Page 1

UG0446

User Guide

SmartFusion2 and IGLOO2 FPGA High Speed DDR

Interfaces

Page 2

Microsemi Headquarters

One Enterprise, Aliso Viejo,

CA 92656 USA

Within the USA: +1 (800) 713-4113

Outside the USA: +1 (949) 380-6100

Sales: +1 (949) 380-6136

Fax: +1 (949) 215-4996

Email: sales.support@microsemi.com

www.microsemi.com

©2019 Microsemi, a wholly owned

subsidiary of Microchip Technology Inc. All

rights reserved. Microsemi and the

Microsemi logo are registered trademarks of

Microsemi Corporation. All other trademarks

and service marks are the property of their

respective owners.

Microsemi makes no warranty, representation, or guarantee regarding the information contained herein or the suitability of

its products and services for any particular purpose, nor does Microsemi assume any liability whatsoever arising out of the

application or use of any product or circuit. The products sold hereunder and any other products sold by Microsemi have

been subject to limited testing and should not be used in conjunction with mission-critical equipment or applications. Any

performance specifications are believed to be reliable but are not verified, and Buyer must conduct and complete all

performance and other testing of the products, alone and together with, or installed in, any end-products. Buyer shall not

rely on any data and performance specifications or parameters provided by Microsemi. It is the Buyer’s responsibility to

independently determine suitability of any products and to test and verify the same. The information provided by Microsemi

hereunder is provided “as is, where is” and with all faults, and the entire risk associated with such information is entirely

with the Buyer. Microsemi does not grant, explicitly or implicitly, to any party any patent rights, licenses, or any other IP

rights, whether with regard to such information itself or anything described by such information. Information provided in this

document is proprietary to Microsemi, and Microsemi reserves the right to make any changes to the information in this

document or to any products and services at any time without notice.

About Microsemi

Microsemi, a wholly owned subsidiary of Microchip Technology Inc. (Nasdaq: MCHP), offers a comprehensive portfolio of

semiconductor and system solutions for aerospace & defense, communications, data center and industrial markets.

Products include high-performance and radiation-hardened analog mixed-signal integrated circuits, FPGAs, SoCs and

ASICs; power management products; timing and synchronization devices and precise time solutions, setting the world's

standard for time; voice processing devices; RF solutions; discrete components; enterprise storage and communication

solutions, security technologies and scalable anti-tamper products; Ethernet solutions; Power-over-Ethernet ICs and

midspans; as well as custom design capabilities and services. Learn more at www.microsemi.com.

50200446. 7.0 6/19

Page 3

Contents

1 Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Revision 7.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Revision 6.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Revision 5.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Revision 4.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.5 Revision 3.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.6 Revision 2.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.7 Revision 1.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.8 Revision 0.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 MDDR Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Memory Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 I/O Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.1 Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5.2 Port List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5.3 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5.4 Details of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.5 MDDR Subsystem Features Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.6 How to Use MDDR in IGLOO2 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.6.1 Configuring MDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.6.2 Accessing MDDR from FPGA Fabric through the AXI Interface . . . . . . . . . . . . . . . . . . . . . . . 43

3.6.3 Accessing MDDR from FPGA Fabric Through the AHB Interface . . . . . . . . . . . . . . . . . . . . . . 48

3.6.4 Accessing MDDR from the HPDMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.7 Timing Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3.8 Timing Optimization Technique for AXI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.9 DDR Memory Device Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.9.1 Example 1: Connecting 32-Bit DDR2 to MDDR_PADs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.9.2 Example 2: Connecting 32-Bit DDR3 to MDDR_PADs with SECDED . . . . . . . . . . . . . . . . . . 59

3.9.3 Example 3: Connecting 16-Bit LPDDR to MDDR_PADs with SECDED . . . . . . . . . . . . . . . . . 60

3.10 Board Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.11 MDDR Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3.11.1 SYSREG Configuration Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3.11.2 DDR Controller Configuration Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

3.11.3 DDR Controller Configuration Register Bit Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.11.4 PHY Configuration Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.11.5 PHY Configuration Register Bit Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.11.6 DDR_FIC Configuration Registers Summary . . . . . . . .

3.11.7 DDR_FIC Configuration Register Bit Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.12 Appendix A: How to Use the MDDR in SmartFusion2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3.12.1 Design Flow Using System Builder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

3.12.2 Design Flow Using SmartDesign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

3.12.3 Use Model 1: Accessing MDDR from FPGA Fabric Through the AXI Interface . . . . . . . . . . 126

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Microsemi Proprietary UG0446 User Guide Revision 7.0 iii

Page 4

3.12.4 Use Model 2: Accessing MDDR from FPGA Fabric Through the AHB Interface . . . . . . . . . . 128

3.12.5 Use Model 3: Accessing MDDR from Cortex-M3 Processor . . . . . . . . . . . . . . . . . . . . . . . . . 130

3.12.6 Use Model 4: Accessing MDDR from the HPDMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4 Fabric DDR Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

4.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

4.2 Memory Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

4.3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

4.4 I/O Utilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4.5 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4.5.1 Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4.5.2 Port List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.6 Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4.6.1 Reset Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4.6.2 ZQ Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

4.6.3 Details of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

4.6.4 FDDR Subsystem Features Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

4.6.5 Memory Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

4.6.6 Bus Width Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

4.6.7 Burst Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4.6.8 Configuring Dynamic DRAM Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

4.6.9 Dynamic DRAM Bank Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

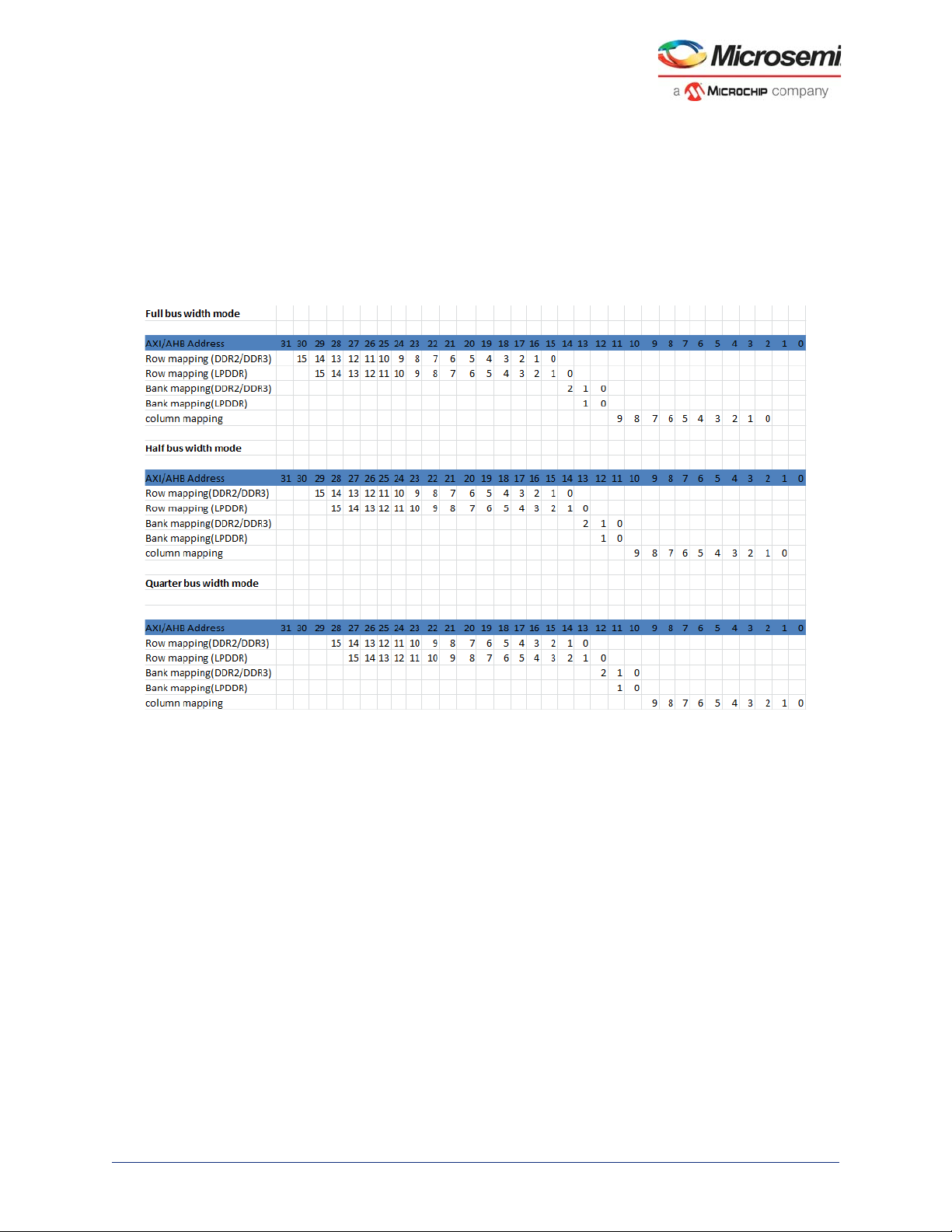

4.6.10 Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

4.7 How to Use FDDR in IGLOO2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

4.7.1 Configuring FDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

4.7.2 Accessing FDDR from FPGA Fabric through the AXI Interface . . . . . . . . . . . . . . . . . . . . . . 166

4.7.3 Accessing FDDR from FPGA Fabric through the AHB Interface . . . . . . . . . . . . . . . . . . . . . . 171

4.8 DDR Memory Device Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

4.8.1 Example 1: Connecting 32-Bit DDR2 to FDDR_PADs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

4.8.2 Example 2: Connecting 32-Bit DDR3 to FDDR_PADs with SECDED . . . . . . . . . . . . . . . . . . 173

4.8.3 Example 3: Connecting 16-Bit LPDDR to FDDR_PADs with SECDED . . . . . . . . . . . . . . . . 174

4.9 FDDR Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

4.9.1 FDDR SYSREG Configuration Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

4.9.2 FDDR SYSREG Configuration Register Bit Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

4.10 Appendix A: How to Use the FDDR in SmartFusion2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

4.10.1 Design Flow Using System Builder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

4.10.2 Design Flow Using SmartDesign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4.10.3 Use Model 1: Accessing FDDR from FPGA Fabric Through AXI Interface . . . . . . . . . . . . . . 196

4.10.4 Use Model 2: Accessing FDDR from FPGA Fabric Through AHB Interface . . . . . . . . . . . . . 199

4.11 Appendix B: Register Lock Bits Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.11.1 Lock Bit File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.11.2 Lock Bit File Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.11.3 Locking and Unlocking a Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

5 DDR Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

5.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

5.1.1 Architecture Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

5.1.2 Details of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

5.2 How to Use DDR Bridge in IGLOO2 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

5.2.1 Configuring the DDR Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

5.2.2 High-Speed Data Transactions from HPDMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

5.2.3 Selecting Non-Bufferable Region . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

5.3 SYSREG Control Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

5.4 DDR Bridge Control Registers in MDDR and FDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

5.5 Appendix A: How to Use DDR Bridge in SmartFusion2 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

5.5.1 Use Model 1: High Speed Data Transactions from Cortex-M3 Processor . . . . . . . . . . . . . . 217

Microsemi Proprietary UG0446 User Guide Revision 7.0 iv

Page 5

5.5.2 Use Model 2: Selecting Non-Bufferable Region . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

6 Soft Memory Controller Fabric Interface Controller . . . . . . . . . . . . . . . . . . . . . . . . 219

6.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

6.1.1 Port List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

6.2 How to Use SMC_FIC in IGLOO2 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

6.3 SYSREG Control Register for SMC_FIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

6.4 Appendix A: How to Use SMC_FIC in SmartFusion2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

6.4.1 Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

6.4.2 Use Model 1: Accessing SDRAM from MSS Through CoreSDR_AXI . . . . . . . . . . . . . . . . . . 228

Microsemi Proprietary UG0446 User Guide Revision 7.0 v

Page 6

Figures

Figure 1 System Level MDDR Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2 MDDR Subsystem Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3 Reset Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 4 DDR_FIC Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 5 AXI Transaction Controller Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 6 DDR Controller Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 7 DDR RMW Operation (32-Bit DDR Bus Width and Burst Length 8) . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 8 DDR RMW Operation (16-Bit DDR Bus Width and Burst Length 8) . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9 DDR RMW Operation (8-Bit DDR Bus Width and Burst Length 8) . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 10 Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 11 System Builder—Device Features Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 12 MDR Initialization Path . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 13 I/O Drive Strength Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 14 Selecting I/O Standard as LVCMOS18 or LPDDRI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 15 Memory Initialization Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 16 Memory Timing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 17 System Builder - Peripherals Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 18 MDDR_CLK Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 19 DDR_FIC_CLK Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 20 I/O Editor Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 21 MDDR with AXI Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 22 System Builder - Device Features Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 23 Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 24 Peripherals Tab with the Master Added and Configure Icon Highlighted . . . . . . . . . . . . . . . . . . . . 46

Figure 25 AMBA Master Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 26 System Clocks Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 27 SmartDesign Connections (Top Level View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 28 MDDR with Single AHB-Lite Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 29 MDDR with HPDMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 30 System Builder - Device Features Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 31 Memory Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 32 Clocks Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

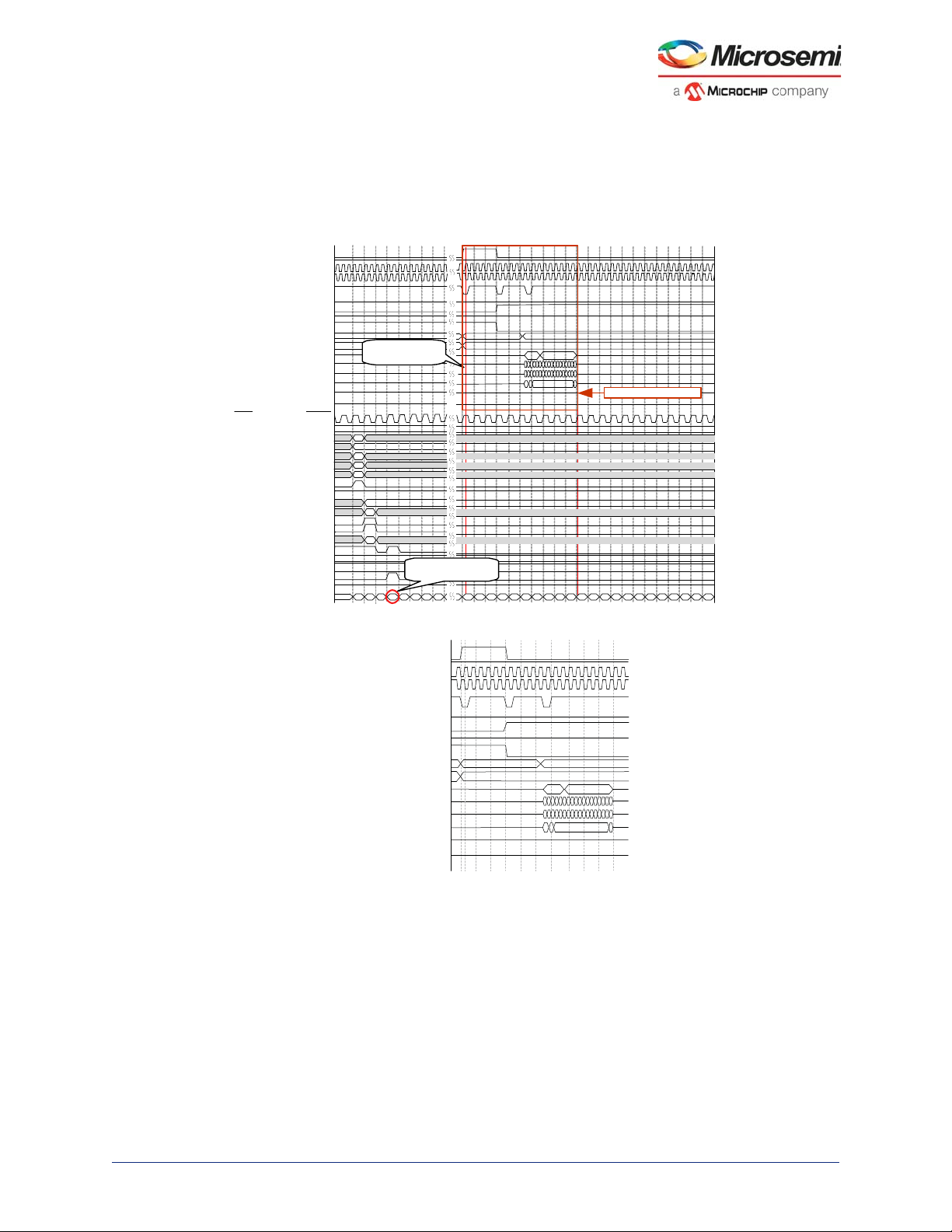

Figure 33 AXI Single Write Transaction and Corresponding DDR Controller Commands . . . . . . . . . . . . . . . 52

Figure 34 DDR Controller Command Sequence for Single AXI Write Transaction . . . . . . . . . . . . . . . . . . . . . 52

Figure 35 AXI Single Read Transaction and Corresponding DDR Controller Commands . . . . . . . . . . . . . . . 53

Figure 36 AXI INCR16 Write Transaction and Corresponding DDR Controller Commands . . . . . . . . . . . . . . 53

Figure 37 AXI INCR16 Write Transaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 38 DDR Controller Command Sequence for AXI INCR16 Write Transaction . . . . . . . . . . . . . . . . . . . 54

Figure 39 AXI INCR-16 Read Transaction and Corresponding DDR Controller Commands . . . . . . . . . . . . . 54

Figure 40 DDR Controller Command Sequence for AXI INCR-16 Read Transaction . . . . . . . . . . . . . . . . . . 55

Figure 41 AXI Timing Optimization Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 42 Timing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 43 x16 DDR2 SDRAM Connected to MDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 44 ×8 DDR3 SDRAM Connection to MDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 45 ×16 LPDDR1 SDRAM Connection to MDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 46 System Builder - Device Features Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 47 MSS External DDR Memory Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Figure 48 I/O Drive Strength Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Figure 49 Selecting I/O Standard as LVCMOS18 or LPDDRI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Figure 50 DDR Memory initialization Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 51 DDR Memory Timing Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Figure 52 MSS DDR FIC Subsystem Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Figure 53 MDDR Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Figure 54 DDR_FIC Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

. . . . . . . . 46

. . . . . . 117

Microsemi Proprietary UG0446 User Guide Revision 7.0 vi

Page 7

Figure 55 Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 56 MDDR Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Figure 57 Memory Interface Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 58 MSS External DDR Memory Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Figure 59 MDDR Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 60 MDDR Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Figure 61 FIC_2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 62 I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Figure 63 MDDR with AXI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 64 MSS External Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 65 Configuring FIC_2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 66 MDDR Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 67 SmartDesign Canvas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Figure 68 MDDR with Single AHB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Figure 69 MDDR with Dual AHB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Figure 70 Accessing MDDR from Cortex-M3 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 71 MSS External Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Figure 72 Configuring MDDR_CLK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Figure 73 Accessing MDDR from HPDMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Figure 74 System Level FDDR Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Figure 75 FDDR Subsystem Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Figure 76 Reset Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Figure 77 DDR_FIC Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Figure 78 AXI Transaction Controller Block Diagram . . . . . . .

Figure 79 DDR Controller Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Figure 80 Address Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Figure 81 System Builder - Device Features Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Figure 82 System Builder - Device Features Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Figure 83 Fabric DDR Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Figure 84 Selecting I/O Standard as LVCMOS18 or LPDDRI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Figure 85 Memory Initialization Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Figure 86 Memory Timing Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Figure 87 System Builder - Peripherals Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Figure 88 FDDR Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 89 I/O Editor Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Figure 90 FDDR Subsystem with AXI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Figure 91 System Builder - Device Features Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 92 Memory Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Figure 93 Fabric DDR Subsystem Configuration Dialog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 94 AMBA Master Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Figure 95 Clocks Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Figure 96 SmartDesign Connections (Top Level View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Figure 97 FDDR with AHB-Lite interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Figure 98 x16 DDR2 SDRAM Connected to FDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Figure 99 x8 DDR3 SDRAM Connection to FDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Figure 100 x16 LPDDR1 SDRAM Connection to FDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Figure 101 System Builder - Device Features Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Figure 102 MSS External DDR Memory Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Figure 103 Fabric DDR Memory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 104 Selecting I/O Standard as LVCMOS18 or LPDDRI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Figure 105 DDR Memory initialization Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Figure 106 DDR Memory Timing Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Figure 107 MSS DDR FIC Subsystem Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Figure 108 FDDR Clock Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Figure 109 Design Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Figure 110 Fabric External Memory DDR Controller Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Figure 111 FIC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Figure 112 I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Figure 113 FDDR with AXI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Microsemi Proprietary UG0446 User Guide Revision 7.0 vii

Page 8

Figure 114 FDDR Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Figure 115 Fabric CCC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 116 SmartDesign Canvas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Figure 117 Accessing FDDR Subsystem Through Dual AHB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Figure 118 FIC_2 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 119 MSS CCC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Figure 120 FDDR Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Figure 121 Fabric CCC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Figure 122 CoreConfigP IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Figure 123 CoreConfigP IP Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Figure 124 SmartDesign Canvas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Figure 125 Lock Bit Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Figure 126 Register Lock Bit Settings Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Figure 127 DDR Bridges in the SmartFusion2/IGLOO2 FPGA Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Figure 128 DDR Bridge Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Figure 129 WCB Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Figure 130 Flow Chart for Read Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Figure 131 System Builder - Device Features Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Figure 132 Configuring HPMS DDR Bridge for HPDMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Figure 133 Configuring HPMS DDR Bridge For Non-Bufferable Region . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Figure 134 Configuring DDR Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Figure 135 Configuring MSS DDR Bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Figure 136 Configuring MSS DDR Bridge for Use Model 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 137 Configuring MSS DDR Bridge for Use Model 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Figure 138 System Level SMC_FIC Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Figure 139 SMC_FIC Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 140 HPMS External Memory Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Figure 141 HPMS SMC_FIC Subsystem Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Figure 142 CoreSDR_AXI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Figure 143 MSS External Memory Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Figure 144 Core_AXI Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Figure 145 Subsystem Connections in SmartDesign . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

. . . . . . . . 220

Microsemi Proprietary UG0446 User Guide Revision 7.0 viii

Page 9

Tables

Table 1 Additional Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 2 Supported Memory (DDR2, DDR3 and LPDDR1) Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3 DDR Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 4 I/O Utilization for SmartFusion2 and IGLOO2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 5 MDDR Subsystem Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 6 AXI Slave Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 7 AHB Slave Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 8 MDDR APB Slave Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 9 MDDR_CLK to FPGA Fabric Clock Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 10 Priority Level Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 11 SECDED DQ Lines at DDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 12 Supported Bus Widths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 13 Supported Burst Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 14 Dynamically Enforced Bank Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 15 Dynamically-Enforced Bank Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 16 Dynamic DRAM Global Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 17 DDR Memory Regions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 18 Accessed DDR Memory Regions (Based on Mode Settings for 4 GB Memory) . . . . . . . . . . . . . . 31

Table 19 Accessed DDR Memory Regions Based on Mode Settings for a 2 GB Memory . . . . . . . . . . . . . . 32

Table 20 Accessed DDR Memory Regions Based on Mode Settings for a 1 GB Memory . . . . . . . . . . . . . . 32

Table 21 Supported Address Width Range for Row, Bank and Column Addressing in DDR/LPDDR . . . . . . 35

Table 22 DDR I/O Standard is Configured Based on I/O Drive Strength Setting . . . . . . . . . . . . . . . . . . . . . 35

Table 23 MDDR Throughput (for AHB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 24 Number of Cycles for AXI/AHB Transactions to MDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 25 I/O Standards and Calibration Resistance Requirements for MDDR/FDDR . . . . . . . . . . . . . . . . . 61

Table 26 Address Table for Register Interfaces . . . . . . . .

Table 27 SYSREG Configuration Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 28 DDR Controller Configuration Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 29 DDRC_DYN_SOFT_RESET_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 30 DDRC_DYN_REFRESH_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 31 DDRC_DYN_REFRESH_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Table 32 DDRC_DYN_POWERDOWN_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 33 DDRC_MODE_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 34 DDRC_ADDR_MAP_BANK_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Table 35 DDRC_ADDR_MAP_COL_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 36 DDRC_ADDR_MAP_COL_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Table 37 DDRC_ADDR_MAP_ROW_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Table 38 DDRC_ADDR_MAP_ROW_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 39 DDRC_INIT_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 40 DDRC_CKE_RSTN_CYCLES_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Table 41 DDRC_ CKE_RSTN_CYCLES_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 42 DDRC_INIT_MR_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Table 43 DDRC_INIT_EMR_CR . . . . . . . . . . . . . . . . . . .

Table 44 DDRC_INIT_EMR2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 45 DDRC_INIT_EMR3_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 46 DDRC_DRAM_BANK_TIMING_PARAM_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Table 47 DDRC_DRAM_RD_WR_LATENCY_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 48 DDRC_DRAM_RD_WR_PRE_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 49 DDRC_DRAM_MR_TIMING_PARAM_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table 50 DDRC_DRAM_RAS_TIMING_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 51 DDRC_DRAM_RD_WR_TRNARND_TIME_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Table 52 DDRC_DRAM_T_PD_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 53 DDRC_DRAM_BANK_ACT_TIMING_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 54 DDRC_ODT_PARAM_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Microsemi ProprietaryUG0446 User Guide Revision 7.0 ix

Page 10

Table 55 DDRC_ODT_PARAM_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 56 DDRC_ADDR_MAP_COL_3_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Table 57 DDRC_MODE_REG_RD_WR_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 58 DDRC_MODE_REG_DATA_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Table 59 DDRC_PWR_SAVE_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 60 DDRC_PWR_SAVE_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table 61 DDRC_ZQ_LONG_TIME_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 62 DDRC_ZQ_SHORT_TIME_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 63 DDRC_ZQ_SHORT_INT_REFRESH_MARGIN_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Table 64 DDRC_ZQ_SHORT_INT_REFRESH_MARGIN_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 65 DDRC_PERF_PARAM_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Table 66 DDRC_HPR_QUEUE_PARAM_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 67 DDRC_HPR_QUEUE_PARAM_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 68 DDRC_LPR_QUEUE_PARAM_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Table 69 DDRC_LPR_QUEUE_PARAM_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 70 DDRC_WR_QUEUE_PARAM_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 71 DDRC_PERF_PARAM_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Table 72 DDRC_PERF_PARAM_3_CR . . . . . . . . . . . . . . . . .

Table 73 DDRC_DFI_RDDATA_EN_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Table 74 DDRC_DFI_MIN_CTRLUPD_TIMING_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 75 DDRC_DFI_MAX_CTRLUPD_TIMING_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 76 DDRC_DYN_SOFT_RESET_ALIAS_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Table 77 DDRC_AXI_FABRIC_PRI_ID_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 78 DDRC_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Table 79 DDRC_SINGLE_ERR_CNT_STATUS_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 80 DDRC_DOUBLE_ERR_CNT_STATUS_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Table 81 DDRC_LUE_SYNDROME_1_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 82 DDRC_LUE_SYNDROME_2_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Table 83 DDRC_LUE_SYNDROME_3_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table 84 DDRC_LUE_SYNDROME_4_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 85 DDRC_LUE_SYNDROME_5_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Table 86 DDRC_LUE_ADDRESS_1_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 87 DDRC_LUE_ADDRESS_2_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Table 88 DDRC_LCE_SYNDROME_1_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 89 DDRC_LCE_SYNDROME_2_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Table 90 DDRC_LCE_SYNDROME_3_SR . . . . . . . . . . . . . . . .

Table 91 DDRC_LCE_SYNDROME_4_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 92 DDRC_LCE_SYNDROME_5_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Table 93 DDRC_LCE_ADDRESS_1_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 94 DDRC_LCE_ADDRESS_2_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 95 DDRC_LCB_NUMBER_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Table 96 DDRC_LCB_MASK_1_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 97 DDRC_LCB_MASK_2_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Table 98 DDRC_LCB_MASK_3_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 99 DDRC_LCB_MASK_4_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Table 100 DDRC_ECC_INT_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Table 101 DDRC_ECC_INT_CLR_REG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Table 102 PHY Configuration Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 103 PHY_DATA_SLICE_IN_USE_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 104 DDR_FIC Configuration Register Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Table 105 DDR_FIC_NB_ADDR_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 106 DDR_FIC_NBRWB_SIZE_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 107 DDR_FIC_BUF_TIMER_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 108 DDR_FIC_HPD_SW_RW_EN_CR . . . . . . . . . . . . . . .

Table 109 DDR_FIC_HPD_SW_RW_INVAL_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 110 DDR_FIC_SW_WR_ERCLR_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 111 DDR_FIC_ERR_INT_ENABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Table 112 DDR_FIC_NUM_AHB_MASTERS_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 113 DDR_FIC_HPB_ERR_ADDR_1_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Microsemi ProprietaryUG0446 User Guide Revision 7.0 x

Page 11

Table 114 DDR_FIC_HPB_ERR_ADDR_2_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 115 DDR_FIC_SW_ERR_ADDR_1_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 116 DDR_FIC_SW_ERR_ADDR_2_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Table 117 DDR_FIC_HPD_SW_WRB_EMPTY_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 118 DDR_FIC_SW_HPB_LOCKOUT_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Table 119 DDR_FIC_SW_HPD_WERR_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 120 DDR_FIC_LOCK_TIMEOUTVAL_1_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 121 DDR_FIC_LOCK_TIMEOUTVAL_2_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Table 122 DDR_FIC_LOCK_TIMEOUT_EN_CR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 123 DDR_FIC_RDWR_ERR_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Table 124 DDR I/O Standard Configured Based on I/O Drive Strength Setting . . . . . . . . . . . . . . . . . . . . . . 114

Table 125 Supported Memory (DDR2, DDR3, and LPDDR1) Configurations . . . . . . . . . . . . . . . . . . . . . . . . 135

Table 126 DDR Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Table 127 I/O Utilization for SmartFusion2 and IGLOO2 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Table 128 FDDR Subsystem Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Table 129 FDDR AXI Slave Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Table 130 FDDR AHB Slave Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Table 131 FDDR APB Slave Interface Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Table 132 FDDR_CLK to FPGA Fabric Clock Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Table 133 SECDED DQ Lines at DDR . . . . . . . . . . . . . . .

Table 134 Supported Bus Widths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Table 135 Supported Burst Modes for M2S150 and M2GL150 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Table 136 Dynamically Enforced Bank Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Table 137 Dynamically Enforced Bank Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Table 138 Dynamic DRAM Global Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Table 139 Supported Address Width Range for Row, Bank and Column . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Table 140 DDR I/O Standard is Configured based on I/O Drive Strength Setting . . . . . . . . . . . . . . . . . . . . . 160

Table 141 FDDR Throughput (for AHB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Table 142 Address Table for Register Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Table 143 FDDR SYSREG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Table 144 PLL_CONFIG_LOW_1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Table 145 PLL_CONFIG_LOW_2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Table 146 PLL_CONFIG_HIGH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Table 147 FDDR_FACC_CLK_EN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Table 148 FDDR_FACC_MUX_CONFIG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Table 149 FDDR_FACC_DIVISOR_RATIO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Table 150 PLL_DELAY_LINE_SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Table 151 FDDR_SOFT_RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Table 152 FDDR_IO_CALIB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Table 153 FDDR_INTERRUPT_ENABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Table 154 F_AXI_AHB_MODE_SEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Table 155 PHY_SELF_REF_EN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Table 156 FDDR_FAB_PLL_CLK_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Table 157 FDDR_FPLL_CLK_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Table 158 FDDR_INTERRUPT_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Table 159 FDDR_IO_CALIB_SR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Table 160 FDDR_FATC_RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Table 161 Supported Address Width Range for Row, Bank and Column Addressing in DDR/LPDDR . . . . . 186

Table 162 DDR I/O Standard is Configured Based on I/O Drive Stre

Table 163 SmartFusion2 and IGLOO2 FPGA DDR Bridge Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Table 164 SYSREG Control Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Table 165 DDR Bridge Control Registers in MDDR and FDDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Table 166 SMC_FIC 64-bit AXI Port List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Table 167 SMC_FIC 32-bit AHB-Lite Port List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Table 168 MDDR_CR Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

ngth Setting . . . . . . . . . . . . . . . . . . . . 186

Microsemi ProprietaryUG0446 User Guide Revision 7.0 xi

Page 12

Revision History

1 Revision History

The revision history describes the changes that were implemented in the document. The changes are

listed by revision, starting with the most current publication.

1.1 Revision 7.0

The following is a summary of the changes in this revision.

• Read and Write leveling is not supported. Removed information about all the Read and Write

leveling registers.

• Most of the PHY registers have been reserved.

1.2 Revision 6.0

The following is a summary of the changes in this revision.

• Updated I/O Utilization, page 7, I/O Utilization, page 136, DDRIO Calibration, page 16, and DDRIO

Calibration, page 145 (SAR 81073).

1.3 Revision 5.0

The following is a summary of the changes in this revision.

• Updated MDDR Subsystem, page 5 and Fabric DDR Subsystem, page 134 (SARs 62955 and

62858).

• Updated Table 2, page 7, Ta bl e 4 , page 7, Table 11, page 24 (SAR 78912).

• Updated Initialization, page 16 and Power Saving Modes, page 24 (SAR 52819).

• Updated Table 86, page 95, Table 87, page 95, Table 93, page 99, Table 94, page 99 (SAR 75057).

• Updated Architecture Overview, page 136 (SAR 79005).

• Added DDR Memory Initialization Time, page 18 (SAR 72725).

• Updated Appendix B: Register Lock Bits Configuration, page 204 (SAR 79864).

1.4 Revision 4.0

The following is a summary of the changes in this revision.

• Merged SmartFuion2 and IGLOO2 User Guides.

• Updated Additional Documentation, page 3 (SAR 68482).

• Updated MDDR Subsystem, page 5 and Fabric DDR Subsystem, page 134 (SARs 55467, 54300,

49186, 52819, 54053, 51933, 55041, 52727, 48832).

• Updated MDDR Subsystem, page 5 (SARs 62441, 66225, 60914, 69568, 66860, 69611, 69261,

68400, 64575, 65164, and 69655).

• Updated Fabric DDR Subsystem, page 134 (SARs 62441, 60914, 66860, 69144, and 54429).

• Updated DDR Bridge, page 207.

• Updated Soft Memory Controller Fabric Interface Controller, page 219.

1.5 Revision 3.0

The following is a summary of the changes in this revision.

• Updated the Part Numbers (M2S075 to M2S090, M2S080 to M2S100, and M2S120 to M2S150) as

required (SAR 47554).

• Updated MDDR Subsystem, page 5 (SARs 47919, 48832, 49947, 50561, 50732, 62858, and

62955).

• Updated Fabric DDR Subsystem, page 134 (SARs 62858 and 62955).

• Updated Soft Memory Controller Fabric Interface Controller, page 219 (SAR 48330).

1.6 Revision 2.0

The following is a summary of the changes in this revision.

Microsemi Proprietary UG0446 User Guide Revision 7.0 1

Page 13

Revision History

• Restructured the user guide (SARs 47314, 45974, 45616, 43424, 46149, 46446).

• Updated MDDR Subsystem, page 5 (SARs 55041, 58032, 51465, 58034, 58035, 58037, 51933,

58038, 57034, and 57207).

• Updated Fabric DDR Subsystem, page 134 (SARs 58034, 58035, 58037, 51933, 58038, 57034,

57207, and 58038).

• Updated Soft Memory Controller Fabric Interface Controller, page 219 (SAR 54036).

• Updated MDDR Memory Map, page 30 (SAR 44198).

• Updated Address Mapping, page 155 (SAR 45761).

1.7 Revision 1.0

The following is a summary of the changes in this revision.

• Restructured the user guide.

• Updated the user guide (SAR 42443).

• Updated MDDR Subsystem, page 5, Fabric DDR Subsystem, page 134, and DDR Bridge, page 207

(SAR 50157).

• Updated MDDR Subsystem, page 5 and Fabric DDR Subsystem, page 134 (SAR 41901).

• Updated MDDR Subsystem, page 5 (SAR 42751).

• Updated Fabric DDR Subsystem, page 134 (SAR 41979).

1.8 Revision 0.0

The first publication of this document.

Microsemi Proprietary UG0446 User Guide Revision 7.0 2

Page 14

Overview

2 Overview

This user guide describes the high speed memory interfaces in SmartFusion®2 System-on-Chip (SoC)

field programmable gate array (FPGA) and IGLOO

microcontroller/memory subsystem double-data rate (MDDR) subsystem and fabric DDR (FDDR)

subsystem provide access to DDR memories for high-speed data transfers. The DDR subsystems

functionality, configurations, and their use models are discussed in this user guide.

®

2 FPGA devices. The high speed interfaces

2.1 Contents

This user guide contains the following chapters:

• "MDDR Subsystem"

• "Fabric DDR Subsystem"

• "DDR Bridge"

• "Soft Memory Controller Fabric Interface Controller"

2.2 Additional Documentation

The following table describes additional documentation available for the SmartFusion2 and IGLOO2

devices. For more information, refer to the SmartFusion2 Documentation Page and IGLOO2

Documentation Page online. (continued)

Table 1 • Additional Documents

Document Description

PB0115: SmartFusion2 System-on-Chip FPGAs

Product Brief and PB0121: IGLOO2 FPGA Product

Brief

DS0128: IGLOO2 and SmartFusion2 Datasheet This datasheet contains SmartFusion2 and IGLOO2 DC and

DS0124: IGLOO2 Pin Descriptions Datasheet This document contains IGLOO2 pin descriptions, package

DS0115: SmartFusion2 Pin Descriptions Datasheet This document contains SmartFusion2 pin descriptions, package

UG0445: IGLOO2 FPGA and SmartFusion2 SoC

FPGA Fabric User Guide

UG0331: SmartFusion2 Microcontroller Subsystem

User Guide

UG0448: IGLOO2 High Performance Memory

Subsystem User Guide

This product brief provides an overview of SmartFusion2 and

IGLOO2 family, features, and development tools.

switching characteristics.

outline drawings, and links to pin tables in Excel format.

outline drawings, and links to pin tables in Excel format.

SmartFusion2 and IGLOO2 FPGAs integrate fourth generation

flash-based FPGA fabric. The FPGA fabric is comprised of Logic

Elements which consist of a 4 input look up table (LUT), includes

embedded memories and Mathblocks for DSP processing

capabilities. This document describes the SmartFusion2 and

IGLOO2SmartFusion2 and IGLOO2 FPGA fabric architecture,

embedded memories, Mathblocks, fabric routing, and I/Os.

SmartFusion2 devices integrate a hard microcontroller

subsystem (MSS). The MSS consists of a ARM Cortex-M3

processor with embedded trace macrocell (ETM), instruction

cache, embedded memories, DMA engines, communication

peripherals, timers, real-time counter (RTC), general purpose

I/Os, and FPGA fabric interfaces. This document describes the

SmartFusion2 MSS and its internal peripherals.

IGLOO2 devices integrate a hard high performance memory

subsystem (HPMS) consists of embedded memories, DMA

engines, and FPGA fabric interfaces. This document describes

the IGLOO2 HPMS and its internal peripherals.

Microsemi Proprietary UG0446 User Guide Revision 7.0 3

Page 15

Overview

Table 1 • Additional Documents (continued)

Document Description

UG0447: IGLOO2 and SmartFusion2 High Speed

Serial Interfaces User Guide

SmartFusion2 and IGLOO2 devices integrate hard high-speed

serial interfaces (PCIe, XAUI/XGXS, SERDES). This document

describes the SmartFusion2 and IGLOO2SmartFusion2 and

IGLOO2 high-speed serial interfaces.

UG0449: SmartFusion2 and IGLOO2 Clocking

Resources User Guide

SmartFusion2 and IGLOO2 clocking resources include on-chip

oscillators, FPGA fabric global network, and clock conditioning

circuitry (CCCs) with dedicated phase-locked loops (PLLs).

These clocking resources provide flexible clocking schemes to

the on-chip hard IP blocks—HPMS, fabric DDR (FDDR)

subsystem, and high-speed serial interfaces (PCIe, XAUI/XGXS,

SERDES)—and logic implemented in the FPGA fabric.

UG0444: SmartFusion2 and IGLOO2 Low Power

Design User Guide

In addition to low static power consumption during normal

operation, the SmartFusion2 and IGLOO2 devices support an

ultra-low-power Static mode (Flash*Freeze mode) with power

consumption less than 1 mW. Flash*Freeze mode retains all the

SRAM and register data which enables fast recovery to Active

mode. This document describes the SmartFusion2 and IGLOO2

Flash*Freeze mode entry and exit mechanisms.

UG0443: SmartFusion2 and IGLOO2 FPGA

Security and Reliability User Guide

The SmartFusion2 and IGLOO2 devices incorporate essentially

all the security features that made third generation Microsemi

SoC devices the gold standard for security in the PLD industry.

Also included are unique design and data security features and

use models new to the PLD industry. SmartFusion2 and IGLOO2

flash-based FPGA fabric has zero FIT configuration rate due to

its single event upset (SEU) immunity, which is critical in reliability

applications. This document describes the SmartFusion2 and

IGLOO2 security features and error detection and correction

(EDAC) capabilities.

UG0450: SmartFusion2 SoC and IGLOO2 FPGA

System Controller User Guide

The system controller manages programming of the

SmartFusion2 and IGLOO2 devices and handles system service

requests. The subsystems, interfaces, and system services in the

system controller are discussed in this user guide.

UG0450: SmartFusion2 SoC and IGLOO2 FPGA

System Controller User Guide

Describes different programming modes supported in the

SmartFusion2 and IGLOO2 devices. High level schematics of

these programming methods are also provided as a reference.

Important board-level considerations are discussed.

®

Libero SoC User Guide Libero

System-on-Chip (SoC) is the most comprehensive and

powerful FPGA design and development software available,

providing start-to-finish design flow guidance and support for

novice and experienced users alike. Libero SoC combines

Microsemi SoC Products Group tools with such EDA

powerhouses as Synplify

discusses the usage of the software and design flow.

and ModelSim. This user guide

Microsemi Proprietary UG0446 User Guide Revision 7.0 4

Page 16

MDDR Subsystem

3 MDDR Subsystem

The MDDR is a hardened ASIC block for interfacing the DDR2, DDR3, and LPDDR1 memories. The

MDDR subsystem is used to access DDR memories for high-speed data transfers and code execution.,

and includes a DDR memory controller, DDR PHY, and arbitration logic to support multiple masters. DDR

memory connected to the MDDR subsystem can be accessed by the MSS/HPMS masters and master

logic implemented in the FPGA fabric (FPGA fabric master).

The MSS/HPMS masters communicate with the MDDR subsystem through an MSS/HPMS DDR bridge

that provides an efficient access path. FPGA fabric masters communicate with the MDDR subsystem

through AXI or AHB interfaces.

3.1 Features

• Integrated on-chip DDR memory controller and PHY

• Capable of supporting LPDDR1, DDR2, and DDR3 memory devices

• Up to 667 Mbps (333.33 MHz DDR) performance

• Supports memory densities upto 4GB

• Supports 8/16/32-bit DDR standard dynamic random access memory (SDRAM) data bus width

modes

• Supports a maximum of 8 memory banks

• Supports single rank memory

• Single error correction and double error detection (SECDED) enable/disable feature

• Supports DRAM burst lengths of 4, 8, or 16, depending on the bus-width mode and DDR type

configuration

• Support for sequential and interleaved burst ordering

• Programs internal control for ZQ short calibration cycles for DDR3 configurations

• Supports dynamic scheduling to optimize bandwidth and latency

• Supports self refresh entry and exit on command

• Supports deep power-down entry and exit on command

• Flexible address mapper logic to allow application specific mapping of row, column, bank, and rank

bits

• Configurable support for 1T or 2T timing on the DDR SDRAM control signals

• Supports autonomous DRAM power-down entry and exit caused by lack of transaction arrival for

programmable time

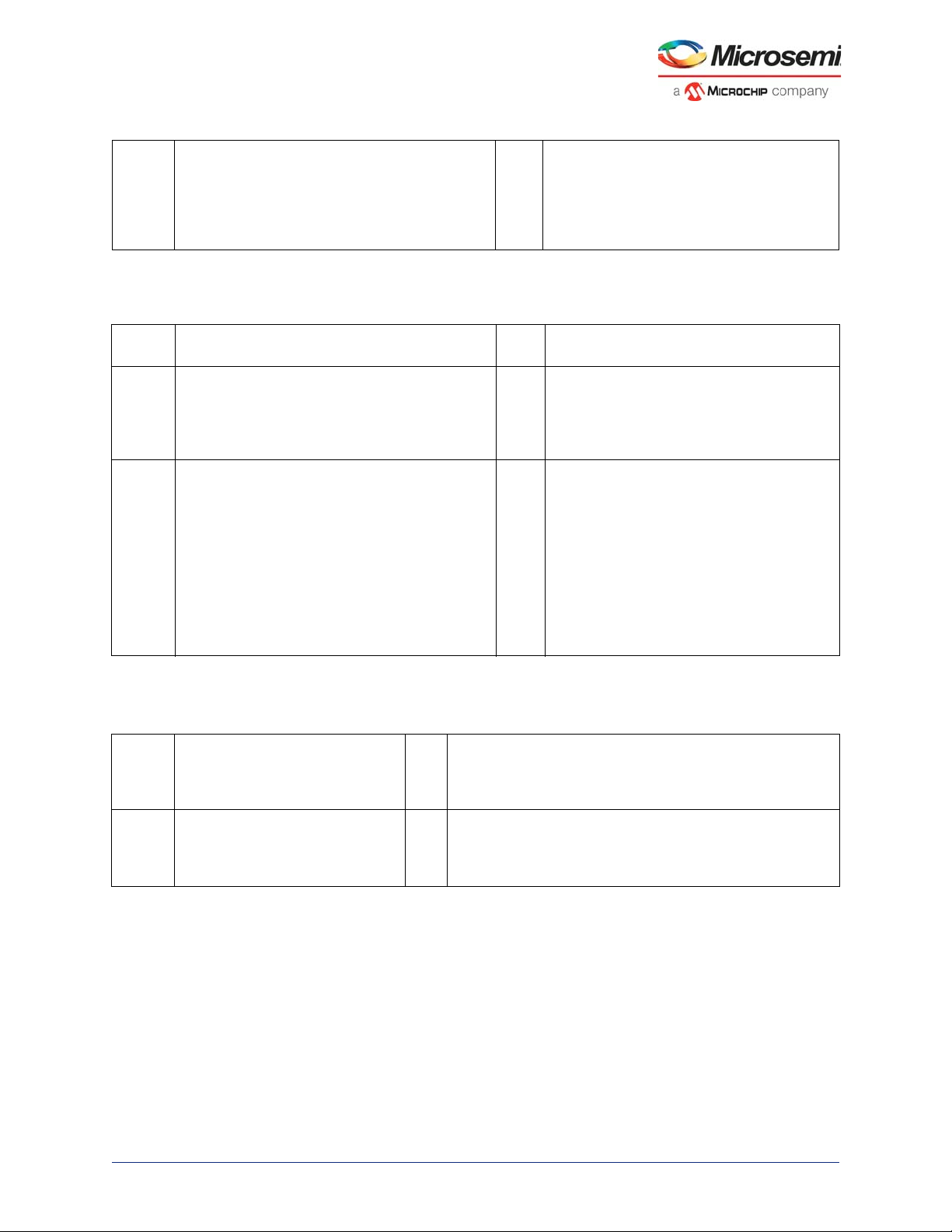

The following illustration shows the system level block diagram of the MDDR subsystem.

Microsemi Proprietary UG0446 User Guide Revision 7.0 5

Page 17

MDDR Subsystem

Cache

Controller

SD IC

Cortex-M3

Microcontroller

SD I

IDC

DS

FIC_0 FIC_1

AHB Bus Matrix

DDR

I/O

FPGA Fabric

AXI/AHB

Master

MSS/HPMS

DDR

Bridge

SmartFusion2/IGLOO2

Blocks in SmartFusion2

DDR

Controller

DDR

PHY

APB Config.

Register

MDDR

AXI

Transaction

Controller

DDR_FIC

64-Bit AXI

HPDMA

MSS/HPMS

DDR

SDRAM

APB

Master

64-Bit AXI /

Single 32-Bit AHBL /

Dual 32-Bit AHBL

16-Bit APB

APB_2

Figure 1 • System Level MDDR Block Diagram

The MDDR subsystem accepts data transfer requests from AXI or AHB interfaces. Any read/write

transactions to the DDR memories can occur from the following four paths:

• High performance DMA (HPDMA) controller can access DDR memories through the MSS/HPMS

DDR bridge for high speed data transactions.

• Other MSS/HPMS masters (for example, FIC_0, FIC_1, and PDMA) can access DDR memories

through the MSS/HPMS DDR bridge.

• AXI or AHBL masters in the FPGA fabric can access DDR memories through DDR_FIC interface.

Note: The Cortex-M3 processor can access DDR memories through the MSS DDR bridge for data and code

execution in SmartFusion2.

Note: The maximum DDR3 data rate supported by MDDR is 333MHz/667Mbps. Therefore, Write Leveling is

not mandatory and the interface works if the board layout includes length matching and follows AC393

SmartFusion2 and IGLOO2 Board Design Guidelines Application Note. For Read Leveling, Libero SOC

auto-generates pre-defined static delay ratios for MDDR initialization. These delay values are sufficient if

the board layout follows the SmartFusion2/IGLOO2 board-level guidelines.

3.2 Memory Configurations

The SmartFusion2 and IGLOO2 FPGA MDDR subsystem supports a wide range of common memory

types, configurations, and densities, as shown in the following table. If SECDED mode is enabled in the

MDDR controller, the external memory module must be connected to the following:

• Data lines MDDR_DQ_ECC[3:0] when data width is x32

• Data lines MDDR_DQ_ECC[1:0] when data width is x16

Microsemi Proprietary UG0446 User Guide Revision 7.0 6

Page 18

MDDR Subsystem

• Data line MDDR_DQ_ECC[0] when data width is x8