Page 1

PAC1921

High-Side Current/Power Sensor

Evaluation Board

User’s Guide

2015 Microchip Technology Inc. DS50002376A

Page 2

Note the following details of the code protection feature on Microchip devices:

YSTEM

CERTIFIED BY DNV

== ISO/TS 16949 ==

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR

IMPLIED, WRITTEN OR ORAL, STATUTORY OR

OTHERWISE, RELATED TO THE INFORMATION,

INCLUDING BUT NOT LIMITED TO ITS CONDITION,

QUALITY, PERFORMANCE, MERCHANTABILITY OR

FITNESS FOR PURPOSE. Microchip disclaims all liability

arising from this information and its use. Use of Microchip

devices in life support and/or safety applications is entirely at

the buyer’s risk, and the buyer agrees to defend, indemnify and

hold harmless Microchip from any and all damages, claims,

suits, or expenses resulting from such use. No licenses are

conveyed, implicitly or otherwise, under any Microchip

intellectual property rights.

Trademarks

The Microchip name and logo, the Microchip logo, dsPIC,

FlashFlex, flexPWR, JukeBlox, K

LANCheck, MediaLB, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, PICSTART, PIC

SST, SST Logo, SuperFlash and UNI/O are registered

trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

The Embedded Control Solutions Company and mTouch are

registered trademarks of Microchip Technology Incorporated

in the U.S.A.

Analog-for-the-Digital Age, BodyCom, chipKIT, chipKIT logo,

CodeGuard, dsPICDEM, dsPICDEM.net, ECAN, In-Circuit

Serial Programming, ICSP, Inter-Chip Connectivity, KleerNet,

KleerNet logo, MiWi, MPASM, MPF, MPLAB Certified logo,

MPLIB, MPLINK, MultiTRAK, NetDetach, Omniscient Code

Generation, PICDEM, PICDEM.net, PICkit, PICtail,

RightTouch logo, REAL ICE, SQI, Serial Quad I/O, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan,

WiperLock, Wireless DNA, and ZENA are trademarks of

Microchip Technology Incorporated in the U.S.A. and other

countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

Silicon Storage Technology is a registered trademark of

Microchip Technology Inc. in other countries.

GestIC is a registered trademarks of Microchip Technology

Germany II GmbH & Co. KG, a subsidiary of Microchip

Technology Inc., in other countries.

All other trademarks mentioned herein are property of their

respective companies.

© 2015, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

ISBN: 978-1-63277-460-6

EELOQ, KEELOQ logo, Kleer,

32

logo, RightTouch, SpyNIC,

QUALITY MANAGEMENT S

DS50002376A-page 2 2015 Microchip Technology Inc.

Microchip received ISO/TS-16949:2009 certification for its worldwide

headquarters, design and wafer fabrication facilities in Chandler and

Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures

are for its PIC

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

®

MCUs and dsPIC® DSCs, KEELOQ

®

code hopping

Page 3

Object of Declaration: PAC1921 High-Side Current/Power Sensor Evaluation Board

2015 Microchip Technology Inc. DS50002376A-page 3

Page 4

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

NOTES:

DS50002376A-page 4 2015 Microchip Technology Inc.

Page 5

PAC1921

HIGH-SIDE CURRENT/POWER SENSOR

EVALUATION BOARD USER’S GUIDE

Table of Contents

Preface ........................................................................................................................... 7

Introduction............................................................................................................ 7

Document Layout .................................................................................................. 7

Conventions Used in this Guide ............................................................................ 8

Warranty Registration............................................................................................ 8

Recommended Reading........................................................................................ 9

The Microchip Web Site ........................................................................................ 9

Customer Support ................................................................................................. 9

Document Revision History ................................................................................... 9

Chapter 1. Product Overview

1.1 Introduction ................................................................................................... 11

1.2 PAC1921 Evaluation System ........................................................................ 11

1.3 What is the PAC1921 High-Side Current/Power Sensor Evaluation Board? ..... 12

1.3.1 Board Layout ............................................................................................. 12

1.4 What the PAC1921 High-Side Current/Power Sensor Evaluation

Board Kit Contains................................................................................... 13

Chapter 2. Installation and Operation

2.1 Getting Started .............................................................................................. 15

2.1.1 System Requirements ................................................................................ 15

2.2 Installing the Evaluation Board Software....................................................... 15

2.3 Microchip USB Bridge Installation ................................................................. 19

Chapter 3. Hardware Description

3.1 Introduction.................................................................................................... 21

3.1.1 Power Source ............................................................................................. 21

3.2 USB-to-SMBus Bridge................................................................................... 21

3.2.1 Direct SMBus Connect Option ................................................................... 21

3.3 Operating Mode............................................................................................. 22

3.3.1 SMBus Mode .............................................................................................. 22

3.4 LED Indicators............................................................................................... 22

3.5 Jumper Settings ............................................................................................ 23

3.6 Test Points .................................................................................................... 24

3.7 Demo Mode Setup and Operation................................................................. 25

3.8 Sys Mode Setup and Operation .................................................................... 25

3.8.1 Jumper Positions ........................................................................................ 25

3.8.2 Load Connection ........................................................................................ 25

2015 Microchip Technology Inc. DS50002376A-page 5

Page 6

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

Chapter 4. Software Description

4.1 Overview ....................................................................................................... 27

4.1.1 Tips for Using the Evaluation Board GUI ...................................................28

4.2 Interface Description and Operation.............................................................. 29

4.2.1 Panel Control Section .................................................................................29

4.2.2 Main Configuration Panel............................................................................31

4.2.3 Overflow Status Panel ................................................................................32

4.2.4 R

4.2.5 Panel and Integration Control Panel ...........................................................32

4.2.6 EVB Demo Configuration Panel..................................................................33

4.3 Tab Descriptions ........................................................................................... 34

4.3.1 Vbus & Vsense Tab ....................................................................................34

4.3.2 Vbus, Vsense and Vpower Tabs.................................................................35

4.3.3 Calculations/File IO Tab..............................................................................36

4.3.4 Integration Table Tab ..................................................................................38

4.4 Evaluation Board Examples .......................................................................... 39

4.4.1 Power Pin-Controlled Integration Example .................................................39

4.4.2 Power Free-Run Integration Example.........................................................42

4.5 Troubleshooting............................................................................................. 45

4.5.1 GUI Controls Unresponsive After Installation .............................................45

4.5.2 GUI Freezes................................................................................................45

Panel ...............................................................................................32

sense

Appendix A. Schematic and Layouts

A.1 Introduction ................................................................................................... 47

A.2 Board – PAC1921 Current Shunt and Power Monitor Schematic................. 48

A.3 Board – USB Bridge and Sig Gen Schematic............................................... 49

A.4 Board – Top Silk ........................................................................................... 50

A.5 Board – Top Copper and Silk........................................................................ 50

A.6 Board – Top Copper ..................................................................................... 51

A.7 Board – Bottom Copper ................................................................................ 51

A.8 Board – Bottom Copper and Silk .................................................................. 52

A.9 Board – Bottom Silk ...................................................................................... 52

Appendix B. Bill of Materials (BOM) ...........................................................................53

Worldwide Sales and Service .....................................................................................56

DS50002376A-page 6 2015 Microchip Technology Inc.

Page 7

PAC1921

HIGH-SIDE CURRENT/POWER SENSOR

EVALUATION BOARD USER’S GUIDE

Preface

NOTICE TO CUSTOMERS

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs

and/or tool descriptions may differ from those in this document. Please refer to our web site

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXXXXA”, where “XXXXXXXX” is the document number and “A” is the revision level

of the document.

For the most up-to-date information on development tools, see the MPLAB

Select the Help menu, and then Topics to open a list of available on-line help files.

®

IDE on-line help.

INTRODUCTION

This chapter contains general information that will be useful to know before using the

PAC1921 High-Side Current/Power Sensor Evaluation Board. Items discussed in this

chapter include:

• Document Layout

• Conventions Used in this Guide

• Warranty Registration

• Recommended Reading

• The Microchip Web Site

• Customer Support

• Document Revision History

DOCUMENT LAYOUT

This document describes how to use the PAC1921 High-Side Current/Power Sensor

Evaluation Board as a development tool to emulate and debug firmware on a target

board. The manual layout is as follows:

• Chapter 1. “Product Overview” – Important information about the PAC1921

High-Side Current/Power Sensor Evaluation Board.

• Chapter 2. “Installation and Operation” – Includes instructions on installing and

starting the application.

• Chapter 3. “Hardware Description” – Shows hardware details of the PAC1921

High-Side Current/Power Sensor Evaluation Board.

• Chapter 4. “Software Description” – Describes the main operations in the software.

• Appendix A. “Schematic and Layouts” – Shows the schematic and layout

diagrams for the PAC1921 High-Side Current/Power Sensor Evaluation Board.

• Appendix B. “Bill of Materials (BOM)” – Lists the parts used to build the

PAC1921 High-Side Current/Power Sensor Evaluation Board.

2015 Microchip Technology Inc. DS50002376A-page 7

Page 8

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

CONVENTIONS USED IN THIS GUIDE

This manual uses the following documentation conventions:

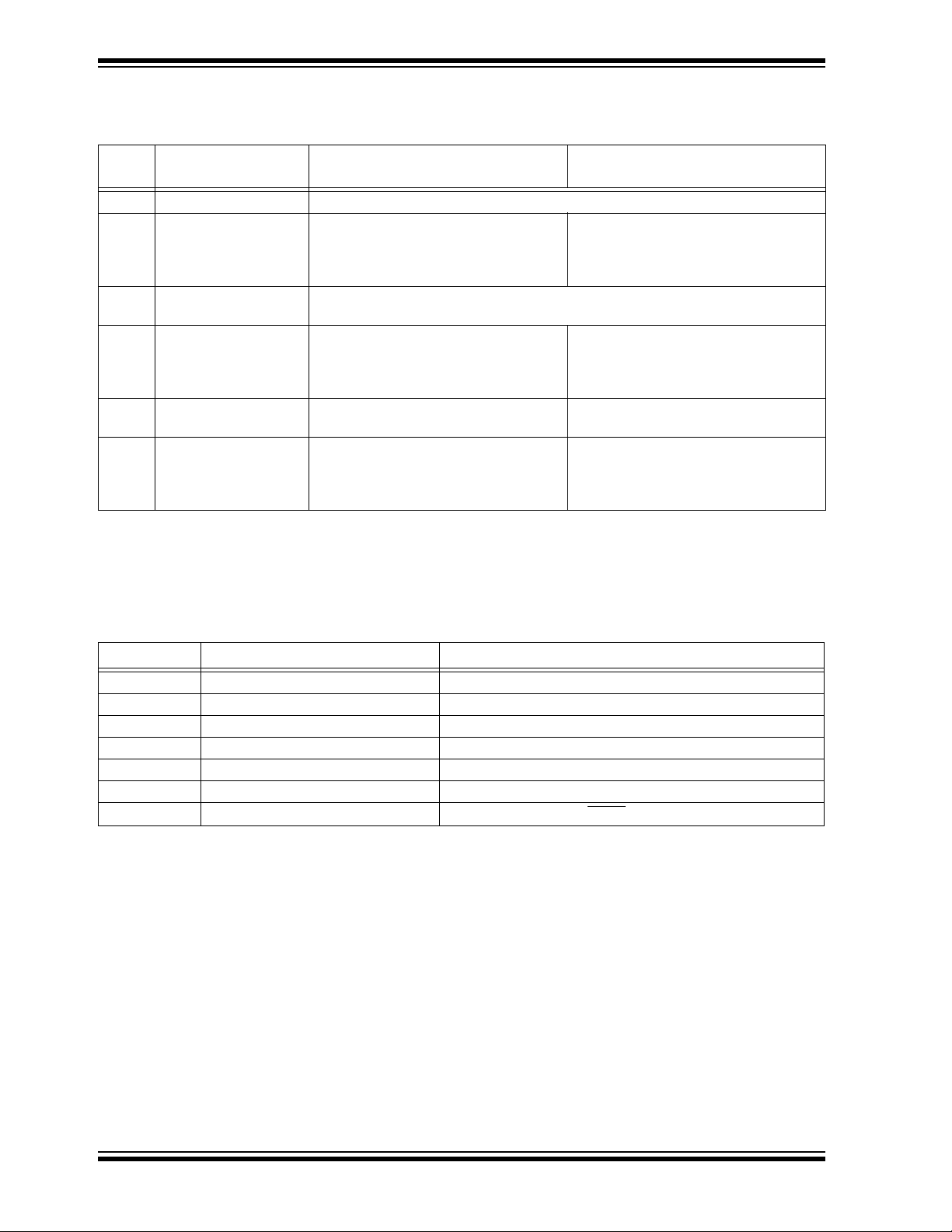

DOCUMENTATION CONVENTIONS

Description Represents Examples

Arial font:

Italic characters Referenced books MPLAB

Emphasized text ...is the only compiler...

Initial caps A window the Output window

A dialog the Settings dialog

A menu selection select Enable Programmer

Quotes A field name in a window or

dialog

Underlined, italic text with

right angle bracket

Bold characters A dialog button Click OK

N‘Rnnnn A number in verilog format,

Text in angle brackets < > A key on the keyboard Press <Enter>, <F1>

Courier New font:

Plain Courier New Sample source code #define START

Italic Courier New A variable argument file.o, where file can be

Square brackets [ ] Optional arguments mcc18 [options] file

Curly brackets and pipe

character: { | }

Ellipses... Replaces repeated text var_name [,

A menu path File>Save

A tab Click the Power tab

where N is the total number of

digits, R is the radix and n is a

digit.

Filenames autoexec.bat

File paths c:\mcc18\h

Keywords _asm, _endasm, static

Command-line options -Opa+, -Opa-

Bit values 0, 1

Constants 0xFF, ‘A’

Choice of mutually exclusive

arguments; an OR selection

Represents code supplied by

user

“Save project before build”

4‘b0010, 2‘hF1

any valid filename

[options]

errorlevel {0|1}

var_name...]

void main (void)

{ ...

}

®

IDE User’s Guide

WARRANTY REGISTRATION

Please complete the enclosed Warranty Registration Card and mail it promptly.

Sending in the Warranty Registration Card entitles users to receive new product

updates. Interim software releases are available at the Microchip web site.

DS50002376A-page 8 2015 Microchip Technology Inc.

Page 9

RECOMMENDED READING

This user’s guide describes how to use PAC1921 High-Side Current/Power Sensor

Evaluation Board. Other useful documents are listed below. The following Microchip

documents are available and recommended as supplemental reference resources.

PAC1921 Data Sheet (DS20005293)

This data sheet describes the operation and features of the PAC1921 high-side

power/current monitor device with a configurable analog output.

THE MICROCHIP WEB SITE

Microchip provides online support via our web site at www.microchip.com. This web

site is used as a means to make files and information easily available to customers.

Accessible by using your favorite Internet browser, the web site contains the following

information:

• Product Support – Data sheets and errata, application notes and sample

programs, design resources, user’s guides and hardware support documents,

latest software releases and archived software

• General Technical Support – Frequently Asked Questions (FAQs), technical

support requests, online discussion groups, Microchip consultant program

member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip

press releases, listing of seminars and events, listings of Microchip sales offices,

distributors and factory representatives

Preface

CUSTOMER SUPPORT

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or field application engineer

(FAE) for support. Local sales offices are also available to help customers. A listing of

sales offices and locations is included in the back of this document.

Technical support is available through the web site at:

http://www.microchip.com/support

DOCUMENT REVISION HISTORY

Revision A (June 2015)

• Initial Release of this Document.

2015 Microchip Technology Inc. DS50002376A-page 9

Page 10

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

NOTES:

DS50002376A-page 10 2015 Microchip Technology Inc.

Page 11

HIGH-SIDE CURRENT/POWER SENSOR

USB Cable

PC with 3$& GUI and

Microchip USB Bridge Driver

Microchip

3$&

Device

3$&(YDOXDWLRQ%RDUG

EVALUATION BOARD USER’S GUIDE

Chapter 1. Product Overview

1.1 INTRODUCTION

The PAC1921 is a dedicated power monitoring device with a configurable output. The

PAC1921 High-Side Current/Power Sensor Evaluation Board package provides users

with the means to exercise device functionality while connected either to target

systems (Sys mode) or while utilizing on-board sources (Demo mode).

1.2 PAC1921 EVALUATION SYSTEM

The evaluation system has three major parts, as shown in Figure 1-1:

• Customer-provided Windows

• Microchip PAC1921 Graphical User Interface (GUI) (based on

National Instruments™ LabVIEW™ software)

• Microchip PAC1921 High-Side Current/Power Sensor Evaluation Board

• USB Cable for GUI communications (Standard-A plug to Mini-B plug)

®

PC with an available USB port

PAC1921

2015 Microchip Technology Inc. DS50002376A-page 11

FIGURE 1-1: PAC1921 Evaluation System.

Note: Screen captures in this document were taken on a PC with Windows® 7

Professional using the default desktop colors. The colors on your screen

may vary, especially if a Windows theme has been applied on the PC.

Page 12

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

1.3 WHAT IS THE PAC1921 HIGH-SIDE CURRENT/POWER SENSOR EVALUATION BOARD?

The evaluation system is comprised of the ADM00592 and a LabVIEW software-based

application which allows the user to do the following:

• View and change register values

• Saving settings of all registers allowing for quick configuration at a later time

• Graphing registers

The hardware platform provides the following features to the user:

• Headers for connecting a sense resistor

• USB-to-SMBus bridge for communications

• Capability to connect directly to an external SMBus master

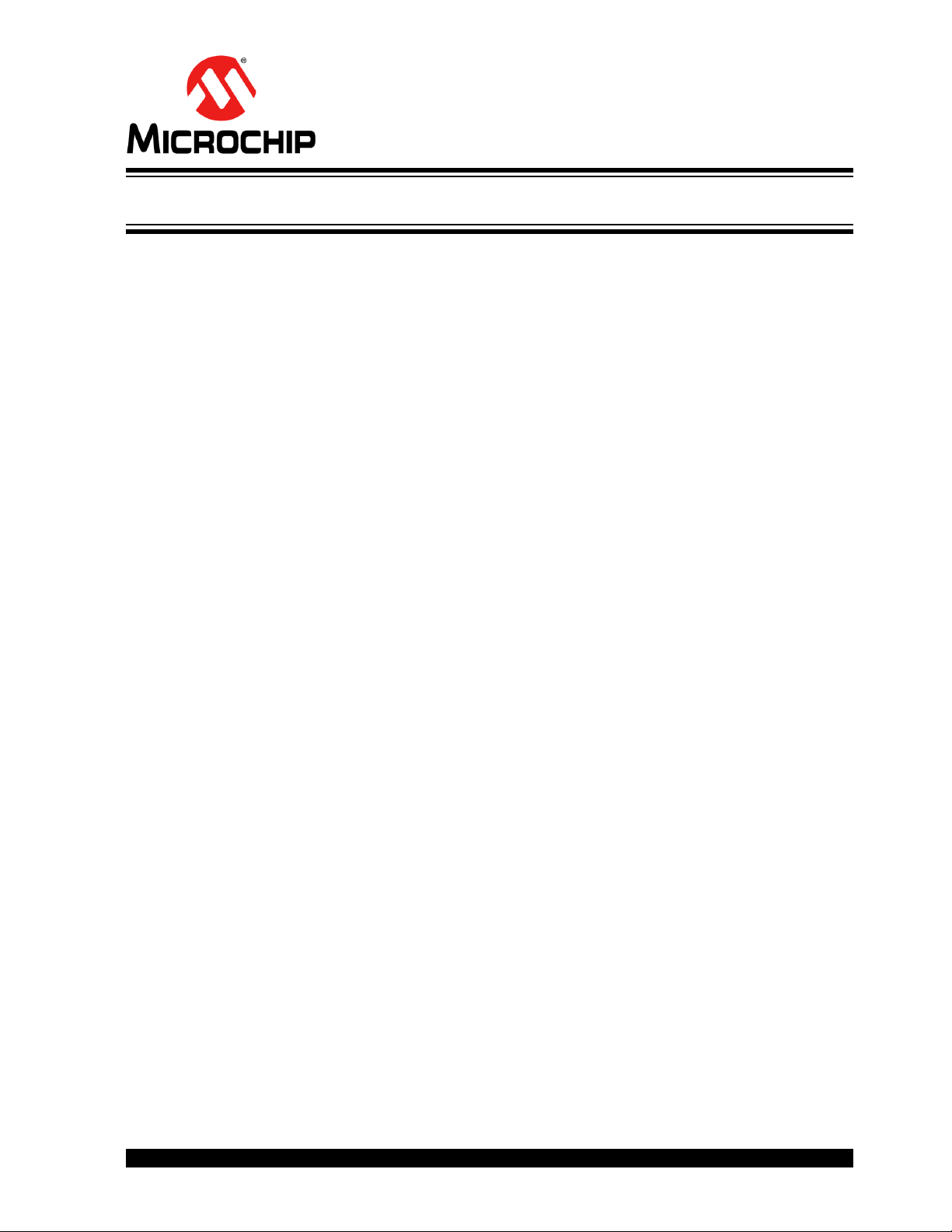

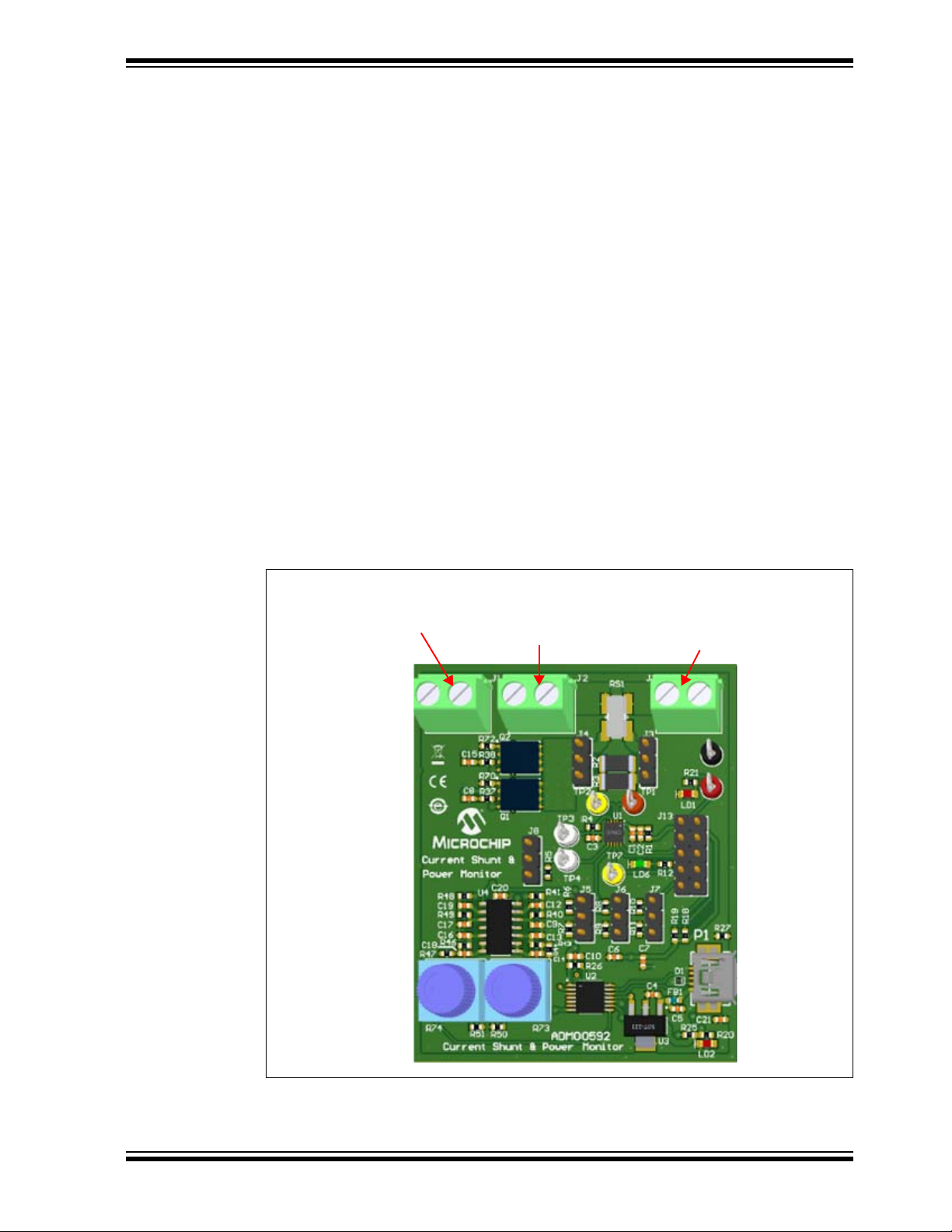

1.3.1 Board Layout

The evaluation board was designed for ease of use and user experimentation.

Figure 1-2 shows the top silkscreen for the board.

FIGURE 1-2: PAC1921 High-Side Current/Power Sensor Evaluation Board – Top Silkscreen.

DS50002376A-page 12 2015 Microchip Technology Inc.

Page 13

Product Overview

1.4 WHAT THE PAC1921 HIGH-SIDE CURRENT/POWER SENSOR EVALUATION BOARD KIT CONTAINS

This PAC1921 High-Side Current/Power Sensor Evaluation Board kit includes:

• PAC1921 High-Side Current/Power Sensor Evaluation Board (ADM00592)

• Supplied USB Mini Connector Cable

• Important Information Sheet

2015 Microchip Technology Inc. DS50002376A-page 13

Page 14

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

NOTES:

DS50002376A-page 14 2015 Microchip Technology Inc.

Page 15

HIGH-SIDE CURRENT/POWER SENSOR

EVALUATION BOARD USER’S GUIDE

Chapter 2. Installation and Operation

2.1 GETTING STARTED

2.1.1 System Requirements

To use the PAC1921 High-Side Current/Power Sensor Evaluation Board, the following

are required:

•A PC running the Microsoft

• A display resolution of 800x600 or larger, for viewing several windows

simultaneously

• An available USB port

2.2 INSTALLING THE EVALUATION BOARD SOFTWARE

Follow these steps in order to install the board’s Graphical User Interface (GUI):

1. Download the software archive from the board’s web page, unzip it and

double-click the Setup.exe to start the installation. Figure 2-1 shows the initial

installation screen, which displays briefly as the setup program loads.

®

Windows® operating system

PAC1921

FIGURE 2-1: Software Installation – Initialize Window.

2015 Microchip Technology Inc. DS50002376A-page 15

Page 16

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

2. Click Next in the Destination Directory window, shown in Figure 2-2. For proper

operation, the files must be installed in the default locations. The default location

for the software files is C:\Program Files (x86)\Microchip\PAC1921

and for the LabVIEW™ software is C:\Program Files\

National Instruments.

FIGURE 2-2: Software Installation – Setting the Destination Directory.

DS50002376A-page 16 2015 Microchip Technology Inc.

Page 17

Installation and Operation

3. Read and accept the license agreement, then click Next.

FIGURE 2-3: Software Installation – Software License Agreement.

4. To use the LabVIEW software, read and accept the license agreement, then click

Next.

FIGURE 2-4: Software Installation – LabVIEW™ Software License Agreement.

2015 Microchip Technology Inc. DS50002376A-page 17

Page 18

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

5. Follow the on-screen instructions to complete the installation. During installation,

shortcuts will be created on the Windows Start Menu under Programs>

and on the desktop.

PAC1921

FIGURE 2-5: Software Installation – LabVIEW™ Software Installation Screen.

FIGURE 2-6: Software Installation – LabVIEW™ Software Installation Complete.

DS50002376A-page 18 2015 Microchip Technology Inc.

Page 19

Installation and Operation

When the installation is complete, the program will automatically run (see Figure 2-7).

FIGURE 2-7: PAC1921 GUI Start-up Screen.

2.3 MICROCHIP USB BRIDGE INSTALLATION

Connect the USB mini connector to the evaluation board and the standard USB connector to any available USB port on the PC. If the Microchip USB bridge driver has not

previously been installed on the selected USB port, download the MCP2221 Windows

driver and installer from www.microchip.com at:

http://www.microchip.com/wwwproducts/Devices.aspx?product=MCP2221

Follow the on-screen instructions to complete the installation process.

2015 Microchip Technology Inc. DS50002376A-page 19

Page 20

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

NOTES:

DS50002376A-page 20 2015 Microchip Technology Inc.

Page 21

Chapter 3. Hardware Description

3.1 INTRODUCTION

The PAC1921 High-Side Current/Power Sensor Evaluation Board provides the means

to evaluate features, and to view and modify registers. There are two modes for using

the evaluation board:

• Demo mode: Monitors an on-board power source

• Sys mode: Monitors an external power source

LEDs indicate status information and test points are included to monitor system

voltages with a user-provided voltmeter or oscilloscope.

The PAC1921 device is an SMBus-compliant, high-side current/power monitor in a

10-pin, 3 mm x 3 mm DFN package. For details regarding the PAC1921 device, refer

to the “PAC1921 Data Sheet” (DS20005293).

3.1.1 Power Source

The board requires only one Universal Serial Bus (USB) connection to power the

board. USB bus voltage is provided to the on-board test power sources and the

USB-to-SMBus bridge. The evaluation board circuitry uses the on-board regulator to

regulate the +5V USB power to +3.3V.

PAC1921

HIGH-SIDE CURRENT/POWER SENSOR

EVALUATION BOARD USER’S GUIDE

3.2 USB-TO-SMBus BRIDGE

The USB-to-SMBus is based on the MCP2221 USB-to-I2C™ protocol converter, which

provides the interface between the USB and the SMBus. Power is sourced to the

microcontroller from the USB interface for device power and communication.

3.2.1 Direct SMBus Connect Option

It is also possible to connect an external SMBus master to the PAC1921 High-Side

Current/Power Sensor Evaluation Board. A few modifications to the board are

required, as explained below:

• Remove the jumpers on J13 and connect the SMBus master to the

SMBus_DATA, SMBus_CLK and #READ/INT pins, as well as an external supply

for +3.3V. Note that a return is also provided on this header for convenience

(GND).

• The +3.3V can be supplied by the SMBus bridge by leaving the +3.3V jumper in

place and retaining the USB connection.

2015 Microchip Technology Inc. DS50002376A-page 21

Page 22

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

LED 1

V

DD

Power

LED 2

USB Power

LED 6

READ/INT

3.3 OPERATING MODE

3.3.1 SMBus Mode

By default, the evaluation board is configured so that the PAC1921 operates in SMBus

mode with an SMBus address of, 1001_100xb (98h). The address can be changed to

1001_101xb (9Ah) by moving jumper J8 to position 2-3. Cycle power to the evaluation

board in order for the change to take effect.

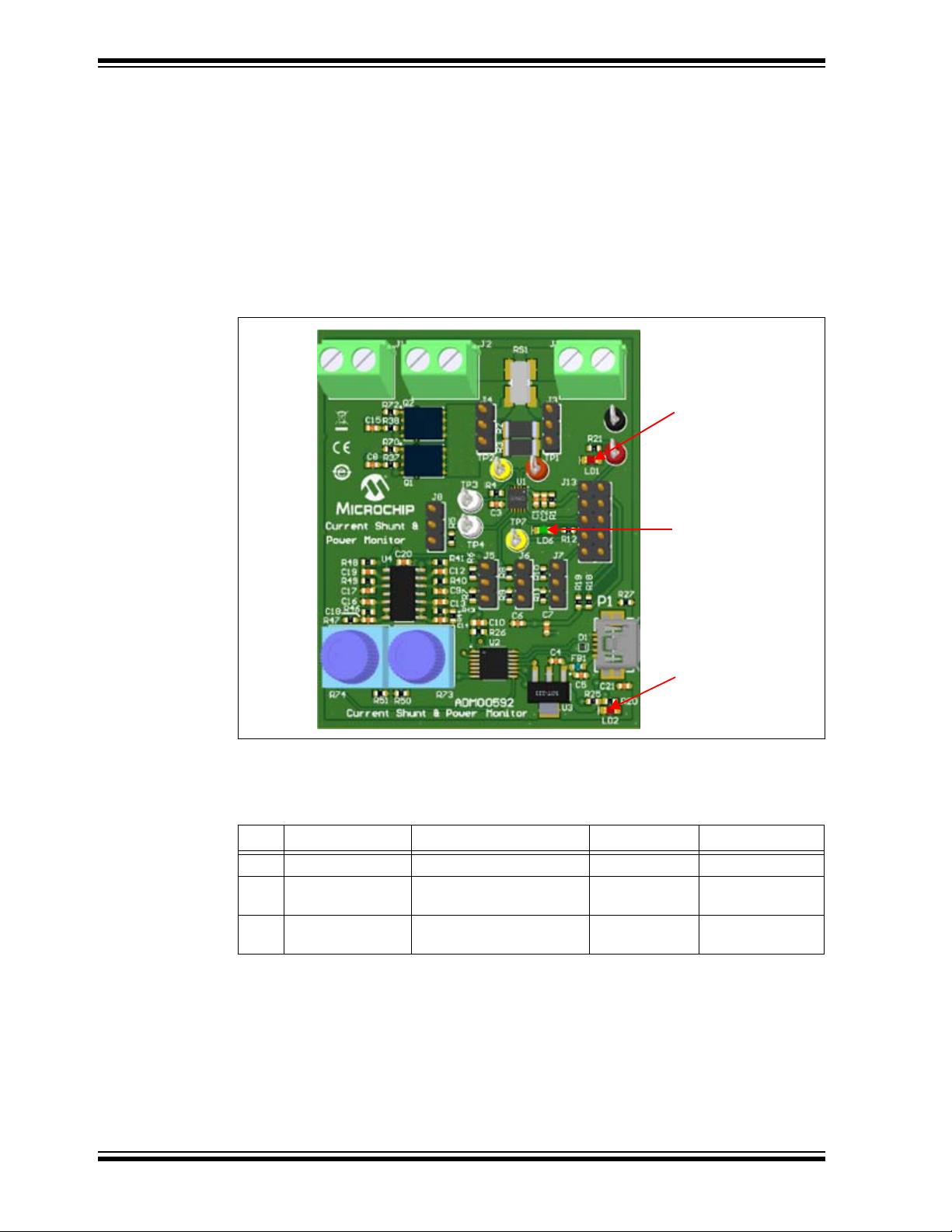

3.4 LED INDICATORS

LED locations are indicated in Figure 3-1.

FIGURE 3-1: LED Indicator Locations.

LEDs indicate the status of the signals, as described in Ta bl e 3- 1:

TABLE 3-1: LED STATUS INDICATORS

LED Signal OFF Green Red

LD1 V

LD2 +5V USB Power USB power is not present N/A +5V USB power is

LD6 READ/INT Pin is not asserted

DS50002376A-page 22 2015 Microchip Technology Inc.

Power VDD is not present N/A VDD is present

DD

(Read State)

Pin is asserted

(Integrate State)

present

N/A

Page 23

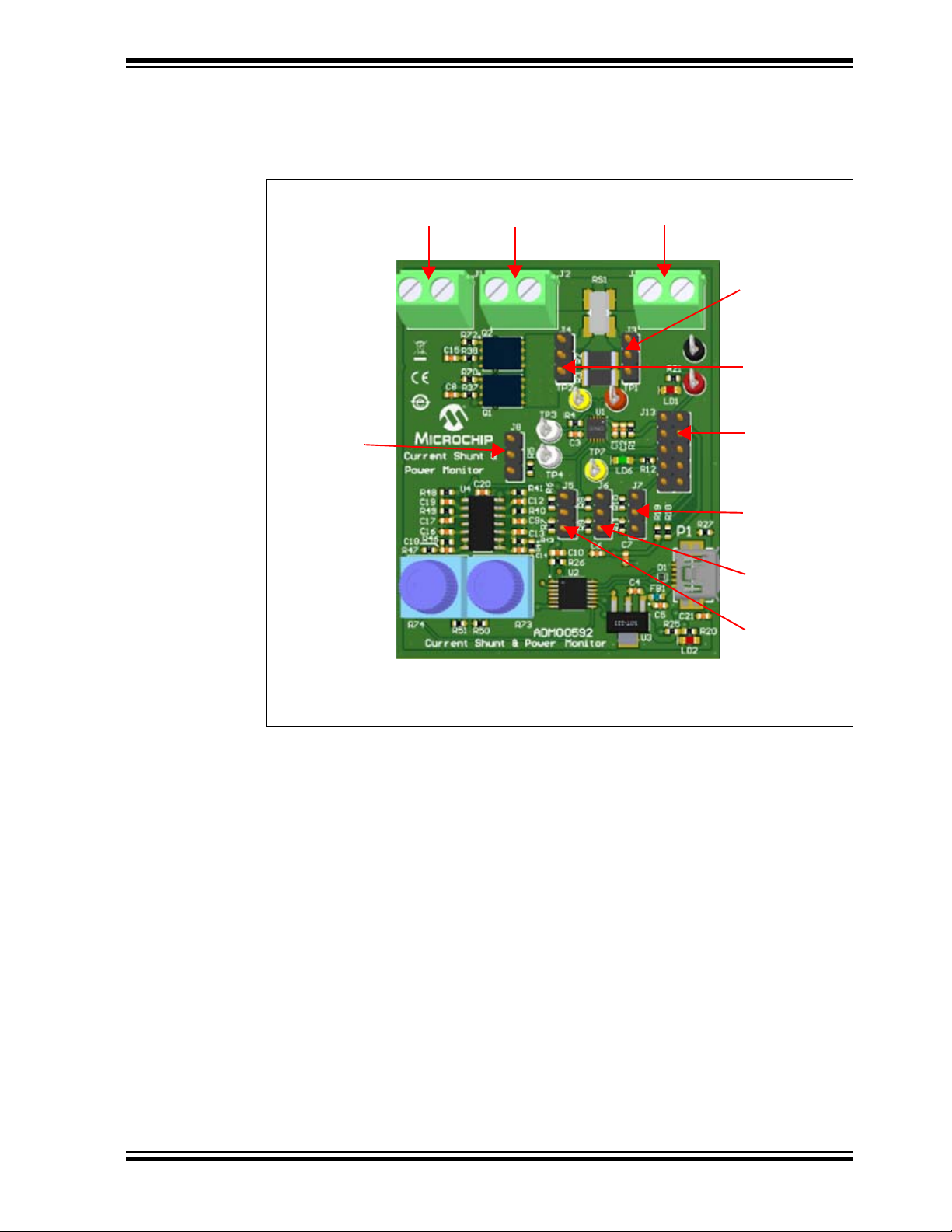

3.5 JUMPER SETTINGS

J11

GND

J2

V

SOURCE-

J1

V

SOURCE+

J3

Demo Sys

J4

Demo Sys

J13

Connections

J5

Reserved

J6

Reserved

J7

Reserved

J8

ADDR/SEL

Note: Refer to Appendix A. “Schematic and Layouts” to see the

connections of each jumper position.

This evaluation board has pin headers and jumper configurations to evaluate the

features of the PAC1921. Jumper locations are indicated in Figure 3-2.

Hardware Description

FIGURE 3-2: Jumper and External Connection Locations.

2015 Microchip Technology Inc. DS50002376A-page 23

Page 24

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

Jumper settings are described in Tab le 3 - 2.

TABLE 3-2: JUMPER SETTINGS

Pin

Header

J1, J2 Vsource+, Vsource- External power source terminals. (See Section 3.8.2 “Load Connection”.)

J3, J4 Demo Sys Select Demo mode R

J5, J6, J7Reserved Reserved for future use

Label Default Position Alternate Position(s)

Positions 3-2 are jumpered on both

SENSE+/-

jumpers. (See Section 3.7 “Demo

Mode Setup and Operation”.)

.

Select Sys mode R

Positions 1-2 are jumpered on both

jumpers. (See Section 3.8 “Sys Mode

Setup and Operation”.)

SENSE+/-

.

J8 J8 (ADDR_SEL)

(See

Section 3.3.1 “SMBus

Mode”)

J11 GND Connect ground from external source for

J13 GND, #READ/INT,

SMBus_DATA,

SMBus_CLK, VDD

In SMBus mode, sets SMBus address to

1001_100b at power-up.

Positions 1-2 are jumpered.

USB bridge generates on-board 3.3V

and provides SMBus host.

Positions 1-2, 3-4, 5-6, 7-8, 9-10 are all

jumpered.

In SMBus mode, sets SMBus address to

1001_101b at power-up.

Positions 2-3 are jumpered.

Sys mode.

(See Section 3.2.1 “Direct SMBus

Connect Option”.)

3.6 TEST POINTS

The PAC1921 High-Side Current/Power Sensor Evaluation Board provides test points

for ground reference and signal access. Table 3-3 summarizes these test points.

TABLE 3-3: TEST POINTS

Test Point Marking Signal Function Monitored

1 Vsense+ (orange) SENSE+

2 Vsense- (yellow) SENSE-

3 OUT (white) OUT Pin

4 ADDR_SEL SMBus Address Select

5 Vdd (red) V

6 GND (black) Ground

7 #READ/INT (yellow) READ

DD

/INT Pin

DS50002376A-page 24 2015 Microchip Technology Inc.

Page 25

3.7 DEMO MODE SETUP AND OPERATION

J11 GND

Connect to

System Ground

J2 V

SOURCE-

Connect to

System DC

Load or Supply

J1 V

SOURCE+

Connect to

System DC

Load or Supply

Demo mode uses an on-board current source to exercise and demonstrate the features

of the PAC1921 power monitor. The 100 mV constant-current source is provided using

a +5V USB as the supply. Parallel sense resistors are provided to convert the current

to a corresponding voltage for the PAC1921 to read at the SENSE+ and SENSEinputs. The evaluation board is assembled with jumpers J3 and J4 positioned for Demo

mode (see Section 3.5 “Jumper Settings”). Current is controlled by the evaluation

board Demo Configuration section of the evaluation board GUI (see

Section 4.2.6 “EVB Demo Configuration Panel”).

3.8 SYS MODE SETUP AND OPERATION

Sys mode uses external current sources to exercise and demonstrate the features of

the PAC1921 power monitor.

3.8.1 Jumper Positions

To use Sys mode, reposition jumpers J3 and J4 (see Table 3-2) to disconnect the

on-board demonstration current sources.

3.8.2 Load Connection

Hardware Description

A 5 milliohm (1% tolerance) sense resistor, connected between J1 and J2, is provided

on-board the PAC1921 evaluation board to measure system current.

Load connections to the system can be established, as shown in Figure 3-3.

.

.

FIGURE 3-3: Load Connection Location.

2015 Microchip Technology Inc. DS50002376A-page 25

Page 26

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

NOTES:

DS50002376A-page 26 2015 Microchip Technology Inc.

Page 27

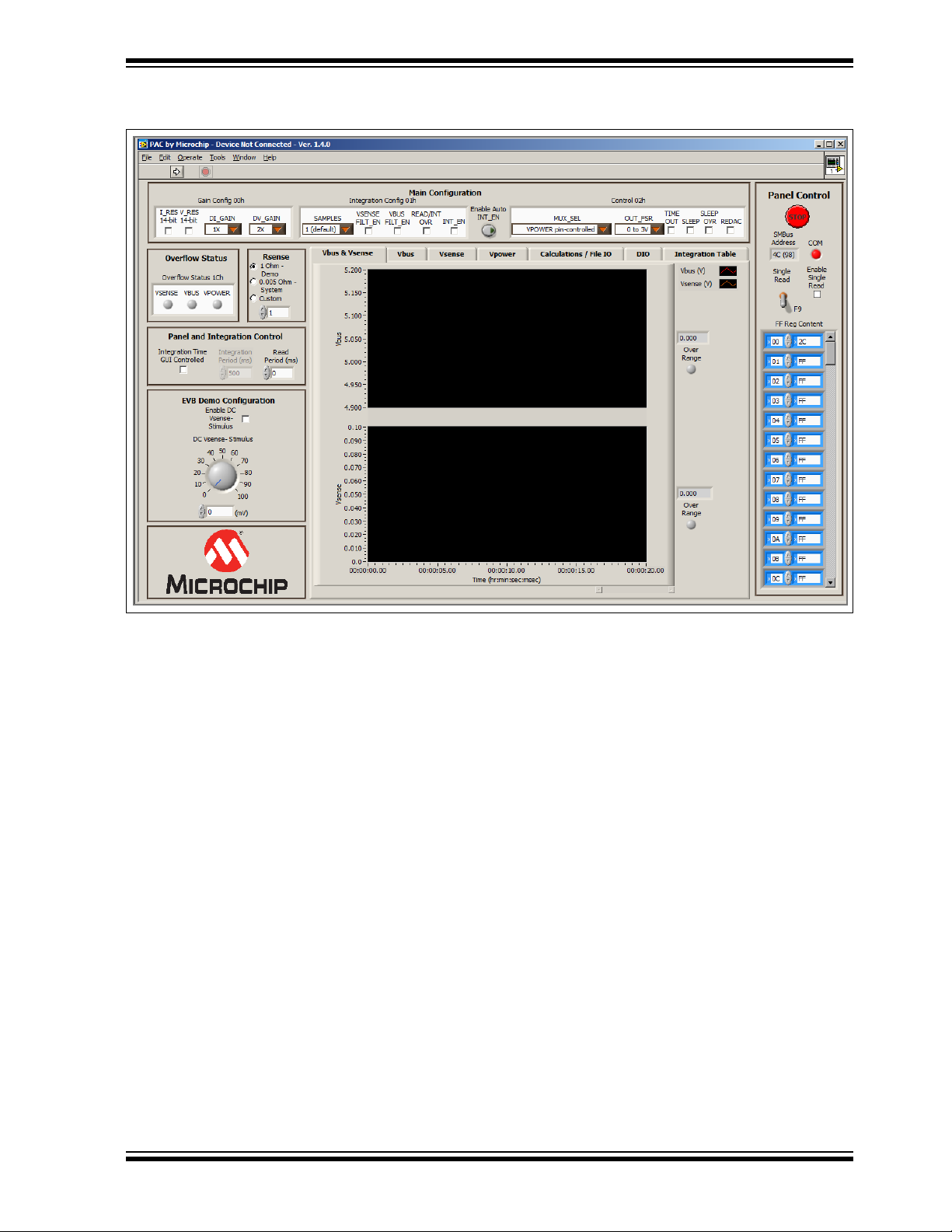

4.1 OVERVIEW

Panel Control

Main Configuration Panel

Panel and Integration Control

Rsense Option Panel

EVB Demo Configuration Panel

Configuration/View Tabs

Overflow Status Panel

To get the Graphical User Interface (GUI) and the Evaluation Board (EVB) running,

follow these instructions:

1. Start the PAC1921 GUI software: from the Windows Start menu, select

2. Connect the USB mini connector end of the cable to the board and the standard

The PAC1921 High-Side Current/Power Sensor Evaluation Board Graphical User

Interface (GUI) is shown in Figure 4-1.

PAC1921

HIGH-SIDE CURRENT/POWER SENSOR

EVALUATION BOARD USER’S GUIDE

Chapter 4. Software Description

Programs

USB connector of the cable to any available USB port on the PC. The V

USB power LEDs (LD1 and LD2, respectively) will illuminate RED, indicating that

the PAC1921 is powered up and the MCP2221 USB bridge is connected to the PC.

>PAC1921.

DD

and

FIGURE 4-1: GUI Interface Panel.

2015 Microchip Technology Inc. DS50002376A-page 27

Page 28

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

When the evaluation board is connected or disconnected, a message displays as

shown in Figure 4-2. With the evaluation board connected, click Auto-detect Address

to restart communications.

FIGURE 4-2: Communications Failure Message.

4.1.1 Tips for Using the Evaluation Board GUI

• After a power-up of the evaluation board, the default settings are loaded. Users

can save the setting configurations to user-named files, which can be reloaded at

any time for quick reconfiguration (see Section 4.3.3.1 “Configuration Save and

Load”).

• To configure the GUI and PAC1921 for free-run integration power measurement,

press the <F2> function key on the keyboard.

• To reload the PAC1921 register defaults, press the <F6> function key on the

keyboard.

• When using the GUI, the PAC1921 can enter a Sleep state; however, it wakes to

service the GUI SMBus communications, then returns to Sleep. For this reason,

the current consumption will be slightly higher than expected in Sleep state when

using the GUI.

• When the PAC1921 enters Sleep state, the PAC1921 clears the measurement

registers, and consequently, the GUI Calculations/File IO tab is cleared. To

prevent the PAC1921 from entering Sleep, check the “SLEEP OVR” box in the

Main Configuration section.

DS50002376A-page 28 2015 Microchip Technology Inc.

Page 29

4.2 INTERFACE DESCRIPTION AND OPERATION

COM Status

Indicator

SMBus

Address

Indicator

Stop Button

Enable Single

Read Option

Register Content

Run Button

4.2.1 Panel Control Section

The Panel Control section on the right side of the GUI, shown in Figure 4-3, affects the

GUI operation.

Software Description

FIGURE 4-3: Panel Control Section.

4.2.1.1 STOP AND RUN BUTTONS

Pressing the Stop button, as shown in Figure 4-3, interrupts the GUI software communications with the evaluation board. When the Stop button is clicked, the Run button is

displayed on the menu bar (see Figure 4-4).

FIGURE 4-4: Run Button.

2015 Microchip Technology Inc. DS50002376A-page 29

Page 30

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

SMBus

Address

Indicator

COM Status

Indicator

Single Read

Button

To restart the communication between the software and the evaluation board, click the

Run button. The arrow button disappears when the communications resume.

Note 1: Stopping and restarting the GUI does not affect register settings. To

restore default register settings, disconnect power from the evaluation

board, then reconnect power.

2: Stopping the GUI clears the “Enable DC Vsense- Stimulus” box (see

Section 4.2.6 “EVB Demo Configuration Panel”).

To close the program, use the Close (X) button in the upper right corner of the window.

4.2.1.2 SMBus ADDRESS

The “SMBus Address” box, shown in Figure 4-5, indicates the selected SMBus

address. The SMBus address can be changed by moving a jumper (see

Section 3.3.1 “SMBus Mode”).

FIGURE 4-5: SMBus Address Indicator.

4.2.1.3 COM STATUS INDICATOR

The “COM” status indicator, on the right side of the panel as shown in Figure 4-5,

indicates the status of communications over the SMBus. During normal operation, the

“COM” indicator is black. If the SMBus communications fail, the “COM” indicator turns

red.

4.2.1.4 SINGLE READ/CONTINUOUS READ

The panel defaults to continuous register reads (toggle switch in down position, as

shown in Figure 4-5). To stop continuous register reads, check the “Enable Single

Read” box. In order to capture the register values at a given time, click the switch, which

will briefly flip to “Single Read”.

4.2.1.5 REGISTER CONTENT

“Reg Content”, shown in Figure 4-3, is a scrollable list of the PAC1921 registers and

the last read value. It is important to note that not all addresses are physical memory

locations on the device; these registers will read ‘0’. Likewise, some registers shown

(undocumented in the data sheet) may have data. Editing these registers can cause

unexpected results.

To update a register value, locate the register address in the left column, type the new

value in the corresponding cell in the right column, and press Enter on the keyboard or

click on another part of the GUI.

DS50002376A-page 30 2015 Microchip Technology Inc.

Page 31

Software Description

4.2.1.5.1 Numbering Systems Views

The “Reg Content” section allows values to be displayed using different numbering

systems: Decimal, Hex, Octal, Binary or SI Notation.

To view a value using a different numbering system, click the indicator to the left of the

value in the cell, shown circled in Figure 4-6.

FIGURE 4-6: Numbering System Indicators.

4.2.2 Main Configuration Panel

The Main Configuration section, shown in Figure 4-7, contains the PAC1921 configuration controls in registers 00h, 01h and 02h. Refer to the data sheet for register bit

descriptions.

FIGURE 4-7: Main Configuration Panel.

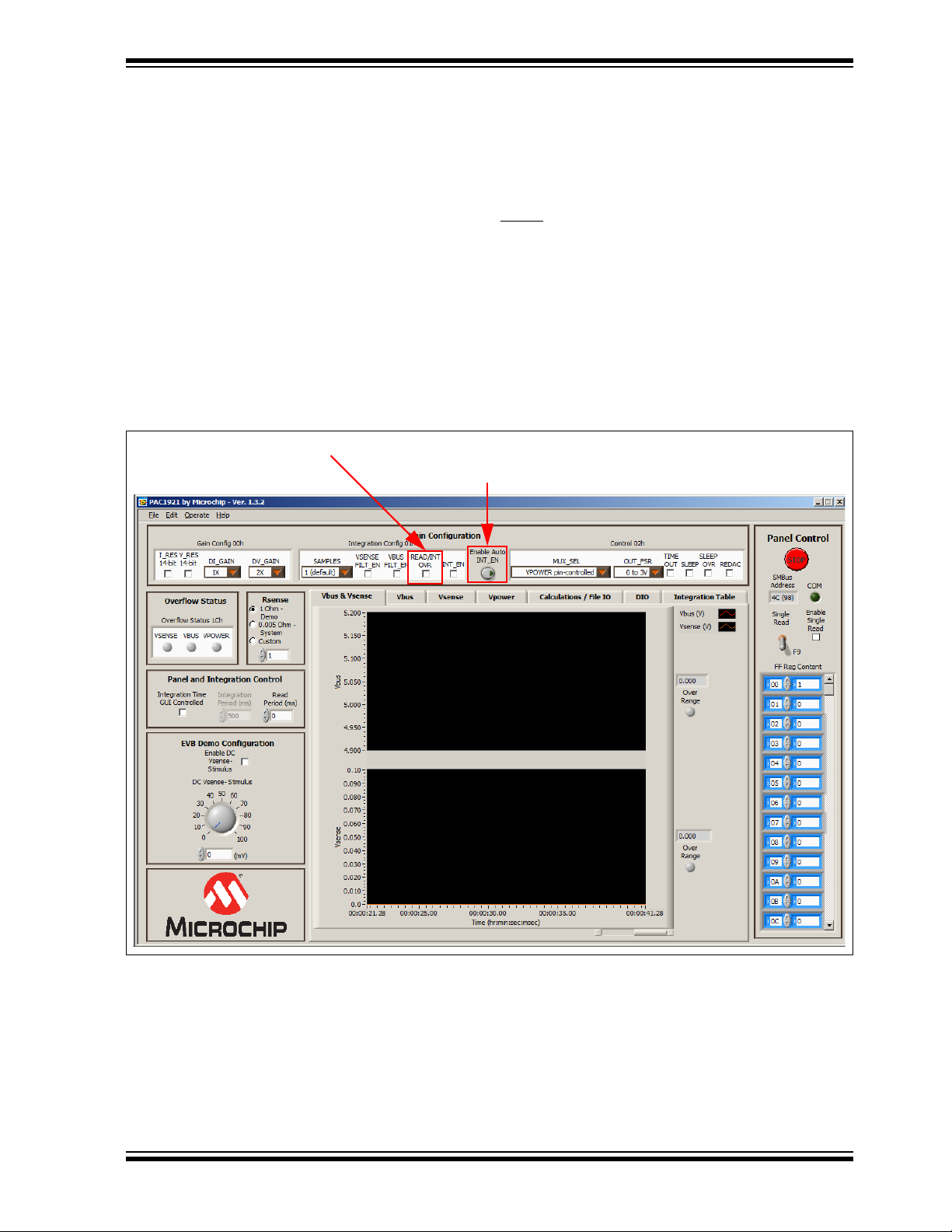

4.2.2.1 ENABLE AUTO INT_EN

The “Enable Auto INT_EN” control is a GUI control convenience. Under normal

operation, for most of the integration parameter settings, changes do not take effect

until the PAC1921 is placed in the Read state. When the “Enable Auto INT_EN” control

is activated (light green – shown as “Enabled” in Figure 4-8), it automatically places the

PAC1921 into the Read state and back to Integrate state whenever a Main Configuration control is changed. It also updates the GUI calculations. When the

“Enable Auto INT_EN” control is disabled (dark green), the user must place the device

in the Read state before the “I_RES”, “V_RES”, “SAMPLES”, “VSENSE FILT_EN” and

“VBUS FILT_EN” changes take effect, and to update the GUI calculations.

It is recommended that the “Enable Auto INT_EN” control be activated when using

the GUI.

FIGURE 4-8: Enable Auto INT_EN GUI Control.

2015 Microchip Technology Inc. DS50002376A-page 31

Page 32

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

“READ/INT OVR” Box is Checked

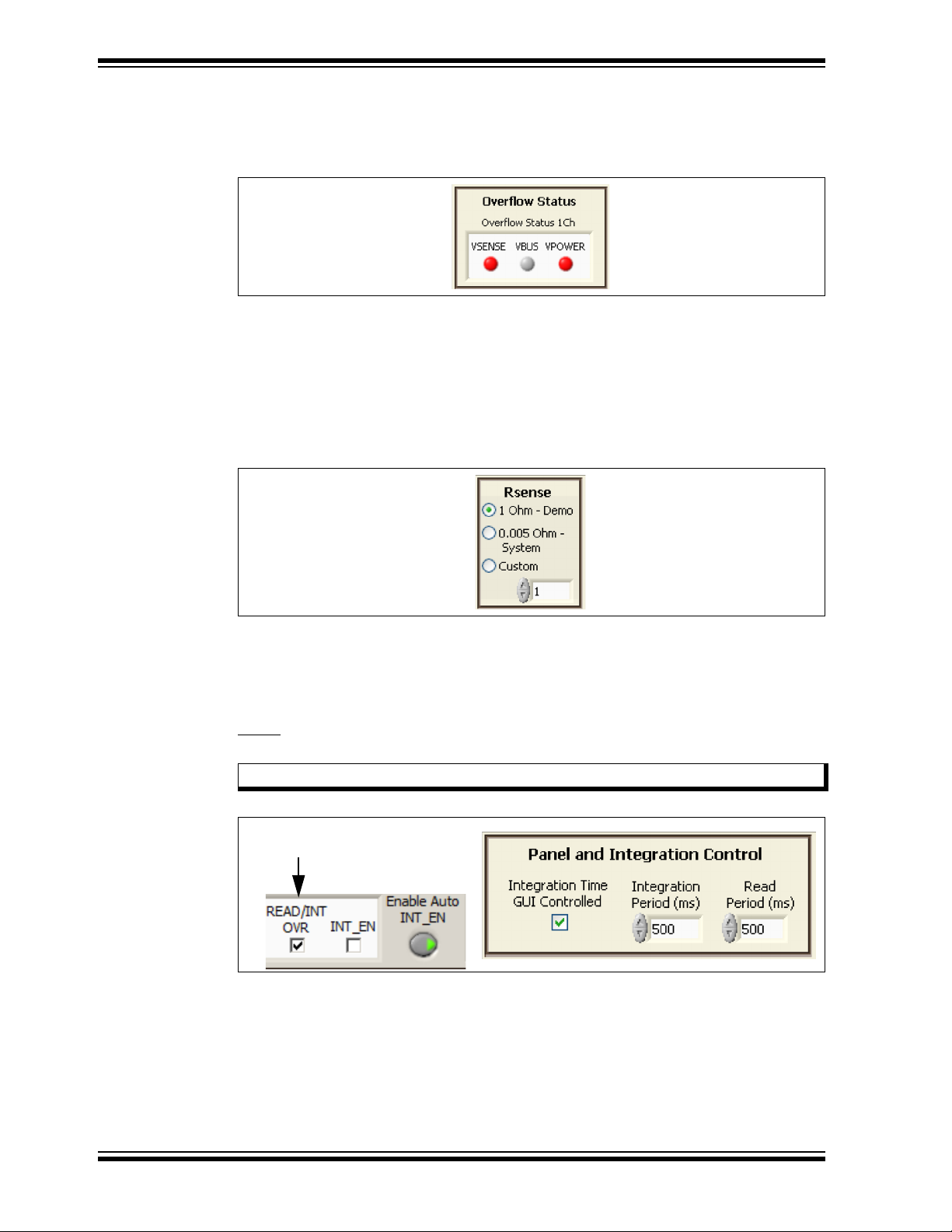

4.2.3 Overflow Status Panel

The Overflow Status section, shown in Figure 4-9, represents the three bits in the

Overflow Status Register 1Ch. When an indicator turns red, it indicates an overflow.

FIGURE 4-9: Overflow Status.

4.2.4 Rsense Panel

The Rsense section, shown in Figure 4-10, needs to reflect the value of the R

resistor in use on the evaluation board. This value is used in calculations done by the

GUI. In Demo mode, select the 1 Ohm - Demo button. In Sys mode, select the

0.005 Ohm - System button. If another resistor is used, check the Custom option

button and fill the corresponding value in the spin box underneath the option.

FIGURE 4-10: Rsense Configuration Panel.

SENSE

4.2.5 Panel and Integration Control Panel

The Panel and Integration Control section, shown in Figure 4-11, contains GUI controls

which set and clear the INT_EN bit. When using these controls, check the “READ/INT

OVR” box in the Main Configuration section to allow the INT_EN bit to override the

READ

/INT pin state.

Note: Read Period (ms) is always enabled.

DS50002376A-page 32 2015 Microchip Technology Inc.

FIGURE 4-11: Panel and Integration Control.

Page 33

Software Description

4.2.6 EVB Demo Configuration Panel

The EVB Demo Configuration panel, shown in Figure 4-12, contains GUI controls

which affect the Demo mode. To inject current onto V

Vsense- Stimulus” box. To set the current level, rotate the “DC Vsense- Stimulus” dial

or type a value between 0 and 100 in the (mV) spin box below the dial.

FIGURE 4-12: Evaluation Board Demo Configuration.

SENSE-

, check the “Enable DC

2015 Microchip Technology Inc. DS50002376A-page 33

Page 34

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

Click to enter new values to scale the plot.

4.3 TAB DESCRIPTIONS

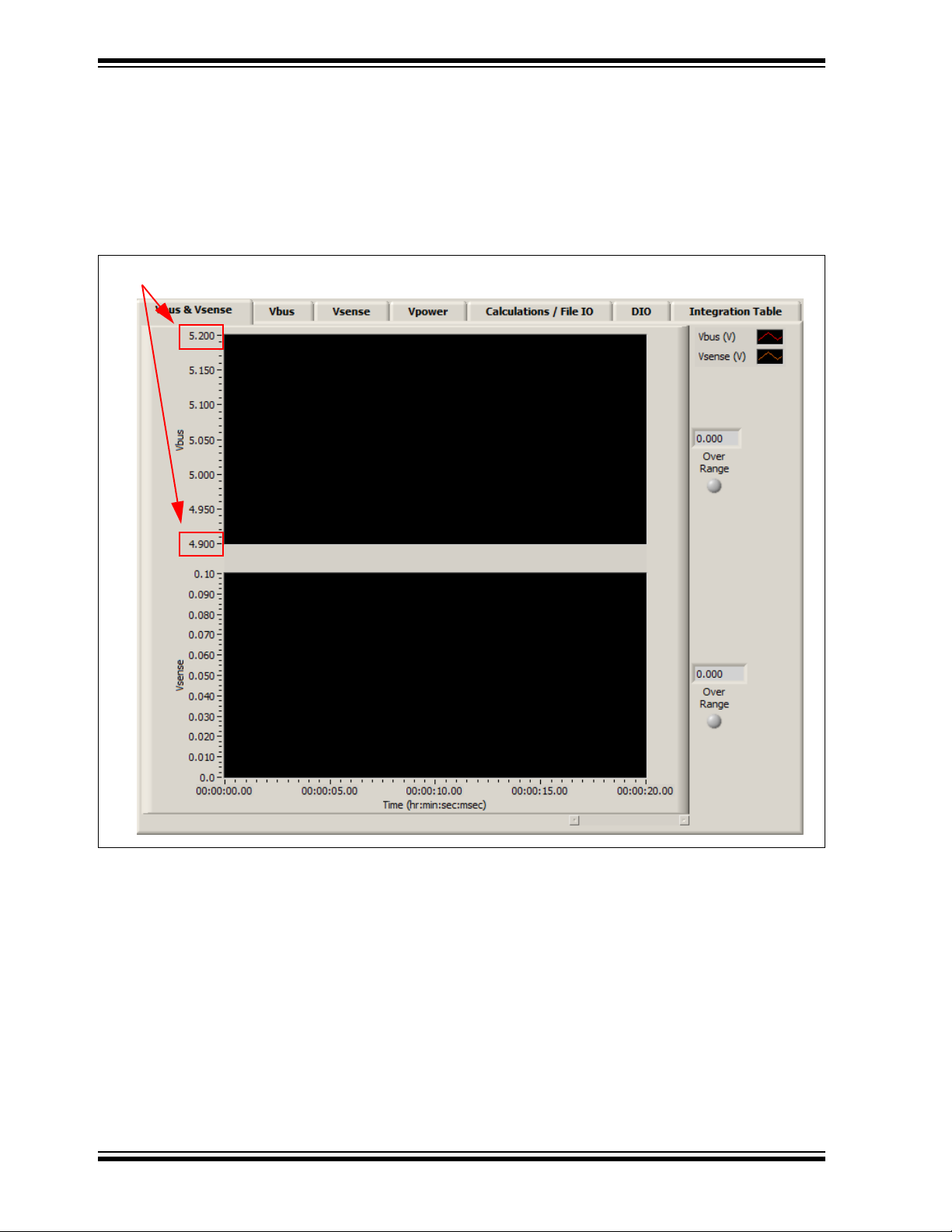

4.3.1 Vbus & Vsense Tab

The Vbus & Vsense tab, shown in Figure 4-13, displays plots for calculated V

volts and calculated V

in volts. The plots are not self-scaling. If the value in the

SENSE

BUS

in

box at the right of the plot (indicated with arrows) falls outside the Y-axis range on the

plot, click the top and/or bottom value on the axis and type in a new value.

FIGURE 4-13: Vbus & Vsense Tab.

DS50002376A-page 34 2015 Microchip Technology Inc.

Page 35

Software Description

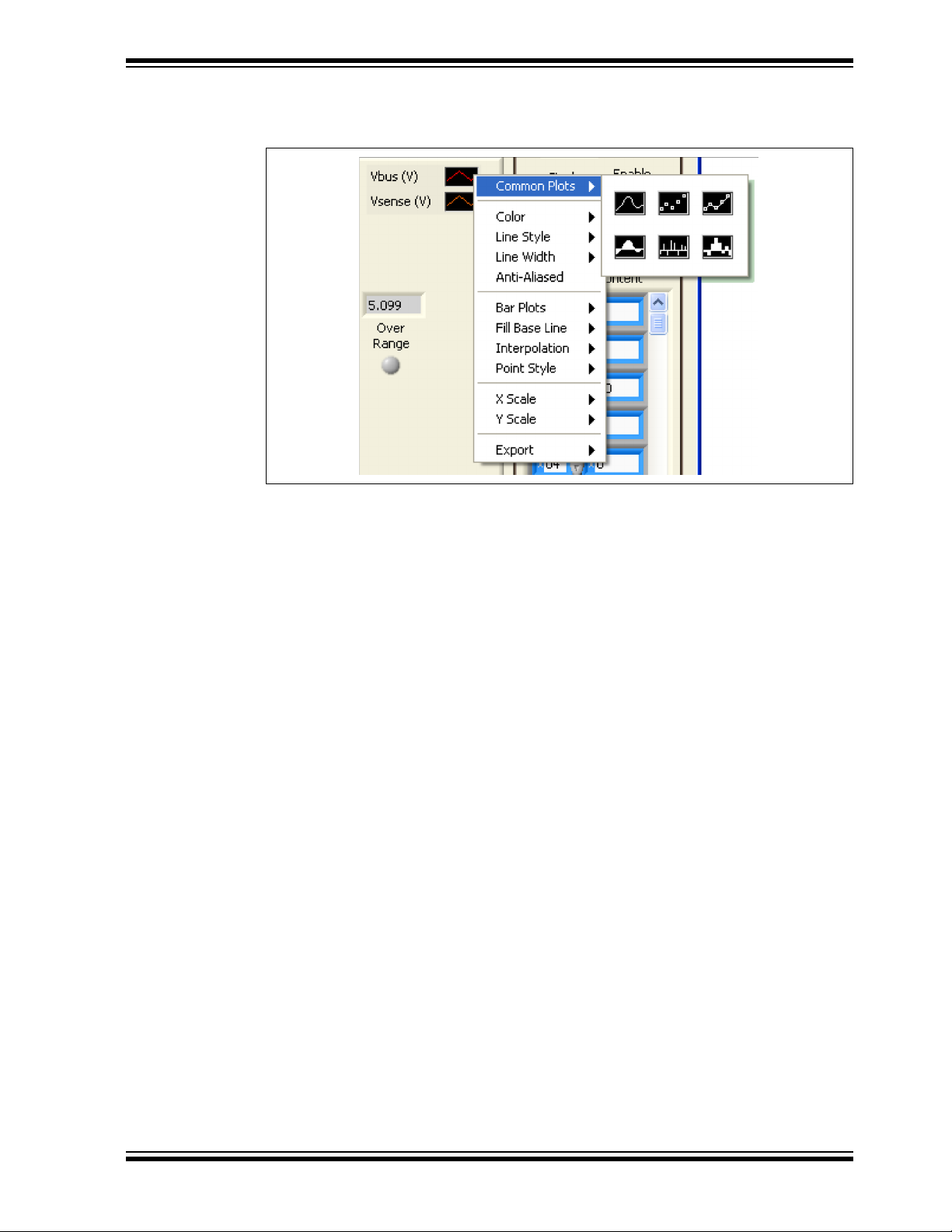

To change the look of the plot lines, click the applicable graphic in the legend on the

right of the tab to display a menu of options, as shown in Figure 4-14.

FIGURE 4-14: Plot Legend Context Menu.

4.3.2 Vbus, Vsense and Vpower Tabs

There are separate tabs to show individual plots for Vbus, Vsense and Vpower. They

operate similarly to the Vbus & Vsense tab described above.

2015 Microchip Technology Inc. DS50002376A-page 35

Page 36

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

1LSB

0.1V

RDI_GAIN

------------ ------------- ------------ ---

32V

DV_GAIN

------------- --------------

1023 2

6

------------- ------------- ------------- ---------- ------------- ------------=

Where:

1LSB = LSB value in watts for V

POWER

Result Registers 1Dh and 1Eh

0.1V = Maximum V

SENSE

voltage

R=Value of R

SENSE

resistor in ohms

DI_GAIN = Digital current gain

32V/DV_GAIN = Maximum voltage

1023 = (210 – 1) = 10-bit FSR

2

6

= Adjustment for 6 unused register bits when read as a 16-bit number

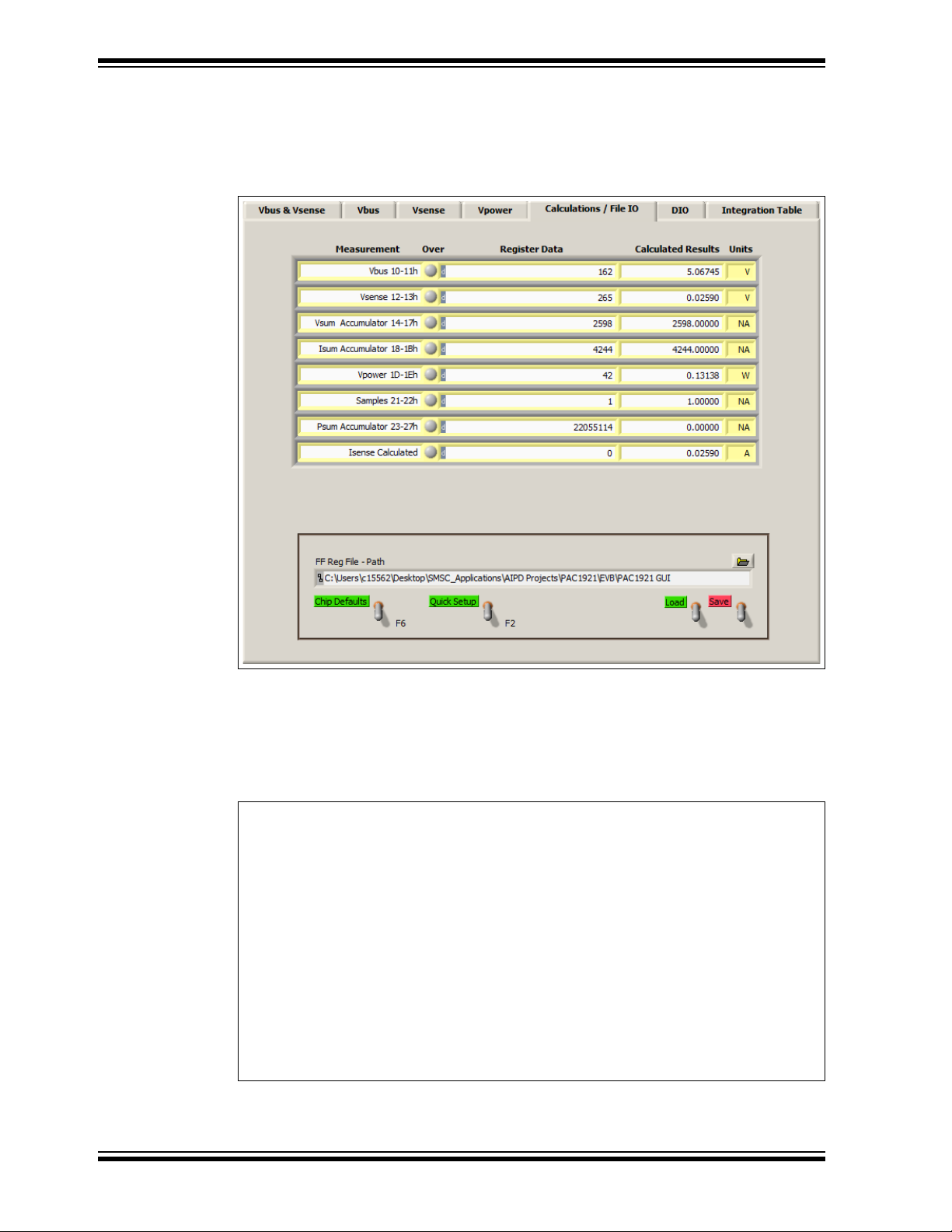

4.3.3 Calculations/File IO Tab

The Calculations/File IO tab, shown in Figure 4-15, displays register data (in decimal

by default). It also shows calculated results which were obtained by applying the data

sheet equations to the register data.

DS50002376A-page 36 2015 Microchip Technology Inc.

FIGURE 4-15: Calculations/File IO Tab.

An example of using the equations to calculate power is as follows.

The value of one LSB in the V

Result registers, in watts, can be calculated

POWER

according to Equation 4-1.

EQUATION 4-1: LSB CALCULATION

Page 37

Software Description

0.1V

1

1

------------- ----

32V

1

----------

1023

------------ ------------- ---------42 0.13138W=

Where:

0.1V = Maximum V

SENSE

voltage

1 = Value of R

SENSE

resistor

1 = Digital current gain

32V/1 = Maximum voltage

1023 = 10-bit FSR

42 = Decimal value of V

POWER

Result Registers 1Dh and 1Eh

The power calculation using the V

POWER

Result registers value from Figure 4-15 is

shown in Equation 4-2.

EQUATION 4-2: POWER CALCULATION

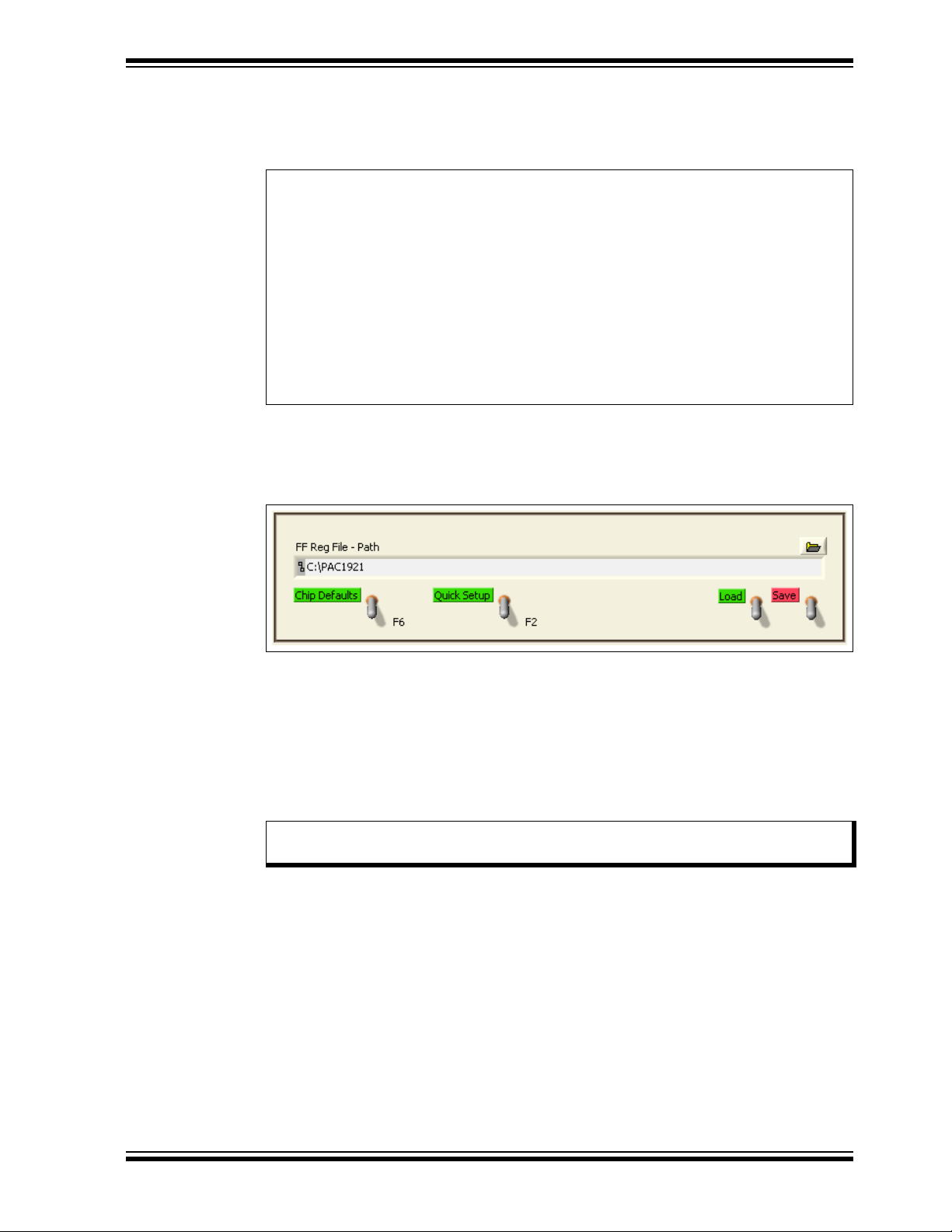

4.3.3.1 CONFIGURATION SAVE AND LOAD

The Calculations/File IO tab contains controls, as shown in Figure 4-16, which save the

settings currently configured in the PAC1921 to allow quick reconfiguration at any time.

2015 Microchip Technology Inc. DS50002376A-page 37

FIGURE 4-16: Save/Load Section.

To save configuration settings, configure the PAC1921 as desired, then display the

Calculations/File IO tab. The “FF Reg File Path” box defaults to where the GUI software is installed. To change the location, type in a path, or click the folder icon to use

a Windows

file will be saved. The file should be named with the.txt extension or similar text file

format. Once a file name and location have been chosen, click the Save switch, and

the file is saved.

Note: If a file with the same name already exists, the file will be overwritten

The data is saved in two columns, separated by tabs. The first column is the register

address and the second column is the register data.

Once a file is saved, it can be recalled at any time by selecting the file in the “FF Reg

File Path” box and clicking the Load switch.

Click the Chip Defaults switch or press the <F6> function key on the keyboard to

reload register defaults on the PAC1921.

®

system-based navigation aid to select the folder where the configuration

without warning and old data will be lost.

Page 38

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

Click the Quick Setup switch or press the <F2> function key on the keyboard to set up

the GUI and PAC1921 for free-run integration power measurement. The Quick Setup

switch does the following:

- Enables the “Enable Auto INT_EN” option.

- Enables the “READ/INT OVR” option.

- Enables the “INT_EN” option.

- Sets “MUX_SEL” to VPOWER free-run.

- Enables the “Enable DC Vsense- Stimulus” option.

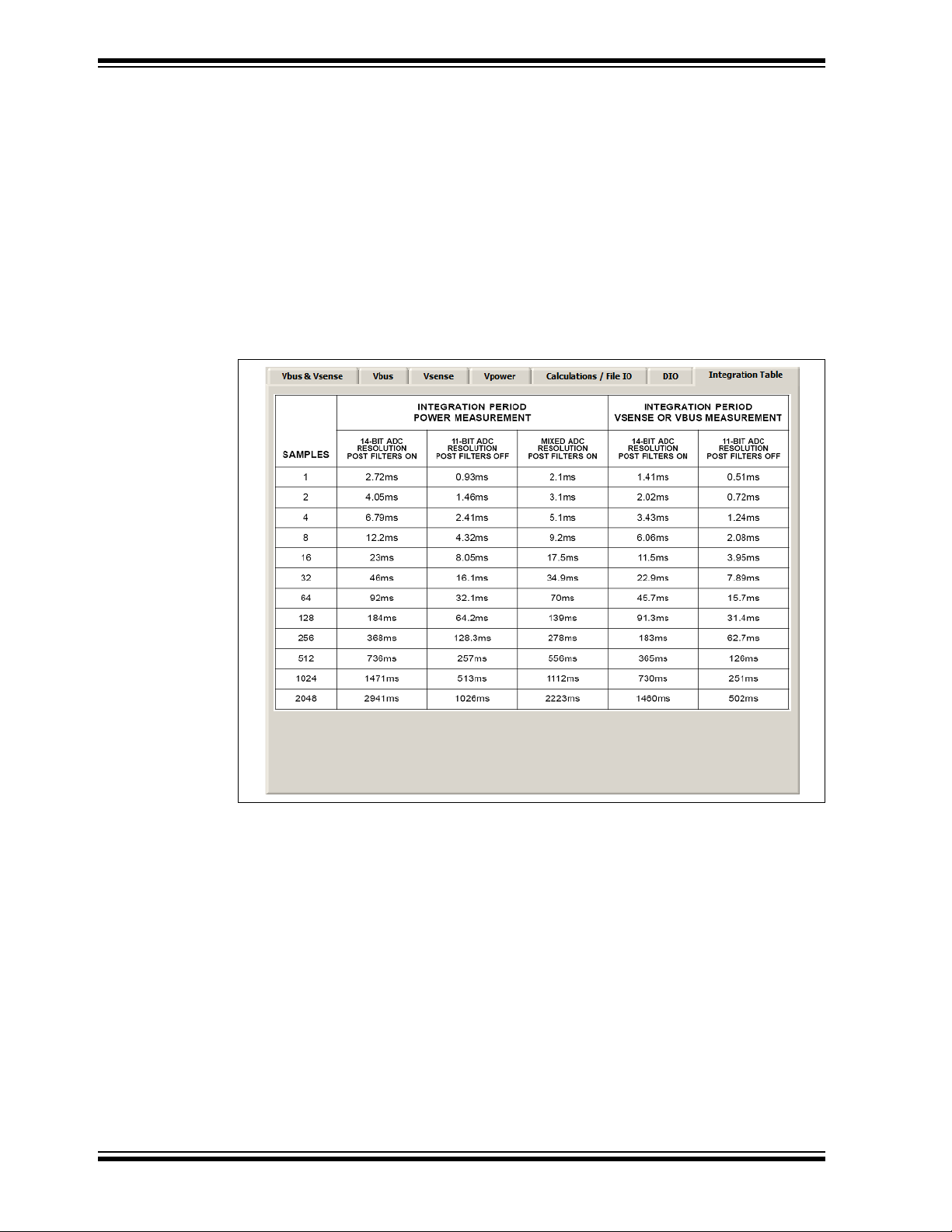

4.3.4 Integration Table Tab

The Integration Table tab, shown in Figure 4-17, shows the maximum integration

periods for a selected number of samples with various settings.

FIGURE 4-17: Integration Table Tab.

DS50002376A-page 38 2015 Microchip Technology Inc.

Page 39

4.4 EVALUATION BOARD EXAMPLES

Check the “READ/INT OVR” Box

Check the “Enable Auto INT_EN” Control

4.4.1 Power Pin-Controlled Integration Example

This example provides steps to experiment with pin-controlled integration in SMBus

mode and see the effects of gain.

1. In the Main Configuration section, check the “READ/INT OVR” box. This allows

the INT_EN bit to override the READ

INT_EN” control to set automatic GUI updates.

2. In the Panel and Integration Control section, check the “Integration Time GUI

Controlled” box, and set the “Read Period (ms)” to 500 ms. This causes the

INT_EN bit to toggle between high for 500 ms (putting the PAC1921 in the

Integrate state) and low for 500 ms (putting the device in the Read state).

3. In the EVB Demo Configuration section, check the “Enable DC Vsense-

Stimulus” box and type 40 mV in the “DC Vsense- Stimulus (mV)” box.

4. Observe the plots on the Vbus & Vsense tab, as shown in Figure 4-18. The

evaluation board demo V

BUS

/INT pin state. Also check the “Enable Auto

is ~5.1V and V

Software Description

is ~0.04V.

SENSE

FIGURE 4-18: Pin-Controlled Integration, No Gain.

2015 Microchip Technology Inc. DS50002376A-page 39

Page 40

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

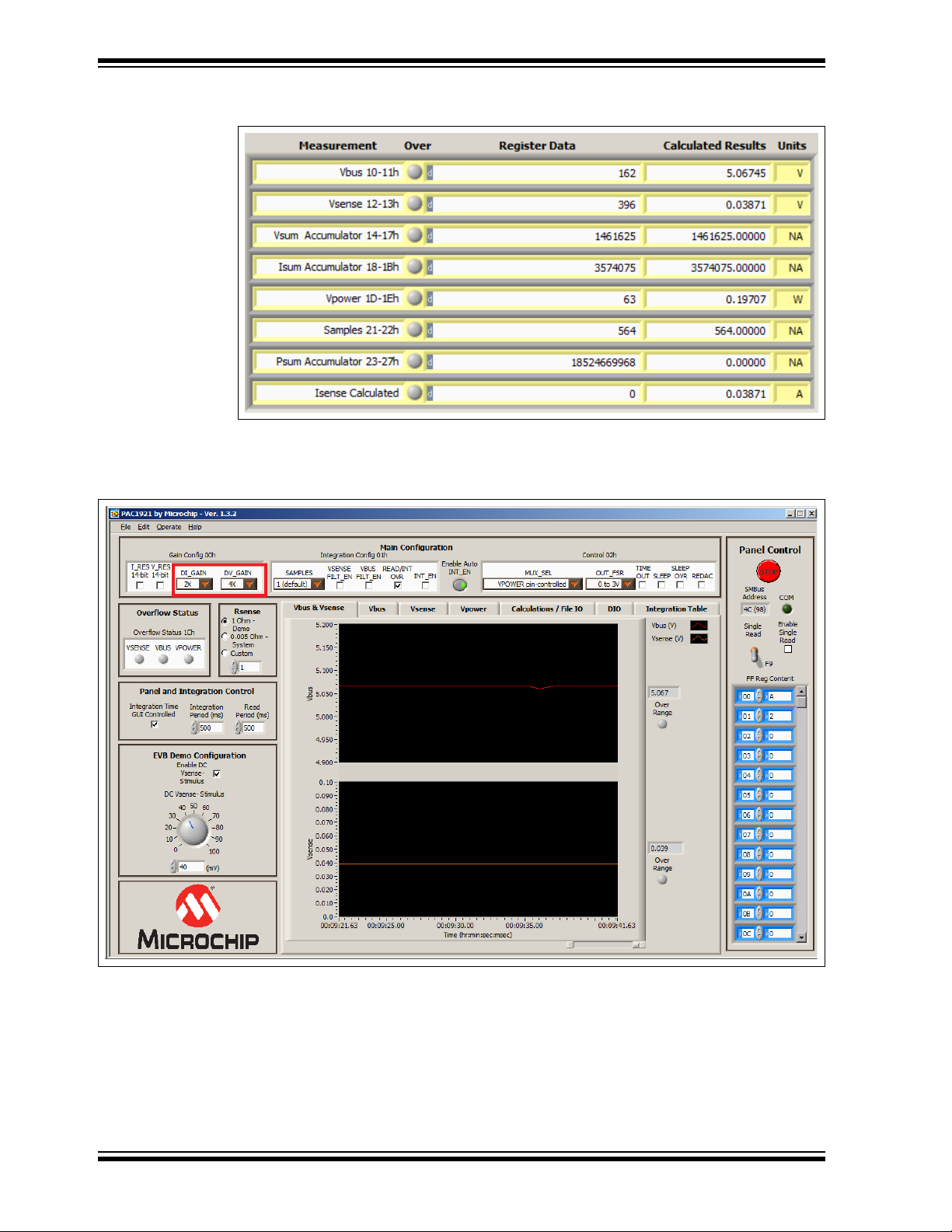

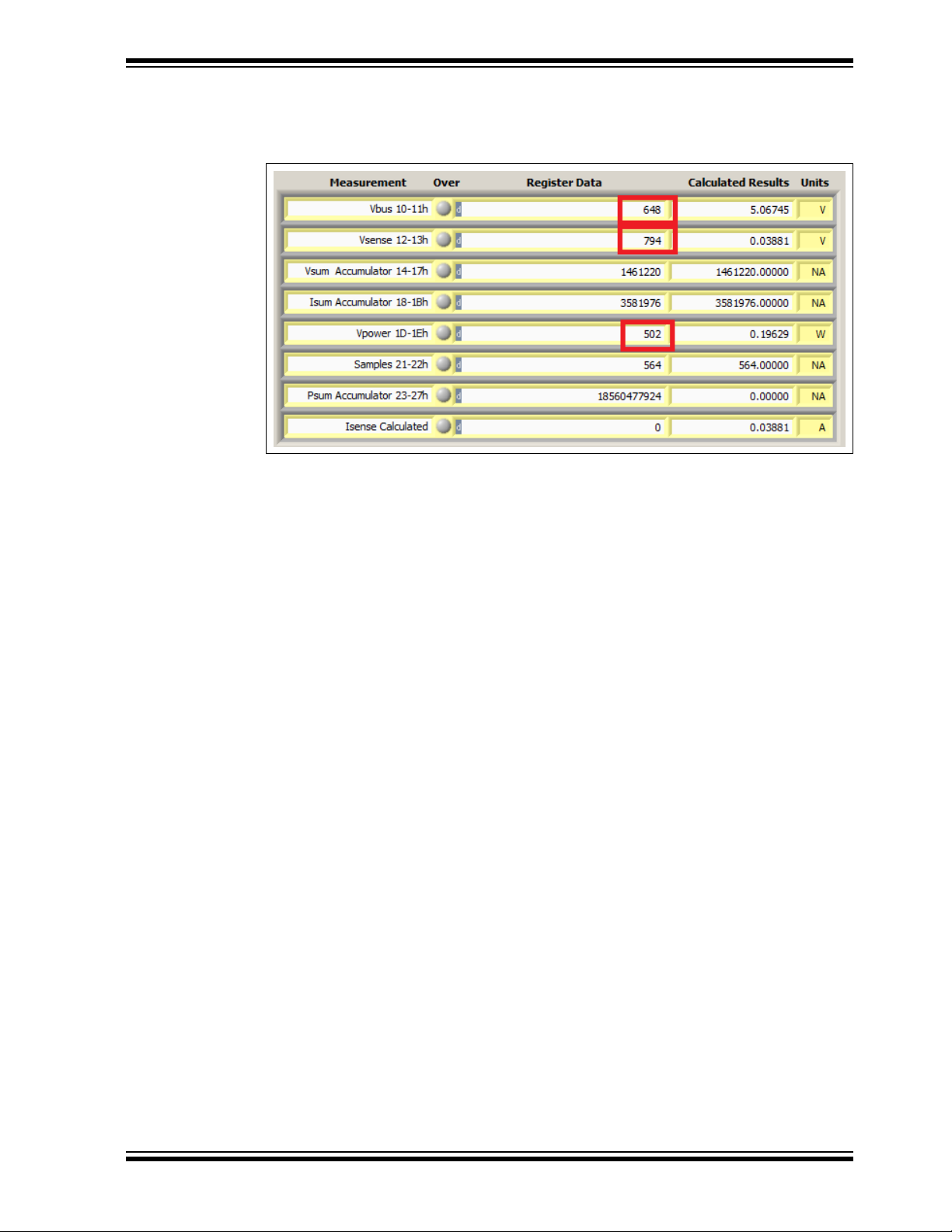

5. Observe the data on the Calculations/File IO tab, as shown in Figure 4-19.

FIGURE 4-19: Pin-Controlled Integration without Gain.

6. To see the effects of gain, change “DI_GAIN” to 2X and “DV_GAIN” to 4X in the

Gain Config 00h section, as shown in Figure 4-20.

FIGURE 4-20: Pin-Controlled Integration with Gain.

DS50002376A-page 40 2015 Microchip Technology Inc.

Page 41

Software Description

7. Observe the data on the Calculations/File IO tab, as shown in Figure 4-21.

Notice that the Register Data values (with the exception of the accumulators)

reflect the gain.

FIGURE 4-21: Pin-Controlled Integration with Gain.

2015 Microchip Technology Inc. DS50002376A-page 41

Page 42

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

4.4.2 Power Free-Run Integration Example

This section provides steps to experiment with free-run integration in SMBus mode and

see the effects of filtering, resolution and sampling. It starts by showing the fastest

integration period and progressively shows higher accuracy.

1. Press the <F2> function key on the keyboard. This performs Quick Setup, which

checks the “READ/INT OVR” box, the “INT_EN” bit box and the “Enable DC

Vsense- Stimulus” box, enables the “Enable Auto INT_EN” control and sets

“MUX_SEL” to VPOWER free-run. Integration begins using the 1 sample default.

2. In the Main Configuration section, click the “I_RES” and “V_RES” boxes so 11-bit

shows; this lowers the resolution from 14 bits to 11 bits.

3. In the Main Configuration section, uncheck the “VSENSE FILT_EN” and “VBUS

FILT_EN” boxes to disable the ADC post filters.

4. In the EVB Demo Configuration section, type 40 mV in the “DC VsenseStimulus” spin box.

5. Observe the plots on the Vbus & Vsense tab, as shown in Figure 4-22, adjusting

the Y-axis values as desired. These settings result in the shortest integration

period.

FIGURE 4-22: Free-Run Integration, Shortest Period.

DS50002376A-page 42 2015 Microchip Technology Inc.

Page 43

Software Description

6. Check the “VSENSE FILT_EN” and “VBUS FILT_EN” boxes to enable the ADC

post filters, and observe the improvement in the plots on the Vbus & Vsense tab,

as shown in Figure 4-23.

FIGURE 4-23: Free-Run Integration with ADC Post Filters Enabled.

2015 Microchip Technology Inc. DS50002376A-page 43

Page 44

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

7. Uncheck the “I_RES” and “V_RES” boxes to enable 14-bit resolution, and

observe the improvement in the plots on the Vbus & Vsense tab, as shown in

Figure 4-24.

FIGURE 4-24: Free-Run Integration with 14-Bit Resolution.

DS50002376A-page 44 2015 Microchip Technology Inc.

Page 45

Software Description

8. Change the number of “SAMPLES” to 8 and observe the improvement in the

plots on the Vbus & Vsense tab, as shown in Figure 4-25.

FIGURE 4-25: Increased Sample Effect.

4.5 TROUBLESHOOTING

4.5.1 GUI Controls Unresponsive After Installation

Restart the computer. In some cases, a restart is required after installation.

4.5.2 GUI Freezes

If the GUI freezes for unknown reasons, communications cannot be stopped and the

program cannot be closed. Disconnect the USB cable from the evaluation board, then

close the program. Reconnect the evaluation board, then restart the GUI.

2015 Microchip Technology Inc. DS50002376A-page 45

Page 46

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

NOTES:

DS50002376A-page 46 2015 Microchip Technology Inc.

Page 47

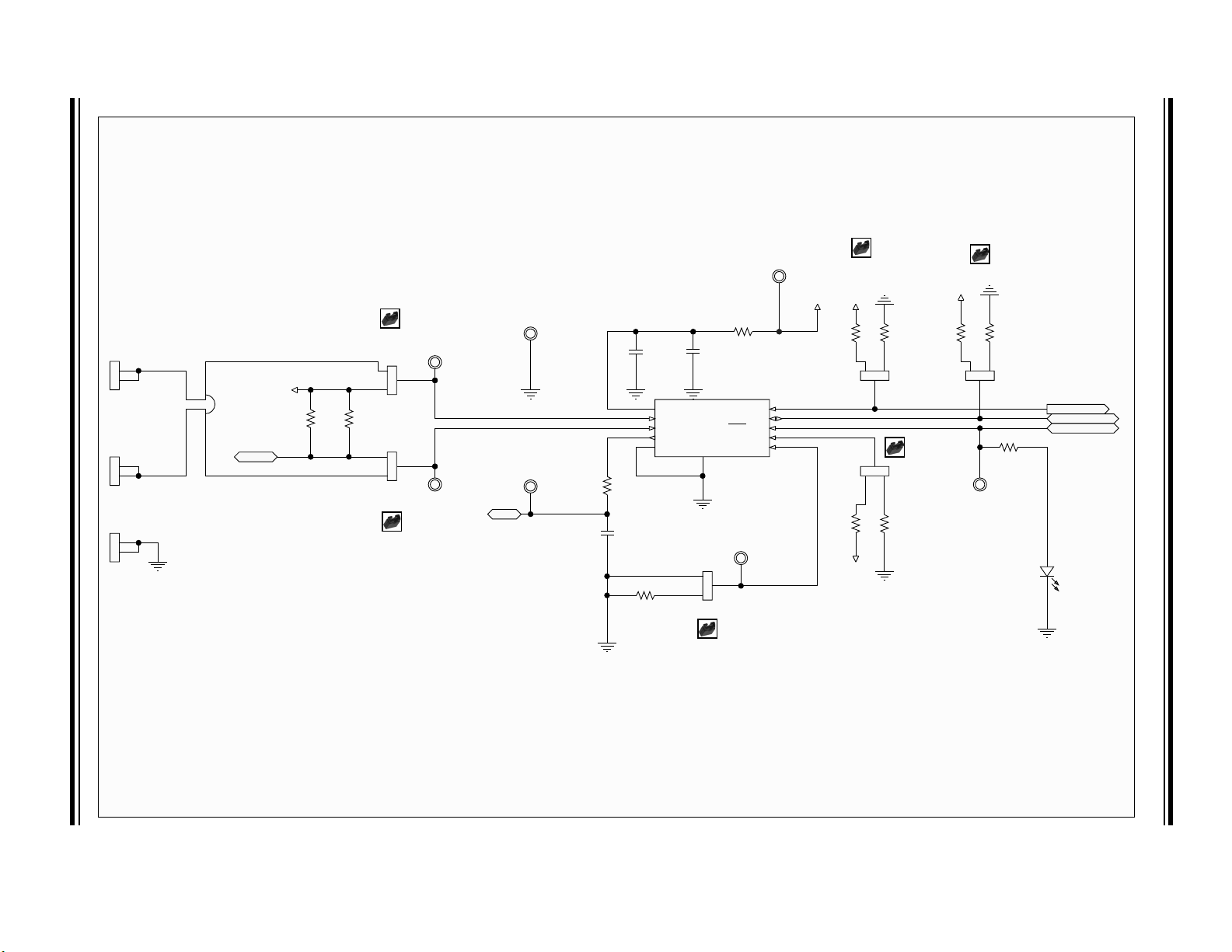

Appendix A. Schematic and Layouts

A.1 INTRODUCTION

This appendix contains the following schematics and layouts for the PAC1921

High-Side Current/Power Sensor Evaluation Board:

• Board – PAC1921 Current Shunt and Power Monitor Schematic

• Board – USB Bridge and Sig Gen Schematic

• Board – Top Silk

• Board – Top Copper and Silk

• Board – Top Copper

• Board – Bottom Copper

• Board – Bottom Copper and Silk

• Board – Bottom Silk

PAC1921

HIGH-SIDE CURRENT/POWER SENSOR

EVALUATION BOARD USER’S GUIDE

2015 Microchip Technology Inc. DS50002376A-page 47

Page 48

DS50002376A-page 48 2015 Microchip Technology Inc.

V

SENSE+

V

SENSE-

V

SOURCE-

V

SOURCE+

+5V_USB

V

DD

V

DD

V

DD

V

DD

Demo

Sys

Sys

V

SENSE+

V

SENSE-

Demo

Out

#READ/INT

#READ/INT

GND

J8, 1-2 C lose (default) = 1001_100xb -> 98h

J8, 2-3 Close (alternative) = 1001_101x b -> 9Ah

J8, Open (alternative) = Apply external resistor

for GAIN_SEL function in Stand- Alone mode.

Read the data sheet for more information

ADDR_SEL

/GAIN_SEL

V

DD

SMBUS_CLK

SMBUS_DATA

#READ/INT

IDEMO

Idemo

OUT

GP2

COMM_SEL

SMBus_CLK

SMBus_DATA

#READ/INT

TP LOOP Yellow

TP2

TP LOOP Orange

TP1

TP LOOP Black

TP6

TP LOOP White

TP3

TP LOOP White

TP4

TP LOOP Red

TP5

TP LOOP Yellow

TP7

EDZ250/2

J1

EDZ250/2

J2

EDZ250/2

J11

2R

2010

5%

R2

2R

2010

5%

R3

HDR-2.54 Male 1x3

J3

123

HDR-2.54 Male 1x3

J4

123

HDR-2.54 Male 1x3

J6

123

HDR-2.54 Male 1x3

J7

HDR-2.54 Male 1x3

J8

123

HDR-2.54 Male 1x3

J5

Shunt 2.54 mm 1x2 Handle

JP3

Shunt 2.54 mm 1x2 Handle

JP4

Shunt 2.54mm 1x2 Handle

JP5

Shunt 2.54 mm 1x2 Handle

JP6

Shunt 2.54mm 1x2 Handle

JP7

Shunt 2.54 mm 1x2 Handle

JP8

0.1 μF

16V

0603

C1

0.001 μF

50V

0603

C3

1 μF

16V

0603

C2

12.1k

0603

1%

R8

12.1k

0603

1%

R9

12.1k

0603

1%

R10

12.1k

0603

1%

R11

12.1k

0603

1%

R6

12.1k

0603

1%

R7

120R

0603

1%

R4

120R

0603

1%

R5

100R

0603

1%

R1

GREEN

LD6

2k

0603

1%

R12

V

DD

1

SENSE+

2

SENSE-

3

OUT

4

GND

5

ADDR_SEL

6

COMM_SEL

7

READ/INT

8

SM_DATA

9

SM_CLK

10

EP

11

PAC1921-1

U1

1 2

3

4

0.005R

1%

RS1

3 2 1

3 2 1

21

2121

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

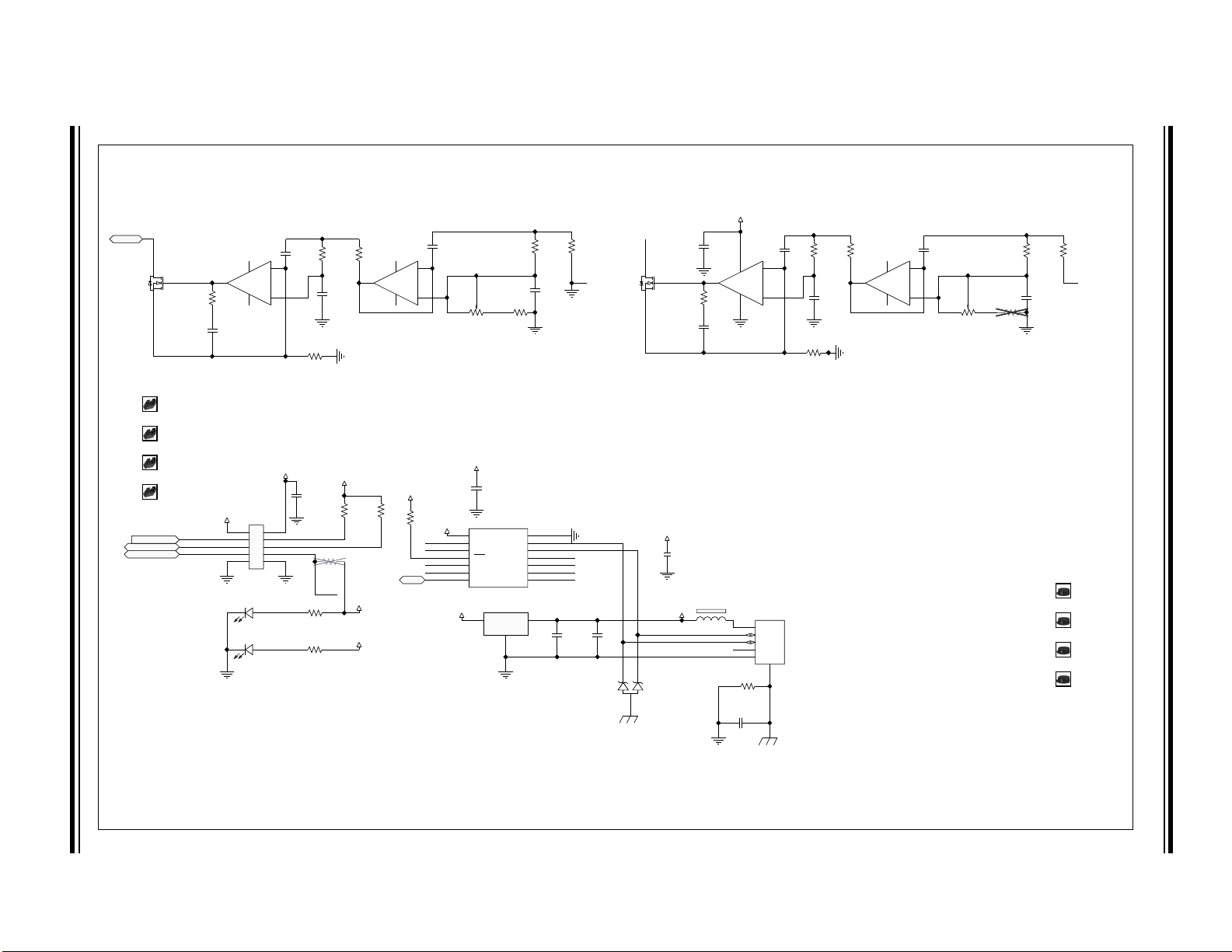

A.2 BOARD – PAC1921 CURRENT SHUNT AND POWER MONITOR SCHEMATIC

Page 49

2015 Microchip Technology Inc. DS50002376A-page 49

GP1 GP3

+3.3V

V

DD

+5V_USB

+5V_USB

V

DD

+5V_USB

Steady state current generator Waveform Current Generator

VDD Power

USB Power

OUT

IDEMO

#READ/INT

SMBUS_DATA

SMBUS_CLK

Idemo

Idemo

SMBus_CLK

SMBus_DATA

#READ/INT

SMBusCLK

SMBusDATA

ID

4

V

BUS

1

GND

5

D-

2

D+

3

0

USB MINI-B Female

P1

0.47 μF

6.3V

0603

C10

SMBusDATA

SMBusCLK

+3.3V

+3.3V

+3.3V

+3.3V

RX

TX

GP2 GP3

GP0

GP1

RESET +3.3V

+3.3V

+3.3V

GP0

Rubber Pad Cyl D7.9H5.3

PAD1

Rubber Pad Cyl D7.9H5.3

PAD2

Rubber Pad Cyl D7.9H5.3

PAD3

Rubber Pad Cyl D7.9H5.3

PAD4

DD+

V

BUS

1k

0603

1%

R20

1k

0603

1%

R21

12.1k

0603

1%

R18

12.1k

0603

1%

R19

12.1k

0603

1%

R26

1M

0603

1%

R27

3.32k

0603

1%

R44

12.1k

0603

1%

R41

7.5k

0603

1%

R43

12.1k

0603

1%

R50

15.4k

0603

1%

R40

20R

0603

1%

R70

120R

0603

1%

R37

3.32k

0603

1%

R47

12.1k

0603

1%

R48

7.5k

0603

1%

R46

12.1k

0603

1%

R51

15.4k

0603

1%

R49

20R

0603

1%

R72

120R

0603

1%

R38

0.022 μF

50V

0603

C14

2200 pF

50V

0603

C13

100 pF

50V

0603

C21

10 μF

10V

0603

C4

RED

LD2

RED

LD1

FB1

2200 pF

50V

0603

C12

2200 pF

50V

0603

C9

Shunt 2.54 mm 1x2 Handle

JP9

Shunt 2.54 mm 1x2 Handle

JP10

Shunt 2.54 mm 1x2 Handle

JP11

Shunt 2.54 mm 1x2 Handle

JP12

1 μF

16V

0603

C15

1 μF

16V

0603

C8

10 μF

10V

0603

C7

+A

3

-A

2

OUTA

1

V

SS

V

DD

11 4

MCP6004

U4A

+B

5

-B

6

OUTB

7

V

SS

V

DD

11 4

MCP6004

U4B

+C

10

-C

9

OUTC

8

V

SS

V

DD

11 4

MCP6004

U4C

+D

12

-D

13

OUTD

14

V

SS

V

DD

11 4

MCP6004

U4D

2

13

10k

3386F

10%

R73

2

1 3

10k

3386F

10%

R74

1

3

2

ESD5V3

D1

0.1 μF

16V

0603

C5

0.1 μF

16V

0603

C6

0.1 μF

16V

0603

C16

0.1 μF

16V

0603

C17

0.1uF

16V

0603

C18

0.1 μF

16V

0603

C19

0.1 μF

16V

0603

C20

V

IN

1

GND

2

V

OUT

3

MCP1825S/3.3V

U3

D

G

S

MCP87050

Q1

D

G

S

MCP87050

Q2

2k

0603

1%

R25

V

DD

1

GP0

2

GP1

3

RST

4

UART RX

5

UART TX

6

GP27GP3

8

SDA

9

SCL

10

V

USB

11

D-

12

D+

13

V

SS

14

MCP2221

U2

1

2

3

4

5

6

7

8

9

10

HDR-2.54 Male 2x5

J13

A.3 BOARD – USB BRIDGE AND SIG GEN SCHEMATIC

Schematic and Layouts

Page 50

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

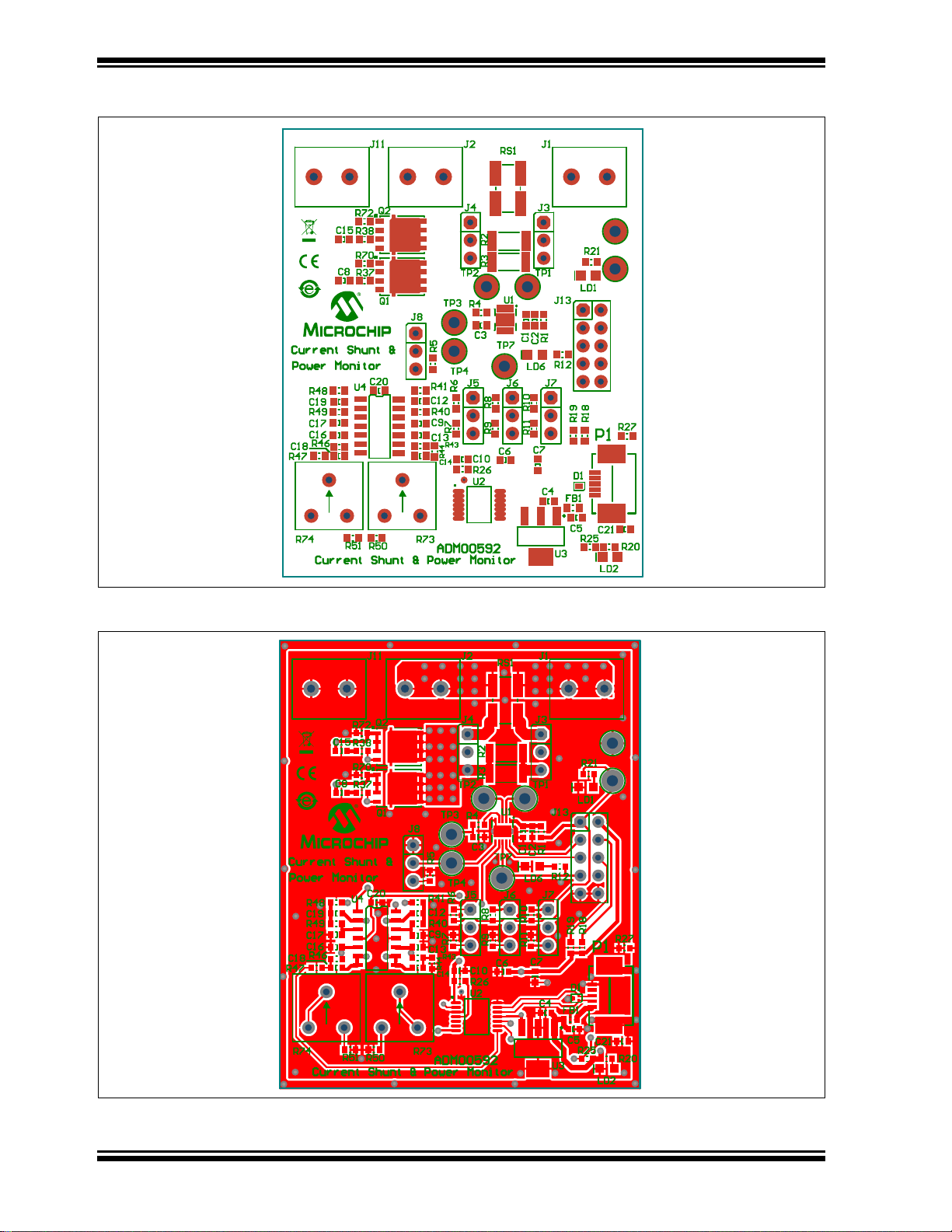

A.4 BOARD – TOP SILK

A.5 BOARD – TOP COPPER AND SILK

DS50002376A-page 50 2015 Microchip Technology Inc.

Page 51

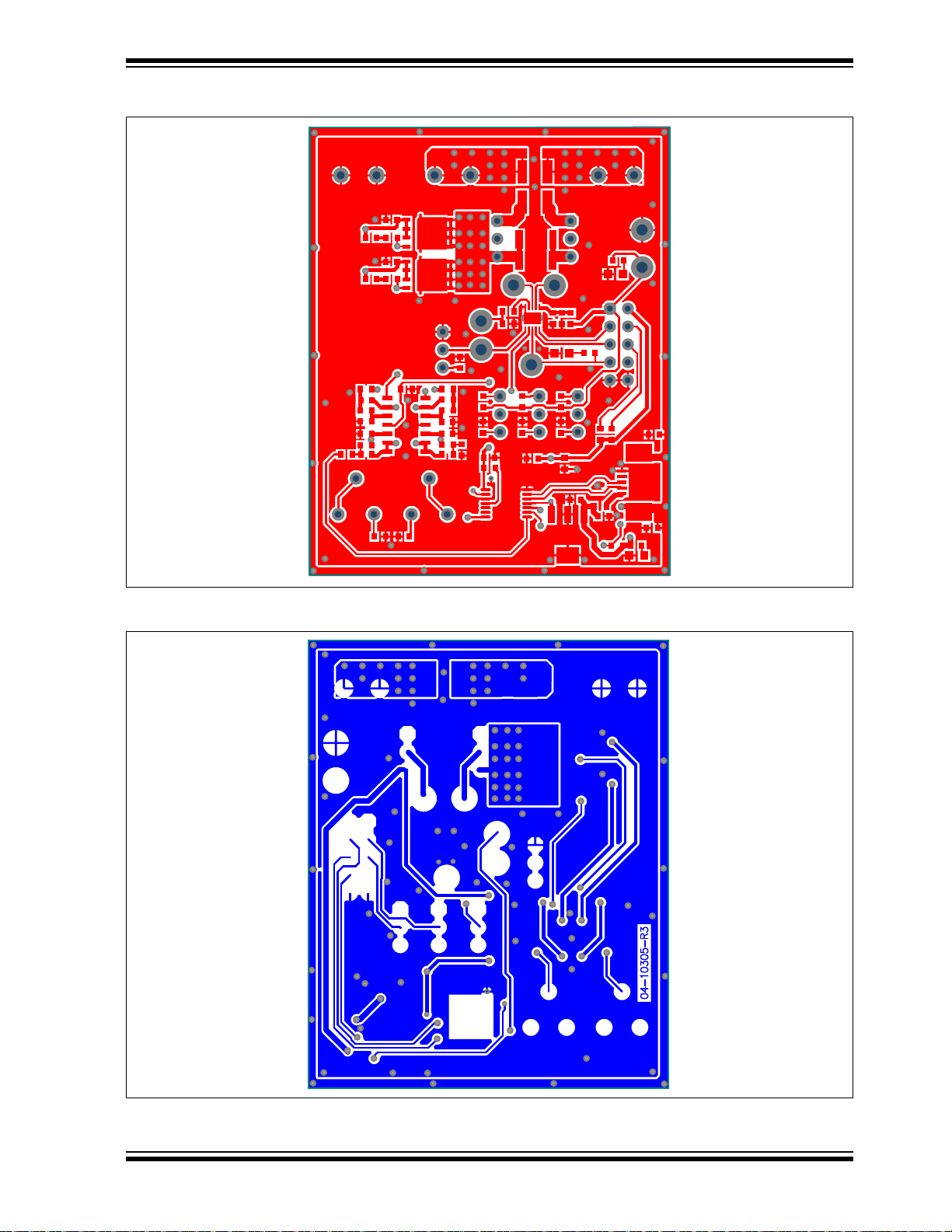

A.6 BOARD – TOP COPPER

Schematic and Layouts

A.7 BOARD – BOTTOM COPPER

2015 Microchip Technology Inc. DS50002376A-page 51

Page 52

PAC1921 High-Side Current/Power Sensor Evaluation Board User’s Guide

A.8 BOARD – BOTTOM COPPER AND SILK

A.9 BOARD – BOTTOM SILK

DS50002376A-page 52 2015 Microchip Technology Inc.

Page 53

HIGH-SIDE CURRENT/POWER SENSOR

EVALUATION BOARD USER’S GUIDE

Appendix B. Bill of Materials (BOM)

PAC1921

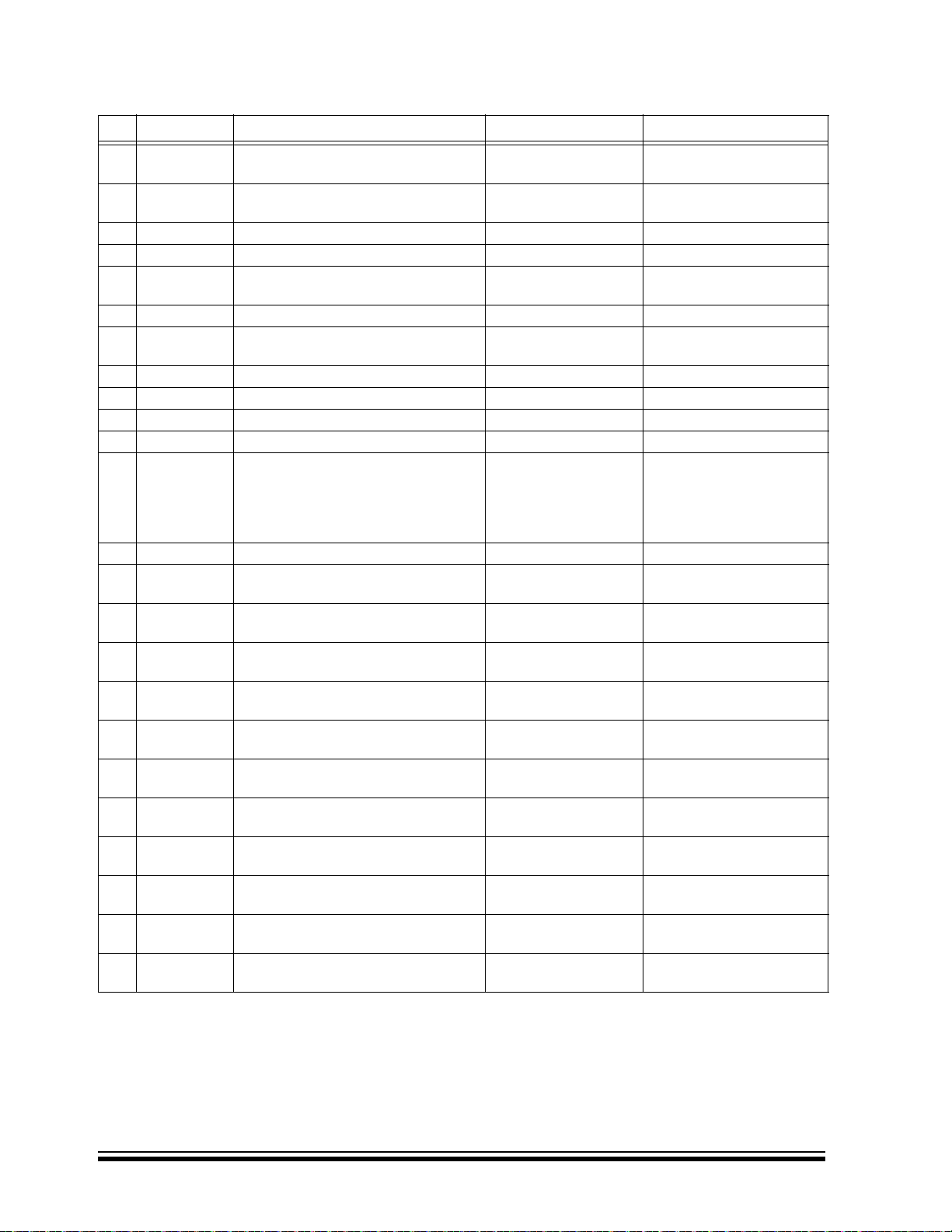

TABLE B-1: BILL OF MATERIALS (BOM)

Qty Reference Description Manufacturer Part Number

8 C1, C5, C6,

C16, C17,

C18, C19, C20

1 C10 Cap. Ceramic, 0.47 µF, 6.3V, 10%,

1 C14 Cap. Ceramic, 0.022 µF, 50V, 10%,

3 C2, C8, C15 Cap. Ceramic, 1 µF, 16V, 10%, X7R,

1 C21 Cap. Ceramic, 100 pF, 50V, 1%, C0G,

1 C3 Cap. Ceramic, 0.001 µF, 50V, 20%,

2 C4, C7 Cap. Ceramic, 10 µF, 10V, 20%, X5R,

3 C9, C12, C13 Cap. Ceramic, 2200 pF, 50V, 10%,

1 D1 DIO TVSARR, ESD5V3U2U, 5.3V,

1 FB1 Ferrite, 500 mA, 0.1R, SMD, 0603 Laird-Signal Integrity LI0603E470R-10

3 J1, J2, J11 Conn. Terminal, 5.08 mm, 15A,

1 J13 Conn. HDR-2.54, Male, 2x5, 0.100"

6 J3, J4, J5, J6,

J7, J8

10 JP3, JP4, JP5,

JP6, JP7, JP8,

JP9, JP10,

JP11, JP12

2 LD1, LD2 DIO LED Red, 1.95V, 20 mA, 220 mcd,

1 LD6 DIO LED Green, 2V, 30 mA, 120 mcd,

1 P1 Conn. USB Mini-B Female, SMD, R/A Hirose Electric Co., Ltd. UX60SC-MB-5ST(80)

4PAD1, PAD2,

PAD3, PAD4

2 Q1, Q2 MCHP Analog PWM Controller, 1 MHz,

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

Cap. Ceramic, 0.1 µF, 16V, 10%, X7R,

SMD, 0603

X5R, SMD, 0603

X7R, SMD, 0603

SMD, 0603

SMD, 0603

X7R, SMD, 0603

SMD, 0603

X7R, SMD, 0603

SMD, SOT-883

Female, 1x2, TH R/A

(2.54 mm), TH Vert.

Conn. HDR-2.54, Male, 1x3, Tin,

5.84 MH, TH Vert.

Mech. HW Jumper, 2.54 mm, 1x2,

Handle Gold

Clear, SMD, 0805

Diffuse, SMD, 0805

Mech. HW Rubber Pad, Cylindrical,

D7.9, H5.3, Black

MCP87050-U/MF, PDFN-8

(1)

NIC Components Corp. NMC0603X7R104K16TRPF

Murata Electronics

TDK Corporation C1608X7R1H223K

Taiyo Yuden Co., Ltd. EMK107B7105KA-T

TDK Corporation C1608C0G1H101F

KEMET™ C0603C102M5RAC

Panasonic

KEMET C0603C222K5RACTU

Infineon Technologies ESD5V3U2U-03LRH E6327

On Shore Technology

Inc.

Samtec, Inc. TSW-105-07-G-D

Samtec, Inc. TSW-103-07-T-S

TE Connectivity, Ltd. 881545-2

Kingbright Corp. APT2012SURCK

Avago Technologies US

Inc.

3M SJ61A11

Microchip Technology

Inc.

®

®

GRM188R60J474KA01D

ECJ-1VB1A106M

EDZ250/2

HSMM-C170

MCP87050T-U/MF

2015 Microchip Technology Inc. DS50002376A-page 53

Page 54

PAC1921

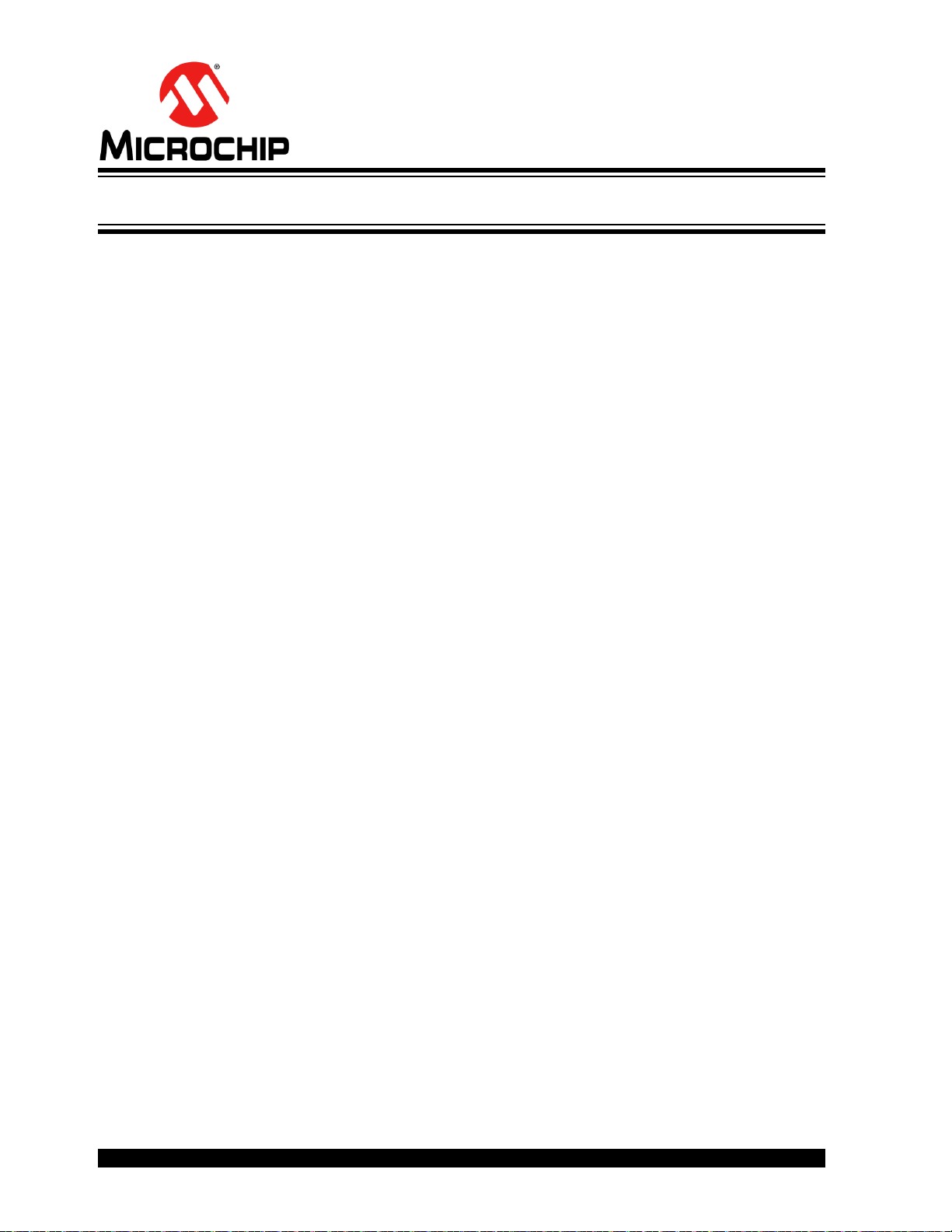

TABLE B-1: BILL OF MATERIALS (BOM)

(1)

(CONTINUED)

Qty Reference Description Manufacturer Part Number

1 R1 Res., TKF, 100R, 1%, 1/10W, SMD,

ROHM Semiconductor MCR03EZPFX1000

0603

1 R12, Res., TKF, 2k, 1%, 1/10W, SMD, 0603 Stackpole Electronics,

RMCF0603FT2K00

Inc.

2 R2, R3 Res., TKF, 2R, 5%, 3/4W, SMD, 2010 Panasonic® - ECG ERJ-12ZYJ2R0U

2 R20, R21 Res., TKF, 1k, 1%, 1/10W, SMD, 0603 Panasonic - ECG ERJ-3EKF1001V

1 R25 Res., TKF, 2k, 1%, 1/10W, SMD, 0603 Stackpole Electronics,

RMCF0603FT2K00

Inc.

1 R27 Res., TKF, 1M, 1%, 1/10W, SMD, 0603 Panasonic

4 R4, R5, R37,

Res., TKF, 120R, 1%, 1/10W, SMD, 0603 Panasonic

- ECG ERJ-3EKF1004V

- ECG ERJ-3EKF1200V

R38

2 R40, R49 Res., TKF, 15.4k, 1%, 1/10W, SMD, 0603 Panasonic

- ECG ERJ-3EKF1542V

2 R43, R46 Res., TKF, 3.32k, 1%, 1/10W, SMD, 0603 ROHM MCR03EZPFX3321

2 R43, R46 Res., TKF, 7.5k, 1%, 1/10W, SMD, 0603 Panasonic

- ECG ERJ-3EKF7501V

1 R51 Res., TKF, 12.1k, 1%, 1/10W, SMD, 0603 Panasonic - ECG ERJ-3EKF1212V

12 R6, R7, R8,

Res., TKF, 12.1k, 1%, 1/10W, SMD, 0603 Panasonic

- ECG ERJ-3EKF1212V

R9, R10, R11,

R18, R19,

R26, R41,

R48, R50

2 R70, R72 Res., TKF, 20R, 1%, 1/10W, SMD, 0603 Panasonic

2 R73, R74 Res., Trimmer Cermet, 10k, 10%,

Bourns

- ECG ERJ-3EKF20R0V

®

, Inc. 3386F-1-103TLF

500 mW, TH, 3386F

®

1 RS1 Res., Shunt, 0.005R, 1%, 2W, 1%,

Ohmite

Manufacturing LVK25R005FER

2412

1 TP1 Conn. TP Loop, Orange, TH Keystone Electronics

5013

Corp.

2 TP2, TP7 Conn. TP Loop, Yellow, TH Keystone Electronics

5014

Corp.

2 TP3, TP4 Conn. TP Loop, White, TH Keystone Electronics

5012

Corp.

1 TP5 Conn. TP Loop, Red, TH Keystone Electronics

5010

Corp.

1 TP6 Conn. TP Loop, Black, TH Keystone Electronics

5011

Corp.

1 U1 MCHP Analog Current Sense Monitor,

PAC1921-1-AIA-TR, DFN-10

1 U2 MCHP Interface USB I

2

C™ UART,

MCP2221-I/ST, TSSOP-14

1 U3 MCHP Analog LDO, 3.3V,

MCP1825ST-3302E/DB, SOT-223-3

1 U4 MCHP Analog Op Amp, 4-Ch, 1 MHz,

MCP6004-I/SL, SOIC-14

Microchip Technology

Inc.

Microchip Technology

Inc.

Microchip Technology

Inc.

Microchip Technology

Inc.

PAC1921-1-AIA-TR

MCP2221-I/ST

MCP1825S-3302E/DB

MCP6004-I/SL

Note 1: The components listed in this Bill of Materials are representative of the PCB assembly. The released BOM

used in manufacturing uses all RoHS-compliant components.

DS50002376A-page 54 2015 Microchip Technology Inc.

Page 55

NOTES:

Bill of Materials (BOM)

2015 Microchip Technology Inc. DS50002376A-page 55

Page 56

Worldwide Sales and Service

AMERICAS

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Cleveland

Independence, OH

Tel: 216-447-0464

Fax: 216-447-0643

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Canada - Toronto

Tel: 905-673-0699

Fax: 905-673-6509

ASIA/PACIFIC

Asia Pacific Office

Suites 3707-14, 37th Floor

Tower 6, The Gateway

Harbour City, Kowloon

Hong Kong

Tel: 852-2943-5100

Fax: 852-2401-3431

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

China - Beijing

Tel: 86-10-8569-7000

Fax: 86-10-8528-2104

China - Chengdu

Tel: 86-28-8665-5511

Fax: 86-28-8665-7889

China - Chongqing

Tel: 86-23-8980-9588

Fax: 86-23-8980-9500

China - Dongguan

Tel: 86-769-8702-9880

China - Hangzhou

Tel: 86-571-8792-8115

Fax: 86-571-8792-8116

China - Hong Kong SAR

Tel: 852-2943-5100

Fax: 852-2401-3431

China - Nanjing

Tel: 86-25-8473-2460

Fax: 86-25-8473-2470

China - Qingdao

Tel: 86-532-8502-7355

Fax: 86-532-8502-7205

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8864-2200

Fax: 86-755-8203-1760

China - Wuhan

Tel: 86-27-5980-5300

Fax: 86-27-5980-5118

China - Xian

Tel: 86-29-8833-7252

Fax: 86-29-8833-7256

ASIA/PACIFIC

China - Xiamen

Tel: 86-592-2388138

Fax: 86-592-2388130

China - Zhuhai

Tel: 86-756-3210040

Fax: 86-756-3210049

India - Bangalore

Tel: 91-80-3090-4444

Fax: 91-80-3090-4123

India - New Delhi

Tel: 91-11-4160-8631

Fax: 91-11-4160-8632

India - Pune

Tel: 91-20-3019-1500

Japan - Osaka

Tel: 81-6-6152-7160

Fax: 81-6-6152-9310

Japan - Tokyo

Tel: 81-3-6880- 3770

Fax: 81-3-6880-3771

Korea - Daegu

Tel: 82-53-744-4301

Fax: 82-53-744-4302

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Malaysia - Kuala Lumpur

Tel: 60-3-6201-9857

Fax: 60-3-6201-9859

Malaysia - Penang

Tel: 60-4-227-8870

Fax: 60-4-227-4068

Philippines - Manila

Tel: 63-2-634-9065

Fax: 63-2-634-9069

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Hsin Chu

Tel: 886-3-5778-366

Fax: 886-3-5770-955

Taiwan - Kaohsiung

Tel: 886-7-213-7828

Taiwan - Taipei

Tel: 886-2-2508-8600

Fax: 886-2-2508-0102

Thailand - Bangkok

Tel: 66-2-694-1351

Fax: 66-2-694-1350

EUROPE

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Dusseldorf

Tel: 49-2129-3766400

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Pforzheim

Tel: 49-7231-424750

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Venice

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Poland - Warsaw

Tel: 48-22-3325737

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

01/27/15

DS50002376A-page 56 2015 Microchip Technology Inc.

Page 57

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Microchip:

ADM00592

Loading...

Loading...