Microchip Technology Inc 25LC160T-I-SN, 25LC160T-I-P, 25LC160T-SN, 25LC160T-P, 25LC160-I-SN Datasheet

...

1996 Microchip Technology Inc.

Preliminary

DS21145D-page 1

FEATURES

• SPI modes 0,0 and 1,1

• 3 MHz Clock Rate

• Single supply with programming operation down

to 2.5V

• Low Power CMOS Technology

- Max Write Current: 5 mA

- Read Current: 1.0 mA

- Standby Current: 1 µ A typical

• Organization

- 1024 x 8 for 25LC080

- 2048 x 8 for 25LC160

• 16 Byte Page

• Sequential Read

• Self-timed ERASE and WRITE Cycles

• Block Write Protection

- Protect none, 1/4, 1/2, or all of Array

• Built-in Write Protection

- Power On/Off Data Protection Circuitry

- Write Latch

- Write Protect Pin

• High Reliability

- Endurance: 10M cycles (guaranteed)

- Data Retention: >200 years

- ESD protection: >4000 V

• 8-pin PDIP/SOIC Packages

• Temperature ranges supported

DESCRIPTION

The Microchip Technology Inc. 25LC080/160 are 8K

and 16K bit Serial Electrically Erasable PROMs. The

memory is accessed via a simple Serial Peripheral

Interface (SPI) compatible serial bus. The bus signals

required are a clock input (SCK) plus separate data in

(SI) and data out (SO) lines. Access to the device is

controlled through a chip select (CS

) input, allowing any

number of devices to share the same bus.

There are two other inputs that provide the end user

with additional flexibility. Communication to the device

can be paused via the hold pin (HOLD

). While the

device is paused, transitions on its inputs will be

ignored, with the exception of chip select, allowing the

host to service higher priority interrupts. Also, write

operations to the Status Register can be disabled via

the write protect pin (WP

).

- Commercial (C): 0 ° C to +70 ° C

- Industrial (I): -40 ° C to +85 ° C

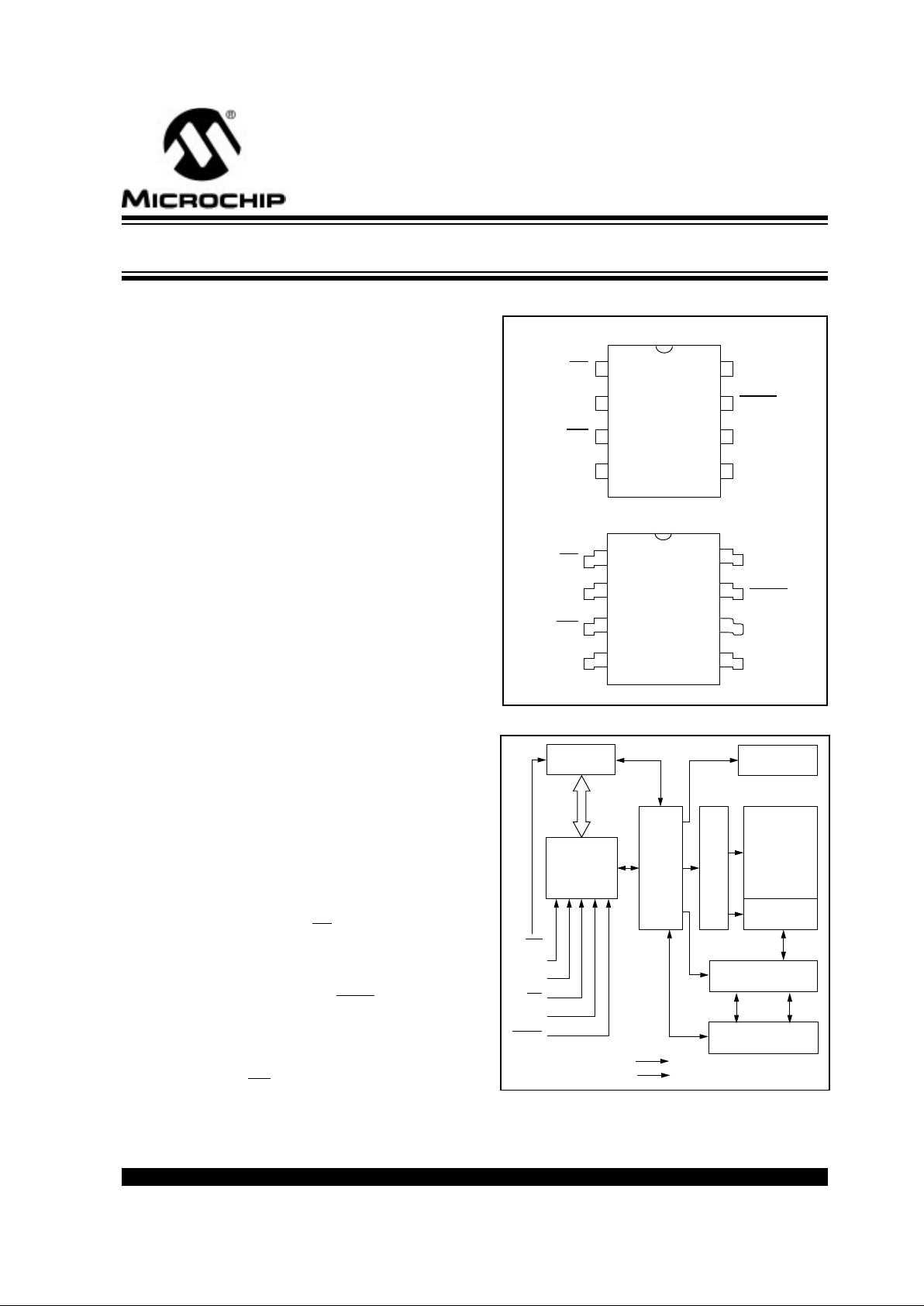

PACKAGE TYPES

BLOCK DIAGRAM

25LC080/160 25LC080/160

CS

SO

WP

VSS

1

2

3

4

VCC

HOLD

SCK

SI

8

7

6

5

V

CC

HOLD

SCK

SI

CS

SO

WP

VSS

1

2

3

4

8

7

6

5

PDIP

SOIC

SI

SO

SCK

CS

HOLD

WP

Status

Register

I/O Control

Memory

Control

Logic

X

Dec

HV Generator

EEPROM

Array

Page Latches

Y Decoder

Sense Amp.

R/W Control

Logic

Vcc

Vss

25LC080/160

8K/16K 2.5V SPI

Bus Serial EEPROM

SPI is a trademark of Motorola.

25LC080/160

DS21145D-page 2

Preliminary

1996 Microchip Technology Inc.

1.0 ELECTRICAL

CHARACTERISTICS

1.1 Maxim

um Ratings*

V

CC

........................................................................7.0V

All inputs and outputs w.r.t. V

SS

......-0.6V to V

CC

+1.0V

Storage temperature.............................-65˚C to 150˚C

Ambient temperature under bias...........-65˚C to 125˚C

Soldering temperature of leads (10 seconds)...+300˚C

ESD protection on all pins...................................... 4kV

*

Notice : Stresses abov e those listed under ‘Maximum ratings’

may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at those or

any other conditions above those indicated in the operational

listings of this specification is not implied. Exposure to maximum rating conditions for extended period of time may affect

device reliability

TABLE 1-1: PIN FUNCTION TABLE

Name Function

CS

Chip Select Input

SO Serial Data Output

SI Serial Data Input

SCK Serial Clock Input

WP

Write Protect Pin

V

SS

Ground

V

CC

Supply V oltage

HOLD

Hold Input

FIGURE 1-1: AC TEST CIRCUIT

1.2 A

C Test Conditions

AC Waveform:

V

LO

= 0.2V

V

HI

= Vcc - 0.2V (Note 1)

V

HI

= 4.0V (Note 2)

Timing Measurement Reference Level

Input 0.5 V

CC

Output 0.5 V

CC

Note 1: For V

CC

≤

4.0V

2: For V

CC

> 4.0V

Vcc

SO

100 pF

1.8 K

2.25 K

TABLE 1-2: DC CHARACTERISTICS

Applicable over recommended operating ranges shown below unless otherwise noted.

V

CC

= +2.5V to +5.5V

Commercial (C): Tamb = 0˚C to +70˚C

Industrial (I): Tamb = -40˚C to +85˚C

Parameter Symbol Min Max Units Test Conditions

High level input voltage V

IH1

2.0 V

CC

+1 V V

CC

≥

2.7V

V

IH2

0.7 V

CC

V

CC

+1 V V

CC

< 2.7V

Low level input voltage V

IL1

-0.3 0.8 V V

CC

≥

2.7V

V

IL2

-0.3 0.3 V

CC

VV

CC

< 2.7V

Low level output voltage V

OL

— 0.4 V I

OL

=2.1 mA

High level output voltage V

OH

V

CC

-0.5 — V I

OH

=-400 µ A

Input leakage current I

LI

-10 10

µ

ACS=V

IH

, V

IN

=V

SS

to V

CC

Output leakage current I

LO

-10 10

µ

ACS

=V

IH

, V

OUT

=V

SS

to V

CC

Internal Capacitance

(all inputs and outputs)

C

INT

— 7 pF Tamb=25˚C, F

CLK

=3.0 MHz,

V

CC

=5.5V (Note)

Operating Current I

CC

WRITE

—

—

5

3

mAmAV

CC

=5.5V

V

CC

=2.5V

I

CC

READ

—

—

1

500

mA

µ

A

V

CC

=5.5V; 3 MHz

V

CC

=2.5V; 2 MHz

Standby Current I

CCS

—

—

5

2

µ A µ

A

CS

=V

CC

=5.5V; Vin=0V or V

CC

CS

=V

CC

=2.5V; Vin=0V or V

CC

Note: This parameter is periodically sampled and not 100% tested.

1996 Microchip Technology Inc.

Preliminary

DS21145D-page 3

25LC080/160

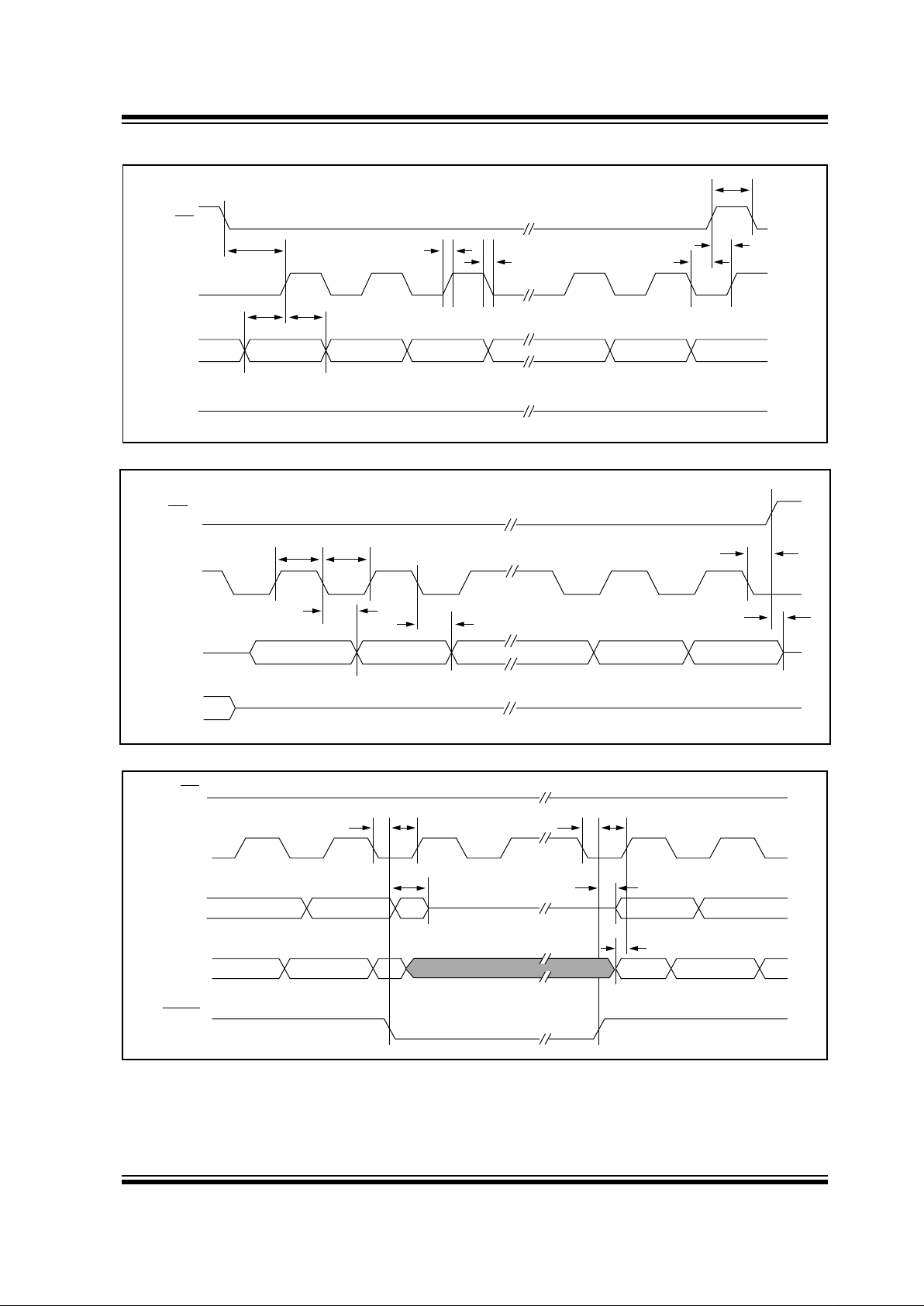

FIGURE 1-2: SERIAL INPUT TIMING

FIGURE 1-3: SERIAL OUTPUT TIMING

FIGURE 1-4: HOLD TIMING

CS

SCK

SI

SO

t

CSS

t

HD

t

SU

t

F

t

R

t

CSD

t

CLD

t

CSH

LSB inMSB in

high impedance

CS

SCK

SO

t

LO

t

HI

t

HO

t

V

MSB out

LSB out

t

CSH

t

DIS

don’t care

SI

CS

SCK

SO

SI

HOLD

t

HH

t

HS

t

HS

t

HH

t

HV

t

HZ

don’t care

t

SU

high impedance

n+2 n+1 n n-1

n

n+2 n+1 n

n

n-1

25LC080/160

DS21145D-page 4

Preliminary

1996 Microchip Technology Inc.

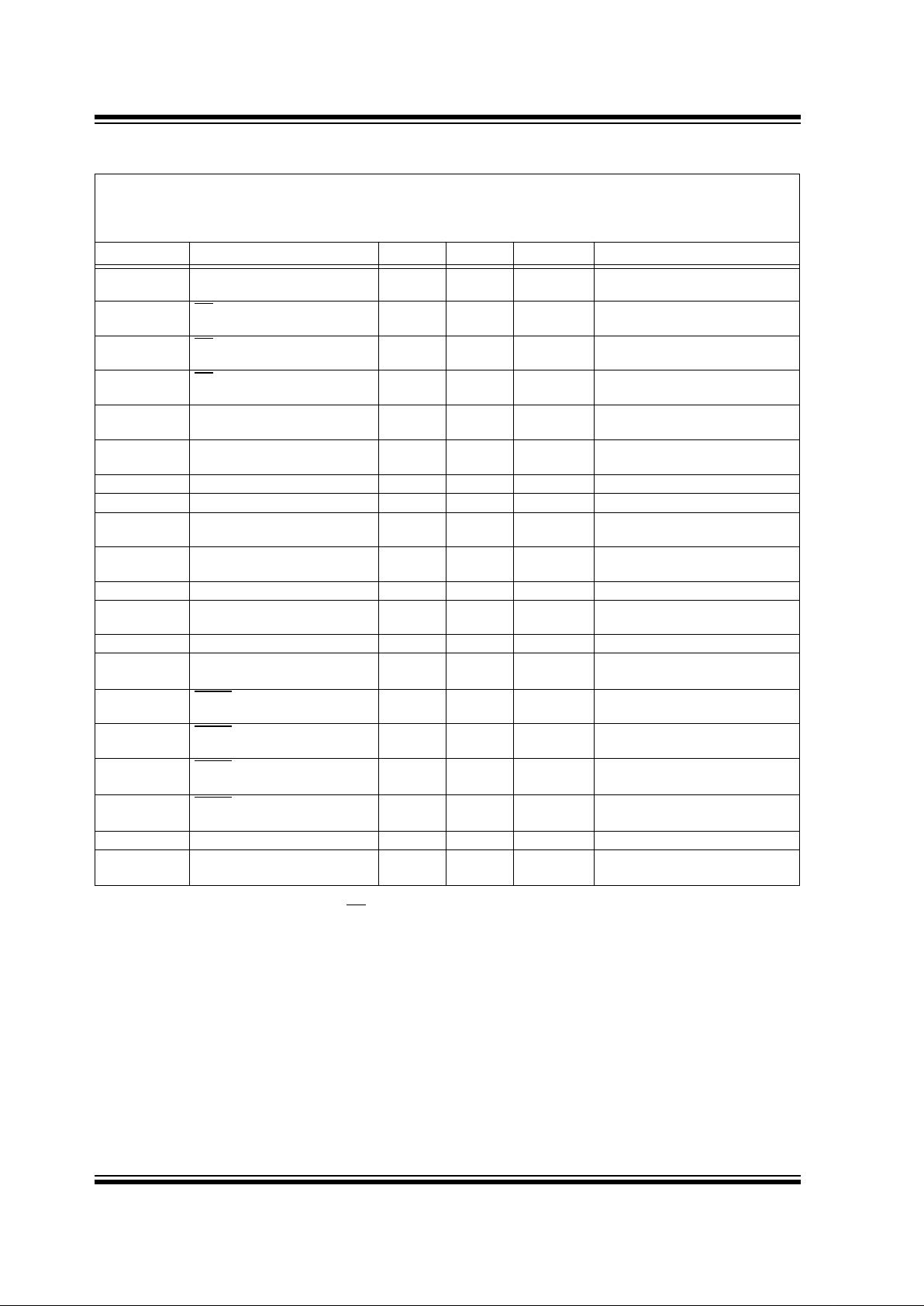

TABLE 1-3: AC CHARACTERISTICS

Applicable over recommended operating ranges shown below unless otherwise noted.

V

CC

= +2.5V to +5.5V

Commercial (C): Tamb = 0˚C to +70˚C

Industrial (I): Tamb = -40˚C to +85˚C

Symbol Parameter Min Max Units Test Conditions

f

SCK

Clock Frequency —

—

3

2

MHz

MHz

V

CC

=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

CSS CS Setup Time 100

250

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

CSH CS Hold Time 100

250

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

CSD CS Disable Time 250

500

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

SU Data Setup Time 30

50

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

HD Data Hold Time 50

100

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

R CLK Rise Time — 2 µs

(Note 1)

t

F CLK Fall Time — 2 µs

(Note 1)

t

HI Clock High Time 150

250

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

LO Clock Low Time 150

250

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

CLD Clock Delay Time 50 — ns

t

V Output Valid from

Clock Low

—

—

150

250

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

HO Output Hold Time 0 — ns

t

DIS Output Disable Time —

—

200

250

ns

ns

V

CC=4.5V to 5.5V (Note 1)

V

CC=2.5V to 4.5V (Note 1)

t

HS HOLD Setup Time 100

100

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

HH HOLD Hold Time 100

100

—

—

ns

ns

VCC=4.5V to 5.5V

V

CC=2.5V to 4.5V

t

HZ HOLD Low to Output High-Z 100

150

—

—

ns

ns

V

CC=4.5V to 5.5V (Note 1)

V

CC=2.5V to 4.5V (Note 1)

t

HV HOLD High to Output Valid 100

150

—

—

ns

ns

V

CC=4.5V to 5.5V (Note 1)

V

CC=2.5V to 4.5V (Note 1)

t

WC Internal Write Cycle Time — 5 ms

(Note 2)

— Endurance 10M — E/W Cycles 25°C, Vcc = 5.0V, Block Mode

(Note 3)

Note 1: This parameter is periodically sampled and not 100% tested.

2: t

WC begins on the rising edge of CS after a valid write sequence and ends when the internal self-timed write

cycle is complete.

3: This parameter is not tested but guaranteed b y characterization. For endurance estimates in a specific appli-

cation, please consult the Total Endurance Model which can be obtained on our BBS or website.

1996 Microchip Technology Inc. Preliminary DS21145D-page 5

25LC080/160

2.0 PRINCIPLES OF OPERATION

The 25LC080/160 is an 1024/2048 byte EEPROM

designed to interface directly with the Serial Peripheral

Interface (SPI) port of many of today’s popular microcontroller families, including Microchip’s midrange

PIC16CXX microcontrollers. It may also interface with

microcontrollers that do not have a built-in SPI port by

using discrete I/O lines programmed properly with software.

The 25LC080/160 contains an 8-bit instruction register.

The part is accessed via the SI pin, with data being

clocked in on the rising edge of SCK. If the WPEN bit in

the status register is set, the WP

pin must be held high

to allow writing to the non-volatile bits in the status register.

T able 2-1 contains a list of the possible instruction bytes

and format for device operation. All instructions,

addresses and data are transferred MSB first, LSB last.

Data is sampled on the first rising edge of SCK after CS

goes low. If the clock line is shared with other peripheral

devices on the SPI bus, the user can assert the HOLD

input and place the 25LC080/160 in ‘HOLD’ mode.

After releasing the HOLD

pin, operation will resume

from the point when the HOLD

was asserted.

2.1 Write Enable (WREN) and Write

Disable (WRDI)

The 25LC080/160 contains a write enable latch. This

latch must be set before any write operation will be

completed internally. The WREN instruction will set the

latch, and the WRDI will reset the latch. The following is

a list of conditions under which the write enable latch

will be reset:

• Power-up

• WRDI instruction successfully executed

• WRSR instruction successfully executed

• WRITE instruction successfully executed

2.2 Read Status Register (RDSR)

The RDSR instruction provides access to the status

register. The status register may be read at any time,

even during a write cycle. The status register is formatted as follows:

The Write-In-Process (WIP) bit indicates whether the

25LC080/160 is busy with a write operation. When set

to a ‘1’ a write is in progress, when set to a ‘0’ no write

is in progress. This bit is read only.

The Write Enable Latch (WEL) bit indicates the status

of the write enable latch. When set to a ‘1’ the latch

allows writes to the array and status register, when set

to a ‘0’ the latch prohibits writes to the array and status

register. The state of this bit can always be updated via

7 654 3 2 1 0

WPEN X X X BP1 BP0 WEL WIP

the WREN or WRDI commands regardless of the state

of write protection on the status register. This bit is read

only .

The Block Protection (BP0 and BP1) bits indicate

which blocks are currently write protected. These bits

are set by the user issuing the WRSR instruction.

These bits are non-volatile.

The Write Protect Enable (WPEN) bit is a non-volatile

bit that is available as an enable bit for the WP

pin. The

Write Protect (WP

) pin and the Write Protect Enable

(WPEN) bit in the status register control the programmable hardware write protect feature. Hardware write

protection is enabled when WP

pin is low and the

WPEN bit is high. Hardware write protection is disab led

when either the WP

pin is high or the WPEN bit is low.

When the chip is hardware write protected, only writes

to non-volatile bits in the status register are disabled.

See Table 2-2 for matrix of functionality on the WPEN

bit and Figure 2-1 for a flowchart of Table 2-2.

See Figure 3-5 for RDSR timing sequence.

TABLE 2-1: INSTRUCTION SET

Instruction

Name

Instruction

Format

Description

WREN 0000 0110 Set the write enable

latch (enable write

operations)

WRDI 0000 0100 Reset the write

enable latch (disable

write operations)

RDSR 0000 0101 Read status register

WRSR 0000 0001 Write status register

(write protect enable

and block write protection bits)

READ 0000 0011 Read data from

memory array beginning at selected

address

WRITE 0000 0010 Write data to memory

array beginning at

selected address

25LC080/160

DS21145D-page 6 Preliminary 1996 Microchip Technology Inc.

TABLE 2-2: WRITE PROTECT FUNCTIONALITY MATRIX

FIGURE 2-1: WRITE TO STATUS REGISTER AND/OR ARRAY FLOWCHART

WPEN WP WEL Protected Blocks Unprotected Blocks Status Register

0 X 0 Protected Protected Protected

0 X 1 Protected Writable Writable

1 Low 0 Protected Protected Protected

1 Low 1 Protected Writable Protected

X High 0 Protected Protected Protected

X High 1 Protected Writable Writable

CS Returns High

Continue

Write to Status

Reg?

WEL = 1? WEL = 1?

WP is low?

WPEN = 1?

Write

Write to

Status Register

Do not write to

Status Register

Write to the

Unprotected Block

Do not write to

Array

No

No

No

No

YesYes

YesYes

No

Yes

No

Yes

To other

Commands

From other

Commands

to array?

1996 Microchip Technology Inc. Preliminary DS21145D-page 7

25LC080/160

2.3 Write Status Register (WRSR)

The WRSR instruction allows the user to select one of

four protection options for the array by writing to the

appropriate bits in the status register. The array is

divided up into four segments. The user has the ability

to write protect none, one, two, or all four of the segments of the array. The partitioning is controlled as illustrated in table below.

See Figure for WRSR timing sequence.

TABLE 2-3: ARRAY PROTECTION

3.0 DEVICE OPERATION

3.1 Clock and Data Timing

Data input on the SI pin is latched on the rising edge of

SCK. Data is output on the SO pin after the f alling edge

of SCK.

3.2 Read Sequence

The part is selected by pulling CS low. The 8-bit read

instruction is transmitted to the 25LC080/160 followed

by the 16-bit address, with the five (25LC160) or six

(25LC080) MSBs of the address being don’t care bits.

After the correct read instruction and address are sent,

the data stored in the memory at the selected address

is shifted out on the SO pin. The data stored in the

memory at the next address can be read sequentially

by continuing to provide clock pulses. The internal

address pointer is automatically incremented to the

next higher address after each byte of data is shifted

out. When the highest address is reached ($3FF for

25LC080, $7FF for 25LC160) the address counter rolls

over to address $000 allowing the read cycle to be continued indefinitely. The read operation is terminated by

setting CS

high (see Figure 3-1).

3.3 Write Sequence

Prior to any attempt to write data to the 25LC080/160,

the write enable latch must be set by issuing the WREN

instruction (Figure 3-2). This is done by setting CS

low

and then clocking the proper instruction into the

25LC080/160. After all eight bits of the instruction are

transmitted, the CS

must be brought high to set the

BP1 BP0

Array Addresses

Write Protected

0 0 none

0 1 upper 1/4

300h-3FFh for 25LC080

600h-7FFh for 25LC160

1 0 upper 1/2

200h-3FFh for 25LC080

400h-7FFh for 25LC160

1 1 all

000h-3FFh for 25LC080

000h-7FFh for 25LC160

write enable latch. If the write operation is initiated

immediately after the WREN instruction without CS

being brought high, the data will not be written to the

array because the write enable latch will not hav e been

properly set.

Once the write enable latch is set, the user may proceed by setting the CS

low, issuing a write instruction,

followed by the 16-bit address, with the five (25LC160)

or six (25LC080) MSBs of the address being don’t care

bits, and then the data to be written. Up to 16 bytes of

data can be sent to the 25LC080/160 before a write

cycle is necessary. The only restriction is that all of the

bytes must reside in the same page. A page address

begins with XXXX XXXX XXXX 0000 and ends with

XXXX XXXX XXXX 1111. If the internal address

counter reaches XXXX XXXX XXXX 1111 and the

clock continues, the counter will roll back to the first

address of the page and overwrite any data in the page

that may have been written.

For the data to be actually written to the array, the CS

must be brought high after the least significant bit (D0)

of the n

th

data byte has been clocked in. If CS is brought

high at any other time, the write operation will not be

completed. Ref er to Figure 3-3 and Figure 3-4 f or more

detailed illustrations on the byte write sequence and the

page write sequence, respectively.

While the write is in progress, the status register may

be read to check the status of the WPEN, WIP, WEL,

BP1, and BP0 bits. A read attempt of a memory array

location will not be possible during a write cycle. When

a write cycle is completed, the write enable latch is

reset

3.4 Data Protection

The following protection has been implemented to prevent inadvertent writes to the array:

• The write enable latch is reset on power-up.

• A write enable instruction must be issued to set

the write enable latch.

• After a successful byte write, page write, or status

register write, the write enable latch is reset.

•CS

must be set high after the proper number of

clock cycles to start an internal write cycle.

• Access to the array during an internal write cycle

is ignored and programming is continued.

3.5 Power On State

The 25LC080/160 powers on in the following state:

• The device is in low power standby mode (CS=1).

• The write enable latch is reset.

• SO is in high impedance state.

• A low level on CS

is required to enter active state.

25LC080/160

DS21145D-page 8 Preliminary 1996 Microchip Technology Inc.

FIGURE 3-1: READ SEQUENCE

FIGURE 3-2: WRITE ENABLE SEQUENCE

FIGURE 3-3: WRITE SEQUENCE

SO

SI

SCK

CS

0 234567891011 21222324252627282930311

0100000 1 15 14 13 12 210

76543210

INSTRUCTION

16 BIT ADDRESS

DATA OUT

HIGH IMPEDANCE

SCK

0 2345671

SI

HIGH IMPEDANCE

SO

CS

010000 01

SO

SI

CS

91011 2122232425262728293031

0000000 1 15 14 13 12

21076543210

instruction 16 bit address data byte

high impedance

SCK

0 2345671

8

T

wc

1996 Microchip Technology Inc. Preliminary DS21145D-page 9

25LC080/160

FIGURE 3-4: PAGE WRITE SEQUENCE

FIGURE 3-5: READ STATUS REGISTER SEQUENCE

WRITE STATUS REGISTER SEQUENCE

SI

CS

9 1011 2122232425262728293031

0000000 1 15 14 13 12 21076543210

instruction

16 bit address data byte 1

SCK

0 2345671

8

SI

CS

41 42 43 46 47

76543210

data byte n (16 max)

SCK

32 34 35 36 37 38 3933

40

76543210

data byte 3

76543210

data byte 2

44 45

SO

SI

CS

9101112131415

11000000

7654 210

instruction

data from status register

high impedance

SCK

0 2345671

8

3

SO

SI

CS

9101112131415

01000000

7654

210

instruction data to status register

high impedance

SCK

0 2345671

8

3

25LC080/160

DS21145D-page 10 Preliminary 1996 Microchip Technology Inc.

4.0 PIN DESCRIPTIONS

4.1 Chip Select (CS)

A low level on this pin selects the device. A high level

deselects the device and forces it into standby mode.

However, a programming cycle which is already in

progress will be completed, regardless of the CS

input

signal. If CS

is brought high during a program cycle, the

device will go into standby mode as soon as the programming cycle is complete. As soon as the device is

deselected, SO goes to the high impedance state,

allowing multiple parts to share the same SPI bus. A

low to high transition on CS

after a valid write sequence

initiates an internal write cycle. After power-up, a low

level on CS

is required prior to any sequence being ini-

tiated.

4.2 Serial Input (SI)

The SI pin is used to transfer data into the device. It

receives instructions, addresses, and data. Data is

latched on the rising edge of the serial clock.

It is possible for the SI pin and the SO pin to be tied

together. With SI and SO tied together, two way communication of data can occur using only one microcontroller I/O line.

4.3 Serial Output (SO)

The SO pin is used to transfer data out of the 25LC080/

160. During a read cycle, data is shifted out on this pin

after the falling edge of the serial clock.

It is possible for the SI pin and the SO pin to be tied

together. With SI and SO tied together, two way communication of data can occur using only one microcontroller I/O line.

4.4 Serial Clock (SCK)

The SCK is used to synchronize the communication

between a master and the 25LC080/160. Instructions,

addresses, or data present on the SI pin are latched on

the rising edge of the clock input, while data on the SO

pin is updated after the falling edge of the clock input.

4.5 Write Protect (WP)

This pin is used in conjunction with the WPEN bit in the

status register to prohibit writes to the non-volatile bits

in the status register. When WP

is low and WPEN is

high, writing to the non-volatile bits in the status register

is disabled. All other operations function normally.

When WP

is high, all functions, including writes to the

non-volatile bits in the status register operate normally.

If the WPEN bit is set WP

low during a status register

write sequence will disable writing to the status register.

If an internal write cycle has already begun, WP

going

low will have no effect on the write.

The WP

pin function is blocked when the WPEN bit in

the status register is low. This allows the user to install

the 25LC080/160 in a system with WP

pin grounded

and still be able to write to the status register. The WP

pin functions will be enabled when the WPEN bit is set

high.

4.6 Hold (HOLD)

The HOLD pin is used to suspend transmission to the

25LC080/160 while in the middle of a serial sequence

without having to re-transmit the entire sequence over

at a later time. It should be held high an y time this function is not being used. Once the device is selected and

a serial sequence is underway, the HOLD

pin may be

pulled low to pause further serial communication without resetting the serial sequence. The HOLD

pin must

be brought low while SCK is low, otherwise the HOLD

function will not be invoked until the next SCK high to

low transition. The 25LC080/160 must remain selected

during this sequence. The SI, SCK, and SO pins are in

a high impedance state during the time the part is

paused and transitions on these pins will be ignored. To

resume serial communication, HOLD

must be brought

high while the SCK pin is low, otherwise serial communication will not resume.

25LC080/160

1996 Microchip Technology Inc. Preliminary DS21145D-page 11

25LC080/160 Product Identification System

To order or to obtain information (e.g., on pricing or delivery), please use the listed part numbers, and refer to the factory or the listed

sales offices.

Package: P = Plastic DIP (300 mil body), 8 lead

SN = Plastic SOIC (150 mil body), 8 lead

Temperature Blank = 0°C to +70°C

Range: I = -40°C to +85°C

Device:

25LC080/160

SPI Bus Serial EEPROM

25LC080T/160T SPI Bus Serial EEPROM (Tape and Reel)

25LC080/160 - /P

Sales and Support

Products supported by a preliminary Data Sheet may possibly have an errata sheet describing minor operational differences and

recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

Your local Microchip sales office (see next page)

The Microchip Corporate Literature Center U.S. FAX: (602) 786-7277

The Microchip’s Bulletin Board, via your local CompuServe number (CompuServe membership NOT required).

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

For latest version information and upgrade kits for Microchip Development Tools, please call 1-800-755-2345 or 1-602-786-7302.

1.

2.

3.

DS21145D-page 12 Preliminary 1996 Microchip Technology Inc.

Information contained in this publication regarding device applications and the like is intended through suggestion only and may be superseded by updates. No representation or warranty is given and no liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement

of patents or other intellectual property rights arising from such use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with express written approval by Microchip . No licenses are conveyed, implicitly or otherwise, under any intellectual property rights. The Microchip logo and

name are registered trademarks of Microchip Technology Inc. All rights reserved. All other trademarks mentioned herein are the property of their respective companies.

WORLDWIDE SALES & SERVICE

ASIA/PACIFIC

Hong Kong

Microchip T echnology

RM 3801B, Tower Two

Metroplaza

223 Hing Fong Road

Kwai Fong, N.T. Hong Kong

Tel: 852 2 401 1200 Fax: 852 2 401 3431

India

Microchip T echnology

No. 6, Legacy, Convent Road

Bangalore 560 025 India

Tel: 91 80 526 3148 Fax: 91 80 559 9840

Korea

Microchip T echnology

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku,

Seoul, Korea

Tel: 82 2 554 7200 Fax: 82 2 558 5934

Shanghai

Microchip T echnology

Unit 406 of Shanghai Golden Bridge Bldg.

2077 Yan’an Road West, Hongiao District

Shanghai, Peoples Republic of China

Tel: 86 21 6275 5700

Fax: 011 86 21 6275 5060

Singapore

Microchip T echnology

200 Middle Road

#10-03 Prime Centre

Singapore 188980

Tel: 65 334 8870 Fax: 65 334 8850

Taiwan, R.O.C

Microchip T echnology

10F-1C 207

Tung Hua North Road

T aipei, Taiwan, ROC

Tel: 886 2 717 7175 Fax: 886 2 545 0139

EUROPE

United Kingdom

Arizona Microchip Technology Ltd.

Unit 6, The Courtyard

Meadow Bank, Furlong Road

Bourne End, Buckinghamshire SL8 5AJ

Tel: 44 1628 850303 Fax: 44 1628 850178

France

Arizona Microchip Technology SARL

Zone Industrielle de la Bonde

2 Rue du Buisson aux Fraises

91300 Massy - France

Tel: 33 1 69 53 63 20 Fax: 33 1 69 30 90 79

Germany

Arizona Microchip Technology GmbH

Gustav-Heinemann-Ring 125

D-81739 Muenchen, Germany

Tel: 49 89 627 144 0 Fax: 49 89 627 144 44

Italy

Arizona Microchip Technology SRL

Centro Direzionale Colleone Pas Taurus 1

Viale Colleoni 1

20041 Agrate Brianza

Milan Italy

Tel: 39 39 6899939 Fax: 39 39 689 9883

JAPAN

Microchip Technology Intl. Inc.

Benex S-1 6F

3-18-20, Shin Yokohama

Kohoku-Ku, Yokohama

Kanagawa 222 Japan

Tel: 81 45 471 6166 Fax: 81 45 471 6122

11/7/96

AMERICAS

Corporate Office

Microchip T echnology Inc.

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 602 786-7200 Fax: 602 786-7277

Technical Support:

602 786-7627

Web:

http://www.microchip.com

Atlanta

Microchip T echnology Inc.

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770 640-0034 Fax: 770 640-0307

Boston

Microchip T echnology Inc.

5 Mount Royal Avenue

Marlborough, MA 01752

Tel: 508 480-9990 Fax: 508 480-8575

Chicago

Microchip T echnology Inc.

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 708 285-0071 Fax: 708 285-0075

Dallas

Microchip T echnology Inc.

14651 Dallas Parkway, Suite 816

Dallas, TX 75240-8809

Tel: 972 991-7177 Fax: 972 991-8588

Dayton

Microchip T echnology Inc.

Suite 150

Two Prestige Place

Miamisburg, OH 45342

Tel: 513 291-1654 Fax: 513 291-9175

Los Angeles

Microchip T echnology Inc.

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 714 263-1888 Fax: 714 263-1338

New Y ork

Microchip T echnology Inc.

150 Motor Parkway, Suite 416

Hauppauge, NY 11788

Tel: 516 273-5305 Fax: 516 273-5335

San Jose

Microchip T echnology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408 436-7950 Fax: 408 436-7955

Toronto

Microchip T echnology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905 405-6279 Fax: 905 405-6253

All rights reserved. 1996, Microchip Technology Incorporated, USA. 11/96

Printed on recycled paper.

Loading...

Loading...