Microchip Technology Inc 25C320T-I-ST, 25C320T-I-SN, 25C320T-I-P, 25C320T-E-ST, 25C320T-E-SN Datasheet

...

1996 Microchip Technology Inc.

Preliminary

DS21159B-page 1

FEATURES

• SPI modes 0,0 and 1,1

• 3.0 MHz Clock Rate

• Single 5V Supply

• Low Power CMOS Technology

- Max Write Current: 5 mA

- Read Current: 1.0 mA at 5.5V, 3MHz

- Standby Current: 1 µ A typical

• 4096 x 8 Organization

• 32 Byte Page

• Sequential Read

• Self-timed ERASE and WRITE Cycles

• Block Write Protection

- Protect none, 1/4, 1/2, or all of Array

• Built-in Write Protection

- Power On/Off Data Protection Circuitry

- Write Enable Latch

- Write Protect Pin

• High Reliability

- Endurance: 1M cycles (guaranteed)

- Data Retention: >200 years

- ESD protection: >4000V

• 8-pin PDIP/SOIC, 14-pin TSSOP

• Temperature ranges supported

DESCRIPTION

The Microchip Technology Inc. 25C320 is a 32K-bit

serial Electrically Erasable PROM (EEPROM). The

memory is accessed via a simple Serial Peripheral

Interface (SPI) compatible serial bus. The bus signals

required are a clock input (SCK) plus separate data in

(SI) and data out (SO) lines. Access to the device is

controlled through a chip select (CS

) input, allowing any

number of devices to share the same bus.

There are two other inputs that provide the end user

with additional flexibility. Communication to the device

can be paused via the hold pin (HOLD

). While the

device is paused, transitions on its inputs will be

ignored, with the exception of chip select, allowing the

host to service higher priority interrupts. Also write

operations to the Status Register can be disabled via

the write protect pin (WP

).

- Commercial (C): 0 ° C to +70 ° C

- Industrial (I): -40 ° C to +85 ° C

- Automotive (E): -40 ° C to +125 ° C

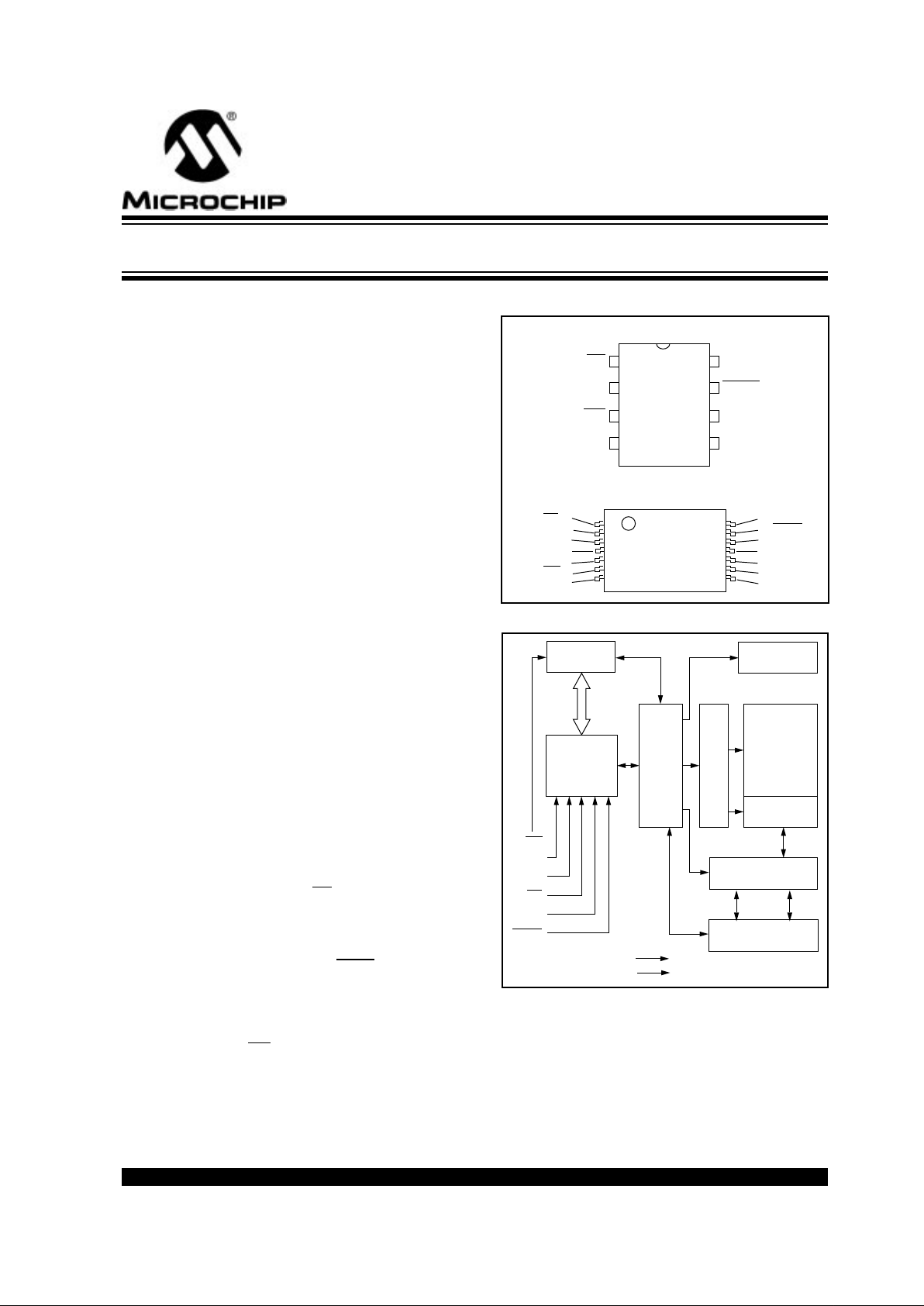

PACKAGE TYPES

BLOCK DIAGRAM

DIP/SOIC

25C320

CS

SO

WP

VSS

1

2

3

4

8

7

6

5

VCC

HOLD

SCK

SI

25C320

14

13

12

11

10

9

8

VCC

HOLD

NC

NC

NC

SCK

SI

1

2

3

4

5

6

7

CS

SO

NC

NC

NC

WP

VSS

TSSOP

SI

SO

SCK

CS

HOLD

WP

Status

Register

I/O Control

Memory

Control

Logic

X

Dec

HV Generator

EEPROM

Array

Page Latches

Y Decoder

Sense Amp.

R/W Control

Logic

Vcc

Vss

25C320

32K 5.0V SPI

Bus Serial EEPROM

SPI is a trademark of Motorola.

25C320

DS21159B-page 2

Preliminary

1996 Microchip Technology Inc.

1.0 ELECTRICAL

CHARACTERISTICS

1.1 Maxim

um Ratings*

V

CC

........................................................................7.0V

All inputs and outputs w.r.t. V

SS

.......-0.6V to V

CC

+1.0V

Storage temperature............................ -65 ° C to 150 ° C

Ambient temperature under bias..........-65 ° C to 125 ° C

Soldering temperature of leads

(10 seconds) .................................................... +300 ° C

ESD protection on all pins..................................... 4 kV

*Notice: Stresses above those listed under ‘Maximum ratings’

may cause permanent damage to the device. This is a stress rating only and functional operation of the device at those or any

other conditions above those indicated in the operational listings

of this specification is not implied. Exposure to maximum rating

conditions for extended period of time may affect device reliability

TABLE 1-1: PIN FUNCTION TABLE

Name Function

CS

Chip Select Input

SO Serial Data Output

SI Serial Data Input

SCK Serial Clock Input

WP

Write Protect Pin

V

SS

Ground

V

CC

Supply V oltage

HOLD

Hold Input

NC No Connect

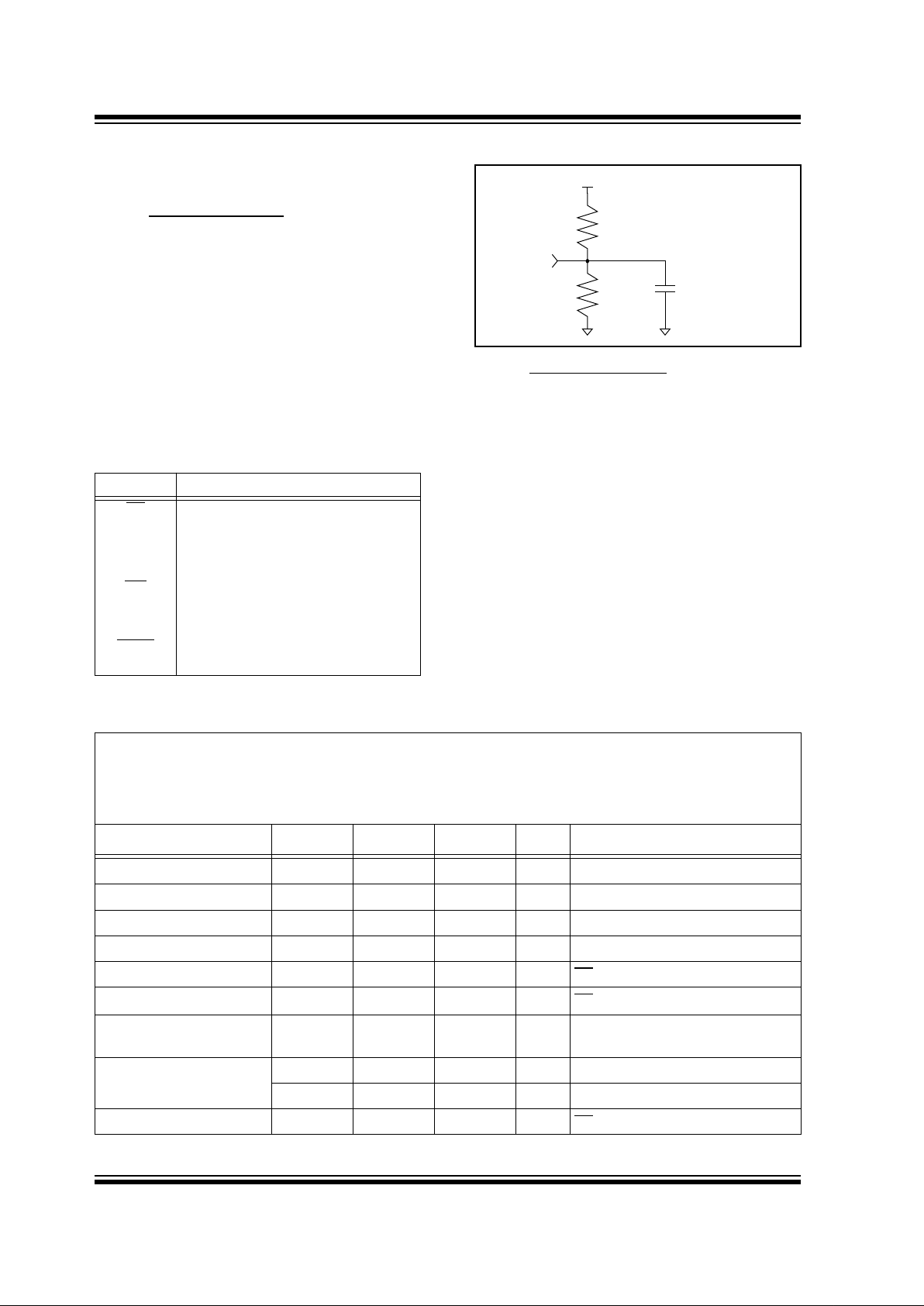

FIGURE 1-1: AC TEST CIRCUIT

1.2 A

C Test Conditions

AC Waveform:

V

LO

= 0.2V

V

HI

= Vcc - 0.2V

(Note 1)

V

HI

= 4.0V

(Note 2)

Timing Measurement Reference Level

Input 0.5 V

CC

Output 0.5 V

CC

Note 1: For V

CC

≤

4.0V

2: For V

CC

> 4.0V

Vcc

SO

100 pF

1.8 K

2.25 K

TABLE 1-2: DC CHARACTERISTICS

Applicable over recommended operating ranges shown below unless otherwise noted:

V

CC

= 4.5V to 5.5V

Commercial (C): Tamb = 0 ° C to +70˚C

Industrial (I): Tamb =-40˚C to +85˚C

Automotive (E): Tamb = -40 ° C to +125 ° C

Parameter Symbol Min Max Units Test Conditions

High level input voltage V

IH

2.0 V

CC

+1 V

Low level input voltage V

IL

-0.3 0.8 V

Low level output voltage V

OL

— 0.4 V I

OL

=2.1 mA

High level output voltage V

OH

V

CC

-0.5 — V I

OH

=-400 µ A

Input leakage current I

LI

-10 10

µ

ACS

=V

IH

, V

IN

=GND to V

CC

Output leakage current I

LO

-10 10

µ

ACS

=V

IH

, V

OUT

=GND to V

CC

Internal Capacitance

(all inputs and outputs)

C

INT

— 7 pF Tamb=25 ° C, F

CLK

=1.0 MHz,

V

CC

=5.5V (Note)

Operating Current I

CC write

—— 5 mA V

CC

=5.5V; SO=Open

I

CC

read

— 1 mA V

CC

=5.5V; SO=Open, F

CLK

=3.0 MHz

Standby Current I

CCS

—5

µ

ACS

=V

CC

=5.5V; V

IN

=Gnd or V

CC

Note: This parameter is periodically sampled and not 100% tested.

1996 Microchip Technology Inc.

Preliminary

DS21159B-page 3

25C320

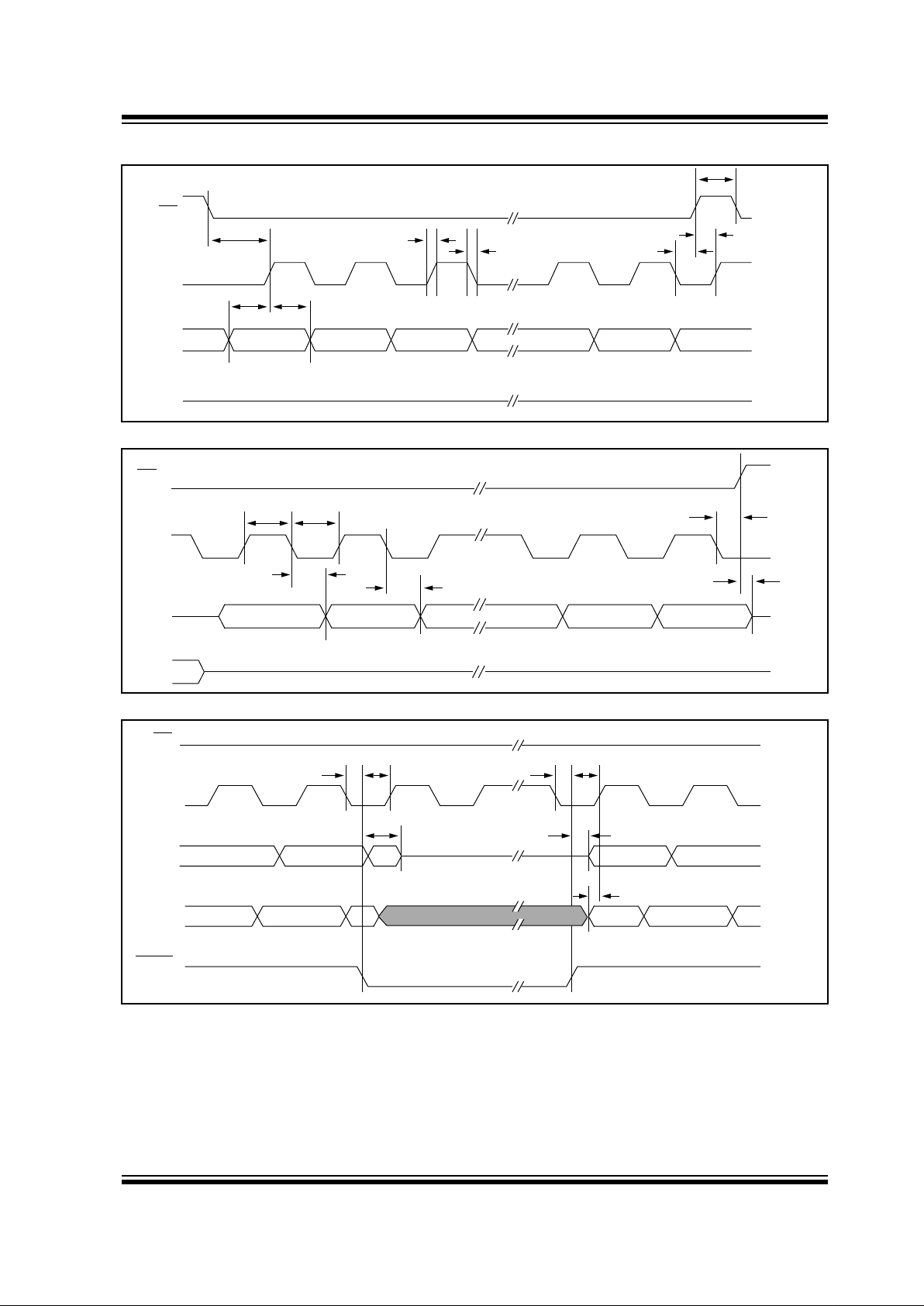

FIGURE 1-2: SERIAL

INPUT TIMING

FIGURE 1-3: SERIAL OUTPUT TIMING

FIGURE 1-4: HOLD TIMING

CS

SCK

SI

SO

t

CSS

t

HD

t

SU

t

F

t

R

t

CSD

t

CLD

t

CSH

lsb inmsb in

high impedance

CS

SCK

SO

t

LO

t

HI

t

HO

t

V

msb out

lsb out

t

CSH

t

DIS

don’t care

SI

CS

SCK

SO

SI

HOLD

t

HH

t

HS

t

HS

t

HH

t

HV

t

HZ

don’t care

t

SU

high impedance

n+2 n+1 n n-1

n

n+2 n+1 n

n

n-1

25C320

DS21159B-page 4

Preliminary

1996 Microchip Technology Inc.

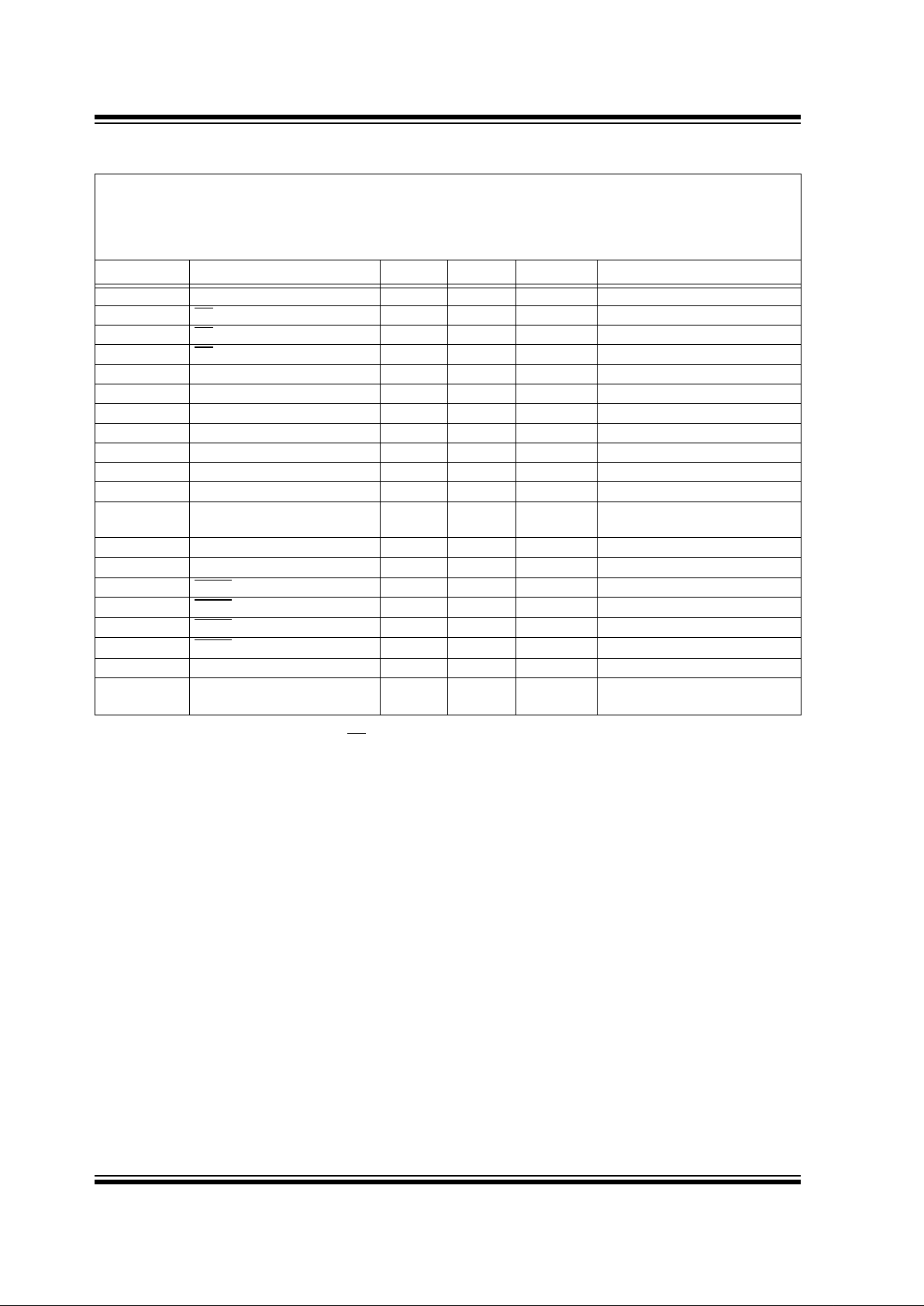

TABLE 1-3: AC CHARACTERISTICS

Applicable over recommended operating ranges shown below unless otherwise noted:

V

CC

= 4.5V to 5.5V

Commercial (C): Tamb = 0 ° C to +70 ° C

Industrial (I): Tamb = +40 ° C to +85C

Automotive (E): Tamb = -40 ° C to +125 ° C

Symbol Parameter Min Max Units Test Conditions

f

SCK Clock Frequency — 3 MHz

t

CSS CS Setup Time 100 — ns

t

CSH CS Hold Time 100 — ns

t

CSD CS Disable Time 250 — ns

t

SU Data Setup Time 30 — ns

t

HD Data Hold Time 50 — ns

t

R CLK Rise Time — 2 µs (Note 1)

t

F CLK Fall Time — 2 µs (Note 1)

t

HI Clock High Time 150 — ns

t

LO Clock Low Time 150 — ns

t

CLD Clock Delay Time 50 — ns

t

V Output V alid from

Clock Low

— 150 ns

t

HO Output Hold Time 0 — ns

t

DIS Output Disable Time — 200 ns

(Note 1)

t

HS HOLD Setup Time 100 — ns

t

HH HOLD Hold Time 100 — ns

t

HZ HOLD Low to Output High-Z 100 — ns

(Note 1)

t

HV HOLD High to Output Valid 100 — ns

(Note 1)

t

WC Internal Write Cycle Time — 5 ms (Note 2)

— Endurance 1M — E/W Cycles 25°C, Vcc = 5.0V, Block Mode

(Note 3)

Note 1: This parameter is periodically sampled and not 100% tested.

2: t

WC begins on the rising edge of CS after a valid write sequence and ends when the internal self-timed write

cycle is complete.

3: This parameter is not tested but guaranteed b y characterization. For endurance estimates in a specific appli-

cation, please consult the Total Endurance Model which can be obtained on our BBS or website.

Loading...

Loading...