Datasheet PIC16C712-JW, PIC16C716-04-P, PIC16C716-04-SO, PIC16C716-20I-P, PIC16C716-20I-SO Datasheet (Microchip Technology)

...

1999 Microchip Technology Inc.

Preliminary DS41106A-page 1

Devices included in this Data Sheet:

• PIC16C712 • PIC16C716

Microcontroller Core Features:

• High-performance RISC CPU

• Only 35 single word instructions to learn

• All single cycle instructions except for program

branches which are two cycle

• Operating speed: DC - 20 MHz clock input

DC - 200 ns instruction cycle

• Interrupt capability

(up to 7 internal/external interrupt sources)

• Eight level deep hardware stack

• Direct, indirect and relative addressing modes

• Power-on Reset (POR)

• Power-up Timer (PWRT) and

Oscillator Start-up Timer (OST)

• Watchdog Timer (WDT) with its own on-chip RC

oscillator for reliable operation

• Brown-out detection circuitry for

Brown-out Reset (BOR)

• Programmable code-protection

• Power saving SLEEP mode

• Selectable oscillator options

• Low-power, high-speed CMOS EPROM

technology

• Fully static design

• In-Circuit Serial Programming (ICSP)

• Wide operating voltage range: 2.5V to 5.5V

• High Sink/Source Current 25/25 mA

• Commercial, Industrial an d Extended temp erature

ranges

• Low-power consumption:

- < 2 mA @ 5V, 4 MHz

- 22.5 µA typical @ 3V, 32 kHz

-< 1 µA typical standby current

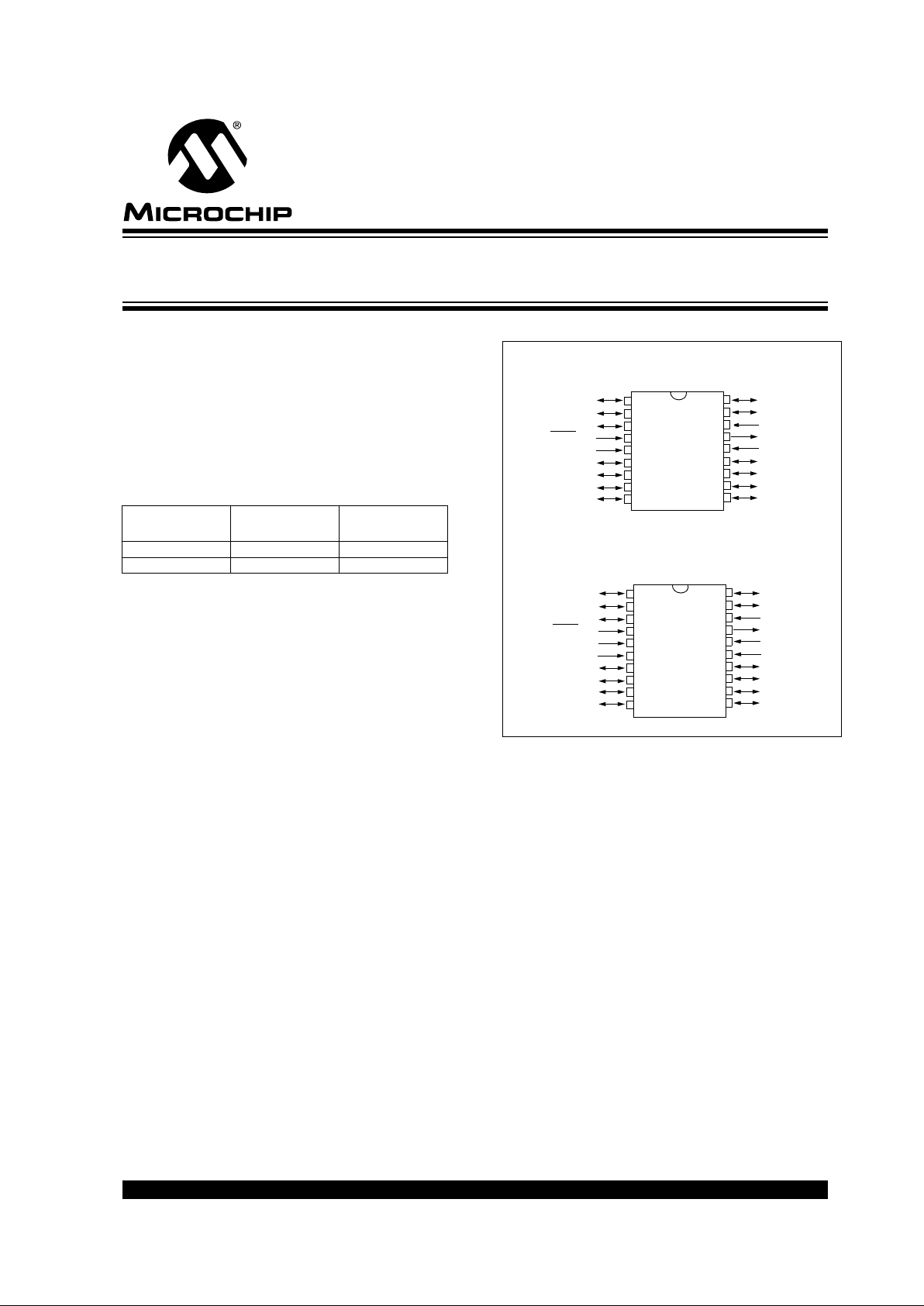

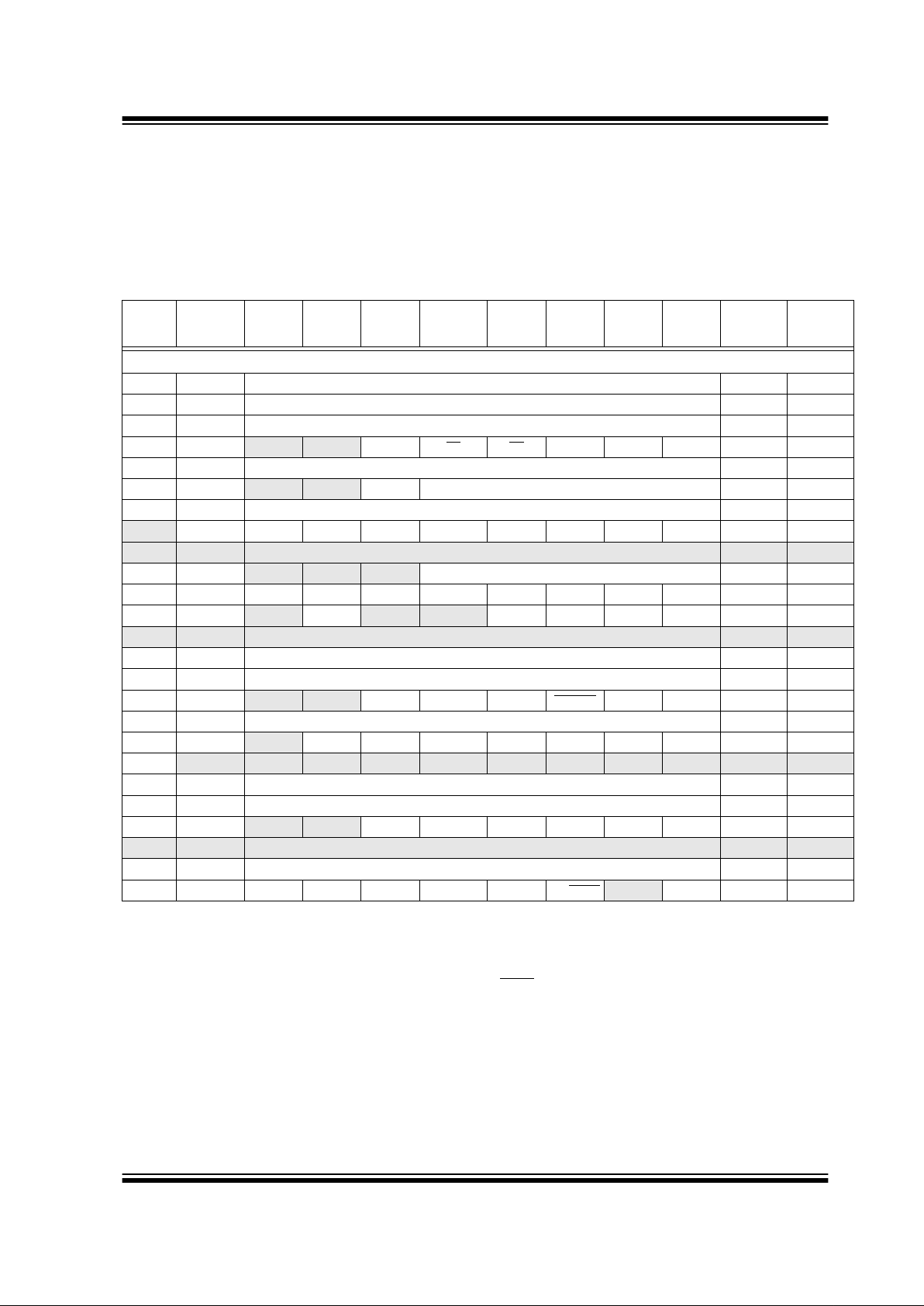

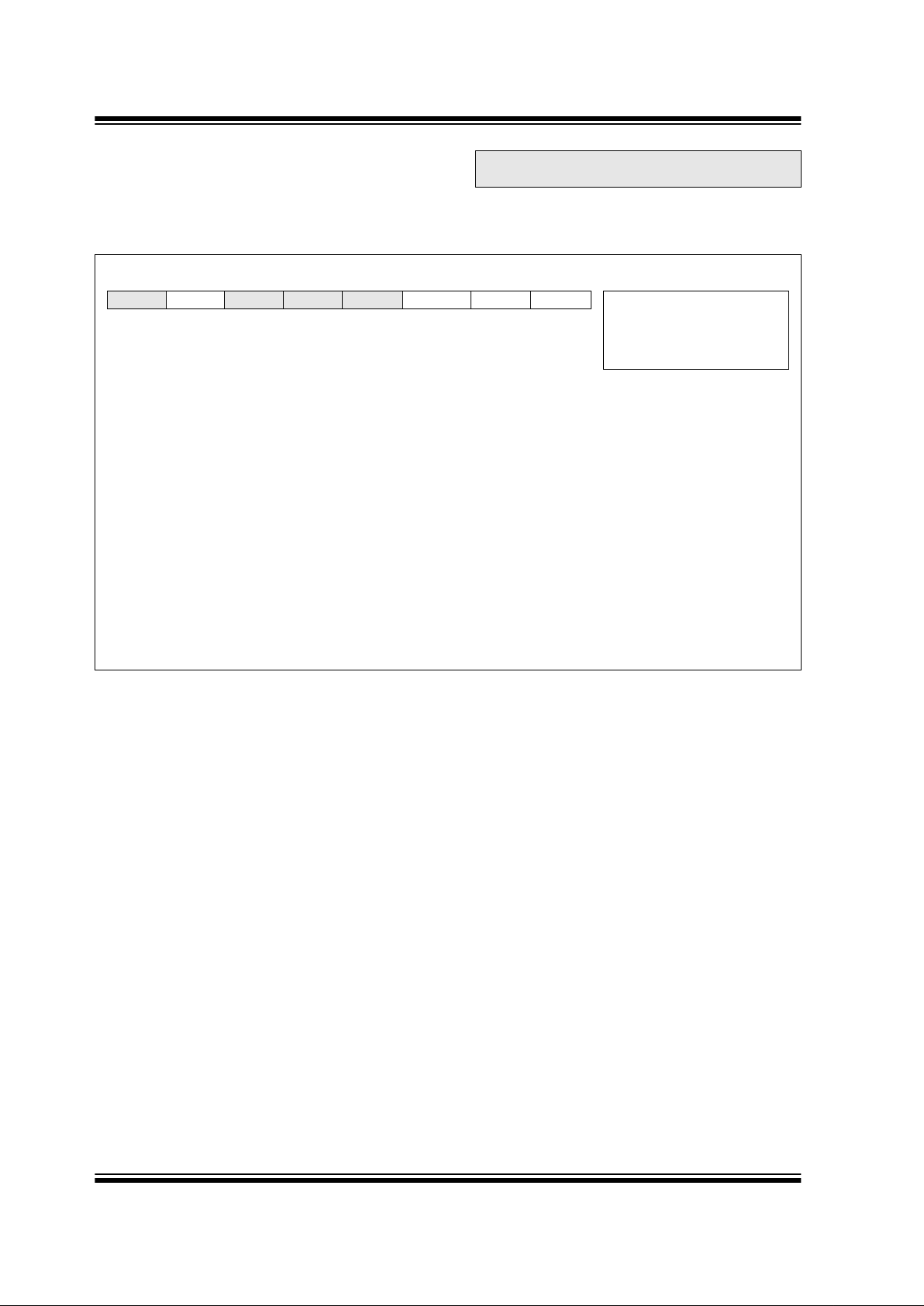

Pin Diagrams

Peripheral Features:

• Timer0: 8-bit timer/counter with 8-bit prescaler

• Timer1: 16-bit timer/counter with prescaler

can be incremented during sleep via ex ternal

crystal/clock

• Timer2: 8-bit timer/counter with 8-bit period

register, prescaler and postscaler

• Capture, Compare, PWM module

• Capture is 16-bit, max. resolution is 12.5 ns,

Compare is 16-bit, max. resolution is 200 ns,

PWM maximum resolution is 10-bit

• 8-bit multi-channel Analo g-to - Digi tal converter

Device

Program

Memory

Data Memory

PIC16C712 1K 128

PIC16C716 2K 128

PIC16C712

RA2/AN2

RA4/T0CKI

RB0/INT

RB1/T1OSO/T1CKI

RA0/AN0

OSC1/CLKIN

RB7

RB6

1

2

3

4

5

6

7

18

17

16

15

14

13

12

8

9

11

10

18-pin PDIP, SOIC, Windowed CERDIP

MCLR/VPP

RA3/AN3/VREF

RB2/T1OSI

RB3/CCP1

RB4

RB5

RA1/AN1

VDD

OSC2/CLKOUT

VSS

PIC16C716

PIC16C712

RA2/AN2

RA4/T0CKI

RB0/INT

RB1/T1OSO/T1CKI

RA0/AN0

OSC1/CLKIN

RB7

RB6

1

2

3

4

5

6

7

20

19

18

17

16

15

14

8

9

13

12

20-pin SSOP

MCLR/VPP

RA3/AN3/VREF

RB2/T1OSI

RB3/CCP1

RB4

RB5

RA1/AN1

VDD

OSC2/CLKOUT

VSS

PIC16C716

10

VSS

VDD

11

PIC16C712/716

8-Bit CMOS Microcontrollers with A/D Converter

and Capture/Compare/PWM

PIC16C712/716

DS41106A-page 2 Preliminary

1999 Microchip Technology Inc.

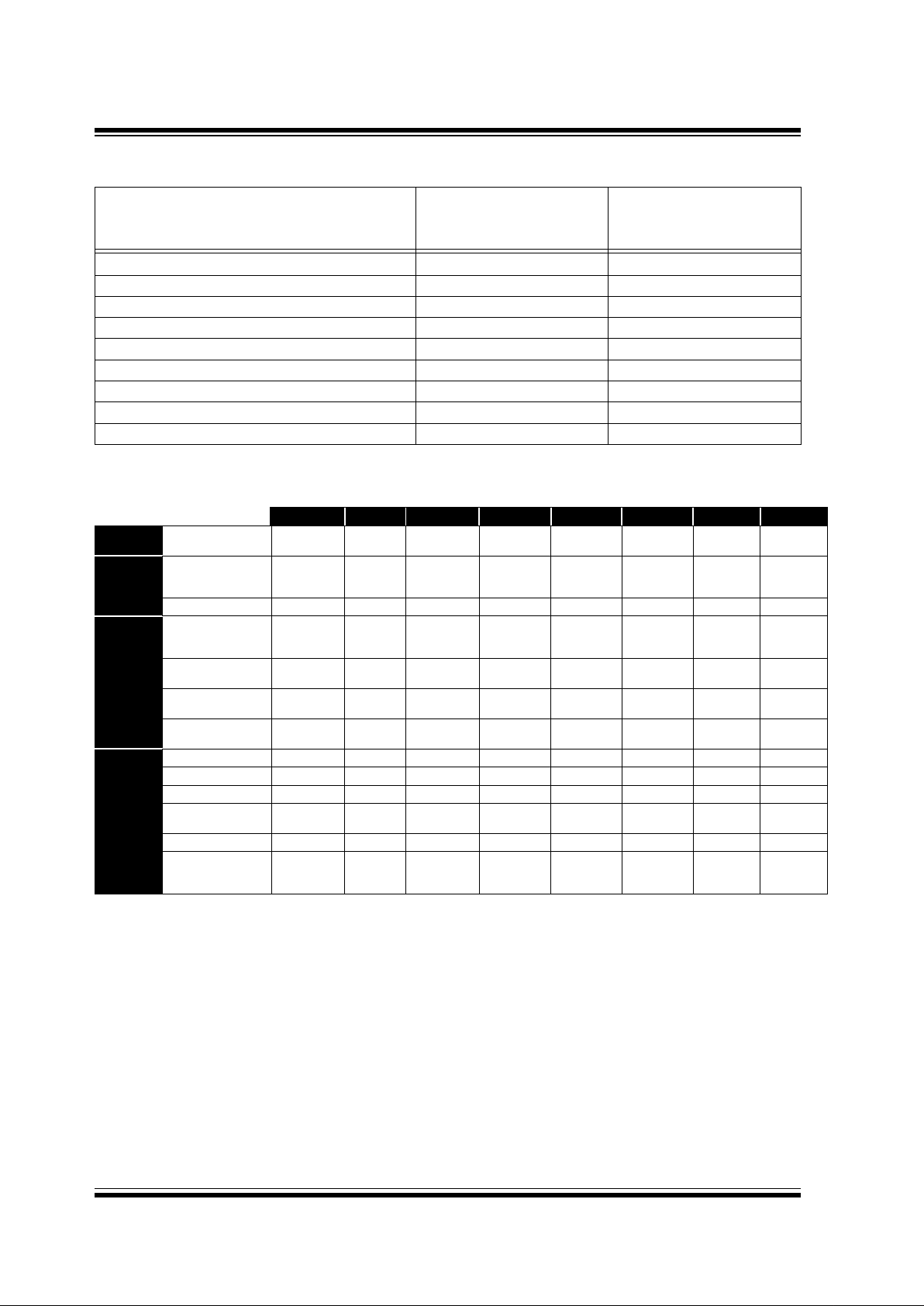

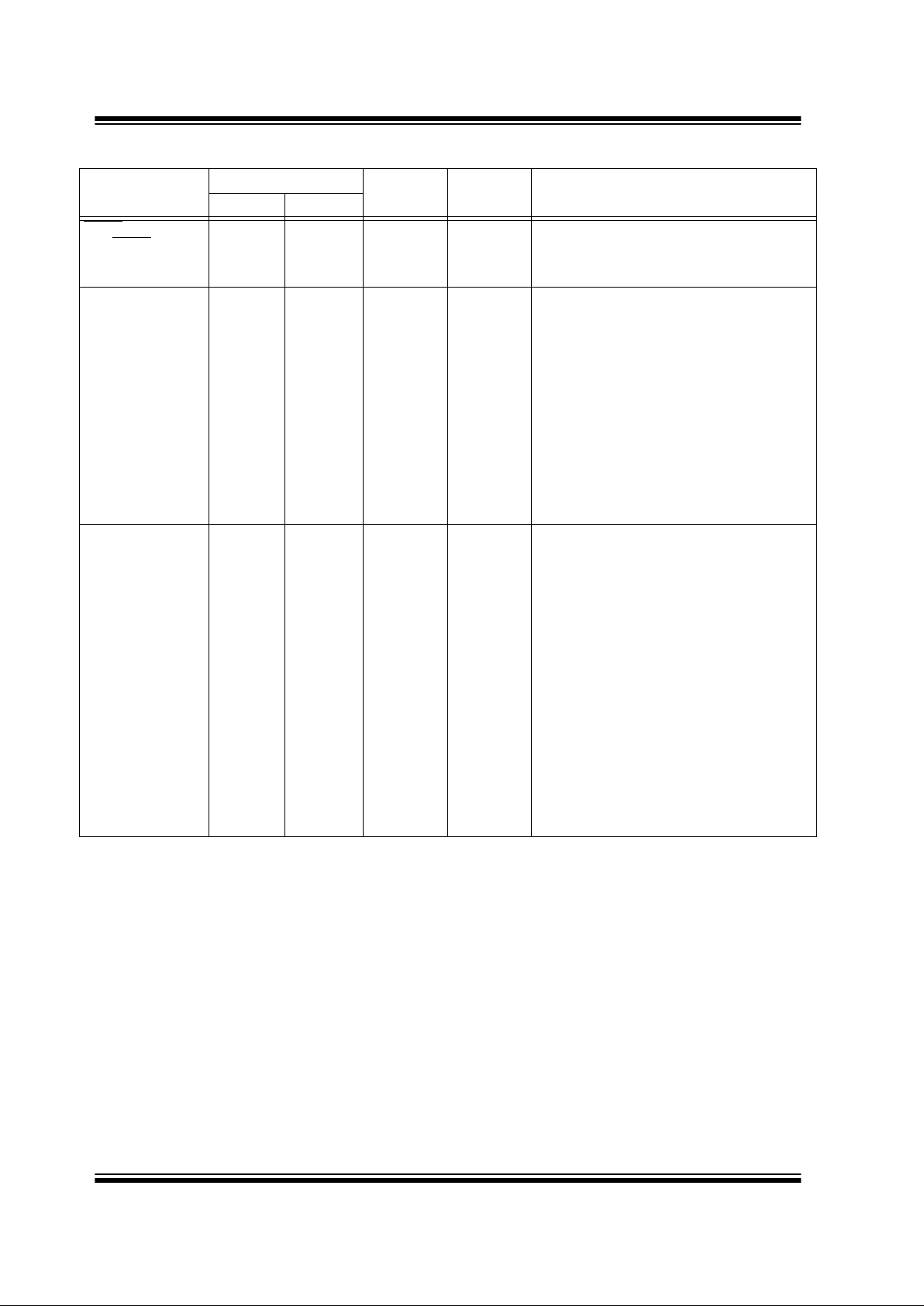

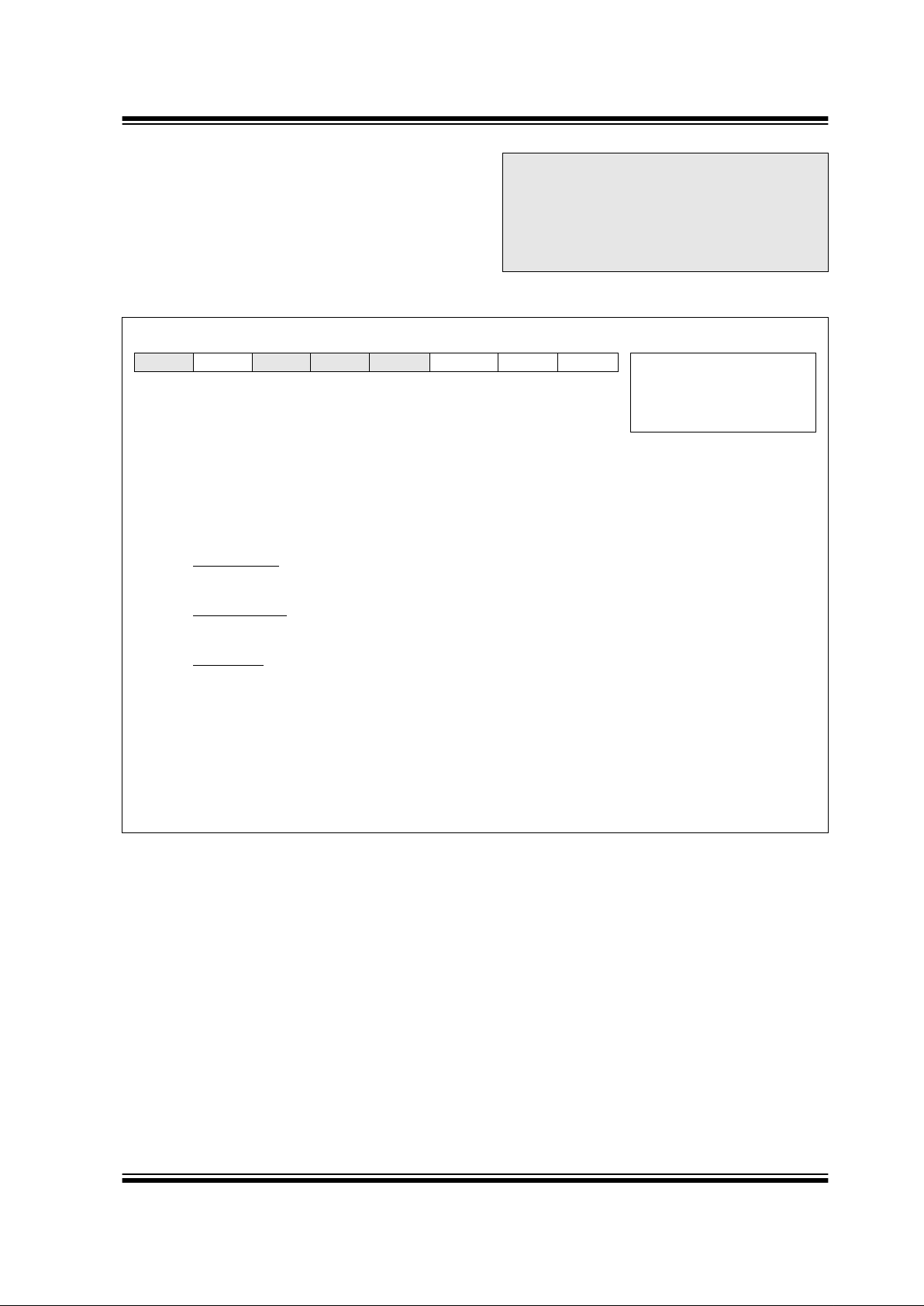

PIC16C7XX FAMILY OF DEVICES

Key Features

PICmicro

™

Mid-Range Reference Manual

(DS33023)

PIC16C712 PIC16C716

Operating Frequency DC - 20 MHz DC - 20 MHz

Resets (and Delays) POR, BOR (PWRT, OST) POR, BOR (PWRT, OST)

Program Memory (14-bit words) 1K 2K

Data Memory (bytes) 128 128

Interrupts 7 7

I/O Ports Ports A,B Ports A,B

Timers 3 3

Capture/Compare/PWM modules 1 1

8-bit Analog-to-Digital Module 4 input channels 4 input channels

PIC16C710 PIC16C71 PIC16C711 PIC16C712 PIC16C715 PIC16C716 PIC16C72A PIC16C73B

Clock

Maximum Frequency

of Operation (MHz)

20 20 20 20 20 20 20 20

Memory

EPROM Program

Memory

(x14 words)

512 1K 1K 1K 2K 2K 2K 4K

Data Memory (bytes) 36 36 68 128 128 128 128 192

Peripherals

Timer Module(s) TMR0 TMR0 TMR0 TMR0

TMR1

TMR2

TMR0 TMR0

TMR1

TMR2

TMR0

TMR1

TMR2

TMR0

TMR1

TMR2

Capture/Compare/

PWM Module(s )

——— 1 — 1 1 2

Serial Port(s)

(SPI/I

2

C, USART)

— — — — — — SPI/I

2

CSPI/I2C,

USART

A/D Converter (8-bit)

Channels

444 4 4 4 55

Features

Interrupt Sources 4 4 4 7 4 7 8 11

I/O Pins 13 13 13 13 13 13 22 22

Voltage Range (Volts) 2.5-6.0 3.0-6.0 2.5-6.0 2.5-5.5 2.5-5.5 2.5-5.5 2.5-5.5 2.5-5.5

In-Circuit Serial

Programming

Yes Yes Yes Yes Yes Yes Yes Yes

Brown-out Reset Yes — Yes Yes Yes Yes Yes Yes

Packages 18-pin DIP,

SOIC;

20-pin SSOP

18-pin DIP,

SOIC

18-pin DIP,

SOIC;

20-pin SSOP

18-pin DIP,

SOIC;

20-pin SSOP

18-pin DIP,

SOIC;

20-pin SSOP

18-pin DIP,

SOIC;

20-pin SSOP

28-pin SDIP,

SOIC, SSOP

28-pin SDIP,

SOIC

1999 Microchip Technology Inc.

Preliminary DS41106A-page 3

PIC16C712/716

Table of Contents

1.0 Device Overview................................ .................................. ..... ...... ..... ...... ...... ................................. ...... ..... ...... ..5

2.0 Memory Organization..........................................................................................................................................9

3.0 I/O Ports ............................................................................................................................................................21

4.0 Timer0 Module...................................................................................................................................................29

5.0 Timer1 Module...................................................................................................................................................31

6.0 Timer2 Module...................................................................................................................................................36

7.0 Capture/Compare/PWM (CCP) Module(s)........................................................................................................39

8.0 Analog-to-Digital Converter (A/D) Module.........................................................................................................45

9.0 Special Features of the CPU .............................................................................................................................51

10.0 Instruction Set Summary...................................................................................................................................67

11.0 Development Support........................................................................................................................................69

12.0 Electrical Characteristics...................................................................................... ...... ..... ...... ............................75

13.0 DC and AC Characteristics Graphs and Tables................................................................................................91

14.0 Packaging Information.......................................................................................................................................93

Revision History ...........................................................................................................................................................99

Conversion Consideration s ...................................................... ...... ..... .................................. .. ... ...... ...... ..... ...... ..... ......99

Migration from Base-line to Mid-Range Devices ..........................................................................................................99

Index...........................................................................................................................................................................101

On-Line Support..........................................................................................................................................................105

Reader Response.......................................................................................................................................................106

PIC16C712/716 Product Identification System...........................................................................................................107

To Our Valued Customers

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number. e.g., DS30000A is version A of document DS30000.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

Errata

An errata sheet may exist for current devices, describing minor operational differences (from the data sheet) and recommended

workarounds. As device/documentation issues become known to us, w e will pub lish an errata sheet. The errata will specify the re vision of silicon and revision of document to which it applies.

To deter mine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

• The Microchip Corporate Literature Center; U.S. FAX: (480) 786-7277

When contacting a sales office or the literature center, please specify which device, revision of silicon and data sheet (include liter-

ature number) you are using.

Corrections to this Data Sheet

We constantly strive to improve the quality of all our products and documentation. We have spent a great deal of time to ensure

that this document is correct. However , w e realize that we ma y have missed a few things. If you find any inf ormation that is missing

or appears in error, please:

• Fill out and mail in the reader response form in the back of this data sheet.

• E-mail us at webmaster@microchip.com.

We appreciate your assistance in making this a better document.

PIC16C712/716

DS41106A-page 4 Preliminary

1999 Microchip Technology Inc.

NOTES:

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 5

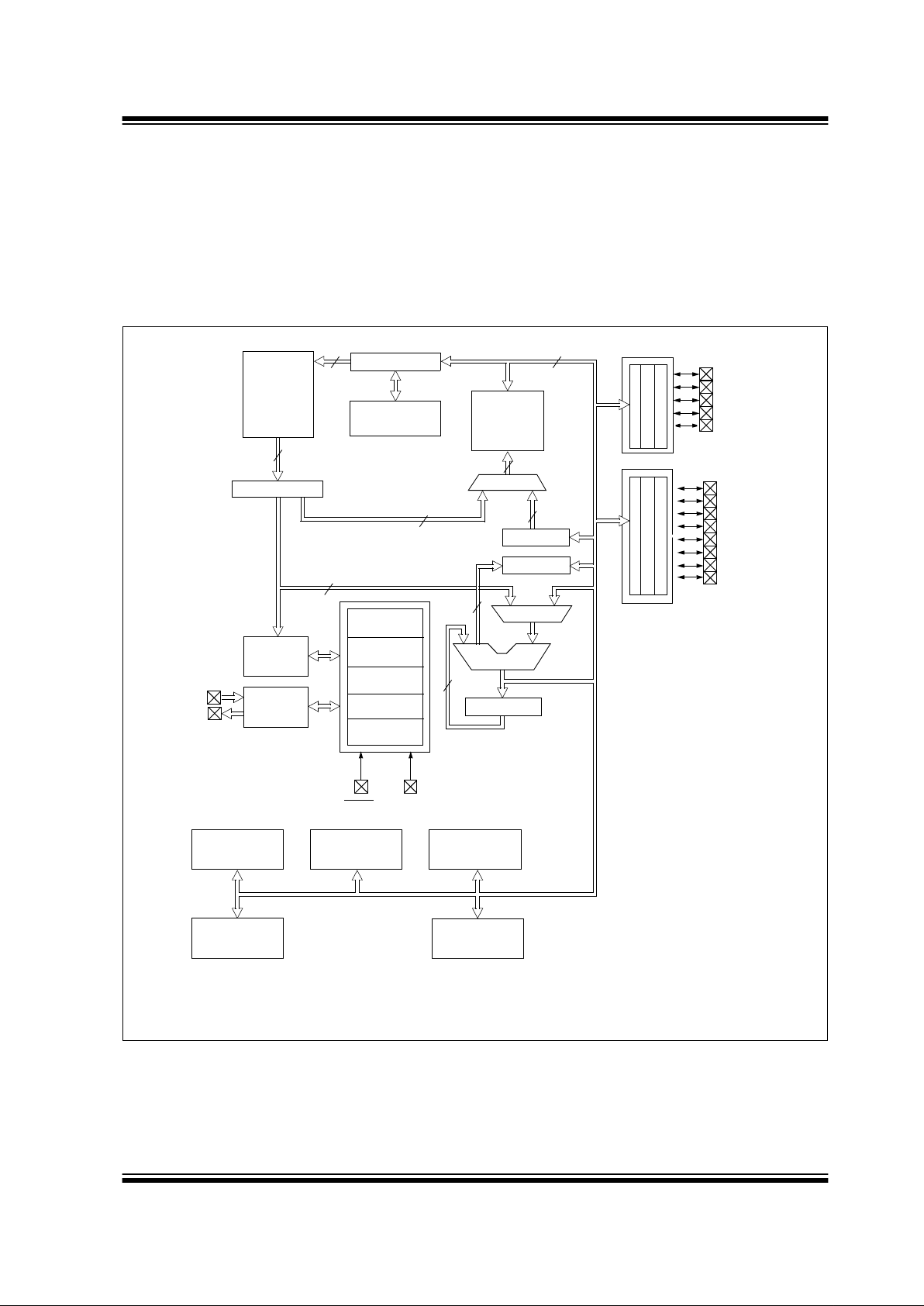

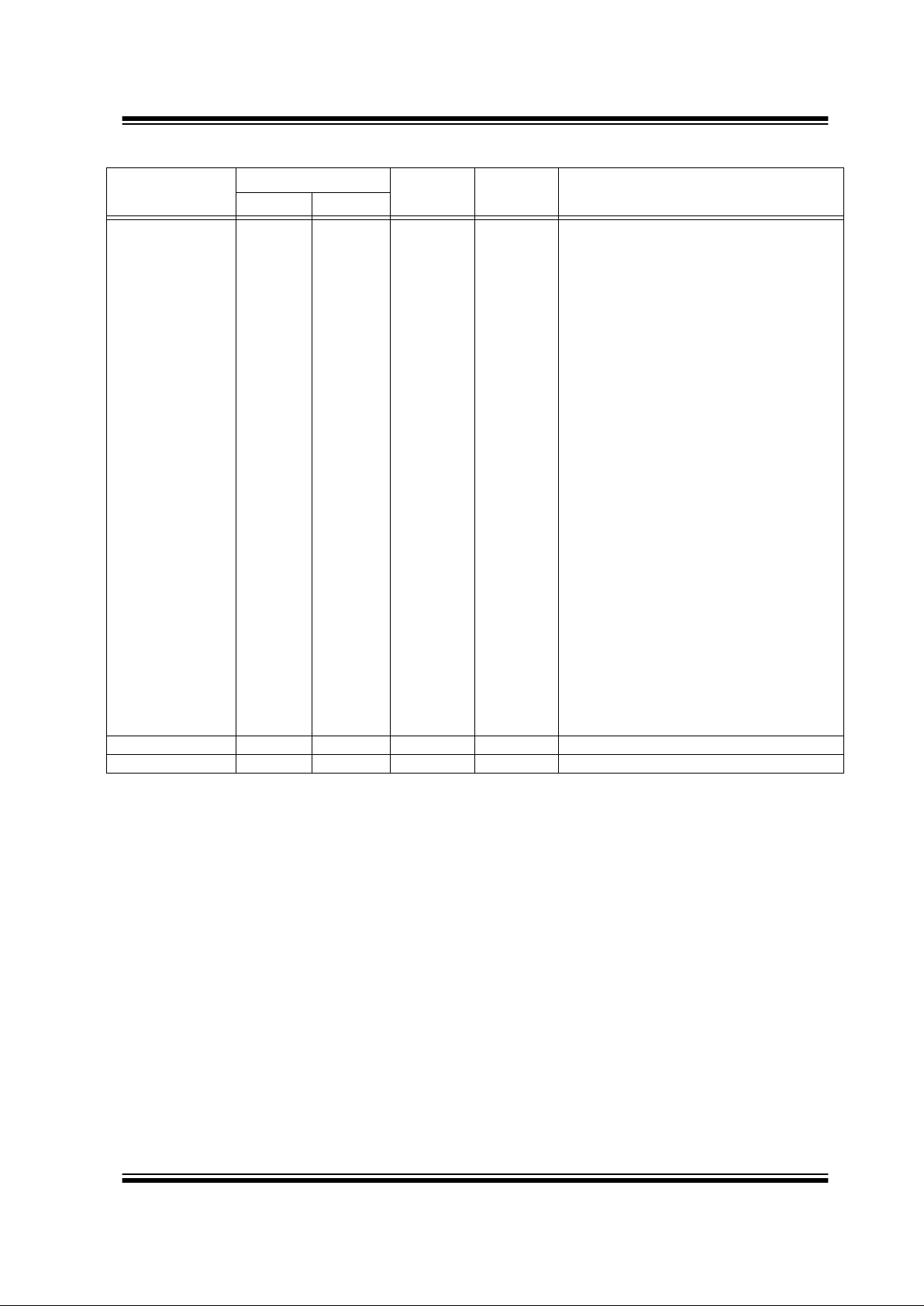

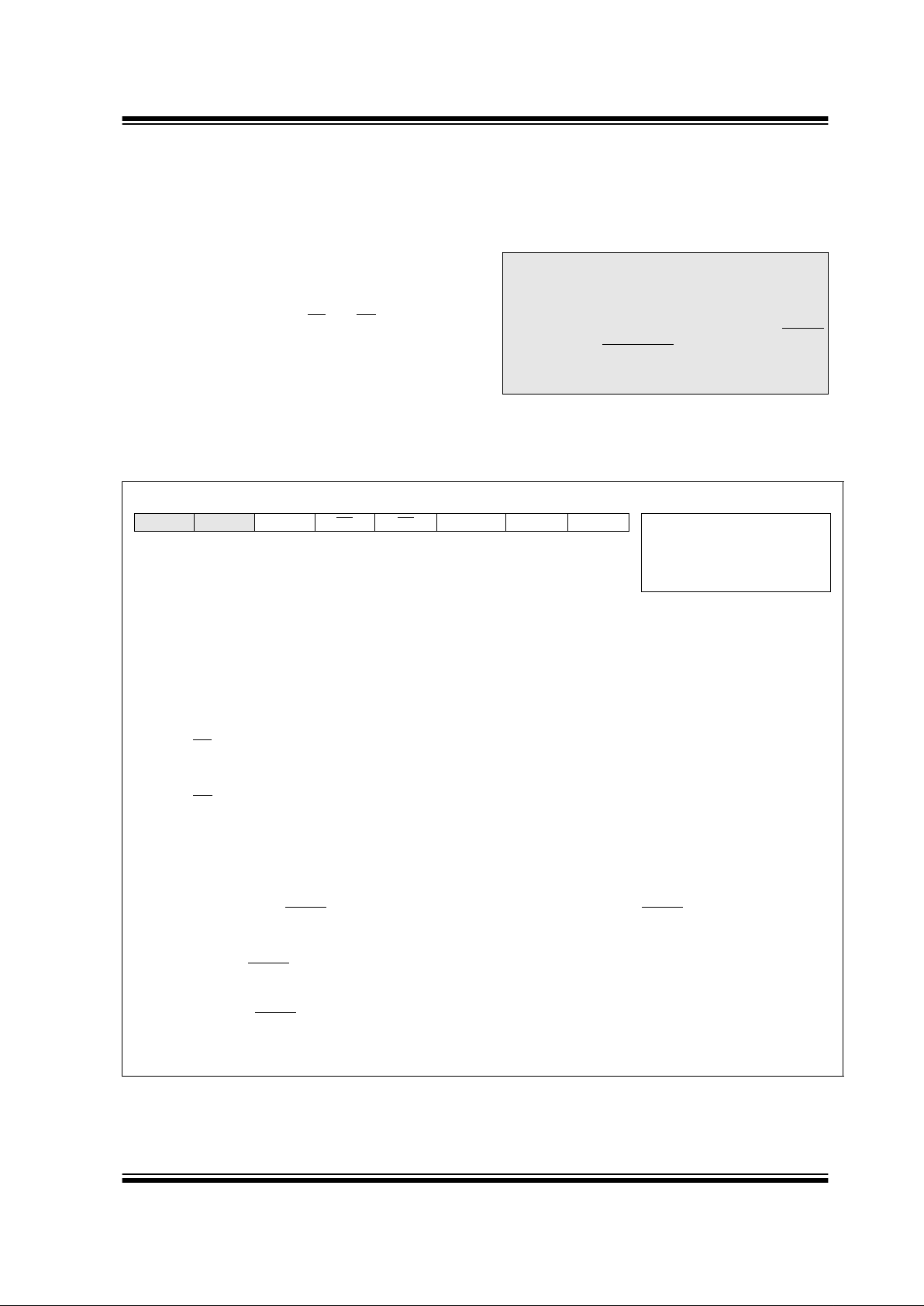

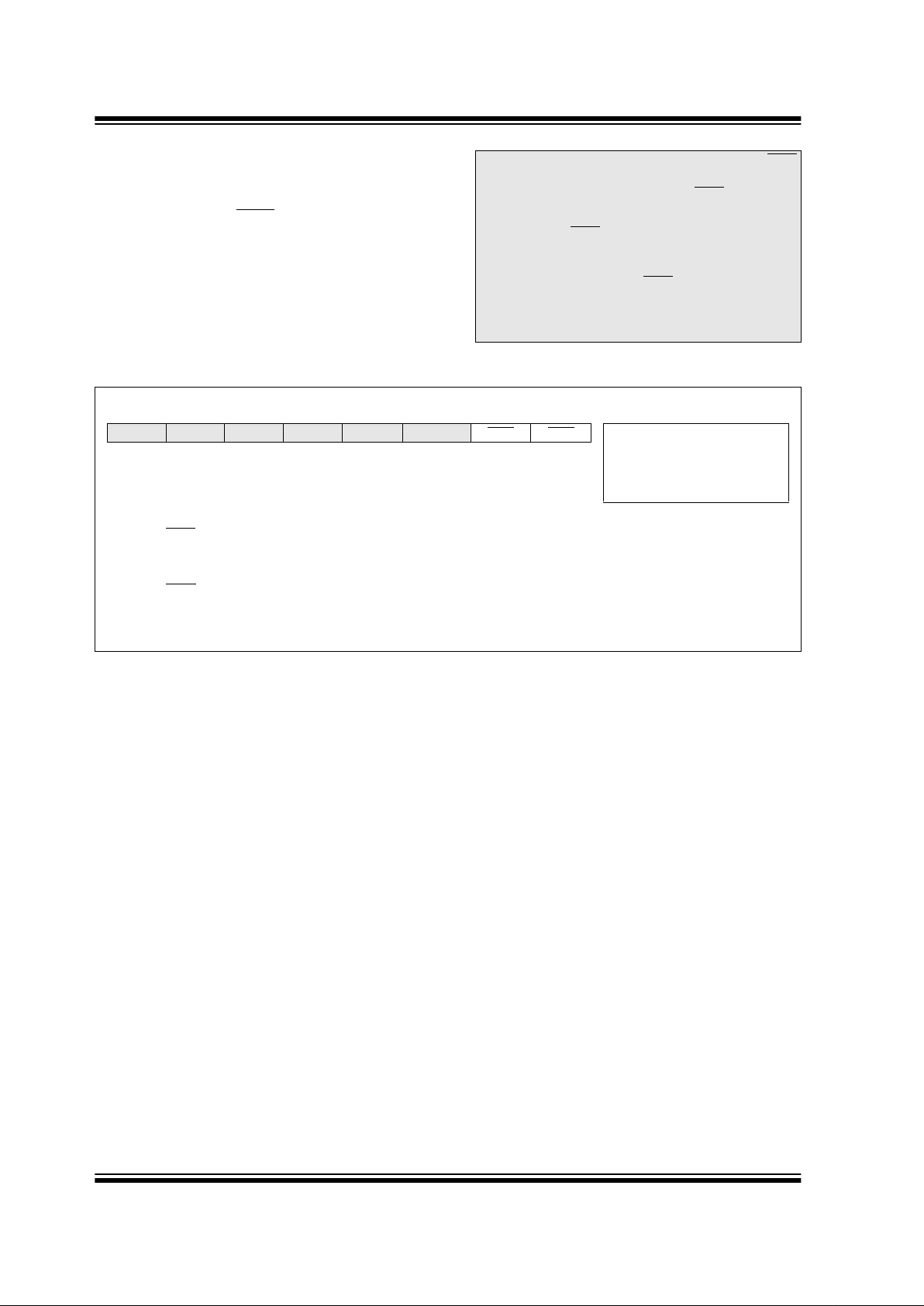

1.0 DEVICE OVERVIEW

This document contains device-specific information.

Additional information may be found in the PICmicro™

Mid-Range Reference Manual, (DS33023), which may

be obtained from your local Microchip Sales Representative or downloaded from the Microchip website. The

Reference Manual should be considered a complementary document to this data she et, and is high ly rec-

ommended reading for a better understanding of the

device architecture and operation of the peripheral

modules.

There are two devices (PIC16C712, PIC16C716) covered by this datasheet.

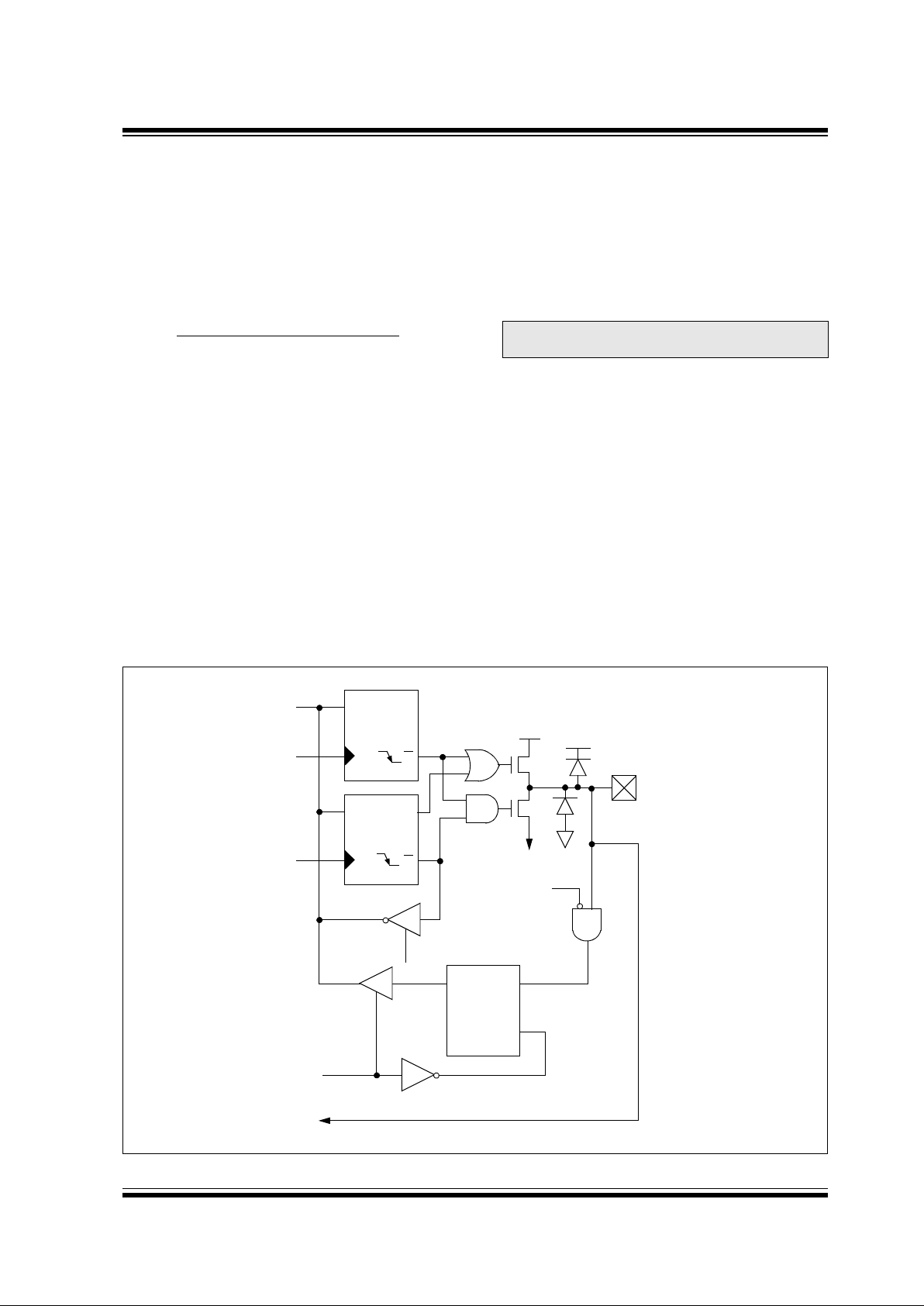

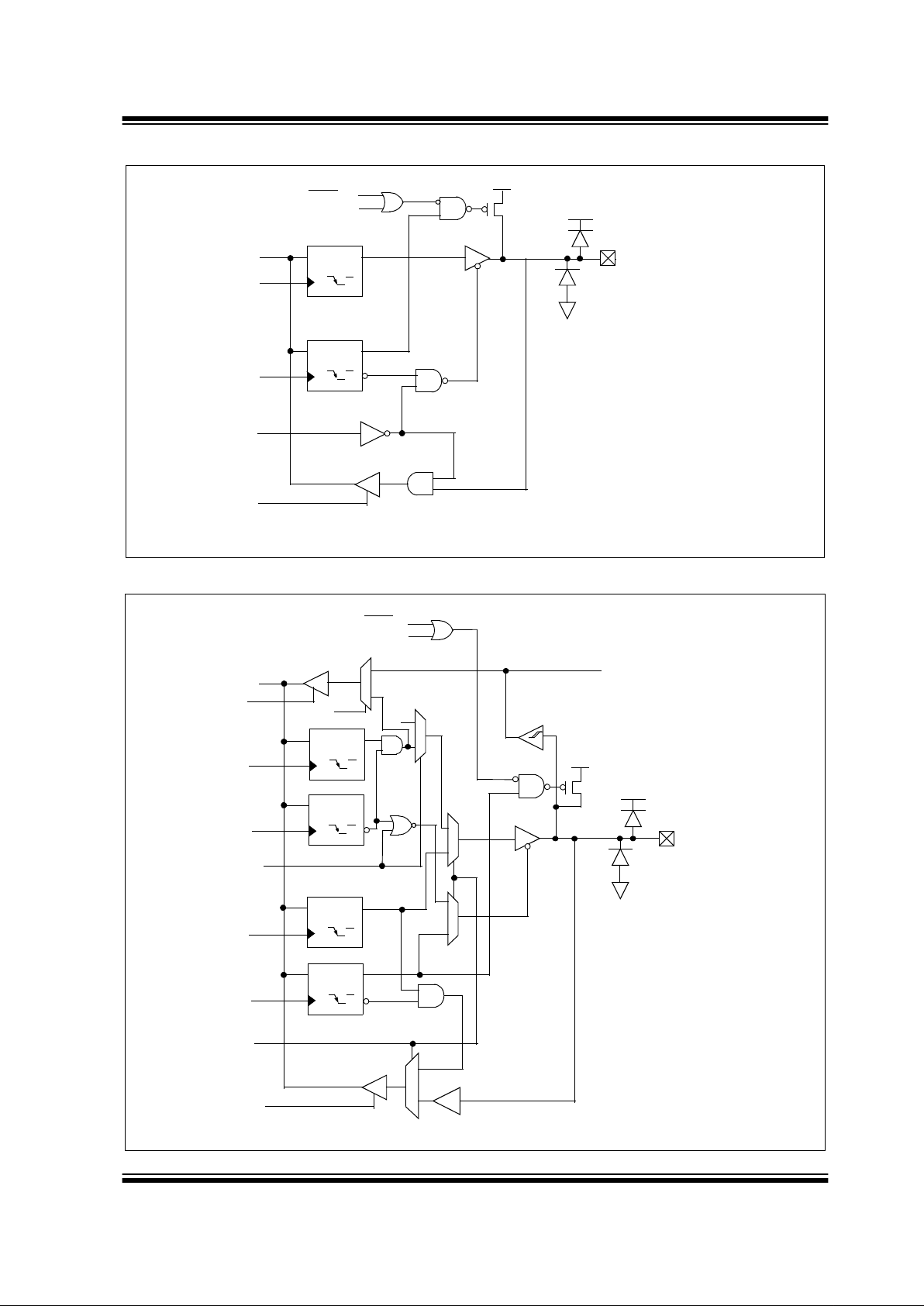

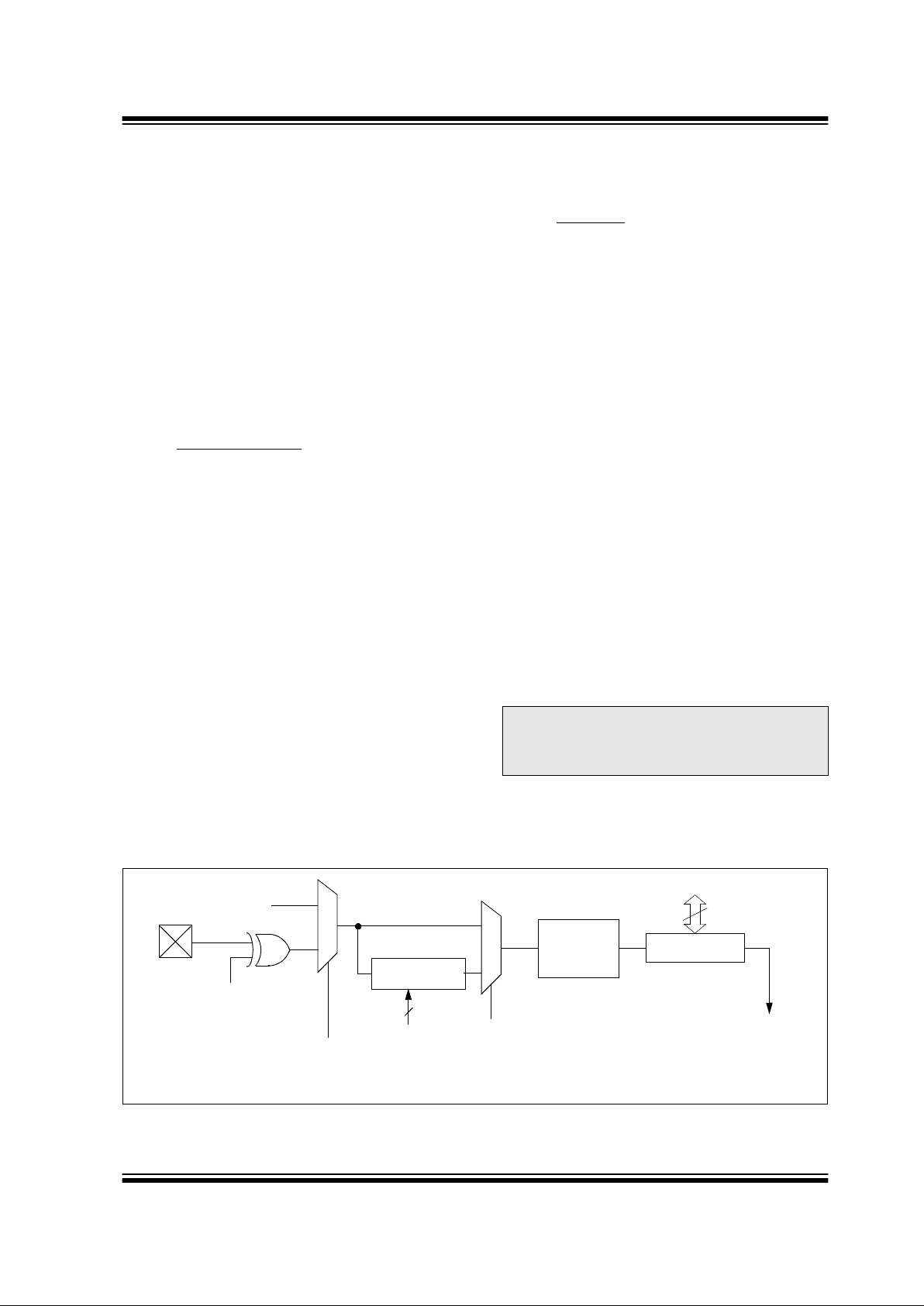

Figure 1- 1 is the block diagram for both devices. The

pinouts are listed in Table 1-1.

FIGURE 1-1: PIC16C712/716 BLOCK DIAGRAM

EPROM

Program

Memory

13

Data Bus

8

14

Program

Bus

Instruction reg

Program Counter

8 Leve l Stack

(13-bit)

RAM

File

Registers

Direct Addr

7

RAM Addr

(1)

9

Addr MUX

Indirect

Addr

FSR reg

STATUS reg

MUX

ALU

W reg

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Instruction

Decode &

Control

Timing

Generation

OSC1/CLKIN

OSC2/CLKOUT

MCLR

VDD, VSS

PORTA

PORTB

RB0/INT

RB1/T1OSO/T1CKI

RB2/T1OSI

RB3/CCP1

RB4

RB5

RB6

RB7

8

8

Brown-out

Reset

Note 1: Higher order bits are from the STATUS register.

CCP1

A/D

Timer0 Timer1 Timer2

RA4/T0CKI

RA3/AN3/VREF

RA2/AN2

RA1/AN1

RA0/AN0

8

3

1K X 14

128 x 8

or

2K x 14

PIC16C712/716

DS41106A-page 6 Preliminary

1999 Microchip Technology Inc.

TABLE 1-1 PIC16C712/716 PINOUT DESCRIPTION

Pin PIC16C712/716 Pin Buffer

Name DIP, SOIC SSOP Type Type Description

MCLR/VPP

MCLR

VPP

44

I

P

ST Master clear (reset) input. This pin is an

active low reset to the device.

Programming voltage input

OSC1/CLKIN

OSC1

CLKIN

16 18

I

I

ST

CMOS

Oscillator crystal input or external clock

source input. ST buffer when configured in

RC mode. CMOS otherwi se.

External clock source input.

OSC2/CLKOUT

OSC2

CLKOUT

15 17

O

O

—

—

Oscillator crystal output. Connects to

crystal or resonator in crystal oscillator

mode.

In RC mode, OSC2 pin outputs CLKOUT

which has 1/4 the frequenc y of OSC1, and

denotes the instruction cycle rate.

PORTA is a bi-directional I/O port.

RA0/AN0

RA0

AN0

17 19

I/O

I

TTL

Analog

Digital I/O

Analog input 0

RA1/AN1

RA1

AN1

18 20

I/O

I

TTL

Analog

Digital I/O

Analog input 1

RA2/AN2

RA2

AN2

11

I/O

I

TTL

Analog

Digital I/O

Analog input 2

RA3/AN3/V

REF

RA3

AN3

VREF

22

I/O

I

I

TTL

Analog

Analog

Digital I/O

Analog input 3

A/D Reference Voltage input.

RA4/T0CKI

RA4

T0CKI

33

I/O

I

ST/OD

ST

Digital I/O. Open drain when configured

as output.

Timer0 external clock input

Legend: TTL = TTL-compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels

OD = Open drain output

SM = SMBus compatible input. An external resistor is required if this pin is used as an output

NPU = N-channel pull-up PU = Weak internal pull-up

No-P diode = No P-diode to V

DD AN = Analog input or output

I = input O = output

P = Power L = LCD Driver

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 7

PORTB is a bi-directional I/O port. PORTB

can be software programmed for internal

weak pull-ups on all inputs .

RB0/INT

RB0

INT

67

I/O

I

TTL

ST

Digital I/O

External Interrupt

RB1/T1OSO/T1CKI

RB1

T1OSO

T1CKI

78

I/O

O

I

TTL

—

ST

Digital I/O

Timer1 oscillator output. Connects to

crystal in oscillator mode.

Timer1 external clock input.

RB2/T1OSI

RB2

T1OSI

89

I/O

I

TTL

—

Digital I/O

Timer1 oscillator input. Connects to

crystal in oscillator mode.

RB3/CCP1

RB3

CCP1

910

I/O

I/O

TTL

ST

Digital I/O

Capture1 input, Compa re1 output, PWM1

output.

RB4 10 12 I/O TTL Digital I/O

Interrupt on change pin.

RB5 11 12 I/O TTL Digital I/O

Interrupt on change pin.

RB6 12 13 I/O

I

TTL

ST

Digital I/O

Interrupt on change pin.

ICSP programming clock.

RB7 13 14 I/O

I/O

TTL

ST

Digital I/O

Interrupt on change pin.

ICSP programming data.

V

SS 5 5, 6 P — Ground reference for logic and I/O pins.

V

DD 14 15, 16 P — Positive supply for logic and I/O pins.

Legend: TTL = TTL-compatible input CMOS = CMOS compatible input or output

ST = Schmitt Trigger input with CMOS levels

OD = Open drain output

SM = SMBus compatible input. An external resistor is required if this pin is used as an output

NPU = N-channel pull-up PU = Weak internal pull-up

No-P diode = No P-diode to V

DD AN = Analog input or output

I = input O = output

P = Power L = LCD Driver

TABLE 1-1 PIC16C712/716 PINOUT DESCRIPTION (Cont.’d)

Pin PIC16C712/716 Pin Buffer

Name DIP, SOIC SSOP Type Type Description

PIC16C712/716

DS41106A-page 8 Preliminary

1999 Microchip Technology Inc.

NOTES:

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 9

2.0 MEMORY ORGANIZATION

There are two memory blocks in each of these

PICmicro

®

microcontr oller devices. Each blo ck (Program Memor y and Data Memor y) has its own bus so

that concurrent access can occur.

Additional inf ormation on de vice m emory may be f ound

in the PICmicro Mid-Range Reference Manual,

(DS33023).

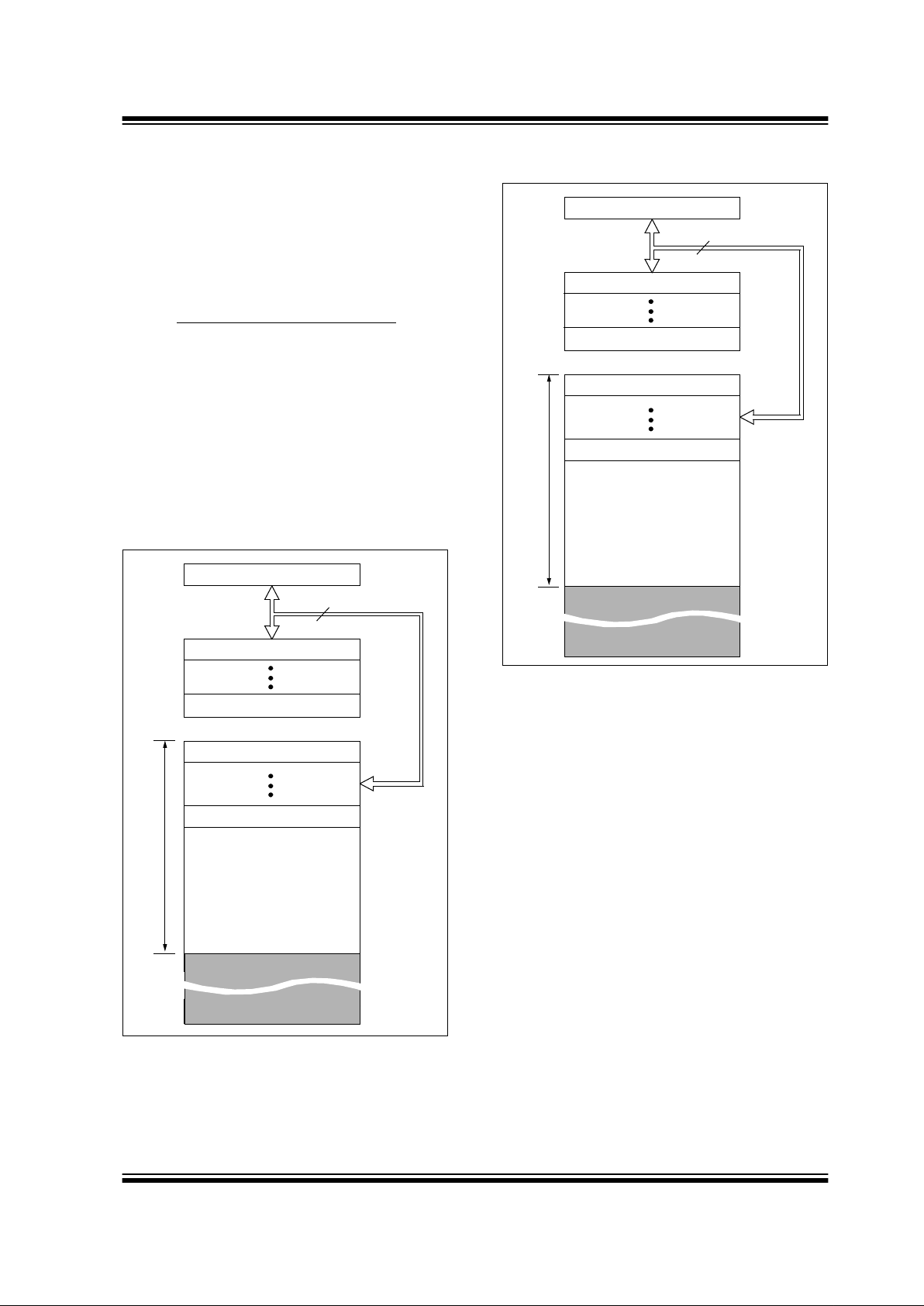

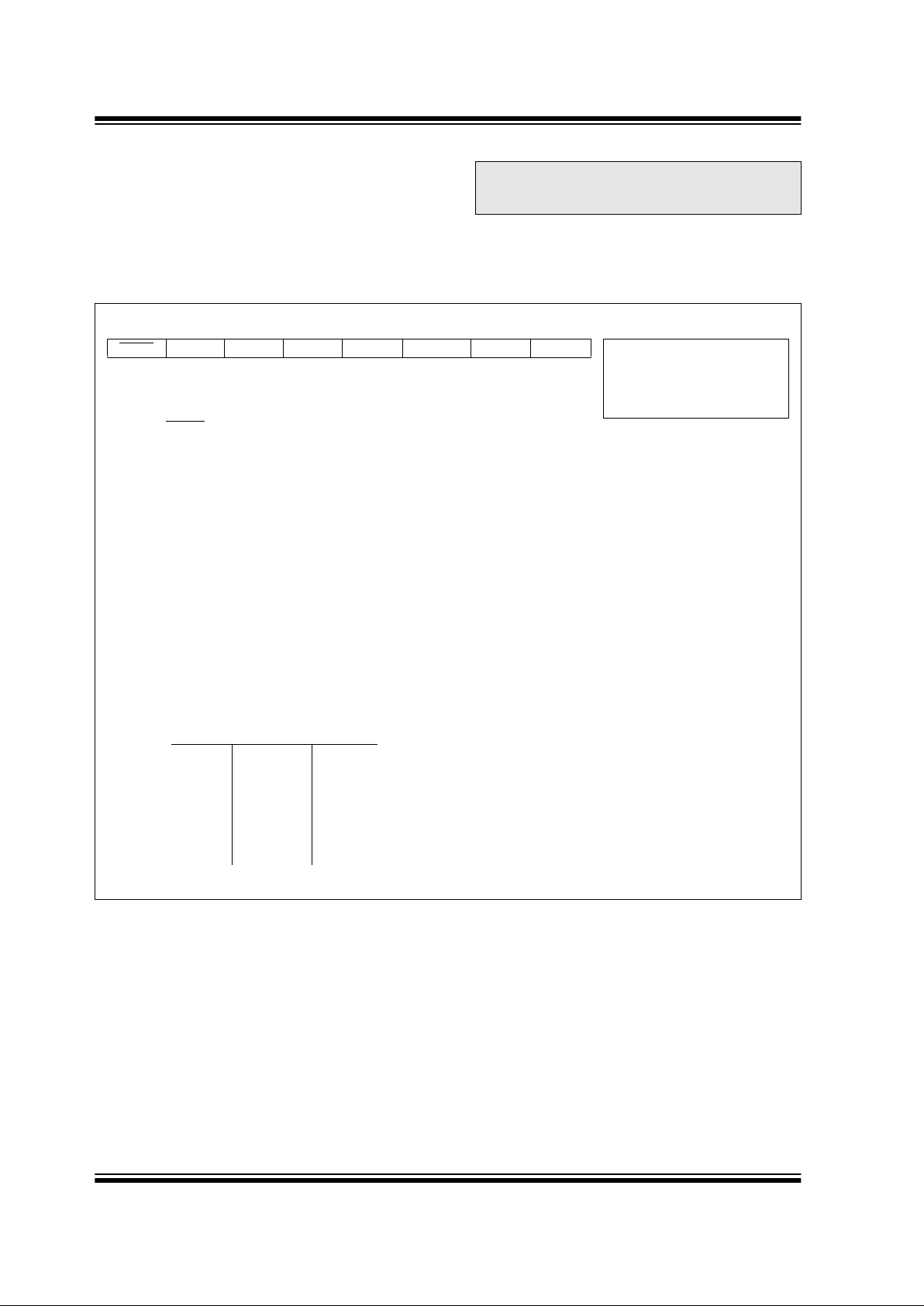

2.1 Program Memory Organization

The PIC16C712/716 has a 13-bit program counter

capable of addressing an 8K x 14 program memory

space. PIC16C712 has 1K x 14 words of program

memory and PIC16C716 has 2K x 14 words of progr am

memory. Accessing a location above the physically

implemented address will cause a wraparound.

The reset vector is at 0000h and the interrupt vector is

at 0004h.

FIGURE 2-1: PROGRAM MEMORY MAP

AND STACK OF THE

PIC16C712

FIGURE 2-2: PROGRAM MEMORY MAP

AND STACK OF PIC16C716

PC<12:0>

13

0000h

0004h

0005h

03FFh

1FFFh

Stack Level 1

Stack Level 8

Reset Vector

Interrupt Vector

On-chip Program

Memory

CALL, RETURN

RETFIE, RETLW

0400h

User Memory

Space

PC<12:0>

13

0000h

0004h

0005h

07FFh

0800h

1FFFh

Stack Level 1

Stack Level 8

Reset Vector

Interrupt Vector

On-chip Program

Memory

CALL, RETURN

RETFIE, RETLW

User Memory

Space

PIC16C712/716

DS41106A-page 10 Preliminary

1999 Microchip Technology Inc.

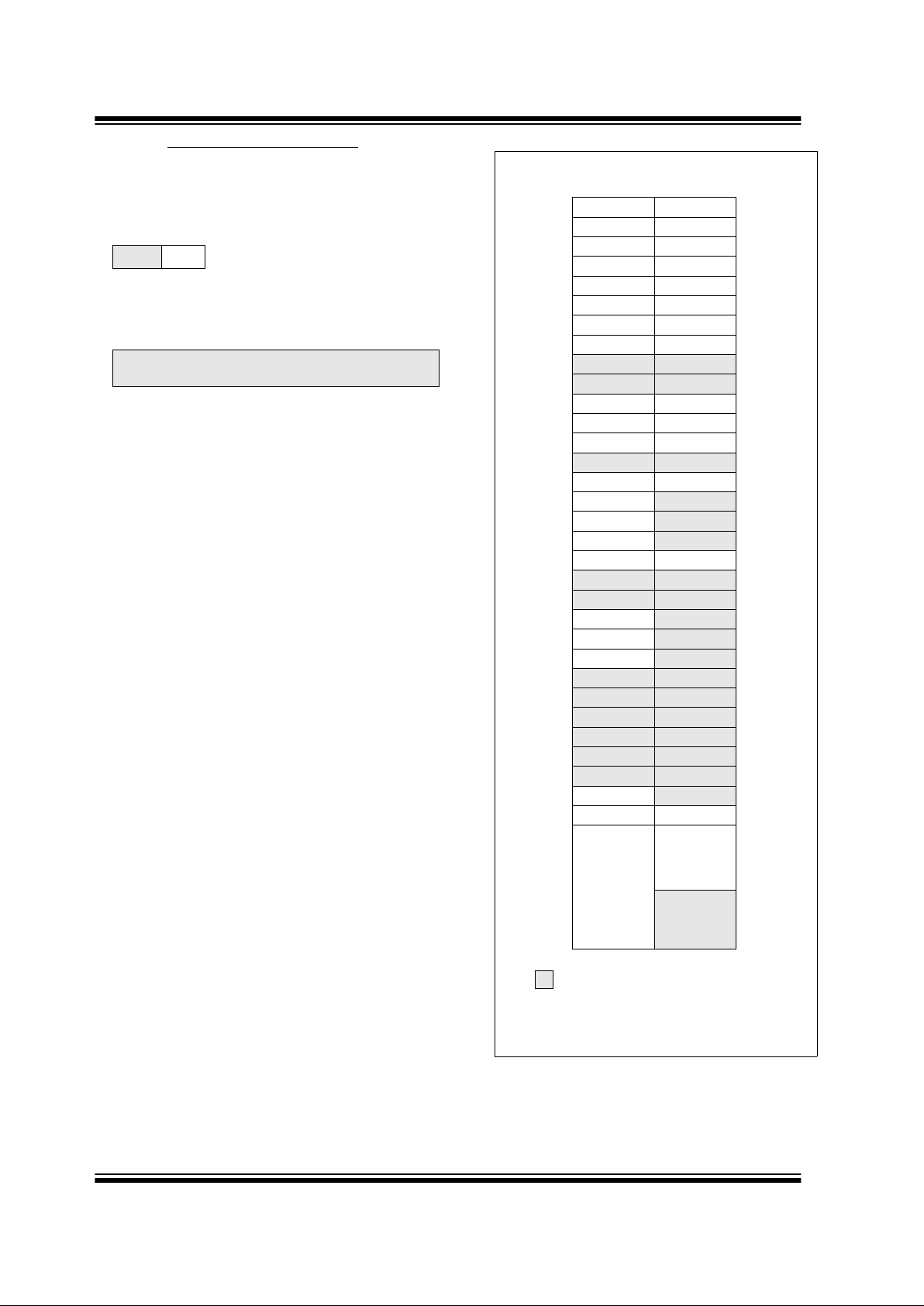

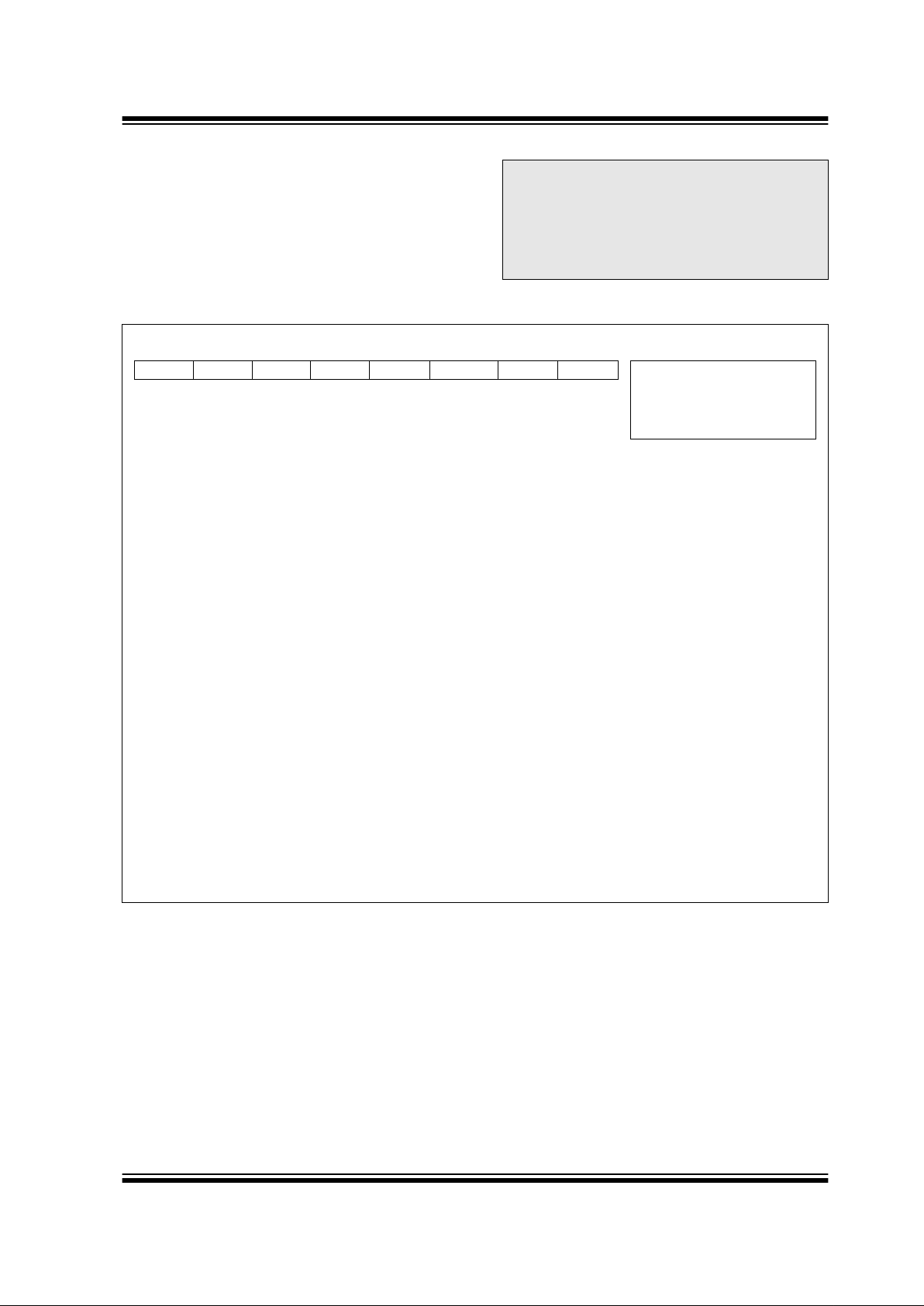

2.2 Data Memory Organization

The data memory is partitioned into multiple banks

which contain the General Purpose Registers and the

Special Function Registers. Bits RP1 and RP0 are the

bank select bits.

= 00 → Bank0

= 01 → Bank1

= 10 → Bank2 (not implemented)

= 11 → Bank3 (not implemented)

Each bank extends up to 7Fh (128 bytes). The lower

locations of each bank are reserved for the Special

Function Registers . Abo v e the Sp ecial Functi on Regi sters are General Purpose Registers, implemented as

static RAM. All implemented banks contain special

function registers. Some “high use” special function

registers from one bank may be mirrored in another

bank for code reduction and quicker access.

2.2.1 GENERAL PURPOSE REGISTER FILE

The register file can be accessed either directly, or indi-

rectly through the File Select Register FSR

(Section 2.5).

FIGURE 2-3: REGISTER FILE MAP

RP1

(1)

RP0 (STATUS<6:5>)

Note 1: Maintain this bit clear to ensure upward compati-

bility with future products.

Unimplemented data memory locations,

read as ’0’.

Note 1: Not a physical register.

File

Address

File

Address

00h INDF

(1)

INDF

(1)

80h

01h TMR0

OPTION_REG

81h

02h PCL PCL 82h

03h STATU S S TATUS 83h

04h FSR FSR 84h

05h PORTA TRISA 85h

06h PORTB TRISB 86h

07h DATA CCP TRISCCP 87h

08h

88h

09h

89h

0Ah PCLATH PCLATH 8Ah

0Bh INTCON INTCON 8Bh

0Ch PIR1 PIE1 8Ch

0Dh

8Dh

0Eh TMR1L PCON 8Eh

0Fh TRM1H

8Fh

10h T1CON

90h

11h TRM2

91h

12h T2CON PR2 92h

13h

93h

14h

94h

15h CCPR1L

95h

16h CCPR1H

96h

17h CCP1CON

97h

18h

98h

19h

99h

1Ah

9Ah

1Bh

9Bh

1Ch

9Ch

1Dh

9Dh

1Eh ADRES

9Eh

1Fh ADCON0 ADCON1 9Fh

20h

General

Purpose

Registers

96 Bytes

General

Purpose

Registers

32 Bytes

A0h

BFh

C0h

7Fh FFh

Bank 0 Bank 1

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 11

2.2.2 SPECIAL FUNCTION REGISTERS

The Special Function Registers are registers used by

the CPU and Peripheral Modules for controlling the

desired operation of the device. These registers are

implemented as static RAM. A list of these registers is

give in Table 2-1.

The special fu nction re gisters can be classifi ed into two

sets; core (CPU) and periphe ral. Those registers associated with the core functions are described in detail in

this section. Those related to the operation of the

peripheral features are described in detail in that

peripheral feature section.

TABLE 2-1 SPECIAL FUNCTION REGISTER SUMMARY

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

(4)

Bank 0

00h INDF

(1)

Addressing this location uses contents of FSR to address data memory (not a physical register) 0000 0000 0000 0000

01h TMR0 Timer0 module’s register xxxx xxxx uuuu uuuu

02h PCL

(1)

Program Counter's (PC) Least Significant Byte 0000 0000 0000 0000

03h STATUS

(1)

IRP

(4)

RP1

(4)

RP0 TO PD ZDCCrr01 1xxx rr0q quuu

04h FSR

(1)

Indirect data memory address pointer xxxx xxxx uuuu uuuu

05h PORTA

(5,6)

— ——

(7)

PORTA Data Latch when written: PORTA pins when read --xx xxxx --xu uuuu

06h PORTB

(5,6)

PORTB Data Latch when written: PORTB pins when read xxxx xxxx uuuu uuuu

07h DATACCP —

(7)

—

(7)

—

(7)

—

(7)

—

(7)

DCCP

—

(7)

DT1CK

xxxx xxxx xxxx xuxu

08h-09h — Unimplemented — —

0Ah PCLATH

(1,2)

— — — Write Buffer for the upper 5 bits of the Program Counter ---0 0000 ---0 0000

0Bh INTCON

(1)

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

0Ch PIR1

—ADIF— — — CCP1IF TMR2IF TMR1IF -0-- 0000 -0-- 0000

0Dh — Unimplemented — —

0Eh TMR1L Hold ing register for the Least Significant Byte of the 16-bi t TMR1 regis ter xxxx xxxx uuuu uuuu

0Fh TMR1H Holding register for the Most Significant Byte of the 16-bit TMR1 register xxxx xxxx uuuu uuuu

10h T1CON

— — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON --00 0000 --uu uuuu

11h TMR2 Timer2 module’s register 0000 0000 0000 0000

12h T2CON

— TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0 -000 0000 -000 0000

13h-14h

15h CCPR1L Capture/Compare/PWM Register1 (LSB) xxxx xxxx uuuu uuuu

16h CCPR1H Capture/Compare/PWM Register1 (MSB) xxxx xxxx uuuu uuuu

17h CCP1CON

— — DC1B1 DC1B0 CCP1M3 CCP1M2 CCP1M1 CCP1 M0 --00 0000 --00 0000

18h-1Dh — Unimplemented — —

1Eh ADRES A/D Result Register xxxx xxxx uuuu uuuu

1Fh ADCON0 ADCS1 ADCS0 CHS2 CHS1 CHS0 GO/DONE

—ADON0000 00-0 0000 00-0

Legend: x = unknown, u = unchanged, q = value depends on condition, - = unimplemented, read as ’0’,

Shaded locations are unimplemented, read as ’0’.

Note 1: These registers can be addressed from either bank.

2: The upper byte of the program counter is not directly accessible. PCLATH is a holding register for PC<12:8> whose contents

are transferred to the upper byte of the program counter.

3: Other (non power-up) resets include: external reset through MCLR

and the Watchdog Timer Reset.

4: The IRP and RP1 bits are reserved. Always maintain these bits clear.

5: On any device reset, these pins are configured as inputs.

6: This is the value that will be in the port output latch.

7: Reserved bits; Do Not Use.

PIC16C712/716

DS41106A-page 12 Preliminary

1999 Microchip Technology Inc.

Bank 1

80h INDF

(1)

Addressing this location uses contents of FSR to address data memory (not a physical register) 0000 0000 0000 0000

81h

OPTION_

REG

RBPU

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

82h PCL

(1)

Program Counter’s (PC) Least Significant Byte 0000 0000 0000 0000

83h STATUS

(1)

IRP

(4)

RP1

(4)

RP0 TO PD ZDCCrr01 1xxx rr0q quuu

84h FSR

(1)

Indirect data memory address pointer xxxx xxxx uuuu uuuu

85h TRISA

— ——

(7)

PORTA Data Direction Register --x1 1111 --x1 1111

86h TRISB PORTB Data Direction Register 1111 1111 1111 1111

87h TRISCCP —

(7)

—

(7)

—

(7)

—

(7)

—

(7)

TCCP

—

(7)

TT1CK

xxxx x1x1 xxxx x1x1

88h-89h — Unimplemented — —

8Ah PCLATH

(1,2)

— — — Write Buffer for the upper 5 bits of the Program Counter ---0 0000 ---0 0000

8Bh INTCON

(1)

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

8Ch PIE1

—ADIE— — — CCP1IE TMR2IE TMR1IE -0-- -000 -0-- -000

8Dh — Unimplemented — —

8Eh PCON

— — — — — —PORBOR ---- --qq ---- --uu

8Fh-91h — Unimplemented — —

92h PR2 Timer2 Period Register 1111 1111 1111 1111

93h-9Eh — Unimplemented — —

9Fh ADCON1

— — — — — PCFG2 PCFG1 PCFG0 ---- -000 ---- -000

Legend: x = unknown, u = unchanged, q = value depends on condition, - = unimplemented, read as ’0’,

Shaded locations are unimplemented, read as ’0’.

Note 1: These registers can be addressed from either bank.

2: The upper byte of the program counter is not directly accessible. PCLATH is a holding register for PC<12:8> whose contents

are transferred to the upper byte of the program counter.

3: Other (non power-up) resets include: external reset through MCLR

and the Watchdog Timer Reset.

4: The IRP and RP1 bits are reserved. Always maintain these bits clear.

5: On any device reset, these pins are configured as inputs.

6: This is the value that will be in the port output latch.

7: Reserved bits; Do Not Use.

TABLE 2-1 SPECIAL FUNCTION REGISTER SUMMARY (Cont.’d)

Addr Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

(4)

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 13

2.2.2.1 STATUS REGISTER

The STATUS register, shown in Figure 2-4, contains

the arithmetic status of th e ALU , the RE SET status an d

the bank select bits for data memory.

The STATUS register can be the destination for any

instruction, as with any other register. If the STATUS

register is the destination for an instruction that affects

the Z, DC or C bits, then the write to these three bits is

disabled. The se bi ts ar e set or c leared a ccordi ng to the

device logic. Fur th erm ore, the TO

and PD bits are not

writable. Therefore, the result of an instruction with the

STATUS regi ster as destina tion may be different th an

intended.

For example, CLRF STATUS will clear the up p er -t h ree

bits and set the Z bit. T his lea v e s the STATUS register

as 000u u1uu (where u = unchanged).

It is recommended, therefore, that only BCF, BSF,

SWAPF and MOVWF instructions are used to alter t he

STATUS register because these instructions do not

affect the Z, C or DC b its from the STA TU S regist er . F or

other instructions, not affecting any status bits, see the

"Instruction Set Summary."

FIGURE 2-4: STATUS REGISTER (ADDRESS 03h, 83h)

Note 1: These devices do not use bits IRP and

RP1 (STATUS<7:6>). Maintain these bits

clear to ensure upward compatibility with

future products.

Note 2: The C and DC bits operate as a borrow

and digit borrow bit, respectively, in subtraction. See the SUBLW and SUBWF

instructions for examples.

R/W-0 R/W-0 R/W-0 R-1 R-1 R/W-x R/W-x R/W-x

IRP RP1 RP0 TO PD Z DC C R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: IRP: Register Bank Select bit (used for indirect addressing)

1 = Bank 2, 3 (100h - 1FFh) - not implemented, maintain clear

0 = Bank 0, 1 (00h - FFh) - not implemented, maintain clear

bit 6-5: RP1:RP0: Register Bank Select bits (used for direct addressing)

01 = Bank 1 (80h - FFh)

00 = Bank 0 (00h - 7Fh)

Each bank is 128 bytes

Note: RP1 = not implemented, maintain clear

bit 4: TO

: Time-out bit

1 = After power-up, CLRWDT instruction, or SLEEP instructi on

0 = A WDT time-out occurred

bit 3: PD

: Power-down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

bit 2: Z: Zero b i t

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

bit 1: DC: Digit carry/borrow

bit (ADDWF, ADDLW,SUBLW,SUBWF instructions) (for borro w the polarity is reversed)

1 = A carry-out from the 4th low order bit of the result occurred

0 = No carry-out from the 4th low order bit of the result

bit 0: C: Carry/borrow

bit (ADDWF, ADDLW,SUBLW,SUBWF instructions)

1 = A carry-out from the most significant bit of the result occurred

0 = No carry-out from the most significant bit of the result occurred

Note: For borrow

the polarity is rev ersed. A subtractio n is execut ed by adding the tw o’s complement of the

second operand. For rotate (RRF, RLF) instructions, this bit is loaded with either the high or low order bit of

the source register.

PIC16C712/716

DS41106A-page 14 Preliminary

1999 Microchip Technology Inc.

2.2.2.2 OPTION_REG REGISTER

The OPTION_REG register is a readable and writable

register , which contai ns various c ontrol bits to c onfigure

the TMR0 prescaler/WDT postscaler (single assignable regist er kno wn also as the prescale r), the Ext ernal

INT Interrupt, TMR0 and the w eak pull-up s on PORTB.

FIGURE 2-5: OPTION_REG REGISTER (ADDRESS 81h)

Note: To achieve a 1:1 prescaler assignme nt for

the TMR0 register, assign the prescaler to

the Watchdog Timer.

R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1 R/W-1

RBPU

INTEDG T0CS T0SE PSA PS2 PS1 PS0 R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: RBPU: PORTB Pull-up Enable bit

1 = PORTB pull-ups are disabled

0 = PORTB pull-ups are enab led b y ind iv idu al port latch va lue s

bit 6: INTEDG: Interrupt Edge Select bit

1 = Interrupt on rising edge of RB0/INT pin

0 = Interrupt on falling edge of RB0/INT pin

bit 5: T0CS: TMR0 Clock Source Select bit

1 = Transition on RA4/T0CKI pin

0 = Internal instruction cycle clock (CLKOUT)

bit 4: T0SE: TMR0 Source Edge Select bit

1 = Increment on high-to-low transition on RA4/T0CKI pin

0 = Increment on low-to-high transition on RA4/T0CKI pin

bit 3: PSA: Prescaler Assignment bit

1 = Prescaler is assigned to the WDT

0 = Prescaler is assigned to the Timer0 module

bit 2-0: PS2:PS0: Prescaler Rate Select bits

000

001

010

011

100

101

110

111

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

1 : 256

1 : 1

1 : 2

1 : 4

1 : 8

1 : 16

1 : 32

1 : 64

1 : 128

Bit Value TMR0 Rate WDT Rate

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 15

2.2.2.3 INTCON REGISTER

The INTCON Regi ster i s a rea dab le a nd w ritabl e regi s-

ter which contains various enable and flag bits for the

TMR0 register overflow, RB Port change and External

RB0/INT pin interrupts.

FIGURE 2-6: INTCON REGISTER (ADDRESS 0Bh, 8Bh)

Note: Interrupt flag bits get set when an interrupt

condition occurs , re ga rdle ss of the state of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User software should ensure the appropriate interrupt flag bits are clear prior to enabling an

interrupt.

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-x

GIE PEIE T0IE INTE RBIE T0IF INTF RBIF R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: GIE: Global Interrupt Enable bit

1 = Enables all un-masked interrupts

0 = Disables all interrupts

bit 6: PEIE: Peripheral Interrupt Enable bit

1 = Enables all un-masked peripheral interrupts

0 = Disables all peripheral interrupts

bit 5: T0IE: TMR0 Overflow Interrupt Enable bit

1 = Enables the TMR0 interrupt

0 = Disables the TMR0 interrupt

bit 4: IINTE: RB0/INT External Interrupt Enable bit

1 = Enables the RB0/INT external interrupt

0 = Disables the RB0/INT external interrupt

bit 3: RBIE: RB Port Change Interrupt Enable bit

1 = Enables the RB port change interrupt

0 = Disables the RB port change interrupt

bit 2: T0IF: TMR0 Overflow Interrupt Flag bit

1 = TMR0 register has overflowed (must be cleared in software)

0 = TMR0 register did not overflow

bit 1: INTF: RB0/INT External Interrupt Flag bit

1 = The RB0/INT external interrupt occurred (must be cleared in software)

0 = The RB0/INT external interrupt did not occur

bit 0: RBIF: RB Port Change Interrupt Flag bit

1 = At least one of the RB7:RB4 pins changed state (must be cleared in software)

0 = None of the RB7:RB4 pins have changed state

PIC16C712/716

DS41106A-page 16 Preliminary

1999 Microchip Technology Inc.

2.2.2.4 PIE1 REGI STER

This register contains the individual enable bits for the

peripheral interrupts.

FIGURE 2-7: PIE1 REGISTER (ADDRESS 8Ch)

Note: Bit PEIE (INTCON<6>) must be set to

enable any peripheral interrupt.

U-0 R/W-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0

— ADIE — — — CCP1IE TMR2IE TMR1IE R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: Unimplemented: Read as ‘0’

bit 6: ADIE: A/D Converter Interrupt Enable bit

1 = Enables the A/D interrupt

0 = Disables the A/D interrupt

bit 5-3: Unimplemented: Read as ‘0’

bit 2: CCP1IE: CCP1 Interrupt Enable bit

1 = Enables the CCP1 interrupt

0 = Disables the CCP1 interrupt

bit 1: TMR2IE: TMR2 to PR2 Match Interrupt Enable bit

1 = Enables the TMR2 to PR2 match interrupt

0 = Disables the TMR2 to PR2 match interrupt

bit 0: TMR1IE: TMR1 Overflow Interrupt Enable bit

1 = Enables the TMR1 overflow interrupt

0 = Disables the TMR1 overflow interrupt

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 17

2.2.2.5 PIR1 REGISTER

This register contains the individual flag bits for the

peripheral interrupts.

FIGURE 2-8: PIR1 REGISTER (ADDRESS 0Ch)

Note: Interrupt flag bits get set when an interrupt

condition occurs , re ga rdle ss of the state of

its corresponding enable bit or the global

enable bit, GIE (INTCON<7>). User software should ensure the appropriate interrupt flag bits are clear prior to enabling an

interrupt.

U-0 R/W-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0

— ADIF — — — CCP1IF TMR2IF TMR1IF R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: Unimplemented: Read as ‘0’

bit 6: ADIF: A/D Converter Interrupt Flag bit

1 = An A/D conversion completed (must be cleared in software)

0 = The A/D conversion is not complete

bit 5-3: Unimplemented: Read as ‘0’

bit 2: CCP1IF: CCP1 Interrupt Flag bit

Capture Mode

1 = A TMR1 register capture occurred ( must be cleared in software)

0 = No TMR1 register capture occurred

Compare Mode

1 = A TMR1 register compare match occurred (must be cleared in software)

0 = No TMR1 register compare match occurred

PWM Mode

Unused in this mode

bit 1: TMR2IF: TMR2 to PR2 Match Interrupt Flag bit

1 = TMR2 to PR2 match occurred (must be cleared in software)

0 = No TMR2 to PR2 match occurred

bit 0: TMR1IF: TMR1 Overflow Interrupt Flag bit

1 = TMR1 register overflowed (must be cleared in software)

0 = TMR1 register did not overflow

PIC16C712/716

DS41106A-page 18 Preliminary

1999 Microchip Technology Inc.

2.2.2.6 PCON REGISTER

The Power Control (PCON) register contains a flag bit

to allow differentiation between a Power-on Reset

(POR) to an external MCLR

Reset or WDT Reset.

These devices contain an additional bit to differentiate

a Brown-out Reset condition from a Power-on Reset

condition.

FIGURE 2-9: PCON REGISTER (ADDRESS 8Eh)

Note: If the BODEN configuration bit is set, BOR

is ’1’ on Power-on Reset. If the BODEN

configuration bit is clear, BOR

is unknown

on Power-on Reset.

The BOR status bit is a "don't care" and is

not necessarily predictab le if the brow n-out

circuit is disabled (the BODE N configuration bit is clear). BOR

must then be set by

the user and checked on subsequent

resets to see if it is clear, indicating a

brown-out has occurred.

U-0 U-0 U-0 U-0 U-0 U-0 R/W-0 R/W-q

— — — — — —PORBOR R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7-2: Unimplemented: Read as ’0’

bit 1: POR

: Power-on Reset Status bit

1 = No Power-on Reset occurred

0 = A Power-on Reset occurred (must be set in software after a Power-on Reset occurs)

bit 0: BOR

: Brown-out Reset Status bit

1 = No Brown-out Reset occurred

0 = A Brown-out Reset occurred (must be set in software after a Brown-out Reset occurs)

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 19

2.3 PCL and PCLATH

The program counter (PC) specifies the address of the

instruction to fetch for execution. The PC is 13 bits

wide. The low byte is called the PCL register. This register is readable and writable. The high byte is called

the PCH register. This register contains the PC<12:8>

bits and is not directly readable or w ritable. All update s

to the PCH register go through the PCLATH register.

2.3.1 STACK

The stack a llows a co mbination o f up to 8 pr ogram ca lls

and interrupts to occur. The stack contains the return

address from this branch in program execution.

Midrange devices have an 8 level deep x 1 3-bit wide

hardware stack. T he stack space is not part of either

program or data space and the stack pointer is not

readable or writab le. The PC is PUSHed onto the stac k

when a CALL instruction is executed or an interrupt

causes a branch. The stack is POPed in the event of a

RETURN, RETLW or a RETFIE instruction execution.

PCLATH is not modified when the stack is PUSHed or

POPed.

After the stac k has been PUSHed e ight tim es, th e ninth

push overw rites th e value that was stored from the first

push. The tenth push overwrites the sec ond pus h (an d

so on).

2.4 Program Memory Paging

The CALL and GOTO instructions provide 11 bits of

address to allow branching within any 2K program

memory page. When d oing a CALL or G OTO instruction,

the upper bit of the address is provided by

PCLATH<3>. When doing a CALL or GOTO instruction,

the user must ensure that the page select bit is programmed so that the desired progr am me mo ry page is

addressed. If a return from a CALL inst ruct ion (o r interrupt) is executed, the entire 1 3-bit PC is pushed onto

the stack. Therefore, manipulation of the PCLATH<3>

bit is not required for the return instructions (which

POPs the address from the stack).

PIC16C712/716

DS41106A-page 20 Preliminary

1999 Microchip Technology Inc.

2.5 Indirect Addressing, INDF and FSR

Registers

The INDF register is no t a physical r egis ter. Addressing INDF actually addresses the register whose

address is contained in the FSR register (FSR is a

pointer

). This is indirect ad dressi ng .

EXAMPLE 2-1: INDIRECT ADDRESSING

• Register file 05 contains the value 10h

• Register file 06 contains the value 0Ah

• Load the value 05 into the FSR register

• A read of the INDF register will return the v alue of

10h

• Increment the value of the FSR register by one

(FSR = 06)

• A read of the INDR register now will return the

value of 0Ah.

Reading INDF itself indirectly (FSR = 0) will produce

00h. Writing to the INDF register indirectly results in a

no-operation (although STATUS bits may be affected).

A simple program to clear RAM locations 20h-2Fh

using indirect addressing is shown in Example 2-2.

EXAMPLE 2-2: HOW TO CLEAR RAM

USING INDIRECT

ADDRESSING

movlw 0x20 ;initialize pointer

movwf FSR ; to RAM

NEXT clrf INDF ;clear INDF register

incf FSR ;inc pointer

btfss FSR,4 ;all done?

goto NEXT ;NO, clear next

CONTINUE

: ;YES, continue

An effective 9-bit addres s is o btai ne d by concatenatin g

the 8-bit FSR register an d the IRP bit (S TATUS<7>), as

shown in Figure 2-10. However, IRP is not used in the

PIC16C712/716.

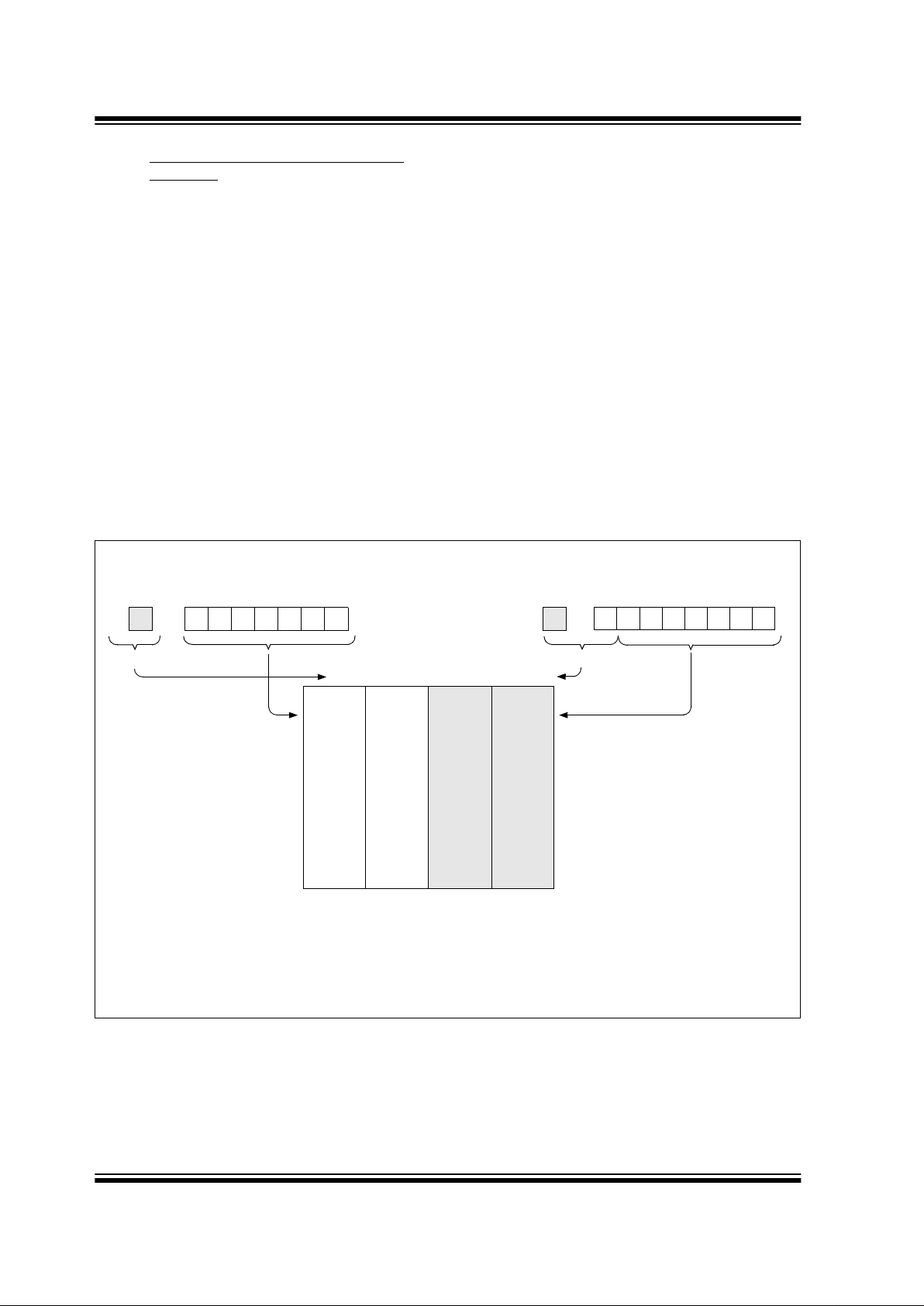

FIGURE 2-10: DIRECT/INDIRECT ADDRESSING

Note 1: For register file map detail see Figure 2-3.

2: Maintain clear for upward compatibility with future products.

3: Not implemented.

Data

Memory(1)

Indirect AddressingDirect Addressing

bank select location select

RP1:RP0 6

0

from opcode

IRP FSR register

7

0

bank select

location select

00 01 10 11

Bank 0 Bank 1 Bank 2 Bank 3

FFh

80h

7Fh

00h

17Fh

100h

1FFh

180h

(3) (3)

(2)

(2)

1998 Microchip Technology Inc.

Preliminary DS41106A-page 21

PIC16C712/716

3.0 I/O PORTS

Some pins for these I/O ports are multiplexed with an

alternate function for the peripheral features on the

device. In general, when a peripheral is enabled, that

pin may not be used as a general purpose I/O pin.

Additional information on I/O ports ma y b e found in the

PICmicro™ Mid-Range Reference Manual,

(DS33023).

3.1 PORTA and the TRISA Register

PORTA is a 5-bit wide bi-directional port. The corresponding data direction register is TRISA. Setting a

TRISA bit (=1) will m ak e the corresponding PO RTA pin

an input, (i.e., put the corresponding output driver in a

hi-impedance mode). Clearing a TRISA bit (=0) will

make the corresp onding POR TA pin an output, (i .e., put

the contents of the output latch on the selected pin).

Reading the PORTA register reads the status of the

pins whereas writing to it will write to the port latch. All

write operations are read-modify-write operations.

Therefore a write to a port implies that the port pins are

read, the value is modified, and then written to the port

data latch.

Pin RA4 is multiplexed with the Timer0 module clock

input to become the RA4/T0CKI pin. The RA4/T0CKI

pin is a Schmitt Trigger input and an open d r a in ou tpu t.

All other RA port pins have TTL input levels and full

CMOS output drivers .

PORTA pins, RA3:0, are m ultiplex ed with ana log inputs

and analog V

REF input. The operation of each pin is

selected by clearing/setting the control bits in the

ADCON1 register (A/D Control Register1).

The TRISA register controls the direction of the RA

pins, even when they are being used as analog inputs.

The user must ensure the bi ts in the TRISA register are

maintained set when using them as analog inputs.

EXAMPLE 3-1: INITIALIZING PORTA

BCF STATUS, RP0 ;

CLRF PORTA ; Initialize PORTA by

; clearing output

; data latches

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0xEF ; Value used to

; initialize data

; direction

MOVWF TRISA ; Set RA<3:0> as inputs

; RA<4> as outputs

BCF STATUS, RP0 ; Return to Bank 0

Note: On a Power-on Reset, these pins are con-

figured as analog inputs and read as '0'.

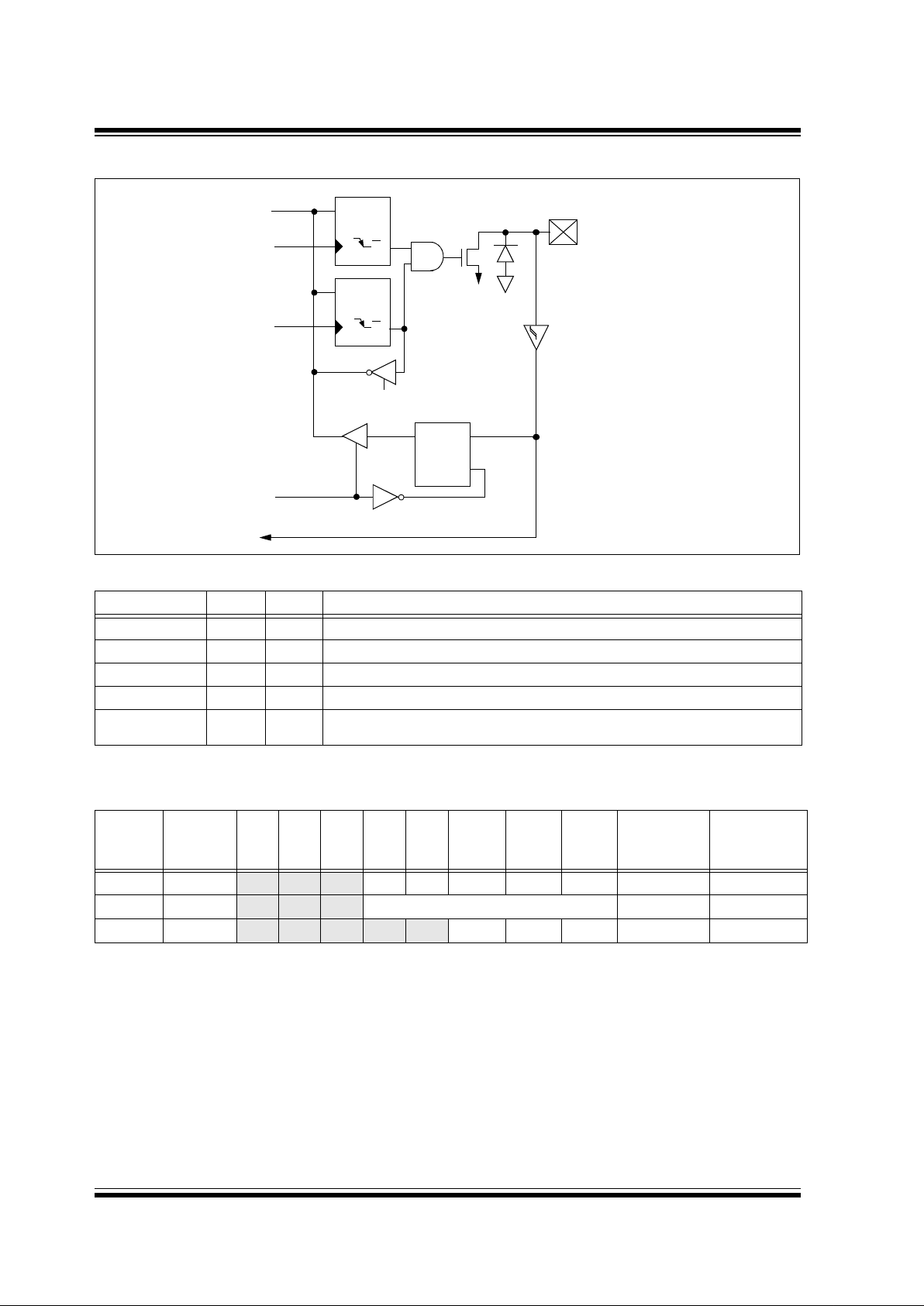

FIGURE 3-1: BLOCK DIAGRAM OF RA3:RA0

DATA

BUS

QD

Q

CK

QD

Q

CK

QD

EN

P

N

WR

PORT

WR

TRIS

Data Latch

TRIS Latch

RD TRIS

RD PORT

V

SS

VDD

I/O pin

Analog

input

mode

TTL

Input

Buffer

To A/D Conver ter

VSS

VDD

PIC16C712/716

DS41106A-page 22 Preliminary

1998 Microchip Technology Inc.

FIGURE 3-2: BLOCK DIAGRAM OF RA4/T0CKI PIN

TABLE 3-1 PORTA FUNCTIONS

TABLE 3-2 SUMMARY OF REGISTERS ASSOCIATED WITH PORTA

Name Bit# Buffer Function

RA0/AN0 bit0 TTL Input/output or analog input

RA1/AN1 bit1 TTL Input/output or analog input

RA2/AN2 bit2 TTL Input/output or analog input

RA3/AN3/V

REF bit3 TTL Input/output or analog input or VREF

RA4/T0CKI bit4 ST

Input/output or external clock input for Timer0

Output is open drain type

Legend: TTL = TTL input, ST = Schmitt Trigger input

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on

POR,

BOR

Value on all

other resets

05h PORTA

— — —

(1)

RA4 RA3 RA2 RA1 RA0 --xx xxxx --xu uuuu

85h TRISA

— — —

(1)

PORTA Data Direction Register --11 1111 --11 1111

9Fh ADCON1

— — — — — PCFG2 PCFG1 PCFG0 ---- -000 ---- -000

Legend: x = unknown, u = unchanged, - = unimplemented locations read as '0'. Shaded cells are not used by

PORTA.

Note 1: Reserved bits; Do Not Use.

DA TA

BUS

WR

PORT

WR

TRIS

RD PORT

Data Latch

TRIS Latch

RD TRIS

Schmitt

Trigger

Input

Buffer

N

V

SS

I/O Pin

TMR0 Clock Input

QD

Q

CK

QD

Q

CK

EN

QD

EN

VSS

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 23

3.2 PORTB and the TRISB Register

PORTB is an 8-bit wide bi-directional port. The corresponding data direction register is TRISB. Setting a

TRISB bit (=1) will make the correspon ding POR TB pin

an input, (i.e., put the corresponding output driver in a

hi-impedance mode). Clearing a TRISB bit (=0) will

make the corresponding PORTB pin an output, (i.e.,

put the contents of the output latch on the selected pin).

EXAMPLE 3-1: INITIALIZING PORTB

BCF STATUS, RP0 ;

CLRF PORTB ; Initialize PORTB by

; clearing output

; data latches

BSF STATUS, RP0 ; Select Bank 1

MOVLW 0xCF ; Value used to

; initialize data

; direction

MOVWF TRISB ; Set RB<3:0> as inputs

; RB<5:4> as outputs

; RB<7:6> as inputs

Each of the PORTB pins has a weak internal pull-up. A

single control bit can turn on all the pull-u ps. This is performed by clea ring bi t RBPU

(OPTION_REG<7>). The

weak pull-up i s automa tical ly tur ned off when the p or t

pin is configured as an output. The pull-ups are disabled on a Power-on Reset.

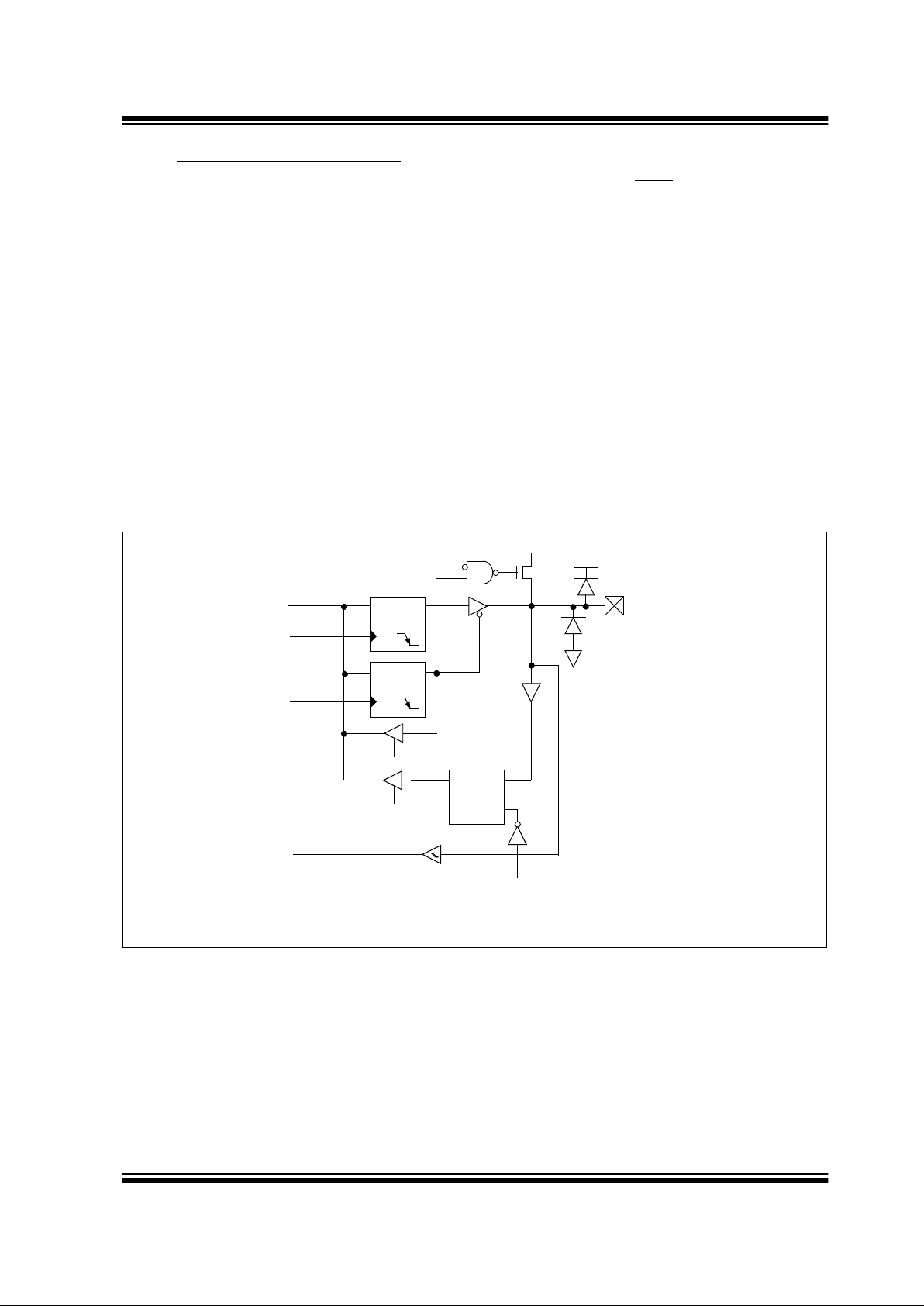

FIGURE 3-3: BLOCK DIAGRAM OF RB0 PIN

Data Latch

RBPU

(1)

P

V

DD

QD

CK

QD

CK

QD

EN

DATA BUS

WR PORT

WR TRIS

RD TRIS

RD PORT

weak

pull-up

RD PORT

RB0/INT

I/O

pin

TTL

Input

Buffer

Schmitt Trigger

Buffer

TRIS Latch

Note 1: To enable weak pull-ups, set the appropriate TRIS bit(s) and clear the RBPU bit (OPTION_REG<7>).

VSS

VDD

PIC16C712/716

DS41106A-page 24 Preliminary

1999 Microchip Technology Inc.

PORTB pins RB3:RB1 are multiplexed with several

peripheral functions (T able 3-3). PORTB pins RB3:RB0

have Schmitt Trigger input buffers.

When enabling peripheral functions, care should be

taken in defining TRIS bits for each PORTB pin. Some

peripherals override the TRIS bit to make a pin an output, while other peripherals override the TRIS bit to

make a pin an input. Since the TRIS bit override is in

effect while the peripheral is enabled, read-modifywrite instructions (BSF, BCF, XORWF) with TRISB as

destination shou ld be a voi ded. The us er should refe r to

the corresponding peripheral section for the correct

TRIS bit settings.

Four of PORTB’s pins, RB7:RB4, have an interrupt on

change feature. Only pins configured as inputs can

cause this interrupt to oc cur (i.e . any RB7:RB4 pin configured as an output is excluded from the interrupt on

change comparison). The input pins, RB7:RB4, are

compared with th e o ld value latche d o n the la st read of

PORTB. The “mismatch” outputs of RB7:RB4 are

OR’ed together to generate the RB Port Change Interrupt with flag bit RBIF (INTCON<0>).

This interrupt can wake the device from SLEEP. The

user, i n the interrupt service routine , can clea r the interrupt in the following manner:

a) Any read or write of PORTB will end the mis-

match condition.

b) Clear flag bit RBIF.

A mismatch condition will continue to set flag bit RBIF.

Reading PORTB will end the mismatch condition and

allow flag bit RBIF to be cleared.

The interrupt on change feature is recommended for

wake-up on key depression operation and opera tions

where PORTB is only us ed for the in terrupt on change

feature. Polling of PORTB is not recommended while

using the interrupt on change feature.

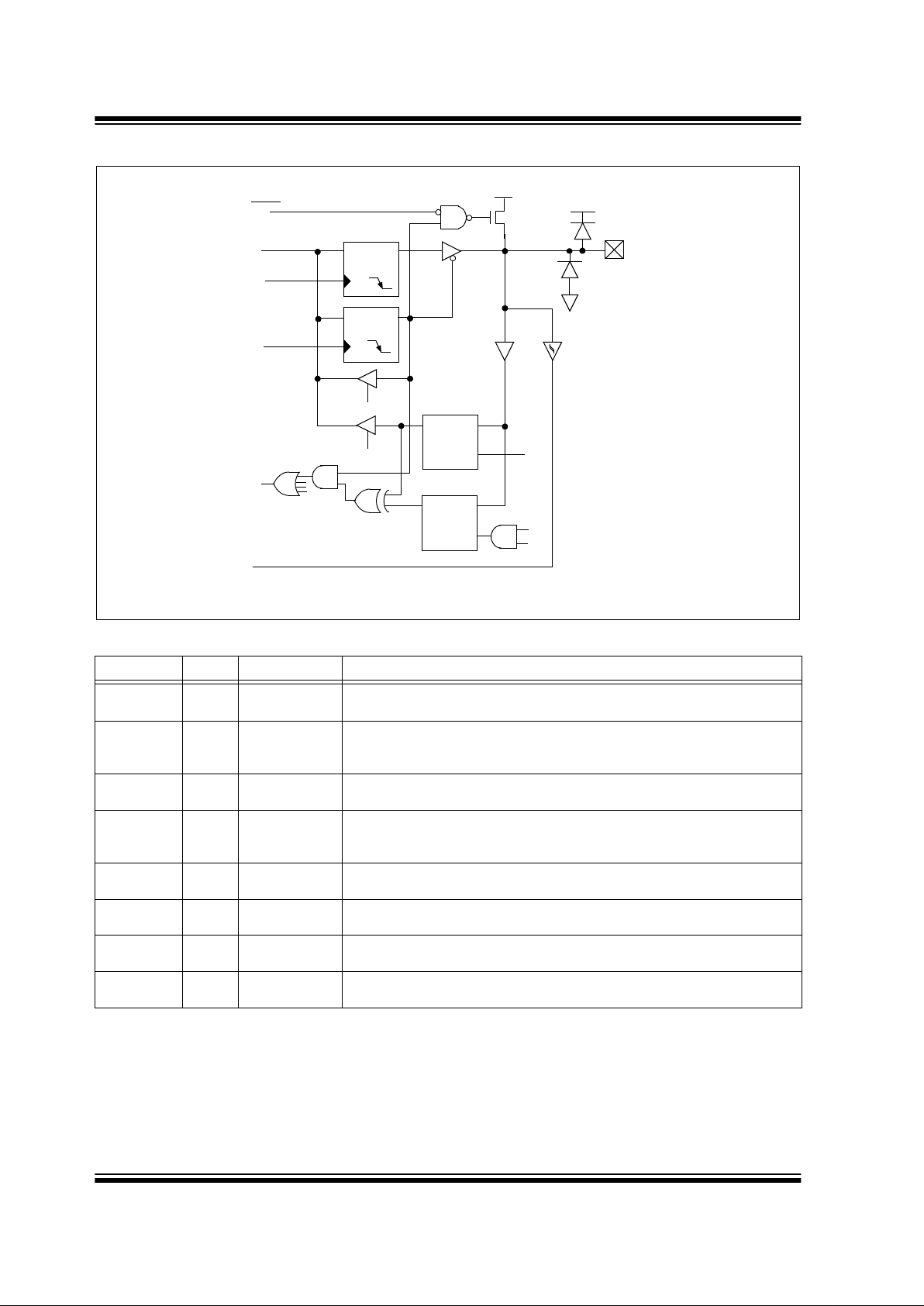

FIGURE 3-4: BLOCK DIAGRAM OF RB1/T1OSO/T1CKI PIN

0

1

QD

Q

CK

QD

Q

CK

QD

Q

CK

QD

Q

CK

0

1

0

1

TTL Buffer

TRISB<1>

PORTB<1>

TRISCCP<0>

DATACCP<0>

RB1/T1OSO/T1CKI

RD

DA TA BUS

WR

WR

WR

WR TRISB

T1OSCEN

RD PORTB

TMR1CS

DATACCP

DATACCP

TRISCCP

PORTB

T1CLKIN

ST

Buffer

P

V

DD

weak

pull-up

RBPU

(1)

T1OSCEN

T1CS

VSS

VDD

Note 1: To enable weak pull-ups, set the appropriate TRIS bit(s) and clear the RBPU bit (OPTION_REG<7>).

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 25

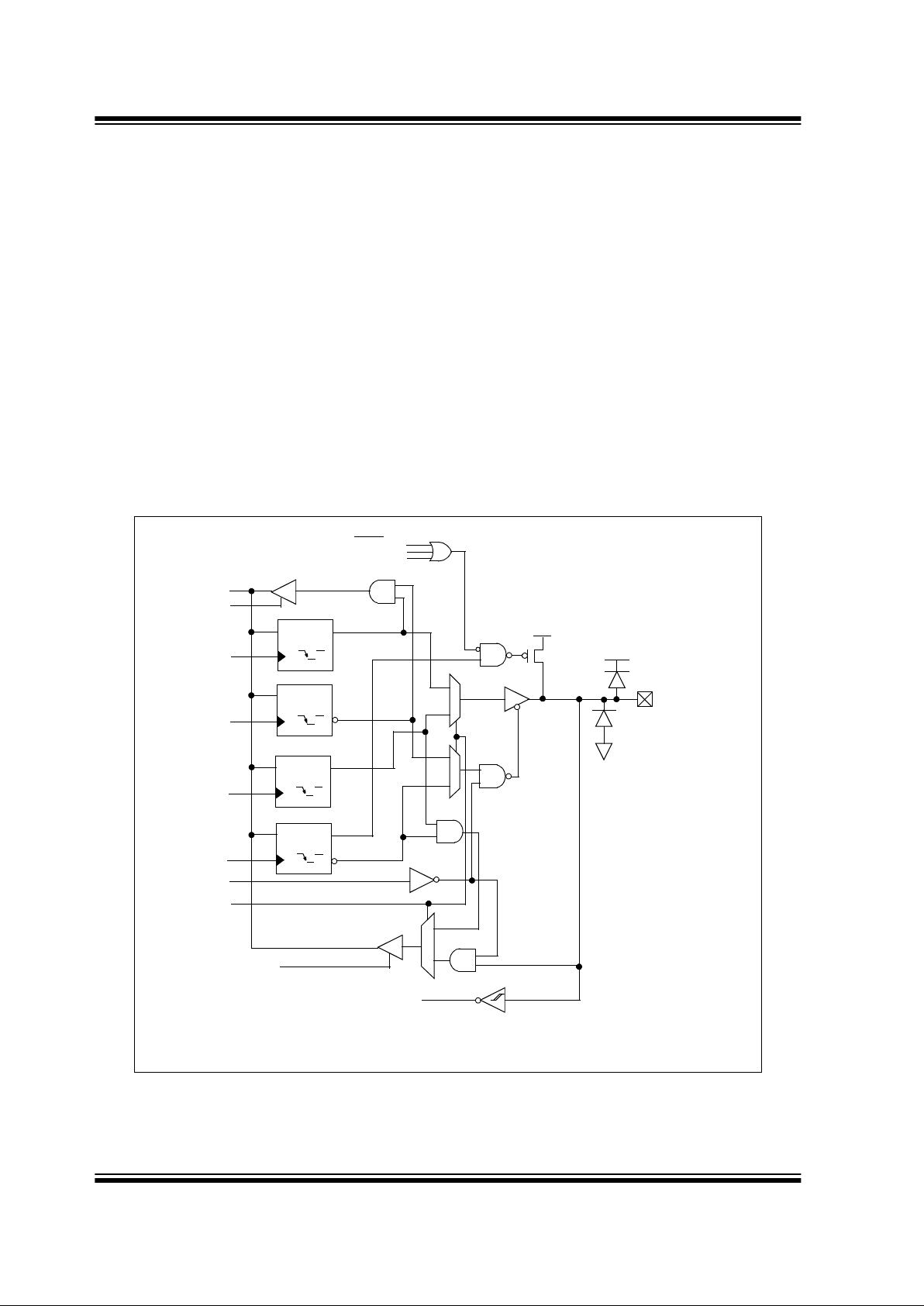

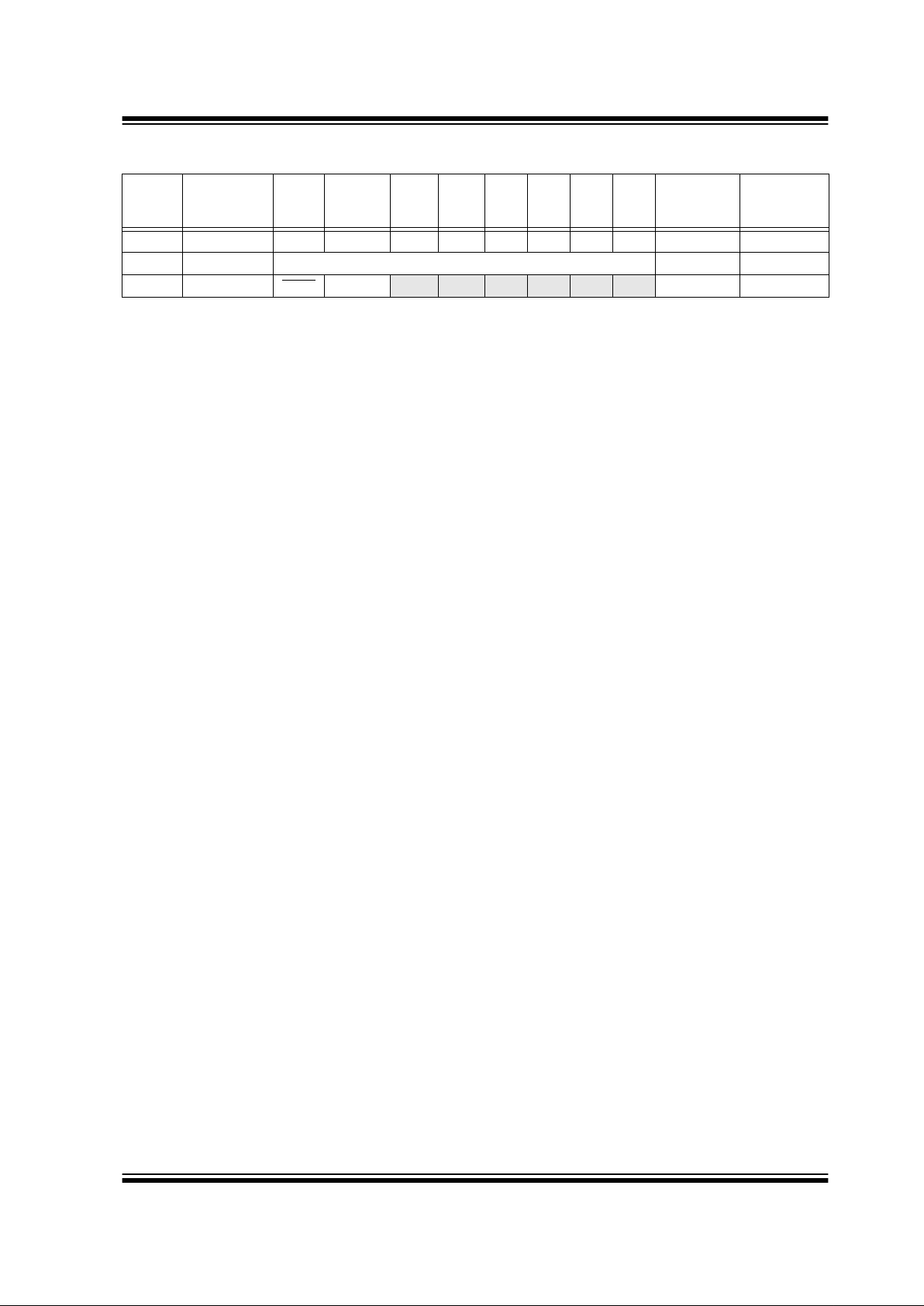

FIGURE 3-5: BLOCK DIAGRAM OF RB2/T1OSI PIN

FIGURE 3-6: BLOCK DIAGRAM OF RB3/CCP1 PIN

P

V

DD

weak

pull-up

QD

Q

CK

QD

Q

CK

TTL Buffer

TRISB<2>

PORTB<2>

DATA B US

WR PORTB

WR TRISB

T1OSCEN

RD PORTB

RB1/T1OSO/T1CKI

RBPU

(1)

T1OSCEN

VSS

VDD

Note 1: To enable weak pull-ups, set the appropriate TRIS bit(s) and clear the RBPU bit (OPTION_REG<7>).

0

1

QD

Q

CK

QD

Q

CK

QD

Q

CK

QD

Q

CK

0

1

0

1

TRISB<3>

PORTB<3>

TRISCCP<2>

DATACCP<2>

RB3/CCP1

RD

DATA BUS

WR

WR

WR

WR

RD PORTB

CCPON

TTL Buffer

0

1

0

1

CCPOUT

CCPIN

CCPON

DATACCP

DATACCP

TRISCCP

PORTB

TRISB

CCP

Output

Mode

P

V

DD

weak

pull-up

RBPU

(1)

CCPON

VSS

VDD

Note 1: To enable weak pull-ups, set the appropr iate TRIS b it(s)

and clear the RBPU bit (OPTION_REG<7>).

PIC16C712/716

DS41106A-page 26 Preliminary

1999 Microchip Technology Inc.

FIGURE 3-7: BLOCK DIAGRAM OF RB7:RB4 PINS

TABLE 3-3 PORTB FUNCTIONS

Name Bit# Buffer Function

RB0/INT bit0 TTL/ST

(1)

Input/output pin or external interrupt input. Internal software

programmable weak pull-up.

RB1/T1OS0/

T1CKI

bit1

TTL/ST

(1)

Input/output pin or Timer 1 os cilla tor outpu t, or Tim er 1 cl oc k input. Inte rnal

software programmable weak pull-up. See Timer1 section for detailed

operation.

RB2/T1OSI bit2

TTL/ST

(1)

Input/output pin or T imer 1 os cilla tor in put. Internal s oftw are pro g ram mab le

weak pull-up. See Timer1 section for detailed operation.

RB3/CCP1 bit3

TTL/ST

(1)

Input/output pin or Captu re 1 input , or Compare 1 output, or PWM1 output.

Internal software programmable weak pull-up. See CCP1 section for

detailed operation.

RB4 bit4 TTL Input/output pin (with interrupt on chang e). Internal so ftware prog ramm ab le

weak pull-up .

RB5 bit5 TTL Input/output pin (with interrupt on chang e). Internal so ftware prog ramm ab le

weak pull-up .

RB6 bit6 TTL/ST

(2)

Input/output pin (with in terrupt on ch ange). In ternal softw are prog ramm ab le

weak pull-up. Serial programming clock.

RB7 bit7 TTL/ST

(2)

Input/output pin (with in terrupt on ch ange). In ternal softw are prog ramm ab le

weak pull-up. Serial programming data.

Legend: TTL = TTL input, ST = Schmitt Trigger input

Note1: This buffer is a Schmitt Trigger input when configured as the external interrupt or peripheral input.

2: This buffer is a Schmitt Trigger input when used in serial programming mode.

Data Latch

From other

RBPU

(1)

P

V

DD

I/O

QD

CK

QD

CK

QD

EN

QD

EN

DATA BUS

WR PORT

WR TRIS

Set RBIF

TRIS Latch

RD TRIS

RD PORT

RB7:RB4 pins

weak

pull-up

RD PORT

Latch

TTL

Buffer

pin

ST

Buffer

RB7:RB6 in serial programming mode

Q3

Q1

Note 1: To enable weak pull-ups, set the appropriate TRIS bit(s) and clear the RBPU bit (OPTION_REG<7>).

VSS

VDD

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 27

TABLE 3-4 SUMMARY OF REGISTERS ASSOCIATED WITH PORTB

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

06h PORTB RB7 RB6 RB5 RB4 RB3 RB2 RB1 RB0 xxxx xxxx uuuu uuuu

86h TRISB PORTB Data Direction Register 1111 1111 1111 1111

81h OPTION_REG RBPU

INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

Legend: x = unknown, u = unchanged. Shaded cells are not used by PORTB.

PIC16C712/716

DS41106A-page 28 Preliminary

1999 Microchip Technology Inc.

NOTES:

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 29

4.0 TIMER0 MODUL E

The Timer0 module ti mer/count er has the f ollo wing f eatures:

• 8-bit timer/counter

• Readable and writable

• Internal or external clock select

• Edge select for external clock

• 8-bit sof tware programmable prescaler

• Interrupt on overflow from FFh to 00h

Figure 4-1 is a simplified block diagram of the Timer0

module.

Additional information on timer modules is available in

the PICmicro™ Mid-Range Reference Manual,

(DS33023).

4.1 Timer0 Operation

Timer0 can operate as a timer or as a counter.

Timer mode is selected by clearing bit T0CS

(OPTION_REG<5>). In timer mode, the Timer0 module will increment every instruction cycle (without prescaler). If the TMR0 register is written, the increment is

inhibited for the following two instruction cycles. The

user can work around this by writing an adjusted value

to the TMR0 register.

Counter mode is selected by setting bit T0CS

(OPTION_REG<5>). In counter mode, Timer0 will

increment on every rising or falling edge of pin

RA4/T0CKI. The incrementing edge is determined by

the Timer0 Source Edge Select bit T0SE

(OPTION_REG<4>). Clearing bit T0 SE sel ec ts the rising edge. Restrictions on the external clock input are

discussed below.

When an ex ternal clock i nput is used f or Timer0 , it must

meet certain requirements. The requirements ensure

the external cloc k can be synchron ized with the internal

phase clock (T

OSC). Also, there is a delay in the actual

incrementing of Timer0 after synchronization.

Additional information on external clock requirements

is available in the PICmicro™ Mid-Range Reference

Manual, (DS33023).

4.2 Prescaler

An 8-bit counter is available as a prescaler for the

Timer0 module or as a postscaler for the Watchdog

Timer, respectively (Figure 4-2). For simplicity, this

counter is being referred to as “prescaler” throughout

this data sheet. Note that there is only one prescaler

avail able, whic h is mutually exclus ively shar ed between

the Timer0 module and the Watchdog Timer. Thus, a

prescaler assignment for the Timer0 module means

that there is no prescaler for the Watchdog Timer and

vice-versa.

The prescaler is not readable or writable.

The PSA and PS2:PS0 bits (OPTION_REG<3:0>)

determine the prescaler a ssignment an d prescale ratio .

Clearing bit PSA will assign the prescaler to the Time r0

module. When the prescaler is assigned to the Timer0

module, prescale values of 1:2, 1:4, ..., 1:256 are

selectable.

Setting bit PSA will assign the prescaler to the Watchdog Timer (WDT). When the prescaler is assigned to

the WDT, prescale values of 1:1, 1:2, ..., 1:128 are

selectable.

When assigned to the Timer0 module, all instructions

writing to the TMR0 register (e.g . CLRF 1, MOVWF 1,

BSF 1,x....etc.) will clear the prescaler. When

assigned to WDT, a CLRWDT instruction will clear the

prescaler along with the WDT.

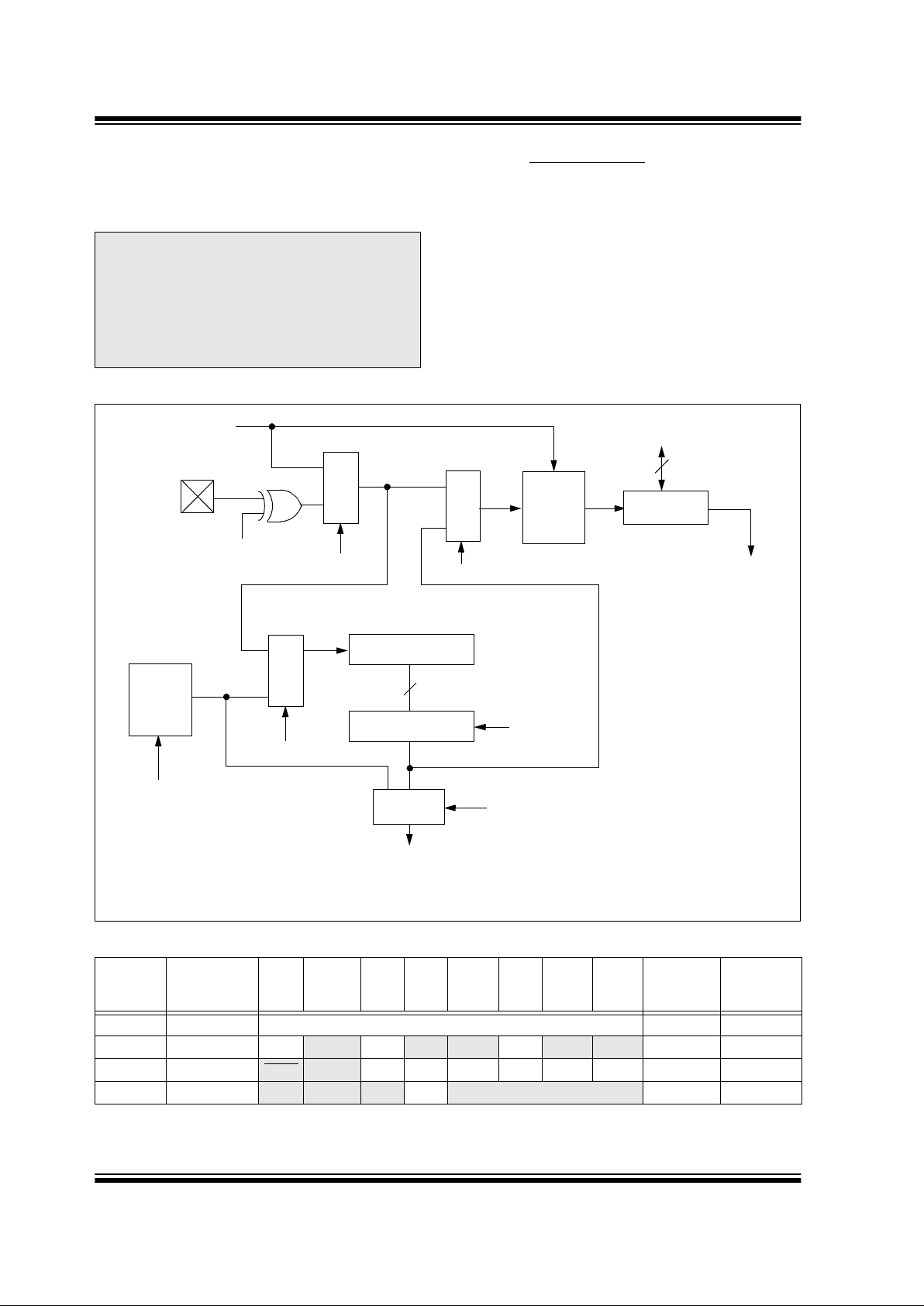

FIGURE 4-1: TIMER0 BLOCK DIAGRAM

Note: Writing to TMR0 when the prescaler is

assigned to Timer0 will clear the prescaler

count, but will not change the prescaler

assignment.

Note 1: T0CS, T0SE, PSA, PS2:PS0 (OPTION_REG<5:0>).

2: The prescaler is shared with Watchdog Timer (refer to Figure 4-2 for detailed block diagram).

RA4/T0CKI

T0SE

(1)

0

1

1

0

pin

T0CS

(1)

FOSC/4

Programmable

Prescaler

(2)

Sync with

Internal

clocks

TMR0

PSout

(2 cycle delay)

PSout

Data Bus

8

PSA

(1)

PS2, PS1, PS0

(1)

Set interrupt

flag bit T0IF

on overflow

3

PIC16C712/716

DS41106A-page 30 Preliminary

1999 Microchip Technology Inc.

4.2.1 SWITCHING PRESCALER ASSIGNMENT

The prescaler assignment is fully under software con-

trol, i.e., it can be changed “on the fly” during program

ex ecution.

4.3 Timer0 Interrupt

The TMR0 interrupt is generated when the TMR0 register overflows from FFh to 00 h. This overflow sets bit

T0IF (INTC ON<2>). The inter rupt can be mas ked by

clearing bit T0IE (INTCON<5>). Bit T0IF must be

cleared in softwa re b y th e Tim er0 mo dule interrupt s ervice routine before re-enabling this interrupt. The

TMR0 interrupt cannot awaken the processor from

SLEEP since the timer is shut off during SLEEP.

FIGURE 4-2: BLOCK DIAGRAM OF THE TIMER0/WDT PRESCALER

TABLE 4-1 REGISTERS ASSOCIATED WITH TIMER0

Note: To avoid an unintended d evice RESET, a

specific instruction sequence (shown in

the PICmicro™ Mid-Range Reference

Manual, DS33023) must be executed

when changing the prescaler a ssignment

from Timer0 to the WDT. This sequence

must be followed even if the WDT is disabled.

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on:

POR,

BOR

Value on all

other resets

01h TMR0 Timer0 module’s register xxxx xxxx uuuu uuuu

0Bh,8Bh INTCON GIE

PEIE T0IE INTE RBIE T0IF INTF RBIF 0000 000x 0000 000u

81h OPTION_REG

RBPU INTEDG T0CS T0SE PSA PS2 PS1 PS0 1111 1111 1111 1111

85h TRISA

— — —

(1)

Bit 4 PORTA Data Direction Register --11 1111 --11 1111

Legend: x = unknown, u = unchanged, - = unimplemented locations read as '0'. Shaded cells are not used by Timer0.

Note 1: Reserved bit; Do Not Use.

RA4/T0CKI

T0SE

pin

M

U

X

CLKOUT (=Fos c/4 )

SYNC

2

Cycles

TMR0 reg

8-bit Prescaler

8 - to - 1MUX

M

U

X

M U X

Watchdog

Timer

PSA

0

1

0

1

WDT

Time-out

PS2:PS0

8

Note: T0CS, T0SE, PSA, PS2:PS0 are (OPTION_REG<5:0>).

PSA

WDT Enable bit

M

U

X

0

1

0

1

Data Bus

Set flag bit T0IF

on Overflow

8

PSA

T0CS

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 31

5.0 TIMER1 MODUL E

The Timer1 module timer/co unter has th e fol lowing f eatures:

• 16-bit timer/counter

(Two 8-bit registers; TMR1H and TMR1L)

• Readable and writable (Both registers)

• Internal or external clock select

• Interrupt on overflow from FFFFh to 0000h

• Reset from CCP module trigger

Timer1 has a control register, shown in Figure 5-1.

Timer1 can be enabled/disabled by setting/clearing

control bit TMR1ON (T1CON<0>).

Figure 5-2 is a simplified block diagram of the Timer1

module.

Additional information on timer modules is available in

the PICmicro™ Mid-Range Reference Manual,

(DS33023).

5.1 Timer1 Operation

Timer1 can operate in one of these modes:

•As a timer

• As a synchronous counter

• As an asynchronous counter

The operating mode is determined by the clock select

bit, TMR1CS (T1CON<1>).

In timer mode, Timer1 increments every instruction

cycle. In coun ter mo de, it in crement s on every risi ng

edge of the external clock input.

When the Timer1 oscillator is enabled (T1OSCEN is

set), the RB2/T1OSI and RB1/T1OSO/T1CKI pins

become inputs. That is, the TRISB<2:1> value is

ignored.

Timer1 also has an in ternal “reset input ”. This reset can

be generated by the CCP module (Section 7.0).

FIGURE 5-1: T1CON: TIMER1 CONTROL REGISTER (ADDRESS 10h)

U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

— — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON

R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7-6: Unimplemented: Read as ’0’

bit 5-4: T1CKPS1:T1CKPS0: Timer1 Input Clock Prescale Select bits

11 = 1:8 Prescale val ue

10 = 1:4 Prescale val ue

01 = 1:2 Prescale val ue

00 = 1:1 Prescale val ue

bit 3: T1OSCEN: Timer1 Oscillator Enable Control bit

1 = Oscillator is enabled

0 = Oscillator is shut off

Note: The oscillator inverter and feedback resistor are turned off to eliminate power drain

bit 2: T1SYNC

: Timer1 External Clock Input Synchronization Control bit

TMR1CS = 1

1 = Do not synchronize external clock input

0 = Synchronize external clock input

TMR1CS = 0

This bit is ignored. Timer1 uses the internal clock when TMR1CS = 0.

bit 1: TMR1CS: Timer1 Clock Source Select bit

1 = External clock from pin RB1/T1OSO/T1CKI (on the rising edge)

0 = Internal clock (F

OSC/4)

bit 0: TMR1ON: Timer1 On bit

1 = Enables Timer1

0 = Stops Timer1

PIC16C712/716

DS41106A-page 32 Preliminary

1999 Microchip Technology Inc.

FIGURE 5-2: TIMER1 BLOCK DIAGRAM

5.2 Timer1 Module and PORTB Operation

When Timer1 is configured as timer running from the

main oscillator, PORTB<2:1> operate as normal I/O

lines. When Timer1 is configured to function as a

counter however, the clock source selection may affect

the operation of PORTB<2:1>. Multiplexing details of

the Timer1 clock sel ection on POR TB are shown in Figure 3-4 and Figure 3-5.

The clock source for Timer1 in the counter mode can

be from one of the following:

1. External circuit connected to the

RB1/T1OSO/T1CKI pin

2. Firmware controlled DATACCP<0> bit, DT1CKI

3. Timer1 oscillator

Table 5-1 shows the details of Timer1 mod e selecti ons,

control bit settings, TMR1 and PORTB operations.

TMR1H

TMR1L

T1OSC

T1SYNC

TMR1CS

T1CKPS1:T1CKPS0

SLEEP input

T1OSCEN

Enable

Oscillator

(1)

FOSC/4

Internal

Clock

TMR1ON

on/off

Prescaler

1, 2, 4, 8

Synchronize

det

1

0

0

1

Synchronized

clock input

2

RB1/T1OSO/T1CKI

RB2/T1OSI

Note 1: When the T1OSCEN bit is cleared, the inverter and feedback resistor are turned off. This eliminates power drain.

Set flag bit

TMR1IF on

Overflow

TMR1

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 33

TABLE 5-1 TMR1 MODULE AND PORTB OPERATION

TMR1

Module

Mode

Clock Source Control Bits TMR1 Module Operation PORTB<2:1> Operation

Off N/A T1CON = --xx 0x00 Off PORTB<2:1> function as normal

I/O

Timer Fosc/4 T1CON = -- xx 0x01 TMR1 module uses the main

oscillator as clock source.

TMR1ON can turn on or turn off

Timer1.

PORTB<2:1> function as normal

I/O

Counter

External circuit T1CON = --xx 0x11

TR1SCCP = ---- -x-1

TMR1 module uses the external

signal on the

RB1/T1OSO/T1CKI pin as a

clock source. TMR1ON can turn

on or turn off Timer1. DT1CK

can read the signal on the

RB1/T1OSO/T1CKI pin.

PORTB<2> functions as normal

I/O. PORTB<1> always reads 0

when configured as input . If

PORTB<1> is configured as output, reading POR TB< 1> wi ll read

the data latch. Writing to

PORTB<1> will always store the

result in the data latch, but not to

the RB1/T1OSO/T1CKI pin. If

the TMR1CS bit is cleared

(TMR1 reverts to the timer

mode), then pin PORTB<1> will

be driven with the value in the

data latch.

Firmware T1CON = --xx 0x11

TR1SCCP = ---- -x-0

DATACCP<0> bit drives

RB1/T1OSO/T1CKI and produces the TMR1 clock source.

TMR1ON can turn on or turn off

Timer1. The DATACCP<0> bit,

DT1CK, can read and write to

the RB1/T1OSO/T1CKI pin.

Timer1 osci llator T1CON = --xx 1x11 RB1/T1OSO/T1CKI and

RB2/T1OSI are configured as a

2 pin crystal oscillator.

RB1/T1OSI/T1CKI is the clock

input for TMR1. TMR1ON can

turn on or turn off Timer1.

DATACCP<1> bit, DT1CK,

always rea ds 0 as in put and ca n

not write to the

RB1/T1OSO/T1CK1 pin .

PORTB<2:1> always read 0

when configured as inputs. If

PORTB<2:1> are config ured as

outputs, reading PORTB<2:1>

will read the data latche s. Writing

to PORTB<2:1> will always store

the result in the data latches, but

not to the RB2/T1OSI and

RB1/T1OSO/T1CKI pins. If the

TMR1CS and T1OSCEN bits are

cleared (TMR1 reverts to the

timer mode and TMR1 oscillator

is disabled), then pin

PORTB<2:1> will be driven with

the value in the data latches.

PIC16C712/716

DS41106A-page 34 Preliminary

1999 Microchip Technology Inc.

5.3 Timer1 Oscillator

A crystal oscillator circuit is b uilt in betw een pins T1OSI

(input) and T1OSO (amplifier output). It is enabled by

setting control bit T1OSCEN (T 1CON<3>). The oscill ator is a low power oscillator rated up to 200 kHz. It will

continue to run during SLEEP. It is primarily intended

for a 32 kHz crystal. Table 5-2 shows the capacitor

selection for the Timer1 oscillator.

The Timer1 oscillator is identical to the LP oscillator.

The user must provide a software time delay to ensure

proper oscillator start-up.

TABLE 5-2 CAPACITOR SELECTION FOR

THE TIMER1 OSCILLATOR

5.4 Timer1 Interrupt

The TMR1 Register pair (TMR1H:TMR1L) increments

from 0000h to FFFFh and rolls over to 0000h. The

TMR1 interrupt, if enabled, is generated on overflow

which is latched in int errupt flag bit TMR1IF (P IR1<0>).

This interrupt can be enab led/disa bled by se tting/cle aring TMR1 interrupt enable bit TMR1IE (PIE1<0>).

5.5 Resetting Timer1 using a CCP T rigger

Output

If the CCP module is configured in compare mode to

generate a “special event trigger" (CCP1M3:CCP1M0

= 1011), this signal will reset Timer1 and start an A/D

conversion (if the A/D module is enabled).

Timer1 must be configured for either timer or synchronized counter mode to tak e advan tage of this fea ture. If

Timer1 is running in asynchronous counter mode, this

reset operation may not work.

In the ev ent that a write t o Timer1 coinc ides with a sp ecial event trigger from CCP1, the write will take precedence.

In this mode of op erati on, the CC PR1H:CCPR 1L registers pair effectively becomes the period register for

Timer1.

TABLE 5-3 REGISTERS ASSOCIATED WITH TIMER1 AS A TIMER/COUNTER

Osc Type Freq C1 C2

LP 32 kHz 33 pF 33 pF

100 kHz 15 pF 15 pF

200 kHz 15 pF 15 pF

These values are for design guidance only.

Note 1: Higher capacitance increases the stability

of oscillator but also increases the start-up

time.

2: Since each resonator/crystal has its own

characteristics, the user should consult the

resonator/crystal manufacturer for app ropriate values of external components.

Note: The special event triggers from the CCP1

module will not set interrupt flag bit

TMR1IF (PIR1<0>).

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on

POR,

BOR

Val ue on

all other

resets

0Bh,8Bh INTCON GIE PEIE

T0IE INTE RBIE T0IF INTF RBIF

0000 000x 0000 000u

0Ch PIR1

— ADIF — — — CCP1IF TMR2IF TMR1IF

-0-- -000 -0-- -000

8Ch PIE1

— ADIE — — — CCP1IE TMR2IE TMR1IE

-0-- -000 -0-- -000

0Eh TMR1L Holding register for the Least Significant Byte of the 16-bit TMR1 register

xxxx xxxx uuuu uuuu

0Fh TMR1H Holding register for the Most Significant Byte of the 16-bit TMR1 register

xxxx xxxx uuuu uuuu

10h T1CON

— — T1CKPS1 T1CKPS0 T1OSCEN T1SYNC TMR1CS TMR1ON

--00 0000 --uu uuuu

07h DATACCP

— — — — — DCCP —DT1CK

---- -x-x ---- -u-u

87h TRISCCP

— — — — — TCCP —TT1CK

---- -1-1 ---- -1-1

Legend: x = unknown, u = unchanged, - = unimplemented read as '0'. Shaded cells are not used by the Timer1 module.

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 35

NOTES:

PIC16C712/716

DS41106A-page 36 Preliminary

1999 Microchip Technology Inc.

6.0 TIMER2 MODULE

The Timer2 module timer has the following features:

• 8-bit timer (TMR2 register)

• 8-bit period register (PR2)

• Readable and writable (Both registers)

• Software programmable prescaler (1:1, 1:4, 1:16)

• Software programmable postscaler (1:1 to 1:16)

• Interrupt on TMR2 match of PR2

Timer2 has a control register, shown in Figure 6-1.

Timer2 can be shut off by clearing con trol bi t T MR 2ON

(T2CON<2>) to minimize power consumption.

Figure 6-2 is a simplified block diagram of the Timer2

module.

Additional information on timer modules is available in

the PICmicro™ Mid-Range Reference Manual,

(DS33023).

FIGURE 6-1: T2CON: TIMER2 CONTROL REGISTER (ADDRESS 12h)

FIGURE 6-2: TIMER2 BLOCK DIAGRAM

U-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

— TOUTPS3 TOUTPS2 TOUTPS1 TOUTPS0 TMR2ON T2CKPS1 T2CKPS0 R = Readable bit

W = Writable bit

U = Unimplemented bit,

read as ‘0’

- n = Value at POR reset

bit7 bit0

bit 7: Unimplemented: Read as '0'

bit 6-3: TOUTPS3:TOUTPS0: Timer2 Output Postscale Select bits

0000 = 1:1 Postscale

0001 = 1:2 Postscale

0010 = 1:3 Postscale

0011 = 1:4 Postscale

0100 = 1:5 Postscale

0101 = 1:6 Postscale

0110 = 1:7 Postscale

0111 = 1:8 Postscale

1000 = 1:9 Postscale

1001 = 1:10 Postscale

1010 = 1:11 Postscale

1011 = 1:12 Postscale

1100 = 1:13 Postscale

1101 = 1:14 Postscale

1110 = 1:15 Postscale

1111 = 1:16 Postscale

bit 2: TMR2ON: Timer2 On bit

1 = Timer2 is on

0 = Timer2 is off

bit 1-0: T2CKPS1:T2CKPS0: Timer2 Clock Prescale Select bits

00 = Prescaler is 1

01 = Prescaler is 4

1x = Prescaler is 16

Comparator

TMR2

Sets flag

TMR2 reg

output

Reset

Postscaler

Prescaler

PR2 reg

2

F

OSC/4

1:1 1:16

1:1, 1:4, 1:16

EQ

4

bit TMR2IF

to

PIC16C712/716

1999 Microchip Technology Inc.

Preliminary DS41106A-page 37

6.1 Timer2 Operation

Timer2 can be used as the PWM time-base for PWM

mode of the CCP module.

The TMR2 register is readable and writable, and is

cleared on any device reset.

The input clock (F

OSC/4) has a prescale option of 1:1,

1:4 or 1:16, selected by control bits

T2CKPS1:T2CKPS0 (T2CON<1:0>).

The match output of TMR2 goes through a 4-bit

postscaler (which gives a 1:1 to 1:16 scaling inclusive)

to generate a TMR2 interrupt (latched in flag bit

TMR2IF, (PIR1<1>)).

The prescaler and postscaler counters are cleared

when any of the following occurs:

• a write to the TMR2 register

• a write to the T2CON register

• any device reset (Power-on Reset, MCLR

reset,

Watchdog Timer reset, or Brown-out Reset)

TMR2 is not cleared when T2CON is written.

6.2 Timer2 Interrupt

The Timer2 module has an 8-bit period register PR2.

Timer2 increments from 00h until it matches PR2 and

then resets to 00h on the next increment cycle. PR2 is

a readable and writable regi ster. The PR2 register is initialized to FFh upon reset.

TABLE 6-1 REGISTERS ASSOCIATED WITH TIMER2 AS A TIMER/COUNTER

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Value on

POR,

BOR

Value on

all other

resets

0Bh,8Bh INTCON GIE PEIE

T0IE INTE RBIE T0IF INTF RBIF

0000 000x 0000 000u

0Ch PIR1

— ADIF — —

—

CCP1IF TMR2IF TMR1IF

-00- -000 0000 -000

8Ch PIE1

— ADIE — —

—

CCP1IE TMR2IE TMR1IE

-0-- -000 0000 -000

11h TMR2 Timer2 module’s register

0000 0000 0000 0000

12h T2CON