Page 1

RN2483 LoRa® Technology

Module Command Reference

User’s Guide

2015-2018 Microchip Technology Inc. DS40001784G

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights unless otherwise stated.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

QUALITY MANAGEMENT S

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR,

AVR logo, AVR Freaks, BitCloud, CryptoMemory, CryptoRF,

dsPIC, FlashFlex, flexPWR, Heldo, JukeBlox, KeeLoq, Kleer,

LANCheck, LINK MD, maXStylus, maXTouch, MediaLB,

megaAVR, MOST, MOST logo, MPLAB, OptoLyzer, PIC,

picoPower, PICSTART, PIC32 logo, Prochip Designer, QTouch,

SAM-BA, SpyNIC, SST, SST Logo, SuperFlash, tinyAVR, UNI/O,

and XMEGA are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

ClockWorks, The Embedded Control Solutions Company,

EtherSynch, Hyper Speed Control, HyperLight Load, IntelliMOS,

mTouch, Precision Edge, and Quiet-Wire are registered

trademarks of Microchip Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any

Capacitor, AnyIn, AnyOut, BodyCom, chipKIT, chipKIT logo,

CodeGuard, CryptoAuthentication, CryptoAutomotive,

CryptoCompanion, CryptoController, dsPICDEM, dsPICDEM.net,

Dynamic Average Matching, DAM, ECAN, EtherGREEN, InCircuit Serial Programming, ICSP, INICnet, Inter-Chip

Connectivity, JitterBlocker, KleerNet, KleerNet logo, memBrain,

Mindi, MiWi, motorBench, MPASM, MPF, MPLAB Certified logo,

MPLIB, MPLINK, MultiTRAK, NetDetach, Omniscient Code

Generation, PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart,

PureSilicon, QMatrix, REAL ICE, Ripple Blocker, SAM-ICE, Serial

Quad I/O, SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II,

Total Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated in

the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip

Technology Inc. in other countries.

GestIC is a registered trademarks of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2015-2018, Microchip Technology Incorporated, All Rights

Reserved.

978-1-5224-3534-1

ISBN:

DS40001784G-page 2 2015-2018 Microchip Technology Inc.

Page 3

RN2483 LoRaTECHNOLOGY MODULE

COMMAND REFERENCE USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 6

Chapter 1. Introduction

1.1 Overview ...................................................................................................... 11

1.2 Features ....................................................................................................... 12

1.3 Configuration ................................................................................................ 12

1.4 UART Interface ............................................................................................. 13

Chapter 2. Command Reference

2.1 Command Syntax ......................................................................................... 15

2.2 Command Organization ............................................................................... 15

2.3 System Commands ...................................................................................... 16

2.3.1 sys sleep <length> .................................................................................... 17

2.3.2 sys reset .................................................................................................... 17

2.3.3 sys eraseFW ............................................................................................. 17

2.3.4 sys factoryRESET ..................................................................................... 17

2.3.5 System Set Commands ............................................................................. 18

2.3.5.1 sys set nvm <address> <data> ................................................. 18

2.3.5.2 sys set pindig <pinName> <pinState> ....................................... 18

2.3.5.3 sys set pinmode <pinname> <pinmode> ................................... 18

2.3.6 System Get Commands ............................................................................ 19

2.3.6.1 sys get ver ................................................................................. 19

2.3.6.2 sys get nvm <address> ............................................................. 19

2.3.6.3 sys get vdd ................................................................................ 19

2.3.6.4 sys get hweui ............................................................................. 20

2.3.6.5 sys get pindig <pinname> .......................................................... 20

2.3.6.6 sys get pinana <pinName> ........................................................ 20

2.4 MAC Commands .......................................................................................... 21

2.4.1 mac reset <band> ..................................................................................... 21

2.4.2 mac tx <type> <portno> <data> ................................................................ 22

2.4.3 mac join <mode> ....................................................................................... 24

2.4.4 mac save ................................................................................................... 25

2.4.5 mac forceENABLE .................................................................................... 26

2.4.6 mac pause ................................................................................................. 26

2.4.7 mac resume ............................................................................................... 26

2.4.8 MAC Set Commands ................................................................................ 27

2.4.8.1 mac set appkey <appKey> ........................................................ 27

2.4.8.2 mac set appskey <appSessKey> .............................................. 28

2.4.8.3 mac set ar <state> ..................................................................... 28

2.4.8.4 mac set bat <level> ................................................................... 28

2.4.8.5 MAC Set Channel Commands .................................................. 29

2.4.8.6 mac set class <class> ............................................................... 31

2.4.8.7 mac set devaddr <address> ...................................................... 31

2015-2018 Microchip Technology Inc. DS40001784G-page 3

Page 4

2.4.8.8 mac set deveui <devEUI> ......................................................... 31

2.4.8.9 mac set dnctr <FCntDown> ...................................................... 32

2.4.8.10 mac set dr <dataRate> ............................................................ 32

2.4.8.11 mac set linkchk <linkCheck> ................................................... 32

2.4.8.12 mac set mcast <state> ............................................................ 33

2.4.8.13 mac set mcastappskey <mcastApplicationSessionkey> ......... 33

2.4.8.14 mac set mcastdevaddr <mcastAddress> ................................ 33

2.4.8.15 mac set mcastdnctr <fMcastCntDown> ................................... 34

2.4.8.16 mac set mcastnwkskey <mcastNetworkSessionkey> ............. 34

2.4.8.17 mac set nwkskey <nwkSessKey> ........................................... 34

2.4.8.18 mac set pwridx <pwrIndex> ..................................................... 35

2.4.8.19 mac set retx <reTxNb> ............................................................ 35

2.4.8.20 mac set rx2 <dataRate> <frequency> ..................................... 35

2.4.8.21 mac set rxdelay1 <rxDelay> .................................................... 36

2.4.8.22 mac set sync <synchWord> ................................................... 36

2.4.8.23 mac set upctr <fCntUp> .......................................................... 36

2.4.9 MAC Get Commands ................................................................................ 37

2.4.9.1 mac get adr ................................................................................ 37

2.4.9.2 mac get appeui .......................................................................... 37

2.4.9.3 mac get ar .................................................................................. 38

2.4.9.4 MAC Get Channel Commands .................................................. 38

2.4.9.5 mac get class ............................................................................. 40

2.4.9.6 mac get dcycleps ....................................................................... 40

2.4.9.7 mac get devaddr ........................................................................ 40

2.4.9.8 mac get deveui .......................................................................... 40

2.4.9.9 mac get dnctr ............................................................................. 40

2.4.9.10 mac get dr ................................................................................ 40

2.4.9.11 mac get gwnb .......................................................................... 41

2.4.9.12 mac get mcast ......................................................................... 41

2.4.9.13 mac get mcastdevaddr ............................................................ 41

2.4.9.14 mac get mcastdnctr ................................................................. 41

2.4.9.15 mac get mrgn ........................................................................... 41

2.4.9.16 mac get pwridx ........................................................................ 41

2.4.9.17 mac get retx ............................................................................. 42

2.4.9.18 mac get rx2 <freqband> .......................................................... 42

2.4.9.19 mac get rxdelay1 ..................................................................... 42

2.4.9.20 mac get rxdelay2 ..................................................................... 42

2.4.9.21 mac get status ......................................................................... 42

2.4.9.22 mac get sync ........................................................................... 42

2.4.9.23 mac get upctr ........................................................................... 43

2.5 Radio Commands ......................................................................................... 44

2.5.1 radio rx <rxWindowSize> .......................................................................... 45

2.5.2 radio tx <data> .......................................................................................... 45

2.5.3 radio cw <state> ........................................................................................ 46

2.5.4 rxstop ......................................................................................................... 46

2.5.5 Radio Set Commands ............................................................................... 47

2.5.5.1 radio set afcbw <autoFreqBand> .............................................. 47

2.5.5.2 radio set bitrate <fskBitrate> ...................................................... 47

2.5.5.3 radio set bt <gfBT> .................................................................... 47

2.5.5.4 radio set bw <bandWidth> ......................................................... 48

2.5.5.5 radio set cr <codingRate> ......................................................... 48

2015-2018 Microchip Technology Inc. DS40001784G-page 4

Page 5

2.5.5.6 radio set crc < crcHeader > ....................................................... 48

2.5.5.7 radio set fdev <freqDev> ........................................................... 48

2.5.5.8 radio set freq <frequency> ......................................................... 48

2.5.5.9 radio set iqi <iqInvert> ............................................................... 48

2.5.5.10 radio set mod <mode> ............................................................. 49

2.5.5.11 radio set prlen <preamble> ...................................................... 49

2.5.5.12 radio set pwr <pwrOut> ........................................................... 49

2.5.5.13 radio set rxbw <rxBandwidth> ................................................. 49

2.5.5.14 radio set sf <spreadingFactor> ................................................ 49

2.5.5.15 radio set sync <syncWord> ..................................................... 50

2.5.5.16 radio set wdt <watchDog> ....................................................... 50

2.5.6 Radio Get Commands ............................................................................... 51

2.5.6.1 radio get afcbw .......................................................................... 51

2.5.6.2 radio get bitrate .......................................................................... 51

2.5.6.3 radio get bt ................................................................................. 51

2.5.6.4 radio get bw ............................................................................... 52

2.5.6.5 radio get cr ................................................................................. 52

2.5.6.6 radio get crc ............................................................................... 52

2.5.6.7 radio get fdev ............................................................................. 52

2.5.6.8 radio get freq ............................................................................. 52

2.5.6.9 radio get iqi ................................................................................ 53

2.5.6.10 radio get mod ........................................................................... 53

2.5.6.11 radio get prlen .......................................................................... 53

2.5.6.12 radio get pwr ............................................................................ 53

2.5.6.13 radio get rssi ............................................................................ 53

2.5.6.14 radio get rxbw .......................................................................... 53

2.5.6.15 radio get sf ............................................................................... 54

2.5.6.16 radio get snr ............................................................................. 54

2.5.6.17 radio get sync .......................................................................... 54

2.5.6.18 radio get wdt ............................................................................ 54

Chapter 3. Bootloader Usage

3.1 Bootloader Hosts .......................................................................................... 55

3.2 Protocol ........................................................................................................ 56

3.3 RN Module Bootloader Commands .............................................................. 56

3.4 Command Details ......................................................................................... 57

3.5 Bootloader Usage Examples ........................................................................ 59

3.5.1 Using Bootloader with an Embedded Host ................................................ 59

3.5.2 Using Bootloader with a PC Host .............................................................. 59

3.5.2.1 Update RN2483 Module Firmware Using LoRaDevUtility ......... 59

3.5.2.2 LoRaDevUtility - Boot Load Recover ......................................... 60

3.5.2.3 Bootloading Operation complete ............................................... 60

Appendix A. Current Firmware Features and Fixes

Worldwide Sales and Service .................................................................................... 64

2015-2018 Microchip Technology Inc. DS40001784G-page 5

Page 6

RN2483 LoRaTECHNOLOGY MODULE

COMMAND REFERENCE USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs and/

or tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

INTRODUCTION

®

IDE online help.

This chapter contains general information that will be useful to know before using the

RN2483 module. Topics discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Website

• Development Systems Customer Change Notification Service

• Customer Support

• Revision History

DOCUMENT LAYOUT

This command reference user’s guide provides information for configuring the RN2483

low-power long-range LoRa technology transceiver module, including a description of

communication and command references. The document is organized as follows:

• Chapter 1. “Introduction” – Introduces the RN2483 module and provides a brief

overview of its features.

• Chapter 2. “Command Reference” – Provides information on the commands

used to configure the RN2483 module with examples.

• Chapter 3. “Bootloader Usage” - Gives further information on the bootloader

usage and protocol commands.

• Appendix A. “Current Firmware Features and Fixes ” – Provides information

on the release notes for each revision of the firmware.

2015-2018 Microchip Technology Inc. DS40001784G-page 6

Page 7

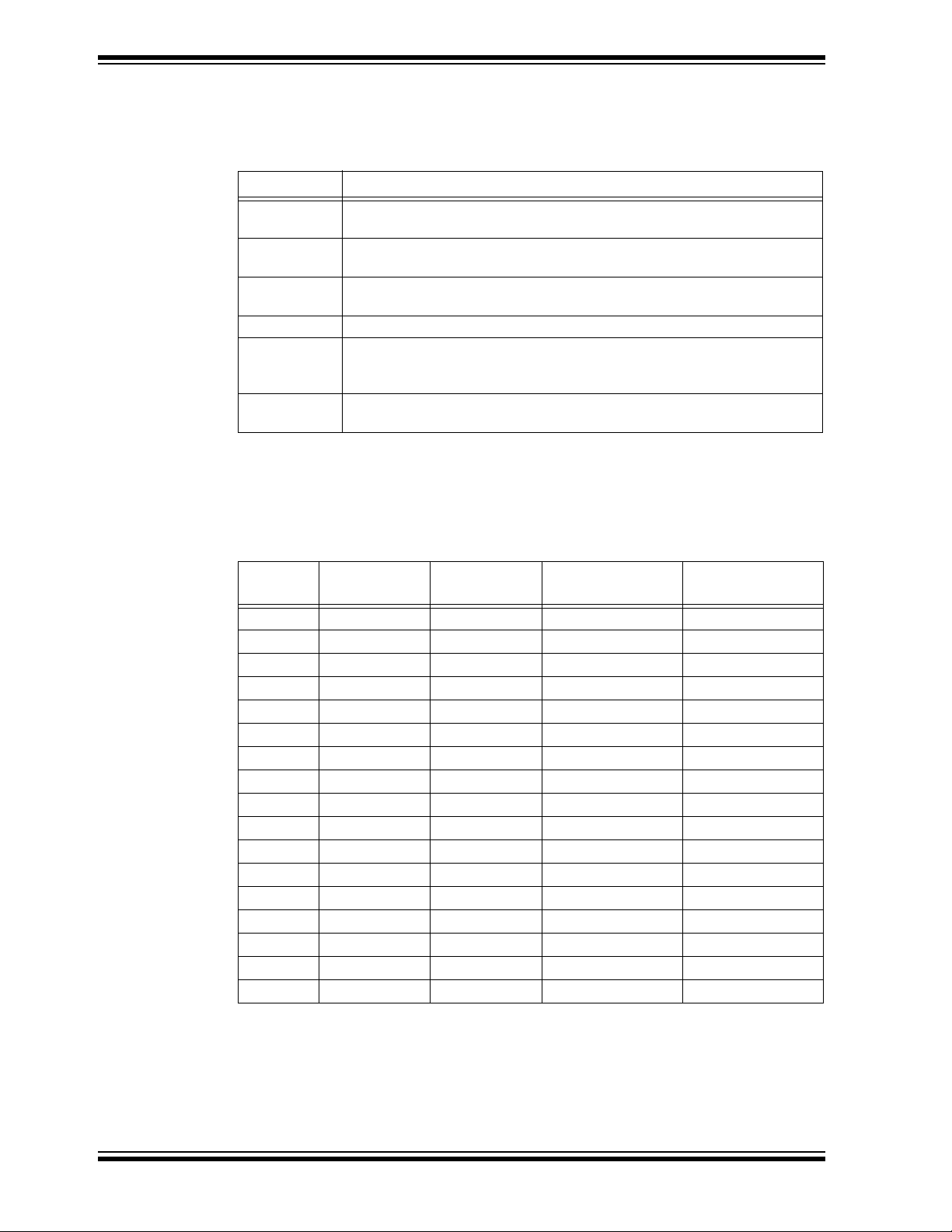

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

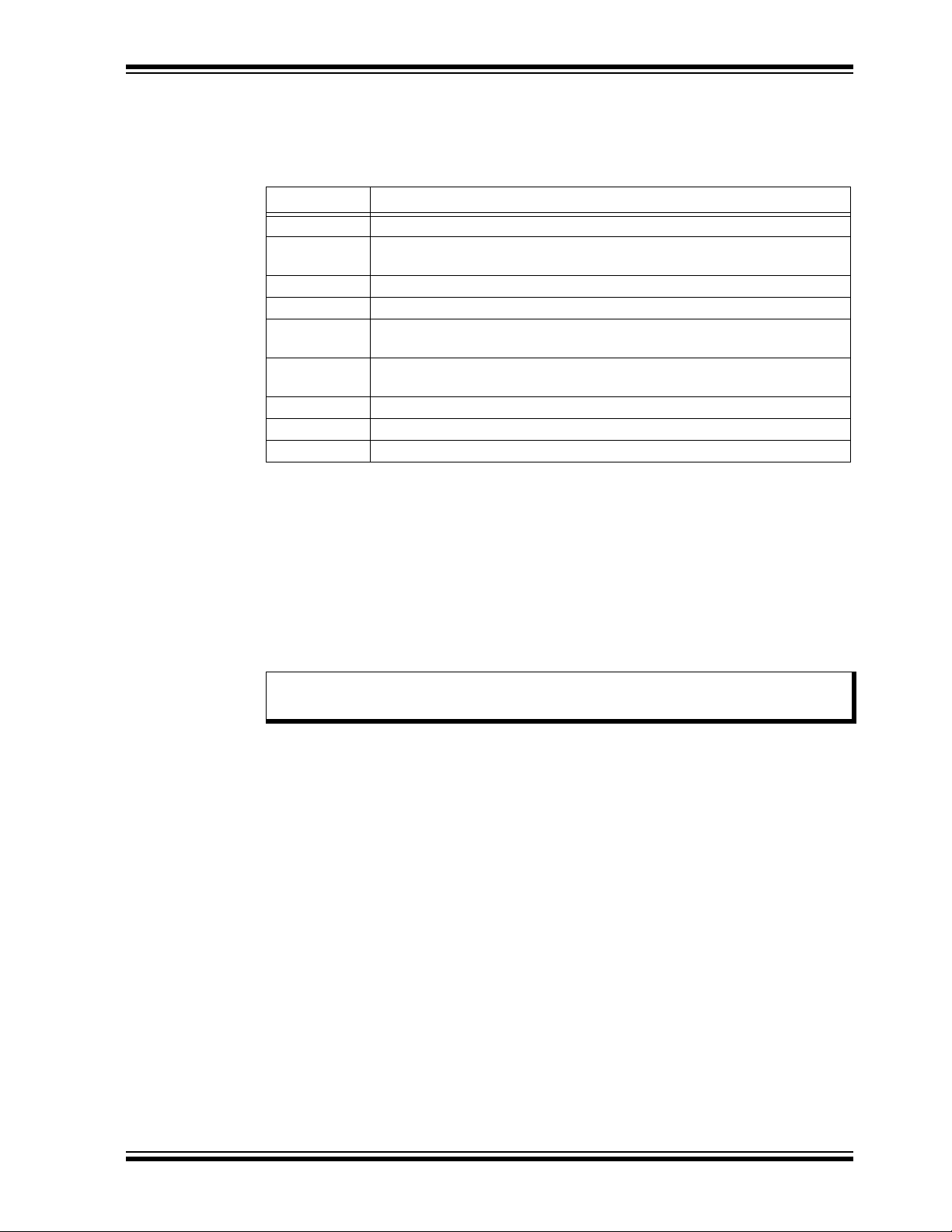

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Initial caps A window the Output window

Quotes A field name in a window or

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

Preface

®

IDE User’s Guide

Emphasized text ...is the only compiler...

A dialog the Settings dialog

A menu selection select Enable Programmer

“Save project before build”

dialog

A menu path File>Save

A tab Click the Power tab

4‘b0010, 2‘hF1

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

any valid filename

[options]

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

2015-2018 Microchip Technology Inc. DS40001784G-page 7

Page 8

RECOMMENDED READING

This command reference user’s guide describes how to configure the RN2483 module.

The module-specific data sheet contains current information on the module specifications.

Other useful documents are listed below. The following documents are available and

recommended as supplemental reference resources:

RN2483 Low-Power Long-Range LoRa® Technology Transceiver Module

Data Sheet (DS50002346)

This data sheet provides detailed specifications for the RN2483 module.

LoRa® Alliance: LoRaWAN™ Specification V1.0.2

This document describes the LoRaWAN Class A protocol, which is optimized for

battery-powered end devices. This specification is available from the LoRa Alliance at

http://www.lora-alliance.org.

To obtain any of Microchip’s documents, visit the Microchip website at

www.microchip.com.

THE MICROCHIP WEBSITE

Microchip provides online support via our website at www.microchip.com. This website

is used as a means to make files and information easily available to customers. Accessible by using your favorite Internet browser, the website contains the following information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

2015-2018 Microchip Technology Inc. DS40001784G-page 8

Page 9

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip website at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers, assemblers, linkers

and other language tools. These include all MPLAB C compilers; all MPLAB

assemblers (including MPASM™ assembler); all MPLAB linkers (including

MPLINK™ object linker); and all MPLAB librarians (including MPLIB™ object

librarian).

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB REAL ICE™ and MPLAB ICE 2000 in-circuit emulators.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debuggers. This includes MPLAB ICD 4 and PICkit™ 4 in-circuit debuggers.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB IDE Project Manager, MPLAB Editor and

MPLAB SIM simulator, as well as general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

production programmers such as MPLAB REAL ICE in-circuit emulator, MPLAB

ICD 4 in-circuit debugger and MPLAB PM3 device programmers. Also included

are non-production development programmers such as the PICkit 3.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the website at:

http://www.microchip.com/support.

2015-2018 Microchip Technology Inc. DS40001784G-page 9

Page 10

REVISION HISTORY

Revision A (March 2015)

Initial release of the document.

Revision B (March 2015)

Update to Section 1.4.

Revision C (November 2015)

Added 2.3.6.5, 2.3.6.6, 2.3.6.7, 2.4.8.16, 2.4.8.17 sections; Updated 2-4, 2-6, 2-8 and

2-14 Tables, Updated 2.3.5.2, 2.4.4, 2.4.9.7, 2.4.9.18, and 2.5.5.17 sections; Other

minor corrections.

Revision D (February 2016)

Added a new Note box in section 2.4.9.2, updated section 2.4.9.16 and Figure 2-1,

added A.3 section; Other minor corrections.

Revision E (February 2016)

Removed Version 1.0.2 in section A.4; Other minor corrections.

Preface

Revision F (March 2017)

Added Chapter 3 (Bootloader Usage); Other minor corrections.

Revision G (September 2018)

Updated Note in section 1.4; Updated section 2-2 and Table 2-4; Added a new Note

box in section 2.3.6.6; Updated 2.4.4 and 2.4.6; Updated Table 2-6 and added sections

2.4.8.11, 2.4.8.12, 2.4.8.13, 2.4.8.14, 2.4.8.15, and 2.4.8.16; Updated Table 2-8,

Figure 2-1, added sections 2.4.9.5, 2.4.9.12, 2.4.9.13, and 2.4.9.14; Added section 3.1,

3.1.1 and 3.1.2; Updated section 3.2, 3.3, 3.4; Other minor corrections.

2015-2018 Microchip Technology Inc. DS40001784G-page 10

Page 11

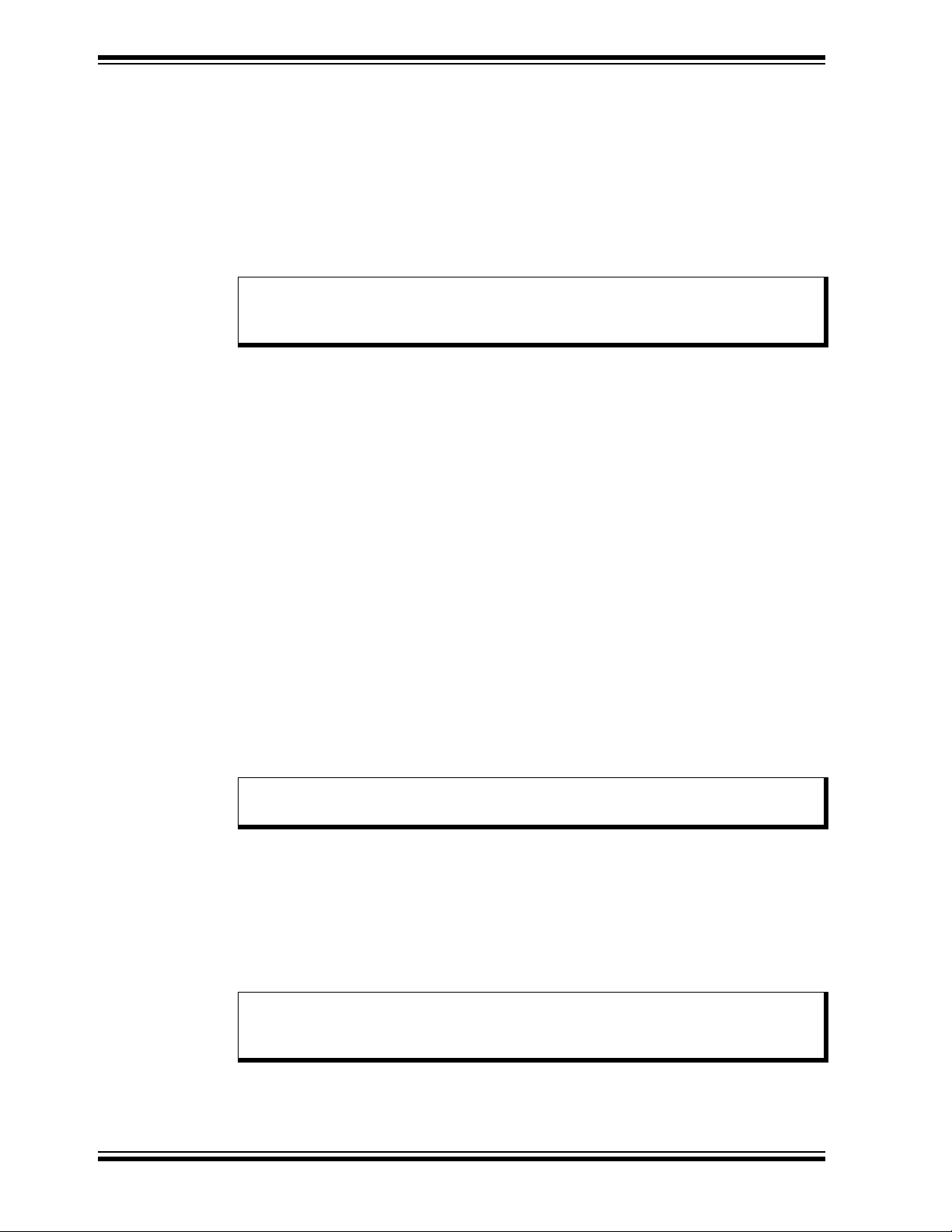

1.1 OVERVIEW

Network Server

RN2483

UART

LoRaTMend device

UART

PC with

terminal

software

Sensor

Sensor reading: 0x23A5 mac tx uncnf 30 23A5

40340120030000001EADBC E2ABFFDA

Encrypted data

IP Connection

Application Server

[…]1E[…]ADBC[…]

IP Connection

Application

Port: 30

Data: 23A5

Development platform

These devices deal with

plaintext application data

These entities hold secret keys

that can encrypt/decrypt

application data

These devices relay encrypted

application data without being

able to decrypt it

)))

LoRaTMGateway

(((

RN2483

Host

MCU

)

))

The Microchip RN2483 module provides LoRaWAN™ protocol connectivity using a

simple UART interface. This module handles the LoRaWAN Class A and Class C

protocols and provides an optimized text command/response interface to the host

system. This document is intended to describe an implementation of the LoRaWAN

Class A and Class C protocols. LoRaWAN protocol terms are described in more detail

in the LoRaWAN™ Specification V1.0.2 available from the LoRa Alliance

(http://www.lora-alliance.org). Thus, it is recommended to review the LoRaWAN™

Specification V1.0.2 before using the RN2483 module.

The required configuration for accessing a LoRa technology network is minimal and

can be stored in the module’s EEPROM, allowing for factory configuration of these

parameters, lowering the requirements for the host system while also increasing

system security. The module also features GPIO pins that can be configured through

the UART interface.

A simple use case is described in Figure 1-1 where an end device, containing a host

MCU which reads a sensor, commands the RN2483 to transmit the sensor reading

over the LoRa network. Data are encrypted by the RN2483 and the radio packet is

received by one or multiple gateways which forward it to the network server. The

network server sends the data to the application server which has the key to decrypt

the application data. Similarly, a development platform may consist of an RN2483

directly connected over UART to a PC which becomes the host system in this case.

Users can then type commands into the module using a terminal program.

RN2483 LoRaTECHNOLOGY MODULE

COMMAND REFERENCE USER’S GUIDE

Chapter 1. Introduction

FIGURE 1-1: SIMPLE LoRa

®

TECHNOLOGY NETWORK DIAGRAM

2015-2018 Microchip Technology Inc. DS40001784G-page 11

Page 12

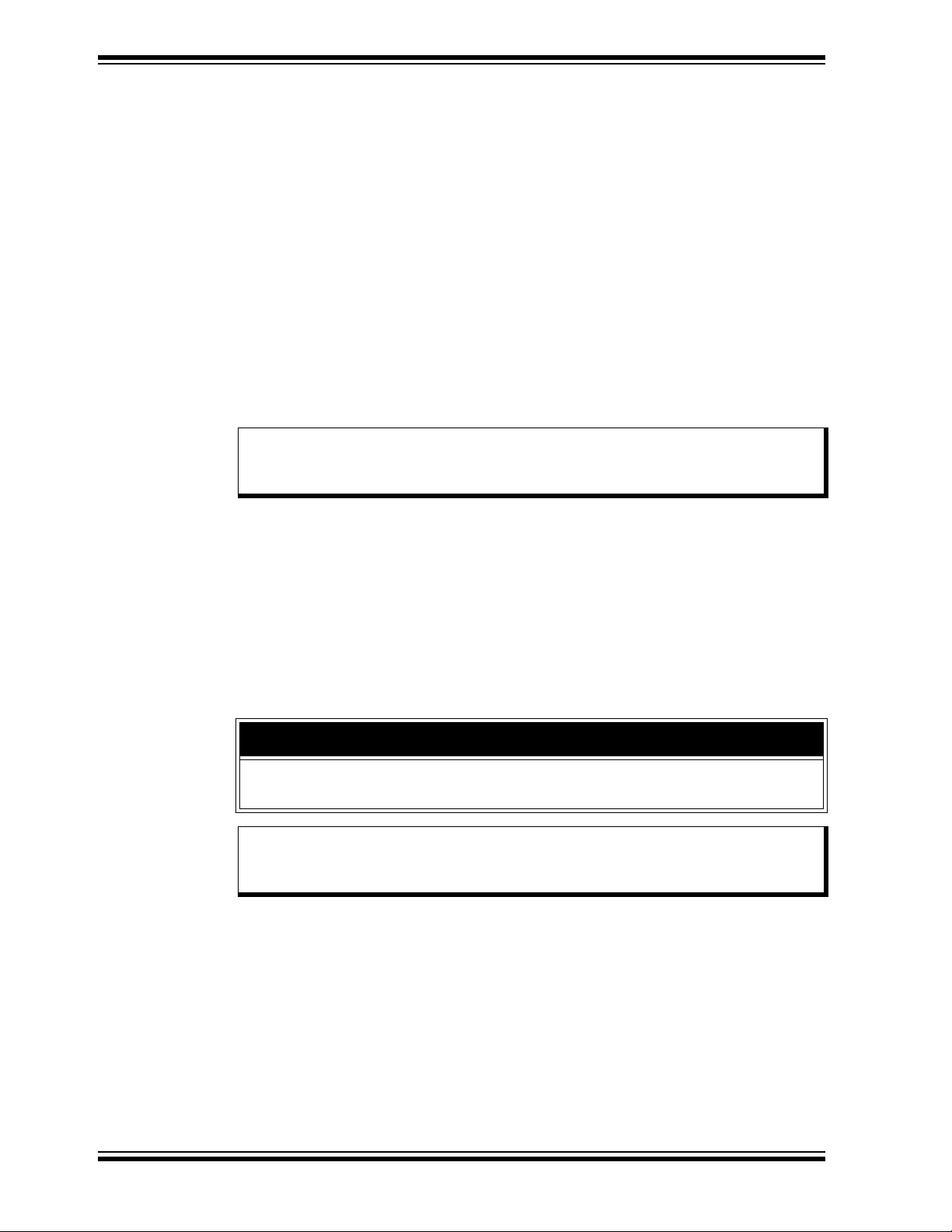

RN2483 LoRa Technology Module Command Reference User’s Guide

Command Interface

Radio driver

LoRaWANTMProtocol

mac

commands

radio

commands

Hardware (GPIO, System timer, etc.)

sys

commands

Radio hardware

The flow of data can be followed as it gets generated by an end device and transported

on the network.

1.2 FEATURES

• LoRaWAN Class A and Class C protocol compliance

• Integrated FSK, GFSK and LoRa technology transceiver allowing the user to

transmit custom packets using these protocols

• Globally unique 64-bit identifier (EUI-64™)

• Configurable GPIOs

• Intelligent Low-Power mode with programmable/on-demand wake up

• Bootloader for firmware upgrade

• All configuration and control done over UART using simple ASCII commands

Refer to the RN2483, Low-Power Long-Range LoRa

Data Sheet

(DS50002346) for details on the hardware specifications of the module.

®

T echnology Transceiver Module

1.3 CONFIGURATION

The RN2483 module’s architecture is described in Figure 1-2 from the command

interface point of view. There are three types of commands that can be used, and each

allows access to different module functions:

• LoRaWAN Class A and Class C configuration and control, using the mac group of

commands

• Low-level radio configuration and control, using the radio group of commands

• Other module functions, using the sys group of commands

FIGURE 1-2: RN2483 COMMAND INTERFACE (YELLOW) AND ITS

RELATIONSHIP TO THE MODULE’S INTERNAL

COMPONENTS

The available commands can be used to configure and control the LoRaWAN protocol

layer, the radio driver and some system peripherals.

In order to communicate with a LoRa network, a specific number of parameters need

to be configured. Since two distinctive methods are offered for a device to become part

of the network, each of these requires different parameters:

• Over-the-Air Activation (OTAA), where a device negotiates network encryption

keys at the time it joins the network. For this, the device EUI, application EUI and

application key need to be configured and then the OTAA procedure can start.

• Activation by Personalization (ABP) where the device already contains the

network keys and can directly start communication with the network. Configuring

DS40001784G-page 12 2015-2018 Microchip Technology Inc.

the device address, network session key and application session key is sufficient

Page 13

for this type of initialization.

For increased security, these parameters can be configured and stored in the module’s

EEPROM during manufacturing of devices requiring LoRaWAN connectivity. Thus, the

keys do not need to be sent over the UART interface by the host system every time the

device powers up.

1.4 UART INTERFACE

All of the RN2483 module’s settings and commands are transmitted over UART using

the ASCII interface.

All commands need to be terminated with <CR><LF> and any replies they generate will

also be terminated by the same sequence.

The default settings for the UART interface are 57600 bps, 8 bits, no parity, 1 Stop bit,

no flow control. The baud rate can be changed by triggering the auto-baud detection

sequence of the module. To do this, the host system needs to transmit a Break

condition to the module followed by a 0x55 character at the new baud rate. The

auto-baud detection mechanism can also be triggered during sleep to wake the module

up before the predetermined time has expired.

Note: A break condition is signaled to the module by keeping the UART_RX pin

Introduction

low for longer than the time to transmit a complete character. For example,

at the default baud rate of 57600 bps, keeping the UART_RX pin low for

226 s is a valid 13-bit break condition, whereas at 9600 bps this may be

interpreted as a 0x00 character. Thus, the Break condition needs to be

long enough to still be interpreted as such at the baud rate that is currently

in use. At 9600 bps a valid 13-bit Break condition must need to be 1,350 s.

Break condition calculation is as follows:

T

= Nb/bps

b

Where:

= time required for Break condition

* T

b

* Nb = number of bits required for Break condition

* bps = current bit rate

= 13/57600

T

b

= 226 s

T

b

2015-2018 Microchip Technology Inc. DS40001784G-page 13

Page 14

RN2483 LoRa Technology Module Command Reference User’s Guide

NOTES:

DS40001784G-page 14 2015-2018 Microchip Technology Inc.

Page 15

Chapter 2. Command Reference

The RN2483 LoRa technology module supports a variety of commands for

configuration. This section describes these commands in detail and provides

examples.

2.1 COMMAND SYNTAX

To issue commands to the RN2483 module, the user sends keywords followed by

optional parameters. Commands (keywords) are case-sensitive, and spaces must not

be used in parameters. Hex input data can be uppercase or lowercase. String text data,

such as OTAA used for the join procedure, can be uppercase or lowercase.

The use of shorthand for parameters is NOT supported.

Depending on the command, the parameter may expect values in either decimal or

hexadecimal form; refer to the command description for the expected form. For

example, when configuring the frequency, the command expects a decimal value in

Hertz such as 868100000 (868.1 MHz). Alternatively, when configuring the LoRaWAN

device address, the hex value is entered into the parameter as aabbccdd. To enter a

number in hex form, use the value directly. For example, the hex value 0xFF would be

entered as FF.

RN2483 LoRa TECHNOLOGY MODULE

COMMAND REFERENCE USER’S GUIDE

2.2 COMMAND ORGANIZATION

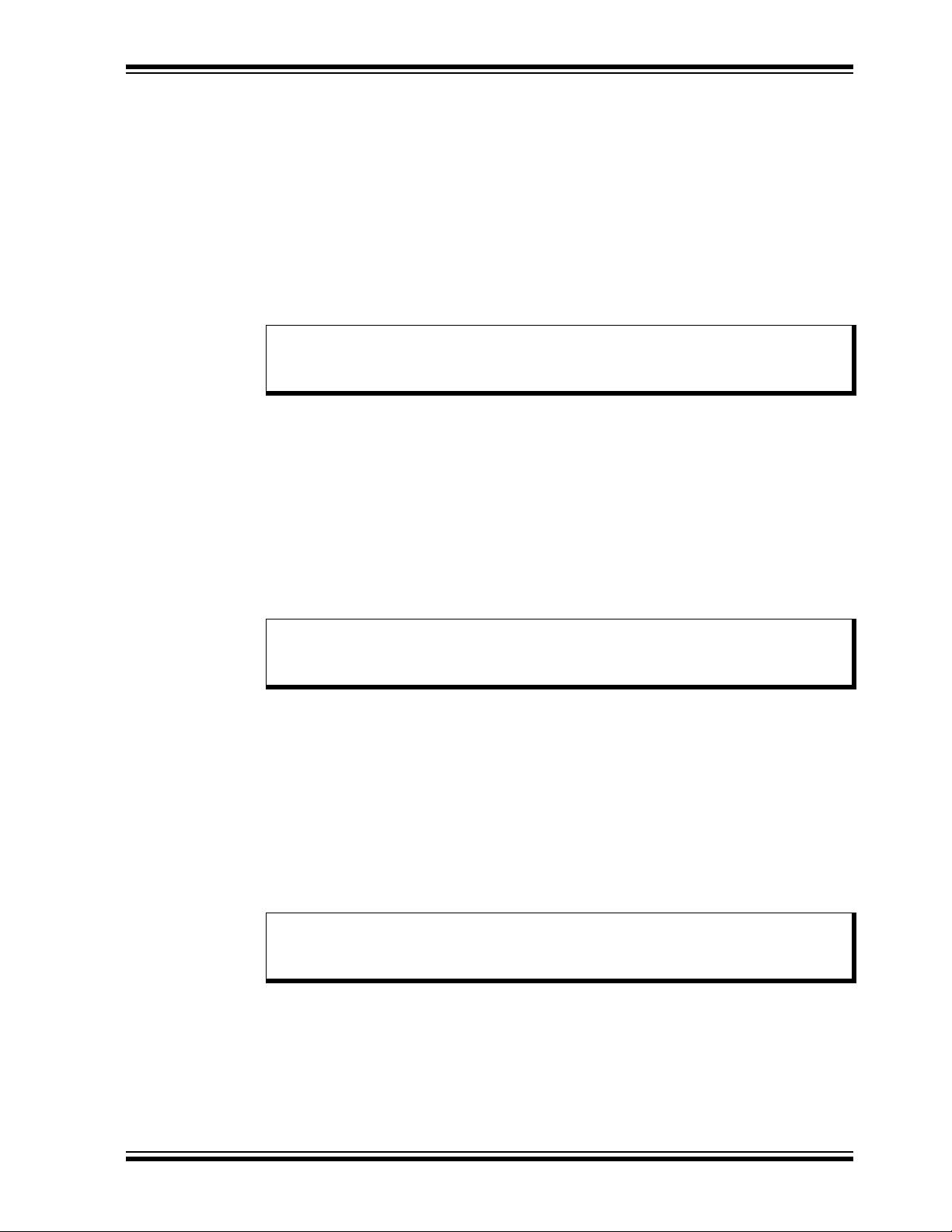

There are three general command categories, as shown in Table 2-1.

TABLE 2-1: COMMAND TYPES

Command Type Keyword Description

System <sys> Issues system level behavior actions, gathers status

LoRaWAN™ Class A

and Class C Protocols

Transceiver commands <radio> Issues radio specific configurations, directly accessing

information on the firmware and hardware version, or

accesses the module user EEPROM memory.

<mac> Issues LoRaWAN Class A and Class C protocols

network communication behaviors, actions and

configuration commands.

and updating the transceiver setup.

2015-2018 Microchip Technology Inc. DS40001784G-page 15

Page 16

RN2483 LoRa Technology Module Command Reference User’s Guide

After configuring the LoRaWAN protocol settings, the user must save them to

EEPROM with the mac save command. Once the settings have been saved, they will

be retained after a reboot or Reset.

Note: Upon successful reception a command, based on the specific command,

the module will respond with one of the following:

• ok

• busy

• fram_counter_err_rejoin_needed

• invalid_class

• invalid_data_len

• invalid_param

• keys_not_init

• mac_paused

• multicast_keys_not_set

• no_free_ch

• not_joined

• silent

• err

Note: To facilitate the sharing of the radio between user custom applications and

the LoRaWAN MAC, refer to the mac pause and mac resume commands.

Since no sharing exists between sys and other types of commands, there

is no need for additional pause commands.

2.3 SYSTEM COMMANDS

System commands begin with the system keyword <sys> and include the categories

shown in Ta b le 2 - 2, Ta bl e 2 - 3 and Table 2-4.

TABLE 2-2: SYSTEM COMMANDS

Parameter Description

sleep Puts the system in sleep for a finite number of milliseconds.

reset Resets and restarts the RN2483 module.

eraseFW Deletes the current RN2483 module application firmware and prepares it for

factoryRESET Resets the RN2483 module’s configuration data and user EEPROM to

(1)

set

(1)

get

Note 1: Refer to

summaries.

firmware upgrade. The RN2483 module bootloader is ready to receive new

firmware.

factory default values and restarts the RN2483 module.

Sets specified system parameter values.

Gets specified system parameter values.

Table 2-3 for system <set> and Table 2-4 for system <get> command

DS40001784G-page 16 2015-2018 Microchip Technology Inc.

Page 17

Command Reference

2.3.1 sys sleep <length>

<length>: decimal number representing the number of milliseconds the system is

put to sleep, from 100 to 4294967296.

Response: ok after the system gets back from Sleep mode

invalid_param if the length is not valid

This command puts the system to sleep for the specified number of milliseconds. The

module can be forced to exit from sleep by sending the UART a Break condition

followed by a 0x55 character. Forcing the module from sleep in the manner also

triggers the UART auto baud detection. The module will adjust the UART baud rate to

match the baud rate at which the 0x55 character was sent. Refer to the note box in

1.4 “UART Interface”.

Example: sys sleep 120 // Puts the system to sleep for 120 ms.

2.3.2 sys reset

Response: RN2483 X.Y.Z MMM DD YYYY HH:MM:SS, where X.Y.Z is firmware

version, MMM is month, DD is day, YYYY is year, HH:MM:SS is hour,

minutes, seconds (format: [HW] [FW] [Date] [Time]). [Date] and [Time] refer

to the release of the firmware.

This command resets and restarts the RN2483 module; stored LoRaWAN protocol

settings will be loaded automatically upon reboot.

Example: sys reset // Resets and restarts the RN2483 module.

2.3.3 sys eraseFW

Response: no response

This command deletes the current RN2483 module application firmware and prepares

it for firmware upgrade. The RN2483 module bootloader is ready to receive new

firmware.

Example: sys eraseFW // Deletes the current RN2483 module

application firmware.

2.3.4 sys factoryRESET

Response: RN2483 X.Y.Z MMM DD YYYY HH:MM:SS, where X.Y.Z is firmware

version, MMM is month, DD is day, YYYY is year, HH:MM:SS is hour,

minutes, seconds (format: [HW] [FW] [Date] [Time]). [Date] and [Time] refer

to the release of the firmware.

This command resets the module’s configuration data and user EEPROM to factory

default values and restarts the module. After factoryRESET, the RN2483 module will

automatically reset and all configuration parameters are restored to factory default

values. All LoRaWAN protocol settings set by the user will be lost.

Example: sys factoryRESET // Restores factory default values.

2015-2018 Microchip Technology Inc. DS40001784G-page 17

Page 18

RN2483 LoRa Technology Module Command Reference User’s Guide

2.3.5 System Set Commands

TABLE 2-3: SYSTEM SET COMMANDS

Parameter Description

nvm Stores <data> to a location <address> of user EEPROM.

pindig Allows user to set and clear available digital pins.

pinmode Allows user to set the functionality of a pin to either digital input, digital output

or analog input (if available).

2.3.5.1 sys set nvm <address> <data>

<address>: hexadecimal number representing user EEPROM address, from 300 to

3FF

<data>: hexadecimal number representing data, from 00 to FF

Response: ok if the parameters (address and data) are valid

invalid_param if the parameters (address and data) are not valid

This command allows the user to modify the user EEPROM at <address> with the

value supplied by <data>. Both <address> and <data> must be entered as hex

values. The user EEPROM memory is located inside the MCU on the module.

Example: sys set nvm 300 A5 // Stores the value 0xA5 at user EEPROM

address 0x300.

2.3.5.2 sys set pindig <pinname> <pinstate>

<pinname>: string representing the pin. Parameter can be: GPIO0 - GPIO13,

UART_CTS, UART_RTS, TEST0, TEST1

<pinstate>: decimal number representing the state. Parameter values can be: 0 or

1.

Response: ok if the parameters (<pinname>, <pinstate>) are valid

invalid_param if the parameters (<pinname>, <pinstate>) are not

valid

This command allows the user to modify the unused pins available for use by the

module. The selected <pinname> is driven high or low depending on the desired

<pinstate>.

Default: GPIO0-GPIO13, UART_CTS, UART_RTS, TEST0 and TEST1 are driven low

(value 0).

Example: sys set pindig GPIO5 1 // Drives GPIO5 high 1, V

DD.

Note: In order for the pin to be driven to a value, make sure you have first

configured the pin to be a digital output using the command sys set

pinmode <pinname> digout.

2.3.5.3 sys set pinmode <pinname> <pinmode>

<pinname>: string representing the pin. Parameters can be: GPIO0 - GPIO13,

UART_CTS, UART_RTS, TEST0, TEST1

<pinmode>: string representing the functional mode of the pin. Parameters can be:

digout, digin or ana.

Response: ok if all the parameters are valid

invalid_param if any of the parameters are not valid

This command allows the user to configure the functional mode of a pin. A pin can be

DS40001784G-page 18 2015-2018 Microchip Technology Inc.

Page 19

Command Reference

configured as digital output by using the digout parameter. A pin can be configured

as digital input by using the digin parameter. A pin can be configured as analog input

by using the ana parameter.

Note: Not all pins have analog input functionality.

Example: sys set pinmode GPIO0 ana //Configures GPIO0 as analog input

Note: This command must be called prior to reading or setting the value of a pin

in order to have correct behavior.

2.3.6 System Get Commands

TABLE 2-4: SYSTEM GET COMMANDS

Parameter Description

ver Returns the information on hardware platform, firmware version, release

date.

nvm Returns data from the requested user EEPROM <address>.

vdd Returns measured voltage in mV.

hweui Returns the preprogrammed EUI node address.

pindig Returns the state of a digital input.

pinana Returns the state of an analog input.

2.3.6.1 sys get ver

Response: RN2483 X.Y.Z MMM DD YYYY HH:MM:SS, where X.Y.Z is firmware

version, MMM is month, DD is day, YYYY is year, HH:MM:SS is hour,

minutes, seconds

(format: [HW] [FW] [Date] [Time]). [Date] and [Time] refer to the release of

the firmware.

This command returns the information related to the hardware platform, firmware

version, release date and time stamp on firmware creation.

Example: sys get ver // Returns version-related information.

2.3.6.2 sys get nvm <address> <address>: hexadecimal number representing user EEPROM address, from 300 to

3FF

Response: 00 – FF (hexadecimal value from 00 to FF) if the address is valid

invalid_param if the address is not valid

This command returns the data stored in the user EEPROM of the RN2483 module at

the requested <address> location.

Example: sys get nvm 300 // Returns the 8-bit hex value stored at

300.

2.3.6.3 sys get vdd

Response: 0–3600 (decimal value from 0 to 3600)

This command informs the RN2483 module to do an ADC conversion on the V

DD. The

measurement is converted and returned as a voltage (mV). Example: sys get vdd // Returns mV measured on the V

DD

module.

2015-2018 Microchip Technology Inc. DS40001784G-page 19

Page 20

RN2483 LoRa Technology Module Command Reference User’s Guide

2.3.6.4 sys get hweui

Response: hexadecimal number representing the preprogrammed EUI node

address

This command reads the preprogrammed EUI node address from the RN2483 module.

The value returned by this command is a globally unique number provided by

Microchip.

Example: sys get hweui // Reads the preprogrammed EUI node

address.

Note: The preprogrammed EUI node address is a read-only value and cannot be

changed or erased. This value can be used to configure the device EUI

using the mac set deveui command (see Section 2.4.8.8).

2.3.6.5 sys get pindig <pinname>

<pinname>: string representing the pin. Parameters can be: GPIO0 - GPIO13,

UART_CTS, UART_RTS, TEST0, TEST1

Response: decimal number representing the state (either 0 or 1).

This command allows the user to read the state of a digital input. To be used as a

digital input, a pin needs to be configured using the sys set pinmode command.

Example: sys get pindig GPIO0 //Reads the state of the GPIO0 digital input

Note: The sys set pinmode <pinname> digin command must be

called to configure the function of the pin prior to reading its digital input

value.

2.3.6.6 sys get pinana <pinname>

<pinname>: string representing the pin. Parameters can be: GPIO0 - GPIO3,

GPIO5 - GPIO13

Response: decimal number representing the result of the conversion, from 0 to 1023,

where 0 represents 0V and 1023 is V

DD, the supply voltage of the module.

This command allows the user to read the state of an analog input. To be used as an

analog input, a pin needs to be configured using the sys set pinmode command.

Example: sys get pinana GPIO0 //Reads the state of the GPIO0 analog input

Note: The sys set pinmode <pinname> ana command must be

called to configure the functional mode of the pin prior to reading its

analog input value.

DS40001784G-page 20 2015-2018 Microchip Technology Inc.

Page 21

2.4 MAC COMMANDS

LoRaWAN protocol commands begin with the system keyword mac and include the

categories shown in Table 2-5.

TABLE 2-5: MAC COMMANDS

Parameter Description

reset Resets the RN2483 module to a specific frequency band.

tx Sends the data string on a specified port number and sets default values for

join Informs the RN2483 module to join the configured network.

save Saves LoRaWAN Class A configuration parameters to the user EEPROM.

forceENABLE Enables the RN2483 module after the LoRaWAN network server

pause Pauses LoRaWAN stack functionality to allow transceiver (radio)

resume Restores the LoRaWAN stack functionality.

set Accesses and modifies specific MAC related parameters.

get Reads back current MAC related parameters from the module.

2.4.1 mac reset <band>

Command Reference

most of the LoRaWAN™ parameters.

commanded the end device to become silent immediately.

configuration.

<band>: decimal number representing the frequency band, either 868 or 433

Response: ok if band is valid

invalid_param if band is not valid

This command will automatically reset the software LoRaWAN stack and initialize it

with the default parameters.

Example: mac reset 868 // Sets the default values and selects the 868

default band.

Note: This command will set default values for most of the LoRaWAN

parameters. Everything set prior to this command will lose its set value.

2015-2018 Microchip Technology Inc. DS40001784G-page 21

Page 22

RN2483 LoRa Technology Module Command Reference User’s Guide

2.4.2 mac tx <type> <portno> <data>

<type>: string representing the uplink payload type, either cnf or uncnf (cnf –

confirmed, uncnf – unconfirmed)

<portno>: decimal number representing the port number, from 1 to 223

<data>: hexadecimal value. The length of <data> bytes capable of being

transmitted are dependent upon the set data rate (for further details, refer

to the LoRaWAN™ Specification V1.0.2).

Response: this command may reply with two responses. The first response will be

received immediately after entering the command. In case the command is

valid (ok reply received), a second reply will be received after the end of the

uplink transmission. For further details, refer to the LoRaWAN™

Specification V1.0.2.

Response after entering the command:

• ok – if parameters and configurations are valid and the packet was forwarded to

the radio transceiver for transmission

• invalid_param – if parameters (<type> <portno> <data>) are not valid

• not_joined – if the network is not joined

• no_free_ch – if all channels are busy

• silent – if the module is in a Silent Immediately state

• frame_counter_err_rejoin_needed – if the frame counter rolled over

• busy – if MAC state is not in an Idle state

• mac_paused – if MAC was paused and not resumed back

• invalid_data_len if application payload length is greater than the maximum

application payload length corresponding to the current data rate

Response after the first uplink transmission attempt:

• mac_tx_ok if uplink transmission was successful and no downlink data was

received back from the server;

• mac_rx <portno> <data> if transmission was successful, <portno>: port

number, from 1 to 223; <data>: hexadecimal value that was received from the

server;

• mac_err if transmission was unsuccessful, ACK not received back from the

server

• invalid_data_len if application payload length is greater than the maximum

application payload length corresponding to the current data rate. This can occur

after an earlier uplink attempt if retransmission back-off has reduced the data rate.

A confirmed message will expect an acknowledgment from the server; otherwise, the

message will be retransmitted by the number indicated by the command mac set

retx <value>, whereas an unconfirmed message will not expect any

acknowledgment back from the server. For further details, refer to the LoRaWAN™

Specification V1.0.2.

The port number allows multiplexing multiple data streams on the same link. For

example, the end device can send measurements on one port number and

configuration data on another. The server application can then distinguish the two types

of data based on the port number.

Example: mac tx cnf 4 5A5B5B // Sends a confirmed frame on port 4 with

application payload 5A5B5B.

DS40001784G-page 22 2015-2018 Microchip Technology Inc.

Page 23

Command Reference

If the automatic reply feature is enabled and the server sets the Frame Pending bit or

initiates downlink confirmed transmissions, multiple responses will be displayed after

each downlink packet is received by the module. A typical scenario for this case would

be (prerequisites: free LoRaWAN channels available and automatic reply enabled):

• The module sends a packet on port 4 with application payload 0xAB

• Radio transmission is successful and the module will display the first response:

ok

• The server needs to send two separate downlink confirmed packets back on port

1 with the following data: 0xAC, then 0xAF. First it will transmit the first one (0xAC)

and will set the Frame Pending bit. The module will display the second response

mac_rx 1 AC

• The module will initiate an automatic uplink unconfirmed transmission with no

application payload on the first free channel because the Frame Pending bit was

set in the downlink transmission

• The server will send back the second confirmed packet (0xAF). The module will

display a third response mac_rx 1 AF

• The module will initiate an automatic unconfirmed transmission with no application

payload on the first free channel because the last downlink transmission was

confirmed, so the server needs an ACK

• If no reply is received back from the server, the module will display the fourth

response after the end of the second Receive window: mac_tx_ok

• After this scenario, the user is allowed to send packets when at least one enabled

channel is free

Based on this scenario, the following responses will be displayed by the module:

• mac tx cnf 4 AB

• ok

• mac_rx 1 AC

• mac_rx 1 AF

• mac_tx_ok

2015-2018 Microchip Technology Inc. DS40001784G-page 23

Page 24

RN2483 LoRa Technology Module Command Reference User’s Guide

2.4.3 mac join <mode>

<mode>: string representing the join procedure type (case-insensitive), either otaa

or abp (otaa – over-the-air activation, abp – activation by

personalization).

Response: this command may reply with two responses. The first response will be

received immediately after entering the command. In case the command is

valid (ok reply received) a second reply will be received after the end of the

join procedure. For further details, refer to the LoRaWAN™ Specification

V1.0.2.

Response after entering the command:

• ok – if parameters and configurations are valid and the join request packet was

forwarded to the radio transceiver for transmission

• invalid_param – if <mode> is not valid

• keys_not_init – if the keys corresponding to the Join mode (otaa or abp)

were not configured

• no_free_ch – if all channels are busy

• silent – if the device is in a Silent Immediately state

• busy – if MAC state is not in an Idle state

• mac_paused – if MAC was paused and not resumed back

Response after the join procedure:

• denied if the join procedure was unsuccessful (the module attempted to join the

network, but was rejected);

• accepted if the join procedure was successful;

This command informs the RN2483 module it should attempt to join the configured

network. Module activation type is selected with <mode>. Parameter values can be

otaa (over-the-air activation) or abp (activation by personalization). The <mode>

parameter is not case sensitive. Before joining the network, the specific parameters for

each activation type should be configured (for over the air activation: device EUI,

application EUI, application key; for activation by personalization: device address,

network session key, application session key).

Example: mac join otaa // Attempts to join the network using

over-the-air activation.

DS40001784G-page 24 2015-2018 Microchip Technology Inc.

Page 25

Command Reference

2.4.4 mac save

Response: ok

The mac save command must be issued after configuration parameters have been

appropriately entered from the mac set <cmd> commands. This command will save

LoRaWAN Class A protocol configuration parameters to the user EEPROM. When the

next sys reset command is issued, the LoRaWAN Class A protocol configuration will

be initialized with the last saved parameters.

The LoRaWAN protocol configuration savable parameters are:

• adr: ADR state

• appeui: Application Identifier

• appkey: Application Key

• appskey: Application Session key

• ch: All Channel Parameters

- drrange: Data Rate Range

- status: Status

• class: LoRaWAN operating Class

• devaddr: End-Device Address

• deveui: End-Device Identifier

• dnctr: Downlink Frame Counter

• dr:Data Rate

• join flags: Join parameter flags

- appeui: Application Identifier set

- appmultiskey: Application Multicast Session Key set

- appskey: Application Key set

- devaddr: End-Device Address set

- deveui: End-Device Identifer set

- devmultiskey: End-Device Multicast Session Key set

- nwkmultiskey: Network Multicast Session Key set

- nwkskey: Network Session Key set

• mcast: Multicast State

• mcastappskey: Multicast Application Session Key

• mcastdevaddr: Multicast End Device Address

• mcastnwkskey: Multicast Network Session Key

• nwkskey: Network Session Key

• rx2 parameters: RX Window 2 parameters

- freq: Frequency

- status: Status

• upctr: Uplink Frame Counter

Example: mac save // Saves the LoRaWAN Class A protocol

configuration parameters to the user

EEPROM.

2015-2018 Microchip Technology Inc. DS40001784G-page 25

Page 26

RN2483 LoRa Technology Module Command Reference User’s Guide

2.4.5 mac forceENABLE

Response: ok

The network can issue a certain command (Duty Cycle Request frame with parameter

255) that would require the RN2483 module to go silent immediately. This mechanism

disables any further communication of the module, effectively isolating it from the

network. Using mac forceENABLE after this network command has been received

restores the module’s connectivity by allowing it to send data.

Example: mac forceENABLE // Disables the Silent Immediately state.

Note: The silent immediately status bit of the MAC status register

indicates the device has been silenced by the network. Refer to Figure

2-1: “MAC Status bit-Mapped Register (1)”.

2.4.6 mac pause

Response: 0 – 4294967295 (decimal number representing the number of milliseconds

the mac can be paused)

This command pauses the LoRaWAN stack functionality to allow transceiver (radio)

configuration. Through the use of mac pause, radio commands can be generated

between a LoRaWAN Class A protocol uplink application (mac tx command), and the

LoRaWAN Class A protocol Receive windows (second response for the mac tx

command). This command will reply with the time interval in milliseconds that the

transceiver can be used without affecting the LoRaWAN functionality. The maximum

value (4294967295) is returned whenever the LoRaWAN stack functionality is in Idle

state and the transceiver can be used without restrictions. ‘0’ is returned when the

LoRaWAN stack functionality cannot be paused.

For example, when operating in LoRaWAN Class C mode, the receiver is continuously

in receive. The mac pause command will return ‘0’ indicating that the LoraWAN stack

cannot be paused.

After the radio configuration is complete, the mac resume command must be used to

return to LoRaWAN protocol commands.

Example: mac pause // Pauses the LoRaWAN stack

functionality if the response is different

from 0.

Note: If already joined to a network, this command MUST be called BEFORE

configuring the radio parameters, initiating radio reception, or transmission.

2.4.7 mac resume

Response: ok

This command resumes LoRaWAN stack functionality, in order to continue normal

functionality after being paused.

Example: mac resume // Resumes the LoRaWAN stack functionality.

Note: This command MUST be called AFTER all radio commands have been

issued and all the corresponding asynchronous messages have been

replied.

DS40001784G-page 26 2015-2018 Microchip Technology Inc.

Page 27

Command Reference

2.4.8 MAC Set Commands

TABLE 2-6: MAC SET COMMANDS

Parameter Description

appkey Sets the application key for the RN2483 module.

ar Sets the state of the automatic reply.

appskey Sets the application session key for the RN2483 module.

bat Sets the battery level needed for Device Status Answer frame command

response.

ch Allows modification of channel related parameters.

class Sets the LoRaWAN operating class.

devaddr Sets the unique network device address for the RN2483 module.

deveui Sets the globally unique identifier for the RN2483 module.

dnctr Sets the value of the downlink frame counter that will be used for the next

downlink reception.

dr Sets the data rate to be used for the next transmissions.

linkchk Sets the time interval for the link check process to be triggered.

mcast Sets the Multicast state to on, or off.

mcastappskey Sets the multicast application session key.

mcastdevaddr Sets the multicast network device address.

mcastdnctr Sets the value of the multicast downlink frame counter that will be used for

the next multicast downlink reception.

mcastnwkskey Sets the multicast network session key.

nwkskey Sets the network session key for the RN2483 module.

pwridx Sets the output power to be used on the next transmissions.

retx Sets the number of retransmissions to be used for an uplink confirmed

packet.

rx2 Sets the data rate and frequency used for the second Receive window.

rxdelay1 Sets the value used for the first Receive window delay.

sync Sets the synchronization word for the LoRaWAN communication.

upctr Sets the value of the uplink frame counter that will be used for the next

uplink transmission.

2.4.8.1 mac set appkey <appKey>

<appKey>: 16-byte hexadecimal number representing the application key

Response: ok if key is valid

invalid_param if key is not valid

This command sets the application key for the module. The application key is used to

derive the security credentials for communication during over-the-air activation.

Example: mac set appkey 00112233445566778899AABBCCDDEEFF

Note: If this parameter was previously saved to user EEPROM by issuing the

mac save command, after modifying its value, the mac save command

should be called again.

2015-2018 Microchip Technology Inc. DS40001784G-page 27

Page 28

RN2483 LoRa Technology Module Command Reference User’s Guide

2.4.8.2 mac set appskey <appSesskey> <appSessKey>: 16-byte hexadecimal number representing the application session

key

Response: ok if key is valid

invalid_param if key is not valid

This command sets the application session key for the module. This key provides

security for communication between module and application server.

Example: mac set appskey AFBECD56473829100192837465FAEBDC

Note: If this parameter was previously saved to user EEPROM by issuing the

mac save command, after modifying its value, the mac save command

should be called again.

2.4.8.3 mac set ar <state> <state>: string value representing the state, either on or off.

Response: ok if state is valid

invalid_param if state is not valid

This command sets the state of the automatic reply. By enabling the automatic reply,

the module will transmit a packet without a payload immediately after a confirmed

downlink is received, or when the Frame Pending bit has been set by the server. If set

to OFF, no automatic reply will be transmitted.

Example: mac set ar on // Enables the automatic reply process

inside the module.

Note: The RN2483 module implementation will initiate automatic transmissions

with no application payload if the automatic reply feature is enabled and the

server sets the Frame Pending bit or initiates a confirmed downlink

transmission. In this case, if all enabled channels are busy due to duty cycle

limitations, the stack will wait for the first channel that will become free to

transmit. The user will not be able to initiate uplink transmissions until the

automatic transmissions are done.

2.4.8.4 mac set bat <level> <level>: decimal number representing the level of the battery, from 0 to 255. ‘0’

means external power, ‘1’ means low level, 254 means high level, 255

means the end device was not able to measure the battery level.

Response: ok if the battery level is valid

invalid_param if the battery level is not valid

This command sets the battery level required for Device Status Answer frame in use

with the LoRaWAN Class A protocol.

Example: mac set bat 127 // Battery is set to ~50%.

DS40001784G-page 28 2015-2018 Microchip Technology Inc.

Page 29

Command Reference

2.4.8.5 MAC SET CHANNEL COMMANDS

TABLE 2-7: MAC SET CHANNEL COMMANDS

Parameter Description

freq Sets the module operation frequency on a given channel ID.

dcycle Sets the module operation duty cycle on a given channel ID.

drrange Sets the module allowed data rate range (min.- max.) allowed on a given

channel ID.

status Sets the use of the specified channel ID.

2.4.8.5.1 mac set ch freq <channelID> <frequency>

<channelID>: decimal number representing the channel number, from 3 to 15.

<frequency>: decimal number representing the frequency, from 863000000 to

870000000 or from 433050000 to 434790000, in Hz.

Response: ok if parameters are valid

invalid_param if parameters are not valid

This command sets the operational frequency on the given channel ID. The default

channels (0-2) cannot be modified in terms of frequency.

Example: mac set ch freq 13 864000000 // Define frequency for channel

13 to be 864 MHz.

Note: If this parameter was previously saved to user EEPROM by issuing the

mac save command, after modifying its value, the mac save command

should be called again.

2.4.8.5.2 mac set ch dcycle <channelID> <dutyCycle>

<channelID>: decimal number representing the channel number, from 0 to 15.

<dutyCycle>: decimal number representing the duty cycle, from 0 to 65535.

Response: ok if parameters are valid

invalid_param if parameters are not valid

This command sets the duty cycle used on the given channel ID on the module. The

<dutyCycle> value that needs to be configured can be obtained from the actual duty

cycle X (in percentage) using the following formula: <dutyCycle> = (100/X) – 1. The

default settings consider only the three default channels (0-2), and their default duty

cycle is 0.33%. If a new channel is created either by the server or by the user, all the

channels (including the default ones) must be updated by the user in terms of duty

cycle to comply with the ETSI regulations.

Example: mac set ch dcycle 13 9 // Defines duty cycle for channel 13 to be

10%. Since (100/10) – 1 = 9, the

parameter that gets configured is 9.

Note: If this parameter was previously saved to user EEPROM by issuing the

mac save command, after modifying its value, the mac save command

should be called again.

2015-2018 Microchip Technology Inc. DS40001784G-page 29

Page 30

RN2483 LoRa Technology Module Command Reference User’s Guide

2.4.8.5.3 mac set ch drrange <channelID> <minRange> <maxRange>

<channelID>: decimal number representing the channel number, from 0 to 15

<minRange>:

<maxRange>:

Response: ok if parameters are valid

This command sets the operating data rate range, min. to max., for the given

<channelID>. By doing this the module can vary data rates between the

<minRange> and <maxRange> on the specified <channelID>. For the actual values

of the data rates and the corresponding spreading factors (SF), refer to the

LoRaWAN™ Specification.

Example: mac set ch drrange 13 0 2 // Using EU863-870 band: on channel

Note: If this parameter was previously saved to user EEPROM by issuing the

decimal number representing the minimum data rate, from 0 to 7

decimal number representing the maximum data rate, from 0 to 7

invalid_param if parameters are not valid

13 the data rate can range from 0

(SF12/125 kHz) to 2 (SF10/125 kHz)

as required.

mac save command, after modifying its value, the mac save command

should be called again.

2.4.8.5.4 mac set ch status <channelID> <status>

<channelID>: decimal number representing the channel number, from 0 to 15.

<status>: string value representing the state, either on or off.

Response: ok if parameters are valid

invalid_param if parameters are not valid

This command sets the operation of the given <channelID>.

Example: mac set ch status 4 off // Channel ID 4 is disabled from use.

WARNING

<channelID> parameters (frequency, data range, duty cycle) must be issued prior

to enabling the status of that channel.

Note: If this parameter was previously saved to user EEPROM by issuing the

mac save command, after modifying its value, the mac save command

should be called again.

DS40001784G-page 30 2015-2018 Microchip Technology Inc.

Page 31

Command Reference

2.4.8.6 mac set class <class>

<class>: A letter representing the LoRaWAN device class, either a or c.

Response: ok if class is valid

invalid_param if the class is not valid

This command sets the end device LoRaWAN operating class. The default end device

class is Class A. When the class is configured as Class C, the end device will enter

Class C continuous receive mode after the next uplink message is sent. The LoRaWAN

network server must also configure this node as a Class C node. The network server

configuration is performed out of band from LoRaWAN communications. For more

information on the description of operating in Class C mode, refer to the LoRaWAN™

Specification V1.0.2.

Example: mac set class c

Note: If this parameter had previously been saved to user EEPROM by issuing

the mac save command, after modifying its value, the mac save

command should be called again.

2.4.8.7 mac set devaddr <address>

<address>: 4-byte hexadecimal number representing the device address, from

00000000 – FFFFFFFF

Response: ok if address is valid

invalid_param if address is not valid

This command configures the module with a 4-byte unique network device address

<address>. The <address> MUST be UNIQUE to the current network. This must be

directly set solely for activation by personalization devices. This parameter must not be

set before attempting to join using over-the-air activation because it will be overwritten

once the join process is over.

Example: mac set devaddr ABCDEF01

Note: If this parameter had previously been saved to user EEPROM by issuing

the mac save command, after modifying its value, the mac save

command should be called again.

2.4.8.8 mac set deveui <devEUI>

<devEUI>: 8-byte hexadecimal number representing the device EUI

Response: ok if address is valid

invalid_param if address is not valid

This command sets the globally unique device identifier for the module. The identifier

must be set by the host MCU. The module contains a pre-programmed unique EUI and

can be retrieved using the sys get hweui command (see Section 2.3.6.4) or user

provided EUI can be configured using the mac set deveui command.

Example: mac set deveui 0004A30B001A55ED

Note: If this parameter was previously saved to user EEPROM by issuing the

mac save command, after modifying its value, the mac save command

should be called again.

2015-2018 Microchip Technology Inc. DS40001784G-page 31

Page 32

RN2483 LoRa Technology Module Command Reference User’s Guide

2.4.8.9 mac set dnctr <fCntDown> <fCntDown>: decimal number representing the value of the downlink frame counter

that will be used for the next downlink reception, from 0 to

4294967295.

Response: ok if parameter is valid

invalid_param if parameter is not valid

This command sets the value of the downlink frame counter that will be used for the

next downlink reception.

Example: mac set dnctr 30

Note: If this parameter had previously been saved to user EEPROM by issuing

the mac save command, after modifying its value, the mac save

command should be called again.

2.4.8.10 mac set dr <dataRate> <dataRate>: decimal number representing the data rate, from 0 and 7, but within the

limits of the data rate range for the defined channels.

Response: ok if data rate is valid

invalid_param if data rate is not valid

This command sets the data rate to be used for the next transmission. For the

description of data rates and the corresponding spreading factors, refer to the

LoRaWAN™ Specification V1.0.2.

Example: mac set dr 5 // On EU863-870; SF7/125 kHz.

Note: If this parameter had previously been saved to user EEPROM by issuing

the mac save command, after modifying its value, the mac save

command should be called again.

2.4.8.11 mac set linkchk <linkCheck> <linkCheck>: decimal number that sets the time interval in seconds for the link check

process, from 0 to 65535

Response: ok if the time interval is valid

invalid_param if the time interval is not valid

This command sets the time interval for the link check process to be triggered

periodically. A <value> of ‘0’ will disable the link check process. When the time

interval expires, the next application packet that will be sent to the server will include

also a link check MAC command. For more information on the Link Check MAC

command, refer to the LoRaWAN™ Specification V1.0.2.

Example: mac set linkchk 600 // The module will attempt a link check

process at 600-second intervals.

Note: If the command mac reset is issued, the link check process will be set as

disabled.

DS40001784G-page 32 2015-2018 Microchip Technology Inc.

Page 33

Command Reference

2.4.8.12 mac set mcast <state>

<state>: string value representing the state, either on or off.

Response: ok if state is valid

invalid_param if the state is not valid

This command sets the end device Multicast state (mcast) to either be enabled or dis-