Page 1

MODEL 226 / 426

DIRECT THERMA L PRINTER

USER’S GUIDE

PART NUMBER 880018-0110

Revised: December 13, 2004 CPC

© Copyright 2004 by Microcom Corporation, Lewis Center, Ohio – All rights reserved.

Printed in the United States of America

Page 2

This Page Intentionally Left Blank

Page 3

This Page Intentionally Left Blank

Page 4

Proprietary Statement

This manual contains information proprietary to Microcom Corporation. This information is

intended solely for the use of parties operating and maintaining such equipment described

herein.

Product Enhancements

Microcom Corporation is committed to the continual improvement of performance and

quality in our products. For this reason, specifications are subject to change without notice.

Liability Disclaimer

Microcom Corporation makes every effort to assure that all information and specifications

contained in this manual are accurate; however, mistakes are sometimes made. Microcom

Corporation shall not be liable for any damages resulting in the use or misuse of this

product. The exclusion or limitation involving consequential or incidental damage does not

apply to all states; therefore limitation mentioned above may or may not apply.

FCC Compliance Statement

This equipment is tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy, and

if not installed and used in accordance with the instructions contained in this manual, may

cause harmful interference to radio communications.

HyperTerminal® and HyperAccess® are trademarks of Hilgraeve Inc.

Centronics® is a registered trademark of Data Computer Corporation.

HP® and LaserJet II® are trademarks of Hewlett-Pack ard Company.

Arial® is a registered trademark of The Monotype Corporation.

TrueType® is a registered trademark of Apple Computer, Inc.

Microsoft®, Windows®, Windows NT® are registered trademarks of Microsoft Corporation.

Other products and company names mentioned herein may be trademarks of their respective owners.

Page 5

Table of Contents

Introduction ................................................................................................. 1

Chapter 1: Printer Specifications .............................................................. 3

1.1 General Specifications.........................................................................................3

1.2 Printing Specifications.........................................................................................3

1.3 Media Specifications............................................................................................4

Chapter 2: Features and Options.............................................................. 5

2.1 Fonts ...................................................................................................................5

2.2 Graphics..............................................................................................................5

2.3 Bar codes............................................................................................................5

2.4 Special Features .................................................................................................5

2.5 Options................................................................................................................6

Chapter 3: Getting Started .........................................................................7

3.1 Unpacking and Inspection...................................................................................7

3.2 Connecting the Printer.........................................................................................8

3.2.1 Printer Power.................................................................................................8

3.2.2 Communication Interfaces.............................................................................8

3.3 Loading Media.....................................................................................................9

3.4 Front Panel Button and Indicator Light..............................................................10

3.4.1 Front Panel Button.......................................................................................11

3.4.2 Indicator Light..............................................................................................11

Chapter 4: Printer Modes .........................................................................13

4.1 Idle Mode...........................................................................................................13

4.2 Halted Mode......................................................................................................13

4.2.1 Enquiry Responses .....................................................................................13

4.2.2 Fatal Error Responses.................................................................................16

4.2.3 Basic Status Responses..............................................................................20

4.3 Paused Mode....................................................................................................25

4.4 Diagnostic Mode................................................................................................25

4.4.1 Entering Diagnostic Mode...........................................................................26

226/426 User’s Guide i

Page 6

4.1.2 Status Label.................................................................................................26

Chapter 5: Communications.................................................................... 29

5.1 RS-232 Serial....................................................................................................29

5.1.1 RS-232 Printer Cables.................................................................................30

5.2 10BASE-T Ethernet...........................................................................................30

5.3 160P Stacker / Auxiliary Interface......................................................................30

Chapter 6: Maintenance and Adjustments............................................. 33

6.1 Maintenance Schedule......................................................................................33

6.2 Thermal Printer Card.........................................................................................34

6.3 Internal Cleaning................................................................................................37

6.4 Print head Maintenance.....................................................................................38

6.5 Cleaning the Dr ive Roller...................................................................................39

6.6 Exterior Cleaning...............................................................................................40

6.7 Gap Detector Adjustment ..................................................................................40

6.8 Auxiliary Button..................................................................................................41

6.9 Flash Memory Update.......................................................................................41

3.2 MCA Compressed File Recovery.......................................................................43

Chapter 7: Troubleshooting..................................................................... 45

7.1 Troubleshooting Tips.........................................................................................45

Appendix A ................................................................................................ 47

Limited Warranty........................................................................................................47

Appendix B ................................................................................................ 49

Return Material Authorization (RMA) Procedure ........................................................49

Glossary..................................................................................................... 51

Index........................................................................................................... 55

User Notes ................................................................................................. 59

ii 226/426 User’s Guide

Page 7

List of Tables

Table 1 General Specifications...............................................................................3

Table 2 Printing Specifications...............................................................................3

Table 3 Media Specifications..................................................................................4

Table 4 Front Panel Button Description................................................................11

Table 5 Indicator Light Description.......................................................................11

Table 6 Enquiry Responses .................................................................................16

Table 7 RS-232 Cable Configurations.................................................................. 29

Table 8 Recommended Maintenance Schedule...................................................33

226/426 User’s Guide iii

Page 8

iv 226/426 User’s Guide

Page 9

List of Figures

Figure 1 426 Front Angled View.............................................................................vi

Figure 2 426 Rear Angled View..............................................................................vi

Figure 3 Standard Printer Accessories.................................................................... 7

Figure 4 Connecting the Printer...............................................................................8

Figure 5 Tag Bracket...............................................................................................9

Figure 6 Loading Media...........................................................................................9

Figure 7 Front Panel Button and Indicator Light....................................................10

Figure 8 ^D960)1 or ^K Test Pattern .....................................................................26

Figure 9 ^D323-List Enablements Example...........................................................26

Figure 10 ^D326-List Settings Example................................................................27

Figure 11 ^D325-List Selections Example............................................................27

Figure 12 ^D324-List Statistics Example..............................................................28

Figure 12 426 Interface Connections....................................................................31

Figure 13 Ethernet Port - 10BASE-T....................................................................31

Figure 14 Insertion of Thermal Cleaning Card......................................................35

Figure 15 Thermal Card Removal ........................................................................35

Figure 16 Removal of top cover............................................................................36

Figure 17 Unlatching of Print head.......................................................................36

Figure 18 Internal Cleaning..................................................................................37

Figure 19 Print head Thermal Elements...............................................................38

Figure 20 Gap Detector........................................................................................40

Figure 21 Auxiliary Button.....................................................................................41

226/426 User’s Guide v

Page 10

Figure 1 426 Front Angled View

Figure 2 426 Rear Angled View

vi 226/426 User’s Guide

Page 11

Introduction

The Models 226 and 426 are high performance, Direct Thermal tag/label printers that are

economically priced to fit everyone’s budget. The extensive list of standard features

combined with an easy to operate and maintain design provides continuous and reliable

printing at true high volume throughput. The Model 226 printer is a smaller version of the

Model 426 with the only differences being the AC power plug orientation, the print head size

and the lack of the Auxiliary Port.

This manual provides the information needed to operate and maintain the printers on a daily

basis. The resident Label Design Software II (LDSII) is a powerful and easy-to-use control

language that allows the creation of custom label formats. The software is ASCII text based

and can be interfaced to PC’s, mini-computers, main frames, and other special purpose

machines. The LDSII language uses inches as the default unit of measure but may be set

to use millimeters. All commands and parameters, unless noted otherwise, should be

entered using the selected unit of measure. The conversion values for the printer, using the

standard 203 dpi print head, are 8 dots per millimeter , 203 dots per inch, or 0.0049” per dot.

Refer to the LDSII Programming Guide (part# 880019-xxxx) for additional informati on

regarding LDSII programming instructions where the –xxxx represents the latest version.

Among many other features, LDSII supports downloadable graphics and fonts, serial

numbering, flexible character spacing, reverse video, resident fonts and many of the most

popular bar code symbologies. Bitmapped fonts and bar codes may be multiplied in size in

the X and Y directions while being printed in 0, 90, 180, and 270 degree rotations. Graphic

images and custom designed label formats may also be stored in the printer’s flash memory

for high-speed access to achieve greater throughput performance.

The printers are capable of printing on most types of labels, pre-printed tickets, fax papers,

and tag stocks or varying thickness. The printers are also capable of detecting many

registration marks that enable it to print using media that contains die-cut, blow-hole, blackline sense marks and continuous media. The printers also provides three different cutter

types; full guillotine, full/partial guillotine and rotary cutter. These cutter options provide a

means of cutting media of varying thickness to handle even the most demanding

applications.

Many printer applications use the same label format, but change the data on every label.

This is not a problem for the 226/426 printers, data may be changed without downloading

the same fixed format or fixed data field. This, along with the available serial

communication speeds, increases data access time and productivity. Providing the user

with high performance desired for a low cost.

Contact Microcom Corporation about the availability of Windows® drivers and WYSIWYG

(What You See Is What You Get) software packages which allow quick and easy on-screen

label designing.

226/426 User’s Guide 1

Page 12

2 226/426 User’s Guide

Page 13

Chapter 1: Printer Specifications

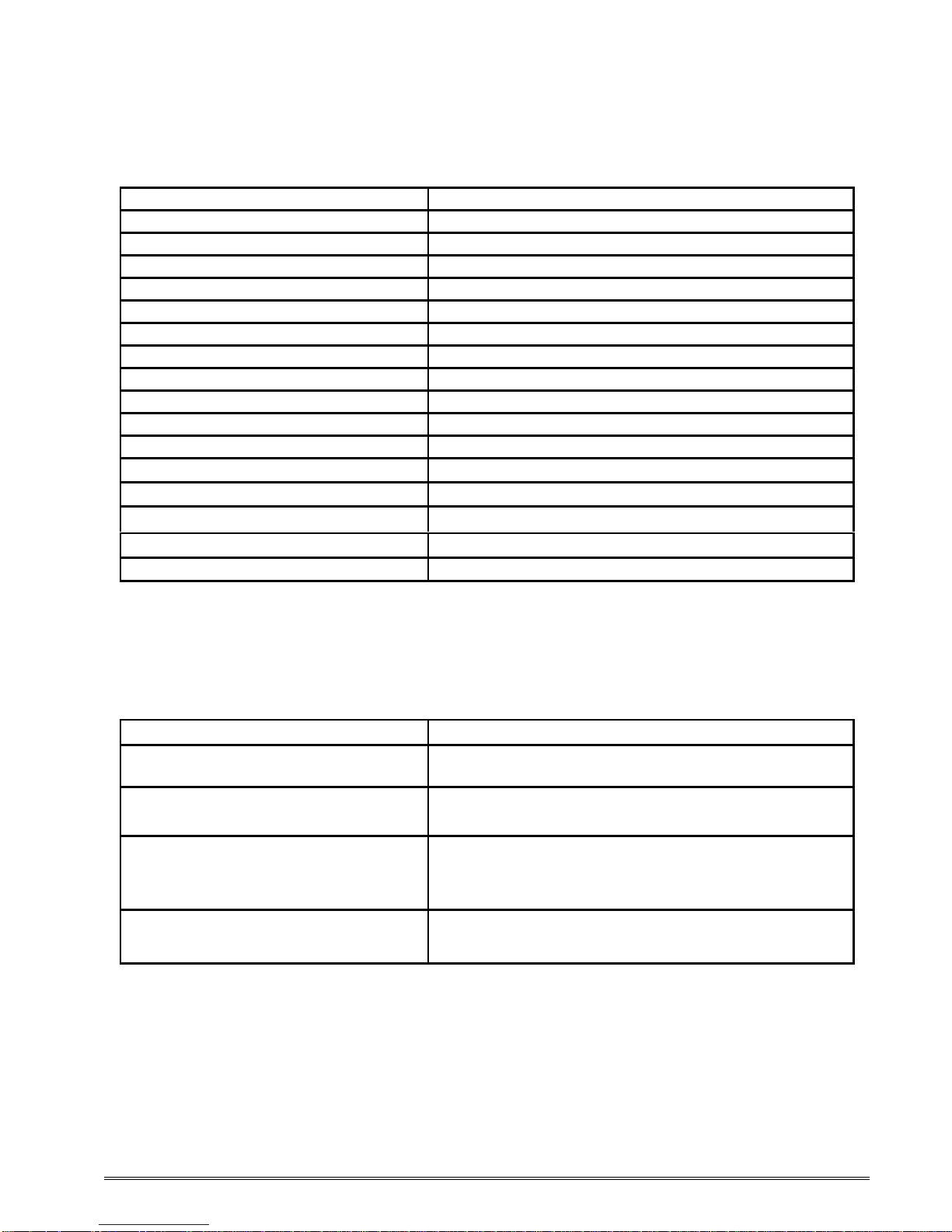

1.1 General Specifications

Width 226 - 6.6” (167mm); 426 - 8.5” (216mm)

Height 226 - 6.9” (175mm); 426 - 6.9” (175mm)

Depth 226 - 4.8” (122mm); 426 - 4.8” (122mm)

Weight 226 - 6 lbs (2.7kg); 426 - 7.8 lbs. (3.5kg)

Electrical Auto-sensing 120/230 VAC ; 50-60 Hz

4 Amps maximum

Temperature 40° F – 77° F (5° C – 25° C) Operating

Humidity 10% – 85%, non-condensing

SRAM Memory 16MB

Flash Memory 4MB

Agency Approvals CUL, CE, and complies with FCC Class A.

Interface Communications

RS-232 Serial Network Connectivity

RS-232, 9 pin D-Sub connector (DCE) 10BASE-T

Flow Control: XON, XOFF, and CTS

Parity: Odd, Even, and None Protocols: TCP/IP

Data Bits: 7 or 8

Table 1 General Specifications

Hosts: Windows® NT, 95, 98, and 2000

1.2 Printing Specifications

Print Type Direct Thermal

Print Resolution

Maximum Print Speed

Maximum Print Width

Print Length

Table 2 Printing Specifications

203 DPI (8 dots/mm)

300 DPI (11.808 dots/mm) – option on 426 only.

6”/sec. (152mm/sec.)

4”/sec. (102mm/sec.) with optional 300 DPI

226 - 2.205 inches or 448 dots (56 mm)

426 - 4.1 inches or 832 dots (104mm)

426 - 4.26 inches or 1280 dots (108mm) with 300 DPI

50” (1270mm) using standard memory

25” (635mm) with optional 300 DPI print head

226/426 User’s Guide 3

Page 14

Printer Specifications Chapter 1

1.3 Media Specifications

Media Types

Maximum Media Thickness

Maximum Media Width

Table 3 Media Specifications

The 426P printer is optimally configured with a fixed tag bracket to assist in the installation

of direct thermal rolled or fanfold tag stock. The printer m ay use many other types of media

with varying widths using the standard paper line guides.

*NOTE: The printer may print on thicker media types depending on the pliability of the

material, however this requires testing and eval uation. Contact your authorized Microcom

Corporation representative for additional infor mation regarding testing and evaluation of

thicker media types.

**NOTE: The printer’s media path has a maximum width of 4.5” while the actual printable

width will vary depending on the print head installed.

Continuous, die-cut, preprinted and tag stock either

rolled or fanfold.

.010” (.25mm) * see note below.

4.5” (114.3mm) ** see note below.

4 226/426 User’s Guide

Page 15

2.1 Fonts

19 smooth bitmapped alphanumeric fonts from 6pt to 28pt including OCR-A

and OCR-B.

Downloadable font support.

Bitmapped fonts expandable in height and width.

Reverse image printing.

Rotated: 0º, 90º, 180º, and 270º.

Chapter 2: Features and Options

2.2 Graphics

Lines and boxes.

Direct Monochrome BMP image support.

Store fonts, scripts and/or graphics.

Rotated: 0º, 90º, 180º, and 270º.

2.3 Bar codes

One-dimensional: Code 39, Interleaved 2 of 5, Code 128 (A, B, C and Auto),

Code 93, Codabar, Modified Plessey, UPC-A, UPC-E, EAN 8, EAN 13,

UCC/EAN 128, and Postnet.

Two-dimensional: PDF-417 and Data Matrix

Rotated: 0º, 90º, 180º, and 270º.

2.4 Special Features

Durable steel case that protects your investment, even in harsh environments.

Head lift lever for easy media loading.

Rotating head mechanism for easy print head cleaning.

226/426 User’s Guide 5

Page 16

Features and Options Chapter 2

Adjustable media guides for easy label centering or fixed tag bracket.

Software controlled contrast adjustm ent.

Downloadable monochrome BMP image support.

Internal statistical counters for inches and labels printed.

Remote printer interrogation.

Ethernet capability.

Detects label gap, blackline, and blowhole using reflective and transmissive

sensors.

Field incrementing, decrementing and serialization.

Powerful Label Design Software (LDSII) that is easy to master.

Auto-sensing 100-240 VAC 50-60 Hz Internal power supplies.

2.5 Options

Full or partial cutter available in 3” (76.2 mm) or 4” (101.6 mm) versions.

4” (101.6 mm) Rotary cutter available for the 426.

Model 160P vertical media stacker for the 426.

Catch Tray for the 426.

Configurable sensor (Input 1) that may be customized for different

applications.

External media supply holder (8” (203mm) o.d. maximum).

300 DPI (11.8 dots/mm) resolution print head for the 426.

Pinch Roller for Peel-n-Dispense operation.

Cleaning kit.

6 226/426 User’s Guide

Page 17

Chapter 3: Getting Started

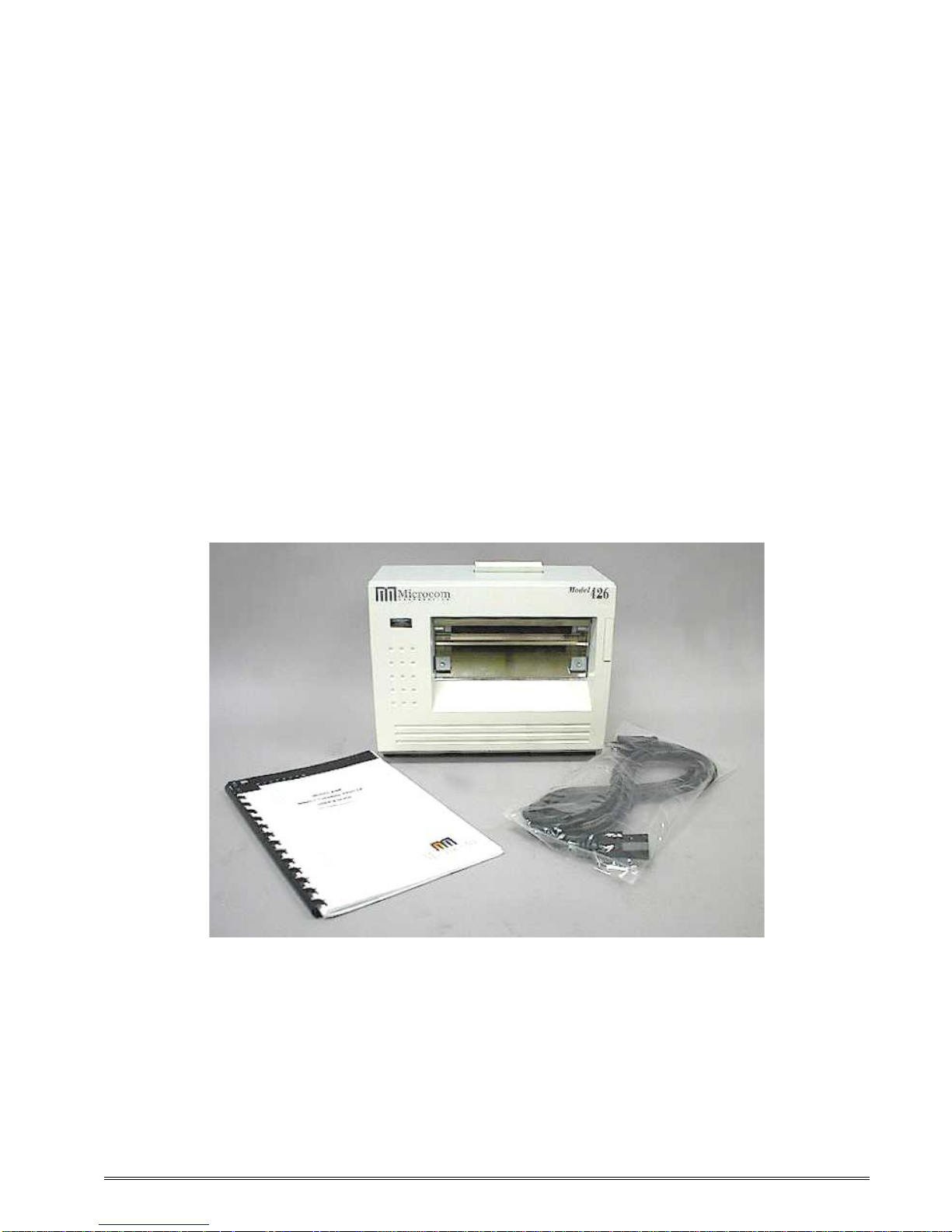

3.1 Unpacking and Inspection

The printer has been packaged to help reduce the damage that may occur during the

shipment of product.

Inspect the shipping container(s) for signs of damage. If damage is evident, contact the

shipping company immediately to file a damage claim.

After the printer is removed from the container(s), verify that all the parts are present and in

good condition (see Figure 3).

The foam and shipping container(s) should be kept and used if the printer is to be shipped.

Additional shipping materials may be ordered by contacting the Microcom Corporation

Service Department in the event the printer needs to be shipped at a later date and the

original packaging materials were not saved.

Figure 3 Standard Printer Accessories

226/426 User’s Guide 7

Page 18

Getting Started Chapter 3

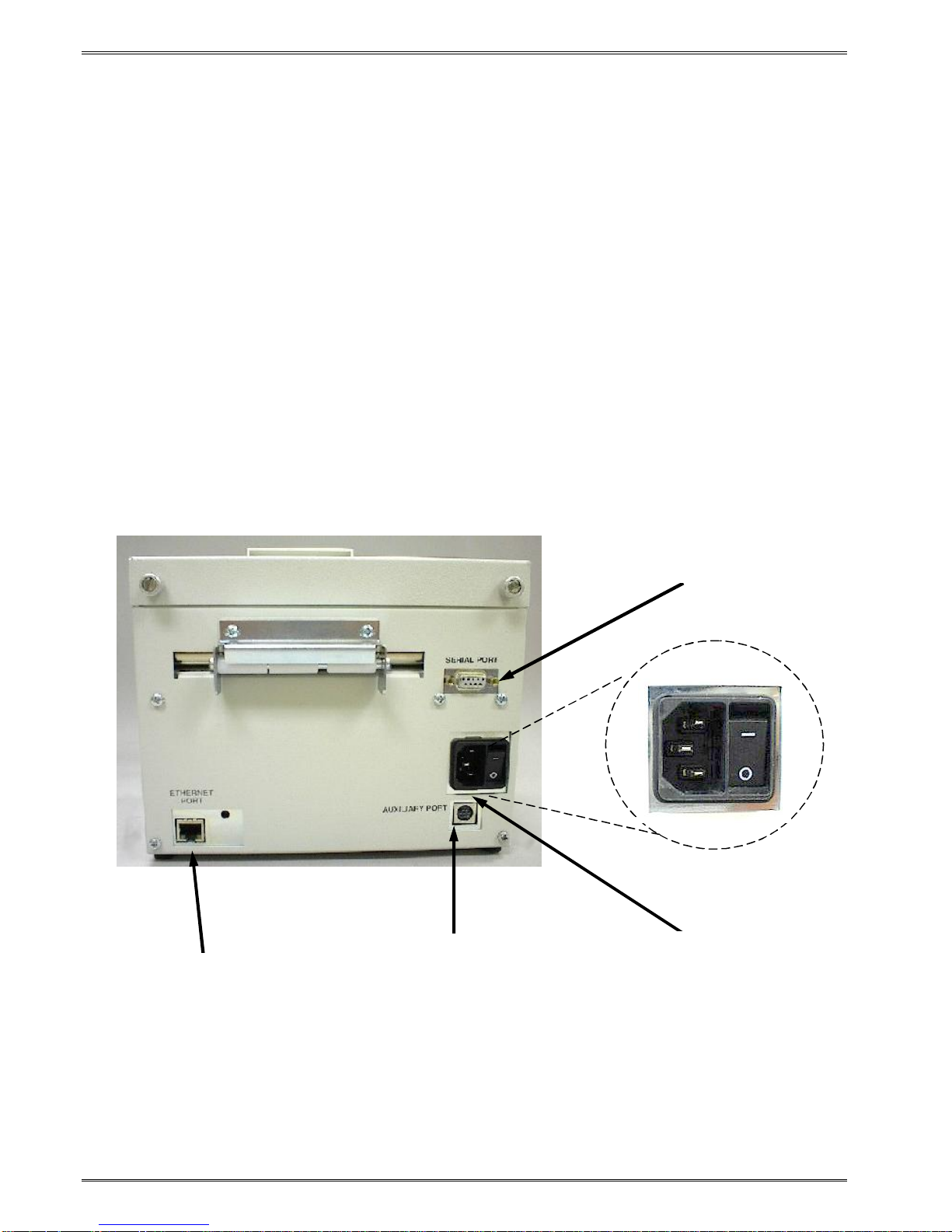

AC Power Connection

10BASE

-

T Ethernet

3.2 Connecting the Printer

Refer to Figure 4 below for proper connections.

3.2.1 Printer Power

The printers use a universal auto-sensing internal power supply that operates in the 100240 VAC; 50-60 Hertz range. The three-prong female end of the power cord plugs into the

mating connector located on the back of the printer. The Model 226 printer’s AC power

connection is the same internally but rotated 90° counter clockwise externally.

Note: Verify that the printer’s ON/OFF switch is switched to OFF before plugging the power

cord into an electrical outlet.

3.2.2 Communication Interfaces

The printers may be interfaced to PC’s, mini-computers, main frames, and special purpose

machines. This printer offers standard serial RS-232 and 10BASE-T Ethernet.

Auxiliary Port - only available

on the Model 426

Figure 4 Connecting the Printer

RS-232 Serial Port

8 226/426 User’s Guide

Page 19

Chapter 3 Getting Started

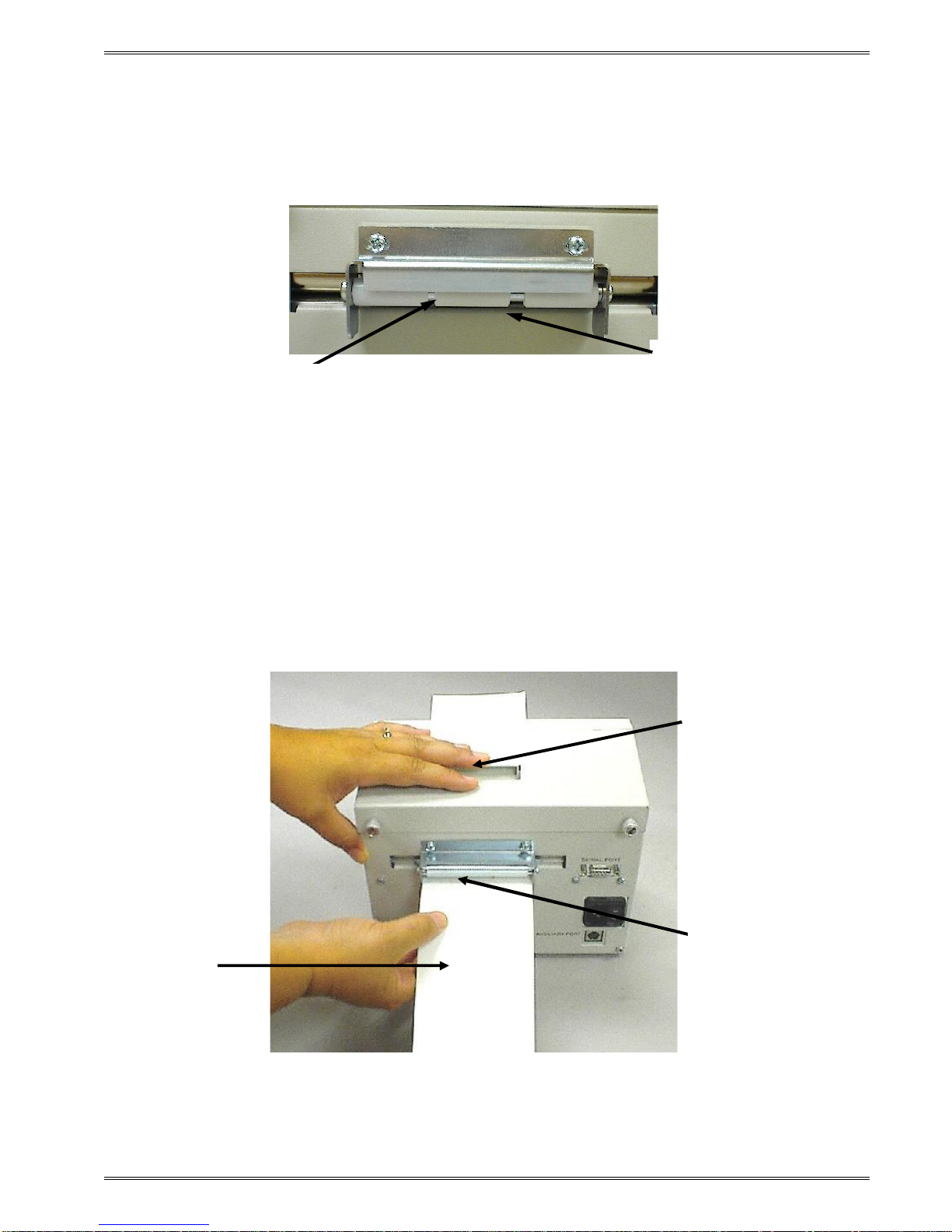

3.3 Loading Media

The 426P printer has been designed to make loading fanfold or continuous media a simple

process. With the fixed Tag bracket installed, no adjustments are needed when installing

media, thus reducing down time. Follow the instructions below to properly load the media.

1. Feed the media below the Line Guide Idler (see Figure 5.), located on the back of the

printer, until you feel resistance.

2. Push down on the Head Lift Lever and continue feeding the media until it passes

through to the front of the printer (see Figure 6.).

Media

Line Guide Idler

Figure 5 Tag Bracket

Note: The Tag bracket has a fixed opening of 3.37” (85.73mm).

Figure 6 Loading Media

Media Path

Head Lift Lever

Line Guide Idler

226/426 User’s Guide 9

Page 20

Getting Started Chapter 3

3.4 Front Panel Button and Indicator Light

The front panel button and the indicator light (see Figure 7) are used to identify and perform

many functions. This section provides a brief description of the standard configuration to

familiarize you with the basic function of the button and light. Refer to Chapter 4: Printer

Modes for more detailed information. The font panel button is configurable by using the

“^D541)” command, so this section only discusses the standard configuration. Refer to the

LDSII Programming Guide for additional information regarding the button use.

Figure 7 Front Panel Button and Indicator Light

Front Panel Button and indicator

10 226/426 User’s Guide

Page 21

Chapter 3 Getting Started

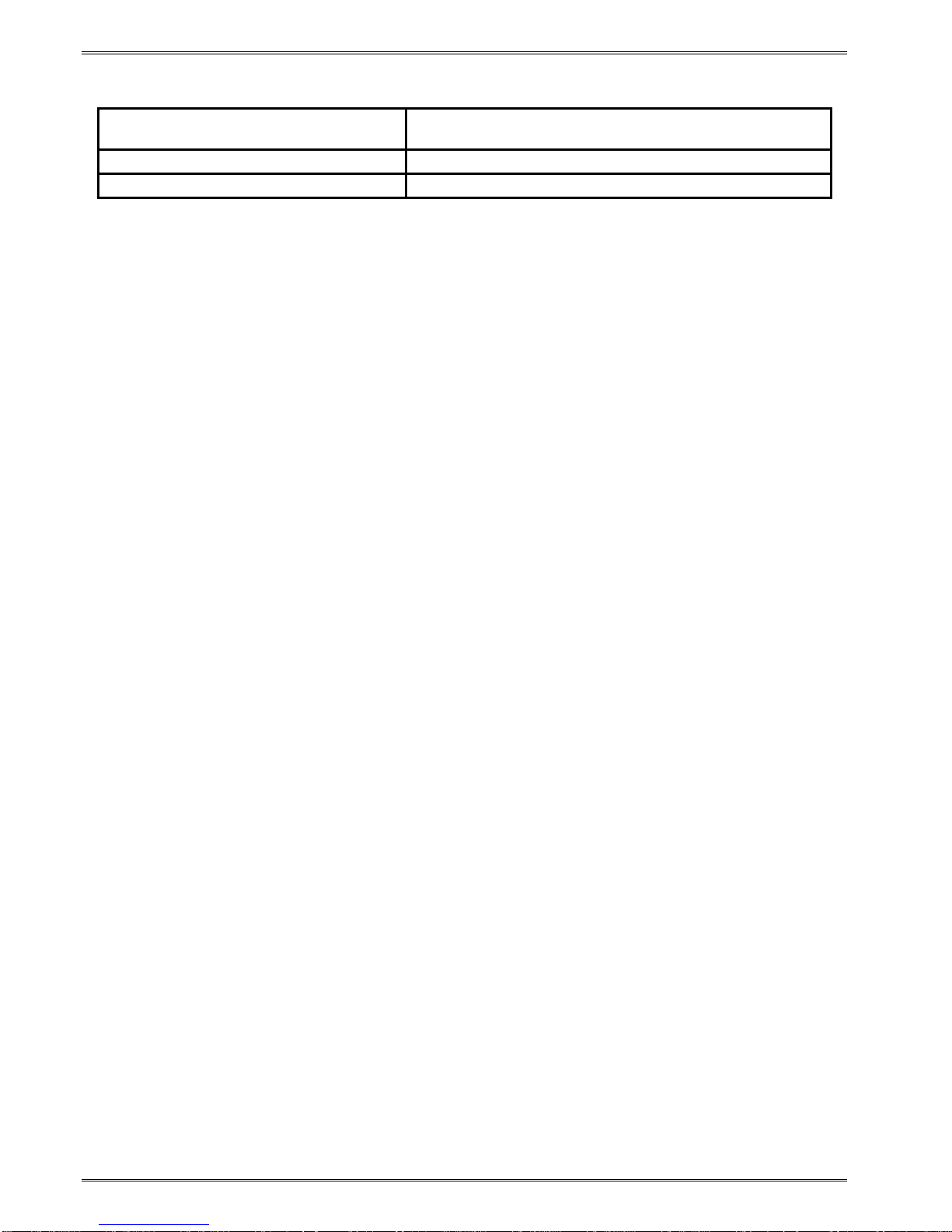

3.4.1 Front Panel Button

Operation Description

A button press while the printer is idle or paused will reprint the

Printing a

label.

last label or after a cold start, a power up label will print.

Note: If a power up label has not been enabled or if one does not

exist, the printer will print a blank label.

Printer Pause.

A brief-button press while printing will cause the printer to pause.

Feeding

Labels.

Hold the button down while the printer is idle to feed labels. The

printer will continue feeding labels until the button is released.

Note: Press the button again to continue printing.

Table 4 Front Panel Button Description

3.4.2 Indicator Light

Light Color Description

Solid Green. Indicates that the power is on, the printer is in a ready state, and

is either in LOCKOUT or BASIC access levels.

Solid Am ber.

Solid Red.

Indicates that the printer is busy or is in a tag/tear mode other

Indicates that the printer is either in SERVICE, FACTORY, or

than Advance When Idle (3).

DEVELOPER access levels.

Flashing

Amber.

Indicates an error has occurred. The printer will r emain in this

Flashing

Red.

Note: Refer to Chapter 7: Troubleshooting for helpful hints.

Alternating

Green/Amber.

Alternating

Indicates that the printer is updating or loading a new code

Amber/Red.

Table 5 Indicator Light Description

226/426 User’s Guide 11

Indicates that the printer is paused.

state until the condition is removed.

Indicates that the printer is Initializing the RAM memory.

revision to Flash memory.

Page 22

12 226/426 User’s Guide

Page 23

Chapter 4: Printer Modes

4.1 Idle Mode

Idle Mode is when the printer is not printing and has no pending activity. The indicator light

is green, which indicates that the printer is ready to receive label scripts and/or commands.

The front panel button has a couple of different functions while in the Idle Mode. Pressing

the button will reprint the last label or the power-up label if the printer was recently turned on

and no formats were sent to the printer. If no power up label exists, or if powers up labels

are not enabled, then the printer prints a blank label. Pressing and holding the button in,

causes the printer to feed labels until the button is released.

4.2 Halted Mode

Halted Mode is when the printer has stopped due to an error condition that needs

immediate attention. The indicator light flashes red when the printer enters the Halted

Mode. The printer remains in this mode until the error is corrected. The error is cleared by

pressing the front panel button after the condition causing the error is removed. If it is not

possible for the printer to execute the previous information, the printer will enter the Paused

Mode (see Paused Mode below for additional information). Refer to Chapter 7:

Troubleshooting for information on how to correct error conditions.

4.2.1 Enquiry Responses

Enquiry responses provide a method of determining the current status of the printer as well

as identifying different error conditions. This is possible by sending either the “Ctrl+E”

combination, issuing the “^D327)” command, or by enabling any of the auto-reporti ng

commands; Refer to the ^D72x series commands. Fatal error responses are triggered from

the printer to the host when they occur and halt the printers operation until resolved. Status

responses do not halt the printers operation but are simply a status of the printer’s current

state.

Refer to the table below and the following sections for more information about the various

types of responses.

226/426 User’s Guide 13

Page 24

Printer Modes Chapter 4

Byte Mode

Responses

Text and Verbose Mode Responses Definition

(ASCII Hex)

0x01 >STOCK OUT< Out of Media

0x02 >STOCK OVERADVA NCED<

0x03 >STOCK JAMMED< Media is jammed.

0x04 >INCORRECT STOCK<

0x06 >OK<

0x10 >CUTTER JAMMED< The cutter has jammed.

0x11 >CUTTER INOPERATIVE< The cutter is not detected

0x12

0x13

0x15 >OPERATION FAILED<

0x1C >MISSING LABEL<

>CUTTER WATCHDOG STOPPED

CUTTER<

>CUTTER WATCHDOG

WON’T RESET<

Excess media past LPD

preventing a TOF operation.

Problem encountered trying to

realign media.

ACK message used with the

^D726)1 command.

The software shut the cutter off

for safety issues.

The software cannot reset the

cutter after a stopped condition.

The operation failed to execute

properly.

Generated if more than one die-

cut label has been detected.

0x1D >INCOMPLETE FORM<

0x20 >CATCH TRAY FULL<

0x21 >INPUT 1<

0x22 >INPUT 2<

0x30 >SCRIPT ERROR<

0x31 >INVALID PARAMETER<

0x32 >PARSER ERROR<

0x40 >COMM ERROR<

0x51 >FLASH ERROR<

0x80 >RESTARTED<

A complete script did not print on

a >STOCK OUT< condition.

The PMH has reached its

capacity.

The Input 1 sensor has been

actuated.

The Input 2 sensor has been

actuated.

An error with the script has been

detected.

The printer has detected an

invalid parameter.

An error with the printer’s parser

has occurred.

A Communication error has

been detected.

The flash memory has

encountered an error.

The printer has been powered

on or the power has been reset.

14 226/426 User’s Guide

Page 25

Chapter 4 Printer Modes

Byte Mode

Responses

Text and Verbose Mode Responses Definition

(ASCII Hex)

0x81 >READY<

0x82 >BUSY< The printer is currently busy.

0x83 >PAUSED< The printer has been paused.

0x84 >PRINTING< The printer is currently printing.

0x85 >FEEDING<

0x86 >LABEL/TAG PRESENT<

0x87 >STOCK ADVANCED< The media has been advanced.

0x8A >FLASH DEFRAGMENTING<

0x8F >STOCK NOT LOADED<

0x90 >RETRACTION DELAY<

The printer is in ready to receive

data.

The printer is currently feeding

media.

Media has been presented in a

dispense mode.

Flash file system is optimizing

memory.

The printer was powered up with

out media installed.

The retraction has been

delayed.

0x91 >PRINT DELAY< The printing has been delayed.

0xB0 >FLASH MEMORY LOW<

0xC0 >BUTTON 1 TAPPED<

0xC1 >BUTTON 1 HELD< The print button has been held.

0xD0 >TEMPERATURE OUT OF RANGE<

0xD1 >NONEXISTENT COMMAND<

0xD2 >INCOMPLETE COMMAND<

0xD3 >ZIP FILE ERROR<

0xD4 >FILE CONVERSION ERROR<

0xD5 >UNSUPPORTED FILE TYPE<

The Flash memory file space is

95% full.

The print button has been

pressed.

The print head temperature is

out of operating range.

The received command does not

exist.

The received command is not

complete.

The received Zipped file has an

error.

The file was not converted

properly.

The received file is not

recognized.

0xD6 >FILE NOT FOUND<

226/426 User’s Guide 15

The requested file does not exist

or cannot be found.

Page 26

Printer Modes Chapter 4

Byte Mode

Responses

Text and Verbose Mode Responses Definition

(ASCII Hex)

0xD7 >INADEQUATE ACCESS MODE<

0xD9 >FILE IS READ ONLY<

0xDA >INADEQUATE FLAS H SPACE<

0xDB >I/O FAILURE<

0xDC >FONT/GRAPHIC NOT FOUND<

0xE1 >SWITCH 0 ACTUATED< Switch 0 has been actuated.

0xE2 >SWITCH 1 ACTUATED< Switch 1 has been actuated.

0xE3 >SWITCH 2 ACTUATED> Switch 2 has been actuated.

0xE4 >TOF SWITCH ACTUATED<

0xF0 >FIELD OFF IMAGE<

0xF1 >COMPOSITION ERROR<

Incorrect password to a higher

access level.

File is read only and cannot be

deleted.

Cannot save an item to the flash

memory due to lack of space.

The Input/Output circuitry has

failed.

The requested file does not exist

or cannot be found.

The TOF switch has been

actuated.

An image placemen t

coordinates exceed the print

head or form size.

A script cannot be printed onto a

label due to i ncorrect size.

0xF2 >GRAPHIC TOO LARGE<

0xFF >POWERED DOWN<

The sent graphic exceeds the

available memory.

The printer’s power has been

removed.

Table 6 Enquiry Responses

4.2.2 Fatal Error Responses

Fatal error responses are enquiry responses that halt the printer’s current operation and

cause the indicator light or LED to flash RED in color. A fatal error condition persists until

the condition causing the error is removed and the error is cleared. These enquiry

responses are sent from the printer to the host, when the appropriate condition occurs, by

issuing the “Ctrl+E” (^E) combination or by issuing the queued “^D327)1” command. The

printer may be configured to automatically reports errors and status messages by using the

^D72x series commands. The following sections provide further explanations of the various

fatal error responses. Refer to the ^D550) command regarding the types of enquiry

response sets.

16 226/426 User’s Guide

Page 27

Chapter 4 Printer Modes

NOTE: The following section titles are the responses that the printer will generate once the

associating condition occurs and the printer processes an enquiry command. The first

response (between and including the “>” and “<” characters) is generated if text and

verbose responses have been enabled using the ^D550) command. The ASCII hex value

listed between the parenthesis characters, indicate the enquiry response if byte mode has

been enabled.

4.2.2.1 >STOCK OUT< (01)

The “>STOCK OUT<” error response is generated when the printer runs out of stock or

media while in text and verbose modes. If the printer is configured for byte responses, the

code ASCII 0x01 will be issued from the printer in response to an enquiry command.

4.2.2.2 >STOCK OVERADVANCED< (02)

This error response is typically generated when the printer has an excess amount of media

fed out of the printer and a Top-of-Form operation is executed. If the printer is configured

for byte responses, the code ASCII 0x02 will be issued from the printer in response to an

enquiry command.

4.2.2.3 >STOCK JAMMED< (03)

The “>STOCK JAMMED<” error response indicates that media is jammed and requires

correction before the printer can continue printing while in text and verbose modes. A stock

jam condition may be detected by two separate methods depending if the printer is

configured with a Label Present Detector or LPD. If the printer is configured for byte

responses, the code ASCII 0x03 will be issued from the printer in response to an enquiry

command.

When the printer is configured with an LPD and selected by the “^D509)” command, a stock

jam is detected by the LPD when the leading edge of the media did not arrive after the

motor stepped through the Print head to LPD distance (“^D643) command”) plus 0.2 inches.

This detection method does not work if media is not detected at the LPD once printing starts

and is used in conjunction with the “^D311)” TOF command.

When the printer is configured without an LPD, not selected by the “^D509)” command, or if

media is blocking a configured LPD once printing commences, a stock jam condition is

detected using the registration mark detectors. The stock jam condition is reported when a

registration mark does not arri ve after the entire script repeat distance plus 0.2 inches.

4.2.2.4 >INCORRECT STOCK< (04)

This error response is generated when the printer detects a registration mark that is too high

or too short or if the registration mark is detected too soon or too late. The >INCORRECT

STOCK< message is generated once this condition exists when the printer is configured for

text and verbose response sets. If the printer is configured for byte responses, the code

ASCII 0x04 will be issued from the printer in response to an enquiry command.

226/426 User’s Guide 17

Page 28

Printer Modes Chapter 4

4.2.2.5 >CUTTER JAMMED< (10)

The “>CUTTER JAMMED<” error response is generated when the cutter is in a jammed

condition and cannot complete a full cycle while in text and verbose modes. If the printer is

configured for byte responses, the code ASCII 0x10 wil l be issued from the printer in

response to an enquiry command.

4.2.2.6 >CUTTER INOPERATIVE< (11)

This error response is typically generated if the cutter is not detected by the printer while in

text and verbose modes. If the printer is configured for byte responses, the code ASCII

0x11 will be issued from the printer in response to an enquiry command.

4.2.2.7 >CUTTER WATCHDOG STOPPED CUTTER< (12)

This error response is generated when the cutter cannot complete a full rotation and has

typically jammed while in text and verbose modes. The cutter watchdog timer wil l disable

the power to the cutter to prevent damage from occurring. The printer power should to be

cycled to properly clear this error after the jam has been cleared from the cutter blades. If

the printer is configured for byte responses, the code ASCII 0x12 will be issued from the

printer in response to an enquiry command.

4.2.2.8 >CUTTER WATCHDOG WON”T RESET< (13)

This error response is generated when the cutter watchdog timer cannot be reset and the

printer power is required to be cycled to clear this error while in text and verbose modes.

The cutter watchdog timer will disabl e the power to the cutter to prevent damage from

occurring. The printer power should to be cycled to properly clear this error after the jam

has been cleared from the cutter blades. If the printer is configured for byte responses, the

code ASCII 0x13 will be issued from the printer in response to an enquiry command.

4.2.2.9 >OPERATION FAILED< (15)

The “>OPERATION FAILED<” response is generated when the current operation could not

be completed while in text or verbose response modes. If the printer is configured for byte

responses, the code ASCII 0x15 will be issued from the printer in response to an enquiry

command.

4.2.2.10 >MISSING LABEL< (1C)

The “>MISSING LABEL<” response indicates that the printer has detected only the backing

material when using die-cut media indicating a missing label while in text or verbose

response modes. If the printer is configured for byte responses, the code ASCII 0x1C i s

issued from the printer in response to an enquiry command.

4.2.2.11 >INCOMPLETE FORM< (1D)

The “>INCOMPLETE FORM<” response indicates that the printer did not complete the

current script while in text or verbose response modes. If the printer i s configured for byte

responses, the code ASCII 0x1D is issued from the printer in response to an enquiry

18 226/426 User’s Guide

Page 29

Chapter 4 Printer Modes

command. This response appears in conjunction with the >STOCK OUT< error and a

printer configured with the “^D581)2” Finish Label command.

4.2.2.12 >CATCH TRAY FULL< (20)

The “>CATCH TRAY FULL<” response is generated when the optional Catch Tray has

reached its capacity while in text or verbose response modes. If the printer is configured for

byte responses, the code ASCII 0x20 is issued from the printer in response to an enquiry

command.

4.2.2.13 >SCRIPT ERROR< (30)

The “>SCRIPT ERROR<” response is generated when a script contains an error and cannot

be processed while in text and verbose response sets. If the printer is configured for byte

responses, the code ASCII 0x30 will be issued from the printer in response to an enquiry

command.

4.2.2.14 >INVALID PARAMETER< (31)

This error response indicates that a received command contains an invalid parameter or

illegal structure while in tex t and verbose response sets. If the printer is configured for byte

responses, the code ASCII 0x31 will be issued from the printer in response to an enquiry

command.

4.2.2.15 >PARSER ERROR< (32)

The “>PARSER ERROR<” indicates that the printer has detected an internal error with the

parser while in text and verbose response sets. If the printer is configured for byte

responses, the code ASCII 0x32 will be issued from the printer in response to an enquiry

command.

4.2.2.16 >COMM ERROR< (40)

The “>COMM ERROR<” indicates that the printer has detected a communication error while

in text or verbose response modes. If the printer is configured for byte responses, the code

ASCII 0x40 is issued from the printer in response to an enquiry command. This error

response is generated if the serial communication timeout period of 10 seconds plus 100

times the transfer has occurred.

4.2.2.17 >FLASH ERROR< (51)

The “>FLASH ERROR<” indicates that an error has occurred with the flash memory while in

text and verbose response sets. The printer power should be cycled in the event that this

error message has been received. If the printer is configured for byte responses, the code

ASCII 0x51 will be issued from the printer in response to an enquiry command.

226/426 User’s Guide 19

Page 30

Printer Modes Chapter 4

4.2.3 Basic Status Responses

Basic status responses are enquiry responses that are not immediate. These enquiry

responses are sent from the printer to the host, when the appropriate condition occurs, by

issuing the “Ctrl+E” (^E) combination or by issuing the “^D327)” command. The following

sections provide further explanations of the non-immediate basic status responses. Refer to

the ^D550) command regarding the types of enquiry response sets.

NOTE: The following section titles are the responses that the printer will generate once the

associating condition occurs. The first response (between and including the “>” and “<”

characters) is generated if text and verbose responses have been enabled using the ^D550)

command. The ASCII hex value listed between the parenthesis characters, indicate the

enquiry response if byte mode has been enabled.

4.2.3.1 >OK< (06)

The “>OK<” response is generated in conjunction with the “^D726)1” command and

indicates that a command completed successfully while in text or verbose response modes.

If the printer is configured for byte responses, the code ASCII 0x06 is issued from the printer

in response to an enquiry command.

4.2.3.2 >INPUT 1< (21)

The “>INPUT 1<” response indicates that the INPUT 1 sensor option is tripped whi le in text

or verbose response modes. If the printer is configured for byte responses, the code ASCII

0x21 is issued from the printer in response to an enquiry command. This sensor and

response is intended to provide the user with the flexibility for custom configurations.

4.2.3.3 >INPUT 2< (22)

The “>INPUT 2<” response indicates that the INPUT 2 sensor option is tripped while in text

or verbose response modes. If the printer is configured for byte responses, the code ASCII

0x22 is issued from the printer in response to an enquiry command. This sensor and

response is intended to provide the user with the fl exibility for custom configurations.

4.2.3.4 >RESTARTED< (80)

The “>RESTARTED<” response is issued the first time the printer’s status is queried after a

power up or reset condition while in verbose and/or semi byte responses. If the printer is

configured for byte responses, the code ASCII 0x80 will be issued from the printer in

response to an enquiry command.

4.2.3.5 >REA DY < (81)

The “>READY<” response indicates that the printer is in the normal operating state and that

it is ready to accept data while in text and verbose response sets. If the printer is configured

for byte responses, the code ASCII 0x81 will be issued from the printer in response to an

enquiry command.

20 226/426 User’s Guide

Page 31

Chapter 4 Printer Modes

4.2.3.6 >BUSY< (82)

The “>BUSY<” response indicates that the printer is performing an operation that prevents

the printer from accepti ng data while in text and verbose response sets. If the printer is

configured for byte responses, the code ASCII 0x82 will be issued from the printer in

response to an enquiry command.

4.2.3.7 >PA US ED< (83)

The “>PAUSED<” response indicates that the printer’s printing capabilities have been

paused while in text and verbose response sets.. The printer will continue to receive data

while in the >PAUSED< state. The printer may be put into the paused condition by either

issuing the “Ctrl+X” combination or by pressing the print button while the printer is printing.

Issuing the “Ctrl+X” combination or pressing the print button a second time will cause the

printer to resume. If the printer is configured for byte responses, the ASCII code 0x83 will

be issued from the pr inter in response to an enquiry command.

4.2.3.8 >PRINTING< (84)

The “>PRINTING<” response indicates that the printer is currently printing while in text and

verbose response sets. If the printer is configured for byte responses, the code ASCII 0x84

will be issued from the printer in response to an enquiry command.

4.2.3.9 >FEEDING< (85)

The “>FEEDING<” response indicates that the printer is currently feeding media while in text

and verbose response sets. If the printer is configured for byte responses, the code ASCII

0x85 will be issued from the printer in response to an enquiry command.

4.2.3.10 >LABEL/TAG PRESENT< (86)

This response indicates that media is blocking the Label Present Sensor (LPS) and

protruding out the front of the printer. If the printer is configured for byte responses, the

code ASCII 0x86 will be issued from the printer in response to an enquiry command.

4.2.3.11 >STOCK ADVANCED< (87)

The “>STOCK ADVANCED<” response indicates that the media has been advanced after

printing when a Dispense Mode (^D597) command) is being used while in text and verbose

response sets. If the printer is configured for byte responses, the code ASCII 0x87 will be

issued from the printer in response to an enquiry command.

4.2.3.12 >FLASH DEFRAGMENTING< (8A)

The “>FLASH DEFRAGMENTING<” response indicates that the printer is optimizing the

flash memory and is not currently available while in text and verbose response sets. If the

printer is configured for byte responses, the code ASCII 0x8A will be issued from the printer

in response to an enquiry command.

226/426 User’s Guide 21

Page 32

Printer Modes Chapter 4

4.2.3.13 >STOCK NOT LOADED< (8F)

The “>STOCK NOT LOADED<” response indicates that media is not being detected in the

printer on power up while in text and verbose response sets. If the printer is configured for

byte responses, the code ASCII 0x8F is issued from the printer in response to an enquiry

command. This message persists until media is detected at the registration mark sensors

but does not prevent commands from being processed.

4.2.3.14 >RETRA CTION DELAY< (90)

The “>RETRACTION DELAY<” response indicates that the printer has been configured

with a delay before retracting, refer to the ^D641) command, while in text and verbose

response sets. If the printer is configured for byte responses, the code ASCII 0x90 will be

issued from the printer in response to an enquiry command.

4.2.3.15 >PRINT DELAY< (91)

The “>PRINT DELAY<” response indicates that the printer has been configured with a delay

between labels, refer to the ^D640) command, while in text and verbose response sets. If

the printer is configured for byte responses, the code ASCII 0x91 will be issued from the

printer in response to an enquiry command.

4.2.3.16 >FLASH MEMORY LOW< (B0)

The “>FLASH MEMORY LOW<” response indicates that the user storage area of the flash

memory is 95% full while in text and verbose response sets. This message will continue to

be received until files are removed from flash memory or until the printer performs garbage

collecting and defragmenting. If the printer is configured for byte responses, the code ASCII

0xB0 will be issued from the printer in response to an enquiry command.

4.2.3.17 >BUTTON 1 TAPPED< (C0)

The “>BUTTON 1 TAPPED<” response occurs when the ^D541) command is configured for

the “tapped” response while in text and verbose response sets. This may be used for

custom configuration and definition of the print button press or tapped condition. If the

printer is configured for byte responses, the code ASCII 0xC0 will be issued from the printer

in response to an enquiry command.

4.2.3.18 >BUTTON 1 HELD< (C1)

The “>BUTTON 1 HELD<” response occurs when the ^D541) command is configured for

the “held” response while in text and verbose response sets. This may be used for custom

configuration and definition of the print button held condition. If the printer is configured for

byte responses, the code ASCII 0xC1 will be issued from the printer in response to an

enquiry command.

4.2.3.19 >TEMPERATURE OUT OF RANGE< (D0)

The “>TEMPERATURE OUT OF RANGE<” response indicates that the printer’s print head

is not within the proper operating range while in text and verbose response sets. This

response will not allow the printer to print until the print head returns to the proper operating

22 226/426 User’s Guide

Page 33

Chapter 4 Printer Modes

range. If the printer is configured for byte responses, the code ASCII 0xD0 will be issued

from the printer in response to an enquiry command.

4.2.3.20 >NONEXISTENT COMMAND< (D1)

The “>NONEXISTENT COMMAND<” response indicates that the printer has received data

that is in the LDSII command structure that does not exist or has not yet been implemented

while in text and verbose response sets. If the printer is configured for byte responses, the

code ASCII 0xD1 will be issued from the printer in response to an enquiry command.

4.2.3.21 >INCOMPLETE COMMAND< (D2)

The “>INCOMPLETE COMMAND<” response indicates that the printer has received a

command that does not contain all of the required parameters for proper operation while in

text and verbose response sets. If the printer is configured for byte responses, the code

ASCII 0xD2 will be issued from the printer in response to an enquiry command.

4.2.3.22 >ZIP FILE ERROR< (D3)

The “>ZIP FILE ERROR<” response indicates that the printer has received a zip file that is

either not complete or that the file contains errors while in text and verbose response sets.

If the printer is configured for byte responses, the code ASCII 0xD3 will be issued from the

printer in response to an enquiry command.

4.2.3.23 >FILE CONVERSION ERROR< (D4)

This enquiry response indicates that the printer encountered an error while performing an

internal conversion of the received file while in text and verbose modes. If the printer is

configured for byte responses, the code ASCII 0xD4 will be issued from the printer in

response to an enquiry command.

4.2.3.24 >UNSUPPORTED FILE TYPE< (D5)

This enquiry response i ndicates that the printer does not recognize the type of the received

file while in text and verbose modes. If the printer is configured for byte responses, the

code ASCII 0xD5 will be issued from the printer in response to an enquiry command.

4.2.3.25 >FILE NOT FOUND< (D6)

The “>FILE NOT FOUND<” response typically indicates that the printer is being instructed to

recall and process a file that does not exist in the printer’s memory while in text and verbose

response sets. If the printer is configured for byte responses, the code ASCII 0xD6 will be

issued from the printer in response to an enquiry command.

4.2.3.26 >INADEQUA TE ACCESS MODE< (D7)

This enquiry response is typically issued when the user is attempting to issue a persistent

command that is not allowed by the current access mode level or is attempting to enter an

access mode that has a higher security level. If the printer is configured for byte responses,

the code ASCII 0xD7 will be issued from the pri nter in response to an enquiry command.

226/426 User’s Guide 23

Page 34

Printer Modes Chapter 4

4.2.3.27 >FILE IS READ ONLY< (D9)

This enquiry response typicall y indicates that a save or delete command is being issued to

the printer and that the file is a protected file stored in the printer. If the printer is configured

for byte responses, the code ASCII 0xD9 will be issued from the pri nter in response to an

enquiry command.

4.2.3.28 >INADEQUA TE FLASH SPACE< (DA)

This enquiry response i ndicates that the available flash memory is less than the total size of

a file being saved to flash memory. If the printer is configured for byte responses, the code

ASCII 0xDA will be issued from the printer in response to an enquiry command.

4.2.3.29 >I/O FAILURE< (DB)

This enquiry response i ndicates that the printer has a failure with either the I/O hardware or

with the I/O firmware. If the printer is configured for byte responses, the code ASCII 0xDB

will be issued from the printer in response to an enquiry command.

4.2.3.30 >FONT/GRAPHIC NOT FOUND< (DC)

This enquiry response typicall y indicates that a font being specified a script file does not

exist in flash memory. If the printer is configured for byte responses, the code ASCII 0xDC

will be issued from the printer in response to an enquiry command.

4.2.3.31 >SWITCH 0 ACTUATED< (E1)

This enquiry response typicall y indicates that switch 0 is actuated while in text or verbose

response sets. If the printer is configured for byte responses, the code ASCII 0xE1 is

issued from the printer in response to an enquiry command.

4.2.3.32 >SWITCH 1 ACTUATED< (E2)

This enquiry response typicall y indicates that switch 1 is actuated while in text or verbose

response sets. If the printer is configured for byte responses, the code ASCII 0xE2 is

issued from the printer in response to an enquiry command.

4.2.3.33 >SWITCH 2 ACTUATED< (E3)

This enquiry response typicall y indicates that switch 2 is actuated while in text or verbose

response sets. If the printer is configured for byte responses, the code ASCII 0xE3 is

issued from the printer in response to an enquiry command.

4.2.3.34 >TOF SWITCH ACTUATED< (E4)

This enquiry response typicall y indicates that the Top-Of-Form (TOF) switch is actuated

while in text or verbose response se ts. If the printer is configured for byte responses, the

code ASCII 0xE4 is issued from the printer in response to an enquiry command.

24 226/426 User’s Guide

Page 35

Chapter 4 Printer Modes

4.2.3.35 >FIELD OFF IMAGE< (F0)

The “>FIELD OFF IMAGE<” response indicates that a fields size and placement coordinates

will not allow the field to fit on the print image or script layout while in text and verbose

modes. The given field that is being placed off the image will not be printed on to the

media. If the printer is configured for byte responses, the code ASCII 0xF0 wil l be issued

from the printer in response to an enquiry command.

4.2.3.36 >COMPOSITION ERROR< (F1)

This enquiry response i s typically issued when the printer detects that the installed media is

not the proper size for the given script file. If the printer is configured for byte responses,

the code ASCII 0xF1 wil l be issued from the printer in response to an enquiry command.

4.2.3.37 >GRAPHIC TOO LARGE< (F2)

This enquiry response i ndicates that the graphic sent to the pri nter is larger than the

available memory while in text or verbose response sets. If the printer is configured for byte

responses, the code ASCII 0xF2 is issued from the printer in response to an enquiry

command.

4.2.3.38 >POWERED DOWN< (FF)

The “>POWERED DOWN<” response indicates that the printer’s power has been

interrupted while in text and verbose modes. If the printer is configured for byte responses,

the code ASCII 0xFF will be issued from the printer in response to an enquiry command.

This message also indicates that the printer was successful writing pending updates to flash

on a power loss situation.

4.3 Paused Mode

Paused Mode is when the printer has pending activity and has stopped, but is not in an

error condition. The indicator light is flashing amber in color when the printer is in Paused

Mode. The printer enters the Paused Mode by issuing the ^X command or by pressing the

front panel button while the printer is printing. The printer will remain paused until the ^X is

reissued, the button is pressed again, or the printer power is cycled. Additional examples of

the printers Paused Mode includes a label script that does not include a print command, or

after the printer fails to execute the pending data after an error condition.

4.4 Diagnostic Mode

Diagnostic Mode temporarily powers the printer using factory default parameters while

printing out the printer’s current configuration on what is called the Status Label. This

information is used to help diagnose and troubleshoot printer configuration issues. The

default baud rate is set to 9600 and is used when entering the diagnostic mode. The printer

continues using the factory default parameters until printer power is cycled. The printer will

then return to the previous configuration in use before entering the diagnostic mode.

226/426 User’s Guide 25

Page 36

Printer Modes Chapter 4

4.4.1 Entering Diagnostic Mode

To enter the di agnostic mode, press and hold the print button in while turni ng on the printer.

Release the button after the status light indicator starts to blink and the printer will power up

into diagnostic mode.

4.1.2 Status Label

The printer will print the Status label after the printer performs a powered up and enters the

diagnostic mode. The status label prints out the reports that are generated by the ^D323),

^D326), ^D325), and ^D324) commands.

Figure 8 ^D960)1 or ^K Test Pattern

Enablements (D323 or <Ctrl> Y)

User Interface

Software flow control: (D770) enabled

Hardware flow control: (D771) disabled

Format

Operational

Auto power-up label: (D720) disabled

Auto top-of-form alignment: (D722) disabled

Auto media sizing: (D723) disabled

Auto alignment after error: (D724) disabled

Cutter: (D740) disabled

PMH: (D741) disabled

Figure 9 ^D323-List Enablements Example

26 226/426 User’s Guide

Page 37

Chapter 4 Printer Modes

Settings (D326 or <Ctrl> V)

Operational

Print Speed: (D635) 6.0 ips

Detector mode: (D636) 0 (none)

Slew Speed: (D645) 6.0 ips

Darkness: (D690) 75 (Dark)

Retraction delay: (D641) 0.5 sec.

Print delay: (D640) 0.0 sec.

Labels printed: (D655) 42

Distances

Label wi dth (LSX): (D631) 3.34 inches

Label height (LSY): (D632) 1.5.12 inches

Reg. mark height (GAP): (D633) 0.148 inches

To reg’n mark (DRM): (D634) 0.0 inches

X offset (OFX): (D637) 0.0 inches

Y offset (OFY): (D638) 0.0 inches

Dist. Past Gap (DPG): (Auto) 1.225 inches

Activate Gap Det (AGD) (Auto) 0.0 inches

Advance/retract: (D642) 0.512 inches

Serial port settings (D670) 9600,N,8,1

Ethernet Active at 10/100

MAC: 0x000257795634

Printer IP: (D675) 192.168 .200.3

Server/Host IP: (D675) 192.168.200.1

Gateway IP: (D675) 192.168.200.1

Broadcast Mask: (D675) 192.168.200.255

Net Mask: (D675) 255.255.255.0

USB port settings Not installed

Thresholds

Gap: 29

Black line: 98

Stock: 110

High head temperature: 147

Low head temperature: 24

PWM periods

Gap: 64

Black line: 41

Label Present: 64

Stacker: 64

NOTE: Some items may not be correct until after a scripted

label is printed or Auto-size (D310) is run.

Figure 10 ^D326-List Settings Example

Selections (D325 or <Ctrl> U)

Operational

Dispense mode: (D597) 3

Emulation: (D501) Microcom 426

Cutter Type: (D506) NONE

PMH Type: (D507) NONE

Button Mode: (D541) 1

Response Mode: (D550) verbose

Automatic responses: (D580) Errors

Power-up label: (D586) 1

Detector mode: (D636) 0 (none)

General

Measurement units: (D564) 1 (inches)

Speed units: (D565) 1 (ips)

Temperature units: (565) 1 (Fahrenheit)

Figure 11 ^D325-List Selections Example

226/426 User’s Guide 27

Page 38

Printer Modes Chapter 4

Statistics (D324 or <Ctrl> W)

Identity

Model number: (D501) Microcom 426

Language: (Auto) LDS2

Serial number: 01234567890

Accumulated operation

Labels printed: (D655) 44

Inches printed: 97 inches (246 cm)

Total inches run: 109 inches (276 cm)

Power on time: 2 hours

Printhead

Width: (D910) 4.094 inches

Resolution: (D910) 203.2 dpi

Temperature: 80 Fahrenheit

Cutter

Detected at power-up: false

Type installed: (D506) NONE

Operation enabled: (D740) false

Total cycle count: 0

PMH

Type installed: (D507) NONE

Operation enabled: (D741) false

Flash

Installed: 4 MB

Available in file area: 964 KB

RAM:

Installed: 16.0 MB

Available: 5.39 MB

Code:

Revision: 1.02.030521b

Part number: 950000-0102

Size: 1851552

Checksum: 0x88c1777

CRC32: 0x70c6cc74

Bootloader revision: 1.04 .030519b

Analog PIC revision: 4.5

Figure 12 ^D324-List Statistics Example

28 226/426 User’s Guide

Page 39

Chapter 5: Communications

5.1 RS-232 Serial

The printers provide a 9 pin female D-Sub connector, on the rear panel, for RS-232 serial

communication. The printer is configured as DCE (Data Circuit-terminating Equipment) so a

NULL modem cable is not necessary. A serial data cable is required to use serial

communications, refer to Table 7 below for correct cable configurations.

The factory settings, unless otherwise requested, are set at 9600 baud, 8 data bits, 1 stop

bit, and no parity with both hardware and software handshaking. The baud rate is user

selectable from 1200 to 115,200 and uses software XON/XOFF flow control and/or

hardware CTS handshaki ng.

9 to 9 Pin Cable 9 to 25 Pin Cable

DE-9

State

XX 1 DCD DCD

XX 2 TXD RXD

XX 3 RXD TXD 3 XX 3 RXD TXD 2

HI 4 DTR DSR

LO 5 GND GND

HI 6 DSR DTR 6 HI 6 DSR DTR 6

DC 7 RTS CTS 7 DC 7 RTS CTS 4

XX 8 CTS RTS 8 XX 8 CTS RTS 5

HI 9 +5V +5V 9 HI 9 +5V -

Pin#

Signals /

Directions

PC

DE-9

Pin#

1 HI 1 DCD DCD 8

2 XX 2 TXD RXD 3

4 HI 4 DTR DSR 20

5 LO 5 GND GND 7

State

DE-9

Pin#

Signals / Directions

PC

DB-25

Pin#

DC = DO NOT CARE XX = INDETERMINATE

Table 7 RS-232 Cable Configurations

If XON/XOFF handshaking is used, only signals RXD, TXD, and GND are required for

proper operation. If the hardware handshaki ng is used the CTS and RTS signals are

required. The other signals are offered in the event that the host computer requires them.

226/426 User’s Guide 29

Page 40

Communications Chapter 5

5.1.1 RS-232 Printer Cables

The printers use standard cables that may be purchased through Microcom Corporation or a

local computer supply company. A NULL-modem cable is not required because the printer

is configured as DCE.

For a 25-pin serial communication port – Use a 25-pin female to 9-pin male cable.

For a 9-pin serial communication port – Use a 9-pin female to 9-pin male cable.

CAUTION: Connection of a serial port to a parallel port may

result in damage to the printer and / or computer.

5.2 10BASE-T Ethernet

Refer to Figure 13.

The printers provide an auto-sensing, auto switching 10BASE-T Fast Ethernet port with full

duplex operation capability.

(A) = RJ45 connector for Ethernet port connection.

(B) = Solid green light i ndicates that a connection i s present.

(C) = Flashing yellow light indicates that the port has acti vity.

5.3 160P St acker / Auxiliary Interface

The 426 printer provides an 8 pin Mini-din connector on the rear panel for auxiliary

interfaces. This port can be used to power and operate the 160P stacker as well as other

auxiliary functions. For more information about the 160P, please consult the 160P Stacker

User Guide part number 880021-0100.

NOTE: The Auxiliary Interface or Port is not available on the Model 226 printer.

30 226/426 User’s Guide

Page 41

Chapter 5 Communications

Auxiliary Port

RS-232 Serial Port

10BASE-T Ethernet Port

Figure 12 426 Interface Connections

(A)

(C)

(B)

Figure 13 Ethernet Port - 10BASE-T

226/426 User’s Guide 31

Page 42

32 226/426 User’s Guide

Page 43

Chapter 6: Maintenance and Adjustments

6.1 Maintenance Schedule

It is important to note that optimum print quality and print head life is achieved by

maintaining a clean printer and print head. A Microcom Corporation approved cleaning kit

(part # 040005-0000) is available. Contact your sales representative for purchasing

information.

AREA METHOD INTERVAL

Foam tipped swab, cotton

tipped swab, or thermal

Print head

Drive Roller

Peel Edge

Interior Cleaning

Exterior Cleaning

Table 8 Recommended Maintenance Schedule

CAUTION: Microcom Corporation will not be held responsible for

damage caused by any non-approved solvent, cleaning material

and/or method and the use of such non-approved materials and /or

methods may void appropriate expressed or implied warranties.

printer cleaning card

dampened with Isopropyl

Alcohol.

See section 6.4

Foam tipped swab, cotton

tipped swab, thermal

printer cleaning card, or

lint-free cloth dampened

with Isopropyl Alcohol

See Section 6.5

Foam tipped swab, cotton

tipped swab, thermal

printer cleaning card, or

lint-free cloth dampened

with Isopropyl Alcohol

See section 6.3

Compressed air, soft-

bristle brush, and/or lint-

free cloth dampened with

Isopropyl Alcohol.

See section 6.3

Lint-free cloth dampened

with a mild, non-abrasive

general purpose cleaner.

See section 6.6

After every roll of media

or every 512 feet of tag

stock or fanfold media.

After every roll of media

or every 512 feet of tag

stock or fanfold media.

As Needed.

As Needed.

As Needed.

226/426 User’s Guide 33

Page 44

Maintenance and Adjustments Chapter 6

6.2 Thermal Printer Card

Decline in print quality, voids, or drop out areas in bar codes and/or gr aphics may indicate

that the print head is dirty and needs to be cleaned. The necessary cleaning materials can

be purchased through Microcom Corporation by contacting your sales representative and

ordering the Cleaning Kit, part # 040005-0000. The print head should be cleaned after every

roll of media or after every 512 feet (a typical stack of tag or fanfold media is about 3200

tags).

A thermal printer card is the quickest and easiest way to clean the print head, drive roller,

and peel edge all at the same time. Follow the steps below for the proper cleaning

procedure.

1. Remove any installed media.

2. Dampen both sides of one end of the c leaning card with isopropyl alc ohol.

3. While pushing down on the Head Lift Lever, insert the card into the front of the printer

between the print head and the peel edge (See Figure 14).

4. Continue inserting the card until you fee l resistance, now release the Head Lift Lever.

5. Using both hands, slowly pull the card out of the printer at a 45º down angle (See

Figure 15).

6. Repeat as necessary

7. Reinstall media.

Thermal cleaning cards should not be used more than three times each and extremely dirty

cards should be disposed of immediately.

CAUTION: Never touch or clean the print head with any abrasive

solvents and/or with any metal or sharp object.

34 226/426 User’s Guide

Page 45

Chapter 6 Maintenance and Adjustments

Figure 14 Insertion of Thermal Cleaning Card

226/426 User’s Guide 35

Figure 15 Thermal Card Removal

Page 46

Maintenance and Adjustments Chapter 6

(A)

(A)

Figure 16 Removal of top cover

CAUTION: Unplug the power cord before removing the printer

covers to avoid possible personal injury or damage to the printer.

Figure 17 Unlatching of Print head

36 226/426 User’s Guide

Page 47

Chapter 6 Maintenance and Adjustments

Roller

6.3 Internal Cleaning

The overall internal cleaning of the printer is important to hel p reduce the dust and other

contaminates residing in the printer. Contaminates may attach to the print head or drive

roller and affect the printer’s performance. Refer to Figure 18 for common areas needing

cleaned.

1. Remove any installed media.

2. Turn the printer power OFF.

3. Unplug and remove the power cord.

4. Loosen captive screw (A on Figure 16) and remove the top cover from the printer.

5. Using the two Head Release Levers (See Figure 17), unlatch and r aise the print

head.

6. Basic internal cleaning can be done using a combination of compressed air, softbristle brushes, foam/cotton tipped swabs, and/or lint-free cloths dampened in

alcohol. Using any combination of these materials, remove dust or other

contaminants from the printer. See section 6.4 for the proper print head maintenance

procedure.

7. When finished, latch the print head completely and reinstall the top cover and media.

8. Reattach the power cord and turn the printer power ON.

Print head

Elements

Driver

Media Path

Peel Edge

Figure 18 Internal Cleaning

CAUTION: Unplug the power cord before removing the printer

covers to avoid possible personal injury or damage to the printer.

226/426 User’s Guide 37

Page 48

Maintenance and Adjustments Chapter 6

6.4 Print head Maintenance

If print quality has not improved after cleaning using a thermal cleaning card or if one is not

available, foam or cotton tipped swabs dampened in isopropyl alcohol may be used. Refer

to Figure 19 and follow the steps below for the proper cleaning procedure.

1. Remove any installed media.

2. Turn the power to the printer OFF.

3. Unplug and remove the power cord.

4. Loosen captive screw (A on Figure 16) and remove the top cover from the printer.

5. Using the two Head Release Levers (Figure 17), unlatch and raise the print head.

6. With a foam or cotton tipped swab dampened in isopropyl alcohol, clean the thermal

elements by gently rubbing the swab down the length of the print head. Allow for the

alcohol to evaporate then repeat if necessary.

7. The Drive Roller, Peel Edge, and other basic internal cleaning may also be

performed at this time. See the appropriate sections for more information.

8. Latch the print head completely and reinstall the top cover and medi a.

9. Reattach the power cord and turn the printer power ON.

Figure 19 Print head Thermal Elements

Thermal elements

are located in the

black area running

the entire width of

the print head.

CAUTION: When performing maintenance inside the printer,

always make sure that the print head is latched completely before

installing the top cover. Failure to do so may result in damage to

38 226/426 User’s Guide

the print head.

Page 49

Chapter 6 Maintenance and Adjustments

6.5 Cleaning the Drive Roller

Maintaining a clean drive roller not only helps to extend the life of the roller but also helps to

reduce print quality issues and media slips that may occur due to dust, label adhesive and

other forms of contamination. The drive roller should be cleaned after every roll of media or

after every 512 feet (a typical stack of tag or fanfold media is about 3200 tags). See the

previous section Thermal Printer Card for a quick and easy way to clean the drive roller or

follow the steps below.

1. Remove any installed media.

2. Turn the printer power OFF.

3. Unplug and remove the power cord.

4. Loosen captive screw (A on Figure 16) and remove the top cover from the printer.

5. Using the two Head Release Levers (Figure 17), unlatch and raise the print head.

6. With a lint-free cloth dampened in alcohol, clean the drive roller. Manually rotate the

drive roller by the drive gear located to the left (from the front of the printer) or by

manually rotating the drive roller itself to clean the entire drive roller surface.

7. Print head, Peel Edge, and Internal cleaning may also be performed at this time, see

the appropriate sections for more informati on.

8. Latch the print head completely and reinstall the top cover and medi a.

9. Reattach the power cord and turn the printer power ON.

CAUTION: Isopropyl Alcohol should be used to clean the drive

roller. The use of other cleaning solvents or materials is not

recommended and may degrade the performance of the drive roller.

226/426 User’s Guide 39

Page 50

Maintenance and Adjustments Chapter 6

6.6 Exterior Cleaning

Although cleaning the exterior surfaces does not affect the printer’s performance, it will help

the overall appearance of the printer. The use of any mild, non-abrasive general purpose

cleaner with a lint-free cloth may be used to clean the exterior surfaces. This cleaning

should be performed on an as needed basis.

6.7 Gap Detector Adjustment

Refer to Figure 20. The gap detector assembly is centered in the media path at the factory

and should work for almost every type of media. For applications (for example - media that

has a Blowhole gap, whi ch is offset) the gap detector can be adjusted as needed. To adjust

the gap detector, simply move the assembly to the desired location. Care should be taken

to assure that the top and bottom sensors are aligned with each other. If the sensors are

not aligned properly, the gap detector may not work properly.

Figure 20 Gap Detector

40 226/426 User’s Guide

Page 51

Chapter 6 Maintenance and Adjustments

6.8 Auxiliary Button

The auxiliary button is used for factory adjustments and updating the flash memory.

Press and hold the

Auxiliary Button in while

powering up the printer.

Figure 21 Auxiliary Button

6.9 Flash Memory Update

This method is used to update the firmware stored in flash memory. To update the printer’s

firmware the following are required: a compressed MCB or MCA (ZIP file), a host computer

equipped with a RS-232 serial port, and a Terminal Emulation Program (i.e., HyperAccess,

HyperTerminal, Procomm Plus, Tera Term Pro...). The printer is configured at the factory

with serial parameters of 9600,n, 8,1 and the terminal emulation program will need the serial

parameters set to 9600,n, 8, 1.

It is a good idea to completely read through the procedure before an update attempt is

made. Do not send any unnecessary characters or remove the printer’s power during the

update or the printer may become i noperable. Refer to section 3.2 in the event the printer

does not function properly after an update and the printer has become inoperable.

1. Make sure the RS-232 serial connection is made between the host and the printer

including the proper Baud rate.

2. It is recommended to use the fastest Baud rate up to 115200 to reduce transfer time.

Refer to the “^D670)” command regarding the printer’s serial port parameters. If the

printer does not update properly, use a slower Baud rate to transfer the update.

3. Contact the Microcom Corporation support de partment and/or visit the following web

address www.microcomcorp.com to acquire the desired MCA file.

226/426 User’s Guide 41

Page 52