TC850

15-Bit, Fast Integrating CMOS A/D Converter

Features

• 15-bit Resolution Plus Sign Bit

• Up to 40 Conversions per Second

• IntegratingADC Technique

- Monotonic

- High Noise Immunity

- Auto Zeroed Amplifiers Eliminate Offset

Trimming

• Wide Dynamic Range: 96dB

• Low Input Bias Current: 30pA

• Low Input Noise: 30µV

P-P

• Sensitivity: 100µV

• Flexible Operational Control

• Continuous or On Demand Conversions

• Data Valid Output

• Bus Compatible, 3-State Data Outputs

-8-BitDataBus

-SimpleµP Interface

- Two Chip Enables

- Read ADC Result Like Memory

• ± 5V Power Supply Operation: 20mΩ

• 40-Pin Dual-in-Line or 44-Pin PLCC Packages

Applications

• Precision Analog Signal Processor

• PrecisionSensor Interface

• High Accuracy DC Measurements

Device Selection Table

Part Number Package

TC850CPL 40-Pin PDIP 0°Cto+70°C

TC850IJL 40-Pin CERDIP -25°Cto+85°C

TC850CLW 44-Pin PLCC 0°Cto+70°C

TC850ILW 44-Pin PLCC -25°Cto+85°C

Temperature

Range

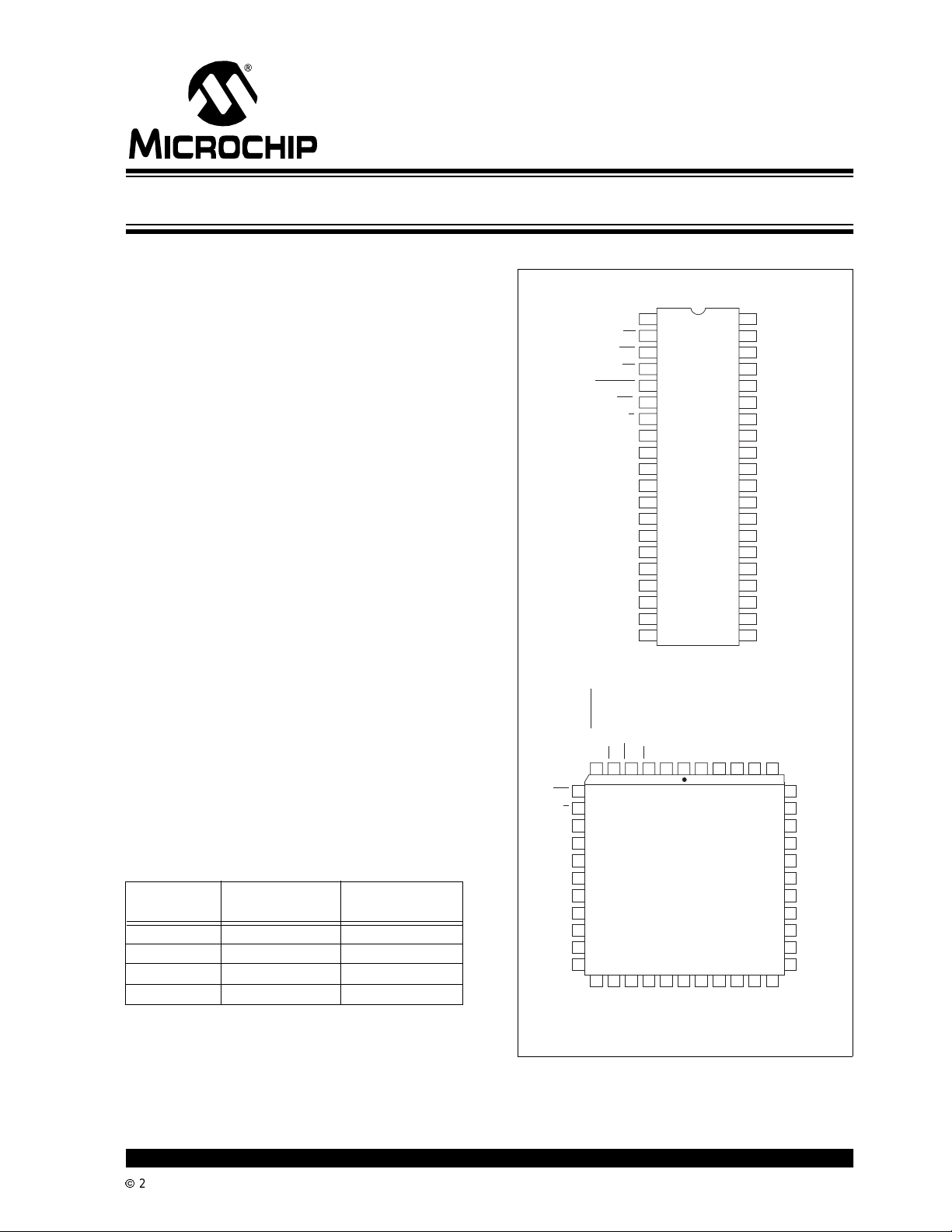

Package Types

CS

CE

WR

RD

CONT/DEMAND

OVR/POL

L/H

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0

BUSY

OSC

OSC

TEST

DGND

CONT/DEMAND

RD

6543 1442

OVR/POL

7

8

L/H

9

DB7

10

DB6

11

DB5

12

NC

13

DB4

DB3

DB2

DB1

DB0

18 19 20 21 23 24

BUSY

1

OSC

NC = No Internal Connection

40-Pin PDIP/CERDIP

1

2

3

4

5

6

7

TC850CPL

8

TC850IJL

9

10

11

12

13

14

15

16

17

1

18

2

19

20

44-Pin PLCC

WR

CE

CS

NC

VDDREF

43 42 41 40

TC850CLW

TC850ILW

DGND

25 26 27 28

NC

COMP

2

OSC

22

TEST

40

V

DD

REF1+

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

+

+

1

REF1

C

SS

OUT

V

INT

C

REF1

C

REF1

REF-

C

REF2

C

REF2

REF

+

2

IN+

INANALOG

COMMON

C

INTB

C

INTA

C

BUFA

C

BUFB

BUFFER

INT

IN

INT

OUT

V

SS

COMP

-

REF1

C

REF-

39

38

37

36

35

34

33

3214

3115

3016

2917

IN

INT

BUFFER

+

-

-

+

C

REF2

C

REF2

REF

IN+

IN-

NC

ANALOG

COMMON

C

INTB

C

INTA

C

BUFA

C

BUFB

-

+

+

2

2002 Microchip TechnologyInc. DS21479B-page 1

TC850

General Description

The TC850 is a monolithic CMOS A/D converter (ADC)

with resolution of 15-bitsplus sign. It combines a chopper-stabilized buffer and i ntegrator with a unique multiple-slope integration technique that increases

conversion speed. The result is 16 times improvement

in speed over previous 15-bit, monolithic integrating

ADCs (from 2.5 conversions per second up to 40 per

second). Faster conversion speed is especially welcome in systems with human interface, such as digital

scales.

The TC850 incorporates an ADC and a µP-compatible

digital interface. Only a voltage reference and a few,

noncritical, passive components are required to form a

complete 15-bit plus sign ADC. CMOS processing provides the TC850 with high-impedance, differential

inputs. Input bias current is typically only 30pA, permitting direct interface to sensors. Input sensitivity of

100µV per least significant bit (LSB) eliminates the

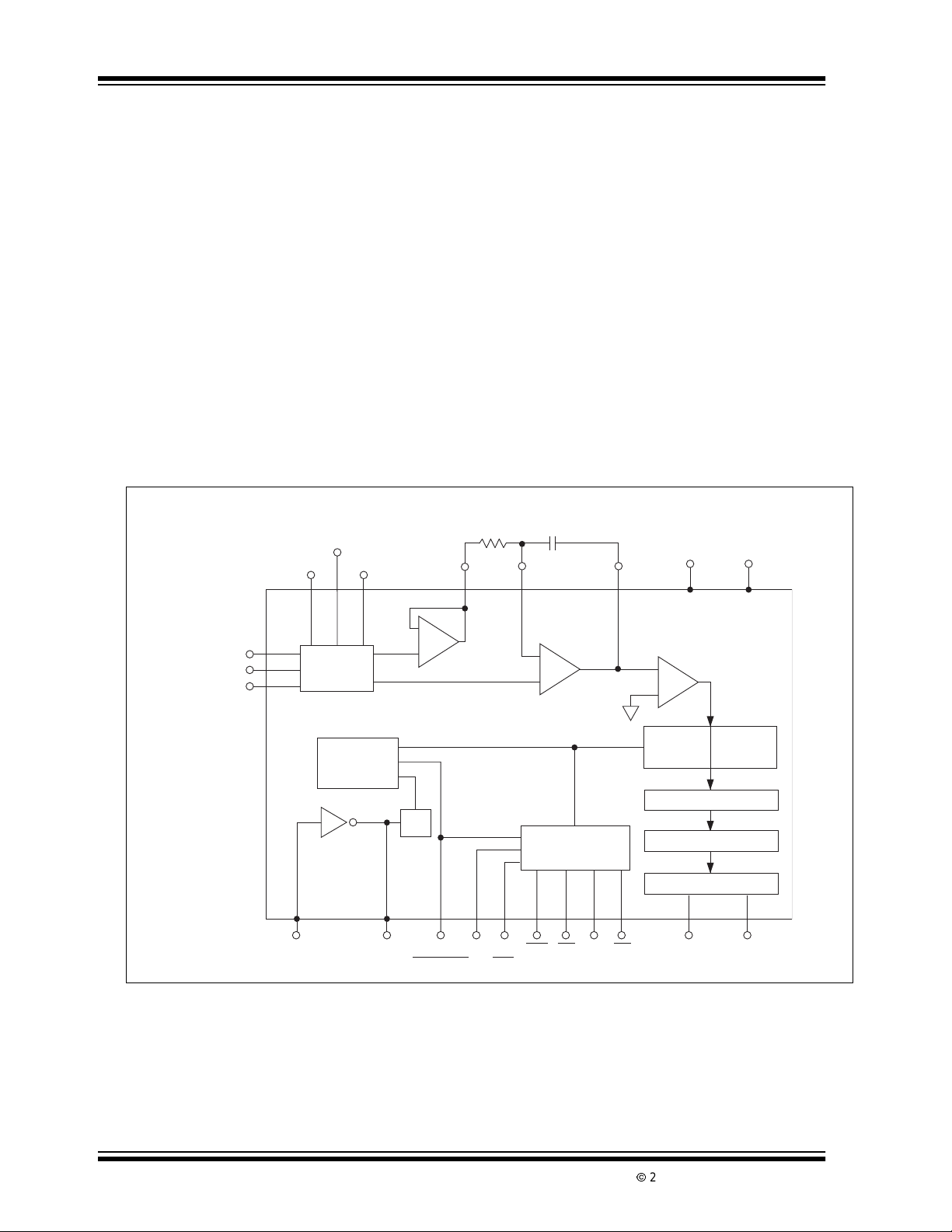

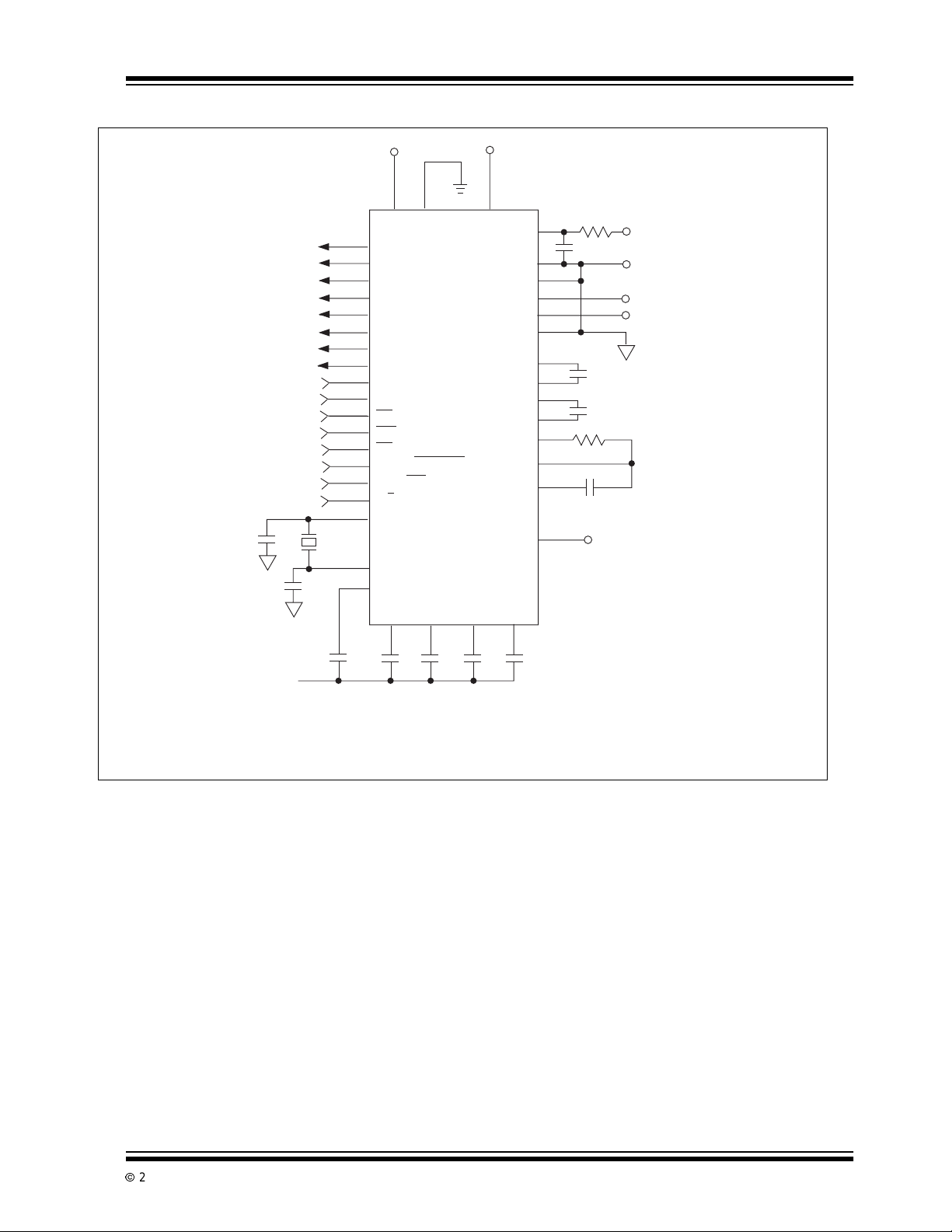

Functional Block Diagram

Pinout of 40-Pin Package

REF2+

+

REF

REF-

1

BUF

R

INT

INT IN

need for precision external amplifiers. The internal

amplifiers are auto zeroed, ensuring a zero digital output, with 0V analog input. Zero adjustment

potentiometers or calibrations are not required.

The TC850 outputsdataonan8-bit,3-statebus.Digital

inputs are CMOS compatible while outputs are TTL/

CMOS compatible.Chip-enable and byte-selectinputs,

combined with an end-of-conversion output, ensures

easy interfacing to a wide variety of microprocessors.

Conversions can be performed continuously or on

command. In continuous mode, data is read as three

consecutivebytes and manipulation of address lines i s

not required.

Operating from ±5V supplies, the TC850 dissipates

only 20mΩ. The TC850 i s packaged in a 40-pin plastic

or ceramic dual-in-line package (DIPs) and in a 44-pin

plastic leaded chip carrier (PLCC), surface-mount

package.

C

INT

INT OUT

+5V–5V

IN+

IN-

COMMON

-

32

31

30

Analog

Mux

A/D

Control

Sequencer

Clock

Oscillator

17 7

OSC

1

18

OSC

+

Buffer

÷4

53

CONT/

2

DEMAND

L/H6OVR/

POL

-

+

Integrator

TC850

Bus Interface

Decode Logic

4RD1CS2

WR

232425363439

CE

22 40

Comparator

+

-

6-Bit

Up/Down

Counter

Data Latch

Octal 2-Input Mux

3-State Data Bus

15 8

DB0

9-Bit

Up/Down

Counter

. . . .

DB7

DS21479B-page 2

2002 Microchip TechnologyInc.

TC850

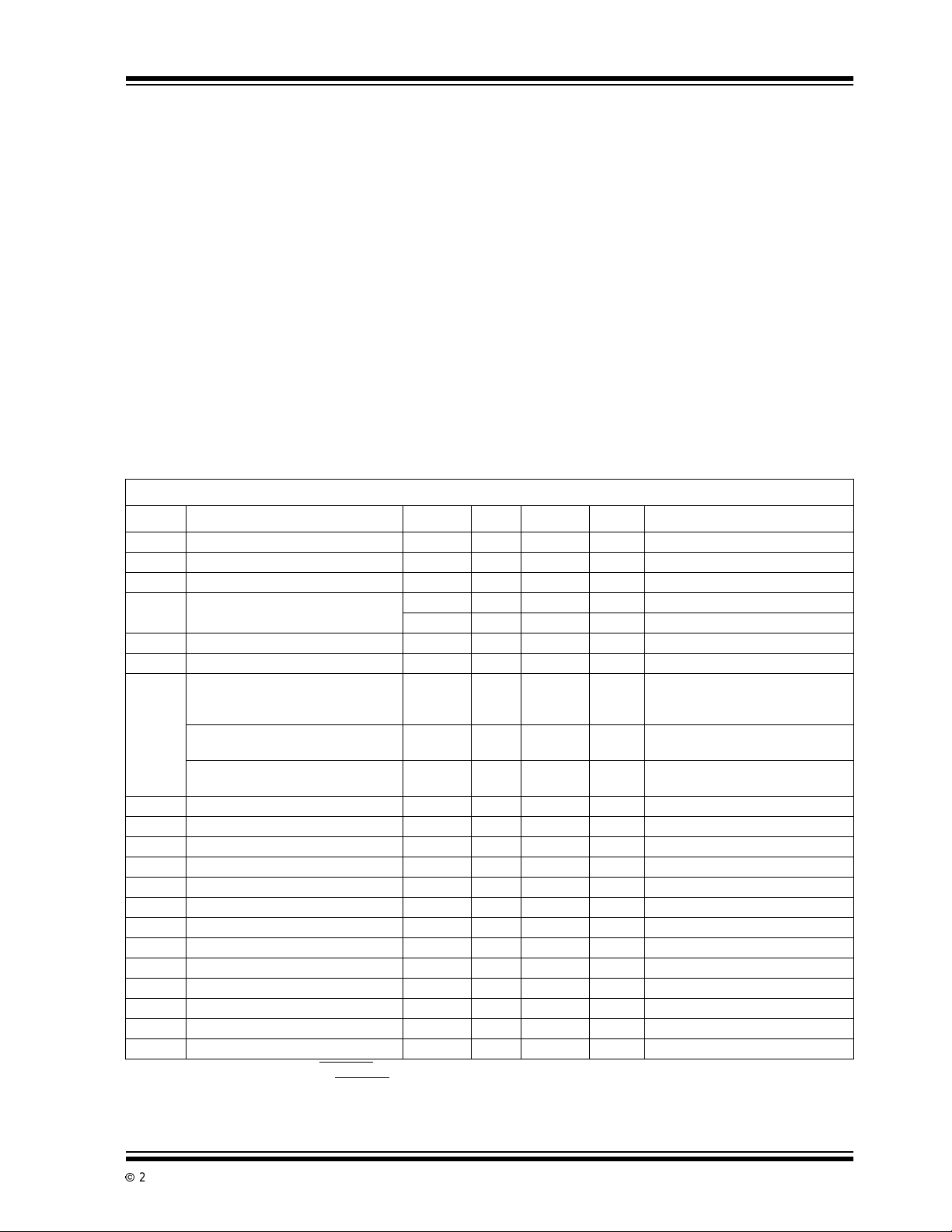

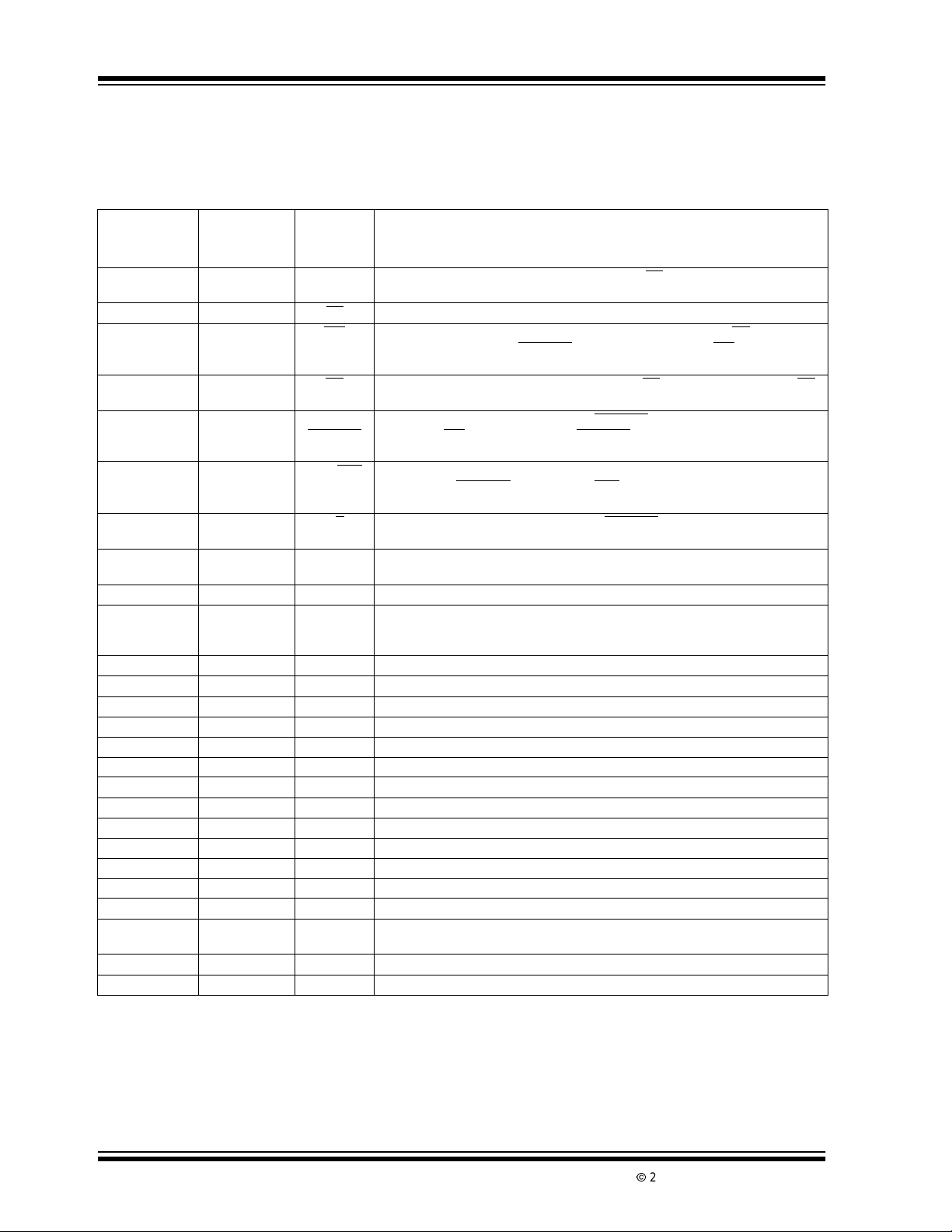

1.0 ELECTRICAL SPECIFICATIONS

Absolute Maximum Ratings*

Positive Supply Voltage..........................................+6V

Negative Supply Voltage.......................................- 9V

Analog Input Voltage (IN+ pr IN-).............. V

DD

to V

SS

*Stresses above those listed under "Absolute Maximum Ratings"maycause permanentdamage to thedevice.These are

stress ratings only and functional operation of the device at

these or any other conditions above those indicated in the

operation sections of the specifications is not implied. E xposure to Absolute Maximum R ating conditions for extended

periodsmay affectdevice reliability.

Voltage Reference Input:

(REF

+, REF1–, REF2+).................. VDDto V

1

SS

Logic Input Voltage.............VDD+0.3VtoGND–0.3V

Current Into Any Pin............................................10mA

While Operating ......................................100µA

Ambient Operating Temperature Range

C Device.......................................0°C to +70°C

I Device......................................-25°C to +85°C

Package Power Dissipation (T

≤ 70°C)

A

CerDIP .....................................................2.29Ω

Plastic DIP................................................1.23Ω

Plastic PLCC ...........................................1.23Ω

TC850 ELECTRICAL SPECIFICATIONS

Electrical Characteristics: VS=±5V;F

Symbol Parameter Min Typ Max Unit Test Conditions

ZeroScaleError ±0.25 ±0.5 LSB V

End PointLinearity Error — ±1 ±2 LSB -V

Differential Nonlinearity — ±0.1 ±0.5 LSB

InputLeakage Current — 30 75 pA VIN=0V,TA=25°C

I

IN

V

CommonMode Voltage Range VSS+1.5 — VSS– 1.5 V Over OperatingTemperatureRange

CMR

CMRR Common M ode Rejection Ratio — 80 — dB V

Full Scale Gain Temperature

Coefficient

Zero Scale Error

Temperature Coefficient

Full Scale Magnitude

Symmetry Error

InputNoise — 30 — µV

e

N

+ Positive Supply Current — 2 3.5 mA

I

S

– Negative Supply Current — 2 3.5 mA

I

S

Output High Voltage 3.5 4.9 — V IO=500µA

V

OH

Output Low Voltage — 0.15 0.4 V IO=1.6mA

V

OL

Output Leakage Current — 0.1 1 µA Pins 8 -15, High-Impedance State

I

OP

InputHighVoltage 3.5 2.3 — V Note 3

V

IH

Input Low Voltage — 2.1 1 V Note 3

V

IL

Input Pull-Up Current — 4 — µA Pins2,3,4,6,7;VIN=0V

I

PU

InputPull-Down Current — 14 — µA Pins1,5;VIN=5V

I

PD

I

C

Oscillator OutputCurrent — 140 — µAPin18,V

OSC

InputCapacitance — 1 — pF Pins 1 - 7, 17

C

IN

Output Capacitance — 15 — pF Pins 8 -15, High-Impedance State

OUT

Note 1: Demand mode, CONT/DEMAND

2: Continuous mode, CONT/DEMAND

3: Digital inputs have CMOS logic levels and internal pull-up/pull-down resistors. For TTL compatibility, external pull-up

resistors to V

are recommended.

DD

= 61.44kHz,VFS= 3.2768V, TA= 25°C, Figure 1-1, unless otherwise specified.

CLK

=0V

IN

≤ VIN≤ +V

FS

—1.13 nA-25°≤ T

=0V,VCM=±1V

IN

≤ +85°C

A

FS

— 2 5 ppm/°C External Ref. Temperature

Coefficient = 0 ppm/°C

=0V

IN

= ±3.275V

IN

≤ +70°C

A

≤ +70°C

A

OUT

=2.5V

0°C ≤ T

—0.32

µV/°C V

0°C ≤ T

—0.52LSBV

Not Exceeded 95% of Time

P-P

= LOW. Figure 8-5 timing diagram. CL= 100pF.

= HIGH. Figure 8-7 timing diagram.

2002 Microchip TechnologyInc. DS21479B-page 3

TC850

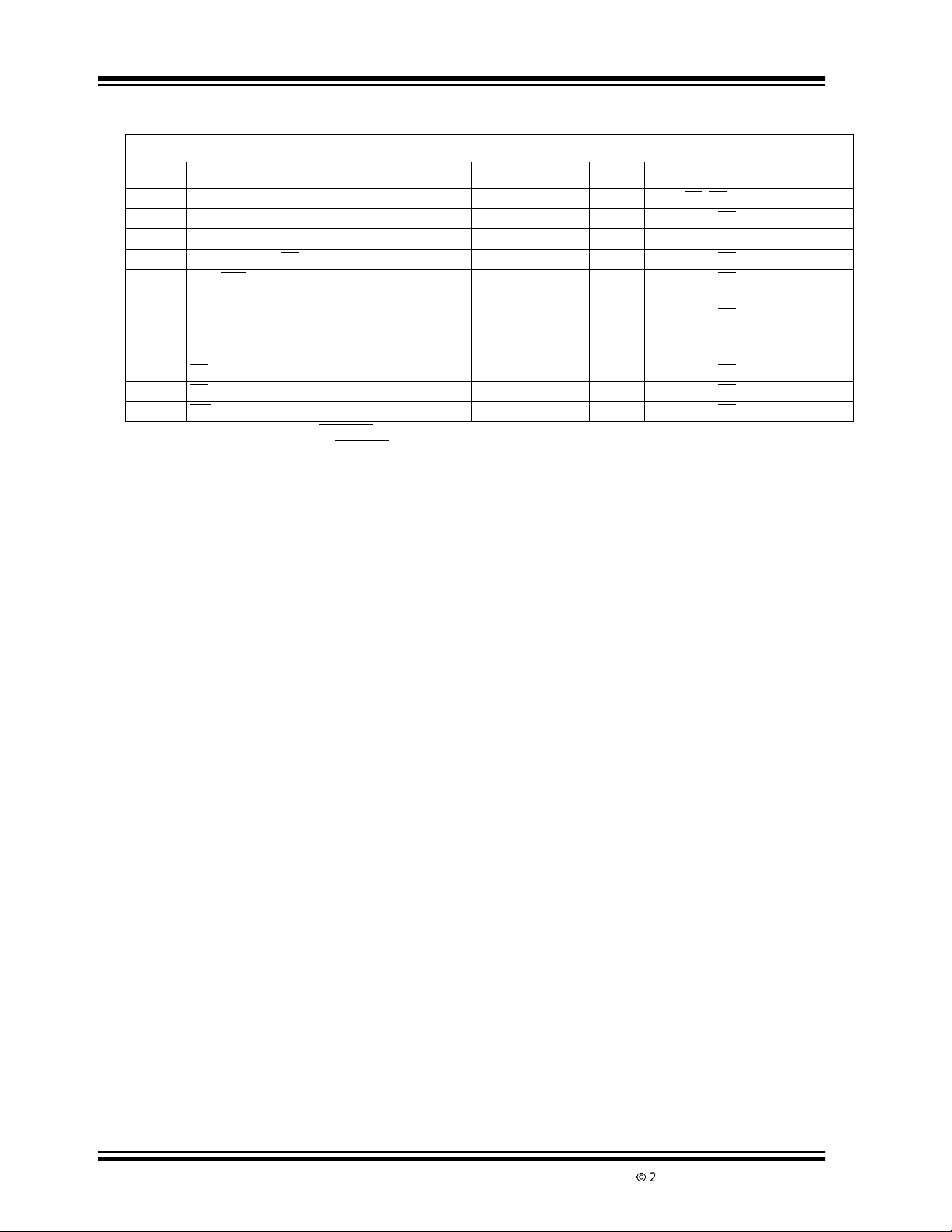

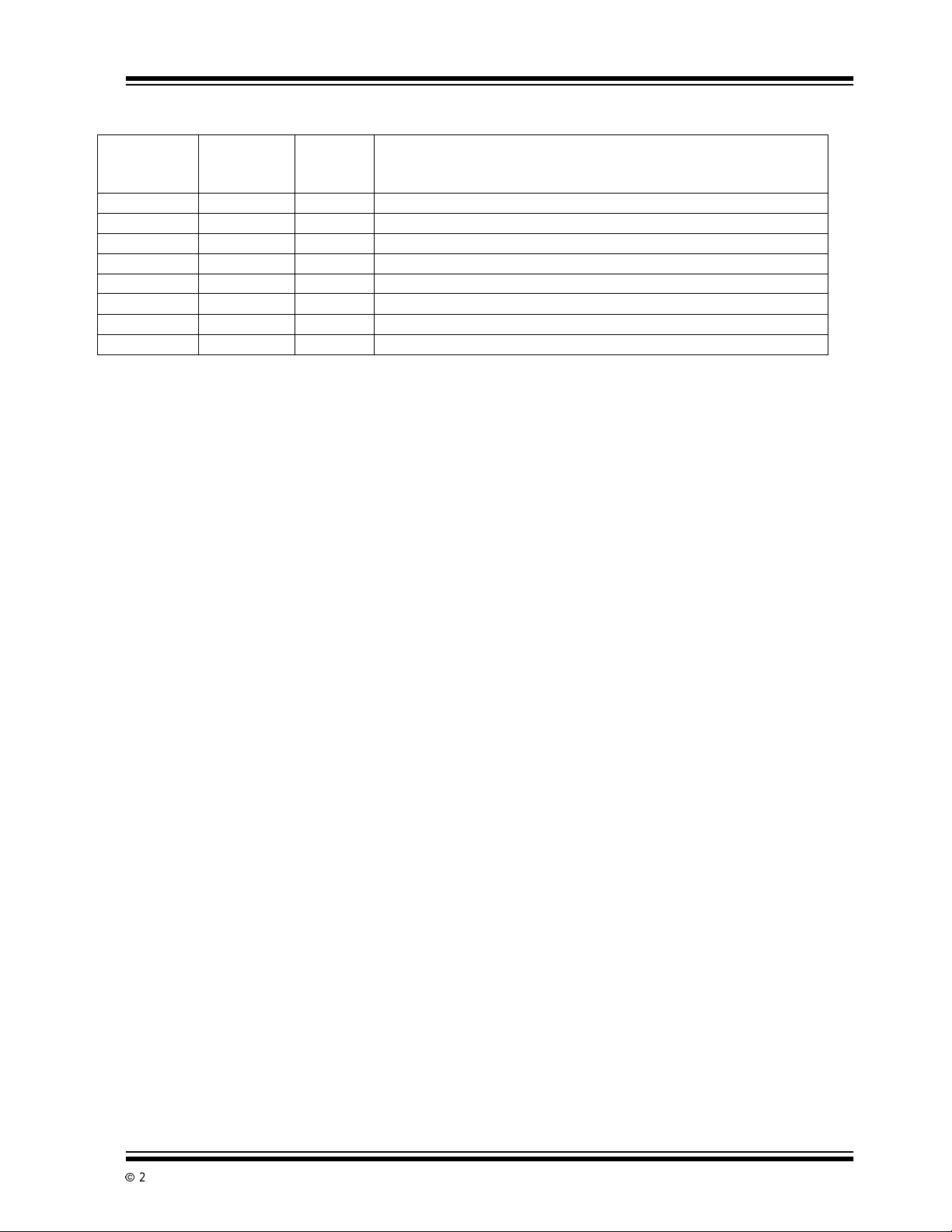

TC850 ELECTRICAL SPECIFICATIONS (CONTINUED)

Electrical Characteristics: VS=±5V;F

Symbol Parameter Min Typ Max Unit Test Conditions

T

Chip-Enable Access Time — 230 450 nsec CS or CE,RD=LOW(Note1)

CE

Read-Enable Access Time — 190 450 nsec CS = HIGH, CE =LOW,(Note1)

T

RE

T

T

Data Hold From CS or CE —250450nsecRD=LOW,(Note1)

DHC

Data Hold From RD —210450nsecCS=HIGH,CE=LOW,(Note1)

DHR

OVR/POL Data Access Time — 140 300 nsec CS = HIGH, CE =LOW,

T

OP

Low/High Byte Access Time — 140 300 nsec CS = HIGH, CE =LOW,

T

LH

ClockSetupTime 100 — — nsec Positive or NegativePulse Width

T

T

T

RD Minimum Pulse Width 450 230 — nsec CS= HIGH, CE =LOW,(Note2)

WRE

RD Minimum Delay Time 150 50 — nsec CS = HIGH, CE =LOW,(Note2)

WRD

WR Minimum Pulse Width 75 25 — nsec CS = HIGH, CE =LOW,(Note1)

WWD

Note 1: Demand mode, CONT/DEMAND

2: Continuous mode, CONT/DEMAND

3: Digital inputs have CMOS logic levels and internal pull-up/pull-down resistors. For TTL compatibility, external pull-up

resistors to V

are recommended.

DD

= 61.44kHz,VFS= 3.2768V, TA= 25°C, Figure 1-1, unless otherwise specified.

CLK

RD

=LOW,(Note1)

RD = LOW, (Note 1)

= LOW. Figure 8-5 timing diagram. CL= 100pF.

= HIGH. Figure 8-7 timing diagram.

DS21479B-page 4

2002 Microchip TechnologyInc.

FIGURE 1-1: STANDARD TEST CIRCUIT CONFIGURATION

TC850

+5V

20

V

DGND

DD

16

BUSY

8

DB7

9

DB6

10

11

12

13

14

15

1

2

3

4

5

6

7

17

18

21

0.1

µF

OSC

OSC

COMP

C

**

61.44 kHz

**

ANALOG COMMON

DB5

DB4

DB3

DB2

DB1

DB0

CS

CE

WR

RD

CONT/DEMAND

OVR/POL

L/H

TC850

1

2

C

INTBCBUFACBUFB

INTA

28 2729

0.1

µF

0.1

µF

-5V

2240

V

SS

REF

REF

REF-

C

REF1

C

REF1

C

REF2

C

REF2

BUFFER

INT

INT

OUT

TEST

0.1

µF

IN+

IN-

1

2

IN

26

+

+

+

+

-

0.1

µF

32

31

30

39

33

36

38

37

34

35

120MkΩ

25

24

23

19

100MΩ

0.01µF Input

+1.6384V

+0.0256V

*

1µF

*

1µF

R

INT

0.1µF

C

INT

NC

NOTES: Unless otherwise specified, all 0.1µF capacitors are film dielectric.

Ceramic capacitors are not recommended.

NC = No Connection

*Polypropylene capacitors.

** 100pF Mica capacitors.

2002 Microchip TechnologyInc. DS21479B-page 5

TC850

2.0 PIN DESCRIPTIONS

The descriptions of the pins are listed in Table .

TABLE 2-1: PIN FUNCTION TABLE

Pin Number

(40-Pin

PDIP/CERDIP)

1 2 CS Chip select, active HIGH. Logically ANDed, with CE

23CE

34WR

45RD

5 6 CONT/

67OVR/POL

78L/H

8 9 DB7 Most significant data bit output. When reading the A/D conversionresult, the

9-15 10-17 DB6-DB0 Data outputs DB6-DB0. 3-state, bus compatible.

16 18 BUSY A/D conversion status output. BUSY goes to a logic HIGH at the beginning of the

17 19 OSC

18 20 OSC

19 21 TEST For factory testing purposes only. Do not make external connectionto this pin.

20 22 DGND Digital groundconnection.

21 24 COMP Connection for comparator auto zero capacitor. Bypass to V

22 25 V

23 26 INT

24 27 INT

25 28 BUFFER Output of the input buffer.Connect to R

26 29 C

27 30 C

28 31 C

29 32 C

30 33 ANALOG

31 35 IN– Negative differential analog input.

32 36 I N+ Positive differentialanalog input.

Note 1: This pin incorporates a pull-down resistortoDGND.

2: This pin incorporatesa pull-upresistor to V

3: Pins 1, 23 and 34 (44-PLCC) package are NC “No Internal connection.

Pin Number

(44-Pin PLCC)

Symbol Description

inputs (Note 1).

Chip enable, active LOW (Note 2).

Writeinput,activeLOW.Whenchipisselected(CS=HIGHandCE= LOW) and

in demand mode (CONT/DEMAND

conversion (Note 1).

Read input,active LOW. When CS = HIGH and CE = LOW, a logic LOW on RD

enables the 3-state data outputs(Note 2).

Conversion control input. When CONT/DEMAND = LOW, conversionsareiniti-

DEMAND

ated by the WR

performed continuously (Note 1).

Overrange/polarity data-select input.Whenmakingconversionsin the demand

mode (CONT/DEMAND

whenthehigh-orderbyteisactive(Note2).

Low/high byte-select input. When CONT/DEMAND = LOW, this input controls

whetherlow-byte or high-byte data is enabled on DB0 through DB7 (Note 2).

polarity, overrange and DB7 data are output on this pin.

de-integratephase,thengoesLOWwhen conversion is complete.The falling

edge of BUSY can be used to generate a

Crystal oscillatorconnection or externaloscillator input.

1

Crystal oscillator connection.

2

SS

BUFB

BUFA

INTA

INTB

Negative power supply connection, typically -5V.

Outputof the integrator amplifier.Connect to C

OUT

Input to the integrator amplifier. Connect to summing node of R

IN

Connection for buffer auto zero capacitor. Bypass to VSSwith 0.1µF.

Connection to buffer auto zero capacitor. Bypass to VSSwith 0.1µF.

Connection for integrator auto zero capacitor. Bypass to VSSwith 0.1µF.

Connection for integrator auto zero capacitor. Bypass to VSSwith 0.1µF.

Analog common.

COMMON

.

DD

to enable read and write

=LOW),alogicLOWonWRstartsa

input. When CONT/DEMAND = HIGH, conversions are

= LOW), OVR/POL controlsthedataoutputonDB7

µP interrupt.

SS

.

INT

.

INT

with 0.1µF.

and C

INT

INT

.

DS21479B-page 6

2002 Microchip TechnologyInc.

TABLE 2-1: PIN FUNCTION TABLE (CONTINUED)

Pin Number

(40-Pin

PDIP/CERDIP)

33 37 REF2+ Positiveinputfor reference voltage V

34 38 C

35 39 C

36 40 REF– Negative input for reference voltages.

37 41 C

38 42 C

39 43 REF

40 44 V

Note 1: This pin incorporates a pull-down resistortoDGND.

2: This pin incorporatesa pull-upresistor to V

3: Pins 1, 23 and 34 (44-PLCC) package are NC “No Internal connection.

Pin Number

(44-Pin PLCC)

Symbol Description

+ Positive connection for V

REF2

– Negative connection for V

REF2

– Negative connection for V

REF1

+ Positive connection for V

REF1

+ Positiveinputfor V

1

DD

Positive power supply connection, typically +5V.

.

DD

REF1

reference capacitor.

REF2

reference capacitor.

REF2

reference capacitor.

REF1

reference capacitor.

REF1

.

REF2

.(V

REF2=VREF1

TC850

/64)

2002 Microchip TechnologyInc. DS21479B-page 7

TC850

3.0 DETAILED DESCRIPTION

The TC850 is a multiple-slope, integrating A/D converter ( ADC). The multiple-slope conversion process,

combined with chopper-stabilized amplifiers, results in

a significant increase in ADC speed, while maintaining

very high resolution and accuracy.

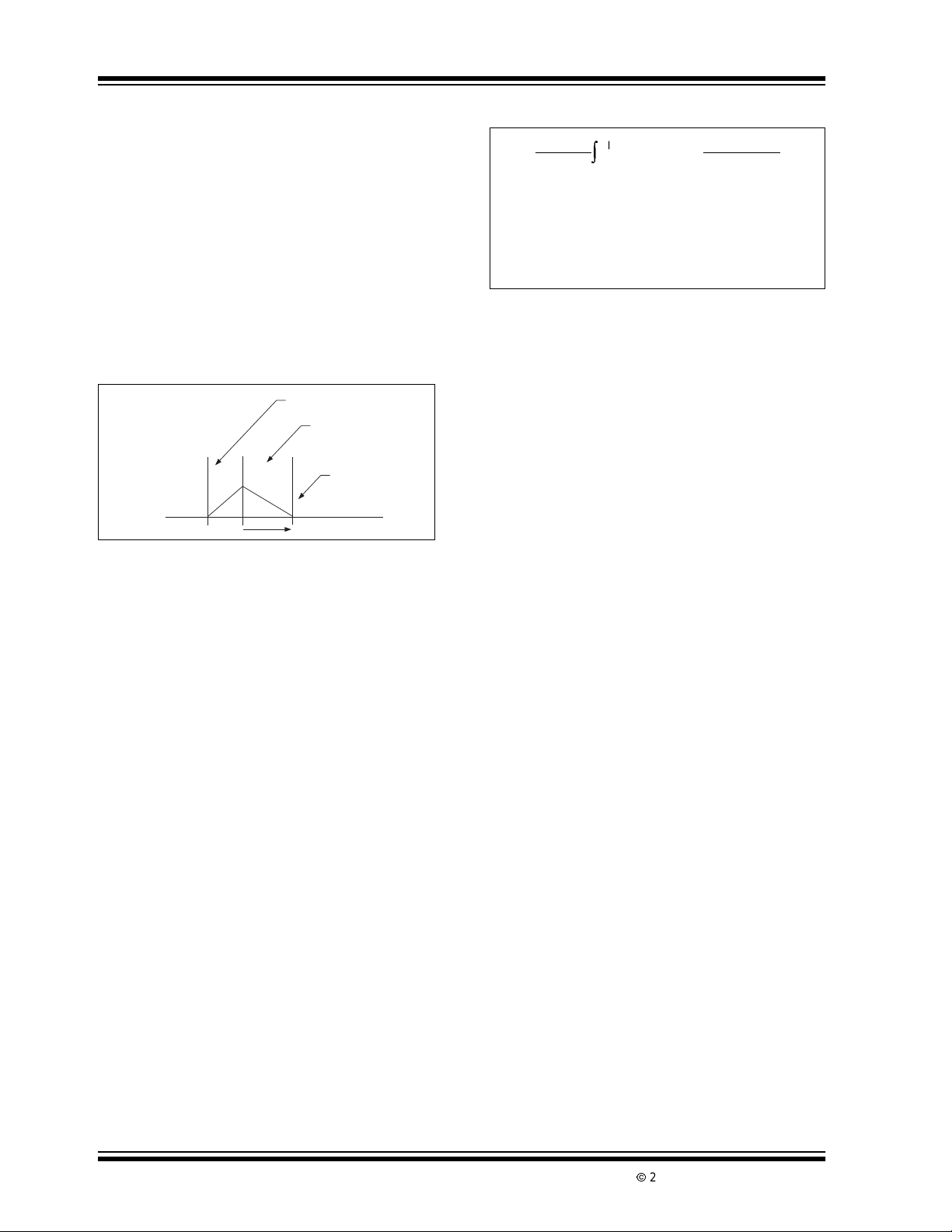

3.1 Dual Slope Conversion P rinciples

The conventional dual slope converter measurement

cycle (shown in Figure 3-1) has two distinct phases:

1. Input signal integration

2. Reference voltage integration (de-integration).

FIGURE 3-1: DUAL SLOPE ADC CYCLE

Signal De-integrate

Reference

De-integrate

End of Conversion

Integrator

Output

The input signal being converted is integrated for a

fixed time period, measured by counting clock pulses.

An opposite polarity constant reference voltage is then

de-integrateduntil the integrator output voltage returns

to zero. The reference integration time is directly

proportionalto the input signal.

In a simple dual slope converter, complete conversion

requires the i ntegrator output to "ramp-up" and "rampdown." Most dual slope converters add a third phase,

auto zero. During auto zero, offset voltages of the input

buffer, integrator and comparator are nulled, thereby

eliminating the need for zero offset adjustments.

Dual slope converter accuracy is unrelated t o the integrating resistor and capacitor values, as long as they

are stable during a measurement cycle. By converting

the unknown analog input voltage into an easily measured function of time, the dual slope converter

reduces the need for expensive, precision passive

components.

Noise immunity is an inherent benefit of the integrating

conversion method. Noise spikes are integrated, or

averaged, to zero during the integration period. I ntegrating ADCs are immune to t he large conversion

errors that plague successive approximation

converters in high-noise environments.

A simple mathematical equation relates the input signal, reference voltage and integration time:

Auto

Zero

Time

0V

EQUATION 3-1:

where:

1

R

INTCINT

V

REF

T

INT

T

DEINT

T

INT

VIN(T)DT =

∫

0

= Reference voltage

= Signal integration time (fixed)

= Reference voltage integration time

(variable).

V

REFTDEINT

R

INTCINT

3.2 Multiple Slope Conversion

Principles

One limitation of the dual slope measurement technique is conversion speed. In a typical dual slope

method, the auto zero and integrate times are each

one-half of the de-integrate time. For a 15-bit conver-

14+214+215

sion,2

for auto zero, integrate and de-integrate phases,

respectively. The large number of clock cycles effectively limits the conversion rate to about 2.5 conversions per second, when a typical analog CMOS

fabricationprocess is used.

The TC850 uses a multiple slope conversiontechnique

to increase conversion speed ( Figure 3-2). This technique m akes use of a two-slope de-integration phase

and permits 15-bit resolution up to 40 conversions per

second.

During the TC850's de-integration phase, the integration capacitor is rapidly dischargedto yield a resolution

of 9 bits. At this point, some charge will remain on the

capacitor. This remaining charge is then slowly deintegrated, producing an additional 6 bits of resolution.

The result is 15 bits of resolution achieved with only

9+26

2

(512 + 64, or 576) clock pulses for deintegration.A complete conversioncycle occupies only

1280 clock pulses.

In order to generate "fast-slow" de-integration phases,

two voltage references are required. The primary reference (V

(typically V

) is set to one-half of the full scale voltage

REF1

REF1

secondaryvoltagereference (V

(typically 25.6 mV). To maintain 15-bit linearity, a tolerance of 0.5% for V

(65,536)clockpulsesare required

= 1.6384V, and VFS= 3.2768V). The

is recommended.

REF2

)issettoV

REF2

REF1

/64

DS21479B-page 8

2002 Microchip TechnologyInc.

TC850

p

FIGURE 3-2: “FAST S LOW”

REFERENCE DE-

4.0 ANALOG SECTION

DESCRIPTION

INTEGRATION CYCLE

The TC850 analog section consists of an input buffer

amplifier, integrator amplifier, comparator and analog

switches. A simplified block diagram is shown in

Figure 4-1.

Signal Integrate

"Fast" Reference

De-integrate

(9-Bit Resolution)

"Slow" Reference De-integrate

(6-Bit Resolution)

4.1 Conversion Timing

End of Conversion

Auto

Integrator

Output

Zero

0V

Time

FIGURE 4-1: ANALOG SECTION SIMPLIFIED SCHEMATIC

C

REF2

-

REF2+

-

DE1

(-)

IN+

C

REF1

INT

C

REF1

DE

DE1

(+)

REF1-

C

REF2

C

REF1

DE DE

REF1+

+

DE

DE1

(-)

Each conversion consists of three phases:

1. Zero Integrator

2. Signal Integrate

3. Reference Integrate (or De-integrate)

Each conversion cycle requires 1280 internal clock

cycles (Figure 4-2).

-

DE1

(+)

C

REF2

BUFF

-

+

Buffer*

INT

C

INT

IN

Integrator*

–

+

INT

OUT

–

+

Comparator*

To Digital

Section

R

INT

ANALOG

COMMON

IN-

*Auto Zeroed Am

INT

lifiers

DE1

(+)

INT

DE1

(-)

FIGURE 4-2: CONVERSION TIMING

Internal

Clock

Conversion

Phase

. . . . . . .

246 256 778

Zero Integrator Reference Integrate

DE2

(+)

1280 Clock Cyles

Signal Integrate

DE2

(-)

Z1

TC850

. . . . . . . . . . . . . .

2002 Microchip TechnologyInc. DS21479B-page 9

TC850

4.2 Zero Integrator Phase

During the zero integrator phase, the differential input

signalis disconnected from the circuit by openinginternal analog gates. The internal nodes are shorted to

analog common (ground) t o establish a zero input condition. At the same time, a feedback loop is closed

around the input buffer, integrator and comparator.The

feedback loop ensures the integrator output is near 0V

before the signal integrate phase begins.

During this phase, a chopper-stabilization technique i s

used t o cancel offset errors in the input buffer, integrator and comparator. Error voltages are stored on the

C

BUFF,CINT

phase requires 246 clock cycles.

and COMP capacitors. The zero integrate

4.3 Signal Integrate Phase

The z ero integrator loop is opened and the internal differentialinputs are connectedtoIN

ential input signal is i ntegrated for a fixed time period.

The TC850 signal integrateperiodis256 clock periods,

or counts. The crystal oscillator frequency is ÷4 before

clocking the internal counters.

The i ntegration t ime period is:

EQUATION 4-1:

INT

=

4 x 256

F

T

+ and IN-. The differ-

OSC

4.4 Reference Integrate Phase

Duringreferenceintegratephase,the charge stored on

the integrator capacitor is discharged. The time

required to discharge the capacitor is proportional to

the analog input voltage.

The referenceintegratephase is dividedintothreesubphases:

1. Fast

2. Slow

3. Overrange de-integrate

During fast de-integrate, V

analog common and V

viously-chargedreferencecapacitor (C

gratorcapacitoris rapidly dischargedfor a maximumof

512 internal clock pulses, yielding 9 bits of resolution.

During the slow de-integrate phase, the internal V

node i s now connected to the C

residual charge on the integrator capacitor is further

dischargeda maximumof 64clock pulses.Atthispoint,

the analog input voltage has been converted with 15

bits of resolution.

If the analog input is greater than full scale, the TC850

performs up to three overrange de-integrate subphases. Each subphase occupies a maximum of 64

clock pulses. The overrange feature permits analog

inputs up to 192 LSBs greater than full scale to be correctly converted. This feature permits t he user to digitallynullup to 192 counts of input offset, while retaining

full 15-bit resolution.

In addition to 512 counts of fast, 64 counts of slow and

192 counts of overrange de-integrate, t he reference

integrate phase uses 10 clock pulses to permit internal

nodes to settle. Therefore, the reference integrate

cycle occupies 778 clock pulses.

- is internally connected to

IN

+ is connected across the pre-

IN

REF2

). The inte-

REF1

capacitorand the

IN

+

DS21479B-page 10

2002 Microchip TechnologyInc.

5.0 PIN DESCRIPTION (ANALOG)

5.1 Differential Inputs (IN+ and IN–)

The analog signal to be measured is applied at the IN+

and I N– inputs. The differential input voltage must be

within the Common mode range of the converter. The

input Common mode range extends from V

V

+1.5V. Within this Common mode voltage range,

SS

an 80 dB CMRR is typical.

The integrator output also follows the Common mode

voltage. The integrator output must not be allowed to

saturate. A worst-case condition exists, for example,

when a large, positive Common mode voltage, with a

near full scale negative differential input voltage, is

applied. The negative input signal drives the integrator

positive when most of its available s wing has been

used up by the positive Common mode voltage. For

applications where maximum Common mode range is

critical,integrator swing can be reduced.Theintegrator

output can swing within 0.4V of either supply without

loss of linearity.

-1.5Vto

DD

TC850

5.2 Differential Reference (V

The TC850 requires two reference voltage sources in

order to generate the "fast-slow" de-integrate phases.

The main voltage reference (V

the REF

(V

The reference voltage inputs are fully differential and

the reference voltage can be generated anywhere

within the power supply voltage of the converter. However, to minimize rollover error, especially at high conversion rates, keep the reference Common mode

voltage (i.e., REF-) near or at the analog common

potential. All voltage reference inputs ar e high impedance. Average reference input current is typically only

30pA.

+ and REF- pins. The secondary reference

1

) is applied between the REF2+ and REF- pins.

REF2

) is applied between

REF1

REF

)

5.3 Analog Com mon (ANALOG

COMMON)

Analog common is used as the IN- return during the

zero integrator and de-integrate phases of each conversion. If IN- is at a different potential than analog

common, a Common mode voltage exists in the system. This signal is rejected by the 80dB CMRR of the

converter.However,inmostapplications,IN- will be set

at a fixed, known voltage (power supply common, for

instance). In this case, analog common should be tied

to the same point so t hat the Common mode voltageis

eliminated.

2002 Microchip TechnologyInc. DS21479B-page 11

TC850

6.0 DIGITAL SECTION

DESCRIPTION

The TC850 digital section consists of two sets of conversion counters, control and sequencing logic, clock

oscillator and divider, data latches and an 8-bit, 3-state

interface bus. A simplified schematic of the bus interfacelogicisshowninFigure6-1

6.1 Clock Oscillator

The TC850 includes a crystaloscillatoron-chip.Allthat

is required is to connect a crystal across OSC

OSC

pins and to add two inexpensive capacitors

2

and

1

(Figure 1-1). The oscillator output is ÷ 4 prior to clocking the A/D i nternal counters. For example, a 100kHz

crystal produces a system clock frequency of 25kHz.

Since each conversion requires 1280 clock periods, i n

this case the conversion rate will be 25,000/1280, or

19.5 conversionsper second.

In most applications, however, an external clock is

divided down from the microprocessor clock. In this

case, the OSC

input and OSC

driver should swing from digital ground to V

function is active f or both external clock and crystal

oscillatoroperations.

FIGURE 6-1: BUS INTERFACE SIMPLIFIED S CHEMAT IC

8

DBO–DB7

L/H

RD

CE

CS

POL/OVR

3-State

Buffer

8

Output

Enable

Octal

2-Input Mux

8 7

Select

TC850

pin is used as the external oscillator

1

is left unconnected. The external clock

2

Low-Byte

Up/Down

Counter

High-Byte

Up/Down

Counter

.The÷4

DD

To A/D

Control Logic

WR

CONT/

DEMAND

6.2 Digital Operating Modes

Two modes of operation are available with the TC850,

continuous conversions and on-demand. The operating mode is controlled by the CONT/DEMAND

The bus interface method is different for continuous

and demand modes of operation.

6.2.1 DEMAND MODE OPERATION

When CONT/DEMAND is low,theTC850 performsone

conversion each time the chip is selected and the WR

input is pulsed low. Data is valid on the falling edge of

the BUSY output and can be accessed using the interface truth table (Table 6-1).

6.2.2 CONTINUOUS MODE OPERATION

input.

Select

2-Input Mux

Start

Conversion

End of Conversion

Thelow/high(L/H

(OVR/POL

) inputs are disabled during continuous

Polarity

Overrange

) byte-select and overrange/polarity

mode operation. Data must be read in three consecutive bytes, as shown in Table 6-1.

Note: In continuous mode, the conversion resultmust

be read within 443-1/2 clock cycles of the BUSY

output falling edge. After this time (i.e.,1/2 clock

cycle before BUSY goes high) the internal

counters are reset and the data is lost.

When CONT/DEMAND is high, the TC850 continuously performs conversions. Data will be valid on the

falling edge of the BUSY output and remains valid for

443-1/2 clock cycles.

DS21479B-page 12

2002 Microchip TechnologyInc.

TABLE 6-1: BUS INTERFACE TRUTH TABLE

TC850

CE •CS

Pins 1 and 2

0 0 0 0 0 "1" = Input Positive Data Bits14 - 8

0 0 0 0 1 "1" = Input Overrange

0 0 0 1 X Data Bit 7 Data Bits 6 - 0

00 1 XX Note3

0 1 X X X High-Impedance State

1 X X X X High-Impedance State

Note 1: Pinnumbersreferto40-pinPDIP.

2: Extended overrangeoperation:Although rated at 15 bits (±32,767counts) of resolution, the TC850provides an addi-

tional 191 counts above full scale. For example, with a full-scale input of 3.2768V, the maximum analog input voltage

which will be properly converted is 3.2958V. The extended resolution is signified by the overrange bit being high and the

low-order byte contentsbeing between 0 and 190. For example,witha full-scale voltageof 3.2768V:

3: Continuous mode data transfer:

RD

Pin 4

V

IN

3.2767V Low 255

3.2768V High 000

3.2769V High 001

3.2867V High 099

a. In continuous mode, data MUST be read in three sequential bytes after the BUSY output goes low:

(1) The first byte read will be the high-order byte,with DB7 = polarity.

(2) The second byte read will contain the low-order byte.

(3) The third byte read will again be the high-orderbyte,butwithDB7= overrange.

b. All three data bytes must be read within 443-1/2clock cycles after the fallingedge of BUSY.

c. The c

However, the CS and CE

CONT/DEMAND

Pin 5

Overrange Bit Low Byte Data Bits 14–8

inputmustgohighafter each byte is read, so that the internalbyte counter will be incremented.

inputs can remain enabled through the entire data transfer sequence.

L/H

Pin 7

OVR/POL

Pin 6

10

10

10

10

127

0

0

0

10

10

10

10

DB7

Pin 8

(Note 2)

Pin 9-Pin 15 (Note 1)

Data Bits 14 - 8

DB6–DB0

2002 Microchip TechnologyInc. DS21479B-page 13

TC850

6.3 Pin De scription (Digital)

6.3.1 CHIP SELECT AND CHIP ENABLE

(CS AND CE

The CS and CE inputs permit easy interfacingto a variety of digital bus systems. CE

is active HIGH. These inputs are logically ANDed

internally and are used to enable the RD

inputs.

6.3.2 WRITE ENABLE INPUT (WR)

The write inputis used to initiate a conversion when the

TC850 is in demand mode. CS and CE

for the WR

databus is meaningless during the WR

no data is actually written into the TC850.

input to be recognized. The status of the

6.3.3 READ ENABLE INPUT (RD)

The read input, combined with CS and CE, enable the

3-statedatabus outputs.Also,in continuous mode, the

rising edge of the RD

counter to sequentially read the three data bytes.

6.3.4 LOW/HIGH BYTE SELECT (L/H)

The L/H input determines whet her the l ow (least significant) byte or high (most significant) byte of data is

placedon the 3-statedatabus. This input is meaningful

only when the TC850 is in the demand mode. In the

continuous mode, data must be read in three

predeterminedbytes, so the L/H

)

is active LOW while CS

and WR

must be active

pulse,because

input activates an internal byte

input is ignored.

6.3.6 CONTINUOUS/DEMAND M ODE

INPUT (CONT/DEMAND)

This input controls the TC850 operating mode. When

CONT/DEMAND

sions continuously. In continuous mode, data m ust be

read in the prescribed sequence shown in Table 6-1.

Also, all three data bytes must be read within 443-1/2

internal clock cycles after the BUSY output goes low.

After 443-1/2 clock cycles data will be lost.

When CONT/DEMAND

conversioneach time CS and CE

being pulsed LOW. The conversion is complete and

datacan be read after the falling edge of theBUSY output.Indemandmode,datacanbereadinany

sequence and remains valid until WR

LOW.

is HIGH, the TC850 performs conver-

is LOW, the TC850 begins a

are active and WR is

is again pulsed

6.3.7 BUSY OUTPUT (BUSY)

The BUSY output i s used to convey an end-of-conversion to external logic. BUSY goes HIGH at the beginning of the de-integrate phase and goes LOW at the

end of the conversion cycle. Data is valid on the falling

edge of BUSY. The output-high period is fixed at 836

clock periods, regardless of t he analog input value.

BUSY is active during continuous and demand mode

operation.

This output can also be used to generate an end-ofconversion i nterrupt in µP-based systems.

Noninterrupt-driven systems can poll BUSY to determine when data is valid.

6.3.5 OVERRANGE/POLARITY BIT

SELECT (OVR/POL

The TC850 provides 15 bits of resolution, plus polarity

and overrangebits. Thus,17 bitsofinformation must be

transferredonan8-bitdatabus.Toaccomplishthis,the

overrangeand polaritybits are multiplexedontodatabit

DB7 of the most significant byte. When OVR/POL

HIGH,DB7ofthehighbytecontainstheoverrangestatus(HIGH=analoginputoverrange,LOW=inputwithin

full scale). When OVR/POL

positive analog input polarity and LOW for negative

polarity. The OVR/POL

CS, CE

most significant byte is selected). OVR/POL

when the TC850 is in continuous mode.

and RD are active, and L/H is LOW (i.e., the

input is meaningful only when

)

is

is LOW, DB7 is HIGH for

is ignored

DS21479B-page 14

2002 Microchip TechnologyInc.

TC850

7.0 ANALOG SECTION TYPICAL

APPLICATIONS

7.1 Component S election

7.1.1 REFERENCE VOLTAGE

The typical value for reference voltage V

1.6384V. This value yields a full scale voltage of

3.2768V and resolution of 100µV per step. The V

value is derived by dividing V

V

value is 1.6384V/64, or 25.6mV. The V

REF2

by 64. Thus, typical

REF1

value should be adjusted within ±1% to maintain15-bit

accuracy for the total conversion process;

EQUATION 7-1: :

±1%

V

V

REF

REF1

=

64

The referencevoltageisnotlimitedtoexactly1.6384V,

however, because the TC850 performs a ratiometric

conversion. Therefore, the conversion result will be:

EQUATION 7-2:

V

Digital Counts = • 16384

The full scale voltage can range from 3.2V to 3.5V. Full

scale voltages of less than 3.2V will result in increased

noise in the least significant bits, while a full scale

above 3.5V will exceed the input common-moderange.

V

IN

REF1

REF1

REF2

REF2

7.1.3 INTEG RATION CAPACITOR

The integration capacitor should be selected to produce an integrator swing of ≈ 4 V at full scale. The

capacitorvalue is easily calculated:

EQUATION 7-4:

is

where:

F

is the crystal or external oscillator

CLOCK

frequency and V

The integration capacitor should be selected for low

dielectric absorption to prevent rollover errors. A

polypropylene, polyester or polycarbonate dielectric

capacitoris recommended.

C=

V

FS

R

INT

is the m aximum input voltage.

FS

•

4 • 256

4V F

CLOCK

7.1.4 RE F ERENCE CAPACITORS

The reference capacitors require a low-leakage dielectric, such as polypropylene, polyester or polycarbonate. A value of 1µF i s recommended for operation over

the temperaturerange.Ifhigh-temperature operationis

not required, the C

values can be reduced.

REF

7.1.5 AUTO ZERO CAPACITORS

Five capacitors are r equired t o auto zero the input

buffer, integrator amplifier and comparator. Recommended capacitors ar e 0.1µF film dielectric (such as

polyester or polypropylene). Ceramic capacitors are

not recommended.

7.1.2 INTEGRATION RESISTOR

The TC850 buffer supplies 25µA of integrator charging

current with minimal linearity error. R

is easily calcu-

INT

lated:

EQUATION 7-3:

V

=

FULLSCALE

25µA

INT

R

INT

For a full scale voltage of 3.2768V, values of R

between 120kΩ and 150kΩ are acceptable.

2002 Microchip TechnologyInc. DS21479B-page 15

TC850

8.0 DIGITAL SECTION TYPICAL

APPLICATIONS

8.1 Oscillator

The TC850 may operate with a crystal oscillator. The

crystal selected should be designed for a Pierce oscillator,suchas anAT-cutquartzcrystal.Thecrystaloscillator schematic is shown in Figure 8-1.

Since low frequency crystals are very large and

ceramic resonators are too lossy, the TC850 clock

should be derived from an external source, such as a

microprocessorclock. The clock should be input on the

OSC

pin and no connection should be made to the

1

OSC

pin. The external clock should swing between

2

DGND and V

Since oscillator frequency is ÷4 internally and each

conversion requires 1280 internal clock cycles, the

conversion time will be:

EQUATION 8-1:

Conversion Time =

An important advantage of the integrating ADC is the

abilitytorejectperiodic noise.Thisfeatureismostoften

used to reject line frequency (50Hz or 60Hz) noise.

Noise rejection is accomplished by selecting the integration period equal to one or more line frequency

cycles. The desired clock frequency is selected as

follows:

EQUATION 8-2:

where:

F

NOISE

4 r epresents the clock divider,

256 is the number of integrate cycles.

For example, 60Hz noise will be rejected with a clock

frequency of 61.44kHz, giving a conversion rate of 12

conversions/sec. Integer submultiples of 61.44kHz

(suchas30.72kHz,etc.)willalsoreject 60Hz noise.For

50Hz noise rejection, a 51.2kHz frequency is

recommended.

If noise rejection is not important, other clock frequencies can be used. The TC850 will typically operate at

conversionrates ranging from 3 to 40 conversions/sec,

corresponding to oscillator frequencies from 15.36kHz

to 204.8kHz.

.

DD

4 x 1280

F

CLOCK

F

CLOCK=FNOISE

x 4 x 256

is the noise frequency to be rejected,

FIGURE 8-1: CRYS TAL OSCILLATOR

SCHEMATIC

10MΩ

¸4

System

Clock

TC850

17

61.44kHz

100pF 100pF

18

8.2 Data Bus Interfacing

The TC850 provides an easy and flexible digital interface. A 3-state data bus and six control inputs permit

the TC850 to be treated as a memory device, in most

applications. The conversion result can be accessed

over an 8-bit bus or via a µP I/O port.

AtypicalµP bus interface for the TC850 is shown in

Figure 8-2. In this example, the TC850 operates in the

demand mode and conversion begins when a write

operation is performed to any decoded address space.

The BUSY output interrupts the µP at the end-of-conversion.

The A/D conversion result is read as three memory

bytes.The two LSBs of theaddressbus selecthigh/low

byte and overrange/polarity bit data, while high-order

address lines enable the CE

input.

FIGURE 8-2: INTERFACE TO TYPICAL

µP DATA BUS

TC850

Data Bus

DB0

DB1

DB2

DB3

DB4

DB5

µP

DB6

DB7

A2

. . .

A15

A0

A1

RD

WR

INTERRUPT

OVR/POL

CONT/DEMAND

Address

X00

X01

X10

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

CE

L/H

RD

WR

BUSY

CS

Address

Decode

+5V

High Byte Polarity

Low Byte

High Byte Overrange

DS21479B-page 16

2002 Microchip TechnologyInc.

TC850

Figure 8-3 shows a typical interface to a µP I/O port or

single-chip µC. The TC850 operates in the continuous

mode and can either interrupt t he µC/µP or be polled

with an input pin.

FIGURE 8-3: INTERFACE TO TYPICAL

µP I/O P O RT OR SINGLE-

CHIP

µC

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

BUSY

RD

CONT/DEMAND

CS

CE WR

NC

+5V

TC850

Since the PA0-PA7inputs are dedicated to reading A/D

data, the A/D CS/CE

inputs can be enabled continuously. In continuous mode, data must be read in 3

bytes, as shown in Table 6-1. The required RD

are provided by a µC/µP output pin.

The circuit of Figure 8-3 can also operate i n the

demandmode,withthestart-upconversionstrobegenerated by a µC/µP output pin. In this case, the L/H

CONT/DEMAND

and t he RD

inputs can be controlled by I/O pins

input connected to digital ground.

PA0

PA1

PA2

PA3

PA4

µC OR µP

PA5

I/O PORT

PA6

PA7

INTERRUPT

PB0

pulses

and

8.3 Demand Mode Interface Timing

When CONT/DEMAND input is LOW, the TC850 performs a conversion each time CE

and WR

is strobed LOW.

and CS are active

The demand mode conversion timing is shown in

Figure 8-4. BUSY goes LOW and data is valid 1155

clock pulses after WR goes LOW. After BUSY goes

low, 125 additionalclock cycles are r equired before the

next conversion cycle will begin.

Once conversion is started, WR

is i gnored for 1100

internal clock cycles. After 1100 clock cycles, another

WR

pulse is recognized and initiatesa new conversion

when the present conversion is complete. A negative

edge on WR

is required to begin conversion. If WR is

held LOW, conversions will not occur continuously.

The A/D conversion data is valid on the falling edge of

BUSY and remains valid until one-half internal clock

cycle before BUSY goes HIGH on the succeeding

conversion. BUSY can be monitored with an I/O pin to

determine end of conversion or to generate a µPinterrupt.

In demand mode, the three data bytes can be read i n

any desired order. The TC850 is simply regarded as

three bytes of memory and accessed accordingly. The

bus output timing is shown in Figure 8-5.

8.4 Continuous Mode Interface Timing

When the CONT/DEMAND input is HIGH, the TC850

performs conversions continuously. Data will be valid

on the falling edge of BUSY and all three bytesmust be

readwithin443-1/2internalcl ock cycles of BUSY going

LOW.The timing diagram is shown in Figure 8-6.

In continuous mode, O VR/POL

inputs are ignored. The TC850 automatically cycles

through three data bytes, as shown in Table 6-1. Bus

output timing in the continuous mode is shown in

Figure 8-7.

and L/H byte-select

2002 Microchip TechnologyInc. DS21479B-page 17

TC850

FIGURE 8-4: CONVERSION TIMING, DEMAND MODE

Internal Clock

CS . CE

WR

BUSY

DB0-DB7

. . . .

319 Clock

Cycles

Previous Conversion

Data Valid

1100 Clock Cycles

WR Pulses are Ignored

. . . . . . . .

836 Clock Cycles

Data Meaningless

FIGURE 8-5: BUS OUTPUT TIMING, DEMAND MODE

T

CE

CS . CE

Next Convert

Command will be

Recognized

125 Clock

Cycles

New Conversion Data Valid

T

DHC

Next Conversion

can Begin

RD

DB0-DB6

DB7

OVR/POL

L/H

HI-Z

HI-Z

T

Data Bit 7

DHR

High Impedance

Don't Care

Don't Care

T

RE

*

Data Bits 8 to 14 High Impedance

"1"= Input

Overrange

t

OP

"1"= Positive

Polarity

T

LH

Data Bits 0 tp 6

NOTE: CONT/DEMAND = LOW

*RD (as well as CS and CE) can go HIGH after each byte is read (i.e., in a µP bus interface)

or remain LOW during the entire DATA-READ sequence (i.e., µP I/O port interface).

DS21479B-page 18

2002 Microchip TechnologyInc.

FIGURE 8-6: CONVERSION TIMING, CONTINUOUS MODE

TC850

Internal

Clock

Busy

DB0-DB7

. . . . . . .

1280 Internal Clock Cycles

836 Clock Cycles

Data Meaningless

FIGURE 8-7: BUS OUTPUT TIMING, C ONTINUO US MODE

CONT/DEMAND

BUSY

T

WRE

RD

T

RE

T

WRD

. . . . . . . . . .

443-1/2 Clock

Cycles

Data Valid

1/2 Clock Cycle

Data Meaningless

DB0-DB7

NOTES: CS = HIGH; CE = LOW

HI-Z

Data Bits 8-14

Polarity

Data Bits 0-7

Data Bits 8-14

Overrange

High Impedance

State

2002 Microchip TechnologyInc. DS21479B-page 19

TC850

)

9.0 PACKAGING INFORMATION

9.1 Package Marking Information

Package marking data not available at this time

9.2 Taping Form

Component Taping Orientation for 44-Pin PLCC Devices

User Direction of Feed

PIN 1

W

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

44-Pin PLCC 32 mm 24 mm 500 13 in

NOTE: Drawing does not represent total number of pins.

9.3 Package Dimensions

40-Pin CERDIP (Wide)

.098 (2.49) MAX.

.210 (5.33)

.170 (4.32)

.200 (5.08)

.125 (3.18)

.110 (2.79)

.090 (2.29)

.065 (1.65)

.045 (1.14)

2.070 (52.58)

2.030 (51.56)

Standard Reel Component Orientation

for TR Suffix Device

.020 (0.51)

.016 (0.41)

P

.540 (13.72)

.510 (12.95)

.030 (0.76) MIN.

.060 (1.52)

.020 (0.51)

PIN 1

.150 (3.81)

MIN.

.015 (0.38)

.008 (0.20)

.620 (15.75)

.590 (15.00)

.700 (17.78)

.620 (15.75)

3

˚

MIN.

DS21479B-page 20

Dimensions: inches (mm

2002 Microchip TechnologyInc.

9.3 Package Dimensions (Continued)

)

TC850

40-Pin PDIP (Wide)

.200 (5.08)

.140 (3.56)

.150 (3.81)

.115 (2.92)

.110 (2.79)

.090 (2.29)

44-Pin PLCC

2.065 (52.45)

2.027 (51.49)

.070 (1.78)

.045 (1.14)

.022 (0.56)

.015 (0.38)

PIN 1

PIN 1

.555 (14.10)

.530 (13.46)

.040 (1.02)

.020 (0.51)

.015 (0.38)

.008 (0.20)

.610 (15.49)

.590 (14.99)

.700 (17.78)

.610 (15.50)

Dimensions: inches (mm

3

˚

MIN.

.695 (17.65)

.685 (17.40)

.656 (16.66)

.650 (16.51)

.656 (16.66)

.650 (16.51)

.695 (17.65)

.685 (17.40)

.050 (1.27) TYP.

.021 (0.53)

.013 (0.33)

.630 (16.00)

.591 (15.00)

.032 (0.81)

.026 (0.66)

.020 (0.51) MIN.

.120 (3.05)

.090 (2.29)

.180 (4.57)

.165 (4.19)

Dimensions: inches (mm)

2002 Microchip TechnologyInc. DS21479B-page 21

TC850

NOTES:

DS21479B-page 22

2002 Microchip TechnologyInc.

TC850

SALES AND SUPPORT

Data Sheets

Products supportedby a preliminary DataSheetmayhave an erratasheetdescribingminor operationaldifferences and recommendedworkarounds.To determineif an errata sheetexists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip CorporateLiterature Center U.S. FAX: (480)792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Pleasespecify which device, revision of silicon and Data Sheet (includeLiterature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn)to receive the most currentinformationon our products.

S

2002 Microchip Technology Inc. DS21479B-page23

TC850

NOTES:

DS21479B-page 24 2002 Microchip Technology Inc.

TC850

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringementof

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLab,

K

EELOQ,microID,MPLAB,PIC,PICmicro,PICMASTER,

PICSTART, PRO MA TE, SEEVAL and The Embedded Control

SolutionsCompany areregiste red trademarksof MicrochipTechnologyIncorp or ated in the U.S.A. and other countries .

dsPIC, ECONOMONI TOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

MXDEV, PICC, PICDEM, PICDEM.net, rfPIC, Select M ode

and TotalEndurancearetrademarksofMicrochipTechnology

Incorporated in the U.S.A.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip TechnologyIncorporated in t he U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

®

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systemsisISO 9001certified.

2002 Microchip TechnologyInc. DS21479B-page 25

8-bit MCUs, KEELOQ®code hopping

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip T echnology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip T echnology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86766200 Fax: 86-28-86766599

China - Fuzhou

Microchip T echnology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Shanghai

Microchip T echnology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip T echnology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1315, 13/F , Shenzhen Kerry Centre,

Renminnan Lu

Shenzhen 518001, China

Tel: 86-755-2350361 Fax: 86-755-2366086

China - Hong Kong SAR

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology Taiwan

11F-3, No. 207

Tung HuaNorth Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Gustav-Heinemann Ring 125

D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Microchip Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, EnglandRG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

04/20/02

DS21479B-page 26

*DS21479B*

2002 Microchip Technology Inc.

Loading...

Loading...