Page 1

LDS II

PROGRAMMING

GUIDE

PART NUMBER 880019-0123

Revised: September 5, 2006 CPC

© Copyright 2006 by Microcom Corporation, Lewis Center, Ohio – All rights reserved.

Printed in the United States of America

Page 2

This Page Intentionally Left Blank

Page 3

This Page Intentionally Left Blank

Page 4

Proprietary Statement

This manual contains information proprietary to Microcom Corporation. This information is

intended solely for the use of parties operating and maintaining such equipment described

herein.

Product Enhancements

Microcom Corporation is committed to the continual improvement of performance and

quality in our products. For this reason, specifications are subject to change without notice.

Liability Disclaimer

Microcom Corporation makes every effort to assure that all information and specifications

contained in this manual are accurate; however, mistakes are sometimes made. Microcom

Corporation shall not be liable for any damages resulting in the use or misuse of this

product. The exclusion or limitation involving consequential or incidental damage does not

apply to all states; therefore limitation mentioned above may or may not apply.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions contained in this

manual, may cause harmful interference to radio communications.

SolarWinds® is a registered trademark of SolarWinds.Net, Inc.

Tera Term Pro® is a registered trademark of T. Teranishi.

HyperTerminal® and HyperAccess® are trademarks of Hilgraeve Inc.

Centronics® is a registered trademark of Data Computer Corporation.

Procomm Plus® is a registered trademark of Intuitive Communications.

Arial® is a registered trademark of The Monotype Corporation.

TrueType® is a registered trademark of Apple Computer, Inc.

Microsoft®, Windows 95®, Windows 98®, Windows 2000®, Windows NT

Microsoft Corporation.

IBM® products and name are registered trademarks of International Business Machines Corporation.

Other products and company names mentioned herein may be trademarks of their respective owners.

®,

Windows Notepad® are registered trademarks of

Page 5

Table of Contents

INTRODUCTION.............................................................................................................1

CHAPTER 1: DESIGNING USING LDSII.......................................................................3

1.1 SPECIAL CONTROL CODES .....................................................................................3

1.2 SCRIPT CREATION: AN OVERVIEW...........................................................................5

1.3 BEGIN SCRIPT - ^A)FILENAME .................................................................................6

1.4 SCRIPT HEADER ....................................................................................................6

1.4.1 LSX (Label Width).......................................................................................7

1.4.2 LSY (Label Height)......................................................................................7

1.4.3 GAP (Gap Size)...........................................................................................7

1.4.4 DRM (Distance to Registration Mark)..........................................................8

1.4.5 SPD (Print Speed).......................................................................................8

1.4.6 DET (Detection Method)..............................................................................8

1.4.7 OFX (Offset X Direction)..............................................................................9

1.4.8 OFY (Offset Y Direction)..............................................................................9

1.5 FORMAT ENTRY COMMAND - ^FN)...........................................................................9

1.5.1 XB (X Coordinate) .....................................................................................10

1.5.2 YB (Y Coordinate) .....................................................................................10

1.5.3 CI (Conversion Identifier)..........................................................................10

1.5.4 SW (Size Width).........................................................................................13

1.5.5 SH (Size Height)........................................................................................13

1.5.6 AI (Attribute Index).....................................................................................14

1.5.7 DN (Direction).............................................................................................15

1.5.8 FO (Field Orientation)................................................................................15

1.5.9 FJ (Field Justification).................................................................................15

1.5.10 FW (Field Width)........................................................................................16

1.5.11 CS (Character Spacing) .............................................................................16

1.5.12 FC (First Character)...................................................................................17

1.5.13 CC (Character Count).................................................................................17

1.6 TEXT ENTRY COMMAND - ^TN)..............................................................................17

CHAPTER 2: PRINTER COMMANDS..........................................................................19

2.1 SCRIPT MANAGEMENT COMMANDS........................................................................19

LDSII Programming Guide - 880015-0123 i

Page 6

2.1.1 Begin Script - ^A)filename...........................................................................20

2.1.2 Begin Temporary Script - ^AT)filename......................................................20

2.1.3 Format Entry Command - ^Fn)XB,YB,CI,SW,SH,AI,DN,FO,FJ,FW,CS,FC,CC .......20

2.1.4 Text Entry Command - ^Tn)text data..........................................................20

2.2 2XX SERIES COMMANDS.......................................................................................21

2.2.1 ^D200) LSX, LSY, GAP, DRM, SPD, DET, OFX, OFY (Script Header) ......21

2.2.2 ^D202)n (Text Replacement Header) .......................................................21

2.3 3XX SERIES COMMANDS.......................................................................................22

2.3.1 ^D300)n (Print Command) ........................................................................23

2.3.2 ^D305)1 (Infinity Print Command).............................................................23

2.3.3 ^D311)1 (Top-OF-Form)...........................................................................23

2.3.4 ^D312)n (Form Feed) ...............................................................................23

2.3.5 ^D313)n1,n2 (Advance Media) ..................................................................23

2.3.6 ^D315)n (Calibrate Sensor Thresholds)....................................................23

2.3.7 ^D323)n (List Enablements).....................................................................24

2.3.8 ^D324)n (List Statistics)............................................................................24

2.3.9 ^D325)n (List Selections)..........................................................................24

2.3.10 ^D326)n (List Settings)............................................................................ 24

2.3.11 ^D327)1 (List Status) ................................................................................24

2.3.12 ^D340)filename (Load/Save File)...............................................................25

2.3.13 ^D341)type (List Catalog) ........................................................................25

2.3.14 ^D342)filename (Delete File) .....................................................................25

2.3.15 ^D343)filename (List Script).......................................................................26

2.3.16 ^D345)filename (Load Volatile File)...........................................................26

2.3.17 ^D346)1 (Defragment Flash Files)............................................................26

2.3.18 ^D350)filename (Execute Script) ...............................................................27

2.3.19 ^D360)1 (List Memory Available)..............................................................27

2.3.20 ^D365)? (List Status Response List)........................................................27

2.3.21 ^D390)1 (Reset Printer)............................................................................29

2.3.22 ^D391)1 (Restore Configuration Defaults) ................................................29

2.3.23 ^D392)1 (Restore Property Defaults)........................................................29

2.3.24 ^D394)1 (Draw Platen Roller Compensation Line) ...................................30

2.4 5XX SERIES COMMANDS.......................................................................................30

2.4.1 ^D501)n (Select Emulation Mode)............................................................30

ii LDSII Programming Guide - 880015-0123

Page 7

2.4.2 ^D506)n (Select Cutter Type)...................................................................30

2.4.3 ^D507)n (Select Printed Media Handler) ..................................................31

2.4.4 ^D508)n (Select Label Present Detector Type) ........................................31

2.4.5 ^D509)n (Select INPUT1 Response Polarity and Action) .........................31

2.4.6 ^D541)n (Select Button 1 Response) .......................................................32

2.4.7 ^D550)n (Select Printer Response Set)....................................................32

2.4.8 ^D564)n (Select Measurement Units).......................................................33

2.4.9 ^D565)n (Select Speed Units) ..................................................................33

2.4.10 ^D566)n (Select Temperature Units) ........................................................34

2.4.11 ^D567)filename (Select Power-up Script).................................................34

2.4.12 ^D570)n (Select Active Port) ....................................................................34

2.4.13 ^D581)n (Select Stock Out Handling Method)..........................................34

2.4.14 ^D597)n (Select Dispense Mode).............................................................35

2.5 6XX SERIES COMMANDS.......................................................................................36

2.5.1 ^D631)n (Set Media Width) ......................................................................36

2.5.2 ^D632)n (Set Media Height) .....................................................................36

2.5.3 ^D633)n (Set GAP Size)...........................................................................36

2.5.4 ^D634)n (Distance To Registration Mark).................................................36

2.5.5 ^D635)n (Set Print Speed)........................................................................37

2.5.6 ^D636)n (Set Detection Mode) ................................................................37

2.5.7 ^D637)n (Offset X Direction).....................................................................39

2.5.8 ^D638)n (Offset Y Direction).....................................................................39

2.5.9 ^D639)n (Set Centering Offset) ................................................................39

2.5.10 ^D640)n (Set Delay Time Between Labels)..............................................39

2.5.11 ^D641)n (Set Retraction Delay Time).......................................................39

2.5.12 ^D642)n (Set Advance/Retract Distance).................................................40

2.5.13 ^D643)n (Set Print Head to LPD Distance)..............................................40

2.5.14 ^D644)n (Set Idle Recognition Delay)......................................................40

2.5.15 ^D645)n1 (Set Advance/Retract Speed)..................................................40

2.5.16 ^D646)n (Set Platen Roller Compensation).............................................40

2.5.17 ^D647)dc,dp (Set Print Head Parameters) ...............................................41

2.5.18 ^D648)n (Set Blackline Sensor to Print Head Distance)...........................41

2.5.19 ^D649)n (Set Gap Sensor to Print Head Distance)...................................42

2.5.20 ^D655)n (Set Labels Printed) ...................................................................42

LDSII Programming Guide - 880015-0123 iii

Page 8

2.5.21 ^D670) (Set Serial Port)..........................................................................42

2.5.22 ^D674)n (Set Ethernet Port Number)........................................................43

2.5.23 ^D675)n (Set Printer IP Address)..............................................................43

2.5.24 ^D676)n (Set Server/Host IP Address) .....................................................43

2.5.25 ^D677)n (Set Gateway IP Address)..........................................................43

2.5.26 ^D678)n (Set Broadcast Mask Address)...................................................44

2.5.27 ^D679)n (Set Net Mask Address) .............................................................44

2.5.28 ^D680)n (Set Gap Threshold)...................................................................44

2.5.29 ^D681)n (Set Blackline Threshold) ...........................................................44

2.5.30 ^D682)n (Set Stock Sensor Threshold).................................................... 44

2.5.31 ^D683)n (Set LPD PWM)..........................................................................44

2.5.32 ^D690)n (Set Darkness Range)................................................................45

2.6 7XX SERIES COMMANDS.......................................................................................45

2.6.1 ^D701)n (Enable Force LDS1 on Power-up).............................................45

2.6.2 ^D720)n (Enable Auto Power-Up Script) .................................................. 45

2.6.3 ^D721)n (Enable Auto Enquiry After Print)................................................45

2.6.4 ^D723)n (Enable Auto TOF on Power up) ................................................45

2.6.5 ^D726)n (Enable Auto ACK/NAK).............................................................46

2.6.6 ^D727)n (Enable Auto Error Reporting) ....................................................46

2.6.7 ^D735)n (Enable Immediate Graphic Printing)..........................................46

2.6.8 ^D736)n (Enable Immediate Graphic Centering) ......................................46

2.6.9 ^D740)n (Enable Cutter)...........................................................................47

2.6.10 ^D741)n (Enable PMH)............................................................................. 47

2.6.11 ^D760)n (Enable Auto Defrag on Power-up).............................................47

2.6.12 ^D770)n (Enable Software Flow Control)..................................................47

2.6.13 ^D771)n (Enable Hardware Flow Control) ................................................47

2.7 9XX SERIES COMMANDS.......................................................................................48

2.7.1 ^D900)d, s (Diagnostic Tic-Tic Mode).......................................................48

2.7.3 ^D930)level (Get Access Code Key).........................................................53

2.7.4 ^D931)level, password (Change Access Level).........................................53

2.7.5 ^D932) (List Access Passwords) .............................................................53

2.7.6 ^D945)n (List Diagnostic Dump) ...............................................................53

2.7.7 ^D960)n (Print Test Pattern).....................................................................54

2.7.8 ^D971)n (Edit Inches Printed Statistic) .....................................................54

iv LDSII Programming Guide - 880015-0123

Page 9

2.7.9 ^D972)n (Edit Total Inches Run Statistic).................................................54

2.7.10 ^D973)n (Edit Power on Time Statistic)....................................................54

2.7.11 ^D974)n (Edit Head Up Cycles Statistic)..................................................54

2.7.12 ^D975)n (Clear All Statistics)....................................................................55

2.7.13 ^D976)n (Edit Unit Serial Number) ...........................................................55

2.7.14 ^D977)n (Edit Cutter Cycles Statistic).......................................................55

2.7.15 ^D978)0xn (Edit Ethernet MAC Address) .................................................55

2.7.16 ^D979)n (Edit CPU Serial Number)..........................................................55

2.7.17 ^D980)n (Calibrate Sensors) ....................................................................55

CHAPTER 3: UPDATING FLASH MEMORY...............................................................57

3.1 COMPRESSED FILE UPDATE..................................................................................57

3.2 MCA COMPRESSED FILE RECOVERY.....................................................................58

CHAPTER 4: SPECIAL FEATURES............................................................................61

4.1 REVERSE VIDEO ..................................................................................................61

4.2 LINE DRAW..........................................................................................................62

CHAPTER 5: BAR CODES ..........................................................................................65

5.1 GENERATING BAR CODES.....................................................................................65

5.1.1 CI Parameter ..............................................................................................65

5.1.2 SW Parameter............................................................................................65

5.1.3 SH Parameter.............................................................................................65

5.1.4 AI Parameter..............................................................................................65

5.2 LINEAR BAR CODES .............................................................................................66

5.2.1 Codabar (Rationalized)...............................................................................66

5.2.2 Code 128 (Manual Compression)...............................................................66

5.2.3 Code 128 (Automatic Compression)...........................................................67

5.2.4 Code 39......................................................................................................68

5.2.5 Code 93......................................................................................................68

5.2.6 Code I2of5 (Interleaved 2 of 5)...................................................................68

5.2.7 MSI0 (Modified Plessey).............................................................................68

5.2.8 MSI1 (Modified Plessey).............................................................................68

5.2.9 MSI2 (Modified Plessey).............................................................................69

5.2.10 Postnet .......................................................................................................69

5.3 2D BAR CODES ...................................................................................................69

LDSII Programming Guide - 880015-0123 v

Page 10

5.3.1 Data Matrix .................................................................................................69

5.3.2 PDF-417 .....................................................................................................74

CHAPTER 6: DIAGNOSTICS AND TROUBLESHOOTING........................................77

6.1 DIAGNOSTIC MODE...............................................................................................77

6.1.1 Entering Diagnostic Mode...........................................................................77

6.1.2 Status Label................................................................................................77

6.2 ENQUIRY RESPONSES ..........................................................................................80

6.3 FATAL ERROR RESPONSES...................................................................................83

6.3.1 >STOCK OUT< (01) ...................................................................................83

6.3.2 >STOCK OVERADVANCED< (02).............................................................84

6.3.3 >STOCK JAMMED< (03)............................................................................84

6.3.4 >INCORRECT STOCK< (04)......................................................................84

6.3.5 >CUTTER JAMMED< (10)..........................................................................84

6.3.6 >CUTTER INOPERATIVE< (11).................................................................84

6.3.7 >CUTTER WATCHDOG STOPPED CUTTER< (12)..................................85

6.3.8 >CUTTER WATCHDOG WON”T RESET< (13) .........................................85

6.3.9 >MISSING LABEL< (1C) ............................................................................85

6.3.10 >INCOMPLETE FORM< (1D).....................................................................85

6.3.11 >CATCH TRAY FULL< (20)........................................................................85

6.3.12 >SCRIPT ERROR< (30).............................................................................85

6.3.13 >INVALID PARAMETER< (31)...................................................................85

6.3.14 >PARSER ERROR< (32)............................................................................86

6.3.15 >COMM ERROR< (40)...............................................................................86

6.3.16 >FLASH ERROR< (51)...............................................................................86

6.4 BASIC STATUS RESPONSES ..................................................................................86

6.4.1 >OK< (06)...................................................................................................86

6.4.2 >INPUT 1< (21) ..........................................................................................87

6.4.3 >INPUT 2< (22) ..........................................................................................87

6.4.4 >RESTARTED< (80)...................................................................................87

6.4.5 >READY< (81)............................................................................................87

6.4.6 >BUSY< (82) ..............................................................................................87

6.4.7 >PAUSED< (83) .........................................................................................87

6.4.8 >PRINTING< (84) .......................................................................................87

vi LDSII Programming Guide - 880015-0123

Page 11

6.4.9 >FEEDING< (85)........................................................................................88

6.4.10 >LABEL/TAG PRESENT< (86)...................................................................88

6.4.11 >STOCK ADVANCED< (87).......................................................................88

6.4.12 >FLASH DEFRAGMENTING< (8A)............................................................88

6.3.13 >STOCK NOT LOADED< (8F)...................................................................88

6.4.14 >RETRACTION DELAY< (90)....................................................................88

6.4.15 >PRINT DELAY< (91) ................................................................................88

6.4.16 >FLASH MEMORY LOW< (B0)..................................................................89

6.4.17 >BUTTON 1 TAPPED< (C0) ......................................................................89

6.4.18 >BUTTON 1 HELD< (C1)...........................................................................89

6.4.19 >TEMPERATURE OUT OF RANGE< (D0) ................................................89

6.4.20 >NONEXISTENT COMMAND< (D1)..........................................................89

6.4.21 >INCOMPLETE COMMAND< (D2)............................................................89

6.4.22 >ZIP FILE ERROR< (D3) ...........................................................................89

6.4.23 >FILE CONVERSION ERROR< (D4).........................................................90

6.4.24 >UNSUPPORTED FILE TYPE< (D5).........................................................90

6.4.25 >FILE NOT FOUND< (D6)..........................................................................90

6.4.26 >INADEQUATE ACCESS MODE< (D7).....................................................90

6.4.27 >FILE IS READ ONLY< (D9)......................................................................90

6.4.28 >INADEQUATE FLASH SPACE< (DA)......................................................90

6.4.29 >I/O FAILURE< (DB)..................................................................................90

6.4.30 >FONT/GRAPHIC NOT FOUND< (DC) .....................................................91

6.3.31 >SWITCH 0 ACTUATED< (E1) ..................................................................91

6.3.32 >SWITCH 1 ACTUATED< (E2) ..................................................................91

6.3.33 >SWITCH 2 ACTUATED< (E3) ..................................................................91

6.3.34 >TOF SWITCH ACTUATED< (E4).............................................................91

6.4.35 >FIELD OFF IMAGE< (F0).........................................................................91

6.3.36 >GRAPHIC TOO LARGE< (F2)..................................................................91

6.4.37 >POWERED DOWN< (FF).........................................................................91

CHAPTER 7: COMMUNICATIONS............................................................................93

7.1 RS-232 SERIAL...................................................................................................93

7.1.1 RS-232 Printer Cables................................................................................93

7.2 ETHERNET - 10/100 BASE-T...............................................................................94

LDSII Programming Guide - 880015-0123 vii

Page 12

7.3 USB PORT ..........................................................................................................94

APPENDIX A – ASCII CHART......................................................................................95

GLOSSARY .................................................................................................................. 97

INDEX..........................................................................................................................101

USER NOTES ............................................................................................................. 103

viii LDSII Programming Guide - 880015-0123

Page 13

List of Tables

Table 1 Resident Bitmapped Fonts................................................................................ 11

Table 2 Bar Code Index ................................................................................................. 12

Table 3 Attribute Index................................................................................................... 14

Table 4 Field Justifications............................................................................................. 16

Table 5 ^Dxxx Series Commands .................................................................................. 19

Table 6 ^D365) Status Response List............................................................................ 29

Table 7 Print Head Parameters...................................................................................... 41

Table 8 Blackline Sensor to Print Head Distance........................................................... 42

Table 9 Gap Sensor to Print Head Distance................................................................... 42

Table 10 ^D670) Parameters ........................................................................................... 43

Table 11 ^D900) and ^D902) Parameters........................................................................ 48

Table 12 Access Levels ................................................................................................... 53

Table 13 Code 128 Special Function Access................................................................... 66

Table 14 Data Matrix Configuration Parameters .............................................................. 71

Table 15 Data Matrix Encoding Schemes ........................................................................ 71

Table 16 ASCII Codeword Values.................................................................................... 72

Table 17 Data Matrix Special Characters......................................................................... 74

Table 18 PDF-417 Error Correction Level........................................................................ 75

Table 19 Enquiry Responses........................................................................................... 83

Table 20 RS-232 Cable Configurations............................................................................ 93

LDSII Programming Guide - 880015-0123 ix

Page 14

x LDSII Programming Guide - 880015-0123

Page 15

List of Figures

Figure 1 Sample Script Format.......................................................................................... 6

Figure 2 Script Parameters................................................................................................ 7

Figure 3 Distance-to-Registration Mark (DRM).................................................................. 8

Figure 4 Format Entry Command ...................................................................................... 9

Figure 5 Text Entry Command......................................................................................... 18

Figure 6 Detection Mode - None...................................................................................... 37

Figure 7 Detection Mode - Blackline................................................................................ 38

Figure 8 Detection Mode - Die-cut and Blowhole ............................................................ 39

Figure 9 ^D900 Blackline Listing ..................................................................................... 49

Figure 10 ^D900 Blackline Threshold Example .............................................................. 50

Figure 11 ^D900 Die-cut Listing...................................................................................... 51

Figure 12 ^D900 Die-cut Threshold Example................................................................. 52

Figure 13 Auxiliary Button............................................................................................... 60

Figure 14 Reverse Video................................................................................................ 61

Figure 15 Line Draw Reverse Video............................................................................... 62

Figure 16 Line Draw Feature.......................................................................................... 63

Figure 17 Two Lines....................................................................................................... 63

Figure 18 Box Creation................................................................................................... 64

Figure 19 Code 128 Subset Switching ........................................................................... 67

Figure 20 Data Matrix Format Structure ......................................................................... 69

Figure 21 PDF-417 Format Structure............................................................................. 74

Figure 22 ^D323) - List Enablements Example.............................................................. 77

Figure 23 ^D326) - List Settings Example...................................................................... 78

Figure 24 ^D325) - List Selections Example................................................................... 79

LDSII Programming Guide - 880015-0123 xi

Page 16

Figure 25 ^D324) - List Statistics Example.....................................................................79

Figure 26 ^D960)1 or ^K Test Pattern.............................................................................80

Figure 27 10/100 BASE-T Ethernet Port.........................................................................94

xii LDSII Programming Guide - 880015-0123

Page 17

Introduction

This programming guide provides the user with an overview of the LDSII command structure

and label formatting requirements.

The Label Design Software (LDSII) is the resident printer control language that is used to

create, store and print label scripts, while also controlling the other various printer features.

LDSII can be used in conjunction with mini-computers, mainframes, personal computers,

and most other special purpose computers. The examples provided within this guide use

®

an IBM

emulation software program (i.e., Procomm Plus, HyperTerminal, HyperAccess or Tera

Term Pro). Microcom Corporation printers are shipped with serial parameters set to 9600baud, no parity, 8 data bits, and 1 stop bit unless setup with a custom configuration. The

emulator program will have to be set to these parameters for proper serial communication.

LDSII printers require the use of hardware flow control (CTS/RTS) for proper data

management to occur.

During the power-up, the indicator light will flash amber and green, the printer copies the

current application (source code or firmware) to the RAM memory. This allows for faster

transfer and operation after the printer has been powered-up. The second phase of the

power up is the printer’s initialization process and flash file system restore. This process

restores all of the files saved in the flash memory. The power-up process will vary in time

depending on the files that have been saved into the printer’s flash memory

compatible personal computer with an available serial port, and a terminal

LDSII Programming Guide - 880015-0123 1

Page 18

2 LDSII Programming Guide - 880015-0123

Page 19

Chapter 1: Designing Using LDSII

Label formats or scripts are very easy to design using LDSII by following these basic steps

below. LDSII printers require the use of hardware flow control (CTS/RTS) for proper data

management to occur. Software flow control should not be used to manage data being sent

to an LDSII printer.

1. Determine the media type, media size, and print speed desired for your application;

enter this data into the script header.

2. Determine the type of handling operation desired and use the appropriate LDSII

printer control commands.

3. Define the formatting instructions for the type and placement of data.

4. Enter the text data that corresponds to the formatting instructions.

5. Send the script to the printer.

1.1 Special Control Codes

The printer can accept either the one-character control code (“Ctrl + E”) or the two-character

caret (^) plus alpha character (“^E”). Control codes are processed immediately while the

^Dxx commands are processed in the order they are issued. It is recognized that some

mainframe and mini-computers cannot use the ASCII carat “^” character. The ASCII pipe

symbol “|” can be used as a substitute for these instances. Below is a list of special control

codes used by LDSII. A one (1) second delay should follow all control codes before

executing the next command to assure that the code and/or command executed correctly.

^A Begin Script: Marks the beginning of an LDSII script file entry.

^C Clear Halting Error: When issued five consecutive times with a one second delay

between each ^C the printer will clear blocking or halting error conditions returning

^Dxx command responsiveness. If the printer has remaining jobs in the queue, the

printer will return to a >PAUSED< state instead of the >READY< state. Please note

that if the condition that caused the error still exists, pressing the print button and/or

sending further scripts will cause this error to be reported again. Halting error

messages are conditions that must be corrected before printing may resume. Refer

to section 6.3 for additional information regarding error conditions.

^D Standard Command Preface: Combined with three-digit number issues a

command. See Chapter 2 for more information regarding ^D commands.

^E Printer Enquiry: Causes the printer to list its current status to an active

communications port.

^H Back Space: Causes the printer to issue a back space.

LDSII Programming Guide - 880015-0123 3

Page 20

Designing Using LDSII Chapter 1

^J Line Feed: Represents a Line Feed (LF) character or 0x0A.

^K Print Test Label: Causes the printer to print a test pattern consisting of diagonal

lines used to test the condition of the dots on the print head.

^L Form Feed: Scrolls one label out of the printer using the previous formats layout.

^M Carriage Return: Represents a Carriage Return (CR) character or 0x0D.

^O Top-of-Form (TOF): Instructs the printer to perform a TOF operation which uses the

Label Present Detector (LPD) in order to retract the media to the proper alignment in

regards to the print head.

^P Print: Causes the printer to print. Note: If no label scripts are loaded or stored in the

printer’s memory, the printer will not print a label until a script is processed.

^Q Send Data: Instructs the printer to send data or resume sending data (XON).

^R Reset Printer: Instructs the printer to perform a reset through software that

duplicates a hard reset. Issuing the ^R causes the reset to occur immediately,

bypassing commands sent but not yet processed. The ^D390)0 command is a

queued or serialized version of the ^R and should be used if a reset condition is

desired programmatically.

^S Stop Sending Data: Instructs the printer to stop sending data (XOFF).

^U List Selections: Causes the printer to list the current configured selections of the

printer through an active communications port.

^V List Settings: Causes the printer to list the current configured settings of the printer

through an active communications port.

^W List Statistics: Causes the printer to list the current statistics of the printer through

an active communications port.

^X Toggle Pause: Pauses the printer if printing, resumes if the printer is currently

paused.

^Y List Enablements: Causes the printer to list the current configured enablements of

the printer through an active communications port.

^Z End Script: Marks the end of a script file.

^] Cancel All Jobs: Causes all jobs currently queued to be deleted returning the printer

to its idle state. Refer to the ^D330 command.

4 LDSII Programming Guide - 880015-0123

Page 21

Chapter 1 Designing Using LDSII

1.2 Script Creation: An Overview

This section is intended to show a sample script file that will be used to explain the

individual components of the script.

A script consists of printer commands, a script header, field formats, and text data. The

script is initiated by sending an “^A)” (Begin Script) and continues until a “^Z)” (End Script)

has been received. All commands, unless otherwise noted, are terminated with either

another command or carriage return (ASCII 0x0D) character. The printer ignores the LF

(0x0A) character so it may be helpful to terminate each line with a CR+LF to assist in the

creation and troubleshooting of script files. Script files may contain up to a maximum total of

20,000 characters and up to 1000 different commands. Each command may contain up to

a total of 20 characters for the argument. This provides the flexibility in script creation to

handle even the most demanding applications.

The sample label script is listed below and will be referred to as the individual components

are discussed in the subsequent sections of Chapter 1. The actual programming

instructions that have been typed into a text file, using Windows Notepad, are in bold

typeface. These instructions are followed by a brief explanation shown within the

parentheses “()”.

^A)Sample Script

(^A indicates the beginning of the script file followed by an optional script title)

^D200)3.3, 1.9, 0.125, 1.063, 5 , 1 , 0, 0

(Script header used to define the label format or script file. Units have been entered

using inches as the unit of measure in this example.)

^F1)0.15, 1.50, @normal_14

(Field #1 formatting instructions containing text using a normal 14 point font)

^F2)0.30, 0.50,@code128auto, 3, 0.70

(Field #2 formatting instructions containing a Code128 bar code using automatic

compression)

^F3)0.60, 0.13, @normal_10

(Field #3 formatting instructions containing text using a normal 10 point font)

^T1)MICROCOM CORPORATION

(Text data for field #1)

^T2)12345678901234567

(Text data for field #2)

^T3)12345 678 90123 45 6 7 8901234

(Text data for field #3)

^D300 )1

(Instructs the printer to print one copy once the ^Z instruction is received)

^Z) (Marks the end of the script file)

LDSII Programming Guide - 880015-0123 5

Page 22

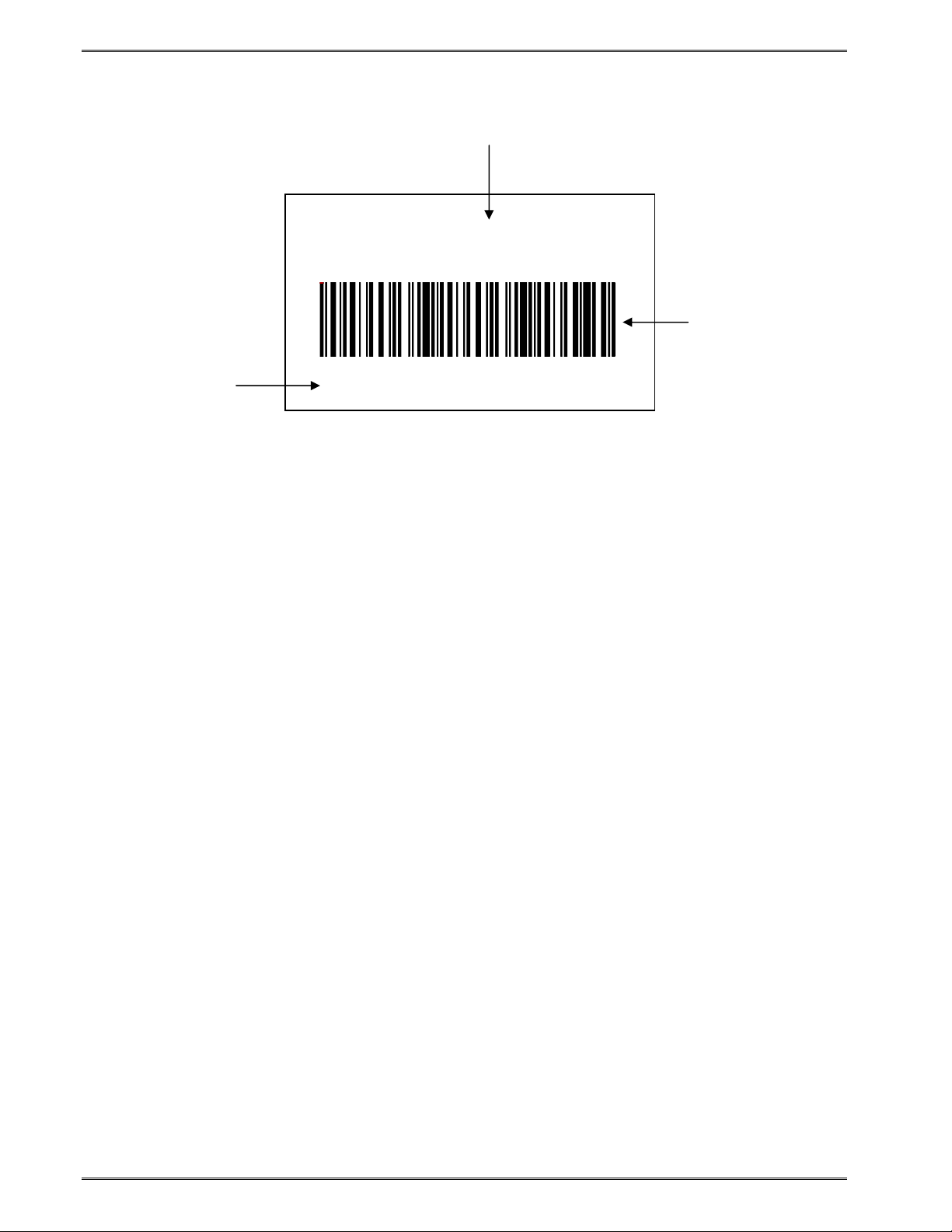

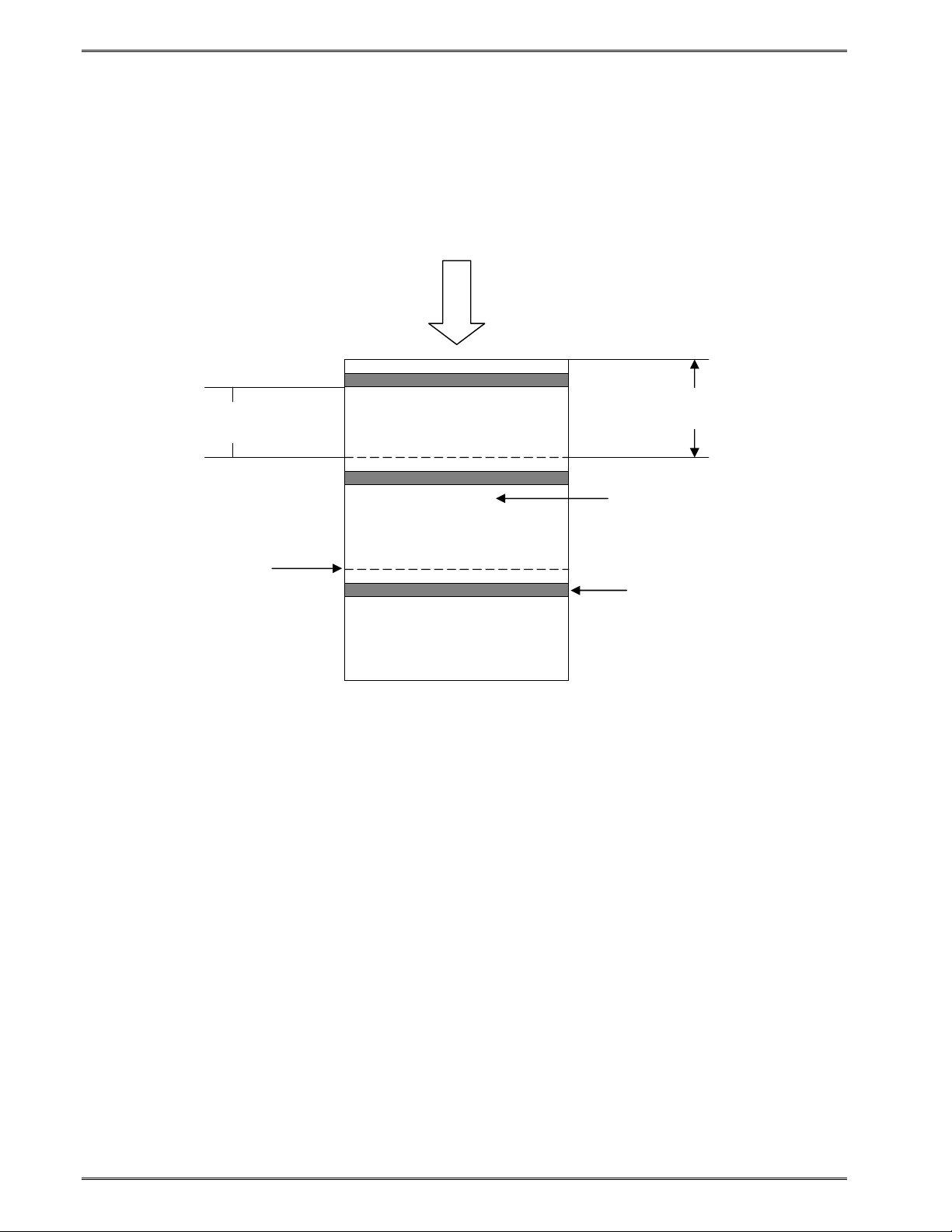

Designing Using LDSII Chapter 1

12345 678 90123 45 6 7 8901234

Field #1 –

The ^F1) and ^T1) commands

are formatting this field.

MICROCOM CORPORATION

Field #3 –

The ^F3) and

^T3) commands

are used to

format this field.

Field #2 –

The ^F2) and

^T2) commands

are used to

format this bar

code.

Figure 1 Sample Script Format

1.3 Begin Script - ^A)filename

This command is used to mark the beginning of a script file. The script may be saved into

the printer’s non-volatile flash memory if a title or filename is placed after the command.

The filename may contain to a maximum of 20 characters in length and include any

character from ASCII 0x20 and 0x41 to 0x7A (alphabetical characters plus [\]_’and SP

(space character)) with the exception of the caret (^) character. Script filenames can not

use a leading zero (“0”) or 0x30 characters. A script that contains a “filename” will only save

the script and will not process and print. The “^D350)filename” would be issued to recall

and process the saved script. If the script does not contain a “filename”, the script is

processed normally and will be volatile in nature.

For Example: The previous example script’s first line is “^A)Sample Script” which would

save this script into the printer’s flash memory (non-volatile) as “Sample Script”.

1.4 Script Header

The script header consists of the “^D200)” command followed by eight parameters that

control the media layout as well as printer operation. The parameters must be separated by

a delimiter, comma by default, and are entered using the current unit of measure selected

by the “^D564)” command. The origin or the starting coordinate is always the lower left

corner as the media exits the printer. This command may be issued from outside a script

but is typically created within a script file.

The script header is used to temporarily override the individual header parameters when

issued from within a script file. The parameters may be defaulted to the current persistent

value by not entering a value between the delimiters. Each of the header parameters has

an “^D6xx)” command equivalent that when set outside a script file remains persistent.

For Example: “^D200)LSX,LSY,,DRM”, would cause the “GAP” parameter to be defaulted

to the current “^D633)” value that was set outside a script file.

6 LDSII Programming Guide - 880015-0123

Page 23

Chapter 1 Designing Using LDSII

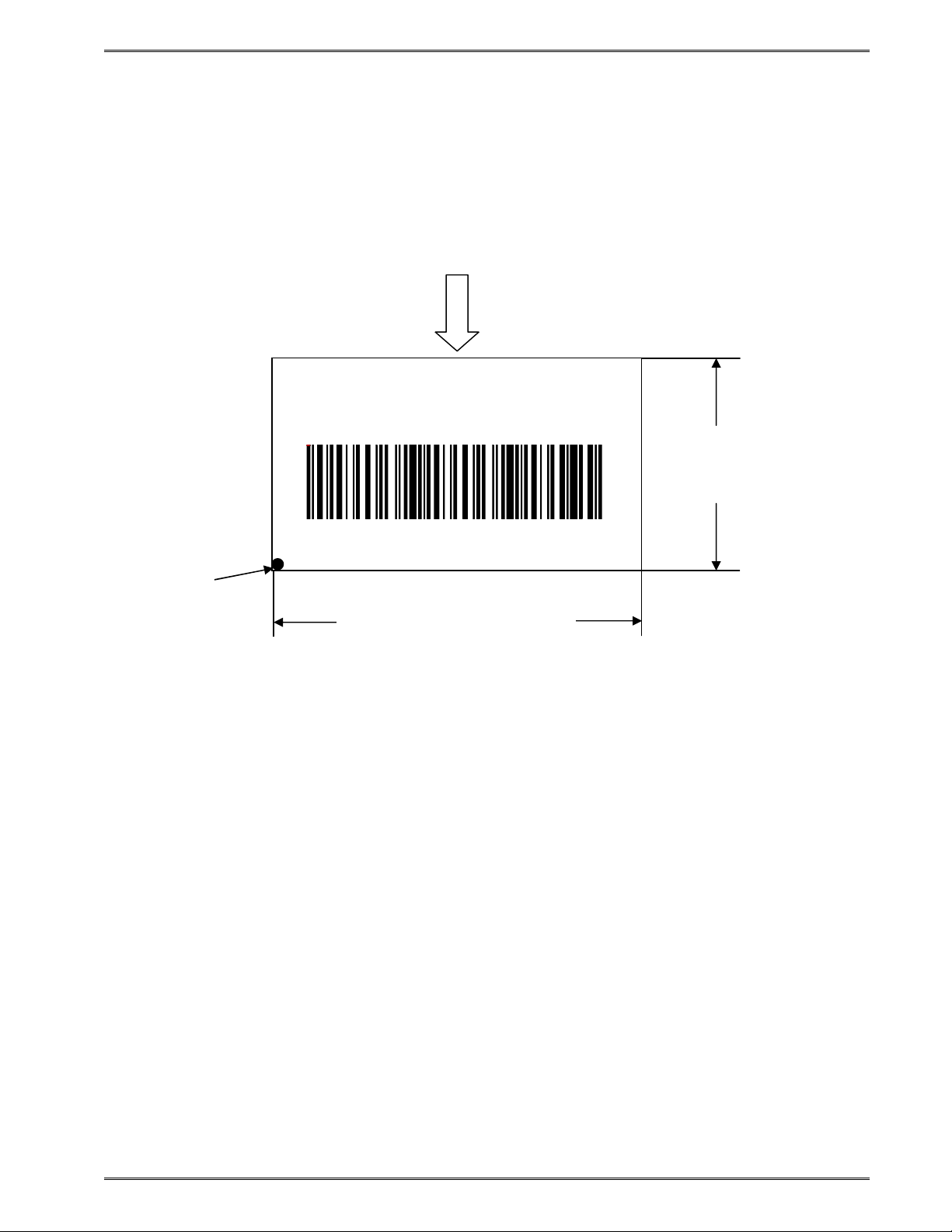

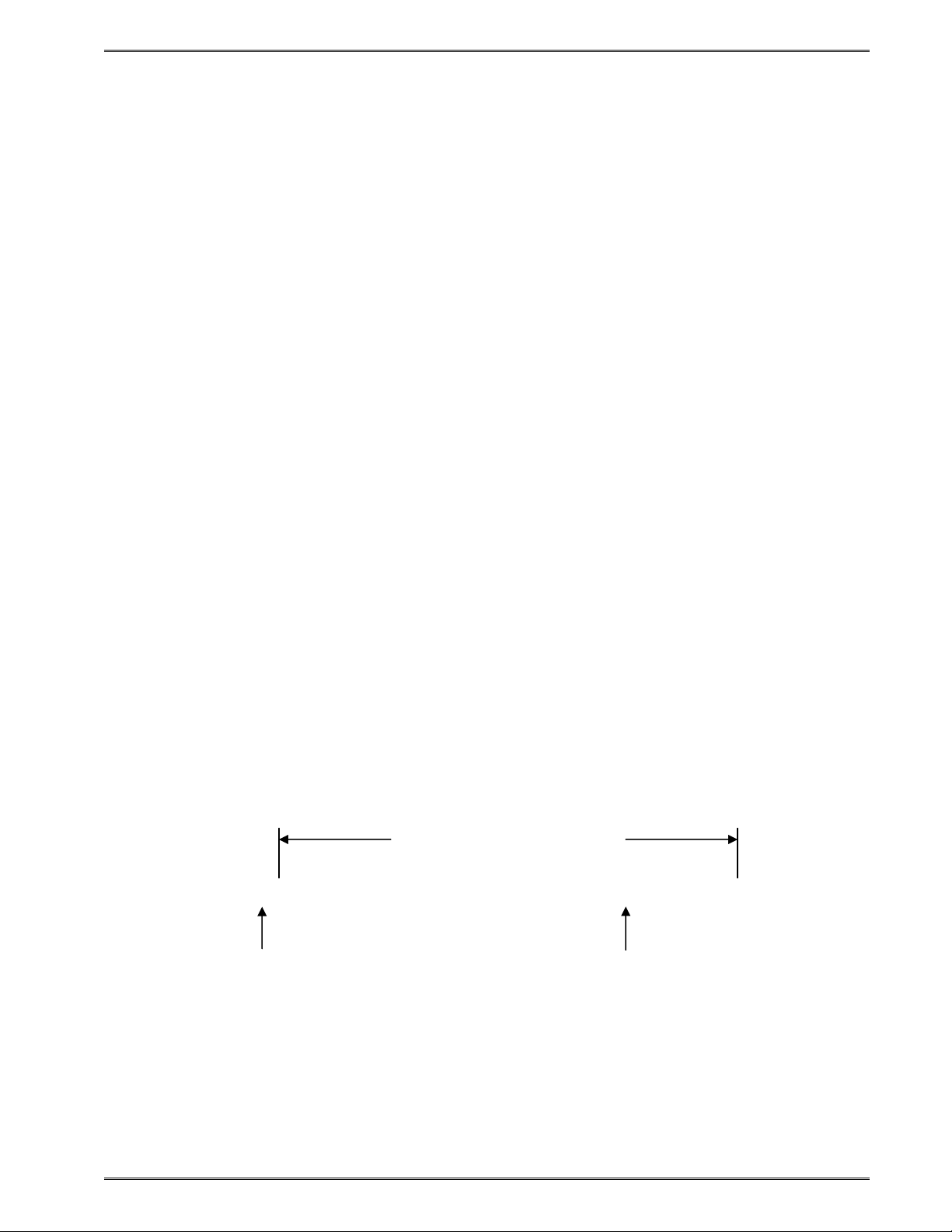

LSY

–

Y Direction

12345 678 90123 45 6 7 8901234

LSX

–

X Direction

This

The persistent commands are helpful in setting the printer up for a basic configuration and

then override them within the script. It is recommended that a script header contain values

for each and every parameter if access to the persistent command listings is not available.

^D200)LSX, LSY, GAP, DRM, SPD, DET, OFX, OFY

MICROCOM CORPORATION

is the

origin

1.4.1 LSX (Label Width) LSX

Specifies the width or “X” direction of the label in the unit of measure selected by the

“^D564)” command. The maximum LSX is the width of the print head installed in the printer.

This parameter is always required for proper script operation. See also ^D631)n command.

1.4.2 LSY (Label Height) LSX,

Specifies the height or “Y” direction of the label in the unit of measure selected by the

“^D564)” command. The maximum LSY height is 24”. This parameter is always required

for proper script operation. See also ^D632)n command.

1.4.3 GAP (Gap Size) LSX, LSY,

The GAP is the height of the registration mark on each label and/or tag. This would be the

backing material found between die-cut labels, blowhole sense mark, and/or the blackline

height. The value is entered using the current unit of measure selected by the “^D564)”

command. See also ^D633)n command.

Print Direction

(Print head limitation)

Figure 2 Script Parameters

, LSY, GAP, DRM, SPD, DET, OFX, OFY

LSY

, GAP, DRM, SPD, DET, OFX, OFY

GAP

(Virtually unlimited)

, DRM, SPD, DET, OFX, OFY

LDSII Programming Guide - 880015-0123 7

Page 24

Designing Using LDSII Chapter 1

an offset registration

1.4.4 DRM (Distance to Registration Mark) LSX, LSY, GAP, DRM, SPD, DET, OFX, OFY

This parameter is typically only used when the registration mark is not located at the edge of

the media. The “DRM” is the distance from the leading edge of the media to the beginning

of the registration mark. The DRM is entered using the current selected unit of measure

selected by the “^D564)” command. See also ^D634)n command.

Print Direction

DRM, (0.72”)

Media height (LSY)

The perforation

indicates the

separation of

individual tags.

Media that contains

mark.

Registration

Mark

(Black line)

Figure 3 Distance-to-Registration Mark (DRM)

1.4.5 SPD (Print Speed)

LSX, LSY, GAP, DRM,

SPD

, DET, OFX, OFY

This is the speed of the printer while printing, which is defined in either “inches/second (ips)”

or “centimeters/second (cms) as selected by the “^D564)” command. The print speed can

be adjusted anywhere from 1 ips (2.54 cms) to 6 ips (15.24 cms). See also ^D635)n

command.

1.4.6 DET (Detection Method)

LSX, LSY, GAP, DRM, SPD,

DET

, OFX, OFY

This parameter selects the type of method the printer uses for detecting registration marks

on different media types. A selection of a “0” disables registration detection and is used in

conjunction with media that does not contain a registration mark like continuous media. The

detectors are only used to detect Stock Out conditions when a selection of “0” is selected. A

selection of a “1” uses the reflective detection method and is used when detecting

registration marks located on the bottom side of the media. A selection of a “2” uses the

transmissive detection method which requires both the upper and the lower gap detectors to

be installed on the printer. This method can be used with any type of media but is not

recommended when only detecting registration marks located on the bottom side of the

media. A selection of a “3” also uses the transmissive detection method and is used in

8 LDSII Programming Guide - 880015-0123

Page 25

Chapter 1 Designing Using LDSII

^Fn) XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

conjunction with media containing a blowhole. The blowhole and die-cut selections differ on

how they detect an out of stock condition. See also ^D636)n command.

0 None (gap sensors are disabled)

1 Blackline (lower gap sensor is enabled)

2 Die-cut (upper and lower gap sensors are enabled)

3 Blowhole (upper and lower gap sensors are enabled)

1.4.7 OFX (Offset X Direction)

LSX, LSY, GAP, DRM, SPD, DET, OFX, OFY

This parameter moves or offsets all fields in the “X” direction without altering the field’s

insertion points. The value is entered using the current unit of measure selected by the

“^D564)” command. See also ^D637)n command.

1.4.8 OFY (Offset Y Direction)

LSX, LSY, GAP, DRM, SPD, DET, OFX,

OFY

This parameter moves or offsets all fields in the “Y” direction without altering the field’s

insertion points. The value is entered using the current unit of measure selected by the

“^D564)” command. See also ^D638)n command.

1.5 Format Entry Command - ^Fn)

The Format Entry command is used to define the characteristics, placement and

representation of the corresponding text data of the individual fields. This command starts

with the “^Fn)” structure which is then followed by thirteen different parameters that define

and control the desired field. The “n” is an identifier that represents the field number being

formatted and corresponds to the equivalent “^Tn)” line. As with the ^Dxxx commands,

multiple parameters must be separated by the comma (“,”) delimiter. The format entry

command can be issued from outside a script but is typically created within a script file.

Unlike the “^Dxx)” commands and the script header, the Format Entry Command typically

does contain default values as there are no equivalent commands for the individual

parameters. The default values are discussed under the individual parameter descriptions.

The “n” identifies the field

number which always

starts at “1” and not “0”.

Figure 4 Format Entry Command

Field parameters

The comma delimiter

LDSII Programming Guide - 880015-0123 9

Page 26

Designing Using LDSII Chapter 1

1.5.1 XB (X Coordinate) XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

This parameter is used to set the X coordinate of the field. The X coordinate is measured

from the left edge of the media, as viewed from the front of the printer. The value is entered

using the current unit of measure selected by the “^D564)” command and may contain any

number of digits desired. A leading zero before the decimal point is not required but should

be used to make trouble shooting scripts easier (i.e., .75 should be entered as 0.75). This

parameter does not contain a default value and is required.

1.5.2 YB (Y Coordinate)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

This parameter is used to set the Y coordinate of the field. The Y coordinate is measured

from the bottom edge of the media, as viewed from the front of the printer. The value is

entered using the current unit of measure selected by the “^D564)” command and may

contain any number of digits desired. A leading zero before the decimal point is not

required but should be used to make trouble shooting scripts easier (i.e., .75 should be

entered as 0.75). This parameter does not contain a default value and is required.

1.5.3 CI (Conversion Identifier)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

The Conversion Identifier (CI) determines how the associated text field will be rendered.

This parameter can be used to select from the available fonts, graphics, line draw feature,

and/or bar codes that will be used to render the associated Text Entry command line

(“^Tn)”). Objects that are stored in the printer’s flash memory are selected using the system

character (“@”) and the appropriate text identifier. This parameter can also be used to

select other user stored files by entering the name of the saved file into the CI parameter.

The entered values for the CI parameter are not case sensitive because the printer will

internally translate as lower case.

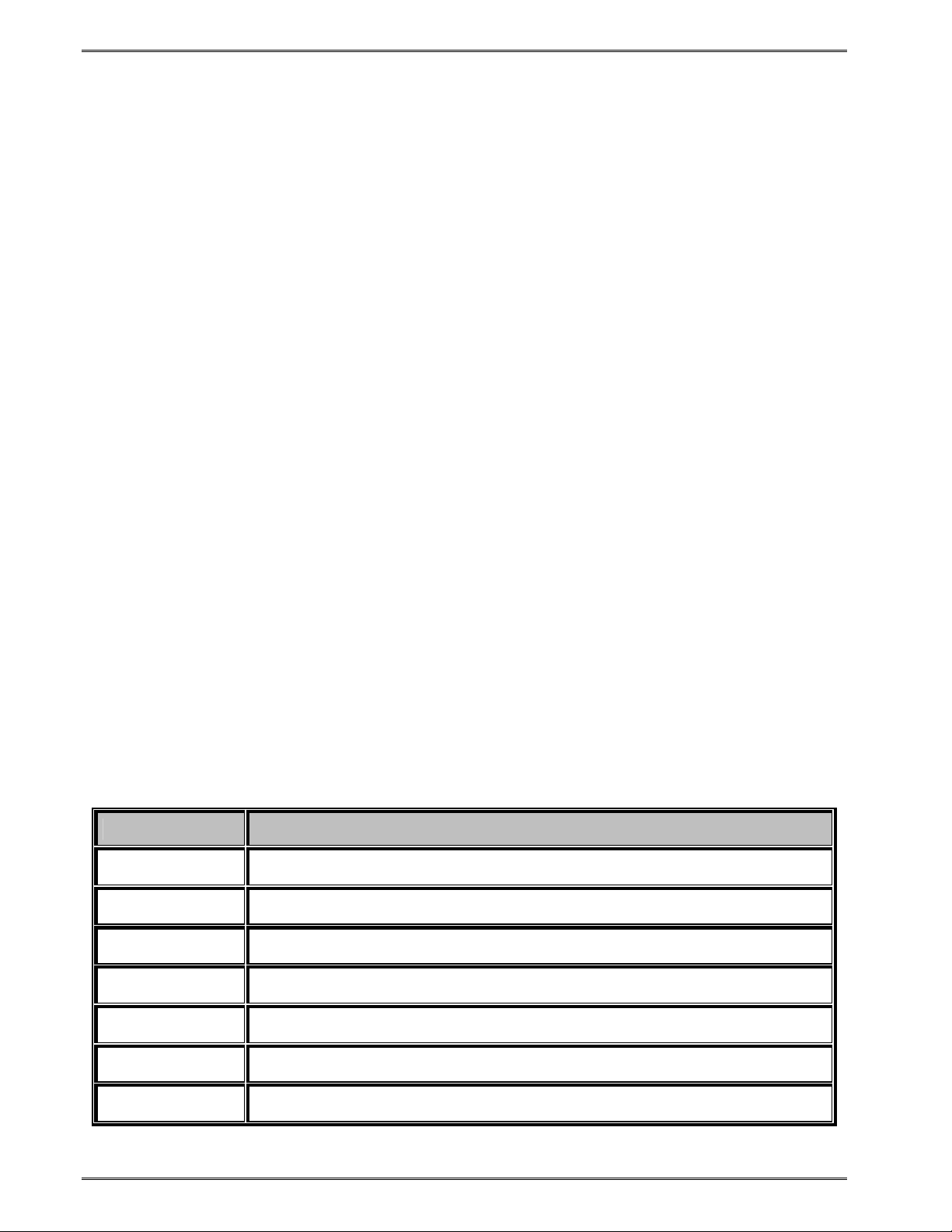

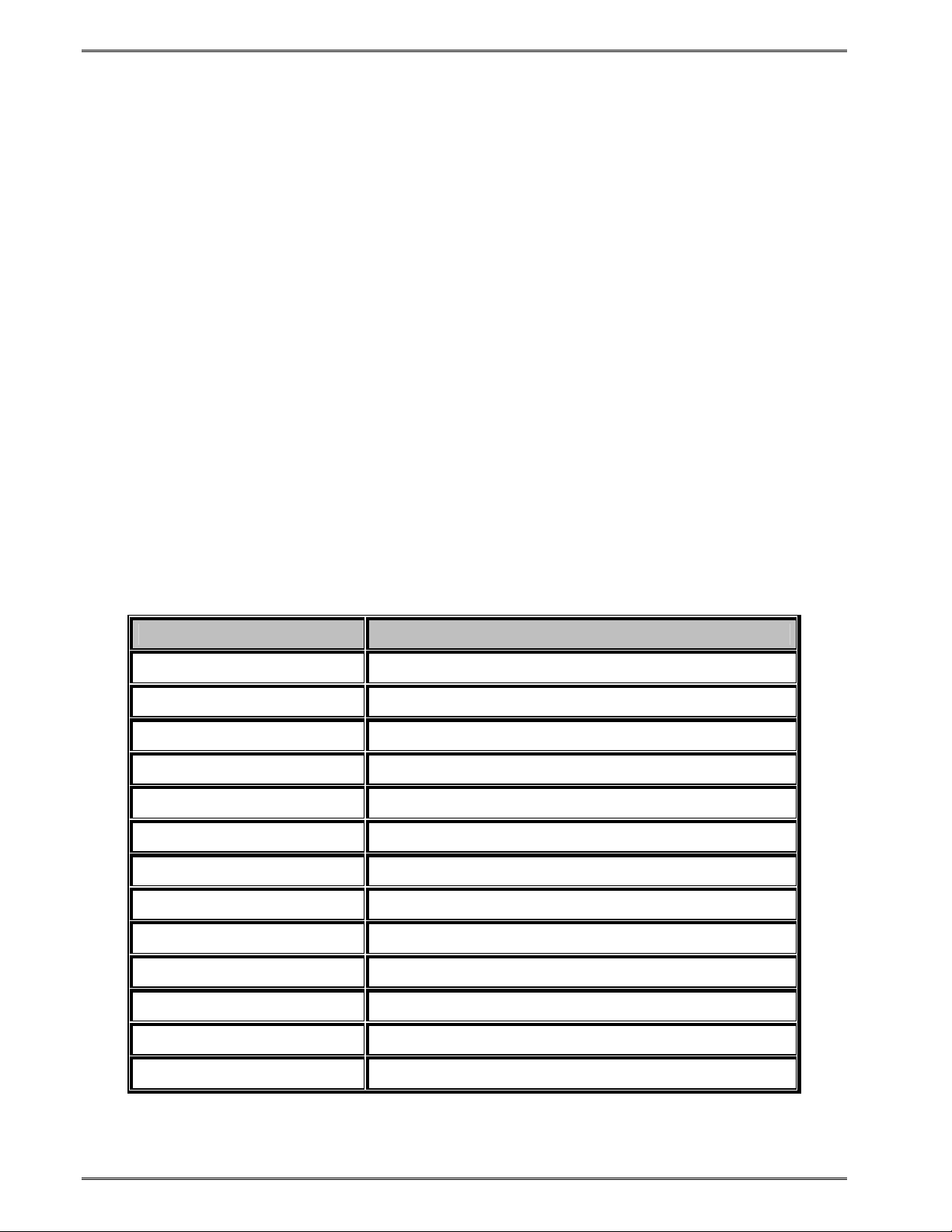

Resident Bitmapped Fonts

The resident fonts stored in the printer are listed in the table below. To access the resident

fonts, enter the appropriate Font Name into the CI parameter. The printer may store up to

nineteen bitmapped fonts and custom font sets are available upon request.

CI - Font Name

@normal_06

@bold_06

@normal_08

@bold_08

@normal_10

@bold_10

@normal_12

6 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxwy

6 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijk lmnopqrstuvwxwy

8 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxwy

8 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZabcdefghijklmnopqrstuvwxwy

10 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZab

10 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZa

12 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZab

Font Sample

10 LDSII Programming Guide - 880015-0123

Page 27

Chapter 1 Designing Using LDSII

CI - Font Name

@bold_12

@normal_14

@bold_14

@normal_16

@bold_16

@normal_20

@bold_20

@normal_24

@bold_24

@ocra_12

Font Sample

12 Point – 01234567890ABCDEFGHIJKLMNOPQRSTUVWXYZa

14 Point – 01234567890ABCDEFGHIJKLMNOPQRSTU

14 Point – 01234567890ABCDEFGHIJKLMNOPQRST

16 Point – 01234567890ABCDEFGHIJKL

16 Point – 01234567890ABCDEFGHIJKL

20 Point – 01234567890ABCDEFGHIJ

20 Point – 01234567890ABCDEFGHI

24 Point – 0123456ABCDEGabc

24 Point – 012345ABCabcdefgh

12 Point – 0123456789ABCDEFGHIJKLMNOPQRUSTUWXYZabc

@ocrb_08

@ocrb_12

Font File Type Example:

If a normal 8 point font is desired then “@normal_08” should be entered for the CI

parameter in order for the proper font to be printed. Fonts are accessed by entering the

system character “@”, font name followed by the underscore character and then the point

size into the CI parameter.

Line Draw

The line draw feature is selected by entering “@line” into the CI parameter. The line draw

feature easily creates lines by using the XB and YB coordinates as an insertion point for the

line to start and then adjusting the SW and SH parameters to define the width and the

height of the line.

Line Draw Example:

^A)

^D200)3.3, 1.9, 0.125, 1.063, 5, 1

^F1)1.0, 1.0,@line, 1.11, 0.01

^F1)1.0, 1.0,@normal_14

^T1)Line Draw Feature

^D300)1

^Z)

8 Point – 1234567890ABCDEFGHIJKLMNOPQRSTUVWXZYabcdefghijklmnopqr

12 Point – 1234567890ABCDEFGHIJKLMNOPQRSTUV

Table 1 Resident Bitmapped Fonts

LDSII Programming Guide - 880015-0123 11

Page 28

Designing Using LDSII Chapter 1

This script would cause a line to be inserted an inch from the left side and an inch from the

bottom. The line would be 1.11” in width or length (X direction) and would be 0.01” in height

(Y direction). The “^Fn)” field must reference a “^Tn)” field for proper operation. The line

draw does not have to reference its own specific Text Entry command (“^Tn)”) and may

reference an existing Text Entry field in the script file as demonstrated in the above

example. Refer to Ch apter 4 for additional information regarding the line draw feature.

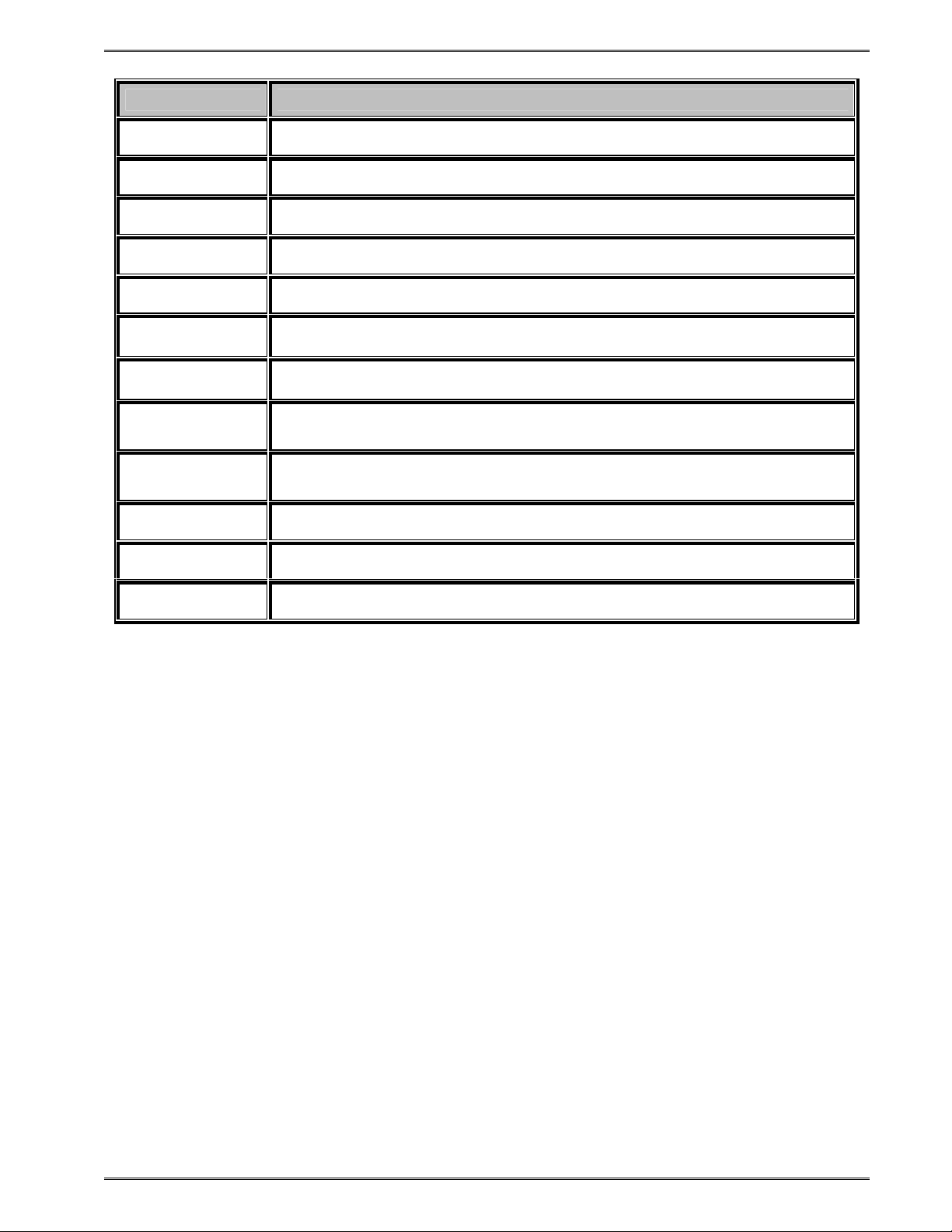

Bar Codes

The bar codes or symbologies are stored in the printer and can be selected by entering the

system character “@” followed by the text equivalent code of the desired symbology in the

CI parameter, refer to Table 2 for the available bar codes.

The bar codes that provide optional check digits can be accessed and printed by entering

“cs” immediately following the bar code text equivalent code. This is helpful to meet the

individual bar code specifications.

For example: If the user wanted to generate a human readable MSI1 that included the

check digits, “msi1cs_hr” would then be entered while “msi1_hr” would not include the check

digits in human readable form.

See Chapter 5 for more detailed information pertaining to bar codes and their individual

formatting requirements.

CI - Barcode Name Bar code Type

@codabar Codabar

@code128 Code 128 using manual compression

@code128auto Code 128 using automatic compression

@code39 Code 3 of 9

@code93 Code 93

@codei2of5 Code I2 of 5

@msi0 Modified Plessey, User provides both check digits

@msi1 Modified Plessey, User provides one check digit

@msi2 Modified Plessey, User provides no check digits

@postnet POSTNET

@uccean128 UCC/EAN 128

@data Data Matrix 2D Bar code

@pdf417 PDF417 2D Bar code

Table 2 Bar Code Index

12 LDSII Programming Guide - 880015-0123

Page 29

Chapter 1 Designing Using LDSII

Graphics

The printer is capable of processing monochrome 1-bit bitmaps. If color 1-bit bitmaps are

used, it is recommended that the user use Burkes dithering method at the print resolution of

the printer. The bitmap graphic does not need a separate converter to convert to the

printer’s recognized graphic structure as the printer will do this internally. The actual “.bmp”

may be saved to the printer’s non-volatile flash memory using the “^D340)” command or into

volatile RAM using the “^D345)” command. User definable graphic images are accessed

and printed by entering the file name of the appropriate stored graphic, that was used to

save the graphic using the “^D340)” command, into the CI parameter.

Graphics may also be sent to the printer in “zipped” (.zip file extensions) form without

specifying the file size. The file size would be provided by the zipped files header and

should not be included in the command line. This also reduces the transfer time of sending

the graphic to the printer improving throughput.

Graphic File Type Example:

If a BMP graphic is saved as “my graphic” then “my graphic” should be entered for the CI

parameter in order for the graphic to be printed.

1.5.4 SW (Size Width)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

This parameter is used to adjust the width multiple of fonts, bar codes and/or lines.

Bitmapped Fonts

For bitmapped fonts, the SW can be used to adjust the width multiple of the font chosen

using the CI parameter. The parameter is entered in as an integer and has a valid range of

1 to 256. The SW default for bitmapped fonts is set a 1.

Bar Codes

The SW has a different effect when used in conjunction with bar codes. When a 0 or 180

degree bar code is selected using the CI parameter, the SW is used to modify the bar code

width by a multiple of the narrowest rendition. This means that a value of “1” will produce

the narrowest rendition related to the bar elements while a value of “3” would produce a Bar

code that is three times this width. The default value of “1” will be used if a bar code is

selected and this field is left blank. For 90 or 270 degree bar codes, the SW field would

specify the actual width or height using the current selected unit of measure. The default

SW height, 90 and 270 degree rotations, is set a value of 0.5 inches or 12.7mm depending

on the current unit of measure (“^D564)” command) setting with the default for 0 and 180

degree rotation being set to a 1.

Line Draw

The SW determines the width of a line when the CI field has selected the line draw feature.

This is a required field when used in conjunction with the line draw feature.

1.5.5 SH (Size Height)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

This parameter is used to adjust the height multiple of fonts, bar codes and/or lines.

LDSII Programming Guide - 880015-0123 13

Page 30

Designing Using LDSII Chapter 1

Bitmapped Fonts

For bitmapped fonts, the SH can be used to adjust the height of the font chosen using the

CI parameter. The parameter is entered in as an integer and has a valid range of 1 to 256.

The SH default for bitmapped fonts is set a 1.

Bar Codes

The SH has a different effect when used in conjunction with bar codes. When a 90 or 270

degree bar code is selected using the CI parameter, the SH is used to modify the bar code

width by a multiple of the narrowest rendition. This means that a value of “1” will produce

the narrowest rendition related to the bar elements while a value of “3” would produce a bar

code that is three times this width. The default value of “1” will be used if a bar code is

selected and this field is left blank. For 0 or 180 degree bar codes, the SH field would

specify the actual height of the bar code using the current selected unit of measure. The

default SH height, 0 and 180 degree rotations, is set a value of 0.5 inches or 12.7mm

depending on the current unit of measure (“^D564)” command) setting with the default for

90 and 270 degree rotation being set to a 1.

Line Draw

The SH determines the height of a line when the CI field has selected the line draw feature.

This is a required field when used in conjunction with the line draw feature.

1.5.6 AI (Attribute Index)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

The attribute index controls the type of effect that is placed on text and/or bar codes. The

default is a setting of “0”, which is normal text or a method called OR. This causes new

black dots to be placed regardless of existing dots that may be black or white. Also, a white

area added to an existing black area does not become white, but the original black dots stay

black. The default value may be entered in as “1” or may be omitted by just entering the

comma delimiter (“,,” would use the default value). The valid values for the AI parameter

are listed in Table 3 below.

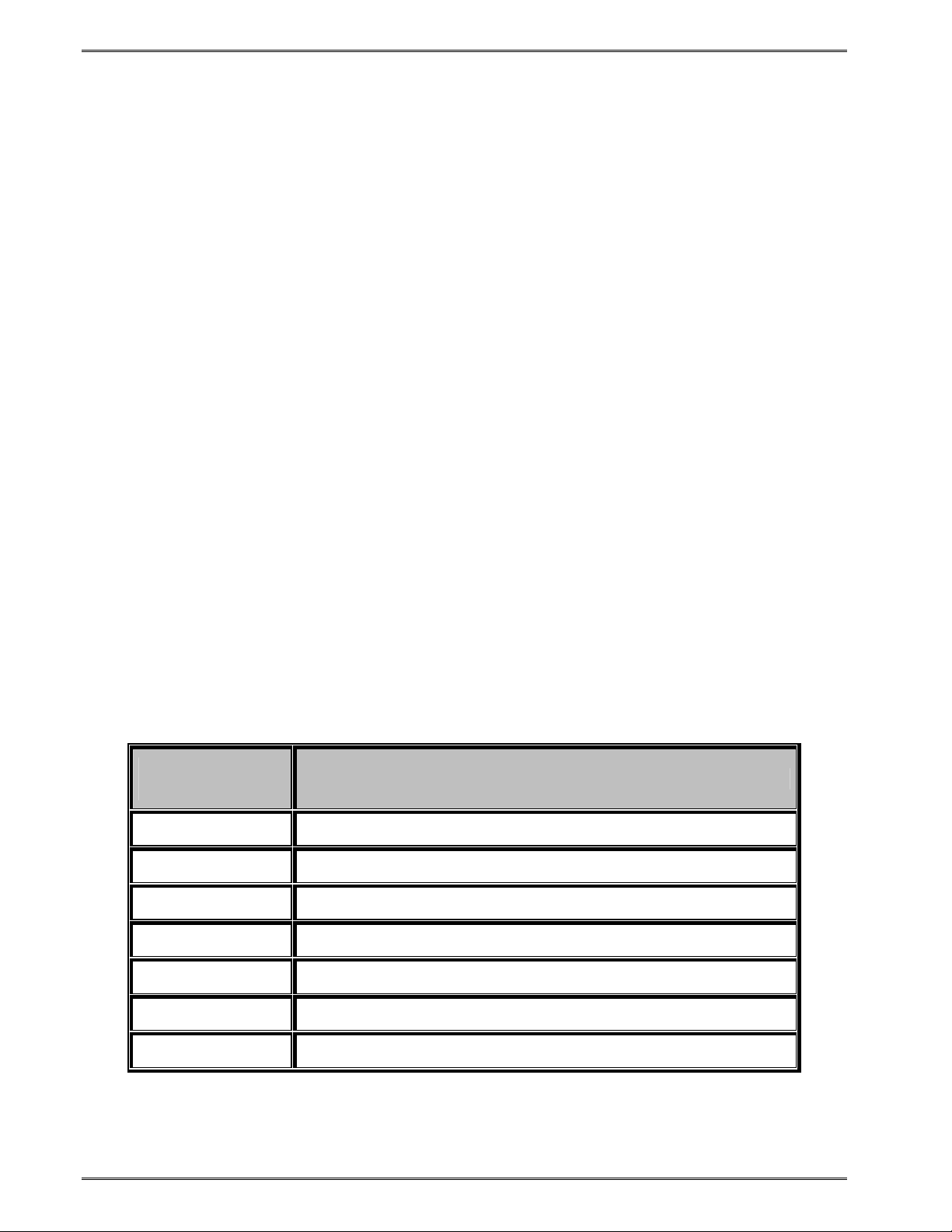

Attribute Index

Value

Conversion / Effect

0 OR (Default)

2 Reverse Video

2:1 Wide to Narrow Bar Ratio

3:1 Wide to Narrow Bar Ratio

4:2 Wide to Narrow Bar Ratio (3:1 bar; 4:2 space)

5:2 Wide to Narrow Bar Ratio

8:3 Wide to Narrow Bar Ratio

Table 3 Attribute Index

14 LDSII Programming Guide - 880015-0123

Page 31

Chapter 1 Designing Using LDSII

Reverse Video

The reverse video function inserts a black rectangle that is one dot larger than the contents

of the text string field that will be printed. The result would be that the text would be placed

as white on a black background area. This effect is the same as if the image was XOR’ed

onto a black box or line. In fact, if the automatic black box is too small, the line draw feature

may be used to increase the size of the background black box. Refer to section 4.1 for

additional information regarding the reverse video function.

Ratios

The ratios are used in conjunction with the Codabar, Code 39, and I2 of 5 bar codes. This

value determines the size of the wide to narrow bar ratio. The narrow bar module is always

one dot by default. The actual size of the dot is based on the type of print head installed on

the printer. By using the SW and/or SH parameters, it is possible to multiply the narrow bar

module and then apply the various ratios to create the desired bar code size.

For example: An 8 dot per mm or 203 dots per inch print head has a dot every 0.0049”.

This would mean that the narrow bar module by default is 0.0049” and that a 2:1 ratio would

result in the wide bars equaling 0.0098”. Using the SW and/or SH parameters, depending

on the orientation of the bar code, it is possible to multiply and adjust the narrow bar

module. This would mean that for a 0 degree bar code, a SW value of 2 (2 x 0.0049) would

adjust the narrow bar module to 0.0098” and then applying a 2:1 ratio would produce wide

bars of 0.0196”(0.0098 x 2).

1.5.7 DN (Direction)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

This parameter is used to select the direction of the text. The only valid parameter for

direction is rightwards text. A selection of rightwards text would cause the characters to be

printed left to right.

1 Rightwards Direction (default)

1.5.8 FO (Field Orientation)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

The values entered in this parameter are expressed in degrees. The normal orientation (0º)

is right side up as viewed from the front of the printer. The valid arguments are 0, 90, 180

and 270. The rotation is measured counter-clockwise.

0 0 degree (default)

90 90 degree

180 180 degree

270 270 degree

1.5.9 FJ (Field Justification)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

The field justification or FJ controls the alignment, kerning, and the proportionality of text

and/or bar codes with respect to the type of composition used. Alignment is done side-toside (left, right, centered, or full justified to span the entire LSY distance) and vertically (on

or below baseline, which is an imaginary line extending from the starting coordinates along

the direction of the text), relative to the default (0 degree) orientation of text and/or bar

codes and the insertion point of the field. This means that whatever the direction and

LDSII Programming Guide - 880015-0123 15

Page 32

Designing Using LDSII Chapter 1

orientation may be; left will always be the left edge of the characters when the media exits

the printer.

Kerning is when one character in a proportional font can be slid under another character to

achieve a more appealing result. Kerning is enabled and used by default unless a value for

the FJ parameter is entered. If a value is entered then kerning would have to be selected

by adding “100” to the justification value.

Proportionality refers to whether the characters are all different widths or all the same. A

proportional font has characters that are mostly different widths. A mono-spaced font has

characters that are all the same width, except generally for punctuation.

When selecting the alignment value, text and/or bar codes will be aligned from the XB and

YB insertion point. The justified function, to be aligned, can be specified by using a

combination of the insertion point and the FW (Field Width) parameter so that the text is

spaced to run this entire distance.

The desired alignment value can be determined from the table below:

Composition Horizontal Alignment

Horizontal Vertical Left Center Right Justified

Vertical

Alignment

Above

Baseline

Below

Baseline

Top 11 12 13 14

Bottom 31 32 33 34

Add 100 for kerning and add 200 for mono-spacing to the FJ value to produce effects.

Table 4 Field Justifications

For Example: A typical European language would be left horizontal and normal vertical

alignment, which would be a value of “11” for the “FJ” parameter. If kerning was also

desired, the proper value would then be “111” and for mono spacing it w ould be “211”.

1.5.10 FW (Field Width)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

The field width parameter sets the width of a text field, using the current unit of measure,

along the direction of composition. This is used to limit the physical width of the cell where

the appropriate data is to be placed. If the desired data is longer than the field width setting,

then characters outside the cell width setting will not be printed.

1.5.11 CS (Character Spacing)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

This parameter adjusts the spacing between each character or the inter-character spacing.

The change is made relative to a default, where omitting this parameter or entering a “0”

causes the default to be used. The specified spacing value is in units of typesetting points,

where 1 point = 1/72”. Positive point values increase the default spacing while negative

16 LDSII Programming Guide - 880015-0123

Page 33

Chapter 1 Designing Using LDSII

values reduce the default spacing. The point values are accurate to a single digit following

the decimal place (1.4 for example).

1.5.12 FC (First Character)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC, CC

The FC parameter is used to select the first character to be used as data within the text

string data. This parameter is helpful in allowing several fields to use sections of the same

text string minimizing the amount of data transmitted. If the value specified for the FC

parameter is equal to or greater than the included data, the entire data string will be printed.

For Example, for the text string 0123456789, a FC value of 5 would start the data on the

fifth character and the resulting data would be 456789. This parameter is typically used in

conjunction with the CC (Character Count) parameter listed below.

1.5.13 CC (Character Count)

XB, YB, CI, SW, SH, AI, DN, FO, FJ, FW, CS, FC,

CC

This parameter is used to determine the number of characters that will be used as data

within a text string. If the number of characters in the selected text string is more than the

quantity specified by the CC, then the remainder of the text string is ignored. If this

parameter is left blank then the entire text string will be used as the data. Using the same

example described in section 1.4.12, a CC value of 2 in conjunction with a FC value of 5,

would result in a value of 45 to be used as the data.

1.6 Text Entry Command - ^Tn)

The Text Entry command is used to define the actual data to be ren dered using the output

identified by the CI parameter. This command starts with the “^Tn)” structure and then is

followed by the subject text or data. The “n” is an identifier that represents the subject text

lines and will use the formatting that has been placed in the corresponding “n” of the format

entry command (“Fn)”).

For features like graphics and/or line draw, this command is simply a placeholder for the

equivalent “^Fn)” command, so any text may be entered. When printing graphics, text

containing the graphic name or simply the word graphic should be entered and can be

helpful for debugging purposes. The same would be true when using the line draw feature

by entering the word “line” in the “^Tn)”, this also assists in debugging easier.

Note: To print either the caret (“^”) or the pipe (“|”) characters simply enter them twice

(example - “^^”).

LDSII Programming Guide - 880015-0123 17

Page 34

Designing Using LDSII Chapter 1

^Tn)Your subject text is typed here.

Identifies the subject text

line number and

corresponds with the

same format line number.

Subject data is entered

immediately after the command

with no space between the

command and the text.

Figure 5 Text Entry Command

This text is what will

print out on the media.

18 LDSII Programming Guide - 880015-0123

Page 35

Chapter 2: Printer Commands

The script management commands may be issued inside a script file while the ^Dxx printer

control commands may be issued from inside or outside a script file. Commands will be

persistent and non-volatile if issued from outside a script file and temporary if issued from

inside a script. Commands that are issued from inside a script file will override the

persistent setting during the processing of the script file and then return to the value of the

previous persistent command. The commands require a “)” between the command and the

first parameter or argument. Commands that contain multiple parameters must be

separated with the comma delimiter. The printer control commands follow the standard

command preface (“^Dxxx”) structure and are divided into eight sub-categories. These

categories are identified by the “hundreds” digit as listed below. The commands are also

executed in the order that they are issued with the only exceptions being the ^D391, ^D566,

^D565, and ^D564 commands. Commands will return the current status and/or setting if the

^Dxx command is entered without an argument. Entering a question mark (“?”) after the

^Dxx command causes the printer to report the commands current setting as well as the

verbose description and help text associated with that particular command.

^Dxxx Series

Number

2xx Formatting Commands

3xx Operation Commands

4xx Volatile Selection and Setting Commands

5xx Configurable Selection Commands

6xx Configurable Setting Commands

7xx Configurable Enablement Commands

8xx

9xx Self Test and Factory Commands

Reserved for future use.

Table 5 ^Dxxx Series Commands

Series Number Command Definition

2.1 Script Management Commands

The script management commands deal specifically with scripts and control how scripts are

processed and executed. These commands are only valid when sent inside a script file.

Refer to the previous chapter for detailed description on working with script files and their

formatting requirements. Certain commands are always processed before other commands

with disregard to their placement. These commands include the ^D391, ^D566, ^D565,

^D564, and then the ^D200 command. The commands are processed in this order, if

present, and after processed the remaining commands are executed in the order they are

issued.

LDSII Programming Guide - 880015-0123 19

Page 36

Printer Commands Chapter 2

2.1.1 Begin Script - ^A)filename

This command is used to mark the beginning of a script file. The script may be saved into

the printer’s non-volatile flash memory if a title or filename is placed after the command.

The filename may contain to a maximum of 20 characters in length and include any

character from ASCII 0x20 and 0x41 to 0x7A (alphabetical characters plus [\]_’and SP

(space character)) with the exception of the caret (^) character. Script filenames can not

use a leading zero (“0”) or 0x30 characters. A script that contains a “filename” will only save

the script and will not process and print. The “^D350)filename” would be issued to recall

and process the saved script. If the script does not contain a “filename”, the script is

processed normally and will be volatile in nature.

2.1.2 Begin Temporary Script - ^ AT)filename

This command is used to mark the beginning of a temporary or transient script file. The

script may be saved into the printer’s volatile RAM if a title or filename is placed after the

^AT) command. The filename may contain to a maximum of 20 characters in length and

include any character from ASCII 0x20 and 0x41 to 0x7A (alphabetical characters plus

[\]_’and SP (space character)) with the exception of the caret (^) character. Script filenames