Page 1

PICDEM™ Lab

Development Board

User’s Guide

© 2009 Microchip Technology Inc. DS41369A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

PICSTART, rfPIC, SmartShunt and UNI/O are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

FilterLab, Linear Active Thermistor, MXDEV, MXLAB,

SEEVAL, SmartSensor and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, CodeGuard,

dsPICDEM, dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, In-Circuit Serial

Programming, ICSP, ICEPIC, Mindi, MiWi, MPASM, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, PICkit, PICDEM,

PICDEM.net, PICtail, PIC

32

logo, PowerCal, PowerInfo,

PowerMate, PowerTool, REAL ICE, rfLAB, Select Mode, Total

Endurance, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2009, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS41369A-page ii © 2009 Microchip Technology Inc.

Page 3

Chapter 1. Overview

1.1 Introduction ..................................................................................................... 5

1.2 Highlights ........................................................................................................ 5

1.3 PICDEM™ Lab Development Kit Contents .................................................... 5

1.4 PICDEM™ Lab Development Board Construction and Layout ...................... 6

1.5 Target Power .................................................................................................. 7

1.6 Connecting the PICkit™ 2 Programmer/Debugger ........................................ 8

1.7 Solderless Prototyping Area Strip Configuration ............................................ 9

Chapter 2. Getting Started

2.1 Introduction ................................................................................................... 11

2.2 Prerequisites ................................................................................................ 11

2.3 The Software Control Loop .......................................................................... 11

2.4 MPLAB

2.5 Installing the Included Lab Files ................................................................... 16

®

IDE Download Instructions ............................................................ 12

PICDEM™LAB DEVELOPMENT

BOARD USER’S GUIDE

Table of Contents

Chapter 3. General Purpose Input/Output Labs

3.1 Introduction ................................................................................................... 17

3.2 General Purpose Input/Output Labs ............................................................. 17

3.3 GPIO Output Labs ........................................................................................ 18

3.3.1 Reference Documentation ......................................................................... 18

3.3.2 Equipment Required for GPIO Output Labs .............................................. 18

3.3.3 PICDEM Lab Development Board Setup for GPIO Output Labs ............... 18

3.3.4 Lab 1: Light LEDs ...................................................................................... 19

3.3.5 Lab 2: Flash LEDs (Delay Loop) ............................................................... 25

3.3.6 Lab 3: Simple Delays Using Timer0 .......................................................... 29

3.3.7 Lab 4: Rotate LEDs ................................................................................... 34

3.4 GPIO Input Labs ........................................................................................... 38

3.4.1 Reference Documentation ......................................................................... 38

3.4.2 Equipment Required for GPIO Input Labs ................................................. 38

3.4.3 PICDEM Lab Development Board Setup for GPIO Input Labs ................. 38

3.4.4 Lab 5: Adding a Push Button ..................................................................... 39

3.4.5 Lab 6: Push Button Interrupt ..................................................................... 48

3.4.6 Lab 7: Push Button Interrupt-on-Change .................................................. 53

3.4.7 Lab 8: Using Weak Pull-Ups ..................................................................... 58

© 2009 Microchip Technology Inc. DS41369A-page iii

Page 4

PICDEM™Lab Development Board User’s Guide

Chapter 4. Comparator Peripheral Labs

4.1 Introduction ................................................................................................... 61

4.2 Comparator Labs .......................................................................................... 61

4.2.1 Reference Documentation .........................................................................61

4.2.2 Comparator Labs .......................................................................................61

4.2.3 Equipment Required ..................................................................................61

4.2.4 Lab 1: Simple Compare .............................................................................62

4.2.5 Lab 2: Using the Comparator Voltage Reference ......................................64

4.2.6 Lab 3: Higher Resolution Sensor Readings Using a Single Comparator ...68

Chapter 5. Analog-to-Digital Converter Peripheral Labs

5.1 Introduction ................................................................................................... 75

5.2 ADC Labs ..................................................................................................... 75

5.2.1 Reference Documentation .........................................................................75

5.2.2 Equipment Required ..................................................................................75

5.2.3 Lab 1: Simple ADC ....................................................................................76

5.2.4 Lab 2: Audible Temperature Sensor ..........................................................85

Appendix A. Schematic

A.1 PICDEM Lab Development Kit Schematic ................................................... 91

DS41369A-page iv © 2009 Microchip Technology Inc.

Page 5

PICDEMTM LAB DEVELOPMENT

BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

INTRODUCTION

®

IDE on-line help.

This chapter contains general information that will be useful to know before using the

PICDEM

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the PICDEM TMLab Development Board as a

development tool to emulate and debug firmware on a target board. The manual layout

is as follows:

• Chapter 1. “Overview ”

• Chapter 2. “Getti ng Started”

• Chapter 3. “Gener al Purpo se Inp ut/Ou tp ut Lab s”

• Chapter 4. “Comparator Periphera l Labs”

• Chapter 5. “Analog- to -Di gital Converter Peri phe ral Labs”

• Appendix A. “Schematic”

TM

Lab Development Board. Items discussed in this chapter include:

© 2009 Microchip Technology Inc. DS41369A-page 1

Page 6

PICDEMTM Lab Development Board User’s Gu ide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS41369A-page 2 © 2009 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This user’s guide describes how to use the PICDEM™ Lab Development Kit. Other

useful documents are listed below. The following Microchip documents are available

and recommended as supplemental reference resources.

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB

contain update information and known issues that may not be included in this user’s

guide.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

®

IDE installation directory. The Readme files

© 2009 Microchip Technology Inc. DS41369A-page 3

Page 8

PICDEMTM Lab Development Board User’s Gu ide

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (February 2009)

• Initial Release of this Document.

DS41369A-page 4 © 2009 Microchip Technology Inc.

Page 9

1.1 INTRODUCTION

The PICDEM Lab Development Board supports Microchip’s 8, 14, 18 and 20-pin 8-bit

MCUs including accommodation for PIC10F products in the 8-pin PDIP package.

Dual-row expansion headers on either side of each socket provide connectivity to all

pins on the connected PIC

explore a relatively large number of application examples without making permanent

modifications to the board. Components permanently mounted to the board are interfaced using expansion headers to the user’s application via jumper wires. A variable

supply voltage allows user’s to supply voltages between 1.2V to 5V to each of the PIC

MCU connection sockets.

1.2 HIGHLIGHTS

This chapter discusses:

• PICDEM™ Lab Development Kit Contents

• PICDEM™ Lab Development Board Construction and Layout

• Target Power

• Connecting the PICkit™ 2 Programmer/Debugger

• Solderless Prototyping Area Strip Configuration

PICDEMTM LAB DEVELOPMENT

BOARD USER’S GUIDE

Chapter 1. Overview

®

MCU. A solderless prototyping area allows the user to

1.3 PICDEM™ LAB DEVELOPMENT KIT CONTENTS

The PICDEM™ Development Kit contains the following items:

1. The PICDEM™ Lab Development Board

2. Lab component kit including:

• (1) PIC16F616 DIP

• (1) PIC12F615 DIP

• (4) 10kΩ Resistors

•(4) 1kΩ Resistors

• (8) 470Ω Resistors

• (4) 220Ω Resistors

• (4) 100Ω Resistors

• (1) 10kΩ NTC Thermistor

• (4) Green LEDs

• (4) Red LEDs

• (4) 1N4148 Diodes

•(2) 0.1μF Capacitors

•(2) 1μF Capacitors

•(2) 10μF Capacitors

• (4) Push buttons

• (10) 5” Jumper Wires

• (10) 3” Jumper Wires

© 2009 Microchip Technology Inc. DS41369A-page 5

Page 10

PICDEMTM Lab Development Board User’s Gu ide

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

• (10) 1” Jumper Wires

• (4) IRFD9020 P-CH MOSFETs

• (4) IRFD010 N-CH MOSFETs

• (2) 100kΩ Potentiometers

3. PICkit™ 2 Programmer/Debugger with USB Cable

4. CD-ROM including:

- “PICDEM™ Lab Development Board User’s Guide and Labs” (DS41369)

- “PIC16F631/677/685/687/689/690 Data Sheet” (DS41262)

- “Introduction to MPLAB

MCU Family Lite Mode Compiler Tutorial” (DS41322)

- Timer: Timer0 Tutorial (Part 1) (DS51682)

- Timer: Timer0 Tutorial (Part 2) (DS51702)

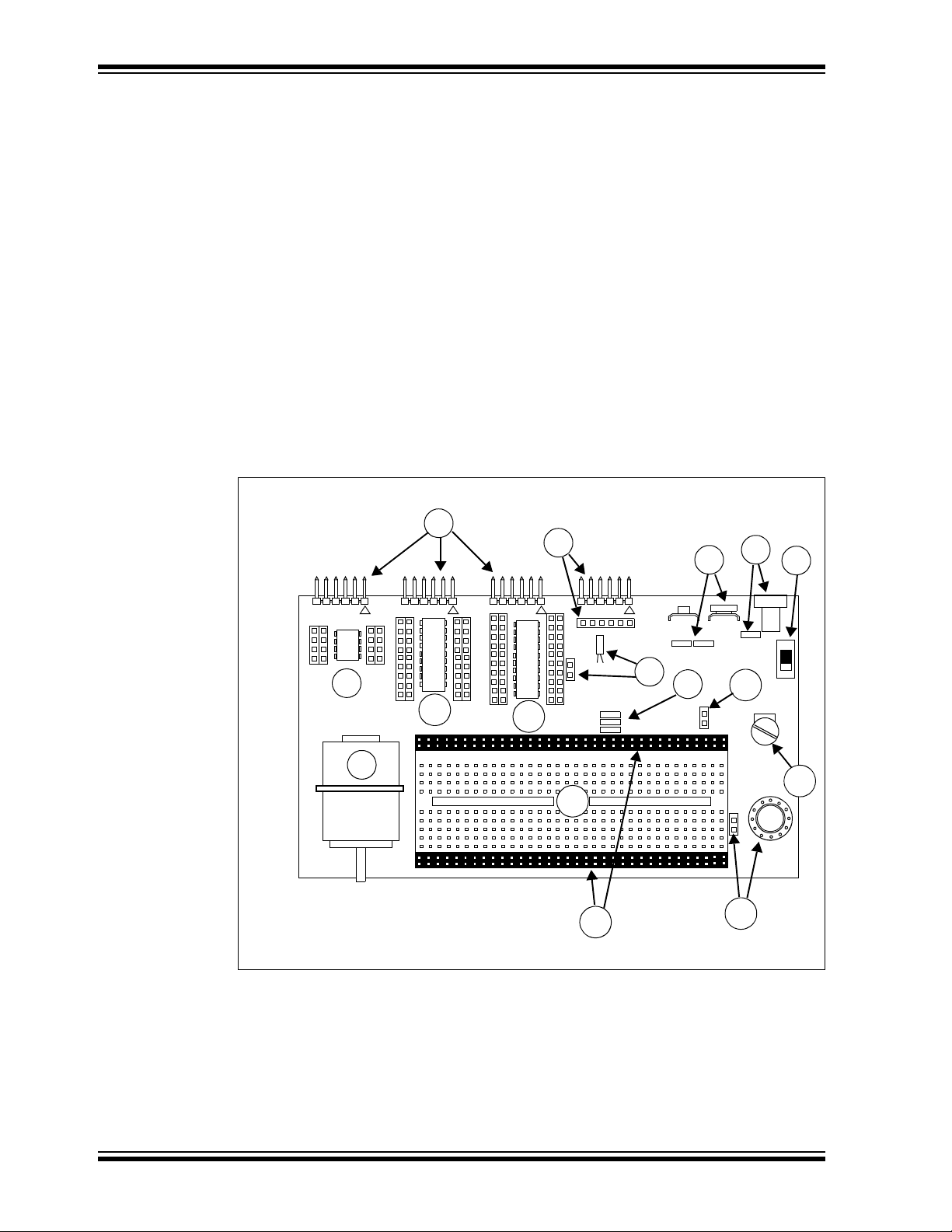

1.4 PICDEM™ LAB DEVELOPMENT BOARD CONSTRUCTION AND LAYOUT

The Low Pin Count USB Development Board and populated components are shown in

Figure 1-1.

FIGURE 1-1: PICDEM™ LAB DEVELOPMENT BOARD

®

IDE and HI-TECH C® PRO for the PIC10/12/16

DS41369A-page 6 © 2009 Microchip Technology Inc.

1. PICkit™ 2 Programmer/Debugger Connection Headers (J13, J12 and J6)

a) J13 dedicated to PIC

b) J12 dedicated to PIC

c) J6 dedicated to PIC

2. PICkit™ Serial Analyzer Connection Header (J11) and Receptacle (J15)

To use the PICkit™ Serial Analyzer, connect to appropriate PIC MCU expansion

header using jumper wires from receptacle.

®

microcontroller socket U5

®

microcontroller socket U3

®

microcontroller socket U2

Page 11

Overview

3. 32 kHz Crystal Oscillator (Y1) and Connection Header (J7)

4. V

DD Connect/Disconnect Jumpers (J3, J4, J5)

a) J3 jumper connects/disconnects V

U2

b) J4 jumper connects/disconnects V

U3

c) J5 jumper connects/disconnects V

U5

5. Battery Clip Connection (BT1) for 9V Battery and Jumpers (J14)

J14 jumpers connect/disconnect battery terminals for use in future lab on battery

chargers.

6. 9 V

DC Supply Connector (J1) and Connect/Disconnect Jumper (J2)

7. Power ON Switch (SW1)

8. 8-Pin PDIP PIC10F MCU Socket (U5) and Bilateral Dual-Row Expansion

Headers (J10 and J18)

Dual-row expansion headers provide connectivity to each pin on the PIC10F206

MCU populating socket U5.

9. 5V Brushed DC Motor

10. 18-Pin PDIP PIC MCU Socket (U3) and Bilateral Dual-Row Expansion Head-

ers (J17 and J16)

Dual-row expansion headers provide connectivity to each pin on the PIC16F819

MCU populating socket U3.

11. 8, 14, 20-Pin PDIP PIC MCU Socket (U2) and Bilateral Dual-Row Expansion

Headers (J8 and J9)

Dual-row expansion headers provide connectivity to each pin on the PIC16F690

MCU populating socket U2.

12. Solderless Prototyping Area

13. Bilateral Dual-Row Supply Headers (J22 and J23)

Provide both V

DD and VSS connectivity bilaterally to the solderless prototyping

area.

14. 0.2 Watt, 8-Ohm Speaker (LS1) with Connection Header (J19)

J19 connector used to connect speaker LS1 to user application using jumper

wires.

15. Battery Positive (CP+) and Negative (CP-) Connection Header (J26)

Provides connectivity of positive and negative battery terminals to the user application using jumper wires.

16. Variable V

DD Potentiometer (R1)

Potentiometer used to vary PIC MCU supply voltage from approximately 1.3V to

approximately 5V.

DD1 supply to PIC16F690 MCU in socket

DD2 supply to PIC16F819 MCU in socket

DD3 supply to PIC10F206 MCU in socket

1.5 TARGET POWER

The PICDEM™ Lab Development Board can be powered in one of three ways:

1. Using a 9-12 V

(MIcrochip part #AC162039 recommended)

Ensure that connect/disconnect jumper J2 is in place.

© 2009 Microchip Technology Inc. DS41369A-page 7

DC power supply connected to connector J1

Page 12

PICDEMTM Lab Development Board User’s Gu ide

2. Using a 9V battery connected to connector BT1

Ensure that connect/disconnect jumpers J14 are in place.

3. A PICkit™ 2 Programmer/Debugger connected to any one of the three PICkit™

Programmer/Debugger connectors J13, J12 and J6 (recommended for

low-power applications only).

Note: When using the PICkit™ 2 Programmer/Debugger as the power source,

the variable V

When using methods 1 or 2, each PIC

connect/disconnect jumper that, when in place, enables the positive supply voltage to

the respective V

DD pins. The VDD jumpers connect to the following PIC

troller sockets:

DD1 (J3) connects/disconnects supply voltage to the PIC

1. V

populating U2.

2. V

DD2 (J4) connects/disconnects supply voltage to the PIC

populating U3.

3. V

DD3 (J5) connects/disconnects supply voltage to the PIC

populating U5.

Using methods 1 or 2 enables the use of the variable V

supply voltages from approximately 1.3 to 5V. Rotating the potentiometer clockwise will

raise the supply voltage while rotating the potentiometer counterclockwise will

decrease the supply voltage.

DD potentiometer (R1) will not vary the supply voltage.

®

microcontroller has an associated

®

®

microcontroller

®

microcontroller

®

microcontroller

DD potentiometer (R1) to control

microcon-

1.6 CONNECTING THE PICkit™ 2 PROGRAMMER/DEBUGGER

The three PIC® microcontrollers populating sockets U5, U3 and U2 have their own

PICkit™ Programmer/Debugger (ICSP™) connectors so that each can be programmed or debugged individually. The ICSP™ connect to the following PIC

controller sockets:

1. ICSP1 (J6) connects to the PIC

2. ICSP2 (J12) connects to the PIC

3. ICSP3 (J13) connects to the PIC

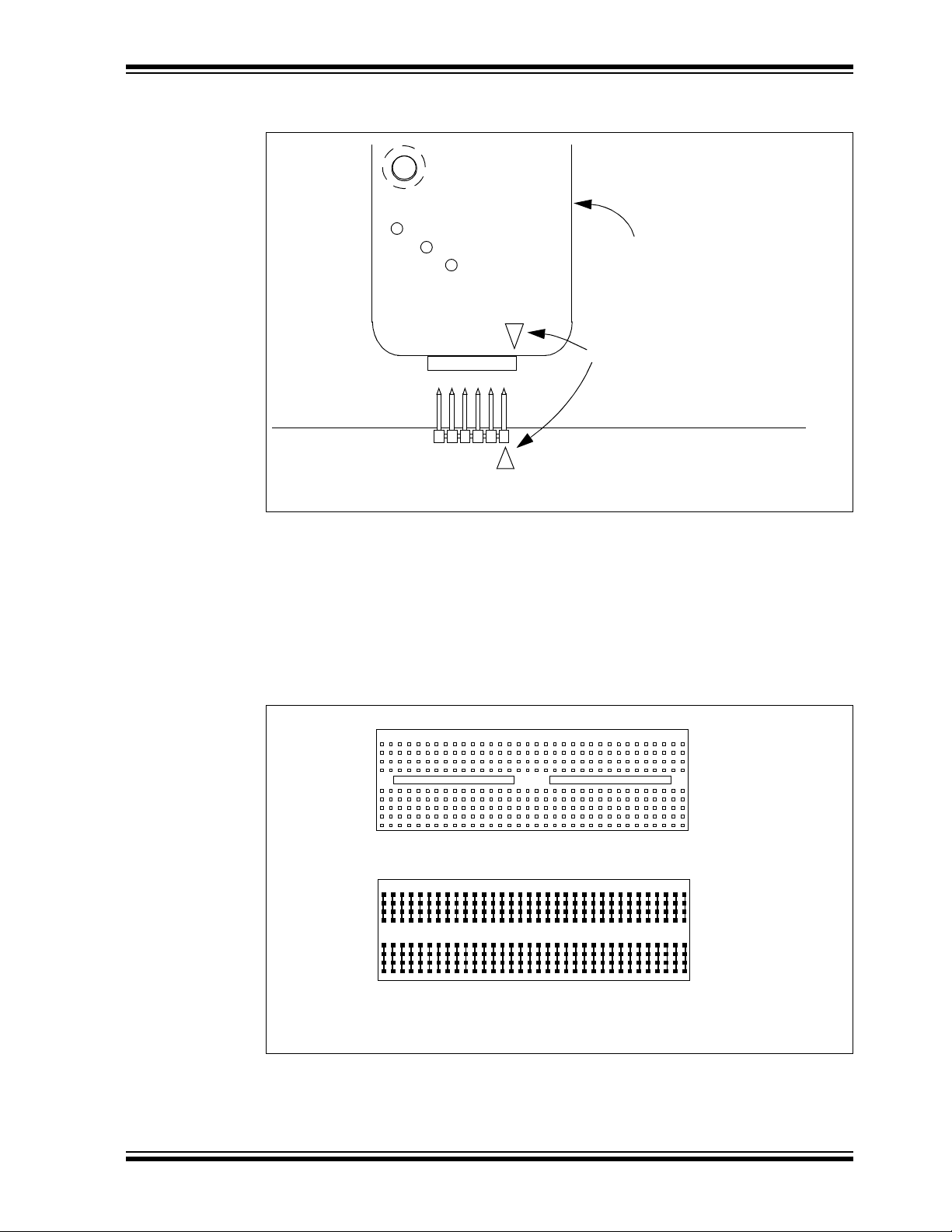

The PICkit™ Programmer/Debugger connects to the ICSP™ connector as shown in

Figure 1-2.

®

microcontroller populating U2.

®

microcontroller populating U3.

®

microcontroller populating U5.

®

micro-

DS41369A-page 8 © 2009 Microchip Technology Inc.

Page 13

Overview

ICSP™ CONNECTOR

P

o

we

r

T

a

r

g

e

t

B

u

s

y

PICkit™ Programmer/Debugger

Denotes Pin 1

Solderless Prototyping Area

Solderless Prototyping Area

Showing Strip Connections

FIGURE 1-2: CONNECTING THE PICkit™ PROGRAMMER/DEBUGGER TO

AN ICSP™ CONNECTOR

The PICkit™ 2 Programmer/Debugger is then connected to an available USB port on

the PC using the included USB cable.

1.7 SOLDERLESS PROTOTYPING AREA STRIP CONFIGURATION

The solderless prototyping area contains a variety of strips under the perforated plastic

block. These strips “short” vertical rows of holes together as shown in Figure 1-3.

FIGURE 1-3: SOLDERLESS PROTOTYPING AREA STRIP

CONFIGURATION

© 2009 Microchip Technology Inc. DS41369A-page 9

Page 14

PICDEMTM Lab Development Board User’s Gu ide

NOTES:

DS41369A-page 10 © 2009 Microchip Technology Inc.

Page 15

PICDEMTM LAB DEVELOPMENT

main()

Loop Forever

Timing()

Initialize()

Get_Inputs()

Decide()

Do_Outputs()

Chapter 2. Getting Started

2.1 INTRODUCTION

This chapter is intended to prepare the reader to complete the labs in the remaining

chapters of this user’s guide.

2.2 PREREQUISITES

The labs contained within this lab manual assumes the user:

1. Has a basic understanding of the C programming language.

2. Understands basic circuit analysis.

3. Has completed or understands the concepts contained within the introductory

tutorial: “Introduction to MPLAB

MCU Family Lite Mode Compiler Tutorial” (DS41322B) provided on the

accompanying CD-ROM.

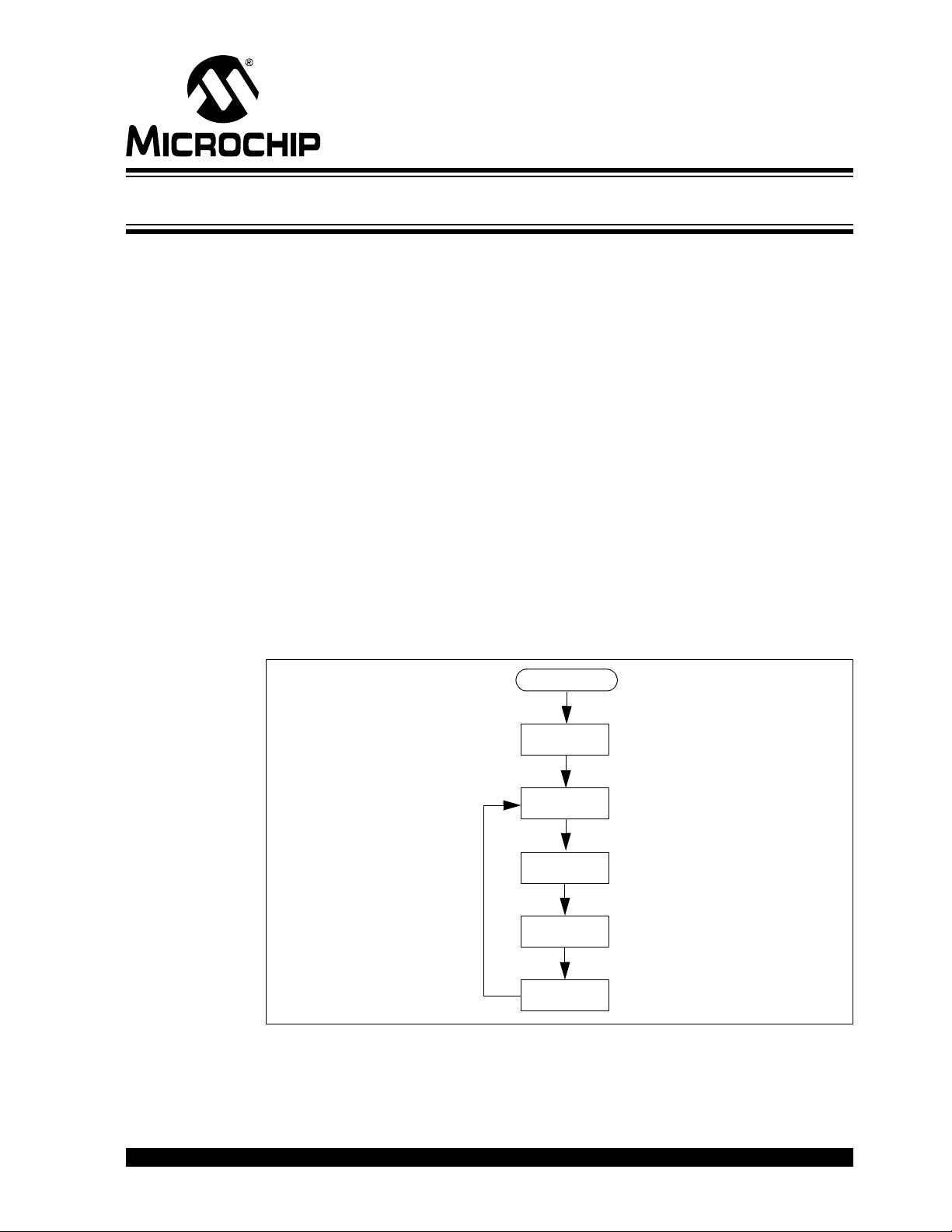

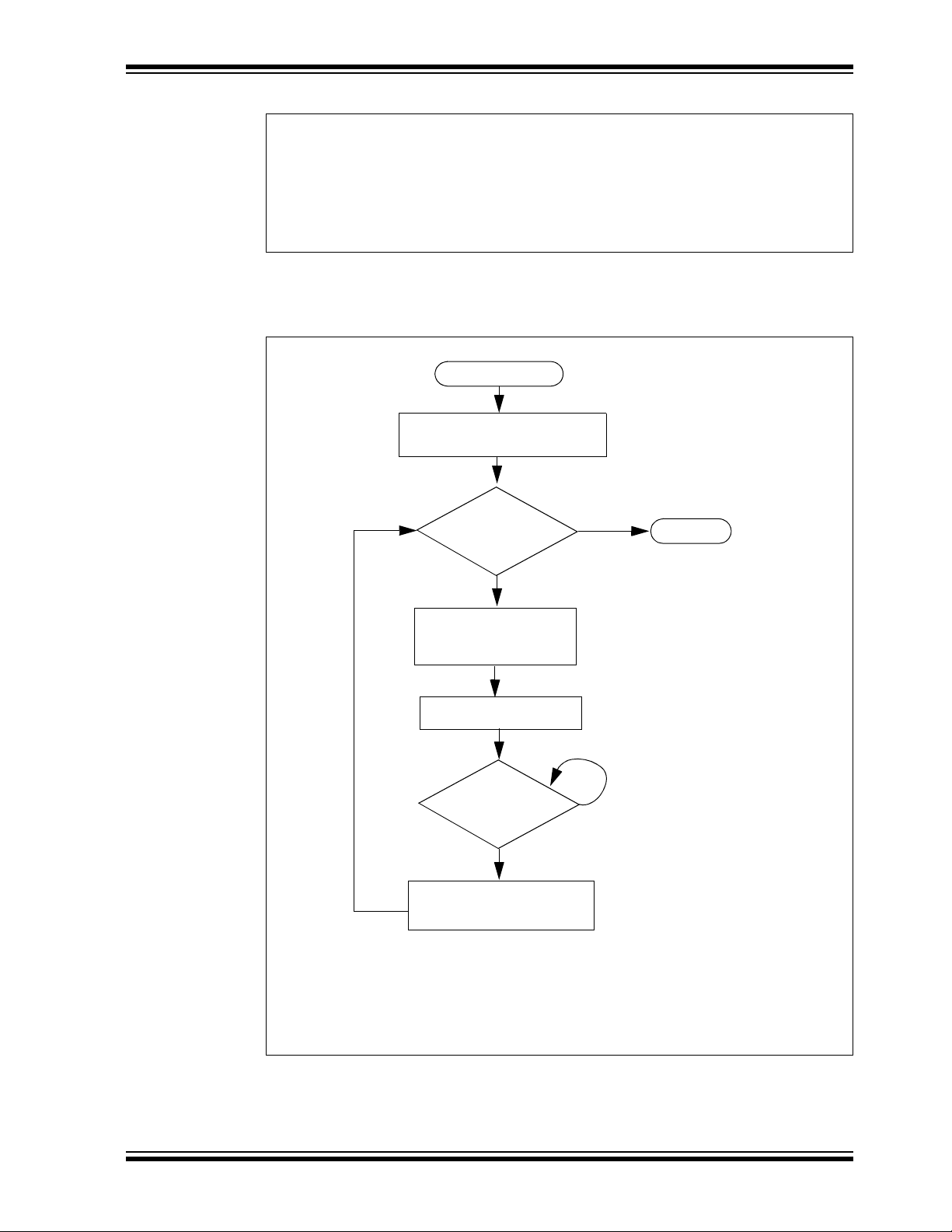

2.3 THE SOFTWARE CONTROL LOOP

BOARD USER ’S GUIDE

®

IDE and HI-TECH C® PRO for the PIC10/12/16

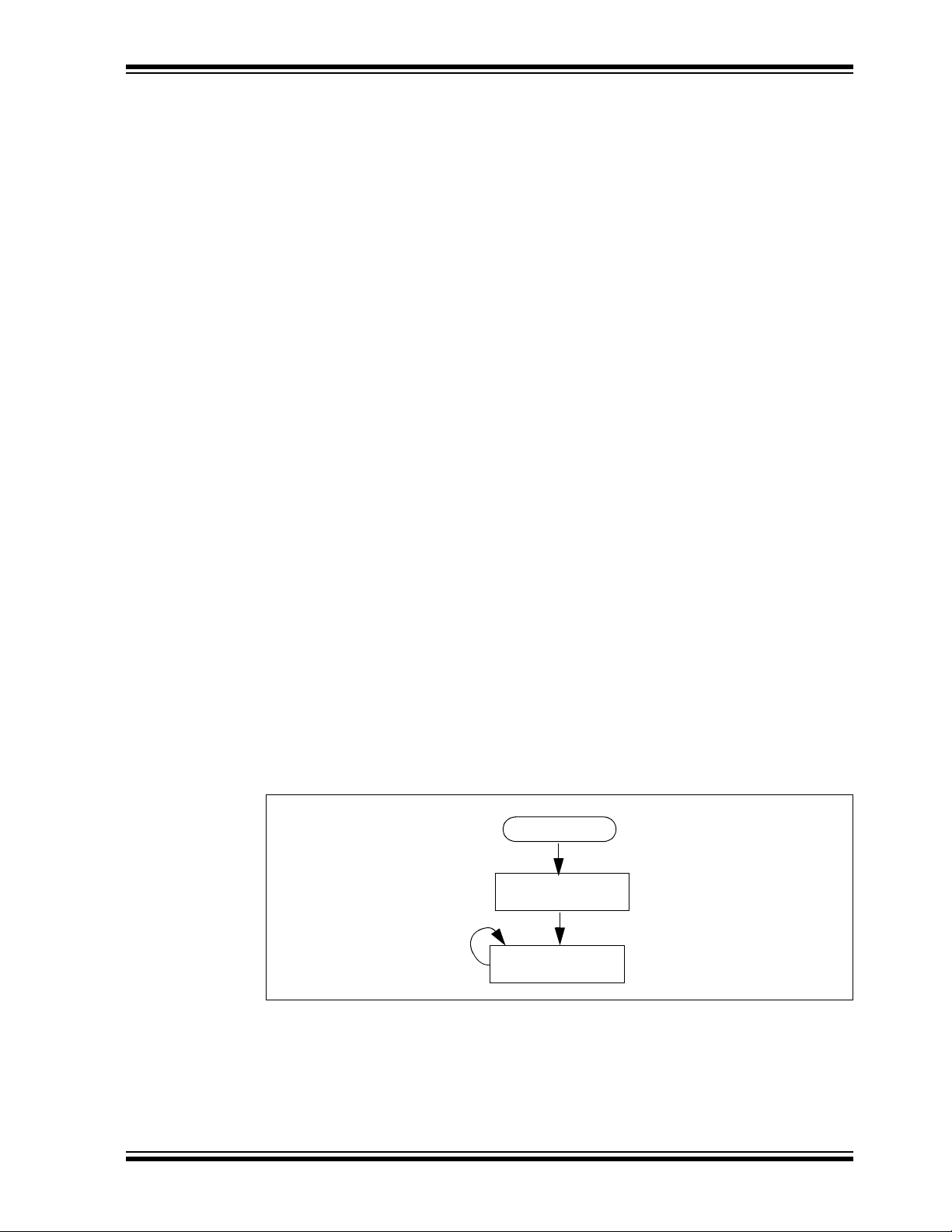

The labs used in this user’s guide implement a software control loop in various

configurations but always in the same sequence as shown in Example 2-1.

FIGURE 2-1: MAIN() SOFTWARE CONTROL LOOP FLOWCHART FOR

USED IN LABS

Each block of the software control loop represents a function that organizes tasks into

logical, organized groupings that are called from the main function (main()). Notice

© 2009 Microchip Technology Inc. SD41369A-page 11

the Initialize() is called only once while the remaining functions are executed

repeatedly. This method organizes the embedded firmware application into a logic

sequence of events:

Page 16

PICDEMTM Lab Development Board User’s Gu ide

void main(void)

{

Initialize(); //Initialize the relevant registers

while(1)

{

Decide();//Make any decisions

Do_Outputs(); //Perform any outputs

Timing();//Sets execution rate of the

//Software Control Loop

}

}

1. Initalize():

- Initializes the microcontroller, the peripherals used in the application and any

global variables used by multiple functions.

2. Get_Inputs():

- Obtains any input information either on-chip (from internal registers, etc...) or

off-chip (pin voltage levels).

3. Decide():

- Makes decisions based on the input information gathered in the previous

function to manipulate global variables.

4. Do_Outputs():

- Based on the decisions made in the previous function, this function outputs

data onto the pins of the microcontroller or to registers within the device.

5. Timing():

- This function determines how fast the software control loop executes.

Example 2-1 shows a typical main() calling the various functions that make up the

software control loop.

EXAMPLE 2-1: TYPICAL SOFTWARE CONTROL LOOP MAIN() USED IN

LABS

An infinity loop will be used by all labs in this user’s guide created using a while

loop that repeatedly call the functions within the curly braces as long as there is power

to the microcontroller.

Global variables are used wherever needed in lieu of passing variables between

functions.

2.4 MPLAB® IDE DOWNLOAD INSTRUCTIONS

SD41369A-page 12 © 2009 Microchip Technology Inc.

The following steps outline how to download the latest version of the MPLAB IDE and

HI-TECH C

mended that all open programs and applications are closed to expedite the installation

process.

®

PRO for the PIC10/12/16 MCU Families compiler. It is strongly recom-

Page 17

Getting Started

1. Using a PC that is connected to the internet, navigate to the MPLAB® IDE down-

load page at the following url:

www.microchip.com/mplab

This page outlines the MPLAB IDE and also features downloadable plug-ins, User’s

Guides and other useful information.

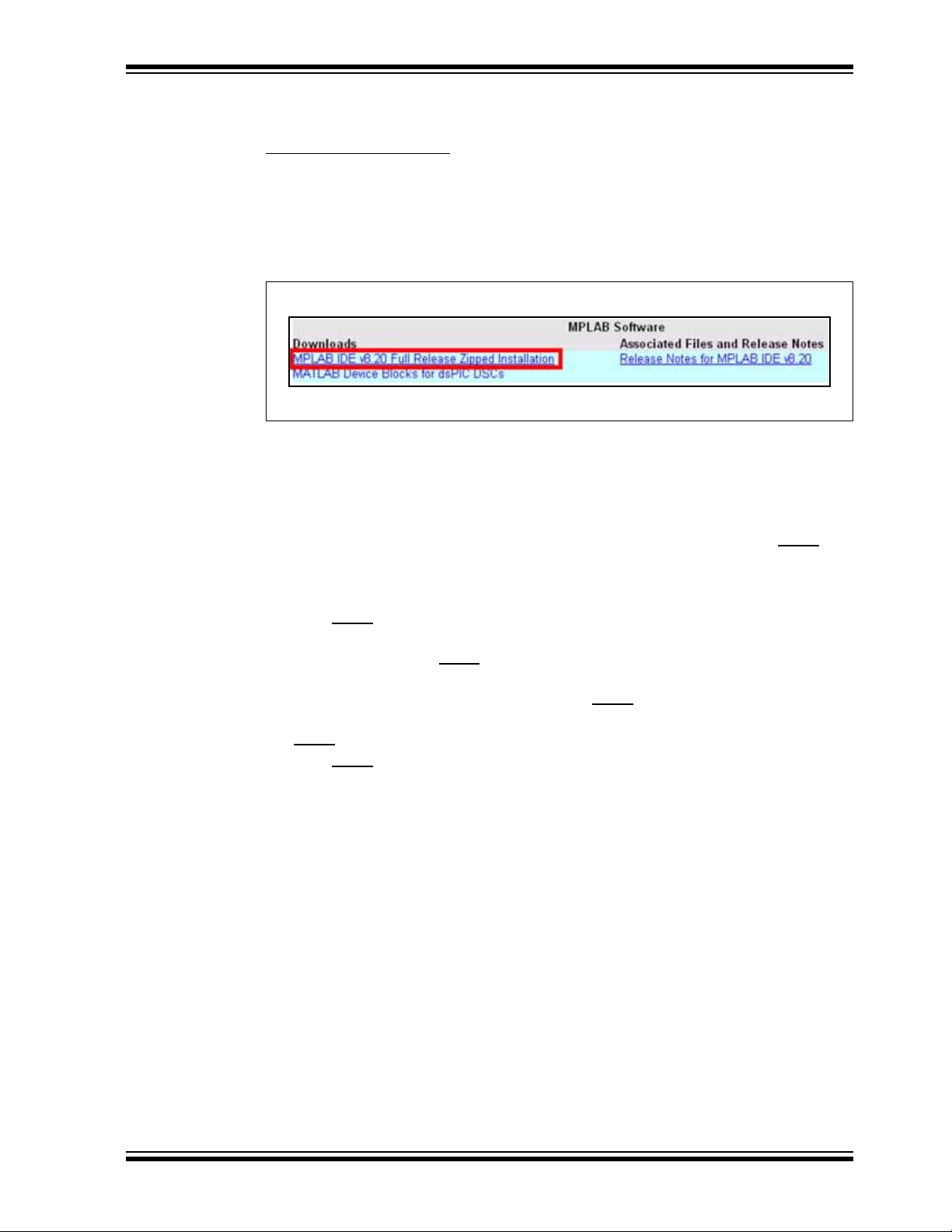

2. Scroll down to the Downloads section of the page and select the latest full

release zip file for MPLAB IDE vx.xx. (See Figure 2-2.)

FIGURE 2-2: MPLAB ZIP FILE

3. When prompted open the .zip file and extract all contents to a new folder named

something meaningful such as “MPLAB” created in a directory such as Desktop

or another location easily accessible.

4. Once all files are extracted, navigate to the folder created and double click on the

Install_MPLAB_vxxx.exe file to start the installation process.

5. The MPLAB

proceed with the installation.

6. In the next window, read through the MPLAB IDE License Agreement and ensure

that the I accept the terms of the license agreement radio button is selected.

Click Next>

7. In the Setup Type window select the setup type (complete is recommended for

new users) and click Next>

8. In the Choose Destination Location it is recommended to use the default direct

C:\Program Files\Microchip\. Click Next>

9. Accept the Application Maestro License agreement in the next window and click

Next>

to continue.

10. Click Next>

take several minutes to complete).

11. During the installation process, the user will be prompted to install the free

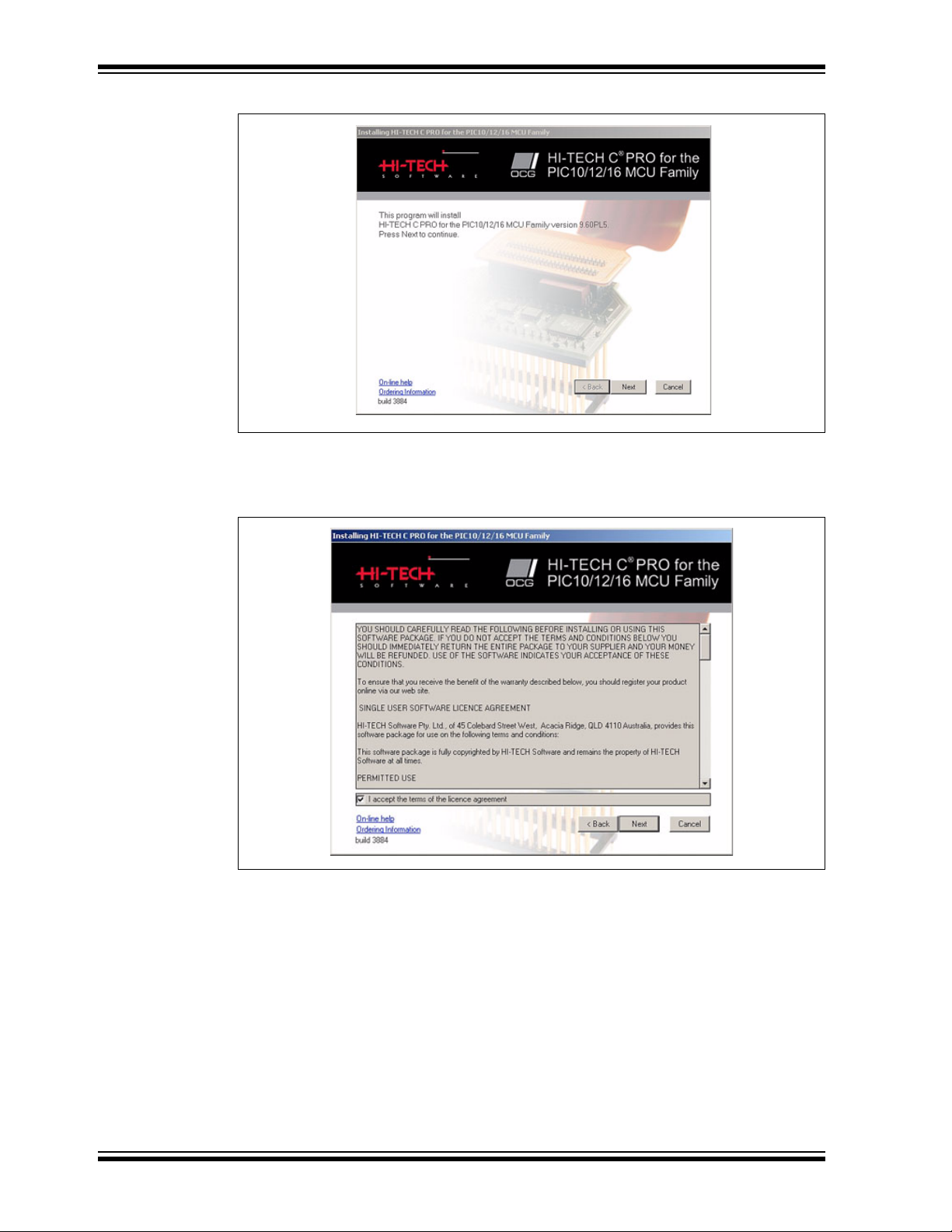

HI-TECH C

the user install the compiler at this point. Select Yes to launch the installer. In the

installer window, click Next to continue. (See Figure 2-3.)

Tools x.xx Installation window should now be open. Click Next> to

®

to continue with the installation.

to continue.

to continue.

in the Start Copying Files window to start the installation (this may

®

PRO for the PIC10/12/16 MCU Compiler. It is recommended that

© 2009 Microchip Technology Inc. SD41369A-page 13

Page 18

PICDEMTM Lab Development Board User’s Gu ide

FIGURE 2-3: HI TECH INSTALLER WINDOW

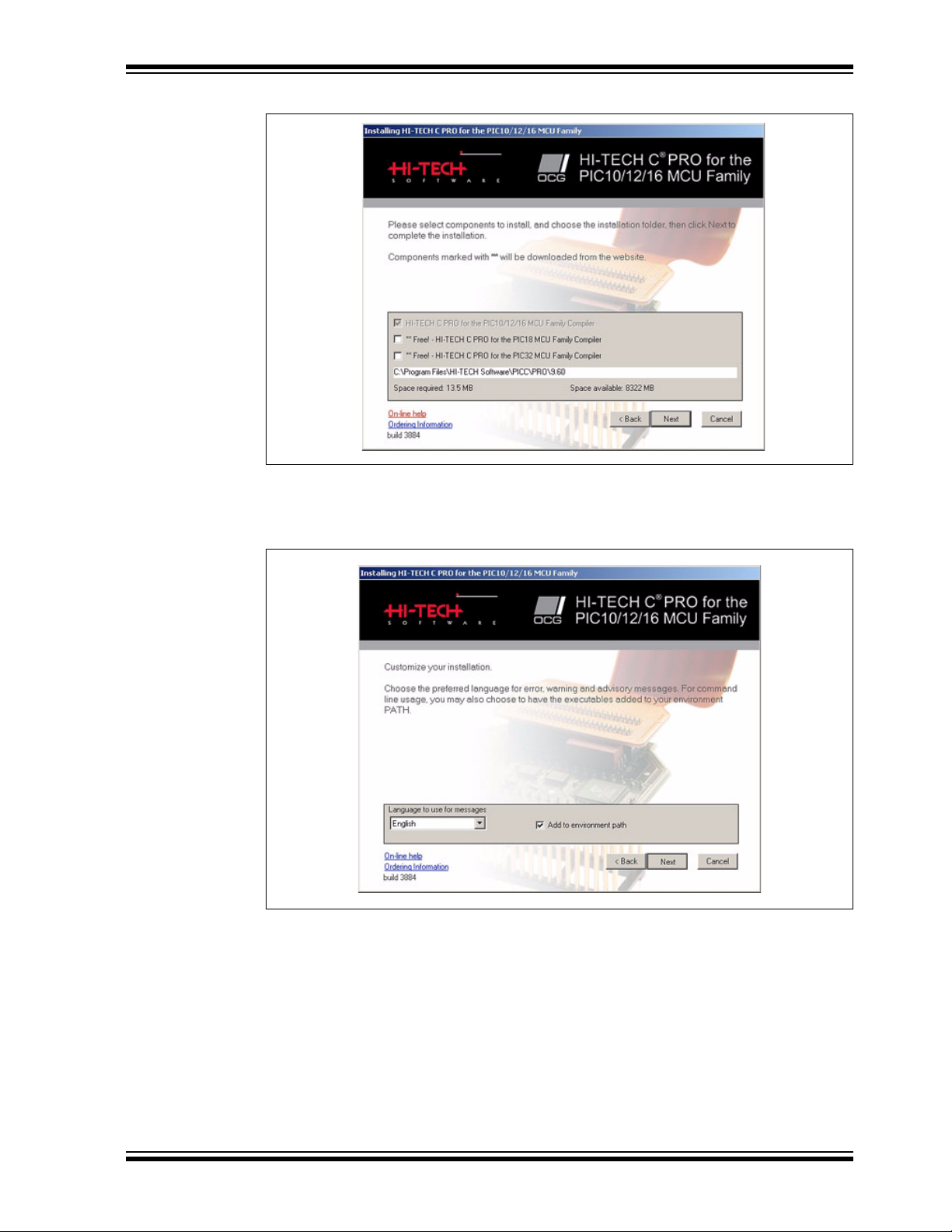

12. In the next window, accept the terms of the license agreement and click Next to

continue. (See Figure 2-4.)

FIGURE 2-4: HI TECH LICENSE AGREEMENT

13. In the next window, select any components in addition to the HI-TECH C

the PIC10/12/16 MCU Family Compiler to install (additional components are not

required to complete the labs in this user's guide) and click Next to continue.

(See Figure 2-5.)

®

Pro for

SD41369A-page 14 © 2009 Microchip Technology Inc.

Page 19

Getting Started

FIGURE 2-5: HI TECH COMPONENTS

14. In the next window, choose the language of preference, select the Add to

environment path radio button and click Next to continue. (See Figure 2-6.)

FIGURE 2-6: HI TECH LANGUAGE PREFERENCES

The installation process will now begin.

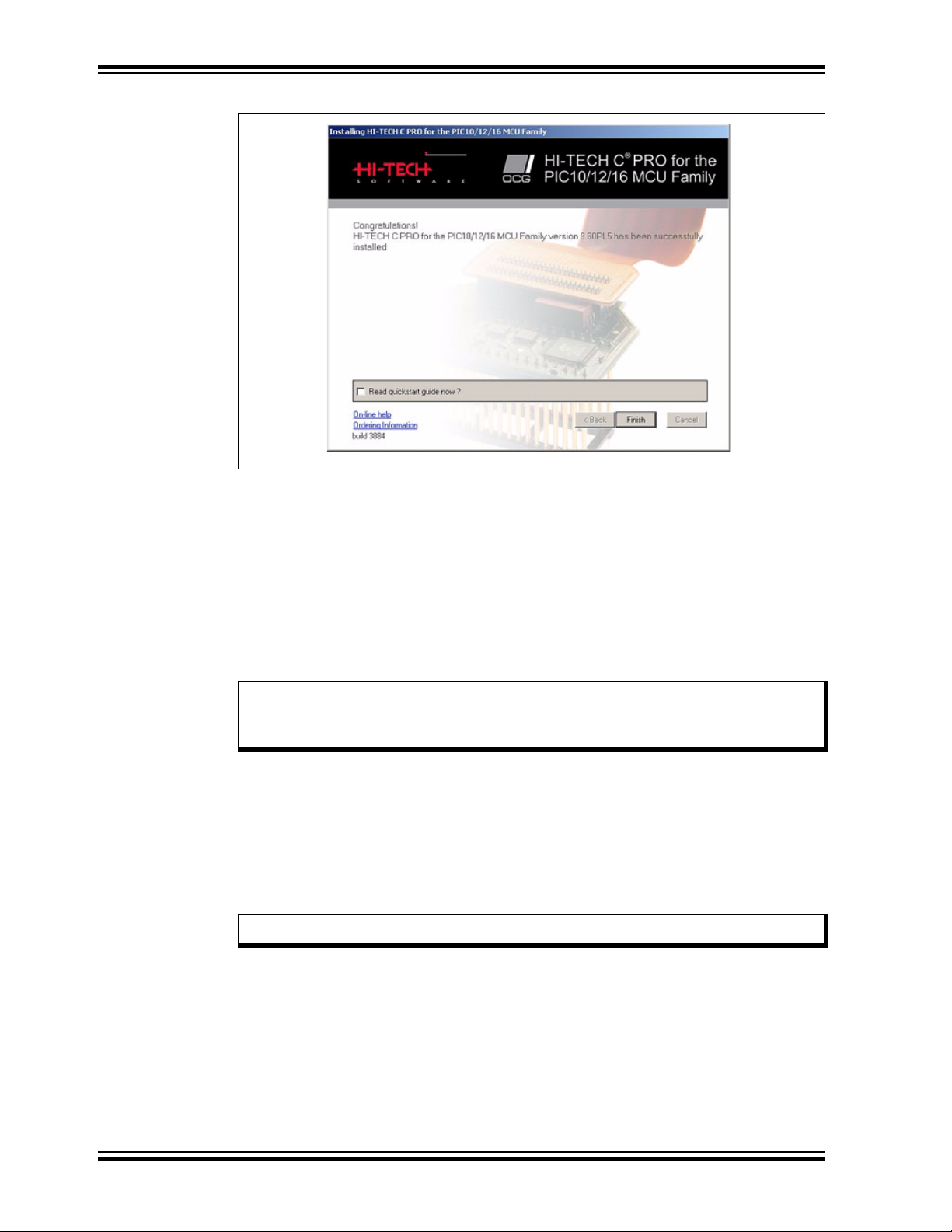

15. Once the installation is complete, a confirmation window will open. Select or

de-select the Read quick start gui de now? radio button and click Finish to

proceed. (See Figure 2-7.)

© 2009 Microchip Technology Inc. SD41369A-page 15

Page 20

PICDEMTM Lab Development Board User’s Gu ide

FIGURE 2-7: HI TECH INSTALL CONFIRMATION

16. The MPLAB

and prompt the user to restart the computer before using the software. To begin

using the tools, select the Yes, I want to restart my computer radio button and

click Finish to end the installation process and restart the computer.

Following restart, the user will be given the option to view a variety of documentation.

To view a document, simply highlight and click View Selected File.

The MPLAB

Compiler are now both installed and ready to use. The user is now ready to complete

the labs included in this user’s guide.

Note: A comprehensive introduction to the “HI-TECH C® PRO for the

®

Tools Install Shield Wizard Complete window should soon open

®

IDE and HI-TECH C® PRO for the PIC10/12/16 MCU Family Lite Mode

PIC10/12/16 MCU Family Lite Mode Compiler Tutorial” (DS41322) is

provided on the accompanying CD-ROM.

2.5 INSTALLING THE INCLUDED LAB FILES

The PICDEM™ Lab Development Kit CD-ROM includes a .zip file called

PICDEM_Lab.zip. This file provides a location for the user to save any projects

created while completing the labs in this user's guide and contains solutions for each

lab in a folder labeled solution. To install this folder, simply extract the contents of

the .zip file to the C:\ directory.

Note: Lab folders must be installed to the C:\ to be used by the MPLAB IDE.

SD41369A-page 16 © 2009 Microchip Technology Inc.

Page 21

Chapter 3. General Purpose Input/Output Labs

3.1 INTRODUCTION

The following labs cover some of the fundamental features of the General Purpose

Input/Output (GPIO) peripherals available on the PIC16F690. As the name implies,

these peripherals are used for general purpose applications that can monitor and

control other off-chip devices. Some PIC

peripherals on-chip including the PIC16F690 used in the following labs. Therefore, the

PORTx naming convention is used. Available ports on the PIC16F690 are:

•PORTA

•PORTB

•PORTC

Reading through the data sheet highlights some of the unique characteristics associated with each port and the reader is encouraged to explore these in greater detail once

comfortable with the labs in this user’s guide. The labs will focus on two of the port

peripherals: PORTC and PORTA. Labs will be naturally divided into two sections since

these are General Purpose Input/Output peripherals:

• Output Labs

• Input Labs

Output labs will introduce the reader to concepts necessary to configuring these peripherals for output to off-chip devices using applicable registers by lighting 8 LEDs connected to the PORTC pins

The Input labs will then add a push button interfacing to one of the PORTA pins to highlight concepts necessary for configuring these peripherals to receive information from

off-chip devices. Finally, interrupts will be used to optimize the application for different

purposes.

PICDEMTM LAB DEVELOPMENT

BOARD USER’S GUIDE

®

microcontrollers have multiple GPIO

3.2 GENERAL PURPOSE INPUT/OUTPUT LABS

• Output Labs:

- Lab 1: Light LEDs

- Lab 2: Flash LEDs (Delay Loop)

- Lab 3: Simple Delays Using Timer0

- Lab 4: Rotate LEDs

• Input Labs:

- Lab 5: Adding a Push Button

- Lab 6: Push Button Interrupt

- Lab 7: Push Button Interrupt-on-Change

- Lab 8: Using Weak Pull-ups

© 2009 Microchip Technology Inc. DS41369A-page 17

Page 22

PICDEMTM Lab Development Board User’s Gu ide

U2

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

RC0

RC1

RC2

RC3

RC4

RC5

RC6

RC7

J9J8

R8

470Ω

R4

470Ω

R7

470Ω

R6

470Ω

R5

470Ω

R3

470Ω

R2

470Ω

R1

470Ω

LED8 LED7 LED6 LED4 LED3 LED2 LED1LED5

V

SS

3.3 GPIO OUTPUT LABS

3.3.1 Reference Documentation

All documentation is available on the PICDEM™ Lab Development Kit accompanying

CD-ROM.

• PIC16F690 Data Sheet (DS41262)

- Section 2.2.2.2: Option Register

- Section 2.2.2.3: Interrupt Control Register INTCON

- Section 4: I/O Ports

- Section 5: Timer0 Module

• Timers: Timer0 Tutorial (Part 1) (DS51628)

• Timers: Timer0 Tutorial (Part 2) (DS51702)

• “Introduction to MPLAB

Family Lite Mode Compiler Tutorial” (DS41322)

3.3.2 Equipment Required for GPIO Output Labs

To complete the labs in this section, the following components are required:

1. 8 – Light Emitting Diodes

2. 8 – 470Ω resistors

3. PIC16F690 populating socket U2

4. Assorted jumper wires

®

IDE and HI-TECH C® PRO for the PIC10/12/16 MCU

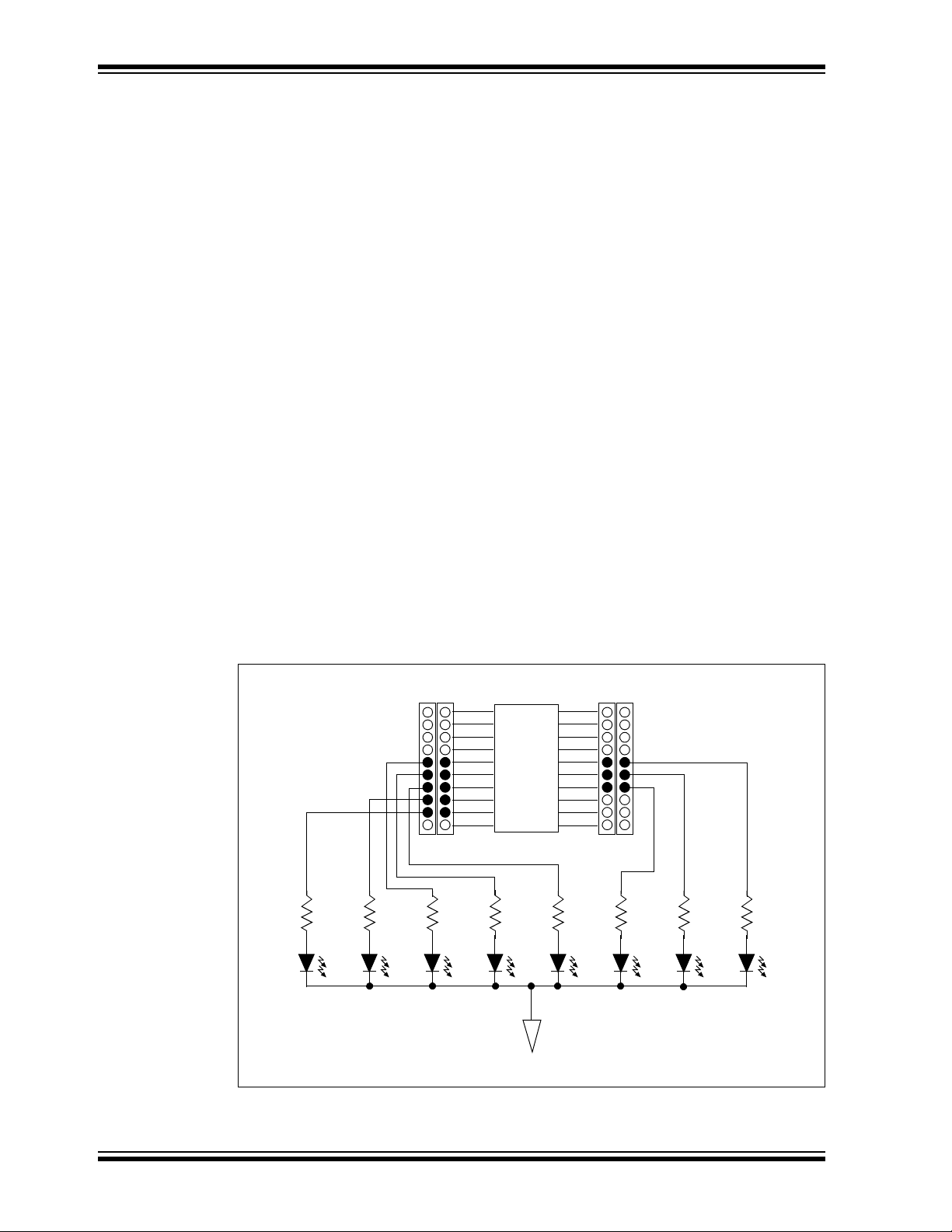

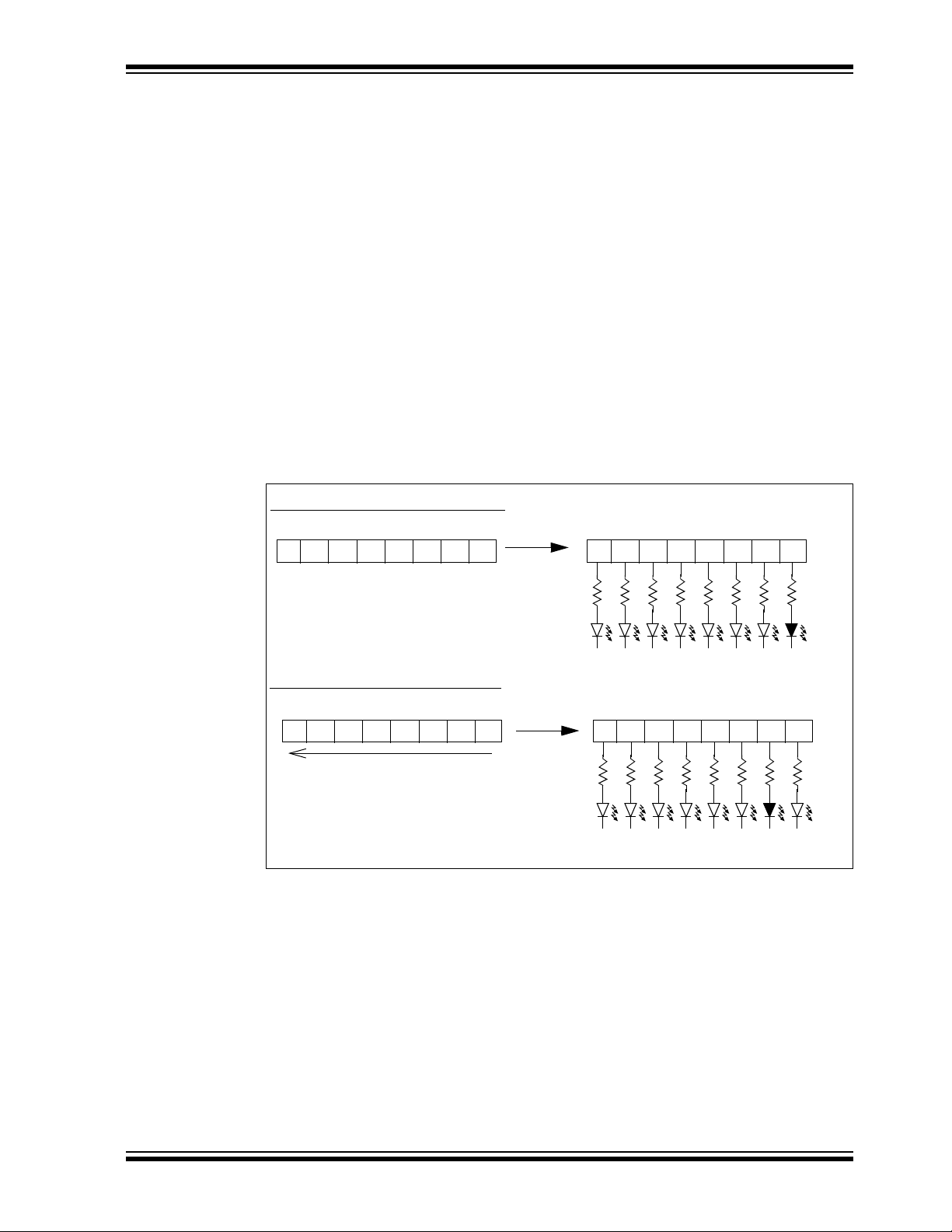

3.3.3 PICDEM Lab Development Board Setup for GPIO Output Labs

The GPIO output labs will require that the PICDEM Lab Development Board be configured as shown in Figure 3-1 using the components listed in the previous section.

FIGURE 3-1: PICDEM LAB SCHEMATIC FOR GPIO OUTPUT LABS

DS41369A-page 18 © 2009 Microchip Technology Inc.

Page 23

General Purpose Input/Output Labs

main()

Initialize()

Do_Outputs()

Loop Forever

Special care should be observed when connecting the LED jumper wires to the

expansion headers surrounding the PIC16F690, as the PORTC pins are not in

sequential order. The 470Ω resistors are used to limit the current across the LEDs to

manufacturer specifications. Furthermore, the PIC16F690 Data Sheet electrical

specifications (see Section 17.0) specify that each port pin should not source/sink more

than 25 mA. The maximum output current sourced/sunk by all port pins combined

should not exceed 200 mA. The 470Ω resistors keep all source current well within

these specifications.

3.3.4 Lab 1: Light LEDs

3.3.4.1 NEW REGISTERS USED IN THIS LAB

To configure the peripherals used in this lab, the following registers are used:

1. PORTC Register: PORTC (Register 4-11 in Section 4 of the PIC16F690 Data

Sheet).

- 8-bit bidirectional port.

2. PORTC Tri-State Register: TRISC (Register 4-12 in Section 4 of the PIC16F690

Data Sheet).

- Configures corresponding bits in PORTC as either input or output.

3. Analog Select Register High and Analog Select Register Low: ANSELH and

ANSEL (Registers 4-4 and 4-3 in Section 4 of the PIC16F690 Data Sheet).

- Configure associated pins for analog or digital input signals.

3.3.4.2 OVERVIEW

This first lab demonstrates how to output data from the PORTC peripheral on the

PIC16F690 to its associated pins. LEDs connected to PORTC pins will light when the

associated pin is driven high (approx. V

(approx. V

need to be configured as output using the TRISC register. Also, PORTC pins RC0,

RC1, RC2, RC3, RC6 and RC7 are configurable for both analog and digital signals. On

start-up, any analog/digital functional pin is defaulted to analog. Therefore, this

application will require that these pins be configured as digital by configuring the

associated bits in the ANSEL and ANSELH analog select registers.

FIGURE 3-2: MAIN() SOFTWARE CONTROL LOOP FLOWCHART FOR

SS). The port peripherals will all default to input on start-up and will therefore

LAB 1

DD) or turn the LED OFF when driven low

© 2009 Microchip Technology Inc. DS41369A-page 19

Page 24

PICDEMTM Lab Development Board User’s Gu ide

Figure 3-2 shows the software control loop that will be implemented in this lab. At

device power-up, the first functional block called from the main() is Initialize().

This function will initialize the PORTC peripheral as follows:

• Clear the PORTC register data

• Configure the ANSEL and ANSELH bits so that all associated PORTC pins are

digital

• Configure the associated PORTC pins as all output using the TRISC register

Note: The PORT register should always be initialized to a known value before

configuring the associated TRIS bit. This avoids unexpected voltage levels

on the associated pins since at start-up port bit values are unknown.

The next function called from main() is Do_Outputs(). This function will assign

values to the PORTC register that will drive the associated pins high or low to light the

LEDs connected.

3.3.4.3 PROCEDURE

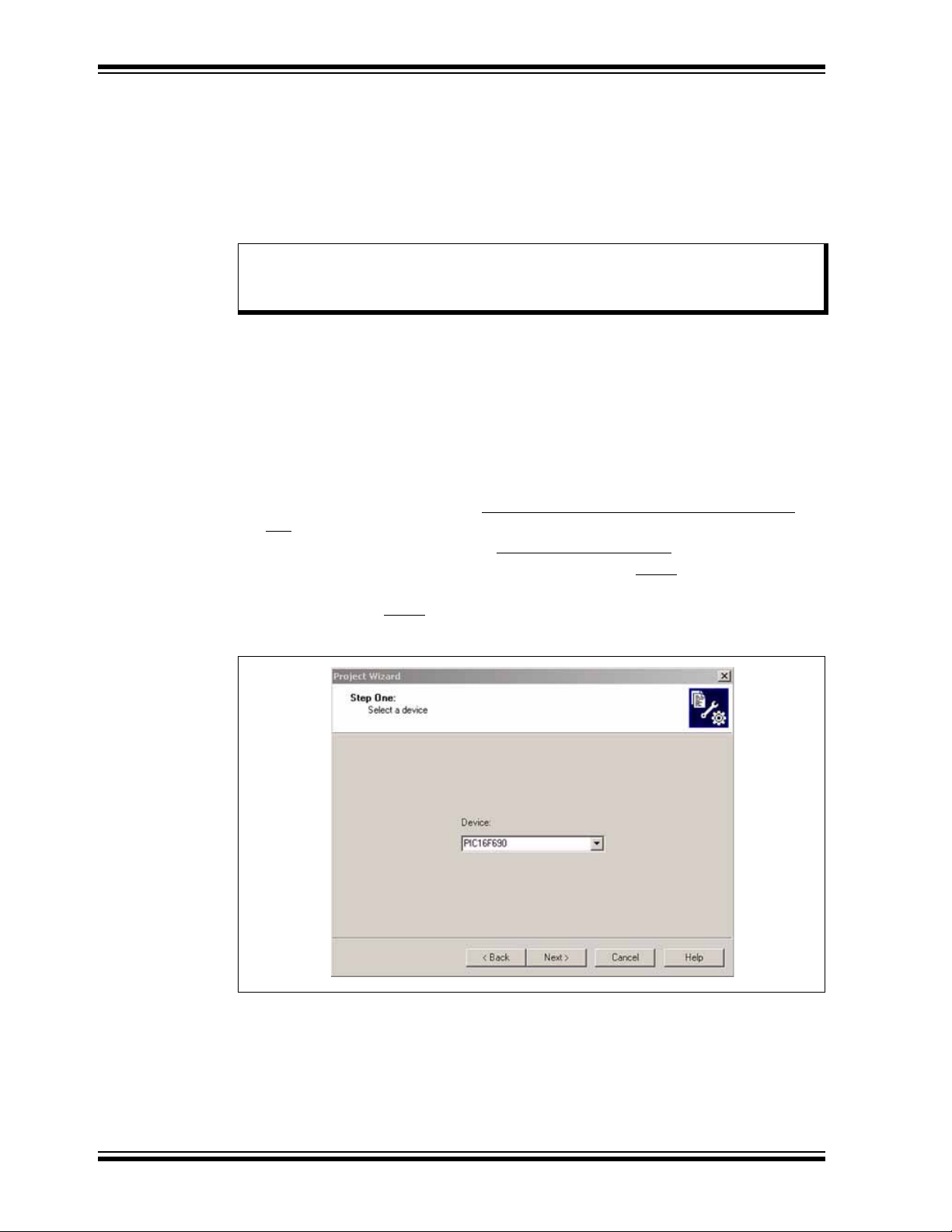

The following steps will demonstrate how to create a new project in MPLAB

more in-depth tutorial is provided in the document “Introduction to MPLA B

HI-TECH C

(DS41322) included on the accompanying CD-ROM.

1. Open MPLAB IDE by selecting Start>Microchip>MPLAB IDE vX.XX>MPLAB

IDE.

2. In the MPLAB IDE toolbar, select Project>Project Wizard....

3. The Welcome dialog box should now be open. Select Next> to proceed.

4. In the Step One: window, select the PIC16F690 from the Device: drop-down

menu and select Next>

®

PRO for the PIC10/12/16 MCU Family Lite Mode Compiler Tutorial”

to continue. (See Figure 3-3.)

®

IDE. A

®

IDE and

FIGURE 3-3: STEP ONE

5. In the Step Two: window, select the HI TECH Universal ToolSuite from the Active

Toolsuite drop down menu. The window should now resemble Figure 3-4.

DS41369A-page 20 © 2009 Microchip Technology Inc.

Page 25

General Purpose Input/Output Labs

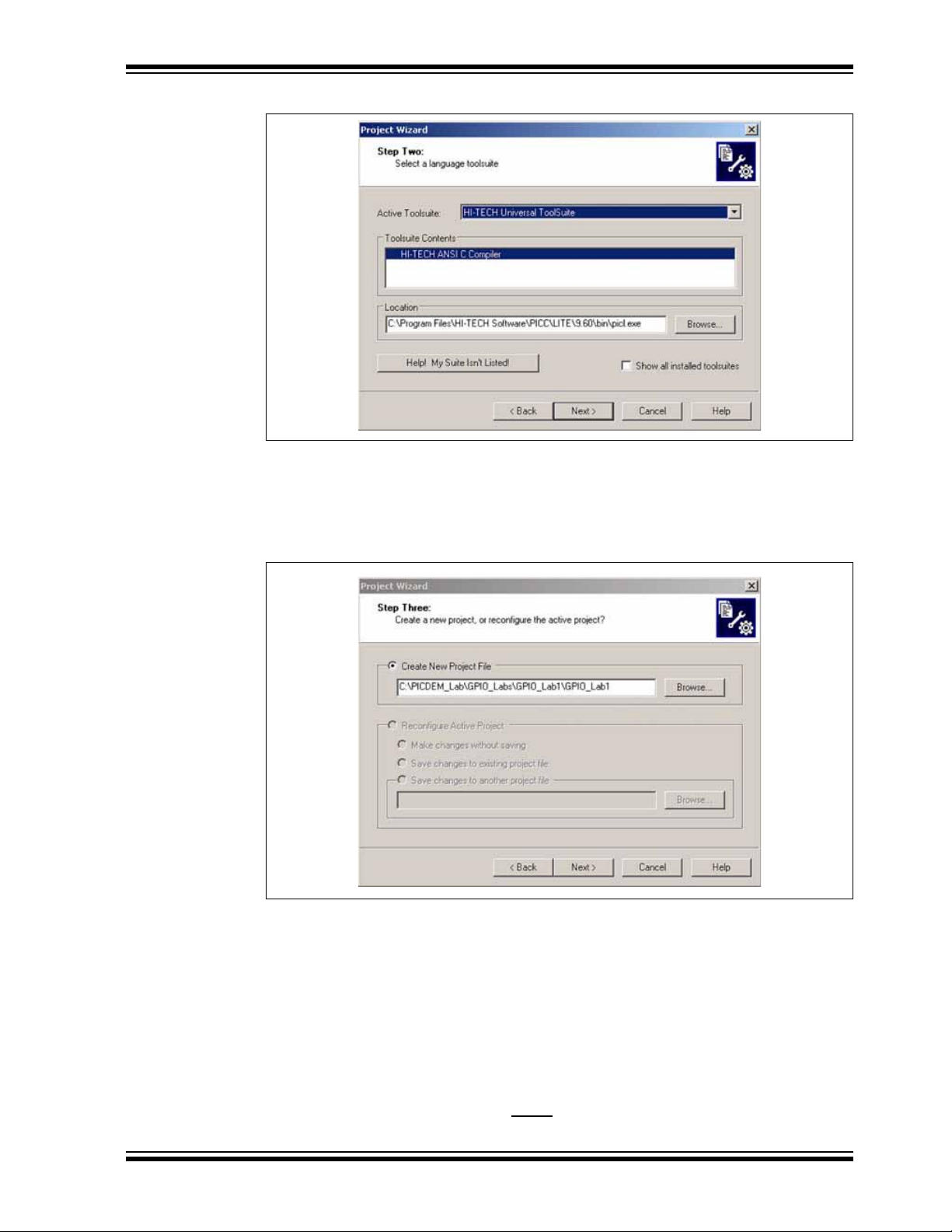

FIGURE 3-4: STEP TWO

6. In the Step Three: window, use the Browse button and navigate to a new folder

on the C:\ drive to store this project. Alternately, the reader may wish to use the

C:\PICDEM_Lab\GPIO_Labs\GPIO_Lab1 folder created earlier. (See

Figure 3-5.)

FIGURE 3-5: STEP THREE

7. In the Step Four: files are added to the project. A Lab_Template.c file has

been provided in the C:\PICDEM_Lab\Lab_Template.c directory that can be

used as the basis for all labs in this manual. To use the Lab_Template.c file,

select it from the right menu and click the Add>> button. Click on the large letter

‘A’ that appears next to the added file in the right window until it becomes a ‘C’.

This indicates that a copy of the Lab_Template.c will be included in the project

directory. Otherwise, changes made to the file during the course of the lab will

alter the original file.

Finally, rename the Lab_Template.c file in the right window to GPIO_Lab1.c by

clicking on it three times to enable editing the name. The Step Four: window should

now resemble Figure 3-6. Click Next>

to continue.

© 2009 Microchip Technology Inc. DS41369A-page 21

Page 26

PICDEMTM Lab Development Board User’s Gu ide

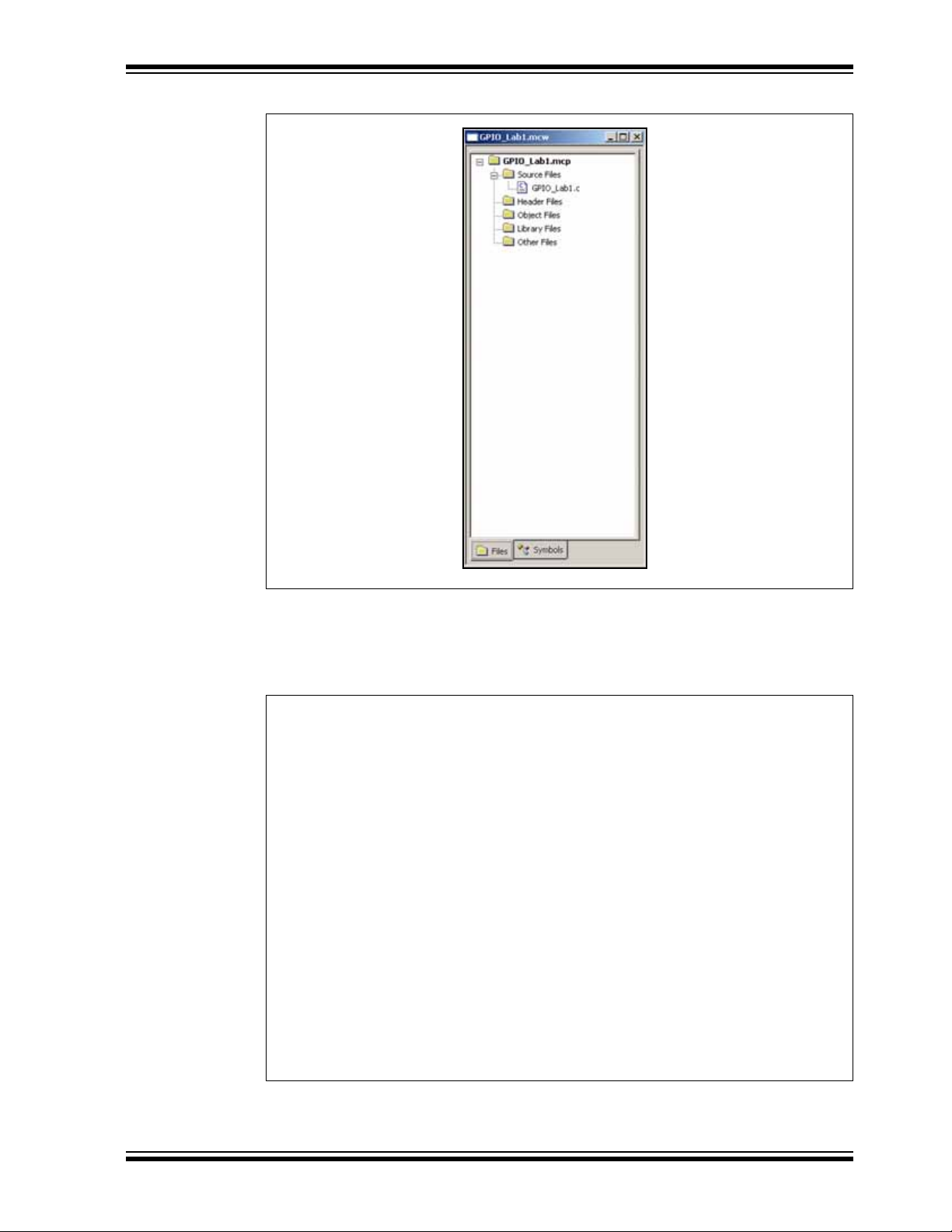

FIGURE 3-6: STEP FOUR

8. Finally, the Summary window should appear showing the selected device, the

tool suite and the new project file name. Click Finish to exit the Project Wizard.

FIGURE 3-7: SUMMARY

9. The MPLAB

visible, it can be opened by selecting View>Project

resemble Figure 3-8.

®

IDE Workspace should now be open. If the Project window is not

. The Project window should

DS41369A-page 22 © 2009 Microchip Technology Inc.

Page 27

General Purpose Input/Output Labs

//Clear PORTC to a known state

PORTC = 0b00000000;

//Configure PORTC's ANALOG/DIGITAL pins as all Digital

ANS4 = 0;//Associated with RC0

ANS5 = 0;//Associated with RC1

ANS6 = 0;//Associated with RC2

ANS7 = 0;//Associated with RC3

ANS8 = 0;//Associated with RC6

ANS9 = 0;//Associated with RC7

//Configure PORTC pins as all output

//i.e. 1 = Input, 0 = Output

TRISC0 = 0;//Make RC0 (pin 16) output

TRISC1 = 0;//Make RC1 (pin 15) output

TRISC2 = 0;//Make RC2 (pin 14) output

TRISC3 = 0;//Make RC3 (pin 7) output

TRISC4 = 0;//Make RC4 (pin 6) output

TRISC5 = 0;//Make RC5 (pin 5) output

TRISC6 = 0;//Make RC6 (pin 8) output

TRISC7 = 0;//Make RC7 (pin 9) output

FIGURE 3-8: PROJECT WIN DOW

10. Double click on the GPIO_Lab1.c source file in the Project window to open.

11. Copy/paste the code in Example 3-1 into the Initialize() section labeled:

//ADD INITIALIZE CODE HERE

EXAMPLE 3-1: INITIALIZE() CODE FOR LAB 1

© 2009 Microchip Technology Inc. DS41369A-page 23

Page 28

PICDEMTM Lab Development Board User’s Gu ide

RC0 = 1;//Make RC0 (pin 16) HIGH (approx. Vdd)

RC1 = 0;//Make RC1 (pin 15) LOW (approx. Vss)

RC2 = 1;//Make RC2 (pin 14) HIGH (approx. Vdd)

RC3 = 1;//Make RC3 (pin 7) HIGH (approx. Vdd)

RC4 = 0;//Make RC4 (pin 6) LOW (approx. Vss)

RC5 = 1;//Make RC5 (pin 5) HIGH (approx. Vdd)

RC6 = 0;//Make RC6 (pin 8) LOW (approx. Vss)

RC7 = 1;//Make RC7 (pin 9) HIGH (approx. Vdd)

Initialize(); //Initialize the relevant registers

while(1) //Code within curly braces will loop forever

{

Do_Outputs(); //Perform any outputs

}

12. Copy/paste the code in Example 3-2 into the Do_Outputs() section labeled:

//ADD DO_OUTPUTS CODE HERE

EXAMPLE 3-2: DO_OUTPUT() CODE FOR LAB 1

13. Copy/paste the code in Example 3-3 into the main() section labeled:

//ADD MAIN CODE HERE

EXAMPLE 3-3: MAIN() CODE FOR LAB 1

The project is now ready to compile and download to the PIC16F690.

14. Compile the project ensuring no errors.

15. Connect the PICkit™ 2 Programmer/Debugger to an available USB port on the

PC and then to the ICSP™ connector ICSP1 (J6) on the PICDEM Lab Development Board. The PICkit 2 should recognize if a power source is not connected to

the PIC16F690 and provide target power.

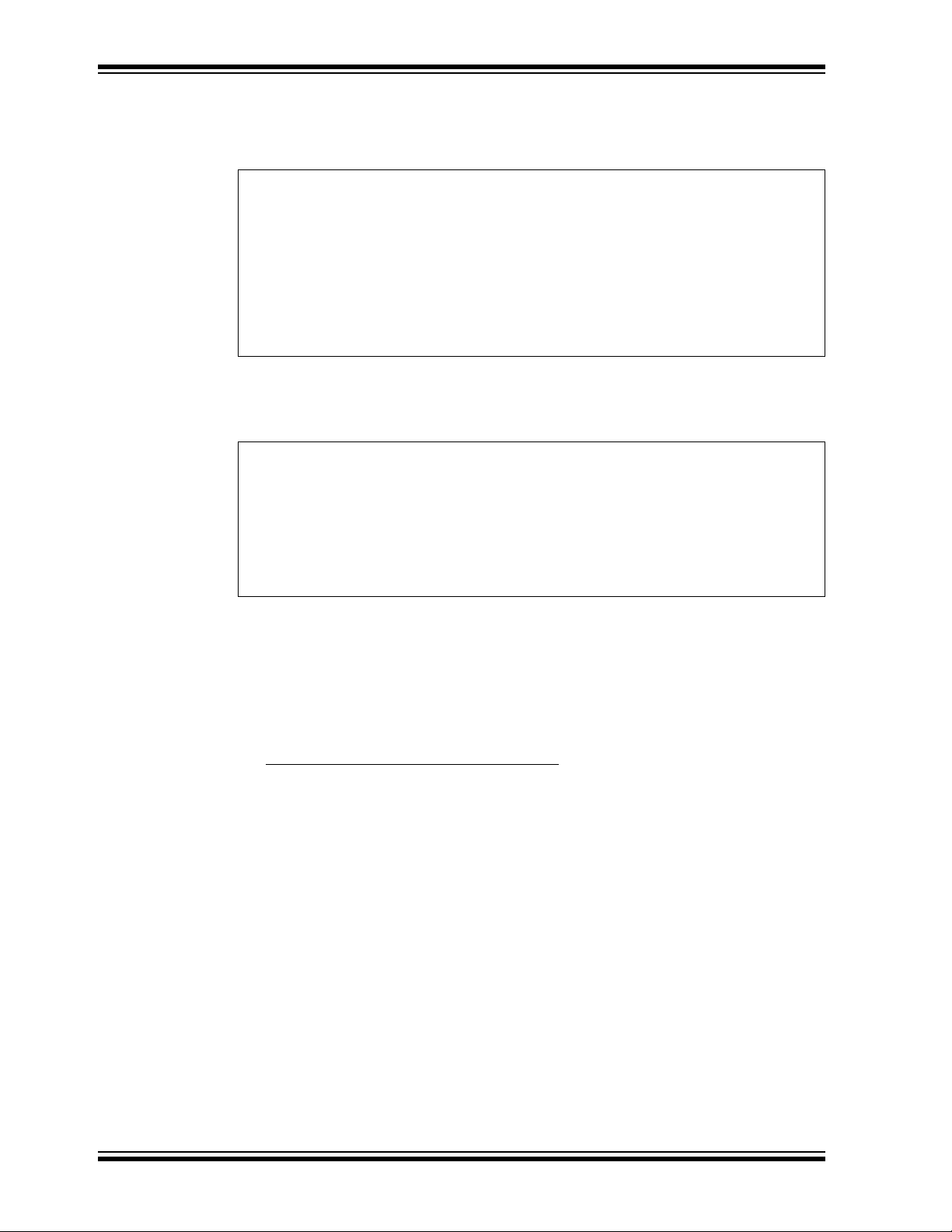

16. In the MPLAB™ IDE Project Workspace, select

Programmer>Select Programmer>PICkit 2

.

17. The PICkit 2 Programmer/Debugger toolbar should now be visible in the

workspace as shown in Figure 3-9.

DS41369A-page 24 © 2009 Microchip Technology Inc.

Page 29

General Purpose Input/Output Labs

Legend:

1. Program the target device

2. Read target device memories

3. Read the target EEDATA memory

4. Verify the contents of the target device

5. Erase the target device memories

6. Verify that target memories are erased

7. Bring target MCLR

to VDD

8. Bring target MCLR to VIL

9. Re-establish PICkit 2 connection

1 2 3 4 5 6 7 8 9

R8

470Ω

R4

470Ω

R7

470Ω

R6

470Ω

R5

470Ω

R3

470Ω

R2

470Ω

R1

470Ω

LED8 LED7 LED6 LED4 LED3 LED2 LED1LED5

V

SSLED ON LED OFF

FIGURE 3-9: PICkit 2 PROGRAMMER/DEBUGGER TOOLBAR

© 2009 Microchip Technology Inc. DS41369A-page 25

8. Press button1 shown in Figure 3-9 to program the PIC16F690.

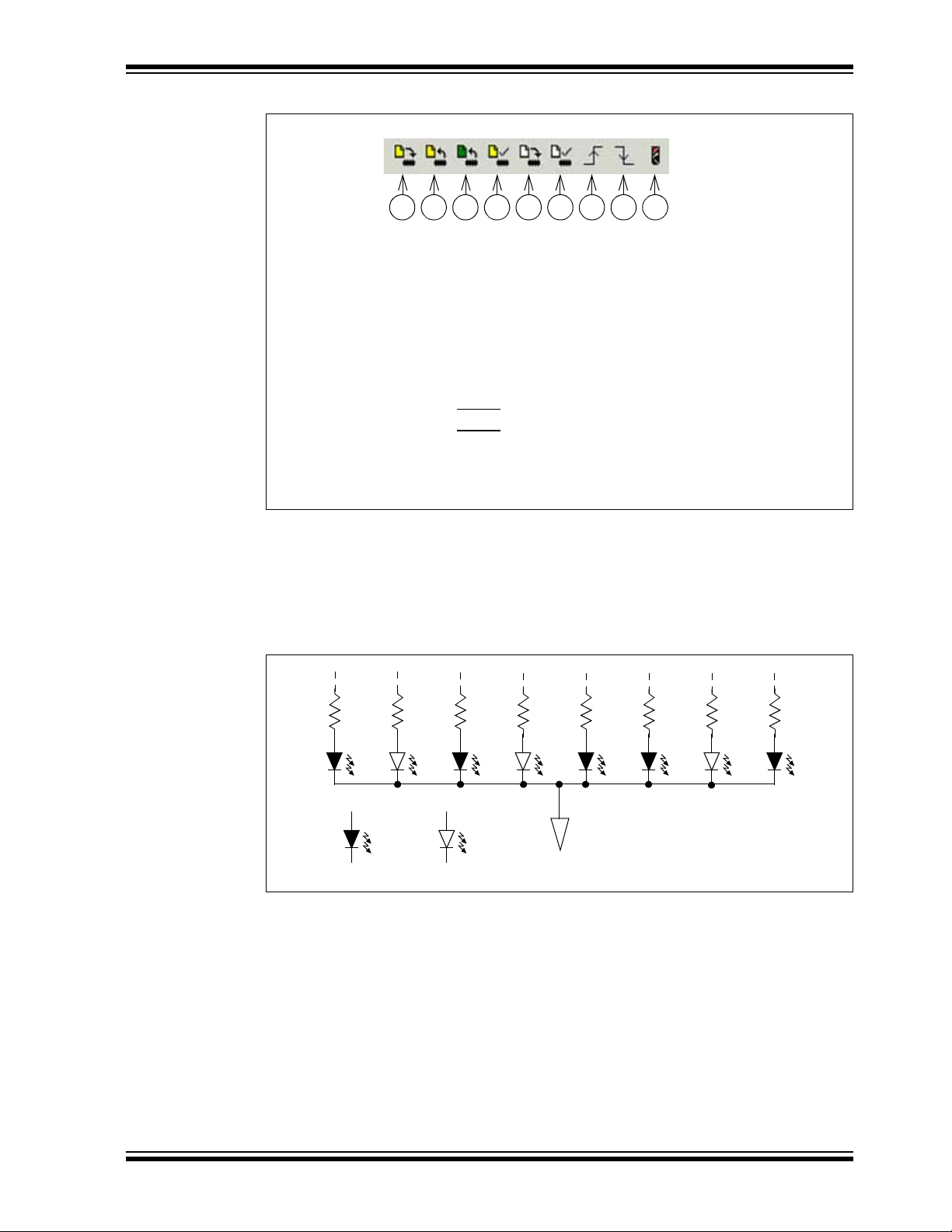

3.3.4.4 TESTING THE APPLICATION

Once programmed, the LEDs connected to the individual PORTC pins should now

resemble the output shown in Figure 3-10.

FIGURE 3-10: LAB 1 LED OUTPUT

The solution for this project is located in the

C:\PICDEM_Lab\GPIO_Labs\GPIO_Lab1\solution directory.

3.3.5 Lab 2: Flash LEDs (Delay Loop)

3.3.5.1 OVERVIEW

This lab implements a software delay to flash the LEDs connected to the PORTC pins

on/off in 1 second intervals. As configured, the PIC16F690 executes 1 million instructions per second. At this rate, the software loop execution needs to be slowed down so

that the LED flashing is visible to the eye. This is done using a delay routine within the

Timing() functional block called from the main() software control loop as shown in

Figure 3-11.

Page 30

PICDEMTM Lab Development Board User’s Gu ide

main()

Initialize()

Do_Outputs()

Loop Forever

Timing()

TIMING()

Create two 8-bit variables:

• delay_var1 = 45571

• delay_var2 = 3

delay_var2 - 1 = 0

?

delay_var1 - 1 = 0

?

END

delay_var1 = 45571

YES

YES

NO

NO

FIGURE 3-11: MAIN() SOFTWARE CONTROL LOOP FLOWCHART FOR

LAB 2

The Timing() delay routine is shown in Figure 3-12.

FIGURE 3-12: TIMING() DELAY ROUTINE FLOWCHART FOR LAB 2

Two variables are used delay_var1 and delay_var2. The delay_var2 is decremented by 1 each time delay_var1 is decremented from 45571 to 0. These values

have been determined through trial and error using a test procedure detailed in the

“Timers: Timer0 Tutorial (Part 1)” (DS51682.pdf) included on the PICDEM™ Lab

Development Kit CD. This delay ties the up the processor for 1 second when using the

4 MHz internal oscillator.

The Initialize() configures the PORTC as follows:

•PORTC

- Set all bits in the PORTC register HIGH

- Configure all PORTC pins as digital outputs

DS41369A-page 26 © 2009 Microchip Technology Inc.

Page 31

General Purpose Input/Output Labs

//Set all PORTC bits HIGH (to a known state)

PORTC = 0b11111111;

//Configure PORTC's ANALOG/DIGITAL pins as all Digital

ANS4 = 0;//Associated with RC0

ANS5 = 0;//Associated with RC1

ANS6 = 0;//Associated with RC2

ANS7 = 0;//Associated with RC3

ANS8 = 0;//Associated with RC6

ANS9 = 0;//Associated with RC7

//Configure PORTC pins as all output

//i.e. 1 = Input, 0 = Output

TRISC0 = 0;//Make RC0 (pin 16) output

TRISC1 = 0;//Make RC1 (pin 15) output

TRISC2 = 0;//Make RC2 (pin 14) output

TRISC3 = 0;//Make RC3 (pin 7) output

TRISC4 = 0;//Make RC4 (pin 6) output

TRISC5 = 0;//Make RC5 (pin 5) output

TRISC6 = 0;//Make RC6 (pin 8) output

TRISC7 = 0;//Make RC7 (pin 9) output

The Do_Outputs() changes somewhat from the previous lab by implementing the

XOR operator to toggle the value in each PORTC bit location each time through the

software loop. The XOR operator is implemented in code as follows:

RCx ^= 1;

This translates to: “Make RCx equal to the current value in RCx XOR’d with 1”

When a value is XOR’d with itself, the result is ‘0’ (i.e., 1 XOR’d with 1 = 0, 0 XOR’d

with 0 = 0). When a value is XOR’d with a value different than itself, the result is ‘1’ (i.e.,

1 XOR’d with 0 = 1). Therefore, each time through the loop PORTC bits will toggle from

1-to-0 or 0-to-1 depending on its current value.

3.3.5.2 PROCEDURE

Using the code developed in the previous lab, make the following changes:

1. Copy/paste the code in Example 3-4 over the Initialize() code from the

previous lab.

Note: The reader may wish to create a new project as per the previous lab called

GPIO_Lab2.mcp

EXAMPLE 3-4: INITIALIZE() CODE FOR LAB 2

The only change from the previous lab is that the PORTC bits are all set high to 1.

2. Copy/paste the code in Example 3-5 over the Do_Outputs() code from the

© 2009 Microchip Technology Inc. DS41369A-page 27

previous lab to accommodate the XOR bit toggle.

Page 32

PICDEMTM Lab Development Board User’s Gu ide

RC0 ^= 1;//XOR current RC0 value with 1

RC1 ^= 1;//XOR current RC1 value with 1

RC2 ^= 1;//XOR current RC2 value with 1

RC3 ^= 1;//XOR current RC3 value with 1

RC4 ^= 1;//XOR current RC4 value with 1

RC5 ^= 1;//XOR current RC5 value with 1

RC6 ^= 1;//XOR current RC6 value with 1

RC7 ^= 1;//XOR current RC7 value with 1

//--------DELAY 1second------------------------//Variable used in delay loop

unsigned int delay_var1 = 45571;

unsigned char delay_var2 = 3;

//Nested while loops to implement a 1 second delay

//Decrement delay_var2, if 0 jump out of loop

while(--delay_var2)

{

//Decrement delay_var1, if 0 jump out of loop

while(--delay_var1);

}

Initialize(); //Initialize the relevant registers

while(1)

{

Do_Outputs(); //Perform any outputs

Timing();//Sets execution rate of the

//Software Control Loop

}

EXAMPLE 3-5: DO_OUTPUT() CODE FOR LAB 2

3. Copy/paste the code in Example 3-6 into the Timing() section labeled:

//ADD TIMING CODE HERE

EXAMPLE 3-6: TIMING() FOR LAB 2

4. Copy/paste the code in Example 3-7 over the main() code from the previous lab

to incorporate the Timing().

EXAMPLE 3-7: MAIN() CODE FOR LAB 2

Compile the project. There should be no errors.

3.3.5.3 TESTING THE APPLICATION

DS41369A-page 28 © 2009 Microchip Technology Inc.

Program the PIC16F690. The LEDs connected to the individual PORTC pins should

now all flash on/off in 1 second intervals.

The solution for this project is located in the

C:\PICDEM_Lab\GPIO_Labs\GPIO_Lab2\solution directory.

Page 33

General Purpose Input/Output Labs

TMR0 Overflow Period = (4/FOSC) x 256 = 1 μSecond x 256 = 256 μSeconds

TMR0 Overflow Period = (4/FOSC) x 256 x prescaler

Using a 1:32 prescaler setting as an example and a 4 MHz internal oscillator

TMR0 Overflow Period = 1

μS x 256 x 32 = 8.192mS

3.3.6 Lab 3: Simple Delays Using Timer0

3.3.6.1 NEW REGISTERS USED IN THIS LAB

To configure the peripherals used in this lab, the following registers are used:

1. Timer0 Module Register: TMR0

- Holds a count value of the number of selected edge transition of a clock

source.

2. OPTION Register: OPTION_REG (Register 5-1 in Section 5 of the PIC16F690

Data Sheet).

- Selects clock source used to increment TMR0 result register.

- Selects clock source edge transition to increment TMR0.

3. Software configurable prescaler to determine the number of clock source edge

transitions before incrementing TMR0 register value.

4. Interrupt Control Register: INTCON (Register 2-3 in Section 2 of the PIC16F690

Data Sheet).

- Contains a flag that when 1, indicates a TMR0 register overflow has occurred.

3.3.6.2 OVERVIEW

To implement a more accurate delay, the Timer0 peripheral can be used. Timer0 is an

8-bit timer/counter that uses a clock source to increment an 8-bit register called TMR0.

Since this register is 8 bits, it can increment up 2

(00000000

TMR0 overflows, a Timer0 Overflow Flag (T0IF) in the OPTION register is set to ‘1’.

This register also features a prescaler that determines how many clock source cycles

it takes to increment TMR0 by ‘1’. In this way, simply by tracking the T0IF, very accurate

delays can be implemented. In this lab, the TMR0 register is configured to increment

on the low-to-high transition of an available internal instruction clock on the PIC16F690.

This internal instruction clock runs at the rate of the internal oscillator frequency F

divided by 4. Therefore, when the PIC16F690 is configured to operate using the internal 4 MHz oscillator, this internal instruction clock runs at a rate of

F

OSC/4 = 4MHz/4 = 1MHz. This is a period of 1/1MHz = 1 μS. If it is known that TMR0

increments every 1 μS, and it takes 256 internal instruction clock cycles to cause a

TMR0 overflow (i.e., 0-255 inclusive), then Equation 3-1 can be derived:

- 111111112) inclusive then rollover or overflow back to ‘0’. Whenever

2

8

= 256 times or 010 - 25510

OSC

EQUATION 3-1: TMR0 OVERFLOW PERIOD USING FOSC/4

As mentioned, Timer0 also features a prescaler that can be configured to increment the

value in TMR0 every 2, 4, 8, 16, 32, 64, 128, or 256 clock source transitions. Therefore,

this feature can be added to Equation 3-1 to create Equation 3-2.

EQUATION 3-2: TMR0 OVERFLOW PERIOD WHEN INCLUDING THE

PRESCALER

© 2009 Microchip Technology Inc. DS41369A-page 29

Page 34

PICDEMTM Lab Development Board User’s Gu ide

Desired TMR0 Overflow Period = (4/FOSC) x (256 - Preload Value) x prescaler

Using a 1:64 prescaler setting, a 4 MHz internal oscillator and requiring a 10 mS

overflow period:

10mS = 1

μSecond x (256 - Preload Value) x 64

10mS/(1

μSecond x 64) = 256 - Preload Value

Preload Value = 256 - [10mS/(1

μSecond x 64)]

Preload Value = 99.75 rounded up becomes 100

Therefore, to produce a 10 mS overflow period, using the internal instruction

clock with a 4 MHz internal oscillator and a TMR0 prescaler value of 1:64

requires that TMR0 be preloaded with a value of 100.

Delay_10mS()

END

YES

NO

Preload TMR0 register with 100

Clear the TMR0 overflow flag

(T0IF)

T0IF = 0?

Finally, TMR0 is a writable register. Meaning that a value can be added to the register

to offset the number of counts it takes for the overflow to occur. Equation 3-3 demon-

strates how to calculate the value to preload the TMR0 register with to create a 10mS

overflow period.

EQUATION 3-3: CALCULATING A TMR0 PRELOAD VALUE TO GENERATE A

10MS OVERFLOW PERIO D

The software flowchart to implement a 10mS delay is shown in Figure 3-13.

FIGURE 3-13: DELAY_10MS() USING TIMER0

The maximum overflow period that can be achieved using Timer0 only utilizes a 1:256

prescaler is as shown in Equation 3-4.

DS41369A-page 30 © 2009 Microchip Technology Inc.

Page 35

General Purpose Input/Output Labs

TMR0 Overflow Period = (4/FOSC) x 256 x prescaler

using a maximum prescaler setting of 1:256 and the 4MHz internal oscillator

TMR0 Overflow Period = 1 μS x 256 x 256 = 65.5mS

Delay_1S()

END

YES

NO

counter variable value determined as follows:

1 second/65.5mS = 15.25 or rounded down to 15

Create an 8-bit variable counter and

initialize to 0

Clear the TMR0 register

Clear the TMR0 overflow flag

(T0IF)

T0IF = 0?

counter < or = 15?

Increment counter value by 1

NO

YES

EQUATION 3-4: MAXIMUM TMR0 OVERFLOW PERIOD

Therefore, to implement delays greater than 65.5mS, a counter variable is

implemented as shown in the flowchart of Figure 3-14 for a 1 second delay.

FIGURE 3-14: DELAY_1S() USING TIMER0

© 2009 Microchip Technology Inc. DS41369A-page 31

Page 36

PICDEMTM Lab Development Board User’s Gu ide

/*---------------------------------------------------------

Subroutine: Delay_1S

Parameters: none

Returns:nothing

Synopsis:Creates a 1S delay when called

---------------------------------------------------------*/

void Delay_1S(void)

{

//Create an 8-bit variable called counter

//and initialize it to 0

unsigned char counter = 0;

while(counter <= 15)

{

//Make sure the T0IF is cleared

T0IF = 0;

//Clear the TMR0 register

TMR0 = 0;

//Sit here and wait for Timer0 to overflow

while (T0IF == 0);

++counter;

}

}

The Initialize() now configures the PIC16F690 peripherals as follows:

•PORTC

- Set all bits in PORTC high

- Make all PORTC pins digital output

•Timer0

- Use the internal instruction clock (F

- Increment TMR0 register on low-to-high transition of F

- Assign the prescaler to Timer0 and configure to increment on every 256th

transition of F

OSC/4

3.3.6.3 PROCEDURE

Using the firmware developed in the previous lab, make the following changes:

1. Copy/paste the code in Example 3-8 at the top of the main firmware source file

under the heading labeled:

/**SUPPORT ROUTINES**********************************/

EXAMPLE 3-8: DELAY_1S() CODE FOR LAB 3

OSC/4) as the TMR0 register clock source

OSC/4

DS41369A-page 32 © 2009 Microchip Technology Inc.

2. Copy/paste the code in Example 3-9 into the Initialize() over the code from

the previous lab.

Page 37

General Purpose Input/Output Labs

//Set all PORTC bits HIGH (to a known state)

PORTC = 0b11111111;

//Configure PORTC's ANALOG/DIGITAL pins as all Digital

ANS4 = 0;//Associated with RC0

ANS5 = 0;//Associated with RC1

ANS6 = 0;//Associated with RC2

ANS7 = 0;//Associated with RC3

ANS8 = 0;//Associated with RC6

ANS9 = 0;//Associated with RC7

//Configure PORTC pins as all output

//i.e. 1 = Input, 0 = Output

TRISC0 = 0;//Make RC0 (pin 16) output

TRISC1 = 0;//Make RC1 (pin 15) output

TRISC2 = 0;//Make RC2 (pin 14) output

TRISC3 = 0;//Make RC3 (pin 7) output

TRISC4 = 0;//Make RC4 (pin 6) output

TRISC5 = 0;//Make RC5 (pin 5) output

TRISC6 = 0;//Make RC6 (pin 8) output

TRISC7 = 0;//Make RC7 (pin 9) output

//Configure Timer0 as follows:

T0CS = 0; //Use the internal instruction clock

//FOSC/4 as the clock source

T0SE = 0;//Increment TMR0 on low-to-high

//FOSC/4 transition

PSA = 0;//Assign the prescaler to

//Timer0

//Configure Timer0 prescaler to increment

//TMR0 every 256 FOSC/4 clock transitions

PS0 = 1;

PS1 = 1;

PS2 = 1;

Delay_1S(); //Call the 1 second delay

EXAMPLE 3-9: INITIALIZE() CODE FOR LAB 3

3. Finally, copy/paste the code in Example 3-10 into the Timing() over the code

from the previous lab

EXAMPLE 3-10: TIMING() CODE FOR LAB 3

4. The remaining code from the previous lab remains the same. Compile the proj-

ect. There should be no errors.

3.3.6.4 TESTING THE APPLICATION

Program the PIC16F690. The application should behave exactly as it did in the

previous lab. Using an oscilloscope to test individual PORTC pin level transitions would

be useful to analyze the accuracy of the delay.

The solution for this project is located in the

C:\PICDEM_Lab\GPIO_Labs\GPIO_Lab3\solution directory.

Note: More in-depth tutorials on the Timer0 peripheral are covered in “Timers:

Timer0 Tutorial (Part 1)” (5162a.pdf) and “Timers: Timer0 Tutorial (Part 2)”

(51702a.pdf) files included on the PICDEM™ Lab Development Kit CD.

© 2009 Microchip Technology Inc. DS41369A-page 33

Page 38

PICDEMTM Lab Development Board User’s Gu ide

main()

Initialize()

Do_Outputs()

Loop Forever

Timing()

Decide()

Global Variables:

• 8-bit LED_Output

Decide()

LED_Output = 0b10000000

or

LED_Output = 0b00000000

?

END

Shift contents of LED_Output

variable left by 1 bit position

YES

NO

LED_Output = 0b00000001

LED_Output variable initialize to 0b00000001

in Initialize()

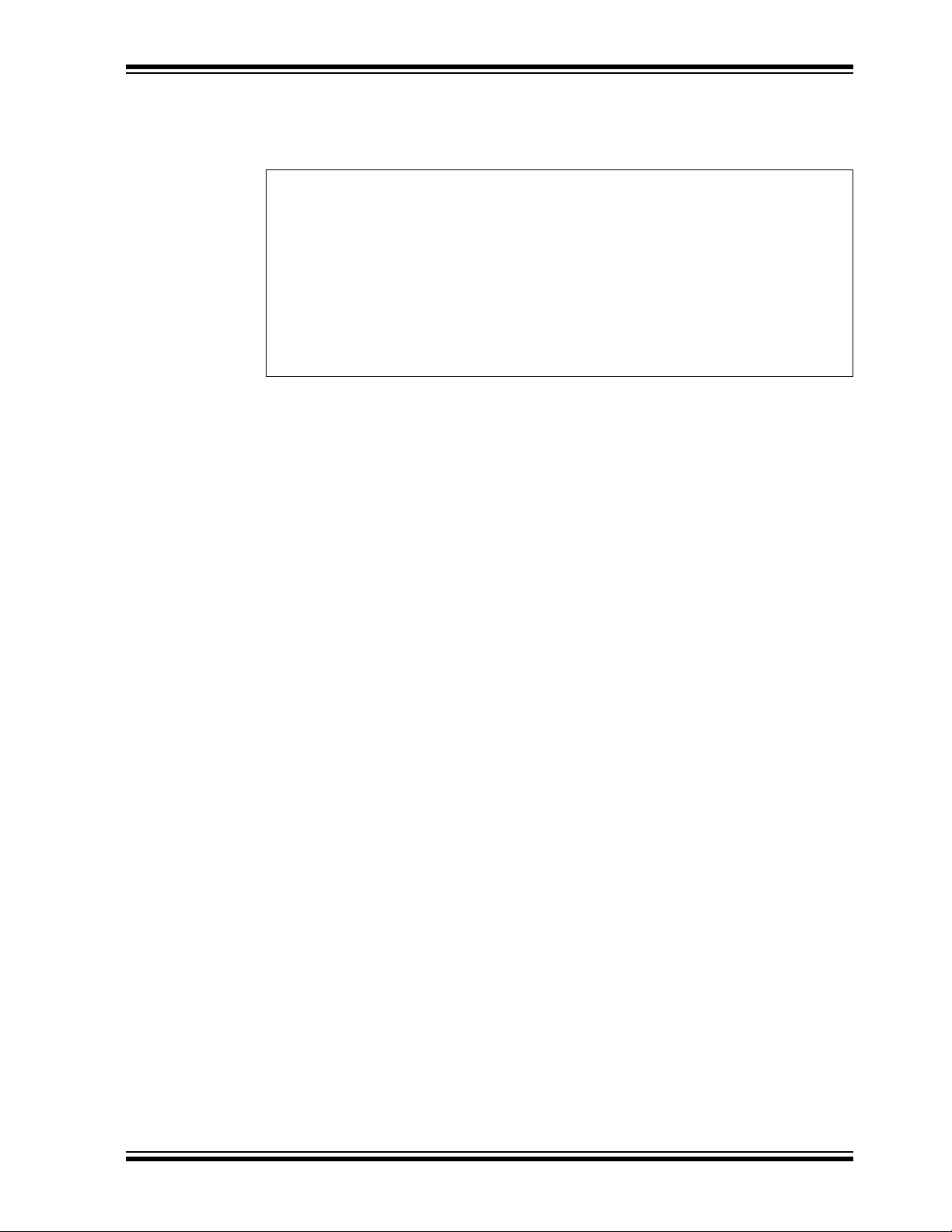

3.3.7 Lab 4: Rotate LEDs

3.3.7.1 OVERVIEW

This lab shifts a high bit in the PORTC register from right-to-left each time through the

software loop sequentially lighting the LEDs connected to the PORTC pins in 1 second

intervals as dictated by the Timing(). This lab adds some new functional blocks to

the main() software control loop as shown in Figure 3-15.

FIGURE 3-15: MAIN() SOFTWARE CONTROL LOOP FLOWCHART FOR

LAB 4

DS41369A-page 34 © 2009 Microchip Technology Inc.

The addition of an 8-bit global variable (can be manipulated by any function) called

LED_Output is used. This variable will be acted upon by the new Decide() by shifting a high bit in LED_Output from right-to-left each time this function is called. The

flowchart for the Decide() is shown in Figure 3-16.

FIGURE 3-16: DECIDE() FLOWCHART FOR LAB 4

Page 39

General Purpose Input/Output Labs

Do_Outputs()

assigns

LED_Output to

PORTC

LED_Output variable

10000000

10000000

PORTC

Do_Outputs()

assigns

LED_Output to

PORTC

01000000

01000000

LED_Output variable

PORTC

Decide() shifts contents of

LED_Output Left by 1 bit position

Corresponding LED lights

Corresponding LED lights

First time through main():

Next time through main():

Initialize() determines initial

contents of LED_Output

The Decide() first checks the current value in LED_Output for two specific conditions:

• Is the Most Significant bit ‘1’? This means that on the next shift, the contents will

be all ‘0’s.

• Is the value currently a ‘0’?

If either condition exists, the function re-initializes LED_Output to set the Least Significant bit. Otherwise, there will be a period when none of the LEDs are lit.

The shift is implemented in code as follows:

LED_Output <<= 1;

This translates to: “LED_Output is equal to the current contents of LED_Output

shifted to the left by 1 bit position”

Conversely, to shift the bit to the right the code would be as follows:

LED_Output >>= 1;

The Do_Outputs() will then assign the contents of the LED_Output variable to the

PORTC register and whichever bit is high will light the connected LED. (See

Figure 3-17.)

FIGURE 3-17: RESULTS OF DO_OUTPUT()

© 2009 Microchip Technology Inc. DS41369A-page 35

The Initialize() now configures the PIC16F690 peripherals as follows:

•PORTC

- Initialize PORTC so that the 7 Most Significant bits are ‘0’ and the Least

Significant bit is ‘1’

- Make all PORTC pins digital output

•Timer0

- Use the internal instruction clock (F

- Increment TMR0 register on low-to-high transition of F

- Assign the prescaler to Timer0 and configure to increment on every 256th

• Initialize the LED_Output variable to ‘0’

transition of F

OSC/4

OSC/4) as the TMR0 register clock source

OSC/4

Page 40

PICDEMTM Lab Development Board User’s Gu ide

unsigned char LED_Output;//Variable used to set/clear PORTC bits

//Clear PORTC to a known state

PORTC = 0b00000001;

//Configure PORTC's ANALOG/DIGITAL pins as all Digital

ANS4 = 0;//Associated with RC0

ANS5 = 0;//Associated with RC1

ANS6 = 0;//Associated with RC2

ANS7 = 0;//Associated with RC3

ANS8 = 0;//Associated with RC6

ANS9 = 0;//Associated with RC7

//Configure PORTC pins as all output

//i.e. 1 = Input, 0 = Output

TRISC0 = 0;//Associated with RC0

TRISC1 = 0;//Associated with RC1

TRISC2 = 0;//Associated with RC2

TRISC3 = 0;//Associated with RC3

TRISC4 = 0;//Associated with RC4

TRISC5 = 0;//Associated with RC5

TRISC6 = 0;//Associated with RC6

TRISC7 = 0;//Associated with RC7

//Configure Timer0 as follows:

T0CS = 0; //Use the internal instruction clock

//FOSC/4 as the clock source

T0SE = 0;//Increment TMR0 on low-to-high

//FOSC/4 transition

PSA = 0;//Assign the prescaler to

//Timer0

//Configure Timer0 prescaler to increment

//TMR0 every 256 FOSC/4 clock transitions

PS0 = 1;

PS1 = 1;

PS2 = 1;

//Initialize LED_Output to all zeros

LED_Output = 0b00000000;

3.3.7.2 PROCEDURE

Using the code developed in the previous lab, make the following changes:

1. The LED_Output variable will need to be declared before it can be used.

Copy/paste the code in Example 3-11 to the beginning of the source file under

the section marked:

//-----------------DATA MEMORY------------------------

EXAMPLE 3-11: LED_OUTPUT VARIABLE DECLARATION FOR LAB 4

2. Copy/paste the code in Example 3-12 over the Initialize() code from the

previous lab.

EXAMPLE 3-12: INITIALIZE() CODE FOR LAB 4

DS41369A-page 36 © 2009 Microchip Technology Inc.

Page 41

General Purpose Input/Output Labs

//First check if LED_Output variable has most significant bit

//set to 1 or if LED_Output variable is all 0's.

//If so, re initialize the LED_Output variable so that the

//least significant bit is set to 1 and all other bits are

//cleared to 0

if((LED_Output == 0b10000000) || (LED_Output == 0b00000000))

LED_Output = 0b00000001;

//If neither of these conditions are true, simply shift

//the LED_Output variable's contents to the Left by 1 bit

//position

else LED_Output <<=1;

//Assign the manipulated contents of the

//LED_Output variable to the PORTC register

PORTC = LED_Output;

Initialize(); //Initialize the relevant registers

while(1)

{

Decide(); //Make any decisions

Do_Outputs(); //Perform any outputs

Timing();//Sets execution rate of the

//Software Control Loop

}

Changes from the previous lab include PORTC initialization so that all bits are ‘0’

except for the Least Significant bit (LSb) and the initialization of the LED_Output

variable.

3. Copy/paste the code in Example 3-13 into the Decide() section labeled:

//ADD DECISION CODE HERE

EXAMPLE 3-13: DECIDE()CODE FOR LAB 4

4. Copy/paste the code in Example 3-14 over the Do_Outputs() code from the

previous lab.

EXAMPLE 3-14: DO_OUTPUTS() CODE FOR LAB 4

This code simply assigns the contents of the LED_Output variable to the PORTC

register.

5. Copy/paste the code in Example 3-15 over the main() code from the previous

lab to incorporate the Decide().

EXAMPLE 3-15: MAIN() CODE FOR LAB 4

© 2009 Microchip Technology Inc. DS41369A-page 37

Compile the project. There should be no errors.

Page 42

PICDEMTM Lab Development Board User’s Gu ide

3.3.7.3 TESTING THE APPLICATION

Program the PIC16F690. The LEDs connected to the individual PORTC pins should

now all flash on/off sequentially from right-to-left in 1 second intervals.

The solution for this project is located in the

C:\PICDEM_Lab\GPIO_Labs\GPIO_Lab4\solution directory.

3.4 GPIO INPUT LABS

3.4.1 Reference Documentation

PIC16F690 Data Sheet

• Section 2: Memory Organization

• Section 4: I/O Ports

• Section 5: Timer0 Module

3.4.2 Equipment Required for GPIO Input Labs

To complete the labs in this section, the following components are required:

1. 1 – push button

2. 8 – Light Emitting Diodes

3. 1 – 10 K

4. 8 – 470Ω resistors

5. PIC16F690 populating socket U2

6. Assorted jumper wires

Ω

3.4.3 PICDEM Lab Development Board Setup for GPIO Input Labs

The GPIO input labs will require that the PICDEM Lab Development Board be

configured as shown in Figure 3-12 using the components listed in the previous

section.

DS41369A-page 38 © 2009 Microchip Technology Inc.

Page 43

General Purpose Input/Output Labs

U2

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

RC0

RC1

RC2

RC3

RC4

RC5

RC6

RC7

J9J8

R8

470Ω

R4

470Ω

R7

470Ω

R6

470Ω

R5

470Ω

R3

470Ω

R2

470Ω

R1

470Ω

LED8 LED7 LED6 LED4 LED3 LED2 LED1LED5

V

SS

V

SS

V

DD

R9

10KΩ

SW1

RA2

FIGURE 3-18: PICDEM LAB SCHEMATIC FOR GPIO INPUT LABS

The only change from the previous section is the inclusion of a push button connected

to RA2 with associated pull-up resistor.

3.4.4 Lab 5: Adding a Push Button

3.4.4.1 NEW REGISTERS USED IN THIS LAB

To configure the peripherals used in this lab, the following registers are used:

1. PORTA Register: PORTA (Register 4-1 in Section 4 of the PIC16F690 Data

Sheet)

- 8-bit bidirectional port

2. PORTA Tri-State Register: TRISA (Register 4-2 in Section 4 of the PIC16F690

Data Sheet)

- Configures corresponding bits in PORTA as either input or output

3.4.4.2 OVERVIEW

This lab expands upon Lab 4 by adding a push button interface to change the direction

of the sequential shift in the PORTC register.

Mechanical switches play an important and extensive role in practically every

computer, microprocessor and microcontroller application. Mechanical switches are

inexpensive, simple and reliable. However, switches can be very noisy electrically. The

apparent noise is caused by the closing and opening action that seldom results in a

clean electrical transition. The connection makes and breaks several, perhaps even

hundreds, of times before the final switch state settles. The problem is known as switch

bounce. Some of the intermittent activity is due to the switch contacts actually bouncing

off each other. Also, switch contacts are not perfectly smooth. As the contacts move

against each other, the imperfections and impurities on the surfaces cause the

electrical connection to be interrupted. The result is switch bounce. The consequences

© 2009 Microchip Technology Inc. DS41369A-page 39

Page 44

PICDEMTM Lab Development Board User’s Gu ide

main()

Initialize()

Do_Outputs()

Loop Forever

Timing()

Decide()

Global Variables:

• 8-bit variable LED_Output will be used to

light the LEDs connected to PORTC

• 1-bit variable direction used to determine the direction of the s e que ntial LED

flashing

0 = shift PORTC bits right-to-left

1 = shift PORTC bits left-to-right

Get_Inputs()

of uncorrected switch bounce can range from being just annoying to catastrophic. The

classic solution involves filtering, such as through a resistor-capacitor circuit, or through

resettable shift registers. These methods are still effective but they involve additional

cost in material, installation and board real estate. Debouncing in software eliminates

these additional costs.

One of the simplest ways to switch debounce is to sample the switch until the signal is

stable or continue to sample the signal until no more bounces are detected. How long

to continue sampling requires some investigation. However, 5 mS is usually adequate,

while still reacting fast enough that the user won't notice it.

The software flowchart for this application is shown in Figure 3-19.

FIGURE 3-19: MAIN() SOFTWARE CONTROL LOOP FLOWCHART FOR

LAB 5

The Initialize() now configures the following:

•PORTC

- Configure PORTC pins as per the previous labs

•PORTA

- Clear PORTA register.

- Configure RA2 as a digital input pin

• Timer0 will be configured to implement the 5mS delay as follows:

- Use the internal instruction clock F

- Increment TMR0 on the low-to-high transition of F

- Assign the prescaler to TMR0 and configure 1:64.

• Initialize the LED_Output variable to ‘0’

• Initialize the direction bit variable to ‘0’

- This is a global variable that will be manipulated by the new Get_Inputs()

DS41369A-page 40 © 2009 Microchip Technology Inc.

(see Registers 4-1 and 4-2 in Section 4.1 of the PIC16F690 Data Sheet).

OSC/4 as the TMR0 clock source.

OSC/4.

and used to determine PORTC shift direction by the Decide().

Page 45

General Purpose Input/Output Labs

Get_Inputs()

RA0 = 0

?

END

Contents of direction

remain unchanged

YES

NO

Delay_5mS()

RA0 = 0

?

Toggle contents of

direction

YES

NO

Debounces signal

on RA2

A new function called Get_Inputs() is used to check the RA2 pin voltage. Referring

to Figure 3-12, the RA2 pin connected to the push button (SW1) is pulled to V

a 10 KΩ

resistor. This pull-up resistor eliminates noise on the pin that could trigger

“false” push button presses. The second terminal of the push button is connected to

V

SS. In this way, when a user presses the push button the voltage present on RA2 will

transition from V

DD

(high or ‘1’) to VSS (low or ‘0’). The software flowchart for the

Get_Inputs() is shown in Figure 3-20.

FIGURE 3-20: GET_INPUTS() SOFTWARE FLOWCHART FOR LAB 5

DD using

Referring to the flowchart in Figure 3-20, the Get_Inputs() first checks the voltage

level on the RA2 pin. If the voltage is logic low (= 0 or V

SS), a 5mS delay is implemented

using a new support routine called Delay_5mS() to allow any switch bouncing to settle. The Delay_5mS() is based off of the Timer0 peripheral as discussed in Lab 3. The

software flowchart for Delay_5mS() is shown in Figure 3-21.

© 2009 Microchip Technology Inc. DS41369A-page 41

Page 46

PICDEMTM Lab Development Board User’s Gu ide

Delay_5mS()

T0IF = 1

(i.e., TMR0 overflow)

?

END

Clear the Timer0 overflow

flag (T0IF)

YES

NO

Preload the Timer0 result

register (TMR0) with 100

Timer0 configured in the Initialize() as fol-

lows:

• Using the internal F

OSC/4 (4MHz/4) clock

source

• TMR0 increments on low-to-high transition

of F

OSC/4

• Prescaler configured for 1:32

Desired Timer0 Overflow Rate = (4/F

OSC) x number of counts to overflow x prescaler

5mS = 1μSeconds x (256 – TMR 0 preload value) x 32

TMR0 preload value = 256 – 5mS = 99.75 rounded to 100

1μSeconds x 32

TMR0 preload valu e det er m ined as follows:

FIGURE 3-21: DELAY_5MS() SOFTWARE FLOWCHART FOR LAB 5

The RA2 pin voltage is then checked again. If still low, a push button press is indicated