Page 1

Section 66. 16-Bit Sigma-Delta A/D Converter

HIGHLIGHTS

66

16-Bit Sigma-De lt a

A/D Converter

This section of the manual contains the following major topics:

66.1 Introduction.................................................................................................................66-2

66.2 Registers.....................................................................................................................66-4

66.3 SD A/D Module Configuration.....................................................................................66-8

66.4 Interrupt Modes.........................................................................................................66-14

66.5 Offset Calibration......................................................................................................66-14

66.6 Gain Error Calibration...............................................................................................66-15

66.7 Operation During Sleep and Idle Modes ...................................................................66-21

66.8 Effects of a Reset......................................................................................................66-21

66.9 Register Map............................................... ..............................................................66-22

66.10 Design Tips...............................................................................................................66-23

66.11 Related Application Notes.........................................................................................66-24

66.12 Revision History........................................................................................................66-25

© 2013 Microchip Technology Inc. DS30687A-page 66-1

Page 2

PIC24F Family Reference Manual

66.1 INTRODUCTION

The PIC24F 16-bit Sigma-Delta Analog-to-Digital (SD A/D) Converter has the following key

features:

• Sigma-Delta Conversion

• Programmable Data Rate up to 62.5 ksps

• Differential inputs with Gain Settings

• Dithering Option and Adjustable Oversampling Ratios

• Independent Module Reset Option

The SD A/D Converter module accepts the analog signal and converts it to a corresponding

digital value. The 16-bit SD A/D Converter can have up to eight differential analog inputs

(channels). Some of the channels can be configured as single-ended inputs or can be used for

the external voltage reference connection. The actual number of analog inputs and the external

voltage reference input configuration c an vary with the device. For mo re information on th e actual

number and type of channels available in the device, refer to the specific device data sheet.

The SD A/D Converter contains the following sections:

• Analog Input Selection

• Output Buffer

• Timing and Control Functions

The 16-bit SD A/D Converter samples an input signal less than Nyquist Frequency. The analog

input multiplexer selects the signal to be converted from multiple analog input pins. The

differential analog input signal can be positive or negative (i.e., bipolar). The sampled voltage is

converted to a digital value, which represents the ratio of input voltage to a reference voltage.

The reference voltages can be configured to either external references or SV

The input signal can be amplified up to 32 times using the gain settings. Dithering averages the

nonlinearity of the Digital-to-Analog Converter (DAC) and thereby reduces harmonic distortion.

The bandwidth of the input amplifier can be selected using the power level option.

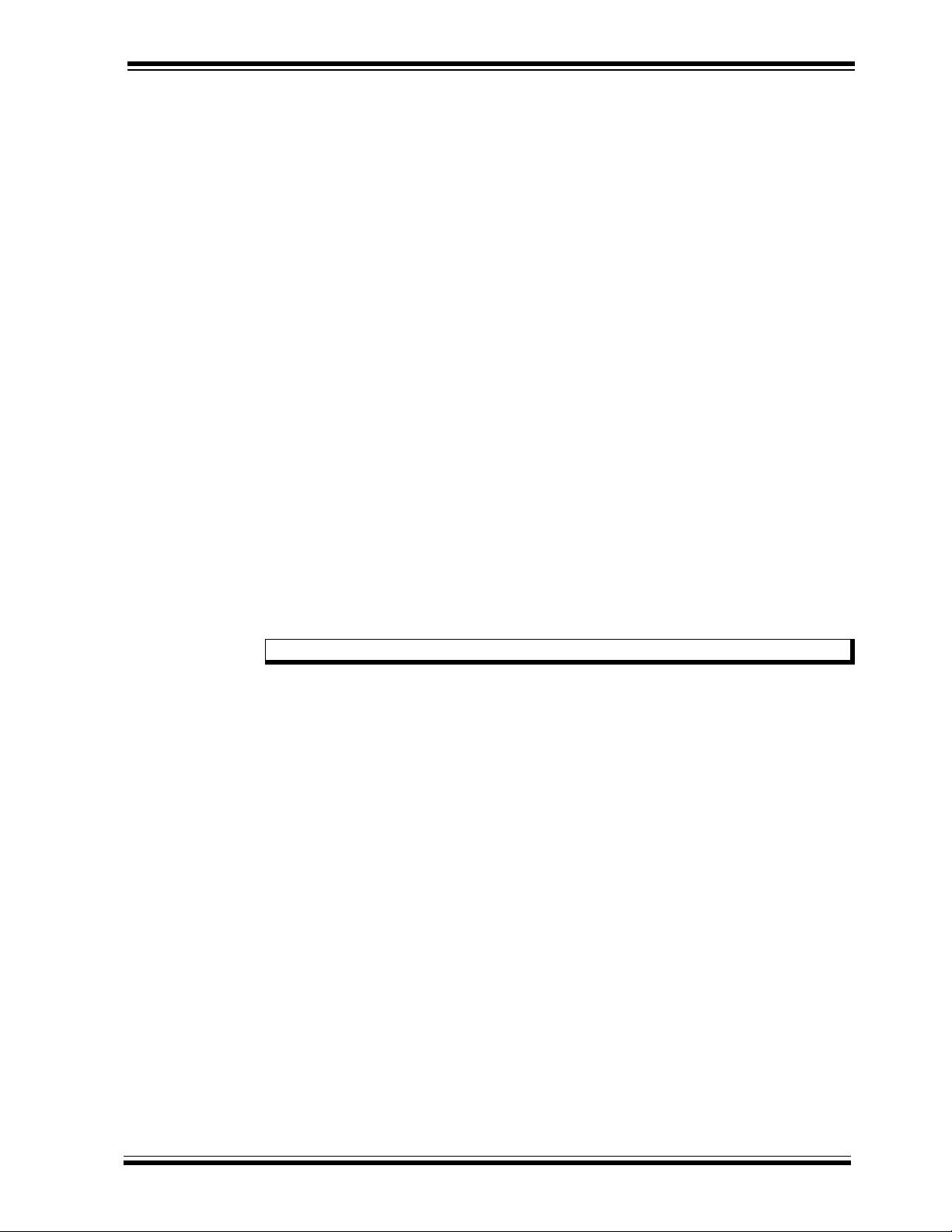

A simplified block diagram for the SD A/D Converter is shown in Figure 66-1.

Note: The Nyquist Frequency is half the sampling frequency of the SD A/D Converter.

DD and SVSS.

DS30687A-page 66-2 © 2013 Microchip Technology Inc.

Page 3

Section 66. 16-Bit Sigma-Delta A/D Converter

CH1+

CHn+

Clock

Generation

SINC

3

PGA

Modulator

SV

REF-

V

REF-

-

Filter/Sample

Control and

Interrupt Logic

SDAxIF

SDxRESH

SDxRESL

Low-Pass

Primary OSC

FRC

Fc

Y

DITHER<1:0>

SDGAIN<2:0>

SDDIV<2:0>

SDCS<1:0>

FILTDIS

SDINT<1:0>

SDWM<1:0>

RNDRES<1:0>

Filter

CH0CH1-

CHn-

V

REF-

SDCH<2:0>

(1)

SVSS

SDREFN

SVREF+

SVDD

VREF+

SDREFP

CH0+

V

REF+

Note 1: Refer to the specific device data sheet for more information on the actual number and type of channels available.

—

—

–

+

Figure 66-1: 16-Bit Sigma-Delta A/D Converter Block Diagram

66

16-Bit Sigma-De lt a

A/D Converter

© 2013 Microchip Technology Inc. DS30687A-page 66-3

Page 4

PIC24F Family Reference Manual

66.2 REGISTERS

The 16-bit SD A/D Converter uses five registers for its operation:

• SDxCON1: SD A/Dx Control Register 1

• SDxCON2: SD A/Dx Control Register 2

• SDxCON3: SD A/Dx Control Register 3

• SDxRESH: SD A/Dx Result Register High Word

• SDxRESL: SD A/Dx Result Register Low Word

All registers are mapped in the data memory space. The SDxCON1, SDxCON2 and SDxCON3

registers (Register 66-1, Register 66-2 and Register 66-3) control the ove rall operation of the SD

A/D module. This includes enabling the module, configuring the conversion clock and voltage

reference source s, se ttin g dithering scheme, ga in of the input amplifier, ov er s am pl ing fre que nc y

and so on.

DS30687A-page 66-4 © 2013 Microchip Technology Inc.

Page 5

Section 66. 16-Bit Sigma-Delta A/D Converter

Register 66-1: SDxCON1: SD A/Dx Control Register 1

R/W-0 U-0 R/W-0 R/W-0 r-0 R/W-0 R/W-0 R/W-0

SDON — SDSIDL SDRST r SDGAIN2 SDGAIN1 SDGAIN0

bit 15 bit 8

R/W-0 R/W-0 U-0 R/W-0 U-0 R/W-0 R/W-0 R/W-0

DITHER1 DITHER0 —VOSCAL— SDREFN SDREFP PWRLVL

bit 7 bit 0

Legend: r = Reserved bit

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 15 SDON: SD A/D Module Enable bit

1 = Sigma-Delta A/D module is enabled

0 = Sigma-Delta A/D module is disabled

bit 14 Unimplemented: Read as ‘0’

bit 13 SDSIDL: SD A/D Stop in Idle Mode bit

1 = Discontinues module operation when device enters Idle mode

0 = Continues module operation in Idle mode

bit 12 SDRST: SD A/D Reset bit

1 = Resets all SD A/D module circuitry (analog section remains in Reset as long as SDRST bit is set)

0 = Releases from Reset (Run mode)

bit 11 Reserved: Always maintain as ‘0’ for proper A/D operation

bit 10-8 SDGAIN<2:0>: SD A/D Gain Control bits

11x = Reserved ; do not use

101 = 1:32

100 = 1:16

011 = 1:8

010 = 1:4

001 = 1:2

000 = 1:1

bit 7-6 DITHER<1:0>: Dithering Mode Select bits

11 = High Dither mode (preferred with higher Oversampling Ratio (OSR) and positive reference

below SV

10 = Medium Dither mode (preferred for low-to-medium OSR and positive reference below SV

01 = Low Dither mode (preferred when the positive reference is at or near SV

00 = No Dither mode

bit 5 Unimplemented: Read as ‘ 0’

bit 4 VOSCAL: Internal Offset Measurement Enable bit

1 = Converter is configured to sample its own internal offset error

0 = Converter is configured for normal operation

bit 3 Unimplemented: Read as ‘ 0’

bit 2 SDREFN: SD A/D Negative Voltage Reference Configuration bit

REF- pin

1 = SV

SS

0 = SV

bit 1 SDREFP: SD A/D Positive Voltage Reference Configuration bit

1 = SVREF+ pin

DD

0 = SV

bit 0 PWRLVL: Analog Amplifier Bandwidth Select bit

1 = 2x bandwidth (higher po wer consumption compared to normal bandwidth)

0 = Normal ba ndwidth

DD)

DD)

DD)

66

16-Bit Sigma-De lt a

A/D Converter

© 2013 Microchip Technology Inc. DS30687A-page 66-5

Page 6

PIC24F Family Reference Manual

Register 66-2: SDxCON2: SD A/Dx Control Register 2

R/W-0 R/W-0 R/W-0 R/W-0 U-0 U-0 R/W-0 R/W-0

CHOP1 CHOP0 SDINT1 SDINT0

bit 15 bit 8

U-0 U-0 U-0 R/W-0 R/W-0 U-0 U-0 HS/C-0

— — — RNDRES1 RNDRES0 — — SDRDY

bit 7 bit 0

Legend: HS = Hardware Settable bit C = Clearable bit

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 15-14 CHOP<1:0>: Amplifier Chopping Enable bits

11 = Chopping is enabled

10 = Reserved

01 = Reserved

00 = Chopping is disabled

bit 13-12 SDINT<1:0>: SD A/D Interrupt Event Generation Select bits

11 = Interrupt on every data output

10 = Interrupt on every fifth data output

01 = Interrupt when the new result is less than the old result

00 = Interrupt when the new result is greater than the old result

bit 11-10 Unimplemented: Read as ‘0’

bit 9-8 SDWM<1:0>: SD A/D Output Result Register Write Mode bits

11 = Reserved ; do not use

10 = SDxRESH/SDxRESL are never updated (used for > or < threshold compare)

01 = SDxRESH/SDxRESL are updated on every interrupt

00 = SDxRESH/SDxRESL are upda ted on ev ery interrupt a fter SDRDY is cleare d to ‘0’ by the soft ware

bit 7-5 Unimplemented: Read as ‘0’

bit 4-3 RNDRES<1:0>: Round Data Control bits

11 = Round result to 8 bits

10 = Round result to 16 bits

01 = Round result to 24 bits

00 = No Rounding (32 bits)

bit 2-1 Unimplemented: Read as ‘0’

bit 0 SDRDY: SD A/D Filter Data Ready bit (set by hardware)

1 = SINC filter delay is satisfied (clear this bit in software)

0 = SINC filter delay is not satisfied

— —SDWM1SDWM0

DS30687A-page 66-6 © 2013 Microchip Technology Inc.

Page 7

Section 66. 16-Bit Sigma-Delta A/D Converter

Register 66-3: SDxCON3: SD A/Dx Control Register 3

R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0 R/W-0

(1)

SDDIV2

bit 15 bit 8

U-0 U-0 U-0 U-0 U-0 R/W-0 R/W-0 R/W-0

— — — — — SDCH2

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

SDDIV1

(1)

SDDIV0

(1)

SDOSR2 SDOSR1 SDOSR0 SDCS1 SDCS0

(3)

SDCH1

(3)

SDCH0

(3)

66

16-Bit Sigma-De lt a

A/D Converter

bit 15-13 SDDIV<2:0>: SD A/D Input Clock Divider/Postscaler Ratio bits

111 = Reserved

110 = 64

101 = 32

100 = 16

011 = 8

010 = 4

001 = 2

000 = 1 (No divider, clock selected by SDCS<1:0> is provided directly to A/D)

bit 12-10 SDOSR<2:0>: SD A/D Oversampling Ratio (OSR) Selection bits

111 = Reserved

110 = 16 (fastest conversion results, low quality)

101 = 32

100 = 64

011 = 128

010 = 256

001 = 512

000 = 1024 (slowest conversion results, best quality)

bit 9-8 SDCS<1:0>: SD A/D Clock Source Select bits

11 = Reserved

10 = Primary Oscillator (OSCI/CLKI)

01 = FRC (8 MHz)

00 = System clock (FOSC/2)

bit 7-3 Unimplemented: Read as ‘0’

bit 2-0 SDCH<2:0>: SD A/D Analog Channel Input Select bits

(2)

(3)

(1)

Note 1: To avoid overclocking or underclocking the module, set SDDIV<2:0> to obtain an A/D clock frequency

(input frequency selected by SDCS<1:0> is divided by the SDDIVx postscaler) at or between 1 MHz and

4 MHz.

2: The 8 MHz FRC output is used directly, prior to the FRCDIV<2:0> postscaler.

3: Refer to the specific device data sheet for more information on the actual number and type of channels

available.

© 2013 Microchip Technology Inc. DS30687A-page 66-7

Page 8

PIC24F Family Reference Manual

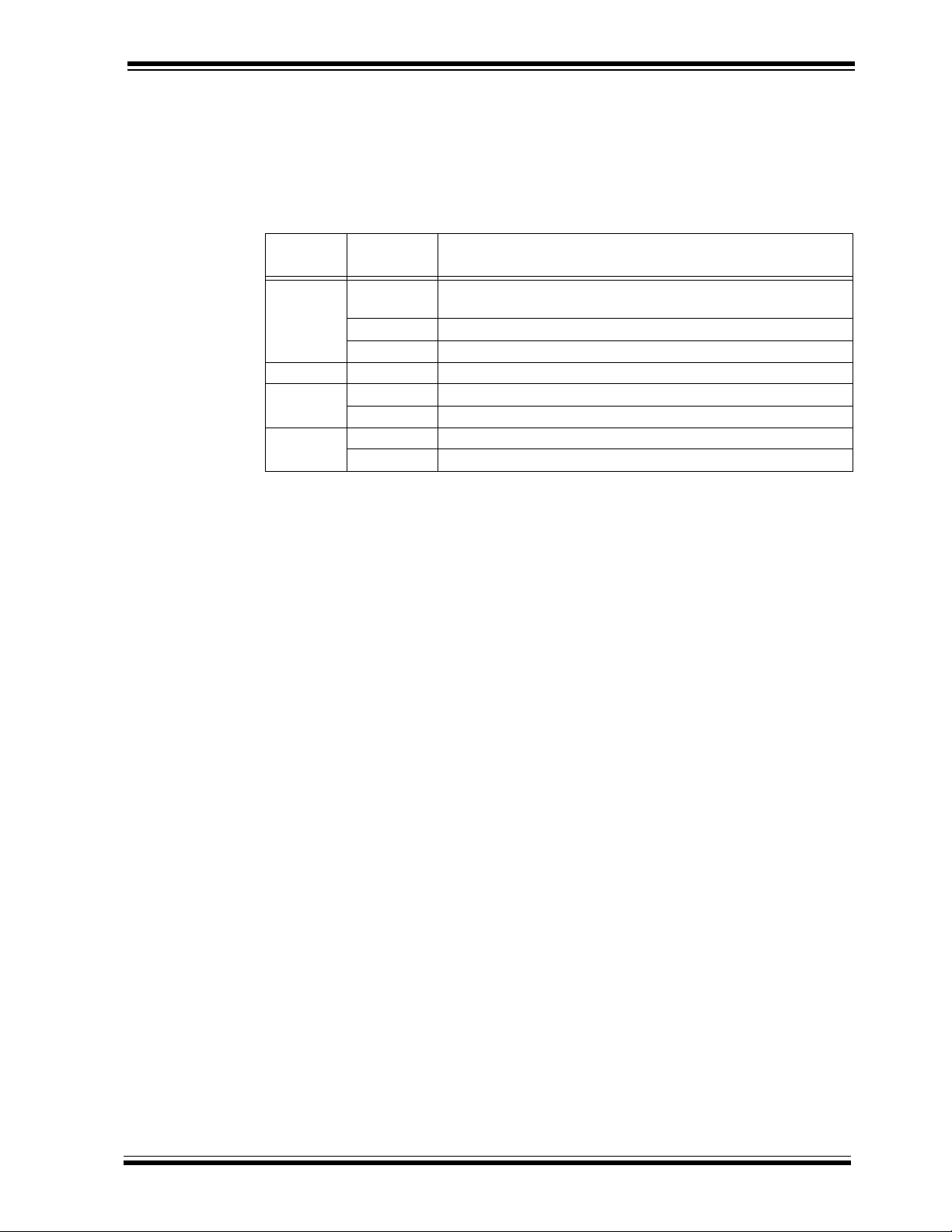

66.3 SD A/D MODULE CONFIGURATION

All of the registers d escribed in the p revious section must be configu red for the module o peration.

The various configuration and control functions of the module are distributed throughout the

module’s thre e co ntr o l r e gi ste r s. Control fun ct ion s ca n b e so r ted i n to fou r g rou ps: in pu t , t i mi ng ,

conversion and output. Table 66-1 shows the location of the control or status bits by register.

Table 66-1: SD A/D Module Functions by Registers and Bits

SD A/D

Function

Input SDxCON1 PWRLVL, SDREFP, SDREFN, VOSCAL, DITHER<1:0>,

Timing SDxCON3 SDCS<1:0>, SDDIV<2:0>

Conversion SDxCON1 SDON, SDSIDL

Output SDxCON2 RNDRES<1:0>, SDWM<1:0>

The following steps should be followed for performing an SD A/D conversion.

1. Configure the SD A/D module:

a) Select the power l evel

b) Select the volta ge reference sou rce to match th e expected rang e on the ana log inputs

c) Set the dither value

d) Set the gain

e) Select the output resolution

f) Select the Data Overwrite mode

g) Select the Chopping Clock mode

h) Select the input channel

i) Select the SD A/D module clock source

j) Select the desired output data rate

k) Select the sampling frequency

2. Configure the SD A/D interrupt (if required):

a) Select the Interrupt mode

b) Clear the SDAxIF bit

c) Select the SD A/D interrupt priority

3. Turn on the SD A/D module.

The options for each co nfiguratio n step are des cribed in th e subseque nt section s. Example 66-1

shows the possible initialization sequence.

Register(s) Specific Bits

SDGAIN<2:0>

SDxCON2 CHOP<1:0>

SDxCON3 SDCH<2:0>

SDxCON2 SDINT<1:0>

SDxCON3 SDOSR<2:0>

DS30687A-page 66-8 © 2013 Microchip Technology Inc.

Page 9

Section 66. 16-Bit Sigma-Delta A/D Converter

signed short int count;

signed short int result;

// Configure the SD A/D module

SD1CON1bits.PWRLVL = 0; // Low power, normal bandwidth

SD1CON1bits.SDREFP = 0; // Positive Voltage Reference is SVDD

SD1CON1bits.SDREFN = 0; // Negative Voltage Reference is SVSS

SD1CON1bits.VOSCAL = 0; // Internal Offset Measurement is disabled

SD1CON1bits.DITHER = 1; // Low Dither

SD1CON1bits.SDGAIN = 0; // Gain is 1:1

SD1CON2bits.RNDRES = 2; // Round result to 16-bit

SD1CON2bits.SDWM = 1; // SDxRESH/SDxRESL updated on every Interrupt

SD1CON2bits.CHOP = 3; // Chopping should be enabled

SD1CON3bits.SDCH = 0; // Channel 0 (see the specific device data sheet)

SD1CON3bits.SDCS = 1; // Clock Source is a 8 MHz FRC

SD1CON3bits.SDOSR = 0; // Oversampling Ratio (OSR) is 1024 (best quality)

SD1CON3bits.SDDIV = 1; // Input Clock Divider is 2 (SD ADC clock is 4MHz)

// Configure SD A/D interrupt

SD1CON2bits.SDINT

= 3; // Interrupt on every data output

IFS6bits.SDA1IF

= 0; // Clear interrupt flag

// Turn on the SD A/D module

SD1CON1bits.SDON = 1;

// Wait for a minimum of five interrupts to be generated. Need to throw at least

// the first four away when using interrupt every period option, since the

// low pass SINC filter needs to be flushed with new data when we change

// ADC channel or initialize the ADC.

for(count=0; count<8; count++)

{

//Clear interrupt flag.

IFS6bits.SDA1IF = 0;

//Wait for the result ready.

while(IFS6bits.SDA1IF == 0);

}

// Channel #0 conversion result.

result = SD1RESH;

Example 66-1: Channel Measurement

66

16-Bit Sigma-De lt a

A/D Converter

66.3.1 Selecting the Voltage Reference Source

The voltage references for SD A/D conversions are selected using the SDREFN and SDREFP

control bits (SDx CON1 <2:1 >). T he upper voltage refe ren ce (V

applied on the SV

applied on the SV

© 2013 Microchip Technology Inc. DS30687A-page 66-9

REF+ pin. The lower voltage reference (VREF-) can be SVSS or the voltage

REF- pin.

REF+) can be SVDD or the voltag e

Page 10

PIC24F Family Reference Manual

SINC

3

Low-Pass

Filter

SDOSR<2:0>

SDDIV<2:0>

Primary

Oscillator

FRC

FCY

SDCS<1:0>

1/4

SDxRESH

SDxRESHL

Sampling

Circuit

Modulator

-

Prescaler

SDCLK

OSR Select

66.3.2 Gain C o n tr o l

The Programmable Gain Amplifier (PGA) block can be used to amplify very low signals, but the

differential in put range of the SD A/D module shou ld not be excee ded to avoid a sa turated output

result code. The PGA is controlled by the SDGAIN<2:0> bits in the SDxCON1 register.

Table 66-2 shows the PGA configuration settings.

Table 66-2: PGA Configuration Setting

SDGAIN<2:0>

000 1 0 ± |Reference|

001 2 6 ± (|Reference| /2)

010 4 12 ± (|Reference| /4)

011 8 18 ± (|Reference| /8)

100 16 24 ± (|Reference| /16)

101 32 30 ± (|Reference| /32)

66.3.2.1 SELECTION OF ANALOG AMPLIFIER BANDWIDTH

Setting the PWRLVL bit in the SDxCON1 register improves the bandwi d th and response time of

the input amplifier, but at the cost of consuming more power. Smaller response time decreases

the settling error in amplifier stages, and thereby, improves harmonic distortions. The PWRLVL

bit can be cleared to save power.

Gain

(V/V)

Gain

(dB)

Differential V

IN Range (V)

66.3.3 Selecting the SD A/D Module Clock Source

The clock source to the SD A/D Converter (SDCLK) can be one of the following three possible

clocks:

• Primary Oscillator

•FRC (8 MHz)

• System Clock (F

The selection can be done using the SDCS<1:0> bits in the SDxCON3 register. The A/D

Converter source clock is divided inside of the module, as shown in Figure 66-2.

Figure 66-2: SD A/D Module Clocking Details

CY)

DS30687A-page 66-10 © 2013 Microchip Technology Inc.

Page 11

Section 66. 16-Bit Sigma-Delta A/D Converter

66.3.3.1 SELECTING THE SD A/D CONVERTER SAMPLING FREQUENCY AND

OUTPUT DATA RATE

The selected source clock (see SDCLK in Figure 66-2) is divided by the selected ratio determined by the SDDIV<2 :0> bit s in the SDx CON3 register. The resulting clock must be i n the range

of 1 MHz to 4 MHz.

The module clock is further divided by the s ele cte d ra tio determined by the SDOSR< 2:0> bits in

the SDxCON3 register . The result i s the rate at which the SD A/D outputs n ew data. To determine

the SDOSR<2:0> setting for the required output data rate, see Table 66-3.

Table 66-3: Data Rate Settings

Data Rate

(ksps)

62.500 4 110

31.2500

15.6250

7.8125

3.90625

1.953125

0.9765625

0.4883

0.2441 1 000

A/D Clock Frequency (MHz) SDOSR<2:0>

4 101

2 110

4 100

2 101

1 110

4 011

2 100

1 101

4 010

2 011

1 100

4 001

2 010

1 011

4 000

2 001

1 010

2 000

1 001

66

16-Bit Sigma-De lt a

A/D Converter

© 2013 Microchip Technology Inc. DS30687A-page 66-11

Page 12

PIC24F Family Reference Manual

66.3.4 Selection of Dither

Dithering helps in suppressing the Idle tones present in the SD A/D module. Dithering is the process of intentionally adding a small error to the SD A/D feedback loop in order to “decorrelate”

the outputs and “b reak ” the Idle tones’ behavior. The dithering process scrambles the Idle tone s

into baseband white noi se and ensures th at dynamic parame ters (SNR, SINAD, THD, SF DR) are

less signal dependent.

The baseband white noise can then be filtered and averaged through the internally provided

hardware Oversampling Ratio (OSR) to achieve better result quality. It is therefore, generally

recommended to enable dithering in most applications. However, the optimum dithering setting

for a given application depends on the OSR selecte d and the relative volta ge of the applied A/D

reference to the SV

The higher OSR settings (e.g., 128 to 1024) are better at averaging the baseband white noise in troduced by dithering. At the higher OSR settings, enabling dithering improves overall performance

and is recommended. At lower OSR settings (e.g., 16 to 64), the averaging is not as effective and

the extra noise injected by dithering can potentially decrease the SNR, even though it may help to

suppress Idle tones. At the very low OSR settings, this results in a performance trade-off, and in

some cases (at very low OSR), it may be preferable to disable dithering. The dithering can be

enabled by the DITHER<1:0> bits in the SDxCON1 register.

66.3.5 Chop Clock Select Mode

Chopping Select bit s (C HOP<1:0 > bit s in the SDxCON 2 regis ter) are ma inly u sed to re move t he

1/f noise from the signal band in the modulator. To obtain 16-bit resolution, chopping should

always be enabled.

DD voltage.

66.3.6 SINC3 Filter and Rounding of Result

The SD A/D module includes a decimation filter that is a third-order SINC (or notch) filter. This

filter processes the multibit stream into 8, 16, 24 or 32-bit words (depending on the

RNDRES<1:0> bits in the SDxCON2 register). The settling time of the fil ter is three data rate periods. It is recommended to discard unsettled data. This can be done by polling the SDRDY bit in

the SDxCON2 register. The output of the SINC filter is padded with Least Significant zeros for

any resolution less than 32 bits.

66.3.7 Data Write Modes

The Write mode bits, SDWM<1:0> (SDxCON2) determine when the Result register is updated.

There are three options in Write mode:

• Result register is never updated (useful for the Threshold Compare feature)

• Res ult register is updated on every interrupt

• Result register is updated on every interrupt, after the SDRDY bit (SDxCON2<0>) is

cleared to ‘0’ in software

66.3.7.1 RESULT DATA READY

The conversion result value is valid only when the SDRDY bit (SDxCON2<0>) reads as ‘1’ and

the A/D module interrupt is generated. The SDRDY bit can only be cleared by software or on a

device Reset. If the user sets the SDWM<1:0> bits (SDxCON2<9:8>) to ‘00’, then the SD A/D

Converter does not update the Result register with the result until the SDRDY bit is cleared in

software.

If SDWM<1:0> = 01, then the SD A/D Converter updates the Result register, regardless of the

SDRDY bit.

DS30687A-page 66-12 © 2013 Microchip Technology Inc.

Page 13

Section 66. 16-Bit Sigma-Delta A/D Converter

66.3.7.2 SD A/D RESULT REGISTER

The SD A/D Converter result is stored in the SDxRESH:SDxRESL registers as a 32-bit

2’s complement signed number. When rounding is enabled (RNDRES<1:0> bits in the

SDxCON2 register), the Least Significant bits (LSbs) which are rounded off will read as ‘0’. Additionally, when operating the A/D at OSR values l ess than 1 024, not eno ugh dat a will be int ernall y

generated by the hardware to fi ll al l 3 2 bi ts of th e SDx R ES H/ S DxR E SL re gister pair. Therefore,

especially when operating at OSR values less than 1024, some of the LSbs will be fully meaningless and may read b ac k as static values. The Mos t Sig ni fic ant bits (MSbs) of the 32-b it result

will remain meaningful, but will be restricted by the result quality for a given OSR setting.

66.3.8 Input Channel Selection

The input analog channel can be selected usi ng the SDCH<2:0> bits in the SDxCON3 regi ster. The

SD A/D Converter comprises both single-ended and differential channels. The number of

single-ended and differential channels available is device-specific. For more information, refer to

the specific device data sheet. Each differential channel has inverting (CHn-) and non-inverting

inputs (CHn+). If any channel is not used, both CHn- and CHn+ should be connected to SV

Single-ended channels are available as the positive input to the SD A/D Converter. The negative

input for these channels will always be SVSS. This performs a single-ended conversion on the

selected channel. When performing single-ended conversions, the A/D module s till produces two’s

complement signed numbers. It is therefore possible for slightly negative number results to occur

due to offset error . The application firmware should ch eck for negative results, and tre at all negative

numbers as ‘0’, if true unsigned single-ended behavior is desired. The module also facilitates a

dedicated differential channel used for gain error measurements. For more information on gain

error measurements, see Section 66.6 “Gain Error Calibration”.

SS.

66

16-Bit Sigma-De lt a

A/D Converter

66.3.9 Channel Switching

When the channel is switched, five data rate clocks are required to flush the previous contents

from the SINC

The results c an ha ve residual volta ge information from th e p r evious selected chan nel due to the

low-pass filtering effect of the SINC filter. Therefore, it is recommended to select an interrupt on

every fifth d ata output by setting the SDINT<1:0 > bits to ‘10’, and upon first interrupt, the require d

interrupt can be selected.

3

filter (low-pass filter). During this time, the results generated may not be valid.

66.3.10 Enabling the Module

The SD A/D is enabl ed by s ett ing the SDON bit (SDxC ON1 <15> ) to ‘ 1’. Af te r SDON i s set to ‘1’,

the module requires a power-up analog settling time of about 10 µs, during which time, the A/D

Converter may not gen erate ac curate results . The appl icatio n firmwa re should theref ore thro w

away the initial results associated with the analog settling time and the time it takes to flush the

low-pass SINC filter with new data. When SDON is set to ‘0’, the module is disabled; the digital

and analog portions of the module are turned off for maximum current savings.

The module should be configured to the required settings and the SDRDY bit (SDxCON2<0>)

should be cleared before turning on the SD A/D.

Note: When the module is enabled (SDON = 1), the firmware may change the channel

selection (SDCH<2:0> or VOSCAL bit settings). If other A/D module settings must

be changed, the module should be disabled first (SDON = 0).

© 2013 Microchip Technology Inc. DS30687A-page 66-13

Page 14

PIC24F Family Reference Manual

Offset Corrected Result = (New SDxRES Result) – (VOSCAL Result)

66.4 INTERRUPT MODES

There are four Interrupt modes:

• Interrupt on Every Data Ready mode

• Interrupt on every Fifth Data Ready mode

• Interrupt on Threshold Current Value Lesser than the Previous Value mode

• Interrupt on Threshold Current Value Greater than the Previous Value mode

The four modes are controlled by the SDINT<1:0> bits in the SDxCON2 register.

66.4.1 Interrupt on Every Data Ready

This mode is use ful af ter the first dat a is read. No te that the frequenc y of the dat a rate cl ock mu st

be less than F

66.4.2 Interrupt on Every Fifth Data Ready

This mode is useful immediat ely afte r the module is enabled, wh en the inpu t channel is switch ed

or when the device wake s up from Sle ep. The mo dule t akes five dat a rate cl ocks for flushi ng old

values from the SINC3 filter.

66.4.3 Interrupt on Threshold Compare

The SDINT<1:0> bits allow the user to have interrupts, only if the data coming out of the filter is

greater than, or less than, the value currently in the Result register. If the user wishes to retain

the threshold value, the SDWM<1:0> bits must be set to ‘10’. If SDWM<1:0> are set to ‘01’ or

‘00’, the threshold compare function turns into a “find the lowest/highest sampled value” type of

operation.

CY/2 to avoid missing the samples.

66.5 OFFSET CALIBRATION

The SD A/D module includes a feature for measuring internal offset error. Application firmware

can enable this feature by fully configuring the A/D module and setting the VOSCAL bit in the

SDxCON1 register.

When the VOSCAL bit is set, the A/D module ignores the currently selected SDCH<2:0> channel

select bits, and instead, performs conversions on an internal channel that generates

SDxRESH/SDxRESL results which represent the offset error of the A/D Converter. After the

SINC filter delay has bee n satisfie d, the applic ation firmw are shoul d save the resu lt value (w hich

will be formatted a s a s ign ed two’s complem ent value, the same as n orm al A/D m odule results).

After the offs et error measurement result data ha s been saved, th e application fi rmware can clear

the VOSCAL bit to switch the A/D module back into Normal Channel Measurement mode.

The application firmware can then correct for offset error in subsequent analog channel

measurements by subtracting the offset error value from all future results. Equation 66-1 shows

the method for correcting offset error.

Equation 66-1: Correcting Offset Error

Example 66-2 shows a example C code for the offset calibration.

DS30687A-page 66-14 © 2013 Microchip Technology Inc.

Page 15

Section 66. 16-Bit Sigma-Delta A/D Converter

Legend:

G

ECF

= Floating-point gain error correction factor

ADRES

EXPECTED

= The expected A/D result (with no offset or gain error) based on the

applied input voltage. When the A/D is configured to measure the references in 1x Gain

mode, the expected result is 32767.

ADRES

RAW

= The raw , unco rrected 1 6-bit s igned result read from the SDxRESH re giste r.

ADRES

VOSCAL

= The 16-bit value representing the offset error measured with the A/D

“VOSCAL” feature.

G

ECF

ADRES

EXPECTED

ADRES

RAW

ADRES

VOSCAL

–

-------------------------------------------------------------------------- -=

66.6 GAIN ERROR CALIBRATION

The SD A/D module has a dedicated channel for gain error measurements. Selecting this

channel allows the module to internally sample the reference voltages as an input to the A/D

Converter. In theory, if the A/D module has no offset or gain error, this always generates an

SDxRESH result of 32767 (maximum full-scale value). In practice, it is normal for a real world

Sigma-Delta A/D to have a significant, but highly correctable, gain error. In this design, the A/D

Converter has a gai n error, which will cause the A/D Conv erter to generat e a result that is somewhat less than the theoretical 32767 full-scale result value. Gain error varies depending on the

SDGAIN<2:0> bits (SDxCON1<10:8>) selection, and some part, to part variations. Equation 66-2

shows the method for calculating a floating-point “gain error correction factor”, which can be

multiplied against subsequent result values to com pensate for gai n error.

Equation 66-2: G ain Error Correction Factor

66

16-Bit Sigma-De lt a

A/D Converter

Example 66-2 shows the proces s to perform a channel measurement, which uses offset correction

and gain error correction to compute a fully calibrated result value.

66.6.1 Considerations for Gain Error

The following needs to be considered for gain error correction:

1. Gain error of the A/D Converter can be measured by intentionally inputting a well-known

analog voltag e and comp aring the outpu t result code w ith the theoret ically expe cted result

code.

2. If the V

3. Due to the internal g ain error of the A/D design, th e actual val ue will be les s than full scale.

4. A floating-point gain error correc tion factor ca n be compute d using the raw A/D Con verter

5. Once the gain error correction factor is known, it can be saved in the firmware. While

REF+/VREF- reference sources are measured (with a gain setting of 1), the result

code should theoretically be full scale (e.g., 32767).

result (e.g., when measuring the references) and the expected result, as shown in

Example 66-2.

carrying out A/D Converter measurements on other channels/input voltage sources, the

gain error correction factor can be multiplied by the raw result (after offset correction

through VOSCAL) to compensate for the A/D Converter gain error.

© 2013 Microchip Technology Inc. DS30687A-page 66-15

Page 16

PIC24F Family Reference Manual

unsigned char count;

signed short int offset;

signed long int maxValue;

const double expectedMaxValue = 32767; // 0x7FFF

double gain;

signed long int channelValue;

double calibratedResult;

// ADC initialization.

SD1CON1bits.PWRLVL = 0; // Low power, normal bandwidth

SD1CON1bits.SDREFP = 0; // Positive Voltage Reference is SVDD

SD1CON1bits.SDREFN = 0; // Negative Voltage Reference is SVSS

SD1CON1bits.VOSCAL = 1; // Internal Offset Measurement Enable

SD1CON1bits.DITHER = 1; // Low Dither

SD1CON1bits.SDGAIN = 0; // Gain is 1:1

SD1CON2bits.RNDRES = 2; // Round result to 16-bit

SD1CON2bits.SDWM = 1; // SDxRESH/SDxRESL updated on every Interrupt

SD1CON2bits.SDINT = 3; // Interrupt on every data output

SD1CON2bits.CHOP = 3; // Chopping should be enabled

SD1CON3bits.SDCH = 0; // Channel 0 (see the specific device data sheet)

SD1CON3bits.SDCS = 1; // Clock Source is a 8 MHz FRC

SD1CON3bits.SDOSR = 0; // Oversampling Ratio (OSR) is 1024 (best quality)

SD1CON3bits.SDDIV = 1; // Input Clock Divider is 2 (SD ADC clock is 4MHz)

// Enable ADC.

SD1CON1bits.SDON = 1;

// Wait for a minimum of five interrupts to be generated. Need to throw at least

// the first four away when using interrupt every period option, since the

// low pass SINC filter needs to be flushed with new data when we change

// ADC channel or initialize the ADC.

for(count=0; count<8; count++)

{

//Clear interrupt flag.

IFS6bits.SDA1IF = 0;

//Wait for the result ready.

while(IFS6bits.SDA1IF == 0);

}

// Save the initial VOSCAL offset value from the ADC.

// This value will be used to correct the offset error for all

// subsequent ADC measurements.

offset = SD1RESH;

// Configure ADC for normal operation.

SD1CON1bits.VOSCAL = 0;

// Measures the reference selected by SDREFP/SDREFN

// (see the specific device data sheet).

SD1CON3bits.SDCH = 3;

Example 66-2: Channel Conversion with Offset and Gain Correction

DS30687A-page 66-16 © 2013 Microchip Technology Inc.

Page 17

Section 66. 16-Bit Sigma-Delta A/D Converter

// Wait for a minimum of five interrupts to be generated.

for(count=0; count<8; count++)

{

//Clear interrupt flag.

IFS6bits.SDA1IF = 0;

//Wait for the result ready.

while(IFS6bits.SDA1IF == 0);

}

// Save the maximum value to calculate the gain.

maxValue = (signed short int) SD1RESH;

// Calculate gain.

gain = expectedMaxValue/((double)(maxValue-offset));

// Select channel #0 for the measurement.

// (see the specific device data sheet).

SD1CON3bits.SDCH = 0;

// Adjust loop end value for desired settling time (value must be >= 5).

for(count=0; count<8; count++)

{

// Clear interrupt flag.

IFS6bits.SDA1IF = 0;

// Wait for the result ready.

while(IFS6bits.SDA1IF == 0);

}

// Not corrected channel #0 result.

channelValue = (signed short int) SD1RESH;

// Correct offset.

channelValue -= offset;

// Correct gain.

calibratedResult = gain*channelValue;

Example 66-2: Channel Conversion with Offset and Gain Correction (Continued)

66

16-Bit Sigma-De lt a

A/D Converter

© 2013 Microchip Technology Inc. DS30687A-page 66-17

Page 18

PIC24F Family Reference Manual

1.2345 1.2345 2182

18

=

1.23456 1.23456 262144 262144 323623 262144=

// This is fixed point location

#define FIXED_POINT_POS 15

unsigned char count;

signed long int offset;

signed long int maxValue;

signed long int expectedMaxValue;

signed long int gain;

signed long int channelValue;

signed short int calibratedResult;

// ADC initialization.

SD1CON1bits.PWRLVL = 0; // Low power, normal bandwidth

SD1CON1bits.SDREFP = 0; // Positive Voltage Reference is SVDD

SD1CON1bits.SDREFN = 0; // Negative Voltage Reference is SVSS

SD1CON1bits.VOSCAL = 1; // Internal Offset Measurement Enable

SD1CON1bits.DITHER = 1; // Low Dither

SD1CON1bits.SDGAIN = 0; // Gain is 1:1

SD1CON2bits.RNDRES = 2; // Round result to 16-bit

SD1CON2bits.SDWM = 1; // SDxRESH/SDxRESL updated on every Interrupt

SD1CON2bits.SDINT = 3; // Interrupt on every data output

SD1CON2bits.CHOP = 3; // Chopping should be enabled

SD1CON3bits.SDCH = 0; // Channel 0 (see the specific device data sheet)

SD1CON3bits.SDCS = 1; // Clock Source is a 8 MHz FRC

SD1CON3bits.SDOSR = 0; // Oversampling Ratio (OSR) is 1024 (best quality)

SD1CON3bits.SDDIV = 1; // Input Clock Divider is 2 (SD ADC clock is 4MHz)

66.6.2 Gain Error Correction Using Integer Math

Floating-point math is easy and convenient to use, but is often undesirable during actual

execution because it generally consumes a large amount of CPU execution time and code space

to perform. Fortunately, it is possible to correct for A/D gain error using pure in teger-base d math.

In mathematical theory, if an expression is multiplied by a cons tan t and then di vided by the same

constant, the expression stays the same (Equation 66-3).

Equation 66-3: Math Example

In this example, mul tiplying an d divid ing by a co nst ant number (218 or 262144) does n ot ch ange

the value of the expre ssio n. U sing t his approach, it is possible to c on vert floa tin g-point numbers

into integers with minimal truncation error (Equation 66-4).

Equation 66-4: Converting Floating Point Number into Integer Example

The final expression (323623/262144) is very easy and quick to evaluate by the microcontroller

during run time, as it is equ ivalent to taki ng a 32-bit integer and arithmetically shif ting it to the right

by 18 bit positions (equivalent to dividing by 262144). This mathematical principle can therefore

be used to perform traditional floating-point math operations, using integer math with very little

error, provided that the constant number being multiplied and divided by is a very large number

18

(ex: 2

Sigma-Delta A/D gain error quickly during application run time.

or larger). Example 66-3 shows how this principle can be used to correct for the

Example 66-3: Channel Conversion with Offset and Gain Correction Using Integer Math

DS30687A-page 66-18 © 2013 Microchip Technology Inc.

Page 19

Section 66. 16-Bit Sigma-Delta A/D Converter

// Enable ADC

SD1CON1bits.SDON = 1;

// Wait for a minimum of five interrupts to be generated. Need to throw at least

// the first four away when using interrupt every period option, since the

// low pass SINC filter needs to be flushed with new data when we change

// ADC channel or initialize the ADC.

for(count=0; count<8; count++)

{

//Clear interrupt flag.

IFS6bits.SDA1IF = 0;

//Wait for the result ready.

while(IFS6bits.SDA1IF == 0);

}

// Save the initial VOSCAL offset value from the ADC.

// This value will be used to correct the offset error for all

// subsequent ADC measurements.

offset = (signed short int)SD1RESH;

// Configure ADC for normal operation.

SD1CON1bits.VOSCAL = 0;

// Measures the reference selected by SDREFP/SDREFN

// (see the specific device data sheet).

SD1CON3bits.SDCH = 3;

// Wait for a minimum of five interrupts to be generated.

for(count=0; count<8; count++)

{

//Clear interrupt flag.

IFS6bits.SDA1IF = 0;

//Wait for the result ready.

while(IFS6bits.SDA1IF == 0);

}

// Save the maximum value to calculate the gain.

maxValue = (signed short int)SD1RESH;

// Correct offset.

maxValue -= offset;

// Calculate gain.

expectedMaxValue = ((signed long int)32767)<<FIXED_POINT_POS;

gain = expectedMaxValue/maxValue;

// Select channel #0 for the measurement.

// (see the specific device data sheet).

SD1CON3bits.SDCH = 0;

Example 66-3: Channel Conversion with Offset and Gain Correction Using Integer Math (Continued)

66

16-Bit Sigma-De lt a

A/D Converter

© 2013 Microchip Technology Inc. DS30687A-page 66-19

Page 20

PIC24F Family Reference Manual

// Adjust loop end value for desired settling time (value must be >= 5).

for(count=0; count<8; count++)

{

// Clear interrupt flag.

IFS6bits.SDA1IF = 0;

// Wait for the result ready.

while(IFS6bits.SDA1IF == 0);

}

// Not corrected channel #0 result.

channelValue = (signed short int)SD1RESH;

// Correct offset.

channelValue -= offset;

// Correct gain.

channelValue = gain*channelValue;

// 16-bit signed result

calibratedResult = channelValue>>FIXED_POINT_POS;

Example 66-3: Channel Conversion with Offset and Gain Correction Using Integer Math (Continued)

DS30687A-page 66-20 © 2013 Microchip Technology Inc.

Page 21

Section 66. 16-Bit Sigma-Delta A/D Converter

66.7 OPERATION DURING SLEEP AND IDLE MODES

The SD A/D module supports the following power modes:

• Idle mode

• Sleep mode

66.7.1 Idle Mode

The SDSIDL bit (SDxCON1<13>) determines whether the module st op s or continu es operatio n in

Idle mode. If SDSIDL = 0, the module will continue normal operation when the device enters Idle

mode. If the SD A/D interrupt is enabled (SDAxIE = 1), the device will wake-up from Idle mode

when the SD A/D Interrupt Flag (SDAxIF = 1) occurs. Program execution will resume at the SD A/D

Interrupt Service Routine (ISR) if the SD A/D interrupt is greater than the current CPU priority.

Otherwise, execution will continue from the instruction after the PWRSAV #IDLE instruction (or

Idle();) that placed the device in Idle mode.

If SDSIDL = 1, the module will stop in Idle. If the device enters Idle mode in the middle of a

conversion, the conversion is aborted. The converter will not resume a partially completed

conversion on exiting from Idle mode.

66.7.2 Sleep Mode

If the device enters Sleep mode while the module is operating, the module will be suspended in

its current state until clock execution resumes. The output value will retain the last value before

Sleep.

66

16-Bit Sigma-De lt a

A/D Converter

66.8 EFFECTS OF A RESET

A device Reset forces all registers to their Reset state. This forces the SD A/D module to be

turned off and an y conve rsion in pro gress to b e aborted. Al l pins tha t are multi plexed wit h analo g

inputs will be configured as analog inputs. The corresponding TRIS bits will be set to ‘1’.

66.8.1 Use of SDRST

With the SDON bit set, the SDRST bi t ca n be us ed for the module to switch between activ e an d

inactive modes quickly, without any delay that is associated with the SDON bit.

© 2013 Microchip Technology Inc. DS30687A-page 66-21

Page 22

© 2013 Microchip Technology Inc. page 66-22

66.9 REGISTER MAP

Table 66-4: SD A/D Converter Register Map

File Name Bit 15 Bit 14 Bit 13 Bit 12 Bi t 11 Bit 10 Bit 9 Bit 8 Bit 7 Bit 6 Bit 5 B it 4 Bit 3 Bit 2 Bit 1 Bit 0

SDxCON1 SDON

SDxCON2 CHOP1 CHOP0 SDINT1 SDINT0

SDxCON3 SDDIV2 SDDIV1 SDDIV0 SDOSR2 SDOSR1 SDOSR0 SDCS1 SDCS0

SDxRESH Sigma-Delta A/D Result Register (bits 31-16) 0000

SDxRESL Sigma-Delta A/D Result Register (bits 15-0) 0000

Legend: — = unimplemented, read as ‘0’. Reset values are shown in hexadecimal.

— SDSIDL SDRST r SDGAIN2 SDGAIN1 SDGAIN0 DITHER1 DITHER0 —VOSCAL— SDREFN SDREFP PWRLVL 0000

— —SDWM1SDWM0— — — RNDRES1 RNDRES0 — — SDRDY 0000

— — — — — SDCH2 SDCH1 SDCH0 0000

Resets

PIC24F Family Reference Manual

All

Page 23

66.10 DESIGN TIPS

Question 1: Can we scan more than one channel?

Answer: Yes. However, it is recommended that you “flush” the pipeline before moving to the

next channel or the result will be erroneous.

Section 66. 16-Bit Sigma-Delta A/D Converter

66

16-Bit Sigma-De lt a

A/D Converter

© 2013 Microchip Technology Inc. DS30687A-page 66-23

Page 24

PIC24F Family Reference Manual

66.11 RELATED APPLICATION NOTES

This section lists application notes that are related to this section of the manual. These

application notes may not be written specifically for the PIC24F device family, but the concepts

are pertinent and could be used with modification and possible limitations. The current

application notes related to the 16-Bit A/D Converter module are:

Title Application Note #

Designing with the MCP3901 Dual Channel Analog-to-Digital Converters AN1300

Note: Please visit the Microchip web site (www.microchip.com) for additional application

notes and code examples for the PIC24F family of dev ices.

DS30687A-page 66-24 © 2013 Microchip Technology Inc.

Page 25

Section 66. 16-Bit Sigma-Delta A/D Converter

66.12 REVISION HISTORY

Revision A (April 2013)

This is the initial released revision of this document.

66

16-Bit Sigma-De lt a

A/D Converter

© 2013 Microchip Technology Inc. DS30687A-page 66-25

Page 26

PIC24F Family Reference Manual

NOTES:

DS30687A-page 66-26 © 2013 Microchip Technology Inc.

Page 27

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market t oday, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are com mitted to continuously improving the c ode prot ection f eatures of our

products. Attempts to break Microchip’s code protection feature may be a violation of t he Digit al Mill ennium Copyright Act. If such act s

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by updat es . I t is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, K

PICSTART, PIC

and UNI/O are registered trademarks of Microchip T echnology

Incorporated in the U.S.A. and other countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MTP, SEEVAL and The Embedded Control Solutions

Company are registered trademarks of Microchip Technology

Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

Analog-for-the-Digital Age, Application Maestro, BodyCom,

chipKIT, chipKIT logo, CodeGuard, dsPICDEM,

dsPICDEM.net, dsPICworks, dsSPEAK, ECAN,

ECONOMONITOR, FanSense, HI-TIDE, In-Circuit Serial

Programming, ICSP, Mindi, MiWi, MPASM, MPF, MPLAB

Certified logo, MPLIB, MPLINK, mTouch, Omniscient Code

Generation, PICC, PICC-18, PICDEM, PICDEM.net, PICkit,

PICtail, REAL ICE, rfLAB, Select Mode, SQI, Serial Quad I/O,

Total Endurance, TSHARC, UniWinDriver, WiperLock, ZENA

and Z-Scale are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip T echnology Incorporated

in the U.S.A.

GestIC and ULPP are registered trademarks of Microchip

Te c hnology Germ any II GmbH & C o. KG, a subsidiary of

Microchip T echnology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2013, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-62077-164-8

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro,

32

logo, rfPIC, SST, SST Logo, SuperFlash

QUALITY MANAGEMENT S

2013 Microchip Technology Inc. DS30687A-page 66-27

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 28

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Te chn ic al Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819-3187

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2943-5100

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Tai wan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7828

Fax: 886-7-330-9305

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

11/29/12

DS30687A-page 66-28 2013 Microchip Technology Inc.

Loading...

Loading...