Page 1

MODEL 485TC

DIRECT THERMAL PRINTER

OPERATOR’S MANUAL

PART NUMBER: 880058-0100

January 3, 2018 CPC

Copyright © 2018 by Microcom Corporation, Lewis Center, Ohio – All rights reserved.

Printed in the United States of America

Page 2

Page 3

Proprietary Statement

This manual contains information proprietary to Microcom Corporation. This information is

intended solely for the use of parties operating and maintaining such equipment described

herein.

Product Enhancements

Microcom Corporation is committed to the continual improvement of performance and

quality in our products. For this reason, specifications are subject to change without notice.

Liability Disclaimer

Microcom Corporation makes every effort to assure that all information and specifications

contained in this manual are accurate; however, mistakes are sometimes made. Microcom

Corporation shall not be liable for any damages resulting in the use or misuse of this

product. The exclusion or limitation involving consequential or incidental damage does not

apply to all states; therefore limitation mentioned above may or may not apply.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions contained in this

manual, may cause harmful interference to radio communications.

Products and company names mentioned herein may be trademarks of their respective

owners.

Page 4

Page 5

Table of Contents

INTRODUCTION ............................................................................................. V

CHAPTER 1: PRINTER SPECIFICATIONS 1-1

1.1 General Specifications 1-1

1.2 Printing Specifications 1-1

1.3 Media Specifications 1-2

CHAPTER 2: FEATURES AND OPTIONS 2-1

2.1 Fonts 2-1

2.2 Graphics 2-1

2.3 Bar codes 2-1

2.4 Special Features 2-2

2.5 Options 2-2

CHAPTER 3: GETTING STARTED 3-1

3.1 Unpacking and Inspection 3-1

3.2 Printer Power 3-2

3.3 RS232 Serial Communication Interface 3-2

3.3.1 RS-232 Serial Cables ................................................................................... 3-3

3.3.2 RS-232 Serial RJ-12 ..................................................................................... 3-3

3.4 USB Communication Interface 3-4

3.5 Host USB Interface 3-4

3.6 Ethernet Communication Interface 3-4

3.7 Cash Drawer Option 3-4

3.7.1 Cash Drawer RJ12 Adapter Option ............................................................... 3-5

3.8 AUX Option 3-5

3.9 Loading Media 3-6

3.10 Print Button and Status Indicator Light 3-7

3.10.1 Print Button ................................................................................................... 3-7

3.10.2 Status Indicator Light .................................................................................... 3-8

3.11 Printer Modes 3-8

3.11.1 Ready Mode: GREEN .................................................................................. 3-8

3.11.2 Halted Mode: RED ................................................................ ....................... 3-8

3.11.3 Diagnostic Mode ........................................................................................... 3-9

3.11.3.1 Entering Diagnostic Mode ......................................................................... 3-9

3.11.3.2 Statistics Label .......................................................................................... 3-9

3.11.3.3 Test Ticket ............................................................................................... 3-10

3.12 TOF Sensor 3-10

3.13 Media Roll Holder Option 3-12

3.14 Ticket Catch Tray Option 3-12

3.15 Wristband Media Adapter Option 3-13

3.16 Qualsoft Windows Driver 3-14

3.16.1 Installing the Windows Driver ...................................................................... 3-14

3.16.2 Configuring the Driver ................................................................................. 3-18

3.16.3 Printer Properties Page - General tab ......................................................... 3-19

485TC Operator’s Manual - 880058-0100 i

Page 6

3.16.4 Printer Properties Page - Ports tab ............................................................. 3-20

3.16.5 Printing Preferences - About tab ................................................................. 3-21

3.16.6 Printing Preferences - Print tab ................................................................... 3-21

3.16.6.1 Print tab - Advanced ................................................................................ 3-22

3.16.7 Print tab - Halftone Adjustment ................................................................... 3-22

3.16.8 Print tab - Halftone Properties ..................................................................... 3-23

3.16.9 Print tab - User Commands ......................................................................... 3-23

3.16.10 Printing Preferences - Paper tab ................................................................. 3-24

3.16.10.1 Paper tab - Rotation ............................................................................. 3-24

3.16.10.2 Paper tab - Units .................................................................................. 3-24

3.16.10.3 Paper tab - Page Sizes ........................................................................ 3-24

3.16.10.4 Paper tab - Mirror ................................................................................. 3-24

3.16.10.5 Paper tab - Default ............................................................................... 3-25

3.16.11 Printing Preferences - Media tab ................................................................. 3-25

3.16.11.1 Media tab - Settings ............................................................................. 3-25

3.16.11.2 Media tab - Feed Options ..................................................................... 3-26

3.16.12 Printing Preferences - Presenter tab ........................................................... 3-27

3.16.12.1 Presenter tab - Configuration ............................................................... 3-28

3.16.12.2 Configuration - Modes .......................................................................... 3-28

3.16.12.3 Configuration - Advanced ..................................................................... 3-29

3.16.13 Printing Preferences - Modification tab ....................................................... 3-29

3.16.13.1 Modification - No of Labels ................................................................... 3-29

3.16.13.2 Modification - Print Speed (inch/s) ....................................................... 3-29

3.16.13.3 Modification - Disable Status ................................................................ 3-29

3.16.14 Printing Preferences - Save/Restore tab ..................................................... 3-31

3.16.14.1 Save/Restore - Restore settings from file… ......................................... 3-31

3.16.14.2 Save/Restore - Save settings to file….................................................. 3-31

3.16.14.3 Save/Restore - Restore factory defaults… ........................................... 3-31

3.16.15 Status Messages ......................................................................................... 3-31

3.16.15.1 PRINTER_STATUS_WAITING ............................................................ 3-32

3.16.15.2 PRINTER_STATUS_BUSY ................................................................. 3-32

3.16.15.3 PRINTER_STATUS_PAPER_OUT...................................................... 3-32

3.16.15.4 PRINTER_STATUS_PAPER_JAM ...................................................... 3-32

3.16.15.5 PRINTER_STATUS_PAPER_PROBLEM ............................................ 3-32

3.16.15.6 PRINTER_STATUS_USER_INTERVENTIO N .................................... 3-32

3.16.15.7 PRINTER_STATUS_OFFLINE ............................................................ 3-32

3.16.15.8 PRINTER_STATUS_OUTPUT_BIN_FULL .......................................... 3-32

3.16.15.9 PRINTER_STATUS_DOOR_OPEN .................................................... 3-32

3.16.15.10 PRINTER_STATUS_IO_ACTIVE ........................................................ 3-32

3.17 Configuration Application 3-33

3.17.1 Selecting a Device ...................................................................................... 3-33

3.17.1.1 Configuration Application - Serial (USB / RS-232) ................................... 3-33

3.17.1.2 Configuration Application - USB HID ....................................................... 3-34

3.17.1.3 Configuration Application - Ethernet ........................................................ 3-34

3.17.2 Configuring a device ................................................................................... 3-34

3.17.2.1 Applying changes .................................................................................... 3-35

3.17.2.2 Reverting changes ................................................................................... 3-35

3.17.2.3 Saving/loading configuration files ............................................................ 3-35

3.17.3 Application preferences ............................................................................... 3-35

ii 485TC Operator’s Manual - 880058-0100

Page 7

CHAPTER 4 PRINTER MAINTENANCE 4-1

4.1 Maintenance Schedule 4-1

4.2 Thermal Printer Cleaning Card 4-1

4.3 Internal Cleaning 4-3

4.4 Print Head Maintenance 4-4

4.5 Replacing the Drive Roller 4-5

4.6 Adjusting Printhead Pressure 4-7

CHAPTER 5: TROUBLESHOOTING 5-1

5.1 Troubleshooting Tips 5-1

INDEX 6-1

General Index 6-1

List of Figures 6-5

List of Tables 6-7

APPENDIX 7-1

Appendix A: Limited Warranty 7-1

Appendix B: RMA Procedure 7-3

Glossary 7-5

Appendix C: User Notes 7-9

485TC Operator’s Manual - 880058-0100 iii

Page 8

iv 485TC Operator’s Manual - 880058-0100

Page 9

Introduction

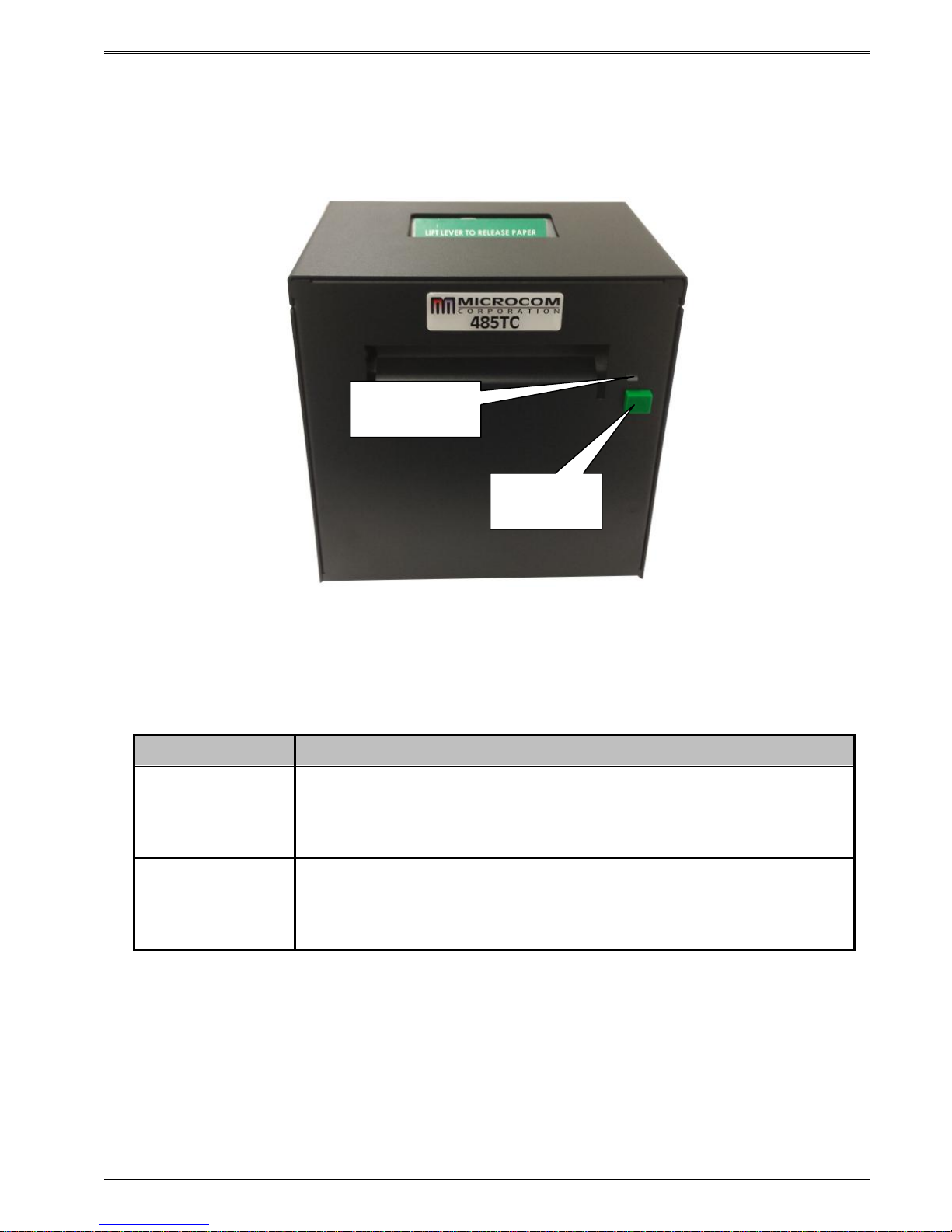

The Model 485TC printer has been designed to provide solutions for the ticketing industry.

The printer uses the same reliable print mechanism found in the Model 428TM and 438TM

printers. The print mechanism has been designed with a 4” printhead capable of printing up

to 8” per second and is available in 203 or 300 dpi. The printer may be used as a graphics

printer or as an FGL emulation printer.

485TC Rear Side View

485TC Front Side View

485TC Operator’s Manual - 880058-0100 v

Page 10

vi 485TC Operator’s Manual - 880058-0100

Page 11

Chapter 1: Printer Specifications

1.1 General Specifications

Width* 7.3” (185 mm)

Height* 7.4” (188 mm)

Depth* 5.8” (148 mm)

Weight* 10.2 lbs. (4.6 kg)

Electrical +24 VDC

Current 3.5 Amps maximum

Temperature 40° F – 104° F (5° C – 40° C), operating

Humidity 10% – 85%, non-condensing

RAM Memory 256 Mb

Flash Memory 512 Mb

Agency Approvals RoHS, FCC Class A, cTUVus

Interface Communications RS232, USB, and Ethernet Ports

Flow Control CTS/RTS Hardware

Baud Rate Up to 115200

Parity Odd, Even, and None

Data Bits 7 or 8

Table 1-1 General Specifications

* NOTE: Listed specifications are based on a standard print mechanism and may vary

based on final configuration.

1.2 Printing Specifications

Print Type Direct Thermal

Print Resolution

Maximum Print Speed Up to 10”/sec. (250 mm/sec.)

Maximum Print Width

Maximum Print Length 26” (660 mm)

Minimum Print Length 0.25” (6 mm)

Table 1-2 Printing Specifications

203 DPI (8 dots/mm = 0.0049” per dot)

300 DPI (12 dots/mm = 0.0032” per dot)

203 DPI = 4.098” (104.10mm); 832 dots

300 DPI = 4.252” (108 mm); 1,280 dots

485TC Operator’s Manual - 880058-0100 1-1

Page 12

Printer Specifications Chapter 1

1.3 Media Specifications

Media Types

Maximum Media Thickness* .011” (.28 mm)

Maximum Media Width

Continuous, die-cut, preprinted and tag stock either rolled

or fanfold

4.375” (111 mm)

*NOTE: The printers may print on thicker media types depending on the pliability of the

material; however, this requires testing and evaluation. Contact your authorized Microcom

Corporation representative for additional information regarding testing and evaluation of

thicker or rigid media types.

Table 1-3 Media Specifications

1-2 485TC Operator’s Manual - 880058-0100

Page 13

2.1 Fonts

· 16 resident bitmapped alpha-numeric fonts.

· Downloadable scalable fonts.

· All bitmapped fonts expandable in height and width.

· Reverse image printing.

· Rotated: 0 º, 90 º, 180 º, and 270 º.

2.2 Graphics

· Resident Lines feature.

· Storage of fonts, label formats and graphics in both volatile RAM and non-

volatile FLASH memory.

· Rotated: 0 º, 90 º, 180 º, and 270 º.

2.3 Bar codes

Chapter 2: Features and Options

· One-dimensional

· Code 39

· Interleaved 2 of 5

· Code 128 (A, B, C and

Auto)

· Code 93

· Codabar

· Modified Plessey

· UPC-A

· UPC-E

· EAN 8

· EAN 13

· UCC/EAN 128

· Postnet.

· Planet Code

· Two-dimensional

· GS1 Databar

Omni Directional

Truncated

Stacked

Stacked Omni-

directional

Limited

Expanded

· PDF-417

· Maxi code

· GS1 Data matrix

· Aztec

· Softstrip

· QR Code

· Rotated: 0 º, 90 º, 180 º, and

270 º.

· Expandable in height and

width.

485TC Operator’s Manual - 880058-0100 2-1

Page 14

Features and Options Chapter 2

2.4 Special Features

· Easy print head cleaning

· Tool less platen roller replacement

· Adjustable media guides for easy label centering

· Automatically adjustable reflective blackline sensor in media guide

· Software controlled contrast adjustment

· Detects label gap, black line, and blow-hole using reflective and

transmissive sensors

· Internal statistical counters for inches and labels printed

· Remote printer interrogation

· On-site programmable flash memory updates

· Autoload / Alignment of media

2.5 Options

· +24 VDC Universal 100W Desktop Power Supply

· 300 dpi print head

· Heavy Duty Rotary Cutter

· Ethernet Port

· Pre-Stock Out Sensor Assembly

· Low Paper Sensor Assembly

· Wristband Option

· Paper Supply Holders

· Media Catch Trays

· Cleaning kit

2-2 485TC Operator’s Manual - 880058-0100

Page 15

Chapter 3: Getting Started

3.1 Unpacking and Inspection

The printer has been packaged in protective foam to help reduce the damage during

shipment.

Inspect the shipping container(s) for signs of damage. If damage is evident, contact the

shipping company immediately to file a damage claim.

After the printer is removed from the container(s), verify that all the items on the packing list

are present and in good condition. The picture below (See Figure 3-1) shows a 438TC and

optional power cord. Your shipment may contain different items.

The foam and shipping container(s) should be kept and used if the printer is to be shipped

at a later time. Additional shipping materials can be ordered by contacting the Microcom

Corporation Service Department.

Figure 3-1 Typical Printer Accessories

485TC Operator’s Manual - 880058-0100 3-1

Page 16

Getting Started Chapter 3

RS232 Port

USB Port

Ethernet Port

ON/OFF Switch

Power

Connection

Figure 3-2 Printer Rear Panel

External Media

Entry Slot

Optional Rj12

Serial

Optional Cash

Drawer Port

AUX Port

Host USB Port

3.2 Printer Power

The printer has a universal auto-sensing internal power supply that operates in the 100-240

VAC; 50-60 Hertz range. The three-prong female end of the power cord plugs into the

mating connector located on the back of the printer.

3.3 RS232 Serial Communication Interface

The printer provides a 9-pin female D-Sub connector, on the rear panel, for RS-232 serial

communication. The printer is configured as DCE (Data Circuit-terminating Equipment) so a

NULL modem cable is not necessary. A serial data cable is required to use serial

communications, refer to Table 3-1 below for correct cable configurations.

The factory settings, unless otherwise requested, are set at 115200 baud, 8 data bits, 1 stop

bit and no parity with hardware handshaking enabled. The baud rate is user selectable from

110 to 115,200 and uses software XON/XOFF flow control and/or hardware CTS/RTS

handshaking.

If XON/XOFF handshaking is used, the only signals that the printer requires are the RXD,

TXD, and GND signals. If the hardware handshaking is used, then the CTS and RTS signals

are required. The other signals are offered in the event that the host computer would

require them.

3-2 485TC Operator’s Manual - 880058-0100

Page 17

Chapter 3 Getting Started

PC

PC

Pin 1

RJ12

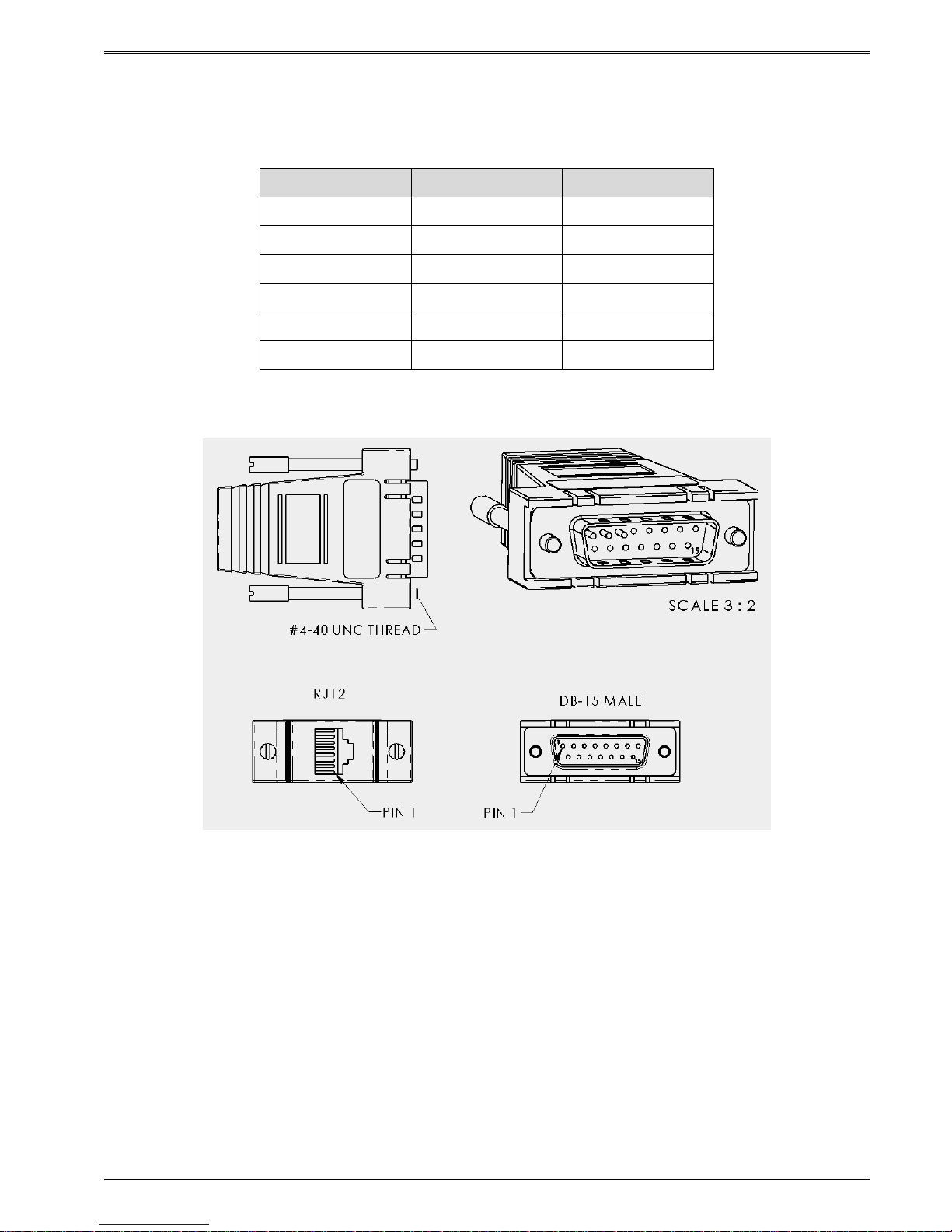

3.3.1 RS-232 Serial Cables

The printer uses a standard through serial cable, typically referred to as a modem cable,

which may be purchased through Microcom Corporation or a local computer supply

company.

For a 25-pin serial communication port – Use a 25-pin female to 9-pin male cable.

For a 9-pin serial communication port – Use a 9-pin female to 9-pin male cable.

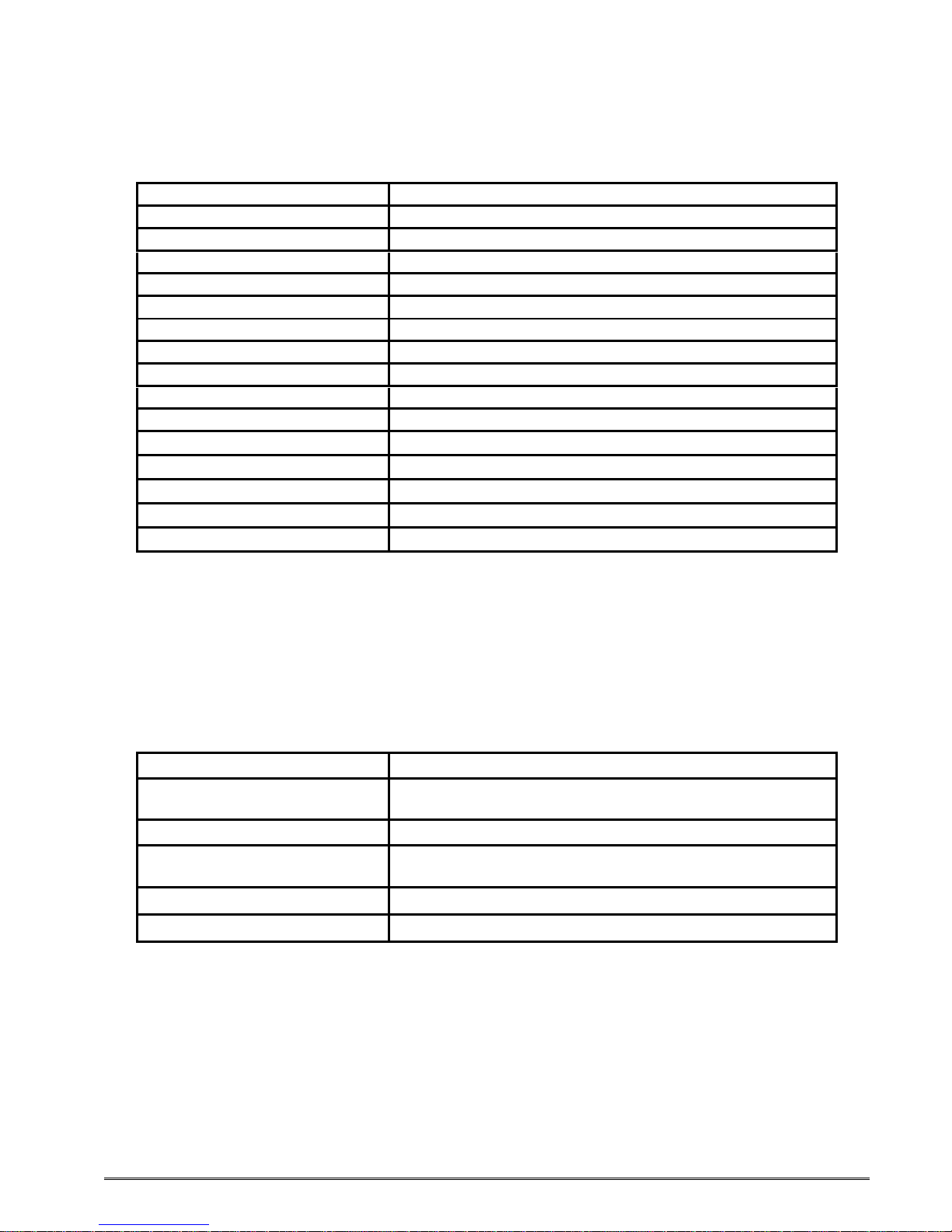

9 to 9 Pin Cable 9 to 25 Pin Cable

DE-9

State

XX 1 DCD

XX 2 TXD

XX 3 RXD

HI 4 DTR

LO 5 GND

HI 6 DSR

DC 7 RTS

XX 8 CTS

HI 9 +5V

Pin #

Signals /

Directions

DE-9

Pin #

DCD

RXD 2 XX 2 TXD

TXD 3 XX 3 RXD

DSR 4 HI 4 DTR

GND

DTR 6 HI 6 DSR

CTS 7 DC 7 RTS

RTS 8 XX 8 CTS

+5V 9 HI 9 +5V -

State

1 HI 1 DCD

5 LO 5 GND

DE-9

Pin #

Signals /

Directions

DB-25

Pin #

DCD 8

RXD 3

TXD 2

DSR 20

GND 7

DTR 6

CTS 4

RTS 5

DC = DO NOT CARE XX = INDETERMINATE

Table 3-1 RS-232 Cable Configurations

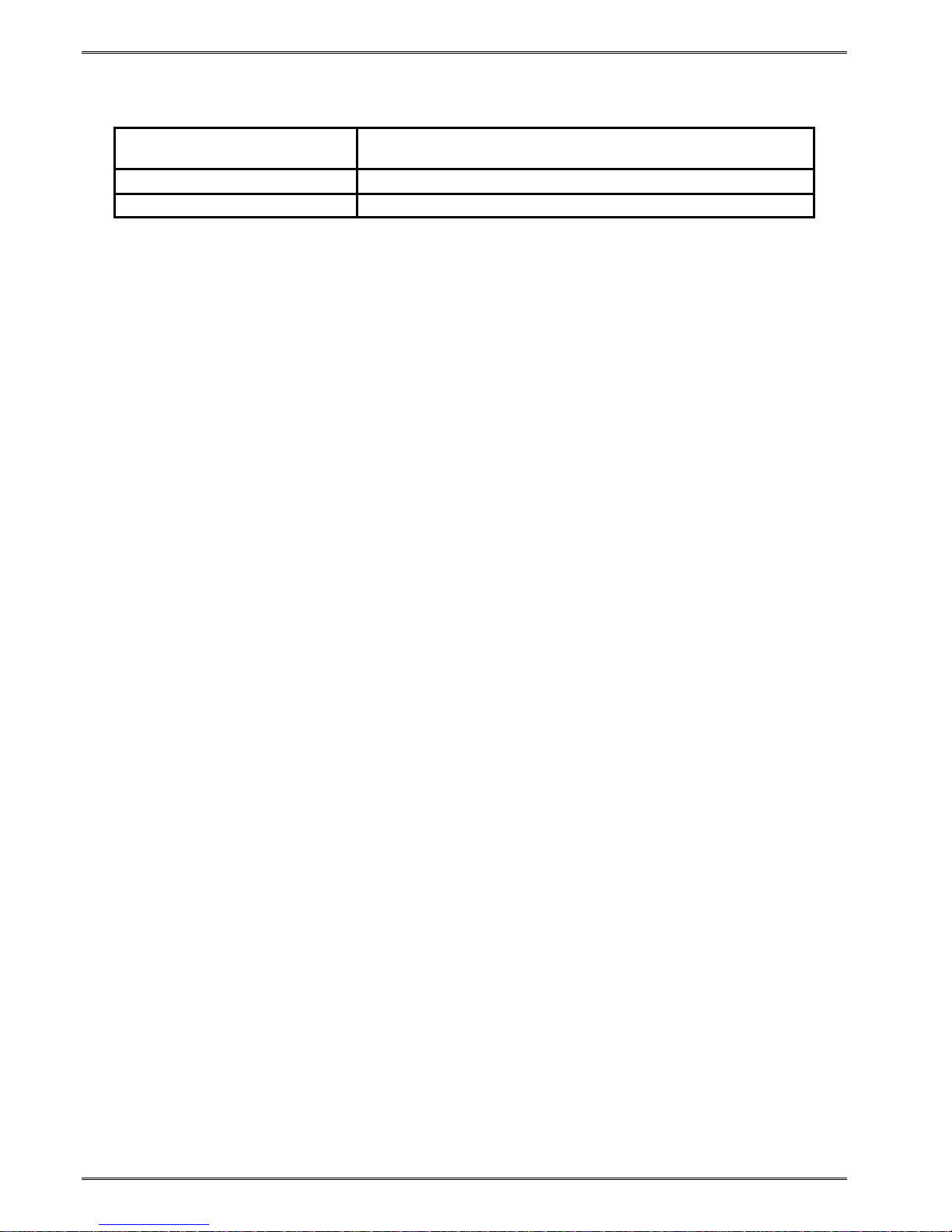

3.3.2 RS-232 Serial RJ-12

The printer is configured with a DB9 RS232 connecter by default but may be also

configured with the optional RJ12 connector. The figure below shows the wiring diagram of

the RJ12 connection.

9 Pin RJ12 Signal

2 2 TXD

3 3 RXD

5 4 GND

6 1 DTR

8 6 CTS

485TC Operator’s Manual - 880058-0100 3-3

Figure 3-3 RJ12 Serial Option Wiring

Page 18

Getting Started Chapter 3

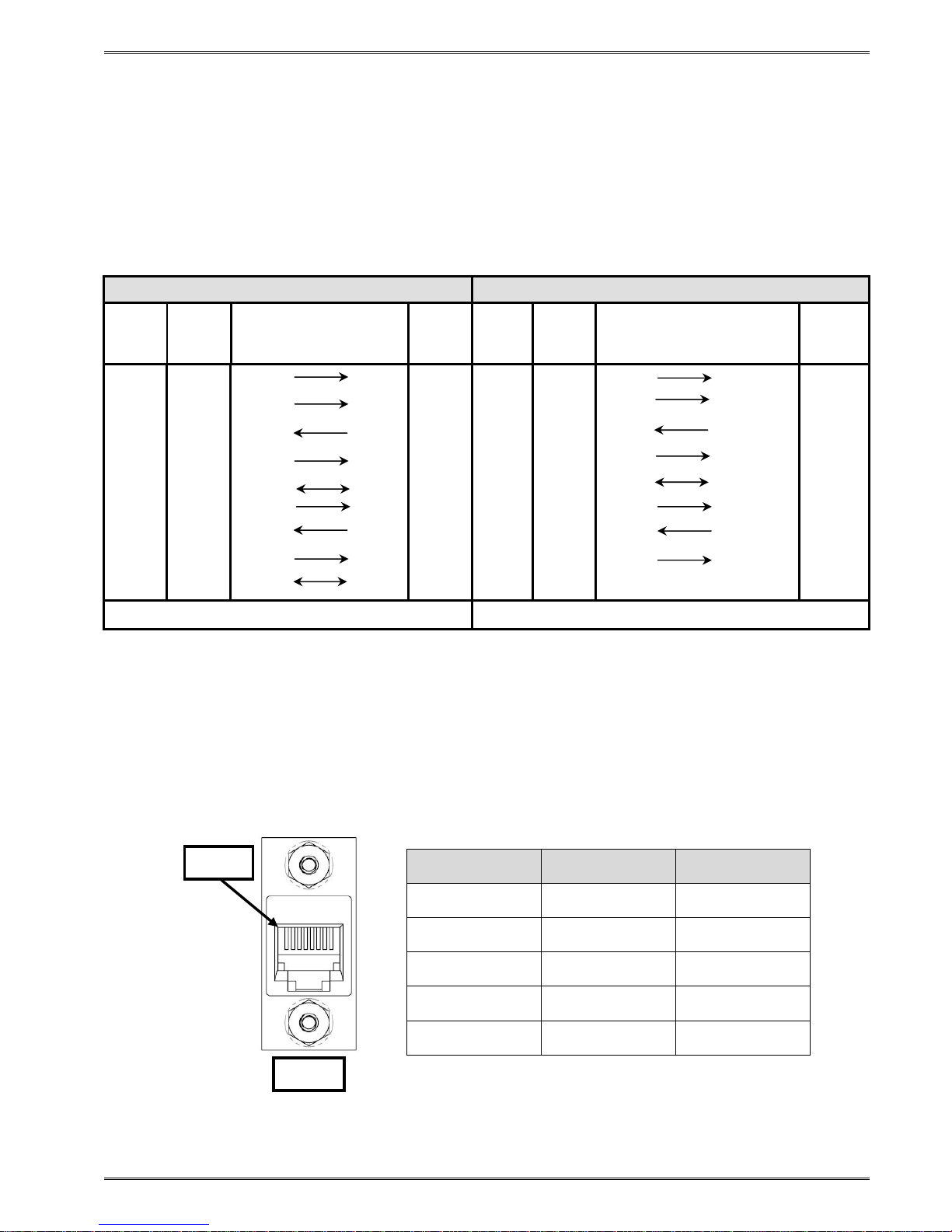

Pin 1

- DR1

Pin 3

- DR2

Pin 2

- DO

3.4 USB Communication Interface

The printer is configured as a USB HID device so no specific drivers need to be installed.

Connecting the printer to the HOST system will install the printer.

3.5 Host USB Interface

The Host USB connector on the rear panel of the printer is used for updating the printer’s

application, Bootloader, and the fonts stored in the printer. Contact your Sales

Representative for additional information.

3.6 Ethernet Communication Interface

The printer is configured with a 10/100 BASE T Ethernet that is configured for DHCP out of

the box. After one minute of idle time after a power up, if a connection is not established,

the printer will switch to a static IP Address of 192.168.200.3 with a Subnet of

255.255.255.0 on port 9100.

The printer also has a resident Web Server running on IP 192.168.200.3 that may be used

to configure the printer as well.

3.7 Cash Drawer Option

The printer provides a DB15 connector to support the use of 24v cash drawer applications.

The Draw Kick-out solenoid current must be 1 amp or less to avoid current overloads. This

option is only available when using the FGL Emulation mode.

Figure 3-4 Cash Drawer Pin-out

3-4 485TC Operator’s Manual - 880058-0100

Page 19

Chapter 3 Getting Started

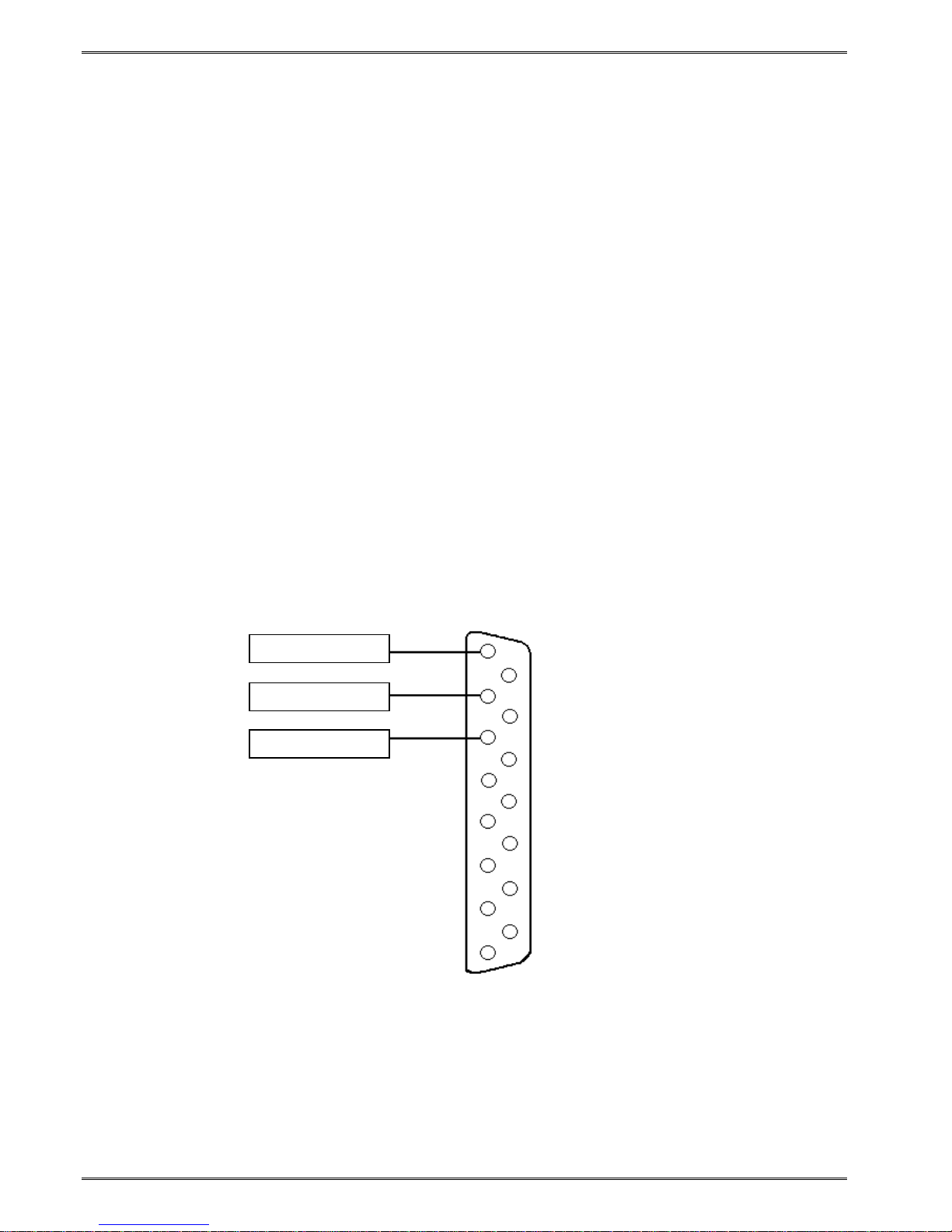

3.7.1 Cash Drawer RJ12 Adapter Option

Some cash drawers may use a RJ12 connector instead of the DB15 connector. The RJ12

adapter (060437-1000) is available as an optional component for these applications.

RJ12 Wire Color DB-15

1 WHITE X

2 BLACK 1

3 RED X

4 GREEN 2

5 YELLOW 3

6 BLUE X

Table 3-2 RJ12 Adapter Pin-out

Figure 3-5 Cash Drawer RJ12 Adapter

3.8 AUX Option

The AUX port option or auxiliary port on the printer is for custom application support.

485TC Operator’s Manual - 880058-0100 3-5

Page 20

Getting Started Chapter 3

3.9 Loading Media

Loading media into the printer is an easy process. Follow the instructions below to properly

adjust the paper guides and load the media.

1. Loosen the green thumbscrew at the back of the printer to adjust the green media

guides so that the media contacts both sides of the green guides.

2. Retighten the green thumbscrew once the guides have been adjusted.

3. Feed the media into the paper path, between the green guides, until you feel

resistance.

4. Once the printer detects paper in the printer, it will automatically feed and align the

paper so that it is properly positioned.

5. If the Autoload feature is disabled, you may also manually feed the paper through the

printer by lifting the print head release at the top of the printer and feeding the paper

through the printer.

6. Also, if the print button is pushed and held, the printer will manually feed the media

through the printer.

7. Once the media exits the front of the printer, release the Print Button.

Loosen thumb

screw to adjust the

guide, retighten the

thumbscrew when

finished

Figure 3-6 Loading Media

Insert media

between the

guides until

resistance is felt

3-6 485TC Operator’s Manual - 880058-0100

Page 21

Chapter 3 Getting Started

3.10 Print Button and Status Indicator Light

The Print Button and the Status Indicator Light are used to identify and perform many

functions. This section provides a description to familiarize you with the basic function of

the Print Button and the Status Indicator Light.

Figure 3-7 Print Button and Status Indicator Light

Status Light

Print

Button

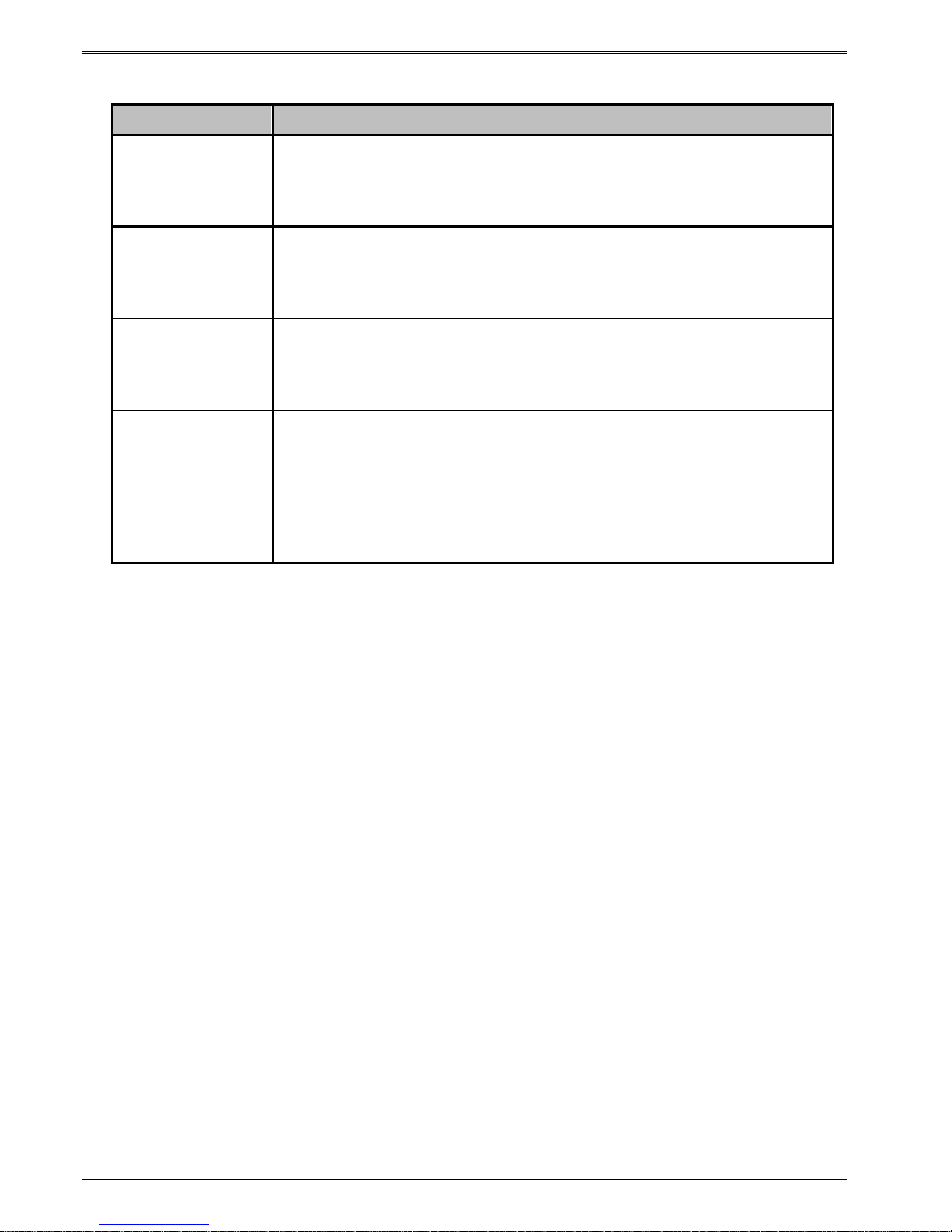

3.10.1 Print Button

Operation Description

Button Press A button press is used to generate a Test Ticket and to clear

errors.

Button Pressed

and Held In

485TC Operator’s Manual - 880058-0100 3-7

Pressing and holding the button in will cause a line feed in certain

language modes.

Table 3-3 Print Button Description

Page 22

Getting Started Chapter 3

3.10.2 Status Indicator Light

Light Color Description

Solid Green

Solid Red

Indicates that the power is on and the printer is in a ready state.

Indicates an error has occurred. The printer will remain in this

state until the condition is removed. If an unexplained error

persists, contact your Service Representative.

Solid Amber

Flashing Red

Indicates that the printer is in the Boot Loader mode (MCB) and is

not running the printer application program.

A cutter error has occurred.

OR

A memory download operation was not successful.

OR

Power Spike or low voltage on the AC line. (The printer will

remain in this mode until the condition is removed and the printer

power is cycled.)

Table 3-4 Status Indicator Light Description

3.11 Printer Modes

The printer has three primary modes of operation. The different types of modes have an

impact on how the Print Button and the Status Indicator Light operate. This section is

intended to provide the user with an explanation of these different modes.

3.11.1 Ready Mode: GREEN

The printer is in the READY Mode when it is ready to print or has no pending activity. The

indicator light is GREEN, which indicates that the printer is ready to receive label formats

and/or commands.

Pressing the print button while in this mode generates a test ticket that contains setup

information about the printer. It is helpful to determine what mode it is in, what

communication port is active, and general operational details/

3.11.2 Halted Mode: RED

The printer is in the HALTED Mode when it has stopped due to an error condition. The

Status Indicator Light will be solid red in color when the printer has entered the HALTED

Mode. The printer will remain in this mode until the error has been corrected and cleared.

Once the error has been cleared, the printer will return to the Ready mode.

Pressing the button in this mode will cause the printer to attempt to clear the error and

return the printer to Ready mode.

3-8 485TC Operator’s Manual - 880058-0100

Page 23

Chapter 3 Getting Started

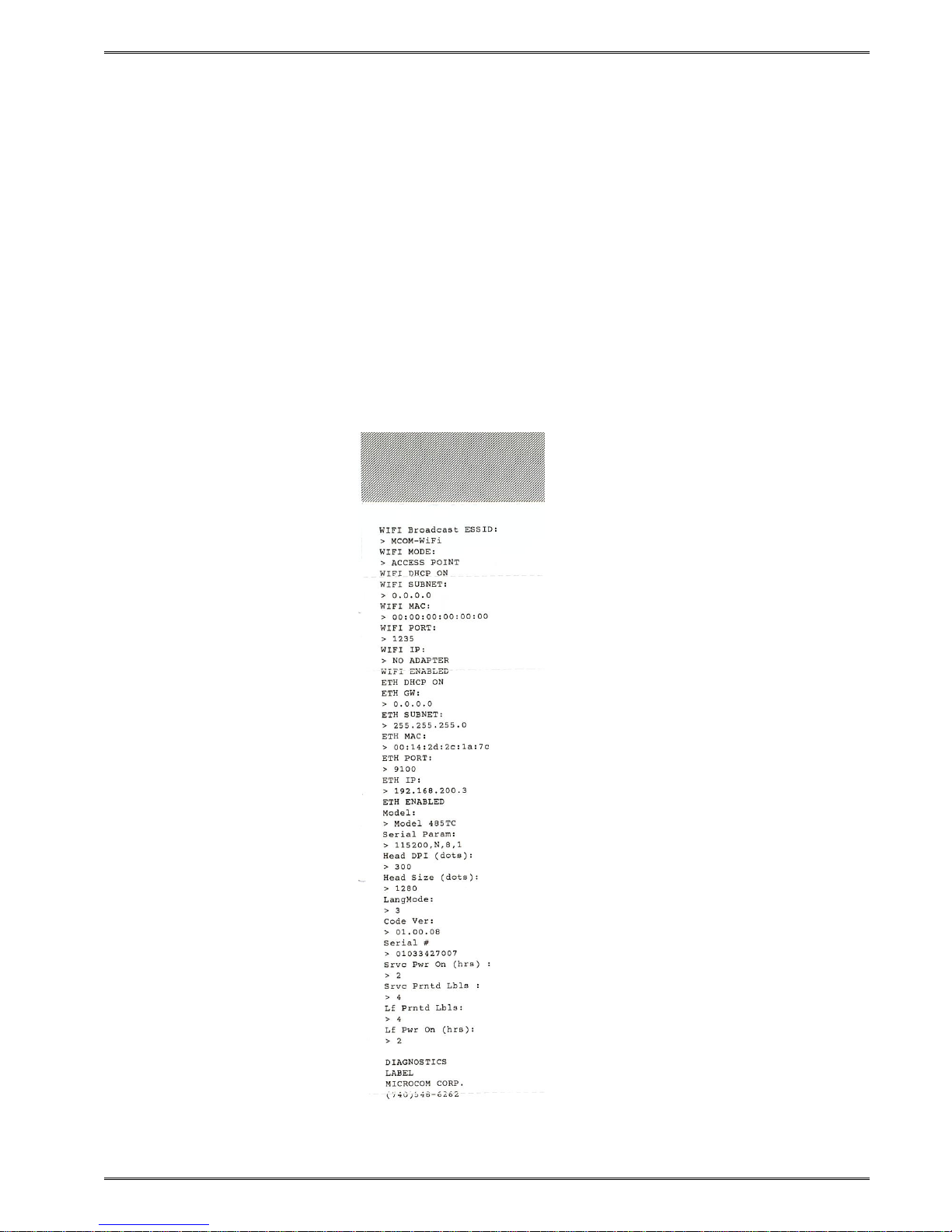

3.11.3 Diagnostic Mode

The Diagnostic Mode temporarily powers up the printer using factory default parameters.

Also, the printer’s current user configuration parameters and statistical information are

printed out on a Status Label. This provides useful information to help diagnose and

troubleshoot problems. The printer will use the factory default parameters until the printer

has been reset using a soft reset or by cycling power. The printer will then return to the

configuration shown on the Status Label.

3.11.3.1 Entering Diagnostic Mode

To enter the Diagnostic Mode, press and hold the Print Button “IN” while turning the printer

“ON.” Release the Print Button after printer light changes to green. The printer will enter

the DIAGNOSTICS Mode, and print the Statistics label and a print test pattern.

3.11.3.2 Statistics Label

The Statistics Label may be printed by entering the DIAGNOSTICS Mode.

Figure 3-8 Statistics Label Example

485TC Operator’s Manual - 880058-0100 3-9

Page 24

Getting Started Chapter 3

3.11.3.3 Test Ticket

The test ticket does not require that the printer be in the Diagnostics mode but it extremely

useful while troubleshooting the printer if problems arise. To generate a Test Ticket, simply

press the button and the test ticket prints out.

Figure 3-9 Test Ticket Example

3.12 TOF Sensor

The TOF Sensor is used to detect when media is present and is used in conjunction with the

Top-Of-Form operation. A TOF is when the printer uses the sensor to detect the edge of

the media and retracts the configured distance. See the D121 and D123 commands for

more details regarding the TOF operation.

A potentiometer adjusts the distance over which the LPD sensor will detect reflections. The

maximum range may be adjusted over a distance of 0.20” to 0.85”. Distances are

measured from the surface of the sensor to the reflecting surface. The sensor is set to the

maximum detection at the factory. This pot may be used to decrease sensor range to avoid

false reflections from stationary objects such as a cutter.

3-10 485TC Operator’s Manual - 880058-0100

Page 25

Chapter 3 Getting Started

The TOF Sensor is

located in front of

the cutter assembly

TOF sensor when

the cutter assembly

is not installed.

Figure 3-10 TOF (Top-Of-Form) Sensor

485TC Operator’s Manual - 880058-0100 3-11

Page 26

Getting Started Chapter 3

3.13 Media Roll Holder Option

The printer may be configured with an optional media holder for media wound on rolls. The

holder is designed to hold media cores of 1.5” or larger and contains media guides intended

to help prevent unnecessary unwinding of media.

Figure 3-11 Rolled Media Holder

3.14 Ticket Catch Tray Option

The printer may be configured with an optional ticket catch tray that is used to catch the

printed tickets. The trays are available in a couple of standard sizes.

Figure 3-12 Ticket Catch Tray

3-12 485TC Operator’s Manual - 880058-0100

Page 27

Chapter 3 Getting Started

3.15 Wristband Media Adapter Option

When 1” wide wristband media is being used, the wristband option should be installed. The

wristband guide is inserted into the media guide and is locked into place.

Wristband Guide

Insert into media guide

making sure that it is

flush against the green

media guide

Figure 3-13 Wristband Media Adapter

Loosen locking nut and

slide guide into place

and retighten into place

485TC Operator’s Manual - 880058-0100 3-13

Page 28

Getting Started Chapter 3

3.16 Qualsoft Windows Driver

3.16.1 Installing the Windows Driver

This section explains the driver installation process. The Qualsoft Windows print driver may

be used with Windows 7, 8.1, and 10 operating systems. If the printer is intended to be

used on a USB connection, the appropriate USB driver must be installed before the printer

is able to be used with the driver. The X38 based products use an FTDI based driver while

the X85 based products use a Microcom Corporation based driver.

The driver requires that the User has ADMIN privileges in order to install the driver. The

installation process sample shows the Windows 7 installation.

1. Right click on the installer, and select “Run as administrator”.

2. Click the “Next” to continue the installation.

3-14 485TC Operator’s Manual - 880058-0100

Page 29

Chapter 3 Getting Started

3. Wait for the installer to finish setting up the driver files.

4. Select the New install or Uninstall existing driver if already running a Qualsoft version or if

installing more than one printer, select the Install another printer model (Copy n).

485TC Operator’s Manual - 880058-0100 3-15

Page 30

Getting Started Chapter 3

5. Select the Model number of the printer being installed.

6. Select the communication port that is going to be used with the printer.

3-16 485TC Operator’s Manual - 880058-0100

Page 31

Chapter 3 Getting Started

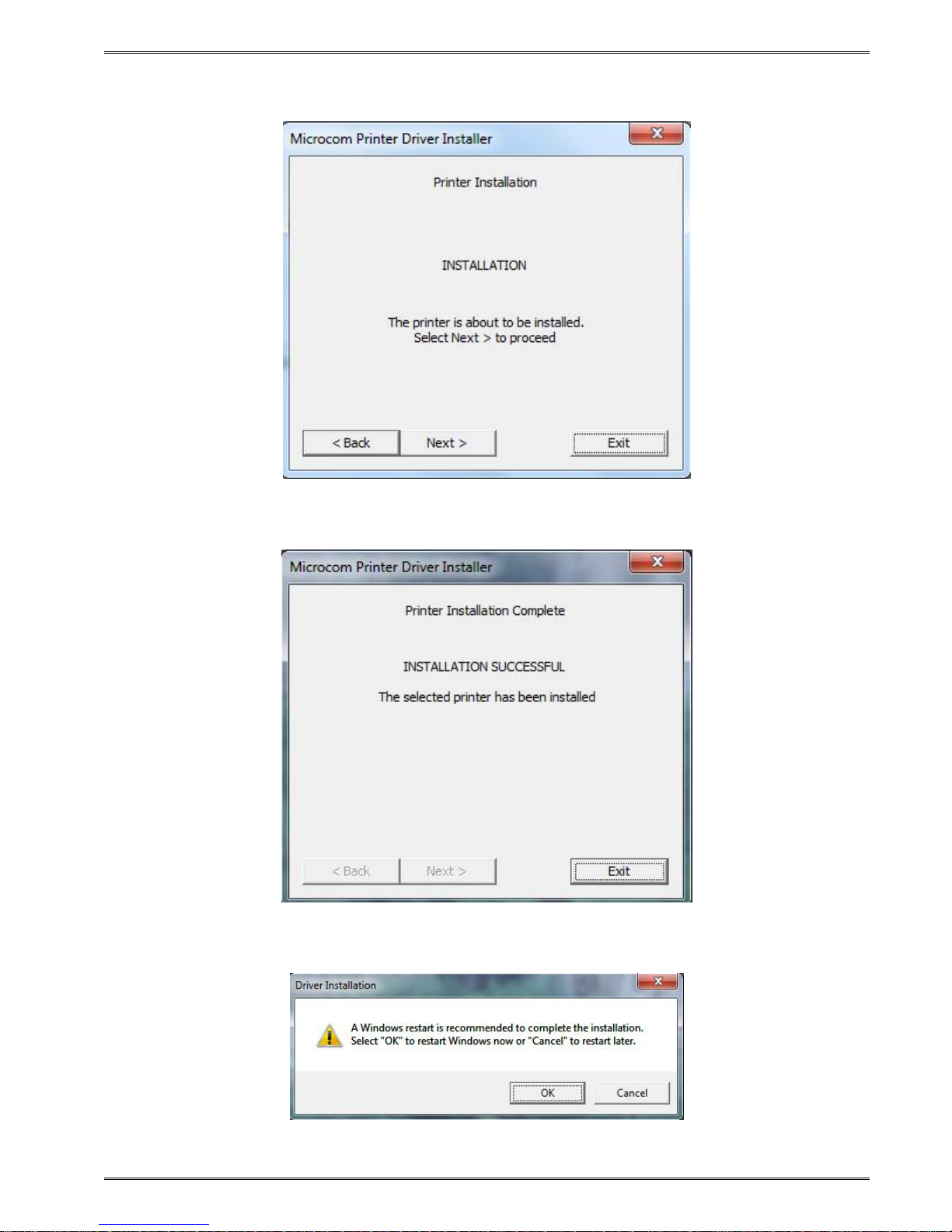

7. Select next to start the installation.

8. Once the installation is complete, select “Exit” to finish the installation.

9. Select “OK” if prompted to restart and complete the installation.

485TC Operator’s Manual - 880058-0100 3-17

Page 32

Getting Started Chapter 3

3.16.2 Configuring the Driver

This section will explain how to configure the Windows Driver for proper operation. The

example below also shows a Microcom Thermal Printer under Unspecified devices. This is

the USB driver that is loaded when the printer is powered on and the printer USB port is

connected to the printer.

Under Devices and Printers, you should see the printer model that was installed. Right click

on the icon and select Printer properties to setup and to change the driver settings.

3-18 485TC Operator’s Manual - 880058-0100

Page 33

Chapter 3 Getting Started

3.16.3 Printer Properties Page - General tab

This opens the printer properties page. From this screen, Print Test Page may be selected

to generate a test page that is sent to the printer. The test page is printed on the media size

and type that are specified in the driver preferences.

485TC Operator’s Manual - 880058-0100 3-19

Page 34

Getting Started Chapter 3

3.16.4 Printer Properties Page - Ports tab

Selecting the Ports tab at the top allows the printer port to be changed if connecting to a

different printer communication port.

3-20 485TC Operator’s Manual - 880058-0100

Page 35

Chapter 3 Getting Started

3.16.5 Printing Preferences - About tab

Selecting the Preferences icon at the bottom left of the Printing properties window opens the

driver “About” tab. This shows the driver version number and release date.

3.16.6 Printing Preferences - Print tab

The Print tab shows the available options that may be set. Typically, these are already set

for proper operation and do not need to be adjusted.

485TC Operator’s Manual - 880058-0100 3-21

Page 36

Getting Started Chapter 3

3.16.6.1 Print tab - Advanced

The Advanced tab is used to specify the print resolution and the printhead width. This tab is

automatically set when selecting the printer model to install and should be ignored. This

screen is typically used for development testing and custom solutions.

3.16.7 Print tab - Halftone Adjustment

The Halftone Adjustment icon opens the dialog windows below. This allows the user to

manipulate the image settings that the driver uses to produce images.

3-22 485TC Operator’s Manual - 880058-0100

Page 37

Chapter 3 Getting Started

3.16.8 Print tab - Halftone Properties

The Halftone Properties page allows for dithering options and additional image manipulation

to alter the image that is produced and printed.

3.16.9 Print tab - User Commands

The User commands tab allows for the user to pass printer commands directly into the data

stream. This is typically used for either troubleshooting or custom override commands.

485TC Operator’s Manual - 880058-0100 3-23

Page 38

Getting Started Chapter 3

3.16.10 Printing Preferences - Paper tab

The Paper tab is where the user adds custom form sizes and adjusts minor handling effects.

The form sizes that are created here are added to the Windows Print Server Properties for

the model installed.

3.16.10.1 Paper tab - Rotation

The rotation setting rotates the image being printed. This is used when Portrait or

Landscape is used. The “A” image shows the rotation setting impact.

3.16.10.2 Paper tab - Units

This is used to select the units that the driver uses for most measurements. Some units are

in dots or pixels and should be entered as such.

3.16.10.3 Paper tab - Page Sizes

This is where the user enters forms to the Print Server Properties of the driver. Select the

drop down menu to select standard forms that have been installed with the driver or enter

the size of your form and select the New icon to create a form size that matches your media.

3.16.10.4 Paper tab - Mirror

Selecting this option will cause the image to appear like it being observed in a mirror.

3-24 485TC Operator’s Manual - 880058-0100

Page 39

Chapter 3 Getting Started

3.16.10.5 Paper tab - Default

This button will cause the driver to load in its default settings for the model driver installed.

Please note that this default may not represent your media type or size.

3.16.11 Printing Preferences - Media tab

The Media tab is used to set specific setting of the media size and operations that in a form

that the printer requires to maintain correct registration.

3.16.11.1 Media tab - Settings

The Settings control the Type of registration that the printer will use to align the media being

used and the Darkness of the image being printed.

3.16.11.1.1 Settings - Type

This field sets the registration method that the printer will use to register job to job. This

type should be set to the type of registration mark that is used to indicate the form size. The

Continuous setting instructs the printer to ignore registration marks and will move media

based on the form size settings. The Blackline setting cause the printer’s reflective sensor

to look for a blackline mark and register based on the other Feed options. The Diecut and

485TC Operator’s Manual - 880058-0100 3-25

Page 40

Getting Started Chapter 3

Blowhole settings cause the printer to use its transmissive sensor to detect the backing

material between labels or an actual hole in the media.

3.16.11.1.2 Settings - Darkness

This sets the darkness or contrast that the printer uses to image. As the value increases,

the higher the thermal temperature setting is used for imaging. The lowest temperature that

produces quality images should be used to extend the printhead life.

3.16.11.2 Media tab - Feed Options

The Feed options handle post printing dispensing and media options that are used by the

printer to properly register the media from page to page.

3.16.11.2.1 Feed Options - Mode

The Mode is used to select the type of dispense option used after the printer has printed.

The options include None, Advance when idle, Advance every label, Cut after label, and Cut

with LPD.

Selecting the “None” option will disable the dispense modes. The printer will print the job

and then stop without performing any dispense option.

The Advance when idle dispense option causes the printer to advance the Dispense

Distance after the printer’s communication port has gone idle. This mode does not require a

label present sensor to function. For example: If printing 5 jobs, the printer would advance

after printing the fifth job.

The Advance every label is a dispense mode that does use the printer’s label present

sensor. The printer will print a job and then advance the job by the Dispense Distance. A

second job will not be processed until the printed/dispensed job has been taken (the LPD no

longer detects the advanced job). Once the job has been taken, the printer will process the

next print job. The Advance/Retract delay is also used in conjunction with this command.

This delay starts after the label has been taken.

Cut after label causes the printer to advance the Dispense Distance after the job has been

printed and then cycles the cutter. This mode does not use the Label Present Sensor.

The Cut with LPD is a mode that the printer will advance the Dispense Distance after

printing and cut the label. The LPD is used to prevent the next job from printing until the

current job has been taken by the user.

3.16.11.2.2 Feed Options - Gap Height

This field is used to specify the height of the backing material between labels typically found

on die cut media types. As the media is moved through the printer, the height of the Gap

would be what the printer’s transmissive sensor would detect and use for page to page

registration.

3.16.11.2.3 Feed Options - Blackline/Blowhole Height

This field is used to specify the height of the blackline or Blow hole that is used for

registration on media types containing a blackline of blowhole. The printer uses its reflective

sensor to detect the blackline as the media is passed through the printer and would use its

transmissive sensor to detect the blowhole.

3-26 485TC Operator’s Manual - 880058-0100

Page 41

Chapter 3 Getting Started

3.16.11.2.4 Feed Options - Dispense Distance

This is the distance that the printer uses to move the media forward to dispense and it used

in conjunction with the Mode. The printer moves out this distance and then would retract

the same distance so it does not impact registration.

3.16.11.2.5 Feed Options - Advance/Retract Delay

This field is used to specify how long the printer will wait in msec after the media has been

taken when the Advance every label mode or Cut with LPD modes are used.

3.16.11.2.6 Feed Options - Registration Offset (DRM)

The registration offset is used by the printer to calculate the correct SPG (Steps Past Gap)

value that the printer will use for registration. This distance is from the first printable area of

the media to beginning of the registration mark as it would pass through the printer.

3.16.11.2.7 Feed Options - Dot2Gap

This field is the distance of the registration sensors to the dot row and is used to calculate

the Steps past gap or SPG value used to align the print from page to page. This value is

fixed value for each printer model. Some printer models have a different sensor location for

the blackline reflective sensor and the Transmissive Gap sensor. Please review the printer

manual for more information regarding the correct value for the Dot2Gap. The value

entered is in dots or pixels.

3.16.11.2.8 Feed Options - SPG

The Steps Past Gap (SPG) is a format header parameter that the printer uses to register the

page properly. If the Auto SPG is checked, the driver will automatically calculate the proper

SPG based on the other entered fields. If unchecked, the SPG is entered in manually. This

value is entered in as dots.

3.16.11.2.9 Feed Options - Activate Gap Detection (dots)

The Activate Gap Detection is the distance in dots that the printer will move media before

trying to detect a registration mark. The default of 1 typically works for most media types. If

the media being used contains preprint in the sensor area, the AGD may need to be used to

disable registration detection until passing over the preprinted areas.

3.16.12 Printing Preferences - Presenter tab

The Presenter tab controls the operation of the optional presenter available on some printer

models. A presenter is a post printing device that typically takes a printed and cut form and

presents it to the user only after is has printed completely. Not every printer model is

capable of running a presenter. Check with your printer model operator’s manual to see if a

presenter is supported. This tab is ignored on models that do not support the use of a

presenter.

485TC Operator’s Manual - 880058-0100 3-27

Page 42

Getting Started Chapter 3

3.16.12.1 Presenter tab - Configuration

The fields listed under the Configuration section control the Presenter operation on printer

model that are compatible with the presenter.

3.16.12.2 Configuration - Modes

This is used to select the mode of the presenter. The valid modes are enabled,

passthrough, and disabled. When selecting Enabled, the printer with presenter would

present the media using the other fields for operation while selecting Passthrough mode will

simply cause the presenter to run while the printer is printing.

3.16.12.2.1 Configuration - Take-Label/Retract Timeout (secs)

This field controls the time that the presenter will present the paper before retracting into the

waste bin.

3.16.12.2.2 Configuration - Maximum Present Distance (inch)

This is the maximum size that the printer will present when using the enabled mode. This

value is in inches.

3-28 485TC Operator’s Manual - 880058-0100

Page 43

Chapter 3 Getting Started

3.16.12.2.3 Configuration - Loop Height (1/10 inch)

The Loop Height is a value in 1/10 inch that the printer uses to delay the presentation of the

media. The printer would print and form a loop at the presenter and once this value is

reached, the presenter would present.

3.16.12.3 Configuration - Advanced

The Advanced button is included as a manual override of the recommended settings that

the presenter will use for the various speeds. Typically, these values do not need to be

adjusted for the presenter to function.

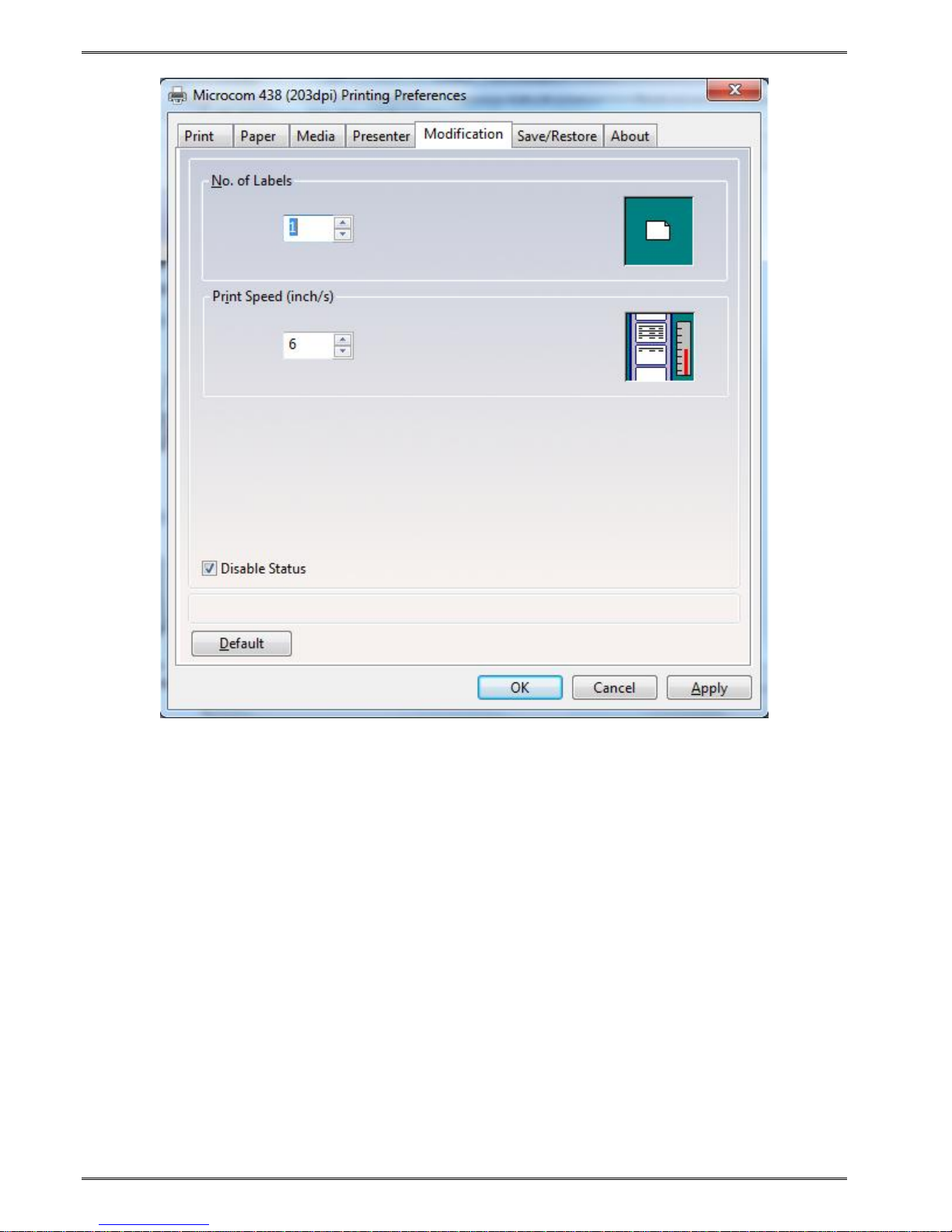

3.16.13 Printing Preferences - Modification tab

This tab is used to control the number of copies, print speed, and port monitor status

enable.

3.16.13.1 Modification - No of Labels

This field controls how many copies of the current page will be printed.

3.16.13.2 Modification - Print Speed (inch/s)

The Print Speed filed controls the print speed that the printer uses to print a page.

3.16.13.3 Modification - Disable Status

The Disable Status checkbox is used to control whether the Port Monitor Status popup

window is displayed or not. This is used to get real time status from the printer while

printing via the Windows driver.

485TC Operator’s Manual - 880058-0100 3-29

Page 44

Getting Started Chapter 3

3-30 485TC Operator’s Manual - 880058-0100

Page 45

Chapter 3 Getting Started

3.16.14 Printing Preferences - Save/Restore tab

The Save/Restore tab is used to export or import driver settings and to force back to the

factory defaults based on the printer model installed.

3.16.14.1 Save/Restore - Restore settings from file…

This is used to import or restore driver settings from a .MDS file. The driver settings are

contained within a .MDS file and may be restored or configured if imported using the

Restore feature.

3.16.14.2 Save/Restore - Save settings to file…

This is used to export or save the current settings in a .MDS file. This file contains the driver

setup used to configure the driver.

3.16.14.3 Save/Restore - Restore factory defaults…

This will force the driver defaults of the printer model installed.

3.16.15 Status Messages

This section describes the Windows compatible Status messages that are displayed in

spooler and the Status Monitor feature found on the Modification tab. These messages may

485TC Operator’s Manual - 880058-0100 3-31

Page 46

Getting Started Chapter 3

be extracted using the GetPrinterData MSDN API call. The standard message and the

printer meaning are listed below.

3.16.15.1 PRINTER_STATUS_WAITING

This message indicates that the printer is okay and ready to print. LDS1 control language

printer message would be the >READY<.

3.16.15.2 PRINTER_STATUS_BUSY

Message indicates that the printer is busy printing a job. No LDS1 equivalent control

language printer message.

3.16.15.3 PRINTER_STATUS_PAPER_OUT

This message indicates that the printer does not detect media in the printer or has run out of

media. The LDS1 equivalent control language printer message would be >STOCK NOT

LOADED< or >LOW STOCK<.

3.16.15.4 PRINTER_STATUS_PAPER_JAM

Message is used to indicate that the printer has detected a media jam. The LDS1 control

language printer message would be the >LPD STOCK JAM<.

3.16.15.5 PRINTER_STATUS_PAPER_PROBLEM

This message is used to indicate that the optional >INPUT 1< sensor is active. The >INPUT

1< message is the equivalent LDS1 control language printer message that is reported.

3.16.15.6 PRINTER_STATUS_USER_INTERVENTIO N

This message indicates that the printer is in an error condition that needs to be corrected

before the printer may continue. The LDS1 messages that generate this error would be

>CUTTER ERROR<, >DATA ERROR<, >FAIL TIMEOUT<, or >FAIL SIZE< LDS1 control

messages.

3.16.15.7 PRINTER_STATUS_OFFLINE

Message indicates that the printer is powered down or the driver is unable to communicate

with the printer. No LDS1 equivalent control language printer message.

3.16.15.8 PRINTER_STATUS_OUTPUT_BIN_FULL

This message is used to report that the printer is reporting that its catch tray is full or that the

printer’s media is advanced blocking the LPD sensor while in a dispense mode. The LDS1

control language messages that generate this message would be the >TRAY FULL< and

>TAKE LABEL< messages.

3.16.15.9 PRINTER_STATUS_DOOR_OPEN

This message is generated when the printer detects that its printhead assembly is not fully

closed. Not all printers support this feature. The LDS1 control language message

equivalent would be the >HEAD UP< message.

3.16.15.10 PRINTER_STATUS_IO_ACTIVE

This message is used to indicate that the optional >INPUT 2< sensor is active. The >INPUT

2< message is the equivalent LDS1 control language printer message that is reported.

3-32 485TC Operator’s Manual - 880058-0100

Page 47

Chapter 3 Getting Started

3.17 Configuration Application

The 485 Configuration Application and its dependencies are installed by running the

provided setup utility. Most modern versions of Windows require Administrator privileges to

perform this type of installation.

For 32-bit Windows systems, run Microcom485ConfigurationAppSetup_x86.exe. For 64-bit

Windows systems, run Microcom485ConfigurationAppSetup_x64.exe.

The setup utility will guide you through the installation process. Take note of the installation

directory. By default, application package files will be placed in either the “C: Program Files”

or “Program Files (x86)” directory.

3.17.1 Selecting a Device

The 485 Configuration Application allows a printer to be configured via an RS-232 serial,

USB serial, USB HID, or Ethernet connection to a computer. With the exception of RS-232,

all of these interfaces can be enabled/disabled on the printer. To determine which

interfaces are enabled, a diagnostic label may be printed by powering down the printer and

powering it back on while holding the front panel button OR simply by pressing the front

panel button while in FGL mode. Once you know which interface to use, simply select it on

the left panel, choose it from the selection list on the right, and click OK.

3.17.1.1 Configuration Application - Serial (USB / RS-232)

RS-232 and USB CDC (USB serial) connections will be recognized as COM devices by

Windows. Typically, more than one COM device will be found by the application. To

determine which COM port is bound to the Model 485, check the ‘Devices and Printers’

menu in the Windows Control Panel. The printer should be listed as Microcom 485 Thermal

Printer (COM#) - choose this same COM device within the 485 Configuration Application to

configure the printer using RS-232 or USB ser i al as the active interface.

485TC Operator’s Manual - 880058-0100 3-33

Page 48

Getting Started Chapter 3

3.17.1.2 Configuration Application - USB HID

A USB Human Interface Device (USB HID) is a generic classification of an input device.

Windows comes pre-loaded with the USB HID drivers necessary to communicate with the

Model 485, which means there is nothing for the user to install.

As is the case with COM devices, the 485 Configuration Application will typically find more

than one USB HID device. Microcom printers are identified as such and will be listed as

“Microcom - <Model> - <Serial Number>”. For example, the device selection box would list

a Microcom 485 as “Microcom - 485 - 123456”. Choose the desired printer from the

selection list. If more than one Microcom 485 is connected to your computer and you do not

know the serial number, press the push button on the printer to print a test ticket while in

FGL mode or a double press while in Graphics mode.

3.17.1.3 Configuration Application - Ethernet

If your Microcom 485 and computer share an ethernet network connection, the 485

Configuration Application can use the printer IP address and port to communicate. In the

text field, enter the printer’s IPv4 address in its usual format of “aaa.bbb.ccc.ddd”, then enter

the port that the printer is configured to listen on. If you do not know the port or the IP

address, press the push button on the printer to print a test ticket with this information (FGL

mode only). The default IP address and port are 192.168.200.3 and 9100, respectively.

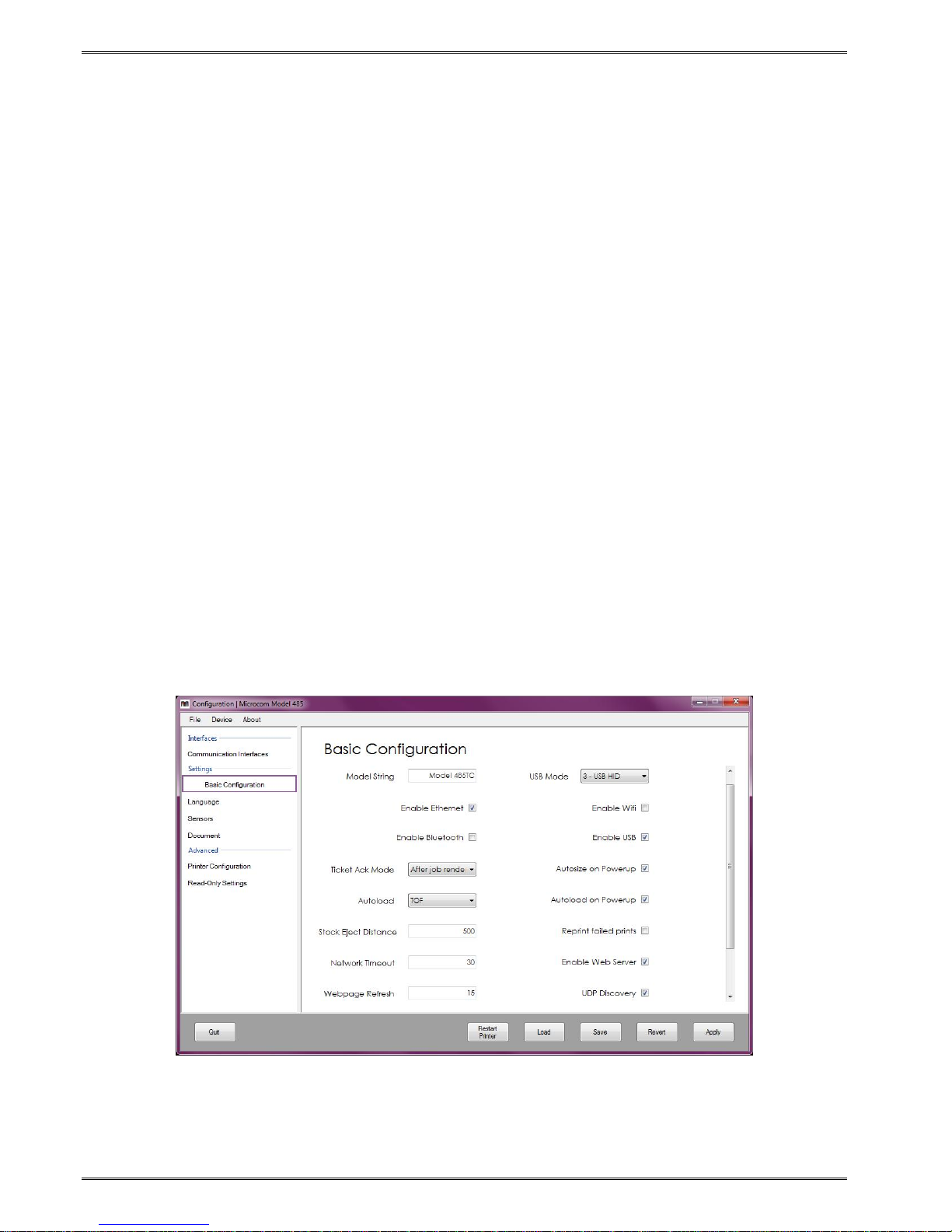

3.17.2 Configuring a device

Once you have chosen the appropriate interface and successfully connected to the 485

printer, the configuration window will appear. The window is essentially made up of three

panels: the configuration categories (left), configuration values (right), and printer control

button panel (bottom). Configuring your 485 is as simple as changing the value, clicking

Apply, and then clicking Restart.

3-34 485TC Operator’s Manual - 880058-0100

Page 49

Chapter 3 Getting Started

3.17.2.1 Applying changes

To apply all configuration changes to the printer, click the Apply button. When this button is

clicked, the values held by the on-screen controls are sent to the printer. The printer must

be restarted for the changes to take effect. A restart can be performed by clicking the

Restart button or by manually turning off and on the power switch on the printer. When the

printer reboots, the changes will be in place.

3.17.2.2 Reverting changes

When the Revert button is clicked, the values held by the on-screen controls will change

back to what they were when the device was first connected to when the application started.

In other words, the revert point is the point at which the Configuration window is first loaded.

If you have applied changes but have not restarted the printer for them to take effect,

clicking Revert will undo all the changes even if the Apply button has been clicked.

3.17.2.3 Saving/loading configuration files

A configuration file is generated by the application when the Save button is clicked, or when

the File->Save configuration menu option is selected. Clicking either of these two options

will open a Windows Save As dialog in the application output directory. A unique filename is

generated by default to avoid overwritten configurations.

To load a configuration file, click the Load button or the File->Load configuration menu

option. The application will open a file dialog in the application output directory. Select a

configuration file, and click “Open” to update the on-screen controls with the configuration

values contained in the file. Note that loading a file does not send the configuration to the

printer until the Apply button is clicked.

3.17.3 Application preferences

The Preferences window can be accessed by selecting File->Preferences from the menu

bar. Within the preferences you can change the application output directory, gain access to

read-only settings (with a password of course), and more.

485TC Operator’s Manual - 880058-0100 3-35

Page 50

Getting Started Chapter 3

3-36 485TC Operator’s Manual - 880058-0100

Page 51

Chapter 4 Printer Maintenance

4.1 Maintenance Schedule

It is important to note that the optimum print quality and print head life is achieved by

maintaining a clean printer and print head. A Microcom Corporation approved cleaning kit

(part # 040005-0000) is available; contact your sales representative for purchasing

information.

AREA METHOD INTERVAL

Foam tipped swab, cotton tipped

Print Head

Drive Roller

Peel Edge

Interior Cleaning

Exterior Cleaning

Table 4-1 Recommended Maintenance Schedule

CAUTION: Microcom Corporation will not be held responsible for

damage caused by any non-approved solvent, cleaning material and/or

method. The use of such non-approved materials and/or methods may

void appropriate expressed or implied warranties.

swab, or thermal printer cleaning

card dampened with Isopropyl

Alcohol.

Foam tipped swab, cotton tipped

swab, thermal printer cleaning

card, or lint-free cloth dampened

with Isopropyl Alcohol

Foam tipped swab, cotton tipped

swab, thermal printer cleaning

card, or lint-free cloth dampened

with Isopropyl Alcohol

Compressed air, static protected

vacuum cleaner, soft-bristle

brush, and/or lint-free cloth

dampened with Isopropyl Alcohol.

Lint-free cloth dampened with a

mild, non-abrasive general

purpose cleaner.

After every roll of

media or every 512

feet of tag stock or

fanfold media.

After every roll of

media or every 512

feet of tag stock or

fanfold media.

As Needed.

As Needed.

As Needed.

4.2 Thermal Printer Cleaning Card

Any decline in print quality, voids or dropout areas in bar codes and/or graphics may

indicate that the print head is dirty and needs to be cleaned. The necessary cleaning

materials can be purchased through Microcom Corporation by contacting your sales

representative and ordering the Cleaning Kit, part # 040005-0000. The print head should be

cleaned after every roll of media or after every 512 feet of fanfold media (a typical stack of

tag or fanfold media is approximately 3,200 tags).

485TC Operator’s Manual - 880058-0100 4-1

Page 52

Printer Maintenance Chapter 4

A thermal printer card is the quickest and easiest way to clean the print head, drive roller,

and peel edge all at the same time. Follow the steps below for the proper cleaning

procedure.

1. Remove any installed media.

2. Dampen both sides, on one end, of the cleaning card with isopropyl alcohol or use a

pre-moistened cleaning card.

3. Release the printhead assembly to insert the cleaning card under the printhead.

Figure 4-1 Releasing the Printhead Assembly

Figure 4-2 Rotate the Printhead Assembly to the Open Position

4-2 485TC Operator’s Manual- 880058-0100

Page 53

Chapter 4 Printer Maintenance

4. Re-latch the printhead assembly, hold the printer, and slowly pull the cleaning card

(you will feel resistance) out of the printer.

Figure 4-3 Remove the Cleaning Card

5. Reinstall the media and check print quality.

6. Repeat cleaning steps if necessary.

Thermal cleaning cards should not be used more than three times each. Extremely dirty

cards should be disposed of immediately.

4.3 Internal Cleaning

The overall internal cleaning of the printer is important to help reduce the dust and other

contaminates residing in the printer that may attach to the print head or drive roller and

affect the printer’s performance.

1. Remove any installed media.

2. Turn the printer power “OFF.”

3. Release the printhead assembly and rotate to the open position.

4. The exposed Drive Roller, Printhead, and Paper Path may be cleaned using a cotton

swab or lint-free wiping rag dampened with is opropyl alcohol.

485TC Operator’s Manual - 880058-0100 4-3

Page 54

Printer Maintenance Chapter 4

Blow dust out with

compressed air or

vacuum with anti-static

vacuum cleaner.

Clean Paper Path with

lint-free cloth or swabs

dampened with isopropyl

alcohol.

Clean Drive Roller with

lint-free cloth or swabs

dampened with isopropyl

alcohol. (Drive Roller

can be rotated by hand.)

Figure 4-4 Internal Cleaning

4.4 Print Head Maintenance

If print quality has not improved after using a thermal cleaning card, or if one is not

available, foam or cotton tipped swabs or a clean lint-free cloth dampened with isopropyl

alcohol may be used. Follow the steps below to clean the print head.

1. Release the Print Head Assembly and rotate to the open position.

2. With a foam or cotton tipped swab or soft, lint-free cloth dampened with isopropyl

alcohol, clean the thermal elements by gently rubbing the swab down the length of

the print head dot row. Allow for the alcohol to evaporate, then repeat if necessary.

3. Reinstall media and run labels to check print quality.

4. If poor print quality persists, print head or other parts may be damaged.

CAUTION: Isopropyl Alcohol or other approved non-Abrasive

solution should be used to clean the drive roller. The use of other

cleaning solvents or materials is not recommended and may

degrade the performance of the drive roller.

4-4 485TC Operator’s Manual- 880058-0100

Page 55

Chapter 4 Printer Maintenance

The printhead dot row

should be cleaned to

remove any

contaminates that may

impact print quality.

Figure 4-5 Cleaning the Print Head

4.5 Replacing the Drive Roller

Over time, the platen may harden and cause print issues and need to be replaced. The

printer is equipped with an easy replaceable drive roller assembly.

1. Loosen and unscrew the 2 pressed in captive screw that holds the top cover in place

and rotate to the open position.

Figure 4-6 Releasing the Print Mechanism

2. Release the Print Head Assembly and rotate to the open position.

485TC Operator’s Manual - 880058-0100 4-5

Page 56

Printer Maintenance Chapter 4

3. Unscrew the Cutter or Tear Assembly using the mounting screw that is located in the

bottom center on the front of the Print Mechanism.

Cutter or Tear

Assembly

Mounting Screw.

Figure 4-7 Cutter or Tear Assembly Mounting Screw

4. Squeeze the white plastic bushing together on both sides of the platen to release

from the sheet metal and lift the platen assembly up and out of the printer.

Squeeze the tabs

together on both

sides and lift the

roller out of the

printer.

Figure 4-8 Removing the Platen

4-6 485TC Operator’s Manual- 880058-0100

Page 57

Chapter 4 Printer Maintenance

5. Replace the assembly with a new platen assembly making sure that the bushings

snap into the sheet metal.

6. Reattach the cutter or tear assembly taking care to locate the top lip of the assembly

to the hook detail in the sheet metal.

Hook detail that

the cutter or tear

assemblies are

attached too

Figure 4-9 Cutter or Tear Assembly Mounting Hook

7. Close the printhead assembly to the home position and latch into place.

8. Reinstall the front and top covers and tighten the top cover thumbscrews.

4.6 Adjusting Printhead Pressure

The printer has two head pressure settings to support both narrow and wide media types.

The printhead pressure is typically changed to a lighter pressure when the media being

used is 2” wide or less. Extra drag on the platen may cause feeding issues if a heavy spring

pressure is used with the narrow stock types.

The heavy spring pressure is typically used on media that is over 2” wide. The spring

pressure is not intended to overcome print quality issues. If light print is detected, please

adjust your printer’s contrast setting (^D36) and/or verify that the thermal coating on the

media is sufficient.

485TC Operator’s Manual - 880058-0100 4-7

Page 58

Printer Maintenance Chapter 4

Figure 4-10 Narrow Media Light Spring Setting

Figure 4-11 Wide Media Heavy Spring Setting

4-8 485TC Operator’s Manual- 880058-0100

Page 59

Chapter 5: Troubleshooting

5.1 Troubleshooting Tips

The printer fails to turn “ON” and the status indicator light fails to light:

ü Verify that the power cord is connected to the printer, as well as the AC outlet.

ü Verify that the printer power switch is in the “ON” position.

ü Verify that the AC outlet is functioning properly.

ü Contact your Service Representative.

The printer has no communication:

ü Verify that the communication cable is properly connected to the printer and an

available communication port on the host computer.

ü Verify that the host communication port is functioning properly.

ü Verify that the printer and the host communication parameters are set correctly.

ü Verify that nothing else is configured on the same port.

ü Is the printer in an Error?

ü Contact your Service Representative.

Vertical blank or light lines appear on printed areas:

ü Clean the print head.

ü Print head may need to be replaced.

ü Contact your Service Representative.

The print does not align to my media:

ü Verify that the media contains some sort of registration mark.

ü Verify that the printer is received proper formatting instructions.

ü Verify that nothing is blocking the internal registration mark sensors.

ü Contact your Service Representative.

485TC Operator’s Manual - 880058-0100 5-1

Page 60

Troubleshooting Chapter 5

The status indicator light is solid amber in color:

ü Indicates that the printer is the Bootloader, make sure that an application has been

installed.

ü Contact your Service Representative.

The status indicator light is solid red in color:

ü The printer has an error and requires service before printing will continue.

ü Verify that media has been loaded in the printer properly.

ü Press the print button to attempt to clear the error.

ü Cycle power to reset the printer.

The status indicator light is flashing red in color:

ü Generally due to a power fail error.

ü Verify that the AC line-voltage is present at the AC outlet.

ü Cycle power.

5-2 485TC Operator’s Manual - 880058-0100

Page 61

Index

General Index

Agency Approvals................................................................................................................................................. 1-1

Alphanumeric ...................................................................................................................................................... 7-5

Bar codes ................................................................................................................................................................1

Barcode ............................................................................................................................................................... 7-5

Black-line............................................................................................................................................................. 7-5

Blow-hole ............................................................................................................................................................ 7-5

Cleaning Kit .................................................................................................................................................. 2-2, 4-1

Communication

RS-232C Serial ................................................................................................................................................. 3-2

Continuous media ................................................................................................................................................ 7-5

CTS ..................................................................................................................................................................... 7-5

Cutter ................................................................................................................................................................. 7-5

Data Bits .............................................................................................................................................................. 1-1

DCD .................................................................................................................................................................... 7-5

DCE ..................................................................................................................................................................... 7-5

Die-cut media ...................................................................................................................................................... 7-5

Direct Thermal ..................................................................................................................................................... 7-5

DPI ...................................................................................................................................................................... 7-5

Drive Roller ................................................................................................................................................... 4-1, 7-5

DSR ..................................................................................................................................................................... 7-5

DTE ..................................................................................................................................................................... 7-5

DTR ..................................................................................................................................................................... 7-6

Electrical ............................................................................................................................................................. 1-1

Ethernet .............................................................................................................................................................. 7-6

Fanfold media ...................................................................................................................................................... 7-6

Flash Memory ...................................................................................................................................................... 1-1

FLASH memory .................................................................................................................................................... 7-6

Flow Control ................................................................................................................................................. 1-1, 3-2

Fonts ................................................................................................................................................................... 2-1

GND .................................................................................................................................................................... 7-6

Graphics .............................................................................................................................................................. 2-1

Guillotine cutter ................................................................................................................................................... 7-6

Humidity ............................................................................................................................................................. 1-1

Indicator Light.................................................................................................................................3-7, 3-8, 5-1, 5-2

Inspection ........................................................................................................................................................... 3-1

Isopropyl Alcohol .......................................................................................................................................... 4-2, 4-4

LDSII ................................................................................................................................................................... 7-6

Limited Warranty ................................................................................................................................................. 7-1

Maintenance ........................................................................................................................................ 6-7, 4-1, 4-4

Exterior ........................................................................................................................................................... 4-1

Interior ........................................................................................................................................................... 4-3

Printhead ........................................................................................................................................................ 4-4

Schedule ................................................................................................................................................ 6-7, 4-1

Thermal Card................................................................................................................................................... 4-1

Media ................................................................................................................................................... 6-5, 6-6, 1-2

Loading ......................................................................................................................................................... 6-5

Maximum Thickness ........................................................................................................................................ 1-2

Maximum Width .............................................................................................................................................. 1-2

Specifications ......................................................................................................................................... 6-6, 1-2

Types .........................................................................................................................................1-2, 7-5, 7-6, 7-7

Media Width ....................................................................................................................................................... 1-2

Memory ................................................................................................................................................ 1-1, 7-6, 7-7

485TC Operator’s Manual - 880058-0100 6-1

Page 62

Flash ............................................................................................................................................................... 1-1

SDRAM ............................................................................................................................................................ 7-7

SRAM ....................................................................................................................................................... 1-1, 7-7

Modes ................................................................................................................................................................. 3-8

Diagnostic ....................................................................................................................................................... 3-9

Operation

Indicator Light ................................................................................................................................................. 3-8

Options ............................................................................................................................................................... 2-1

Packaging ............................................................................................................................................................ 3-1

Parity .................................................................................................................................................................. 1-1

Peel Edge ............................................................................................................................................................. 4-1

Platen .................................................................................................................................................................. 7-6

Print Button .................................................................................................................................................. 3-7, 3-8

Print Length ......................................................................................................................................................... 1-1

Print Resolution ................................................................................................................................................... 1-1

Print Speed .......................................................................................................................................................... 1-1

Print Type ............................................................................................................................................................ 1-1

Print Width .......................................................................................................................................................... 1-1