z

4-1/2 Digit A/D Converter

TC7135

Features

• Low Rollover Error: ±1 Count Max

• Nonlinearity Error: ±1 Count Max

• Reading for 0V Input

• True Polarity Indication at Zero for Null Detection

• Multiplexed BCD Data Output

• TTL-Compatible Outputs

• Differential Input

• Control Signals Permit Interface to UARTs and

Microprocessors

• Blinking Display Visually Indicates Overrange

Condition

• Low Input Current: 1pA

• Low Zero Reading Drift: 2µV/°C

• Auto-Ranging Supported with Overrange and

Underrange Signals

• Available in PDIP and Surface-Mount Packages

Applications

• Precision Analog Signal Processor

• PrecisionSensor Interface

• High Accuracy DC Measurements

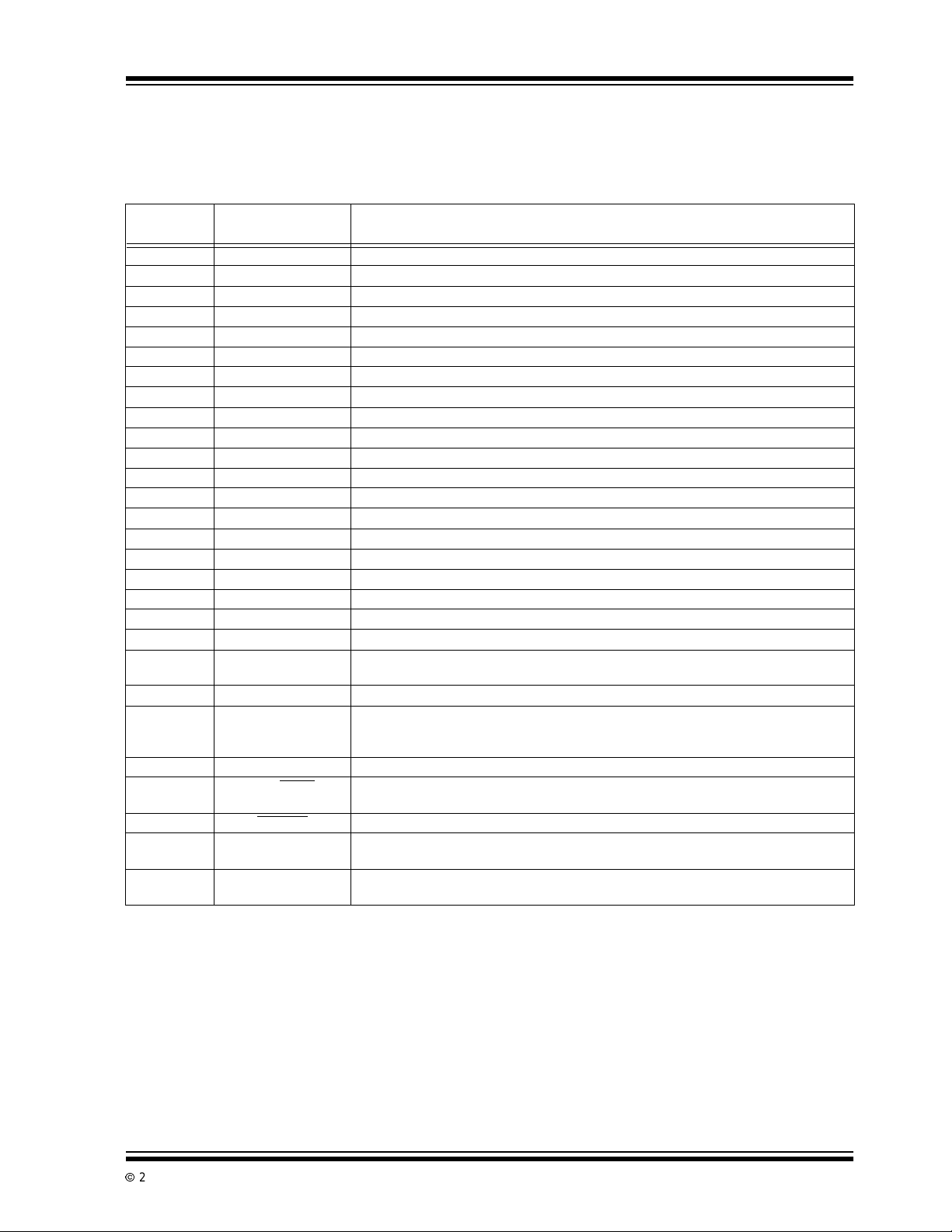

Device Selection Table

Part Number Package Temperature Range

TC7135CLI 28-Pin PLCC 0°Cto+70°C

TC7135CPI 28-PinPDIP 0°Cto+70°C

TC7135CBU 64-PinPQFP 0°Cto+70°C

General Description

The TC7135 4-1/2 digit A/D converter ( ADC) offers

50ppm (1 part in 20,000) resolution with a maximum

nonlinearity error of 1 count. An auto zero cycle

reduces zero error to below 10µV and zero drift to

0.5µV/°C. Source impedance errors are m inimized by

a 10pA maximum input current.Rollover error is limited

to ±1 count.

Microprocessorbased measurement systems are supported by BUSY,STROBE

and RUN/HOLD control signals. Remote data acquisition systems with data

transfer via UARTs are also possible. The additional

control pins and mul tiplexed BCD outputs make the

TC7135 the ideal converter for display or

microprocessorbased measurement systems.

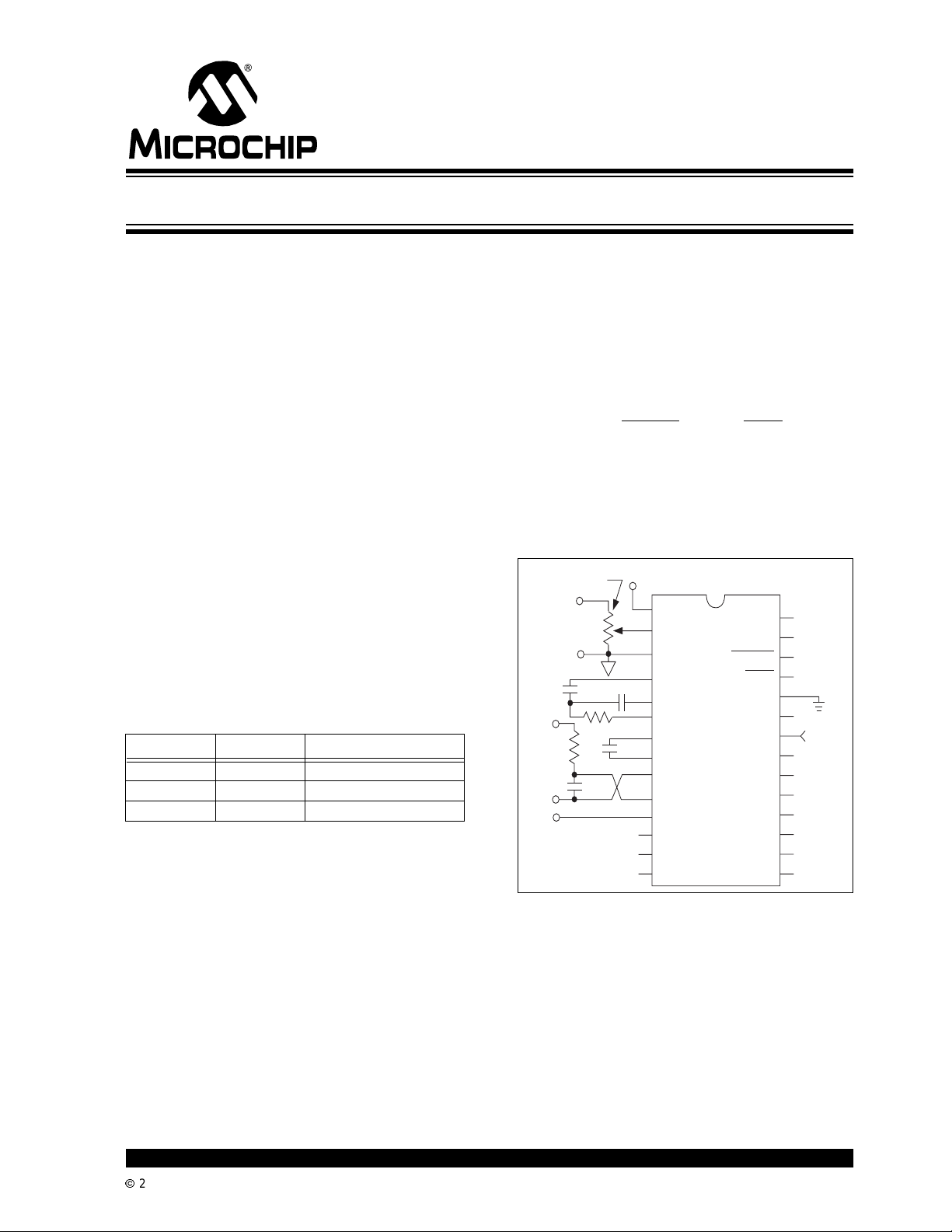

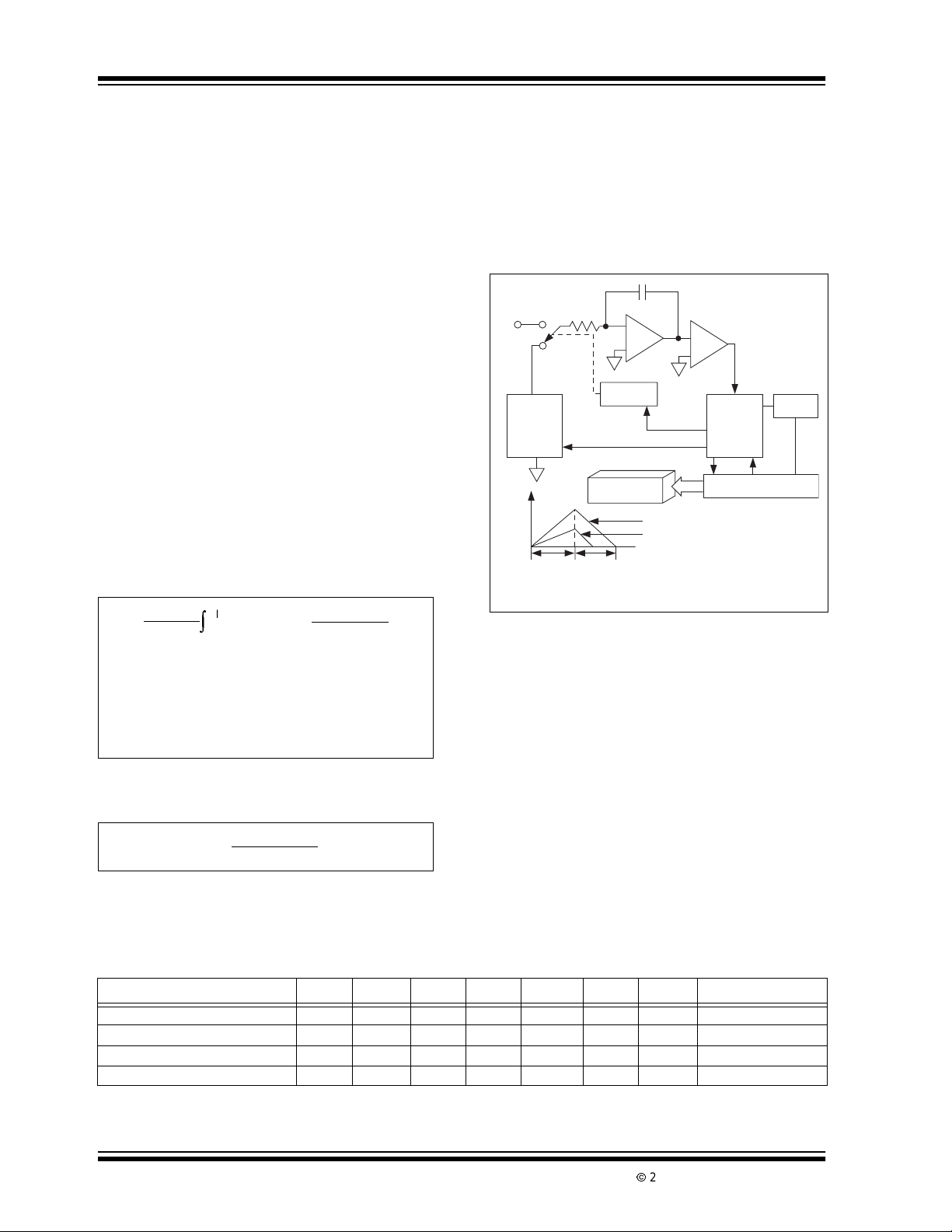

Functional Block Diagram

SET V

REF

IN

V

REF

100kΩ

Analog GND

0.47µF

Signal

Input

+

5V

= 1V

100kΩ

100

kΩ

0.1µF

–5V

1µF

1µF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

TC7135

V-

UNDERRANGE

REF IN

ANALOG

COMMON

INT OUT

AZ IN

BUFF OUT

C

C

-INPUT

+INPUT

V+

D5 (MSD)

B1 (LSB)

B2

REF

REF

+

OVERRANGE

STROBE

RUN/HOLD

DIGTAL GND

POLARITY

CLOCK IN

BUSY

(LSD) D1

D2

D3

D4

(MSB) B8

B4

28

27

26

25

24

23

22

21

20

19

18

17

16

15

Clock

Input

120kH

2002 Microchip TechnologyInc. DS21460B-page 1

TC7135

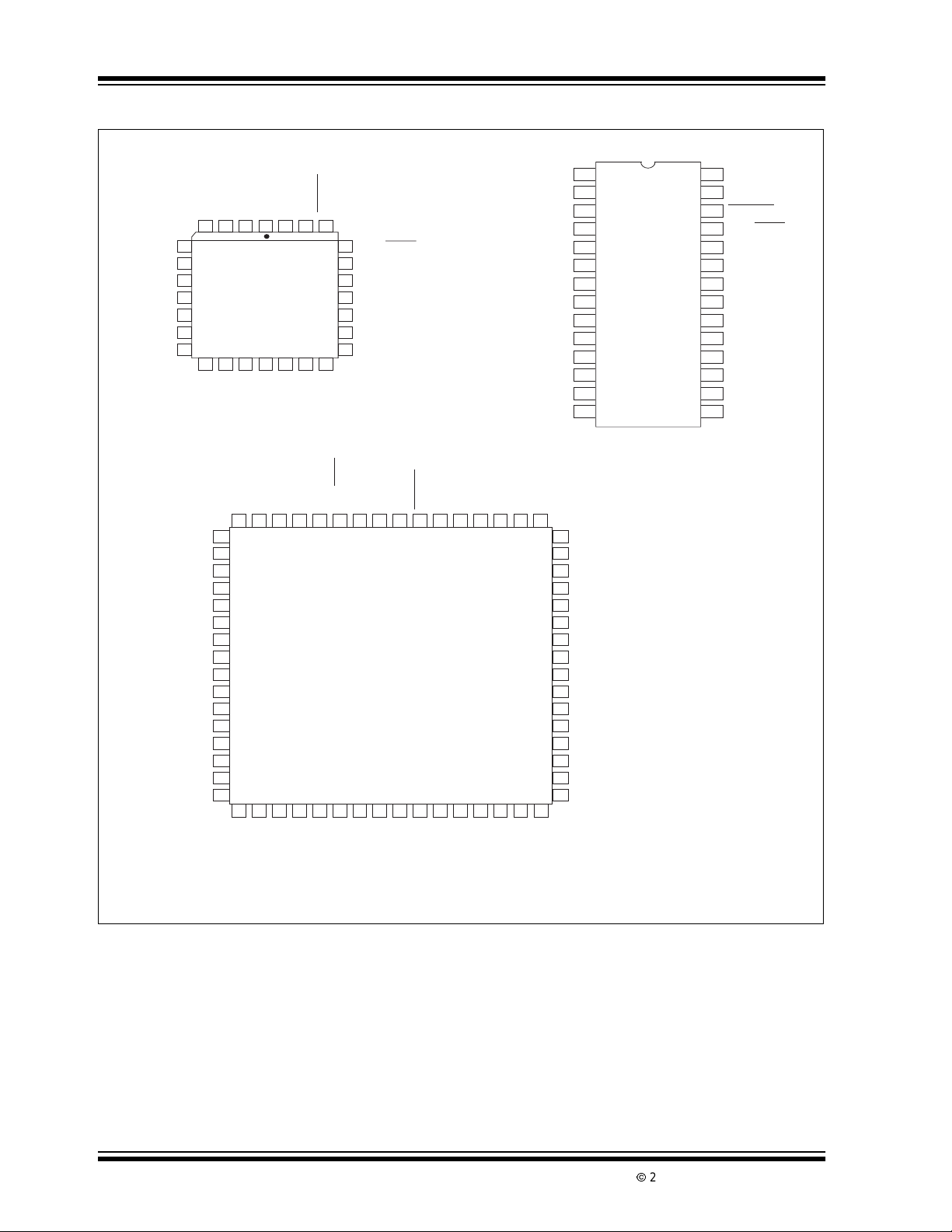

Package Types

AZ IN

BUFF OUT

REF CAP–

REF CAP+

–INPUT

+INPUT

V+

OVERRANGE

UNDERRANGE

ANALOG COM

28-Pin PDIP

INT OUT

ANALOG

COM

4 3 2 1 27 2628

5

6

7

8

9

10

11

12 13 14 15 17 18

REF INV–URORSTROBE

TC7135

B2

(LSB) B1

(MSD) D5

NC

63 61 60 59 58 57 56 55 545352 51 50 4964

1

l

NC

2

NC

3

NC

4

NC

5

NC

6

NC

7

8

9

NC

10

V-

11

REF IN

12

13

NC

14

NC

15

NC

16

NC

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

NC

16

B4

(MSB) B8

NCNCNC

62

NC

AZ IN

INT OUT

D4

D3

STROBE

NC

25

RUN/HOLD

24

DIGTAL GND

23

POLARITY

22

CLOCK IN

21

BUSY

20

D1 (LSD)

19

D2

64-Pin PQFP

DGND

POLNCCLOCK IN

RUN/HOLD

TC7135

NC

REF

C

BUFF OUT

NC

+

REF

C

BUSYD2D1

NC

–INPUT

NC

REF IN

ANALOG

INT OUT

BUFF OUT

C

– INPUT

+INPUT

(MSD) D5

(LSB) B1

NC

NC

NC

+INPUT

AZ IN

C

32

COM

REF

REF

NC

V+

V+

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

28-Pin PDIP

UNDERRANGE

1

V-

2

3

4

5

6

-

7

+

B2

NC

NC

NC

D3

D4

B8

B4

B2

NC

B1

D5

NC

NC

NC

NC

NC

TC7135

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

OVERRANGE

STROBE

RUN/HOLD

DIGTAL GND

POLARITY

CLOCK IN

BUSY

D1 (LSD)

D2

D3

D4

B8 (MSB)

B4

NOTE: NC = No internal connection.

DS21460B-page 2

2002 Microchip TechnologyInc.

TC7135

1.0 ELECTRICAL SPECIFICATIONS

Absolute Maximum Ratings*

Positive Supply Voltage..........................................+6V

Negative Supply Voltage.......................................- 9V

Analog Input Voltage (Pin 9 or 10)....V+ to V- (Note 2)

*Stresses above those listed under "Absolute Maximum Ratings"maycause permanentdamage to thedevice.These are

stress ratings only and functional operation of the device at

these or any other conditions above those indicated in the

operation sections of the specifications is not implied. E xposure to Absolute Maximum R ating conditions for extended

periodsmay affectdevice reliability.

Reference Input Voltage (Pin 2)...................... V+ to V-

Clock Input Voltage........................................ 0V to V+

Operating Temperature Range ...............0°C to +70°C

StorageTemperature Range............– 65°C to +150°C

Package Power Dissipation;(T

≤ 70°C)

A

28-Pin PDIP ..................................... 1.14Ω

28-Pin PLCC .................................... 1.00Ω

64-Pin PQFP.....................................1.14Ω

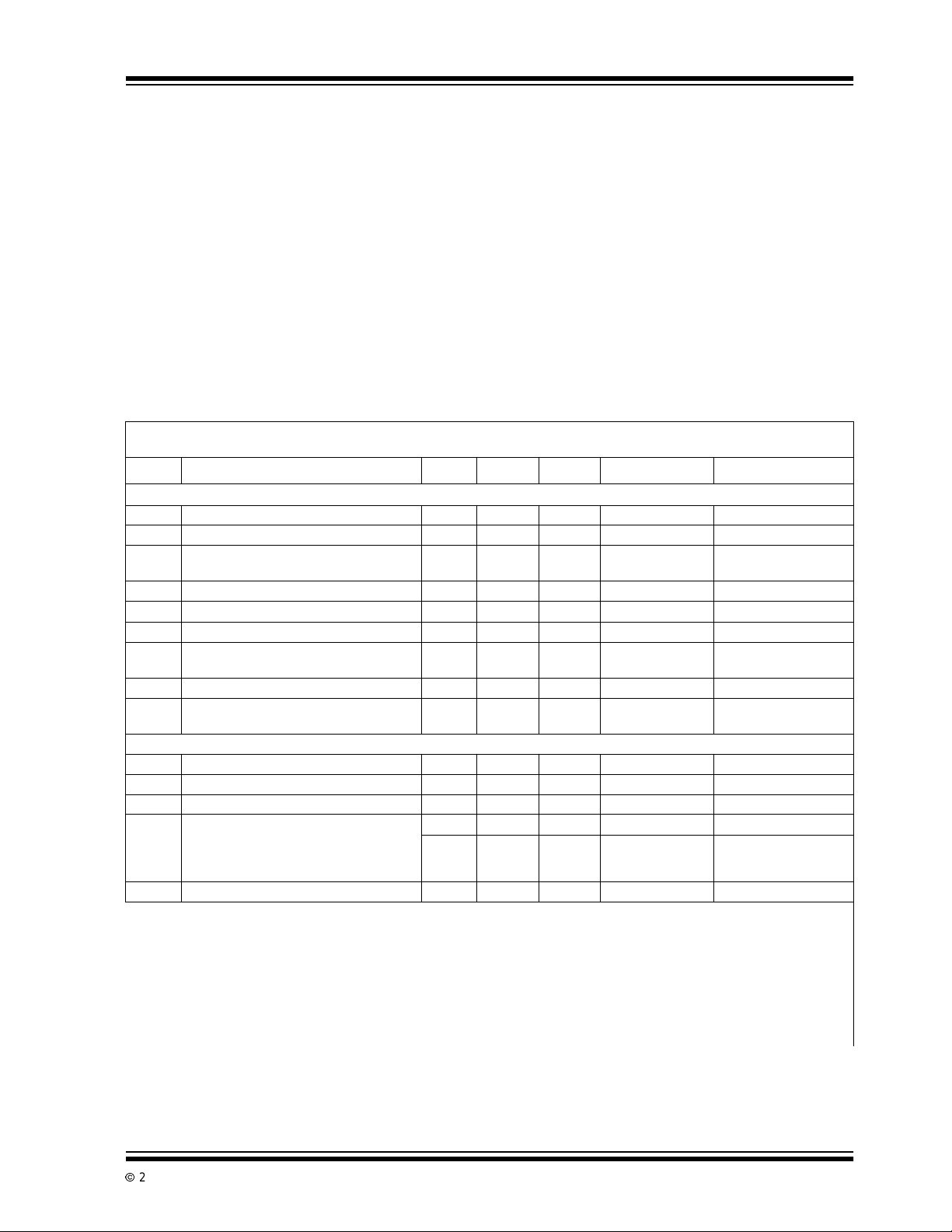

TC7135 ELECTRICAL S PECIFICATIONS

Electrical Characteristics: TA=+25°C,F

(see Functional Block Diagram).

Symbol Parameter Min Typ Max Unit Test Conditions

Analog

Display Reading with Zero VoltInput -0.0000 ±0.0000 +0.0000 D isplay Reading Note 2 and Note 3

Zero Reading Temperature Coefficient — 0.5 2 µV/°C VIN=0V,(Note4)

TC

Z

TC

±FSE ± Full Scale Symmetry Error

Digital

Note 1: Limit input current to under 100µA if input voltages exceedsupply voltage.

Full ScaleTemperature Coefficient — — 5 ppm/°C VIN=2V,

FS

NL Nonlinearity Error — 0.5 1 Count Note 6

DNL Differential LinearityError — 0.01 — LSB Note 6

Display Reading in Ratiometric Operation +0.9996 +0.9999 +1.0000 Display Reading V

(Rollover Error)

Input Leakage Current — 1 10 pA Note 3

I

IN

Noise — 15 — µV

e

N

Input Low Current — 10 100 µAV

I

IL

Input High Current — 0.08 10 µAV

I

IH

OutputLowVol tage — 0.2 0.4 V IOL=1.6mA

V

OL

OutputHighVoltage;

V

OH

B

1,B2,B4,B8,D1–D5

Busy, Polarity,Overrange,

Underrange, Strobe

ClockFrequency 0 200 1200 kHz Note8

F

CLK

2: Full scalevoltage = 2V.

=0V.

3: V

IN

4: 30°C ≤ T

5: .External referencetemperaturecoefficientless than 0.01ppm/°C.

6: -2V ≤ V

7: IV

IN

8: Specification related to clock frequency range over which the TC7135 correctly performs its various functions. Increased

≤ +70°C

A

≤ +2V. Error of readingfrom best fit straightline.

IN

| = 1.9959.

errors result at higher operating frequencies.

= 120kHz, V+ = +5V, V- = -5V,unless otherwise specified

CLOCK

— 0.5 1 Count -V

2.4 4.4 5 V I

4.9 4.99 5 V I

P-P

(Note4andNote5)

=+V

(Note 2)

(Note 7)

IN,

IN=VREF,

IN

Peak-to-Peak Valuenot

Exceeded 95% of Time

=0V

IN

=+5V

IN

=1mA

OH

=10µA

OH

2002 Microchip TechnologyInc. DS21460B-page 3

TC7135

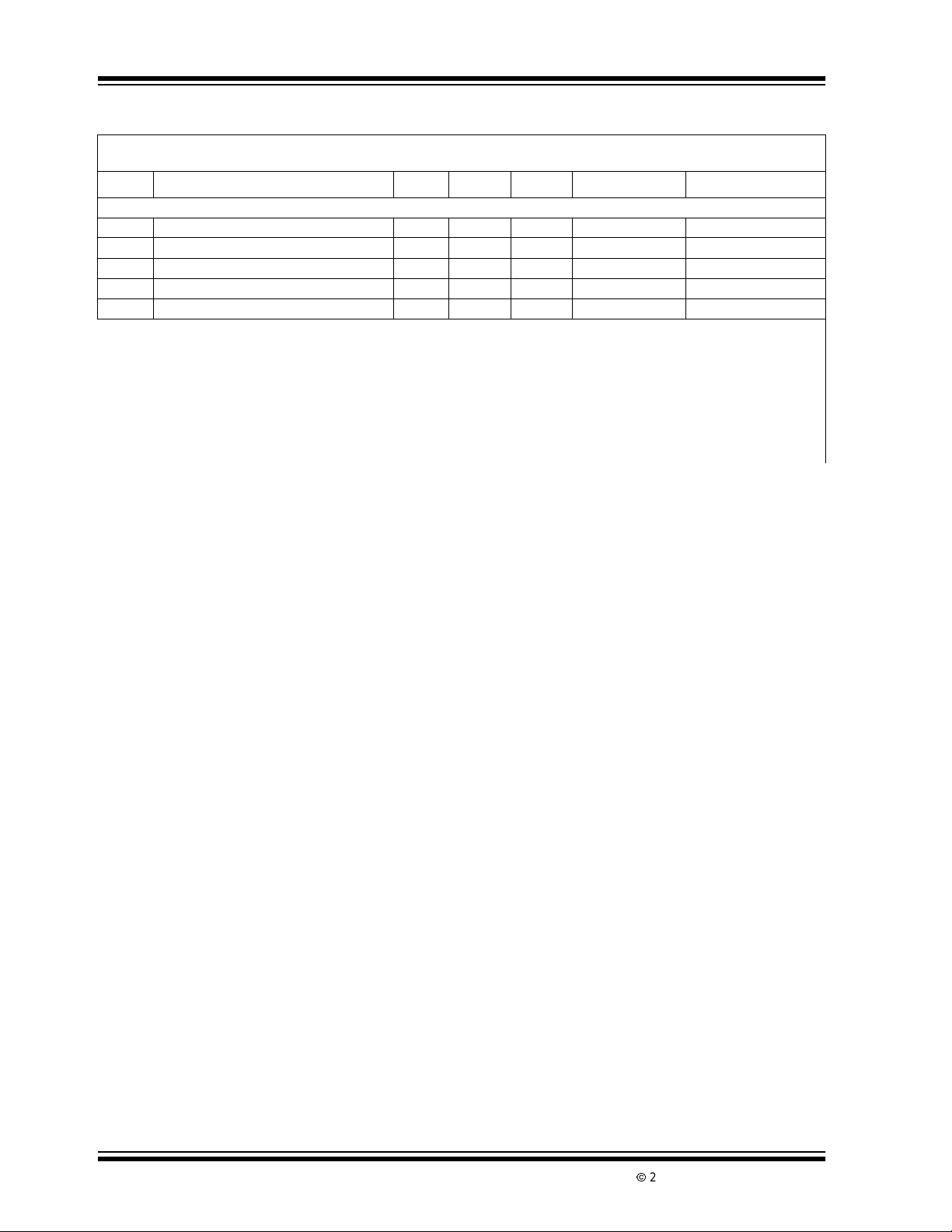

TC7135 ELECTRICAL S PECIFICATIONS (CONTINUED)

Electrical Characteristics: TA=+25°C,F

(see Functional Block Diagram).

Symbol Parameter Min Typ Max Unit Test Conditions

Power Supply

V+ Positive Supply Voltage 4 5 6 V

V- Negative Supply Voltage -3 -5 -8 V

I+ Positive Supply Current — 1 3 mA F

I- Negative Supply Current — 0.7 3 mA F

PD Power Dissipation — 8.5 30 mW F

Note 1: Limit input current to under 100µA if input voltages exceedsupply voltage.

2: Full scalevoltage = 2V.

=0V.

3: V

IN

4: 30°C ≤ T

5: .External referencetemperaturecoefficientless than 0.01ppm/°C.

6: -2V ≤ V

7: IV

IN

8: Specification related to clock frequency range over which the TC7135 correctly performs its various functions. Increased

errors result at higher operating frequencies.

≤ +70°C

A

≤ +2V. Error of readingfrom best fit straightline.

IN

| = 1.9959.

= 120kHz, V+ = +5V, V- = -5V,unless otherwise specified

CLOCK

CLK

CLK

CLK

=0Hz

=0Hz

=0Hz

DS21460B-page 4

2002 Microchip TechnologyInc.

2.0 PIN DESCRIPTIONS

The description of t he pins are listed in Table 2-1.

TABLE 2-1: PIN FUNCTION TABLE

TC7135

Pin Number

28-Pin PDIP

1 V- Negative power supplyinput.

2 REF IN External reference input.

3 ANALOG COMMON Reference point for REF IN.

4 INT OUT Integrator output. Integratorcapacitor connection.

5 AZ IN Auto zero inpt. Auto-zero capacitor connection.

6 BUFF OUT Analog input buffer output. Integrator resistor connection.

7C

8C

9 -INPUT Analoginput. Analog input negativeconnection.

10 +INPUT Analog input. Analog input positive connection.

11 V+ Positive power supplyinput.

12 D5 Digit drive output. Most Significant Digit (MSD)

13 B1 Binary Coded Decimal(BCD) output.LeastSignificantBit (LSB)

14 B2 BCD output.

15 B4 BCD output.

16 B8 BCD output. Most Significant Bit (MSB)

17 D4 Digit drive output.

18 D3 Digit drive output.

19 D2 Digit drive output.

20 D1 Digit drive output. Least Significant Digit (LSD)

21 BUSY Busy output.At the beginningof the signal-integration phase, BUSY goes High and

22 CLOCK IN Clock input. Conversion clock connection.

23 POLARITY Polarity output.A positive input is indicated by a logicHighoutput. The polarity outputis

24 DGND Digitallogicreference input.

25 RUN/HOLD

26 STROBE

27 OVERRANGE Over range output. A logic High indicates that the analog input exceeds the full scale input

28 UNDERRANGE Under range output.A logic High indicates that the analog input is less than 9% of the full

Symbol Description

- Reference capacitor input. Referencecapacitornegative connection.

REF

+ Reference capacitor input. Reference capacitorpositive connection.

REF

remainsHighuntilthefirstclockpulseafter the integratorzerocrossing.

valid at the beginning of the reference integrate phase andremains valid until determined

duringthenext conversion.

Run / Hold input. When at a logic High, conversions are performedcontinuously.A logic

Low holds the current data as long as the Low condition exists.

Strobe output. The STROBE output pulses low in the center of the digit drive outputs.

range.

scaleinputrange.

2002 Microchip TechnologyInc. DS21460B-page 5

TC7135

3.0 DETAILED DESCRIPTION

(All Pin Designations Refer to 28-Pin DIP)

3.1 Dual Slope Conversion P rinciples

The TC7135 is a dual slope, integrating A/ D converter.

An understanding of the dual slope conversion technique will aid i n following the detailed TC7135

operational theory.

The conventional dual slope converter measurement

cycle has two distinct phases:

1. Input signal integration

2. Reference voltage integration ( de-integration)

The input signal being converted is integrated for a

fixed time period. Time is measured by counting clock

pulses.An opposite polarity constant referencevoltage

is then integrated until the integrator output voltage

returns to zero. The reference integration time is

directly proportional to the input signal.

In a simple dual slope converter, a complete conversion requires the integrator output to "ramp-up" and

"ramp-down."

A simple mathematical equation relates the input signal, reference voltage, and integration time:

EQUATION 3-1:

T

1

R

INTCINT

INT

∫

0

VIN(T)DT =

where:

V

T

T

= Reference voltage

REF

= Signal integration time (fixed)

INT

= Reference voltage integration time

DEINT

(variable).

For a constant VIN:

EQUATION 3-2:

V

REFTDEINT

VIN=

The dual slope converter accuracy is unrelated to the

integrating resistor and capacitor values, as long as

they are stable during a measurement cycle. An inher-

T

INT

V

REFTDEINT

R

INTCINT

ent benefit is noise immunity. Noise spikes are integrated, or averaged, to zero during the integration

periods.

Integrating ADCs are immune to the large conversion

errors that plague successive approximation converters in high-noise environments(see Figure 3-1).

FIGURE 3-1: BASIC DUAL SLOPE

CONVERTER

Analog Input

Signal

REF

Voltage

Output

Integrator

Fixed

Signal

Integrate

Time

Integrator

-

+

Switch

Drive

Polarity Control

Display

Variable

Reference

Integrate

Time

Phase

Control

V

IN

V

IN

≈ V

REF

≈ 1/2 V

Comparator

-

+

Control

Logic

REF

Clock

Counter

3.2 TC7135 Operational Theory

The TC7135 incorporates a system zero phase and

integratoroutputvoltage zero phase to the normal twophase dual-slope measurement cycle. Reduced system errors, fewer calibration steps, and a shorter overrange recovery time result.

The TC7135 measurement cycle contains four phases:

1. System zero

2. Analog i nput signal integration

3. Reference voltage integration

4. Integrator output zero

Internal analog gate status for each phase is shown in

Figure 3-1.

TABLE 3-1: INTERNAL ANALOG GATE STATUS

Conversion Cycle Phase SWISWRI+SWRI-SWZSW

System Zero Closed Closed Closed Figure 3-2

InputSignal Integration Closed Figure 3-3

Reference Voltage Integration Closed* Closed Figure 3-4

Integrator OutputZero Closed Closed Figure 3-5

*Note: Assumes a positive polarity input signal. SW

DS21460B-page 6

would be closed for a negative input signal.

RI

SW

R

SW

1

2002 Microchip TechnologyInc.

Reference Figures

IZ

TC7135

A

A

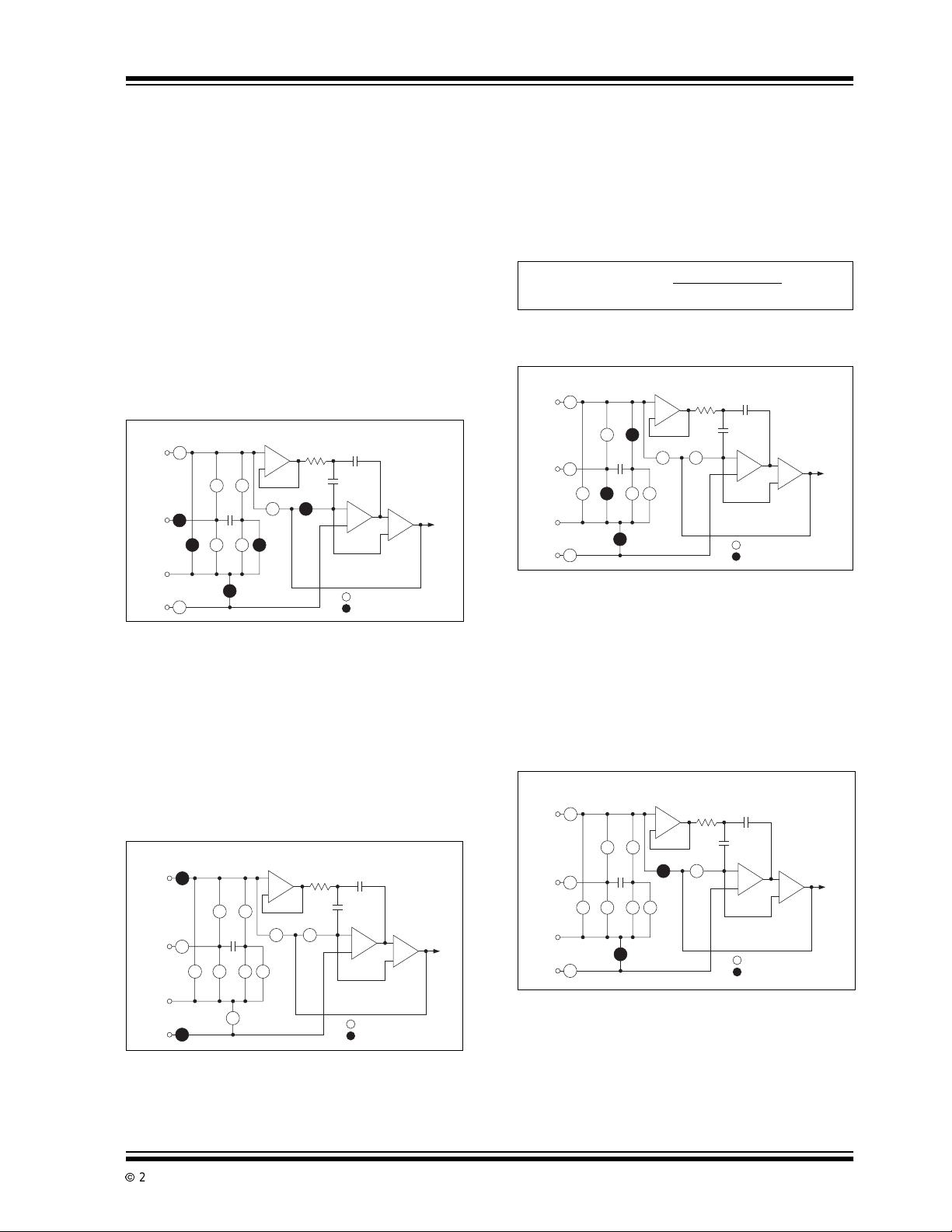

3.2.1 SYSTEM ZERO

During this phase, errors due to buffer, integrator, and

comparator offset voltages are compensated for by

charging C

(auto zero capacitor) with a compensat-

AZ

ing error voltage. With a zero input voltage the integrator output will remain at zero.

The externalinputsignal is disconnectedfromtheinternal circuitry by opening the t wo SW

switches. The

I

internal input points connect to ANALOG COMMON.

The reference capacitor charges to the reference voltage potential through SW

around the integrator and comparator, chargesthe C

. A feedback loop, closed

R

AZ

capacitorwithavoltage to compensate for bufferamplifier, integrator, and comparator offset voltages (see

Figure 3-2).

FIGURE 3-2: SYSTEM ZERO PHASE

Analog

SWRI+

C

REF

Input Buffer

SW

1

+

-

SWIZSW

SW

Z

C

R

INT

INT

C

SZ

Z

-

Comparator

+

+

-

Integrator

Switch Open

Switch Closed

To Digital

Section

+IN

REF

Analog

Common

–

SW

I

SWRI-

SW

R

IN

SW

Z

SWRI+SWRI-

SW

I

IN

3.2.2 ANALOG INPUT SIGNAL

INTEGRATION

The TC7135 integratesthe differentialvoltage between

the +INPUT and -INPUT pins. The differential voltage

must be within the device Common mode range; - 1V

from either supply rail, typically. The input signal polarity is determined at the end of this phase.

SeeFigure2-3

FIGURE 3-3: INPUT SIGNAL

INTEGRATION PHASE

Analog

SW

Input Buffer

+

-

+SWRI-

RI

SW

SW

SW

IZ

SW

Z

1

C

REF

C

R

INT

INT

C

SZ

Z

-

Comparator

+

+

-

Integrator

Switch Open

Switch Closed

To

Digital

Section

nalog

Common

.

+IN

REF

–

SW

I

SW

R

IN

SW

Z

SWRI+SWRI-

SW

I

IN

3.2.3 REFERENCE VOLTAGE

INTEGRATION

The previously-charged reference capacitor is connected with the proper polarity to ramp the integrator

output back to zero

(see Figure 3-4). The digital

reading displayed is:

EQUATION 3-3:

Reading = 10,000

[Differential I nput]

V

REF

FIGURE 3-4: REFERENCE VOLTAGE

INTEGRATION CYCLE

Analog

SWRI+

-

C

REF

+SWRI-

Input Buffer

SW

1

C

R

INT

INT

+

-

SW

IZ

SW

Z

C

SW

SZ

Z

-

Comparator

+

+

-

Integrator

Switch Open

Switch Closed

To Digital

Section

+IN

REF

Analog

Common

–

SW

I

SW

RI

SW

R

IN

SW

Z

SW

RI

SW

I

IN

3.2.4 INTEGRATOR OUTPUT ZERO

This phase ensures the integrator output is at 0V when

the system zero phase is entered. It also ensures that

the true system offset voltages are compensated for.

This phase normally lasts 100 to 200 clockcycles. If an

overrange condition exists, t he phase is extended to

6200 clock cycles (see Figure 3-5).

FIGURE 3-5: INTEGRATOR OUTPUT

ZERO PHASE

Analog

Input Buffer

SWRI+SWRI-

C

REF

SW

1

SW

R

SW

INTCINT

C

SW

IZ

Z

SZ

Z

-

+

Integrator

Switch Open

Switch Closed

Comparator

+

-

To Digital

Section

+

-

+

IN

REF

IN

nalog

Common

–

IN

SW

SW

SW

SW

I

R

Z

SWRI+SWRI-

I

2002 Microchip TechnologyInc. DS21460B-page 7

TC7135

4.0 ANALOG SECTION

FUNCTIONAL DESCRIPTION

4.1 Differential Inputs

The TC7135 operates with differential voltages

(+INPUT, pin 10 and -INPUT, pin 9) within the input

amplifierCommonmode range,which extendsfrom1V

below the positive supply to 1V above the negative

supply. Within this Common mode voltage range, an

86dB Common mode rejection ratio is typical.

The integrator output also follows the Common mode

voltage and must not be allowed to saturate. A worstcase condition exists, for example, when a large positive Common mode voltage with a near full scale negative differential input voltage is applied. The negative

input signal drives the integrator positive when most of

its swing has been used up by the positive Common

mode voltage. For these critical applications, the

integrator swing can be reduced to less than the

recommended 4V full scale swing, with some loss of

accuracy. The integrator output can swing within 0.3V

of either supply without loss of linearity.

4.2 Analog Comm on Input

ANALOG COMMON is used as the -INPUT return during auto zero and de-integrate. If -INPUT is different

from ANALOG COMMON, a Common mode voltage

existsin the system. However, this signal is rejected by

the excellent CMRR of the converter. In most applications, –INPUT will be set at a fixed, known voltage

(power supply common, for instance). In this application, ANALOG COMM ON should be tied to the same

point, thus removing the Common mode voltage from

the converter. The reference voltage is referenced to

ANALOG COMMON.

FIGURE 4-1: USING AN EXTERNAL

REFERENCE

V+

TC7135

REF

IN

ANALOG

COMMON

10k

10k

MCP1525

2.5 V

REF

1µF

Analog Ground

V+

4.3 Reference Voltage Input

The reference voltage input (REF IN) must be a positivevoltagewithrespecttoANALOGCOMMON.A

reference voltage circuit is shown in Figure 4-1.

DS21460B-page 8

2002 Microchip TechnologyInc.

5.0 DIGITAL SECTION

FUNCTIONAL DESCRIPTION

The major digital subsystems within the TC7135 are

illustrated in Figure 5-1, with timing relationships

shown in Figure 5-2. The multiplexed BCD output data

can be displayed on LCD or LED displays. The digital

section is best described through a di scussion of the

control signals and data outputs.

FIGURE 5-1: DIGITAL SECTION FUNCTIONAL DIAGRAM

TC7135

Polarity

From

Analog

Section

Polarity

FF

Zero

Cross

Detect

24 22 25 27 28 26 21

DGND Clock

In

D5 D4 D3 D2 D1

MSB Digit Drive Signal LSB

Multiplexer

Latch Latch Latch Latch Latch

Counters

Control Logic

RUN/

HOLD

Overrange STROBE BusyUnderrange

Data

Output

13 B1

14 B2

15 B4

16 B8

2002 Microchip TechnologyInc. DS21460B-page 9

TC7135

FIGURE 5-2: TIMING DIAGRAMS FOR

OUTPUTS

Integrator

Output

Busy

Overrange when

Applicable

Underrange when

Applicable

Digit Scan

STROBE

Digit Scan

for Overrange

Signal

Integrate

System

10,000

Zero

Counts

10,001

(Fixed)

Counts

Full Measurement Cycle

40,002 Counts

Expanded Scale Below

100

Counts

Auto Zero

*

D5

D4

D3

D2

D1

Reference

Integrate

20,001

Counts (Max)

D5

D4

D3

D2

D1

First D5 of System Zero and

*

Reference Integrate One Count

Longer

*

Reference

Integrate

Signal

Integrate

5.1 RUN/HOLD Input

When left open, this pin assumes a logic "1" level. With

a RUN/HOLD

continuously, with a new measurement cycle beginning

every 40,002 clock pulses.

When RUN/HOLD

ment cyclein progresswillbecompleted,dataheldand

displayed, as long as the logic "0" condition exists.

A positive pulse (>300nsec) at RUN/HOLD

new measurement cycle. The measurement cycle in

progress when RUN/HOLD

"0" state must be completed before the positive pulse

can be recognized as a single conversion run

command.

The new measurement cycle begins with a 10,001count auto zero phase. At the end of this phase the

busy signal goes high.

= 1, the TC7135 performs conversions

changestoa logic "0," the measure-

initiates a

initially assumed the logic

5.2 STROBE Output

During the measurement cycle, the STROBE control

line is pulsed l ow five times. The five low pulses occur

in the center of the digit drive signals (D

(see Figure 5-3).

D

(MSD) goes high for 201 counts when the measure-

5

ment cycles end. I n the center of the D

clock pulses after the end of the measurement cycle,

the first STROBE

the D

digit s trobe, D4goes high for 200 clock pulses.

5

The STROBE

occurs for one half clock pulse. After

then goes low 100 clock pulses after D

goes high. This continues through the D1digit drive

pulse.

The digit drive signals will continue to permit display

scanning.STROBE

pulsesarenotrepeateduntilanew

measurement is completed. The digit drive signals will

not continue if the previous signal resulted in an

overrange condition.

TheactivelowSTROBE

pulses aid BCD data transfer

to UARTs, pr ocessors and external latches. For more

information,please refer to Application Note 784.

FIGURE 5-3: STROBE SIGNAL LOW

FIVE TIMES PER

CONVERSION

TC835

Outputs

Busy

B1–B8

STROBE

D5

D4

D3

D2

D1

*Delay between Busy going Low and First STROBE pulse is

dependent on Analog Input.

End of Conversion

*

D5 (MSD)

Data

200

Counts

201

Counts

D4

Data

200

Counts

D3

DataD2Data

200

Counts

200

Counts

1,D2,D3,D5

pulse, 101

5

D1 (LSD)

DataD5Data

Note Absence of

STROBE

Counts

200

Counts

200

)

4

DS21460B-page 10

2002 Microchip TechnologyInc.

5.3 BUSY O utput

At the beginning of the signal integration phase, BUSY

goes high and remains high until the first clock pulse

after the i ntegrator zero crossing. BUSY returns to the

logic "0" state after the measurement cycle ends in an

overrange condition. The internal display latches are

loaded during the first clock pulse after BUSY and are

latched at the clock pulse end. The BUSY signal does

not go high at the beginningof the measurementcycle,

which starts with the auto zero cycle.

5.4 OVERRANGE Output

If the input signal causes the reference voltage integration time to exceed 20,000 clock pulses, the OVERRANGE output i s set to a logic "1." The overrange

output register is set when BUSY goes low and is reset

at the beginning of the next reference integration

phase.

5.5 UNDERRANGE Output

If the output count is 9% of full scale or less (-1800

counts), the underrange register bit is set at the end of

BUSY. The bit is s et low at the next signal integration

phase.

TC7135

5.6 POLARITY Output

A positive input is registered by a logic "1" polarity signal. The polarity bit is valid at the beginning of reference integrate and remains valid until determined

during the next conversion.

The polarity bit is valid even for a zero reading. Signals

lessthan the converter'sLSB will have the signal polarity determined correctly. This is useful in null

applications.

5.7 Digit Drive Outputs

Digit drive signals are positive-going signals. The scan

sequence is D

pulses wide, with the exception D

pulses wide.

All five digits are scanned continuously, unless an

overrange condition occurs. In an overrange condition,

all digit drives are held low from the final STROBE

pulseuntil the beginning of the next referenceintegrate

phase. The scanning sequence is then repeated. This

provides a blinking visual display indication.

to D1. All positive pulses are 200 clock

5

, which is 201 clock

5

5.8 BCD Da ta Outputs

The binarycodeddecimal(BCD)bitsB8,B4,B2,and B

are positive-true logic signals. The data bits become

active at the same time as the digit drive signals. In an

overrangecondition, all data bitsareata logic "0" state.

1

2002 Microchip TechnologyInc. DS21460B-page 11

TC7135

6.0 TYPICAL APPLICATIONS

6.1 Component Value Selection

6.1.1 INTEGRATING RESISTOR

The i ntegrating resistor R

scale input voltage and the output current of the buffer

used to charge the integrator capacitor, C

bufferamplifier and the integrator havea class A output

stage, with 100µA of quiescent current. A 20µAdrive

current gives negligible linearity errors. Values of 5µA

to 40µA gi ve good results. The exact value of an

integrating resistor for a 20µA current is easily

calculated.

EQUATION 6-1:

R

Full scale voltage

=

INT

6.1.2 INTEGRATING CAPACITOR (

The productof integratingresistor and capacitorshould

be selected to give the maximum voltage swing that

ensures the tolerance buildup will not saturate the integrator swing (approximately 0.3V from either supply).

For ±5V supplies and ANALOG COMMON tied to supply ground, a ±3.5V to ±4V full scale integratorswing is

adequate. A 0.10µFto0.47µF is recommended. In

general, the value of C

EQUATION 6-2:

C

INT

[10,000 x clock period] x I

=

Integrator output voltage swing

(10,000) (clock period) (20µA)

=

Integrator output voltage swing

is determined by the full

INT

20µA

is given by:

INT

. Both the

INT

C

INT

INT

)

The dielectricabsorption of the referenceandautozero

capacitors are only important at power-on or when the

circuit is recovering from an overload. Smaller or

cheaper capacitors can be used if accurate readings

are not required for t he first few seconds of recovery.

6.1.4 REFERENCE VOLTAGE

The analog input required to generate a full scale output is V

IN

=2V

REF

.

The stabilityofthe referencevoltage is a major factor in

the overall absolute accuracy of the converter. For this

reason,it is recommendedthata high-qualityreference

be used where high-accuracy absolute measurements

are being made.

6.2 Conversion Timing

6.2.1 LINE FREQUENCY REJECTION

A signal integrationperiod at a multipleof the 60Hz line

frequency will maximize 60Hz "line noise" rejection. A

100kHz clock f requency will reject 50Hz, 60Hz and

400Hz noise. This corresponds to five readings per

second (see Table 6-1 and Table 6-2).

TABLE 6-1: CONVERSION RATE VS.

CLOCK FREQUEN CY

Oscillator Frequency

(kHz)

100 2.5

120 3

200 5

300 7.5

400 10

800 20

1200 30

Conversion Rate

(Conv./Sec.)

A very importantcharacteristicof the integratingcapacitor C

is that it has low dielectric absorption t o pre-

INT

vent rollover or ratiometric errors. A good test for

dielectric absorption is to use the capacitor with the

input tied to the reference. This ratiometric condition

should read half scale 0.9999, with any deviation

probably due to dielectric absorption. Polypropylene

capacitorsgiveundetectable errors at reasonablecost.

Polystyreneand polycarbonatecapacitorsmay also be

used in less critical applications.

6.1.3 AUTO ZERO AND REF ERENCE

CAPACITORS

The size of the auto zero capacitor has some influence

on the noise of the system. A large capacitor reduces

the noise. The reference capacitor should be large

enough such that stray capacitance t o ground from its

nodes is negligible.

DS21460B-page 12

2002 Microchip TechnologyInc.

TC7135

TABLE 6-2: LINE FREQUENCY

REJECTION VS. CLOCK

FREQUENCY

Oscillator Frequency

(kHz)

300 60

200

150

120

100

40

33-1/3

250 50

166-2/3

125

100

100 50,60,400

The c onversion rate is easily calculated:

Line Frequency Rejection

(Hz)

EQUATION 6-3:

Reading 1/sec =

Clock Frequency (Hz)

4000

6.3 High Speed Operation

The maximum conversion rate of most dual slope A/D

converters is limited by the f requency response of the

comparator. The comparator in this circuit follows the

integrator ramp with a 3µsecdelay,ataclockfrequency of 160 kHz (6µsec period), Half of the first reference integrate clock period is lost in delay. This

means that the meter reading will change from 0 t o 1

witha50µV input, 1 to 2 with 150µV,2to3at250µV,

etc. This transition at midpoint is considered desirable

by most users. However, if the clock frequency is

increased appreciably above 200kHz, the instrument

will flash "1" on noise peaks, even when the input is

shorted.

For many dedicated applications where the input signal

is always of one polarity, the delay of the comparator

need not be a limitation. Since the nonlinearity and

noisedonotincreasesubstantiallywith frequency, clock

ratesofupto~1MHzmaybeused.Forafixedclockfrequency, the extracount,orcounts, causedby comparator delay, will be a constant and can be subtracted out

digitally.

The clock frequency may be extended above 160kHz

without this error, however, by using a low value resistor in series with the integrating capacitor. The effect of

the resistor is to introduce a small pedestal voltage on

to the integrator output at the beginning of the reference integrate phase. By careful selection of the ratio

between this resistor and the integrating resistor (a few

tens of ohms in the recommended circuit),the compar-

ator delay can be compensated and the maximum

clock frequency extended by approximately a factor of

3. At higher frequencies, ringing and second-order

breaks will cause significant nonlinearities in the first

few counts of the instrument.

The minimum clock frequency is established by leakage on the auto zero and reference capacitors. W ith

most devices, measurement cycles as long as 10 seconds give no measurable leakage error.

The clock used should be free from significant phaseor

frequency jitter. Several suitable low-cost oscillators

are shown in Section 6.0, Typical Applications. The

multiplexed output means that if the display takes significant current from the logic supply, the clock should

have good PSRR.

6.4 Zero Crossing Flip Flop

The flip flop interrogates the data once every clock

pulseafterthetransientsofthe previousclockpulseand

half clock pulse have died down. False zero crossings

caused by clock pulses are not recognized. Of course,

the flip flop delays the true zero crossing by up to one

count in every instance. If a correction were not made,

the display would always be one count too high. Therefore, the counter is disabled for one clock pulse at the

beginning of the reference integrate (de-integrate)

phase.Thisone-count delaycompensates for the delay

of the zero crossing flip flop and allows the correct number to be latched into the display. Similarly, a one-count

delay at the beginning of auto zero gives an overload

displayof0000instead of 0001.Nodelayoccursduring

signal integrate so that true ratiometric readings result.

6.5 Generating a Negative Supply

A negative voltage can be generated from the positive

supply by using a TC7660 (see Figure 6-1).

FIGURE 6-1: NEGATIVE SUPPLY

VOLTAGE GENERATOR

+5V

11

TC7135

24

V+

V –

1

(-5V)

10µF

+

5

8

TC7660

4

10µF

+

23

2002 Microchip TechnologyInc. DS21460B-page 13

TC7135

A

FIGURE 6-2: 4-1/2 DIGIT ADC WITH MULTIPLEXED COMMON ANODE LED DISPLAY

20 19 18 17 12

D1 D2 D3 D4 D5

4

1µF

1µF

5

6

22

10

9

3

–5V

INT OUT

AZ IN

BUFF

OUT

TC7135

F

IN

+INPUT

–INPUT

ANALOG

COMMON

REF

V–

IN

21

100kΩ

POL

C

REF

C

REF

MCP1525

1µF

B8

B4

B2

B1

V+

4.7kΩ

23

7

-

1µF

8

+

16

15

14

13

11

V+

Blank MSD On Zero

bc

6

D

2

C

1

B

7

A

7777

X7

9–15

5

RBI

DM7447A

16

+

nalog

Input

–

0.33µF

100kΩ

200kHz

100kΩ

+5V

+5V

FIGURE 6-3: RC OSCILLATOR CIRCUIT FIGURE 6-4: COMPARATOR CLOCK

16kΩ

16kΩ

CIRCUITS

2

+

LM311

3

-

4

+5V

2

+

6

LM311

3

4

1

56kΩ

8

R4

2kΩ

7

7

1

C2

10pF

+5V

1kΩ

30kΩ

390pF

R3

50kΩ

V

V

OUT

OUT

R

2

R

1

C

F

O

Gates are 74C04

0.22µF

1. FO=

2C(0.41 R

1

+0.7R1)

P

,R

R1R

=

P

2

R1+R

2

a. If R1=R2=R1,F≅ 0.55/RC

b. If R

>> R1,F≅ 0.45/R1C

2

c. If R

<< R1,F≅ 0.72/R1C

2

2. Examples:

R2

100kΩ

a. F = 120kHz, C = 420pF

R

b. F = 120kHz, C = 420pF, R

R

c. F = 120 kHz, C = 220 pF, R

R

1

1=R2

= 8.93kΩ

1

= 27.3k Ω

≈ 10.9 kΩ

= 50kΩ

2

=5kΩ

2

R2

100kΩ

C1

0.1µF

DS21460B-page 14

2002 Microchip TechnologyInc.

TC7135

V

FIGURE 6-5: 4-1/2 DIGIT ADC W ITH MULTIPLEXED COMMON CATHODE LED DISPLAY

+5V

MCP1525

SIG

IN

1µF

100

+

–

Analog

0.33µF

kΩ

100

GND

0.1

µF

kΩ

1µF

100 kΩ

1µF

+5V

SET V

–5V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

= 1V

REF

V-

TC7135

REF IN

ANALOG

GND

INT

OUT

AZ IN

BUFF

OUT

C

+

REF

-

C

REF

–INPUT

+INPUT

V+

D5 (MSD)

B1 (LSB)

B2

UR

OR

STROBE

RUN/HOLD

DGND

POLARITY

CLK IN

BUSY

(LSD) D1

D2

D3

D4

(MSB) B8

B4

+5V

28

27

150Ω

26

47

kΩ

25

24

23

22

21

20

19

18

17

16

15

F

= 200kHz

OSC

150Ω

10

11

12

13

14

15

16

17

18

MC14513

9

8

7

6

5

4

3

2

1

+5

2002 Microchip TechnologyInc. DS21460B-page 15

TC7135

7.0 PACKAGING INFORMATION

7.1 Package Marking Information

Package marking data not available at this time.

7.2 Taping Forms

Component Taping Orientation for 28-Pin PLCC Devices

PIN 1

User Direction of Feed

W

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

28-Pin PLCC 24 mm 16 mm 750 13 in

Component Taping Orientation for 64-Pin PQFP Devices

DS21460B-page 16

User Direction of Feed

PIN 1

W

P

Standard Reel Component Orientation

for TR Suffix Device

Carrier Tape, Number of Components Per Reel and Reel Size

Package Carrier Width (W) Pitch (P) Part Per Full Reel Reel Size

64-Pin PQFP 32 mm 24 mm 250 13 in

NOTE: Drawing does not represent total number of pins.

2002 Microchip TechnologyInc.

7.3 Package Dimensions

TC7135

28-Pin PDIP (Wide)

.200 (5.08)

.140 (3.56)

.150 (3.81)

.115 (2.92)

.110 (2.79)

.090 (2.29)

1.465 (37.21)

1.435 (36.45)

.070 (1.78)

.045 (1.14)

.022 (0.56)

.015 (0.38)

PIN 1

.555 (14.10)

.530 (13.46)

.040 (1.02)

.020 (0.51)

.015 (0.38)

.008 (0.20)

.610 (15.49)

.590 (14.99)

.700 (17.78)

.610 (15.50)

Dimensions: inches (mm)

˚

MIN.

3

28-Pin PLCC

.495 (12.58)

.485 (12.32)

.456 (11.58)

.450 (11.43)

.456 (11.58)

.450 (11.43)

.495 (12.58)

.485 (12.32)

PIN 1

.050 (1.27) TYP.

.180 (4.57)

.165 (4.19)

Dimensions: inches (mm)

.021 (0.53)

.013 (0.33)

.430 (10.92)

.032 (0.81)

.390 (9.91)

.026 (0.66)

.020 (0.51) MIN.

.120 (3.05)

.090 (2.29)

2002 Microchip TechnologyInc. DS21460B-page 17

TC7135

)

7.3 Packaging Dimensions (Continued)

64-Pin PQFP

˚

MAX.

7

.018 (0.45)

.012 (0.30)

.031 (0.80) TYP.

PIN 1

.555 (14.10)

.547 (13.90)

.687 (17.45)

.667 (16.95)

.555 (14.10)

.547 (13.90)

.687 (17.45)

.667 (16.95)

.009 (0.23)

.005 (0.13)

.130 (3.30) MAX.

Dimensions: inches (mm

.041 (1.03)

.031 (0.78)

.010 (0.25) TYP.

.120 (3.05)

.100 (2.55)

DS21460B-page 18

2002 Microchip TechnologyInc.

TC7135

SALES AND SUPPORT

Data Sheets

Products supportedby a preliminary DataSheetmayhave an erratasheetdescribing minor operationaldifferences and recommendedworkarounds.To determine if an errata sheetexists for a particular device,please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX:(480)7 92-7277

3. The Microchip Worldwide Site (www.microchip.com)

Pleasespecify which device, revision of silicon and Data Sheet (includeLiterature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn)to receive the most currentinformationon our products.

2002 Microchip Technology Inc. DS21460B-page19

TC7135

NOTES:

DS21460B-page 20 2002 Microchip Technology Inc.

TC7135

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with

express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, FilterLab,

K

EELOQ,microID,MPLAB,PIC,PICmicro,PICMASTER,

PICSTART, PRO MATE, SEEVAL and The Embedded Control

SolutionsCompany areregiste red trademarksof MicrochipTechnologyIncorp or ated in the U.S.A. and other countries .

dsPIC, ECONOMONI TOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

MXDEV, PICC, PICDEM, PICDEM.net, rfPIC, Select Mo de

and Total Enduranceare trademarksof MicrochipTechnology

Incorporated in the U.S.A.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999

and Mountain View, California in March 2002.

The Company’s quality system processes and

procedures are QS-9000 compliant for its

®

PICmicro

devices, Serial EEPROMs, microperipherals,

non-volatile memory and analog products. In

addition, Microchip’s quality system for the

design and manufacture of development

systemsisISO 9001certified.

2002 Microchip TechnologyInc. DS21460B-page 21

8-bit MCUs, KEELOQ®code hopping

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200 Fax: 480-792-7277

Technical Support: 480-792-7627

Web Address: http://www.microchip.com

Rocky Mountain

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7966 Fax: 480-792-7456

Atlanta

500 Sugar Mill Road, Suite 200B

Atlanta, GA 30350

Tel: 770-640-0034 Fax: 770-640-0307

Boston

2 Lan Drive, Suite 120

Westford, MA 01886

Tel: 978-692-3848 Fax: 978-692-3821

Chicago

333 Pierce Road, Suite 180

Itasca, IL 60143

Tel: 630-285-0071 Fax: 630-285-0075

Dallas

4570 Westgrove Drive, Suite 160

Addison, TX 75001

Tel: 972-818-7423 Fax: 972-818-2924

Detroit

Tri-Atria Office Building

32255 Northwestern Highway, Suite 190

Farmington Hills, MI 48334

Tel: 248-538-2250 Fax: 248-538-2260

Kokomo

2767 S. Albright Road

Kokomo, Indiana 46902

Tel: 765-864-8360 Fax: 765-864-8387

Los Angeles

18201 Von Karman, Suite 1090

Irvine, CA 92612

Tel: 949-263-1888 Fax: 949-263-1338

New York

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

6285 Northam Drive, Suite 108

Mississauga, Ontario L4V 1X5, Canada

Tel: 905-673-0699 Fax: 905-673-6509

ASIA/PACIFIC

Australia

Microchip Technology Australia Pty Ltd

Suite 22, 41 Rawson Street

Epping 2121, NSW

Australia

Tel: 61-2-9868-6733 Fax: 61-2-9868-6755

China - Beijing

Microchip Technology Consulting (Shanghai)

Co., Ltd., Beijing Liaison Office

Unit 915

Bei Hai Wan Tai Bldg.

No. 6 Chaoyangmen Beidajie

Beijing, 100027, No. China

Tel: 86-10-85282100 Fax: 86-10-85282104

China - Chengdu

Microchip Technology Consulting (Shanghai)

Co., Ltd., Chengdu Liaison Office

Rm. 2401, 24th Floor,

Ming Xing Financial Tower

No. 88 TIDU Street

Chengdu 610016, China

Tel: 86-28-86766200 Fax: 86-28-86766599

China - Fuzhou

Microchip Technology Consulting (Shanghai)

Co., Ltd., Fuzhou Liaison Office

Unit 28F, World Trade Plaza

No. 71 Wusi Road

Fuzhou 350001, China

Tel: 86-591-7503506 Fax: 86-591-7503521

China - Shanghai

Microchip Technology Consulting (Shanghai)

Co., Ltd.

Room 701, Bldg. B

Far East International Plaza

No. 317 Xian Xia Road

Shanghai, 200051

Tel: 86-21-6275-5700 Fax: 86-21-6275-5060

China - Shenzhen

Microchip Technology Consulting (Shanghai)

Co., Ltd., Shenzhen Liaison Office

Rm. 1315, 13/F , Shenzhen Kerry Centre,

Renminnan Lu

Shenzhen 518001, China

Tel: 86-755-2350361 Fax: 86-755-2366086

China - Hong Kong SAR

Microchip Technology Hongkong Ltd.

Unit 901-6, Tower2, Metroplaza

223 Hing Fong Road

Kwai Fong, N.T., Hong Kong

Tel: 852-2401-1200 Fax: 852-2401-3431

India

Microchip Technology Inc.

India Liaison Office

Divyasree Chambers

1 Floor, Wing A (A3/A4)

No. 11, O’Shaugnessey Road

Bangalore, 560 025, India

Tel: 91-80-2290061 Fax: 91-80-2290062

Japan

Microchip Technology Japan K.K.

Benex S-1 6F

3-18-20, Shinyokohama

Kohoku-Ku, Yokohama-shi

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Korea

Microchip Technology Korea

168-1, Youngbo Bldg. 3 Floor

Samsung-Dong, Kangnam-Ku

Seoul, Korea 135-882

Tel: 82-2-554-7200 Fax: 82-2-558-5934

Singapore

Microchip Technology Singapore Pte Ltd.

200 Middle Road

#07-02 Prime Centre

Singapore, 188980

Tel: 65-6334-8870 Fax: 65-6334-8850

Taiwan

Microchip Technology Taiwan

11F-3, No. 207

Tung HuaNorth Road

Taipei, 105, Taiwan

Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

EUROPE

Denmark

Microchip Technology Nordic ApS

Regus Business Centre

Lautrup hoj 1-3

Ballerup DK-2750 Denmark

Tel: 45 4420 9895 Fax: 45 4420 9910

France

Microchip Technology SARL

Parc d’Activite du Moulin de Massy

43 Rue du Saule Trapu

Batiment A - ler Etage

91300 Massy, France

Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Germany

Microchip Technology GmbH

Gustav-Heinemann Ring 125

D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Italy

Microchip Technology SRL

Centro Direzionale Colleoni

Palazzo Taurus 1 V. Le Colleoni 1

20041 Agrate Brianza

Milan, Italy

Tel: 39-039-65791-1 Fax: 39-039-6899883

United Kingdom

Microchip Ltd.

505 Eskdale Road

Winnersh Triangle

Wokingham

Berkshire, England RG415TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

04/20/02

DS21460B-page 22

*DS21460B*

2002 Microchip Technology Inc.

Loading...

Loading...