Page 1

MODEL 322M

DIRECT THERMAL PRINTER

OPERATOR’S MANUAL

PART NUMBER 880022-0106

Revised: August 18, 2005 CPC

© Copyright 2003 by Microcom Corporation, Lewis Center, Ohio – All rights reserved.

Printed in the United States of America

Page 2

This Page Intentionally Left Blank

Page 3

This Page Intentionally Left Blank

Page 4

Proprietary Statement

This manual contains information proprietary to Microcom Corporation. This information is

intended solely for the use of parties operating and maintaining such equipment described

herein.

Product Enhancements

Microcom Corporation is committed to the continual improvement of performance and

quality in our products. For this reason, specifications are subject to change without notice.

Liability Disclaimer

Microcom Corporation makes every effort to assure that all information and specifications

contained in this manual are accurate; however, mistakes are sometimes made. Microcom

Corporation shall not be liable for any damages resulting in the use or misuse of this

product. The exclusion or limitation involving consequential or incidental damage does not

apply to all states; therefore limitation mentioned above may or may not apply.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy, and if not installed and used in accordance with the instructions contained in this

manual, may cause harmful interference to radio communications.

®

HyperTerminal

Centronics

and HyperAccess® are trademarks of Hilgraeve Inc.

®

a registered trademark of Data Computer Corporation.

is

HP® and LaserJet II® are trademarks of Hewlett-Packard Company.

Arial® is a registered trademark of The Monotype Corporation.

TrueType® is a registered trademark of Apple Computer, Inc.

Microsoft®, Windows®, Windows NT® are registered trademarks of Microsoft Corporation.

®

Instapak

is a registered trademark of Sealed Air Corporation.

Other products and company names mentioned herein may be trademarks of their

respective owners.

Page 5

Table of Contents

Introduction........................................................................................... 9

Chapter 1: Printer Specifications .................................................... 11

1.1 General Specifications................................................................................... 11

1.2 Printing Specifications...................................................................................11

1.3 Media Specifications......................................................................................11

Chapter 2: Features and Options .................................................... 13

2.1 Fonts 13

2.2 Graphics........................................................................................................13

2.3 Bar codes......................................................................................................13

2.4 Special Features...........................................................................................14

2.5 Options..........................................................................................................14

Chapter 3: Getting Started............................................................... 15

3.1 Unpacking and Inspection.............................................................................15

3.2 Connecting the Printer...................................................................................15

3.2.1 Printer Power...........................................................................................16

3.2.2 RS232 Serial Communication Interface...................................................16

3.2.3 Optional Cutter Interface .........................................................................16

3.3 Loading Media...............................................................................................16

3.4 Print Button and Status Indicator Light..........................................................17

3.4.1 Print Button..............................................................................................18

3.4.2 Status Indicator Light...............................................................................18

3.5 Printer Modes................................................................................................19

3.5.1 Idle Mode.................................................................................................19

3.5.2 Halted Mode............................................................................................19

3.5.3 Paused Mode ..........................................................................................19

3.5.4 Diagnostic Mode...................................................................................... 19

3.5.4.1 Entering Diagnostic Mode .................................................................19

3.5.4.2 Statistics Label ..................................................................................20

Chapter 4: Communication..............................................................21

322M Operator’s Manual i

Page 6

4.1 RS-232D Serial............................................................................................. 21

4.1.1 RS-232 Printer Cables............................................................................22

Chapter 5: Designing Labels Using LDS .........................................23

5.1 Control Characters........................................................................................ 23

5.2 LDS Design Exercises..................................................................................23

5.2.1 PC Connection (Serial)...........................................................................23

5.2.2 Format Creation...................................................................................... 24

5.3 Label Design: An Overview .......................................................................... 25

5.4 Label Header................................................................................................ 26

5.4.1 HFM (Number of Fields in Layout).......................................................... 27

5.4.2 LSX (Label Size X) ................................................................................. 28

5.4.3 LSY (Label Size Y) ................................................................................. 28

5.4.4 WEB (Web Size)..................................................................................... 28

5.4.5 GAP (GAP Size) ..................................................................................... 28

5.4.6 DPS (Print Speed) .................................................................................. 28

5.4.7 LCB (Label Control Byte)........................................................................ 29

5.4.7.1 Die-Cut and Blow-Hole Media............................................................29

5.4.7.2 Black Line Media (Transmissive).......................................................29

5.4.7.3 Continuous Media..............................................................................30

5.4.7.4 Black Line Media (Reflective)............................................................30

5.4.8 AGD (Activate Gap Detector).................................................................. 30

5.4.9 SPG (Steps Past Gap)............................................................................ 30

5.4.10 OFX (Offset X Direction)......................................................................... 31

5.4.11 OFY (Offset Y Direction)......................................................................... 31

5.5 Sample Header............................................................................................. 31

5.6 Label Format Fields...................................................................................... 32

5.6.1 TSN (Text String Number)..................................................................... 32

5.6.2 XB (X Beginning Coordinate).................................................................. 32

5.6.3 YB (Y Beginning Coordinate).................................................................. 32

5.6.4 CC (Character Count)............................................................................. 32

5.6.5 TCI (Text Conversion Identifier).............................................................. 33

5.6.6 CGN (Character Generator Number)...................................................... 34

5.6.6.1 Embedded Fonts ...............................................................................34

ii 322M Operator’s Manual

Page 7

5.6.6.2 Downloadable Fonts and Graphics....................................................34

5.6.6.3 Embedded Bar Codes.......................................................................34

5.6.7 FO (Field Orientation)..............................................................................36

5.6.8 FJ (Field Justification).............................................................................36

5.6.9 CMX (Character Multiplier X Direction)....................................................36

5.6.10 CMY (Character Multiplier Y Direction)....................................................37

5.6.11 CS (Character Spacing) ..........................................................................37

5.6.12 TSP (Text Starting Position)....................................................................37

5.6.13 ,,, (Reserved Spaces)............................................................................. 37

5.6.14 AN (Attribute Number).............................................................................37

5.7 Line Draw......................................................................................................37

5.7.1 TSN (Text String Number).......................................................................38

5.7.2 XB (X Beginning Coordinate) ..................................................................38

5.7.3 YB (Y Beginning Coordinate) ..................................................................38

5.7.4 ,, (CONSTANT FIELD)..........................................................................38

5.7.5 TCI (Text Conversion Identifier)..............................................................38

5.7.6 ,,,, (CONSTANT FIELDS).......................................................................38

5.7.7 XS (X Size)..............................................................................................38

5.7.8 YS (Y Size)..............................................................................................38

5.7.9 ,,,,, (CONSTANT FIELDS).......................................................................38

5.7.10 AN (Attribute Number)............................................................................. 39

5.7.11 Line Draw Sample...................................................................................39

5.8 Reverse Video...............................................................................................40

Chapter 6: Printer Commands......................................................... 41

6.1 Special Printer Control Codes.......................................................................41

6.2 Printer Enquires.............................................................................................42

6.3 Sending ^D Printer Commands.....................................................................43

6.3.1 Software DIP Switches and Non-Volatile Commands.............................43

6.3.2 Printing Commands.................................................................................48

6.3.3 Auto-sizing and Valid GAP Commands...................................................49

6.3.4 Serial Number Commands......................................................................50

6.3.5 Saving Format Commands......................................................................52

6.3.6 Dispensing Commands ...........................................................................54

322M Operator’s Manual iii

Page 8

6.3.7 Text String Commands........................................................................... 57

Chapter 7: Downloadable Graphics.................................................59

7.1 Using the Graphic Conversion Utilities .........................................................59

7.1.1 PCX2MIC.exe Program.......................................................................... 59

7.1.2 BMP2MIC.exe Program.......................................................................... 59

7.2 Graphic Image Download Methods............................................................... 60

7.2.1 Compressed Binary Image (^D107)........................................................ 60

7.2.2 Uncompressed Image (^D104)............................................................... 61

7.3 Graphic Image Data Format......................................................................... 62

7.4 Downloadable Graphics Command Summary.............................................. 64

Chapter 8: Downloadable Fonts.......................................................65

8.1 Using the Font Conversion Utilities...............................................................65

8.1.1 SFP2MIC.exe Program........................................................................... 65

8.1.2 TTF2MIC.exe Program........................................................................... 65

8.2 Font Download Methods............................................................................... 66

8.2.1 Compressed Binary Image (^D107)........................................................ 66

8.2.2 Uncompressed Image (^D104)............................................................... 67

8.3 Font Structure...............................................................................................68

8.4 Downloadable Font Command Summary..................................................... 69

Chapter 9: Bar Codes........................................................................71

9.1 Types of Bar Codes...................................................................................... 71

9.1.1 Universal Product Code – Version A (UPC-A), TCI 12........................... 71

9.1.2 Universal Product Code – Version E (UPC-E), TCI 13........................... 71

9.1.3 Universal Product Code (UPC-E, send 6 digits), TCI 14......................... 72

9.1.4 Interleaved 2 of 5 (I2of5), TCI 15............................................................ 72

9.1.5 Code 3 of 9 (Code39), TCI 16................................................................. 73

9.1.6 European Article Numbering System 13 (EAN-13), TCI 20.................... 73

9.1.7 European Article Numbering System 8 (EAN-8), TCI 21........................ 73

9.1.8 Modified Plessey (MSI 1), TCI 24........................................................... 73

9.1.9 Modified Plessey (MSI 2), TCI 25........................................................... 73

9.1.10 Modified Plessey (MSI 3), TCI 26 ........................................................... 73

9.1.11 Postnet (ZIP+4), TCI 36.......................................................................... 74

iv 322M Operator’s Manual

Page 9

9.1.12 Postnet (ZIP+6), TCI 37 ..........................................................................74

9.1.13 MaxiCode, TCI 38....................................................................................74

9.1.14 Code 128 (Automatic Compression), TCI 40...........................................77

9.1.15 Code 128 (Manual Compression), TCI 41...............................................77

9.1.16 Codabar (Rationalized), TCI 42...............................................................78

9.1.17 Code 93, TCI 43...................................................................................... 78

9.1.18 AS-10, TCI 44..........................................................................................78

9.1.19 PDF-417, TCI 46.....................................................................................79

9.1.20 UCC/EAN 128, TCI 50.............................................................................82

9.1.21 UCC/EAN Text Information, TCI 51.........................................................86

9.2 Bar Code Rotation.........................................................................................86

9.3 Bar Code Human Readable Text ..................................................................87

Chapter 10: Printer Maintenance...................................................... 89

10.1 Maintenance Schedule................................................................................89

10.2 Thermal Printer Card...................................................................................90

10.3 Internal Cleaning.........................................................................................92

10.4 Print head Maintenance...............................................................................93

10.5 Cleaning the Drive Roller...............................................................................94

10.6 Exterior Cleaning...........................................................................................94

10.7 Gap Detector Adjustment.............................................................................. 94

Chapter 11: Troubleshooting........................................................... 95

11.1 Troubleshooting Tips.....................................................................................95

Appendix A: Limited Warranty........................................................... 97

Appendix B: RMA Procedure.......................................................... 98

Appendix C: Quick Reference Command Summary........................ 99

Glossary............................................................................................ 107

Index..................................................................................................111

User Notes......................................................................................... 115

322M Operator’s Manual v

Page 10

List of Tables

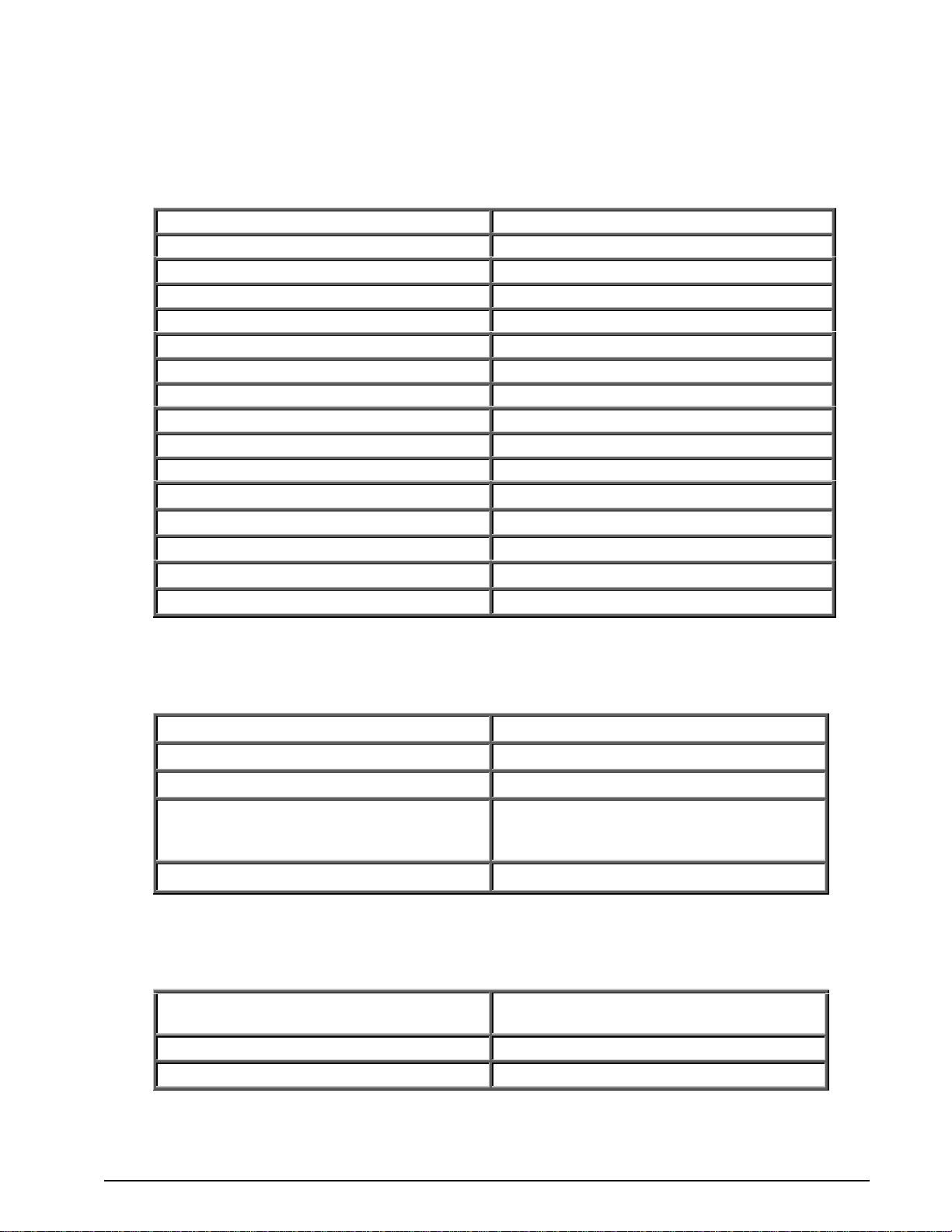

Table 1 General Specifications.......................................................................... 11

Table 2 Printing Specifications.......................................................................... 11

Table 3 Media Specifications............................................................................. 11

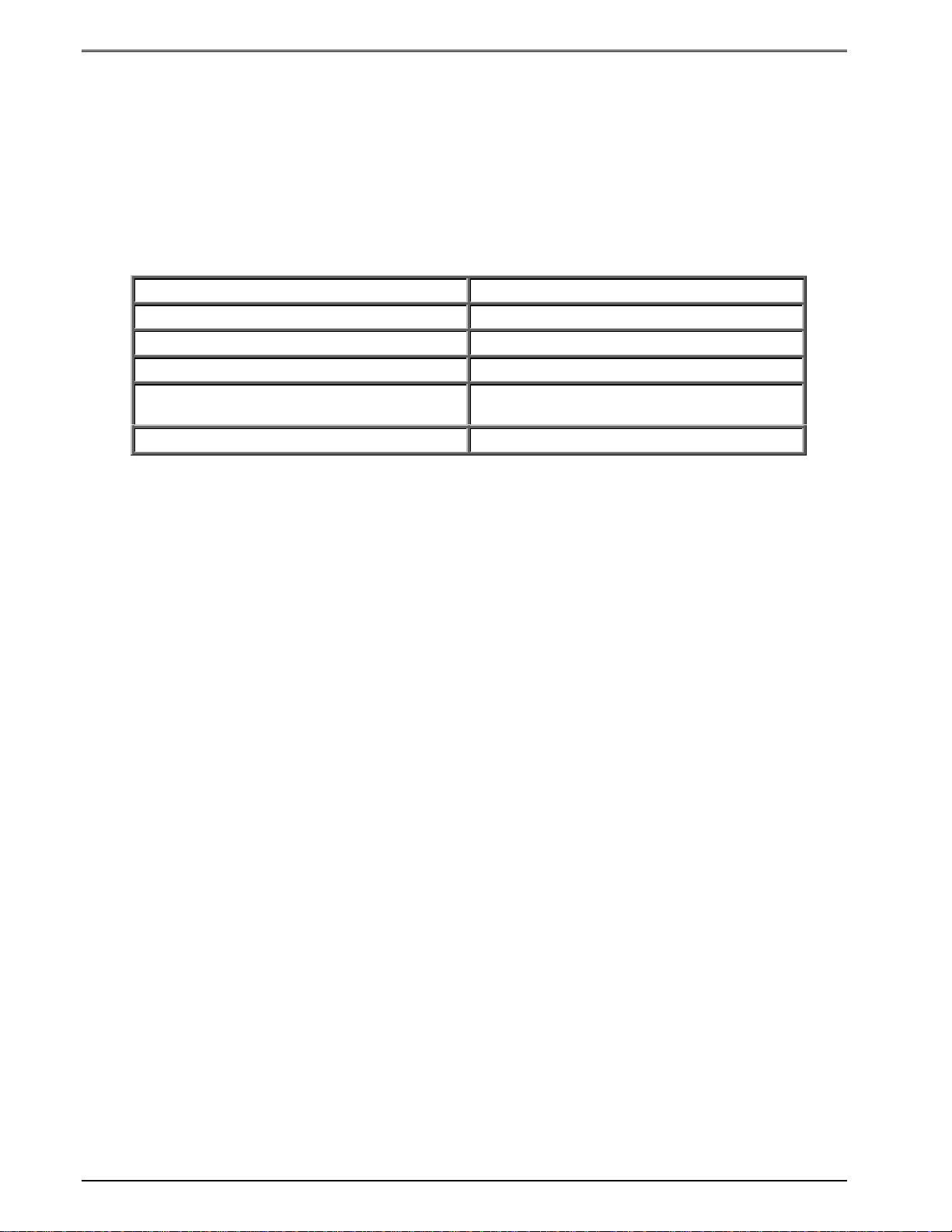

Table 4 Power Adapter Specifications............................................................... 16

Table 5 Print Button Description........................................................................ 18

Table 6 Status Indicator Light Description......................................................... 18

Table 7 RS-232 Cable Configurations............................................................... 21

Table 8 DPS Values.......................................................................................... 29

Table 9 TCI Values............................................................................................ 33

Table 10 CGN – Embedded Fonts...................................................................... 34

Table 11 CGN – Bar Code Symbologies............................................................. 35

Table 12 FO & FJ Character Starting Positions................................................... 36

Table 13 Enquiry Responses.............................................................................. 43

Table 14 UPC-E Zero Reduction Format............................................................ 72

Table 15 MaxiCode Control Code Equivalents.................................................... 76

Table 16 Code128 Special Function Access....................................................... 77

Table 17 PDF-417 Error Correction Level...........................................................80

Table 18 UCC/EAN Application Identifiers .......................................................... 85

Table 19 Human Readable/Extended Bars TCI’s................................................87

Table 20 Recommended Maintenance Schedule................................................ 89

vi 322M Operator’s Manual

Page 11

List of Figures

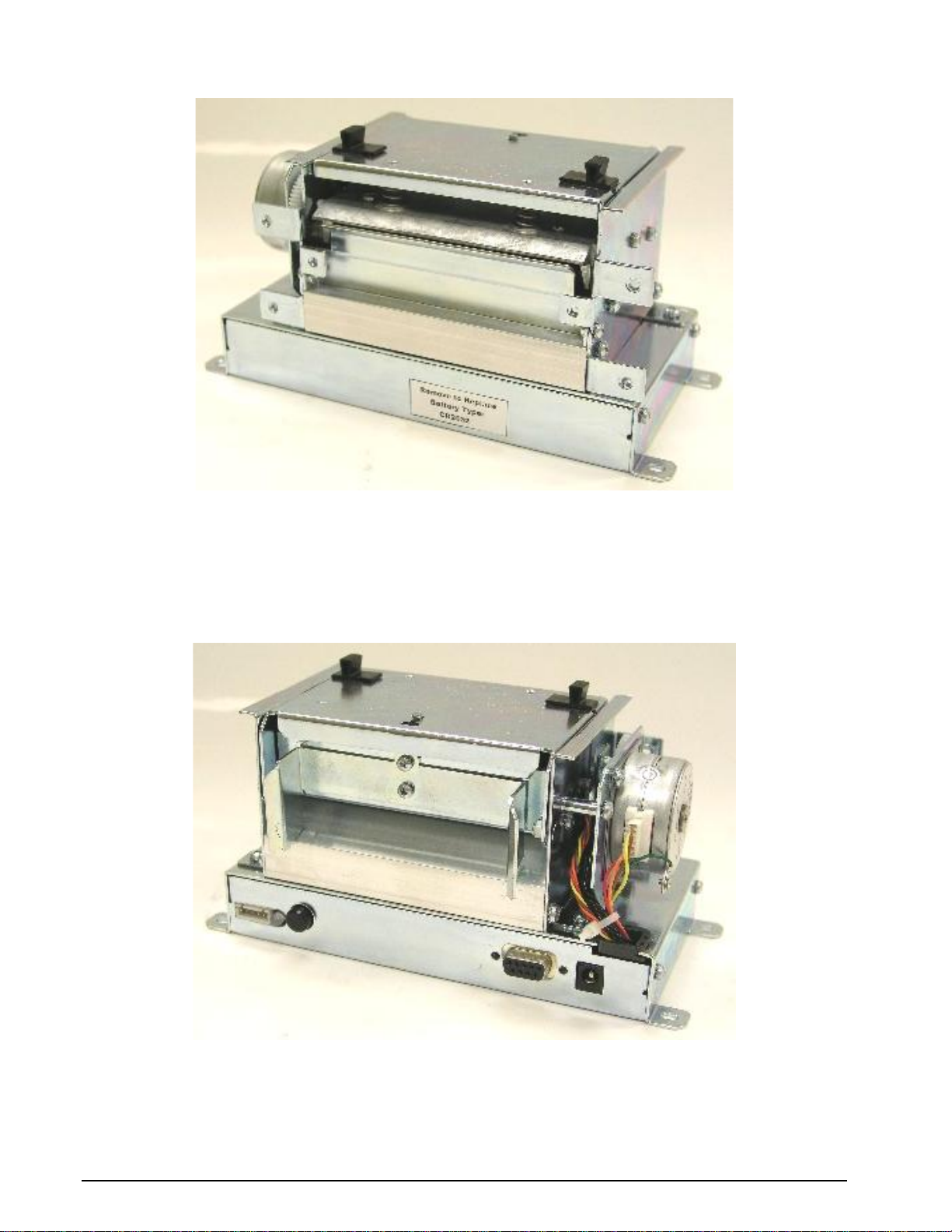

Figure 1 322M Front Angled View.......................................................................viii

Figure 2 322M Rear Angled View........................................................................viii

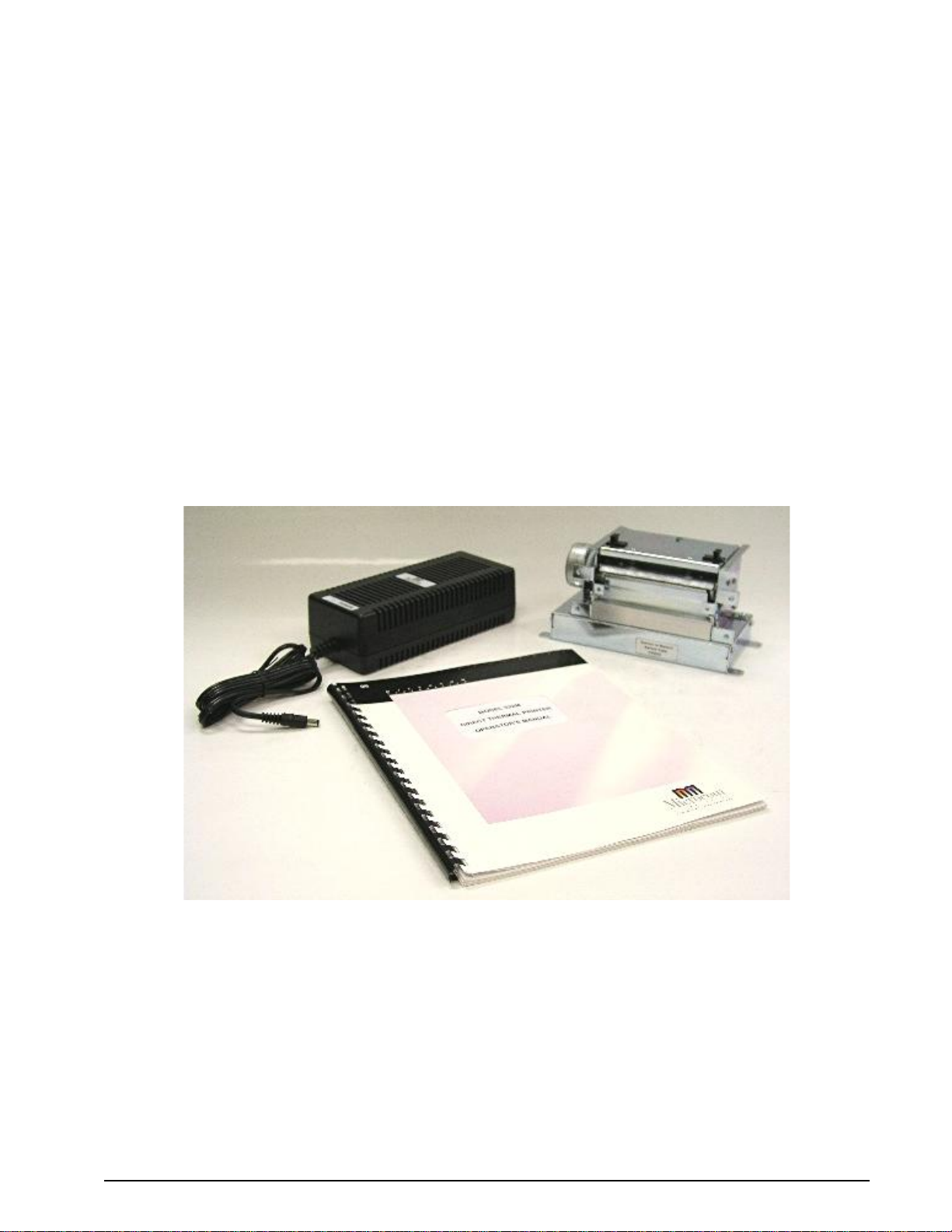

Figure 3 Typical Printer Accessories...................................................................15

Figure 4 Connecting the Printer...........................................................................17

Figure 5 Print Button and Status Indicator Light..................................................17

Figure 6 Statistics Label......................................................................................20

Figure 7 HyperTerminal™ Window Example ......................................................24

Figure 8 3x3 Sample Label.................................................................................26

Figure 9 Header Elements ..................................................................................27

Figure 10 Line Draw Sample.................................................................................39

Figure 11 Reverse Video Sample..........................................................................40

Figure 12 ^D58 - File #2 Print Sample ..................................................................54

Figure 13 ^D58 - File#3 Print Sample ...................................................................54

Figure 14 ASCII-HEX Conversions .......................................................................62

Figure 15 Code 128 Subset Switching..................................................................78

Figure 16 PDF-417 Sample Format #1 .................................................................81

Figure 17 PDF-417 Sample Format #2 .................................................................81

Figure 18 Bar Code Rotations...............................................................................87

Figure 19 UPC-A Text/Extended Bars...................................................................88

Figure 20 Unlatching the Print head......................................................................91

Figure 21 Removal of Thermal Card.....................................................................91

Figure 22 Internal Cleaning...................................................................................92

Figure 23 Print head Thermal Elements................................................................93

322M Operator’s Manual vii

Page 12

Figure 1 322M Front Angled View

Figure 2 322M Rear Angled View

viii 322M Operator’s Manual

Page 13

Introduction

The Model 322M is a high performance Direct Thermal open frame printer that is

economically sized and priced to fit everyone’s budget. The extensive list of standard

features combined with an easy to operate and maintain design provides continuous and

reliable printing at true high volume throughput. The Model 322M comes equipped with a

high resolution (575 dots, 8-dots/mm) thermal printhead with a print width of 2.83”.

The resident Label Design Software (LDS) is a powerful and easy-to-use control language

that allows the creation of custom label formats. The software is ASCII text based and can

be interfaced to PC’s, mini-computers, main frames and other special purpose machines.

The LDS uses thermal dots as the unit of measure. All commands and parameters, unless

noted otherwise, should be entered using dots. The conversion values for the printer are 8

dots per millimeter, 203 dots per inch or 0.0049” per dot. For example: To enter the width

of a label that is 2” wide, the value entered would be 406 (2” X 203 = 406).

Among many other features, LDS supports downloadable graphics and fonts, serial

numbering, flexible character spacing, reverse video, resident fonts and many of the most

popular bar code symbologies. Bitmapped fonts, bar codes, and graphic images can be

multiplied in size in the X and Y directions while being printed in 0, 90, 180, and 270 degree

rotations. Graphic images and custom designed label formats can also be stored in the

printer’s memory for high-speed access and greater throughput performance.

The Model 322M is capable of printing on most types of labels, pre-print tickets, fax papers,

and tag stocks. The printer is also capable of detecting many registration marks such as:

media that contain die-cut, blow-hole, black-line sense marks and continuous rolled stock as

well. The printer also provides three different cutter types, which include a full guillotine,

full/partial guillotine and rotary cutter. These cutter options provide a means of cutting

media of varying thickness to handle even the most demanding applications.

Many printer applications use the same label format, but change the data on every label.

This is not a problem for the 322M printer. Data may be changed without downloading the

same fixed format or fixed data field, time after time. This, along with the available serial

communication speeds, increases data access time and productivity providing the user with

high performance for a low cost.

®

Contact Microcom Corporation regarding the availability of Windows

WYSIWYG (What You See Is What You Get) software packages that allow quick and easy

on-screen label designing.

drivers and

322M Operator’s Manual 9

Page 14

10 322M Operator’s Manual

Page 15

Chapter 1: Printer Specifications

1.1 General Specifications

Width 7.63” (194mm)

Height 4.0” (102mm)

Depth 3.63” (92mm)

Weight 3.5 lbs. (1.6 kg)

Electrical Universal +24 VDC

Current 3 Amps maximum

Temperature 40° F – 104° F (5° C – 40° C) Operating

Humidity 10% – 85%, non-condensing

SRAM Memory 512K bytes

Flash Memory 512K bytes

Agency Approvals CUL, CE, and complies with FCC Class A.

RS-232D Serial RS-232D, 9 pin D-Sub c onnector (DCE)

Flow Control: XON, XOFF, and CTS

Baud Rates: 110 to 115200

Parity: Odd, Even, and None

Data Bits: 7 or 8

Table 1 General Specifications

1.2 Printing Specifications

Print Type Direct Thermal

Print Resolution 203 DPI (8 dots/mm or 0.0049” per dot)

Maximum Print Speed 6”/sec. (152mm/sec.)

Maximum Print Width

Print Length 50” (1270mm) using standard memory

Table 2 Printing Specifications

1.3 Media Specifications

2.83 inches or 575 dots (72mm)

3.15” or 640 dots (80mm) – When used

with the Heavy Media Printing Option

Media Types

Maximum Media Thickness .006” (.15mm)

Maximum Media Width 3.5” (89mm)

Continuous, die-cut, preprinted and tag

stock either rolled or fanfold.

Table 3 Media Specifications

322M Operator’s Manual 11

Page 16

12 322M Operator’s Manual

Page 17

2.1 Fonts

7 smooth bitmapped alpha-numeric fonts from 6pt to 14pt including OCR-A

and OCR-B.

Converted HP LaserJet™ and/or TrueType® font capability.

All bitmapped fonts expandable in height and width.

Reverse image printing.

Rotated: 0 º, 90 º, 180 º, and 270 º.

Chapter 2: Features and Options

2.2 Graphics

Resident Lines feature.

Storage of fonts, label formats and/or graphics in battery backed memory.

Converted PCX and BMP images.

Rotated: 0 º, 90 º, 180 º, and 270 º.

2.3 Bar codes

One-dimensional: Code 39, Interleaved 2 of 5, Code 128 (A, B, C and Auto),

Code 93, Codabar, Modified Plessey, UPC-A, UPC-E, EAN 8, EAN 13,

UCC/EAN 128, and Postnet.

Two-dimensional: PDF-417 and Maxicode.

Rotated: 0 º, 90 º, 180 º, and 270 º.

Expandable in height and width.

322M Operator’s Manual 13

Page 18

Features and Options Chapter 2

2.4 Special Features

High performance for a Low cost.

Rotating head mechanism for easy print head cleaning.

Adjustable media guides for easy label centering or custom fixed guide

brackets.

Software controlled contrast adjustment.

Detects label gap, blackline, and blowhole using reflective and

transmissive sensors.

Field incrementing, decrementing and serialization.

Downloadable fonts and graphics (with data compression).

Internal statistical counters for inches and labels printed.

Remote printer interrogation.

Automatic detection for optional cutter types

Two types of mounting methods for kiosk installation flexibility.

2.5 Options

3” (76.2 mm) Full or Full/Partial Guillotine cutter available.

3” (76.2 mm) Rotary cutter available.

+24 VDC Universal Power Supply.

User configurable sensor (Input 1).

Label Present Sensor (LPS)

Heavy Media Printing.

Printed Media Presenter (PMP).

Cleaning kit.

14 322M Operator’s Manual

Page 19

Chapter 3: Getting Started

3.1 Unpacking and Inspection

The printer has been packaged to help reduce the damage that may occur during the

shipment of product.

Inspect the shipping container(s) for signs of damage. If damage is evident, contact the

shipping company immediately to file a damage claim.

After the printer is removed from the container(s), verify that all the parts purchased are

present and in good condition (see Figure 3).

The packaging material and shipping container(s) should be kept and used if the printer is to

be shipped. Additional shipping materials can be ordered by contacting the Microcom

Corporation Service Department.

Figure 3 Typical Printer Accessories

3.2 Connecting the Printer

Refer to Figure 4 for proper connections.

322M Operator’s Manual 15

Page 20

Getting Started Chapter 3

3.2.1 Printer Power

Microcom Corporation offers a universal power adapter as an option for the Model 322M.

Any power adapter that conforms to the necessary specifications, listed below, may be

used. The printer requires a universal +24VDC power supply that operates in the 100-240

VAC; 50-60 Hertz range; 2 Amps. The power adapter should operate in an “output foldback

mode” during an overload situation rather than a shutdown and restart attempt; sometimes

referred to as a “Hiccup” mode. Contact your Microcom Corporation representative for any

questions regarding power adapter requirements and/or specifications.

AC Input: 100-240 VAC, 50/60HZ, 2A

DC Output: +24V @ 0.2 ~4.16A +/- 5%

Power Rating: 45 to 60 Watts

Overload Protection: Output Voltage Foldback Mode

Maximum Transient Load:

Printer Power Connector: Standard 2.5mm Barrel Jack

Table 4 Power Adapter Specifications

12 cycles @ 2.1ms rep. rate;

35A, 650µs pulse

Note: Verify that the power adapter jack is plugged into the printer before

plugging the power cord into an electrical outlet.

3.2.2 RS232 Serial Communication Interface

The 322M can be interfaced to PC’s, mini-computers, main frames, and special purpose

machines. This printer offers a standard serial RS-232D port. The factory serial port

configuration is set to 9600 bits per second, no parity, 8 data bits, and 1 stop bit with both

hardware and software flow control hand-shaking enabled. Refer to Chapter 4 for additional

information.

3.2.3 Optional Cutter Interface

The 322M also provides a connector on the rear panel for the optional cutter interface. Use

this connector (see Figure 4) when a cutter is installed on the printer. To prevent damage to

the printer and/or cutter, connect the cutter when the printer power is off.

3.3 Loading Media

The easy to release printhead makes loading media into the Model 322M printer an easy

process. Follow the instructions below to properly load the media.

1. Feed the media into the paper path (see Figure 4), located on the back of the printer,

until you feel resistance.

2. Push and hold the Print Button to feed the media through the printer.

3. Once the media exits the front of the printer, release the button.

16 322M Operator’s Manual

Page 21

Chapter 3 Getting Started

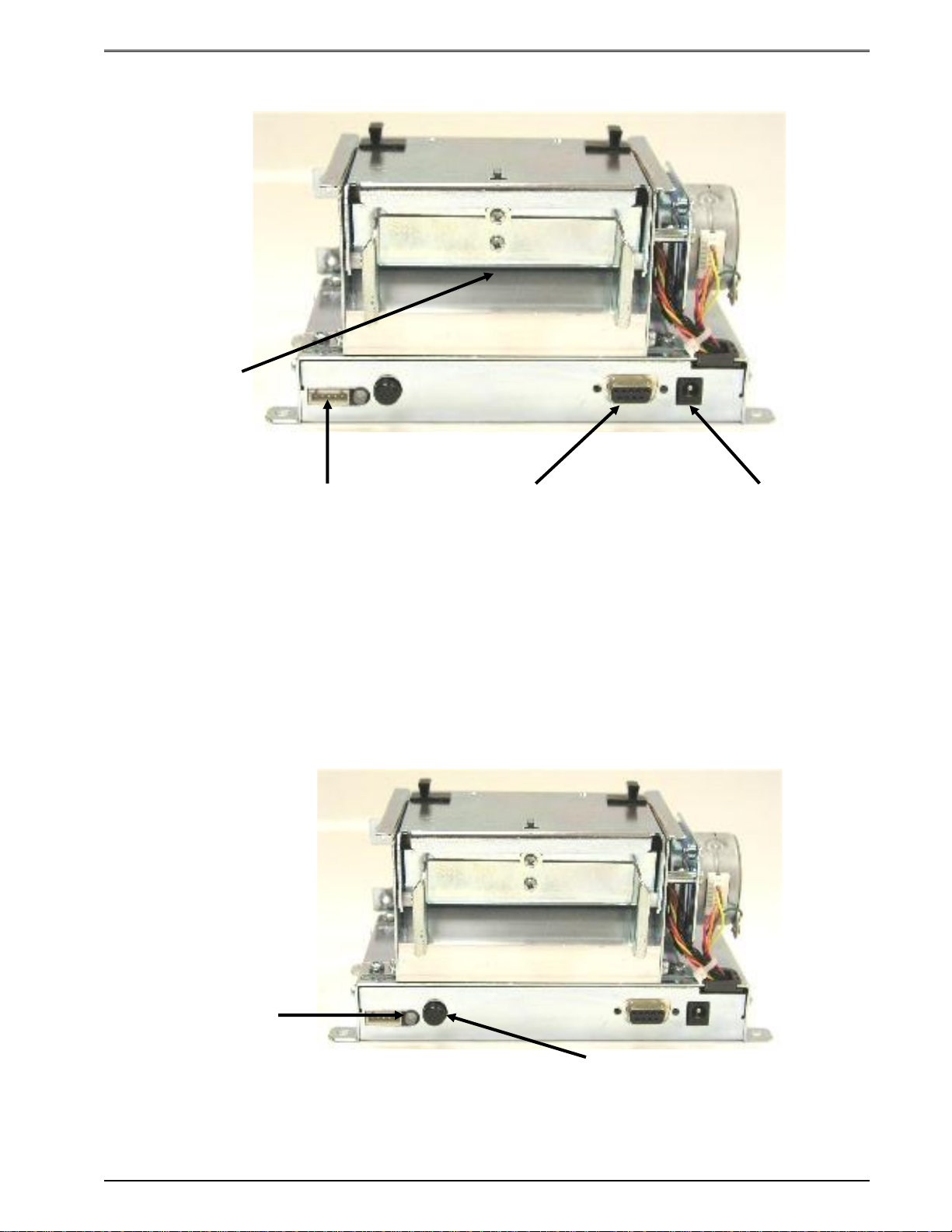

Button

Media

Path

Cutter Option

Connector

Figure 4 Connecting the Printer

RS-232D

Serial Port

+24VDC

Power Jack

3.4 Print Button and Status Indicator Light

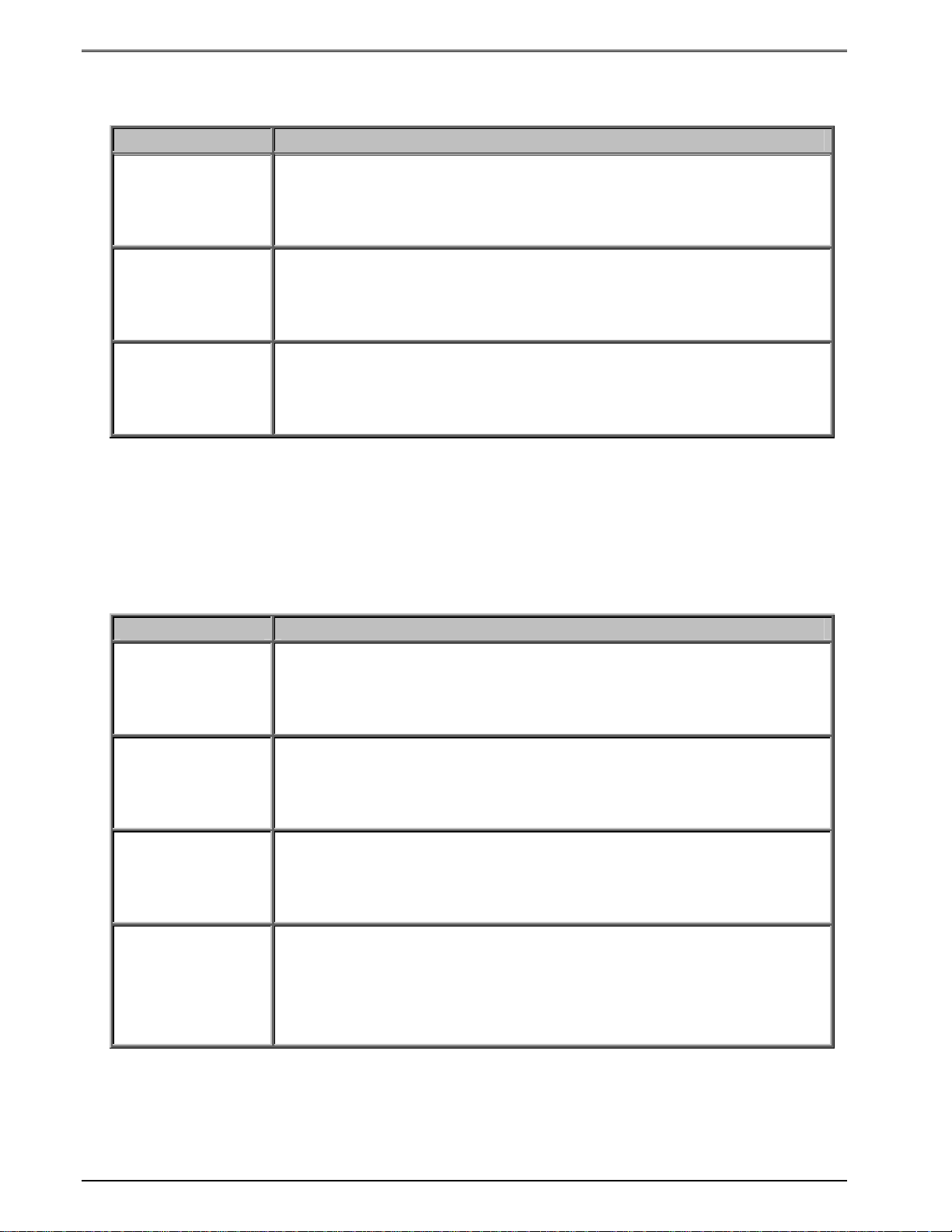

The print button and the status indicator light (see Figure 5) are used to identify and perform

many functions. This section provides a description to familiarize you with the basic function

of the button and light.

Indicator

Light

Print

Figure 5 Print Button and Status Indicator Light

322M Operator’s Manual 17

Page 22

Getting Started Chapter 3

3.4.1 Print Button

Operation Description

Printing a label

Printer Pause

Feeding Labels

Press the print button while the printer is idle or paused will

reprint the last label or after a cold start, a power up label will

print.

Press the print button while the printer is printing will cause the

printer to enter the paused mode.

Note: Press the print button again to continue printing.

Hold the print button down while the printer is idle to feed labels.

The printer will continue feeding labels until the button is

released.

Table 5 Print Button Description

3.4.2 Status Indicator Light

Light Color Description

Solid Green.

Solid Red.

Solid Amber.

Flashing Red.

Indicates that the power is on and the printer is in a ready state.

Indicates an error has occurred. The printer will remain in this

state until the condition is removed. If an unexplained error

persists, contact your Service Representative.

Note: Refer to Chapter 11: Troubleshooting for helpful hints.

Indicates that the printer has been paused, or a tag/tear mode

has been enabled.

LED Flashes Red during a download indicates that the memory

operation was not successful.

Power Spike or low voltage on the AC line. The unit will remain

in this mode until the condition is removed and the printer power

is cycled.

Table 6 Status Indicator Light Description

18 322M Operator’s Manual

Page 23

Chapter 3 Getting Started

3.5 Printer Modes

The printer has four primary modes of operation. The different types of modes have an

impact on how the rear panel print button and indicator lights are treated. This section is

intended to provide the user with an explanation of these different modes.

3.5.1 Idle Mode

Idle Mode is when the printer is not printing and has no pending activity. The indicator light

is green, which indicates that the printer is ready to receive label formats and/or commands.

The Print Button has a couple of different functions while in the Idle Mode. Pressing the

button will reprint the last label or the power-up label if the printer was recently turned on

and no formats were sent to the printer. Pressing and holding the button in, causes the

printer to feed labels until the button is released.

3.5.2 Halted Mode

Halted Mode is when the printer has stopped due to an error condition that needs to be

corrected. The indicator light will be solid red in color when the printer has entered the

Halted Mode. The printer will remain in this mode until the error has been corrected and

then cleared. Once the error has been cleared, the printer will attempt to execute the

previous format and/or commands.

3.5.3 Paused Mode

Paused Mode is when the printer has pending activity and has stopped, but is not in an

error condition. The indicator light is a solid amber color when the printer is in Paused

Mode. The printer enters this mode when the rear panel button is pressed while the printer

is printing. Pressing the button again causes the printer to resume. Another situation that

causes the printer to enter the Paused Mode is when a Dispense command (^D97 and/or

^D98) has been enabled and the label is present. See these commands for additional

information.

3.5.4 Diagnostic Mode

Diagnostic Mode temporarily powers up using factory default parameters while printing out

the printer’s current configuration on what is called the Status Label. This provides useful

information that can be used to help diagnose and troubleshoot problems. The printer will

use the factory default parameters until the printer has been reset using a soft reset or by

cycling power. The printer will then return to the previous configuration that was in use

before entering the Diagnostic Mode.

3.5.4.1 Entering Diagnostic Mode

To enter Diagnostic Mode, press and hold the rear panel button in while turning on the

printer. Release the button after three seconds and the printer will enter Diagnostic Mode

and print the Statistics label and print head test pattern.

322M Operator’s Manual 19

Page 24

Getting Started Chapter 3

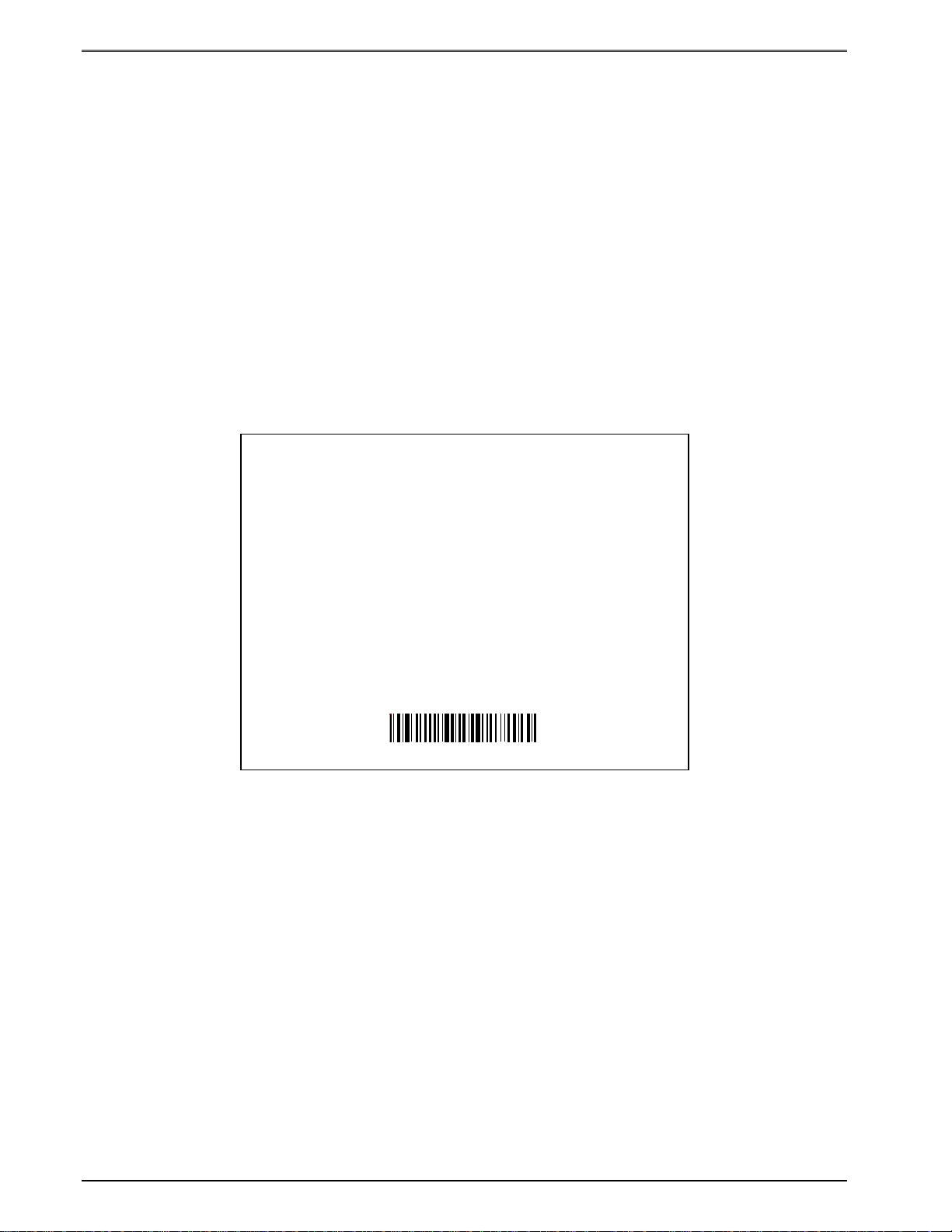

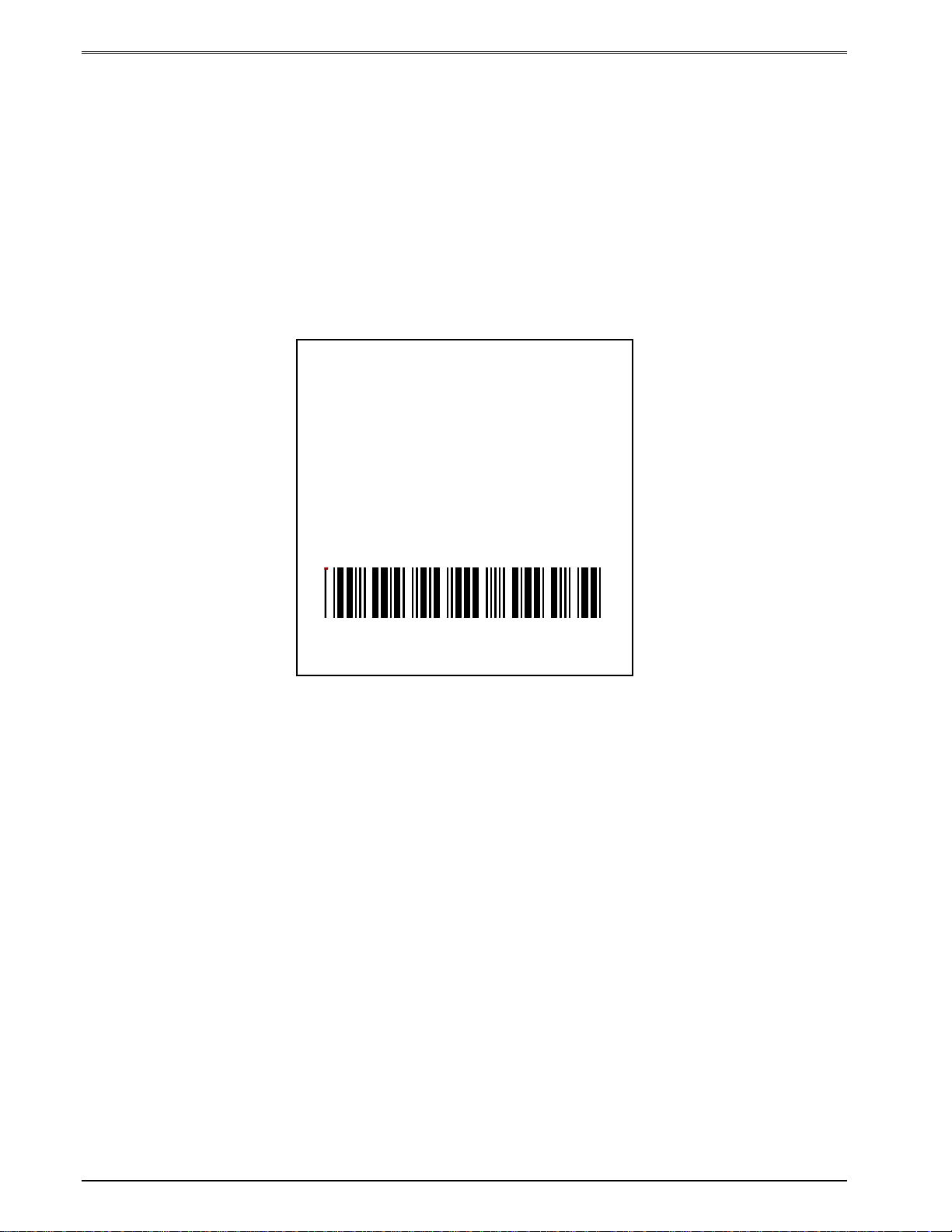

3.5.4.2 Statistics Label

The printer prints the statistics label once the printer enters the Diagnostics Mode. When

the statistics label is generated, the printer temporarily powers-up using factory default

parameters. The statistical and configuration information represents the previous setup of

the printer. The printer will return to the previous setup after a power cycle or upon

receiving a soft reset command (^D32).

The Printed Labels field represents the number of labels printed to date and can be reset by

the user. The Printed inches can also be reset by the user while the Total Inches field is set

at the factory and is not user adjustable. The Printed Labels and Printed Inches are reset

using the ^D29 command. Other useful information on the statistics label include the

printer’s serial number, power-on hours, serial parameters, soft switch bank configurations,

firmware revision, and cutter information if installed. Refer to Chapter 6 for additional

information regarding the soft switch bank settings.

PRINTER SERIAL #: 1234567890

PRINTED LABELS: 303

PRINTED INCHES: 1533

TOTAL INCHES: 1571

POWER ON HOURS: 32

CUTTER TYPE: Guillotine

CUTTER ENABLED: NO

CUTTER COUNTS: 303

SWITCH BANK 1: 10001011

SWITCH BANK 2: 01010000

SWITCH BANK 3: 00000010

SWITCH BANK 4: 00000000

SERIAL PARAMETERS: 9600-N-8-1

322 REV 1.00 070000-0100 01/28/03

Figure 6 Statistics Label

20 322M Operator’s Manual

Page 25

Chapter 4: Communication

4.1 RS-232D Serial

The printer provides a 9 pin female D-Sub connector, on the rear panel, for RS-232D serial

communication. The printer is configured as DCE (Data Circuit-terminating Equipment) so a

NULL modem cable is not necessary. A serial data cable is required to use serial

communications, refer to Table 7 below for correct cable configurations.

The factory settings, unless otherwise requested, are set at 9600 baud, 8 data bits, 1 stop

bit and no parity with both hardware and software handshaking enabled. The baud rate is

user selectable from 1200 to 115,200 and uses software XON/XOFF flow control and/or

hardware CTS handshaking.

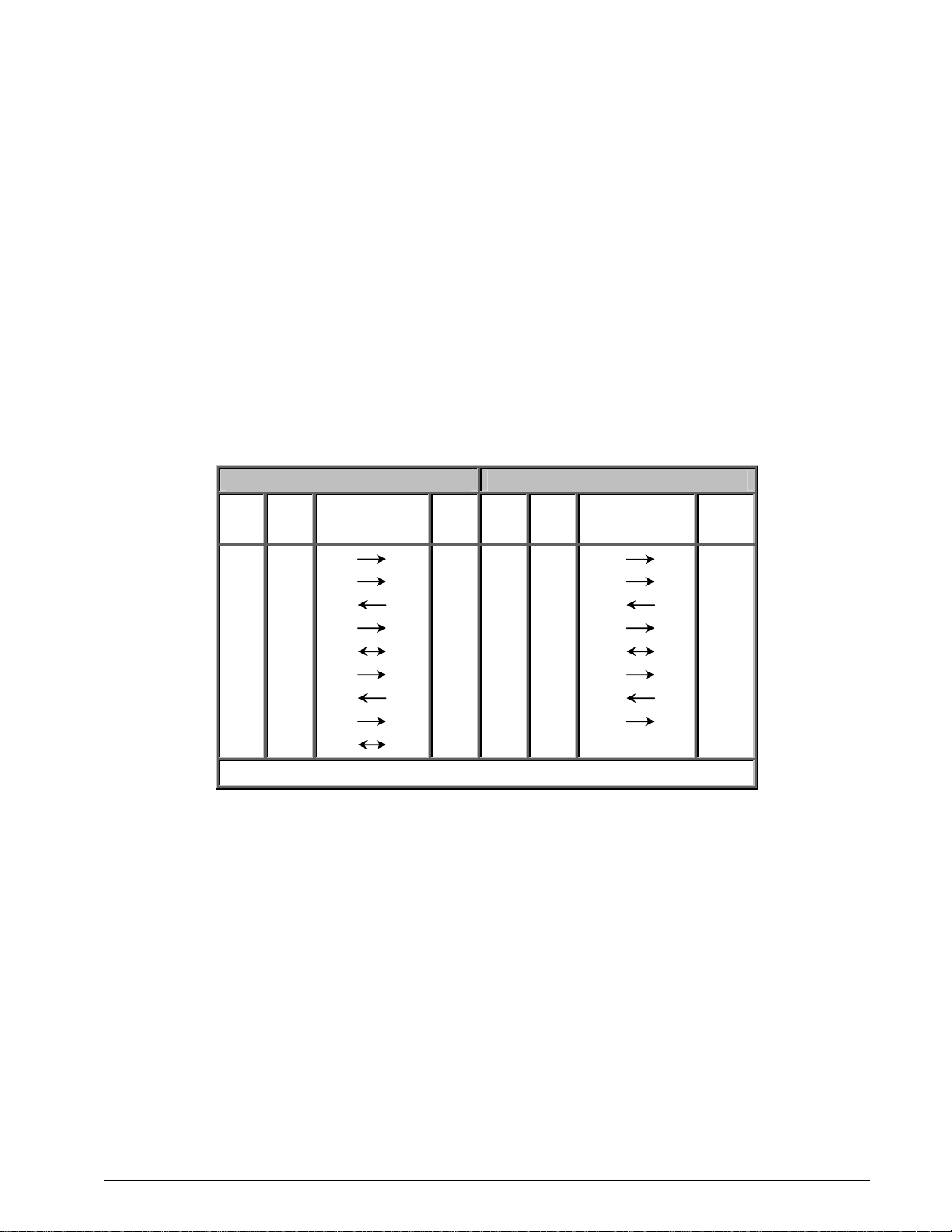

9 to 9 Pin Cable 9 to 25 Pin Cable

322M

State

DE-9

Pin #

XX 1 DCD DCD 1 HI 1 DCD DCD 8

XX 2 TXD RXD 2 XX 2 TXD RXD 3

XX 3 RXD TXD 3 XX 3 RXD TXD 2

HI 4 DTR DSR 4 HI 4 DTR DSR 20

LO 5 GND GND 5 LO 5 GND GND 7

HI 6 DSR DTR 6 HI 6 DSR DTR 6

DC 7 RTS CTS 7 DC 7 RTS CTS 4

XX 8 CTS RTS 8 XX 8 CTS RTS 5

HI 9 +5V +5V 9 HI 9 +5V -

Signals /

Direction

PC

DE-9

Pin #

State

322M

DE-9

Pin #

Signals /

Directions

PC

DB-25

Pin #

DC = DO NOT CARE XX = INDETERMINATE

Table 7 RS-232 Cable Configurations

If XON/XOFF handshaking is used, the only signals that the printer requires are the RXD,

TXD, and GND signals. If the hardware handshaking is used the CTS and RTS signals are

required. The other signals are offered in the event that the host computer would require

them.

322M Operator’s Manual 21

Page 26

Communication Chapter 4

4.1.1 RS-232 Printer Cables

The printer uses a standard through serial cable, typically referred to as a modem cable,

which may be purchased through Microcom Corporation or a local computer supply

company. A NULL-modem cable is not required because the printer is configured as DCE.

For a 25-pin serial communication port – Use a 25-pin female to 9-pin male cable.

For a 9-pin serial communication port – Use a 9-pin female to 9-pin male cable.

CAUTION: Connection of a serial port to a parallel port may

result in damage to the printer and / or computer.

22 322M Operator’s Manual

Page 27

Chapter 5: Designing Labels Using LDS

Label Design Software (LDS) refers to the control language resident in the printer used to

create labels. All bitmapped fonts, character sets and bar codes are resident in the printer.

Additional fonts and graphic images may be sent from a host and stored in the printer’s

memory.

A label format is produced by a series of 5 steps:

1. Control commands to define printer operation.

2. A format header to define the label height, width, print speed, etc…

3. Field data that defines the placement of text, bar codes, graphics or lines.

4. Actual text data to place in the Field data strings.

5. Control commands to initiate printing.

5.1 Control Characters

Throughout this manual there are references to control characters. In order to print them in

this manual, they have been written using standard characters and icons. Escape

characters are represented by <ESC> and a carriage return is represented by <CR>. It is

important to note that all printer functions, unless otherwise noted, must be followed or

terminated with a carriage return (<CR> or HEX OD).

5.2 LDS Design Exercises

There are many different machines capable of sending information to the printer including

main frames, mini-computers, special purpose computers and PC’s. For the purpose of

simplicity, the design exercises contained in this manual will use one of the easiest methods

by using an IBM compatible PC and a VT-100 terminal emulation software program. This

method of connection will allow two-way, serial communication with the printer.

Items required:

- A computer with at least one unused serial communication port (COM1, COM2…).

- A serial interface cable (see section 4.1.1).

- A VT-100 terminal emulation program such as HyperTerminal™.

- A text editor that does not add formatting characters such as Microsoft® Notepad.

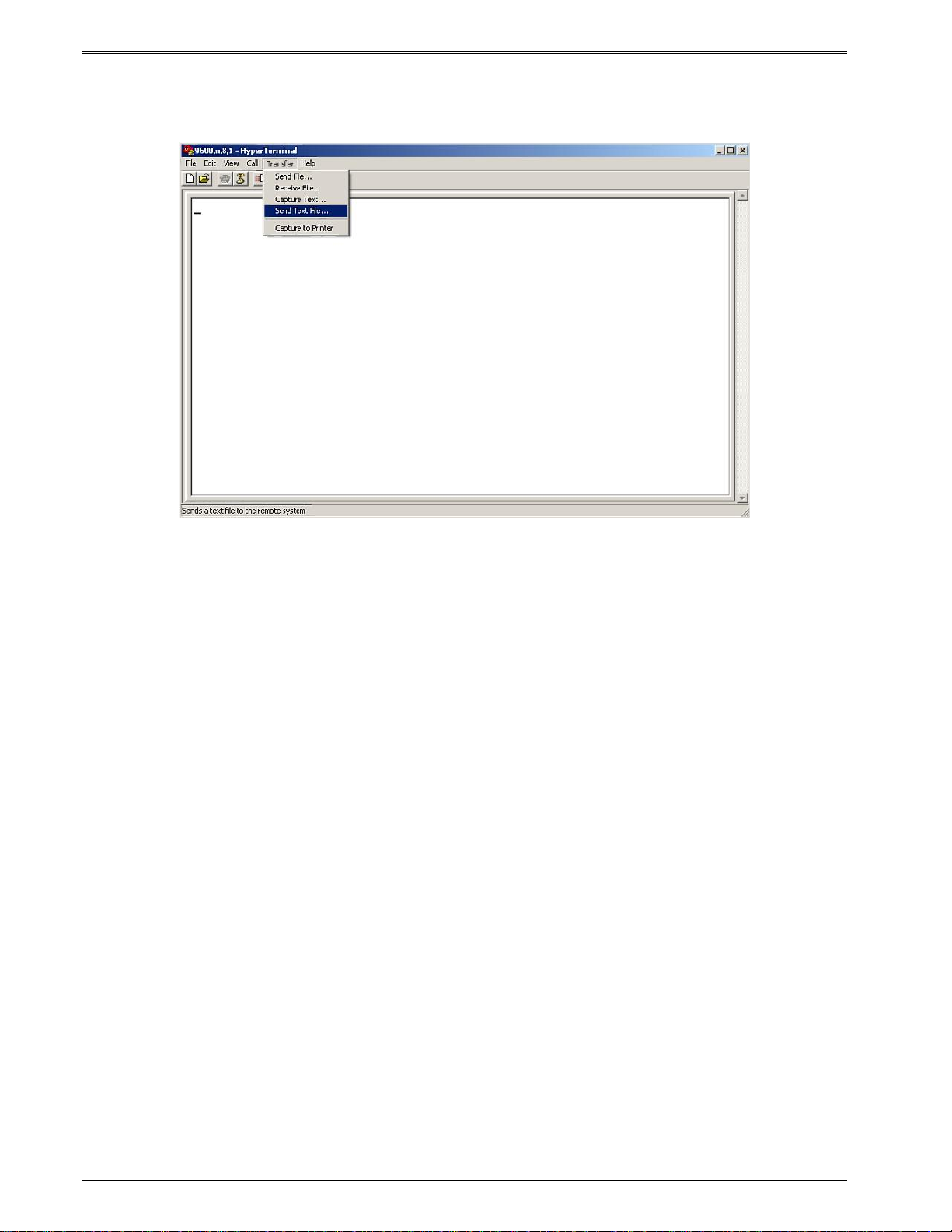

5.2.1 PC Connection (Serial)

The printer ships with serial communication parameters set to 9600 bits per second, no

parity, 8 data bits, and 1 stop bit (9600-N-8-1). This means that for proper communication,

the PC’s communication port will have to be set to these parameters. If a terminal program

is not available, it is possible to send files to the printer using the DOS COPY (for example:

C:\>COPY FILENAME COM1) command. When using DOS, it is a good idea to set the

communications port up using the DOS MODE (for example: C:\>MODE

COM1:9600,n,8,1,p) command before copying the files to the port. Create a text file, enter

“^D3” <CR> (carriage return) and save it as “D3.txt”. Send the file to the printer by either

322M Operator’s Manual 23

Page 28

Designing Labels Using LDS Chapter 5

using the DOS COPY (C:\>copy d3.txt com1) command or by using a terminal program (see

Figure 7).

Figure 7 HyperTerminal™ Window Example

5.2.2 Format Creation

Special Control code functions (see section 6.1) and/or label formats may be entered

directly through the keyboard but is not the most efficient method if entering a large amount

of data or numerous commands. Large formats and/or numerous commands should be

entered in an ASCII text editor and then uploaded to the printer. Microsoft® Notepad has is

used for the creation of label designs contained within this manual because it is simple to

use and does not add formatting characters.

The LDS uses thermal dots as the unit of measure. All commands and parameters, unless

noted otherwise, should be entered using dots. The conversion values for the printer are 8

dots per millimeter, 203 dots per inch, or 0.0049” per dot. For example: To enter the width

of a label that is 2” wide, the value entered would be 406 (2” X 203 = 406).

The printer can accept either the one-character control code (“Ctrl + E” (HEX05)) or the two-

character caret (^) plus alpha character (“^E”). In other words, for a PC keyboard, the same

command can be generated either by holding down the “Ctrl” key and pressing the alpha

character or by entering the two characters; the “^” (the character generated when you

press the “Shift” key and the “6”) plus the alpha character. See Chapter 5 for additional

information regarding control codes and printer commands.

There are some special features offered by the printer that assist in label design. For

example, the auto-si ze command (^A2^D39 <CR>) provides most of the header format

information needed to define the different properties of the media being used. The current

state of the printer is accessed through the enquiry command (^D5 <CR>, Ctrl E, or 5

NULL characters (HEX 00) if binary compression has been enabled). The statistical

24 322M Operator’s Manual

Page 29

Chapter 5 Designing Labels Using LDS

information of the printer is made available through the use of the ^A0^D29 <CR> or more

simply ^D29 <CR> command.

The following sections of this chapter are intended to provide the user an overview of the

LDS language. The overview will include information regarding the label format, header

definition, and list the different types of field information available. The combination of these

sections and Chapter 5 should provide the user with the information required for easy format

creation and printing. Once some understanding of these basis concepts are achieved, use

the Quick Reference Guide in Appendix C for expedient label design.

5.3 Label Design: An Overview

A label format consists of a header record and field records, followed by the text data to be

printed. The records describe how the label is to be printed. The header contains

information about the label itself such as label height, width, print speed, etc. The field

records refer to the data section and contain information about positioning coordinates, and

the type of character generation such as text, graphics, bar codes, etc. The number of

fields is limited only by the amount of free memory available.

Below is a sample label format. We will refer to this format as we break down the steps and

components to produce the format. Refer to Figure 8 for a printed representation.

^D57 <CR> A label format is coming.

5,575,609,,25,35,0,1,285,0,0 <CR> Header Information.

1,300,500,8,1,5,0,4,2,2,,,,,0 <CR> Field #1 format information.

2,300,400,11,1,5,0,4,2,2,,,,,0 <CR> Field #2 format information.

3,300,300,26,1,5,0,4 <CR> Field #3 format information.

4,300,200,6,1,5,0,4 <CR> Field #4 format information.

4,300,100,6,16,3,,4,3,75 <CR> Field #4 format information.

^D56 <CR> Select RAM format.

^D2 <CR> Text data is coming.

Microcom <CR> Text data string #1.

Corporation <CR> Text data string #2.

Thermal Printing Solutions <CR> Text data string #3.

012345 <CR> Text data string #4.

^D3 <CR> Print label.

The command ^D57<CR> on the first line informs the printer that a format is coming and

causes the printer to enter the format entry mode.

The next line is the header information that sets the label size and other pertinent

information.

The next five lines are layout and configuration for each data field in the format.

The command ^D56<CR> selects the user’s layout or more simply the end of the formatting

information.

The command ^D2<CR> instructs the printer to start accepting data for each of the defined

field’s strings that are entered into the previous format received (between the ^D57 and

322M Operator’s Manual 25

Page 30

Designing Labels Using LDS Chapter 5

^D56 commands). Field #1 defines the placement and configuration for Text Data String

#1; Field #2 defines the placement and configuration for Text Data String #2, etc… The

label is printed from the bottom left corner to the top of the label.

The next three lines are the text data for the associated field format lines.

Text Data String #4 is being accessed twice. The format places the Text “012345” on the

label and then is accessed again placing a Code39 symbol representing “012345” on the

label.

The command ^D3<CR> instructs the printer to print.

The sample label design (Figure 8) is based on a label that is 3” x 3”. You will notice that

the header value that determines the LSX (Label Size X direction) or width is set to “575” (or

2.83”), this is the maximum print head size of the Model 322M printer and should always be

used for the LSX size. The following chapters will go into greater detail about the header

and field format parameters as well as a more in-depth description on their functionality.

Thermal Printing Solutions

Figure 8 3x3 Sample Label

Microcom

Corporation

012345

5.4 Label Header

The label header consists of eleven parameters that control the media layout as well as

printer configuration. A comma (,) delimiter is used to separate the different parameters and

a carriage return is required to terminate the header. If a parameter is left blank, then a

default value will be used. Some parameters, for the Model 322M, are required for proper

operation and should always be included in the script header. These required parameters

are listed in the individual descriptions below.

The value of measurement for many of the header elements is a thermal dot or pixel. The

conversion values for the printer are 8 dots per millimeter, 203 dots per inch, or 0.0049” per

dot. For example: To enter the width of a label that is 2” wide, the value entered would be

26 322M Operator’s Manual

Page 31

Chapter 5 Designing Labels Using LDS

LSX (Always 575)

WEB

GAP

406 (2” X 203 = 406). There is a maximum of 575 dots in the X direction (width), while the Y

direction (height) is virtually unlimited with the standard print head. The auto-size command

(^A2^D39 <CR>) provides most of the header format information needed to define the

different properties of the media being used. This provides a good starting point in

determining the proper values.

Below is a list of the header element mnemonics and their default values:

HFM, LSX, LSY, WEB, GAP, DPS, LCB, AGD, SPG, OFX, OFY

0, 832, 614, 13, 24, 35, 0, 1, 285, 0, 0

Label

Thermal Printing Solutions

This is the

origin; 1, 1

Figure 9 Header Elements

Microcom

Corporation

012345

Die-cut label

backing

LSY

5.4.1 HFM (Number of Fields in Layout)

This parameter is used to specify the number of fields in the layout. If more format fields are

defined than specified in the HFM parameter, they will be ignored and will not print. The

HFM was set to a value of 5 in the format used to create the sample in Figure 8. This

means that a total of five format fields are to be generated. If the HFM was changed to 4,

only the first four format fields would be generated.

322M Operator’s Manual 27

Page 32

Designing Labels Using LDS Chapter 5

5.4.2 LSX (Label Size X)

This parameter is used to specify the width of the label using dots as the unit of measure.

The maximum width of the LSX parameter is the width of the printhead. LDS has been

specifically designed for use with a print head that is 4” in width. The Model 322M printer

has a print head width of 2.83” or 575 dots. For proper print registration the LSX should

always be 575 when using the Model 322M printer.

5.4.3 LSY (Label Size Y)

This parameter is used to specify the height of the label using dots as the unit of measure.

The maximum height is virtually unlimited and is dependant on the memory available in the

printer as well as the intensity of the label design. The sample used to generate Figure 8

has the LSY set to 609 or 3” (609/203 = 3).

5.4.4 WEB (Web Size)

The WEB parameter is the width, measured in dots, of the webbing or backing material that

is found on the left side of the label. This parameter is used to introduce an offset to

accommodate the backing of die-cut media. The Figure 8 sample does not have a value for

the WEB parameter so the default of 13 would be used.

5.4.5 GAP (GAP Size)

This parameter is the height distance, measured in dots, of the registration mark used to

identify the media size. This is the backing material found between die-cut labels, blowhole

sense mark, and/or blackline height. The default value of 24 will be used if a value is not

entered in the GAP parameter. The Figure 8 sample has a value of 25 or 0.123” (25/203 =

0.123).

5.4.6 DPS (Print Speed)

This parameter is used to set the speed the printer will print, referred to as print speed.

Refer to Table 8 for the list of print speeds, DPS values, and inches per second values. The

printer has a default speed of 2 inches per second (IPS) which is a DPS value of 35. To

print at greater speeds, change the DPS value to a lower setting as shown on Table 8.

Generally, better print quality is achieved by printing at lower speeds, however this is also

dependant on the media and contrast settings as well.

Labels per minute can be calculated by the equation below:

IPS x 60 seconds

Labels per Minute =

Label Height

28 322M Operator’s Manual

Page 33

Chapter 5 Designing Labels Using LDS

PRINT SPEED

DPS VALUE

25 76.8 3.0 180

26 74.2 2.9 174

27 71.7 2.8 168

28 69.1 2.7 162

29 66.6 2.6 156

30 64.0 2.5 150

31 61.4 2.4 144

32 58.9 2.3 138

33 56.3 2.2 132

34 53.8 2.1 126

35 51.2 2.0 120

36 48.6 1.9 114

37 46.1 1.8 108

MM PER

SECOND

INCHES PER

SECOND

INCHES PER

MINUTE

38 43.5 1.7 102

39 41.0 1.6 96

40 38.4 1.5 90

Table 8 DPS Values

5.4.7 LCB (Label Control Byte)

This parameter selects the method the printer uses for detecting registration marks on the

different media types. The Model 322M has both upper (transmissive) and lower (reflective)

gap detectors as standard equipment. The following sections discuss the LCB settings for

the different media types.

5.4.7.1 Die-Cut and Blow-Hole Media

A selection of “0” in the LCB parameter instructs the printer to detect the leading edge of the

label or Blow-Hole to identify the start of the next label. This method uses both the upper

and lower sensors for a type of detection referred to as transmissive. When using media

that contains a blow-hole, the software switch 4 (^D24 command) will have to enable “Blow-

hole Sensing” for proper stock out detection.

5.4.7.2 Black Line Media (Transmissive)

The Transmissive Black Line method is used w hen media using a black line for a

registration mark and transmissive detection is desired; a “1” should be entered in the LCB

parameter. This setting will detect the leading edge of the black line by using both upper

322M Operator’s Manual 29

Page 34

Designing Labels Using LDS Chapter 5

and lower sensors. This method may be used, it is however not the preferred method for

detecting media containing a black line. See Black Line Media (Reflective) below.

5.4.7.3 Continuous Media

If the LCB parameter is set to a value of “2”, the printer will not search for a registration

mark. The gap detectors are only used for stock out conditions when set for continuous

media types. The printer will print all fields that contain data and then advance the media by

the amount specified in the SPG parameter of the header when the default AGD of “1” is

entered in the header. This means that fields that are left blank or text data for the

associating format fields are left empty will not print.

For example: Imagine a receipt format that contains 100 lines. If data is provided for the

first 50 lines, the printer will not advance for the remaining 50 lines that have been left blank.

The printer would stop immediately after printing the 50th line and then advance the media

by the amount specified in the SPG header parameter.

When the AGD header parameter is set to “0”, the printer will advance the same amount of

media even when text data fields are left blank. In this case, the advance distance is

determined by adding the SPG parameter and LSY parameter values.

For example: Imagine the same format as mentioned above that has a LSY value of 609

(3” x 203 = 609), an SPG value of 285, and an AGD value of “0” that contains 100 format

lines. If text data is provided for the first 50 lines and the remaining 50 lines are left empty,

then the printer will print the first 50 lines, advance the next 50 lines, advance the remaining

LSY value, and then finally advance the SPG or 285 dots. Regardless of the format fields, if

the LSY is set to 609 and the SPG is set to 285 the printer will advance a total of 881 dots

(609+285=881).

5.4.7.4 Black Line Media (Reflective)

The Reflective Black Line method is used when media using a black line for a registration

mark and reflective detection is desired; a “3” should be entered in the LCB parameter. This

setting will detect the leading edge of the black line by using the lower reflective sensor.

This method is the preferred method for detecting media containing a black line and should

be used when possible.

5.4.8 AGD (Activate Gap Detector)

This parameter sets the number of steps (dots) that the printer will advance with detection of

registration marks or gaps disabled. This value has a default of “1” and is generally used. It

should not be defaulted when the LCB is set to continuous media and the form or label size

is desired to stop after the last printed data (see section 5.3.7.3 Continuous Media).

Another situation where the AGD should not be defaulted is when using media that contains

a heavy concentration of pre-print or gaps that may cause false detection of a registration

mark. If this is the case, the value entered for the AGD parameter should be the distance

from the registration mark to the trailing edge of the pre-print or gap that could cause false

detection.

5.4.9 SPG (Steps Past Gap)

This parameter is used to specify the number of steps (thermal dots) to advance the media

after a registration mark has been detected. This parameter is required to properly position

the next label to the dot row. The proper SPG setting for the Model 322M printer is “285” for

30 322M Operator’s Manual

Page 35

Chapter 5 Designing Labels Using LDS

media that contains an LSY value greater than “285”. For media that has a LSY value less

than “285”, the SPG will need to be calculated.

If the label height is greater than or equal to 285 then the SPG = 285.

If the label height is less than 285, subtract (LSY+GAP) from 285 until the answer is

negative, then add (LSY+GAP) until the result is positive again. Subtract the AGD value

and the result will be the proper SPG value.

5.4.10 OFX (Offset X Direction)

This parameter is used to move or offset all format fields in the X direction without altering

the format fields coordinates themselves.

5.4.11 OFY (Offset Y Direction)

This parameter is used to move or offset all format fields in the Y direction without altering

the format fields coordinates themselves.

5.5 Sample Header

This is the header for the format used to generate the printed sample in Figure 8 followed by

a summary of the header values.

5, 575, 609, ,25 ,35 ,0 ,1 ,285, 0, 0 <CR>

5 = 5 format fields are following the header.

575 = Label width (LSX) of 575 (575 / 203 = 2.83”).

609 = Label height (LSY) of 609 (609 / 203 = 3”).

, , = Default WEB value of 13 will be used.

25 = GAP between labels of 25 (25 / 203 = .123”).

35 = Print speed (DPS) of 35 = 2 inches per second.

0 = LCB of 0 for die-cut labels.

1 = AGD of 1 step.

285 = SPG of 285 for proper placement of the next label.

0 = No X offset.

0 = No Y offset.

<CR> = A carriage return must follow the header.

322M Operator’s Manual 31

Page 36

Designing Labels Using LDS Chapter 5

5.6 Label Format Fields

The Label Format Fields are used to define the characteristics, placement and

representation of the corresponding text data of the individual fields. A format field is

broken down into many different parameters. It is not necessary to enter values for all of the

parameters (default value will be used if a parameter is left blank) but each parameter must

be separated with the comma delimiter (“,”). A carriage return must follow each format field

for proper operation to occur. The values entered must be positive integers for all of the

parameters of the format field.

Below is a list of the format field element mnemonics and their default values:

TSN, XB, YB, CC, TCI, CGN, FO, FJ, CMX, CMY, CS, TSP, , , AN

1, 0, 0, *, 1, **, 0, 0, 1, 1, *, 1, , , 0

* The default value depends on the character generator (CGN) used.

** The default value depends on the text conversion identifier (TCI) used.

5.6.1 TSN (Text String Number)

The parameter determines which line of text data will be used for formatting. This allows for

more than one field to use the same text data. A TSN of “1” accesses the first line of data.

A TSN of “2” accesses the second line of data, and so forth. The text data is the text that

follows the “^D2<CR>” command in the label’s layout. A graphic image field must point to a

text string that contains at least one character. The maximum value for a TSN is 65536.

5.6.2 XB (X Beginning Coordinate)

The X coordinate of the field is measured in thermal dots. The far left edge of the label, as

viewed from the front of the printer, is X coordinate “1”. There is no X coordinate of “0”. The

X coordinates increase in size from the left to right. An XB of 203 would place the field one

inch (203/203 = 1) from the left side of the label.

5.6.3 YB (Y Beginning Coordinate)

The Y coordinate of the field is measured in thermal dots. A YB of 1 would be the bottom

edge of the label as viewed front the front of the printer. The Y coordinates increase in size

from the bottom to the top of the label. A YB of 203 would place the insertion point one inch

from the bottom of the label.

5.6.4 CC (Character Count)

This parameter determines the number of characters that will be used by the format field. If

the number of characters in the selected text string is greater than the quantity specified by

the CC, the remainder of the text string will be ignored. If the text string has less than the

number specified by the CC, then only those characters defined by the text string will be

printed. For example, the text string “character count” should have a CC of “15” including

the space character. This parameter should be set to a value of “1” if the field is a graphic

image.

32 322M Operator’s Manual

Page 37

Chapter 5 Designing Labels Using LDS

5.6.5 TCI (Text Conversion Identifier)

The TCI parameter determines how the text string will be generated. The TCI is used to

select text, bar codes, lines, downloadable font and graphics. The TCI values can be

determined using Table 9 below. For example, a TCI of “1” for the text string data “012345”

would print the text “012345” while a TCI of “15” would produce an I 2 of 5 symbology.

TCI VALUE TCI DESCRIPTION

1 Regular Text (standard embedded fonts)

2 Text Surrounded by Asterisks

3* Text with UPC-A / UPC-E Checksum Digit Added

6 Line Draw

8 Downloadable Fonts and Graphics

12 UPC-A Symbol

13 UPC-E Symbol (Send 11 Digits)

14 UPC-E Symbol (Send 7 Digits)

15 Interleaved 2 of 5 Symbol

16 Code 39 Symbol

17* Text with UPC-E Checksum and Extended Bars Added

20 EAN-13 Symbol

21 EAN-8 Symbol

22* Text with EAN-13 Checksum and Extended Bars Added

23* Text with EAN-8 Checksum and Extended Bars Added

24 MSI 1 Symbol (Modified Plessey)

25 MSI 2 Symbol (Modified Plessey)

26 MSI 3 Symbol (Modified Plessey)

28* Text with MSI Checksum Added – Type 1

29* Text with MSI Checksum Added – Type 2

32* Text with UPC-A Checksum and Extended Bars Added

33* Text with UPC-A with Extended Bars Added

36 Postnet Symbol (Zip+4)

37 Postnet Symbol (Zip+6)

38 MaxiCode Symbol

40 Code 128 Symbol (Automatic Compression)

42 Codabar Symbol

43 Code 93 Symbol

44 AS-10 Symbol

50 UCC/EAN 128 Symbol

51 Text with EAN 128 Information

Table 9 TCI Values

* Refer to Section 9.3

322M Operator’s Manual 33

Page 38

Designing Labels Using LDS Chapter 5

5.6.6 CGN (Character Generator Number)

The CGN parameter is a numeric entry that determines the representation and size of

embedded font and bar codes as well as the memory location of graphic images that have

been selected by the TCI parameter.

5.6.6.1 Embedded Fonts

The Model 322M has seven resident Helvetica style embedded fonts that can be selected

using the CGN when text is selected by the appropriate TCI value.

Embedded Bitmapped Fonts

CGN

VALUE

1 6 Swiss™721 Bold

2 8 Swiss™721 Normal

3 10 Swiss™721 Normal

4 12 Swiss™721 Normal

5 14 Swiss™721 Normal

7 12 OCR-A

8 12 OCR-B

POINT

SIZE

FONT TYPE FONT SAMPLE

6pt ABCDEFGHIJKLMNOPQRSTUVWXYZ1234567890

8pt ABCDEFGHIJKLMNOPQRSTUVWXYZ1234567890

10pt ABCDEFGHIJKLMNOPQRSTUVWXYZ

12pt ABCDEFGHIJKLMNOPQRSTU

14pt ABCDEFGHIJKLMNOPQR

ABCDEFGHIJKLMNOPQRSTUVWXYZ

ABCDEFGHIJKLMNOPQRSTUVW

XYZ

Table 10 CGN – Embedded Fonts

5.6.6.2 Downloadable Fonts and Graphics

When selecting downloadable fonts and graphics using TCI value of “8”, the CGN denotes

the memory slot (1-255) where the font or graphic has been stored. See Chapters 7 and 8

for additional information regarding downloadable fonts and graphics.

For example: If you had stored a graphic into memory slot 1 (see Chapter 7 for additional

information), the proper TCI would be “8” and the CGN value would be “1”.

5.6.6.3 Embedded Bar Codes

Certain bar codes can be printed using various ratios and character spacing options. The

following table (Table 11) illustrates these options. See Chapter 9 for more detailed

information on designing label formats using bar code symbologies. Some bar codes do not

require a CGN value and should be omitted by entering the comma delimiter.

For Example: If a TCI of 40 is selected the CGN will be omitted by entering nothing for the

CGN and surrounding the parameter with the comma delimiter.

1,200,200,10,40,,0,0,100,1

34 322M Operator’s Manual

Page 39

Chapter 5 Designing Labels Using LDS

Bar Code Symbologies

SYMBOL

Code 39

I 2 of 5

UPC / EAN * - 40 % 1 - 0123

UPC Readable * - 40 % 1 - 0123

Code 128 & UCC / EAN 128 *

Codabar

CGN

VALUE

2

3

5

8

2

3

5

- 40 % 1 - 0123

2

3

5

RATIO HEIGHT SPACING FO **

2:1

3:1

5:2

8:3

2:1

3:1

5:2

2:1

3:1

5:2

1

1

1

1

1

1

1

1

1

1

2

2

2

3

-

-

-

-

-

-

0123

0123

0123

0123

0123

0123

0123

0123

0123

0123

Code 93 - 2:1 1 - 0123

AS-10 - 2:1 1 - 0123

2

3

Maxicode (CGN = Mode)

MSI (Modified Plessey) - 1:1 1 - 0123

Table 11 CGN – Bar Code Symbologies

* These Symbologies must use the CMX or CMY multipliers by 2 to produce a 80% ratio.

** The “FO” field represents the available Field Orientation or print rotation. See section

5.6.7.

4

5

6

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

0123

0123

0123

0123

0123

322M Operator’s Manual 35

Page 40

Designing Labels Using LDS Chapter 5

5.6.7 FO (Field Orientation)

This parameter defines the rotation of the format field on the label. The point of rotation is

determined from the Field Justification parameter.

0 0 degrees (normal rotation)

1 180 degrees (upside-down rotation)

2 90 degrees (left rotation)

3 270 degrees (right rotation)

5.6.8 FJ (Field Justification)

This parameter defines the justification of the format field on the label.

0 Left Justified above the base-line

1 Right Justified above the base-line

2 Left Justified below the base-line

3 Right Justified below the base-line

4 Centered above the base-line

5 Centered below the base-line

Table 12 shows how to obtain the proper character placement or starting positions relative

to the format field’s orientations and justifications.

ROTATION FIELD ORIENTATION and JUSTIFICATION

0 – Left justified above the base-line

1 – Right justified above the base-line

0 & 180 Degrees

90 & 270 Degrees

2 – Left justified below the base-line

3 – Right justified below the base-line

4 – Centered above the base-line

5 – Centered below the base-line

0 – Left justified above the base-line

1 – Right justified above the base-line

2 – Left justified below the base-line

3 – Right justified below the base-line

4 – Centered on the Y axis, right of X coordinate

5 – Centered on the Y axis, left of the X coordinate

Table 12 FO & FJ Character Starting Positions

5.6.9 CMX (Character Multiplier X Direction)

The CMX parameter multiplies each character in the X direction. The valid range is 1 to

65536. For bar codes with a FO of 0 & 180 degree rotation, the CMX would be the

multiplier while the CMY would be the actual height in thermal dots. For bar codes with a

36 322M Operator’s Manual

Page 41

Chapter 5 Designing Labels Using LDS

FO of 90 & 270 degree rotation, the CMX would be the actual height in thermal dots while

the CMY parameter would be the multiplier.

5.6.10 CMY (Character Multiplier Y Direction)

The CMY parameter multiplies each character in the Y direction. The valid range is 1 to

65536. For bar codes with a FO of 90 & 270 degree rotation, the CMY would be the

multiplier while the CMX would be the actual height in thermal dots. For bar codes with a

FO of 0 & 180 degree rotation, the CMY would be the actual height in thermal dots while the

CMX parameter would be the multiplier.

5.6.11 CS (Character Spacing)

This parameter adjusts the spacing between each character. If this parameter is omitted,

then the default for the selected character generator (CGN) is used. The values (0-127) add

dots while (128-255) subtract dots. For example, a value of 4 would insert 4 dots between

the characters while a value of 131 would subtract 4 dots between the characters. Bar

codes have default spacing according to the indicated multiplier. Multiplying a text string will

not multiply the spacing between characters. This element may be used to properly space

the characters to create the desired printed effect.

5.6.12 TSP (Text Starting Position)

This parameter marks the starting position of the character in the text string to be used as

data. This is useful for allowing several fields to use sections of the same text string,

minimizing the amount of data transmitted. For example, for the text string 0123456789, a

TSP of 5 and a CC (Character Count) of 2 would print 45.

5.6.13 ,,, (Reserved Spaces)

These are spaces reserved for future use and nothing should be entered between the

comma delimiters.

5.6.14 AN (Attribute Number)

The AN parameter has four different effects. If set to a value of “0” the character spacing is

proportional. Reverse Text (white on black) is created by setting the AN to a value of “1”

and printing a black box on top of the text using the Line Draw function. (Special Note: The

AN of the line field should also be set to a “1” for proper reverse imaging.) If the AN

parameter is set to a value of “2”, the character spacing will be fixed / non-proportional. A

setting of “3” will print both fixed/non-proportional character spacing and reversed text.

0 Proportional Character Spacing

1 Reverse Video

2 Fixed / Non-proportional Character Spacing

3 Fixed / Non-proportional Character Spacing and Reverse Video

5.7 Line Draw

The Line Draw function uses ten different parameters to generate lines. The first position

may point to any valid text string but it is a good idea to always use “1” to make troubleshooting formats easier. The next positions are the XB and YB or placement coordinates

for the line. The following parameter is always left blank but is still surrounded by the

comma delimiter. The next parameter is a TCI of 6 (Line Draw) followed by three blank or

322M Operator’s Manual 37

Page 42

Designing Labels Using LDS Chapter 5

empty positions. Then the XS and YS parameters are used to specify the x and y size of

the line. Finally there is the AN or Attribute Number position. All fields defaulted must be

separated by the comma delimiter and a carriage return must follow each Line Draw format

field. All values for the Line Draw format line must be entered as positive integers.

The following is a list of the Line Draw field mnemonics and their default values:

TSN, XB, YB, , TCI, , , , XS, YS, , , , , AN

1, 1, 1, , 6, , , , 1, 1, , , , , 0

5.7.1 TSN (Text String Number)

The TSN parameter may point to any valid text string but it is a good idea to always use “1”

to make trouble-shooting formats easier. The text string that the TSN is pointing to must

contain at least one character in order for a line to print properly. A line will not print if the

TSN is pointing to a blank text string.

5.7.2 XB (X Beginning Coordinate)

The X coordinate of the field is measured in thermal dots. The far left edge of the label, as

viewed from the front of the printer, is X coordinate “1”. There is no X coordinate of “0”. The