Page 1

PIC10(L)F320/322

Data Sheet

6/8-Pin, High-Performance,

Flash Microcontrollers

2011 Microchip Technology Inc. Preliminary DS41585A

Page 2

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

K

EELOQ, KEELOQ logo, MPLAB, PIC, PICmicro, PICSTART,

32

PIC

logo, rfPIC and UNI/O are registered trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

FilterLab, Hampshire, HI-TECH C, Linear Active Thermistor,

MXDEV, MXLAB, SEEVAL and The Embedded Control

Solutions Company are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, chipKIT,

chipKIT logo, CodeGuard, dsPICDEM, dsPICDEM.net,

dsPICworks, dsSPEAK, ECAN, ECONOMONITOR,

FanSense, HI-TIDE, In-Circuit Serial Programming, ICSP,

Mindi, MiWi, MPASM, MPLAB Certified logo, MPLIB,

MPLINK, mTouch, Omniscient Code Generation, PICC,

PICC-18, PICDEM, PICDEM.net, PICkit, PICtail, REAL ICE,

rfLAB, Select Mode, Total Endurance, TSHARC,

UniWinDriver, WiperLock and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2011, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

ISBN: 978-1-61341-380-7

Microchip received ISO/TS-16949:2002 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

DS41585A-page 2 Preliminary 2011 Microchip Technology Inc.

Page 3

PIC10(L)F320/322

6/8-Pin Flash-Based, 8-Bit Microcontrollers

High-Performance RISC CPU:

• Only 35 Instructions to Learn:

- All single-cycle instructions, except branches

• Operating Speed:

- DC – 16 MHz clock input

- DC – 250 ns instruction cycle

• Up to 512 Words of Flash Program Memory

• 64 Bytes Data Memory

• Eight-level Deep Hardware Stack

• Interrupt Capability

• Processor Self-Write/Read access to Program

Memory

• Pinout Compatible to other 6-Pin PIC10FXXX

Microcontrollers

Special Microcontroller Features:

• Low-Power 16 MHz Internal Oscillator:

- Software selectable frequency range from

16 MHz to 31 kHz

- Factory calibrated to 1%, typical

• Wide Operating Range:

- 1.8V to 3.6V (PIC10LF320/322)

- 2.3V to 5.5V (PIC10F320/322)

• Power-on Reset (POR)

• Power-up Timer (PWRT)

• Brown-out Reset (BOR)

• Ultra Low-Power Sleep Regulator

• Extended Watchdog Timer (WDT)

• Programmable Code Protection

• Power-Saving Sleep mode

• Selectable Oscillator options (EC mode or Internal

Oscillator)

• In-Circuit Serial Programming™ (ICSP™) (via

Two Pins)

• In-Circuit Debugger Support

• Fixed Voltage Reference (FVR) with 1.024V,

2.048V and 4.096V (‘F’ variant only) Output

Levels

• Integrated Temperature Indicator

• 40-year Flash Data Retention

Low-Power Features (PIC10LF320/322):

• Standby Current:

- 20 nA @ 1.8V, typical

• Operating Current:

-25A @ 1 MHz, 1.8V, typical

• Watchdog Timer Current:

- 500 nA @ 1.8V, typical

Peripheral Features:

• 4 I/O Pins:

- 1 input-only pin

- High current sink/source for LED drivers

- Individually selectable weak pull-ups

- Interrupt-on-Change

• Timer0: 8-Bit Timer/Counter with 8-Bit

Programmable Prescaler

• Timer2: 8-Bit Timer/Counter with 8-Bit Period

Register, Prescaler and Postscaler

• Two PWM modules:

- 10-bit PWM, max. frequency 16 kHz

- Combined to single 2-phase output

• A/D Converter:

- 8-bit resolution with 3 channels

• Configurable Logic Cell (CLC):

- 8 selectable input source signals

- Two inputs per module

- Software selectable logic functions including:

AND/OR/XOR/D Flop/D Latch/SR/JK

- External or internal inputs/outputs

- Operation while in Sleep

• Numerically Controlled Oscillator (NCO):

- 20-bit accumulator

- 16-bit increment

- Linear frequency control

- High-speed clock input

- Selectable Output modes

- Fixed Duty Cycle (FDC)

- Pulse Frequency (PF) mode

• Complementary Waveform Generator (CWG):

- Selectable falling and rising edge dead-band

control

- Polarity control

- 2 auto-shutdown sources

- Multiple input sources: PWM, CLC, NCO

2011 Microchip Technology Inc. Preliminary DS41585A-page 3

Page 4

PIC10(L)F320/322

1

2

3

4

5

6

PIC10(L)F320

PIC10(L)F322

RA3/MCLR/V

PP

VDD

RA2

ICSPCLK/RA1

ICSPDAT/RA0

V

SS

SOT-23

1

2

3

4

5

6

7

8

PIC10(L)F320

PIC10(L)F322

RA3/MCLR/V

PP

VSS

N/C

RA0/ICSPDAT

ICSPCLK/RA1

N/C

V

DD

RA2

PDIP, DFN

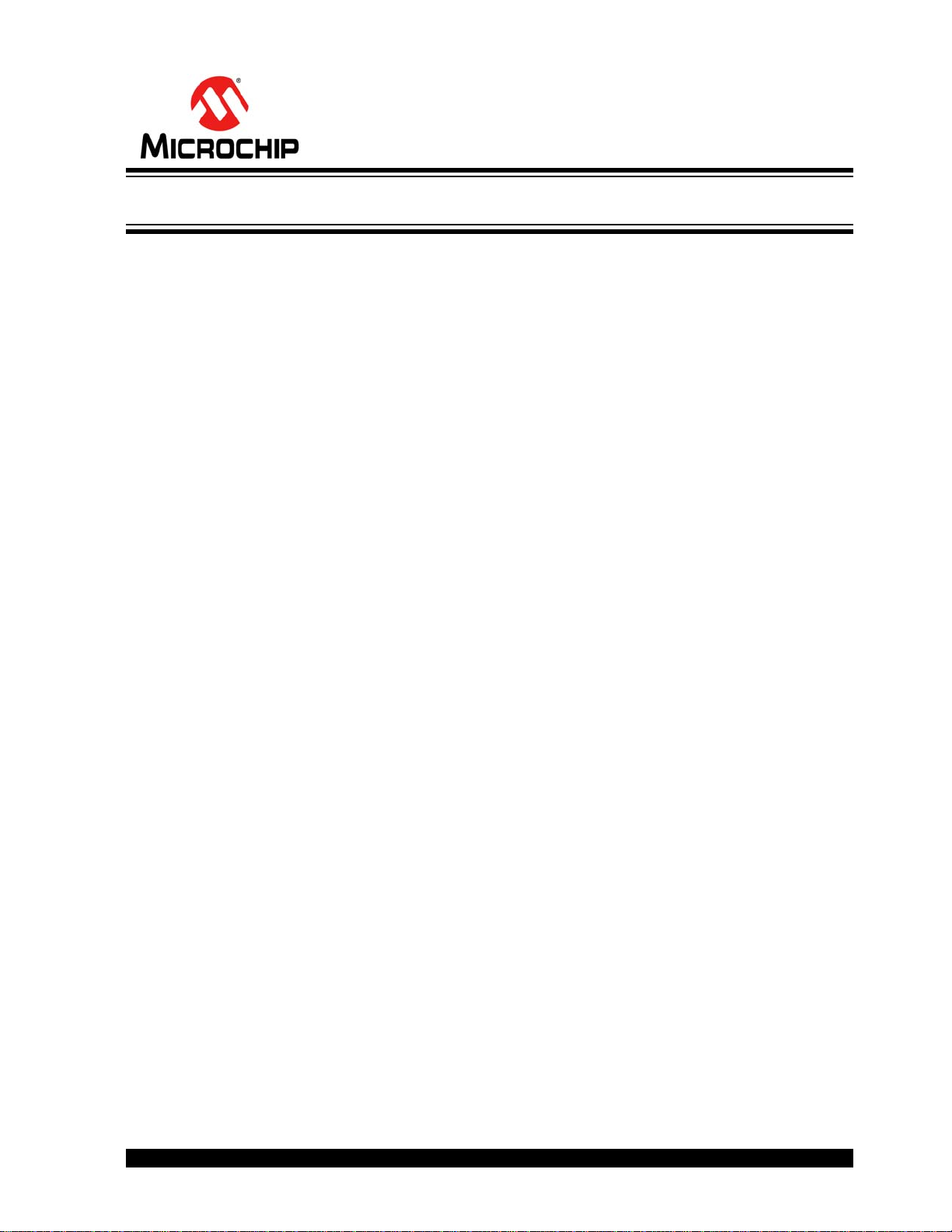

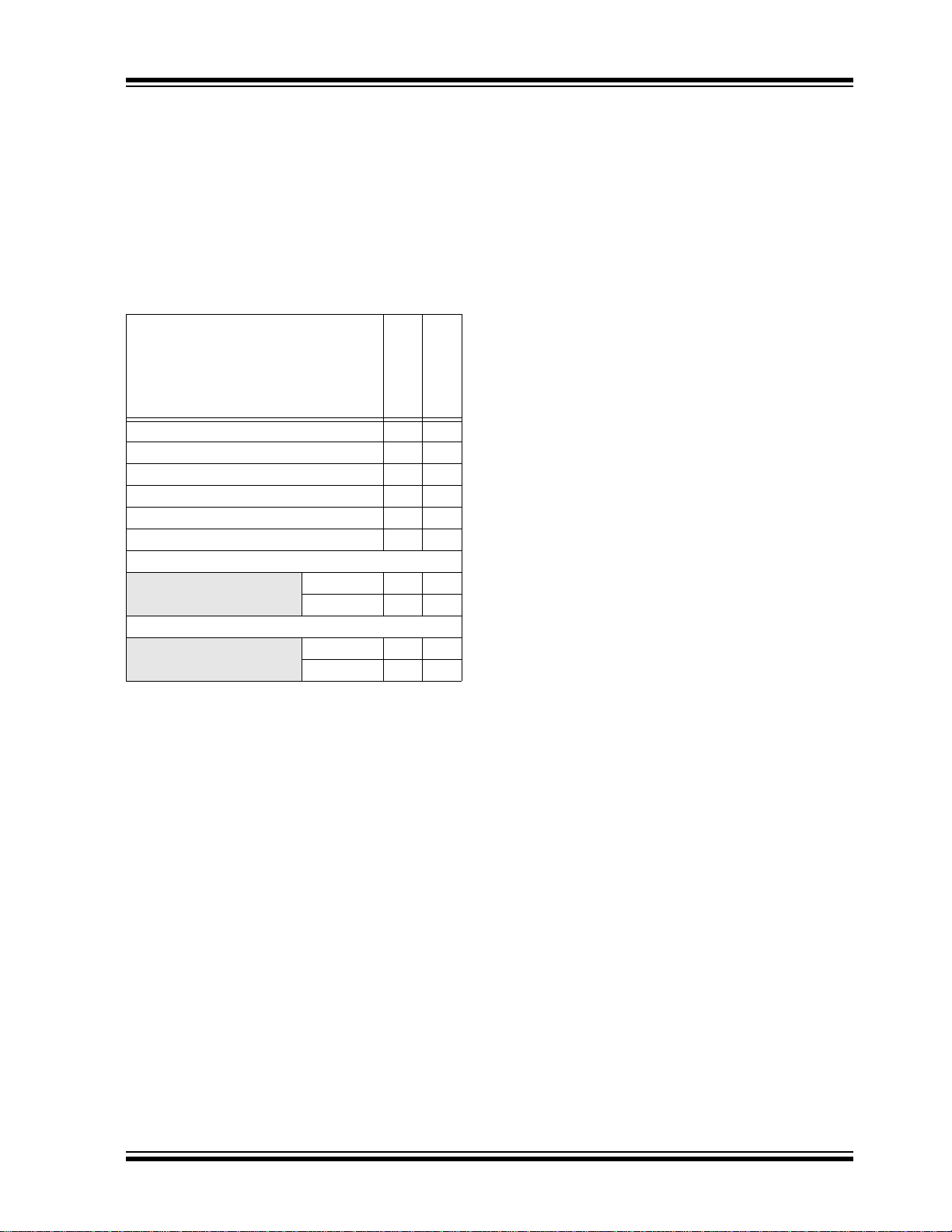

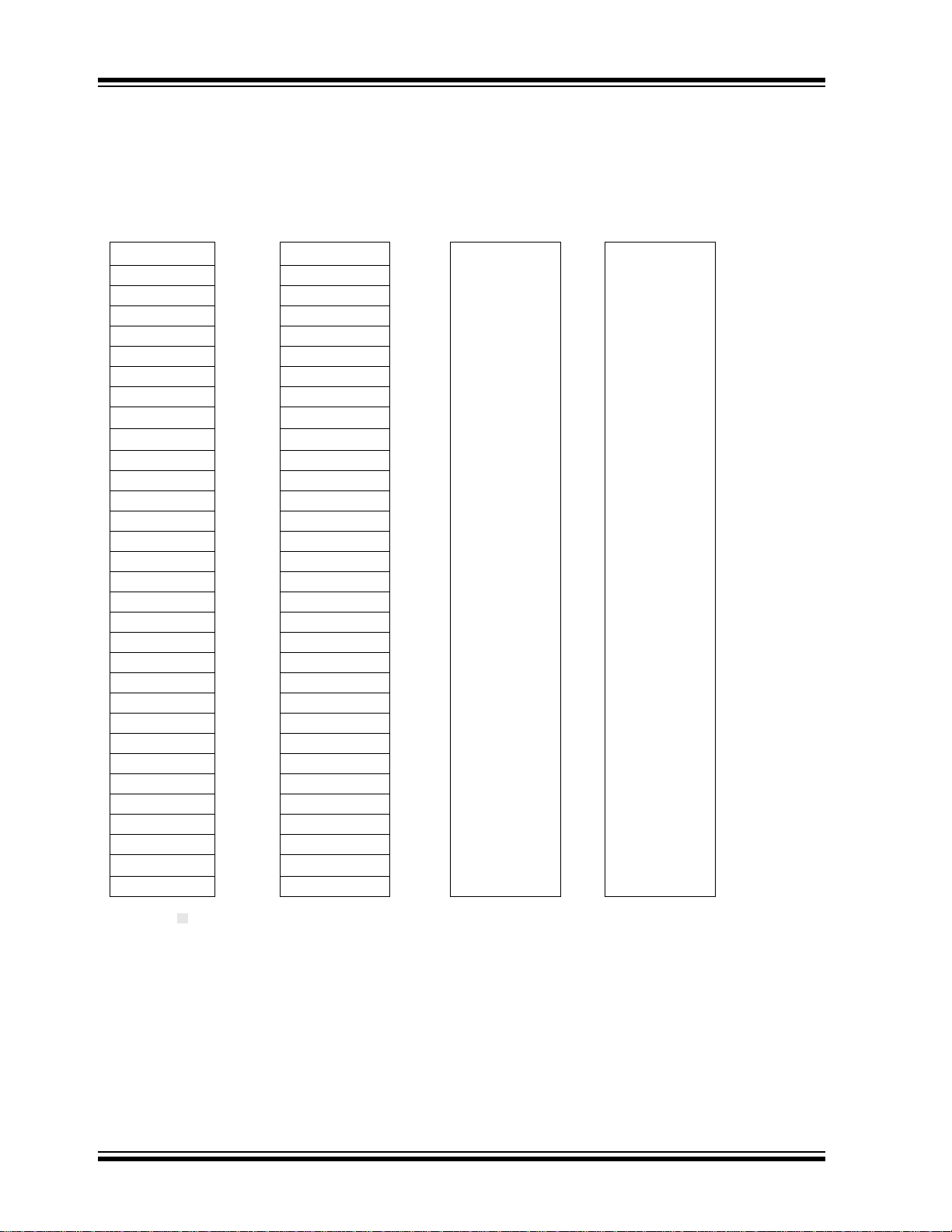

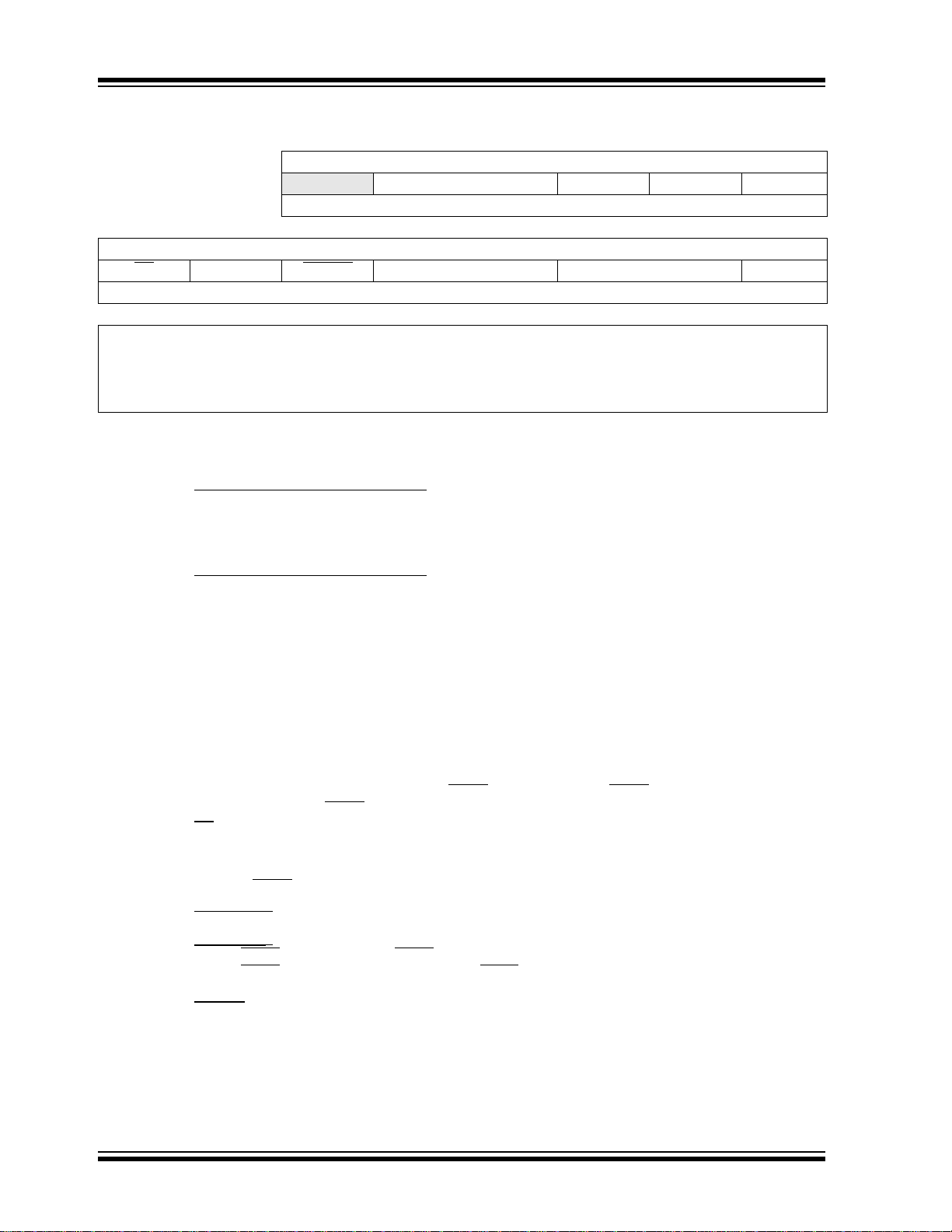

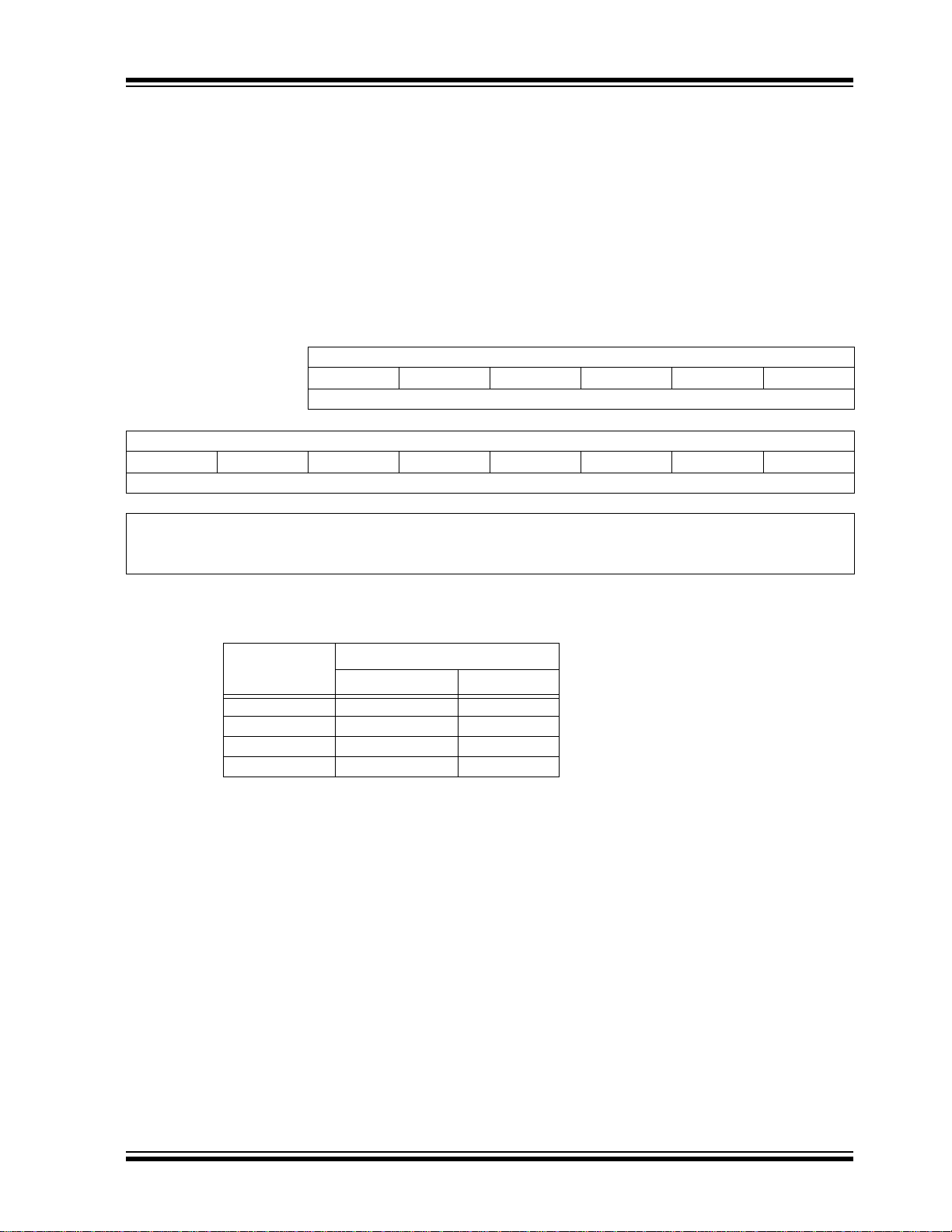

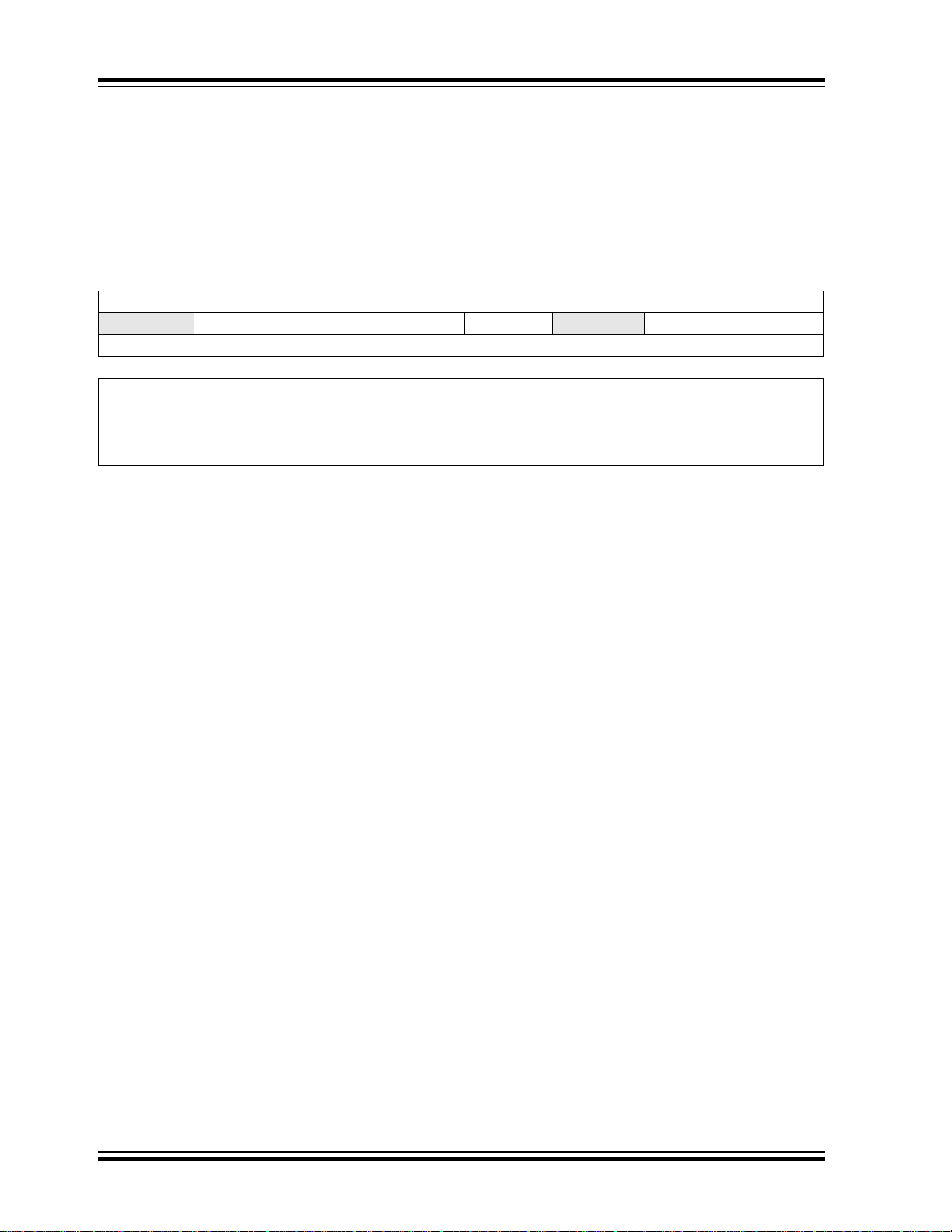

TABLE 1: PIC10(L)F320/322 FEATURE SUMMARY

Program

Device

Memory

Flash

(words)

PIC10F320 256 64 4 3 1 2 2 1 1

PIC10LF320 256 64 4 3 1 2 2 1 1

PIC10F322 512 64 4 3 1 2 2 1 1

PIC10LF322 512 64 4 3 1 2 2 1 1

Note1: One pin is input-only.

FIGURE 1: 6-PIN DIAGRAM, PIC10(L)F320/322

SRAM

(bytes)

I/O

(1)

8-bit A/D (ch) CLC

10-bit

PWM

Timers

8-bit

NCO CWG

FIGURE 2: 8-PIN DIAGRAM, PIC10(L)F320/322

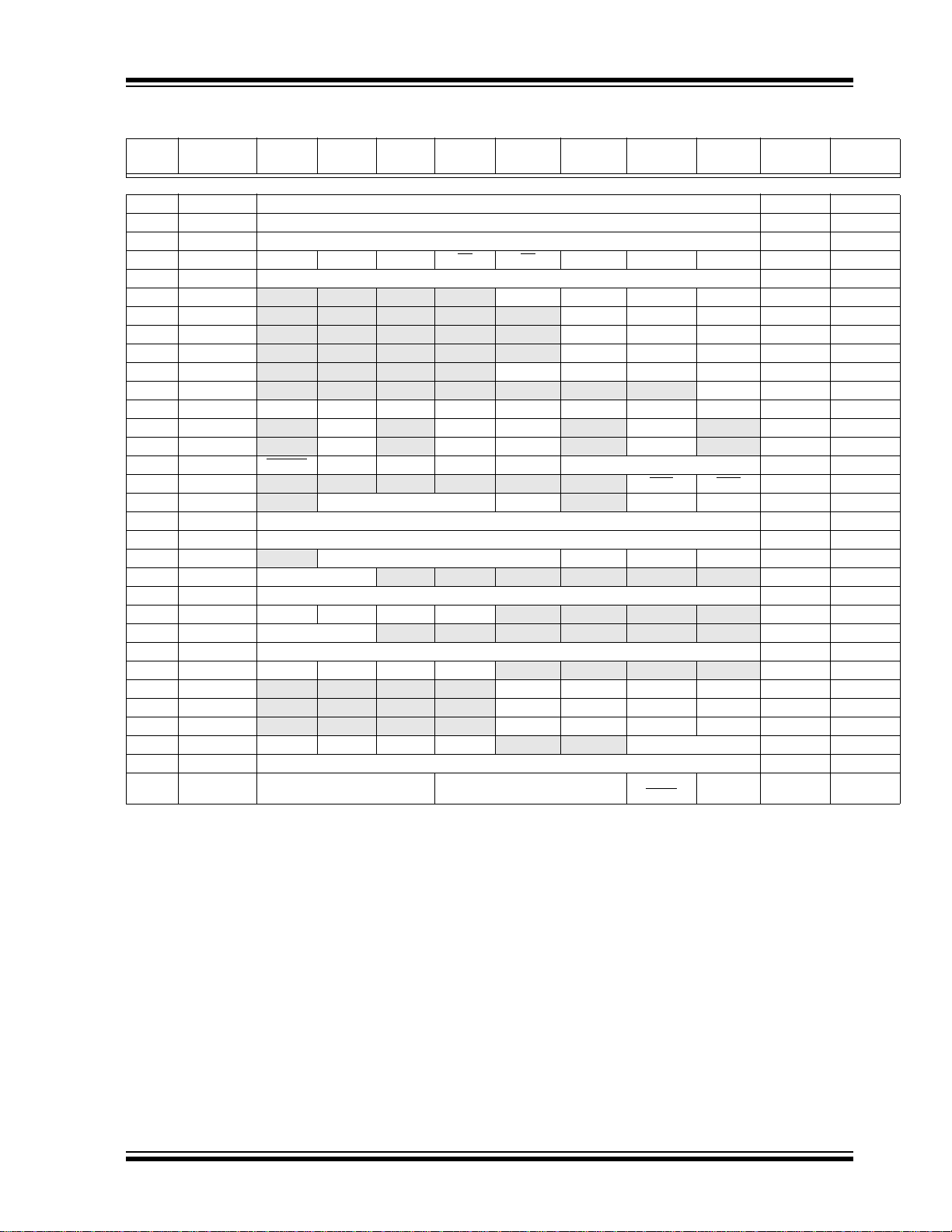

TABLE 2: 6 AND 8-PIN ALLOCATION TABLE (PIC10(L)F320/322)

I/O 6-Pin 8-Pin Analog Timer PWM Interrupts Pull-ups CWG NCO CLC Basic ICSP

RA0 1 5 AN0 — PWM1 IOC0 Y CWG1A — CLC1IN1 — ICSPDAT

RA1 3 4 AN1 — PWM2 IOC1 Y CWG1B NCO1CLK CLC1 CLKIN ICSPCLK

RA2 4 3 AN2 T0CKI — INT/IOC2 Y CWG1FLT NCO1 CLC1IN2 CLKR

RA3 6 8 — — — IOC3 Y — — — MCLR VPP

N/C — 1 — — — — — — — — — —

N/C — 6 — — — — — — — — — —

VDD 5 2 — — — — — — — — VDD —

SS 27 — —— — — — — — VSS —

V

DS41585A-page 4 Preliminary 2011 Microchip Technology Inc.

Page 5

PIC10(L)F320/322

Table of Contents

1.0 Device Overview .......................................................................................................................................................................... 7

2.0 Memory Organization ................................................................................................................................................................. 11

3.0 Device Configuration.................................................................................................................................................................. 21

4.0 Oscillator Module........................................................................................................................................................................ 27

5.0 Resets ........................................................................................................................................................................................ 33

6.0 Interrupts .................................................................................................................................................................................... 41

7.0 Power-Down Mode (Sleep) ........................................................................................................................................................ 51

8.0 Watchdog Timer (WDT) ............................................................................................................................................................. 53

9.0 Flash Program Memory Control ................................................................................................................................................. 57

10.0 I/O Port....................................................................................................................................................................................... 75

11.0 Interrupt-On-Change .................................................................................................................................................................. 81

12.0 Fixed Voltage Reference (FVR) ................................................................................................................................................. 85

13.0 Internal Voltage Regulator (IVR) ................................................................................................................................................ 87

14.0 Temperature Indicator Module ................................................................................................................................................... 89

15.0 Analog-to-Digital Converter (ADC) Module ................................................................................................................................ 91

16.0 Timer0 Module ......................................................................................................................................................................... 101

17.0 Timer2 Module ......................................................................................................................................................................... 105

18.0 Pulse Width Modulation (PWM) Module................................................................................................................................... 107

19.0 Configurable Cell Logic (CLC).................................................................................................................................................. 113

20.0 Numerically Controlled Oscillator (NCO) Module ..................................................................................................................... 129

21.0 Complementary Waveform Generator (CWG) Module ............................................................................................................ 139

22.0 In-Circuit Serial Programming™ (ICSP™) ............................................................................................................................... 155

23.0 Instruction Set Summary.......................................................................................................................................................... 159

24.0 Electrical Specifications............................................................................................................................................................ 169

25.0 DC and AC Characteristics Graphs and Charts ....................................................................................................................... 187

26.0 Development Support............................................................................................................................................................... 189

27.0 Packaging Information.............................................................................................................................................................. 193

Appendix A: Data Sheet Revision History .......................................................................................................................................... 201

Index .................................................................................................................................................................................................. 203

The Microchip Web Site..................................................................................................................................................................... 207

Customer Change Notification Service .............................................................................................................................................. 207

Customer Support .............................................................................................................................................................................. 207

Reader Response .............................................................................................................................................................................. 208

Product Identification System ............................................................................................................................................................ 209

2011 Microchip Technology Inc. Preliminary DS41585A-page 5

Page 6

PIC10(L)F320/322

TO OUR VALUED CUSTOMERS

It is our intention to provide our valued customers with the best documentation possible to ensure successful use of your Microchip

products. To this end, we will continue to improve our publications to better suit your needs. Our publications will be refined and

enhanced as new volumes and updates are introduced.

If you have any questions or comments regarding this publication, please contact the Marketing Communications Department via

E-mail at docerrors@microchip.com or fax the Reader Response Form in the back of this data sheet to (480) 792-4150. We

welcome your feedback.

Most Current Data Sheet

To obtain the most up-to-date version of this data sheet, please register at our Worldwide Web site at:

http://www.microchip.com

You can determine the version of a data sheet by examining its literature number found on the bottom outside corner of any page.

The last character of the literature number is the version number, (e.g., DS30000A is version A of document DS30000).

Errata

An errata sheet, describing minor operational differences from the data sheet and recommended workarounds, may exist for current

devices. As device/documentation issues become known to us, we will publish an errata sheet. The errata will specify the revision

of silicon and revision of document to which it applies.

To determine if an errata sheet exists for a particular device, please check with one of the following:

• Microchip’s Worldwide Web site; http://www.microchip.com

• Your local Microchip sales office (see last page)

When contacting a sales office, please specify which device, revision of silicon and data sheet (include literature number) you are

using.

Customer Notification System

Register on our web site at www.microchip.com to receive the most current information on all of our products.

DS41585A-page 6 Preliminary 2011 Microchip Technology Inc.

Page 7

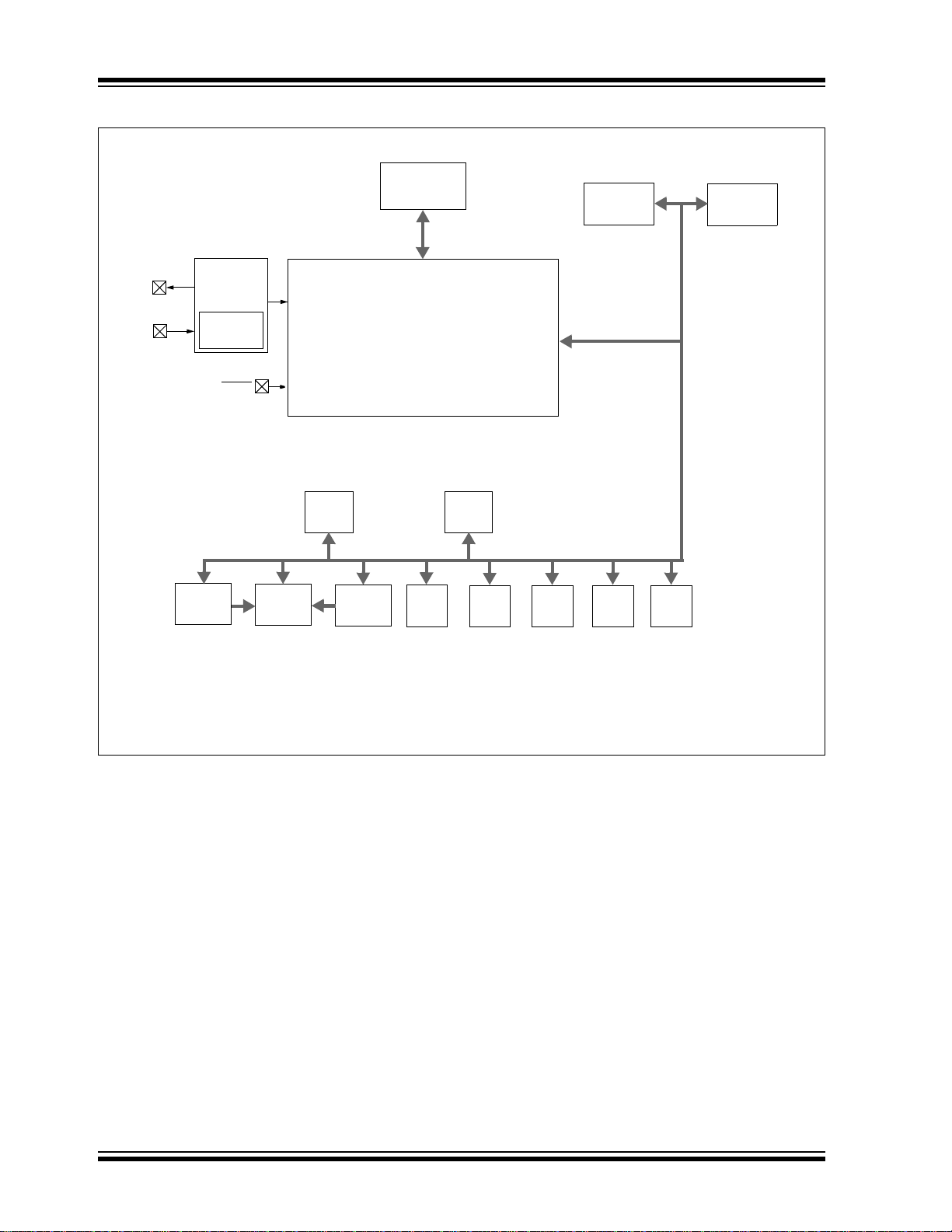

1.0 DEVICE OVERVIEW

The PIC10(L)F320/322 are described within this data

sheet. They are available in 6/8-pin packages. Figure 1-1

shows a block diagram of the PIC10(L)F320/322

devices. Ta b le 1- 2 shows the pinout descriptions.

Reference Tab le 1- 1 for peripherals available per

device.

TABLE 1-1: DEVICE PERIPHERAL

SUMMARY

Peripheral

PIC10(L)F322

PIC10(L)F320

Analog-to-Digital Converter (ADC) ●●

Configurable Logic Cell (CLC) ●●

Complementary Wave Generator (CWG) ●●

Fixed Voltage Reference (FVR) ●●

Numerically Controlled Oscillator (NCO) ●●

Temperature Indicator ●●

PWM Modules

PWM1 ●●

PWM2 ●●

Timers

Timer0 ●●

Timer2 ●●

PIC10(L)F320/322

2011 Microchip Technology Inc. Preliminary DS41585A-page 7

Page 8

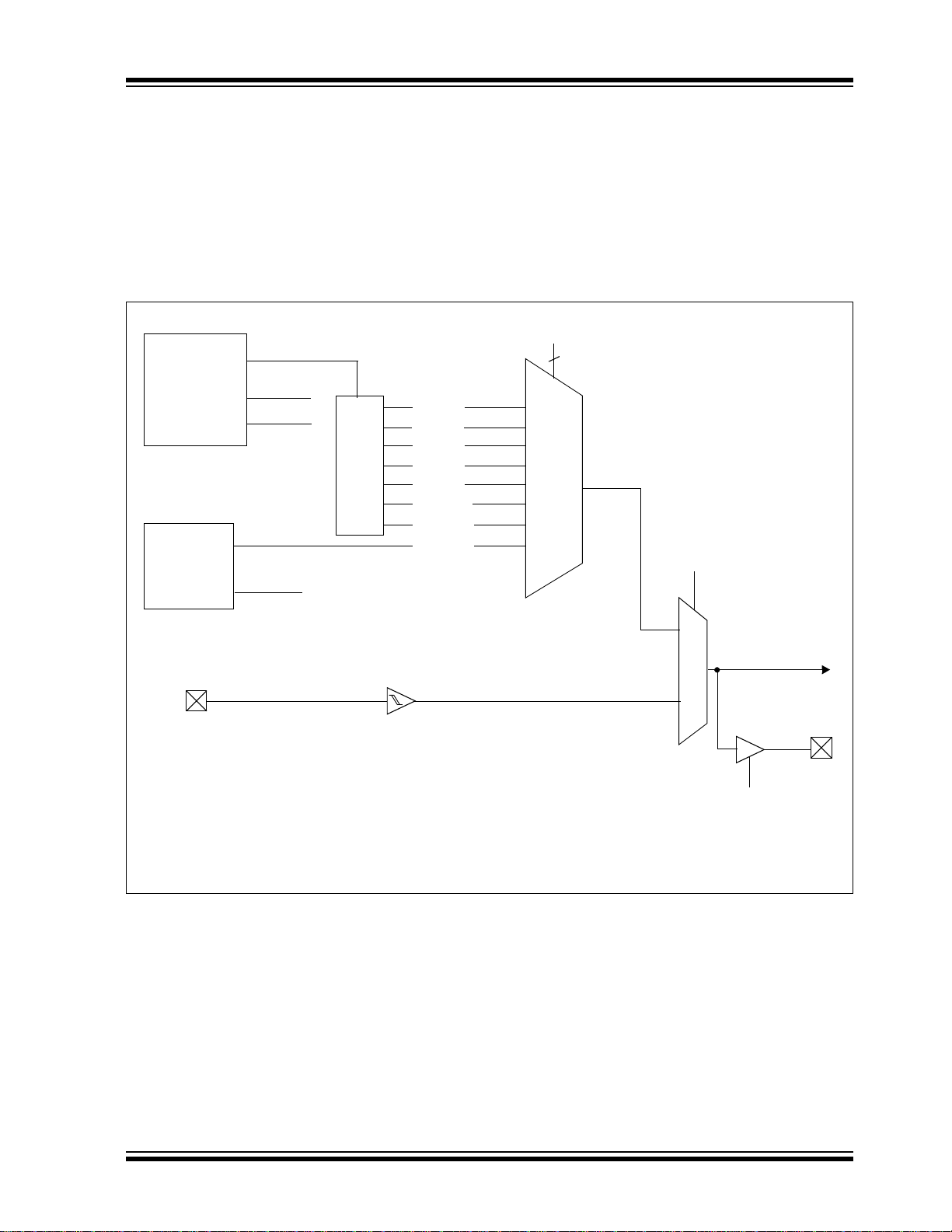

PIC10(L)F320/322

PORTA

Note 1: See applicable chapters for more information on peripherals.

CPU

Program

Flash Memory

RAM

Timing

Generation

INTRC

Oscillator

MCLR

Figure 2-1

CLKIN

CLKR

ADC

8-Bit

FVR

Te mp .

Indicator

Timer2Timer0

PWM1

PWM2 NCO

CLC CWG

FIGURE 1-1: PIC10(L)F320/322 BLOCK DIAGRAM

DS41585A-page 8 Preliminary 2011 Microchip Technology Inc.

Page 9

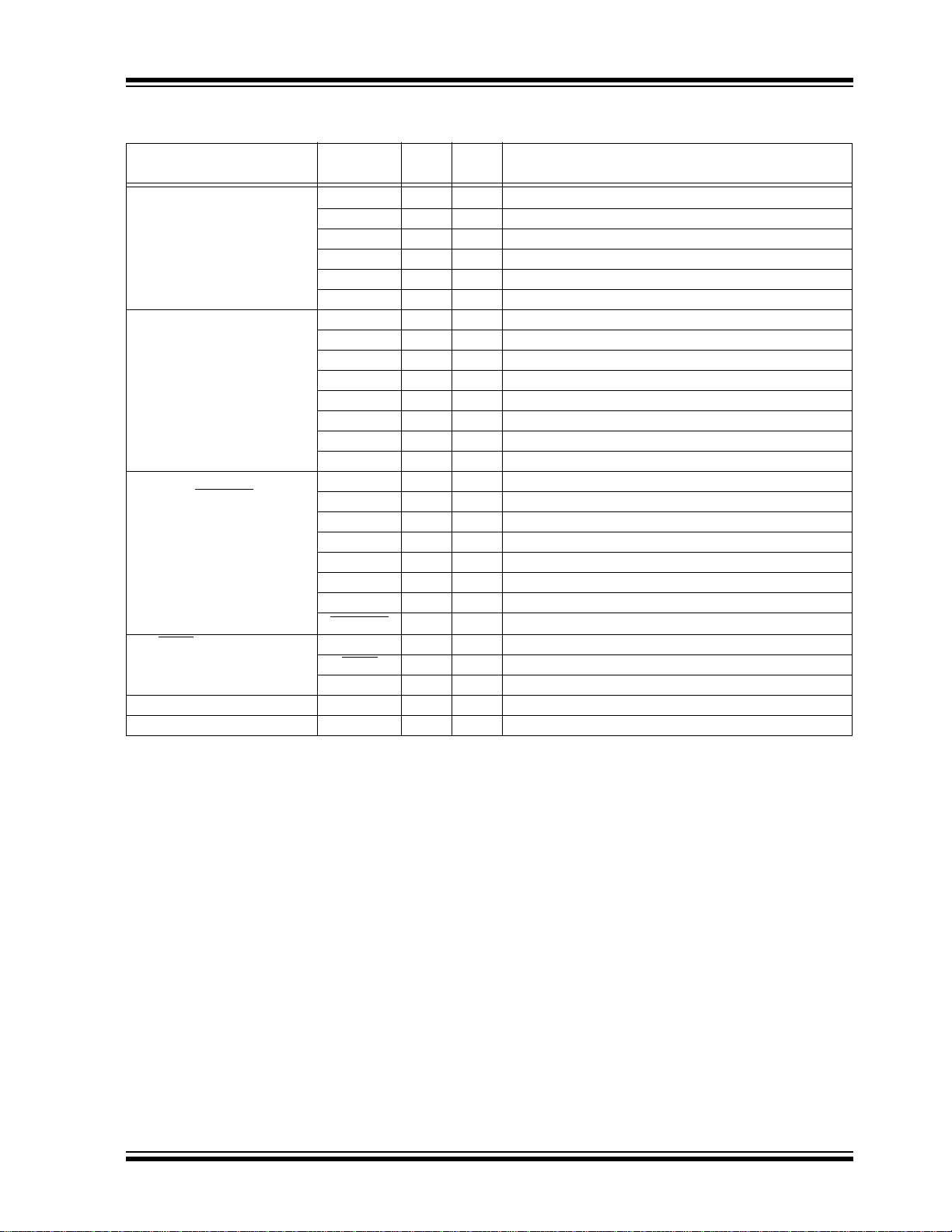

T ABLE 1-2: PIC10(L)F320/322 PINOUT DESCRIPTION

Input

Name Function

Type

Output

Type

PIC10(L)F320/322

Description

RA0/PWM1/CLC1IN1/CWG1A/

AN0/ICSPDAT

RA1/PWM2/CLC1/CWG1B/AN1/

CLKIN/ICSPCLK/NCO1CLK

RA2/INT/T0CKI/NCO1/CLC1IN2/

CLKR/AN2/CWG1FLT

RA3/MCLR

V

DD VDD Power — Positive supply.

SS VSS Power — Ground reference.

V

Legend: AN = Analog input or output CMOS = CMOS compatible input or output

/VPP RA3 TTL — General purpose input.

TTL = CMOS input with TTL levels ST = CMOS input with Schmitt Trigger levels

HV = High Voltage

RA0 TTL CMOS General purpose I/O with IOC and WPU.

PWM1 — CMOS PWM output.

CLC1IN1

CWG1A —

AN0 AN — A/D Channel input.

ICSPDAT ST CMOS ICSP™ Data I/O.

RA1 TTL CMOS General purpose I/O with IOC and WPU.

PWM2 — CMOS PWM output.

CLC1 — CMOS

CWG1B — CMOS

AN1 AN — A/D Channel input.

CLKIN ST — External Clock input (EC mode).

ICSPCLK ST — Serial Programming Clock.

NCO1CLK ST — Numerical Controlled Oscillator external clock input.

RA2 TTL CMOS General purpose I/O with IOC and WPU.

INT ST — External interrupt.

T0CKI ST — Timer0 clock input.

NCO1 — CMOS Numerically Controlled Oscillator output.

CLC1IN2 ST —

CLKR — CMOS Clock Reference output.

AN2 AN — A/D Channel input.

CWG1FLT

MCLR

PP HV — Programming voltage.

V

ST

CMOS CWG primary output.

ST — Complementary Waveform Generator Fault 1 source input.

ST — Master Clear with internal pull-up.

CLC input.

—

CLC output.

CWG complementary output.

CLC input.

2011 Microchip Technology Inc. Preliminary DS41585A-page 9

Page 10

PIC10(L)F320/322

NOTES:

DS41585A-page 10 Preliminary 2011 Microchip Technology Inc.

Page 11

PIC10(L)F320/322

2.0 MEMORY ORGANIZATION

These devices contain the following types of memory:

• Program Memory

- Configuration Words

- Device ID

-User ID

- Flash Program Memory

• Data Memory

- Core Registers

- Special Function Registers

- General Purpose RAM

- Common RAM

The following features are associated with access and

control of program memory and data memory:

• PCL and PCLATH

•Stack

• Indirect Addressing

TABLE 2-1: DEVICE SIZES AND ADDRESSES

Device Program Memory Space (Words) Last Program Memory Address

PIC10(L)F320 256 00FFh

PIC10(L)F322 512 01FFh

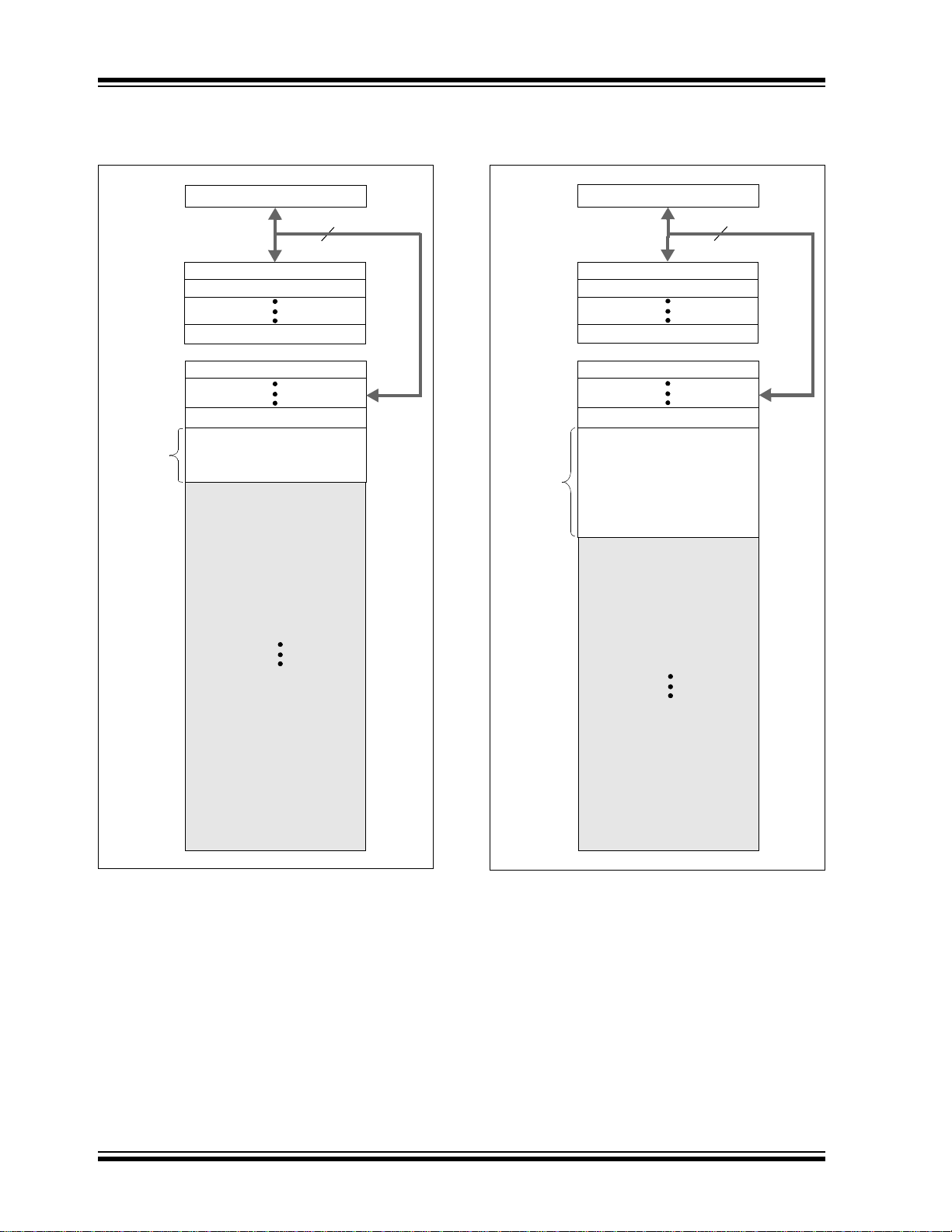

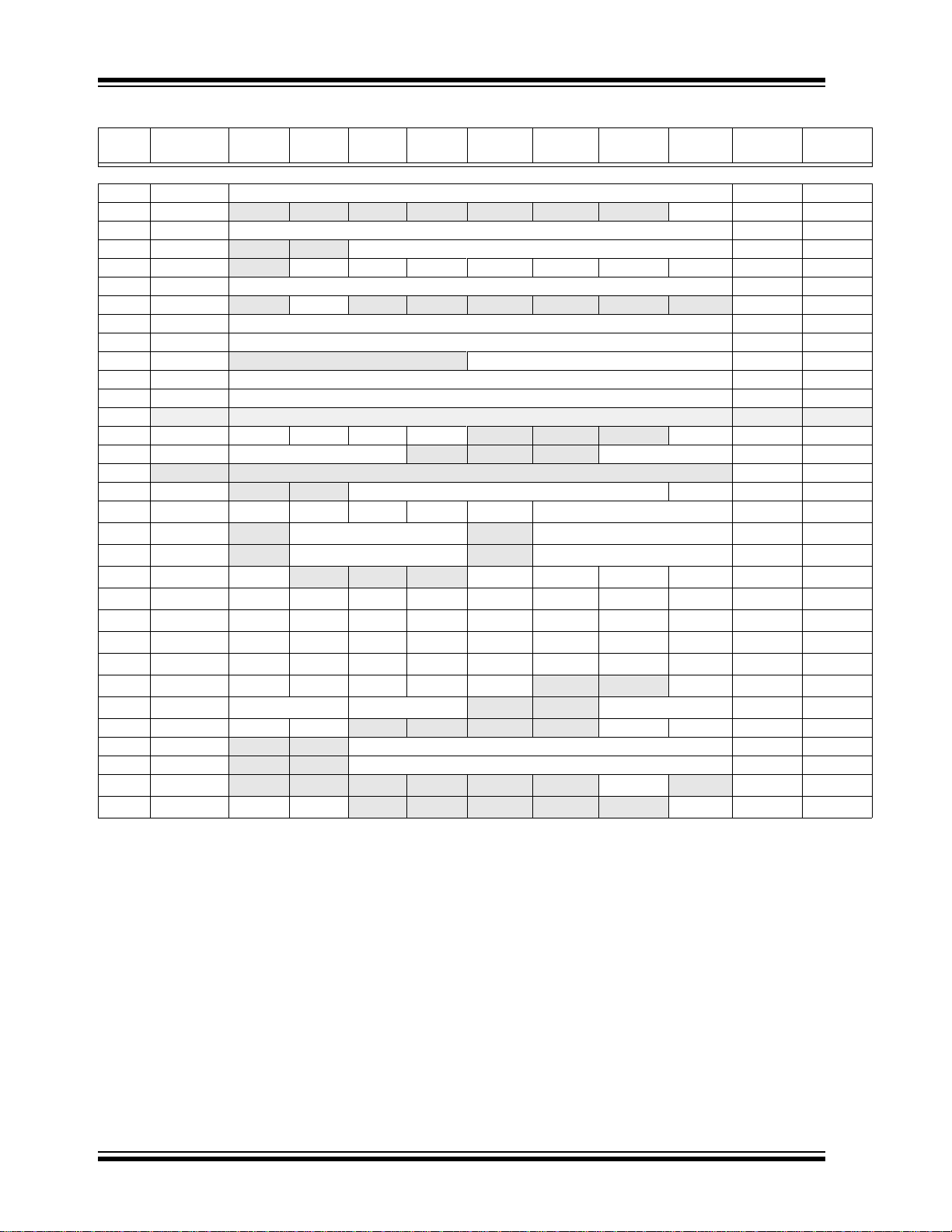

2.1 Program Memory Organization

The mid-range core has a 13-bit program counter

capable of addressing 8K x 14 program memory space.

This device family only implements up to 512 words of

the 8K program memory space. Table 2-1 shows the

memory sizes implemented for the PIC10(L)F320/322

family. Accessing a location above these boundaries will

cause a wrap-around within the implemented memory

space. The Reset vector is at 0000h and the interrupt

vector is at 0004h (see Figures 2-1, and 2-2).

2011 Microchip Technology Inc. Preliminary DS41585A-page 11

Page 12

PIC10(L)F320/322

PC<12:0>

13

0000h

0004h

Stack Level 0

Stack Level 8

Reset Vector

Interrupt Vector

Stack Level 1

0005h

On-chip

Program

Memory

Page 0

00FFh

Wraps to Page 0

Wraps to Page 0

Wraps to Page 0

0100h

CALL,

RETURN, RETLW

RETFIE

Rollover to Page 0

Rollover to Page 0

FFFh

PC<12:0>

13

0000h

0004h

Stack Level 0

Stack Level 8

Reset Vector

Interrupt Vector

Stack Level 1

0005h

On-chip

Program

Memory

Page 0

01FFh

Wraps to Page 0

Wraps to Page 0

0200h

CALL

RETURN, RETLW

RETFIE

Rollover to Page 0

Rollover to Page 0

FFFh

FIGURE 2-1: PROGRAM MEMORY MAP

AND STACK FOR

PIC10(L)F320

FIGURE 2-2: PROGRAM MEMORY MAP

AND STACK FOR

PIC10(L)F322

DS41585A-page 12 Preliminary 2011 Microchip Technology Inc.

Page 13

PIC10(L)F320/322

2.2 Data Memory Organization

The data memory is in one bank, which contains the

General Purpose Registers (GPR) and the Special

Function Registers (SFR). The RP<1:0> bits of the

STATUS register are the bank select bits.

RP0

RP1

00 Bank 0 is selected

The bank extends up to 7Fh (128 bytes). The lower

locations of the bank are reserved for the Special Function Registers. Above the Special Function Registers

are the General Purpose Registers, implemented as

Stati c RAM.

2.2.1 GENERAL PURPOSE REGISTER

FILE

The register file is organized as 64 x 8 in the

PIC10(L)F320/322. Each register is accessed, either

directly or indirectly, through the File Select Register

(FSR) (see Section 2.4 “Indirect Addressing, INDF

and FSR Registers”).

2.2.2 SPECIAL FUNCTION REGISTERS

The Special Function Registers are registers used by

the CPU and peripheral functions for controlling the

desired operation of the device (see Tab le 2- 3 ). These

registers are static RAM.

The special registers can be classified into two sets:

core and peripheral. The Special Function Registers

associated with the “core” are described in this section.

Those related to the operation of the peripheral features

are described in the section of that peripheral feature.

2011 Microchip Technology Inc. Preliminary DS41585A-page 13

Page 14

PIC10(L)F320/322

2.2.2.1 STATUS Register

The STATUS register, shown in Register 2-1, contains:

• the arithmetic status of the ALU

• the Reset status

• the bank select bits for data memory (SRAM)

The STATUS register can be the destination for any

instruction, like any other register. If the STATUS

register is the destination for an instruction that affects

the Z, DC or C bits, then the write to these three bits is

disabled. These bits are set or cleared according to the

device logic. Furthermore, the TO

writable. Therefore, the result of an instruction with the

STATUS register as destination may be different than

intended.

For example, CLRF STATUS will clear the upper three

bits and set the Z bit. This leaves the STATUS register

as ‘000u u1uu’ (where u = unchanged).

It is recommended, therefore, that only BCF, BSF,

SWAPF and MOVWF instructions are used to alter the

STATUS register, because these instructions do not

affect any Status bits. For other instructions not affecting any Status bits (see Section 23.0 “Instruction Set

Summary”).

and PD bits are not

Note 1: Bits IRP and RP1 of the STATUS register

are not used by the PIC10(L)F320 and

should be maintained as clear. Use of

these bits is not recommended, since this

may affect upward compatibility with

future products.

2: The C and DC bits operate as a Borrow

and Digit Borrow out bit, respectively, in

subtraction.

DS41585A-page 14 Preliminary 2011 Microchip Technology Inc.

Page 15

PIC10(L)F320/322

REGISTER 2-1: STATUS: STATUS REGISTER

R/W-0/0 R/W-0/0 R/W-0/0 R-1/q R-1/q R/W-x/u R/W-x/u R/W-x/u

IRP RP1 RP0 TO PD ZDCC

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

u = Bit is unchanged x = Bit is unknown -n/n = Value at POR and BOR/Value at all other Resets

‘1’ = Bit is set ‘0’ = Bit is cleared q = Value depends on condition

bit 7 IRP: Reserved

bit 6-5 RP<1:0>: Reserved

bit 4 TO: Time-out bit

1 = After power-up, CLRWDT instruction or SLEEP instruction

0 = A WDT time-out occurred

bit 3 PD

bit 2 Z: Zero bit

bit 1 DC: Digit Carry/Borrow

bit 0 C: Carry/Borrow bit (ADDWF, ADDLW, SUBLW, SUBWF instructions)

Note1: For Borrow

second operand. For rotate (RRF, RLF) instructions, this bit is loaded with either the high or low-order bit of

the source register.

2: Maintain as ‘0’.

: Power-Down bit

1 = After power-up or by the CLRWDT instruction

0 = By execution of the SLEEP instruction

1 = The result of an arithmetic or logic operation is zero

0 = The result of an arithmetic or logic operation is not zero

1 = A carry-out from the 4th low-order bit of the result occurred

0 = No carry-out from the 4th low-order bit of the result

1 = A carry-out from the Most Significant bit of the result occurred

0 = No carry-out from the Most Significant bit of the result occurred

, the polarity is reversed. A subtraction is executed by adding the two’s complement of the

(2)

(2)

bit (ADDWF, ADDLW, SUBLW, SUBWF instructions)

(1)

(1)

2011 Microchip Technology Inc. Preliminary DS41585A-page 15

Page 16

PIC10(L)F320/322

Legend: = Unimplemented data memory locations, read as ‘0’.

* = Not a physical register.

INDF

(*)

00h

PMADRL

20h

General

Purpose

Registers

32 Bytes

40h

5Fh

General

Purpose

Registers

32 Bytes

60h

7Fh

TMR0 01h PMADRH 21h

PCL 02h PMDATL 22h

STATUS 03h PMDATH 23h

FSR 04h PMCON1 24h

PORTA 05h PMCON2 25h

TRISA 06h CLKRCON 26h

LATA 07h NCO1ACCL 27h

ANSELA

08h

NCO1ACCH

28h

WPUA

09h

NCO1ACCU

29h

PCLATH 0Ah NCO1INCL 2Ah

INTCON 0Bh NCO1INCH 2Bh

PIR1 0Ch Reserved 2Ch

PIE1 0Dh NCO1CON 2Dh

OPTION_REG 0Eh NCO1CLK 2Eh

PCON 0Fh Reserved 2Fh

OSCCON 10h WDTCON 30h

TMR2 11h CLC1CON 31h

PR2 12h CLC1SEL1 32h

T2CON 13h CLC1SEL2 33h

PWM1DCL 14h CLC1POL 34h

PWM1DC 15h CLC1GATE1 35h

PWM1CON 16h CLC1GATE2 36h

PWM2DCL 17h CLC1GATE3 37h

PWM2DC 18h CLC1GATE4 38h

PWM2CON 19h CWG1CON0 39h

IOCAP 1Ah CWG1CON1 3Ah

IOCAN 1Bh CWG1ASD 3Bh

IOCAF 1Ch CWG1RC 3Ch

FVRCON 1Dh CWG1FC 3Dh

ADRES

1Eh

VREGCON

3Eh

ADCON 1Fh

BORCON

3Fh

2.2.3 DEVICE MEMORY MAPS

The memory maps for PIC10(L)F320/322 are as shown

in Table 2-2.

TABLE 2-2: PIC10(L)F320/322 MEMORY MAP (BANK 0)

DS41585A-page 16 Preliminary 2011 Microchip Technology Inc.

Page 17

PIC10(L)F320/322

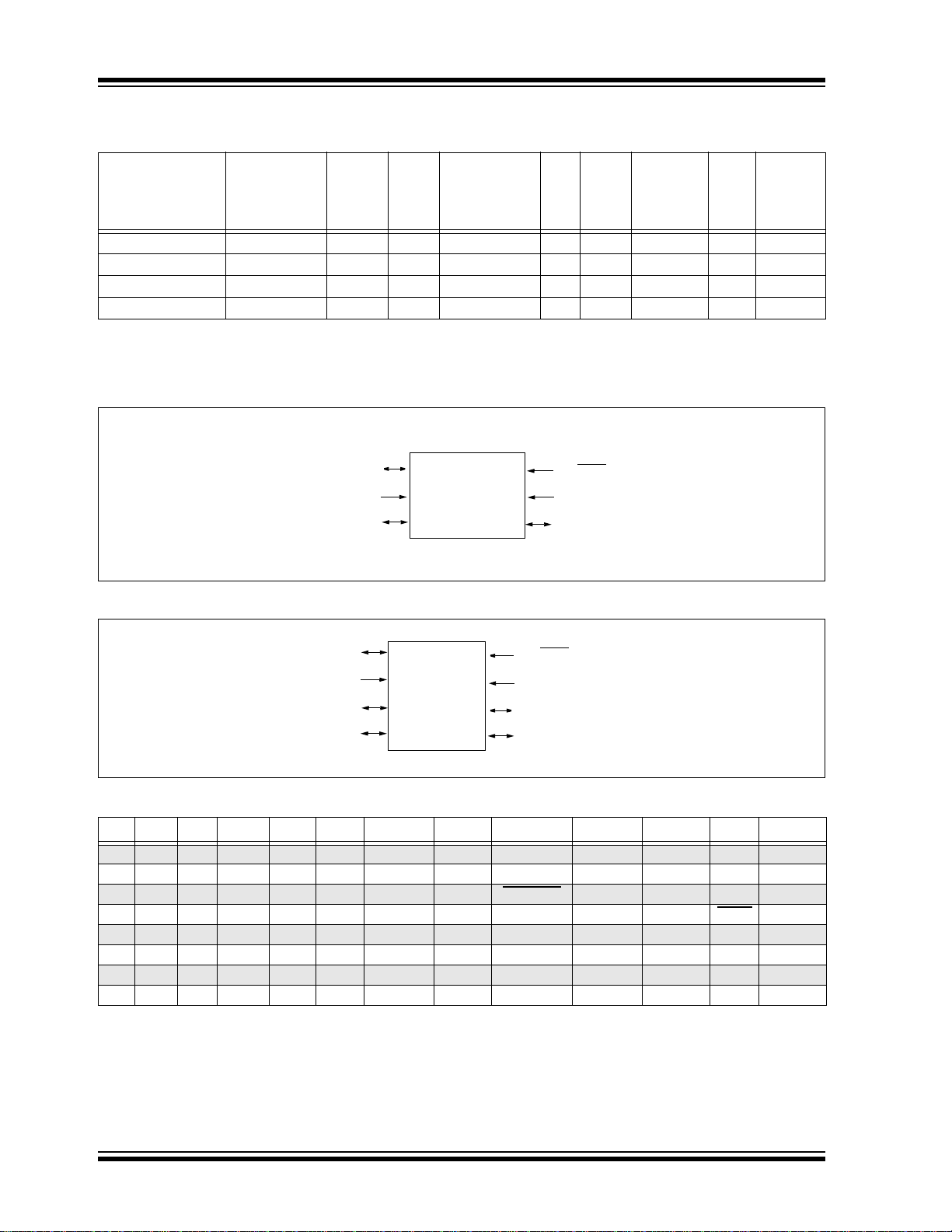

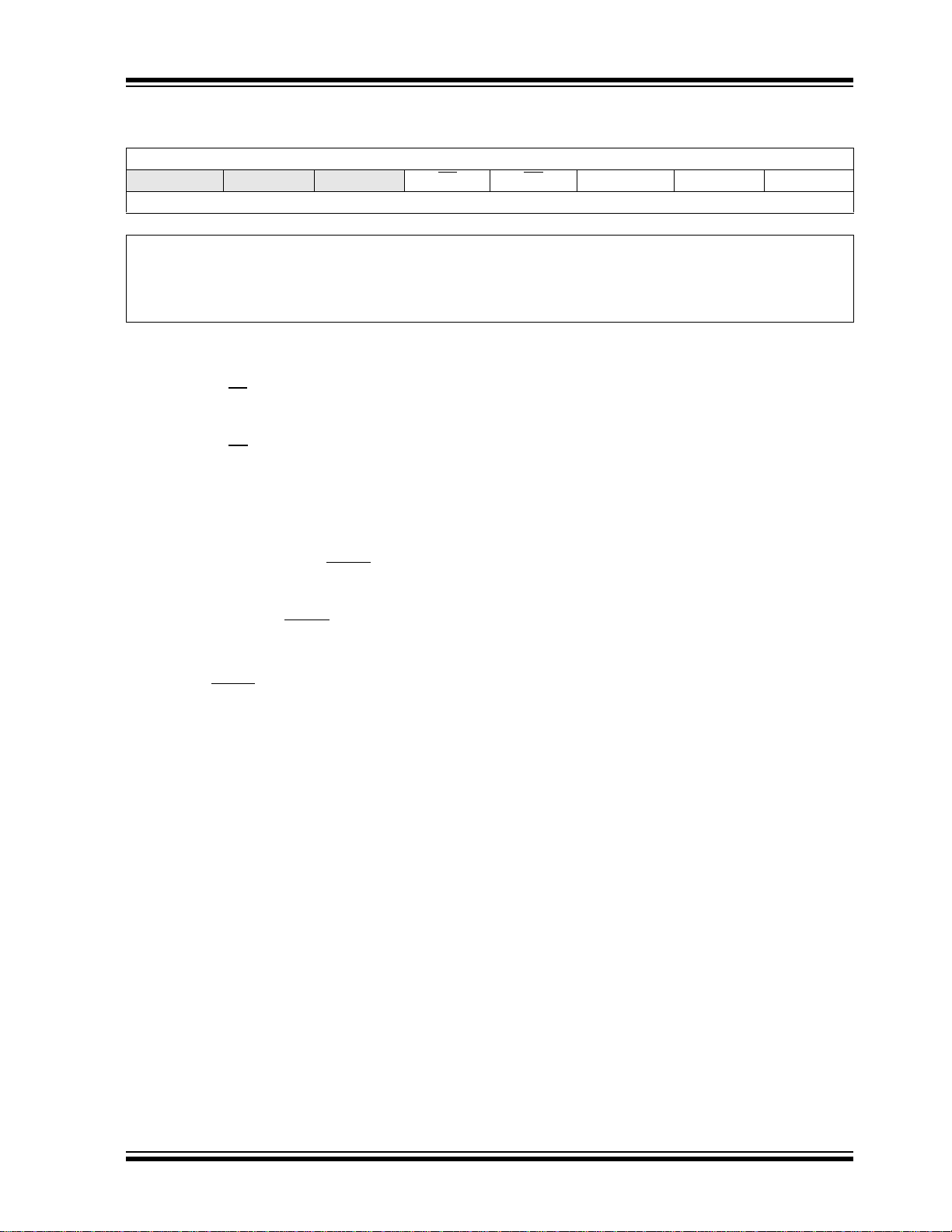

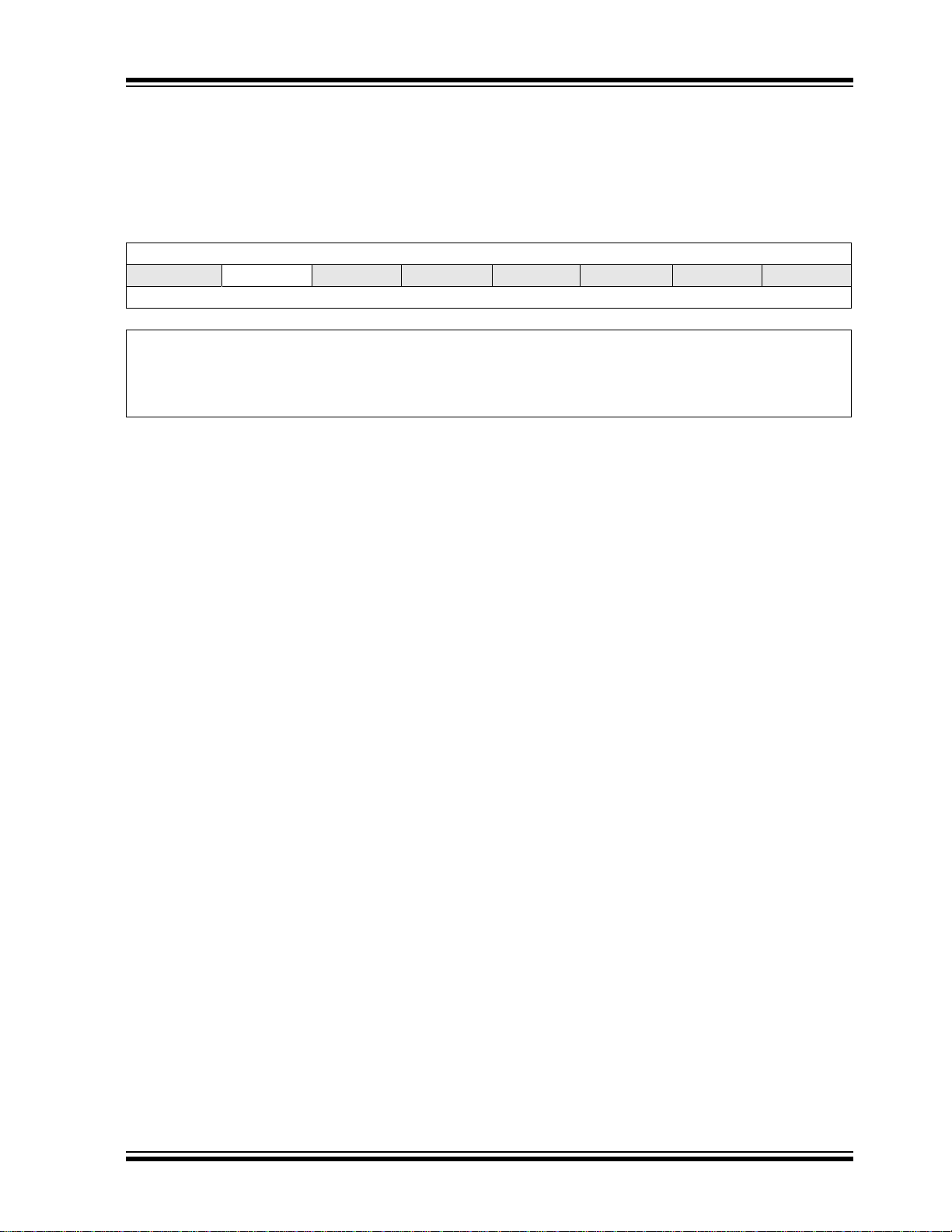

TABLE 2-3: SPECIAL FUNCTION REGISTER SUMMARY (BANK 0)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 0

00h INDF Addressing this location uses contents of FSR to address data memory (not a physical register) xxxx xxxx xxxx xxxx

01h TMR0 Timer0 Module Register xxxx xxxx uuuu uuuu

02h PCL Program Counter (PC) Least Significant Byte 0000 0000 0000 0000

03h STATUS IRP RP1 RP0 TO

04h FSR Indirect Data Memory Address Pointer xxxx xxxx uuuu uuuu

05h PORTA

06h TRISA

07h LATA

08h ANSELA

09h WPUA

0Ah PCLATH

0Bh INTCON GIE PEIE TMR0IE INTE IOCIE TMR0IF INTF IOCIF 0000 0000 0000 000u

0Ch PIR1

0Dh PIE1

0Eh OPTION_REG WPUEN

0Fh

10h OSCCON

11h TMR2 Timer2 Module Register 0000 0000 0000 0000

12h PR2 Timer2 Period Register 1111 1111 1111 1111

13h T2CON

14h PWM1DCL PWM1DCL<1:0>

15h PWM1DCH PWM1DCH<7:0> xxxx xxxx uuuu uuuu

16h PWM1CON

17h PWM2DCL PWM2DCL<1:0>

18h PWM2DCH PWM2DCH<7:0> xxxx xxxx uuuu uuuu

19h PWM2CON

1Ah IOCAP

1Bh IOCAN

1Ch IOCAF

1Dh FVRCON FVREN FVRRDY TSEN TSRNG

1Eh ADRES A/D Result Register xxxx xxxx uuuu uuuu

1Fh ADCON ADCS<2:0> CHS<2:0>

Legend: x = unknown, u = unchanged, q = value depends on condition, - = unimplemented, read as ‘0’, r = reserved.

Note 1: Unimplemented, read as ‘1’.

PCON — — — — — —PORBOR ---- --qq ---- --uu

Shaded locations are unimplemented, read as ‘0’.

— — — — RA3 RA2 RA1 RA0 ---- xxxx ---- uuuu

— — — — —

— — — — — LATA2 LATA1 LATA0 ---- -xxx ---- -uuu

— — — — — ANSA2 ANSA1 ANSA0 ---- -111 ---- -111

— — — — WPUA3 WPUA2 WPUA1 WPUA0 ---- 1111 ---- 1111

— — — — — — — PCLH0 ---- ---0 ---- ---0

—ADIF— NCO1IF CLC1IF —TMR2IF— -0-0 0-0- -0-0 0-0-

—ADIE— NCO1IE CLC1IE —TMR2IE— -0-0 0-0- -0-0 0-0-

INTEDG T0CS T0SE PSA PS<2:0> 1111 1111 uuuu uuuu

— IRCF<2:0> HFIOFR — LFIOFR HFIOFS -110 0-00 -110 0-00

— TOUTPS<3:0> TMR2ON T2CKPS1 T2CKPS0 -000 0000 -000 0000

— — — — — — xx-- ---- uu-- ----

PWM1EN PWM1OE PWM1OUT PWM1POL — — — —

— — — — — — xx-- ---- uu-- ----

PWM2EN PWM2OE PWM2OUT PWM2POL

— — — — IOCAP3 IOCAP2 IOCAP1 IOCAP0 ---- 0000 ---- 0000

— — — — IOCAN3 IOCAN2 IOCAN1 IOCAN0 ---- 0000 ---- 0000

— — — — IOCAF3 IOCAF2 IOCAF1 IOCAF0 ---- 0000 ---- 0000

PD ZDCC0001 1xxx 000q quuu

(1)

TRISA2 TRISA1 TRISA0 ---- 1111 ---- 1111

— — — — 0000 ---- 0000 ----

— —ADFVR<1:0>0x00 --00 0x00 --00

GO/

DONE

ADON 0000 0000 0000 0000

Value on

POR, BOR

0000 ---- 0000 ----

Value on all

other resets

2011 Microchip Technology Inc. Preliminary DS41585A-page 17

Page 18

PIC10(L)F320/322

TABLE 2-3: SPECIAL FUNCTION REGISTER SUMMARY (BANK 0) (CONTINUED)

Address Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Bank 0 (Continued)

20h PMADRL PMADR<7:0> 0000 0000 0000 0000

21h PMADRH

22h PMDATL PMDAT<7:0> xxxx xxxx uuuu uuuu

23h PMDATH

24h PMCON1

25h PMCON2 Program Memory Control Register 2 (not a physical register) 0000 0000 0000 0000

26h CLKRCON

27h NCO1ACCL NCO1 Accumulator <7:0> 0000 0000 0000 0000

28h NCO1ACCH NCO1 Accumulator <15:8> 0000 0000 0000 0000

29h NCO1ACCU

2Ah NCO1INCL NCO1 Increment <7:0> 0000 0001 0000 0001

2Bh NCO1INCH NCO1 Increment <15:8> 0000 0000 0000 0000

2Ch

2Dh NCO1CON N1EN N1OE N1OUT N1POL

2Eh NCO1CLK

2Fh

30h WDTCON

31h

32h

33h

34h

35h

36h

37h

38h

39h CWG1CON0

3Ah CWG1CON1

3Bh CWG1CON2 G1ASE G1ARSEN

3Ch CWG1DBR

3Dh CWG1DBF

3Eh

3Fh

Legend: x = unknown, u = unchanged, q = value depends on condition, - = unimplemented, read as ‘0’, r = reserved.

Note 1: Unimplemented, read as ‘1’.

— Unimplemented — —

Reserved Reserved xxxx xxxx uuuu uuuu

CLC1CON

CLC1SEL0

CLC1SEL1

CLC1POL

CLC1GLS0

CLC1GLS1

CLC1GLS2

CLC1GLS3

VREGCON

BORCON

Shaded locations are unimplemented, read as ‘0’.

— — — — — — — PMADR8 ---- ---0 ---- ---0

— —PMDAT<13:8>--xx xxxx --uu uuuu

— CFGS LWL O FR EE WRERR WREN WR RD 1000 0000 1000 q000

—CLKROE— — — — — — -0-- ---- -0-- ----

— NCO1 Accumulator <19..16> --- - 00 00 ---- 0000

— — —N1PFM0000 ---0 00x0 ---0

N1PWS<2:0> — — —N1CKS<1:0>

— —WDTPS<4:0>SWDTEN--01 0110 --01 0110

LC1EN LC1OE LC1OUT LC1INTP LC1INTN LC1MODE<2:0> 00x0 -000 00x0 -000

— LC1D2S<2:0> — LC1D1S<2:0> -xxx -xxx -uuu -uuu

— LC1D4S<2:0> — LC1D3S<2:0> -xxx -xxx -uuu -uuu

LC1POL

LC1G1D4T LC1G1D4N LC1G1D3T LC1G1D3N LC1G1D 2T LC1G 1D2N LC1G1D1 T LC1G 1D1N

LC1G2D4T LC1G2D4N LC1G2D3T LC1G2D3N LC1G2D 2T LC1G 2D2N LC1G2D1 T LC1G 2D1N

LC1G3D4T LC1G3D4N LC1G3D3T LC1G3D3N LC1G3D 2T LC1G 3D2N LC1G3D1 T LC1G 3D1N

LC1G4D4T LC1G4D4N LC1G4D3T LC1G4D3N LC1G4D 2T LC1G 4D2N LC1G4D1 T LC1G 4D1N

G1EN G1OEB G1OEA G1POLB G1POLA

G1ASDLB<1:0> G1ASDLA<1:0>

— —CWG1DBR<5:0>--xx xxxx --uu uuuu

— —CWG1DBF<5:0>--xx xxxx --uu uuuu

— — — — — —VREGPM1Reserved ---- --01 ---- --01

SBOREN BORFS — — — — — BORRDY 10-- ---q uu-- ---u

— — — LC1G4POL LC1G3POL LC1G2POL LC1G1POL 0--- xxxx 0--- uuuu

— —

— —

— — — — G1ASDCLC1 G1ASDFLT xx-- --xx uu-- --uu

G1CS0

G1IS<1:0>

Value on

POR, BOR

000- --00 000- --00

xxxx xxxx uuuu uuuu

xxxx xxxx uuuu uuuu

xxxx xxxx uuuu uuuu

xxxx xxxx uuuu uuuu

0000 0--0 0000 0--0

xxxx --xx uuuu --uu

Value on all

other resets

DS41585A-page 18 Preliminary 2011 Microchip Technology Inc.

Page 19

PIC10(L)F320/322

PC

12 8 7 0

5

PCLATH<4:0>

PCLATH

Instruction with

ALU Result

GOTO, CALL

OPCODE <10:0>

8

PC

12 11 10 0

11

PCLATH<4:3>

PCH PCL

87

2

PCLATH

PCH PCL

PCL as

Destination

MOVLW 0x40 ;initialize pointer

MOVWF FSR ;to RAM

NEXT CLRF INDF ;clear INDF register

INCF FSR ;inc pointer

BTFSS FSR,7 ;all done?

GOTO NEXT ;no clear next

CONTINUE ;yes continue

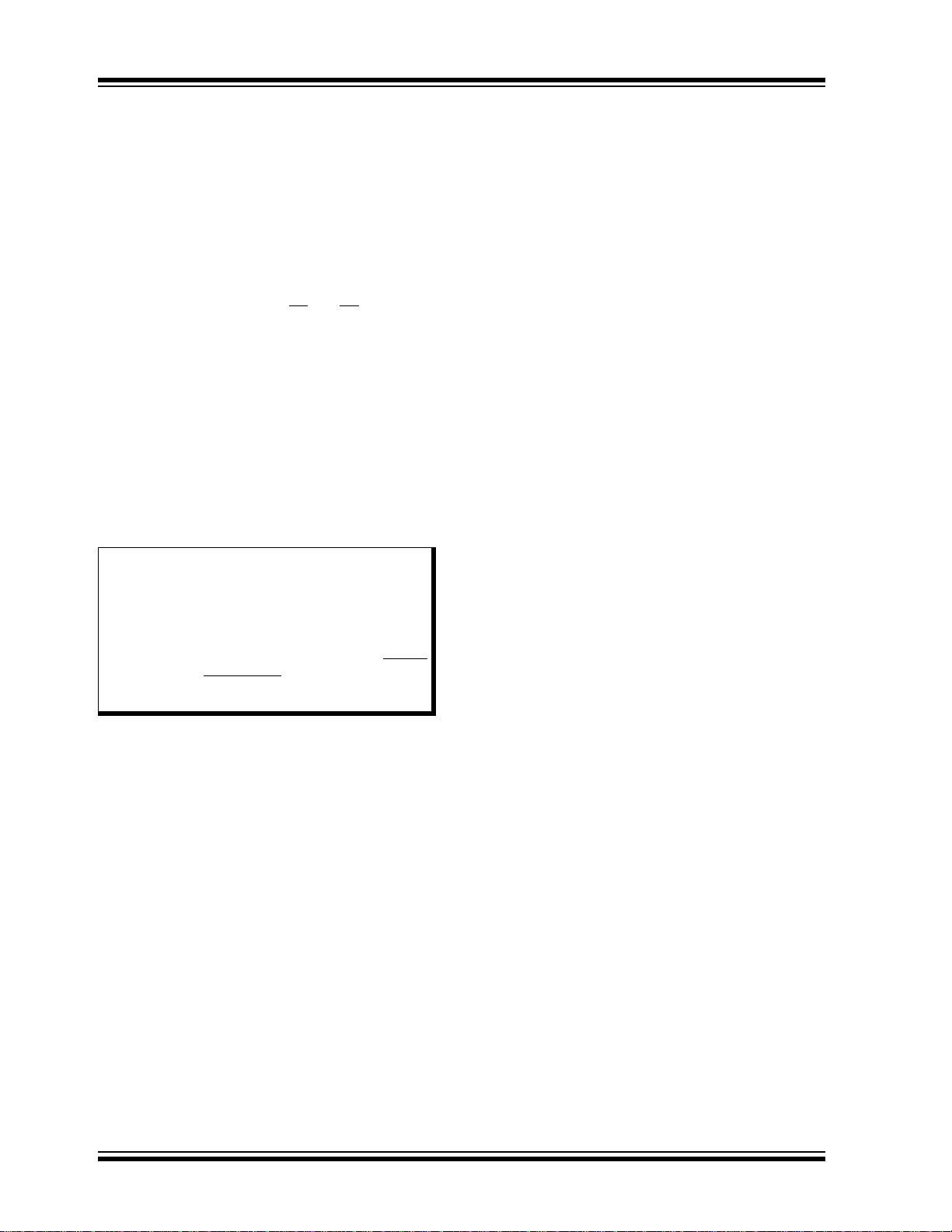

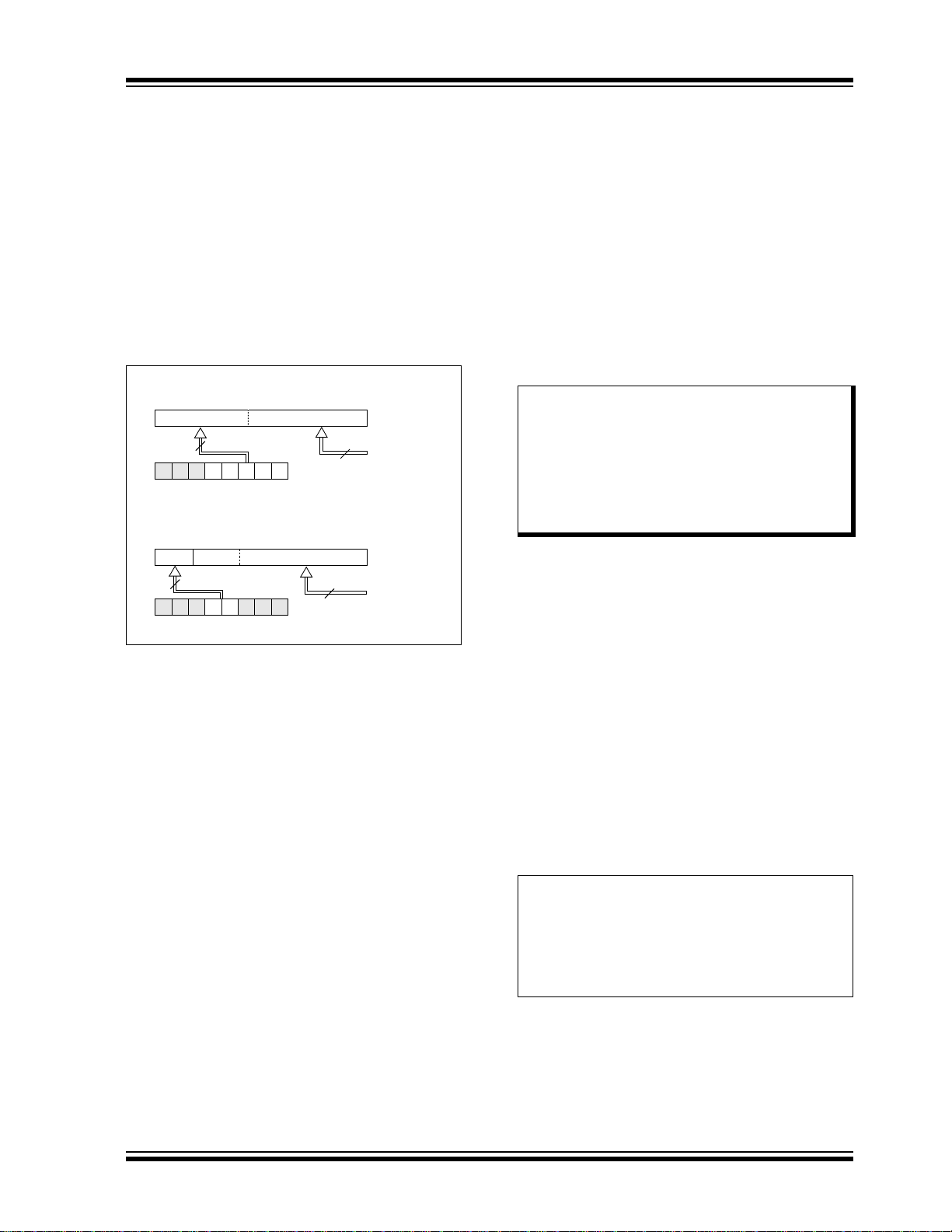

2.3 PCL and PCLATH

The Program Counter (PC) is 13 bits wide. The low byte

comes from the PCL register, which is a readable and

writable register. The high byte (PC<12:8>) is not directly

readable or writable and comes from PCLATH. On any

Reset, the PC is cleared. Figure 2-3 shows the two

situations for the loading of the PC. The upper example

in Figure 2-3 shows how the PC is loaded on a write to

PCL (PCLATH<4:0> PCH). The lower example in

Figure 2-3 shows how the PC is loaded during a CALL or

GOTO instruction (PCLATH<4:3> PCH).

FIGURE 2-3: LOADING OF PC IN

DIFFERENT SITUATIONS

2.3.2 STACK

All devices have an 8-level x 13-bit wide hardware

stack (see Figure 2-1). The stack space is not part of

either program or data space and the Stack Pointer is

not readable or writable. The PC is PUSHed onto the

stack when a CALL instruction is executed or an interrupt causes a branch. The stack is POPed in the event

of a RETURN, RETLW or a RETFIE instruction execution. PCLATH is not affected by a PUSH or POP operation.

The stack operates as a circular buffer. This means that

after the stack has been PUSHed eight times, the ninth

push overwrites the value that was stored from the first

push. The tenth push overwrites the second push (and

so on).

Note 1: There are no Status bits to indicate Stack

Overflow or Stack Underflow conditions.

2: There are no instructions/mnemonics

called PUSH or POP. These are actions

that occur from the execution of the

CALL, RETURN, RETLW and RETFIE

instructions or the vectoring to an

interrupt address.

2.4 Indirect Addressing, INDF and

FSR Registers

2.3.1 MODIFYING PCL

Executing any instruction with the PCL register as the

destination simultaneously causes the Program

Counter PC<12:8> bits (PCH) to be replaced by the

contents of the PCLATH register. This allows the entire

contents of the program counter to be changed by

writing the desired upper 5 bits to the PCLATH register.

When the lower 8 bits are written to the PCL register, all

13 bits of the program counter will change to the values

contained in the PCLATH register and those being

written to the PCL register.

A computed GOTO is accomplished by adding an offset

to the program counter (ADDWF PCL). Care should be

exercised when jumping into a look-up table or

program branch table (computed GOTO) by modifying

the PCL register. Assuming that PCLATH is set to the

table start address, if the table length is greater than

255 instructions or if the lower 8 bits of the memory

address rolls over from 0xFF to 0x00 in the middle of

the table, then PCLATH must be incremented for each

address rollover that occurs between the table

beginning and the target location within the table.

For more information refer to Application Note AN556,

“Implementing a Table Read” (DS00556).

The INDF register is not a physical register. Addressing

the INDF register will cause indirect addressing.

Indirect addressing is possible by using the INDF

register. Any instruction using the INDF register

actually accesses data pointed to by the File Select

Register (FSR). Reading INDF itself indirectly will

produce 00h. Writing to the INDF register indirectly

results in a no operation (although Status bits may be

affected). An effective 9-bit address is obtained by

concatenating the 8-bit FSR and the IRP bit of the

STATUS register, as shown in Figure 2-4.

A simple program to clear RAM location 40h-7Fh using

indirect addressing is shown in Example 2-1.

EXAMPLE 2-1: INDIRECT ADDRESSING

2011 Microchip Technology Inc. Preliminary DS41585A-page 19

Page 20

PIC10(L)F320/322

Data

Memory

Indirect AddressingDirect Addressing

Location Select

6

0

From Opcode

File Select Register

7

0

Location Select

00h

7Fh

Bank 0

For memory map detail, see Figure 2-2.

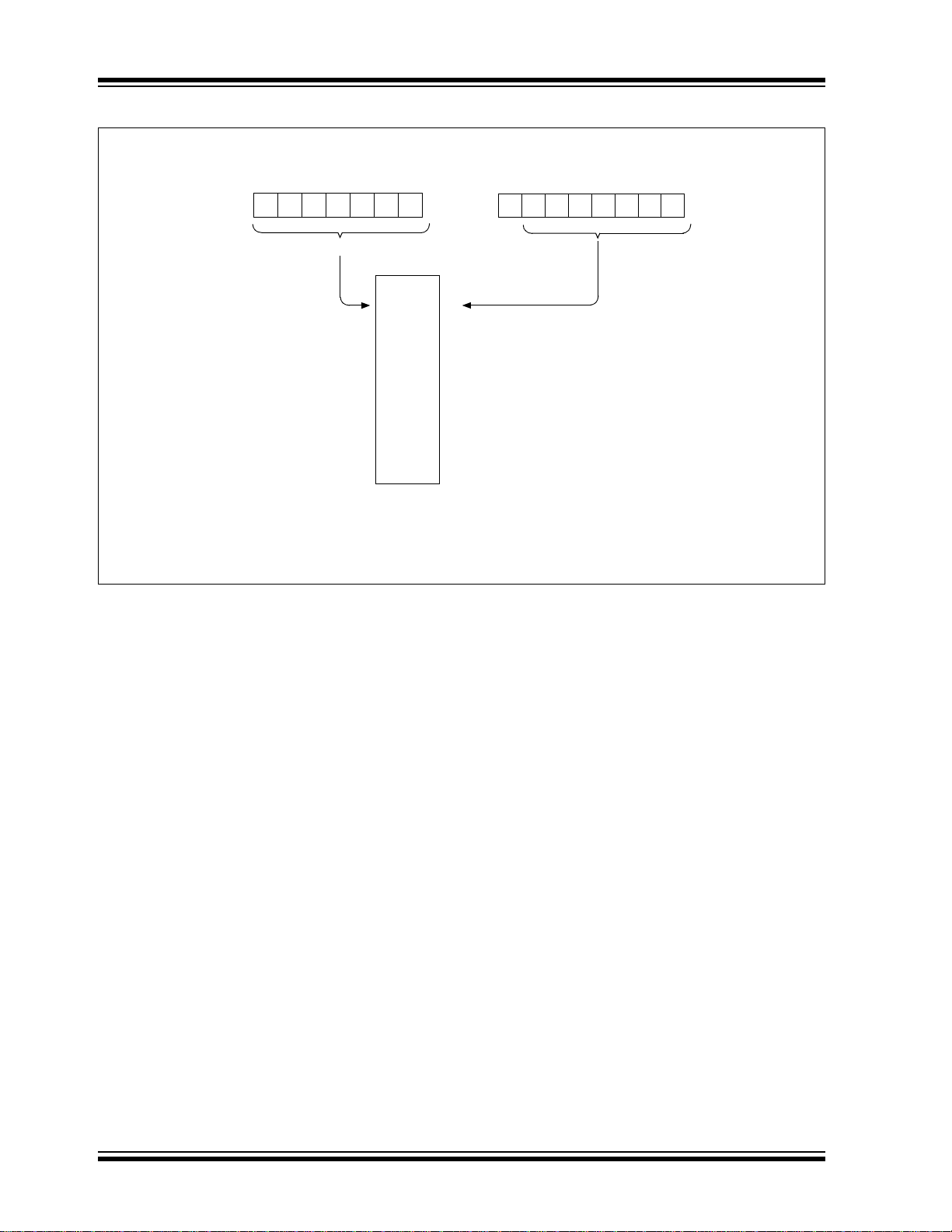

FIGURE 2-4: DIRECT/INDIRECT ADDRESSING PIC10(L)F320/322

DS41585A-page 20 Preliminary 2011 Microchip Technology Inc.

Page 21

3.0 DEVICE CONFIGURATION

Device Configuration consists of Configuration Word

and Device ID.

3.1 Configuration Word

There are several Configuration Word bits that allow

different oscillator and memory protection options.

These are implemented as Configuration Word at

2007h.

PIC10(L)F320/322

2011 Microchip Technology Inc. Preliminary DS41585A-page 21

Page 22

PIC10(L)F320/322

REGISTER 3-1: CONFIG: CONFIGURATION WORD

U-1 R/P-1/1 R/P-1/1 R/P-1/1 R/P-1/1

— WRT<1:0> BORV LPBOR

bit 13 bit 8

R/P-1/1 R/P-1/1 R/P-1/1 R/P-1/1 R/P-1/1 R/P-1/1 R/P-1/1

CP MCLRE PWRTE WDTE<1:0> BOREN<1:0>

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

u = Bit is unchanged x = Bit is unknown -n/n = Value at POR and BOR/Value at all other Resets

‘1’ = Bit is set ‘0’ = Bit is cleared P = Programmable bit

bit 13 Unimplemented: Read as ‘1’

bit 12-11 WRT<1:0>: Flash Memory Self-Write Protection bits

256 W Flash memory: PIC10(L)F320:

11 =Write protection off

10 =000h to 03Fh write-protected, 040h to 0FFh may be modified by PMCON control

01 =000h to 07Fh write-protected, 080h to 0FFh may be modified by PMCON control

00 =000h to 0FFh write-protected, no addresses may be modified by PMCON control

512 W Flash memory: PIC10(L)F322:

11 =Write protection off

10 =000h to 07Fh write-protected, 080h to 1FFh may be modified by PMCON control

01 =000h to 0FFh write-protected, 100h to 1FFh may be modified by PMCON control

00 =000h to 1FFh write-protected, no addresses may be modified by PMCON control

bit 10 BORV: Brown-out Reset Voltage Selection bit

1 = Brown-out Reset Voltage (V

0 = Brown-out Reset Voltage (V

bit 9 LPBOR: Low-Power Brown-out Reset Enable bit

1 = Low-power Brown-out Reset is enabled

0 = Low-power Brown-out Reset is disabled

bit 8 LVP: Low-Voltage Programming Enable bit

1 = Low-Voltage Programming enabled. MCLR

0 = High Voltage on MCLR

bit 7 CP

bit 6 MCLRE: MCLR

bit 5 PWRTE

: Code Protection bit

1 = Program memory code protection is disabled

0 = Program memory code protection is enabled

If LVP bit =

This bit is ignored.

If LVP bit = 0:

1 =MCLR

0 =MCLR

1 = PWRT disabled

0 = PWRT enabled

1:

/VPP pin function is MCLR; Weak pull-up enabled.

/VPP pin function is digital input; MCLR internally disabled; Weak pull-up under control of

WPUA3 bit.

: Power-up Timer Enable bit

/VPP Pin Function Select bit

(2)

BOR) set to 1.9V (PIC10LF320/322) or 2.4V (PIC10F320/322)

BOR) set to 2.7V

/VPP pin function is MCLR.

/VPP must be used for programming

(1)

R/P-1/1

LVP

R/P-1/1

FOSC

Note 1: Enabling Brown-out Reset does not automatically enable Power-up Timer.

2: Once enabled, code-protect can only be disabled by bulk erasing the device.

DS41585A-page 22 Preliminary 2011 Microchip Technology Inc.

Page 23

PIC10(L)F320/322

REGISTER 3-1: CONFIG: CONFIGURATION WORD (CONTINUED)

bit 4-3 WDTE<1:0>: Watchdog Timer Enable bit

11 = WDT enabled

10 = WDT enabled while running and disabled in Sleep

01 = WDT controlled by the SWDTEN bit in the WDTCON register

00 = WDT disabled

bit 2-1 BOREN<1:0>: Brown-out Reset Enable bits

11 = Brown-out Reset enabled; SBOREN bit is ignored

10 = Brown-out Reset enabled while running, disabled in Sleep; SBOREN bit is ignored

01 = Brown-out Reset controlled by the SBOREN bit in the BORCON register

00 = Brown-out Reset disabled; SBOREN bit is ignored

bit 0 FOSC: Oscillator Selection bit

1 = EC on CLKIN pin

0 = INTOSC oscillator I/O function available on CLKIN pin

Note 1: Enabling Brown-out Reset does not automatically enable Power-up Timer.

2: Once enabled, code-protect can only be disabled by bulk erasing the device.

2011 Microchip Technology Inc. Preliminary DS41585A-page 23

Page 24

PIC10(L)F320/322

3.2 Code Protection

Code protection allows the device to be protected from

unauthorized access. Program memory protection and

data memory protection are controlled independently.

Internal access to the program memory and data

memory are unaffected by any code protection setting.

3.2.1 PROGRAM MEMORY PROTECTION

The entire program memory space is protected from

external reads and writes by the CP

Word. When CP

program memory are inhibited and a read will return all

‘0’s. The CPU can continue to read program memory,

regardless of the protection bit settings. Writing the

program memory is dependent upon the write

protection setting. See Section 3.3 “Write

Protection” for more information.

= 0, external reads and writes of

3.3 Write Protecti on

Write protection allows the device to be protected from

unintended self-writes. Applications, such as boot

loader software, can be protected while allowing other

regions of the program memory to be modified.

The WRT<1:0> bits in Configuration Word define the

size of the program memory block that is protected.

bit in Configuration

3.4 User ID

Four memory locations (2000h-2003h) are designated

as ID locations where the user can store checksum or

other code identification numbers. These locations are

readable and writable during normal execution. See

Section 3.5 “Device ID and Revision ID” for more

information on accessing these memory locations.

more information on checksum calculation, see the

“PIC10(L)F320/322 Flash Memory Programming

Specification” (DS41572).

For

DS41585A-page 24 Preliminary 2011 Microchip Technology Inc.

Page 25

PIC10(L)F320/322

Device

DEVICEID<13:0> Values

DEV<8:0> REV<4:0>

PIC10F320 10 1001 101 x xxxx

PIC10LF320 10 1001 111 x xxxx

PIC10F322 10 1001 100 x xxxx

PIC10LF322 10 1001 110 x xxxx

3.5 Device ID and Revision ID

The memory location 2006h is where the Device ID and

Revision ID are stored. The upper nine bits hold the

Device ID. The lower five bits hold the Revision ID. See

Section 9.4 “User ID, Device ID and Configuration

Word Access” for more information on accessing

these memory locations.

Development tools, such as device programmers and

debuggers, may be used to read the Device ID and

Revision ID.

REGISTER 3-2: DEVICEID: DEVICE ID REGISTER

RRRRRR

DEV8 DEV7 DEV6 DEV5 DEV4 DEV3

bit 13 bit 8

RRRRRRRR

DEV2 DEV1 DEV0 REV4 REV3 REV2 REV1 REV0

bit 7 bit 0

(1)

Legend: U = Unimplemented bit, read as ‘0’

R = Readable bit W = Writable bit ‘0’ = Bit is cleared

-n = Value at POR ‘1’ = Bit is set x = Bit is unknown

bit 13-5 DEV<8:0>: Device ID bits

bit 4-0 REV<4:0>: Revision ID bits

These bits are used to identify the revision.

Note 1: This location cannot be written.

2011 Microchip Technology Inc. Preliminary DS41585A-page 25

Page 26

PIC10(L)F320/322

NOTES:

DS41585A-page 26 Preliminary 2011 Microchip Technology Inc.

Page 27

PIC10(L)F320/322

HFINTOSC

16 MHz

HFIOFR

(1)

HFIOFS

(1)

Divider

16 MHz

8 MHz

4 MHz

2 MHz

1 MHz

500 kHz

250 kHz

MUX

111

110

101

100

011

010

001

LFINTOSC

31 kHz

000

IRCF<2:0>

INTOSC

LFIOFR

(1)

CLKIN

EC

MUX

FOSC

(Configuration

Word)

System Clock

(CPU and

Peripherals)

CLKROE

CLKR

31 kHz

0

1

3

Note 1: HFIOFR, HFIOFS and LFIOFR are Status bits in the OSCCON register.

4.0 OSCILLATOR MODULE

4.1 Overview

The oscillator module has a variety of clock sources and

selection features that allow it to be used in a range of

applications while maximizing performance and

minimizing power consumption. Figure 4-1 illustrates a

block diagram of the oscillator module.

The system can be configured to use an internal

calibrated high-frequency oscillator as clock source, with

a choice of selectable speeds via software.

Clock source modes are configured by the FOSC bit in

Configuration Word (CONFIG).

1. EC oscillator from CLKIN.

2. INTOSC oscillator, CLKIN not enabled.

FIGURE 4-1: PIC10(L)F320/322 CLOCK SOURCE BLOCK DIAGRAM

2011 Microchip Technology Inc. Preliminary DS41585A-page 27

Page 28

PIC10(L)F320/322

4.2 Clock Source Modes

Clock source modes can be classified as external or

internal.

• Internal clock source (INTOSC) is contained

within the oscillator module, which has eight

selectable output frequencies, with a maximum

internal frequency of 16 MHz.

• The External Clock mode (EC) relies on an

external signal for the clock source.

The system clock can be selected between external or

internal clock sources via the FOSC bit of the

Configuration Word.

4.3 Internal Clock Modes

The internal clock sources are contained within the

oscillator module. The internal oscillator block has two

internal oscillators that are used to generate all internal

system clock sources: the 16 MHz High-Frequency

Internal Oscillator (HFINTOSC) and the 31 kHz

(LFINTOSC).

The HFINTOSC consists of a primary and secondary

clock. The secondary clock starts first with rapid startup time, but low accuracy. The secondary clock ready

signal is indicated with the HFIOFR bit of the OSCCON

register. The primary clock follows with slower start-up

time and higher accuracy. The primary clock is stable

when the HFIOFS bit of the OSCCON register bit goes

high.

4.3.2 FREQUENCY SELECT BITS (IRCF)

The output of the 16 MHz HFINTOSC is connected to

a divider and multiplexer (see Figure 4-1). The Internal

Oscillator Frequency Select bits (IRCF) of the

OSCCON register select the frequency output of the

internal oscillator:

•HFINTOSC

-16 MHz

- 8 MHz (default after Reset)

-4 MHz

-2 MHz

-1 MHz

-500 kHz

-250 kHz

•LFINTOSC

-31 kHz

Note: Following any Reset, the IRCF<2:0> bits

of the OSCCON register are set to ‘110’

and the frequency selection is set to

8 MHz. The user can modify the IRCF bits

to select a different frequency.

There is no delay when switching between HFINTOSC

frequencies with the IRCF bits. This is because the

switch involves only a change to the frequency output

divider.

Start-up delay specifications are located in

Section 24.0 “Electrical Specifications”.

4.3.1 INTOSC MODE

When the FOSC bit of the Configuration Word is

cleared, the INTOSC mode is selected. When INTOSC

is selected, CLKIN pin is available for general purpose

I/O. See Section 3.0 “Device Configuration” for

more information.

DS41585A-page 28 Preliminary 2011 Microchip Technology Inc.

Page 29

PIC10(L)F320/322

4.3.3 REFERENCE CLOCK OUTPUT CONTROL

FOSC/4 output is enabled via the CLKROE bit of

CLKRCON register. The signal drives the pin

regardless of the TRIS setting.

REGISTER 4-1: CLKRCON – REFERENCE CLOCK CONTROL REGISTER

U-0 R/W-0/0 U-0 U-0 U-0 U-0 U-0 U-0

—CLKROE— — — — — —

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

-n = Value at POR ‘1’ = Bit is set ‘0’ = Bit is cleared x = Bit is unknown

q = Value depends on condition

bit 7 Unimplemented: Read as ‘0’

bit 6 CLKROE: Reference Clock Output Enable bit

1 = Reference Clock output (CLKR), regardless of TRIS

0 = Reference Clock output disabled

bit 5-0 Unimplemented: Read as ‘0’

2011 Microchip Technology Inc. Preliminary DS41585A-page 29

Page 30

PIC10(L)F320/322

4.4 Oscillator Control Registers

4.4.1 OSCILLATOR CONTROL

The Oscillator Control (OSCCON) register (Register 4-2)

displays the oscillator readiness, stability and allows

frequency selection of the internal oscillator (INTOSC)

system clock.

REGISTER 4-2: OSCCON: OSCILLATOR CONTROL REGISTER

U-0 R/W-1/1 R/W-1/1 R/W-0/0 R-0/0 U-0 R-0/0 R-0/0

— IRCF<2:0> HFIOFR —LFIOFRHFIOFS

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

u = Bit is unchanged x = Bit is unknown -n/n = Value at POR and BOR/Value at all other Resets

‘1’ = Bit is set ‘0’ = Bit is cleared q = Value depends on condition

bit 7 Unimplemented: Read as ‘0’

bit 6-4 IRCF<2:0>: INTOSC (F

111 = 16 MHz

110 = 8 MHz (default value)

101 = 4 MHz

100 = 2 MHz

011 = 1 MHz

010 = 500 kHz

001 = 250 kHz

000 = 31 kHz (LFINTOSC)

bit 3 HFIOFR: High-Frequency Internal Oscillator Ready bit

1 = 16 MHz Internal Oscillator (HFINTOSC) is ready

0 = 16 MHz Internal Oscillator (HFINTOSC) is not ready

bit 2 Unimplemented: Read as ‘0’

bit 1 LFIOFR: Low-Frequency Internal Oscillator Ready bit

1 = 31 kHz Internal Oscillator (LFINTOSC) is ready

0 = 31 kHz Internal Oscillator (LFINTOSC) is not ready

bit 0 HFIOFS: High-Frequency Internal Oscillator Stable bit

1 = 16 MHz Internal Oscillator (HFINTOSC) is stable

0 = 16 MHz Internal Oscillator (HFINTOSC) is not stable

OSC) Frequency Select bits

DS41585A-page 30 Preliminary 2011 Microchip Technology Inc.

Page 31

PIC10(L)F320/322

4.5 External Clock Mode

4.5.1 EC MODE

The External Clock (EC) mode allows an externally

generated logic level as the system clock source. When

operating in this mode, an external clock source is

connected to the CLKIN input.

TABLE 4-1: SUMMARY OF REGISTERS ASSOCIATED WITH CLOCK SOURCES

Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

CLKRCON

OSCCON

Legend: x = unknown, u = unchanged, – = unimplemented locations read as ‘0’. Shaded cells are not used by ECWG.

—CLKROE — — — — — — 29

— IRCF<2:0> HFIOFR

—

LFIOFR HFIOFS 30

TABLE 4-2: SUMMARY OF CONFIGURATION WORD WITH CLOCK SOURCES

Name Bits Bit -/7 Bit -/6 Bit 13/5 Bit 12/4 Bit 11/3 Bit 10/2 Bit 9/1 Bit 8/0

CONFIG

Legend: — = unimplemented location, read as ‘0’. Shaded cells are not used by clock sources.

13:8

7:0

— — — WRT<1:0> BORV LPBOR

CP MCLRE PWRTE WDTE<1:0> BOREN<1:0> FOSC

LVP

Register

on Page

Register

on Page

22

2011 Microchip Technology Inc. Preliminary DS41585A-page 31

Page 32

PIC10(L)F320/322

NOTES:

DS41585A-page 32 Preliminary 2011 Microchip Technology Inc.

Page 33

PIC10(L)F320/322

Note 1: See Ta bl e 5 -1 for BOR active conditions.

Device

Reset

Power-on

Reset

WDT

Time-out

Brown-out

Reset

LPBOR

Reset

ICSP™ Programming Mode Exit

MCLRE

Sleep

BOR

Active

(1)

PWRTE

LFINTOSC

VDD

PWRT

R

Done

5.0 RESETS

There are multiple ways to reset this device:

• Power-on Reset (POR)

• Brown-out Reset (BOR)

• Low-Power Brown-out Reset (LPBOR)

•MCLR Reset

•WDT Reset

• Programming mode exit

To allow V

can be enabled to extend the Reset time after a BOR

or POR event.

A simplified block diagram of the On-Chip Reset Circuit

is shown in Figure 5-1.

FIGURE 5-1: SIMPLIFIED BLOCK DIAGRAM OF ON-CHIP RESET CIRCUIT

DD to stabilize, an optional Power-up Timer

2011 Microchip Technology Inc. Preliminary DS41585A-page 33

Page 34

PIC10(L)F320/322

5.1 Power-on Reset (POR)

The POR circuit holds the device in Reset until VDD has

reached an acceptable level for minimum operation.

Slow rising V

performance may require greater than minimum V

The PWRT, BOR or MCLR

extend the start-up period until all device operation

conditions have been met.

5.1.1 POWER-UP TIMER (PWRT)

The Power-up Timer provides a nominal 64 ms timeout on POR or Brown-out Reset.

The device is held in Reset as long as PWRT is active.

The PWRT delay allows additional time for the V

rise to an acceptable level. The Power-up Timer is

enabled by clearing the PWRTE bit in Configuration

Word.

The Power-up Timer starts after the release of the POR

and BOR.

For additional information, refer to Application Note

AN607, “Power-up Trouble Shooting” (DS00607).

TABLE 5-1: BOR OPERATING MODES

BOREN<1:0> SBOREN Device Mode BOR Mode

DD, fast operating speeds or analog

DD.

features can be used to

DD to

11 X X Active Waits for BOR ready

5.2 Brown-Out Reset (BOR)

The BOR circuit holds the device in Reset when VDD

reaches a selectable minimum level. Between the

POR and BOR, complete voltage range coverage for

execution protection can be implemented.

The Brown-out Reset module has four operating

modes controlled by the BOREN<1:0> bits in Configuration Word. The four operating modes are:

• BOR is always on

• BOR is off when in Sleep

• BOR is controlled by software

• BOR is always off

Refer to Tab le 5 -1 for more information.

The Brown-out Reset voltage level is selectable by

configuring the BORV bit in Register 3-1.

DD noise rejection filter prevents the BOR from trig-

A V

gering on small events. If V

duration greater than parameter T

will reset. See Figure 5-2 for more information.

Device Operation upon:

Release of POR/Wake- up from Sleep

DD falls below VBOR for a

BORDC, the device

(1)

10 X

01

00 X XDisabled

Note 1: Even though this case specifically waits for the BOR, the BOR is already operating, so there is no delay in

start-up.

1 XActive

5.2.1 BOR IS ALWAYS ON

When the BOREN bits of Configuration Word are

programmed to ‘11’, the BOR is always on. The device

start-up will be delayed until the BOR is ready and VDD

is higher than the BOR threshold.

BOR protection is active during Sleep. The BOR does

not delay wake-up from Sleep.

5.2.2 BOR IS OFF IN SLEEP

When the BOREN bits of Configuration Word are

programmed to ‘10’, the BOR is on, except in Sleep.

The device start-up will be delayed until the BOR is

ready and V

BOR protection is not active during Sleep. The device

wake-up will be delayed until the BOR is ready.

DD is higher than the BOR threshold.

Awake Active

Sleep Disabled

5.2.3 BOR CONTROLLED BY SOFTWARE

When the BOREN bits of Configuration Word are

programmed to ‘01’, the BOR is controlled by the

SBOREN bit of the BORCON register. The device startup is not delayed by the BOR ready condition or the

DD level.

V

BOR protection begins as soon as the BOR circuit is

ready. The status of the BOR circuit is reflected in the

BORRDY bit of the BORCON register.

BOR protection is unchanged by Sleep.

Waits for BOR ready

Begins immediately0 XDisabled

DS41585A-page 34 Preliminary 2011 Microchip Technology Inc.

Page 35

FIGURE 5-2: BROWN-OUT SITUATIONS

TPWRT

(1)

VBOR

V

DD

Internal

Reset

VBOR

V

DD

Internal

Reset

TPWRT

(1)

< TPWRT

TPWRT

(1)

VBOR

V

DD

Internal

Reset

Note 1: TPWRT delay only if PWRTE bit is programmed to ‘0’.

PIC10(L)F320/322

REGISTER 5-1: BORCON: BROWN-OUT RESET CONTROL REGISTER

R/W-1/u R/W-0/u U-0 U-0 U-0 U-0 U-0 R-q/u

SBOREN BORFS

bit 7 bit 0

Legend:

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

u = Bit is unchanged x = Bit is unknown -n/n = Value at POR and BOR/Value at all other Resets

‘1’ = Bit is set ‘0’ = Bit is cleared q = Value depends on condition

bit 7 SBOREN: Software Brown-out Reset Enable bit

If BOREN <1:0> in Configuration

SBOREN is read/write, but has no effect on the BOR.

If BOREN <1:0> in Configuration

1 = BOR enabled

0 = BOR disabled

bit 6 BORFS: Brown-out Reset Fast Start bit

If BOREN<1:0> = 11 (Always on) or BOREN<1:0> = 00 (Always off)

BORFS is read/write, but has no effect.

If BOREN <1:0> =

bit 5-1 Unimplemented: Read as ‘0’

bit 0 BORRDY: Brown-out Reset Circuit Ready Status bit

1 = Band gap is forced on always (covers Sleep/wake-up/operating cases)

0 =Band gap operates normally, and may turn off

1 = The Brown-out Reset circuit is active

Note 1: BOREN<1:0> bits are located in Configuration Word.

0 = The Brown-out Reset circuit is inactive

— — — — —BORRDY

Word 01:

Word = 01:

(1)

10 (Disabled in Sleep) or BOREN<1:0> = 01 (Under software control):

2011 Microchip Technology Inc. Preliminary DS41585A-page 35

Page 36

PIC10(L)F320/322

5.3 Low-Power Brown-out Reset (LPBOR)

The Low-Power Brown-Out Reset (LPBOR) is an

essential part of the Reset subsystem. Refer to

Figure 5-1 to see how the BOR interacts with other

modules.

The LPBOR is used to monitor the external V

When too low of a voltage is detected, the device is

held in Reset. When this occurs, a register bit (BOR) is

changed to indicate that a BOR Reset has occurred.

The same bit is set for both the BOR and the LPBOR.

Refer to Register 5-2.

DD pin.

5.3.1 ENABLING LPBOR

The LPBOR is controlled by the LPBOR bit of

Configuration Word. When the device is erased, the

LPBOR module defaults to disabled.

5.3.1.1 LPBOR Module Output

The output of the LPBOR module is a signal indicating

whether or not a Reset is to be asserted. This signal is

OR’d together with the Reset signal of the BOR module to provide the generic BOR

the PCON register and to the power control block.

signal which goes to

5.4 MCLR

The MCLR is an optional external input that can reset

the device. The MCLR

MCLRE and the LVP bit of Configuration Word (Table 5-

2).

TABLE 5-2: MCLR CONFIGURATION

MCLRE LVP MCLR

00Disabled

10Enabled

x1Enabled

function is controlled by the

5.5 Watchdog Timer (WDT) Reset

The Watchdog Timer generates a Reset if the firmware

does not issue a CLRWDT instruction within the time-out

period. The TO

changed to indicate the WDT Reset. See Section 8.0

“Watchdog Tim er” for more information.

and PD bits in the STATUS register are

5.6 Programming Mode ICSP Exit

Upon exit of Programming mode, the device will

behave as if a POR had just occurred.

5.7 Power-Up Timer

The Power-up Timer optionally delays device execution

after a BOR or POR event. This timer is typically used to

allow VDD to stabilize before allowing the device to start

running.

The Power-up Timer is controlled by the PWRTE

Configuration Word.

bit of

5.8 Start-up Sequence

Upon the release of a POR or BOR, the following must

occur before the device will begin executing:

1. Power-up Timer runs to completion (if enabled).

2. MCLR

The total time-out will vary based on oscillator configuration and Power-up Timer configuration. See

Section 4.0 “Oscillator Module” for more informa-

tion.

The Power-up Timer runs independently of MCLR

Reset. If MCLR is kept low long enough, the Power-up

Timer will expire. Upon bringing MCLR

will begin execution immediately (see Figure 5-3). This

is useful for testing purposes or to synchronize more

than one device operating in parallel.

must be released (if enabled).

high, the device

5.4.1 MCLR ENABLED

When MCLR is enabled and the pin is held low, the

device is held in Reset. The MCLR

V

DD through an internal weak pull-up.

The device has a noise filter in the MCLR

The filter will detect and ignore small pulses.

Note: A Reset does not drive the MCLR

pin is connected to

Reset path.

pin low.

5.4.2 MCLR DISABLED

When MCLR is disabled, the pin functions as a general

purpose input and the internal weak pull-up is under

software control.

DS41585A-page 36 Preliminary 2011 Microchip Technology Inc.

Page 37

FIGURE 5-3: RESET START-UP SEQUENCE

TMCLR

TPWRT

VDD

Internal POR

Power-Up Timer

MCLR

Internal RESET

Oscillator Modes

Internal Oscillator

Oscillator

F

OSC

External Clock (EC)

CLKIN

F

OSC

PIC10(L)F320/322

2011 Microchip Technology Inc. Preliminary DS41585A-page 37

Page 38

PIC10(L)F320/322

5.9 Determining the Cause of a Reset

Upon any Reset, multiple bits in the STATUS and

PCON register are updated to indicate the cause of the

Reset. Ta b le 5 - 3 and Ta b l e 5 - 4 show the Reset conditions of these registers.

TABLE 5-3: RESET STATUS BITS AND THEIR SIGNIFICANCE

POR BOR TO PD Condition

0x11Power-on Reset

u011Brown-out Reset

uu0uWDT Reset

uu00WDT Wake-up from Sleep

uuuuMCLR

uu10MCLR

TABLE 5-4: RESET CONDITION FOR SPECIAL REGISTERS

Condition

Power-on Reset 0000h 0001 1000 ---- --0x

Reset during normal operation

Reset during Sleep

Program

Counter

STATUS

Register

PCON

Register

MCLR

Reset during normal operation 0000h 000u uuuu ---- --uu

MCLR Reset during Sleep 0000h 0001 0uuu ---- --uu

WDT Reset 0000h 0000 uuuu ---- --uu

WDT Wake-up from Sleep PC + 1 0000 0uuu ---- --uu

Brown-out Reset 0000h 0001 1uuu ---- --u0

Interrupt Wake-up from Sleep PC + 1

Legend: u = unchanged, x = unknown, - = unimplemented bit, reads as ‘0’.

Note1: When the wake-up is due to an interrupt and Global Enable bit (GIE) is set, the return address is pushed on

the stack and PC is loaded with the interrupt vector (0004h) after execution of PC + 1.

(1)

0001 0uuu

---- --uu

DS41585A-page 38 Preliminary 2011 Microchip Technology Inc.

Page 39

PIC10(L)F320/322

5.10 Power Control (PCON) Register

The Power Control (PCON) register contains flag bits

to differentiate between a:

• Power-on Reset (POR

• Brown-out Reset (BOR)

The PCON register bits are shown in Register 5-2.

REGISTER 5-2: PCON: POWER CONTROL REGISTER

U-0 U-0 U-0 U-0 U-0 U-0 R/W/HC-q/u R/W/HC-q/u

— — — — — —

bit 7 bit 0

Legend:

HC = Bit is cleared by hardware

R = Readable bit W = Writable bit U = Unimplemented bit, read as ‘0’

u = Bit is unchanged x = Bit is unknown -n/n = Value at POR and BOR/Value at all other Resets

‘1’ = Bit is set ‘0’ = Bit is cleared q = Value depends on condition

)

POR

BOR

bit 7-2 Unimplemented: Read as ‘0’

bit 1 POR

bit 0 BOR

: Power-on Reset Status bit

1 = No Power-on Reset occurred

0 = A Power-on Reset occurred (must be set in software after a Power-on Reset occurs)

: Brown-out Reset Status bit

1 = No Brown-out Reset occurred

0 = A Brown-out Reset occurred (must be set in software after a Power-on Reset or Brown-out Reset

occurs)

TABLE 5-5: SUMMARY OF REGISTERS ASSOCIATED WITH RESETS

Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

BORCON SBOREN BORFS

PCON

STATUS

WDTCON

Legend: — = unimplemented location, read as ‘0’. Shaded cells are not used by Resets.

— — — — — —PORBOR 39

IRP RP1 RP0 TO PD Z DC C 15

— — WDTPS<4:0> SWDTEN 55

— — — — — BORRDY 35

TABLE 5-6: SUMMARY OF CONFIGURATION WORD WITH RESETS

Name Bits Bit -/7 Bit -/6 Bit 13/5 Bit 12/4 Bit 11/3 Bit 10/2 Bit 9/1 Bit 8/0

CONFIG

Legend: — = unimplemented location, read as ‘0’. Shaded cells are not used by clock sources.

13:8

7:0

— — — WRT<1:0> BORV LPBOR LVP

CP MCLRE PWRTE WDTE<1:0> BOREN<1:0> FOSC

Register

on Page

Register

on Page

22

2011 Microchip Technology Inc. Preliminary DS41585A-page 39

Page 40

PIC10(L)F320/322

NOTES:

DS41585A-page 40 Preliminary 2011 Microchip Technology Inc.

Page 41

6.0 INTERRUPTS

TMR0IF

TMR0IE

INTF

INTE

IOCIF

IOCIE

Interrupt

to CPU

Wake-up

(If in Sleep mode)

GIE

(TMR2IF) PIR1<0>

PIRn<7>

PIEn<7>

PEIE

Peripheral Interrupts

(TMR2IE) PIE1<0>

The interrupt feature allows certain events to preempt

normal program flow. Firmware is used to determine

the source of the interrupt and act accordingly. Some

interrupts can be configured to wake the MCU from

Sleep mode.

This chapter contains the following information for

Interrupts:

• Operation

• Interrupt Latency

• Interrupts During Sleep

•INT Pin

• Context Saving during Interrupts

Many peripherals produce Interrupts. Refer to the

corresponding chapters for details.

A block diagram of the interrupt logic is shown in

Figure 6-1.

FIGURE 6-1: INTERRUPT LOGIC

PIC10(L)F320/322

2011 Microchip Technology Inc. Preliminary DS41585A-page 41

Page 42

PIC10(L)F320/322

6.1 Operation

Interrupts are disabled upon any device Reset. They

are enabled by setting the following bits:

• GIE bit of the INTCON register

• Interrupt Enable bit(s) for the specific interrupt

events)

• PEIE bit of the INTCON register (if the Interrupt

Enable bit of the interrupt event is contained in the

PIE1 register)

The INTCON and PIR1 registers record individual interrupts via interrupt flag bits. Interrupt flag bits will be set,

regardless of the status of the GIE, PEIE and individual

interrupt enable bits.

The following events happen when an interrupt event

occurs while the GIE bit is set:

• Current prefetched instruction is flushed

• GIE bit is cleared

• Current Program Counter (PC) is pushed onto the

stack

• PC is loaded with the interrupt vector 0004h

The firmware within the Interrupt Service Routine (ISR)

should determine the source of the interrupt by polling

the interrupt flag bits. The interrupt flag bits must be

cleared before exiting the ISR to avoid repeated

interrupts. Because the GIE bit is cleared, any interrupt

that occurs while executing the ISR will be recorded

through its interrupt flag, but will not cause the

processor to redirect to the interrupt vector.

The RETFIE instruction exits the ISR by popping the

previous address from the stack, and setting the GIE

bit.

For additional information on a specific interrupt’s

operation, refer to its peripheral chapter.

Note 1: Individual interrupt flag bits are set,

regardless of the state of any other

enable bits.

2: All interrupts will be ignored while the GIE

bit is cleared. Any interrupt occurring

while the GIE bit is clear will be serviced

when the GIE bit is set again.

6.2 Interrupt Latency

Interrupt latency is defined as the time from when the

interrupt event occurs to the time code execution at the

interrupt vector begins. The latency for synchronous

interrupts is 3 or 4 instruction cycles. For asynchronous

interrupts, the latency is 3 to 5 instruction cycles,

depending on when the interrupt occurs. See Figure 6-2

and Sect ion 6.3 “Inter rupts During Sleep” for more

details.

DS41585A-page 42 Preliminary 2011 Microchip Technology Inc.

Page 43

Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4

INTO SC

CLKR

PC 0004h 0005h

PC

Inst(0004h)NOP

GIE

Q1 Q2 Q3 Q4Q1 Q2 Q3 Q4

1 Cycle Instruction at PC

PC

Inst(0004h)NOP

2 Cycle Instruction at PC

FSR ADDR PC+1 PC+2 0004h 0005h

PC

Inst(0004h)NOP

GIE

PCPC-1

3 Cycle Instruction at PC

Execute

Interrupt

Inst(PC )

Interrupt Sam pled

during Q1

Inst(PC)

PC-1 PC+1

NOP

PC

New PC/

PC+1

0005hPC-1

PC+1/FSR

ADDR

0004h

NOP

Interrupt

GIE

Interrupt

INST(PC) NOPNOP

FSR ADDR PC+1 PC+2 0004h 0005h

PC

Inst(0004h)NOP

GIE

PCPC-1

3 Cycle Instruction at PC

Interrupt

INST(PC) NOPNOP

NOP

Inst(0005h)

Execute

Execute

Execute

PIC10(L)F320/322

FIGURE 6-2: INTERRUPT LATENCY

2011 Microchip Technology Inc. Preliminary DS41585A-page 43

Page 44

PIC10(L)F320/322

Q2Q1 Q3 Q4 Q2Q1 Q3 Q4 Q2Q1 Q3 Q4 Q2Q1 Q3 Q4 Q2Q1 Q3 Q4

INTOSC

CLKR

INT pin

INTF

GIE

INSTRUCTION FLOW

PC

Instruction

Fetched

Instruction

Executed

Interrupt Latency

PC PC + 1

PC + 1

0004h

0005h

Inst (0004h)

Inst (0005h)

Forced NOP

Inst (PC)

Inst (PC + 1)

Inst (PC – 1)

Inst (0004h)

Forced NOP

Inst (PC)

—

Note 1: INTF flag is sampled here (every Q1).

2: Asynchronous interrupt latency = 3-5 T

CY. Synchronous latency = 3-4 TCY, where TCY = instruction cycle time.

Latency is the same whether Inst (PC) is a single cycle or a 2-cycle instruction.

3: For minimum width of INT pulse, refer to AC specifications in Section 24.0 “Electrical Specifications”.

4: INTF is enabled to be set any time during the Q4-Q1 cycles.

(1)

(2)

(3)

(4)

(1)

FIGURE 6-3: INT PIN INTERRUPT TIMING

DS41585A-page 44 Preliminary 2011 Microchip Technology Inc.

Page 45

PIC10(L)F320/322

MOVWF W_TEMP ;Copy W to TEMP register

SWAPF STATUS,W ;Swap status to be saved into W

;Swaps are used because they do not affect the status bits

MOVWF STATUS_TEMP ;Save status to bank zero STATUS_TEMP register

:

:(ISR) ;Insert user code here

:

SWAPF STATUS_TEMP,W ;Swap STATUS_TEMP register into W

;(sets bank to original state)

MOVWF STATUS ;Move W into STATUS register

SWAPF W_TEMP,F ;Swap W_TEMP

SWAPF W_TEMP,W ;Swap W_TEMP into W

6.3 Interrupts During Sleep

Some interrupts can be used to wake from Sleep. To

wake from Sleep, the peripheral must be able to

operate without the system clock. The interrupt source

must have the appropriate Interrupt Enable bit(s) set

prior to entering Sleep.

On waking from Sleep, if the GIE bit is also set, the

processor will branch to the interrupt vector. Otherwise,

the processor will continue executing instructions after

the SLEEP instruction. The instruction directly after the

SLEEP instruction will always be executed before

branching to the ISR. Refer to the Section 7.0 “Power-

Down Mode (Sleep)” for more details.

6.4 INT Pin

The INT pin can be used to generate an asynchronous

edge-triggered interrupt. This interrupt is enabled by

setting the INTE bit of the INTCON register. The

INTEDG bit of the OPTION_REG register determines on

which edge the interrupt will occur. When the INTEDG

bit is set, the rising edge will cause the interrupt. When

the INTEDG bit is clear, the falling edge will cause the

interrupt. The INTF bit of the INTCON register will be set

when a valid edge appears on the INT pin. If the GIE and

INTE bits are also set, the processor will redirect

program execution to the interrupt vector.

6.5 Context Saving During Interrupt s

During an interrupt, only the return PC value is saved

on the stack. Typically, users may wish to save key

registers during an interrupt (e.g., W and STATUS

registers). This must be implemented in software.

Temporary holding registers W_TEMP and

STATUS_TEMP should be placed in the last 16 bytes

of GPR (see Figure 2-2). These 16 locations are