Page 1

PICkit™ 2

Programmer/Debugger

User’s Guide

© 2008 Microchip Technology Inc. DS51553E

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

PICSTART, PRO MATE, rfPIC and SmartShunt are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

FilterLab, Linear Active Thermistor, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, In-Circuit Serial

Programming, ICSP, ICEPIC, Mindi, MiWi, MPASM, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, PICkit, PICDEM,

PICDEM.net, PICtail, PIC

32

logo, PowerCal, PowerInfo,

PowerMate, PowerTool, REAL ICE, rfLAB, Select Mode, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2008, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS51553E-page ii © 2008 Microchip Technology Inc.

Page 3

PICkit™ 2 USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 1

Chapter 1. PICkit 2 Programmer/Debugger Overview

1.1 Introduction ..................................................................................................... 7

1.2 PICkit 2 Development Programmer/Debugger Contents ............................... 7

1.3 PICkit 2 Development Programmer/Debugger ............................................... 7

1.4 PICkit 2 Programmer Application ................................................................. 10

Chapter 2. PICkit 2 Programmer Getting Started

2.1 Introduction ................................................................................................... 15

2.2 Installing the PICkit 2 Hardware ................................................................... 15

2.3 Installing and Launching the PICkit 2 Programmer Application ................... 16

2.4 Connecting to the Device ............................................................................. 16

2.5 Selecting Target Power ................................................................................ 18

2.6 Importing a Hex File ..................................................................................... 19

2.7 Writing the Program to the Device ............................................................... 20

2.8 Verifying the Device ..................................................................................... 23

2.9 Reading Device Memory .............................................................................. 23

2.10 Code Protecting the Device ........................................................................ 23

2.11 Erasing and Blank Checking the Device .................................................... 24

2.12 Automating Write/Read Procedures ........................................................... 24

2.13 PICkit 2 Calibration and Unit ID .................................................................. 25

Chapter 3. Using In-Circuit Serial Programming™ (ICSP™)

3.1 Introduction ................................................................................................... 27

3.2 Isolate V

3.3 Isolate ICSPCLK or PGC and ICSPDAT or PGD pins ................................. 28

3.4 V

DD ............................................................................................................... 29

3.5 V

SS ............................................................................................................... 30

3.6 Cable Lengths .............................................................................................. 30

3.7 Serial EEPROM and KeeLoq HCS Devices ................................................. 30

PP/MCLR/Port Pin ........................................................................... 28

Chapter 4. PICkit 2 Debug Express

4.1 Introduction ................................................................................................... 31

4.2 PICkit 2 Debug Express Kit Contents ........................................................... 31

4.3 Installing the Hardware and Software .......................................................... 32

4.4 Using PICkit 2 Debug Express ..................................................................... 32

4.5 Debug Express Tutorial ................................................................................ 36

© 2008 Microchip Technology Inc. DS51553E-page iii

Page 4

PICkit™ 2 User’s Guide

Chapter 5. Troubleshooting

5.1 Introduction ................................................................................................... 49

5.2 Frequently Asked Questions ........................................................................ 49

5.3 PICkit 2 Debug Express MPLAB IDE Errors ................................................ 54

Chapter 6. Updating the PICkit 2 Operating System

6.1 Introduction ................................................................................................... 61

6.2 Updating the PICkit 2 OS - PICkit 2 Programmer Application ...................... 61

6.3 Updating the PICkit 2 OS – MPLAB IDE ...................................................... 62

Chapter 7. PICkit 2 UART Tool

7.1 Introduction ................................................................................................... 65

7.2 Connecting the PICkit 2 UART Tool ............................................................. 65

7.3 The PICkit 2 UART Tool Window ................................................................. 66

Appendix A. MPLAB IDE Reference

A.1 Introduction .................................................................................................. 71

A.2 Debugging Functions ................................................................................... 71

A.3 Programming Functions ............................................................................... 73

A.4 Settings Dialog ............................................................................................. 75

Appendix B. PICkit 2 Schematics

Index .............................................................................................................................79

Worldwide Sales and Service .....................................................................................82

DS51553E-page iv © 2008 Microchip Technology Inc.

Page 5

PICkit™ 2

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using

PICkit™ 2 . Items discussed include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

© 2008 Microchip Technology Inc. DS51553E-page 1

Page 6

PICkit™ 2 User’s Guide

DOCUMENT LAYOUT

This document describes how to use the PICkit 2 as a development tool to emulate

and debug firmware on a target board. The manual layout is as follows:

• Chapter 1. PICkit 2 Programmer/Debugger Overview – Provides an overview

of the PICkit 2 Programmer/Debugger.

• Chapter 2. PICkit 2 Programmer Getting Started – Provides Instructions on

how to get started using the PICkit 2 Programmer/Debugger to program

Flash-based PIC

• Chapter 3. Using In-Circuit Serial Programming™ (ICSP™) – Describes pro-

gramming with the PICkit 2 Programmer/Debugger using In-Circuit Serial

Programming

• Chapter 4. PICkit 2 Debug Express – Provides a tutorial on using the PICkit™ 2

Debug Express debugger program.

• Chapter 5. Troubleshooting – Provides information on solving common

problems and Debug Express errors.

• Chapter 6. Updating the PICkit 2 Operating System – Provides instruction on

how to update your PICkit 2 Programmer/Debugger’s Operating System.

• Chapter 7. PICkit 2 UART Tool – Provides information on using the PICkit 2 as a

serial UART terminal interface for communicating with a PIC microcontroller

• Appendix A. MPLAB IDE Reference – Describes how the PICkit 2

Programmer/Debugger works with MPLAB IDE.

• Appendix B. PICkit 2 Schematics – Illustrates the PICkit 2

Programmer/Debugger hardware schematic diagrams.

®

Microcontroller Units (MCUs).

™

(ICSP™).

DS51553E-page 2 © 2008 Microchip Technology Inc.

Page 7

CONVENTIONS USED IN THIS GUIDE

The following conventions may appear in this documentation:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic Referenced books MPLAB

Initial caps A window the Output window

Quotes A field name in a window or

Underlined, italic with right

angle bracket

Bold characters A dialog button Click OK

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Sample source code #define START

Italic A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mpasmwin [options]

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

Preface

®

IDE User’s Guide

Emphasized text ...is the only compiler...

A dialog the Settings dialog

A menu selection select Enable Programmer

“Save project before build”

dialog

A menu path File>Save

A tab Click the Power tab

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF,’A’

any valid filename

file [options]

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

© 2008 Microchip Technology Inc. DS51553E-page 3

Page 8

PICkit™ 2 User’s Guide

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user's guide describes how to use PICkit 2 . Other useful documents are listed

below. The following Microchip documents are available and recommended as

supplemental reference resources.

44-Pin Demo Board User’s Guide (DS41296)

Consult this document for instructions on how to use the 44-Pin demo board as a

development tool to emulate and debug firmware on a target board.

Low Pin Count Demo Board User’s Guide (DS51556)

Consult this document for instructions on how to use Microchip Technology’s low pin

count device (8-pin, 14-pin and 20-pin). This document includes a series of tutorials.

MPLAB

Describes how to set up the MPLAB IDE software and use it to create projects and

program devices.

MPLAB

Consult this document for more information pertaining to the installation and features

of the MPLAB Integrated Development Environment (IDE) software. An on-line Help

version is also available.

In-Circuit Serial Programmer™ (ICSP™) Guide (DS30277)

This document contains helpful design guidelines for successful ICSP programming. It

includes application notes on hardware designs and the ICSP programming

specifications.

MPASM™ Assembler, MPLINK™ Object Linker, MPLIB™ Object Librarian User’s

Guide (DS33014)

Describes how to use the Microchip PIC

(MPLINK linker), and librarian (MPLIB librarian).

README for PICkit™ 2 Debug Express

For the latest information on using the PICkit 2 Debug Express, read the “Readme for

PICkit 2.htm” file (an HTML file) in the Readmes subdirectory of the MPLAB IDE

installation directory. The Readme file contains updated information and known issues

that may not be included in this user’s guide.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain updated information and known issues that may not be included in this user’s

guide.

®

IDE Quick Start Guide (DS51281)

®

IDE User’s Guide/Help (DS51519)

®

MCU assembler (MPASM assembler), linker

DS51553E-page 4 © 2008 Microchip Technology Inc.

Page 9

Preface

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C18 and MPLAB C30 C compilers; MPASM™

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB REAL ICE™ and MPLAB ICE 2000 in-circuit emulators.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debuggers. This includes the MPLAB ICD 2 and PICkit™ 2.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB IDE Project Manager, MPLAB Editor and

MPLAB SIM simulator, as well as general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 device programmer and the PICSTART

PICkit 2 development programmers.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

, click on Customer

®

Plus, PICkit 1 and

© 2008 Microchip Technology Inc. DS51553E-page 5

Page 10

PICkit™ 2 User’s Guide

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document. See our web site

for a complete, up-to-date listing of sales offices.

Technical support is available through the web site at: http://support.microchip.com

.

DS51553E-page 6 © 2008 Microchip Technology Inc.

Page 11

PICkit™ 2 USER’S GUIDE

Chapter 1. PICkit 2 Programmer/Debugger Overview

1.1 INTRODUCTION

This chapter introduces the PICkit 2 Development Programmer/Debugger features and

PICkit 2 Programmer application menu functions.

This chapter discusses:

• PICkit

• PICkit 2 Development Programmer/Debugger

• PICkit 2 Programmer Application

1.2 PICkit 2 DEVELOPMENT PROGRAMMER/DEBUGGER CONTENTS

The PICkit 2 Development Programmer/Debugger kit contains the following items:

1. The PICkit 2 Development Programmer/Debugger

2. USB cable

3. PICkit Starter Kit and MPLAB IDE CD-ROMs

Additionally, the PICkit 2 Starter Kit and PICkit 2 Debug Express kit both contain a

demo board with a PIC microcontroller device.

2 Development Programmer/Debugger Contents

1.3 PICkit 2 DEVELOPMENT PROGRAMMER/DEBUGGER

The PICkit 2 Development Programmer/Debugger is a low-cost development programmer. It is capable of programming most of Microchip’s Flash microcontrollers and serial

EEPROM devices. For specific device support, see the README file included on the

PICkit 2 Starter Kit CD-ROM.

Note: The PICkit 2 is intended for development programming. For production

programming, please consider the MPLAB PM3 device programmer or

other third party programmers designed for a production environment.

New device support can be added by updating the programming software. The latest

software is available on Microchip’s web site page for the PICkit 2:

w

ww.microchip.com/pickit2.

The PICkit 2 also may be used to debug selected devices. See Chapter 4. “PICkit 2

Debug Express” for more details.

© 2008 Microchip Technology Inc. DS51553E-page 7

Page 12

PICkit™ 2 User’s Guide

The PICkit 2 unit is shown in Figure 1-1.

FIGURE 1-1: PICkit™ 2 MCU PROGRAMMER/DEBUGGER

1

3

2

4

6

Legend:

1 – Status LEDs 3 – Lanyard Connection 5 – Pin 1 Marker

2 – Push Button 4 – USB Port Connection 6 – Programming Connector

5

1.3.1 USB Port Connection

The USB port connection is a USB mini-B connector. Connect the PICkit 2 to the PC using

the supplied USB cable.

1.3.2 Status LEDs

The Status LEDs indicate the status of the PICkit 2.

1. Power (green) – Power is applied to the PICkit 2 via the USB port.

2. Tar g e t (yellow) – The PICkit 2 is powering the target device.

3. Busy (red) – The PICkit 2 is busy with a function in progress, such as

programming.

1.3.3 Push Button

The push button may be used to initiate the Write Device programming function when

Programmer>Write on PICkit Button

application menu (see item labeled 2 in Figure 1-1.)

The push button may also be used to put the PICkit 2 unit operating system firmware

into Bootloader mode. For more information on this feature, see Chapter 6. “Updating

the PICkit 2 Operating System”.

is checked on the PICkit 2 Programmer

1.3.4 Programming Connector

The programming connector is a 6-pin header (0.100" spacing) that connects to the

target device. See the pinout specification in Figure 1-2.

For more information on how to use the PICkit 2 with In-Circuit Serial Programming

(ICSP), refer to Chapter 3. “Using In-Circuit Serial Programming™ (ICSP™)”.

DS51553E-page 8 © 2008 Microchip Technology Inc.

Page 13

PICkit 2 Programmer/Debugger Overview

FIGURE 1-2: PICkit™ 2 PROGRAMMER CONNECTOR PINOUT

Pin 1 Indicator

Pin Description*

1 = V

1

2

3

4

5

6

* The 6-pin header (0.100" spacing) accepts 0.025" square pins.

Note: The programming connector pin functions are different for programming

Serial EEPROMS and HCS devices. See the ReadMe file (Help>Readme)

included with the PICkit 2 programming software for these pinouts.

PP/MCLR

2 = VDD Target

3 = V

SS (ground)

4 = ICSPDAT/PGD

5 = ICSPCLK/PGC

6 = Auxiliary

1.3.5 Lanyard Connection

To help prevent possible loss of the PICkit 2, a convenient lanyard connection is

available on the programmer.

© 2008 Microchip Technology Inc. DS51553E-page 9

Page 14

PICkit™ 2 User’s Guide

1.4 PICkit 2 PROGRAMMER APPLICATION

The PICkit 2 Programmer application allows you to program all supported devices

listed in the PICkit 2 Readme file. The programming interface appears as shown in

Figure 1-3. Its controls are listed in the following sections.

For more information on how to install and use the PICkit 2 Programmer application,

see Chapter 2. “PICkit 2 Programmer Getting Started”.

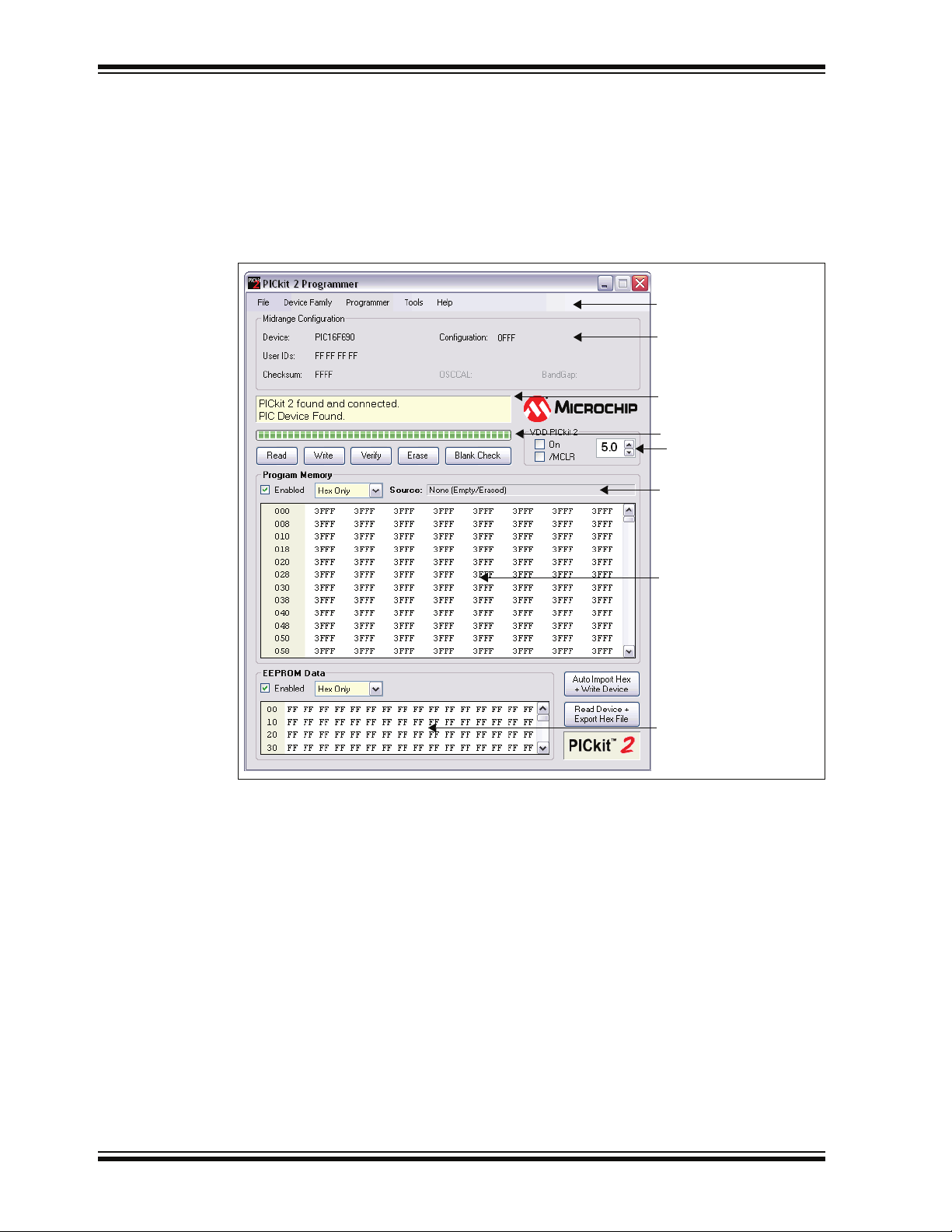

Figure 1-3: PICkit™ 2 Programmer Application

Menu Bar

Device Configuration

Status Window

Progress Bar

Device V

Memory Source

DD

Program Memory

EEPROM Data Memory

DS51553E-page 10 © 2008 Microchip Technology Inc.

Page 15

PICkit 2 Programmer/Debugger Overview

1.4.1 Menu Bar

The menu bar selects various functions of the PICkit 2 Programmer application. A

summary of the functions are:

File

•Import Hex – Import a hex file for programming. The hex file format INHX32 is

supported.

• Export Hex

INHX32 format.

• File History

These recent hex files may be selected to quickly import them. Note that the file

history will initially be blank on a new installation until a hex file is imported.

•Exit

– Exit the program.

Device Family

Select a device family to search for a connected device in that family. Selecting the

device family of the current part will clear all device data.

Some families which cannot be auto-detected (such as Baseline) will bring up a drop

down box from which supported devices may be selected.

– Export a hex file read from a device.The hex file is created in the

– Up to the last four hex files opened are displayed with their filepath.

Programmer

• Read Device – Reads program memory, data EEPROM memory, ID locations and

Configuration bits.

• Write Device

Configuration bits.

•Verify

•Erase

• Blank Check

• Verify on Write

• Hold Device in Reset

• Write on PICkit Button

– Verifies program memory, data EEPROM memory, ID locations and

Configuration bits read from the target MCU against the code stored in the

programming application.

– Performs a Bulk Erase of the target MCU. OSCCAL and band gap values

are preserved on parts with these features.

memory, ID locations and Configuration bits.

programming on a Write (recommended). When unchecked, the device will be

programmed but not verified on a Write.

(asserted). When unchecked, the pin is released (tri-stated), allowing an external

pull-up to bring the device out of Reset.

pressing the PICkit 2 push button.

– Writes program memory, data EEPROM memory, ID locations and

– Performs a Blank Check of program memory, data EEPROM

– When checked, the device will be immediately verified after

– When checked, the MCLR (VPP) pin is held low

– When checked, a Write operation will be initiated by

Tools

• Enable Code Protect – Enables code protection features of the microcontroller on

future Write operations.

Note: To disable code protect, all device memory must be erased and rewritten.

•E

nable Data Protect – Enables data protection feature of microcontrollers with

data EEPROM memory on future Write operations.

Note: To disable data protect, all device memory must be erased and rewritten.

© 2008 Microchip Technology Inc. DS51553E-page 11

Page 16

PICkit™ 2 User’s Guide

•Set OSCCAL – Allows the OSCCAL value to be changed for devices where it is

stored in the last location of Program Memory.

• Targe

•Calibrate

•Use V

•Fast Programming

• Check Communication

• UART Tool…

• Troubleshoot

• Download

t VDD Source

-Auto-Detect – The PICkit 2 will automatically detect whether the target device

has its own power supply or needs to be powered by the programmer on each

operation.

-Force

PICkit 2 – The PICkit 2 will always attempt to supply VDD to the target

device.

- Force Target

– The PICkit 2 will always assume the target has its own power

supply.

VDD & Set Unit ID – Opens a wizard that steps the user through calibrat-

ing the PICkit 2 V

DD supplied voltage so it is more accurate, and optionally

assigning a Unit ID to identify between multiple PICkit 2 devices.

PP First Program Entry – When checked, it allows the PICkit 2 to connect to

and program devices with configurations and code that interferes with the ICSP

signal pins, preventing PICkit 2 from detecting them. Using this feature requires

that the PICkit 2 supplies V

– When checked, the PICkit 2 will attempt to program the

device as fast as possible. When unchecked, the PICkit 2 will slow down ICSP

communication. This may be helpful for targets with loaded ICSP lines.

communication with a target device by attempting to identify the connected device

by its device ID.

- Puts the PICkit 2 in UART Mode and opens a terminal-like

interface for communicating with a PIC MCU device program through the USART

pins. See Chapter 7. “PICkit 2 UART Tool” for more information.

... – Opens a wizard to help with troubleshooting connectivity from

the PICkit 2 to the target device. This is most useful where the programmer is

unable to detect the target device at all.

PICkit 2 Programmer Operating System – Performs a download of the

PICkit 2 operating system (firmware).

DD to the target.

– Verifies USB communication with the PICkit 2 and ICSP

Help

•PICkit2 User’s Guide – Attempts to launch the user’s guide PDF (Adobe® Reader

must be installed).

• 44-Pin Demo Board Guide

– Attempts to launch the 44-Pin Demo Board User’s

Guide PDF (Adobe Reader must be installed).

• LPC Demo Board Guide

– Attempts to launch the Low Pin Count Demo Board

User’s Guide PDF (Adobe Reader must be installed).

• PICkit 2 P

rogrammer on the web – Opens www.microchip.com/pickit2 in the

default web browser.

• Readme

• About

– Opens the PICkit 2 Readme.txt file.

– Opens a dialog with the PICkit 2 Programmer application version, device

file version and firmware version.

1.4.2 Device Configuration

The Device Configuration window displays the device, User ID, Configuration Word

and Checksum. It also displays OSCCAL and Band Gap for parts with those features.

For baseline (12-bit core) devices, serial EEPROM devices, and KeeLoq

devices, you must select the device from the Device drop-down menu.

DS51553E-page 12 © 2008 Microchip Technology Inc.

®

HCS

Page 17

PICkit 2 Programmer/Debugger Overview

All other part family devices will be detected by their device ID and the part name will

be displayed on the Device line.

1.4.3 Status Window

The status window displays text status of the operations in progress. If an operation is

successful, the status window will display a green background. If an operation fails, the

status window will display red. If an operation alerts a caution, the status window will

display yellow.

1.4.4 Progress Bar

The progress bar displays the progress of an operation.

1.4.5 Device VDD

The PICkit 2 VDD may be turned on and off by clicking the checkbox “On”. The voltage

may be set in the box on the right either by typing it directly or using the up/down arrows

to adjust it a tenth of a volt at a time. The maximum and minimum allowed voltages will

vary depending on the target device.

If the “On” checkbox is unchecked, PICkit 2 will automatically turn on the V

voltage during any requested programming operation.

DD at the set

FIGURE 1-4: PICKIT™ 2 SUPPLIED V

DD

If the target device has its own power supply, then the PICkit 2 will display the detected

V

DD voltage in the box on the right, which will be grayed out to prevent being changed.

The checkbox text changes to “check”, and clicking on the checkbox will update the

detected V

checkbox will revert the V

DD voltage value. If Ta rg e t V DD>Auto-Detect is selected, clicking on the

DD mode back to PICkit 2 supplied VDD if a target power

supply is no longer detected.

FIGURE 1-5: TARGET SUPPLIED V

DD

1.4.6 Device MCLR State

The “/MCLR” checkbox shown in Figure 1-4 and Figure 1-5 has the same functionality

as the menu selection Programmer

the target device will be held in Reset. When unchecked, the target circuit is allowed to

pull MCLR

up to VDD to release the device from Reset. This function can be used to

prevent a device from executing code before and after programming.

>Hold Device in Reset. When the box is checked

Note: If the target device allows the MCLR pin to be configured as an input port,

and it is configured as such, PICkit 2 will not be able to hold the device in

Reset.

© 2008 Microchip Technology Inc. DS51553E-page 13

Page 18

PICkit™ 2 User’s Guide

1.4.7 Memory Source

The Source bar displays the source of the currently loaded device data. If read from a

hex file, it will display the hex file name. If read from a device, it will display the part

name. None (Empty/Erased) indicates the buffers are empty, and it will display

Edited once Program Memory or Data EEPROM Memory has been edited in the

window.

1.4.8 Program Memory

Program code can be loaded into the PICkit 2 Programmer application by selecting

File>Import HEX

The origin of the code is displayed in the Source block. The Program Memory window

displays the program code in hexadecimal. The code may be edited in the window.

The checkbox next to the Program Memory window is only available on devices with

EEPROM data memory. If the box is checked, then Program Memory, User IDs, and

Configuration Words are written to, read from, and verified on the device. If the box is

unchecked, then Program Memory, User IDs, and Configuration Words will not be

erased or altered during a Write Device operation, and will not be read or verified. The

checkbox does not affect Erase Device or Blank Check operations. Both memory

window checkboxes may not be cleared at the same time.

For supported serial EEPROM devices, the device contents are displayed in the Program Memory window instead of the Data EEPROM Memory window for easier viewing

in the larger display area.

to import a hex file or by clicking Read to read the device memory.

1.4.9 Data EEPROM Memory

Similar to Program Memory above, data EEPROM code can be loaded into the PICkit 2

Programmer application by selecting File>Import HEX

Read to read the device memory. The origin of the code is displayed in the Source

block. The Data EEPROM Memory window displays the program code in hexadecimal.

The code may be edited in the window.

The check box next to the EEPROM Data window controls whether the EEPROM Data

memory is written, read and verified. If the box is checked, then the device EEPROM

will be overwritten with the window data. If the box is not checked, then the device

EEPROM will not be erased or altered during a Write Device operation. The checkbox

does not affect Erase Device or Blank Check operations. Both memory window

checkboxes may not be cleared at the same time.

to import a hex file or by clicking

DS51553E-page 14 © 2008 Microchip Technology Inc.

Page 19

Chapter 2. PICkit 2 Programmer Getting Started

2.1 INTRODUCTION

This chapter gives instruction on how to get started using the PICkit 2 Development

Programmer/Debugger to program Flash-based PIC microcontroller units.

For information on how to use the PICkit 2 with In-Circuit Serial Programming™

(ICSP™), refer to Chapter 3. “Using In-Circuit Serial Programming™ (ICSP™)”.

For information on how to update the PICkit 2 operating system (firmware), refer to

Chapter 6. “Updating the PICkit 2 Operating System”.

For information on using the PICkit 2 as a debugger in MPLAB IDE, see Chapter

4. “PICkit 2 Debug Express”.

• Installing the PIC

• Installing and Launching the PICkit 2 Programmer Application

• Connecting to the Device

• Selecting Target Power

• Importing a Hex File

• Writing the Program to the Device

• Verifying the Device

• Reading Device Memory

• Code Protecting the Device

• Erasing and Blank Checking the Device

• Automating Write/Read Procedures

PICkit™ 2 USER’S GUIDE

kit 2 Hardware

2.2 INSTALLING THE PICkit 2 HARDWARE

To install the PICkit 2 hardware:

• Plug one end of the USB cable into PICkit 2 USB connector. Plug the other end

into a USB port on your PC.

• Connect the PICkit 2 to a target board via a 6-pin connector. The target board can

be the included demo board or any target equipped with the appropriate 6-pin

connector.

• Do not connect the PICkit 2 to a target board that has its own power supply if it is

not connected to a powered USB port.

• To connect the PICkit 2 to a target with an MPLAB ICD 2 style RJ-11 connector,

the AC164110 RJ-11 to ICSP Adapter kit is required.

When plugging the PICkit 2 into the USB, it is recommended to disconnect it from any

target board first. Similarly, when starting up or rebooting the host PC, ensure it is

disconnected from a target.

For more information about the PICkit 2 hardware, see Section 1.3 “PICkit 2

Development Programmer/Debugger”.

© 2008 Microchip Technology Inc. DS51553E-page 15

Page 20

PICkit™ 2 User’s Guide

2.3 INSTALLING AND LAUNCHING THE PICkit 2 PROGRAMMER APPLICATION

Insert the PICkit 2 Starter Kit CD-ROM into the CD-ROM drive. In a few moments, the

introductory screen should be displayed. Follow the directions on the screen for

installing the PICkit 2 Programmer application.

If the introductory screen does not appear, browse to the CD-ROM directory and open

the PICkit_Starter_Kit_Welcome.htm file.

Once installed, start the PICkit 2 Programmer application by selecting

Start>Programs>Microchip>PICkit 2

Figure 2-1. A listing of its features and functions may be found in Section 1.4 “PICkit 2

Programmer Application”.

FIGURE 2-1: PICkit™ 2 PROGRAMMING APPLICATION

. The programming interface appears as shown in

2.4 CONNECTING TO THE DEVICE

The PICkit 2 is capable of programming a variety of Flash-based Microchip PIC microcontrollers and serial EEPROM devices. Supported devices are listed in the PICkit 2

Readme file on the CD-ROM, which can also be viewed by selecting Help>Readme

When the PICkit 2 Programmer application is first opened, it will attempt to identify the

connected device by the device ID and display it in the Configuration window as shown

in Figure 2-2.

DS51553E-page 16 © 2008 Microchip Technology Inc.

.

Page 21

PICkit 2 Programmer Getting Started

FIGURE 2-2: IDENTIFY DEVICE

If the device on the target is not correctly identified, check the target power

(Section 2.5 “Selecting Target Power”) and device ICSP connections before

attempting to reselect or change the device.

At any time, the device family may be selected to search for connectivity to a device in

that family. To connect to a device once the application is already running, select the

device family by clicking on the Device Family menu as shown in Figure 2-3.

FIGURE 2-3: SELECT DEVICE FAMILY

If the Baseline (12-bit core), K

must select the specific device from the device drop-down box as shown in Figure 2-4.

These devices do not have a device ID and do not support automatic detection.

EELOQ

®

HCS or EEPROMs device family is selected, you

CAUTION

Ensure that the correct Baseline has been selected. These devices do not contain a

device ID to confirm device selection. Choosing the wrong Baseline may cause an

erasing of the OSCCAL value stored in the last memory location.

© 2008 Microchip Technology Inc. DS51553E-page 17

Page 22

PICkit™ 2 User’s Guide

FIGURE 2-4: SELECT BASELINE FLASH DEVICE

2.5 SELECTING TARGET POWER

The PICkit 2 can supply power to the target or the target may be powered externally.

2.5.1 Target Powered from PICkit 2

If you are going to power the target board from the PICkit 2, do not attach a power supply to the target or the PICkit 2 will sense it and not give you the option to use PICkit 2

power. For a target board not connected to an external power supply, you will see the

options displayed in Figure 2-5.

FIGURE 2-5: ENABLE POWER FROM PICkit™ 2

voltage

box

To enable power to the target device, check the V

The default setting is “Off”, i.e., the checkbox is unchecked.

Note: If a target power supply is not detected, the PICkit 2 will always supply

power to the target during programming, regardless of the V

“On” checkbox state.

The voltage supplied to the target may be adjusted before or after enabling power by

adjusting the V

If a short or heavy current load is detected on the programmer-supplied V

will receive an error and V

DD PICkit 2 voltage box (Figure 2-5).

DD will be automatically disabled. Refer to Figure 2-6.

DD PICkit 2 “On” checkbox as shown.

DD PICkit 2

DD, then you

CAUTION

The USB port current limit is set to 100 mA. If the target plus the PICkit 2 exceed this

current limit, the USB port may turn off. The target may be powered externally if

more power is required.

DS51553E-page 18 © 2008 Microchip Technology Inc.

Page 23

PICkit 2 Programmer Getting Started

FIGURE 2-6: VDD ERROR

To avoid heavy current load errors, it is recommended to keep the target current

consumption below 25 mA. Large V

slow down the V

DD risetime. The allowed VDD rise time is 500 μs or less.

2.5.2 Target Powered from External Supply

The target device may also be powered externally. By default, the PICkit 2 will automatically detect an externally powered board. The heading “V

to “V

DD Target”, the “On” checkbox will be replaced by a checkbox named “Check”, and

the detected V

Clicking the “Check” checkbox will update the detected V

voltage box. If no V

will return to supplying V

Note: The maximum external VDD that may be used with the PICkit 2 is 5.0 Volts.

DD voltage is displayed in the grayed out voltage box as in Figure 2-7.

DD voltage is detected when the checkbox is clicked, then PICkit 2

DD power to the target device.

The minimum external V

DD capacitances should also be avoided as they

DD PICkit 2” will be changed

DD voltage displayed in the

DD that may be used with the PICkit 2 is 2.5 Volts.

FIGURE 2-7: EXTERNALLY POWERED TARGET

2.6 IMPORTING A HEX FILE

To import a compiled program (hex file) to be programmed into the target device, select

File>Import HEX

FIGURE 2-8: IMPORT HEX FILE

Example source code and hex files may be found under the Install\Lessons\

directory for the appropriate kit demo board on the PICkit 2 Starter Kit CD-ROM. The

hex file Reversible.hex from the folder 07 Reversible will be used.

as shown in Figure 2-8.

© 2008 Microchip Technology Inc. DS51553E-page 19

Page 24

PICkit™ 2 User’s Guide

Browse for the hex file and click Open. The code is displayed in the Program Memory

and EEPROM Data windows. The name of the hex file is displayed in the Source block

under Program Memory.

Note: The example lesson code is meant to be installed to the local hard drive

from the CD-ROM using the Setup files in the CD-ROM directory

Install/Lessons/. The lessons are covered in the user’s guide for the

included kit Demo Board, and this guide should be read before using the

lesson projects and source code.

FIGURE 2-9: EXAMPLE HEX FILE IMPORTED

The PICkit 2 Programmer application will warn you if the hex file does not contain any

Configuration Words. You can be sure these are included in the hex file by selecting

File>Export

MPLAB IDE usage, see Chapter 4. “PICkit 2 Debug Express”.)

You will also be warned that the hex file is larger than the selected device if the hex file

contains memory locations that do not exist in the current device. Any data for

non-existent locations will not be imported.

in MPLAB IDE to save a hex file including configuration memory. (For

2.7 WRITING THE PROGRAM TO THE DEVICE

After a device family has been selected and a hex file has been imported, the target

device can be programmed by clicking Write (Figure 2-10). The device will be erased

and programmed with the hex code previously imported.

DS51553E-page 20 © 2008 Microchip Technology Inc.

Page 25

PICkit 2 Programmer Getting Started

When erasing the device during programming, a Bulk Erase method is used. All Baseline, Mid-Range, and many dsPIC30F and PIC18F devices require a minimum V

the Bulk Erase. Some of these devices support a low voltage row erase method that

can be used at lower voltages, but this method takes longer to erase the device. See

the Readme file under Help>Readme

does not support row erasing, a dialog will pop up to warn you if the device V

the minimum required for a Bulk Erase.

Note: If any Code Protect, Data Protect, Write Protect, or Read Protect configu-

ration bits are currently set in the device, the Bulk Erase method must be

used prior to programming. The lower voltage row erase procedure will not

succeed.

FIGURE 2-10: BUTTONS – WRITE

The status of the Write operation is displayed in the status bar located under the Device

Configuration window. If the write is successful, the status bar turns green and displays

“Programming Successful”, as shown in Figure 2-11.

for devices that support this feature. If a device

DD for

DD is below

FIGURE 2-11: WRITE SUCCESSFUL STATUS

If the write fails, the status bar turns red and displays “Programming Failed”, as shown

in Figure 2-12. This error indicates that the data was corrupted during the programming

sequence. If this error is displayed, try writing the program to the device again. If the

error continues, see Chapter 5. “Troubleshooting” for assistance.

FIGURE 2-12: WRITE ERROR STATUS

Other write issues may be displayed as warnings and will turn the status bar yellow as

in Figure 2-13. In this case, the PICkit 2 and demo board had become disconnected.

© 2008 Microchip Technology Inc. DS51553E-page 21

Page 26

PICkit™ 2 User’s Guide

FIGURE 2-13: WRITE WARNING STATUS

2.7.1 Writing to Specific Memory Regions

If a device has EEPROM data memory, the “Enabled” checkbox next to Program

Memory and EEPROM Data will become available.

The checkboxes select which memory regions’ programming operations will be

affected. Refer to Table 2-1 for a description of how programming operations are

affected by the checkboxes. Erase and Blank Check always operate on all memory

regions.

TABLE 2-1: MEMORY REGION SELECTION

Program

Memory Enabled

Checked Checked All Memory Regions All Memory Regions

Checked — Program Memory

— Checked EEPROM only All Memory Regions

—— Not Allowed

EEPROM Data

Enabled

Write/Read/Verify Erase/Blank Check

All Memory Regions

User IDS

Configuration

During a Write, regions that are unchecked will remain unchanged in the device.

For example, if Program Memory is unchecked while EEPROM Data is checked, then

a Write operation will only write EEPROM Data, while Program Memory, User IDs and

Configuration Words in the device will remain unchanged.

If Program Memory is checked while EEPROM Data is unchecked, then a Write

operation will program Program Memory, User IDs and Configuration Words, while

EEPROM Data in the device will remain unchanged.

Due to programming constraints in some devices, the PICkit 2 Programmer application

may read and re-write EEPROM data memory during a Write to preserve it.

It is not allowed to have both memory regions unchecked.

2.7.2 Automatic File Reload

Prior to each Write, the imported hex file time stamp is compared to the version on the

disk. If the version on the disk is newer, it is reloaded. This occurs only when a hex file

has been read from the disk.

This feature ensures that the latest version built will be written to the device. It may be

used with the Tools>Program on PICkit Button

IDE build without switching to the PICkit 2 Programmer software simply by pressing the

PICkit 2 unit push button.

feature to program the latest MPLAB

DS51553E-page 22 © 2008 Microchip Technology Inc.

Page 27

PICkit 2 Programmer Getting Started

2.8 VERIFYING THE DEVICE

The Verify function verifies that the program in device memory matches the hex file

imported into the PICkit 2 Programmer application. It compares all areas of memory

including program memory, data EEPROM memory, ID and Configuration bits.

To verify the code, import the hex file and click Verify (Figure 2-14).

Note that a Write operation is automatically verified if Programmer>Verify on Write

checked.

FIGURE 2-14: BUTTONS - VERIFY

If the code is the same, the status bar turns green and displays “Device Verified”. If a

discrepancy is found, the status bar turns red and displays where the error is located:

“Error in Program Memory, Data EEPROM Memory, or Configuration Bits”.

Table 2-1 illustrates how Verify is affected by the memory region checkboxes.

2.9 READING DEVICE MEMORY

To view the code written to the device, click Read (Figure 2-15).

is

FIGURE 2-15: BUTTONS - READ

The code is displayed in the Program Memory and EEPROM Data windows for your

review. If all zeros are displayed, it is possible that the device is code-protected (See

Section 2.10 “Code Protecting the Device”.)

Table 2-1 illustrates how Read is affected by the memory region checkboxes.

2.10 CODE PROTECTING THE DEVICE

The Code and Data Protect functions enable the read protection features of the device.

To protect the program memory code, complete the following steps:

1. Import hex file.

2. Select Tools>Enable Code Protect

3. Click Write.

Devices that have EEPROM data memory may protect it by selecting Tools>Enable

Data Protect.

as shown in Figure 2-16.

© 2008 Microchip Technology Inc. DS51553E-page 23

Page 28

PICkit™ 2 User’s Guide

FIGURE 2-16: ENABLE CODE PROTECT

Note: If the device is read after it has been protected, the protected memory

regions will display all zeros.

Simply unchecking “Enable Code Protect” will not allow you to read the

region. You must erase and reprogram all device memory before you can

read that memory region again.

2.11 ERASING AND BLANK CHECKING THE DEVICE

The Erase function erases the program memory, data EEPROM memory, ID and

Configuration bits, regardless of the state of the Program Memory and EEPROM Data

“Enabled” checkboxes. However, this function is not normally needed since the Write

function performs an erase operation prior to programming the device.

To erase the device, click Erase (Figure 2-17).

Note: The PICkit 2 Erase function always uses the Bulk Erase method that

requires a minimum V

Write function. You will be warned if V

connected device.

FIGURE 2-17: BUTTONS – ERASE

The Blank Check function will read the entire device to determine if Program Memory,

EEPROM Data memory, User IDs and Configuration bits are erased. All memory

regions will be examined, regardless of the state of the Program Memory and EEPROM

Data “Enabled” checkboxes.

To Blank Check the device, click Blank Check (Figure 2-17).

DD, even on devices that support row erasing for the

DD is below the minimum for the

2.12 AUTOMATING WRITE/READ PROCEDURES

The PICkit 2 Programmer application has two buttons for automating multiple

functions.

DS51553E-page 24 © 2008 Microchip Technology Inc.

Page 29

PICkit 2 Programmer Getting Started

FIGURE 2-18: AUTOMATING BUTTONS

2.12.1 Auto Import Hex + Write Device Button

This features allows the PICkit 2 Programmer application to automatically import a hex

file and write it to a connected device when the hex file is updated; for example, on a

new firmware build.

To use this feature, click Auto Import Hex + Write Device. This will bring up an Import

Hex file dialog defaulting to the first hex file in the file history under the File menu. After

selecting a file, it will be written to the device. The PICkit 2 Programmer application will

now monitor the selected hex file for updates. When the file has been updated (has a

newer time stamp), the application will automatically re-import the hex file and write to

the target device.

While this feature is enabled, other programming operations are disabled. The Auto

Import Hex + Write Device button will remain depressed while this feature is active.

To stop using this feature, click Auto Import Hex + Write Device again.

If an error is encountered during hex file importing or device programming, the

application will automatically exit this feature mode.

2.12.2 Read Device + Export Hex File Button

When clicked, this button will read the target device and open an Export Hex File

dialog.

2.13 PICKIT 2 CALIBRATION AND UNIT ID

The PICkit 2 VDD may be calibrated to account for variations in the unit hardware and

the USB voltage of the port it is connected to. A Unit ID string may also be assigned to

a PICkit 2 unit to provide unique identification.

2.13.1 Calibrating the PICkit 2 VDD

Calibration allows greater accuracy both in the VDD voltage supplied to the target from

PICkit 2, and the voltage detected on a powered target and reported in the software.

The calibration is stored in the PICkit 2 unit nonvolatile memory, so the unit will remain

calibrated even when used from within MPLAB IDE.

It is important to note, however, that as the calibration is dependent on the USB voltage,

moving the PICkit 2 unit to a different USB port, to or from a USB hub or to another

computer port may invalidate the calibration.

To calibrate the PICkit 2 unit, a multi-meter or other means of accurately measuring

voltages is required. Disconnect the PICkit 2 unit from the target and select

Too ls >C al

in the wizard to complete the calibration process.

ibrate Vdd & Set Unit ID… to bring up the calibration wizard. Follow the steps

Note: Even when calibrated, the PICkit 2 VDD voltage is limited by the available

USB port voltage. PICkit 2 is unable to provide a V

a Schottky diode drop below the USB port voltage. This voltage can be as

low as 4.2 Volts, especially in laptop computer ports.

© 2008 Microchip Technology Inc. DS51553E-page 25

DD voltage greater than

Page 30

PICkit™ 2 User’s Guide

2.13.2 The PICkit 2 Unit ID

During the calibration procedure, the PICkit 2 may optionally be assigned a Unit ID

string to identify it uniquely.

Once assigned, the PICkit 2 Unit ID will display in the PICkit 2 Programmer software

title bar, and in the Status Window when first connecting to the PICkit 2. An example is

shown in Figure 2-19 where the Unit ID is “Lab B-1”.

The Unit ID is also displayed in the MPLAB IDE Output window when first selecting

PICkit 2 as a Programmer or Debugger.

FIGURE 2-19: UNIT ID

DS51553E-page 26 © 2008 Microchip Technology Inc.

Page 31

PICkit™ 2 USER’S GUIDE

Chapter 3. Using In-Circuit Serial Programming™ (ICSP™)

3.1 INTRODUCTION

The PICkit 2 Development Programmer/Debugger can program microcontroller

devices that are installed in an application circuit using In-Circuit Serial Programming

(ICSP). ICSP requires five signals:

•V

PP – Programming Voltage; when applied, the device goes into Programming

mode.

• ICSPCLK or PGC – Programming Clock; a unidirectional synchronous serial clock

line from the programmer to the target.

• ICSPDAT or PGD – Programming Data; a bidirectional synchronous serial data line.

•V

DD – Power Supply positive voltage.

SS – Power Supply ground reference.

•V

However, the application circuit must be designed to allow all the programming signals

to be connected to the device without distorting the programming signals. Figure 3-1

shows a typical circuit as a starting point when designing an application circuit for ICSP.

For successful ICSP programming, the precautions in the following sections need to be

followed.

Note: For details on how a specific device is programmed, refer to the device

programming specification available from the Microchip web site at

www.microchip.com

.

FIGURE 3-1: TYPICAL ICSP™ APPLICATION CIRCUIT

Isolation Circuitry:

Resistor or Schottky-type diode

+5V

+5V

10k*

470 Ohm*

0.1 μF*

OR

1

2

3

4

VDD

RA5

RA4

RA3/MCLR

RA0/ICSPDAT

RA1/ICSPCLK

/VPP

Target Microcontroller

Device

SS

V

RA2

8

7

6

5

PICkit™ 2

Programming

Header

1

VPP/MCLR

2

VDD

3

VSS

ICSPDAT/PGD

4

ICSPCLK/PGC

5

AUX

6

To Application

Circuit

* Typical Values

© 2008 Microchip Technology Inc. DS51553E-page 27

Page 32

PICkit™ 2 User’s Guide

3.2 ISOLATE VPP/MCLR/PORT PIN

When VPP voltage is applied, the application circuit needs to take into consideration

that the typical V

If the VPP pin is used as a MCLR pin

The application circuit is typically connected to a pull up resistor/capacitor circuit, as

recommended in the device data sheet. Care must be taken so that the V

slew rate is not slowed down and exceeds the rise time in the programming

specification (typically 1 μs).

If a supervisory circuit or a push button is interfaced to the MCLR

recommended that they be isolated from the V

diode or limiting resistor as shown in Figure 3-1. For more information about using

supervisory circuits with ICSP, see Application Note AN820 “System Supervisors in

ICSP™ Architectures” (DS00820).

If the VPP pin is used as an I/O port pin

The application circuit that connects to the I/O pin may not be able to handle the +12V

voltage. It is recommended to use a Schottky-type diode or limiting resistor as shown

in Figure 3-1 to isolate the circuitry.

PP voltage is +12V. This may be an issue in the following situations:

PP voltage

pin, it is

PP voltage by using a Schottky-type

3.3 ISOLATE ICSPCLK OR PGC AND ICSPDAT OR PGD PINS

The ICSPCLK or PGC and ICSPDAT or PGD pins need to be isolated from the

application circuit to prevent the programming signals from being affected by the

application circuitry. ICSPCLK or PGC is a unidirection synchronous serial

programming clock line from the programmer to the target. ICSPDAT or PGD is a

bidirectional synchronous serial programming data line.

If the design permits, dedicate these pins for ICSP. However, if the application circuit

requires that these pins be used in the application circuit, design the circuitry in a

manner that does not alter the signal level and slew rates. Isolation circuitry will vary

according to the application. Figure 3-1 shows one possibility by using series resistors

to isolate the ICSP signals from the application circuit.

DS51553E-page 28 © 2008 Microchip Technology Inc.

Page 33

3.4 VDD

Using In-Circuit Serial Programming™ (ICSP™)

During ICSP programming, the device needs to be powered in accordance with the

device specification. Typically, the device supply voltage is connected to the application

circuit supply voltage. The application circuit can be powered by the PICkit 2 or externally. There are a few precautions that need to be observed in the situations covered

in the following three sections.

3.4.1 The application circuit is powered by the PICkit 2

The PICkit 2 supply voltage may set between the maximum and minimum voltages

allowed by the device programming specification, unless the minimum is below +2.5V.

Be sure to set the voltage box to the appropriate voltage before programming the

device or turning on V

The USB port current limit is set to 100 mA. If the target plus the programmer

exceeds this current limit, the USB port may turn off. The target may be powered

externally if more power is required.

Note: Current draw should be limited to 25 mA when using the programmer to

power the application circuit. Ensure that the application circuit does not

slow the V

DD.

CAUTION

DD rise time to longer than 500 μs.

3.4.2 The application circuit is powered externally

The PICkit 2 may be used with application circuits powered externally between +5.0V

and +2.5V.

3.4.3 Bulk Erase is used

Some devices use a Bulk Erase function to erase program memory, data EEPROM

memory, ID locations, and Configuration bits. Typically, the Bulk Erase function

requires a supply voltage (V

specification for device specific requirements).

This voltage range can be a problem if the application circuit is designed to operate at

a different supply voltage range. In order to Bulk Erase the device, the application

circuit needs to take into consideration the Bulk Erase voltage requirement while

protecting any voltage sensitive circuitry.

If the application circuit V

will warn the user before attempting to erase the device.

DD) of 4.5 to 5.5 Volts (refer to the device programming

DD is below the minimum required for the Bulk Erase, a dialog

© 2008 Microchip Technology Inc. DS51553E-page 29

Page 34

PICkit™ 2 User’s Guide

3.5 VSS

The power supply ground reference, VSS, must be at the same potential as the

application circuit.

3.6 CABLE LENGTHS

Minimize the distance the ICSP signals must travel by placing the ICSP connector as

close to the application circuit device as possible. Minimize any cable length between

the PICkit 2 and application circuit device. The goal is to keep the ICSP signals within

the level and slew rate specifications for successful programming.

3.7 SERIAL EEPROM AND KEELOQ HCS DEVICES

The programming signals and connections for these devices are different than those

for microcontrollers as described in Section 3.1 “Introduction” and Figure 3-1. See

the PICkit 2 Programmer Readme file, Help>Readme

connectivity for these devices.

Additionally, these devices are not intended to be programmed in-circuit. Attempting to

program serial EEPROM devices while in-circuit may fail due to conflicts with other

devices on the serial bus.

, for programming signal

DS51553E-page 30 © 2008 Microchip Technology Inc.

Page 35

Chapter 4. PICkit 2 Debug Express

4.1 INTRODUCTION

PICkit™ 2 USER’S GUIDE

In addition to the PICkit 2 Programmer application, the PICkit 2 Development

Programmer/Debugger may be used with MPLAB

ment environment available on Microchip’s website. MPLAB IDE allows the PICkit 2 to

be used as an in-circuit debugger as well as a programmer (for selected devices only).

In-circuit debugging allows you to run, examine and modify your program while the

device is embedded in your target hardware. This greatly assists you in debugging your

firmware and hardware together.

Special PICkit 2 Debug Express software interacts with the MPLAB IDE application to

run, stop and single-step through programs. One or more breakpoints can be set and

the processor can be reset. Once the processor is stopped, the register’s contents can

be examined and modified.

For more information on how to use MPLAB IDE, reference the following

documentation:

• MPLAB

• MPLAB

• MPLAB

®

IDE User’s Guide (DS51519)

®

IDE Quick Start Guide (DS51281)

®

IDE On-line Help

4.2 PICkit 2 DEBUG EXPRESS KIT CONTENTS

The PICkit 2 Debug Express kit (DV164121) contains the following items:

1. The PICkit 2 Development Programmer/Debugger

2. USB cable

3. 44-Pin Demo Board with device*

4. PICkit 2 Starter Kit and MPLAB IDE CD-ROMs

* The following boards may also be used to debug:

- To use the Low Pin Count Demo Board from the Starter Kit, the AC162061 ICD

Header and AC164110 adapter will be required.

- To use the Explorer 16 board, be aware that the connector labeled “PICKIT2”

incorrectly shows the location of PICkit 2 pin 1 on the silkscreen. That is, pin 1 is

actually pin 6.

®

IDE, the free integrated develop-

© 2008 Microchip Technology Inc. DS51553E-page 31

Page 36

PICkit™ 2 User’s Guide

4.3 INSTALLING THE HARDWARE AND SOFTWARE

Install the PICkit 2 hardware as specified in Section 2.2 “Installing the PICkit 2

Hardware”.

Note: Debug Express requires 4.7k Ohm pull down resistors on ICSPCLK and

ICSPDAT. Newer PICkit 2 units have a Red button and have the pull downs

internally. Older PICkit 2 units have a Black button and require that the pull

downs be added on the target board.

Obtain a copy of the MPLAB IDE software application from the Microchip website

CD-ROM enclosed with the kit and install it as directed.

Note: Debug Express requires MPLAB IDE version 7.50 or later.

4.4 USING PICKIT 2 DEBUG EXPRESS

4.4.1 Determining Device Support

For a list of current devices supported by PICkit 2 Debug Express, see the “Readme

for PICkit 2.htm” file in the “Readmes” subdirectory of the MPLAB IDE installation

directory.

When selecting a device as discussed in Section 4.5 “Debug Express Tutorial”, the

“Select Device” dialog shown in Figure 4-11 shows the level of support for the selected

device by Debug Express. In the “Debuggers” section of the dialog, the color of the

circle next to “PICkit 2” indicates the support level:

Red – The device is not currently supported by PICkit 2 Debug Express

Yellow – The device has beta support in PICkit 2 Debug Express

Green – The device has full support in PICkit 2 Debug Express

Beta support indicates that the device is supported, but has not yet undergone internal

certification testing by Microchip.

4.4.2 Reserved Resources

or

Due to the built-in in-circuit debugging capability of ICD devices and the ICSP function

offered by the debugger, the PICkit 2 Debug Express uses some on-chip resources

when debugging. It also uses program memory and file register locations in the target

device during debugging. These locations are not available for use by user code. In

MPLAB IDE, registers marked with an “R” in register displays represent reserved

registers.

For information on device resources that are needed for in-circuit debugging, please

refer to the MPLAB ICD 2 Help, found in the MPLAB IDE under Help>Topics

device reserved resource information found under “Resources Used By MPLAB ICD 2”

is the same for the PICkit 2 Debug Express.

. The

4.4.3 Using an ICD Header

All Baseline and some Mid-Range PIC microcontrollers require a special –ICD device

mounted on a debug header circuit board to enable the debugging feature. For a list of

these devices and the required ICD header board part number, please see the “Header

Board Specification” (DS51292). The Header Board Specification is included on the

PICkit 2 CD-ROM, and is available online at www.microchip.com.

DS51553E-page 32 © 2008 Microchip Technology Inc.

Page 37

PICkit 2 Debug Express

Each ICD header board comes with the necessary –ICD device, and is used on the target board instead of the production microcontroller. However, most header boards have

an RJ-11 debug connector which requires the AC164110 RJ-11 to ICSP adapter kit to

connect it to PICkit 2. Figure 4-1 illustrates using the AC162061 ICD Header for the

PIC16F690 with the AC164110 adapter kit and Low Pin Count Demo Board.

FIGURE 4-1: USING THE PIC16F690 ICD HEADER BOARD

AC164110 ICSP™ to RJ-11 Adapter ICD Header

This diagram shows how to connect the PICkit™ 2 to an ICD

header with the ICSP to RJ-11 Adapter. The AC162061 ICD

header for the PIC16F690 is shown, plugging into the

DM164120-1 Low Pin Count Demo Board.

Debug Target

Board

Many Mid-Range PIC microcontrollers and all PIC18 and 16-bit PIC microcontroller

devices do not require an ICD header and can be debugged directly through the ICSP

programming connections. This is true of the PIC16F887 included on the 44-Pin Demo

Board, which can be debugged by simply connecting the demo board to the PICkit 2

as shown in Figure 4-2.

FIGURE 4-2: CONNECTING THE DEMO BOARD TO THE PICKIT™ 2

PIC® microcontrollers that don’t require an ICD

Header may be debugged directly over the In-Circuit

Serial-Programming™ (ICSP™) connections.

The DM164120-2 44-Pin Demo Board with

PIC16F887 is shown.

© 2008 Microchip Technology Inc. DS51553E-page 33

Debug Target Board

Page 38

PICkit™ 2 User’s Guide

4.4.4 Configuration Bits and Debug Express

PIC microcontroller devices that do not require an ICD Header and may be debugged

directly contain a DEBUG

the debug mode on the PIC microcontroller.

This bit is automatically set appropriately by the MPLAB IDE when using PICkit 2

Debug Express and should not be specified in source code configuration settings.

The DEBUG configuration bit value should not be specified in source code Configuration settings under normal conditions. Doing so may cause the bit to be asserted when

programming a device outside the debugger. This will cause the device to function

improperly or not all at in the application circuit.

Many 16-bit PIC microcontroller devices such as PIC24 and dsPIC33 families have

multiple ICSP programming and debugging port pins labeled PGC1/EMUC1 and

PGD1/EMUD1, PGC2/EMUC2 and PGD2/EMUD2, etc. While any ICSP port may be

used for programming, only one port is active at a time for debugging. The active EMU

port is set in the device Configuration bits. If the active port setting does not match the

EMU port to which the PICkit 2 is connected, the device will be unable to enter debug

mode. In the MPLAB IDE Configuration Bits dialog, these bits are usually referred to as

the “Comm Channel Select” bits.

bit in the Configuration Word(s) that enables and disables

CAUTION

4.4.5 Debug Express Breakpoints

The number of active breakpoints supported by PICkit 2 Debug Express depends on

the target device. Most Baseline and Mid-Range devices support 1 breakpoint, with

more breakpoints supported in some PIC18 and 16-bit devices.

The number of active breakpoints available for the current device in MPLAB IDE can

be seen by selecting Debugger>Breakpoints…

showing any currently set breakpoints in Program Memory. The “Active Breakpoint

Limit:” text box shows how many total breakpoints are available for the current device.

The “Available Breakpoints:” text box shows how many breakpoints are currently

unused.

FIGURE 4-3: BREAKPOINTS DIALOG FOR PIC16F887

. This will open a dialog (Figure 4-3)

Some PIC18 and 16-bit devices also support advanced breakpoints. Advanced breakpoints allow breakpoints to be set in File Register memory, and will halt execution when

a specific File Register is read from or written to. This breakpoint may also be set so it

will only halt when a specific value is read from or written to a register. Additionally, a

DS51553E-page 34 © 2008 Microchip Technology Inc.

Page 39

PICkit 2 Debug Express

“Pass Count” may be set on any breakpoint type. The pass count is the number of times

the breakpoint condition is met before it halts execution. For example, setting a pass

count of “2” on a Program Memory breakpoint means that instruction will execute twice

without halting execution, and the third time the instruction is executed the breakpoint

will halt execution. The default pass count for all breakpoints is “0”, which means

execution will halt the first time the breakpoint is encountered.

If advanced breakpoints are supported by the current device, the MPLAB IDE menu

option Debugger>Advanced Breakpoints…

breakpoint dialog. If the current device does not support advanced breakpoints, this

menu option will be grayed out or absent. Select the breakpoint to edit with the “Break

Point #” combo box.

FIGURE 4-4: ADVANCED BREAKPOINTS DIALOG

will be available to open the advanced

Note: The Advanced Breakpoint dialog will display any breakpoints already set in

Program Memory. However, the dialog may not be used to set or clear

breakpoints in Program Memory or to edit the address of an existing Program Memory breakpoint. Only the Pass Count value for Program Memory

breakpoints may be edited in the Advanced Breakpoint dialog. To edit, set,

or clear Program Memory breakpoints, use the MPLAB IDE editor or the

Debugger>Breakpoints…

menu dialog.

4.4.6 Breakpoint Skidding

The in-circuit debug implementation on PIC microcontrollers will halt execution on the

instruction after the breakpoint instruction. This means the breakpoint instruction will

have executed when the debugger halts. This is referred to as “breakpoint skidding”.

As a result, there are some breakpoint behaviors to be aware of. When a breakpoint is

set on a GOTO, CALL, or RETURN instruction, the debugger will halt at the destination

instruction, as the program branch instruction with the breakpoint will have executed.

Also, when using the debugger Step Over function, a breakpoint will be set on the

instruction after the CALL instruction that the debugger is “stepping over” if there is an

available breakpoint. If the CALL instruction is followed immediately by another CALL

instruction, this will result in the debugger halting at the destination of the second CALL

instruction. To prevent this, a NOP may be placed between the CALL instructions.

Note that 16-bit devices will halt two instructions after the breakpoint instruction.

© 2008 Microchip Technology Inc. DS51553E-page 35

Page 40

PICkit™ 2 User’s Guide

4.4.7 Linker Scripts

If your project uses a linker script, special ICD linker script files must be used when

debugging that reserve the resources used by the PICkit 2 Debug Express. Each

device has a separate debug linker file, which contains an “i” at the end of the device

name.

For example:

16F877i.lkr – In-Circuit Debug linker file for the PIC16F877 device

18F4520i.lkr – In-Circuit Debug linker file for the PIC18F4520 device

When debugging with PICkit 2 Debug Express, the ICD linker file should be used

instead of the standard linker file.

4.5 DEBUG EXPRESS TUTORIAL

This tutorial is intended to be used with the PICkit 2 44-Pin Demo Board and

PIC16F887 microcontroller. This demo board comes with the PICkit 2 Debug Express