Page 1

8-Bit Wireless Development Kit

User’s Guide

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2011-2012, Microchip Technology Incorporated, Printed in

the U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-61341-991-5

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

T empe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memo ry and

analog products. In addition, Microchip’s quality system for the desig n

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS70654B-page 2 Preliminary © 2011-2012 Microchip Technology Inc.

Page 3

8-BIT WIRELESS

DEVELOPMENT KIT

USER ’S GUIDE

Table of Contents

Preface ...........................................................................................................................5

Overview ........................................................................................................................9

Introduction ........................................................................................................... 9

8-Bit Wireless Development Kit Contents ............................................................ 9

Wireless Daughter Boards ...................................................................................9

8-Bit Wireless Development Kit ..........................................................................10

PIC18 Wireless Development Board .........................................................................11

Board Layout and Features ................................................................................11

Getting Started ............................................................................................................15

Introduction ......................................................................................................... 15

Hardware Requirements ....................................................................................15

Demo Setup .......................................................................................................15

Pre-programmed Tutorial Operation ..................................................................16

Additional Tutorials ....................................................................................................21

Introduction ......................................................................................................... 21

Extended 8-bit WDK Demo with Hyper-terminal Program .................................21

Network Freezer .................................................................................................23

Reduced Function Device (RFD) Demonstrating Sleep Capability .................... 25

Chat Window Demo ........................................................................................... 27

Ping-Pong Demo ................................................................................................ 29

8-bit Wireless Development Kit with Additional Nodes .......................................32

Introduction ......................................................................................................... 33

PIC18 Wireless Development Board Schematic ................................................ 33

PIC18 Wireless Development Board PCB Layout ..............................................36

PIC18 Wireless Development Board Bill of Materials ........................................ 38

Worldwide Sales and Service ....................................................................................41

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 3

Page 4

8-Bit Wireless Development Kit User’s Guide

NOTES:

DS70654B-page 4 Preliminary © 2011-2012 Microchip Technology Inc.

Page 5

8-BIT WIRELESS

DEVELOPMENT KIT

USER ’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

For the most up-to-date information on development tools, see the MPLAB® IDE on-line help.

Select the Help menu, and then Topics to open a list of available on-line help files.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

8-bit Wireless Development Kit User’s Guide. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Development Systems Customer Change Notification Service

• Customer Support

DOCUMENT LAYOUT

This document describes how to use the 8-Bit Wireles s Deve lo pm e nt kit to evalu a te

and experiment with Microchip wireless solutions. The manual layout is as follows:

• Chapter 1. “Overview”: This chapter describes the 8-bit Wireless Development

Kit and how it works.

• Chapter 2. “PIC18 Wireless Development Board”: This chapter details the

hardware information of the PIC18 Wireless Development Board.

• Chapter 3. “Getting Started”: This chapter describes what you ne ed to kn ow to

start using the 8-bit Wireless Development Kit.

• Chapter 4. “Additional Tutorials”: This chapter provides ad dit ion a l tu to rial pro -

grams that demonstrate the additional features of 8-bit Wireless Development Kit.

• Appendix A. “PIC18 Wireless Development Board Schematic”: This appendix

provides the PCB layout, BOM and PIC18 Wireless Development Board

schematics.

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 5

Page 6

8-Bit Wireless Development Kit User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

sArial font:

Italic characters Referenced books MPLAB® IDE User’s Guide

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: {|}

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{...

}

DS70654B-page 6 Preliminary © 2011-2012 Microchip Technology Inc.

Page 7

WARRANTY REGISTRATION

Please complete the enclosed Warran ty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

RECOMMENDED READING

This user’s guide describes how to use 8-bit Wireless Development Kit User’s Guide.

Other useful documents are listed below. The following Microchip documents are

available and recommended as supple me n tal refere nce re sou r ces .

Readme Files

For the latest information on using other tools, read the tool-specific Readme files in

the Readmes subdirectory of the MPLAB IDE installation directory. The Readme files

contain update information and known issues that may not be included in this user’s

guide.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser , the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 7

Page 8

8-Bit Wireless Development Kit User’s Guide

DEVELOPMENT SYSTEMS CUSTOMER CHANGE NOTIFICATION SERVICE

Microchip’s customer notification service helps keep customers current on Microchip

products. Subscribers will receive email notification whenever there are changes,

updates, revisions or errata related to a spec ified product family or development tool of

interest.

To register, access the Microchip web site at www.microchip.com, click on Customer

Change Notification and follow the registration instructions.

The Development Systems product group categories are:

• Compilers – The latest information on Microchip C compilers a nd other language

tools. These include the MPLAB C18 and MPLAB C30 C compilers; MPASM™

and MPLAB ASM30 assemblers; MPLINK™ and MPLAB LINK30 object linkers;

and MPLIB™ and MPLAB LIB30 object librarians.

• Emulators – The latest information on Microchip in-circuit emulators.This

includes the MPLAB ICE 2000 and MPLAB ICE 4000.

• In-Circuit Debuggers – The latest information on the Microchip in-circuit

debugger , MPLAB ICD 2.

• MPLAB® IDE – The latest information on Microchip MPLAB IDE, the Windows®

Integrated Development Environment for development systems tools. This list is

focused on the MPLAB IDE, MPLAB SIM simulator, MPLAB IDE Project Manager

and general editing and debugging features.

• Programmers – The latest information on Microchip programmers. These include

the MPLAB PM3 and PRO MATE

Plus and PICkit™ 1 development programmers.

®

II device programmers and the PICSTART®

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sa les of fices ar e also available to help cu stomers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DS70654B-page 8 Preliminary © 2011-2012 Microchip Technology Inc.

Page 9

DOCUMENT REVISION HISTORY

Revision A (March 2011)

This is the initial release of the document.

Revision B (January 2012)

This revision includes the following updates:

• Added MRF89XAM8A868 MHz PICtail/PICtail Plus Daughter Boards or

MRF89XAM9A915 MHz PICtail/PICtail Plus Daughter Boards in 1.3 “Wireless Daughter

Boards”

• Added rows, MRF24J40MC and MRF89XAM9A PICtail/PICtail Plus Daughter Board, in

Table 1-1: “Compatible PICtail™ Daughter Boards”

• Added a new bullet in 3.3 “Demo Setup”, 4.2.1 “Set up”, 4.3.1 “Setup”,

4.5.1 “Setup”, 4.6.1 “Set up”

• Updated 4.3 “Network Freezer”

• Replaced all instances of MRF24J40MA Daughter Boards with Radio Daughe r

Boards

Preface

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 9

Page 10

8-Bit Wireless Development Kit User’s Guide

DS70654B-page 10 Preliminary © 2011-2012 Microchip Technology Inc.

Page 11

DEVELOPMENT KIT

Chapter 1. Overview

1.1 INTRODUCTION

This chapter introduces the 8-Bit Wireless Development Kit features and its

requirements.

The topics discussed in this chapter include:

• 8-Bit Wireless Development Kit Contents

• Wireless Daughter Boards

• 8-Bit Wireless Development Kit

1.2 8-BIT WIRELESS DEVELOPMENT KIT CONTENTS

The 8-Bit Wireless Development Kit contains the following items:

• Two PIC18 Wireless Development Boards with PIC18F46J50 XLP Microcontroller

• Two PICtail™/PICtail Plus Daughter Boards (See Table 1-1)

•Two LCD Serial Accessory Boards

• Two RS232 Serial Accessory Boards

• Two USB A to Mini-B 1 meter Cables

• Two RS232 Serial Cables

8-BIT WIRELESS

USER ’S GUIDE

1.3 WIRELESS DAUGHTER BOARDS

The 8-Bit Wireless Development Kit, includes either MRF24J40MA 2.4 GHz IEEE

802.15.4 complaint PICtail/PICtail Plus Daughter Boards or MRF89XAM8A 868 MHz

PICtail/PICtail Plus Daughter Boards or MRF89XAM9A 915 MHz PICtail/PICtail Plus

Daughter Boards. The PIC18 Wireless Development Board is compatible with many

other wireless PICtail daughter Boards.

PICtail daughter boards that are compatible with the PIC18 Wireless Development

Board.

TABLE 1-1: COMPATIBLE PICtail™ DAUGHTER BOARDS

Description Part Number

MRF24J40MA PICtail/PICtail Plus Daughter Board AC164134-1

MRF24J40MB PICtail/PICtail Plus Daughter Board AC164134-2

MRF24J40MC Pictail/PICtail Plus Daughter Board AC164134-3

MRF49XA PICtail Plus Daughter Board (433.92 MHz) AC164137-1

MRF49XA PICtail Plus Daughter Board (868/915 MHz) AC164137-2

MRF89XAM8A PICtail/PICtail Plus Daughter Board (868 MHz) AC164138-1

MRF89XAM9A PICtail/PICtail Plus Daughter Board (915 MHz) AC164138-2

Table 1-1 lists the part number of the wireless

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 9

Page 12

8-Bit Wireless Development Kit User’s Guide

The PIC18 Wireless Development Board provides PICtail connectivity, which is

compatible with the existing and future radio and sensor daughter boards from

Microchip. For more information on compatibility, refer to the Microchip website

http://www.microchip.com/wireless

Note: Individual Wireless PICtail Daughter Boards require .hex files for the

specific RF transceiver. For more information, refer to the 8-Bit Wireless

Development Kit product web page at http://www.microchip.com/wireless.

1.4 8-BIT WIRELESS DEVELOPMENT KIT

The Wireless Development Kit allows developers to evaluate and experiment with

sub-GHz and 2.4 GHz RF solutions from Microchip. The Wireless Development Kit

provides two RF hardware nodes which can be used to create a simple two-node

wireless network. More nodes can be added by purchasing 8-Bit Wireless

Development Kit or individual components.

The 8-Bit Wireless Development Kit is pre-programmed with a wireless demo prog ram

that allows multiple operational configurations to be tested without writing any firmware.

For more information on how to operate the pre-programmed demo program and how

to develop other applications, see

customer to evaluate Microch ip’s proprietary wireless stacks. The Microchip wireless

stacks and additional application demo source codes can be downloaded from the

Microchip web site

The PIC18 Wireless Development Board provides all the necessary components

required to build an extreme low-power wireless sensor application. The Serial

Accessory Port can interface external sensors or modules, like LCD Serial Accessory

Board or RS232 Serial Accessory Board. The platform provides USB connectivity and

supports different XLP microcontroller options.

http://www.microchip.com/wireless.

Chapter 3. “Getting Started”. It also enables

DS70654B-page 10 Preliminary © 2011-2012 Microchip Technology Inc.

Page 13

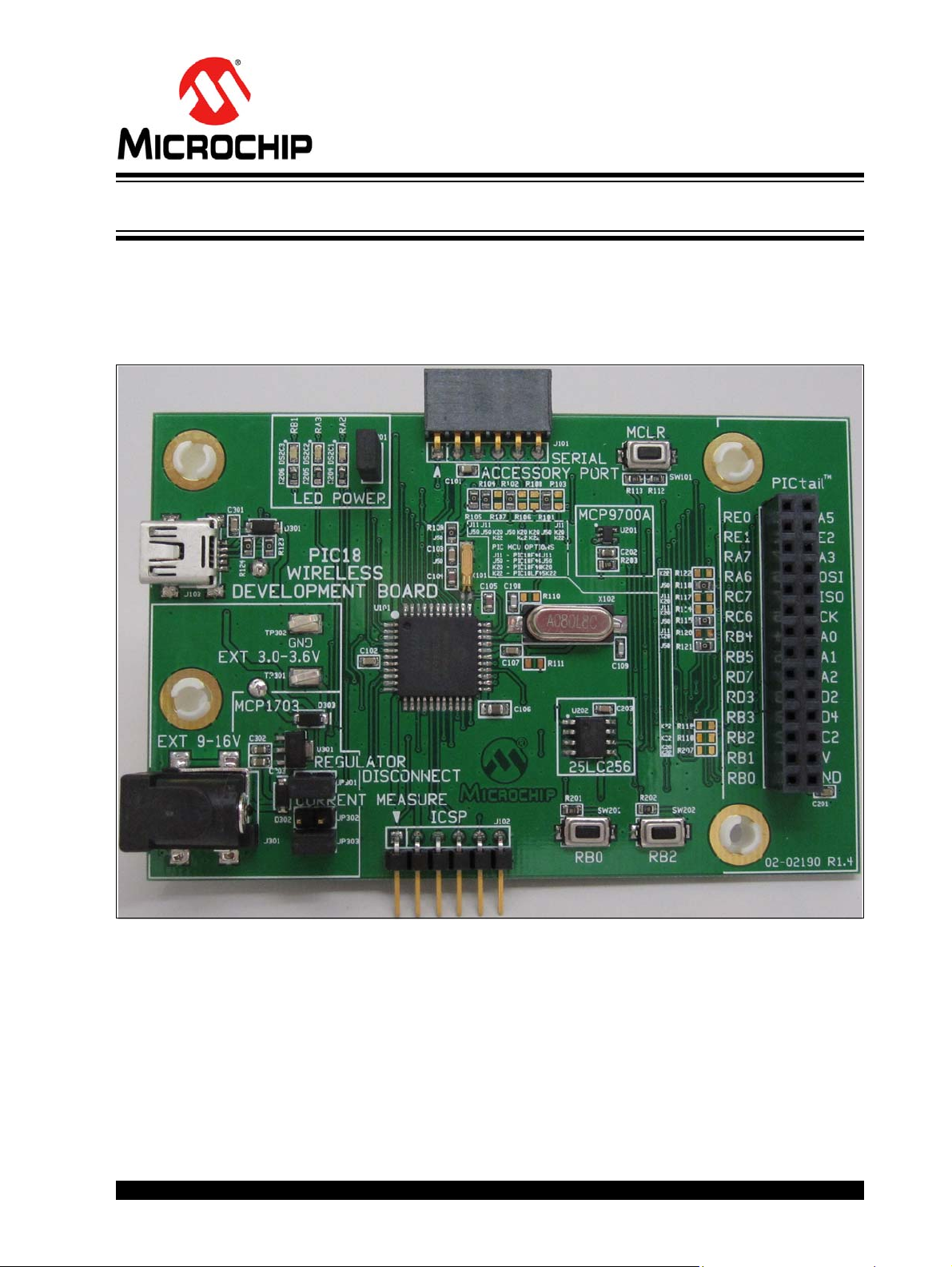

Chapter 2. PIC18 Wireless Development Board

2.1 BOARD LAYOUT AND FEATURES

This chapter describes the PIC18 Wireless Development Board hardware. It also

features the components shown in

FIGURE 2-1: PIC18 WIRELESS DEVELOPMENT BOARD

Figure 2-1.

8-BIT WIRELESS

DEVELOPMENT KIT

USER ’S GUIDE

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 11

Page 14

8-Bit Wireless Development Kit User’s Guide

The PIC18 Wireless Development Board supports the XLP microcontroller options

such as PIC18F46J11, PIC18F46J50, PIC18F46K20 and PIC18LF45K22.

The default microcontroller option is PIC18F46J50. Different microcontroller options

require different components to populate on the PIC18 Wireless Development Board.

Note 1: Missing components on the PIC18 Wireless Development Board does

not indicate a defect. Population of these missing components depend on

the Microcontroller being used. For more information about using

different Microcontrollers, see the Section A.2 “PIC18 Wireless

Development Board Schematic”.

2: Take pre cautionary measure while changing the microcon troller option as

improper tools or poor handling could harm the copper tracks on the

surface of the Board, it might destroy it.

The following main blocks are defined on the Board:

• Serial Accessory Port

• USB Interface Port

• PICtail Port

• Push Buttons

• Onboard Temperature Sensor

• Onboard Serial EEPROM

• Debug LEDs

• Power Supply

2.1.1 Serial Accessory Port

Serial Accessory Port provides a simple serial interface for the external modules.

These modules may be either external sensor or accessory board. For more

information about existing accessory boards refer to the

http://www.microchip.com or

“LCD Serial Accessory Board User’s Guide” (DS70650) or “RS232 Serial Accessory

Board User’s Guide” (DS70649).

The following interfaces are supported by the Serial Accessory Port:

• 3 or 4 wire SPI

•I2C™

• USART

These interfaces are selected by the software without modifying the hardware. User

should be attentive when different interfaces use the same hardware or sh are the same

port pins of the microcontroller. For more information on the port pin assignment, see

Figure A-1.

2.1.2 USB Interface Port

The PIC18F46J50 microcontroller provides USB v2.0 compliant full-speed Universal

Serial Bus (USB) interface, which helps suppling power to the PIC18 Wireless

Development Board. The relevant USB components are included with the

PIC18F46J50 microcontroller option.

DS70654B-page 12 Preliminary © 2011-2012 Microchip Technology Inc.

Page 15

PIC18 Wireless Development Board

//Initialize RB2

TRISBbits.TRISB2 = 1; // RB2 is an input

ANCON1 |= 0x01; // RB2 is a digital pin

/*

User code

*/

//Evaluating RB2

INTCON2bits.RBPU = 0; // PortB pull ups are enabled

if (PORBbits.RB2 == 0) // RB2 is pushed

{

/*

RB2 PB code...

*/

}

INTCON2bits.RBPU = 1; // PortB pull ups are disabled

2.1.3 PICtail Port

PICtail Port is a 28-pin interface port that supports Microchip’s RF based daughter

cards. PICtail Port provides the following interfaces to the daughter cards:

• Power supply

• SPI interface

• Interrupt request lines

Note: User must be careful about the PICtail port pins that share different

functions of the board. The user needs to check the schematics before

assigning functions for any port pins.

2.1.4 Push Buttons

PIC18 Wireless Development board contains two push buttons, RB0 and RB2. These

buttons are assigned to the individual interrupt lines of the microcontroller and are not

driven by external pull-up circuitry to save power consumption. The user software must

enable the Port B pull-ups of the microcontroller before evaluating the button state.

Example 2-1 illustrates a possible solution to evaluate the state of RB2.

EXAMPLE 2-1: CODE EXAMPLE FOR EVALUATING THE STATE OF RB2

2.1.5 Onboard Temperature Sensor

The temperature sensor used is the Microchip’s MC9700A, which is a low-power Linear

Active Thermistor™ IC. To minimize power consumption, the sensor is powered from

a port pin. After powering up, the sensor output can be measured after a minute. The

internal AD converter of the microcontroller is used to measure the temperature value.

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 13

2.1.6 Onboard Serial EEPROM

The Onboard Serial EEPROM is a low-power, Microchip’s 25LC256 256K SPI Bus

Serial EEPROM, which shares the SPI interface with the PICtail port. But Onboard

Serial EEPROM has its own active low chip select line connected to the RD5 port pin.

2.1.7 Debug LEDs

The PIC18 Wireless Development Board contains three LEDs for debug purposes. To

conserve battery power , LEDs power can be disconnected by removing the JP20 1 and

LED power jumper .

Page 16

8-Bit Wireless Development Kit User’s Guide

2.1.8 Power Supply

The board can be powered from any one of these sources:

• 2xAA onboard battery pack is available at the bottom of the PIC18 Wireless

Development Board

• USB port

• External 9-16V charger power supply through the standard coaxial power

connector

• External 3.0-3.6V power source through test points TP301 and TP302

USB Port and external coaxial port power are stabilized by MCP1703, 250 mA, 3.3V,

low quiescent current LDO regulator. The battery operated applications that do not

require LDO can be disconnected by removing the JP301, Regulator Disconnect

jumper.

Note: The 9V wall adapter is not included in the kit. A 9V wall adapter may be

ordered from

wall adapter is AC162039.

2.1.8.1 CURRENT CONSUMPTION MEASUREMENT

ThePIC18 Wireless Development Board contains two jumpers, JP302 and JP303, to

measure the current consumption of the kit. These jumpers can measure current

consumption of the entire kit without disturbin g it.

Measuring the operational current:

1. Ensure that either JP302 or JP303, has one jumper connected to it. Only one

jumper is required.

2. Connect the current meter to the jumper that is empty. Because the jumpers are

electrically parallel, it can be either JP302 or JP303.

3. Set the current measure range of the current meter above 250 mA.

4. Remove the jumper.

http://www.microchipdirect.com/ . The part number of the 9V

Note: Some current meters set the measuring range automatically, which can

cause interruptions in the power line while changing the range. If

interruption in the power line occurs, use manual range settings.

DS70654B-page 14 Preliminary © 2011-2012 Microchip Technology Inc.

Page 17

3.1 INTRODUCTION

This chapter provides a tutorial to familiarize users with the 8-bit Wireless Development

Kit. It also explains how to run the pre-programmed demo. The source code for the

demo is available along with the MiWi

MiWi stack, by default the file is saved at the following location

C:\Microchip Solutions\MiWi DE Demo\8-bit Wireless Development Kit –

(Transciver)\8-bit WDK Demo

The demo programs use the MiWi Development Environment. For more information

about MiWi, refer to

Note: To run the demo using the PIC18 Wireless out of the box demo boards, the

The following topics are discussed in this chapter:

• Hardware Requirements

•Demo Setup

• Pre-programmed Tutorial Operation

8-BIT WIRELESS

DEVELOPMENT KIT

USER ’S GUIDE

Chapter 3. Getting Started

TM

stack. After unzipping the latest version of the

.

www.microchip.com/MiWi.

user need not re-program them. Otherwise, the user needs to program this

with the 8-bit WDK

Demo.hex file.

3.2 HARDWARE REQUIREMENTS

The following hardwares are required to run the pre-programmed demo application:

• Two pre-programmed PIC18 Wireless Development Boards

• Two Radio Daughter Boards

•Two LCD Serial Accessory Boards

• Four fresh AA batteries or a two 9V external power supply or two USB cables

3.3 DEMO SETUP

This section demonstrates how to create a two node MiWi Wireless Network. Create a

network using the two push buttons (RB0 and RB2) available on the PIC18 Wireless

Development board (RB0 to create the network and RB2 to join the network). After

setting up the network the nodes in the network read the temperature sensor

(MCP9700A) and broadcast this information over the network.

Follow these steps to set up the 8-bit WDK demo:

1. Connect the LCD Serial Accessory board J1 port to the J101 connector on the

PIC18 Wireless Development Board (See

2. Plug in the Radio PICtail Daughter board at slot J201 on the PIC18 Wireless

Development Board.

3. To power using AA batteries, remove the jumper at JP301 (Regulator

Disconnect). To power through 9V external power supply or USB, ensure JP301

is connected (jumper installed).

4. Insert a jumper at JP201 (LED power) on the PIC18 Wireless Development Board.

Figure 3-1).

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 15

Page 18

8-Bit Wireless Development Kit User’s Guide

5. Ensure that the jumper is disconnected at JP1 position on the LCD Serial

Accessory Board. This ensures that the LCD Seria l Accessory Board is used in

2

I

C mode and not in SPI mode. The 8-bit WDK Demo program uses the LCD

Serial Accessory board in I

6. Wireless demo board can be powered using any of these options:

• Two AA Batteries

• 9V External Power Supply

• USB port

• External 3.0-3.6V power source through test points TP301and TP302

7. Insert a jumper at either JP302 or JP303 (Current Measure) on the PIC18

Wireless Development Board.

FIGURE 3-1: PIC18 WIRELESS DEVELOPMENT BOARD CONNECTED TO LCD SERIAL

ACCESSORY BOARD

AND MRF24J40MA PICTAIL DAUGHTER BOARD

2

C mode.

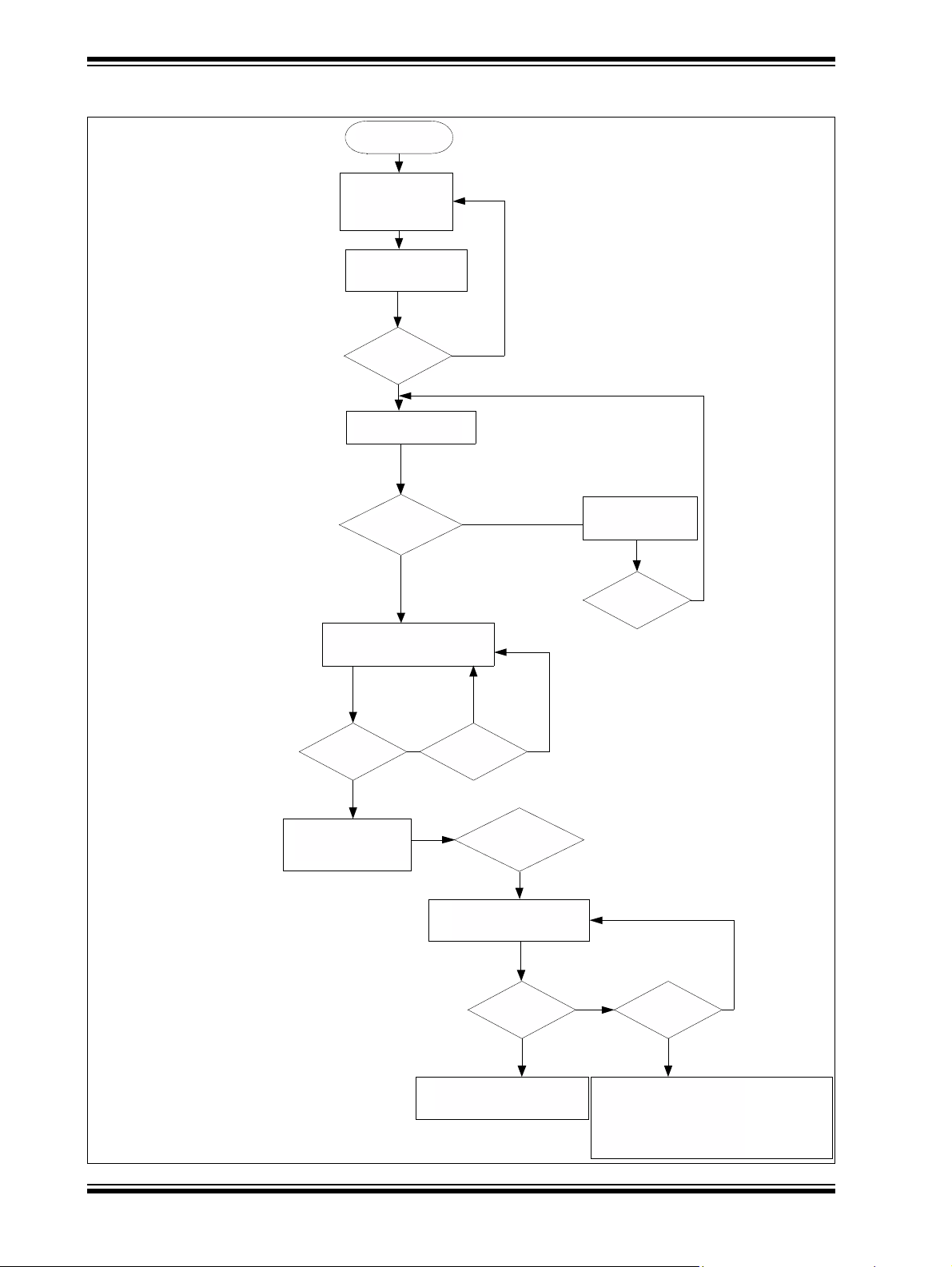

3.4 PRE-PROGRAMMED TUTORIAL OPERATION

The pre-programmed demo is used to demonstrate the basic concepts of the MiWi

networking and also to demonstrate the features of the 8-bit Wirel ess Development Kit.

Figure 3-2 illustrates the 8-bit Wireless Development Kit program flow.

DS70654B-page 16 Preliminary © 2011-2012 Microchip Technology Inc.

Page 19

Power Up

Display

8-bit Wireless

Development Kit

Display

RB0: Create NWK

RB2: Join NWK

Is RB0

pressed?

Display

Created network

successfully

If networks

were found?

Scan for networks

Display

Local Temp

MAC Address: 21C/70F

Display 0

Network Found

RB2: Re-Scan

A1

A3

A2

No

No

Yes

Is RB2

pressed?

If RB0

Pressed?

If RB2

Pressed?

Read temperature sensor

and broadcast information

over the network

Display

Local/Remote Temp

MAC Address:21C/70F

Rotates Display

Information between local

and Remote temperatures

with every RB2 press

Display

RB0: (PC) 010203

RB2: Additional NW - 0

If RB2 is

pressed?

If RB0 is

pressed?

Display Join status

(Success/Failure)

If Join status =

success

A3

Connect

to A1

A2

No

Yes

No

No

If RB2 is

pressed?

If RB0 is

pressed?

No

No

Yes

No

Yes

Yes

No

Display next node

information if available

Yes

Yes

MAC Address: Last 3 Byte MAC Address in HEX

RB0: RB0 Push Button on Wireless Development Board

RB2:

RB2 Push Button on Wireless Development Board

PC:

PAN Coordinator

Local Temp:

Temperature sensor reading at current node

Remote Temp:

Temperature sensor reading at Remote node

Yes

Yes

Yes

No

FIGURE 3-2: 8-BIT WIRELESS DEVELOPMENT KIT DEMO PROGRAM

Getting Started

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 17

Page 20

8-Bit Wireless Development Kit User’s Guide

For more information on MiWi networking concepts, such as PAN Coordinator, Coordinator and RFD or End Device, refer to the application note, AN1066 “Microchip MiWi

Wireless Networking Protocol Stack” (DS01066B).

This demo highlights the following features:

• Creating a MiWi Network

• MCP9700A Temperature Sensor

• MAC Address EEPROM on the Radio Daughter Boards

• LCD Serial Accessory Board

3.4.1 Creating a MiWi Network

3.4.1.1 TO CREATE A MiWi NETWORK

Follow these steps to create a MiWi Network:

1. Configure one node as PAN Coordinator (“Create NWK”) and another as

Coordinator (“Join NWK”).

2. Use the Coordinator to join the PAN Coordinator, “8-bit Wireless Development

Kit” message will be displayed on the LCD after powering the nodes. After a few

seconds the display changes to:

• RB0: Create NWK

• RB2: Join NWK

3.4.1.1.1 To Configure the node as PAN Coordinator

Follow these steps to configure the node as PAN Coordinator

1. On one node press RB0 push button to create the network.

After the node is configured as PAN Coordinator, “Created Network

Successfully” message will be displayed on the LCD. After the device is

configured as P AN Co ordinator , it measur es the temperature sensor for every 3 0

seconds (the timer can be modified in the application) and updates the LCD with

the temperature information in °C (Celsius) and °F (Fahrenheit). The last three

bytes of the MAC address in HEX format are also displayed on the line two of the

LCD:

• Local Temp

• 010203: 21C/ 70F

3.4.1.1.2 To Join the network as Coordinator

Follow these steps for joining the network as Coordinator

1. On the second node press RB2 push button to join the available networks. This

initiates an active scan command. The available network information will be

displayed on the LCD:

• RB0: (PC) 010203

• RB2: Addtnl NW-0

2. Press RB0 to join P AN Coordinator , with the address of 0x010203, created in the

previous step.

The LCD displays “Joined Network Successfully” message. After the node is

successfully joined the P AN Coordinator , it measures the temperature sensor for

every 30 seconds and broadcasts the information over the network along with its

MAC Address. The LCD is also updated with the temperature sensor reading:

• Local Temp

• F1F2F3: 20°C/ 68°F

DS70654B-page 18 Preliminary © 2011-2012 Microchip Technology Inc.

Page 21

Getting Started

3. Press RB2 push button to display the remote temperature (PAN Coordinator):

• Remote Temp

• 010203: 21°C/ 70°F

3.4.2 MCP9700A Temperature Sensor

This demo uses the on-board MCP9700A Temperature Sensor . The readings are noted

every 30 seconds and the information is broadcasted in the network. Both the nodes

store the local and remote temperature data and display it on the LCD.

To re-measure the temperature value, press RB0 push button on the PIC18 Wireless

Development Board. This also initiates the broadcast message to all the nodes in the

network. To scroll through the rotating display of local temperature and remote

temperature, use RB2 push button on the PIC18 Wireless Development Board. The

two node network can also be expanded to a mul ti-node network, for more info rmation,

see tutorial in

Nodes”.

3.4.3 MAC Address EEPROM on Radio Daughter Boards

All the Radio daughter cards have a MAC Address EEPROM. The 6 byte MAC Ad dress

in this EEPROM is used for the addressing scheme in MiWi.

3.4.4 LCD Serial Accessory Board

Section 4.7 “8-bit Wireless Development Kit with Additional

The LCD Serial Accessory board can be used either in the SPI mode or I2C mode. This

demo uses the LCD Serial Accessory Board in I

light mode versus the automatic backlight mode. With the manual backlight mode, the

power consumption can be kept to the minimum.

2

C mode. The demo uses manual back-

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 19

Page 22

8-Bit Wireless Development Kit User’s Guide

NOTES:

DS70654B-page 20 Preliminary © 2011-2012 Microchip Technology Inc.

Page 23

Chapter 4. Additional Tutorials

4.1 INTRODUCTION

This chapter covers the additional tutorial programs for the 8-bit Wireless Development

Kit.

Note: To run few tutorials in this chapter, users must program the PIC18 Wireless

The following tutorials are discussed in this chapter:

• Extended 8-bit WDK Demo with Hyper-Terminal Program

• Network Freezer

• RFD Device demonstrating Sleep Capability

• Chat Window Demo

• Ping-Pong Demo

• 8-Bit WDK Demo with Additional Nodes.

8-BIT WIRELESS

DEVELOPMENT KIT

USER ’S GUIDE

Development Board with new

Development board, use either ICD3 or REAL ICE or PICKit™ 3 program

mers. If using MPLAB® ICD3 or MPLAB REAL ICE, use AC1641 10 adapter

board. For more information, refer to the tools User’s Guides, “MPLAB

ICD 3 In-Circuit Debugger User’s Guide” (DS51766B), “MPLAB REAL ICE

In-Circuit Emulator User’s Guide” (DS51616C) and “PICKit 3

Programmer/Debugger User’s Guide” (DS51795).

.hex files. To program the P IC18 Wireless

-

®

4.2 EXTENDED 8-BIT WDK DEMO WITH HYPER-TERMINAL PROGRAM

This tutorial demonstrates how to extend the functionality of the pre-programmed demo

using the RS232 Serial Accessory Board. Using the hyper terminal program, users can

view the connection status, battery status and recorded temperature sensor readings

of the node. This demo uses the R S23 2 Ser ial A ccessory Boar d to c omm unica te with

the PC.

To run this tutorial, no need to re-program the PIC18 Wireless Development Board,

instead, a pre-programmed

The following hardwares are required to run this tutorial:

• Two pre-programmed PIC18 Wireless Development Boards

• Two Radio Daughter Boards

•Two LCD Serial Accessory Boards

• Two RS232 Serial Accessory Boards

• Four fresh AA batteries or a Two 9V External Power Supply or two USB cables

• Two RS232 to USB adapter (if required)

• Computer with a terminal program

8-bit WDK Demo.hex file can be used.

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 21

Page 24

8-Bit Wireless Development Kit User’s Guide

The following are the connection settings for terminal progra m:

• Baud Rate: 19200 kbps

• Data Bits: 8

• Parity: None

• Stop Bits: 1

• Flow Control: None

4.2.1 Set up

Follow these steps to set up the extended 8-bit Wireless Development Kit demo:

1. Connect the LCD Serial Accessory Board J1 port to the J2 or J3 I2C port of the

RS232 Serial Accessory Board (see

2. Connect the J1 port on the RS232 Serial Accessory Board to the J101 connector

on the PIC18 Wireless Development Board.

3. Plug in the Radio PICtail Daughter board at slot J201 on the PIC18 Wireless

Development Board.

4. To power from an external power source (9V or USB), insert a jumper at JP301

(Regulator Disconnect) on the PIC18 Wireless Development Board. To power

from batteries, remove the jumper at JP301.

5. Insert a jumper at JP201 (LED power) on the PIC1 8 Wire le ss Dev elop me n t

Board.

6. Ensure that the jumper is disconnected at the JP1 position on the LCD Serial

Accessory Board. This ensures that the LCD Seria l Accessory Board is used in

2

I

C mode and not in SPI mode. The 8-bit WDK demo uses the LCD Serial

Accessory board in I

7. Wireless demo board can be powered using any one of these options:

• Two AA batteries

• 9V external power supply

• USB port

• External 3.0-3.6V power source through test points TP301and TP302

8. Insert a jumper at either JP302 or JP303 (Current Measure) on the PIC18

Wireless Development Board.

9. Connect a RS232 cable between the RS232 Port on RS232 Serial Accessory

Board and the PAN Coordinator (PC).

10. Run the terminal program from the PC with the previous settings.

2

C mode.

Figure 4-1).

Note: Windows 98 or Windows XP operating systems (OS) users can use the

hyper-terminal program, and Windo ws 7 or any ot he r OS us er s can

download other terminal software programs from the web.

DS70654B-page 22 Preliminary © 2011-2012 Microchip Technology Inc.

Page 25

Additional Tutorials

FIGURE 4-1: CONNECTING RS232 SERIAL ACCESSORY BOARD

4.2.2 Tutorial Operation

To use the demo program, set up the nodes as described in

Section 3.4 “Pre-programmed Tutorial Oper ation”.

4.2.2.1 USING THE HYPER-TERMINAL PROGRAM:

Follow these steps to use the hyper-terminal program:

1. Press ‘Esc’ key from the hyper-terminal program to switch to an interactive

mode. The interactive mode provides these extended features:

• Displays connection status: In this mode, the node displays the parent-child

information.

• Displays battery status: This mode can be used to estimate the duration of the

battery lasts for that node.

• Displays node’s temperature sensor readings: In this mode, the node displays

the previous 20 temperature sensor readings on the screen.

• Scrolling display of all the node’s temperature sensor readings: In this mode,

the node displays the local and remote temperatures for every 30 seconds.

2. Press “Ctrl+Z” to exit from the interactive mode.

4.3 NETWORK FREEZER

The tutorial demonstrates the Network Freezer mode available in the MiWi stack.

Network Freezer mode enables the device to save network setup time. Af ter a network

is established, if the network is powered down for any reason, the network freezer

option aids in recovering the network to the original state.

To simulate the power down, use MCLR and RB2 push buttons together. For more

information about Network Freezer mode, refer to the Application Note, AN1284

Microchip Wireless (MiWi™) Application Programming Interface (DS01284A).

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 23

Page 26

8-Bit Wireless Development Kit User’s Guide

The following hardwares are required to run this tutorial:

• Two pre-programmed PIC18 Wireless Development Boards

• Two Radio Daughter Boards

•Two LCD Serial Accessory Boards

• Four fresh AA batteries or Two 9V External Power Supply or two USB cables

This tutorial also highlights the 256 Kbit EEPROM that is available on the PIC18

Wireless Development Board. The Network Freezer mode uses the on-board

EEPROM to store the network setup information.

To run this tutorial, no need to re-program the PIC18 Wireless Development Board

instead, a pre-programmed“

4.3.1 Setup

Follow these steps to set up the Network Freezer demo:

1. Connect the LCD Serial Accessory board J1 port to the J101 connector on the

PIC18 Wireless Development Board (see

2. Plug in the Radio PICtail Daughter board at slot J201 on the PIC18 Wireless

Development Board.

3. To power the PIC18 Wireless Development Board from external power (9V or

USB), insert a jumper at JP301 (Regulator Disconnect) on the PIC18 Wireless

Development Board. To power PIC18 Wireless Development Board from batter

ies, remove the jumper on JP301.

4. Insert a jumper at JP201 (LED Power) on the PIC18 Wireless Development

Board.

5. Ensure that the jumper is disconnected at JP1 position on the LCD Serial Acces sory Board. This ensures that the LCD Serial Accessory Board is used in I2C

mode and not in SPI mode. The 8-bit WDK demo uses the LCD Serial Accessory

board in I

6. Wireless demo board can be powered using any one of these options:

• Two AA Batteries

• 9V External Power Supply

• USB Port

• External 3.0-3.6V power source through test points TP301and TP302

7. Insert a jumper at either JP302 or JP303 (Current Measure) on the PIC18

Wireless Development Board.

2

C mode.

8-bit WDK Demo.hex file can be used.

Figure 3-1).

-

DS70654B-page 24 Preliminary © 2011-2012 Microchip Technology Inc.

Page 27

Additional Tutorials

4.3.2 Tutorial Operation

To use the de m o prog r am , follo w th ese ste ps:

1. Create a MiWi network as described in Section 3.4.1 “Creating a MiWi

Network”.

2. Simulate Network Freezer mode by pres sin g and ho ld ing the MCLR and RB2

push button, then release the

the RB2 button.

3. LCD display will prompt the following message:

• Network Freezer?

• Yes[RB0]/No[RB2]

4. Press RB0 push button to start the network setup information available in the

EEPROM.

The Network will start functioning as it was set up previously before hitting the MCLR

push button.

4.4 REDUCED FUNCTION DEVICE (RFD) DEMONSTRATING SLEEP CAPABILITY

This tutorial program demonstrates the lowest sleep configuration for a device to

extend battery life.

The following hardwares are required to run this tutorial:

• Two PIC18 Wireless Development Boards

• Two Radio Daughter Boards

• Four fresh AA batteries or Two 9V External Power Supply or two USB cables

To run this tutorial, program one of the PIC18 Wireless Development Boards with the

RFD Demo.hex file. The RFD Demo.hex file is located in the 8-bit Wireless Development Kit – (Transceiver)\RFD Demo\. Program another board with the 8-bit

WDK Demo.hex

file.

MCLR and wait for 10 seconds before releasing

4.4.1 Set up

Follow these steps to set up the RFD Sleep Capability demo:

1. Plug in the Radio PICtail Daughter board at slot J201 on the PIC18 Wireless

Development Board (See

2. To power from an external source (9V or USB), insert a jumper at JP301

(Regulator Disconnect) on the PIC18 Wireless Development Board. To power

from batteries, remove the jumper on JP301.

3. Insert a jumper at JP201 (LED Power) on the PIC18 Wireless Development

Board

4. Insert a jumper at either JP302 or JP303 (Current Measure) on the PIC18

Wireless Development Board.

Figure 3-1).

4.4.2 Tutorial Operation

To run the program, use the node with the 8-bit WDK Demo.hex file to create the P AN

Coordinator. To run the tutorial program, refer to

T utorial Operation”. From the second node (RFD Demo.hex) join the P AN Coordinator .

By using the RFD node, user can estimate the lowest powe r profile for the board.

The program flow for the RFD Device is shown in Figure 4-2.

Section 3.4 “Pre-programmed

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 25

Page 28

8-Bit Wireless Development Kit User’s Guide

Power Up

Display

8-bit Wireless

Development Kit

Display

RFD Demo

RB2: Join NWK

If networks

were found?

Scan for networks

Display

Local Temp

MAC Address: 21C/70F

Display 0

Network Found

RB2: Re-Scan

No

No

Is RB2

pressed?

If RB0

Pressed?

If RB2

Pressed?

Read temperature sensor

and broadcast information

over the network

Display Local/Remote Temp

MAC Address:21C/70F

Rotates display information between

Display

RB0: (PC) MAC Address

RB2: Additional NW - 0

If RB2 is

pressed?

If RB0 is

pressed?

Connect to the NW

Display Join status

(Success/Failure)

If Join status =

success?

No

Yes

No

No

If RB2 is

pressed?

Yes

No

Yes

Yes

No

Display next node

information if available

Yes

Yes

Yes

Yes

MAC Address: Last 3 Byte MAC Address in HEX

RB0: RB0 Push Button on Wireless Developmen t B oard

RB2: RB2 Push Button on Wireless Developmen t B oard

PC: PAN Coordinator

Local Temp: Temperature sensor reading at current node

Remote Temp: Temperature sensor reading at

Remote node

local and remote temperatures with

every RB2 press

FIGURE 4-2: RFD FLOW CHART

DS70654B-page 26 Preliminary © 2011-2012 Microchip Technology Inc.

Page 29

4.5 CHAT WINDOW DEMO

This tutorial program can be used to setup a wire less chatting service over the network.

The Chat Window demo uses MiWi Peer-to-Peer (P2P) pr otocol and can be extended

to use the MiWi protocol.

The following hardwares are required to run this tutorial:

• Two PIC18 Wireless Development Boards

• Two Radio Daughter Boards

•Two LCD Serial Accessory Boards

• Two RS232 Serial Accessory Boards

• Four fresh AA batteries or Two 9V External Power Supply or two USB cables

• Computer with a terminal program

The following are the connection settings for terminal prog ram:

• Baud Rate: 19200 kbps

•Data Bits: 8

• Parity: None

• Stop Bits: 1

• Flow Control: None

Program both of the PIC18 Wireless Development boards with “Chat Window

Demo.hex

” file located in “8-bit Wireless Development Kit\8-bit WDK Demo\”.

Additional Tutorials

4.5.1 Setup

Follow these steps to set up the Chat Window demo:

1. Connect the LCD Serial Accessory Board J1 port to the J2 or J3 I2C port of

RS232 Serial Accessory Board.

2. Connect the J1 port on RS232 Serial Accessory Board to th e J101 connector on

the PIC18 Wireless Development Board (See

3. Plug in the Radio PICtail Daughter board at slot J201 on the PIC18 Wireless

Development Board.

4. To power the PIC18 Wireless Development Board from external power (9V or

USB), insert a jumper at JP301 (Regulator Disconnect) on the PIC18 Wireless

Development Board. To power it from batteries, remove the jumper on JP301.

5. Insert a jumper at JP201 (LED Power) on the PIC18 Wireless Development

Board.

6. Ensure that the jumper is disconnected at JP1 position on the LCD Serial

Accessory Board. This ensures that the L CD Serial Accessory Board is used in

2

I

C mode and not in SPI mode. The Chat Window demo uses the LCD Serial

Accessory board in I

7. Wireless demo board can be powered using any one of these options:

• Two AA Batteries

• 9V External Power Supply

• USB Port

• External 3.0-3.6V power source through test points TP301and TP302

8. Insert a jumper at either JP302 or JP303 (Current Measure) on the PIC18

Wireless Development Board.

2

C mode.

Figure 4-1).

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 27

Page 30

8-Bit Wireless Development Kit User’s Guide

Power Up

Display

8-bit Wireless

Development Kit

Display

Connecting Peer

on channel 23

Display

Joined Network

Successfully

Use hyperterminal

or similar console

application for

chatting wirelessly

Power Up

Display

8-bit Wireless

Development Kit

Display

Connecting Peer

on channel 23

Display

Joined Network

Successfully

Use hyperterminal

or similar console

application for

chatting wirelessly

9. Connect a RS232 cable between the RS232 Port on the RS23 2 Serial Accessory

Board and the PC.

10. Open two instances of the terminal programs from the PC with the previous settings.

Note: Windows 98 or Windows XP OS users can use the hyper-terminal program.

Windows 7 or any other OS users can download other terminal software

programs available from the web.

4.5.2 Tutorial Operation

The Chat Window demo program flow is described in Figure 4-3.

1. Press the MCLR push button on both the nodes to reset the program.

(The demo uses a small window frame to scan and join the network, else it

creates two separate networks. Therefore, both the nodes must be powered

simultaneously, so that they can establish connection with one another.)

2. The LCD screen displays the welcome message “8-bit Wireless Development

Kit” and then it changes to “Connecting peer on Channel 23”.

3. After the connection is established with the peer, the display changes to “joined

network successfully”

4. Users can use the hyper-terminal program to chat with the peer node.

FIGURE 4-3: CHAT WINDOW DEMO PROGRAM

DS70654B-page 28 Preliminary © 2011-2012 Microchip Technology Inc.

Page 31

4.6 PING-PONG DEMO

This tutorial program is used for range testing and for measuring the Received Signal

Strength Indication (RSSI). In the Ping-Pong demo, as the name indicates, one node

transmits data while the other node receives dat a. After the transmission phase is com

plete (10 packets) they switch their roles.

The following hardwares are required to run this tutorial:

• Two PIC18 Wireless Development Boards

• Two Radio Daughter Boards

•Two LCD Serial Accessory Boards

• Four fresh AA batteries or Two 9V External Power Supply or two USB cables

Program both the PIC18 Wireless Development boards with the Ping-Pong Demo.hex

file from the

Demo\

.

4.6.1 Set up

Follow these steps to set up the Ping-Pong demo:

1. Connect the LCD Serial Accessory board J1 port to the J101 connector on the

PIC18 Wireless Development Board (See

2. Plug in the Radio PICtail Daughter board at slot J201 on the PIC18 Wireless

Development Board.

3. To power the PIC18 Wireless Development Board from external power (9V or

USB), insert a jumper at JP301 (Regulator Disconnect) on the PIC18 Wireless

Development Board. To power it from batteries, remove the jumper on JP301.

4. Insert a jumper at JP201 (LED power) on the PIC18 Wire le ss Dev elo p me n t

Board

5. Ensure that the jumper is disconnected at JP1 position on the LCD Serial

Accessory Board. This ensures that the L CD Serial Accessory Board is used in

2

I

C mode and not in SPI mode. The Ping-Pong demo uses the LCD Serial

Accessory board in I

6. Wireless demo board can be powered using any one of these options:

• Two AA Batteries

• 9V External Power Supply

• USB Port

• External 3.0-3.6V power source through test points TP301and TP302

7. Insert a jumper at either JP302 or JP303 (Current Measure) on the PIC18

Wireless Development Board.

Additional Tutorials

8-bit Wireless Development Kit – (Transceiver)\Ping-Pong

Figure 3-1).

2

C mode.

-

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 29

Page 32

8-Bit Wireless Development Kit User’s Guide

4.6.2 Tutorial Operation

The Ping-Pong demo program flow is described in Figure 4-4.

1. Power both the development kits simultaneously. This demo uses the MiWi P2P

protocol, switching both the nodes simultaneously ensures that th ey connect with

one-another.

2. After powering the demo board a welcome message “8-b it Wireless

Development Kit” will be displayed on the LCD screen, and later it changes to

“Connecting Peer on Channel 23”.

3. After the MiWi P2P connection is established between the nodes, the LCD

display on both the screens change to “Joined Network successfully”.

4. After few seconds, the LCD screen prompts the user to initiate the Ping-Pong test

with the following display:

• Ping-Pong demo

• RB0 (Tx) RB2 (Rx)

5. Initiate one node in Tx mode and the other node in Rx mode.

6. On one node (Node 1), press RB0 pu sh button and then on the other node (Node

2) press RB2 push button. Both the nodes will start exchanging data immediately .

• On Node 1:

- LCD Display line1: Transmitting

- LCD Display line2: Count: 1

• On Node 2:

- LCD Display line1: Receiving 1

- LCD Display line2: RSSI (dB): -40

Count reads from 1-10 and then Node 2 moves to Transmit mode and Node 1 moves

to Receive mode.

DS70654B-page 30 Preliminary © 2011-2012 Microchip Technology Inc.

Page 33

FIGURE 4-4: PING-PONG PROGRAM DEMO

Power Up

Display

8-bit Wireless

Development Kit

Display

Connecting Peer

on channel 23

Display

Joined Network

Successfully

Display

Ping-Pong demo

RBO (Tx) RB2 (Rx)

Initiate one node in Tx

mode and the other in Rx

mode

If RBO

Pressed?

If RB2

Pressed?

Display

Transmitting...

Count: 1

LCD Display

Receiving.. 1

RSSI(dB): -40

No

Yes

Yes

No

Display

Transmitting...

Count: 10

LCD Display

Receiving.. 10

RSSI (dB): -40

LCD Display

Receiving.. 1

RSSI (dB): -40

Display

Transmitting...

Count: 1

Display

Transmitting...

Count: 10

LCD Display

Receiving.. 10

RSSI (dB): -40

Additional Tutorials

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 31

Page 34

8-Bit Wireless Development Kit User’s Guide

PC

C RFD

C

Node 3

Node 4

Node 2

Node 1

PC: Pan Coordinator

C: Coordinator

RFD: End Device

PC

C C

RFD

Node 4

Node 3

Node 2

Node 1

PC: Pan Coordinator

C: Coordinator

RFD: End Device

4.7 8-BIT WIRELESS DEVELOPMENT KIT WITH ADDITIONAL NODES

The 8-bit Wireless Development kit demo can be expanded using additional nodes. As

8-bit Wireless Development kit demo uses MiWi protocol (see AN1066), a network that

can support up to four hops can be created. Users can create either a Star Network or

a Mesh Network.

Figure 4-5 and Figure 4-6 illustrates the sample networks using two additional nodes.

Program PIC18 Wireless Development board with the 8-bit WDK Demo.hex file for creating a PAN Coordinator (PC) or Coordinator (C). Program PIC18 Wireless

Development board with the

(RFD).

FIGURE 4-5: STAR CONFIGURATION

RFD Demo.hex file to create a Reduced Function Device

FIGURE 4-6: MESH CONFIGURATION

DS70654B-page 32 Preliminary © 2011-2012 Microchip Technology Inc.

Page 35

8-BIT WIRELESS

DEVELOPMENT KIT

USER ’S GUIDE

Appendix A. PIC18 Wireless Development Board Schematic

A.1 INTRODUCTION

This appendix includes:

• PIC18 Wireless Development Board schematics

• PIC18 Wireless Development Board PCB Layout

• PIC18 Wireless Development Board Bill of Materials (BOM)

Component reference IDs are structured to help in finding them on the sheets of

schematics. The first digit of the ID is the sheet number and the last second digits are

reference IDs. For example, BT301 battery holder can be found on the third schematics

sheet.

A.2 PIC18 WIRELESS DEVELOPMENT BOARD SCHEMATIC

Figure A-1, Figure A-2 and Figure A-3 illustrate the PIC18 Wireless Development

Board schematics.

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 33

Page 36

DS70654B-page 34 Preliminary © 2011-2012 Microchip Technology Inc.

FIGURE A-1: PIC18 WIRELESS DEVELOPMENT BOARD SCHEMATIC

8-Bit Wireless Development Kit User’s Guide

Page 37

PIC18 Wireless Development Board Schematic

FIGURE A-2: PIC18 WI RELESS DEVELOPMENT BOARD SCHEMATIC

FIGURE A-3: PIC18 WI RELESS DEVELOPMENT BOARD SCHEMATIC

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 35

Page 38

PIC18 Wireless Development Board Schematic

A.3 PIC18 WIRELESS DEVELOPMENT BOARD PCB LAYOUT

The PIC18 Wireless Development Board is a two-layer, FR4, 0.062 inch, plated

through-hole PCB construction.

layout of the PIC18 Wireless Development Board.

FIGURE A-4: PIC18 WIRELESS DEVELOPMENT BOARD TOP

SILK-SCREEN

Figure A-4 through Figure A-7 illustrates the PCB

FIGURE A-5: PIC18 WIRELESS DEVELOPMENT BOARD TOP COPPER

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 36

Page 39

PIC18 Wireless Development Board Schematic

FIGURE A-6: PIC18 WIRELESS DEVELOPMENT BOARD BOTTOM

SILK-SCREEN – MIRRORED

FIGURE A-7: PIC18 WIRELESS DEVELOPMENT BOARD BOTTOM

COPPER – MIRRORED

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 37

Page 40

PIC18 Wireless Development Board Schematic

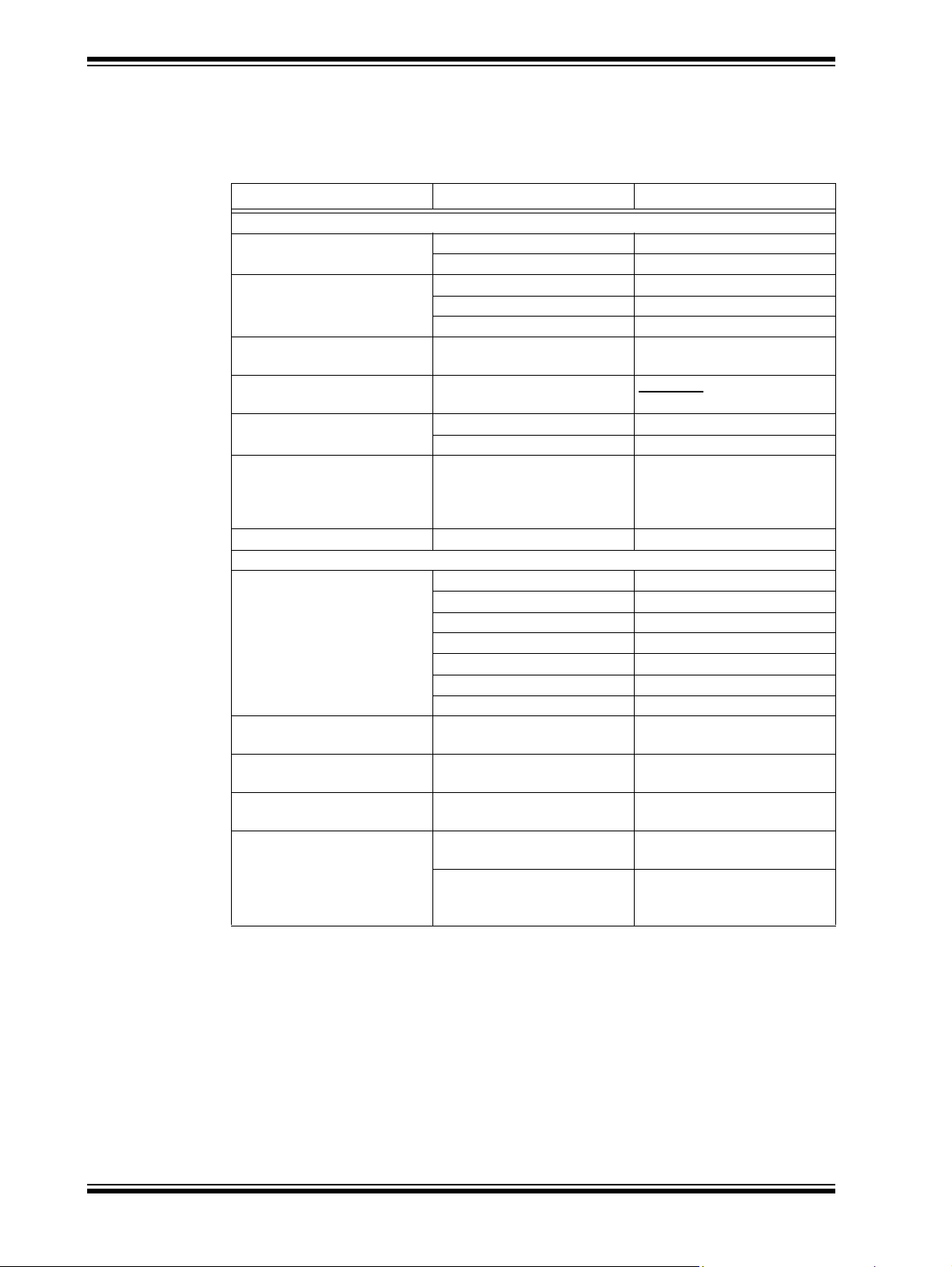

A.4 PIC18 WIRELESS DEVELOPMENT BOARD BILL OF MATERIALS

TABLE A-1: PIC18 WIRELESS DEVELOPMENT BOARD BILL OF MATERIALS

Reference IDs Qty Type/Value Description Manufacturer Manufacturer P/N

BT301 1 3V Battery Holder, 2 cell,

AA, PC Mount

C104, C105 2 8 pF CAP CER 8.0PF 50V

C0G 0603

C101, C102,

C103, C107,

C201, C203,

C301

C106 1 10 µF Capacitor, Ceramic,

C108, C109 2 33 pF Capacitor, Ceramic,

C202, C302,

C303

D301 D302

D303

DS201, DS202,

DS203

J101 1 Accessory

J102 1 ICSP Port Connector, Header,

J103 1 USB Port Connector, USB, Mini-B,

J201 1 PICtail Port Connector, Header,

J301 1 EXT 9-16V CONN POWER JACK

JP201, JP301,

JP302, JP303

— 3 Shunt Shunt Tyco Electronics 382811-6

R101, R102,

R104, R105,

R109, R115,

R118, R121,

R123, R124

R112 1 10k ohms Resistor, SMT 0603 Stackpole

R113, R201,

R202, R203

R204, R205,

R206

7 0.1 µF Capacitor, Ceramic,

25V, 10%, X7R, SMT

0603

6.3V, 20%, X5R, SMT

0805

50V, 5%, C0G, SMT

0603

3 1 µF Capacitor, Ceramic,

6.3V, 10%, X5R, SMT

0603

3 MBR0520L Diode, Schottky, 0.5A,

20V, SMT SOD-123

3 LED LED, SMT 0603, Green Osram Opto

Connector, Socket,

Port

4 Connector, Header,

10 0 ohms Resistor, SMT 0603 Stackpole

4 100 ohms Resistor, SMT 0603 Stackpole

3 1k ohms Resistor, SMT 0603 Stackpole

Right Angle, 0.100"

spacing, 0.025" sq.

Right Angle, 0.100"

spacing, 0.025" sq.

SMT

2x14 pin, 0.100" spac-

ing, 0.025" sq.

2.5X5.5MM SMD

2-pin, 0.100" spacing

Keystone Elec-

tronics

Murata GRM1885C1H8R0DZ01D

Panasonic – ECG ECJ-1VB1E104K

Panasonic – ECG ECJ-2FB0J106M

Murata GRM1885C1H330JA01D

Panasonic – ECG ECJ-1VB0J105K

Fairchild

Semiconductor

LG Q971-KN-1-0-20-R18

Semiconductors

Inc

Mill-Max 801-43-006-20-001000

Mill-Max 800-10-006-20-001000

Kycon KMBX-SMT-5S-S-30TR

Samtec SSW-114-01-G-D

CUI Inc PJ002-B-SMT

SPC Technology SPC20481

Electronics Inc.

RMCF 1/16 10K 5% R

Electronics Inc.

RMCF 1/16 100 5% R

Electronics Inc.

RMCF 1/16 1K 5% R

Electronics Inc.

2462

MBR0520L

RMCF 1/16 0 R

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 38

Page 41

PIC18 Wireless Development Board Schematic

TABLE A-1: PIC18 WIRELESS DEVELOPMENT BOARD BILL OF MATERIALS (CONTINUED)

Reference IDs Qty Type/Value Description Manufac turer Manufacturer P/N

SW101,

SW201, SW202

TP301, TP302 2 — 5016K Test Point, SMT Keystone Elec-

U101 1 PIC18F46J50

U201 1 MCP9700AT-

U202 1 25LC256-I/SN Serial EEPROM, 256K,

U301 1 MCP1703T-3

X101 1 32 kHz Crystal, tuning-fork,

X102 1 8 MHz CRYSTAL 8.000MHZ

— 4 Stand-off SP ACER ST ACKING #4

— 1 Double sided glue tape,

3 — Switch, Pushbutton,

Momentary, 6x3mm

SMT

PIC18F46J50T-I/PT Microchip

-I/PT

Temperature Sensor,

E/L

302E/MB

SMT SC-70-5

SPI, SOIC-8

LDO, 250 mA, 3.3V,

SMT SOT-89

32.768 kHz, 9.0pF, SMT

18PF FUND SMD

SCREW NYLON

cca 2.5cm*2.5cm

C&K Components PTS635SL25SMTR LFS

5016

tronics

PIC18F46J50T-I/PT

Technology Inc.

Microchip

Technology Inc.

Microchip

Technology Inc.

Microchip

Technology Inc.

Micro Crystal MS3V-T1R

Abracon Corpora-

tion

Keystone Elec-

tronics

— —

MCP9700AT-E/LT

25LC256-I/SN

MCP1703T-3302E/MB

ABLS-8.000MHZ-B2-T

8834

Unpopulated Board

Components

R103, R106, R107, R108,

R1 10, R111, R114, R116,

R117, R119, R120, R122,

R207

12 0 ohm Resistor, SMT

0603

Stackpole

Electronics Inc.

RMCF 1/16 0 R

© 2011-2012 Microchip Technology Inc. Preliminary DS70654B-page 39

Page 42

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Santa Clara

Santa Clara, CA

Tel: 408-961-6444

Fax: 408-961-6445

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2401-1200

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Hangzhou

Tel: 86-571-2819-3187

Fax: 86-571-2819-3189

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Osaka

Tel: 81-66-152-7160

Fax: 81-66-152-9310

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-330-9305

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

11/29/11

DS70654B-page 40 Preliminary © 2011-2012 Microchip Technology Inc.

Loading...

Loading...