Page 1

SAMA5D27 SOM1 Kit1

SIP

(System-In-Package)

SOM (System-On-Module)

Baseboard

SAMA5D27 SOM1 Kit1 User's Guide

Scope

This user's guide provides detailed information on the overall design of the SAMA5D27 SOM1 Kit1 and

describes how to use the kit.

The kit is the evaluation platform for the SAMA5D27 SIP (System-In-Package) and SOM (System-OnModule), and comprises:

• a baseboard

• a SAMA5D27 SOM soldered on the baseboard

• a SAMA5D27 SIP soldered on the SOM

• a USB cable

See the figure below.

Figure 1. SAMA5D27 SOM1 Kit1 Overview

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 1

Page 2

SAMA5D27 SOM1 Kit1

Table of Contents

Scope.............................................................................................................................. 1

1. Introduction................................................................................................................3

1.1. Document Layout......................................................................................................................... 3

1.2. Reference Documents..................................................................................................................3

2. Product Overview...................................................................................................... 4

2.1. Kit Contents..................................................................................................................................4

2.2. Features....................................................................................................................................... 4

2.3. Specifications............................................................................................................................... 5

2.4. Power Sources............................................................................................................................. 5

3. Baseboard Components............................................................................................7

3.1. Baseboard Overview.................................................................................................................... 7

3.2. Function Blocks.......................................................................................................................... 10

3.3. External Interfaces..................................................................................................................... 27

3.4. Debugging Capabilities.............................................................................................................. 33

3.5. PIO Usage on Expansion Connectors........................................................................................39

4. Installation and Operation........................................................................................46

4.1. System and Configuration Requirements...................................................................................46

4.2. Baseboard Setup........................................................................................................................46

5. Errata.......................................................................................................................47

5.1. Incorrect NRST and WKUP Push Button Markings....................................................................47

6. Appendix: Schematics and Layouts........................................................................ 48

7. Revision History.......................................................................................................58

The Microchip Web Site................................................................................................ 59

Customer Change Notification Service..........................................................................59

Customer Support......................................................................................................... 59

Microchip Devices Code Protection Feature................................................................. 59

Legal Notice...................................................................................................................60

Trademarks................................................................................................................... 60

Quality Management System Certified by DNV.............................................................61

Worldwide Sales and Service........................................................................................62

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 2

Page 3

1. Introduction

1.1 Document Layout

The document is organized as follows:

• Introduction

• Product Overview – Important information about the kit

• Board Components – Specifications of the kit and high-level description of the major components

and interfaces

• Installation and Operation – Instructions on how to get started with the kit

• Errata

• Appendix: Schematics and Layouts – Kit schematics and layout diagrams

1.2 Reference Documents

The following Microchip documents are available and recommended as supplemental reference

resources:

SAMA5D27 SOM1 Kit1

Introduction

Type Document Title Available Ref. No./Product

Data Sheet SAMA5D2 www.microchip.com/SAMA5D2 DS60001476

Data Sheet

Data Sheet

SAMA5D2 System-On-Module

(SOM)

SAMA5D2 System-In-Package

(SIP)

www.microchip.com/ATSAMA5D27-

SOM1

www.microchip.com/SAMA5D2 SIP DS60001484

DS60001521

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 3

Page 4

2. Product Overview

2.1 Kit Contents

The kit includes the following:

• One baseboard with soldered SOM

• One USB cable

2.2 Features

The kit comprises a baseboard with a soldered SAMA5D27 SOM1 module. The module features a

SAMA5D27-D1G-CU SIP embedding a 1-Gbit DDR2 SDRAM. The SOM offers a reliable and costeffective embedded platform for building end products, as well as a small form factor, complemented by

many connectivity interfaces. The SOM is a fully-featured industrially-certified single board computer

designed for integration into customer applications.

The SOM module is a purpose-built small footprint hardware platform equipped with a wide array of highspeed connectivity engineered to support various applications such as IoT endpoints, wearables,

appliances or industrial equipment.

SAMA5D27 SOM1 Kit1

Product Overview

The SOM integrates a 1-Gbit DDR2 SDRAM, a QSPI memory and a 10/100 Mbps Ethernet controller.

128 GPIO pins are provided by the SOM for general use in the system. All GPIO pins are independent

and can be configured as inputs or outputs, with or without pull-up/pull-down resistors.

The baseboard features a wide range of peripherals, as well as a user interface and expansion options,

including two mikroBUS™ click interface headers to support over 300 MikroElektronika click boards™ and

one Pmod™ interface.

Table 2-1. Baseboard Features

Characteristics Specifications Components

Memory One QSPI Flash (unmounted) Tested with Macronix MX25L25673GM2I-08G

Crypto One CryptoAuthentication™ device ATECC608

USB Com Port One USB host

One USB device

One USB HSIC

Ethernet One Ethernet interface RJ45 connector

CAN One CAN interface ATA6561

Video One LCD RGB 24-bit interface

One ISC 12-bit interface

Connector type C

Connector type microAB

2-pin header (not populated)

50-pin FPC connector

2x15 male connector

Storage One standard SD card interface

One microSD card interface

© 2018 Microchip Technology Inc.

With 3.3V/1.8V power switch

–

User Guide

DS50002667C-page 4

Page 5

SAMA5D27 SOM1 Kit1

...........continued

Characteristics Specifications Components

Product Overview

Debug port One J-Link-OB and J-Link-CDC

Board Monitor One RGB (Red, Green, Blue) LED

Expansion One tamper connector

Board Supply From USB A and/or USB J-Link-OB 5 VDC

Power saving SuperCap –

Refer to www.microchip.com for:

• Sample code and technical support

• Linux® software and demos

2.3 Specifications

Table 2-2. Kit Specifications

One JTAG interface

Four push button switches

One Pmod connector

Two mikroBUS interfaces

Microchip SAM3U micro-controller with

embedded J-Link firmware

–

–

Power ON, Reset, Wakeup, User Free

10-pin male connector

6-pin female connector

2x8-pin female connector

Characteristic Specification

Ordering code ATSAMA5D27-SOM1-EK1

Board supply voltage USB-powered

Temperature Operating: 0°C to +70°C

Relative humidity 0 to 90% (non-condensing)

Baseboard dimensions 135 × 90 × 20 mm

RoHS status Compliant

2.4 Power Sources

Two options are available to power up the baseboard:

• USB powering through the USB Micro-AB connector (J17 - default configuration)

• Powering through the USB Micro-AB connector on the J-Link-OB Embedded Debugger interface

(J10)

The two power sources can coexist. A priority mechanism manages the automatic switching between the

two. The priority source is J-Link (J10), the secondary source is the USB port (J17).

Storage: –40°C to +85°C

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 5

Page 6

SAMA5D27 SOM1 Kit1

Product Overview

Table 2-3. Electrical Characteristics

Electrical Parameter Value

Input voltage 5VCC

Maximum input voltage 6VCC

Maximum 3.3VDC current available 1.2A

I/O voltage 3.3V only

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 6

Page 7

3. Baseboard Components

This section covers the specifications of the SAMA5D27 SOM1 Kit1 baseboard and provides a high-level

description of the baseboard's major components and interfaces. This document is not intended to

provide a detailed documentation about the processor or about any other component used on the

baseboard. It is expected that the user will refer to the appropriate documents of these devices to access

detailed information.

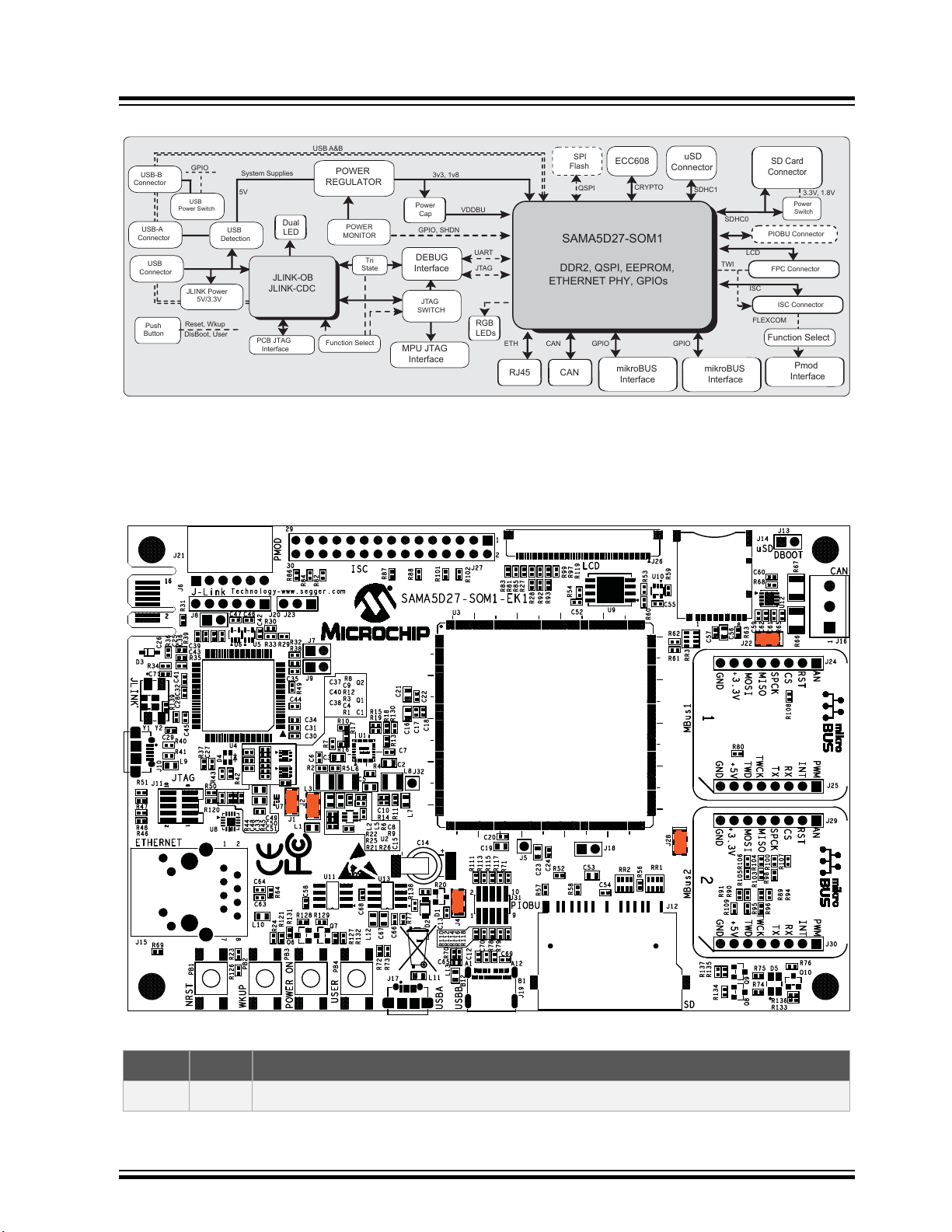

3.1 Baseboard Overview

The fully-featured SAMA5D27 SOM1 Kit1 baseboard integrates multiple peripherals and interface

connectors, as shown in the figure below.

Figure 3-1. SAMA5D27 SOM1 Kit1 Baseboard Overview

SAMA5D27 SOM1 Kit1

Baseboard Components

The following picture illustrates the kit block diagram.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 7

Page 8

Figure 3-2. SAMA5D27 SOM1 Kit1 Block Diagram

PCB JTAG

Interface

SPI

Flash

System Supplies

POWER

REGULATOR

GPIO, SHDN

UART

MPU JTAG

Interface

JTAG

LCD

ISC

TWI

FLEXCOM

RJ45

ETH

CAN

CAN

mikroBUS

Interface

mikroBUS

Interface

GPIO

USB A&B

SDHC0

SDHC1

RGB

LEDs

USB

Detection

DEBUG

Interface

Push

Button

Reset, Wkup

DisBoot, User

Pmod

Interface

PIOBU Connector

ISC Connector

3v3, 1v8

Power

Cap

VDDBU

JTAG

SWITCH

USB-A

Connector

USB-B

Connector

uSD

Connector

SD Card

Connector

5V

GPIO

USB

Power Switch

3.3V, 1.8V

FPC Connector

POWER

MONITOR

SAMA5D27-SOM1

DDR2, QSPI, EEPROM,

ETHERNET PHY, GPIOs

JLINK-OB

JLINK-CDC

Dual

LED

Function Select

QSPI

GPIO

Function Select

Power

Switch

CRYPTO

ECC608

Tri

State

JLINK Power

5V/3.3V

USB

Connector

3.1.1 Default Jumper Settings

The figure below shows the default jumper settings. Jumpers in red are configuration items and current

measurement points. The following table describes the functionality of the jumpers.

SAMA5D27 SOM1 Kit1

Baseboard Components

Figure 3-3. Default Jumper Settings

Table 3-1. Jumper Settings

Jumper Default Function

J1 Closed VDD_MAIN_5V current measurement

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 8

Page 9

...........continued

WARNING

Jumper Default Function

J2 Closed VDD_3V3 SOM current measurement

J4 Closed VDDBU current measurement

J7 Open Enables J-Link-OB (closed=disable)

Erases SAM3U firmware code (closed=erase at power-up)

SAMA5D27 SOM1 Kit1

Baseboard Components

J8 Open

J9 Open Enables JTAG-CDC (closed=disable)

J13 Open Disables SOM boot memories (closed=disable)

J22 Closed Enables 3.3V power mikroBUS1 (closed=enable)

J28 Closed Enables 3.3V power mikroBUS2 (closed=enable)

3.1.2 Baseboard Connectors

The following table describes the interface connectors on the SAMA5D27 SOM1 Kit1 baseboard.

Table 3-2. Baseboard Interface Connectors

Connector Interfaces to

J5 CLK_AUDIO test point (not populated)

J6 PCB-edge JTAG connector for factory-programming the J-Link-OB

J10 USB-A MicroAB, J-Link-OB port

J11 MPU SAMA5D27 JTAG 10-pin IDC connector

Must remain open. If closed, the SAM3U contents are erased and J-Link

functionality is discarded.

J12 Standard SDMMC0 connector

J14 microSD connector

J15 Ethernet RJ45 connector

J16 CAN 3-pin screw connector

J17 USB-A MicroAB connector

J18 HSIC 2-point header

J19 USB-B type C connector

J20-J23 Jumper to select Pmod functions

J21 Pmod connector

J24-25 mikroBUS1 connectors

J26 Expansion TFT LCD connector for display module

J27 ISC connector

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 9

Page 10

...........continued

MPU + DDR2 1Gb

SAMA5D27C-D1G-CU

LFBGA289

64Mbit Serial QUAD I/O

Flash Memory

SST26VF064BT-104I/MF

1K Serial EEPROM

with EUI-48

Node Identity

24AA02E48T-I/OT

ΤΜ

10BASE-T / 100BASE-TX

PHY With RMII Support

KSZ8081RNAIA

Power Management

Unit

MIC2800-G1JJYML

VDDSDHC VDDISC VDDBU

MAIN

3.3V

TWI Interface

103 I/O Available

CLASS-D Stereo

eMMC Interface

QSPI Interface

Camera Interface

Up to 4 * ADC Inputs

TWI Interface

Up to 4 * UART

2 * SPI Interfaces

Up to 4 * FLEXCOM

LCD Interface up to 24-bit

SSC Interface

Mono PDMIC Interface

Up to 2 * CAN

I²S Interface

SDIO Interface

SD-CARD Interface

External

QSPI

Connection

JTAG & DBGU Interfaces

DEBUG

SYSTEM

MISC

USB Dev.

USB Host

HSIC

BACKUP

7 * PIOBU

RXD

WAKEUP

RESET

SHUTDOWN

CLK_AUDIO

COMPP / COMPN

Disable Boot

USB Device Connector

USB Host Connector

HSIC Device

Physical

Receiver

Transceiver

Interface

Connector Interfaces to

J29-J30 mikroBUS2 connectors

J31 Tamper and analog comparator connector

J32 SHDN test point (not populated)

3.2 Function Blocks

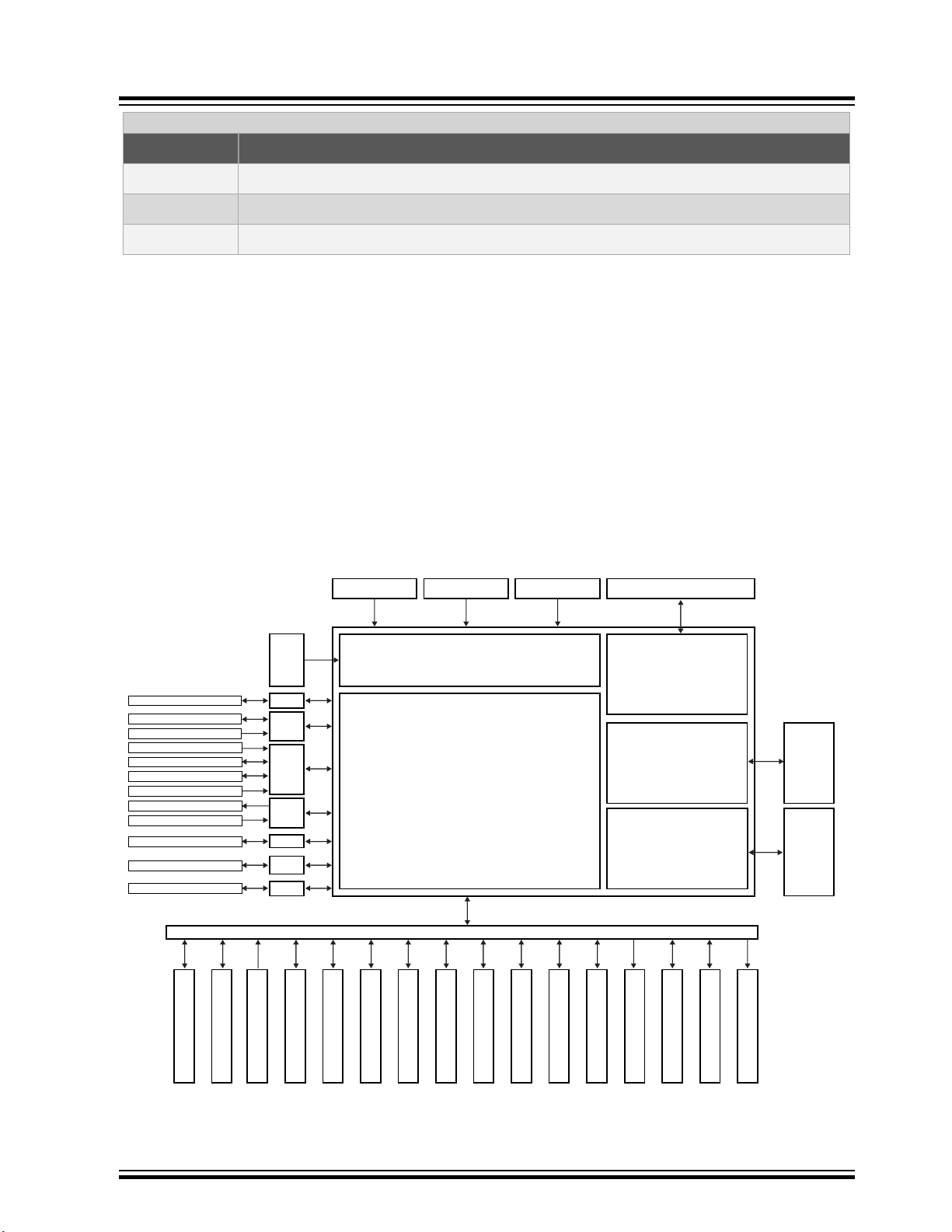

3.2.1 SAMA5D27 SOM1

The SAMA5D27 SOM1 main features are as follows:

• Ultra-small SIP (SAMA5D27-D1G-CU) embedding an ultra-low-power SAMA5D27 Arm® Cortex®A5 processor and a 1 Gbit DDR2 SDRAM memory

• SST26VF064 64 Mb QSPI Flash

• 24AA02E48 2 Kb serial E2PROM with preprogrammed EUI node identity

• MIC2800 power management device

• KSZ8081RNA Ethernet Phy 10/100 MHz RMII

SAMA5D27 SOM1 Kit1

Baseboard Components

Refer to the SAMA5D27 SOM1 datasheet for more information.

Figure 3-4. SAMA5D27 SOM1 Block Diagram

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 10

Page 11

3.2.2 Power Supply Topology and Power Distribution

100k

0402

1%

R8

5

8 4

3

DMP2160

Q1B

1 2

J1

5

8 4

3

DMP2160

Q2B

0.1uF

50V

0402

C4

10k

0402

5%

R3

0.1uF

50V

0402

C9

2

71

6

DMP2160

Q2A

2

71

6

DMP2160

Q1A

100k

0402

1%

R12

0.1uF

50V

0402

C1

100k

0402

1%

R1

VBUS_JLINK VDD_MAIN_5V

VBUS_USBA

Shunt 2.54mm 1x2

CAUTION

3.2.2.1 Input Power Options

The board power source can come through either a USB connector (J10 or J17) connected to a PC or a

5V DC-USB power supply unit. These USB power sources are sufficient to supply the board in most

applications.

Important: In case of an external device connected through the USB-B port, it is

recommended to use the 5V DC-USB power supply unit as the main power source for the entire

system rather than a PC or a USB hub, which are limited to 500 mA typical.

The baseboard embeds a local power management stage comprising two sets of load switches,

respectively implemented by MOSFET DMP2160 and DC/DC converter MIC23451.

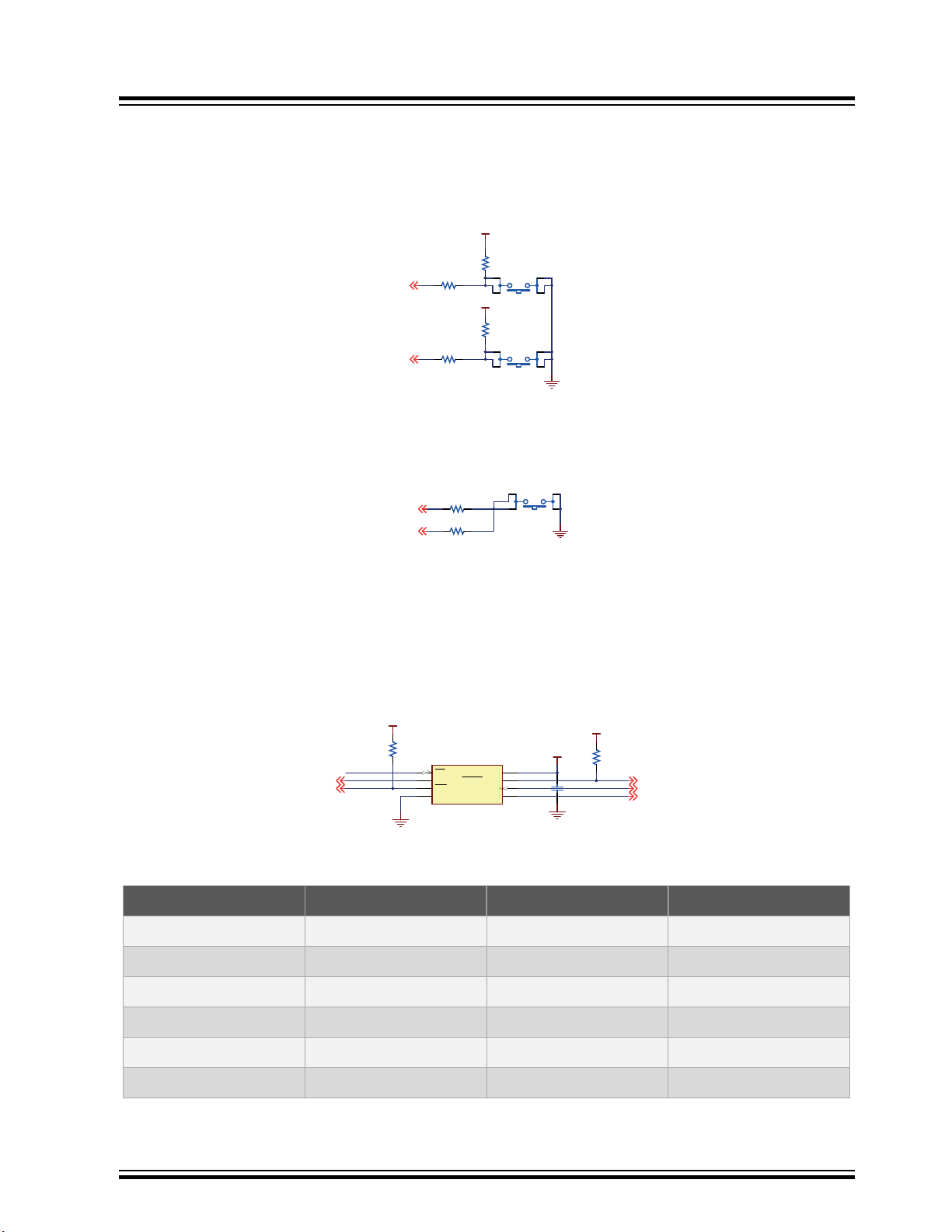

The following figure is a schematic of the power options.

Figure 3-5. Input Powering

SAMA5D27 SOM1 Kit1

Baseboard Components

Note: PC/USB-powered operation eliminates additional wires and batteries. It is the preferred mode of

operation for any project that requires only a 5V source at up to 500 mA.

Jumper J1 is used to perform MAIN_5V current measurements on the baseboard.

3.2.2.2 Power Supply Requirements and Restrictions

Detailed information on the device power supplies is provided in tables “SAMA5D2 Power Supplies” and

“Power Supply Connections” in the SAMA5D2 Series datasheet.

3.2.2.3 Power-up and Power-down Considerations

Power-up and power-down considerations are described in section “Power Considerations” of the

SAMA5D2 Series datasheet.

The power-up and power-down sequences provided in the SAMA5D2 Series datasheet must be

respected for reliable operation of the device. These are respected by the on-board MIC23451.

3.2.2.4 Power Management

The baseboard power management uses a MIC23451 PMIC, which is a triple synchronous buck regulator

with HyperLight Load® mode featuring a power good indicator. The triple DC-DC step down power

regulator delivers two outputs: 3.3V/2A and 1.8V/2A.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 11

Page 12

10uF

25V

0603

C2

0R

0402

R130

10k 04025%

R16

158k

0402

1%

R9

180R

L1

4.7uF

10V

0402

C6

180R

L2

309k

0402

1%

R11

10k

0402

5%

R10

1 2

HDR-2.54 Male 1x2

J1

0R0402

R17

1uH

L6

301k

0402

1%

R6

4.7uF

10V

0402

C8

71.5k

0402

1%

R5

100R

0402

5%

R4

0R0402

R19

10k

0402

5%

R13

10uF

25V

0603

C3

PGND

1

PGND

2

AVIN1

3

SW2

4

PVIN2

5

AVIN2

6

SW3

7

PVIN3

8

AVIN3

9

PGND10AGND

11

SNS3

12

PG3

13

FB3

14

EN3

15

PG2

16

FB2

17

SNS2

18

EN2

19

PG1

20

EN1

21

SNS1

22

FB1

23

AGND

24

PVIN1

25

SW1

26

MIC23451

U1

4.7uF10V

0402

C7

309k

0402

1%

R2

10k 04025%

R7

1 2

HDR-2.54 Male 1x2

J2

1uH

L8

10k 04025%

R18

10k 04025%

R15

10uF

25V

0603

C5

4.7uF

10V

0402

C10

71.5k

0402

1%

R14

180R

L7

1uH

L3

180R

L5

VOUT1

VOUT2 VDD_SDHC_1V8

VDDIN_3V3

VOUT3

VDD_3V3

VDD_MAIN_5V

VOUT2

VOUT1

VOUT3

VDD_SDHC_3V3

PD8

BB_PWR_GOOD

Shunt 2.54mm 1x2

JP2

Shunt 2.54mm 1x2

SAMA5D27 SOM1 Kit1

Baseboard Components

While the external power is being applied, the baseboard can be shut down by software and then woken

up by action on the PB2 push button, which activates the WKUP signal.

The figure below shows the power management scheme.

Figure 3-6. Baseboard Power Management

One PIO (PD8) is used to check the status of the main regulator.

Table 3-3. Power Good Signal

PIO Mnemonic Signal Description

PD8 BB_PWR_GOOD High level = power is established

3.2.2.5 Supply Group Configuration

The main regulator provides the 3.3V for the SOM and all power supplies required by the baseboard:

• 3.3V SOM (VDDIN_3V3)

• 3.3V VDDSDHC (3.3V or 1.8V)

• 3.3V baseboard (VDD_3V3)

• 3.3V VDDBU

© 2018 Microchip Technology Inc.

and at correct level

User Guide

DS50002667C-page 12

Page 13

Figure 3-7. SOM Power Lines

2.2uF

16V

0603

C21

0.1uF

50V

0402

C17

0.1uF

50V

0402

C24

0.1uF

50V

0402

C18

2.2uF

16V

0603

C16

2.2uF

16V

0603

C19

0.1uF

50V

0402

C20

2.2uF

16V

0603

C23

0.1uF

50V

0402

C22

VDDIN_3V3

VDDBU

VDDSDHC

VDDIN_3V3

VDDBU

55

VDDIN_3V3_1

16

VDDIN_3V3_2

17

VDDISC

15

VDDSDHC

65

GND_1

10

GND_2

18

GND_3

26

GND_4

31

GND_5

39

GND_6

42

GND_7

43

GND_8

50

GND_9

56

GND_10

62

GND_11

66

GND_12

69

GND_13

72

GND_14

75

GND_15

88

GND_16

89

GND_17

98

GND_18

107

GND_19

130

GND_20

131

GND_21

149

GND_22

166

GND_23

171

GND_24

176

GND_0

1

SAMA5D27-SOM1

U3F

BAT54C

2

3

1

D1

1 2

HDR-2.54 Male 1x2

J4

220mF

3.3V

P8.3L11.7D6.8H1.8

C14

0.1uF

50V

0402

C13

RB160M-60TR

D2

100R

0402

5%

R20

VDDBU

VDD_3V3

(Super)-Capacitor

energy storage

Shunt 2.54mm 1x2

JP3

0R DNP

0402

R131

100k

0402

1%

R132

100k

0402

1%

R129

3

1

2

BSS138

Q7

3

1

2

BSS138

Q6

10k

0402

5%

R128

10k

0402

5%

R127

1 4

2

3

TACT SPST

PB3

VDDBU VDD_MAIN_5V

SHDN

POWER

ON

3.2.2.6 Backup Power Supply

The baseboard features a power source in order to permanently power the backup area of the SAMA5D2

device (refer to the SAMA5D2 Series datasheet). A super capacitor (C14) sustains such permanent

power to VDDBU when all system power sources are off.

Figure 3-8. VDDBU Powering Options

SAMA5D27 SOM1 Kit1

Baseboard Components

3.2.3 Shutdown Circuitry

On the baseboard, this circuitry is implemented but inhibited by default (R131 is not populated).

The SHDN signal, output of the shutdown controller, signals the shutdown request to the power supply.

This output signal is supplied by VDDBU that is present in Backup mode.

The shutdown controller manages the main power supply and is connected to the ENABLE input pin of

the DC/DC converter providing the main power supplies of the system.

Figure 3-9. Shutdown Controller

3.2.4 Push Button Switches

The baseboard features four push buttons:

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 13

Page 14

100R

0402

5%

R23

100k

0402

1%

R126

100R

0402

5%

R24

10k

0402

5%

R121

1 4

2 3

TACT SPST

PB1

1 4

2 3

TACT SPST

PB2

VDDBU

VDDBU

NRST

WKUP

NRST

WAKE UP

1 4

2 3

TACT SPST

PB4

100R

DNP

04025%

R72

100R 04025%

R73

PIOBU1

PA29

CS_QSPI1

10k

0402

5%

R53

0.1uF

50V

0402

C52

10k

0402

5%

R54

VDD_3V3

VDD_3V3

PB5

PB7

PB8

PB9

PB10

QSPI Flash

QSPI1_SCK

QSPI1_IO0

QSPI1_IO1

QSPI1_IO2

QSPI1_IO3

CE

1

SO/SIO1

2

WP/SIO2

3

VSS4SI/SIO0

5

SCK

6

HOLD/SIO3

7

VDD

8

SST26VF064B

U9 DNP

VDD_3V3

SAMA5D27 SOM1 Kit1

Baseboard Components

• One reset push button (PB1). When pressed and released, the baseboard is reset.

• One wake-up push button (PB2) connected to the SAMA5D27 WKUP pin, used to exit the

processor from Backup mode.

• One power-on button (PB3).

Figure 3-10. System Push Buttons

• One user momentary push button (PB4) connected to PIO PA29, and optionally to PIOBU1.

The wake-up is available only if the shutdown controller is used (see figure Shutdown Controller).

Figure 3-11. User Push Button

3.2.5 Additional Memories

One additional memory, QSPI device U9, can be soldered on the baseboard. This QSPI Flash memory

uses the same PIOs as the SOM QSPI. Such configuration makes it possible to choose between two

bootable memories.

The figure below illustrates the QSPI memory implementation.

Figure 3-12. Optional QSPI Serial Data Flash on Baseboard

Table 3-4. QSPI Signal Descriptions

PIO Mnemonic Shared PIO Signal Description

PB5 QSPI1_SCK QSPI on SOM Clock

PB6 QSPI1_CS QSPI on SOM Chip select

PB7 QSPI0_IO0 QSPI on SOM Data0

PB8 QSPI0_IO1 QSPI on SOM Data1

PB9 QSPI0_IO2 QSPI on SOM Data2

PB10 QSPI0_IO3 QSPI on SOM Data3

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 14

Page 15

3.2.5.1 CS Disable Boot

PB6

CS_QSPI1

1 2

HDR-2.54 Male 1x2

J13

10k

0402

5%

R59

10k

0402

5%

R60

0.1uF

50V

0402

C55

OE

1

A

2

Y

4

GND

3

VCC

5

NL17SZ125-D

U10

DNP

VDD_3V3

VDD_3V3

DISABLE_BOOT

PB6

QSPI1_CS

(SOM)

One jumper (J13) controls the selection (CS#) of the bootable memory components (QSPI) using a noninverting 3-state buffer.

Figure 3-13. CS Disable Boot

The rule of operation is:

• PB1 (RESET) pressed and J13 open = booting from QSPI on SOM

• PB1 (RESET) pressed and J13 closed = booting from QSPI on baseboard if fitted. The QSPI on

SOM is disabled.

Refer to the SAMA5D2 Series datasheet for more information on standard boot strategies and

sequencing.

SAMA5D27 SOM1 Kit1

Baseboard Components

3.2.6 Secure Digital Multimedia Card (SDMMC) Interface

The SD (Secure Digital) Card is a non-volatile memory card format used as a mass storage memory in

mobile devices.

3.2.6.1 Secure Digital Multimedia Card (SDMMC) Controller

The baseboard features two Secure Digital Multimedia Card (SDMMC) interfaces that support the

MultiMedia Card (e.MMC) Specification V4.41, the SD Memory Card Specification V3.0, and the SDIO

V3.0 specification. It is compliant with the SD Host Controller Standard V3.0 Specification.

• The SDMMC0 interface is connected to a standard SD card interface.

• The SDMMC1 interface is connected to a microSD card interface.

3.2.6.2 SDMMC0 Card Connector (J12)

A standard MMC/SD card connector, connected to SDMMC0, is mounted on the top side of the

baseboard. The SDMMC0 communication is based on a 12-pin interface (clock, command, write protect,

power switch and data (8)). A card detection switch is included.

The figure below illustrates the SDMMC0 interface implementation.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 15

Page 16

Figure 3-14. SDMMC0

10k

0402

5%

R56

0R

0402

R52

10k

0402

5%

R58

10uF

25V

0603

C53

123

4 5

678

68k

1206

5%

RR2

0.1uF

50V

0402

C54

1

2

3

4 5

6

7

8

68k

1206

5%

RR1

10k

0402

5%

R57

VDDSDHC

VDD_3V3

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

PA8

PA9

PA12

PA13

SDMMC0_CD

SDMMC0_DA1

SDMMC0_DA0

SDMMC0_CK

SDMMC0_CDA

SDMMC0_DA3

SDMMC0_DA2

SDMMC0_DA4

SDMMC0_DA5

SDMMC0_DA6

SDMMC0_DA7

SDMMC0_WP

8

5

7

6

4

3

2

1

9

14

15

16

13

12

11

10

J12

SD_MMCPlus_CARD

Figure 3-15. Standard SD Socket J12 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of SDMMC connector J12.

Table 3-5. Standard SD Socket J12 Pin Assignment

© 2018 Microchip Technology Inc.

Pin No Mnemonic PIO Signal Description

1 SDMMC0_DAT3_PA5 PA5 Data line

2 SDMMC0_CMD_PA1 PA1 Command/response line

User Guide

DS50002667C-page 16

Page 17

...........continued

10k

0402

5%

R62

0.1uF

50V

0402

C57

DAT2

P1

CD/DAT3

P2

CMD

P3

VDD

P4

CLK

P5

VSS

P6

DAT0

P7

DAT1

P8

POL

G4

DET

G5

GND

G1

GND

G2

GND

G3

GND

G6

DM3AT-SF-PEJM5

J14

CON FLASH Micro SD Card w DET + GND

0R

0402

R61

10k

0402

5%

R63

10uF

25V

0603

C56

1

2

3

4 5

678

68k

1206

5%

RR3

VDD_3V3

PA18

PA19

PA20

PA21

PA22

PA28

PA30

SDMMC1_CD

SDMMC1_DAT0

SDMMC1_DAT1

SDMMC1_CK

SDMMC1_CDA

SDMMC1_DAT3

SDMMC1_DAT2

Pin No Mnemonic PIO Signal Description

3 GND – GND

SAMA5D27 SOM1 Kit1

Baseboard Components

4

VDDSDHC (3.3V or

1.8V)

5 SDMMC0_CK_PA0 PA0 Clock line

6 SDMMC0_CD_PA13 PA13 Card detect

7 SDMMC0_DAT0_PA2 PA2 Data line

8 SDMMC0_DAT1_PA3 PA3 Data line

9 SDMMC0_DAT2_PA4 PA4 Data line

10 SDMMC0_DAT4_PA6 PA6 Data line

11 SDMMC0_DAT5_PA7 PA7 Data line

12 SDMMC0_DAT6_PA8 PA8 Data line

13 SDMMC0_DAT7_PA9 PA9 Data line

14 SDMMC0_WP_PA12 PA12 Write protect signal

15 GND – GND

16 GND – GND

Table 3-6. SDMMC1 Power Command

–

Power line

PIO Mnemonic Signal Description

PA11 SDMMC0_VDDSEL Select 3.3V or 1.8V

3.2.6.3 SDMMC1 Card Connector (J14)

A microSD card connector, connected to SDMMC1, is mounted on the top side of the baseboard. The

SDMMC1 communication is based on a 6-pin interface (clock, command and four data). A card detection

switch is included. The microSD connector can be used to connect any microSD card for mass storage.

Figure 3-16. SDMMC1 microSD

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 17

Page 18

Figure 3-17. microSD Socket J14 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of microSD connector J14.

Table 3-7. microSD Socket J14 Pin Assignment

Pin No Mnemonic PIO Signal Description

1 SDMMC1_DAT2 PA20 Data bit 2

2 SDMMC1_DAT3 PA21 Data bit 3

3 SDMMC1_CDA PA28 Command

4 VCC – 3.3V supply voltage

5 SDMMC1_CK PA22 Clock

6 GND – Common ground

7 SDMMC1_DAT0 PA18 Data bit 0

8 SDMMC1_DAT1 PA19 Data bit 1

9 SW1 GND Ground

10 SDMMC1_CD PA30 Card detection switch

11 GND – Common ground

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 18

Page 19

ATECC608A-SSHDA

GND

4

SDA

5

SCL

6

VCC

8

U11

0.1uF

50V

0402

C58

VDD_3V3

PD21

PD22

TWD0

TWCK0

SAMA5D27 SOM1 Kit1

...........continued

Pin No Mnemonic PIO Signal Description

12 GND – Common ground

13 GND – Common ground

14 GND – Common ground

Baseboard Components

3.2.6.4 CryptoAuthentication

ATECC608A is a member of the CryptoAuthentication family of crypto engine authentication devices with

highly secure hardware-based key storage.

The ATECC608A features a flexible command set enabling use in many applications, including

network/IoT node protection, anti-counterfeiting, firmware or media protection, secure data storage and

user password checking.

The device (U11) is mounted in an 8-lead UDFN package.

For more information, refer to the ATECC608A datasheet on www.microchip.com.

Figure 3-18. CryptoAuthentication ATECC608

Table 3-8. ATECC608 PIO Signal Descriptions

PIO Mnemonic Shared Signal Description

PD21 TWD0 SOM E2PROM

PD22 TWCK0 SOM E2PROM

™

TWI data

24AA02E48

TWI clock

24AA02E48

3.2.7 Communication Interfaces

This section describes the signals and connectors related to the ETH, USB and CAN communication

interfaces.

3.2.7.1 Ethernet 10/100 (GMAC) Port

The on-board SOM integrates a 10/100 Mbps Ethernet controller (KSZ8081RNA) allowing direct

connection to any 10/100 Mbps Ethernet-based Local Area Network, for full interaction with local servers

and wide area networks such as the Internet.

ETH signals from the SOM are connected to a RJ45 MagJack. Additionally, for monitoring and control

purposes, a LED functionality is carried on the RJ45 connector to indicate link status.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 19

Page 20

Figure 3-19. Ethernet PHY

ETH_LED0

0.1uF

50V

0402

C64

0.1uF

50V

0402

C63

470R

R69

EARTH_ETH

EARTH_ETH

GND_ETH

VDD_3V3

ETH_LED0

TX+

TX-

RX+

RX-

LINK

1

2

3

6

4

5

7

8

75

75

75 75

1nF

TD+

TD-

CT

NC

RD-

CT

TX+

TX-

RX+

RX-

RD+

Left Green LEDRight yellow LED

1

2

7

8

3

6

5

4

9

10

11

12

13

14

15

16

RJ45

J15

RJ45 J00-0061

TX_P

TX_N

RX_N

RX_P

Figure 3-20. Ethernet RJ45 Connector J15 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of Ethernet connector J15.

Table 3-9. Ethernet RJ45 Connector J15 Pin Assignment

Pin No Mnemonic Signal Description

1 TX+ Transmit positive differential pair

2 TX- Transmit negative differential pair

3 RX+ Receive positive differential pair

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 20

Page 21

SAMA5D27 SOM1 Kit1

...........continued

Pin No Mnemonic Signal Description

4 Decoupling capacitor –

5 Decoupling capacitor –

6 RX- Receive negative differential pair

7 NC –

8 EARTH / GND Common ground

9 ACT LED (A) LED activity (not used)

10 ACT LED (K) LED activity (not used)

11 LINK LED (K) LED link connection

12 LINK LED (A) LED link connection

13 EARTH / GND Common ground

14 EARTH / GND Common ground

Baseboard Components

15 NC –

16 NC –

3.2.7.2 USB Interfaces

The USB (Universal Serial Bus) is a hot-pluggable general-purpose high-speed I/O standard for computer

peripherals. The standard defines connector types, cabling, and communication protocols for

interconnecting a wide variety of electronic devices. The USB 2.0 Specification defines data transfer rates

as high as 480 Mbps (also known as High Speed USB). A USB host bus connector uses 4 pins: a power

supply pin (5V), a differential pair (D+ and D- pins) and a ground pin.

The baseboard features three USB communication ports named USB-A to USB-C:

• USB-A device interface

– One USB device standard micro-AB connector.

– This port offers a VBUS detection function through the R81-R83 resistor ladder.

– The USB-A port is used as a secondary power source and as a communication link for the

baseboard, and derives power from the PC over the USB cable. In most cases, this port is

limited to 500 mA.

• USB-B (host port B high- and full-speed interface)

– One USB host type C connector.

– The USB-B host port is equipped with a 500 mA high-side power switch.

• USB-C (High-Speed Inter-Chip/HSIC port)

– One USB high-speed host port with an HSIC interface.

– The port is connected to a single 2-pin header (not populated).

3.2.7.3 USB-A Interface

The figure below shows the USB implementation on the USB-A port terminated on a micro USB type

microAB connector.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 21

Page 22

100k

0402

1%

R70

USB2.0 MICRO-B FEMALE

ID

4

VBUS

1

GND

5

D-

2

D+

3

0

J17

20pF

50V

0402

C65

0.1uF

50V

0402

C12

200k

0402

1%

R71

EARTH_USB_A

VBUS_USBA

USBA_DM

USBA_DP

PD20

USBA_VBUS_5V

USBA_N

USBA_P

SAMA5D27 SOM1 Kit1

Baseboard Components

The USB-A port (J17) features a VBUS insert detection function through ladder-type resistors R70 and

R71.

Figure 3-21. USB-A Type microAB Connector

Table 3-10. USB-A PIO Signal Description

PIO Mnemonc Shared Signal Description

PD20 USBA_VBUS_5V – VBUS insertion

detection

Figure 3-22. USB-A Type microAB Connector J17 Location

The table below describes the pin assignment of USB-A connector J17.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 22

Page 23

Table 3-11. USB-A Connector J17 Pin Assignment

USBB_VBUS_5V

36k

0402

1%

R79

330pF

0402

C69

VBUS1

A4

GND8

28

GND5

25

GND3

B12

GND2

A12

GND1

A1

VBUS4

B4

VBUS2

A9

VBUS3

B9

GND4

B1

TX1+

A2

TX1-

A3

RX1+

B11

RX1-

B10

D1+

A6

D1-

A7

D2+

B6

D2-

B7

CC1

A5

TX2+

B2

TX2-

B3

RX2+

A11

RX2-

A10

SBU1

A8

SBU2

B8

CC2

B5

GND7

27

GND6

26

USB 3.1 C

J19

36k

0402

1%

R78

330pF

0402

C70

EARTH_USB_B

EARTH_USB_B

VDD_3V3

USBB_DP

USBB_DM

USBB_P

USBB_N

Pin No Mnemonic Signal Description

1 VBUS 5V power

2 DM Data minus

3 DP Data plus

4 ID On-the-go identification

5 GND Common ground

3.2.7.4 USB-B Interface

The figure below shows the USB implementation on the USB-B port terminated on USB Type C

connector J19.

Figure 3-23. USB-B Type C Connector

SAMA5D27 SOM1 Kit1

Baseboard Components

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 23

Page 24

Figure 3-24. USB-B Type C Connector J19 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of USB-B connector J19.

Table 3-12. USB-B Connector J19 Pin Assignment

Pin No Mnemonic Signal Description

A1 GND Ground return

A2 SSTXp1 SuperSpeed differential pair #1, TX, positive (NOT USED)

A3 SSTXn1 SuperSpeed differential pair #1, TX, negative (NOT USED)

A4 VBUS Bus power

A5 CC1 Configuration channel

A6 DP1 USB 2.0 differential pair, position 1, positive

A7 DN1 USB 2.0 differential pair, position 1, negative

A8 SBU1 Sideband use (SBU)

A9 VBUS Bus power

A10 SSRXn2 SuperSpeed differential pair #2, RX, negative (NOT USED)

A11 SSRXp2 SuperSpeed differential pair #2, RX, positive (NOT USED)

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 24

Page 25

USBB_VBUS_5V

EN

1

FLG2GND

3

NC

4

NC

5

OUT6IN

7

OUT

8

USB Power Switch

U13

10k

0402

5%

R138

10uF

25V

0603

C67

0.1uF

50V

0402

C68

180R

L12

0.1uF

50V

0402

C66

10k

0402

5%

R77

VDD_MAIN_5V

VDD_3V3

PD19

PA27

EN:Active High

USBB_POWR_EN

USBB_OVCUR

SAMA5D27 SOM1 Kit1

Baseboard Components

...........continued

Pin No Mnemonic Signal Description

A12 GND Ground return

B12 GND Ground return

B11 SSRXp1 SuperSpeed differential pair #1, RX, positive (NOT USED)

B10 SSRXn1 SuperSpeed differential pair #1, RX, negative (NOT USED)

B9 VBUS Bus power

B8 SBU2 Sideband use (SBU)

B7 DN2 USB 2.0 differential pair, position 2, negative

B6 DP2 USB 2.0 differential pair, position 2, positive

B5 CC2 Configuration Channel

B4 VBUS Bus power

B3 SSTXn2 SuperSpeed differential pair #2, TX, negative (NOT USED)

B2 SSTXp2 SuperSpeed differential pair #2, TX, positive (NOT USED)

B1 GND Ground return

3.2.7.4.1 USB-B Power Switch

The USB-B Host port is equipped with a 500 mA high-side power switch for self-powered and buspowered applications. If the client device is bus-powered, the carrier can supply a 5V, 500mA power to

the client device. The USBB_EN_5V_PA27 signal controls the power switch and current limiter, the

Microchip MIC2025, which in turn supplies power to a bus-powered client device. Per the USB

specification, bus-powered USB 2.0 devices are limited to a maximum of 500 mA. The MIC2025 limits the

current and indicates an overcurrent with the USBB_OVCUR_PD19 signal.

Figure 3-25. USB-B Power Switch

Table 3-13. Power Switch PIO Signal Descriptions

PIO Mnemonic Shared Signal Description

PA27 USBB_POWR_EN USBB_EN_5V

PD19 USBB_OVCUR

© 2018 Microchip Technology Inc.

– Power switch enable

(active high)

– Indicates overcurrent

(open drain)

User Guide

DS50002667C-page 25

Page 26

3.2.7.5 HSIC Interface

1 2

HDR-2.54 Male 1x2

J18

HSIC_DATA

HSIC_STRB

62R

1210

1%

R66

0R

0402

R68

0.1uF

50V

0402

C59

0.1uF

50V

0402

C61

1

2

3

1727023

J16

4.7uF

10V

0402

C60

62R

1210

1%

R67

0R

0402

R65

15pF

50V

0402

C62

VDD_3V3

VDD_MAIN_5V

PC26

PC27

CANTX1

CANRX1

RXD

4

TXD

1

GND

2

VCC

3

VIO

5

CANL

6

CANH

7

STBY

8

EP

9

ATA6561-GBQW

U12

High-Speed Inter-Chip (HSIC) is a standard for USB chip-to-chip interconnect with a 2-signal (strobe,

data) source synchronous serial interface using 240 MHz DDR signaling to provide only high-speed 480

Mbps data rate.

The interface operates at high speed, 480 Mbps, and is fully compatible with existing USB software

stacks. It meets all data transfer needs through a single unified USB software stack.

The HSIC interface is connected to two-point header J18. This connector is not mounted.

Figure 3-26. HSIC Interface J18

3.2.7.6 CAN Interface

This section lists the signals related to the Controller Area Network (CAN) interface.

The CAN interface transmits and receives signals from the SOM. CAN PIOs PC26 and PC27 are

connected to the CAN transceiver (ATA6561) and the output signals from the transceiver are connected

to the screw connector (J16) physically located on top of the baseboard.

SAMA5D27 SOM1 Kit1

Baseboard Components

Figure 3-27. CAN Interface

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 26

Page 27

Figure 3-28. CAN Connector J16 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

Table 3-14. CAN Connector J16 Pin Assignment

Pin Mnemonic Signal Description

1 CANH Differential positive

2 CANL Differential negative

3 GND Ground

3.3 External Interfaces

3.3.1 LCD TFT Interface

The baseboard provides a FPC connector with 24 bits of data and control signals to the LCD interface.

Other signals are used to control the LCD and are available on connector J26: TWI, SPI, two GPIOs for

interrupt, 1-wire and power supply lines.

This connector is used to connect LCD display type TM43xx series, TM5000 series or TM7000 series

from PDA Inc. (www.pdaatl.com).

A 50-pin FPC (J26) header is provided on the baseboard to interface the LCD module with 24-bit parallel

RGB.

The connector provides two PIOs as interrupts, one SPI and a TWI port to interface the MaXTouch

touch controller or QTouch® button controller embedded on the LCD module.

®

In order to operate correctly out of the processor with various LCD modules, two voltage lines are

available: 3.3V and 5VCC (default). Both are selected by 0R resistors R81 and R83.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 27

Page 28

Figure 3-29. LCD Expansion Header Interface

TWD_LCD

TWCK_LCD

0R0402

R81 DNP

100R

0402

5%

R119

0R0402

R85

0R0402

R83

VDD_3V3VDD_MAIN_5V

PB12

PB13

PB14

PB15

PB16

PB17

PB18

PB19

PB20

PB21

PB22

PB23

PB24

PB25

PB26

PB27

PB28

PB29

PB30

PB31

PC0

PC1

PC2

PC5

PC6

PC7

PC8

PA14

PC4

PA15

PA16

PA17

PD1

PC25

LCD_PWM_PC3

NRST

PB11

PA17

SPI0_ SPCK

SPI0_ MOSI

SPI0_ MISO

SPI0_NPCS0

LCDDAT0

LCDDAT6

LCDDAT5

LCDDAT4

LCDDAT3

LCDDAT2

LCDDAT1

LCDDAT11

LCDDAT10

LCDDAT9

LCDDAT8

LCDDAT7

LCDDAT16

LCDDAT15

LCDDAT14

LCDDAT13

LCDDAT12

LCDDAT22

LCDDAT21

LCDDAT20

LCDDAT19

LCDDAT18

LCDDAT17

LCDDEN

LCDHSYNC

LCDVSYNC

LCDPCK

LCDDAT23

IRQ1

IRQ2

LCDPWM

LCDDISP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

MNT

FFC

FFC/FPC 50P Female

J26

SAMA5D27 SOM1 Kit1

Baseboard Components

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 28

Page 29

Figure 3-30. LCD Connector J26 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of LCD connector J26.

Table 3-15. LCD Connector J26 Pin Assignment

Pin No Signal PIO Signal RGB Interface Function

1 ID PA17 ID Shared with SPI_NPCS0 pin 40

2 GND GND GND GND

3 LCDDAT0 PB11 D0 Data line (BLUE0)

4 LCDDAT1 PB12 D1 Data line (BLUE1)

5 LCDDAT2 PB13 D2 Data line (BLUE2)

6 LCDDAT3 PB14 D3 Data line (BLUE3)

7 – – GND GND

8 LCDDAT4 PB15 D4 Data line (BLUE4)

9 LCDDAT5 PB16 D5 Data line (BLUE5)

10 LCDDAT6 PB17 D6 Data line (BLUE6)

11 LCDDAT7 PB18 D7 Data line (BLUE7)

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 29

Page 30

SAMA5D27 SOM1 Kit1

Baseboard Components

...........continued

Pin No Signal PIO Signal RGB Interface Function

12 – GND GND GND

13 LCDDAT8 PB19 D8 Data line (GREEN0)

14 LCDDAT9 PB20 D9 Data line (GREEN1)

15 LCDDAT10 PB21 D10 Data line (GREEN2)

16 LCDDAT11 PB22 D11 Data line (GREEN3)

17 – – GND GND

18 LCDDAT12 PB23 D12 Data line (GREEN4)

19 LCDDAT13 PB24 D13 Data line (GREEN5)

20 LCDDAT14 PB25 D14 Data line (GREEN6)

21 LCDDAT15 PB26 D15 Data line (GREEN7)

22 – GND GND GND

23 LCDDAT16 PB27 D16 Data line (RED0)

24 LCDDAT17 PB28 D17 Data line (RED1)

25 LCDDAT18 PB29 D18 Data line (RED2)

26 LCDDAT19 PB30 D19 Data line (RED3)

27 – – GND GND

28 LCDDAT20 PB31 D20 Data line (RED4)

29 LCDDAT21 PC0 D21 Data line (RED5)

30 LCDDAT22 PC1 D22 Data line (RED6)

31 LCDDAT23 PC2 D23 Data line (RED7)

32 – GND GND GND

33 LCDPCK PC7 PCLK Pixel clock

34 LCDVSYNC PC5 VSYNC/CS Vertical sync

35 LCDHSYNC PC6 HSYNC/WE Horizontal sync

36 LCDDEN PC8 DATA_ENABLE Data enable

37 SPI_SPCK PA14 SPI_SCK SPI clock

38 SPI_MOSI PA15 SPI_MOSI SPI Master OUT Slave IN

39 SPI_MISO PA16 SPI_MISO SPI Master IN Slave OUT

40 SPI_NPCS0 PA17 SPI_CS SPI chip select

41 LCDDISP PC4 ENABLE Display enable signal

42 TWD PD4 TWI_SDA I2C data line (maXTouch)

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 30

Page 31

...........continued

TWD_ISC

PC22

PC21

PC19

TWCK_ISC

PC18

PC20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

22

2123

24

25

26

27

28

29

30

J27

VDD_3V3

PC9

PC10 PC11

PC12 PC13

PC14 PC15

PC16 PC17

PC23

PC24

PD6 PD7

ISC_D10

ISC_D8

ISC_D6

ISC_D4

ISC_D2

ISC_D0

ISC_PCK

ISC_HSYNC

ISC_VSYNC

ISC_MCK

ISC_PWD

ISC_D11

ISC_D9

ISC_D7

ISC_D5

ISC_D3

ISC_RST

ISC_D1

Pin No Signal PIO Signal RGB Interface Function

43 TWCK PD5 TWI_SCL I2C clock line (maXTouch)

44 GPIO PD1 IRQ1 maXTouch interrupt line

45 GPIO PC25 IRQ2 Interrupt line for other I2C devices

46 LCDPWM PC3 PWM Backlight control

47 RESET nRST RESET Reset for both display and maXTouch

48 Main_5V/3V3 VCC VCC 3.3V or 5V supply (R81/R83 selected)

49 Main_5V/3V3 VCC VCC 3.3V or 5V supply (R81/R83 selected)

50 GND GND GND GND

3.3.2 Image Sensor (ISC) Interface

This section describes the signals and connectors related to the ISC interface.

The Image Sensor Controller (ISC) system manages incoming data from a parallel or serial CSI-2 based

CMOS/CCD sensor. The system supports a single active interface, as well as the ITU-R BT 656/1120 422

protocol with an 8-bit or 10-bit data width and raw Bayer format. The internal image processor includes

adjustable white balance, color filter array interpolation, color correction, gamma correction, 12-bit to 10bit compression, programmable color space conversion, as well as horizontal and vertical chrominance

subsampling module.

SAMA5D27 SOM1 Kit1

Baseboard Components

Figure 3-31. ISC Interface

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 31

Page 32

Figure 3-32. ISC Connector J27 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of ISC connector J27.

Table 3-16. ISC Connector J27 Pin Assignment

SAMA5D27 Signal Pin No Signal SAMA5D27

Function PIO PIO Function

3.3V power – VDD_3V3 1 2 GND – Ground

3.3V power – VDD_3V3 3 4 GND – Ground

Reset PD6 ISC_RST 5 6 ISC_PWD PD7 Power

down

TWI clock PD5 TWCK_ISC 7 8 TWD_ISC PD4 TWI data

Ground – GND 9 10 ISC_MCK PC24 Master

clock

Ground – GND 11 12 ISC_VSYNCPC22 Vertical

sync

Ground – GND 13 14 ISC_HSYNCPC23 Horizontal

sync

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 32

Page 33

...........continued

2.2k

0402

5%

R74

10k

0402

5%

R137

3

1

2

BSS138

Q9

100R

0402

5%

R136

GREEN

BLUE

2

1

RED

4

3

RED, GREEN, BLUE

D5

LED_RGB_CLV1A

3

1

2

BSS138

Q8

3

1

2

BSS138

Q10

100R

0402

5%

R135

1k

0402

5%

R76

10k

0402

5%

R133

100R

0402

5%

R134

2.2k

0402

5%

R75

VDD_3V3

PB1

PA31

PA10

LED_Red

LED_Green

LED_blue

SAMA5D27 Signal Pin No Signal SAMA5D27

Function PIO PIO Function

Ground – GND 15 16 ISC_PCK PC21 Clock

Ground – GND 17 18 ISC_D0 PC9 Data0

Data1 PC10 ISC_D1 19 20 ISC_D2 PC11 Data2

Data3 PC12 ISC_D3 21 22 ISC_D4 PC13 Data4

Data5 PC14 ISC_D5 23 24 ISC_D6 PC15 Data6

Data7 PC16 ISC_D7 25 26 ISC_D8 PC17 Data8

Data9 PC18 ISC_D9 27 28 ISC_D10 PC19 Data10

Data11 PC20 ISC_D11 29 30 GND – Ground

Note: ISC and LCD share the same TWI interface.

3.3.3 RGB LED

The baseboard features one RGB LED which can be controlled by the user. The three LED cathodes are

controlled via GPIO PWM or timer/counter pins.

SAMA5D27 SOM1 Kit1

Baseboard Components

Figure 3-33. RGB LED Indicators

Table 3-17. RGB LED PIOs

Signal Shared PIO Function

LED_RED – PA10 TIOA1

LED_GREEN PWM MBUS1 PB1 PWML1

3.4 Debugging Capabilities

The baseboard includes two main debugging interfaces to provide debug-level access to the SAMA5D2:

© 2018 Microchip Technology Inc.

LED_BLUE PWM MBUS2 PA31 PWML0

User Guide

DS50002667C-page 33

Page 34

• One UART through USB J-Link-CDC

JTAG_TDO

NRST

JTAG_TMS

JTAG_TDI

JTAG_TCK

RTCK_IN

100k

0402

1%

R48

100k

0402

1%

R46

100k

0402

1%

R47

100R

0402

5%

R51

1

2

3

4

5

6

7

8

9

10

HDR-1.27 Male 2x5

J11

0R

0402

R50

10k

0402

5%

R120

VDD_3V3

VDD_3V3

• Two JTAG interfaces, one connected from the MPU using connector J11 and one through the JLink-OB interface USB port J10

3.4.1 Debug JTAG

This section describes the signals and connectors related to the JTAG interface.

A 10-pin JTAG header is provided on the baseboard to facilitate software development and debugging

using various JTAG emulators. The interface signals have a voltage level of 3.3V.

Figure 3-34. JTAG Interface

Figure 3-35. JTAG Connector J11 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of JTAG connector J11.

Table 3-18. JTAG/ICE Connector J11 Pin Assignment

Pin No Mnemonic Signal Description

1 VTref. 3.3V power This is the target reference voltage (main 3.3V).

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 34

Page 35

SAMA5D27 SOM1 Kit1

Baseboard Components

...........continued

Pin No Mnemonic Signal Description

2 TMS TEST MODE SELECT JTAG mode set input into target processor

3 GND Common ground

TCK TEST CLOCK - Output timing signal,

4

for synchronizing test logic and control

register access

5 GND Common ground

TDO JTAG TEST DATA OUTPUT - Serial

6

data input from the target

RTCK - Input return test clock signal from

7

the target

TDI TEST DATA INPUT - Serial data output

8

line, sampled on the rising edge of the TCK

signal

JTAG clock signal into target processor

JTAG data output from target processor

Some targets with a slow system clock must

synchronize the JTAG inputs to internal clocks. In

the present case, such synchronization is

unneeded and TCK is merely looped back into

RTCK.

JTAG data input into target processor

9 GND Common ground

10 nRST RESET

3.4.2 Embedded Debugger (J-Link-OB) Interface

The baseboard includes a built-in SEGGER J-Link-On-Board device. The functionality is implemented

with an ATSAM3U4C microcontroller in an LQFP100 package. The ATSAM3U4C provides JTAG

functions and a bridge USB/Serial debug port (CDC). One dual LED D4 mounted on the baseboard

shows the status of the J-Link-On-Board device.

J-Link-OB-ATSAM3U4C was designed in order to provide an efficient, low-cost, on-board alternative to

the standard J-Link.

The internal J-Link-OB connects to the target only after it receives a first command; otherwise, it remains

disabled.

The USB J-Link-OB port is used as a secondary power source and as a communication link for the

baseboard, and derives power from the PC over the USB cable. This port is limited in most cases to 500

mA. A single PC USB port is sufficient to power the baseboard.

Active-low reset signal. Target processor reset

signal.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 35

Page 36

Figure 3-36. J-Link-OB Interface

NRST_3U

TDI_3U

TDO_3U

TCK_3U

TMS_3U

ENSPI

ENSPI

TRSTIN

TRSTOUT

TRESOUT

3U_PA26

LED1_3U

TDI_IN

TX_3U

TMS_IN

TCK_OUT

TMS_OUT

TDO_IN

TDI_OUT

TCK_IN

TCK_OUT

LED2_3U

RX_3U

Xin

Xout

Xout Xin

VDDout

NRST

VDDout

3U_PA25

RTCK_IN

Xin

39R 04021%

R40

0.1uF

50V

0402

C34

10000pF

16V 0402

C25

1N4148

D3

100k 04021%

R39

4.7uF

10V

0402

C33

12MHz

Y1

0R

0402

R139

0.1uF

50V

0402

C31

39R 04021%

R41

0.1uF

50V

0402

C71

6.8k04021%

R37

ID

4

VBUS

1

GND

5

D-

2

D+

3

0

USB2.0 MICRO-B FEMALE

J10

220R 04025%

R43

0.1uF

50V

0402

C40

10k 04025%

R34

0.1uF

50V

0402

C41

10pF 50V

0402

C27

150R

R33

10000pF

16V

0402

C26

12

J8 DNP

0.1uF

50V

0402

C45

VDDANA

1

ADVREF

2

GNDANA

3

AD12BVREF

4

PA22/PGMD12

5

PA30

6

PB37PB4

8

VDDCORE_3

9

PA13/PGMD5

10

GND2

61

PA15/PGMD7

12

PA16/PGMD8

13

PA17/PGMD9

14

PB1615PB15

16

PA18/PGMD10

17

PA19/PGMD11

18

PA20/PGMD12

19

PA21/PGMD13

20

PA23/PGMD15

21

XIN32

50

PA24

23

PA25

24

PA26

25

PA0/PGMNCMD

26

PA1/PGMRDY

27

PA2/PGMNOE

28

PA3/PGMNVALID

29

PA4/PGMM0

30

PA5/PGMM1

31

PA6/PGMM2

32

NRST

57

VDDCORE_4

34

GND1

35

VDDIO_336VDDCORE_5

59

DFSDM

80

GND3

89

VDDUTMI79VDDIN

53

FWUP

42

ERASE

43

TEST

44

XIN

75

XOUT32

49

VDDIO_4

22

TDI

51

VDDOUT

52

PA12/PGMD4

41

TDO/TRACESWO

54

TMS/SWDIO

55

TCK/SWCLK

56

PA7/PGMM3

33

PB24

58

PA8/PGMD0

37

VDDIO_2

60

PA14/PGMD6

11

PB2362PB22

63

PB1469PB10

70

PB9

71

GNDPLL

72

PB8

100

PB799PB6

98

PB13

95

PB12

94

PB11

93

PB292PB191PB0

90

PA10/PGMD2

39

VDDIO_1

88

VDDCORE_1

87

PA31

86

PA29

85

PA28

84

VDDCORE_2

83

GNDUTMI

82

DFSDP

81

DHSDM

77

DHSDP

76

NRSTB

47

XOUT

74

VDDPLL

73

PA11/PGMD3

40

PA9/PGMD1

38

PB2065PB1966PB1867PB17

68

PB5

97

PA27

96

PB21

64

VDDBU

45

GNDBU

46

VBG

78

JTAGSEL

48

ATSAM3U4CA-AU

U4

0.1uF

50V

0402

C39

2 1

43

GREEN

RED

RED, GREEN

D4

0.1uF

50V

0402

C43

100R

0402

5%

R31

180R

L9

0.1uF

50V

0402

C36

8.2pF

50V

0402

C29

0.1uF

50V

0402

C35

4.7uF

10V

0402

C38

0.1uF

50V

0402

C32

220R 04025%

R42

100R

0402

5%

R30

0.1uF

50V

0402

C30

0R0402

R36

EN

1

GND2OUT

3

VDD

4

12MHz

Y2

0.1uF

50V

0402

C42

0.1uF

50V

0402

C37

8.2pF

50V

0402

C28

0R0402

R29

0.1uF

50V

0402

C44

100R

0402

5%

R35

VDD_3V3_3U

VDD_3V3_3U

EARTH0

VDD_3V3_3U

VDD_3V3_3U

VDD_3V3_3U

VDD_3V3_3U

VBUS_JLINK

VDD_3V3_3U

VDD_3V3_3U

NRST

TRESIN

JLINK

SAM3U

BOT TOP

SideSide

1 2

3 4

7 8

9 10

11 12

131514

16

J6

padson PCB

J10_USB_N

J10_USB_P

DHSD_N

DHSD_P

3U_PA26

10k

0402

5%

R32

12

HDR-2.54 Male 1x2

J7

VDD_3V3_3U

Disable JLINK JTAG

3U_PA25

12

HDR-2.54 Male 1x2

J9

10k

0402

5%

R38

VDD_3V3_3U

Disable JLINK CDC

SAMA5D27 SOM1 Kit1

Baseboard Components

3.4.2.1 Disabling J-Link-OB (ATSAM3U4C)

© 2018 Microchip Technology Inc.

Jumper J7 disables the J-Link-OB-ATSAM3U4C JTAG functionality. When the jumper is installed, it

grounds pin 25 (PA26) of the ATSAM3U4C that is normally pulled high.

• Jumper J7 not installed: J-Link-OB-ATSAM3U4C is enabled and fully functional.

• Jumper J7 installed: J-Link-OB-ATSAM3U4C is disabled and an external JTAG controller can be

used through the 10-pin JTAG port J11.

Jumper JP9 disables only the J-Link functionality. The debug serial com port that is emulated through a

Communication Device class (CDC) of the same USB connector remains operational (if J9 is open).

Figure 3-37. Enabling/Disabling J-Link-OB and J-Link-CDC

Jumper J7 disables the JTAG functionality only. The debug serial com port that is emulated through a

CDC of the same USB connector remains operational.

Jumper J7 J-Link-OB JTAG MPU

When J7 is on and the J-Link-OB-ATSAM3U4C JTAG disabled, the JTAG function is available through

connector J11. A quad analog switch (NLAS3899B) is used to select and isolate the JTAG interface.

Table 3-19. J-Link-OB and J-Link-CDC Jumper J7 Settings

Open Active Inactive

Closed Inactive Active

User Guide

DS50002667C-page 36

Page 37

Table 3-20. J-Link-OB and J-Link-CDC Jumper J9 Settings

JTAG_TDI

3U_PA26 TCK_OUT

TCK_IN

3U_PA26

TMS_OUT

TMS_IN

TDI_OUT

TDI_IN

TDO_IN

JTAG_TCK

JTAG_TDO

JTAG_TMS

150R

R45

NCA

1

A-B IN

2

NOB

3

COMB

4

NCB

5

GND

6

NOC

7

COMC

8

NCC

9

C-D IN

10

NOD

11

COMD

12

NCD

13

VCC

14

NOA

15

COMA

16

EP

17

NLAS3899B

U8

0.1uF

50V

0402

C48

150R

R44

150R

R49

VDD_3V3_3U

PD28

PD29

PD30

PD27

SOM_TDI

SOM_TD0

SOM_TMS

SOM_TCK

TX_3U

RX_3U

3U_PA25

0.1uF

50V

0402

C47

OE

1

A

2

Y

4

GND

3

VCC

5

NL17SZ126-D

U5

0.1uF

50V

0402

C46

OE

1

A

2

Y

4

GND

3

VCC

5

NL17SZ126-D

U6

VDD_3V3_3U

VDD_3V3_3U

PD3

PD2

DBGU_TXD

DBGU_RXD

VDD_3V3_3U

Jumper J9 J-Link-CDC

Open Active

Closed Inactive

Figure 3-38. JTAG Switch

SAMA5D27 SOM1 Kit1

Baseboard Components

3.4.3 Hardware UART via J-Link-CDC

In addition to the J-Link-OB functionality, the ATSAM3U4C microcontroller provides a bridge to a debug

serial port (UART DBGU) of the processor on a SOM board. The port is made accessible over the same

USB connection used by JTAG by implementing Communication Device Class (CDC), which allows

terminal communication with the target device.

This feature is enabled only if microcontroller pin 24 (PIO PA25) is not grounded. The pin is normally

pulled high and controlled by jumper J9.

• Jumper J9 not installed: the J-Link-CDC is enabled and fully functional.

• Jumper J9 installed: the J-Link-CDC device is disabled.

The USB Communications Device Class (CDC) enables conversion of the USB device into a serial

communication device. The target device running USB-Device CDC is recognized by the host as a serial

interface (USB2COM, virtual COM port) without the need to install a special host driver (since the CDC is

standard). All PC software using a COM port work without modifications with this virtual COM port. Under

Windows®, the device shows up as a COM port; under Linux, as a /dev/ACMx device. This enables the

user to use host software which was not designed to be used with USB, such as a terminal program.

Figure 3-39. Debug COM Port Isolation

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 37

Page 38

SAMA5D27 SOM1 Kit1

Table 3-21. Debug COM Port PIOs Signal Descriptions

PIO Mnemonic Shared Signal Description

PD2 DBGU_RXD - Receive data

PD3 DBGU_TXD - Transmit data

Figure 3-40. J-Link-OB and CDC USB Connector J10 Location

Baseboard Components

The table below describes the pin assignment of USB connector J14.

Table 3-22. USB Connector J14 Pin Assignment

Pin No Mnemonic Signal Description

1 VBUS 5V power

2 DM Data minus

3 DP Data plus

4 ID Not used

5 GND Common ground

3.4.3.1 Baseboard Edge Connector

This connector (J6) is used to upgrade or download code to the ATSAM3U4C microcontroller JLINK-OB.

The J-Link-OB software is factory-programmed.

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 38

Page 39

3.5 PIO Usage on Expansion Connectors

330R 04021%

R113

0R 0402

R118

330R 04021%

R111

330R 04021%

R114

330R 04021%

R112

0R 0402

R117

0R 0402

R115

330R 04021%

R110

330R 04021%

R116

1

2

3

4

5

6

7

8

9

10

FTS-105-01-L-DV

J31

PIOBU2

PIOBU4

PIOBU6

PIOBU7

PIOBU3

PIOBU5

RXD

COMPP

COMPN

This section describes the signals and connectors related to the PIO usage on expansion connectors.

The baseboard includes numerous peripherals. Many of these are connected to the GPIO block so that

the I/O pins can be configured to carry out many alternative functions. This provides great flexibility to

select a function multiplexing scheme for the pins that satisfy the interface need for a particular

application.

Note that most pins are configured as GPIO inputs, with a 100 Kohm pull-up resistor, after reset.

3.5.1 PIOBU Interface

The baseboard features eight tamper pins for static or dynamic intrusion detection, UART reception, and

two analog pins for comparison.

For a description of intrusion detection, refer to the SAMA5D2 datasheet, chapter "Security Module

(SECUMOD)".

Figure 3-41. PIOBU Connector

SAMA5D27 SOM1 Kit1

Baseboard Components

Figure 3-42. PIOBU Connector J31 Location

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 39

Page 40

The table below describes the pin assignment of PIOBU connector J31.

TWCK_mBUS1

TWD_mBUS1MOSI_mBUS1

MISO_mBUS1

SPCK_mBUS1

NPCS1

1 2

HDR-2.54 Male 1x2

J22

0R

0402

R80

123456

7

8

HDR-2.54 Female 1x8

J25

HDR-2.54 Female 1x8

123456

7

8

J24

VDD_3V3 VDD_MAIN_5V

PB1

PB2

PD25

PB0

PB3

PB4

TX_mBUS1

RX_mBUS1

INT_mBUS1

PWM_mBUS1

RST_mBUS1

AN_mBUS1

Shunt 2.54mm 1x2

JP4

Table 3-23. PIOBU Connector J31 Pin Assignment

Signal Pin No. Signal

PIOBU2 1 2 PIOBU3

PIOBU4 3 4 PIOBU5

PIOBU6 5 6 RXD

PIOBU7 7 8 COMPP

COMPN 9 10 GND

3.5.2 mikroBUS Interfaces

The SAMA5D27 SOM1 Kit1 hosts two pairs of 8-pin female headers acting as mikroBus interfaces. The

mikroBUS standard defines the main board sockets and add-on boards (a.k.a. "click boards") used for

interfacing microprocessors with integrated modules with proprietary pin configuration and silkscreen

markings. The pinout consists of three groups of communication pins (SPI, UART and TWI), four

additional pins (PWM, interrupt, analog input and reset) and two power groups (+3.3V and GND on the

left, and 5V and GND on the right 1x8 header).

SAMA5D27 SOM1 Kit1

Baseboard Components

Figure 3-43. mikroBUS1 Interface Connectors

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 40

Page 41

Figure 3-44. mikroBUS1 Connectors J24 and J25 Location

SAMA5D27 SOM1 Kit1

Baseboard Components

The table below describes the pin assignment of mikroBUS1 connectors J24 and J25.

Table 3-24. mikroBUS1 Connectors J24 and J25 Pin Assignment

SAMA5D27

Function PIO PIO Function

Analog input PD25 AN 1 1 PWM PB1 PWM

Reset PB2 RST 2 2 RST PB0 Interrupt

SPI chip select PD0 NPCS 3 3 RX PB3 UART receive

SPI clock PC30 SPCK 4 4 TX PB4 UART transmit

SPI MISO PC29 MISO 5 5 TWCK PA23 TWI clock

SPI MOSI PC28 MOSI 6 6 TWD PA24 TWI data

3.3VCC – 3.3V 7 7 +5V NC 5V supply

GROUND – GND 8 8 GND _ GROUND

J24 Signal Pin No. J25 Signal

SAMA5D27

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 41

Page 42

TWCK_mBUS2

TWD_mBUS2

MISO_mBUS2

MOSI_mBUS2

NPCS0

SPCK_mBUS2

0R

0402

R109

1234

56

7

8

HDR-2.54 Female 1x8

J29

1234

56

7

8

HDR-2.54 Female 1x8

J30

1 2

HDR-2.54 Male 1x2

J28

VDD_3V3

VDD_MAIN_5V

PA26

PA31PD26

PA25

PD23

PD24

TX_mBUS2

RX_mBUS2

INT_mBUS2

PWM_mBUS2

RST_mBUS2

AN_mBUS2

Shunt 2.54mm 1x2

JP5

SAMA5D27 SOM1 Kit1

Figure 3-45. mikroBUS2 Interface Connectors

Figure 3-46. mikroBUS2 Interface Connectors J29 and J30 Location

Baseboard Components

The table below describes the pin assignment of mikroBUS2 connectors J29 and J30.

Table 3-25. mikroBUS2 Connectors J29 and J30 Pin Assignment

SAMA5D27

Function PIO PIO Function

Analog input PD26 AN 1 1 PWM PA31 PWM

Reset PA26 RST 2 2 RST PA25 Interrupt

SPI chip select PC31 NPCS 3 3 RX PD23 UART receive

SPI clock PC30 SPCK 4 4 TX PD24 UART transmit

SPI MISO PC29 MISO 5 5 TWCK PA23 TWI clock

SPI MOSI PC28 MOSI 6 6 TWD PA24 TWI data

3.3VCC – 3.3V 7 7 +5V NC 5V supply

© 2018 Microchip Technology Inc.

J29 Signal Pin No. J30 Signal

User Guide

SAMA5D27

DS50002667C-page 42

Page 43

...........continued

PMOD_3

PMOD_2

PMOD_1

PMOD_4

HDR-2.54 Female 1x6

1

2

3

4

5

6

J21

VDD_3V3

SAMA5D27

SAMA5D27 SOM1 Kit1

Baseboard Components

SAMA5D27

Function PIO PIO Function

GROUND – GND 8 8 GND _ GROUND

3.5.3 Pmod Interface

Pmod devices are Digilent’s line of small I/O interface boards that offer an ideal way to extend the

capabilities of programmable logic and embedded control boards. They allow sensitive signal conditioning

circuits and high-power drive circuits to be placed where they are most effective - near sensors and

actuators.

The Pmod interface on the baseboard is a 6-pin connector. The 6-pin version provides four digital I/O

signal pins, one power pin and one ground pin.

Note: The Pmod interface is shared with the ISC interface. Thus, the ISC and Pmod interfaces cannot

be used at the same time.

Figure 3-47. Pmod Interface Connector

J29 Signal Pin No. J30 Signal

© 2018 Microchip Technology Inc.

User Guide

DS50002667C-page 43

Page 44

Figure 3-48. Pmod Connector J21 Location

PMOD_1

PMOD_2

Flexcom3_IO0_MOSI

PMOD_3

Flexcom3_IO3_NPCS0

PMOD_4

Flexcom3_IO4_NPCS1

PC19 Flexcom3_IO1_MISO

PC20 Flexcom3_IO0_MOSI

PC21 Flexcom3_IO3_NPCS0

PC22 Flexcom3_IO4_NPCS1

PC18 Flexcom3_IO2_SPCK

Flexcom3_IO2_SPCK

Flexcom3_IO1_MISO

1

2

3