+PWR 10 .. 50 V

Impedance R

in

33,3 kOhm

I

out

2 A maximum

Switching Level 0,5 * V+PWR

Page 33

Pinning Digital Signals

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 33

6

6.3 Pinning

The terminal block of the μCAN.8.dio-BOX is designed to

connect digital sensors with 3 wires. The sensor gets the positive

supply voltage (V+PWR) from terminal row B. The ground potential is located in terminal row C (V-PWR).

The binary control lines are connected to row A. The state of each

line is displayed by means of bi-color LEDs.

Modul IDBaud

Term

Off/On

CAN_H

CAN_L

GND

V+

V-PWR

V+PWR

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

I/O_8

NS

MS

A

B

C

Abb. 13: Terminals for signal lines

All

Attention !

signal lines may only be connected in power off state in order

to prevent a damage of the electronic.

Page 34

Diagnosis

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 34

7

7. Diagnosis

All modules of the μCAN family have LEDs to display the operating state and to signalize an error state. The light of the LEDs can

be seen through beam waveguides on top of the housing.

The μCAN.8.dio-BOX has two Duo-LEDs (green/red) labeled

with "NS" (Network Status) and "MS" (Module Status) on the

PCB.

On the case cover the LEDs are marked as ON/CAN for the network

Note

status and ERROR for the module status.

The state of the digital I/O terminals is displayed by eight bi-color

LEDs (position 7 in the figure below).

Modul IDBaud

Term

Off/On

CAN_H

CAN_L

GND

V+

V-PWR

V+PWR

I/O_1

I/O_2

I/O_3

I/O_4

I/O_5

I/O_6

I/O_7

I/O_8

NS

MS

1

2

4

3

6

5

7

8

Abb. 14: Position of LEDs on the module

In normal operation all LEDs should have a green or orange color.

A

Note

red steady light or a red blinking of a LED indicates an error

condition.

Page 35

Diagnosis Network Status

Page

35 MicroControl Version 2.00 μCAN.8.dio-BOX

7

7.1 Network Status

The LED marked with Network Status" (on the case cover denoted as ON/CAN) displays the status of the communication link.

7.1.1 Signalling of CAN controller status

The red LED is signalling the status of the CAN controler. Only in

fault condition the red LED will show the status.

Initialisation (Autobaud Detection)

NMT Status: Device in "Stopped" state

NMT Status: Device in "Pre-operational" state

NMT Status: Device in "Operational" state

CAN Status: Controller in "Warning" state

CAN Status: Controller in "Error Passive" state

CAN Status: Controller in "Bus-Off" state

Page 36

Module Status Diagnosis

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 36

7

7.1.2 Signalling of Network and CAN status

In combination there will be shown the network status and the

controler status.

7.2 Module Status

The LED marked with Module Status" (on the case cover denoted

as Error) displays the status of the device hardware.

Device in "Pre-operational" state, CAN Controller in "Warning" state

Device in "Operational" state, Controller in "Error Passive" state

Modul Status: Function/Power OK ( No short circuit / overload )

Modulstatus: Wrong setting of Baudrate DIP switches

Modulstatus: Wrong setting of Address DIP switches

Modulstatus: Short circuit / Overload on output ( Not available in LS Version )

Page 37

Diagnosis Signal Status

Page

37 MicroControl Version 2.00 μCAN.8.dio-BOX

7

7.3 Signal Status

The eight LEDs above the terminal block indicate the state of the

digital signal present on each input / output.

7.3.1 High Side Version

Tabelle 6: LED for Signal Status / High Side

Signal LED is To indicate

Green Digital high-signal at terminal ( Input )

Orange Terminal configured as output, output has been

switched on

Red Terminal configured as output, short-circuit on

output driver

7.3.2 Low Side Version

Tabelle 7: LED for Signal Status / Low Side

Signal LED is To indicate

Green Digital high-signal at terminal ( Input )

Orange not applicable

Red Terminal configured as output, output has been

switched on

Page 38

CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 38

8

8. CANopen Protocol

This chapter provides detailed information on how to connect

the modules of the μCAN-series to a CANopen-Manager. A CANopen-Manager can be a PLC, a PC with a CAN interface or any

other CAN-Device with NMT functionality.

For more information about CANopen manager please refer to

the supplied manuals of your CANopen master device.

This documentation provides the actual implemented functions

and services of the μCAN.8.dio-BOX.

Page 39

CANopen Protocol Introduction

Page

39 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.1 Introduction

The identifiers of the μCAN.8.dio-BOX are set up according to

the Pre-defined Connection Set, which is described in the

CANopen communication profile DS-301 in detail. The following

table gives an overview of the supported services.

Tabelle 8: Identifier values according to the Pre-defined Connection Set

Object COB-ID (dec.) COB-ID (hex)

Network Management 0 0x000

SYNC 128 0x080

EMERGENCY 129 - 255 0x081 - 0x0FF

PDO 1 (Transmit) 385 - 511 0x181 - 0x1FF

PDO 1 (Receive) 513 - 639 0x201 - 0x27F

SDO (Transmit) 1409 - 1535 0x581 - 0x5FF

SDO (Receive) 1537 - 1663 0x601 - 0x67F

Heartbeat / Boot-Message 1793 - 1919 0x701 - 0x77F

The direction (Transmit / Receive) has to be seen from the devices point of view.

Page 40

Network Management CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 40

8

8.2 Network Management

By means of the Network Management (NMT) messages the

state of a CANopen node can be changed (Stopped / Pre-Operational / Operational).

Start Node

ID DLC B0 B1

0 2 01h Nod

e

Start Node

Node = module address, 0 = all modules

By transmitting the "Start Node" command the CAN-node will be

set into Operational mode. This means that the node can handle

PDO-communication.

Stop Node

ID DLC B0 B1

0 2 02h Nod

e

Stop Node

Node = module address, 0 = all modules

By transmitting the "Stop Node" command the CAN-node will be

set into Stopped mode. This means that the node can not handle

any services except NMT commands.

Pre-Operational

ID DLC B0 B1

0 2 80h Nod

e

Enter Pre-Operational

Node = module address, 0 = all modules

By transmitting the „Enter Pre-Operational“ command the CANnode will be set into Pre-Operational mode. In this state the node

can not handle PDO messages.

Page 41

CANopen Protocol Network Management

Page

41 MicroControl Version 2.00 μCAN.8.dio-BOX

8

Reset Node

ID DLC B0 B1

0 2 81h Nod

e

Reset Node

Node = module address, 0 = all modules

By transmitting the „Reset Node“ command the CAN-node will

issue a reset operation. After reset the node will send a "Boot-up

Message" (refer to “Heartbeat Protocol” on page 57) and enter

the Pre-operational state automatically.

Page 42

SDO Communication CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 42

8

8.3 SDO Communication

All parameters of the devices (organized in an object dictionary)

are accessed via the SDO service (Service Data Object). A SDO

message has the following contents:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

8 CMD Index Sub-

In-

dex

Data

For calculation of the SDO message identifier please refer to “Introduction” on page 39.

The Command Byte (CMD) has the following meaning:

Master wants to read from Slave 40h

Slave answers on the read-request

42h

Master wants to write to Slave 22h

Slave answers on the write-request 60h

The

Note

byte order for the fields "Index" and "Data" is least significant

byte first (Intel format).

The

Attention !

minimum time delay between two succeeding SDO-commands must be greater than 20ms. Faster communication might

lead to an unpredictible device status.

Page 43

CANopen Protocol SDO Communication

Page

43 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.3.1 SDO Abort Protocol

The SDO abort protocol is used to signalize a fault when accessing an object. This SDO abort protocol has the following format:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

8 80h Index Sub-

In-

dex

Abort Code

The identifier as well as the index and sub-index correspond to

the SDO request.

The abort code may have the following values:

Tabelle 9: SDO abort codes

Abort code Description

0504 0001h Client / Server command specifier not vali

d / unknown

0601 0000h Unsupported access to an object

0601 0001h Attempt to read a "write-only" object

0601 0002h Attempt to write a "read-only" object

0602 0000h Object does not exist in the object dictionary

0609 0011h Sub-index does not exist

Page 44

Object Dictionary CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 44

8

8.4 Object Dictionary

This chapter describes the implemented objects for the digital

module μCAN.8.dio-BOX. For further information please refer to

the CANopen communication profile DS-301 and the device profile DS-401.

Page 45

CANopen Protocol Object Dictionary

Page

45 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.4.1 Communication Profile

The module μCAN.8.dio-BOX supports the following objects

from the communication profile DS-301:

Tabelle 10: Supported objects of the communication profile

Index Name

1000h Device Profile

1001h Error Register

1003h Predefined Error-Register

1005h COB-ID SYNC-Message

1008h Manufacturer Device Name

1009h Manufacturer Hardware Version

100Ah Manufacturer Software Version

1010h Store Parameters

1011h Restore Default Parameters

1014h COB-ID Emergency-Message

1017h Heartbeat Producer Time

1018h Identity Object

1400h 1

st

Receive PDO Parameter

1600h 1

st

Receive PDO Mapping

1800h 1

st

Transmit PDO Parameters

1A00h 1

st

Transmit PDO Mapping

Page 46

Object Dictionary CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 46

8

Device Profile

Index 1000h The object at index 1000h describes the type of device and its

functionality.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned32 ro Device Profile 0003 0191h

The object is read-only. Only sub-index 0 is supported. An access

to other sub-indices will lead to an error message.

Beispiel: read parameter, module ID = 2, index = 1000h

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

602h 8 40h 00h 10h 00h 00h 00h 00h 00h

As response the μCAN.8.dio-BOX will send:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

582h 8 42 00 01h 00 91h 01h 03h 00

Byte 5 + Byte 6 = 0191h = 401d (Device Profile Number)

Byte 7 + Byte 8 = 0003h = 3 (Additional Information)

Error Register

Index 1001h The object at index 1001h is an error register for the device.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Error Register 00h

The object is read-only. Only sub-index 0 is supported. An access

to other sub-indices will lead to an error message.

Beispiel: read parameter, module ID = 2, Index = 1001h

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

602h 8 40h 01h 10h 00 00 00 00 00

Page 47

CANopen Protocol Object Dictionary

Page

47 MicroControl Version 2.00 μCAN.8.dio-BOX

8

As response the module will return its error register value. The following error types are supported:

Generic Error Bit 0 is set to ’1’. The generic error is set due to hardware faults.

Communication

Error

Bit 4 is set to ’1’. The communication error is set due to faults on

the CAN bus.

The object is read-only. Only sub-index 0 is supported. An access

to other sub-indices will lead to an error message.

Pre-defined Error Field

Index 1003 The object at index 1003h holds the errors that have occured on

the device. The object stores a maximum of 10 error conditions.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 rw Number of errors 00h

1 .. 10 Unsigned32 ro Standard error field 0000 0000h

The object supports the sub-indices 0 to 10. An access to other

sub-indices will lead to an error message. Writing to sub-index 0

will clear the error history.

Beispiel: read parameter, module ID = 2, Index = 1003h

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

602h 8 40h 03h 10h 05h 00h 00h 00h 00h

As response the module will return the error value at position 5

in the history.

Page 48

Object Dictionary CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 48

8

Manufacturer Device Name

Index 1008 The object at index 1008h contains the manufacturer device na-

me.

Sub-Index Data Type Acc. Name Default Value

0 Visible String ro Device name μCAN.8.dio

The object is read-only. Only sub-index 0 is supported. An access

to other sub-indices will lead to an error message.

Manufacturer Hardware Version

Index 1009h The object at index 1009h contains the manufacturer hardware

version.

Sub-Index Data Type Acc. Name Default Value

0 Visible String ro Hardware version HW-1.1

The object is read-only. Only sub-index 0 is supported. An access

to other sub-indices will lead to an error message.

Manufaturer Software Version

Index 100Ah The object at index 100Ah contains the manufacturer software

version.

Sub-Index Data Type Acc. Name Default Value

0 Visible String ro Software version SW-1.0

The object is read-only. Only sub-index 0 is supported. An access

to other sub-indices will lead to an error message.

Page 49

CANopen Protocol Object Dictionary

Page

49 MicroControl Version 2.00 μCAN.8.dio-BOX

8

Store Parameters

Index 1010h The object at index 1010h supports the saving of parameters in

a non volatile memory.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Number of objects 3

1 Unsigned32 rw Save all parameters 1

2 Unsigned32 rw Save communication 1

3 Unsigned32 rw Save application 1

In order to avoid storage of parameters by mistake, storage is

only executed when a specific signature is written to the appropriate sub-index. The signature is "save".

Beispiel: save all parameters, module ID = 2, index = 1010h

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

602h 8 22h 10h 10h 01h 73h 61h 76h 65h

As response the μCAN.8.dio-BOX will send:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

582h 8 60h 10h 10h 01h 00h 00h 00h 00h

Page 50

Object Dictionary CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 50

8

Restore Default Parameters

Index 1011h The object at index 1011h supports the restore operation of de-

fault parameters.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Number of objects 3

1 Unsigned32 rw Restore all param. 1

2 Unsigned32 rw Restore commun. 1

3 Unsigned32 rw Restore application 1

In order to avoid the restoring of default parameters by mistake,

restoring is only executed when a specific signature is written to

the appropriate sub-index. The signature is "load".

Beispiel: restore all parameters, module ID = 2, Index = 1011h

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

602h 8 22h 11h 10h 01h 6Ch 6Fh 61h 64h

As response the μCAN.8.dio-BOX will send:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

582h 8 60h 11h 10h 01h 00h 00h 00h 00h

Page 51

CANopen Protocol Object Dictionary

Page

51 MicroControl Version 2.00 μCAN.8.dio-BOX

8

Identity Object

Index 1018h The object at index 1018h contains general information about

the device.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 4

1 Unsigned32 ro Vendo r ID 0000 000Eh

2 Unsigned32 ro Product Code 0013 9F70h

3 Unsigned32 ro Revision Number 0001 0000h

4 Unsigned32 ro Serial Number -

The object is read-only. Only sub-indices 0 to 4 are supported. An

access to other sub-indices will lead to an error message.

Vendor ID The Vendor ID contains a unique value allocated to each manu-

facturer. The numbers are managed by the CAN in Automation

(http://www.can-cia.org).

Product Code The Product Code identifies a specific device version.

Revision Number The Revision Number consists of a major revision num

ber (upper

word) and a minor revision number (lower word). The major revision number identifies a specific CANopen behaviour. The minor revision number identifies different versions with the same

CANopen behaviour.

Serial Number The Serial Number identifies a specific device.

Page 52

Object Dictionary CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 52

8

8.4.2 Device Profile

In this section you will find all device profile (DS-401) specific indices for the μCAN.8.dio-BOX.

Tabelle 11: Supported objects of device profile DS-401

Index Name

6000h Read Input 8-Bit

6002h Polarity Input 8-Bit

6005h Global Interrupt Enable Digital

6006h Interrupt Mask Any Cha

nge 8-bit

6007h Interrupt Mask Low-to-High 8-bit

6008h Interrupt Mask High-to-Low 8-bit

6200h Write Output 8-Bit

6202h Change Polarity Output 8-Bit

6206h Error Mode Output 8-Bit

6207h Error Value Output 8-Bit

Page 53

CANopen Protocol Object Dictionary

Page

53 MicroControl Version 2.00 μCAN.8.dio-BOX

8

Digital Input Value

Index 6000h By a read operation of index 6000h the state of the digital inputs

can be retrieved.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 01h

1 Unsigned8 ro Read Input 8-Bit -

The object is read-only. Only sub-indices 0 and 1 are supported.

An access to other sub-indices will lead to an error message.

Beispiel: read digital inputs

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

601h 8 40h 00h 60h 01h 00h 00h 00h 00h

, module address = 1

As response the μCAN.8.dio-BOX will send:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

581h 8 42h 00h 60h 01h 01h 00h 00h 00h

In this example the digital input 1 has a high level, all other inputs have a low leveI.

Input Polarity

Index 6002h With the object at index 6002h the polarity of the digital inputs

can be changed..

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 01h

1 Unsigned8 rw Polarity Input 8-Bit 00h

Only sub-indices 0 and 1 are supported. An access to other subindices will lead to an error message.

Page 54

Object Dictionary CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 54

8

Global Interrupt

Index 6005h The object at index 6005h enables and disables globally the in-

terrupt behaviour without changing the interrupt masks.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 01h

1 Unsigned8 rw Global Interrupt FFh

Only sub-indices 0 and 1 are supported. An access to other subindices will lead to an error message.

The default value of FFh enables transmission of a PDO for each

digital input. Each bit corresponds to a digital input. Setting a value of ’0’ will disable the transmissions of a PDO.

The object is used in combination with the objects at index

6006h,

Note

6007h and 6008h.

Interrupt Mask

Index 6006h The object at index 6006h determines, which input port lines

shall activate an interrupt by positive or/and negative edge detection.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 01h

1 Unsigned8 rw Interrupt Any Change FFh

Only sub-indices 0 and 1 are supported. An access to other subindices will lead to an error message.

Each bit corresponds to a digital input. A value of ’0’ means the

interrupt is disabled.

Page 55

CANopen Protocol Object Dictionary

Page

55 MicroControl Version 2.00 μCAN.8.dio-BOX

8

Digital Outputs

Index 6200h The object at index 6200h accesses the digital outputs of the mo-

dule.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 01h

1 Unsigned8 rw Write Output 00h

Only sub-indices 0 and 1 are supported. An access to other subindices will lead to an error message.

Beispiel: Set output 8 to high level

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

601h 8 22h 20h 62h 01h 80h 00h 00h 00h

As response the μCAN.8.dio-BOX will send:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

581h 8 60h 20h 62h 00h 00h 00h 00h 00h

A digital output can only be set, if the specified output terminal

is configured

Note

properly (port direction = output). This is done via

the object 5FF5h (refer to “Port Direction” on page 56).

Output Polarity

Index 6202h With the object at index 6002h the polarity of the digital inputs

can be changed.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 01h

1 Unsigned8 rw Polarity Output 8-Bit 00h

Only sub-indices 0 and 1 are supported. An access to other subindices will lead to an error message.

Page 56

Object Dictionary CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 56

8

8.4.3 Manufacturer Specific Objects

In this section you will find all manucaturer specific indices for the

μCAN.8.dio-BOX

Tabelle 12: Manufacturer specific objects

Index Name

5FF5 Port Direction

Port Direction

Index 5FF5h The object at index 5FF5h is used to modify the port direction of

each terminal.

Sub-Index Data Type Acc Name Default Value

0 Unsigned8 rw Port direction 00h

Only sub-index 0 is supported. An access to other sub-indices will

lead to an error message. Writing a ’1’ will define the terminal as

output.

Beispiel: Configure terminals 1 - 4 as outputs

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

601h 8 22h F5h 5Fh 00h 0Fh 00h 00h 00h

As result the μCAN.8.dio-BOX will send the following message:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

581h 8 60h F5h 5Fh 00h 00h 00h 00h 00h

By default all terminals are configured as digital inputs. The outputs

Note

can only be set, if they have been configured properly with

the object 5FF5h.

Page 57

CANopen Protocol Heartbeat Protocol

Page

57 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.5 Heartbeat Protocol

The Heartbeat Protocol is used in order to survey other CANopen

nodes in the network and retrieve their network state.

Heart Beat ID The Identifier for the Heartbeat Protocol is set to 700h + module

address. The Identifier can not be changed. The message repetition time (called "Heartbeat Producer Time") is configured with

object 1017h.

The Heartbeat Protocol transmits one byte of data, which represents the network state.

Tabelle 13: Status Information for Heartbeat

Network State Code (dec.) Code (hex)

Bootup 0 00h

Stopped 4 04h

Operational 5 05h

Pre-Operational 127 7Fh

After Power-on / Reset the module will send the "Bootup message" to signal that it finished the initialization sequence.

Beispiel: Power-on of module with address 2

ID DLC B0

702h 1 00h

Page 58

Heartbeat Protocol CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 58

8

Producer Heartbeat Time

Index 1017h The object at index 1017h defines the cycle time of the heart-

beat. The producer heartbeat time is 0 if it is not used. The time

is a multiple of 1ms.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned16 rw Producer Time 0000h

Only sub-index 0 is supported. An access to other sub-indices will

lead to an error message.

Beispiel: Producer Time 1000 ms, module address 1

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

601h 8 22h 17h 10h E8h 03h 00h 00h 00h

The answer you will receive from the module is:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

581h 8 60h 17h 10h 00h 00h 00h 00h 00h

The Heartbeat Producer Time is not saved inside the non-volatile

Note

memory autonomously. It is necessary to store this parameter via

object 1010h (refer to “Store Parameters” on page 49).

Page 59

CANopen Protocol PDO Communication

Page

59 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.6 PDO Communication

The real-time data transfer is performed by means of "Process

Data Objects" (PDO). The transfer of PDOs is performed with no

protocol overhead.

Note

PDO communication is only possible in the network state "Operational".

Page 60

PDO Communication CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 60

8

8.6.1 Transmission Modes

Event Driven

Message transmission is triggered by the occurrence of an object

specific event. For synchronous PDOs this is the expiration of the

specified transmission period, synchronised by the reception of

the SYNC object. For acyclically transmitted synchronous PDOs

and asynchronous PDOs the triggering of a message transmission is a device-specific event specified in the device profile.

Timer Driven

Message transmission is either triggered by the occurrence of a

device-specific event or if a specified time has elapsed without

occurrence of an event.

Page 61

CANopen Protocol PDO Communication

Page

61 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.6.2 Receive-PDO

Index 1400h The object at index 1400h defines communication parameters

for the Receive-PDO.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 2

1 Unsigned32 rw COB-ID for PDO 200h + Node

2 Unsigned8 rw Transmission Type FFh

Only sub-indices 0 to 2 are supported. An access to other subindices will lead to an error message.

COB-ID for PDO Sub-Index 1 defined the identifier for the Receive PDO. The 32-

bit value has the following structure.

Tabelle 14: Definition of COB-ID for PDO

Bit 31 Bit 30 Bit 29 Bit 28 - 0

PDO valid,

0 = valid

1 = not valid

RTR allowed,

0 = yes

1 = no RTR

Frame type,

0 = 11 Bit

1 = 29 Bit

Identifier,

In order to enable the PDO the most significant bit (Bit 31) must

be set to 0. In order to disable the PDO the most significant bit

must be set to 1. In the default setting the PDO is active (Bit 31 =

0).

Transmission Type The transmission type defines the transmission character of the

PDO.

Tabelle 15: Einstellung des Transmission Type

Transmission Type Description

00h acyclic synchronous,

01h - F0h

(1 - 240 dez)

cyclic synchronous,

The Receive-PDO processes a message with 1 byte process data.

The contents is copied into object 6200h (refer to “Digital Outputs” on page 55) and modifies the digital outputs.

Page 62

PDO Communication CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 62

8

Beispiel: Set outputs 1 - 4, module address = 1

ID DLC B0

201h 1 0Fh

A communication with PDOs is only possible in Operational Mode.

Note

A digital output can only be set, if the specified output terminal is configured properly (port direction = output). This is done

via the object 5FF5h (refer to “Port Direction” on page 56).

Page 63

CANopen Protocol PDO Communication

Page

63 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.6.3 Transmit PDO

Index 1800h The object at index 1800h defines communication parameters

for the Transmit-PDO.

Sub-Index Data Type Acc. Name Default Value

0 Unsigned8 ro Largest Sub-Index 5

1 Unsigned32 rw COB-ID for PDO 180h + Node

2 Unsigned8 rw Transmission Type FFh

5 Unsigned16 rw Event Timer 0000h

Only sub-indices 0 to 2 and 5 are supported. An access to other

sub-indices will lead to an error message.

COB-ID for PDO Sub-Index 1 defined the identifier for the Transmit-PDO. The 32-

bit value has the following s

tructure.

Tabelle 16: Definition of COB-ID for PDO

Bit 31 Bit 30 Bit 29 Bit 28 - 0

PDO valid,

0 = valid

1 = not valid

RTR allowed,

0 = yes

1 = no RTR

Frame type,

0 = 11 Bit

1 = 29 Bit

Identifier,

In order to enable the PDO the most significant bit (Bit 31) must

be set to 0. In order to disable the PDO the most significant bit

must be set to 1. In the default setting the PDO is active (Bit 31 =

0).

Transmission Type The transmission type defines the transmission character of the

PDO.

Tabelle 17: Setup of Transmission Type

Transmission Type Description

00h acyclic synchronous,

01h - F0h

(1 - 240 dez)

cyclic synchronous,

FFh

(255 dez)

event driven,

PDO is sent when Event Timer elapses

Page 64

PDO Communication CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 64

8

The Transmit-PDO has 1 byte of process data. The contents is copied from object 6000h (refer to “Digital Input Value” on page

53) into the PDO.

Beispiel: Input 1 was changed from 0 to 1, module address = 1

ID DLC B0

181h 1 01h

The PDO is also transmitted on change of a digital output. Transmission

Note

of the PDO is only possible in Operational Mode. By me-

ans of objects 6005h to 6008h the interrupt behav

iour of the

PDO can be changed.

Page 65

CANopen Protocol PDO Communication

Page

65 MicroControl Version 2.00 μCAN.8.dio-BOX

8

8.6.4 Synchronisation Message

Index 1005h The object at index 1005h defines the identifier for the SYNC-

message. On reception of a message with this identifier the transmission of PDOs is triggered (refer to “Transmit PDO” on page

63)..

Sub-Index Data Type Acc. Name Default Value

0 Unsigned32 rw COB-ID SYNC 80h

Only sub-index 0 is supported. An access to other sub-indices will

lead to an error message.

Beispiel: Set SYNC-ID to 10, module address 1

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

601h 8 22h 05h 10h 0Ah 00h 00h 00h 00h

As answer you will get the following message:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

581h 8 60h 05h 10h 00h 00h 00h 00h 00h

The default identifier is 80h in order to ensure a high priority of

the SYNC-message.

The SYNC-identifier is not saved inside the non-volatile

Note

memory

autonomously. It is necessary to store this parameter via object

1010h (refer to “Store Parameters” on page 49)

Page 66

Emergency Message CANopen Protocol

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 66

8

8.7 Emergency Message

Emergency objects are triggered by the occurrence of a device

internal error situation and are transmitted from an emergency

producer on the device.

Note

An emergency is different from a SDO Error Message. The last

one only holds the access error to the object dictionary, whereas

an emergency display a severe hardware/software failure.

The emergency identifier has the default value 128d + moduleaddress. The emergency message has the following structure:

ID DLC B0 B1 B2 B3 B4 B5 B6 B7

8 Error Code 00h Manufacturer Specific Error Field

The following emergency error codes are supported:

Tabelle 18: Emergency Error Codes

Error Code (hex) Description

0000 Error Reset or No Error

1000 Generic Error

2300 Current, Device Output

5000 Device-Hardware

6000 Device-Software

Page 67

CANopen Protocol Emergency Message

Page

67 MicroControl Version 2.00 μCAN.8.dio-BOX

8

Page 68

Technical Data

μCAN.8.dio-BOX

MicroControl Version 2.00 Page 68

9

9. Technical Data

Power Supply

Supply Voltage, U

PWR

8 .. 60 V DC, reverse current protected

Power Consumption 1,5 W (60 mA @ 24 V DC) without load

Isolation Fieldbus/Supply: 500 Veff

Physical Interface

Terminal Block (2,5 mm

2

)

CAN-Bus

Baudrates 10 kBit/s .. 1 MBit/s

Status on the bus active node

Protocol CANopen, DS-401

Physical Interface

Terminal Block (2,5 mm2 )

EMC

Electromagnetic immunity according to EN 50082-2

Electrostatic discharge 8 kV air discharge, 4 kV contact discharge,

according to EN 6

1000-4-2

Electromagnetic fields 10 V/m, according to ENV 50204

Burst 5 kHz, 2 kV according to EN 6100-4-4

Conducted RF-Disturbance 10 V, according to EN 61000-4-6

Electromagnetic emission according to EN 50081-2

Page 69

Mechanic

Case Aluminium

Dimensions 125 * 80 * 57 mm (L * B * H)

Weight 540 g

Protection class IP65

Digital Inputs

Impedance 24,2 kOhm

Valid Low-Level U

in

< 0,4 * U

PWR

Valid High-Level U

in

> 0,6 * U

PWR

Digital Outputs / High Side

Type Highside Power-MOSFET

Maximum voltage 50 V

Maximum current 1,4 A

Short circuit detection 5 A, each output short circuit protected

Module maximum current 6 A

Digital Outputs / Low Side

Type Lowside Power-MOSFET

Maximum voltage 50 V

Maximum current 2 A

Short circuit protection each output is short circuit protected

Module maximum current 6 A

Technical Data

Page

69 MicroControl Version 2.00 μCAN.8.dio-BOX

9

Page 70

Index

μCAN.8.dio-BOX MicroControl Version 2.00 Page 70

I

A

Address selection 27

B

Baudrate

bus length 13

setup 28

Bootup message 57

C

CANopen

DS-301 39

DS-401 52

Communication Profile 44

D

Device Profile 46

I

Identity Object 51

M

Manufacturer Device Name 48

Module Status 36

LED 34

N

Network Management 40

Enter Pre-Operational 40

Reset Node 41

Start Node 40

Stop Node 40

Network Status 35

LED 34

NMT

see Network Management

O

Object

1000h 46

1001h 46

1003h 47

1005h 65

1008h 48

1009h 48

100Ah 48

1010h 49

1011h 50

1018h 51

1400h 61

1800h 63

5FF5h 56

6000h 53

6002h 53

6005h 54

6006h 54

6202h 55

P

Pre-defined Connection Set 39

Pre-defined Error Field 47

T

Terminal

binary control lines 33

CAN bus 26

power supply 24

Termination 29

Page 71

71 μCAN.8.dio-BOX

Loading...

Loading...