Page 1

PICkit

™

Serial Analyzer

USER’S GUIDE

© 2007 Microchip Technology Inc. DS51647A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digit al Millennium Copyright Act. If suc h a c t s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, microID, MPLAB, PIC,

PICmicro, PICSTART, PRO MATE, PowerSmart, rfPIC, and

SmartShunt are registered trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

AmpLab, FilterLab, Linear Active Thermistor, Migratable

Memory, MX DEV, MXLAB, PS logo, SEEVAL, SmartSensor

and The Embedded Control Solutions Company are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, ECAN,

ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

In-Circuit Se rial Program ming, ICSP, ICEPIC, Mindi, MiWi ,

MPASM, MPLAB Certified logo, MPLIB, MPLINK, PICkit,

PICDEM, PICDEM.net, PICLAB, PICtail, PowerCal,

PowerInfo, PowerMate, PowerTool, REAL ICE, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology In corporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2007, Microchip Technology Incorporated, Pr inted in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona, Gresham, Oregon and Mountain View, California. The

Company’s quality system processes and procedures are for its PIC

MCUs and dsPIC® DSCs, KEELOQ

EEPROMs, microperipherals, nonvolatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

®

code hopping devices, Serial

DS51647A-page ii © 2007 Microchip Technology Inc.

®

Page 3

PICkit™ SERIAL ANALYZER

USER’S GUIDE

Table of Contents

Preface ... ............... .............. .............. ............ ............... .............. ............... .. 1

Chapter 1. PICkit™ Serial Analyzer Overview

1.1 Introduction ..................................................................................... 5

1.2 Highlights ........................................................................................ 5

1.3 PICkit™ Serial Analyzer Contents ..................................................5

1.4 PICkit™ Serial Analyzer Development System .............................. 5

1.5 PICkit™ Serial Analyzer Hardware .................................................6

1.6 PICkit™ Serial Analyzer Software ..................................................8

Chapter 2. Getting Started

2.1 Introduction ..................................................................................... 9

2.2 Highlights ........................................................................................ 9

2.3 Installing the PICkit™ Serial Analyzer Software .............................9

2.4 Connecting the PICkit™ Serial Analyzer to the PC ........................9

2.5 Connecting the PICkit™ Serial Analyzer to the 28-Pin

Demo Board ..................................................................................10

2.6 Starting the PICkit™ Serial Analyzer Program ............................. 10

2.7 Running the 28-Pin Demo I2C™ Demonstration Program ...........11

2

2.8 I

2.9 28-Pin Demo I

C™ Communications – Basic Operations ..................................14

2

C™ Source Code and Firmware ..........................15

Chapter 3. PICkit™ Serial Analyzer PC Program

3.1 Introduction ................................................................................... 17

3.2 Highlights ...................................................................................... 17

3.3 Installing the PICkit™ Serial Analyzer Software ...........................17

3.4 Starting the Program .....................................................................17

3.5 Configuration Wizard ....................................................................18

3.6 Main Window ................................................................................21

3.7 Serial Communications Modes .....................................................25

© 2007 Microchip Technology Inc. DS51647A-page iii

Page 4

PICkit™ Serial Analyzer User’s Guide

Chapter 4. I2C™ Master Communications

4.1 Introduction ...................................................................................27

4.2 Highlights ......................................................................................27

4.3 PICkit Serial Pin Assignments .......................................................27

4.4 Selecting Communications Mode ..................................................27

4.5 Configuring I2C Communications Mode ........................................28

4.6 Communications: Basic Operations ..............................................30

4.7 Script Builder .................................................................................31

4.8 Script Execute ...............................................................................35

Chapter 5. SPI Master Communications

5.1 Introduction ...................................................................................37

5.2 Highlights ......................................................................................37

5.3 PICkit™ Serial Analyzer Pin Assignments ....................................37

5.4 Selecting Communications Mode ..................................................37

5.5 Configurating SPI Communications Mode ....................................38

5.6 Communications: Basic Operations ..............................................40

5.7 Script Builder .................................................................................42

5.8 Script Execute ...............................................................................46

Chapter 6. USART Asynchronous Communications

6.1 Introduction ...................................................................................49

6.2 Highlights ......................................................................................49

6.3 PICkit Serial Pin Assignments .......................................................49

6.4 Selecting Communications Mode ..................................................50

6.5 Configuring USART Asynchronous Communications Mode .........50

6.6 Communications: Basic Operations ..............................................52

6.7 Script Builder .................................................................................52

6.8 Script Execute ...............................................................................57

Chapter 7. USART Master Synchronous Communications

7.1 Introduction ...................................................................................59

7.2 Highlights ......................................................................................59

DS51647A-page iv © 2007 Microchip Technology Inc.

Page 5

PICkit™ SERIAL ANALYZER

Table of Contents

7.3 PICkit Serial Pin Assignments ......................................................59

7.4 Selecting Communications Mode ................................................. 59

7.5 Configuring USART Synchronous Master Communications

Mode .............................................................................................60

7.6 Communications: Basic Operations ..............................................62

7.7 Script Builder ................................................................................62

7.8 Script Execute ...............................................................................67

Chapter 8. User Defined Templates

8.1 Introduction ................................................................................... 69

8.2 Highlights ...................................................................................... 69

USER’S GUIDE

8.3 Create Templates .........................................................................69

8.4 My Templates ...............................................................................71

Chapter 9. PICkit™ Serial Analyzer Firmware

9.1 Introduction ................................................................................... 73

9.2 Highlights ...................................................................................... 73

9.3 Overview ....................................................................................... 73

9.4 EXEC ............................................................................................ 75

9.5 COMM ..........................................................................................78

9.6 I2CM Communications ..................................................................82

9.7 SPI Communications ....................................................................87

9.8 USART Communications .................................. ..... ..... .... ..... ......... 90

Chapter 10. PICkit™ Serial Analyzer DLL

10.1 Introduction ................................................................................... 95

10.2 Highlights ...................................................................................... 95

10.3 Summary of Functions ..................................................................95

10.4 Programming Example ....................... ..... ..... ................................99

© 2007 Microchip Technology Inc. DS51647A-page v

Page 6

PICkit™ Serial Analyzer User’s Guide

Chapter 11. Troubleshooting

11.1 Introduction .................................................................................101

11.2 Frequently Asked Questions .......................................................101

Appendix A. PICkit Serial Analyzer Schematics ...............................103

A.1 Introduction .................................................................................103

Appendix B. 28-Pin Demo Board I2C™ Demonstration Firmwa r e...107

B.1 Introduction .................................................................................107

B.2 Highlights ....................................................................................107

B.3 Hardware .....................................................................................107

B.4 Firmware .....................................................................................107

B.5 I2C Communications ...................................................................108

B.6 Slave Devices .............................................................................109

B.7 Functions .....................................................................................112

Worldwide Sal e s a nd Se r vi c e .............................................. .................114

DS51647A-page vi © 2007 Microchip Technology Inc.

Page 7

PICkit™ SERIAL ANALYZER

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

PICkit™ Serial Analyzer User’s Guide. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the PICkit™ Serial Analyzer as a development

tool to communicate with embedded development systems via serial protocols. The

manual layout is as follows:

• Chapter 1: PICkit™ Serial Analyzer Overview

• Chapter 2: Getting Started

• Chapter 3: PICkit™ Serial Analyzer PC Program

• Chapter 4: I

• Chapter 5: SPI Master Communications

• Chapter 6: USART Asynchronous Communications

• Chapter 7: USART Master Synchronous Communications

• Chapter 8: User Defined Templates

• Chapter 9: PICkit™ Serial Analyzer Firmware

• Chapter 10: PICkit™ Serial Analyzer DLL

2

C™ Master Communications

© 2007 Microchip Technology Inc. DS51647A-page 1

Page 8

PICkit™ Serial Analyzer User’s Guide

• Chapter 11: Troubleshooting

• Appendix A: Hardware Schematics

• Appendix B: 28-Pin Demo Board I

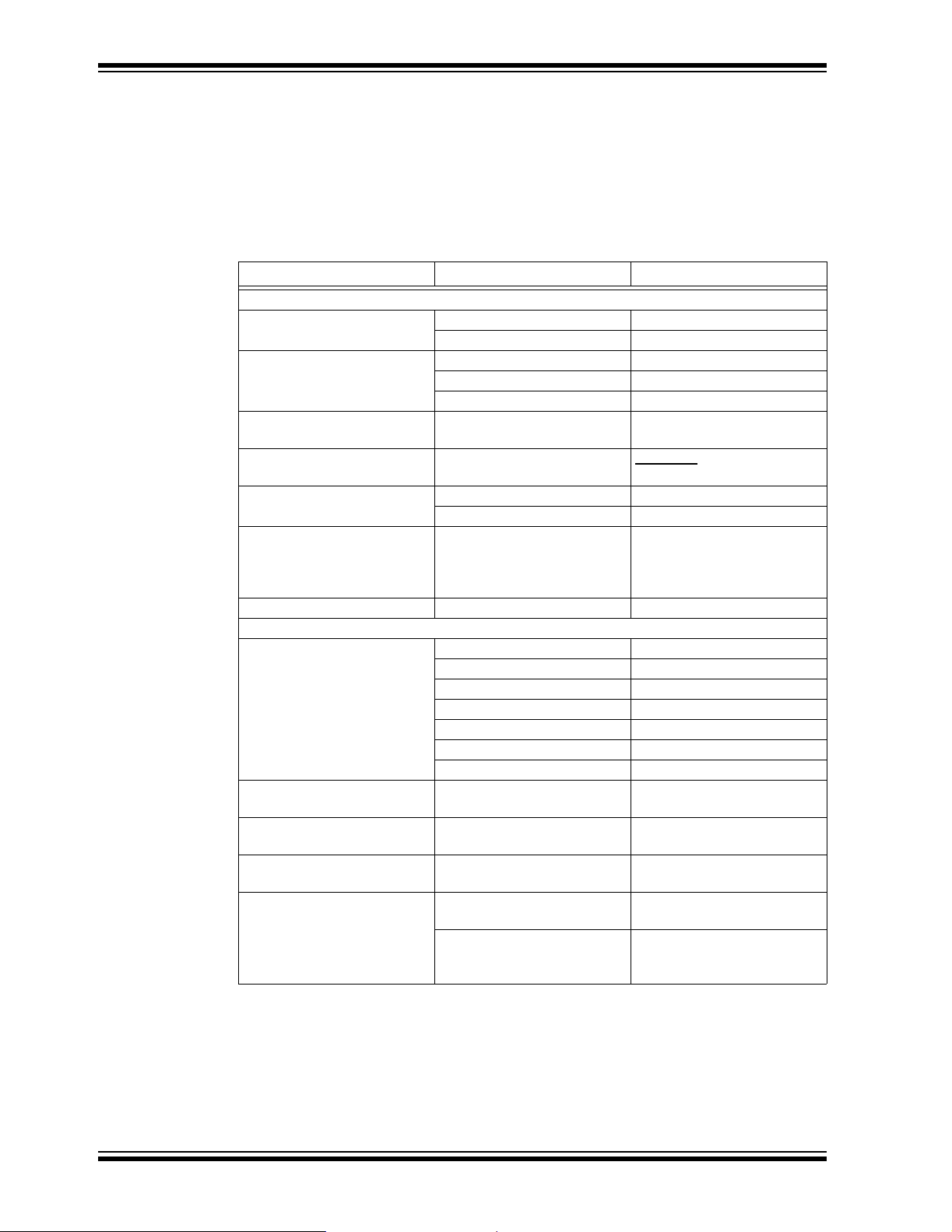

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Initial caps A window the Output window

Quotes A field name in a window or

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sam ple source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

Emphasized text ...is the only comp ile r...

A dialog the Settings dialog

A menu selection select Enable Programmer

dialog

A menu path File>Save

A tab Click the Power tab

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

2

C™ Demo Firmware

®

IDE User’s Guide

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS51647A-page 2 © 2007 Microchip Technology Inc.

Page 9

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the PICkit™ Serial Analyzer. Other useful

documents are listed below. The following Microchip documents are available and

recommended as supplemental reference resources.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB ICE 2000 and MPLAB ICE 4000.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

© 2007 Microchip Technology Inc. DS51647A-page 3

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

C18 and MPLAB C30 C compilers; MPASM™

Page 10

PICkit™ Serial Analyzer User’s Guide

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 and PRO MATE

Plus and PICkit™ 2 development programmers.

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (January 2007)

®

II device programmers and the PICSTART®

• Initial release of this document.

DS51647A-page 4 © 2007 Microchip Technology Inc.

Page 11

Chapter 1. PICkit™ Serial Analyzer Overview

1.1 INTRODUCTION

The PICkit™ Serial Analyzer development system enables a personal computer (PC)

to communicate with embedded development systems via serial protocols such as

2

I

C™, SPI, asynchronous and synchronous USART. The PC program uses a graphical

interface to enter data and commands to communicate to the target device. Data and

commands can be entered using basic or scripting commands. The PICkit™ Serial

Analyzer connects to the embedded development system using a 6-pin header.

The PICkit™ Serial Analyzer is a sophisticated and highly configurable device. Please

take a few moments to familiarize yourself with the hardware interface and PC program

by reading this user’s guide. Chapter 2. “Getting Started” will guide you through

installing the PC program and running a simple demonstration program on the 28-Pin

Demo Board (DM164120-3) using the I

1.2 HIGHLIGHTS

This chapter discusses:

• PICkit™ Serial Analyzer Contents

• PICkit™ Serial Analyzer Development System

• PICkit™ Serial Analyzer Hardware

• PICkit™ Serial Analyzer PC Software

PICkit™ SERIAL ANALYZER

USER’S GUIDE

2

C serial protocol.

1.3 PICkit™ SERIAL ANALYZER CONTENTS

The PICkit™ Serial Analyzer serial communications development system contains the

following items:

1. The PICkit™ Serial Analyzer

2. USB cable

3. PICkit™ Serial Analyzer CD-ROM

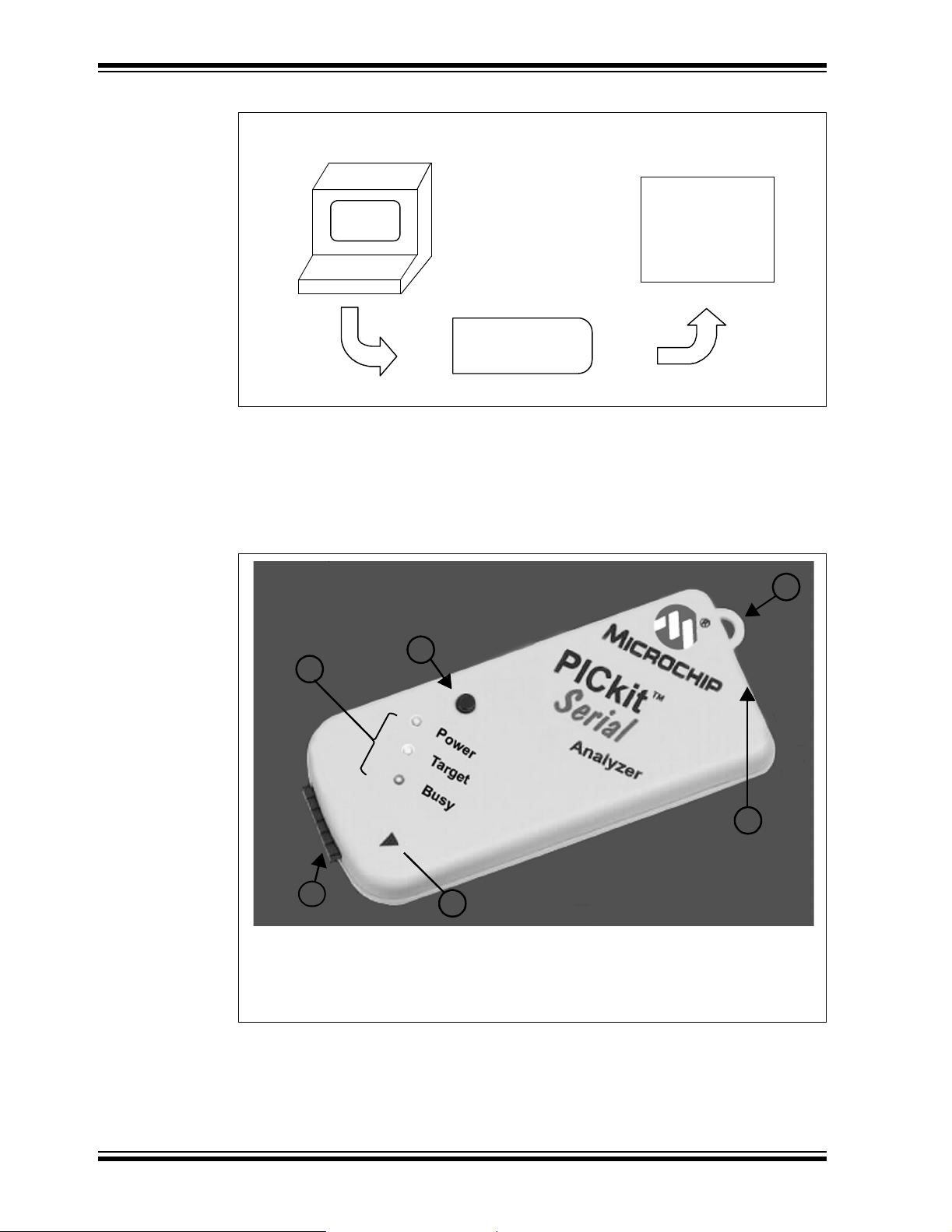

1.4 PICkit™ SERIAL ANALYZER DEVELOPMENT SYSTEM

The PICkit™ Serial Analyzer consists of several components that together make an

embedded serial communications development system. The PC program runs on

Microsoft

Analyzer connects to the PC using a USB cable. Finally, the PICkit™ Serial Analyzer

interface s t o t h e t a r g et de vi ce us in g a 6- pin header. Figu r e1-1 illustrates t he PIC ki t ™

Serial Analyzer embedded serial communications development system.

®

Windows® compatible computers with a USB port. The PICkit™ Serial

© 2007 Microchip Technology Inc. DS51647A-page 5

Page 12

PICkit™ Serial Analyzer User’s Guide

FIGURE 1-1: PICkit™ SERIAL ANALYZER DEVELOPMENT SYSTEM

PC

Target

Device

USB

PICkit™ Serial Analyzer

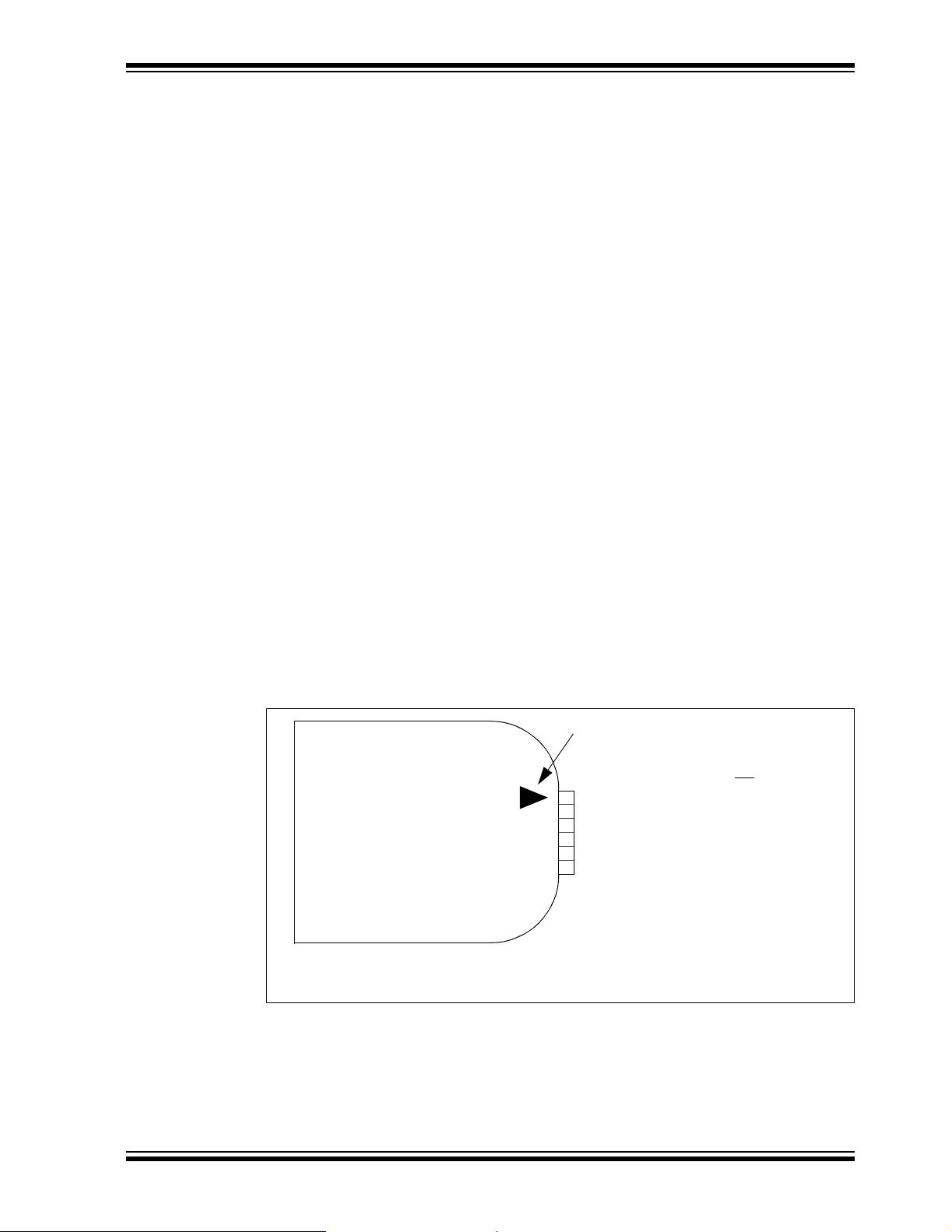

1.5 PICkit™ SERIAL ANALYZER HARDWARE

The PICkit™ Serial Analyzer connects to a Microsoft® Windows® compatible computer

using a USB port. It interfaces to the target device using a 6-pin header. Figure 1-2

shows an overview of the PICkit™ Serial Analyzer.

FIGURE 1-2: PICkit™ SERIAL ANALYZER

2

1

I2C™

SPI

USART

3

4

6

Legend:

1 – Status LEDs 3 – Lanyard Connection 5 – Pin 1 Marker

2 – Push Button 4 – USB Port Connection 6 – Communications Connector

DS51647A-page 6 © 2007 Microchip Technology Inc.

5

Page 13

PICkit™ Serial Analyzer Overview

1.5.1 Status LEDs

The Status LEDs indicate the status of the PICkit™ Serial Analyzer.

1. Power (green) – Power is applied to the PICkit™ Serial Analyzer by the USB

port.

2. Target (yellow) – The PICkit™ Serial Analyzer is communicating with the target

device.

3. Busy (red) – The PICkit™ Serial Analyzer is communicating with the target

device.

1.5.2 Push Button

The push button is available for future implementation.

1.5.3 Lanyard Connection

To help prevent possible loss of the PICkit™ Serial Analyzer, a convenient lanyard

connection is available.

1.5.4 USB Port Connection

The USB Port Connection is a USB mini-B connector. Connect the PICkit™ Serial

Analyzer to the PC using the supplied cable.

1.5.5 Pin 1 Marker

The Pin 1 marker assists in aligning the PICkit™ Serial Analyzer with the target device.

Pin assignments are shown in Figure 1-3.

1.5.6 Communication Connector

The communication connector connects to the target device using an inexpensive

6-pin, 0.100" pitch spacing, 0.025” square pin header. Pin assignments are shown in

Figure 1-3.

FIGURE 1-3: PICkit™ SERIAL ANALYZER PIN ASSIGNMENTS

Pin 1 Indicator

Pin Description

2

C™ SPI USART

I

1

2

3

4

5

6

1— CS

2+V +V +V

3 GND GND GND

4SDASDI —

5SCLSCK—

6— SDORX

TX

Note: The 6-pin header (0.100" spacing) accepts 0.025" square pins.

© 2007 Microchip Technology Inc. DS51647A-page 7

Page 14

PICkit™ Serial Analyzer User’s Guide

1.6 PICkit™ SERIAL ANALYZER SOFTWARE

1.6.1 PC Program

The PICkit™ Serial Analyzer PC program uses a graphical interface to enter data

and commands to comm unica te to th e target dev ice . Data and c omma nds can be

entered using basic or scr ipting commands. Chapter 3. “PICkit™ Serial Analyzer

PC Program” explains the installation and operation of the program. Following

Chapter 3 there are individual chapters that explain the specific serial communications modes and their operation.

1.6.2 Dynamically Linked Library (DLL)

The PICkit™ Serial Analyzer DLL is explained in Chapter 10. “PICkit™ Serial

Analyzer DLL”.

1.6.3 Firmware

The PICkit™ Serial Analyzer firmware is explained in Chapter 9. “PICkit™ Serial

Analyzer Firmware”.

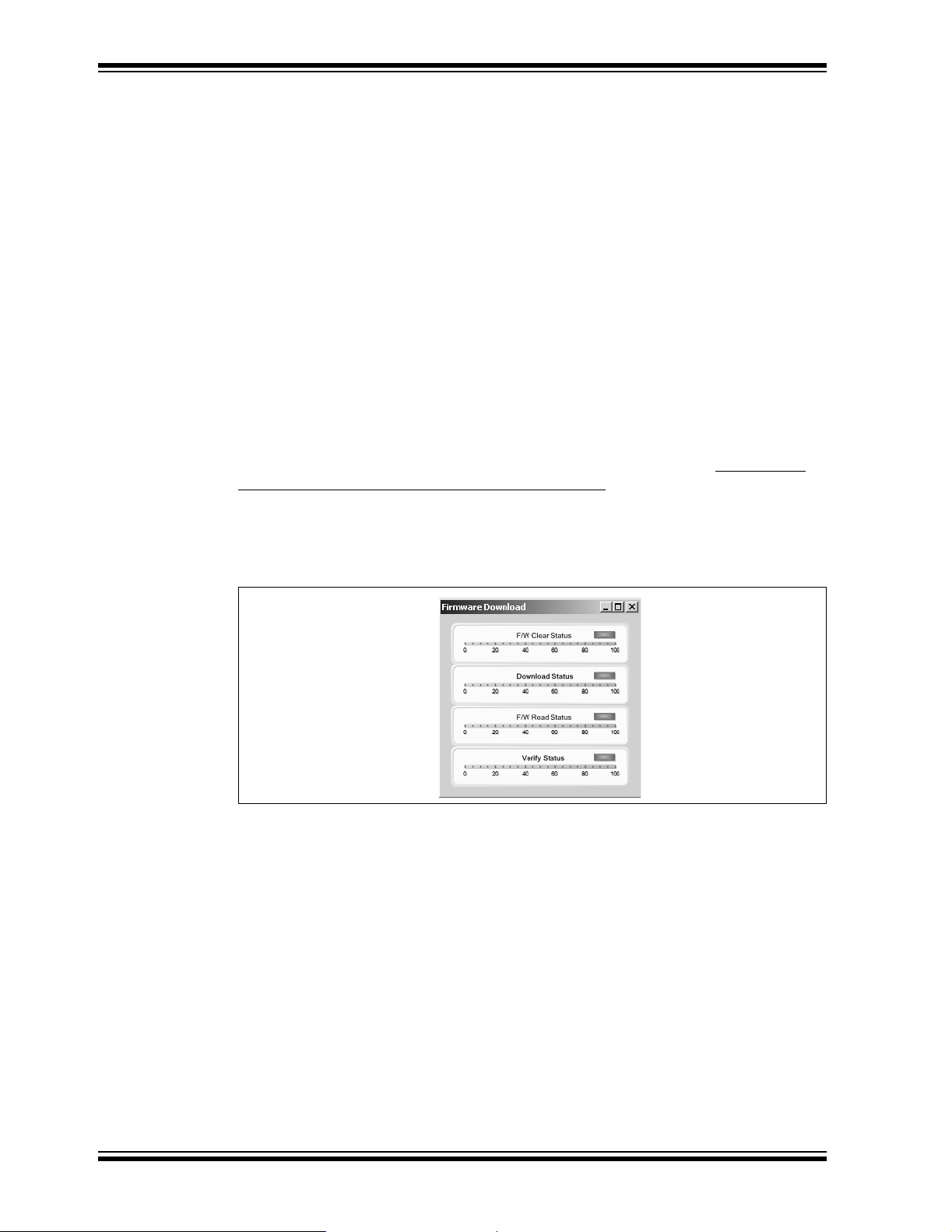

The latest version of the PICkit™ Serial Analyzer firmware can be downloaded from the

Microchip Technology web site. The firmware is updated by selecting PICkit Serial

Analyzer > Download PICkit Serial Analyzer Firmware from the menu bar. An open file

window will open. Select the *.hex file to be uploaded to the PICkit™ Serial Analyzer

and click on the Open button. The Firmware Download window will open as shown in

Figure 1-4 to indicate the status of the firmware update.

FIGURE 1-4: FIRMWARE DOWNLOAD WINDOW

DS51647A-page 8 © 2007 Microchip Technology Inc.

Page 15

2.1 INTRODUCTION

This chapter will get you started using the PICkit™ Serial Analyzer with the 28-Pin

Demo Board. In this demo, the PICkit™ Serial Analyzer will communicate with the

28-Pin Demo Board using the I

2

the I

C Master and the 28-Pin Demo Board will be the I2C Slave device. The 28-Pin

Demo board is programmed to emulate an I

For more information about the 28-Pin Demo Board hardware, see the 28-Pin Demo

Board User’s Guide (DS41 3 01).

For more information about the 28-Pin Demo Board I

Appendix B. “28-Pin Demo Board I

The demo program source code and *.hex file can be found on the PICkit™ Serial

CD-ROM at D:\28-pin Demo Board\Firmware\

2.2 HIGHLIGHTS

This chapter discusses:

• Installing the PICkit™ Serial Analyzer Software

• Connecting the PICkit Serial Analyzer to the PC

• Connecting the PICkit Serial Analyzer to the 28-Pin Demo Board

• Starting the PICkit Serial Analyzer Program

• Running The 28-Pin Demo I

2

•I

C Communications – Basic Operations

• 28-Pin Demo I

PICkit™ SERIAL ANALYZER

Chapter 2. Getting Started

2

C serial protocol. The PICkit™ Serial Analyzer will be

2

C real-time clock and Serial EEPROM.

2

2

C™ Demonstration Firmware”.

.

2

C™ Demonstration Program

2

C™ Source Code and Firmware

C™ demo firmware, see

USER’S GUIDE

2.3 INSTALLING THE PICkit™ SERIAL ANALYZER SOFTWARE

Insert the PICKit™ Serial Analyzer CD-ROM into the CD-ROM drive. In a few moments

the introductory screen should be displayed. Follow the directions on the screen to

install the PICkit Serial Analyzer software.

If the introductory screen does not appear, browse to the CD-ROM directory and select

the AutorunPro.exe program.

Note: The PICkit™ Serial Analyzer program requires the Microsoft

Framework Version 2.0. If the .NET Framework is not installed on your

computer (or if in doubt), select the application plus Microsoft

Framework installation.

®

.NET

®

.NET

2.4 CONNECTING THE PICkit™ SERIAL ANALYZER TO THE PC

Connect the PICkit Serial Analyzer to the PC using the supplied USB cable. There are

no USB drivers to install. The green Power indicator should light indicating that the

PICkit Serial Analyzer is powered.

© 2007 Microchip Technology Inc. DS51647A-page 9

Page 16

PICkit™ Serial Analyzer User’s Guide

2.5 CONNECTING THE PICkit™ SERIAL ANALYZER TO THE 28-PIN DEMO BOARD

Connect the PICkit Serial Analyzer to P3 on the 28-Pin Demo Board as shown in Figure

2-1. The PICkit Serial Analyzer will supply power to the 28-Pin Demo Board and

perform a power on routine:

• LEDs will flash in sequence DS1, DS2, DS3, DS4, DS3, DS2, and DS1 twice

• All LEDs will turn off

• All LEDs will turn on

• All LEDs will turn off

• LEDs will display in hexadecimal: A, D, C

• LEDs will display the top 4 bits of the ADC value read from potentiometer RP1

FIGURE 2-1: CONNECTING PICkit™ SERIAL TO THE 28-PIN DEMO

BOARD

2.6 STARTING THE PICkit™ SERIAL ANALYZER PROGRAM

You can start the program by:

• Clicking on the desktop icon, or

• Navigating to Start>All Pr ograms>Microchip>PICkit Serial Analyzer

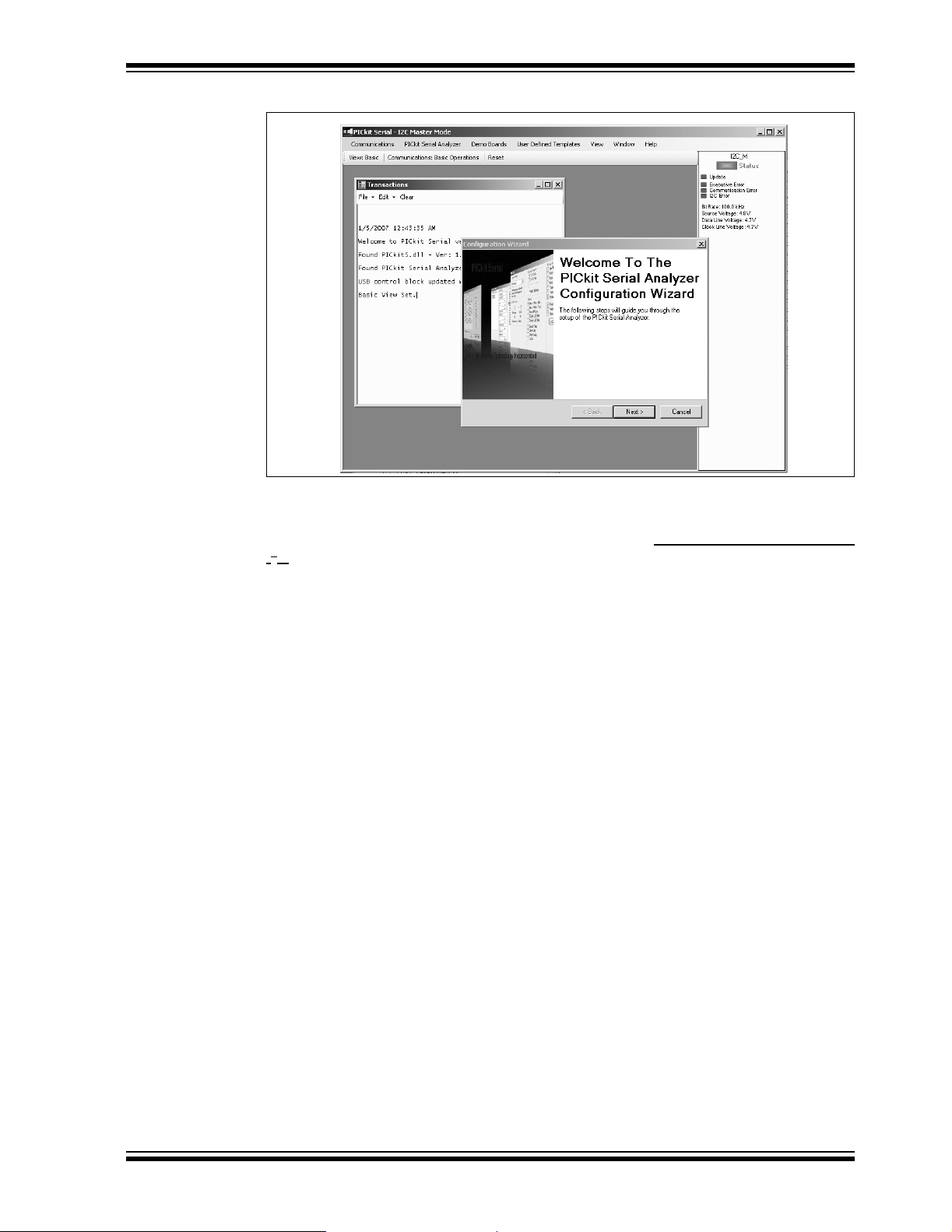

After a few moments, the program will start and display the main window as shown in

Figure 2-2.

If this is the first time you are running the program, the Configuration Wizard will auto-

matically run. Click on the Next button and accept the default settings for I

mode. For more information about using the I

Master Communications.”

2

C Master mode, see Chapter 4. “I2C™

2

C Master

DS51647A-page 10 © 2007 Microchip Technology Inc.

Page 17

Getting Started

FIGURE 2-2: PICkit™ SERIAL ANALYZER MAIN WINDOW

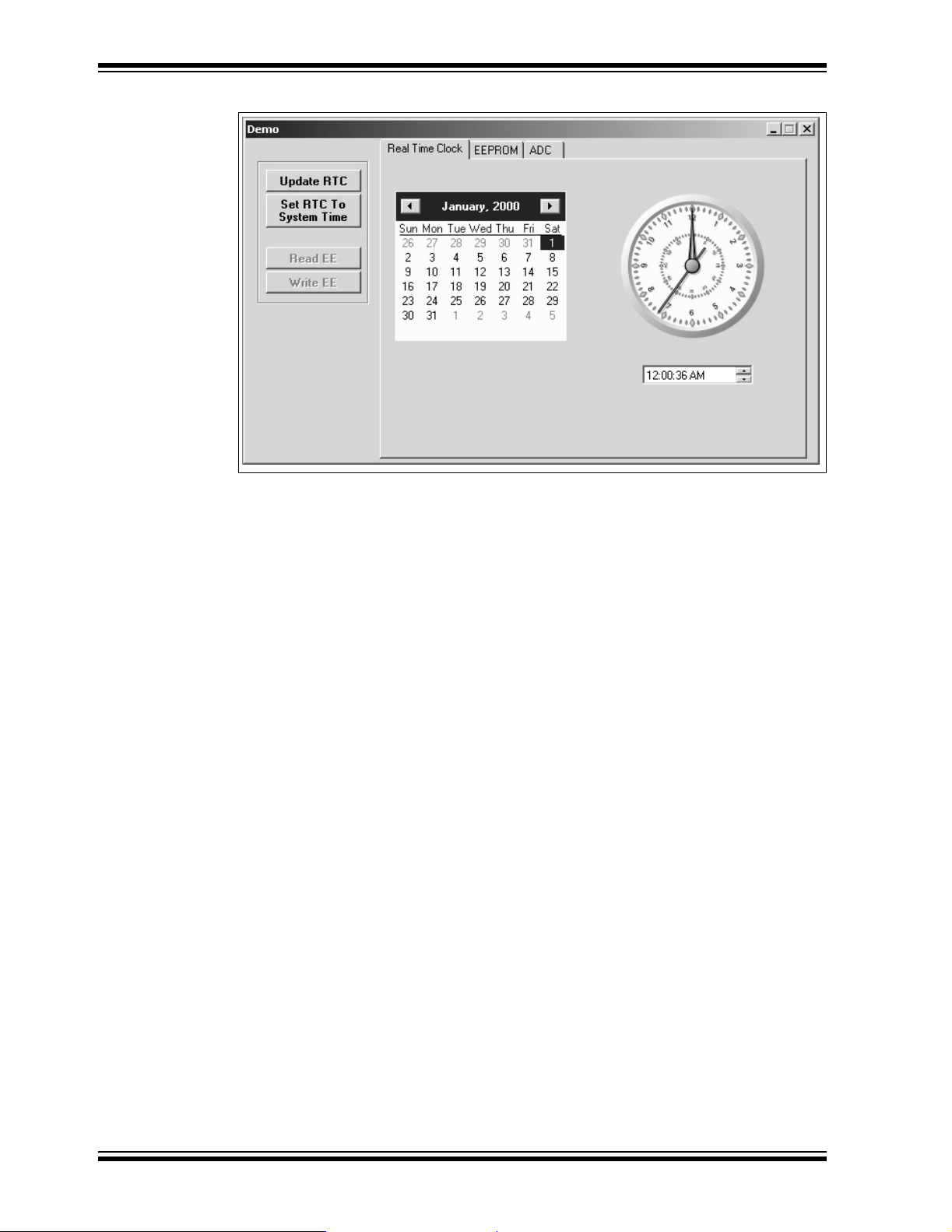

2.7 RUNNING THE 28-PIN DEMO I2C™ DEMONSTRATION PROGRAM

Select the 28-Pin Demo I2C demonstration by clicking on Demo Boards > 28 Pin Demo

I2C from the menu bar. The 28-Pin Demo I2C demonstration window will be displayed

as shown in Figure 2-3.

The Real-Time Clock (RTC) will be displayed first. Note the tabs to select between the

RTC, EEPROM and ADC demonstrations. The demonstration program will constantly

poll the 28-Pin Demo Board and display the contents of the real-time clock and the

ADC.

2.7.1 Real-Time Clock (RTC)

Clicking on the Real-Time Clock tab will display calendar and clock contents of the

real-time clock function running on the 28-Pin Demo Board. The 28-Pin Demo Board

has been programmed to emulate a stand-alone serial I

2

I

C commands are very similar to the commands used in these devices. The demonstration program will constantly poll the 28-Pin Demo Board and display the contents

of the real-time clock.

The Real-Time Clock window displays calendar and clock controls. Notice the date and

time when the 28-Pin Demo Board has first been powered on. The date and time start

at January 1, 2000 at midnight (12:00 AM).

The user can manually enter calendar and clock values and send the values to the

real-time clock by clicking on the Update RTC button. Or the user can click on the Set

RTC to System Time button to set the real-time clock to the date and time of the

computer.

2

C clock-calendar device. The

© 2007 Microchip Technology Inc. DS51647A-page 11

Page 18

PICkit™ Serial Analyzer User’s Guide

FIGURE 2-3: 28-PIN DEMO I2C™ – RTC

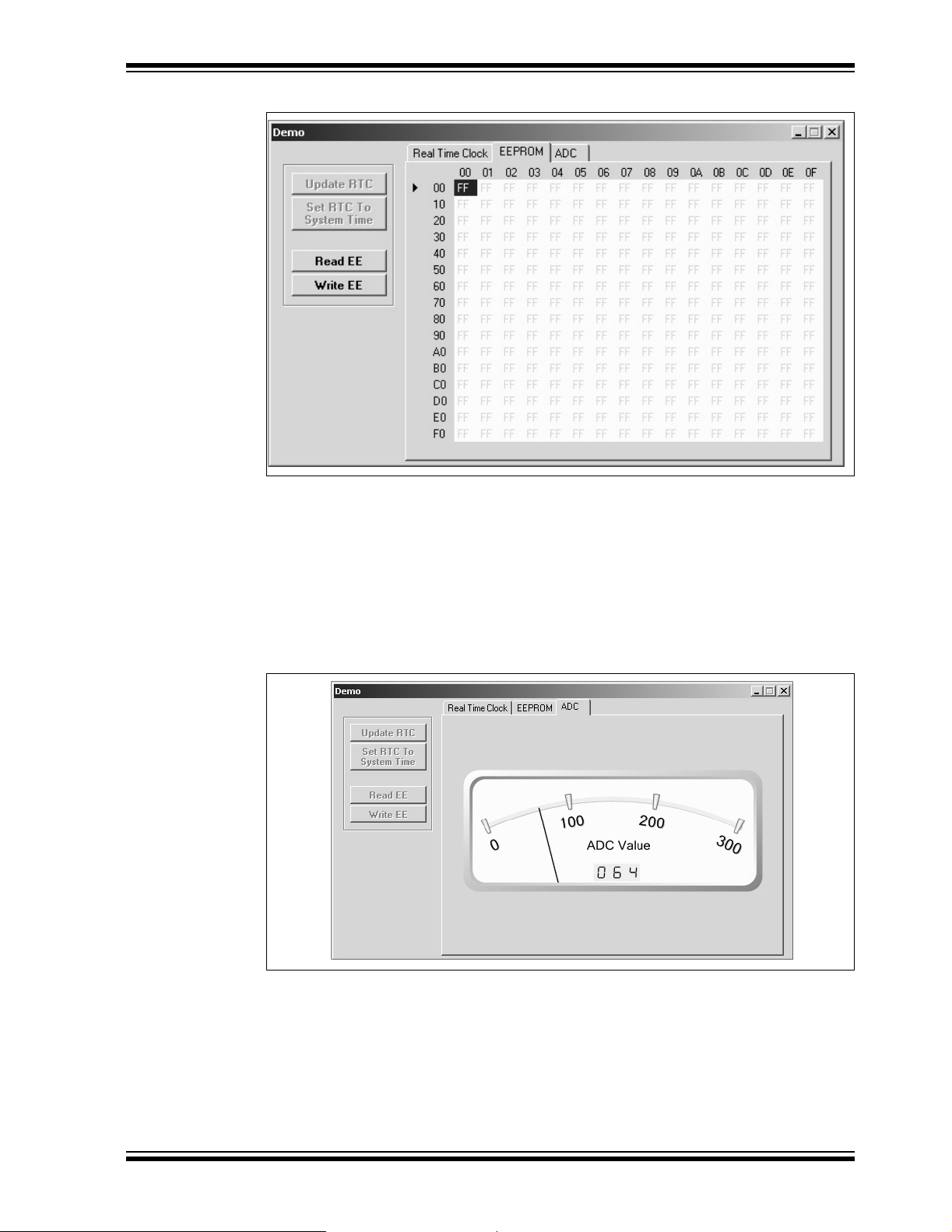

2.7.2 Serial EEPROM (EEPROM)

Clicking on the EEPROM tab will display the 256 byte array of EEPROM memory as

shown in Figure 2-4. The 28-Pin Demo Board has been programmed to emulate a

stand-alone serial I

very similar to the commands used in these devices.

The Serial EEPROM tab displays the contents of a serial EEPROM implemented on

the 28-Pin Demo Board. When this tab is first displayed, the values are grayed out. This

means that the display does not match the contents of the emulated serial EEPROM.

Click on Read EE button and the program will read and display the contents of the

28-Pin Demo Board. Notice that the displayed values are now black.

Individual memory locations can be changed by clicking on the value and typing in a

new value in hexadecimal. Notice that the changed values will be displayed in red. This

means the value has changed but has not been written to the emulated serial

EEPROM. Click on the Write EE button and the values will be written. The color of the

value will turn to black indicating that the value has been written and the display

matches the contents of the emulated serial EEPROM.

2

C EEPROM device such as a 24LC02. The I2C commands are

DS51647A-page 12 © 2007 Microchip Technology Inc.

Page 19

FIGURE 2-4: 28-PIN DEMO I2C™ – EEPROM

Getting Started

2.7.3 Analog-to-Digital Converter (ADC)

Clicking on the ADC tab will show a meter gauge displaying the value of the ADC as

read from potentiometer RP1 as shown in Figure 2-5.

The meter gauge displays the Most Significant 8 bits of the 10-bit ADC internal to the

®

PIC

microcontroller. Rotate potentiometer RP1 and the display changes almost

instantaneously. The demonstration program will constantly poll the 28-Pin Demo

Board and display the contents of the ADC.

FIGURE 2-5: 28-PIN DEMO I

2

C™ – ADC

© 2007 Microchip Technology Inc. DS51647A-page 13

Page 20

PICkit™ Serial Analyzer User’s Guide

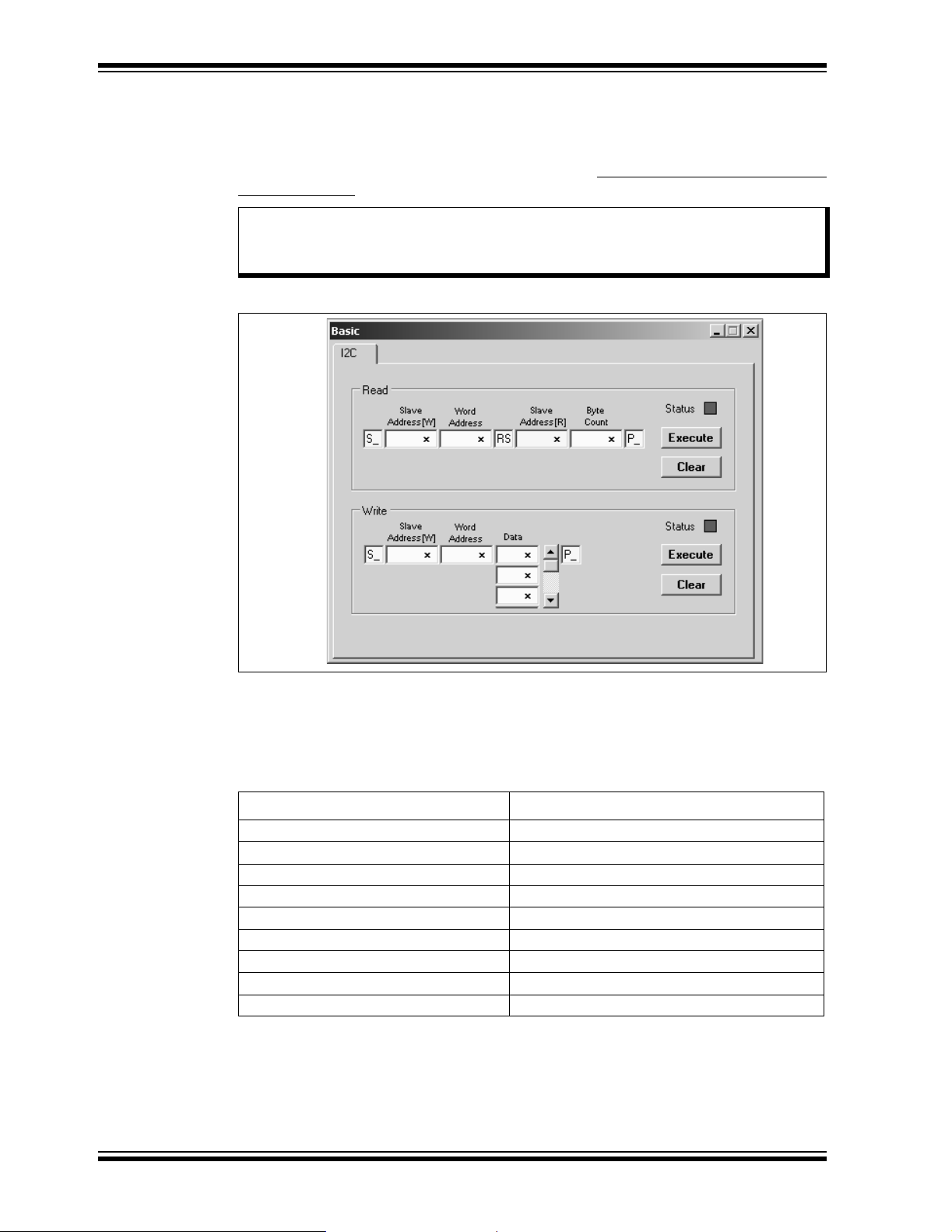

2.8 I2C™ COMMUNICATIONS – BASIC OPERATIONS

Individua l I2C commands and data can be read and written to the 28-Pin Demo Board

from the Basic Operations window as shown in Figure 2-6. Ensure that the PICkit Serial

Analyzer program is in I

figuration Wizard from the menu bar and selecting I2C Master.

2

C Master mode by selecting PICkit Serial Analyzer > Run Con-

Note: The 28-Pin Demo I

opened at the same time. When the 28-Pin Demo I

the Basic Operations window will automatically close.

FIGURE 2-6: I

2

C™ BASIC OPERATIONS

2

C window and the Basic Operations window cannot be

2

C window is opened,

2.8.1 Real-Time Clock (RTC)

The Slave address for the emulated real-time clock on the 28-Pin Demo Board is

hexadecimal A2 (0xA2). The Word Address selects the following memory locations:

TABLE 2-1: MEMORY LOCATIONS

Word Address Contents

0x00 Configuration 1

0x01 Configuration 2

0x02 Seconds

0x03 Minutes

0x04 Hours

0x05 Days

0x06 Weekdays

0x07 Months

0x08 Years

DS51647A-page 14 © 2007 Microchip Technology Inc.

Page 21

Getting Started

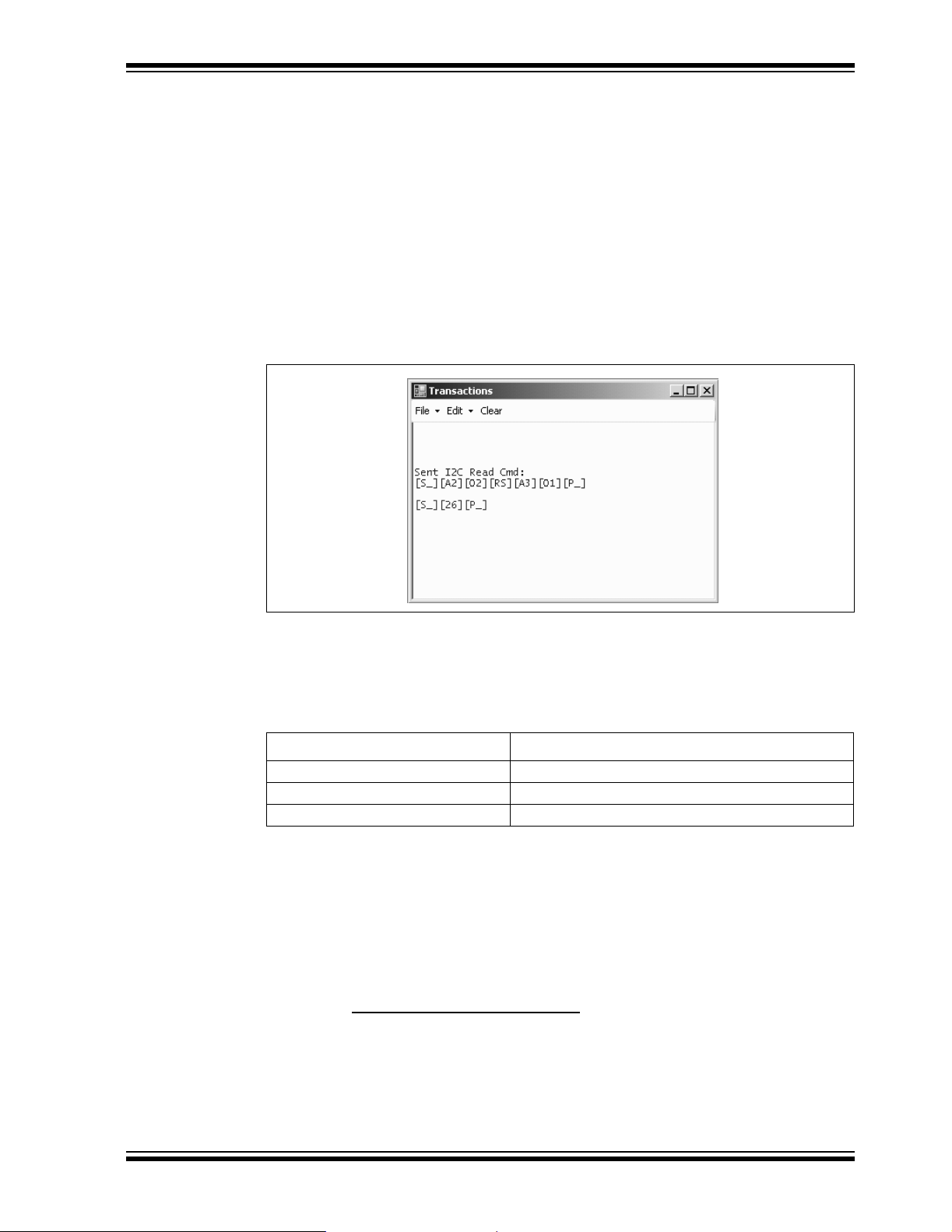

For example, to read seconds from the real-time clock:

Step 1 – Enter 0xA2 into the Slave Address[W] block in the Read section of the Basic

Operations window (top half of window)

Step 2 – Enter 0x02 into the Word Address block

Step 3 – Note that the Slave Address[R] has already been entered for you (the Read

bit is set).

Step 4 – Enter 0x01 into the Byte Count block

Step 5 – Click on the Execute button

2

The I

C combination command (Write then Read) will be sent to the 28-Pin Demo

Board. The command and the contents of Word Address 0x02 (seconds) will be

displayed in the transaction window as shown in Figure 2-7.

FIGURE 2-7: RTC TRANSACTIONS DEMO

2.8.2 EEPROM

The Slave address for the emulated Serial EEPROM on the 28-Pin Demo Board is

hexadecimal A8 (0xA8). The Word Address selects one of 256 8-bit memory locations:

TABLE 2-2: WORD ADDRESS CONTENTS

Word Address Contents

0x00 Memory Contents

… …

0xFF Memory Contents

2.8.3 ADC

The Slave address for the ADC on the 28-Pin Demo Board is hexadecimal AA (0xAA).

The Word Address 0x01 selects the memory location containing the Most Significant 8

bits of the 10-bit ADC of the PIC microcontroller.

2.9 28-PIN DEMO I2C™ SOURCE CODE AND FIRMWARE

The demo program source code and *.hex file can be found on the PICkit Serial

CD-ROM at D:\28-pin Demo Board\Firmware\

.

© 2007 Microchip Technology Inc. DS51647A-page 15

Page 22

PICkit™ Serial Analyzer User’s Guide

NOTES:

DS51647A-page 16 © 2007 Microchip Technology Inc.

Page 23

PICkit™ SERIAL ANALYZER

USER’S GUIDE

Chapter 3. PICkit™ Serial Analyzer PC Program

3.1 INTRODUCTION

This chapter covers the installation, starting and high level operations of the PICkit

Serial Analyzer program. Detailed information about the entering of data and commands for specific serial communications modes are given in the following chapters.

3.2 HIGHLIGHTS

This chapter discusses:

• Installing The PICkit Serial Analyzer Software

• Starting the Program

• Configuration Wizard

• Main Window

• Specific Communications Modes

3.3 INSTALLING THE PICkit™ SERIAL ANALYZER SOFTWARE

Insert the PICKit Serial Analyzer CD-ROM into the CD-ROM drive. In a few moments

the introductory screen should be displayed. Follow the directions on the screen to

install the PICkit Serial Analyzer software.

If the introductory screen does not appear, browse to the CD-ROM directory and select

the AutorunPro.exe program.

Note: The PICkit Serial Analyzer program requires the Microsoft

Framework Version 2.0.

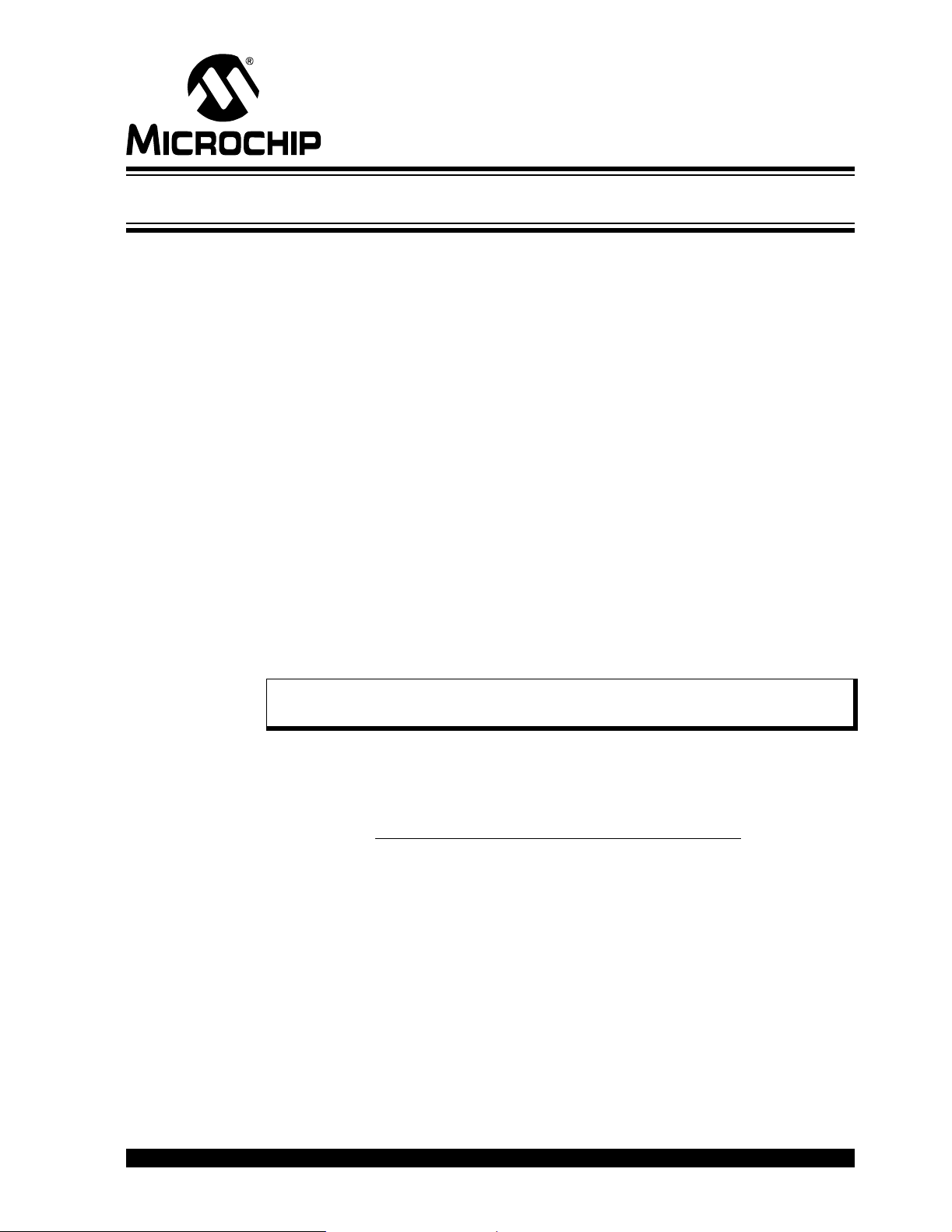

3.4 STARTING THE PROGRAM

You can start the program by

• Clicking on the desktop icon, or

• Navigating to Start>All Pr ograms>Microchip>PICkit Serial Analyzer

After a few moments, the program will start and display the main window as shown in

Figure 3-1.

®

.NET

© 2007 Microchip Technology Inc. DS51647A-page 17

Page 24

PICkit™ Serial Analyzer User’s Guide

FIGURE 3-1: PICkit™ SERIAL ANALYZER MAIN WINDOW

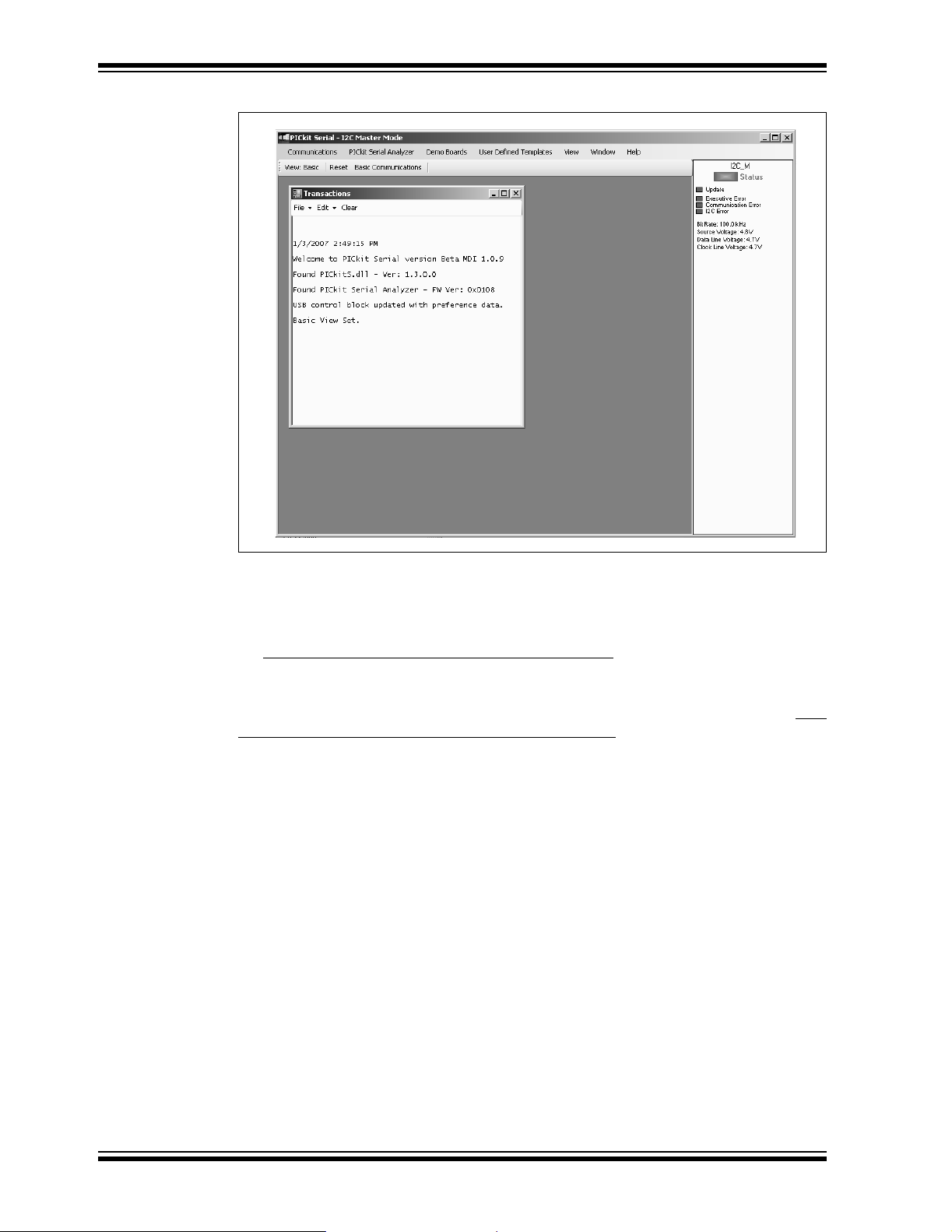

3.5 CONFIGURATION WIZARD

If it is the first time that the PICkit Serial Analyzer program is run, the Configuration Wizard will run automatically . The Configuration Wizard can be manually invoked by selecting PICkit Serial Analyzer > Run Configuration Wizard

The Configuration Wizard will guide you through the basic steps to configure the PICkit

Serial Analyzer program for a specific communications mode (I

Advanced configuration can be done from the Configuration Window by selecting PIC-

kit Serial Analyzer > Configure Communications Mode from the menu bar.

As an example, Figure 3-2 through Figure 3-7 show how to configure for I

mode. Refer to the specific communications chapter for detailed information on the

Configuration Wizard for that communications mode.

The Configuration Wizard Welcome window is shown in Figure 3-2. You may choose

to continue by clicking on the Next button or canceling the wizard by clicking on the

Cancel button.

from the menu bar.

2

C, SPI, USART).

2

C Master

DS51647A-page 18 © 2007 Microchip Technology Inc.

Page 25

PICkit™ Serial Analyzer PC Program

FIGURE 3-2: CONFIGURATION WIZARD – WELCOME

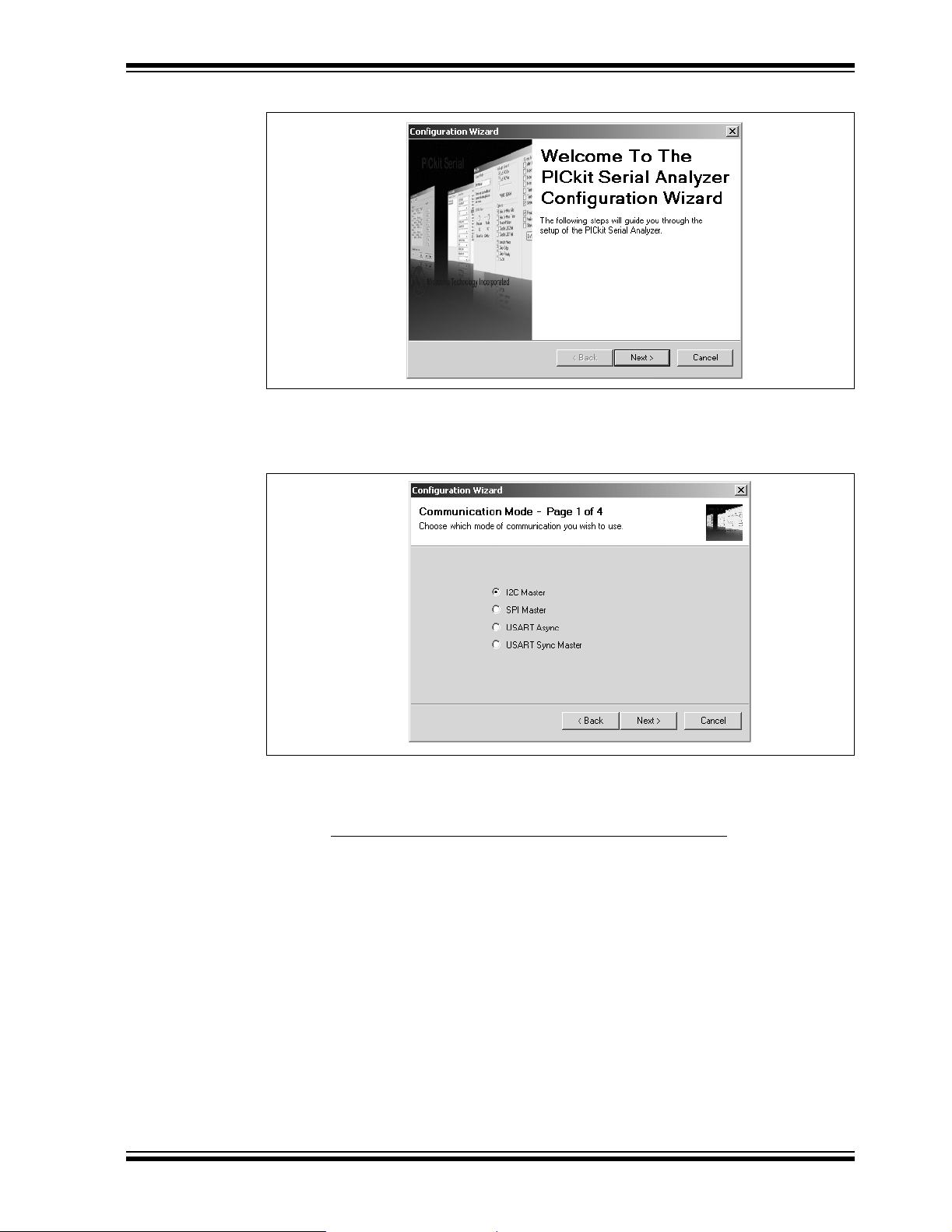

The Configuration Wizard Page 1 of 4, as shown in Figure 3-3, displays the available

communications modes and allows you to choose one of the modes.

FIGURE 3-3: CONFIGURATION WIZARD – PAGE 1 OF 4

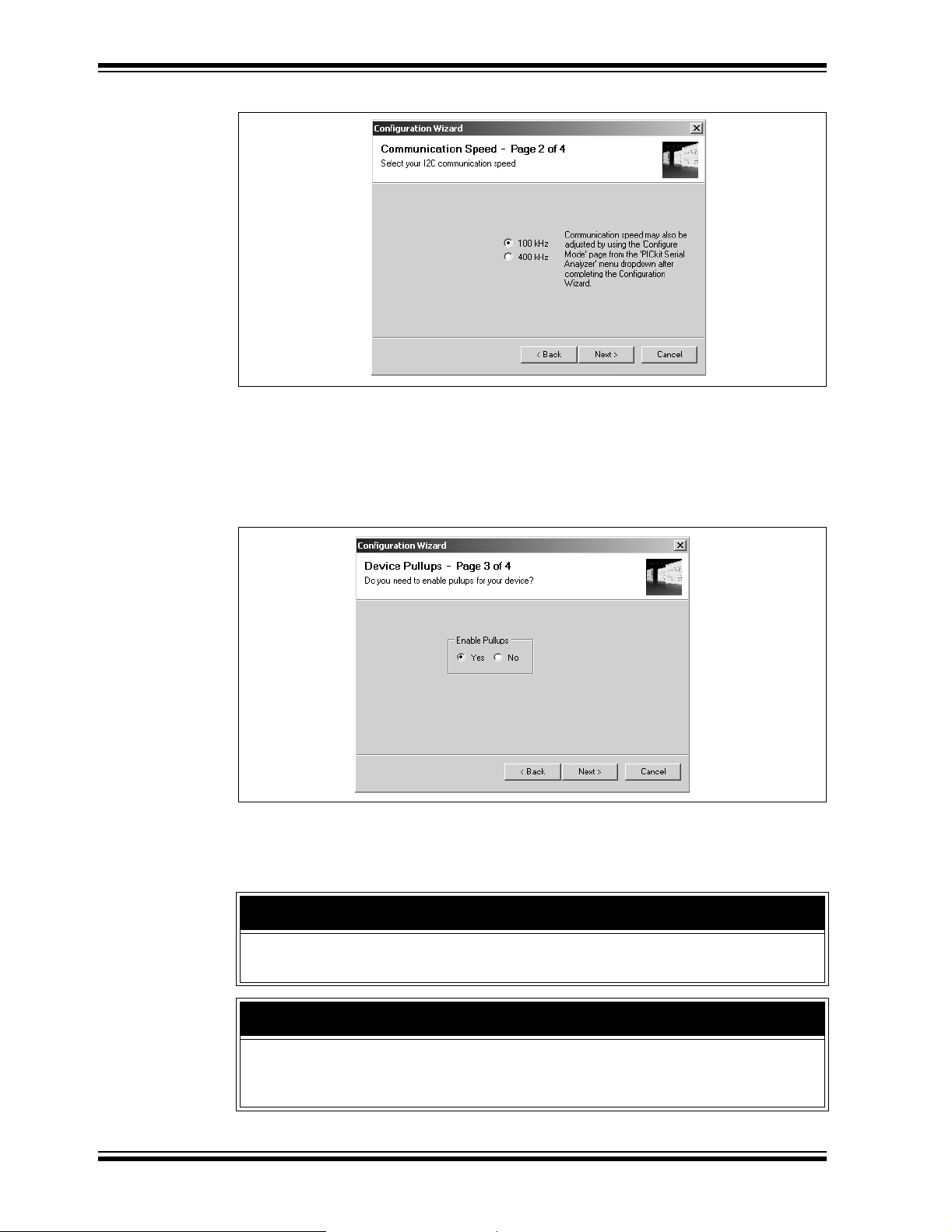

In this example, I

2

C Master Communication’s mode is selected. The Configuration

Wizard Page 2 of 4, as shown in Figure 3-4, allows you to select the bus speed. A more

comprehensive list of bus speeds can be chosen from the Configuration Window by

selecting PICkit Serial Analyzer > Configure Communications Mode

© 2007 Microchip Technology Inc. DS51647A-page 19

from the menu bar.

Page 26

PICkit™ Serial Analyzer User’s Guide

FIGURE 3-4: CONFIGURATION WIZARD – PAGE 2 OF 4

2

C bus requires pull-up resistors. The PICkit Serial Analyzer has the ability to

The I

enable internal 2.2 kΩ pull-up resistors. If the target device does not have pull-up resistors installed, then enable pull-ups by selecting the Yes radio button as shown in

Figure 3-5. If the target device has the pull-up resistors installed, you can disable the

internal pull-ups by selecting the No radio button.

FIGURE 3-5: CONFIGURATION WIZARD – PAGE 3 OF 4

The PICkit Serial Analyzer can power the target device from 0 to 5 V

total current limit of 100 mA (PICkit Serial Analyzer plus target device). The Configuration Wizard Page 4 of 4, as shown in Figure 3-6, allows you to choose between

powering the target device and selecting the specific target voltage.

DC at a combined

CAUTION

Even though the voltage can be set as low as 0 VDC, it is up to the user to verify the

required operating voltage of the target device.

CAUTION

The USB port current limit is set to 100 mA. If the target plus PICkit Serial Analyzer

exceeds this current limit, the USB port will turn off. The target may be powered

externally if more power is required.

DS51647A-page 20 © 2007 Microchip Technology Inc.

Page 27

PICkit™ Serial Analyzer PC Program

FIGURE 3-6: CONFIGURATION WIZARD – PAGE 4 OF 4

Once all pages of the Configuration Wizard are completed, you can choose to not

display the wizard at start up by checking the Do not show this wizard on start-up again

check box.

FIGURE 3-7: CONFIGURATION WIZARD – Y OU’RE DONE!

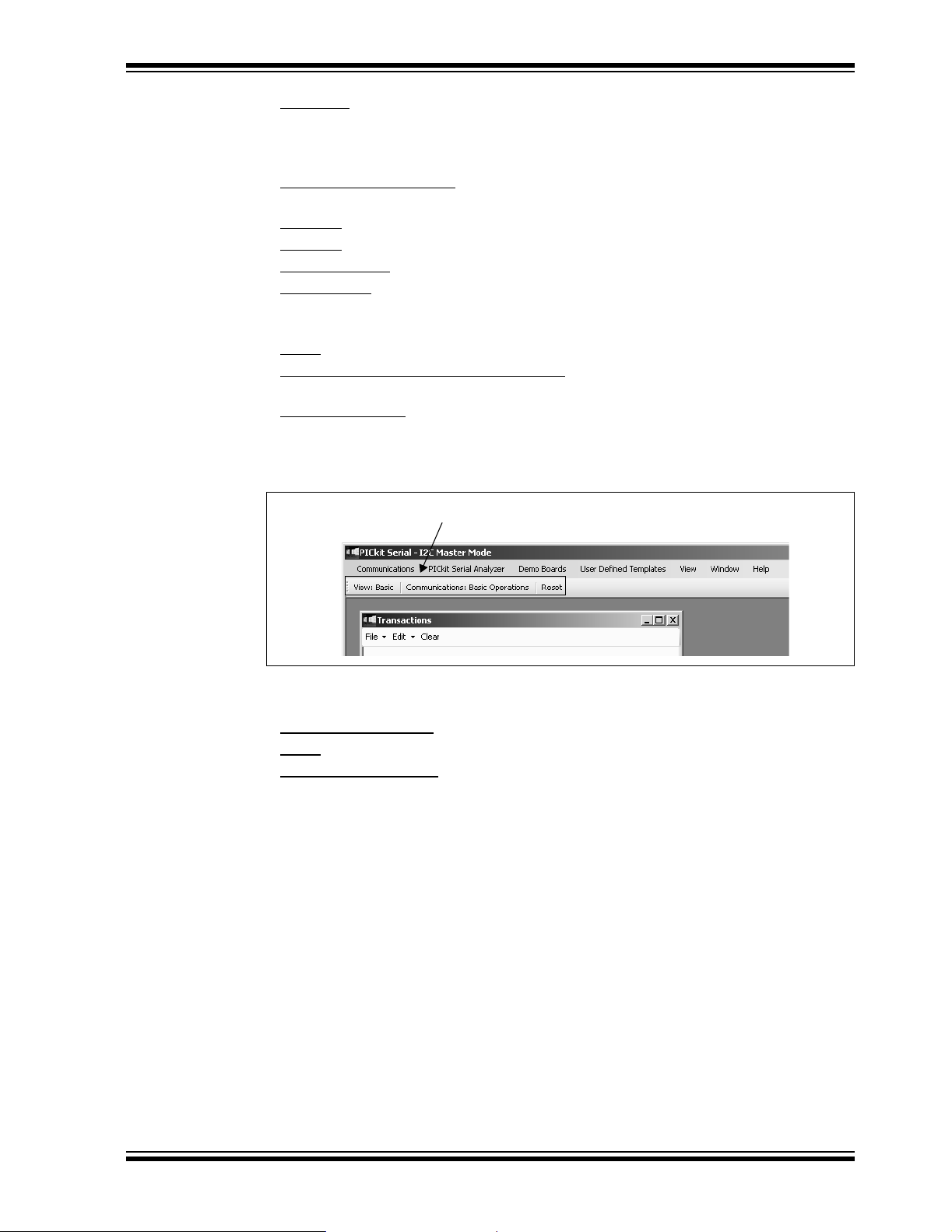

3.6 MAIN WINDOW

3.6.1 Menu Bar

The menu bar selects various functions of the PICkit Serial Analyzer program. A

summary of the functions are:

FIGURE 3-8: MENU BAR

Menu Bar

© 2007 Microchip Technology Inc. DS51647A-page 21

Page 28

PICkit™ Serial Analyzer User’s Guide

COMMUNICATIONS

The Communications menu selections display operation windows to enter data and

commands to communicate with the target device.

• Basic Operations

mode selected (see PICkit Serial Analyzer -> Select Communications Mode)

•Script

PICkit™ SERIAL ANALYZER

The PICkit Serial Analyzer menu selection commands the PICkit Serial Analyzer

hardware.

• Select Communications Mode

• Configure Communications Mode

• Download PICkit Serial Analyzer Firmwa re

• Run Configuration Wizard

• Perform Syste m Reset

• Reset PICkit Serial Analyzer

• PICkit Serial Analyzer No.

>

- Script Builder

- Script Execute

2

-I

C Master – Puts the PICkit Serial Anal yzer in I2C Master Communications

mode

-SPI Master

mode

- USART Asynchronous

nous Communications mode

- USART Synchronous Master

Synchronous Master Communications mode

Mode window for the communications mode selected (see PICkit Serial Analyzer

-> Select Communications Mode)

window. Firmware updates are available from the Microchip Technology web site.

PICkit Serial Analyzer

condition is present

from the PC software. The number is assigned to the hardware as it enumerates

on the USB bus.

– Displays the Basic Operations window for the communications

– Displays the Script Builder window

– Displays the Script Execute window

>

– Puts the PICkit Serial Analyzer in SPI Master Communications

– Puts the PICkit Serial Analyzer in USART Asynchro-

– Puts the PICkit Serial Analyzer in USART

– Displays the Configuration Communications

– Displays the Firmware Download

– Displays the Configurat ion Wizard

– Closes and then reinitializes USB communications to the

– Resets the PICkit Serial Analyzer if an error

– Up to four PICkit Serial Analyzers can be controlled

DEMO BOARDS

The Demo Boards menu selection displays the selected demonstration window. The

PICkit Serial Analyzer program will be automatically configured for the communications

mode of the selected demonstr ation.

•28

-Pin Demo I2C – Displays the 28-Pin Demo Board I2C demo graphical user

interface. For more informati on se e Appendix B. “28-Pin Demo Board I

Firmware.”

USER DEFINED TEMPLATES

• Create Template

•My Templates

VIEW

•Basic

DS51647A-page 22 © 2007 Microchip Technology Inc.

– The PICkit Serial Analyzer program will display basic commands and

status view

– Displays the Parameter Template creation window

– Selects and displays template windows created by the user

2

C™

Page 29

PICkit™ Serial Analyzer PC Program

• Advanced – The PICkit Serial Analyzer program will display advanced commands

and status view

WINDOW

• New Transaction Window

transaction windows can be opened as needed for logging communications.

•Close All

• Cascade

• Tile Horizontally

• Tile Vertically

HELP

• About

• Show PICkit Serial Analyzer Connections

communications mode

• Show Even t By tes

– Closes all windows

– Cascade windows

– Tile windows horizontally

– Tile windows vertically

– Displays program version information

– Displays Event Marker code for current communication mode

– Opens new or additional transaction window. Multiple

– Displays pinout for current

3.6.2 Tool Bar

FIGURE 3-9: TOOL BAR

Tool Bar

The Tool Bar gives quick access to often used commands. These commands are also

available from the Menu Bar.

•View: Basic

• Reset

• Basic Communications

communications mode selected

/Advanced – toggles between Basic and Advanced views

– Resets the PICkit Serial Analyzer if an error condition is present

– Displays the Basic Operations window for the

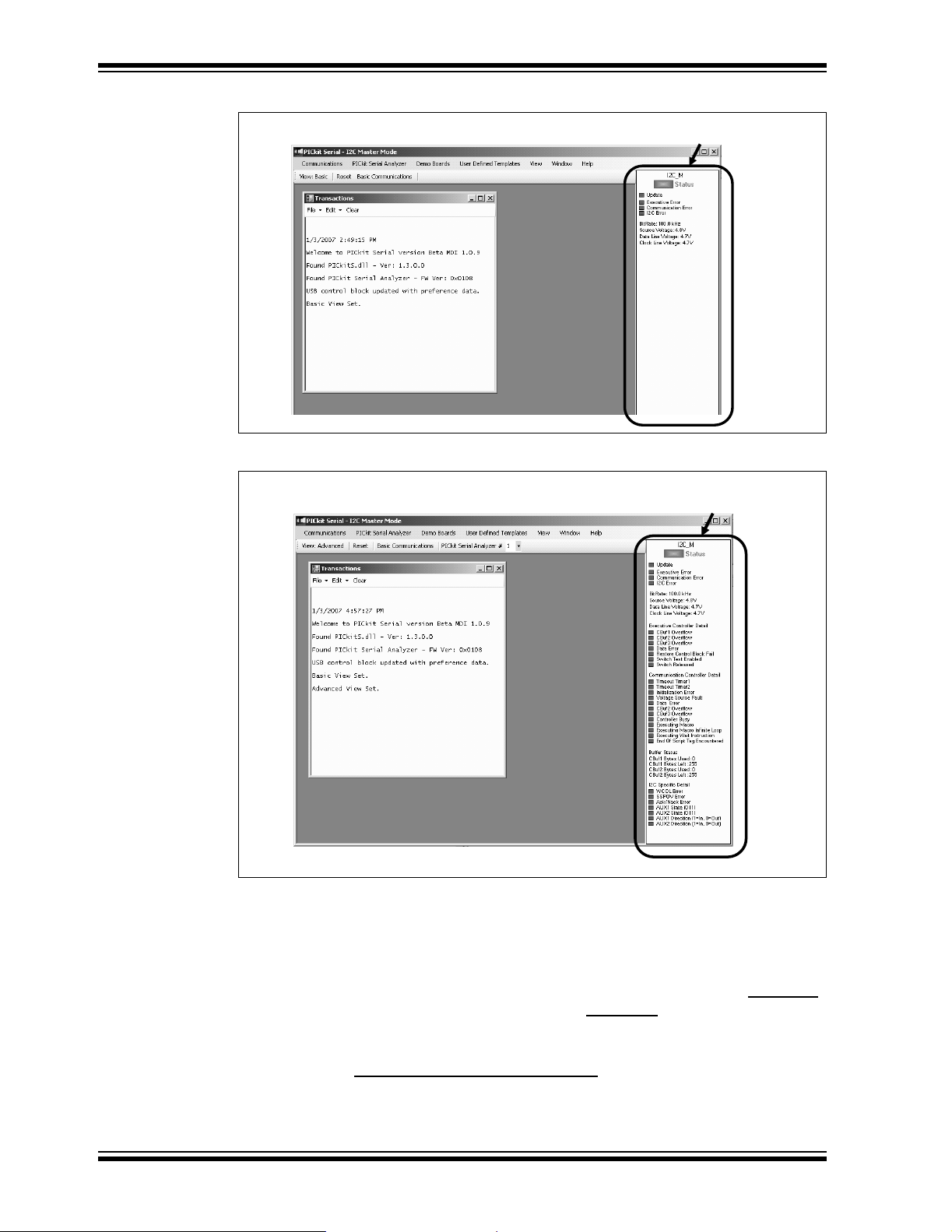

3.6.3 Status Col umn

The Status Column displays status information for the selected serial communications

mode. In Ba sic V iew m ode, a simpl ified st atus i s disp layed a s show n in Fi gure 3-10. In

Advanced View mode additional status information is displayed for the communications

mode selected as shown in Figure 3-11.

The status information that is displayed depends on the selected communications

mode (I

status window for the particular serial communications mode.

2

C, SPI, USART). The following chapters give more detailed explanation of the

© 2007 Microchip Technology Inc. DS51647A-page 23

Page 30

PICkit™ Serial Analyzer User’s Guide

FIGURE 3-10: STATUS COLUMN (BASIC VIEW)

FIGURE 3-11: STATUS COLUMN (ADVANCED VIEW)

Status Column

Status Column

3.6.4 Tr ansactions Window

The Transactions window, shown in Figure 3-12, keeps a running log of the commands

and data that are communicated between the PICkit Serial Analyzer program and

target device.

From the menu bar on the Transaction window, the contents can be saved (File>Save

to a *.txt or *.rtf file. The file can later be retrieved (File>Open

Transactions window.

Additional Transactions windows can be displayed. From the PICkit Serial Analyzer

menu bar , sel ect Window > New Transaction Window

will log the current commands and data.

DS51647A-page 24 © 2007 Microchip Technology Inc.

. The active Transactions window

) and displayed in the

)

Page 31

PICkit™ Serial Analyzer PC Program

FIGURE 3-12: TRANSACTIONS WINDOW

Transactions Window

FILE

• Open

•Save

•Close

– Opens a *.txt or *.rtf file and displays it in the Transactions window

– Saves the contents of the Transactions window to a *.txt or *.rtf file

– Closes the selected Transactions window

EDIT

•Copy

– The selected contents of the Transactions window will be copied to the

clipboard

•Paste

•Select

•Clear All

– The contents of the clipboard will be pasted into the Transactions window

All – contents of the Transactions window will be selected

– The contents of the Transactions window will be cleared

The Transaction window also allows usage of the common keyboard shortcuts Ctrl-X,

Ctrl-C, Ctrl-V to cut, copy and paste from the clipboard.

CLEAR – The contents of the Transactions window will be cleared

3.7 SERIAL COMMUNICATIONS MODES

Detailed information about the entering of data and commands for specific serial

communications modes are given in the following chapters.

© 2007 Microchip Technology Inc. DS51647A-page 25

Page 32

PICkit™ Serial Analyzer User’s Guide

NOTES:

DS51647A-page 26 © 2007 Microchip Technology Inc.

Page 33

Chapter 4. I2C™ Master Communications

4.1 INTRODUCTION

This chapter describes the I2C Master Communications mode. I2C data and

commands can be entered using a Basic Communications window or by creating Script

Commands.

It is assumed that the user is familiar with the I

• The I

Semiconductor (formerly Philips Semiconductor) web site at

http://www.nxp.com/acrobat_download/literature/9398/39340011.pdf

2

•An I

web site. Click on the links: Support -> Getting Started -> PIC MCU Tutorials ->

I2C Master Mode

• Several application notes are available on the Microchip Technology web site.

Click on links: Design -> App Notes -> Function: Communications -> I2C

4.2 HIGHLIGHTS

PICkit™ SERIAL ANALYZER

USER’S GUIDE

2

C protocol . For more information see:

2

C-Bus Specification Version 2.1 January 2000 is available from NXP

C Master Communications tutorial is available on the Microchip Technology

This chapter discusses:

• PICkit Serial Pin Assignments

• Selecting Communications Mode

• Configuring I

• Communications: Basic Operations

• Script Builder

• Script Execute

2

C Communications Mode

4.3 PICkit SERIAL PIN ASSIGNMENTS

The PICkit Serial Analyzer pin assignments for I2C Master mode are:

TABLE 4-1: PIN ASSIGNMENTS

Pin Label Type Description

1 AUX1 Input/Output Auxiliary I/O port pin No. 1

2 +V Power Target Power

3 GND Power Ground

4 SDA Input/Output Serial Data

5 SCL Power Serial Clock

6 AUX2 Input/Output Auxiliary I/O port pin No. 2

4.4 SELECTING COMMUNICATIONS MODE

The I2C Master Communications mode is selected from the Configuration Wizard or

menu bar.

Configuration Wizard – Select PICkit Serial Analyzer > Run Configuration Wizard

from the menu bar

© 2007 Microchip Technology Inc. DS51647A-page 27

Page 34

PICkit™ Serial Analyzer User’s Guide

Menu Bar – Select PICkit Serial Analyzer > Select Communications Mode > I2C

Master

4.5 CONFIGURING I2C COMMUNICATIONS MODE

Once the communications mode has been selected, it is configured from the Configuration Wizard or menu bar.

Configuration Wizard – Select PICkit Serial Analyzer > Run Configuration Wizard

from the menu bar

Menu Bar – Select

The Configure Mode window will open. Depending on the View selected, the Basic

View (Figures 4-1) displays a minimum choice of configurations commands. In the

Advanced View (Figures 4-2) displays an extended choice of configuration commands.

Save the configuration by clicking on the Save Changes button.

PICkit Serial Analyzer > Configure Communications Mode

FIGURE 4-1: I

OPTIONS

• Enable Event Markers

• Enable Time Markers

• Enable Pull

tion lines

VOLTAGE

-ups – Enable internal 2.2 kΩ pull-ups on SDA and SCL communica-

2

C™ CONFIGURE COMMUNICATIONS MODE – BASIC VIEW

– Enable event markers

– Enable ‘time’ stamp to accompany all event markers

• PICkit Serial will power my device

power the target device. The target can be powered at 5 V

variable voltage.

– Select the check box if the PICkit Serial will

DC or a user selectable

CAUTION

Even though the voltage can be set as low as 0 VDC, it is up to the user to verify the

required operating voltage of the target device.

CAUTION

The USB port current limit is set to 100 mA. If the target plus PICkit Serial Analyzer

exceeds this current limit, the USB port will turn off. The target may be powered

externally if more power is required.

DS51647A-page 28 © 2007 Microchip Technology Inc.

Page 35

I2C™ Master Communications

COMM I2CM BIT RATE

Select the desired I2C bus bit rate using the drop down box.

FIGURE 4-2: I

EVENT MARKERS

•Abrt Mac Exe

• Macro Loop

• Mac Lp 65536

• Mac Lp Done

• Timeout Timer1

• Timeout Timer2

• Status Error

– Enable event marker: abort ‘macro’ execution

– Enable event marker: top of ‘macro’ loop

– Enable event marker: ‘macro’ loop count overflow (i.e., 65536)

– Enable event marker: ‘macro’ loop iterations complete

– Enable event marker: Timer1 expired

– Enable event marker: Timer2 expired

– Enable event marker: change in status byte

2

C™ CONFIGURE COMMUNICATIONS MODE – ADVANCED

VIEW

•Start Bit

• Stop Bit

•Restart Bit

• Ack/Nack TX

• Ack/Nack RX

• Write Byte

• Read Byte

•TX Error

• Status Error

ADVANCED OPTIONS

• Disable LED2 Default

LED)

• Disable LED1 Default

• Enable Switch Test

- Switch Off (not depressed) – blink LED1, LED2 off

- Switch ON (depressed) – blink LED2, LED1 off

• AUX1 Default State

• AUX2 Default State

•AUX1 Direction

– Enable event marker – Start bit

– Enable event marker – Stop bit

– Enable event marker – Restart bit

– Enable event marker – Ack or Nack byte transmit

– Enable event marker – Ack or Nack byte received

– Enable event marker – write byte

– Enable event marker – read byte

– Enable event marker – TX error

– Enable event marker – change in I2C status byte

– Disable default LED2 behavior (LED2 = Yellow ‘Target’

– Disable default LED1 behavior (LED1 = Red ‘Busy’ LED)

– Enable low level switch test:

– AUX1 communication line – default state (0 | 1)

– AUX2 communication line – default state (0 | 1)

– AUX1 communication line – direction: 1: input, 0: output

© 2007 Microchip Technology Inc. DS51647A-page 29

Page 36

PICkit™ Serial Analyzer User’s Guide

• AUX2 Direction – AUX2 communication line – direction: 1: input, 0: output

4.6 COMMUNICATIONS: BASIC OPERATIONS

The I2C Basic Operations window can be opened by selecting:

• Communications: Basic Operations

• Communications > Basic Operations

2

The I

C Basic Operations window is shown in Figures 4-3. There are two basic

communications commands, Read and Write.

Read performs a combination Write then Read commands to the target device (refer to

2

the I

C Specification reference in Section 4.1 “Introduction” above). The basic

structure of the command is:

• Start bit (S_)

• Slave Address[W] – Enter the slave address of the device to communicate with.

The write bit should be cleared to indicate a write operation

• Word Address – Enter the word address

• Restart (RS),

• Slave Address[R] – The slave address with the write bit set will be automatically

entered when the Slave Address[W] has been entered

• Byte Count – Enter the number of bytes to be read

• Stop bit (P_)

from the tool bar, or

from the menu bar

Note: The “x” indicates the value is a hexadecimal number. Clicking on “x” will

toggle it to a “d” indicating that the value is a decimal number.

Write performs a write operation to the target device (refer to The I

reference in Section 4.1 “Introduction” above). The basic structure of the command

is:

• Start bit (S_)

• Slave Address[W] – Enter the slave address of the device to communicate with.

The write bit should be cleared to indicate a write operation.

• Word Address – Enter the word address

• Data – Enter up to eight bytes of data

• Stop bit (P_)

The command will be logged in the Transactions window. A listing of the command

abbreviations is given in Table 4-2.

2

C Specification

DS51647A-page 30 © 2007 Microchip Technology Inc.

Page 37

FIGURE 4-3: I2C™ BASIC OPERATIONS

4.7 SCRIPT BUILDER

I2C commands can be combined into scripts, saved, and used over again. The Script

Builder window is opened by selecting Communications > Script > Script Builder

the menu ba r. The Script Builder is shown in Figures 4-4.

The Script Builder window is divided into four columns as shown in Figures 4-5 through

4-8.

I2C™ Master Communications

from

FIGURE 4-4: I

2

C™ SCRIPT BUILDER

4.7.1 Script Commands

The left most column contains the Script Commands as shown in Figures 4-5.

•Script Name

• Save Script

• Execute Script

column

•Clear Script

• Del User Scripts

•Show Array

may be entered. This data can be included in the script by right clicking in a Script

Detail cell and choosing “Insert Array”.

– Enter the name of the script

– Saves the script

– Executes (performs) the script displayed in the Script Detail

– Clears the Script Detail column

– Deletes scripts from the User Scripts column.

– Displays a spreadsheet-like table in which large amounts of data

© 2007 Microchip Technology Inc. DS51647A-page 31

Page 38

PICkit™ Serial Analyzer User’s Guide

FIGURE 4-5: I2C™ SCRIPT BUILDER – SCRIPT COMMANDS

Script Commands

4.7.2 Example Scripts

The second column contains Example Scripts as shown in Figures 4-6. These can be

studied to learn how to create or to edit custom scripts. T o load the example script into

the Script Detail column, either double click or right click and select from the local

menu.

FIGURE 4-6: I

2

C™ SCRIPT BUILDER – EXAMPLE SCRIPTS

Example Scripts

4.7.3 Script Detail

The third column contains Script Detail as shown in Figures 4-7. This column is used

to create the script or view an existing script. More information about creating a custom

script is discussed in Section 4.7.5 “Creating A Script”.

To load a user script from the User Scripts column into the Script Detail column, the

user can double click or right click and select from the local menu.

Note: The “x” indicates the value is a hexadecimal number. Clicking on “x” will

toggle it to a “d” indicating that the value is a decimal number.

DS51647A-page 32 © 2007 Microchip Technology Inc.

Page 39

I2C™ Master Communications

FIGURE 4-7: I2C™ SCRIPT BUILDER – SCRIPT DETAIL

Script Detail

4.7.4 User Scripts

The fourth column contains User Scripts as shown in Figures 4-8. User scripts that are

created, n amed, and saved are displayed in the User Scripts column.

To load a user script from the User Scripts column into the Script Detail column, the

user can double click or right click and select from the local menu.

User Scripts can be deleted by right clicking and selecting Delete Script from the local

menu.

FIGURE 4-8: I

2

C™ SCRIPT BUILDER – USER SCRIPTS

User Scripts

4.7.5 Creating A Script

Scripts are created by placing the cursor into the Script Detail column and right clicking.

A local menu will be displayed as shown in Figures 4-9. Select from the choice of

commands or script macro commands.

The sequence of macro commands are executed from top to bottom. Macro commands

are entered by right clicking in the box and selecting from the local menu as shown in

Figures 4-9.

© 2007 Microchip Technology Inc. DS51647A-page 33

Page 40

PICkit™ Serial Analyzer User’s Guide

Macro commands are entered according to the sequence of events as defined by the

2

I

C bus protocol. Studying the example scripts is a good way to learn the sequence of

events. The example scripts can also be modified and saved under a different name.

CAUTION

The choice of macro commands is very flexible. Therefore, the correctness of the

script has to be verified by the user. The PICkit Serial Analyzer program does not

verify the correctness of the script.

A complete listing of the available macro commands is given in Table 4-2. The macro

command abbreviation will be displayed in the Transactions Window. The Transactions

window keeps a running log of the commands and data sent to and from the target

device.

FIGURE 4-9: I

2

C™ SCRIPT BUILDER – CREATING A SCRIPT

TABLE 4-2: I2C™ SCRIPT MACRO COMMAND

Macro Command

I2CINIT [I_] I

I2CSTART [S_] I2C™ Start

I2CSTOP [P_] I2C™ Stop

I2CRESTART [RS] I2C™ Restart

I2CWRTBYT [W_] I2C™ Write Bytes. Next byte is the byte count,

I2CRDBYT [R_] I2C™ Read Bytes. Next byte is the byte count.

I2CRDBLK [RB] I2C™ Read Block

I2CBITRATE [BR] Set I2C™ Bit Rate - min:0 = 35k, ma x:127 = 100k.

I2CRESET [RE] Reset MSSP module

I2CRDBYTNLB [RN] Read bytes - NACK last byte. Next byte is the byte

I2CRDBLKNLB [RBN] Read block - NACK last byte

I2CAUX1RST [A1RST] Reset AUX1

Command

Abbreviation

Description

2

C™ Initialization

followed by the data.

Next byte is the bit rate.

count

DS51647A-page 34 © 2007 Microchip Technology Inc.

Page 41

TABLE 4-2: I2C™ SCRIPT MACRO COMMAND (CONTINUED)

I2CAUX1SET [A1RST] Set AUX1

I2CAUX1OUT [A1OUT] Set AUX1 direction to Output

I2CAUX1IN [A1IN] Set AUX1 direction to Input

I2CAUX1W0 [A1W0] AUX1 Wait 0

I2CAUX1W1 [A1W1] AUX1 Wait 1

I2CAUX2RST [A2RST] Reset AUX2

I2CAUX2SET [A2RST] Set AUX2

I2CAUX2OUT [A2OUT] Set AUX2 direction to Output

I2CAUX2IN [A2IN] Set AUX2 direction to Input

I2CAUX2W0 [A2W0] AUX2 Wait 0

I2CAUX2W1 [A2W1] AUX2 Wait 1

4.8 SCRIPT EXECUTE

The Script Execute window is shown in Figures 4-10. Once scripts are created using

the Script Builder, they can be assigned to buttons in the Script Execute window. This

makes a convenient window to execute multiple scripts either individually or iteratively.

Script executing will be logged in the Transactions window. The Script Execute window

is opened by selecting Communications > Script > Script Execute

I2C™ Master Communications

from the menu bar.

FIGURE 4-10: I

2

C™ SCRIPT EXECUTE

4.8.1 Assignable Buttons

User created scripts will be displayed in the central I2C Scripts column. To assign a

script to a button, click on the script name and drag it to the desired Assignable Buttons

in the right column. The script will be executed once each time the button is clicked.

The Assignable Buttons can be cleared by clicking on the Cle ar Buttons button.

© 2007 Microchip Technology Inc. DS51647A-page 35

Page 42

PICkit™ Serial Analyzer User’s Guide

4.8.2 Iteration

Scripts can be executed a user defined number of times at a specified interval of time.

Figures 4-11 shows an example. A script named Read_Memory has been assigned to

the Iteration button in the left column. The number of iterations are entered in the

Iterations box and the delay in millisecond in the Delay box. A summary of the iterations

is displayed in the left column. The macro is executed when the Iteration button is

clicked.

FIGURE 4-11: I

2

C™ SCRIPT EXECUTE – EXAMPLE

DS51647A-page 36 © 2007 Microchip Technology Inc.

Page 43

Chapter 5. SPI Master Communications

5.1 INTRODUCTION

This chapter describes the SPI Master Communications mode. SPI data and commands can be entered using a Basic Communications window or by creating Script

Commands.

It is assumed that the user is familiar with the SPI protocol. For more information see:

An SPI tutorial is available on the Microchip Technology web site. Click on the links:

Support -> Getting Started -> PIC MCU Tutorials -> SPI - PICmicro Serial Peripheral

Interface

Several application notes are available on the Microchip Technology web site. Click on

links: Design -> App Notes -> Function: Communications -> SPI

5.2 HIGHLIGHTS

This chapter discusses:

• PICkit Serial Analyzer Pin Assignments

• Selecting Communications Mode

• Configurating SPI Communications Mode

• Communications: Basic Operations

• Script Builder

• Script Execute

PICkit™ SERIAL ANALYZER

USER’S GUIDE

5.3 PICkit™ SERIAL ANALYZER PIN ASSIGNMENTS

The PICkit Serial Analyzer pin assignments for SPI Master mode are:

TABLE 5-1: PIN ASSIGNMENTS

Pin Label Type Description

1 CS Output Chip Select (Active Low)

2 +V Power Targ et Power

3 GND Power Ground

4 SDI Input Serial Data In (with respect to the

5 SCK Output Serial Clock

6 SDO Output Serial Data Out (with respect to the

5.4 SELECTING COMMUNICATIONS MODE

The SPI Master Communications mode is selected from the Configuration Wizard or

menu bar.

Configuration Wizard – Select PICkit Serial Analyzer > Run Configuration Wizard

from the menu bar

PICkit Serial Analyzer)

PICkit Serial Analyzer)

© 2007 Microchip Technology Inc. DS51647A-page 37

Page 44

PICkit™ Serial Analyzer User’s Guide

Menu Bar – Select PICkit Serial Analyzer > Select Communications Mode > SPI

Master

5.5 CONFIGURATING SPI COMMUNICATIONS MODE

Once the communications mode has been selected, it is configured from the Configuration Wizard or menu bar.

Configuration Wizard – Select PICkit Serial Analyzer > Run Configuration Wizard

from the menu bar

Menu Bar – Select PICkit Serial Analyzer > Configure Communications Mode

The Configure Mode window will open. Depending on the View selected, the Basic

View (Figure 5-1) displays a minimum choice of configurations commands. In the

Advanced View (Figure 5-2) displays an extended choice of configuration commands.

Save the configuration by clicking on the Save Changes button.

FIGURE 5-1: SPI CONFIGURE COMMUNICATIONS MODE – BASIC VIEW

OPTIONS

• Enable Event Markers

• Enable Time Markers

VOLTAGE

• PICkit Serial will power my device

power the target device. The target can be powered at 5 V

variable voltage.

– Enable event markers

– Enable ‘time’ stamp to accompany all event markers

– Select the check box if the PICkit Serial will

DC or a user selectable

CAUTION

Even though the voltage can be set as low as 0 VDC, it is up to the user to verify the

required operating voltage of the target device.

CAUTION

The USB port current limit is set to 100 mA. If the target plus PICkit Serial Analyzer

exceeds this current limit, the USB port will turn off. The target may be powered

externally if more power is required.

DS51647A-page 38 © 2007 Microchip Technology Inc.

Page 45

SPI Master Communications

SPI BIT RATE

Select the desired SPI bit rate by selecting the radio button for the desired range and

then selecting the bit rate using the slider.

FIGURE 5-2: SPI CONFIGURE COMMUNICATIONS MODE – ADVANCED

VIEW

EVENT MARKERS

•Abrt Mac Exe

• Macro Loop

• Mac Lp 65536

• Mac Lp Done

• Timeout Timer1

• Timeout Timer2

• Status Error

• Write Byte

• Read Byte

•Status Err

ADVANCED OPTIONS

• Disable LED2 Default

LED)

• Disable LED1 Default

• Enable Switch Test

- Switch Off (not depressed)

- Switch ON (depressed)

• Sample Phase

• Clock Edge Select

• Clock Polarity

• Auto Output Disable

SDO lines to be shorted for 3-wire communication.

– Enable event marker: abort ‘macro’ execution

– Enable event marker: top of ‘macro’ loop

– Enable event marker: ‘macro’ loop count overflow (i.e., 65536)

– Enable event marker: ‘macro’ loop iterations complete

– Enable event marker: Timer1 expired

– Enable event marker: Timer2 expired

– Enable event marker: change in status byte

– Enable event marker – write byte

– Enable event marker – read byte

– Enable event marker – change in SPI status byte

– Disable default LED2 behavior (LED2 = Yellow ‘Target’

– Disable default LED1 behavior (LED1 = Red ‘Busy’ LED)

– Enable low level switch test:

– blink LED1, LED2 off

– blink LED2, LED1 off

– SPI transaction configuration: Sample phase

– SPI transaction configuration: Clock Edge

– SPI transaction configuration: Clock Polarity

– Disables output during input. Allows the SDI lines and the

© 2007 Microchip Technology Inc. DS51647A-page 39

Page 46

PICkit™ Serial Analyzer User’s Guide

5.6 COMMUNICATIONS: BASIC OPERATIONS

The SPI Basic Operations window can be opened by selecting:

• Communications: Basic Operations

• Communications > Basic Operations

The SPI Basic Operations window is shown in Figure 5-3. The Basic Operations win-

dow is organized into five columns. Individual columns are enabled by clicking on the

Enable check box.

The Send button indicates that the column boxes are used to enter data bytes that will

be transmitted to the target device. Clicking on the Send button toggles the column

mode to Rcv (Receive) and the number of received bytes is entered as shown in

Figure 5-4.

Clicking on the Execute button will execute the enabled columns in order from left to

right.

The Clear button clears all boxes.

Note: The “x” indicates the value is a hexadecimal number. Clicking on “x” will

toggle it to a “d” indicating that the value is a decimal number.

The commands will be logged in the Transactions window. A listing of the command

abbreviations is given in Table 5-2.

from the tool bar, or

from the menu bar

FIGURE 5-3: SPI BASIC OPERATION S

DS51647A-page 40 © 2007 Microchip Technology Inc.

Page 47

SPI Master Communications

FIGURE 5-4: SPI BASIC OPERATION S

5.6.1 Basic Communications – Serial EEPROM Example

Figures 5-5 through 5-7 demonstrates how to communicate with a 25LC020A SPI

serial EEPROM. Refer to the 25LC020A Data Sheet (DS21833) for a detailed

explanation of its SPI communications.

Before data can be written to the 25LC020A, the write enable (WREN) latch must be

set. This requires that CS

Figure 5-5 shows only Group 0 enabled. All other groups are disabled. Clicking on the

Execute button will transmit only the WREN command. The command will be logged

in the Transactions window.

be enabled, command 0x06 transmitted, and CS disabled.

FIGURE 5-5: SEEPROM EXAMPLE – WREN COMMAND

Once the WREN latch has been enabled, data can be written to the 25LC020A.

Figure 5-6 shows that Group 0 has been disabled, and Group 1 enabled. Clicking on

the Execute button will send the Write command (0x02), the memory address (0x00),

followed by three bytes of data: 0xAA, 0xBB, and 0xCC. The command will be logged

in the Transactions window.

© 2007 Microchip Technology Inc. DS51647A-page 41

Page 48

PICkit™ Serial Analyzer User’s Guide

FIGURE 5-6: SEEPROM EXAMPLE – WRITE BYTES

Figure 5-7 shows how to read data from the 25LC020A. Groups 0 and 1 are disabled,

and Groups 2 and 3 are enabled. This example shows how data is transmitted and

received in one transaction (Chip Select, CS

Execute button will send the Read command (0x03) and memory address (0x00) of

Group 2 followed by a Read Ten Bytes command in Group 3. The commands and

received data are displayed in the transactions window.

, active) between Groups. Clicking on the

FIGURE 5-7: SEEPROM EXAMPLE – READ BYTES

5.7 SCRIPT BUILDER

SPI commands can be combined into scripts, saved, and used over again. The Script

Builder window is opened by selecting Communications > Script > Script Builder

the menu bar. The Script Builder is shown in Figure 5-8.

The Script Builder window is divided into four columns as shown in Figures 5-9 through

5-12.

from

DS51647A-page 42 © 2007 Microchip Technology Inc.

Page 49

SPI Master Communications

FIGURE 5-8: SPI SCRIPT BUILDER

5.7.1 Script Commands

The left most column contains the Script Commands as shown in Figure 5-9.

•Script Name

• Save Script

• Execute Script

column

•Clear Script

• Del User Scripts

•Show Array

may be entered. This data can be included in the script by right clicking in a Script

Detail cell and choosing “Insert Array”.

– Enter the name of the script

– Saves the script

– Executes (performs) the script displayed in the Script Detail

– Clears the Script Detail column

– Deletes scripts from the User Scripts column.

– Displays a spreadsheet-like table in which large amounts of data

FIGURE 5-9: SPI SCRIPT BUILDER – SCRIPT COMMANDS

Script Commands

5.7.2 Example Scripts

The second column contains Example Scripts as shown in Figure 5-10. These can be

studied to learn how to create or to edit custom scripts. T o load the example script into

the Script Detail column, either double click or right click and select from the local

menu.

© 2007 Microchip Technology Inc. DS51647A-page 43

Page 50

PICkit™ Serial Analyzer User’s Guide

FIGURE 5-10: SPI SCRIPT BUILDER – EXAMPLE SCRIPTS

Example Scripts

5.7.3 Script Detail

The third column contains Script Detail as shown in Figure 5-11. This column is used

to create the script or view an existing script. More information about creating a

customer script is discussed in Section 5.7.5 “Creating A Script”.

To load a user script from the User Scripts column into the Script Detail column, the

user can double click or right click and select from the local menu.

Note: The “x” indicates the value is a hexadecimal number. Clicking on “x” will

toggle it to a “d” indicating that the value is a decimal number.

FIGURE 5-11: I

2

C™ SCRIPT BUILDER – SCRIPT DETAIL

Script Detail

5.7.4 User Scripts

The fourth column contains User Scripts as shown in Figure 5-12. User scripts that are