Page 1

MGC3140

MGC3140 GestIC® Tuning User's Guide

Preface

Important: Notice to customers:

All documentation becomes dated, and this manual is no exception. Microchip tools and

documentation are constantly evolving to meet customer needs, so some actual dialogs and/or

tool descriptions may differ from those in this document. Please refer to our website

(www.microchip.com) to obtain the latest documentation available.

Documents are identified with a “DS” number. This number is located on the bottom of each

page, in front of the page number. The numbering convention for the DS number is

“DSXXXXXA”, where “XXXXX” is the document number and “A” is the revision level of the

document.

Introduction

This document describes how to tune GestIC® systems that consist of an MGC3140 gesture controller

based on Microchip's GestIC technology and Gesture sensor.

Recommended Reading

For the latest information on using the device, read the “MGC3140 3D Tracking and Gesture Controller

Data Sheet” (DS40002037) located on the Microchip website. The release notes (Readme) contain

update information and known issues that may not be included in this user’s guide. For the latest

information on using the Aurea GUI, refer to the “Aurea Graphical User Interface User’s Guide”

(DS40001681) located on the Microchip website.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 1

Page 2

MGC3140

Table of Contents

Preface............................................................................................................................ 1

1. Introduction................................................................................................................3

1.1. Aurea............................................................................................................................................3

2. Tuning Flow............................................................................................................... 4

3. Tuning........................................................................................................................5

3.1. Electrode Mapping....................................................................................................................... 5

3.2. Extended Parameterization.......................................................................................................... 6

4. Reference Material.................................................................................................. 21

5. Revision History.......................................................................................................22

The Microchip Web Site................................................................................................ 23

Customer Change Notification Service..........................................................................23

Customer Support......................................................................................................... 23

Microchip Devices Code Protection Feature................................................................. 23

Legal Notice...................................................................................................................24

Trademarks................................................................................................................... 24

Quality Management System Certified by DNV.............................................................25

Worldwide Sales and Service........................................................................................26

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 2

Page 3

1. Introduction

The MGC3140 Gesture IC (GestIC) has two types of parameters:

1. Run-time parameters that control basic functions such as selecting which of the five preset

frequencies (between 1 and 5) to use, enabling and disabling gestures and forcing a recalibration

(baseline). These are controlled by the host over the I2C interface using messages defined in the

MGC3140 run-time library interface specification reference.

2. Design-specific design-time parameters, which are configured once per project at design time and

control design characteristics, such as electrode weighting, gesture timings, and signal thresholds.

These parameters are configured using the Aurea Graphical User Interface application.

This document describes the tuning process for both the run-time and the design-time parameters.

1.1 Aurea

The Aurea Graphical Interface User’s Guide describes the use of the Aurea graphical interface to:

• Monitor the output of the MGC3140

• Control MGC3140 run-time parameters

• Configure MGC3140 design-time parameters

• Load design-time parameter files onto the MGC3140

• Program the MGC3140

• Update the MGC3140 bootloader

• Save the MGC3140 firmware and parameterization data in order to provide a final firmware (FW)

and parameterization combination for manufacture

MGC3140

Introduction

(1)

Note:

1. Combines the FW and parameters that are in Aurea that were loaded onto the device. Aurea does

not read firmware from the device.

1.1.1 Firmware and Parameter Update Using Aurea

Aurea uses a compressed file containing MGC3140 firmware, bootloader and parameterization data as

an image source for programming the MGC3140. It can also save the parameterization file and the

existing firmware from the .enz file

extension .enz.

Note:

1. The firmware cannot be read back from the IC. A newly created .enz file will create FW from the

parameters tuned in Aurea (on the PC) and the FW used by Aurea to download to the MGC3140.

1.1.1.1 Aurea .enz File Format

An .enz file is simply a zip container containing a number of files including a special file called

contents.json which describes the content of the .enz file.

• Library.hex – Contains MGC3140 firmware and bootloader in standard Intel® HEX format.

• Library.settings – A text description of design-time parameter settings.

• Loader.hex – Contains the MGC3140 bootloader in standard Intel HEX format.

• Content.json – Describes the contents of the .enz file.

Note: Aurea will not program the bootloader if the current bootloader in the MGC3140 has the same

version as in this file.

(1)

into a new compressed file. This file is noted by the

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 3

Page 4

2. Tuning Flow

Map electrodes

Load F irmw are and

starting parameters

Select parameters to

enable and data

output

Position

Important?

Set sensing area

and height limits

Adjust jitter

reduction

Tune Gestures

Tune Calibration

Tune Presence

Hold and

Approach

Tune electrode

touch i f required

Yes

Tuning Complete

Electrode w eighting

Configure electrode

dimensions

E-Field Linearization

Select Tx

Frequencies

No

It has to be noted that the implemented tuning steps will depend on the customer requirements.

Positional accuracy or reporting, some gestures or GestIC electrode touch, approach and power-saving

may or may not be required.

The following flowchart shows the tuning flow.

Figure 2-1. MGC3140 Tuning Flow

MGC3140

Tuning Flow

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 4

Page 5

3. Tuning

During the setup process, tuning parameters are adjusted using slide bars that are dragged using the

mouse. For fine tuning, click on the Slider and use the left-right arrow keys to adjust the parameter value.

In order to tune the design-time parameters, select the Setup tab in Aurea and press the 3D

Parameterization button.

Figure 3-1. Aurea Parameterization

MGC3140

Tuning

The Aurea Setup tab has two top-level menu items on the left:

• Basic – Allows basic setup of the Analog Front-End by mapping the receive electrodes to the

MGC3140 receive pins. This feature provides Printed Circuit Board (PCB) layout flexibility.

• Extended – Allows detailed tuning.

Figure 3-2. Setup - Basic Menu

3.1 Electrode Mapping

The Analog Front-End (AFE) settings comprising of Electrode Selection and Electrode Mapping can be

modified on this page. They adjust the connection between the MGC3140 and the external electrodes.

The settings are adjusted using the corresponding radio buttons or sliders.

• Electrode Selection

The optional Center electrode can be enabled or disabled by checking the four electrodes (no

Center) or five electrodes (with Center) check boxes.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 5

Page 6

– Four electrodes

Only the four frame electrodes (North, East, South, and West) are used for signal processing.

– Five electrodes

All four frame electrodes and the Center electrode are used for signal processing.

• Electrode Mapping

The electrode mapping allocates the MGC3140 RX pins to the outlying electrodes. The correct

electrode mapping can be verified by touching the electrode and monitoring the signals in the

Signals tab. The corresponding electrode signal in the Rx Signals tab should then increase.

3.2 Extended Parameterization

When selected, the Extended menu item opens up the Firmware Selection window. The use of this

window ensures that the correct firmware is loaded onto the MGC3140 for the design-time

parameterization process.

3.2.1 Firmware

Load the firmware and parameter file which will be used as a basis for the tuning using this window, as

described in the "Aurea Graphical User Interface User's Guide" (DS40001681). Remember to select the

“Keep the current AFE parameters” check box unless the AFE electrode selection and mapping of the

parameters that are about to be downloaded are going to be used instead.

MGC3140

Tuning

Once the firmware has been loaded, the full Extended Parameter window becomes available providing

the following menu options. See figure below.

Note: The extended parameter options are only available after firmware and parameter download. They

disappear after exiting the Setup tab, or disconnecting or resetting the MGC3140, and require another

firmware and parameter download before becoming visible again.

Figure 3-3. Extended Parameter Window

3.2.2 System Start-up Window

This window provides the following features:

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 6

Page 7

• Tx frequency selection

• Active features

• Sensor data output

• Start change notification

3.2.2.1 Tx Frequency Selection

The Tx frequency selection is available from the System Start-up window.

A range of five frequencies may be selected or deselected to avoid noise. The MGC3140 constantly

monitors the noise levels on all selected frequencies and will hop to the lowest noise level frequency

when the current frequency noise gets too high. The automatic frequency hopping can be limited by

unchecking one or more frequencies in the list. The following frequencies are available: 42 kHz, 43 kHz,

44 kHz, 45 kHz, and 100 kHz.

3.2.2.2 Active Features

The Colibri Suite features can be active or inactive on MGC3140 start-up.

• Approach Detection – Selects if the Approach Detection feature is enabled at start-up.

• Touch Detection – Selects if the Touch Detection feature is enabled at start-up.

• Gestures – Selects if a particular gesture is active at start-up.

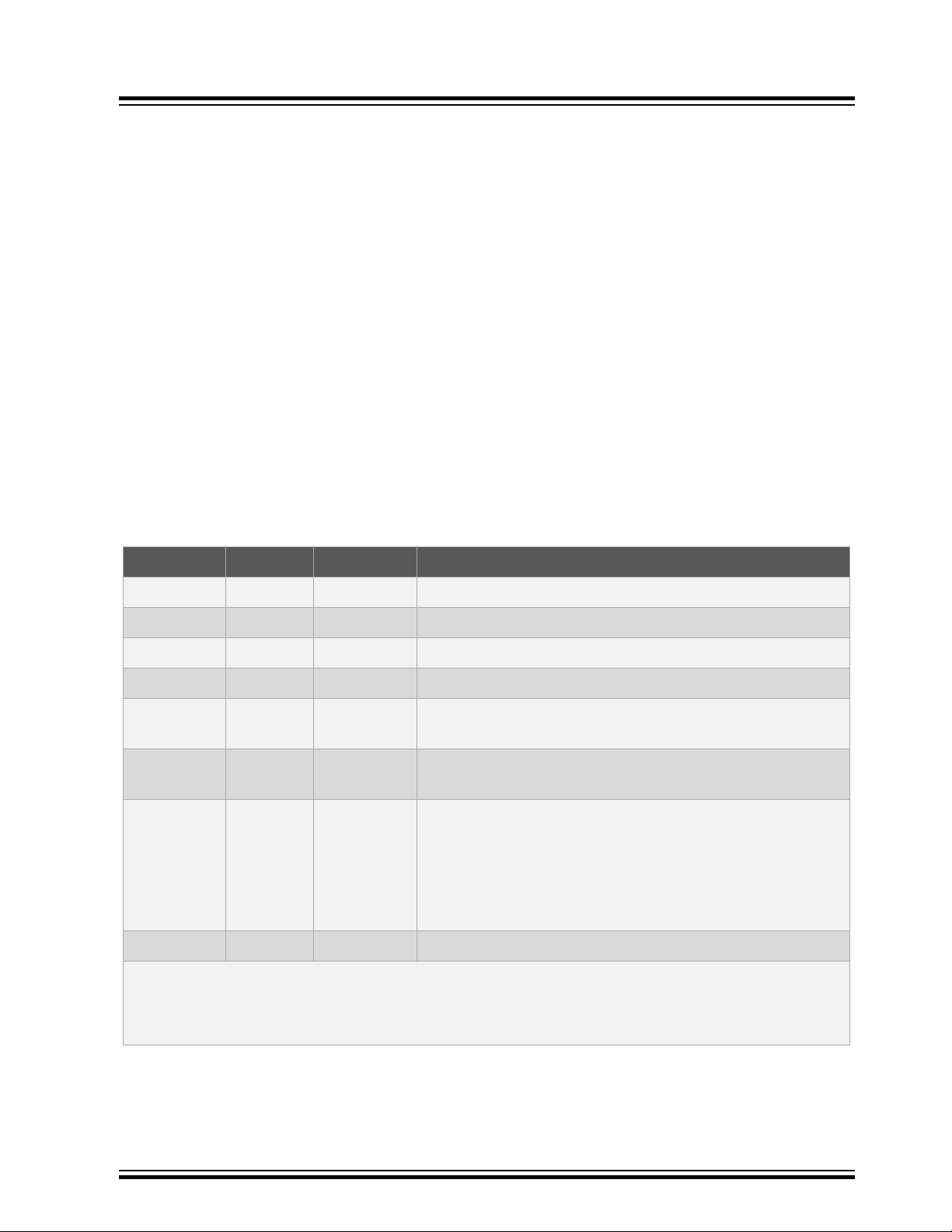

• Flicks – Flick selection has the behavior shown in the table below.

MGC3140

Tuning

Table 3-1. Flick Selection

Double Flick Edge Flick Normal Flick Description

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

1 0 1

1 1 0

1 1 1

Note:

1. 0 = Not selected

2. 1 = Selected

None Active

Only Normal Flick reported

Only Edge Flick reported

Normal and Edge Flicks reported

Double Flick reported. Disables Normal and Edge Flicks.

Normal and Edge Flicks are never reported.

Double Flick is reported. Disables Normal Flicks and Edge

Flicks. Normal and Edge Flicks are never reported.

Double Flick reported. Disables Normal and Edge Flicks.

Normal and Edge Flicks are never reported. If calibration

after flick is enabled in the Gestures menu by selecting the

'triggers calib' option, then calibrations may still be triggered

when the hand leaves the sensing area after flicks, or in the

middle of a Double Flick.

These settings should not be selected.

• Circles/AirWheel: Discrete Circles and AirWheel are exclusive. The Airwheel has higher priority

than discrete circles. When the AirWheel is enabled, only AirWheel information will be reported. To

use the Discrete Circle gestures, AirWheel must be disabled.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 7

Page 8

MGC3140

Tuning

Sensor Data Output

The Sensor Data Output I2C message (ID 0x91) contains all data which are generated in MGC3140. That

includes recognized gestures as well as continuous data like position or raw sensor data.

A detailed description of the I2C message format can be found in the "MGC3140 GestIC® Library

Interface Description User's Guide" (DS40001875).

If selected, data (On or Dynamic) will be added as a payload element to the sensor data output I2C

message.

There are three options for data selection:

• Off – Data will never be sent.

• On – Data are sent with every packet.

• Dynamic – Only changes will be sent to minimize data traffic.

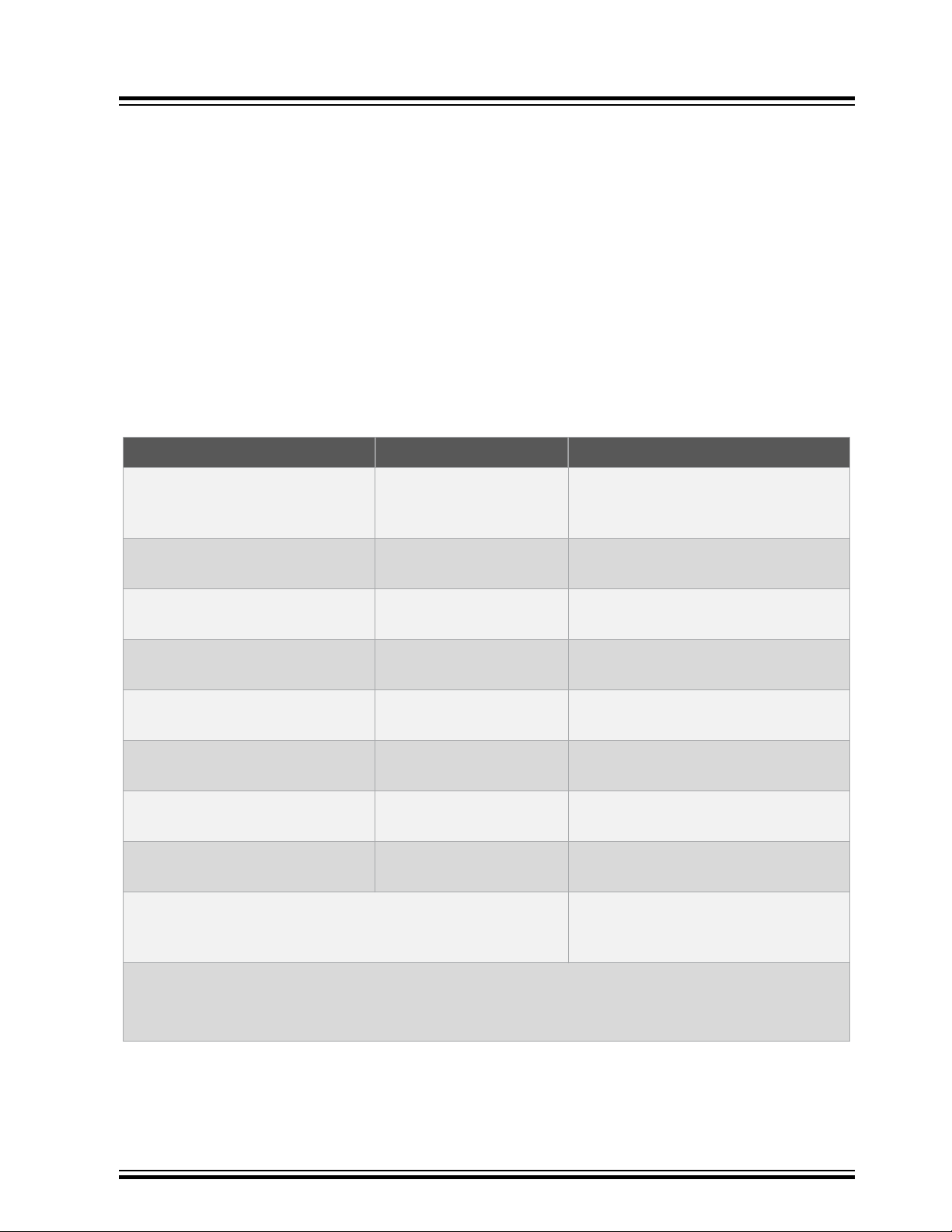

The following table lists the payload elements of the sensor data output message.

Table 3-2. Sensor Data Output Payload Elements

Data/Payload

DSP Status

Gesture Data

Touch Data

AirWheel Data

Position Data

Noise Power

Uncalibrated Signal Data

Signal Deviation Data

(1)

Element Library Command Description

DSPStatus

GestureInfo

TouchInfo

AirWheelInfo

xyzPosition

NoisePower

CICData

SDData

This field contains the Calibration

events information and the currently

used Tx frequency.

This field contains the recognized

gestures.

This field contains the Touch events

information.

This field contains the AirWheel

information.

This field contains the X, Y and Z

position data.

This field contains the current

measured signal variance.

This field contains the Uncalibrated

Signal (CIC) data.

This field contains the Signal Deviation

(SD) data.

AirWheel counter decimated by factor 4 If set, AirWheel counter is only

reported when a change of at least four

bits has occurred.

Note:

1. Payload Element names are those defined in the "MGC3140GestIC® Library Interface Description

User's Guide" (DS40001875).

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 8

Page 9

MGC3140

Tuning

State Change Notification

The sensor has also the possibility to report some Boolean states and, according to the same principle in

the previous section, some can be ignored to minimize the number of messages.

These Boolean states are reported as part of two payload elements: 'System Data', always present in a

message, and 'Gesture Data', that is present depending on the selection of the sensor data output (see

Table 3-2).

The following table describes the Boolean states and to which payload element they belong to.

Table 3-3. Boolean State Descriptions

Payload Element

SystemInfo

SystemInfo

GestureInfo

GestureInfo

GestureInfo

GestureInfo

GestureInfo

None

(1)

Flag Description

Noise indication The bit reports that environmental noise

has been detected.

DSP running The bit reports that system is running (not

sleeping).

Gesture in progress indication The bit reports that a gesture evaluation is

ongoing.

Garbage The bit de/activates the report of Garbage

gesture.

Hand Presence The bit reports that object is present in

sensitive region.

Hand Inside The bit reports that object is present and

above the sensor.

Hand Hold The bit reports that object is present and

not moving.

Timestamp overflow indication De/activates the 8-bit counter (timestamp)

overflow message. This has impact on

TouchInfo and AirWheelInfo

messages.

Note:

1. Payload element names are those defined in the "MGC3140GestIC® Library Interface Description

User's Guide" (DS40001875).

3.2.3 Calibration Tuning

Baseline calibration can be caused by a number of triggers:

1. User absent time-out – where no user movement or presence is detected within the User Absent

Calibration Time-out period (configured in the Calibration Time-out window).

2. User present time-out – where an SD that is greater than the threshold set for presence detection

on any electrode indicates the presence of a hand which has not changed position for a specified

time while the Hold flag is triggered (configured in the Calibration Time-out window).

3. Touch time-out – where a touch has been detected for the Touch Calibration Time-out period

(configured in the Calibration Time-out window).

4. Negative Value – when SD achieves invalid negative values less than -4 for 100 ms (cannot be

configured).

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 9

Page 10

5. Gesture – flick gestures may be configured to perform a baseline calibration on completion of the

flick (configured in the Gesture Control window).

6. Externally forced – host forces baseline calibration with an I2C message.

The baseline calibration should be set to meet customer requirements.

It should be noted that the User Absent and Present Calibration Time-outs have an impact on the

Approach Detection Idle Time-out before the system enters the Self Wake-up mode.

Related Links

3.2.6 Approach Detection

3.2.5 Presence, Hold and Approach

3.2.4 Gesture Tuning

The Gesture recognition and AirWheel windows permit the configuration of the following gestures:

• Normal Flicks (Gesture recognition window)

• Edge Flicks (Gesture recognition window)

• Double Flicks (Gesture recognition window)

• Circles (Gesture recognition window)

• AirWheels (AirWheel window)

MGC3140

Tuning

3.2.4.1 Gesture Recognition Window

Check the “Triggers Calib” box if baseline calibration is required after a flick has exited the sensitive

area. As the hand has to have left the sensing area before the calibration is performed, the sensor is not

influenced by the user during calibration.

The idle system is properly calibrated when the signal deviation of all channels is at or near zero.

Immediate feedback is given by the calibration indication in the Aurea status bar. Each time a selected

gesture is performed and the system calibrated, the calibration indication blinks. Note that only flicks that

cross the entire sensitive area will trigger calibration scans.

Larger Sensors – Gesture Duration

Default values are normally good but maximum gesture duration may need increasing for larger sensors

or potential slower swipe speeds.

Detection Sensitivity

Detection Sensitivity is a gain which needs to be adjusted depending on the expected system noise. With

low-detection sensitivity values, the gestures have to be performed very close to the electrodes. High

values increase sensitivity but are also less robust to noise. The Detection Sensitivity slider 1 can take

values between 0 and 3.

The figure below shows the variation of the SD against sensitivity to provide reliable gesture detection.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 10

Page 11

Figure 3-4. Minimum Signal Deviation for Reliable Gesture Detection

0

50

100

150

200

250

300

350

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6

Signal Deviation

Detection Sensitivity

MGC3140

Tuning

To adjust Detection Sensitivity, proceed as follows:

• For maximum robustness to noise:

1. Perform gestures as far away from the sensitive area as allowed by the application.

2. Reduce Detection Sensitivity until gestures are no longer detected.

3. At this point, amplitude from performed gestures is not enough to trigger gesture start. This is

approximately the minimum sensitivity of the application.

• For maximum system sensitivity:

1. Perform gestures close to the sensitive area.

2. Increase Detection Sensitivity until gestures are no longer detected.

3. At this point, noise amplitude is enough to trigger gesture start. Noise is mixed with the performed

gesture signal and no valid gesture is recognized. This is approximately the maximum sensitivity of

the application.

Gesture Suppression Time

Gesture Suppression Time is a parameter utilized to prevent a user unintentionally triggering a gesture

after touching the sensor and then removing the hand. This parameter can prevent that situation by

blocking all gestures during a certain time after sensor touch is released. While gestures are blocked, the

time is adjusted with this slider 1 taking values from 0 to 1.25s.

If Gesture Suppression Time is active (>0), touch detection also aborts ongoing gesture recognition.

If the Touch Detection feature is disabled, this feature has no impact.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 11

Page 12

3.2.4.2 AirWheel Tuning Window

The AirWheel is part of the circular gestures suite. It provides a counter which is either increased or

decreased for clockwise (CW) or counterclockwise circles (CCW), respectively. The direction can be

inverted while AirWheel is ongoing. The counter will reflect the change in direction immediately.

The AirWheel counter (eight bits) accumulates the angle change during the circular movement. The lower

five bits of the counter represent the current angular position with a resolution of 32 counts for each full

revolution. Each time the angular position crosses 0, a full revolution is counted in the upper three bits. If

rotation is in the CW direction, it adds one revolution, and if it is in the CCW direction, it subtracts one.

Figure 3-5 shows the positive sense of rotation and the mapping between the value of the lower five bits

and the angular position.

Figure 3-5. AirWheel Positive Direction and Minimum Arc Representation

MGC3140

Tuning

Though it is expected to work out-of-the-box with most designs, the AirWheel functionality can be

adjusted to suit a specific application.

Minimum Arc

Minimum Arc adjusts how many quadrants the user may rotate before the AirWheel counter starts. A

higher value means that a bigger arc has to be performed before the counter starts. The value can be

adjusted in the range between 1 and 8 quadrants; default is 3.

Figure 3-5 shows the three quadrants required between 'Start of position tracking', when the user starts

rotating, until 'Start of AirWheel counter', when the counter starts to be updated. Higher Minimum Arc

means the user may rotate more before the counter starts updating. Low Minimum Arc may lead to

unintended AirWheel recognition when the user is performing other movement in the sensitive area.

Note: Minimum Arc also affects the Discrete Circle gestures. The same arc has to be performed to

recognize a Discrete Circle gesture.

Note: Discrete Circle gestures and AirWheel are mutually exclusive. The AirWheel has priority over the

Discrete Circles. When the AirWheel is enabled, then only AirWheel information will be reported. To use

the Discrete Circles gestures, the application has to enable the clockwise and/or counterclockwise

gestures and disable the AirWheel.

Related Links

3.2.2 System Start-up Window

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 12

Page 13

3.2.5 Presence, Hold and Approach

The MGC3140 detects the presence of a hand when the following conditions are met:

1. Whenever the SD of any single electrode exceeds the Presence Threshold Single Electrode

Threshold parameter.

2. Whenever the SD of all Rx electrodes exceed the Presence Threshold All Electrodes Threshold

parameter.

Once the MGC3140 has detected the presence of a hand, it does the following:

1. Sets a Hand Presence flag. This flag can be seen in the Presence Hold State window.

2. Starts a timer for Hand Present gesture event.

When the hand-present timer reaches the Presence Duration time, the presence is reported, and a Hand

Present is indicated in the Gestures window.

Figure 3-6. Hand Present Symbol

When the hand-hold timer reaches the hand-hold duration time, the Hand Hold is reported and a Hand

Present is indicated in the Gestures window.

MGC3140

Tuning

Figure 3-7. Hand Hold Symbol

The Hand Hold flag remains set unless the hand moves. The amount of movement allowed in order to

keep the Hand Hold flag set is controlled by the Hand Tremble Threshold. This parameter specifies the

amount of movement that a hand can move and still be classified as holding.

• Low values – only a small movement is necessary to clear the Hand Hold flag.

• High values – the hand can move and the Hand Hold flag will stay high.

If the amount of movement is sufficient to clear the Hand Hold flag, then:

1. The hand-hold timer is restarted, providing the hand is still present.

2. Any hand-hold indication in the Gesture window is cleared.

3. The ending of the Hand Hold is reported.

The Default Presence and Hold Default parameters are generally acceptable to most users, although the

Hold Tremble Threshold may require some tuning.

The ActiveOutside parameter chooses if Hand Hold flag and Presence gesture can be active when the

user is outside the sensor, but still in sensing space.

• ActiveOutside checked (default) means that Hand Presence is required to set Hand Hold and that

Presence Duration starts counting on the rising edge of the Hand Presence Status flag.

• ActiveOutside unchecked means that Hand Inside is required to set Hand Hold and that Presence

Duration starts counting on the rising edge of the Hand Inside Status flag.

The use of the Active Outside flag requires accurate knowledge of the sensor dimensions and accurate

position reporting.

Related Links

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 13

Page 14

3.2.8 Position Tracking

0%

5%

10%

15%

20%

25%

30%

35%

40%

0

0.5

1

1.5

2

2.5

0 50 100 150 200 250 300 350 400 450 500

Current mA

Approach scan period ms

Current Consumption Variation with Approach Scan Period

120 Second AFA scan

600 Second AFA scan

% AFA difference

3.2.10 Sensing Area

3.2.6 Approach Detection

Approach Detection is used to preserve power, by placing the MGC3140 into a Lower-Power Sleep mode

with infrequent scans.

If configured, any combination of the Rx electrodes can be enabled for Approach Detection, and a hand

will be detected by just one electrode. The Approach Electrode Selection window controls which

electrodes are enabled for Approach Detection.

3.2.6.1 Approach Detection Power Tuning

A lack of activity for a specified time by the Idle Time-out parameter will result in the MGC3140 entering

Sleep mode. When in Sleep mode, the MGC3140 periodically performs a scan looking for the presence

of a hand. The interval between scans is set by the Approach Scan Interval parameter. The bigger the

interval, the lower the power consumption, as shown in Figure 3-8.

When detecting a hand, the MGC3140 leaves Approach mode and reverts to normal continuous

scanning.

Figure 3-8. Current Consumption Variation with Approach Scan Period and AFA Frequency

MGC3140

Tuning

Note: AFA = Automatic Frequency Adaption

3.2.6.2 Approach Range

The approach range is determined by the sensor configuration, size and sensitivity setting, as shown in

the figure below.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 14

Page 15

Figure 3-9. Approach Detection Height Against Sensitivity

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 20 40 60 80 100

Detection Height as percentage of detection range

Sensitivity

Height as % of

detection range

MGC3140

Tuning

The Sensitivity slider 1 selects how much signal change is necessary to wake up the system. The value

can be adjusted in the range from 1 to 100; default is 76.

• High values will lead to a sensitive wake-up behavior. This means that small signal changes are

enough to wake up the system. This results in higher detection range in the Self Wake-up mode,

but may also lead to unintended wake-ups due to increased noise levels.

• Low values will lead to a less sensitive wake-up behavior. This means that higher signal changes

are necessary to wake up the system. This results in smaller detection range in the Self Wake-up

mode but, at the same time, the system will be less prone to unwanted wake-ups in case of

increased noise levels.

3.2.7 Touch Detection

The Touch Threshold North, East, South, West, Center fields specify the SD values that have to be

exceeded to validate the touch event. The range is 0 to 32768. The horizontal darker line in the Level

window is adjusted according to the slider value.

• Touch each electrode in its geometric center and move the finger to the borders of the electrode

while touching.

• Adjust corresponding Touch Threshold 1 according to the displayed SD value while the finger is

positioned on the electrode. If touches are missed, the Touch Threshold might be needed to be

decreased.

Note: The values in the Level window are shown in log scale.

The touched state is exited if the SD value drops below the Release Threshold. This threshold (horizontal

lighter line in the Level window) is an adjustable percentage of the Touch Threshold. The percentage of

the Touch Detection Threshold can be adjusted between 50% and 100%. To adjust it, proceed as follows:

• Touch each electrode in its geometric center and change the hand posture. If Touch state becomes

released although the user is still touching, the Release Threshold needs to be decreased.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 15

Page 16

• If the finger is lifted from the surface, but a Touch state is still reported, the Release Threshold has

SOUTH

EAST

WEST

NORTH

Electrode X distance

Electrode Y distance

Sensing Space

to be increased.

3.2.7.1 Approach Speed

The Minimum Approach Speed parameter adjusts the minimum approach speed required to detect a

touch event.

• If touch is only detected if the finger approaches quickly, decrease Minimum Approach Speed.

However, when Minimum Approach Speed is too low, false alarms may occur when a finger is

approaching slowly, but not touching.

• If Minimum Approach Speed is set to 0, the touch detection is not dependent on speed and it is

only configured by the thresholds on the SD level.

3.2.7.2 Tap Settings

• Max. Tap Time

A Single Tap is detected only when the time between a touch press and the consecutive release is

smaller than the Max. Tap Time. Higher values allow taps with longer duration.

The time can be adjusted using the corresponding slider, with values between 0 and 1s.

• Max. Double Tap Interval

The Double Tap is detected when the time between the release of a Single Tap and the consecutive

touch press is smaller than the Max. Double Tap Interval. Higher values allow longer intervals

between taps. The time can be adjusted using the corresponding slider 1, that can take values

between 0 and 1s.

• Air Taps

If Air Taps are required, set the threshold low, depending on the height of the tap required and set

the approach speed to a low value or even 0.

MGC3140

Tuning

3.2.8 Position Tracking

3.2.8.1 Electrode Dimensions

To start position parameterization, the user needs to input the electrode dimensions. The figure below

shows how to measure the electrode dimensions. Adjust the electrode X and Y distances by using the

respective slider.

Figure 3-10. Electrode Dimensions

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 16

Page 17

Default values are set for Emerald Development Kit V1.0 with default 95x60 mm Electrode (4-layer/1.5

mm PCB).

• Electrode X Distance corresponds to the distance between the inner edges of West and East

electrodes.

• Electrode Y Distance corresponds to the distance between the inner edges of North and

South electrodes.

3.2.8.2 Electrode Weighting

The Electrode Weighting is an optional step to adjust parameters for position tracking. Five

measurements with the artificial hand and five reference measurements without it are conducted at a

constant height of 30 mm. Always use the 30-mm Styrofoam spacer to establish the height. The drawing

in the Electrode Weighting step will show the correct placement of the artificial hand for each

measurement (West, North, East, South and Center).

The Start Measurement button will trigger the measurement. After pressing the button, a bar will show

the progress of the measurement.

The reference needs to be measured within the next 10s to avoid influences from signal drifts. A down

counter is displayed in the Visualization window. If the reference measurement was not acquired during

these 10 seconds, a pop-up window will be displayed. The measurement needs to be repeated.

MGC3140

Tuning

Removing the artificial hand and pressing the Start Measurement button will trigger the reference

measurement. The measurement table displays the signal level with artificial hand (hand brick), without it

(reference) and the difference between them (Delta).

The measurement process checks if the measured data is valid and if the environment is noisy.

When the data is not valid, it is displayed in red in the measurement table. If the variance of the signal

was higher than ten digits during measurements, the noise indicator in the status bar blinks and Aurea

shows a red message reporting that there was noise detected during the last measurement:

"Measurement variance exceeded threshold". If the Delta is negative, meaning that the reference level

was higher than the one with artificial hand, a red message will be displayed: "The Delta is negative".

The user has to check the measurement setup and repeat the measurement.

Typical reasons for failed measurements are:

• User activity in the sensing space while measuring

• PC not grounded

• Artificial hand is not grounded

• Artificial hand is shaking and the setup was not mechanically stable

• External noise sources (conducted or irradiated)

Once the Electrode Weighting step is finished, press the OK button.

It is not necessary to adjust/correct the 30-mm Styrofoam spacer brick for the thickness of the target

device housing or for a decoration layer covering the electrodes.

The collected data corresponds to the Signal Deviation Mean (SDM) of the electrodes signal levels.

3.2.9 E-Field Linearization

The E-Field Linearization is an optional step to adjust parameters for position tracking. Four

measurements with the artificial hand centered with the system and four reference measurements without

it are conducted at different heights (10 mm, 30 mm, 50 mm and 80 mm). Always use a Styrofoam spacer

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 17

Page 18

SOUTH

EAST

WEST

NORTH

Hand Path

MGC3140

Tuning

to establish the height. The drawing in the E-Field Linearization step in Aurea shows the spacer to be

used.

The Start Measurement button will trigger the measurement. After pressing the button, a bar will show

the progress of the measurement.

The reference needs to be measured within the next 10s to avoid influences from signal drifts. A down

counter is displayed in the Visualization window. If the reference measurement was not acquired during

these 10s, a pop-up window will be displayed. The measurement needs to be repeated.

Removing the artificial hand and pressing the Start Measurement button will trigger the reference

measurement. The measurement table displays the signal level with artificial hand (hand brick), without it

(reference) and the difference between them (Delta).

The measurement process checks if the measured data is valid and if the environment is noisy. When the

data is not valid, it is displayed in red in the measurement table. If the variance of the signal was higher

than ten digits during measurements, the noise indicator in the status bar blinks and Aurea shows a red

message reporting that there was noise detected during the last measurement: "Measurement variance

exceeded threshold". If the Delta is negative, meaning that the reference level was higher than the one

with artificial hand, a red message will be displayed: "The Delta is negative".

The user has to check the measurement setup and repeat the measurement.

Typical reasons for failed measurements are:

• User activity in the sensing space while measuring

• PC not grounded

• Artificial hand not grounded

• Artificial hand is shaking and the setup was not mechanically stable

• External noise sources (conducted or irradiated).

Once the E-Field Linearization step is finished, press the OK button.

Note: The collected data corresponds to the Signal Deviation Mean (SDM) of the electrodes signals

levels.

3.2.10 Sensing Area

The Sensing Area parameterization step is intended to adapt the calculated XY position to the real

electrode dimensions of the system. This is done by setting the four scaling parameters X POS MIN, X

POS MAX, Y POS MIN and Y POS MAX. The grid of the 2D-position plot in the Visualization window will

be scaled if a slider of these parameters is moved.

Figure 3-11. Sensing Area Hand Path

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 18

Page 19

MGC3140

Tuning

The Apply button will apply the current setting and will rescale the Visualization window according to the

current setting. The Clear button will reset the position drawing.

The sub-steps within the Sensing Area step are as follows:

• While touching the device, move the hand posture, which is typical for the application, along the

maximum XY positions which the user would like to reach in the application. Repeat the hand

moving along the maximum XY position about ten times to get a more meaningful drawing. The 2Dsignal plot in the Visualization window draws the calculated position based on the hand movement.

It is likely that the real position does not fit the calculated position.

• Use the slider of the four scaling parameters to reduce the grid size until it fits within the deformed

position drawing.

• Press Apply and check if reaching all XY positions with the same hand movement is now possible.

• If all positions can be reached, continue with the next parameterization step. If not, adjust the

sliders and press Apply again until the positioning meets expectation.

The following graphic shows a typical position drawing and the parameter setting of the corresponding

parameterization step. The grid and thus the scaling are changing with the parameter settings.

Figure 3-12. Sensing Area Tuning Examples

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 19

Page 20

Note: Experiment with those settings to improve the system linearity. Typically, the system has a more

linear behavior for smaller grid sizes.

3.2.11 Minimum Z Level

Minimum Z level tuning is similar to the Sensing Area step which was intended to adjust the XY

positioning; the Z positioning step is intended to adjust the Z position calculation. The Z position is

adjusted through two steps: minimum and maximum Z level. The first step is to adjust the minimum Z

distance level (Z = 0) by configuring the Z POS MIN parameter. This parameter can be modified by using

the respective slider. For fine tuning, click on the slider and use the arrow keys on the PC keyboard.

• Touch the surface of the sensing area with a typical hand posture for the application and keep the

touch.

• Adjust the slider Z POS MIN until the green Z level illustrated in the 3D-signal plot hits the zero

level. In this manner, the zero level is the lowest level which is possible to reach in the 3D-signal

plot.

• The Z position must increase while the hand is moving up from the surface.

3.2.12 Maximum Z Level

The second step of the Z level adjustment is to identify the maximum Z distance level. This parameter

setting can be modified by using the respective slider. For fine tuning, click on the slider and use the

arrow keys on the PC keyboard.

MGC3140

Tuning

The sub-steps within the Maximum Distance Level step are as follows:

• Set Z POS MAX to its maximum value.

• Touch the surface and then slowly remove the hand in Z direction with a hand posture that is typical

for the application.

• The Z position will stop following the user's hand at some point.

• Adjust Z POS MAX such that the top of the grid is aligned with the green Z level.

3.2.13 Jitter Reduction

Jitter control is configured in the Filter Adjustment window. The filter adjustments are used to reduce the

system jitter (position error when hand is stable) and to define the desired hand tracking speed.

3.2.13.1 Jitter Reduction

Place the hand on the corner, close to the electrodes (where the jitter is more visible), hold it for a few

seconds and watch the position using the Position Tracking window. The position should not have high

deviation in a distance.

Increase the Jitter Reduction parameter value to reduce system jitter. High values will lead to a more

lethargic system behavior and will also slow down the tracking speed. Low values will lead to a more

responsive system behavior and will speed up the tracking speed.

3.2.13.2 Speed

Perform hand gestures to check the tracking speed in the Position Tracking window. Adjust the Speed

parameter value to speed up or to slow down the tracking speed.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 20

Page 21

4. Reference Material

• MGC3140 GestIC® Library Interface Description User’s Guide (DS40001875)

• Aurea Graphical User Interface User's Guide (DS40001681)

• GestIC® Design Guide (DS40001716)

• MGC3140 3D Tracking and Gesture Controller Data Sheet (DS40002037)

MGC3140

Reference Material

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 21

Page 22

5. Revision History

Revision Description Date

A Initial release September, 2018

MGC3140

Revision History

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 22

Page 23

MGC3140

The Microchip Web Site

Microchip provides online support via our web site at http://www.microchip.com/. This web site is used as

a means to make files and information easily available to customers. Accessible by using your favorite

Internet browser, the web site contains the following information:

• Product Support – Data sheets and errata, application notes and sample programs, design

resources, user’s guides and hardware support documents, latest software releases and archived

software

• General Technical Support – Frequently Asked Questions (FAQ), technical support requests,

online discussion groups, Microchip consultant program member listing

• Business of Microchip – Product selector and ordering guides, latest Microchip press releases,

listing of seminars and events, listings of Microchip sales offices, distributors and factory

representatives

Customer Change Notification Service

Microchip’s customer notification service helps keep customers current on Microchip products.

Subscribers will receive e-mail notification whenever there are changes, updates, revisions or errata

related to a specified product family or development tool of interest.

To register, access the Microchip web site at http://www.microchip.com/. Under “Support”, click on

“Customer Change Notification” and follow the registration instructions.

Customer Support

Users of Microchip products can receive assistance through several channels:

• Distributor or Representative

• Local Sales Office

• Field Application Engineer (FAE)

• Technical Support

Customers should contact their distributor, representative or Field Application Engineer (FAE) for support.

Local sales offices are also available to help customers. A listing of sales offices and locations is included

in the back of this document.

Technical support is available through the web site at: http://www.microchip.com/support

Microchip Devices Code Protection Feature

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the

market today, when used in the intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of

these methods, to our knowledge, require using the Microchip products in a manner outside the

operating specifications contained in Microchip’s Data Sheets. Most likely, the person doing so is

engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 23

Page 24

MGC3140

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their

code. Code protection does not mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the

code protection features of our products. Attempts to break Microchip’s code protection feature may be a

violation of the Digital Millennium Copyright Act. If such acts allow unauthorized access to your software

or other copyrighted work, you may have a right to sue for relief under that Act.

Legal Notice

Information contained in this publication regarding device applications and the like is provided only for

your convenience and may be superseded by updates. It is your responsibility to ensure that your

application meets with your specifications. MICROCHIP MAKES NO REPRESENTATIONS OR

WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, STATUTORY

OR OTHERWISE, RELATED TO THE INFORMATION, INCLUDING BUT NOT LIMITED TO ITS

CONDITION, QUALITY, PERFORMANCE, MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and its use. Use of Microchip devices in life

support and/or safety applications is entirely at the buyer’s risk, and the buyer agrees to defend,

indemnify and hold harmless Microchip from any and all damages, claims, suits, or expenses resulting

from such use. No licenses are conveyed, implicitly or otherwise, under any Microchip intellectual

property rights unless otherwise stated.

Trademarks

The Microchip name and logo, the Microchip logo, AnyRate, AVR, AVR logo, AVR Freaks, BitCloud,

chipKIT, chipKIT logo, CryptoMemory, CryptoRF, dsPIC, FlashFlex, flexPWR, Heldo, JukeBlox, KeeLoq,

Kleer, LANCheck, LINK MD, maXStylus, maXTouch, MediaLB, megaAVR, MOST, MOST logo, MPLAB,

OptoLyzer, PIC, picoPower, PICSTART, PIC32 logo, Prochip Designer, QTouch, SAM-BA, SpyNIC, SST,

SST Logo, SuperFlash, tinyAVR, UNI/O, and XMEGA are registered trademarks of Microchip Technology

Incorporated in the U.S.A. and other countries.

ClockWorks, The Embedded Control Solutions Company, EtherSynch, Hyper Speed Control, HyperLight

Load, IntelliMOS, mTouch, Precision Edge, and Quiet-Wire are registered trademarks of Microchip

Technology Incorporated in the U.S.A.

Adjacent Key Suppression, AKS, Analog-for-the-Digital Age, Any Capacitor, AnyIn, AnyOut, BodyCom,

CodeGuard, CryptoAuthentication, CryptoAutomotive, CryptoCompanion, CryptoController, dsPICDEM,

dsPICDEM.net, Dynamic Average Matching, DAM, ECAN, EtherGREEN, In-Circuit Serial Programming,

ICSP, INICnet, Inter-Chip Connectivity, JitterBlocker, KleerNet, KleerNet logo, memBrain, Mindi, MiWi,

motorBench, MPASM, MPF, MPLAB Certified logo, MPLIB, MPLINK, MultiTRAK, NetDetach, Omniscient

Code Generation, PICDEM, PICDEM.net, PICkit, PICtail, PowerSmart, PureSilicon, QMatrix, REAL ICE,

Ripple Blocker, SAM-ICE, Serial Quad I/O, SMART-I.S., SQI, SuperSwitcher, SuperSwitcher II, Total

Endurance, TSHARC, USBCheck, VariSense, ViewSpan, WiperLock, Wireless DNA, and ZENA are

trademarks of Microchip Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated in the U.S.A.

Silicon Storage Technology is a registered trademark of Microchip Technology Inc. in other countries.

GestIC is a registered trademark of Microchip Technology Germany II GmbH & Co. KG, a subsidiary of

Microchip Technology Inc., in other countries.

All other trademarks mentioned herein are property of their respective companies.

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 24

Page 25

MGC3140

©

2018, Microchip Technology Incorporated, Printed in the U.S.A., All Rights Reserved.

ISBN: 978-1-5224-3493-1

Quality Management System Certified by DNV

ISO/TS 16949

Microchip received ISO/TS-16949:2009 certification for its worldwide headquarters, design and wafer

fabrication facilities in Chandler and Tempe, Arizona; Gresham, Oregon and design centers in California

and India. The Company’s quality system processes and procedures are for its PIC® MCUs and dsPIC

DSCs, KEELOQ® code hopping devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design and manufacture of development

systems is ISO 9001:2000 certified.

®

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 25

Page 26

Worldwide Sales and Service

AMERICAS ASIA/PACIFIC ASIA/PACIFIC EUROPE

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://www.microchip.com/

support

Web Address:

www.microchip.com

Atlanta

Duluth, GA

Tel: 678-957-9614

Fax: 678-957-1455

Austin, TX

Tel: 512-257-3370

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Novi, MI

Tel: 248-848-4000

Houston, TX

Tel: 281-894-5983

Indianapolis

Noblesville, IN

Tel: 317-773-8323

Fax: 317-773-5453

Tel: 317-536-2380

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

Tel: 951-273-7800

Raleigh, NC

Tel: 919-844-7510

New York, NY

Tel: 631-435-6000

San Jose, CA

Tel: 408-735-9110

Tel: 408-436-4270

Canada - Toronto

Tel: 905-695-1980

Fax: 905-695-2078

Australia - Sydney

Tel: 61-2-9868-6733

China - Beijing

Tel: 86-10-8569-7000

China - Chengdu

Tel: 86-28-8665-5511

China - Chongqing

Tel: 86-23-8980-9588

China - Dongguan

Tel: 86-769-8702-9880

China - Guangzhou

Tel: 86-20-8755-8029

China - Hangzhou

Tel: 86-571-8792-8115

China - Hong Kong SAR

Tel: 852-2943-5100

China - Nanjing

Tel: 86-25-8473-2460

China - Qingdao

Tel: 86-532-8502-7355

China - Shanghai

Tel: 86-21-3326-8000

China - Shenyang

Tel: 86-24-2334-2829

China - Shenzhen

Tel: 86-755-8864-2200

China - Suzhou

Tel: 86-186-6233-1526

China - Wuhan

Tel: 86-27-5980-5300

China - Xian

Tel: 86-29-8833-7252

China - Xiamen

Tel: 86-592-2388138

China - Zhuhai

Tel: 86-756-3210040

India - Bangalore

Tel: 91-80-3090-4444

India - New Delhi

Tel: 91-11-4160-8631

India - Pune

Tel: 91-20-4121-0141

Japan - Osaka

Tel: 81-6-6152-7160

Japan - Tokyo

Tel: 81-3-6880- 3770

Korea - Daegu

Tel: 82-53-744-4301

Korea - Seoul

Tel: 82-2-554-7200

Malaysia - Kuala Lumpur

Tel: 60-3-7651-7906

Malaysia - Penang

Tel: 60-4-227-8870

Philippines - Manila

Tel: 63-2-634-9065

Singapore

Tel: 65-6334-8870

Taiwan - Hsin Chu

Tel: 886-3-577-8366

Taiwan - Kaohsiung

Tel: 886-7-213-7830

Taiwan - Taipei

Tel: 886-2-2508-8600

Thailand - Bangkok

Tel: 66-2-694-1351

Vietnam - Ho Chi Minh

Tel: 84-28-5448-2100

Austria - Wels

Tel: 43-7242-2244-39

Fax: 43-7242-2244-393

Denmark - Copenhagen

Tel: 45-4450-2828

Fax: 45-4485-2829

Finland - Espoo

Tel: 358-9-4520-820

France - Paris

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

Germany - Garching

Tel: 49-8931-9700

Germany - Haan

Tel: 49-2129-3766400

Germany - Heilbronn

Tel: 49-7131-67-3636

Germany - Karlsruhe

Tel: 49-721-625370

Germany - Munich

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Germany - Rosenheim

Tel: 49-8031-354-560

Israel - Ra’anana

Tel: 972-9-744-7705

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Italy - Padova

Tel: 39-049-7625286

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

Norway - Trondheim

Tel: 47-72884388

Poland - Warsaw

Tel: 48-22-3325737

Romania - Bucharest

Tel: 40-21-407-87-50

Spain - Madrid

Tel: 34-91-708-08-90

Fax: 34-91-708-08-91

Sweden - Gothenberg

Tel: 46-31-704-60-40

Sweden - Stockholm

Tel: 46-8-5090-4654

UK - Wokingham

Tel: 44-118-921-5800

Fax: 44-118-921-5820

© 2018 Microchip Technology Inc.

User Guide

DS40002055A-page 26

Loading...

Loading...