Datasheet HCS410T-I-ST, HCS410T-I-SN, HCS410T-I-P, HCS410-I-ST, HCS410-I-SN Datasheet (Microchip Technology Inc)

...Page 1

1997 Microchip Technology Inc.

Preliminary

DS40158C-page 1

M

HCS410

FEATURES

Security

• Two programmable 64-bit encoder keys

• 16/32-bit bi-directional challenge and response

using one of two keys

• 69-bit transmission length

• 32-bit unidirectional code hopping, 37-bit

nonencrypted portion

• Encoder keys are read protected

• Programmable 28/32-bit serial number

• 60/64-bit, read-protected seed for secure learning

• Three IFF encryption algorithms

• Delayed increment mechanism

• Asynchronous transponder communication

• Queuing information transmitted

Operating

• 2.0V to 6.6V operation, 13V encoder only

operation

• Three switch inputs [S2, S1, S0]—sev en functions

• Batteryless bi-directional transponder

• Selectable baud rate and code word blanking

• Automatic code word completion

• Battery low signal transmitted

• Nonvolatile synchronization

• PWM or Manchester RF encoding

• Combined transmitter, transponder operation

• Anti-collision of multiple transponders

• Passive proximity activation

• Device protected against reverse battery

• Intelligent damping for high Q LC-circuits

Other

• 37-bit nonencrypted part contains 28/32-bit serial

number, 4/0-bit function code, 1-bit battery low,

2-bit CRC, 2-bit queue

• Simple programming interface

• On-chip tunable RC oscillator ( ± 10%)

• On-chip EEPROM

• 64-bit user EEPROM in transponder mode

• Battery-low LED indication

• SQTP serialization quick-time programming

• 8-pin PDIP/SOIC/TSSOP and die

Typical Applications

• Automotive remote entry systems

• Automotive alarm systems

• Automotive immobilizers

• Gate and garage openers

• Electronic door locks (Home/Office/Hotel)

• Burglar alarm systems

• Proximity access control

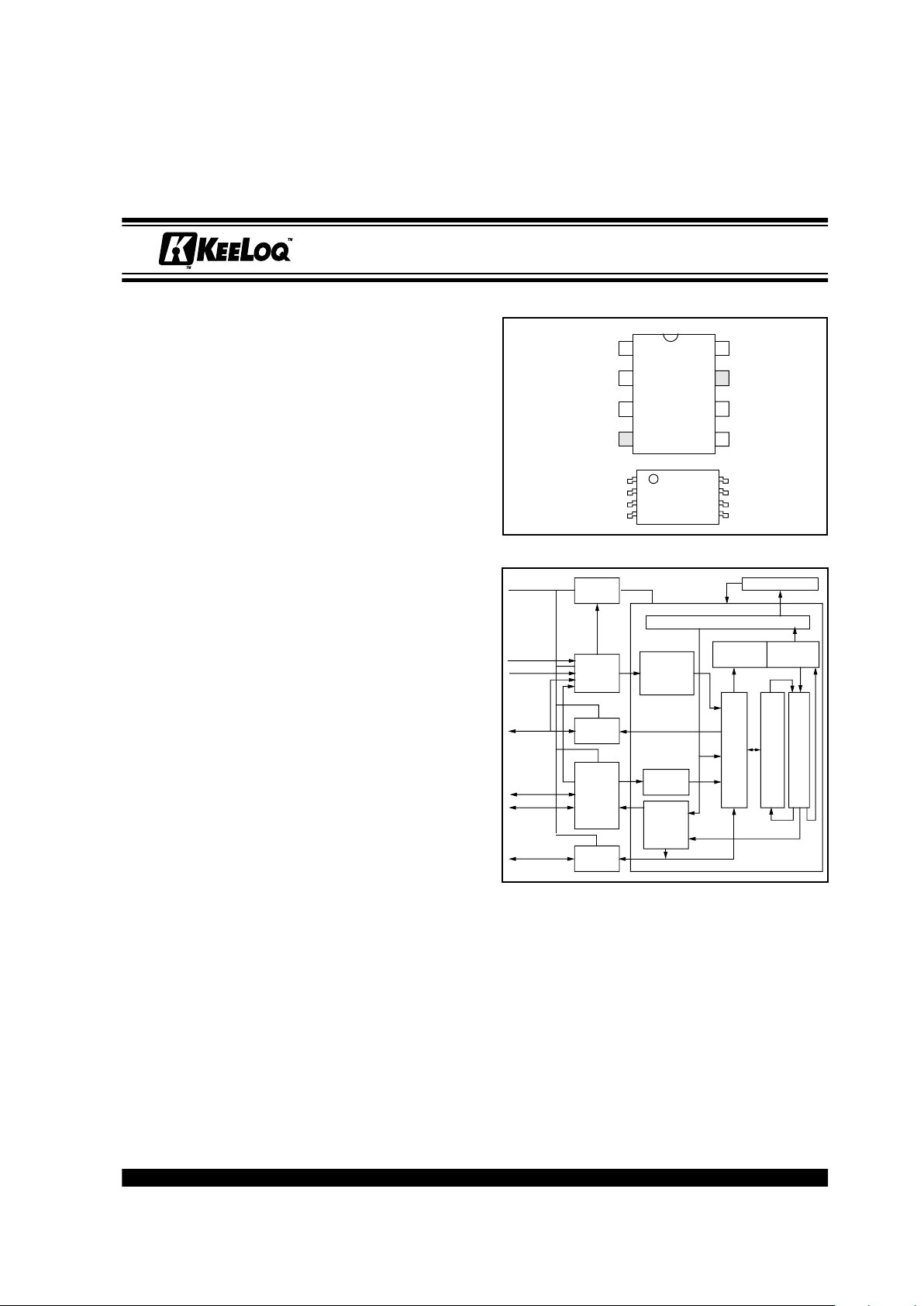

PACKA GE TYPES

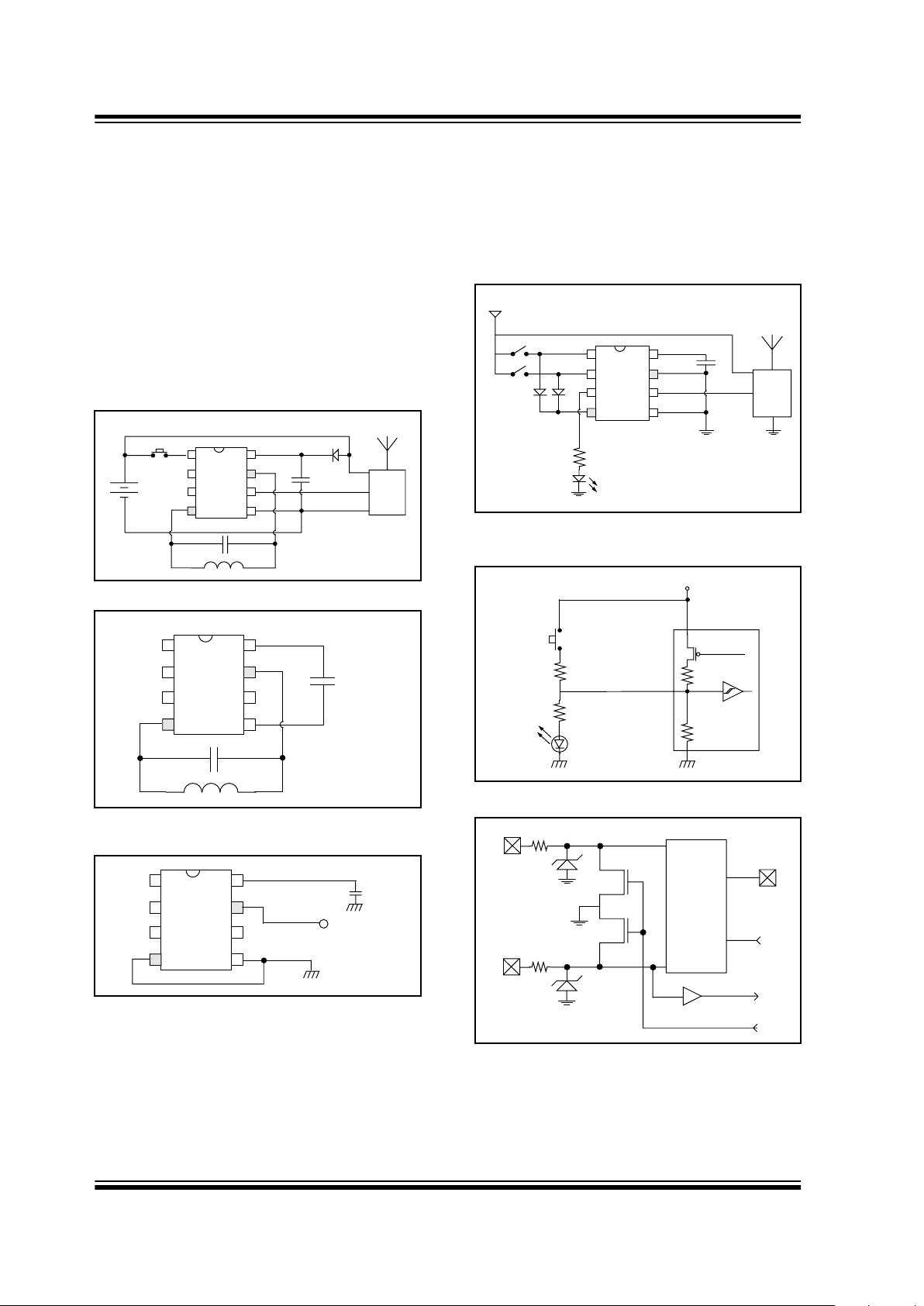

BLOCK DIAGRAM

HCS410

S0

S1

S2/LED

LC1

VDD

LC0

PWM

GND

18

2

3

4

7

6

5

PDIP, SOIC

HCS410

S2/LED

LC1

GND

PWM

1

2

3

4

8

7

6

5

S1

S0

V

DD

LC0

TSSOP

Oscillator

Configuration Register

Power

Control

Wakeup

Logic

Address

Decoding

EEPROM

Debounce

Control

and

Queuer

LED

Control

PWM

Driver

PPM

Detector

PWM

PPM

Manch.

Encoder

Transponder

Circuitry

Control Logic

and Counters

Encryption/Increment

Logic

Register

VDD

S0

S1

S2

LCI0

LCI1

PWM

Code Hopping Encoder and Transponder*

K

EE

L

OQ

is a registered trademark of Microchip Technology Inc.

*Code hopping encoder patents issued in Europe, U.S.A., R.S.A.—U.S.A.: 5,517,187; Europe: 0459781

Page 2

HCS410

DS40158C-page 2

Preliminary

1997 Microchip Technology Inc.

Table of Contents

1.0 System Overview ....................................................................................................................................................3

1.1 Key Terms ........................................................................................................................................................3

1.2

K

EELOQ

Code Hopping Encoders .....................................................................................................................4

1.3 K

EE

L

OQ

IFF ......................................................................................................................................................5

2.0 Device Operation ....................................................................................................................................................6

2.1 Pinout Description ............................................................................................................................................7

2.2 Code Hopping Mode (CH Mode) .....................................................................................................................8

2.3 Code Hopping Mode Special Features ..........................................................................................................11

2.4 IFF Mode ........................................................................................................................................................14

2.5 IFF Opcodes ..................................................................................................................................................17

2.6 IFF Special Features ......................................................................................................................................18

2.7 LED Indicator .................................................................................................................................................18

3.0 EEPROM Organization and Configuration ............................................................................................................19

3.1 Encoder Key 1 and 2 .....................................................................................................................................19

3.2 Discrimination Value and Overflow ................................................................................................................19

3.3 16-bit Synchronization Counter ......................................................................................................................19

3.4 60/64-bit Seed Word/Transport Code ............................................................................................................20

3.5 Encoder Serial Number ..................................................................................................................................20

3.6 User Data .......................................................................................................................................................20

3.7 Configuration Data .........................................................................................................................................21

4.0 Integrating the HCS410 into a System ..................................................................................................................23

4.1 Key Generation ..............................................................................................................................................23

4.2 Learning an HCS410 to a Receiver ...............................................................................................................24

4.3 CH Mode Decoder Operation ........................................................................................................................25

4.4 IFF Decoder Operation ..................................................................................................................................27

5.0 Electrical Characteristics .......................................................................................................................................28

HCS410 Product Identification System ........................................................................................................................35

Page 3

HCS410

1997 Microchip Technology Inc.

Preliminary

DS40158C-page 3

DESCRIPTION

The HCS410 is a code hopping transponder device

designed for secure entry systems. The HCS410 utilizes the patented K

EELOQ

code hopping system and

bi-directional challenge-and-response for logical and

physical access control. High security learning mechanisms make this a turnkey solution when used with the

K

EELOQ

decoders. The encoder keys and synchronization information are stored in protected on-chip

EEPROM.

A low cost batteryless transponder can be implemented with the addition of an inductor and two capacitors. A packaged module including the inductor and

capacitor will also be offered.

A single HCS410 can be used as an encoder for

Remote Keyless Entry (RKE) and a transponder for

immobilization in the same circuit and thereby dramatically reducing the cost of hybrid transmitter/transponder circuits.

1.0 SYSTEM OVERVIEW

1.1 Key Terms

• Anticollision

– Allows two transponders to be in

the files simultaneously and be verified individually.

• CH Mode

– Code Hopping Mode. The HCS410

transmits a 69-bit transmission each time it is activated, with at least 32-bits changing each time the

encoder is activated.

•E

ncoder Key – A unique 64-bit k ey gener ated and

programmed into the encoder during the manufacturing process. The encoder key controls the

encryption algorithm and is stored in EEPROM on

the encoder device.

• IFF

– Identify friend or foe is a means of validating

a token. A decoder sends a random challenge to

the token and checks that the response of the

token is a valid response.

•K

EE

L

OQ

Encr

yption Algorithm – The high security

level of the HCS410 is based on the patented

K

EE

L

OQ

technology. A block cipher encryption

algorithm based on a block length of 32 bits and a

key length of 64 bits is used. The algorithm

obscures the information in such a way that even

if the unencrypted/challenge information differs by

only one bit from the information in the previous

transmission/challenge, the next coded transmission/response will be totally different. Statistically,

if only one bit in the 32-bit string of information

changes, approximately 50 percent of the coded

transmission will change.

•L

earn – The HCS product family f acilitates sev eral

learning strategies to be implemented on the

decoder. The following are examples of what can

be done.

Normal Learn –The receiver uses the same infor-

mation that is transmitted during normal operation to

derive the transmitter’s encoder key, decrypt the discrimination value and the synchronization counter.

Secure Learn* – The transmitter is activ ated through

a special button combination to transmit a stored

60-bit value (random seed) that can be used for key

generation or be part of the key. Transmission of the

random seed can be disabled after learning is completed.

•M

anufacturer’s Code – A 64-bit word, unique to

each manufacturer, used to produce a unique

encoder key in each transmitter (encoder).

•P

assive Proximity Activ ation – When the HCS410

is brought into in a magnetic field without a

command given by the base station, the HCS410

can be programmed to give an RF transmission.

•T

ransport Code – A 32-bit transport code needs

to be given before the HCS410 can be inductiv ely

programmed. This prevents accidental

programming of the HCS410.

*Secure Learn patent pending.

Page 4

HCS410

DS40158C-page 4

Preliminary

1997 Microchip Technology Inc.

1.2 K

EE

L

OQ

Code Hopping Encoders

When the HCS410 is used as a code hopping encoder

device, it is ideally suited to keyless entry systems,

primarily for vehicles and home garage door openers.

It is meant to be a cost-effective, yet secure solution to

such systems. The encoder portion of a keyless entry

system is meant to be carried by the user and operated

to gain access to a vehicle or restricted area.

Most keyless entry systems transmit the same code

from a transmitter every time a button is pushed. The

relative number of code combinations for a low end

system is also a relatively small number. These

shortcomings provide the means for a sophisticated

thief to create a device that ‘grabs’ a transmission and

retransmits it later or a device that scans all possible

combinations until the correct one is found.

The HCS410 employs the K

EE

L

OQ

code hopping technology and an encryption algorithm to achieve a high

level of security. Code hopping is a method by which

the code transmitted from the transmitter to the

receiver is different every time a button is pushed. This

method, coupled with a transmission length of 69 bits,

virtually eliminates the use of code ‘grabbing’ or code

‘scanning’.

The HCS410 has a small EEPROM array which must

be loaded with several parameters before use. The

most important of these values are:

• A 28/32-bit serial number which is meant to be

unique for every encoder

• 64-bit seed value

• A 64-bit encoder key that is generated at the time

of production

• A 16-bit synchronization counter value.

• Configuration options

The 16-bit synchronization counter value is the basis

for the transmitted code changing for each transmission, and is updated each time a button is pressed.

Because of the complexity of the code hopping encryption algorithm, a change in one bit of the synchronization counter value will result in a large change in the

actual transmitted code.

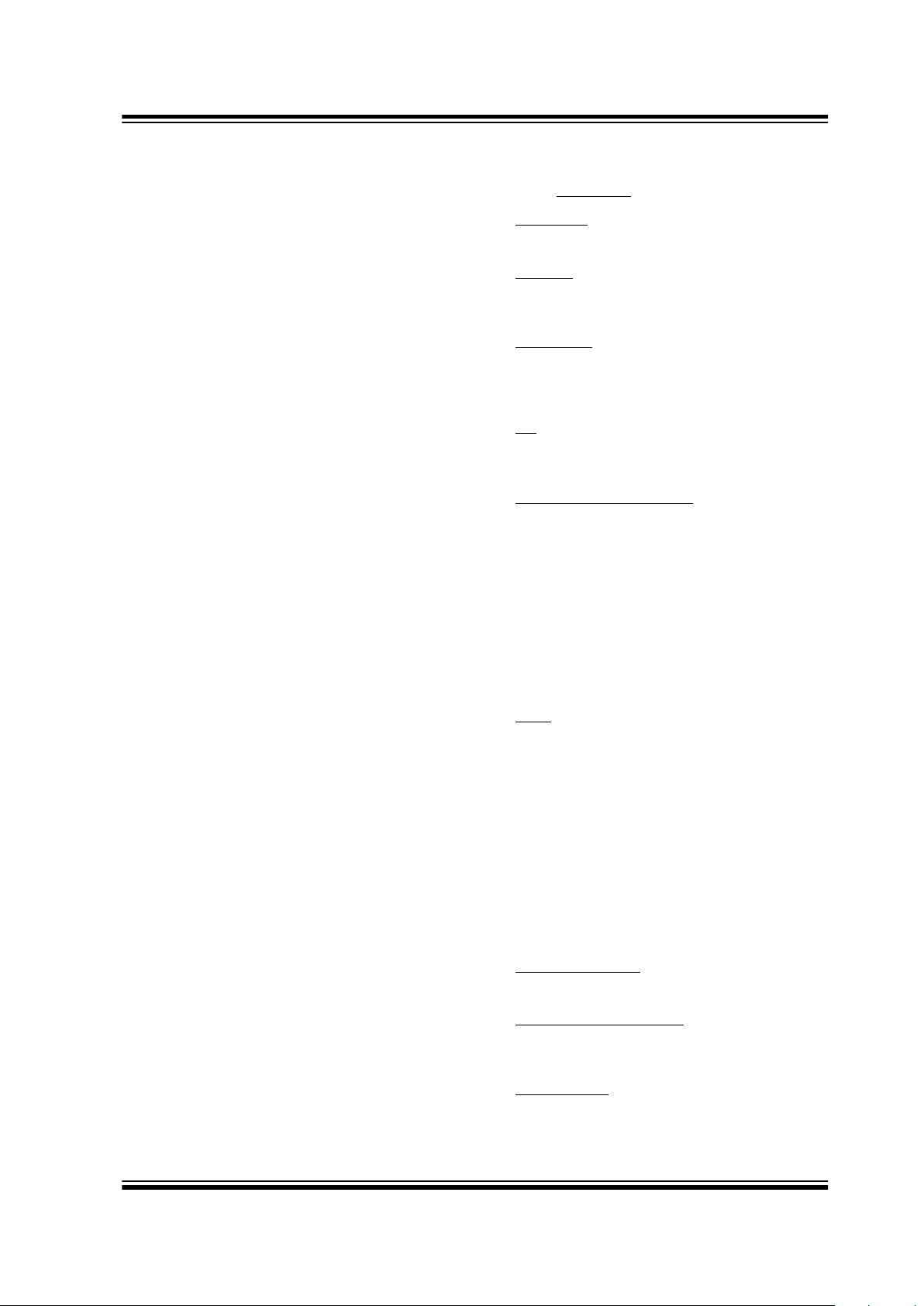

Once the encoder detects that a button has been

pressed, the encoder reads the button and updates the

synchronization counter. The synchronization counter

value, the function bits, and the discrimination value are

then combined with the encoder key in the encryption

algorithm, and the output is 32 bits of encrypted information (Figure 1-1). The code hopping portion provides up to four billion changing code combinations.

This data will change with every button press, hence, it

is referred to as the code hopping portion of the code

word.

The 32-bit code hopping portion is combined with the

button information and the serial number to form the

code word transmitted to the receiver. The code word

format is explained in detail in Section 2.2.

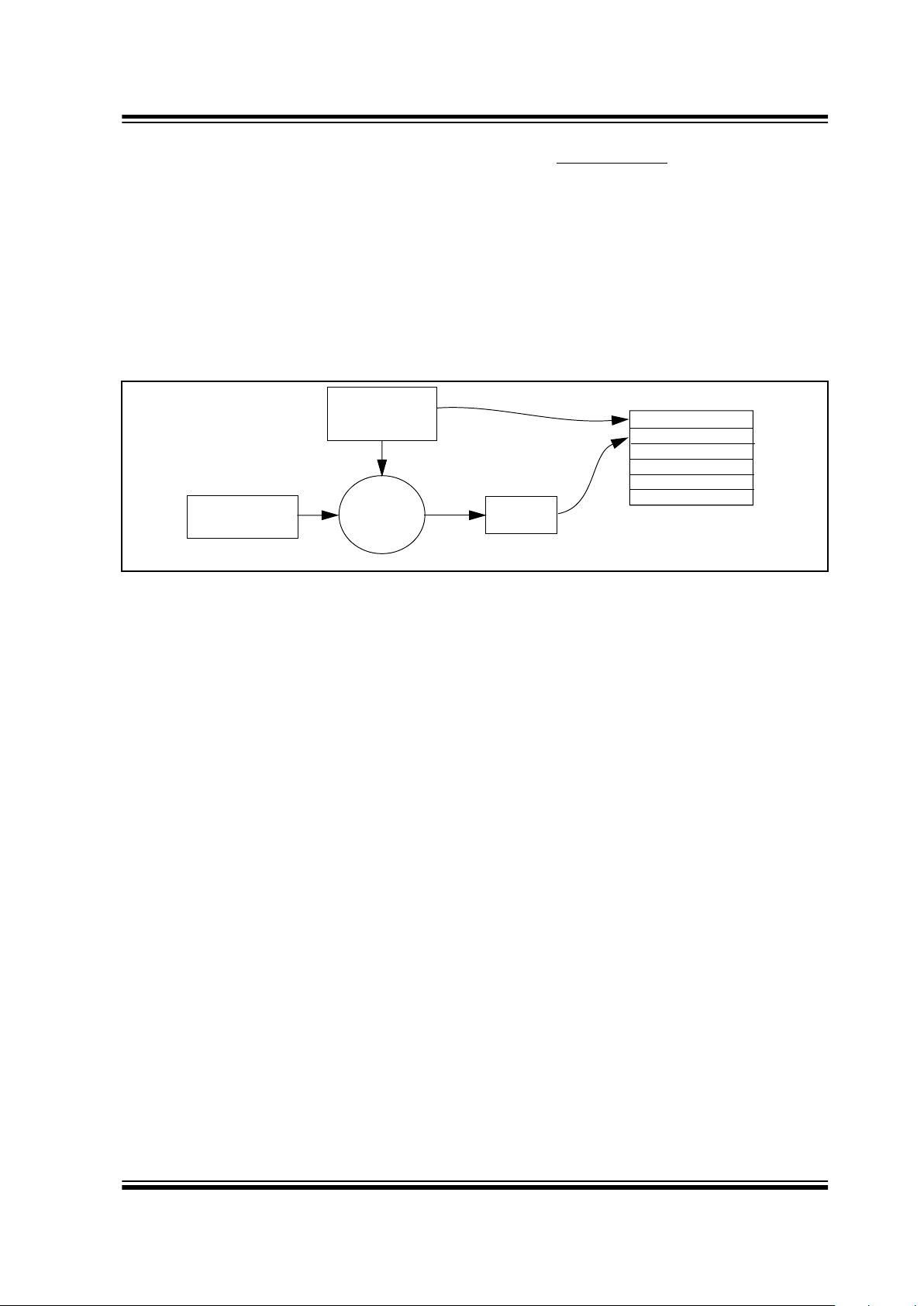

FIGURE 1-1: BASIC OPERATION OF A CODE HOPPING TRANSMITTER (ENCODER)

KEELOQ

Algorithm

Button Press

Information

Encryption

EEPROM Array

32 Bits of

Encrypted Data

Serial Number

Transmitted Information

Encoder Key

Sync Counter

Serial Number

Page 5

HCS410

1997 Microchip Technology Inc.

Preliminary

DS40158C-page 5

1.3 K

EE

L

OQ

IFF

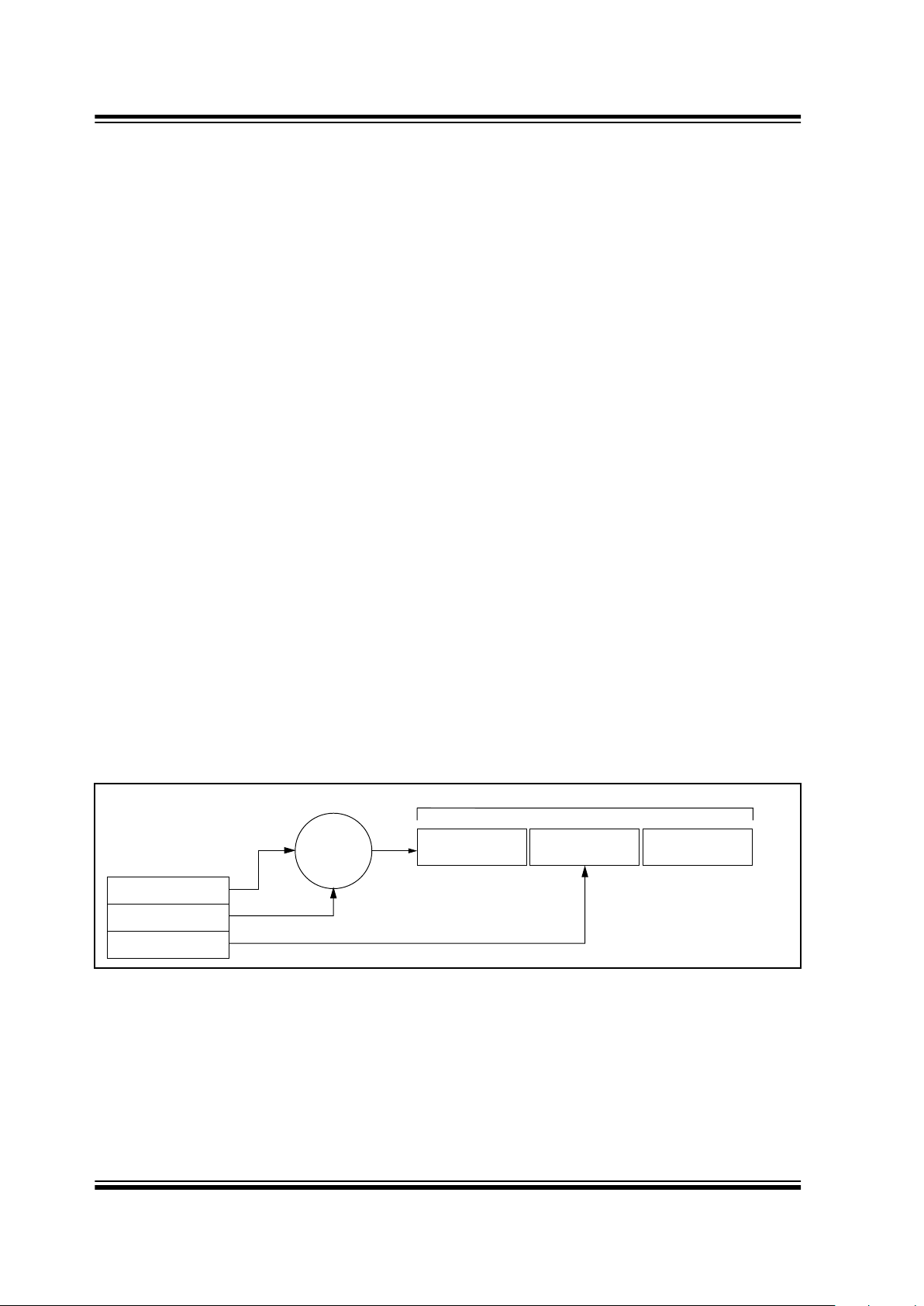

The HCS410 can be used as an IFF transponder for

verification of a token. In IFF mode the HCS410 is ideally suited for authentication of a key before disarming

a vehicle immobilizer. Once the key has been inserted

in the car’s ignition the decoder would inductively poll

the key validating it before disarming the immobilizer.

IFF validation of the token inv olves a r andom challenge

being sent by a decoder to a token. The token then generates a response to the challenge and sends this

response to the decoder (Figure 1-2). The decoder calculates an expected response using the same challenge. The expected response is compared to the

response received from the token. If the responses

match, the token is identified as a valid token and the

decoder can take appropriate action.

The HCS410 can do either 16 or 32-bit IFF. The

HCS410 has two encryption algorithms that can be

used to generate a response to a challenge. In addition

there are up to two encoder keys that can be used by

the HCS410. Typically each HCS410 will be programmed with a unique encoder key(s).

In IFF mode, the HCS410 will wait for a command from

the base station and respond to the command. The

command can either request a read/write from user

EEPROM or an IFF challenge response. A given 16 or

32-bit challenge will produce a unique 16/32-bit

response, based on the IFF key and IFF algorithm

used.

FIGURE 1-2: IBASIC OPERATION OF AN IFF TOKEN

IFF Key

Serial Number

KEELOQ

IFF

Algorithm

Serial Number

EEPROM Array

Challenge Received from Decoder

Response

Read by Decoder

Page 6

HCS410

DS40158C-page 6

Preliminary

1997 Microchip Technology Inc.

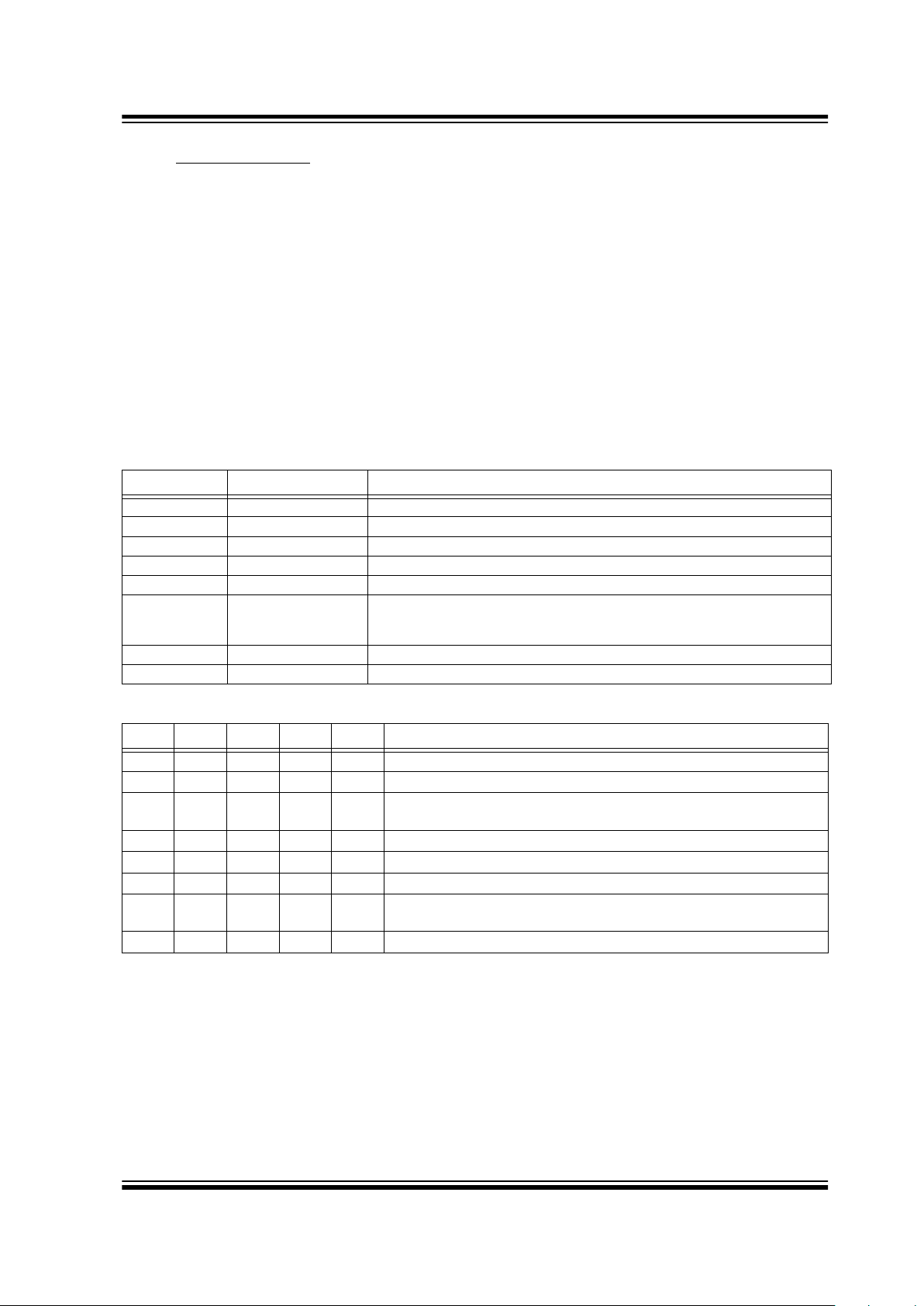

2.0 DEVICE OPERATION

The HCS410 can either operate as a normal code hopping transmitter with one or two IFF keys (Figure 2-1) or

as purely an IFF token with two IFF keys (Figure 2-2

and Figure 2-3). When used as a code hopping transmitter the HCS410 only needs the addition of buttons

and RF circuitry for use as a transmitter. Adding the

transponder function to the transmitter requires the

addition of an inductor and two capacitors as shown in

Figure 2-1 and Figure 2-2. A description of each pin is

given in Table 2-1. Table 2-2 shows the function codes

for using the HCS410.

FIGURE 2-1: COMBINED TRANSMITTER/

TRANSPONDER CIRCUIT

FIGURE 2-2: TRANSPONDER CIRCUIT

FIGURE 2-3: 2-WIRE, 1 OR 2-KEY IFF

TOKEN

Figure 2-4 shows how to use the HCS410 with a 12V

battery as a code hopping transmitter. The circuit uses

the internal regulator, normally used for charging a

capacitor/battery in LC mode, to generate a 6V supply

for the HCS410.

FIGURE 2-4: HCS410 ENCODER WITH 12V

BATTERY

FIGURE 2-5: LED CONNECTION TO

S2/LED OUTPUT

FIGURE 2-6: LC PIN BLOCK DIAGRAM

18

RF

2

3

4

7

6

5

1 µF

18

2

3

4

7

6

5

1 µF

18

2

3

4

7

6

5

1 µF

Data I/O

18

RF

2

3

4

7

6

5

6.3V

12V

Pulse

VDD

S2/LED

220Ω

220Ω

60k

30Ω

VDD

6.7V

Damp

Out

MOD

Detector

Rectifier,

Damping,

Clamping

15V

15V

100Ω

100Ω

LCI1

LCI0

Page 7

HCS410

1997 Microchip Technology Inc.

Preliminary

DS40158C-page 7

2.1 Pinout Description

The HCS410 has the same footprint as all of the other

devices in the K

EE

L

OQ

family, except for the two pins

that are reserved for transponder operations and the

LED that is now located at the same position as the S2

switch input.

• S[0:1] – are inputs with Schmitt Trigger detectors

and an internal 60k Ω (nominal) pull-down

resistors.

• S2/LED – uses the same input detection circuit as

S0/S1 but with an added PMOS transistor connected to V

DD

capable of sourcing enough current

to drive an LED.

• LC[0:1] – is the transponder interface pins to be

connected to an LC circuit for inductive communication. LC0 is connected to a detector for data

input. Data output is achieved by clamping LC0

and LC1 to GND through two NMOS transistors.

These pins are also connected to a rectifier and a

regulator, providing power to the rest of the logic

and for charging an external power source (Battery/Capacitor) through V

DD

.

TABLE 2-1: PINOUT DESCRIPTION

Name Pin Number Description

S0 1 Switch input 0

S1 2 Switch input 1

S2/LED 3 Switch input 2/LED output, Clock pin for programming mode

LC1 4 Transponder interface pin

V

SS

5 Ground reference connection

PWM 6 Pulse width modulation (PWM)

output pin/Data pin for

programming mode

LC0 7 Transponder interface pin.

V

DD

8 Positive supply voltage connection

TABLE 2-2: FUNCTION CODES

LC0 S2 S1 S0 Comments

10001Normal Code Hopping transmission

20010Normal Code Hopping transmission

30011

Delayed seed transmission if allowed by SEED and TMPSD/Normal

Code Hopping transmission

40100Normal Code Hopping transmission

50101Normal Code Hopping transmission

60110Normal Code Hopping transmission

70111

Immediate seed transmission if allowed by SEED and TMPSD/Normal

Code Hopping transmission

81000Transponder mode

Page 8

HCS410

DS40158C-page 8

Preliminary

1997 Microchip Technology Inc.

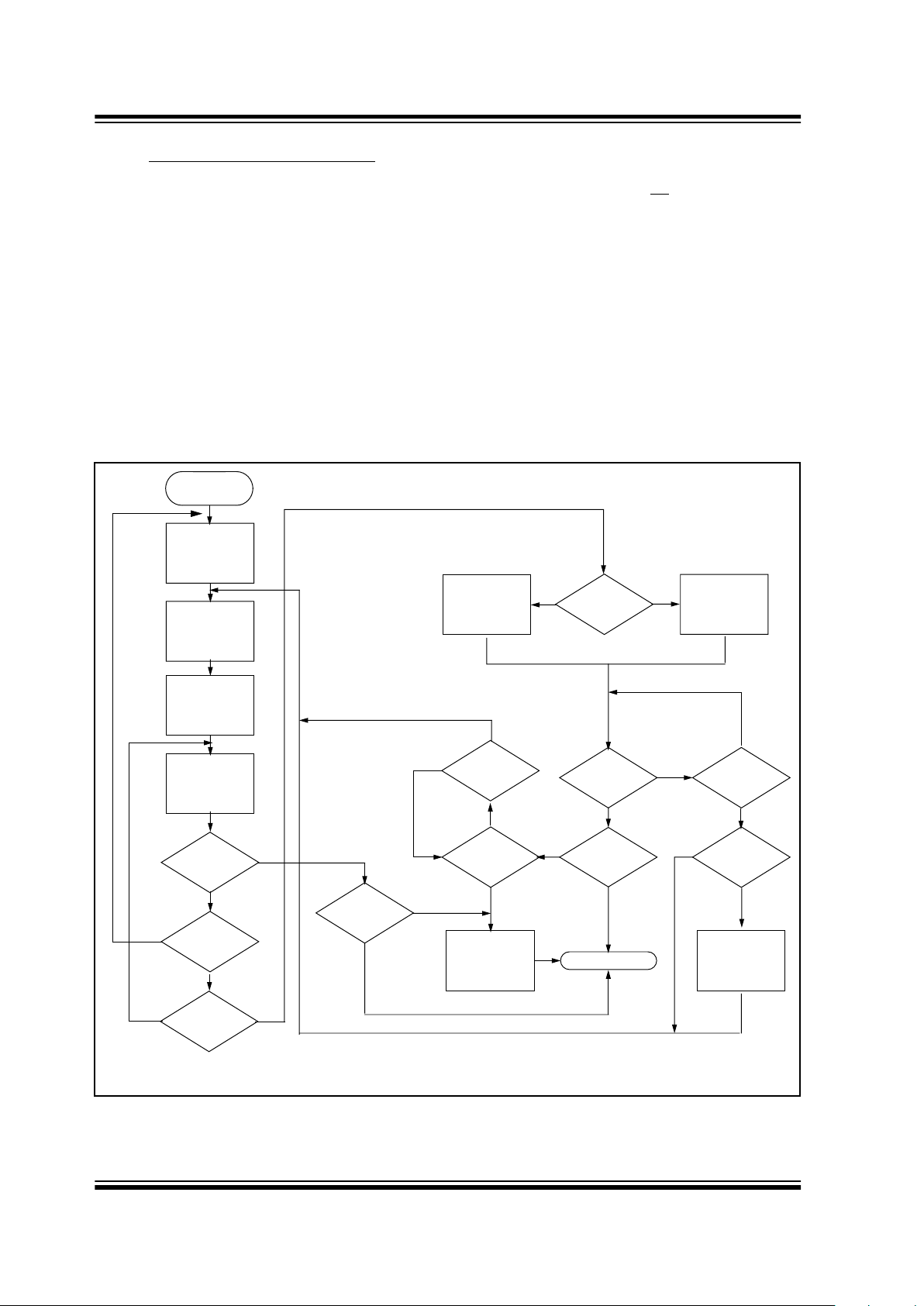

2.2 Code Hopping Mode (CH Mode)

The HCS410 wakes up upon detecting a switch closure

and then delays approximately 30 ms for switch

debounce (Figure 2-7). The synchronization counter

value, fixed information, and switch information are

encrypted to form the code hopping portion. The

encrypted or code hopping portion of the transmission

changes every time a button is pressed, even if the

same button is pushed again. Keeping a button

pressed for a long time results in the same code word

being transmitted until the button is released or timeout occurs. A code that has been transmitted will not

occur again for more than 64K transmissions. Overflow

information programmed into the encoder can be used

by the decoder to extend the number of unique transmissions to more than 192k.

If, during the transmit process, it is detected that a new

button(s) has been added, a reset will immediately be

forced and the code word will not

be completed. Please

note that buttons removed will not have any effect on

the code word unless no buttons remain pressed in

which case the current code word will be completed

and the power down will occur. If, after a button combination is pressed, and the same button combination is

pressed again within 2 seconds of the first press, the

current transmission will be aborted and a new transmission will start with the queue counter (QUE)

incremented.

FIGURE 2-7: CODE HOPPING ENCODER OPERATION

20-second

timeout

No

Transmitted

2 second

time-out

completed?

All buttons

released?

Sample Inputs

Update Sync Info

Encrypt With

T ransmit

Encoder Key

Power-up

(A button has been

pressed (Note1)

Buttons added?

Yes

Yes

Yes

No

(Note 1)

7 complete code

words?

Complete current

code word while

checking buttons

(Note 2)

Stop transmitting

DINC Set?

Power down

Buttons

pressed?

(Note 1)

Same as

previous

press?

Increment queue

counter

20 second

time-out

completed?

Buttons

pressed?

(Note 1)

Increase sync

counter

by 12

immediately

Yes

Yes

No

Yes

Yes

No

No

No

Yes

No

Yes

No

No

Note 1: 30 ms debounce on press and release of all buttons.

2: Completes a minimum of 3 code words if MTX3 is set.

No

DINC

Set?

Yes

Yes

No

Page 9

HCS410

1997 Microchip Technology Inc.

Preliminary

DS40158C-page 9

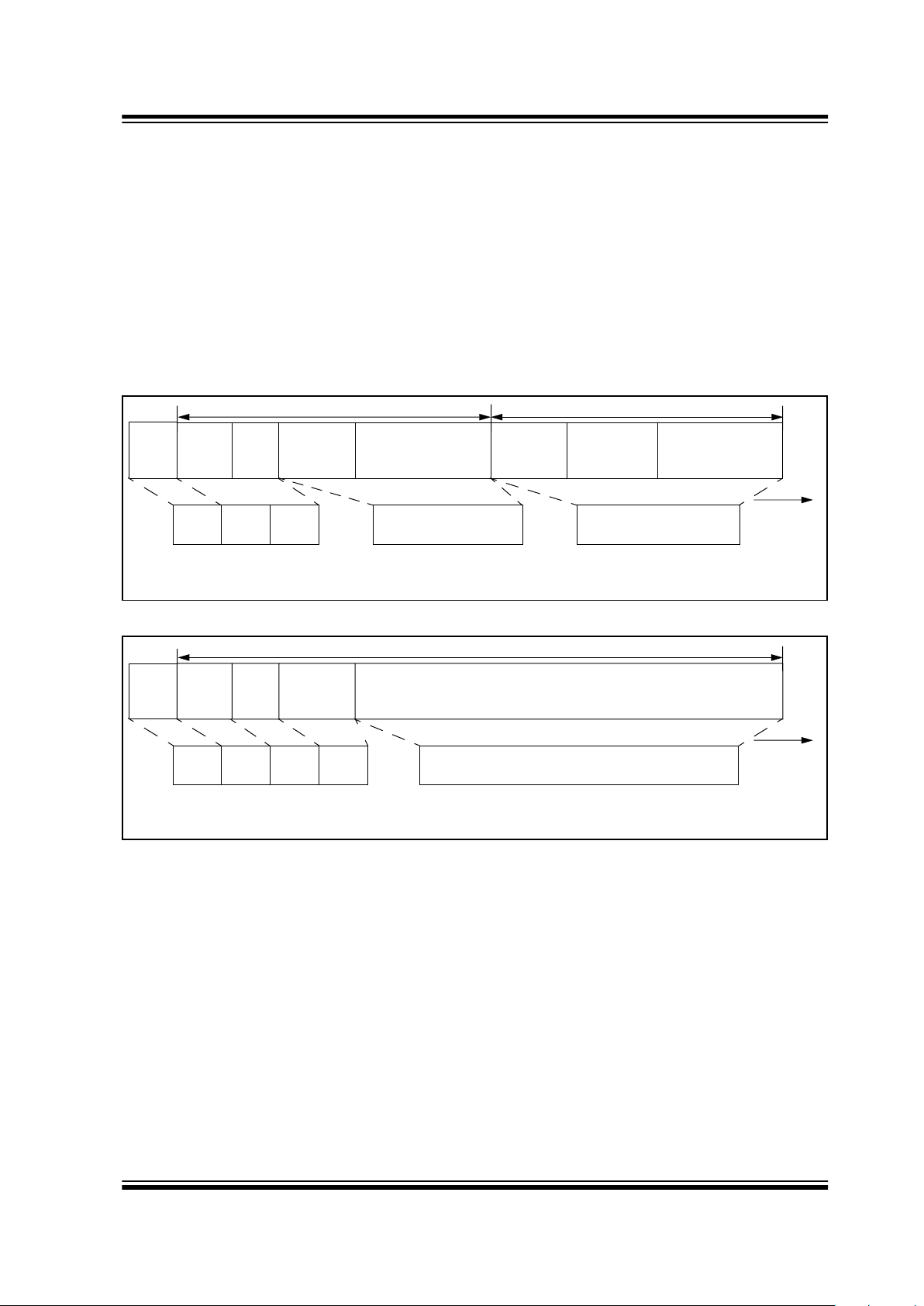

2.2.1 TRANSMISSION DATA FORMAT

The HCS410 transmission (CH Mode) is made up of

several parts (Figure 2-10 and Figure 2-11). Each

transmission is begun with a preamble and a header,

followed by the encrypted and then the fixed data. The

actual data is 69 bits which consists of 32 bits of

encrypted data and 37 bits of fixed data. Each transmission is followed by a guard period before another

transmission can begin. Refer to Table 5-4

and Table 5-5 for transmission timing specifications.

The combined encrypted and nonencrypted sections

increase the number of combinations to 1.47 x 10

20

.

The HCS410 transmits a 69-bit code word when a button is pressed. The 69-bit word is constructed from a

Fixed Code portion and Code Hopping portion

(Figure 2-8).

The Encrypted Data is generated from 4 function bits,

2 overflow bits, and 10 discrimination bits, and the 16bit synchronization counter value (Figure 2-8).

The Nonencrypted Code Data is made up of 2 QUE

bits, 2 CRC bits, a V

LOW

bit, 4 function bits, and the

28-bit serial number. If the extended serial number

(32 bits) is selected, the 4 function code bits will not be

transmitted (Figure 2-8).

FIGURE 2-8: HOP CODE WORD ORGANIZATION (RIGHT-MOST BIT IS CLOCKED OUT FIRST)

FIGURE 2-9: SEED CODE WORD ORGANIZATION

Fixed Code Data Encrypted Code Data

69 bits

of Data

Transmitted

MSB LSB

CRC

(2 bit)

VLOW

(1 bit)

Button

Status*

(4 bits)

28-bit

Serial Number

Overflow (2 bits)

bits (10 bits)

16-bit

Synchronization

CRC

(2 bits)

VLOW

(1 bit)

+

Serial Number and

Button Status (32 bits)

+ 32 bits of Encrypted Data

QUE

QUE

(Q1, Q0

S2 S1 S0 0

Button

Status

(4 bits)

S2 S1 S0 0

(2 bits)

bit)

Counter Value

Discrimination

and

* Optional.

Fixed Code Data

69 bits

of Data

Transmitted

CRC

(2 bit)

VLOW

(1 bit)

Button*

Status

(4 bits)

CRC

(2 bits)

VLOW

(1 bit)

+

QUE

QUE0

(Q1, Q0

S2 S1 S0 0

(2 bits)

bit)

Unencrypted

Button

(4 bits)

SEED

(60 bits)

+

SEED

* Optional.

Page 10

HCS410

DS40158C-page 10

Preliminary

1997 Microchip Technology Inc.

2.2.2 TRANSMISSION DATA MODULE

The Data Modulation Format is selectable between

Pulse Width Modulation (PWM) format and Manchester

encoding. Both formats are preceded by a preamble

and synchronization header, followed by the 69-bits of

data. Manchester encoding has a leading and closing

‘1’ for each code word.

The same code word is continuously sent as long as

the input pins are kept high with a guard time separating the code words. All of the timing values are in multiples of a Basic Timing Element (T

E), which can be

changed using the baud rate option bits.

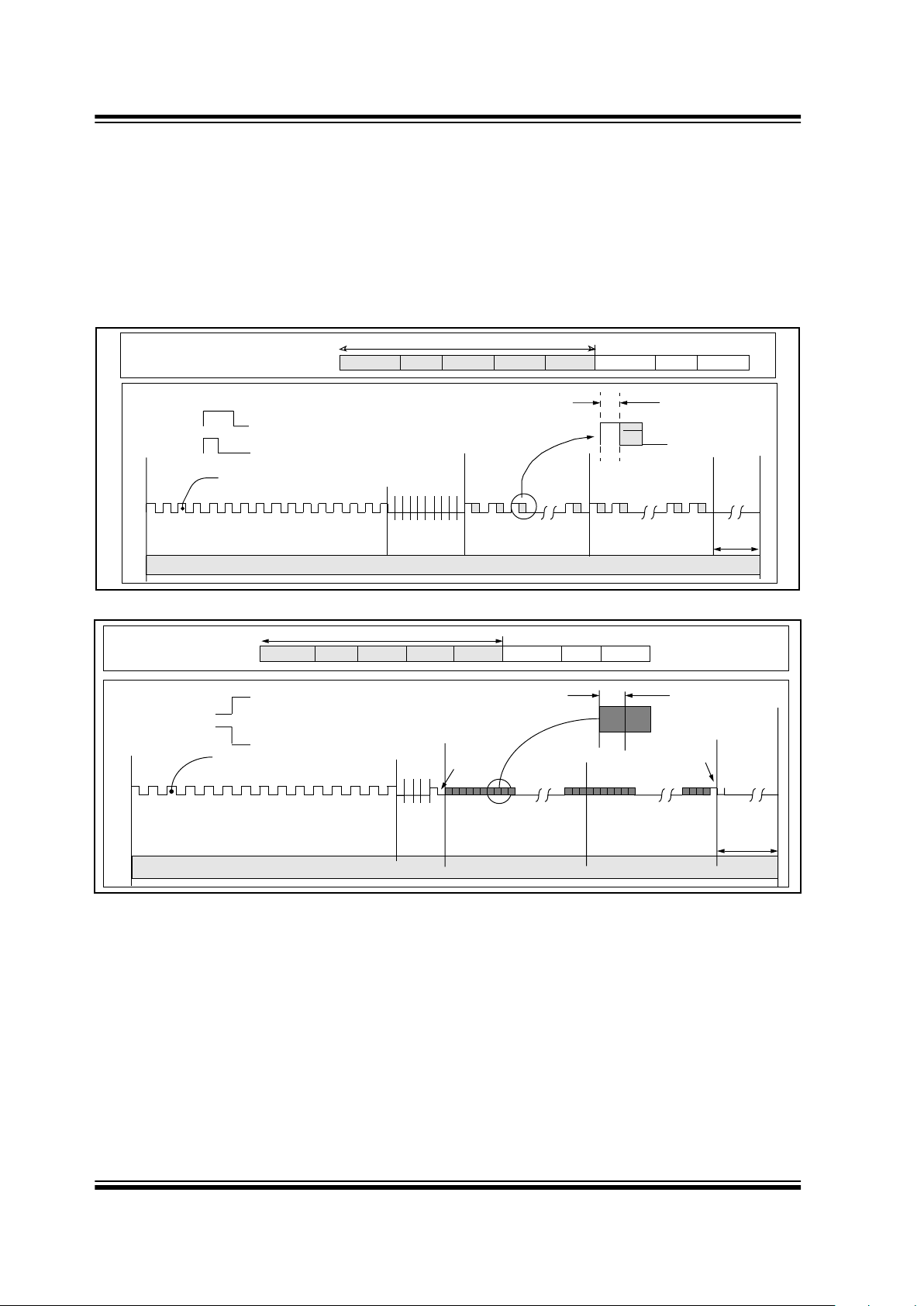

FIGURE 2-10: TRANSMISSION FORMAT—MANCH = 0

FIGURE 2-11: TRANSMISSION FORMAT—MANCH = 1

LOGIC "1"

Code Word

Guard

Time

Preamble

Sync

Encrypted

TX Data

Fixed Code

BIT

LOGIC "0"

123579

46810

TE

CODE WORD:

TOTAL TRANSMISSION:

Preamble

Sync

Encrypt

Fixed

Guard

1 CODE WORD

12 456

Preamble Sync Encrypt

14 15 16

TE

Data

TE

Guard

Preamble Sync

Encrypted

Fixed Code

LOGIC "0"

123

4

BPW

CODE WORD:

TOTAL TRANSMISSION:

Sync Encrypt Fixed Guard

1 CODE WORD

12 456

Preamble Sync Encrypt

14 15 16

LOGIC "1"

Start bit

Stop bit

CODE WORD

Preamble

Time

Data

Data

Page 11

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 11

2.3 Code Hopping Mode Special Features

2.3.1 CODE WORD COMPLETION

Code word completion is an automatic feature that

ensures that the entire code word is transmitted, even

if the button is released before the transmission is complete. The HCS410 encoder powers itself up when a

button is pushed and powers itself down after the command is finished (Figure 2-7). If MTX3 is set in the configuration word, a minimum of three transmissions will

be transmitted when the HCS410 is activated, even if

the buttons are released.

If less than seven words have been transmitted when

the buttons are released, the HCS410 will complete the

current word. If more than seven words have been

transmitted, and the button is released, the PWM output is immediately switched off.

2.3.2 CODE WORD BLANKING ENABLE

Federal Communications Commission (FCC) part 15

rules specify the limits on fundamental power and

harmonics that can be transmitted. Power is calculated

on the worst case average power transmitted in a

100ms window. It is therefore advantageous to

minimize the duty cycle of the transmitted word. This

can be achieved by minimizing the duty cycle of the

individual bits and by blanking out consecutive words.

Code Word Blanking Enable (CWBE) is used for

reducing the average power of a transmission

(Figure 2-12). Using the CWBE allows the user to

transmit a higher amplitude transmission if the

transmission length is shorter. The FCC puts

constraints on the average power that can be

transmitted by a device, and CWBE eff ectively pre vents

continuous transmission by only allowing the transmission of every second or fourth word. This reduces the

average power transmitted and hence, assists in FCC

approval of a transmitter device.

The HCS410 will either transmit all code words, 1 in 2

or 1 in 4 code words, depending on the baud rate

selected and the code word blanking option. See

Section 3.7 for additional details.

2.3.3 CRC (CYCLE REDUNDANCY CHECK) BITS

The CRC bits are calculated on the 65 previously trans-

mitted bits. The CRC bits can be used by the receiver

to check the data integrity before processing starts. The

CRC can detect all single bit and 66% of double bit

errors. The CRC is computed as follows:

EQUATION 2-1: CRC CALCULATION

and

with

and Di

n

the nth transmission bit 0 ≤ n ≤ 64

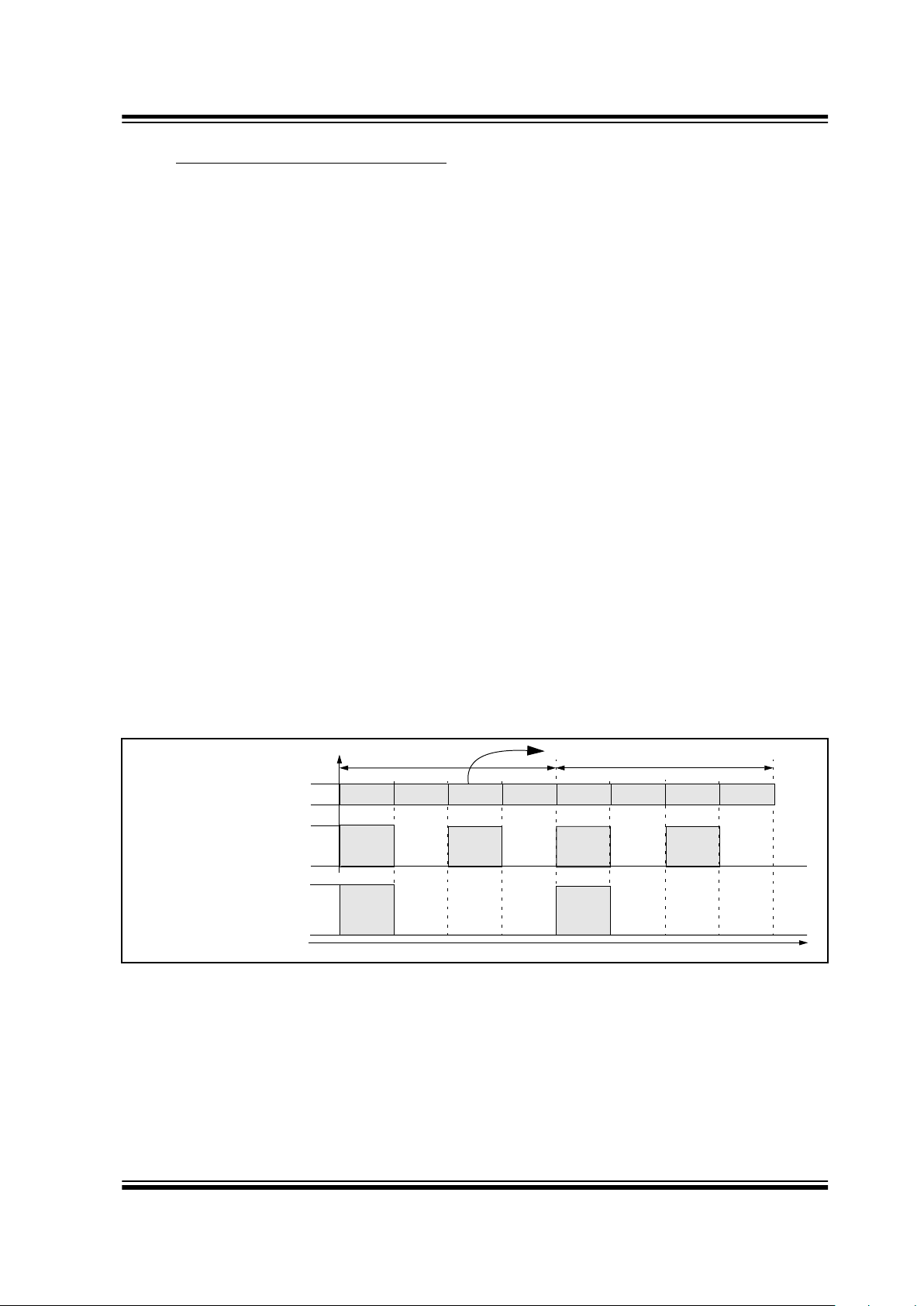

FIGURE 2-12: CODE WORD BLANKING ENABLE

CRC 1[]

n 1+

CRC 0[]nDin⊕=

CRC 0[]

n 1+

CRC 0[]nDin⊕()CRC 1[]

n

⊕=

CRC 10,[]

0

0=

One Code Word

CWBE Disabled

(All words transmitted)

CWBE Enabled

(1 out of 2 transmitted)

A

2A

Amplitude

CWBE Enabled

(1 out of 4 transmitted)

4A

Time

Page 12

HCS410

DS40158C-page 12 Preliminary 1997 Microchip Technology Inc.

2.3.4 SEED T R ANSMISSION

In order to increase the level of security in a system, it

is possible for the receiver to implement what is known

as a secure learning function. This can be done by utilizing the seed value on the HCS410 which is stored in

EEPROM. Instead of the normal key generation

method being used to create the encoder key, this seed

value is used and there should not be any mathematical relationship between serial numbers and seeds for

the best security. See Section 3.7.3 for additional

details.

2.3.5 PASSIVE PROXIMITY ACTIVATION

If the HCS410 is brought into a magnetic field it enters

IFF mode. In this mode it sends out ACK pulses on the

LC lines. If the HCS410 doesn't receive any response

to the first set of ack pulses within 50 ms the HCS410

will transmit a normal code hopping transmission for 2

seconds if XPRF is set in the configuration word. The

function code during this transmission is S2:S0 = 000.

2.3.6 AUTO-SHUTOFF

The Auto-shutoff function automatically stops the

device from transmitting if a button inadvertently gets

pressed for a long period of time. This will prevent the

device from draining the battery if a button gets

pressed while the transmitter is in a pocket or purse.

Time-out period is approximately 20 seconds.

2.3.7 V

LOW: VOLTAGE LOW INDICATOR

The V

LOW bit is transmitted with every transmission

(Figure 2-8). V

LOW is set when the operating voltage

has dropped below the low voltage trip point, approximately 2.2V or 4.4V selectable at 25°C. This V

LOW sig-

nal is transmitted so the receiver can give an indication

to the user that the transmitter battery is low.

2.3.8 QUE0:QUE1: QUEUING INFORMATION

If a button is pressed, released for more than 30 ms,

and pressed again within 2 seconds of the first press,

the QUE counter is incremented (Figure 2-7). The

transmission that the HCS410 is busy with is aborted

and a new transmission is begun with the new QUE bits

set. These bits can be used by the decoder to perform

secondary functions using only a single button without

the requirement that the decoder receive more than

one completed transmission. F or example if none of the

QUE bits are set the decoder only unlocks the driver’s

door, if QUE0 is set (double press on the transmitter)

the decoder unlocks all the doors.

FIGURE 2-13: QUE COUNTER TIMING DIAGRAM

Note 1: The QUE will not overflow.

2: The button must be pressed f or more than

50 ms.

Input

Sx

DIO

Transmission

1st Button Press All Buttons Released 2nd Button Press

T

LOW>30 ms

t = 0

t > 50 ms

t <2S

t = 0

QUE = 00

2

QUE = 01

2

•Patents have been applied for.

Page 13

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 13

2.3.9 LED OUTPUT

The S2/LED line can be used to drive a LED when the

HCS410 is transmitting. If this option is enabled in the

configuration word the S2 line is driven high periodically when the HCS410 is transmitting as shown in

Figure 2-14. The LED output operates with a 30 ms on

and 480 ms off duty cycle when the supply voltage is

above the level indicated by the V

LOW bit in the config-

uration word. When the supply v oltage drops below the

voltage indicated by the VLOW bit the HCS410 will indicate this by turning the LED on for 200ms at the start of

a transmission and remain off for the rest of the transmission.

2.3.10 DELAYED INCREMENT

The HCS410 has a delayed increment feature that

increments the counter by 12, 20 seconds after the last

button press occurred. The 20-second time-out is reset

and the queue counter will increment if another press

occurs before the 20 seconds expires. The queue

counter is cleared after the buttons have been released

for more than 2 seconds. Systems that use this f eature

will circumvent the latest jamming-code grabbing

attackers.

2.3.11 OTHER CONFIGURABLE OPTIONS

Other configurable code hopping options include an

• Transmission-rate selection

• Extended serial number.

These are described in more detail in Section 3.7.

FIGURE 2-14: LED INDICATION DURING TRANSMISSION

200 ms 280 ms

400 ms

30 ms

S Input

LED

VDD = VLOW Level

LED

V

DD < VLOW LEVEL

Page 14

HCS410

DS40158C-page 14 Preliminary 1997 Microchip Technology Inc.

2.4 IFF Mode

IFF mode allows the decoder to perform an IFF validation, to write to the user EEPROM and to read from the

user EEPROM. Each operation consists of the decoder

sending an opcode data and the HCS410 giving a

response.

There are two IFF modes: IFF1 and IFF2. IFF1 allows

only one key IFF, while IFF2 allows two keys to be used.

It is possible to use the HCS410 as an IFF token without using a magnetic field for coupling. The HCS410

can be directly connected to the data line of the

decoder as shown in Figure 2-3. The HCS410 gets its

power from the data line as it would in normal transponder mode. The communication is identical to the communication used in transponder mode.

2.4.1 IFF MODE ACTIVATION

The HCS410 will enter IFF mode if the capacitor/induc-

tor resonant circuit generates a voltage greater than

approximately 1.0 volts on LC0. After the verified application of power and elapse of the normal reset period,

the device will start responding by pulsing the DAT A line

(LC0/1) with pulses as shown in Figure 2-17. This

action will continue until the pulse train is terminated by

receiving a start signal of duration 2T

E, on the LC

inputs before the next expected marker pulse. The

device now enters the IFF mode and expects to receiv e

an ‘Opcode’ and a 0/16/32-bit Data-stream to react on.

The data rate (T

E) is determined by the TBSL bits in the

configuration word. See Section 3.0 for additional

details.

2.4.2 IFF DECODER COMMANDS

As shown in Figure 2-15, a logic 1 and 0 are differenti-

ated by the time between two rising edges. A long pulse

indicates a 1; a short pulse, a 0.

FIGURE 2-15: MODULATION FOR IFF COMMUNICATION

FIGURE 2-16: OVERVIEW OF IFF OPERATION

Note: When IFF2 is enabled, seed transmissions

will not be allowed.

0

1

3 TE

1TE

5 TE

0

1

TE TE

2 TE TE

Start or

previous

bit

1 TE

PPM Decoder Commands PPM Encoder Response

Activate Opcode

32/16-bit Challenge 32/16-bit IFF Response

Opcode

Activate

Opcode 16 bit Data OK Opcode

Activate Opcode 16 bit Data

IFF

WRITE

READ

Opcode

Page 15

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 15

FIGURE 2-17: DECODER IFF COMMANDS AND WAVEFORMS

Ack pulses Opcode

Transport

Code

32 bits

Ack

Writing

bit0

bit1

bit2

bit3

bit4

TBITC

TE

Data

16 bits

TOTD TTTD

TWR

Only when writing Serial

Number, Config or IFF

programming

Serial number

1 to 32 bits

Encoder

Select

Ack

0

0

000

Ack pulses

Challenge

16/32 bits

Response

16/32 bits

Ack pulses Opcode TOTD

Response

Start TRT

16 bits

01

Ack pulsesRead

Write/Program

Challenge

Encoder Select

2 TE

Repeat 18 times for programming

TABLE 2-3: IFF TIMING PARAMETERS

Parameter Symbol Minimum Typical Maximum Units

Time Element

IFFB = 0

IFFB = 1

TE —

—

200

100

—

—

µs

PPM Command Bit Time

Data = 1

Data = 0

TBITC 3.5

5.5

4

6

—

—

TE

PPM Response Bit Time

Data = 1

Data = 0

T

BITR —

—

2

3

—

—

TE

PPM Command Minimum High Time TPMH 1.5 — — TE

Response Time (Minimum for Read) TRT 6.5 — — ms

Opcode to Data Input Time T

OTD 1.8 — — ms

Transport Code to Data Input Time T

TTD 6.8 — — ms

IFF EEPROM Write Time (16 bits) T

WR — — 30 ms

Page 16

HCS410

DS40158C-page 16 Preliminary 1997 Microchip Technology Inc.

2.4.3 HCS410 RESPONSES

The responses from the HCS410 are in PPM format.

See Figure 2-17 for additional information

2.4.4 IFF RESPONSE

The 16/32-bit response to a 16/32-bit challenge, is

transmitted once, after which the device is ready to

accept another command. The same applies to the

result of a Read command. The opcode written to the

device specifies the challenge length and algorithm

used.

2.4.5 IFF WRITE

The decoder can write to USER[0:3], SER[0:1], and the

configuration word in the EEPROM.

After the HCS410 has written the word into the

EEPROM, it will give two ackno wledge pulses (T

E wide

and T

E apart) on the LC pins.

When writing to the serial number or configuration

word, the user must send the transport code before the

write will begin (Section 3.4) .

2.4.6 IFF READ

The decoder can read USER[0:3], SER[0:1], and the

configuration word in the EEPROM. After the data has

been read, the device is ready to receive a command

again.

Each read command is followed by a 16-bit data

response. The response always starts with a leading

preamble of 01

2

and then the 16-bits of data.

2.4.7 IFF PROGRAMMING

Upon receiving a programming opcode and the trans-

port code, the EEPROM is erased (Section 3.4).

Thereafter, the first 16 bits of data can be written. After

indicating that a write command has been successfully

completed the device is ready to receive the next 16

bits. After a complete memory map was receiv ed, it will

be transmitted in PPM format on the LC pins as 16-bit

words. This enables wireless programming of the

device.

After the EEPROM is erased, the configuration word is

reloaded. This results in oscillator tuning bits of 0000

being used during programming. When using IFF programming, the user should read the configuration word

and store the oscillator bits in the memory map to be

programmed. A program command should be sent and

the next set of ACK pulses transmitted by the HCS410

should be used to determine the T

E. A second prog ram

command can then be sent, and the device programmed using the T

E just calibrated.

FIGURE 2-18: IFF INDUCTIVE IN RF OUT

Note: If the configuration word is written, the

device must be reset to allow the new configuration settings to come into effect.

Preamble

Header

Response

(32 bits)

Fixed Code

(37 bits)

PWM

LCI0/1

32-bit Response

16-bit

Response

16-bit

Response

Encoder

Select ACK

Opcode

(Read)

Response

(16 bits)

Next

Ack

Page 17

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 17

2.5 IFF Opcodes

TABLE 2-4: LIST OF IFF COMMANDS

Command Description Expected data In Response

00000 Select HCS410, used if Anticolli-

sion enabled

1 to 32 bits of the serial number

(SER)

Encoder select acknowledge if

SER match

00001 Read configuration word None 16-bit configuration word

00010 Read high serial number None Higher 16 bits of serial number

(SER1)

00011 Read low serial number None Lower 16 bits of serial number

(SER0)

00100 Read user area 0 None 16 Bits of User EEPROM USR0

00101 Read user area 1 None 16 Bits of User EEPROM USR1

00110 Read user area 2 None 16 Bits of User EEPROM USR2

00111 Read user area 3 None 16 Bits of User EEPROM USR3

01000 Program HCS410 EEPROM Transport code (32 bits); Com-

plete memory map: 18 x 16 bit

words (288 bits)

Write acknowledge pulse after

each 16-bit word, 288 bits trans-

mitted in 18 bursts of 16-bit

words

01001 Write configuration word Transport code (32 bits); 16 Bit

configuration word

Write acknowledge pulse

01010 Write high serial number Transport code (32 bits); Higher

16 bits of serial number (SER1)

Write acknowledge pulse

01011 Write low serial number Transport code (32 bits); Lower

16 bits of serial number (SER0)

Write acknowledge pulse

01100 Write user area 0 16 Bits of User EEPROM USR0 Write acknowledge pulse

01101 Write user area 1 16 Bits of User EEPROM USR1 Write acknowledge pulse

01110 Write user area 2 16 Bits of User EEPROM USR2 Write acknowledge pulse

01111 Write user area 3 16 Bits of User EEPROM USR3 Write acknowledge pulse

1X000 IFF1 using key-1 and IFF

algorithm

32-Bit Challenge 32 Bit Response

1X001 IFF1 using key-1 and HOP

algorithm

32-Bit Challenge 32 Bit Response

1X100 IFF2 32-bit using key-2 and IFF

algorithm

32-Bit Challenge 32 Bit Response

1X101 IFF2 32-bit using ke y-2 and HOP

algorithm

32-Bit Challenge 32 Bit Response

Page 18

HCS410

DS40158C-page 18 Preliminary 1997 Microchip Technology Inc.

2.6 IFF Special Features

2.6.1 ANTI-COLLISION (ACOLI)

When the ACOLI bit is set in the configuration word,

anti-collision mode is entered. The HCS410 will start

sending ACK pulses when it enters a magnetic field.

The ACK pulses stop as soon as the HCS410 detects

a start bit from the decoder. A ‘select encoder’ opcode

(00000) is then sent out by the decoder, followed by a

32-bit serial number. If the serial number matches the

HCS410’s serial number, the HCS410 will acknowledge with the acknowledge sequence as shown in

Figure 2-19. The HCS410 can then be addressed as

normal. If the serial number does not match, the IFF

encoder will stop transmitting ACK pulses until it is

either removed from the field or the correct serial number is given.

FIGURE 2-19: SERIAL NUMBER CORRECT

ACKNOWLEDGE SEQUENCE

2.6.2 TRANSPONDER IN/RF OUT

When in transponder mode with ACOLI and XPRF set,

the outputs of the HCS410’s LC0:LC1 pins are echoed

on the PWM output line. After transmitting the data on

the LC pins, the data is then transmitted on the PWM

line. The transmission format mirrors a code hopping

transmission. The response replaces the 32-bit code

hopping portion of the transmission. If the response is

a 16-bit response, the 16 bits are duplicated to make up

the 32-bit code hopping portion. The preamble, serial

number, CRC, and queuing bits are all transmitted as

normal (Figure 2-18).

This feature will be used in applications which use RF

for long distance unidirectional authentication and

short distance IFF.

2.6.3 INTELLIGENT DAMPING

If the LC circuit on the transponder has a high Q-factor ,

the circuit will keep on resonating for a long time after

the field has been shut down by the decoder. This

makes fast communication from the decoder to the

HCS410 difficult. If the IDAMP bit is set to 0, the

HCS410 will clamp the LC pins for 5 µs every 1/4 T

E,

whenever the HCS410 is expecting data from the

decoder. Refer to Figure 2-18 for timing details. This

option can be set in the configuration word.

2.7 LED Indicator

If a signal is detected on LC0, the LED pin goes high for

30 ms every 8s (IFFB = 0) or 4s (IFFB 1) to indicate that

the power source is charging.

FIGURE 2-20: LED INDICATOR WHEN CHARGING POWER SOURCE

LC0/1

TE

TE

3 TE

LC0

LED

IFFB = 0

LED

IFFB = 1

4s

8s

30 ms

2s 4s 30 ms

Page 19

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 19

3.0 EEPROM ORGANIZATION AND

CONFIGURATION

The HCS410 has nonvolatile EEPROM memory which

is used to store user programmable options. This information includes encoder keys, serial number , and up to

64-bits of user information.

The HCS410 has two modes in which it operates as

specified by the configuration word. In the first mode

the HCS410 has a single encoder key which is used for

encrypting the code hopping portion of a CH Mode

transmission and generating a response during IFF validation. Seed transmissions are allowed in this mode.

In the second mode the HCS410 is a transponder

device with two encoder keys.

The two different operating modes of the HCS410 lead

to different EEPROM memory maps.

In IFF1 mode, the HCS410 can act as a code hopping

encoder with Seed transmission, and as an IFF token

with one key.

In IFF2 mode, the HCS410 is able to act as a code hopping transmitter and an IFF token with two encoder

keys.

3.1 Encoder Key 1 and 2

The 64-bit encoder key1 is used by the transmitter to

create the encrypted message transmitted to the

receiver in Code Hopping Mode. An IFF operation, can

use encoder key1 or key2 to generate the response to

a challenge received. The key(s) is created and programmed at the time of production using a key generation algorithm. Inputs to the key generation algorithm

are the serial number or seed for the particular

transmitter being used and a secret manufacturer’s

code. While a number of key generation algorithms are

supplied by Microchip, a user may elect to create their

own method of key generation. This may be done providing that the decoder is programmed with the same

means of creating the key for decryption purposes. If a

seed is used (CH Mode), the seed will also form part of

the input to the key generation algorithm.

3.2 Discrimination Value and Overflow

The discrimination value forms part of the code hopping portion of a code hopping transmission. The least

significant 10 bits of the discrimination value are typically set to the least significant bits of the serial number.

The most significant 2 bits of the discrimination value

are the overflow bits (OVR1: O VR0). These are used to

extend the range of the synchronization counter . When

the synchronization counter wraps from FFFF

16

to

0000

16

OVR0 is cleared and the second time a wrap

occurs OVR1 is cleared.

Once cleared, the overflow bits cannot be set again,

thereby creating a permanent record of the counter

overflow.

3.3 16-bit Synchronization Counter

This is the 16-bit synchronization counter value that is

used to create the code hopping portion for transmission. This value will be changed after every transmission. The synchronization counter is not used in IFF

mode.

IFF1 Mode

64-bit Encoder Key 1

64-bit Seed/Transport Code

(SEED0, SEED1, SEED2, SEED3)

32-bit Serial Number

(SER0, SER1)

64-bit User Area

(USR0, USR1, USER2, USR3)

10-bit Discrimination Value and 2 Overflow Bits.

16-bit Synchronization Counter

Configuration Data

IFF2 Mode

64-bit Encoder Key 1

64-bit Encoder Key 2/Transport Code

32-bit Serial Number

(SER0, SER1)

64-bit User EEPROM

(USR0, USR1, USER2, USR3)

10-bit Discrimination Value and 2 Overflow Bits.

16-bit Synchronization Counter

Configuration Data

*Patents have been applied for.

Page 20

HCS410

DS40158C-page 20 Preliminary 1997 Microchip Technology Inc.

3.4 60/64-bit Seed Word/Transport Code

This is the 60-bit seed code that is transmitted when

seed transmission is selected. This allows the system

designer to implement the secure learn feature or use

this fixed code word as part of a different key generation/tracking process or purely as a fixed code transmission. The seed is not available in IFF2-mode. A

Seed transmission can be initiated in two ways,

depending on the button inputs (Figure 3-1)

Seed transmission is available for function codes

(Table 2-2) S[2:0] = 111 and S[2:0] = 011 (delayed).

The delayed seed transmission starts with a normal

code hopping transmission being transmitted for 3 seconds, before switching to a seed tr ansmission. The two

seed transmissions are shown in Figure 3-1.

The least significant 32-bits of the seed are used as the

transport code. The transport code is used to write-protect the serial number, configuration word, as well as

preventing accidental programming of the HCS410

when in IFF mode.

3.5 Encoder Serial Number

There are 32 bits allocated for the serial number and a

selectable configuration bit (XSER) determines

whether 32 or 28 bits will be transmitted. The serial

number is meant to be unique for every transmitter.

3.6 User Data

The 64-bit user EEPROM can be reprogrammed and

read at any time using the IFF interface.

FIGURE 3-1: SEED TRANSMISSION

Note: If both SEED and TMPSD are set, IFF2

mode is enabled.

All examples shown with XSER = 1 & SEED = 1

When S[2:0] = 111, the 3-second delay is not applicable:

Que [1:0], CRC [1:0], SEED_3 (12 bits) SEED_2 SEED_1 SEED_0

Data transmission direction

For S[2:0] = 011 before the 3-second delay:

16-bit Data Word 16-bit Counter

Encrypt

SER_1 SER_0 Encrypted Data

For S[2:0] = 011 after the 3-second delay (Note 1):

Data transmission direction

Note 1: For Seed Transmission, SEED_3 and SEED_2 are transmitted instead of SER_1 and SER_0, respectively.

SEED_3 (12 bits) SEED_2 SEED_1 SEED_0

Data transmission direction

VLOW, S[2:0]

Que [1:0], CRC [1:0]

+ VLOW, S [2:0]

Que [1:0], CRC [1:0],

VLOW, S [2:0]

*Patents have been applied for.

Page 21

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 21

3.7 Configuration Data

The configuration data is used to select various

encoder options. Further explanations of each of the

bits are described in the following sections.

3.7.1 CWBE: CODE WORD BLANKING ENABLE

BSL: BAUD RATE SELECT

Selecting this option allows code blanking as shown in

Table 3-3. If this option is not selected, all code words

are transmitted.

3.7.2 IDAMP: INTELLIGENT DAMPING

If IDAMP is set to ‘1’ intelligent damping is disabled.

3.7.3 SEED, TMPSD: SEED TRANSMISSION

3.7.4 OSC: OSCILLATOR TUNING BITS

These bits allow the onboard oscillator to be tuned to

within 10% of the nominal oscillator speed over both

temperature and voltage.

TABLE 3-1: CONFIGURATION OPTIONS

SEED

Symbol Description

CWBE Code Word Blanking Enable

IDAMP Intelligent Damping for High Q LC Tank.

SEED/

IFF2

Enable Seed Transmissions

TMPSD/

IFF2

Temporary Seed Transmissions

OSC0:3 Onboard Oscillator Tuning Bits

MTX3 Minimum 3 Code Words Transmitted

VLOW Low Voltage Trip Point Selection

LED Enable LED output

BSL0:1 Baudrate Select

TBSL Transponder Baud Page

MANCH Manchester Modulation Mode

ACOLI Anti Collision Communication Enable

XPRF Passive Proximity Activation

DINC Delayed Increment Enable

XSER Extended Serial Number

SEED TMPSD Description

0 0 No Seed

0 1 Seed Limited

1 0 Always Enabled

1 1 IFF2/No Seed

TABLE 3-2: OSCILLATOR TUNING

OSC Description

1000 Fastest

1001

1010

•

•

•

1111

Faster

0000 Nominal

0001

0010

•

•

•

0110

Slower

0111 Slowest

TABLE 3-3: BAUD RATE SELECTION

Code Hopping Transmissions (TE) Transponder Communication (TE)

BSL 1 BSL 0 PWM Manchester

Codes Wor d

T ransmitted*

TBSL PPM

0 0 400 µs 800 µs All 0 200 µs

0 1 200 µs 400 µs 1 of 2 — —

1 0 100 µs 200 µs 1 of 2 — —

1 1 100 µs 200 µs 1 of 4 1 100 µs

*If code word blanking is enabled.

Page 22

HCS410

DS40158C-page 22 Preliminary 1997 Microchip Technology Inc.

3.7.5 MTX3: MINIMUM CODE WORDS

COMPLETED

If this bit is set, the HCS410 will transmit a minimum of

3 words before it powers itself down. If this bit is

cleared, the HCS410 will only complete the current

transmission. This feature will only work if V

DD is con-

nected directly to the battery as shown in Figure 2-1.

3.7.6 V

LOW: LOW V OLTAGE TRIP POINT

The low voltage trip point select bit is used to tell the

HCS410 what Vdd le v el is being used. This inf ormation

will be used by the device to determine when to send

the voltage low signal to the receiver. When this bit is

set, the Vdd level is assumed to be operating from a 5

volt or 6 volt supply. If the bit is cleared, then the Vdd

level is assumed to be 3.0 v olts. Refer to Figure 5-3 f or

voltage trip point. When the battery reaches the Vlow

point, the LED will flash once for 200 ms on during a

code hopping transmission.

3.7.7 LED: OUTPUT ENABLE

If this bit is set, the S2 doubles as an LED output line.

If this bit is cleared (0), S2 is only used as an input.

3.7.8 TBSL: TRANSPONDER BAUD RATE

SELECT

This option selects the baud rate for IFF communication between a T

E of 100 µs or 200 µs.

3.7.9 MANCH: MANCHESTER CODE

ENCODING

MANCH selects between Manchester code modulation

and PWM modulation in code hopping mode. If

MANCH = 1, Manchester code modulation is selected.

If MANCH is cleared, PWM modulation is selected.

3.7.10 ACOLI: ANTI-COLLISION

COMMUNICATION AND

XPRF: TRANSPONDER ECHOING

ON PWM OUTPUT

ACOLI = 1, XPRF = 0

If ACOLI is set the anti-collision operation during bidirectional transponder mode (IFF) is enabled. This

feature is useful in situations where multiple transponders enter the magnetic field simultaneously.

ACOLI = 0, XPRF = 1

If XPRF is set, and ACOLI is cleared, proximity activation is enabled. the HCS410 star ts sending out ACK

pulses when it detects a magnetic field. If the HCS410

doesn’t receive a start bit from the decoder within 50

ms of sending the first set of ACK pulses, the HCS410

will transmit a code hopping transmission on LC and

PWM pins for 2 seconds.

ACOLI = 1, XPRF = 1

If both the ACOLI and XPRF are set, all of the HCS410

transponder responses are echoed on the PWM output, as described in Section 2.6.2.

3.7.11 DINC: DELAYED INCREMENT

If DINC is set to ‘1’, the delayed increment feature is

enabled. If DINC is cleared, the counter only increments once each time the button is pressed.

3.7.12 XSER: EXTENDED SERIAL NUMBER

If XSER is set, the full 64-bit SEED number is

transmitted. If XSER is cleared, the four most significant bits of the serial number are substituted by

S[2:0] = S2:S1:S0: 0 and is compatible with the

HCS200/300/301.

Page 23

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 23

4.0 INTEGRATING THE HCS410

INTO A SYSTEM

Use of the HCS410 in a system requires a compatible

decoder. This decoder is typically a microcontroller with

compatible firmware. Firmware routines that accept

transmissions from the HCS410, decrypt the code hopping portion of the data stream and perform IFF functions are available. These routines provide system

designers the means to develop their own decoding

system.

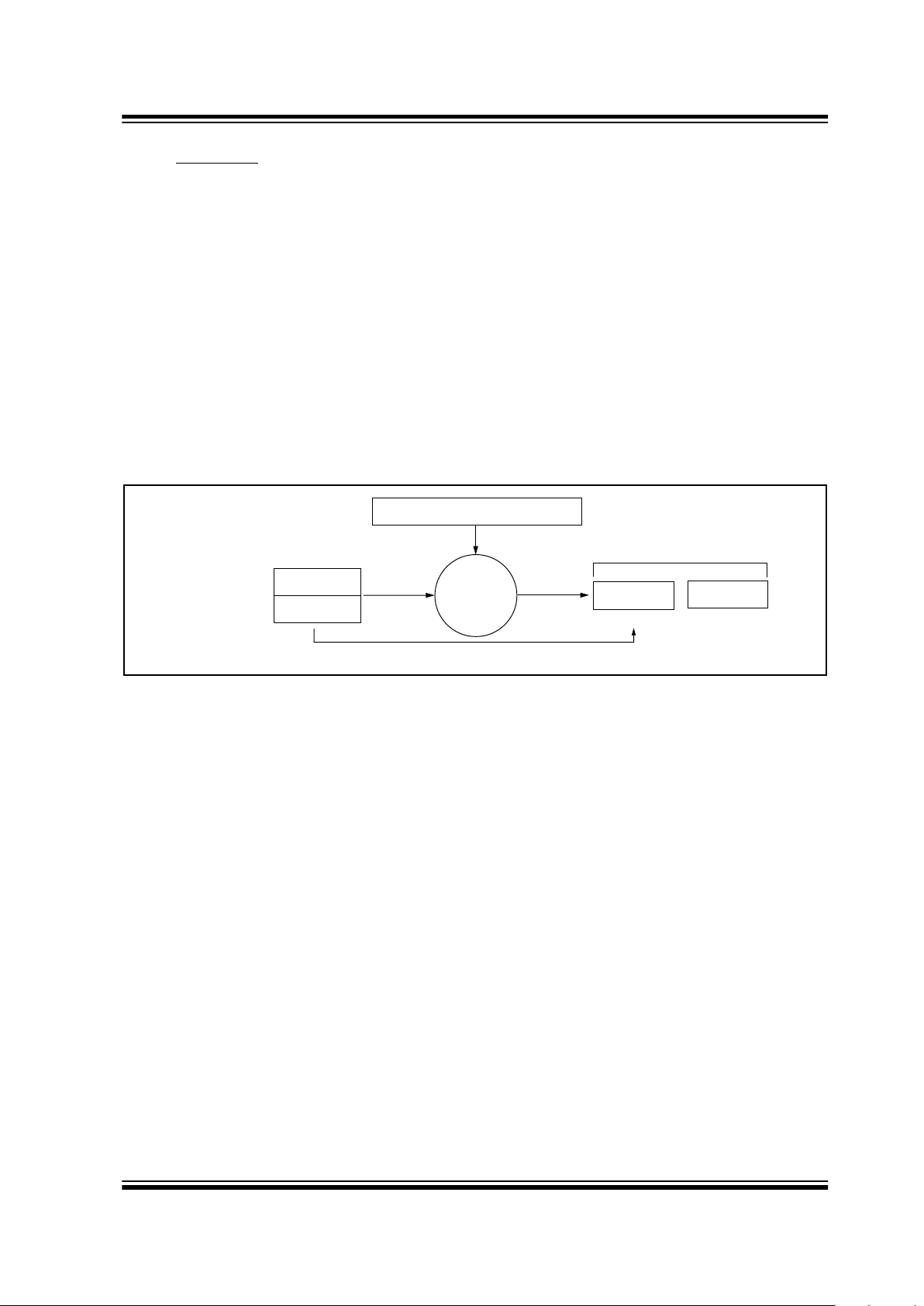

4.1 Key Generation

The serial number for each transmitter is programmed

by the manufacturer at the time of production. The

generation of the encoder key is done using a ke y generation algorithm (Figure 4-1). Typically, inputs to the

key generation algorithm are the serial number of the

transmitter or seed value, and a 64-bit manufacturer’s

code. The manuf acturer’ s code is chosen by the system

manufacturer and must be carefully controlled. The

manufacturer’s code is a pivotal part of the overall

system security.

FIGURE 4-1: CREATION AND STORAGE OF ENCODER KEY DURING PRODUCTION

Transmitter

Manufacturer’s

Serial Number or

Code

Encoder

Key

Key

Generation

Algorithm

Serial Number

Encoder Key

Sync Counter

.

.

.

HCS410 EEPROM Array

Seed

Page 24

HCS410

DS40158C-page 24 Preliminary 1997 Microchip Technology Inc.

4.2 Learning an HCS410 to a Receiver

In order for a transmitter to be used with a decoder , the

transmitter must first be ‘learned’. Several learning

strategies can be followed in the decoder implementation. When a transmitter is learned to a decoder, it is

suggested that the decoder stores the serial number

and current synchronization counter value (synchronization counter stored in CH Mode only) in EEPROM.

The decoder must keep track of these values for every

transmitter that is learned (Figure 4-2 and Figure 4-3).

FIGURE 4-2: TYPICAL CH MODE LEARN

SEQUENCE

The maximum number of transmitters that can be

learned is only a function of how much EEPROM

memory storage is available. The decoder must also

store the manufacturer’s code in order to learn an

HCS410, although this value will not change in a typical

system so it is usually stored as part of the microcontroller ROM code. Storing the manufacturer’s code as

part of the ROM code is also better for security reasons.

FIGURE 4-3: TYPICAL IFF LEARN

SEQUENCE

Enter Learn

Mode

Wait for Reception

of a Valid Code

Generate Key

from Serial Number

Use Generated Key

to Decrypt

Compare Discrimination

Value with Fixed Value

Equal

Wait for Reception

of Second Valid Code

Compare Discrimination

Value with Fixed Value

Use Generated Key

to Decrypt

Equal

Counters

Encoder key

Serial number

Synchronization counter

Sequential

?

?

?

Exit

Learn successful Store:

Learn

Unsuccessful

No

No

No

Yes

Yes

Yes

Enter Learn

Wait for token

to be detected

Read

Generate Key

From Serial

Perform IFF

with T ok en

Compare T ok en

and expected

response

Token and

Response

Equal?

Exit

Serial Number

No

Yes

Learn successful

Serial number

Encoder key

Number

Store:

Mode

Page 25

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 25

4.3 CH Mode Decoder Operation

In a typical decoder operation (Figure 4-4), the key

generation on the decoder side is done by taking the

serial number from a transmission and combining that

with the manufacturer’s code to create the same

encoder key that is stored in the HCS410. Once the

encoder key is obtained, the rest of the transmission

can be decrypted. The decoder waits for a tr ansmission

and immediately checks the serial number to

determine if it is a learned transmitter. If it is, the code

hopping portion of the transmission is decrypted using

the stored key. It uses the discrimination bits to determine if the decryption was valid. If everything up to this

point is valid, the synchronization counter value

is evaluated.

FIGURE 4-4: TYPICAL CH MODE

DECODER OPERATION

?

Transmission

Received

Does

Serial Number

Match

?

Decrypt T ransmission

Is

Decryption

Valid

?

Is

Counter

Within 16

?

Is

Counter

Within 32K

?

Update

Counter

Execute

Command

Save Counter

in T emp Location

Start

No

No

No

No

Yes

Yes

Yes

Yes

Yes

and

No

No

Page 26

HCS410

DS40158C-page 26 Preliminary 1997 Microchip Technology Inc.

4.3.1 SYNCHRONIZATION WITH DECODER

The K

EELOQ

technology features a sophisticated

synchronization technique (Figure 4-5) which does not

require the calculation and storage of future codes. If

the stored counter value for that particular transmitter

and the counter value that was just decrypted are

within a window of say 16, the counter is stored and the

command is executed. If the counter value was not

within the single operation window, but is within the

double operation window of say 32K window , the tr ansmitted synchronization counter value is stored in temporary location and it goes back to waiting for another

transmission. When the next valid transmission is

received, it will compare the new value with the one in

temporary storage. If the two v alues are sequential, it is

assumed that the counter had just gotten out of the single operation ‘window’, but is now back in sync, so the

new synchronization counter value is stored and the

command executed. If a transmitter has somehow gotten out of the double operation window, the transmitter

will not work and must be relearned. Since the entire

window rotates after each valid transmission, codes

that have been used are part of the ‘blocked’ (32K)

codes and are no longer valid. This eliminates the possibility of grabbing a previous code and retransmitting

to gain entry.

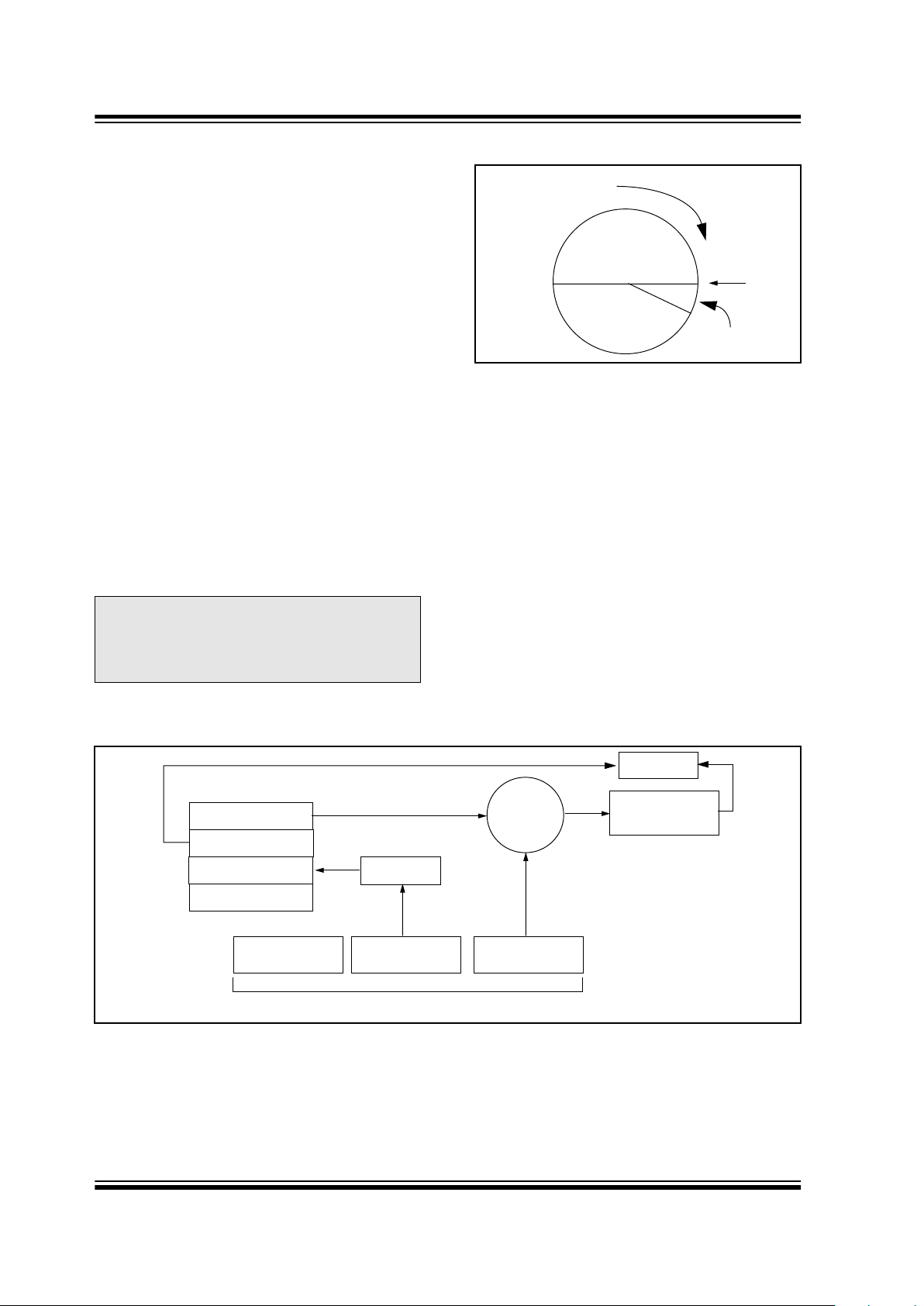

FIGURE 4-5: SYNCHRONIZATION WINDOW

FIGURE 4-6: BASIC OPERATION OF A CODE HOPPING RECEIVER (DECODER)

Note: The synchronization method described in

this section is only a typical

implementation and because it is usually

implemented in firmware, it can be altered

to fit the needs of a particular system

Blocked

Entire Window

rotates to eliminate

use of previously

used codes

Current

Position

(32K Codes)

Double

Operation

(32K Codes)

Single Operation

Window (16 Codes)

Button Press

Information

EEPROM Array

Encoder Key

32 Bits of

Encrypted Data

Serial Number

Received Information

Decrypted

Synchronization

Counter

Check for

Match

Check for

Match

KEELOQ

Algorithm

Decryption

Sync Counter

Serial Number

Manufacturer Code

Page 27

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 27

4.4 IFF Decoder Operation

In a typical IFF decoder, the key generation on the

decoder side is done by reading the serial number from

a token and combining that with the manufacturer’s

code to recreate the encoder key that is stored on the

token. The decoder polls for the presence of a token.

Once detected the decoder reads the serial number. If

the token has been learned, the decoder sends a challenge and reads the token’s response. The decoder

uses the encoder key stored in EEPROM and decrypt

response. The decrypt response is compared to the

challenge. If they match the appropriate output is activated.

FIGURE 4-7: TYPICAL IFF DECODER

OPERATION

FIGURE 4-8: BASIC OPERATION OF AN IFF RECEIVER (DECODER)

Start

Token

Detected?

Read Serial

Does

Serial Number

Match?

Send Challenge

and Read

Decrypt the

Response

Does

Challenge &

Match?

Execute Command

No

No

No

Yes

Yes

Yes

Response

Number

Decrypt response

IFF Key

Serial Number

KEELOQ

IFF

Algorithm

Decrypted

EEPROM Array

Manufacturer

Code

Serial Number Response

Check for

Match

Response

Written to HCS410

Challenge

Information read from HCS410

Page 28

HCS410

DS40158C-page 28 Preliminary 1997 Microchip Technology Inc.

5.0 ELECTRICAL CHARACTERISTICS

TABLE 5-1: ABSOLUTE MAXIMUM RATING

Symbol Item Rating Units

V

DD Supply voltage -0.3 to 6.6 V

V

IN* Input voltage -0.3 to VDD + 0.3 V

V

OUT Output voltage -0.3 to VDD + 0.3 V

I

OUT Max output current 50 mA

T

STG Storage temperature -55 to +125 C (Note)

T

LSOL Lead soldering temp 300 C (Note)

V

ESD ESD rating (Human Body Model) 4000 V

Note: Stresses above those listed under “ABSOLUTE MAXIMUM RATINGS” may cause permanent damage to

the device.

* If a battery is inserted in reverse, the protection circuitry switches on, protecting the device and draining the

battery.

TABLE 5-2: DC AND TRANSPONDER CHARACTERISTICS

Commercial (C): Tamb = 0°C to 70°C

Industrial (I): Tamb = -40°C to 85°C

2.0V < V

DD < 6.3V

Parameter Symbol Min Typ

1

Max Unit Conditions

Average operating current

2

IDD (avg) —

50

160

100

300

µA

V

DD = 3.0V

V

DD = 6.3V

Programming current

I

DDP

— 1.0

2.2

1.8

3.5

mA

VDD = 3.0V

V

DD = 6.3V

Standby current I

DDS — 0.1 100 nA

High level input voltage V

IH 0.55 VDD —VDD + 0.3 V

Low level input voltage V

IL -0.3 — 0.15 VDD V

High level output voltage V

OH

0.8 VDD

0.8 VDD

——

V

VDD = 2V, IOH =- .45 mA

V

DD = 6.3V, IOH,= -2 mA

Low level output voltage V

OL

—

—

—

—

0.08 VDD

0.08 VDD

V

V

DD = 2V, IOH = 0.5 mA

V

DD = 6.3V,IOH = 5mA

LED output current I

LED 3.0 4.0 7.0 mA VDD = 3.0V, VLED = 1.5V

Switch input resistor RS 40 60 80 kΩ

PWM input resistor R

PWM 80 120 160 kΩ

LC input current I

LC — — 10.0 mA VLCC=15 VP-P

LC input clamp voltage VLCC —15— VILC <10 mA

LC induced output current V

DDI — 5.0 mA VLCC > 10V

LC induced output voltage

V

DDV

5.0

4.5

6.3

5.6

6.8

6.8

V

10 V < VLCC, IDD = 0 mA

10 V < V

LCC, IDD = -1 mA

Carrier frequency

f

c — 125 — kHz

External LC Inductor value L — 900 — µH

External LC Capacitor value C — 1.8 — pF

Note 1: Typical values at 25°C.

2: No load connected.

3: LC inputs are clamped at 15 volts.

Page 29

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 29

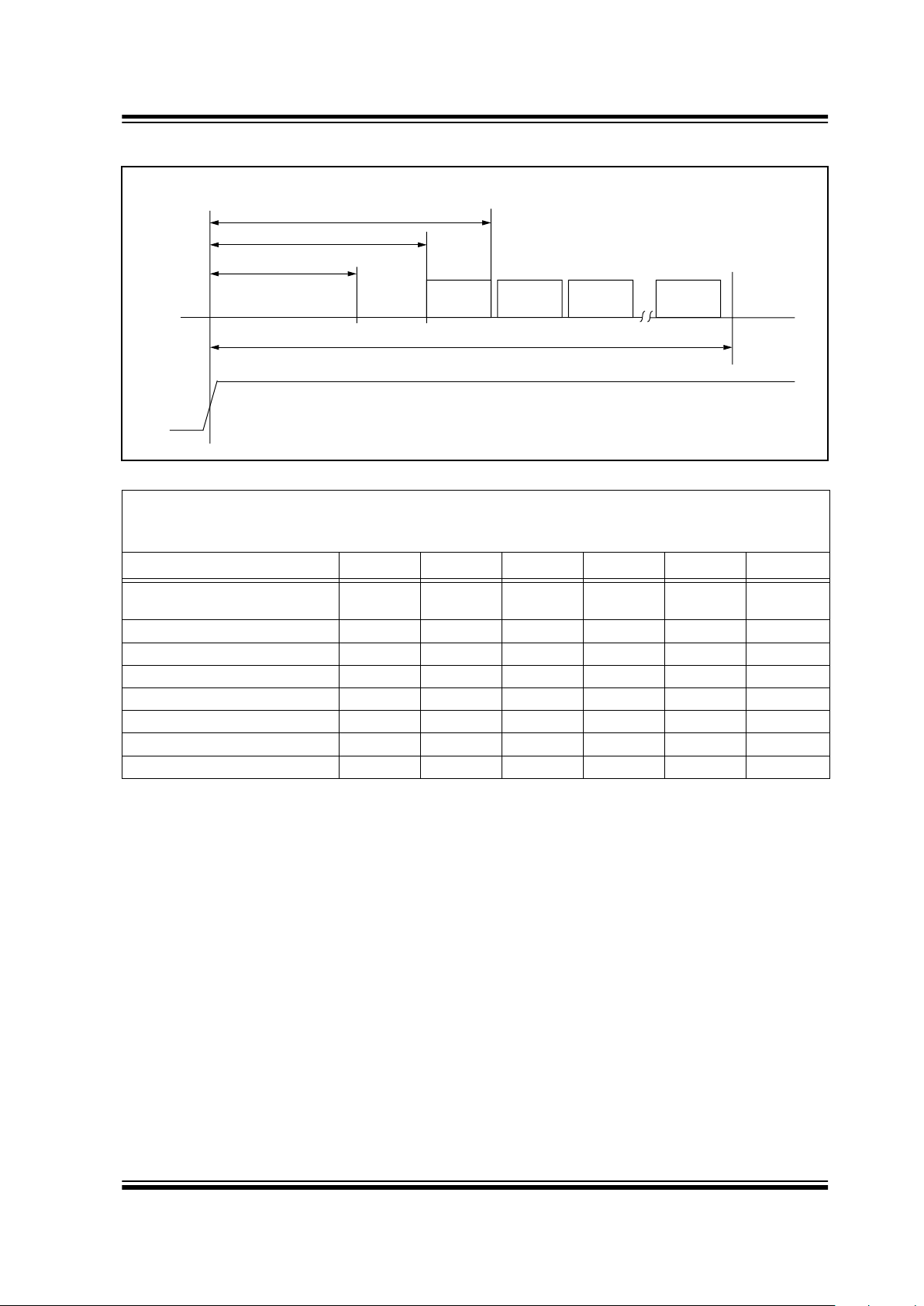

FIGURE 5-1: POWER UP AND TRANSMIT TIMING

TABLE 5-3: POWER UP AND TRANSMIT TIMING REQUIREMENTS

VDD = +2.0 to 6.3V

Commercial (C):Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Parameter Symbol Min Typ. Max Unit Remarks

Time to second button press T

BP 34 + Code

Word Time

38 + Code

Word Time

42 + Code

Word Time

ms (Note 1)

Transmit delay from button detect T

TD 34.2 38 41.8 ms (Note 2)

Debounce delay T

DB 27 30 33 ms

Auto-shutoff time-out period T

TO 18 20 22 s (Note 3)

Time to first LED on T

LST — 240 — ms

LED high-time T

LH —25—ms

LED high-time when battery low T

LHV — 200 — ms

LED low-time T

LL — 480 — ms

Note 1: T

BP is the time in which a second button can be pressed without completion of the first code word and the

intention was to press the combination of buttons.

2: Transmit delay maximum value if the previous transmission was successfully transmitted.

3: The auto-shutoff timeout period is not tested.

Button Press

Sn

Detect

T

DB

PWM

TTD

Code Word Transmission

TTO

Code

Word

1

Code

Word

2

Code

Word

3

Code

Word

n

T

BP

Page 30

HCS410

DS40158C-page 30 Preliminary 1997 Microchip Technology Inc.

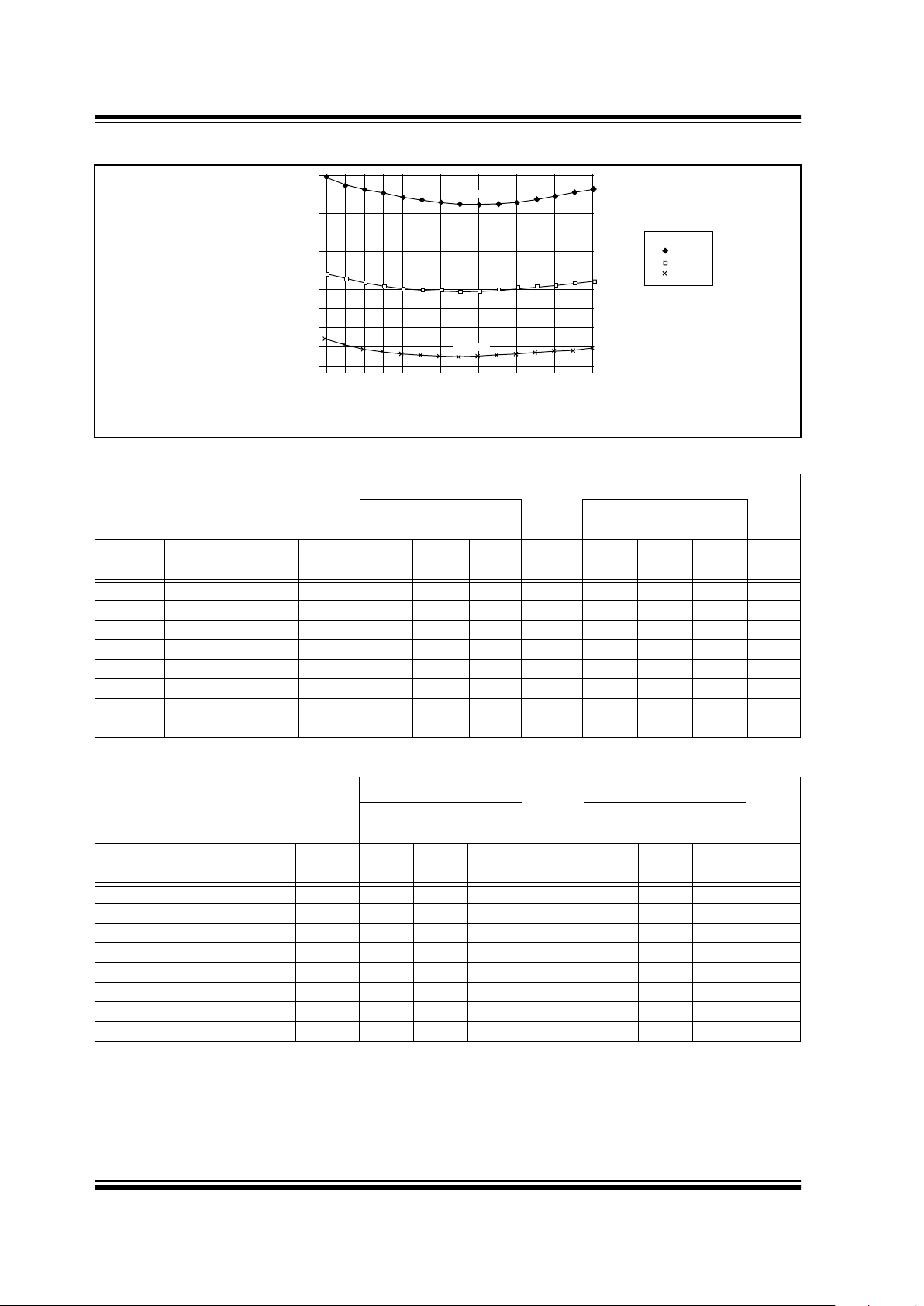

FIGURE 5-2: HCS410 NORMALIZED TE VS. TEMP

TABLE 5-4: CODE WORD TRANSMISSION TIMING PARAMETERS—PWM MODE

VDD = +2.0V to 6.3V

Commercial (C):Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Code Words T ransmitted

BSL1 = 0,

BSL0 = 0

BSL1 = 0,

BSL0 = 1

Symbol Characteristic

Number

of TE

Min. Typ. Max.

Number

of TE

Min. Typ. Max. Units

TE Basic pulse element 1 360 400 440 1 180.0 200.0 220.0 µs

TBP PWM bit pulse width 3 1080 1200 1320 3 540.0 600.0 660.0 µs

TP Preamble duration 32 12 12.8 14 32 5.76 6.0 7.04 ms

TH Header duration 10 3.6 4.0 4.4 10 1.80 2.0 2.20 ms

THOP Code hopping duration 96 35 38.4 42 96 17.28 19.20 21.12 ms

TFIX Fixed code duration 111 39.96 44.4 48.84 111 19.98 22.20 24.42 ms

TG Guard time 46 16.6 18.4 20.2 46 8.3 9.6 10.1 ms

— Total transmit time 295 106.2 118.0 129.8 295 53.1 59.0 64.9 ms

Note: The timing parameters are not tested but derived from the oscillator clock.

VDD = +2.0V to 6.3V

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Code Words T ransmitted

BSL1 = 1,

BSL0 = 0

BSL1 = 0,

BSL0 = 1

Symbol Characteristic

Number

of TE

Min. Typ. Max.

Number

of TE

Min. Typ. Max. Units

TE Basic pulse element 1 180.0 200.0 220.0 1 90.0 100.0 110.0 µs

TBP PWM bit pulse width 3 540.0 600.0 660.0 3 270.0 300.0 330.0 µs

TP Preamble duration 32 5.76 6.0 7.04 32 2.88 3.0 3.52 ms

TH Header duration 10 1.80 2.0 2.20 10 0.90 1.0 1.10 ms

THOP Code hopping duration 96 17.28 19.20 21.12 96 8.64 9.60 10.56 ms

T

FIX Fixed code duration 111 19.98 22.2 24.42 111 9.99 11.1 12.21 ms

TG Guard time 46 8.3 9.6 10.1 46 41 4.6 5.1 ms

— Total transmit time 295 53.1 59.0 64.9 295 26.6 29.5 32.5 ms

Note: The timing parameters are not tested but derived from the oscillator clock.

0.94

1.10

1.08

1.06

1.04

1.02

1.00

0.98

0.96

0.92

0.90

TE Min.

TE Max.

VDD LEGEND

= 2.0V

= 3.0V

= 6.0V

Typical

TE

Temperature °C

-50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90

Note: Values are for calibrated oscillator.

Page 31

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 31

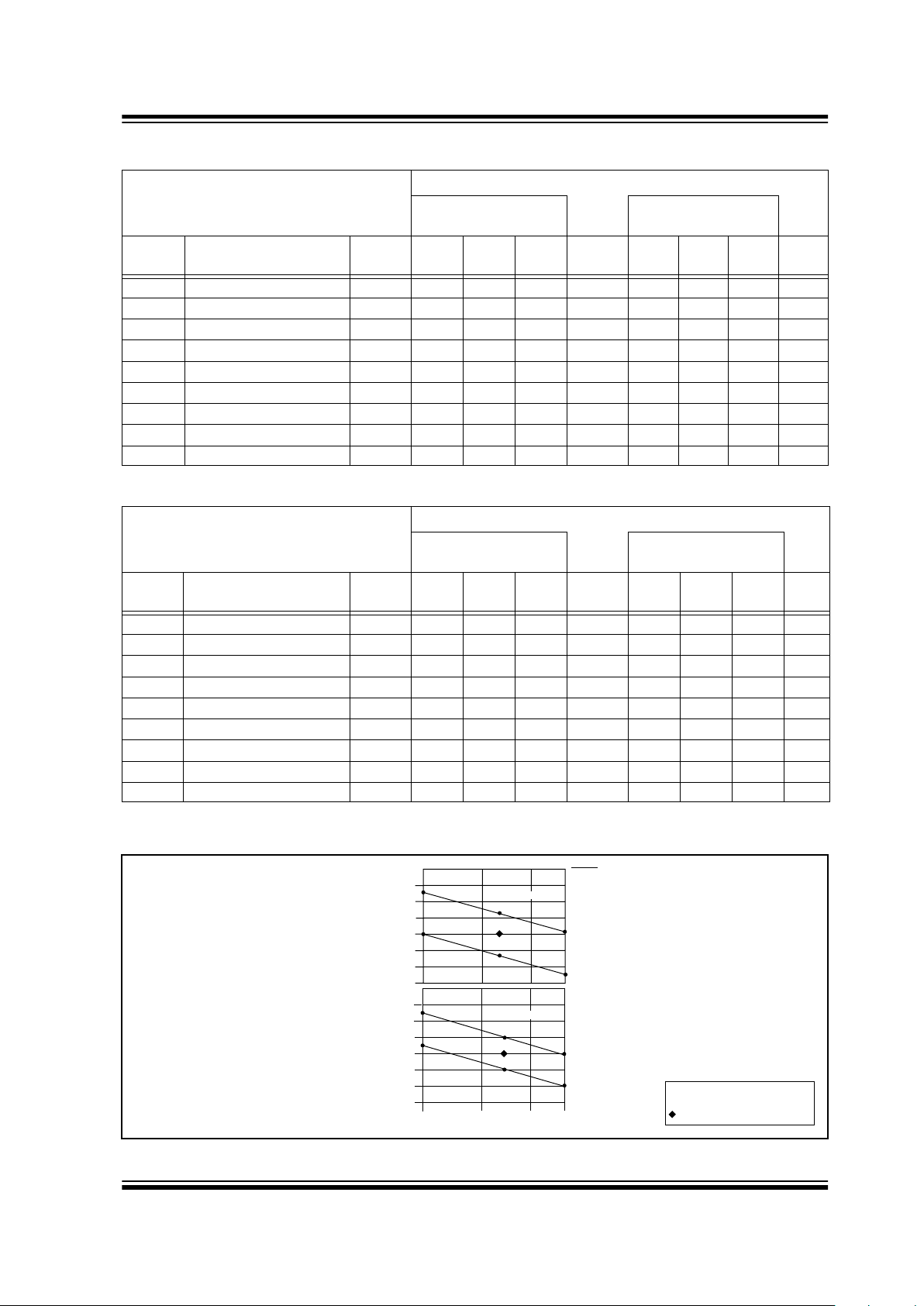

FIGURE 5-3: TYPICAL VOLTAGE TRIP POINTS

TABLE 5-5: CODE WORD TRANSMISSION TIMING PARAMETERS—MANCHESTER MODE

VDD = +2.0V to 6.3V

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Code Words T ransmitted

BSL1 = 0,

BSL0 = 0

BSL1 = 0,

BSL0 = 1

Symbol Characteristic

Number

of TE

Min. Typ. Max.

Number

of TE

Min. Typ. Max. Units

TE

Basic pulse element 1 720.0 800.0 880.0 1.0 360.0 400.0 440.0 µs

TP

Preamble duration 32 23.04 25.60 28.16 32.0 11.52 12.80 14.08 ms

TH

Header duration 4 2.88 3.20 3.52 4.0 1.44 1.60 1.76 ms

TSTART

Start bit 2 1.44 1.60 1.76 2.0 0.72 0.80 0.88 ms

THOP

Code hopping duration 64 46.08 51.20 56.32 64.0 23.04 25.60 28.16 ms

TFIX

Fixed code duration 74 53.28 59.20 65.12 74 26.64 29.60 32.56 ms

TSTOP

Stop bit 2 1.44 1.60 1.76 2.0 0.72 0.80 0.88 ms

TG

Guard time 32 23.0 25.6 28.2 32 11.5 12.8 14.1 ms

— Total transmit time 210 151.2 168 184.8 210 75.6 84.0 92.4 ms

Note: The timing parameters are not tested but derived from the oscillator clock.

VDD = +2.0V to 6.3V

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Code Words T ransmitted

BSL1 = 1,

BSL0 = 0

BSL1 = 1,

BSL0 = 1

Symbol Characteristic

Number

of TE

Min. Typ. Max.

Number

of TE

Min. Typ. Max. Units

TE

Basic pulse element 1 360.0 400.0 440.0 1.0 180.0 200.0 220.0 µs

TP

Preamble duration 32 11.52 12.80 14.08 32.0 5.76 6.40 7.04 ms

TH

Header duration 4 1.44 1.60 1.76 4.0 0.72 0.80 0.88 ms

TSTART

Start bit 2 0.72 0.80 0.88 2.0 0.36 0.40 0.44 ms

THOP

Code hopping duration 64 23.04 25.60 28.16 64.0 11.52 12.80 14.08 ms

TFIX

Fixed code duration 74 26.64 29.60 32.56 74 13.32 14.8 16.28 ms

TSTOP

Stop bit 2.0 0.72 0.80 0.88 2.0 0.36 0.40 0.44 ms

TG

Guard time 32 11.5 12.8 14.1 32 5.8 6.4 7.0 ms

— Total transmit time 210 75.6 84.0 92.4 210 37.8 42.0 46.2 ms

Note: The timing parameters are not tested but derived from the oscillator clock.

VLOW

Volts (V)

-40

05085

2.0

1.6

1.8

2.2

2.4

2.6

Temp (C)

VLOW sel = 0

4.4

4.0

4.2

3.8

4.6

4.8

5.0

VLOW sel = 1

2.8

Nominal VLOW trip point

Legend

Page 32

HCS410

DS40158C-page 32 Preliminary 1997 Microchip Technology Inc.

NOTES:

Page 33

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 33

NOTES:

Page 34

HCS410

DS40158C-page 34 Preliminary 1997 Microchip Technology Inc.

NOTES:

Page 35

HCS410

1997 Microchip Technology Inc. Preliminary DS40158C-page 35

HCS410 PRODUCT IDENTIFICATION SYSTEM