Page 1

UCS81003

Evaluation Board

User’s Guide

2014 Microchip Technology Inc. DS50002300A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, flexPWR, JukeBlox, K

LANCheck, MediaLB, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, PICSTART, PIC

SST, SST Logo, SuperFlash and UNI/O are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

The Embedded Control Solutions Company and mTouch are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, BodyCom, chipKIT, chipKIT logo,

CodeGuard, dsPICDEM, dsPICDEM.net, ECAN, In-Circuit

Serial Programming, ICSP, Inter-Chip Connectivity, KleerNet,

KleerNet logo, MiWi, MPASM, MPF, MPLAB Certified logo,

MPLIB, MPLINK, MultiTRAK, NetDetach, Omniscient Code

Generation, PICDEM, PICDEM.net, PICkit, PICtail,

RightTouch logo, REAL ICE, SQI, Serial Quad I/O, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

GestIC is a registered trademarks of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2014, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

ISBN: 978-1-63276-598-7

EELOQ, KEELOQ logo, Kleer,

32

logo, RightTouch, SpyNIC,

QUALITY MANAGEMENT S

DS50002300A-page 2 2014 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

UCS81003 Evaluation Board User’s Guide

Object of Declaration: UCS81003 Evaluation Board

2014 Microchip Technology Inc. DS50002300A-page 3

Page 4

UCS81003 Evaluation Board User’s Guide

NOTES:

DS50002300A-page 4 2014 Microchip Technology Inc.

Page 5

UCS81003 EVALUATION BOARD

USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................7

Introduction............................................................................................................ 7

Document Layout .................................................................................................. 7

Conventions Used in this Guide ............................................................................ 8

Recommended Reading........................................................................................ 9

The Microchip Web Site ........................................................................................ 9

Customer Support ................................................................................................. 9

Document Revision History ................................................................................... 9

Chapter 1. Product Overview

1.1 Introduction ................................................................................................... 11

1.2 UCS81003 Evaluation System ..................................................................... 11

1.3 What the UCS81003 Evaluation Board Kit Contains .................................... 12

Chapter 2. Installation and Operation

2.1 Introduction ................................................................................................... 13

2.2 Connectors on the Evaluation Board ............................................................ 13

2.3 LEDs on the Evaluation Board ..................................................................... 14

2.4 Jumpers on the Evaluation Board ................................................................ 15

2.5 Data Test Points on the Evaluation Board ................................................... 17

2.6 Ground Test Points on the Evaluation Board ............................................... 18

2.7 Software Installation ..................................................................................... 19

Chapter 3. Hardware Description

3.1 UCS81003 Device ........................................................................................ 21

3.2 Evaluation Board Power Source .................................................................. 21

3.3 MCP2221 USB-to-SMBus Bridge ................................................................. 22

3.4 MCP23018 I/O expander .............................................................................. 22

3.5 Direct SMBus Connect Option ..................................................................... 22

Chapter 4. Software Description

4.1 Overview ...................................................................................................... 23

4.1.1 Tips for Using the EVB GUI ....................................................................... 24

4.1.2 GUI Abbreviations ..................................................................................... 24

4.1.3 Keyboard Shortcuts ................................................................................... 24

4.2 Interface Description and Operation ............................................................. 25

4.2.1 Panel Controls ........................................................................................... 25

4.2.2 Pin State and Attach Status Panel ............................................................ 27

4.2.3 Pin State & Attach Status Panel ................................................................ 27

2014 Microchip Technology Inc. DS50002300A-page 5

Page 6

UCS81003 Evaluation Board User’s Guide

4.2.4 Active Mode Selection ...............................................................................28

4.3 Tabs Description .......................................................................................... 29

4.3.1 Main Tab ....................................................................................................29

4.3.2 Configuration and General Status Tab ......................................................33

4.3.3 Custom Charging Tab ................................................................................35

4.3.4 Register Set Tab ........................................................................................37

4.3.5 Demo Tab ..................................................................................................39

4.4 Troubleshooting ............................................................................................ 41

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 43

A.2 Board – Schematic ....................................................................................... 44

A.3 Board – Top Silk .......................................................................................... 45

A.4 Board – Top Copper and Silk ....................................................................... 45

A.5 Board – Top Copper .................................................................................... 46

A.6 Board – Inner Plans GND 1 ......................................................................... 46

A.7 Board – Inner Plans GND 2 ......................................................................... 47

A.8 Board – Bottom Copper ............................................................................... 47

A.9 Board – Bottom Copper and Silk ................................................................. 48

A.10 Board – Bottom Silk ................................................................................... 48

Appendix B. Bill of Materials

Worldwide Sales and Service .....................................................................................51

DS50002300A-page 6 2014 Microchip Technology Inc.

Page 7

UCS81003 EVALUATION BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

UCS81003 Evaluation Board. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the UCS81003 Evaluation Board. The manual

layout is as follows:

• Chapter 1. “Product Overview” – Important information about the UCS81003

Evaluation Board.

• Chapter 2. “Installation and Operation” – Includes instructions on how to

configure the board.

• Chapter 3. “Hardwa re Desc ript ion ” – Describes the UCS81003 Evaluation

Board features and functionalities.

• Chapter 4. “Software Description” – Describes the PC Graphical User Interface

that operates the UCS81003 Evaluation Board.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the UCS81003 Evaluation Board.

• Appendix B. “Bill of Materials” – Lists the parts used to build the UCS81003

Evaluation Board.

2014 Microchip Technology Inc. DS50002300A-page 7

Page 8

UCS81003 Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS50002300A-page 8 2014 Microchip Technology Inc.

Page 9

RECOMMENDED READING

This user's guide describes how to use UCS81003 Evaluation Board. Other useful

documents are listed below. The following Microchip documents are available and

recommended as supplemental reference resources.

• UCS81003 Data Sheet - “Automotive USB Port Power Controller with

Charger Emulation” (DS20005334)

• MCP2221 Data Sheet - “USB 2.0 to I

GPIO” (DS200005292)

• AN24.14 - “UCS1002 Fundamentals of Custom Charger Emulation”

(DS200005234)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

2

C™/UART Protocol Converter with

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (September 2014)

• Initial Release of this Document.

2014 Microchip Technology Inc. DS50002300A-page 9

Page 10

UCS81003 Evaluation Board User’s Guide

NOTES:

DS50002300A-page 10 2014 Microchip Technology Inc.

Page 11

Chapter 1. Product Overview

Portable

Device

PC running UCS81003 GUI

UCS81003

Device

UCS81003 Evaluation Board

OEM USB

Charging Cable

V

S

Cable

USB Cable

1.1 INTRODUCTION

This document provides a description of the software and hardware used to evaluate

the features of the UCS81003.

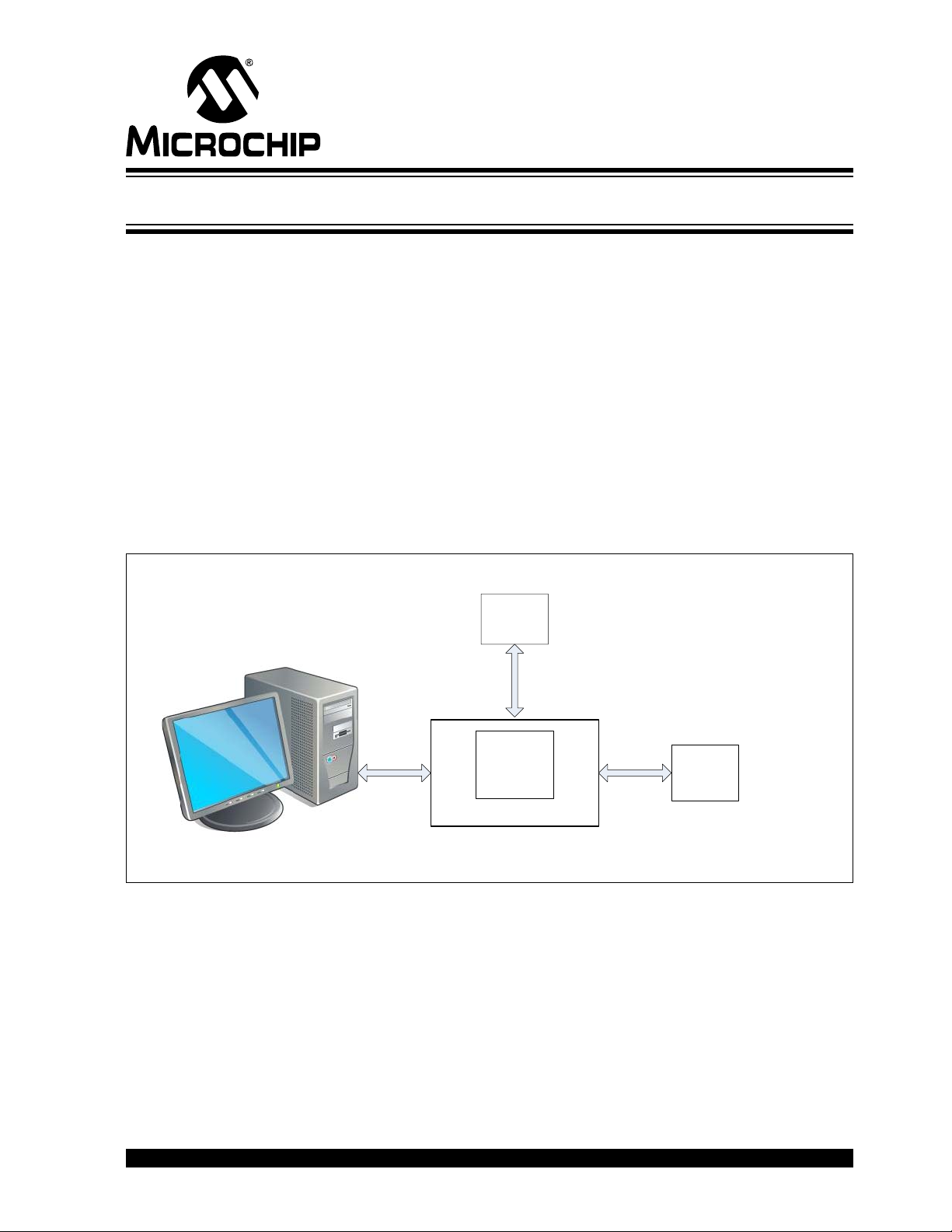

1.2 UCS81003 EVALUATION SYSTEM

The evaluation system has several components, as shown in Figure 1-1:

• Customer-provided Windows

• UCS81003 graphical user interface (GUI) program

• UCS81003 Evaluation Board

• USB Cable for GUI communications (Standard-A plug to mini-B plug)

• 5V power source (V

• Customer-provided portable device and OEM USB charging cable

(with Standard-A plug at board’s end)

)

S

®

UCS81003 EVALUATION

BOARD USER’S GUIDE

PC

FIGURE 1-1: UCS81003 Evaluation System.

2014 Microchip Technology Inc. DS50002300A-page 11

Page 12

UCS81003 Evaluation Board User’s Guide

USB STD-A PLUG

(Data & Power

From Host)

AUX Input (Power)

UCS81003

USB STD-A

RECPT

(To Portable

Device)

USB Bridge

MCP2221

USB MINI-B

RECPT

Control/Status

Manual/Bridge

Configuration &

Status

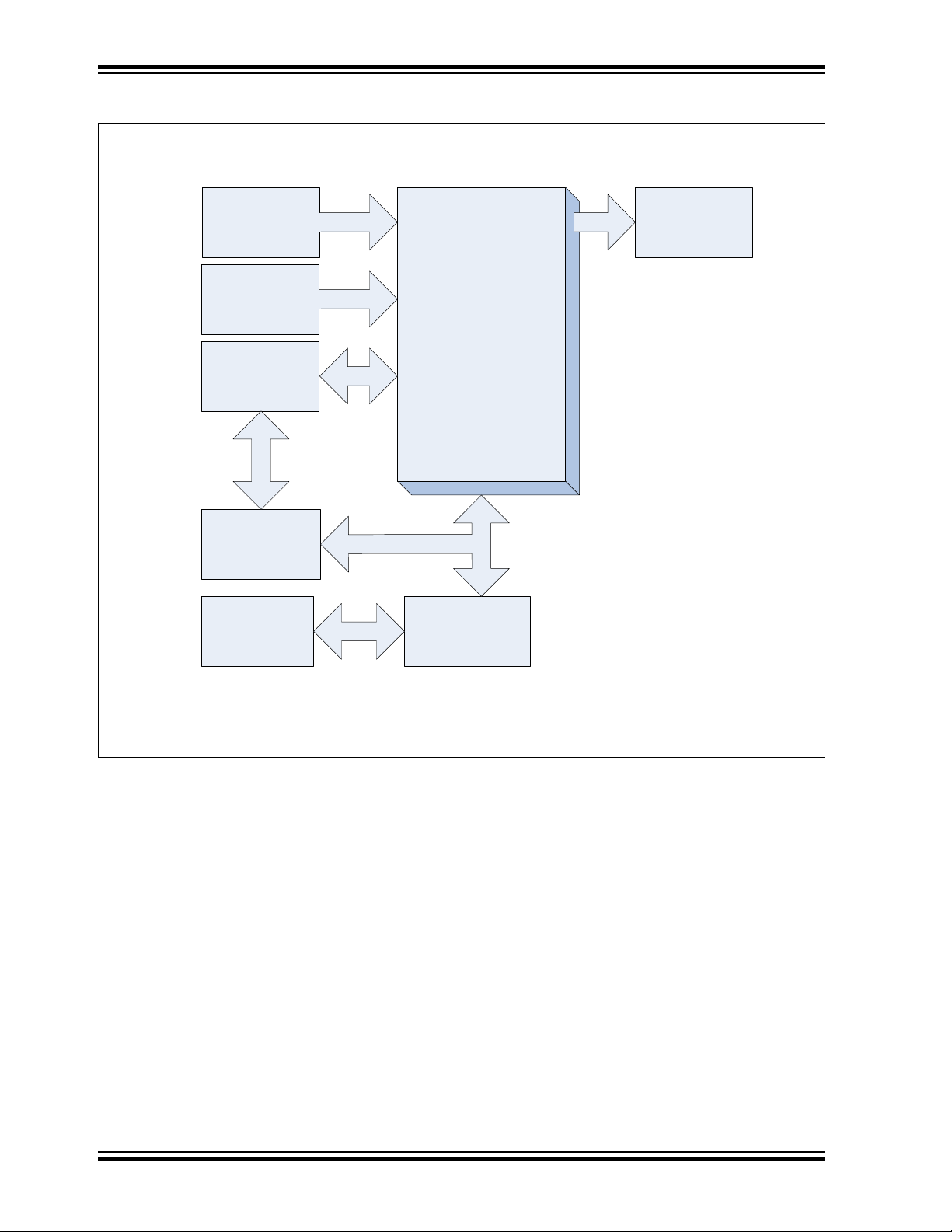

A block diagram of the UCS81003 Evaluation Board is shown in Figure 1-2 below:

FIGURE 1-2: UCS81003 Evaluation Board Block Diagram.

1.3 WHAT THE UCS81003 EVALUATION BOARD KIT CONTAINS

This UCS81003 Evaluation Board kit includes:

• UCS81003 Evaluation Board (ADM00561)

• Important Information Sheet

• 5V AC-DC Wall Adapter

• Standard-A plug to mini-B plug USB Cable

DS50002300A-page 12 2014 Microchip Technology Inc.

Page 13

UCS81003 EVALUATION

J2

USB Mini-B

receptacle

to PC

J10

USB Standard-A receptacle

to portable device

J3

USB Stanadrd-A plug to

USB host / USB Power

J1

Auxiliary power connector

to external power supply

BOARD USER’S GUIDE

Chapter 2. Installation and Operation

2.1 INTRODUCTION

This chapter identifies the main connectors, LEDs, jumpers and test points that can be

found on the UCS81003 Evaluation Board. It also explains the steps to install the

board’s graphical user interface.

2.2 CONNECTORS ON THE EVALUATION BOARD

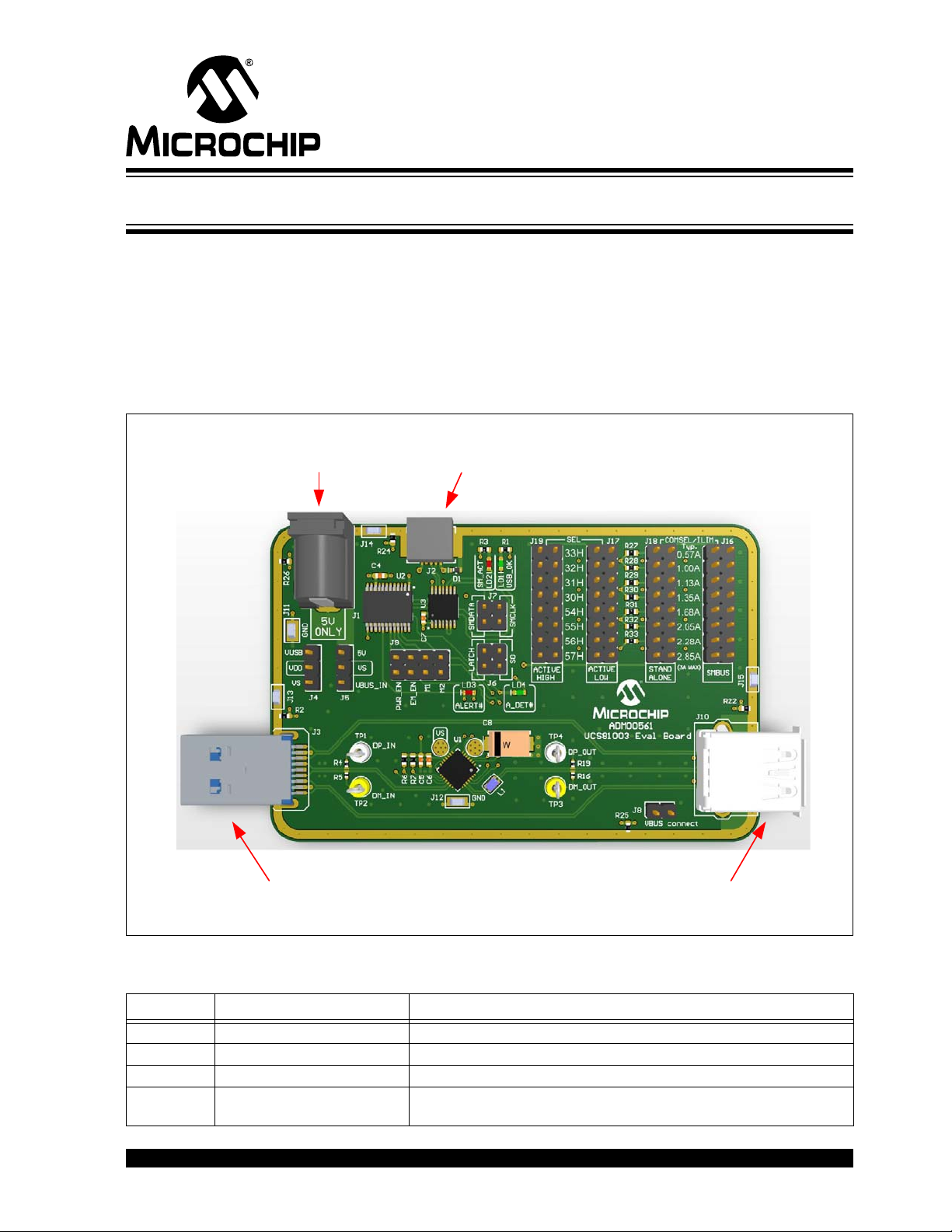

Figure 2-1 shows the top of the evaluation board and highlights the connectors.

FIGURE 2-1: UCS81003 Evaluation Board Top View – Connectors.

TABLE 2-1: CONNECTOR DESCRIPTIONS

Designator Connector Type Description

J1 Power jack External 5V power supply

J2 USB Mini-B receptacle This connects the board to the PC with the GUI software

J3 USB Standard-A plug This connects the evaluation board to the USB host

J10 Right-Angle USB Standard-A

receptacle

This connects the board to the portable device

2014 Microchip Technology Inc. DS50002300A-page 13

Page 14

UCS81003 Evaluation Board User’s Guide

LED4

Attach Detection (green)

LED1

USB_OK

(green)

LED3 ALERT

(red)

LED2

SMBus Activity

(red)

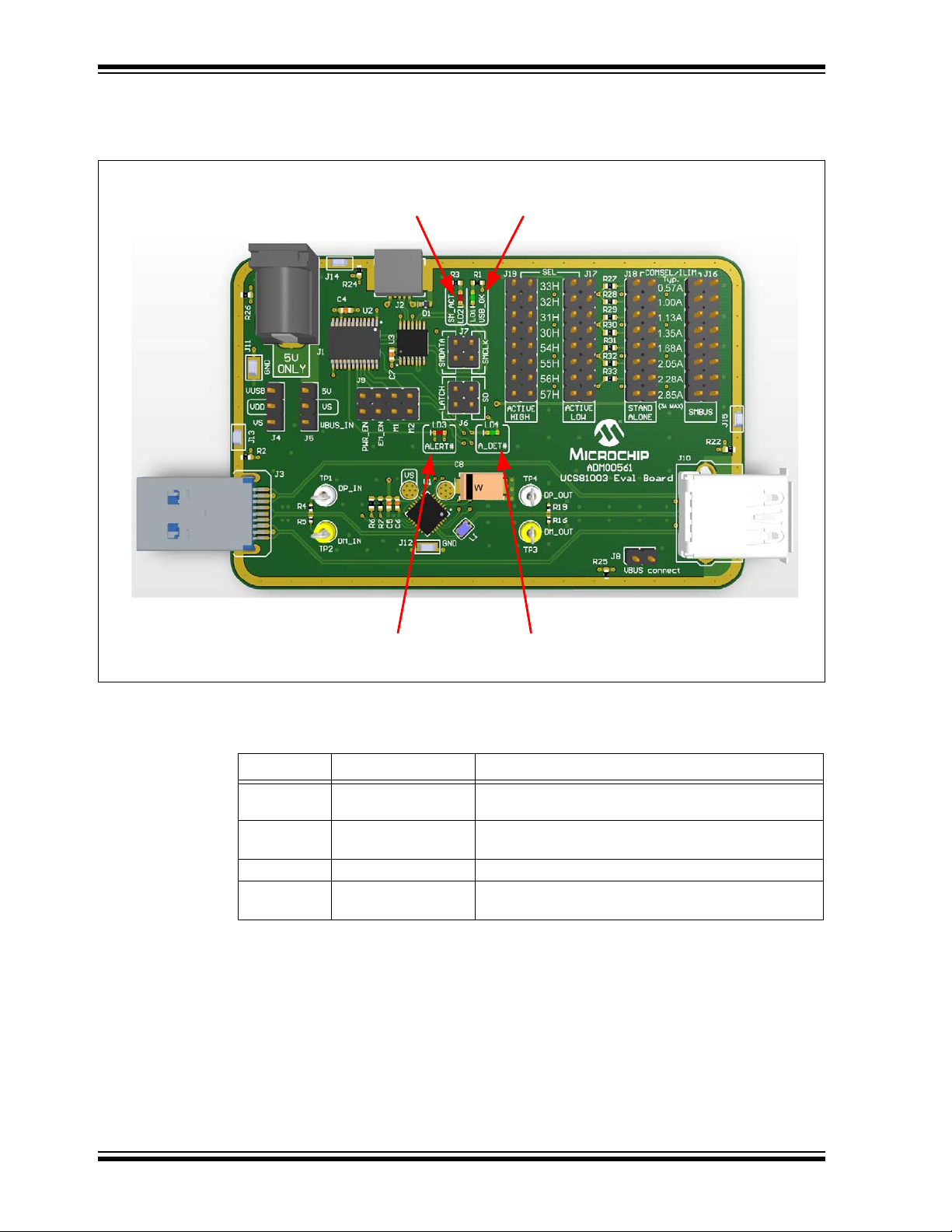

2.3 LEDS ON THE EVALUATION BOARD

Figure 2-2 shows the top of the Evaluation Board and highlights the LEDs.

FIGURE 2-2: Evaluation Board Top View – LEDs.

TABLE 2-2: LED DESCRIPTIONS

Designator Function Description

LD1 USB OK When lit, this green LED means the MCP2221 USB

LD2 SMBus Activity When flashing, this green LED indicates SMBus

LD3 ALERT# When lit, this red LED indicates an alert signal is active.

LD4 A_DET# When lit, this green LED indicates a device is attached

bridge is connected to the PC.

communication activity.

for the UCS81003.

DS50002300A-page 14 2014 Microchip Technology Inc.

Page 15

Installation and Operation

J16

Current Limit,

SMBus mode

J18

Current Limit,

Stand-Alone mode

J8

Connects

UCS81003 V

BUS

output to J10

J9

PWR_EN,

EM_EN,

M1, M2

J17

Address Selection,

PWR_EN Active Low

J19

Address Selection,

PWR_EN Active High

J6

LATCH,

S0

J7

SMBus

data,

clock

J5

V

S

source

selection:

5V from J1 or

from J3 V

BUS

J4

VDD source

selection:

Vs or

V

BUS

from J2

J1

J2

J3 J10

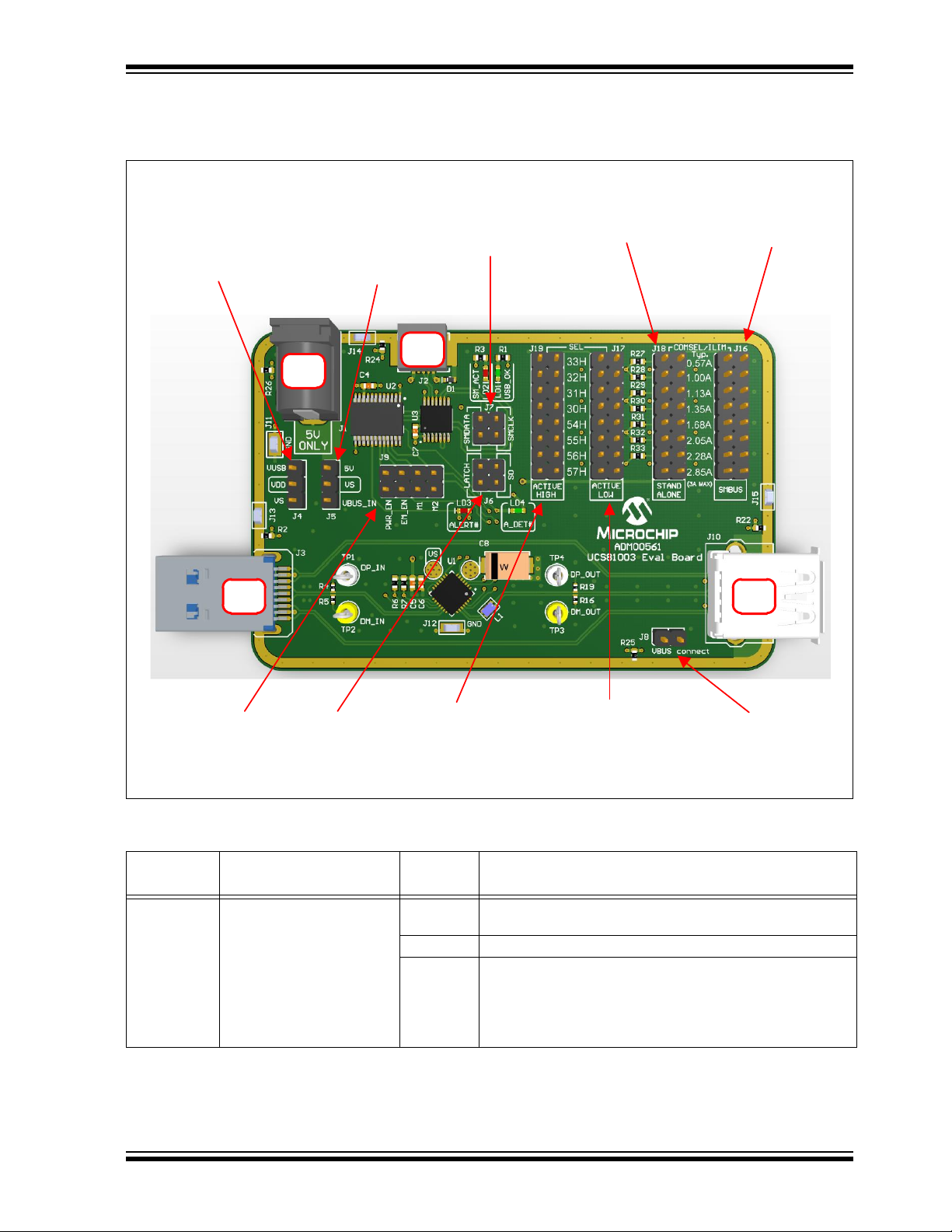

2.4 JUMPERS ON THE EVALUATION BOARD

Figure 2-3 shows the top of the Evaluation Board and highlights the jumpers.

FIGURE 2-3: Evaluation Board Top View – Jumpers.

TABLE 2-3: JUMPER DESCRIPTIONS

Designator Function

J4 V

source selection The jumper populated on this header selects the VDD

DD

Jumper

Position

1-2 V

2-3 V

supply source for the digital circuits on the board.

is connected to V

DD

is connected to VS. This is the recommended

DD

configuration when evaluating the Attach Detection feature

of the UCS81003. If the board is evaluated with a PC

running the GUI, then the V

USB cable is plugged into the J2 connector.

BUS

Description

pin of the J2 USB connector

must be supplied after the

S

2014 Microchip Technology Inc. DS50002300A-page 15

Page 16

UCS81003 Evaluation Board User’s Guide

TABLE 2-3: JUMPER DESCRIPTIONS (CONTINUED)

Designator Function

J5 VS source selection The jumper populated on this header selects the voltage

J6 LATCH, S0

Logic Inputs settings

J7 SMBus data and clock lines If the UCS81003 is in SMBus mode (as selected by using

J8 V

output connection This jumper connects the 5V pin of connector J10 to the

BUS

J9 PWR_EN, EM_EN, M1, M2

Logic Inputs settings

J16 Current Limit

SMBus mode

J18 Current Limit

Stand-alone mode

J17 SMBus Address

PWR_EN active low

Jumper

Position

Description

input source for the power switch inside the UCS81003.

1-2 V

source is the J1 power connector (external 5V power

S

supply).

2-3 V

is connected to V

S

of the J3 USB connector. Use this

BUS

configuration only if the USB host can deliver the necessary

current for charging.

The jumpers must be left off for SMBus communication to

be enabled.

If the UCS81003 is in Stand-Alone mode (as selected by

using J18 instead of J16), then the header pins have the

following functions:

1-2 Jumper placed S0=Logic Low - Detect Power state disabled

No jumper S0=Logic High - Detect Power state enabled

3-4 Jumper placed LATCH=Logic Low - “Auto-retry” fault

handler enabled

No jumper LATCH=Logic High - “Latch” fault handler

enabled

J16 instead of J18), then two jumpers must be populated in

1-2 and 3-4 positions to connect the clock and data lines to

the MCP2221 USB bridge.

The jumpers must be left off if UCS81003 is in Stand-alone

mode.

UCS81003 V

power output pins. A current probe or a

BUS

multimeter can be connected to this header for measuring

the charging current and the voltage, close to the USB

connector.

When a jumper is installed, the corresponding UCS81003

input pin will be in Logic Low state. Otherwise, the

corresponding pin will be in Logic High state.

1-2 PWR_EN

3-4 EM_EN

5-6 M1

7-8 M2

Placing one jumper on this header selects the current limit

and sets the UCS81003 in SMBus mode. In this case, no

jumper must be populated on J18 header.

Placing one jumper on this header selects the current limit

and sets the UCS81003 in Stand-alone mode. In this case,

no jumper must be populated on J16 header.

Placing one jumper on this header selects the SMBus

address and sets the PWR_EN control to be active low. In

this case, no jumper must be populated on J19 header.

DS50002300A-page 16 2014 Microchip Technology Inc.

Page 17

Installation and Operation

TP1

DP_IN

TP3

DM_OUT

TP2

DM_IN

TP4

DP_OUT

TABLE 2-3: JUMPER DESCRIPTIONS (CONTINUED)

Designator Function

J19 SMBus Address

PWR_EN active high

Note: The following headers must be populated with one jumper for the UCS81003

Evaluation Board to be functional:

• J4, J5, J8

• J16 or J18

• J17 or J19

• If

UCS81003 is configured in SMBus mode (as selected by using J16 instead of J18), two

jumpers must be populated on J7 and J6 must be left unpopulated.

configured in Stand-Alone mode, the jumpers on J7 must be left off.

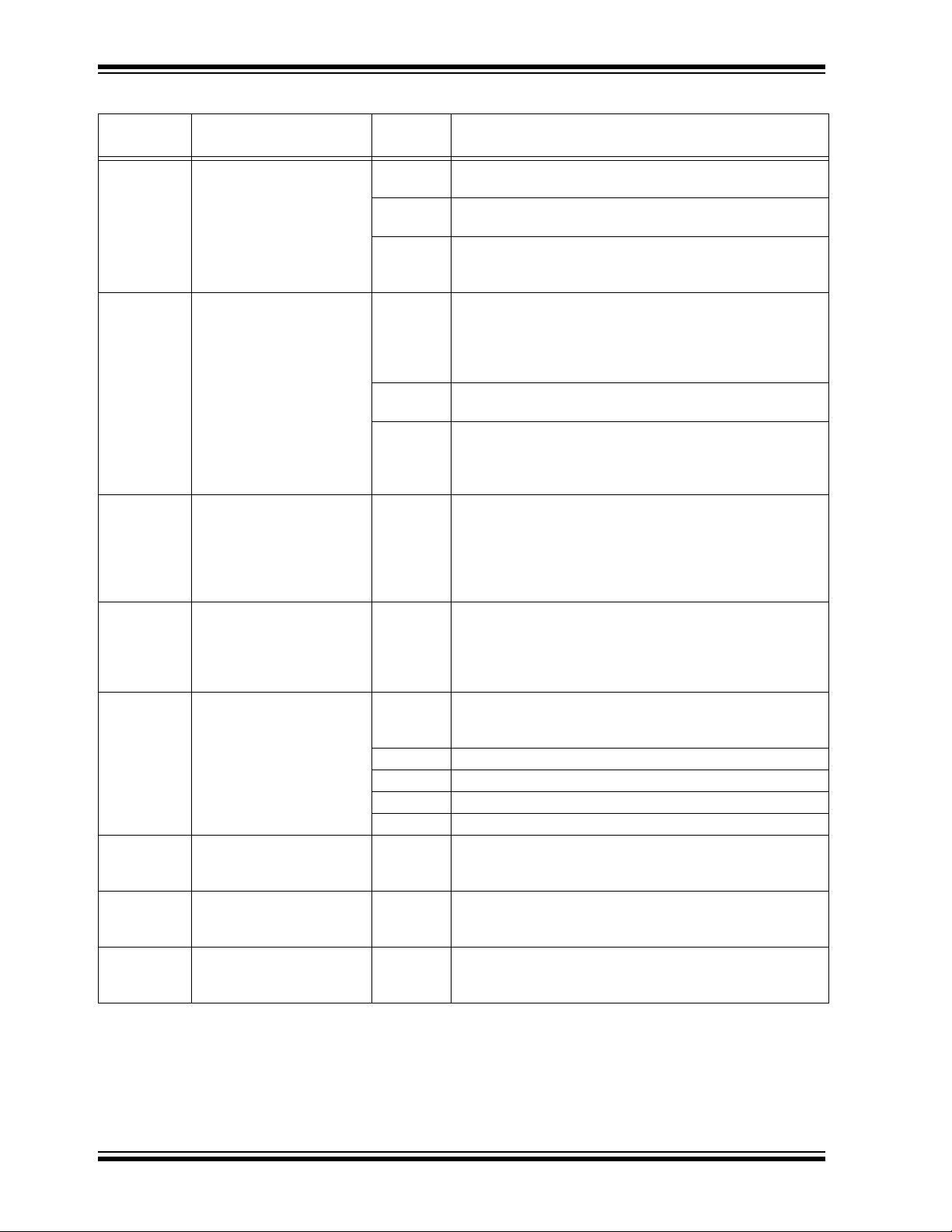

2.5 DATA TEST PO INTS ON THE EVALUATION BOARD

Figure 2-4 shows the top of the board and highlights the USB data line test points.

Jumper

Position

Placing one jumper on this header selects the SMBus

address and sets the PWR_EN control to be active high. In

this case, no jumper must be populated on J17 header.

Description

If UCS81003 is

FIGURE 2-4: Evaluation Board Top View – Data Test Points.

TABLE 2-4:

Designator Assigned Pin Description

TP1 DP_IN This test point connects to the D

TP2 DM_IN This test point connects to the D

TP3 DM_OUT This test point connects to the D

TP4 DP_OUT This test point connects to the D

2014 Microchip Technology Inc. DS50002300A-page 17

data line through a 1 MΩ series resistor.

PIN

data line through a 1 MΩ series resistor.

MIN

data line through a 1 MΩ series resistor.

MOUT

data line through a 1 MΩ series resistor.

POUT

Page 18

UCS81003 Evaluation Board User’s Guide

Signal

Ground

Signal

Ground

Earth

Ground

Earth

Ground

Earth

Ground

2.6 GROUND TEST POINTS ON THE EVALUATION BOARD

Figure 2-5 shows the top of the board and highlights the ground test points.

FIGURE 2-5: Evaluation Board Top View – Ground Test Points.

TABLE 2-5:

Designator Test Point Type Description

J11, J12 Signal Ground These test points connect to the signal ground of the board.

J13, J14, J15 Earth Ground These test points connect to the earth ground of the board (the

These are the ground reference for the UCS81003.

shield of the USB connectors).

DS50002300A-page 18 2014 Microchip Technology Inc.

Page 19

2.7 SOFTWARE INSTALLATION

To begin using the UCS81003 Evaluation Board, software must be installed on a

Windows

1. Download the software archive from the board’s web page, unzip it and

®

-based computer with a USB port.

double-click the Setup.exe, to start the installation. Figure 2-6 shows the initial

installation screen, which displays briefly as the setup program loads.

Installation and Operation

FIGURE 2-6: Software Installation – Initialize Window.

2. Click

Next

in the Destination Directory window, as shown in

operation, the files must be installed in the default locations. The default location

for the software files is

while for the LabVIEW software is

Instruments

.

C:\Program Files(x86)\Microchip\UCS81003\

C:\Program Files(x86)\National

Figure 2-7

. For proper

,

FIGURE 2-7: Software Installation – Setting the Destination Directory.

2014 Microchip Technology Inc. DS50002300A-page 19

Page 20

UCS81003 Evaluation Board User’s Guide

3. Read and accept the license agreement, then click Next.

FIGURE 2-8: Software Installation – Software License Agreement.

4. To use the LabVIEW software, read and accept the license agreement, then click

Next.

FIGURE 2-9: Software Installation – LabVIEW License Agreement.

On the following screens, select Next and follow the on-screen instructions to complete

the installation. When installation is complete, the program will automatically run. If a

screen appears requiring a restart for the changes to take effect, reboot the computer.

The UCS81003 interface will start with the SMBus communications.

DS50002300A-page 20 2014 Microchip Technology Inc.

Page 21

Chapter 3. Hardware Description

3.1 UCS81003 DEVICE

The UCS81003 provides a single USB port power switch for precise control of up to

3.0A continuous current (2.85A typical) with overcurrent limiting, dynamic thermal

management, latch/auto-recovery upon fault, selectable active low or high enable,

under and overvoltage lockout, and back-drive protection.

USB Charging Port profiles are integrated into the UCS81003 to assure compliance to

multiple standards. In addition to power switching and USB Charging Port profiling, the

UCS81003 provides automatic and configurable USB data line handshaking to enable

charging of USB-IF Battery Charging 1.2 (CDP or DCP modes), Chinese

Telecommunications Industry Standard YD/T 1591-2009, Apple

other mobile devices.

The UCS81003 provides a device attachment detection output, as well as a dedicated

alert output, with current monitoring, charge rationing for controlled delivery of current

regardless of a host’s power state. When the limit is reached, the UCS81003 will

perform the user-programmed behavior (report and disconnect is the default).

UCS81003 EVALUATION

BOARD USER’S GUIDE

®

Inc., RIM® and many

3.2 EVALUATION BOARD POWER SOURCE

The UCS81003 has split power supply support:

is the voltage input to Power Switch. This supply rail is required to charge the

•V

S

portable device. V

follows:

Jumper

Position

1-2 VS is supplied from the external 5V power supply connected to J1 power jack.

2-3 V

is the power supply for chip functionality. The UCS81003 Evaluation Board

•V

DD

contains two additional ICs, MCP2221 USB bridge and MCP23018 I/O expander,

which are also powered from the V

populating a jumper on the J4 header, as follows:

Jumper

Position

1-2 V

2-3 V

source is selected by populating a jumper on J5 header, as

S

is supplied from the V

S

only if the USB host port can supply the charging current for the portable

device.

DD

is supplied from V

DD

board in this configuration and the Attach Detection feature of the UCS81003

is used, the V

data sheet.

is connected to VS. This configuration is recommended when using the

DD

Attach Detection feature. If the board is evaluated with a PC running the GUI,

then the V

connector.

voltage must not exceed VDD + 150 mV, as specified in the

S

must be supplied after the USB cable is plugged into the J2

S

BUS

Definition

pin of the J3 USB connector. Use this option

BUS

supply rail. VDD source is selected by

Definition

pin of the J2 USB connector. When using the

2014 Microchip Technology Inc. DS50002300A-page 21

Page 22

UCS81003 Evaluation Board User’s Guide

USB bridge

SCL pin

SMCLK/S0

UCS81003 pin

USB bridge

SDA pin

SMDATA/LATCH

UCS81003 pin

Ground

3.3 MCP2221 USB-TO-SMBUS BRIDGE

The MCP2221 is a USB-to-UART/I2C bridge that supports SMBus communication. It is

controlled through USB interface by the GUI running on the PC. It is the master device

on the SMBus/I2C bus. It is used to read and write the registers of the two devices

connected to the SMBus/I

3.4 MCP23018 I/O EXPANDER

MCP23018 is a 16-bit I/O Expander with open-drain outputs and I2C interface. Its I2C

address is configured to 0100_000(R/W), different than all possible addresses of the

UCS81003.

The I/O pins used in this application are configured as inputs. They are used to read

the logic state of the following UCS81003 pins: ALERT#, ADET#, PWR_EN, EM_EN,

M1, M2.

3.5 DIRECT SMBUS CONNECT OPTION

It is also possible to connect an external SMBus master to the UCS81003 Evaluation

Board. Remove the jumpers on J7 and connect the SMBus master to the header pins

that are linked directly to UCS81003 pins SMDATA/LATCH and SMCLK/S0. Note that

ground must be connected to one of the test point grounds or header pins on the EVB.

See Figure 3-1 for header pins description.

2

C interface: UCS81003 and MCP23018 I/O expander.

DS50002300A-page 22 2014 Microchip Technology Inc.

FIGURE 3-1: UCS81003-to-SMBus Bridge Jumpers.

Page 23

4.1 OVERVIEW

Ta bs

Fixed Panel

with Controls

To get the graphical interface and the evaluation board running, follow these

instructions:

1. Start the UCS81003 GUI software: from the Windows Start menu, select

2. Connect the USB mini connector end of the cable to the board and the standard

The UCS81003 Evaluation Board interface (Figure 4-1), consists of five tabs (Main,

Configuration & General Status , Custom Charging, Register Set and Demo) as

well as the right side sections that are always visible (Panel Controls, Pi n State &

Attach Status and Active Mode Selection).

UCS81003 EVALUATION

BOARD USER’S GUIDE

Chapter 4. Software Description

Programs >

USB connector of the cable to any available USB port on the PC. If the V

supply is connected to VS (the jumper on J4 header is populated on position 2-3),

then connect the VS supply. The USB Activity LED should light, indicating that

the MCP2221 USB bridge is connected to the PC.

Microchip > UCS81003.

DD

FIGURE 4-1: UCS81003 Evaluation Board Initial Window.

2014 Microchip Technology Inc. DS50002300A-page 23

Page 24

UCS81003 Evaluation Board User’s Guide

4.1.1 Tips for Using the EVB GUI

• For many controls on the GUI panel, placing the mouse cursor over a control will

pop up context help that indicates the register address or provides a description.

• After a power up of the evaluation board, the default settings are loaded. Users

can save setting configurations to user-named files which can be reloaded at any

time for quick reconfiguration (see Section 4.3.4.3 “Configuration Save and

Load”).

• The GUI cannot be used to demonstrate UCS81003 behavior in Stand-Alone

mode since SMBus communication is required.

4.1.2 GUI Abbreviations

Abbreviation Description

BC Battery charging

CDP Charging downstream port

DCE Dedicated charger emulation

DCP Dedicated charging port

EM Emulation

EM_EN Emulation enable

M1 Mode control pin number one

M2 Mode control pin number two

4.1.3 Keyboard Shortcuts

Some GUI controls have keyboard shortcuts, as shown in Table 4-1.

TABLE 4-1: UCS81003 EVALUATION BOARD GUI KEYBOARD SHORTCUTS

GUI Control Shortcut Control Description

Run CTRL + R Section 4.2.1.1 “Stop and Run Buttons”

Stop F12 Section 4.2.1.1 “Stop and Run Buttons”

DS50002300A-page 24 2014 Microchip Technology Inc.

Page 25

4.2 INTERFACE DESCRIPTION AND OPERATION

Register Read

Single Read

Stop

Button

COM Status

Single/

Continuous Read

Mode Switch

Delay Button and Field

Indicator

Enable Check Box

Default

Button

Step

Button

Demo

Button

Run Button

Abort Execution

Button

Extended Menu

4.2.1 Panel Controls

The Panel Controls section on the right side of the GUI, shown in Figure 4-2, affects

GUI operation. This section is always displayed.

Software Description

FIGURE 4-2: Panel Controls.

4.2.1.1 STOP AND RUN BUTTONS

Pressing the Stop button, shown in Figure 4-2, interrupts GUI software communication

with the evaluation board. When this button is clicked, the Run button appears under

an extended menu bar, as shown in Figure 4-3.

FIGURE 4-3: Stop and Run Button.

2014 Microchip Technology Inc. DS50002300A-page 25

Page 26

UCS81003 Evaluation Board User’s Guide

4.2.1.2 RUN BUTTON

To restart communication between the software and the evaluation board, click the Run

button. This button disappears when communication resumes.

Note: Stopping and restarting the GUI does not affect register settings. To restore

default register settings, disconnect power from the board, then reconnect

power.

To close the program, press the Close (X) button on the upper right corner of the

window.

4.2.1.3 COM STATUS INDICATOR

The COM Status indicator shows the status of communications over the SMBus.

During normal operation, COM Status is green. If SMBus communications fails, COM

Status turns red (or alternates red and green).

4.2.1.4 REGISTER READ DELAY

The Register Read Delay sets the GUI control panel update speed. It affects the

speed that the software reads the registers, but will not affect the device’s sampling

time. The default is 25 ms. This number can range from 0 to 5000 ms in increments of

25 ms.

4.2.1.5 SINGLE/CONTINUOUS READ

The panel defaults to continuous register reads (toggle switch in down position, as

shown in Figure 4-2). To stop continuous register reads, check the “Single Read

Enable” box. In order to capture the register values at a given time, click the switch,

which will briefly flip to Single Read.

4.2.1.6 DEFAULT

When this button is pressed, it loads the defaults to all registers of the UCS81003.

4.2.1.7 STEP

When selected, Step will go through the Emulation Profiles in sequence, from Legacy 1

through 7, then BC1.2 DCP, and finally Custom. The actual DCE cycle is slightly

different, please see product’s data sheet for more information.

4.2.1.8 DEMO

The Demo button enables an automated routine to cycle through a user-defined set of

profiles and selects the highest current profile. This feature emulates an external

controller and is not part of the UCS81003 device.

DS50002300A-page 26 2014 Microchip Technology Inc.

Page 27

Software Description

ALERT#

Pin

Indicators

A_DET#

Pin Override

Check Boxes

and

Indicators

4.2.2 Pin State and Attach Status Panel

The Pin State & Attach Status section on the right side of the GUI, shown in Figure 4-4,

provides a quick graphical status reference and allows physical control pin override.

This section is always displayed.

FIGURE 4-4: Pin State and Attach Status.

4.2.3 Pin State & Attach Status Panel

4.2.3.1 ALERT# AND A_DET# INDICATORS

When the ALERT# and A_DET# indicators are green, the signals at the device’s

respective pin are low and the corresponding condition has occurred (alert or device

attached, respectively). When the indicators are dark, the pin states are high.

4.2.3.2 PIN INDICATORS

The pin indicators (SEL, PWR_EN, M1, M2 and EM_EN) shown in Figure 4-4 are

green if the signal on the corresponding pin on the UCS81003 device is high, and dark

if the signal is low. If the “Pin Ignore” box is checked (see Section 4.2.3.3 “Pin

Override”), these indicators will reflect the GUI overrides for these pins.

4.2.3.3 PIN OVERRIDE

For evaluation convenience, the GUI can override the setting of the following pins on

the UCS81003 device: PWR_EN, M1, M2 and EM_EN. Check the “Pin Ignore” box

(see Figure 4-4) to enable pin override. Then, check in the corresponding pin box to set

the value high.

Note 1: Pin override does not affect the actual signal on the pin. It only affects the

register values.

2: The SEL pin is only read once by the UCS81003 at power up, so there is

no pin override for it. To close the port power switch, the PWR_EN state

must match the SEL state (e.g., SEL = high and PWR_EN = high).

2014 Microchip Technology Inc. DS50002300A-page 27

Page 28

UCS81003 Evaluation Board User’s Guide

4.2.4 Active Mode Selection

The Active Mode Selection section on the right side of the GUI, shown in Figure 4-5,

provides a quick reference regarding operating state based on the values of M1, M2

and EM_EN. This section is always displayed.

FIGURE 4-5: Charger Emulation Selection.

DS50002300A-page 28 2014 Microchip Technology Inc.

Page 29

4.3 TAB DESCRIPTIONS

Ta b

Status Panel

Measured

Current

Status

Right-click Wave Box

for Plot Appearance Settings

Current Status

Instantaneous

Current

Measurement

Screen

Selection

4.3.1 Main Tab

The Main tab (Figure 4-6) shows key parameters related to the port power switch,

including the maximum current limit, the present current limit (always equal to or less

than maximum current limit), and power state (e.g. detect, active, error, etc.). When a

portable device has been successfully attached, the screen shows the power state

change from Detect to Active and shows the various handshakes applied. Once it is

determined that the device is charging, the screen shows which emulation profile was

successful, and the graph shows the charging current. Optionally, the user may monitor

the charge delivered or ration the charge delivered to the attached device.

Software Description

FIGURE 4-6: Main Tab Window Overview.

4.3.1.1 DEDICATED CHARGER EMULATION (DCE) CYCLE

As shipped, the UCS81003 is ready to function as a dedicated charger, which will be

applied when there is an attach detection. To view this behavior, perform the following:

1. Connect V

Evaluation Board”). The VS_LOW indicator on the bottom of the Main Tab must

be dark. If the color is red, the voltage is not high enough to charge a portable

device.

2. Connect a portable device to the board. Use the OEM USB charging cable that

comes with the portable device.

3. The UCS81003 should detect an attachment, switch to the Active Power state,

apply an emulation profile and deliver a charge. Figure 4-7 shows the interface

after charging has started.

2014 Microchip Technology Inc. DS50002300A-page 29

to the evaluation board (see Section 2.4 “Jumpers on the

S

Page 30

UCS81003 Evaluation Board User’s Guide

VS_LOW

Indicator

Power State

Indicator

Charger

Emulation

Profile

Indicator

A_DET#

is asserted

Pin Status

Power State

Indicator Changed

A_DET#

is deasserted

Disconnect

showing

Point

in Plot

Pin Status

FIGURE 4-7: Main Tab - Charging Started.

4. Disconnect the portable device from the board.

The UCS81003 should detect a removal, switch to the Detect power state, and stop

delivering a charge. Figure 4-8 shows the interface after a removal was detected.

FIGURE 4-8: Main Tab - Removal Detected.

DS50002300A-page 30 2014 Microchip Technology Inc.

Page 31

Software Description

Data

Pass-Through

Options

4.3.1.2 CHARGING DOWNSTREAM PORT (CDP)

The CDP charging profile is based on the “USB Battery Charging Specification v1.x”.

When a BC1.x-compliant portable device attachment is detected, the UCS81003 and

the portable device do handshaking based on the standard. If handshaking is

successful, charging occurs up to the set current limit.

To select the CDP port power profile, M1, M2 and EM_EN must all be high. This can

be done by removing the jumpers for these pins (from J9 header) or by using the pin

override in the GUI (see Section 4.2.3.3 “Pin Override”).

4.3.1.3 PASS-THROUGH

Data Pass-Through does not apply any type of charger emulation. When selected, it

closes the USB high-speed data switch and supplies current up to the current limit.

To select Data Pass-Through, M1, M2 and EM_EN can be set to any one of the two

DATA PASS-THRU combinations (010 and 110), as shown in Figure 4-9. This can be

done by setting the jumpers for these pins (from J9 header –

see Section 2.4 “Jumpers on the Evaluation Board”) or by using the pin override in

the GUI (see Section 4.2.3.3 “Pin Override”).

FIGURE 4-9: Data Pass-Through Selection Options.

4.3.1.4 CURRENT MONITORING AND CHARGE RATIONING

To view current monitoring and current rationing, perform the following on the Main tab:

1. Set a Ration Limit. The ration limit is expressed in mAh (electric charge).

2. Set rationing behavior. The Ration Completion Behavior defaults to “Report &

Disconnect”. Once the ration limit is reached, portable device charging will

cease, the ALERT# pin will assert, and the Ration Complete bit will be set. If

you do not want the system to behave in this fashion, select one of the other

three options from the Ration Completion Behavior drop-down list: Report,

Report & Sleep or Take No Action.

3. Connect V

Evaluation Board”). The VS_LOW indicator on the bottom of the Main Tab must

be dark. If the VS_LOW indicator is red, the voltage is not high enough to charge

a portable device.

4. Connect a portable device to the evaluation board. Use the OEM USB charging

cable that comes with the portable device.

5. Enable rationing by checking the Ration Enable check box on the Main Tab.

6. Watch the GUI as the device starts charging. Figure 4-10 shows the interface

after the ration limit was reached (for “Report & Disconnect” behavior setting).

to the evaluation board (see Section 2.4 “Jumpers on the

S

2014 Microchip Technology Inc. DS50002300A-page 31

Page 32

UCS81003 Evaluation Board User’s Guide

Power State

Indicator Changed

Pin is

Instantaneous

Ration Limit

Setting

Rationing

Behavior

ALERT#

Complete

Rationing

Indicator

Ration

Enable

Current (mA)

Delivered

Current

Measured

Current

Status

VS_LOW

Indicator

Charge

(mAh)

Asserted

Note: As shown in Figure 4-10, the green trace is the instantaneous current, while

the red diagonal line is the charge being delivered in mAh. Both are also

presented in numeric format in the bottom left boxes. Trace color and

characteristics can be changed by clicking on the waveform boxes to the

left of these numerical values.

FIGURE 4-10: Main Tab - Ration Limit Reached.

DS50002300A-page 32 2014 Microchip Technology Inc.

Page 33

Software Description

Configuration Tab

Selected

Interrupt and General

Status

Emulation Profile

Disable

Emulation

Behavior Option

Comm.,

Fault

Handler,

Controls

General

and

Thermal

Emulation

Settings

4.3.2 Configuration and General Status Tab

The Configuration & General Status tab (Figure 4-11), includes various status

indicators and configuration controls. Items are grouped by function, detailed in the

following sections.

FIGURE 4-11: Configuration & General Status Tab.

4.3.2.1 INTERRUPT STATUS

The indicators in the Interrupt Status section turn green when the corresponding bit is

high, and are dark when the bit is low.

4.3.2.2 GENERAL STATUS

Indicators in the General Status section turn green when the corresponding bit is high

and are dark when the bit is low.

4.3.2.3 EMULATION BEHAVIOR

Check the necessary check box to enable the corresponding emulation behavior.

4.3.2.4 COMMUNICATIONS

SMBus address is displayed. SMBus timeout can be disabled.

4.3.2.5 EMULATION PROFILE DISABLE

Check the Profiles boxes to disable them. They will not be used during emulation. By

selecting the “Disable ALL” will toggle all profile check boxes.

2014 Microchip Technology Inc. DS50002300A-page 33

Page 34

UCS81003 Evaluation Board User’s Guide

4.3.2.6 ATTACH/REMOVE ENABLE

Click the S0_SET box to remove the check mark and disable the function.

4.3.2.7 FAULT HANDLER

These are controls related to fault handling.

4.3.2.8 GENERAL CONTROL

Controls for general parameters.

4.3.2.9 THERMAL REGULATION

Controls for thermal and detection delay parameters.

4.3.2.10 PORT POWER KEEP-OUT

Displays values for the port power parameters.

4.3.2.11 GENERAL EMULATION/CHARGING SETTINGS

Controls for emulation and charging.

4.3.2.12 EMULATION TIMEOUTS

Sets the emulation timeout period for each profile. These timeout periods are not used

if the EM_TIMEOUT_DIS control in the Emulation Behavior section is checked.

4.3.2.13 CHARGING THRESHOLD CURRENT

Controls charging threshold current setting.

4.3.2.14 HIGH SPEED SWITCH CONFIGURATION

Controls the high-speed switch parameters.

DS50002300A-page 34 2014 Microchip Technology Inc.

Page 35

Software Description

Custom Charging Tab

Selected

Custom Emulation

Configuration Setting

Custom Current

Limiting Behavior

Custom Emulation

Quick Load Selection

Custom Emulation

Save Option

Custom Emulation

Timeout Custom Setting

Selection

4.3.3 Custom Charging Tab

The Custom Charging tab (Figure 4-12), provides the means for users to create

custom charger emulator configurations. These configurations include signaling on the

USB data lines, as well as what method of current limiting to employ (Constant Current

or Trip). For more information, refer to the UCS81003 Data Sheet and AN24.14 -

“UCS1002 Fundamentals of Custom Charger Emulation” (DS200005234).

FIGURE 4-12: Custom Charging Tab.

4.3.3.1 CUSTOM EMULATION CONFIGURATION

Creating a custom emulation profile is a two-part process of entering the appropriate

stimulus-response pairs in the provided fields, as well as the desired current limiting

behavior (after emulation is applied, and the portable device starts to draw current).

4.3.3.1.1 Example

Settings shown in Figure 4-12 will apply the Legacy 2 stimulus pair. This includes a

voltage divider on DP and on DM with the values shown under STEP 5 column.

If the portable device draws bus current greater than the charging threshold being

used, it will always operate in Current Limiting Trip mode (with trip point based on the

current limit setting).

2014 Microchip Technology Inc. DS50002300A-page 35

Page 36

UCS81003 Evaluation Board User’s Guide

Region 2

Drop-down List

Click on the arrow

to reveal the options

in the VBus_Min

Drop-down List

Current Limit

4.3.3.2 CUSTOM CURRENT LIMITING BEHAVIOR

The second part of creating custom profiles is to specify the behavior of current limiting

and minimum voltage output. This is accomplished using the Ibus_r2min and

VBus_Min drop-down lists, as shown in Figure 4-13.

FIGURE 4-13: Current -Voltage Behavior Selectio n.

4.3.3.3 CUSTOM EMULATION QUICK LOAD

The Custom Emulation Quick Load drop-down menu allows single-click loading of the

Custom Emulation Configuration registers. Simply select the profile to load from the

menu and registers 41h – 4Ch will be loaded with that profile.

4.3.3.4 SAVE CUSTOM EMULATION CONFIGURATION

Customs Emulation Configuration allows for a quick way to save the necessary registers to configure the UCS81003 for a custom profile to a file. Enter the path and press

the SAVE button. Files will be overwritten if duplicate file names are used.

Registers 40h – 4Ch (Custom Emulation Configuration - Custom Charging tab),

16h (Emulation Behavior - Configuration tab), 19h (ILIM - Main tab), 25h (High Speed

Switch Configuration – Configuration tab) and 51h (Custom Current Limiting Behavior

– Custom Charging tab) will be saved in a two-column format. Comments can be

added at the end of the file for documentation.

DS50002300A-page 36 2014 Microchip Technology Inc.

Page 37

Software Description

Register Set Tab

Selected

Load/Save Register

Register Content List

Product

Section

Information

4.3.4 Register Set Tab

The Register Set tab (Figure 4-14), allows viewing and updating of the UCS81003

registers, identifies the device on the evaluation board and manages configuration files.

FIGURE 4-14: Register Set Tab.

4.3.4.1 REGISTER CONTENT

Register Content shown in Figure 4-14 is a scrollable list of the UCS81003 registers

and the current value. It is important to note that not all addresses are physical memory

locations on the device; these registers will read ‘0’. Likewise, some registers shown,

that are undocumented in the data sheet, may contain data. Editing these registers can

cause unexpected results.

To update a register value, locate the register address in the left column, type the new

value in the corresponding cell in the right column, and press Enter on the keyboard or

click outside the editable field to complete the action.

4.3.4.2 PRODUCT INFORMATION

Product Information panel shows the values of three registers (FDh, FEh and FFh)

which identify the device on the evaluation board.

4.3.4.3 CONFIGURATION SAVE AND LOAD

The Register Set tab contains controls (Figure 4-15) which save the settings currently

configured in the UCS81003 to allow quick reconfiguration at any time.

2014 Microchip Technology Inc. DS50002300A-page 37

Page 38

UCS81003 Evaluation Board User’s Guide

Browse for Location

Buttons

Path Fields

Load/Save All Register

Values Buttons

FIGURE 4-15: Save/Load Section.

To save configuration settings, configure the UCS81003 as desired, then display the

Register Set tab. Type a path in the “File Stored Path” field or press the Browse button

to select the folder where the configuration file will be saved. The file should be named

with the .txt extension or with a similar text file format. Once a file name and location

has been chosen, click the Save All Register V alues switch, and the file is saved.

Note: If a file with the same name already exists, it will be overwritten and the old

data will be lost.

The data is saved in two columns separated by tabs. The first column is the register

address and the second column is the register data.

Once a file is saved, it can be recalled at any time by selecting the file in the “File Load

Path” field and clicking the Load All Register Values switch.

DS50002300A-page 38 2014 Microchip Technology Inc.

Page 39

Software Description

Demo Tab

Selected

Demo Options

Quick

Step 2

Load

Custom

Panel

Option

Demo

Button

Step 1

Configure Device

Emulation

Config

Options

Demo

Results

4.3.5 Demo Tab

The Demo tab (Figure 4-16) demonstrates external controller logic to apply custom

emulation profiles and optimize charging current. This feature uses the LabView engine

to step through the selected files and store the current drawn by the device. Several

options are available to customize the operation of the demo and explore the potential

of the UCS81003.

FIGURE 4-16: Demo Tab.

4.3.5.1 STEP 1: CONFIGURE DEVICE FOR DEMO ROUTINE

The first step in preparing to run the Demo feature is to configure the device to the

desired starting configuration. A file has been preloaded at installation and is ready to

be used, or a new configuration can be created. Each time the Demo button (in the

Panel Control section) is toggled, the Setup.txt file will be loaded.

4.3.5.2 STEP 2: DEFINE CUSTOM EMULATION CONFIGURATIONS

At installation, a set of files are preloaded on the users system (profile1.txt –

profile7.txt) with the default profiles of the UCS81003. These files can be

changed easily by using the Custom Charging tab.

4.3.5.2.1 Active Files

Check the corresponding check box to activate the desired profile in the demo routine.

4.3.5.2.2 Custom Emulation Files

This column contains the full path to the profile file to be loaded. This file should contain

registers 40h – 4Ch, 16h and 25h. This file can be created with the GUI on the Custom

Charging tab.

2014 Microchip Technology Inc. DS50002300A-page 39

Page 40

UCS81003 Evaluation Board User’s Guide

4.3.5.2.3 Current Reading

This column displays the current being drawn from the attached device. If End Value is

selected (from the Demo Options section, Current Reading features), this will update

continuously. If MAX Value is selected, this will store the highest value of current during

the dwell time.

4.3.5.2.4 Dwell Time

Dwell Time column defines the amount of time from PWR_EN set to PWR_EN unset.

Each profile can have a different Dwell Time.

4.3.5.3 DEMO OPTIONS

TABLE 4-2: DEMO OPTIONS DESCRIPTION

Options Description

Repeat if 0 mA When this option is set, it will repeat if all of the profiles read 0 mA,

i.e. no device connected

Repeat Forever When set, it will repeat the set of files until unchecked

Dead Batt. Repeat When set, it will start the demo after the initial cycle after the

specified Dead Batt. Delay time. This is useful when the battery is

completely discharged and the device OS is unable to handshake

with UCS81003.

Dead Batt. Delay This option is defined in minutes. Minimum is 0 minutes, maximum

is 10 minutes.

Current Reading Displays either the End Value (last value before PWR_EN set low)

or MAX Value (highest value during Dwell Time)

4.3.5.4 CUSTOM FILE PATH QUICK LOAD

When starting the UCS81003 interface, the file paths are reset to a default path. If

desired, the user may save the files in an alternate location. This quick load feature

saves the paths of the Setup.txt and all seven profile locations to quickly return or

change files with one click.

4.3.5.5 RUNNING THE DEMO

Once the files and settings are configured as desired, enable the Demo routine by

pressing the Demo switch within the Panel Controls area. The routine begins and the

results are displayed in Profile MAX and Current MAX. By default, the Demo routine

will enable the profile that is indicated by Profile MAX.

• Profile MAX: Stores the profile of the highest value of current draw.

• Current MAX: Stores the highest current associated with the Profile MAX #.

Note: The Demo tab does not need to be visible to activate the Demo routine.

DS50002300A-page 40 2014 Microchip Technology Inc.

Page 41

Software Description

4.4 TROUBLESHOOTING

Ta bl e 4 - 3 identifies possible problems and their solutions to troubleshoot the

UCS81003 software.

TABLE 4-3: TROUBLESHOOTING THE INTERFACE - COMMON PROBLEMS

Problem Solution

GUI Controls Unresponsive

After Installation

GUI Freezes If the GUI freezes for unknown reasons, communications cannot be stopped, and

Random Panel Display When a board is not connected to the PC running the GUI, the panel will be in an

Device Is Not Charging or Not

Charging Optimally

Restart the computer. In some cases, a restart is required after installation.

the program cannot be closed, disconnect the USB cable from the evaluation

board, then close the program. Reconnect the board, then restart the GUI.

all-zero register displayed state. This also occurs when SMBus communications

are disconnected. The panel display is not meaningful. Connect the board and

establish SMBus communications. If this still does not work, there is a problem

with the connection. The cable or the USB port may be defective.

• Check if the current limit jumper is set appropriately.

• The current source may not have high enough capacity from V

• Run the Demo routine to determine highest current profile.

.

S

2014 Microchip Technology Inc. DS50002300A-page 41

Page 42

UCS81003 Evaluation Board User’s Guide

NOTES:

DS50002300A-page 42 2014 Microchip Technology Inc.

Page 43

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics and layouts for the UCS81003

Evaluation Board:

• Board – Schematic

• Board – Top Silk

• Board – Top Copper and Silk

• Board – Top Copper

• Board – Inner Plans GND 1

• Board – Inner Plans GND 2

• Board – Bottom Copper

• Board – Bottom Copper and Silk

• Board – Bottom Silk

UCS81003 EVALUATION

BOARD USER’S GUIDE

2014 Microchip Technology Inc. DS50002300A-page 43

Page 44

2014 Microchip Technology Inc. DS50002300A-page 44

VBUS

G

VDD

0

GP1

UA

GP2

G

SDA

SC

VUS

D

VSS

VSS

NTB

VBUS

SSRX-

+

VBUS

-

A.2 BOARD – SCHEMATIC

SHIELD

J2

VBUS

GND

0

SHIELD

VDD_5V

USB_OK

J1

JACK Power 2.1mm Male

GND

J3

VBUS

GND

SSRX-

SSRX

SSRX+

GND_D

SSTX-

SSTX+

Shield

USB 3.0 A PLUG

0

SHIELD

D1

5V

1

2

D-

3

D+

D+

4

ID

5

ND

USB MINI-B Female

VDD_5V

R1

1k

0603

5%

LD1

GREEN

1

3

2

C1

0603

0.1uF 25V

1

2

D-

D-

3

D+

D+

4

5

SSRX_N

6

SSRX_P

7

GND_DRAIN

8

SSTX_N

9

SSTX_P

R2

0R

0603

VDD_5V

123

USB_N

USB_P

GND

R3

1k

0603

5%

LD2

RED

SM_ACT

5V_IN

GND

VBUS_IN

GND

TP LOOP White

J4

HDR-2.54 Male 1x3

SMDATA/LATCH

SMCLK/S0

J5

123

HDR-2.54 Male 1x3

GND

GND

R4

1M

0402

1%

TP1

DP_IN

VDD_5V

GND

C2

10uF 10V

C3

0.01uF 16V

R5

1M

0402

1%

TP2

TP LOOP Yellow

DM_IN

VS_5V

R6

10k

0603

1%

12

34

J6

HDR-2.54 Male 2x2

VS_5V

0805

0603

D_IN_N

D_IN_P

PWR_EN

EM_EN

M1

M2

VDD_5V

VDD_5V

R8

10k

0603

1%

1

2

GP0

3

GP1

4

RESET

5

RX

6

TX

USB_OK SM_ACT

VDD_5V

R9

R7

10k

0603

J7

1%

HDR-2.54 Male 2x2

R10

2.2k

2.2k

0603

0603

34

1%

1%

12

GND

RESET

VDD_5V

C4

0.1uF

25V

0603

GND

VDD_5V

C5

1uF 16V

C6

0.1uF 25V

U1

12

VDD

9

VS1

10

VS2

11

VS3

20

DMIN

19

DPIN

13

PWR_EN

26

EM_EN

2

M1

3

M2

27

COMM_I_LIM

GND

29

EP

NC

NC14NC

NC21NC

1

GND

15

C7

0.1uF 25V

U3

VDD

GP0

GP

GP1

RST

RST

UART RX

RT RX

UART TX

UART TX

GP27GP3

MCP2221

C11

4.7uF 16V

U2

11

SCL

12

SDA

13

ADDR

14

RESET

16

INTA

15

INTB

10

VDD

1

VSS

MCP23018

0603

0603

GND

4

VBUS1

5

VBUS2

6

VBUS3

23

DMOUT

24

DPOUT

25

A_DET#

18

ALERT#

16

SMDATA

17

SMCLK

7

8

SEL

NC

UCS81003

22

28

0603

0603

VUSB

GPA0

GPA1

GPA2

GPA3

GPA4

GPA5

GPA6

GPA7

GPB0

GPB1

GPB2

GPB3

GPB4

GPB5

GPB6

GPB7

VSS

D+

+

D-

D

B

SCL

L

SDA

P3

VBUS_5V

C8

150uF 10V

D_OUT_N

D_OUT_P

A_DET#

ALERT#

SMDATA/LATCH

SMCLK/S0

COMM_SEL/ILIM

SEL

14

13

12

11

10

9

8

GND

17

18

19

20

21

22

23

24

2

3

4

5

6

7

8

9

SDA

SCL

GND

USB_P

USB_N

VUSB

ALERT#

A_DET#

PWR_EN

EM_EN

M1

M2

TANT-D

L1

CM Choke 90Ohm

VDD_5V

C9

0.47uF 6.3V

GND

L1L1'

L2L2'

LD3

ALERT#

RED

R14

1k

0603

5%

0603

J8

D_OUT_N

D_OUT_P

VDD_5V

GND

VDD_5V

1

2

LD4

A_DET#

GREEN

R18

1k

0603

5%

TP LOOP Yellow

DM_OUT

R27

JP1

Shunt 2.54mm 1x2 Handle11

R17

R20

R21

10k

0603

1%

R23

10k

10k

10k

0603

0603

0603

1%

1%

1%

J9

1 2

3 4

5 6

7 8

HDR-2.54 Male 2x4

GND

GND

47k

R28

56k

R29

68k

R30

82k

R31

100k

R32

120K

R33

150k

R41

0R

R42

10k

R43

12k

R44

15k

R45

18k

R46

22k

R47

27k

R48

33k

VDD_5V

0.57A

1.00A

1.13A

1.35A

1.68A

2.05A

2.28A

2.85A

GND

R34

47k

R35

56k

R36

68k

R37

82k

R38

C10

GND

D4

5V

SOD-882

470pF 50V

SSRX_N

SSRX_P

GND_DRAIN

SSTX_N

SSTX_P

0603

J10

1

VBUS

2

D-

D-

3

D+

D

4

GND

5

6

7

8

9

SSRX-

SSRX+

GND_D

SSTXSSTX+

Shield

SHIELD

J11

GND

J12

GND

USB 3.0 A RCPT

0

J13

1

SHIELD

J14

SHIELD

J15

SHIELD

R24

0R

0603

GND

1

R25

0R

0603

GND

1

R26

0R

0603

GND

SHIELD

1

GND

SHIELD

1

GND

SHIELD

GND

GND

D2

5V

SOD-523

D3

5V

SOD-882

R22

0R

0603

GND

VBUS_OUT

GND

R19

R16

1M

1M

0402

0402

1%

1%

TP3

TP4

TP LOOP White

DP_OUT

100k

R39

120K

R40

150k

R49

0R

R50

10k

R51

12k

R52

15k

R53

18k

R54

22k

R55

27k

R56

33k

VDD_5V

AL_57h

AL_56h

AL_55h

AL_54h

AL_30h

AL_31h

AL_32h

AL_33h

0.57A_SA

1.00A_SA

1.13A_SA

1.35A_SA

1.68A_SA

2.05A_SA

2.28A_SA

2.85A_SA

J16

1

2

3

4

5

6

7

8

9

10

12

11

14

13

16

15

HDR-2.54 Male 2x8

AH_33h

AH_32h

AH_31h

AH_30h

AH_54h

AH_55h

AH_56h

AH_57h

J17

15

16

13

14

11

12

9

10

8

7

6

5

4

3

2

1

HDR-2.54 Male 2x8

J18

COMM_SEL/ILIM

1

2

3

4

5

6

7

8

9

10

12

11

14

13

16

15

HDR-2.54 Male 2x8

COMM_SEL/ILIM

J19

1

2

3

4

5

6

7

8

9

10

12

11

14

13

16

15

HDR-2.54 Male 2x8

SEL

SEL

Schematic and Layouts

Page 45

A.3 BOARD – TOP SILK

Schematic and Layouts

A.4 BOARD – TOP COPPER AND SILK

2014 Microchip Technology Inc. DS50002300A-page 45

Page 46

UCS81003 Evaluation Board User’s Guide

A.5 BOARD – TOP COPPER

A.6 BOARD – INNER PLANS GND 1

DS50002300A-page 46 2014 Microchip Technology Inc.

Page 47

A.7 BOARD – INNER PLANS GND 2

Schematic and Layouts

A.8 BOARD – BOTTOM COPPER

2014 Microchip Technology Inc. DS50002300A-page 47

Page 48

UCS81003 Evaluation Board User’s Guide

A.9 BOARD – BOTTOM COPPER AND SILK

A.10 BOARD – BOTTOM SILK

DS50002300A-page 48 2014 Microchip Technology Inc.

Page 49

UCS81003 EVALUATION

BOARD USER’S GUIDE

Appendix B. Bill of Mater ials

TABLE B-1: BILL OF MATERIALS (BOM)

Qty. Reference Description Manufacturer Part Number

4 C1, C4, C6, C7 Cap. ceramic 0.1 μF 25V 10% X7R

SMD 0603

1 C2 Cap. ceramic 10 μF 10V 10% X7R

SMD 0805

1 C3 Cap. ceramic 0.01 μF 16V 10% X7R

SMD 0603

1 C5 Cap. ceramic 1 μF 16V 10% X7R SMD

0603

1 C8 Cap. tantalum 150 μF 10V 10% 100m

ohm SMD D

1 C9 Cap. ceramic 0.47 μF 6.3V 10% X5R

SMD 0603

1 C10 Cap. ceramic 470 pF 50V 10% X7R

0603

1 C11 Cap. ceramic 4.7 uF 16V 10% X5R

SMD 0603

2 D1, D2 Diode Zener T5V0S5-7 5V 150 mW

SMD SOD-523

2 D3, D4 Diode Zener PESD5V0X1BL 5V SMD

SOD-882

1 J1 Conn. jack power 2.1 mm 16V 2.5A

male th. R/A

11 JP1 Mech. hardware jumper 2.54 mm 1x2

handle gold

1 J2 Conn. USB Mini-B female SMD R/A Hirose Electric Co., Ltd. UX60SC-MB-5ST(80)

1 J3 Conn. USB 3.0 Standard-A plug SMD

R/A

2 J4, J5 Conn. header-2.54 male 1x3 gold

5.84 MH th. vert.

1 J6 Conn. header-2.54 male 2x2 gold

5.84MH th. vert.

1 J7 Conn. header-2.54 male 2x2 gold

5.84MH th. vert.

1 J8 Conn. header-2.54 male 1x2 gold

5.84MH th. vert.

1 J9 Conn. header-2.54 male 2x4 gold

5.84MH th. vert.

1 J10 Conn. USB 3.0 Standard-A rcpt. th. R/A Wurth Elektronik GmbH &

5 J11, J12, J13, J14,

J15

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Conn. TP loop tin SMD FCI 68602-116HLF

Murata Electronics

Murata Electronics GRM21BR71A106KE51L

Samsung Group CL10B103KO8NNNC

Taiyo Yuden Co., Ltd. EMK107B7105KA-T

AVX Corporation TPSD157K010R0100

Murata Electronics GRM188R60J474KA01D

TDK Corporation C1608X7R1H471K

TDK Corporation C1608X5R1C475K080AC

®

Diodes

NXP Semiconductor PESD5V0X1BL,315

CUI Inc. PJ-002A

TE Connectivity, Ltd. 881545-2

Wurth Elektronik GmbH &

Co.

FCI 68000-103HLF

Samtec, Inc. TSW-102-07-G-D

Samtec, Inc. HTSW-102-07-G-D

FCI 68001-202HLF

Samtec, Inc. TSW-104-08-L-D

Co.

Incorporated T5V0S5-7

®

GRM188R71E104KA01D

692112030100

692121030100

2014 Microchip Technology Inc. DS50002300A-page 49

Page 50

UCS81003 Evaluation Board User’s Guide

TABLE B-1: BILL OF MATERIALS (BOM) (CONTINUED)

Qty. Reference Description Manufacturer Part Number

4 J16, J17, J18, J19 Conn. header-2.54 male 2x8 gold

5.84MH th. vert.

1 L1 Inductor choke Common Mode 90 ohm

0805

2 LD1, LD4 Diode LED green 2.2V 25mA 15 mcd

clear SMD 0603

2 LD2, LD3 Diode LED red 1.95V 30 mA 700 mcd

clear SMD 0603

4 R1, R3, R14, R18 Res. TKF 1k 5% 1/10W SMD 0603 Panasonic

7 R2, R22, R24, R25,

R26, R41, R49

4 R4, R5, R16, R19 Res. TKF 1M 1% 1/10W SMD 0402 Panasonic ERJ-2RKF1004X

9 R6, R7, R8, R17,

R20, R21, R23,

R42, R50

2 R9, R10 Res. TKF 2.2k 1% 1/10W SMD 0603 Panasonic ERJ-3EKF2201V

2 R27, R34 Res. TKF 47k 1% 1/10W SMD 0603 Panasonic ERJ-3EKF4702V

2 R28, R35 Res. TKF 56k 1% 1/10W SMD 0603 Stackpole Electronics, Inc. RMCF0603FT56K0

2 R29, R36 Res. TKF 68k 1% 1/10W SMD 0603 Stackpole Electronics, Inc. RMCF0603FT68K0

2 R30, R37 Res. 82K ohm 1/10W 1% 0603 SMD Panasonic ERJ-3EKF8202V

2 R31, R38 Res. TKF 100k 1% 1/10W SMD 0603 Panasonic ERJ-3EKF1003V

2 R32, R39 Res. TKF 120K 1% 1/10W SMD 0603 Panasonic ERJ-3EKF1203V

2 R33, R40 Res. TKF 150k 1% 1/10W SMD 0603 Panasonic ERJ-3EKF1503V

2 R43, R51 Res. TKF 12k 1% 1/10W SMD 0603 Yageo Corporation RC0603FR-0712KL

2 R44, R52 Res. TKF 15k 1% 1/10W SMD 0603 Panasonic ERJ-3EKF1502V

2 R45, R53 Res. TKF 18k 1% 1/10W SMD 0603 ROHM Semiconductor MCR03EZPFX1802

2 R46, R54 Res. TKF 22k 1% 1/10W SMD 0603 Stackpole Electronics, Inc. RMCF0603JT22K0

2 R47, R55 Res. TKF 27k 1% 1/10W SMD 0603 Yageo Corporation RC0603FR-0727KL

2 R48, R56 Res. TKF 33k 1% 1/10W SMD 0603 Stackpole Electronics. Inc. RMCF0603FT33K0

2 TP1, TP4 Conn. TP loop white th. Keystone Electronics

2 TP2, TP3 Conn. TP loop yellow th. Keystone Electronics

1 U1 UCS81003 QFN-28_5X5_EP2.7x3 Microchip Technology Inc. UCS81003AM-C1A

1 U2 Microchip interface GPIO-port Expand.

1 U3 MCP2221 TSSOP-14 Microchip Technology Inc. MCP2221- I/ST

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Res. TKF 0R 1/10W SMD 0603 NIC Components Corp. NRC06Z0TRF

Res. TKF 10k 1% 1/10W SMD 0603 NIC Components Corp. NRC06F1002TRF

I2C 16-port MCP23018-E/SS SSOP-24

FCI 68602-116HLF

Murata Electronics DLW21HN900SQ2L

Kingbright Corp. APT1608SGC

Kingbright Corp. APTD1608SURCK

®

Corp.

Corp.

Microchip Technology Inc. MCP23018-E/SS

ERJ-3GEYJ102V

5012

5014

DS50002300A-page 50 2014 Microchip Technology Inc.

Page 51

NOTES:

Bill of Materials

2014 Microchip Technology Inc. DS50002300A-page 51

Page 52

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/