Page 1

Humidity Sensor

PICtail™ Demo Board

User’s Guide

© 2005 Microchip Technology Inc. DS51594A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of Microchip’s products as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, K

EELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Linear Active Thermistor,

MPASM, MPLIB, MPLINK, MPSIM, PICkit, PICDEM,

PICDEM.net, PICLAB, PICtail, PowerCal, PowerInfo,

PowerMate, PowerTool, Real ICE, rfLAB, rfPICDEM, Select

Mode, Smart Serial, SmartTel, Total Endurance, UNI/O,

WiperLock and Zena are trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

8-bit MCUs, KEELOQ

®

code hopping

DS51594A-page ii © 2005 Microchip Technology Inc.

Page 3

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 1

Introduction............................................................................................................ 1

Document Layout .................................................................................................. 1

Conventions Used in this Guide ............................................................................ 2

Recommended Reading........................................................................................ 3

The Microchip Web Site ........................................................................................ 4

Customer Support ................................................................................................. 4

Document Revision History ................................................................................... 4

Chapter 1. Product Overview

1.1 Introduction ..................................................................................................... 5

1.2 Kit Contents .................................................................................................... 5

1.3 Humidity Sensor PICtail™ Demo Board ......................................................... 5

1.4 Associated Tools ............................................................................................ 7

1.5 Assembly Code Modules ................................................................................ 8

Chapter 2. Setup and Installation

2.1 Introduction ..................................................................................................... 9

2.2 Required Tools ............................................................................................... 9

2.3 Setting up the Humidity Sensor PICtail™ Demo Board ................................. 9

2.4 Connecting to Alternate Tools ...................................................................... 11

Chapter 3. Operation

3.1 Introduction ................................................................................................... 13

3.2 Configuring the Humidity Sensor PICtail™ Demo Board ............................. 13

3.3 Using the Humidity Sensor PC Program ...................................................... 13

3.4 Humidity Sensor Calibration ......................................................................... 15

Chapter 4. Modified Circuit

4.1 Introduction ................................................................................................... 17

4.2 The “Reduced Current” Circuit ..................................................................... 17

© 2005 Microchip Technology Inc. DS51594A-page iii

Page 4

Humidity Sensor PICtail™ Demo Board User’s Guide

Appendix A. Schematic and Layouts

A.1 Introduction .................................................................................................. 19

A.2 Highlights ..................................................................................................... 19

A.3 Demonstration Board Description ................................................................ 19

A.4 The “Reduced Current” Modification ............................................................ 20

A.5 Additional Comments ................................................................................... 20

Appendix B. Bill Of Materials (BOM)

B.1 Humidity Sensor PICtail™ Demo Board BOM ............................................. 25

B.2 BOM for Humidity Sensor and Other Capacitors in Box .............................. 26

B.3 BOM for “Reduced Current” Modifications ................................................... 26

Worldwide Sales and Service .....................................................................................28

DS51594A-page iv © 2005 Microchip Technology Inc.

Page 5

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

Humidity Sensor PICtail™ Demo Board. Items discussed in this chapter include:

• Document Layout

• Conventions Used in this Guide

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the Humidity Sensor PICtail™ Demo Board as a

development tool to emulate and debug firmware on a target board. The manual layout

is as follows:

• Chapter 1. “Product Overview” – This is an introduction to the Humidity Sensor

PICtail™ Demo Board. It covers the kit contents, associated tools and how they

work together.

• Chapter 2. “Setup and Installation” – Covers the initial set-up of the Humidity

Sensor PICtail™ Demo Board. It lists the required tools, shows how to connect

this board and demonstates how to verify the set-up.

• Chapter 3. “Operation” – This chapter discusses using the humidity sensor on

the PCB and using the software PC Application.

• Chapter 4. “Modified Circuit” – Gives the modifications necessary to increase

measurement resolution by a factor of 100 (see AN1016 for details)

• Appendix A. “Schematic and Layouts” – Gives detailed information on the

Humidity Sensor PICtail™ Demo Board. Includes detailed circuit explanation,

schematic and board layouts.

• Appendix B. “Bill Of Materials (BOM)” – Gives detailed information on the

Humidity Sensor PICtail™ Demo Board’s firmware.

© 2005 Microchip Technology Inc. DS51594A-page 1

Page 6

Humidity Sensor PICtail™ Demo Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

DS51594A-page 2 © 2005 Microchip Technology Inc.

Page 7

RECOMMENDED READING

This user's guide describes how to use Humidity Sensor PICtail™ Demo Board. Other

useful documents are listed below and are recommended as supplemental reference

resources.

PICkit™ 2 Microcontroller Programmer User’s Guide (DS51553)

Contains instructions on how to use the PICkit 2 Microcontroller Programmer hardware

and software.

PICkit™ 1 Flash Starter Kit User’s Guide (DS40051)

Contains instructions on how to use the PICkit 1 Flash Starter Kit hardware and

software.

MPLAB

This user’s guide covers Microchip’s low cost, real-time debugger and programmer for

selected PICmicro

(DSCs).

AN1016, “Detecting Small Capacitive Sensors Using the MCP6291 and

PIC16F690 Devices” (DS01016)

Explains the functionality and design of this board’s circuit. Contains measurement

results.

MCP6291/2/3/4/5 Data Sheet (DS21812)

Gives detailed information on the MCP6291/2/3/4/5 Op Amps.

PIC16F685/687/689/690 Data Sheet (DS41262)

Gives detailed information on the microcontroller used on the Humidity Sensor PICtail™

Demo Board.

PIC16C745/765 Data Sheet (DS41124)

Gives detailed information on the PICmicro microcontroller used on the PICkit 1 Flash

Starter Kit.

®

ICD 2 In-Circuit Debugger User’s Guide (DS51331)

Preface

®

Microcontrollers (MCUs) and dsPIC® Digital Signal Controllers

The following document is available on the internet from the company listed, and is

recommended as a supplemental reference resource.

Humirel, “Relative Humidity Sensor HS1100LF / HS1101LF,” Data Sheet, Rev. C,

Sept. 2004.

Gives detailed information on Humirel’s (www.humirel.com) HS1101LF capacitive

relative humidity sensor.

© 2005 Microchip Technology Inc. DS51594A-page 3

Page 8

Humidity Sensor PICtail™ Demo Board User’s Guide

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

• Development Systems Information Line

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at: http://support.microchip.com

DOCUMENT REVISION HISTORY

Revision A (December 2005)

• Initial Release of this Document.

DS51594A-page 4 © 2005 Microchip Technology Inc.

Page 9

Chapter 1. Product Overview

1.1 INTRODUCTION

The Printed Circuit Board (PCB) discussed in this user’s guide is described as follows:

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

• Order Number:

• Assembly Number:

•Board Name:

This board supports the capacitive humidity sensor application note AN1016. It

measures the capacitance of a relative humidity sensor (or capacitor) plugged into the

board. The on-board microcontroller sends the measured and calculated data to a PC

(Personal Computer) for display.

Items discussed in this chapter include:

• Kit Contents

• Humidity Sensor PICtail™ Demo Board

• Associated Tools

• Initial Set-up

1.2 KIT CONTENTS

• Humidity Sensor PICtail™ Demo Board – This is an assembled and tested

Printed Circuit Board (PCB).

• CD-ROM – Provided separately in the shipping box; it contains the files and

literature mentioned in this user’s guide.

• Humidity Sensor (HS1101LF) – Provided separately in the shipping box.

• Bag of Capacitors – Provided separately in the shipping box. These capacitors

are provided for the user’s convenience; they make it easy to try out this board’s

functionality, and to verify its accuracy.

PIC16F690DM-PCTLHS

102-00084R1

Humidity Sensor PICtail™ Demo Board

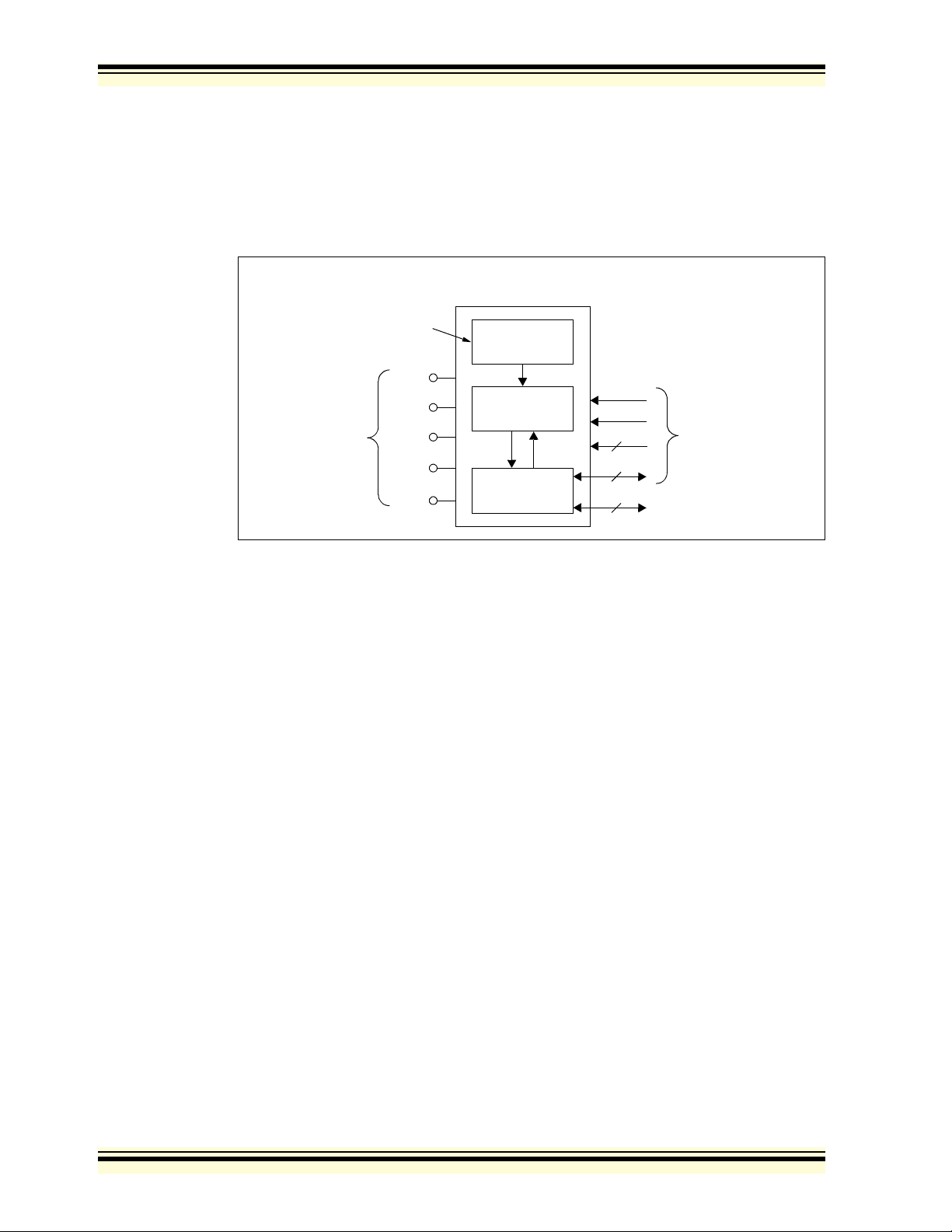

1.3 HUMIDITY SENSOR PICTAIL™ DEMO BOARD

The circuit operation is detailed in AN1016, “Detecting Small Capacitive Sensors Using

the MCP6291 and PIC16F690 Devices” (DS01016)

The Humidity Sensor PICtail™ Demo Board contains the circuitry represented in

Figure 1-1. The ambient relative humidity changes the capacitance of the humidity

sensor (HS1101LF from Humirel). This sensor is connected to a MCP6291 op amp and

a resistor to form an inverting (Miller) integrator. The PIC16F690 microcontroller sends

a square wave to the input of the integrator, which the integrator converts to a triangle

wave at its output. The firmware controls the magnitude of the triangle wave and

measures the integration time. The microcontroller measures the time it takes for the

triangle wave to rise and fall. These times are converted to a capacitance value.

A 14-pin header is provided for connecting to the PICkit™ 1 Flash Starter Kit, which

acts like a docking station. It includes a two-wire serial bus that transfers the data, and

two more wires for board power (+5V and GND inputs). This interface also supports

programming of the on-board PIC16F690.

© 2005 Microchip Technology Inc. DS51594A-page 5

Page 10

Humidity Sensor PICtail™ Demo Board User’s Guide

The +5V single supply voltage from the PICkit™ 1 Flash Starter Kit board is bypassed

with two bulk 1 μF capacitors near the header, and two local 0.1 μF capacitors (one for

each Integrated Circuit (IC)).

A 6-pin header for ICSP™ (In-Circuit Serial Programming™) is available as an alternate

interface for programming the on-board PIC16F690. This allows the user to modify the

program that comes with the Humidity Sensor PICtail™ Demo Board (with the MPLAB

ICD 2 or PICkit™ 2 microcontroller programmer).

Humidity Sensor

PICtail™ Demo Board

Ambient

Humidity

Humidity

Sensor

®

Tes t P oin ts

+5V

GND

Vsen

Vcm

Vint

Op Amp

MCP6291

N.C.

Microcontroller

PIC16F690

+5V

GND

10

2

6

to

PICkit™ 1 Flash

Starter Kit

ICSP™

FIGURE 1-1: Humidity Sensor PICtail™ Demo Board Block Diagram.

The test points make it easier to test key points in the circuit using common lab

equipment. The test points are:

• GND – Is connected to ground plane, and is for any lab equipment

• +5V – Positive supply voltage (at board edge); it provides a means to power this

board with a laboratory power supply (when not connected to the PICkit™ 1 Flash

Starter Kit)

•V

INT – Integrator’s input (a square wave during measurements)

CM – Op amp’s common mode voltage (at its inverting input)

•V

•V

SEN – Integrator’s output of the integrator (a triangle wave during

measurements)

More details on the circuit and on its design can be found in Appendix A. “Schematic

and Layouts” and AN1016, “Detecting Small Capacitive Sensors Using the MCP6291

and PIC16F690 Devices” (DS01016).

DS51594A-page 6 © 2005 Microchip Technology Inc.

Page 11

1.4 ASSOCIATED TOOLS

Figure 1-2 shows the block diagram of the hardware and software tools that the

Humidity Sensor PICtail™ Demo Board is designed to work with. More information on

these tools can be found in the “Recommended Reading” section.

Product Overview

Hardware Software

PC

USB

PICkit™ 1

Flash Starter Kit

14

Humidity Sensor

PICtail™ Demo Board

6

ICSP™

Capacitance.exe

PC Program

PICkit™ 1

Firmware

00084R1.hex

Firmware

FIGURE 1-2: Measurement Set-up Block Diagram.

1.4.1 Humidity Sensor PICtail™ Demo Board

This board is described in Section 1.3 “Humidity Sensor PICtail™ Demo Board”.

1.4.2 Firmware for the Humidity Sensor PICtail™ Demo Board

00084R1.hex is the firmware file that supports the Humidity Sensor PICtail™ Demo

Board application. It implements the measurement routines and the data

communications with the PICkit™ 1 Flash Starter Kit.

1.4.3 ICSP™ Header

The ICSP header provides a means to program the PIC16F690. It is intended for

connection to devices that program the on board PIC16F690, such as the MPLAB

®

ICD 2 (DV164005) and the PICkit™ 2 Microcontroller Programmer (DV164120).

1.4.4 PICkit™ 1 Flash Starter Kit

The PICkit 1 Flash Starter Kit (DV164101) programs PICmicro® microcontrollers. It is

used to program the PIC16F690, and provides a communications link with the PC. The

PICkit™ 1 Flash Starter Kit’s PIC16C745 has a USB port that communicates with the

Humidity Sensor PC Program. It also connects to the Humidity Sensor PICtail™ Demo

Board (the on-board PIC16F690) via a header (see Figure 2-1).

This board provides a single +5V supply voltage for the daughter board. It can drive up

to 5 μF on the supply; a larger capacitance may interfere with program timing.

1.4.5 PICkit™ 1 Firmware

This software resides on the PICkit™ 1 Flash Starter Kit’s PIC16C745 microcontroller.

Use version 2.0.2 or later.

© 2005 Microchip Technology Inc. DS51594A-page 7

Page 12

Humidity Sensor PICtail™ Demo Board User’s Guide

1.4.6 PC Platform

The Personal Computer (PC) shown in Figure 1-2 needs to run on Windows®98 SE or

later. It provides a convenient interface for the user, communicates with the other

boards and provides power through the USB connection.

1.4.7 Humidity Sensor PC Program

The capacitance.exe PC Program communicates with the PIC16F690 MCU on the

Humidity Sensor PICtail™ Demo Board through the USB port on the PICkit™ 1 Flash

Starter Kit. It also imports data through the same connections and displays them.

The user inputs the board configuration, and can select to view either capacitance or

relative humidity (assuming the HS1101LF sensor is plugged in).

1.5 ASSEMBLY CODE MODULES

The following assembly code modules (for the PIC16F690) make up the Humidity

Sensor project:

• main.inc - contains I/O port and global defines used throughout the project

• main.asm - contains the main executive routine including configuration bit

assignments

• initialize_f690.asm - initializes the PIC16F690 to known initial values

• capacitance.asm - reads capacitance using a dual slope integration technique

• humidity.inc - contains PwLI table segment values

• humidity.asm - contains PwLI routine to convert capacitance to %RH humidity

• ssc.asm - contains Synchronous Serial Communications (SSC), which is a

synchronous serial communications protocol between a target PICmicro

controller (MCU) and the PICkit™ 1 Flash Starter Kit or PICkit™ 2 Starter Kit

• 16f690.lkr - linker script for Humidity Sensor project

These files can be downloaded from the Microchip web site (www.microchip.com) and

are contained in the “00084R1.zip” file.

®

micro-

DS51594A-page 8 © 2005 Microchip Technology Inc.

Page 13

Chapter 2. Setup and Installation

2.1 INTRODUCTION

This chapter shows how to set up the Humidity Sensor PICtail™ Demo Board. Items

discussed in this chapter include:

• Required Tools

• Connecting the Humidity Sensor PICtail™ Demo Board

• Set-up Verification

2.2 REQUIRED TOOLS

The PICkit™ 1 Flash Starter Kit User’s Guide explains how to set up the PC and the

PICkit™ 1 Flash Starter Kit. Use firmware version 2.0.2 or later.

The PICkit™ 1 Flash Starter Kit CD-ROM (DS40049) contains many of the necessary

files.

The capacitance.exe PC program comes with the Humidity Sensor PICtail™ Demo

Board CD-ROM (Version v1.07.01 or later).

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

2.3 SETTING UP THE HUMIDITY SENSOR PICTAIL™ DEMO BOARD

This section discusses the primary method for setting up the Humidity Sensor PICtail™

Demo Board. An exploded view of how the different boards connect is shown in

Figure 2-1.

ICSP™ Header

USB Cable

Expansion

Header (J3)

To PC

PIC16C745 Firmware

Version 2.0.2 or later

FIGURE 2-1: Board Connections for PICkit™ 1 Flash Starter Kit.

Humidity Sensor

PICtail™ Demo Board

Remove PICmicro® MCU

Evaluation Socket

PICkit™ 1 Flash Starter Kit

© 2005 Microchip Technology Inc. DS51594A-page 9

Page 14

Humidity Sensor PICtail™ Demo Board User’s Guide

2.3.1 PICkit™ 1 Flash Starter Kit

1. Remove any PICmicro microcontroller that may be in the Evaluation Socket.

2. Connect the USB cable to the PC and to the PICkit™ 1 Flash Starter Kit board.

The status LEDs (green POWER and yellow BUSY in the LED array) should light

up.

It is easiest to use this board when it lays directly on a bench top.

2.3.2 Humidity Sensor PICtail™ Demo Board

1. Setup Board (first time only); connect shunt to jumper JP1 at the 0.1 pF / position

(0.1 pF / count).

2. Plug this board into the PICkit 1 Flash Starter Kit’s expansion header J3 (as

shown in Figure 2-1) without covering the LED array. There should be no change

in the status LEDs on the PICkit™ 1 Flash Starter Kit board after it is plugged in.

The PIC16F690 comes with the 00084R1.hex file already programmed.

2.3.3 Humidity Sensor PC Program

1. Run the installer program, AN1016 install.exe (which places the executable

file capacitance.exe in the desired directory).

2. Run the capacitance.exe PC Program to start the Graphical User Interface

(GUI).

2.3.4 Set-up Verification

1. Check Basic Functionality.

a) Place one of the capacitors that came in the shipping box (nominal values of

10 pF, 180 pF, 1.0 nF and 100 nF) into the Csen socket.

b) Follow the steps 1.a. through 1.g. in Section 3.3 “Using the Humidity

Sensor PC Program”.

c) The reading should be within ±5% (for 10 pF, 180 pF, and 1.0 nF capacitors),

or ±10% (for the 100 nF capacitor only), of the nominal value.

2. Check HS1101LF Sensor.

a) Place the HS1101LF sensor into the Csen socket.

b) Follow the steps 2.a. through 2.f. in Section 3.3 “Using the Humidity

Sensor PC Program”.

c) The reading should be similar to that of a calibrated relative humidity sensor

placed nearby.

DS51594A-page 10 © 2005 Microchip Technology Inc.

Page 15

2.4 CONNECTING TO ALTERNATE TOOLS

2.4.1 PICkit™ 2 Microcontroller Programmer

An exploded view of how the PICkit™ 2 microcontroller programmer connects to the

Humidity Sensor PICtail™ Demo Board is shown in Figure 2-2. This setup is an

alternative way to reprogram the PIC16F690 on the Humidity Sensor PICtail™ Demo

Board.

USB Cable

Setup and Installation

To PC

ICSP™ Header (P2)

PICkit™ 2 Microcontroller Programmer

Humidity Sensor

PICtail™ Demo Board

FIGURE 2-2: Board Connections for PICkit™ 2 Microcontroller Programmer.

2.4.2 MPLAB® ICD 2

An exploded view of how the MPLAB® ICD 2 connects to the Humidity Sensor

PICtail™ Demo Board is shown in Figure 2-3. This setup is an alternative way to

reprogram the PIC16F690 on the Humidity Sensor PICtail™ Demo Board.

USB Cable

To PC

MPLAB

®

ICD 2

Modular Connector Cable

Modular-to-6-Pin Header Adaptor

ICSP™ Header (P2)

Humidity Sensor

PICtail™ Demo Board

®

FIGURE 2-3: Board Connections for MPLAB

© 2005 Microchip Technology Inc. DS51594A-page 11

ICD 2.

Page 16

Humidity Sensor PICtail™ Demo Board User’s Guide

NOTES:

DS51594A-page 12 © 2005 Microchip Technology Inc.

Page 17

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

Chapter 3. Operation

3.1 INTRODUCTION

This demonstration board makes it easy to explore the operation of a humidity sensor

application. Items discussed in this chapter include:

• Configuring the Humidity Sensor PICtail™ Demo Board

• Using the Humidity Sensor PC Program

• Programming the PIC16F690

• Humidity Sensor Calibration

3.2 CONFIGURING THE HUMIDITY SENSOR PICTAIL™ DEMO BOARD

1. Setup the board as explained in Chapter 2. “Setup and Installation”.

2. Place a humidity sensor or capacitor in the C

a) Humirel’s HS1101LF capacitive humidity sensor.

b) A capacitor of known value.

3. Connect the shunt to jumpers JP1 – JP3 according to the measurement

resolution and capacitance values desired; see Table 3-1.

4. Allow sufficient time for the humidity sensor to respond to changes in the

environment (about 30 seconds for the HS1101LF).

SEN

socket.

TABLE 3-1: JUMPER SELECTION – MODIFIED CIRCUIT

Jumper

Selected

JP1 0.1 0.6 pF to 6.5 nF 6.65 M Use for HS1101LF sensor

JP2 1 6 pF to 65 nF 665 k

JP3 10 60pF to 650nF 66.5k

Measurement

Resolution

(pF / count)

C

SEN

Range

3.3 USING THE HUMIDITY SENSOR PC PROGRAM

The capacitance.exe PC Program Graphical User Interface (GUI) is displayed in

Figure 3-1. It is a simple program that helps the user to control the functionality of the

Humidity Sensor PICtail™ Demo Board and to view the results sent back from that

board.

Note: This program is intended as an evaluation tool; it does not check for all

possible errors. It is the user’s responsibility to make sure the GUI and

demo board are used under reasonable conditions.

R

(Ω)

INT

Comments

© 2005 Microchip Technology Inc. DS51594A-page 13

Page 18

Humidity Sensor PICtail™ Demo Board User’s Guide

1.c. 2.d.2.e.

1.e.1.f.

2.d.2.e.

4.a.

4.b.

1.d.

1.g.

3.b.

1.e.

2.d.

3.a.

2.c.

2.f.

3.c.

FIGURE 3-1: “Humidity Sensor PC Program” GUI.

The following steps will help familiarize the user with this GUI. The step numbers are

displayed in Figure 3-1.

1. Measure Capacitance (C

a) Put capacitor in C

SEN

).

SEN

’s socket on the board.

b) Select desired resolution on the board (set by shunt and JP1 – JP3).

c) Input the resolution.

d) Click on the READ CAPACITANCE button.

e) The green light turns on and the status window is updated.

f) Read the current capacitance value (which is updated about once a second).

g) Click on the STOP READING button.

2. Measure Humidity (RH).

a) Put the HS1101LF sensor in C

’s socket on the board.

SEN

b) Select the 0.1 pF / count resolution on the board (put shunt across JP1).

c) Click on the READ HUMIDITY button (a resolution of 0.1 pF / count is assumed

by the GUI).

d) The green lights turn on and the status window is updated.

e) Read the current capacitance value and relative humidity (which are updated

about once a second).

f) Click on the STOP READING button.

3. Check Program Status.

a) Read the status history in the status window.

b) Click the CLEAR STATUS WINDOW button to clear the status history.

c) Click the FIRMWARE VERSION button to see the version displayed in the status

window.

4. Quit the Program.

a) Click the FILE button, then the EXIT button that pops up. Or click on the

WINDOWS’ EXIT button.

DS51594A-page 14 © 2005 Microchip Technology Inc.

Page 19

3.4 HUMIDITY SENSOR CALIBRATION

If desired, the capacitive humidity sensor used on this board can be calibrated. Manufacturing tolerances, aging and changes in circuit operating conditions (i.e., supply

voltage and temperature) may cause errors larger than desired. Many reputable

companies provide humidity calibration equipment and/or services.

There are two common approaches to calibrating these sensors:

1. Put sensor in an atmosphere with well controlled RH.

2. Use another, more accurate sensor to measure the RH.

In both cases, there are two areas of concern. First, the RH can change rapidly across

time and position, making an accurate calibration difficult to do. Second, it takes time

for humidity sensors to settle to an accurate value. Some can take many minutes to

settle properly.

Operation

© 2005 Microchip Technology Inc. DS51594A-page 15

Page 20

Humidity Sensor PICtail™ Demo Board User’s Guide

NOTES:

DS51594A-page 16 © 2005 Microchip Technology Inc.

Page 21

4.1 INTRODUCTION

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

Chapter 4. Modified Circuit

The modifications described here will reduce the current going into the integrator (I

by a factor of 100 ×, so the measurement resolution increases by the same factor.

These modifications are intended for measuring small capacitances. See AN1016 for

more details on this modified circuit’s performance.

4.2 THE “REDUCED CURRENT” CIRCUIT

4.2.1 Modifications

Figure 4-1 shows the Humidity Sensor PICtail™ Demo Board top silk-screen.

Figure 4-1 also shows the locations of the resistors that need to be modified to

implement the “Reduced Current” circuit discussed in application note AN1016:

1. Remove (de-solder) the 1Ω resistor, RA1, already on the board.

2. Refer to Appendix B. “Bill Of Materials (BOM)”, Section B.3 for the BOM for

the three resistors (provided by the user) that need to be soldered onto the board.

-RA1=1MΩ

- RA2=RA3=20kΩ

3. Solder RA1, RA2 and RA3 onto the board.

INT

)

resistors to

to modify

FIGURE 4-1: Resistor Modifications.

© 2005 Microchip Technology Inc. DS51594A-page 17

Page 22

Humidity Sensor PICtail™ Demo Board User’s Guide

4.2.2 Modified Configuration

Configure the Humidity Sensor PICtail™ Demo Board as follows:

1. Start with the configuration in Section 3.2.

2. Connect the shunt to jumpers JP1 – JP3 according to the modified measurement

resolutions and capacitance values desired; see Table 4-1.

TABLE 4-1: JUMPER SELECTION – MODIFIED CIRCUIT

Jumper

Selected

JP1 0.001 0.6 pF to 65 pF 6.65 M

JP2 0.01 6 pF to 650 pF 665 k

JP3 0.1 60 pF to 6.5 nF 66.5 k

4.2.3 Interpreting the Output from the Humidity Sensor PC Program

The capacitance.exe PC program displays measured capacitance values assuming

the Humidity Sensor PICtail™ Demo Board has not been modified. To correct the displayed values, move the displayed decimal point to the left two places (e.g., 321.0 pF is

actually 3.210 pF).

Measurement Resolution

(pF / count)

C

SEN

Range

R

INT

(Ω)

Note: The decimal point must be moved two places to the left by the user for the

modified circuit.

The RH numbers make no sense for measurements produced by the modified board;

they are based on another circuit configuration (see Section 3.2).

DS51594A-page 18 © 2005 Microchip Technology Inc.

Page 23

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the schematics and layouts for the Humidity Sensor PICtail™

Demo Board.

A.2 HIGHLIGHTS

The Humidity Sensor PICtail™ Demo Board is constructed using a two-layer Printed

Circuit Board (PCB). The top layer is for components and traces. The bottom layer is

the ground plane.

Information on this board includes:

• Board Schematic

• Board – Top Silk-screen

• Board – Top Metal Layer

• Board – Bottom Metal Layer

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

A.3 DEMONSTRATION BOARD DESCRIPTION

A schematic is shown in Figure A-1 and Figure A-2. Csen is the humidity sensor or

capacitor. Op amp, U2, and the components, Csen and R

form an inverting (Miller) integrator. The jumpers, JP1 – JP3, select the R

choice (6.65 MΩ, 665 kΩ or 66.5 kΩ), which sets the measurement resolution

(0.1 pF / count, 1 pF / count or 10 pF / count). The microcontroller, U1, sends a square

wave at its pin 14 to the input of the integrator. The integrator converts it to a triangle

wave, which is seen at the microcontroller’s pin 15. There is a comparator internal to

U1 which compares the voltage at pin 15 to one of two reference levels; V

V

or VRH= 0.500 VDD. The microcontroller changes the logic value output at pin 14

DD

each time the triangle wave exceeds one of these two limits.

The microcontroller (U1) measures the time between changes in logic values at pin 14

(“integration times”), and calculates a capacitance value for Csen. This capacitance

value (C

sensor. C

them to the capacitance.exe PC program on the PC via the USB cable.

Note: Converting Csen to RH for other humidity sensors must be done either

RA1 – RA3 are used for the “Op Amp Integrator with Reduced Current” described in

AN1016 and Chapter 4. “Modified Circuit”. Rcm1, Rcm2 and Ccm provide a

mid-supply reference voltage for the op amp, U2.

) is converted to Relative Humidity (RH) for Humirel’s HS1101LF humidity

SEN

and RH are then sent to the PICkit™ 1 Flash Starter Kit, which sends

SEN

manually or by modifying the PIC16F690 firmware (i.e., the linear

interpolation table).

(Rint1, Rint2 or Rint3),

INT

value of

INT

RL

= 0.125

© 2005 Microchip Technology Inc. DS51594A-page 19

Page 24

Humidity Sensor PICtail™ Demo Board User’s Guide

The test points, TP3 – TP5, have 10 kΩ placed in series to isolate the circuit from

external measurement equipment. This will help prevent over-voltage events, and will

help the op amp, U2, operate in a stable condition.

a) This is a two-layer board. It has a solid ground plane on the bottom layer to

minimize EMC issues, and routes the traces in the top layer. The complete

schematic is in Figure A-1 and Figure A-2, the board layer plots in Figure A-3,

Figure A-4 and Figure A-5. The Bill of Materials (BOM) is in Appendix

B. “Bill Of Materials (BOM)”. The Gerber files for this board are available on

the Microchip web site (www.microchip.com) and are contained in the zip file

00084R1.zip.

A.4 THE “REDUCED CURRENT” MODIFICATION

Figure A-1 shows the Humidity Sensor PICtail™ Demo Board as it comes from

Microchip. This board can be modified by the user to implement the “Reduced Current”

circuit discussed in application note AN1016 and Chapter 4. “Modified Circuit”.

A.5 ADDITIONAL COMMENTS

The demonstration board includes test points for convenience on the bench. The “+5V”

and “GND” test points (TP1 and TP2) connect to the board’s supply voltages.

Note: Do NOT connect a power supply to the “+5V” and “GND” test points, unless

the board is NOT connected to the PICkit™ 1 Flash Starter Kit (i.e., it

stands alone).

The “V

square wave into the integrator. The “V

the op amp’s common mode input voltage. The “V

tion to the op amps output to allow the user to monitor the triangle wave at the integrator’s output.

The PICkit™ 1 Flash Starter Kit provides a +5V single supply voltage. It can drive up to

5 μF on the supply; a larger capacitive load causes current loading and timing issues.

This demonstration board also uses the +5V single supply voltage. It has two 1 μF bulk

bypass capacitors and two 0.1 μF local bypass capacitors.

High frequency design practices are used to minimize digital interference:

• Solid ground plane

• Surface mount devices for the analog circuitry

• Separate digital and analog lines and sections

INT” test point (TP3) connects to U1’s pin 14 to allow the user to monitor the

CM” test point (TP4) allows the user to measure

SEN” test point (TP5) allows connec-

DS51594A-page 20 © 2005 Microchip Technology Inc.

Page 25

C

0.1 μF

Schematic and Layouts

+5V

1

U1

PIC16F690/P

20

SS

V

19

18

17

RA0

RA1

16

15

14

13

RC1

RC2

12

11

RA3

1

VDD

2

RA5/T1CKI/OSC1/CLKIN

3

RA4/AN3/T1G/OSC2/CLKOUT

4

RA3/MCLR/V

5

RC5/CCP1/P1A

6

RC4/C2OUT/P1B

7

RC3/AN7/P1C

8

RC6/AN8/SS

9

RC7/AN9/SDO

10

RB7/TX/CK

PP

RA0/AN0/C1IN+/ICSPDAT/ULPWU

RA1/AN1/C12IN-/V

REF/ICSPCLK

RA2/AN2/T0CLKI/INT/C1OUT

RC0/AN4/C2IN+

RC1/AN5/C12IN-

RC2/AN6/P1D

RB4/AN10/SDI/SDA

RB5/AN11/RX/DT

RB6/SCK/SCL

RC1

TP5

V

SEN

R

10 kΩ

2

HS1101LF

C

2

0.1 μF

MCP6291

1

Csen

Humidity

+5VA

U

2

TP4

CM

V

R

INT1

R

3

10kΩ

21

6.65 MΩ

R

INT2

66.5 kΩ

R

INT3

66.5 kΩ

JP1

0.1pF/

JP2

1.0pF/

JP3

10pF/

+5VA

R

A2

OPEN

R

A3

OPEN

R

0Ω

TP3

V

INT

R

4

10 kΩ

A1

RC2

+5VA

5

4

3

+

2

R

CM1

20 kΩ

R

CM2

20 kΩ

C

CM

0.1μF

NOTE: All Resistors are 1%

FIGURE A-1: Board – Schematic.

© 2005 Microchip Technology Inc. DS51594A-page 21

Page 26

Humidity Sensor PICtail™ Demo Board User’s Guide

TP2

TP1

+5V

RA3

RA0

RA1

RA3

RA0

RA1

P1

RA5

1

RA4

2

3

RA3

4

RC5

5

RC4

6

RC3

7

RA0

8

RA1

9

RA2

10

RC0

11

RC1

12

RC2

13

+5V

14

GND

P2

ICSP

1

PP

V

2

VDD

3

GND

4

ICSPDAT

5

ICSPCLK

6

AUX

Expansion Header J3

PICkit™ 1 Flash Starter Kit

+5VA

C

1 μF

GND

R

100Ω

3

+5V

5

C

4

1 μF

FIGURE A-2: Board – Schematic. (Continued)

NOTE: All Resistors are 1%

DS51594A-page 22 © 2005 Microchip Technology Inc.

Page 27

Schematic and Layouts

FIGURE A-3: Board – Top Silk-Screen.

FIGURE A-4: Board – Top Metal Layer.

© 2005 Microchip Technology Inc. DS51594A-page 23

Page 28

Humidity Sensor PICtail™ Demo Board User’s Guide

FIGURE A-5: Board – Bottom Metal Layer.

DS51594A-page 24 © 2005 Microchip Technology Inc.

Page 29

HUMIDITY SENSOR PICTAIL™

DEMO BOARD USER’S GUIDE

Appendix B. Bill Of Materials (BOM)

B.1 HUMIDITY SENSOR PICTAIL™ DEMO BOARD BOM

Table B-1 shows the BOM for the Humidity Sensor PICtail™ Demo Board as it comes

from Microchip.

TABLE B-1: BILL OF MATERIALS

Qty Reference Description Manufacturer Part Number

1C

SEN Ceramic Capacitor, Monolithic, 180 pF, 50V, 5%, C0G,

Radial 0.2"

3C1, C2, C

2 C3, C4 Ceramic Capacitor, 1.0 μF, 16V, 10%, X7R, 0805 SMD Kemet C0805C105K4RACTU

1 P1 Header, 1 × 14, 0.100" Pitch, Vertical, Gold Molex/Waldom

1 P2 Header, 1 × 6, 0.100” Pitch, Right Angle, Gold Molex/Waldom

1 JP1 – JP3 Header, 2 × 3, 0.100” Pitch, Vertical, Gold Molex/Waldom

1 (for JP1 – JP3) Shunt, 1 × 2, With Handle, Gold AMP/Tyco

1 RA1 Chip Resistor, 1.00 Ω, 1/8W, 5%, 0805 SMD (Note 1) Yageo America RC0805FR-071RL

0 RA2, RA3 (not used; left open) (Note 1) ——

1 R5 Chip Resistor, 100 Ω, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-07100RL

3 R2 – R4 Chip Resistor, 10.0 kΩ, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-0710KL

2R

1R

1R

1R

5 TP1 – TP5 PCB Test Point, Compact, SMT Keystone

1 U1 PIC16F690, PICmicro

1 U2 MCP6291, Single Op Amp, 10 MHz, V

2(for C

1 (for U1) IC Socket, 20-pin DIP, Gold Plated, 0.400" Mill-Max

1 (for PCB mounting) Stand-off, Hex, 1.000”, 4 × 40 Thread, Nylon,

1 (for PCB mounting) Machine Screw, Phillips, 4 × 40 Thread, 1/4 in long, Nylon Digi-Key H542-ND

1 PCB Bare Printed Circuit Board — —

Note 1: These resistors are intended for the “Reduced Current” circuit modifications detailed in Table B-3.

CM Ceramic Capacitor, 100 nF, 50V, 10%, X7R, 0805 SMD Kemet C0805C104K5RACTU

CM1, RCM2 Chip Resistor, 20.0 kΩ, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-0720KL

INT3 Chip Resistor, 66.5 kΩ, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-0766K5L

INT2 Chip Resistor, 665 kΩ, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-07665KL

INT1 Chip Resistor, 6.65 MΩ, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-076M65L

®

PDIP-20

SOT-23-5

SEN) Pin Recepticle, 0.015” to 0.025” dia., 0.060” hole dia. Mill-Max

0.285” max. O.D

Microcontroller, 20-pin, 20 MHz,

≤ ±3 mV,

OS

EPCOS Inc. B37979N5181J051

Electronics

Electronics

Electronics

Electronics

Electronics

Microchip PIC16F690-I/P

Microchip MCP6291-E/OT

®

®

Keystone

Electronics

22-28-4143

22-28-8062

10-89-1061

881545-2

5016

0669-0-15-15-30-27-10-0

110-13-420-41-001000

1902C

© 2005 Microchip Technology Inc. DS51594A-page 25

Page 30

Humidity Sensor PICtail™ Demo Board User’s Guide

B.2 BOM FOR HUMIDITY SENSOR AND OTHER CAPACITORS IN BOX

Table B-2 lists capacitors included separately in the Humidity Sensor PICtail™ Demo

Board’s shipping box. These capacitors or the HS1101LF sensor will fit in the Csen pin

recepticles. The capacitors provide a means for quickly evaluating circuit operation.

TABLE B-2: BILL OF MATERIALS FOR HUMIDITY SENSOR AND OTHER CAPACITORS

Qty Reference Description Manufacturer Part Number

1CSEN Relative Humidity Sensor, Capacitive Cell, 180 pF, 5V,

1C

SEN Ceramic Capacitor, Monolithic, 100 pF, 50V, 5%, C0G, Radial 0.2" EPCOS Inc. B37979N5101J000

1C

SEN Ceramic Capacitor, Monolithic, 1.0 nF, 50V, 5%, C0G, Radial 0.2" EPCOS Inc. B37979G5102J000

SEN Ceramic Capacitor, Monolithic, 100 nF, 50V, 10%, X7R, Radial 0.2" EPCOS Inc. B37987F5104K000

1C

1% to 99% RH, -40°C to +140°C

B.3 BOM FOR “REDUCED CURRENT” MODIFICATIONS

Table B-3 shows the components for the “Reduced Current” circuit modifications

discussed in application note AN1016 and Chapter 4. “Modified Circuit”.

TABLE B-3: BILL OF MATERIALS FOR “REDUCED CURRENT” MODIFICATIONS

Humirel HS1101LF

Qty Reference Description Manufacturer Part Number

2 RA2, RA3 Chip Resistor, 20.0 kΩ, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-0720KL

1 RA1 Chip Resistor, 1.00 MΩ, 1/8W, 1%, 0805 SMD Yageo America RC0805FR-071ML

DS51594A-page 26 © 2005 Microchip Technology Inc.

Page 31

NOTES:

Bill Of Materials (BOM)

© 2005 Microchip Technology Inc. DS51594A-page 27

Page 32

WORLDWIDE SALES AND SERVICE

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7250

Fax: 86-29-8833-7256

ASIA/PACIFIC

India - Bangalore

Tel: 91-80-2229-0061

Fax: 91-80-2229-0062

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

India - Pune

Tel: 91-20-2566-1512

Fax: 91-20-2566-1513

Japan - Yokohama

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

Korea - Gumi

Tel: 82-54-473-4301

Fax: 82-54-473-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Penang

Tel: 60-4-646-8870

Fax: 60-4-646-5086

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

UK - Wokingham

Tel: 44-118-921-5869

Fax: 44-118-921-5820

10/31/05

DS51594A-page 28 © 2005 Microchip Technology Inc.

Loading...

Loading...