Page 1

MCP3901 and PIC18F65J90

Energy Meter Reference Design

User’s Guide

© 2012 Microchip Technology Inc. DS51968A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and t he lik e is provided only for your convenience

and may be su perseded by upda t es . It is y our responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life supp ort and/or safety ap plications is entir ely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless M icrochip from any and all dama ges, claims,

suits, or expenses re sulting from such use. No licens es are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2012, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-61341-960-1

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS51968A-page 2 © 2012 Microchip Technology Inc.

Page 3

MCP3901 AND PIC18F65J90

ENERGY METER

REFERENCE DESIGN

Table of Contents

Preface ...........................................................................................................................7

Introduction............................................................................................................7

Document Layout .................................................................................................. 8

Conventions Used in this Guide............................................................................ 9

Recommended Reading.............................................................. .. ......................10

The Microchip Web Site...................................................................................... 10

Customer Support.................... .................................... .................. .....................10

Document Revision History................................................................................. 10

Chapter 1. Product Overview

1.1 Introduction ...................................................................................................11

1.2 What the MCP3901 and PIC18F65J90 Energy Meter

Reference Design Kit Includes ............................................................... 12

1.3 Getting Sta rted .... .................................................................................. ....... 12

Chapter 2. Hardware

2.1 Overview ............. ......................................................................................... 13

2.2 Input and Analog Front End .........................................................................16

Chapter 3. Calculation Engine and Register Description

3.1 Calculati on E n g in e Si g nal Flow Summary ................................................... 17

3.2 Register L is t ................................................................................................. 18

3.3 MODE .......................................................................................................... . 19

3.4 STATUS .......... .. ........................................................................................... 20

3.5 CAL_CONT R O L ........................................................................................... 20

3.6 LINE_CYC ................. .. ................................................................................ 21

3.7 LINE_CYC _ C N T ............. ... ..................................................... .. .. ................ 2 1

3.8 RAW2_I_RMS ..............................................................................................21

3.9 RAW_I_RM S .................... .......................................... .................................. 22

3.10 I_RMS ............... ......................................................................................... 22

3.11 RAW2_V _ R M S ......................................................................................... 22

3.12 RAW_V_ R M S .......................... ........................................................ ......... 22

3.13 V_RMS ....... ... .. ........................................................................................... 22

3.14 LINE_F R E Q UE N CY ............................................... .................................... 23

3.15 RAW_PO WER_ACT ......................................... ........................................ 23

3.16 POWER_ A CT ..................................... .......................................... .............. 23

3.17 POWER_APP ............................................................................................23

3.18 RAW_PO WER_REACT .......... ................ ................................................... 24

3.19 POWER_ R EA CT ...... .. .. ............................. .......................................... ....... 24

© 2012 Microchip Technology Inc. DS51968A-page 3

Page 4

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

3.20 PERIOD .... ....................................................... ........................................... 24

3.21 ENERG Y _ AC T ............. .. ............................ ................................................ 24

3.22 ENERGY_APP ..........................................................................................25

3.23 I_ABS_MAX ...............................................................................................25

3.24 V_ABS _ M A X ............. ... .............................................................................. 2 5

3.25 ENERG Y _ RE A C T ...................................................................................... 25

3.26 PHASE_COMPENSATION ........................................................................ 25

3.27 OFFSE T _ I_ R M S .. .. .................................................................................. . 26

3.28 OFFS ET _ V _RMS . .. ..................................................... .. ... ......................... 2 6

3.29 GAIN_I_RMS ............................................................................................. 26

3.30 GAIN_V _ R MS ............................................................................................ 26

3.31 OFFSE T _ P O WE R _ A CT .................... ...................................................... 26

3.32 GAIN_P O WER_ACT ........ .. ........................................................................ 27

3.33 OFFSE T _ P O WE R _ RE ACT .............. ........................................................ 27

3.34 GAIN_P O WER_REACT ... .................................................................... ...... 27

3.35 GAIN_E N E RGY_ACT ................................................................................ 27

3.36 GAIN_ENERGY_APP ................................................................................ 27

3.37 GAIN_E N E RGY_REACT . .. .. ...................................................................... 27

3.38 CF_PU LSE_WIDTH ............. ...................................................................... 28

3.39 GAIN_D E N R_ENERGY_A C T ......... ................ ........................................... 28

3.40 GAIN_N U MR_ENERGY_ A CT ............................................ ....................... 28

3.41 MODE1 _ D EF ............................................................. .............................. 28

3.42 CAL_ST A T US ........... ... .......................... .. .. ................................................ 28

3.43 MAXIMUM CURRENT ............................................................................. 29

3.44 CALIB R AT ION_VOLTAG E ....... .. ..................................................... .. ... ... 29

3.45 CALIBRATION_CURRENT ......................................................................29

3.46 CALIB R AT ION_FREQUE N CY . ................................................................. 29

3.47 METER _ C ON S T A N T ......................................... ....................................... 2 9

3.48 CALIB R A T I O N _ L INE _ C Y CLE ................................................. ... .. ............ 30

3.49 GAIN_D E N R_ENERGY_R EA C T ............ .. ... ............................................. 30

3.50 GAIN_N U MR_ENERGY_ R E ACT ............. ................................................ 30

3.51 PHASE_COMPENSATION_90 ................................................................. 30

3.52 CREEP_THRSHOLD_MINUTE ................................................................. 30

3.53 CREEP_THRSHOLD_SECOND ................................................................30

Chapter 4. Meter Protocol and Timings

4.1 Protocol ..................................................... .. ... ............................................. 31

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 33

A.2 Schematics and PCB Layout ........................ ......................... .. .. ..................33

A.3 Board – ADC Schematic ............................................................................. 34

A.4 Board – MCU S c he matic ........... .. ............. .. ... ............................................. 35

A.5 Board – LCD and USB Schematic .............. .. ............................... ................36

A.6 Board – Top Silk and Pads ........................ .. ..................... .......................... 37

A.7 Board – Top Copper .................................................................................... 38

DS51968A-page 4 © 2012 Microchip Technology Inc.

Page 5

A.8 Board – Bottom Copper ...............................................................................39

A.9 Board – Bottom Silk and Pads ..................... .. .. .. ............................. .. ...........40

A.10 Board – To p 3 D ............................................................. .. .. ............. ... .. ....... 41

A.11 Board – Bo tt om 3D ...... ............. ... .. ............. .. .. ........................... .. .. ............ 42

Appendix B. Bill of Materials (BOM)

Worldwide Sales and Service ....................................................................................46

© 2012 Microchip Technology Inc. DS51968A-page 5

Page 6

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

DS51968A-page 6 © 2012 Microchip Technology Inc.

Page 7

MCP3901 AND PIC18F65J90

ENERGY METER

REFERENCE DESIGN

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the p age number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available online help files.

®

IDE online help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

MCP3901 and PIC18F65J90 Energy Meter Reference Design User’s Guide. Items

discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

© 2012 Microchip Technology Inc. DS51968A-page 7

Page 8

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

DOCUMENT LAYOUT

This document describes how to use the MCP3901 and PIC18F65J90 Energy Meter

Reference Design as a development tool to emulate and debug firmware on a target

board. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information on using the MCP3901

and PIC18F65J90 Energy Meter Reference Design including a Getting Started

section that describes wiring the line and load connections.

• Chapter 2. “Hardwa re ” – Includes details on the function blocks of the meter

including the analog front end design, phase lock loop circuitry, and power supply

design.

• Chapter 3. “Calculation Engine and Register Description” – This section

describes the digital signal flow for all power output quantities such as RMS

current, RMS voltage, active power, and apparent power. This section also

includes the calibration register’s detail.

• Chapter 4. “Meter Protocol and Timings”– This chapter describes the protocol

used for accessing the registers, including commands that are used to interface to

the meter.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

MCP3901 and PIC18F65J90 Energy Meter Reference Design.

DS51968A-page 8 © 2012 Microchip Technology Inc.

Page 9

CONVENTIONS USED IN THIS GUIDE

This manual uses the following docum entat io n conven tion s:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic chara c ters Referenced books MPLAB

Initial caps A window the Output window

Quotes A field name in a window or

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces r epeated text var_name [,

Preface

®

IDE User’s Guide

Emphasized text ...is the only compiler...

A dialog the Settings dialog

A menu selection select Enable Programmer

“Save project before build”

dialog

A menu path File>Save

A tab Click the Power tab

4‘b0010, 2‘hF1

where N is the tota l number of

digits, R is th e radi x and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

any valid filename

[options]

Choice of mut ually exclus ive

arguments; an OR selection

Represents code supplied by

user

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

© 2012 Microchip Technology Inc. DS51968A-page 9

Page 10

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

RECOMMENDED READING

This user's guide describes how to use the MCP3901 and PIC18F65J90 Energy Meter

Reference Design. Other useful documents are listed below. The following Microchip

documents are available and recommended as supplemental reference resources.

MCP3901 Data Sheet – “Two Channel Analog Front End” (DS22192)

This data sheet provides detailed information regarding the MCP3901 device.

AN994 – “IEC Compliant Active-Energy Meter Design Using the MCP3905A/06A”

(DS00994)

This application note documents the design decisions associated with using the

MCP390X devices for energy meter design and IEC compliance.

THE MICROCHI P WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listin g

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support.

DOCUMENT REVISION HISTORY

Revision A (January 2012)

• Initial Release of this Document.

DS51968A-page 10 © 2012 Microchip Technology Inc.

Page 11

Chapter 1. Product Overview

1.1 INTRODUCTION

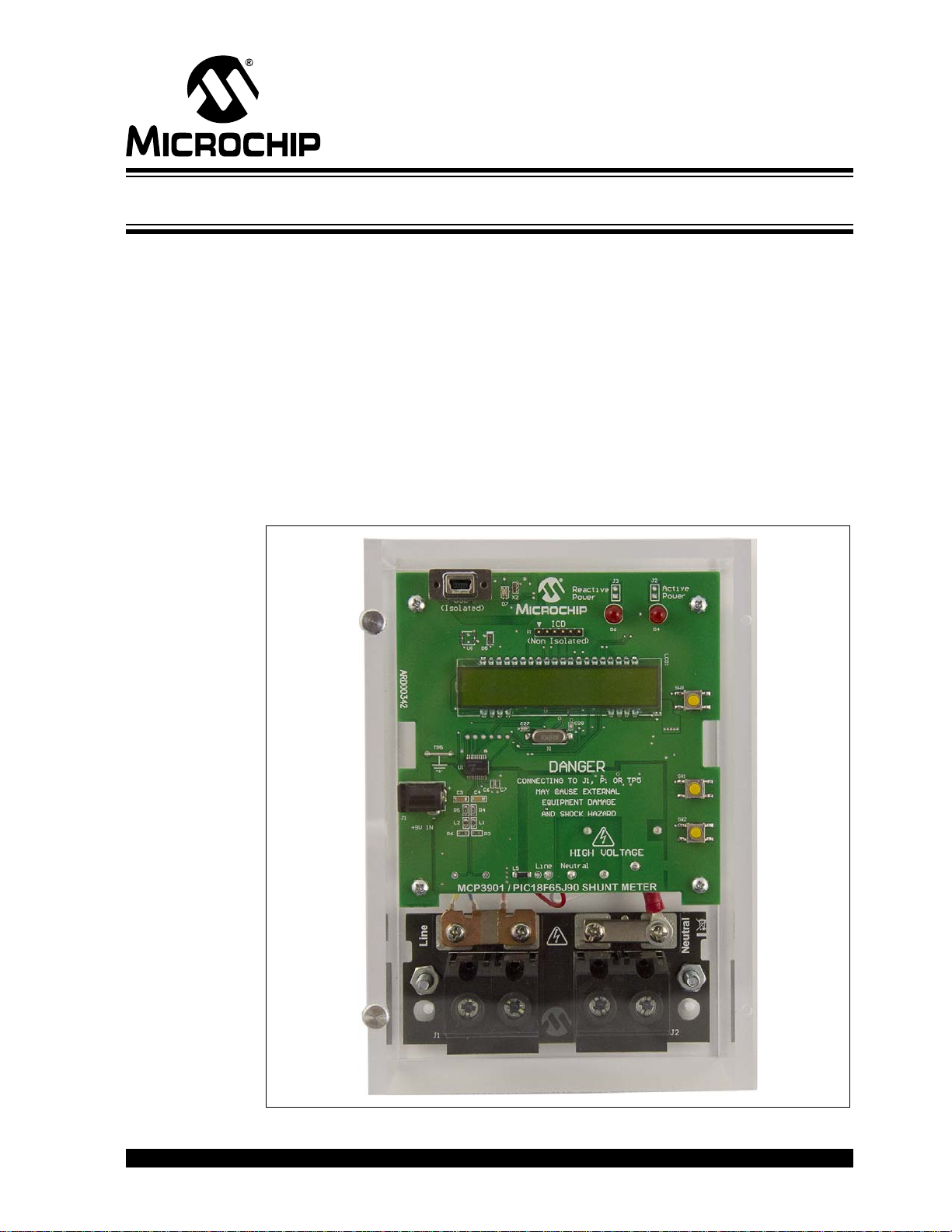

The MCP3901 and PIC18F65J90 Energy Meter Reference Design is a fully functional

IEC Class 0.5 compliant single-phase meter. This low-cost design does not use any

transformers and requires few external components. The PIC18F65J90 directly drives

the LCD, and includes both an isolated USB connection for meter calibration and

access to the device power calculations. The system calculates active energy, active

power, RMS current, RMS voltage, reactive energy, reactive power, apparent power

and other typical power quantities.

The Microchip Energy Meter 1-Phase Software is used to calibrate and monitor the

system, and can be used to create custom calibration setups. For some accuracy

requirements, only a single point calibration may be needed. The energy meter

software offers an automated step-by-step calibration process that can be used to

quickly calibrate energy meters.

MCP3901 AND PIC18F65J90

ENERGY METER

REFERENCE DESIGN

FIGURE 1-1: MCP3901 and PIC18F65J90 Single-Phase Energy Meter.

© 2012 Microchip Technology Inc. DS51968A-page 11

Page 12

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

1.2 WHAT THE MCP3901 AND PIC18F65J90 ENERGY METER REFERENCE DESIGN KIT INCLUDES

This MCP3901 and PIC18F65J90 Energy Meter Reference Design kit includes:

• MCP3901 and PIC18F65J90 Energy Meter Reference Design User’s Guide

• Important Information Sheet

1.3 GETTING STARTED

To describe how to use the MCP3901 and PIC18F65J90 Energy Meter Reference

Design, the following example is given using a two-wire 1-phase, 220 V AC line voltage

and connections using energy meter calibrator equipment, or other programmable load

source. The meter design uses a 5A load for calibration current, and a maximum

current (I

To test a calibrated meter, the following connections apply for a two-wire connection.

1.3.1 Step 1: Wiring Connections

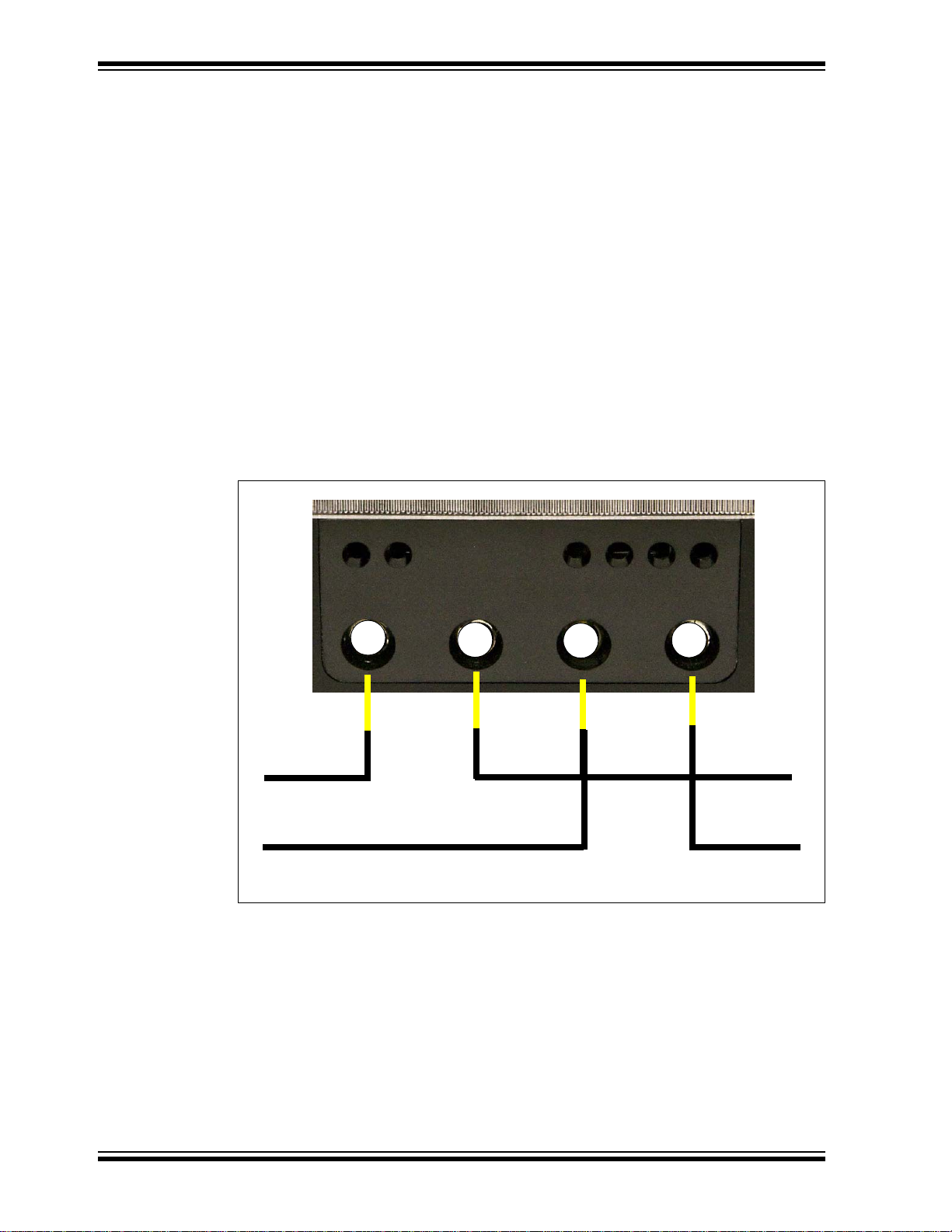

Figure 1-2 identifies the line and load connections of the MCP3901 and PIC18F65J90

Energy Meter Reference Design.

MAX

) of 60A.

1

Line

Neutral

MAIN

2

3

4

Line

Neutral

LOAD

FIGURE 1-2: Example Connections using a 2-Wire System.

1.3.2 Step 2: Turn On Line/Load Power to the Meter (Power the Meter)

The meter will turn on when the line connection has 220V connected. The LCD display

will show the total energy accumulated.

DS51968A-page 12 © 2012 Microchip Technology Inc.

Page 13

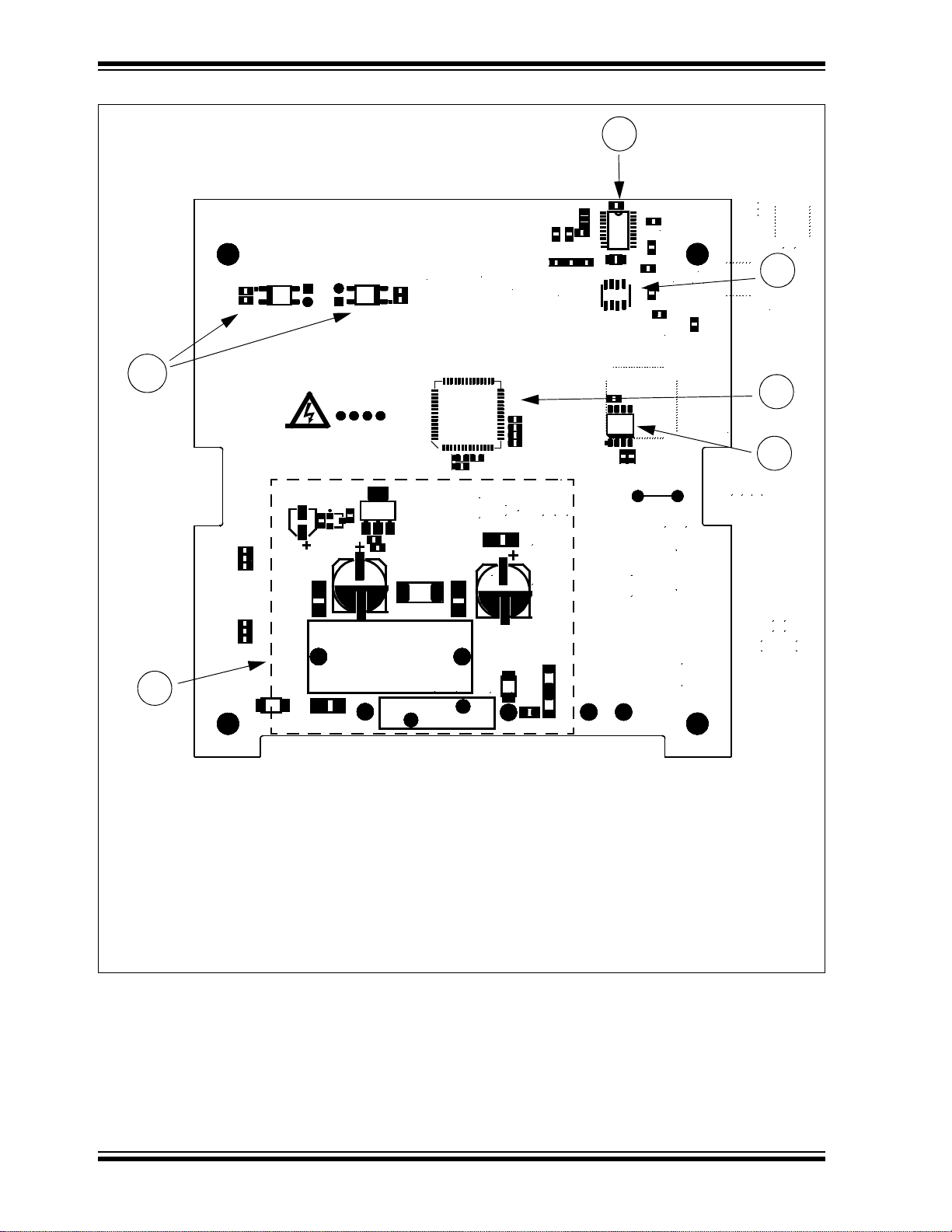

2.1 OVERVIEW

Figures 2-1 and 2-2 show the MCP3901 and PIC18F65J90 and Energy Meter

Reference Design:

MCP3901 AND PIC18F65J90

ENERGY METER

REFERENCE DESIGN

Chapter 2. Hardware

3

1

4

2

10

J2

U1

LCD1

9

D9D8

D1

P1

D3

J4

J3

D2

SW3

8

7

SW1

C40

SW2

DANGER

HIGH VOLTAGE

MCP3901 / PIC18F65J90 SHUNT METER

Legend:

1 = IR for meter communication 7 = Push button Switches

2 = Test points 8 = 9-digit LCD Disp lay with icons for kWh and kVARh

3 = MCP3901 Analog Front End 9 = Pulse Output for Active and Reactive

4 = +9V DC Input (non-isolated) 10 = USB Connection (isolated)

5 = Connections to shunt

current sensing resistor

6 = Connections to Line and Neutral

5

6

(isolated)

FIGURE 2-1: Top View – Hardware Components.

© 2012 Microchip Technology Inc. DS51968A-page 13

Page 14

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

.

17

C40

R21

R20

X2

R28

R27 R26

C32

C24 C25

R19

U7

R17

U4

C7

R29

U2

C39

R33

C37

U5

R30

R34

16

12

13

DANGER

HIGH VOLTAGE

C6

C5

C41

R14

R12

C2

R15

R11

C1

L1

Q1

C38

D5

D4

U8

C30

C27

C21

C22

C10

R31

C23

D6

L2

L3

R24 R25

C19

C17

R18

C16

D7

C4

MOV1

U6

C8

C9

R32

U3

Legend:

12 = Opto-isolators for Pulse outputs

13 = Power supply

14 = Non-volatile memory for calibration constants and energy usage data

15 = PIC18F65J90

16 = Isolation IC

17 = MCP2200 for USB connection

15

14

FIGURE 2-2: Bottom View – Hardware Components.

DS51968A-page 14 © 2012 Microchip Technology Inc.

Page 15

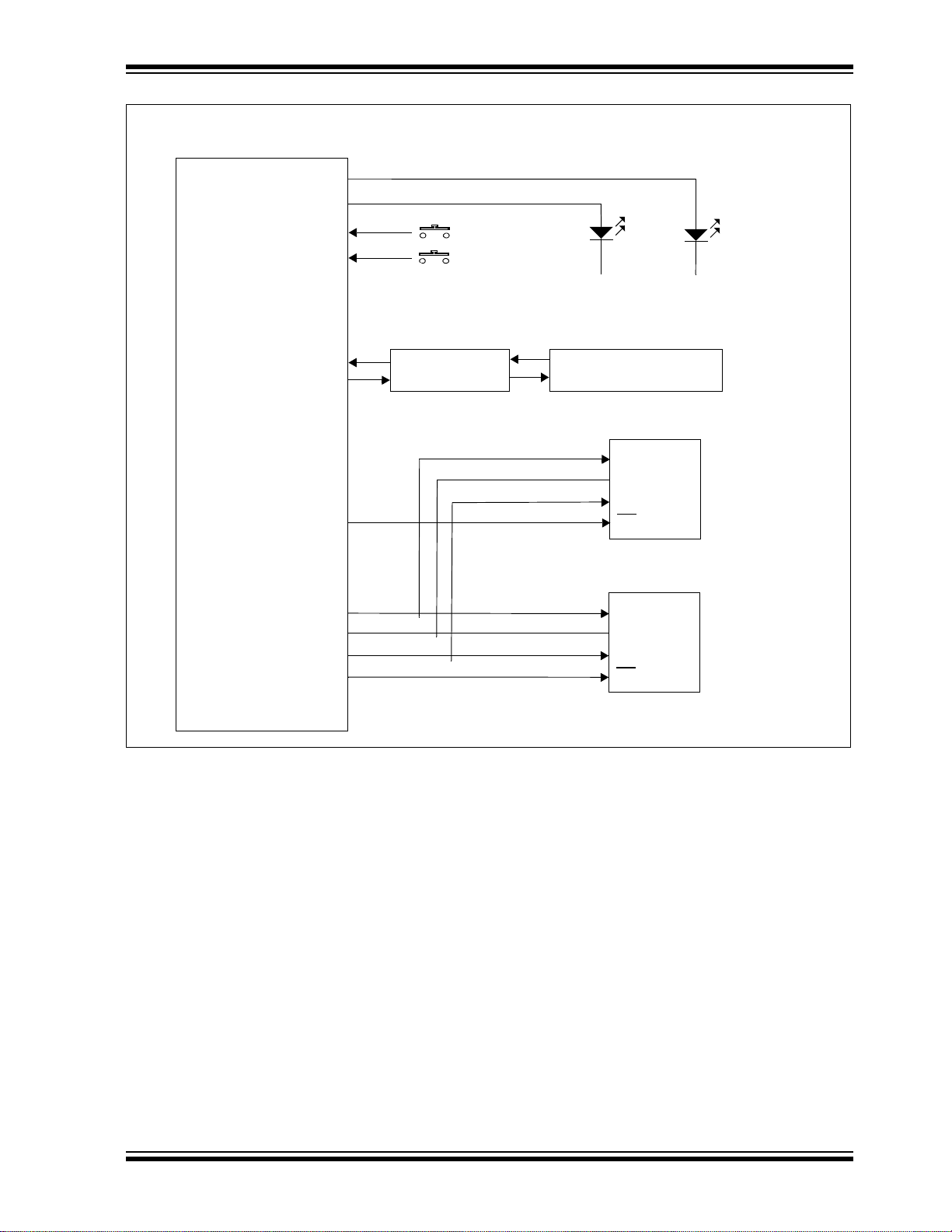

Hardware

PIC18F65J90

RA2

RA3

RG1

RG4

RC7/RX

RC6/TX

RA5

RC3/SCK

RC4/SDI

RC5/SDO

RA1

SWITCH

SWITCH

USB to UART

Converter

MCP2200

Active

Power

Mini - USB Connector

(ISOLATED)

SCK

SDO

SDI

CS

MCP3901

AFE

SCK

SDO

SDI

CS

Reactive

Power

FIGURE 2-3: Digital Connections.

25LC256

SPI - EEPROM

© 2012 Microchip Technology Inc. DS51968A-page 15

Page 16

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

2.2 INPUT AND ANALOG FRONT END

The MCP3901 and PIC18F65J90 and Energy Meter Reference Design comes

populated with components designed for 220V line voltage. At the bottom of the main

board are the high voltage line and neutral connections. There are four connections

that are made from the PCB to the meter casing. They are labeled LINE, NEUTRAL,

SHUNT1, and SHUNT2. The shunt sits on the high or line side of a two-wire system

and the meter employs a hot or “live” ground. The wires going into the shunt to

SHUNT1 and SHUNT2 should be twisted together. The wires going into the LINE and

NEUTRAL side of the meter should be twisted together, and also kept away from the

SHUNT1 and SHUNT2 wires if possible.

The neutral side of the two-wire system goes into a resistor divider on the voltage

channel input. Anti-aliasing low-pass filters will be included on both differential

channels. The voltage channel uses two 332 kΩ resistors to achieve a divider ratio of

664:1. For a line voltage of 230 V

490 mV

PEAK

.

, the channel 1 input signal size will be

RMS

LINE_SHUNT1

Shunt

(external to

PCB part of

meter case)

LINE_SHUNT2

NEUTRAL

150 FB (Note)

150 FB (Note)

332 kΩ

332 k Ω

1.0 kΩ

10-step optional

resistor

ladder

1.0 kΩ

1.0 kΩ

1.0 kΩ

Note: FB = ferrite beads. Ferrite beads have an impedance of the

specified value at 100 MHz.

CH0+

68 nF

CH0-

68 nF

MCP3901

0Ω

CH1+

68 nF

CH1+

68 nF

FIGURE 2-4: Analog Input Circuitry.

DS51968A-page 16 © 2012 Microchip Technology Inc.

Page 17

MCP3901 AND PIC18F65J90 ENERGY

METER REFERENCE DESIGN

Chapter 3. Calculation Engine and Register Description

3.1 CALCULATION ENGINE SIGNAL FLOW SUMMARY

RMS voltage, RMS current, Active Power, Reactive Power and Apparent Power, and

the calibration output pulse are all calculated through the following process described

in Figure 3-1. The calibration registers for each calculation are shown as well as the

16/24-bit

ADC

CURRENT

GAIN_

COMPENSATION

_90:

8

16/24-bit DS ADC

ADC

VOLTAGE

output registers.

ΔΣ

ADC

X

90°

with

Φ

Correction

Φ

OFFSET_I_RMS:

2

X

RMS Current

Reactive Power

O

FFSET_POWER_REACT:32

X

Active Power

PH

ASE_COMPENSATION:8

OFFSET_V_RMS:

OFFSET_POWER_ACT:

16

Σ

Σ

Σ

32

16

X

Apparent Power

8

NUMR_ENERGY_ACT:16

GAIN_

GAIN_DENR_ENERGY_ACT:

/

1/METER_CONSTAT

Σ

imp/kWh

DENR_ENERGY_REACT:8

GAIN_

imp/kVARh

Digital to

Frequency

Converter

Digital to

Frequency

Converter

NUMR_ENERGY_REACT:16

GAIN_

/

Σ

1/METER_CONSTAT

2

X

16

GAIN_POWER_REACT:

X

kVAR

32

POWER_REACT:

Σ

RMS Voltage

16

X

GAIN_ENERGY_REACT:

kVARh

REACT:32

ENERGY_

X

kVA

32

POWER_APP:

16

GAIN_ENERGY_ACT:

kWh

16

16

GAIN_V_RMS:

16

X

V

_RMS:16

V

X

GAIN_I_RMS:

GAIN_POWER_ACT:

A

_RMS:16

I

16

X

GAIN_POWER_APP:

kW

32

POWER_ACT:

16

XX

GAIN_ENERGY_APP:

kVAh

ACT:32

ENERGY_

APP:32

ENERGY_

FIGURE 3-1: PIC18F65J90 Calculation Engine Signal Flow

© 2012 Microchip Technology Inc. DS51968A-page 17

Page 18

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

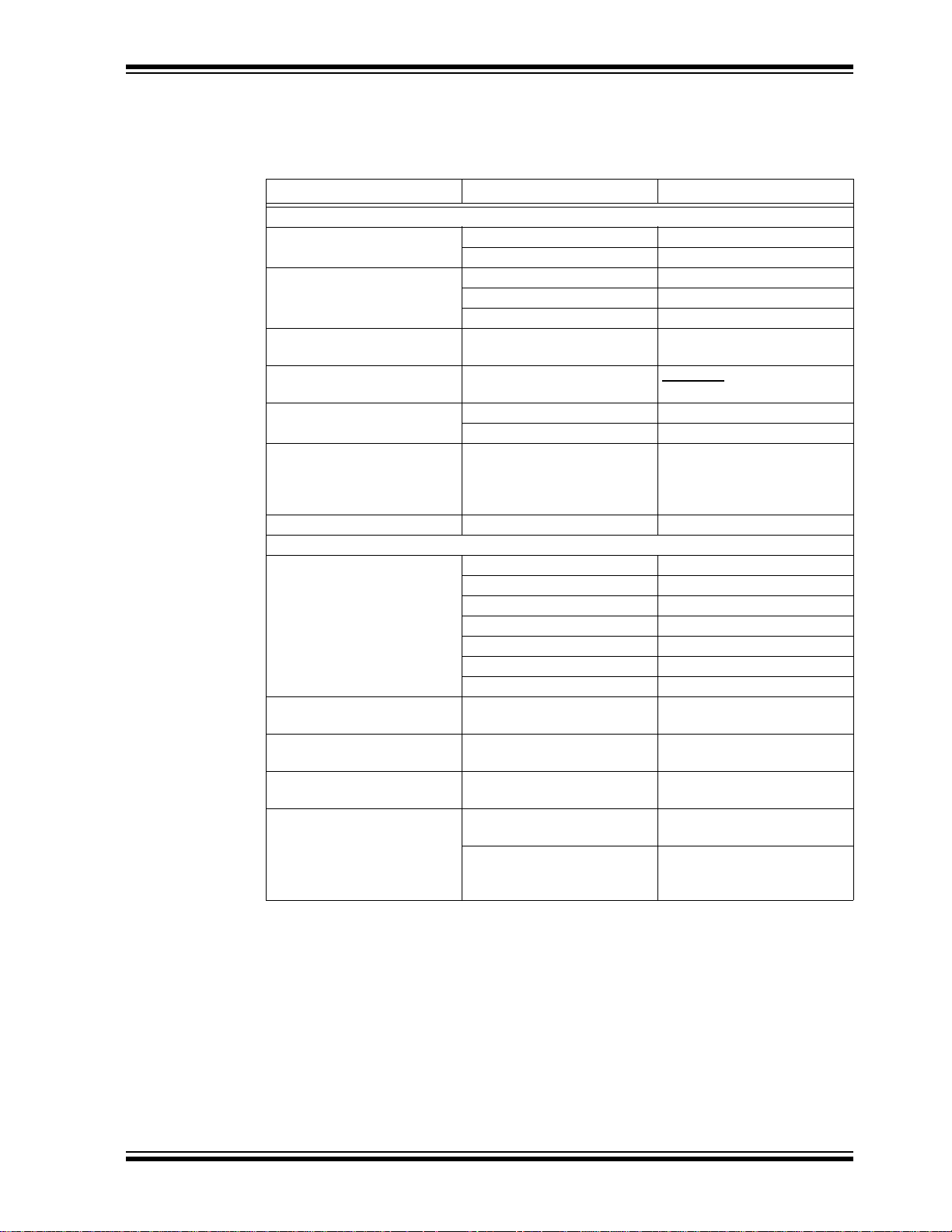

3.2 REGISTER LIST

Note: Important! Not all registers and features

are implemented in this version of

firmware release.

TABLE 3-1: INTERNAL REGISTER SUMMARY

Name Bits R/W Description

MODE 8 R/W Configuration register for operating mode of the meter

STATUS 8 R STATUS register

CAL_CONTROL 8 R/W Configuration register for calibration control

LINE_CYC 16 R/W 2n number of line cycles to be used during energy accumulation

LINE_CYC_CNT 16 R Counter for number of line cycles

2

RAW2_I_RMS 64 R Raw

RAW_I_RMS 16 R Raw RMS value from the current A/D converter in LSBs

I_RMS 16 R RMS value of the current, post Calibration

RAW2_V_RMS 64 R Raw

RAW_V_RMS 16 R Raw RMS value from the voltage A/D converter in LSBs

V_RMS 16 R RMS value of the voltage, post Calibration

LINE_FREQUENCY 16 R Line Frequency

RAW_POWER_ACT 64 R Raw Active Power

POWER_ACT 32 R Final Active Power, units in watts (W)

POWER_APP 32 R Final Apparent Power, units in volt-am peres (VA)

RAW_POWER_REACT 64 R Raw Reactive Power

POWER_REACT 32 R Final Reactive Power, units in volt-amperes-reactive (VAR)

PERIOD 32 R Period register

ENERGY_ACT 32 R Final Active Energy accumulated

RAW_ENERGY_ACT 64 R Raw Active Energy accumulated

ENERGY_APP 32 R Final Apparent Energy accu mulated

RAW_ENERGY_APP 64 R Raw Apparent Energy accumulated

I_ABS_MAX 8 R Not implemented

V_ABS_MAX 8 R Not implemented

ENERGY_REACT 32 R Final Reactive Energy accumulated

RAW_ENERGY_REACT 64 R Final Reactive Energy accumulated

PHASE_COMPENSATION 8 R/W Phase compensation between voltage and current

OFFSET_I_RMS 16 R/W Offset adjustment for RMS current reading

OFFSET_V_RMS 16 R/W Offset adjustment for RMS voltage reading

GAIN_I_RMS 16 R/W Gain adjustment for RMS current

GAIN_V_RMS 16 R/W Gain adjustment for RMS voltage

OFFSET_POWER_ACT 32 R/W Act ive Power offset

GAIN_POWER_ACT 16 R/W Ac tive Power gain adjust

OFFSET_POWER_REACT 32 R/W Offset correction for Reactive Power

GAIN_POWER_REACT 16 R/W Reactive Power gain adjust to produce X VAR/LSB

GAIN_ENERGY_ACT 16 R/W Not implemented

GAIN_ENERGY_APP 16 R/W Not implemented

GAIN_ENERGY_REACT 16 R/W Not implemented

CF_PULSE_WIDTH 8 R/W Defines CF pulse width from 0 to 255 x 0.8192 ms (0.209s)

GAIN_DENR_ENERGY_ACT 8 R/W Active Energy Pulse Output correction factor

RMS value from the current A/D converter in LSBs

2

RMS value from the voltage A/D converter in LSBs

DS51968A-page 18 © 2012 Microchip Technology Inc.

Page 19

Calculation Engi ne and Register Description

TABLE 3-1: INTERNAL REGISTER SUMMARY (CONTINUED)

Name Bits R/W Description

GAIN_NUMR_ENERGY_ACT 16 R/W Active Energy Pulse Output correction factor

MODE1_DEF 16 R/W Power Up Configuration Register

CAL_STATUS 16 R/W Calibration Status

MAXIMUM CURRENT 16 R/W Maximum current of the meter (I

CALIBRATION_VOLTAGE 16 R/W Calibration Voltage of the meter (V

CALIBRATION_CURRENT 16 R/W Calibration Current of the meter (I

CALIBRATION_FREQUENCY 16 R/W Calibration Frequency of the meter

METER_CONSTANT 16 R/W Meter Constant in imp/kWh or imp/kVARh

CALIBRATION_LINE_CYCLE 16 R/W Number of line cycles for calibration

GAIN_DENR_ENERGY_REACT 8 R/W Reactive Energy Pulse Output correction factor

GAIN_NUMR_ENERGY_REACT 16 R/W Reactive Energy Pulse Output correction factor

PHASE_COMPENSATION_90 8 R/W Phase delay for Reactive Power

CREEP_THRSHOLD_MINUTE 8 R/W No Load threshold time (minutes)

CREEP_THRSHOLD_SECOND 8 R/W No Load threshold time (seconds)

ENERGY_ACT 32 R/W Active Energy

ENERGY_REACT 32 R/W Reactive Energy

MAX

CAL

CAL

)

)

)

3.3 MODE

The MODE register controls the operation of the energy meter. The bit functions are

defined by the table below.

REGISTER 3-1: MODE REGISTER

U-0 U-0 U-0 U-0 R/W-0 R/W-0 R/W-0 R/W-0

— — — — CF ABSOLUTE PHASE CREEP

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-4 Unimplemented: Read as ‘0’.

bit 3 CF: Active Energy CF Phase Enable bit

1 = Bit = 1 Phase is enabled to be accumulated into the total energy registers or CF pulse output

0 = Bit = 0 Phase is DISABLED and is not accumulated into the total energy registers or CF pulse

output

bit 2 ABSOLUTE Positive Only Energy Accumulation Mode bit

1 = Bit = 1 Positive energy only

0 = Bit = 0 Both negative and positive energy accumulated (negative energy is subtracted)

bit 1 PHASE: Phase bit

1 = Single-Point Phase Correction

0 = Multi-P oint Phase C orrection ( future)

bit 0 CREEP: No-Load Threshold bit

1 = Enabled

0 = Disabled

© 2012 Microchip Technology Inc. DS51968A-page 19

Page 20

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

3.4 STATUS

The STATUS register contains the operational status of the energy meter. The bit

functions are defined in the table below.

REGISTER 3-2: STATUS REGISTER

U-0 U-0 U-0 U-0 U-0 U-0 R U-0

— — — — — —PH_S—

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-2 Unimplemented: Read as ‘0’

bit 1 PH_S: Phase Sign bit

1 = CT may be in backward (if enabled)

0 = Operation normal

bit 0 Unimplemented: Read as ‘0’

3.5 CAL_CONTROL

This is the Calibration mode control register. Bit 0 enables the Calibration mode. In this

mode, the power meter operates as normal, but no updates are made to the voltage,

current, power or energy registers as long as bit 1 is low. When bit 1 is set high, the

registers are updated for LINE_CYC line cycles (only power and energy registers are

updated). After this time, bit 1 is set low by the PIC18F65J90 and the update of the

registers will stop. This allows the calibration software to set bit 0, clear the registers,

set bit 1 and start reading the desired registers, as well as the CAL_CONTROL register,

to check the status of bit 1. When bit 1 goes low, the LINE_CYC line cycles have

passed and the registers are final. Note that bit 0 takes effect immediately, and bit 1 will

take effect on the very next line cycle. When bit 1 goes low, all registers will be ready

to read.

REGISTER 3-3: CAL_CONTROL REGISTER (NOTE 1)

U-0 U-0 U-0 U-0 U-0 U-0 R/W-0 R/W-0

— — — — — Reserved CAL_UPDATE CAL_MODE

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 7-3 Unimplemented: Read as ‘0’

bit 2 Reserved:

DS51968A-page 20 © 2012 Microchip Technology Inc.

Page 21

Calculation Engi ne and Register Description

REGISTER 3-3: CAL_CONTROL REGISTER (CONTINUED)(NOTE 1)

bit 1 CAL_UPDATE: Calibration Update bit

Power and energy registers upda ted for LINE _CYC lin e cy cl es when cle are d. Bit mu st be set for registers to begin updating, which starts on the next line cycle after bit is set.

1 = When the CAL_MODE bit is set, set the CAL_U PDA TE bit to enable update of power and energy

registers starting on next line cycle. Bit = 1 Single Point Phase Correction.

0 = When the CAL_MODE bit is set and the CAL_UPDATE bit has been set, the CAL_UPDATE bit

will be cleared after LINE_CYC line cycles. At that point, all registers will be updated and no

further updates will be done until the CAL_UPDATE bit is set again, or the CAL_MODE bit is

cleared.

bit 0 CAL_MODE: Calibration Mode bit

This bit enables Calibration mode.

1 = Calibration mode enabled

0 = Calibration mode disabled

Note 1: This register is used in Multi-Point and Single-Point Calibration modes only.

3.6 LINE_CYC

Name Bits Cof

LINE_CYC 16 R/W

Number of line cycles as a power of two. A setting of 0 indicates 20 or one line cycle.

A setting of 1 is two line cycles (2

of eight which is 256 line cycles. When written, this register will not take effect until the

previous number of line cycles has been acquired.

3.7 LINE_CYC_CNT

Name Bits Cof

LINE_CYC_CNT 16 R

This register counts from 0 and finishes at 2

LINE_CYC represents the value in the LINE_CYC register.

3.8 RAW2_I_RMS

Name Bits Cof

RAW2_I_RMS 64 R

This register is the square of the raw RMS value from the current A/D converter in

LSBs. By definition, this register will always contain a positive value, including the situation where power is negative from a backwards CT or otherwise. This register is

overwritten every LINE_CYC line cycle and is written only once, if calibration is

enabled.

1

), a setting of 2 is four lines cycles (22), up to a setting

(LINE_CYC - 1)

. Then it restarts at 0, where

© 2012 Microchip Technology Inc. DS51968A-page 21

Page 22

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

3.9 RAW_I_RMS

Name Bits Cof

RAW_I_RMS 16 R

This register is the raw RMS value from the current A/D converter in LSBs (square root

of the top 32-bits of RAW2_I_RMS + OFFSET_I_RMS). By definition, this register will

always contain a positive value (even if the CT is in backwards). This register is overwritten every LINE_CYC line cycle and is written only once, if calibration is enabled.

3.10 I_RMS

Name Bits Cof

I_RMS 16 R

This register is the RMS value of phase A current in X A/LSB, as determined by the

value in the GAIN _I_RMS regist er . When display ing the RMS curr ent, multiply the (decimal) value in these registers by X to get the display value in amperes. This register is

overwritten every LINE_CYC line cycle (written only once if calibration is enabled).

3.11 RAW2_V_RMS

Name Bits Cof

RAW2_V_RMS 64 R

This register is the square of the raw RMS value from the voltage A/D converter in

LSBs. By definition, it will always contain a positive value. This register is overwritten

every LINE_CYC line cycle (written only once if calibration is enabled).

3.12 RAW_V_RMS

Name Bits Cof

RAW_V_RMS 16 R

This is the raw RMS value from the voltage A/D converter in LSBs (square root of the

top 32-bits of RAW2_V_RMS + OFFSET_V_RMS). By definition, this register will

always contain a positive value. The register is overwritten every LINE_CYC line cycle

(written only once if calibration is enabled).

3.13 V_RMS

Name Bits Cof

V_RMS 16 R

This register is the RMS value of the voltage, in X 0.01 V/LSB, as determined by the

value in the GAIN_V_RMS register. When displaying the RMS voltage, assume a calibrated meter exists and multiply the (decimal) value in these registers by X to get the

display value in volts. This register is overwritten every LINE_CYC line cycle (written

only once if calibration is enabled).

DS51968A-page 22 © 2012 Microchip Technology Inc.

Page 23

Calculation Engi ne and Register Description

3.14 LINE_FREQUENCY

Name Bits Cof

LINE_FREQUENCY 16 R

This register holds the measured line frequency using the zero crossing technique.

3.15 RAW_POWER_ACT

Name Bits Cof

RAW_POWER_ACT 64 R

This register is the raw active power, as it represents the sum of current A/D value times

voltage A/D value results over LINE_CYC line cycles (each line cycle has 128 results).

Each current times voltage multiplication results in a 32-bit word. There are up to 256

line cycles with each line cycle being 128 results, and each result being 32-bit. Thus,

48 bits are needed. This is the register to be read during calibration for calculating the

offset and gain values associated with active power, OFFSET_POWER_ACT and

GAIN_POWER_ACT. This register is overwritten every line cycle, however if calibration

is enabled, the updates will stop once the LINE_CYC line cycles have elapsed.

3.16 POWER_ACT

Name Bits Cof

POWER_ACT 32 R

This register is the value for active power. The goal of the calibration is to get this register value to equal X W/LSB. This is done with the OFFSET_POWER_ACT and

GAIN_POWER_ACT registers. When displaying the power, multiply the (decimal)

value in this register by X to get the display value in watts. This register is overwritten

every LINE_CYC line cycle (written only once if calibration is enabled).

3.17 POWER_APP

Name Bits Cof

POWER_APP 32 R

This is the value of the apparent power. The goal of the calibration is to get this value

to equal X VA/LSB. This is done with the GAIN_POWER_APP registers. When displaying the power for phase A, multiply the (decimal) value in this register by X to get the

display value in watts. This register is overwritten every LINE_CYC line cycle (written

only once if calibration is enabled).

© 2012 Microchip Technology Inc. DS51968A-page 23

Page 24

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

3.18 RAW_POWER_REACT

Name Bits Cof

RAW_POWER_REACT 64 R

This is the raw reactive power. This register is read during the calibration for calculating

the gain values associated with the reactive power and GAIN_POWER_REACT. This

register is overwritten every LINE_CYC line cycle (written only once if calibration is

enabled). This register is accumulated on a line-cycle basis.

3.19 POWER_REACT

Name Bits Cof

POWER_REACT 32 R

This is the value for reactive power. The goal is to get this value to equal X VAR/LSB.

This is done with the GAIN_POWER_REACT register. When displaying the power,

multiply the (decimal) value in this register by X to get the display value in watts. This

register is overwritten every LINE_CYC line cycle (written only once if calibration is

enabled).

3.20 PERIOD

Name Bits Cof

PERIOD 32 R

This 32-bit register represents the total number of clock ticks that elapsed over the most

recent LINE_CYC line cycle. Each LSB represents 1.6 µs with a 4 MHz clock on the

microcontroller. This register is overwritten every LINE_CYC line cycle (written only

once if calibration is enabled).

3.21 ENERGY_ACT

Name Bits Cof

ENERGY_ACT 32 R

RAW_ENERGY_ACT 64 R

The design updates the Energy register using the CF Pulse blink output count. In this

method, the Energy registers increments every pulse by a value equal to

1/(METER_CONSTANT).

ENERGY_ACT = ENERGY_ACT + (1/METER_CONSTANT)

The gain calibration registers GAIN_NUMR_ENERGY_ACT and

GAIN_DENR_ENERGY_ACT operate the same for this method also.

DS51968A-page 24 © 2012 Microchip Technology Inc.

Page 25

Calculation Engi ne and Register Description

3.22 ENERGY_APP

Name Bits Cof

ENERGY_APP 32 R

RAW_ENERGY_APP 64 R

These two registers represent the total apparent energy accumulated so far.

3.23 I_ABS_MAX

Name Bits Cof

I_ABS_MAX 8 R

NOT IMPLEMENTED IN THIS FIRMWARE/SOFTWARE RELEASE.

3.24 V_ABS_MAX

Name Bits Cof

V_ABS_MAX 8 R/W

NOT IMPLEMENTED IN THIS FIRMWARE/SOFTWARE RELEASE.

3.25 ENERGY_REACT

Name Bits Cof

ENERGY_REACT 32 R

RAW_ENERGY_REACT 64 R

The design updates the reactive energy register using the CF Pulse blink output. In this

method, the Energy registers increment every pulse by a value equal to

1/(METER_CONSTANT).

ENERGY_REACT = ENERGY_REACT + (1/METER_CONSTANT)

The gain calibration registers GAIN_NUMR_ENERGY_ACT and

GAIN_DENR_ENERGY_ACT operate the same for this method also.

3.26 PHASE_COMPENSATION

Name Bits Cof

PHASE_COMPENSATION 8 R/W

Phase delay, signed 8-bit value, provides the phase compensation by sampling time/2.

© 2012 Microchip Technology Inc. DS51968A-page 25

Page 26

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

3.27 OFFSET_I_RMS

Name Bits Cof

OFFSET_I_RMS 16 R/W

Square of the offset for RMS current reading, signed 16-bit value. Note that this value

should be similar to the ADC’s noise squared. At a gain of 1, the noise will be about

1 LSB, 2 LSBs at a gain of 2, 6 LSBs at a gain of 8, 11 LSBs at a gain of 16, and

22 LSBs at a gain of 32. There may be other sources of noise. Using the square of the

offset allows for higher accuracy. The value will be added before the square root is

taken when calculating the final RMS value.

3.28 OFFSET_V_RMS

Name Bits Cof

OFFSET_V_RMS 16 R/W

Square of offset for RMS voltage reading, signed 8-bit value. Note that this value

should be similar to the ADC’s noise squared. For the voltage channel, the noise will

be about 1 LSB. There may be other sources of noise. Using the square of the offset

allows for higher accuracy. The value will be added before the square root is taken

when calculating the final RMS value.

3.29 GAIN_I_RMS

Name Bits Cof

GAIN_I_RMS 16 R/W

Current gain to produce X A/LSB. The value is always less than one (for example,

32,767 = 0.9999695).

3.30 GAIN_V_RMS

Name Bits Cof

GAIN_V_RMS 16 R/W

Voltage gain to produce 0.1 V/LSB in the V_RMS register. The value is always less than

one (for example, 32,767 = 0.9999695).

3.31 OFFSET_POWER_ACT

Name Bits Cof

OFFSET_POWER_ACT 32 R/W

Active power offset (this is a straight offset, not the square, as with voltage and current).

A much larger value is needed because the power is a running sum. This is a 32-bit

signed value.

DS51968A-page 26 © 2012 Microchip Technology Inc.

Page 27

Calculation Engi ne and Register Description

3.32 GAIN_POWER_ACT

Name Bits Cof

GAIN_POWER_ACT 16 R/W

Active power gain to produce X W/LSB. The value is always less than one (for example,

32,767 = 0.9999695).

3.33 OFFSET_POWER_REACT

Name Bits Cof

OFFSET_POWER_REACT 32 R/W

Reactive power offset (this is a straight offset, not the square, as with voltage and current). A much larger value is needed because the power is a running sum. This is a

32-bit signed value.

3.34 GAIN_POWER_REACT

Name Bits Cof

GAIN_POWER_REACT 16 R/W

Reactive power gain to produce X W/LSB. The value is always less than one (for example, 32,767 = 0.9999695).

3.35 GAIN_ENERGY_ACT

Name Bits Cof

GAIN_ENERGY_ACT 16 R/W

Active energy gain to produce X Wh/LSB. The value is always less than one (for example, 32,767 = 0.9999695).

3.36 GAIN_ENERGY_APP

Name Bits Cof

GAIN_ENERGY_APP 16 R/W

Apparent energy gain to produce X VAh/LSB. The value is always less than one (for

example, 32,767 = 0.9999695).

3.37 GAIN_ENERGY_REACT

Name Bits Cof

GAIN_ENERGY_REACT 16 R/W

Reactive energy gain to produce X VARh/LSB. The value is always less than one (for

example, 32,767 = 0.9999695).

© 2012 Microchip Technology Inc. DS51968A-page 27

Page 28

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

3.38 CF_PULSE_WIDTH

Name Bits Cof

CF_PULSE_WIDTH 8 R/W

Defines the CF pulse width from 0 to 255. Length of width is valued

* 8 * (1/LINE_FREQUENCY)/128) ms. A maximum of 0.266 seconds for 60 Hz and

0.319 seconds for 50 Hz.

If the value is 0, no CF pulse is produced.

3.39 GAIN_DENR_ENERGY_ACT

Name Bits Cof

GAIN_DENR_ENERGY_ACT 8 R/W

8-bit signed value. Represents the number of shifts for active power energy register

ENERGY_ACT before GAIN_DENR_ENERGY_ACT is applied.

3.40 GAIN_NUMR_ENERGY_ACT

Name Bits Cof

GAIN_NUMR_ENERGY_ACT 16 R/W

Active power gain to produce a specified pulses per watt-hour. The value is always less

than one (for example, 32,767 = 0.9999695).

3.41 MODE1_DEF

Name Bits Cof

MODE1_DEF 16 R/W

MODE default power-up settings. On power-up, this register will be read and placed

into the MODE register.

3.42 CAL_STATUS

The CAL_STATUS register holds the calibration status for each individual phase.

Broken down by phase, these are the values that can be calibrated. Each bit has the

status of 0 = NOT Calibrated, 1 =Calibrated.

REGISTER 3-4: CAL_STATUS REGISTER

R/W-0 R/W-0 R/W-0 U-0 U-0 R/W-0 R/W-0 R/W-0

PHASE_COM

PENSATION

bit 15 bit 8

OFFSET_I_

RMS

OFFSET_V_

RMS

— — GAIN_I_RMS GAIN_V_RMS OFFSET_PO

WER_ACT

U-0 R/W-0 U-0 U-0 U-0 R/W-0 U-0 U-0

— GAIN_POW

ER_ACT

bit 7 bit 0

DS51968A-page 28 © 2012 Microchip Technology Inc.

— — — GAIN_POWE

R_REACT

— —

Page 29

Calculation Engi ne and Register Description

REGISTER 3-4: CAL_STATUS REGISTER (CONTINUED)

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

bit 15-0 All bits: Calibration Register Status bits

1 = This register has been calibrated

0 = This register is NOT calibrated

3.43 MAXIMUM CURRENT

Name Bits Cof

MAXIMUM_CURRENT 16 R/W

This register holds the maximum current for the meter (I

3.44 CALIBRATION_VOLTAGE

Name Bits Cof

CALIBRATION_VOLTAGE 16 R/W

This register holds the calibration voltage of the meter (V

3.45 CALIBRATION_CURRENT

Name Bits Cof

CALIBRATION_CURRENT 16 R/W

This register holds the calibration current of the meter (I

3.46 CALIBRATION_FREQUENCY

Name Bits Cof

CALIBRATION_FREQUENCY 16 R/W

MAX

CAL

CAL

).

).

).

This register holds the calibration frequency of the meter.

3.47 METER_CONSTANT

Name Bits Cof

METER_CONSTANT 16 R/W

This register holds the meter constant in imp/kWh or imp/kVARh.

© 2012 Microchip Technology Inc. DS51968A-page 29

Page 30

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

3.48 CALIBRATION_LINE_CYCLE

Name Bits Cof

CALIBRATION_FREQUENCY 16 R/W

This register holds the number of line cycles used during the calibration.

3.49 GAIN_DENR_ENERGY_REACT

Name Bits Cof

GAIN_DENR_ENERGY_REACT 8 R/W

8-bit signed value. Represents the number of shifts for reactive power energy register,

before GAIN_NUMR_ENERGY_REACT is applied.

3.50 GAIN_NUMR_ENERGY_REACT

Name Bits Cof

GAIN_NUMR_ENERGY_REACT 16 R/W

Reactive power gain to produce a specified pulse per VAR-hour. The value is always

less than one (for example, 32,767 = 0.9999695).

3.51 PHASE_COMPENSATION_90

Name Bits Cof

PHASE_COMPENSATION_90 8 R/W

Phase delay for reactive power, signed 8-bit value, sampling time/2.

3.52 CREEP_THRSHOLD_MINUTE

Name Bits Cof

CREEP_THRSHOLD_MINUTE 8 R/W

This 8-bit register holds the decimal representation of the creep threshold time in

minutes (total creep is minutes + seconds register).

3.53 CREEP_THRSHOLD_SECOND

Name Bits Cof

CREEP_THRSHOLD_SECOND 8 R/W

This 8-bit register holds the decimal representation of the creep threshold time in

seconds (total creep is minutes + seconds register).

DS51968A-page 30 © 2012 Microchip Technology Inc.

Page 31

Chapter 4. Meter Protocol and Timings

4.1 PROTOCOL

The Universal Asynchronous Receiver/Transmitter (UART) of the PIC18F65J90 is

used to access the register map of the meter. In addition to the reading and writing of

the registers, there are also dedicated commands for clearing calibration registers,

loading calibration registers and storing calibration registers to flash. The first byte

UART data is an ASCII character that represents the command, and each command

has a specific protocol. Each command ends with the ASCII character “X”.

4.1.1 Command Description

The first byte of the data (byte 0) is an ASCII character E, L, S, W and R.

• E – Echo All Data Received (ECHO)

• L – Load Calibration Registers from Flash (LOAD)

• S – Store Calibration Registers (STORE)

• W – Write Bytes (WRITE)

• R – Read Bytes (READ)

The last data byte is always an 'X' character. All commands will result in the same

command being returned. The exception is the 'R' (read) command which will return

additional data in lieu of the number of bytes.

MCP3901 AND PIC18F65J90

ENERGY METER

REFERENCE DESIGN

4.1.1.1 “E” ECHO: - ECHO ALL DATA RECEIVED

Example: 'EABCDEFGHIJKLMNOPQRSTUVWYZ1234567890X'.

Returns: 'EABCDEFGHIJKLMNOPQRSTUVWYZ1234567890X'.

4.1.1.2 “L” LOAD: LOAD CALIBRATION REGISTERS FROM FLASH.

Example: 'LX'.

Returns: 'LX'.

This command is used to verify that the calibration values were actually written into

flash (or E EPROM) . Once the so f twa re exe cut es a 'SX' comman d, it shou ld v erif y th at

the values were stored by issuing an 'LX' command and then reading the calibration

values with a 'R' command.

4.1.1.3 “S” STORE: STORE CALIBRATION REGISTERS INTO FLASH

Note that the store command will write all calibration values to internal EEPROM, and

this function takes some time. During that time, the meter is not functional. The store

command should only be used after calibrating the meter, and not while it is in actual

use.

Example: 'SX'.

Returns: 'SX'.

© 2012 Microchip Technology Inc. DS51968A-page 31

Page 32

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

4.1.1.4 “W” WRITE: WRITE STARTING AT SPECIFIED ADDRESS

Write specified bytes.

Example: 'W030000102030405060708090A0B0C0D0E0FX'.

Returns: 'W030000102030405060708090A0B0C0D0E0FX'.

Note: If the number of data characters is odd, the last character (the one just prior

to the 'X') will be ignored.

Command Byte

76543210

ASCII Data

76543210

6543210

7

TABLE 4-1: WRITE COMMAND EXAMPLES

Description Command ASCII Command Hex

WRITE of 255d to

PHA_W_OFF Register

“W 170 00 F F X” 57 31 37 30 30 30 46 46 58

FIGURE 4-1: WRITE Command Protocol.

4.1.1.5 “R” READ: READ STARTING AT SPECIFIED ADDRESS

Example: 'R03010X' (read 16 bytes starting at address 30h).

Returns: 'R030000102030405060708090A0B0C0D0E0FX'

Note: For 16 bytes, there are 32 ASCII characters returned, or two characters per

byte.

3 Address Bytes (ASCII)

543210

76

“X” (ASCII)

76543210

7654321076543210

Command Byte

76543210

# Bytes to Read (2 Bytes ASCII)

76543210

76543210

76543210

3 Address Bytes (ASCII)

76543210 76543210

“X” (ASCII)

76543210

TABLE 4-2: READ COMMAND EXAMPLES

DESCRIPTION COMMAND ASCII COMMAND HEX

READ on ENERGY_ACT_L_RAW Register “R 0D4 06 X” 52 00 44 34 30 36 58

FIGURE 4-2: Read Command Protocol.

DS51968A-page 32 © 2012 Microchip Technology Inc.

Page 33

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics and layouts for the MCP3901 and

PIC18F65J90 Energy Meter Reference Design:

• Board – ADC Schematic

• Board – MCU Schematic

• Board – LCD and USB Schematic

• Board – Top Silk and Pads

• Board – Top Copper

• Board – Bottom Copper

• Board – Bottom Silk and Pads

• Board – Top 3D

• Board – Bottom 3D

MCP3901 AND PIC18F65J90

ENERGY METER

REFERENCE DESIGN

A.2 SCHEMATICS AND PCB LAYOUT

The layer order is shown in Figure A-1.

FIGURE A-1: Layer Order.

Top Layer

Bottom Layer

© 2011 Microchip Technology Inc. DS51968A-page 33

Page 34

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

A.3 BOARD – ADC SCHEMATIC

TP5

(LOW)

(LOW)

TP3

TP1

TP2

MPU_SDO

MPU_SCK

AFE_F0/CS

TP6

TP4

TP7

MPU_SDI

AFE_SYNC

AFE_CLKIN

GNDA

!!! DANGER!!!

AND SHOCK HAZARD

EQUIPMENT DAMAGE

MAY CAUSE EXTERNAL

CONNECTING TO J1, P1 or TP5

+3.3V

CAP-SMT-ELECTRO

C10

10uF

GNDB

C15

100nF

GNDB

OUT

GND

Q1

1

GNDB

IN

MCP1700T-3302E/TT

32

+5V

+5V

AFE_CLKIN

AFE_DR

141516

DR

OSC2

OSC1/CLKI

CH1+

CH1-

CH0-

6

7

NPO

NPO

NPO

100nF

NONE

CP2

13

12

MDAT1

MDAT0

AGND

REFIN/OUT+

8

9

GNDA

C5

100nF

R7

1K

C4

100nF

C3

GNDA

GNDB

11

DGND

REFIN

10

GNDA

GNDA

SSOP20

MCP3901

GNDAGNDA

GNDA

R9

332K

R8

332K

L3

300mA/150

100nF

100nF

NPO

100nF

R10

GNDB

C14

100nF

+5V +5V

C13

10UF

GNDB

C12

100nF

GNDB

3

OUT

C7

GNDA

C6

U2

MCP1703

GND

2

IN

1

GNDA

L5

150

GNDB

GNDA

C11

470UF

1

D1

2

MRA4005T3G

3

1

2

POWER

GNDA

C8

+9V IN

LOW

RAPC722

J1

D2

21

MRA4005T3G

R11

100

C9

GNDA

1K

L4

150 0.47uF

GNDB

GNDB

D3

BZG03C15G

GNDB

MOV1

HIGH

275VAC

CP4

CP5

GNDB

MPU_SCK

MPU_SDO

MPU_SDI

AFE_F0/CS

20

19

17

18

CS

SDI

SDO

SCK

U1

CH0+

RESET

DVDD

AVDD

12345

R2

10

10

AFE_SYNC

C2

100nF

R1

GNDB

GNDA

C1

100nF

R4

R5

1K TF

1K TF

L2

L1

300mA/150

300mA/150

GNDA

R3

NONE

R6

CP1

CP3

Shunt GND

LINE_SHUNT2

LINE_SHUNT1

HIGH

DS51968A-page 34 © 2011 Microchip Technology Inc.

Page 35

A.4 BOARD – MCU SCHEMATIC

Schematic and Layouts

GNDB

+3.3V

+3.3V

+3.3V

+3.3V

+3.3V

100NF

100NF

100NF

100NF

47NF

R12

R17

+3.3V

P1

HDR6X1

C20

GNDB

C19

GNDB

C18

GNDB

C17

GNDB

LCD_4A/4F/4E/4D

49

LCD_4B/4G/4C/4P

50

LCD_3A/3F/3E/3D

51

LCD_1A/1F/1E/1D

52

LCD_2B/2G/2C/2P

53

LCD_2A/2F/2E/2D

54

LCD_3B/3G/3C/3P

55

56

GNDB

+3.3V

57

LCD_1B/1G/1C/1P

58

LCD_V/K2/R/H2

59

LCD_COM4

60

LCD_COM3

61

LCD_COM2

62

LCD_COM1

63

64

C16

NONE

10K

DD

1

VSS

V

MPU_MCLR

GNDB

+3.3V

234

484746

RD7/SEG7

RD6/SEG6

RD5/SEG5

RD4/SEG4

RD3/SEG3

RD2/SEG2

RD1/SEG1

RD0/SEG0

/SEG31

(1)

RE6/COM3

RE5/COM2

RE4/COM1

RE3/COM0

LCDBIAS3

1

C21

47NF

MPU_PGD

MPU_PGC

ICD

5

6

PIC18F65J90

AFE_DR

LCD_5A/5F/RE/5D

LCD_5B/5G/5C/NC

LCD_6B/6G/6C/NC

454443

RB2/INT2/SEG9

RB1/INT1/SEG8

RB0/INT0/SEG30

RB3/INT3/SEG10

RE7/CCP2

RG1/TX2/CK2

RG0/LCDBIAS0

RE1/LCDBIAS2

RE0/LCDBIAS1

4

3

2

C22

47NF

C23

MPU_RG1

47NF

GNDB

GNDB

GNDB

GNDB

SW1

+3.3V

B3S-1002P

R13

4.7K

R14

100NF

1K

MPU_RG4

X1

4MHz

GNDB

MPU_PGC

LCD_7B/7G/7C/NC

LCD_6A/6F/6E/6D

39

424140

SS

V

RB6/KBI2/PGC

RB4/KBI0/SEG11

RB5/KBI1/SEG29

OSC2/CLKO/RA6

U3

PIC18F6XJ90-64TQFP

SS

VDDCORE/VCAP

V

RG4/SEG26

MCLR

RG2/RX2/DT2/VLCAP1

RG3/VLCAP2

7

5

6

9

8

10

MPU_RG4

MPU_MCLR

GNDB

10UF

C26

47NF C24

MOM-NC

PUSH=HI

+3.3V

GNDB

R15

4.7K

C25

27pF

C28

GNDB

GNDB

GNDB

C27

27pF

MPU_SDO

MPU_SDI

MPU_PGD

+3.3V

383736

353433

VDD

RB7/KBI3/PGD

OSC1/CLKI/RA7

RC5/SDO/SEG12

RC4/SDI/SDA/SEG16

RF6/AN11/SEG24

RF4/AN9/SEG22

RF5/AN10/CVREF/SEG23

RF7/AN5/SS/SEG25

11

13

12

14

LCD_9A/0F/9E/9D

GNDB

LCD_9B/9F/9E/NC

LCD_10A/10F/10E/10D

LCD_10B/10G/AOC/NC

GNDB

MOM-NC

PUSH=HI

SW2

B3S-1002P

GNDB

C29

R16

100NF

1K

MPU_RG1

MPU_SCK

AFE_CLKIN

RC2/CCP1/SEG13

RC3/SCK/SCL/SEG17

RF3/AN8/SEG21

RF2/AN7/C1OUT/SEG20

16

15

LCD_8A/8F/8E/8D

LCD_8B/8G/8C/NC

IR_TX

698

R20

REF

DD

+3.3V

100NF

+3.3V

U8

GNDB

D5

GP1US301XP

GL100MN1MP1

RC7/RX1/DT1/SEG28

RC6/TX1/CK1/SEG27

RC0/T1OSO/T13CKI

RC1/T1OSI/CCP2/SEG12

RA4/T0CKI/SEG14

RA5/AN4/SEG15

VDD

V

SS

RA0/AN0

RA1/AN1/SEG18

RA2/AN2//V

RA3/AN3/VREF+

AVSS

AV

ENVREG

RF1/AN6/C2OUT/SEG19

MPU_RX1

32

MPU_TX1

31

IR_TX

30

29

IR_RX

28

27

26

25

24

23

22

21

20

19

18

+3.3V

GNDB

GNDB

+3.3V

+3.3V

AFE_F0/CS

AFE_SYNC

MEM_CS

17

GNDB

C32

IR_RX

2

3

GNDB

41

LCD_V/K1/H1/A/W

CF_REACTIVE

CF_ACTIVE

LCD_7A/7F/7E/7D

GNDB

DNP

U6

PC365N

698

R19

D4

R18

1.2k

CF_ACTIVE

GNDB

SW3

B3S-1002P

U5

MCP130

MCP130T-270/TT

+3.3V

7

8

VCC

U4

CS

1

2

25LC256-I/SM

MEM_CS

+3.3V

2

1

HDR2X1

4

3

1

2

GNDB

RED

GM1JR35200AE

GNDB

ACTIVE PWR

MPU_MCLR

C31

1

VSS

OUT

3

VDD

2

+3.3V

MPU_SCK

+3.3V

5

6

SCK

HOLD

WP

SO

3

4

+3.3V

MPU_SDI

C30

100NF

J2

R22

CF_REACTIVE

100NF

MPU_SDO

SI

VSS

GNDB

GNDB

4

U7

PC365N

1

698

D6

R21

1.2k

GNDB

GNDB

DNP

2

1

J3

HDR2X1

3

2

GNDB

RED

GM1JR35200AE

GNDB

REACTIVE PWR

© 2011 Microchip Technology Inc. DS51968A-page 35

Page 36

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

A.5 BOARD – LCD AND USB SCHEMATIC

LCD

LCD_3B/3G/3C/3P

20

LCD_3A/3F/3E/3D

19

LCD_4B/4G/4C/4P

18

LCD_4A/4F/4E/4D

17

LCD_5B/5G/5C/NC

16

LCD_5A/5F/RE/5D

15

LCD_6B/6G/6C/NC

14

LCD_6A/6F/6E/6D

13

LCD_7B/7G/7C/NC

12

LCD_7A/7F/7E/7D

11

LCD_8B/8G/8C/NC

10

LCD_8A/8F/8E/8D

9

LCD_9B/9F/9E/NC

8

LCD_9A/0F/9E/9D

7

LCD_10B/10G/AOC/NC

6

LCD_10A/10F/10E/10D

5

LCD_11B/11G/11C/NC

4

LCD_11A/AAF/11E/11D

3

LCD_V/K2/R/H2

2

LCD_V/K1/H1/A/W

1

3B/3G/3C/3P

3A/3F/3E/3D

4B/4G/4C/4P

4A/4F/4E/4D

5A/5F/5E/5D

6A/6F/6E/6D

7A/7F/7E/7D

8A/8F/8E/8D

9A/9F/9E/9D

V/K2/r/h2

K1h1/A/W

5B/5G/5C/NC

6B/6G/6C/NC

7B/7G/7C/NC

8B/8G/8C/NC

9B/9G/9C/NC

10B/10G/10C/NC

10A/10F/10E/10D

11B/11G/11C/NC

11A/11F/11E/11D

2A/2F/2E/2D

21

2B/2G/2C/2P

22

1A/1F/1E/1D

23

1B/1G/1C/1P

24

COM1

25

COM2

26

COM3

27

COM4

28

LCD_2A/2F/2E/2D

LCD_2B/2G/2C/2P

LCD_1A/1F/1E/1D

LCD_1B/1G/1C/1P

U9

LCD_COM1

LCD_COM2

LCD_COM3

LCD_COM4

2

1

USB_+5V

C33

D-

0.1uF

3

D+

470

R23

GND

!!! DANGER !!!

AND SHOCK HAZARD

EQUIPMENT DAMAGE

MAY CAUSE EXTERNAL

CONNECTING TO J1, P1, J2 OR TP1

USB_MINIB_VERTICAL

7

6

4

5

GND

D+

D-

VSS

U10

VDD

OSC1

OSC2

GND

C34

0.1uF

VUSB

GP0/SSPND

GP1/USBCFG

RST

GP7/TxLED

GP6/RxLED

+3.3V

U11

GP2

GP5

MPU_TX1

VDD2VDD1

RX

CTS

GP4

GP3

MPU_RX1

VIA

VOB

GND2

VOA

GND1

ADUM1201

VIB

MCP2200_RX

MCP2200_TX

RTS

MCP2200_SSOP20

TX

R25

470

2

3

470

R24

GNDB

GND

GND

+3.3V

D7

100NF

RED

1

4

GREEN

C35

GNDB

USB_+5V

LCD1

INDIA LCD

X2

RESONATOR-CSTCE

12 MHz

GND

DS51968A-page 36 © 2011 Microchip Technology Inc.

Page 37

A.6 BOARD – TOP SILK AND PADS

Schematic and Layouts

© 2011 Microchip Technology Inc. DS51968A-page 37

Page 38

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

A.7 BOARD – TOP COPPER

DS51968A-page 38 © 2011 Microchip Technology Inc.

Page 39

A.8 BOARD – BOTTOM COPPER

Schematic and Layouts

© 2011 Microchip Technology Inc. DS51968A-page 39

Page 40

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

A.9 BOARD – BOTTOM SILK AND PADS

DS51968A-page 40 © 2011 Microchip Technology Inc.

Page 41

A.10 BOARD – TOP 3D

Schematic and Layouts

© 2011 Microchip Technology Inc. DS51968A-page 41

Page 42

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

A.11 BOARD – BOTTOM 3D

DS51968A-page 42 © 2011 Microchip Technology Inc.

Page 43

MCP3901 AND PIC18F65J90

ENERGY METER

REFERENCE DESIGN

Appendix B. Bill of Materials (BOM)

TABLE B-1: BILL OF MATERIALS (BOM)

Qty Refe rence Description Manufac turer Part Number

20 C1, C2, C5, C6

C7, C8, C12,

C14, C15, C17,

C18, C19, C20,

C25, C29, C30,

C31, C33, C34,

C35

2 C3, C4 CAP CER .1UF 25V X7R 1206 FO KEMET

1 C9 CAP .47UF 305VAC Lead Spacing 22.5

1 C10 CAP 10UF 16V ELECT FC SMD Panasonic

1 C11 CAP 470UF 25V ELECT FC SMD Panasonic - ECG EEE-FC1E471P

2 C13, C26 CAP CER 10UF 6.3V X5R 0603 Murata Electronics GRM188R60J106ME47D

5 C16, C21, C22,

C23, C24

2 C27, C28 CAP CER 27PF 50V 5% C0G 0603 TDK Corporation C1608C0G1H270J

2 D1, D2 DIODE SCHOTTKY 40V 1A SMB ON

1 D3 DIODE ZENER 15V 1.5W SMA ON Semiconductor B ZG03C15G

2 D4, D6 LED 1.6X0.8MM 625NM RED CLR SMD Kingbright Corp. APT1608EC

1 D7 LED 2X1.2MM RD/GN WTR CLR SMD Kingbright Corp. APHBM2012SURKCGKC

1 J1 CONN POWERJACK MINI R/A T/H CUI Inc. PJ-102B

3 L1, L2, L3 FERRITE 300MA 150 OHM 1806 SMD Laird-Signal

2 L4, L5 FERRITE 300MA 150 OHM 1806 SMD Laird-Signal

1 LCD1 Energy Meter LCD Display Deepakshi

1 MOV 1 VARISTOR 275V RMS 20MM RADIAL EPCOS Inc. S20K275E2

1 P1 6 X 1 Header 2.54 mm on center 6 mm/2.5 mmSamtec TSW-106-07-G-S

CAP CER .1UF 25V 10% X7R 0603 Murata

Electronics

EPCOS Inc. B32933B3474K000

mm, WxHxL = 10.5 x 16.5 x 26.5

CAP CER 47000PF 25V 10% X7R 0603 Murata Electronics GRM188R71473KA01D

Semiconductor

Integrity Products

Integrity Products

Display Devices

®

®

®

- ECG EEE-FC1C100R

GRM188R71E104KA01D

C1206F104K3RACTU

MBRS140T3G

®

LI1806C151R-10

LI1806C151R-10

DP-093

1 PCB RoHS Compliant Bare PCB, MCP3901

PIC18F65J90 Shunt Meter Ref Des

1 Q1 IC REG LDO 3.3V 250MA SOT23-3 Microchip

Technology Inc.

2 R1, R2 RES 10.0 OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF10R0V

4 R4, R5, R7,

R10

2 R8, R9 RES 332K OHM 1/4 1% 1206 SMD YAGEO Corp. RC1206FR-07332KL

RES 1.00K OHM 1/8W 1% 0805 SMD Panasonic - ECG ERJ-6ENF1001V

— 104-00342

MCP1700T-3302E/TT

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The

released BOM used in manufacturing uses all RoHS-compliant components.

© 2012 Microchip Technology Inc. DS51968A-page 43

Page 44

MCP3901 and PIC18F65J90 Energy Meter Reference De sign

TABLE B-1: BILL OF MATERIALS (BOM) (CONTINUED)

Qty Reference Description Manufacturer Part Number

1 R11 RES 100 OHM 1W 5% 2512 SMD Panasonic - ECG ERJ-1TNF1000U

2 R13, R15 RES 4.70K OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF4701V

2 R14, R16 RES 1.00K OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF1001V

1 R17 RES 10.0K OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF1002V

2 R18, R21 RES 100 OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF1000V

2 R19, R22 RES 698 OHM 1/10W 1% 0603 SMD Rohm

Semiconductor

3 R23, R24, R25 RES 470 OHM 1/10W 1% 0603 SMD Panasonic - ECG ERJ-3EKF4700V

3SW1, SW2,

SW3

1 TP5 Wire Test Point 0.3” Length Component

1 U1 IC ENERGY METER SSOP-20 Microchip

1 U2 IC REG LDO 5V 250MA SOT-223-3 Microchip

1 U3 64/80-Pin, High-Performance Microcon-

1 U4 256K SPI Bus Serial EEPROM SOIC-8 Microchip

2 U6, U7 PHOTOCOUPLER DARL OUT 4-SMD Sharp®

1 U9 CONN RUGGED USB RCPT VERT MINI B Amphenol

1 U10 IC USB TO UART SSOP-20 Microchip

1 U11 IC ISOLATOR DIGITAL DUAL 8-SOIC Analog Devices

1 X1 CRYSTAL 4.000 MHZ 18PF SMD Abracon

1 X2 CER RESONATOR 12.0MHZ SMD Murata Electronics CSTCE12M0G55-R0

SWITCH TACT 6MM 230GF H=4.3MM Omron Electronics B3S-1002P

Corporation

Technology Inc.

Technology Inc.

Microchip

trollers with LCD Driver and nanoWatt Technology TQFP-64

Technology Inc.

Technology Inc.

Electronic Corp.

Commercial

Technology Inc.

Inc.

Corporation

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The

released BOM used in manufacturing uses all RoHS-compliant components.

MCR03EZPFX6980

PJ-202-30

MCP3901AO-I/SS

MCP1703-5002E/DB

PIC18F65J90-I/PTY

25LC256-I/SN

PC36NJ0000F

MUSBB55104

MCP2200-I/SS

ADUM1201CRZ-RL7

ABLS-4.000MHZ-B4-T

TABLE B-2: BILL OF MATERIALS (COMPONENTS NOT INSTALLED)

Qty Reference Description Manufacturer Part Number

1 C32 CAP CER .1UF 25V 10% X7R 0603 — —

1 D5 DO NOT INSTALL — —

2 J2, J3 DO NOT INSTALL — —

2 R3, R6 DO NOT INSTALL — —

1 R12 DO NOT INSTALL — —

1 R20 RES 698 OHM 1/10W 0603 SMD — —

1 U5 Microcontroller Supervisory Circuit

with Open Drain Output SOT23-3

1 C32 CAP CER .1UF 25V 10% X7R 0603 — —

——

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The

released BOM used in manufacturing uses all RoHS-compliant components

DS51968A-page 44 © 2012 Microchip Technology Inc.

Page 45

© 2012 Microchip Technology Inc. DS51968A-page 45

Page 46

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819-3187

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao