Page 1

PICDEM™ PIC18 Explorer

Demonstration Board

User’s Guide

© 2008 Microchip Technology Inc. DS51721B

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

PICSTART, PRO MA TE, rfPIC and SmartShunt are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

FilterLab, Linear Active Thermistor, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, In-Circuit Serial

Programmin g , IC SP, ICEPIC, Mindi, MiW i , MPASM, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, PICkit, PICDEM,

PICDEM.net, PICtail, PIC

32

logo, PowerCal, PowerInfo,

PowerMate, PowerT ool, REAL ICE, rfLAB, Select Mode, Total

Endurance, UNI/O, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2008, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS51721B-page ii © 2008 Microchip Technology Inc.

Page 3

PICDEM™ PIC18 EXPLORER

DEMONSTRATION BOARD

USER’S GUIDE

Table of Contents

Preface ...........................................................................................................................1

Chapter 1. Introduction

1.1 Introduction .....................................................................................................5

1.2 Developm e nt Ki t C o n te n ts ......... ........................................ .. .. ......................... 5

1.3 PICDEM™ P IC1 8 E xp l orer Demonstr a tio n B o ard ..... ........................... .. .. ..... 6

1.4 Sample Devices .... ... .. .................................................................................... 7

1.5 Sample Pro g ram s ................................................. .......................................... 7

Chapter 2. Getting Started

2.1 Board as Stand-Alone Device ...................... ...................... .. ...................... ....9

2.2 Board with In-Circuit Debugger ....................................................................11

2.3 Board with PIM Attached Devices ................................................................12

2.4 Programming the Microcontrollers ............................................................... 16

2.5 Connecting to Host PC for RS-232 Communication ....................................19

Chapter 3. PICDEM™ PIC18 Explorer Demonstration Board Tutorial Program

3.1 Tutorial Pr o g ra m O p e ra tion ... .. ..................................................... .. .. ............ 23

3.2 Source Code and Data Sheets .............................. .......................... .. ...........25

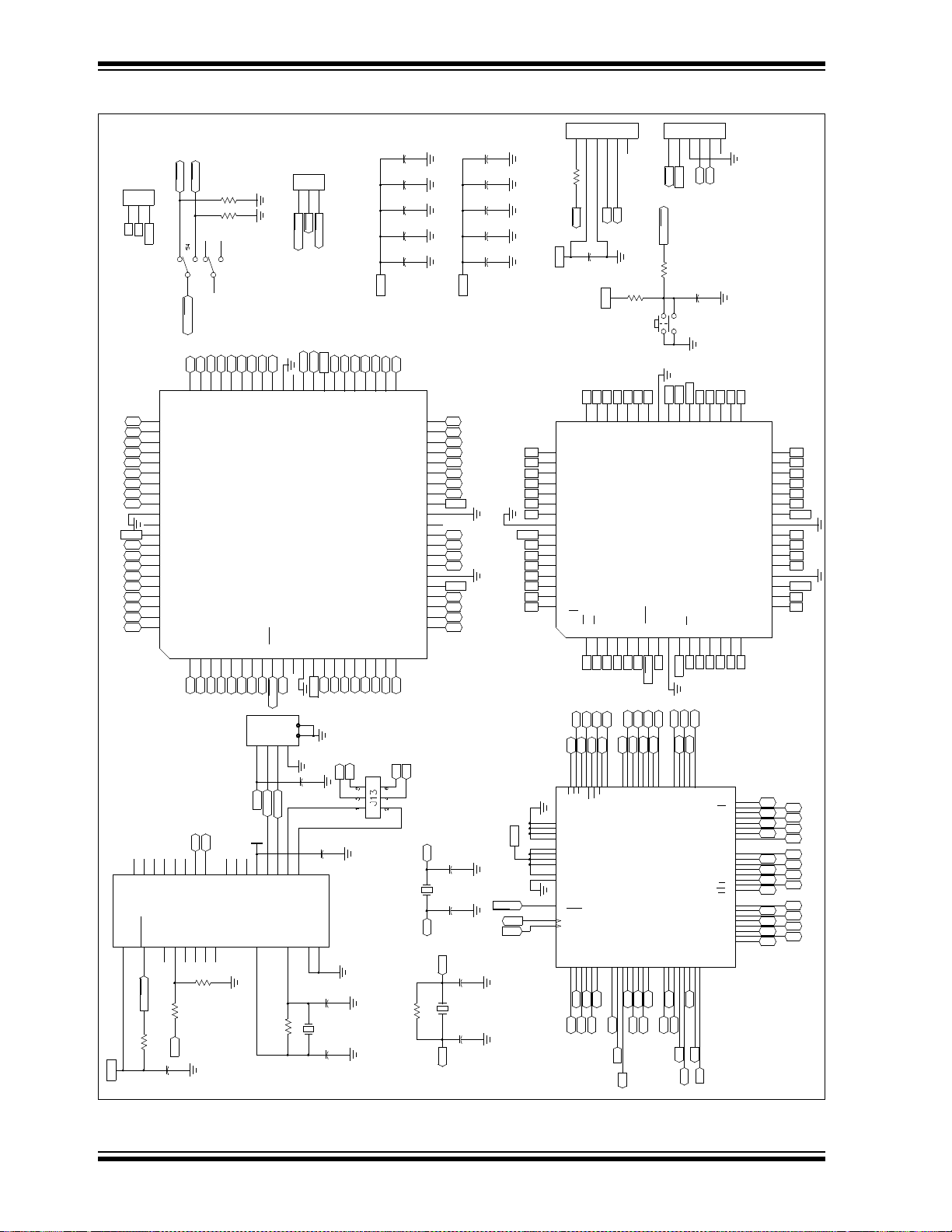

Appendix A. Hardware Details

A.1 Hardware E le ments . .. .......................... .. ... ................................................... 27

A.2 Board Layo u t an d S c h e ma tic s ..................................................................... 30

Worldwide Sales and Service ....................................................................................34

© 2008 Microchip Technology Inc. DS51721B-page iii

Page 4

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

NOTES:

DS51721B-page iv © 2008 Microchip Technology Inc.

Page 5

PICDEM™ PIC18 EXPLORER

DEMONSTRATION BOARD

USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

PICDEM™ PIC18 Explorer Demonstration Board. Items discussed in this chapter

include:

• Document Layout

• Conventions Used in This Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the PICDEM PIC18 Explorer Demonstration

Board as a development tool to emulate and debug firmware on a target board. The

manual layout is as follows:

• Chapter 1. “Introduction” – Overview of the development board and kit

• Chapter 2. “Getting Started” – Description of the different ways to use the board

• Chapter 3. “PICDEM™ PIC18 Explorer Demonstration Board Tutorial Program”

– Explanation of t he tu to ri al prep r ogra mme d o n the sa mpl e d evice s

• Appendix A. “Hardware Details” – Description of the board’s hardware

elements, including layout and schematic drawings

© 2008 Microchip Technology Inc. DS51721B-page 1

Page 6

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

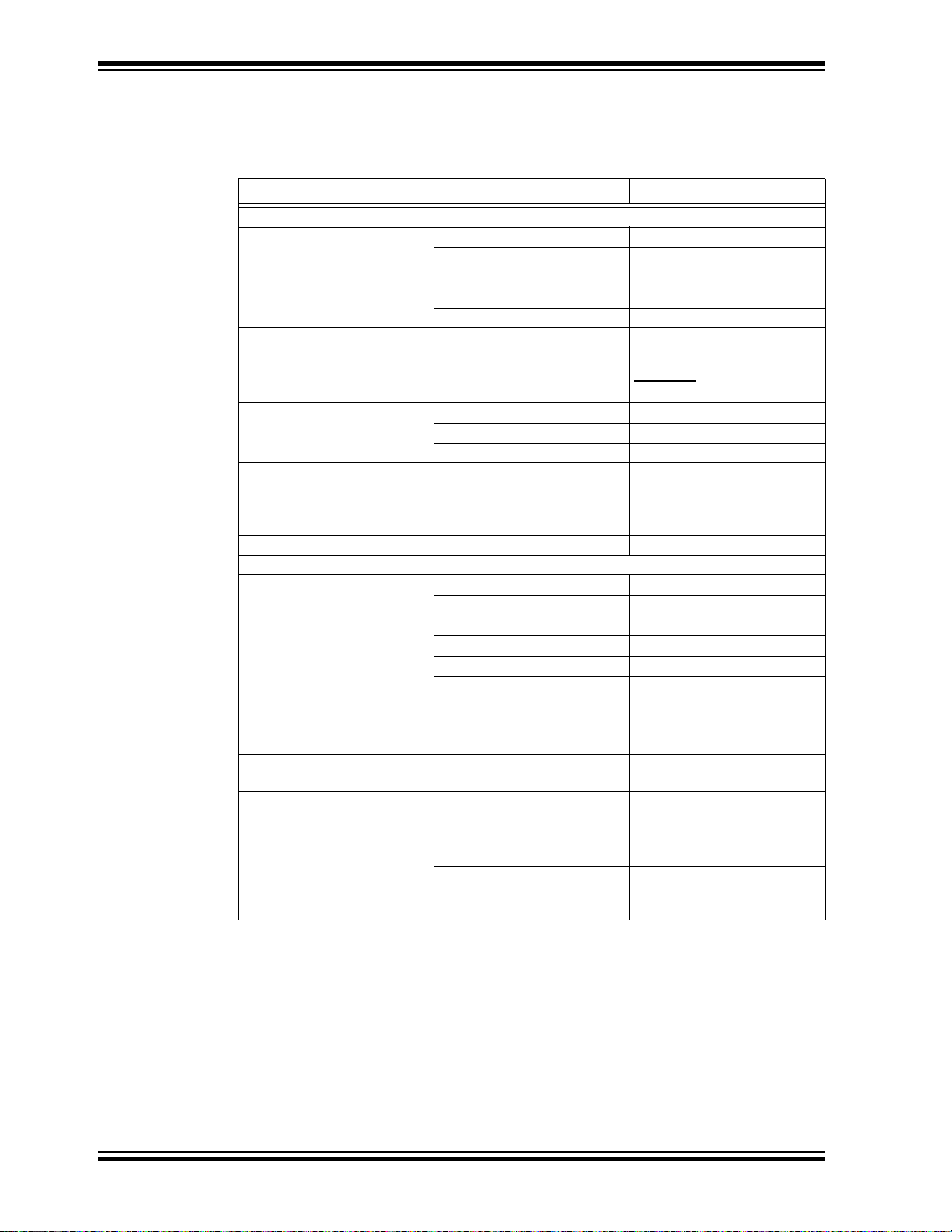

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brac kets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

A menu path File>Save

A tab Click the Power tab

A button on board Press RB0.

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS51721B-page 2 © 2008 Microchip Technology Inc.

Page 7

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use the PICDEM PIC18 Explorer Demonstration

Board. Other useful documents are listed below.

• On the board kit’s CD-ROM:

- Readme file

- Other reference documents

• Other documents, available at http://microchip.com

- “MPLAB

- “PICkit™ 2 Programmer/Debugger User’s Guide” (DS51553)

- “Microchip Development Systems Ordering Guide” (DS 30 177 )

®

ICD 2 In-Circuit Debugger User’s Guide” (DS51331)

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at http://microchip.com. This web

site is used as a means to make files and information easily available to customers.

The web site contains the following information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

:

© 2008 Microchip Technology Inc. DS51721B-page 3

Page 8

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive e-mail notification whenever there are changes,

updates, revisions or errata related to a specified product family or development tool of

interest.

To register, access the Microchip web site at http://microchip.com

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers and other language

tools. These include the MPLAB C18 and MPLAB C30 C compilers; MPASM™

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB ICE 2000 and MPLAB ICE 4000.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger, MPLAB ICD 2.

• MPLAB

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE project manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 and PRO MATE

Plus and PICkit™ 1 development programmers.

®

IDE – The latest information on Microchip MPLAB IDE, the Windows®

®

II device programmers and the PICSTART®

, click on Custome r

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (March 2008)

• Initial release of this document.

Revision B (May 2008)

• Name and title change.

.

DS51721B-page 4 © 2008 Microchip Technology Inc.

Page 9

Chapter 1. Introduction

1.1 INTRODUCTION

The PICDEM™ PIC18 Explorer Demonstration Board is the latest demonstration board

for evaluating Microchip Technology’s PIC18FXXXX and PIC18FXXJXX families of

devices.

The board can be used as a stand-alone device or with an in-circuit debugger, such as

the MPLAB

Sample programs are provided to demonstrate the unique features of the supported

devices. Free software development tools are available for application development

and debugging.

1.2 DEVELOPMENT KI T CON TEN TS

The PICDEM PIC18 Explorer Demonstration Board Kit comes with the following:

• PICDEM™ PIC18 Explorer Demonstration Board (Figure 1-1)

• Board-mounted PIC18F8722 and an alternate PIC18F87J11 mounted on a

Plug-In Module (PIM)

• CD-ROM that contains:

- Sample programs, source code and Hex files

- “PICDEM™ PIC18 Explorer Demonstration Board User’s Guide”

- Other referenced documents

If you are missing any part of the kit, contact your nearest Microchip sales office listed

in the back of this publication.

The MPLAB

software tool set for application development and debugging. Compilers and other

board-compatible software and hardware tools can be purchased.

To download the MPLAB IDE software and documentation, or get information on the

other tools, visit http://microchip.com

®

ICD 2, and host PC.

®

Integrated Development Environment (IDE) is a free, integrated

PICDEM™ PIC18 EXPLORER

DEMONSTRATION BOARD

USER’S GUIDE

.

© 2008 Microchip Technology Inc. DS51721B-page 5

Page 10

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

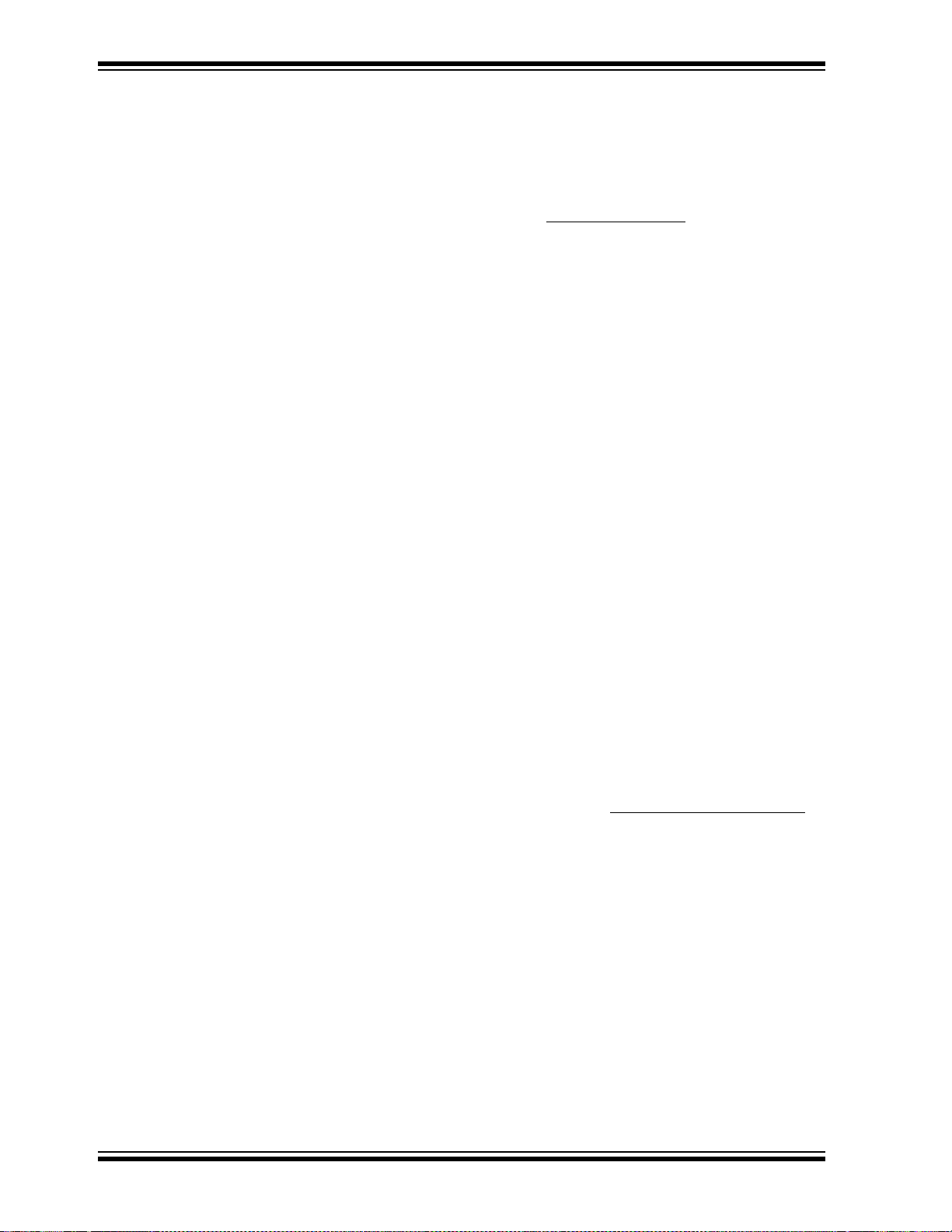

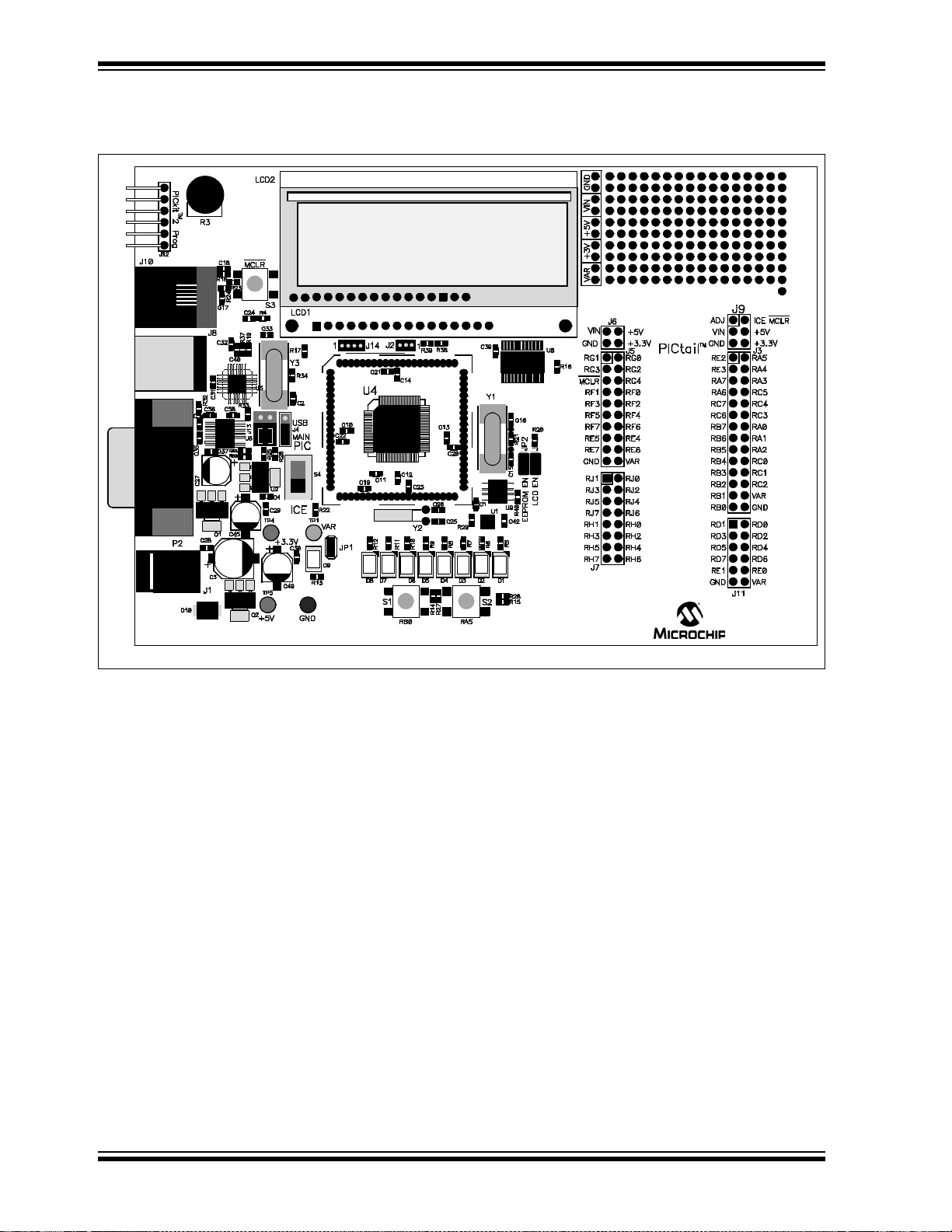

1.3 PICDEM™ PIC18 EXPLORER DEMONSTRATION BOARD

The PICDEM PIC18 Explorer Demonstration Board has the following hardware

features with each feature’s number corresponding to the number in Figure 1-1 that

shows the feature’s location on the board:

1. PIC18F8722 microcontroller – The sample, primary microcontroller mounted on

the board.

2. Male header pins for connecting Plug-In Modules (PIMs). A PIM enables an

alternate PIC18 device to be connected to the board, as the primary

microcontroller.

3. In-Circuit Debugger (ICD) connector.

4. Six-pin, PICkit™ 2 connector.

5. 10 kΩ potentiometer for analog inputs.

6. Push button switch – For external Reset.

7. USB connector – For RS-232 communication.

8. PIC18LF2450 microcontroller – For converting RS-232 communication to USB

protocol for attachment of a host PC.

9. 12 MHz crystal – For the PIC18LF2450 microcontroller.

10. RS-232 DB9 socket and associated hardware – For direct connection to an

RS-232 int erface.

11. Jumper J13 for routing RS-232 communication through either the USB port or

the RS-232 socket.

12. Jumper J4 – For selecting between programming the main PIC

PIC18LF2450, used for USB to RS-232 communication.

13. Switch S4 – For designating the main microcontroller as either the

board-mounted PIC18F8722 or a PIM-mounted microcontroller.

14. LED – For power-on indication.

15. JP1 – For disconnecting the eight display LEDs.

16. Eight LEDs.

17. 32.768 kHz crystal – For Timer1 clock operation.

18. Two push button switches – For external stimulus.

19. Analog temperature sensor, MPC9701A.

20. 25LC256 SPI EEPROM.

21. JP2 – To enable/disable EEPROM.

22. JP3 – To enable/disable LCD.

23. 10 MHz crystal – For the main microcontroller.

24. PICtail™ daughter board connector socket.

25. SPI I/O expander – For LCD display, MCP23S17.

26. Prototype area – For user hardware.

27. LCD display.

28. J2 three-pin, male header – For selecting between a voltage of 3.3V or 5V.

29. J14 four-pin, male header – For use with a PIM, if required, to connect 3.3V or

5V, V

IN and ICE MCLR.

®

device or the

DS51721B-page 6 © 2008 Microchip Technology Inc.

Page 11

FIGURE 1-1: PICDEM™ PIC18 EXPLORER DEMONSTRATION BOARD

29

1

2

3

4

5

6

7

8

9

10

11

12

13

14 15

16

17

18

19

20

21

22

23

24

25

26

27

28

Introduction

1.4 SAMPLE DEVICES

The PICDEM PIC18 Explorer Demonstration Board comes with two sample devices

that alternately can be used as the main microcontroller:

• An 18-pin, 5V PIC microcontroller (the PIC18F8722) mounted on the board

• A 3.3V PIC18 device (PIC18F87J11) mounted on an 80-pin PIM that connects to

the demo board via an 80-pin male

1.5 SAMPLE PROGRAMS

The PICDEM PIC18 Explorer Demonstration Board Kit includes a CD-ROM with

sample demonstration programs. These programs may be used with the included

sample devices and with an In-Circuit Debugger (ICD).

Also provided on the disc is demonstration source code that includes several assembly

source code (ASM) files and one Hex compiled code file.

© 2008 Microchip Technology Inc. DS51721B-page 7

Page 12

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

NOTES:

DS51721B-page 8 © 2008 Microchip Technology Inc.

Page 13

PICDEM™ PIC18 EXPLORER

DEMONSTRATION BOARD

USER’S GUIDE

Chapter 2. Getting Started

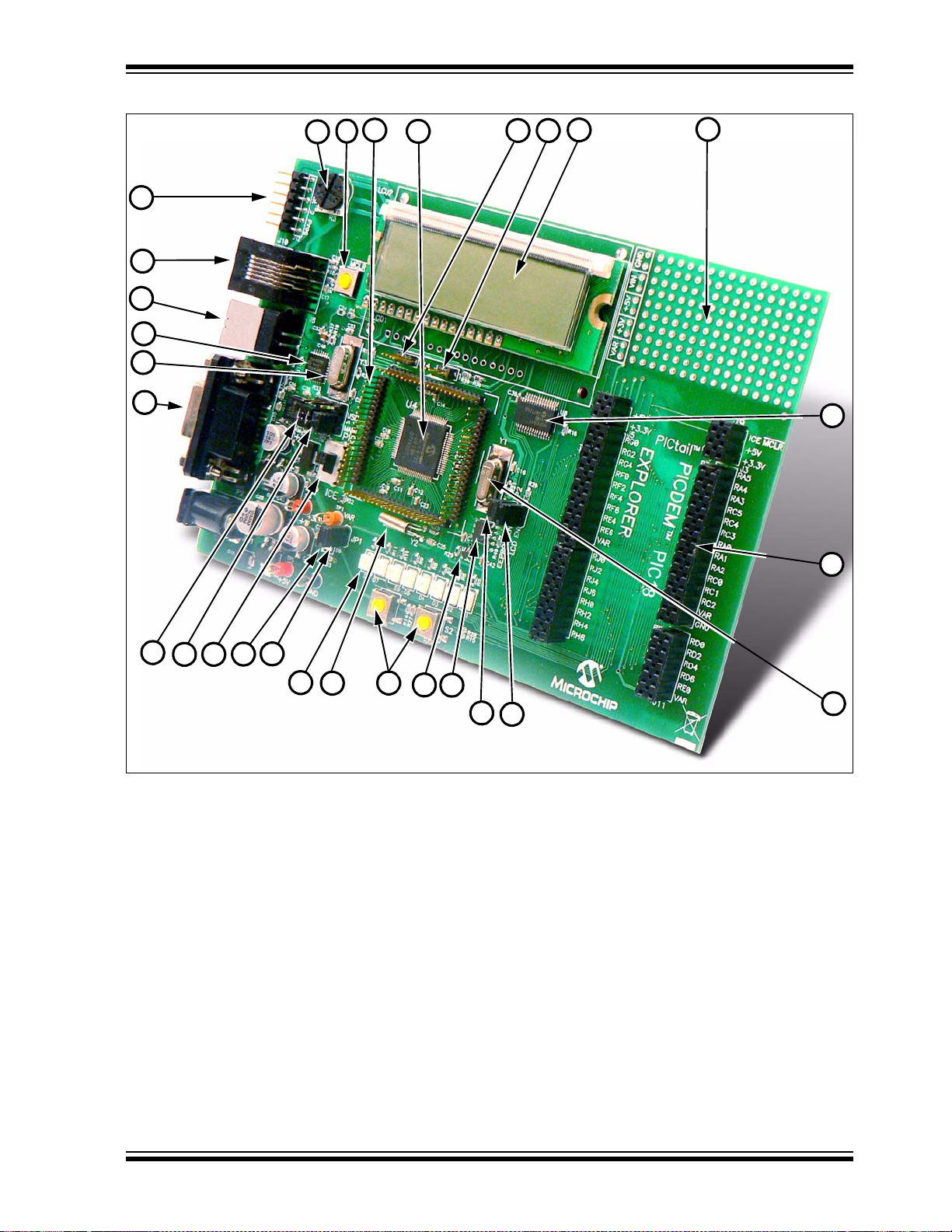

The PICDEM™ PIC18 Explorer Demonstration Board may be used in a variety of

ways. Table 2-1 lists the three primary configurations and the required equipment and

capabilities of each.

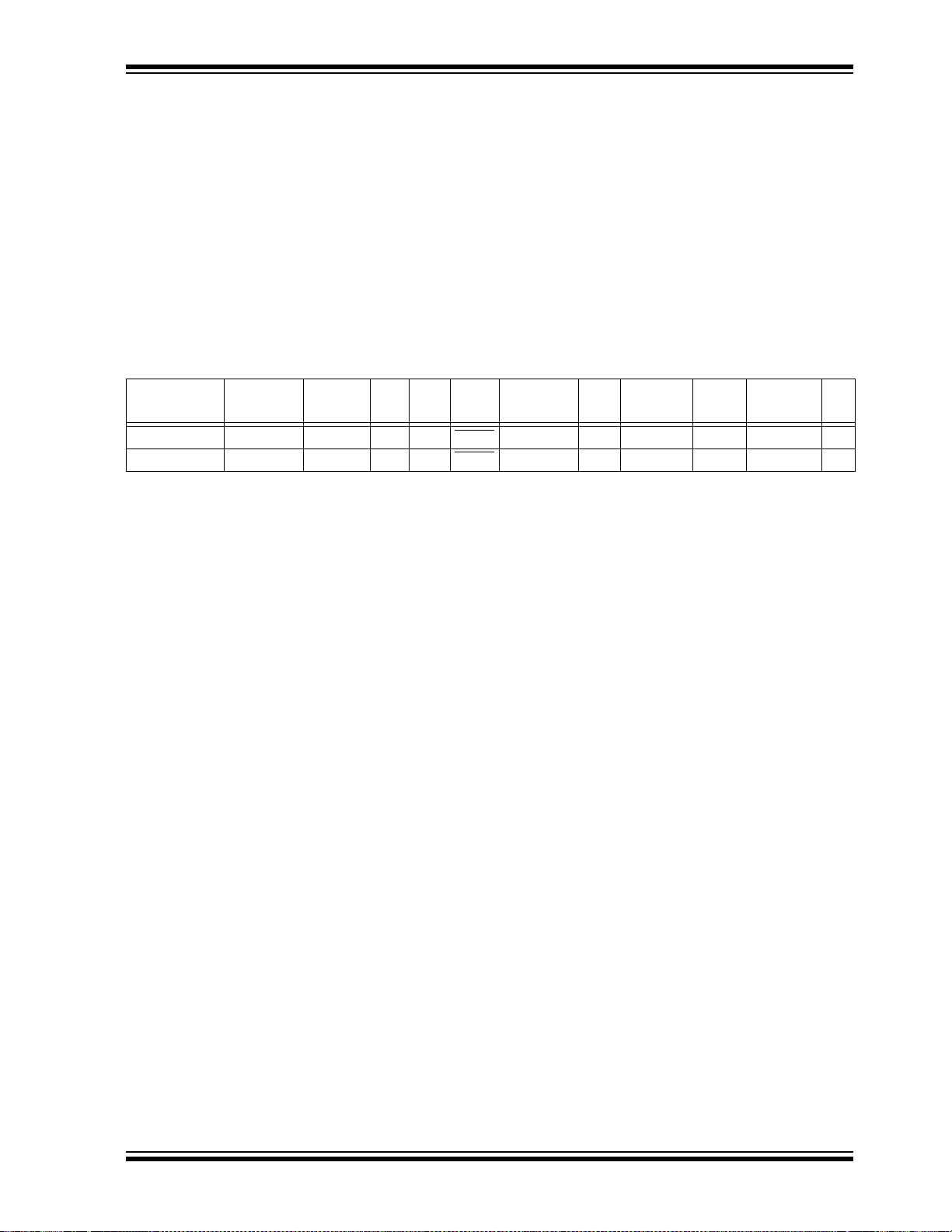

T ABLE 2-1: PICDEM™ PIC18 EXPLORER DEMONSTRATION BOARD CONFIGURATIONS

Configuration Board Connections Board Capabilities

• Access board’s full functionality

• Demonstrate sample code

Stand-alone board Power supply

• Power supply

Board with in-circuit

debugger/programmer

Board with alternate

microcontroller, attached

through a Plug-In Module

(PIM)

† PIM enables 80, 64, 44 and 28-pin devices to be used as the main microcontroller. For information on the

available PIMs, go to

• In-Circuit Debugger (ICD) that

also can be used as a

programmer

• Power supply

• ICD that also can be used as a

programmer

• PIM with mounted microcontroller

http://microchip.com.

• Display functionality with LCD or LEDs

• Connect ICD/programmer for debugging or

programming

• Connect PICtail™ daughter cards

• Access board’s full functionality

• Demonstrate sample code

• Develop and debug code

• Repr ogram micr ocontrollers

• Connect PICtail daughter cards

• Substitute PIM-mounted device as main

microcontroller

• Use 3.3V or 5V devices as main microcontroller

• Demonstrate sample code

• Develop and debug code

• Repr ogram micr ocontrollers

• Connect PICtail daughter cards

†

This chapter describes:

• How to implement each of the uses described in Table 2-1

• How to reprogram the main and RS-232 to USB microcontrollers

• How to connect the demonstration board to a host PC for RS-232 communication

2.1 BOARD AS STAND-ALONE DEVICE

In using the PICDEM PIC18 Explorer Demonstration Board as a stand-alone device,

an implementation can:

• Use the board as is, utilizing the firmware loaded on the main, PIC18F8722

microcontroller and RS-232 to USB PIC18LF2450 microcontroller

• Reprogram the main, PIC18F8722 microcontroller or the RS-232 to USB,

PIC18LF2450 microcontroller and demonstrate user programs

© 2008 Microchip Technology Inc. DS51721B-page 9

Page 14

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

PIC® MCU

S4

ICE

S4 Switch

Switch Location Switch Position

JP2

JP3

JP1

2.1.1 Using the Board As Is

To immed ia tely imp lem ent the PICD EM PIC1 8 Exp lo rer Demo ns tratio n Boar d to

demonstrate the PIC18F8722 microcontroller:

1. Designate the mounted, PIC18F8722 device as the board’s main microcontroller

by moving Switch S4 to PIC MCU, as shown in Figure 2-1.

FIGURE 2-1: S4 SWITCH – SETTING FOR DEFAULT MAIN

MICROCONTROLLER

2. Enable the LEDs by placing a jumper on JP1, as shown in Figure 2-2.

FIGURE 2-2: JP1, JP2 AND JP3 JUMPERS

3. Enable the EEPROM and the LCD by placing a jumper on JP2 and JP3, as

shown in Figure 2-2.

4. Apply power to the board.

For information on acceptable power sources, see Appendix A. “Hardware

Details”.

The device now can be demonstrated using the tutorial program. (See

Section 3.1 “Tutorial Program Operation”.)

DS51721B-page 10 © 2008 Microchip Technology Inc.

Page 15

2.1.2 Reprogramming the Microcontroller

Either or both the main PIC18F8722 microcontroller and RS-232-USB, or the

PIC18LF2450 microcontroller, can be reprogrammed for running the board as a

stand-alone device.

To implement this usage:

1. Reprogram either or both devices, as described in Section 2.4 “Programming

the Microcontrollers”.

2. Disconnect the programming devices.

3. Follow the procedure given in Section 2.1.1 “Using the Board As Is”.

2.2 BOARD WITH IN-CIRCUIT DEBUGGER

The PICDEM PIC18 Explorer Demonstration Board can also be connected to an

In-Circuit Debugger (ICD) that is connected to a host PC. This can be done with the

board’s main microcontroller configured as either the mounted PIC18F8722 device or

an alternate device mounted to a PIM that is plugged into the board. (For information

on PIM attached devices, see Section 2.3 “Board with PIM Attached Devices”.)

The MPLAB

more information, see Section 2.4.1 “Programming Requirements”.) The ICD is

connected, as shown in Figure 2-3, to the ICD connector. For operational information,

see “MPLAB

The PICDEM™ PIC18 Explorer Demonstration Board can alternately use the MPLAB

REAL ICE™ Emulator as a debugger. For more information, see the “Microchip

Development Systems Ordering Guide” (DS30177).

®

ICD 2 In-Circuit Debugger is an inexpensive ICD that could be used. (For

®

ICD 2 In-Circuit Debugger User’s Guide” (DS51331 ).

Getting Started

®

FIGURE 2-3: BOARD WITH MPLAB

ATTACHED

®

ICD 2 IN-CIRCUIT DEBUGGER

For information on other microcontroller compatible ICD or ICE devices, see the

“Microchip Development Systems Ordering Guide” or the Microchip web site at

http://microchip.com

© 2008 Microchip Technology Inc. DS51721B-page 11

.

Page 16

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

Plug-In

Module

(PIM)

2.3 BOARD WITH PIM ATTACHED DEVICES

The PICDEM PIC18 Explorer Demonstration Board also can be used to demonstrate

other PIC18 devices – having them replace the PIC18F8722 mounted on the board as

the board’s main microcontroller. This is done by attaching a Plug-In Module (PIM) that

has the other microcontroller mounted to it.

The PICDEM PIC18 Explorer Demonstration Board comes with the PIC18F87J11 PIM

representing the super set device for the PIC18 J-series of products.

FIGURE 2-4: PICDEM™ PIC18 EXPLORER DEMONSTRATION BOARD WITH PIM

The PIM enables the attachment of 80, 64, 44 or 28-pin devices. Some PIMs also

enable the board’s 5V output to be automatically reset to 3.3V.

For a list of microcontroller-compatible PIMs, see the “Microchip Development Systems

Ordering Guide” (DS30177) or go to http://microchip.com

DS51721B-page 12 © 2008 Microchip Technology Inc.

.

Page 17

Getting Started

PIM Connectors

S4 Switch

PIC® MCU

S4

ICE

2.3.1 Attaching the PIM

To attach the PIM:

1. Seat the PIM in the 80-pin, elevated, male connectors that encircle the

PIC18F8722 (see Figure 2-5).

FIGURE 2-5: PIM CONNECTORS AND S4 SWITCH

Alternately, an In-Circuit Emulator (ICE) can be attached to the male connectors.

This enables in-circuit emulation and user development and debugging of code.

For information on this use, see the Microchip web site (http://microchip.com

2. To designate the PIM-m ounted de vice as th e main mi crocontro ller , set Switch S4

(shown in Figure 2-5) to ICE (see Figure 2-6).

FIGURE 2-6: S4 SWITCH – SETTING FOR PIM-MOUNTED DEVICES

3. If you are converting from the board’s default V

Device Voltage (5V/3.3V)” on page 14.

DD of 5V, see “Varying the

).

© 2008 Microchip Technology Inc. DS51721B-page 13

Page 18

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

2.3.2 Varying the Device Voltage (5V/3.3V)

By default, the PICDEM PIC18 Explorer Demonstration Board’s VDD supply is 5V. The

V

DD can be varied, for PIM-mounted microcontrollers, from 5 to 3.3V to accommodate

devices running at 5 or 3.3V. This V

The PICDEM PIC18 Explorer Demonstration Board enables the voltage change with

PIM connection headers and a variable voltage regulator. PIMs mounted with 3.3V

devices implement the voltage change through two resistors with values that produce

the desired voltage. (See “Calculating Other V

The voltage varying hardware includes:

• An adjustable voltage regulator, the LM317 – Located on the board, left of the PIM

connectors and marked as U2 (recognizable by the TO-220 package commonly

used for transistors)

• Header J2 – Located above the PIM connectors

• Resistors R25 and R26 – Located below jumper J13

• Resistors R101 and R102 – Located on the PIM board

In setting the board’s voltage:

• For the default, 5V voltage –

- For board-mounted PIC18F8722 device:

• Board resistor R25 = 1 kΩ

• Board resistor R26 = 330Ω

- For a PIM-mounted, 5V microcontroller:

• Board resistors R25 and R26 – Same values of 1 kΩ and 330Ω,

respectively

• PIM-mounted resistors R101 and R102 – Unpopulated

DD is named VAR.

DD Values” on page 15.)

• For 3.3V V

DD (achieved only with a PIM with a mounted 3.3V device, such as the

PIC18F87J11) –

- Header J2 goes into the PIM board where resistors R101 and R102 are

inserted in parallel to the board resistors R25 and R26

- PIM board resistor R101 can be unpopulated

- PIM board resistor R102 can be 1.18 kΩ.

Note: For precise adjustment of V

DD, 1% resistors are recommended.

DS51721B-page 14 © 2008 Microchip Technology Inc.

Page 19

Getting Started

V

OUT

V

REF

1

R2

R1

------ -+

⎝⎠

⎛⎞

I

ADJ

R2⋅+=

V

OUT

1.25V 1

R2

R1

------ -+

⎝⎠

⎛⎞

=

R2 R25 R102

||

R25 R102⋅()

R25 R102+()

----------------------------------==

R1 R26 R101

||

R26 R101⋅()

R26 R101+()

----------------------------------==

2.3.3 Calculating Other VDD Valu es

Other VDD values can be produced by the LM317 adjustable voltage regulator by

populating the PIM board’s R101 and R102 with different value resistors.

A brief overview follows, on how to calculate alternate values for these resistors. For

detailed information, see the LM317 data sheet.

EQUATION 2-1: REGULATOR VOLTAGE OUTPUT

I

ADJ is minimized by the LM317, so it can be assumed to be zero, or very small. VREF

is the reference voltage developed by the LM317 between the output and adjustment

terminal and equals 1.25V.

That produces the equations shown in Equation 2-2.

EQUATION 2-2: CALCULATING OUTPUT V OLTAGE

As stated previously, R25 = 1 kΩ, and R26 = 330Ω. Without R102 and R101 being

inserted in parallel on the PIM board, V

To calculate a desired V

OUT:

OUT =1.25V(1+ 1 kΩ/330Ω) = 5.04V.

1. Solve for R2, given R1 = R26 = 330Ω.

2. Now knowing R2 and R25, solve for R102.

3. Determine the nearest available resistor value for R102 and recalculate the

resulting V

DD to make sure it does not exceed the maximum VDD for the part you

will be using.

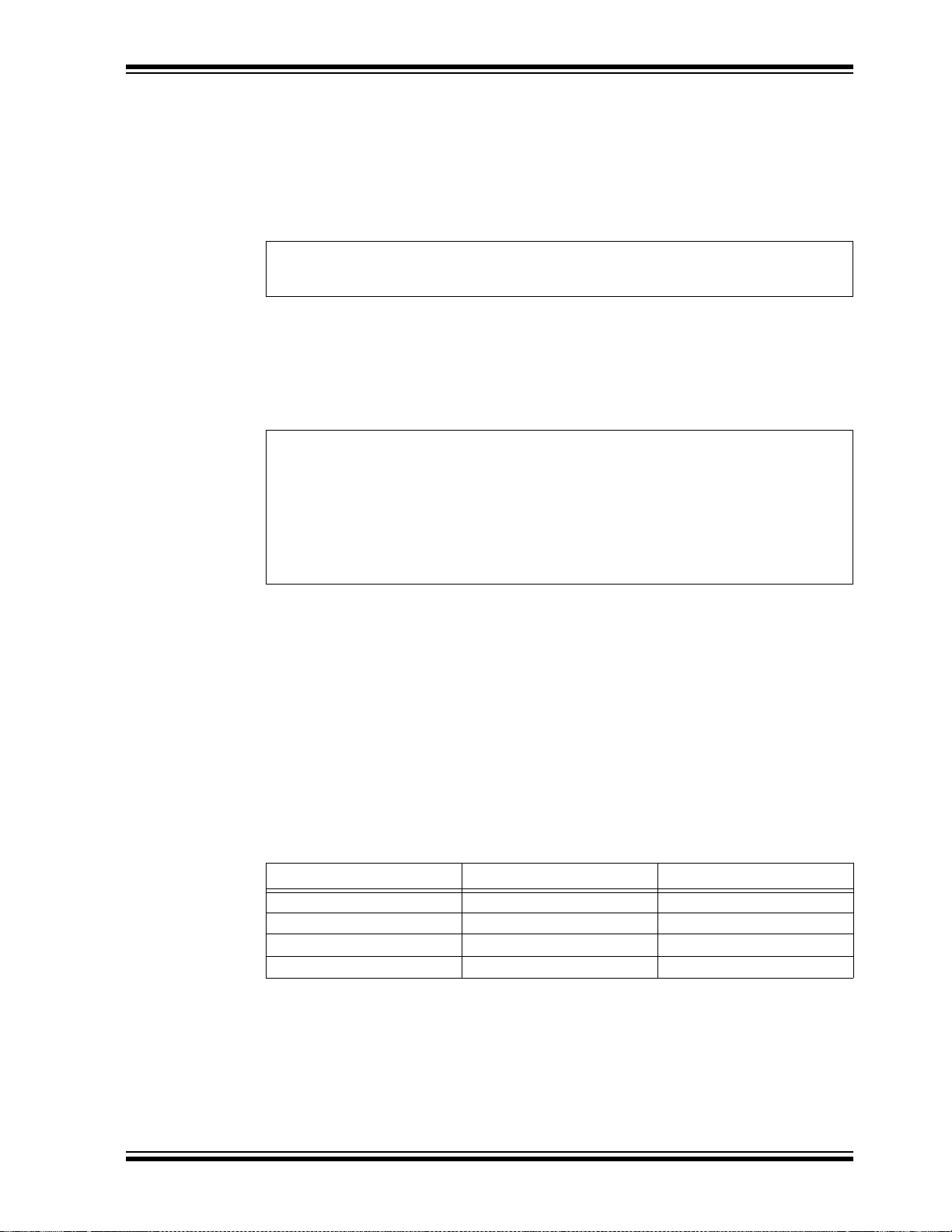

T able 2-2 shows the R101 and R102 resistor values to use for different V

DD values. The

table assumes that the PICDEM PIC18 Explorer Demonstration Board’s R25 and R26

resistors are left at their default values of 1KΩ and 330Ω, respectively.

TABLE 2-2: CALCULATING R101, R102 VALUES FOR V

VDD R101 Value R102 Value

5V Open Open

3.6V Open 1.62 kΩ

3.3V Open 1.18 kΩ

3.0V Open 866 RΩ

† This table assumes that the PICDEM PIC18 Explorer Demonstration Board’s

R25 and R26 resistors are left at their default values of 1 kΩ and 330Ω,

respectively.

DD OUTPUTS

†

© 2008 Microchip Technology Inc. DS51721B-page 15

Page 20

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

2.4 PROGRAMMING THE MICROCONTROLLERS

Either or both the main microcontroller (PIC18F8722) and the RS-232 to USB, or the

PIC18LF2450 microcontroller, can be reprogrammed. The main microcontroller that is

reprogrammed can either be the board-mounted PIC18F8722 device or an alternate

main microcontroller, mounted on a PIM attached to the board.

This section discusses:

• Programming Requirements

• Loading the Program

2.4.1 Programming Requirements

To reprogram a sample device, the following is required:

• Program source code – Sample code is preloaded on the device, but user source

code can be substituted.

If this is done, the sample program can be restored using the file on the board kit’s

CD-ROM.

• An assembler or compiler – Source code must be assembled or compiled into a

Hex file before it can be programmed into the device.

• A programmer – Once the code is in the Hex file format, this device programs the

microcontroller’s Flash memory.

If the code protection bit(s) have not been programmed, the on-chip program

memory can be read out for verification purposes.

In meeting these requirements:

• Code development and debugging –

The free MPLAB

eral other software tools as well as a unified graphical user interface for working

with other Microchip and third-party software and hardware tools.

• Assembler –

The free MPLAB IDE tool includes the MPASM™ assembler.

• Compiler –

Microchip’s MPLAB

integrated for the MPLAB IDE environment.

• Programmer –

Microchip’s MPLAB

used to program the device and both are fully integrated for the MPLAB IDE

environment.

The free MPLAB IDE tool set and its documentation can be downloaded at

http://microchip.com

For a list of the other mentioned devices’ docu mentation, see “Reco mmended

Reading” on page 3.

Other assemblers/compilers can be used. For a list of tools compatible with PIC

microcontrollers, see the Microchip web site (http://microchip.com

®

IDE software development tool includes a debugger and sev-

®

C18 is a C compiler for PIC18 microcontrollers and is fully

®

In-Circuit Debugger (ICD) 2 or PICkit™ Starter Kit can be

.

).

DS51721B-page 16 © 2008 Microchip Technology Inc.

Page 21

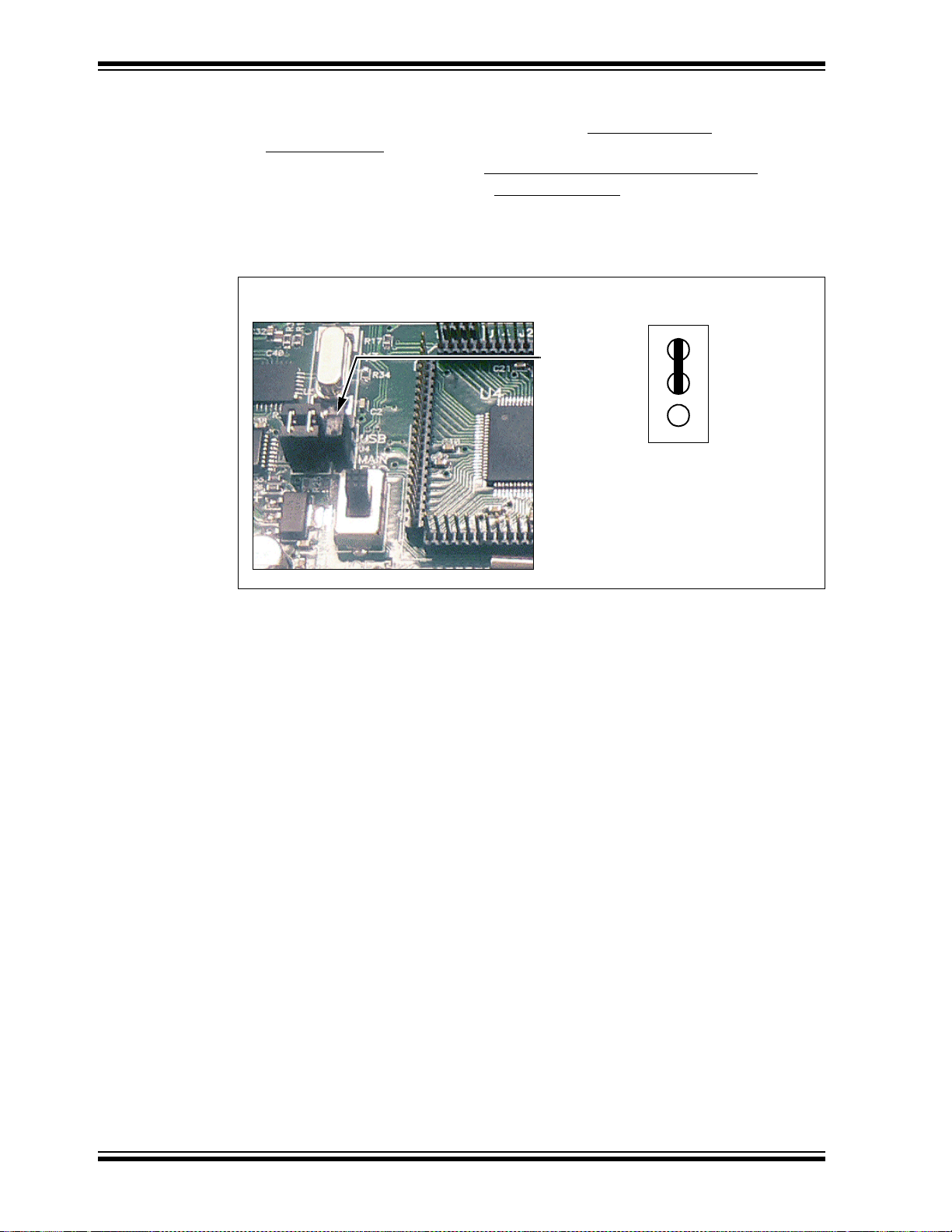

2.4.2 Loading the Program

J4 Jumper

Jumper Location Jumper Setting

USB

J4

Main

Getting Started

This section describes how to program the PICDEM PIC18 Explorer Demonstration

Board using th e MP LA B

Hex code on the compact disc in the PICDEM PIC18 Explorer Demonstration Board’s Kit.

2.4.2.1 REPROGRAMMING WITH THE COMPACT DISC SAMPLE CODE To program the PIC18F8722:

1. Launch the MPLAB IDE application and select Configure>Select

Device>18F8722.

2. To start the programmer, select Programmer>Select Programmer> ICD2

3. To open the Hex code file, select File>Import>Open

CD/Hex/18F8722/Demo8722.hex.

4. Connect the J4 jumper to Main (main controller), as shown in Figure 2-7.

FIGURE 2-7: J4 JUMPER AND ‘MAIN’ SETTING

®

Integrated Development Environment (IDE) and the sample

.

and select

5. Move the S4 switch to PIC MCU, as described in “Using the Board As Is” on

page 10.

To program the PIC18F87J11 on the PIM:

1. Attach the PIM to the demonstration board.

2. Move the S4 switch to ICE.

Note: Both steps 1 and 2 are described in “Attaching the PIM” on p age 13 .

3. Launch the MPLAB IDE application and select Configure>Select

© 2008 Microchip Technology Inc. DS51721B-page 17

Device>18F87J11.

4. To start the programmer, select Programmer>Select Programmer>ICD2

5. To open the Hex code file, select File>Import>Open

CD/Hex/18F87J11/Demo87J11.hex.

6. Connect the J4 jumper to Main (main controller), as shown in Figure 2-7.

and select

.

Page 22

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

J4 Jumper

Jumper Location Jumper Setting

USB

J4

Main

To program the PIC18LF2450 for RS-232 UART communication:

1. Launch the MPLAB IDE application and select Configure>Select

Device>18F2450.

2. To start the programmer, select Programmer>Select Programmer>ICD2

3. To open the Hex code file, select File>Import>Open

CD/Hex/RS232_USB_18F2450/Demo2450.hex.

4. Connect the J4 jumper to USB, as shown in Figure 2-8.

FIGURE 2-8: J4 JUMPER AND ‘USB’ SETTING

and select

.

DS51721B-page 18 © 2008 Microchip Technology Inc.

Page 23

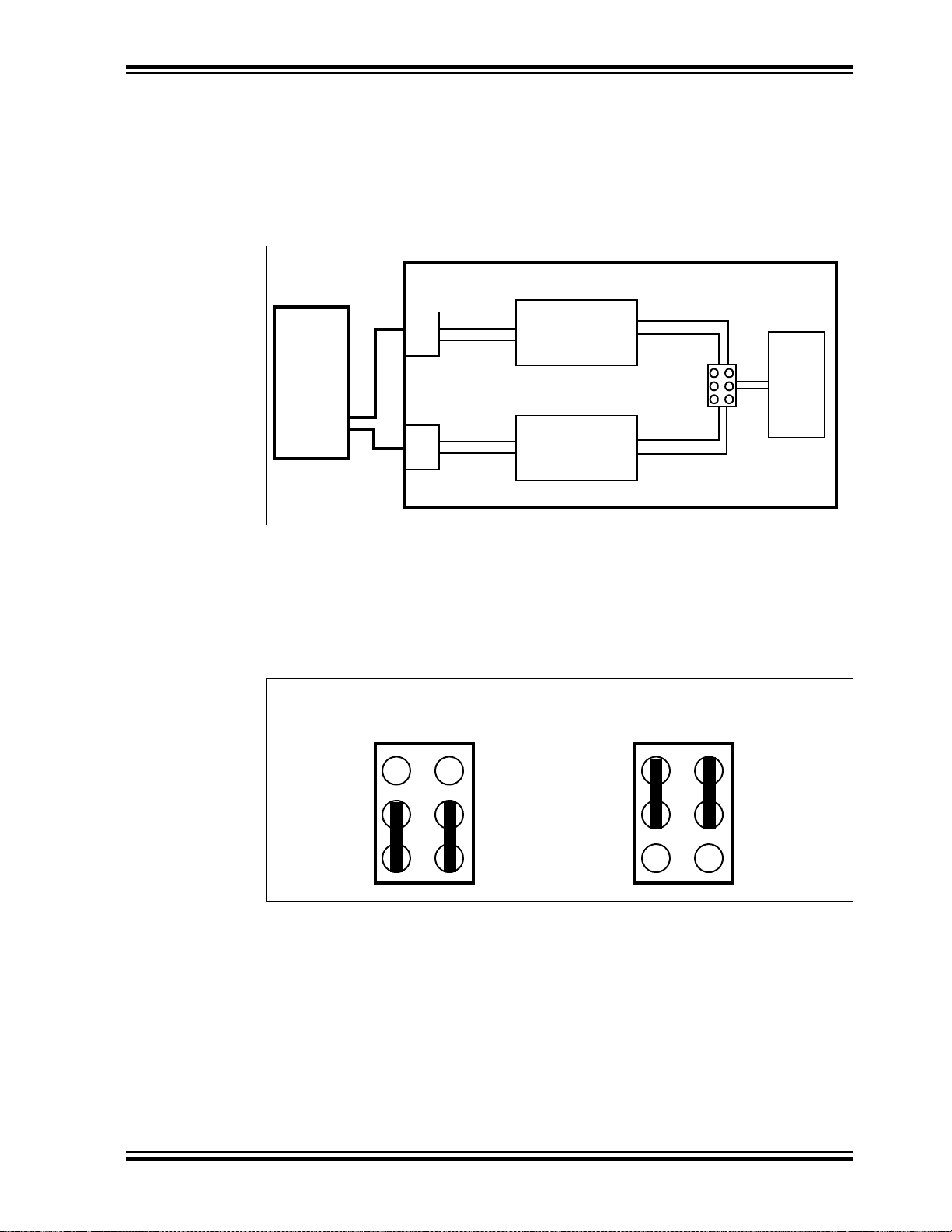

Getting Started

Host

PC

Board

USB

DB9

PIC18LF2450

Microcontroller

J13

Main

PIC

®

MCU

UART Transceiver

Tx

Rx

Tx

Rx

Tx

Rx

X

1

X

2

Connecting to

Nine-Pin RS-232 Port

Connecting to

USB Port

J13

J13

2.5 CONNECTING TO HOST PC FOR RS-232 COMMUNICATION

As shown in Figure 2-9, there are two ways to connect a PC to the PICDEM PIC18

Explorer Demonstration Board.

• Via the USB Port

• Via the DB9 Pin (RS-232 Port)

FIGURE 2-9: BOARD TO PC CONNECTION

2.5.1 PC Connection Via DB9 Pin

To connect the PICDEM PIC18 Explorer Demonstration Board to a host PC via the

nine-pin DB9 connector, set jumper J13, as shown in the first illustration in Figure 2-10.

This routes the main microcontroller’s communications through a transceiver.

FIGURE 2-10: JUMPER J13 – SETTINGS FOR RS-232 OR USB

© 2008 Microchip Technology Inc. DS51721B-page 19

Page 24

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

2.5.2 PC Connection Via USB Port

If the board PC communication is via the USB port, the data will be routed through the

PIC18LF2450 mounted on the board, to convert the RS-232 communication to the USB

protocol.

To connect the PICDEM PIC18 Explorer Demonstration Board to a host PC via the

USB port:

1. Set jumper J13, as shown in the second illustration in Figure 2-10.

2. Install the required file on the host PC. (See the following procedure.)

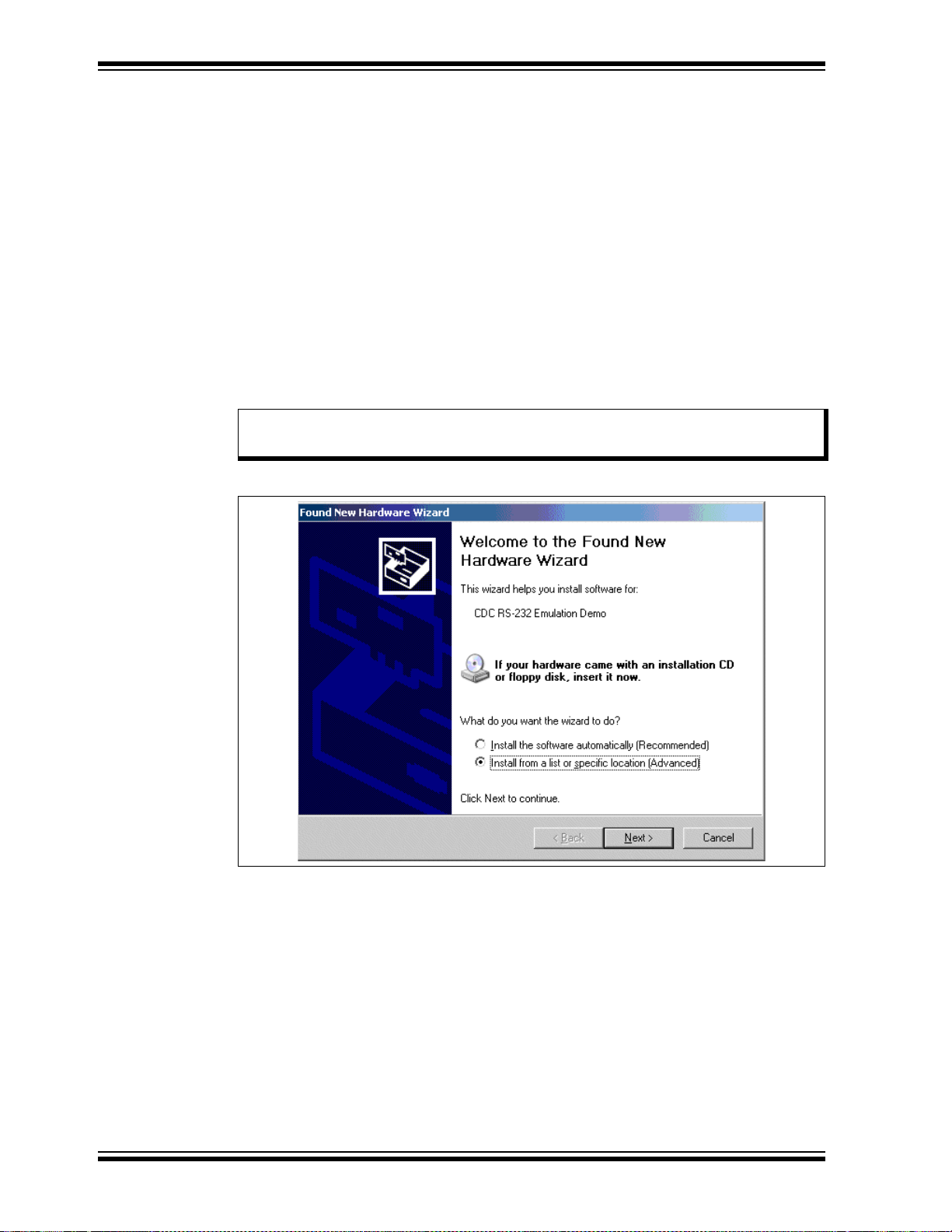

If the USB port is used, an *.inf file must be installed on the host PC. To do this:

1. Create a folder named, HPCINF, anywhere on the host PC’s hard drive.

2. Using the development kit’s CD, copy the file, mchpcdc.inf, into that folder.

3. Connect the board to the PC and power up the board. The pop-up window,

shown in Figure 2-11, appears.

Note: This procedure displays the dialog boxes that appear for the Windows

operating system.

FIGURE 2-11: INSTALLING USB *.inf FILE ON PC – SCREEN 1

®

XP

4. Select the Install from a list or specific location option and click Next. The

screen shown in Figure 2-12 appears.

DS51721B-page 20 © 2008 Microchip Technology Inc.

Page 25

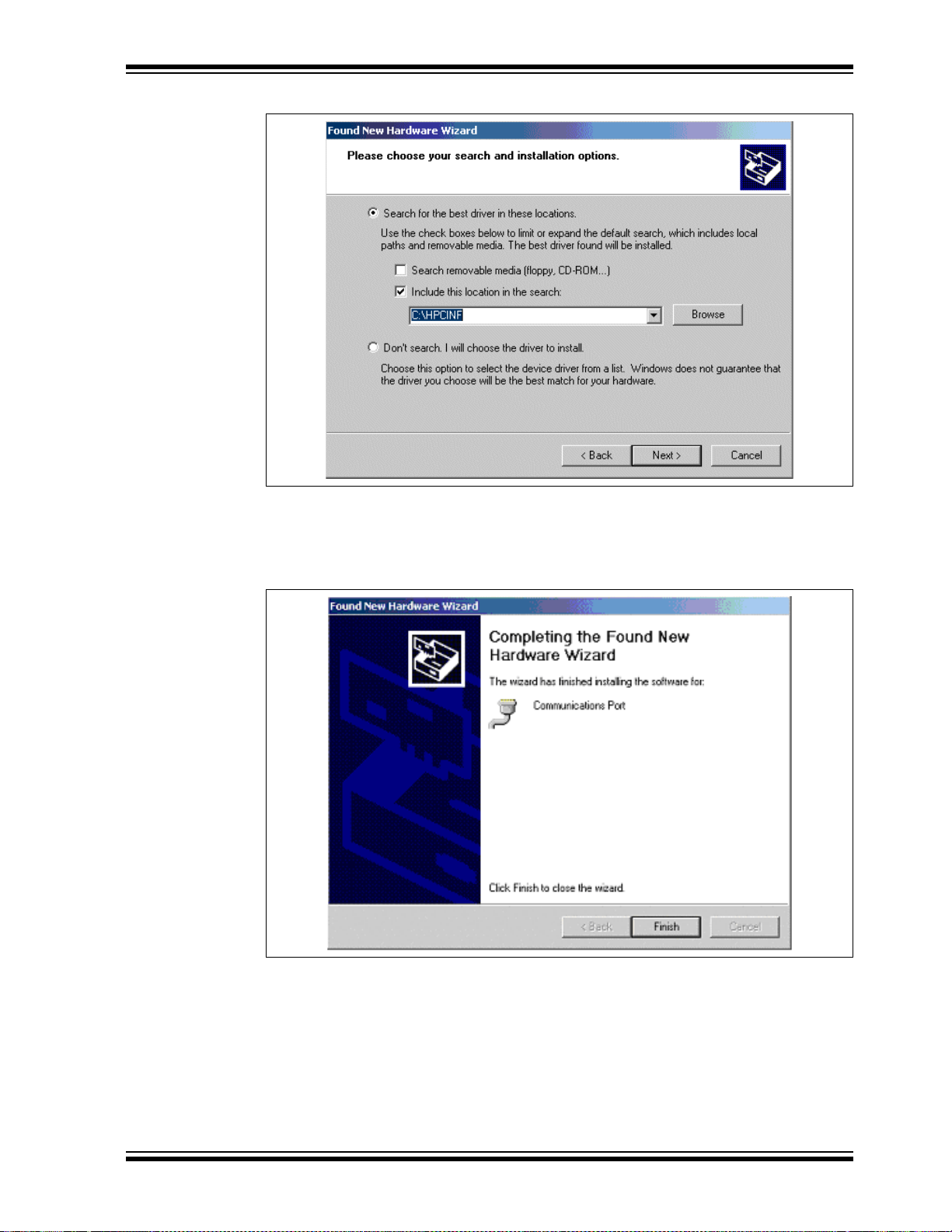

Getting Started

FIGURE 2-12: INSTALLING USB *.inf FILE ON PC – SCREEN 2

5. Select the check box, Include this location in the search, enter the name of

the path (created in Step 1) in the text box below and click Next. The scre en

shown in Figure 2-13 appears.

FIGURE 2-13: INSTALLING USB *.inf FILE ON PC – SCREEN 4

6. Press Finish. The RS-232 to USB functionality is ready to be used.

© 2008 Microchip Technology Inc. DS51721B-page 21

Page 26

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

NOTES:

DS51721B-page 22 © 2008 Microchip Technology Inc.

Page 27

PICDEM™ PIC18 EXPLORER

RB0 Button

RA5 Button

DEMONSTRATION BOARD

USER’S GUIDE

Chapter 3. PICDEM™ PIC18 Explorer Demonstration

Board Tutorial Program

The tutorial program is preprogrammed into the PIC18F8722 on the PICDEM PIC18

Explorer Demonstration Board. This program is also on the PICDEM PIC18 Explorer

Demonstration Board kit’s CD-ROM so that it can be reprogrammed on the sample

device if it the device had been preprogrammed.

For detailed information on the PICDEM PIC18 Explorer Demonstration Board

hardware, see Appendix A. “Hardware Details”.

3.1 T UTORIAL PROGRAM OPERATION

The tutorial program consists of three components that appear sequentially on the

board’s LCD. A flowchart, showing the button navigation through the entire program, is

given in Figure 3-2.

When the board boots up, the device name appears on the LCD and the program

proceeds to the first component.

To select menu options, use the RB0 and RA5 buttons on the bottom of the board (see

Figure 3-1).

FIGURE 3-1: RB0 AND RA5 BUTTONS

1. Voltmeter

This mode uses the Analog-to-Digital Converter (A/D) module to measure the voltage

of the R3 potentiometer and display a value between 0.00V and 5.00V on the LCD. (In

the case of 3.3V devices, the displayed value will be 0.00V to 3.3V.)

The voltage reading is updated continually until the mode is exited by pressing RB0.

2. Temperature

This mode uses an MCP9701A thermal sensor to measure ambient temperature in

Celsius and displays it on the LCD. The program also stores the current temperature,

when exited, by writing to a defined address on the external, on-board EEPROM.

Communication between the micr ocontr ol ler and sens or is done by the A/D mod ule .

To exit this mode, press RB0.

© 2008 Microchip Technology Inc. DS51721B-page 23

Page 28

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

3. Clock

Once this mode is entered from the main menu, a Real-Time Clock (RTC) will start

counting from 00:00:00. The Timer1 module uses a 32-kHz clock crystal to establish

the clock.

The program also sends the time data to the RS-232 serial port using the Universal

Asynchronous Receiver Transmitter (UART) on the microcontroller. This enables the

host PC to display the LCD’s data using the Hyper Terminal application on the PC.

Note: For information on connecting the board’s RS-232 serial port to the PC, see

Section 2.5 “Connecting to Host PC for RS-232 Communication”.

If using the Hyper Terminal application, use the settings given in Table 3-1.

TABLE 3-1: HYPER TE RMINAL SETTINGS

Field Setting

Bits per second

Data bits 8

Parity None

Stop bits 1

Flow control None

9600

To set the clock time:

1. Enter the clock-setting program by pressing RB0. The clock begins running.

2. To set the hours value, press RA5.

3. Increment the hours to the desired value by pressing RB0.

4. To set the minutes value, press RA5.

5. Increment the minutes to the desired value by pressing RB0.

6. T o start the clock with the set time, press RA5. The LCD returns to an active clock

display.

7. To return to the main menu, press RB0.

DS51721B-page 24 © 2008 Microchip Technology Inc.

Page 29

Tutorial Program

Power-up

PICDEM™ PIC18 Explorer

Voltmeter

RA5 = Next

RB0 = Now

Temperature

RA5 = Next

RB0 = Now

Clock

RA5 = Next

RB0 = Now

Volt = n.nnV

RB0 = Exit

Temperature - 022°C

RB0 = Exit

00.00.02

RA5 = Set, RB0 = Menu

00.00.03

RA5 = ->, RB0 = ++

FIGURE 3-2: TUTORIAL PROGRAM FLOWCHART

3.2 SOURCE CODE AND DATA SHEETS

The PICDEM PIC18 Explorer Demonstration Board Kit’s CD-ROM contains the

assembled tutorial program (the Hex files) as well as the source code used to create

those Hex file s. The CD has de vice-specif ic director ies for each set o f source code and

Hex files.

For information on reprogramming the device with new or modified code, see

Section 2.1 “Board as Stand-Alone Device”.

© 2008 Microchip Technology Inc. DS51721B-page 25

Page 30

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

NOTES:

DS51721B-page 26 © 2008 Microchip Technology Inc.

Page 31

Appendix A. Hardware Details

A.1 HARDWARE ELEMENTS

A.1.1 Processor Sockets

The PICDEM PIC18 Explorer Demonstration Board can be populated with 64 and

80-pin devices. Using a Plug-In Module (PIM), the board also can support 28, 44, 64

and 80-pin devices.

For a list of available PIMs, go to the Microchip web site at http://microchip.com

A.1.2 Display

Eight LEDs are connected to PORTD of the PICDEM PIC18 Explorer Demonstration

Board. The PORTD pins are set high to light the LEDs.

These LEDs may be disconnected by removing jumper JP1.

One LED (D9) lights to indicate when the board has power.

PICDEM™ PIC18 EXPLORER

DEMONSTRATION BOARD

USER’S GUIDE

.

A.1.3 Power Supply

The PIC18 Explorer Board does not come with a power supply . It can be powered, via

J1, with an unregulated DC supply of 9V to 15V. The preferred supply is 9V.

For default functionality, a power supply with a current capability of 250 mA is sufficient.

Since the board can serve as a modular development platform connecting to multiple

expansion boards, voltage regulators (Q1 and Q2) are used. Their maximum current

capability is 800 mA. This current capacity may require a power supply of up to 1.6A.

Because the regulators do not have heat sinks, long-term operation at such loads is not

recommended.

When the board is powered, LED D9 is on, indicating the presence of V_VAR.

If an external supply is needed, Microchip’s 9V, 750 mA power supply (part number

AC162039) can be used.

Note: Do not attempt to power the PICDEM PIC18 Explorer Demonstration Board

using the MPLAB ICD 2 module. That module is not designed to be a USB

bus power source.

A.1.4 RS-232 Serial Port

An RS-232, level-shifting integrated circuit has been provided with all the necessary

hardware to support the connection of an RS-232 host through the DB9 connector. The

port can be connected to a PC using a straight-through cable.

The PIC18 receive and transmit pins are tied to the receive and transmit lines of the

MAX3232 transceiver through jumper J13. That jumper can direct where the receive

and transmit pins of the PIC18 are connected, either to:

• The PIC18LF2450 which does the RS-232 to USB communication

• The MAX3232 transceiver

Note: For details on this connection, see Section 2.5 “Connecting to Host PC

for RS-232 Communication”.

© 2008 Microchip Technology Inc. DS51721B-page 27

Page 32

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

A.1.5 Switches

The following switches are available:

• S1 – Active-low switch connected to RB0

• S2 – Active-low switch connected to RA5

• S3 – MCLR

• S4 – MCLR

If the on board, PIC18F8722 microcontroller is being used, set this to PIC MCU.

If an alternate, PIM-mounted microcontroller is being used, set this to ICE.

A.1.6 Oscillator Options

The main oscillator uses a 10 MHz crystal (Y1) which serves as the controller’s primary

oscillator. A second circuit, using a 32.768-kHz (watch type) crystal (Y2), functions as

the Timer1 oscillator, the source for the Real-Time Clock/Calendar (RTCC) and

secondary oscillator.

The PIC18LF2450, the heart of the RS-232 to USB conversion, is independently

clocked with its own 12 MHz crystal (Y3).

A.1.7 Analog Input (Potentiometer)

A 10 kΩ potentiometer is connected through a series resistor to AN0. To provide an

analog input to one of the controller’s Analog-to-Digital (A/D) channels, the

potentiometer can be adjusted from V

to hard reset the processor

select switch.

DD to GND.

A.1.8 ICD Connector

Microchip’s low-cost, in-circuit debugger, MPLAB ICD 2, can be connected to the

modular connector (J10). The ICD connector utilizes RB6 and RB7 for in-circuit

debugging.

Note: For details, see Section 2.4.1 “Programming Requirements”.

A.1.9 PICkit™ 2 Connector

Microchip’s low-cost programmer, PICkit 2, can be connected to the 6-pin interface

provided by J12.

Note: For details, see Section 2.4.1 “Programming Requirements”.

A.1.10 Temperature Sensor

The analog thermal sensor, MCP9701A (U1), is used for monitoring temperature. The

device is connected to the Analog-to-Digital Converter (A/D) module through RA1.

A.1.11 Serial EEPROM

A 25LC256, 256 Kbit (32K x 8) serial EEPROM (U9) is included for nonvolatile storage

of firmware.

The EEPROM also can demonstrate the operation of the Serial Peripheral Interface

(SPI) bus. The EEPROM is enabled or disabled from the SPI bus by jumper JP2.

A.1.12 PICtail™ Daughter Board Connector

The PICtail™ interface enables the PICDEM PIC18 Explorer Demonstration Board to

be connected directly to available PICtail daughter board cards. This provides a

one-to-one connection between the microcontrollers and the cards through SPI/I

interfaces.

DS51721B-page 28 © 2008 Microchip Technology Inc.

2

C™

Page 33

A.1.13 LCD

An LCD display with two lines, 16 characters each, is connected to the SPI I/O

expander, MCP23S17. The two control lines and eight data lines are connected to the

I/O expander.

The I/O expander has an SPI interface that connects it to the microcontroller.The I/O

expander is disabled or enabled from the SPI by jumper JP3.

A.1.14 Sample Devices

A sample part programmed with a simple program is included in the PICDEM PIC18

Explorer Demonstration Board Kit. The devices’ I/O features and port connections are

listed in Table A-1.

TABLE A-1: SAMPLE DEVICE I/O FEATURES AND CONNECTIONS

Device LEDs

RS-232/

USB

S1 S2 S3 LCD

Pot

R3

Hardware Details

EEPROM

Temp

Sensor

ICD/

PICkit™ 2

Y1,

Y2

PIC18F8722 RD7:RD0 RC6/RC7 RB0 RA5 MCLR

PIC18F87J11 RD7:RD0 RC6/RC7 RB0 RA5 MCLR RC3:RC5 RA0 RC3:RC5 RA1 RB6/RB7 Yes

RC3:RC5 RA0 RC3:RC5 RA1 RB6/RB7 Yes

© 2008 Microchip Technology Inc. DS51721B-page 29

Page 34

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

PICDEM™ PIC18

EXPLORER

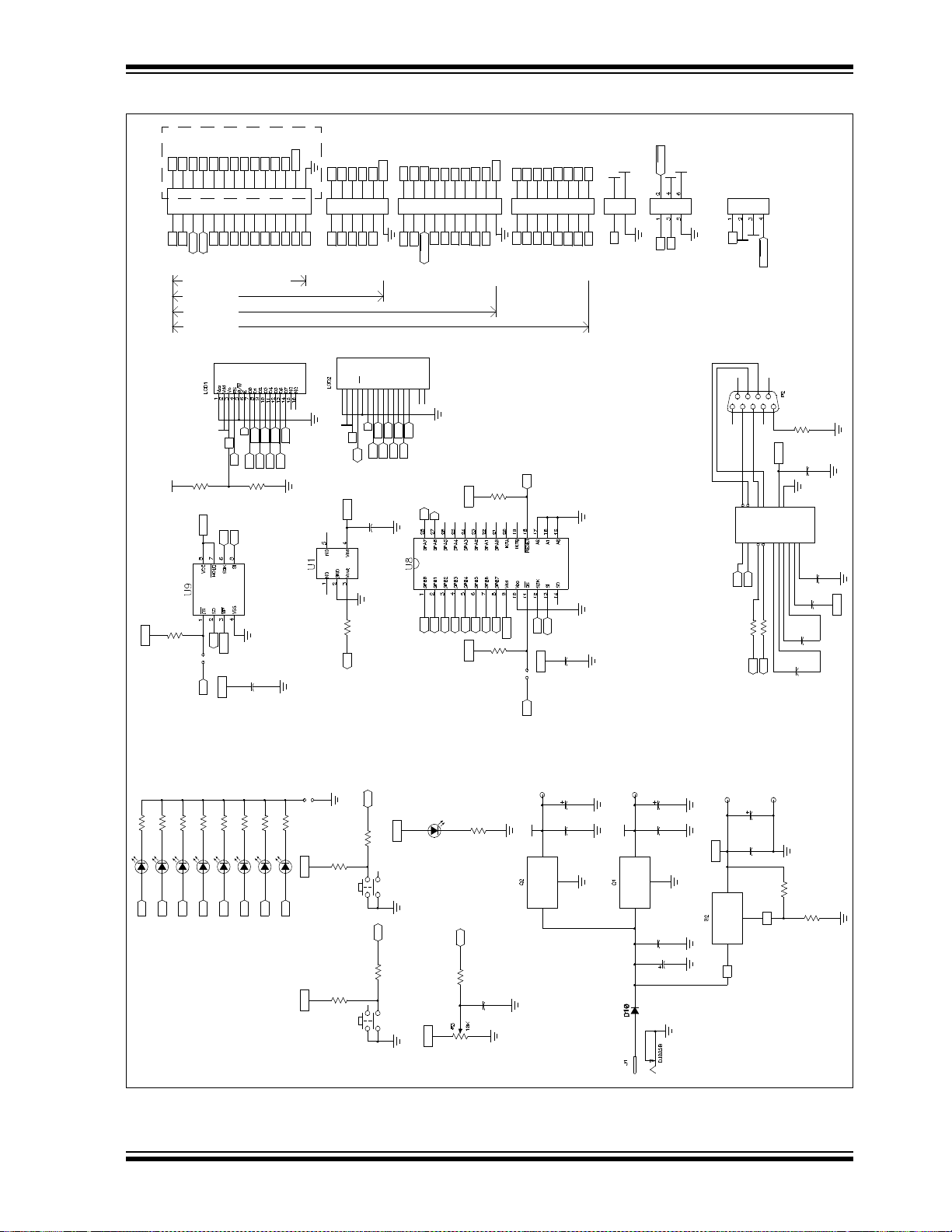

A.2 BOARD LAY O UT AND SCHEMATICS

FIGURE A-1: PICDEM™ PIC18 EXPLORER DEMONSTRATION BOARD LAYOUT

DS51721B-page 30 © 2008 Microchip Technology Inc.

Page 35

Hardware Details

PIC tai l

RA0

RB0

RD7

RD5

RD4

RD2

RD1

1k

R10

1k

R7

RB1

RC5

RC3

V_VAR

DB6

DB5

DB3

DB2

DB0

RA1

V_VAR

RC4

RB2

TXD

RS

V_VAR

RC3

V_VAR

DB4

DB2

VO

DB4

DB2

VO

RH5

RH3

RJ7

RJ5

RJ1

RE7

RE5

RF5

RF3

RG5

RG3

RD7

RD5

RD1

RB0

RB2

RB3

RB5

RB6

RC6

RC7

RA7

RE3

ICEMCLR

RH4

RH2

RJ6

RJ4

RJ0

RE6

RE4

RF4

RF2

RG4

RG2

RD6

RD4

RD0

RC2RC2

RC1RC1

RA2RA2

RA1RA1

RC3RC3

RC4RC4

RA3RA3

RA4RA4

C24

TBD

POT

4

32

1

S1

V_VAR

VIN

Power

330_1%

R26

4

32

1

S2

RD6

RD3

RD0

+3.3V

+5V

D9

1k

R12

1k

R9

1k

R11

1k

R6

1k

R8

1k

R5

RA2

V_VAR

RA3

C35

.1uF

V_VAR

DB7

DB4

V_VAR

DB1

15K

R40

E

C42

.1uF

RC5

V_VAR

C38

.1uF

DB6

RS

DB0

DB6

RS

DB0

RH7

RH1

RJ3

RF7

RF1

RG1

RE1

RD3

RB1

RB4

RB7

RA6

RE2

J9

1 2

3 4

J6

+3.3V

RH6

+3.3V

RH0

RJ2

RF6

RF0

RG0

RE0

RD2

V_VAR

TM

RC0

RA0RA0

RC0

RC5

RA5RA5

RC5

S1GB13

15K

R14

C28

.1uF

C4

.1uF

C29

.1uF

C30

.1uF

V_VAR

R13

1k

R20

15K

V_VAR

C36

.1uF

C37

.1uF

9

PIN98PIN87PIN76PIN6

1

PIN12PIN23PIN34PIN45PIN5

80 - 84 pins

64 - 68 pins

40 - 44 pins

8 - 14 - 18 - 20 - 28 pins

J14

1

14

2

3 4

5 6

7 8

9 10

11 121315 16

17 18

19 20

J5

16

15

9 10

3 4

1413

11 12

5 6

1 2

7 8

J7

1 235

7

468

11 12

9 10

J11

R4

1K

Switch

RXD

RA5

DB7

DB5

DB1

E

Temperature Sensor

DB7

DB5

DB1

E

ICEMCLR

VIN

VIN

ADJ

VIN

RH4RH5

RH2RH3

RJ6RJ7

RJ4RJ5

RJ0RJ1

RE6RE7

RE4RE5

RF4RF5

RF2RF3

RG4PICMCLR

RG2RG3

V_VAR

RD6RD7

RD4RD5

RD0RD1

RB0

RB2

RB3

RB5

RB6

RC6

RC7

OSC1

RE3

C3

220uF ECE-V1EA221UP

V_VAR

R15

1K

TP2

C34

.1uF

TP1

V_VAR

TP4

TP5

Power Indicator

R28

1K

V_VAR

D8

JP1

D5

D6

D7

C1

.1uF

D2

D3

D4

D1

V_VAR

R32

10

RF6

V_VAR

+5V

DB3

+5V

DB3

+5V

+3.3V

+5V

+5V

+5V

RH6RH7

RJ2

RH0

RJ3

RH1

V_VAR

RF6RF7

RG0

RF0

RG1

RF1

RD2

RE0

RD3

RE1

RB1

RB7

RB4

RE2

OSC2

132

ADJ

R25

1K_1%

C27

100uf ECE-V1AA101WR

47uF

C45

47uF

C49

C39

.1uF

JP3

15K

R27

11

DIN110DIN212ROUT19ROUT23C1-1C1+5C2-4C2+6V-2V+

15

GND

16

VCC

8

RIN213RIN1

7

DOUT214DOUT1

U6

MAX3232

R16

15K

MCP23S17

1K

R38

10K

R39

25LC256

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

1 2

3 4

J3

MCP9701A

R36

470

1K

R29

JP2

1

ADJUST

3

IN

2

OUT

LM317

R35

470

1

GND

3

IN

2

OUT

LM1117

LCM-SO1602 DTR/M

1

GND

3

IN

2

OUT

LM1117

15

LED_+13D610D37D04RS1Vss

14D716

LED_-

9D26E3

Vo

11

D48D1

2

Vdd5R/W

12

D5

MDLS-16264 S S-DIF

FIGURE A-2: PICDEM™ PIC18 EXPLORER DEMONSTRATION BOARD SCHEMATIC – 1 OF 2

© 2008 Microchip Technology Inc. DS51721B-page 31

Page 36

PICDEM™ PIC18 Explorer Demonstration Board User’s Guide

RD0

RD1

RD3

RD4 OSC2

RD6

RD7

RE0

RE2

RE3

RE5

RE6

RF1

RF2

RF4

RF5

RF7

RH5

RH4

RF0 RE3

RF0

RE4

V_VAR

RA3 RE6 RA3

RA2 RE7 RA2

RA0 V_VAR RA0

RA5 RD2

V_VAR

RA4 RD3 RA5

RC0

RD5

RC1

RC6

RD6

RC0

RC7

RJ4

PICMCLR

RH1

RH0

RE3

V_VAR RE4

RE6

RE7

V_VAR

RD1

RD2

RD4

RD5

RD7

RJ0

RC7

RC4

RB2

RC6

RC3

RC0

RB4

RB1

RA4

RA0

VBUS

V_VAR

RB7

RC6

RC7

RG0

RG2

RH2

RH4

RJ0

RJ4

RJ6

RF2

RF3

RF5

RF6

V_VAR

PICMCLR

RG3

RG1

RG0

RE1

PIC18F6627

PIC18F6622

RC2

RC3

RC5

RB7

OSC1

OSC2

RB6

RB5

RB3

RB2

RB0

RJ7

RC2

RC4

RC5

V_VAR

OSC1

RB5

RB4

RB2

RB1

RJ3

RJ2

V_VAR

MAIN_

MCLR

RB6

RB7

MCLR

MCLR

MAIN_

MCLR

ADJ

VIN

RB6

RB7

V_VAR

MCLR

C31

.1uF

RB6

RC2

RA2

RB0

C15

22pf

R34

1M

C16

22pf

OSC2

RD2

RE1

RD5

OSC1

RC0

RF3

RE4

RF0

RE7

RC1

+3.3V

RB6

RF6

TXD

RXD

VBUS

RH6

RH0

RG4

RJ2

RF7

RF4

RG2

RG4

RE0

RF1

RE5

RE2

RF1

RA1

PIC18F6527

RD1

RD0 RA1

RC7

RC1

RD7

RD4

RC6

RA4

RC4

RB4

RB1

RJ5

RJ6

RB7

RC3

OSC2

RB6

RB0

RB3

V_VAR

V_VAR

C11

.1uF

USB_MCLR

V_VAR

ICD Connector

C13

.1uF

C14

.1uF

PICMCLR

ICEMCLR

12Mhz

Y3

47K

R19

C25

22pf

C26

22pf

C40

.47uF

C32

.1uF

RE5

RE2

V_VAR

RD0

RD6

RD3

RJ1

C18

.1uF

4.7K

R18

C19

.1uF

R17

47K

C20

.1uF

C21

.1uF

RC1

RB7

RB5

RA3

RA1

R37

33K

USB_MCLR

RG3

PIC18F8627 RH1

PIC18F8527 RH5

RH7

RJ1

RJ3

RJ7

RH7

RF2

RF4

RF5

RF7

V_VAR

USB_D+

RG4

USB_D-

RG3

RG2

RG0

RE0

RH3

RH2

MAIN_

MCLR

RC5

RB3

RA5

OSC1

R21

1M

R33

10K

V_VAR

RG1

PIC18F8622 RH3

RJ5

RH6

RF6

RF3

ICEMCLR

RE1

RG1

V_VAR

4

32

1

S3

R23 1k

C17

.1uF

C10

.1uF

C12

.1uF

10Mhz

Y1

341

2

5 6

J8

C22

.1uF

C23

.1uF

V_VAR

213

J2

R22

47K

123

J4

C2

22pf

C33

22pf

12346

5

J10

R24

100

12345

6

J12

PICKIT2 Programmer

32Khz

Y2

5

VSS

17

VDD

23

RB5

20

RB2

7

OSC2

15

RC7/RX

14

RC6/TX

9

RC18RC0

22

RB421RB3

6

OSC1

16

VSS

11

Vusb

25

RB724RB6

19

RB118RB0

4

RA5/AN4

1

RA2/VREF-27RA0/AN028RA1/AN12RA3/VREF+3RA4/RCV

26

MCLR/RE3

13

RC5/D+/VP

10

RC2/CCP1

12

RC4/D-/VM

U5

PIC18LF2450

72

RD0/PSP0/AD0

67

RD3/PSP3/AD3

64

RD6/PSP6/AD6

78

RE2/CS/A D10

75

RE5/AD13

23

RF1/AN6/ C2OUT

16

RF4/AN9

13

RF7/SS1

49

OSC1/CLKI/RA7

32

VDD

70

VSS

11

VSS

69

RD1/PSP1/AD1

66

RD4/PSP4/AD4

68

RD2/PSP2/AD2

63

RD7/PSP7/AD7

4

RE0/RD/AD8

77

RE3/AD11

74

RE6/AD14

76

RE4/AD12

3

RE1/WR/AD9

18

RF2/AN7/ C1OUT

15

RF5/AN10/ CVREF

24

RF0/AN5

17

RF3/AN8

14

RF6/AN11

26

AVSS

71

VDD

25

AVDD

48

VDD

9

MCLR/VPP

51

VSS

31

VSS

50

OSC2/CLKO/RA6

46

RC5/SDO143RC2/ECCP1

52

RB6/KBI2PGC55RB3/INT3/ECCP258RB0/INT033RA5/AN4/HLVDIN28RA2/AN2/VREF-

7

RG2/RX2/DT2

80

RH1/A17

22

RH4/AN1219RH7/AN15

62

RJ0/ALE

59

RJ3/WRH

41

RJ6/LB

65

RD5/PSP5/AD5

73

RE7/CCP2/AD15

37

RC6/TX1/CK138RC7/RX1/DT1

36

RC0/T1OSO/T13CKI47RB7/KBI3/PGD54RB4/KBI0

35

RC1/T1OSI/CCP2

53

RB5/KBI1/PGM

44

RC3/SCK1/SCL1

57

RB1/INT1

27

RA3/AN3/VREF+30RA0/AN034RA4/T0CKI29RA1/AN1

5

RG0/CCP3

10

RG4/CCP5

79

RH0/A162RH3/A19

8

RG3/CCP4

1

RH2/A18

21

RH5/AN13

60

RJ2/WRL

39

RJ4/BA0

42

RJ7/UB61RJ1/OE

40

RJ5/CE

56

RB2/INT2

45

RC4/SDI1/SDA1

12

VDD

6

RG1/TX2/CK2

20

RH6/AN14

U4

PIC18F8722

1

RE1/WR/P2C2RE0/RD/P2D3RG0/ECCP3/P3A4RG15RG26RG3/P3D7RG5/MCLR/VPP8RG4/P1D9VSS10VDD11RF7/

SS

12

RF6/AN1113RF5/AN10/CVREF14RF4/AN915RF3/AN816RF2/AN7

48

RB0/INT047RB1/INT146RB2/INT245RB3/INT344RB4/KBI0

43

RB5/KBI1/PGM

42

RB6/KBI2/PGC

41

VSS

40

RA6/OSC2/CLKO

39

RA7/OSC1/CLKI

38

VDD

37

RB7/KBI3/PGD

36

RC5/SDO1

35

RC4/SDI1/SDA1

34

RC3/SCK1/SCL1

33

RC2/ECCP1/P1A

17

RF1/AN6

18

RF0/AN5

19

AVDD

20

AVSS

21

RA3/AN3/VREF+

22

RA2/AN2/VREF-

23

RA1/AN1

24

RA0/AN0

25

VSS

26

VDD

27

RA5/AN4/LVDIN

28

RA4/T0CKI

29

RC1/T1OSI/ECCP2/P2A

30

RC0/T1OSO/T13CKI

31

RC6/TX/CK1

32

RC7/RX/DT1

64

RE2/CS/P2B

63

RE3/P3C

62

RE4/P3B

61

RE5/P1C

60

RE6/P1B

59

RE7/ECCP2/P2A

58

RD0/PSP0

57

VDD

56

VSS

55

RD1/PSP1

54

RD2/PSP2

53

RD3/PSP3

52

RD4/PSP4

51

RD5/PSP5

50

RD6/PSP6

49

RD7/PSP7

U7

PIC18F6522

33

RH5

36

RF0

39

RA3

42

RA0

45

VDD

51

RC7

11

RH1

8

RE3

5

RE6

2

VDD

83

RD1

48

RC1/T1OSI

80

RD4

77

RD7

32

RH6

29

RF3

26

RF6

23

VSS

20

RG5/MCLR

17

RG1

14

RE1

54

RJ6

57

RC3

60

RB7

63

OSC2/RA6

66

RB6

69

RB3

72

RB0

27

RF528RF430RF231RH7

21

RG422NC24VDD25RF7

18

RG219RG3

15

RE016RG0

12

RH213RH3

38

AVSS

35

RF1

37

AVDD

41

RA1

43

NC

44

VSS

47

RA4

50

RC6

53

RJ5

58

RC459RC556RC2

55

RJ7

61

VDD

62

OSC1

64

NC

65

VSS

71

RB170RB267RB568RB4

74

RJ273RJ3

6

RE5

9

RE2

7

RE4

3

RD0

1

NC

84

VSS

49

RC0/T1OSO

81

RD3

79

RD5

78

RD6

75

RJ1

34

RH4

40

RA2

46

RA5

52

RJ4

10

RH0

4

RE7

82

RD2

76

RJ0

U1A

ICE MODULE

FIGURE A-3: PICDEM™ PIC18 EXPLORER DEMONSTRATION BOARD SCHEMATIC – 2 OF 2

DS51721B-page 32 © 2008 Microchip Technology Inc.

Page 37

NOTES:

Hardware Details

© 2008 Microchip Technology Inc. DS51721B-page 33

Page 38

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-4182-8400

Fax: 91-80-4182-8422

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

01/02/08

DS51721B-page 34 © 2008 Microchip Technology Inc.

Loading...

Loading...