Page 1

PICkit™ 3 Starter Kit

User’s Guide

2012 Microchip Technology Inc. DS41628B

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, K

PICSTART, PIC

and UNI/O are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MTP, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

Analog-for-the-Digital Age, Application Maestro, BodyCom,

chipKIT, chipKIT logo, CodeGuard, dsPICDEM,

dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, HI-TIDE, In-Circuit Serial

Programming, ICSP, Mindi, MiWi, MPASM, MPF, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, Omniscient Code

Generation, PICC, PICC-18, PICDEM, PICDEM.net, PICkit,

PICtail, REAL ICE, rfLAB, Select Mode, SQI, Serial Quad I/O,

Total Endurance, TSHARC, UniWinDriver, WiperLock, ZENA

and Z-Scale are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

GestIC and ULPP are registered trademarks of Microchip

Technology Germany II GmbH & Co. & KG, a subsidiary of

Microchip Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2012, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 9781620766972

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

32

logo, rfPIC, SST, SST Logo, SuperFlash

QUALITY MANAGEMENT S

DS41628B-page 2 2012 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

PICkit™ 3 STARTER KIT USER’S GUIDE

Table of Contents

Chapter 1. Overview

1.1 Introduction ............................................................................................. 13

1.2 Highlights ................................................................................................ 13

1.3 What’s New ............................................................................................ 13

1.4 Included Items ........................................................................................ 13

1.5 The Low Pin Count Board ...................................................................... 14

1.6 Software Overview ................................................................................. 15

1.7 Running the Demonstrations .................................................................. 15

Chapter 2. PIC® MCU Architecture

2.1 Introduction ............................................................................................. 17

2.2 Core Basics ........................................................................................... 17

2.3 Data/Program Bus .................................................................................. 20

2.4 Accumulator ............................................................................................ 20

2.5 Instructions ............................................................................................. 20

2.6 Byte ........................................................................................................ 21

2.7 Bit ........................................................................................................... 21

2.8 Literal ...................................................................................................... 21

2.9 Control .................................................................................................... 22

2.10 Stack Level ............................................................................................. 25

2.11 Memory Organization ............................................................................. 25

2.12 Program Memory .................................................................................... 25

2.12.1 Flash Program Memory ......................................................................... 25

2.12.2 Configuration Words .............................................................................. 25

2.12.3 Device ID ............................................................................................... 25

2.12.4 Revision ID ............................................................................................ 26

2.12.5 User ID .................................................................................................. 27

2.13 Data Memory .......................................................................................... 27

2.13.1 Core Registers ....................................................................................... 28

2.13.2 Special Function Registers .................................................................... 28

2.13.3 General Purpose RAM .......................................................................... 28

2.13.4 Common RAM ....................................................................................... 28

2.14 Banks ...................................................................................................... 28

2.15 Data EEPROM Memory ......................................................................... 34

2.16 Programming Basics .............................................................................. 34

2.16.1 MPASM™ Assembler Operation ........................................................... 34

2.16.2 XC8 Operation ....................................................................................... 34

2.16.3 Numbers in the Assembler .................................................................... 36

2.16.4 Numbers in the XC8 Compiler ............................................................... 36

2012 Microchip Technology Inc. DS41628B-page 3

Page 4

PICkit™ 3 STARTER KIT USER’S GUIDE

2.17 MPASM Assembler Directives ................................................................ 36

2.17.1 Banksel .................................................................................................36

2.17.2 cblock .....................................................................................................36

2.17.3 Org (addr) ..............................................................................................37

2.17.4 End .........................................................................................................37

2.17.5 Errorlevel ...............................................................................................37

2.17.6 #include ..................................................................................................37

Chapter 3. Lessons

3.1 Lessons .................................................................................................. 40

3.2 Lesson 1: Hello World (Turn on an LED) ................................................ 41

3.2.1 Introduction ............................................................................................41

3.2.2 Hardware Effects ...................................................................................41

3.2.3 Summary ................................................................................................41

3.2.4 New Registers ........................................................................................41

3.2.5 New Instructions ....................................................................................42

3.2.6 Assembly ...............................................................................................43

3.2.7 C Language ...........................................................................................45

3.3 Lesson 2: Blink ....................................................................................... 46

3.3.1 Introduction ............................................................................................46

3.3.2 Hardware Effects ...................................................................................46

3.3.3 Summary ................................................................................................46

3.3.4 New Registers ........................................................................................46

3.3.5 New Instructions ....................................................................................46

3.3.6 Assembly ...............................................................................................47

3.3.7 C Language ...........................................................................................49

3.4 Lesson 3: Rotate ................................................................................... 50

3.4.1 Introduction ............................................................................................50

3.4.2 Hardware Effects ...................................................................................50

3.4.3 Summary ................................................................................................50

3.4.4 New Registers ........................................................................................50

3.4.5 New Instructions ....................................................................................50

3.4.6 Assembly ...............................................................................................51

3.4.7 C Language ...........................................................................................53

3.5 Lesson 4: Analog-to-Digital Conversion ................................................. 54

3.5.1 Introduction ............................................................................................54

3.5.2 Hardware Effects ...................................................................................54

3.5.3 Summary ................................................................................................54

3.5.4 New Registers ........................................................................................54

3.5.5 New Instructions ....................................................................................56

3.5.6 Assembly ...............................................................................................57

3.5.7 C Language ...........................................................................................57

3.6 Lesson 5: Variable Speed Rotate ........................................................... 59

3.6.1 Introduction ............................................................................................59

3.6.2 Hardware Effects ...................................................................................59

3.6.3 Summary ................................................................................................59

3.6.4 New Registers ........................................................................................59

3.6.5 New Instructions ....................................................................................59

3.6.6 Assembly ...............................................................................................61

3.6.7 C Language ...........................................................................................61

DS41628B-page 4 2012 Microchip Technology Inc.

Page 5

3.7 Lesson 6: Debounce ............................................................................... 62

3.7.1 Introduction ............................................................................................ 62

3.7.2 Hardware Effects ................................................................................... 62

3.7.3 Summary ............................................................................................... 63

3.7.4 New Registers ....................................................................................... 63

3.7.5 New Instructions .................................................................................... 63

3.7.6 Assembly ............................................................................................... 63

3.7.7 PIC18 ..................................................................................................... 63

3.7.8 C Language ........................................................................................... 63

3.8 Lesson 7: Reversible Variable Speed Rotate ......................................... 64

3.8.1 Introduction ............................................................................................ 64

3.8.2 Hardware Effects ................................................................................... 64

3.8.3 Summary ............................................................................................... 64

3.8.4 New Registers ....................................................................................... 65

3.8.5 New Instructions .................................................................................... 65

3.8.6 Assembly ............................................................................................... 65

3.8.7 C Language ........................................................................................... 66

3.9 Lesson 8: Pulse-Width Modulation (PWM) ............................................. 67

3.9.1 Introduction ............................................................................................ 67

3.9.2 Hardware Effects ................................................................................... 67

3.9.3 Summary ............................................................................................... 67

3.9.4 New Registers ....................................................................................... 67

3.9.5 Assembly ............................................................................................... 70

3.10 Lesson 9: Timer0 .................................................................................... 71

3.10.1 Introduction ............................................................................................ 71

3.10.2 Hardware Effects ................................................................................... 71

3.10.3 Summary ............................................................................................... 71

3.10.4 New Registers ....................................................................................... 71

3.10.5 Assembly ............................................................................................... 72

3.10.6 C Language ........................................................................................... 72

3.11 Lesson 10: Interrupts and Pull-ups ......................................................... 73

3.11.1 Introduction ............................................................................................ 73

3.11.2 Hardware Effects ................................................................................... 73

3.11.3 Summary ............................................................................................... 73

3.11.4 New Registers ....................................................................................... 75

3.11.5 New Instructions .................................................................................... 76

3.11.6 Assembly ............................................................................................... 76

3.11.7 C Language ........................................................................................... 77

3.12 Lesson 11: Indirect Addressing .............................................................. 78

3.12.1 Introduction ............................................................................................ 78

3.12.2 Hardware Effects ................................................................................... 78

3.12.3 Summary ............................................................................................... 78

3.12.4 New Registers ....................................................................................... 80

3.12.5 New Instructions .................................................................................... 80

3.12.6 Assembly Language .............................................................................. 81

3.12.7 C language ............................................................................................ 82

3.13 Lesson 12: Look-up Table ..................................................................... 83

3.13.1 Intro ....................................................................................................... 83

3.13.2 Hardware Effects ................................................................................... 83

3.13.3 Summary ............................................................................................... 83

2012 Microchip Technology Inc. DS41628B-page 5

Page 6

PICkit™ 3 STARTER KIT USER’S GUIDE

3.13.4 New Registers ........................................................................................83

3.13.5 New Registers ........................................................................................85

3.13.6 New Instructions: ...................................................................................86

3.13.7 Assembly Language ..............................................................................87

3.13.8 C Language ...........................................................................................90

3.14 Lesson 13: EEPROM ............................................................................. 92

3.14.1 Introduction ............................................................................................92

3.14.2 Hardware Effects ...................................................................................92

3.14.3 Summary ................................................................................................92

3.14.4 New Registers ........................................................................................93

3.14.5 New Instructions ....................................................................................93

3.14.6 Assembly Language ..............................................................................93

3.14.7 C Language ...........................................................................................94

Appendix A. Block Diagram and MPLAB® X Shortcuts

A.1 Useful MPLAB® X Shortcuts .................................................................. 96

A.2 Finding Register Names ......................................................................... 96

A.3 PIC MCU Assembly Coding Practices: ................................................... 96

DS41628B-page 6 2012 Microchip Technology Inc.

Page 7

PICkit™ 3 STARTER KIT USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

PICkit™ 3 Starter Kit User’s Guide. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

®

IDE online help.

DOCUMENT LAYOUT

This document describes how to use the PICkit™ 3 Starter Kit User’s Guide as a development tool to emulate and debug firmware on a target board. The manual layout is as

follows:

• Section Chapter 1. “Overview”

• Section Chapter 2. “PIC® MCU Architecture”

• Section Chapter 3. “Lessons”

• Appendix A. “Block Diagram and MPLAB® X Shortcuts”

2012 Microchip Technology Inc. DS41628B-page 7

Page 8

PICkit™ 3 Starter Kit User’s Guide

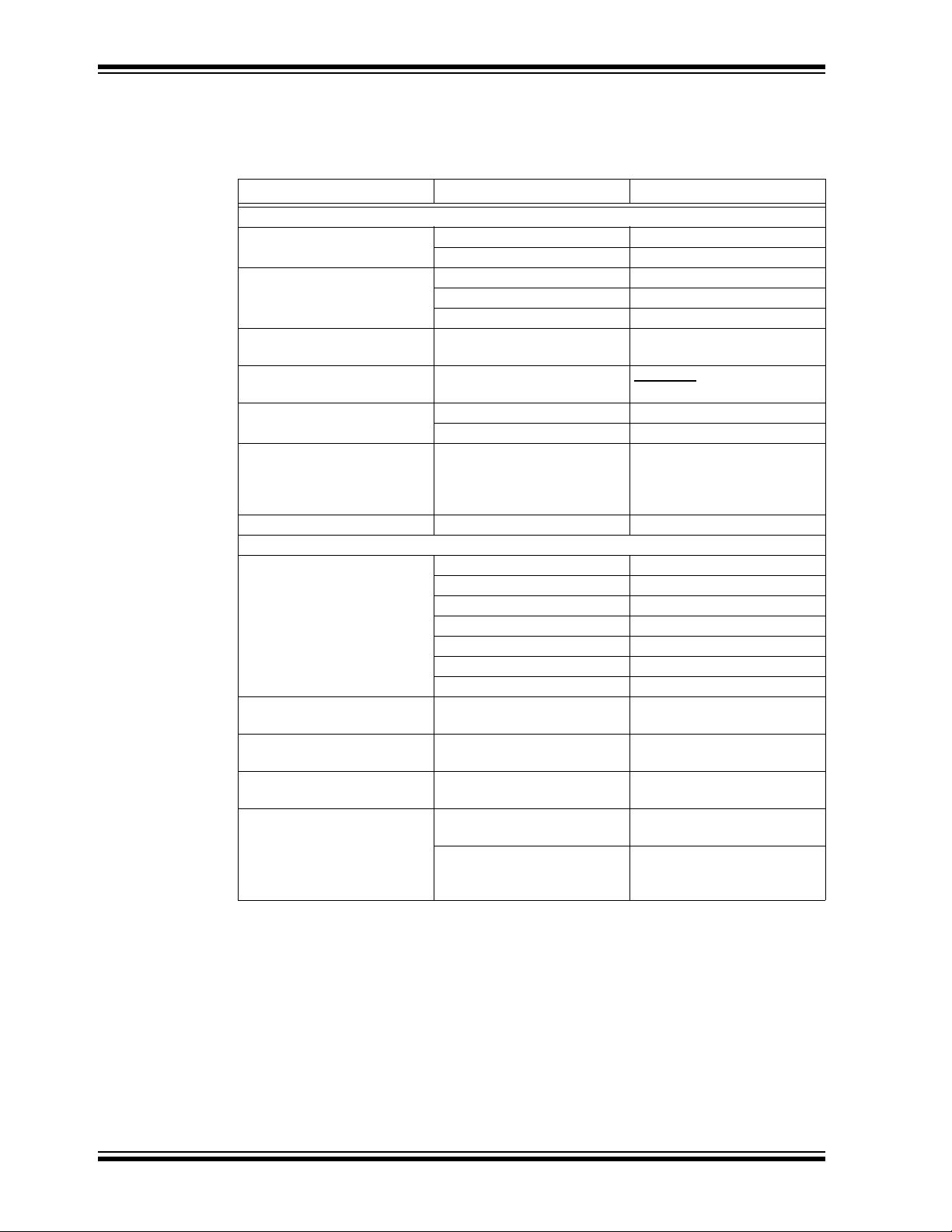

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

®

IDE User’s Guide

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

DS41628B-page 8 2012 Microchip Technology Inc.

Page 9

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the PICkit™ 3 Starter Kit User’s Guide. Other

useful documents are listed below. The following Microchip documents are available

and recommended as supplemental reference resources.

Readme for PICkit™ 3 Starter Kit User’s Guide

For the latest information on using PICkit™ 3 Starter Kit User’s Guide, read the

“Readme for PICkit™ 3 Starter Kit Board User’s Guide.txt” file (an

ASCII text file) in the Readmes subdirectory of the MPLAB IDE installation directory.

The Readme file contains update information and known issues that may not be

included in this user’s guide.

PIC16(L)F1825/29 Data Sheet (DS41440)

This data sheet summarizes the features of the PIC16F1829.

PIC18(L)F1XK22 Data Sheet (DS41365)

This data sheet summarizes the features of the PIC18F14K22.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

Preface

2012 Microchip Technology Inc. DS41628B-page 9

Page 10

PICkit™ 3 Starter Kit User’s Guide

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the HI-TECH C

pilers; MPASM™ and MPLAB ASM30 assemblers; MPLINK™ and MPLAB

LINK30 object linkers; and MPLIB™ and MPLAB LIB30 object librarians.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2, MPLAB ICD 3, PICkit™ 3.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 device programmers and PICkit™ 3 development programmers.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

C16, MPLAB C18 and MPLAB C30 C com-

DS41628B-page 10 2012 Microchip Technology Inc.

Page 11

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (October 2012)

• Initial Release of this Document.

Revision B (November 2012)

• Revised Sections 3.5.3, 3.5.4.1.1, 3.11.3.2, Table 3-15.

Preface

2012 Microchip Technology Inc. DS41628B-page 11

Page 12

PICkit™ 3 Starter Kit User’s Guide

NOTES:

DS41628B-page 12 2012 Microchip Technology Inc.

Page 13

1.1 INTRODUCTION

This chapter introduces the hardware that is included in the kit, as well as a quick start

to downloading and installing the accompanying software.

1.2 HIGHLIGHTS

This chapter discusses:

-What’s New

- Included Items

- The Low Pin Count (LPC) Board Hardware

- Software Overview

- Running the Demonstrations

1.3 WHAT’S NEW

This kit is an update to the PICkit™ 2 Starter Kit. Modifications to the previous LPC

board (DM164120-1) were made so that the full functionality of the code can be

debugged without the need of a debug header. The software has also been rewritten

to accommodate new technologies. The following is a list of new features:

1. Software is in both the ‘C’ and assembler language

2. Extension of the number of lessons and modules covered

3. MPLAB

4. New PIC16 enhanced mid-range and PIC18 routines

5. Uses the universal XC8 compiler

The following is a list of hardware changes to the LPC board:

1. Potentiometer connected to RA4 (formerly to RA0)

2. Switch connected to RA2 (formerly to RA3)

This new LPC board is still backwards compatible. Bridging the old pins to the new pins

will restore functionality.

PICkit™ 3 STARTER KIT USER’S GUIDE

Chapter 1. Overview

®

X support as well as the older MPLAB® 8

1.4 INCLUDED ITEMS

1. 1x PICkit 3 Programmer

2. 1x Micro USB cable

3. 1x LPC Board (Part Number : DM164130-9)

4. 1x PIC16F1829-I/P

5. 1x PIC18F14K22 -I/P

The 13 lessons can be downloaded from the web.

The PIC16F1829 is a new enhanced mid-range device, which supports more features

than the older mid-range PIC16 parts.

2012 Microchip Technology Inc. DS41628B-page 13

Page 14

PICkit™ 3 Starter Kit User’s Guide

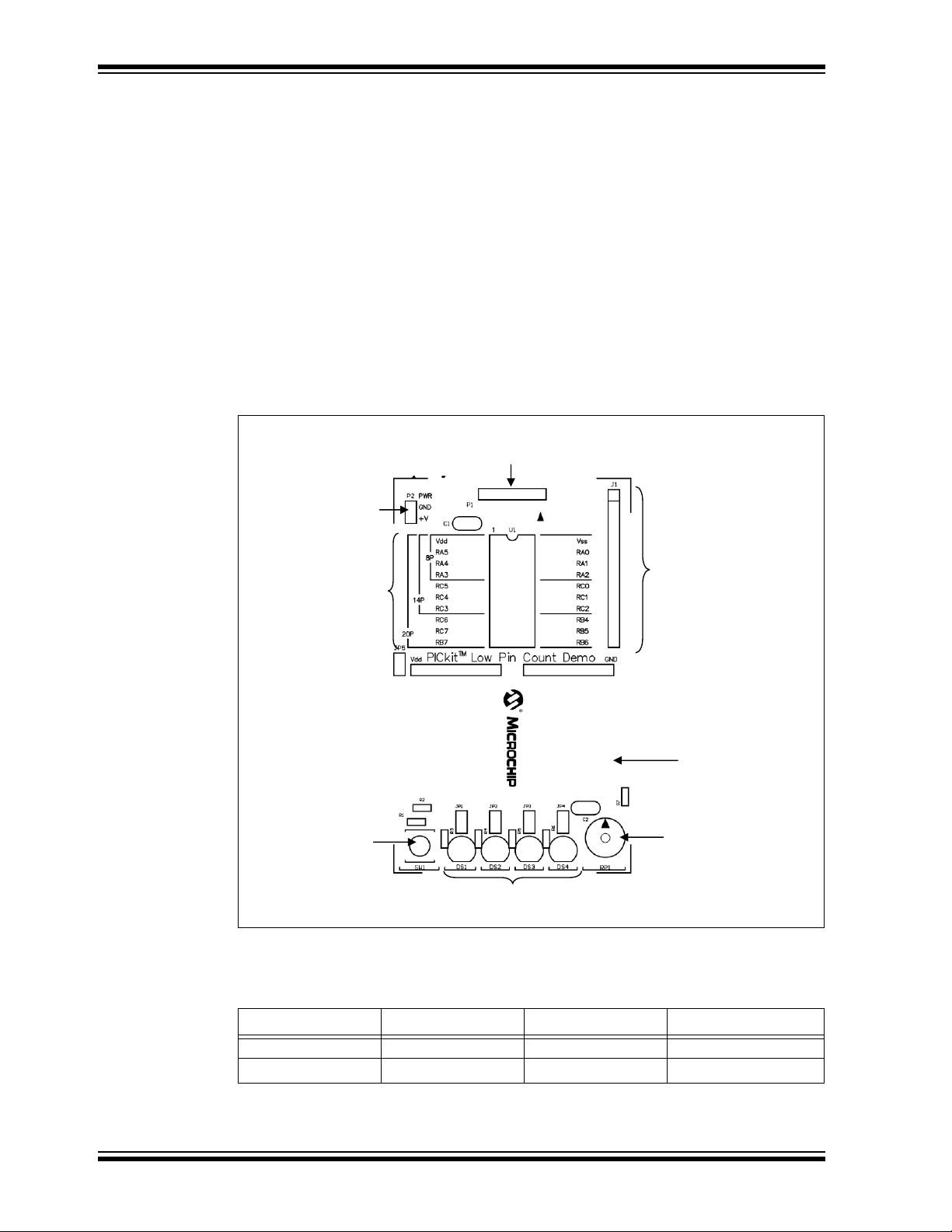

20-pin DIP

Socket

External Power

Push Button

ICSP™ Programming Header

14-pin Expansion Header

Generous Prototyping

Area

Potentiometer

LEDs

The software associated with the kit supports the PIC16F1829 and PIC18F14K22. The

software is intended to run on these two devices, although the software can be easily

ported to other devices.

1.5 THE LOW PIN COUNT BOARD

Support for 18-pin devices requires some board modifications. 14- and 20-pin PIC

devices will have full access to all of the human interface devices. If an 8-pin part is

used, then the LEDs will have to be bridged to the necessary pins on the PIC MCU.

The switch and potentiometer are already connected to pins that are supported by an

8-pin device. The board provides holes next to the LEDs that can be easily soldered to

in order to create any desired hardware changes.

The board is programmable by an In-Circuit Serial Programmer™ (ICSP™), such as a

PICkit™ programmer. The board should be supplied with 5V. Figure 1-1 shows the LPC

Demo Board.

FIGURE 1-1: DEMO BOARD HARDWARE LAYOUT

Ta bl e 1 -1 lists the components that are connected to the two PIC devices that come

with the board.

TABLE 1-1: PIN ASSIGNMENTS

Device LEDs <DS4:DS1> Switch – SW1 Potentiometer – RP1

PIC16F1829 <RC4:RC0> RA2 RA4

PIC18F14K22 <RC4:RC0> RA2 RA4

DS41628B-page 14 2012 Microchip Technology Inc.

Page 15

1.6 SOFTWARE OVERVIEW

This guide will assume that the reader has a basic knowledge of electronics. The

reader does not need to have any programming experience with a PIC MCU before

reading, although a basic knowledge of programming and what the difference between

a bit and byte will help.

The software is written in both assembly and ‘C’ in the MPLAB X and MPLAB 8 integrated design environment (IDE). The assembly version is more complex and requires

more lines of code, however it is closely tied to the PIC device’s hardware and the

reader will gain a much better understanding by doing these lessons in parallel with the

‘C’ routines. The ‘C’ programming language is a higher level language assembly, hence

it provides the reader with an easier to read flow of the program. Each lesson has both

versions and are functionally equivalent.

It is recommended that the lessons be followed sequentially, as presented, since most

of the lessons build up on one another. Each new program will introduce a new peripheral or concept. This guide is not intended to be read without following along in the

code.

The PIC18 and enhanced PIC16 programs will be presented side-by-side and their

differences and similarities explained.

1.7 RUNNING THE DEMONSTRATIONS

Overview

The board comes preprogrammed with a lesson. To use this program, either apply 5V

to the power header (P2), or connect a programmer to the programmer header (P1)

and apply 5V through the programmer in the IDE. The demo program will blink the four

red LEDs in succession. Press the push button (SW1), and the sequence will reverse.

Rotate the potentiometer (RP1), and the light sequence will blink at a different rate. This

demo program is developed through the first seven lessons in this guide.

2012 Microchip Technology Inc. DS41628B-page 15

Page 16

PICkit™ 3 Starter Kit User’s Guide

NOTES:

DS41628B-page 16 2012 Microchip Technology Inc.

Page 17

Chapter 2. PIC® MCU Architecture

Data Bus

8

14

Program

Bus

Instruction reg

Program Counter

8 Level Stack

(13-bit)

Direct Addr

7

12

Addr MUX

FSR reg

STATUS reg

MUX

ALU

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

Instruction

Decode &

Control

Timi ng

Generation

OSC1/CLKIN

OSC2/CLKOUT

V

DD

8

8

Brown-out

Reset

12

3

V

SS

Internal

Oscillator

Block

Configuration

Data Bus

8

14

Program

Bus

Instruction reg

Program Counter

8 Level Stack

(13-bit)

7

Addr MUX

FSR reg

STATUS reg

MUX

ALU

W Reg

Instruction

Decode &

Control

Timi ng

Generation

V

DD

8

8

3

V

SS

Internal

Oscillator

Block

Configuration

15

Data Bus

8

14

Program

Bus

Instruction Reg

Program Counter

16-Level Stack

(15-bit)

7

RAM Addr

Addr MUX

Indirect

Addr

FSR0 Reg

STATUS Reg

MUX

ALU

Instruction

Decode and

Control

Timi ng

Generation

V

DD

8

8

3

V

SS

Internal

Oscillator

Block

Configuration

Flash

Program

Memory

RAM

FSR regFSR reg

FSR1 Reg

15

15

MUX

15

Program Memory

Read (PMR)

12

FSR regFSR reg

BSR Reg

5

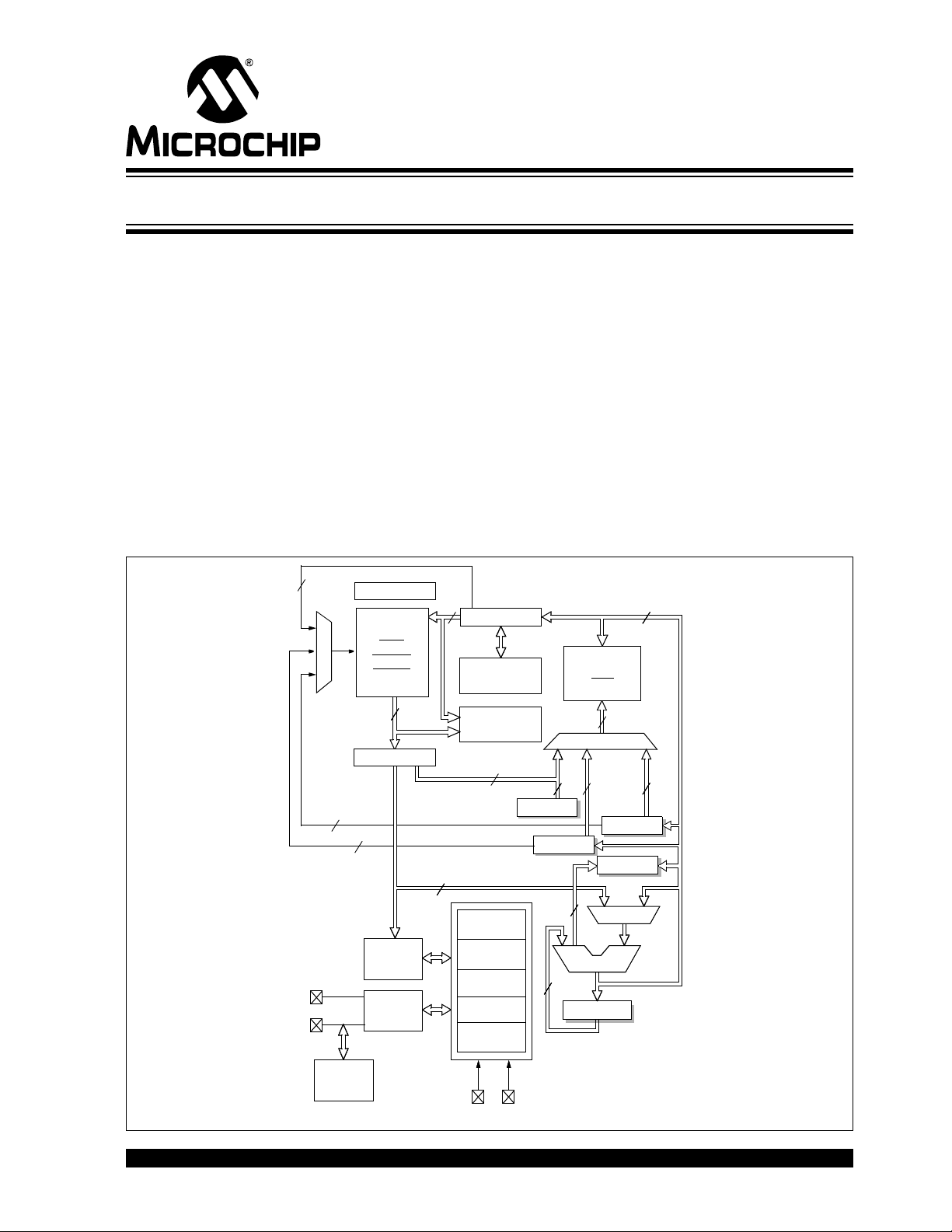

2.1 INTRODUCTION

This chapter describes the architecture of the enhanced mid-range PIC16F1829

(DS41440), as well as the PIC18 (DS41365).

2.2 CORE BASICS

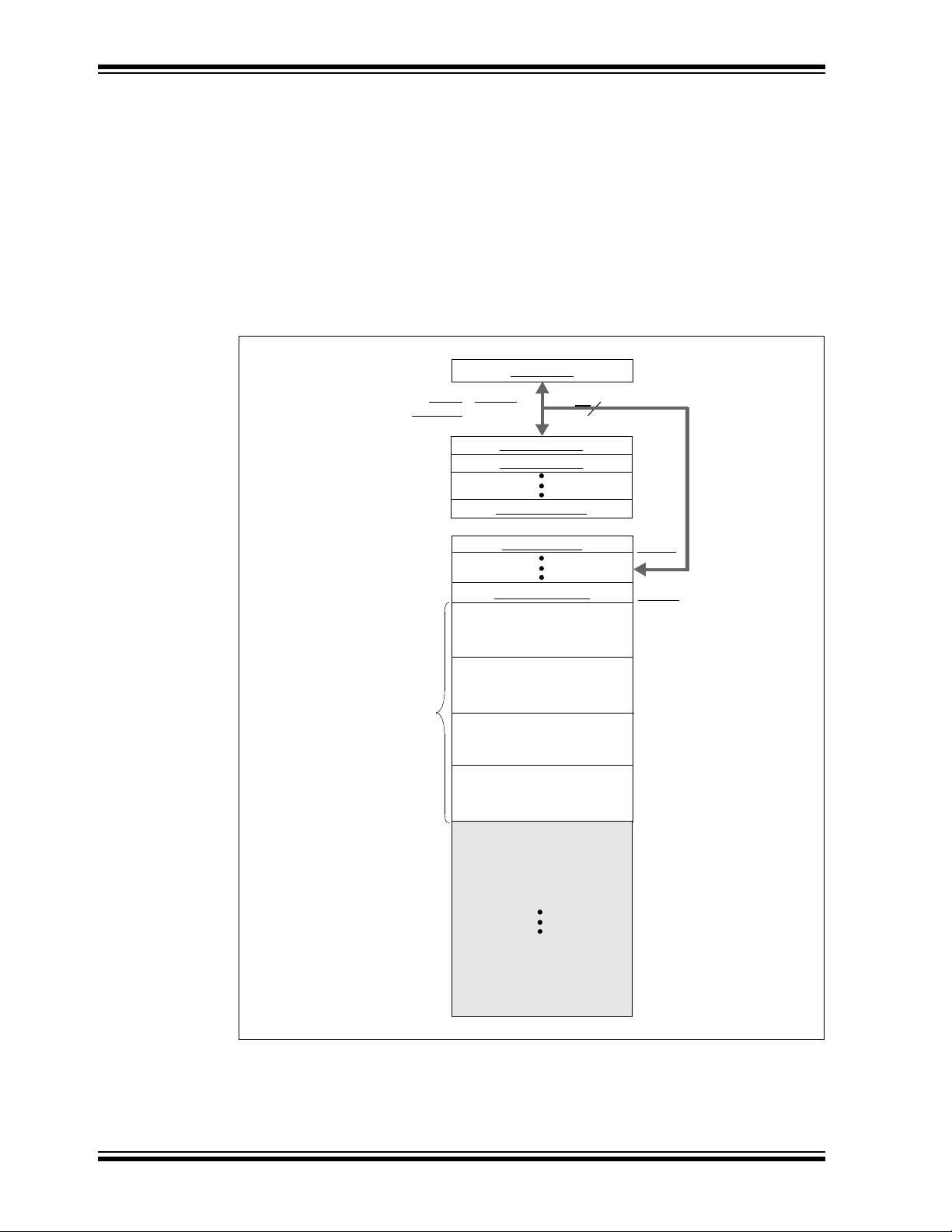

Enhanced PIC16 and PIC18 devices use a modified Harvard architecture, meaning the

code memory and data memory are independent. This allows faster execution because

code instructions and data can be accessed simultaneously. The subsequent instruction is fetched while decoding and executing the current instruction. In Figure 2-1 and

Figure 2-3, the reader should notice the separate lines for data bus and program bus.

This guide will cover nearly all of the registers and modules as seen in the following

figures. The following block diagrams should be referenced while each lesson is being

performed in order to understand the interactions.

PICkit™ 3 STARTER KIT USER’S GUIDE

FIGURE 2-1: SIMPLIFIED ENHANCED MID-RANGE PIC

®

MCU BLOCK DIAGRAM

2012 Microchip Technology Inc. DS41628B-page 17

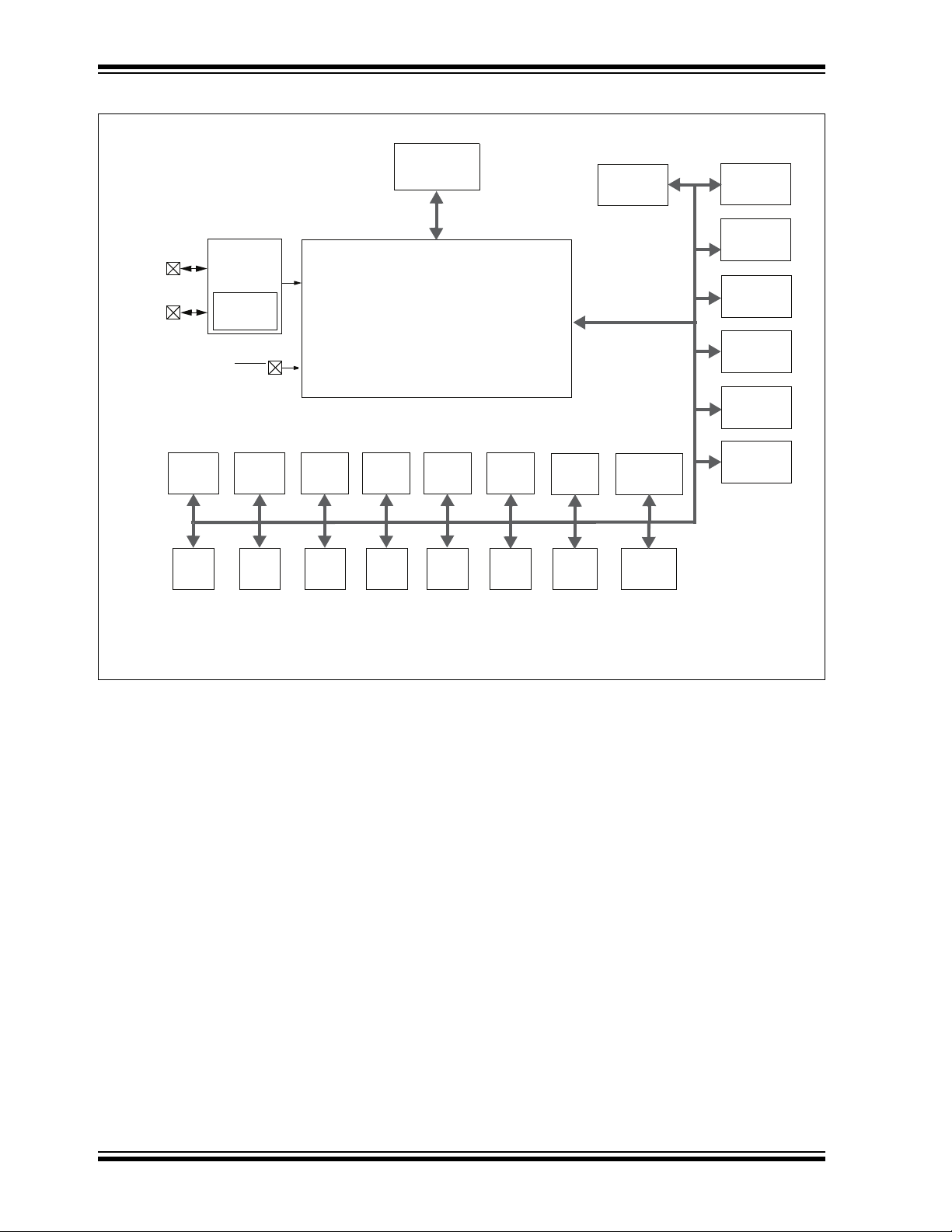

Page 18

PICkit™ 3 Starter Kit User’s Guide

PORTA

EUSART

Comparators

MSSP

Timer2Timer1 Timer4Timer0

ECCP1

ADC

10-Bit

ECCP2 ECCP3 CCP4 CCP5

Timer6

PORTB

PORTC

PORTD

PORTE

LCD

SR

Latch

Note 1: See applicable chapters for more information on peripherals.

CPU

Program

Flash Memory

EEPROM

RAM

Timing

Generation

INTRC

Oscillator

MCLR

OSC1/CLKIN

OSC2/CLKOUT

Figure 2-1

FIGURE 2-2: SIMPLIFIED ENHANCED MID-RANGE PIC® MCU DATA BLOCK DIAGRAM

DS41628B-page 18 2012 Microchip Technology Inc.

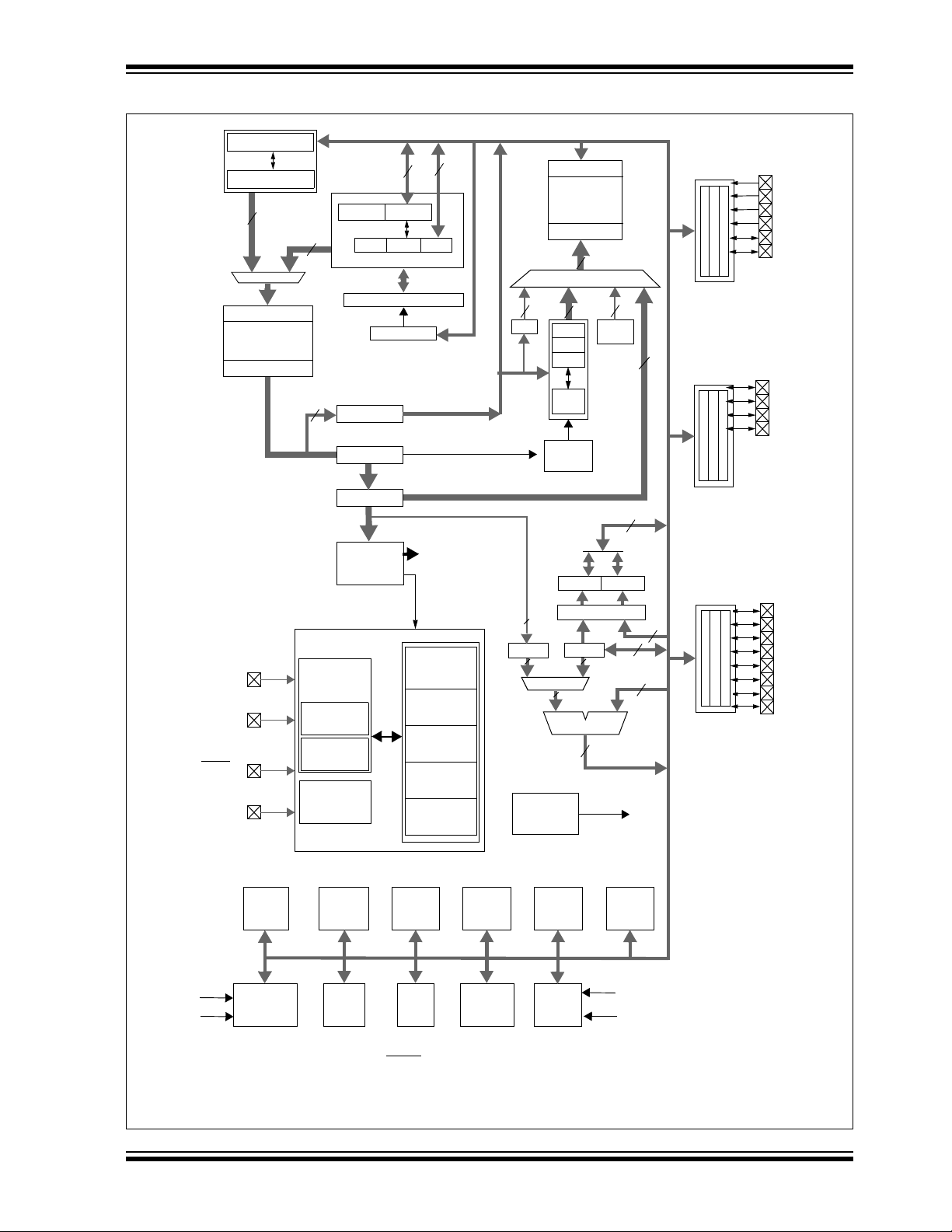

Page 19

FIGURE 2-3: SIMPLIFIED PIC18 BLOCK DIAGRAM

Instruction

Decode and

Control

PORTA

PORTB

PORTC

RA1

RA0

Data Latch

Data Memory

Address Latch

Data Address<12>

12

Access

BSR

FSR0

FSR1

FSR2

inc/dec

logic

Address

4

12

4

PCH PCL

PCLATH

8

31-Level Stack

Program Counter

PRODLPRODH

8 x 8 Multiply

8

BITOP

8

8

ALU<8>

20

8

8

Table Pointer<21>

inc/dec logic

21

8

Data Bus<8>

Table Latch

8

IR

12

3

ROM Latch

PCLATU

PCU

Note 1: RA3 is only available when MCLR functionality is disabled.

2: OSC1/CLKIN and OSC2/CLKOUT are only available in select oscillator modes and when these pins are

not being used as digital I/O.

EUSARTComparator

MSSP

10-bit

ADC

Timer2Timer1 Timer3Time r0

ECCP1

BOR

Data

EEPROM

W

Instruction Bus <16>

STKPTR

Bank

8

State machine

control signals

Decode

8

8

Power-up

Timer

Oscillator

Start-up Timer

Power-on

Reset

Watchdog

Timer

OSC1

(2)

OSC2

(2)

VDD,

Internal

Oscillator

Fail-Safe

Clock Monitor

Precision

Reference

Band Gap

V

SS

MCLR

(1)

Block

LFINTOSC

Oscillator

16 MHz

Oscillator

Single-Supply

Programming

FVR

FVR

FVR

CV

REF

Address Latch

Program Memory

Data Latch

CV

REF

RA3

RA4

RA5

RB4

RB5

RB6

RB7

RC0

RC1

RC2

RC3

RC4

RC5

RC6

RC7

(512/768 bytes)

RA1

PIC® MCU Architecture

2012 Microchip Technology Inc. DS41628B-page 19

Page 20

PICkit™ 3 Starter Kit User’s Guide

T c lock cycle

1

F

OSC

-------------=

4 * T

4

FOSC

-------------

4

4 MHz

------------- ----

1 µs== =

BTFSS PORTA, RA0

2.3 DATA/PROGRAM BUS

The data bus is connected to the outside world via port pins, as well as all of the peripheral registers (timers, ADC, PWM). The program bus connects to the Flash memory

where the program is stored. This is where assembled code is programmed to.

2.4 ACCUMULATOR

There is only one accumulator – the working register (WREG). The accumulator handles all data bus related tasks, such as mathematical operations. The ALU only deals

with 8-bit sized data – hence the categorical names of 8/16/32-bit micros.

2.5 INSTRUCTIONS

Instructions tell what the PIC device should do, whether it is shifting a few bits or jumping to a new line in code. They form the very essence of each program in program

memory. All enhanced mid-range PIC devices have only 49 instructions. The PIC18

has 75 available instructions. Since there are very few instructions needed to learn, the

PIC device can be referred to as a “reduced instruction set computing”, or RISC,

processor.

Each instruction will be explained in detail as they are introduced in each lesson. For

now, the basis of what makes up each instruction will be explained.

One instruction cycle consists of four clock cycles. This means that if the PIC MCU is

running at 4 MHz, each instruction will take one microsecond, as seen in Equation 2-1.

EQUATION 2-1: INSTRUCTION TIME

All instructions are executed in a single instruction cycle, unless a conditional test is

true, or the program counter (PC) is changed. In these cases, the execution takes two

instruction cycles, with the additional instruction cycle executed as a NOP (do nothing),

see Example 2-1.

EXAMPLE 2-1:

This takes two instruction cycles only if pin RA0 is set (active-high), since the skip operation affects the PC.

The PIC18 has a larger word size than the enhanced PIC16 architecture. The PIC18

has a 16-bit wide word containing the operation code (opcode) and all required operands. The enhanced PIC16 has a 14-bit wide word. An opcode is interpreted by the

processor and is unique to each instruction.

The opcodes are broken into four formats:

1. Byte oriented

2. Bit oriented

3. Literal

4. Control

DS41628B-page 20 2012 Microchip Technology Inc.

Page 21

2.6 BYTE

ADDWF data,f

BSF PORTA,RA0

MOVLW ‘A’

PIC® MCU Architecture

All byte instructions on the enhanced PIC16 contain a 6-bit opcode, 7-bit file address,

and a destination bit. All PIC18 byte instructions contain a 6-bit opcode, 8-bit file

address, a destination bit, and a RAM access bit.The sum of all the bit field sizes confirms that the PIC16 enhanced core does indeed have a 14-bit wide word size for

instructions. Likewise, the same can be seen for the PIC18 for its 16-bit wide word

length.

The RAM access bit (a) on the PIC18 is set when the user wishes to use the Bank

Select Register (BSR) for manually selecting the bank. The PIC16 user will always

need to make sure that they are in the correct bank by using the ‘banksel’ directive.

This is explained in the first few lessons.

The destination bit (d) specifies whether the result will be stored in WREG or back in

the original file register. When ‘d’ is zero, the result is placed in the WREG resister.

Otherwise, the result is placed in the file register.

The file register (f) specifies which register to use. This can be a Special Function

Register (SFR) or General Purpose Register (GPR).

EXAMPLE 2-2:

2.7 BIT

2.8 LITERAL

This adds the contents of WREG and data, with the result being saved back to the file

register data.

The PIC18 can move data from one file register directly to another file register, circumventing the WREG. All file moves in the enhanced PIC16 architecture must go through

the WREG.

Bit instructions operate on a specific bit within a file register. These instructions may set

or clear a specific bit within a file register. They may also be used to test a specific bit

within a file register. All bit instructions on the enhanced PIC16 contain a 4-bit opcode,

7-bit file address, and a 3-bit bit address. All PIC18 byte instructions contain a 4-bit

opcode, 8-bit file address, 3-bit bit address and a RAM access bit.

EXAMPLE 2-3:

This sets pin RA0 in the PORTA register.

Literal operations contain the data operand within the instruction. Both architectures

use an 8-bit intermediate value. The rest of the bits are reserved for the opcode.

EXAMPLE 2-4:

This moves the ASCII value of ‘A’ (0x41) into WREG.

2012 Microchip Technology Inc. DS41628B-page 21

Page 22

PICkit™ 3 Starter Kit User’s Guide

2.9 CONTROL

Instructions that dictate what address the PC will select in program memory are called

control instructions. This would include call, goto, and branch. Each has a unique

word length. Please refer to the “Instruction Set Summary” chapter in any PIC

data sheet for more information.

device

DS41628B-page 22 2012 Microchip Technology Inc.

Page 23

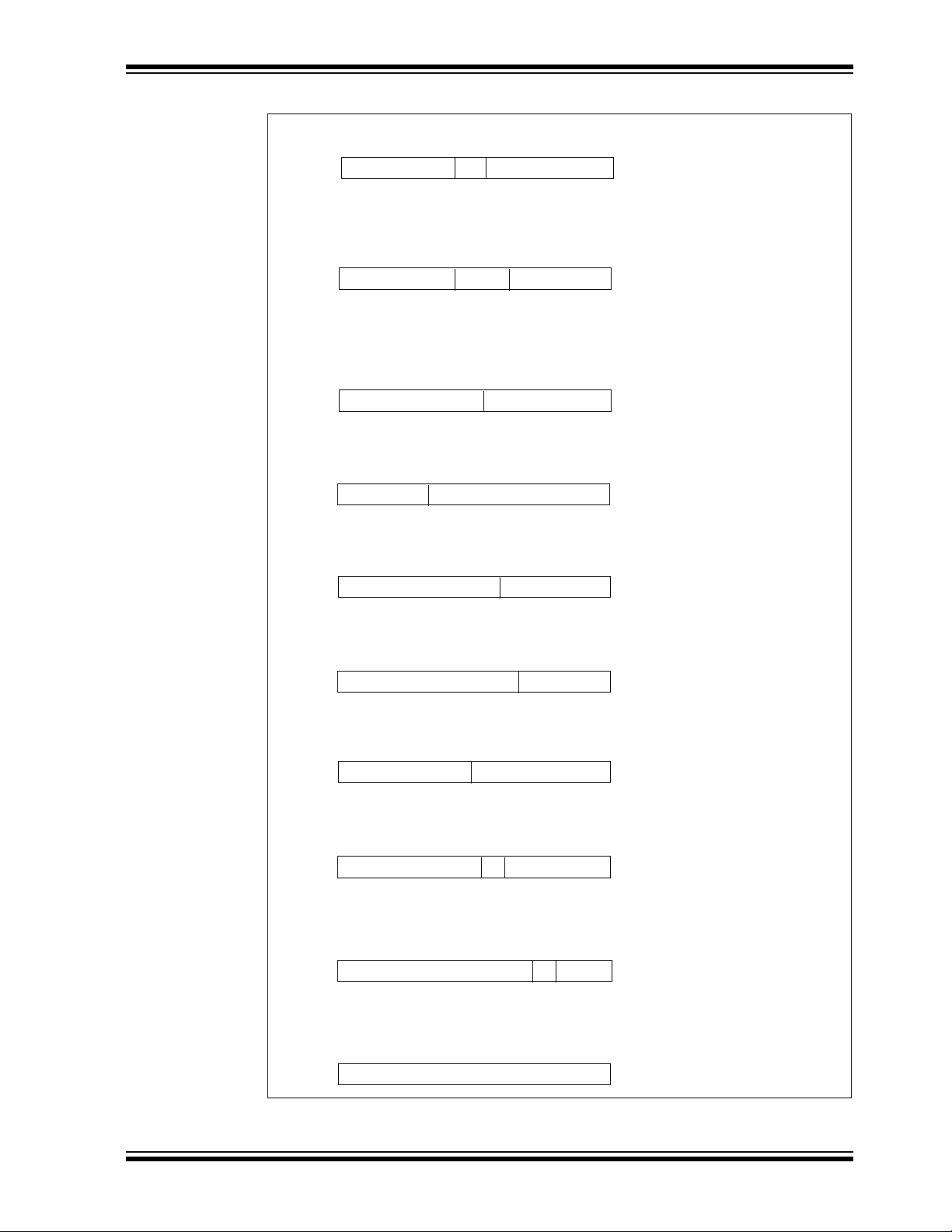

PIC® MCU Architecture

Byte-oriented file register operations

13 8 7 6 0

d = 0 for destination W

OPCODE d f (FILE #)

d = 1 for destination f

f = 7-bit file register address

Bit-oriented file register operations

13 10 9 7 6 0

OPCODE b (BIT #) f (FILE #)

b = 3-bit bit address

f = 7-bit file register address

Literal and control operations

13 8 7 0

OPCODE k (literal)

k = 8-bit immediate value

13 11 10 0

OPCODE k (literal)

k = 11-bit immediate value

General

CALL and GOTO instructions only

MOVLP instruction only

13 5 4 0

OPCODE k (literal)

k = 5-bit immediate value

MOVLB instruction only

13 9 8 0

OPCODE k (literal)

k = 9-bit immediate value

BRA instruction only

FSR Offset instructions

13 7 6 5 0

OPCODE n k (literal)

n = appropriate FSR

FSR Increment instructions

13 7 6 0

OPCODE k (literal)

k = 7-bit immediate value

13 3 2 1 0

OPCODE n m (mode)

n = appropriate FSR

m = 2-bit mode value

k = 6-bit immediate value

13 0

OPCODE

OPCODE only

ADDWF MYREG, W

BSF MYREG, BIT

MOVLW 0x45

CALL LABEL

MOVLP 15

MOVLB 3

BRA LABEL

ADDFSR FSR1, 3

MOVIW ++FSR0

Example Instruction

FIGURE 2-4: ENHANCED PIC16 GENERAL FORMAT FOR INSTRUCTIONS

2012 Microchip Technology Inc. DS41628B-page 23

Page 24

PICkit™ 3 Starter Kit User’s Guide

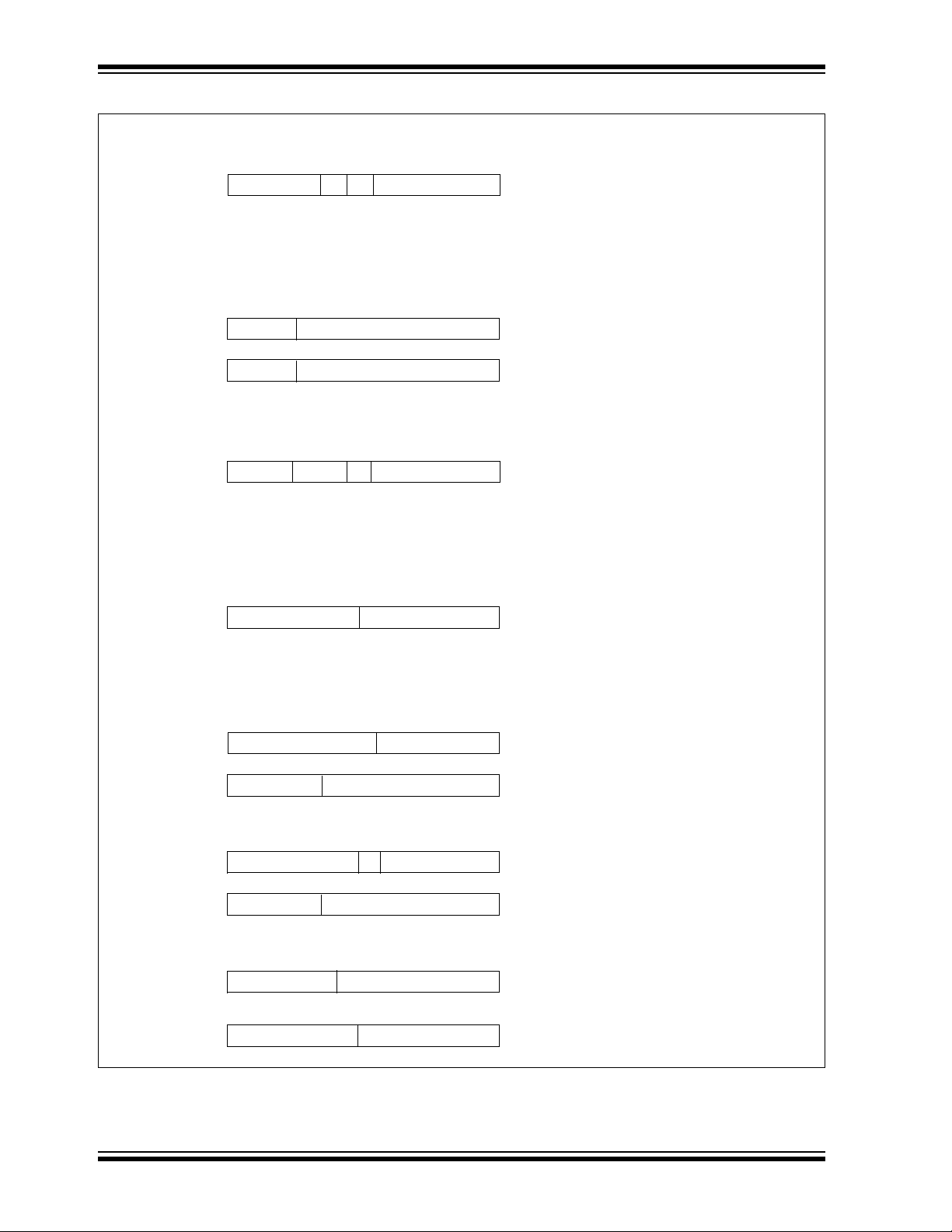

Byte-oriented file register operations

15 10 9 8 7 0

d = 0 for result destination to be WREG register

OPCODE d a f (FILE #)

d = 1 for result destination to be file register (f)

a = 0 to force Access Bank

Bit-oriented file register operations

15 12 11 9 8 7 0

OPCODE b (BIT #) a f (FILE #)

b = 3-bit position of bit in file register (f)

Literal operations

15 8 7 0

OPCODE k (literal)

k = 8-bit immediate value

Byte to Byte move operations (2-word)

15 12 11 0

OPCODE f (Source FILE #)

CALL, GOTO and Branch operations

15 8 7 0

OPCODE n<7:0> (literal)

n = 20-bit immediate value

a = 1 for BSR to select bank

f = 8-bit file register address

a = 0 to force Access Bank

a = 1 for BSR to select bank

f = 8-bit file register address

15 12 11 0

1111 n<19:8> (literal)

15 12 11 0

1111 f (Destination FILE #)

f = 12-bit file register address

Control operations

Example Instruction

ADDWF MYREG, W, B

MOVFF MYREG1, MYREG2

BSF MYREG, bit, B

MOVLW 7Fh

GOTO Label

15 8 7 0

OPCODE n<7:0> (literal)

15 12 11 0

1111 n<19:8> (literal)

CALL MYFUNC

15 11 10 0

OPCODE n<10:0> (literal)

S = Fast bit

BRA MYFUNC

15 8 7 0

OPCODE n<7:0> (literal)

BC MYFUNC

S

FIGURE 2-5: PIC18 GENERAL FORMAT FOR INSTRUCTIONS

There are some subtle differences between the block diagrams in Figure 2-1 and

Figure 2-3. This document will point out a few of the important ones.

DS41628B-page 24 2012 Microchip Technology Inc.

Page 25

2.10 STACK LEVEL

The PIC18 has a deeper stack level of 31, whereas the enhanced core has 16. A

deeper stack allows the PIC device to make more calls in the software before returning

to the original address where the first call was made.

A call or goto modifies the program counter to point to a different place in code. Without these, the code would execute from the top to the bottom. The lessons will show

the significance of this.

The call stack is used to save the return address before going to a new position in

program memory.

As a frame of reference, some of the baseline parts (PIC10/12) devices have a call

stack that is only two levels deep. It is quite a challenge to create modular code with a

limited stack depth.

2.11 MEMORY ORGANIZATION

There are three sections of memory in the PIC16 enhanced mid-range and PIC18

devices:

1. Program Memory

2. Data RAM

3. Data EEPROM

PIC® MCU Architecture

2.12 PROGRAM MEMORY

There are five sections of program memory:

1. Flash Program Memory

2. Configuration Words

3. Device ID

4. Revision ID

5. User ID

2.12.1 Flash Program Memory

All enhanced mid-range and PIC18 devices use Flash memory for programming. Flash

allows the PIC device to be erased and written to hundreds of thousands of times.

2.12.2 Configuration Words

There are several Configuration Word bits, or fuses, that allow different configurations

at run-time. Oscillator selections, memory protection, low-voltage detection, etc., are

some examples of configuration options. Each device has different configuration

options. Enhanced mid-range Configuration bits are read-only during code execution.

PIC18 can read all and write most Configuration bits during code execution. The

Configuration bits are programmed in a special way, as seen in the lesson source files.

2.12.3 Device ID

The Device ID contains the read-only manufacture’s ID for the PIC MCU. The

PIC16F1829 ID is stored in DEVICEID and the PIC18F14K22 is stored in DEVID1 and

DEVID2.

2012 Microchip Technology Inc. DS41628B-page 25

Page 26

PICkit™ 3 Starter Kit User’s Guide

PC<14:0>

15

0000h

0004H

Stack Level 0

Stack Level 15

Reset Vecto r

Interrupt Vector

Stack Level 1

0005h

On-chip

Program

Memory

Page 0

07FFh

Rollover to Page 0

0800h

0FFFh

1000h

7FFFh

Page 1

Rollover to Page 3

Page 2

Page 3

17FFh

1800h

1FFFh

2000h

CALL

, CALLW

RETURN, RETLW

Interrupt, RETFIE

2.12.4 Revision ID

There are five bits in each PIC MCU that indicate the silicon revision of the PIC device.

These bits are read-only and found in the DEVID register. There are usually multiple

revisions of silicon for each PIC device. The errata document, which points out any

errors and their temporary work-arounds, should be read alongside the data sheet.

The PIC18 has a program bus that is 21 bits wide, whereas the enhanced core is only

15 bits wide. A larger program bus infers that the program memory is larger, since it

allows the core to locate a higher address value. The enhanced core program counter

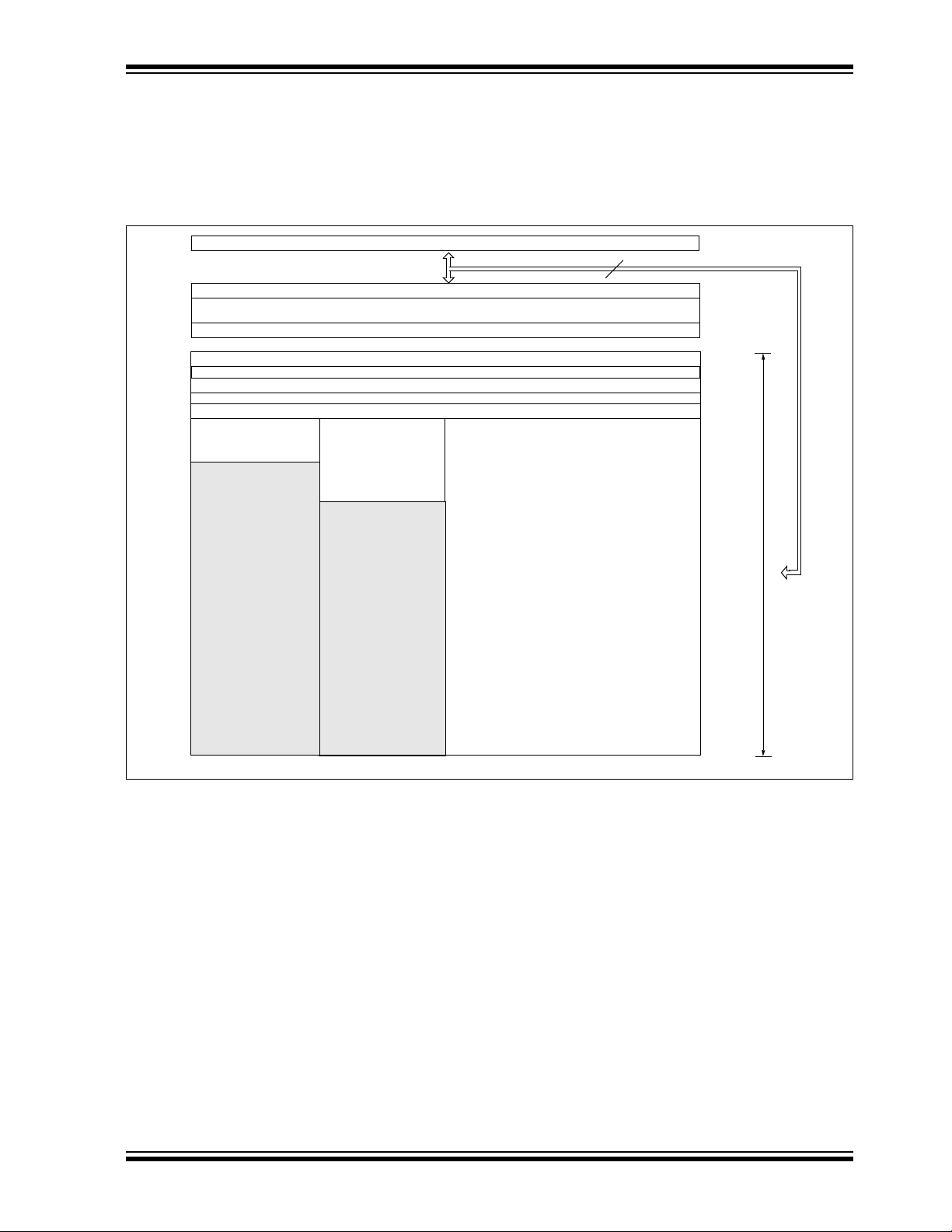

is capable of addressing 32K x 14 program memory space as seen in Figure 2-6.

FIGURE 2-6: ENHANCED MID-RANGE PROGRAM MEMORY MAP AND

CALL STACK

PIC18 devices are capable of addressing a 2-Mbyte program memory space, as seen

in Figure 2-7. PIC18 devices also have two interrupt vectors, whereas the enhanced

PIC devices only have one. A stark difference is that the PIC18 has no concept of

pages, whereas the enhanced core has its program memory split into different pages.

DS41628B-page 26 2012 Microchip Technology Inc.

Page 27

PIC® MCU Architecture

PC<20:0>

Stack Level 1

Stack Level 31

Reset Vector

Low Priority Interrupt Vector

CALL,RCALL,RETURN

RETFIE,RETLW

21

0000h

0018h

High Priority Interrupt Vector

0008h

User Memory Space

1FFFFFh

4000h

3FFFh

200000h

On-Chip

Program Memory

Read ‘0’

1FFFh

2000h

On-Chip

Program Memory

Read ‘0’

PIC18(L)F14K22

PIC18(L)F13K22

Changing pages is necessary in the enhanced core when changing execution from one

page to another. None of the lessons for the enhanced PIC16 occupy more than one

page and, therefore, page changes are not necessary. If the code does overflow into

another page, the assembler will give a warning, indicating that a pagesel may be

required.

FIGURE 2-7: PIC18 PROGRAM MEMORY MAP AND CALL STACK

2.13 DATA MEMORY

2.12.5 User ID

These four memory locations are designated as ID locations where the programmer

can store checksum or other code identification numbers. These are readable and

writable during normal execution.

The data memory layout of the two device families is perhaps the most significant. Data

memory on both families can be split into four types:

1. Core Registers

2. Special Function Registers

3. General Purpose RAM

4. Common RAM

2012 Microchip Technology Inc. DS41628B-page 27

Page 28

PICkit™ 3 Starter Kit User’s Guide

2.13.1 Core Registers

The core registers contain the registers that directly affect the basic operation of the

PIC device, repeated at the top of every data memory bank. Here are three examples

of the 12 core registers:

1. STATUS

2. WREG

3. INTCON

The STATUS register contains the arithmetic status of the ALU. The WREG register is

used to move bits in and out of registers. The INTCON register contains the various

enable and flag bits that would cause the PIC MCU to jump to the Interrupt Vector.

2.13.2 Special Function Registers

The Special Function Registers provide access to the peripheral functions in the

device. The Special Function Registers occupy 20 bytes immediately after the core registers of every data memory bank (addresses x0Ch/x8Ch through x1Fh/x9Fh) on the

enhanced mid-range core. The PIC18 enhanced core has all of its SFRs in Access

RAM, which is discussed in Section 2.14 “Banks”.

2.13.3 General Purpose RAM

2.14 BANKS

GPRs are used for data storage and scratchpad operations in the user’s application.

Think of this as RAM that can be used for your program, but the correct bank must be

selected before using. For the enhanced mid-range PIC devices, there are up to 80

bytes of GPR that follow immediately after the SFR space in each data memory bank.

2.13.4 Common RAM

There are 16 bytes of common RAM accessible from all banks in the enhanced core.

The PIC18 architecture has something similar called Access RAM, which contains up

to 96 bytes.

The PIC18F14K22 data memory is divided into 16 banks that contain 256 bytes each.

The PIC16F1829 data memory is partitioned in 32 memory banks with 128 bytes in

each bank. For the PIC16 enhanced mid-range, each bank consists of:

1. 12 core registers

2. 20 Special Function Registers (SFR)

3. Up to 80 bytes of General Purpose RAM (GPR)

4. 16 bytes of shared RAM (accessible by any bank)

Figure 2-8 shows the above information on the enhanced PIC16.

DS41628B-page 28 2012 Microchip Technology Inc.

Page 29

PIC® MCU Architecture

0Bh

0Ch

1Fh

20h

6Fh

70h

7Fh

00h

Common RAM

(16 bytes)

General Purpose RAM

(80 bytes maximum)

Core Registers

(12 bytes)

Special Function Registers

(20 bytes maximum)

Memory Region

7-bit Bank Offset

FIGURE 2-8: ENHANCED MID-RANGE BANKED MEMORY PARTITIONING

Addresses 70h-7Fh are shared by all of the banks. This is useful for storing a few bytes

of RAM without the need to switch banks each time the byte is used. Figure 2-9 shows

the first eight banks on the PIC16F1829. Notice how the top 12 core registers are

accessible from every bank, as are the 16 bytes of common RAM.

2012 Microchip Technology Inc. DS41628B-page 29

Page 30

DS41628B-page 30 2012 Microchip Technology Inc.

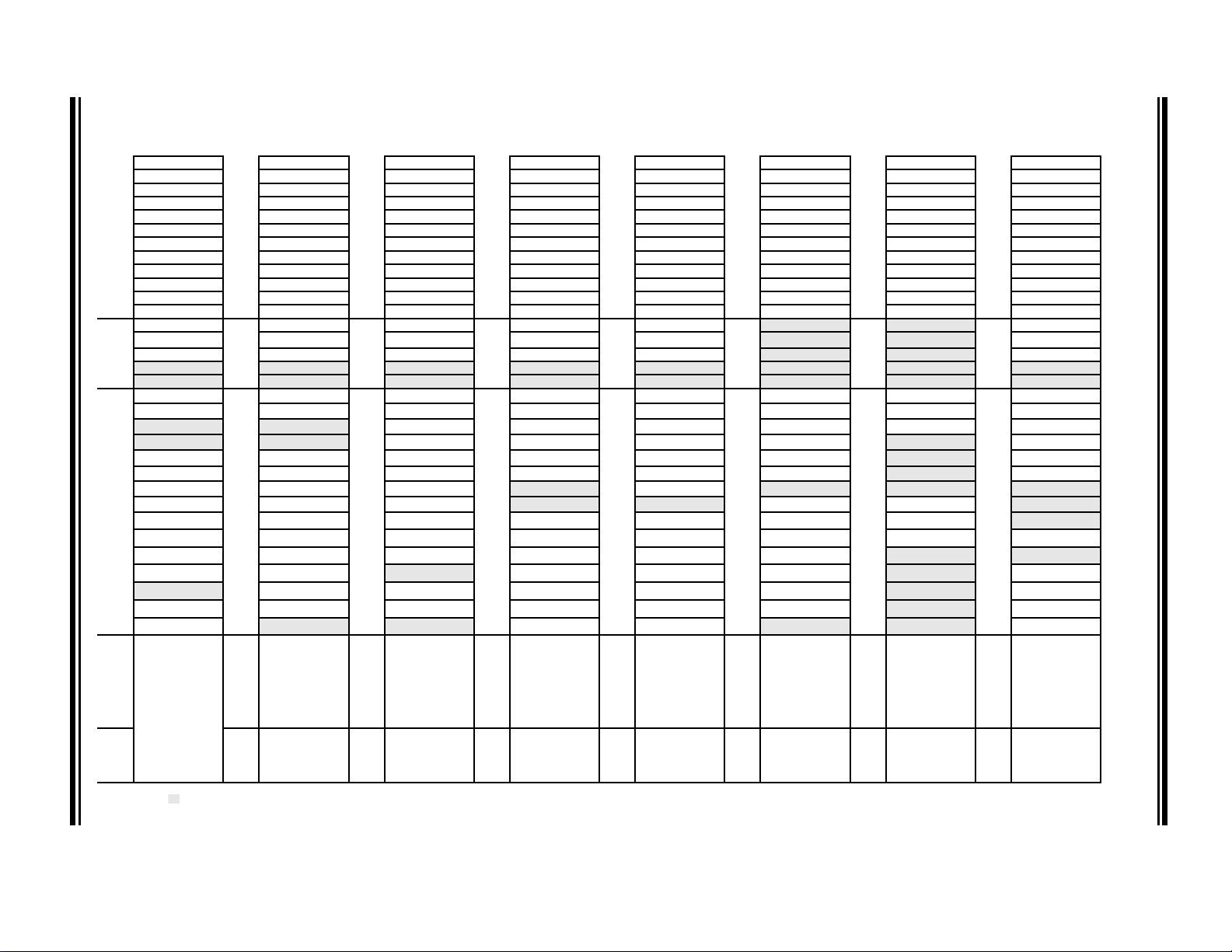

FIGURE 2-9: PIC16F1829 MEMORY MAP – THE CORRECT BANK MUST BE SELECTED BEFORE WRITING/READING FROM A

PICkit™ 3 Starter Kit User’s Guide

REGISTER

BANK 0 BANK 1 BANK 2 BANK 3 BANK 4 BANK 5 BANK 6 BANK 7

000h INDF0 080h INDF0 100h INDF0 180h INDF0 200h INDF0 280h INDF0 300h INDF0 380h INDF0

001h INDF1 081h INDF1 101h INDF1 181h INDF1 201h INDF1 281h INDF1 301h INDF1 381h INDF1

002h PCL 082h PCL 102h PCL 182h PCL 202h PCL 282h PCL 302h PCL 382h PCL

003h STATUS 083h STATUS 103h STATUS 183h STATUS 203h STATUS 283h STATUS 303h STATUS 383h STATUS

004h FSR0L 084h FSR0L 104h FSR0L 184h FSR0L 204h FSR0L 284h FSR0L 304h FSR0L 384h FSR0L

005h FSR0H 085h FSR0H 105h FSR0H 185h FSR0H 205h FSR0H 285h FSR0H 305h FSR0H 385h FSR0H

006h FSR1L 086h FSR1L 106h FSR1L 186h FSR1L 206h FSR1L 286h FSR1L 306h FSR1L 386h FSR1L

007h FSR1H 087h FSR1H 107h FSR1H 187h FSR1H 207h FSR1H 287h FSR1H 307h FSR1H 387h FSR1H

008h BSR 088h BSR 108h BSR 188h BSR 208h BSR 288h BSR 308h BSR 388h BSR

009h WREG 089h WREG 109h WREG 189h WREG 209h WREG 289h WREG 309h WREG 389h WREG

00Ah PCLATH 08Ah PCLATH 10Ah PCLATH 18Ah PCLATH 20Ah PCLATH 28Ah PCLATH 30Ah PCLATH 38Ah PCLATH

00Bh INTCON 08Bh INTCON 10Bh INTCON 18Bh INTCON 20Bh INTCON 28Bh INTCON 30Bh INTCON 38Bh INTCON

00Ch PORTA 08Ch TRISA 10Ch LATA 18Ch ANSELA 20Ch WPUA 28Ch — 30Ch — 38Ch INLVLA

00Dh PORTB

00Eh PORTC 08Eh TRISC 10Eh LATC 18Eh ANSELC 20Eh WPUC 28Eh —30Eh—38EhINLVLC

00Fh

010h

011h PIR1 091h PIE1 111h CM1CON0 191h EEADRL 211h

012h PIR2 092h PIE2 112h CM1CON1 192h EEADRH 212h

013h

014h

015h TMR0 095h OPTION_REG 115h CMOUT 195h EECON1 215h

016h

017h

018h

019h

01Ah

01Bh

01Ch

01Dh

01Eh CPSCON0 09Eh ADCON1 11Eh APFCON1 19Eh TXSTA 21Eh

01Fh CPSCON1 09Fh

020h

06Fh 0EFh 16Fh 1EFh 26Fh 2EFh

070h 0F0h

07Fh 0FFh 17Fh 1FFh 27Fh 2FFh 37Fh 3FFh

Legend: = Unimplemented data memory locations, read as ‘0’.

Note 1: Available only on PIC16(L)F1829.

(1)

08Dh TRISB

(1)

10Dh LATB

(1)

18Dh ANSELB

(1)

20Dh WPUB

(1)

28Dh — 30Dh — 38Dh INLVLB

—08Fh—10Fh—18Fh—20Fh—28Fh—30Fh—38Fh—

—090h—110h—190h—210h—290h— 310h — 390h —

—093h— 113h CM2CON0 193h EEDATL 213h

—094h— 114h CM2CON1 194h EEDATH 214h

TMR1L 096h PCON 116h BORCON 196h EECON2 216h

TMR1H 097h WDTCON 117h FVRCON 197h

T1CON 098h OSCTUNE 118h DACCON0 198h

—217h

—218h

T1GCON 099h OSCCON 119h DACCON1 199h RCREG 219h

TMR2 09Ah OSCSTAT 11Ah SRCON0 19Ah TXREG 21Ah

PR2 09Bh ADRESL 11Bh SRCON1 19Bh SPBRGL 21Bh

T2CON 09Ch ADRESH 11Ch

— 19Ch SPBRGH 21Ch

— 09Dh ADCON0 11Dh APFCON0 19Dh RCSTA 21Dh

—11Fh— 19Fh BAUDCON 21Fh

General

Purpose

0A0h

General

Purpose

Register

80 Bytes

120h

General

Purpose

Register

80 Bytes

1A0h

General

Purpose

Register

80 Bytes

220h

Register

96 Bytes

Accesses

70h – 7Fh

170h

Accesses

70h – 7Fh

1F0h

Accesses

270h

70h – 7Fh

SSP1BUF

SSP1ADD

SSP1MSK

SSP1STAT

SSP1CON

SSP1CON2

SSP1CON3

—

SSP2BUF

SSP2ADD

SSP2MSK

SSP2STAT

SSP2CON

SSP2CON2

SSP2CON3

General

Purpose

Register

80 Bytes

Accesses

70h – 7Fh

291h CCPR1L 311h

292h CCPR1H 312h

293h CCP1CON 313h

294h PWM1CON 314h

295h CCP1AS 315h

296h PSTR1CON 316h

297h — 317h

298h

(1)

299h

(1)

29Ah

(1)

29Bh

(1)

29Ch

(1)

29Dh

(1)

29Eh

(1)

29Fh

CCPR2L

CCPR2H

CCP2CON

PWM2CON

CCP2AS

PSTR2CON

CCPTMRS

—

2A0h

General

Purpose

Register

80 Bytes

2F0h

Accesses

70h – 7Fh

318h

319h

31Ah

31Bh

31Ch

31Dh

31Eh

31Fh

320h

36Fh

370h

CCPR3L

CCPR3H

CCP3CON

—

—

—

—

CCPR4L

CCPR4H

CCP4CON

—

—

—

—

—

General

Purpose

Register

80 Bytes

Accesses

70h – 7Fh

391h IOCAP

392h IOCAN

393h

394h IOCBP

395h IOCBN

396h IOCBF

397h

398h

399h —

39Ah CLKRCON

39Bh

39Ch MDCON

39Dh

39Eh

39Fh

3A0h

3EFh

3F0h

IOCAF

(1)

(1)

(1)

—

—

—

MDSRC

MDCARL

MDCARH

General

Purpose

Register

80 Bytes

Accesses

70h – 7Fh

(1)

Page 31

PIC® MCU Architecture

When using the PIC16F1829 in assembly, the reader will be constantly referring back

to Figure 2-9 to make sure that the right bank is selected before writing to an SFR.

For PIC18 devices, the banking situation was streamlined so that the user does not

have to switch banks when using the access SFRs. The data memory is configured

with an Access Bank, which allows users to access a mapped block of memory without

specifying a Bank Select Register (BSR). The Access Bank consists of the first 96

bytes of memory in Bank 0 and the last 160 bytes of memory in Bank Block 15. This

lower half is known as the “Access RAM” and is composed of GPRs. The upper half is

where the device’s SFRs are mapped (Bank 15). When going through the assembly

lessons, the reader will notice the absence of bank switching. Figure 2-10 and

Figure 2-11 show this improved mapping scheme.

2012 Microchip Technology Inc. DS41628B-page 31

Page 32

PICkit™ 3 Starter Kit User’s Guide

Bank 0

Bank 1

Bank 14

Bank 15

Data Memory Map

BSR<3:0>

= 0000

= 0001

= 1111

060h

05Fh

F60h

FFFh

00h

5Fh

60h

FFh

Access Bank

When ‘a’ = 0:

The BSR is ignored and the

Access Bank is used.

The first 96 bytes are

general purpose RAM

(from Bank 0).

The second 160 bytes are

Special Function Registers

(from Bank 15).

When ‘a’ = 1:

The BSR specifies the bank

used by the instruction.

F5Fh

F00h

EFFh

1FFh

100h

0FFh

000h

Access RAM

FFh

00h

FFh

00h

FFh

00h

GPR

SFR

Access RAM High

Access RAM Low

Bank 2

= 0110

= 0010

(SFRs)

2FFh

200h

3FFh

300h

4FFh

400h

5FFh

500h

6FFh

600h

7FFh

700h

8FFh

800h

9FFh

900h

AFFh

A00h

BFFh

B00h

CFFh

C00h

DFFh

D00h

E00h

Bank 3

Bank 4

Bank 5

Bank 6

Bank 7

Bank 8

Bank 9

Bank 10

Bank 11

Bank 12

Bank 13

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

FFh

00h

= 0011

= 0100

= 0101

= 0111

= 1000

= 1001

= 1010

= 1011

= 1100

= 1101

= 1110

Unused

Read 00h

Unused

F53h

SFR

(1)

Note 1: SFRs occupying F53h to F5Fh address space are not in the virtual bank.

FIGURE 2-10: PIC18F14K22 DATA MEMORY MAP

DS41628B-page 32 2012 Microchip Technology Inc.

Page 33

PIC® MCU Architecture

FIGURE 2-11: PIC18F14K22 SPECIAL FUNCTION REGISTER MAP – ALL OF THESE ARE IN

BANK 15 WHICH IS INCLUDED IN THE “ACCESS RAM”

Address Name Address Name Address Name Address Name Address Name

FFFh TOSU FD7h TMR0H FAFh SPBRG F87h

FFEh TOSH FD6h TMR0L FAEh RCREG F86h —

FFDh TOSL FD5h T0CON FADh TXREG F85h —

FFCh STKPTR FD4h —

(2)

FACh TXSTA F84h —

FFBh PCLATU FD3h OSCCON FABh RCSTA F83h —

FFAh PCLATH FD2h OSCCON2 FAAh —

(2)

F82h PORTC F5Ah —

(2)

—

(2)

(2)

(2)

(2)

F5Fh —

F5Eh —

F5Dh —

F5Ch —

F5Bh —

FF9h PCL FD1h WDTCON FA9h EEADR F81h PORTB F59h —

FF8h TBLPTRU FD0h RCON FA8h EEDATA F80h PORTA F58h —

FF7h TBLPTRH FCFh TMR1H FA7h EECON2

(1)

F7Fh ANSELH F57h —

FF6h TBLPTRL FCEh TMR1L FA6h EECON1 F7Eh ANSEL F56h —

FF5h TABLAT FCDh T1CON FA5h —

FF4h PRODH FCCh TMR2 FA4h —

FF3h PRODL FCBh PR2 FA3h —

(2)

(2)

(2)

F7Dh —

F7Ch —

F7Bh —

(2)

(2)

(2)

F55h —

F54h —

F53h —

FF2h INTCON FCAh T2CON FA2h IPR2 F7Ah IOCB

FF1h INTCON2 FC9h SSPBUF FA1h PIR2 F79h IOCA

FF0h INTCON3 FC8h SSPADD FA0h PIE2 F78h WPUB

(1)

FEFh INDF0

FEEh POSTINC0

FEDh POSTDEC0

FECh PREINC0

FEBh PLUSW0

FEAh FSR0H FC2h ADCON0 F9Ah —

FE9h FSR0L FC1h ADCON1 F99h —

FE8h WREG FC0h ADCON2 F98h —

FE7h INDF1

FE6h POSTINC1

FE5h POSTDEC1

FE4h PREINC1

FE3h PLUSW1

FE2h FSR1H FBAh VREFCON0 F92h TRISA F6Ah

FE1h FSR1L FB9h PSTRCON F91h —

FE0h BSR FB8h BAUDCON F90h

FDFh INDF2

FDEh POSTINC2

FDDh POSTDEC2

FDCh PREINC2

FDBh PLUSW2

FDAh FSR2H FB2h TMR3L F8Ah LATB F62h —

FD9h FSR2L FB1h T3CON F89h LATA F61h —

FD8h STATUS FB0h SPBRGH F88h —

FC7h SSPSTAT F9Fh IPR1 F77h WPUA

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

FB7h PWM1CON F8Fh —

(1)

(1)

(1)

(1)

FC6h SSPCON1 F9Eh PIR1 F76h SLRCON

FC5h SSPCON2 F9Dh PIE1 F75h —

FC4h ADRESH F9Ch —

(2)

F74h —

FC3h ADRESL F9Bh OSCTUNE F73h —

FBFh CCPR1H F97h —

FBEh CCPR1L F96h —

FBDh CCP1CON F95h —

(2)

(2)

(2)

(2)

(2)

(2)

F72h —

F71h —

F70h —

F6Fh SSPMASK

F6Eh —

F6Dh CM1CON0

FBCh VREFCON2 F94h TRISC F6Ch CM2CON1

FBBh VREFCON1 F93h TRISB F6Bh CM2CON0

FB6h ECCP1AS F8Eh —

FB5h —

FB4h —

(2)

(2)

F8Dh —

F8Ch —

(2)

(2)

—

(2)

(2)

(2)

(2)

F69h SRCON1

F68h SRCON0

F67h —

F66h —

F65h —

F64h —

FB3h TMR3H F8Bh LATC F63h —

(2)

F60h —

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

—

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

Legend: = Unimplemented data memory locations, read as ‘0’,

Note 1: This is not a physical register.

2: Unimplemented registers are read as ‘0’.

All of the SFRs in Figure 2-9 are in Bank 15 and do not require banking since this bank

is covered by the Access Bank. Switching banks in the enhanced mid-range core

requires two instructions, so this could potentially save a great number of instructions

in the overall program.

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

2012 Microchip Technology Inc. DS41628B-page 33

Page 34

PICkit™ 3 Starter Kit User’s Guide

code.asm

code.hex Programmer

MPASM™

assembler

MCU

2.15 DATA EEPROM MEMORY

The data EEPROM is a nonvolatile memory array, separate from both the data RAM,

and program memory, which is used for long-term storage of program data. The

EEPROM is not directly mapped in either the register file or program memory space,

but is indirectly addressed through special SFRs. The EEPROM is readable and

writable during normal operation.

The PIC16F1829 and PIC18F14K22 have 256 bytes of EEPROM on board.

The EEPROM is rated for high erase/write cycle endurance. A byte write automatically

erases the location and writes the new data. Please see Section 3.14 “Lesson 13:

EEPROM” for more information.

2.16 PROGRAMMING BASICS

This section will briefly discuss essential assembler and ‘C’ basics. There are better

suited tutorials on ‘C’ programming on the web if the user wishes to learn more.

This guide uses the XC8 compiler v.1.00 for both the PIC16F1829 and PIC18F14K22.

Later versions of the compiler will also work. Looking at the XC8 user’s guide would be

a very good start. One of the great benefits of using ‘C’ is that it is very portable and will

build in most compilers with no problem.

The assembly is not compiled, but rather assembled by a utility called MPASM. This

guide uses MPASM assembler v5.43, which is a universal assembler for all PIC1X

devices.

A key advantage of using a high-level language (such as C) is that the programmer

does not need to understand the architecture of the microprocessor being used. Knowledge of the architecture is left to the compiler which will take the ‘C’ and compile it into

assembly. When using assembly, the programmer must use the PIC device’s instruction set and understand the memory map. A positive benefit of assembly is not only the

knowledge gained, but also the code size will be considerably smaller.

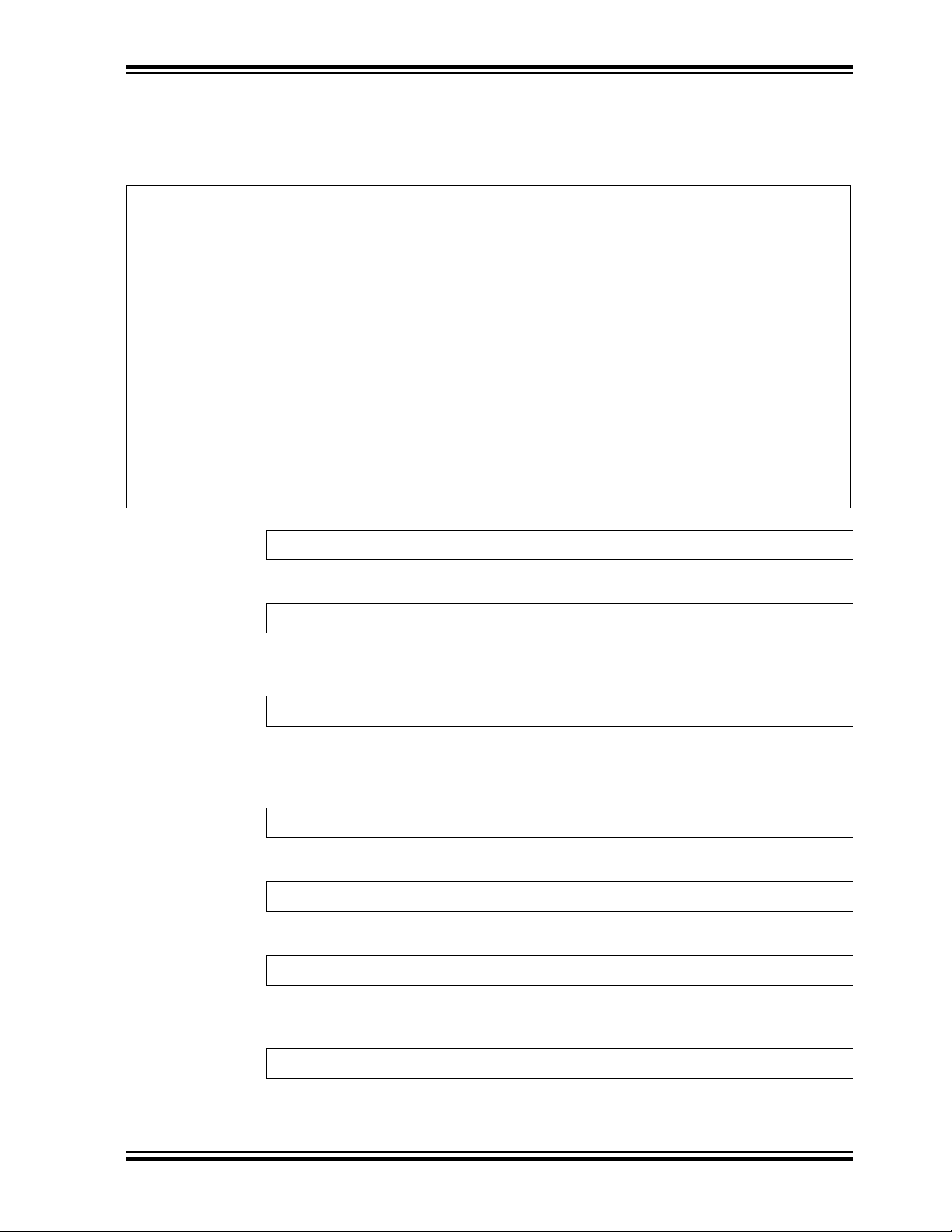

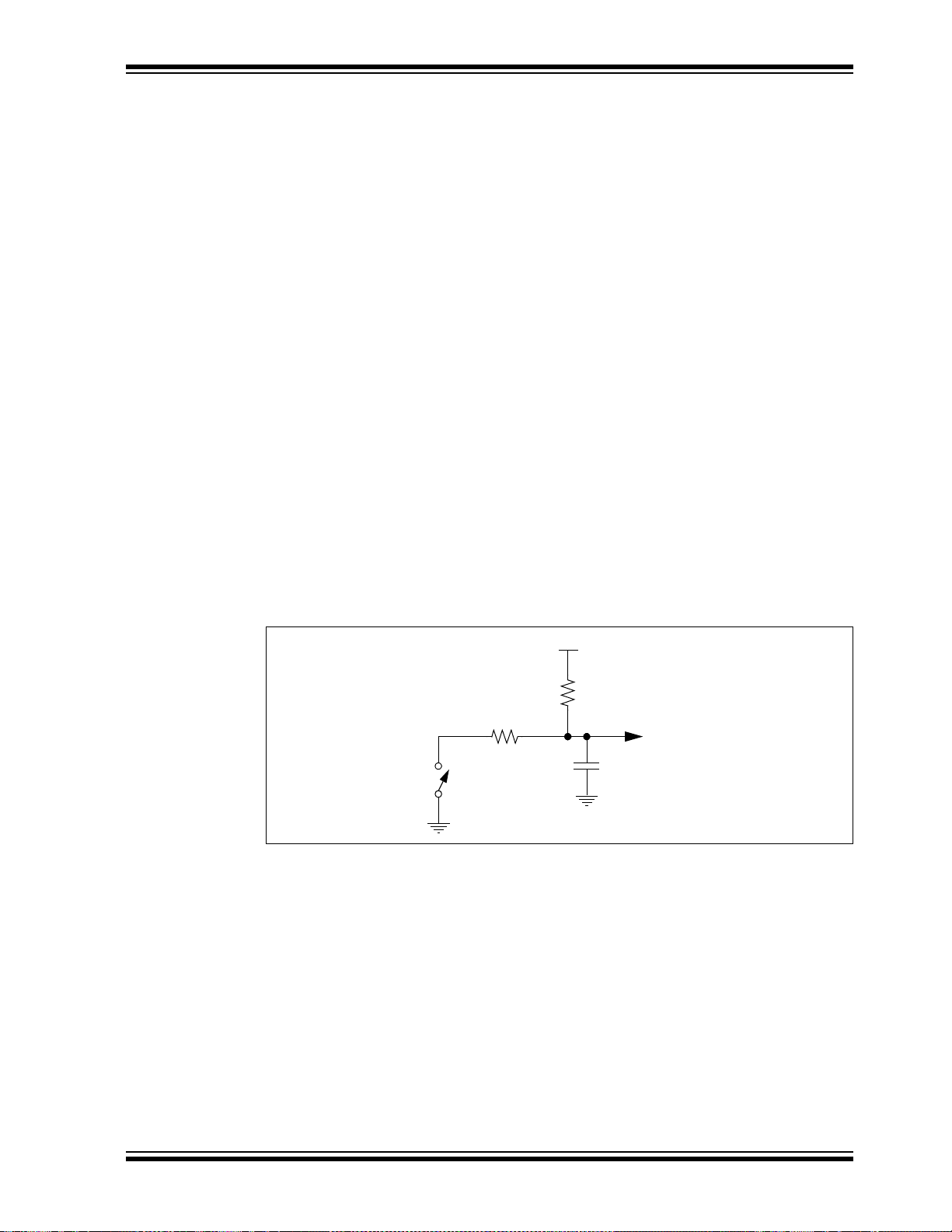

2.16.1 MPASM™ Assembler Operation

All of the lessons written in are absolute code. This means that everything that the

assembler needs is contained in the source files. This process is shown below.

FIGURE 2-12: MPASM ASSEMBLER OPERATION

When a source file is assembled in this manner, all variables and routines used in the

source file must be defined within that source file, or in files that have been explicitly

included by that source file. If assembly proceeds without errors, a hex file will be generated that contains the executable machine code for the targeted PIC device. This file

can then be used by the debugger to test code execution, and by a device programmer

to program the microcontroller.

2.16.2 XC8 Operation

The compiler does all of the translation involved, which is needed to take the high-level

code down to a level in which the PIC device understands. Figure 2-13 explains how

this is done.

DS41628B-page 34 2012 Microchip Technology Inc.

Page 35

FIGURE 2-13: XC8 OPERATION

PIC® MCU Architecture

Notice how the output is the same for both the compiler/assembler – a hex file. The

assembly that the compiler generates can be seen in the disassembly window inside

of the MPLAB

FIGURE 2-14: DISASSEMBLY FIGURE

Figure 2-14 shown above shows part of the disassembly of lesson 5. The ‘C’, which is

indented, is easier to understand and write. The assembly underneath it contains twice

as much code, and includes the PIC MCU specific instructions to achieve the desired

result of the ‘C’ above it.

®

IDE.

2012 Microchip Technology Inc. DS41628B-page 35

Page 36

PICkit™ 3 Starter Kit User’s Guide

cblock [address]

Variable

endc

2.16.3 Numbers in the Assembler

Unless otherwise specified, the assembler assumes any numeric constants in the

program are hexadecimal (base 16). Binary (base 2), octal (base 8), decimal (base 10),

and ASCII coding are also supported.

TABLE 2-1: NUMBERS IN THE ASSEMBLER

Radix Format Example

Hexadecimal # or 0x# or H’#’ 12 or 0x12 or H’12’

Decimal .# or D’#’Octal or O’#’ .12 or D’12’Octal or O’12’

Binary B’#’ B’00010010’

ASCII A’#’ or ‘#’ A’c’ or ‘c’

2.16.4 Numbers in the XC8 Compiler

Unless otherwise specified, the compiler assumes any numeric constants in the

program are decimal (base 10).

TABLE 2-2: NUMBERS IN THE COMPILER

Radix Format Example

Hexadecimal 0x# 0x12

Decimal # 12

Binary 0b# 0b00010010

ASCII ‘#’ ‘c’

2.17 MPASM ASSEMBLER DIRECTIVES

Directives are assembler commands that appear in the source code, but are not usually

translated directly into opcodes. They are used to control the assembler: its input,

output, and data allocation.

Many of the assembler directives have alternate names and formats. These may exist

to provide backward compatibility with previous assemblers from Microchip, and to be

compatible with individual programming practices.

All of the directives for the MPASM assembler can be found inside the IDE under

Help->Help

2.17.1 Banksel

banksel label

This directive is an instruction to the assembler and linker to generate bank selecting

code to set the bank to the bank containing the designated label. The programmer

should always use this directive instead of setting the BSR directly, to avoid the possibility of human error.

2.17.2 cblock

EXAMPLE 2-5:

Contents

DS41628B-page 36 2012 Microchip Technology Inc.

This is used to define a block of variables starting at address address.

Page 37

EXAMPLE 2-6:

“MESSAGE 302 – Operand Not in Bank 0, check to ensure bank bits are correct”

include “include_file”

#include <include_file>

PIC® MCU Architecture

2.17.3 Org (addr)

Org tells the assembler where to start generating code at addr. Normally, the lessons

would start code at address 0x0000.

2.17.4 End

End tells the assembler to stop assembling. There must be one at the end of the

program. It does not necessarily have to be at the end of the file, but nothing after the

end statement will be assembled.

2.17.5 Errorlevel

This is used to suppress warnings that the assembler may give. It is vital that the

programmer understand the message before hiding them from the output window.

2.17.6 #include

EXAMPLE 2-7:

The specified file is read in as source code. The effect is the same as if the entire text