Page 1

PICkit™ 1 Flash

Starter Kit

User’s Guide

2004 Microchip Technology Inc. DS40051D

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

No representation or warranty is given and no liability is

assumed by Microchip Technology Incorporated with respect

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such

use or otherwise. Use of Microchip’s products as critical

components in life support systems is not authorized except

with express written approval by Microchip. No licenses are

conveyed, implicitly or otherwise, under any intellectual

property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, MXDEV, MXLAB, PICMASTER, SEEVAL,

SmartSensor and The Embedded Control Solutions Company

are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Migratable Memory, MPASM,

MPLIB, MPLINK, MPSIM, PICkit, PICDEM, PICDEM.net,

PICLAB, PICtail, PowerCal, PowerInfo, PowerMate,

PowerTool, rfLAB, rfPICDEM, Select Mode, Smart Serial,

SmartTel and Total Endurance are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2004, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEEL

®

OQ

code hopping

DS40051D-page ii 2004 Microchip Technology Inc.

Page 3

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................1

Introduction............................................................................................................ 1

Highlights............................................................................................................... 1

About This Guide................................................................................................... 1

Warranty Registration............................................................................................ 3

Recommended Reading........................................................................................ 3

Troubleshooting..................................................................................................... 3

Microchip On-Line Support.................................................................................... 3

Customer Change Notification Service ................................................................. 4

Customer Support ................................................................................................. 4

Chapter 1. PICkit™1 Flash Starter Kit

1.1 Introduction ..................................................................................................... 5

1.2 Highlights ........................................................................................................ 5

1.3 Running the PICkit 1 Flash Starter Kit Default Demonstration ....................... 5

1.4 PICkit 1 Classic and Baseline Flash Programming Software ......................... 6

1.5 New To Programming PICmicro

®

MCUs ........................................................ 6

Chapter 2. PICkit™1 Classic Software

2.1 Introduction ..................................................................................................... 7

2.2 Using PICkit 1 Classic Programming Software .............................................. 7

Chapter 3. PICkit™1 Baseline Flash Software

3.1 Introduction ................................................................................................... 13

3.2 Using PICkit 1 Baseline Flash Programming Software ............................... 13

Chapter 4. PICkit™1 and MPLAB® IDE

4.1 Introduction ................................................................................................... 19

4.2 Highlights ...................................................................................................... 19

4.3 Using the PIC12F675 Programming Project Source Code .......................... 19

4.4 Project Management in MPLAB IDE ............................................................ 20

Chapter 5. Troubleshooting

5.1 Introduction ................................................................................................... 23

5.2 FAQs ............................................................................................................ 23

Appendix A. Hardware Description

A.1 Introduction .................................................................................................. 27

A.2 Highlights ..................................................................................................... 27

A.3 In-Circuit Serial Programming™ (ICSP™) ................................................... 27

A.4 Programming Hardware ............................................................................... 27

A.5 USB Communications Protocol .................................................................... 29

A.6 Schematic Diagrams .................................................................................... 31

2004 Microchip Technology Inc. DS40051D-page iii

Page 4

PICkit™ 1 Flash Starter Kit User’s Guide

Appendix B. Baseline Flash Microcontroller Programming Schematic Diagram

B.1 Schematic Diagram ...................................................................................... 37

Appendix C. PIC12F675 Programming Projects

C.1 Introduction .................................................................................................. 39

C.2 Highlights ..................................................................................................... 39

C.3 Lesson 1 – Switch Debouncing ................................................................... 39

C.4 Lesson 2 – Introduction to State Machines .................................................. 46

C.5 Lesson 3 – Interrupts ................................................................................... 53

C.6 Lesson 4 – Analog-to-Digital Converters and Comparators ........................ 57

C.7 Lesson 5 – Program Memory Look-up Routines ......................................... 60

C.8 Lesson 6 – Data EE Look-up Routines ........................................................ 63

C.9 Lesson 7 – Frequency Counting with Timer1 Gate ..................................... 66

Worldwide Sales and Service .....................................................................................72

DS40051D-page iv 2004 Microchip Technology Inc.

Page 5

INTRODUCTION

HIGHLIGHTS

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

Preface

This chapter contains general information about this user’s guide and customer support

that will be useful prior to using the PICkit™ 1 Flash Starter Kit.

Items discussed in this chapter are:

• About this Guide

• Warranty Registration

• Recommended Reading

• Troubleshooting

• Microchip On-Line Support

• Customer Change Notification Service

• Customer Support

ABOUT THIS GUIDE

This document describes how to use the PICkit™ 1 Flash Starter Kit. The manual

layout is as follows:

• Chapter 1: PICkit

Starter Kit and instructions on how to use it.

• Chapter 2: PICkit

how to use the PICkit 1 Classic programming software to program 8 and 14-pin

Mid-range Flash Microcontroller (MCU) Family devices.

• Chapter 3: PICkit

tions on how to use the PICkit 1 Baseline Flash programming software to program

8 and 14-pin Baseline (12-bit Core) Flash Microcontroller (MCU) Family devices.

• Chapter 4: PICkit

project in MPLAB IDE and program a device with MPLAB IDE.

• Chapter 5: Troubleshooting – This chapter describes common problems and

possible solutions for solving problems with the PICkit™ 1 Flash Starter Kit.

• Appendix A: PICkit

PICkit 1 hardware description and schematic diagrams.

• Appendix B: Baseline Flash Microcontroller Programmer Hardware

Description – This appendix contains the Baseline Flash Microcontroller

Programmer hardware description and schematic diagram.

• Appendix C: PIC12F675 Programming Projects – This appendix contains

introductory lessons for persons new to PICmicro

• Worldwide Sales and Service – A listing of Microchip sales and service locations

and telephone numbers worldwide.

™

1 Flash Starter Kit – An overview of the PICkit™ 1 Flash

™

1 Classic Software – This chapter provides instructions on

™

1 Baseline Flash Software – This chapter provides instruc-

™

1 and MPLAB® IDE – A quick overview on how to load a

™

1 Hardware Description – This appendix contains the

®

microcontroller units (MCU).

2004 Microchip Technology Inc. DS40051D-page 1

Page 6

PICkit™ 1 Flash Starter Kit User’s Guide

Conventions Used in This Guide

This manual uses the following documentation conventions:

TABLE 1-1: DOCUMENTATION CONVENTIONS

Description Represents Examples

Code (Courier font):

Plain characters Sample code

Filenames and paths

Angle brackets: < > Variables <label>, <exp>

Square brackets [ ] Optional arguments MPASMWIN [main.asm]

Curly brackets and pipe

character: { | }

Lower case characters

in quotes

Ellipses... Used to imply (but not show)

0xnnn A hexadecimal number where n is a

Italic characters A variable argument; it can be either a

Interface (Arial font):

Underlined, italic text

with right arrow

Bold characters A window or dialog button to click OK, Cancel

Characters in angle

brackets < >

Documents (Arial font):

Italic characters Referenced books

Choice of mutually exclusive

arguments; An OR selection

Type of data "filename"

additional text that is not relevant to

the example

hexadecimal digit

type of data (in lower case characters)

or a specific example (in upper case

characters).

A menu selection from the menu bar

A key on the keyboard <Tab>, <Ctrl-C>

#define START

c:\autoexec.bat

errorlevel {0|1}

list

"list_option...,

[

"list_option"]

0xFFFF, 0x007A

char isascii (char,

ch);

File > Save

MPLAB IDE User’s Guide

Documentation Updates

All documentation becomes dated, and this user’s guide is no exception. Since the

PICkit™ 1 Flash Starter Kit

User’s Guide

and other Microchip tools are constantly

evolving to meet customer needs, some PICkit™ 1 Flash Starter Kit actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web

site to obtain the latest documentation available.

Documentation Numbering Conventions

Documents are numbered with a “DS” number. The number is located on the bottom of

each page, in front of the page number. The numbering convention for the DS Number

is: DSXXXXXA,

where:

XXXXX = The document number.

A = The revision level of the document.

DS40051D-page 2 2004 Microchip Technology Inc.

Page 7

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in your Warranty Registration Card entitles you to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the PICkit™ 1 Flash Starter Kit. Other useful

documents are listed below:

PIC12F629/675 Data Sheet (DS41190)

Consult this document for information regarding the PIC12F629/675 8-pin Flash-based

8-bit CMOS microcontroller device specifications.

PIC16F630/676 Data Sheet (DS40039)

Consult this document for information regarding the PIC16F630/676 14-pin Flashbased 8-bit CMOS microcontroller device specifications.

MPLAB

Consult this document for more information pertaining to the installation and features

of the MPLAB Integrated Development Environment (IDE) Software.

To obtain these documents, contact the nearest Microchip sales location (see back

page). These documents are also available on the Microchip web site at:

www.microchip.com.

Microsoft

This manual assumes that users are familiar with the Microsoft Windows operating

system. Many excellent references exist for this software program, and should be

consulted for general operation of Windows.

®

IDE, Simulator, Editor User’s Guide (DS51025)

®

Windows® Manuals

Preface

TROUBLESHOOTING

See the Troubleshooting section for information on common problems.

MICROCHIP ON-LINE SUPPORT

Microchip provides on-line support on the Microchip web site at:

http://www.microchip.com

A file transfer site is also available by using an FTP service connecting to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of services. Users may

download files for the latest development tools, data sheets, application notes,

user guides, articles and sample programs. A variety of Microchip specific business

information is also available, including listings of Microchip sales offices and

distributors. Other information available on the web site includes:

• Latest Microchip press releases

• Technical support section with FAQs

• Design tips

• Device errata

• Job postings

• Microchip consultant program member listing

• Links to other useful web sites related to Microchip products

• Conferences for products, development systems, technical information and more

• Listing of seminars and events

2004 Microchip Technology Inc. DS40051D-page 3

Page 8

PICkit™ 1 Flash Starter Kit User’s Guide

CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip started the customer notification service to help customers stay current on

Microchip products with the least amount of effort. Once you subscribe, you will receive

email notifications whenever we change, update, revise or have errata related to your

specified product family or development tool.

Go to the Microchip web site (www.microchip.com) and click on Customer Change

Notification. Follow the instructions to register.

The Development Systems product group categories are:

• Compilers

•Emulators

• In-Circuit Debuggers

• MPLAB IDE

• Programmers

Here is a description of these categories:

Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C17, MPLAB C18 and MPLAB C30 C Compilers;

MPASM™ and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 linkers;

and MPLIB™ and MPLAB LIB30 librarians.

Emulators – The latest information on Microchip in-circuit emulators. This includes the

MPLAB ICE 2000 and MPLAB ICE 4000.

In-Circuit Debuggers – The latest information on Microchip in-circuit debuggers.

These include the MPLAB ICD and MPLAB ICD 2.

MPLAB – The latest information on Microchip MPLAB IDE, the Windows Integrated

Development Environment for development systems tools. This list is focused on the

MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager and general editing

and debugging features.

Programmers – The latest information on Microchip device programmers. These

include the PRO MATE

programmer.

®

II device programmer and PICSTART® Plus development

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributors

• Local Sales Office

• Field Application Engineers (FAEs)

• Corporate Applications Engineers (CAEs)

• Systems Information and Upgrade Hot Line

Customers should call their distributor or field application engineer (FAE) for support.

Local sales offices are also available to help customers. See the last page of this

document for a listing of sales offices and locations.

Corporate applications engineers (CAEs) may be contacted at (480) 792-7627.

Systems Information and Upgrade Line

The Systems Information and Upgrade Information Line provides system users with a

listing of the latest versions of all of Microchip’s development systems software

products. Plus, this line provides information on how customers can receive the most

current upgrade kits. The Information Line Numbers are:

1-800-755-2345 for U.S. and most of Canada.

1-480-792-7302 for the rest of the world.

DS40051D-page 4 2004 Microchip Technology Inc.

Page 9

Chapter 1. PICkit™1 Flash Starter Kit

1.1 INTRODUCTION

The PICkit 1 Flash Starter Kit is a low-cost introductory programmer and starter kit with

an easy to use PC host program user interface for programming Microchip’s 8/14-pin

Flash family of microcontrollers. The starter kit is designed to help the user get up to

speed quickly using PIC

Starting with Version 2 PC software and PIC16C745 firmware, new Baseline (12-bit

Core) Flash PICmicros

1.2 HIGHLIGHTS

This chapter discusses:

• Running the PICkit 1 Flash Starter Kit Default Demonstration

• PICkit 1 Classic and Baseline Flash Programming Software

• New to Programming PICmicro MCUs

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

®

microcontrollers.

®

can be programmed by the PICkit 1 Flash Starter Kit.

1.3 RUNNING THE PICkit 1 FLASH STARTER KIT DEFAULT DEMONSTRATION

The PICkit 1 Flash Starter Kit comes preprogrammed with a demonstration program.

Connect the PICkit 1 Flash Starter Kit to the PC’s USB port using the USB cable as

shown in Figure 1-1. The demo program will blink the eight red lights in succession.

Press the Push Button Switch, labeled SW1, on the board and the sequence of the

lights will change. Rotate the Variable Resistor, labeled RP1, and the light sequence

will blink at a different rate.

FIGURE 1-1: PICkit 1 FLASH STARTER KIT

Expansion

USB Cable

PIC16C745 Firmware

Header (J3)

Evaluation Socket

PICkit™ 1 Flash Starter Kit

2004 Microchip Technology Inc. DS40051D-page 5

Page 10

PICkit™ 1 Flash Starter Kit User’s Guide

1.4 PICkit 1 CLASSIC AND BASELINE FLASH PROGRAMMING SOFTWARE

There are two PC host programs for the PICkit 1 Flash Starter Kit:

1.4.1

The PICkit 1 Classic programming software programs 8 and 14-pin Mid-range (14-bit

Core) Flash Microcontroller (MCU) Family devices. Instructions on how to use the

PICkit 1 Classic program is given in Chapter 2.

1.4.2

The PICkit 1 Baseline Flash programming software programs 6, 8 and 14-pin Baseline

(12-bit Core) Flash Microcontroller (MCU) Family devices. Instructions on how to use

the PICkit 1 Baseline Flash program is given in Chapter 3.

PICkit 1 Classic

PICkit 1 Baseline Flash

1.5 NEW TO PROGRAMMING PICmicro® MCUs

Appendix C. “PIC12F675 Programming Projects” contains introductory lessons for

persons new to PICmicro

the appendix describe different concepts in controlling the PIC12F675 PICmicro

microcontroller unit (MCU). Each lesson includes instructions for running a program

demo that illustrates basic concepts. It is best to follow the lessons in sequential order,

for each lesson builds upon the previous one. (The hex files and source code for the

lessons can be found on the PICkit 1 Flash Starter Kit CDROM.)

®

microcontroller units (MCU). The programming projects in

®

DS40051D-page 6 2004 Microchip Technology Inc.

Page 11

PICKIT™ 1 FLASH STARTER KIT

Chapter 2. PICkit™1 Classic Software

2.1 INTRODUCTION

This chapter provides instructions on how to use the PICkit 1 Classic programming

software to program 8 and 14-pin Mid-range (14-bit Core) Flash Microcontroller (MCU)

Family devices.

2.2 USING PICkit 1 CLASSIC PROGRAMMING SOFTWARE

USER’S GUIDE

Start the PICkit 1 Classic program by selecting

Starter Kit

Figure 2-1.

FIGURE 2-1: PICkit 1 CLASSIC PROGRAMMING INTERFACE

>

PICkit 1 Classic .

The programming interface appears as shown in

Start > Programs > PICkit 1 Flash

Notice that the Device Power check box is selected. This is a default function indicating

the device power is turned on.

Note: To turn the device power off, deselect the check box.

2004 Microchip Technology Inc. DS40051D-page 7

Page 12

PICkit™ 1 Flash Starter Kit User’s Guide

2.2.1 Import HEX File

To import a compiled program (hex file), select

Figure 2-2. Browse for the hex file and click Open.

FIGURE 2-2: IMPORT HEX FILE

The code is displayed in the Program Memory and EEDATA Memory windows. (For

more information on Program and EEDATA memory, see Lesson 5 and Lesson 6 in

Appendix C. “PIC12F675 Programming Projects”.)

After the hex file is imported, write the program to the device by clicking the

Write Device button. The existing program will be erased and replaced with the new

one. The status of the program write is displayed in the status bar located at the bottom

of the interface window.

If the write is successful, the status bar turns green and displays “Write Successful”, as

shown in Figure 2-3.

FIGURE 2-3: WRITE SUCCESSFUL STATUS BAR

File > Import HEX

, as shown in

If the write fails, the status bar turns red and displays “Checksum verify failed”, as

shown in Figure 2-4. This error indicates the data was corrupted during the

programming sequence. If this error is displayed, try writing the program to the device

again. If this error continues, see Chapter 5. “Troubleshooting” for assistance.

FIGURE 2-4: WRITE ERROR STATUS BAR

2.2.2

Prior to each write, the imported hex file time stamp is compared to the version on the

disk. If the version on the disk is newer, it is reloaded. This occurs only when a hex file

has been read from the disk.

In the normal mode of operation, the hex file is updated with every build in MPLAB

This ensures that the latest version built by MPLAB

Automatic File Reload

IDE will be written to the device.

IDE.

DS40051D-page 8 2004 Microchip Technology Inc.

Page 13

2.2.3 Verify Program Code

This function verifies the program written to the device against a hex file. It compares

all areas of memory including Program, EEDATA and Configuration.

To verify the code, import the hex file and click Verify. If the code is the same, the status

bar turns green and displays “Verified successfully”, as shown in Figure 2-5.

FIGURE 2-5: VERIFY PROGRAM CODE STATUS BAR

If a discrepancy is found, the status bar turns red and displays the error “Verify Failed...

Error in program memory.”, as shown in Figure 2-6. If the Verify fails, it is possible that

the device is code protected.

FIGURE 2-6: CODE ERROR STATUS BAR

2.2.4

Read Device

To view the code written to the device, click Read Device. The code is displayed in the

Program and EEDATA Memory windows for your review. If all zeros are displayed in

the Program Memory window, it is possible that the device is code protected.

2004 Microchip Technology Inc. DS40051D-page 9

Page 14

PICkit™ 1 Flash Starter Kit User’s Guide

2.2.5 Code Protect Device

This function enables the code protection features of the device. To protect the code,

complete the following steps:

1. Import the hex file.

2. Select

3. Click Write Device.

FIGURE 2-7: CODE PROTECT

Note: If the device is read after it has been code protected, the Program and

Tools > Code Protect Device

EEDATA Memory windows will display all zeros.

, as shown in Figure 2-7.

2.2.6

The Erase function erases code from the device. However, this function is not normally

needed since the Write Device function performs an erase prior to writing code to the

device.

To erase the device using the Erase function, click the Erase button or select

Programmer > Erase

FIGURE 2-8: DEVICE ERASE

2.2.7

Unlike the Erase function, the Full Erase allows the user to erase not only the device,

but the OSCCAL and bandgap calibration as well. Performing a full erase is not

recommended or needed in the normal course of events. Only use this function if the

OSCCAL or bandgap data has been corrupted.

To perform a full erase, select

the toolbar menu, as shown in Figure 2-8.

Once the full erase is complete, regenerate the OSCCAL and reset the bandgap

calibration value bits.

Erase

Full Erase

from the toolbar menu, as shown in Figure 2-8.

Programmer > Full Erase (OSCCAL & BG erased)

from

Note: The regenerated OSCCAL function runs a program on the device to

recalculate the oscillator calibration value. See Lesson 7 in

Appendix C. “PIC12F675 Programming Projects” for more details.

DS40051D-page 10 2004 Microchip Technology Inc.

Page 15

2.2.8 Regenerate OSCCAL

To regenerate the OSCCAL, select

Programmer > Regenerate OSCCAL

toolbar menu, as shown in Figure 2-9.

FIGURE 2-9: REGENERATE OSCCAL

2.2.9

To set the bandgap calibration value, select

Value

Set Bandgap Calibration Value

Programmer > Set Bandgap Calibration

from the toolbar menu, as shown in Figure 2-10.

FIGURE 2-10: REGENERATE BANDGAP CALIBRATION VALUE

from the

The Write Bandgap Calibration Value window will appear as shown in Figure 2-11.

Select a bit value from the list and click OK.

FIGURE 2-11: SELECT BANDGAP BIT VALUE

The bandgap bit value will appear in the Device Configuration box, as shown in

Figure 2-12.

2004 Microchip Technology Inc. DS40051D-page 11

Page 16

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE 2-12: DEVICE CONFIGURATION

For more information on the OSCCAL and bandgap calibration, see the device data

sheets located on the CDROM or the Microchip web site (www.microchip.com).

Note: The “Regenerated OSCCAL” and “Set Bandgap Calibration Value”

functions are only available on the PIC12F629/675 and PIC16F630/676

devices.

2.2.10

The 2.5 kHz OSC is a square wave signal that, when selected, is input to pin 3 of the

evaluation socket. See the schematic Figure A-1 in Appendix A.

This function is used by Lesson 7 in Appendix C. “PIC12F675 Programming

Projects”, and for OSCCAL regeneration.

FIGURE 2-13: BOARD CONTROLS

2.5 kHz OSC

DS40051D-page 12 2004 Microchip Technology Inc.

Page 17

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

Chapter 3. PICkit™1 Baseline Flash Software

3.1 INTRODUCTION

This chapter provides instructions on how to use the PICkit 1 Baseline Flash

programming software to program 6, 8 and 14-pin Baseline (12-bit Core) Flash

Microcontroller (MCU) Family devices.

3.2 USING PICkit 1 BASELINE FLASH PROGRAMMING SOFTWARE

Start the PICkit 1 Baseline Flash program by selecting

Flash Starter Kit

shown in Figure 3-1.

FIGURE 3-1: PICkit 1 BASELINE FLASH PROGRAMMING INTERFACE

>

PICkit 1 Baseline Flash .

The programming interface appears, as

Start > Programs > PICkit(tm) 1

Notice that the Device Power check box is selected. This is a default function indicating

the device power is turned on.

Note: To turn the device power off, deselect the check box.

2004 Microchip Technology Inc. DS40051D-page 13

Page 18

PICkit™ 1 Flash Starter Kit User’s Guide

3.2.1 Select Device

The user must first select the device intended for programming. Select the device by

clicking on the Device drop-down menu, as shown in Figure 3-2. The drop-down menu

lists the available devices that can be programmed by the PICkit 1 Baseline Flash

programming software.

Note: Baseline (12-bit core) devices do not contain a Device ID. As a result, the

PICkit 1 programming software cannot determine which device is in the

evalution socket of the PICkit 1 Flash Starter Kit. It is important that the user

verify that the target device and the selected device match. Otherwise

unintended results will happen.

FIGURE 3-2: SELECT DEVICE

3.2.2

To import a compiled program (hex file), select

Figure 3-3. Browse for the hex file and click Open.

FIGURE 3-3: IMPORT HEX FILE

The code is displayed in the Program Memory window.

After the hex file is imported, write the program to the device by clicking the

Write Device button. The existing program will be erased and replaced with the new

one. The status of the program write is displayed in the status bar located at the bottom

of the Interface window.

If the write is successful, the status bar turns green and displays “Write Successful”, as

shown in Figure 3-4.

Import HEX File

File > Import HEX

, as shown in

DS40051D-page 14 2004 Microchip Technology Inc.

Page 19

FIGURE 3-4: WRITE SUCCESSFUL STATUS BAR

If the write fails, the status bar turns red and displays “Checksum verify failed”, as

shown in Figure 3-5. This error indicates the data was corrupted during the

programming sequence. If this error is displayed, write the program to the device again.

If this error continues, see Chapter 5. “Troubleshooting” for assistance.

FIGURE 3-5: WRITE ERROR STATUS BAR

3.2.3

Automatic File Reload

Prior to each write, the imported hex file time stamp is compared to the version on the

disk. If the version on the disk is newer, it is reloaded. This occurs only when a hex file

has been read from the disk.

In the normal mode of operation, the hex file is updated with every build in MPLAB

This ensures that the latest version built by MPLAB

3.2.4

Verify Program Code

IDE will be written to the device.

IDE.

This function verifies the program written to the device against a hex file. It compares

all areas of memory including Program and Configuration.

To verify the code, import the hex file and click Verify. If the code is the same, the status

bar turns green and displays “Verified successfully”, as shown in Figure 3-6.

FIGURE 3-6: VERIFY PROGRAM CODE STATUS BAR

If a discrepancy is found, the status bar turns red and displays the error “Verify Failed

Error in program memory”, as shown in Figure 3-7.

2004 Microchip Technology Inc. DS40051D-page 15

Page 20

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE 3-7: VERIFY PROGRAM CODE ERROR STATUS BAR

3.2.5

To view the code written to the device, click Read Device. The code is displayed in the

Program Memory windows for your review.

3.2.6

This function enables the code protection features of the device. To protect the code,

complete the following steps:

1. Import the hex file.

2. Select

3. Click Write Device.

FIGURE 3-8: CODE PROTECT DEVICE

Note: If the device is read after it has been code protected, the Program Memory

Read Device

Code Protect Device

Tools > Code Protect Device

window displays all zeros.

, as shown in Figure 3-8.

3.2.7

The Erase function erases code from the device. However, this function is not normally

needed since the Write Device function performs an erase prior to writing code to the

device.

To erase the device using the Erase function, click the Erase button, or select

Programmer > Erase

FIGURE 3-9: ERASE

DS40051D-page 16 2004 Microchip Technology Inc.

Erase

from the toolbar menu, as shown in Figure 3-9.

Page 21

3.2.8 2.5 kHz OSC

The 2.5 kHz OSC is a square wave signal that, when selected, is input to pin 3 of the

evaluation socket. See the schematic Figure A-1 in the Appendix A.

FIGURE 3-10: BOARD CONTROLS

2004 Microchip Technology Inc. DS40051D-page 17

Page 22

PICkit™ 1 Flash Starter Kit User’s Guide

NOTES:

DS40051D-page 18 2004 Microchip Technology Inc.

Page 23

Chapter 4. PICkit™1 and MPLAB® IDE

4.1 INTRODUCTION

This chapter provides a quick overview on how to create and load a project in MPLAB

IDE and program a device with MPLAB IDE. The PIC12F675 programming projects

described in Appendix C. “PIC12F675 Programming Projects” are used as

examples in this chapter.

Detail information on MPLAB IDE can be found in the “

Guide”,

the Microchip Technology Inc. website (http://www.microchip.com).

MPLAB IDE is the integrated development environment supplied by Microchip

Technology Inc. for developing software for PIC

to:

• Create source code using the built-in editor.

• Assemble, compile and link source code using various language tools. An

assembler, linker and librarian come with MPLAB IDE. Supported C compilers are

available from Microchip. Third party compilers may be supported also. Check the

release notes or readme files for details.

• Debug the executable logic by watching program flow with the built-in simulator, or

in real time with the MPLAB ICE 2000 emulator or MPLAB ICD 2 in-circuit

debugger. Third party emulators may also be supported. Check the release notes

or readme files for details.

• Make timing measurements with the simulator or emulator.

• View variables in watch windows.

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

MPLAB® IDE v6.xx Quick Start

(DS51025) available on the MPLAB IDE CD-ROM included in the kit or from

®

microcontrollers. MPLAB IDE is used

4.2 HIGHLIGHTS

• Using the PIC12F675 Programming Project Source Code

• Project Management in MPLAB IDE

4.3 USING THE PIC12F675 PROGRAMMING PROJECT SOURCE CODE

If the PIC12F675 Programming Project source code was installed from the PICkit 1

CDROM, and “Lessons” was selected from the options list, the source and hex files will

be installed on the PC harddrive at:

C:\PICkit 1\Classic\Lesson n

Where n indicates the lesson number.

In order to use the lesson source code you will have to:

1. Create a new or open an existing MPLAB IDE project.

2. Configure the project for the PIC12F675.

3. Add the code to the project.

4. Compile the software.

Details for each of these steps can be found on the “

Guide

” available on the MPLAB IDE CD-ROM included with the PICkit 1 Flash Starter

Kit.

2004 Microchip Technology Inc. DS40051D-page 19

MPLAB® IDE v6.xx Quick Start

Page 24

PICkit™ 1 Flash Starter Kit User’s Guide

4.4 PROJECT MANAGEMENT IN MPLAB IDE

Work in MPLAB IDE is done by creating or loading a project. A project contains all the

information needed to write, compile and program a PICmicro MCU device.

4.4.1

1. Select

2. Follow the steps in the wizard to create a project.

FIGURE 4-1: CREATING A PROJECT

4.4.2

Opening a project in MPLAB IDE is accomplished with the following steps:

1. Select

2. Browse and locate the project.

3. Click OPEN.

FIGURE 4-2: OPENING A PROJECT

Creating a Project

Project > Project Wizard

Opening a Project

Project > Open

, as shown in Figure 4-2.

, as shown in Figure 4-2.

4.4.3

After creating or opening a project, it is necessary to compile it. Select

as shown in Figure 4-3.

A window will appear and show the progress. If there are no errors, the program can

be simulated or programmed into the PICkit 1 Flash Starter Kit software. (See

Section 4.4.5 “Programming the Device from MPLAB IDE”.

DS40051D-page 20 2004 Microchip Technology Inc.

Compiling the Project

Project > Make

,

Page 25

FIGURE 4-3: COMPILE PROJECT

4.4.4

Simulating the Project

In order to simulate the program to see what the PIC microcontroller is actually doing

with each instruction, select the MPLAB IDE simulator debugger. Select

Select Tool > MPLAB SIM

, as shown in Figure 4-4.

Debugger >

FIGURE 4-4: MPLAB SIMULATION

Once MPLAB SIM is selected, five buttons will appear on the right end of the menu

toolbar, as shown in Figure 4-5.

FIGURE 4-5: SIMULATION TOOLBAR

These buttons allow the user to:

1. Run code:

2. Pause code:

3. Single Step code, step into functions:

4. Single Step code, step over functions:

5. Reset code:

2004 Microchip Technology Inc. DS40051D-page 21

Page 26

PICkit™ 1 Flash Starter Kit User’s Guide

To view the code in single steps, press the single step button. The code window will

show the instruction that will be executed next, as shown in Figure 4-6.

FIGURE 4-6: CODE WINDOW

In the View toolbar menu there are options to view the special function registers,

program memory and other useful information, as shown in Figure 4-7.

FIGURE 4-7: VIEW MENU OPTIONS

4.4.5

The device can be programmed from MPLAB IDE by selecting PICkit 1 as the programmer as shown in Figure 4-8. The Output window will report the firmware version if the

PICkit 1 is plugged into the computer via the USB port. The Output window will also

report any errors encountered in the selection or programming of the device.

FIGURE 4-8: SELECTING PICkit 1 AS PROGRAMMER

Programming the Device from MPLAB IDE

DS40051D-page 22 2004 Microchip Technology Inc.

Page 27

5.1 INTRODUCTION

This chapter describes common problems and possible solutions for solving problems

with the PICkit 1 Flash Starter Kit.

5.2 FAQS

5.2.1 Program Does Not Work

Question:

My program does not work. What should I check?

Answer:

1. Are the configuration bits set in the source file? PICkit 1 Flash Starter Kit depends

on having the configuration bits set in the hex file. The assembler uses the

_CONFIG directive. When using the PICkit 1 Flash Starter Kit’s on-board

evaluation socket, configure the internal oscillator. The internal oscillator also

frees up two more pins for general I/O use.

The assembler directive to select the internal oscillator, with all other functions

off, might look like this:

_CONFIG (_INTRC_OSC_NOCLKOUT & _WDT_OFF &_BODEN_OFF&_CP_OFF

&_CPD_OFF)

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

Chapter 5. Troubleshooting

The following code shows how to set the configuration bits in Hi-Tech C:

_CONFIG(UNPROTECT & BOREN & MCLRDIS & PWRTEN & WDTDIS & INTIO);

2. Are the pins multiplexed with other functions? If so, does the program initialize

the control registers to select the function desired? A common problem occurs

on PORTA where the analog inputs to the ADC are multiplexed with digital

functions. The pins default to analog input. For digital output, write to the ANSEL

register and make the pins digital I/O.

5.2.2

Question:

The device will not program. All writes end with a “checksum verified failed” error

message.

Answer:

1. Are the code protect bits set in the source code file? Currently, the device can

2. The part may be damaged. Try another device.

Device Will Not Program

only be code protected by selecting the

the PICkit 1 user’s interface.

Tools > Code Protect Device

option in

2004 Microchip Technology Inc. DS40051D-page 23

Page 28

PICkit™ 1 Flash Starter Kit User’s Guide

5.2.3 Device Is Not Recognized

Question:

Receiving message “Insert Device”, but there is a part in the socket.

Answer:

1. Verify the device in the socket is a PICmicro MCU supported by the PICkit 1

Classic or Baseline Flash program.

2. Check for additional circuits attached to pins GP0 and GP1.

3. Check to see if the SW1 switch is pressed.

5.2.4

Question:

Receiving error message “USB Hub Current Limit Exceeded” from Microsoft Windows

2000.

Answer:

Check for shorts on the circuit board.

FIGURE 5-1: USB HUB CURRENT LIMIT EXCEEDED

Current Limit Exceeded

DS40051D-page 24 2004 Microchip Technology Inc.

Page 29

5.2.5 Windows Driver

Question:

After plugging the PICkit 1 into the USB port, Windows 98 SE asks for a driver. Where

is the driver?

Answer:

PICkit 1 uses the drivers included with Windows. When Windows 98 SE prompts for a

driver, select “Search for the best driver for your device.” Then select the check box

next to “Microsoft Windows Update” and click Next. Windows will automatically install

the appropriate driver. Do not use the ICD 2 USB driver.

5.2.6

Question:

When using the PICkit 1 user’s interface to edit the actual contents of the memory, it

will not allow date selection. Why not?

Answer:

The PICkit 1 User’s Interface was developed to program a device. It was not intended

to edit the contents of a device. Please use MPLAB IDE to edit the contents of the

device. The data in the window can be selected to cut and paste into another editor for

use in other applications.

5.2.7

Question:

After moving the tutorial data files to a different location on the hard drive, the MPLAB

IDE simulator behaves strangely. When stepping through the code, a Program Memory

window is displayed without the source code. What is wrong?

Answer:

The MPLAB simulator does not support source level debugging when the path to the

source code is > 62 characters long. Moving the data files to a location with a shorter

path name will fix the problem.

5.2.8

Editing Device Memory

No Source Code

HI-TECH PICC LITE™ C Compiler

Question:

Why does the default demonstration code not work correctly after compiling with the

Hi-Tech PICC LITE™ C Compiler?

Answer:

Download the latest Hi-Tech PICC LITE™ C Compiler from the Hi-Tech web site

www.htsoft.com.

5.2.9

Question:

When the Verify or Read Device buttons are pushed, the Program Memory window

comes up with all zeros. What is wrong?

Answer:

The device may be code protected. Ensure code protection has not been selected in

the configuration word.

2004 Microchip Technology Inc. DS40051D-page 25

Verify and Read Device Return all Zeros

Page 30

PICkit™ 1 Flash Starter Kit User’s Guide

NOTES:

DS40051D-page 26 2004 Microchip Technology Inc.

Page 31

Appendix A. Hardware Description

A.1 INTRODUCTION

This appendix contains the PICkit™ 1 hardware description and schematic diagrams.

A.2 HIGHLIGHTS

This appendix discusses:

• In-Circuit Serial Programming™ (ICSP™)

• Programming Hardware

• USB Communications Protocol

• Schematic Diagrams:

- PICkit 1 Board Diagram

- LED Layout

-V

PP Supply

-USB Control

- Prototype 1

- Prototype 2

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

A.3 IN-CIRCUIT SERIAL PROGRAMMING™ (ICSP™)

In-Circuit Serial Programming (ICSP) allows an engineer to design a circuit that will be

built and then programmed later. ICSP is described in the programming specifications

documentation. These documents can be found on the Microchip web site

(http:\\www.microchip.com). ICSP requires a 12-13V power supply, control of the V

supply and two I/O pins to clock in commands and data.

A.4 PROGRAMMING HARDWARE

The programmer portion of the PICkit 1 Flash Starter Kit circuit is shown in Figure A-1.

Additional circuitry is present to connect to the USB and drive the evaluation LEDs.

Most of the circuitry in the figure is used to generate the +13V required for V

generated by using the CCP of the PIC16C745 to pulse Q2 on and off. By pulsing Q2,

L1 generates a burst of charge that is steered into the capacitor C4 by the diode D13.

Each burst of charge adds to the voltage already in the capacitor. The size of the burst

of charge is proportional to the on time of the PWM signal from CCP. The resistors R10

and R11 form a voltage divider that drops the 13V V

is measured by AN1. Software running in the PIC16C745 periodically samples AN1

and computes a new PWM value. The PWM value is updated just over 500 times every

second. This ensures good voltage regulation of the 13V and leaves enough CPU time

to perform the programming task. The rest of the circuit is used to switch the V

voltage to the V

driver for Q4. Transistor Q1 turns V

The programming I/O signals are generated by software routines on I/O port pins RC6

and RC7 of the PIC16C745, which drive I/O port pins RA0/GP0 (ICSPDAT) and

RA1/GP1 (ICSPCLK) of the target 8 or 14-pin Flash device.

PP pin. Transistor Q4 is the switch for the VPP voltage and Q3 is the

DD on and off allowing the target device to be reset.

DD

PP. This is

PP to a 4.5V feedback signal that

PP

2004 Microchip Technology Inc. DS40051D-page 27

Page 32

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE A-1: PROGRAMMING HARDWARE

DS40051D-page 28 2004 Microchip Technology Inc.

Page 33

A.5 USB COMMUNICATIONS PROTOCOL

The USB protocol used by the PICkit 1 Flash Starter Kit is a very simple

command/response type protocol. Multiple commands can be put together to fill the 8

bytes of a USB packet. If a command cannot fill the 8 bytes and it is not desired to use

a second command to fill the packet, the packet should be padded with ‘Z’ to indicate

no operation.

A.5.1

Commands

• ‘C’ <word> – Configuration Memory Write mode. Word parameter ignored. Use

‘W’ to write to configuration memory.

• ‘c’ – Download Command Table. 15 bytes to follow (two 8 byte packets) containing

the 6-bit commands in the following order:

- Load Configuration memory

- Load data for Program memory

- Load data for EE Data memory

- Read data from Program memory

- Increment Address

- Begin programming (internally timed)

- Begin programming (externally timed)

- End programming (externally timed)

- Bulk Erase Program memory

- Bulk Erase EE Data memory

The last 4 commands are undefined but the second data packet will be filled out.

• ‘D’ <byte> – Write EE Data memory. Data is passed as the byte.

• ‘E’ – Bulk Erase Program memory

• ‘e’ – Bulk Erase Data memory

• ‘g’ – Get n bytes from device (n is a word)

• ‘I’ <word> – Increment Address N times. N is passed as word.

• ‘P’ – Enter Programming mode. Turns V

• ‘p’ – Exit Programming mode. Turns V

PP and VDD on.

DD and VPP off.

• ‘R’ – Read Program memory. ‘R’ always returns 4 words. If the end of PGM

memory is reached, it pads with 0’s. It is the responsibility of the host software to

determine if padding occurred by keeping track of the program counter.

• ‘r’ – Read EE Data memory. ‘r’ always returns 8 bytes. If the end of Data memory

is reached, it pads with 0’s. It is the responsibility of the host software to determine

if padding occurred by keeping track of the program counter.

• ‘S’ <program memory length, data memory length> – Calculates Program

Memory Checksum and Data Memory Checksum. The checksum is calculated on

the first N

memory. N

words of the program memory and the first Nd bytes of the data

p

and Nd are both words passed as the length parameter. The return

p

value is 3 bytes in length: the first word is the Program Memory Checksum, and

the last byte is the Data Memory Checksum.

• ‘t’ – Transmit n bytes to device (n is a word)

• ‘V’ <byte> – Power and special feature control. The byte following command is

used to control. V

DD power to the target and to enable/disable a 2.5 kHz 50%

square wave.

• ‘v’ – Return version information. The following bytes are returned:

<Major><Minor><Dot>.

• ‘W’ <word> – Write Program Memory. Loads the write latch, sends the write

command and increments to the next address.

2004 Microchip Technology Inc. DS40051D-page 29

Page 34

PICkit™ 1 Flash Starter Kit User’s Guide

• ‘w’ – Externally timed write. Loads a word into the write latches, starts the

programming cycle, ends the programming cycle 5 mS later and increments the

PC.

• ‘Z’ – No operation. Use to pad packets to 8 bytes.

• ‘4’ – 4 word write. Loads 4 words prior to write cycle. The 4 14-bit words are

packed into the remaining 7 bytes. The first three words are sent low byte/high

byte. This occupies bytes 1-6 of the packet. The low byte of the fourth word is sent

in byte 7. The high-order 6 bits are sent using the unused bits of the other 3 high

order bytes, as follows:.

‘4’

(Write by Word)

Low-order byte,

Word 0

Word 3

Bits 13, 12

Word 3

Bits 11, 10

Word 3

Bits 9, 8

High-Order 6 Bits

of Word 0

Low-order byte,

Word 1

High-Order 6 Bits

of Word 1

Low-order byte,

Word 2

High-Order 6 Bits

of Word 2

Low-order byte,

Word 3

Note: Word values are sent low byte first.

Source code for the PC host programs are located on the PICkit 1 Flash Starter Kit

CDROM in the unsupported directory.

DS40051D-page 30 2004 Microchip Technology Inc.

Page 35

A.6 SCHEMATIC DIAGRAMS

FIGURE A-1: PICkit™ 1 BOARD DIAGRAM

2004 Microchip Technology Inc. DS40051D-page 31

Page 36

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE A-2: LED LAYOUT

DS40051D-page 32 2004 Microchip Technology Inc.

Page 37

FIGURE A-3: VPP SUPPLY

2004 Microchip Technology Inc. DS40051D-page 33

Page 38

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE A-4: USB CONTROL

DS40051D-page 34 2004 Microchip Technology Inc.

Page 39

FIGURE A-5: PROTOTYPE 1

2004 Microchip Technology Inc. DS40051D-page 35

Page 40

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE A-6: PROTOTYPE 2

DS40051D-page 36 2004 Microchip Technology Inc.

Page 41

Appendix B. Baseline Flash Microcontroller

Programming Schematic

B.1 SCHEMATIC DIAGRAM

FIGURE B-1: BASELINE FLASH MICROCONTROLLER PROGRAMMER

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

SCHEMATIC

M

2004 Microchip Technology Inc. DS40051D-page 37

Page 42

PICkit™ 1 FLASH Starter Kit User’s Guide

NOTES:

DS40051D-page 38 2004 Microchip Technology Inc.

Page 43

Appendix C. PIC12F675 Programming Projects

C.1 INTRODUCTION

This appendix contains introductory lessons for users new to PICmicro® microcontroller units (MCU). The programming projects in this appendix describe different

concepts in controlling the PIC12F675 PICmicro microcontroller unit (MCU). Each

lesson includes instructions for running a program demo that illustrates each of the

concepts listed below in Section C.2. It is best to follow the lessons in sequential order,

for each lesson builds upon the previous one. (The hex files and source code for the

lessons can be found on the PICkit

C.2 HIGHLIGHTS

The following lessons are discussed in this chapter:

Lesson 1 – Switch Debouncing

Lesson 2 – State Machines

Lesson 3 – Interrupts

Lesson 4 – Analog-to-Digital Converters and Comparators

Lesson 5 – Data Tables in Program Memory

Lesson 6 – Using EEPROM Memory

Lesson 7 – Frequency Counting with Timer1 Gate

PICKIT™ 1 FLASH STARTER KIT

USER’S GUIDE

™

1 Flash Starter Kit CDROM.)

C.3 LESSON 1 – SWITCH DEBOUNCING

Mechanical switches play an important and extensive role in practically every

computer, microprocessor and microcontroller application. Mechanical switches are

inexpensive, simple and reliable. In addition, switches can be very noisy. The apparent

noise is caused by the closing and opening action that seldom results in a clean

electrical transition. The connection makes and breaks several, perhaps even

hundreds, of times before the final switch state settles.

The problem is known as switch bounce. Some of the intermittent activity is due to the

switch contacts actually bouncing off each other. Imagine slapping two billiard balls

together. The hard non-resilient material doesn't absorb the kinetic energy of motion.

Instead, the energy dissipates over time and friction in the bouncing action against the

forces push the billiard balls together. Hard metal switch contacts react in much the

same way. Also, switch contacts are not perfectly smooth. As the contacts move

against each other, the imperfections and impurities on the surfaces cause the

electrical connection to be interrupted. The result is switch bounce.

The consequences of uncorrected switch bounce can range from being just annoying

to catastrophic. For example, imagine advancing the TV channel, but instead of getting

the next channel, the selection skips one or two. This is a situation a designer should

strive to avoid.

2004 Microchip Technology Inc. DS40051D-page 39

Page 44

PICkit™ 1 Flash Starter Kit User’s Guide

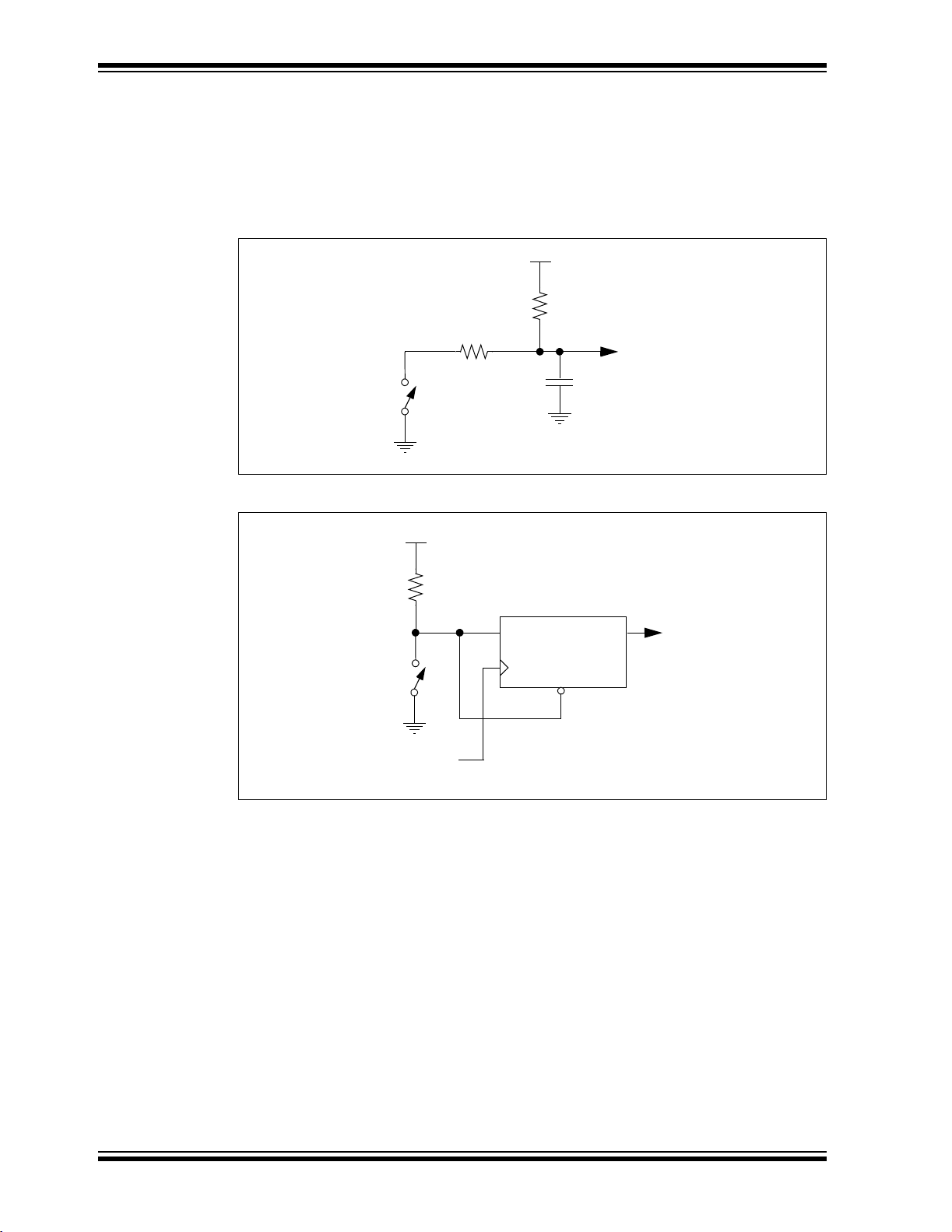

Switch bounce has been a problem even before the earliest computers. The classic

solution involved filtering, such as through a resistor-capacitor circuit, or through

re-settable shift registers (see Figure C-1 and Figure C-2). These methods are still

effective, but they involve additional cost in material, installation and board real estate.

Why suffer the additional expense when software is free and program memory is

abundant.

FIGURE C-1: FILTERING DEBOUNCE SOLUTION

+V

R2

R1

C

1

SW

Filtered

Switch

Output

FIGURE C-2: SHIFT REGISTER DEBOUNCE SOLUTION

+V

R1

Filtered

Switch

Output

SW

Debounce

Clock

D

CLK

Qn

CLR

DS40051D-page 40 2004 Microchip Technology Inc.

Page 45

C.3.1 Design

Switch bounce is intermittent contact and release of the switch contacts. Two

parameters characterize switch bounce: bounce period and bounce duration.

Bounce period is the random length of time the contacts remain open, or closed, while

the bounce is occurring. Bounce periods can vary anywhere from a few nanoseconds

to a few milliseconds.

Bounce duration is the time from the leading edge of the first bounce period to the

trailing edge of the last bounce period. The difficulty is bounce duration is

indeterminate.

Bounce abatement design starts by making assumptions based on empirical data.

The first assumption is bounce period will be absolutely less than 10 milliseconds.

Experience dictates this is a good assumption, however, bench and field-testing are still

essential to ensure the switch selected for the application does not have a longer

bounce period. The second assumption is the total bounce duration is indeterminate.

A good design should work regardless of how long the switch bounces provided that it

eventually does stop bouncing.

C.3.1.1 BRUTE FORCE DEBOUNCE

Consider a simple push button application. In this case, some event should occur when

a button is pushed. Ideally the invoked event will occur immediately, and only once for

each button push. The system should also be ready to respond to a repeat button push

as soon as possible after the button is released. This presents an apparent dilemma.

How is the difference between switch bounce and repeated button pushes determined?

Recall the assumption that the bounce period is less than 10 milliseconds. If the switch

input level is stable for longer than 10 milliseconds, then bouncing has stopped and the

input level represents the pushed or released switch state. The Brute Force method

only cares about a button-push event because this is what invokes the action. It

recognizes the switch release state as the stable state and everything else is

considered unstable. When the switch becomes unstable, the action is invoked

permitting nothing to happen until the switch returns to the released stable state.

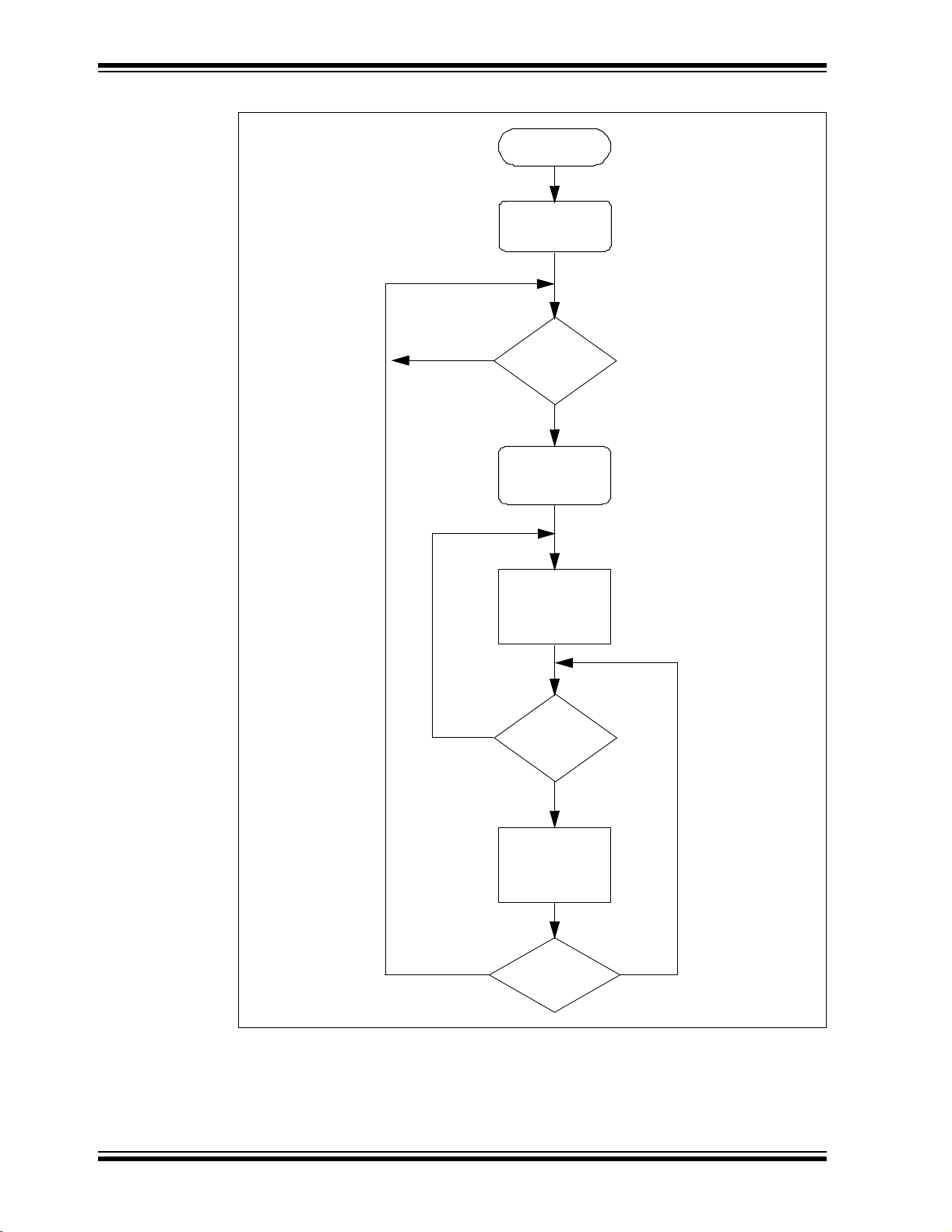

The flowchart in Figure C-3 outlines the software actions necessary to implement the

Brute Force debounce method. Notice that the debounce loop is looking for a stable

released state for 10 milliseconds before returning to the top of the main loop. Any

instability, including a stable button pushed state, resets the debounce 10 millisecond

timer.

2004 Microchip Technology Inc. DS40051D-page 41

Page 46

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE C-3: BRUTE FORCE SWITCH DEBOUNCE

Debounce

Initialize

Yes

No

Switch

Closed?

Yes

Toggle

LED

Set Timer

Count For

10 ms

Switch

Closed?

No

Decrement

Timer

Counter

Yes

DS40051D-page 42 2004 Microchip Technology Inc.

Timeout?

No

Page 47

C.3.1.2 SWITCH FILTER DEBOUNCE

There are situations when both stable switch states must be recognized. It is

undesirable for immediate action to occur if the switch intermittently leaves either the

pushed or released state. A door open or closed sensor switch is a good example of

this. If the door is closed and gets bumped, then the door-open action, such as an

alarm, should not occur because the door is still closed.

The Switch Filter Debounce method delays the response to a changed switch state.

Delay time can even be extended to several times the bounce period. Switch Filter

Debounce incorporates a saturating up/down counter. (A saturating counter is one that

stops counting when the maximum, or minimum, number is reached.) The counter

counts up when the switch is closed, and counts down when the switch is open. The

appropriate action is invoked when the counter reaches either the full up or down count.

Hysteresis is built into the count length. Switch release or contact action is invoked only

upon the first occurrence of counter saturation. The counter must saturate at the

opposite state before the previous state can be re-invoked. During switch bounce, the

counter intermittently counts up and down. The counter will progress up when the

average closed to open period favors contact, and down when the average period

favors release. The faster the switch settles in the closed or open state, the faster the

counter will reach the corresponding saturated condition.

Switch Filtering assumes, when the switch is mostly closed or open, the bouncing will

favor the closed or open levels respectively. It is possible for the counter to saturate

before the switch has stopped bouncing. It is unlikely that the counter will change

saturation state unless the count is too short, or the switch is headed in that direction.

Figure C-4 outlines the software actions necessary to implement the Switch Filtering

Debounce method.

2004 Microchip Technology Inc. DS40051D-page 43

Page 48

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE C-4: TIME AVERAGED SWITCH FILTER DEBOUNCE

Switch

Filter

No

Closed

FilterCount<

MaxCount?

Yes

Increment

FilterCount

Timer0

Overflow?

Yes

Switch

State?

Open

FilterCount>

MinCount?

Yes

Decrement

FilterCount

NoNo

No No

DS40051D-page 44 2004 Microchip Technology Inc.

FilterCount>=

MaxCount?

Yes

Turn LED1 On

Turn LED0 Off

FilterCount<=

MinCount?

Yes

Turn LED0 On

Turn LED1 Off

Page 49

C.3.2 Applications

Reliable, robust software requires debouncing of all mechanical switches. This

includes push buttons of all types, limit switches of all types and even X*Y matrix

keyboards. Matrix keyboards offer a new challenge to debouncing. Keyboards are not

a single line input level but a pattern on several inputs. One pattern represents all keys

released, or the stable state. All other patterns represent keys pressed, or the unstable

states. Reliable keyboards can be designed by debouncing to only the stable state, but

allowing new actions to occur immediately upon a change from one unstable state to

another. The solution is left to the interested student.

C.3.3

Running the Demos

There are three switch debounce demos: Debounce, SwchFltr and DbncFltr. The file

name suffix denotes the source code language for each demo. The suffix “.asm”

denotes assembly language. The suffix “.c” denotes C language. Use the Intel 32-bit

hex file output as the input file to the PICkit 1 Flash Starter Kit demo board. Intel hex

files are denoted by the “.hex” file suffix.

C.3.3.1 DEBOUNCE DEMO

Debounce is the Brute Force Debounce demo. Each button push in this demo causes

LED D0 to toggle on or off.

Perform the following steps to run the Debounce demo:

1. Connect the USB cable to the USB PC port and to the PICkit 1 Flash Starter Kit

demo board.

2. Execute the PICkit 1 Flash Starter Kit programming software.

3. From the toolbar menu, select

File -> Import Hex

. Browse to locate the hex file

named “Debounce.hex”. Select this file and click the Open button.

Note: The Program Memory window displays the program code.

4. Click the Write Device button. The status of the program write is displayed in the

status bar located at the bottom of the interface window.

5. To run the demo, push the SW1 switch on the board and observe that LED D0

toggles as expected.

C.3.3.2 SwchFltr DEMO

SwchFltr is an abbreviation for the Switch Filter Debounce demo. In this demo, LED D1

lights up when SW1 is pushed. When SW1 is released, LED D0 lights up.

Repeat steps 1 through 5 above and load the SwchFltr.hex file to run this demo.

C.3.3.3 DbncFltr DEMO

DbncFltr is an abbreviation for Debounce Filter. This demo is a combination of the

Debounce and Switch Filter demos. DbncFltr also demonstrates timed expansion of

switch functions. This demo initializes in the Switch Filter mode. Holding the button

down for more than 1 second, while in the Switch Filter mode, causes the demo to

change to the Brute Force method. LED D0 will light as an indication of the change.

Holding the button down for more than 1 second, while in the Brute Force mode,

causes the demo to change to the Switch Filter method. LED D1 will light as an

indication of the change.

Repeat steps 1 through 5 above and load the DbncFltr.hex file to run this demo.

2004 Microchip Technology Inc. DS40051D-page 45

Page 50

PICkit™ 1 Flash Starter Kit User’s Guide

C.4 LESSON 2 – INTRODUCTION TO STATE MACHINES

State Machines are an integral part of software programming. State machines make

code more efficient, easier to debug and help organize the program flow. State

machines are not limited to just firmware, they can be used to streamline any system.

However, this document limits the scope of state machines to microcontroller firmware.

C.4.1

C.4.1.1 WHAT IS A STATE MACHINE

A Finite State Machine (FSM) is based on the idea of there being finite number of states

for a given system. For instance, when an application turns an LED on and off, two

states exist; one state is when the LED is on and the other is when it is off. The example

firmware that this document refers to turns on eight LEDs sequentially. Only one LED

is on at a time, therefore eight states exist. Each state consists of one LED being turned

on while all the rest are off.

State machines require a State Variable (SV). The SV is essentially a pointer that keeps

track of the state that the microcontroller is in, and directs the program flow to the

corresponding software module. The SV can be modified in the software modules (or

states) themselves or by an outside function. The example firmware uses an outside

function which detects a button press to advance through the states.

C.4.1.2 BENEFITS OF STATE MACHINES

The introduction briefly mentioned some advantages of state machines. These advan-

tages are worth studying in greater detail because they are what make programming

with state machines so rewarding and beneficial to firmware developers.

The first advantage is using state machines inherently promotes good firmware design

techniques. When beginning to implement an application, think about what states are

necessary to make the application work. List all the pieces, or states, of an application

and then explore how they tie to one another. This will help prevent developing bugs in

the code. This line of thinking also leads to the development of a very useful engineering tool – the flow chart. The following paragraph covers state machine development in

greater detail.

State machines have one characteristic that cause them to be very beneficial. They

always return to one spot (or jump station) in the code at which the program flow is

channeled, by the state variable, to the corresponding software module. This provides

several advantages. First, this characteristic makes calling repetitive tasks on a regular

basis quite simple. Clearing the watchdog timer, checking for I/O button presses or

communicating with a host that requires periodic communication are examples of

repetitive tasks. The alternative to using state machines is to use looping code. In order

for looping code to handle repetitive tasks, the functions that handle these tasks must

be distributed throughout the code in each of the loops. This is not only highly inefficient

but also confusing to understand. Figure C-5 shows a block diagram of what the

example code would look like if a state machine where not used. Compared to

Figure C-6, which shows a block diagram of state machine based code, it is clear that

using a state machine cuts down on code space and the likelihood of missing a

repetitive task call.

Design

DS40051D-page 46 2004 Microchip Technology Inc.

Page 51

FIGURE C-5: STATE MACHINE NOT USED

Initialize Routine

Clear WDT

No

ButtonPress()?

Clear WDT

No

ButtonPress()?

Clear WDT

No

ButtonPress()?

Clear WDT

Yes

Yes

Yes

Turn only

LED0 on

Turn only

LED1 on

Turn only

LED2 on

Clear WDT

No

ButtonPress()?

Clear WDT

No

ButtonPress()?

Clear WDT

No

ButtonPress()?

Clear WDT

Yes

Yes

Yes

Turn only

LED4 on

Turn only

LED5 on

Turn only

LED6 on

No

ButtonPress()?

Yes

Turn only

LED3 on

No

ButtonPress()?

Yes

Turn only

LED7 on

2004 Microchip Technology Inc. DS40051D-page 47

Page 52

PICkit™ 1 Flash Starter Kit User’s Guide

FIGURE C-6: STATE MACHINE BASED CODE

Initialize Routine

Clear WDT

01 2

Turn only

LED0 on

Turn only

LED1 on

Turn only

LED2 on

No

ButtonPress()?

3

Turn only

LED3 on

Yes

Increment

State Variable

State Variable

=

4

Turn only

LED4 on

(1)

5

Turn only

LED5 on

6 7

Turn only

LED6 on

Turn only

LED7 on

Note 1: ButtonPress() detects when Switch 1 is pressed. This function also implements a

debounce routine not shown. See

C.4.2 “Implementation”, for details.

DS40051D-page 48 2004 Microchip Technology Inc.

Page 53

The fact that the state machine based firmware always returns to the same point in the

code also makes the firmware easier to debug. When a bug is encountered, set a break

point at the jump station. Then, step through the program state by state until the bug is

found. An example of a bug would be the SV being modified incorrectly in one of the

states. If this happens, the wrong state will be called the next time the program flow

returns to the jump station. However, because the SV is being monitored, it will be very

easy to see when an unintentional change is made to the SV and in which state the SV

was incorrectly modified.

Note: MPLAB IDE contains a built-in simulator. See the

Start Guide

available on the MPLAB IDE CD-ROM included with the

MPLAB IDE v6.xx Quick

PICkit 1 Flash Starter Kit

Another benefit of state machines is that it naturally promotes modular code. Modular

code has its own list of benefits:

1. Upgrades and special features can be easily added to the code in later revisions

or as a product evolves.

2. Modules can be cut and pasted into other applications quickly and easily.

3. Other developers will be able to understand the code in order to support it. The

jump station, if commented well, can be an index to each of the software

modules.

C.4.2

Implementation

C.4.2.1 GENERAL THOUGHT PROCESS

When implementing a FSM, first brainstorm all the states needed to complete a partic-

ular application. Once this is done, identify the first state. Next, the following question

should be answered: “What needs to happen to exit this state, and what state will it exit

to?” Usually there is more than one answer to this question. Depending on what happens while in a particular state, the state machine may advance a state, decrement a

state or skip several states entirely. As mentioned before, it is generally a good idea to

visually construct the state machine in the form of a flowchart. Finally, create a software

module for each of the states and tie them together according to the flowchart just

created.

2004 Microchip Technology Inc. DS40051D-page 49

Page 54

PICkit™ 1 Flash Starter Kit User’s Guide

C.4.2.2 TRANSLATING STATE MACHINES INTO ASSEMBLY AND C

Implementing a state machine in C is quite simple to visualize. C based state machines

rely on the “switch” statement. The following example code shows a “switch” statement

being used as a state machine.

EXAMPLE C-1: SWITCH STATEMENT

switch (STATE) {

case (State0):

// turn LED0 on

break;

case (State1):

// turn LED1 on

break;

case (State2);

// turn LED2 on

break;

... and so on

default:

STATE = State0 // if for some reason a undefined

state occurs,

// re-initialize the state machine

}

Creating a state machine in assembly is a little more difficult. In assembly, the program

flow is directed to the appropriate software module for a given state by incrementing

the Program Counter by the state variable. Incrementing the Program Counter is

comprised of incrementing PCL and PCLATH (when PCL overflows.) If a provision of

increment PCLATH is not included, then there is a risk of jumping to the wrong spot in

the program if PCL overflows. Immediately following the increment routine is a list of

“goto” statements that direct the program flow to one of the states. This method is

called a “computed goto”. The following example code shows how to use a computed

goto for a state machine.

DS40051D-page 50 2004 Microchip Technology Inc.

Page 55

EXAMPLE C-2: COMPUTED GOTO

Initialize

clrf STATE ;initialize state machine

. . .

Main

call StateMachine

. . .

goto Main

StateMachine

movlw high StateTable ;set high order byte of program

movwf PCLATH ; counter appropriately

movf STATE, W ;mask state variable to keep

andlw 03h ; things under control

addlw low StateTable ;add state variable to ROM address

btfsc STATUS C ; beginning State Table

incf PCLATH, F ;overflows? yes, increment PCLATH

movwf PCL ;move computed goto value into PC

StateTable

goto State0

goto State1

goto State2

goto State3

State0

. . .

incf STATE, F ;goto the next state

return

State1

. . .

return

2004 Microchip Technology Inc. DS40051D-page 51

Page 56

PICkit™ 1 Flash Starter Kit User’s Guide

C.4.3 Implementing this Demo

The flowchart for this demo is shown in Figure C-6, however, the flowchart does not

show the debounce routine implemented in ButtonPress(). The debounce routine

is based on the Brute Force Debounce (described in Lesson 1, Section C.3) with one

slight modification, the debounce routine is implemented as a state machine. The

Debounce state machine differs from the LED state machine where the states themselves modify the state variable. Implementing the debounce routine as a state

machine is easier to understand than implementing it as looping code.

C.4.3.1 APPLICATIONS

As mentioned earlier in Section C.4.1.2, state machines are useful in nearly every

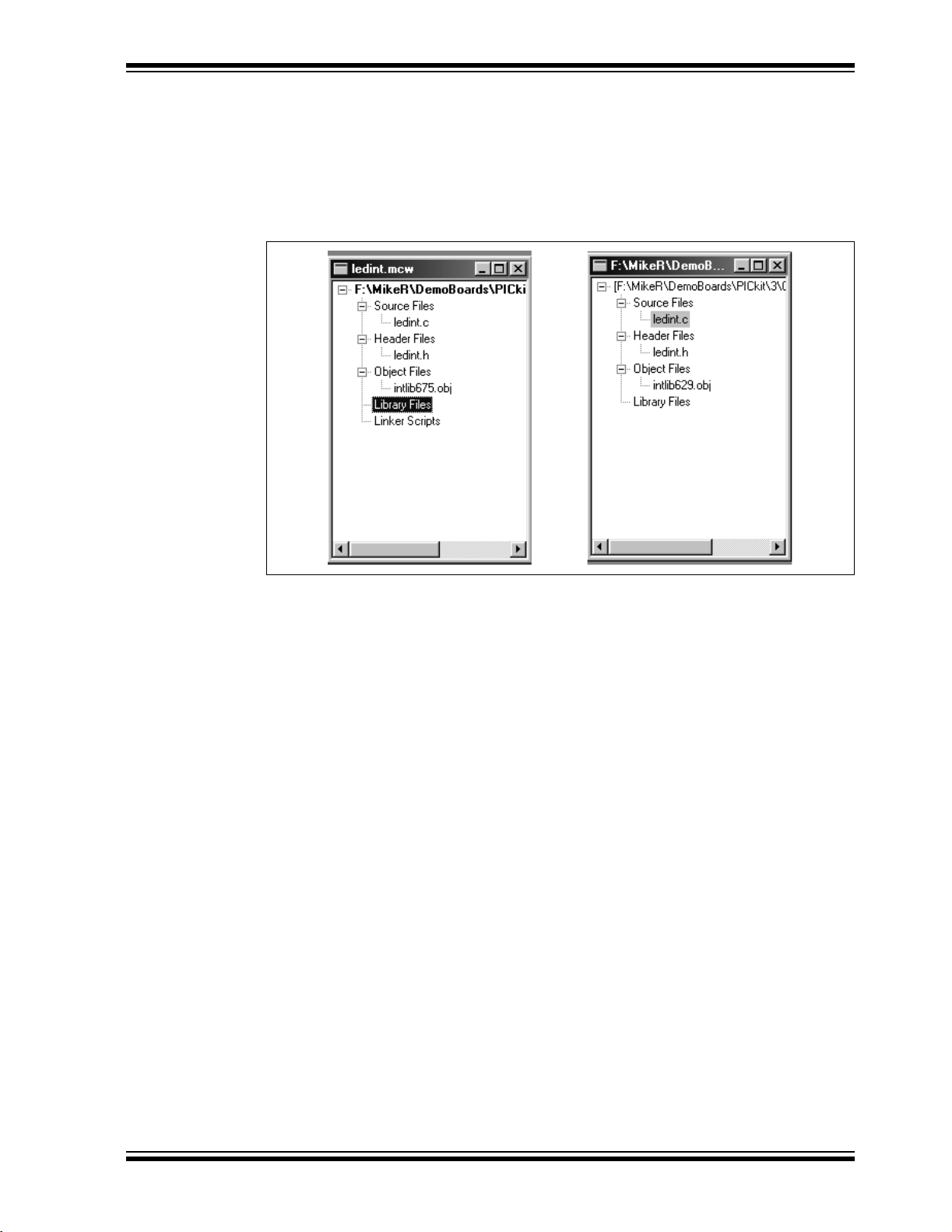

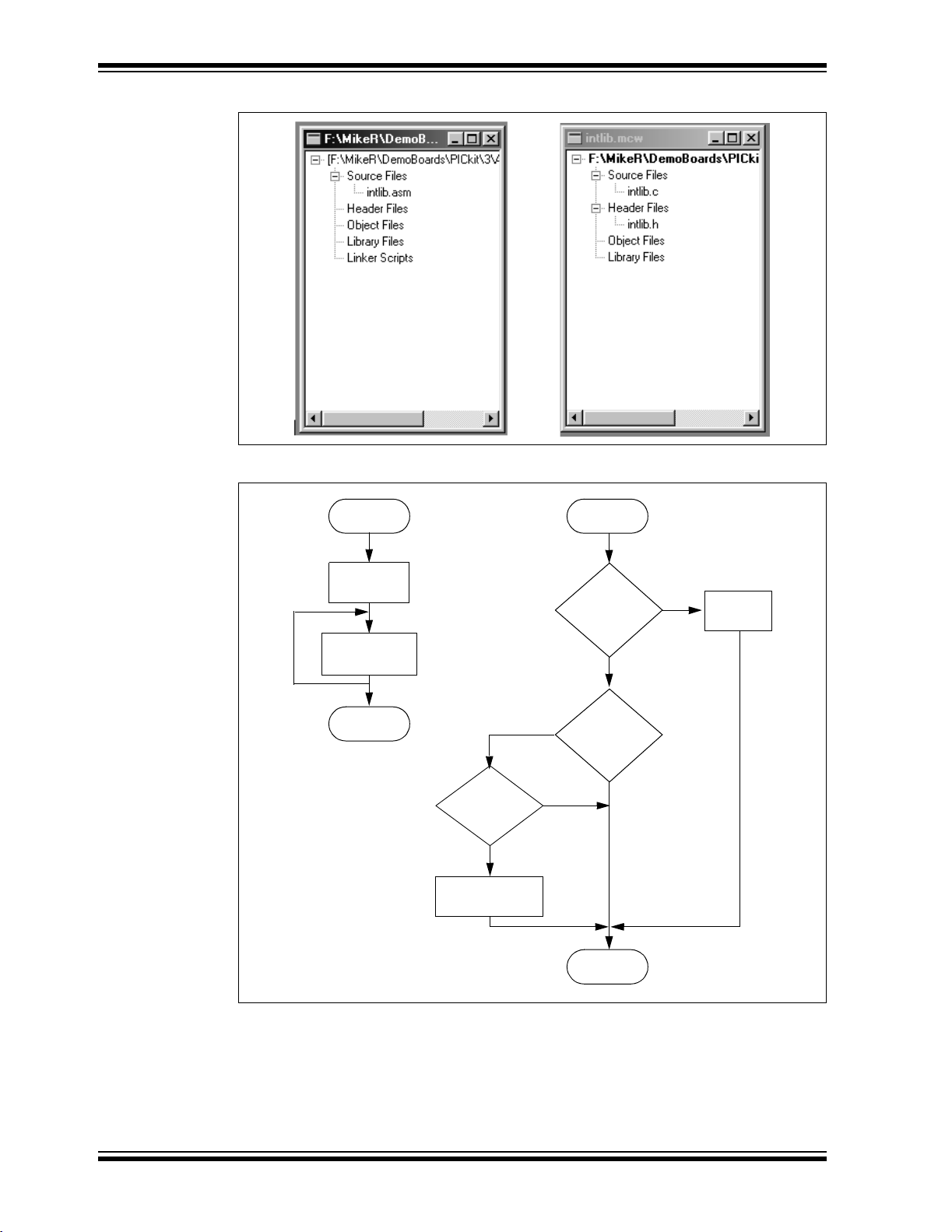

application. The LED library, in subsequent lessons, utilizes state machines to light the