Page 1

PL360

Embedded USI

G3-PLC Stack

PHY + PLC Transceiver

SAM4C

( ITU-T G.9903 )

( IEEE 802.15.4 )

( IETF RFC 4944 )

Adaptation Layer

MAC Layer

PAL Layer

sniffer_if

phy_if

mac_if

adp_if

app_if

Host Controller

PLC

USER APPLICATION

PL360

SPI

PLATFORM

IPv6 STACK

Detect

Interrupt

Carrier

PL360 Host Controller

Introduction

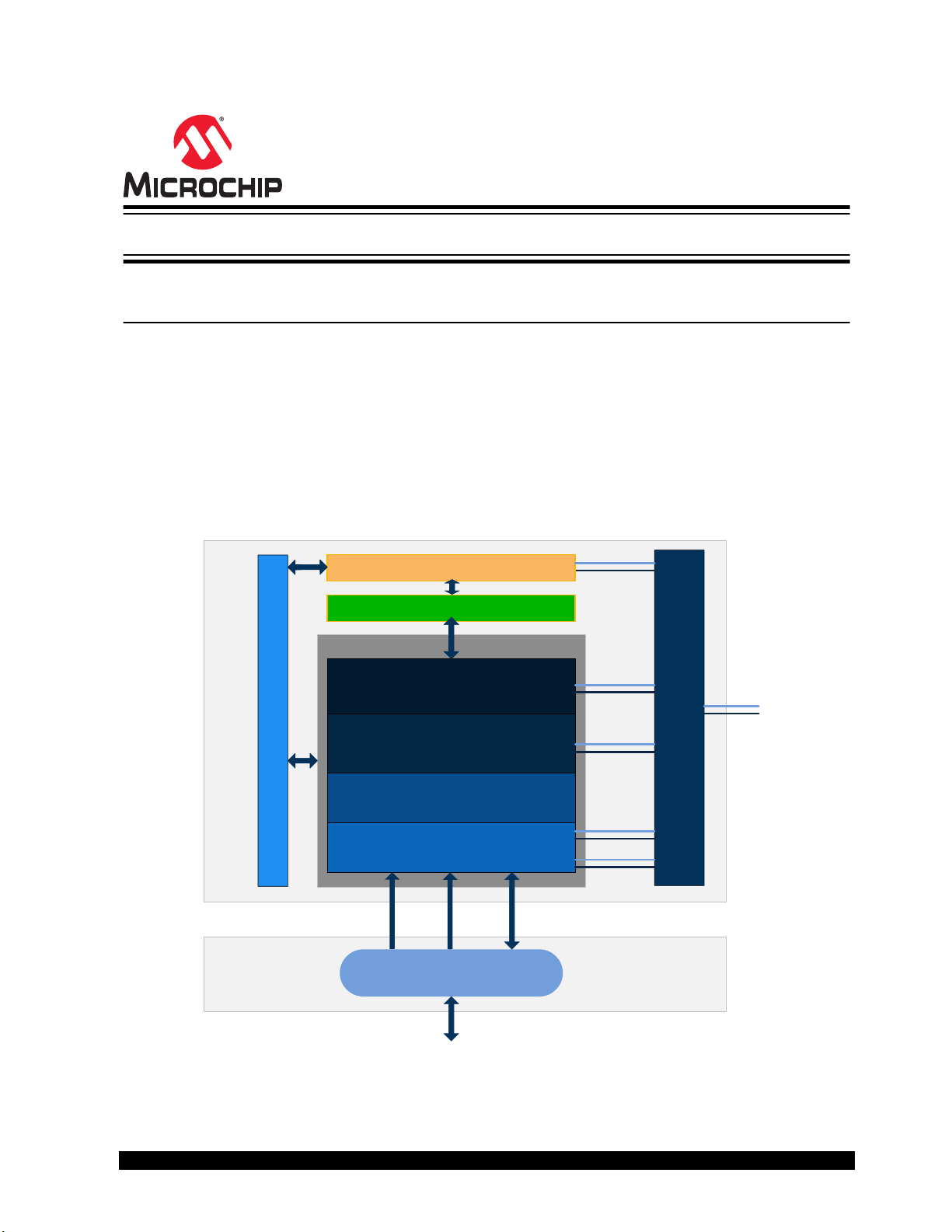

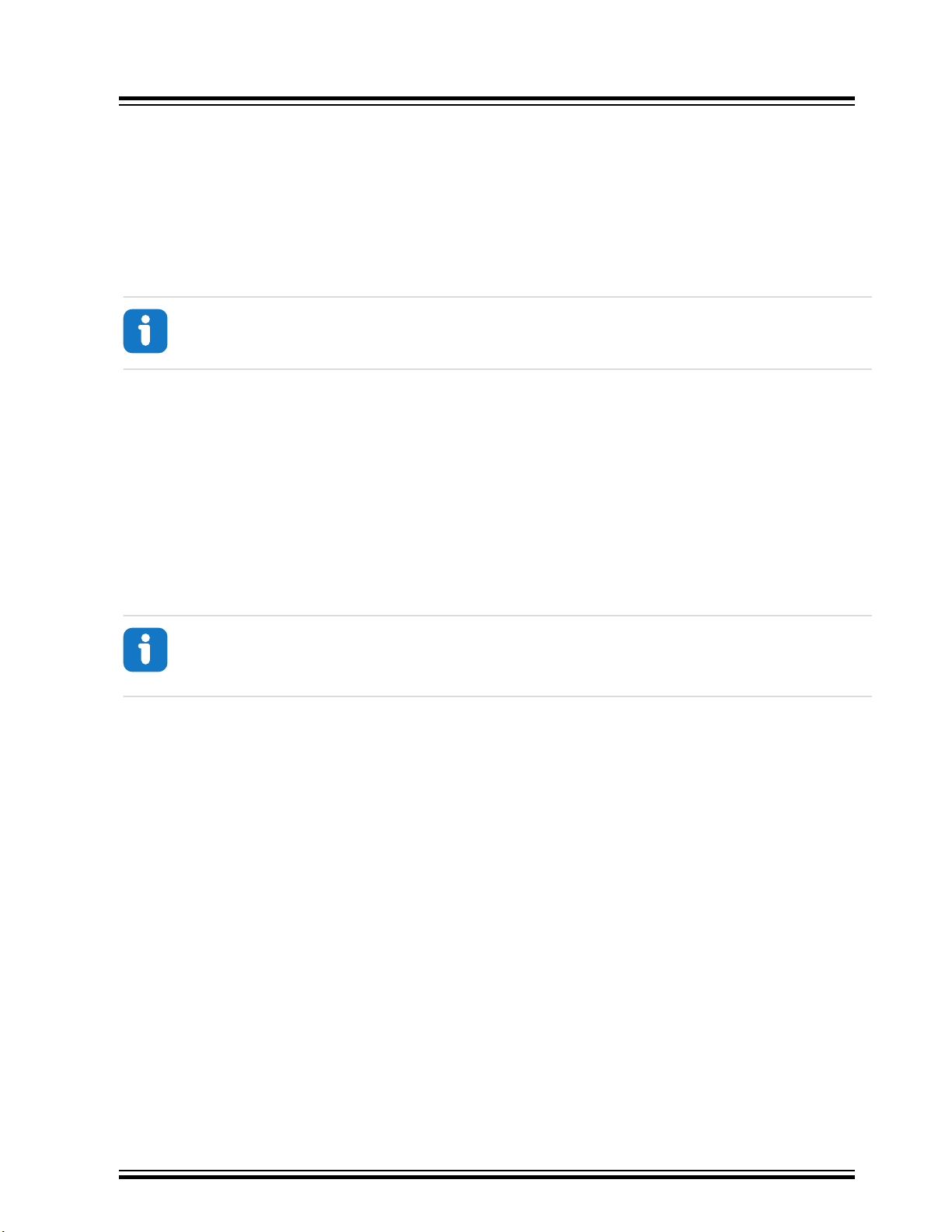

The PL360 is a multi-protocol modem for the Power Line Communication (PLC) device, implementing a

very flexible architecture and allowing the implementation of standard and customized PLC solutions. It

has been conceived to be bundled with an external Microchip MCU, which downloads the corresponding

PLC firmware and controls the operation of the PL360 device.

The purpose of the PL360 Host Controller is to provide the external microcontroller a way to control the

PL360 device and offer upper layers an easy way to get access to PLC communication.

As an example of the PLC system, the figure below shows the system architecture for G3 protocol based

on a PL360 device being controlled by a SAM4C MCU.

Figure 1. G3 System Architecture

The aim of this document is to clarify and detail the user interface of the PL360 Host Controller.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 1

Page 2

Features

• Compliant with PRIME 1.3 Physical Layer

• Compliant with PRIME 1.4 Physical Layer

• Compliant with G3 Physical Layer

• SPI Interface

• Secure Boot Option

PL360

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 2

Page 3

Table of Contents

Introduction......................................................................................................................1

Features.......................................................................................................................... 2

1. PL360 Host Controller Architecture........................................................................... 5

1.1. PL360 Host Controller File Structure............................................................................................5

1.2. PLC Application Interface (API)....................................................................................................6

1.3. PLC Stack Wrapper......................................................................................................................6

1.4. Add-ons........................................................................................................................................7

1.5. Bootloader....................................................................................................................................7

1.6. Hardware Abstraction Layer (HAL).............................................................................................. 7

2. PL360 System Architecture....................................................................................... 8

2.1. Block Diagram.............................................................................................................................. 8

2.2. Bootloader....................................................................................................................................8

2.3. PL360 Memory............................................................................................................................. 9

2.4. PL360 Drivers...............................................................................................................................9

2.5. PHY PLC Service......................................................................................................................... 9

2.6. PHY Host Application................................................................................................................. 10

3. Brief about ASF........................................................................................................11

4. Initialization Example...............................................................................................12

4.1. Init Controller Descriptor.............................................................................................................12

4.2. Set Controller Callbacks.............................................................................................................12

4.3. Enable Controller........................................................................................................................13

4.4. PLC Event Handling................................................................................................................... 13

4.5. Code Example............................................................................................................................14

5. Configuration........................................................................................................... 15

5.1. Configure Application................................................................................................................. 15

5.2. Configure Coupling Parameters................................................................................................. 15

5.3. Configure Secure Mode............................................................................................................. 16

6. Host Interface Management.................................................................................... 17

6.1. Message Transmission...............................................................................................................17

6.2. Message Reception....................................................................................................................17

7. SPI Protocol.............................................................................................................18

7.1. Boot Command Format.............................................................................................................. 18

7.2. Boot Response Format.............................................................................................................. 18

7.3. Firmware Command Format...................................................................................................... 19

7.4. Firmware Response Format.......................................................................................................20

7.5. Firmware Data Memory Regions................................................................................................20

7.6. Message Flow for Basic Transactions........................................................................................22

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 3

Page 4

8. Example Applications.............................................................................................. 33

8.1. PHY Examples........................................................................................................................... 33

9. Supported Platforms................................................................................................35

9.1. Supported MCU Families........................................................................................................... 35

9.2. Supported Transceivers............................................................................................................. 35

9.3. Supported Boards...................................................................................................................... 35

9.4. Platform Porting..........................................................................................................................35

10. Abbreviations...........................................................................................................36

11. References.............................................................................................................. 38

12. Appendix A: PL360 Host Controller API..................................................................39

12.1. Common PHY API......................................................................................................................39

12.2. G3 PHY API............................................................................................................................... 42

12.3. PRIME PHY SAP....................................................................................................................... 59

13. Appendix B: ZC Offset Configuration...................................................................... 74

PL360

14. Revision History.......................................................................................................75

14.1. Rev A – 03/2018.........................................................................................................................75

14.2. Rev B - 10/2018......................................................................................................................... 75

The Microchip Web Site................................................................................................ 76

Customer Change Notification Service..........................................................................76

Customer Support......................................................................................................... 76

Microchip Devices Code Protection Feature................................................................. 76

Legal Notice...................................................................................................................77

Trademarks................................................................................................................... 77

Quality Management System Certified by DNV.............................................................78

Worldwide Sales and Service........................................................................................79

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 4

Page 5

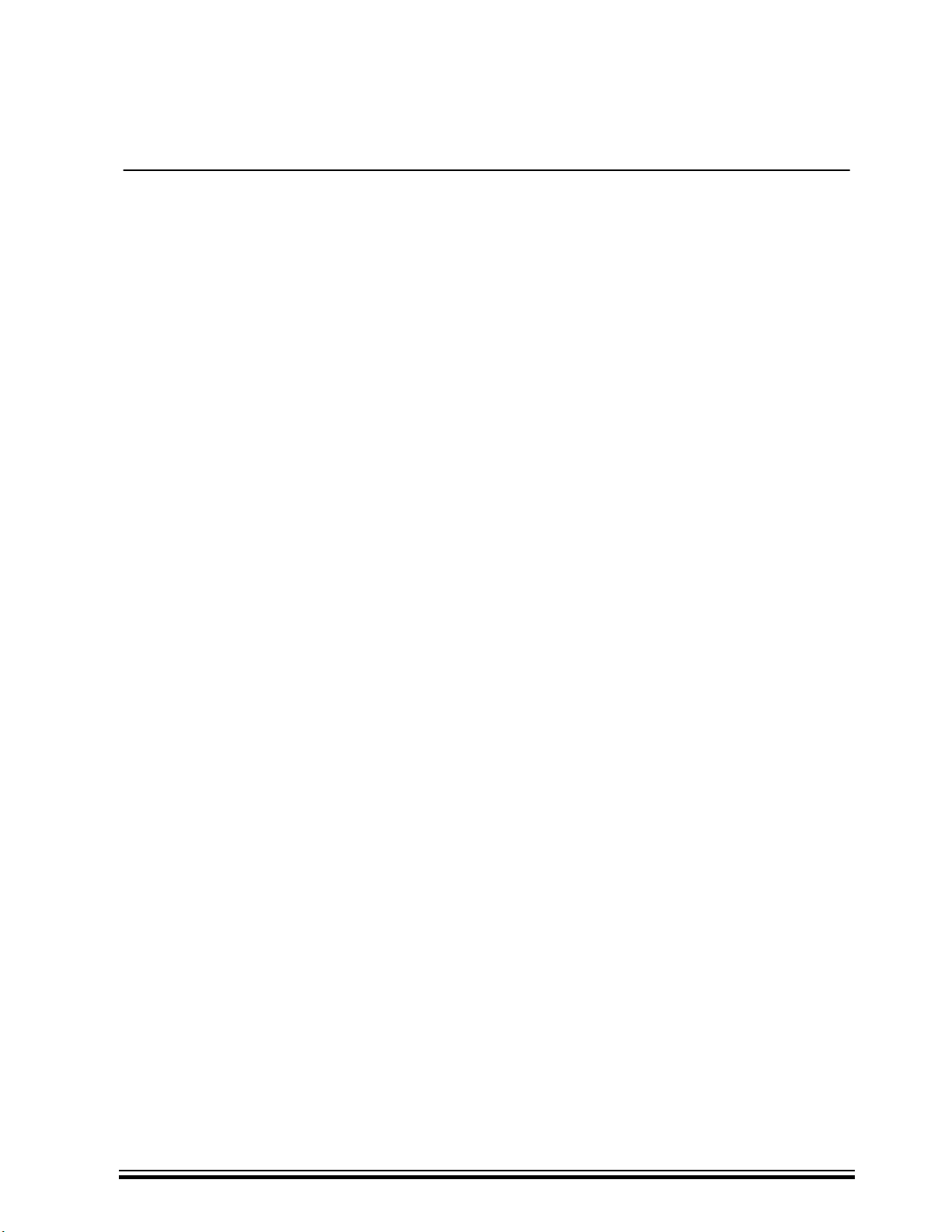

1. PL360 Host Controller Architecture

HOST MCU

PLC Appli cation

PLC Application Interface API

Bootloader PLC Stack Wrapper Add-ons

PL360 Host Controller

Hardware Abstracion Layer

The PL360 Host Controller is a C source code component which provides the host MCU application

access to the API of the Power Line Communications PHY layer running in the PL360 device. Figure 1-1

shows the architecture of the software which runs on the host MCU. The components of the PL360 Host

Controller are described in the following subsections.

Figure 1-1. PL360 Host Controller Architecture

PL360

PL360 Host Controller Architecture

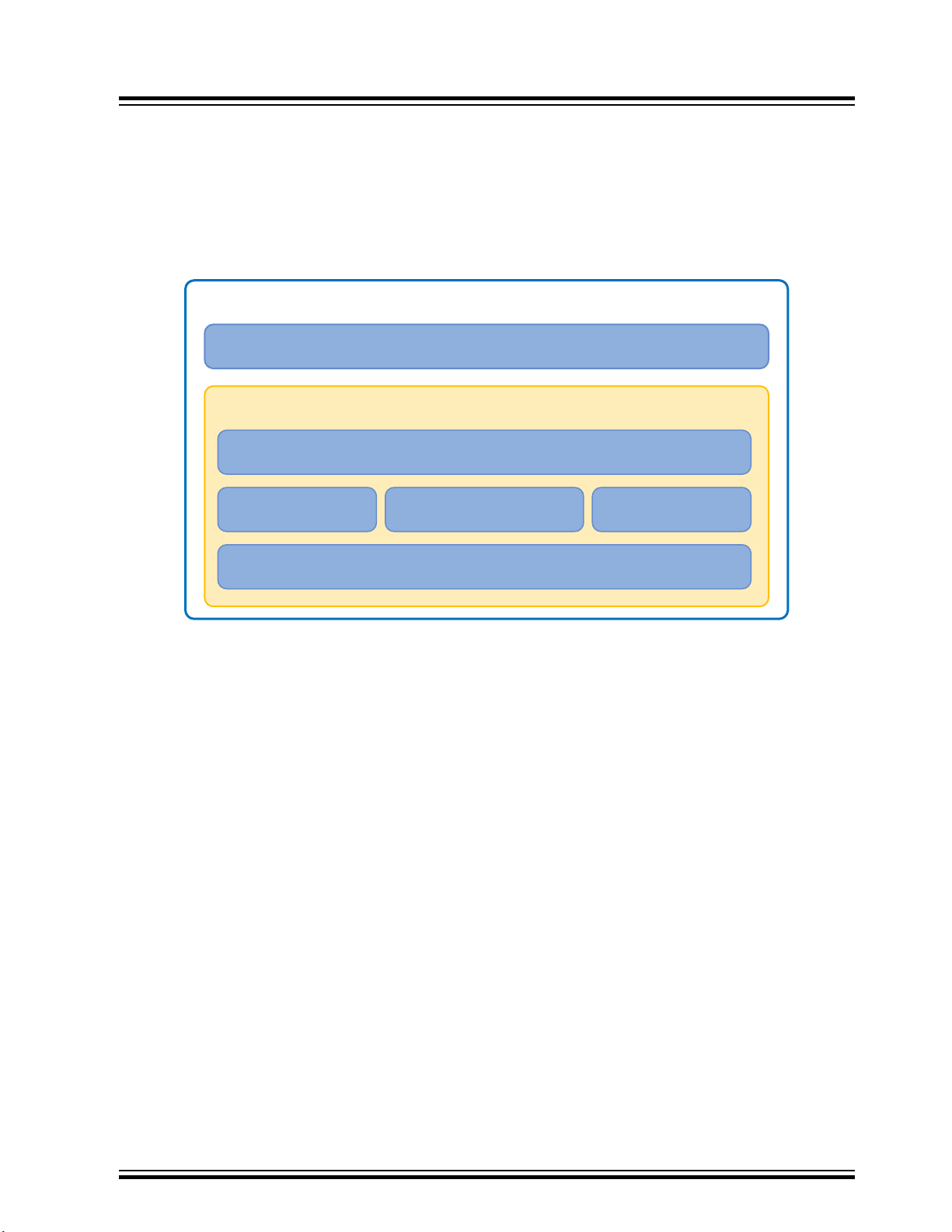

1.1 PL360 Host Controller File Structure

The PL360 Host Controller is provided as a component of ASF (Atmel Software Framework). The image

below shows the location of the main files of the PL360 Host Controller Software. Different blocks provide

different features. The next subsections describe the purpose of each block.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 5

Page 6

Figure 1-2. PL360 Host Controller File Structure

Add

on s

PLC Sta ck W

r

a

pper

Bootl oader

API

&

HAL

PL360

PL360 Host Controller Architecture

1.2 PLC Application Interface (API)

This module provides an interface to the application for all PLC operations.

This API includes the following services:

• Set custom hardware interface

• Manage Bootloader process of the PL360 device

• Manage external configuration of the PL360 device

• Enable / Disable PLC interface

• Enable / Disable secure mode

• Enable / Disable add-on module

This interface is defined in file atpl360.h and some of these services can be configured in file

conf_atpl360.h (see 5.1 Configure Application).

1.3 PLC Stack Wrapper

This module provides an interface compliant with the specific PLC communication stack, G3 or PRIME. It

includes all declarations and definitions relative to the specific communication stack.

The main function of this module is to parse/serialize frames between SPI protocol and API functions in

order to manage information from/to upper layers. It also provides a configuration function to set some

hardware- specific parameters during the initialization process.

For further details, please refer to atpl360_comm.h header file.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 6

Page 7

1.4 Add-ons

This module is responsible for providing compatibility with Microchip PLC tools. Its main function is to

pack/unpack frames so that they can be used by each PLC tool.

There are two add-ons available per PLC communication stack: one to connect with the Microchip PLC

Sniffer PC tool, and another one to connect with the Microchip PLC PHY Tester PC tool.

1.5 Bootloader

The PL360 device is a RAM-based device, so it is required to transfer the binary code to the device after

each reset. The main purpose of this module is to manage the download process.

During the bootloading, the integrity of the SPI communication between the PL360 Host Controller and

the PL360 device is checked in each SPI transaction. If the SPI header does not match the expected

information, the PL360 Host Controller resets the PL360 device and the bootloader downloads the binary

code to the device again. The PL360 Host Controller tries this download process up to three times and

reports a critical failure to upper layers after the last unsuccessful download process.

There are two modes of operation for the bootloader: Normal mode or Secure mode.

PL360

PL360 Host Controller Architecture

The following points should be taken into account in order to enable the Secure Boot mode:

• It is mandatory to include specific metadata in the binary file before downloading it to the PL360

device, such as number of blocks to decypher, init vector and signature. A Microchip Python script

is provided in PLC PHY Workspace as an example about how to include this metadata information

in the binary file

• It is needed to define ATPL360_SEC_BOOT_MODE in conf_atpl360.h file, and make sure that

__ATPL360B__ is defined as symbol in project properties

For further details, please check the bootloader commands defined in atpl360_hal_spi.h header file.

1.6 Hardware Abstraction Layer (HAL)

The Hardware Abstraction Layer provides full hardware compatibility with the host device.

There are four hardware peripherals that depend on customer platform/implementation:

• Access to SPI peripheral

• Access to interrupt system

• Access to delay system

• Access to carrier detect line

For further details, please refer to section 4. Initialization Example.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 7

Page 8

2. PL360 System Architecture

PL360 SoC

PHY Host Application

PHY

UTILS

TX

Chain

Coupling

PHY PLC Service

Application Interface (PHY API)

Bootloader

DACC

PL360 Drivers

ADCC SPI XDMAC XCORR PIO CRC

WDT SPU APMC

RX

Chain

Shared

Memory

Host

Interface

Zero

Cross

Program

Memory

Data

Memory

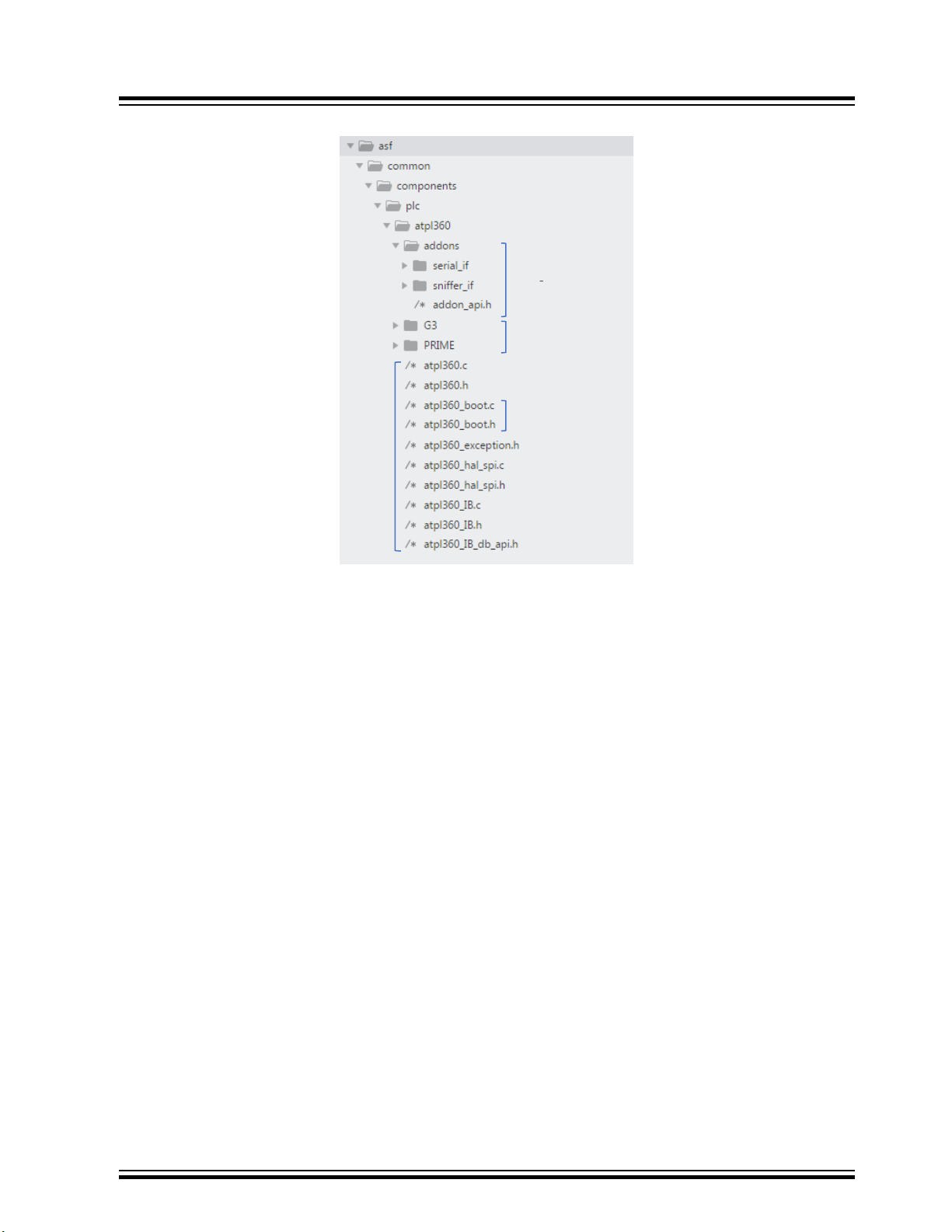

2.1 Block Diagram

Figure 2-1 shows the PL360 system architecture of the embedded firmware. The PL360 device has an

embedded Cortex M7 CPU to run the PLC firmware. This firmware can either implement the G3 or the

PRIME Physical layer depending on what has been loaded by the PL360 Host Controller. The

components of the system are described in the following subsections.

Figure 2-1. PL360 Embedded Firmware Architecture

PL360

PL360 System Architecture

2.2 Bootloader

The bootloader is an Internal Peripheral (IP) designed to load the program from an external master into

the instruction memory of the Cortex M7. This IP can access instruction memory, data memory and

peripheral registers.

For further information, please refer to the PL360 datasheet.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 8

Page 9

2.3 PL360 Memory

There are two memory configurations controlled via MEM_CONFIG bit. In the firmware loading process,

the appropriate memory configuration is established by the PL360 Host Controller according to the

firmware requisites.

MEM_CONFIG Program memory Data memory

0 128 KBytes 64 KBytes

1 96 KBytes 96 KBytes

The PL360 Host Controller code provided by Microchip sets MEM_CONFIG to 1 by default.

For further information, please refer to the PL360 datasheet.

2.4 PL360 Drivers

Each driver is responsible for managing a hardware peripheral:

• WDT: Watchdog system

• SPU: Signal Processing Unit

• APMC: Advanced Power Management Controller

• DACC: Digital to Analog Converter Controller

• ADCC: Analog to Digital Converter Controller

• SPI: Serial Peripheral Interface

• XDMAC: DMA Controller

• XCORR: Correlator

• PIO: Parallel Input/Output Controller

• CRC: Cyclic Redundancy Check

PL360

PL360 System Architecture

2.5 PHY PLC Service

There are several blocks in the PHY PLC service:

• Application Interface: The API provides a set of functions to access the physical medium and

different parameters relative to each communication stack

• Host Interface: This block is in charge of managing the communication with the PL360 Host

Controller through SPI. It is responsible for parsing/serializing the SPI data, managing PLC data

regions and providing control on PLC Interruption PIO

• Coupling: This block contains the hardware configuration associated to the reference design

provided by Microchip. If a customer needs to change this configuration to adapt it to its own

design, please refer to the 5.2 Configure Coupling Parameters chapter

• TX Chain: The TX chain is responsible for handling messages from upper layers (passed through

the API) to the physical output. This block controls all drivers relative to transmission and adapts

signal parameters in order to use functionalities of the transmission chain PHY Utils block:

convolutional encoder, scrambler, interleaver, modulator, IFFT and interpolator. Also, it handles the

result of the transmission in order to report it to upper layers through the API

• RX Chain: The RX chain is responsible for handling messages from the physical input to upper

layers (passed through the API). This block checks if the PLC signal is present on the PLC

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 9

Page 10

medium, synchronizes with this PLC signal and drives the signal through functionalities of the

reception chain in the PHY Utils block: decimator, FFT, demodulator, deinterleaver, descrambler

and Viterbi block. Also, it builds the complete message and reports it to upper layers through the

API

• Shared Memory: This block defines the structure of the data memory to avoid collisions between

TX and RX chains

• Zero Cross: The Zero Cross is responsible for calculating the last Zero Cross value and providing it

to the PLC communication stack in use. For further information, please refer to 13. Appendix B: ZC

Offset Configuration

• PHY Utils: This block contains several functionalities used by the TX/RX chains

2.6 PHY Host Application

The PHY Host Application is responsible for running the main application of the PL360 device. It is in

charge of initializing the hardware and clock systems, checking the watchdog timer and managing the

PL360 PLC service described in the previous chapter.

PL360

PL360 System Architecture

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 10

Page 11

3. Brief about ASF

The Advanced Software Framework (ASF) is a MCU software library providing a large collection of

embedded software for Atmel flash MCUs: megaAVR, AVR XMEGA, AVR UC3 and SAM devices.

For details on ASF please refer to Advanced Software Framework documentation:

• Advanced Software Framework - Website

• [PDF] Atmel AVR4029: Atmel Software Framework - Getting Started

• [PDF] Atmel AVR4030: Atmel Software Framework - Reference Manual

PL360

Brief about ASF

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 11

Page 12

4. Initialization Example

CAUTION

This chapter aims to explain the different steps required during the initialization phase of the system. After

powering up the PL360 device, a set of initialization sequences must be executed in the correct order for

the proper operation of the PL360 device.

The steps are the following:

1. Init controller descriptor

2. Set controller callbacks

3. Enable controller

4. PL360 event handling

Failure to complete any of the these initialization steps will result in failure in the PL360 Host

Controller startup.

PL360

Initialization Example

4.1 Init Controller Descriptor

The PL360 Host Controller is initialized by calling the atpl360_init function in the API. The PL360

Host Controller initialization routine performs the following steps:

• Disable PLC interrupt and component

• Register wrapper for hardware abstraction layer (for further information, please refer to 12.1.1

Initialization Function)

• Reset the PL360 device using corresponding host MCU control GPIOs

• Configure a GPIO as an interrupt source from the PL360 device

• Initialize the SPI driver

• Register an internal event handler for the external PLC interrupt

• If an add-on is required, initialize specific add-on (configured previously). See chapter 5.1

Configure Application

• Return a descriptor to the PL360 Host Controller. This descriptor will be used to manage the PLC

communication

4.2 Set Controller Callbacks

After initializing the PL360 Host Controller, it is important to set callbacks to manage PL360 events.

The PL360 Host Controller reports PLC events using callback functions.

There are 4 callback functions.

• Data indication: Used to report a new incoming message

• Data confirm: Used to report the result of the last transmitted message

• Add-on event: Used to report that a new add-on message is ready to be sent to the PLC application

• Exception event: Used to report if an exception occurs, such as a reset of the PL360 device

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 12

Page 13

4.3 Enable Controller

WARNING

The PL360 Host Controller is enabled by calling the atpl360_enable function in the API. This PL360

Host Controller routine performs the following steps:

• Disable/enable PLC interrupt and component

• Transfer the PL360 firmware to the PL360 device and validate. In case of failure, report a critical

error in host communication with the PL360 device through exception callback

4.4 PLC Event Handling

Once the controller callbacks have been set up, the PL360 Host Controller component must be enabled.

Then, the host MCU application is required to call the PL360 Host Controller API periodically to handle

events from PL360 embedded firmware.

The PL360 Host Controller API allows the host MCU application to interact with the PL360 embedded

firmware. To facilitate interaction, the PL360 Host Controller implements the host interface protocol

described in section 6. Host Interface Management. This protocol defines how to serialize and how to

handle API requests and response callbacks over the SPI bus interface.

PL360

Initialization Example

Some PL360 Host Controller APIs are synchronous function calls, whose return indicates that the

requested action is completed. However, most API functions are asynchronous. This means that when

the application calls an API to request a service, the call is non-blocking and returns immediately, usually

before the requested action is completed. When the requested action is completed, a notification is

provided in the form of a host interface protocol message from the PL360 embedded firmware to the

PL360 Host Controller, which, in turn, delivers it to the application via callback functions. Asynchronous

operation is essential when the requested service, such as a PLC message transmission, may take

significant time to complete. In general, the PL360 embedded firmware uses asynchronous events to

notify the host driver of status changes or pending data.

The PL360 device interrupts the host MCU when one or more events are pending in the PL360

embedded firmware. The host MCU application processes received data and events when the PL360

Host Controller calls the corresponding event callback function(s). In order to receive event callbacks, the

host MCU application is required to periodically call the atpl360_handle_events function in the API.

When host MCU application calls atpl360_handle_events, the PL360 Host Controller checks for

pending unhandled interrupts from the PL360 device. If no interrupt is pending, it returns immediately. If

an interrupt is pending, atpl360_handle_events function dispatches the PLC event data to the

respective registered callback. If the corresponding callback is not registered, the PLC event is discarded.

It is recommended to call this function either:

• From the main loop or from a dedicated task in the host MCU application; or,

• At least once when the host MCU application receives an interrupt from the PL360 embedded

firmware

The Host driver function atpl360_handle_events is non re-entrant. In the operating

system configuration, it is required to protect the PL360 Host Controller from re-entrance.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 13

Page 14

4.5 Code Example

The code example below shows the initialization flow as described in previous sections.

/**

* \brief Handler to receive add-on data from ATPL360.

*/

static void _handler_serial_atpl360_event(uint8_t *px_serial_data, uint16_t us_len)

{

/* customer application */

}

/**

* \brief Main code entry point.

*/

int main( void )

{

atpl360_dev_callbacks_t x_atpl360_cbs;

atpl360_hal_wrapper_t x_atpl360_hal_wrp;

uint8_t uc_ret;

/* ASF function to setup clocking. */

sysclk_init();

/* ASF library function to setup for the evaluation kit being used. */

board_init();

/* Init ATPL360 */

x_atpl360_hal_wrp.plc_init = hal_plc_init;

x_atpl360_hal_wrp.plc_reset = hal_plc_reset;

x_atpl360_hal_wrp.plc_set_handler = hal_plc_set_handler;

x_atpl360_hal_wrp.plc_send_boot_cmd = hal_plc_send_boot_cmd;

x_atpl360_hal_wrp.plc_write_read_cmd = hal_plc_send_wrrd_cmd;

x_atpl360_hal_wrp.plc_enable_int = hal_plc_enable_interrupt;

x_atpl360_hal_wrp.plc_delay = hal_plc_delay;

atpl360_init(&sx_atpl360_desc, &x_atpl360_hal_wrp);

/* Callback configuration. Set NULL as Not used */

x_atpl360_cbs.data_confirm = NULL;

x_atpl360_cbs.data_indication = NULL;

x_atpl360_cbs.exception_event = NULL;

x_atpl360_cbs.addons_event = _handler_serial_atpl360_event;

sx_atpl360_desc.set_callbacks(&x_atpl360_cbs);

/* Enable ATPL360 */

uc_ret = atpl360_enable(ATPL360_BINARY_ADDRESS, ATPL360_BINARY_LEN);

if (uc_ret == ATPL360_ERROR) {

printf("\r\nmain: atpl360_enable call error!(%d)\r\n", uc_ret);

while (1) {

}

}

while (1) {

/* Check ATPL360 pending events */

atpl360_handle_events();

}

}

PL360

Initialization Example

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 14

Page 15

5. Configuration

The PL360 firmware has a set of configurable parameters that control its behavior. There is a set of

configuration APIs provided to the host MCU application to configure these parameters. The configuration

APIs are categorized according to their functionality: application, coupling parameters and secure mode.

Any parameter left unset by the host MCU application will use the default value assigned during the

initialization of the PL360 firmware.

Info: All configuration parameters described in this chapter can be found in conf_atpl360.h file.

5.1 Configure Application

The following parameters can be modified to alter the behavior of the device.

• Use add-on capabilities:

– Serial Interface: provides handling of messages to communicate with the Microchip PLC PHY

Tester PC tool and PLC Python scripts

– Sniffer Interface: provides handling of messages to communicate with the Microchip PLC

Sniffer PC tool

PL360

Configuration

Info: These add-on modules are included in the PLC PHY workspace provided by Microchip.

This workspace contains the projects to use with the Microchip PLC tools commented on

previously.

• Only in case of G3 communication stack, the frequency band can be selected depending on

customer requirements. G3 CEN-A, CEN-B and FCC bands are available using ATPL360_WB

parameter in the file conf_atpl360.h. Take into account that this configuration requires the use

of different firmware binary files in the PL360 device. For further information, please refer to 12.2.1

Bandplan Selection.

5.2 Configure Coupling Parameters

Sometimes the hardware designed by the customer hasn’t got exactly the same performance as the

reference design provided by Microchip, so it is possible that some adjustments are needed in order to

get the best performance.

For that purpose, the following parameters can be modified:

• MAX_RMS_HI_TABLE, MAX_RMS_VLO_TABLE: Coupling parameters to define RMS values in

Hi/Vlo impedance

• TH1_HI_TABLE, TH2_HI_TABLE, TH1_VLO_TABLE, TH2_VLO_TABLE: Coupling parameters

to define threshold values to check in Hi/Vlo impedance

• PREDIST_COEF_HI_TABLE, PREDIST_COEF_VLO_TABLE: Coupling parameters to define

Predistortion Coefficients in Hi/Vlo impedance

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 15

Page 16

PL360

Configuration

IFFT_GAIN_HI_INI, IFFT_GAIN_VLO_INI, IFFT_GAIN_HI_MIN, IFFT_GAIN_VLO_MIN,

•

IFFT_GAIN_HI_MAX, IFFT_GAIN_VLO_MAX : Coupling parameters to define IFFT Gain in Hi/Vlo

impedance

• DACC_CFG_TABLE: Coupling parameters to define DACC behavior

Tip: Microchip provides a specific tool called PHY Calibration Tool with the purpose of helping

customers calculate the best values for all coupling parameters depending on their own

hardware design.

During startup, the PL360 Host Controller verifies that the firmware is running in the PL360 device and

sets custom coupling parameters through the atpl360_comm_set_coup_cfg function in the API,

which should be adapted by customers depending on their hardware requirements. The PL360 Host

Controller calls this function after any unexpected reset of the PL360 device.

Tip: To apply a customized coupling configuration, ATPL360_CFG_COUP_ENABLE must be

uncommented in conf_atpl360.h file.

5.3 Configure Secure Mode

For further information, please contact the Microchip support team.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 16

Page 17

6. Host Interface Management

The PL360 Host Controller services are divided in two categories: synchronous and asynchronous

services. See 4.4 PLC Event Handling.

Most of the services implemented by the PL360 Host Controller are asynchronous.

The synchronous service is only used in the get_config function in order to get specific internal

parameters relative to the communication stack.

When a function from the API is called, a sequence of actions is activated to format the request and to

arrange to transfer it to the PL360 device through the SPI protocol.

When an asynchronous event occurs, the PL360 Host Controller handles the PLC interrupt, checks the

events reported by the PL360 device and extracts the information relative to the notified event.

The associated callback will be invoked in the next call to atpl360_handle_events function.

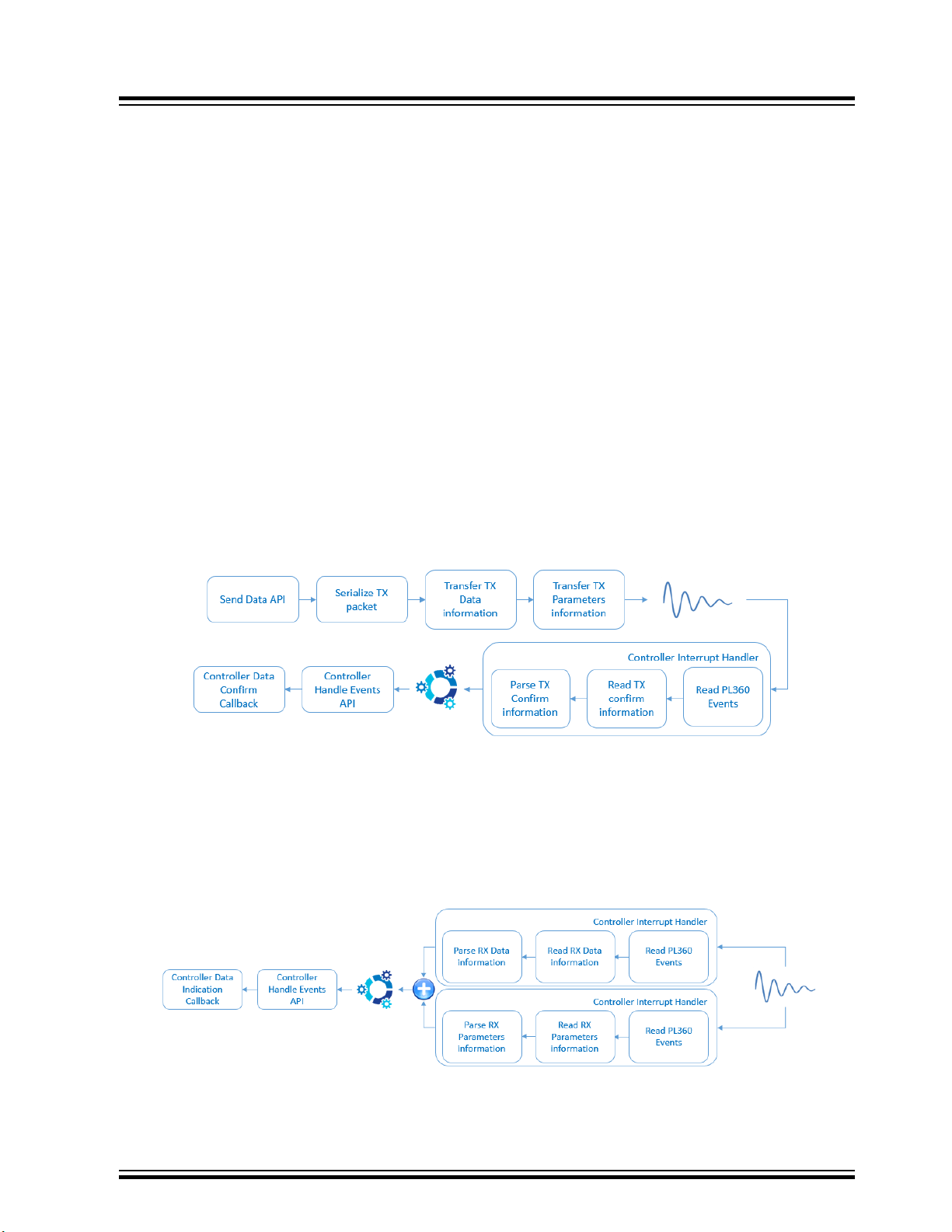

6.1 Message Transmission

The following figure shows the steps involved in the transmission of a message from the PL360 Host

Controller to the PL360 device.

PL360

Host Interface Management

Figure 6-1. Sequence of Message Transmission

6.2 Message Reception

The following figure shows the steps involved in the reception of a message from the PL360 device to the

PL360 Host Controller.

Figure 6-2. Sequence of Message Reception

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 17

Page 18

7. SPI Protocol

The main interface of the PL360 device is the SPI. The PL360 device employs a protocol to allow the

exchange of formatted data with the PL360 Host Controller. The PL360 SPI protocol uses raw bytes

exchanged on the SPI bus to form high level structures like requests and callbacks.

The PL360 SPI protocol consists of two layers:

• Layer 1: bootloader commands to transfer the firmware and configure the PL360 device

• Layer 2: firmware commands to allow the host MCU application to exchange high level messages

(e.g. PLC data transmission or PLC data reception) with the PL360 embedded firmware

The PL360 SPI Protocol is implemented as a command-response transaction and assumes that one part

is the master (PL360 Host Controller) and the other one is the slave (PL360 embedded firmware).

The format of Command, Response and Data frames is described in the following subsections. The

following points apply:

• There is a response for each command

• Transmitted/received data is divided into packets with variable size

• For a write transaction (slave is receiving data packets), the slave sends a response for each data

packet

• For a read transaction (master is receiving data packets), the master does not send any response

• Boot commands require 8-bit transactions. Firmware commands require 16-bit transactions.

PL360

SPI Protocol

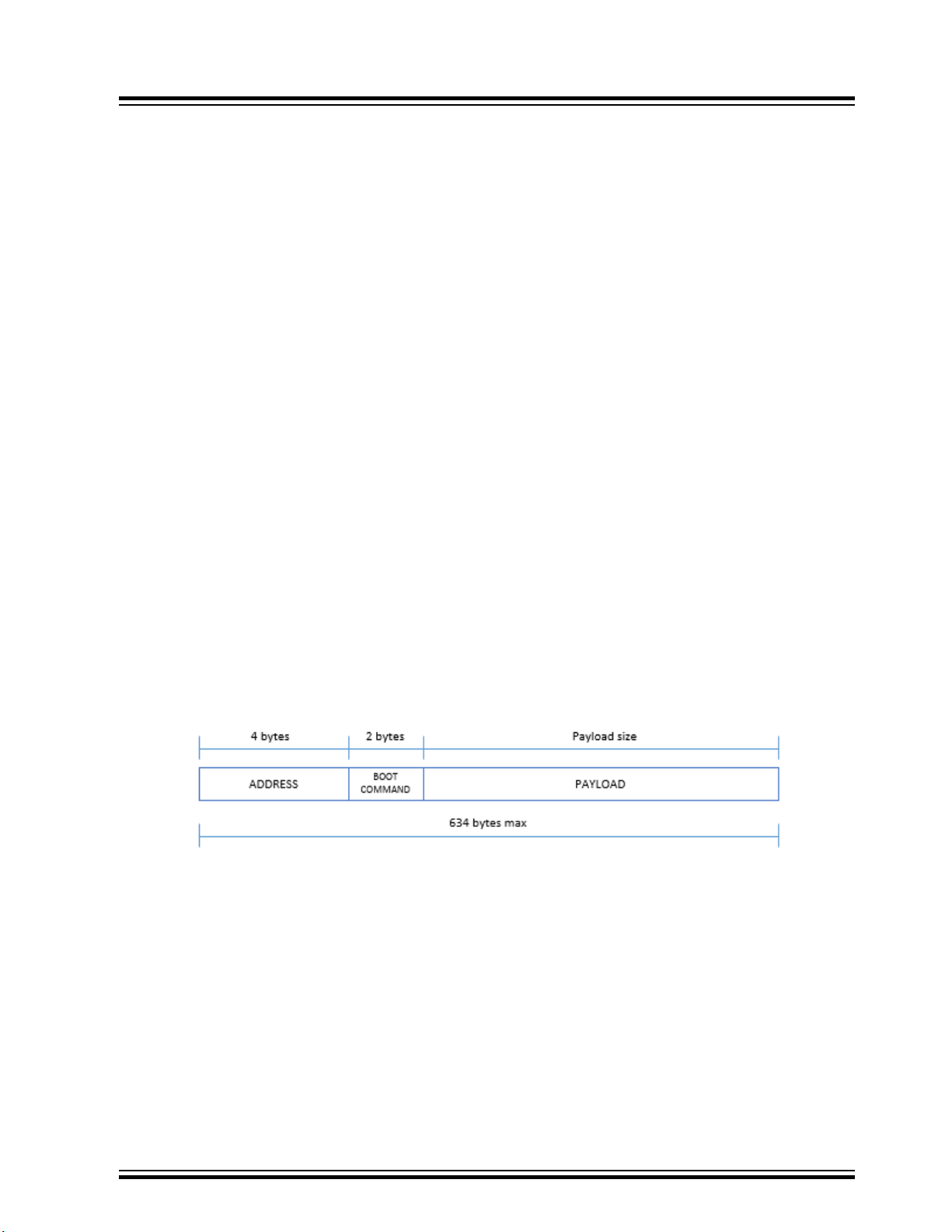

7.1 Boot Command Format

The following frame format is used for boot commands, where the PL360 device supports a DMA address

of four bytes.

Figure 7-1. Boot Command Fields

The address field contains any physical address of the PL360 device.

For further information regarding the boot command and payload fields, please see the PL360 datasheet.

7.2 Boot Response Format

The following frame format is used for boot responses.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 18

Page 19

PL360

SPI Protocol

The header field is formed by the first 15 bits and it contains the boot signature data

(0b010101100011010). This data is fixed by the PL360 device and it is used to identify the status of the

PL360 device.

The flags field contains information about the reset type of the last reset event:

• USER_RST: User reset

• CM7_RST: Cortex reset

• WDG_RST: Watchdog reset

Table 7-1. Boot Signature Data

31 30 29 28 27 26 25 24

0 1 0 1 0 1 1 0

23 22 21 20 19 18 17 16

0 0 1 1 0 1 0 USER_RST

15 14 13 12 11 10 9 8

CM7_RST WDG_RST – – – – – –

7 6 5 4 3 2 1 0

– – – – – – – –

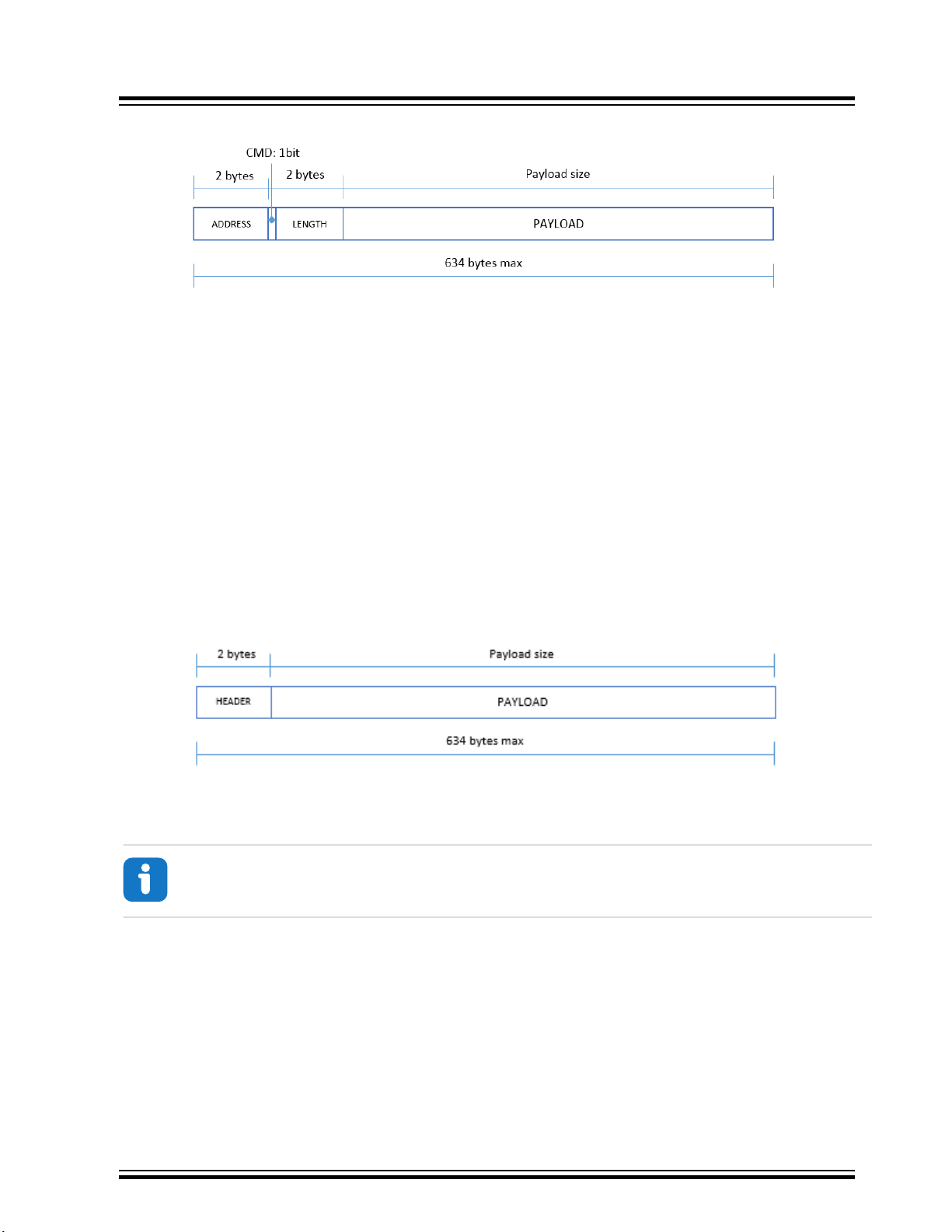

7.3 Firmware Command Format

The following frame format is used for firmware commands, where the PL360 device supports a DMA

address of two bytes.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 19

Page 20

PL360

SPI Protocol

Figure 7-2. Firmware Command Fields

The address field contains the identification number of the region to access data. These region numbers are described in section 7.5 Firmware Data Memory Regions.

The CMD field (1 bit), which is the most significant bit of the length field, contains the SPI command:

• Read command: 0

• Write command: 1

The length field (15 bits) contains the number of 16-bit blocks to read.

The payload field depends on the region number to access and on the communication stack in use, G3 or

PRIME. For further information, please refer to atpl360_comm.h file.

7.4 Firmware Response Format

The following frame format is used for firmware responses.

Figure 7-3. Firmware Response Fields

The header field contains the firmware signature data (0x1122). This field is fixed by the PL360

embedded firmware and is used to check if this firmware runs properly.

Info: Due to the 16-bit configuration used in this SPI firmware transaction, the firmware

signature is stored in memory as 0x2211.

The payload field depends on the PLC communication stack in use (G3 or PRIME). For further

information, please refer to atpl360_comm.h file.

7.5 Firmware Data Memory Regions

This section shows the data memory regions defined in the PL360 device depending on which PLC

communication stack is used.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 20

Page 21

The only difference between PRIME and G3 communication stacks regarding data memory regions is the

CAUTION

number of transmission messages that can be simultaneously queued. In case of G3, only one message

can be queued. In case of PRIME, two transmission messages can be queued simultaneously. This is

possible because there are two transmission buffers defined in the PRIME PL360 embedded firmware,

TX0 and TX1.

In both cases, G3 and PRIME, upper layers are responsible for managing multiple TX times in

order to avoid collisions between them.

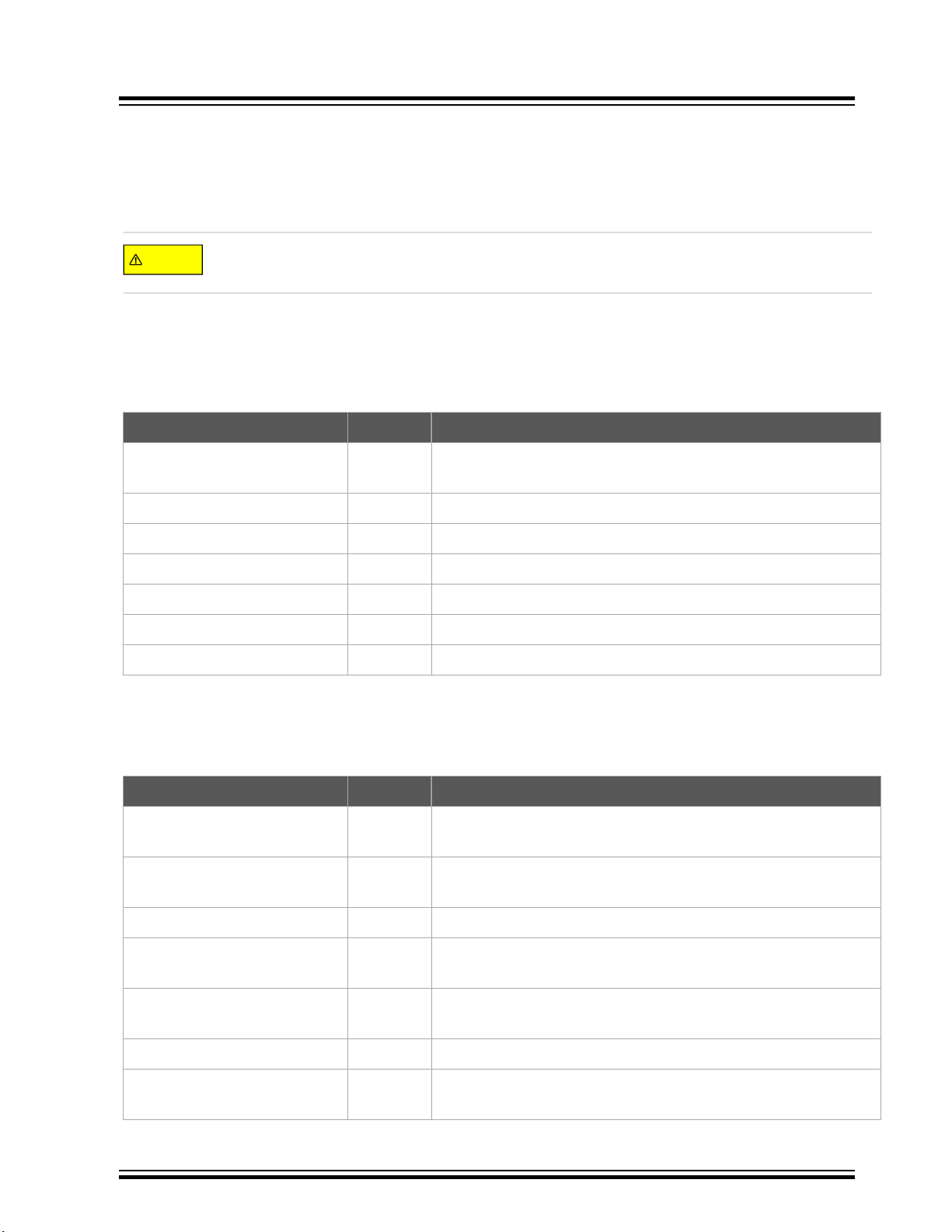

7.5.1 G3 Memory Regions

The following table defines memory regions to use with the G3 communication stack:

Table 7-2. G3 Memory Regions Table

Region Name Value Comments

ATPL360_STATUS_INFO_ID 0 Information relative to the system timer and system events

PL360

SPI Protocol

occurrences in the PL360 firmware

ATPL360_TX_PARAM_ID 1 Information relative to parameters of the last transmission

ATPL360_TX_DATA_ID 2 Information relative to data of the last transmission

ATPL360_TX_CFM_ID 3 Information relative to the confirmation of the last transmission

ATPL360_RX_PARAM_ID 4 Information relative to parameters of the last received message

ATPL360_RX_DATA_ID 5 Information relative to data of the last received message

ATPL360_REG_INFO_ID 6 Information relative to internal registers or PIB’s

7.5.2 PRIME Memory Regions

The following table defines memory regions to use with the PRIME communication stack:

Table 7-3. PRIME Memory Regions Table

Region Name Value Comments

ATPL360_STATUS_INFO_ID 0 Information relative to the system timer and system events

ATPL360_TX0_PARAM_ID 1 Information relative to parameters of the last transmission

ATPL360_TX0_DATA_ID 2 Information relative to data of the last transmission (buffer 0)

ATPL360_TX0_CFM_ID 3 Information relative to the confirmation of the last transmission

occurrences in the PL360 firmware

(buffer 0)

(buffer 0)

ATPL360_TX1_PARAM_ID 4 Information relative to parameters of the last transmission

(buffer 1)

ATPL360_TX1_DATA_ID 5 Information relative to data of the last transmission (buffer 1)

ATPL360_TX1_CFM_ID 6 Information relative to the confirmation of the last transmission

(buffer 1)

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 21

Page 22

...........continued

Region Name Value Comments

ATPL360_RX_PARAM_ID 7 Information relative to parameters of the last received message

ATPL360_RX_DATA_ID 8 Information relative to data of the last received message

ATPL360_REG_INFO_ID 9 Information relative to internal registers or PIB’s

7.6 Message Flow for Basic Transactions

This section shows the essential message exchanges and timings.

Related constants affecting below parameters:

/* ! FLAG MASKs for set G3 events */

#define ATPL360_TX_CFM_FLAG_MASK 0x0001

#define ATPL360_RX_DATA_IND_FLAG_MASK 0x0002

#define ATPL360_CD_FLAG_MASK 0x0004

#define ATPL360_REG_RSP_MASK 0x0008

#define ATPL360_RX_QPAR_IND_FLAG_MASK 0x0010

/* ! G3 Event Info MASKs */

#define ATPL360_EV_DAT_LEN_MASK 0x0000FFFF

#define ATPL360_EV_REG_LEN_MASK 0xFFFF0000

#define ATPL360_GET_EV_DAT_LEN_INFO(x) ((uint32_t)x & ATPL360_EV_DAT_LEN_MASK)

#define ATPL360_GET_EV_REG_LEN_INFO(x) (((uint32_t)x & ATPL360_EV_REG_LEN_MASK) >> 16)

PL360

SPI Protocol

/* ! FLAG MASKs for set PRIME events */

#define ATPL360_TX0_CFM_FLAG_MASK 0x0001

#define ATPL360_TX1_CFM_FLAG_MASK 0x0002

#define ATPL360_RX_DATA_IND_FLAG_MASK 0x0004

#define ATPL360_CD_FLAG_MASK 0x0008

#define ATPL360_REG_RSP_MASK 0x0010

#define ATPL360_RX_QPAR_IND_FLAG_MASK 0x0020

/* ! PRIME Event Info MASKs */

#define ATPL360_EV_DAT_LEN_MASK 0x0000FFFF

#define ATPL360_EV_REG_LEN_MASK 0xFFFF0000

#define ATPL360_GET_EV_DAT_LEN_INFO(x) ((uint32_t)x & ATPL360_EV_DAT_LEN_MASK)

#define ATPL360_GET_EV_REG_LEN_INFO(x) (((uint32_t)x & ATPL360_EV_REG_LEN_MASK) >> 16)

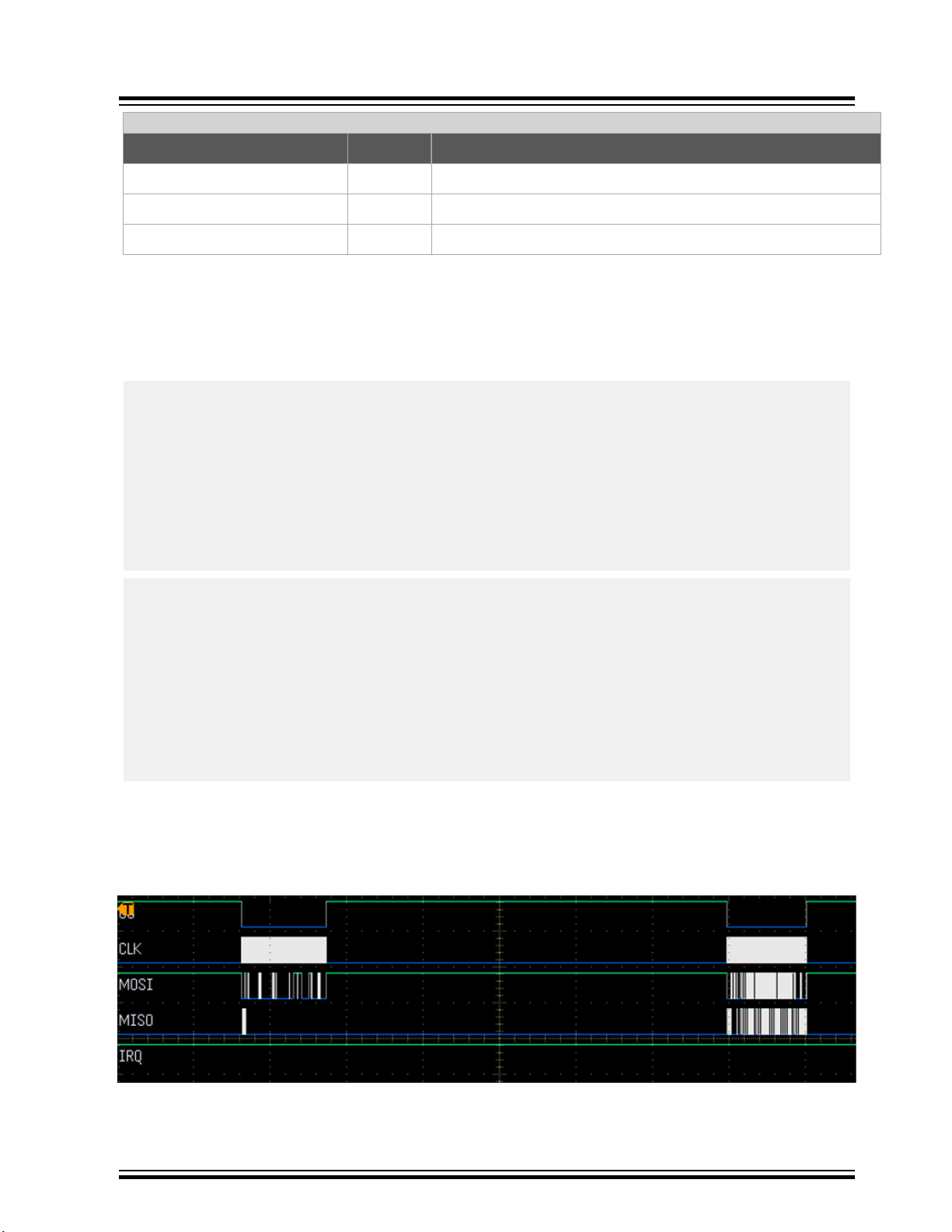

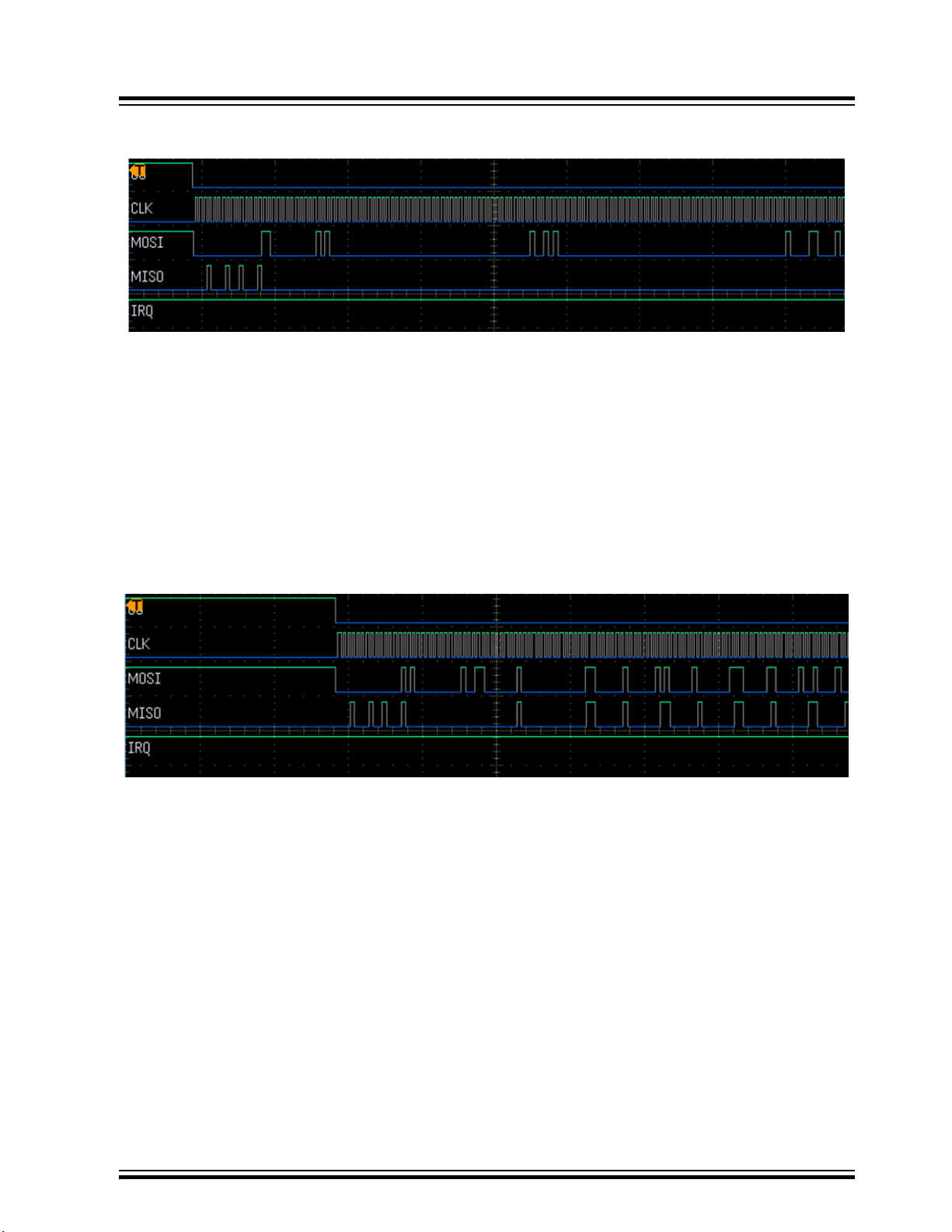

7.6.1 G3: Send Message

In a message transmission, there are 2 SPI blocks. The first one is relative to the transmission of G3

parameters of the message, the second one is relative to the data part of the same message.

Figure 7-4. G3 Send Message SPI Sequence

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 22

Page 23

7.6.1.1 G3: Send Parameters

Figure 7-5. G3 Send Parameters SPI Array

In a transmission of parameters, the following can be seen:

• Master (MOSI):

– Send ID memory region(16 bits): 0x0001 (ATPL360_TX_PARAM_ID)

– Send SPI command (1 bit): 1 (write command)

– Send SPI params length (15 bits) (in blocks of 16-bits): 0x14 (40 bytes)

– Send configuration parameters of G3 transmission (40 bytes) [example in CEN-A band]

• Slave (MISO): PL360 device responds with the Firmware Header (0x1122)

• IRQ is not used in this request operation

PL360

SPI Protocol

7.6.1.2 G3: Send Data

Figure 7-6. G3 Send Data SPI Array

In a transmission of data, the following can be seen:

• Master (MOSI):

– Send ID memory region(16 bits): 0x0002 (ATPL360_TX_DATA_ID)

– Send SPI command (1 bit): 1 (write command)

– Send SPI data length (15 bits) (in blocks of 16-bits): 0x04 (8 bytes)

– Send data of G3 transmission (8 bytes)

• Slave (MISO): PL360 device responds with the Firmware Header (0x1122)

• IRQ is not used in this request operation

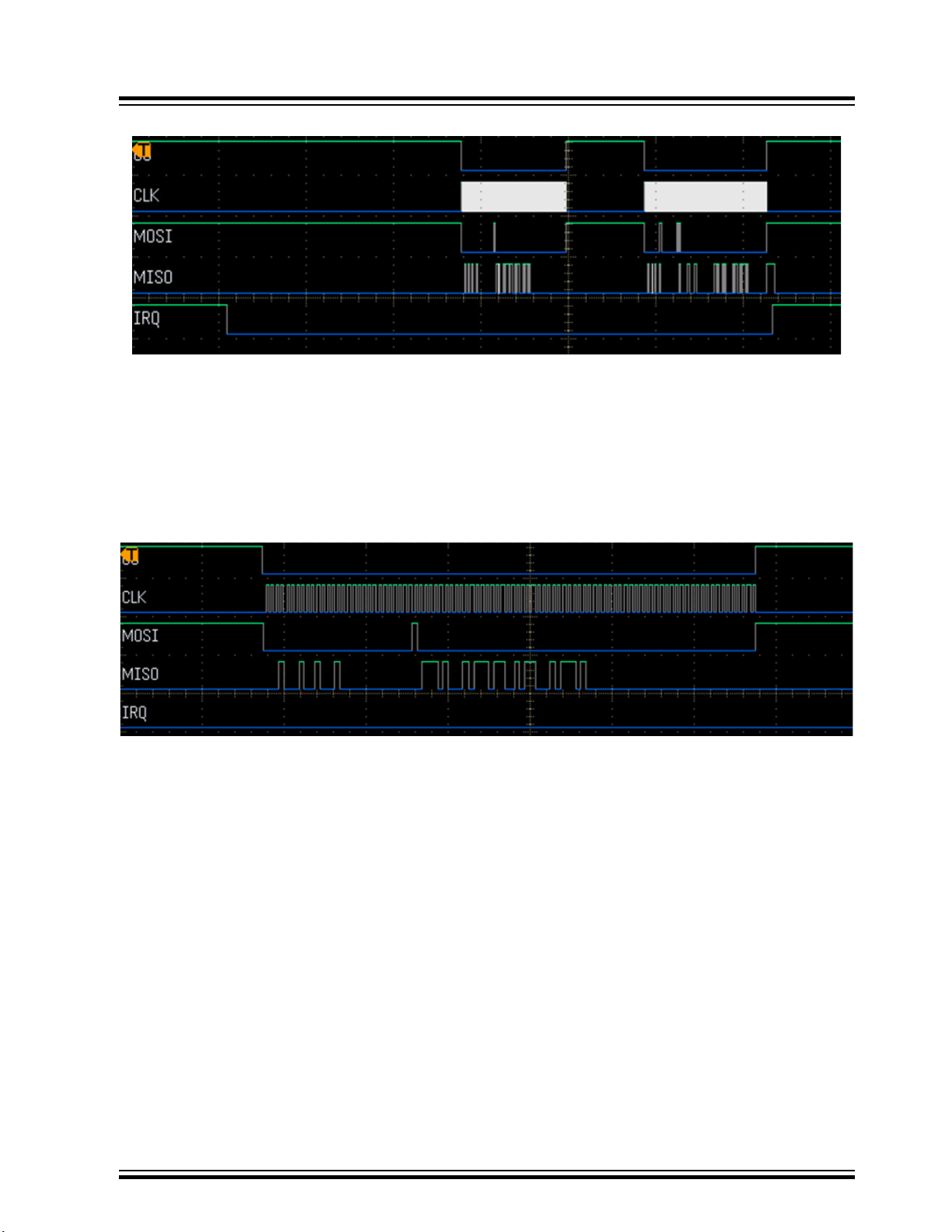

7.6.2 G3: Read TX confirm Information

When message transmission is complete, the PL360 device reports the status of the last transmission.

For that purpose, IRQ is used to notify the PL360 Host Controller that an event has occurred.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 23

Page 24

PL360

SPI Protocol

Figure 7-7. G3 Read TX Confirm SPI Sequence

In the figure above, the following can be seen:

• IRQ is used to notify of PL360 events

• First SPI transaction corresponds to the retrieval of event information from the PL360 device

• Second SPI transaction corresponds to the retrieval of confirmation data from the PL360 device (if

needed)

7.6.2.1 Get Events Information

Figure 7-8. G3 Get Events Information SPI Array

In the retrieval of event information, the following can be seen:

• Master (MOSI):

– Send ID memory region(16 bits): 0x0000 (ATPL360_STATUS_INFO_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16 bits): 0x04 (8 bytes)

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x0001 (ATPL360_TX_CFM_FLAG_MASK)

– Send Firmware Timer reference (32 bits)

– Send Firmware Events Information (32 bits). Only valid in case of data indication

(ATPL360_RX_DATA_IND_FLAG_MASK) or register response (ATPL360_REG_RSP_MASK)

events. It is used to report the length of the data to be read

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 24

Page 25

7.6.2.2 Get Confirmation Data

Figure 7-9. G3 Get Confirmation Data SPI Array

If there is a pending ATPL360_TX_CFM_FLAG_MASK event, it is needed to read information relative to

the TX confirmation event:

• Master (MOSI):

– Send ID memory region(16 bits): 0x0003 (ATPL360_TX_CFM_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16-bits): 0x05 (10 bytes)

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x0001 (ATPL360_TX_CFM_FLAG_MASK)

– Send Firmware TX confirmation data:

• RMS calc value (32 bits)

• Transmission Time (32 bits)

• Transmission Result (8 bits)

PL360

SPI Protocol

If there are no pending events to attend, the nterrupt line is disabled.

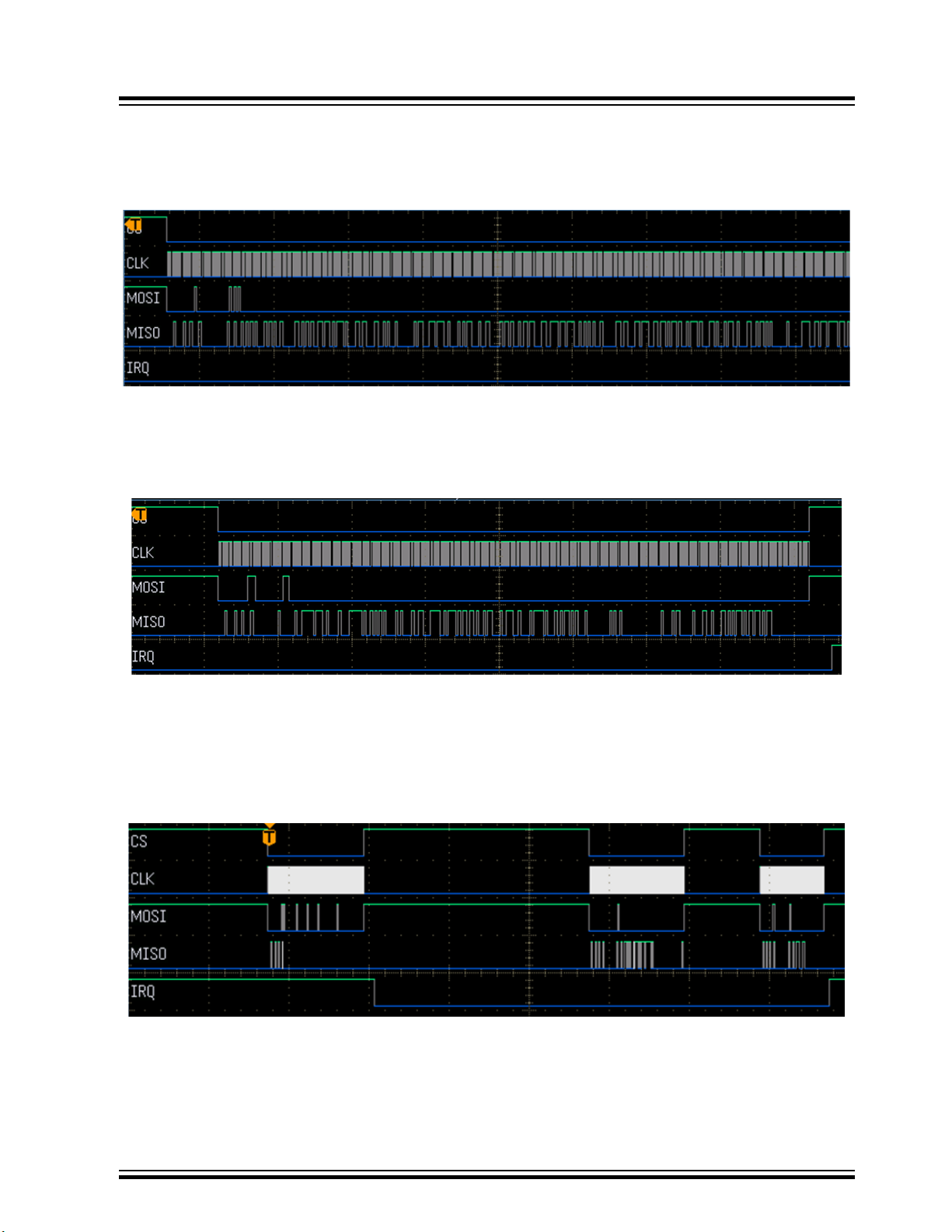

7.6.3 G3: Receive Message

Figure 7-10. G3 Receive Message SPI Sequence

Message reception is composed of four SPI transactions in two interruption blocks:

• IRQ 1: Get data part of the message (two transactions):

– Get Events Information

– Get Data

• IRQ 2: Get parameters part of the message (two transactions):

– Get Events Information

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 25

Page 26

– Get Parameters

7.6.3.1 Get Events Information and Data

Figure 7-11. G3 Get Events Information and Data SPI Arrays

If IRQ occurs (enabled in low), it is first needed to read events reported by the PL360 device.

• Master (MOSI):

– Send ID memory region(16 bits): 0x0000 (ATPL360_STATUS_INFO_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16-bits): 0x04 (8 bytes)

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x0002 (ATPL360_RX_DATA_IND_FLAG_MASK)

– Send Firmware Timer reference (32 bits)

– Send Firmware Events Information (32 bits)

• First 16 bits: Not valid

• Second 16 bits: Length of the data to be read in next transaction (D_LEN)

PL360

SPI Protocol

The next transaction gets the data part of the message:

• Master (MOSI):

– Send ID memory region(16 bits): 0x0005 (ATPL360_RX_DATA_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16-bits): Use (D_LEN/2) obtained in previous

transaction

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x0002 (ATPL360_RX_DATA_IND_FLAG_MASK)

– Send Firmware RX data (variable)

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 26

Page 27

7.6.3.2 Get Events Information and Parameters

Figure 7-12. G3 Get Events Information and Parameters SPI Arrays

If IRQ occurs (enabled in low), first it is needed to read events reported by the PL360 device.

• Master (MOSI):

– Send ID memory region(16 bits): 0x0000 (ATPL360_STATUS_INFO_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16-bits): 0x04 (8 bytes)

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x0010 (ATPL360_RX_QPAR_IND_FLAG_MASK)

– Send Firmware Timer reference (32 bits)

– Send Firmware Events Information (32 bits): Not valid

PL360

SPI Protocol

The next transaction gets the parameters part of the message:

• Master (MOSI):

– Send ID memory region(16 bits): 0x0004 (ATPL360_RX_PARAM_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16-bits): Variable length depending on G3 band

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x0010 (ATPL360_RX_QPAR_IND_FLAG_MASK)

– Send Firmware RX parameters. See rx_msg_t structure in atpl360_comm.h file

7.6.4 PRIME: Send Message (Buffer 0)

In a message transmission, there is only one SPI transaction that includes both parameters and data.

Figure 7-13. PRIME Send Message SPI Array

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 27

Page 28

In the figure above, the following can be seen:

• Master (MOSI):

– Send ID memory region(16 bits): 0x0001 (ATPL360_TX0_PARAM_ID)

– Send SPI command (1 bit): 1 (write command)

– Send SPI params length (15 bits) (in blocks of 16-bits): (param length + data length) / 2,

where param length is 12 bytes

– Send configuration parameters of PRIME transmission (12 bytes)

– Send data part of message (variable)

• Slave (MISO): PL360 responds with Firmware Header (0x1122)

IRQ is not used in this request operation.

7.6.5 PRIME: Read TX confirm Information (Buffer 0)

When message transmission is complete, the PL360 device reports the status of the last transmission.

For that purpose, IRQ is used to notify the PL360 Host Controller that an event has occurred.

Figure 7-14. PRIME TX Confirm Information SPI Sequence

PL360

SPI Protocol

In the figure above, the following can be seen:

• IRQ is used to notify of PL360 events

• First SPI transaction corresponds to the retrieval of event information from the PL360 device

• Second SPI transaction corresponds to the retrieval of confirmation data from the PL360 device (if

needed)

7.6.5.1 Get Events Information (Buffer 0)

Figure 7-15. PRIME Events Information SPI Array

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 28

Page 29

It is similar to the flow described in section 7.6.2.1 Get Events Information, but changing the firmware descriptors for the ones applicable to the PRIME PL360 firmware.

7.6.5.2 Get Confirmation Data (Buffer 0)

Figure 7-16. PRIME Confirmation Data SPI Array

It is similar to the flow described in section 7.6.2.2 Get Confirmation Data, but changing the firmware

descriptors for the ones applicable to the PRIME PL360 firmware.

7.6.6 PRIME: Receive Message

Figure 7-17. PRIME Receive Message SPI Sequence

PL360

SPI Protocol

It is similar to the flow described in section 7.6.3 G3: Receive Message, but changing the firmware

descriptors for the ones applicable to the PRIME PL360 firmware.

In this case, two events are read simultaneously, ATPL360_RX_DATA_IND_FLAG_MASK and

ATPL360_RX_QPAR_IND_FLAG_MASK, so there are two consecutive SPI transactions in order to get

data and parameters information from the PL360 device.

7.6.6.1 Get Events Information

Figure 7-18. PRIME Get Events SPI Array

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 29

Page 30

It is similar to the flow described in section 7.6.3.1 Get Events Information and Data, but changing the

firmware descriptors for the ones applicable to the PRIME PL360 firmware.

7.6.6.2 Get Data Information

Figure 7-19. PRIME Get Data SPI Array

It is similar to the flow described in section 7.6.3.1 Get Events Information and Data, but changing the

firmware descriptors for the ones applicable to the PRIME PL360 firmware.

7.6.6.3 Get Parameters Information

Figure 7-20. PRIME Get Parameters SPI Array

PL360

SPI Protocol

It is similar to the flow described in section 7.6.3.2 Get Events Information and Parameters, but changing

the firmware descriptors for the ones applicable to the PRIME PL360 firmware.

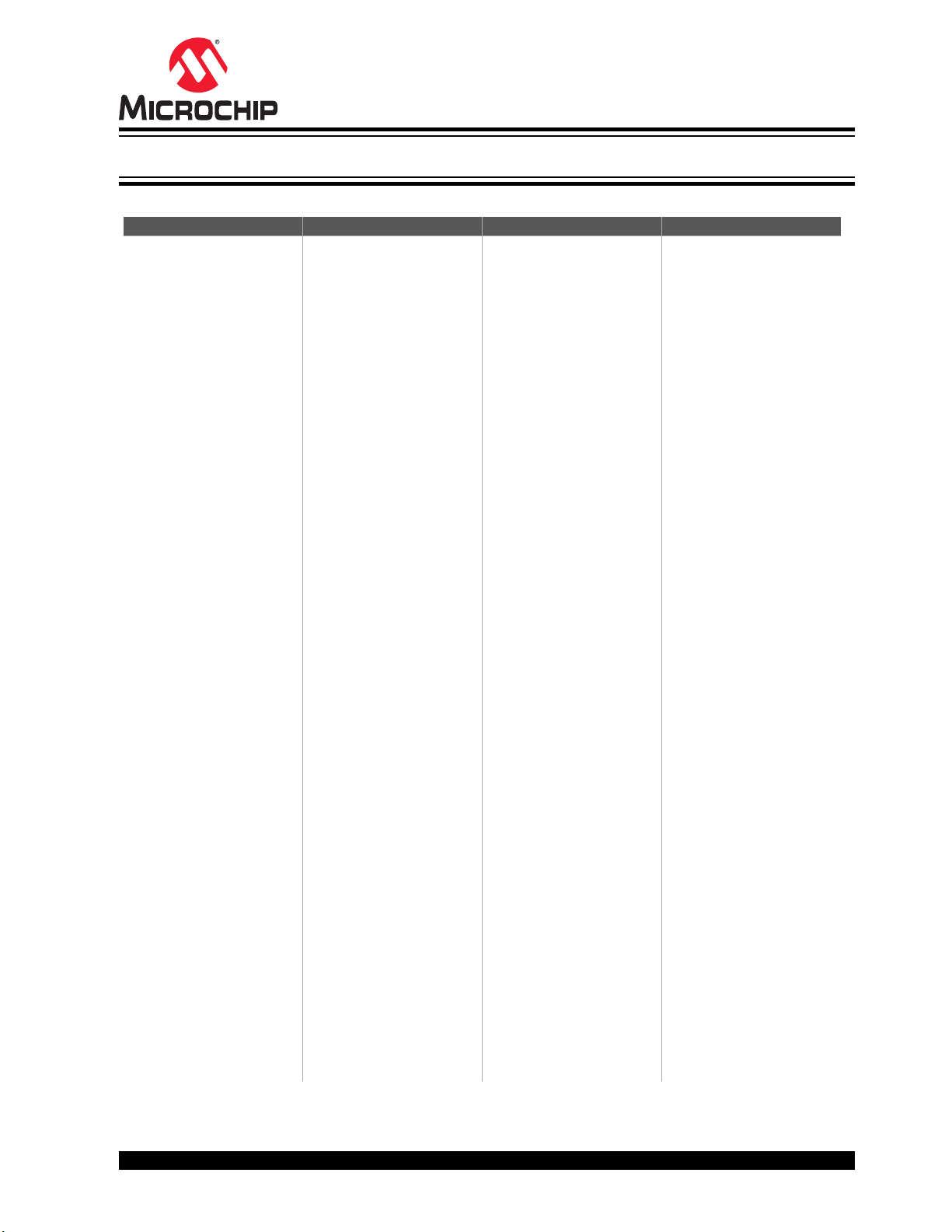

7.6.7 Read Register Information

It is possible to get internal information from the PL360 device.

Figure 7-21. Read Register Information SPI Sequence

In the figure above, three SPI transactions can be seen:

• Request register information

• Get events information

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 30

Page 31

• Get register value

7.6.7.1 Request Register Information

Figure 7-22. Request Register Information Array

• Master (MOSI):

– Send ID memory region(16 bits): 0x0006 (ATPL360_REG_INFO_ID) [example with G3]

– Send SPI command (1 bit): 1 (write command)

– Send SPI params length (15 bits) (in blocks of 16-bits): 0x0004 (8 bytes)

– Send register identification (4 bytes). See section 12.2.5 PIB Objects Specification and

Access (G3) or 12.3.4 PIB Objects Specification and Access (PRIME)

– Send length of the register to read (2 bytes)

• Slave (MISO): PL360 device responds with firmware header (0x1122)

PL360

SPI Protocol

7.6.7.2 Get Events Information

Figure 7-23. Get Events Information Array

• Master (MOSI):

– Send ID memory region(16 bits): 0x0000 (ATPL360_STATUS_INFO_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16 bits): 0x04 (8 bytes)

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x0008 (ATPL360_REG_RSP_MASK)

– Send Firmware Timer reference (32 bits)

– Send Firmware Events Information (32 bits)

• First 16 bits: Length of the register value to read in next transaction. (D_REG)

• Second 16 bits: Not valid

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 31

Page 32

7.6.7.3 Get Register Value

Figure 7-24. Get Register Value SPI Array

• Master (MOSI):

– Send ID memory region(16 bits): 0x0006 (ATPL360_REG_INFO_ID)

– Send SPI command (1 bit): 0 (read command)

– Send SPI data length (15 bits) (in blocks of 16 bits): Variable length depending on register to

read (D_REG)

• Slave (MISO):

– Send Firmware Header (16 bits): 0x1122

– Send Firmware Events (16 bits): 0x008 (ATPL360_REG_RSP_MASK)

– Send Firmware register value. See section 12.2.5 PIB Objects Specification and Access (G3)

or 12.3.4 PIB Objects Specification and Access (PRIME)

PL360

SPI Protocol

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 32

Page 33

8. Example Applications

CAUTION

Please note that all the provided application examples have been configured to work on

Microchip evaluation boards. When using other hardware, the firmware project must define a

Board Support Package (BSP) customized for that hardware.

Along with the PLC communication stacks, specific application examples are provided in order to show

how to integrate the PL360 Host Controller.

In addition, PHY examples using only the PL360 Host Controller are provided in order to evaluate some

low level parameters and to be used together with a Microchip PLC tool for demonstration purposes.

In case of a G3 stack, applications are provided for CENELEC A, CENELEC B and FCC bands (project

folders with suffixes “_cen_a”, “_cen_b” and “_fcc” in each example). Setting the appropriate band in each

project is made by means of conf_atpl360.h file, as explained in section 5.1 Configure Application.

In case of a PRIME stack, applications are provided for CENELEC A and FCC bands (the same project

folder is used in both bands depending on PRIME configured channel. See 12.3.4.27

ATPL360_REG_CHANNEL_CFG (0x4016)).

PL360

Example Applications

8.1 PHY Examples

8.1.1 PHY Tester

The PHY Tester is an application example that demonstrates the complete performance of the Microchip

PLC PHY layer. This example requires a board and a PC tool. In addition, the Microchip PLC PHY Tester

PC tool (available in the Microchip website) has to be installed on the user’s host PC to interface with the

boards.

The Microchip PLC PHY Tester PC tool configures the devices and performs communication tests.

This example uses the serial interface configured through UART0 at 230400bps.

8.1.2 PHY Sniffer

The PHY Sniffer is an application example to monitor data traffic in the PLC network and then send it via

serial communications to a PC tool and the Microchip PLC Sniffer PC tool (available in the Microchip

website), which has to be installed in the user’s host PC to interface with the board. This example

requires only one board and (obviously) a PLC network to be monitored.

This example uses the serial interface configured through UART0 at 230400bps.

8.1.3 TX Console

Due to PC timing, the Microchip PLC PHY Tester PC tool may present limitations in those applications or

tests that require a very short time interval between consecutive frame transmissions.

The PHY TX Console is an application example that demonstrates the complete performance of the

Microchip PLC PHY Layer avoiding the limitations of timing in the PC host. This way, users can perform

more specific PHY tests (e.g., short time interval between consecutive frames).

This application offers an interface to the user by means of a command console. In this console, users

can configure several transmission parameters such as modulation, frame data length and time interval

between frames. In the console it is also possible to test transmission/reception processes.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 33

Page 34

Example Applications

This example uses the serial interface configured through UART0 at 921600bps.

PL360

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 34

Page 35

9. Supported Platforms

This chapter describes which hardware platforms are currently supported with the PL360 Host Controller

source code. Usually, a platform usually is comprised of three major components:

• An MCU

• A transceiver chip

• A specific board or even several boards that contain the MCU or the transceiver chip

9.1 Supported MCU Families

Platforms based in SAM4C family MCUs.

The dedicated code for each device of the family can be found in the corresponding subdirectories of the

FW package.

9.2 Supported Transceivers

Currently the supported transceivers are PL360.

PL360

Supported Platforms

9.3 Supported Boards

The boards currently supported are given below:

• PL360MB

9.4 Platform Porting

Platform porting is available only under demand.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 35

Page 36

10. Abbreviations

AGC Automatic Gain Control

API Application Programming Interface

APP Application

ASF Advanced Software Framework

BER Bit Error Rate

CINR Carrier to Interference + Noise Ratio

DT Delimiter Type

EK Evaluation Kit

EVM Error Vector Magnitude

FCH Frame Control Header

FFT Fast Fourier Transform

PL360

Abbreviations

FW Firmware

GPIO General Purpose Input/Output

HAL Hardware Abstraction Layer

IP Internal Peripheral

IFFT Inverse Fast Fourier Transform

IRQ Interrupt Request

LQI Link Quality Indicator

MCU Microcontroller Unit

MISO Master Input Salve Output

MOSI Master Output Salve Input

PAL Platform Abstraction Layer

PDU Protocol Data Unit

PGA Programmable-Gain Amplifier

PHY Physical Layer

PIB PLC Information Base

PLC Power Line Communication

SPI Serial Peripheral Interface

RD Read

RRC Root Raised Cosine

RS Reed Solomon

RSSI Received Signal Strength Indication

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 36

Page 37

RX Reception

SNR Signal to Noise Ratio

TX Transmission

WR Write

PL360

Abbreviations

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 37

Page 38

11. References

Microchip Smart Energy: http://www.microchip.com/design-centers/smart-energy-products/overview

Microchip Power Line Communications: http://www.microchip.com/design-centers/smart-energy-products/

power-line-communications/overview

Microchip Design Support: http://www.microchip.com/support/hottopics.aspx

G3-PLC Alliance: http://www.g3-plc.com/

PRIME Alliance: http://www.prime-alliance.org/

PL360-EK User Guide, 2018

PL360 Datasheet, 2018

Advanced Software Framework: http://www.microchip.com/avr-support/advanced-software-framework-

(asf)

Atmel Studio: http://www.microchip.com/avr-support/atmel-studio-7

Documents for supported families and boards: http://asf.atmel.com/docs/latest/

PL360

References

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 38

Page 39

Appendix A: PL360 Host Controller API

12. Appendix A: PL360 Host Controller API

This appendix describes all the data structures and functions that are part of the PL360 Host Controller

component.

12.1 Common PHY API

12.1.1 Initialization Function

The PL360 Host Controller must always be initialized when the system starts the execution. The following

function initializes the hardware parameters and configures the controller descriptor:

void atpl360_init(atpl360_descriptor_t *const descr, atpl360_hal_wrapper_t *px_hal_wrapper);

Parameters:

descr Pointer to component descriptor

px_hal_wrapper Pointer to HAL wrapper structure

PL360

This function performs the following actions:

• Sets the handlers for the PLC interruption

• Initializes the PLC SPI service

• And, if necessary, initializes add-on interfaces

The component descriptor offers the customer a set of functions to get access to the PL360 device. It is

defined as a structure of function pointers as follows:

typedef struct atpl360_descriptor {

pf_set_callbacks_t set_callbacks;

pf_send_data_t send_data;

pf_mng_get_cfg_t get_config;

pf_mng_set_cfg_t set_config;

pf_addons_event_t send_addons_cmd;

} atpl360_descriptor_t;

where:

• set_callbacks function is used to set upper layers functions to be executed when a PL360 Host

Controller event has been reported. For further information, please refer to the 12.1.2 Setting

Callbacks chapter.

• send_data function provides a mechanism to send a PLC message through the PL360 device.

For further G3 information, please refer to the G3 12.2.2 PHY-DATA.request chapter. For further

PRIME information, please refer to the PRIME 12.3.1 PHY-DATA.request chapter.

• get_config function provides a read access method to get PL360 internal data. For further

information, please refer to the 12.1.6.2 Get Configuration chapter.

• set_config function provides a write access method to set PL360 internal data. For further

information, please refer to the 12.1.6.1 Set Configuration chapter.

• send_addons_cmd function provides a mechanism to connect PLC Microchip tools to the PL360

device. All information received from these tools should be redirected to this function in order to

pass the information to the PL360 Host Controller

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 39

Page 40

PL360

Appendix A: PL360 Host Controller API

Function pointers are defined as follows:

typedef void (*pf_set_callbacks_t)(atpl360_dev_callbacks_t *dev_cb);

typedef uint8_t (*pf_send_data_t)(tx_msg_t *px_msg);

typedef bool (*pf_mng_get_cfg_t)(uint16_t us_param_id, void *px_value, uint8_t uc_len, bool

b_sync);

typedef bool (*pf_mng_set_cfg_t)(uint16_t us_param_id, void *px_value, uint16_t us_len);

typedef void (*pf_addons_event_t)(uint8_t *px_msg, uint16_t us_len);

The PL360 Host Controller also needs to have access to hardware peripherals. A HAL wrapper structure

is used to separate this hardware and software dependency.

typedef struct atpl360_hal_wrapper {

pf_plc_init_t plc_init;

pf_plc_reset_t plc_reset;

pf_plc_set_handler_t plc_set_handler;

pf_plc_bootloader_cmd_t plc_send_boot_cmd;

pf_plc_write_read_cmd_t plc_write_read_cmd;

pf_plc_enable_int_t plc_enable_int;

pf_plc_delay_t plc_delay;

} atpl360_hal_wrapper_t;

In ASF, Microchip provides a set of example functions to get hardware access. It depends on the

communication stack in use.

• G3: Refer to pplc_if.c/.h files. They are located in

asf.sam.services.plc.pplc_if.atpl360 path

• PRIME. Refer to hal_plc.c/.h files. They are located in asf.thirdparty.prime_ng.hal

path

12.1.2 Setting Callbacks

The user can set their own callbacks using the following function pointer defined in the PL360 Host

Controller descriptor:

typedef void (*pf_set_callbacks_t)(atpl360_dev_callbacks_t *dev_cb);

Parameters:

atpl360_dev_callbacks_t Pointer to callbacks struct

The structure used as input of pf_set_callbacks_t function contains four fields which are the

pointers to the functions to be executed for the different PL360 Host Controller events:

typedef struct atpl360_dev_callbacks {

pf_data_confirm_t data_confirm;

pf_data_indication_t data_indication;

pf_addons_event_t addons_event;

pf_exeption_event_t exception_event;

} atpl360_dev_callbacks_t;

where:

• data_confirm function is used to notify of the result of the last message transmission

• data_indication function is used to notify of the reception of a new message

• addons_event function is used to notify that there is a new message to be sent to a PLC

Microchip Tool

• exception_event function is used to notify of any exception which occurs in the communication

with the PL360 device

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 40

Page 41

Exception values are defined as follow:

typedef enum {

ATPL360_EXCEPTION_UNEXPECTED_SPI_STATUS = 0, /* SPI has detected an unexpected status */

ATPL360_EXCEPTION_SPI_CRITICAL_ERROR, /* SPI critical error. */

ATPL360_EXCEPTION_RESET, /* Reset device */

} atpl360_exception_t;

Tip: SPI critical error means that the PL360 firmware cannot be loaded into the PL360 device.

A possible reason for this would be that the SPI is not working properly.

12.1.3 Enable Function

Once the host descriptor has been initialized and the application callbacks have been set, the PL360

Host Controller must be enabled using the following function:

atpl360_res_t atpl360_enable(uint32_t ul_binary_address, uint32_t ul_binary_len);

Parameters:

PL360

Appendix A: PL360 Host Controller API

ul_binary_address Memory address where the PL360 firmware binary file is located

ul_binary_len Size of the PL360 firmware binary file

This function performs the following actions:

• Disable PLC interrupt

• Transfer firmware binary file to the PL360 device

• Check firmware integrity

• Enable PLC interrupt

12.1.4 Disable Function

The PL360 Host Controller provides a mechanism to disable the notification of PL360 Host Controller

events to the application in order to avoid interrupting the normal flow of the customer application. This

mechanism implies that the PLC activity is stopped in the PL360 device.

void atpl360_disable(void);

12.1.5 Event Handler Function

This function provides a mechanism to notify the PL360 Host Controller events to the customer

application using the previously configured callbacks.

The following function must be called every program cycle or at least once when the host MCU

application receives an interrupt from the PL360 embedded firmware:

void atpl360_handle_events(void);

First, this function checks all PLC events:

• PHY parameters and configuration

• End of transmission of PLC message

• End of reception of PLC message

• Exceptions

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 41

Page 42

And then, it triggers the corresponding PL360 Host Controller callbacks.

12.1.6 Management Primitives

12.1.6.1 Set Configuration

This is done by means of a specific function provided by the controller descriptor:

typedef bool (*pf_mng_set_cfg_t)(uint16_t us_param_id, void *px_value, uint8_t uc_len);

Parameters:

us_param_id PIB ID (see 12.3.4 PIB Objects Specification and Access (PRIME) and

*px_value Pointer to parameter value to set

uc_len Length of parameter

The function returns 0 if the result is invalid, otherwise returns 1.

12.1.6.2 Get Configuration

This is done by means of a specific function provided by the controller descriptor:

PL360

Appendix A: PL360 Host Controller API

12.2.5 PIB Objects Specification and Access (G3))

typedef bool (*pf_mng_get_cfg_t)(uint16_t us_param_id, void *px_value, uint8_t uc_len, bool

b_sync);

Parameters:

us_param_id PIB ID (see 12.3.4 PIB Objects Specification and Access (PRIME) and

*px_value Pointer to parameter value to get

uc_len Length of parameter

b_sync Set synchronous (True) or asynchronous mode (False)

The function returns 0 if the result is invalid, otherwise returns 1.

12.2 G3 PHY API

12.2.1 Bandplan Selection

At compilation time, the G3-PLC bandplan must be defined (i.e.: CENELEC A, CENELEC B, FCC or

ARIB) according to user needs.

In general_defs.h there are four constant options for configuring the bandplan:

/* ! CENELEC A Band Plan (24 - 500 kHz) */

#define ATPL360_WB_CENELEC_A 1

/* ! FCC Band Plan (24 - 500 kHz) */

#define ATPL360_WB_FCC 2

/* ! ARIB Band Plan (24 - 500 kHz) */

#define ATPL360_WB_ARIB 3

/* ! CENELEC-B Band Plan (98 - 122 kHz) */

#define ATPL360_WB_CENELEC_B 4

12.2.5 PIB Objects Specification and Access (G3))

The constant ATPL360_WB has to be set, in file conf_atpl360.h, to the value of one of the constant

options of general_defs.h so that the PHY layer is correctly configured.

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 42

Page 43

12.2.2 PHY-DATA.request

This function sends a frame using the PHY layer. This is done by means of a specific function provided by

the controller descriptor:

typedef uint8_t (*pf_send_data_t)(tx_msg_t *px_msg);

The input parameter structure is the following:

typedef struct tx_msg {

uint8_t *puc_data_buf;

uint32_t ul_tx_time;

uint16_t us_data_len;

uint8_t puc_preemphasis[NUM_SUBBANDS_MAX];

uint8_t puc_tone_map[TONE_MAP_SIZE_MAX];

uint8_t uc_tx_mode;

uint8_t uc_tx_power;

enum mod_types uc_mod_type;

enum mod_schemes uc_mod_scheme;

uint8_t uc_pdc;

uint8_t uc_2_rs_blocks;

enum delimiter_types uc_delimiter_type;

} tx_msg_t;

Fields of the structure:

PL360

Appendix A: PL360 Host Controller API

*puc_data_buf Pointer to data buffer

ul_tx_time Instant when transmission has to start referred to 1μs PHY counter (absolute or

relative value, depending on uc_tx_mode)

us_data_len Length of the data buffer in bytes

puc_preemphasis Preemphasis for transmission. Same as uc_tx_power but for each subband

(Related constants explained below)

puc_tone_map Tone map to use in transmission (Related constants explained below)

uc_tx_mode Transmission mode (forced, delayed, ...) (Related constants explained below)

uc_tx_power Power to transmit [0 = Full gain, 1 = (Full gain - 3dB), 2 = (Full gain - 6dB) and so

on]. Maximum value is 15 (Full gain - 45dBs).

uc_mod_type Modulation type (Related constants explained below)

uc_mod_scheme Modulation scheme (Related constants explained below)

uc_pdc Phase detector counter. Not used; calculated and filled internally by PHY layer

uc_2_rs_blocks Flag to indicate whether 2 RS blocks have to be used (only used in FCC

bandplan)

uc_delimiter_type DT field to be used in header (Related constants explained below)

Related constants affecting above parameters:

/* ! \name TX Mode Bit Mask */

/* ! TX Mode: Forced transmission */

#define TX_MODE_FORCED (1 << 0)

/* ! TX Mode: Absolute transmission */

#define TX_MODE_ABSOLUTE (0 << 1)

/* ! TX Mode: Delayed transmission */

#define TX_MODE_RELATIVE (1 << 1)

/* ! TX Mode: SYNCP Continuous transmission */

#define TX_MODE_SYNCP_CONTINUOUS (1 << 2)

/* ! TX Mode: Symbols Continuous transmission */

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 43

Page 44

Appendix A: PL360 Host Controller API

#define TX_MODE_SYMBOLS_CONTINUOUS (1 << 3)

/* ! TX Mode: Cancel transmission */

#define TX_MODE_CANCEL (1 << 4)

/* Modulation types */

enum mod_types {

MOD_TYPE_BPSK = 0,

MOD_TYPE_QPSK = 1,

MOD_TYPE_8PSK = 2,

MOD_TYPE_QAM = 3,

MOD_TYPE_BPSK_ROBO = 4

};

/* Modulation schemes */

enum mod_schemes {

MOD_SCHEME_DIFFERENTIAL = 0,

MOD_SCHEME_COHERENT = 1

};

/* Frame Delimiter Types */

enum delimiter_types {

DT_SOF_NO_RESP = 0, /* Data frame requiring ACK */

DT_SOF_RESP = 1, /* Data frame Not requiring ACK */

DT_ACK = 2, /* Positive ACK */

DT_NACK = 3 /* Negative ACK */

};

/* ! \name G3 configuration band */

#if ATPL360_WB == ATPL360_WB_CENELEC_A

#define FCH_LEN FCH_LEN_CENELEC_A

#define TONE_MAP_SIZE TONE_MAP_SIZE_CENELEC

#define NUM_SUBBANDS NUM_SUBBANDS_CENELEC_A

#define PROTOCOL_CARRIERS NUM_CARRIERS_CENELEC_A

#define SYNCP_DURATION_US SYNCP_DURATION_CENELEC_A_US

#elif ATPL360_WB == ATPL360_WB_FCC

#define FCH_LEN FCH_LEN_FCC

#define TONE_MAP_SIZE TONE_MAP_SIZE_FCC_ARIB

#define NUM_SUBBANDS NUM_SUBBANDS_FCC

#define PROTOCOL_CARRIERS NUM_CARRIERS_FCC

#define SYNCP_DURATION_US SYNCP_DURATION_FCC_ARIB_US

#elif ATPL360_WB == ATPL360_WB_ARIB

#define FCH_LEN FCH_LEN_ARIB

#define TONE_MAP_SIZE TONE_MAP_SIZE_FCC_ARIB

#define NUM_SUBBANDS NUM_SUBBANDS_ARIB

#define PROTOCOL_CARRIERS NUM_CARRIERS_ARIB

#define SYNCP_DURATION_US SYNCP_DURATION_FCC_ARIB_US

#elif ATPL360_WB == ATPL360_WB_CENELEC_B

#define FCH_LEN FCH_LEN_CENELEC_B

#define TONE_MAP_SIZE TONE_MAP_SIZE_CENELEC

#define NUM_SUBBANDS NUM_SUBBANDS_CENELEC_B

#define PROTOCOL_CARRIERS NUM_CARRIERS_CENELEC_B

#define SYNCP_DURATION_US SYNCP_DURATION_CENELEC_A_US

#endif

#define TONE_MAP_SIZE_MAX TONE_MAP_SIZE_FCC_ARIB

#define NUM_SUBBANDS_MAX NUM_SUBBANDS_FCC

#define PROTOCOL_CARRIERS_MAX NUM_CARRIERS_FCC

PL360

The function returns one of the following transmission result values:

/* TX Result values */

enum tx_result_values {

TX_RESULT_PROCESS = 0, /* Already in process */

TX_RESULT_SUCCESS = 1, /* End successfully */

TX_RESULT_INV_LENGTH = 2, /* Invalid length error */

TX_RESULT_BUSY_CH = 3, /* Busy channel error */

TX_RESULT_BUSY_TX = 4, /* Busy in transmission error */

TX_RESULT_BUSY_RX = 5, /* Busy in reception error */

TX_RESULT_INV_SCHEME = 6, /* Invalid modulation scheme error */

TX_RESULT_TIMEOUT = 7, /* Timeout error */

TX_RESULT_INV_TONEMAP = 8, /* Invalid tone map error */

TX_RESULT_INV_MODE = 9, /* Invalid G3 Mode error */

© 2018 Microchip Technology Inc.

User Guide

50002738B-page 44

Page 45

TX_RESULT_NO_TX = 255, /* No transmission ongoing */

};

12.2.3 PHY-DATA.confirm

This data confirm callback executes the function set by the upper layer at the initialization of the PL360

Host Controller. The pointer to the function is set in:

typedef void (*pf_data_confirm_t)(tx_cfm_t *px_msg_cfm);

The result is reported in the following structure:

typedef struct tx_cfm {

uint32_t ul_rms_calc;

uint32_t ul_tx_time;

enum tx_result_values uc_tx_result;

} tx_cfm_t;

Fields of the structure:

ul_rms_calc RMS_CALC value after transmission. Allows estimation of tx power injected